Patents

Literature

1591results about How to "Uniform performance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

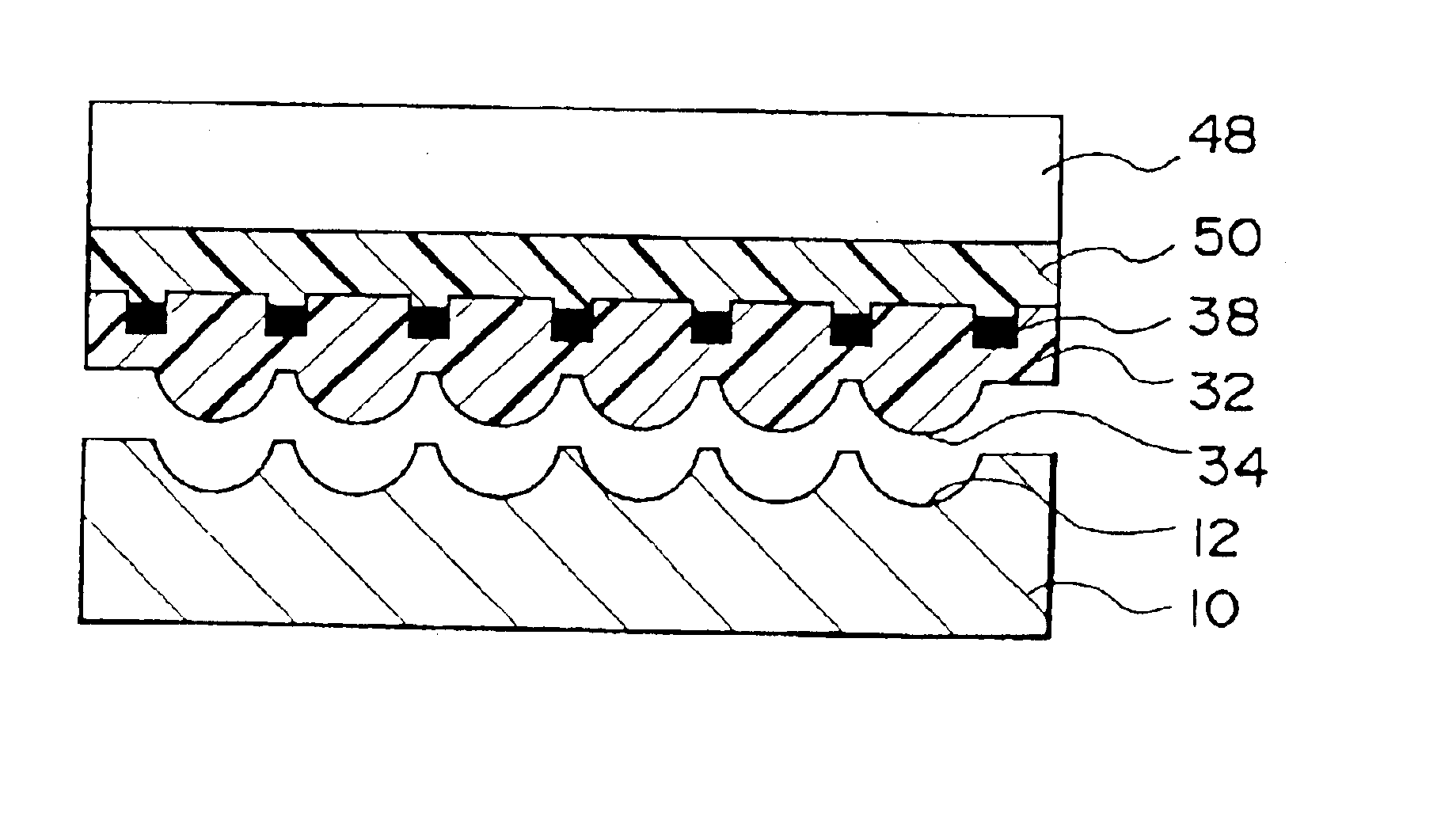

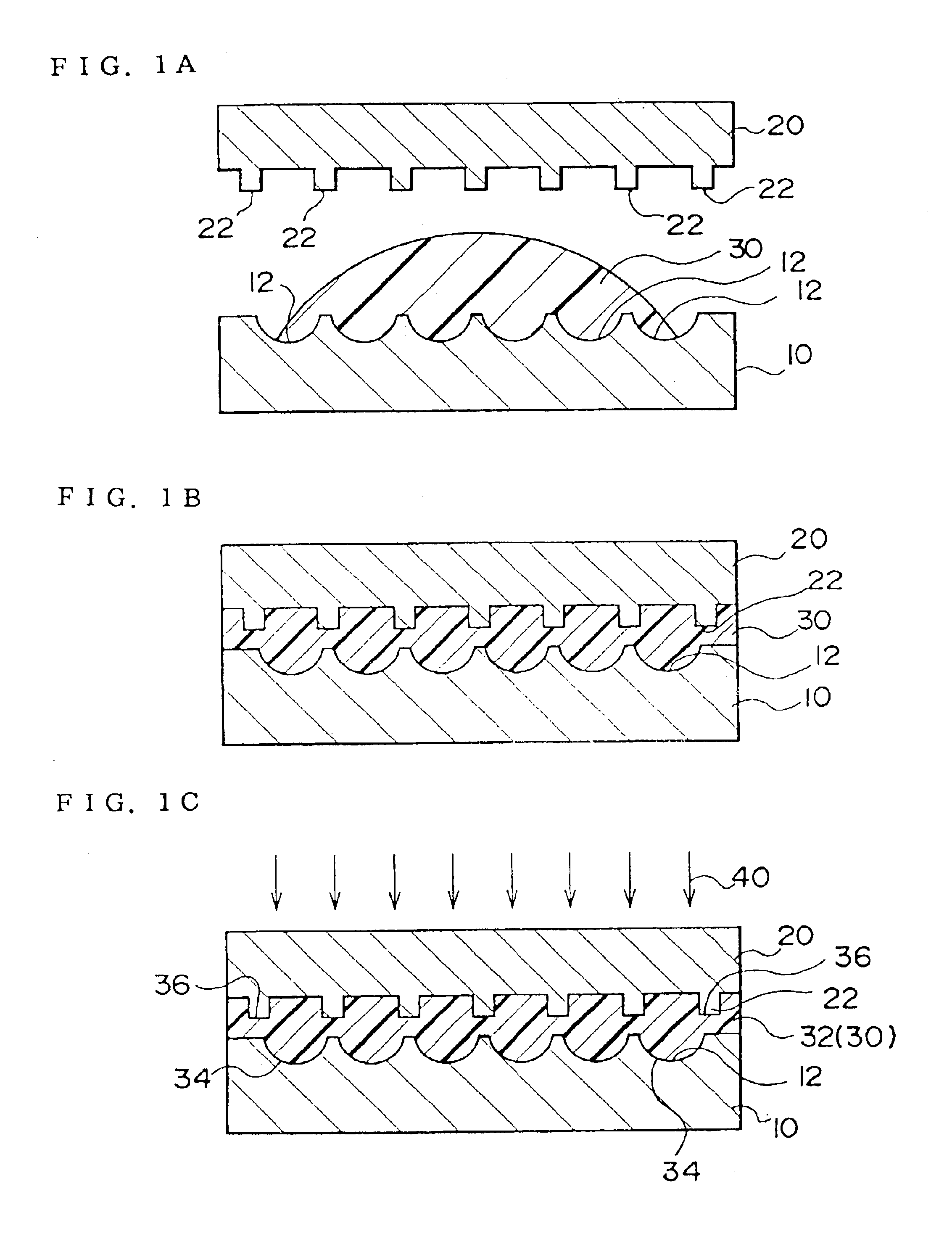

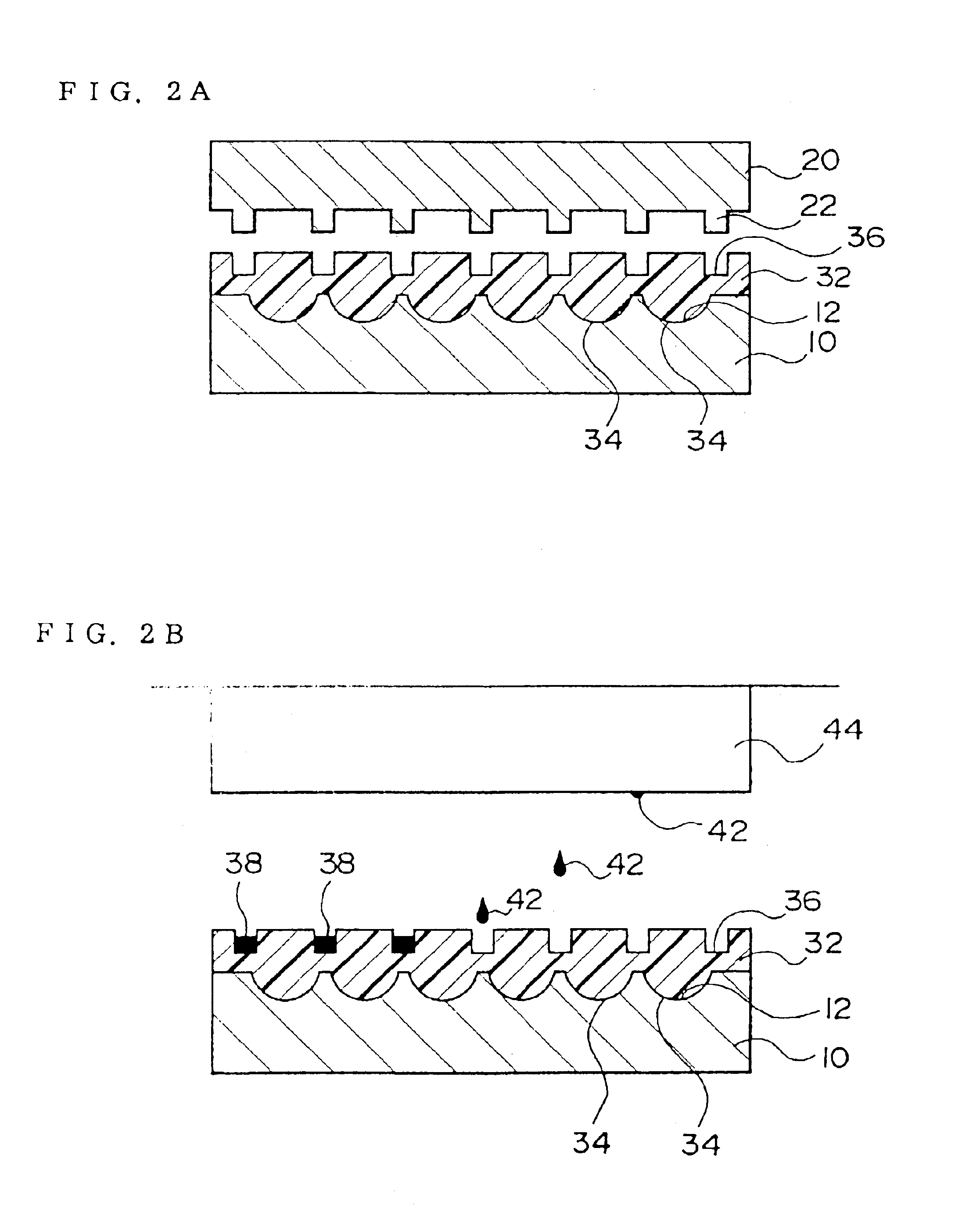

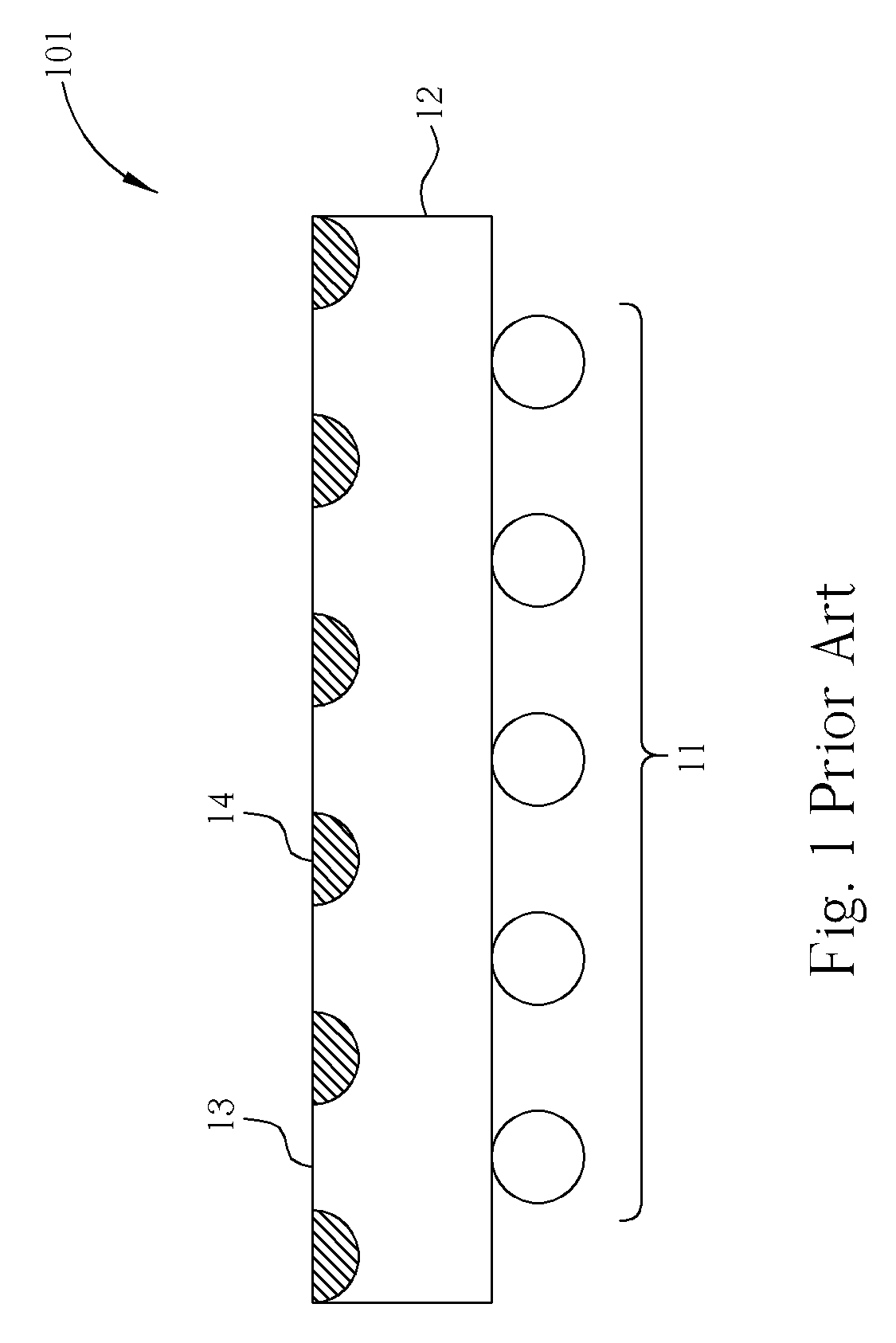

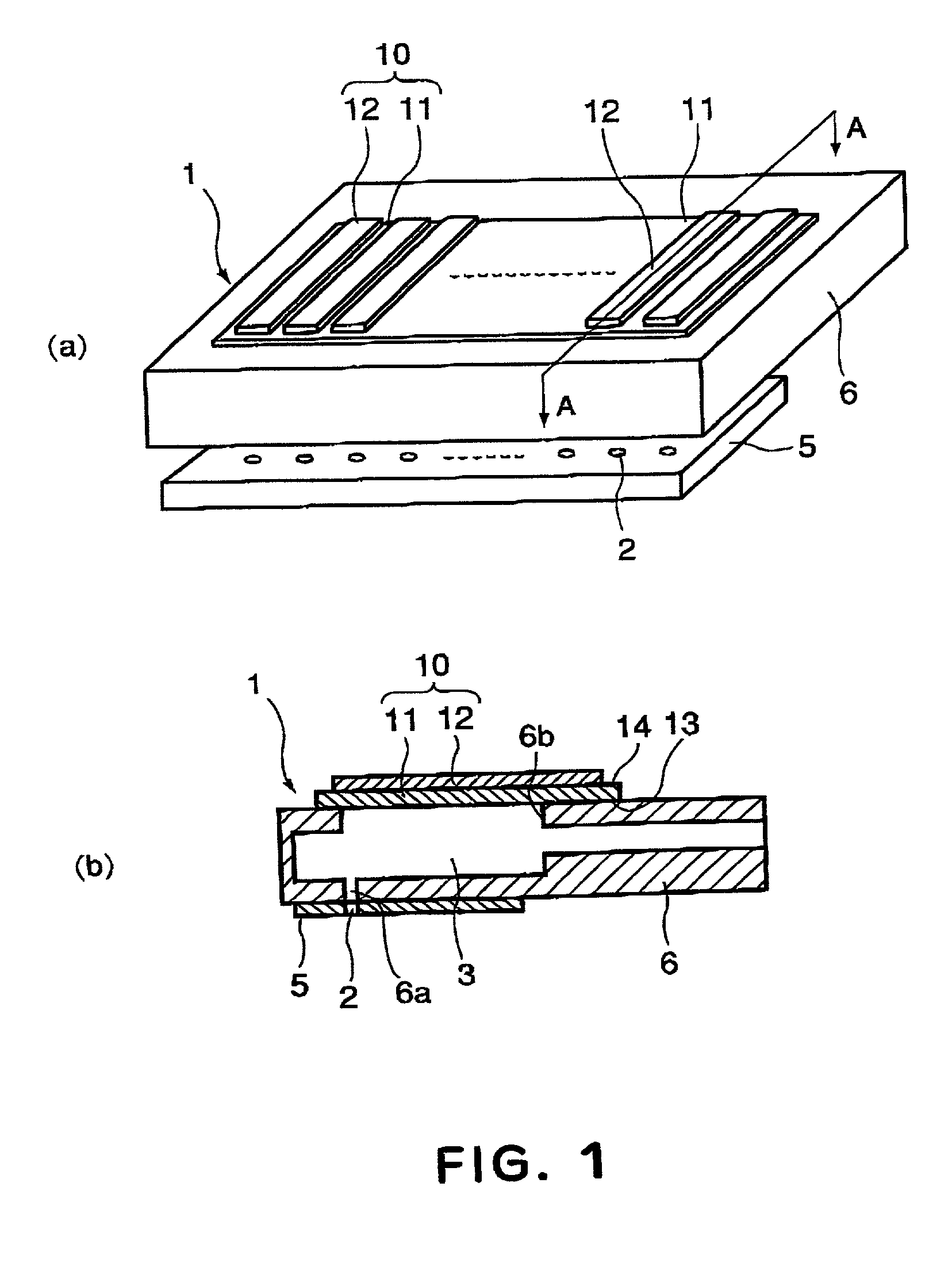

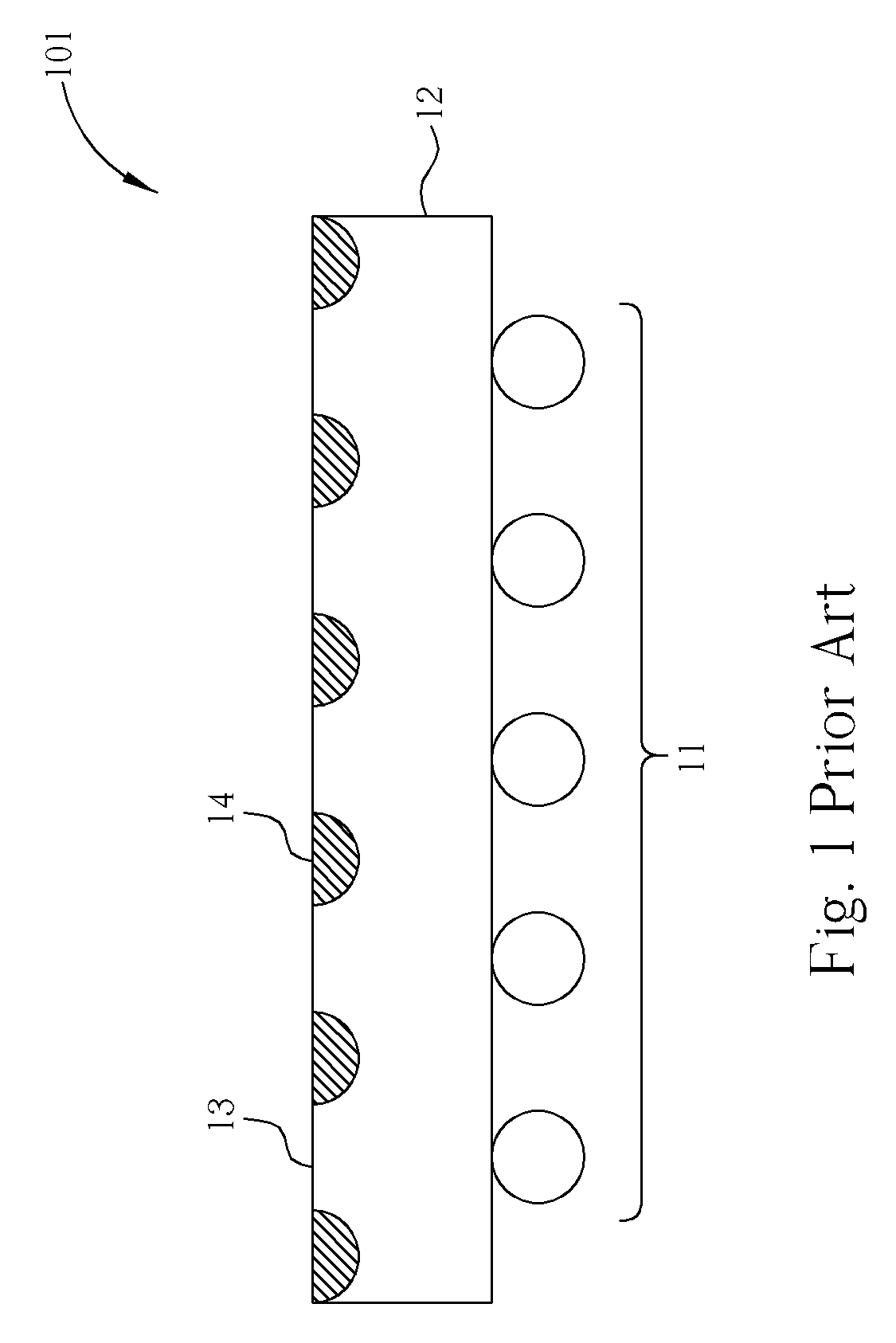

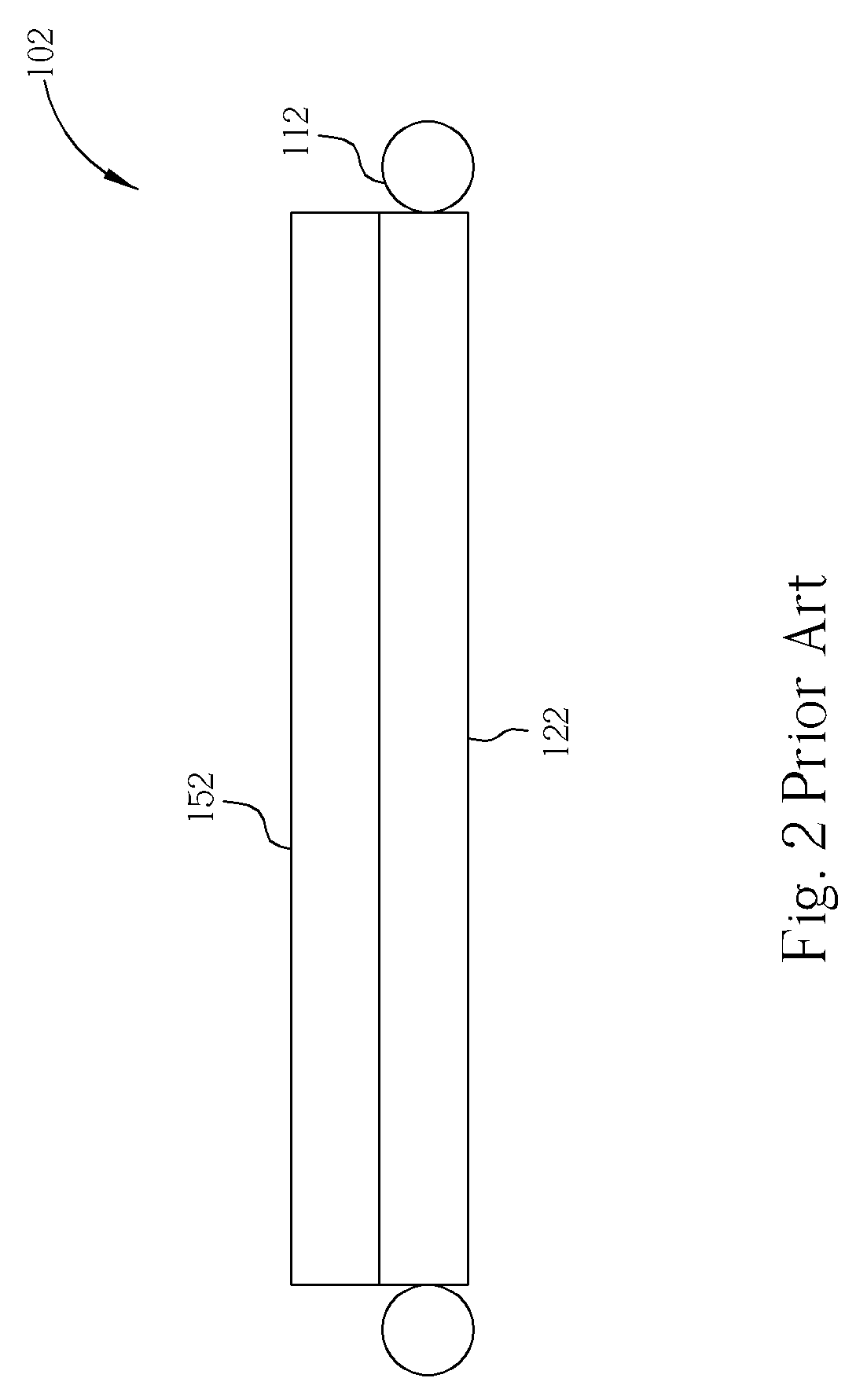

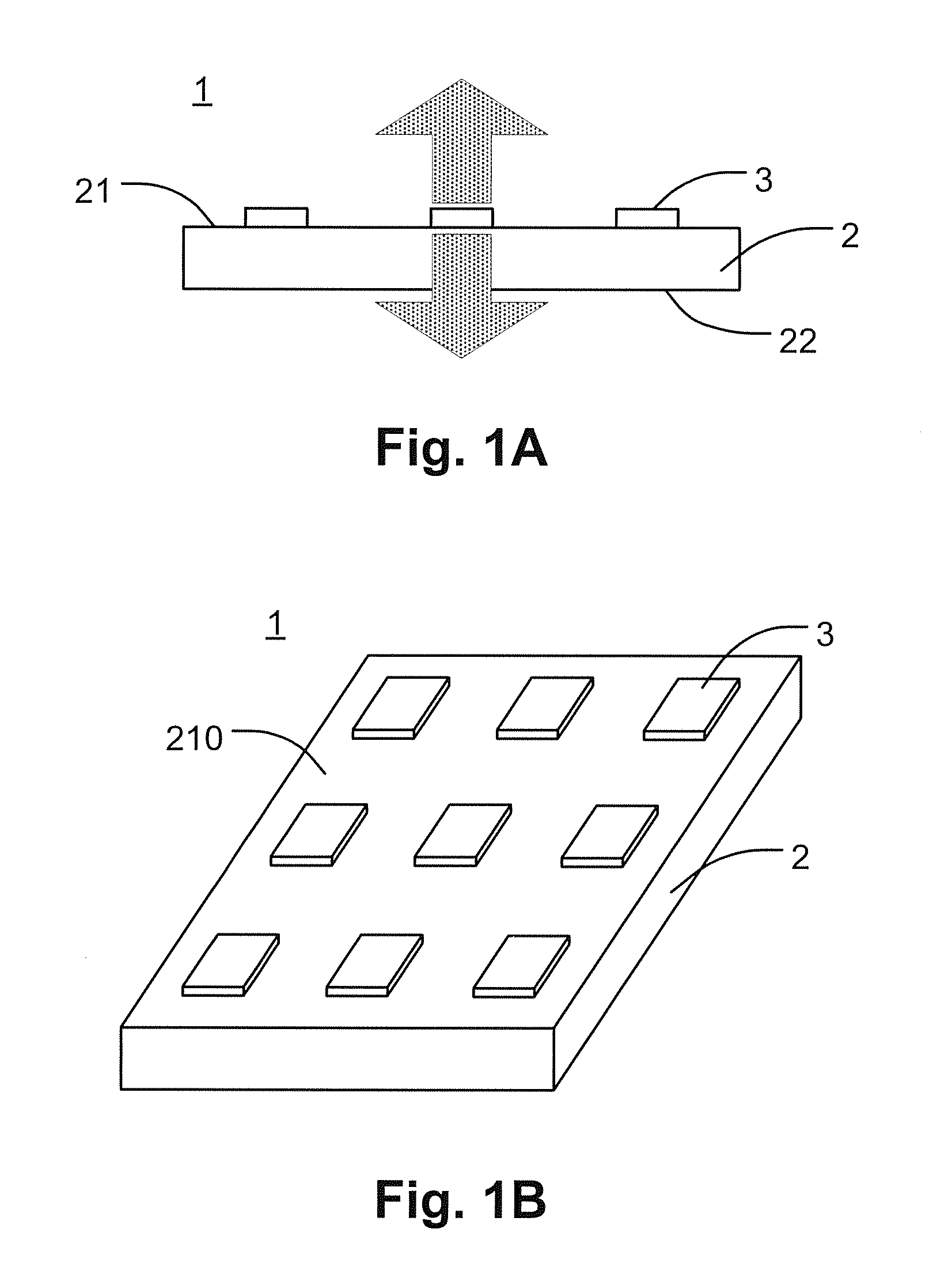

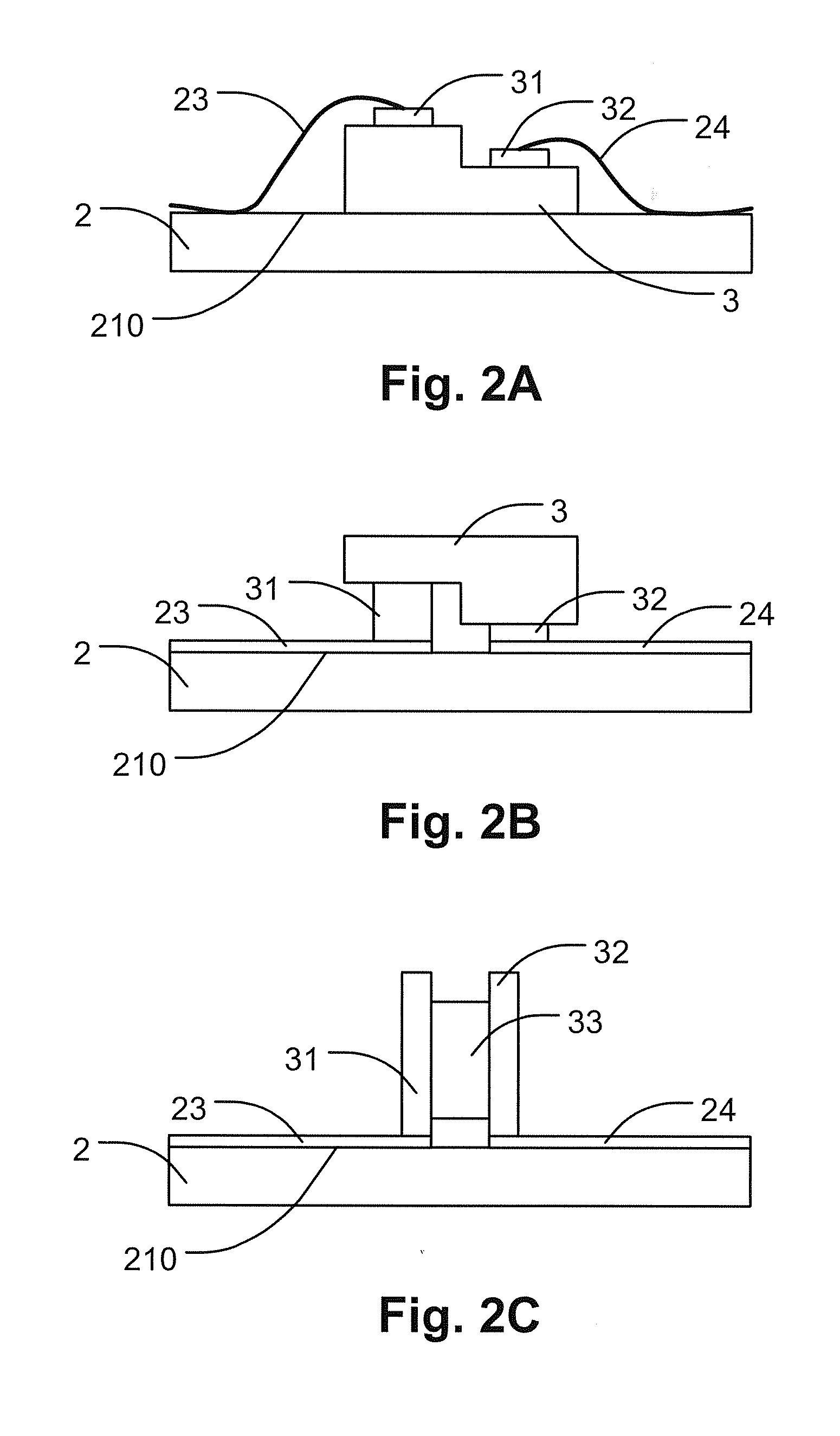

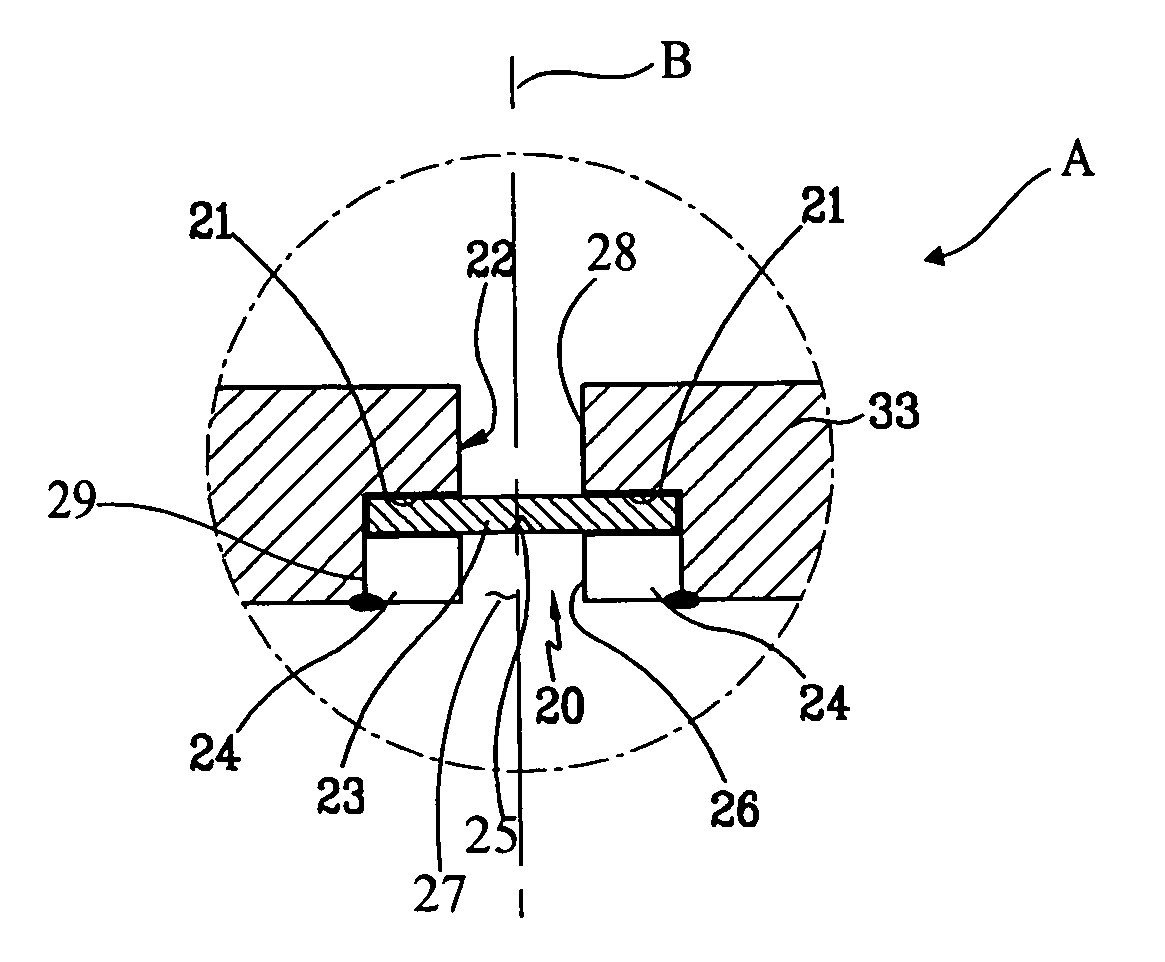

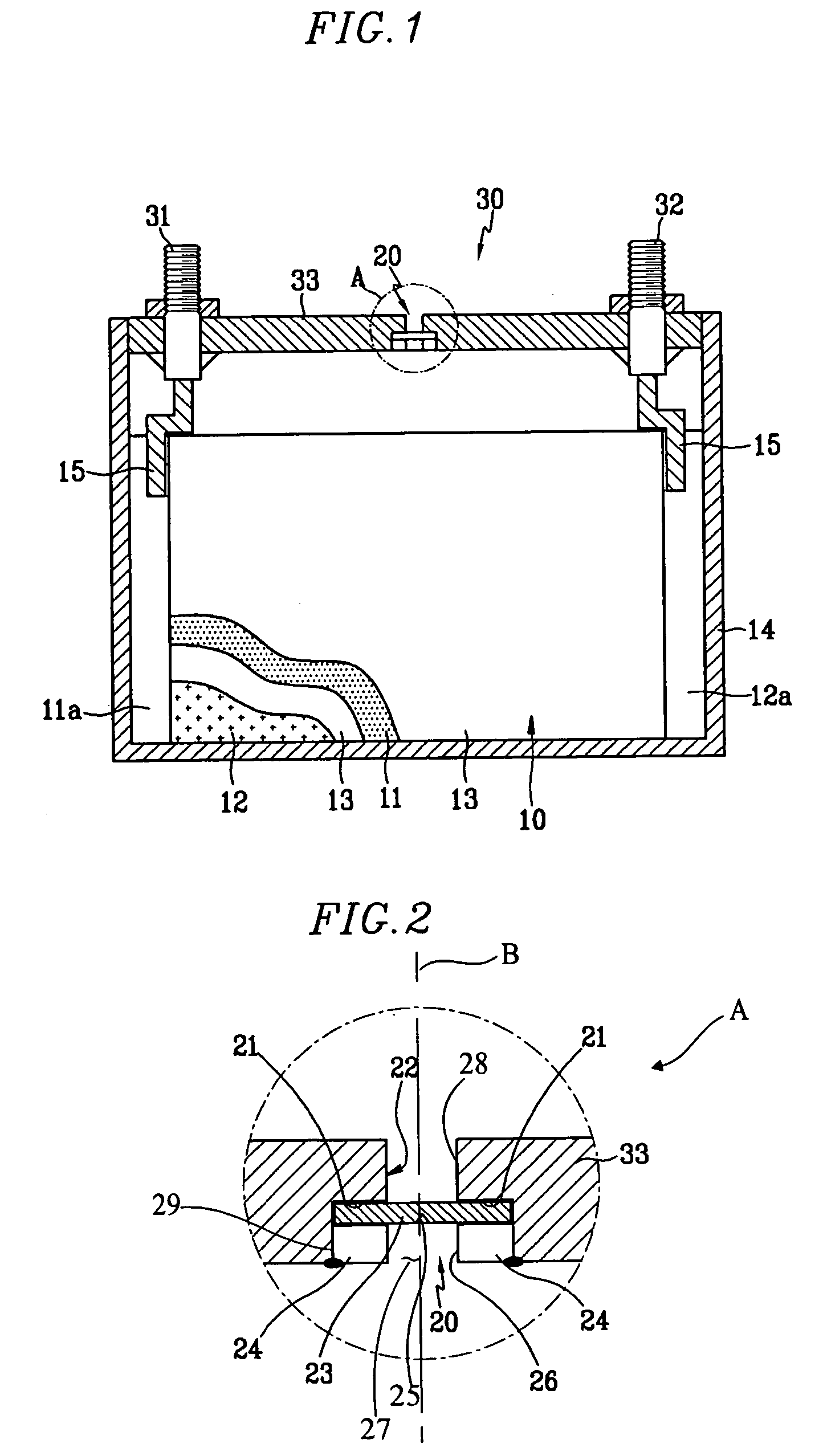

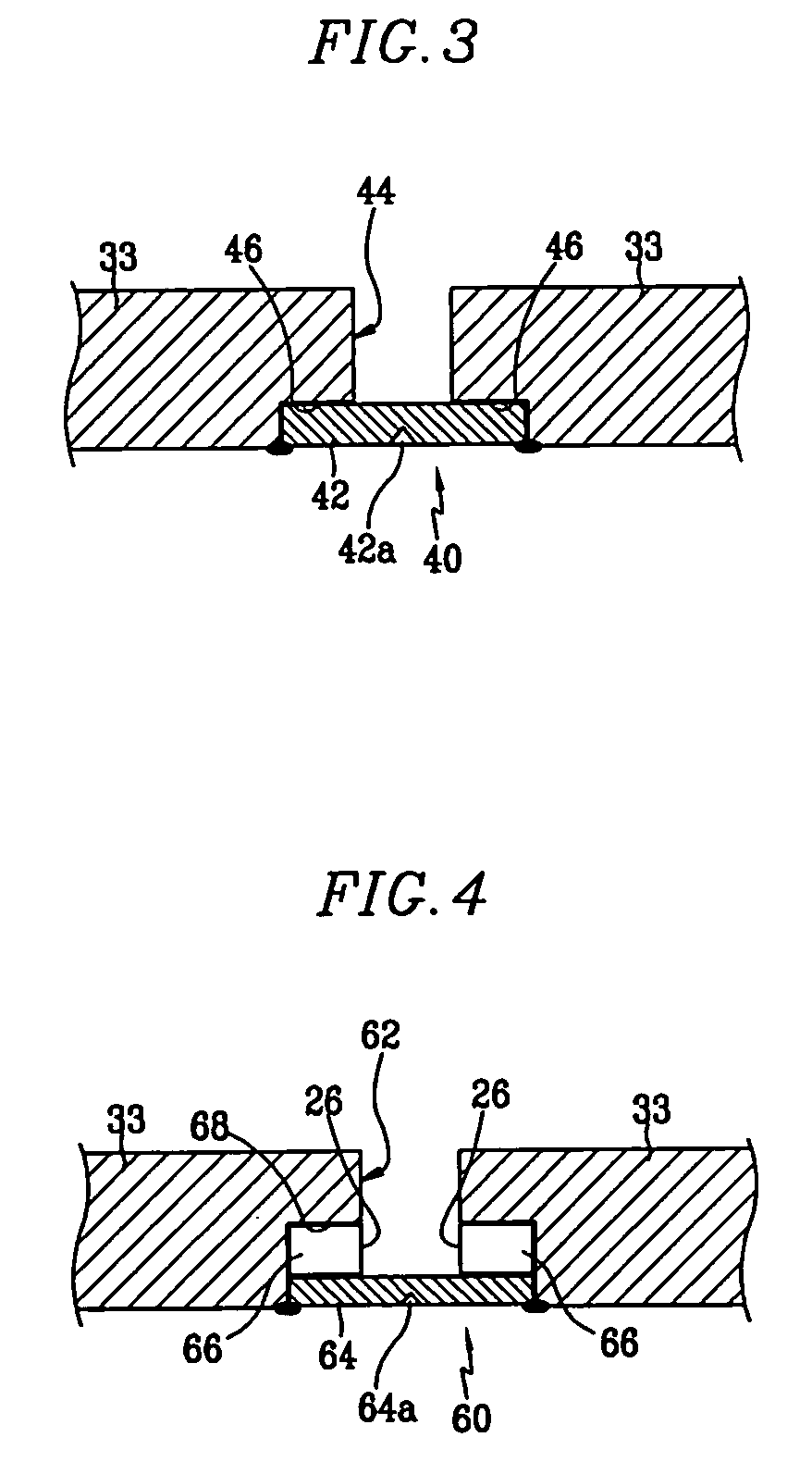

Microlens array substrate, method of manufacturing the same, and display device

InactiveUS6909121B2Well formedBrighter illuminationSemiconductor/solid-state device manufacturingOptical articlesDisplay deviceEngineering

A method of manufacturing a microlens array substrate is provided comprising the steps of: closely providing a substrate precursor (30) between a first master mold (10) having a plurality of curved surfaces (12) and a second master mold (20) having