Patents

Literature

216 results about "Multi enzyme" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

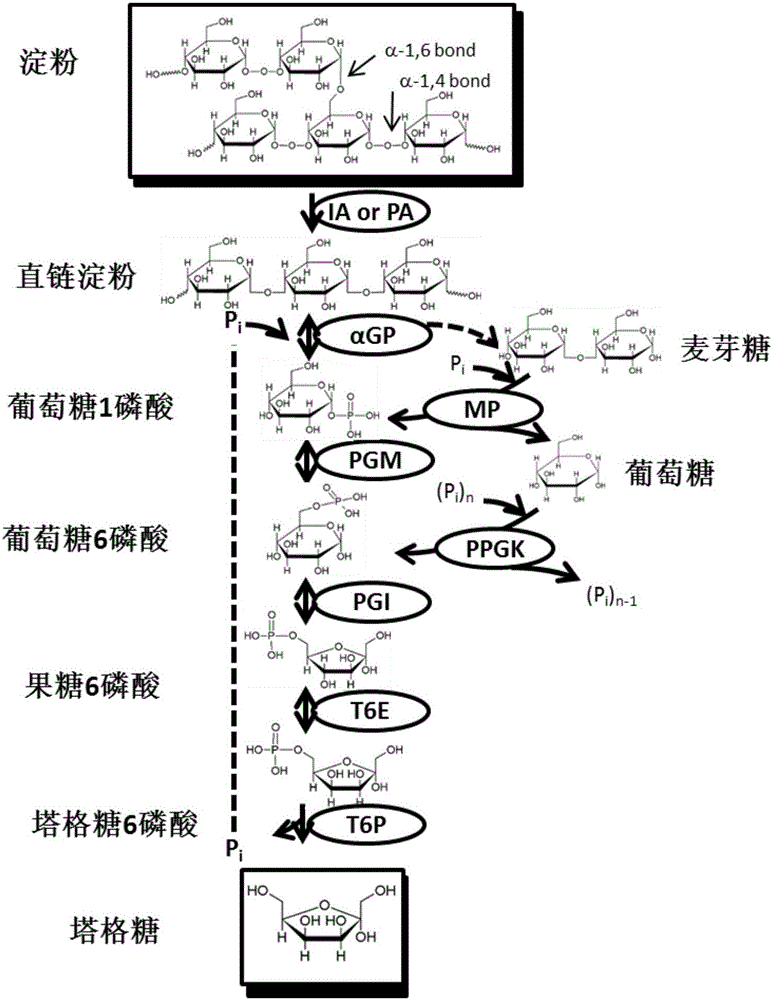

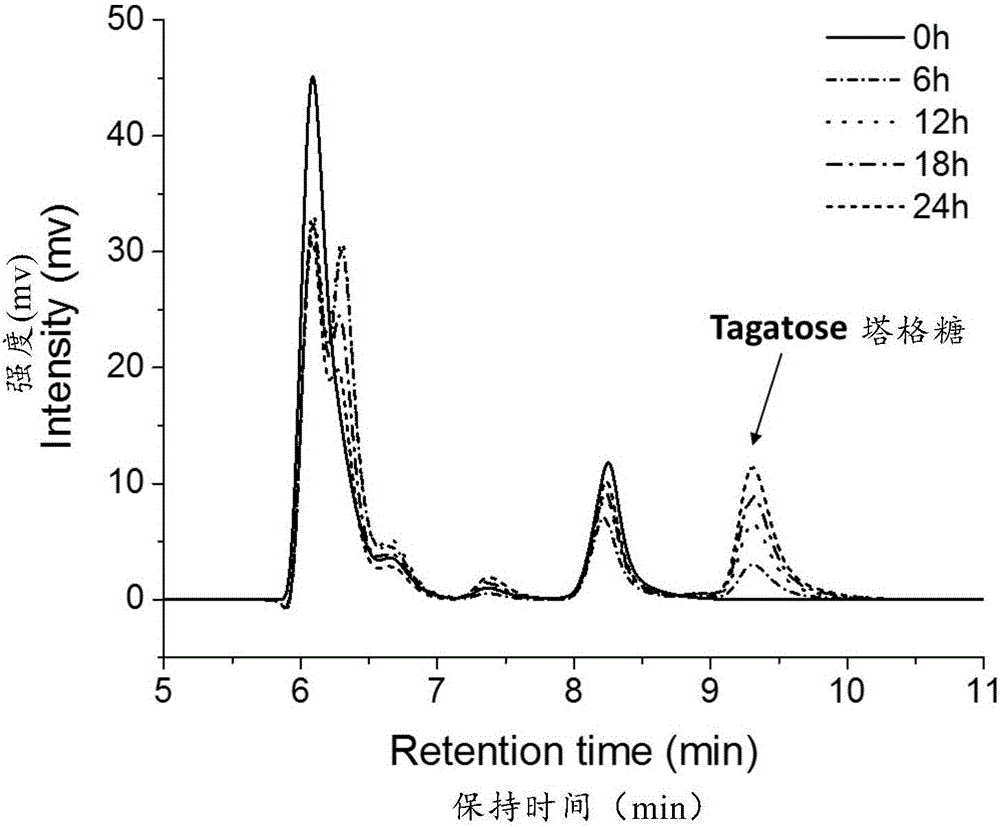

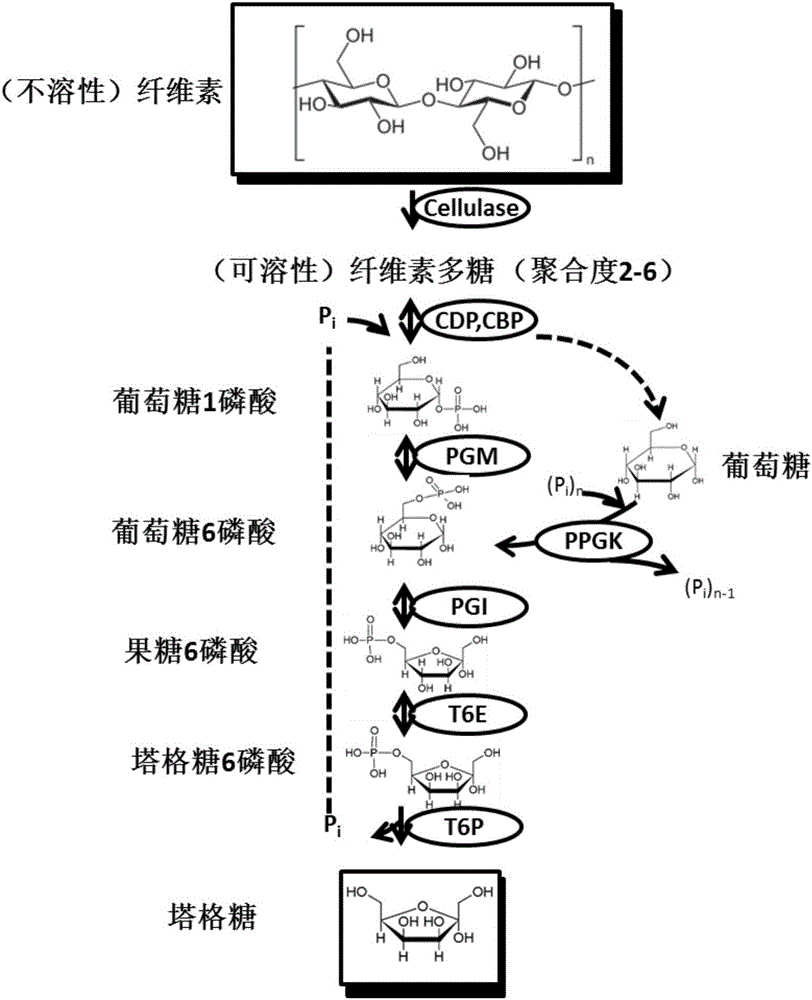

Tagatose preparation method

The invention discloses a tagatose preparation method and belongs to the field of multi-enzyme catalytic preparation of tagatose. Starch, cellulose, or their derivatives, or sucrose is used as substrate, and the substrate is efficiently catalyzed in a multi-enzyme reaction system by an in-vitro multi-enzyme molecular machine into tagatose. By adding enzymes capable of accelerating hydrolysis of starch, cellulose or sucrose and enzymes making use of the byproduct glucose, material conversion rate and tagatose yield are significantly increased. The method of the invention is high in tagatose yield, the materials are cheap, the production cost is low, and the method is suitable for industrial production of tagatose.

Owner:TIANJIN INST OF IND BIOTECH CHINESE ACADEMY OF SCI

Multi-enzyme and multi-steps type method for producing diet cellulose flour from wheat bran

ActiveCN1718107ACompletely hydrolyzedReduce lossesVegetable proteins working-upFood preparationPhytaseCELLULOSE FLOUR

A process for preparing the edible fibre powder from wheat bran by multi-enzyme step treating method includes such steps as treating wheat bran sequentially by endogenous phytase, amylase, proteinase and lipase to obtain high-purity edible fibres, decoloring by sodium hypochlorite and hydrogen peroxide, squeezing, laying aside and superfine pulverizing.

Owner:江苏江南上一道科技股份有限公司

Method for producing multi-vitamins and multi-enzymes high protein microorganic agent by multi-bacteria solid fermentation

InactiveCN1552233AImprove disease resistanceQuality improvementFungiFood processingBacterial strainOrganism

A process for preparing the multi-vitamine multi-enzyme high-protein microbial preparation by the solid fermentation of multiple bacterial strains includes such steps as preparing seed culture media, respectively inoculating reticularia, torula yeast, glutamic corynebacteria, Bacillus subtitis, Aspergillus niger, etc into said seed culture media, culturing at 30-35 deg.C for 15-18 hr, inoculating them into the solid culture medium, fermenting at 33+ / -0.5 deg.C for 70-80 hr, and fast drying. Its can be used as the feed containing living microbes, microbial enzymes, vitamines, etc.

Owner:哈尔滨中冠生物工程有限公司

Preparation method of compound microbial feed additive

The invention relates to a feed additive, in particular to a prepration method of a compound microbial feed additive, which is used for solving the problems that a variety of feed additives have respective different shortcomings in the actual applications. The preparation method comprises the following steps: preparing selenium yeast, iron yeast and zinc yeast which are rich in trace elements, taking vinegar residue, wheat bran, corn flour, compound Daqu, ammonium sulfate and other auxiliary materials as culture media, adding aspergillus niger, aspergillus oryzae, bacillus subtilis, lactobacillus and yeast, producing a multi-bacterial compound enzyme by the solid-state method, and mixing the functional yeast, phytase and the multi-bacterial compound enzyme for producing a biological feed micro-multi-enzyme which has a large number of live bacteria in beneficial bacterial groups, a complete enzyme system of digestive enzymes and non-digestive enzymes needed by animals and high enzyme activity, and is rich in organic trace elements, vitamins, amino acids and unknown growth-promoting factors with functional nutrition for the animals and people; furthermore, the feed additive has the advantages of advanced process, abundant nutrition, abundant bacterial groups, full enzyme spectrum, high activity, greenness, no pollution and the like.

