Patents

Literature

38results about How to "With desulfurization" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Boron-containing fluorine-free fluxing slag-melting agent for electric steelmaking

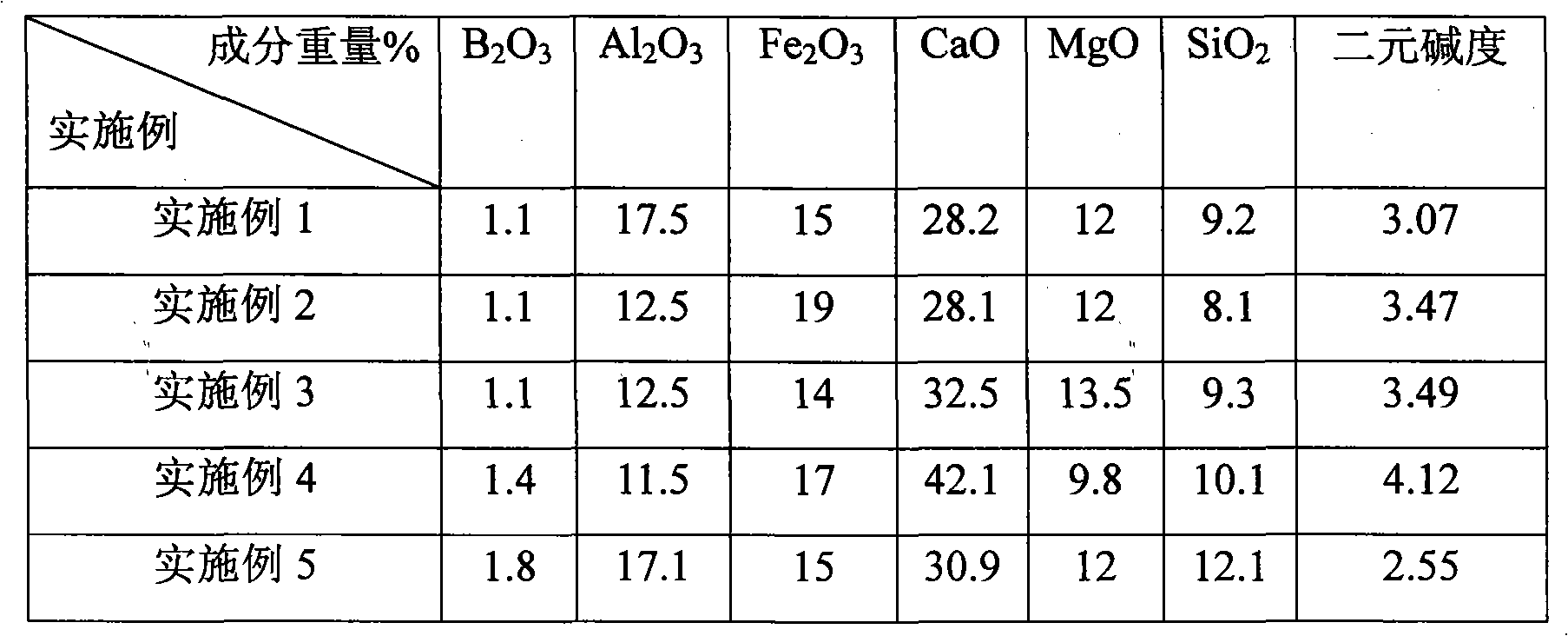

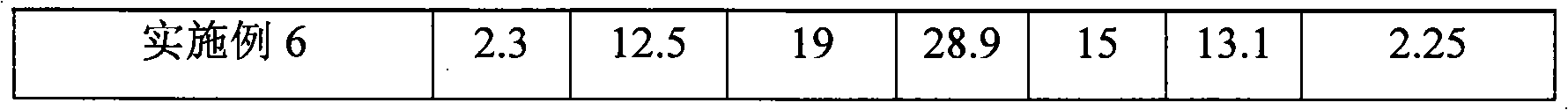

The invention provides a boron-containing fluorine-free fluxing slag-melting agent for electric steelmaking, belonging to the technical field of steelmaking. The slag-melting agent is made from the following components in parts of by weight: 30-50 parts of boron sludge, 20-40 parts of laterite, 20-40 parts of quicklime and 5-15 parts of ferric oxide. The preparation method of the slag-melting agent comprises the following steps: sufficiently drying and dehydrating the raw materials, and weighting and proportioning based on weight parts; and grinding, evenly mixing, and making block slag by a pelleting-drying-sintering method or premelting-cooling-crushing-sieving method. Compared with the prior art, the invention has the following beneficial effects: the product provided by the invention is used as the fluxing agent instead of fluorite, calcium aluminate and ferriferous oxide, thereby eliminating fluorine pollution and relieving the corrosion action of the slag-melting agent on the furnace lining; and particularly, the waste boron sludge are recycled, and high-cost calcium aluminate is replaced with low-cost laterite with abundant reserves, thus the boron-containing fluorine-free fluxing slag-melting agent provided by the invention has important meanings for reasonably and comprehensively utilizing mineral resources, lowering the steelmaking cost, and realizing high-efficiency low-cost low-pollution green steelmaking.

Owner:JIANGSU UNIV

Method for extending initiation time of nodulizer, environment-friendly nodulizer and preparation method thereof

The invention discloses a method for extending initiation time of a nodulizer and a nodulizer with long initiation time (the environment-friendly nodulizer ). The method is characterized by coating a layer of heat insulating materials on the surface of the nodulizer. The nodulizer is protected by the layer of heat insulating materials, the temperature cannot be risen promptly, and detonation cannot occur promptly, thus the initiation time of the nodulizer is extended. The heat insulating material powder is coated on the surface of the nodulizer by mixing with the nodulizer with completely stirring, or by using a binder, or by mixing with a binder to form slurry.

Owner:SHENZHEN FORAL TECH

High-calcium non-silicon aluminium calcium magnesium ferrous alloy for steel-smelting deoxidization and method for preparing the same

The invention discloses a high-calcium no-silicon aluminum-calcium-magnesium-ferric alloy used for steelmaking deoxidization. According to the weight proportion of the components, Ca is more than 15 percent but less than or equal to 28 percent, the proportion of Al to Ca is 1-2:1, 2-6 percent of Mg, the rest is Fe. The optimization scope is 18-25 percent of Ca, the proportion of Al to Ca is 1-1.3:1, 2-4 percent of Mg, the rest is Fe. A preparation method is that: aluminum, calcium, magnesium, low-carbon steel scrap are chosen as raw materials; the materials are smelted into aluminum-magnesium and aluminum-calcium master alloys in a low-frequency furnace; the materials continue being smelted in a high-frequency furnace and aluminum-iron metal liquid is obtained; the master alloy is pressed into the deep of the aluminum-iron metal liquid under a meshed high-temperature resistance container to be melted and at last the master alloy is cast under the protection of argon gas. The obtained alloy can be used for the final deoxidation in smelting low-carbon low-silicon al-killed steel, and can lower the harmful effect of the deoxidation product Al2O3 with good effect in integral deoxidation.

