Patents

Literature

371 results about "Electron acceleration" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

An electron has a constant acceleration of. An electron has a constant acceleration of +3.2 m/s^2. At a certain instant its velocity is 9.6 m/s.

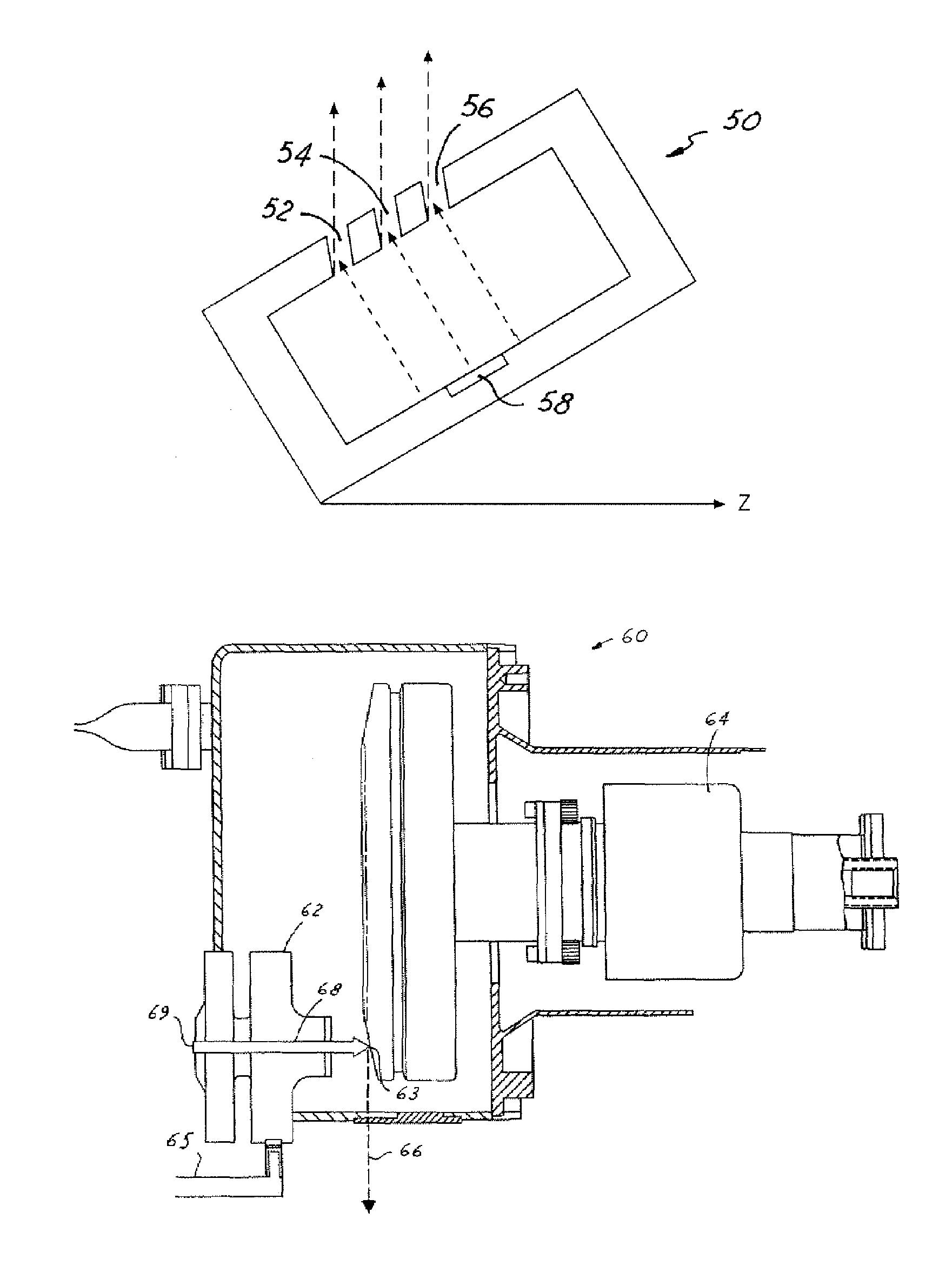