Owner:山西金龙鱼梁汾醋业有限公司

Condensed multi-enzyme medical cleaning agent

InactiveCN102071113AQuick breakdownQuick clearNon-ionic surface-active compoundsDetergent compounding agentsGlycerolCleansing Agents

The invention relates to a condensed multi-enzyme medical cleaning agent. The cleaning agent contains surfactants, a detergent auxiliary agent, a solubilizing agent, an enzymic preparation, a foam inhibitor and a preservative, wherein the surfactants are a non-ion surfactant and an anion surfactant. The cleaning agent comprises the following formula components in percentage by weight: 5 to 10 percent of alkoxyl fatty alcohol, 3 to 5 percent of alkyl polylucoside, 5 to 10 percent of alkanol polyether, 5 to 10 percent of sodium xylene sulfonate, 0.5 to 1.5 percent of sodium sulfate, 0.5 to 1 percent of calcium chloride, 2 to 4 percent of disodium ethylene diaminetetraacetate, 5 to 10 percent of hydrogenated castor oil, 6 to 12 percent of dipropylene glycol monomethyl ether, 5 to 10 percent of glycerol, 2 to 6 percent of proteinase, 1 to 5 percent of amylase, 1 to 5 percent of lipase, 0.5 to 1 percent of cellulase, 0.1 to 0.5 percent of methylparaben and propyl hydroxybenzoate preservative, 0.1 percent of essence, 0.1 percent of pigment and the balance of deionized water. Through the cleaning agent, all the biological residues adhered in and out of a medical apparatus can be quickly and effectively decomposed and cleaned and aluminum oxide playing a role in protection on the metal surface layer is not damaged.

Owner:徐宏汇 +1

Protein feed rich in small peptides and multi-enzyme bacteria and preparation method thereof

InactiveCN101642187AReduce excess residueEnhance physical fitnessFood processingAnimal feeding stuffBiotechnologyFood borne

The invention relates to protein feed rich in small peptides and multi-enzyme strains and a preparation method thereof. The protein feed is prepared by fermenting soybean meal, cottonseed meal, rapeseed meal, bone meal, wheat bran, common salt, light calcium carbonate, water and strains in a fermentation bin. The preparation method of the protein feed comprises the following steps: mixing the soybean meal, the cottonseed meal, the rapeseed meal, the bone meal, the wheat bran, the common salt and the light calcium carbonate in percentage by weight; adding 20-30 percent of water; sending the mixture to an air steamer; adding high-pressure steam to the air steamer so as to increase the air pressure to 1-2 MPa and the temperature to 140-200 DEG C; keeping the pressure for 4-6 minutes; momentarily releasing the mixture in the air steamer; sending the mixture to the fermentation bin; inoculating 3-5 percent of strains when the temperature of the mixture falls to 30-37 DEG C; fermenting for 72 hours at the temperature of 32-37 DEG C; discharging from the bin; and bagging to obtain a finished product. The product has strong disease-resistant function and low cost, increases the productionof animal by-products by more than 20 percent, is nontoxic, harmless and pollution-free and can inhibit food-borne diseases represented in cancers and subhealth phenomena from spreading.

Owner:张培举

Method for preparing nitrogen contained syrup in use for ferment through wheat beta starch multienzyme method

InactiveCN101049133ADoes not affect fermentation useIncrease glucose levelsFermentationFood preparationAmylaseNitrogen

A process for preparing the N-contained syrup from the wheat starch B by multi-enzyme method, which can be used for fermentation, includes such steps as preparing the slurry, liquefying, saccharifying, protein converting, filtering and concentrating. It features that the starch, protein, pentosan and fat, which are the basic components of wheat starch B, are hydrolyzed by the amylase, pentosanase and lipase, and its output rate is almost 100%.

Owner:SOUTH CHINA UNIV OF TECH +1

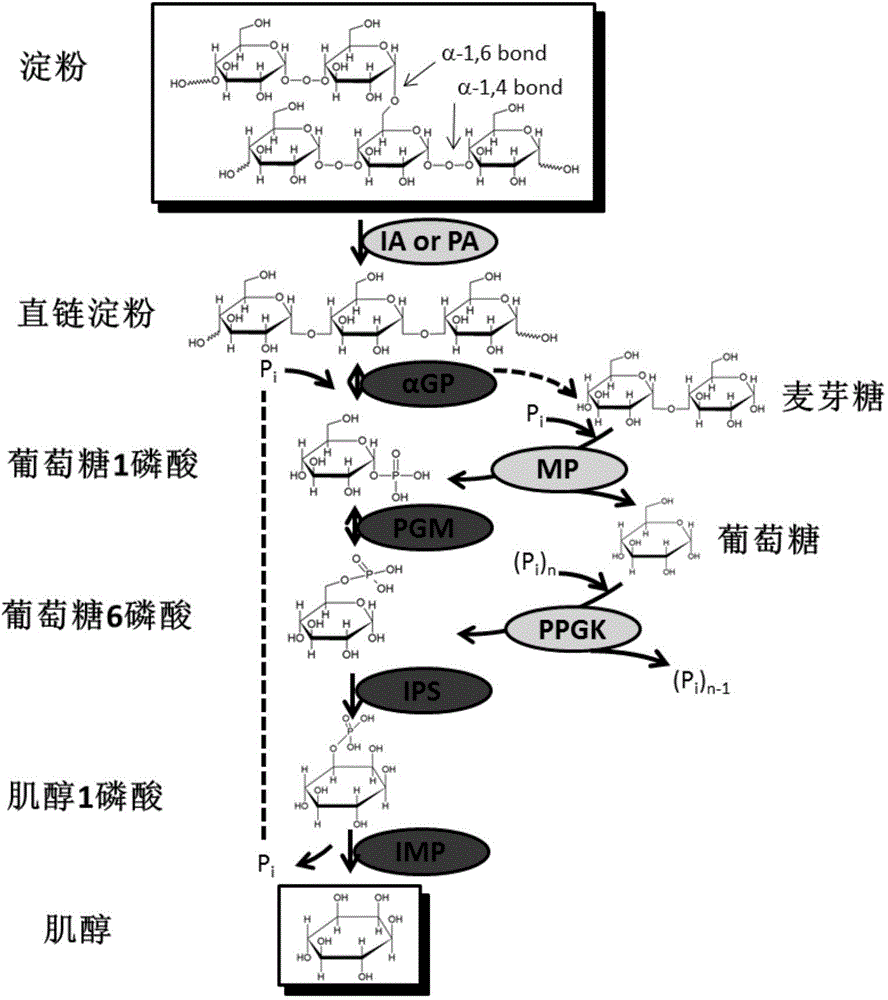

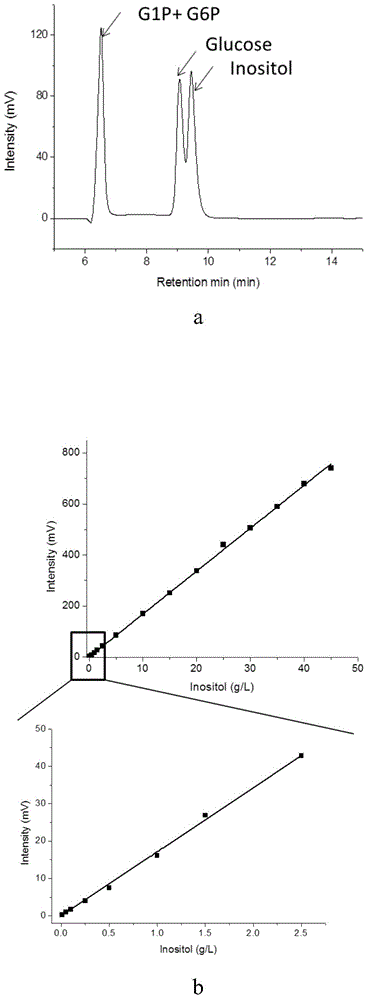

Inositol preparing method

ActiveCN106148425AIncrease profitReduce separation costsHydrolasesFermentationProcess optimizationCellulose

The invention discloses an inositol preparing method and belongs to the field of enzymatic preparation of inositol. According to the method, starch, cellulose or derivatives thereof are used as substrates and converted into inositol in a multi-enzyme reaction system through in-vitro multi-enzyme efficient catalysis. By conducting process optimization, adding enzymes capable of promoting starch or cellulose hydrolysis and utilizing the enzyme of the byproduct glucose, the multi-enzyme reaction system is established, and raw material conversion efficiency and inositol yield are improved remarkably. By the adoption of the method, raw material conversion rate is high, inositol yield is high, steps are simple, production cost is low, influence on the environment is small, and large-scale production of inositol can be achieved.

Owner:CHENGDU BOHAODA BIOLOGICAL TECH CO LTD

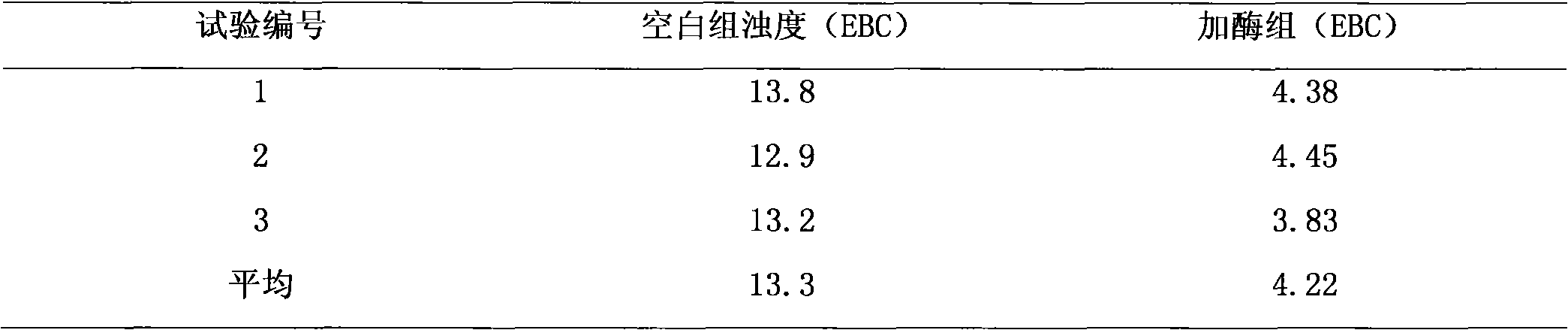

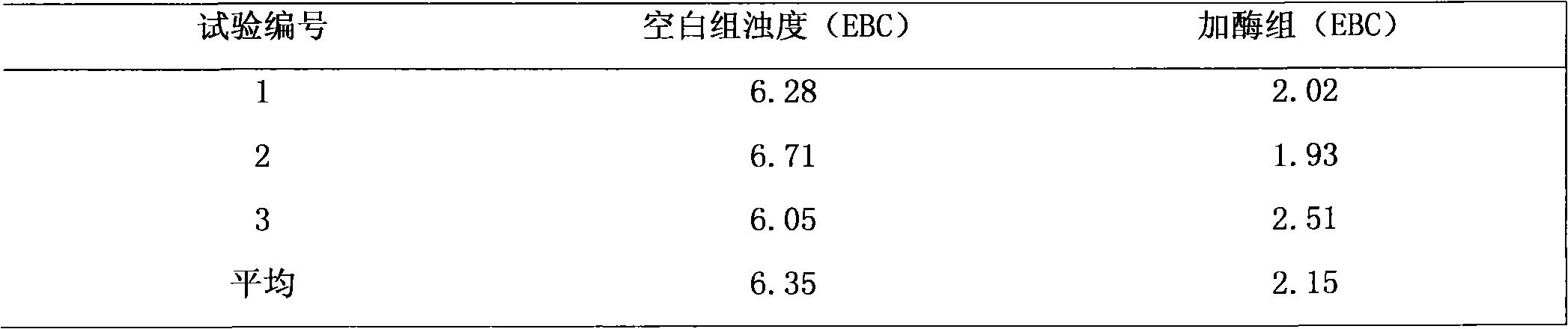

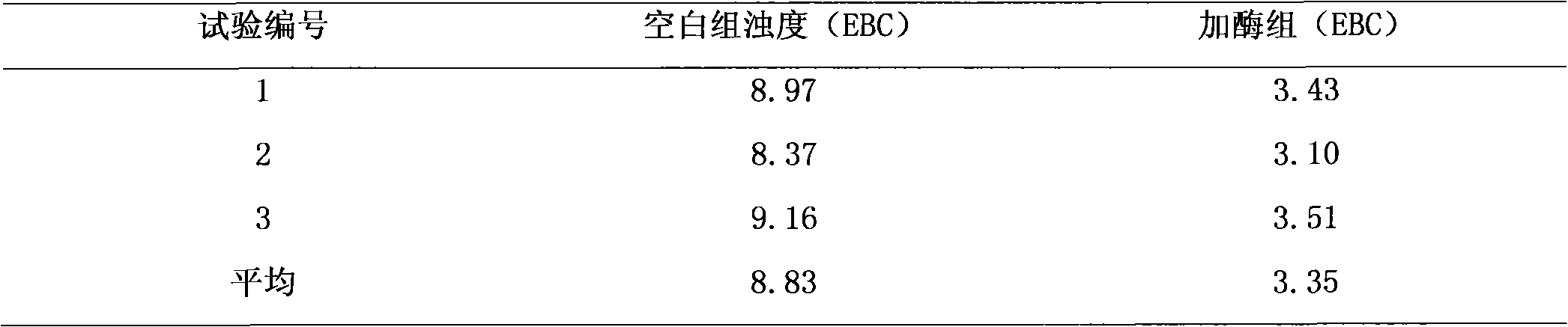

Multi-enzyme preparation capable of effectively reducing malt and beer turbidity

InactiveCN102071173AImproves abiotic stabilityReduce turbidity factorBeer fermentationEnzymesTurbidityMacromolecular Substances

