Patents

Literature

1267results about How to "Reduce the presence of air bubbles" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

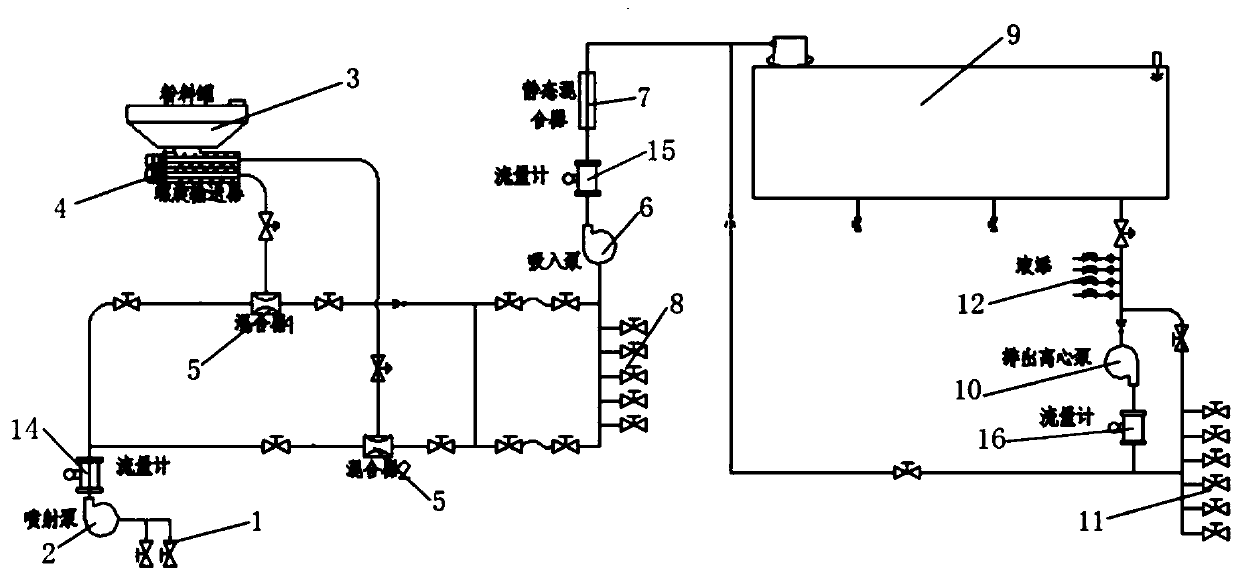

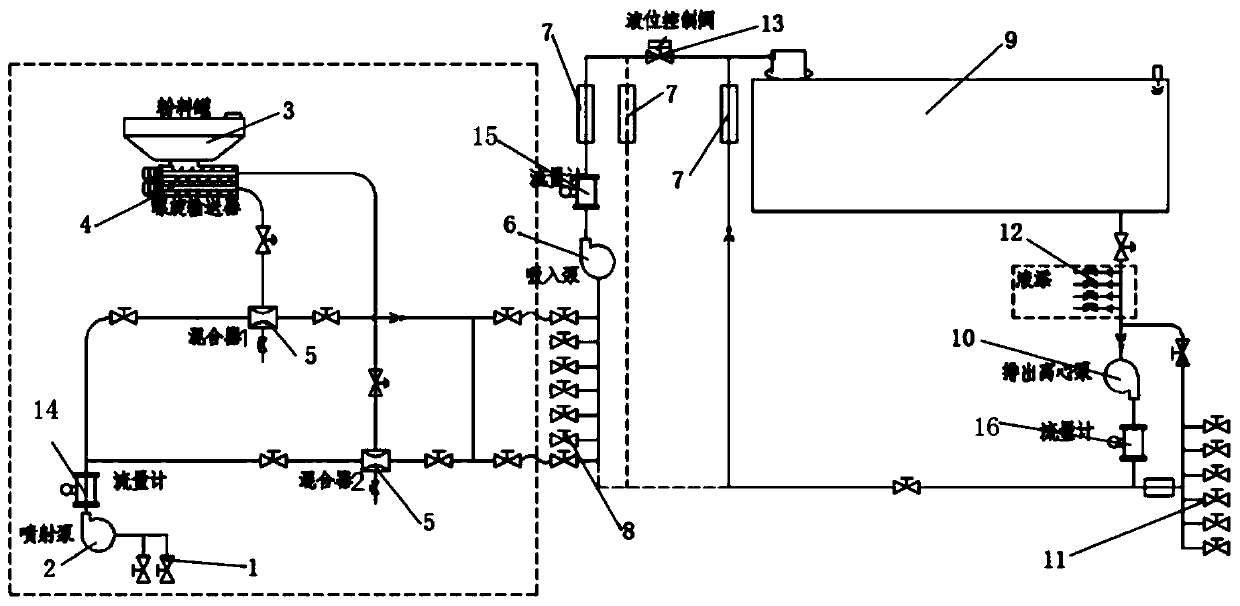

Mixing system

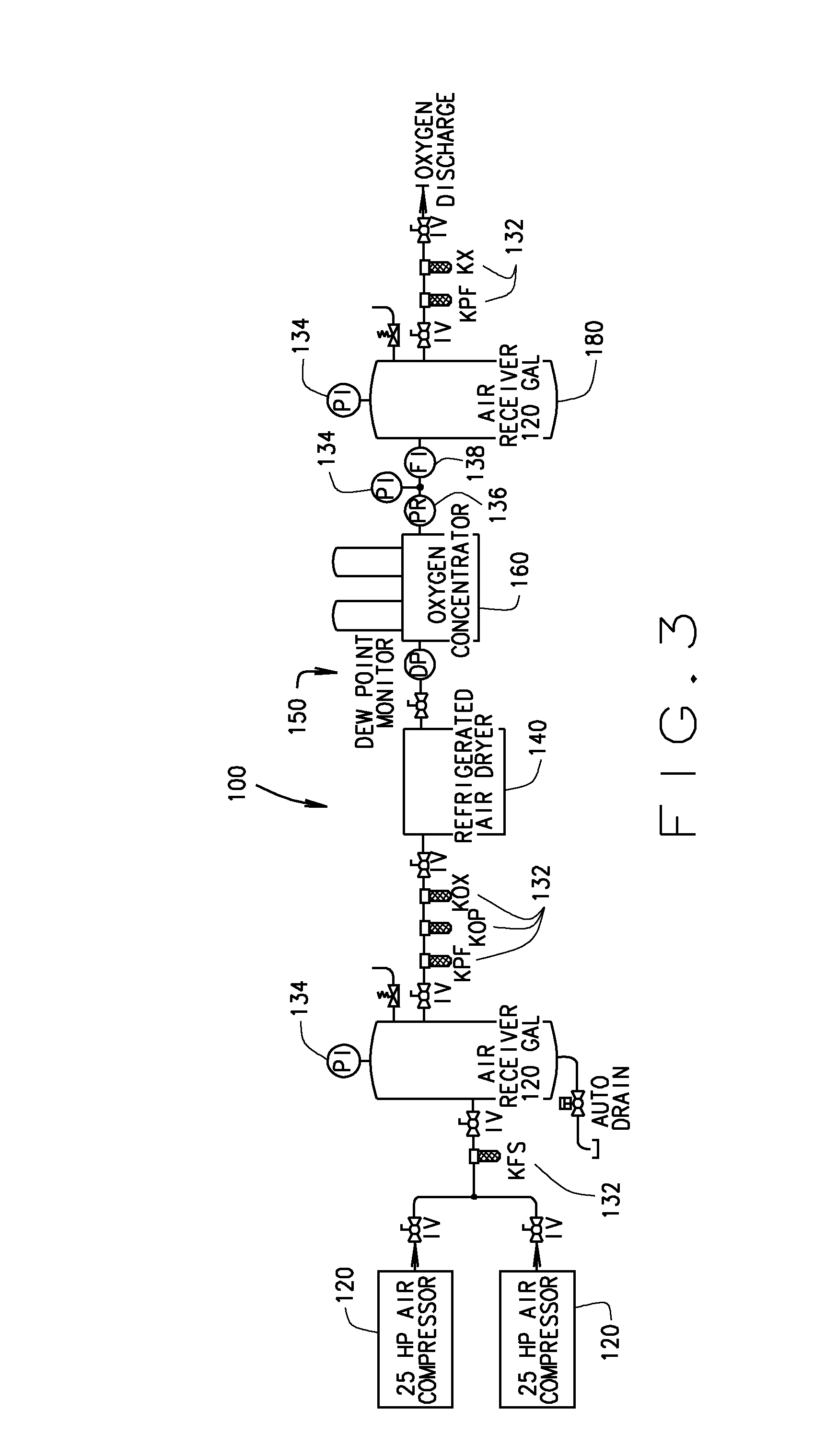

PendingCN110787667AImprove mix qualityImprove mixing efficiencyTransportation and packagingMixing methodsEngineeringStatic mixer

The invention discloses a mixing system. The mixing system comprises a mixing module and an output module, the mixing module comprises a first liquid inlet header, an injection pump, a powder tank anda mixer, the first liquid inlet header is connected with the injection pump, the injection pump is connected with the mixer, and the powder tank provides powder for the mixer; the output module comprises a second liquid inlet header, a suction pump, a second flowmeter, a static mixer, a mixing tank and a liquid discharge manifold, and the second liquid inlet header, the section pump, the second flowmeter, the static mixer, the mixing tank and the liquid discharge manifold are sequentially connected; an outlet of the mixer of the mixing module is connected with an inlet of the suction pump ofthe output module through a valve, and the mixing module and the output module can be used respectively or used in combination as a complete set. The mixing system has the beneficial effects that thesecond liquid inlet header and the static mixer are arranged, mixing with large discharge capacity and high quality can be completed with low energy consumption; and the mixing system is flexible in disassembly and assembly.

Owner:YANTAI JEREH PETROLEUM EQUIP & TECH CO LTD

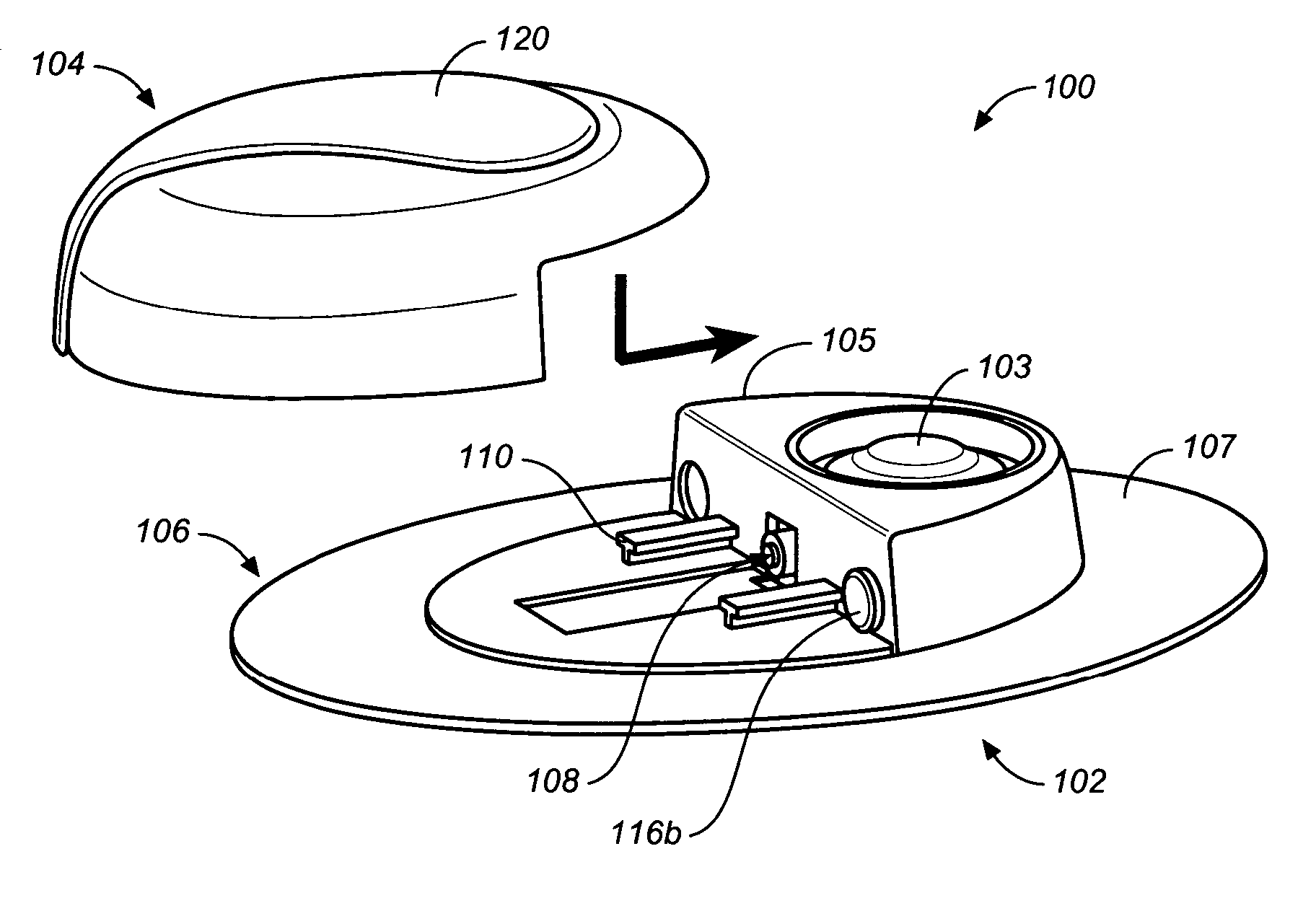

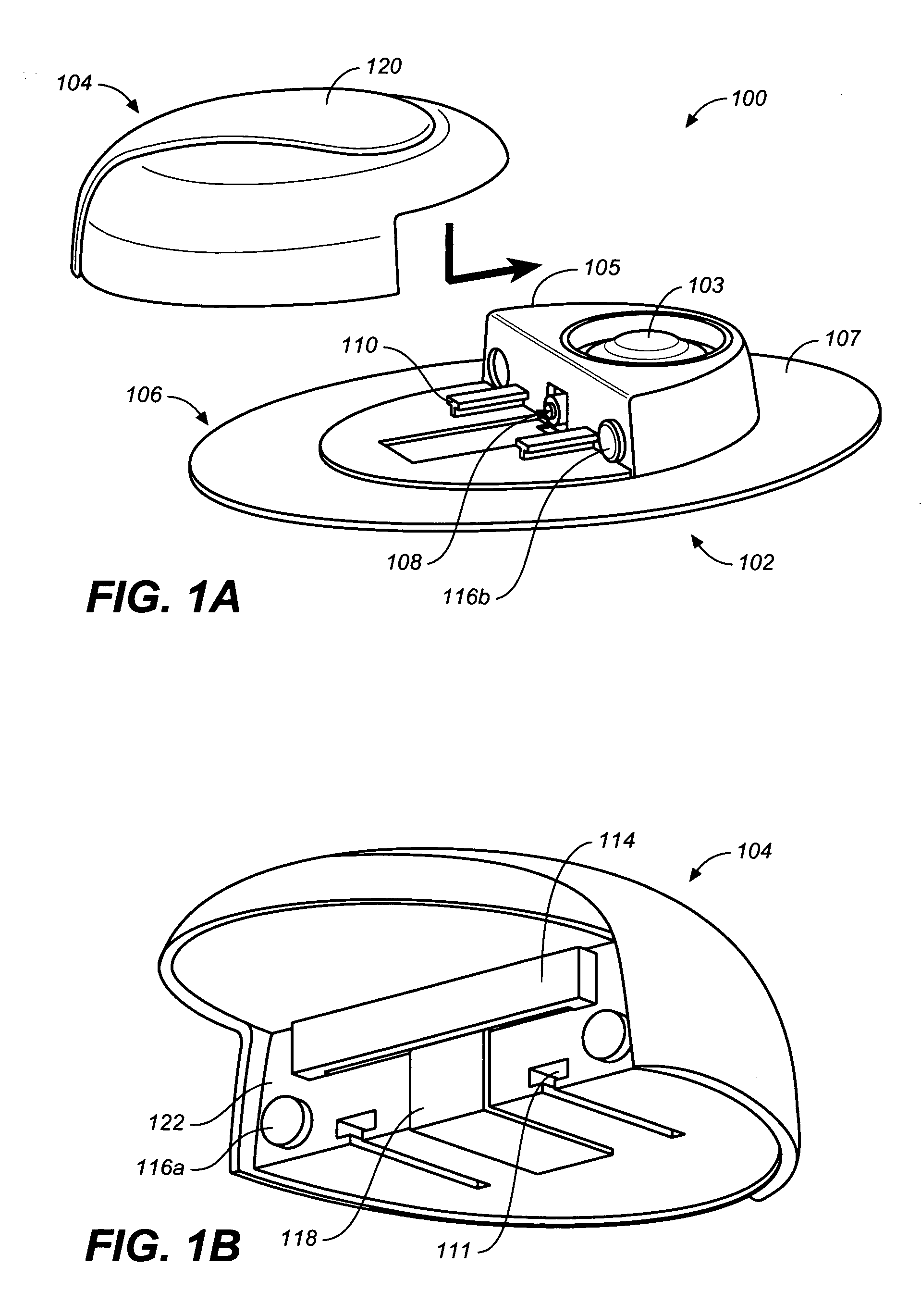

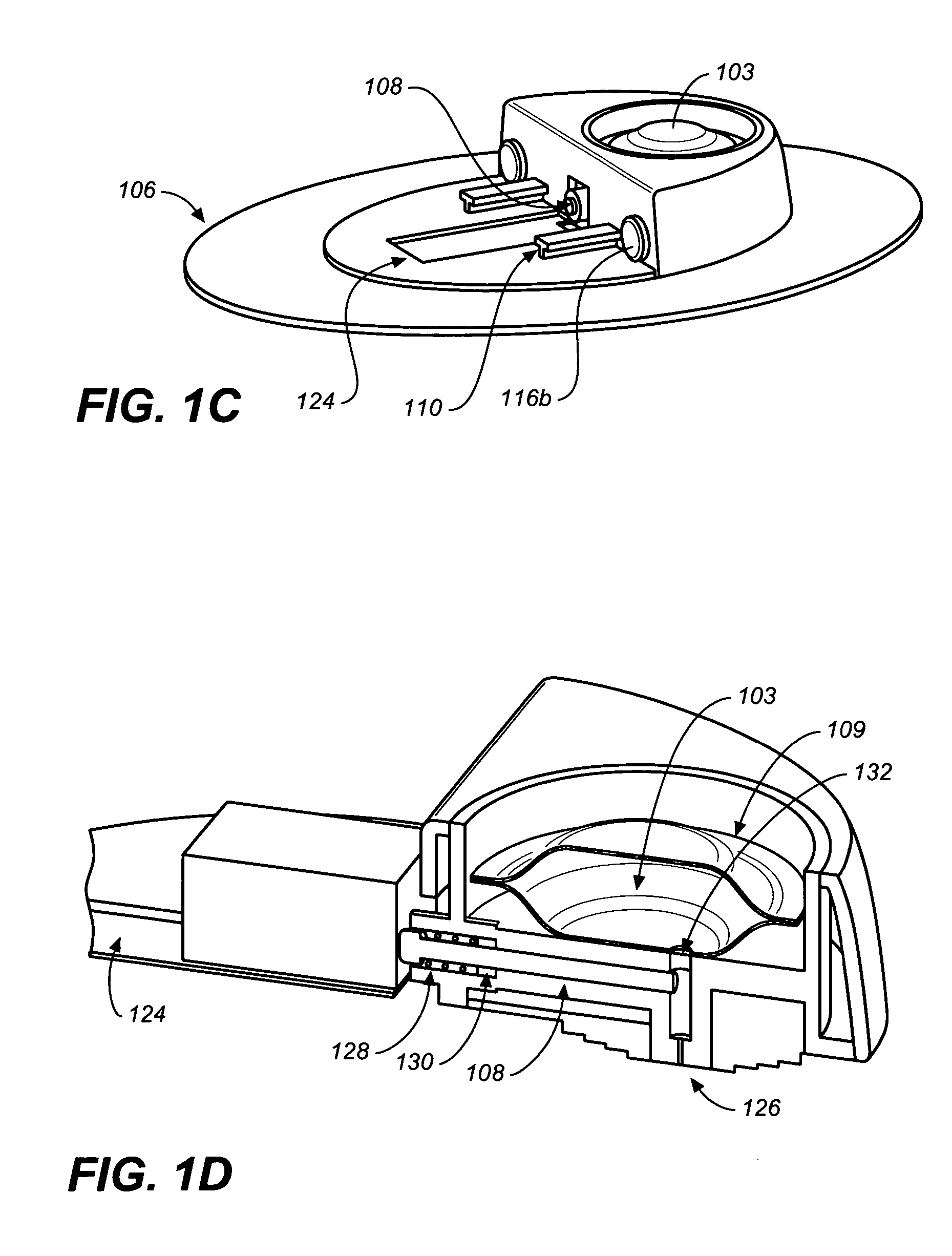

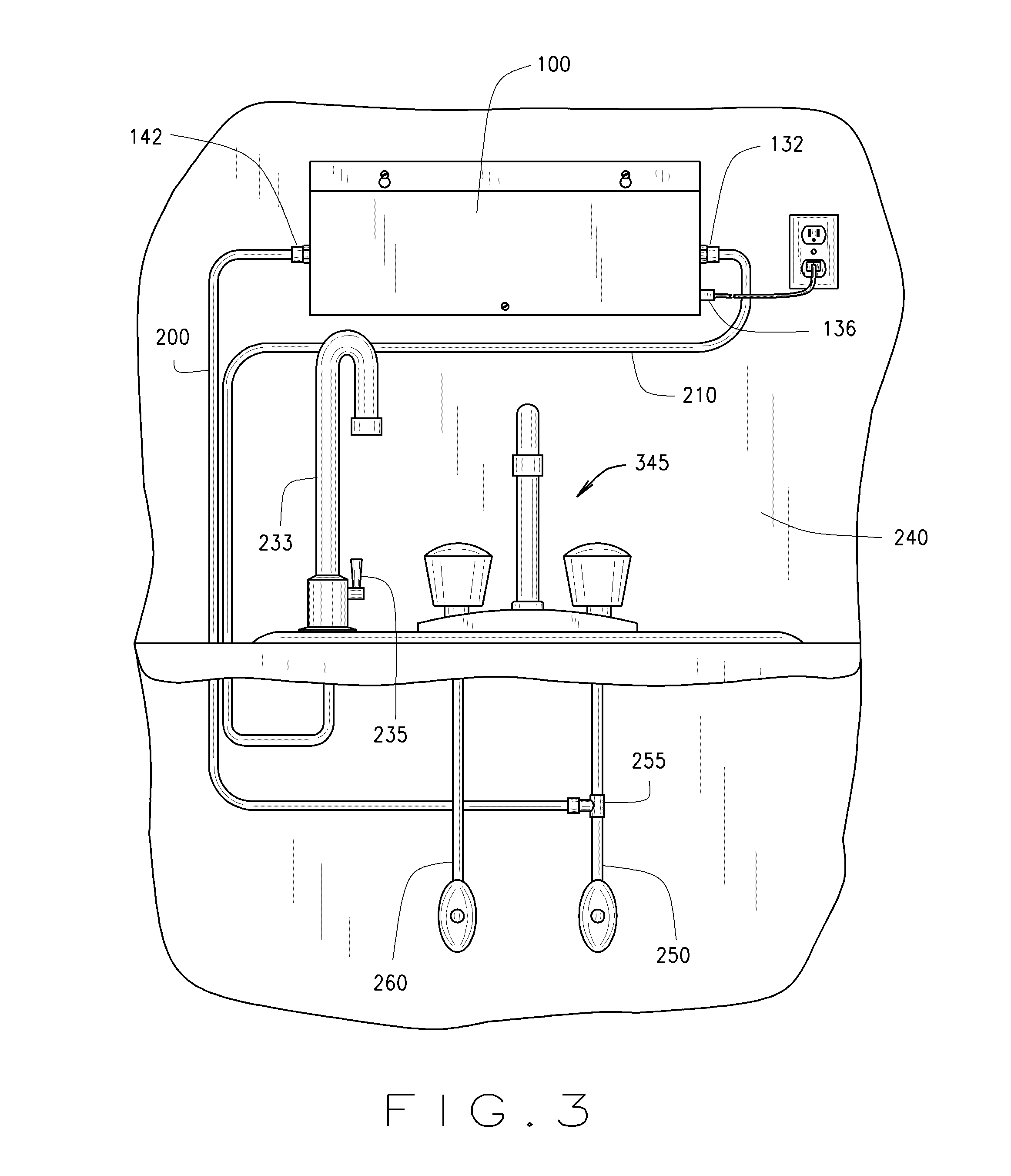

Methods, devices, and kits for microjet drug delivery

ActiveUS20080091139A1Reduce leakageEnhance nozzle contactJet injection syringesIntravenous devicesDrug reservoirEngineering

Described here are methods, devices, and kits for microjet drug delivery. The devices described here may be modular or non-modular. The modular devices typically include a first module having a drug reservoir and a nozzle in fluid communication with the drug reservoir and a second module having an actuator and a power supply. The power supply provides power to the actuator and when the first and second modules are coupled, the actuator is capable of acting on a dispensing member causing it to dispense a drug in liquid form from the drug reservoir via the nozzle at a velocity sufficient to penetrate skin. Other devices described include a nozzle, a reservoir in fluid communication with the nozzle, a dispensing member, and an actuator. In these devices, the nozzle has at least one feature that enhances nozzle contact with the skin in order to reduce lateral drug leakage about the nozzle.

