Patents

Literature

153results about How to "Improve melting quality" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Composition of aluminum boron silicate glass and application

ActiveCN101092280AImprove melting qualityReduce the presence of air bubblesSilicate glassFlat panel display

This invention relates to aluminum borosilicate glass with high elastic modulus and its application. The aluminum borosilicate glass is prepared from: 55-63.5 wt.% SiO2, 8-10.5 wt.% B2O3, 15-21 wt.% Al2O3, 0-3.5 wt.% MgO, 4-10 wt.% CaO, 0-5 wt.% SrO, 1-5.5 wt.% BaO, 0.001-4 wt.% Y2O3, 0-2.5 wt.% La2O3, 0-0.5 wt.% ZnO, 0-0.3 wt.% ZrO2, and 0.005-0.08 wt.% R2O (R = Li, Na or K). The aluminum borosilicate glass has such advantages as high strain point, low expansion coefficient, high elastic modulus and no alkali, and is suitable for flat panel display and TFT-LCD glass substrate.

Owner:HENAN ANCAI HI-TECH +1

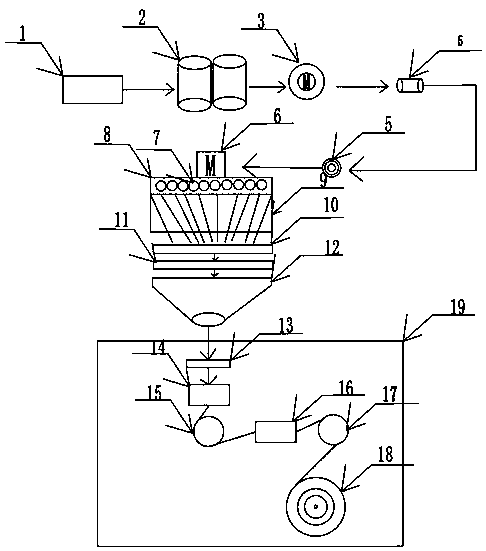

Solar super-white rolling glass and preparation method thereof

InactiveCN102219375AReasonable useReduce dependenceGlass furnace apparatusGlass rolling apparatusSolar powerAntimony trioxide

The invention relates to a piece of solar super-white rolling glass which is calculated according to the mass percent of oxide, and comprises the components according to proportions as follows: 72.0%-75.2% of SiO2, 1.0%-2.4% of Al2O3, 13.2%-15.0% of R2O, 8.5%-10.5% of CaO, 0-3.6% of MgO, 0.15%-0.38% of Sb2O3 and Fe2O3 being smaller than or equal to 0.01%. In addition, the invention also relates to a preparation method of the solar super-white rolling glass, and the preparation method comprises the following steps: step one, selecting quartz sand, aluminum hydroxide or aluminum oxide, limestone, calcined soda, sodium sulfate, dolomite, antimony trioxide and cullet as raw materials, and preparing and mixing the raw materials; step two, melting and clarifying; step three, calendaring; and step four, annealing and obtaining the solar super-white rolling glass. The solar super-white rolling glass produced by the preparation method has the advantages of high light transmission, good corrosion resistance and weather resistance, long service life and the like, and can be used for a solar power generating assembly for photoelectric conversion.

Owner:XINYI PHOTOVOLTAIC IND (ANHUI) HLDG CO LTD

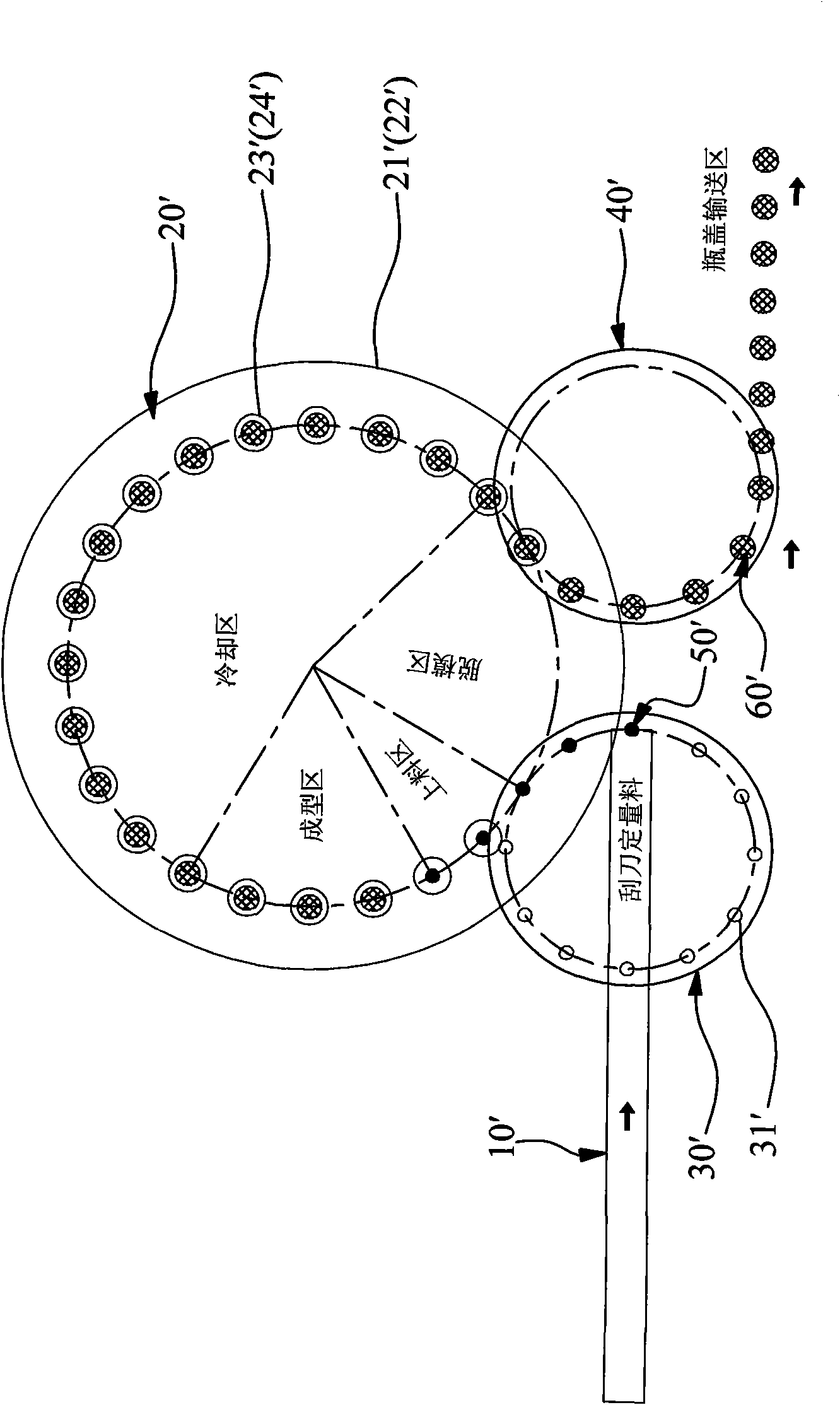

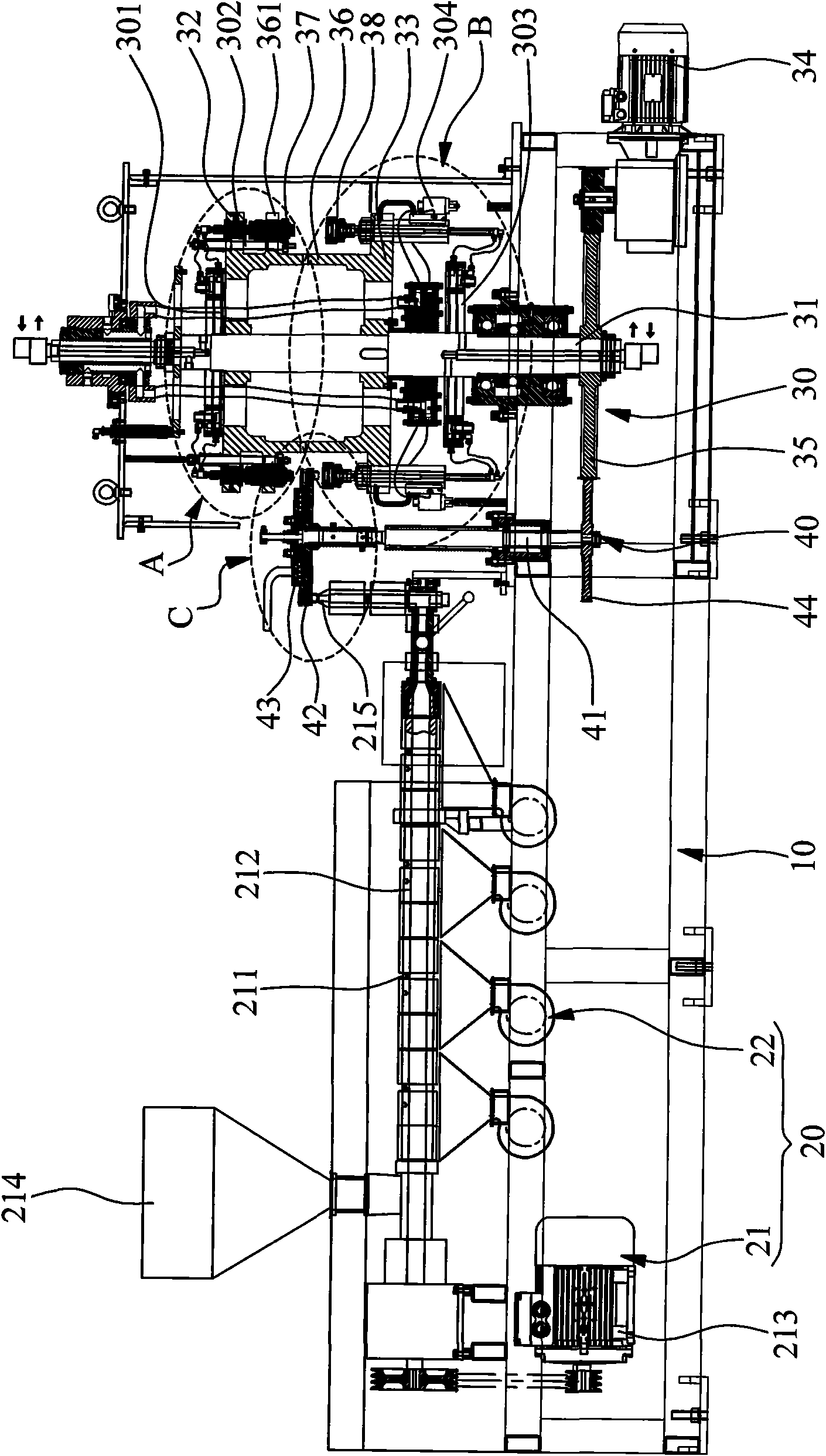

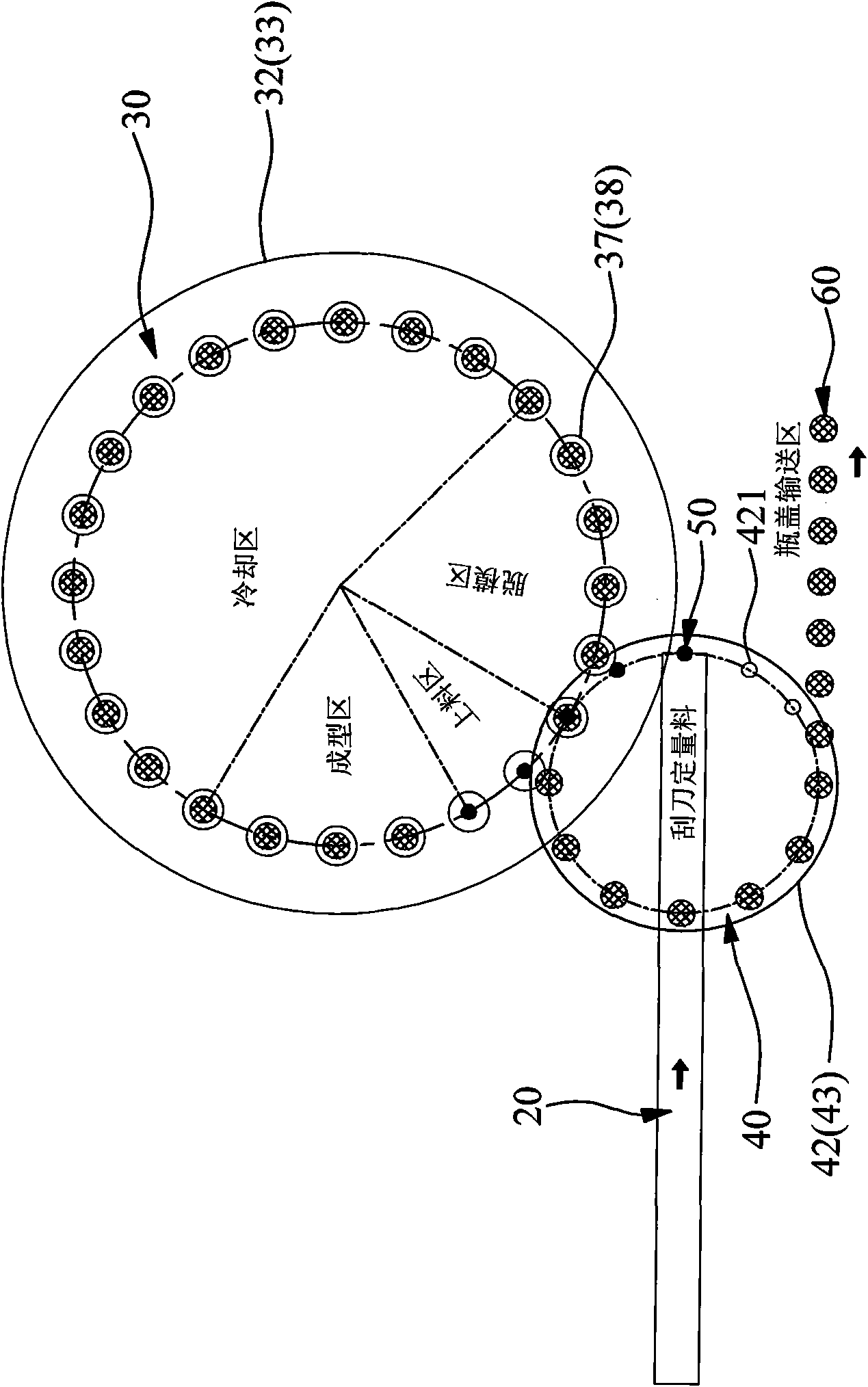

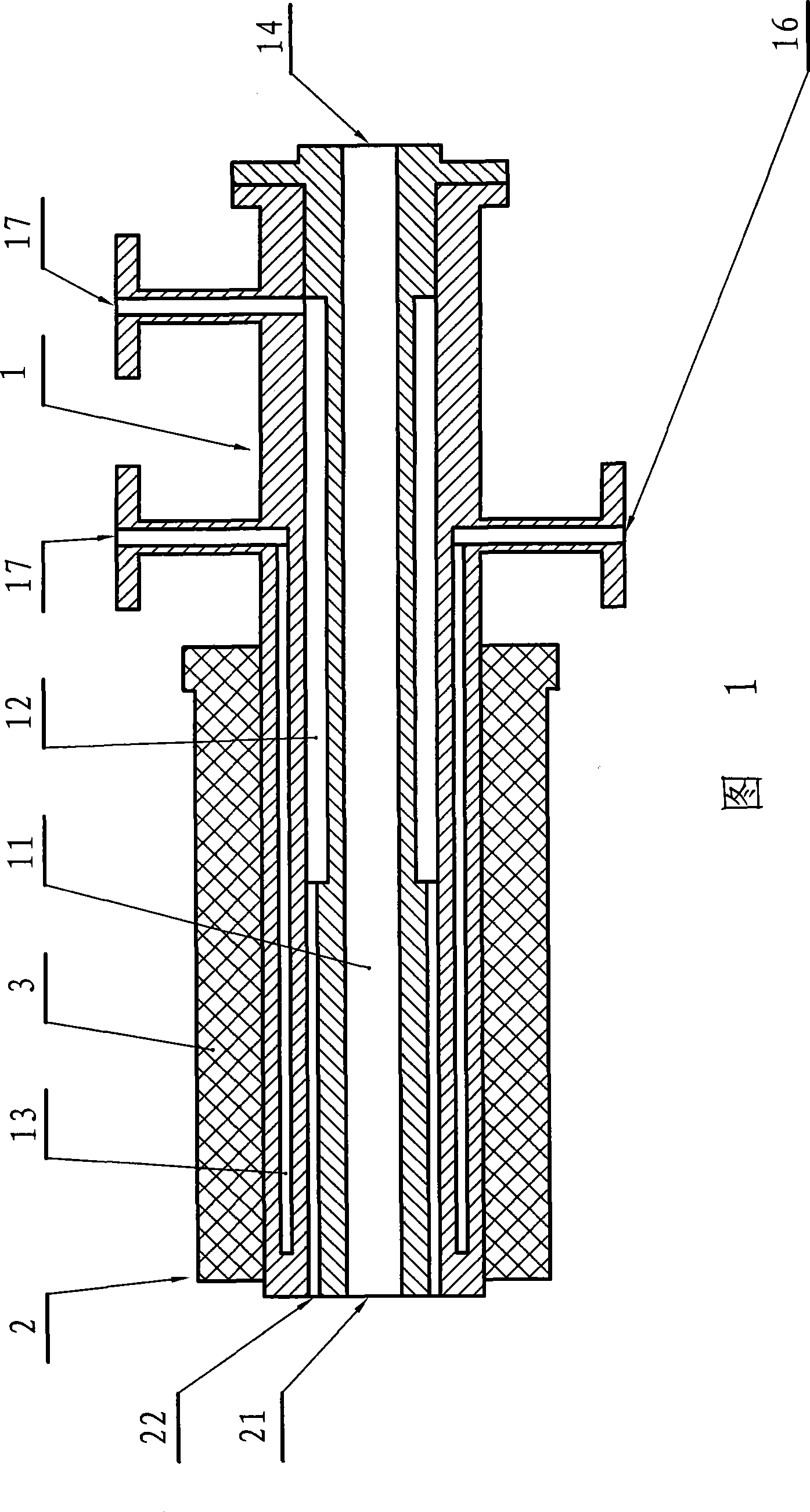

Mould pressing lid maker

The invention discloses a mould pressing lid maker, which comprises a frame and an extrusion mould group, a pressing mould group and a feeding and discharging mechanism that are arranged on the frame; the extrusion mould group has an extrusion port; an upper mould pressing plate and a lower mould pressing plate of the pressing mould group are integrated and are arranged on a first rotating shaft of the pressing mould group; the upper mould pressing plate is provided with upper moulds; the lower mould pressing plate is provided with bottom moulds; the feeding and discharging mechanism is arranged between the extrusion mould group and the pressing mould group and comprises a second rotating shaft and a rotating plate that is arranged on the second rotating shaft, a scraper and a material pushing device are arranged below the rotating plate, and a toggle device is arranged above the rotating plate; and therefore, feeding operation is carried out by utilizing the scraper, and discharging operation is carried out by utilizing the toggle device, thus realizing the feeding and discharging at the same work station. The mould pressing lid maker has compact structure and makes full use of all the upper moulds and the bottom moulds, and the rotating speed of the upper mould pressing plate and the lower mould pressing plate can be set as rapidly as possible, thus enhancing the work efficiency of the mould pressing lid maker and the production capacity.