The invention relates to a multi-enzyme preparation capable of effectively reducing malt and beer turbidity, which is characterized in that the multi-enzyme preparation comprises the following ingredients in percentage by weight: 15 to 20 percent of hemicellulase, 10 to 25 percent of beta-dextranase, 15 to 30 percent of prolease, 5 to 15 percent of alpha-amylase and 10 to 25 percent of pure water. The multi-enzyme preparation belongs to the multi-enzyme preparation capable of effectively reducing the malt and beer turbidity, and the turbidity of partial finished products of malt is obviously higher because the varieties, the production places or the production processes of barley are different. The multi-enzyme preparation can effectively solve the problem that the turbidity of the malt is obviously higher, the contents of macromolecular substances such as beta-dextranase, xylan, protein, starch and the like are reduced, the abiological stability of the beer is improved, and the quality of products is improved.

Owner:张明 +1

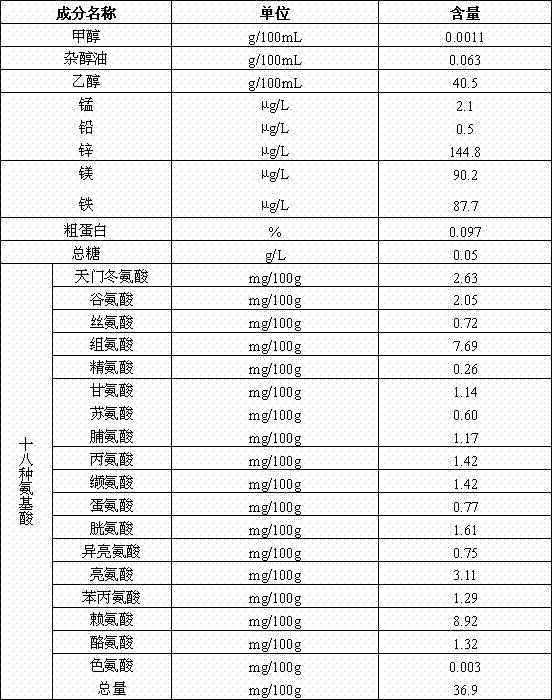

Method for manufacturing fruit ferment

The invention discloses a method for manufacturing fruit ferment. The method includes particular steps of uniformly mixing raw materials and auxiliary materials with one another in cedar barrels and then sealing openings of the cedar barrels; allowing the cedar barrels to stand still in indoor environments and primarily fermenting the raw materials and the auxiliary materials to obtain primary extracting liquid of the fruit ferment; transferring the primary extracting liquid of the fruit ferment to fermentation maturation tanks, maintaining the internal temperatures of the fermentation maturation tanks in the ranges of 35-39 DEG C for 365 days at least so as to obtain fermentation liquid of the fruit ferment; filtering the fermentation liquid of the fruit ferment to obtain the fruit ferment. The raw materials include snow pears, papayas, grapes, dragon fruits, citruses, kiwifruits, apples, pineapples, guavas, tomatoes, bananas and mangosteen, and the sum of weight percentages of the raw materials is one hundred. The auxiliary materials include refined sugar and table salt. The method has the advantages that the fruit ferment manufactured by the aid of the method contains multi-enzyme ferment, proteolytic ferment, lipolytic ferment and amylolytic ferment, further contains diversified natural vitamins, minerals, amino acid, trace elements and the like and has an excellent healthcare function for human bodies.

Owner:GUANGXI UNIV

Method for extracting diosgenin for joint production of starch suger by prehy drolysis of yellow ginger by multienzyme process

InactiveCN1528913AReduce the amount requiredAcid hydrolysis is sufficientSteroidsFermentationAmylaseFiltration membrane

The invention provides a saponin extracting method with multi-enzyme hydrolytic which hydrolyses brown Windsor in advance and produce starch sugar. The method cleans the brown Windsor and grinds it into pulp, then adds in alpha starch enzyme to be liquefied, adds in saccharifying enzyme, heats and carries on deactivation, then the saccharified materials are separated centrifugally, gets the filtered cake and starch sugar liquiud, the sugar liquid is separated with hyperfiltration membrane with 1000-10000daltons aperture catching molecular weight or tiny filtration membrane of 100-200nm and gets the starch sugar liquid, the filter residues are mixed into centrifugated filter cake and gets sugar residue, adds in chlorhydric acid or sulfuric acid to hydrolyse the sugar residue, the hydrolysed product is filtered, cleaned, and dried, extracted by solvent, finally gets the saponin product.

Owner:TAIGU INVESTMENT WUHAN

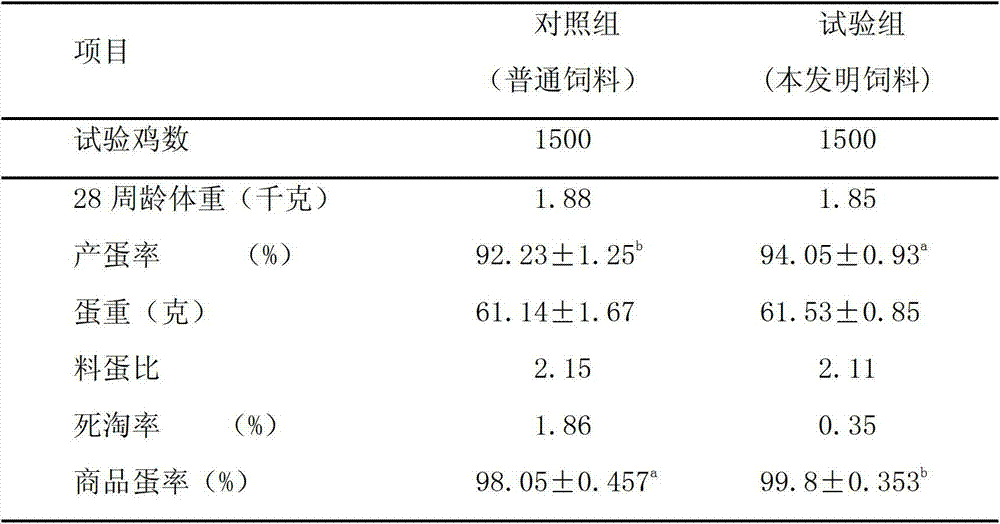

Brood period feed for laying hen

ActiveCN101965917AImprove immunityAnimal feeding stuffAccessory food factorsNosiheptideSodium bicarbonate

The invention discloses a brood period feed for a laying hen. The brood period feed for the laying hen comprises the following components in part by weight: 250 to 320 parts of calcium hydrogen phosphate, 250 to 300 parts of mountain flour, 40 to 60 parts of salt, 20 to 40 parts of sodium bicarbonate, 12 to 20 parts of choline, 30 to 40 parts of trace element composite, 8 to 10 parts of multivitamin, 1 to 3 parts of vitamin C, 25 to 30 parts of methionine, 25 to 40 parts of lysine, 50 to 100 parts of fish meal, 40 to 270 parts of zeolite powder, 1 to 3 parts of nosiheptide, 1 to 3 parts of robenidine, 2 to 5 parts of phytase and 2 to 4 parts of multi-enzyme preparation. The feed of the invention is obtained after years of practice; and a nutritive additive and the like are added into the feed, so that the produced brood period feed can obviously enhance the immunity of the laying hen in a brood period, and make the weight and the phalanx length of the laying hen standard at the end of the brood period.

Owner:荆州市和美华生物科技有限公司

High-efficiency, low-foam and bacteriostasis type multi-enzyme detergent and preparation technology thereof

InactiveCN106544164AInhibit hyperplasiaGood antibacterial effectInorganic/elemental detergent compounding agentsOrganic detergent compounding agentsAmylaseCleansing Agents

The invention discloses a high-efficiency, low-foam and bacteriostasis type multi-enzyme detergent. The multi-enzyme detergent comprises, by mass, 5-10% of protease, 1-5% of amylase, 1-5% of lipase, 20-30% of a non-foaming or low-foaming surfactant, 5-10% of a washing assistant, 1-10% of a solubiliser, 1-5% of an enzyme stabilizer, 0.05-0.25% of an antifoaming agent, 1-10% of triethanolamine, 0.5-1.5% of an antibacterial agent, and the balance of purified water. The invention also discloses a preparation technology of the multi-enzyme detergent. The enzyme stabilizer, the solubiliser, the non-foaming or low-foaming surfactant, the protease, the amylase, the lipase, the antifoaming agent, the washing assistant, the antibacterial agent, the triethanolamine and the balance of purified are sequentially added. The multi-enzyme detergent is a concentrated detergent, has the advantages of good safety, high efficiency, simplicity in use, easiness in biodegradation, low foaming and obvious antibacterial effect, and can be widely applied to cleaning and bacteriostasis of endoscopes, surgical appliances, pipelines, medical plastics and other various medical devices.

Owner:GUANGZHOU RAINHOME PHARM&TECH CO LTD

Fish meal free low-protein ration feed during egg laying period of laying hen

InactiveCN102178085ARich in nutrientsImprove digestion utilizationAnimal feeding stuffAccessory food factorsAnimal sciencePhytase

The invention discloses a fish meal free low-protein ration feed during an egg laying period of a laying hen, comprising the raw materials in part by weight: 80-120 parts of calcium hydrogen phosphate, 260-320 parts of limestone powder, 40-60 parts of common salt, 15-20 parts of choline, 35-40 parts of complex trace element, 8-10 parts of complex vitamin, 10-15 parts of lysine, 18-30 parts of methionine, 100-200 parts of corn protein powder, 100-120 parts of meat and bone meal, 180-280 parts of medical stone, 1-3 parts of bacillus subtilis, 2-5 parts of phytase and 2-5 parts of multi-enzyme preparation. In the invention, by using the method for establishing the specification of the ration by amino acid which can be digested as well as using the corn protein powder, the imported meat and bone meal and the nutrition allocation of the system, the fish meal free low-protein feed during egg laying period of the laying hen is provided; the cost of the feed is low and the influence on the egg laying capability of the laying hen can be avoided; the breeding cost is reduced; and the dilemma that protein raw materials is in shortage is relieved.