Owner:郭庆成

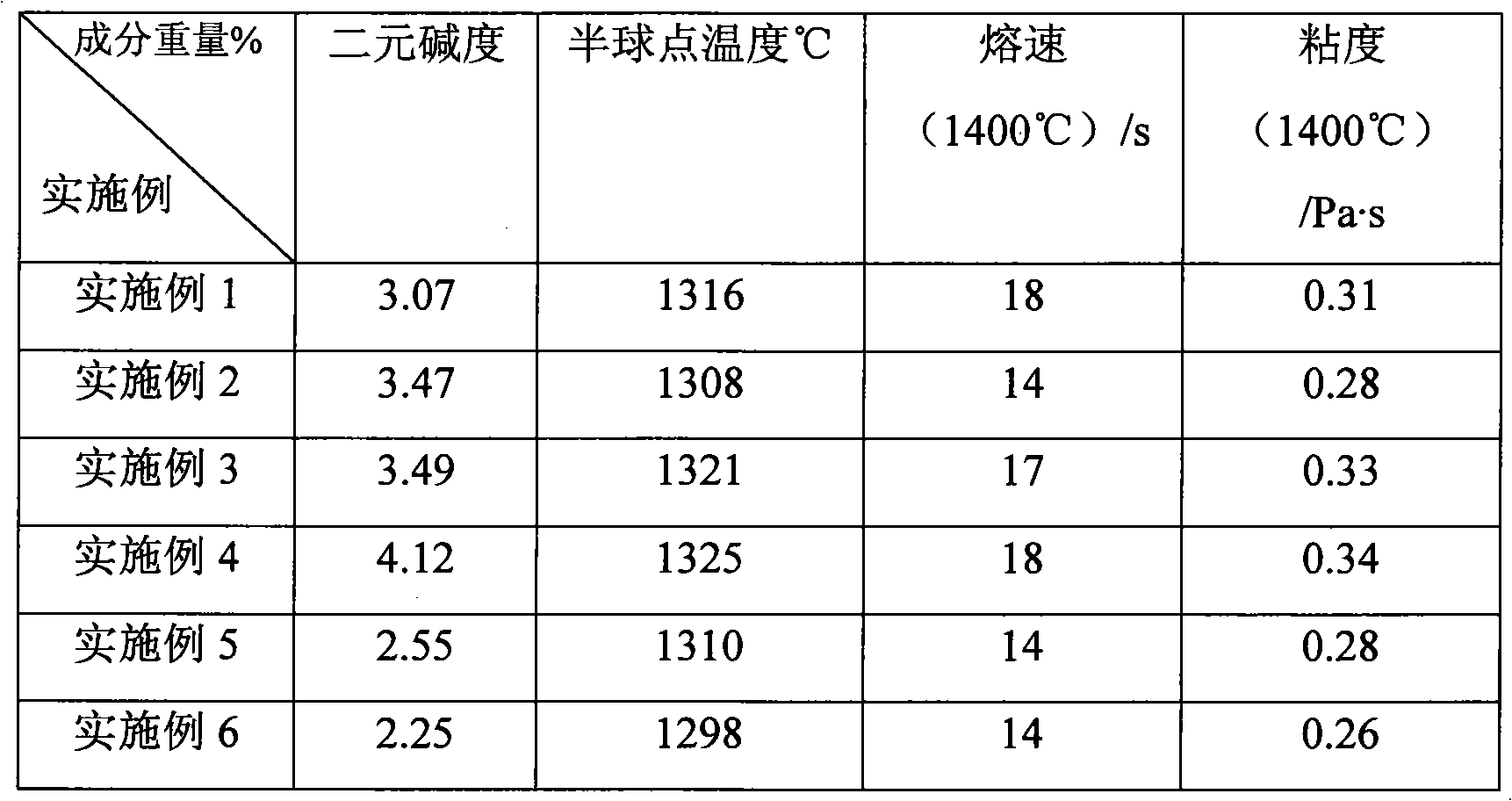

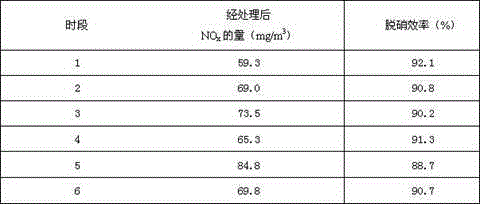

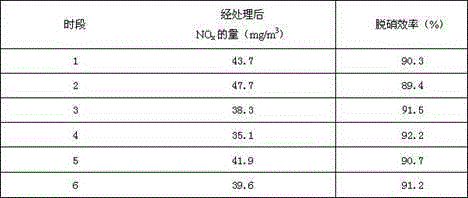

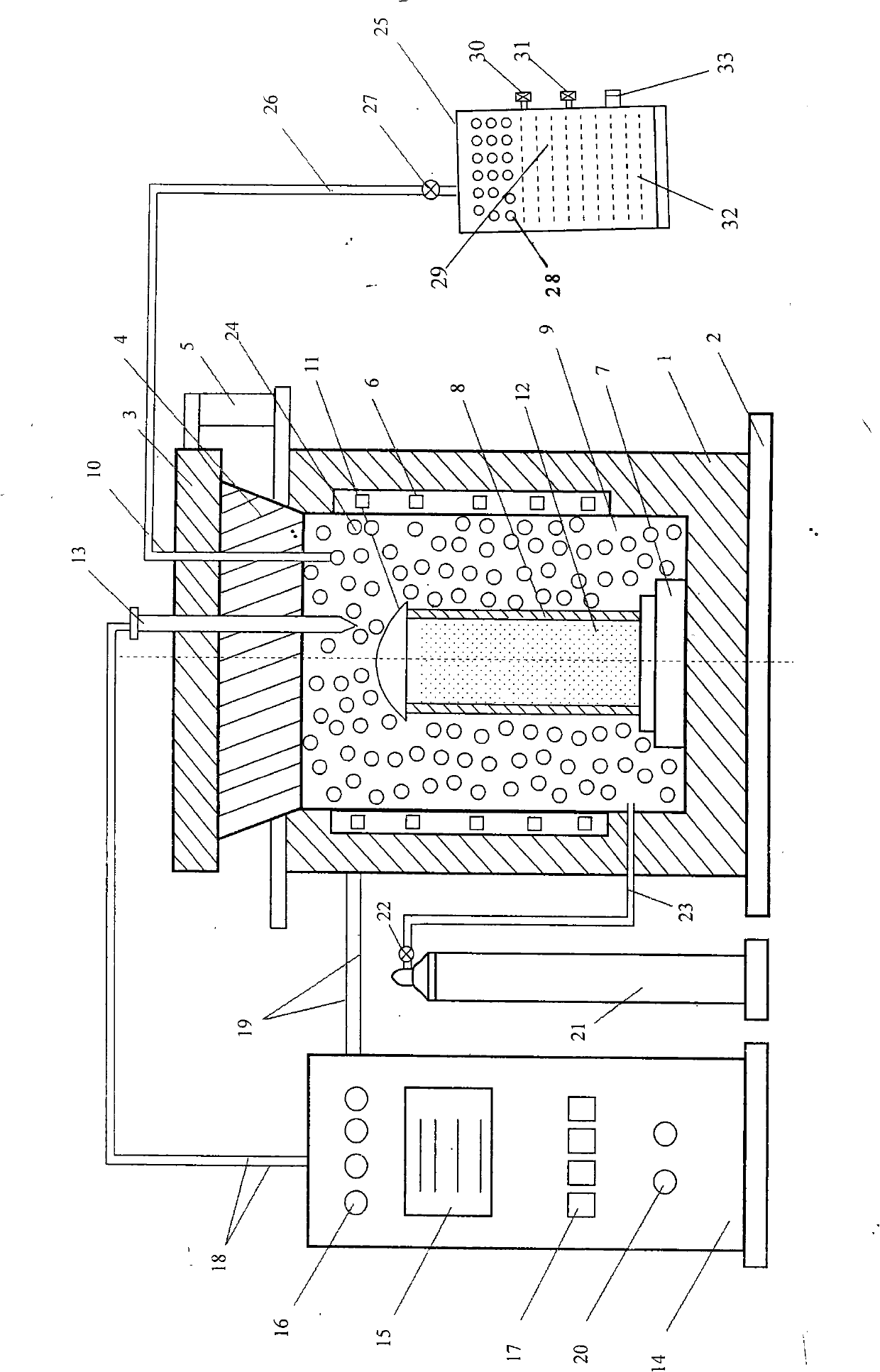

Process and device for carrying out flue gas denitrification by utilizing solid organic denitrifying agent

InactiveCN104383808AEnsure personal health and safetyWill not cause secondary pollutionDispersed particle separationSuperheaterChemical agent

The invention discloses a process and a device for carrying out flue gas denitrification by utilizing a solid organic denitrifying agent. According to the process, an organic denitrifying reducing agent is sprayed into a reaction area at the fume temperature of 500-950 DEG C and gasified and is subjected to selective uncatalyzed reaction with NOx contained in smoke gas, so that the purpose of denitrification is achieved. The core device of the process is highly-integrated integral equipment, is designed according to unit system and mainly comprises a denitrifying agent delivery supply system, a metering distribution system, a fluidic system, a gas delivery system, a chemical agent injection system and an on-line monitoring system. According to the smoke gas denitrification technology of the solid organic denitrifying agent, no change needs to be made on a boiler, and only the injection system needs to be added to the position at the fume temperature of 500-950 DEG C and between the smoke gas outlet of the boiler and a superheater. The process and the device which are disclosed by the invention have the characteristics of low operating cost, high safety, obviousness in denitrification effect and the like.

Owner:天津天和环能科技有限公司

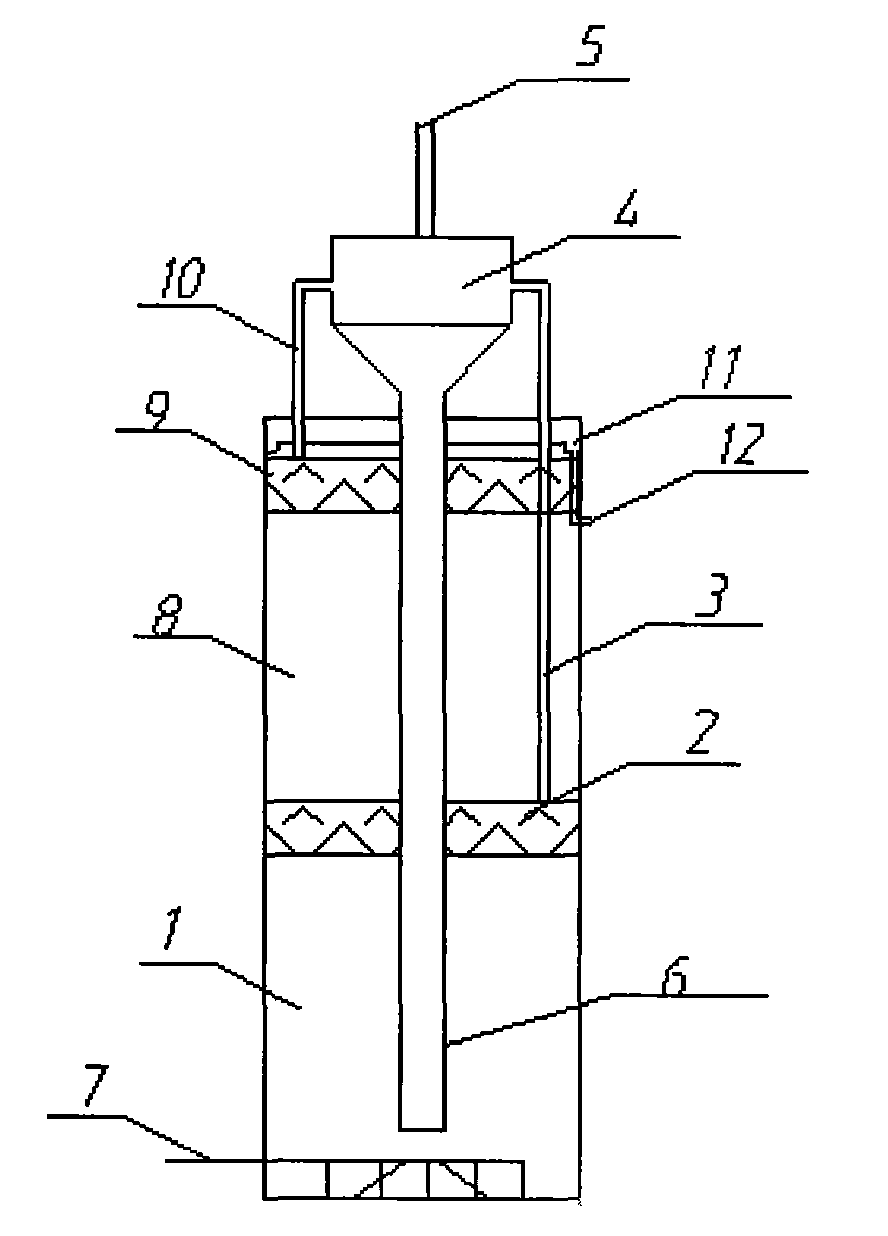

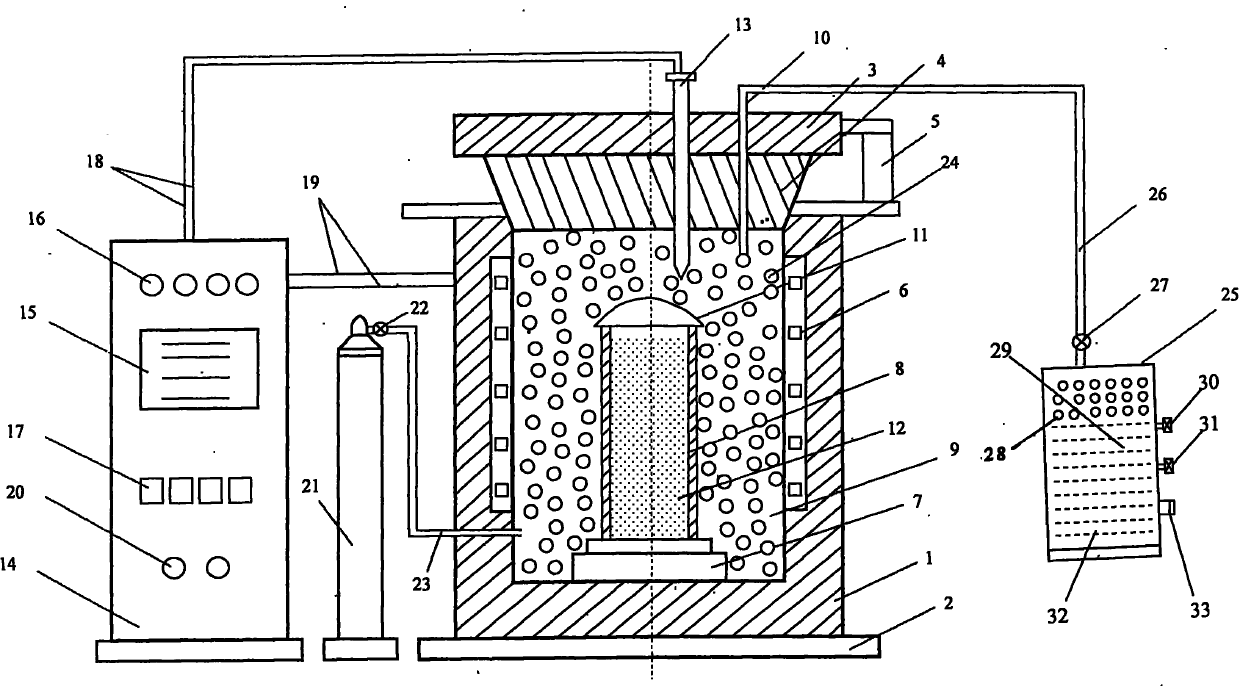

Biogas-lift reinforced anaerobic reactor and application thereof

InactiveCN101597561AImprove stabilityEasy loadingGas production bioreactorsWaste based fuelHigh concentrationReaction rate

A biogas-lift reinforced anaerobic reactor and application thereof belong to the waste recycling processing technical field. In the invention, the anaerobic reactor consists of two anaerobic reaction chambers one above to the other in series. The biogas generated by a first anaerobic chamber at the lower part is taken as power to realize internal recycle of mixed liquid at the lower part, so that reinforced pretreatment can be carried out on waste water; post treatment is continuously carried out on the waste water in a second anaerobic reaction chamber at the upper part, so that water discharge can meet the predetermined treating requirement. The invention has the advantages of high stability and loading and can deal with waste water with high-concentration poisonous substance to generate biogas. In the invention, the composite recycle method containing internal recycle, external recycle and biogas recycle is used to improve mass transferring condition between microorganism and matrix, quicken reaction rate and increase waste water processing efficiency.

Owner:JIANGNAN UNIV

High silicon ball iron injection molding machine template casting preparing method

InactiveCN107513658AImprove mechanical propertiesSolve the shrinkage cavityProcess efficiency improvementSlagMolding machine

Disclosed is a high silicon ball iron injection molding machine template casting preparing method. The method comprises the steps that raw materials comprises, by weight, 40-50% of pig iron, 20-30% of scrap steel, 20-30% of foundry returns, 1-1.4% of silicon iron and 0.004-0.005% of Sb, and are configured; melting is conducted, sampling analysis and blending composition are conducted; firstly, a rare earth magnesium nodularizer and Sb are correspondingly placed on the two sides of a bottom transverse blocking of a nodulizing bag, scrap steel sheets covers the surface of the rare earth magnesium nodularizer, and molten iron is poured into the nodulizing bag with Sb on one side, after the nodulizing reaction begins, a ladle-to-ladle inoculant is added into the nodulizing bag for inoculation, meanwhile, the molten iron is stirred, and melting of the ladle-to-ladle inoculant is promoted; and slag removal and pouring are conducted. The high silicon ball iron injection molding machine template casting preparing method has the advantages that the defects such as shrinkage and shrinkage cavity of a casting can be effectively solved, and the brittleness of the casting can be reduced, thus the scrap rate of during high silicon ball iron injection molding machine template casting manufacturing can be greatly reduced.