Owner:GUANGZHOU JEEPINE INTELLIGENT COMPRESSION MOLDING MACHINE CO LTD

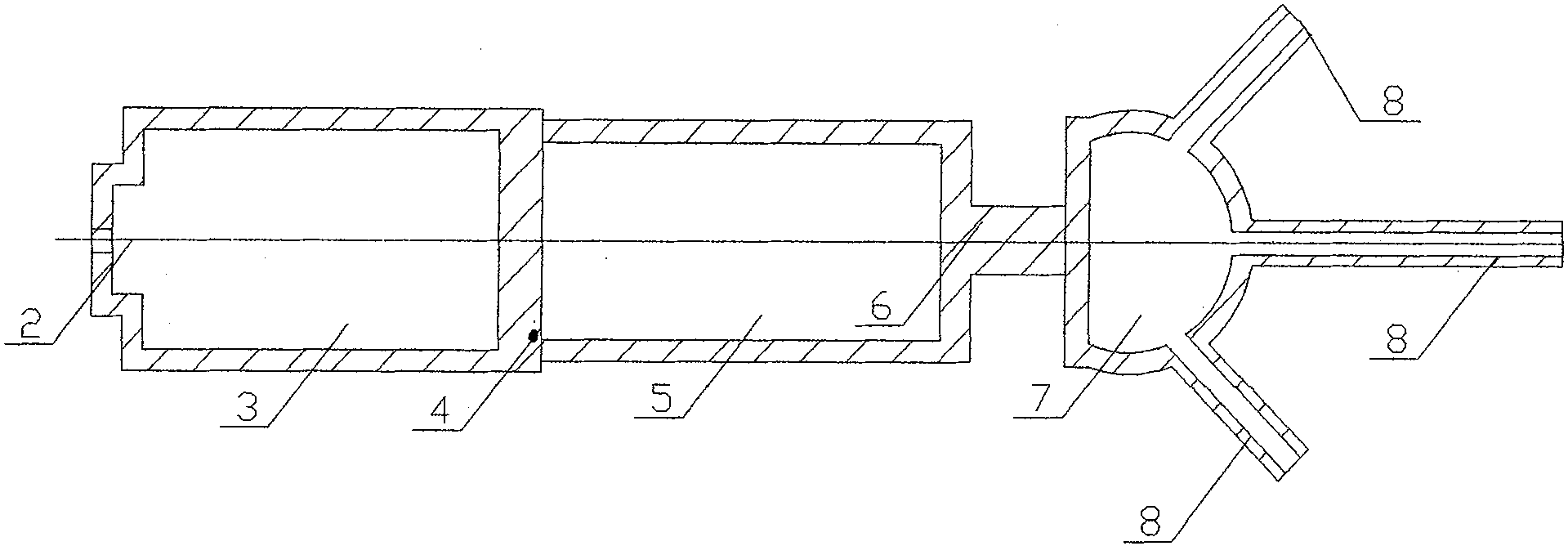

Spray gun of side-blown converter for smelting non-ferrous metal

ActiveCN101382387AImprove combustion performanceSpeed up redox reactionsCharge manipulationCombustionNonferrous metal

The invention discloses a novel side-converter spray gun for smelting nonferrous metals, comprising a spray gun body with a sleeve structure and a spray gun head at the front end of the spray gun body; a central pipeline of the sleeve structure is provided with a connecting interface connected with a fuel conveyor; a sandwich ring channel of the sleeve structure is provided with a connecting interface connected with combustion-supporting gas; the spray gun head is provided with a fuel nozzle which is matched with the central pipeline and a combustion-supporting gas nozzle which is matched with the sandwich ring channel; and the combustion-supporting gas nozzle is provided with a through hole nozzle array.

Owner:CHINA ENFI ENGINEERING CORPORATION

Aluminium borosilicate glass with high elastic modulus and uses thereof

ActiveCN101117270AImprove melting qualityReduce the presence of air bubblesSilicate glassFlat panel display

The invention relates to a calcium-aluminium borosilicate glass with high modulus of elasticity and is prepared and manufactured according to percentage by weight of the following raw materials: 55-63.5SiO2, 8-10.5B2O3, 15-21Al2O3, 0-3.5MgO, 4-10CaO, 0-5SrO, 1-5.5BaO, 0.001-4Y2O3, 0-2.5La2O3, 0-0.5ZnO, 0-0.3ZrO2, 0.005-0.08R2O(R=Li, Na, K). The invention has the advantages of high strain point, low coefficient of expansion, high modulus of elasticity and nonalkali basically; and is fit for a flat panel display, particularly for manufacture of TFT-LCD glass substrate.

Owner:HENAN ANCAI HI-TECH +1

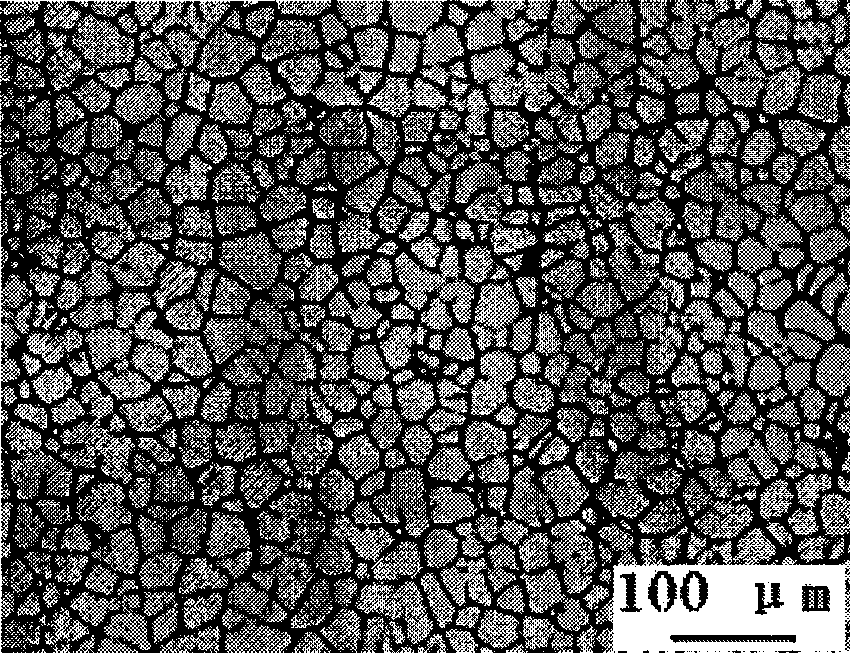

Production method of multi-element aluminum alloy standard sample

ActiveCN101294875AHigh yieldImprove distribution uniformityPreparing sample for investigationColor/spectral properties measurementsMulti elementStandard samples

The invention relates to a method for preparing a standard multi-element aluminum alloy sample. The method comprises the steps of proportioning materials, melting, casting, homogenization processing, extruding and post-processing, and is characterized in that the standard sample contains the following 20 chemical elements in pure aluminum: Si, Fe, Cu, Mg, Mn, Zn, Sn, Pb, Ni, Ti, Cr, Sr, Ca, V, Ga, Zr, Cd, Be, B and P. The standard sample is manufactured sequentially through proportioning materials, melting, casting, homogenization processing, extruding and post-processing, and finally, standard samples are prepared according to the requirements for the standard samples. By adopting the preparation method, the multi-element aluminum alloy sample with uniform composition and good stability can be obtained.

Owner:GUIZHOU BRANCH CHINA ALUMINUM IND

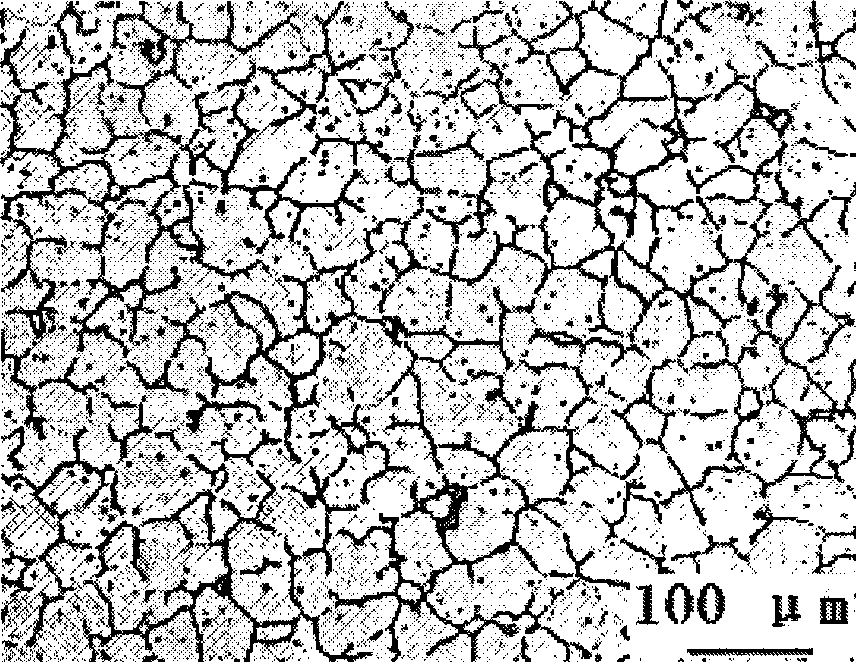

Magnesium alloy electromagnetic low-temperature semicontinuous casting method

The magnesium alloy electromagnetic low-temp. semicontinuous casting method includes the steps of melting magnesium, adding compound fire-resisting elements, adding alloy elements, heat-insulating, standing still and semicontinuous casting under the electromagnetic field. It utilizes the addition of compound fire-resisting elements to implement smelting of magnesium alloy free from coverage or protection so as to shorten technological process and raise melt quality, and utilizes the application of electromagnetic field and optimization of crystallizer structure to implement the low-temp. and high-speed semicontinuous casting of magnesium alloy.

Owner:NORTHEASTERN UNIV

Preparation of nontoxic magnesium alloy material for biological implantation

The invention relates to a method for preparing a magnesium alloy material suitable for biological implantation, which comprises the following steps: preparing raw materials by the following chemical compositions in percentage by weight: 2.0 to 6.0 percent of Zn, 0.5 to 1.9 percent of Mn, 0.6 to 5.0 percent of Ca, less than or equal to 0.1 percent of total impurities, and the balance of Mg; or preparing the raw materials by the following chemical compositions in percentage by weight: 2.0 to 6.0 percent of Zn, 0.3 to 0.9 percent of Zr, 0.5 to 5.0 percent of Ca, less than or equal to 0.1 percent of total impurities, and the balance of Mg; preheating smelting equipment and adding the Mg into the raw materials; heating the mixture under the protection of argon gas with the flow rate of between 5 and 6 L / min and the pressure of 14 MPa; adding a fire retardant into the molten liquid when the temperature of the molten liquid reaches between 650 and 660 DEG C, raising the temperature of the molten liquid to between 700 and 720 DEG C, adding other alloy elements into the molten liquid respectively, and performing melting reaction; and stirring the mixture until the mixture is uniformly mixed after alloy is completely molten, keeping the mixture stand for 30 to 40 minutes, pressing a deslagging agent into the solution for deslagging, casting the alloy solution into a cast die after keeping the alloy solution for 10 to 20 minutes at the temperature of between 690 and 710 DEG C, and preparing a Mg-Mn series or Mg-Zr series biomedical magnesium alloy material ingot.

Owner:NORTHEASTERN UNIV

Production technology for 1070A alloy aluminum foil with ultrahigh strength and high elongation for lithium battery

InactiveCN106929713AImprove mechanical performance indexImprove inner qualityCasting cleaning apparatusNon-aqueous electrolyte accumulator electrodesPerformance indexAlloy

The invention relates to a production technology for 1070A alloy aluminum foil with the ultrahigh strength and the high elongation for a lithium battery. The aluminum foil for the lithium battery comprises, by mass percentage, less than or equal to 0.2% of Fe; less than or equal to 0.1% of Si, less than or equal to 0.1% of Cu, less than or equal to 0.05% of Mn, less than or equal to 0.03% of Mg, less than or equal to 0.03% of Zn, less than or equal to 0.04% of Ti, and greater than or equal to 99% of Al. The preparation method comprises the steps of (1) smelting, and cast rolling; (2) cold rolling; and (3) aluminum foil rolling, specifically, cutting a aluminum foil coil to obtain the finished aluminum foil for the lithium battery. The production technology has the beneficial effects that a newly improved 1070A alloy is adopted, the proportion is reasonable, an electrolytic aluminum liquid with the high purity is adopted, a novel tubular filter box is adopted for production in the cast rolling process, the technology is scientific, the mechanical performance indexes of products can be improved, the tensile strength and the elongation of the products are higher than those of similar products in China, and the use requirements of customers can be met.