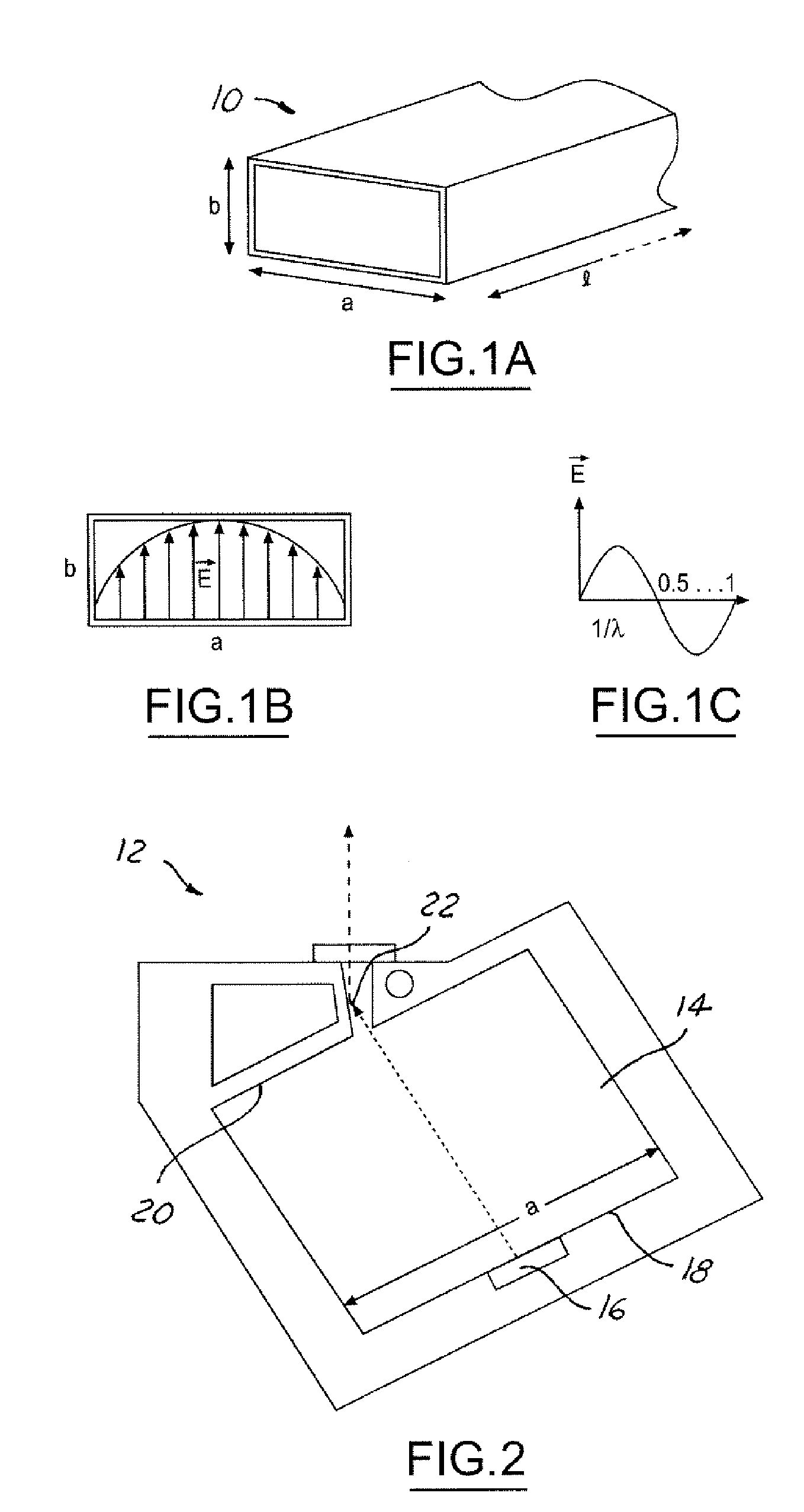

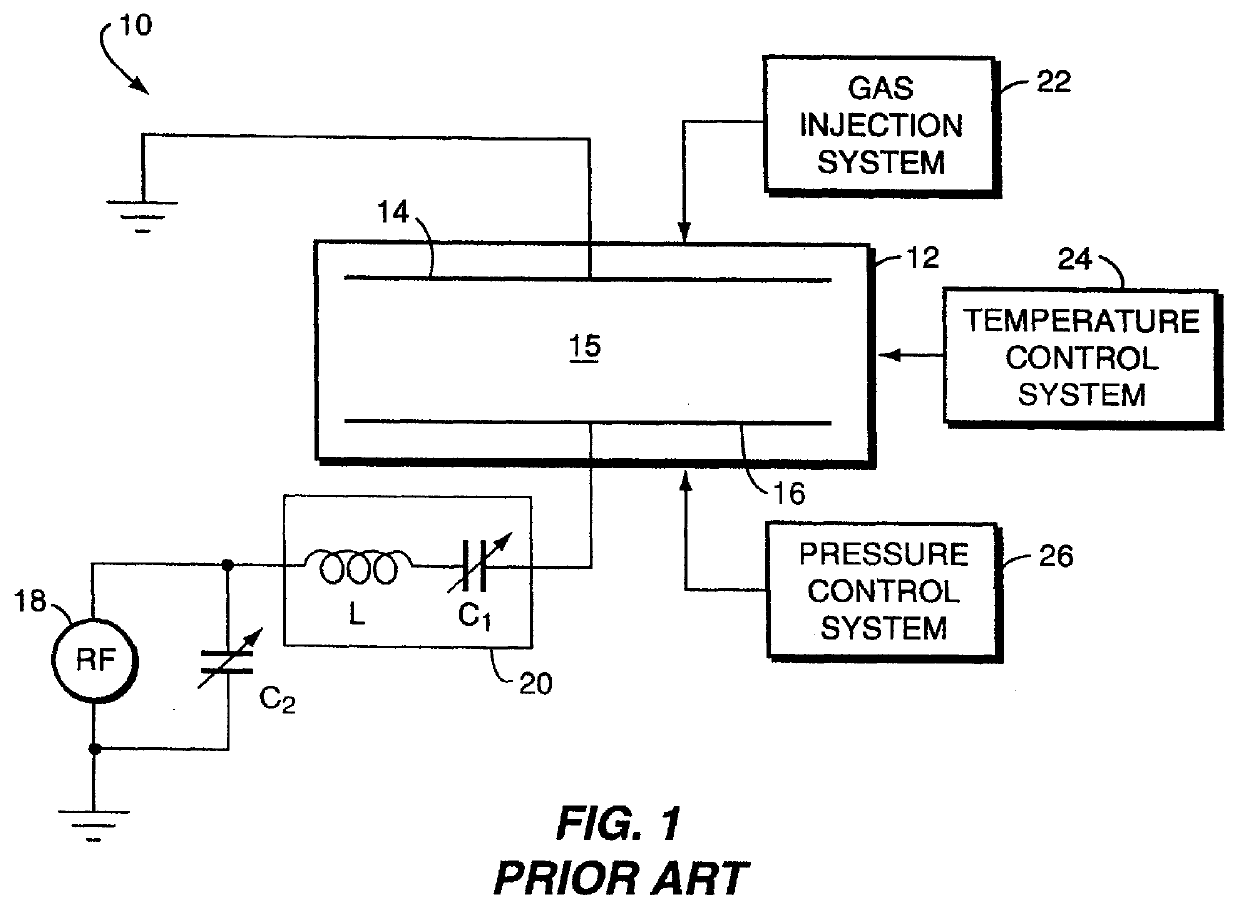

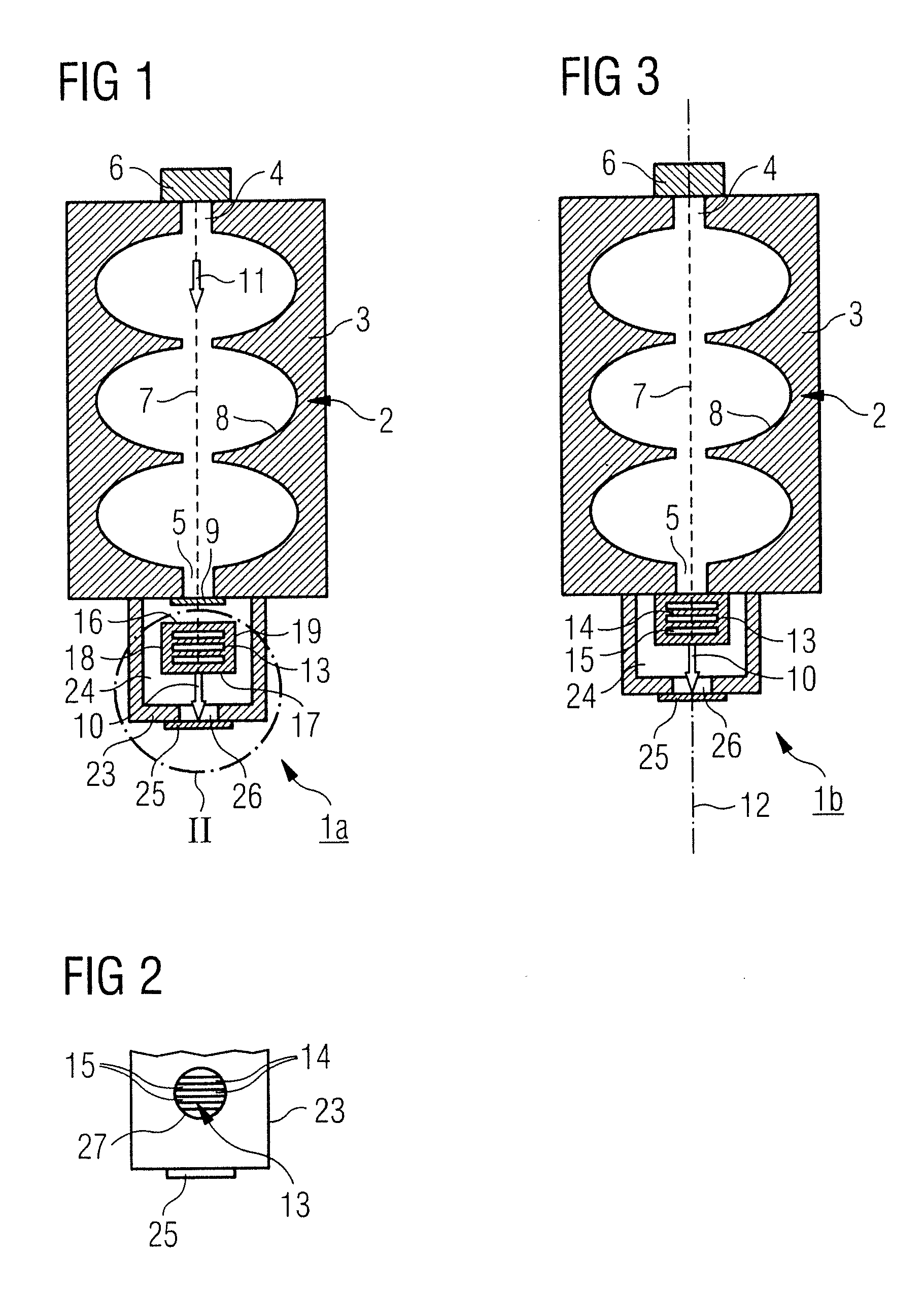

RF accelerator for imaging applications

ActiveUS7206379B2Drawback can be obviatedLower component costsX-ray tube electrodesDischarge tube electron gunsComputed tomographyX-ray