a plurality of projections (22) to form a substrate (32) having a plurality of lenses (34) formed by the curved surfaces (12) and recesses (36) formed by the projections (22); removing the first and second master molds (10, 20) from the substrate (32); and filling the recesses (36) with a shading material (42) after the second master mold (20) is removed.

Owner:SEIKO EPSON CORP

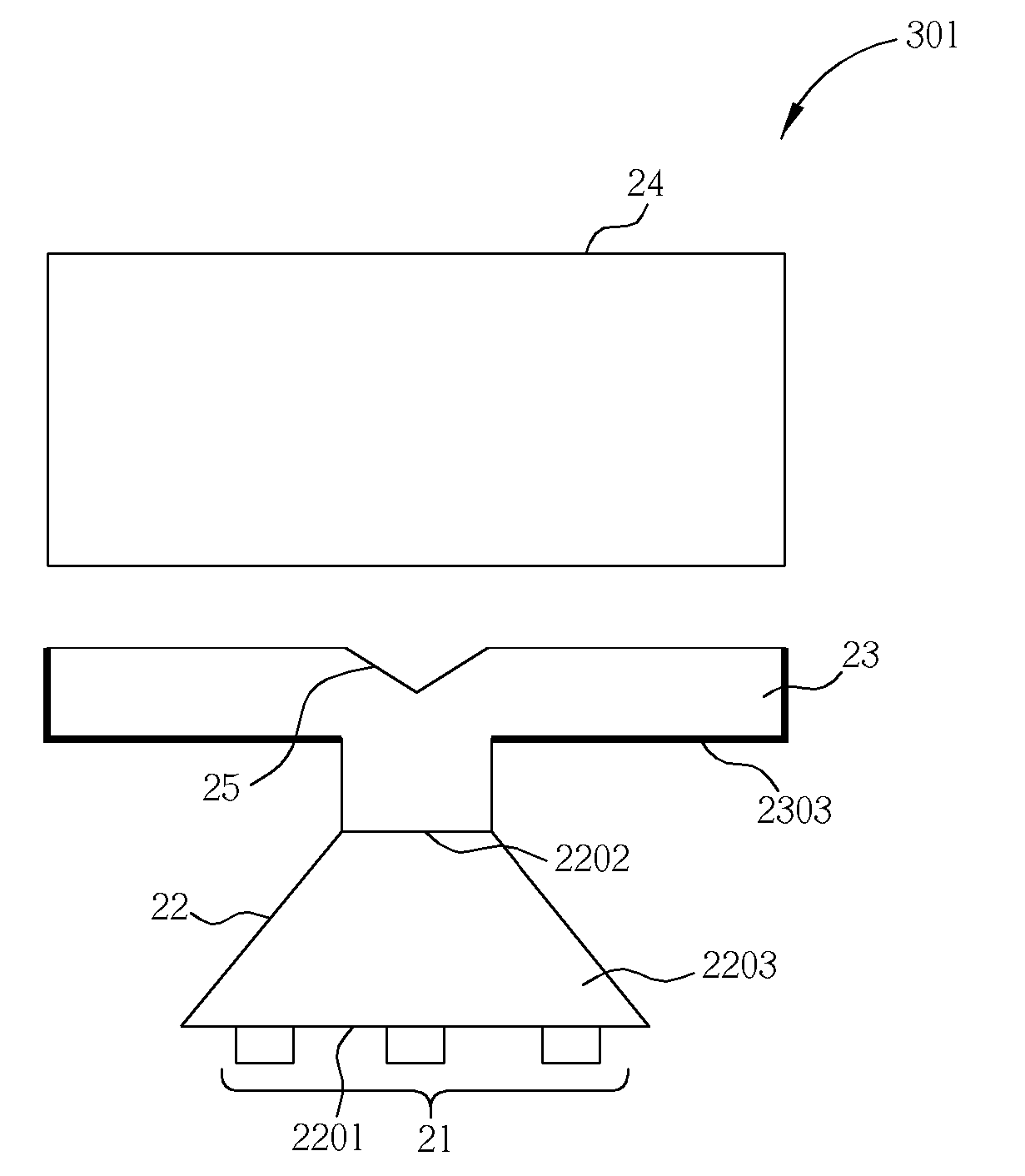

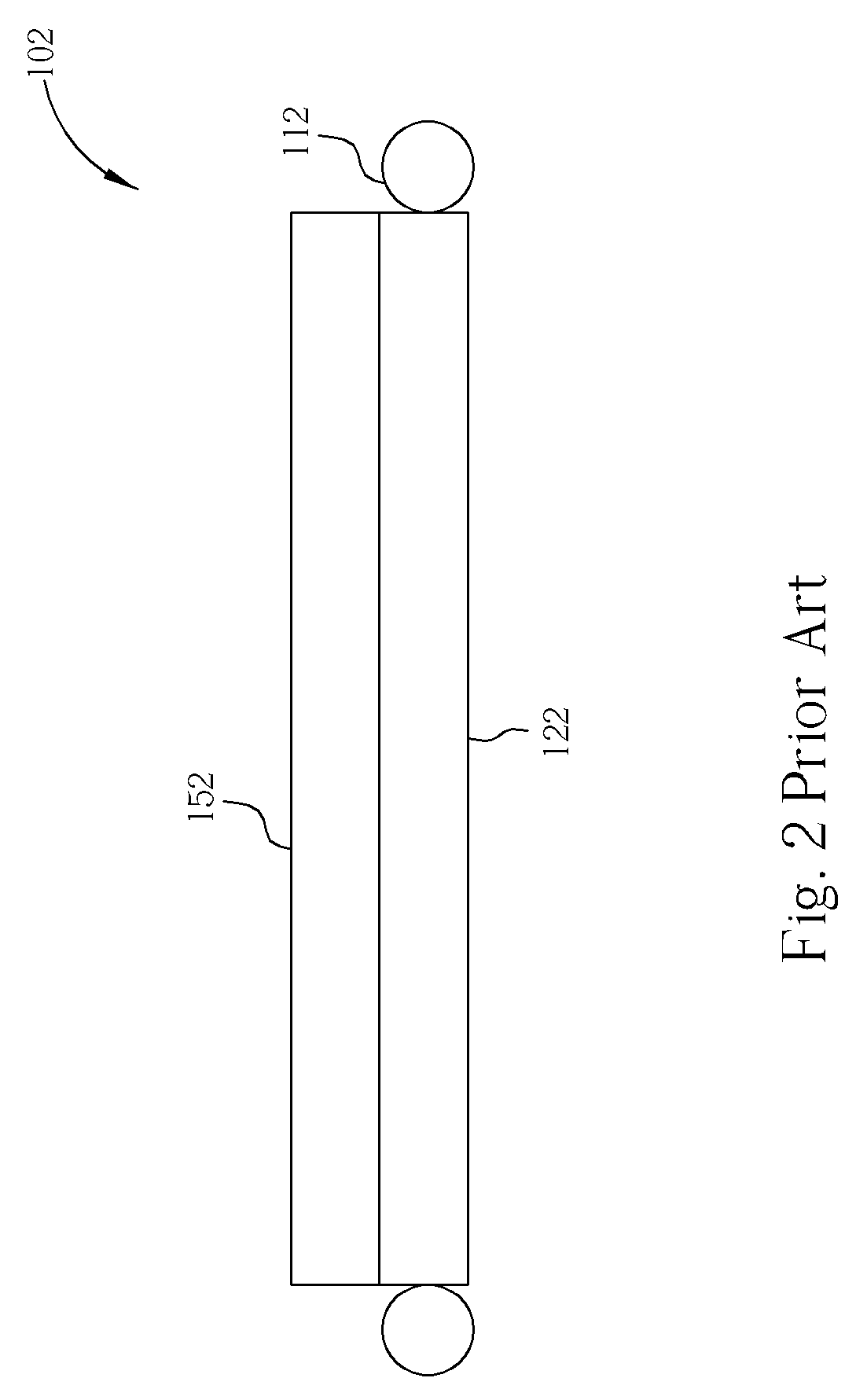

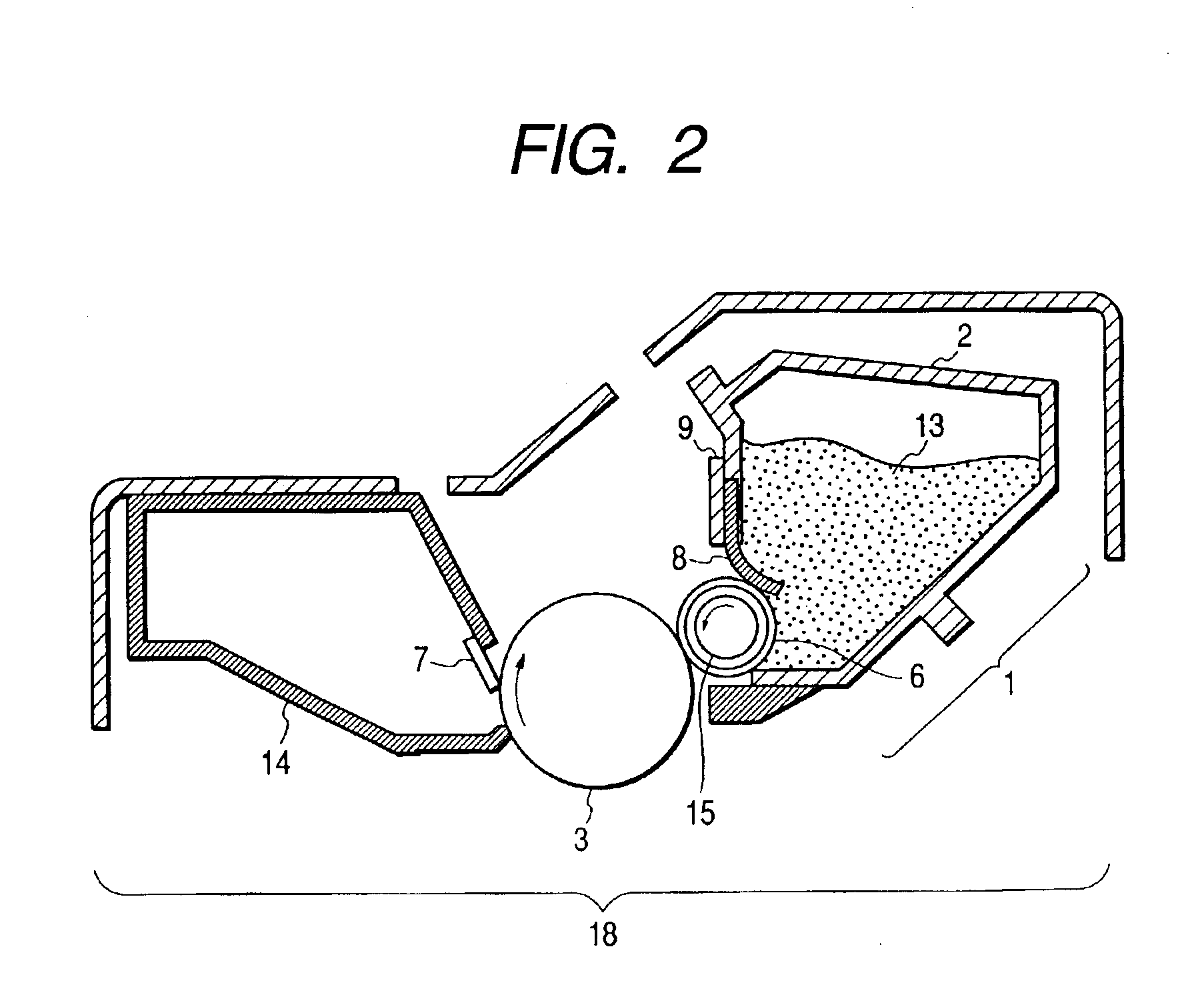

Planar light-emitting device

ActiveUS20050265044A1Uniform performanceMechanical apparatusPoint-like light sourceLight emitting deviceLight source

A planar light-emitting device includes a light source for generating light, a light gathering module for gathering the light generated by the light source and generating mixed light, a linear light generator comprising a light distributing unit for receiving the mixed light and distributing the mixed light to generate linear light, and a planar light generator for receiving the linear light and generating a planar light.