Owner:ZOUPING DELI TECH

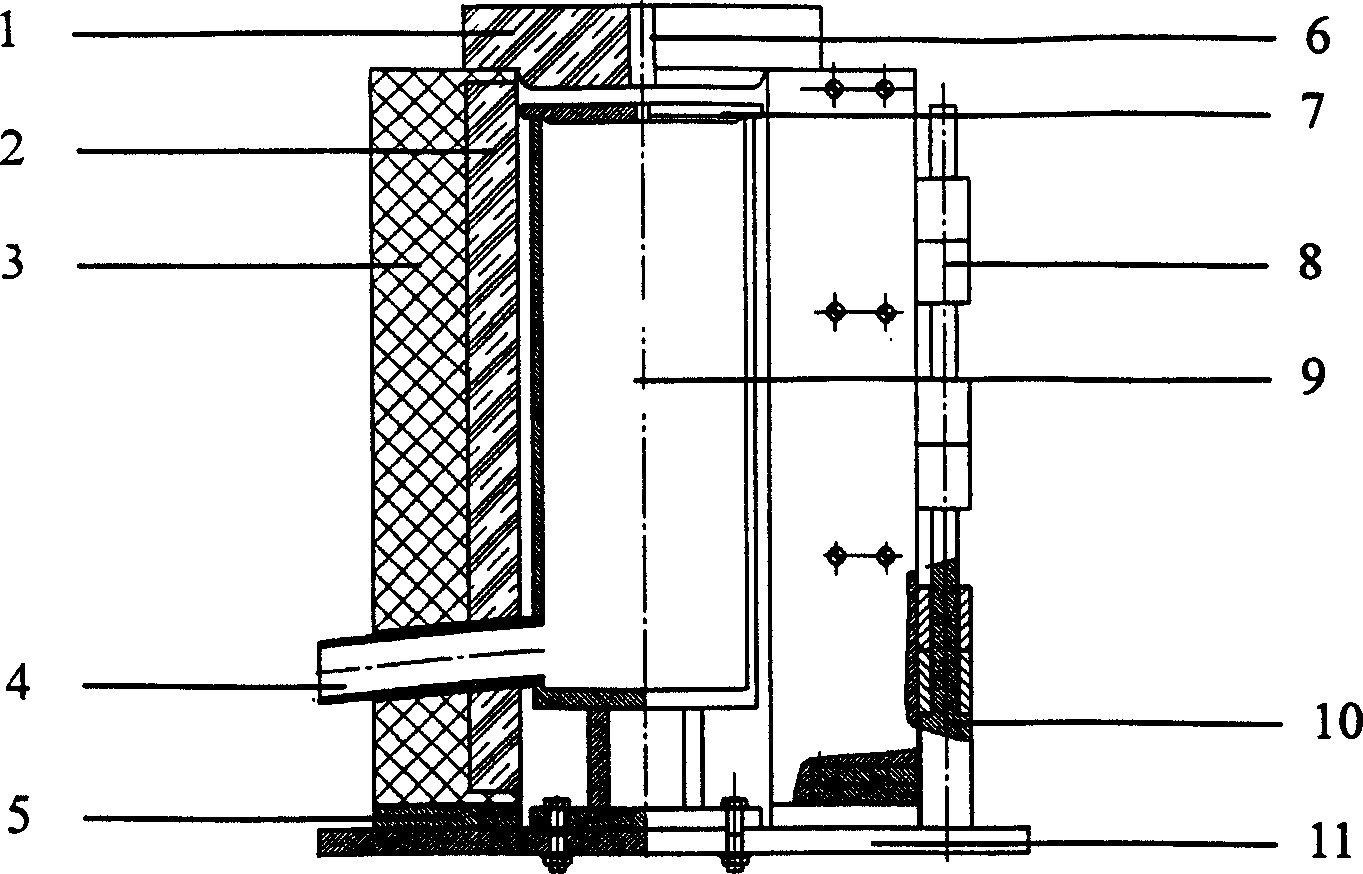

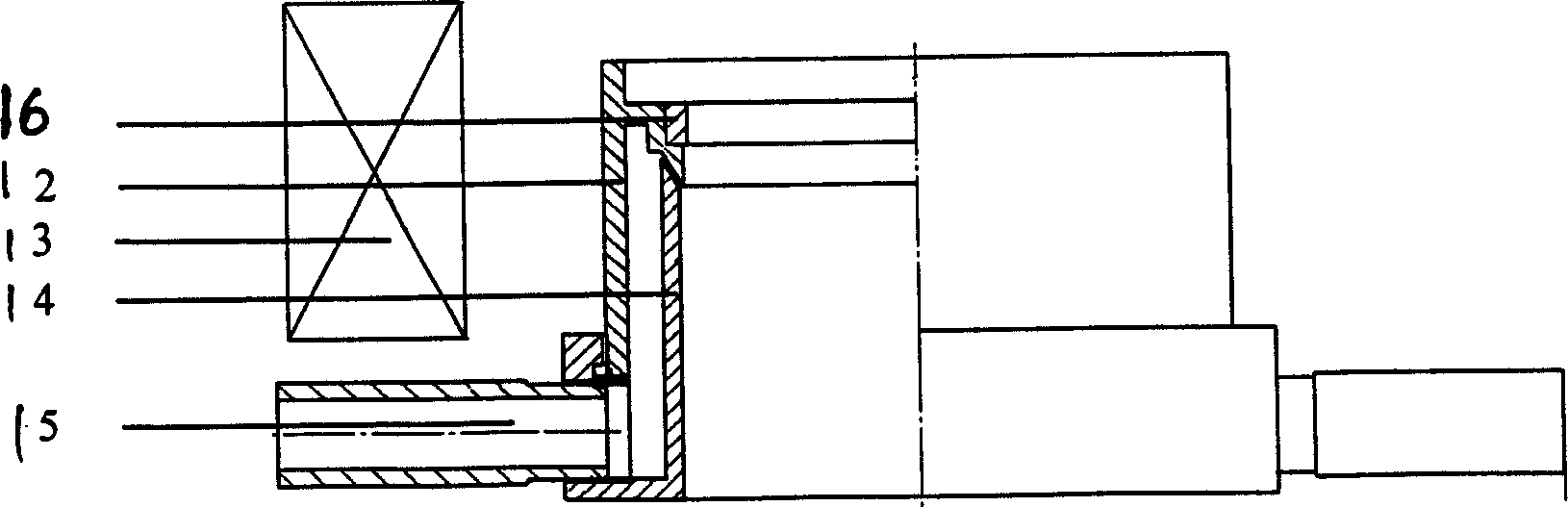

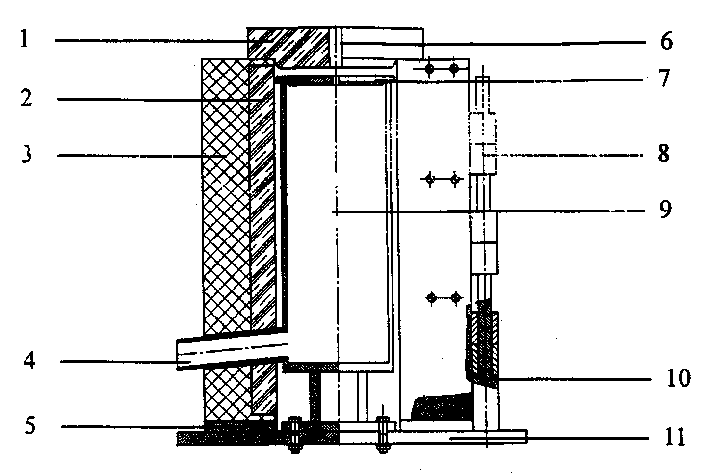

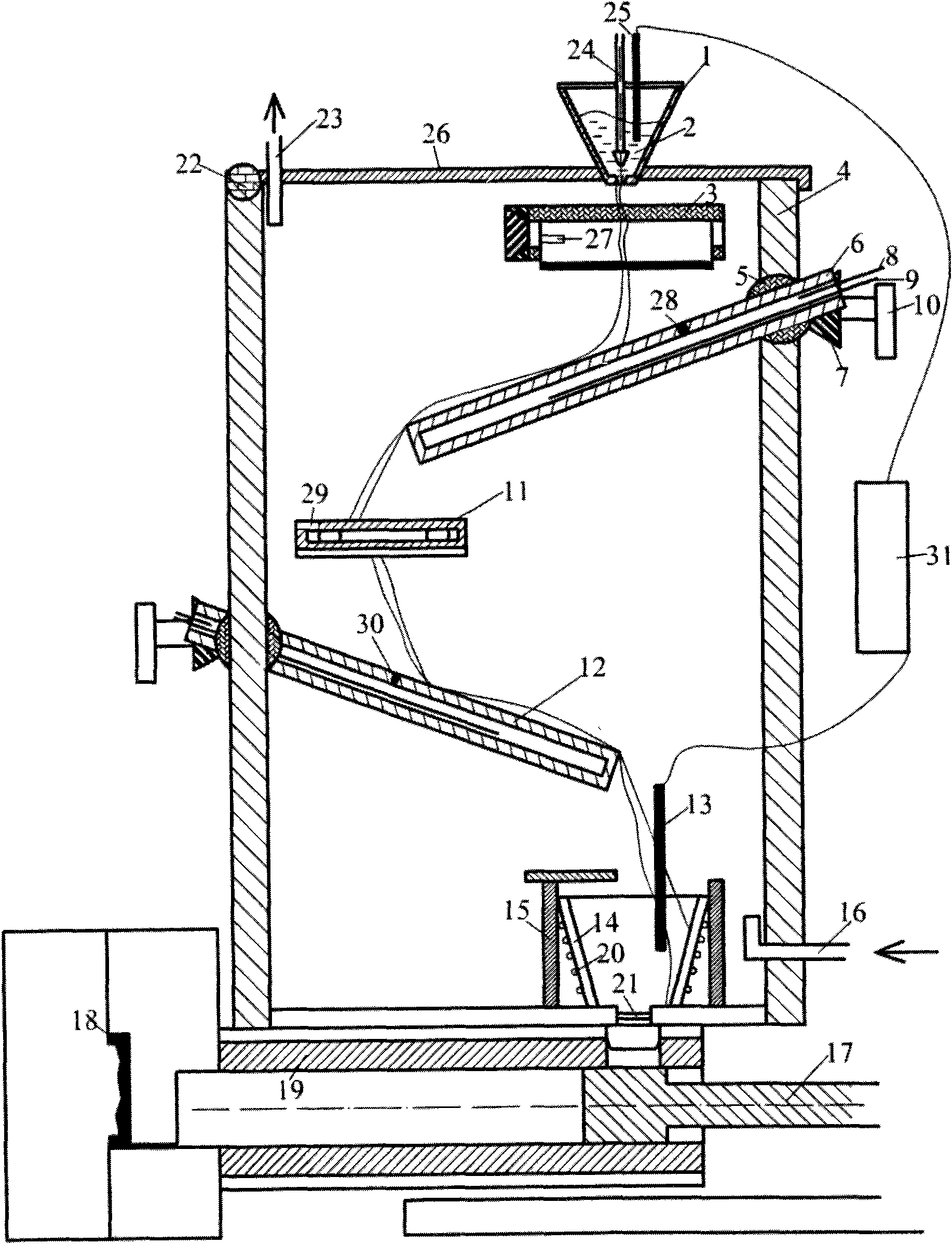

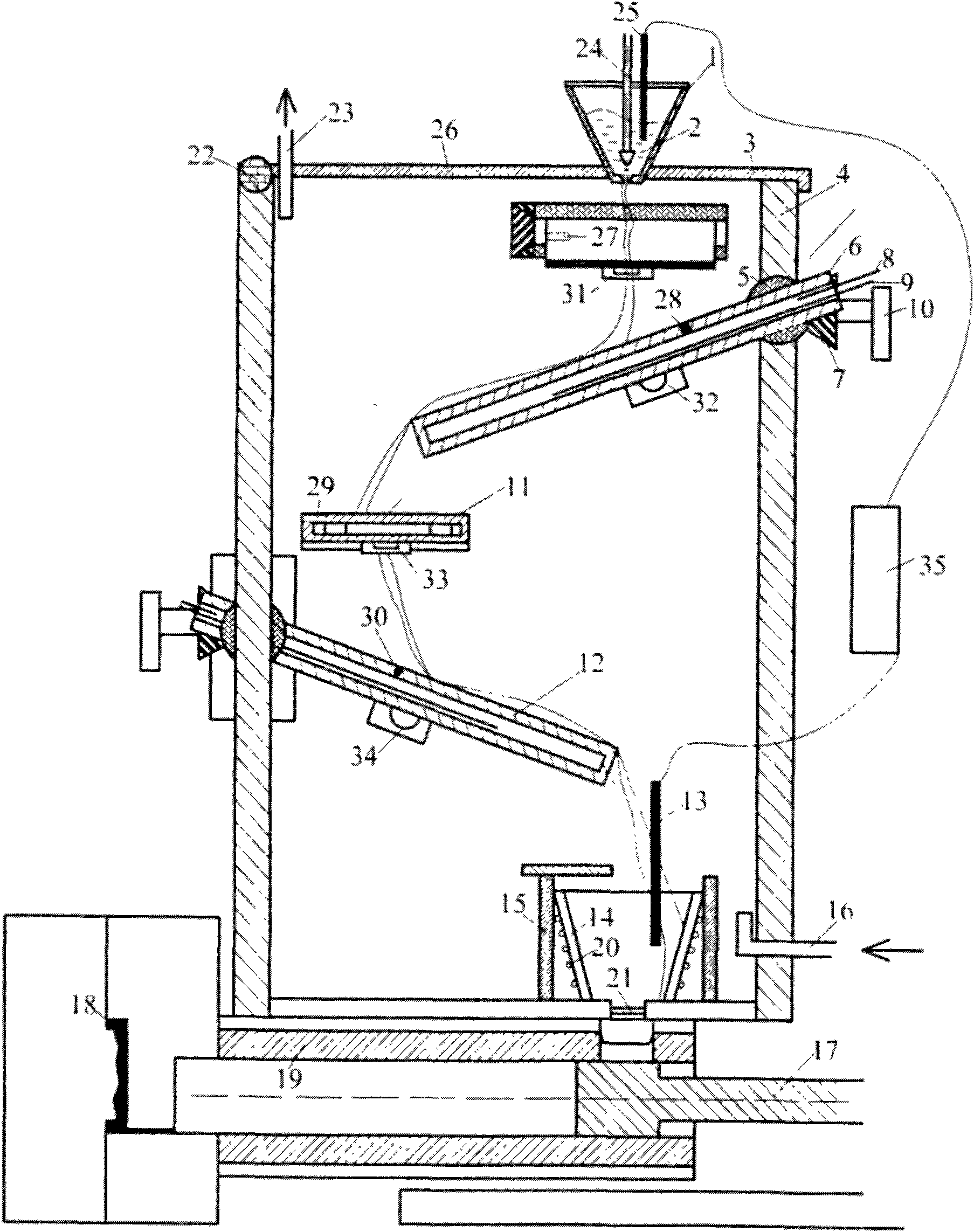

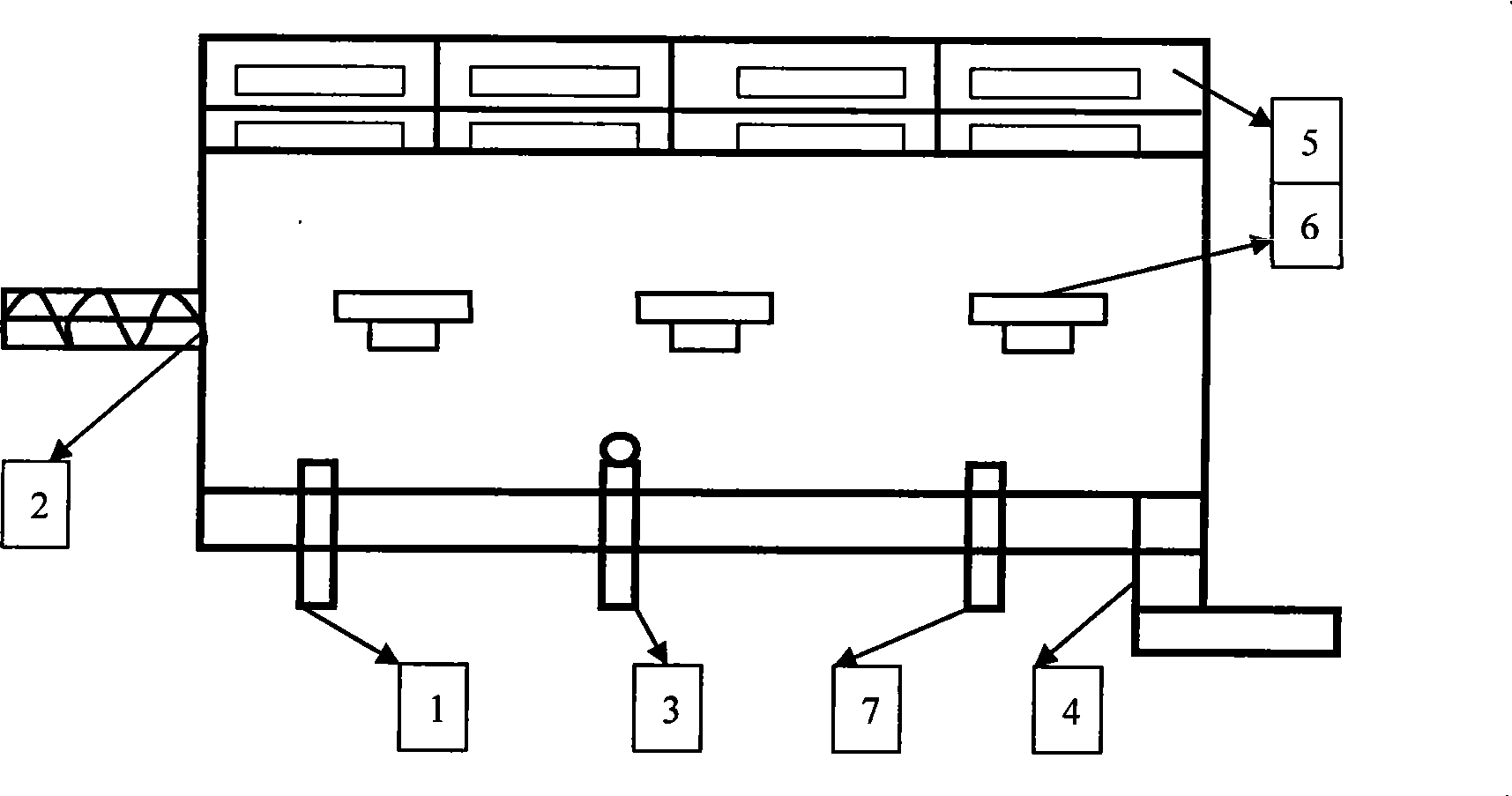

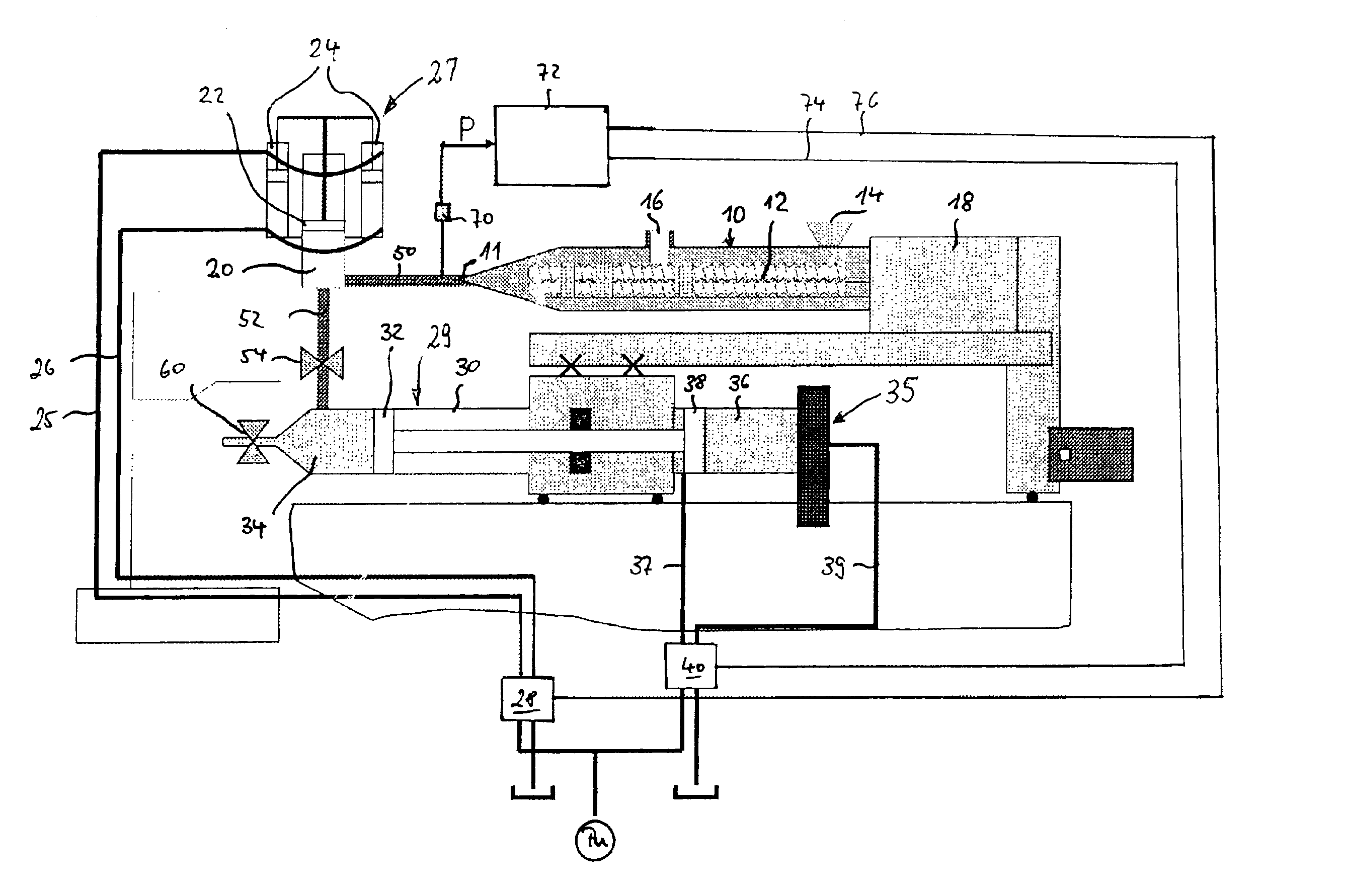

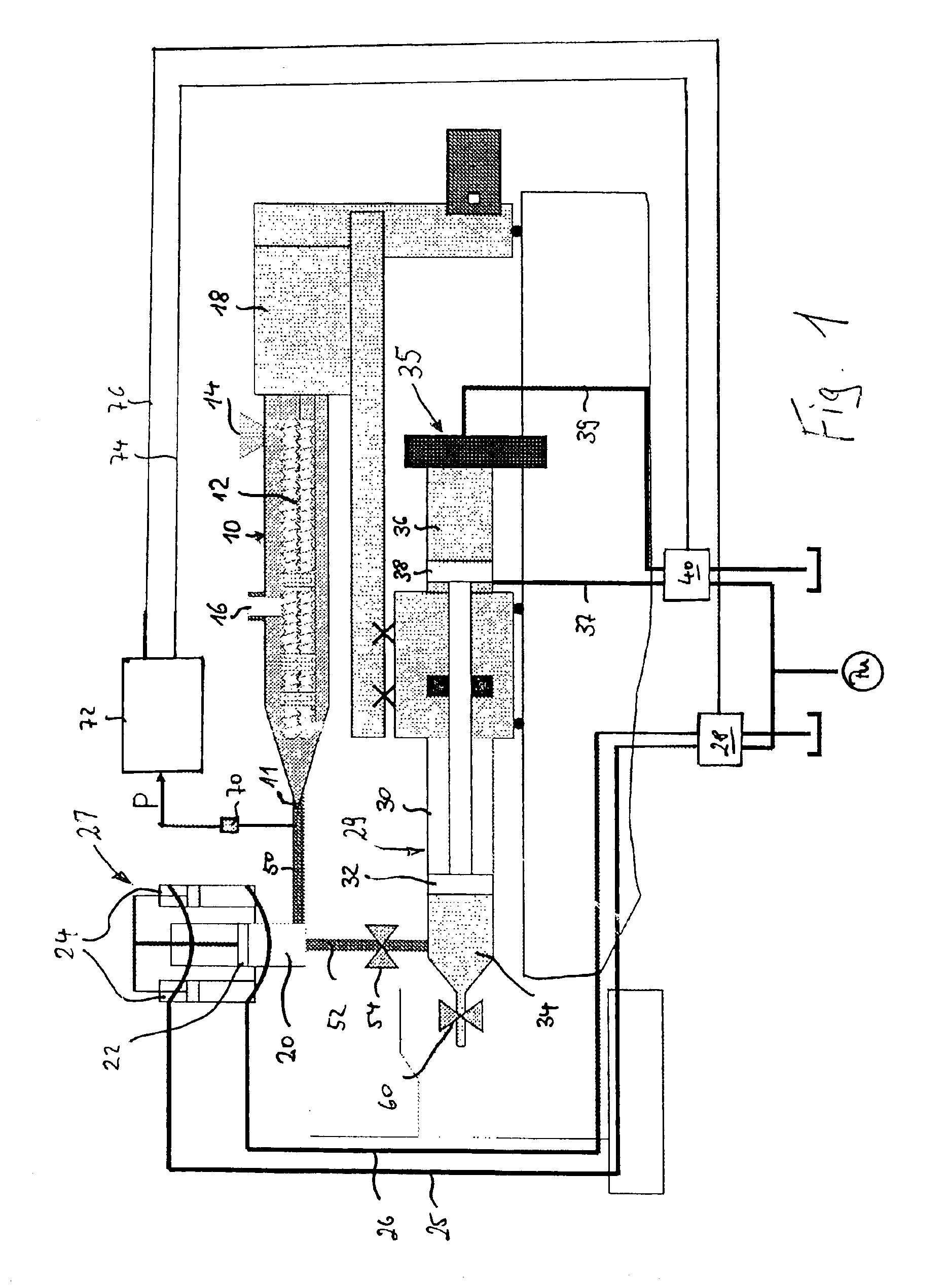

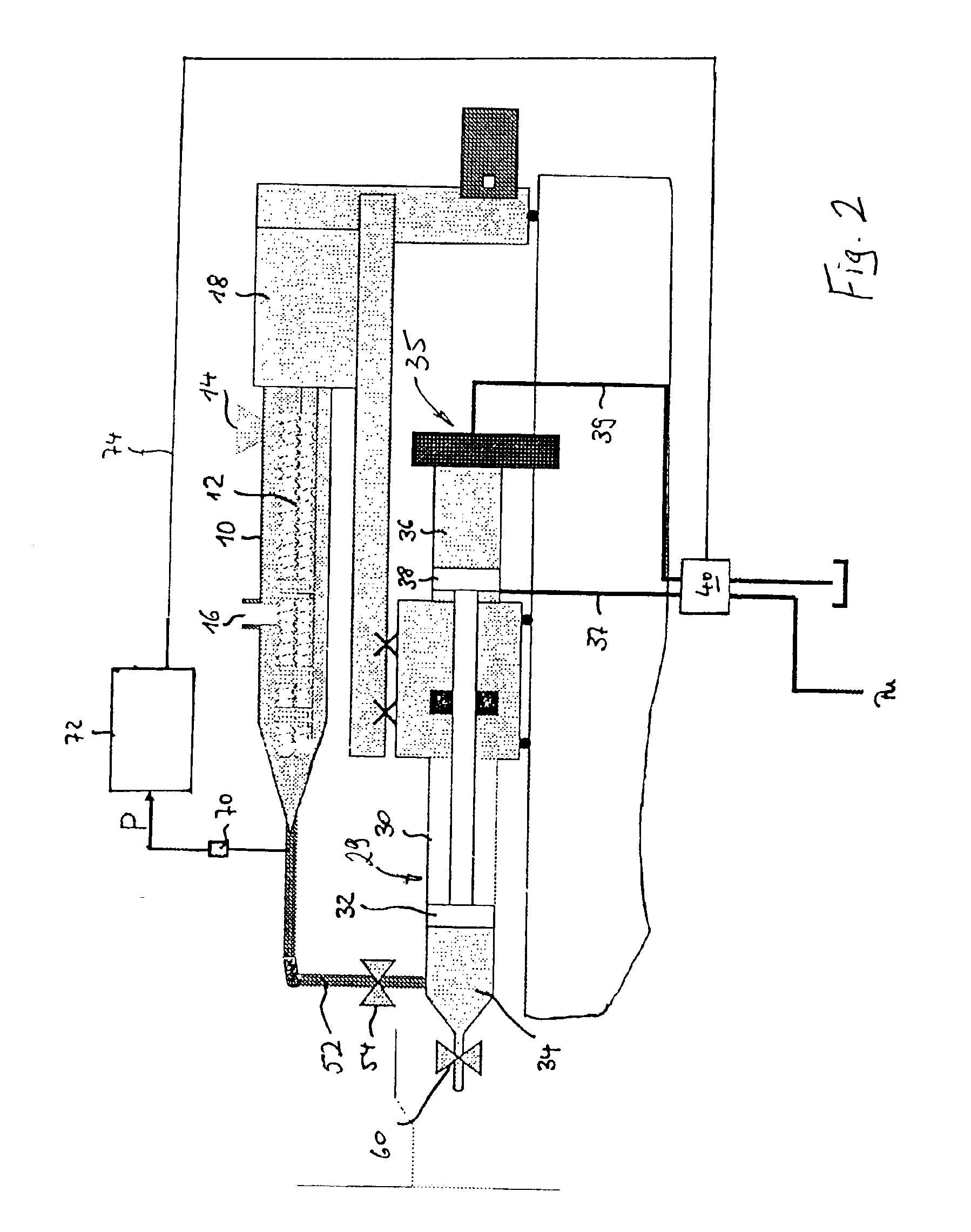

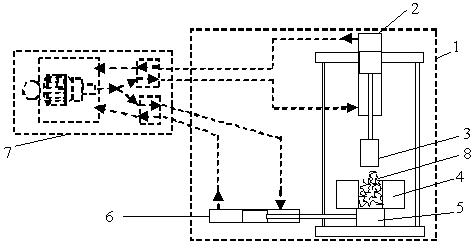

Semi-solid rheological molding device for metal part

The invention relates to a semi-solid rheological molding device for a metal part. The semi-solid rheological molding device is characterized by consisting of a pouring system, a fusant cooling system, a cooling plate adjusting mechanism, a size insulation system, a structure supporting and sealing system, a multichannel temperature monitoring system, an inert gas protection system and a die-casting system. The semi-solid rheological molding device solves the problem that size is difficult to store and transport in the semi-solid rheological molding process, and realizes the integration of semi-solid rheological pulping and molding; the device has a simple and compact structure, saves the space and does not need to make any improvement on the prior die-casting equipment; and a pulping process is simple, has a short flow, is convenient to monitor, can effectively protect gas, prevent oxidation, improve the quality of a fusant, and reduce factors influencing heat exchange of the system, is favorable for controlling the thermal balance of the system and improving the precision and the stability of temperature control, reduces thermal loss, is favorable for energy conservation and consumption reduction, and is in particular suitable for small-and-medium-sized enterprises. The semi-solid rheological molding device has wide application prospect including semi-solid blanking and rheological die-casting of aluminum alloy, magnesium alloy and tin alloy.

