Patents

Literature

130results about How to "Improve grain refinement effect" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

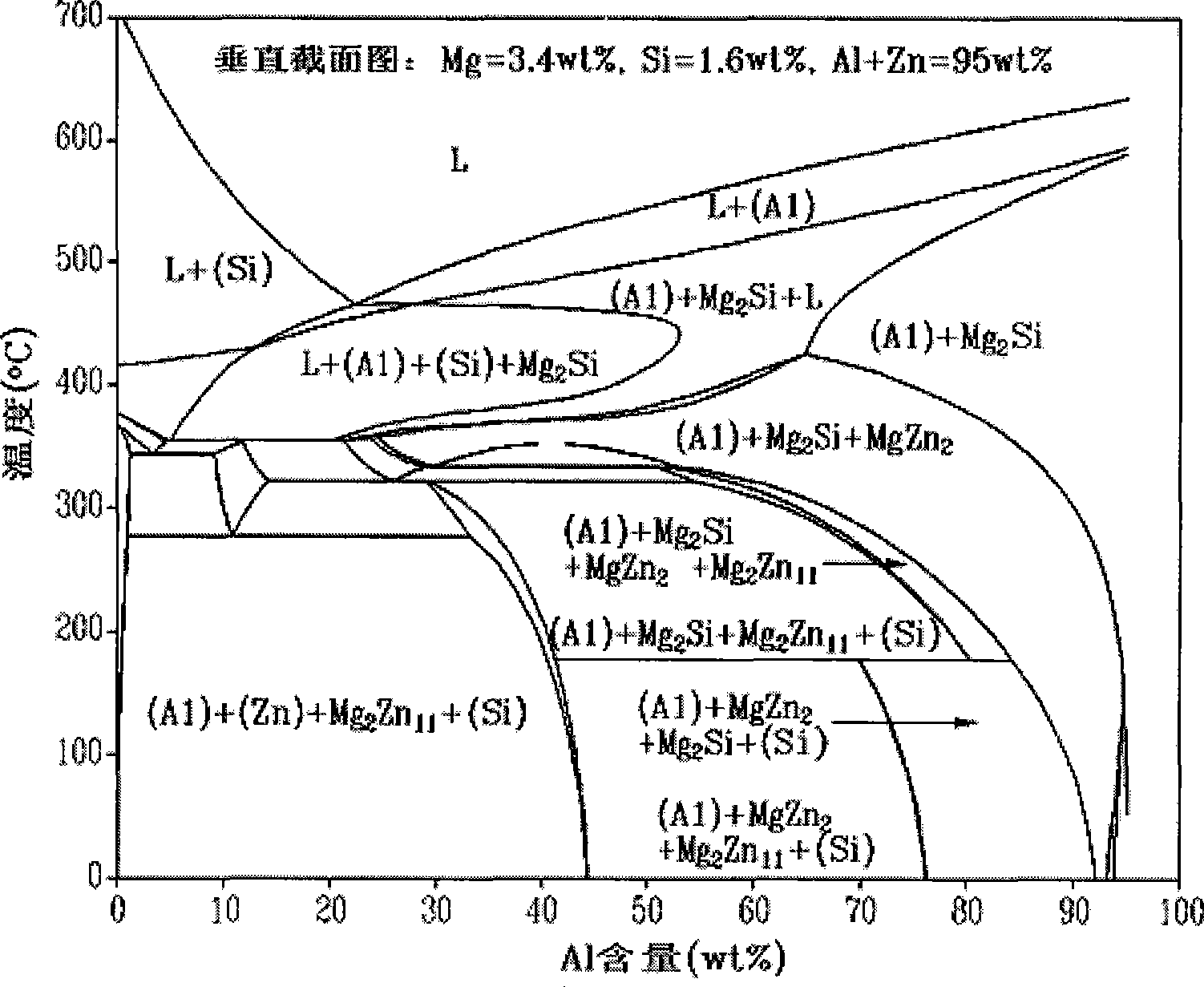

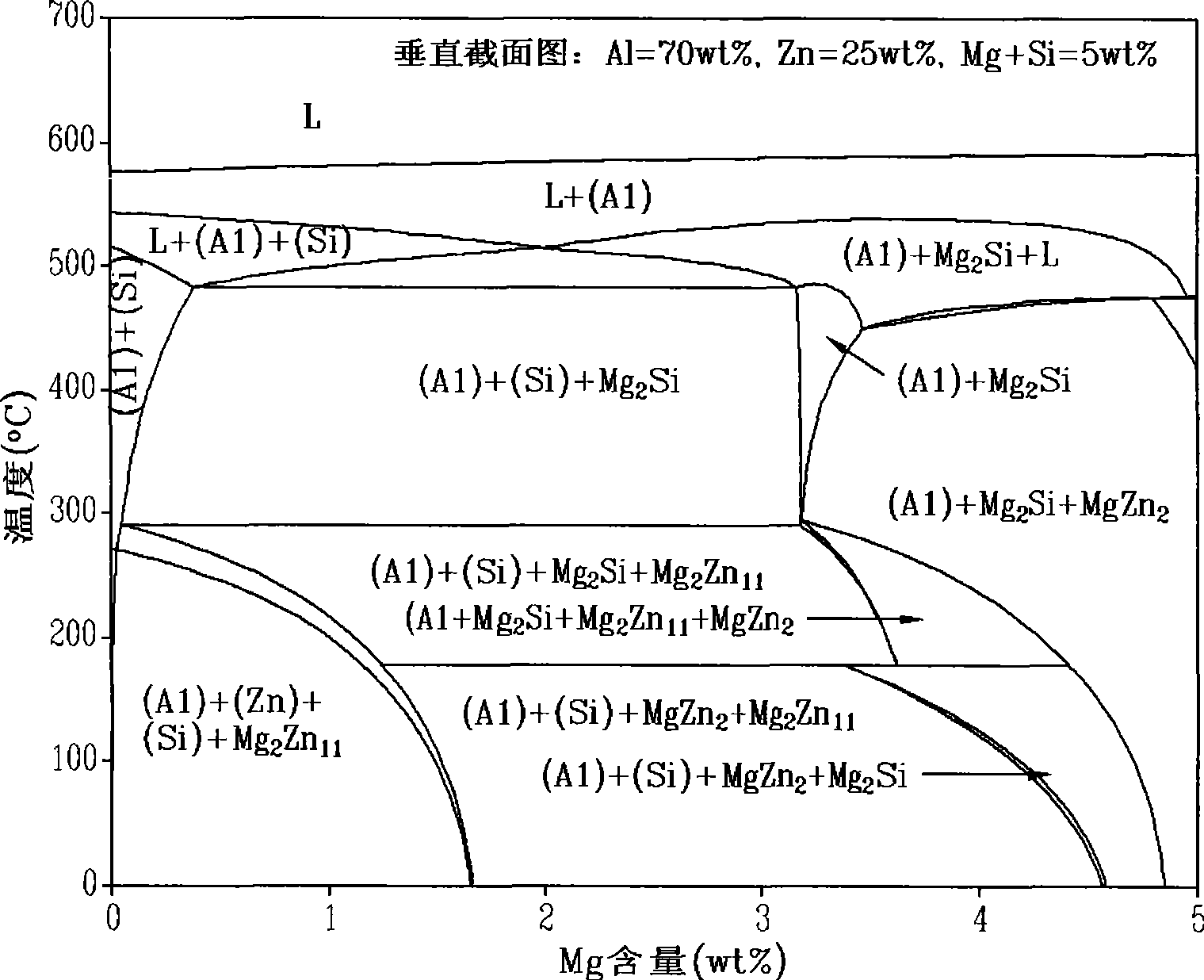

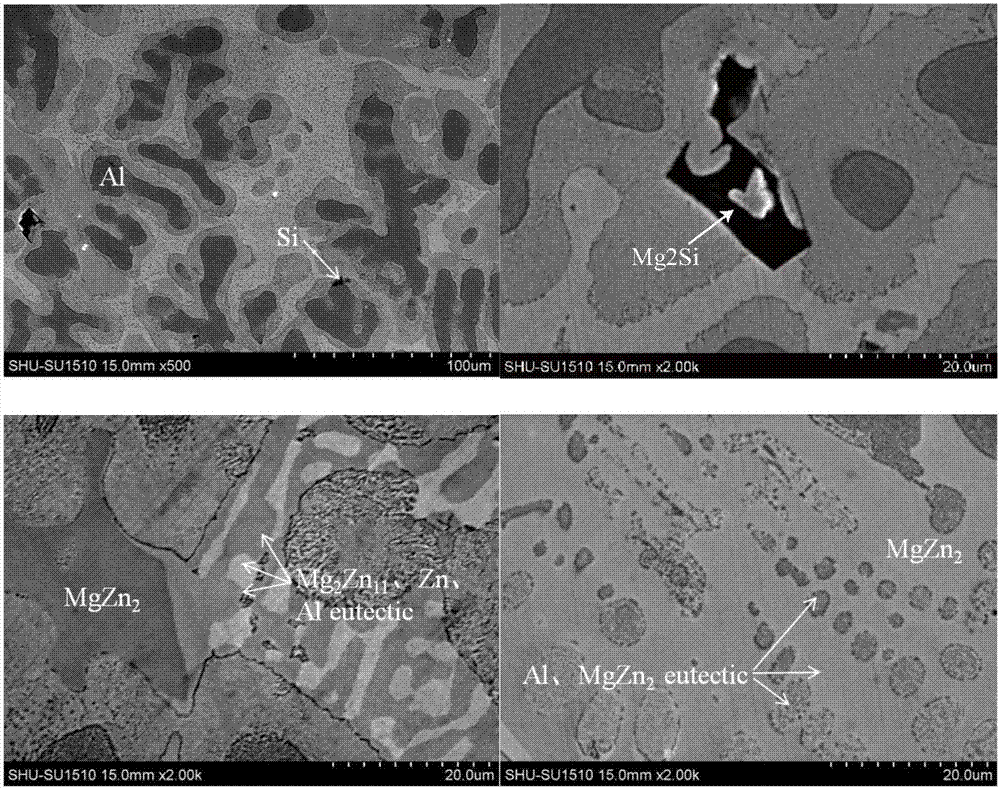

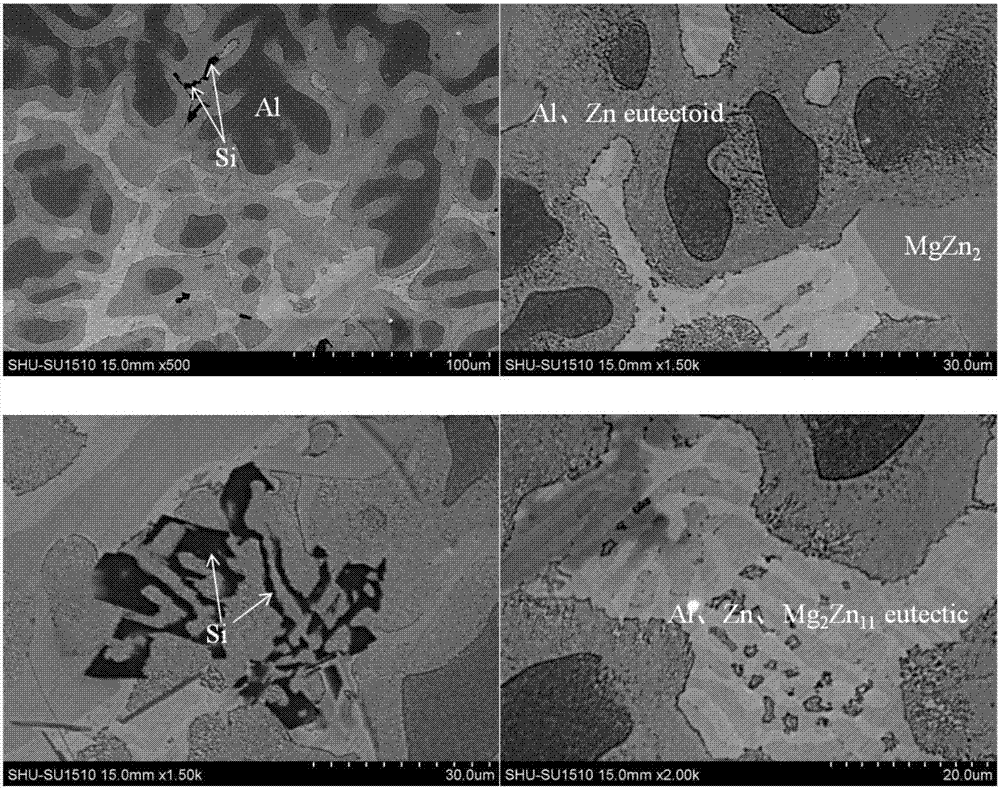

Al-Zn-Mg-Si alloy for hot dipping steel

InactiveCN101457320AAvoid gatheringDeterioration of surface propertiesHot-dipping/immersion processesRare earthZinc alloys

The invention provides a rare earth-containing Al-Zn-Mg-Si alloy with high aluminum content for hot-dipping steel products, comprising the following compositions by weight percent as follows; Al: 50-75%, Mg: 1-5%, Si: 0.5-2.5%, the addition of 0.002-0.1% of Ti, 0.001-0.045% of B and 0.05-1% of rare earth (La or Ce), and the balance of Zn and unavoidable impurities. The invention utilizes corrosion resistance of Mg2Si and grain-refining effect of the rare earth, the Ti and the Bi elements to improve quality of plating solution and obtain a high aluminum content aluminum-zinc alloy cladding with ,a bright and smooth surface and great corrosion resistance property. In addition, the content of aluminum in the alloy is up to 50-75%, thereby lowering production cost.

Owner:SHANGHAI UNIV

Refining agent for crystalline grain of aluminium titanium carbon intermediate alloy

The aluminium titanium carbon intermediate alloy grain thinning agent relates to a AlTiC grain thining agent containing TiC granules for thinning aluminium and aluminium alloy and its preparation method. It is characterized by that said alloy composition contains (wt%) 3%-6% of Ti anjd 0.02%-0.5% of C, the reset is aluminium and inevitable impurity, in which the ratio of Ti:C is 25:1. Its preparation method is characterized by that the carbon powder prepared by using one selected from industrial graphite, natural graphite, amorphous graphite, active carbon and carbon black carbon is introduced into aluminium melt by means of graphite rotor of rotary refining equipment and stirred until the aluminium melt contains no monomer carbon.

Owner:ZHUOZHOU JINGYING ALUMINUM ALLOY MATERIAL

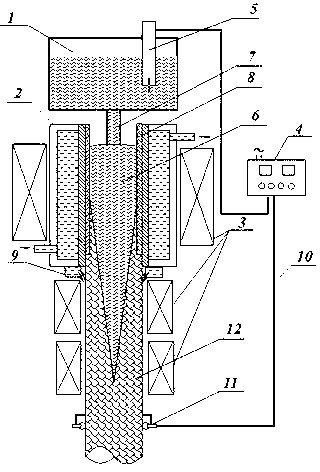

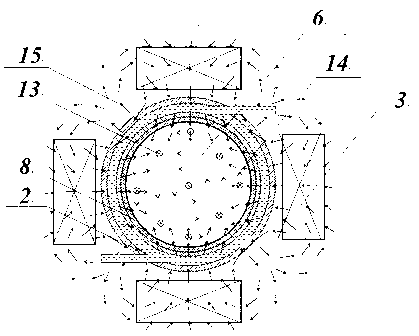

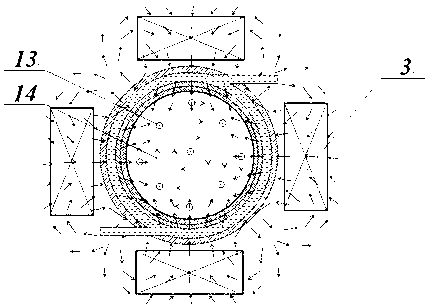

Low-energy-consumption electromagnetic stirring method for continuous casting and metal continuous casting device

The invention discloses a low-energy-consumption electromagnetic stirring method for continuous casting. The hot top composite novel low-energy-consumption electromagnetic stirring technique is used. A hot top is arranged in a crystallizer, a steady magnetic field with no energy consumption and low energy consumption is exerted on the periphery simultaneously, an electrode bar is inserted in a tundish, a roller electrode is arranged at the solidifying tail end of a continuous casting billet, and therefore alternating current can be exerted on all non-solidification metal melts between the crystallizer and the solidifying tail end. The alternating current and an additional steady magnetic field are acted with each other so as to enable all the non-solidification metal melts in the whole continuous casting billet in a continuous casting process to generate electromagnetic stirring force for driving the continuous casting melts to rotate clockwise and counterclockwise, thereby stirring non-solidification structures, smashing dendrites of solidification front edges of the melts, refining the solidification structures, reducing segregation and cracks. The invention further provides a metal continuous casting device which can be applied to a continuous casting process of various molten metals prone in segregation and draw an alloy continuous casting billet with refined solidification structure, small segregation and no crack.

Owner:SHANGHAI UNIV +1

Rapid solidification Al-Ti-B-Sc intermediate alloy refiner and preparation method thereof

InactiveCN103589916AImprove grain refinement effectImprove adsorption capacityRare-earth elementMulti element

The invention provides a rapid solidification Al-Ti-B-Sc intermediate alloy refiner. The refiner is intermediate alloy and comprises, by mass, 3.75%-5% of Ti, 0.75%-1% of B, 0.1%-0.5% of Sc, and the balance Al. The cast structure of the refiner comprises particulate alpha-Al, TiAl3, TiB2, AlB2 and Al3Sc. The aluminum alloy refiner is an Al-Ti-B-Sc multi-element alloy refiner which comprises the rare earth element Sc and is acquired through rapid solidification. When the refiner is added to aluminum alloy, the aluminum alloy can be molten within a short time and can be evenly distributed more easily. When the refiner is applied, melting time can be shortened, and electric energy losses can be reduced.