Owner:EPISTAR CORP

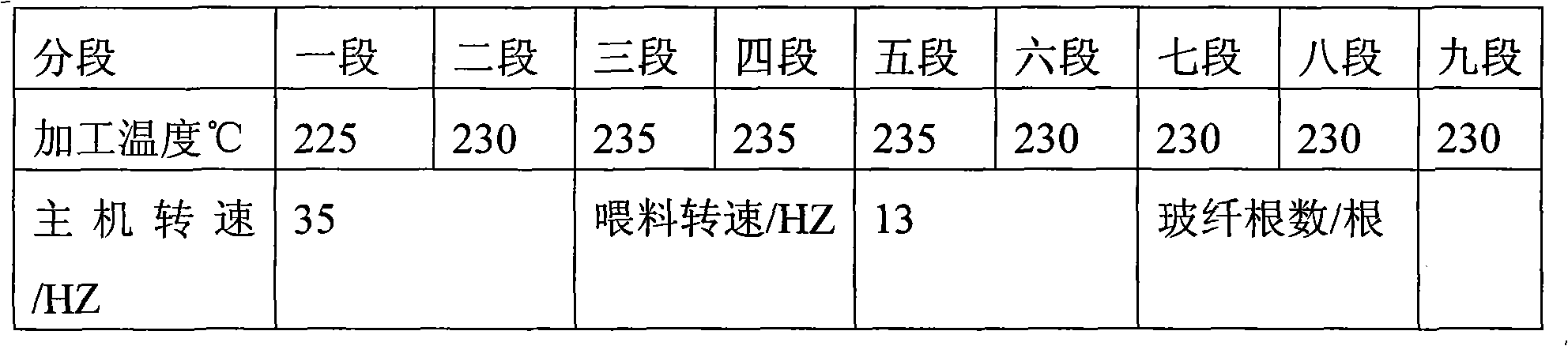

High glowing filament environmental-friendly inflaming retarding reinforced polybutylece terephthalate (PBT)/acrylonitrile butadiene styrene (ABS) alloy material and preparation method thereof

InactiveCN102108187AAvoid decompositionImprove impact performanceGlass fiberPolyethylene terephthalate

The invention relates to a high glowing filament environmental-friendly inflaming retarding reinforced polybutylece terephthalate (PBT) / acrylonitrile butadiene styrene (ABS) alloy material. The material comprises the following components in percentage by weight: 22.5-41% of PBT, 22.5-41% of ABS, 6-20% of complexing inflaming retardant, 3-15% of antimonous oxide, 20-30% of glass fiber, 2-10% of flexibilizer, 0.1-1% of antioxidant and 0.1-1% of lubrication dispersing agent. The preparation method comprises the following steps: putting raw materials weighed based on the weight proportion into a high mixer, mixing for 2-5 minutes, and then discharging; and then extruding and granulating by using an extruding machine at the processing temperature of 230-240 DEG C at the screw rotating speed of 30-40Hz. Compared with the alloy material prepared by the prior art, the high glowing filament environment-friendly inflaming retarding reinforced PBT / ABS alloy material has the advantages of high glowing filament temperature, environmental friendliness, balanced comprehensive performance and the like.

Owner:SHANGHAI SUNNY

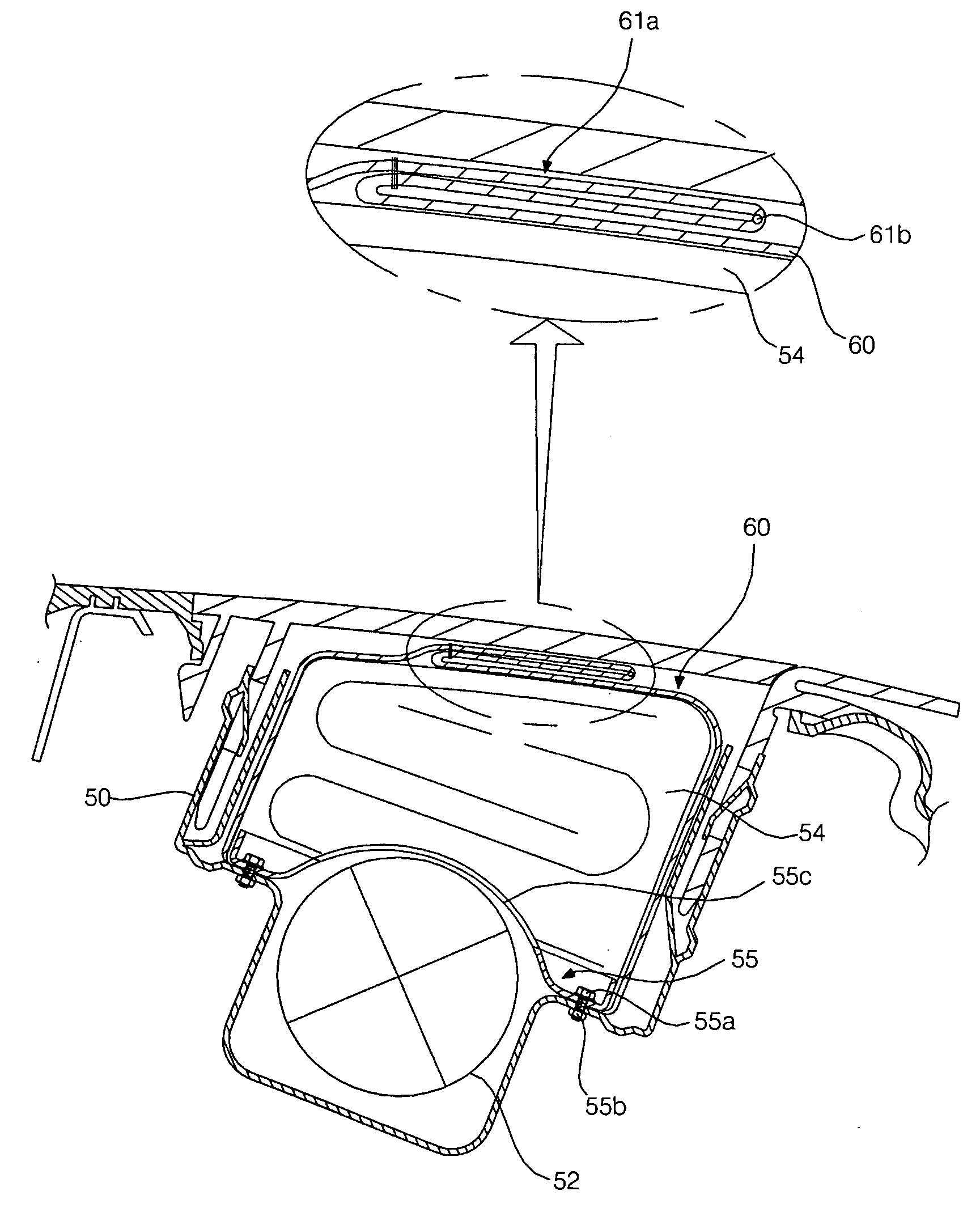

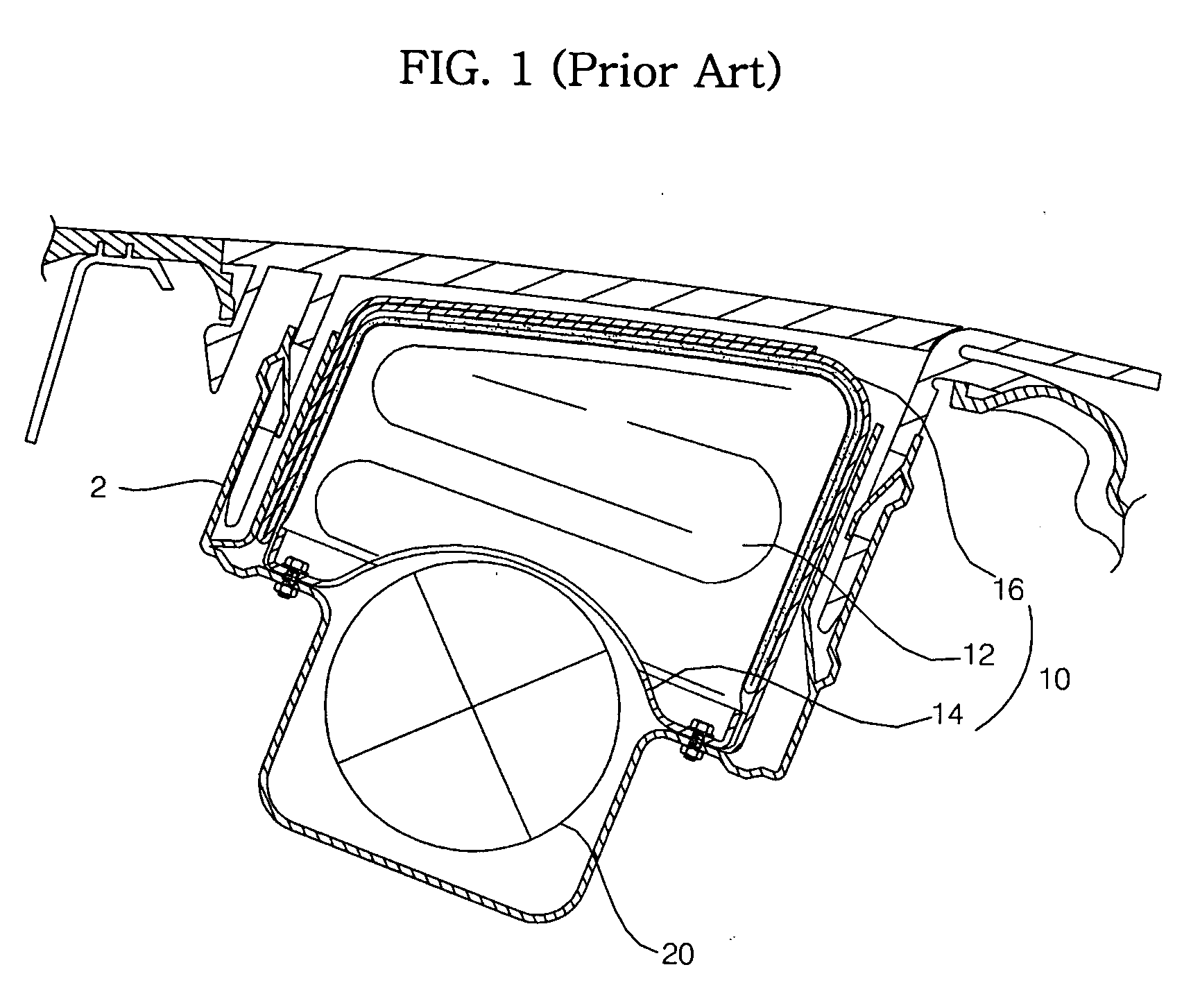

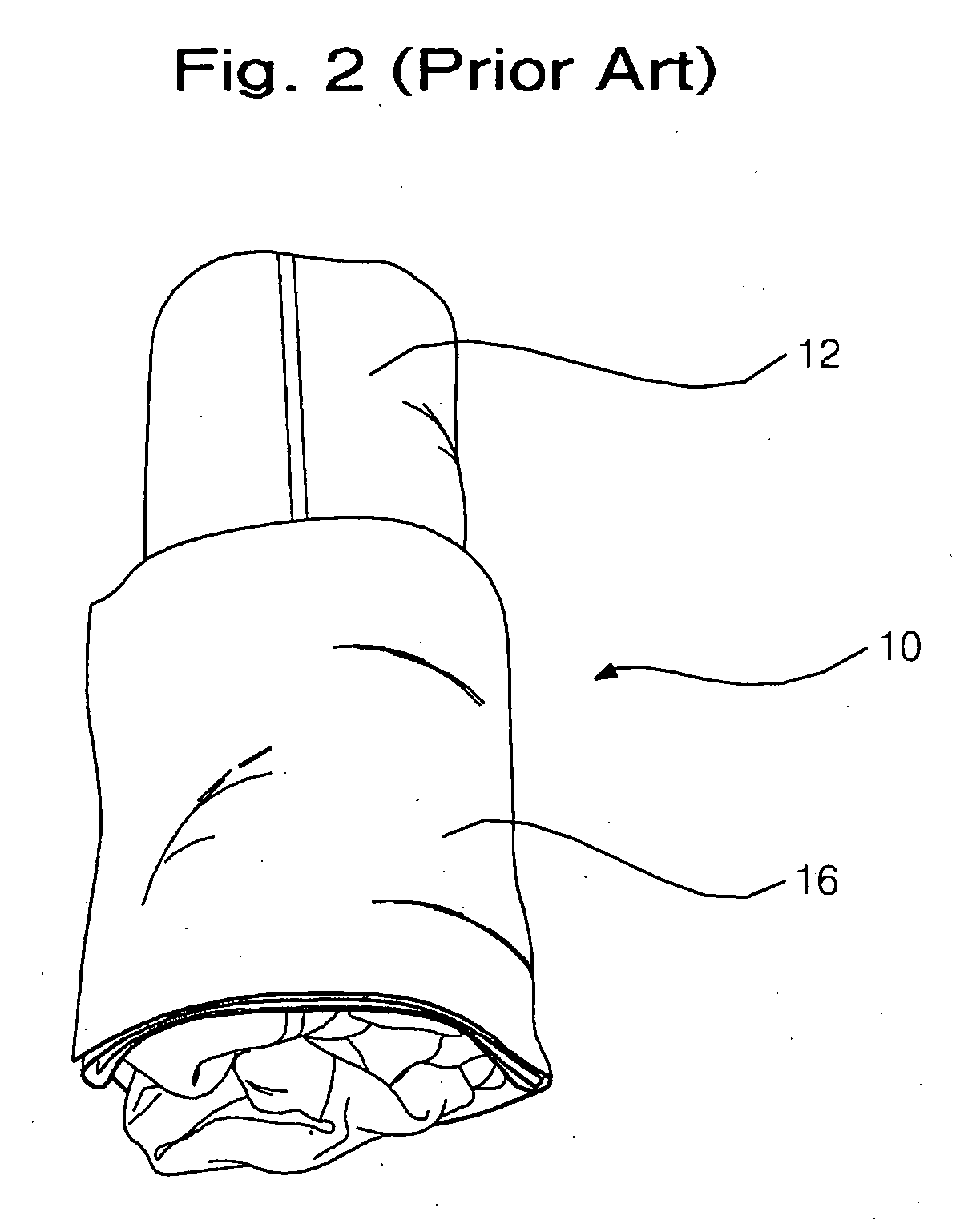

Air bag module

InactiveUS20070057487A1Simple structureEasily manufacturePedestrian/occupant safety arrangementCushionMarine engineering

An air bag module has an outer tether provided on the outer side of a cushion with a sewing portion and a tear line for suppressing an initial forward deployment of the cushion, and thus it is able to simply adjust the forward deployment speed and deployment rate of the cushion by tuning the sewing portion, sewing force and tear line of the outer tether.

Owner:HYUNDAI MOBIS CO LTD

PC/ABS alloy modified engineering plastic dedicated for laptop casings and production method thereof

The invention discloses a PC / ABS alloy modified engineering plastic dedicated for laptop casings. The plastic comprises the following components in percentage by weight: 22% to 65% of polycarbonate, 1% to 10% of compatilizer, 22% to 65% of acrylonitrile-butadiene-styrene, 5% to 40% of mineral filling material, 0.3% to 1% of antioxidant, 3% to 20% of halogen-free fire retardant, 0.5% to 2% of dispersed lubricant, and 3% to 20% of flexibilizer. The invention also discloses a production method of the PC / ABS alloy modified engineering plastic dedicated for laptop casings. The PC / ABS alloy modified engineering plastic dedicated for laptop casings has the advantages of capability of being recycled and utilized, multi-choice of color and outer layer treatment, stable size, good heat radiation property, and high cost performance. The production method has the advantages of simple operation and suitability for mass production.