Owner:CORIUM PHARMA SOLUTIONS INC

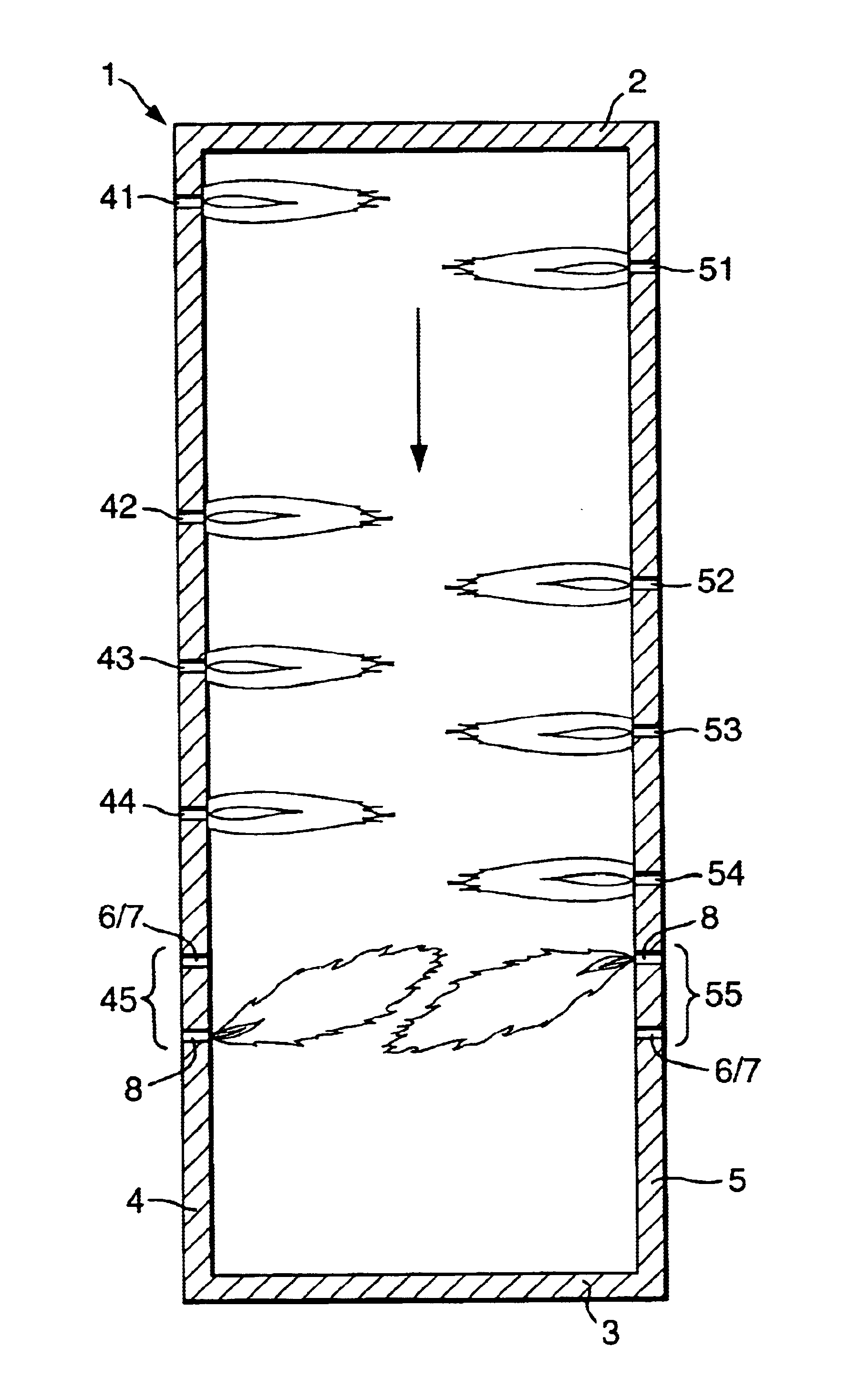

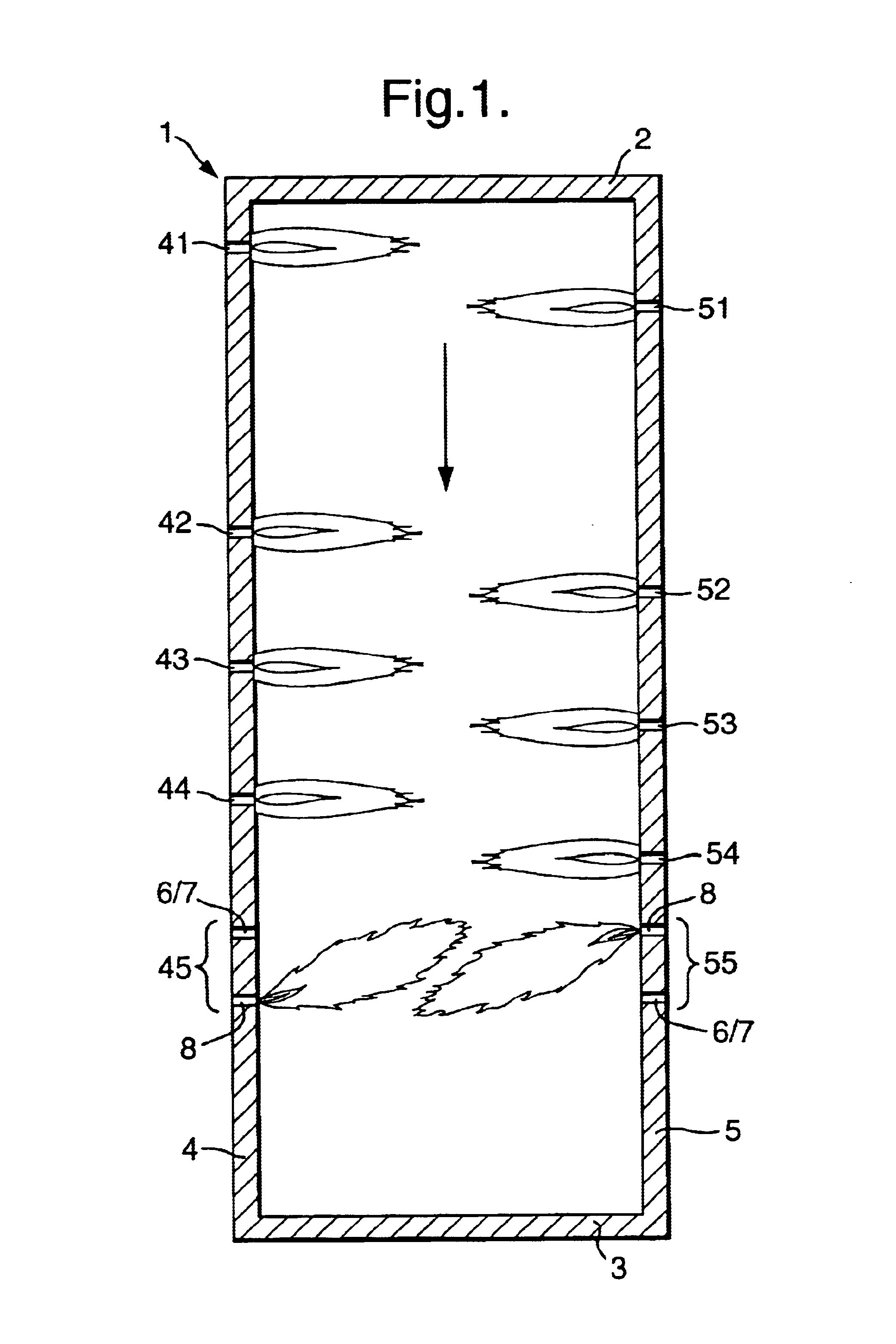

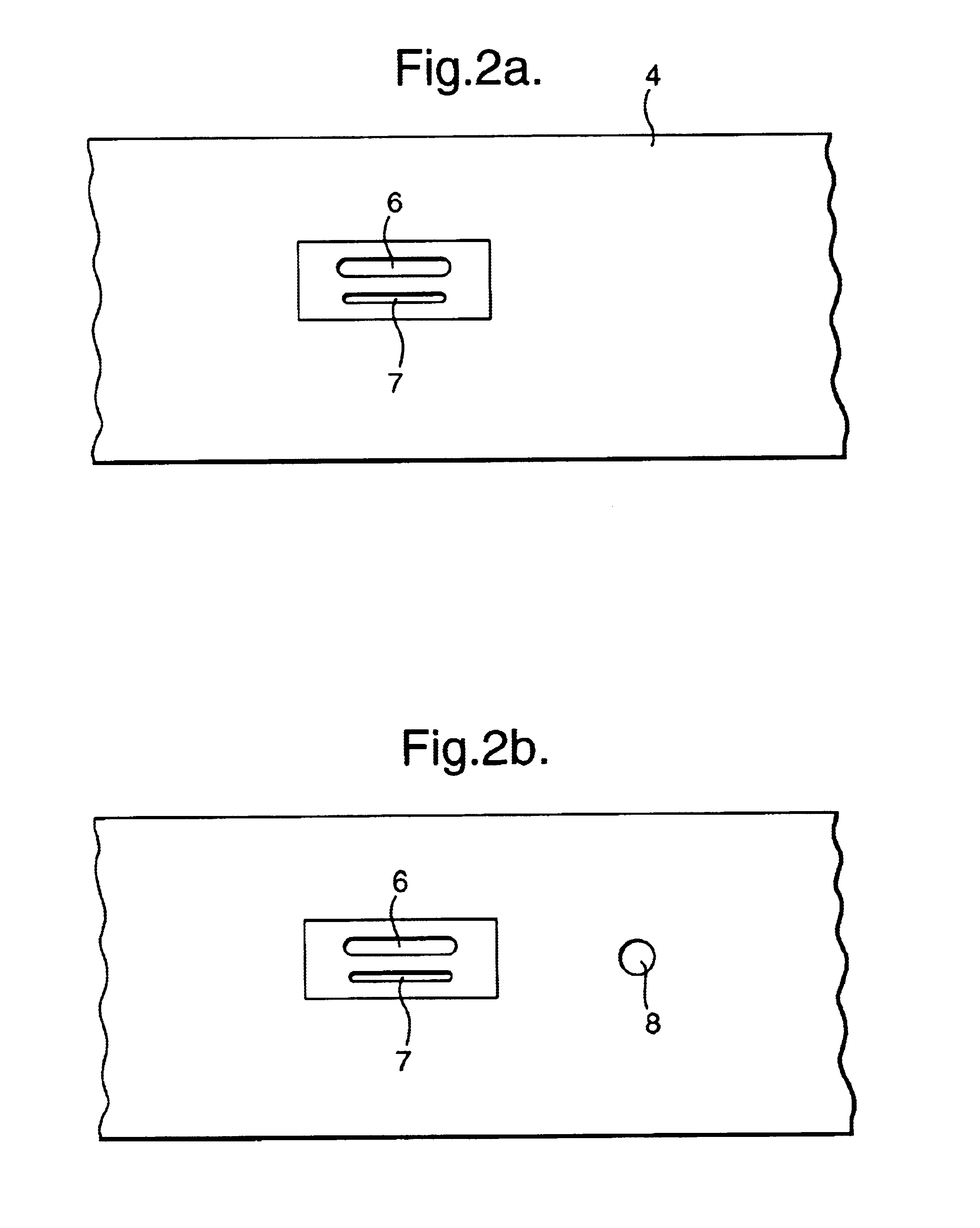

Melting of glass

InactiveUS6715319B2Reduce the presence of air bubblesGlass furnace apparatusGlass rolling apparatusFlat glassMaterials science

A method of producing flat glass in which foam which appears on the surface of molten glass melted using oxy-fuel burners is dispersed by directing a diffuse, luminescent flame onto the surface of the glass carrying the foam.

Owner:PILKINGTON PLC

Melting of glass

InactiveUS20020134112A1Reduce the presence of air bubblesGlass furnace apparatusGlass rolling apparatusOxy-fuelMolten glass

A method of producing flat glass in which foam which appears on the surface of molten glass melted using oxy-fuel burners is dispersed by directing a diffuse, luminescent flame onto the surface of the glass carrying the foam.

Owner:PILKINGTON PLC

Bio-based artificial quartz stone and production process thereof

ActiveCN102898070AReduce environmental pollution problemsAchieve recyclingCeramic shaping apparatusWeather resistanceDefoaming Agents

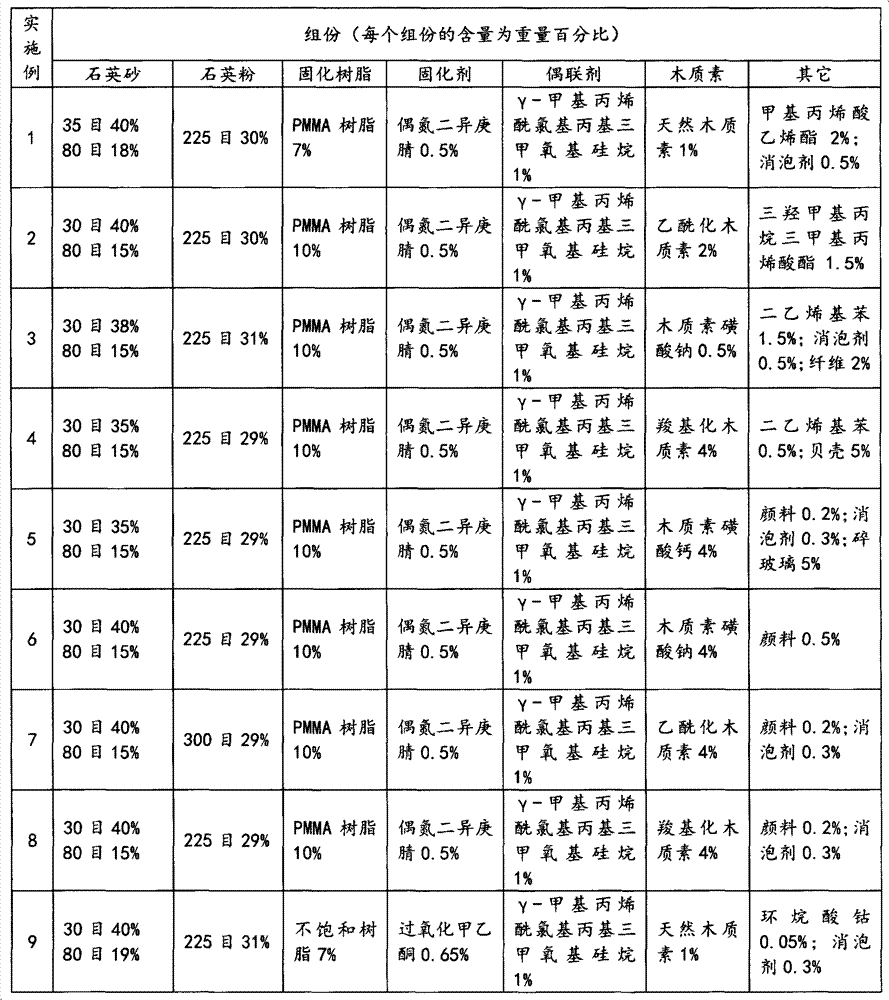

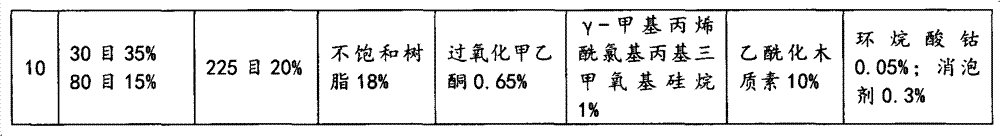

A bio-based artificial quartz stone and a production process thereof are disclosed. The bio-based artificial quartz stone includes the following components by weight: 0-80% of quartz sand; 10-70% of quartz powder; 3-20% of curable resin; 0.05-3% of a curing agent; 0.01-40% of lignin; 0-5% of a crosslinking agent; 0.05-5% of a coupling agent; 0-1% of a promoter; 0-2% of a pigment; and 0-3% of a defoaming agent. According to the invention, the lignin is used in the artificial quartz, the environmental pollution of the lignin is reduced, the cost of the artificial quartz is reduced, and at the same time the weather resistance and light stability of the artificial quartz are improved, thus the artificial quartz has antibacterial ability, is green and environmental-friendly, and is suitable for using in building decoration of living environments.

Owner:SUZHOU TOPOLINE TECH

Resin plug-hole apparatus of PCB back borehole and method thereof

InactiveCN102523699AImprove reliabilityReduce the presence of air bubblesPrinted element electric connection formationEngineeringHigh heat

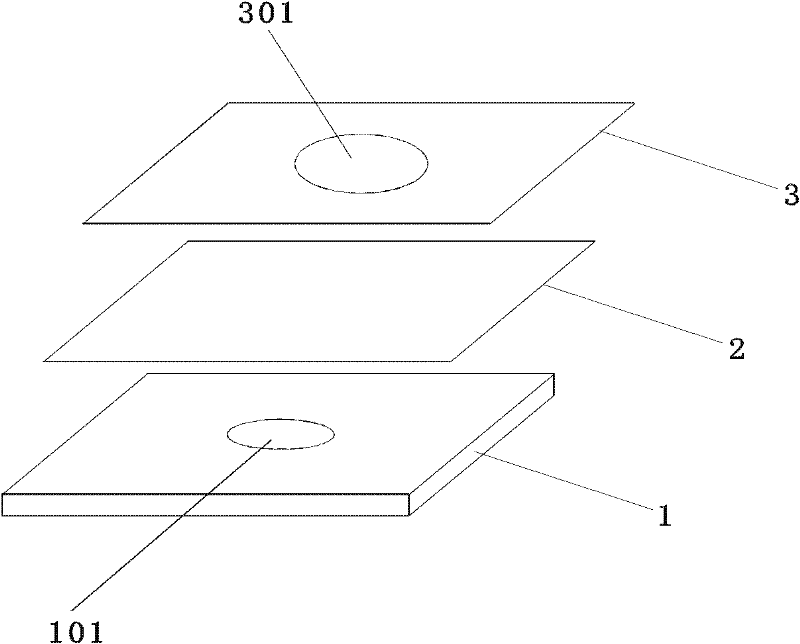

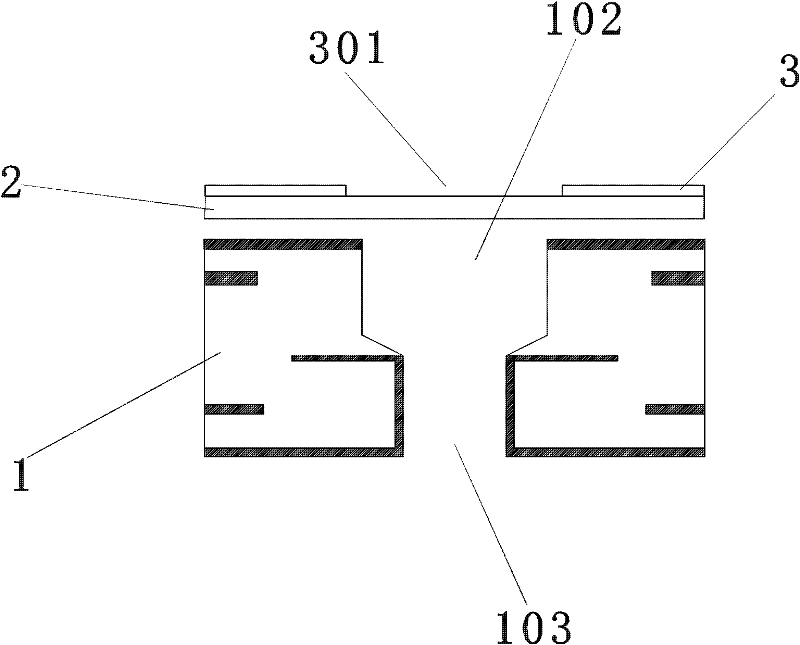

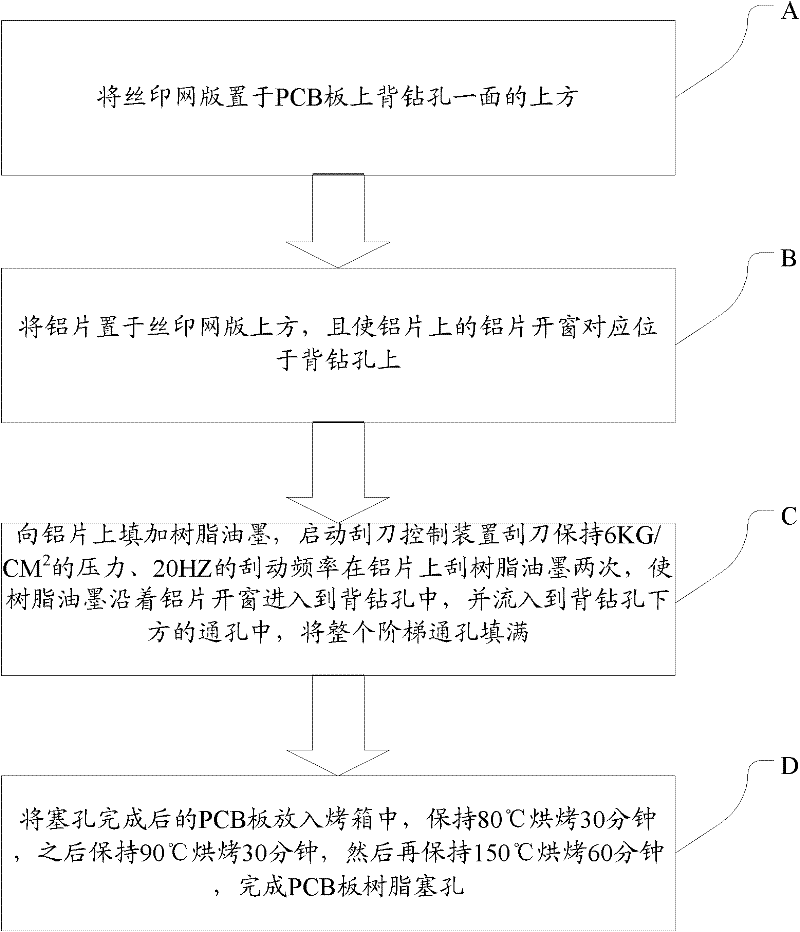

The invention discloses a resin plug-hole apparatus of a PCB back borehole and a method thereof. The apparatus comprises a PCB plate, a silkscreen net plate and an aluminum sheet. The PCB plate is drilled with a step through hole. One end of the step through hole is a back borehole with a large bore diameter, and the other end is a through hole with a small bore diameter. The silkscreen net plate is above one surface with the back borehole of the PCB back borehole and is provided with the aluminum sheet. According to the invention, the surface with the back borehole of the PCB plate is selected to be subjected to resin ink filling, resin ink flows through a larger hole and fills the step through hole, through controlling pressure, speed and times of scrapping, the step through hole is filled up by the resin ink, then the PCB plate is baked through a gradual temperature rise method, the resin ink in the hole is solidified, a volatile ingredient of the resin ink is discharged, a purpose of reducing bubbles in the step through hole is reached, and the reliability of a circuit board is raised.

Owner:SHENZHEN SUNTAK MULTILAYER PCB

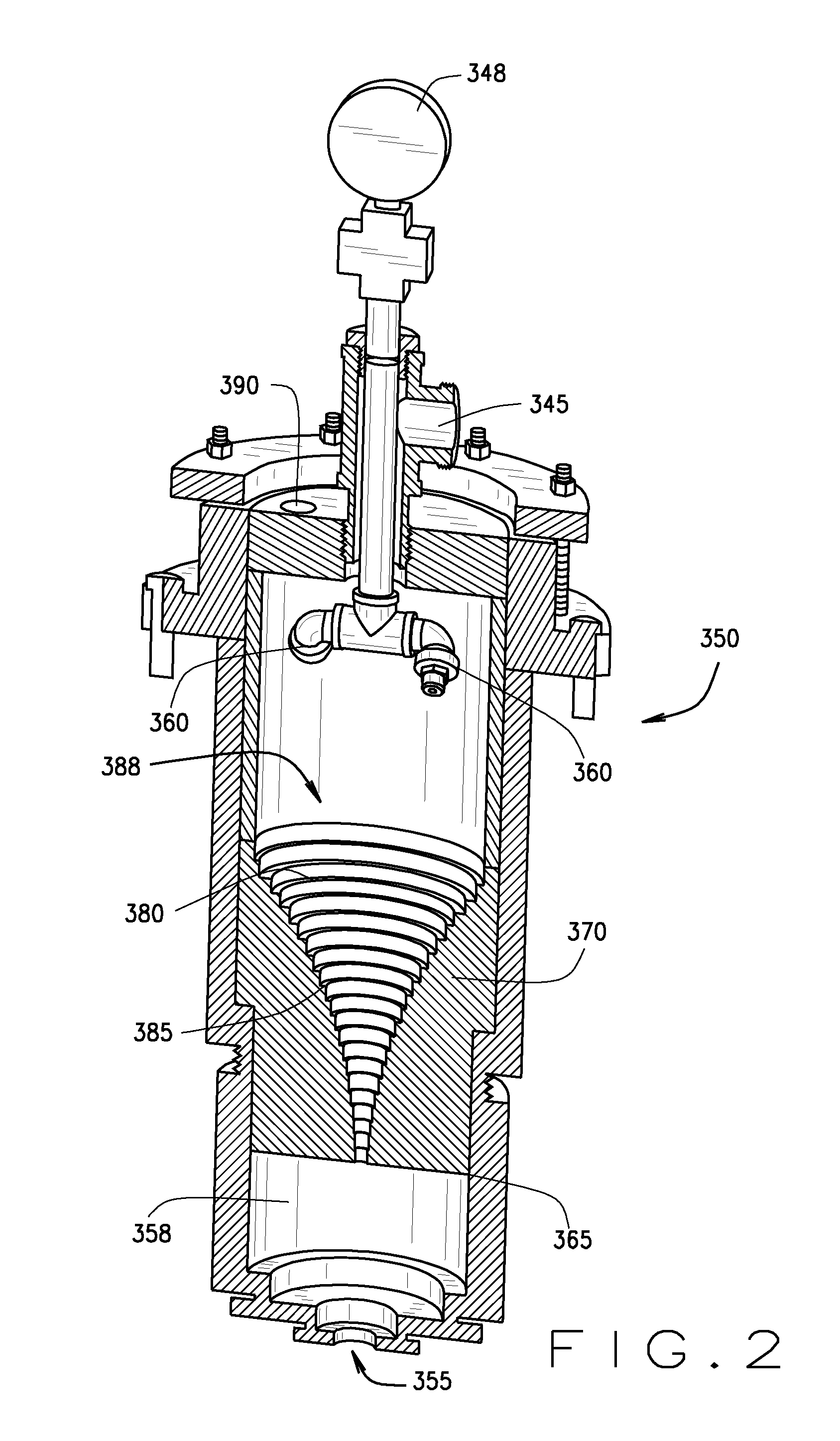

Aqueous ozone solution for ozone cleaning system

ActiveUS20080227680A1Small bubble sizeReduce the amount requiredInorganic/elemental detergent compounding agentsNon-ionic surface-active compoundsChemistryAqueous solution

A method of making an aqueous ozone solution for an industrial cleaning system is described. The method includes providing a reaction vessel for entraining ozone gas in an aqueous solution. The reaction vessel includes a conical-shaped surface having a two or more edges or ridges. The conical-shaped surface defines an interior, and two or more edges or ridges are in contact with the interior. The reaction vessel is in fluidic communication with a supply of water. The reaction vessel is in fluidic communication with a supply of a first aqueous ozone solution. The first aqueous ozone solution is directed to the conical-shaped surface. Water is directed to the conical-shaped surface, and the water and the first aqueous ozone solution are mixed to form a second aqueous ozone solution.Compositions for aqueous ozone solutions are also described. The aqueous ozone solution contains approximately 1 part by volume water mixed with approximately 4 parts by volume to approximately 9 parts by volume of a first aqueous ozone solution to form a second aqueous ozone solution that has an oxidation reaction potential of up to approximately 2.6. The second aqueous ozone solution has an ozone concentration of up to approximately 20 ppm.