Owner:山东和美华农牧科技股份有限公司

Method for production of fermentable sugars from biomass

InactiveUS20120115192A1Efficient in of enzyme costEffective timeEnzymesFermentationNatural sourceFermentable sugar

A process for production of fermentable sugars from biomass using multi-enzyme multi-step system is provided herein. The process disclosed in the present invention provides high yielded sugars in less time period. The multi-enzyme system disclosed in the present invention converts celluloses, hemicelluloses and / or mixture thereof to fermentable sugar with higher efficiency and better economics than the process known in the prior art. Cellulose and hemicelluloses fractions derived from natural sources such as any lignocellulosic biomass are saccharified in a shortened time with higher conversion rates of intermediates with modified enzymatic compositions / groups of the Multi-enzyme system to enhance the rate thus providing an economical cellulose and hemicellulose saccharification process.

Owner:CHEM ENG DEPT INST OF CHEM TECH DEEMED UNIV

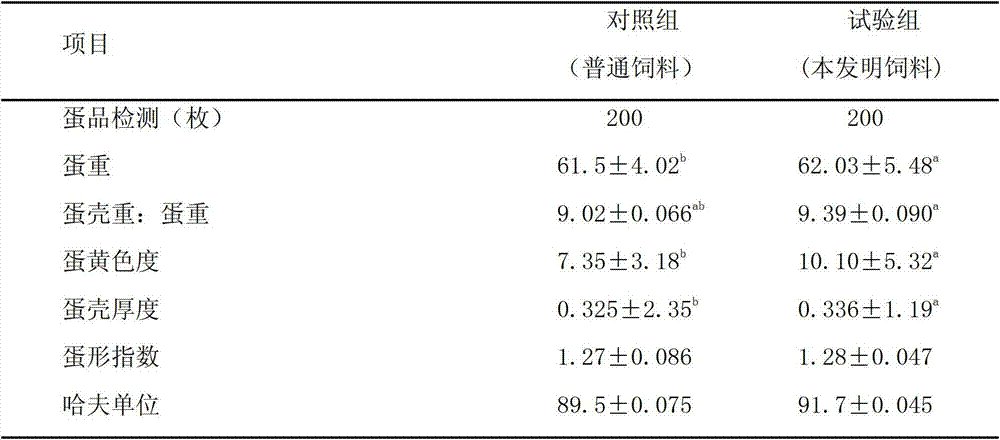

Wheat daily ration feed for promoting yolk pigmentation of laying hen

The invention discloses a wheat daily ration feed for promoting yolk pigmentation of a laying hen. The feed comprises the following materials in parts by weight of: 50-65 parts of wheat, 8-15 parts of bean pulp, 3-9 parts of chrysanthemum meal, 1-5 parts of corn gluten meal, 1-3 parts of bentonite, 5-10 parts of corn DDGS, 1-3 parts of corn oil, 1-6 parts of cottonseed meal, 5-10 parts of mountain flour, 0.5-1.5 parts of calcium hydrophosphate, 0.2-0.4 part of salt, 0.05-0.1 part of probiotics, 0.3-0.8 part of synthetic amino acid, 0.02-0.05 part of glycine betaine, 0.05-0.1 part of choline chloride, 0.04-0.08 part of a multi-enzyme preparation, 0.6-1 part of a compound premix, and 0.01-0.03 part of 50% of vitamin E. The chrysanthemum meal and combined nutrition of the chrysanthemum meal are added to the feed at the egg production period for improving the health state of the intestinal tract of the laying hen; the yolk pigmentation effect is obviously improved; the egg feed cost is reduced; and the egg producing performance of the laying hen is improved.

Owner:LIAONING WELLHOPE AGRI TECH

Method for preparing Rui chang yam white wine

InactiveCN102816670AImprove wine qualityHigh yieldAlcoholic beverage preparationMicroorganism based processesFlavorDistillation

The invention discloses a method for preparing Rui chang yam white wine. The method includes taking dried Rui chang yam as a main wine stock, not adding or adding rice according to a ratio, crushing and refining the mixture, performing high temperature cooking, adding compound bran koji, using compound yeast wine, mixing the mixture according to a ratio of 2:1:2, using a multi-strain and multi-enzyme solid state saccharifying fermentation technology, performing solid state fermentation and solid state distillation to obtain the Rui chang yam white wine which is 30 V% to 60 V% fragrant and mellow and good in quality. The mouth mellow taste of white wine is improved, and defects that the good and the bad are intermingled in flora of traditional wine yeast, the wine yield is low and the wineforeign flavor is heavy are overcome. According to the Rui chang yam white wine prepared by the method, the taste of special mouth sticking and lingering and unique fragrance and special flavors of the Rui chang yam white wine are added on the basis that special flavors of traditional white wine are guaranteed, unique effects of invigorating spleen and supplementing qi and benefiting kidney and solidifying vitality are provided if the Rui chang yam white wine is taken frequently, and a good way is provided for the current Rui chang yam industry.

Owner:付桂明 +4

Method for brewing oil-tea wine by using bio-enzymes

ActiveCN103981054ARaw materials are uniqueWith aromaMicroorganism based processesAlcoholic beverage preparationCamellia oleiferaDecomposition

The invention discloses a method for brewing an oil-tea wine by using bio-enzymes. The method comprises the following steps: (1) cleaning and impurity removal; (2) crushing and sieving; (3) mixing; (4) high-temperature enzyme deactivation; (5) multi-enzyme decomposition; (6) carbohydrate supplementation; (7) fermentation; (8) distillation; and (9) aging and packaging. The method disclosed by the invention is simple in process, less in investment, low in energy consumption, and easy to operate. The oil-tea wine prepared by using the method is bright and transparent, mellow and exquisite in taste and typical in style, and has no suspended matters and precipitates.