Owner:GE MEDICAL SYST GLOBAL TECH CO LLC

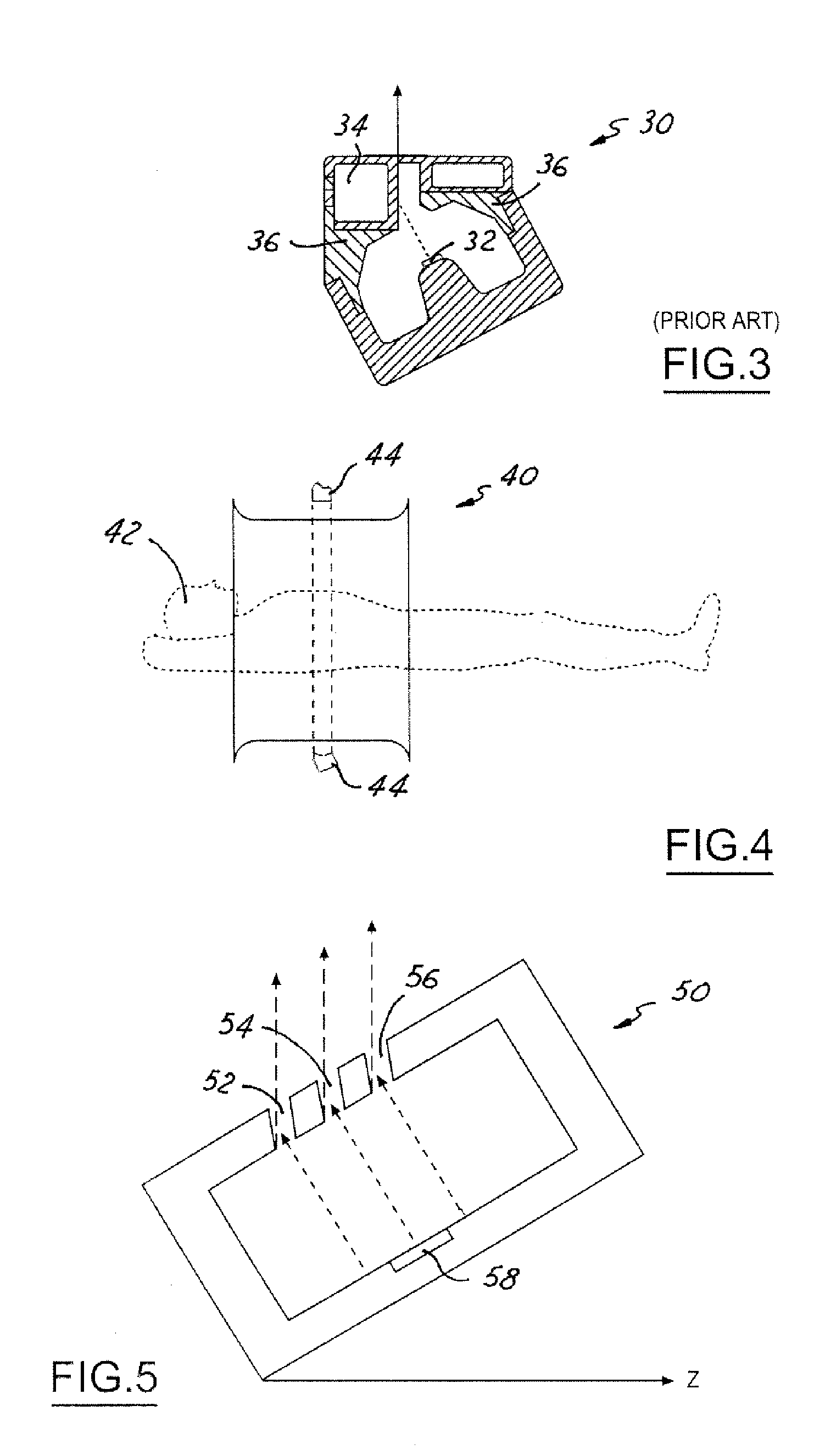

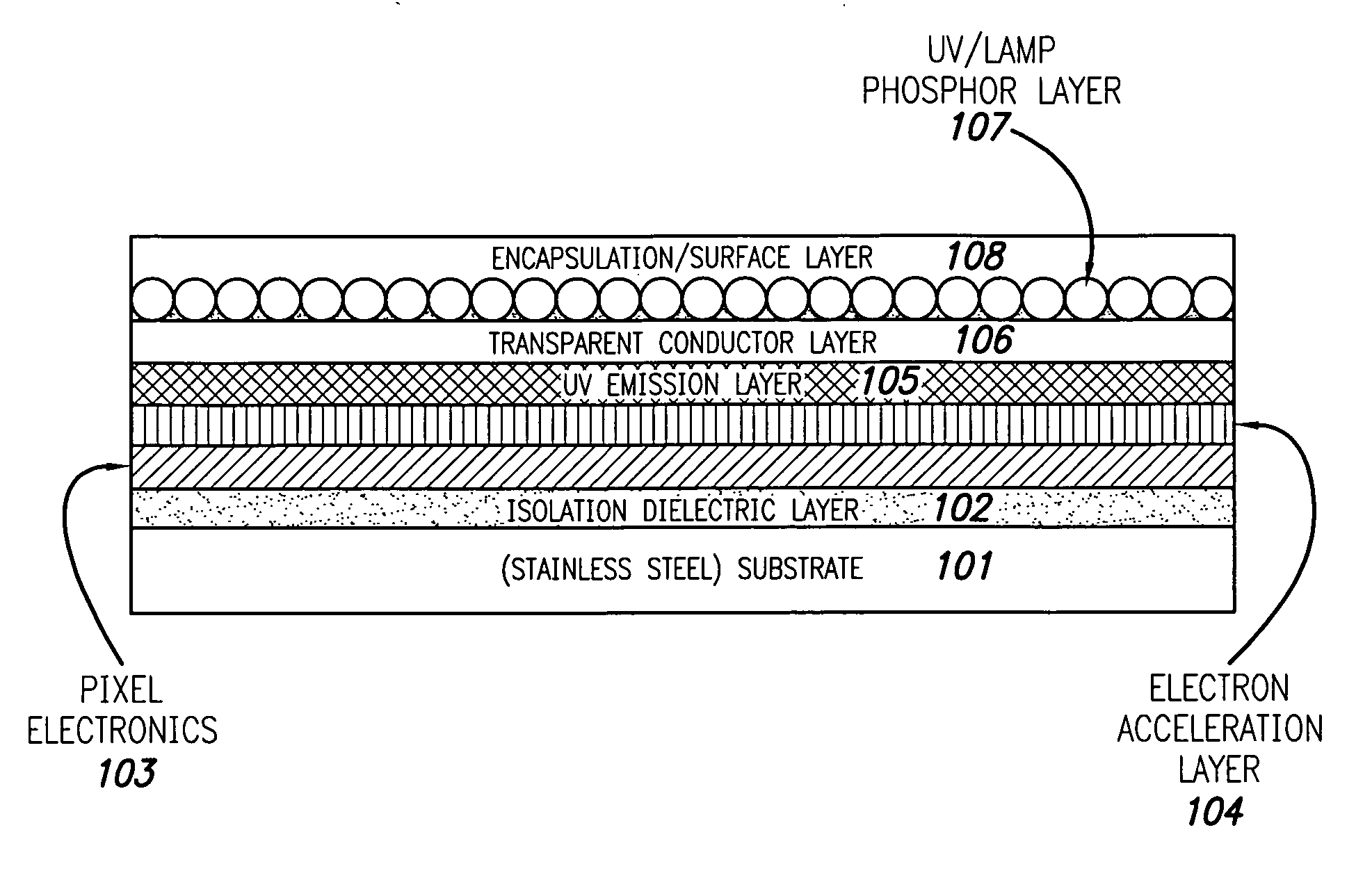

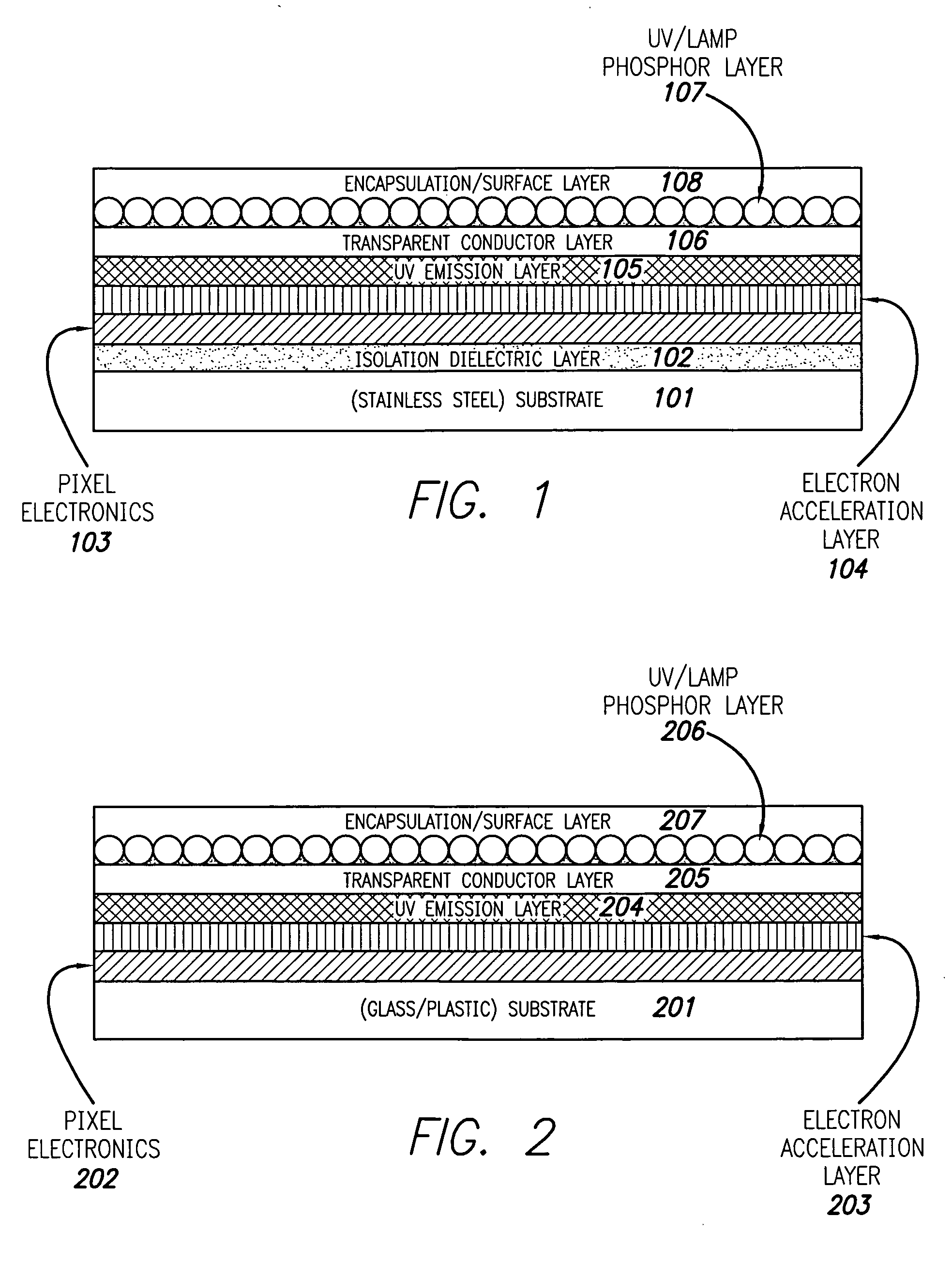

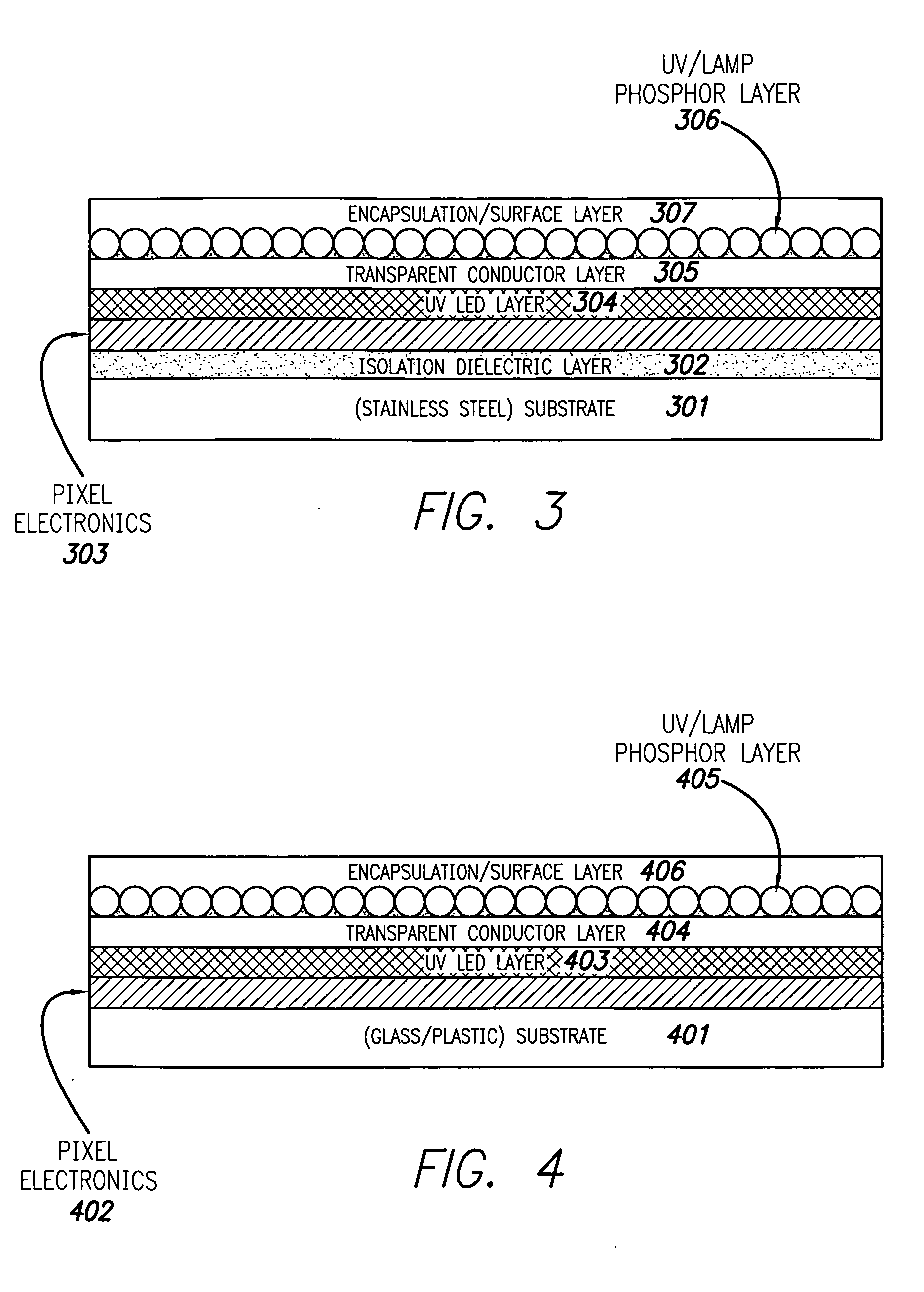

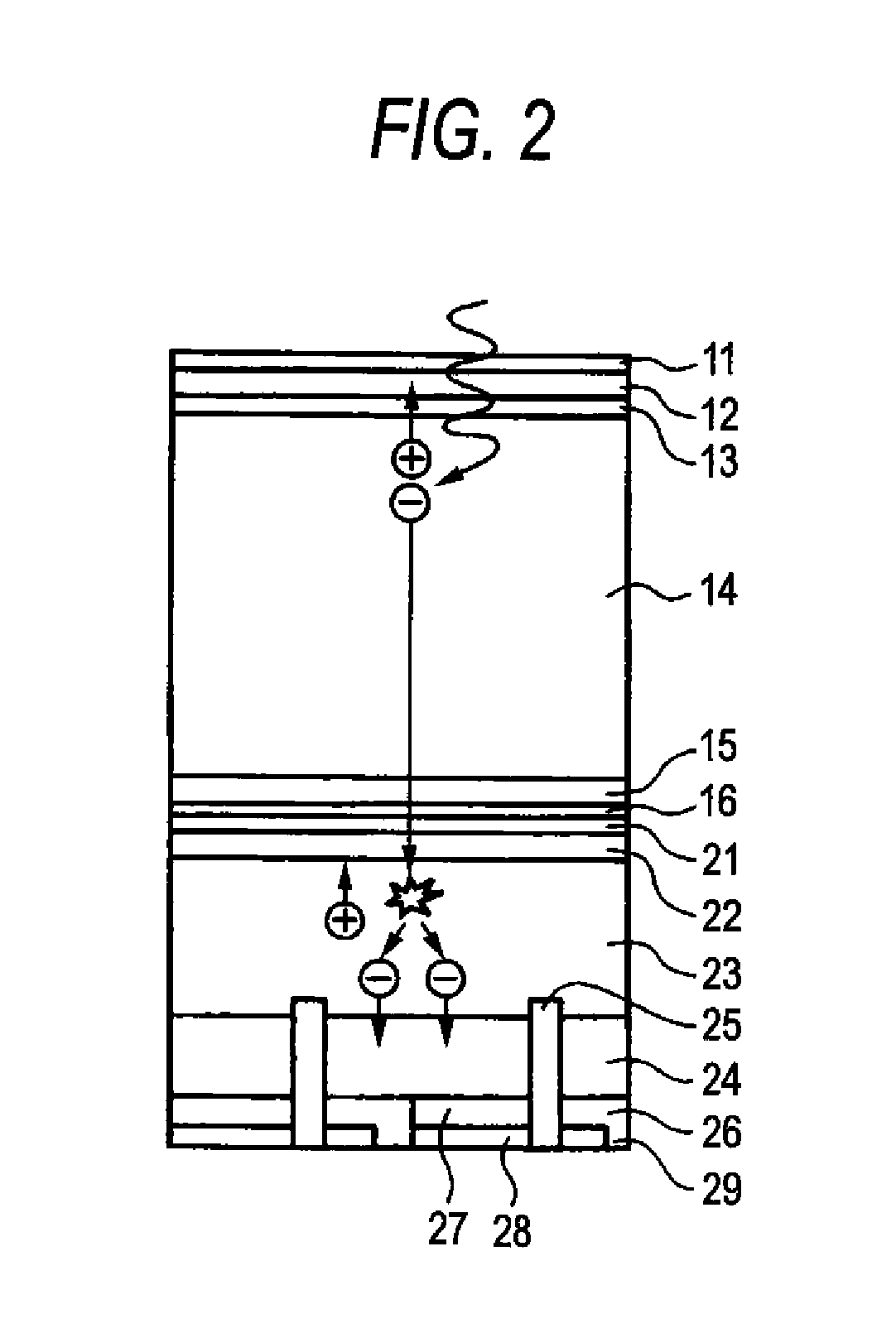

Ultraviolet emitter display

An ultraviolet emitter display apparatus and method for making the display is disclosed. The device includes a substrate layer, a pixel electronics layer positioned above the substrate layer, the pixel electronics layer including electronics to drive the ultraviolet emission display. Ultraviolet (UV) emitters may be located above the pixel electronics layer, where the UV emitters may comprise a layer of UV light emitting diodes (LEDs) or a combination of an electron acceleration layer and a UV emission layer. The design further includes a phosphor layer comprising a plurality of phosphor elements, either white phosphor elements in combination with color filters or color phosphor elements.