Owner:东莞市卡帝德塑化科技有限公司

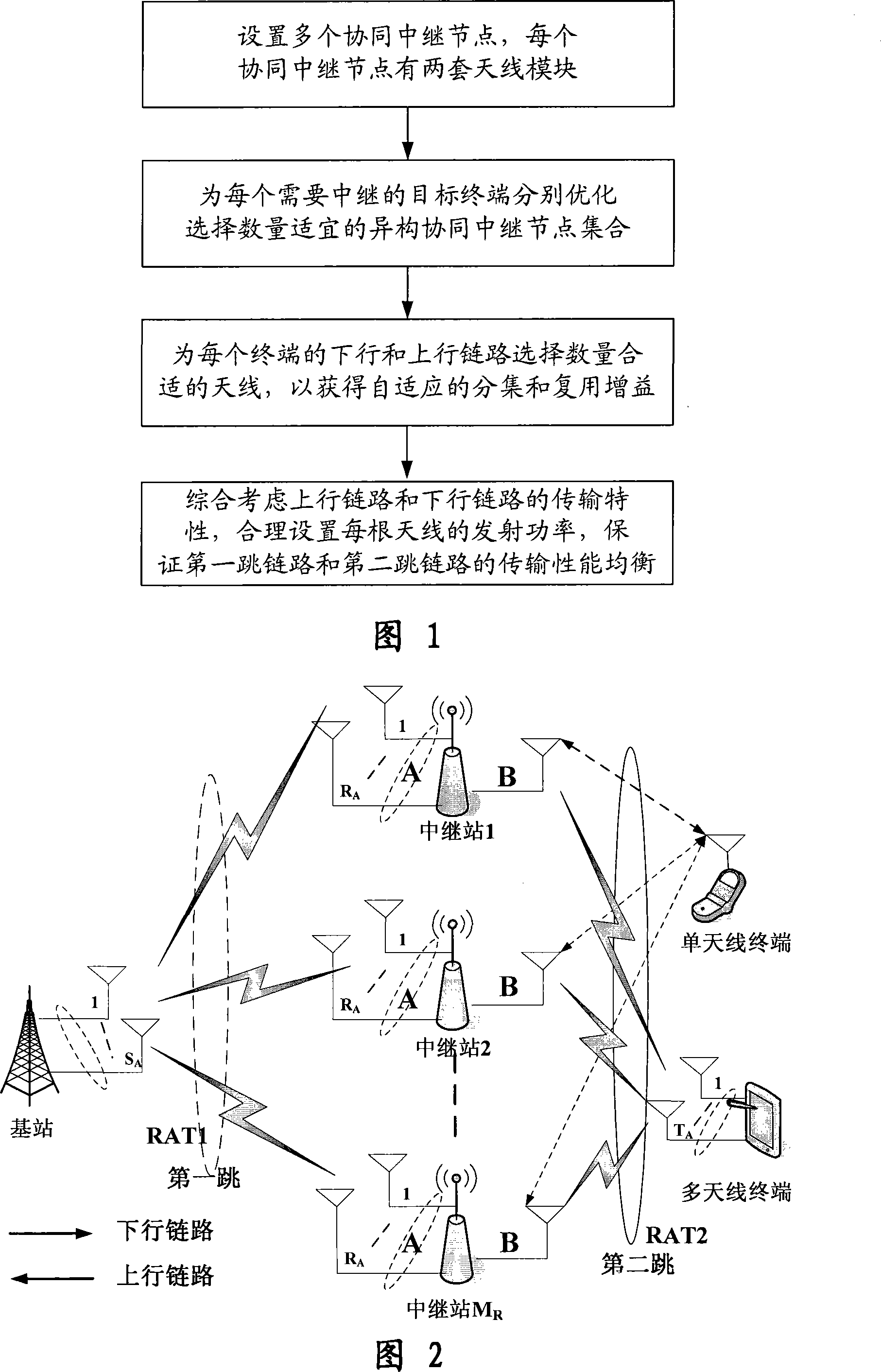

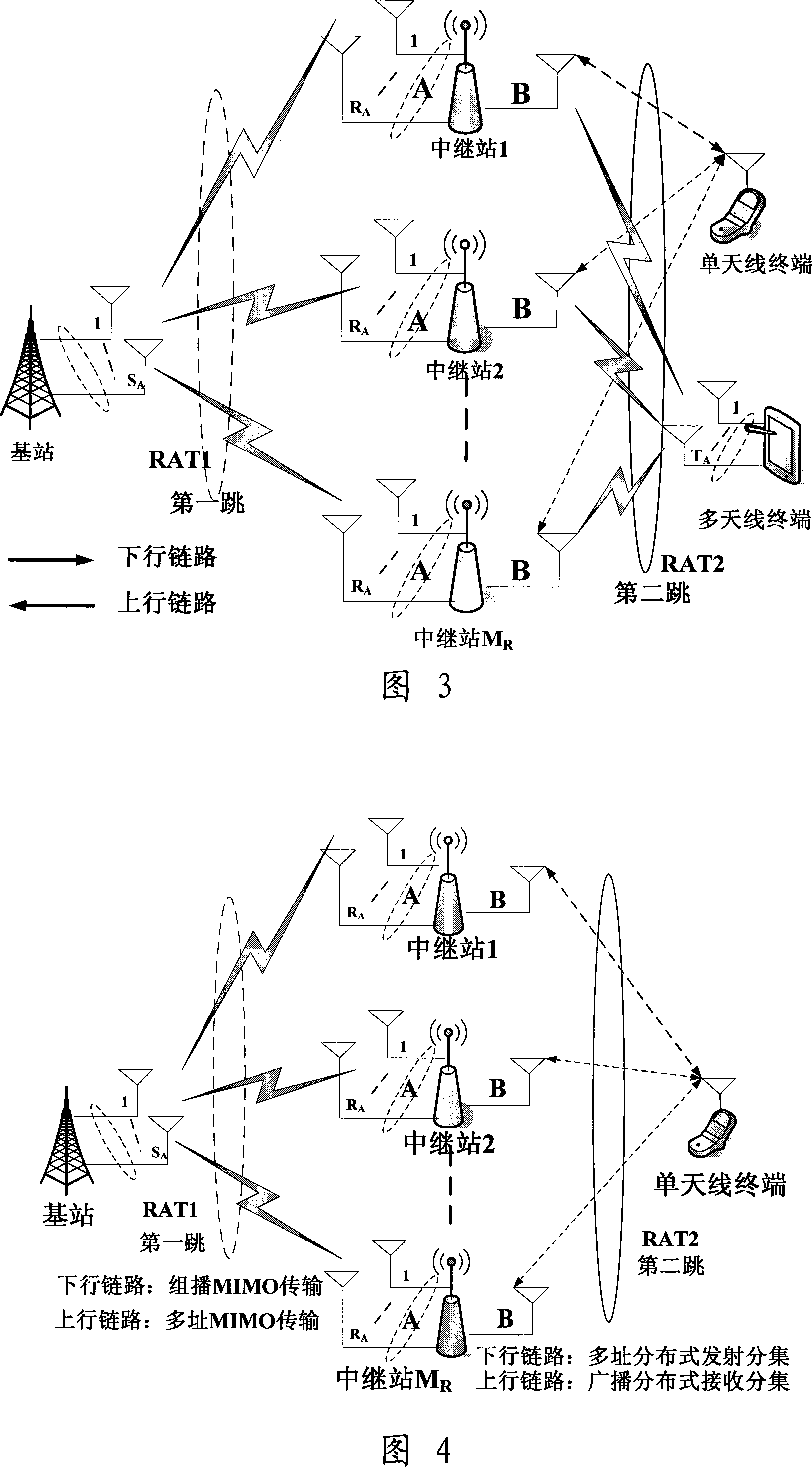

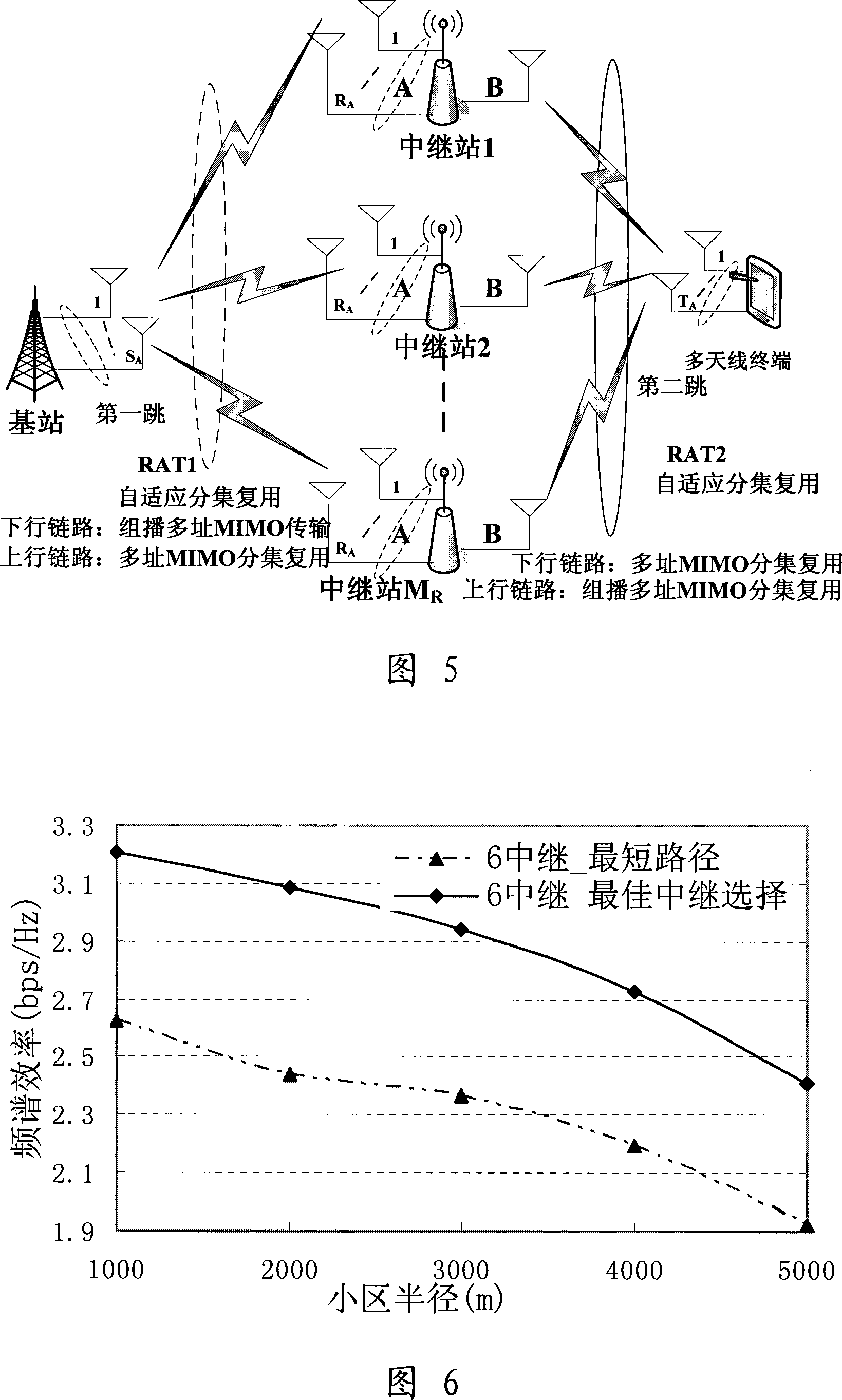

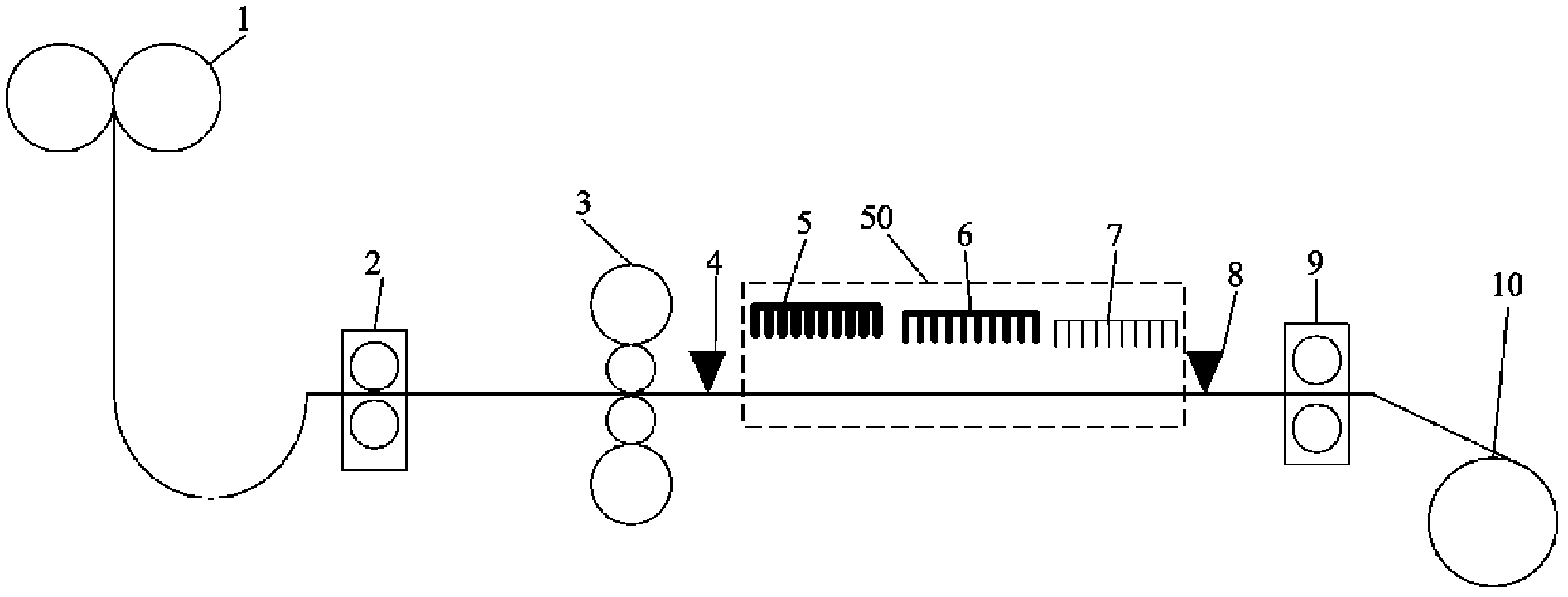

A collaborative transmission method realized in isomerization wireless network with cooperating relay nodes

InactiveCN101217301ARealize interconnectionReduce cache requirementsSpatial transmit diversityDiversity schemeSelf adaptive

The invention discloses a method for implementing heterogeneous and collaborative transmission in a heterogeneous wireless network by using collaborative trunk nodes; one or more collaborative trunk nodes are arranged, and each of which is provided with two set of antenna modules; a base station implements an optimized selection of proper collections of the heterogeneous and collaborative trunk nodes respectively for each destination user terminal that needs trunking, selects and determines antennas with proper number for the uplink and the downlink of each terminal, thus being convenient for acquiring self-adaptive diversity and reuse gain; the emission power of each antenna is reasonably set by comprehensively considering the transmission characteristics of the uplink and the downlink, thus ensuring the balance between the transmission performance of the first-hop link and the second-hop link and optimizing the integrative performance of the system. Based on the sufficient consideration of the existing constructions of wireless network frameworks, the invention discloses two set of antennas creatively, which are respectively used as heterogeneous trunk nodes of two-hips link transmission for implementing heterogeneous transmission, thus having the advantages of simple and convenient operation, flexibility, practicability, less investment, good effectiveness and great application generalization prospect.

Owner:BEIJING UNIV OF POSTS & TELECOMM

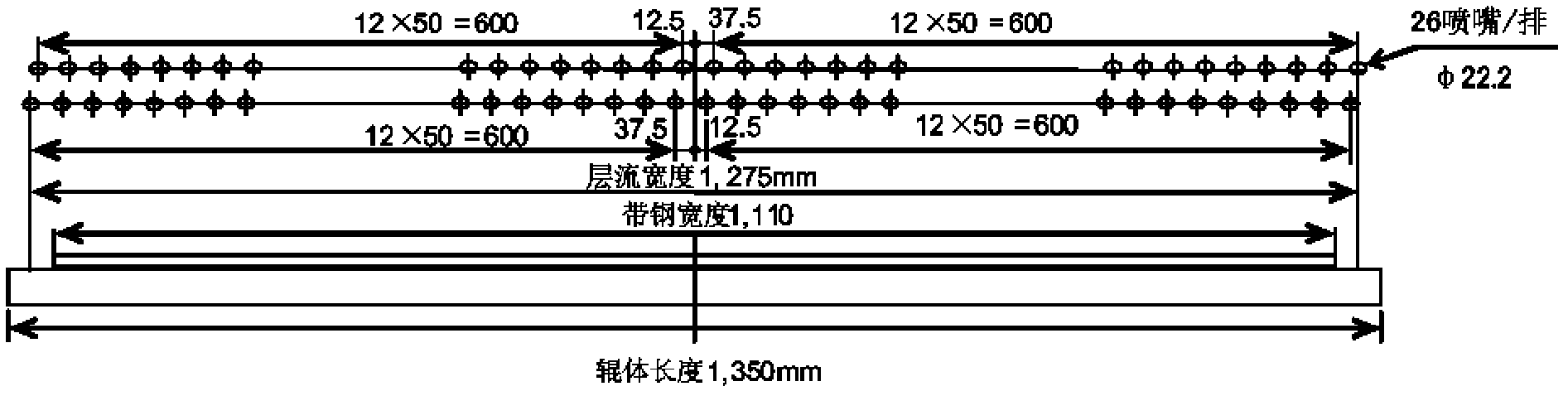

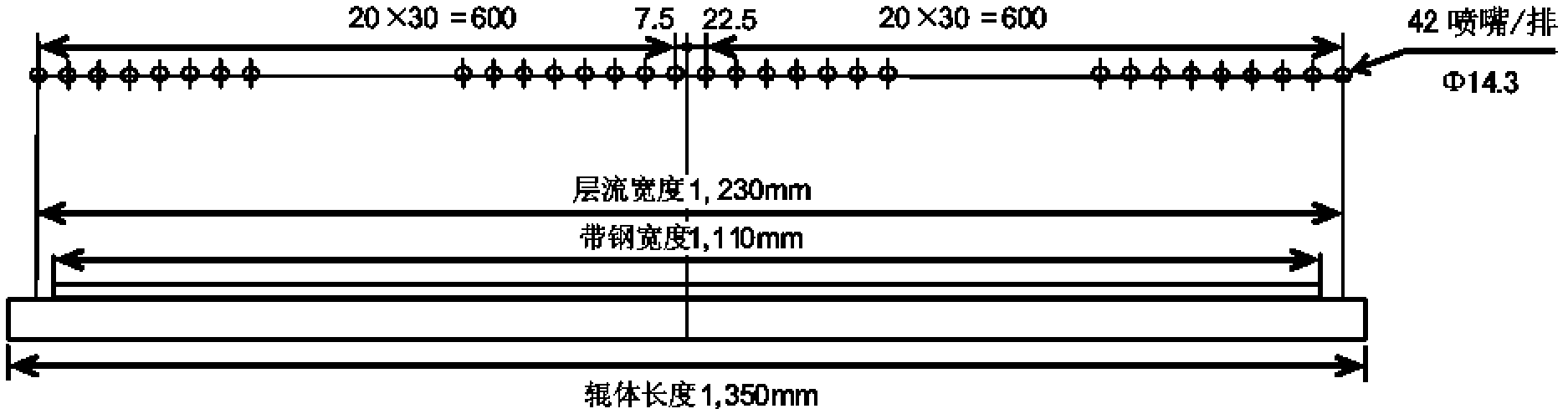

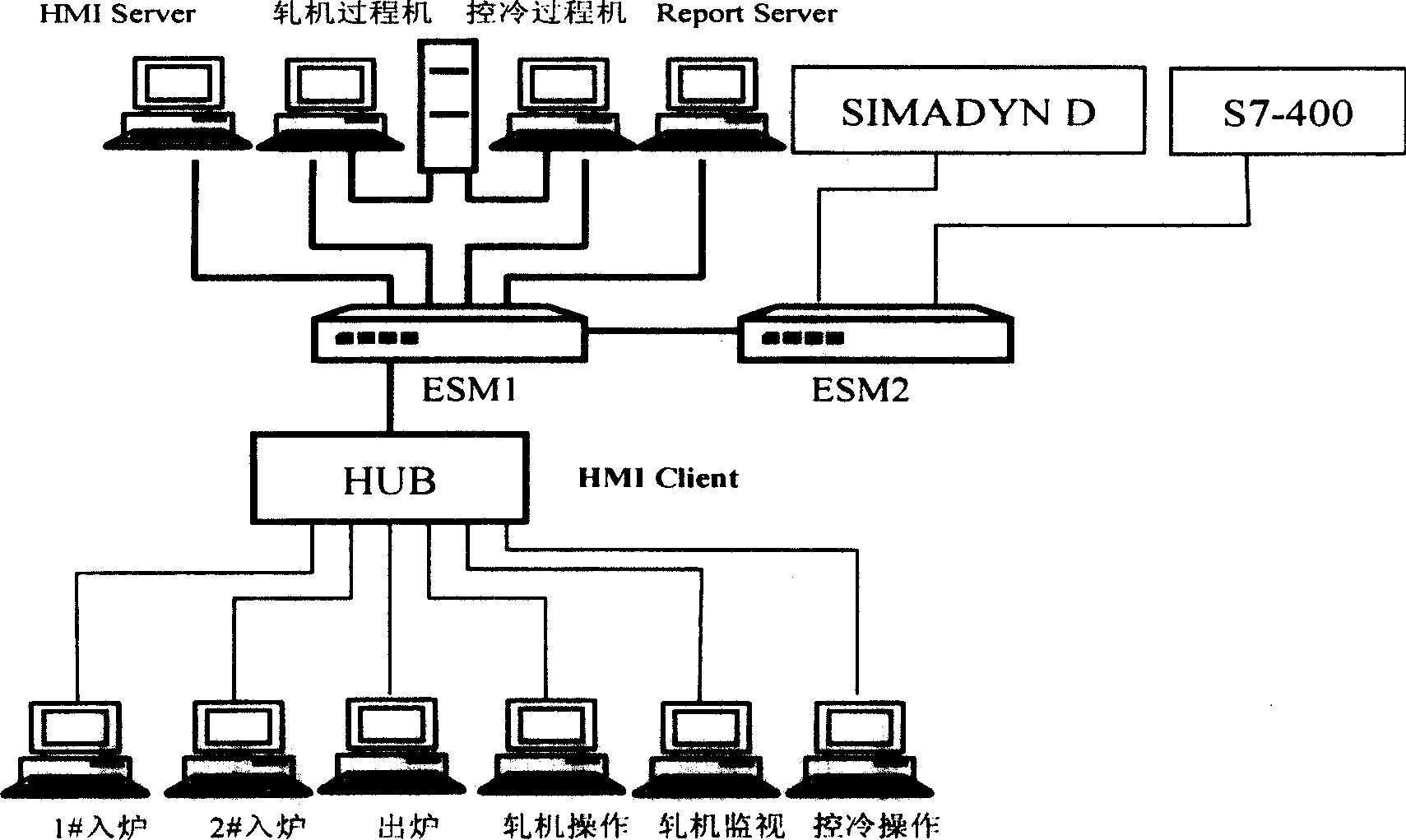

Cooling system for rolled stripe continuously-casting production line and control method thereof

ActiveCN102553950AMeet the temperature dropFulfil requirementsTemperature control deviceWork treatment devicesAdaptive learningLow speed

The invention relates to control devices or methods specially for metal rolling machines and manufacturing products of the metal rolling machines and discloses a cooling system for a rolled stripe continuously-casting production line and a control method of the cooling system. The system comprises a segmented laminar flow cooling device and a cooling control system which are arranged behind an online hot rolling machine, wherein the segmented laminar flow cooling device comprises at least two segmented laminar flow cooling collecting pipe areas, wherein one of the at least two segmented laminar flow cooling pipe collecting areas adopts a nozzle cooling collecting pipe with small pipe diameter, the cooling control system is an online double-closed-loop control system and comprises a double-closed-loop control circuit, the double-closed-loop control circuit comprises a feedforward control module, a precomputation module, a feedback control module, a coiling-ahead temperature measuring module and a self-adaption learning module, the double-closed-loop control circuit selects at least one collecting pipe area of the segmented laminar flow cooling device, the number of open collecting pipes in the selected collecting pipe area can be adjusted by a group of control valves, and the requirements on the accuracy of coiling temperature of steel stripes rolled at a low speed during the variation of speed and thickness in a limited cooling area can be met by the nozzle cooling collecting pipe with the small pipe diameter and the online double-closed-loop control system.

Owner:BAOSHAN IRON & STEEL CO LTD

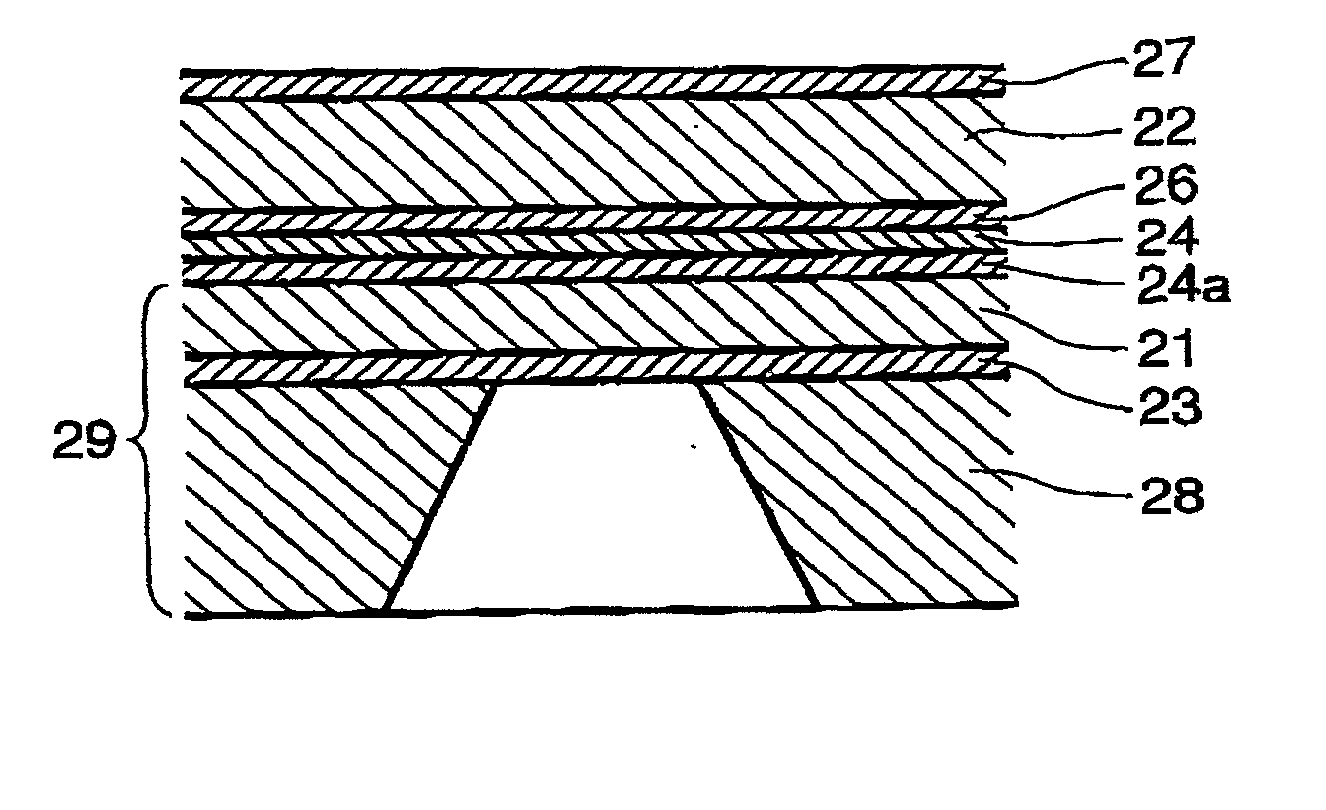

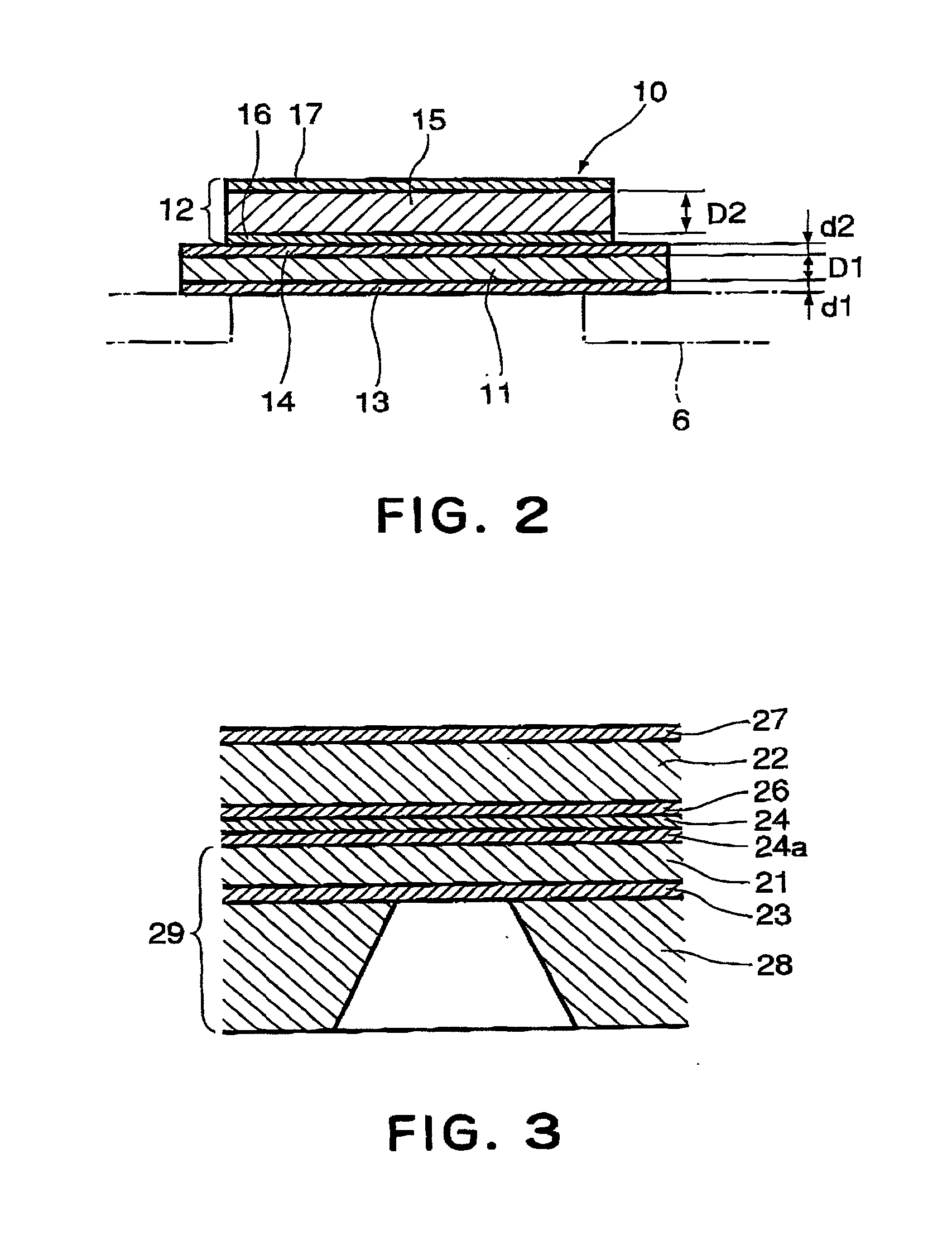

Piezoelectric structure, liquid ejecting head and manufacturing method therefor

InactiveUS20020140320A1Durable devices can be providedMaintain strengthPiezoelectric/electrostrictive device manufacture/assemblyPiezoelectric/electrostriction/magnetostriction machinesLiquid jetSingle crystal

A piezoelectric structure includes a vibrational plate; a piezoelectric film; the vibrational plate including a layer of a monocrystal material, a polycrystal material, a monocrystal material doped with an element which is different from an element constituting the monocrystal material, or a polycrystal material doped with an element which is different from an element constituting the polycrystal materials, and oxide layers sandwiching the aforementioned layer, the piezoelectric film has a single orientation crystal or monocrystal structure.

Owner:CANON KK +1

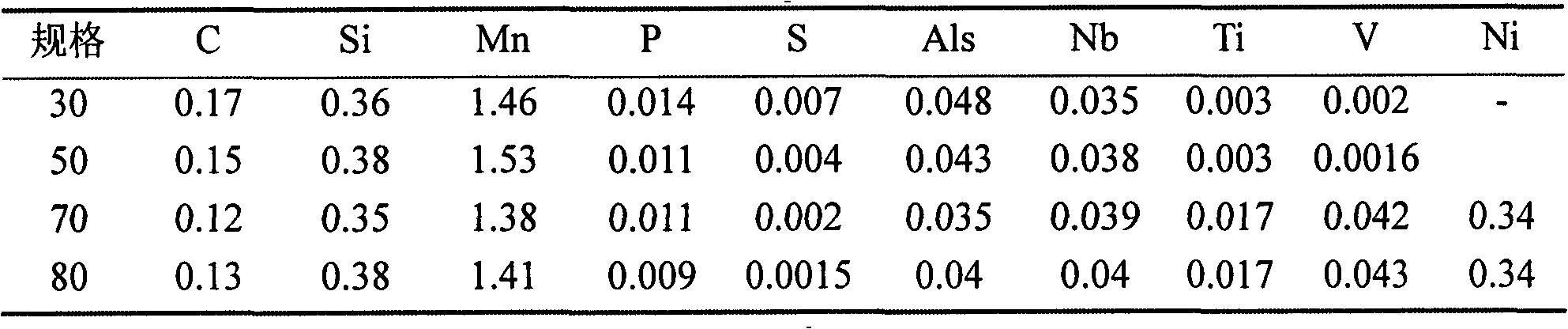

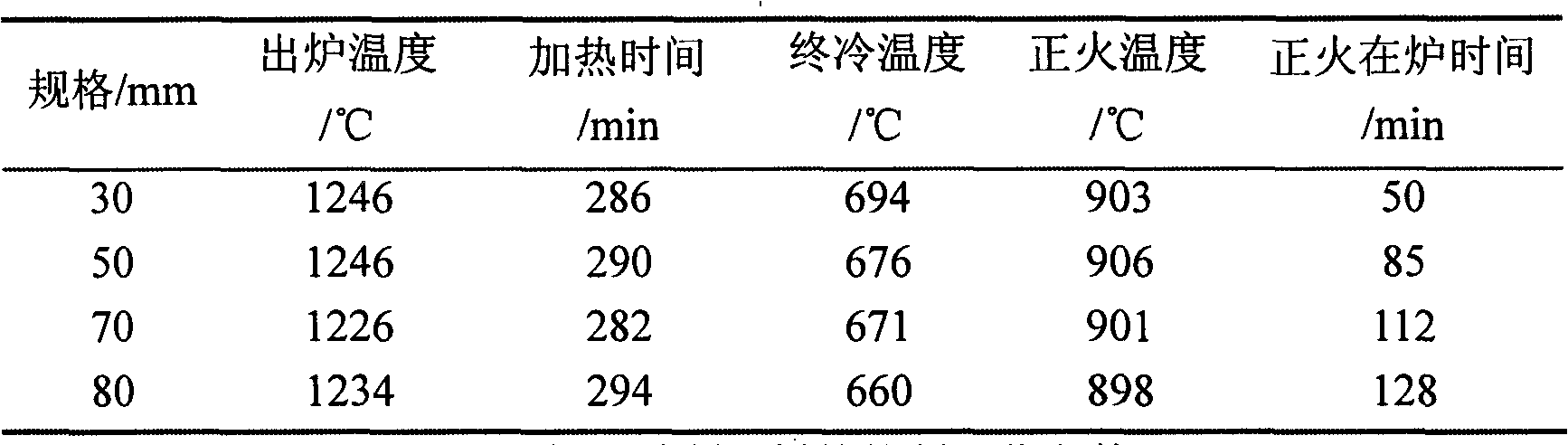

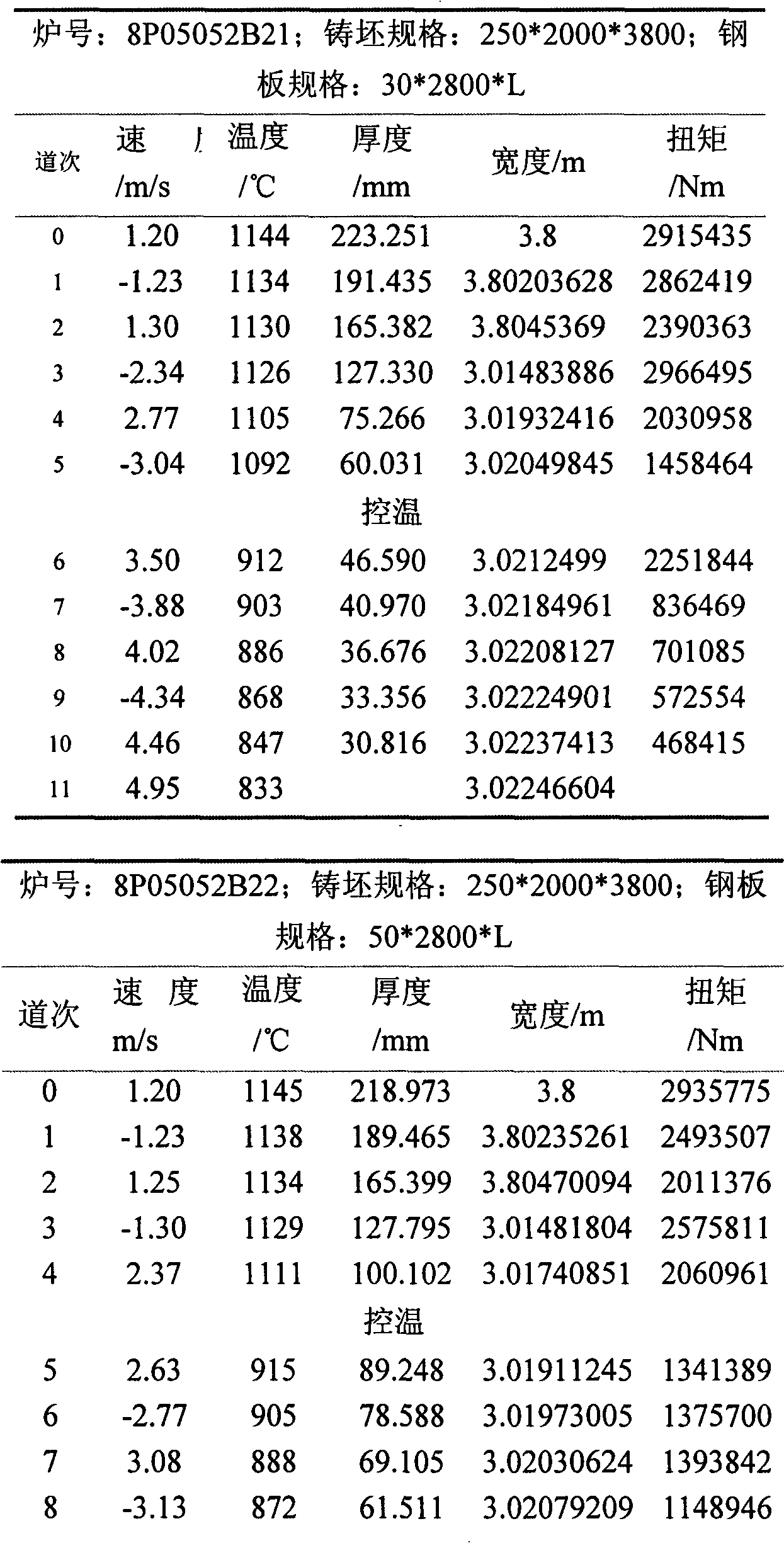

Steel for 36kg-grade ocean platform and production method thereof

The invention relates to steel for a 36kg-grade ocean platform and a production method thereof, belonging to the technical field of a ship body and structural steel for oceanographic engineering. A steel plate with thickness of 5-50mm comprises the following chemical components: 0.14-0.18 percent of C, 0.20-0.50 percent of Si, 1.30-1.60 percent of Mn, 0.02-0.05 percent of Nb, less than or equal to 0.005 percent of S, less than or equal to 0.015 percent of P, 0.020-0.04 percent of Als, and the balance of Fe and inevitable impurities; a steel plate with the thickness of 50-80mm comprises the following chemical components: 0.12-0.18 percent of C, 0.20-0.50 percent of Si, 1.30-1.60 percent of Mn, 0.02-0.05 percent of Nb, 0.02-0.06 percent of V, 0.010-0.020 percent of Ti, 0.10-0.40 percent of Ni, less than or equal to 0.005 percent of S, less than or equal to 0.015 percent of P, 0.020-0.04 percent of Als, and the balance of Fe and inevitable impurities; and in addition, the sum of Nb, V and Ti is less than or equal to 0.12 percent. The production method has the advantages of low production cost, uniform and stable comprehensive performance and good cold bending property.