Owner:HUNAN ACAD OF FORESTRY

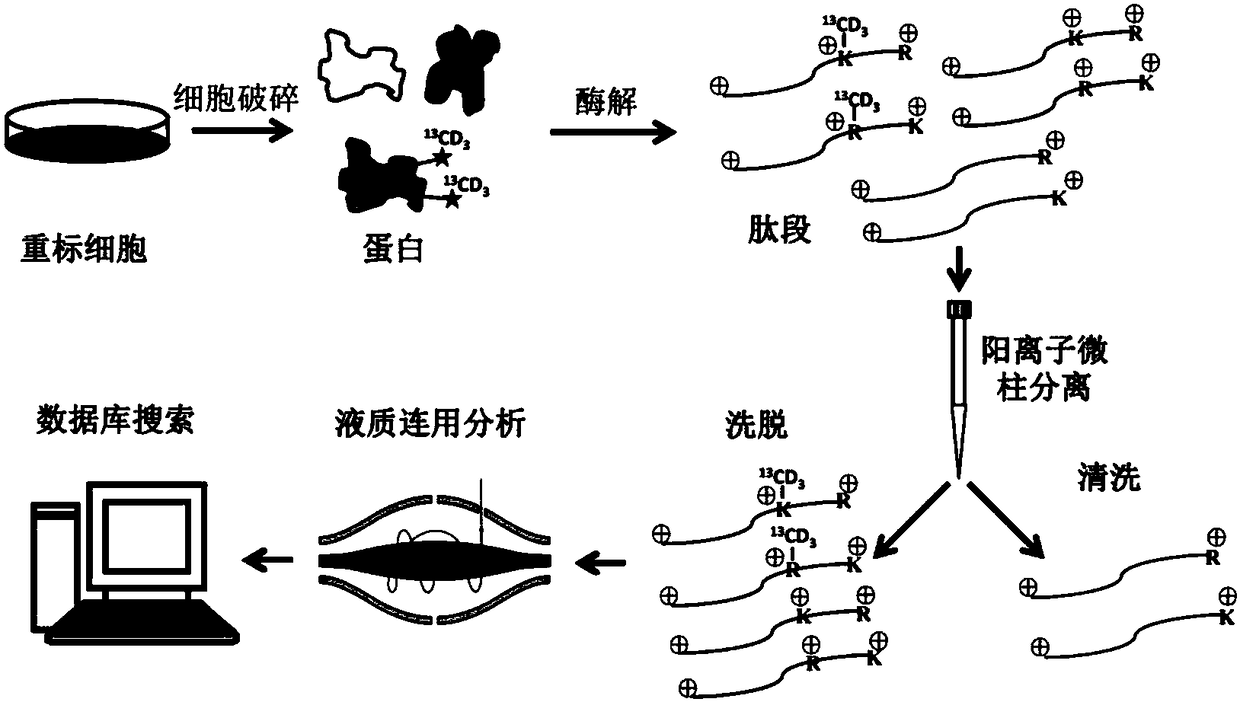

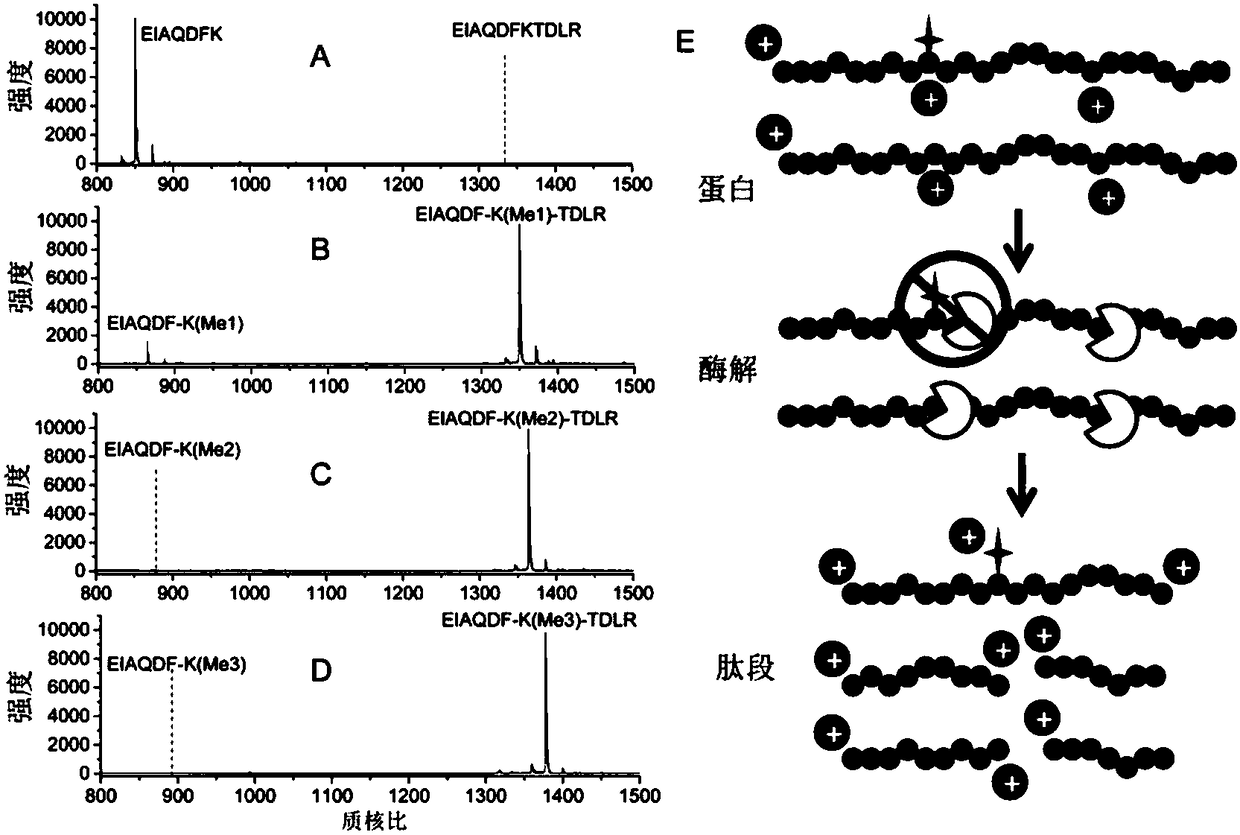

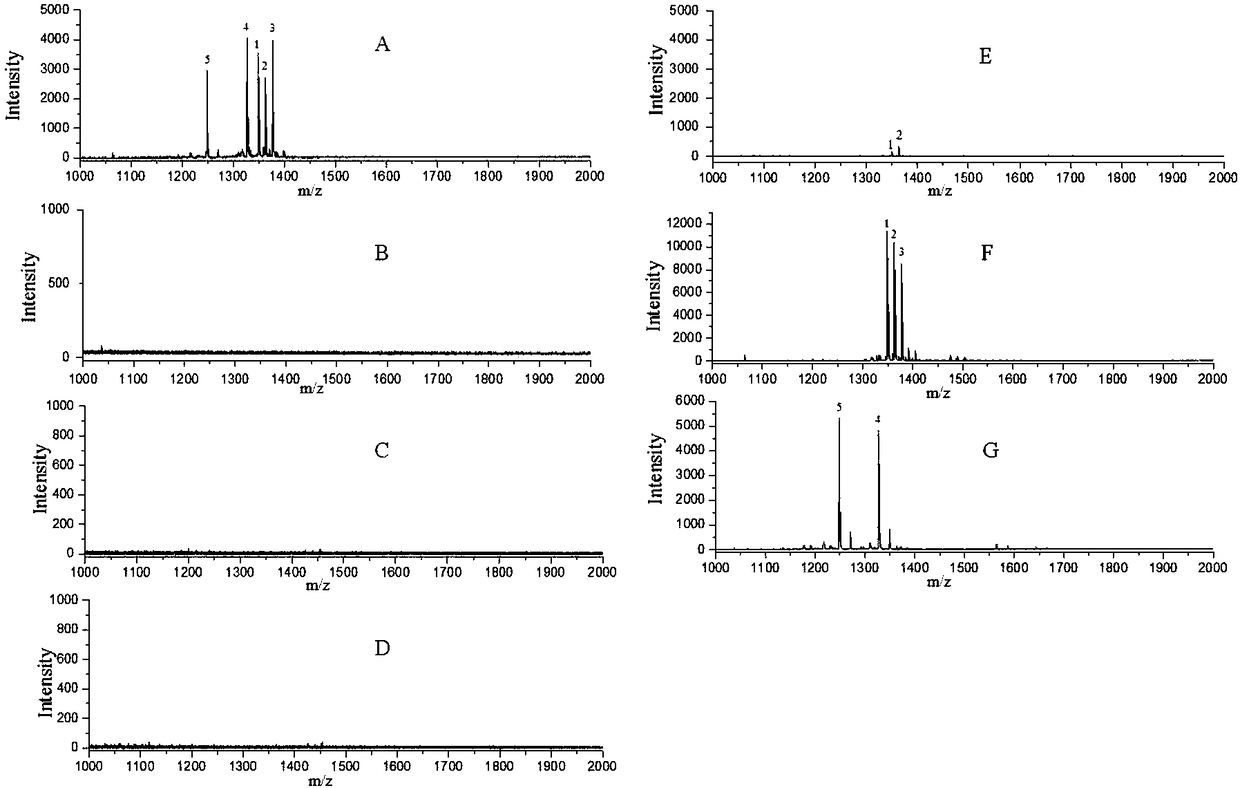

Analytic treatment method for protein methylation and application thereof

InactiveCN108072555AComponent separationPreparing sample for investigationArginineProtein methylation

The invention relates to an analytic treatment method for protein methylation. By utilization of the characteristic that lysine and arginine modified by methylation can inhibit digestion of trypsin, the invention develops a sample treatment method integrating heavy methyl stable isotope labeling by amino acids in cell culture (hM-SILAC), multi-enzyme digestion and separation of strong cation exchange microcolumn (SCXtip), and applies the sample treatment method to large-scale analysis of methylated proteome. The analytic treatment method has the beneficial effects that by combination with a multi-enzyme digestion strategy, the missed digestion sites of non-methylated sources are effectively reduced; by the separation strategy of the strong cation exchange chromatography with high pH range,the interference of peptide fragments containing histidine is effectively overcome, so that the separation specificity of methylated peptide fragments is greatly improved.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