Owner:CLEANCORE SOLUTIONS LLC

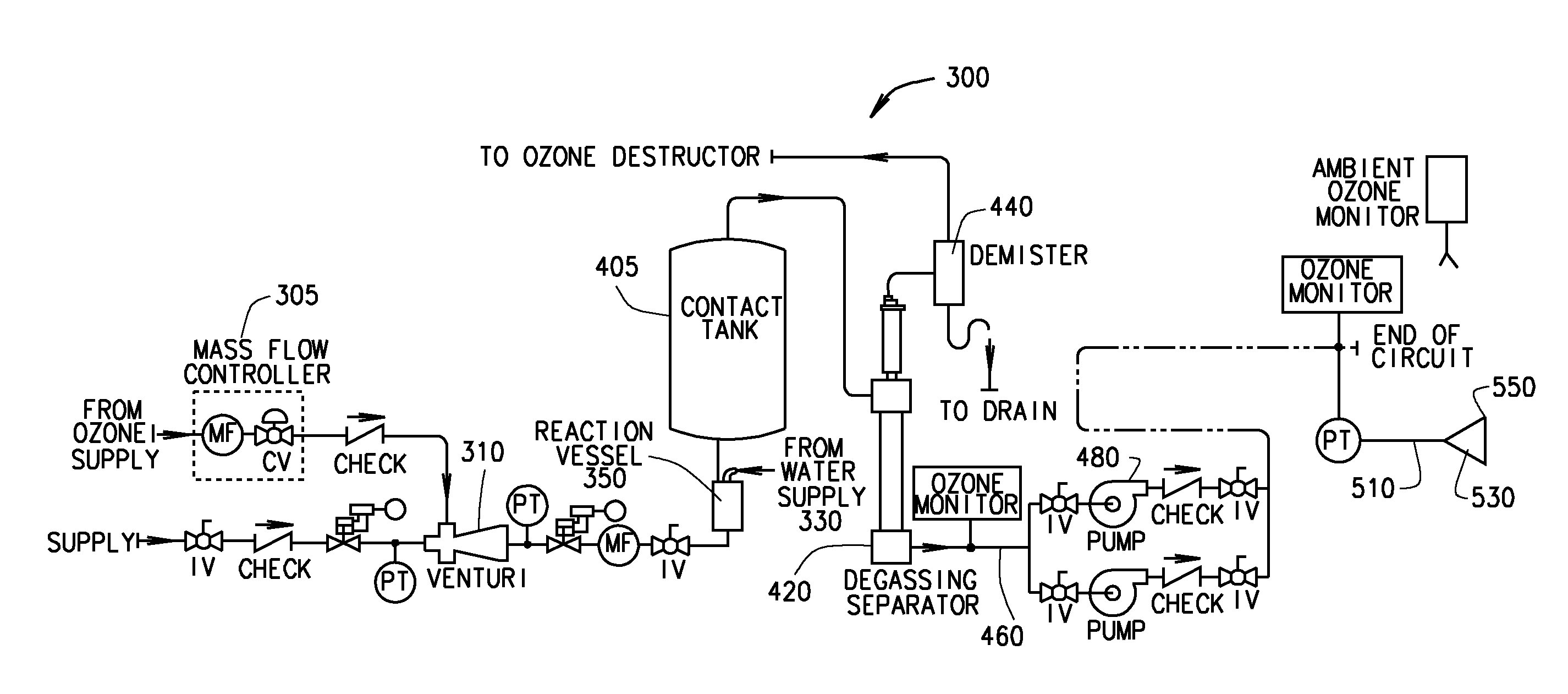

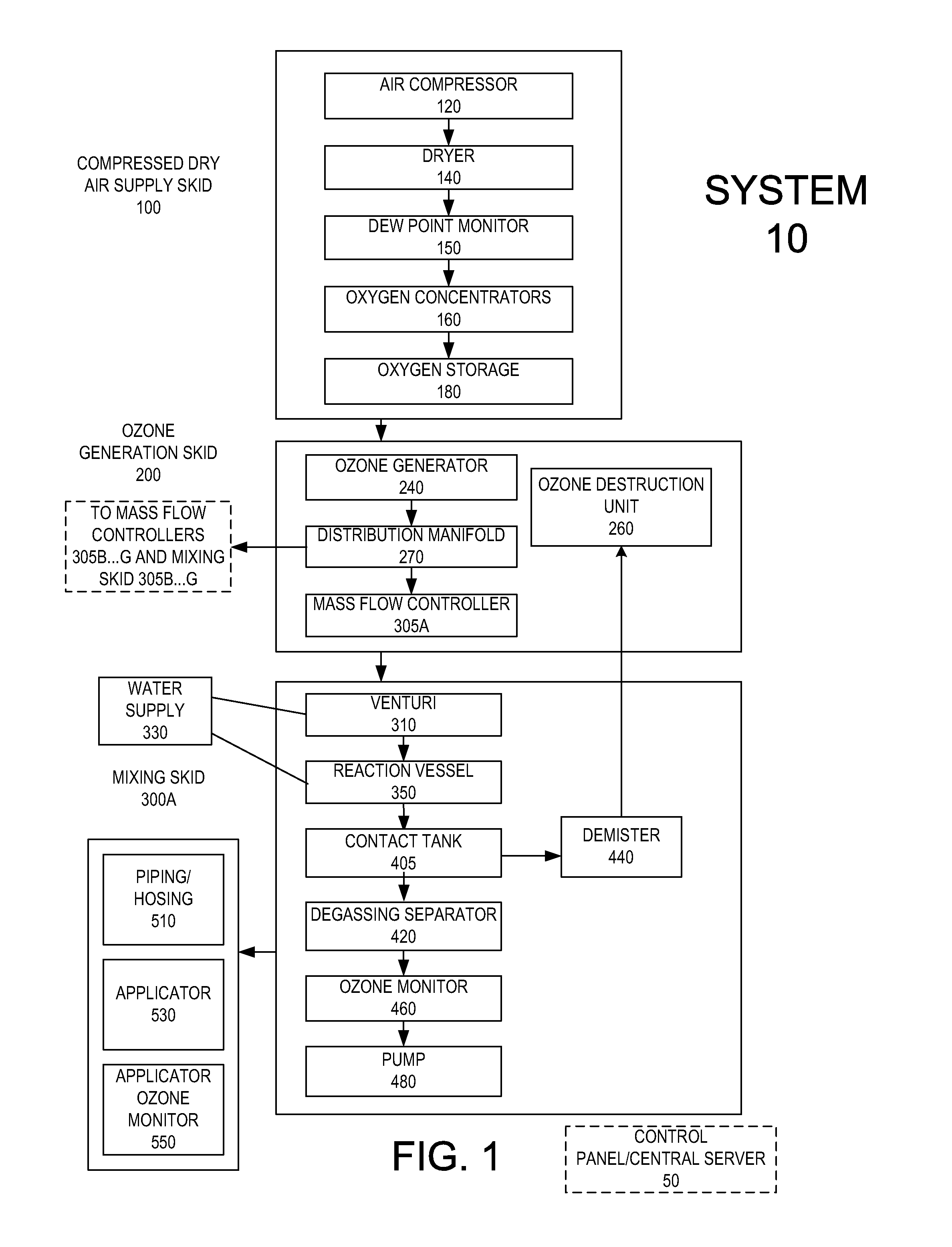

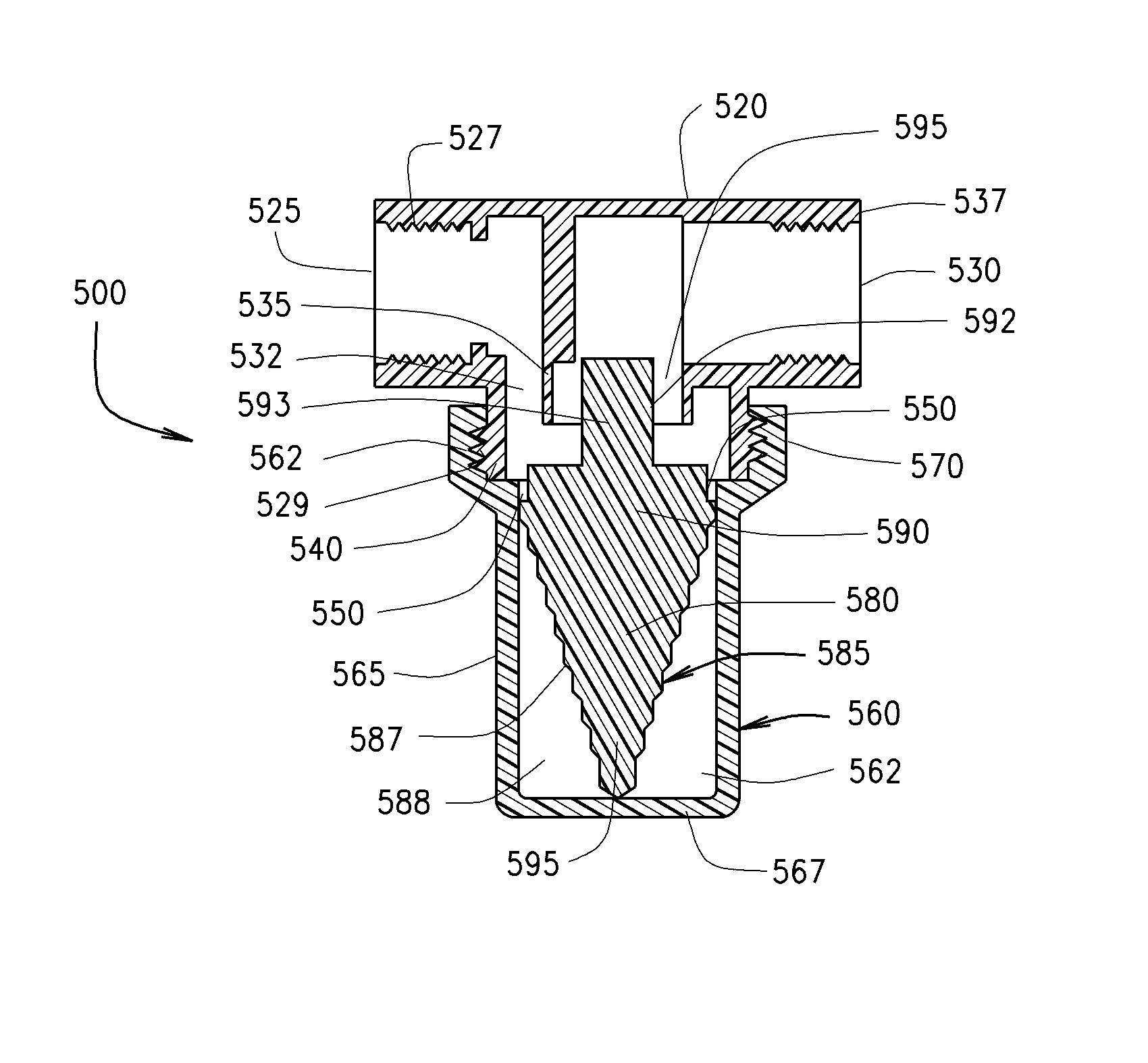

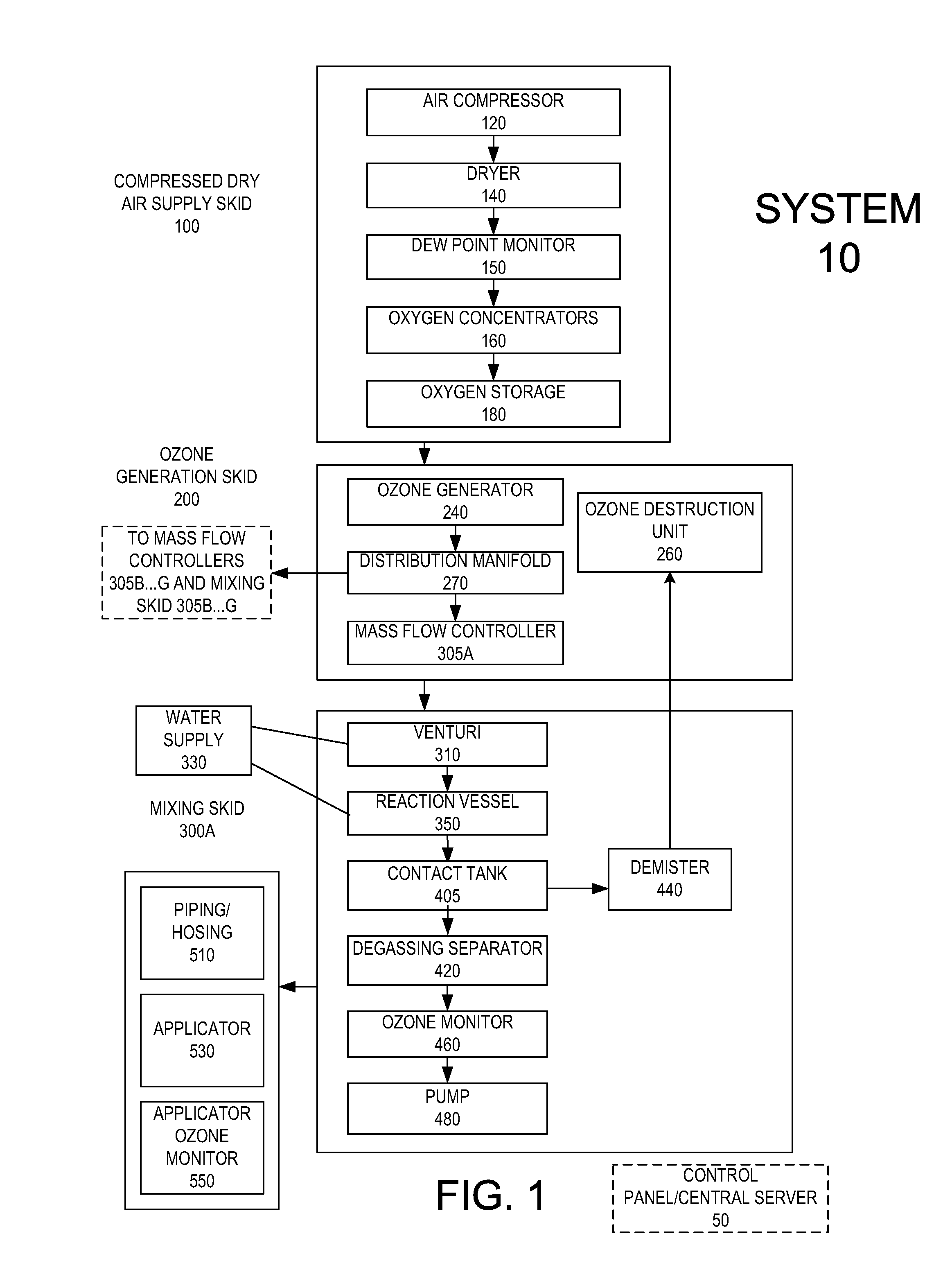

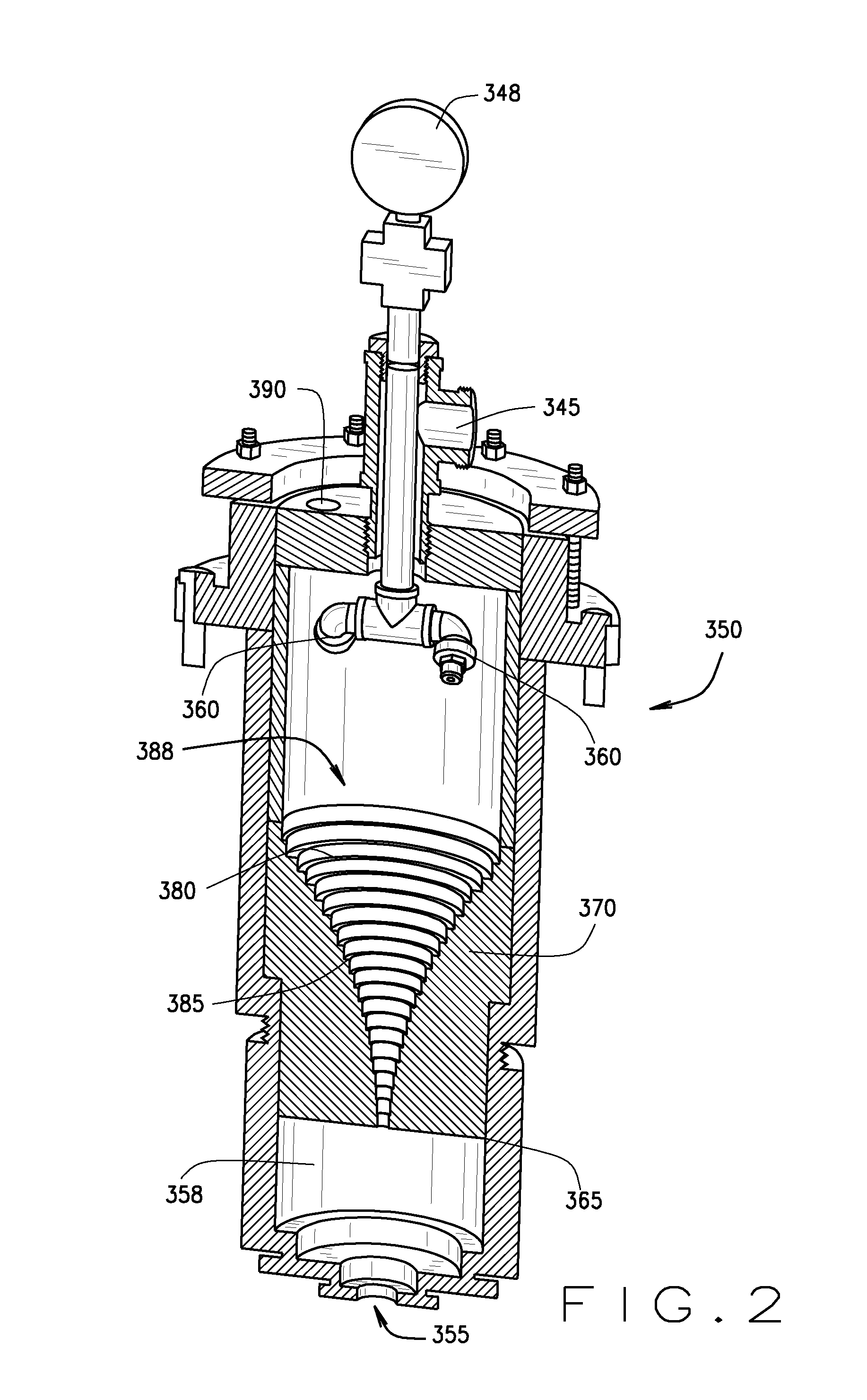

Ozonated liquid dispensing unit

ActiveUS9522348B2Effective and longer lasting cleaning and sanitizing solutionReduce the presence of air bubblesInorganic/elemental detergent compounding agentsFruit and vegetables preservationEngineeringOzone

A reaction vessel and an ozonated liquid dispensing unit are described herein. The unit produces and dispenses an ozonated liquid that may be used to clean and sanitize a variety of articles or used in conjunction with cleaning processes and other apparatus. The reaction vessel is incorporated into the unit to reduce bubbles of ozone gas and to break up bubbles of ozone gas in the ozonated liquid to provide a more effective and longer lasting cleaning and sanitizing solution.

Owner:CLEANCORE SOLUTIONS LLC

Composition of aluminum boron silicate glass and application

ActiveCN101092280AImprove melting qualityReduce the presence of air bubblesSilicate glassFlat panel display

This invention relates to aluminum borosilicate glass with high elastic modulus and its application. The aluminum borosilicate glass is prepared from: 55-63.5 wt.% SiO2, 8-10.5 wt.% B2O3, 15-21 wt.% Al2O3, 0-3.5 wt.% MgO, 4-10 wt.% CaO, 0-5 wt.% SrO, 1-5.5 wt.% BaO, 0.001-4 wt.% Y2O3, 0-2.5 wt.% La2O3, 0-0.5 wt.% ZnO, 0-0.3 wt.% ZrO2, and 0.005-0.08 wt.% R2O (R = Li, Na or K). The aluminum borosilicate glass has such advantages as high strain point, low expansion coefficient, high elastic modulus and no alkali, and is suitable for flat panel display and TFT-LCD glass substrate.

Owner:HENAN ANCAI HI-TECH +1

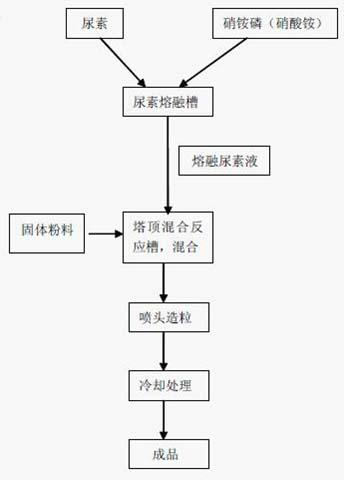

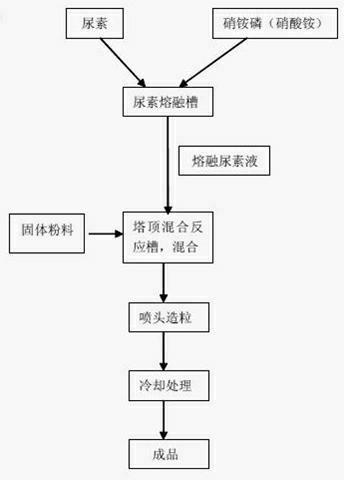

Method for producing urea-based compound fertilizer by high tower granulation

ActiveCN102584395AImprove liquidityReduce the presence of air bubblesFertiliser formsFertilizer mixturesFertilizerChemistry

The invention discloses a method for producing a urea-based compound fertilizer by high tower granulation. The method comprises the following steps of: (1) adding a fluxing agent and urea into a melting tank, melting the urea at low temperature, and adding into a mixing reaction tank on the top of a tower; (2) adding other raw materials into the melted urea solution in the mixing reaction tank on the top of the tower, and mixing and stirring to obtain mixed and melted slurry; and (3) spraying the mixed and melted slurry by using a granulation nozzle in the high tower, and granulating in the tower. The method has the advantages that operating temperature and energy consumption are low, the liquidity of the slurry is high, a few bubbles exist in the mixed slurry, a small amount of biuret is generated, the operating environment is good, and the like; and high tower granulation production can be stably, normally and continuously performed.