Owner:HEBEI UNIV OF TECH

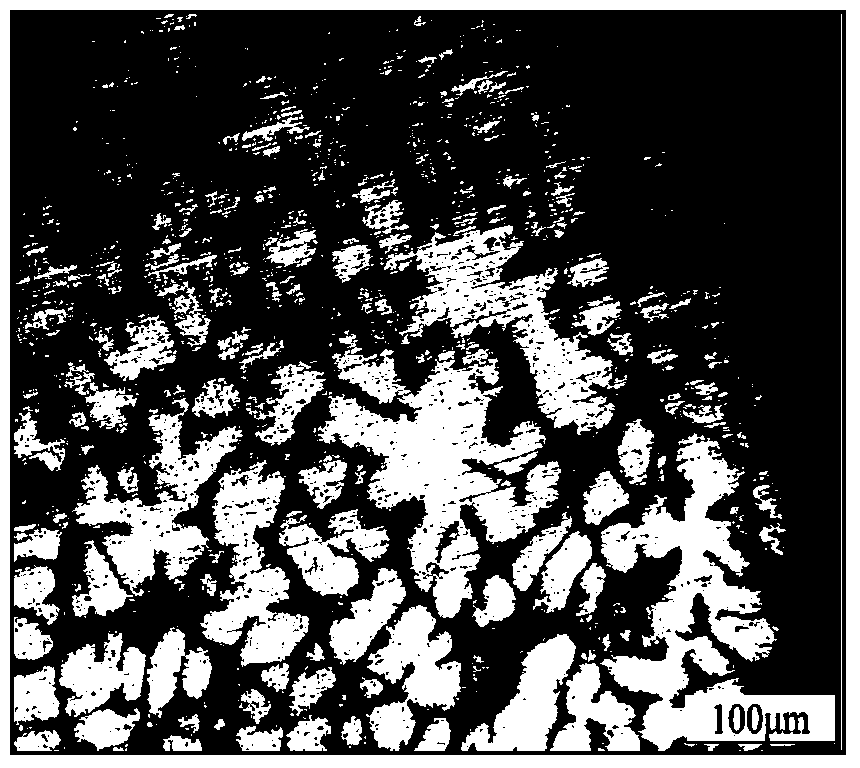

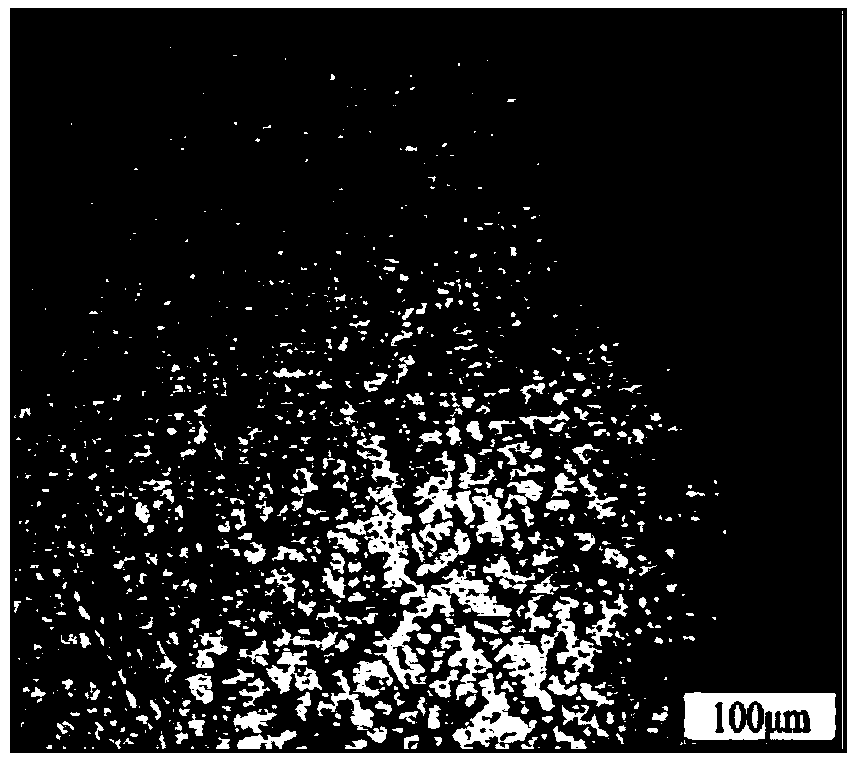

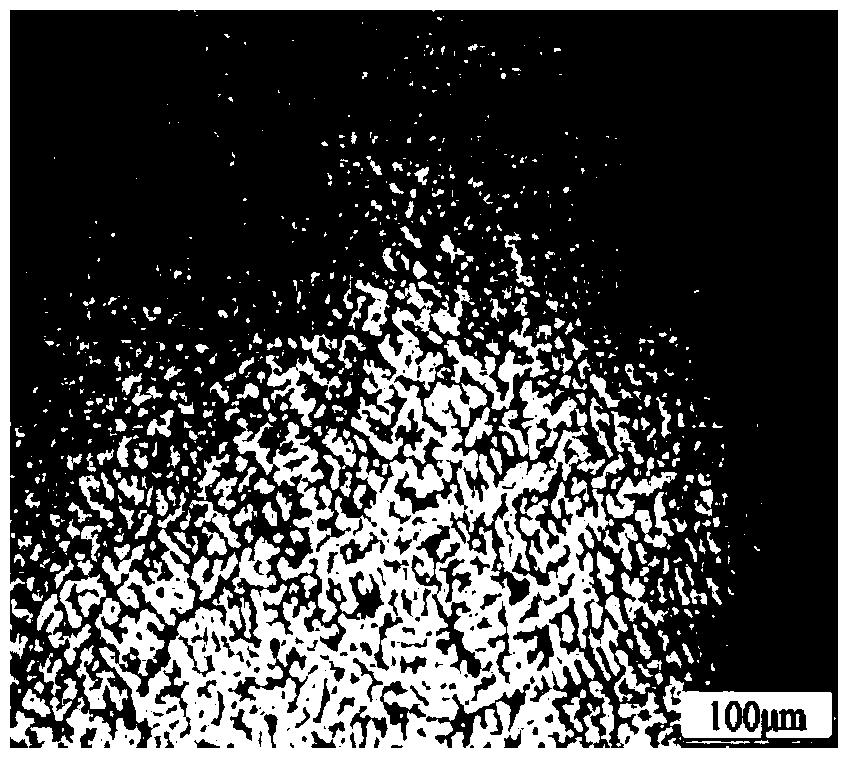

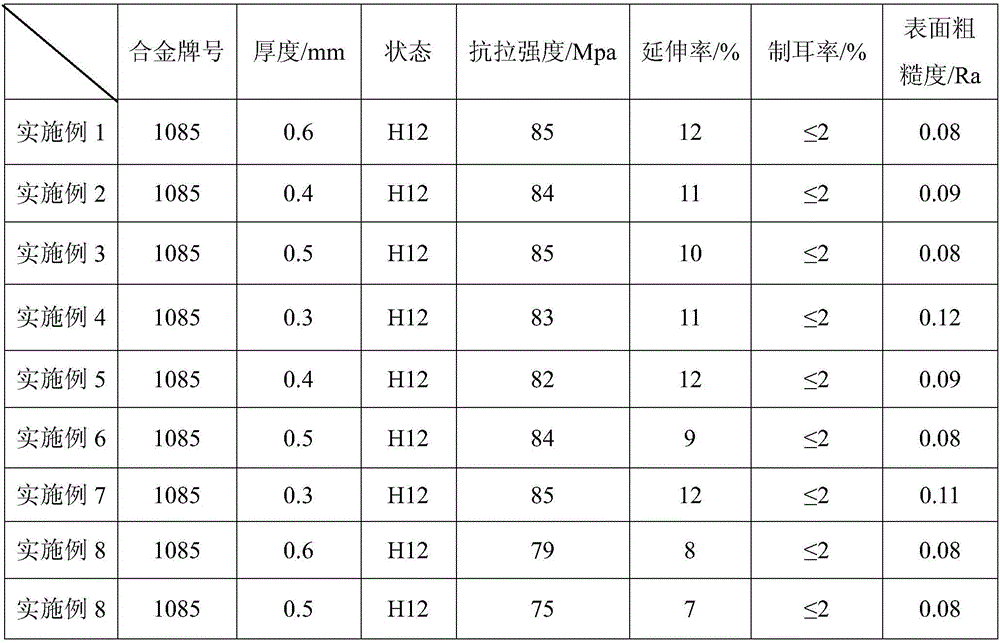

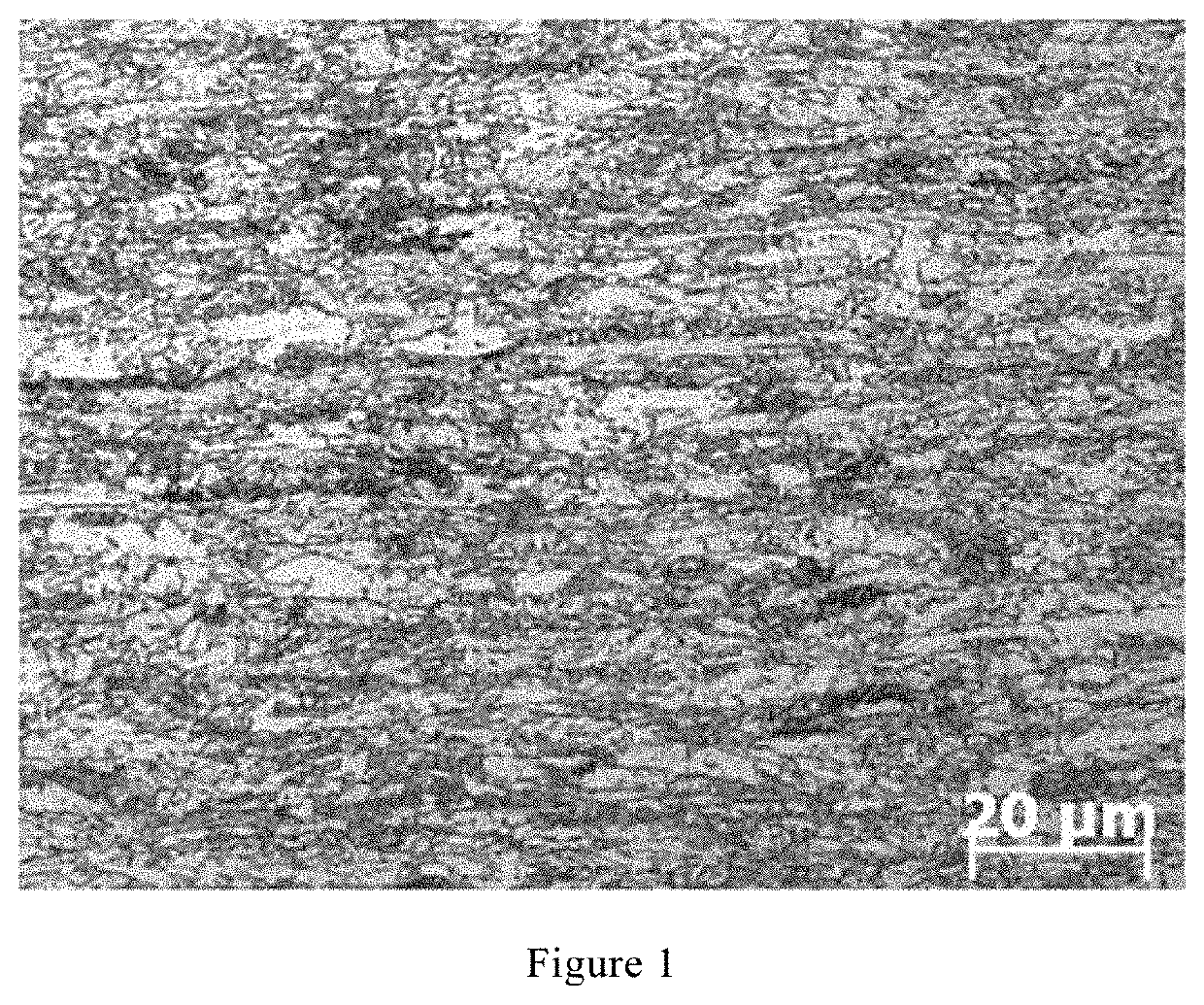

Production method of aluminum plates and aluminum strips for cosmetic mirror surface aluminum caps

ActiveCN106319292ASolve the shortcomings of uneven online refinementEvenly meltedSmelting processDistribution system

The invention relates to a production method of aluminum plates and aluminum strips for cosmetic mirror surface aluminum caps. The manufacturing process comprises the steps of smelting, casting, homogenizing treatment, hot rolling, cold rolling, intermediate annealing and cold rolling of finished products. In the smelting process, a bottom-mounted electromagnetic stirring system is adopted; in the casting process, an automatic speed regulation system is adopted; in the hot rolling system, a hot rough rolling pass automatic distribution system is adopted; and in the intermediate annealing system, a large natural gas furnace is adopted for annealing. Through cooperation of all the procedures, product ingredients can be made uniform, and finished products are uniform in surface roughness, fine, smooth, good in smooth finish, free of surface defects such as stripes, black lines and color difference; the mirror surface effect is good after materials are subjected to anodic oxidation and electroplating, and the application requirements for deep drawing and tensile properties of the aluminum plates and the aluminum strips for the cosmetic mirror surface aluminum caps are met.

Owner:HENAN MINGTAI AL INDUSTRIAL CO LTD

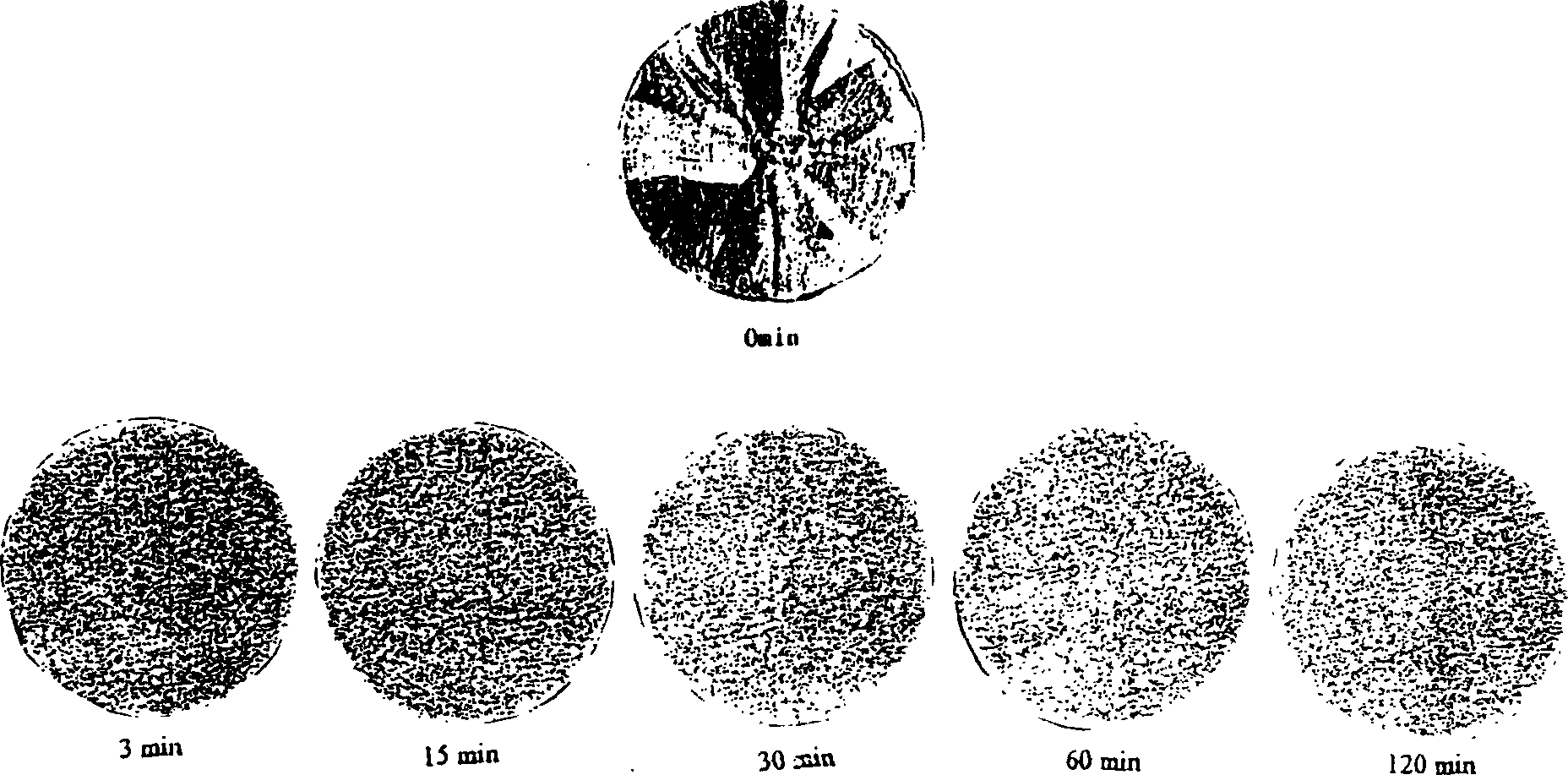

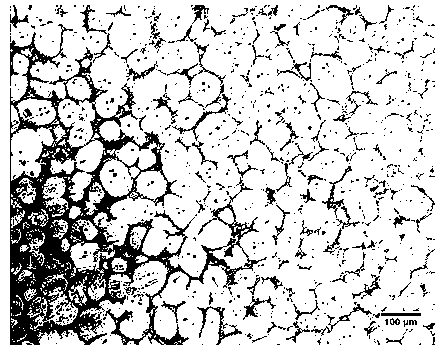

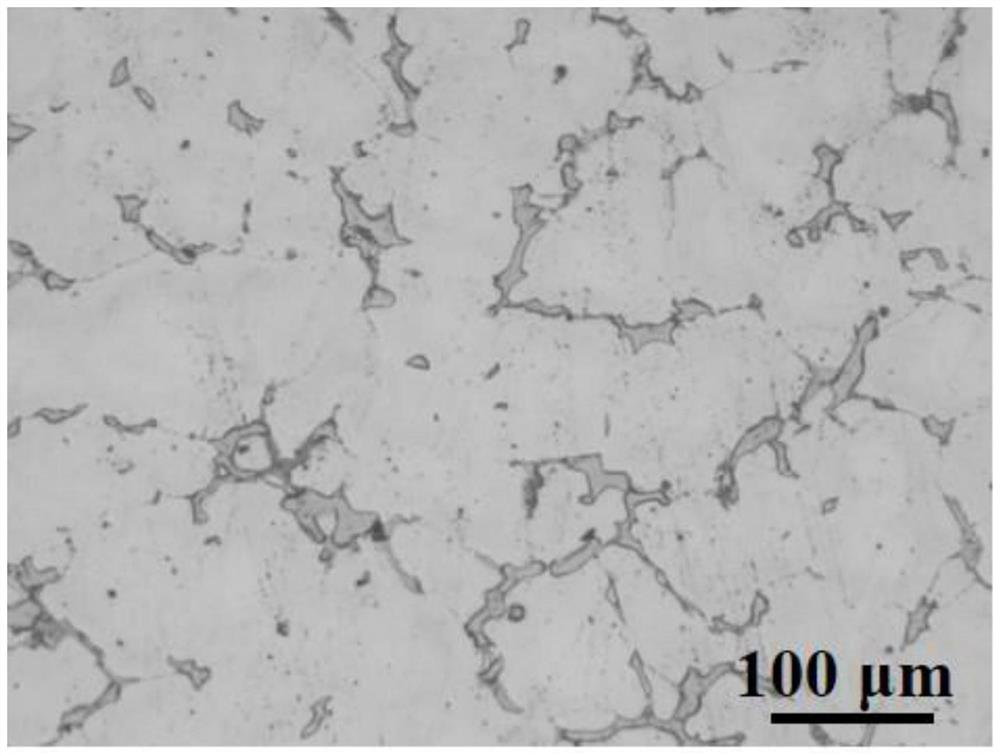

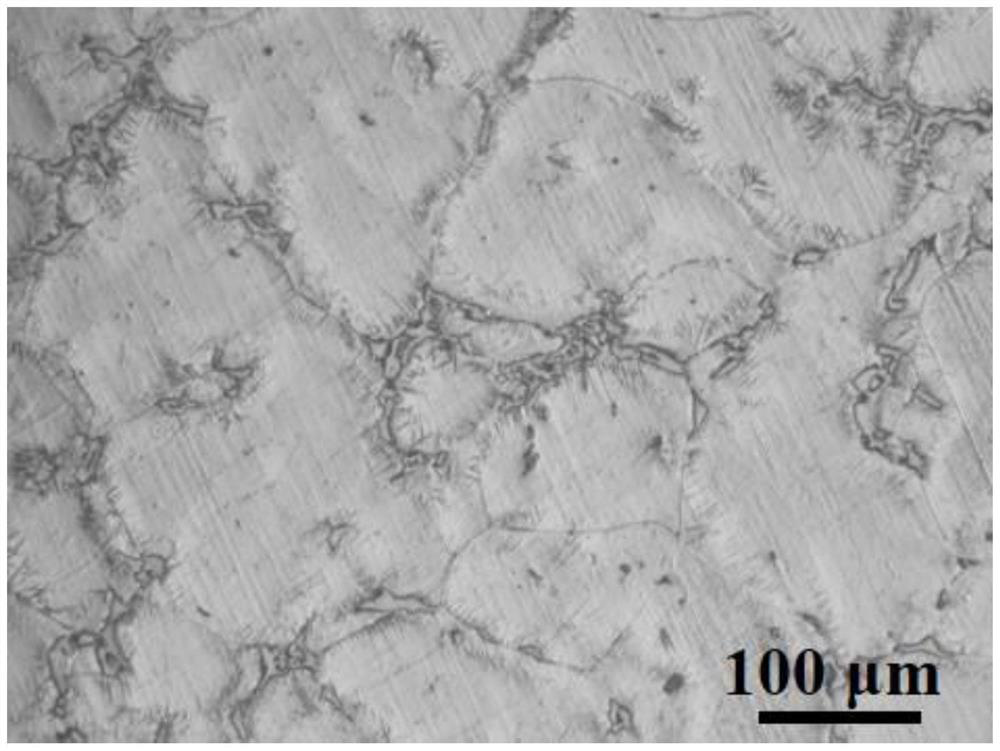

Method for preparing semisolid blank

The invention relates to a method for preparing a semisolid blank, utilizes an improved SIMA (strain induced melt activation) method to prepare the semisolid blank, and belongs to the technical field of metal semisolid blank. The method comprises the following steps of: firstly, measuring a liquid solid phase line point of the semisolid alloy to be prepared, then, heating an alloy blank so as to carry out asynchronization multitrack rolling or pillar squeezing transformation, finally, remelting, and carrying out heat preservation for a long time so as to obtain the required semisolid blank. The asynchronization rolling or pillar squeezing transformation is capable of generating large deformation amount, group bough crystal formed in the blank is destroyed, the asynchronization rolling is utilized to replace pre-deformation processes such as the existing upset, compression, equal diameter angle compression, and the semisolid blank is prepared and has the advantages of uniform formation, high nodularity, and accurate control solid phase rate.