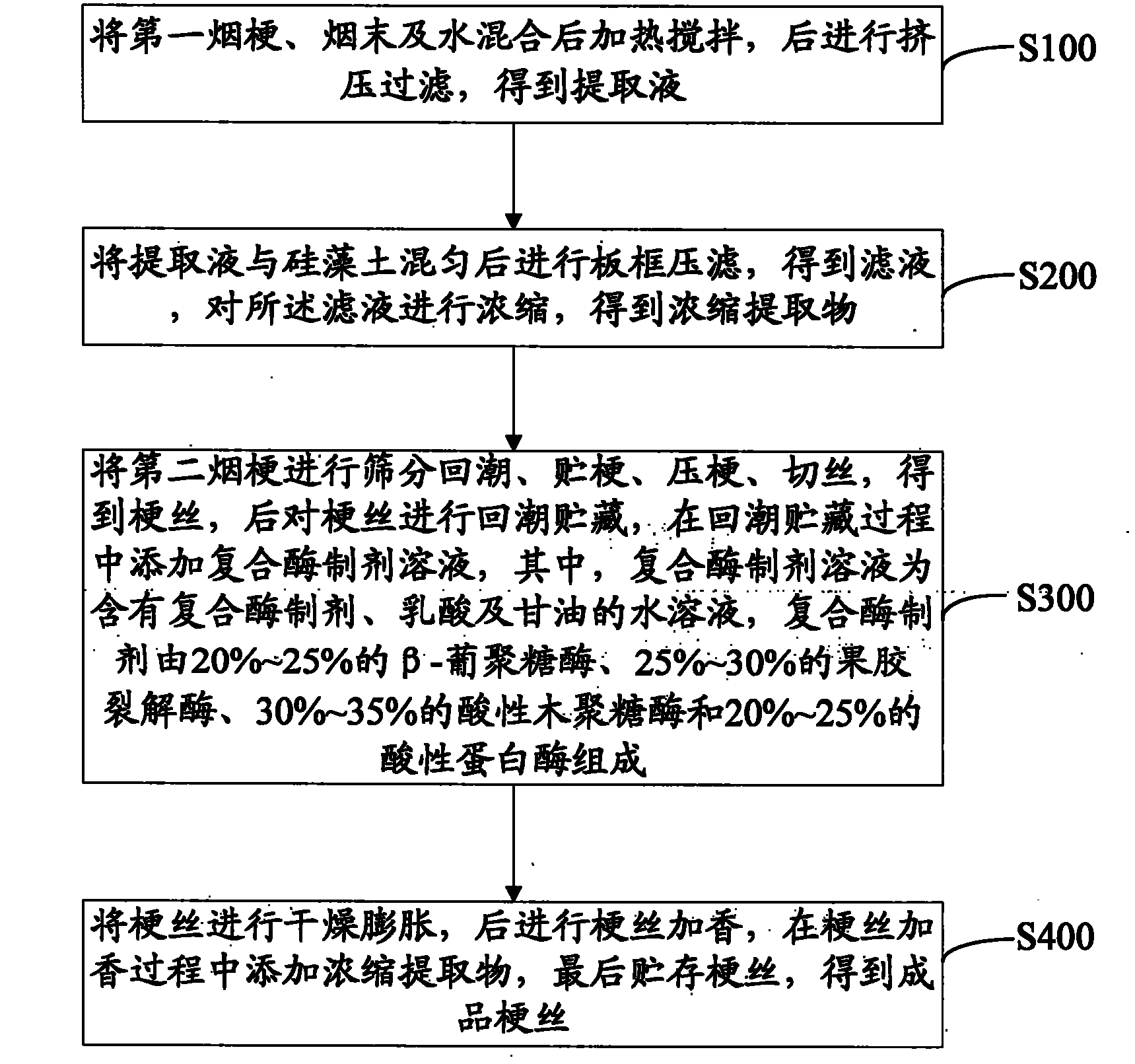

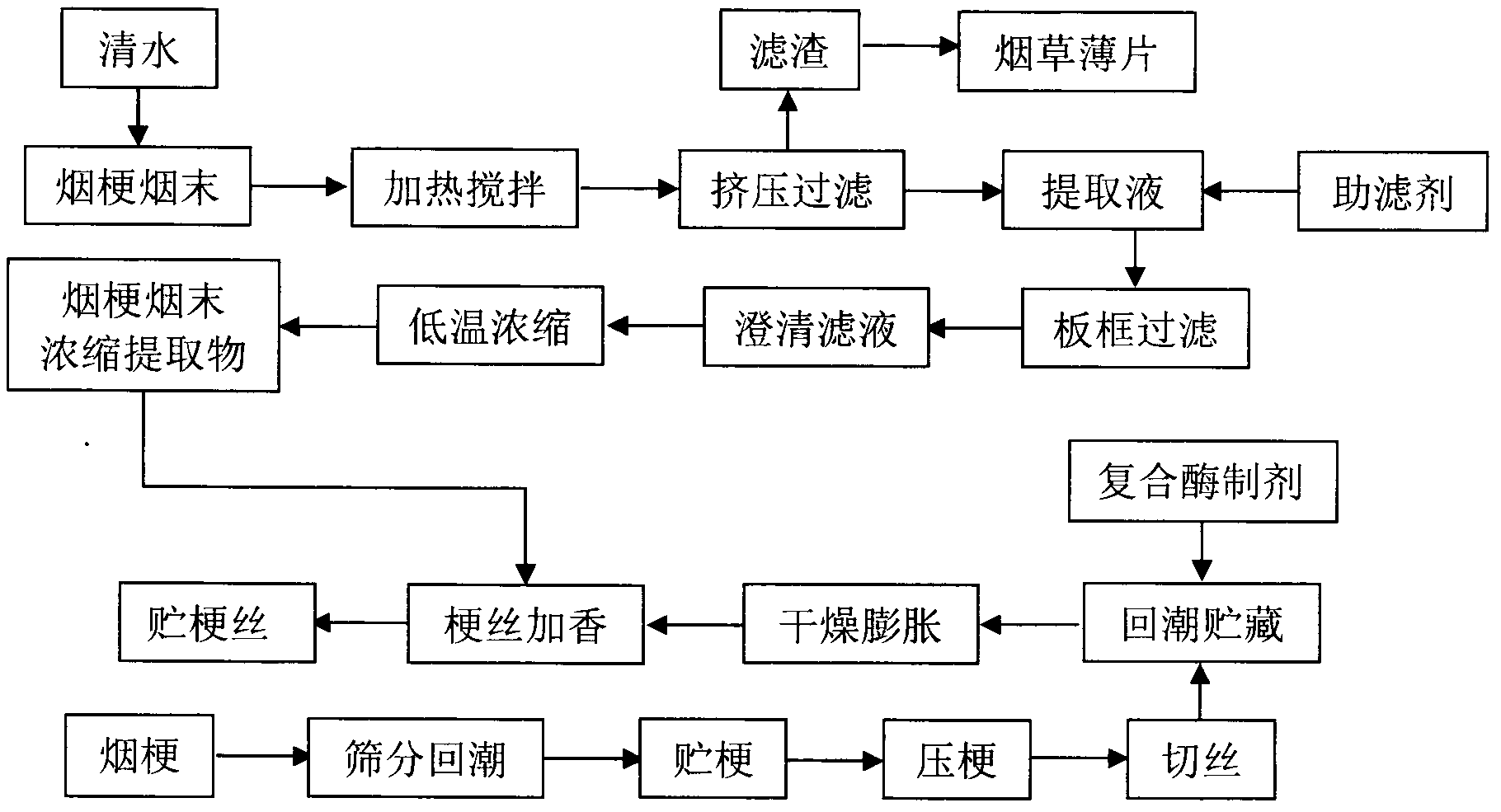

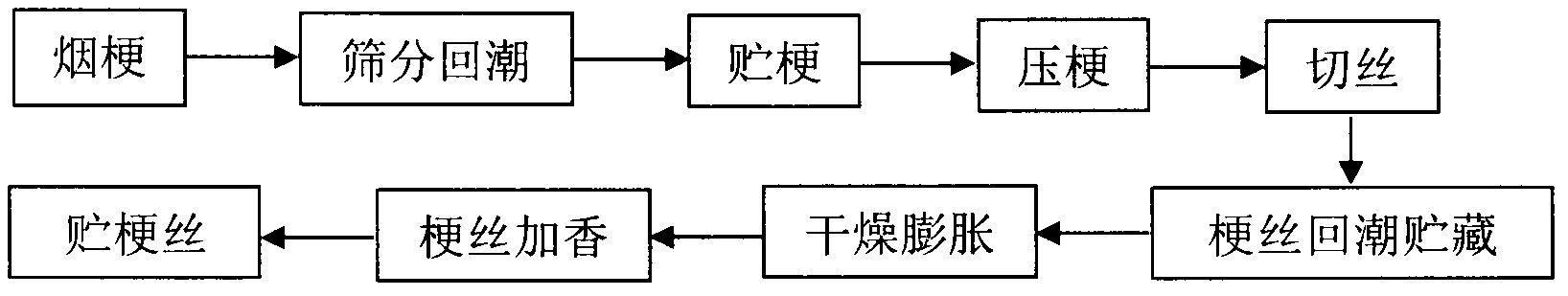

Production technology of reconstituted cut stems

InactiveCN103284315AReduce contentIncrease aroma substancesTobacco preparationTobacco treatmentMoisture regainConcentrated extract

The invention provides a production technology of reconstituted cut stems. The production technology includes the following steps that a first tobacco stem, tobacco smalls and water are mixed and then heated and stirred, then squeezing and filtering are performed, and extracting solution is obtained; after the extracting solution is evenly mixed with diatomite, plate-frame press filtering is performed, filtrate is obtained and concentrated, and concentrated extract is obtained; screening moisture regain, storage, pressing and cutting are performed on a second tobacco stem, the cut stems are obtained, then moisture regain storage is performed on the cut stems, and multi-enzyme preparation solution is added in the process of the moisture regain storage; the cut stems are dried, expanded and then perfumed, the concentrated extract is added in the process of the cut stem perfuming, finally, the cut stems are stored, and the finished cut stems are obtained. Through the production technology of the reconstituted cut stems, the defects that in the process of smoking the cut stems, fragrance is not sufficient, smoking taste is ordinary, impact is small, and pungent smell and wood offensive odor are strong are solved, and finally, the proportion of the cut stems in cigarette raw material is increased.

Owner:SUZHOU KUNLAN BIOTECH

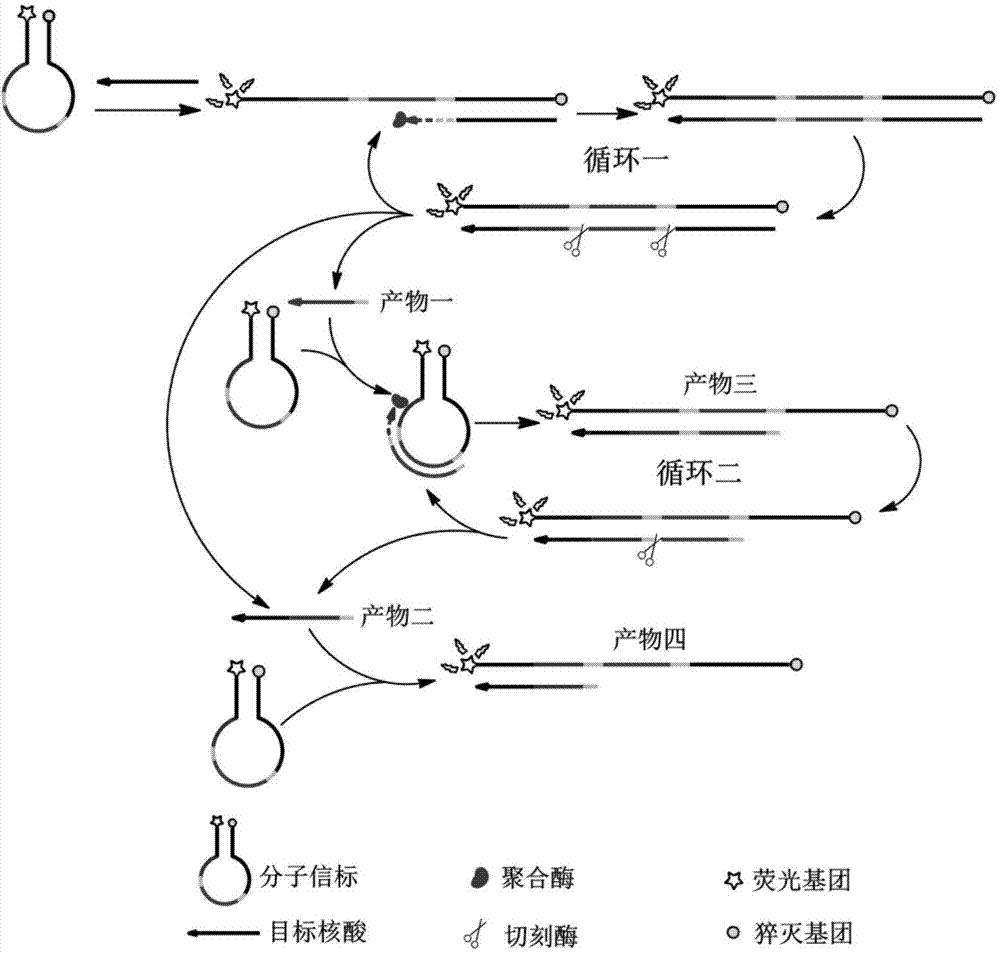

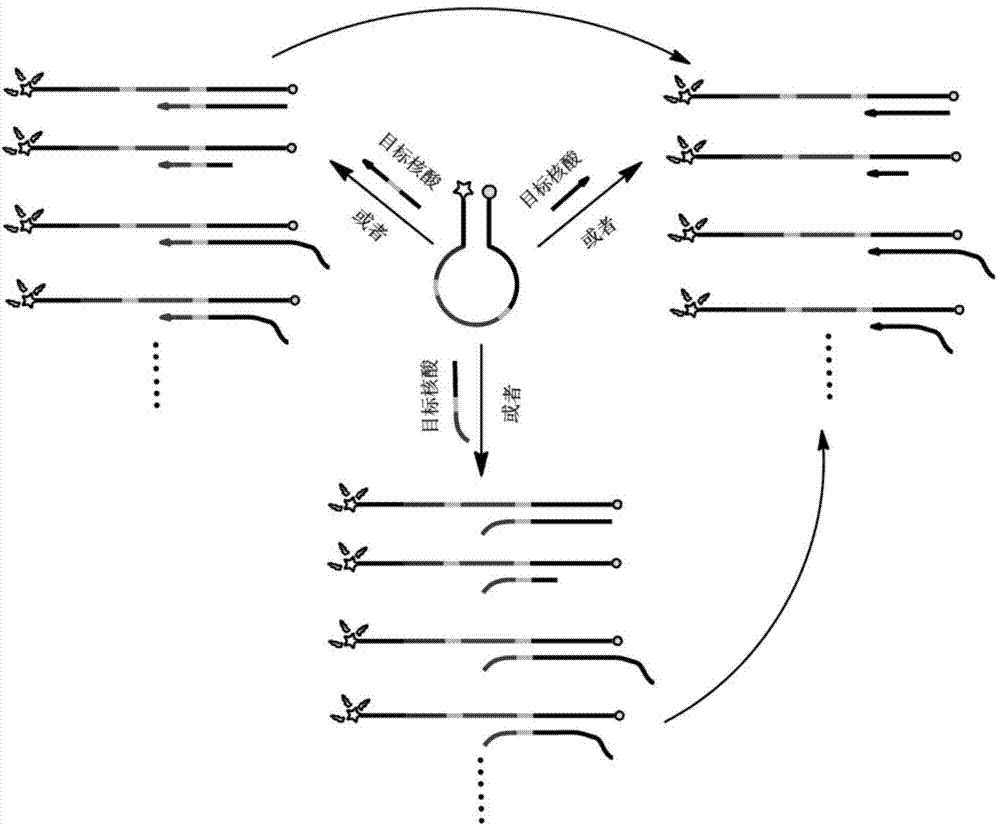

Multi-enzyme cleavage site mediated nucleic acid isothermal amplification detecting method

ActiveCN103571962ASimple structureAvoid mutual interferenceMicrobiological testing/measurementNucleic acid detectionPolymerase L

The invention belongs to the technical field of molecular biology nucleic acid detection, and relates to a multi-enzyme cleavage site mediated nucleic acid isothermal amplification detecting method. Firstly, specific hybridization is conducted on a target nucleic acid and template nucleic acid molecules through base complementary pairing effect; polymerase and cutting enzyme are cooperatively and circularly amplified to continuously generate products 1 and products 2; the products 1 and template nucleic acid are combined for circular amplifying to continuously generate the products 2; finally, the generated products 2 are hybridized with the template nucleic acid to generate signals, and the generated signals are detected under the condition of constant temperature to achieve the detection of nucleic acid isothermal amplification. The detecting method has the advantages of simple detecting technique, quick reaction, short detecting time, high sensitivity and wide application range.

Owner:QINGDAO NAVID BIOTECH CO LTD

Garlic protein zymolysis serial product and its preparation method and use

InactiveCN1579538ALower blood pressureImprove immunityPeptide/protein ingredientsCardiovascular disorderUltrafiltrationFiltration

The invention relates to development application field of plant protein, it uses the residue containing garlic protein after the garlic oil and garlic elements are eliminated, adds in protease and hydrolyzes with enzyme, then it is processed into proteolysis substance which is rich in active peptide. The invention uses single-enzyme hydrolysis and multi-enzyme hydrolysis, the protein enzyme in the garlic residue can be decomposed into active multi-peptide and amino acid substances with 2-10 peptides. The manufacturing method of the enzymolysis liquid includes: garlic dredge crashing, enzymolysis, eccentricity, enzyme eliminating, filtering, superfilter, and acquires the zymolyte. The zymolyte can be processed into different solutions or powder preparations with the post process. The product can reduce the blood pressure of the sufferer through the restraining effect of to blood vessel tension element I conversion enzyme, at the same time, it can upgrade the immunity, regulate the blood fat, and has functions of anti-aged.

Owner:JIANGSU UNIV

Porket feed and processing method

ActiveCN101991010ALow costAvoid wastingAnimal feeding stuffAccessory food factorsFeed conversion ratioAdditive ingredient

The invention relates to porket feed and a processing method. The feed comprises the following various ingredients in percentage by weight: 62.75 percent of corn, 18.5 percent of bean dregs, 3.77 percent of extruded soybeans, 2 percent of plasma protein flour, 2.5 percent of whey mist, 2.5 percent of lactose, 3 percent of bean oil, 1.0 percent of stone dust, 1.3 percent of calcium hydrophosphate,0.25 percent of common salt, 0.4 percent of lysine, 0.04 percent of methionine, 0.09 percent of threonine, 0.2 percent of multi-enzyme preparations, 0.1 percent of acidulants, 0.05 percent of prebiotics and 2.0 percent of premixed materials. The processing method comprises the following steps of: crushing and / or grinding all ingredients in the feed; then, adding all the raw materials into a stirring machine and stirring; finally, bagging and packing the stirred feed. The conversion rate of the feed, the stability quality of the feed and the miscellaneous meal type protein consumption can be improved through the adoption of additives, and therefore, the cost of the feed is reduced, and the porket growth expression can also be maintained or improved.