Owner:WENGFU (GRP) CO LTD

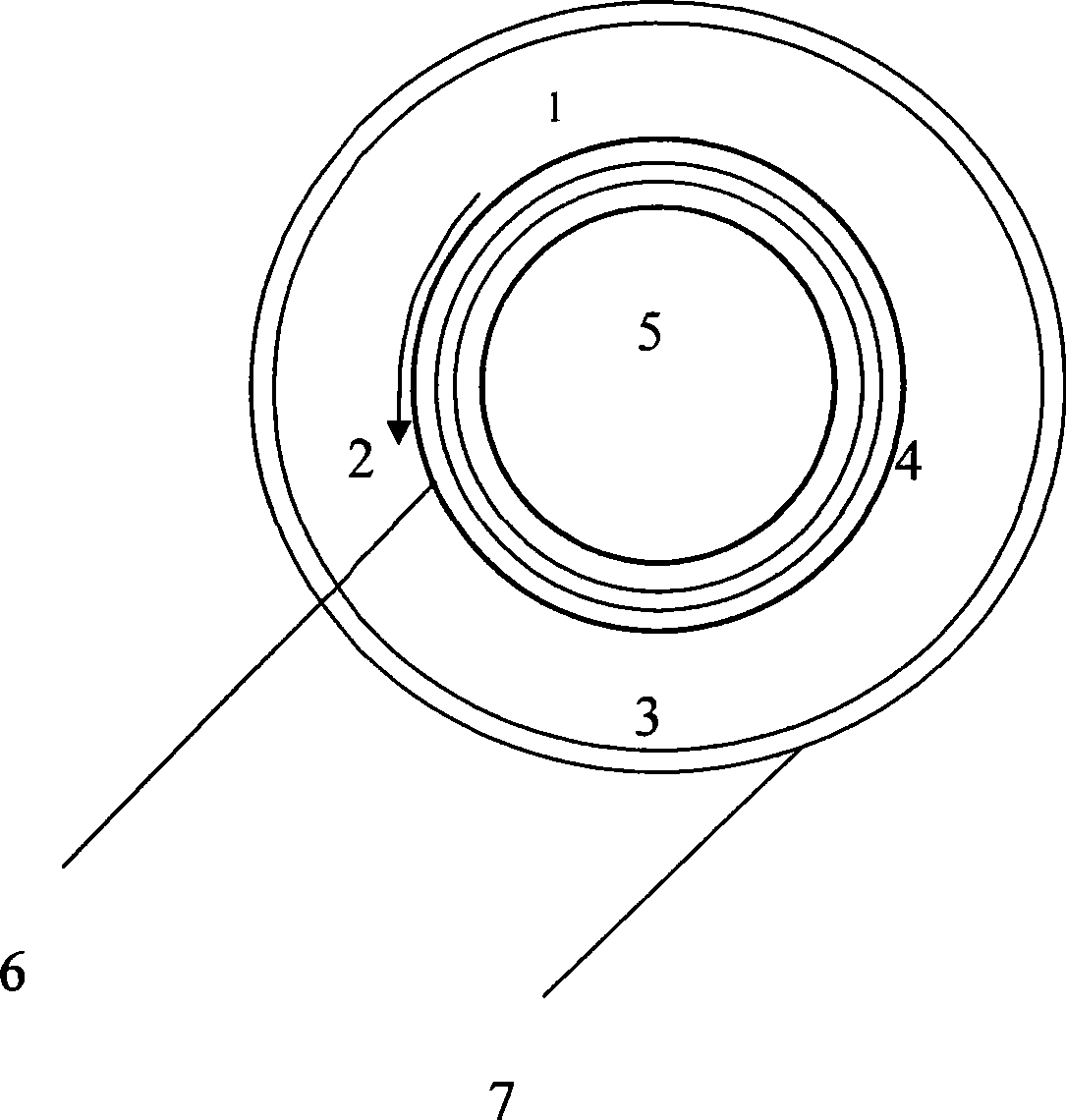

Iron based nanocrystalline magnet core for large power inverter power source and production method

ActiveCN101477868AGood tape making processReduce lossInorganic material magnetismTransformers/inductances magnetic coresPower inverterDownstream processing

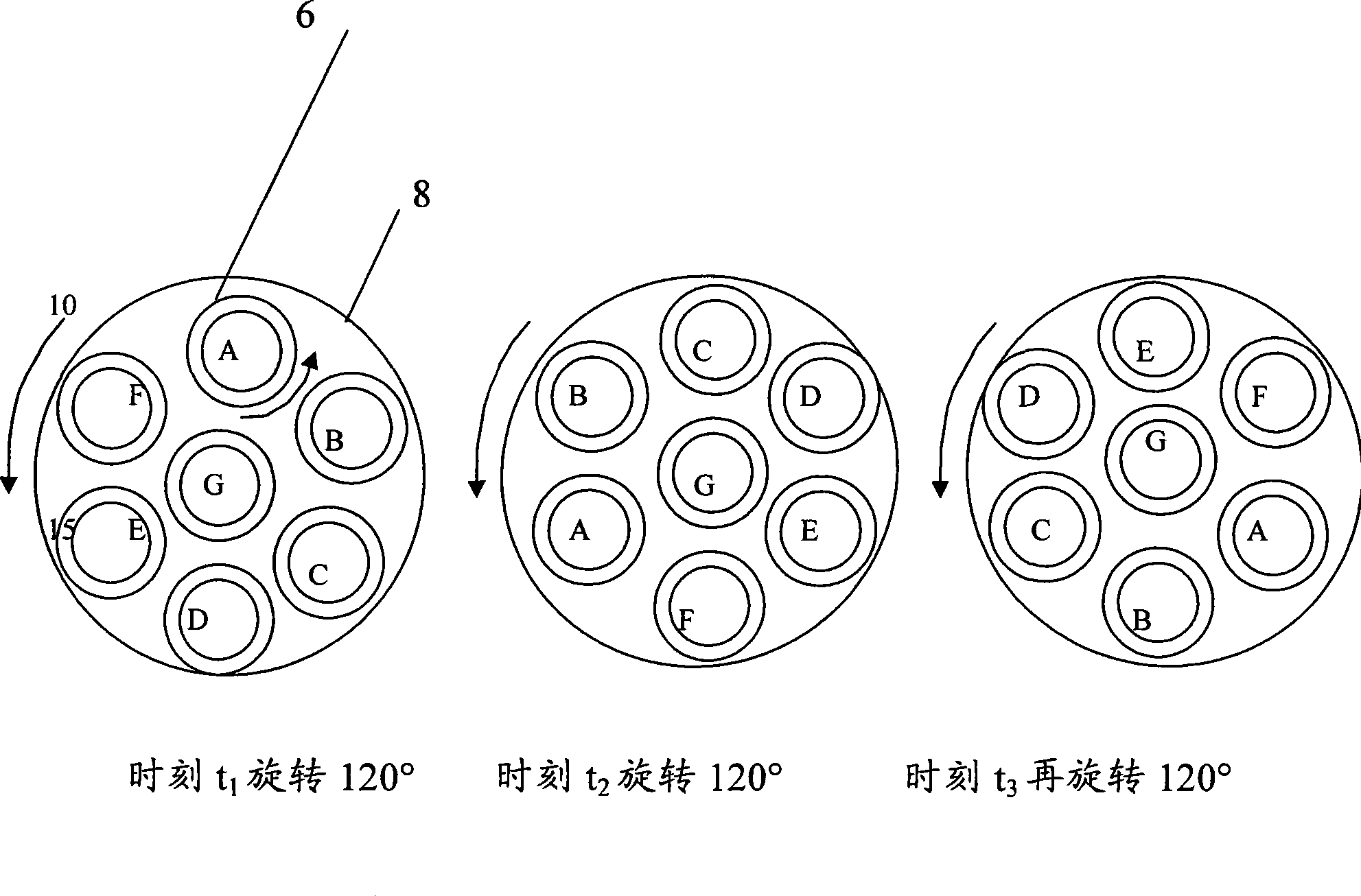

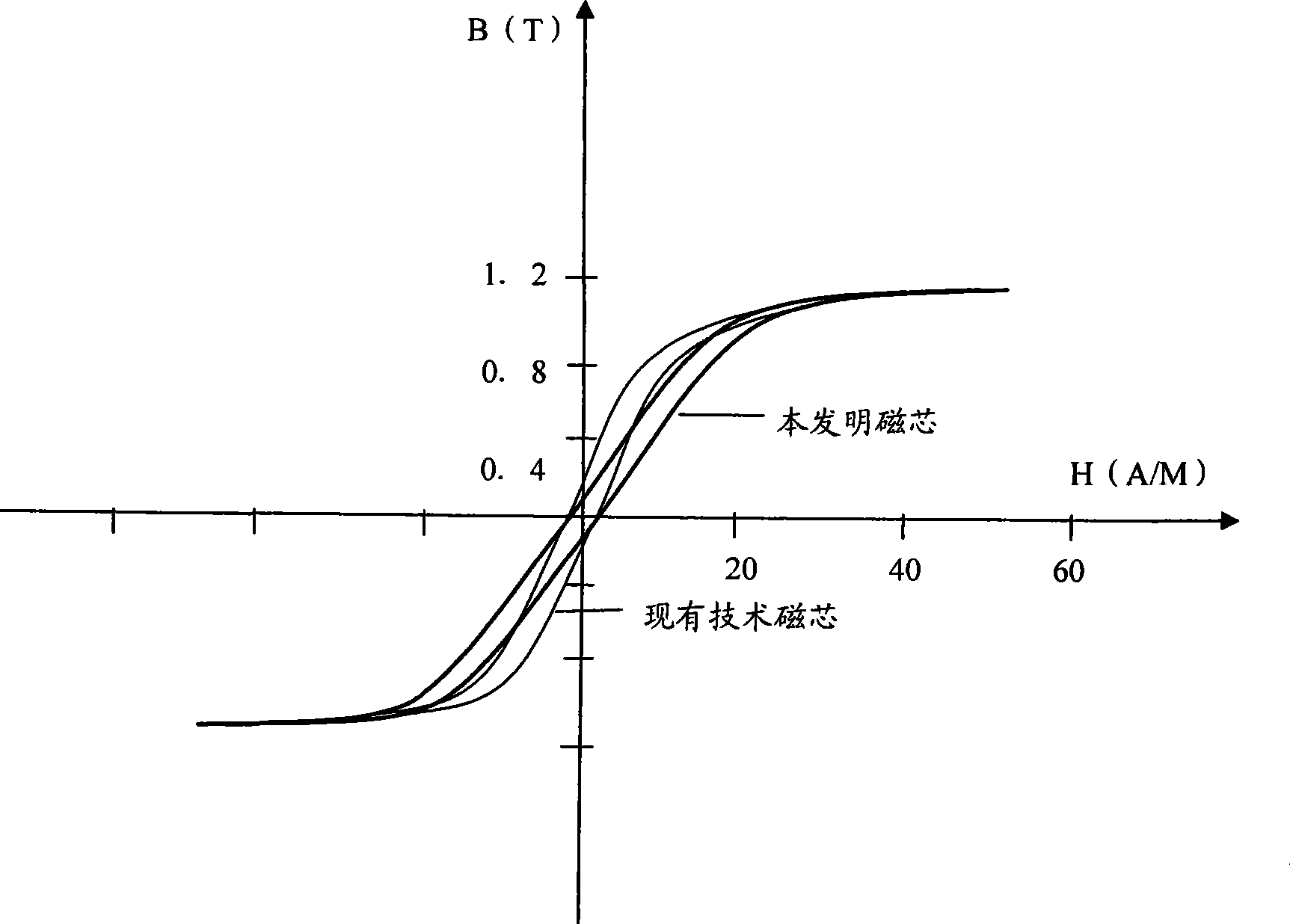

The invention relates to a soft magnetic core used for a high-power inverter power supply, and a manufacturing method thereof. The magnetic core is made of an Fe-based amorphous nano-crystalline belt material through winding , and comprises components according to weight percentages as follows: 81%-85% of Fe, 0.01%-5% of Co, 7%-9% of Si, 1.5%-2.5% of B, 1%-2% of Cu, 4%-7% of M, and 0.001%-0.04% of M', wherein M is one or more of Nb, Mo, V, W and Ta, and M' is at least one of Al and Ti. The magnetic core is subjected to anneal in a protective atmosphere or a vacuum; when in anneal, the position of the magnetic core in a furnace is movable or rotatable, a holding temperature is 520-600 DEG C, the holding time is 1-2 hours, and a temperature rise speed is 100 DEG C per hour. The magnetic core manufactured by adopting the method has lower loss, better manufacturing technique properties, and good soft magnetic characteristics; moreover, the downstream processing after the heat treatment is applicable to various technique methods.

Owner:ADVANCED TECHNOLOGY & MATERIALS CO LTD

FFC glaze with high stain resistance, FFC sanitary ceramic and preparation method of FFC sanitary ceramic

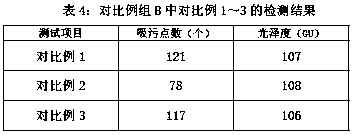

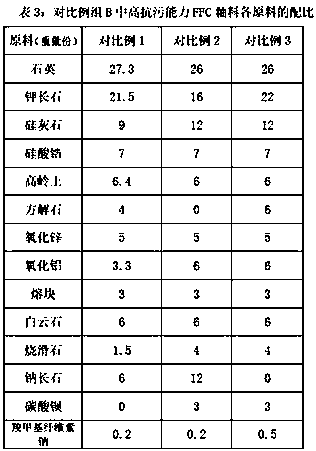

ActiveCN111253071AExtended firing temperature rangeReduce glaze porosityPotassium feldsparSodium carboxymethylcellulose

The invention discloses an FFC glaze with high stain resistance, an FFC sanitary ceramic and a preparation method of the FFC sanitary ceramic. The FFC glaze with high stain resistance comprises the following raw materials in parts by weight: 22-29 parts of quartz, 24-28 parts of potassium feldspar, 6-10 parts of wollastonite, 7-8 parts of zirconium silicate, 5-10 parts of kaolin, 0-5 parts of calcite, 5-7 parts of zinc oxide, 5-7 parts of aluminum oxide, 2-3 parts of frit, 4-8 parts of dolomite, 5-8 parts of calcined talc, 1-4 parts of barium carbonate and 0.2-0.5 part of sodium carboxymethylcellulose. According to the FFC glaze with high stain resistance, multi-alkali effect is utilized, barium carbonate is introduced, the use amount of calcined talc is increased, and the use amount of albite is reduced, so venting of a green body is more smooth, the porosity of a glaze surface is reduced, and microcracks of the glaze surface are reduced. Besides, the FFC glaze with high stain resistance also utilizes the principle of like dissolves like to increase the consumption of aluminum oxide and quartz, improve the bonding property of the blank and a glaze, and further reduce the microcracks on the glaze surface of the sanitary ceramic correspondingly.

Owner:江门市东鹏智能家居有限公司

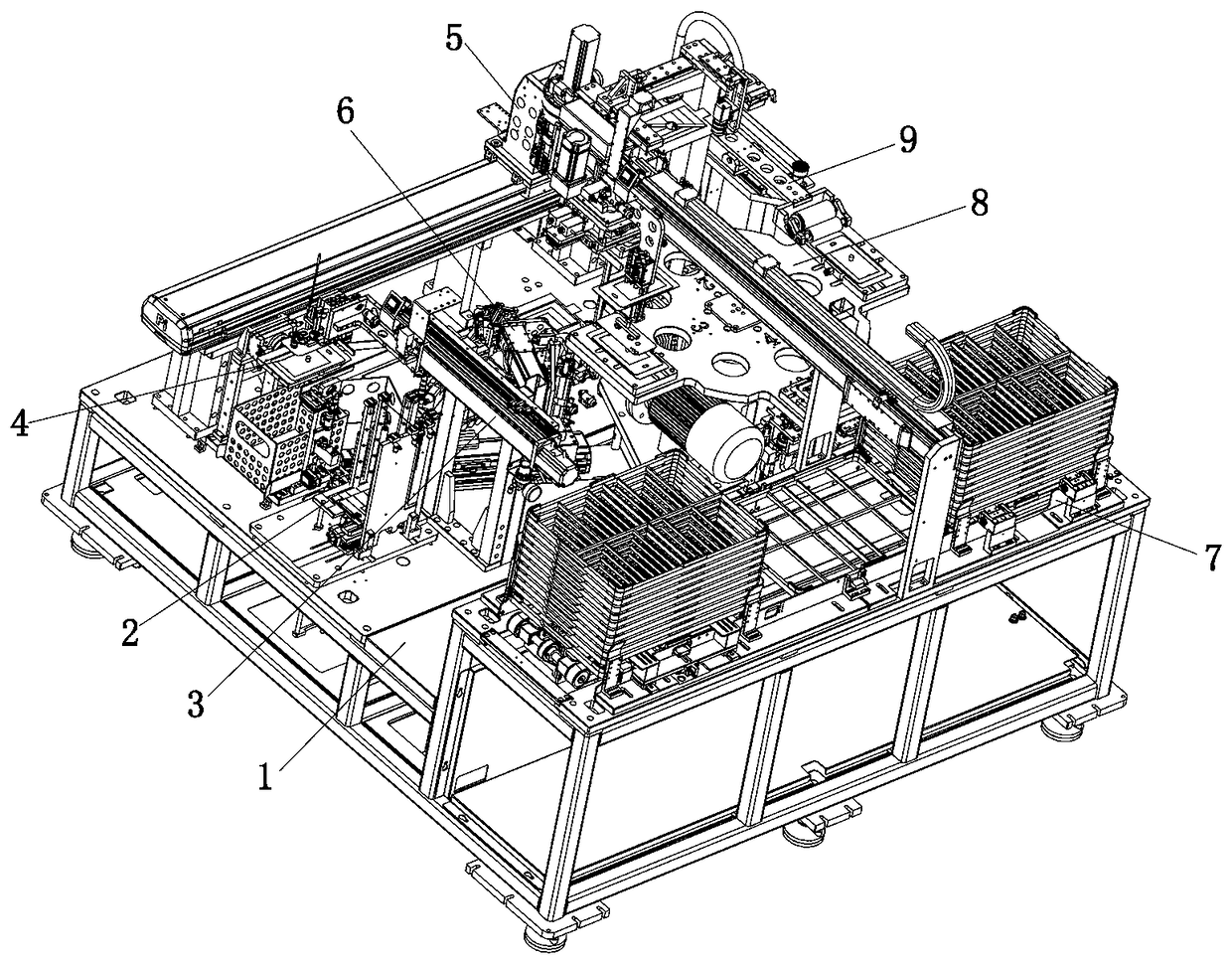

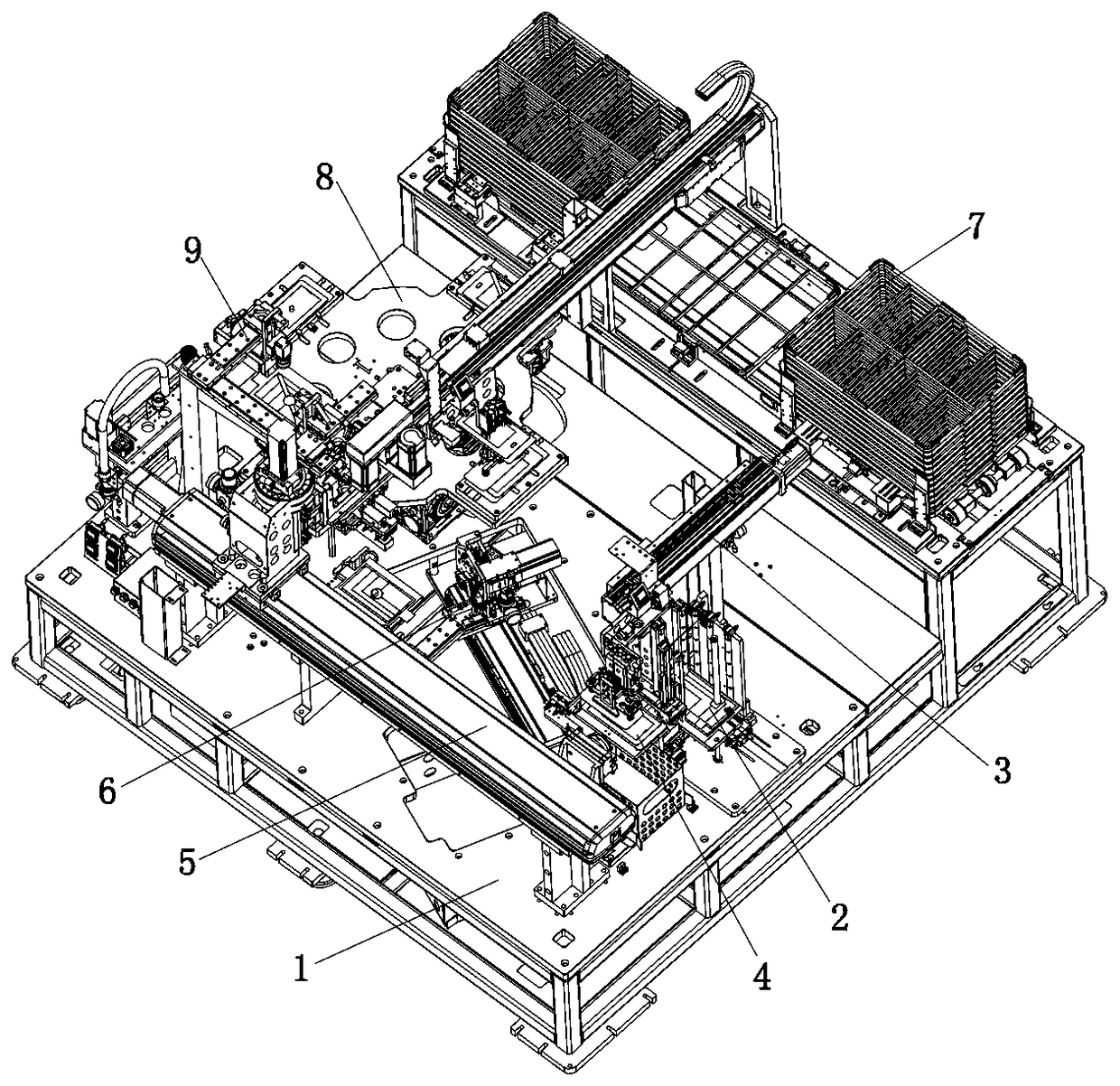

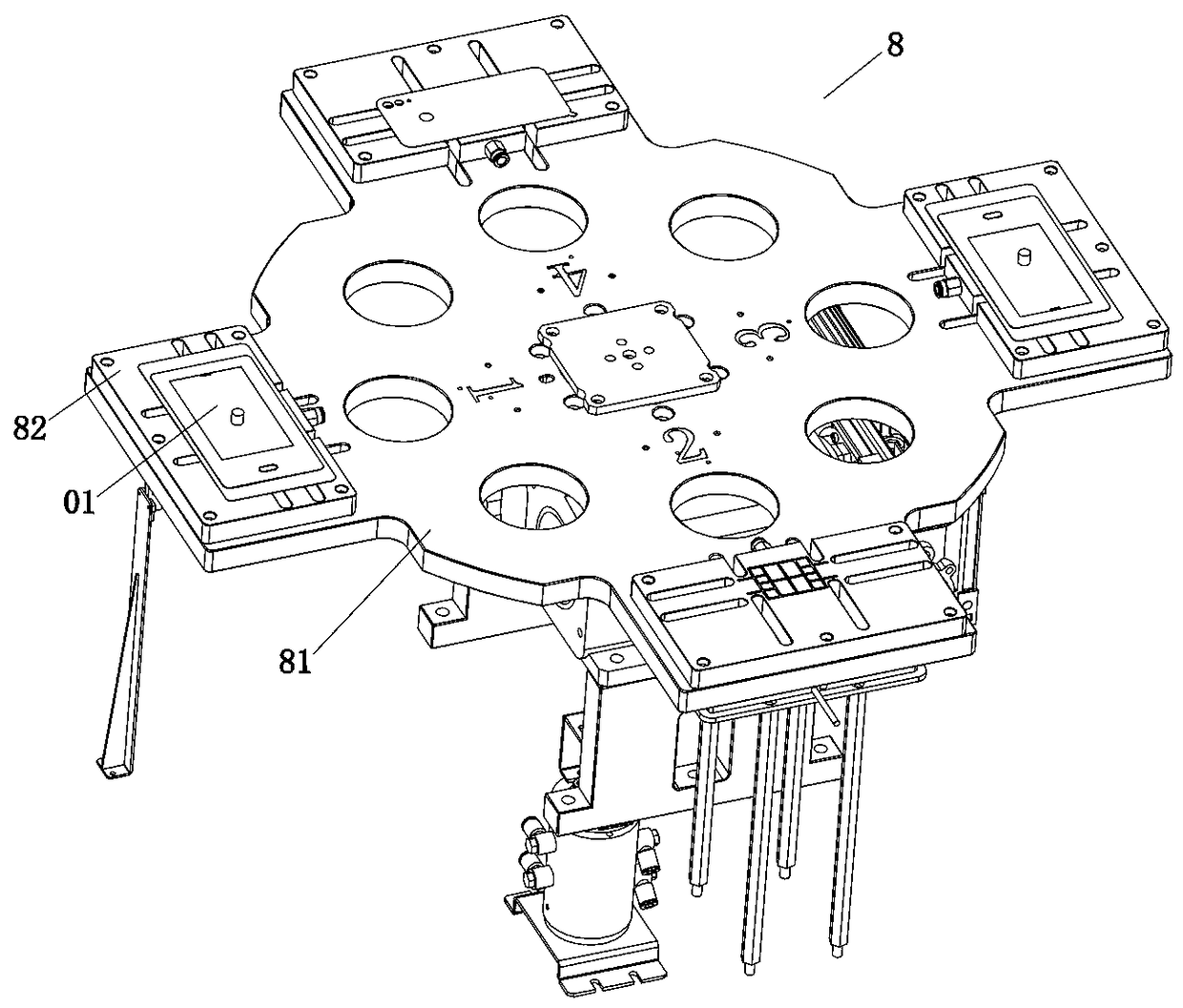

Full-automatic film detecting and pasting production line and film pasting process thereof

ActiveCN109318474AReduce bendingGuaranteed accuracyFinal product manufactureProduction lineGlass sheet

The invention discloses a full-automatic film detecting and pasting production line and a film pasting process thereof. The production line comprises a film feeding assembly, a film taking and detecting mechanical arm, a film transfer table, a correcting and mounting mechanical arm, a film tearing assembly, a glass loading assembly and a turntable; the film pasting process comprises the followingprocess steps of transferring a material frame, picking up the glass sheets and laminating the empty material frames, removing dust of the glass and photographing, film feeding, double-piece detectingand correcting, film recovering and primary correction, film taking and film tearing, membrane position correcting and film pasting. According to the film detecting and pasting production line and afilm pasting process, automatic centralized feeding of the diaphragm and the glass sheet is realized, the production line has a film suction quantity detection function and an automatic film tearing function on the surface of the film, the situation of sticking the double films is effectively avoided, the accuracy of the position of the film pieces in the film tearing process is guaranteed, the bending situation of the film sheet during film tearing is reduced, a sticking head which integrates the functions of film collecting sheet correction and pasting and mounting is adopted, in the film pasting process, the film is in contact rolling with the edge of the glass sheet, so that the situation of film sticking bubbles and crease marks can be effectively reduced, and the film sticking quality can be improved.