Owner:SHOUGANG CORPORATION

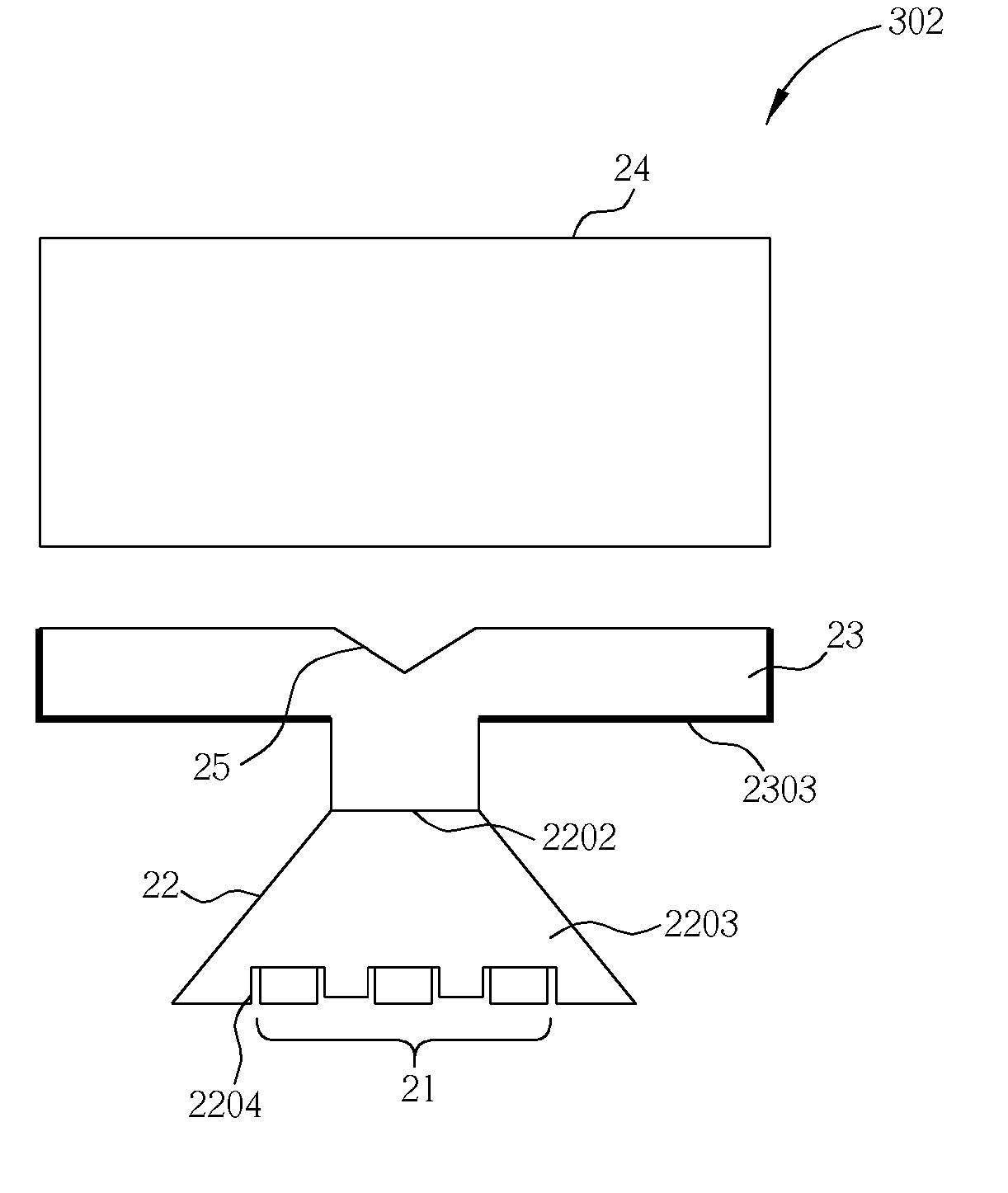

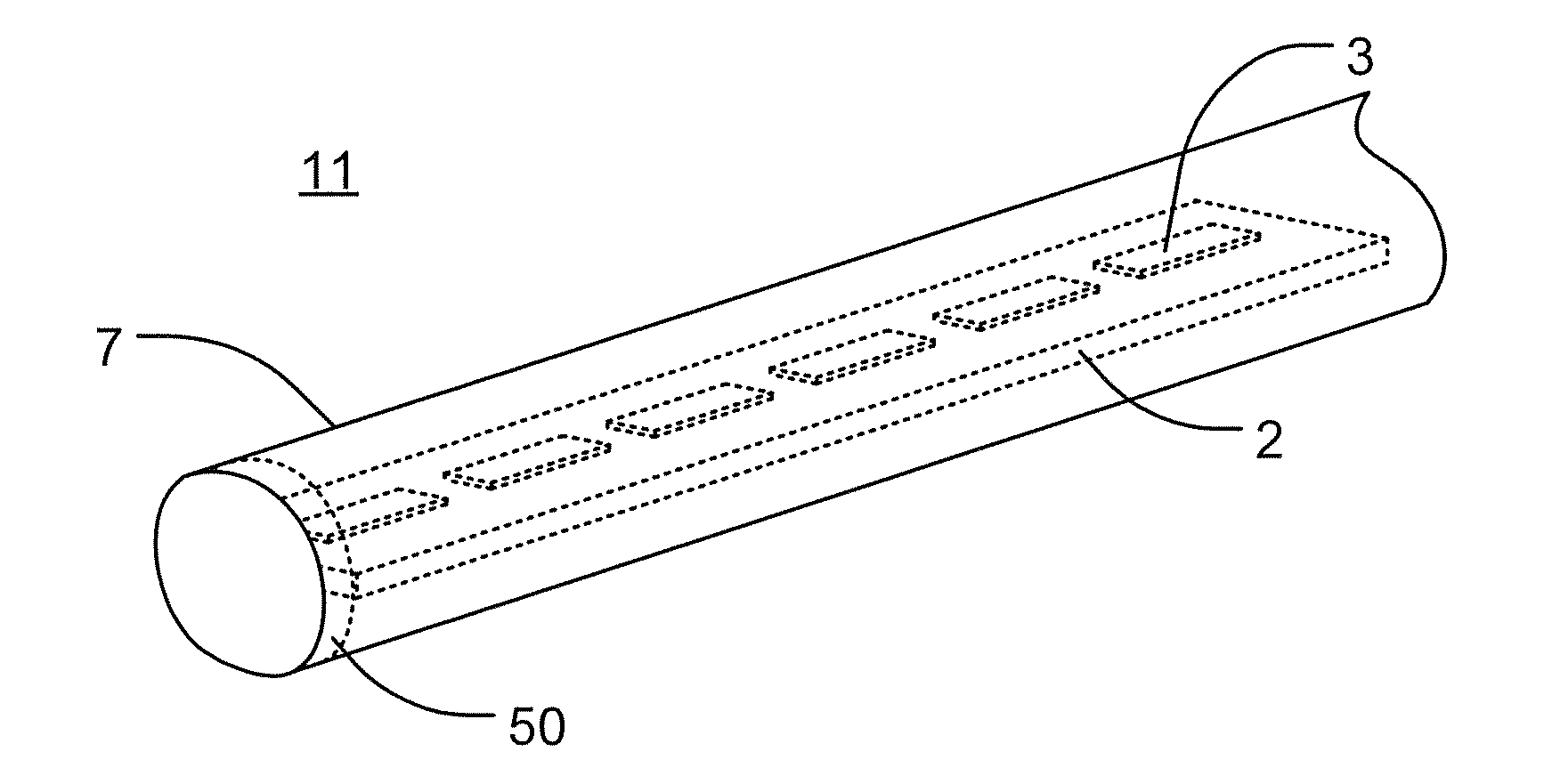

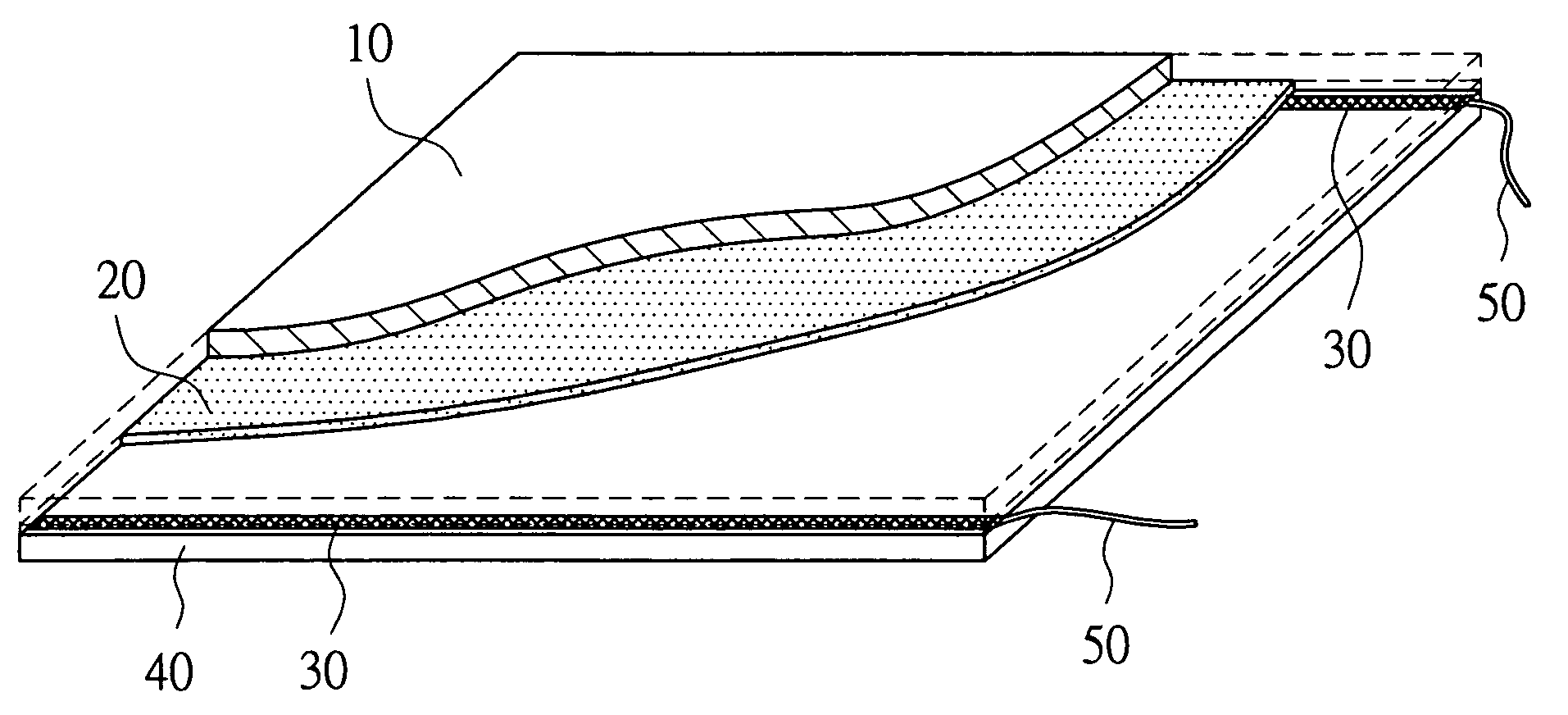

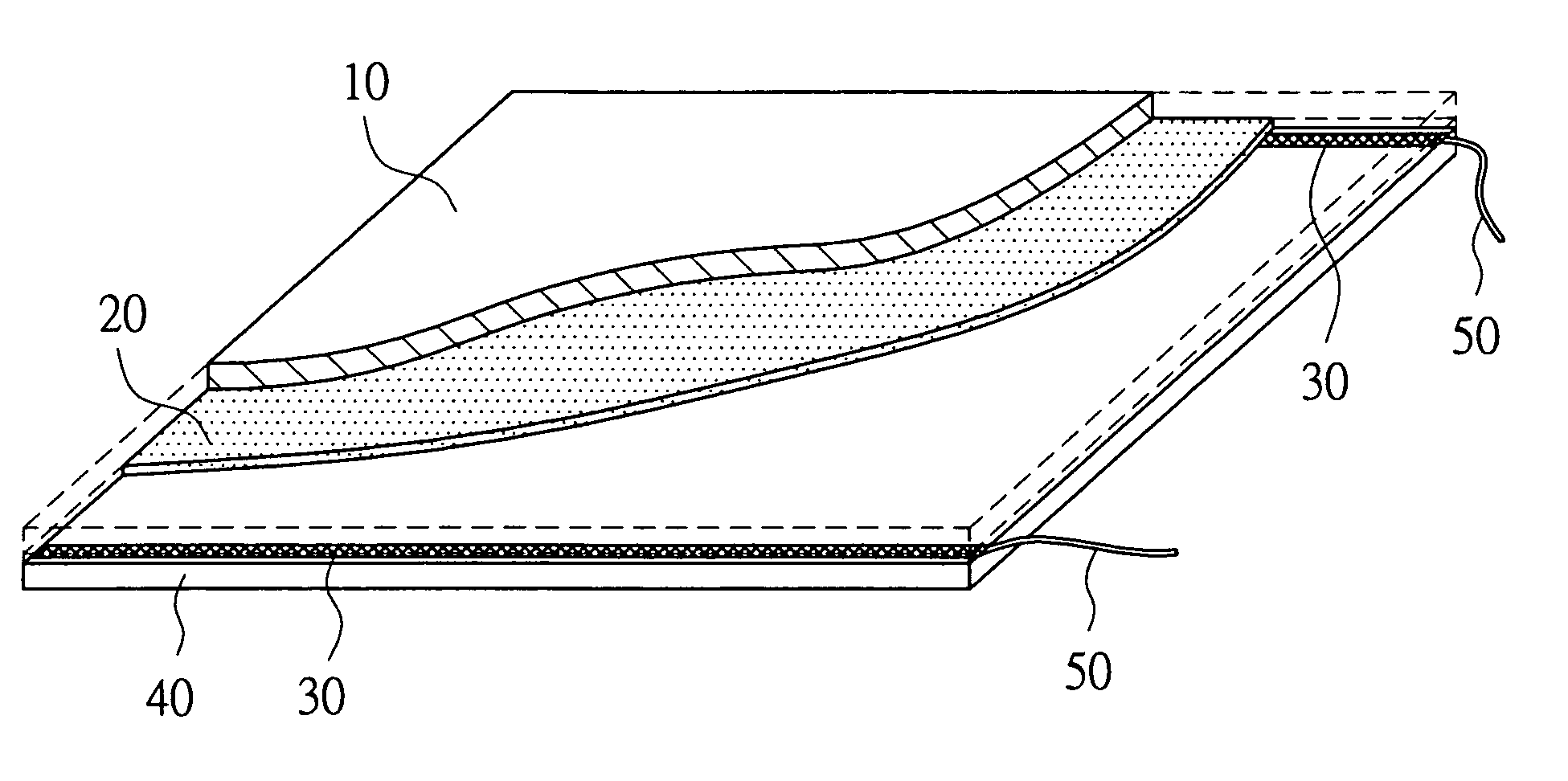

Planar light-emitting device

ActiveUS7178942B2Uniform performanceMechanical apparatusPoint-like light sourceLight emitting deviceLight source

A planar light-emitting device includes a light source for generating light, a light gathering module for gathering the light generated by the light source and generating mixed light, a linear light generator comprising a light distributing unit for receiving the mixed light and distributing the mixed light to generate linear light, and a planar light generator for receiving the linear light and generating a planar light.

Owner:EPISTAR CORP

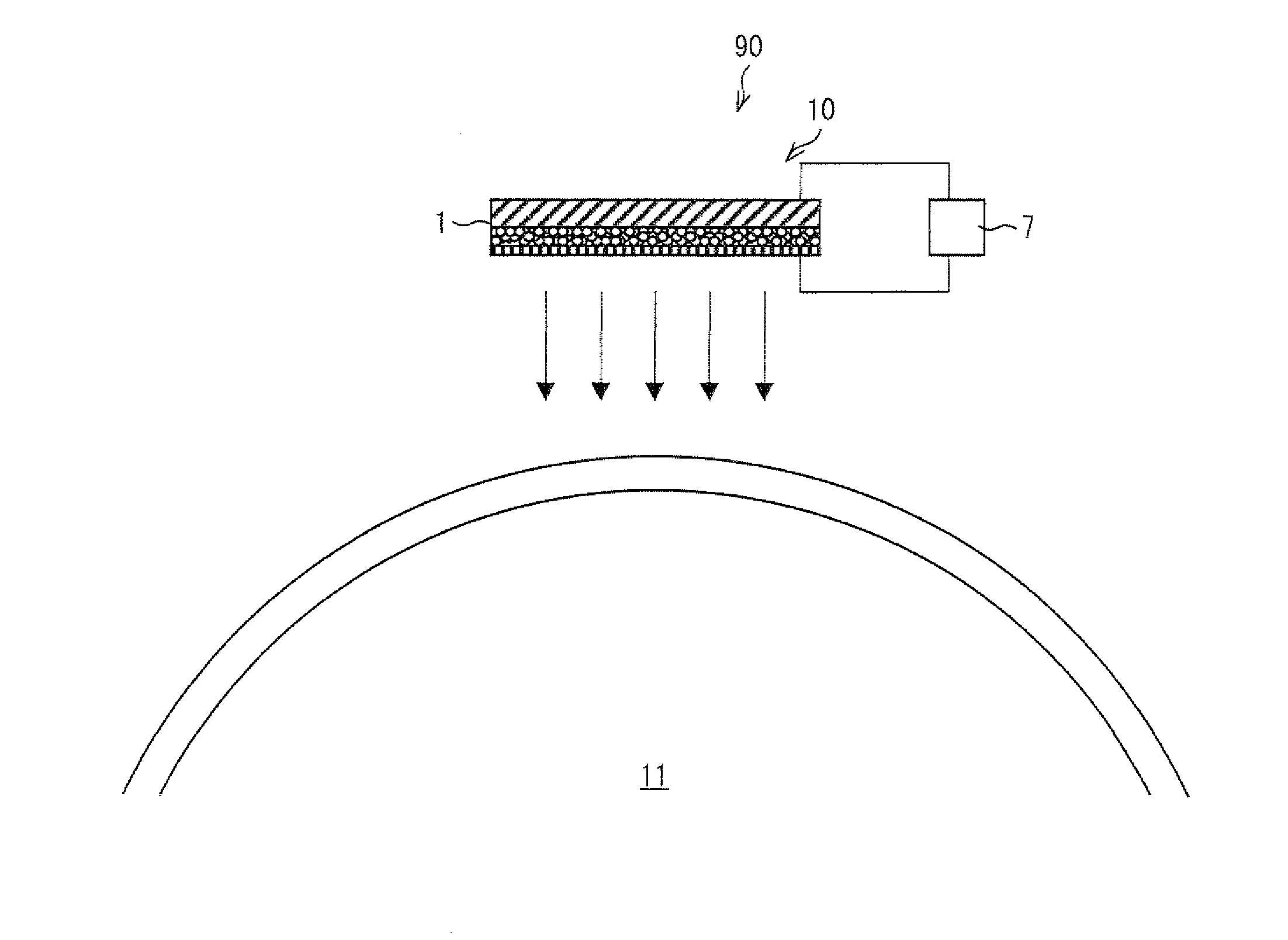

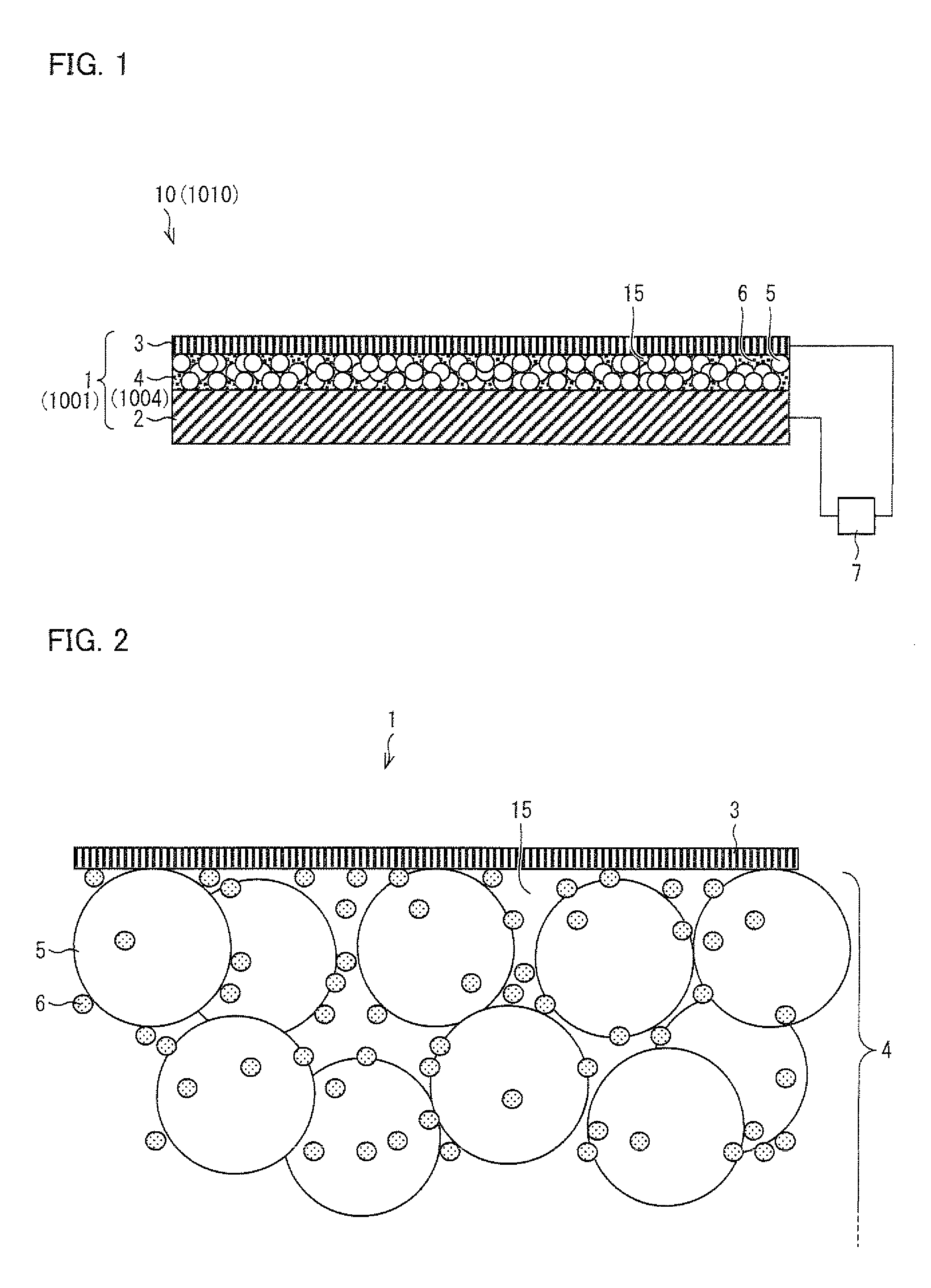

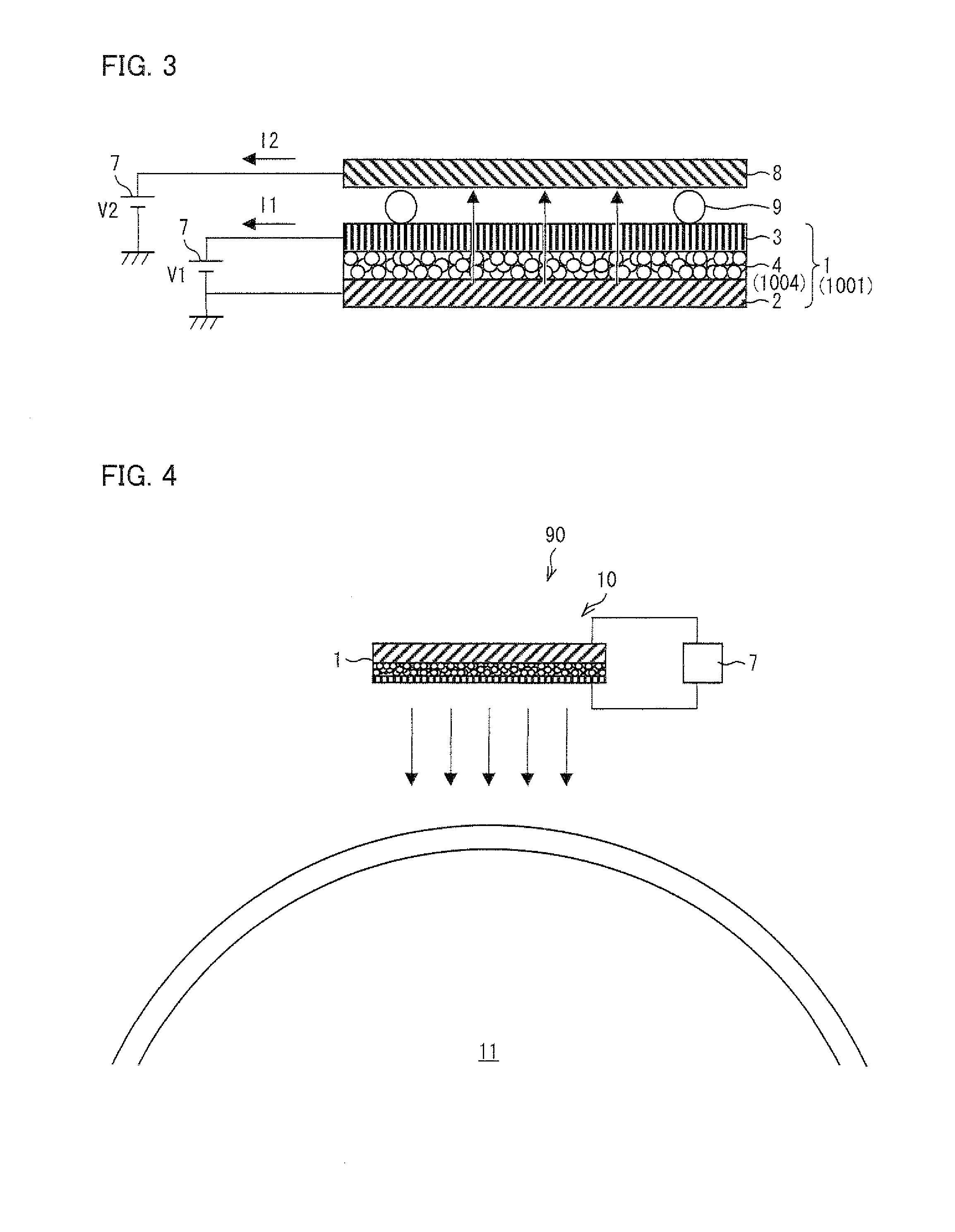

Electron emitting element, electron emitting device, light emitting device, image display device, air blowing device, cooling device, charging device, image forming apparatus, electron-beam curing device, and method for producing electron emitting element

ActiveUS20100215402A1Uniform performanceHigh adhesivenessControl electrodesNanoinformaticsThin film electrodeMolecular physics

An electron emitting element of the present invention includes an electron acceleration layer between an electrode substrate and a thin-film electrode. The electron acceleration layer includes a binder component in which insulating fine particles and conductive fine particles are dispersed. Therefore, the electron emitting element of the present invention is capable of preventing degradation of the electron acceleration layer and can efficiently and steadily emit electrons not only in vacuum but also under the atmospheric pressure. Further, the electron emitting element of the present invention can be formed so as to have an improved mechanical strength.