Owner:RIYUE HEAVY IND

Solid-phase decarburization method of high-carbon Fe-Mn alloy

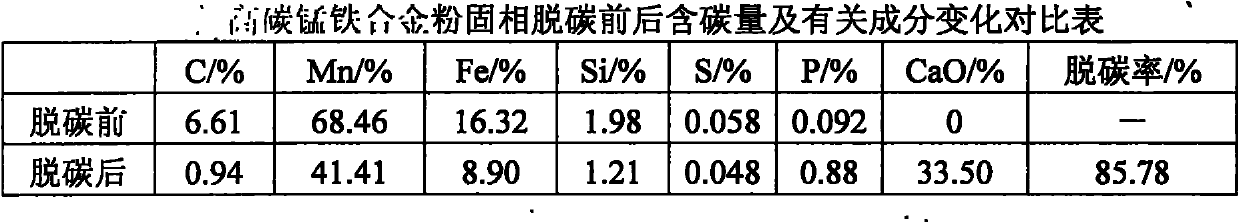

The invention relates to a solid-phase decarburization method of high-carbon Fe-Mn alloy, and the method aims at the actual situation that the carbon content of Fe-Mn alloy powder is high and adopts the solid-phase decarburization technology. The method comprises the following steps: by using calcium carbonate powder as decarbonizer and nitrogen as protective gas for decarburization, decarburization is performed in a microwave decarbonization furnace, wherein the temperature of microwave heating is 1000 DEG C, the heating time is 60min, the specific power of microwave heating is 10KW / kg and the rate of decarburization is up to 85.78%; and the obtained low and medium carbon Fe-Mn alloy is briquetted by a briquetting machine to prepare a block material for use, wherein the calcium oxide in the material is a good desulfurization and dephosphorization agent, and the generated carbon monoxide gas can be recycled. The method does not discharge metallurgical residue and cause the pollutions caused by waste gas, wastewater and residue, is a clean decarburization technology and is an ideal solid-phase decarburization method of high-carbon Fe-Mn alloy.

Owner:TAIYUAN UNIV OF TECH

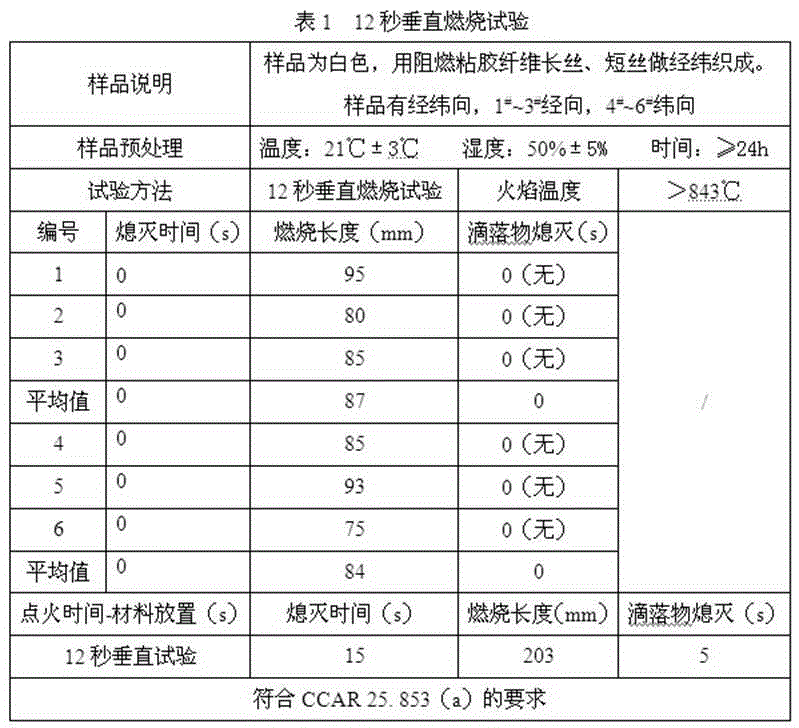

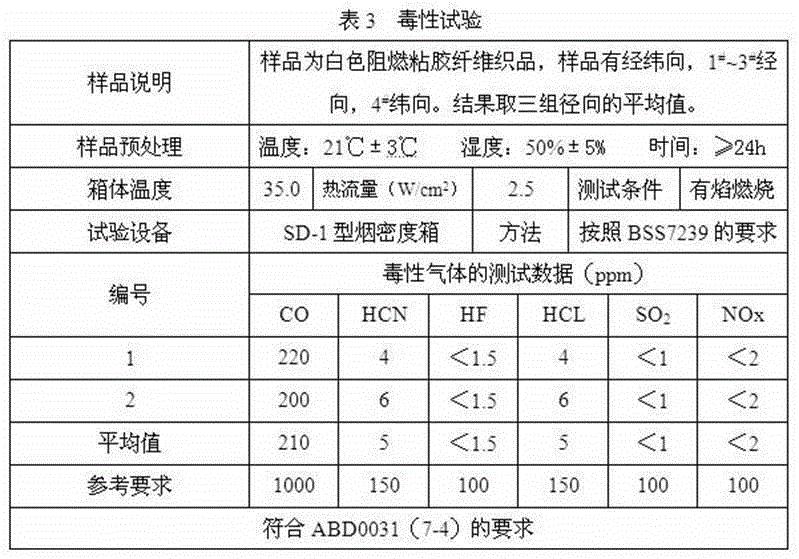

Environment-friendly type fire retardant as well as preparation method and application thereof

ActiveCN104032401BWon't gelRealize large-scale productionArtificial filaments from viscoseCellulose/protein filament chemical after-treatmentSocial benefitsSpinning

The invention discloses an environment-friendly type fire retardant as well as a preparation method and an application thereof. The fire retardant adopts a preparation method for an environment-friendly type fire retardant matched product, which takes organic silicon hydrolyzing dispersion liquid as a main component of the fire retardant and takes a fixed cross-linking agent as a post-treatment component. The other aim of the invention is to develop the application of the environment-friendly type fire retardant in spinning and post-treat of inflaming retarding viscoses and inflaming retarding synthetic fibers. Raw materials for preparing the environment-friendly type fire retardant are wide in source and low in price; the adverse effects on the environment and the safety, caused by traditional halogen-based and phosphorus based flame retardants, are overcome; the social benefits and the economic benefits are very great.

Owner:SOL FLAME RETARDANT FIBER

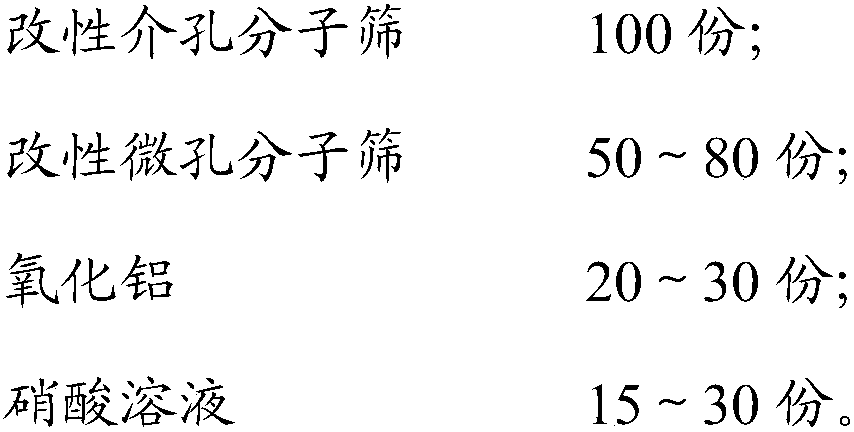

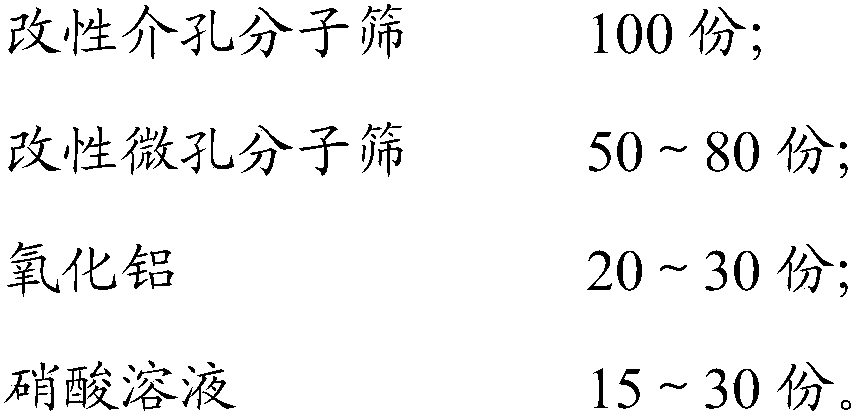

Compound desulfurization adsorbent as well as preparation method and application thereof

ActiveCN108295809AImprove desulfurization effectImprove removal effectOther chemical processesAluminium silicatesMolecular sieveSorbent

The invention discloses a compound desulfurization adsorbent and a preparation method thereof. The compound desulfurization adsorbent is prepared from 100 parts by weight of modified mesoporous molecular sieve, 50 to 80 parts by weight of modified microporous molecular sieve, 20 to 30 parts by weight of aluminum oxide and 15 to 30 parts by weight of nitric acid solution. The preparation method comprises the following steps: uniformly mixing the modified mesoporous molecular sieve, the modified microporous molecular sieve, the aluminum oxide and the nitric acid solution, carrying out extrusionforming to obtain particles and curing at the room temperature; drying the cured particles and carrying out high-temperature activated roasting to obtain the compound desulfurization adsorbent. The application also provides application of the compound desulfurization adsorbent in removing sulfide in sulfur-containing substances. The compound desulfurization adsorbent disclosed by the application can effectively remove various sulfides in the sulfur-containing substances and simplifies the desulfurization process; in addition, the preparation method has the advantages of simple preparation process, easiness in raw material obtaining and lower cost.

Owner:CHINA NAT OFFSHORE OIL CORP +1

Production method of titanium concentrate pellet

The invention relates to a production method of a titanium concentrate pellet, and belongs to the field of steel and iron metallurgy. The technical problem to be solved by the invention is to provide a new production method of the titanium concentrate pellet, so that the titanium concentrate pellet is oxidized and solidified; and cooked spheres with high strength, low sulfur content and uniform particle size are produced. The method comprises the steps of: (A) burdening: 60-80 wt% of titanium concentrate and 20-40 wt% of iron oxide are weighed in percentage by weight; and 1.0-1.5 wt% of bentonite is externally mixed; (B) pelletizing; (C) drying: raw spheres are dried; (D) preheating and roasting; and (E) cooling: the titanium concentrate pellet is obtained through natural cooling. The method mainly uses the intergranular consolidation mechanism of the iron oxide in high-temperature roasting; meanwhile, the additive causes no influence on the grade of titanium slag; the coked pellet with uniform particle size can be obtained; the reaction speed in an electric furnace is stabilized during smelting of the electric furnace; the consumption of high-grade energy is reduced; and meanwhile, the pellet has the desulfurization effect during roasting, so that a brand new method is provided for production of the titanium concentrate pellet.

Owner:PANZHIHUA IRON & STEEL RES INST OF PANGANG GROUP

A kind of production method of titanium concentrate pellet

The invention relates to a production method of a titanium concentrate pellet, and belongs to the field of steel and iron metallurgy. The technical problem to be solved by the invention is to provide a new production method of the titanium concentrate pellet, so that the titanium concentrate pellet is oxidized and solidified; and cooked spheres with high strength, low sulfur content and uniform particle size are produced. The method comprises the steps of: (A) burdening: 60-80 wt% of titanium concentrate and 20-40 wt% of iron oxide are weighed in percentage by weight; and 1.0-1.5 wt% of bentonite is externally mixed; (B) pelletizing; (C) drying: raw spheres are dried; (D) preheating and roasting; and (E) cooling: the titanium concentrate pellet is obtained through natural cooling. The method mainly uses the intergranular consolidation mechanism of the iron oxide in high-temperature roasting; meanwhile, the additive causes no influence on the grade of titanium slag; the coked pellet with uniform particle size can be obtained; the reaction speed in an electric furnace is stabilized during smelting of the electric furnace; the consumption of high-grade energy is reduced; and meanwhile, the pellet has the desulfurization effect during roasting, so that a brand new method is provided for production of the titanium concentrate pellet.