Owner:HENAN MUHE GROUP FEED

Multi-enzyme instant silicon fertilizer and manufacturing method thereof

The invention provides a multi-enzyme instant silicon fertilizer and a manufacturing method thereof. The multi-enzyme instant silicon fertilizer comprises 85% of a multielement silicon fertilizer (80% of liquid sodium silicate; 8% of humic acid; 7% of fulvic acid and 5% of ethylene diamine tetraacetic acid (EDTA), 4% of plant activating enzyme, 3% of 6-butyl acrylate (BA), 2% of bacillus subtilis, 2% of bacillus cereus, 2% of indoleacetic acid and 2% of a- naphthylacetic acid. The manufacturing method includes 1 manufacturing the multielement silicon fertilizer, chelating the liquid sodium silicate, the humic acid, the fulvic acid and the EDTA, putting a chelated product in a high-speed centrifugal machine to perform dehydration, and drying the chelated product by using spraying hot air to obtain the multielement silicon fertilizer; and 2 enabling the 85% of multielement silicon fertilizer, the 4% of plant activating enzyme, the 3% of 6- BA, the 2% of bacillus subtilis, the 2% of bacillus cereus, the 2% of indoleacetic acid and the 2% of a- naphthylacetic acid to be mixed evenly and packaged to obtain the multi-enzyme instant silicon fertilizer.

Owner:丁剑兰

Compound medical equipment multi-enzyme cleaning agent

InactiveCN103834481AReduce the presence of air bubblesImprove visibilityNon-ionic surface-active compoundsOrganic detergent compounding agentsMedical equipmentMegasonic cleaning

The invention relates to a compound medical equipment multi-enzyme cleaning agent, belonging to the technical field of fine chemistry. The compound medical equipment multi-enzyme cleaning agent is characterized by comprising the following components in percentage by mass: (A) 0.5-1.2% of bio-enzyme component; (B) 5-15% of washing auxiliary; (C) 3-7% of surfactant component; (D) 3-10% of foam inhibitor component; (E) 0.05-0.3% of antibacterial component; (F) 0.005%-0.01% of pigment component; (G) 0.001-0.003% of perfume component; (H) the balance of solvent component. The compound medical equipment multi-enzyme cleaning agent provided by the invention is green transparent neutral liquid with a light orange flavor, has the advantages of no environmental pollution, few bubbles generated in use, no corrosion to equipment and the like, and is suitable for cleaning the medical equipment made from the materials such as stainless steel, aluminum, plastics and the like by manual operation, spray and ultrasonic cleaning machines.

Owner:BEI JING BAI XIANG NEW TECH

Multi-enzyme complex capsule

InactiveCN1376519ASimple preparation processLow costPeptide/protein ingredientsDigestive systemIntestinal structureMicrobiology

A complex multi-enzyme capsule is composed of dissolved-in-stomach capsule and dissolved-in-intestine capsule. Said dissolved-in-stomach capsule contains the enzyme playing its role in stomach or themixture of said enzyme and auxiliary. Said dissolved-in-intestine capsule contains the enzyme playing it role in intestine or the mixture of said enzyme and auxiliary. Its advantages are high enzyme activity and stability and simple preparing process.

Owner:北京华方科泰医药有限公司

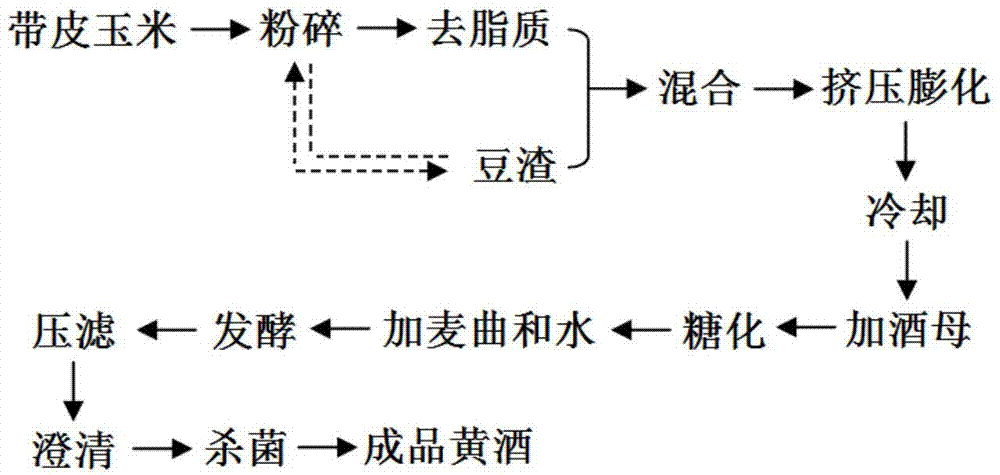

Method for brewing yellow wine rich in soluble dietary fiber

The invention discloses a method for brewing yellow wine rich in soluble dietary fiber. The method comprises the following steps: removing or not removing lipids of corn with husks, carrying out enzymatic or non-enzymatic extrusion swelling treatment on the corn together with bean dregs, and then fermenting and brewing yellow wine. The method disclosed by the invention, by creatively carrying out enzymatic or non-enzymatic extrusion treatment on the mixture of the corn with husks and the bean dregs and by combining with a multi-enzyme system yellow wine fermenting technology, has the characteristics that the product has high yield, good quality, low cost and rich nutrition; in addition, the method disclosed by the invention not only widens the utilization way of corn grains but also realizes the full use of by-products from the processing of such agricultural products as corn husks, bean dregs and the like, so that waste materials are recycled, and resource waste and environmental pollution are reduced.

