Treatment method of waste copper cuttings

A processing method and technology for copper scraps, which are applied in the field of machining, can solve the problems of poor plastic workability, reduced melt quality of copper and copper alloys, and low ingot density, so as to improve processing performance, improve metal recovery, increase quality effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The first step of the method for processing waste copper scraps of the present invention is to make oily, scattered and loose copper scraps into dense blocks; the second step is to heat the oily scrap cakes to 700-850°C to make the The oil stain undergoes a cracking reaction and is discharged. Finally, the pyrolysis products can be burned and purified to achieve standard discharge.

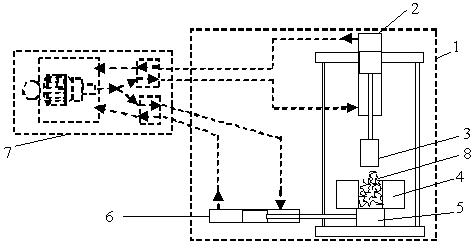

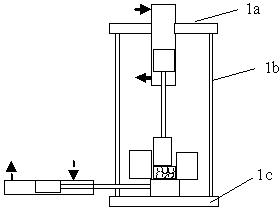

[0014] Pressed lump copper shavings may be chip cakes, see Figure 1-Figure 5 , The cake making process includes: putting copper scraps 8 into the cake mold 4 of the cake maker, hydraulic station 7 drives the cake making pressure head 3 to move downwards, and presses the copper scraps into scrap cakes. Push out the oil cylinder 6 to move to the left to pull out the pad iron 5 at the bottom of the cake, and the cake making pressure head 3 presses down the crumb cake 9; the pad iron 5 resets and pushes out the crumb cake 9. Complete a cake making cycle.

[0015] see Image 6 , The deoiling...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com