Owner:PANZHIHUA IRON & STEEL RES INST OF PANGANG GROUP

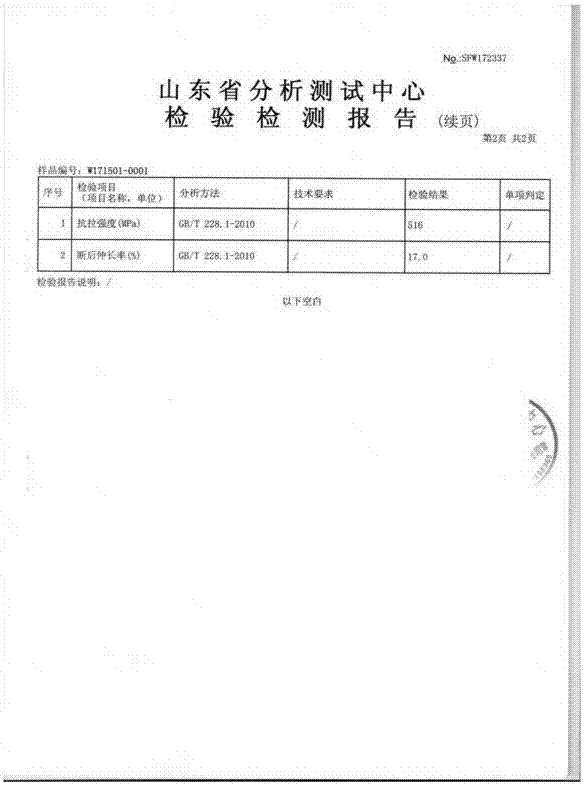

Production process of QT500-12 spheroidal graphite iron casting

The invention discloses a production process of a QT500-12 spheroidal graphite iron casting. The production process comprises the following steps: A, raw material selection: selecting 60-80 parts of scrap steel, 20-40 parts of scrap returns, 2.5-3.5 parts of a carburant, 0.4-1.0 part of 75# ferrosilicon, 0.3-0.6 part of copper, 1-1.2 parts of a spheroidizing agent, 0.8-1.2 parts of a 75# ferrosilicon inoculant and 0.2-0.4 part of a silicon-strontium inoculant; B, weighing; C, smelting; D, spheroidizing; E, secondary inoculation; and F, pouring. The overall performances of the QT500-12 spheroidal graphite iron casting produced by using the production process are improved, and the tensile strength is larger than or equal to 500Mpa on the premise that the elongation percentage is larger than or equal to 12%; the consistency of a matrix structure of the spheroidal graphite iron casting is also realized, and the local function of the spheroidal graphite iron casting is prevented from being deteriorated; and the weight of the spheroidal graphite iron casting is reduced on the premise that the elongation percentage and tensile strength indexes of the spheroidal graphite iron casting reach standards, so that the lightweight of the spheroidal graphite iron casting is realized.

Owner:山东力嘉轻量化科技有限公司

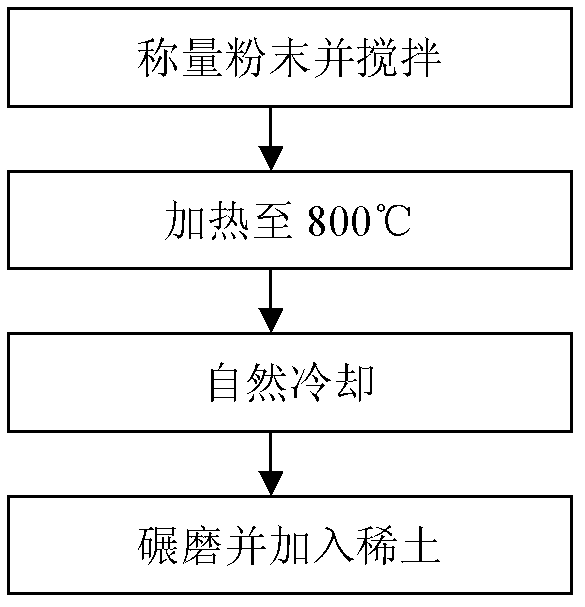

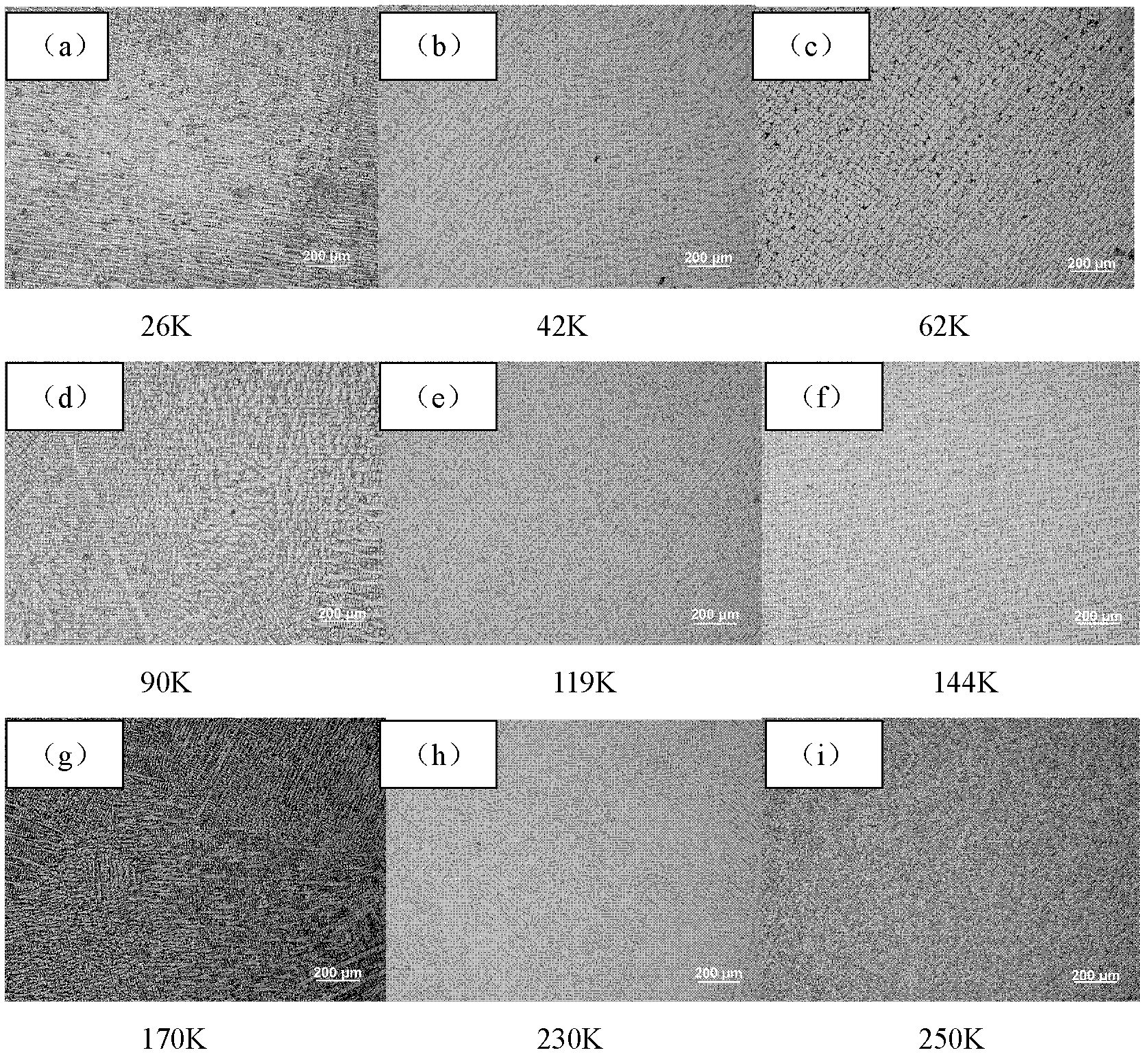

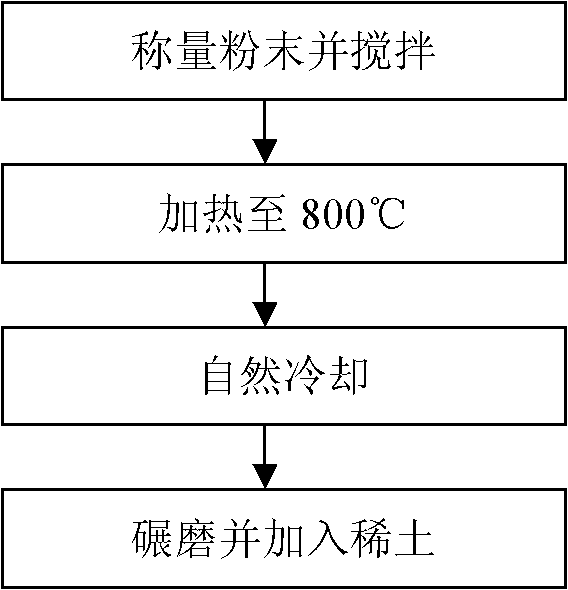

Supercooled IN718 high-temperature alloy purifying agent and preparation method for same

The invention discloses a supercooled IN718 high-temperature alloy purifying agent and a preparation method for the same. The preparation method includes: sufficiently mixing 45-55 parts of CaF2 (calcium fluoride), 8-12 parts of NaCl (sodium chloride), 8-12 parts of KCl (potassium chloride), 18-22 parts of CaO (calcium oxide), 4-6 parts of TiO2 (titanium dioxide), 4-6 parts of MgO (magnesium oxide) and 0.5-1.0 part of AlF3 (aluminum fluoride) to obtain mixed powder; heating the mixed powder to 800 DEG C and then preserving heat for 8 hours; naturally cooling the mixed powder to room temperature after heat preservation; and milling the mixture into powder after crushing the mixture, and adding 0.5-1.0 part of rare earth compound LaCl3 (lanthanum chloride) to obtain the purifying agent. The purifying agent can integrate the functions of overwrite protection, oxidation and volatilization prevention and impurity removal, components of the purifying agent are easy to obtain, the purifying agent is convenient to add, the operating process is simple, and the cost is low.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

Fluorine removal modified active carbon and preparation method thereof

InactiveCN103566891AEfficient removalPromote regenerationOther chemical processesDecompositionMoisture absorption

The invention discloses fluorine removal modified active carbon, which is prepared from the following raw materials in parts by weight: 100-110 parts of active carbon, 6-8 parts of medical stone, 10-14 parts of active aluminum oxide, 6-8 parts of alkaline tourmaline, 7-9 parts of diatomite, 1-2 parts of zirconium nitrate, 1-2 parts of strontium nitrate, 2-4 parts of chitosan, 15-20 parts of acetic acid, 4-5 parts of modified diatomite and a right amount of water. According to the method, active aluminum oxide is used for modify the active carbon, so that the active carbon can effectively remove fluorine in water, catalyses decomposition of organics, and is easy to regenerate; natural stones, such as the medical stone and the alkaline tourmaline, are used for modifying the active carbon, so that the active carbon has functions of anti-bacteria and deodorization, moisture absorption, mildew prevention and desulfurization, and can also catalyze decomposition of organics; the chitosan is also used, so that the active carbon can adsorb metal ions, organic mercury, organics and the like, and is safe and non-toxic. The preparation method of the fluorine removal modified active carbon is simple in technology and suitable for industrial production.