Owner:KUNMING UNIV OF SCI & TECH

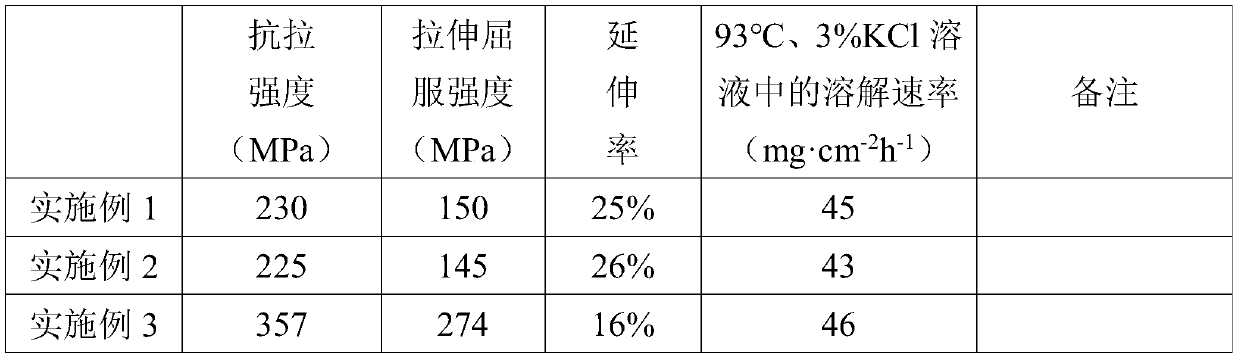

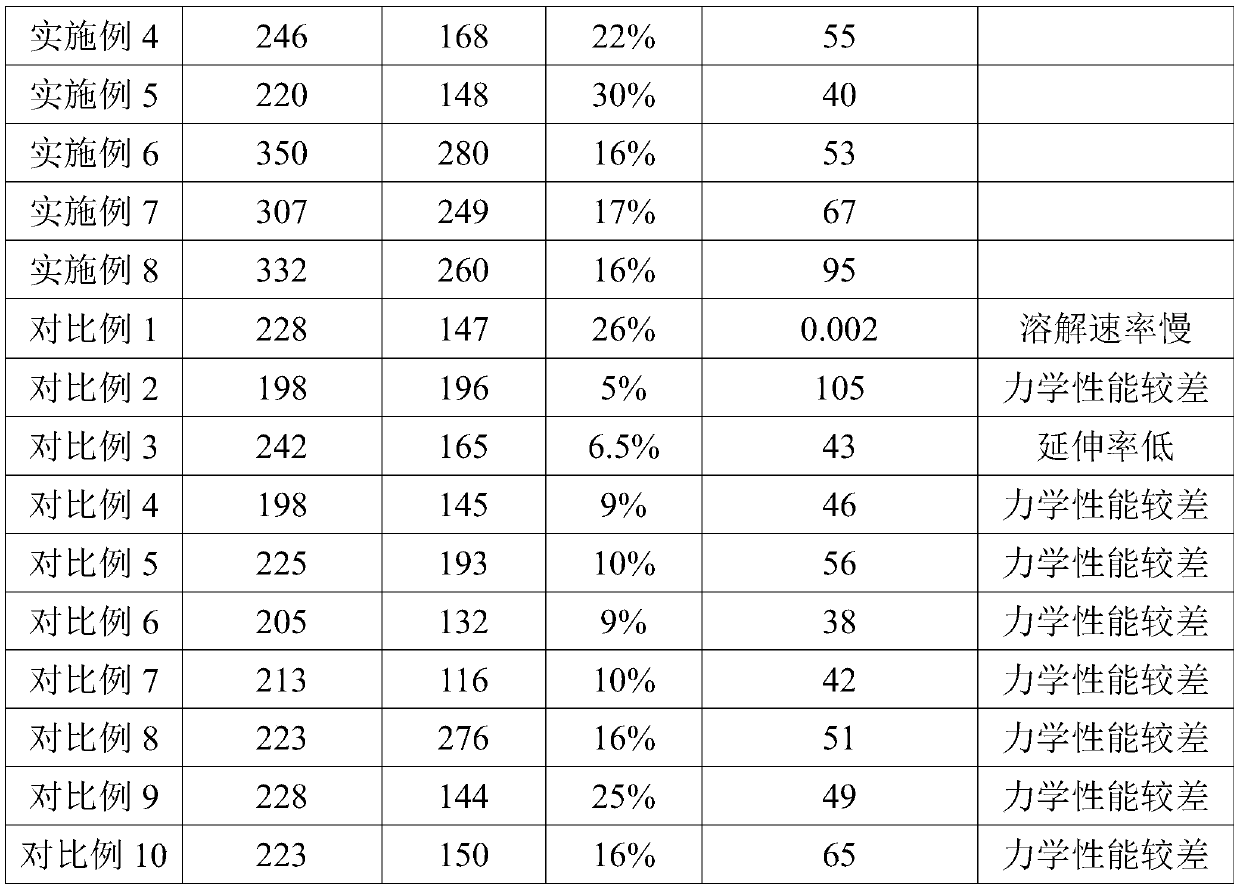

High-strength and high-ductility magnesium alloy capable of being dissolved rapidly and preparation method thereof

ActiveCN110184518AHigh strength and high elongation mechanical strength propertiesIncrease speedFluid removalSealing/packingDuctilityWater soluble

The invention provides a high-strength and high-ductility magnesium alloy capable of being dissolved rapidly and a preparation method thereof. The high-strength and high-ductility magnesium alloy capable of being dissolved rapidly comprises, by mass, 1.0%-22.0% of Gd, 0.001%-5.0% of Y, 0.001%-10% of Al, 0.001%-5.0% of Zn, 0.01%-1.0% of Zr, 0.0001%-1.0% of Sc, 0.01%-10.0% of Cu, 0.01%-3.0% of Li, 0.01%-3.0% of Ni, 0.01%-3.0% of Ga, 0.01%-3.0% of In, and the balance Mg and impurities, wherein the total content of Li, Ga and In is 0.1%-6.0%. The high-strength and high-ductility magnesium alloy capable of being dissolved rapidly can react with a water-soluble medium rapidly so as to be dissolved, has the mechanical strength properties of high strength and high ductility, and can meet the application requirements in various industrial fields.

Owner:FIVE STAR DOWNHOLE SERVICE INC

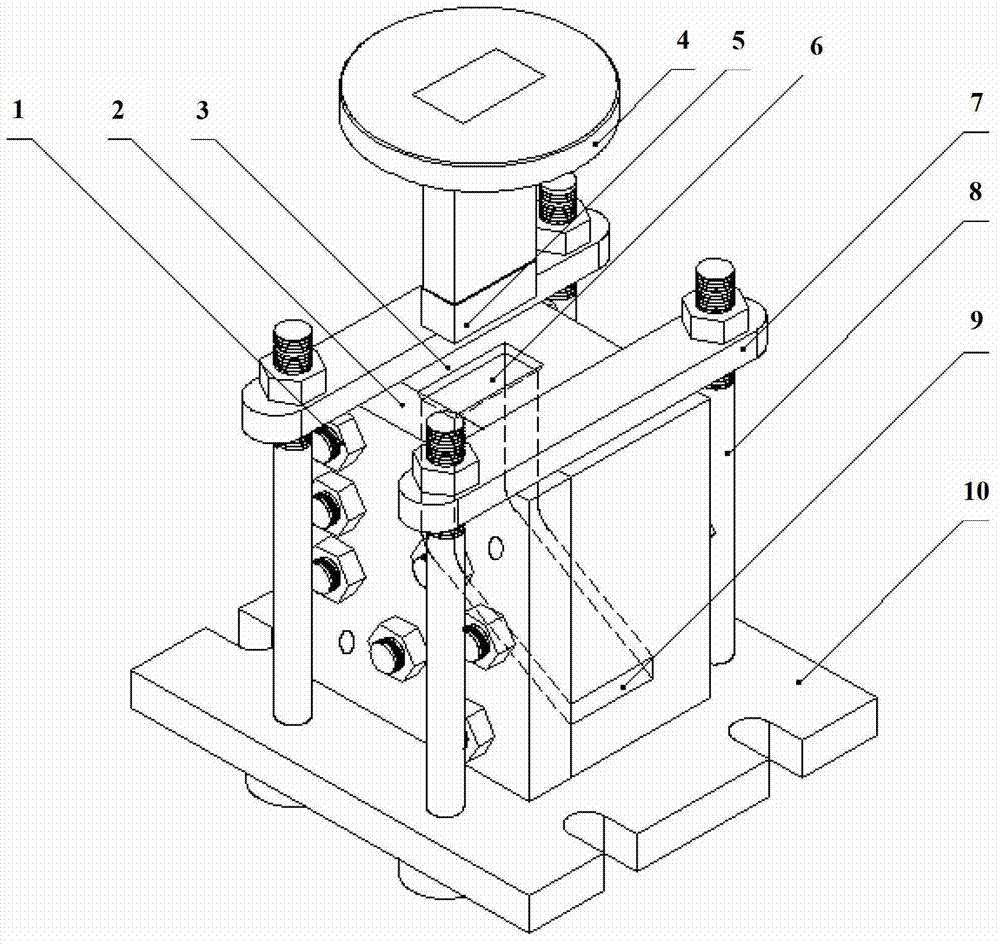

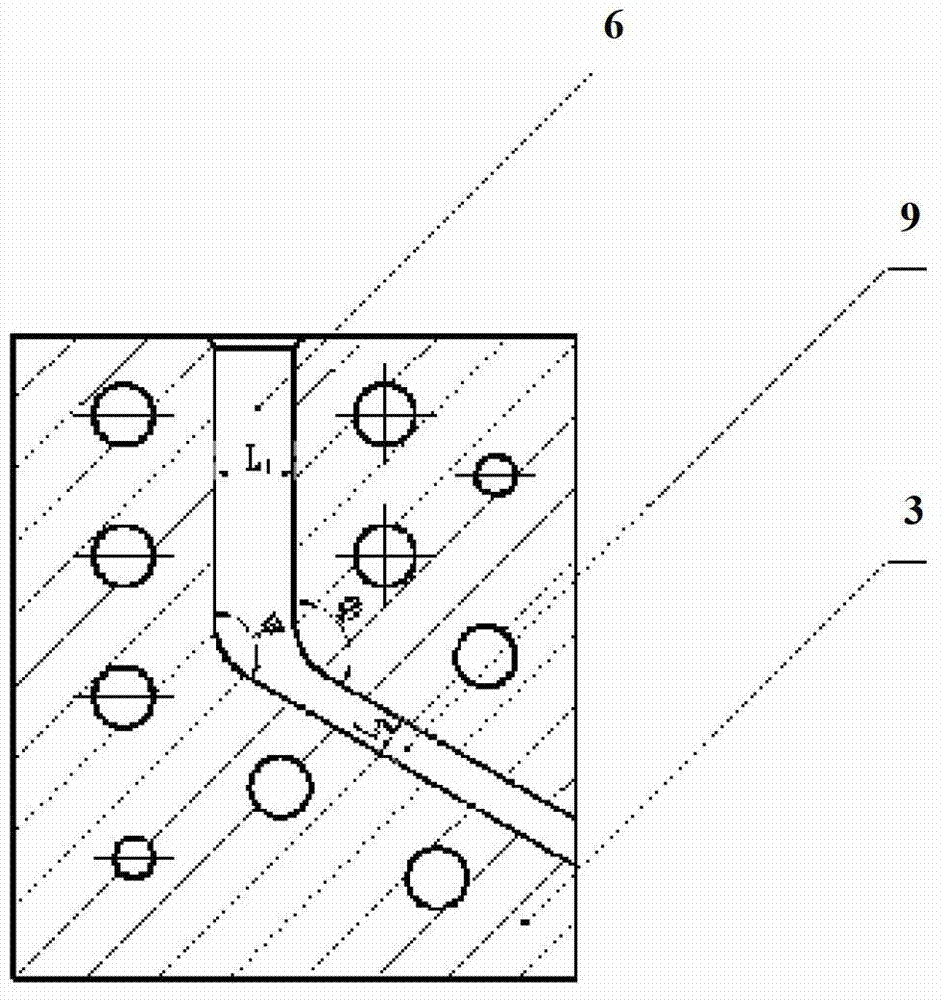

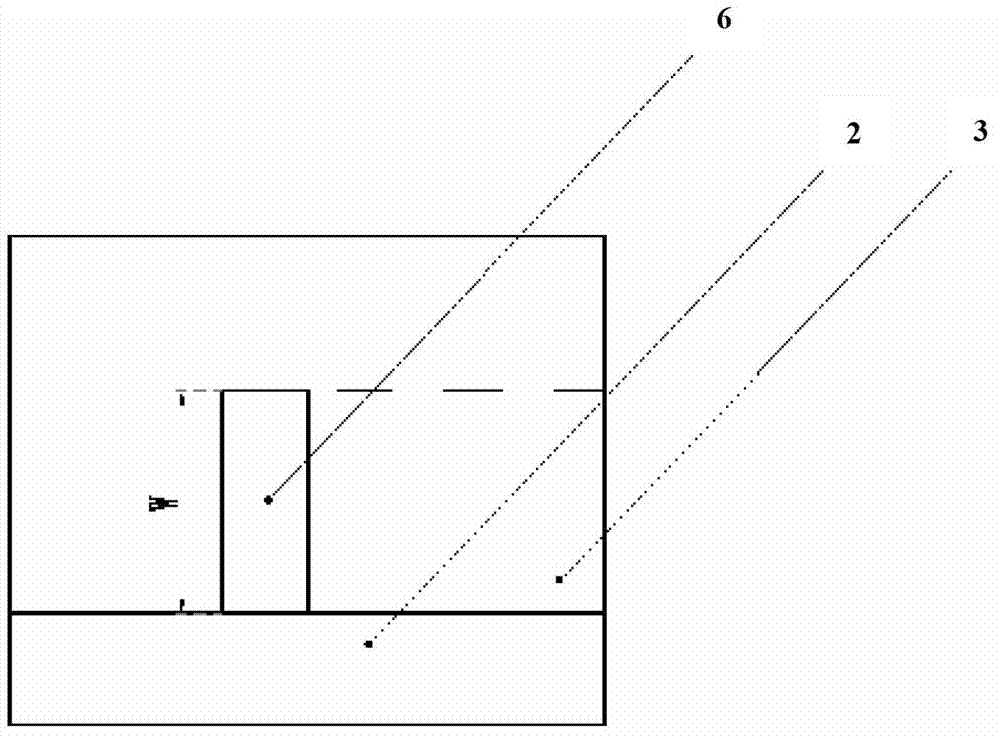

Severe plastic deformation method and severe plastic deformation device for pressing and rolling corner of non-equivalent passage

The invention discloses a severe plastic deformation method and a severe plastic deformation device for pressing and rolling the corner of a non-equal channel. According to the severe plastic deformation method and the severe plastic deformation device for pressing and rolling the corner of the non-equal channel, an equal-channel angular pressing (ECAP) technology and an ARB (Accumulative Roll Bonding) technology are integrated. The concrete process comprises the following steps that pressing force is applied after a test sample, a punching head and a mould are simultaneously preheated to pressing and rolling temperature, so that the test sample passes through the position of the channel corner of the device for pressing and rolling the corner of the non-equal channel completely; compressive deformation is generated when shear deformation is generated by the test sample so as to finish a first pass pressing and rolling process; the test sample is cut into L1 / L2 parts along a length direction, and the L1 / L2 parts are placed in an I channel; and the steps are repeated so as to finish multi-pass pressing and rolling deformation. The mould of the device is provided with the I channel and an II channel which are intersected and also have non-equal sections. The design is reasonable, the structure is simple, and the manufacturing cost is low. According to the method disclosed by the invention, the advantages of the ECAP technology and the ARB technology are integrated, and the mechanical property of a material is effectively enhanced. The process is short in procedure, high in efficiency and low in cost and is simple to operate. The severe plastic deformation method and the severe plastic deformation device for pressing and rolling the corner of the non-equal channel can be widely used for the field of processing metal materials, such as pure metal and alloy.