Owner:SHARP KK

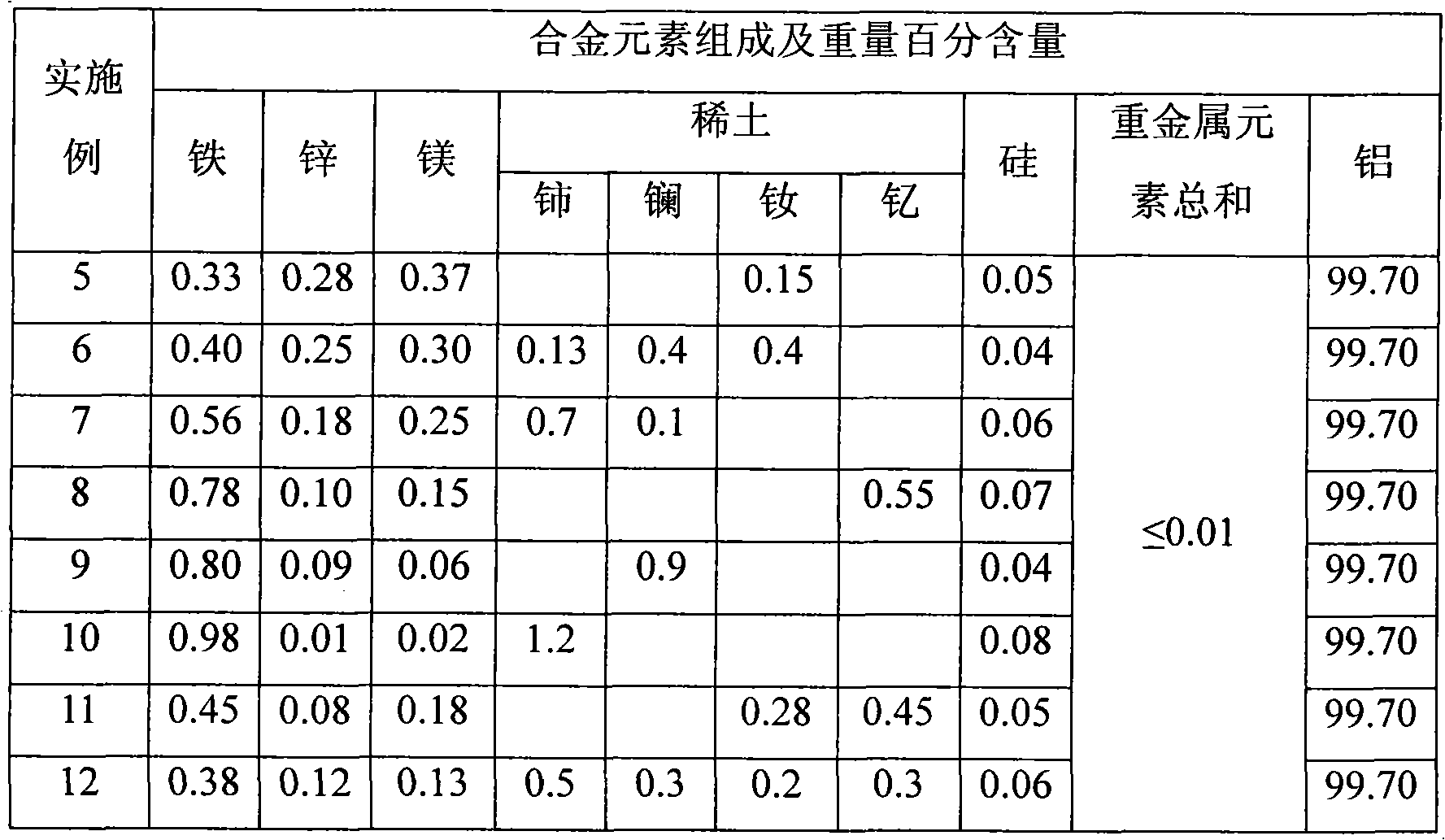

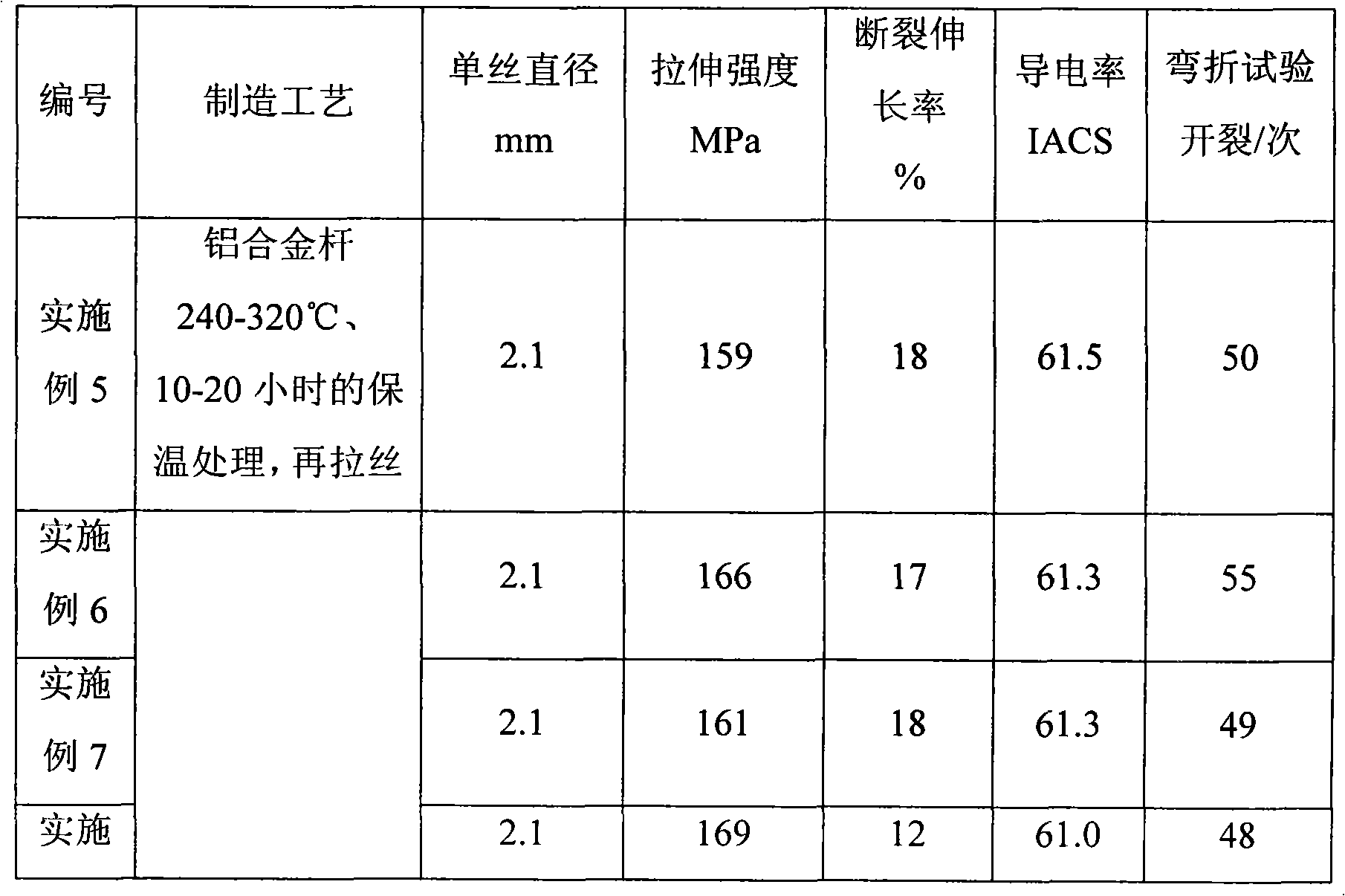

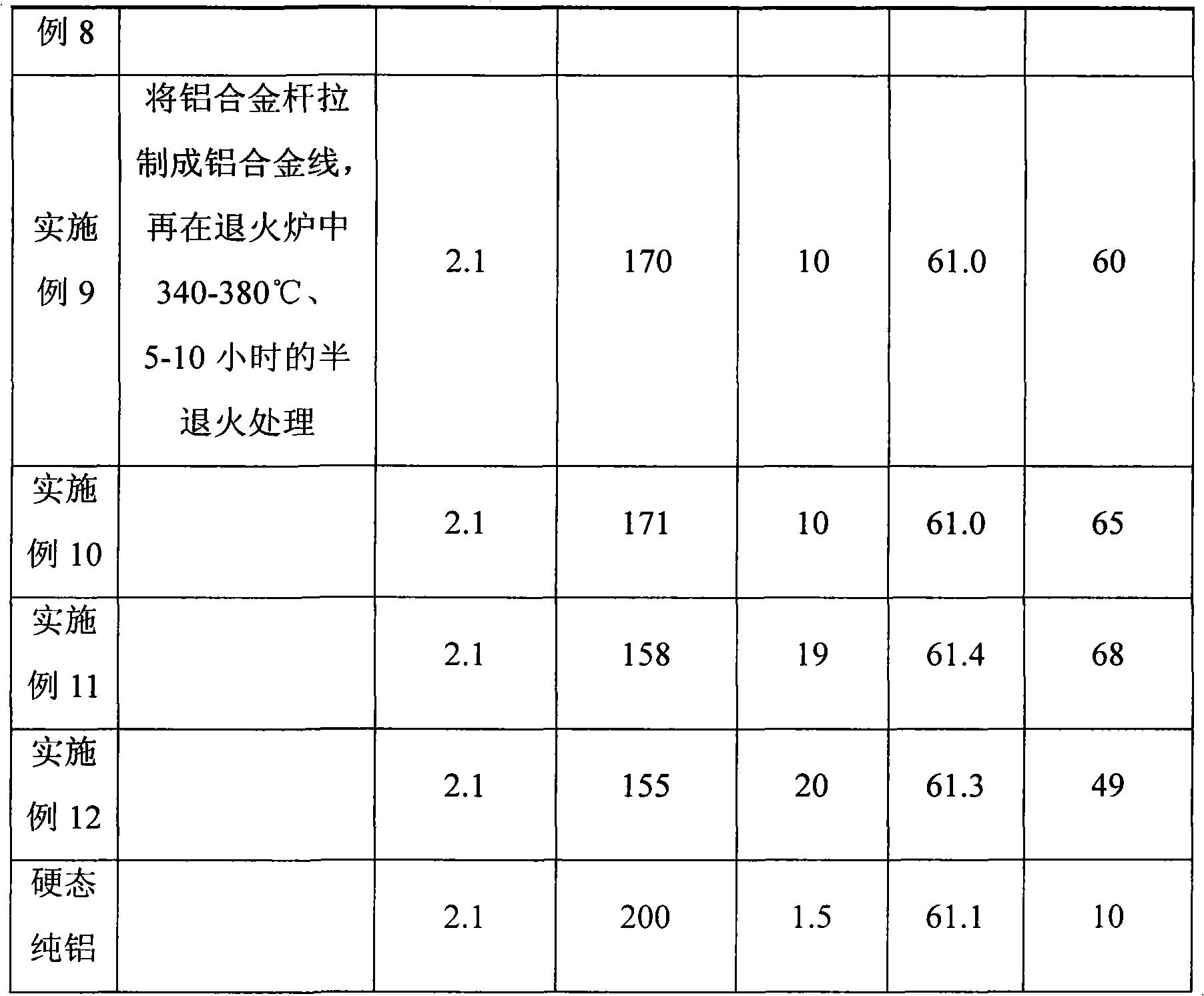

Al-Fe-Zn-Mg rare earth alloy wire and preparation method thereof

InactiveCN101880799AReduce defect densityGood match of strength and toughnessSingle bars/rods/wires/strips conductorsMetal/alloy conductorsAlloy elementRare-earth element

The invention discloses an Al-Fe-Zn-Mg rare earth alloy wire and a preparation method thereof. The aluminum alloy comprises the following elements: 0.3-1.2wt% of Fe, 0.01-0.3wt% of Zn, 0.01-0.4wt% of Mg, 0.1-1.5wt% of rare earth element and the balance of Al and inevitable impurities, wherein the rare earth element is composed of one or more of cerium, lanthanum, neodymium and yttrium. The preparation method of the aluminum alloy wire comprises the following steps: preparing an aluminum alloy rod through smelting, casting and rolling, performing insulation treatment in a heat holding cover at 240-320 DEG C for 10-20 hours, wiredrawing and extruding insulating material on the wire; or preparing an aluminum alloy rod through smelting, casting and rolling, drawing the aluminum alloy rod to prepare the aluminum alloy wire, performing semi-annealing treatment in an annealing furnace at 340-380 DEG C for 5-10 hours, and finally extruding insulating material on the wire. The aluminum alloy wire prepared by the method of the invention has excellent electrical property, mechanical property and corrosion resistance and can be used in the wire and cable conductors.

Owner:ANHUI JOY SENSE CABLE

Steel used for straight seam electric resistance welding petroleum casing and casing manufacturing method

ActiveCN101798654AHigh strengthImprove toughnessFurnace typesProcess efficiency improvementWeld seamElectric resistance welding

The invention relates to a steel used for straight seam electric resistance welding petroleum casing and a casing manufacturing method, which is applied to a straight seam electric resistance welding petroleum casing used for an oil and gas well in petroleum and gas industry. The steel used for the straight seam electric resistance welding petroleum casing comprises the following components in percentage by mass: 0.15-0.28% of C, 1.0-1.6% of Mn, 0.2-0.4% of Si, 0. 02-0.06% of Al, less than or equal to 0.01% of P, less than or equal to 0.005% of S, less than or equal to 0.008% of N, 0.001-0.005% of Ca and the balance of Fe. The preparation method comprises the steps of: preparing hot-rolled plate coils, producing straight seam electric resistance welding steel pipes by the hot-rolled plate coils, carrying out welding seam normalization or overall normalization on the welded steel pipes, straightening and cutting the normalized or tempered welded steel pipes into pipe segments with the length of 10-12m, and processing API standard screw threads. The invention has the advantages that the steel has good strength and toughness, the welding seam has no defect, and the properties of the steel are uniform with those of mother material. The yield strength is greater than or equal to 380-760MPa, the tensile strength is greater than or equal to 520-865MPa, the elongation is greater than or equal to 20%, and the impact energy of a room-temperature transverse full-size V-shaped notch is greater than or equal to 40J.

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

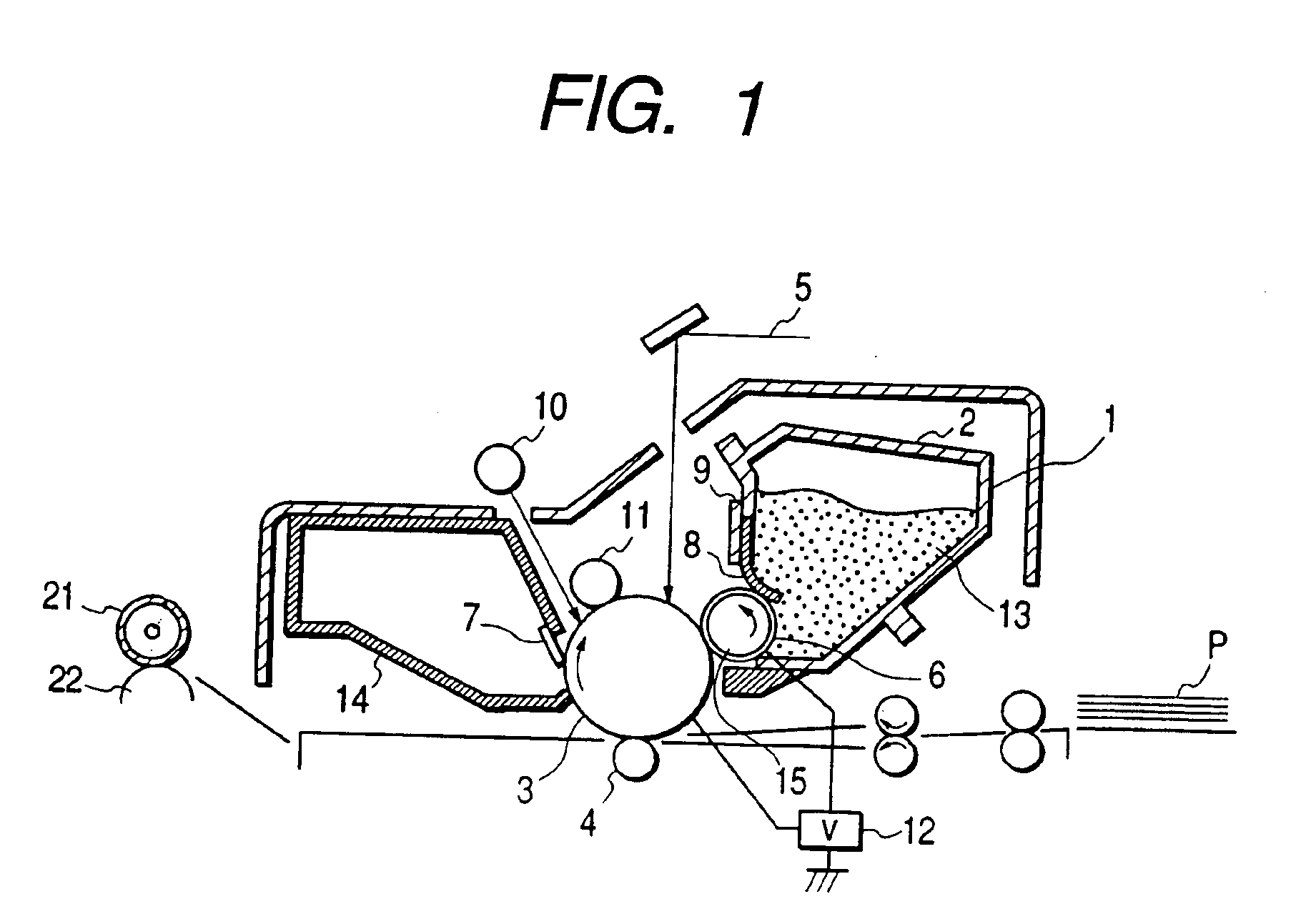

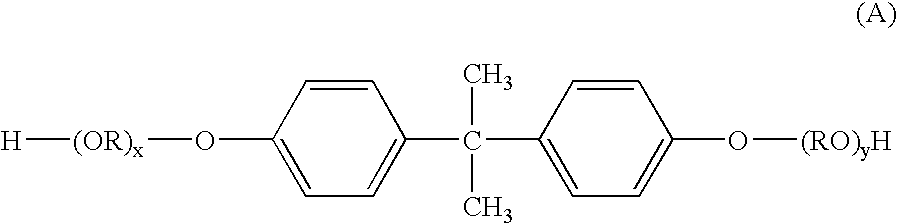

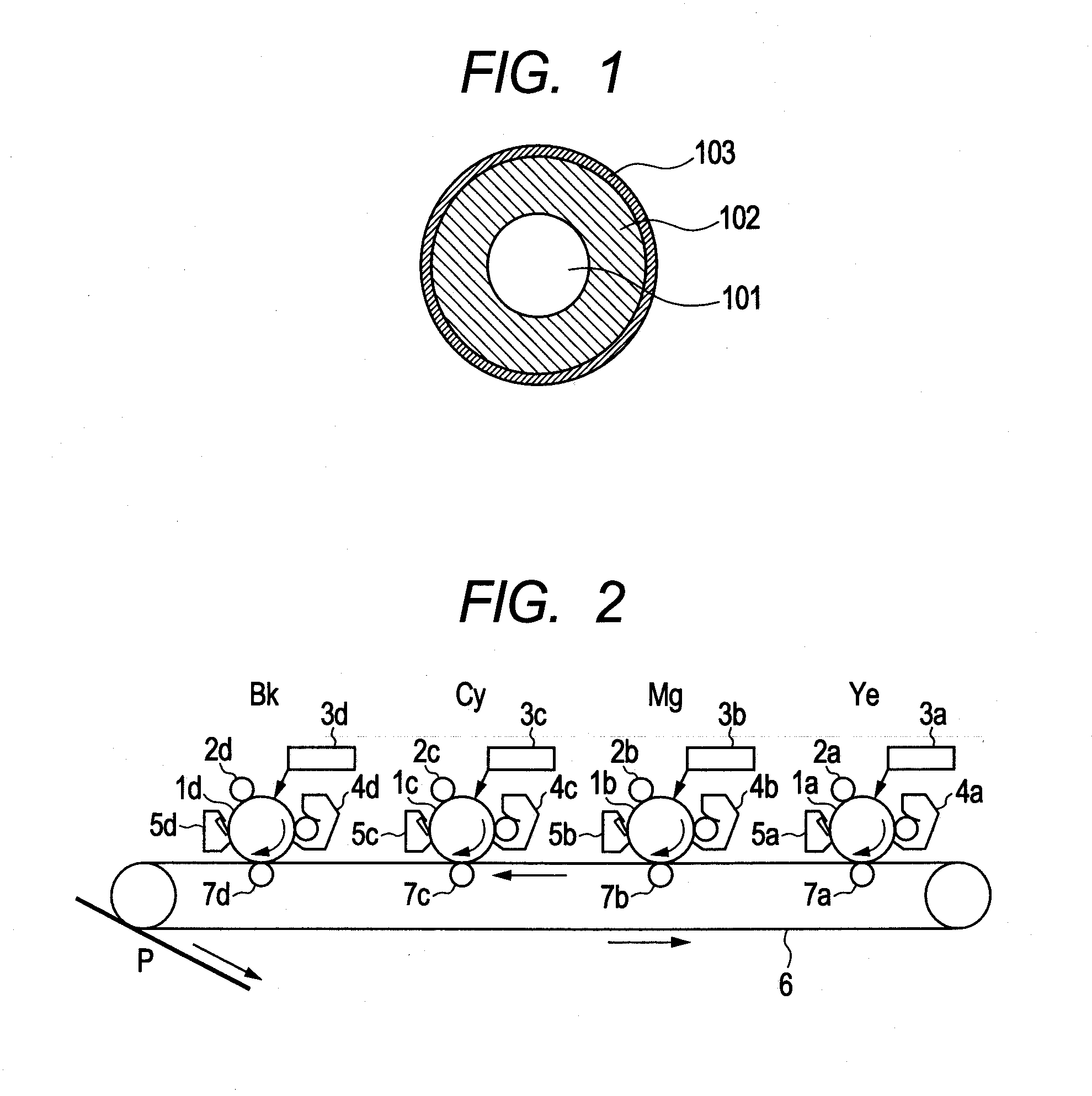

Toner, and process cartridge

ActiveUS6881527B2Improve crushing effectBroad fixable temperature regionDevelopersPolyester resinTetrahydrofuran

In a toner having a polyester resin as a binder resin component, and a colorant, the toner contains (a) in the binder resin component, from 20.0% by weight to 65.0% by weight of a tetrahydrofuran-insoluble matter A1 in 6-hour extraction and from 35.0% by weight to 80.0% by weight of a tetrahydrofuran-soluble matter A2 in 6-hour extraction, (b) in the binder resin component, from 10.0% by weight to 30.0% by weight of a tetrahydrofuran-insoluble matter B1 in 16-hour extraction and from 70.0% by weight to 90.0% by weight of a tetrahydrofuran-soluble matter B2 in 16-hour extraction, and (c) in the binder resin component, from 0.5% by weight to 3.0% by weight of an orthodichloro-benzene-insoluble matter C1 in 6-hour extraction at 185° C. and from 97.0% by weight to 99.5% by weight of an orthodichlorobenzene-soluble matter C2 in 6-hour extraction at 185° C. The proportion of C1 to B1, C1 / B1, is from 0.06 to 0.15, and the A1, B1 and C1 satisfy the following expression (1):A1>B1>C1. Expression (1)A process cartridge makes use of this toner.