Owner:BENGBU HUAFANG FILTER

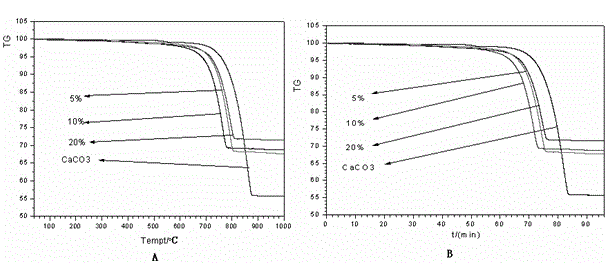

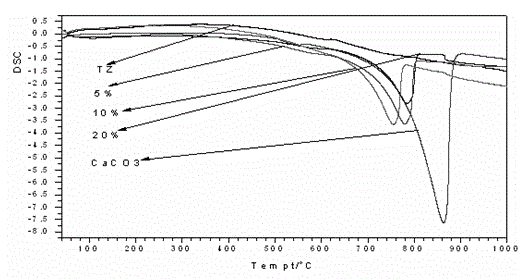

Composite sulfur-fixing agent and application thereof

InactiveCN104548892AWith desulfurizationCatalyticDispersed particle separationSulfurEconomic benefits

The invention discloses a composite sulfur-fixing agent which comprises the following components in percentage by mass: 5-45 percent of copper slag and 55-95 percent of calcium base. The composite sulfur-fixing agent is mainly applied to flue gas desulfurization in the industries such as coal-fired power plants and metallurgy. When the calcium-based / copper slag composite sulfur-fixing agent is at the temperature of 800-1000 DEG C, the specific surface area of the agent is increased, so that the contact area between SO2 in flue gas and the calcium-based / copper slag composite sulfur-fixing agent is increased. According to the determining of the efficiency of the calcium-based / copper slag composite sulfur-fixing agent on an experimental platform, the result shows that the sulfur-fixing rate ranges of the calcium-based / copper slag composite sulfur-fixing agent are that the sulfur-fixing rate is between 85.98 percent and 96.69 percent when a wet process is adopted, the sulfur-fixing rate is between 57.28 percent and 83.84 percent when a semidry method is adopted, and the sulfur-fixing rate is between 45.00 percent and 63.99 percent when a dry method is adopted. Because the copper slag is added into the sulfur-fixing agent, desulfurization reaction is carried out in advance, the desulfurization reaction time is prolonged, SO2 is removed, the energy consumption is reduced, the cost of the sulfur-fixing agent is reduced, and the economic benefits are obvious. The invention aims at providing a method for reutilizing the copper slag discarded after copper smelting.

Owner:KUNMING UNIV OF SCI & TECH

Degradated-spheroidization-resisting composite inoculant and preparation technology of composite inoculant

The invention discloses a degradated-spheroidization-resisting composite inoculant. The composite inoculant comprises the following components of, by mass percent, 55-65% of Si, 1.0-2.0% of Ca, 4.0-6.0% of Ba, 0.5-2.0% of Mg, 0.1-1.5% of RE, 1.5max% of Al and the balance Fe. According to the degradated-spheroidization-resisting composite inoculant, the nodularization effect can be improved, graphite nodules are refined, the quantity of the graphite nodules is increased, the roundness of the graphite nodules is improved, the graphite nodules are distributed uniformly, the degradated spheroidization is lowered, the effective inoculation time is prolonged, and the mechanical properties of nodular iron castings are further improved, the production cost is lowered, and the quality of nodular cast iron is improved.

Owner:南京浦江合金材料股份有限公司

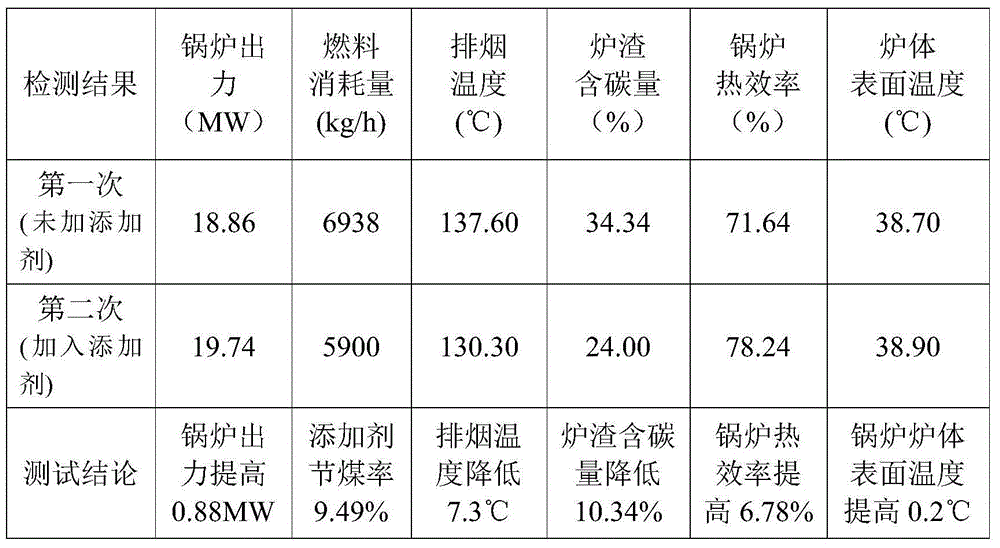

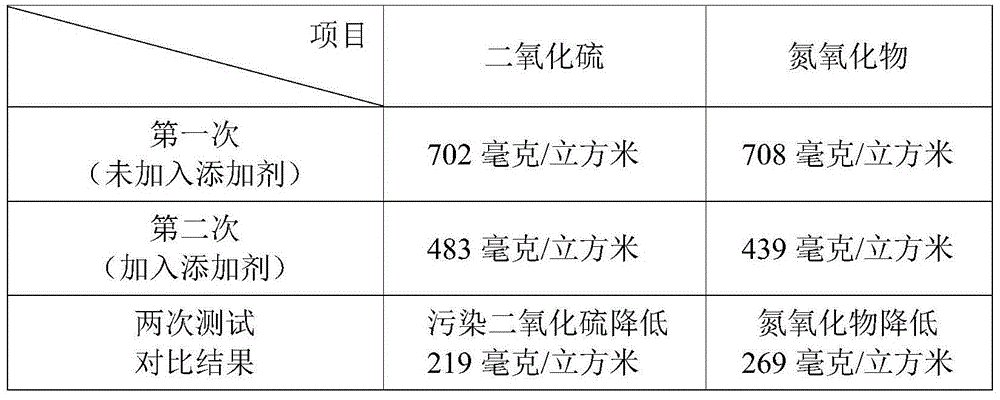

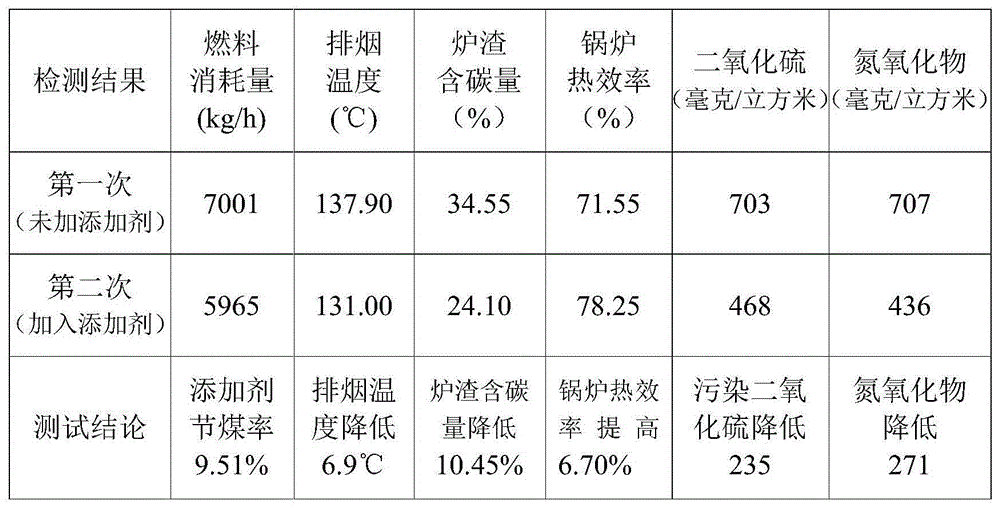

Fuel coal additive and preparation method thereof

The invention belongs to the technical field of fuel coal additives, discloses a fuel coal additive and a preparation method thereof, and solves the problems that the conventional fuel coal additive is high in cost and low in efficiency. The preparation method comprises the following steps: using glycerol as a main raw material to work together with potassium hydroxide or sodium hydroxide, sodium peroxide, borax and sodium silicate, using water as a solvent, and uniformly mixing to prepare an additive stock solution. When in use, the additive is diluted according to the ratio of the additive to water to coal of (1-4):40:4000, and then the solution is uniformly sprayed on the surface of pre-burning coal through a spray nozzle to be put into a boiler to be burnt. Testing results show that the fuel coal additive has the advantages of high coal-saving efficiency, obvious desulfuration, denitration and smoke abatement effects, low use cost and the like, the coal is saved by 5-20%, the sulfur dioxide and nitrogen oxide emission is reduced by 31%-50%, and the slag carbon content is reduced by 10%-12%.

Owner:李克忠

Cold pressing pellet for insulating molten iron

The invention relates to a cold pressing pellet for insulating molten iron. The pellet comprises the components in parts by weight: 60-80 parts of half-calcined dolomite, 5-30 parts of crude vermiculite powder, 0.5-10 parts of feldspar powder, 3-8 parts of clay and 1-10 parts of coal gangue powder. The pellet provided by the invention is cold-pressed to be pelleted by using the half-calcined dolomite as a raw material, so that not only is the problem that a conventional heat preserver is dusty and great in use level and has pollution to the environment solved, but also the pellet has a certain desulfuration effect as well as favorable foaming performance and insulating effect. The pellet is suitable for insulating ladles or molten iron in torpedo ladles.

Owner:武汉钢铁有限公司

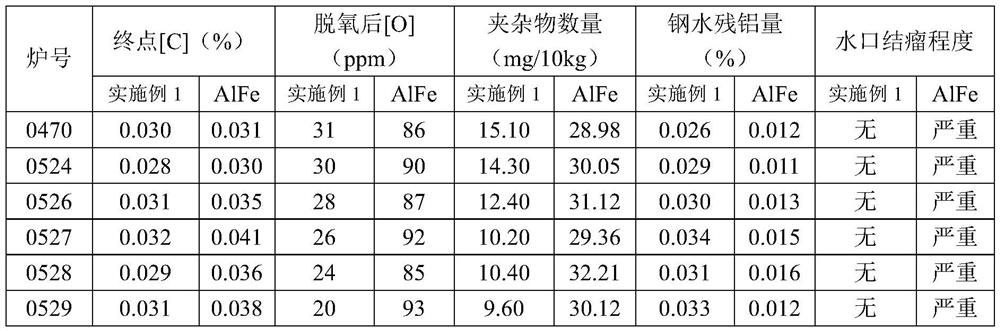

Micro-carbon low-sulfur high-aluminum iron-free aluminum-magnesium-calcium alloy deoxidizer and preparation method and application thereof

The invention discloses a micro-carbon low-sulfur high-aluminum iron-free aluminum-magnesium-calcium alloy deoxidizer and a preparation method and application thereof, and belongs to the technical field of metallurgy. The aluminum-magnesium-calcium alloy deoxidizer comprises the following chemical components in percentage by weight: 70-90% of Al, 1-10% of Mg, 5-25% of Ca, less than or equal to 0.02% of C, less than or equal to 0.02% of S and the balance inevitable impurities. The preparation method of the deoxidizer comprises the following steps: weighing a pure aluminum ingot, a magnesium metal and a calcium metal according to the chemical components of the aluminum-magnesium-calcium alloy deoxidizer, and adding the mixture into a resistance melting furnace for melting to prepare a moltenaluminum-magnesium-calcium alloy; and pouring the molten alloy into a continuous casting machine, and performing cooling and molding to prepare the aluminum-magnesium-calcium alloy deoxidizer. The deoxidizer can convert all or most of an deoxidized product Al2O3 into calcium aluminosilicate (7Al2O3. 12CaO) with a low melting point (1400 DEG C), and the calcium aluminosilicate (7Al2O3. 12CaO) floats on the surface of molten steel to be removed, so that the harmful effect of Al2O3 is reduced to the maximum extent, and the quality of steel is remarkably improved.