Owner:JIANGNAN UNIV

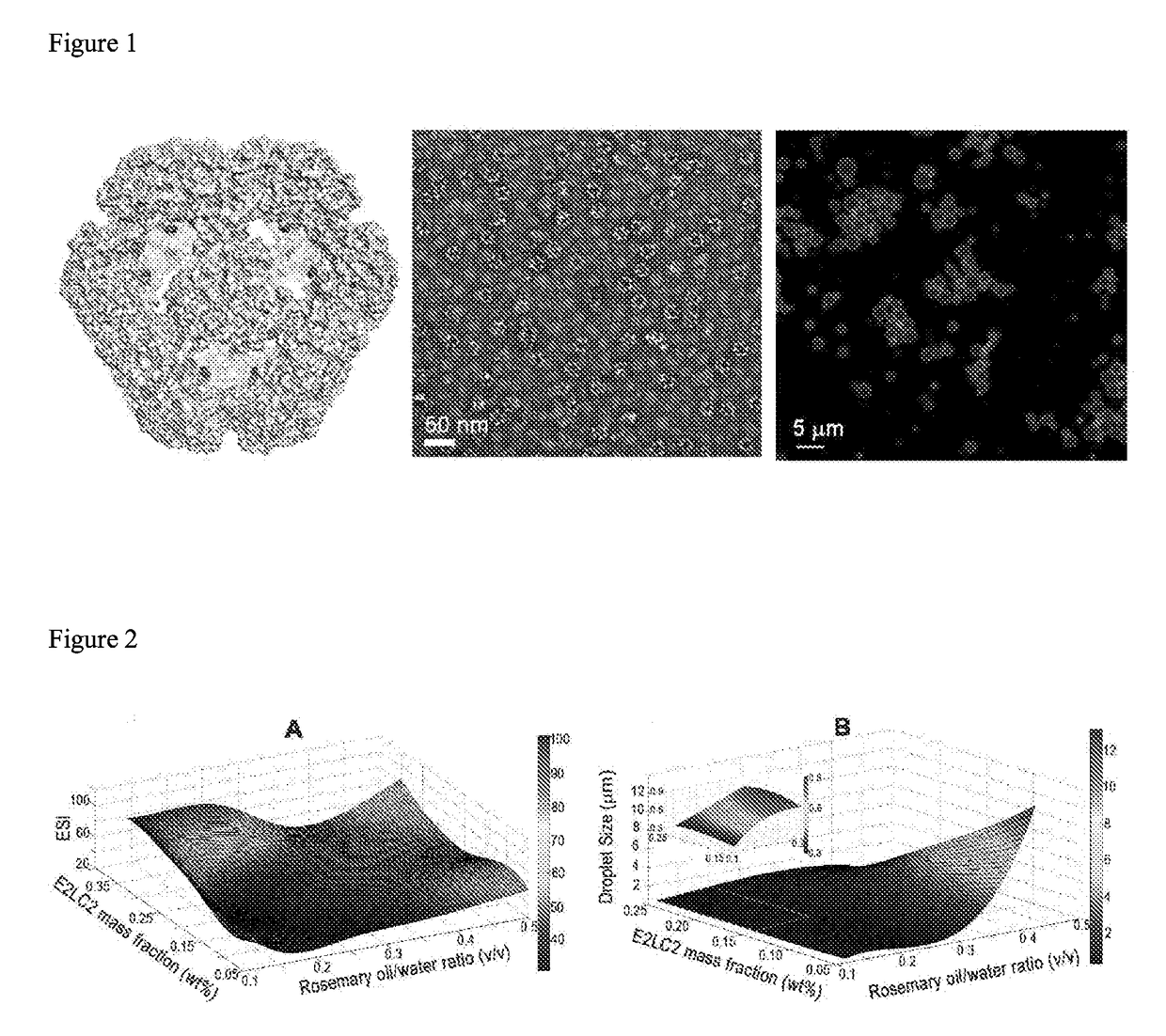

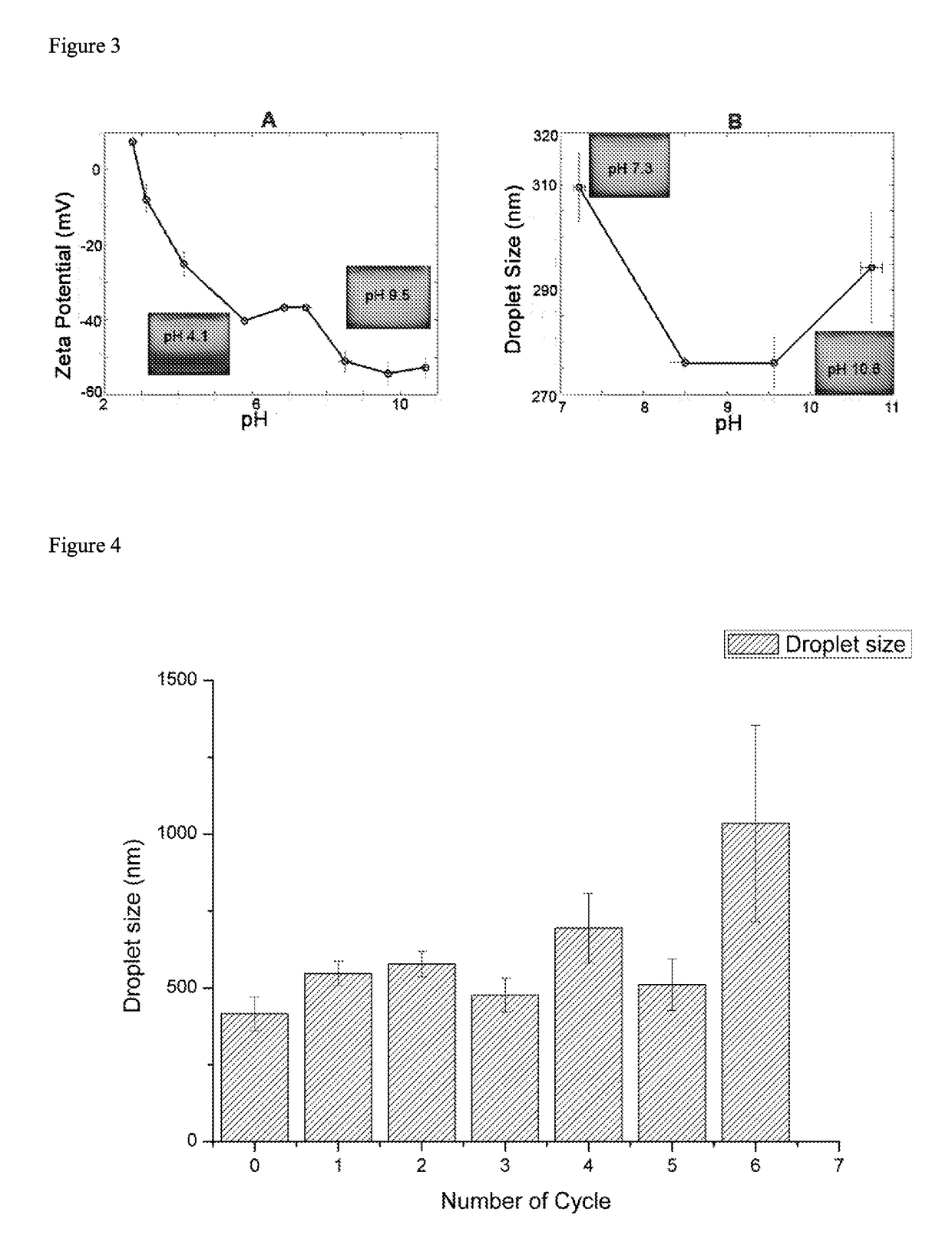

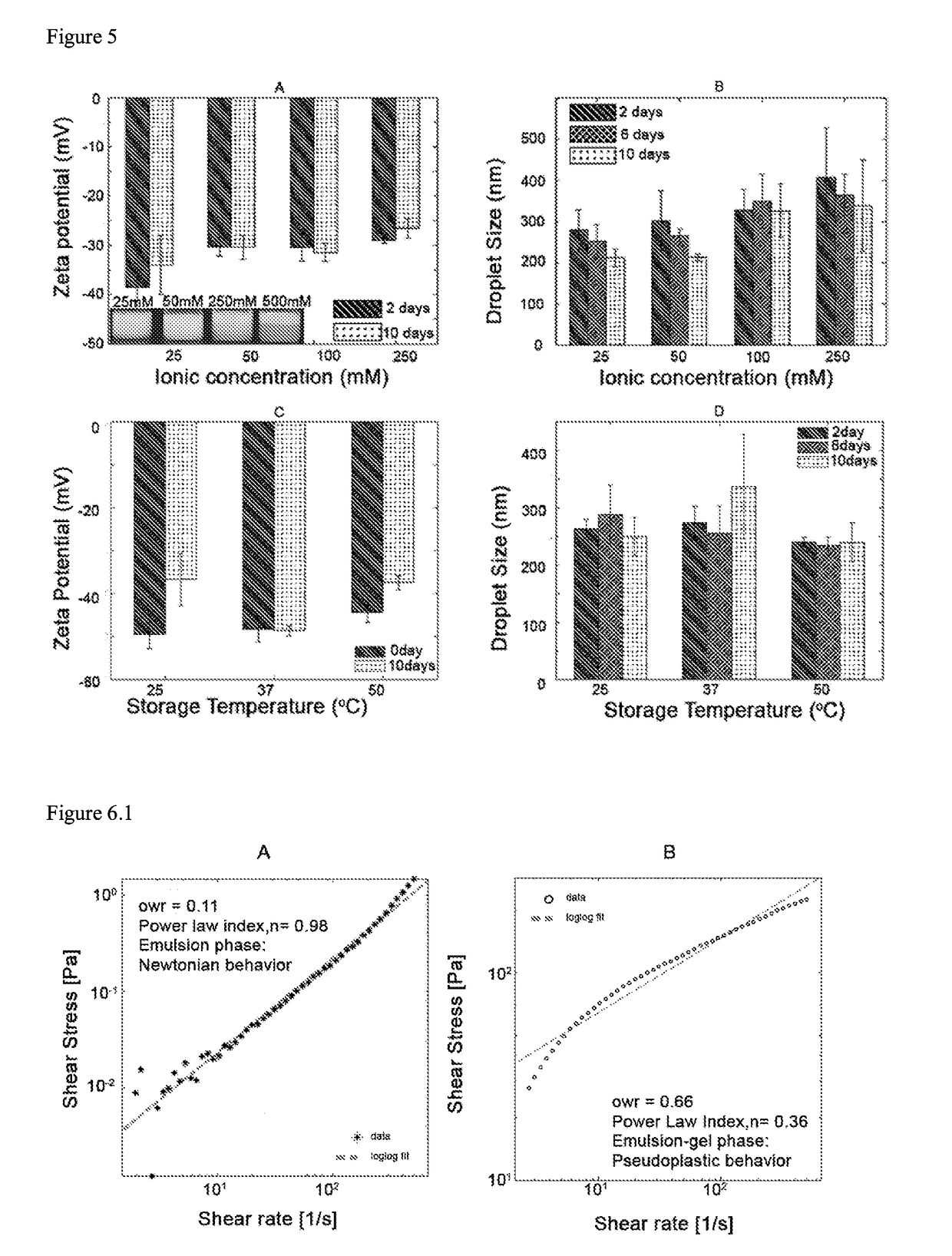

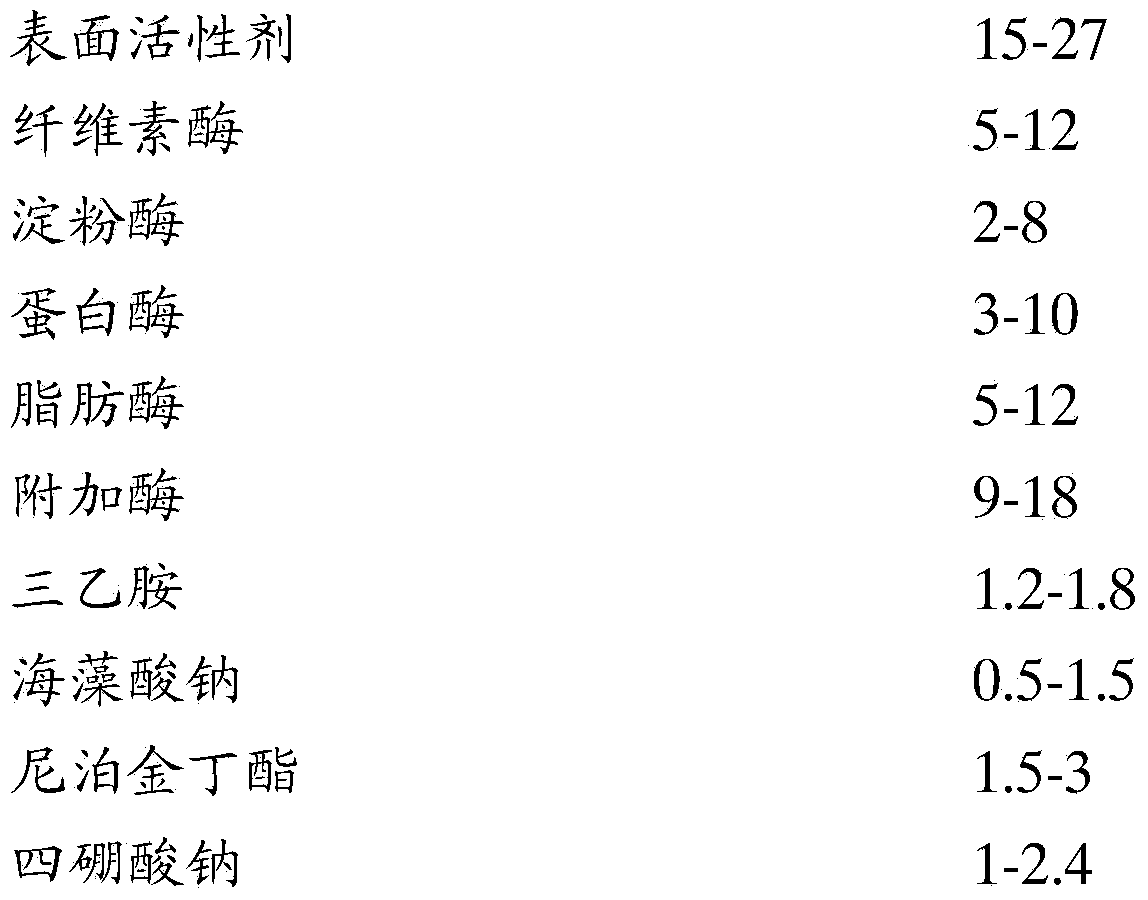

Protein cage-stabilized pickering emulsions and the use thereof

The present invention relates to a Pickering emulsion comprising an aqueous phase, an oil phase and a nanoparticle, wherein the nanoparticle is a protein cage. The protein cage is preferably a Bacillus stearothermophilus E2 protein of pyruvate hydrogenase multi-enzyme complex or an E2LC2 protein. Preferably the aqueous or oil phase of the Pickering emulsion comprises an agent, or the protein cage is coupled to or loaded with an agent, wherein the agent is a therapeutic, nutritional, nutraceutical or cosmetic agent. The invention further includes use of the Pickering emulsions disclosed herein in pharmaceutical, cosmetic, or food applications, or as a controlled release delivery system, and use of protein cages as emulsifiers in Pickering emulsions.

Owner:NANYANG TECH UNIV +1

Liquor mash preparation method based on multi-enzyme system and application of method in vinegar brewing

ActiveCN107034087AAlcohol conversion rate is highImprove conversion rateMicroorganism based processesAlcoholic beverage preparationCellulosePullulanase

The invention discloses a liquor mash preparation method based on a multi-enzyme system and application of the method in vinegar brewing. Sticky rice powder paste combines with a traditional yeast phase by utilizing multiple biological enzyme preparations such as alpha-amylase, pullulanase, saccharifying enzyme, cellulose enzyme, protease and lipase and a traditional yeast, enzymolysis is performed by adopting step-by-step adding method, and then liquor mash is prepared through alcohol fermentation. By adopting the method, raw and auxiliary material utilization rate is further improved based on liquid saccharification, the alcohol conversion rate is improved, the production cost is reduced, and meanwhile a product flavor obtained by adopting a traditional process is retained.

Owner:JIANGSU HENGSHUN VINEGAR IND

Method for cleaning and sterilizing pipe cavity type instruments

InactiveCN103624027AEasy to cleanBroad application prospectsDetergent mixture composition preparationAmpholytes/electroneutral surface-active compoundsPolyethylene glycolButylparaben

The invention provides a method for cleaning and sterilizing instruments, especially pipe cavity type instruments. According to the method, multi-enzyme cleaning fluid is used, and an excellent cleaning effect can be achieved through effective multi-step cleaning. The multi-enzyme cleaning fluid comprises a surface active agent, cellulose, amylase, protease, lipase, additional enzymes, triethylamine, sodium alga acid, butylparaben, sodium tetraborate, ethanol, polyethylene glycol, auxiliaries and water. An excellent synergistic effect is achieved through proper selection of components and proportions of the components of the multi-enzyme cleaning fluid.

Owner:QINGDAO MUNICIPAL HOSPITAL

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com