Owner:SOUTH CHINA UNIV OF TECH

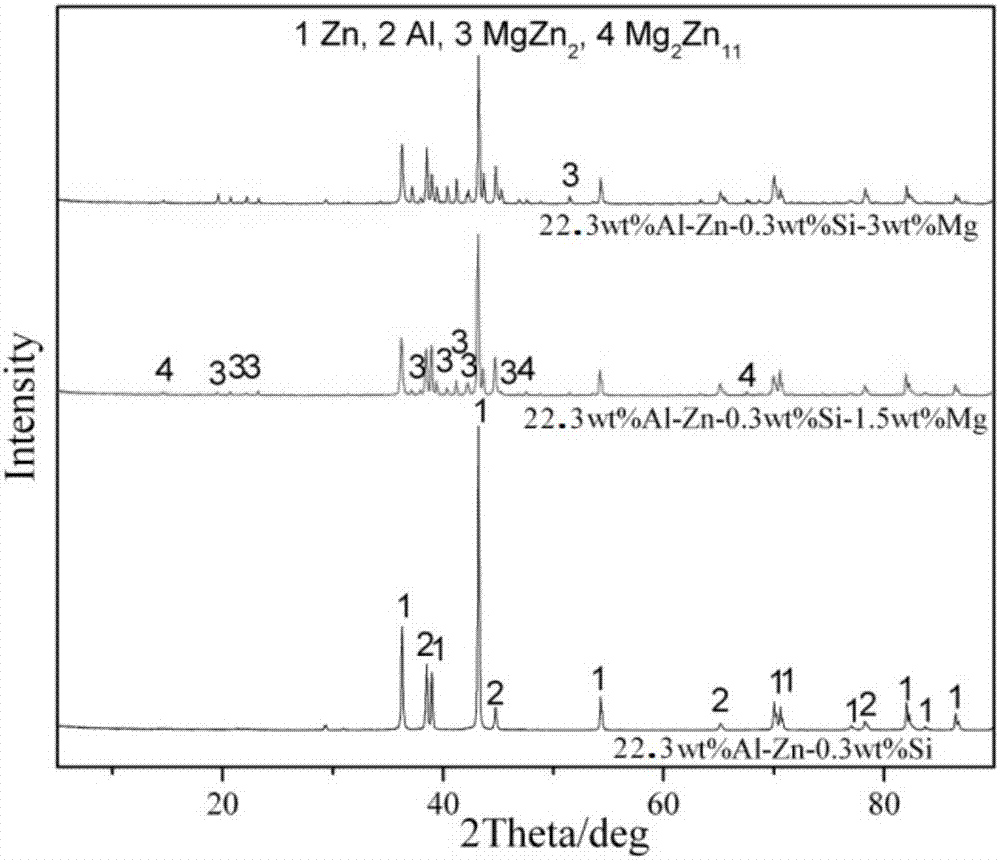

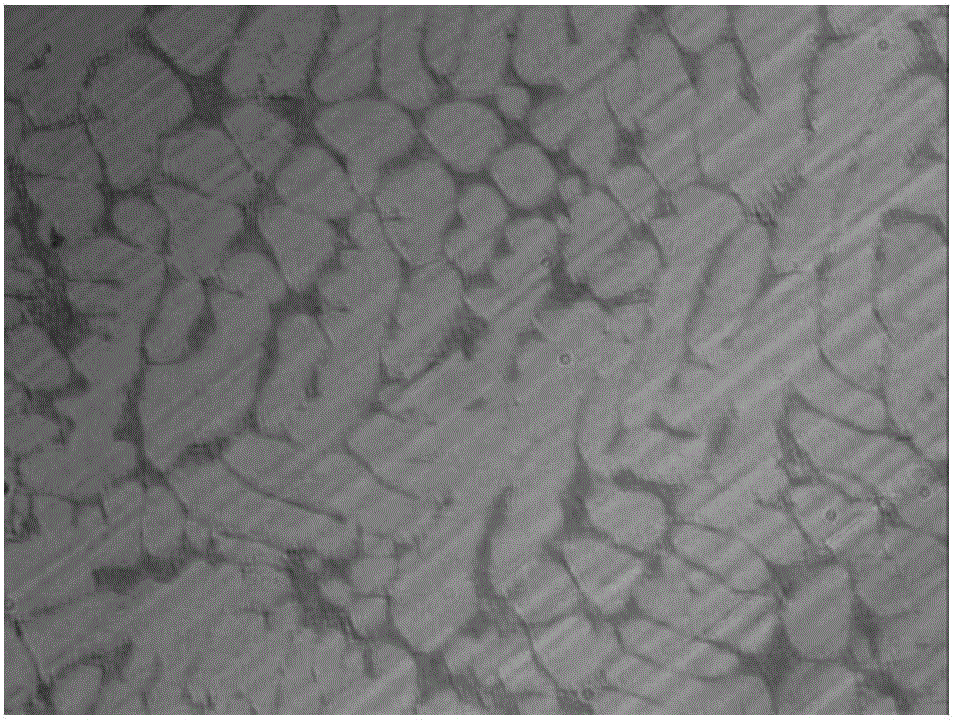

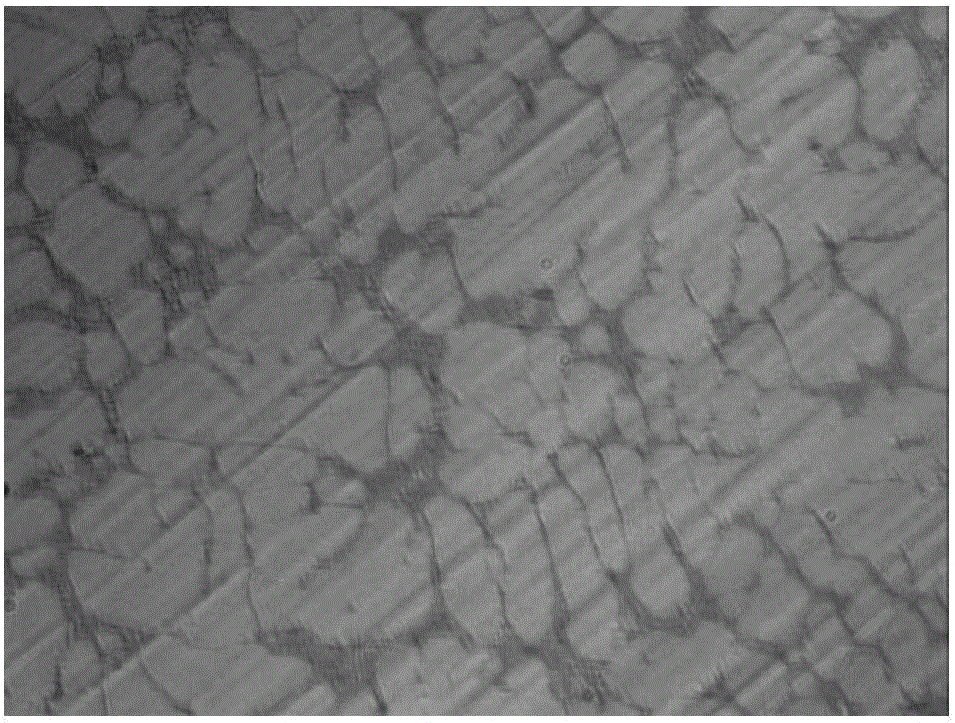

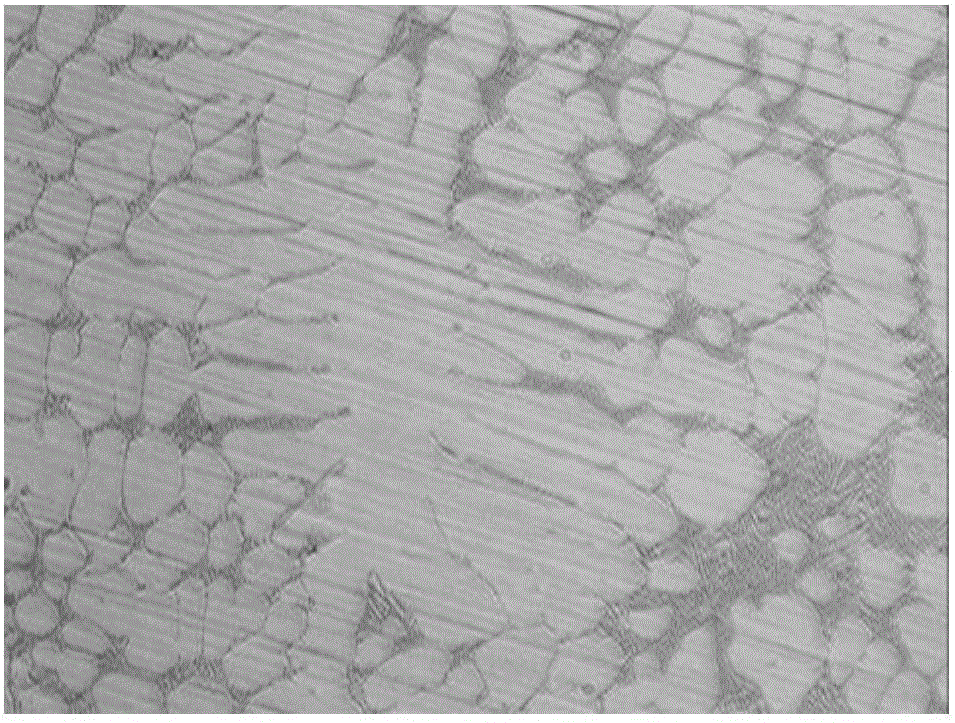

Composite zinc-aluminum alloy coating material and hot-dip plating method

InactiveCN106893888AImprove corrosion resistanceImprove grain refinement effectHot-dipping/immersion processesHydrogenSlag

The invention discloses a composite zinc-aluminum alloy coating material and a hot-dip plating method. A eutectoid composition Zn-Al-Si-Mg-Ti alloy coating for hot-dip plating is prepared and comprises, by mass percentage, 10-30% of Al, 0.1-1% of Si, 0.04-1% of Ti, not larger than 5% of Mg and the balance Zn. A plating solution alloy is melted through a molten salt covering method; a part to be electroplated is put into a zinc pot and pre-reduced in hydrogen-nitrogen mixed gas with the reducing atmosphere of 5-50%, the reducing temperature ranges from 500 DEG C to 680 DEG C, the preheating time ranges from 3 min to 10 min, the zinc pot temperature is controlled within the range of 550-640 DEG C, and the dip plating time is controlled within the range of 3s-30min; and after a plate is taken out of the zinc pot, the thickness of the coating is controlled through an air knife, meanwhile the coating is cooled, and the expected hot-dip plating plate is obtained. By the adoption of the composite zinc-aluminum alloy coating material and the hot-dip plating method, the obtained coating is level in surface, and the amount of bottom slag in a plating solution is small.

Owner:SHANGHAI UNIV

Aluminum alloy refining agent and preparing technology thereof

The invention provides an aluminum alloy refining agent and a preparing technology thereof. The aluminum alloy refining agent comprises, by mass part, 25 parts to 35 parts of sodium chloride, 20 parts to 30 parts of potassium chloride, 5 parts to 10 parts of sodium fluosilicate, 10 parts to 20 parts of sodium fluoride, 5 parts to 10 parts of potassium fluotitanate, 5 parts to 10 parts of potassium fluoborate, 5 parts to 10 parts of sodium carbonate, 10 parts to 20 parts of sodium sulfate, 1 part to 5 parts of potassium nitrate and 2 parts to 5 parts of potassium fluoroaluminate. According to the aluminum alloy refining agent, through the optimized formula, the aluminum alloy refining agent can achieve the aim of refining of deslagging and degassing, the effective grain refining effect is achieved, in the process of deslagging and degassing refining of aluminum alloy melt, the grains are refined, the grains are evenly distributed in the aluminum alloy melt, and therefore the working procedures of intermediate alloy adding and the like in modification of the aluminum alloy melt can be reduced, the production technology of the aluminum alloy is optimized, and the production efficiency of the aluminum alloy is improved.

Owner:ZHEJIANG JINFEI KAIDA WHEEL

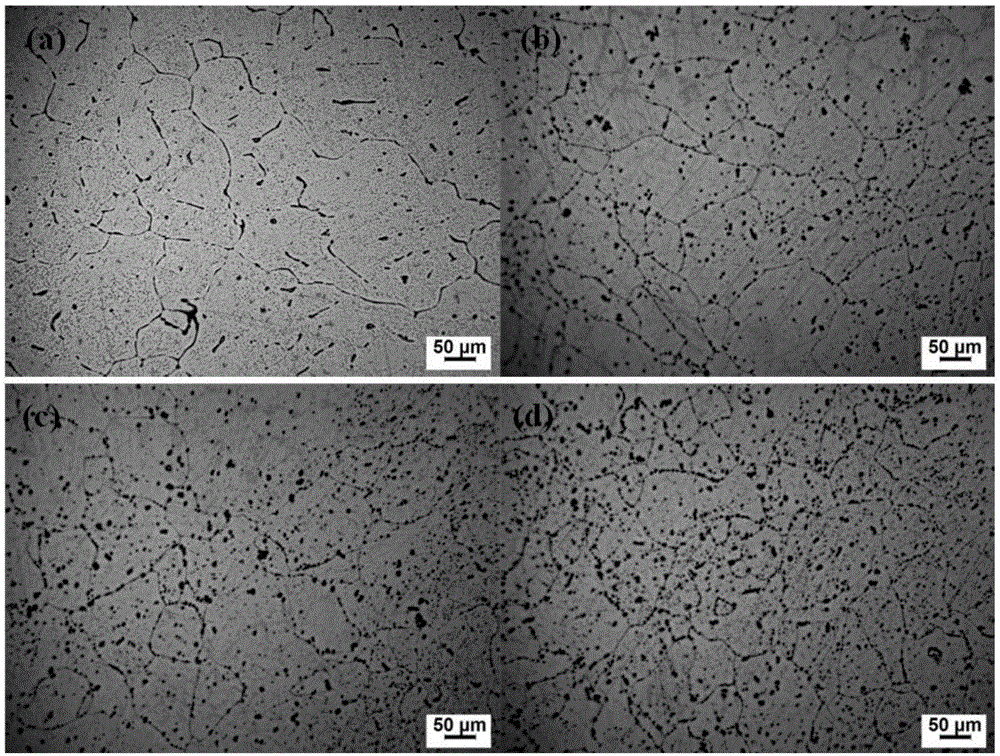

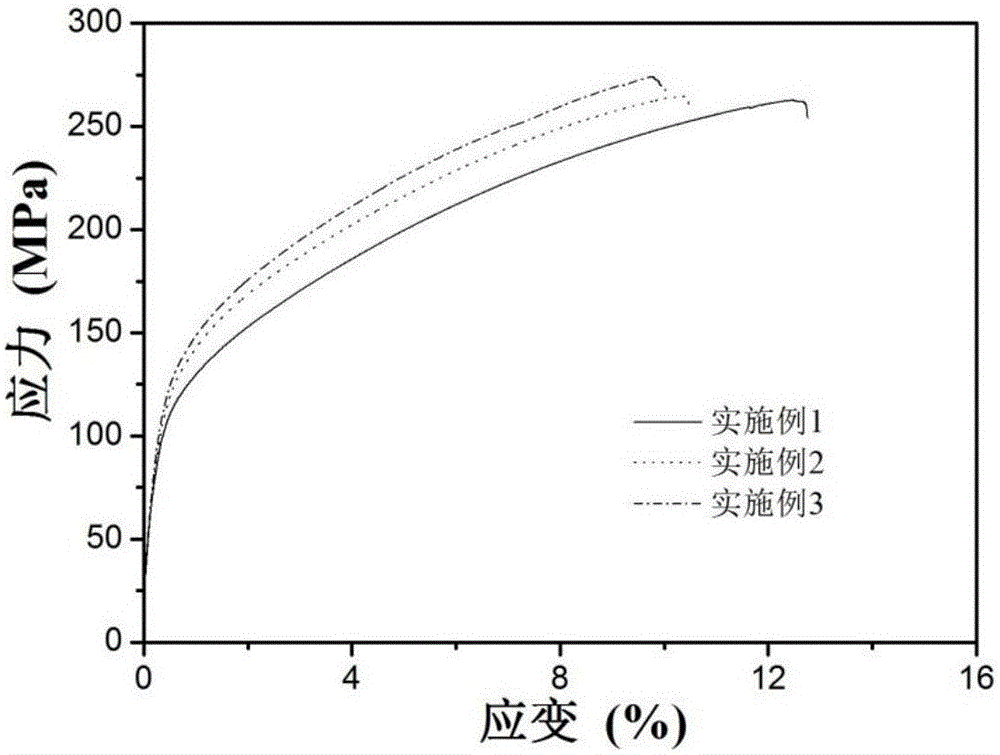

High-strength and high-toughness cast magnesium alloy and preparation method thereof

The invention discloses high-strength and high-toughness cast magnesium alloy. The high-strength and high-toughness cast magnesium alloy is Mg-Bi-Ca-Zn alloy and composed of, by weight, 3.0-8.0% of Bi, 0.1-1.2% of Ca, 0.1-2.0% of Zn and the balance Mg. According to the invention, Bi serves as the main alloy element, lots of Mg3Bi2 phases are formed through the simple alloying way, few Ca elements and Zn elements are adopted for improving the strength of the alloy, the Ca elements effectively improve the morphology and distribution of the Mg3Bi2 phases so as to improve the plasticity of the alloy, and therefore the high-strength and high-toughness cast magnesium alloy can be developed for the Mg-Bi alloy series. The cast magnesium alloy is high in strength and plasticity, the tensile strength of the alloy with the components optimized reaches about 270 MPa, the yield strength of the alloy reaches about 145 MPa, and the ductility of the alloy reaches about 10%. Thus, the strength can be as high as that of rare earth magnesium alloy, and the ductility is high.

Owner:山东汇达蠕墨装备有限公司

Wear-resisting and high-hardness flux core wire

InactiveCN107252994AHigh hardnessHigh strengthWelding/cutting media/materialsSoldering mediaSilicon alloyRare earth

The invention discloses a wear-resisting and high-hardness flux core wire. The wear-resisting and high-hardness flux core wire is composed of a flux core and a low-carbon cold-rolling steel tape sheath wrapped on the outer side of the flux core. The flux core comprises, by weight, 20-25 parts of low-carbon ferrochromium, 1.5-3 parts of titanium powder, 1-2 parts of nickel powder, 5-8 parts of calcium-silicon alloys, 2-4 parts of magnesium-aluminum alloys, 3-5 parts of electrolytic manganese, 1-2 parts of ferromolybdenum, 2.5-4 parts of ferroniobium, 1-2 parts of ferrovanadium, 3-5 parts of rare earth iron alloys, 3-5 parts of carbonate, 3-4 parts of graphite, 120-150 parts of iron powder, 0.5-1.5 parts of tungsten powder and 2-4 parts of calcium fluoride. The wear-resisting and high-hardness flux core wire has good welding performance, deposited metal tissue is compact, air holes and cracks are avoided, combination with base metal is good, performance is stable, and deposited metal has good wear resistance, corrosion resistance, high hardness and other performance.

Owner:天长市通联焊业有限公司

Aluminum preliminary alloy refiner containing titanium and vanadium, aluminum alloy containing titanium and vanadium and preparation method

The invention discloses an aluminum preliminary alloy refiner containing titanium and vanadium, comprising the following components by weight percent: 1 to 99% of aluminum, 0.01 to 77% of vanadium, 0.01 to 77% of titanium, 0 to 20% of carbon and 0 to 23% of nitrogen, wherein at least one of carbon and nitrogen exists in preliminary alloy refiner. Aluminum alloy which contains titanium and vanadium comprises the following chemical components by weight percent: 0.001 to 1% of vanadium and 0.001 to 1% of titanium. The aluminum preliminary alloy refiner containing titanium and vanadium has five preparation methods, and aluminum alloy which contains titanium and vanadium have two preparation methods.