Owner:KUNMING UNIV OF SCI & TECH

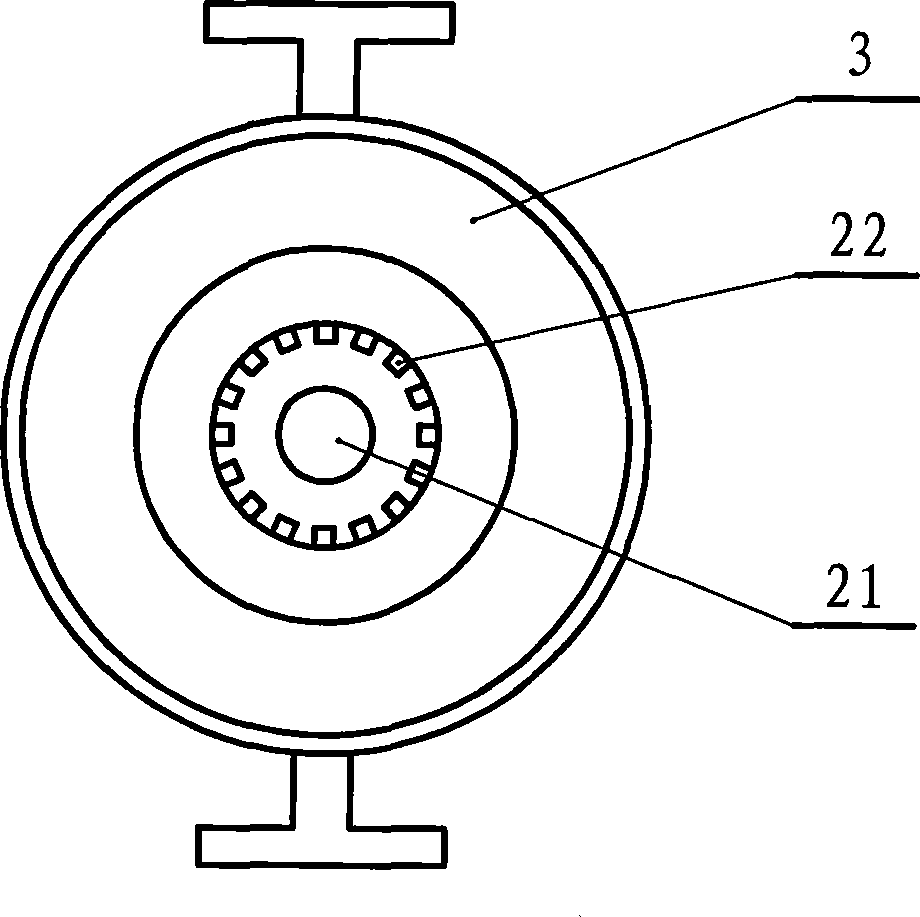

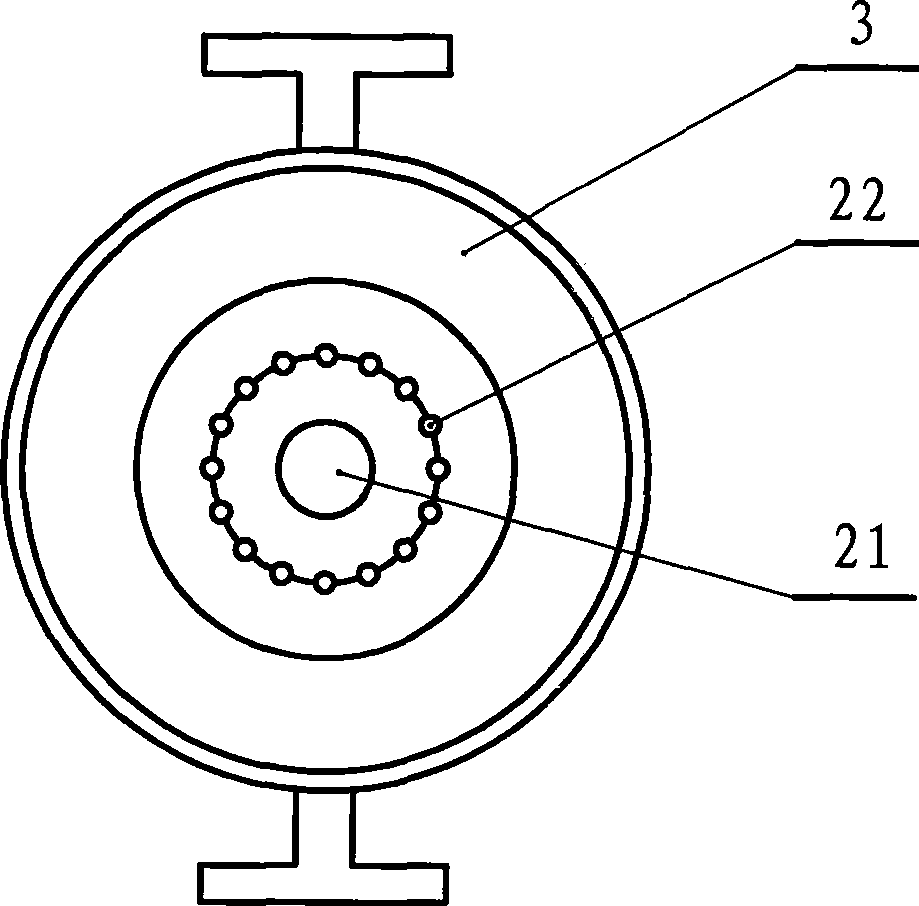

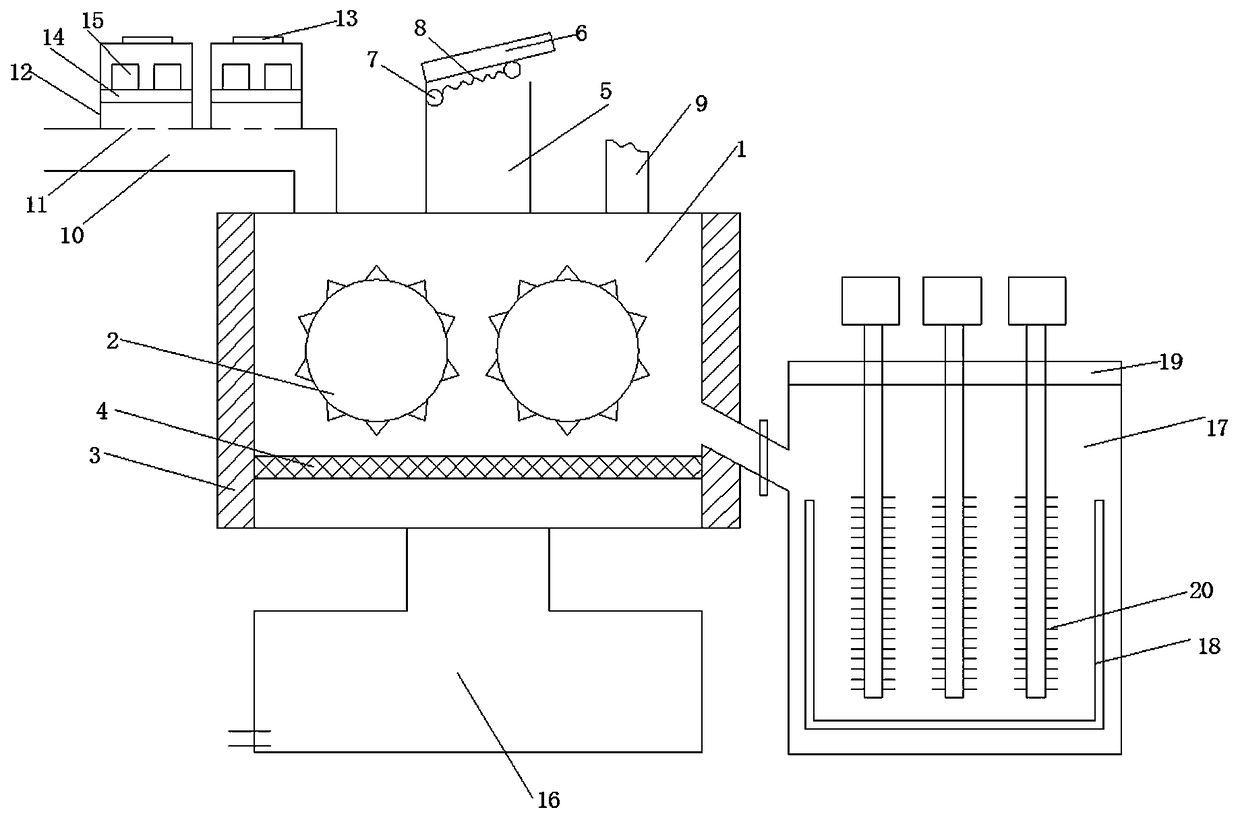

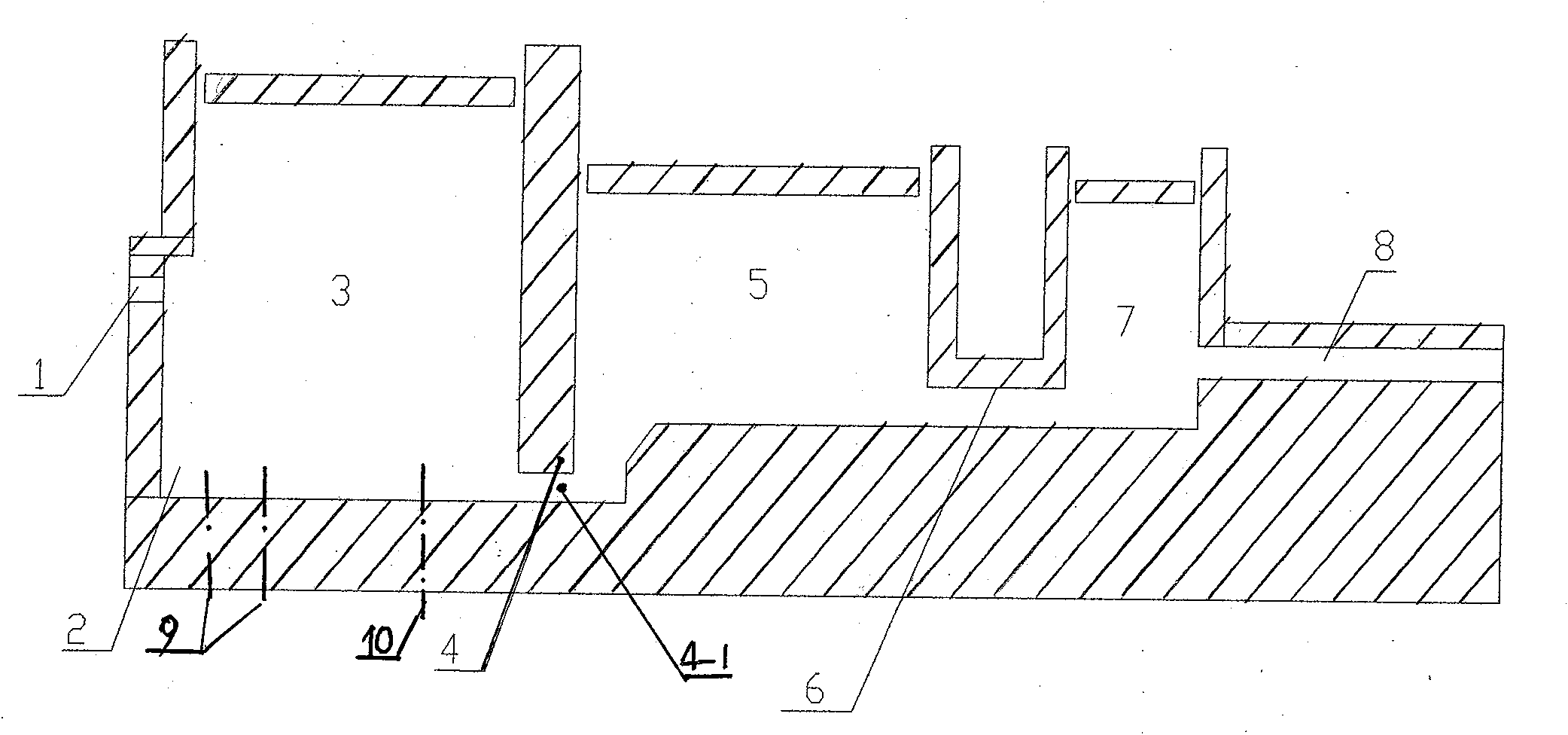

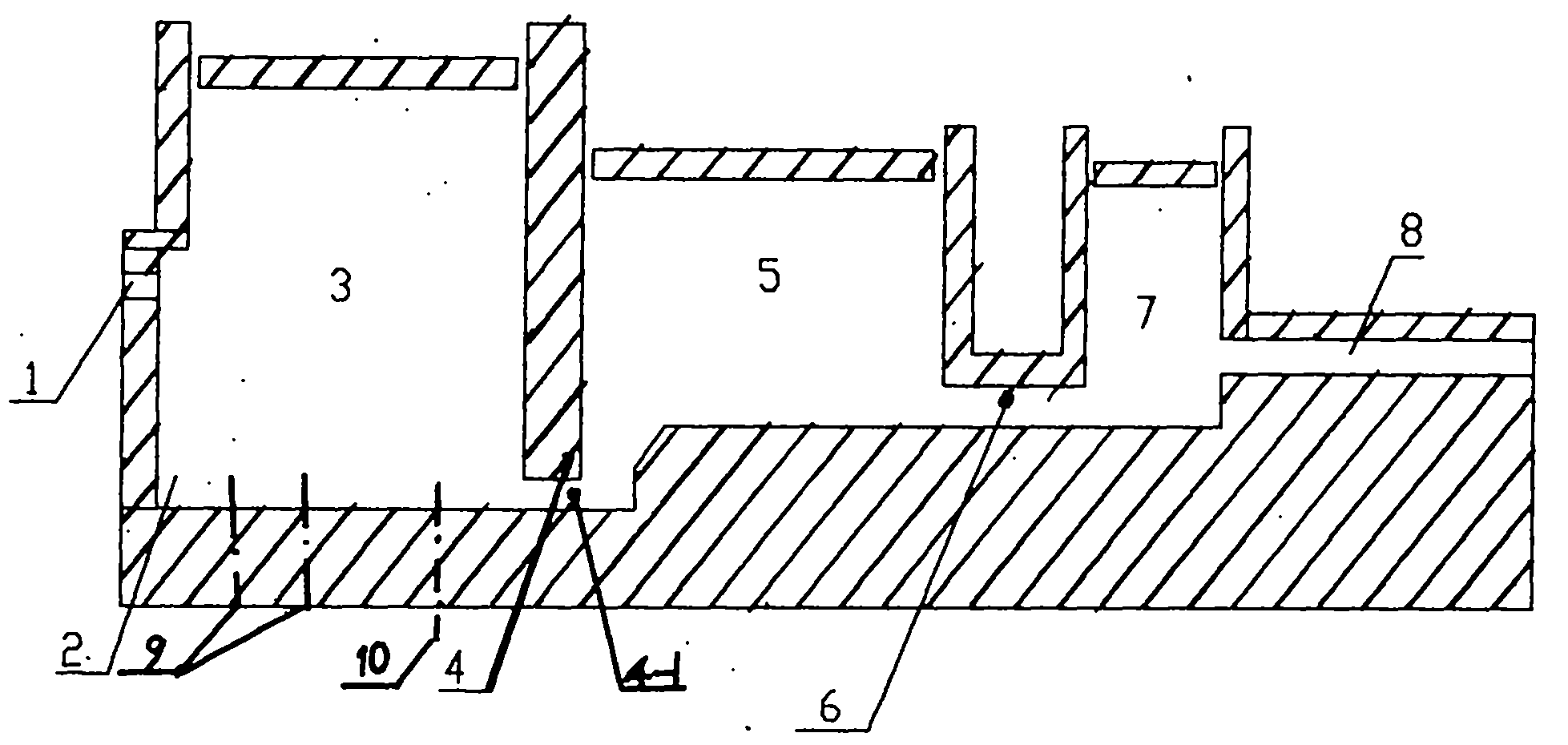

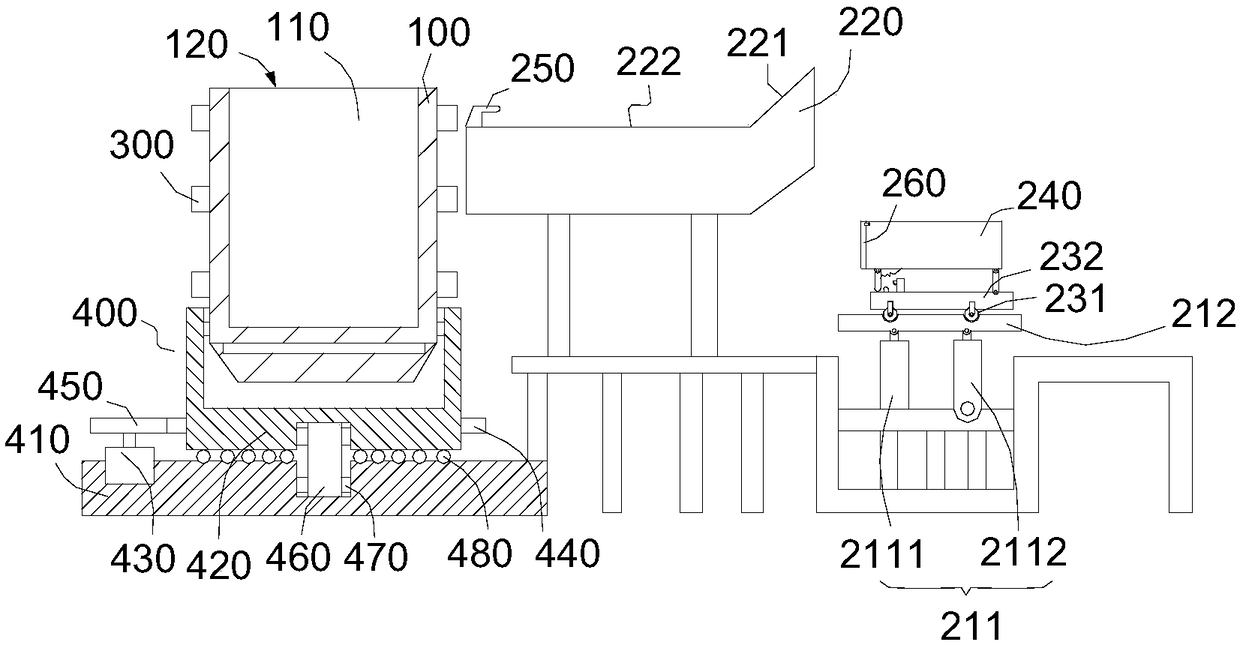

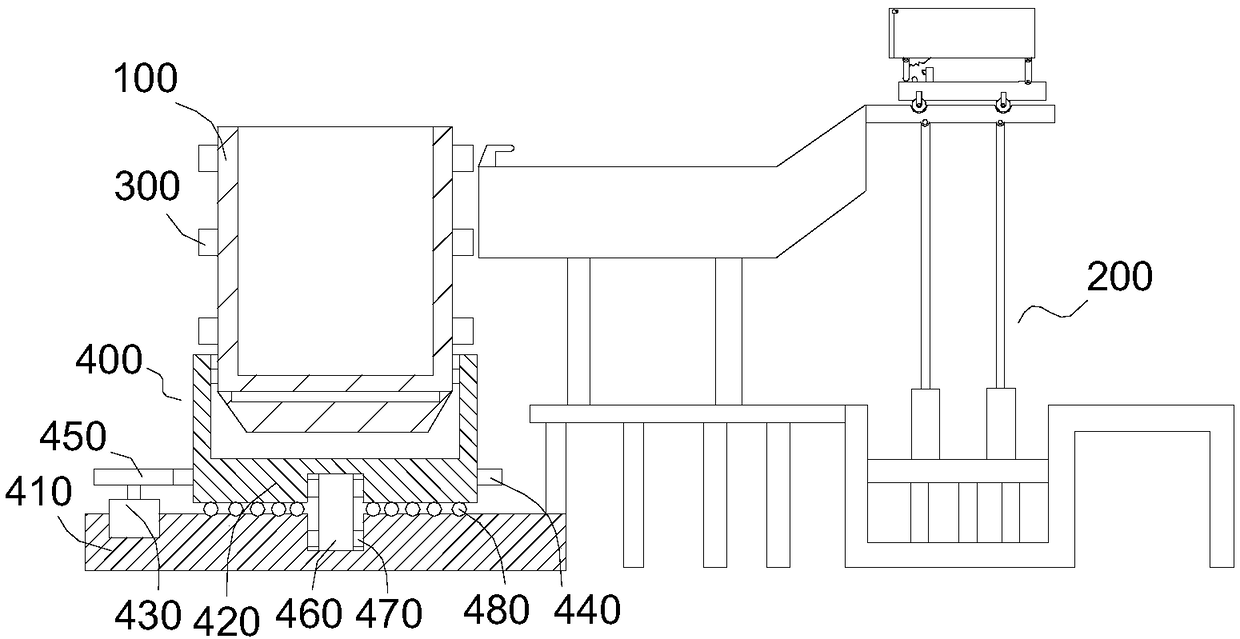

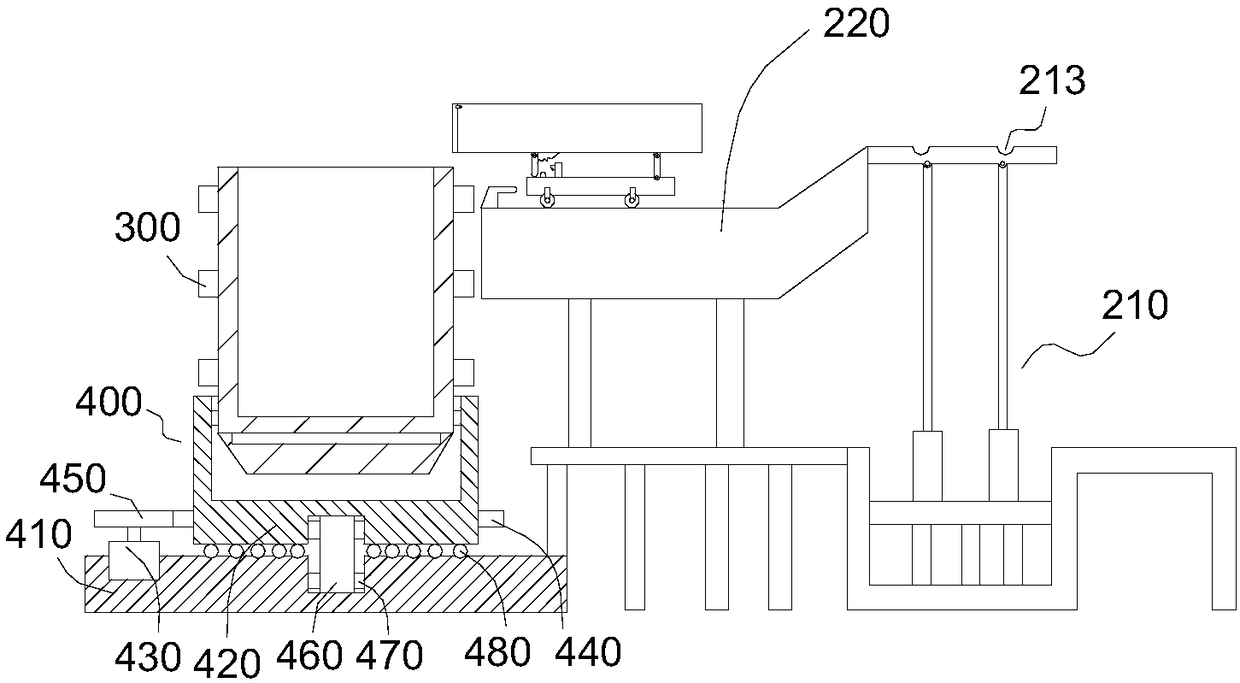

Fluxing apparatus of LCD glass melting furnace

InactiveCN101381197AHigh clarification temperatureClarification temperature is goodGlass furnace apparatusGlass productionViscosityGlass production

The invention relates to a liquid-crystal glass tank furnace fluxing device and a method for solving the difficult problems that liquid-crystal glass is high in melting temperature, high in high temperature viscosity, low in melting rate and high in volatility when melting. A tank bottom between a charging opening and a bubble of a tank furnace is provided with a row of electrodes; the tank bottom in a clarification area close to a liquid flow hole is provided with a row of electrodes as well; and a pure oxygen burner jetting flame into the furnace is arranged on the tank furnace. The device aids in melting through a plurality of fluxing modes, homogenizes the temperature of molten glass, raises the internal temperature of the molten glass, speeds up convection, accelerates glass clarification process, reduces crystallization tendency, and can obtain the glass with higher quality. Therefore, the device is especially applicable to the liquid-crystal glass production harsh in requirement on glass quality.

Owner:HENAN ANFEI ELECTRONICS GLASS

Dark Neutral Green Gray Soda-Lime Glass Composition

ActiveUS20120058879A1Reduce visible light transmittanceImprove melting qualitySoda-lime glassSolar transmittance

The present invention relates to a dark neutral green gray soda-lime glass composition comprising, as a colorant ingredient per 100 weight parts of a base glass composition, 1.4 to 2.5 weight parts of total Fe2O3, 0.02 to 0.04 weight parts of CoO, 0.0001 to 0.004 weight parts of Se, 0.005 to 0.5 weight parts of MnO2, and 0.05 to 1 weight parts of CeO2. The glass composition of the present invention has a visible light transmittance (LTA) of 15% or less, an ultraviolet ray transmittance (Tuv) of 0 to 1%, and a solar transmittance (Tsol) of 15% or less, measured for a reference thickness of 4 mm. As described above, the glass composition of the present invention is excellent in absorbing ultraviolet rays and solar heat, and therefore can be valuably used in privacy glass or a sunroof of a motor vehicle, or in glass used for construction.

Owner:KCC GLASS CORP

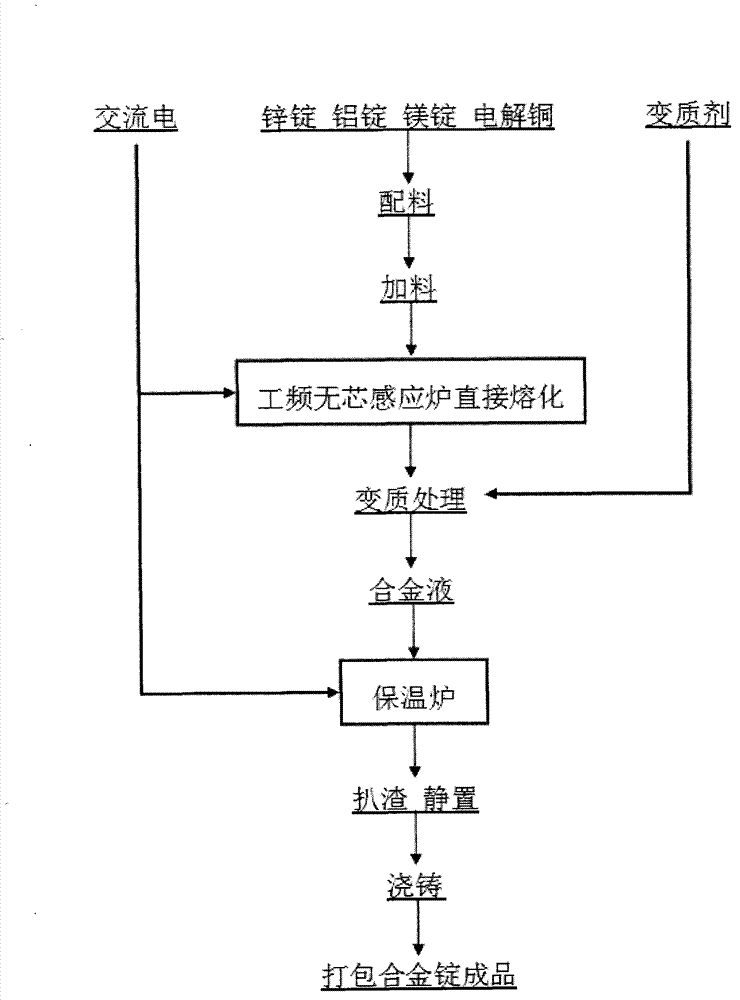

Production method for zinc alloy

A disclosed production method for zinc alloy comprises the following steps: burdening and charging, melting and modification processing, slag removing and standing, casting, alloy ingot finished product packing. Compared with the prior art, the production method has the advantages that: a main frequency coreless induction furnace is utilized for direct melting preparation of the zinc alloy; and compared with conventional melting technologies, the zinc alloy production method by using the main frequency coreless induction furnace has low cost, better melting quality and less metal loss, is more beneficial to promotion of component uniformity and alloying because the metal motion in the main frequency furnace is fierce, and can help to obtain high-quality zinc alloy products.

Owner:GUIZHOU INST OF METALLURGY & CHEM ENG

Device for injection molding of high polymer material

InactiveCN108673822AImprove melting qualityHeating evenly and comprehensivelyGrain treatmentsEngineeringInjection molding machine

The invention discloses a device for injection molding of a high polymer material. The device comprises a crushing box, a fusion box and a stirring heating frame. A cavity is formed in the fusion box.A heating layer is arranged at the position, around the cavity, of the fusion box. Resistance wires distributed in an array manner are arranged in the heating layer. The crushing box is arranged at the upper end of the fusion box. Three through pipes distributed at equal distances are arranged at the lower end of the crushing box. The stirring heating frame is inserted into the fusion box in a penetrating manner and provided with a rotating shaft. A first rotating shaft inner cavity and a second rotating shaft inner cavity are arranged in the rotating shaft. Stirring rods distributed in an array manner are arranged on the rotating shaft. A stirring rod outer cavity and a stirring rod inner cavity are arranged in each stirring rod. According to the device for injection molding of the highpolymer material, heating is uniform and comprehensive, the high polymer material is not prone to adhering to a boiler, the fusion material of the high polymer material is high, and injection moldingis facilitated.

Owner:肇庆益晟商贸有限公司

Compounder-type injection molding machine

InactiveUS6854968B2Melt quality can be ensuredImprove melting qualityAuxillary shaping apparatusFood shapingInjection molding machineInjection device

In a compounder-type injection molding machine having an extruder for continuously producing a melt and at least one injection device is fluidly connected to the extruder to receive melt, a reservoir is provided which is in fluid communication with the extruder as well as with the injection device for temporary storage of melt. In order to maintain a pressure at a desired level at the outlet of the extruder, a pressure sensor is provided for ascertaining a melt pressure state downstream of an outlet of the extruder. The pressure sensor outputs a signal, commensurate with the melt pressure state, to a control unit for activating a drive in the reservoir or a drive in the injection device in response to the signal according a predetermined algorithm.