Owner:SHENZHEN NUOFENG OPTOELECTRONICS EQUIP

Method for preparing polished crystal tile

The invention discloses a method for preparing a polished crystal tile, comprising the following steps of: accumulating a mixture of low-temperature clinkers and high-temperature clinkers on a printed tile surface baked at high temperature; baking; and polishing. The polished crystal tile prepared with the preparation process has high high-temperature viscosity and stable glass network structure, the baked clinker has certain height and has stereoscopic impression and artistic feeling. The action of the skeleton of the high-temperature clinker is favorable to the discharge of bubbles, and the obtained enamel layer has few bubbles, high transparency and high enamel quality. By regulating the proportion of the low-temperature clinkers and the high-temperature clinkers, the preparation method is suitable for different baking temperatures, is convenient and flexible and is suitable for different products.

Owner:广东道氏陶瓷材料有限公司

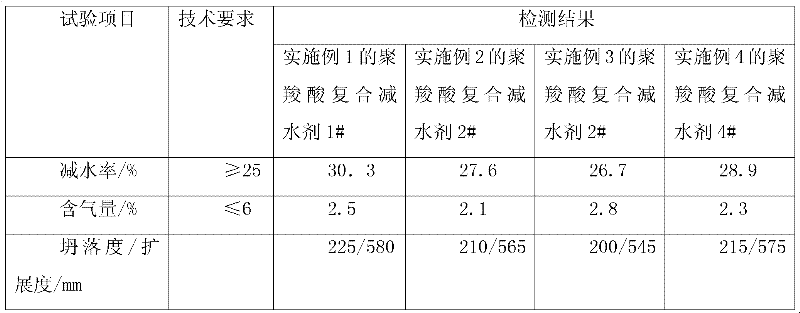

Composite polycarboxylic acid water reducing agent

The invention belongs to the technical field of concrete additives, in particular relates to a water reducing agent, and more particularly a composite polycarboxylic acid water reducing agent. The composite polycarboxylic acid water reducing agent is characterized by being prepared from the following components in percentage by mass: 8-28.6 percent of polycarboxylic acid high-performance water reducing agent, 0.5-7.36 percent of inhibiting agent, 0.001-0.15 percent of functional aid, 0.01-0.65 percent of preservative and the balance of water, wherein the total mass percentage of the components is 100 percent. The composite polycarboxylic acid water reducing agent is applied to freshly mixed concrete. After a template coated with waste engine oil or rosinate soap is dismantled, the surface of hardened concrete is smooth, air bubbles are reduced remarkably, and the construction requirement is fully met. By adopting the composite polycarboxylic acid water reducing agent, the problem of a large quantity of air bubbles on the surface of concrete, produced after the use of demolding agents such as waste engine oil or rosinate soap and the like is solved.

Owner:CHINA STATE CONSTR ENG CORP TIANJIN +1

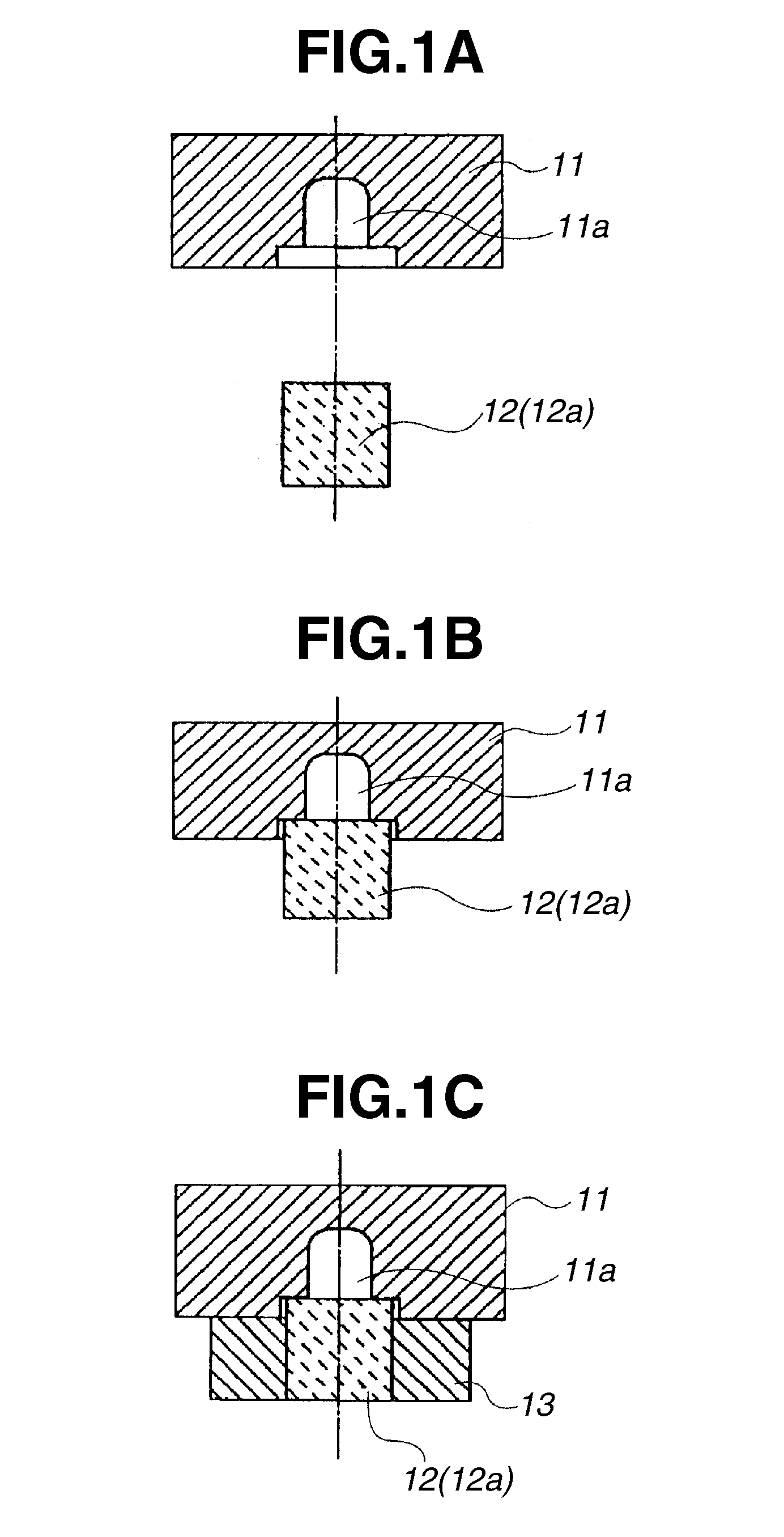

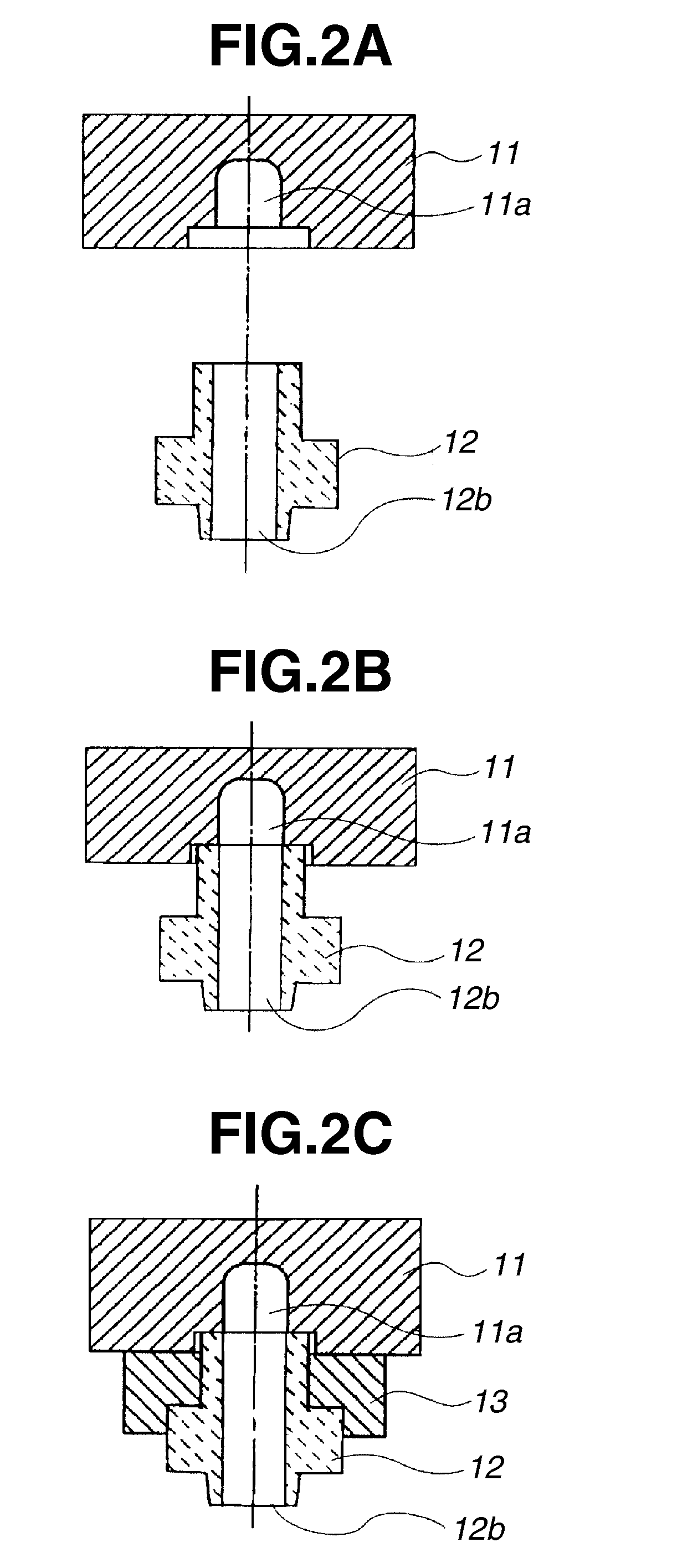

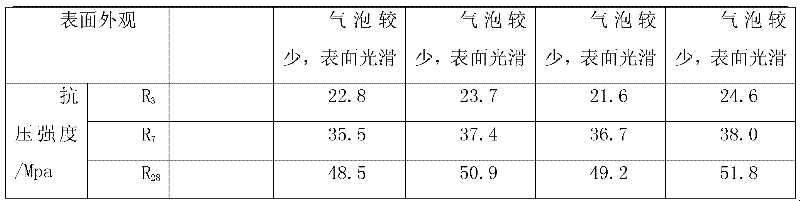

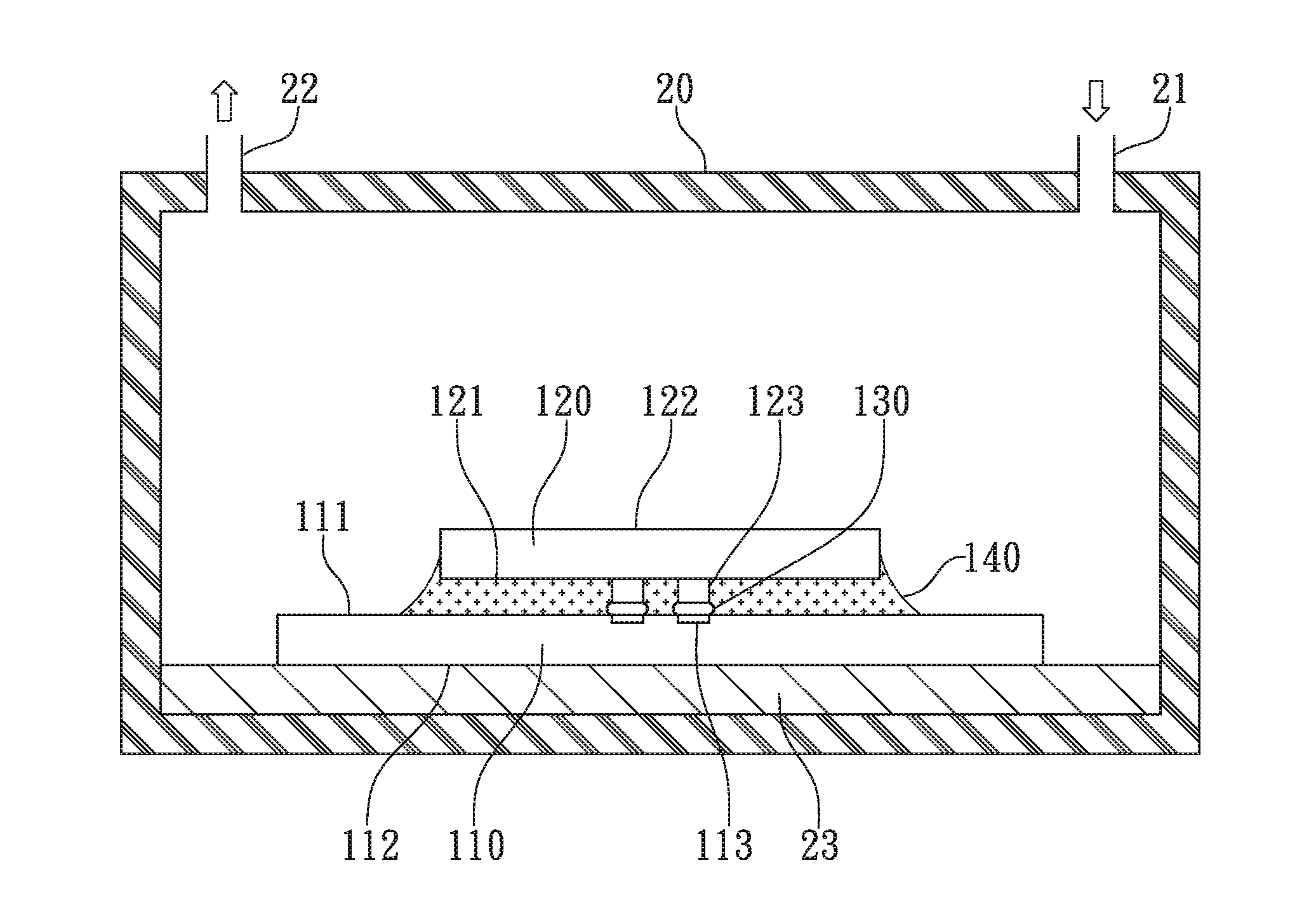

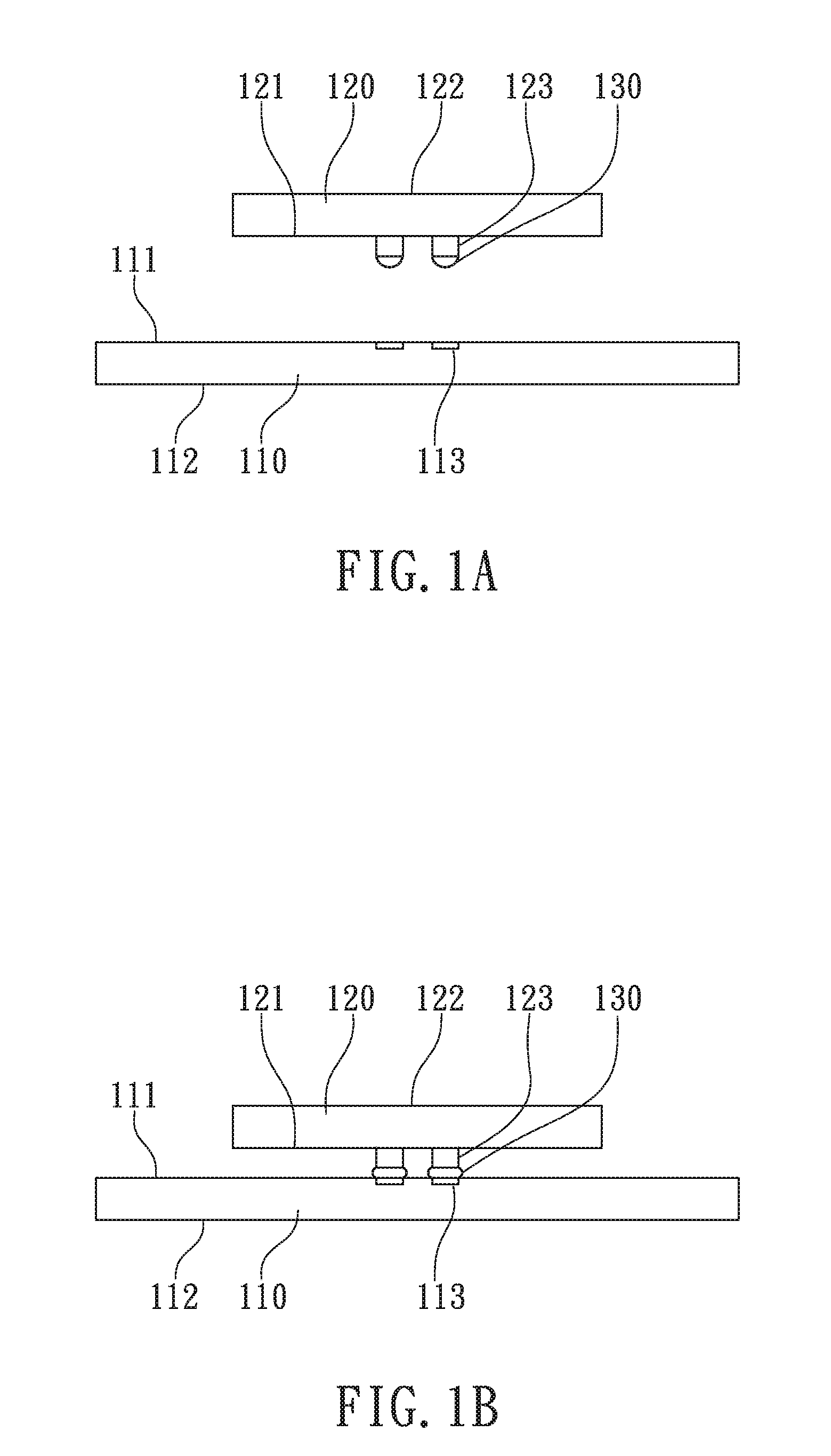

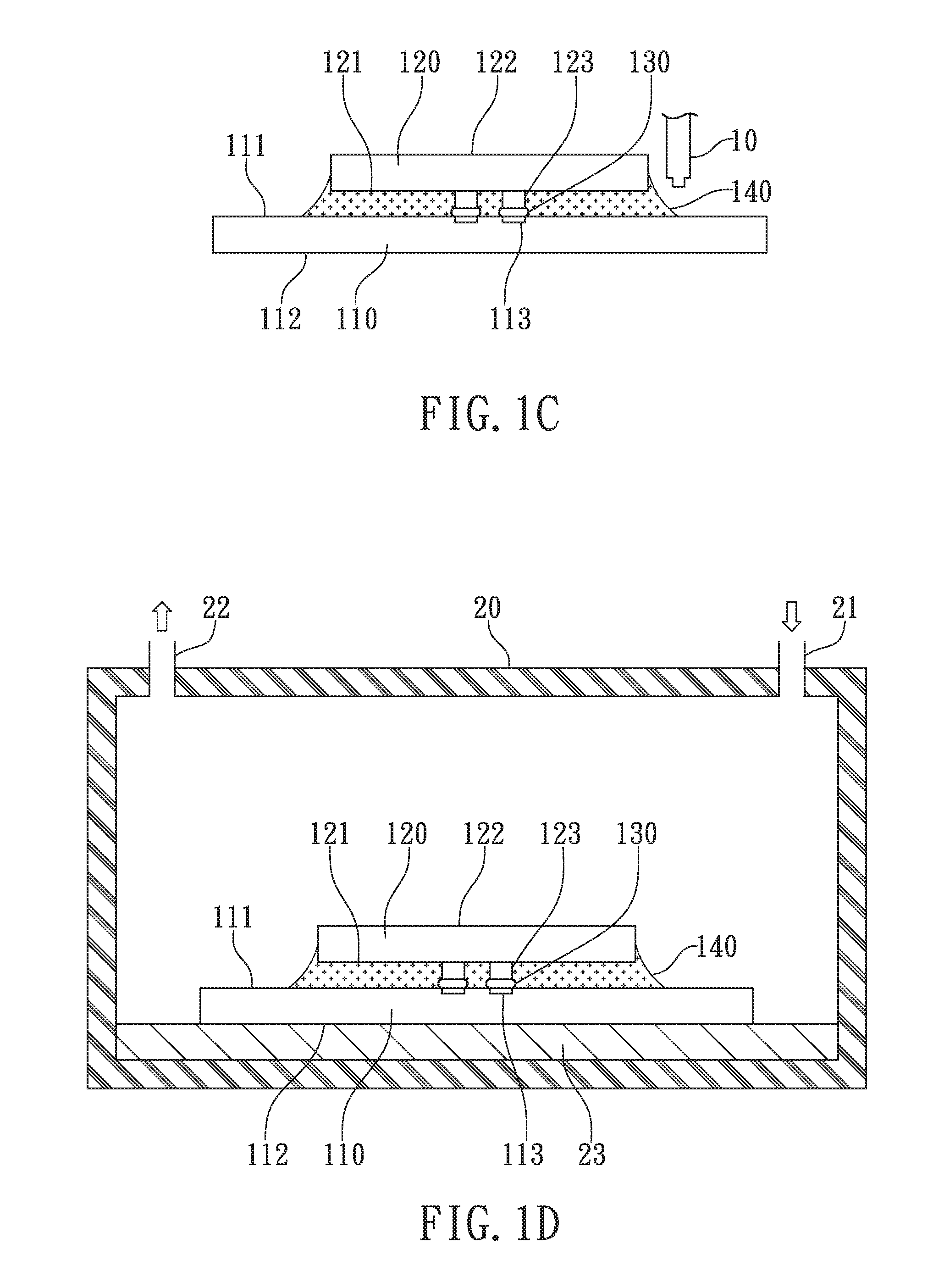

Flip-chip bonding method to reduce voids in underfill material

InactiveUS20120077312A1Reduce materialImprove adhesionSemiconductor/solid-state device detailsSolid-state devicesFilling materialsElectrical and Electronics engineering

Disclosed is a flip-chip bonding method to reduce voids in underfill material. A substrate with connecting pads is provided. At least a chip with a plurality of bumps is bonded on the substrate and then an underfill material is formed between the chip and the substrate. Finally, the substrate is placed in a pressure oven in which a positive pressure greater than one atm is provided, meanwhile, the underfill material is thermally cured with exerted pressures to reduce bubbles or voids trapped inside the underfill material to avoid popcorn issues due to CTE mismatch between the chip and the substrate. In one embodiment, another underfill material is further formed between a plurality of chips and bubbles or voids trapped between the chips are also reduced by the pressurized curing.