Owner:CANON KK

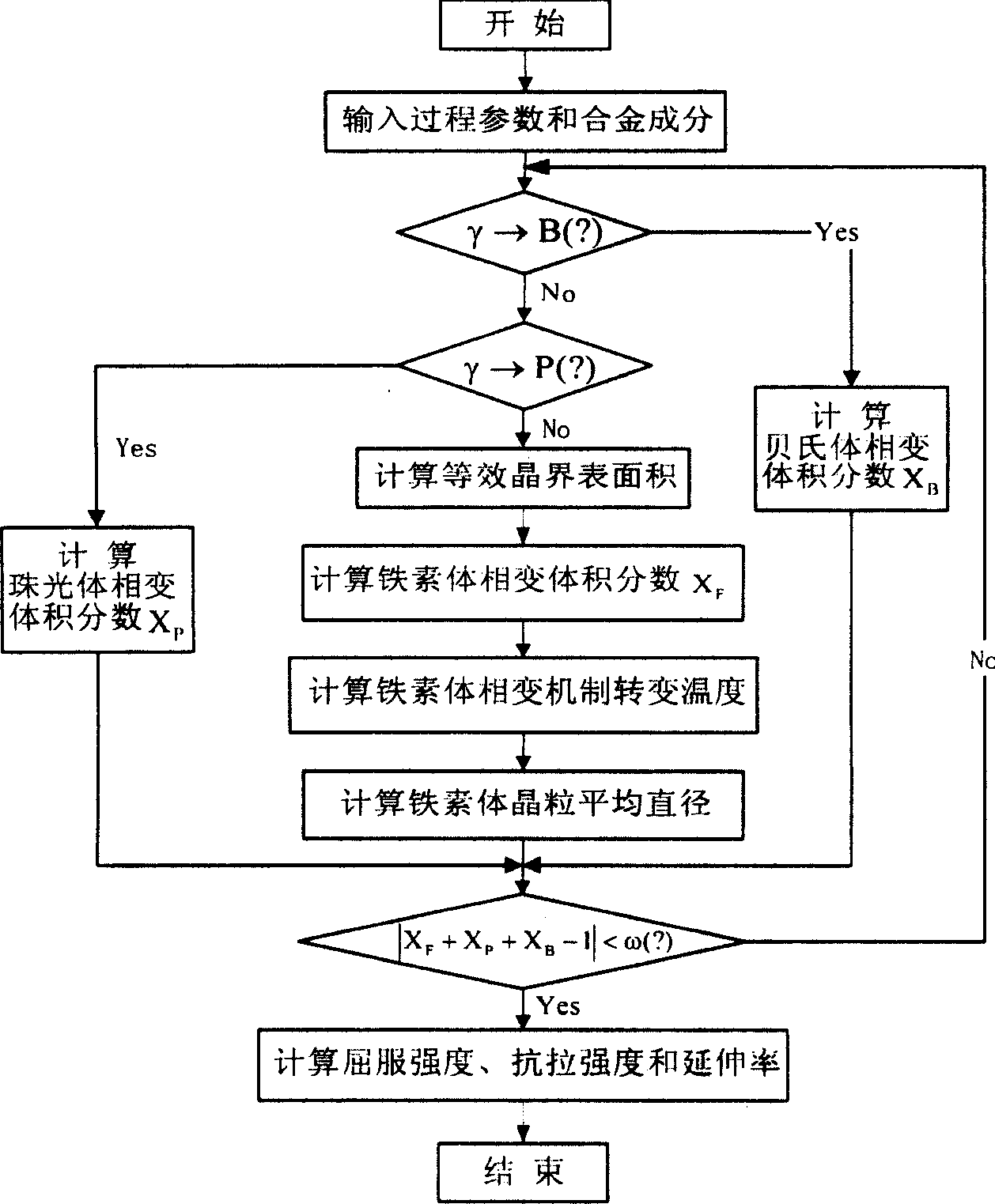

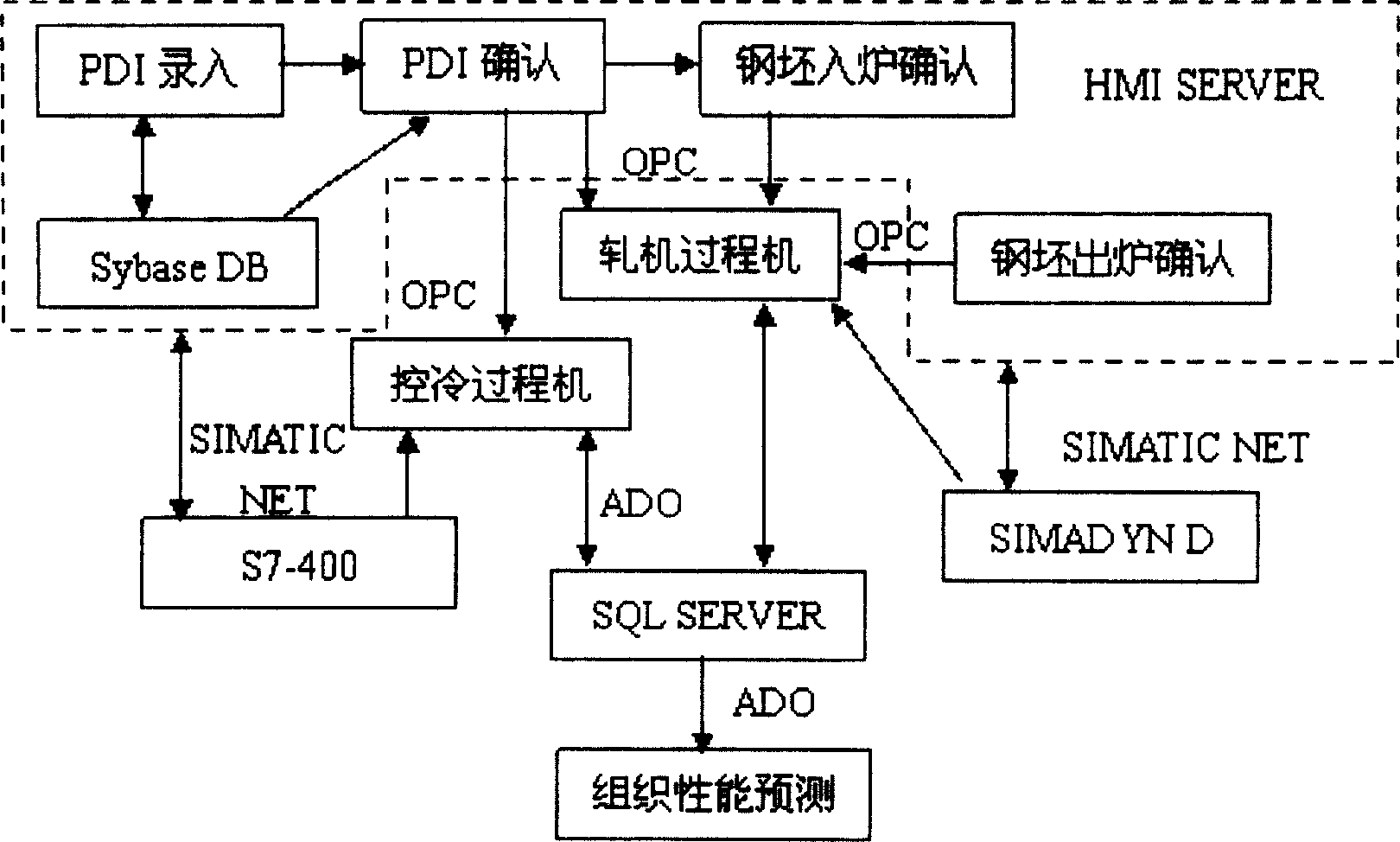

Method for online test of steel plate mechanic property during rolling process

InactiveCN1664550ASufficient reliabilityHigh precisionInvestigating material ductilityInvestigating material hardnessOnline testModel parameters

The invention relates to a method for testing the mechanical of the steel plate on line when rolling, providing a comprehensiveness on-line predicting method based on the physico-metallurgy model and combined with the database, information technology through setting up a corresponding model of microscopic structure, finished size, art component to the mechanical. The method including the following steps: (a) selecting and confirming the parameter of the model; (b) setting up the real-time traffic to the processing machine, calling the art parameter and alloying component dynamic data from the processing database; (c) predicting the ferrite grain size and temperature (d) predicting mechanical of the finished plate. The invention is used specially for low-carbon steel and mini alloyed steel, the adaptive process is heavy and medium plate mill or big mill and finisher in rolling process.

Owner:NORTHEASTERN UNIV

Production method of high-strength steel rope

InactiveCN103352381AMeet the standard requirementsUniform tissueFurnace typesQuenching agentsWater bathsQuenching

The invention provides a production method of a high-strength steel rope. The production method of the high-strength steel rope is characterized that low carbon is selected and used as raw materials of the steel rope, and the production technology comprises a first step of surface processing, wherein wire materials are placed on a pay-off rack, the diameter of the wire materials is 5.5mm, hot-rolled oxide-scale is eliminated through mechanical dephophorization equipment, high-power ultrasonic cleaning is conducted on the wire materials, the wire materials enter phosphating equipment, phosphating is conducted on the wire materials, the wire materials enter drying equipment and are dried finally, and preprocessed wire materials are obtained; a second step of drawing, wherein the preprocessed wire materials obtained from the first step are placed on a drawing machine, multi-pass drawing is conducted on the preprocessed wire materials, semi-finished wire materials are obtained, and winding up is conducted through a spool; a third step of water bath heat treatment and galvanization, wherein the semi-finished wire materials obtained in the second step are placed on the pay-off rack, the semi-finished wire materials are heated in a four-section form heat treatment furnace, quenching, drying, galvanization and cooling are conducted on the semi-finished wire materials, semi-finished wire materials are obtained, and winding up is conducted; a fourth step of wet type drawing, wherein the semi-finished wire materials obtained in the third step are placed on the drawing machine, multi-pass drawing is conducted on the semi-finished wire materials, the compression angle of a wire-drawing die of each pass is 13-14 degrees, dedicated lubricating agent is used as lubricating agent, the concentration of the dedicated lubricating agent is 2%-3%, finished wire materials are obtained, and winding up is conducted through a spool; a fifth step of stranding and rope forming, wherein the finished wire materials are placed on a stranding machine, stranding and laying-up are conducted, and the finished steel stranded rope is obtained.

Owner:ZHANGJIAGANG SHENGDA STEEL ROPE

Polishing film and method for making same

ActiveCN101225281AUniform performanceReduce manufacturing costOther chemical processesPolishing compositionsOrganic solventRoller Coating Method

The invention discloses a polishing film and the preparation method, which adopts the ultrafine micro mist as the grinding material and prepares in flow-casting coating method, namely the powdered or granular resin is dissolved into the organic solvent and then added in functional additive to make the resin adhesive, then the abrasive of surface-modified ultrafine micro mist is added into the resin adhesive and the spread coating liquid can be obtained after fully mixing, finally the paint is painted on the surface of soft base in flow-casting coating method and the polishing film can be obtained after drying and curing. The preparation method of the polishing film has the advantages of small equipment investment, simple operation, high productivity and automation level, steady craft, even film performance and low manufacturing cost. The polishing film can adjust the craft parameters of the flow-casting craft conveniently according to the different quality requirement and standards of the products, and can achieve production in multi-specification and small lot production and overcomes the problems that the rapid transformation of the product specification is difficult due to the limit of the equipment structure in roller coating method.

Owner:HENAN UNION ABRASIVES

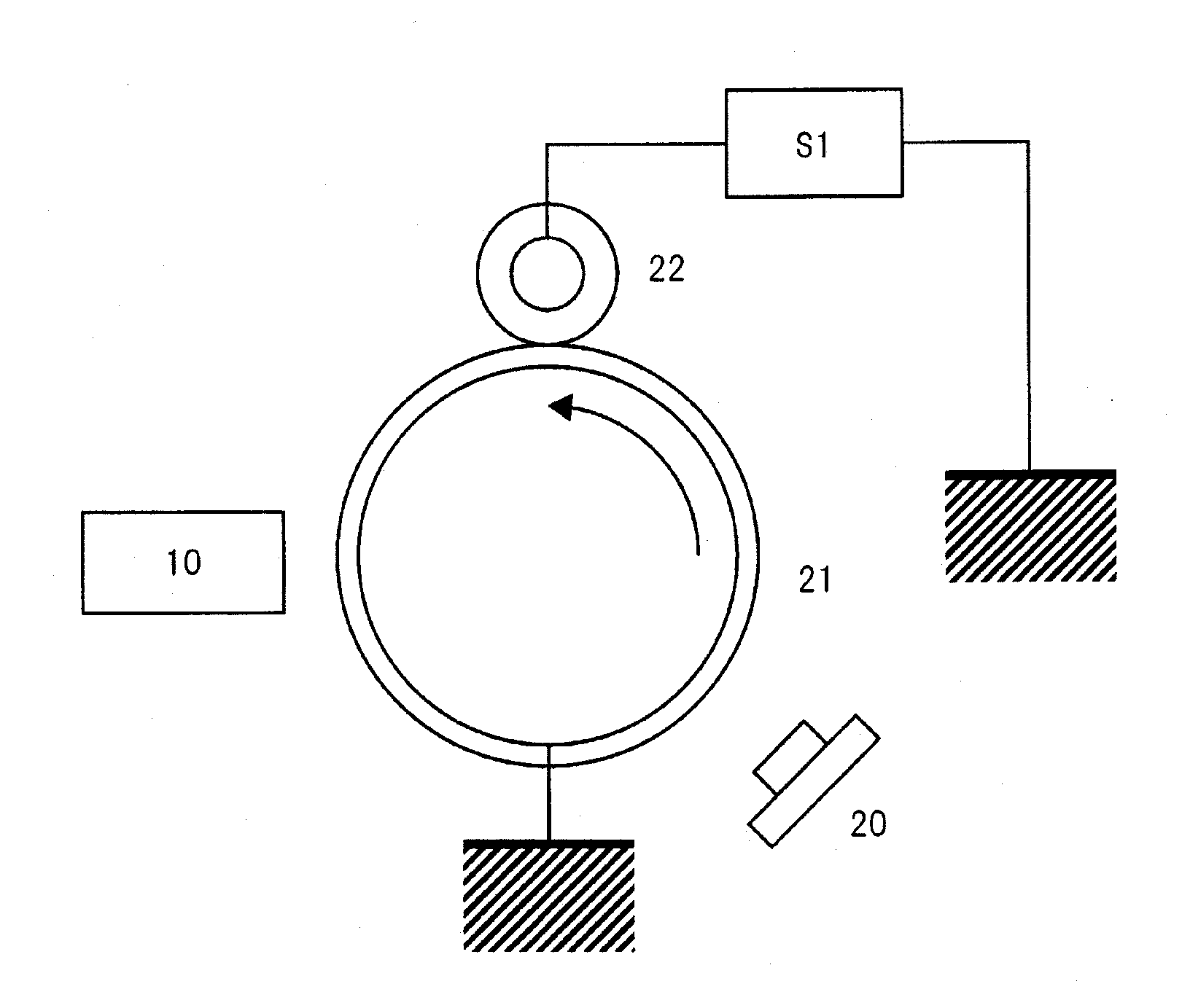

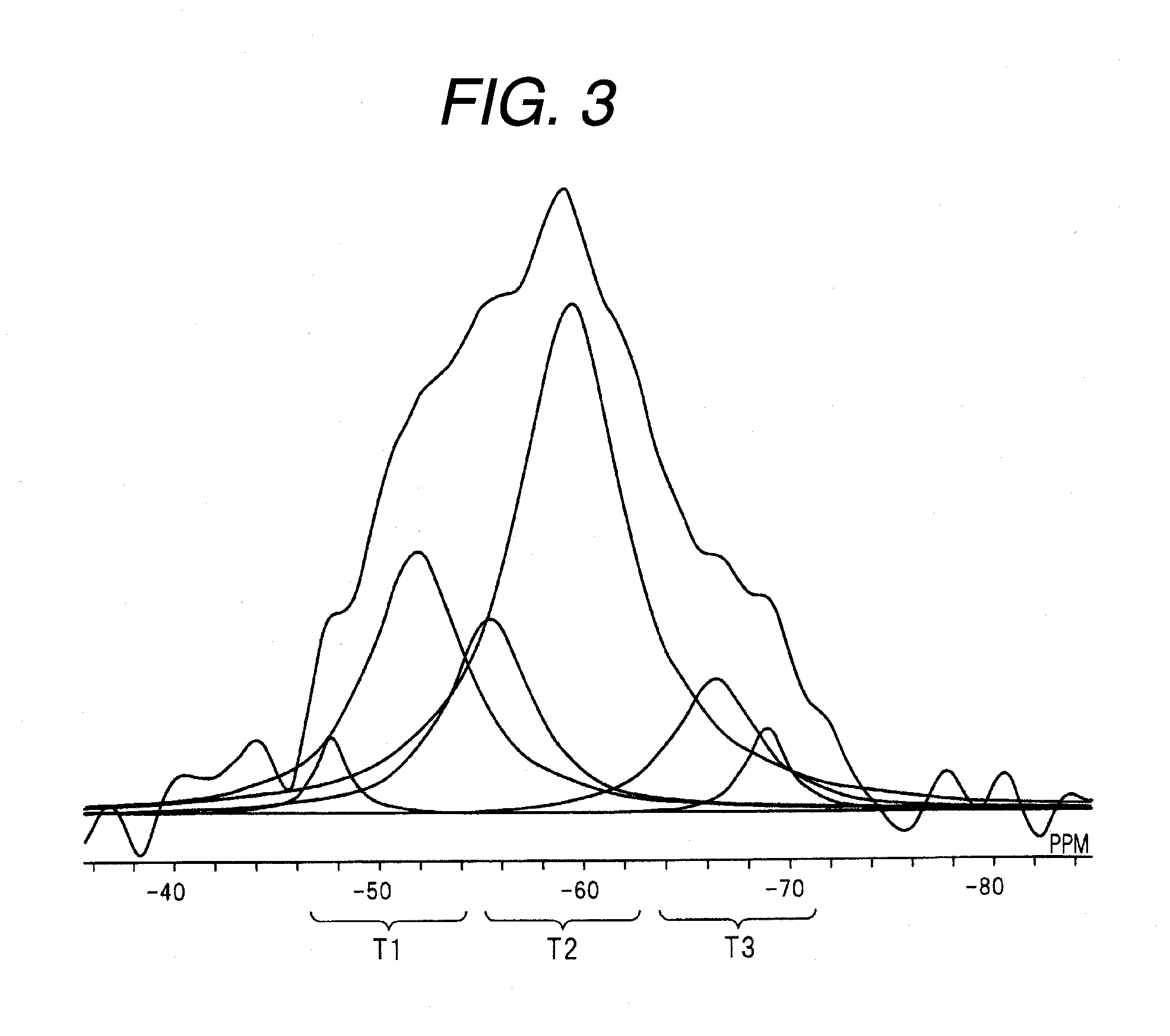

Charging member, process cartridge and electrophotographic apparatus

InactiveUS20130034369A1Sufficient charging performanceUniform chargeElectrographic process apparatusWater-setting substance layered productSurface layerEngineering

A charging member is provided which can uniformly charge a photosensitive member without requiring any pre-exposure means in a low-, medium- or high-speed electrophotographic apparatus, and has a sufficient charging performance. An electrophotographic apparatus and a process cartridge are also provided which can keep multi-color ghost images from occurring and can form high-grade electrophotographic images stably. The charging member has a substrate, an elastic layer and a surface layer, which surface layer contains a high-molecular compound having an Si—O—Nb linkage; the high-molecular compound having a constitutional unit represented by the following formula (1) and a constitutional unit represented by the following formula (2).

Owner:CANON KK

Wire with tensile strength>=2000MPa for bridge cable and production method

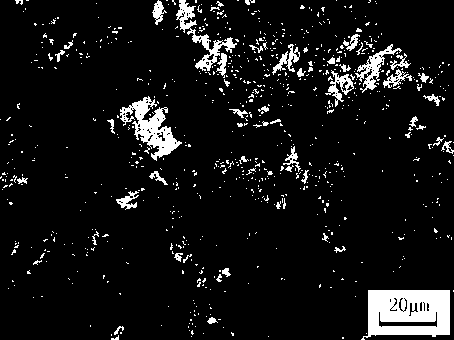

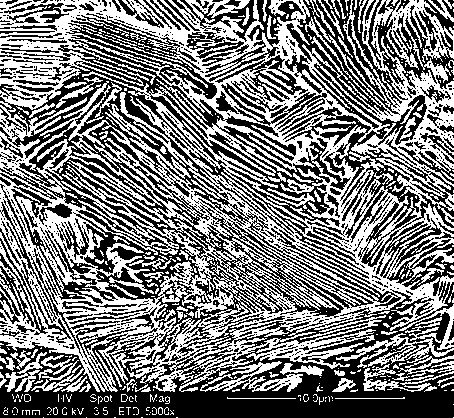

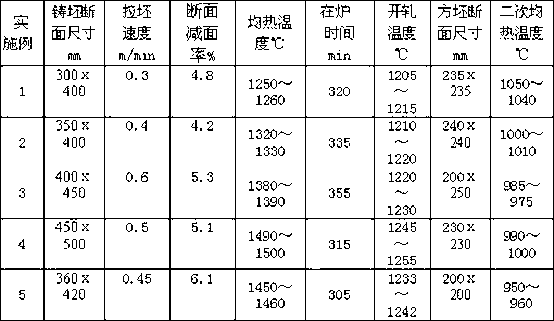

ActiveCN102936688AUniform metallographic structureUniform performanceMetal rolling arrangementsAir volumeRoom temperature

The invention discloses a wire with tensile strength>=2000MPa for a bridge cable and a production method. The wire comprises, by weight, 0.95-1.2% of C, 0.1-0.48% of Si, 0.6-1.0% of Mn, 0.1-0.5% of Cr, 0.01-0.05% of V, Cu<=0.05%, 0.05-0.15% of Al, 0.01-0.03% of N, P<=0.025% and S<=0.015%. The production method includes smelting and continuously casting into blanks; heating the casting blanks; rolling; heating again; high-speed rolling; spinning; air cooling to the room temperature; and placing for standby. According to the wire and the method, continuous casting of blooms, rolling starting of billets and high speed wire rolling are adopted, therefore a metallographic structure and the like of the wire for the bridge cable are even, and grains are better refined; and processes of rapid cooling with a large air volume and the like are adopted, therefore the tensile strength of the wire for the bridge cable is >=2000MPa and stable, a twist number reaches >=15, and wire fracture caused by the wire quality does not happen during cold drawing.

Owner:武汉钢铁有限公司

Light emitting apparatus

ActiveUS20130322072A1Sufficient light intensityUniform light performancePoint-like light sourceLighting support devicesUltimate tensile strengthLight emitting device

The present invention relates to a light emitting apparatus comprising at least one light emitting device and a support mechanism. The light emitting device includes a transparent substrate which light can pass through; at least one LED chip emitting light omni-directionally is disposed on one surface of the substrate, and the light emitted by the LED chip will penetrate into the substrate and at least partially emerge from another surface of the substrate. The support mechanism is coupled to the light emitting device; a first angle is formed between the substrate and the support mechanism. According to the present invention, the light emitting apparatus using LED chips can provide sufficient lighting intensity and uniform lighting performance.

Owner:EPISTAR CORP

Activated carbon fiber soft electric heating product and manufacturing method thereof

InactiveUS20100062667A1Light weightUniform electric heating performanceEnvelope/housing resistor manufactureMedical devicesFiberEpoxy

An activated carbon fiber soft electric heating product and its manufacturing method for overcoming existing problems including uneven temperature rise and heat dissipation at surfaces of the product, unbendable feature, short life and poor safety. An activated carbon fiber cloth and a woven fiber cloth of the activated carbon fiber soft electric heating product are fixed by an epoxy resin layer, and a conducting copper net is disposed between the activated carbon fiber cloth and the epoxy resin layer and coupled to a power input wire. The manufacturing method includes the steps of: (1) spraying an epoxy resin on a surface of the woven fiber cloth, and bake-drying and hot pressing the woven fiber cloth; and (2) connecting the conducting copper net and the power input wire, laying the activated carbon fiber cloth, and performing a second-time hot pressing. Meanwhile, carbon fiber constitutes a heat generating surface with the advantages of a light weight, a soft texture, a bendable feature, a uniform electric heating performance, a fast temperature rise, a highly safe, reliable and long life feature. In addition, the method of the invention involves a simple technical skill and an easy operation.

Owner:PAN

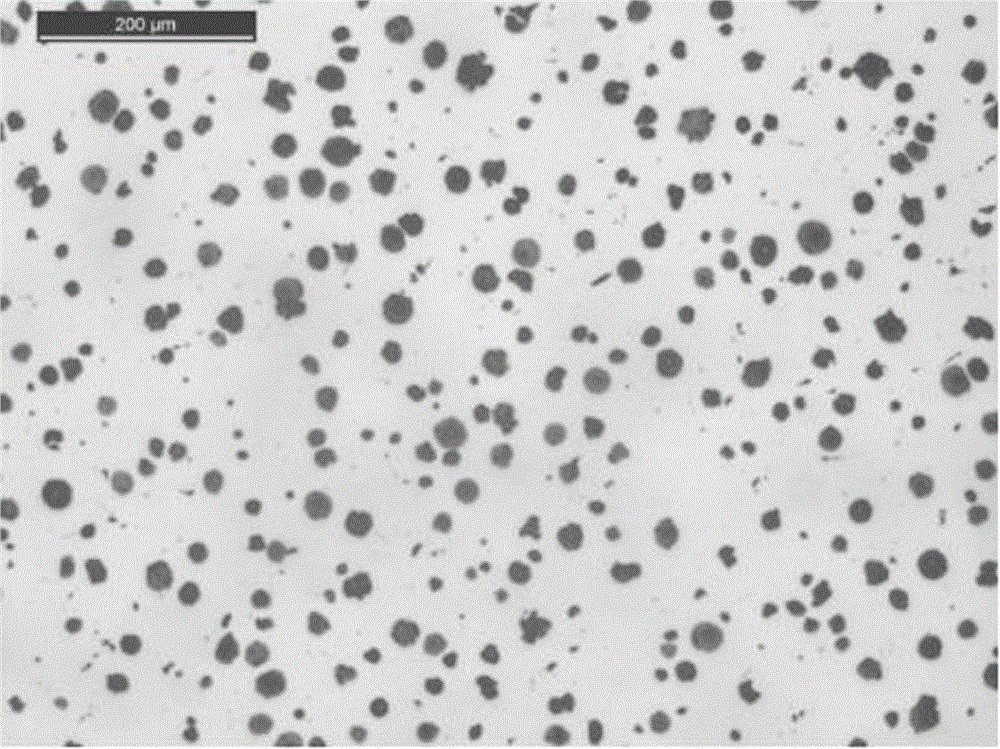

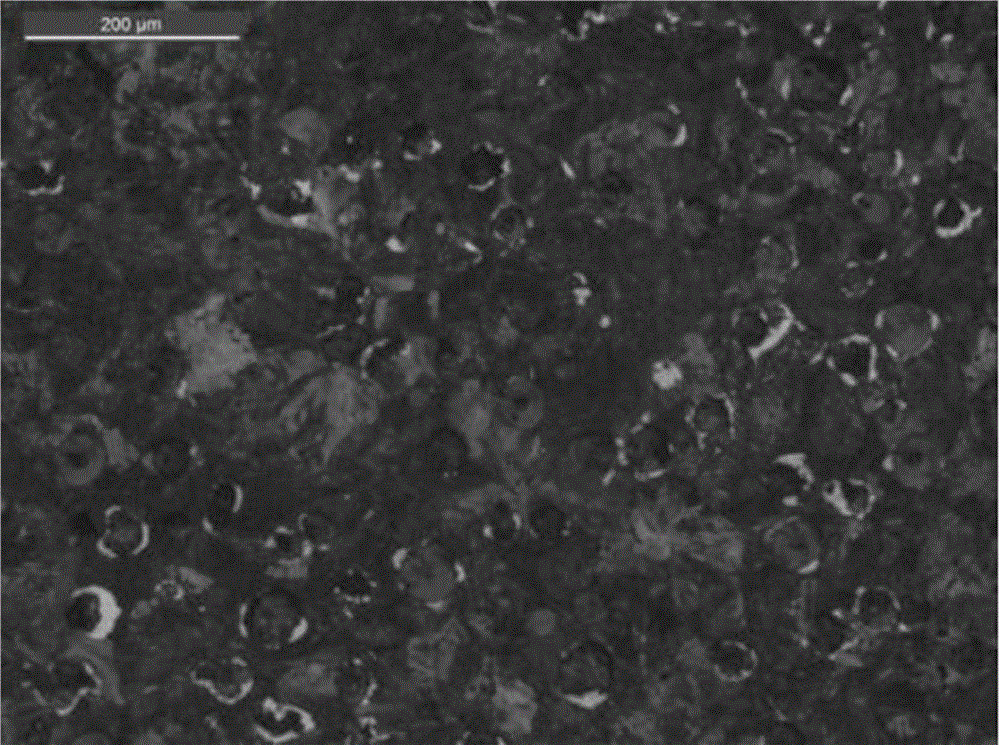

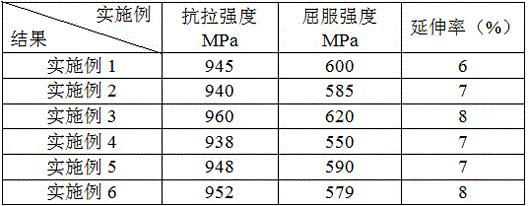

High-strength nodular cast iron QT900-6 and preparation method thereof

ActiveCN106011610AExcellent performanceImprove high temperature mechanical propertiesTrace elementMechanical property

The invention discloses high-strength nodular cast iron QT900-6 which consists of the following elements in percentage by weight: 3.2-3.7% of C, 2.4-2.8% of Si, less than or equal to 0.2% of Mn, less than or equal to 0.03% of P, 0.005-0.02% of S, 0.8-1.4% of Cu and the balance of Fe and unavoidable trace elements. The high-strength nodular cast iron QT900-6 has high compressive strength, high yield strength and excellent mechanical property.