Owner:SICHUAN UNIV

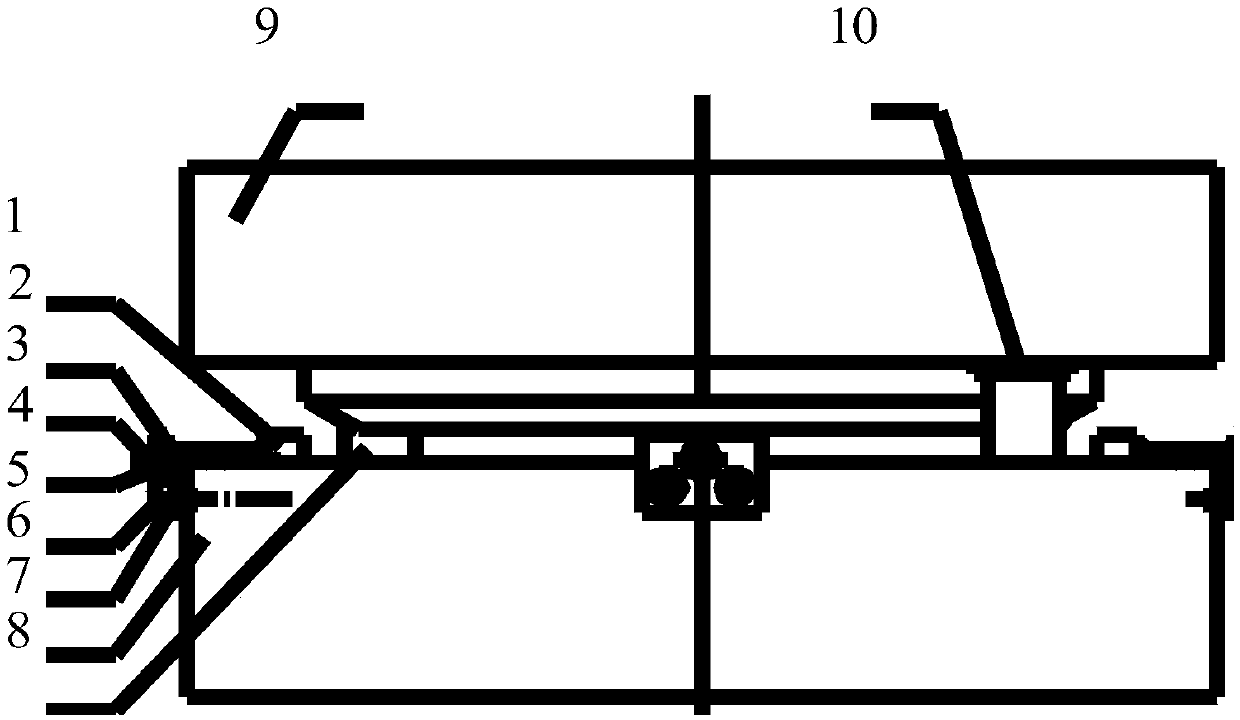

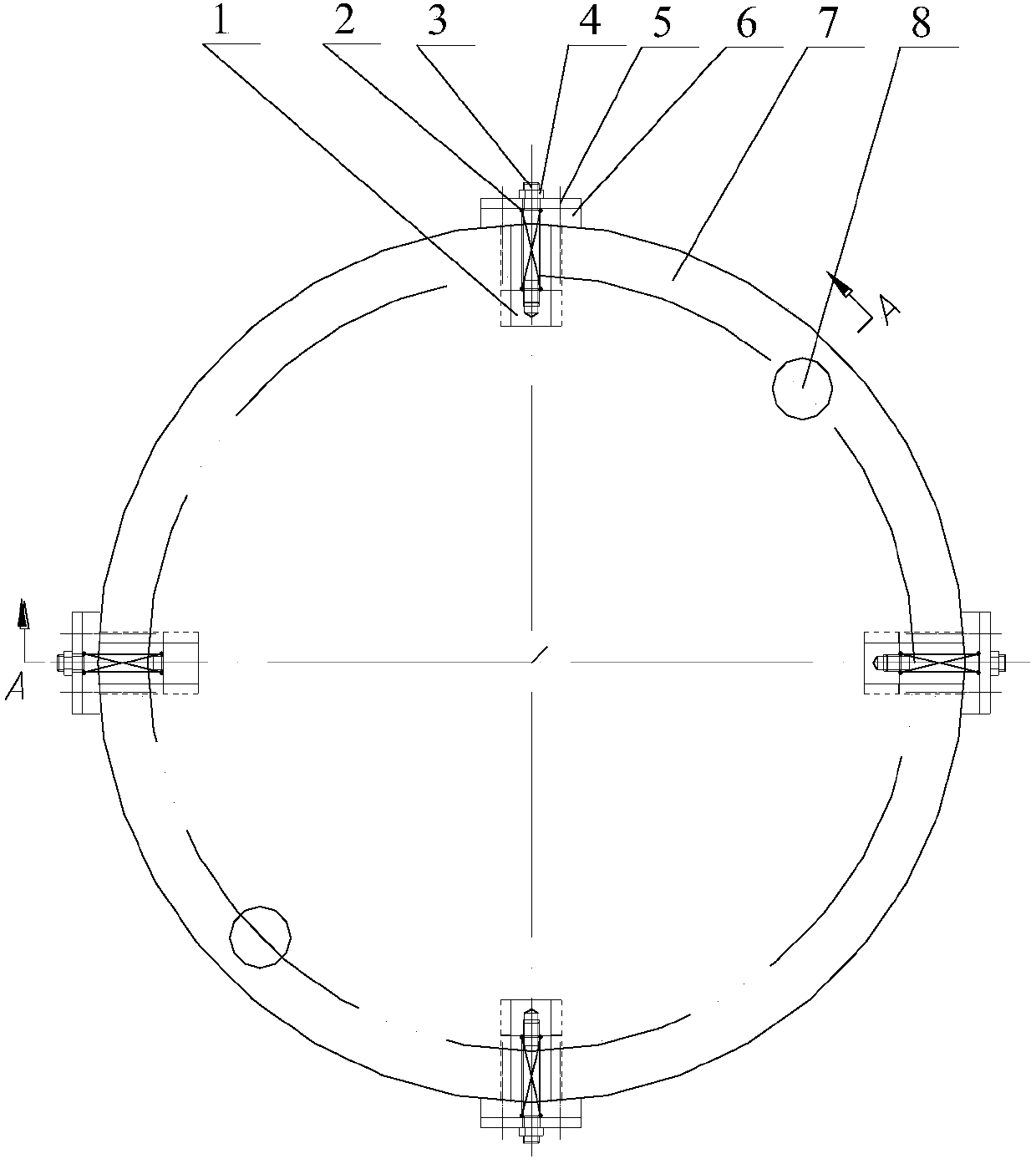

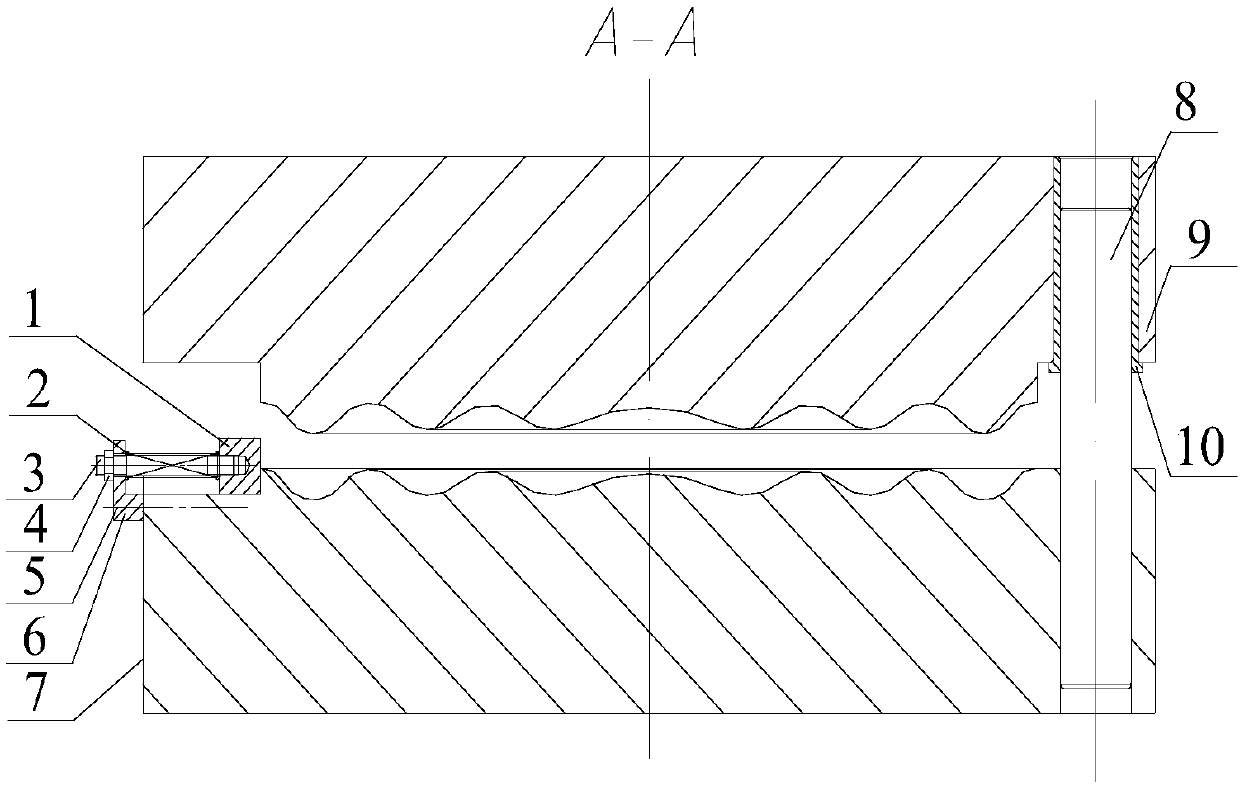

Ring-wave repeated drawing high deformation mold for plate and machining method

InactiveCN107716668AUniform plastic deformationUniform strain distributionGeometric CADShaping toolsWave shapeLarge size

The invention discloses a ring-wave repeated drawing high deformation mold and technology for a plate. The mold comprises two ring-wave mold bodies including the ring-wave mold body A and the ring-wave mold body B, wherein the two ring-wave mold bodies are both of an axially-symmetrical cylindrical structure, the upper surfaces and the lower surfaces of the ring-wave mold bodies are each composedof a plurality rings of convex-concave continuous alternate matchable ring waves, the ring wave radian and length of the axial center are large, the wave height of the axial center is small, and the ring wave radian and length are decreased ring by ring and the wave height is increased ring by ring from the axial center to the exterior. Ring-wave upper mold bodies are movable mold bodies, ring-wave lower mold bodies are fixed mold bodies, and two groups of positioning mechanisms which are radially and symmetrically arranged are arranged at the upper end of each ring-wave lower mold body; and the plate is drawn to be in a set ring wave shape by the ring-wave upper mold bodies and the ring-wave lower mold bodies through mold closing. According to the technology, crystal grains of the plate can be repeatedly drawn, deformed and refined through the mold, and then the size of the crystal grains reaches the micron grade or the submicron grade. The ring-wave repeated drawing high deformationmold is not limited by the plate size, a large-size plate can be machined, and the comprehensive properties of the plate on the physical aspect, the chemical aspect, the mechanical aspect and the likecan be greatly improved.

Owner:YANSHAN UNIV

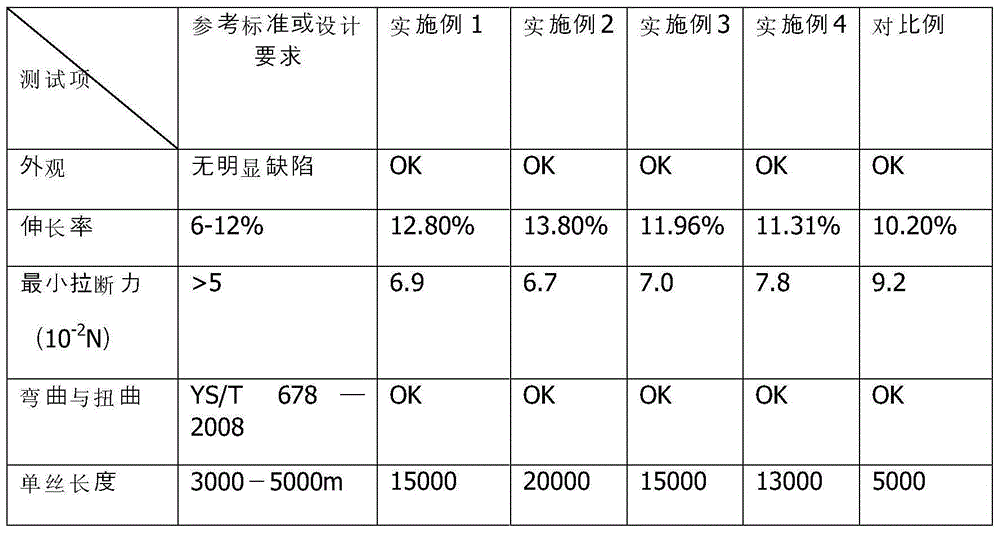

Ultra-thin copper alloy bonding wire for microelectronic packaging and preparing method of ultra-thin copper alloy bonding wire

InactiveCN105132735AImprove performanceImprove grain refinement effectSolid-state devicesSemiconductor devicesRare-earth elementImpurity

An ultra-thin copper alloy bonding wire for microelectronic packaging is characterized by being prepared from 10-50 wt.ppm of Ti, 10-50 wt.ppm of Li, 10-50 wt.ppm of Zr, 10-50 wt.ppm of Fe, 10-50 wt.ppm of Ag, 10-50 wt.ppm of B, 10-50 wt.ppm of a rare earth element and the balance copper and inevitable impurities, wherein the content of O and S in the impurities accounts for 5 wt.ppm or less in the whole copper alloy bonding wire, and the rare earth element is one of Eu, Y and Dy or a combination of Eu, Y and Dy. The invention further provides a preparing method of the ultra-thin copper alloy bonding wire for microelectronic packaging. The copper alloy bonding wire has the good oxidation resistance, good electric and heat conductivity, good weldability, large single wire length and other good performance, and the preparing method of the copper alloy bonding wire is easy and convenient to implement.

Owner:NICHE TECH KAISER SHANTOU

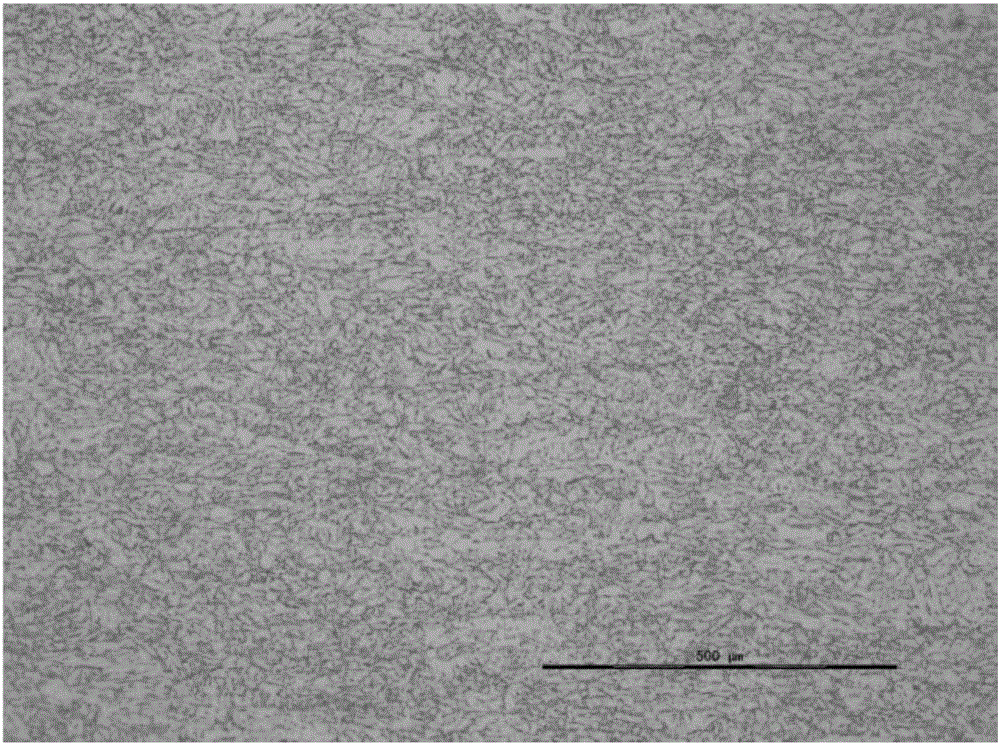

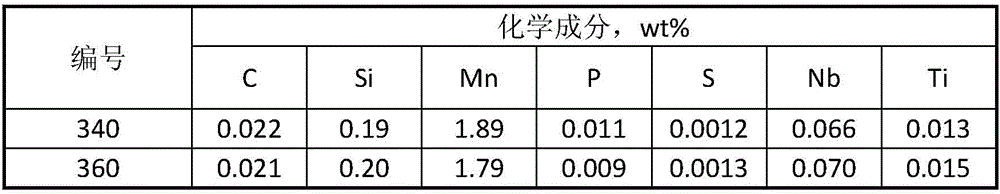

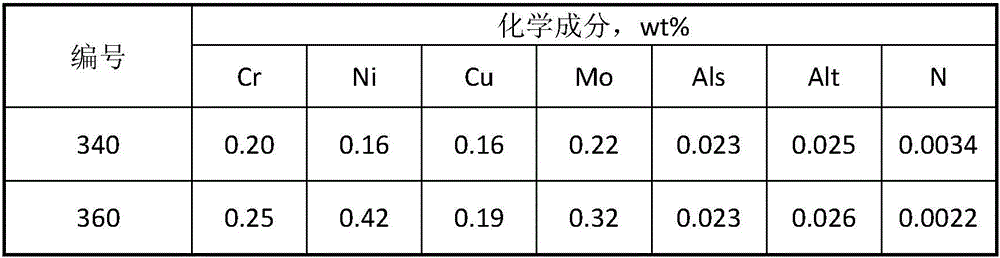

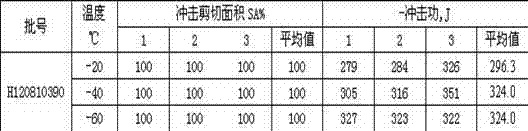

Low-carbon X80 pipeline steel plate roll and manufacturing method thereof

InactiveCN106834932AImprove welding effectImproved anti-HIC performanceChemical compositionSheet steel

The invention provides a low-carbon X80 pipeline steel plate roll. The chemical components of the low-carbon X80 pipeline steel plate roll comprise, by mass percentage (wt%), C<=0.035%, 1.60%<=Mn<=1.90%, Si<=0.30%, 0.050%<Nb<=0.075%, 0.010%<=Ti<=0.020%, 0.20%<=Mo<=0.30%, 0.20%<=Ni<=0.60%, 0.15%<=Cu<=0.30%, 0.15%<=Cr<=0.30%, S<=0.0025wt%, P<=0.0100wt%, and N<=0.0040wt%, wherein 0.60%<=Mo+Cr+Ni+Cu<=1.10%; the microscopic structure contains more than 90% of acicular ferrite and smaller than 5% of granular bainite; and the typical value of the yielding strength is 580 MPa, the typical value of the tensile strength is 680 MPa, and the typical value of the Charpy V type impact energy under -30 DEG C is 400 J.