Owner:WALTON ADVANCED ENG INC

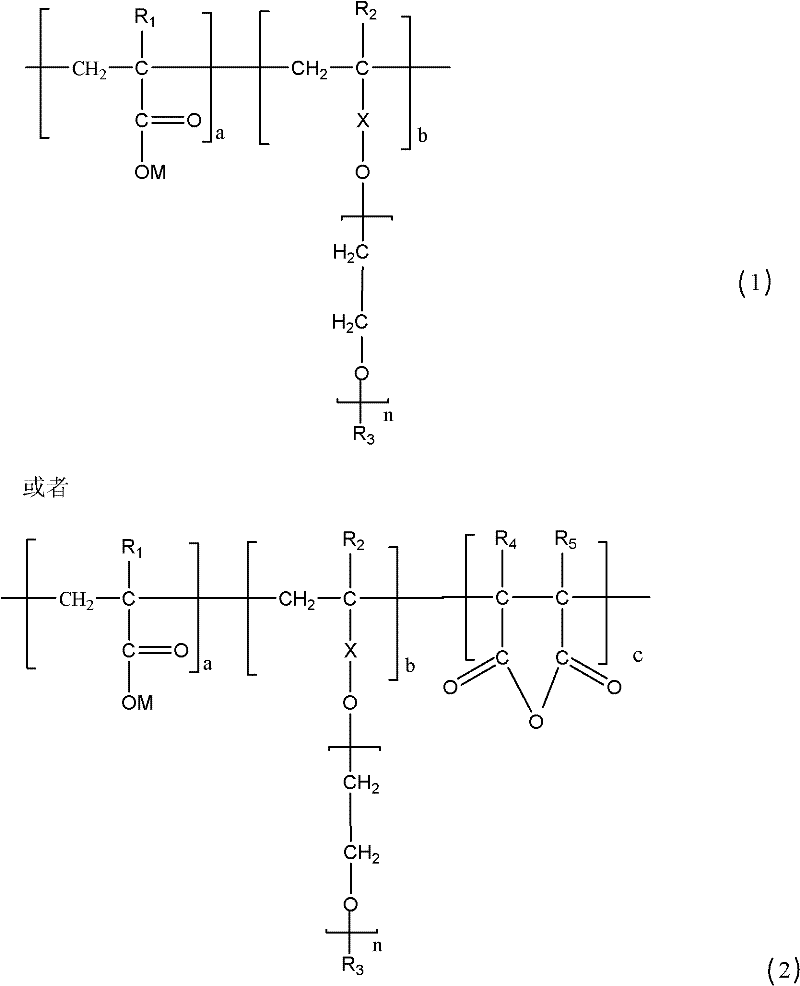

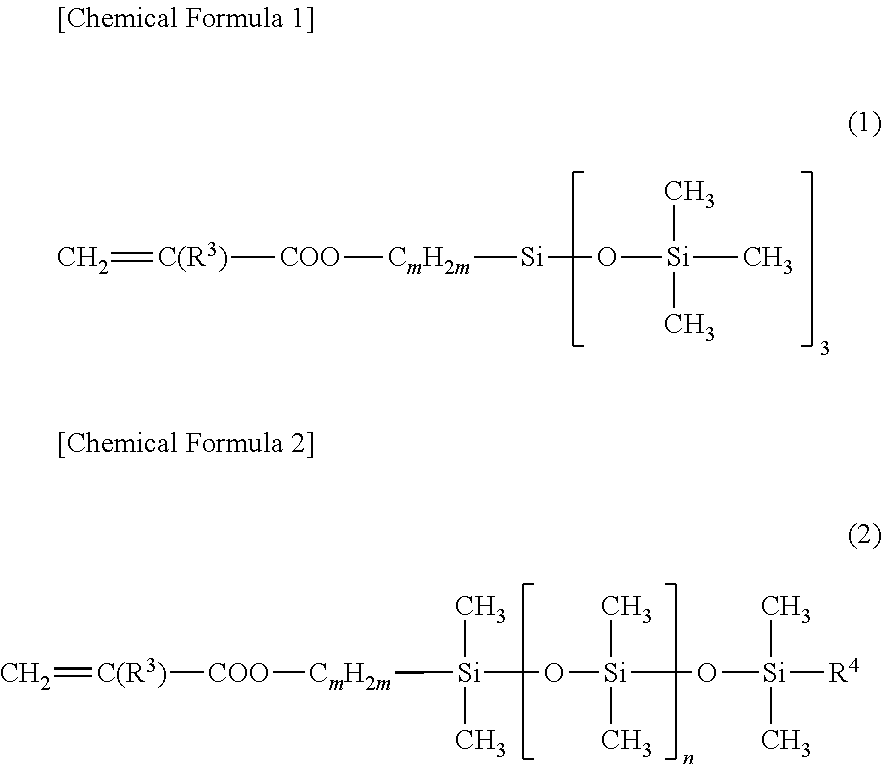

Thickener for excavating slurry, excavating slurry using the the thickener, and cast-in-place underground pile work method and underground continuius wall work method using the excavating slurry

InactiveUS20040121916A1Reduce the presence of air bubblesConstruction works can be stably conductedEmbankmentsExcavationsSlurry wallEmulsion

Subjects for the present invention are to provide a thickening agent for excavation stabilizing slurries which has excellent cement contamination resistance, is difficult to putrefy, and is prevented from bubbling, which may be problematic in construction works, and to provide an excavation stabilizing slurry containing the thickening agent and a cast-in-place underground pile method and an diaphragm wall construction method each using the slurry. The present invention provides a thickening agent for excavation stabilizing slurries which contains an emulsion thickening with an alkali, wherein in a strong agitation bubbling test of a mixture prepared by adding an alkaline substance to the thickening agent, the resulting mixture has an apparent specific gravity of 1.05 g / ml or higher as measured immediately after the strong agitation and has an apparent specific gravity of 1.10 g / ml or higher as measured at 10 minutes after the strong agitation. This thickening agent is used to prepare an excavation stabilizing slurry.

Owner:NIPPON SHOKUBAI CO LTD

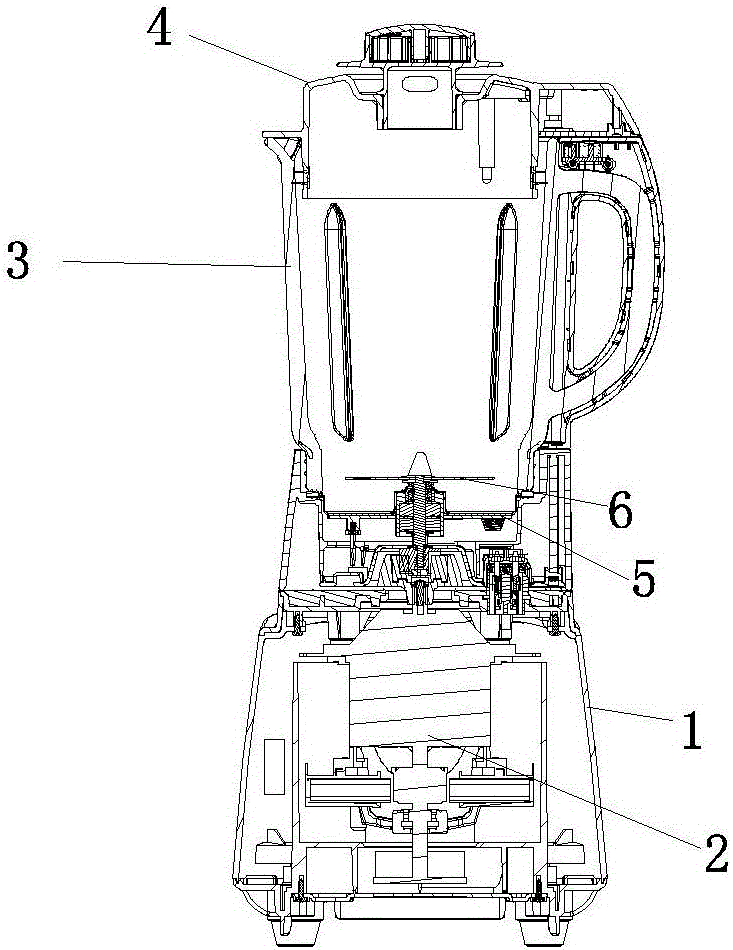

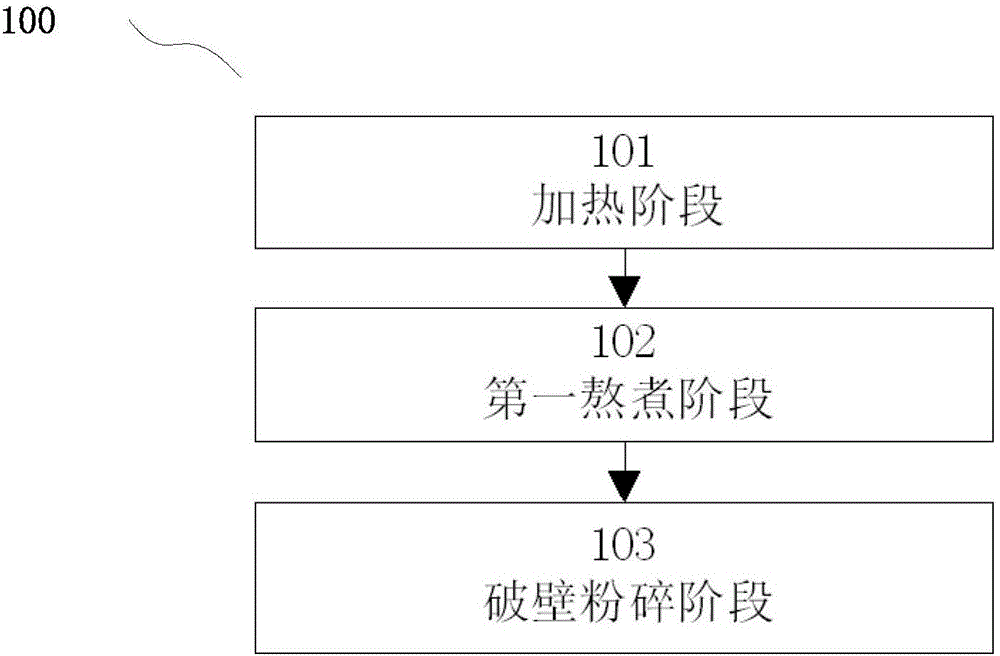

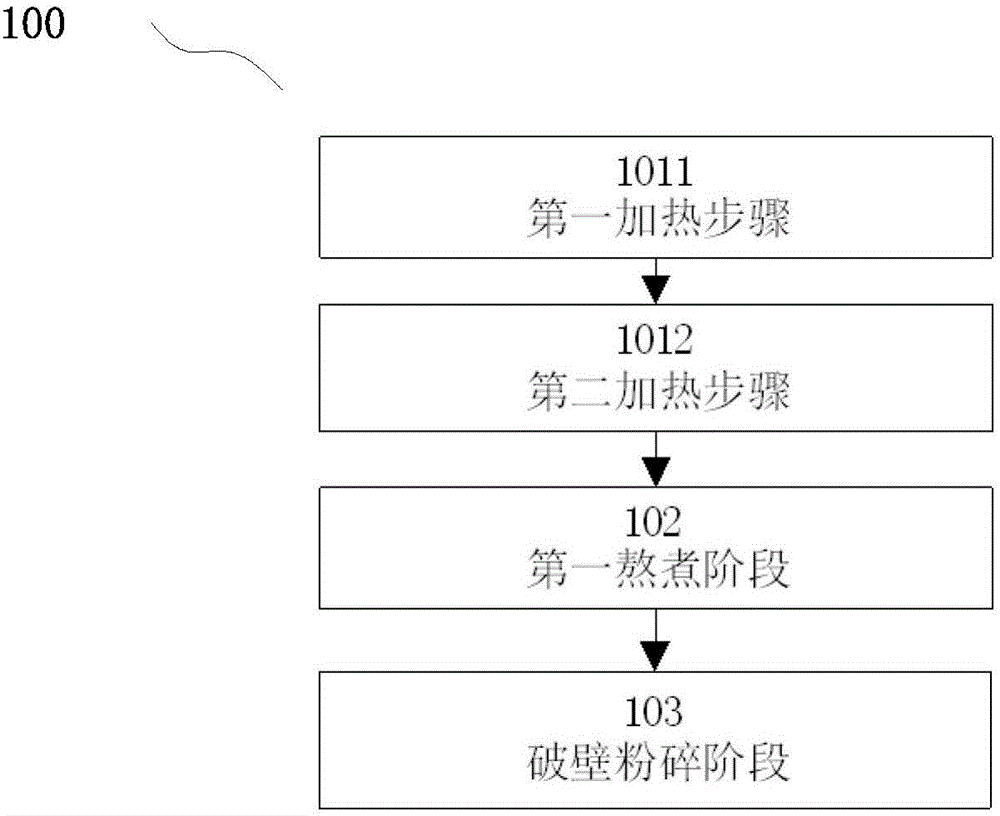

Food processing method of motor under-set-type food processing machine and food processing machine

The invention relates to a food processing method of a motor under-set-type food processing machine and the food processing machine, and belongs to the field of food processing. The food processing method at least comprises a heating stage, a first cooking stage and a wall-breaking and grinding stage, wherein in the heating stage, food in a stirring cup is heated to be boiling by virtue of a heating device; in the first cooking stage, the food in the stirring cup is cooked for a duration of t1 by virtue of the heating device until the food is completely cooked, and during cooking, a grinding cutter is driven to do intermittent rotation at a first rotating speed by virtue of a motor; and in the wall-breaking and grinding stage, the grinding cutter is driven to rotate at a second rotating speed by virtue of the motor so as to grind the cooked food in the stirring cup, and the second rotating speed, which ranges from 20000r / min to 40000r / min, is greater than the first rotating speed, wherein the power of the heating device in the first cooking stage is less than that in the heating stage. The food processing machine using the food processing method provided by the invention can uniformly heat the food, and the phenomenon of over-burnt bottom and spillover cannot occur easily.

Owner:JOYOUNG CO LTD

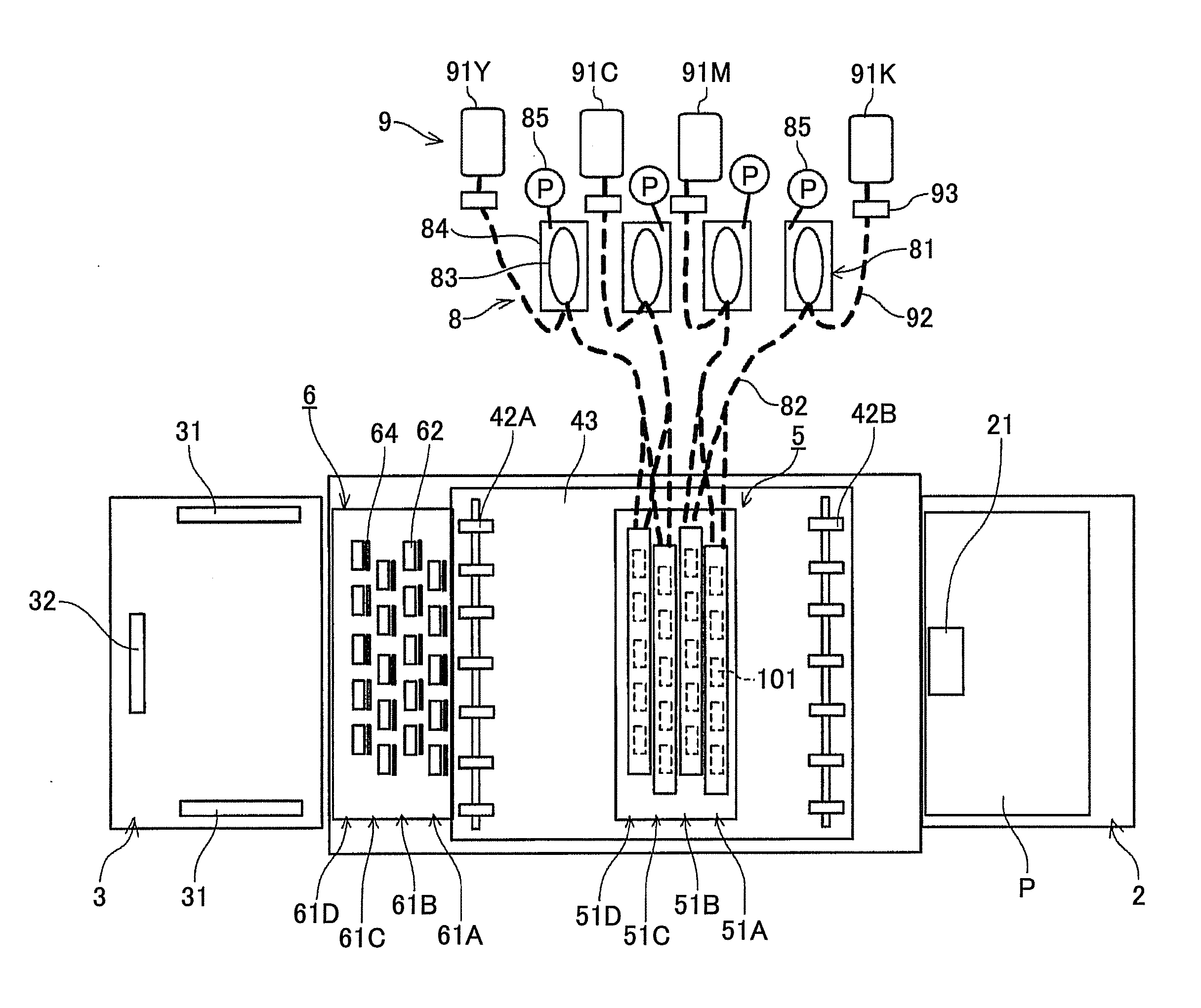

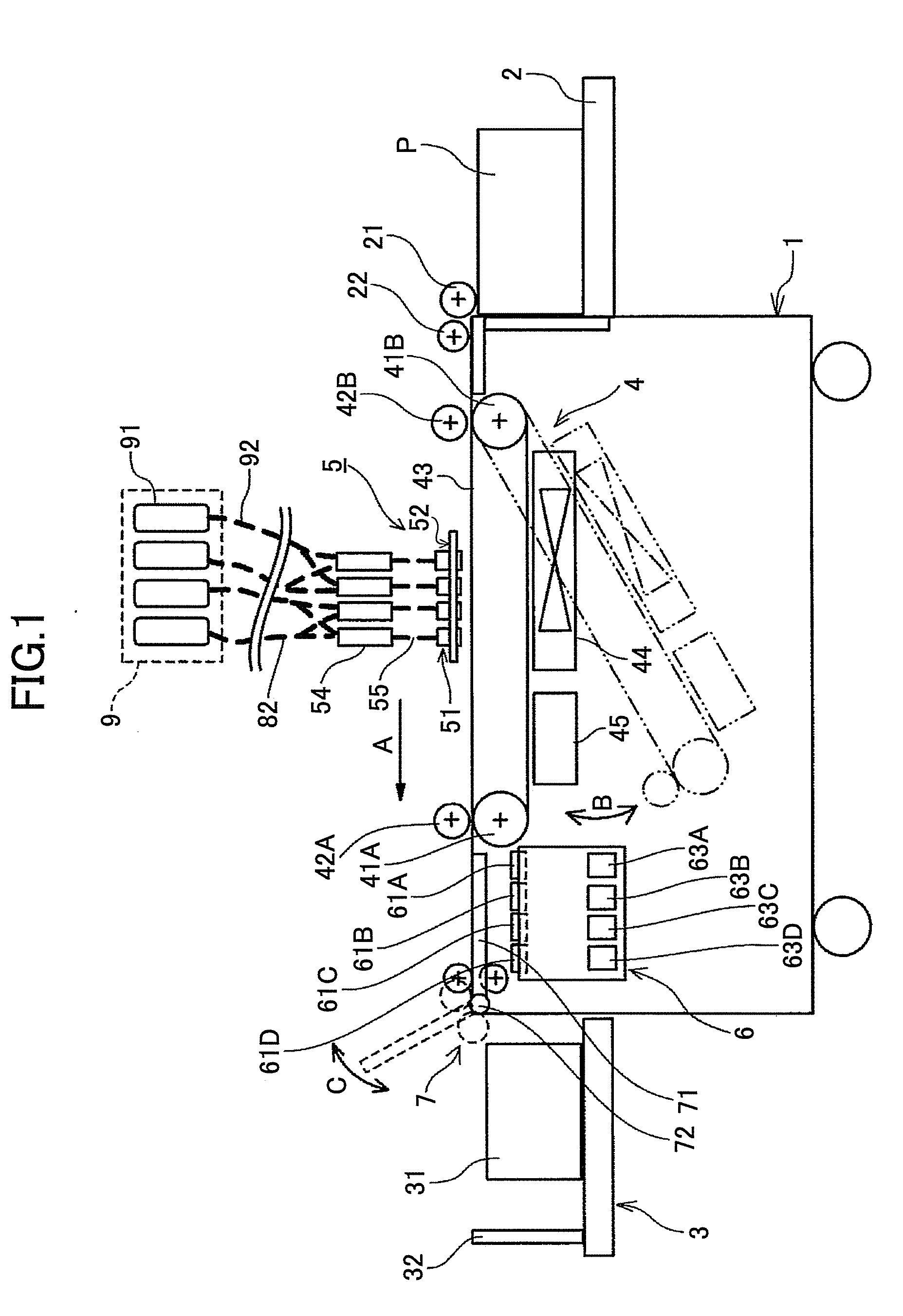

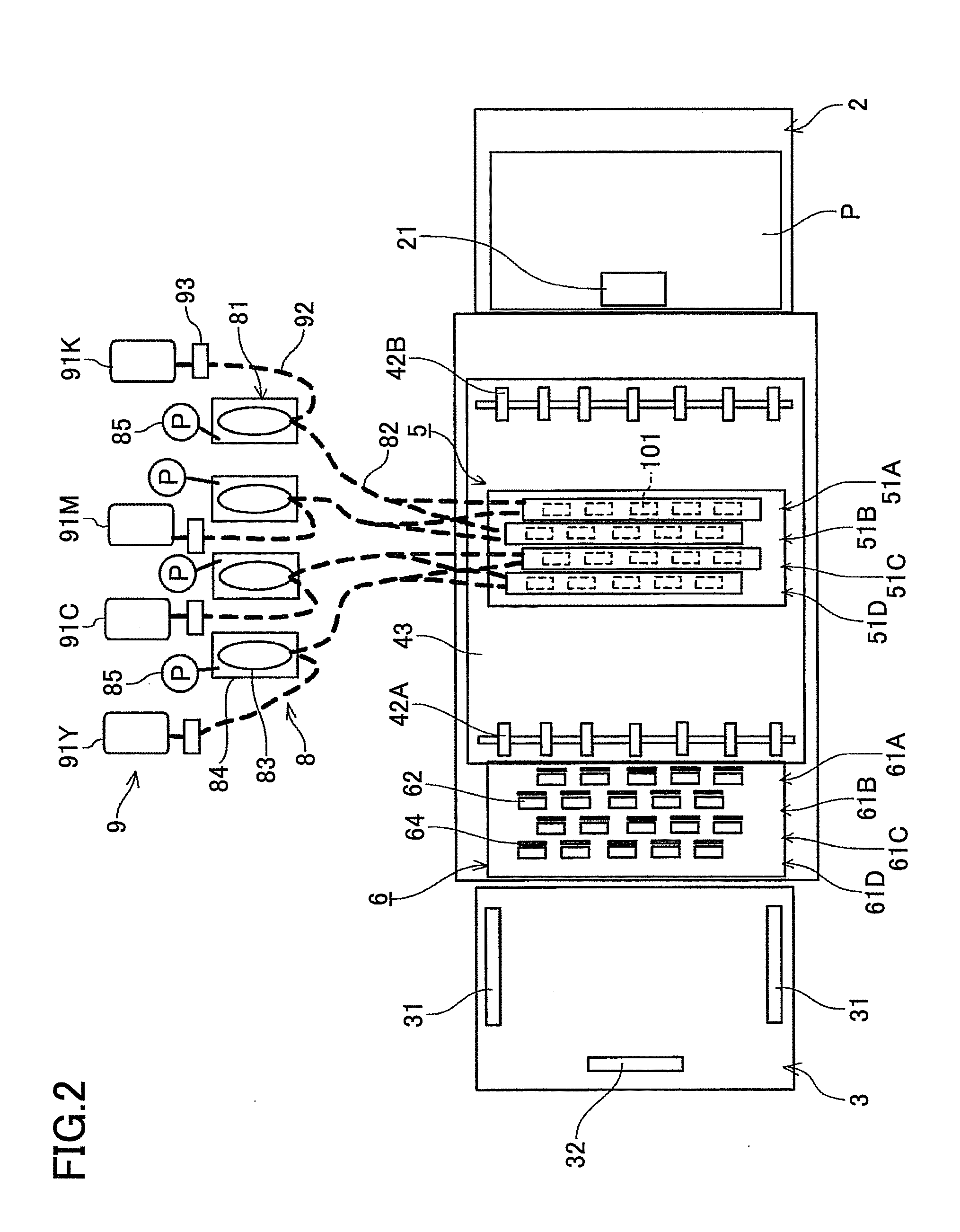

Liquid jetting head unit and image forming apparatus

ActiveUS20110181670A1Reduce the presence of air bubblesInking apparatusSettling tanks feed/dischargeLiquid jetEngineering

In a liquid jetting head unit, a tank case in a head tank includes a first connection path connecting a downstream chamber of the tank case and a discharge path, and a second connection path connecting an upstream chamber of the tank case and the discharge path. The discharge path includes a filter member provided between a first part of the discharge path connected to the first connection path and a second part of the discharge path connected to the second connection path.