Owner:郭鸿鼎

Cast iron deslagging composite material and preparation method thereof

The invention provides a low-cost cast iron deslagging composite material with excellent environmental protection performance and good deslagging performance, and a preparation method thereof. The deslagging composite material comprises the following components in percentage by mass: 7.0 to 8.9 percent of Al2O3, 0.10 to 0.15 percent of V2O3, 4.0 to 5.4 percent of MgO, 15 to 19 percent of CaO, 12 to 14.9 percent of TiO2, 0.001 to 0.01 percent of CeO2, and the balance of SiO2, wherein the grain diameter of the deslagging composite material is 0.2 to 0.6 mm. The preparation method thereof comprises the following steps: mixing the materials; putting the mixed materials into a stirrer, adding water into the materials, taking the materials out after mixing for 10 to 15 minutes and putting the materials into a sintering furnace, wherein the water accounts for 3 to 6 percent of total weight of the mixed materials; controlling the sintering temperature to between 1,150 and 1,230 DEG C, and preserving the heat for 2 to 3 hours; and cooling the materials together with the furnace to room temperature to obtain the cast iron deslagging composite material. The deslagging composite material and the preparation method have the advantages of simple process, low production cost and suitability for industrialized production.

Owner:NANJING UNIV OF INFORMATION SCI & TECH

Cast iron deslagging composite material and preparation method thereof

The invention provides a low-cost cast iron deslagging composite material with excellent environmental protection performance and good deslagging performance, and a preparation method thereof. The deslagging composite material comprises the following components in percentage by mass: 7.0 to 8.9 percent of Al2O3, 0.10 to 0.15 percent of V2O3, 4.0 to 5.4 percent of MgO, 15 to 19 percent of CaO, 12 to 14.9 percent of TiO2, 0.001 to 0.01 percent of CeO2, and the balance of SiO2, wherein the grain diameter of the deslagging composite material is 0.2 to 0.6 mm. The preparation method thereof comprises the following steps: mixing the materials; putting the mixed materials into a stirrer, adding water into the materials, taking the materials out after mixing for 10 to 15 minutes and putting the materials into a sintering furnace, wherein the water accounts for 3 to 6 percent of total weight of the mixed materials; controlling the sintering temperature to between 1,150 and 1,230 DEG C, and preserving the heat for 2 to 3 hours; and cooling the materials together with the furnace to room temperature to obtain the cast iron deslagging composite material. The deslagging composite material and the preparation method have the advantages of simple process, low production cost and suitability for industrialized production.

Owner:NANJING UNIV OF INFORMATION SCI & TECH

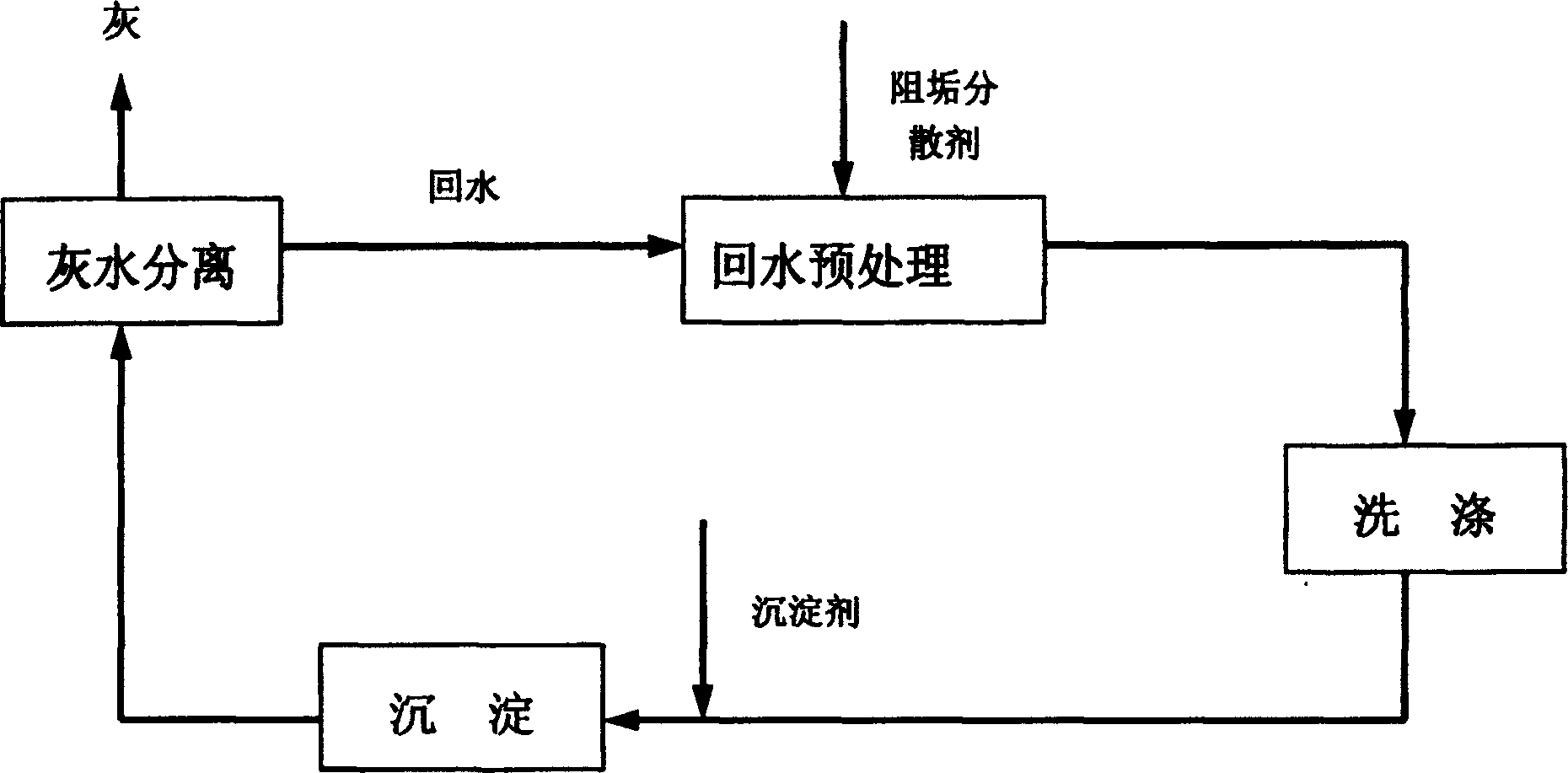

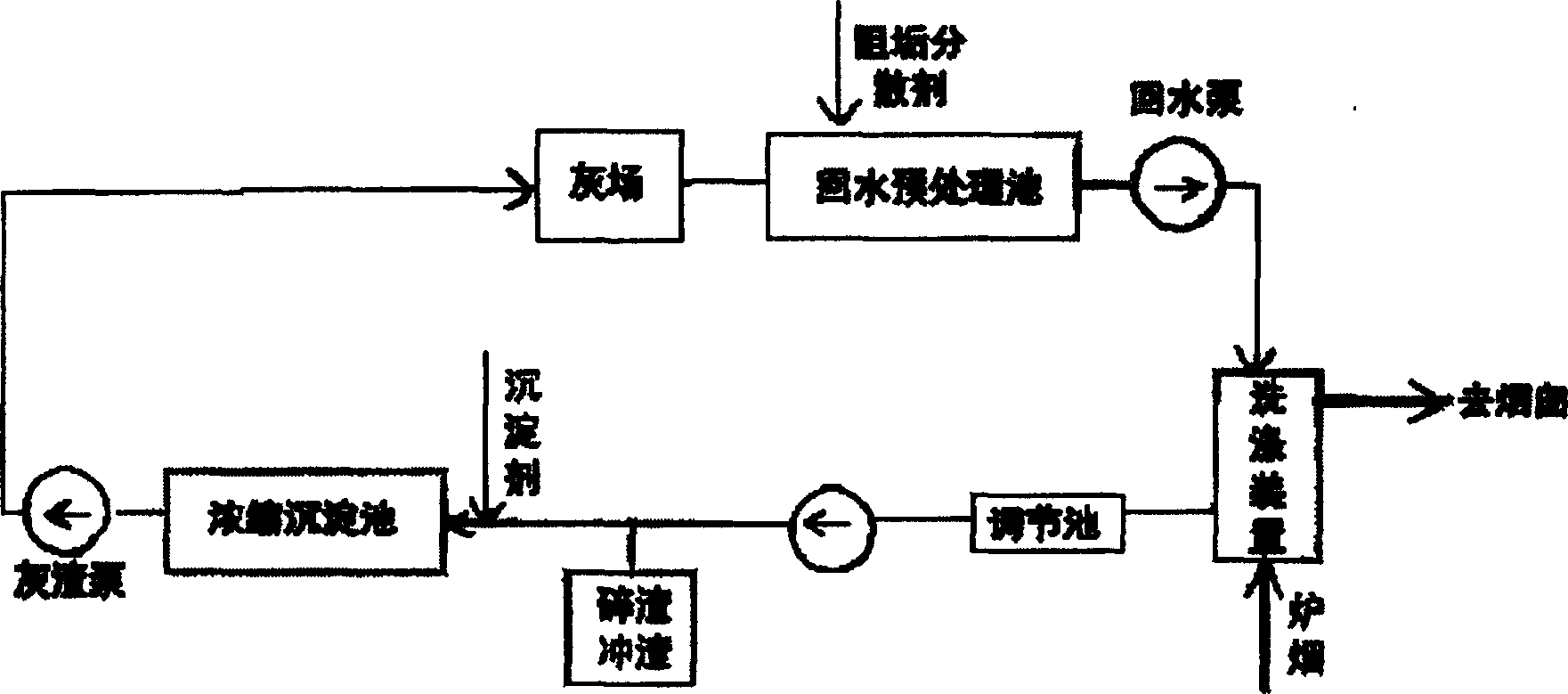

Technology for recovering ash water of coal-fired power plant and system of sealing circulating for recovering thereof

InactiveCN1274614CWith dust removalWith desulfurizationScale removal and water softeningMultistage water/sewage treatmentDust controlProcess engineering

A closed-loop system and technology for reusing the ash-contained water in the power plant using coal as fuel includes such steps as washing, depositing, ash-water separation, adding the scale-inhibiting disperser to the water, washing to remove ash, adding pricipient, complexing for depositing, and ash-water separation.

Owner:NANJING TECH UNIV

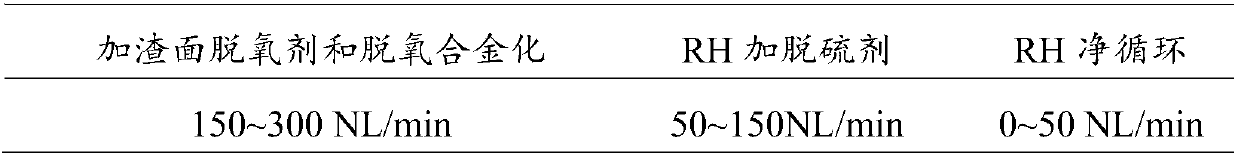

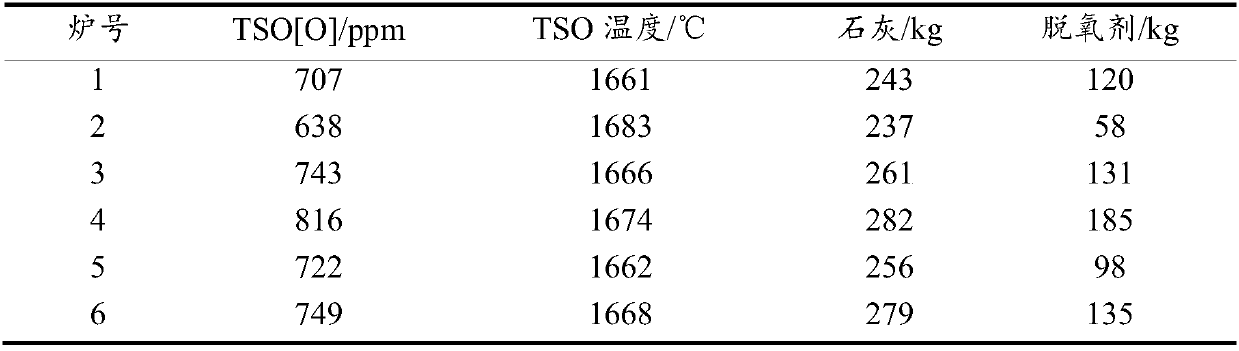

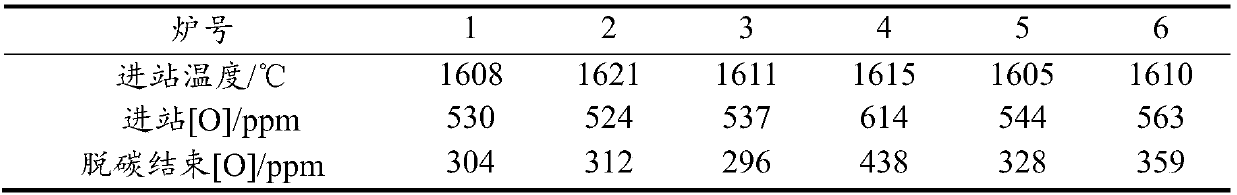

A method for synchronous desulfurization of molten steel and slag in rh vacuum furnace for non-oriented silicon steel

The invention discloses a method for synchronously desulphurizing molten steel and slag of a non-oriented silicon steel RH vacuum oven. The method mainly comprises the following steps: molten steel pretreatment (a KR method), converter smelting and RH vacuum refining, wherein the RH vacuum refining comprises the steps of carrying out vacuumizing and decarbonization on RH entering a station, after the decarbonization of RH is finished, adding a low-carbon steel slag surface deoxidant into the surface of the steel slag, simultaneously carrying out steel ladle bottom blowing to promote the reduction of the low-carbon steel slag surface deoxidant to steel ladle slag, after the low-carbon steel slag surface deoxidant is added, adding metal aluminum, silicon iron and manganese metal into molten steel, carrying out deoxygenation and alloying, carrying out circular processing for 4-7 minutes, adding a desulphurizing agent in different stages, simultaneously adjusting the steel ladle bottom blowing flow to promote slag-metal reaction to realize desulphurization, carrying out desulphurizing molten steel by virtue of the desulphurizing agent and the steel ladle slag so as to improve the desulphurization efficiency, after the desulphurization is finished, carrying out clean circulation for more than 8 minutes, and carrying out vacuum breaking and steel tapping. The sulfur content of an RH end point is less than 30ppm, and the standardized rate is increased from original about 22% to 95% or above.