Owner:MAANSHAN IRON & STEEL CO LTD

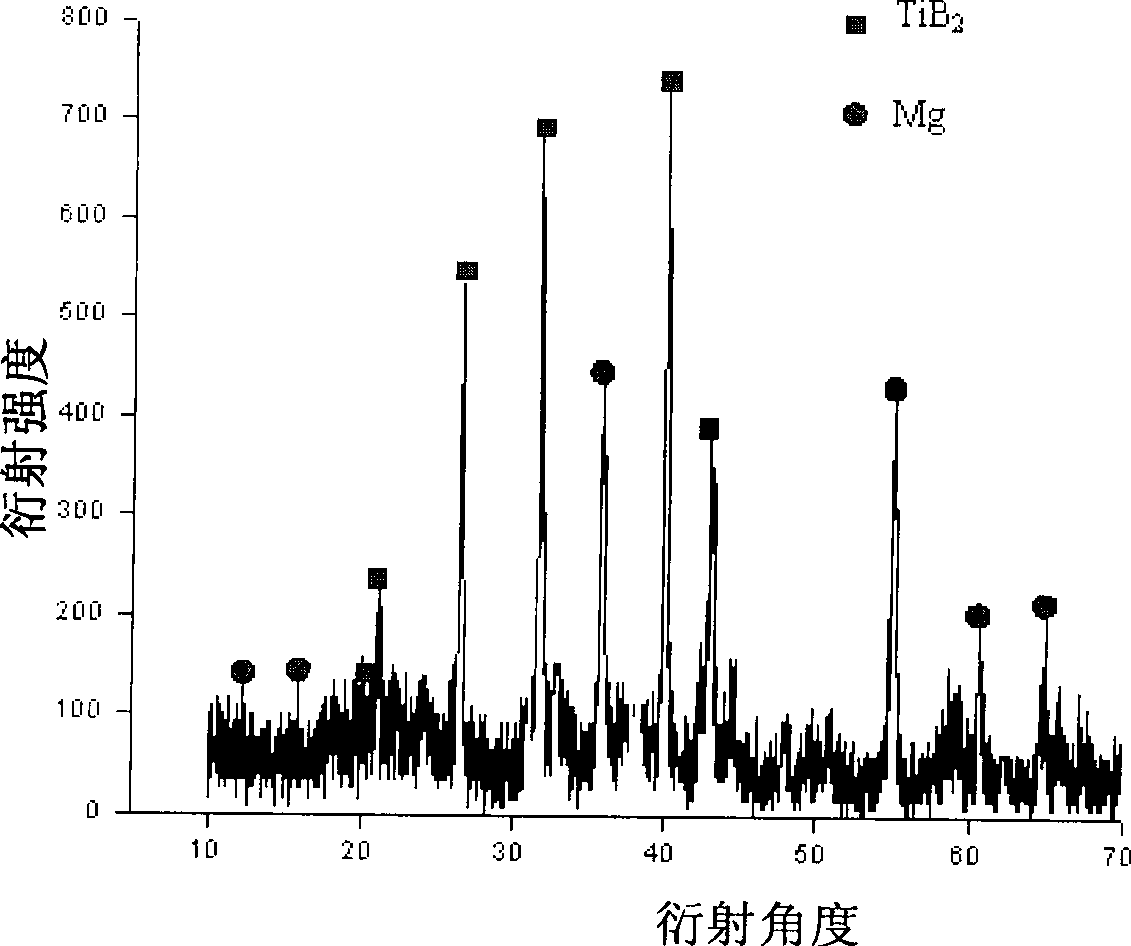

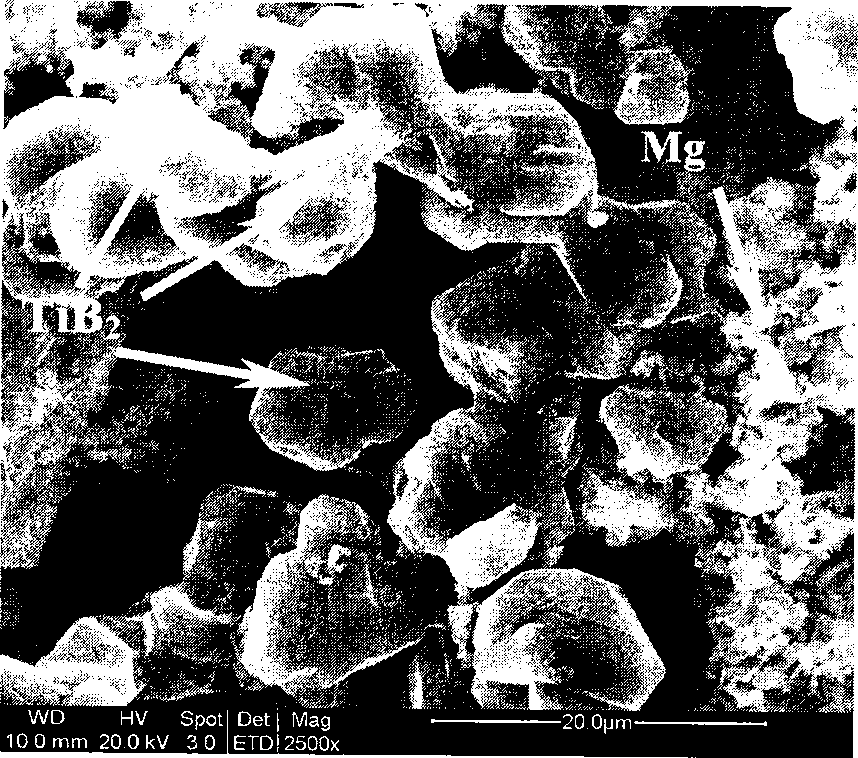

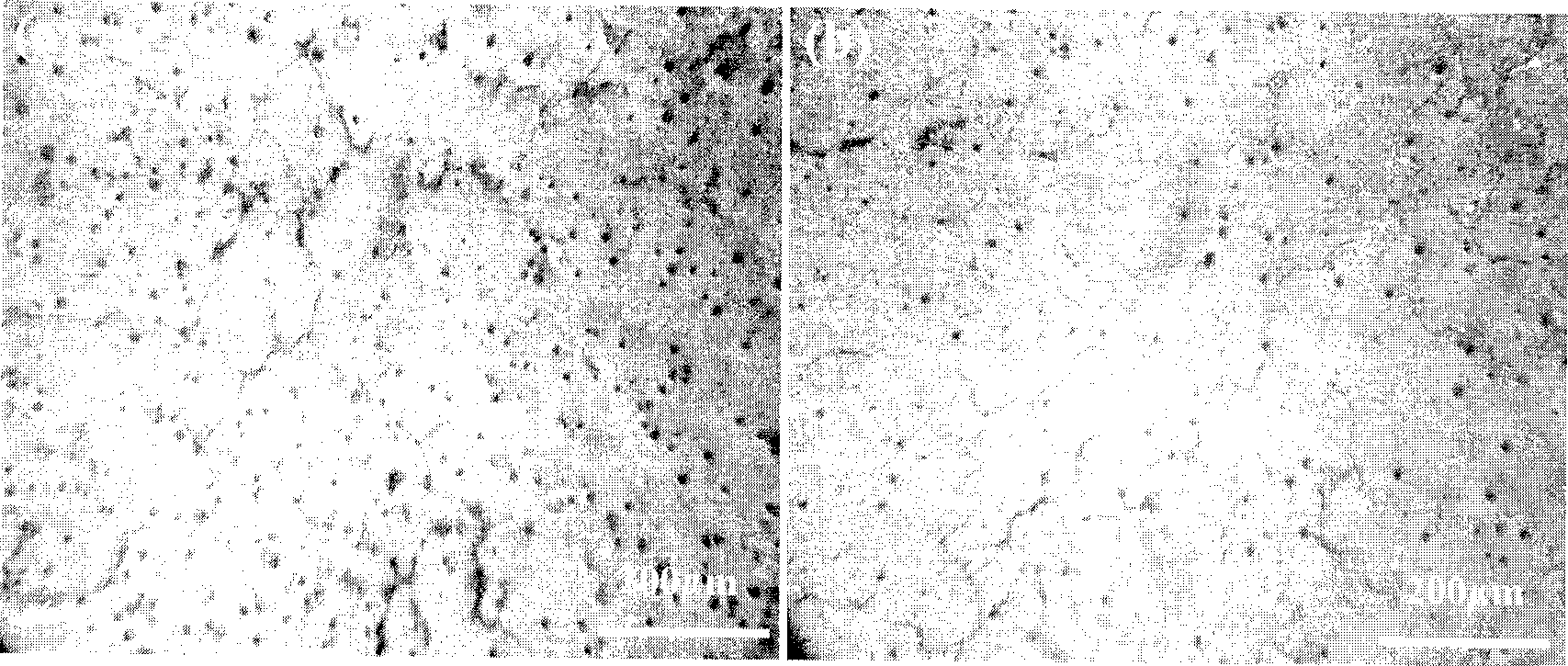

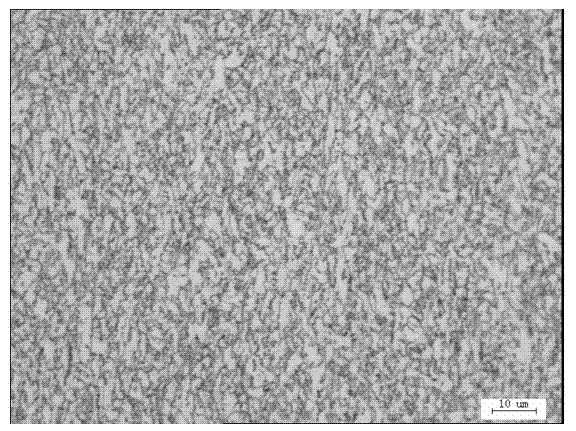

Method for preparing Mg-Ti-B grain refiner for magnesium and magnesium alloy

InactiveCN101457312APrevent oxidative combustionSimple preparation processChemical compositionCrucible

The invention provides a method for preparing a grain refiner for magnesium and magnesium alloy. The chemical compositions of the refiner are as follows (by weight percent): 13.78-55.10% of titanium, 6.22-24.90% of boron and the balance of magnesium. The preparation method comprises the following steps: titanium powder, boron powder and magnesium powders are mixed in a drying status, compacted and dried and then are arranged in a corundum crucible; the crucible is landfilled with fire-resisting powder; an isothermal treatment is carried out at the temperature of 700 to 1000 DEG C in a box-type resistance furnace for 60 to 180 min to prepare the Mg-TiB2 grain refiner. The method is simple in preparation procedure, easy in controlling the content of TiB2 and adding the TiB2, and capable of prominently refining the grain of the magnesium and magnesium alloy.

Owner:WUHAN UNIV OF TECH

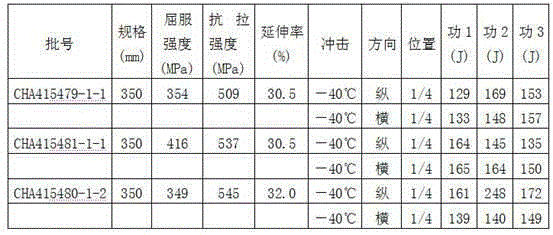

Economical fabrication method of high-toughness X70 pipeline hot rolled steel plate coil

ActiveCN103045945AHigh strengthImprove low temperature impact toughnessHeat treatment process controlLaminar coolingToughness

The invention provides an economical high-toughness X70 pipeline hot rolled steel plate coil and a preparation method thereof. The X70 pipeline hot rolled steel plate coil comprise the following chemical components by weight percentage (%) of: 0.060%<C<=0.075%, 0.15%<=Si<=0.30%, 1.20%<=Mn<=1.65%, 0.070<Nb<=0.080%, 0.010%<=Ti<=0.020%, and Cr<=0.25%. The preparation method includes steps of: a heating procedure, a rough rolling procedure, a finish rolling procedure, a cooling procedure and a coiling procedure, wherein in the finish rolling procedure, the rolling temperature of the first pass of finish rolling is not higher than 1050 DEG C, the deformation for the last pass of finish rolling is less than 8%, the accumulated deformation of the last two passes is less than 16%, and the finishing temperature of the finish rolling is 770-850 DEG C; in the cooling procedure: laminar cooling is conducted at a cooling rate of 18-26 DEG C / s after the finish rolling; and in the coiling procedure, coiling is conducted at 300-400 DEG C after the laminar cooling.

Owner:MAGANG (GROUP) HOLDING CO LTD +1

Extremely-thick low alloy steel plate for E-level high purity ocean platform and production method thereof

The invention discloses an extremely-thick low alloy steel plate for an E-level high purity ocean platform and further relates to a production method of the steel plate. The steel plate comprises, by weight, 0.10%-0.18% of C, 0.15%-0.35% of Si, 0.90%-1.60% of Mn, 0-0.02% of P, 0-0.005% of S, 0.020%-0.030% of Nb, 0.010%-0.080% of Al, 0.035%-0.065% of V, 0-0.025% of Ti, and the balance Fe and inevitable impurities. The production method of the steel plate includes the following steps of electric furnace smelting, LF / VD refining, continuous casting, electroslag remelting, steel ingot heating, rolling, water cooling after rolling, heat stacking, heat treatment and finished product obtaining. The maximum thickness of the steel plate obtained through the method can reach 350 mm, and the characteristics of being good in welding property, excellent in low temperature impact toughness and good in thickness directional property are achieved. Meanwhile, steel is clean, performance evenness is good, high flaw detection and performance requirements can be met, and a wide application prospect is achieved.

Owner:WUYANG IRON & STEEL

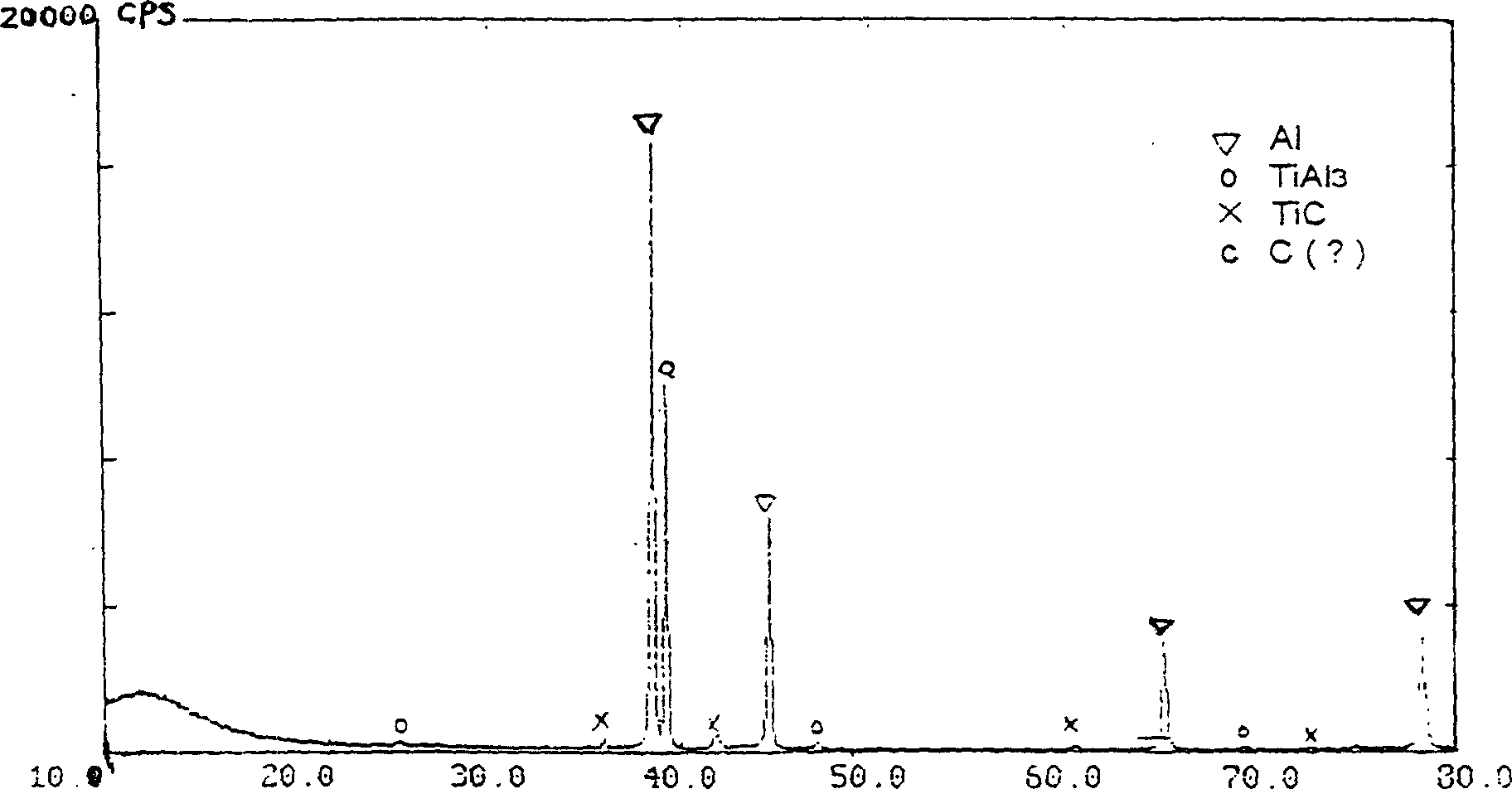

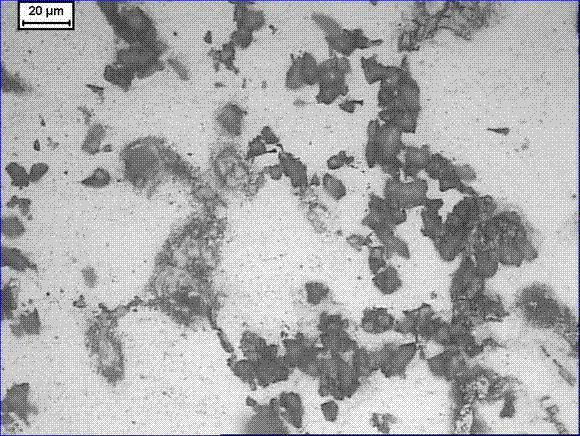

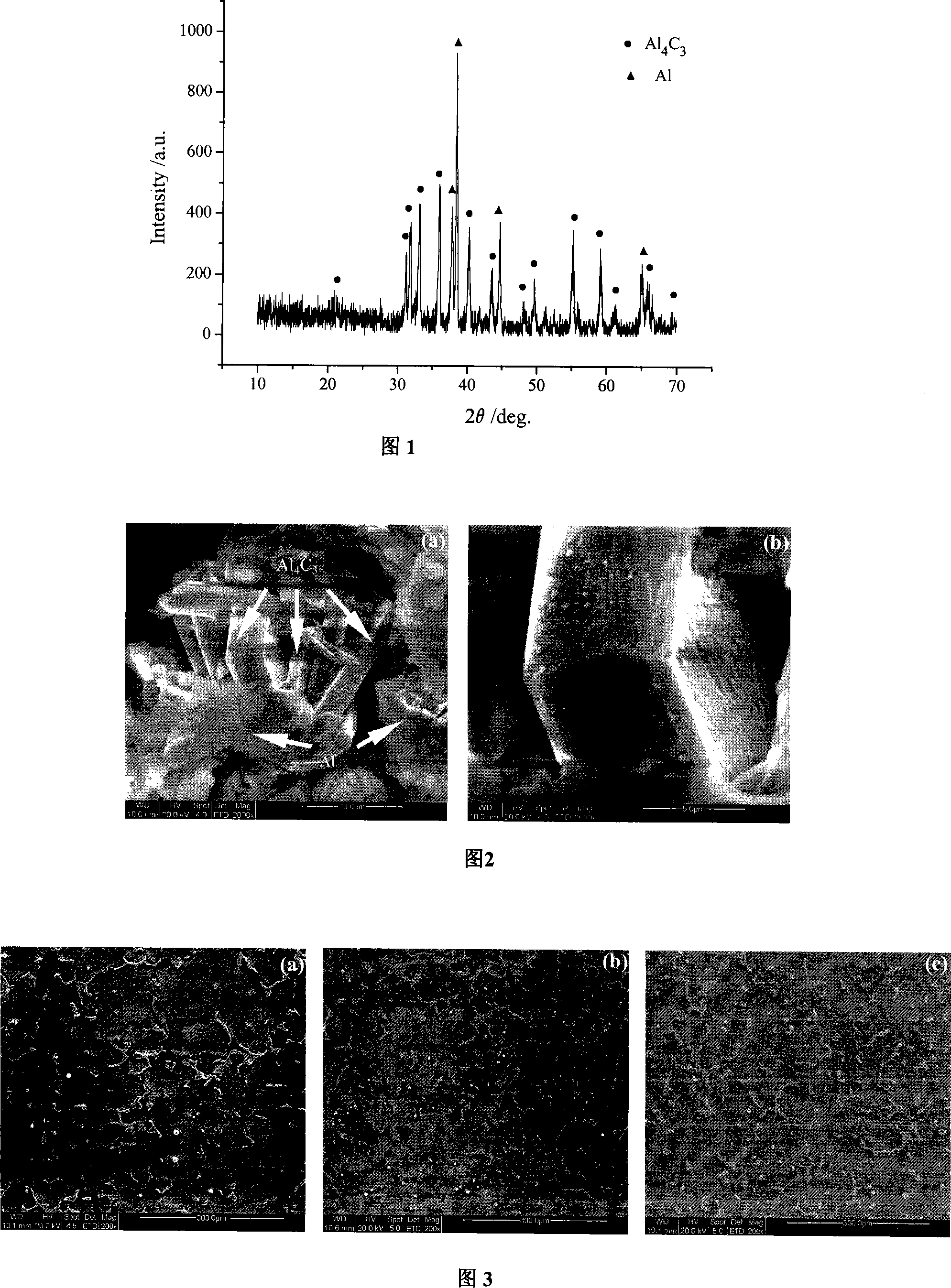

Al-TiO2-C grain refiner, preparation method thereof and commercial-purity aluminum refining method

InactiveCN105002389ARemarkable grain refinement effectImprove grain refinement effectAluminum foilBall mill

The invention discloses an Al-TiO2-C grain refiner, a preparation method thereof and a commercial-purity aluminum refining method. The Al-TiO2-C grain refiner is composed of Al powder, TiO2 powder and C powder. The preparation method of the Al-TiO2-C grain refiner comprises the steps that 1, the Al powder, the TiO2 powder and the C powder are mixed and then processed on a star type ball mill through ball milling for 0.5-2 h; 2, a precast block with the diameter phi being 30 is pressed on a universal tester, wherein 85 KN pressure is used for block pressing; 3, the precast block is wrapped by aluminum foil, and air between the precast block and the aluminum foil is extruded for storage; 4, the precast block is sintered in a high-temperature sintering furnace; and 5, furnace cooling is carried out, then the sintered precast block is taken out, and therefore the prepared Al-TiO2-C grain refiner is obtained. Precipitated phases of the prepared Al-TiO2-C grain refiner are TiC, Al2O3 and Al3Ti phases. The Al-TiO2-C grain refiner has the good grain refining effect. By adjusting the ratio of C to TiO2, the TiO2 addition, pressure needed for precast block preparation and the like, Al2O3 with the appropriate amount is contained in the Al-TiO2-C grain refiner structure and distributed in a relatively dispersed mode, and the better grain refining effect is achieved.