Owner:RICOH KK

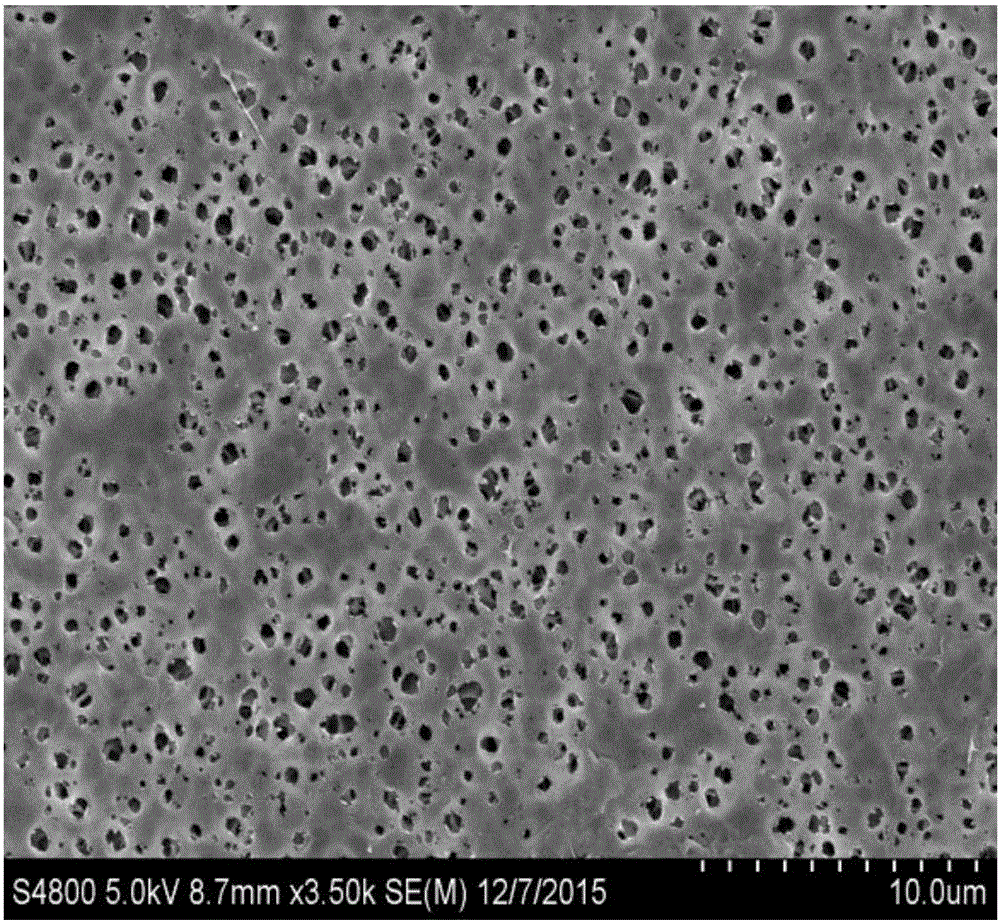

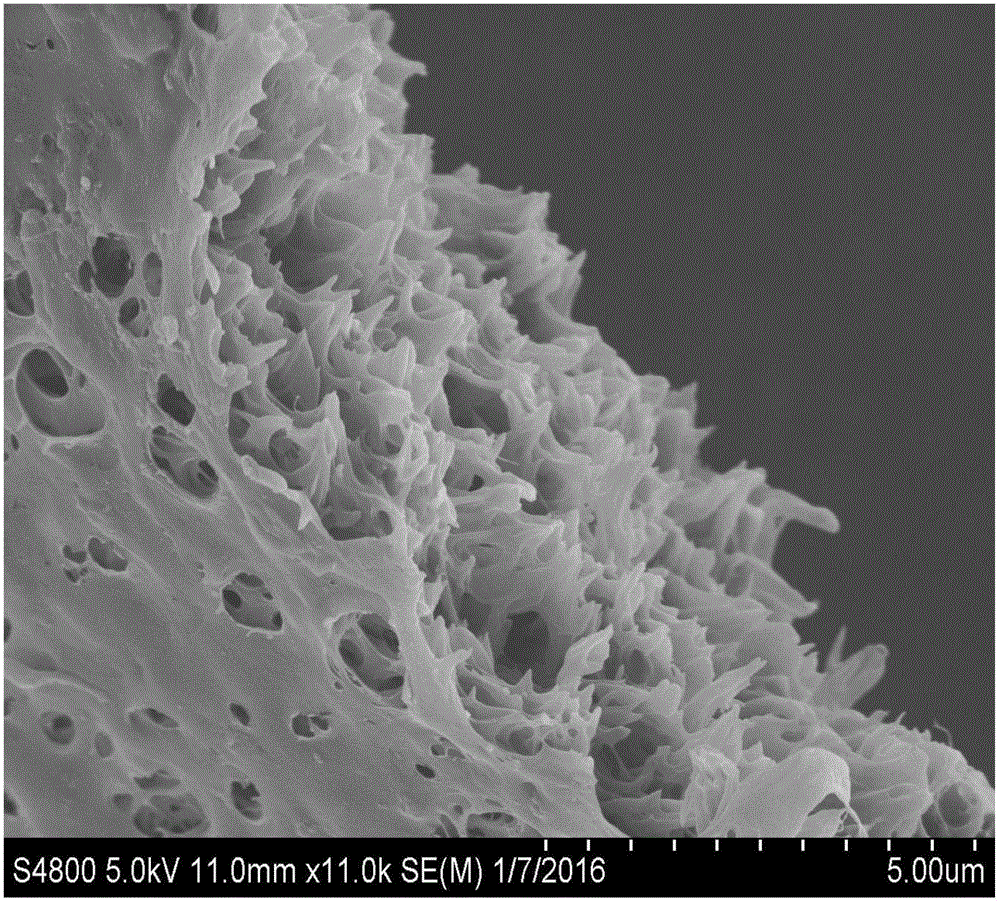

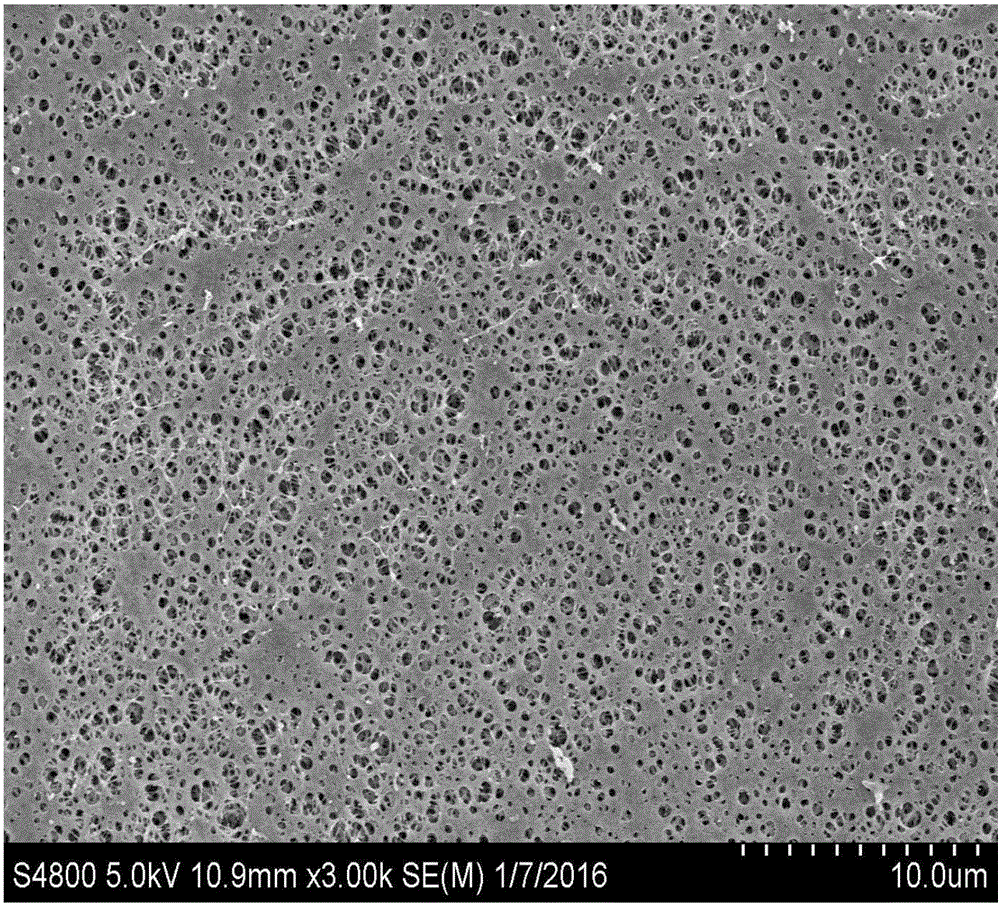

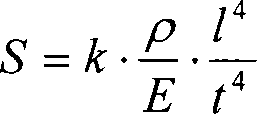

Novel nano-crystalline cellulose modified lithium ion battery diaphragm and preparation method thereof

ActiveCN105720224AGood mechanical propertiesImprove hydrophilicitySecondary cellsCell component detailsPolymer substrateLithium electrode

The invention discloses a novel nano-crystalline cellulose modified lithium ion battery diaphragm and a preparation method thereof, and aiming to provide a novel nano-crystalline cellulose modified lithium ion battery diaphragm which has relatively high hydrophily, liquid absorption rate, liquid retention rate, mechanical property and environmental friendliness and a preparation method thereof. The novel nano-crystalline cellulose modified lithium ion battery diaphragm comprises cellulose nanofiber-lithium and a polymer substrate and is prepared according to the steps of film scraping liquid configuration, defoaming, film scarping and coagulating bath. The cellulose nanofiber-lithium improved lithium ion battery diaphragm prepared according to the method is favorably maintained with a natural cellulose I crystal structure, a composite membrane is endowed with relatively high mechanical performance, and the hydrophily and the stability of the composite membrane are improved; and the method has the advantages of very high industrial production capability and wide application prospect.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY +2

Bottom pouring type vacuum perfusion process

The invention relates to a bottom pouring type vacuum perfusion process. A flow guidance screen is placed below a glass fiber cloth pavement layer, and resin is perfused upwards from the surface of a die so that air bubbles in the resin are led out directly. The resin saturates glass fibers from bottom to top. In order to eliminate micro air bubbles in the resin, a layer of VAP film is paved on the surfaces of the glass fibers. A layer of ventilating felt is paved on the VAP film as a transmission medium of a gas to evenly distribute vacuum, and the ventilating felt is connected with a vacuum pipe, and the vacuum of a whole perfusion system is evenly distributed, but the resin cannot be leaked out. The air bubbles in the resin are greatly reduced so that the compaction rate of a product is improved. The upper surface of the product is an adhesive surface without air bubbles, so the upper surface can be adhered to other parts of a blade very well. The bottom pouring type vacuum perfusion process improves the reliability of the process and is convenient for field control, the most significant characteristic of the resin flow is that the resin flows from the die to a non-die surface of the product, and the bottom pouring type vacuum perfusion process is different from the conventional top pouring type process.

Owner:LIANYUNGANG ZHONGFU LIANZHONG COMPOSITES GRP

Aluminium borosilicate glass with high elastic modulus and uses thereof

ActiveCN101117270AImprove melting qualityReduce the presence of air bubblesSilicate glassFlat panel display

The invention relates to a calcium-aluminium borosilicate glass with high modulus of elasticity and is prepared and manufactured according to percentage by weight of the following raw materials: 55-63.5SiO2, 8-10.5B2O3, 15-21Al2O3, 0-3.5MgO, 4-10CaO, 0-5SrO, 1-5.5BaO, 0.001-4Y2O3, 0-2.5La2O3, 0-0.5ZnO, 0-0.3ZrO2, 0.005-0.08R2O(R=Li, Na, K). The invention has the advantages of high strain point, low coefficient of expansion, high modulus of elasticity and nonalkali basically; and is fit for a flat panel display, particularly for manufacture of TFT-LCD glass substrate.

Owner:HENAN ANCAI HI-TECH +1

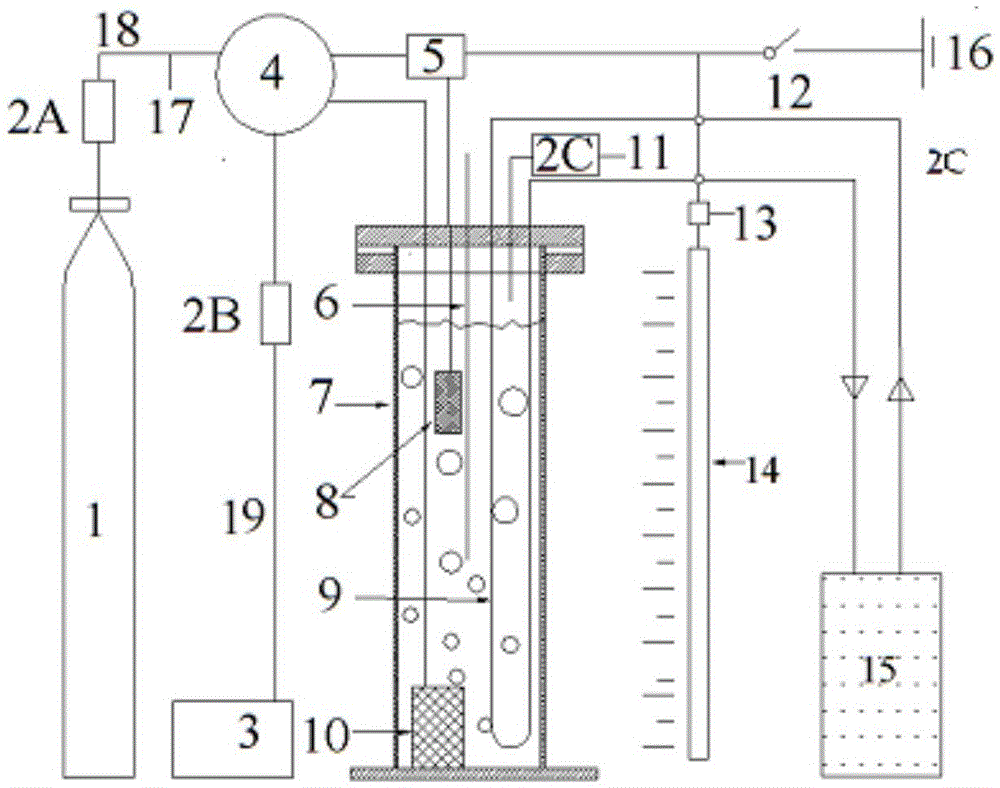

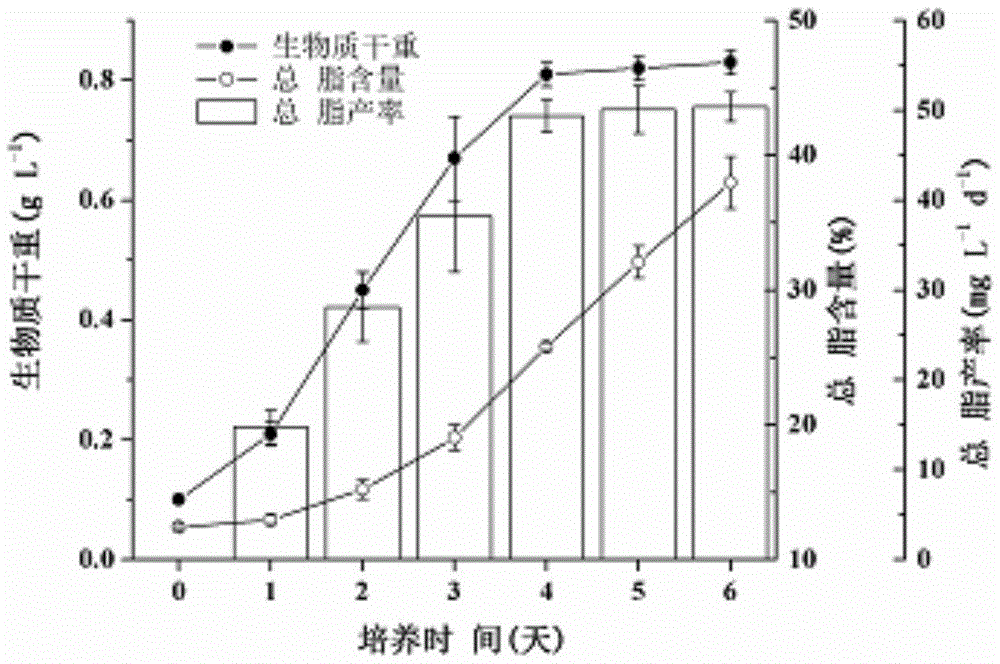

Method and device for synchronously producing oil, sequestrating carbon, desulfurizing and denitrifying by utilizing microalgaes

ActiveCN105483013ASolve technical problemsEliminate "ToxicBioreactor/fermenter combinationsBiological substance pretreatmentsAutomatic controlBiodiesel

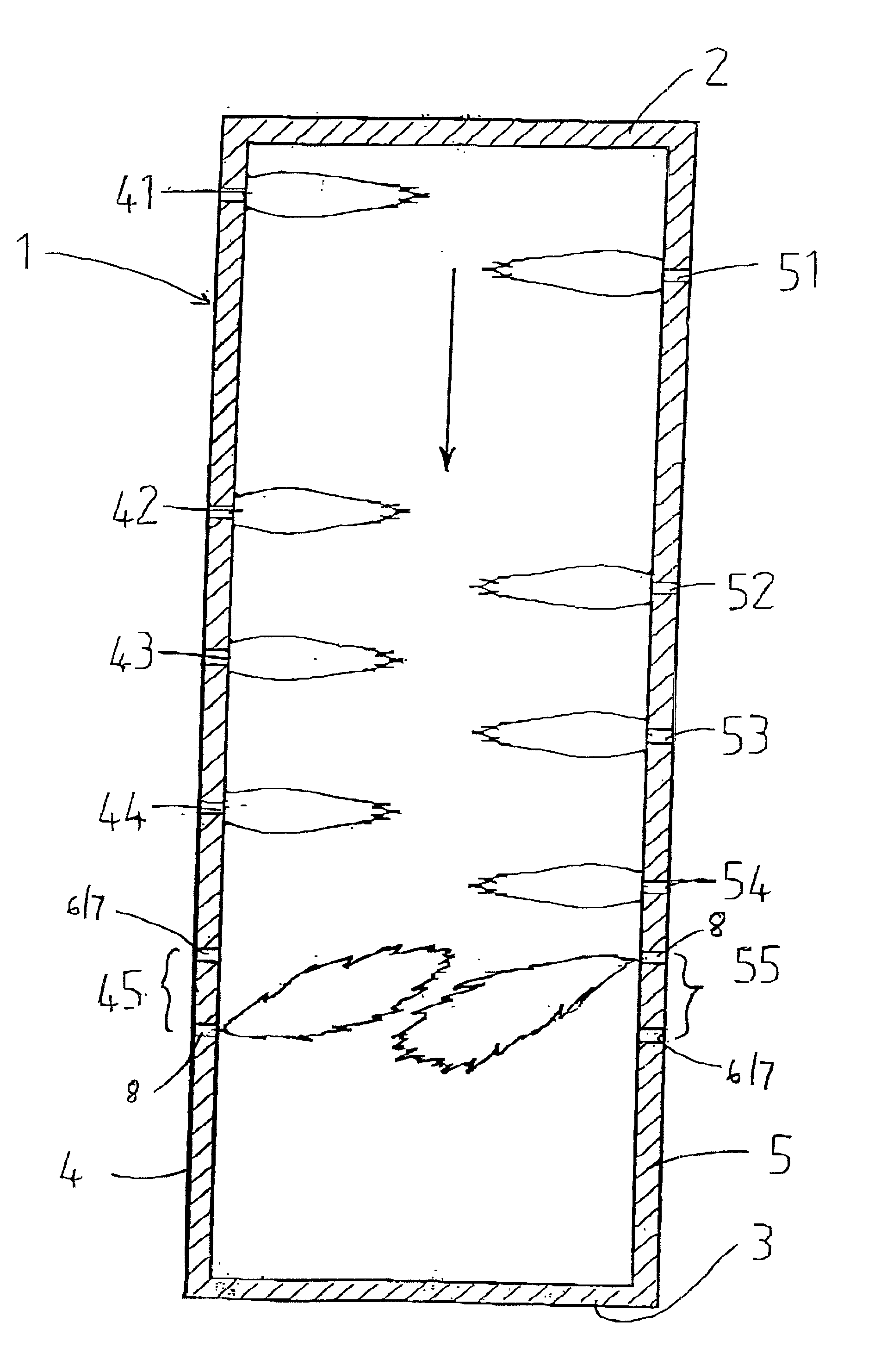

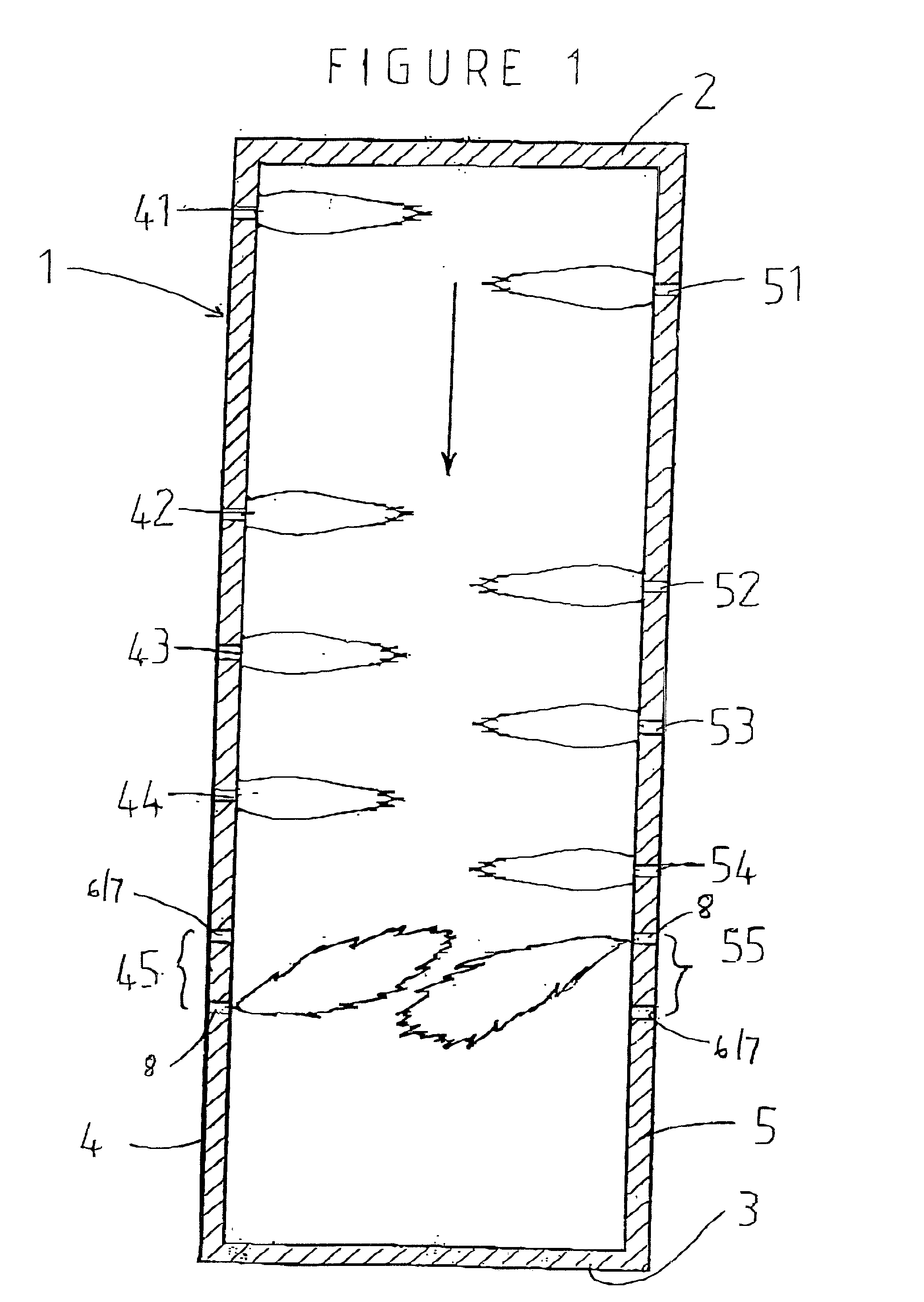

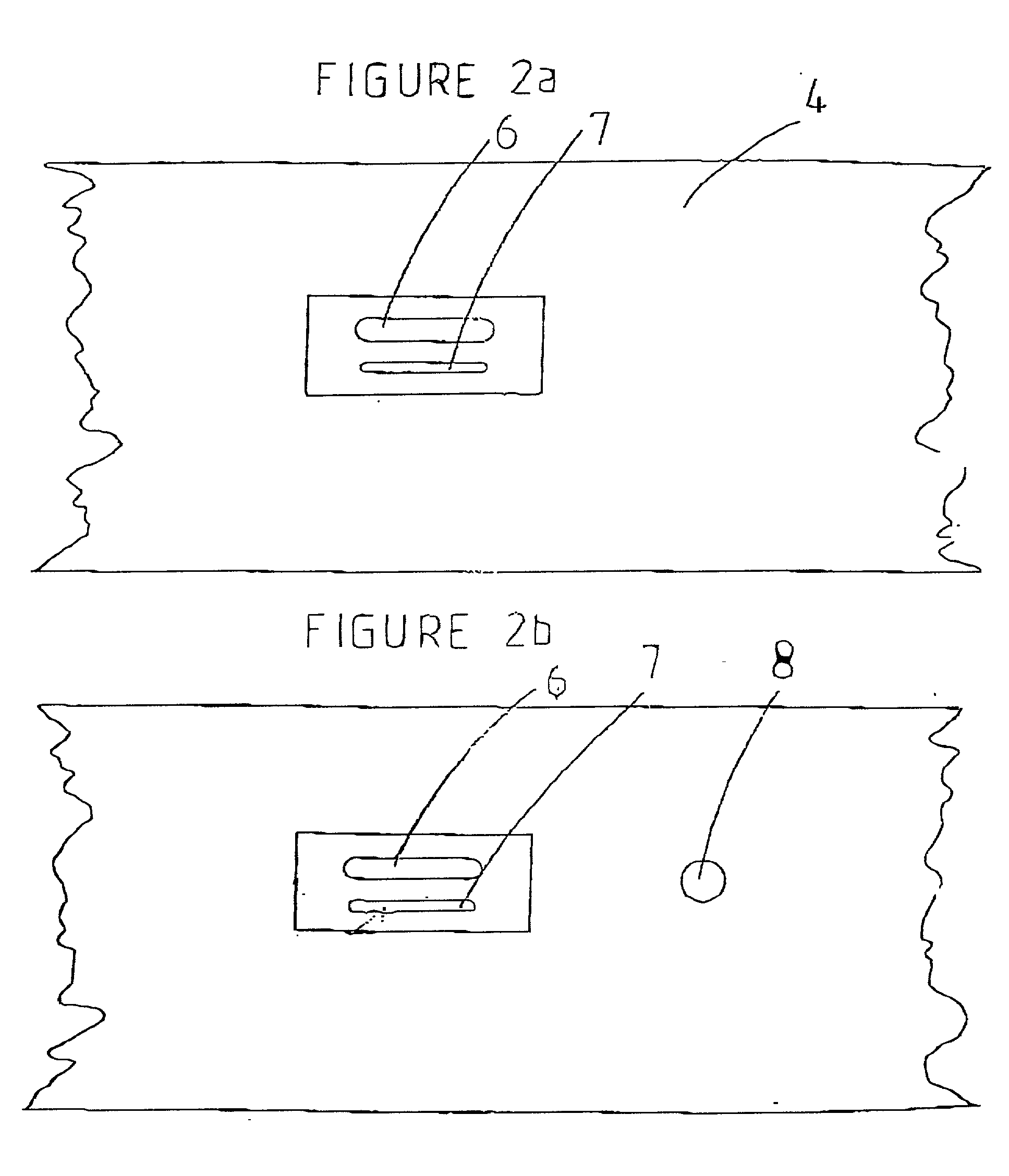

The invention discloses a method for synchronously producing oil, sequestrating carbon, desulfurizing and denitrifying by utilizing microalgaes. The method for synchronously producing oil, sequestrating carbon, desulfurizing and denitrifying by utilizing the microalgaes comprises the following steps: 1, selecting species of microalgaes; 2, preparing a microalgae culture medium; 3, disinfecting a photobioreactor; 4, inoculating the microalgaes; 5, culturing the microalgaes; and 6, harvesting the microalgaes. A device for synchronously producing oil, sequestrating carbon, desulfurizing and denitrifying by utilizing the microalgaes comprises a photobioreactor, a lighting system, a temperature control system, a pH and flue gas control system, an alternating current power supply and a power supply master switch, wherein the systems cooperate with the photobioreactor. The device is specially designed for the method, and the method relies on the device. The method disclosed by the invention has the advantages that the flue gas is directly utilized for culturing oil-producing microalgaes, and microalgae oil (a raw material of microalgae biodiesel) is obtained while biological fixation of CO2 in the flue gas and removal of sulfur oxides (mainly sulfur dioxide SO2) and nitrous oxides (mainly nitric oxide NO) are realized. The device disclosed by the invention is reasonable in structure, automatically controls introduction and close of the flue gas and has high efficiency of removing CO2, SO2 and NO in the flue gas.

