Method for preparing semisolid blank

A semi-solid and blank technology, applied in the field of semi-solid blank preparation, can solve the problems of small sample size, uneven structure and performance, etc., and achieve the effect of high deformation efficiency, uniform performance and refined structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

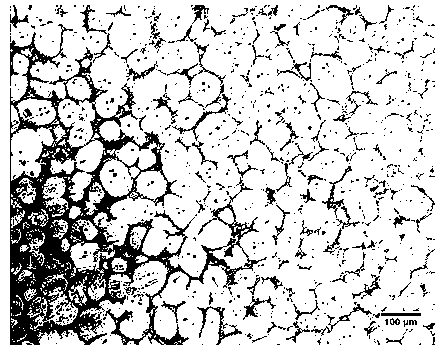

[0023] Embodiment 1: The multi-pass rolling and remelting process of this embodiment prepares CuSn10 tin bronze semi-solid billet preparation method (see figure 1 ):

[0024] (1) Measure the liquidus-solidus line point of the semi-solid billet alloy to be prepared; the alloy in this example is a CuSn10 tin bronze alloy with a size of 25 × 25 × 100mm rectangular material, using differential scanning calorimetry (DSC) The measured solidus temperature of the alloy is 850°C, and the liquidus temperature is 1020°C;

[0025] (2) Heat the alloy billet above the recrystallization temperature, and use the rolling process to perform multi-directional alternate rolling of horizontal rolling and longitudinal rolling on the billet; in this example, heat CuSn10 tin bronze to 450 ° C, and then first Roll the billet in one pass along its axial direction with a reduction of 2 mm; then rotate the billet 90° along its axial direction and roll it with a reduction of 1.5 mm; then rotate the bille...

Embodiment approach 2

[0027] Embodiment 2: The rolling and remelting process of this embodiment prepares the 5083 aluminum alloy semi-solid billet preparation method:

[0028] (1) Measure the liquidus-solidus line point of the semi-solid billet alloy to be prepared; in this example, the alloy is 5083 aluminum alloy, and the rectangular material with a size of 30×30×150mm is measured by differential scanning calorimetry (DSC) The measured solidus temperature of the alloy is 571°C, and the liquidus temperature is 642°C;

[0029](2) Heating the alloy billet above the recrystallization temperature, and using the open billet forging process, the billet is subjected to multi-directional alternate rolling of horizontal rolling and longitudinal rolling; in this embodiment, the 5083 aluminum alloy is heated to 460 ° C, and then First roll the billet one pass along its axial direction with a reduction of 4 mm; then rotate the billet 90° along its axial direction and roll it with a reduction of 5 mm; then rot...

Embodiment approach 3

[0031] Embodiment 3: The rolling and remelting process of this embodiment prepares CuSn10 tin bronze semi-solid billet preparation method:

[0032] (1) Measure the liquidus-solidus line point of the semi-solid billet alloy to be prepared; the alloy in this example is a CuSn10 tin bronze alloy with a size of 25 × 25 × 100mm rectangular material, using differential scanning calorimetry (DSC) The measured solidus temperature of the alloy is 850°C, and the liquidus temperature is 1020°C;

[0033] (2) Heat the alloy billet above the recrystallization temperature, and use the rolling process to perform multi-directional alternate rolling of horizontal rolling and longitudinal rolling on the billet; in this example, heat CuSn10 tin bronze to 450 ° C, and then first Roll the billet in one pass along its axial direction with a reduction of 1 mm; then rotate the billet 90° along its axial direction and roll it with a reduction of 1.5 mm; then rotate the billet along its axial direction ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| temperature | aaaaa | aaaaa |

| liquidus temperature | aaaaa | aaaaa |

| solidus temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com