Owner:KRAUSSMAFFEI TECH GMBH

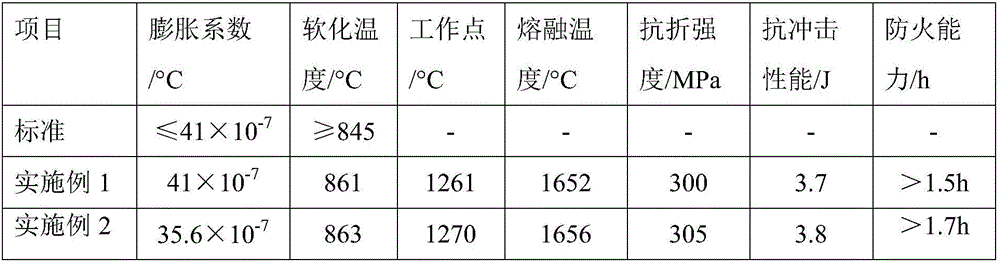

Heat-resistant borosilicate flat glass and preparation method thereof

ActiveCN106587604AEffective control of air bubblesEffective control of striaeFlat glassFire protection

The invention provides heat-resistant borosilicate flat glass and belongs to the technical field of fireproof glass. The heat-resistant borosilicate flat glass is prepared from, by weight, 78.1-82% of SiO2, 1-5% of Al2O3, 9-14% of B2O3, 3-6% of Na2O, 1-5% of CaO, 0.5-2% of K2O, 0.1-3% of ZrO2 and 0.01-2% of GeO2, wherein the total content of SiO2 and B2O3 accounts for 87.1-92% of the total content of all the materials, and the weight ratio of SiO2 to B2O3 is 5.5 to 8.6. The invention further provides a preparation method of the heat-resistant borosilicate flat glass; compared with current borosilicate flat glass in the market, the heat-resistant borosilicate flat glass has a higher glass softening point and a lower linear expansion coefficient, at the same time, the melting temperature and the molding temperature are relatively low; the glass is easy to manufacture and can serve as the fireproof glass applied in the fire protection field after being tempered.

Owner:GLASS TECH RES INST OF SHAHE CITY OF HEBEI PROVINCE

Zip-top can crushing device

InactiveCN108906207AExtended service lifeQuality improvementDirt cleaningCleaning using toolsActivated carbonEngineering

The invention relates to a zip-top can crushing device. The zip-top can crushing device comprises a crushing box and a feeding tube arranged above the crushing box. Two tooth rollers are arranged in the crushing box. A filter net is arranged below the tooth rollers in the crushing box. The lower part of the crushing box is provided with a waste water collection tank through a pipe. An exhaust ductis arranged above the crushing box and is provided with several deodorizing devices. The deodorizing device comprises a deodorizing frame. A support frame with a mesh is arranged in the deodorizing frame. An activated carbon bag is arranged above the support frame. The exhaust duct corresponding to each deodorizing frame is provided with a plurality of exhaust holes. The lower end of one side ofthe crushing box is provided with a discharge pipe. The discharge pipe is connected to a cleaning tank. The zip-top can crushing device improves crushing effects, prolongs a service life, reduces thesmell of the object and improves the quality of the smelting in the later stage.

Owner:唐师正

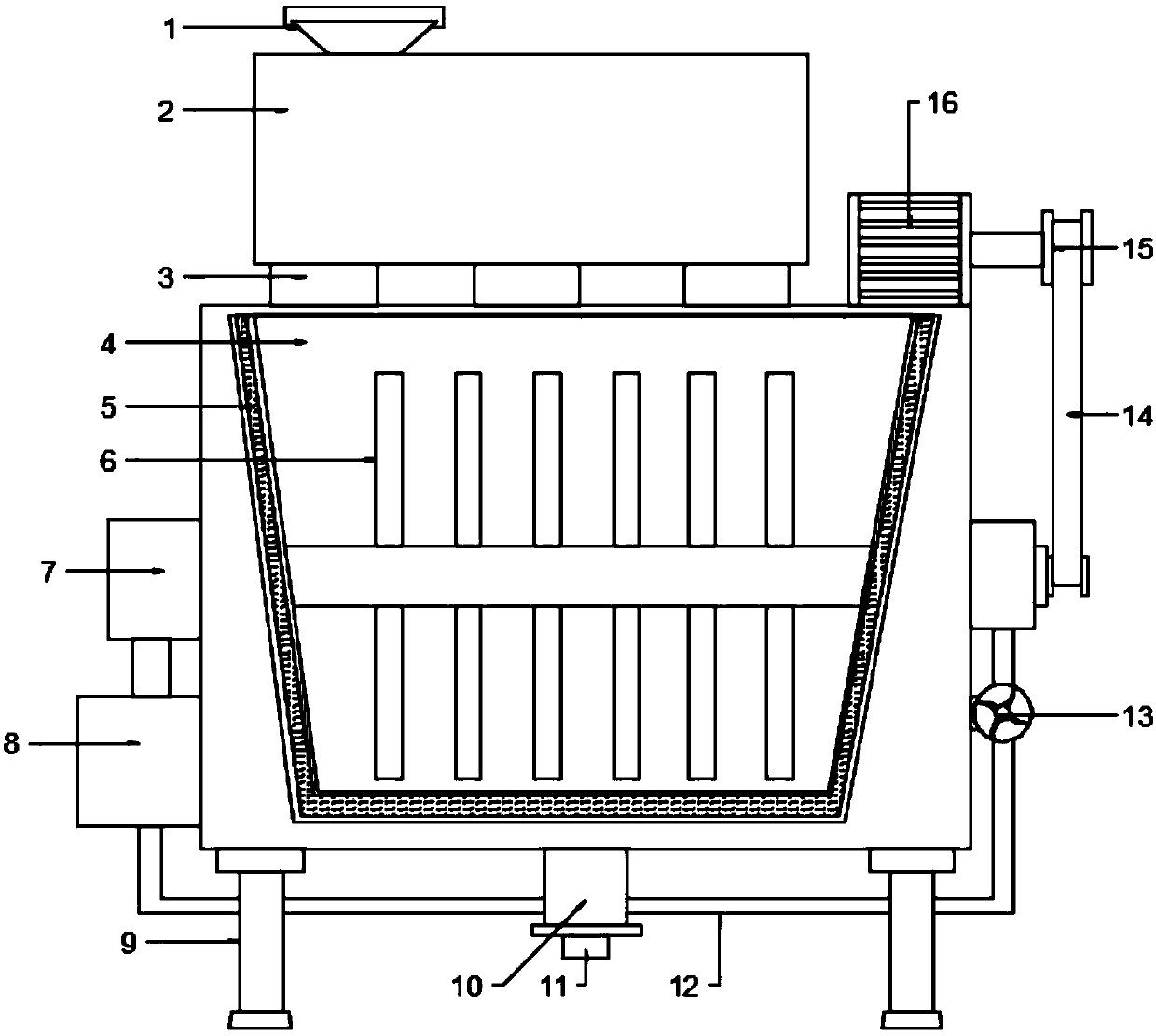

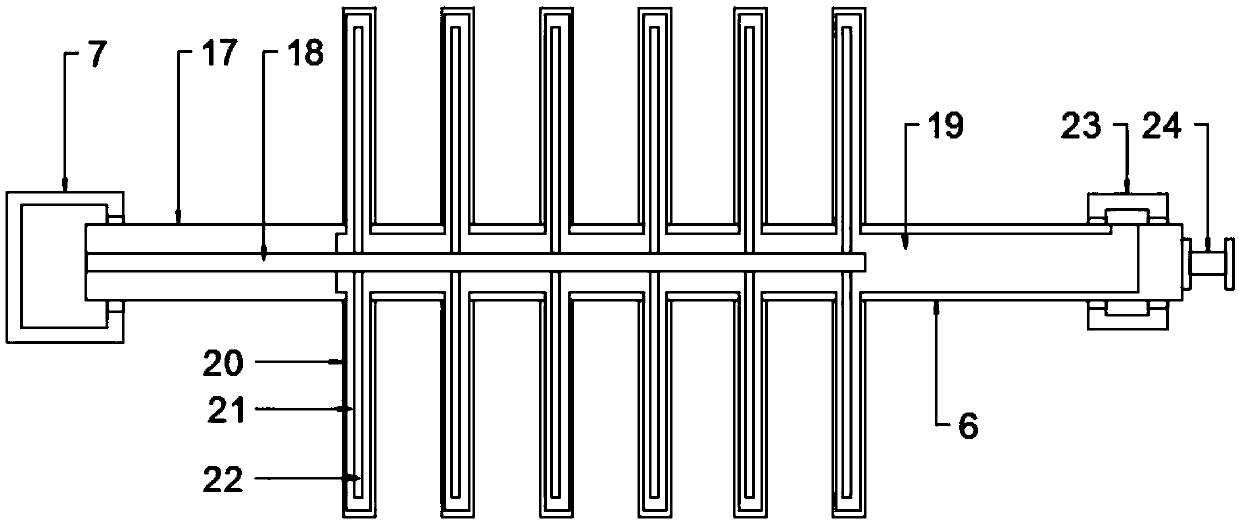

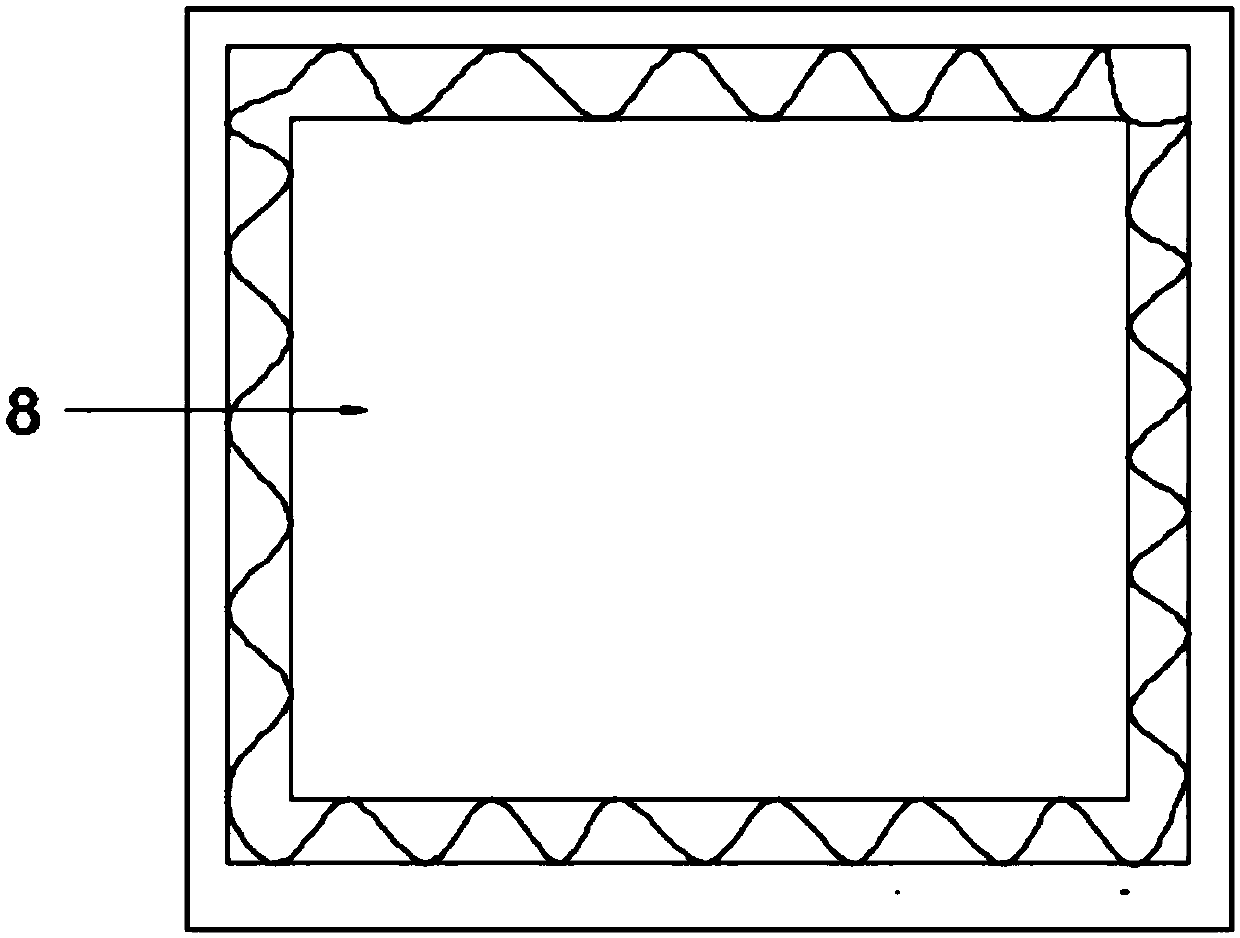

Horizontal type smelting furnace

InactiveCN101324401AImprove heat transfer performanceImprove mass transfer conditionsRotary drum furnacesInsulation layerCoal

A horizontal melting furnace comprises a furnace body support and a furnace body, wherein a housing, a heat insulation layer and a fireproof layer are sequentially arranged on the furnace body from outside to inside; the tail end of the furnace body is connected with a flue; the head of the furnace body is communicated with a pulverized coal inlet; the furnace body is horizontally arranged on the furnace body support; the horizontal melting furnace also comprises a rotating mechanism and a tilting mechanism; the rotating mechanism is arranged between the furnace body; and the tilting mechanism is arranged on the bottom of the furnace body support. The horizontal melting furnace solves the technical problems existing in the prior melting furnace in the background technology, such as poor heat transfer and mass transfer condition in the furnace, difficult material discharge, and environment pollution caused by escaped gas. The horizontal melting furnace has the advantages of high melting quality, simple discharge and no environment pollution.

Owner:XIAN HUAYING INDAL

High-borosilicate glass, and preparation method and application thereof

ActiveCN103626395AImprove melting qualityControllable and adjustable thicknessPlatinumPhotovoltaic detectors

The invention relates to a high-borosilicate glass, and a preparation method and application thereof, belonging to the field of glass making. The preparation method comprises the following steps: weighing high-borosilicate glass raw materials, and uniformly mixing the raw materials; melting the uniformly mixed raw materials into a glass liquid with a platinum crucible, and introducing oxygen gas or liquid oxygen to the bottom of the glass liquid with a platinum tube at the flow rate of 0.5-3 L / minute for 10-60 minutes; and standing for 1-2 hours, stirring the glass liquid with a frame platinum stirrer at the rotation speed of 20-100 rpm for 2-5 hours, cooling, forming, annealing and physically polishing to obtain the high-borosilicate glass. The high-borosilicate glass provided by the invention has higher optical uniformity and no visible bubble, stripe or flash point; the preparation method obviously enhances the melting quality of the high-borosilicate glass and widens the application range of the high-borosilicate glass; and the high-borosilicate glass is especially suitable to be used as a window material in the field of manufacturing of photoelectric detectors, vacuum instruments, integrated circuits and the like.

Owner:CHINA BUILDING MATERIALS ACAD

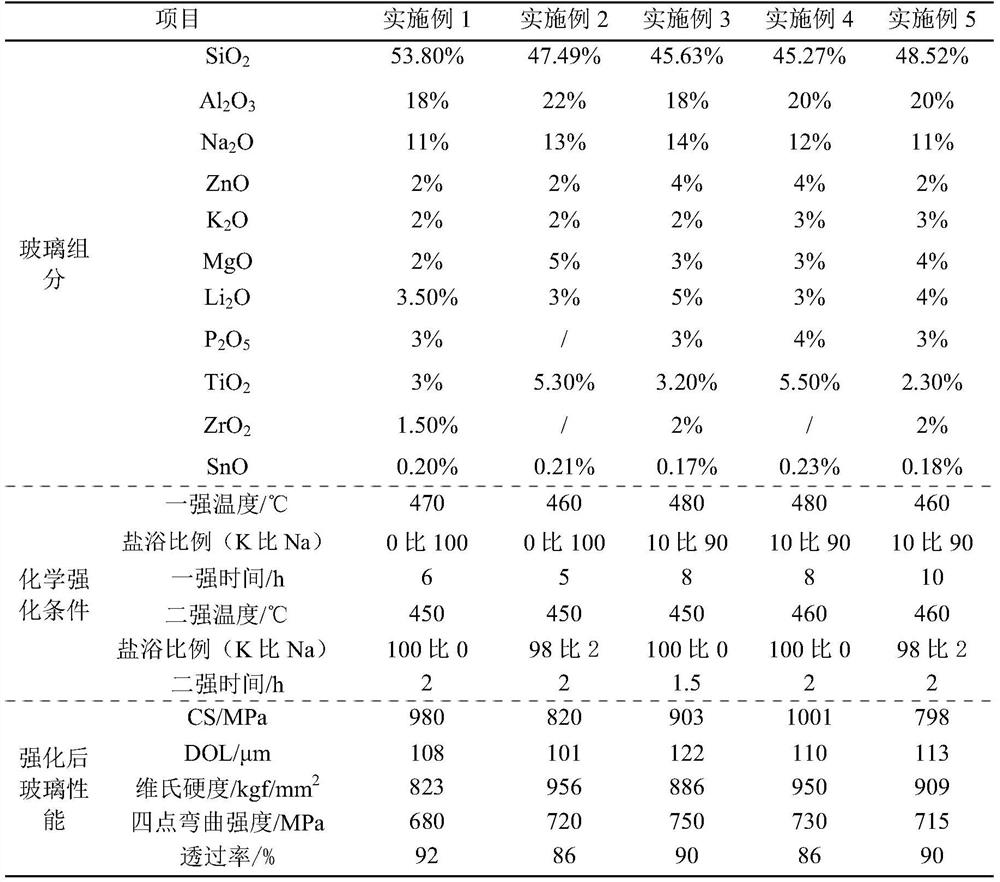

Lithium-aluminum-silicon microcrystalline glass as well as strengthening method and application thereof

InactiveCN112919813AGood chemical stabilityModerate melting temperatureGlass tempering apparatusTelephone set constructionsPotassium nitrateIon exchange

The invention discloses lithium-aluminum-silicon microcrystalline glass as well as a strengthening method and application thereof. The glass comprises the following components in percentage by mass: 45%-75% of SiO2, 10%-25% of Al2O3, 0-4% of ZrO2, 3%-5% of Li2O, 10%-18% of Na2O, 0-5% of K2O, 0-6% of P2O5, 0-7% of TiO2, 2%-7% of MgO, 0-10% of ZnO and 0-1% of SnO. The strengthening method comprises the following steps: preparing raw materials, and performing melting and molding to obtain mother glass; carrying out heat treatment to obtain microcrystalline glass; carrying out ion exchange on the microcrystalline glass in molten salt at the temperature of 390-500 DEG C for 3-10 hours to obtain primarily strengthened microcrystalline glass; and finally, soaking the glass ceramic subjected to primary strengthening in molten salt consisting of potassium nitrate and sodium nitrate for 1-2.5 hours to obtain the lithium-aluminum-silicon glass ceramic.