Owner:武汉植物园园艺中心有限公司

Aqueous ozone solution for ozone cleaning system

ActiveUS20090233839A1Small bubble sizeReduce the amount requiredInorganic/elemental detergent compounding agentsFlow mixersProduct gasAqueous solution

A method of making an aqueous ozone solution for an industrial cleaning system is described. The method includes providing a reaction vessel for entraining ozone gas in an aqueous solution. The reaction vessel includes a conical-shaped surface having a two or more edges or ridges. The conical-shaped surface defines an interior, and two or more edges or ridges are in contact with the interior. The reaction vessel is in fluidic communication with a supply of water. The reaction vessel is in fluidic communication with a supply of a first aqueous ozone solution. The first aqueous ozone solution is directed to the conical-shaped surface. Water is directed to the conical-shaped surface, and the water and the first aqueous ozone solution are mixed to form a second aqueous ozone solution.Compositions for aqueous ozone solutions are also described. The aqueous ozone solution contains approximately 1 part by volume water mixed with approximately 4 parts by volume to approximately 9 parts by volume of a first aqueous ozone solution to form a second aqueous ozone solution that has an oxidation reaction potential of up to approximately 2.6. The second aqueous ozone solution has an ozone concentration of up to approximately 20 ppm.

Owner:CLEANCORE SOLUTIONS LLC

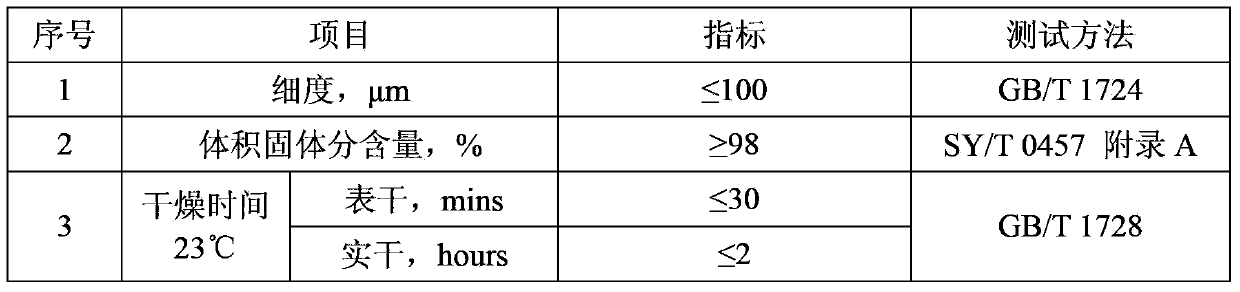

Dissolvent-free polyurethane weather-proof anticorrosive coating for storage tank

ActiveCN103421420AReduces coating bubble problemsGood anti-corrosion performanceLiquid surface applicatorsAnti-corrosive paintsAnoxomerSolvent free

The invention relates to a dissolvent-free polyurethane weather-proof anticorrosive coating for a storage tank. The coating is composed of a component A and a component B, wherein the component A comprises the following components by weight percentage: 20-60 percent of hydroxide radical, 0.3-1.0 percent of dispersant, 0.5-2.0 percent of antifoamer, 0.2-0.6 percent of leveling agent, 2.0-5.0 percent of dehydrator, 0.5-1.0 percent of anti-settling agent, 0.1-1.0 percent of curing accelerator, 1.0-3.0 percent of ultraviolet absorbefacient, 0.5-2.0 percent of photostabilizer, 0.2-1.0 percent of antioxidant, 5.0-20 percent of aluminum dihydrogen tripolyphosphate, 10-25 percent of titanium dioxide, 10-20 percent of barium sulfate and 4.0-6.0 percent of zeolite power, wherein the component hydroxide radical is polyester polyether polylol obtained by chemically modifying castor oil; the component B is a hexamethylene diisocyanate curing agent; the weight ratio of the component A to the component B is 100:25-100:50. Via the selection of the terminal hydroxyl compound and the curing agent in the component A, bubbles in the anticorrosive coating are reduced. The coating has good anticorrosive performance, and besides, the super-high performance of UV aging resistance and salt and fog resistance is suitable for the outer wall construction of the storage tank.

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

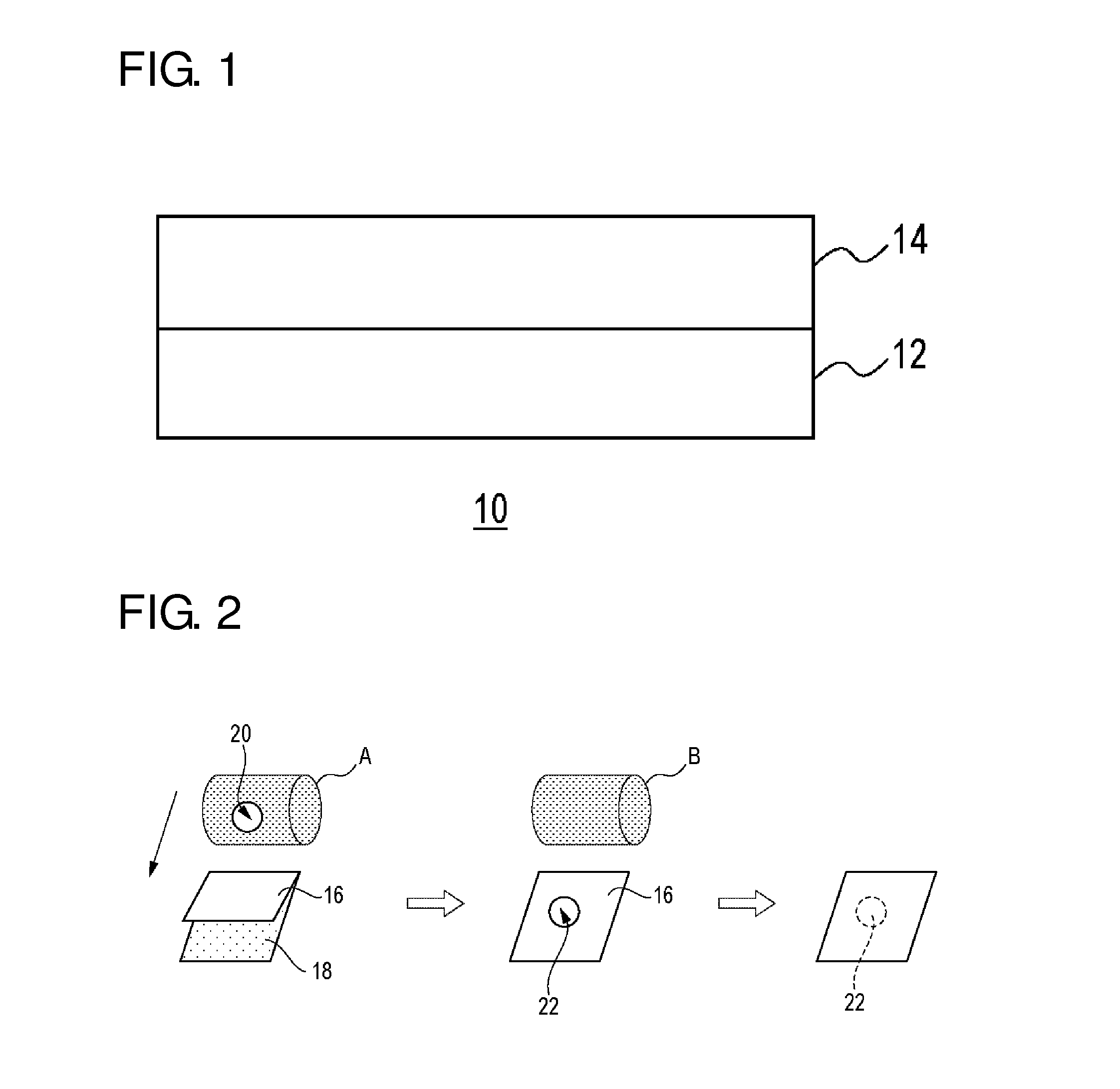

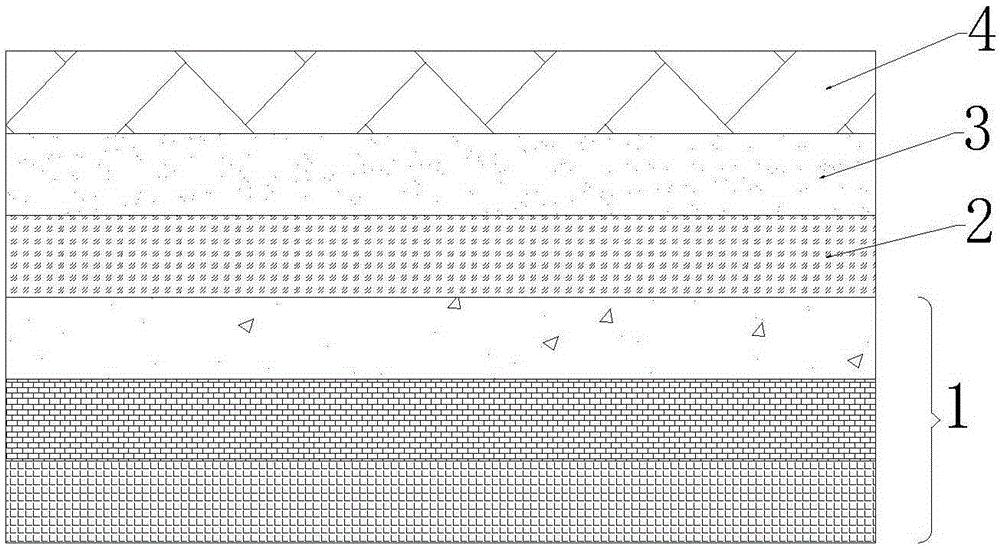

Pressure-sensitive adhesive sheet

ActiveUS20170043566A1Reduce the presence of air bubblesEasy to disassembleLayered product treatmentAdhesive articlesEngineeringPressure sensitive

A pressure-sensitive adhesive sheet has a substrate and a pressure-sensitive adhesive layer laminated on at least one side of the substrate. The sheet is configured such that: pressure-sensitive adhesive force N1, occurring after the pressure-sensitive adhesive layer is attached to a stainless steel plate (430 BA plate) and is left at 23° C. for 10 seconds, is 1.0 [N / 20 mm] or less; pressure-sensitive adhesive force N2, occurring after the pressure-sensitive adhesive layer is attached and is aged at 80° C. for 5 minutes, is 3.0 [N / 20 mm] or more; and N2 / N1 is 5.0 or more.

Owner:NITTO DENKO CORP

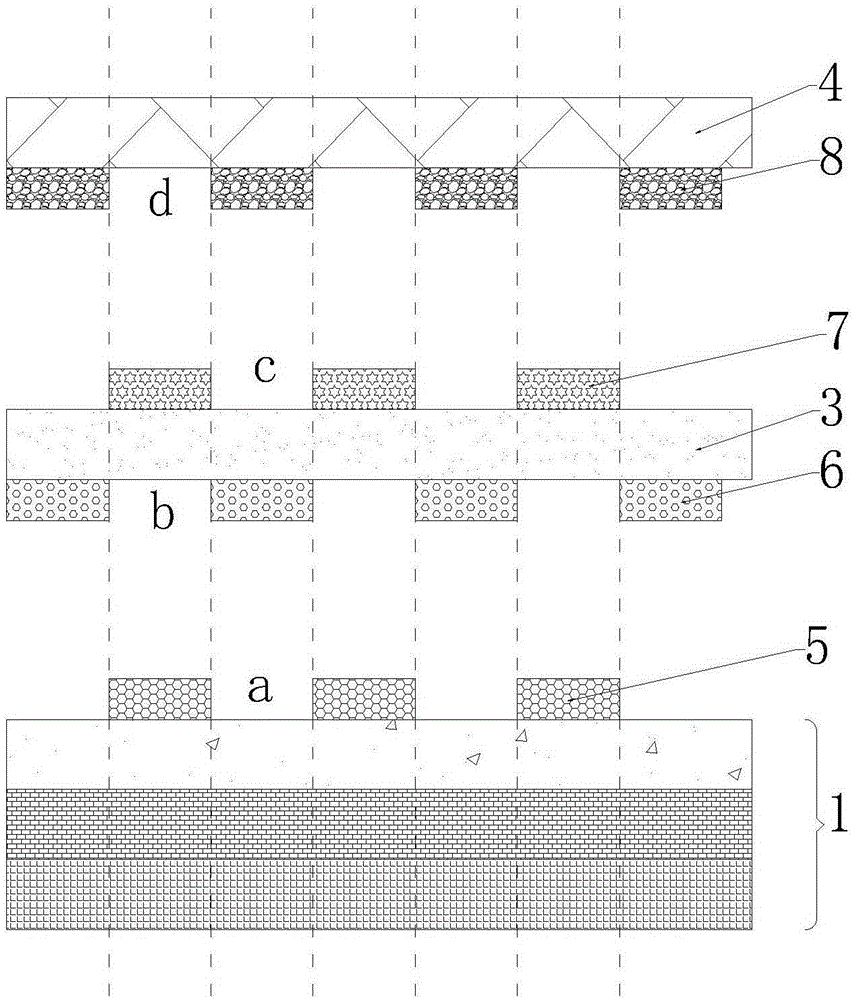

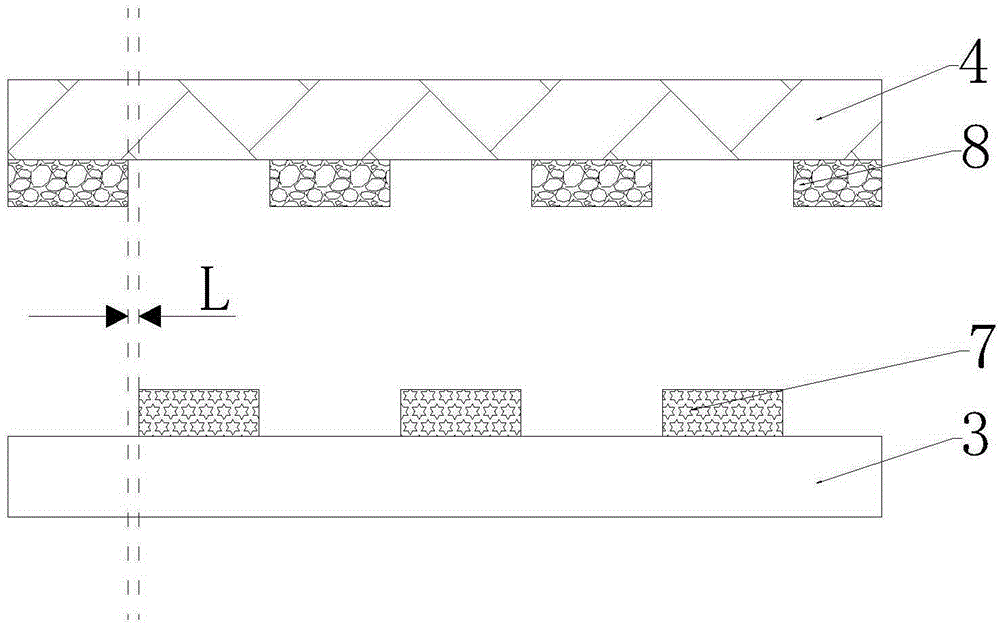

Manufacturing method for display screen and display screen

ActiveCN105206649AImprove adverse effectsReduce the presence of air bubblesSolid-state devicesSemiconductor/solid-state device manufacturingRubber materialDisplay device

The invention relates to the field of semiconductor light-emitting devices, in particular to a manufacturing method for a display screen and the display screen. Adhesive material units which are distributed at intervals are adopted and then attached in a staggered mode, appropriate adhesive materials are selected during early-stage setting, the interval between every two vertical adjacent rubber material units is regulated so that different attaching structures can be obtained, bubbles in attachment space formed after attachment are reduced, the buckling stress can be reduced so that flexible folding display can be better facilitated, adverse effects of the shrinkage effect of the adhesive materials on display devices are effectively eliminated, and the product yield is improved.

Owner:EVERDISPLAY OPTRONICS (SHANGHAI) CO LTD

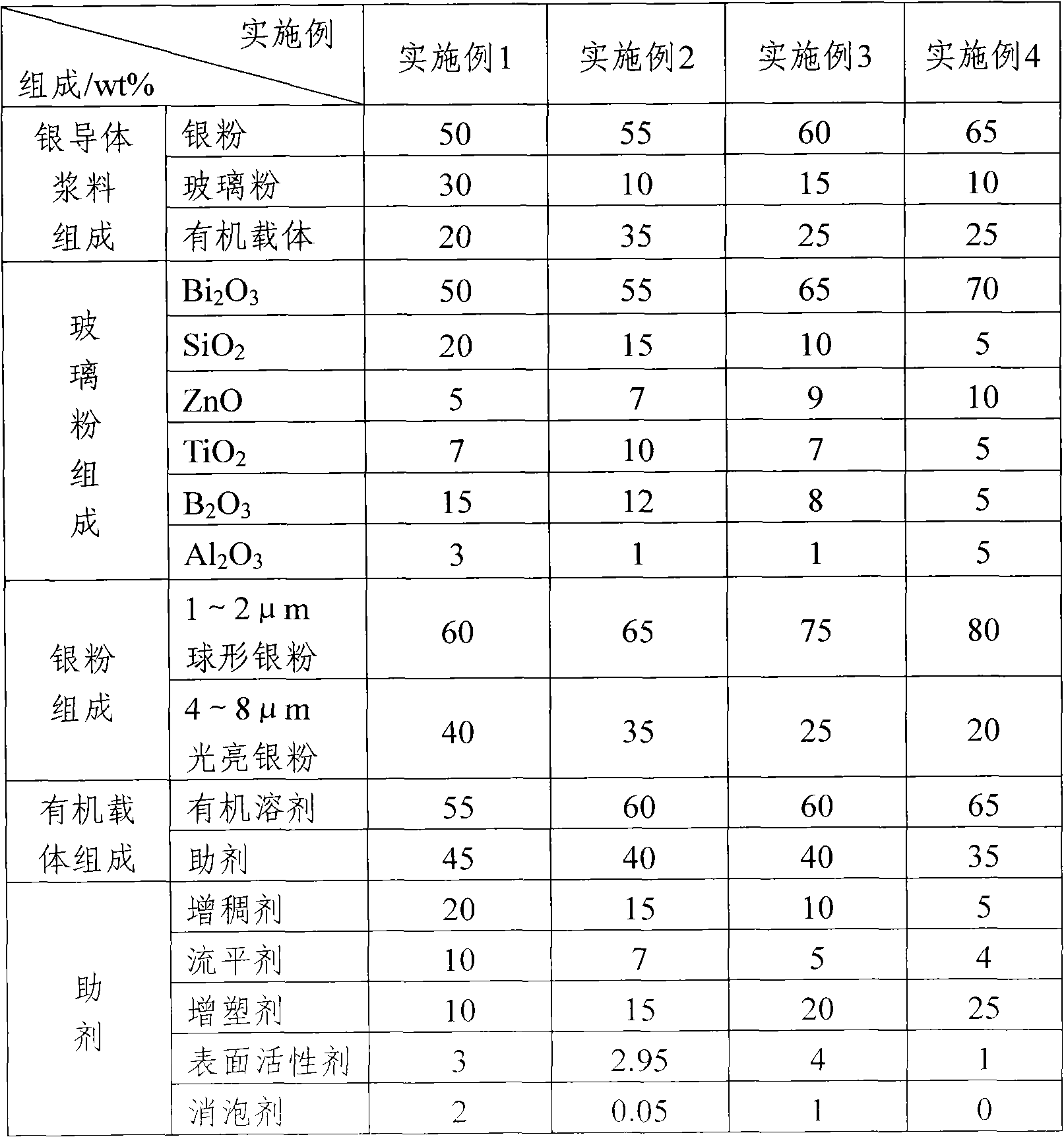

Silver conductor slurry for back electrodes of solar energy battery

ActiveCN102592703AImprove conductivityGood lookingNon-conductive material with dispersed conductive materialSemiconductor devicesElectrical batteryFrit

The invention discloses silver conductor slurry for back electrodes of a solar energy battery. The slurry is composed of, by weight, 50% to 65% of silver powder, 10% to 30% of glass powder, and 20% to 40% of organic carriers, wherein the glass powder is composed of, by weight, 50% to 70% of Bi2O3, 5% to 20% of SiO2, 5% to 10% of ZnO, 5% to 10% of TiO2, 5% to 15% of B2O3, and 1% to 5% of Al2O3. According to the silver conductor slurry for back electrodes of the solar energy battery, metal-oxide frits without lead oxide are used as binders so that the slurry is environment-friendly and is good for import and export; spherical silver powders with high tap density and bright silver powders with high conductivity are collocated according to a certain proportion, a compact network with excellent conductivity is formed after sintering and each of the back electrodes has an attractive appearance; the surface active agent and / or antifoaming agent in the organic carrier can reduce foams in the silver slurry so that the printed pattern is compact, foam-free and airhole-free.

Owner:JIANGSU RUIDE NEW ENERGY TECH

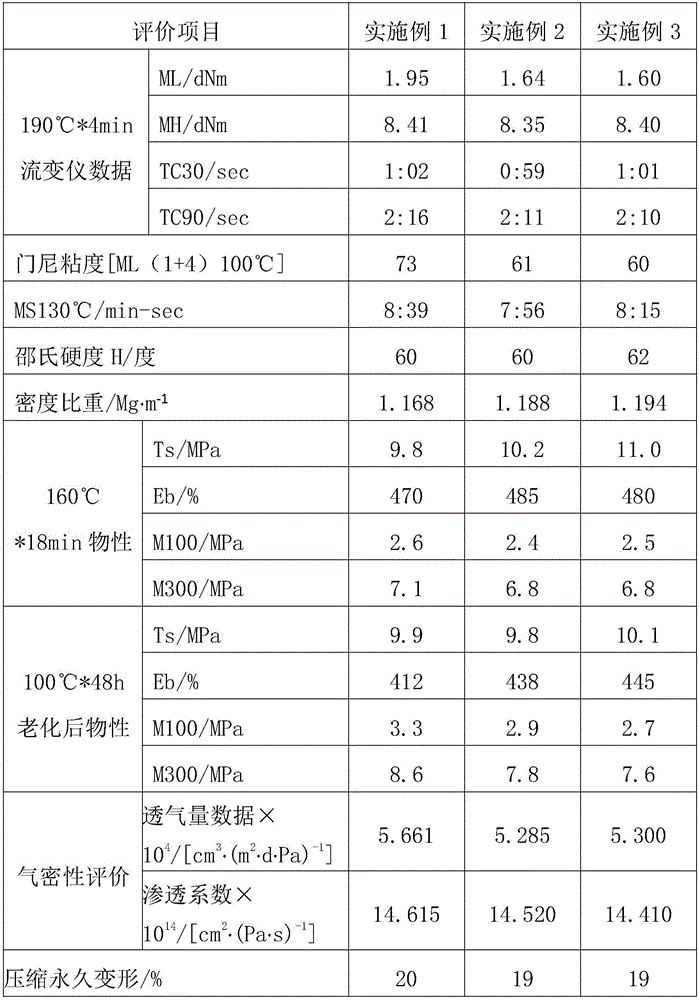

Tire-inner-liner rubber composition and preparing method thereof

The invention belongs to the technical field of rubber tires and chemical manufacturing, and relates to a rubber composition specially suitable for producing a semi-steel radial tire inner liner and a preparing method thereof. The rubber composition is prepared from, by weight, 30-40 parts of natural rubber, 60-70 parts of brominated butyl rubber, 60-70 parts of carbon black, 30-40 parts of reinforcing powder, 10-12 parts of environment-friendly aromatic oil, 4-6 parts of an active agent, 2-4 parts of tackifier resin, 2-4 parts of a dispersing agent, 0.2-0.5 part of magnesium oxide, 1-2 parts of a promoting agent and 1-1.8 parts of sulfur. As two-section rubber mixing is adopted, energy consumption is saved, and transportation and transferring of the production link are reduced; the flowing performance of rubber is improved in the pressing technology process, and particularly, air bubbles of a pressing part are obviously reduced, and the once pass percent of a product is improved; the low preparing cost and the high processability are achieved while the rubber composition for producing the semi-steel radial tire inner liner can meet the requirement for the high breathability resistance of the rubber.

Owner:山东新大陆橡胶科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com