Mg-Al series alloy composite grain refiner and method for making same

A compound crystal and refiner technology, applied in the field of metal materials, can solve the problems of affecting grain growth kinetics, slow Ca atom diffusion speed, low solid solubility, etc., achieve good interface and thermodynamic stability, and be easy to industrialize batches The effect of simple production and preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

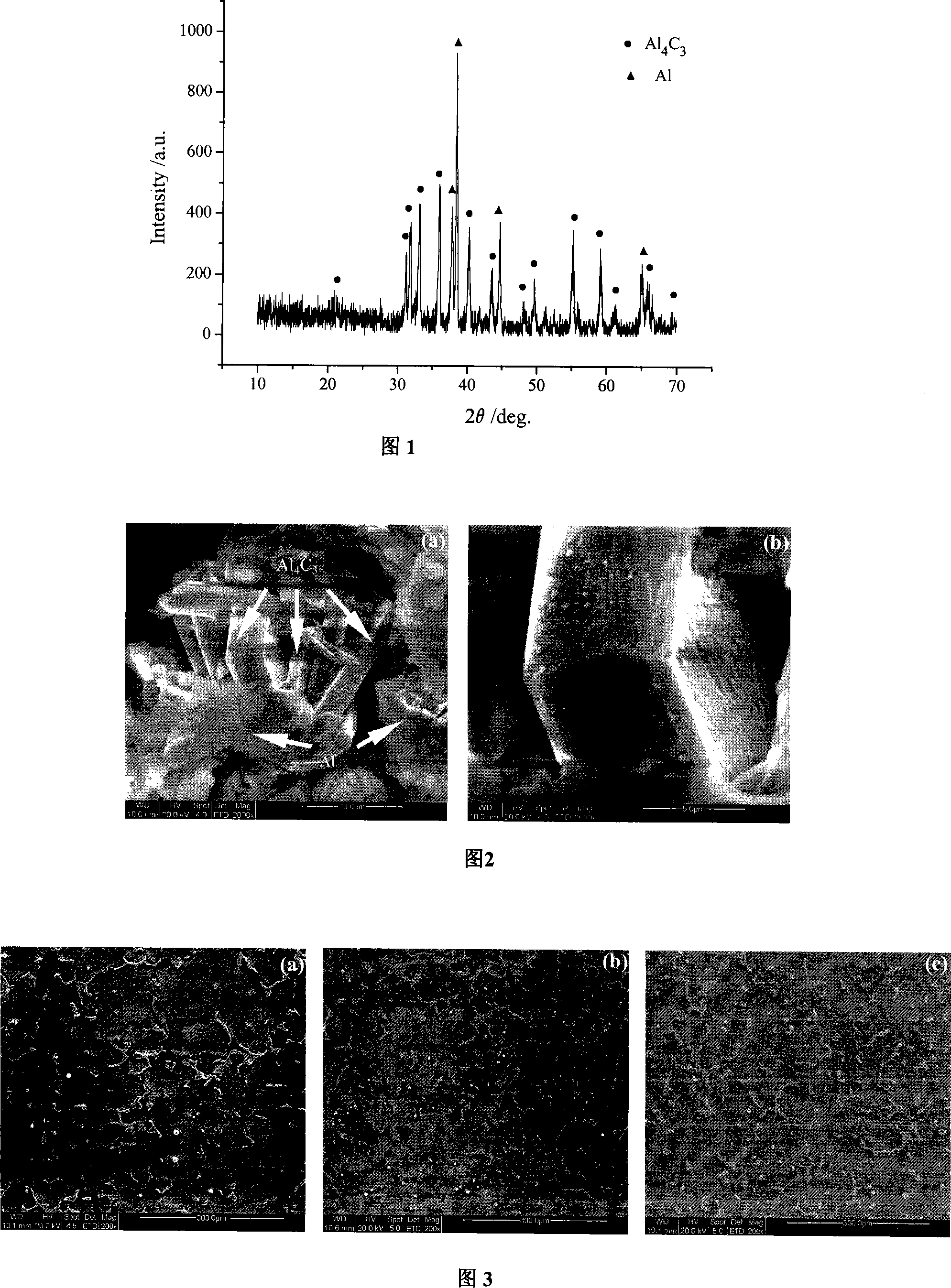

example 1

[0039] Example 1: Al-32% Al 4 C 3 Preparation of -4% Sr Composite Grain Refiner

[0040] (1) Dry mix 80% aluminum powder and 20% carbon powder on a mixer for 6 hours, then cold press into a prefabricated block with a relative density of 50%, wrap it with aluminum foil, dry it and embed it In a corundum crucible;

[0041] (2) Isothermal treatment at 1200°C for 40 minutes in a box-type resistance furnace;

[0042] (3) Take out the prefabricated block and make Al-80%Al 4 C 3 master alloy;

[0043] (4) Al ingot of 20% by weight, 40% of Al-80% Al 4 C 3 Master alloy and 40% Al-10% Sr master alloy are remelted to produce Al-32% Al 4 C 3 -4% Sr composite grain refiner.

[0044] (5) After adding 1.4% of the composite grain refiner to AZ91 magnesium alloy, the grain size can be reduced from 96 μm to 68 μm.

example 2

[0045] Example 2: Al-24%Al 4 C 3 Preparation of -5% Sr Composite Grain Refiner

[0046] (1) Dry mix 85% aluminum powder and 15% carbon powder on a mixer for 12 hours, then cold press into a prefabricated block with a relative density of 46%, wrap it with aluminum foil, dry it and embed it In a corundum crucible;

[0047] (2) Isothermal treatment at 1000°C for 120min in a box-type resistance furnace;

[0048] (3) Take out the prefabricated block and make Al-60%Al 4 C 3 master alloy;

[0049] (4) Al ingot of 10% by weight, 40% Al-60% Al 4 C 3 Master alloy and 50% Al-10% Sr master alloy are remelted to produce Al-24% Al 4 C 3 -5% Sr composite grain refiner.

[0050] (5) After adding 1.0% of the composite grain refiner to AZ91 magnesium alloy, the grain size can be reduced from 96 μm to 70 μm.

example 3

[0051] Example 3: Al-35%Al 4 C 3 Preparation of -21%Ca Composite Grain Refiner

[0052] (1) Dry mix 82.5% aluminum powder and 17.5% carbon powder on a mixer for 10 hours, then cold press into a prefabricated block with a relative density of 47%, wrap it with aluminum foil, dry it and embed it In a corundum crucible;

[0053] (2) Isothermal treatment at 1150°C for 90 minutes in a box-type resistance furnace;

[0054] (3) Take out the prefabricated block and make Al-70%Al 4 C 3 master alloy;

[0055] (4) Al ingot of 20% by weight, 50% of Al-70% Al 4 C 3 Master alloy and 30%Al-70%Ca master alloy are remelted to produce Al-35%Al 4 C 3 -21% Ca complex grain refiner.

[0056] (5) After adding 0.5% of the composite grain refiner to AZ91 magnesium alloy, the grain size of the alloy can be reduced from 96 μm to 74 μm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Size | aaaaa | aaaaa |

| Size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com