Owner:INST OF RES OF IRON & STEEL JIANGSU PROVINCE +2

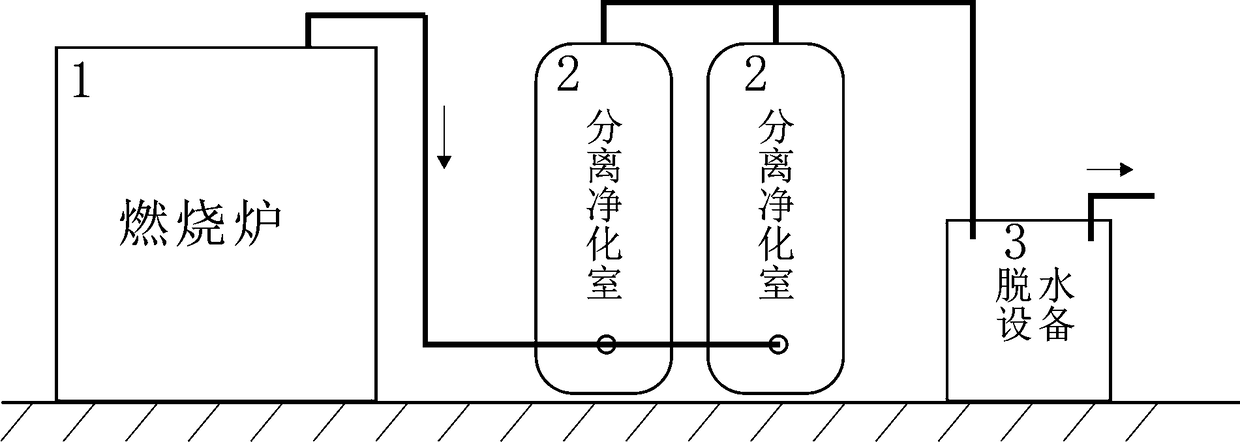

Gaseous hydrocarbon generator

InactiveCN109385314AWith degummingWith degreasingGas treatmentDispersed particle filtrationCombustionDissolution

The present invention provides a gaseous hydrocarbon generator by modification, as shown in FIG. 1, the gaseous hydrocarbon generator comprises a combustion furnace, a plurality of groups of separation and purification chambers, and a dehydration device which are independent; the outlet ends of the combustion furnace is respectively communicated with two groups separation and purification chambersby pipelines, and the output ends of the separation and purification chambers are connected to the dehydration device; the combustion furnace realizes 3 to 8 seconds of self-dissolution, and each separation and purification chamber has a metal filter net. The gaseous hydrocarbon generator not only solves the trouble of treating straw in rural areas, but also obtains a new green energy resource asa raw material, can be used by various power-driven vehicles, is environmentally friendly, economical and safe; in addition, the combustion furnace, the separation and purification chambers, and thedehydration device are independent of each other, and the gaseous hydrocarbon generator is better to install, debug and set up.

Owner:王水全

A kind of cast steel deoxidation alloy and its processing method and using method

The invention discloses a cast steel deoxidized alloy and a processing method and a use method of the cast steel deoxidized alloy, and belongs to the field of cast steel molten steel smelting. The deoxidized alloy comprises, by mass percent, 15-25% of Re, 8-20% of Ca, 5-15% of Ba, 5-20% of Ti, 5-20% of Zr, 5-20% of Si, 0.5-3% of Mg and the balance Fe. The deoxidized alloy is prepared by adopting afusion casting method, the fusion casting method is suitable for casting ordinary carbon steel, alloy steel, stainless steel and other cast steel, the content of oxygen in the cast steel can be effectively reduced, the harmful effects of oxygen on the content of the cast steel are reduced, and the cast steel product quality is improved.

Owner:MAANSHAN RUIHUI ENTERPRISE

High-calcium non-silicon aluminium calcium magnesium ferrous alloy for steel-smelting deoxidization and method for preparing the same

The invention discloses a high-calcium no-silicon aluminum-calcium-magnesium-ferric alloy used for steelmaking deoxidization. According to the weight proportion of the components, Ca is more than 15 percent but less than or equal to 28 percent, the proportion of Al to Ca is 1-2:1, 2-6 percent of Mg, the rest is Fe. The optimization scope is 18-25 percent of Ca, the proportion of Al to Ca is 1-1.3:1, 2-4 percent of Mg, the rest is Fe. A preparation method is that: aluminum, calcium, magnesium, low-carbon steel scrap are chosen as raw materials; the materials are smelted into aluminum-magnesium and aluminum-calcium master alloys in a low-frequency furnace; the materials continue being smelted in a high-frequency furnace and aluminum-iron metal liquid is obtained; the master alloy is pressed into the deep of the aluminum-iron metal liquid under a meshed high-temperature resistance container to be melted and at last the master alloy is cast under the protection of argon gas. The obtained alloy can be used for the final deoxidation in smelting low-carbon low-silicon al-killed steel, and can lower the harmful effect of the deoxidation product Al2O3 with good effect in integral deoxidation.