Owner:CAIHONG GRP SHAOYANG SPECIAL GLASS CO LTD

Glass tank for melting high-boron low-alkali or alkali-free glass

InactiveCN101880120AEasy to manageTimely managementTank furnacesGlass productionMelting tankAlkali free

The invention relates to a glass tank for melting high-boron low-alkali or alkali-free glass and manufacturing a TFT-LED glass substrate. The glass tank comprises a heating system matched with the glass tank and is characterized in that: the internal structure of the glass tank comprises a pre-melting tank with a feed inlet, a cross flame melting tank connected with the pre-melting tank, a cross flame clarification tank communicated with the cross flame melting tank through a lower passage of a flow-limiting diaphragm wall, and a cross flame work pool communicated with the cross flame clarification tank through a pipeline; and a forming passage for delivering molten glass is formed on the cross flame work pool. The glass tank reasonably utilizes energy; and the generated molten glass has the advantages of quick temperature rise, uniformity and high defoaming efficiency.

Owner:TUNGHSU GRP

Waste plastic recycling regenerating device

InactiveCN108372606AImprove melt qualityReduce production laborPlastic recyclingGrain treatmentsAir heaterEngineering

The invention discloses a waste plastic recycling regenerating device, and relates to the technical field of resources. The waste plastic recycling regenerating device comprises an outer frame; the top end of the outside of the outer frame is fixedly connected with a smashing frame; a first rotary shaft is fixedly connected with a smashing gear; the inner wall of the right side of the smashing frame is fixedly connected with fixed smashing engaging teeth; the bottom end of the smashing frame is provided with a smashing outlet; the top end of a supporting plate is fixedly connected with a propulsion device; the right side of the interior of the outer frame is fixedly connected with a heating frame; the middle of the top end of the heating frame is provided with a melting inlet, the right side of the top end of the heating frame is fixedly connected with an air heater, and the middle of the interior of the heating frame is fixedly connected with a melter; and the inner wall of the left side of the outer frame is fixedly connected with a press roll device. According to the waste plastic recycling regenerating device, the purposes that double smashing and sufficient smashing of plasticcan be conducted, the plastic melting quality is improved, the production labor force is reduced, the plastic regenerative quality is improved, and wasted plastic resources are decreased are achieved.

Owner:佛山杰致信息科技有限公司

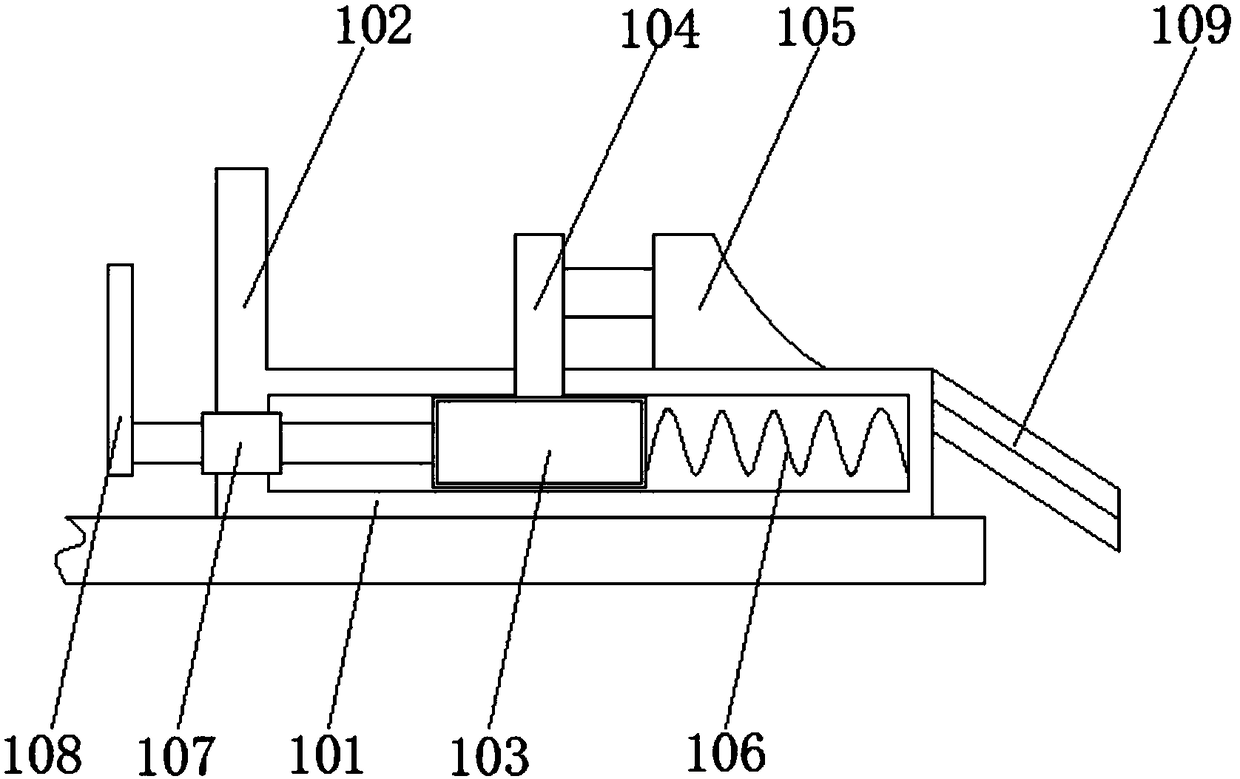

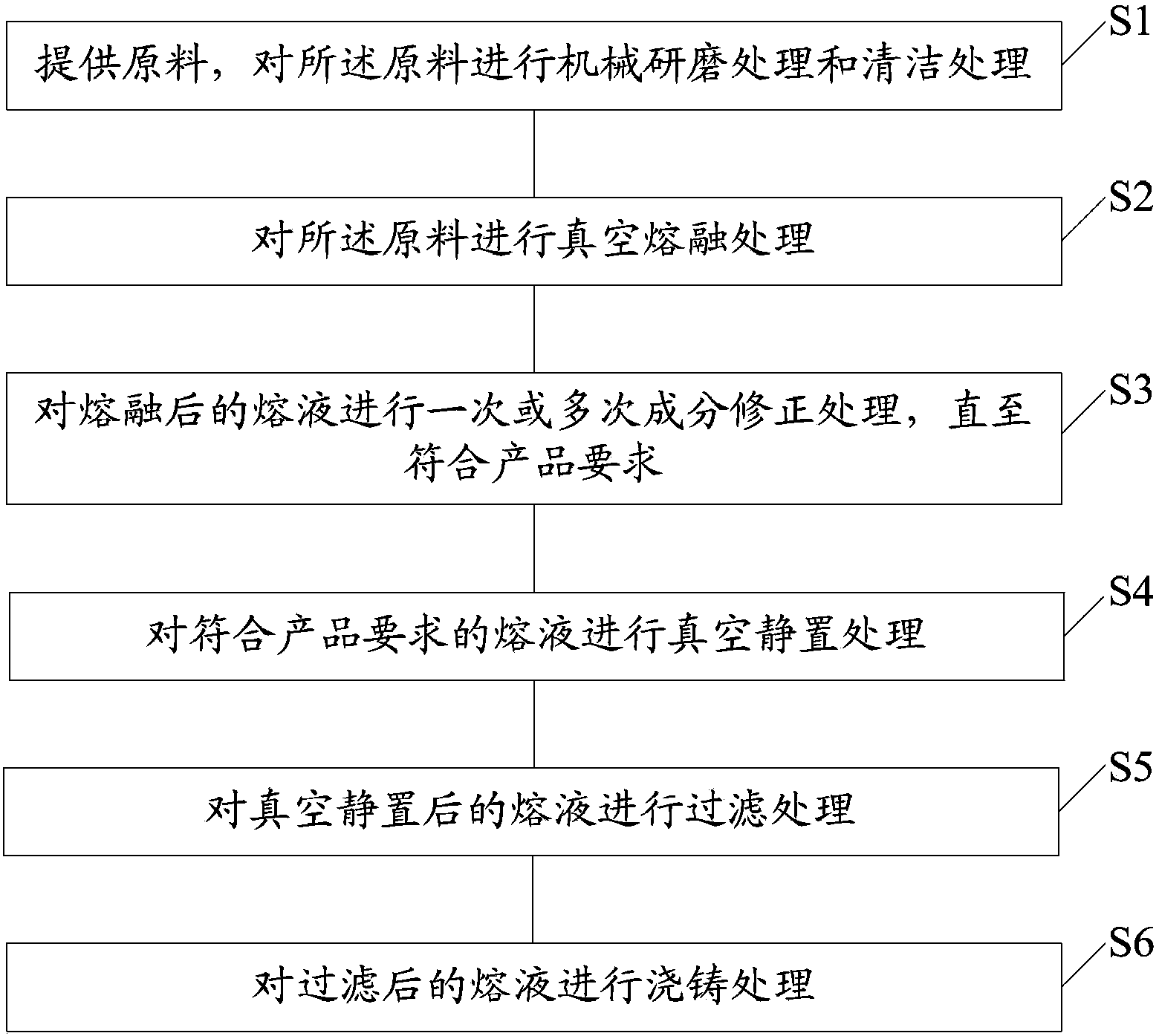

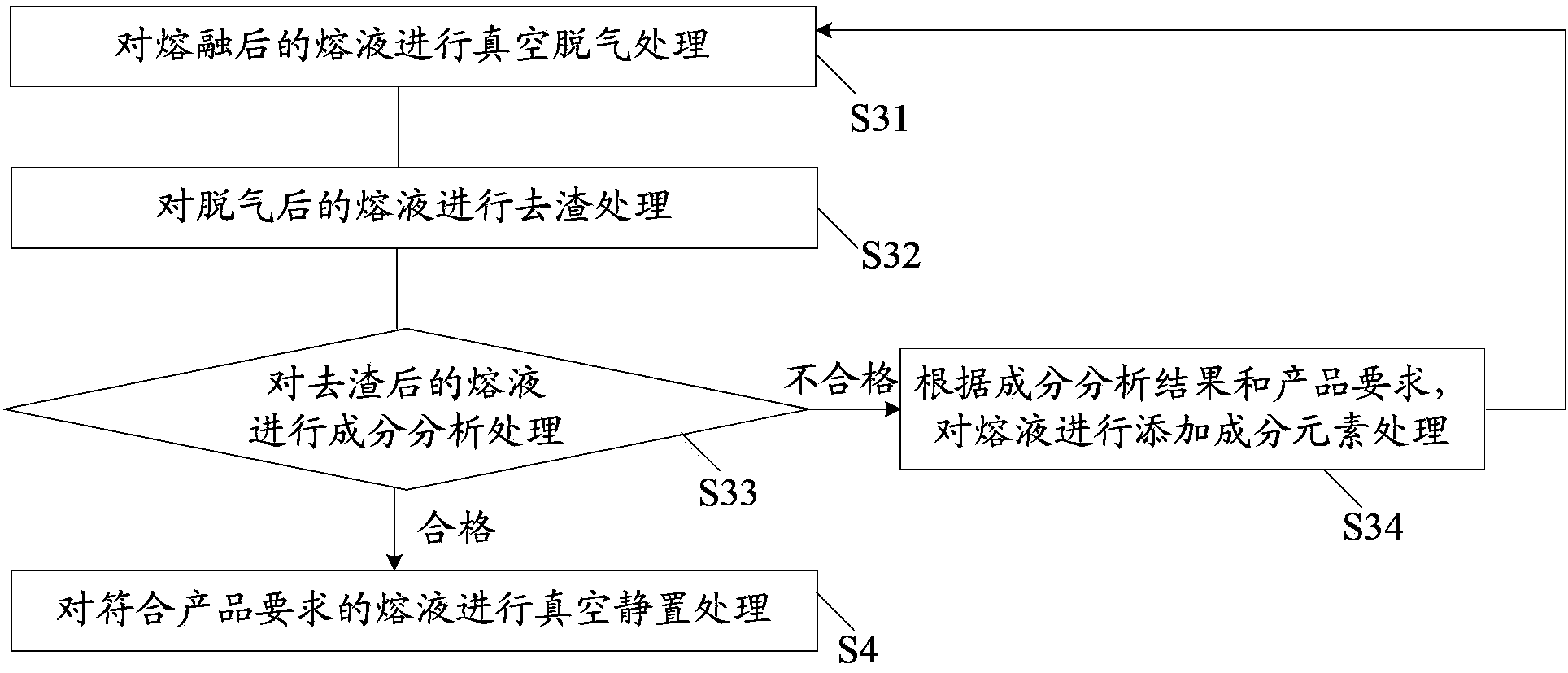

Aluminum alloy casting method

The invention discloses an aluminum alloy casting method. The aluminum alloy casting method comprises the following steps: raw materials are supplied; the vacuum melting treatment is performed for the raw materials; one or more times of component correction treatment is performed for the molten liquid until the product requirements are satisfied; the vacuum standing treatment is performed for the molten liquid satisfying the product requirements; and the filtering treatment and the casting treatment are performed for the molten liquid after the vacuum standing treatment. The aluminum alloy casting method can improve the aluminum alloy purity, and reduce the production cost.

Owner:宁波创润新材料有限公司

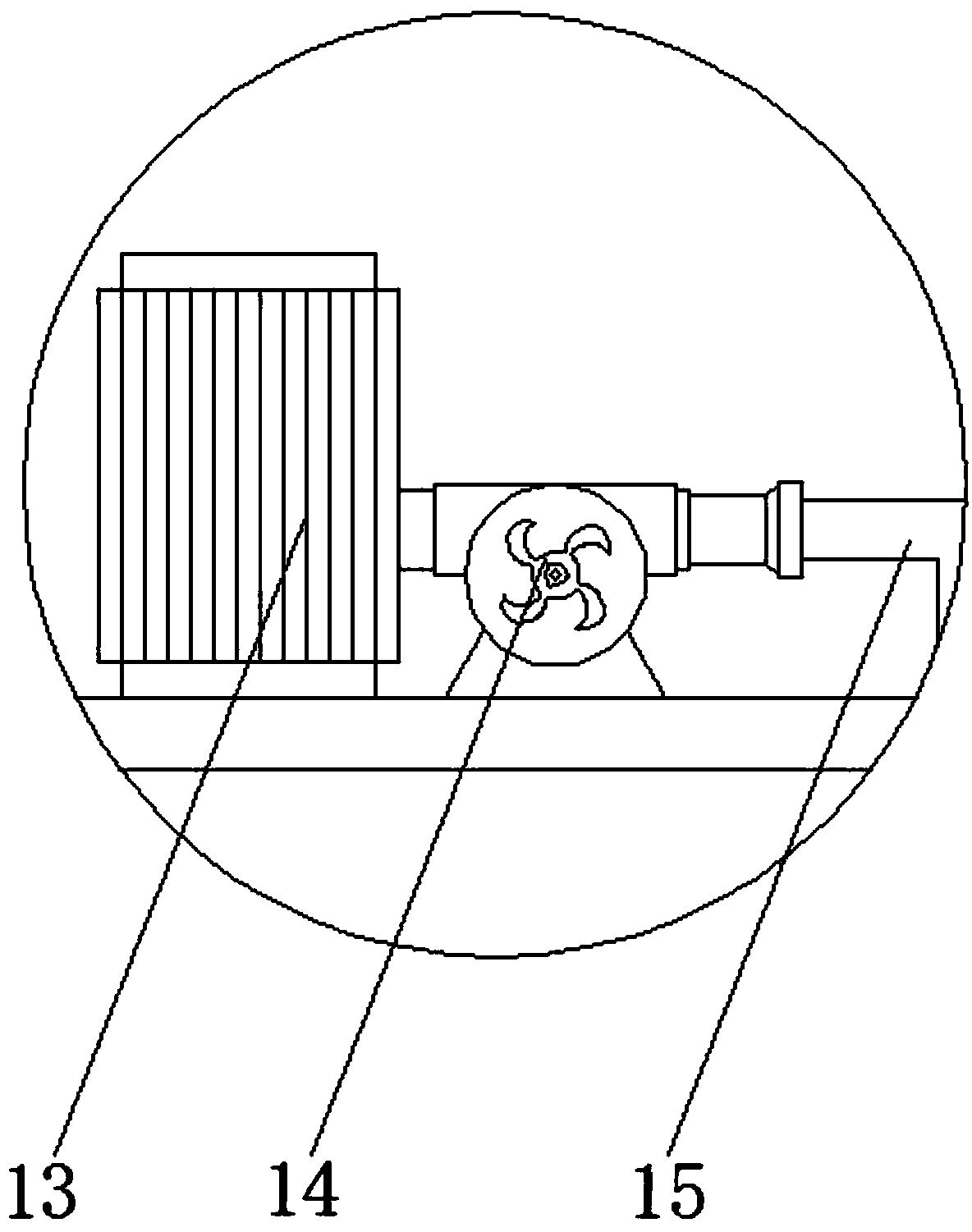

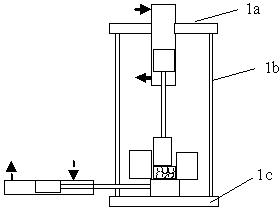

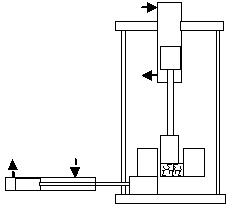

Smelting furnace and smelting machining system of aluminum material

PendingCN108592627ASimple structureEasy to processCharge composition/stateCharge manipulationMachining systemAutomation

The invention discloses a smelting furnace and smelting machining system of an aluminum material. The smelting furnace of the aluminum material comprises a smelting furnace main body, a mounting unit,a feeding unit and a heating unit, wherein the smelting furnace main body is provided with a smelting chamber and a feeding port; the mounting unit is used for mounting the smelting furnace main body, and drives the smelting furnace main body to rotate; the feeding unit comprises a guide assembly, a feeding guide rail, a traveling assembly and a feeding hopper, wherein the feeding guide rail comprises an inclined section and a smooth section which are connected with each other, the guide assembly is used for guiding the feeding hopper into the inclined section, the traveling assembly is mounted on the feeding hopper, and the traveling assembly can travel on the guide assembly and the feeding guide rail, and the feeding hopper is provided with a material discharging hole. The smelting furnace of the aluminum material is high in automation degree in the using process, the probability that workers are scalded by high-temperature gas is reduced, and better safety guarantee is provided forworking of the workers; a material can be uniformly distributed in the furnace body during the material adding process, the material can be heated more uniformly, and the smelting quality is high.

Owner:重庆顺博铝合金股份有限公司

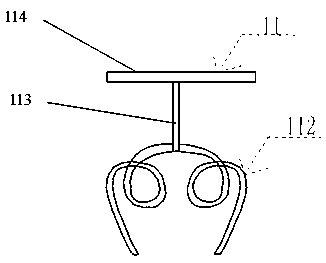

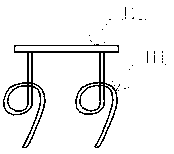

Production equipment of hydrophilic moisture-conducting secondary plied porous fibers and production method of porous fibers

InactiveCN110616469AStrengthen bondageUniform tensionNew-spun product collectionArtificial thread manufacturing machinesPorous fiberMoisture

The invention provides production equipment of hydrophilic moisture-conducting secondary plied porous fibers and a production method of porous fibers. In the production equipment of the hydrophilic moisture-conducting secondary plied porous fibers, a single-rod double-end two-way guider mainly features two-way guidance, so that the binding of the guider to tows is strengthened; the two tows, before being plied, are symmetrically deviated from the angular direction of the guider, the uniform tension of the two tows is ensured, the friction between the two tows before and after plying is reduced, fiber branching and breaking are avoided, and yarn drifting and broken ends are avoided, yarn skipping during winding switching is avoided, the problems, such as hairy fiber falling during cake winding, are avoided, and product quality is improved.