Owner:西峡县内燃机进排气管有限责任公司

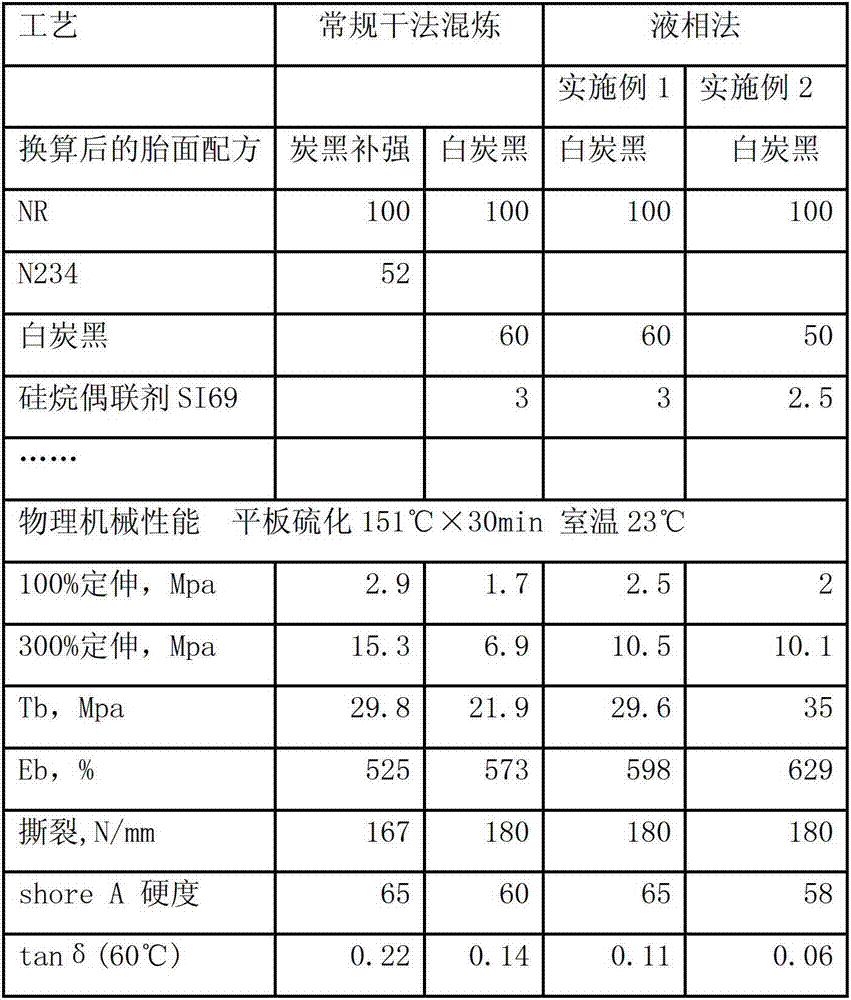

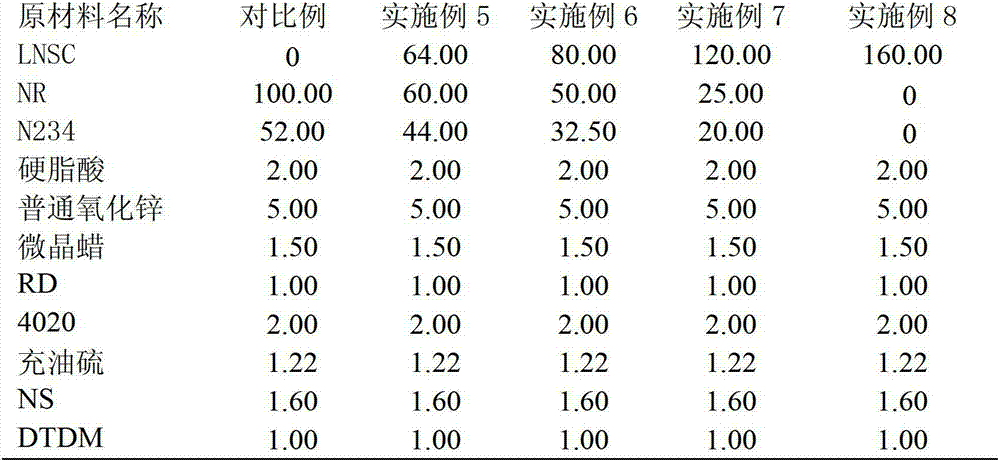

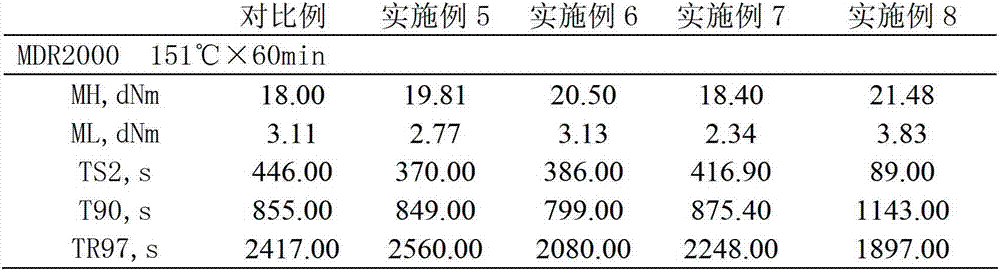

Preparation method for liquid phase stirring and mixing of white carbon black and natural rubber

ActiveCN102775654APreserve the status quoKeep strongSpecial tyresRolling resistance optimizationHysteresisBrute force

The invention relates to the production field of tire rubber sizing materials, in particular to a method for mixing liquid state white carbon black and liquid state natural rubber in a liquid phase. The preparation method for liquid phase stirring and mixing of the white carbon black and the natural rubber comprises the steps of (1) preparing slurry; (2) mixing; (3) solidifying, dehydrating, washing and stoving. The method adopts liquid-liquid high speed stirring and mixing to effectively preserve original states of natural rubber macromoleculars, effectively preserves brute force of the natural rubber and substantially promotes brute force and abrasive resistance of mixed glue. Brute force of sizing materials mixed by using the method is substantially promoted, and themogenesis and hysteresis loss are obviously reduced. The mixed glue produced by the method can be singly used and can also be blended with the natural rubber, rubber polymer, natural rubber carbon black rubber master batch and rubber polymer carbon black rubber master batch according to certain proportion. According to the method, the liquid state white carbon black and the liquid state natural rubber are mixed directly, the process is simple, the land occupation is small, the equipment investment is low, and dust pollution does not exist in a production process.

Owner:ZHONGCE RUBBER GRP CO LTD

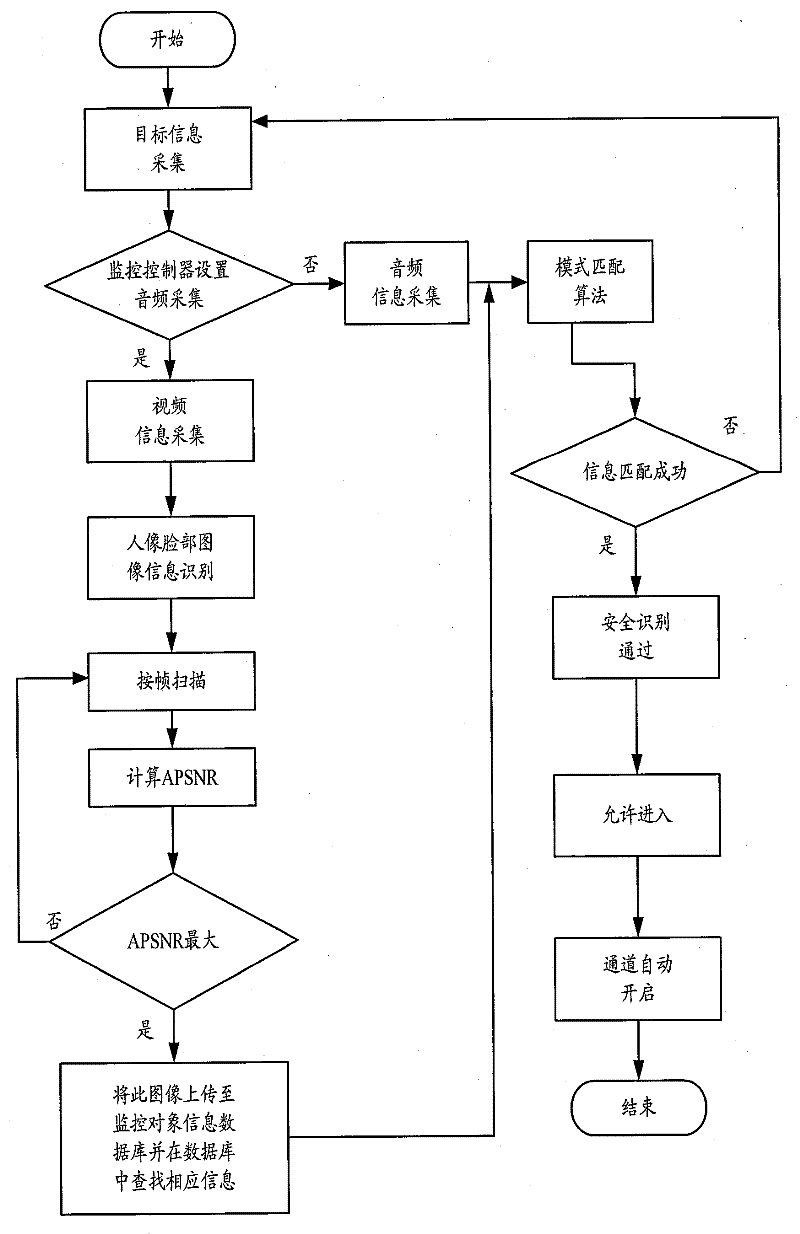

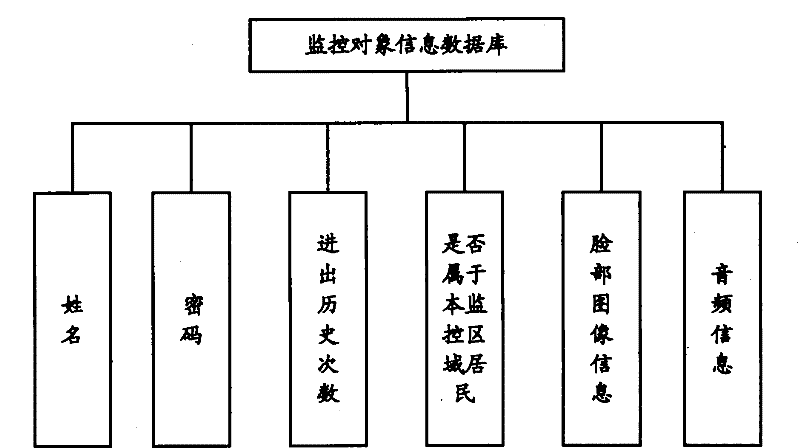

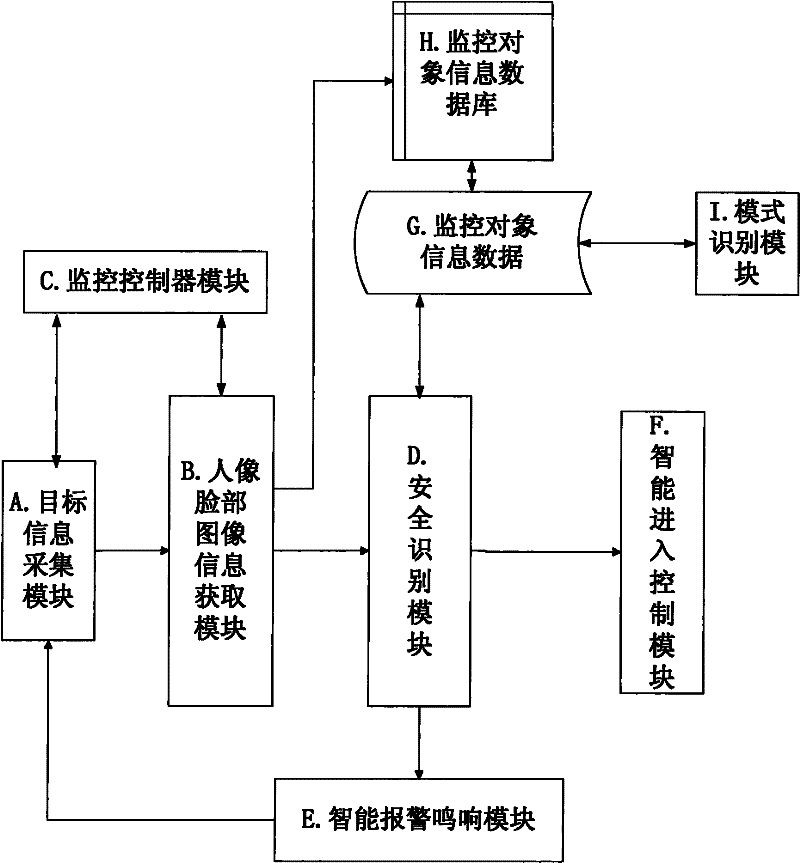

Intelligent monitoring system used for safe access of local cell region and realization method thereof

InactiveCN102176746AImprove reliabilityImprove securityCharacter and pattern recognitionClosed circuit television systemsVideo monitoringCell region

The invention discloses an intelligent monitoring system used for safe access of a local cell region and a realization method thereof, and relates to an image scanning and mode identification technique, and an intelligent video monitoring technique for computer intelligent analysis, processing and collection and classification. The intelligent monitoring system comprises a target information acquisition module, a monitoring controller module, a human face image information acquiring module, an intelligent alarm ringing module, a safe identification module, a monitoring object information database, a mode identification module and an intelligent access control module.

Owner:广东中大讯通信息有限公司

Secondary battery, cap assembly thereof and method of mounting safety valve therefor

ActiveUS20050287422A1Uniform operation performanceEasy to installFinal product manufacturePrimary cellsSafety valveBiomedical engineering

A secondary battery may be manufactured with an electrode assembly having a positive electrode, a negative electrode, and a separator interposed between the positive electrode and the negative electrode. A container encases the electrode assembly. A hole formed on one end of the container with a stepped configuration that opens with different diameters on opposite sides of a cap plate and a safety valve mounted in the stepped surface of the hole, is configured to rupture and tear open upon occurrence of a predetermined internal battery pressure.

Owner:SAMSUNG SDI CO LTD

Preparation method of teflon oriented film of ultra-thin breadth

InactiveCN101491945AUniform performanceNot easy to curlAutomatic control devicesFeeding apparatusPolytetrafluoroethyleneElectronic industry

The invention discloses a method for preparing an ultra-thin broad-width polytetrafluoroethylene oriented film. The polytetrafluoroethylene oriented film is prepared by the following technical measures: screening raw materials, prepressing to make preform, sintering at a high temperature, turning to form films, rolling to orient and the like. The thickness of the oriented film is from 5 mu m to 50 mu m, and the width is more than 200 mm. The oriented film can be used as high-grade insulating pads, protecting sleeves, abrasion reducing materials, chemical industrial antiseptic materials and the like in the electromechanical and electronic industries and can be used for a long time at a temperature of between 200 DEG C below zero and 250 DEG C.

Owner:广州市东泓氟塑料股份有限公司

Vacuum protection atmosphere annealing process of industrial pure titanium roll

InactiveCN101654767AImprove surface qualityUniform tissueFurnace typesHeat treatment furnacesChemical compositionTitanium

The invention discloses a vacuum protection atmosphere annealing process of an industrial pure titanium roll, which comprises the following steps: charging a titanium roll with clean surface into a vacuum protection atmosphere annealing furnace; evacuating and heating to 430-500 DEG C and keeping the temperature for 1.5-2.5 hours; circulating in the furnace by a high-purity inert gas under the condition of micro-negative pressure; heating to 600-750 DEG C to insulate for 2-8 hours and then cooling to 400-550 DEG C; starting a forced cooling system to accelerate cooling; and discharging till the titanium roll is cooled to 170 DEG C. The mechanical performance, the chemical component and the surface quality of the annealed titanium roll can meet the requirements of a user; after the forced cooling system with a heat exchanger is adopted, the inert gas can be cooled by the heat exchanger, thereby greatly shortening the annealing period and reducing the annealing energy consumption and theproduction cost.

Owner:湖南湘投金天钛金属股份有限公司

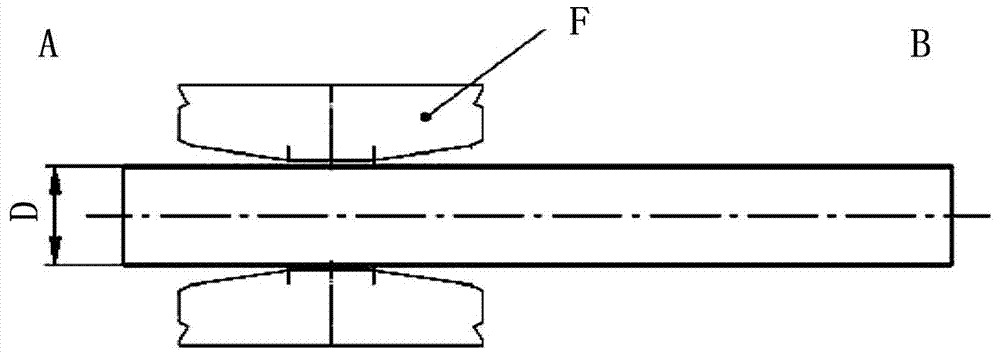

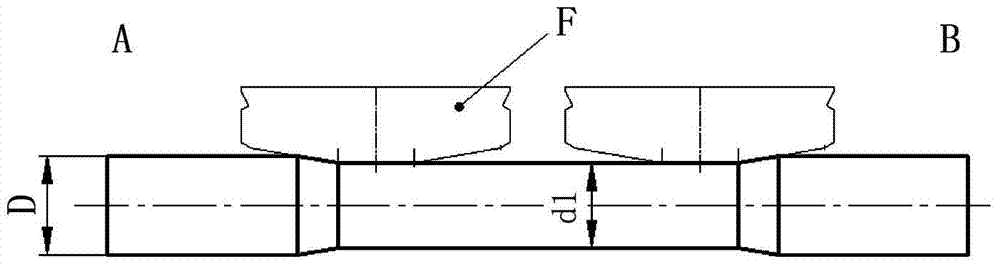

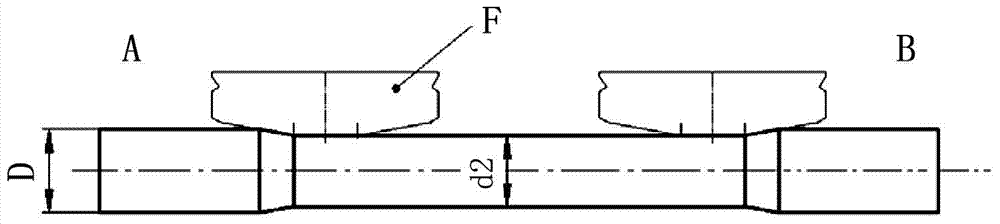

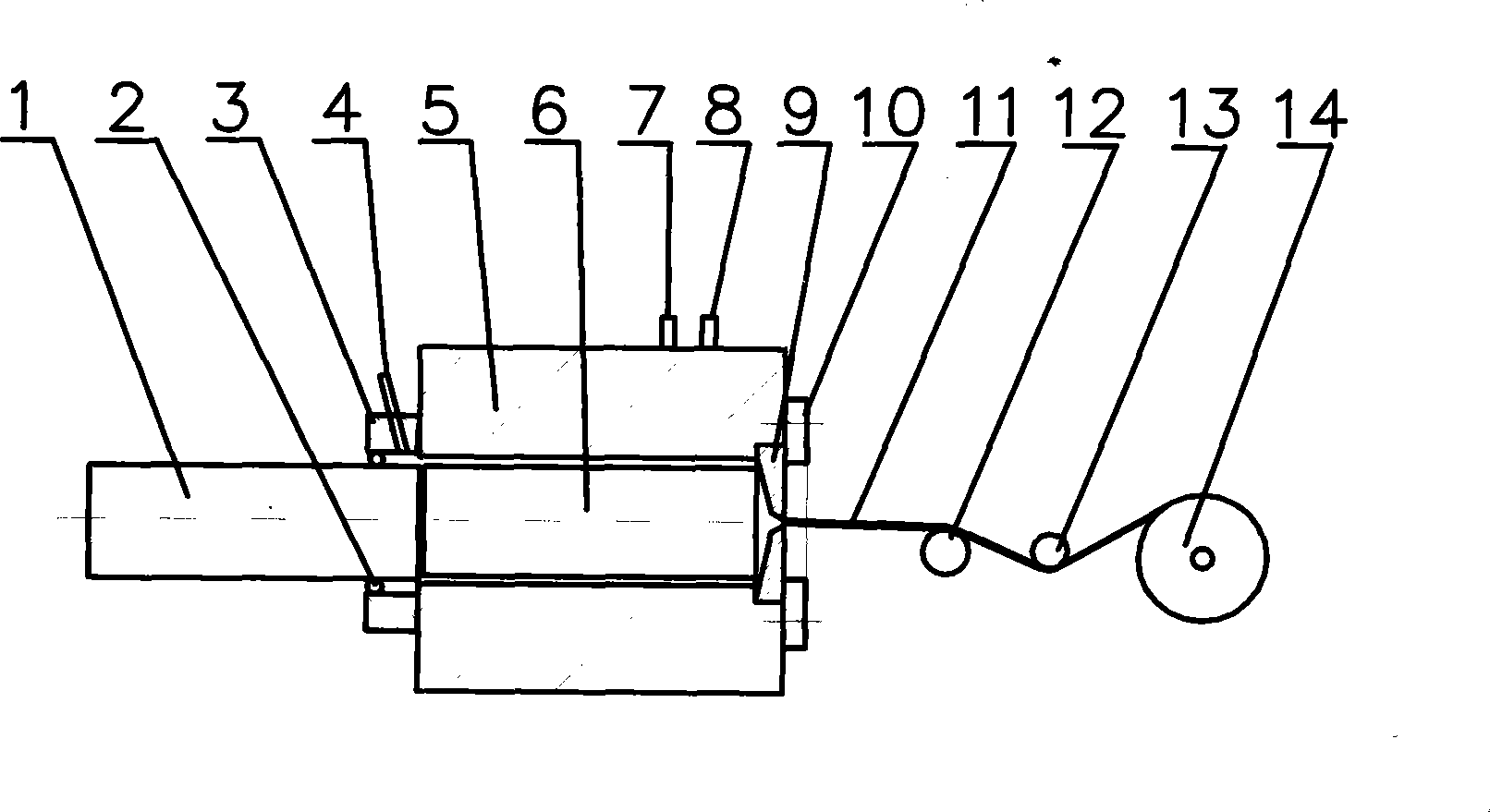

Radial forging method for high temperature alloy step shaft

The invention provides a radial forging method for a high temperature alloy step shaft. The method includes: upsetting and drawing out a steel ingot, and providing a blank to a forging machine; forging the blank in multiple passes, and pre-forging to form a first step shaft; forging the middle of the first step shaft in multiple passages so as to form a middle step shaft, and forming a transition section between the first step shaft and the middle step shaft, wherein pulling speed for forming the first step shaft is controlled to be 3-5.5m / min, deformation of each pass for forming the middle step shaft is controlled to be 10-25%, and pulling speed for forming the middle step shaft is controlled to be 3-5.5m / min. By control on forging frequency, reduction in pass and pull speed of the radial forging method and by control on final forging temperature, the property structure of a step shaft product is controlled, quality stability and structure property uniformity of the product are improved greatly while comprehensive yield and qualified rate of the product are increased greatly.

Owner:PANGANG GROUP JIANGYOU CHANGCHENG SPECIAL STEEL

Method for processing metallic lithium belt

ActiveCN101497088BHigh dimensional accuracyBright surfaceExtrusion control devicesMetallic lithiumEngineering

The invention provides a method for a novel lithium ribbon by vacuum extrusion forming. The lithium ribbon produced by the method has high dimensional precision and bright surface, and a lithium battery made of the lithium ribbon produced by the method has uniform and stable performance.

Owner:CHINA ENERGY LITHIUM

Light high-strength ceramsite and preparation method thereof

ActiveCN106587931AReduce energy consumptionReduce processCeramic materials productionClaywaresRed mudExpanded clay aggregate

The invention provides light high-strength ceramsite comprising, by weight, 100 parts of solid raw materials and 1-15 parts of excitant. The solid raw materials include 100 parts of fly ash, 6-18 parts of high-aluminum fly ash, bauxite and red mud, 1-5 parts of micro-silica, 0.1-3 parts of surfactant and 6-24 parts of plasticizer. The excitant comprises 5-20 parts of alkali metal hydroxides and 80-95 parts of alkali metal silicates. The light high-strength ceramsite product is light and high in strength, the density level is 700-1100 kg / m<3>, the cylinder compressive strength can reach 10-20 MPa, and the ceramsite is not likely to be damaged. The ceramsite can be used for preparing lightweight aggregate high-performance concrete which serves as a load bearing structure and can be used for building wallboards, bridges, pipelines and the like, and has great application value.

Owner:GUANGDONG TSINGDA TONGKE ENVIRONMENTAL PROTECTION TECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com