Owner:INNER MONGOLIA UNIV OF TECH

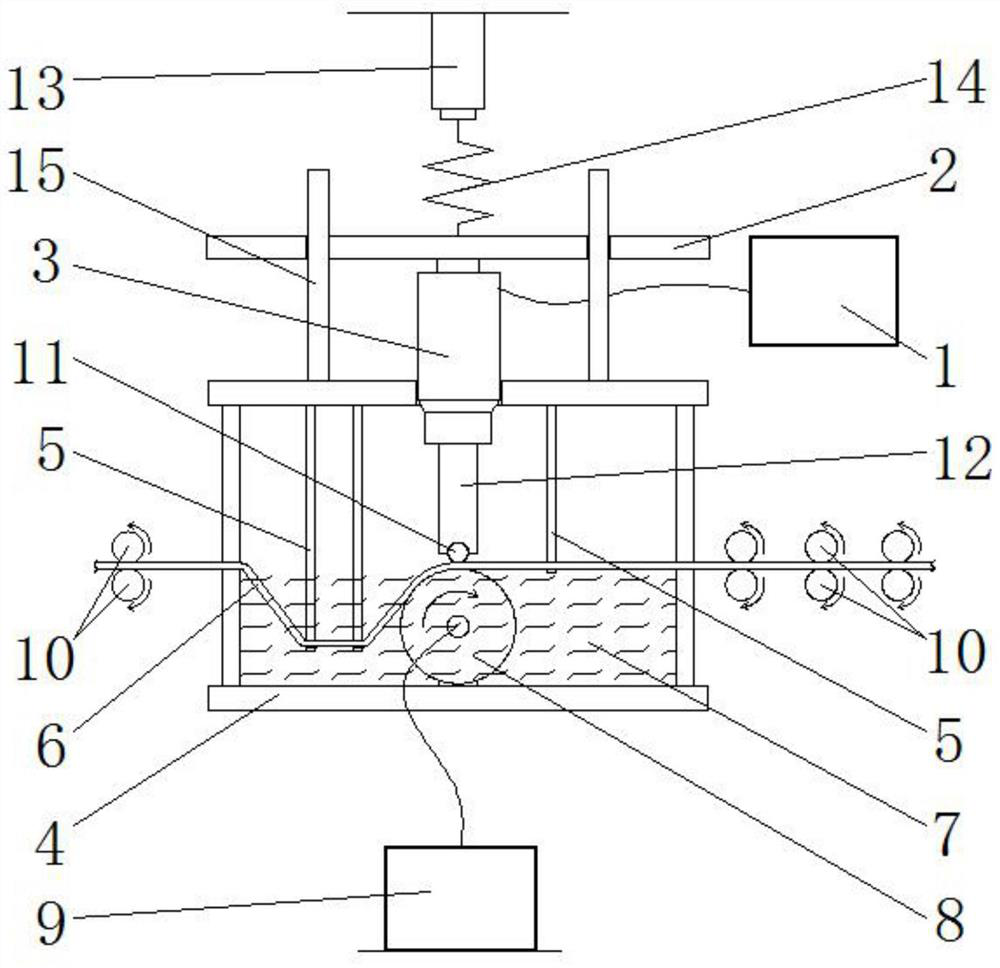

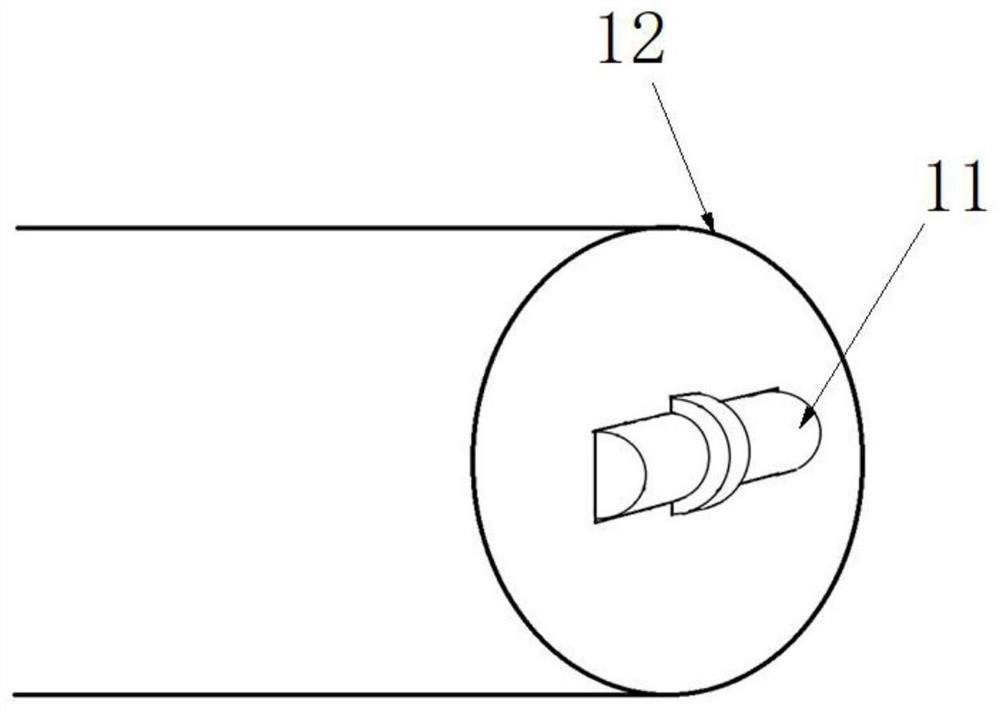

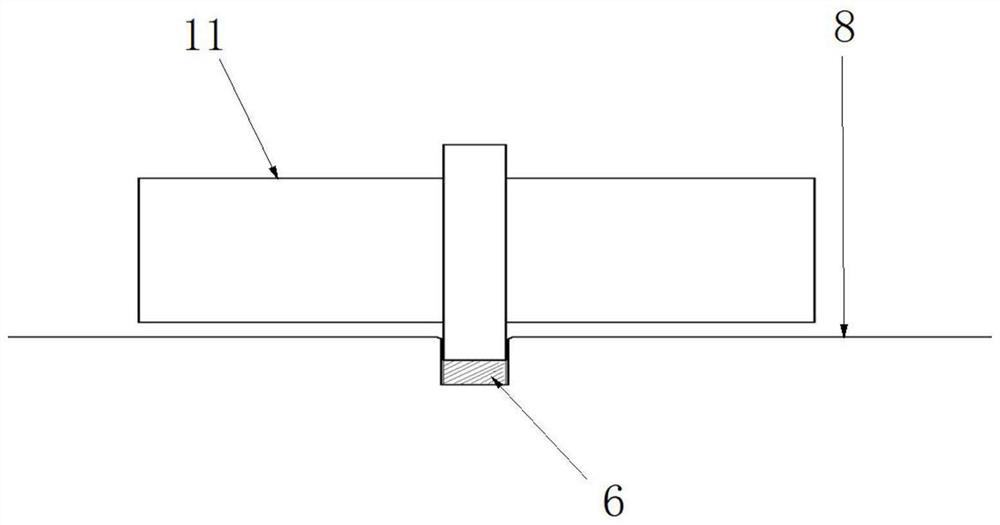

Process method and device for high-performance wire rod production

ActiveCN111842530AImprove mechanical propertiesGrain refinementWork treatment devicesMetal rolling arrangementsMicron scaleUltrasonic sensor

The invention discloses process method and device for high-performance wire rod production, and belongs to the technical field of severe plastic deformation fine grains. The process method can obtaina finished product with an invariable section size through the steps of material selection and cleaning, ultrasonic impact strengthening treatment preparation, ultrasonic impact strengthening treatment, two-piece welding and multi-pass rolling treatment, and a finished product with a uniformly thinned section size can be obtained after one-time ultrasonic impact strengthening treatment; and a low-temperature ultrasonic rolling impact device comprises a closed container filled with cooling liquid, an ultrasonic transducer, an ultrasonic tool head, a rigid impact roller column, an ultrasonic power supply, a rigid roller, a roller driving motor, a pressure cylinder, a spring and a traction transmission mechanism. According to the process method, uniform and efficient grain refinement can be realized on a wire rod or a strip with the micron-sized thickness, and the comprehensive mechanical property of the material is obviously improved; and the device can realize the low-temperature ultrasonic impact SPD strengthening treatment of the wire rod or the strip and can meet requirements of two impact treatment modes.

Owner:ANHUI UNIVERSITY OF TECHNOLOGY AND SCIENCE

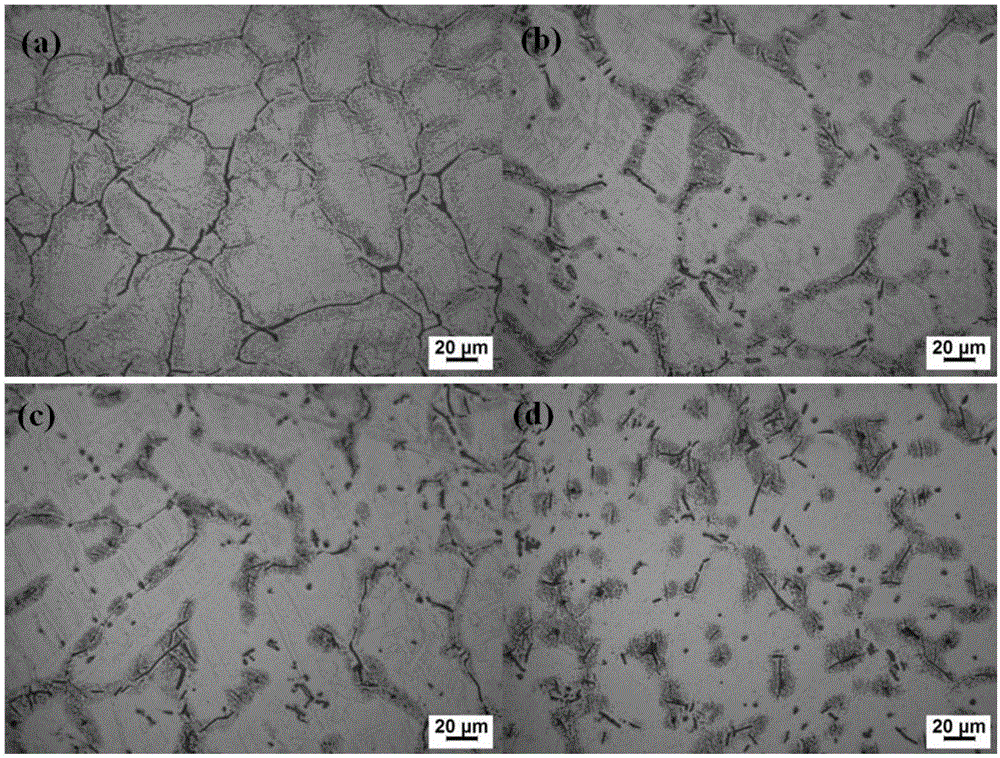

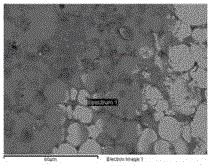

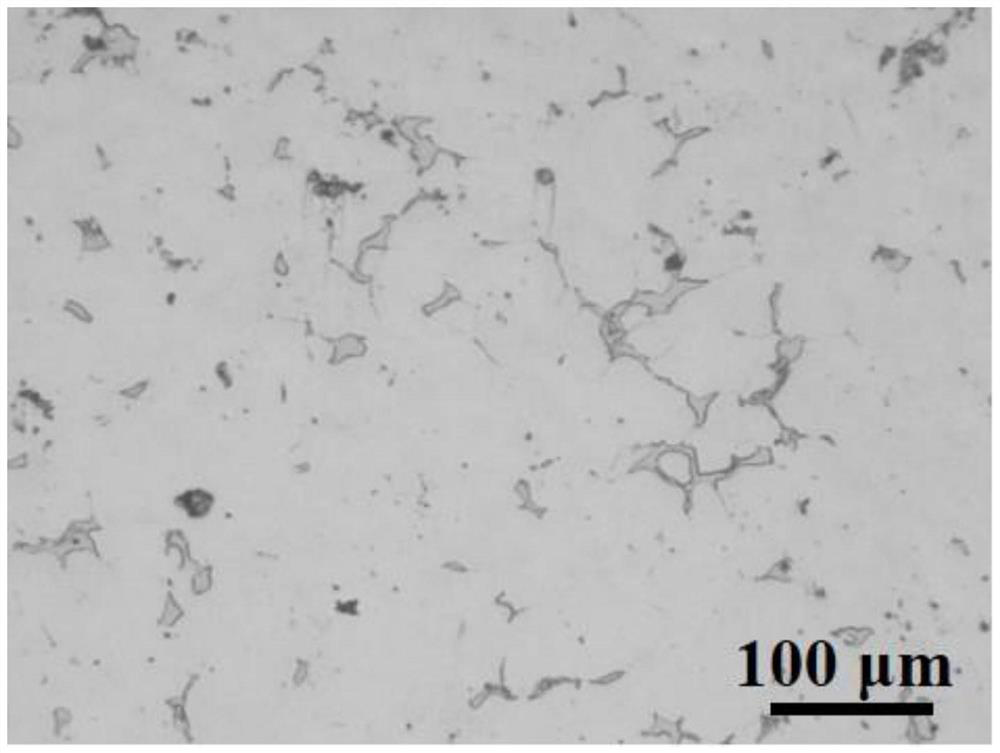

Preparation method of fine-grain cualmn shape memory alloy

The invention discloses a preparing method for a fine grain CuAlMn shape memory alloy and relates to a physical structure changing a copper-base alloy. The preparing method comprises the steps: preparing an Al-based LaScB nucleating agent thin strip; and preparing the fine grain CuAlMn shape memory alloy. By designing the new Al-based LaScB nucleating agent and using its nucleating and refining actions, the fine grain CuAlMn shape memory alloy of which the mechanical property is obviously improved while the high damping characteristic is kept is prepared, and the defects that the grain refining effect of the copper-base shape memory alloy in the prior art is insufficient, and the development trend of the current mechanical equipment to the requirements of high speed, efficiency, intelligentization and automation cannot be met are overcome.

Owner:HEBEI UNIV OF TECH

Aluminum alloy refiner and aluminum alloy produced with the refiner

InactiveCN101294247AImproved post-processing performanceSimplify the joining processCrystalliteAluminium alloy

The invention discloses an aluminum alloy refiner and an aluminum alloy which is prepared by using the refiner. The aluminum alloy refiner is Zr-Cr-Nb, wherein, Zr, Cr, and Nb elements account for 0.2 to 0.5 percent of total mass percent of the alloy which is obtained from the preparation. By using the refiner, the aluminum alloy is prepared and obtained, the grains of which are small. When the refiner is used for preparing the aluminum alloy, the lattice type and the parameter of Al3Zr can be adjusted to form stable a L12 structure, the interfacial energy and the mispairing degree are reduced, the grain refining effect is increased, the fine uniform equiaxial cast structure is facilitated to be formed, and the subsequent processability of the aluminum alloy is increased. The adding technology of the refiner is simple, the price of the Zr, the Cr and the Nb is relatively cheap, and the aluminum alloy refiner and the aluminum alloy are applied to the industrialized production.

Owner:CENT SOUTH UNIV

Method for improving distribution of SiC particles in magnesium matrix composite material under action of low-voltage pulse magnetic field

InactiveCN103924116ANo pollution in the processWill not polluteMagnesium matrix compositeLow voltage

The invention discloses a method for improving distribution of SiC particles in a magnesium matrix composite material under the action of a low-voltage pulse magnetic field. The method comprises the following steps: firstly adding the SiC particles into a magnesium alloy fusant, uniformly stirring, and then pouring the alloy fusant into a die of a pulse magnetic field coagulation device so that the composite material fusant is completely concreted under the action of the low-voltage pulse magnetic field. The method is environmentally friendly, simple in process, convenient to operate, easy to control and less in cost and investment. By utilizing the method, only the intensity of the pulse magnetic field and the coagulation rate of the alloy need to be controlled. By utilizing the method, pollution does not exist, and the pulse magnetic field is not directly contacted with the alloy fusant so as not to generate pollution on the fusant and generate pollution on the environment.