Owner:郭庆成

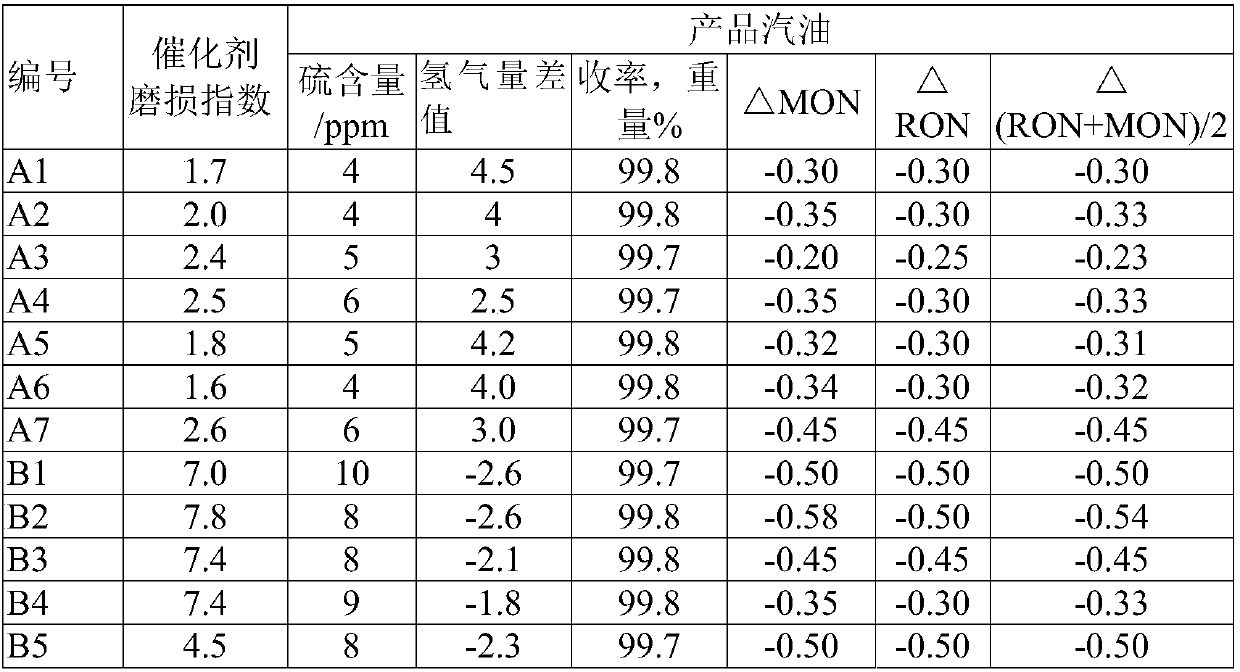

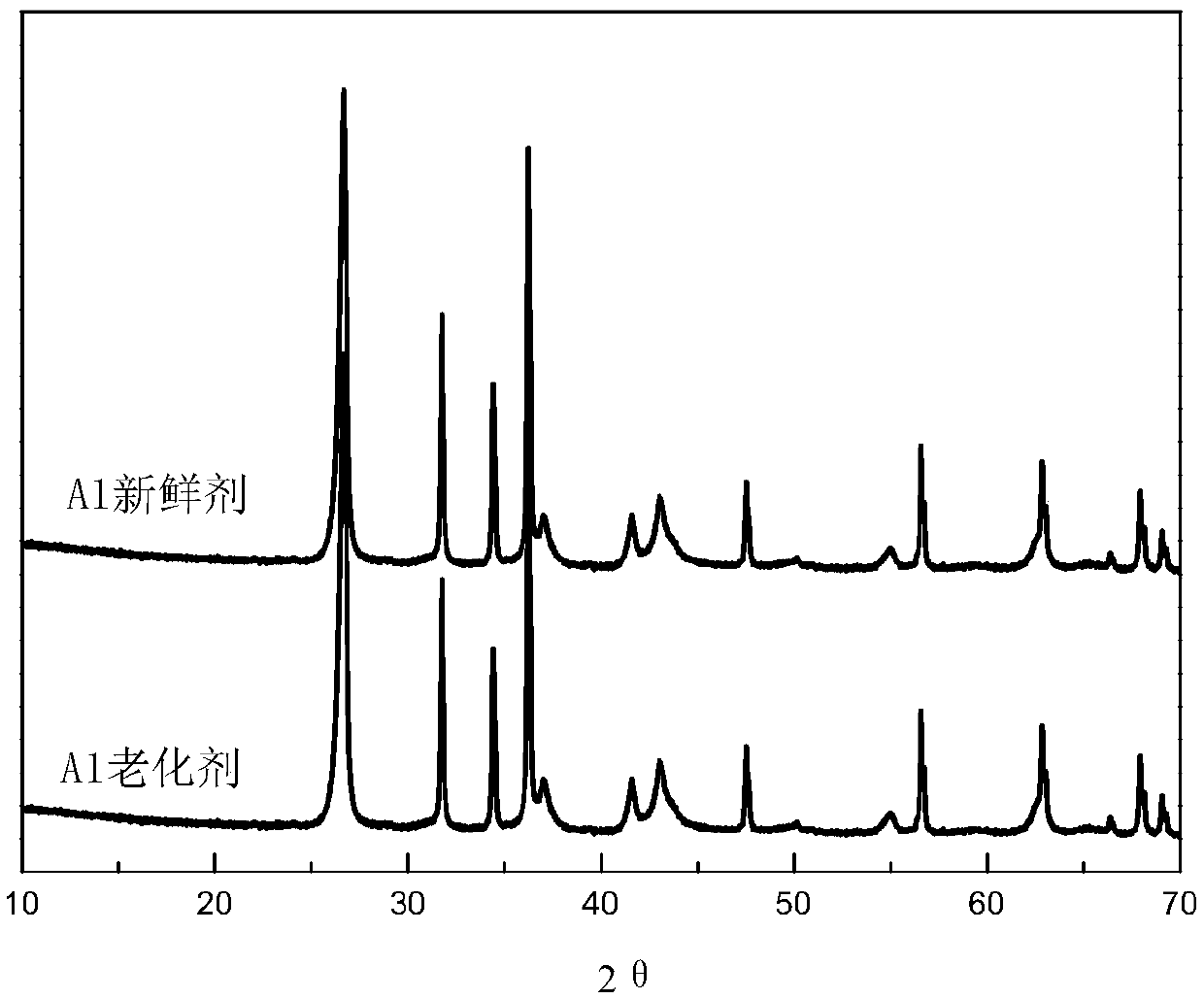

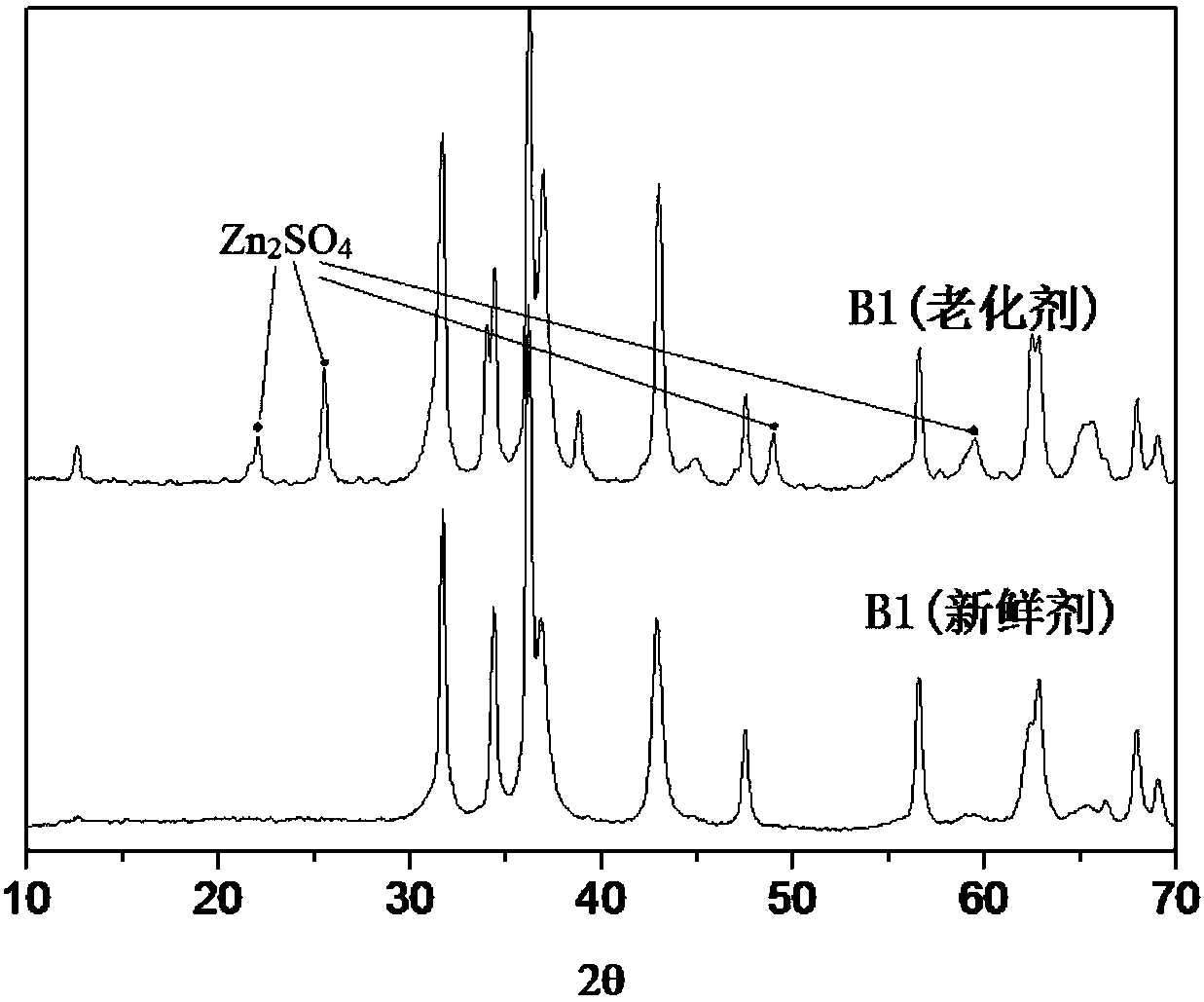

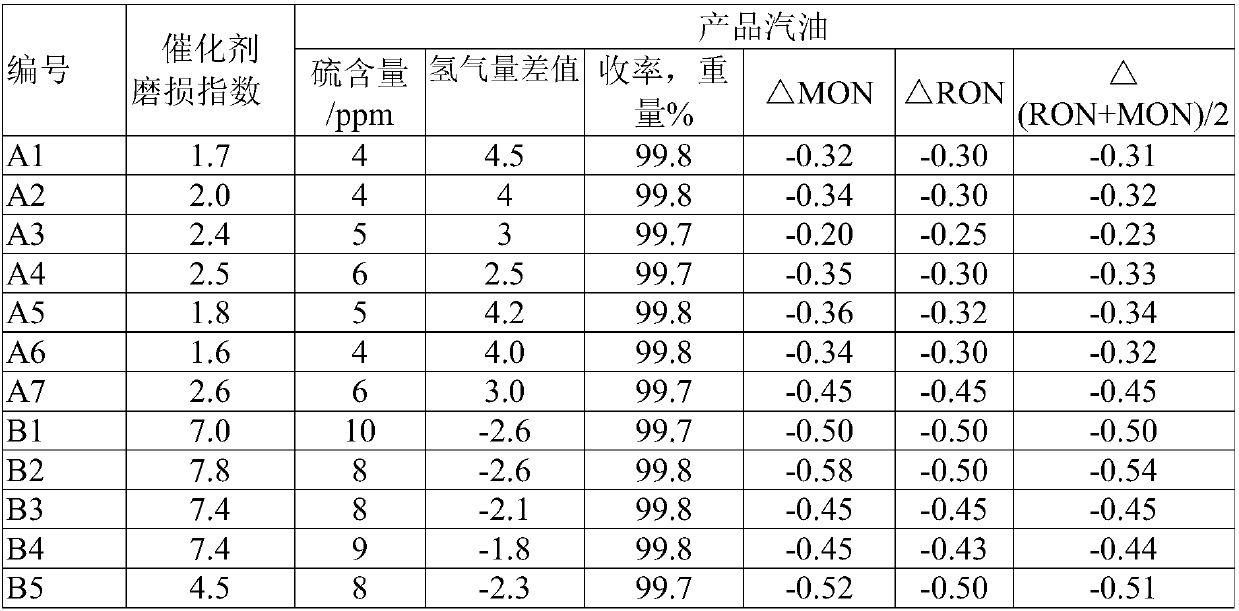

Hydrocarbon oil desulfurization catalyst containing SAPO molecular sieve as well as preparation method of catalyst and hydrocarbon oil desulfurization process

ActiveCN109718847AWith desulfurizationWith dehydrogenation propertiesMolecular sieve catalystsHydrocarbon oils refiningMolecular sieveSulfur

The invention relates to a hydrocarbon oil desulfurization catalyst containing an SAPO molecular sieve as well as a preparation method of the catalyst and a hydrocarbon oil desulfurization process. Based on a weight of the hydrocarbon oil desulfurization catalyst, or a total weight of a sulfur storage metal oxide, an inorganic oxide binding agent, boron nitride, the SAPO molecular sieve and a metal promoter, the hydrocarbon oil desulfurization catalyst contains the following components: 10-80% by weight of the sulfur storage metal oxide based on an oxide, 3-35% by weight of the inorganic oxidebinding agent based on an oxide, 5-40% by weight of the boron nitride, 1-20% by weight of the SAPO molecular sieve on a dry basis and 5-30% by weight of the metal promoter based on a metal element. The hydrocarbon oil desulfurization catalyst provided by the invention has the advantages of high stability, good desulfurization activity and good wear resistance when applied to the hydrocarbon oil desulfurization process.

Owner:CHINA PETROLEUM & CHEM CORP +1

Hydrocarbon oil desulfurization catalyst, preparation method therefor and hydrocarbon oil desulfurization process

ActiveCN109718841AWith desulfurizationWith dehydrogenation propertiesMolecular sieve catalystsHydrocarbon oils refiningMolecular sieveSulfur

The invention relates to an IMF structure molecular sieve and zirconia binder containing hydrocarbon oil desulfurization catalyst, a preparation method therefor and a hydrocarbon oil desulfurization process. Based on the weight of the hydrocarbon oil desulfurization catalyst or the total weight of a sulfur storage metal oxide, a zirconia binder, boron nitride, IMF structure molecular sieves and ametal accelerant, the hydrocarbon oil desulfurization catalyst contains 10wt% to 80wt% (by oxide) of sulfur storage metal oxide, 3wt% to 35wt% (by oxide) of zirconia binder, 5wt% to 40wt% of boron nitride, 1wt% to 20wt% (by dry basis) of IMF structure molecular sieves and 5wt% to 30wt% (by metal element) of metal accelerant. When the hydrocarbon oil desulfurization catalyst provided by the invention is applied to the hydrocarbon oil desulfurization process, the hydrocarbon oil desulfurization catalyst has the advantages of high stability, good desulfurization activity and good wear resistance.

Owner:CHINA PETROLEUM & CHEM CORP +1

Method for treatment of heavy hydrocarbon raw material by up-flow reactor

ActiveCN109897665AImprove hydrogenation performanceGood ability to remove metalsMetal/metal-oxides/metal-hydroxide catalystsRefining to eliminate hetero atomsHydrogenation reactionActive component

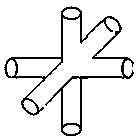

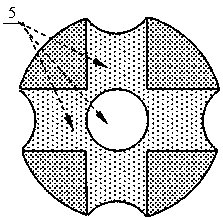

The invention discloses a method for treatment of a heavy hydrocarbon raw material by an up-flow reactor. The method includes adopting at least one up-flow hydrogenation reactor, which internally hasat least two catalyst beds, each of which uses a same hydrogenation treatment catalyst. The hydrogenation treatment catalyst comprises a carrier and active components, wherein the carrier is a spherewith three through channels, the outer diameter of the sphere is 5.0-8.0mm, the three channels are all through-holes that pass through the center of the sphere and are perpendicular to each other in pairs, and the diameter of the through-holes is 30%-60% of the outer diameter of the sphere. The method provided by the invention adopts the specific catalyst, which has good hydrogenation performanceand demetalization and metal accommodation capacity, at the same time has certain desulfurization and carbon residue and asphaltene conversion capability, and has long service life. Moreover, the method overcomes the problems of large catalyst variety, tedious loading and unloading, backmixing of different catalysts and the like in current up-flow reactors.

Owner:CHINA PETROLEUM & CHEM CORP +1

A production process of qt500-12 ductile iron casting

The invention discloses a production process of a QT500-12 spheroidal graphite iron casting. The production process comprises the following steps: A, raw material selection: selecting 60-80 parts of scrap steel, 20-40 parts of scrap returns, 2.5-3.5 parts of a carburant, 0.4-1.0 part of 75# ferrosilicon, 0.3-0.6 part of copper, 1-1.2 parts of a spheroidizing agent, 0.8-1.2 parts of a 75# ferrosilicon inoculant and 0.2-0.4 part of a silicon-strontium inoculant; B, weighing; C, smelting; D, spheroidizing; E, secondary inoculation; and F, pouring. The overall performances of the QT500-12 spheroidal graphite iron casting produced by using the production process are improved, and the tensile strength is larger than or equal to 500Mpa on the premise that the elongation percentage is larger than or equal to 12%; the consistency of a matrix structure of the spheroidal graphite iron casting is also realized, and the local function of the spheroidal graphite iron casting is prevented from being deteriorated; and the weight of the spheroidal graphite iron casting is reduced on the premise that the elongation percentage and tensile strength indexes of the spheroidal graphite iron casting reach standards, so that the lightweight of the spheroidal graphite iron casting is realized.

Owner:山东力嘉轻量化科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com