Owner:JIANGSU DELI CHEM FIBER CO LTD

Preparation method of rock wool

InactiveCN112299701ASolve the conditioning problemDrain cleanGlass making apparatusAlkali freeHeat energy

The invention discloses a preparation method of rock wool, and the method specifically comprises the following steps of: putting raw materials into a kiln, and performing melting and wire drawing to obtain rock wool; wherein the raw materials comprise 50-90wt% of hot melt slag, 5-30wt% of alkali-free glass waste wires and 2-30wt% of basalt. By means of the method, a large amount of alkali-free glass fiber waste silk solid waste can be utilized at present; and on the other hand, the problem of blending and hardening and tempering of mineral cotton produced by hot melt slag is solved. The threeraw materials almost have no silicate reaction during heating, so that the emission of carbon dioxide waste gas is greatly reduced. Due to the fact that the reaction amount is small and the emission amount of carbon dioxide is extremely small, heat energy consumption can be reduced, the heat utilization rate is increased, and fuel consumption is reduced.

Owner:NANJING FIBERGLASS RES & DESIGN INST CO LTD

Aluminum zirconium middle alloy and preparation method thereof

The invention discloses an aluminum zirconium middle alloy and a preparation method thereof; the aluminum zirconium middle alloy is made from main materials and auxiliary materials; the main materials are primary aluminum liquid and sponge zirconium powder; the auxiliary materials are refining agent and covering agent. The invention is characterized in that the alloy comprises the following components by weight: 99 percent to 99.9 percent of zirconium in the sponge zirconium powder; 0.01 percent to 0.1 percent of silicon, 0.01 percent to 0.12 percent of iron and 99.97 percent to 99.99 percent of aluminum in the primary aluminum liquid. The using amount of the alloy and the primary aluminum liquid (calculated according to a 10T furnace) is as follows: 8T to 9T of primary aluminum liquid, 0.39T to 0.5T of sponge zirconium powder, and appropriate amount of refining agent and covering agent. The invention has the advantage of achieving the purpose of energy conservation and environmental protection by using the method of producing aluminum zirconium middle alloy by the primary aluminum liquid, thereby greatly lowering the investment cost, shortening the production period, simplifying the production process, and reducing the processing cost.

Owner:毕祥玉

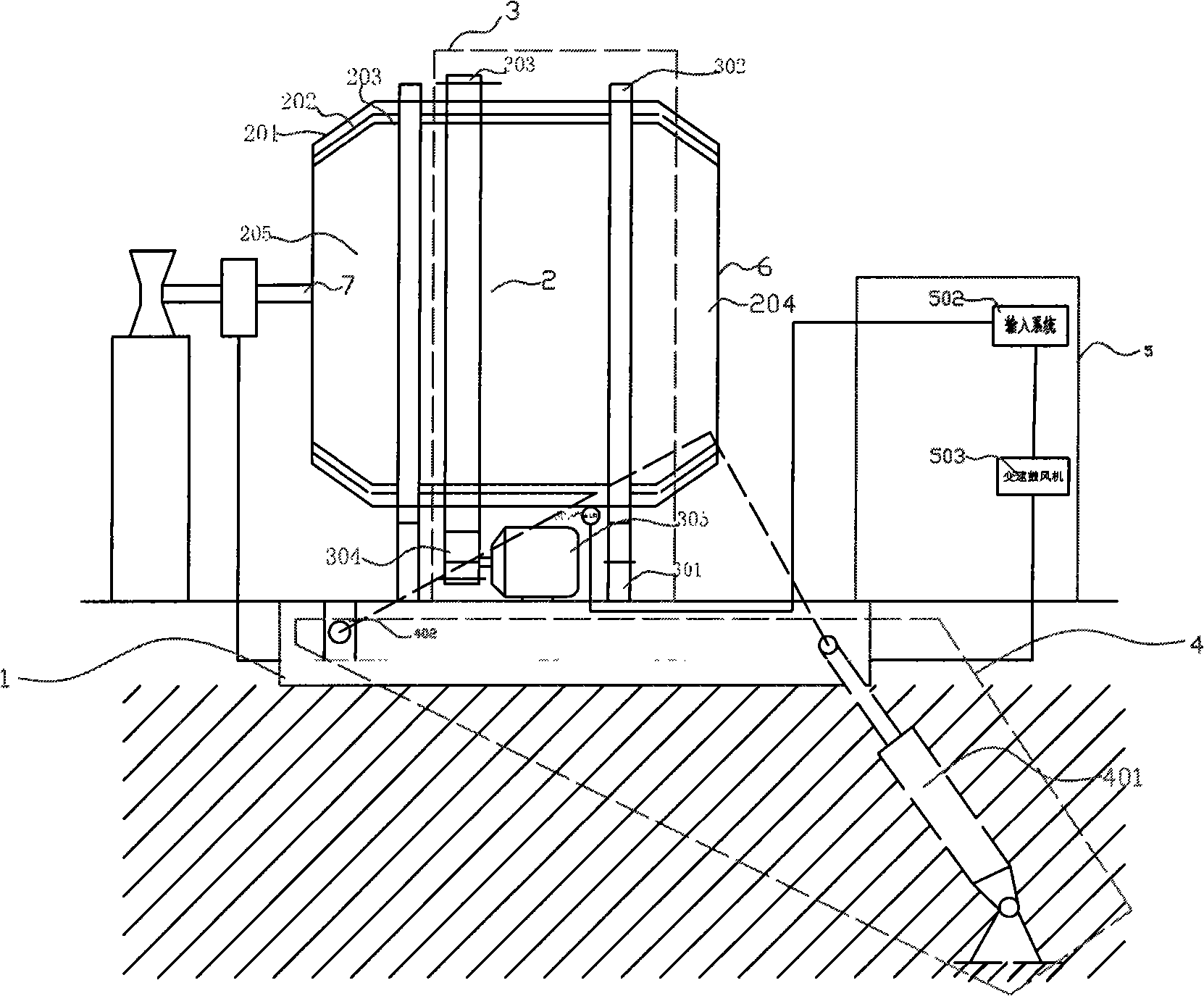

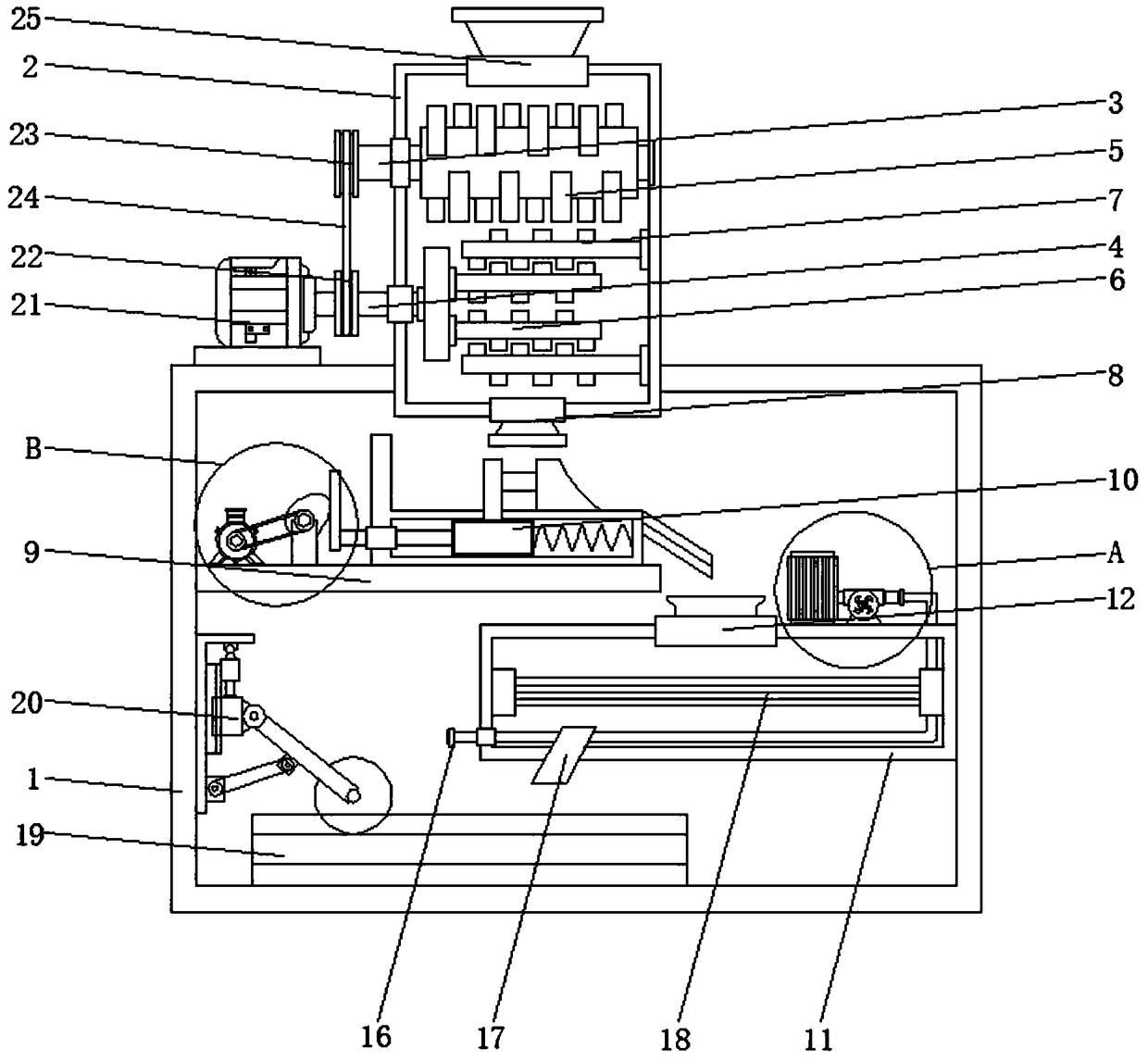

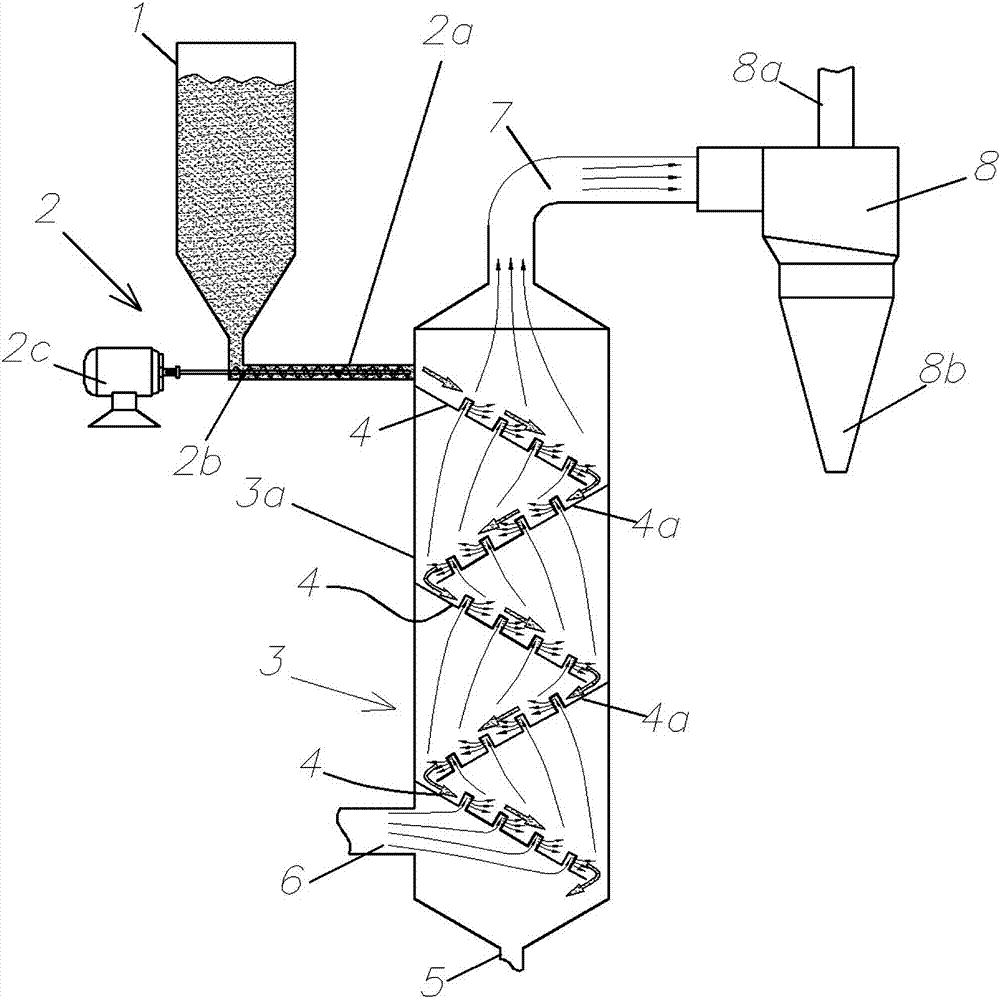

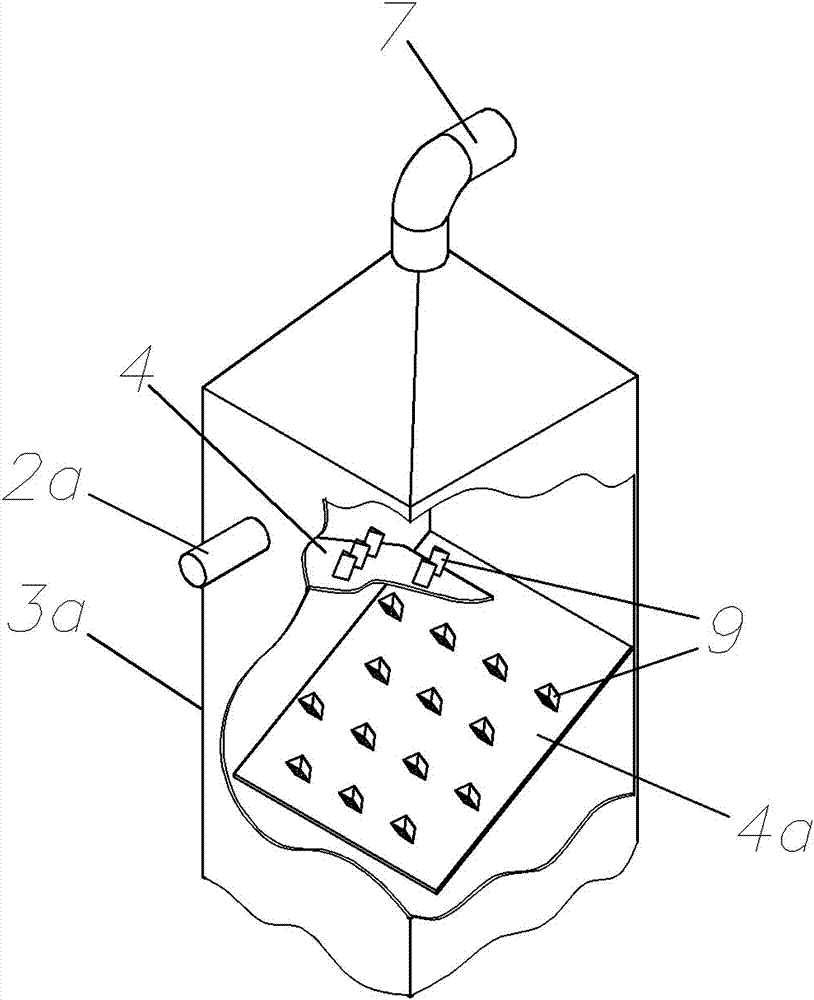

Baffling type glass batch mixture preheating device

PendingCN107879595AReduce energy consumptionImprove melting qualityCharging furnaceGlass productionFlue gasEnergy consumption

The invention provides a baffling type glass batch mixture preheating device. The baffling type glass batch mixture preheating device comprises a batch mixture bin (1). The baffling type glass batch mixture preheating device is characterized in that the batch mixture bin (1) is communicated with a preheater (3) through a feeding device (2), a group of first material-guiding heat-exchanging plates(4) and a group of second material-guiding heat-exchanging plates (4a) are arranged in a shell of the preheater (3), a discharging hole (5) is formed in the bottom of the preheater (3), a flue gas inlet (6) is formed in a shell above the discharging hole (5), and the top of the preheater is communicated with a dust collector (8) through a flue (7). The baffling type glass batch mixture preheatingdevice is simple in structure and convenient to use; and the kiln feeding temperature of the batch mixture is increased, the energy consumption of a kiln can be effectively reduced, the energy sourceis saved, and the glass fusion quality is improved.

Owner:(CNBM) BENGBU DESIGN & RES INST FOR GLASS IND CO LTD

Treatment method of waste copper cuttings

InactiveCN102634665AReduce burning lossAvoid pollutionProcess efficiency improvementCombustionFiltration

The invention discloses a treatment method of waste copper cuttings, which comprises the following steps: (1) pressing the waste copper cuttings into a block; (2) heating the copper cutting block in the step (1) to 700-850 DEG C to remove oil; and finally, carrying out purifying treatment on the oil stain cracked product generated in the oil removal process in the step (2). According to the treatment method of waste copper cuttings, the cutting fluid in the copper cuttings can be removed thoroughly by pyrolysis; and when the cutting cake subjected to oil removal directly returns to the furnace, the cutting cake is immerged in the copper liquid and molten, thereby greatly reducing the burning loss of the copper cuttings and enhancing the metal recovery rate. The invention can prevent the oil stain in the copper cuttings from polluting the copper liquid, enhance the metal melt quality, improve the processability of metal, and increase the processing yield. The cracked oil smoke is subjected to combustion, static electricity collection and filtration treatment, and the concentration of the finally emitted smoke is lower than 2mg / m<3>.

Owner:JINCHUAN GROUP LIMITED

Method for recovering and using glass bulb of worn-out display tube

InactiveCN101092281AImprove melting qualityReduce pollutionSolid waste disposalSocial benefitsGlass recycling

This invention relates to a method for recovering and utilizing glass shell glass of waste kinescope. The method comprises: (1) classifying glass shell glass of waste kinescope into panel glass, cone glass or mixed glass, separating, washing, and pulverizing into 1-5 mm glass particles; (2) sending the glass particles to the production process of kinescope glass shell as the raw material (not higher than 30%). The method can lower the production cost, improve the melting quality of glass shell glass, reduce environmental pollution caused by abandoning glass shell glass of waste kinescope, and has high social benefit.

Owner:HENAN ANCAI HI-TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com