Owner:NANCHANG HANGKONG UNIVERSITY

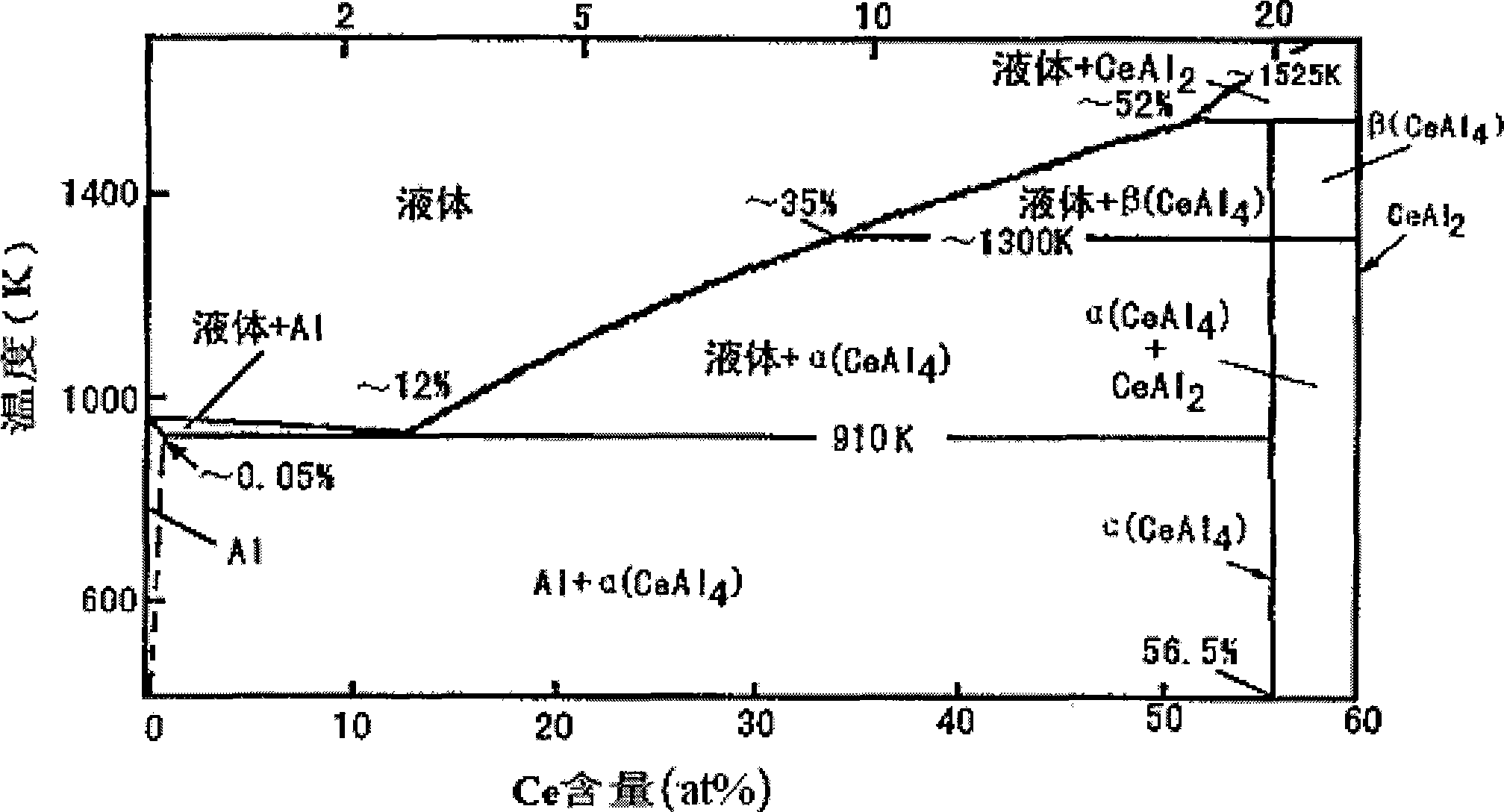

Refining method for aluminum alloy

The invention provides a refining method for aluminum alloy. According to the method, Al-Ce binary amorphous alloy is used as an aluminum alloy refining agent, and the atomic percent of Ce in the Al-Ce binary amorphous alloy is 7 to 10%; and the refining agent is an amorphous material and can provide a great number of uniformly-distributed nanometer nucleation particles after added into an aluminum melt, so the refinement effect of A356.2 alloy is substantially improved. The method is simple, has a short production period and overcomes the disadvantages of complex process, long process time, limited refinement effect and the like in conventional melting and preparation process.

Owner:CITIC DICASTAL +1

Steel for coiled tubing with low yield ratio and ultra-high strength and preparation method thereof

ActiveUS20200255917A1Easy to processPromote formationFurnace typesHeat treatment furnacesChemical compositionCoiled tubing

Steel for coiled tubing with a low yield ratio and ultra-high strength and a preparation method thereof, wherein the chemical composition of the steel in mass percentage is: C: 0.05-0.16%, Si: 0.1-0.9%, Mn: 1.25-2.5%, P≤0.015%, S≤0.005%, Cr: 0.51-1.30%, Nb: 0.005-0.019%, V: 0.010-0.079%, Ti: 0.01-0.03%, Mo: 0.10-0.55%, Cu: 0.31-0.60%, Ni: 0.31-0.60%, Ca: 0.0010-0.0040%, Al: 0.01-0.05%, N≤0.008%, and the rest being Fe and inevitable impurity elements. The chemical composition combines the technologies of low temperature finishing rolling and low temperature coiling to obtain an MA constituent+bainite+ferrite multiphase structure. The steel has a low yield ratio and ultra-high strength with the following specific properties: yield strength≥620 MPa, tensile strength≥750 MPa, elongation≥11%, and yield ratio≤0.83, and is suitable for manufacturing coiled tubing with ultra-high strength having a grade of 110 ksi or higher.

Owner:BAOSHAN IRON & STEEL CO LTD

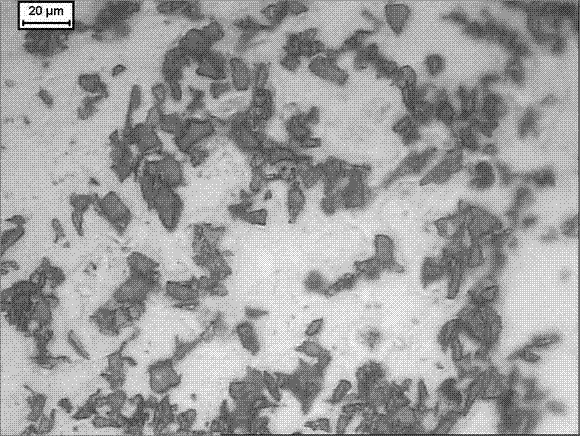

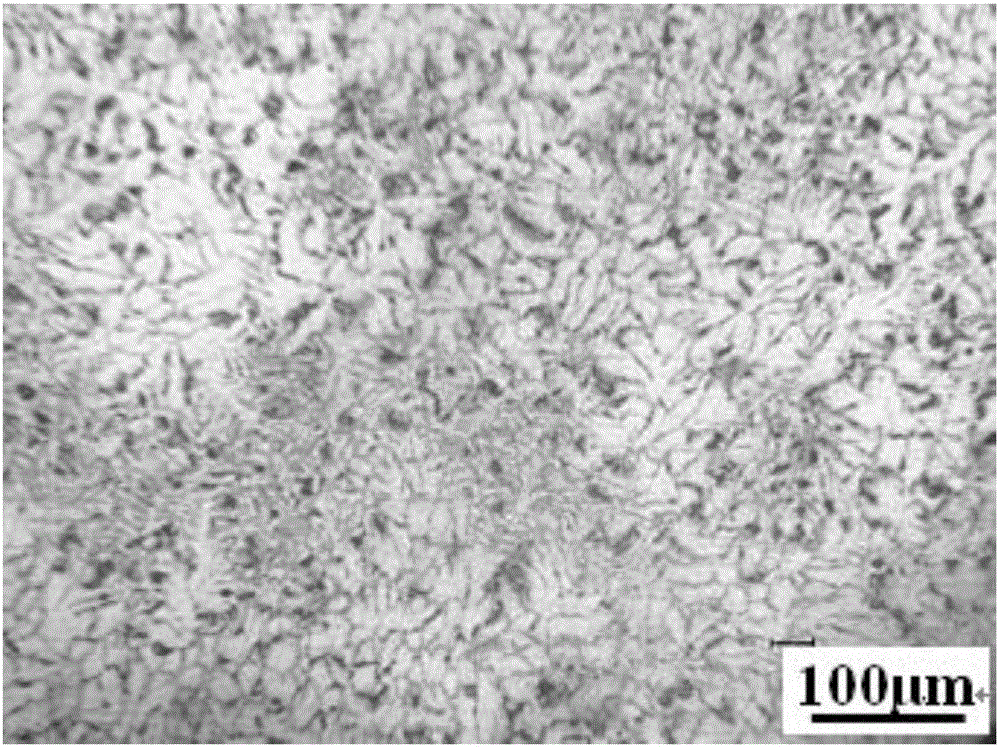

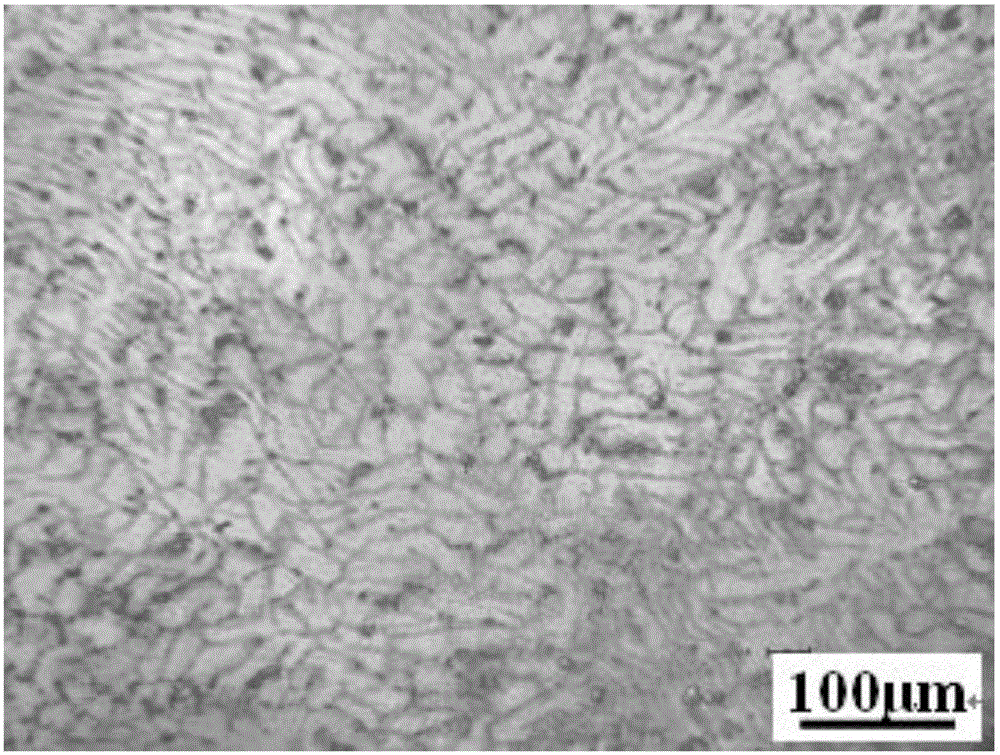

Mg-Al series alloy composite grain refiner and method for making same

The present invention provides one kind of composite grain refiner for Mg-Al alloy and its preparation process. The composite grain refiner has the chemical composition including C 5-15 wt%, calcium 2.8-28 wt% or Ce 3-6 wt%, and Al for the rest. Its preparation process includes the following steps: mixing aluminum powder and carbon powder; pressing into block and stoving, setting inside corundum crucible and covering with refractory powder, isothermal treatment inside a box-type resistance furnace at 1000-1200 deg.c for 30-120 min to prepare intermediate Al-Al4C3 alloy, and remelting together with aluminum ingot and intermediate Al-70 %Ca or Al-10 %Sr alloy to prepare Al-Al4C3-Ca / Sr as composite grain refiner finally. The composite grain refiner can fine grains of Mg-Al alloy obviously.

Owner:WUHAN UNIV OF TECH

Multi-element microalloyed high-strength heat-resistant rare earth magnesium alloy and preparation method thereof

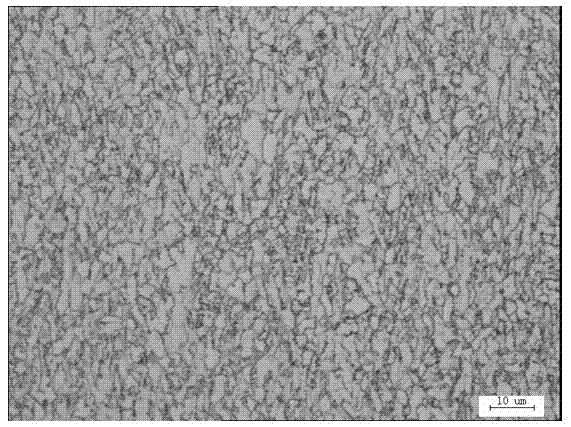

The invention provides a rare earth magnesium alloy. The rare earth magnesium alloy is a modified Mg-Gd-Y-Zr series rare earth magnesium alloy. The as-cast metallographic structure of the rare earth magnesium alloy is provided with an Mg5Gd phase with a round edge; and or the extruded metallographic structure of the rare earth magnesium alloy has a small granular precipitated phase, and the radial size of the granules is 10-150 nm. The microstructure morphology of the alloy is improved through a multi-element microalloying method, the microstructure morphology of the alloy material is improved by adding trace Ag and Sc in a specific proportion, the age hardening and grain refinement effects are improved, and then excellent room-temperature and high-temperature mechanical properties are obtained. On the premise that the total amount of rare earth is not increased, the strength performance index is high, good plasticity is reserved, engineering application is easy to achieve, and the requirements of the current fields of aerospace, missile military industry, rail transit and the like for the mechanical property of a light structural material under the room-temperature and high-temperature environment can be met.

Owner:CHANGCHUN INST OF APPLIED CHEMISTRY - CHINESE ACAD OF SCI

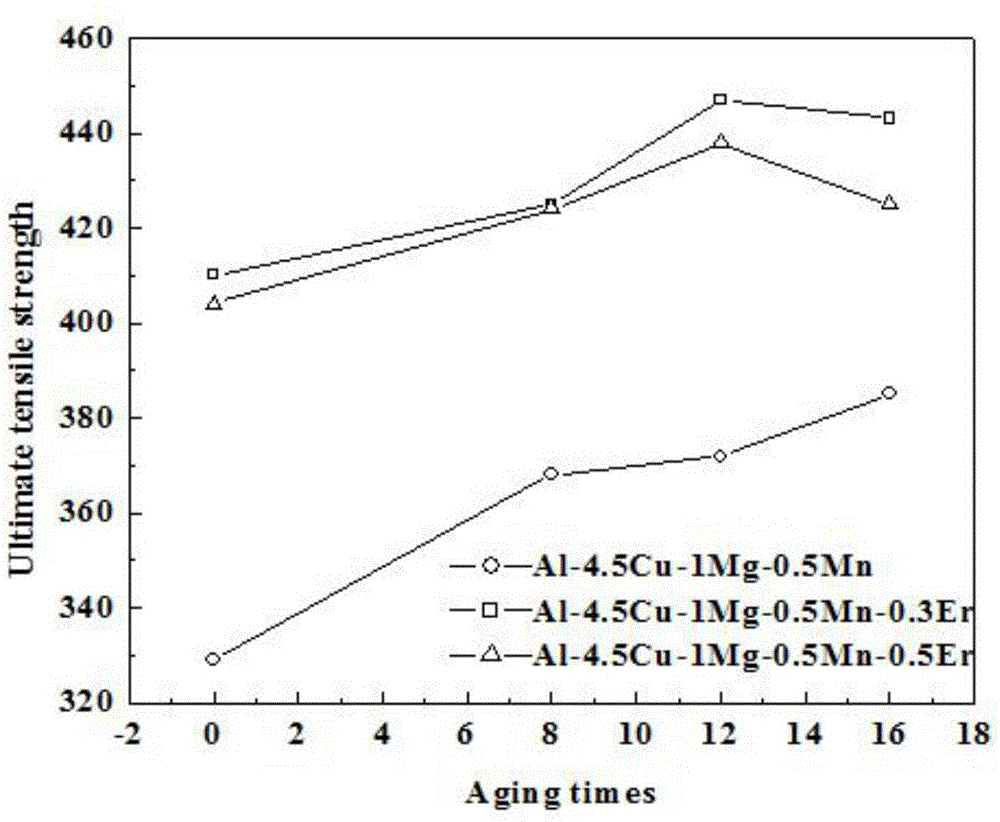

High-strength Al-Cu-Mg-Mn-Er wrought aluminum alloy and preparation method thereof

Owner:SHENYANG POLYTECHNIC UNIV

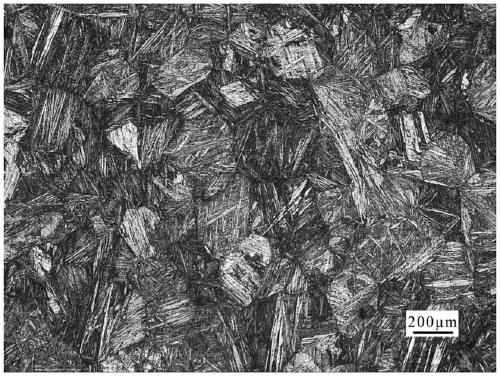

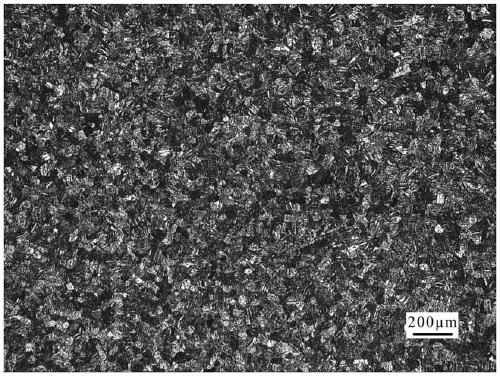

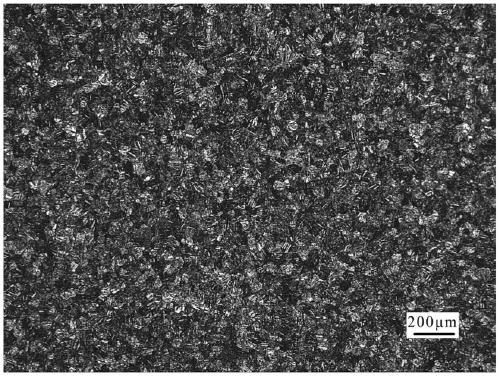

Technological process for performing continuous casting-rolling formation on 42CrMo steel ring piece

The invention discloses a technological process for performing a continuous casting-rolling formation on 42CrMo steel ring piece, and belongs to the technical field of batch production of medium-small scale ring pieces. The technological process is characterized by comprising the following steps of: alloy melting, refining of steel liquid, centrifugal casting of ring blanks, hot rolling, heat treatment and refining, wherein the step of refining of steel liquid is to melt the steel liquid in a basic electric arc furnace at 1680-1700 DEG C; and the step of centrifugal casting of ring blanks is to perform centrifugal pouring on the refined steel water to form ring blanks at 1550-1560 DEG C, demould the ring blanks at 1200-1250 DEG C after the pouring is finished, convey the ring blanks to a radial-axial rolling machine by a conveying system and directly roll and form the ring blanks at 1050 DEG C by utilizing blank casting afterheat. The process has the advantages that the utilization ratio of the material is improved, the technological process is shortened, the production cost is reduced, the quality and the accuracy of the ring piece are improved, the energy source and manpower resources are saved, and the production efficiency is improved.

Owner:TAIYUAN UNIVERSITY OF SCIENCE AND TECHNOLOGY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com