Owner:HEWLETT PACKARD DEV CO LP

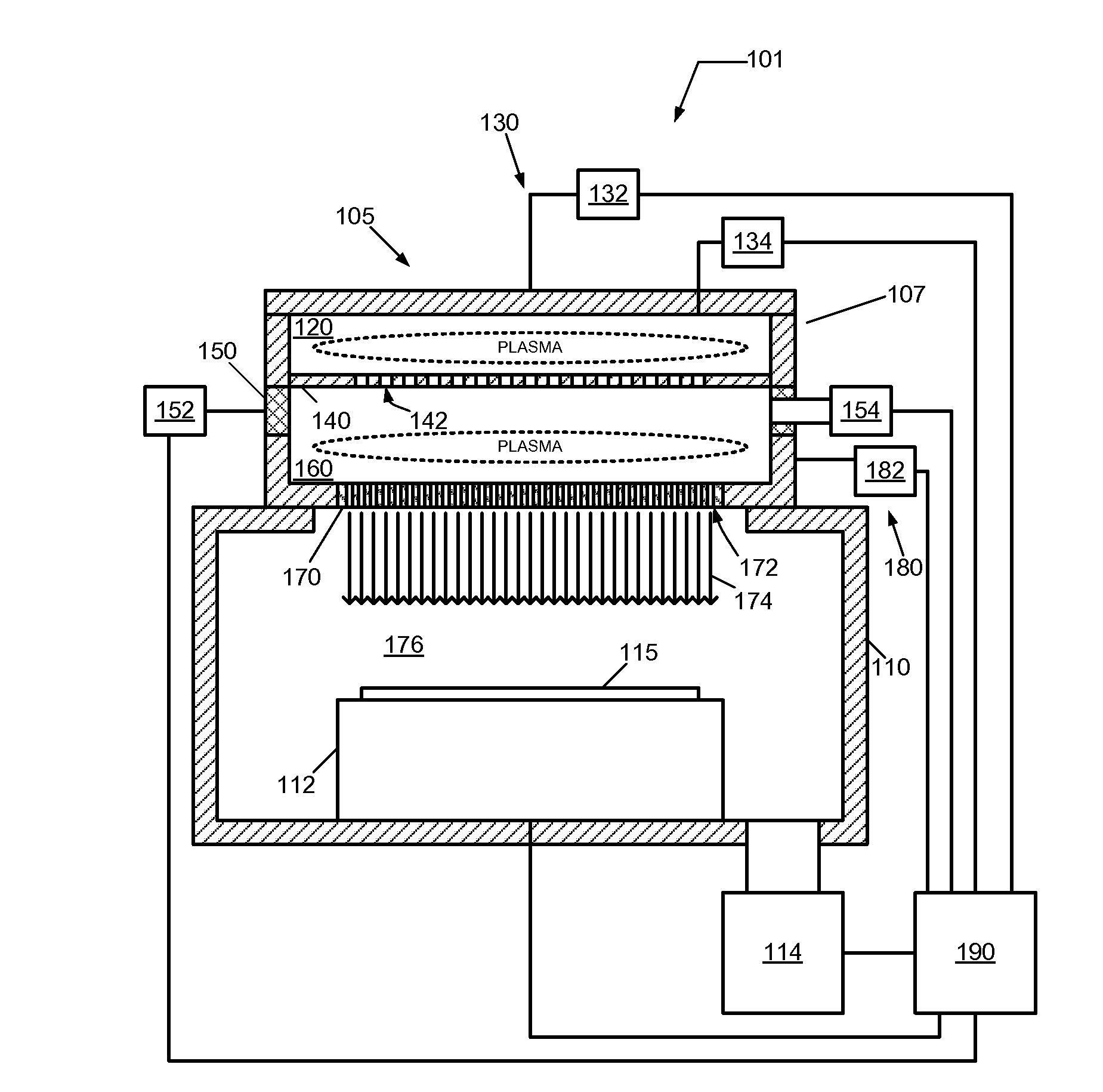

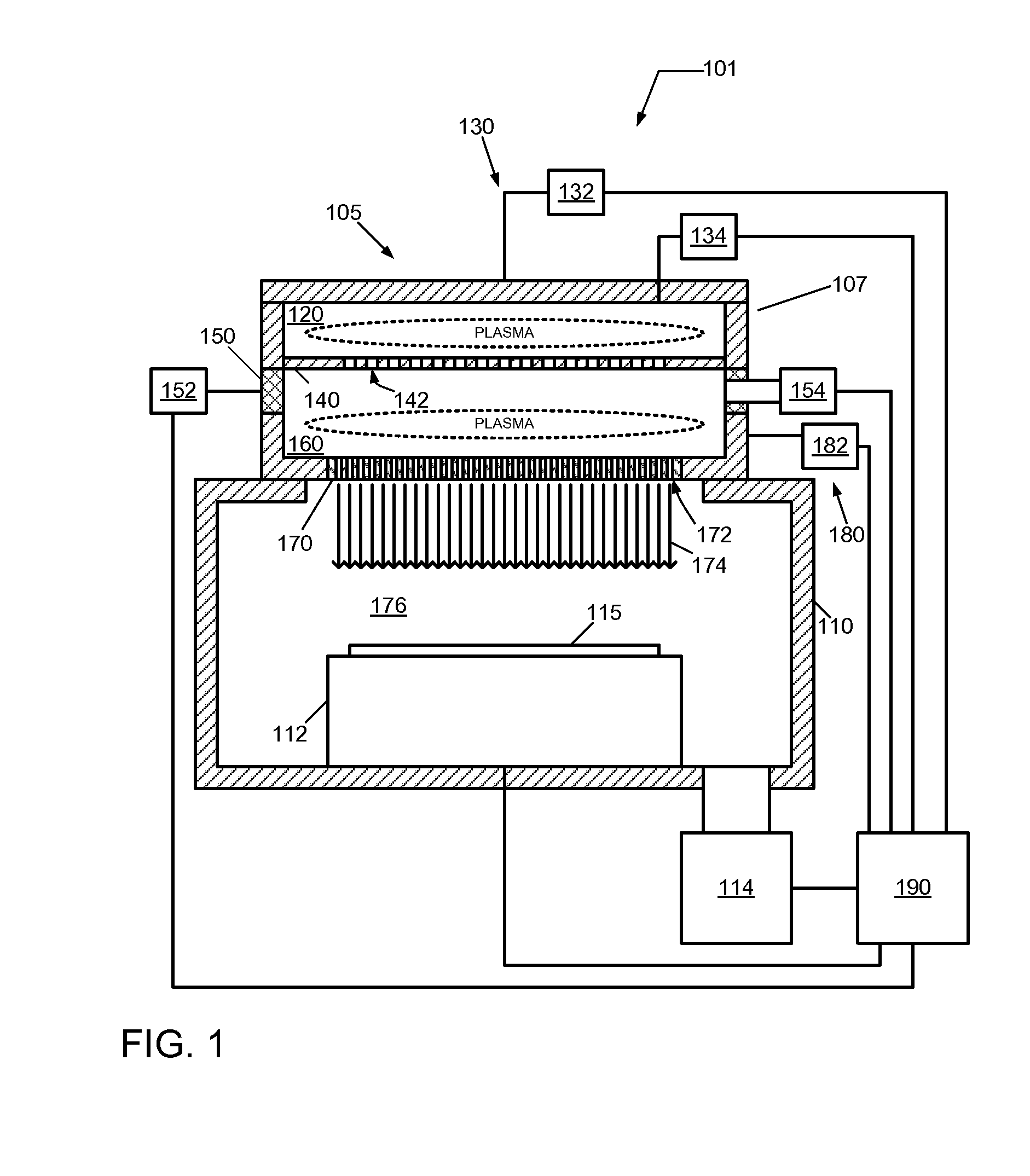

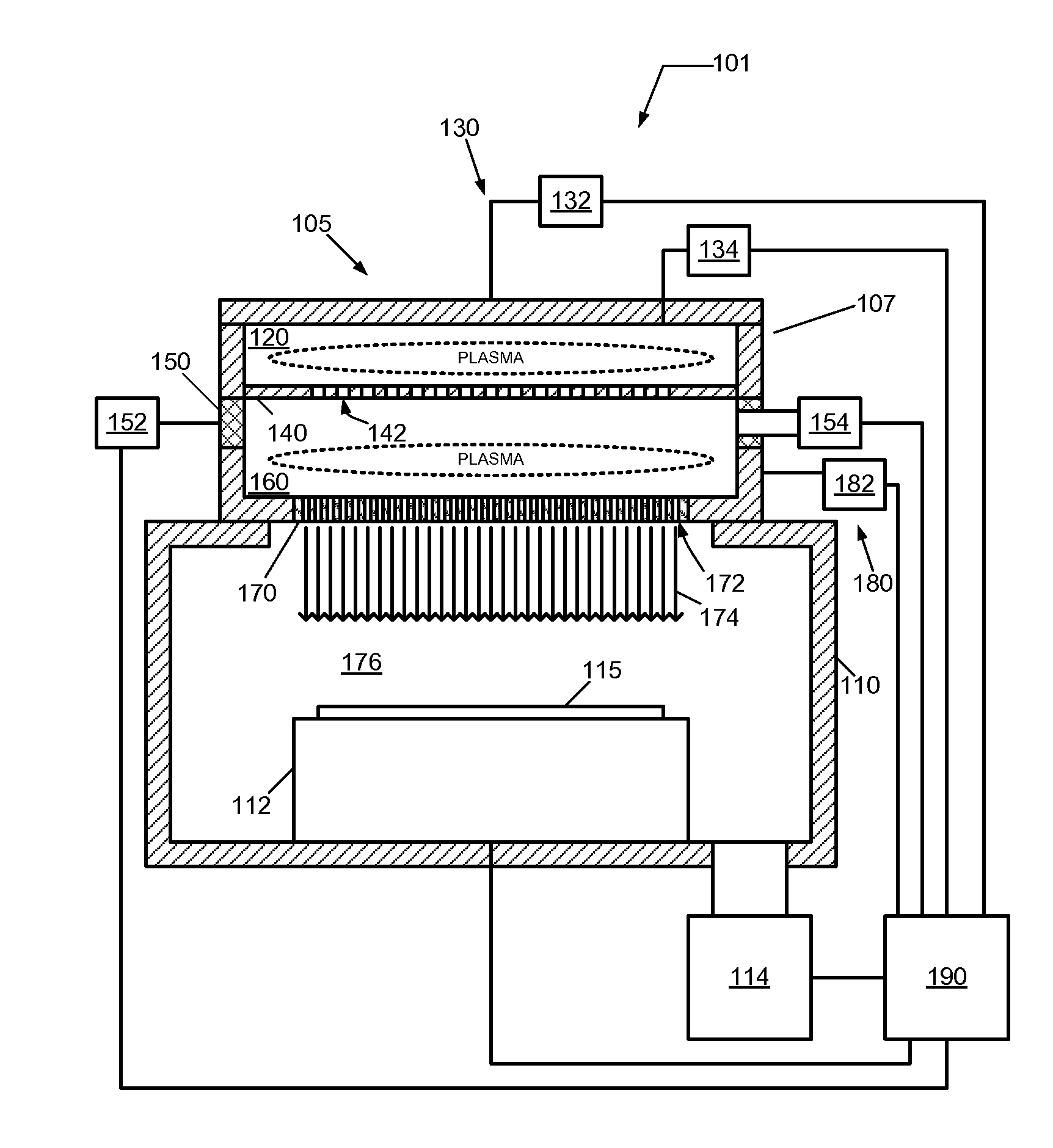

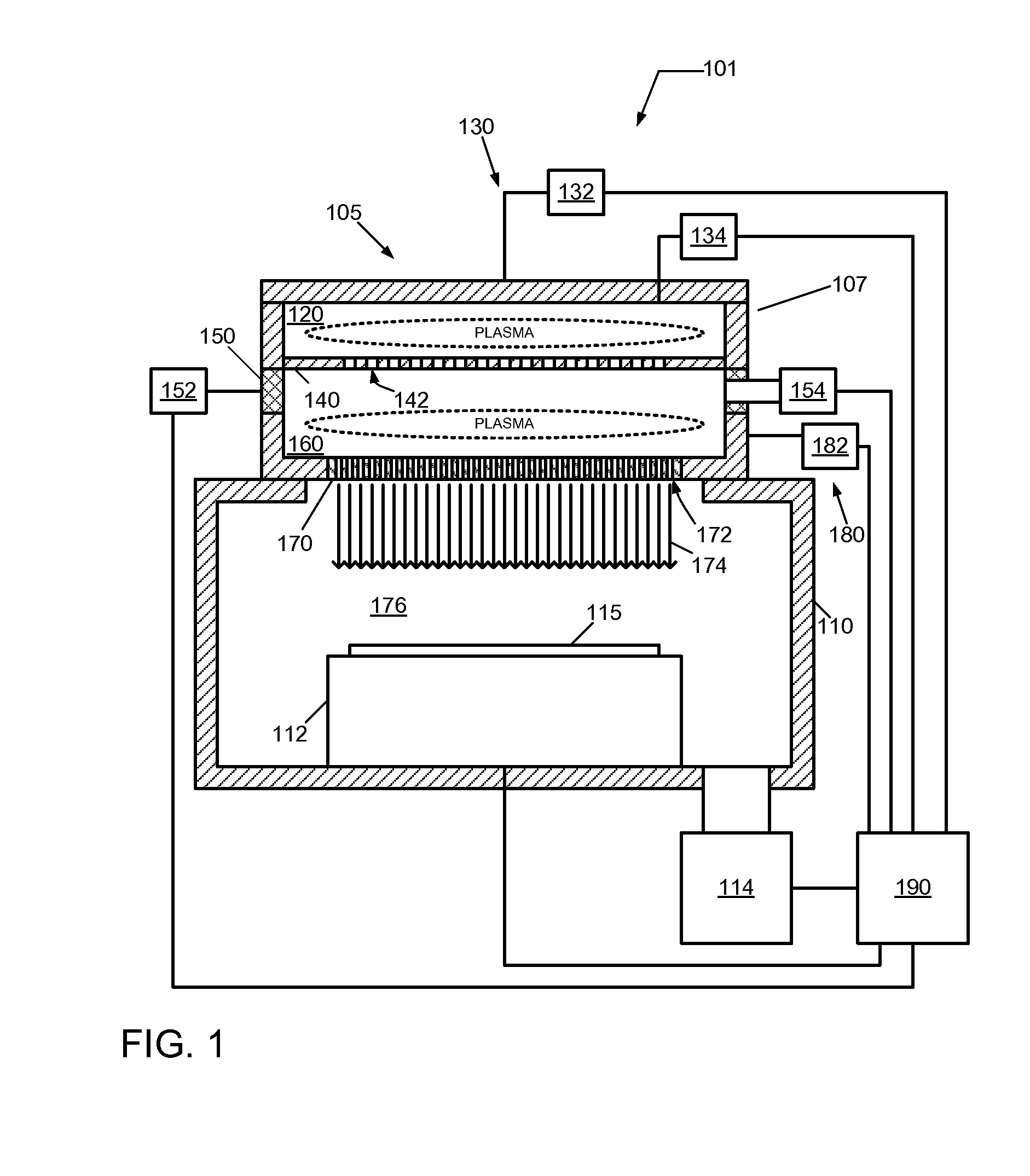

Multi-plasma neutral beam source and method of operating

Method and system for producing a neutral beam source is described. The neutral beam source comprises a plasma generation system for forming a first plasma in a first plasma region, a plasma heating system for heating electrons from the first plasma region in a second plasma region to form a second plasma, and a neutralizer grid for neutralizing ion species from the second plasma in the second plasma region. Furthermore, the neutral beam source comprises an electron acceleration member configured to accelerate the electrons from the first plasma region into the second plasma region. Further yet, the neutral beam source comprises a pumping system that enables use of the neutral beam source for semiconductor processing applications, such as etching processes.

Owner:TOKYO ELECTRON LTD

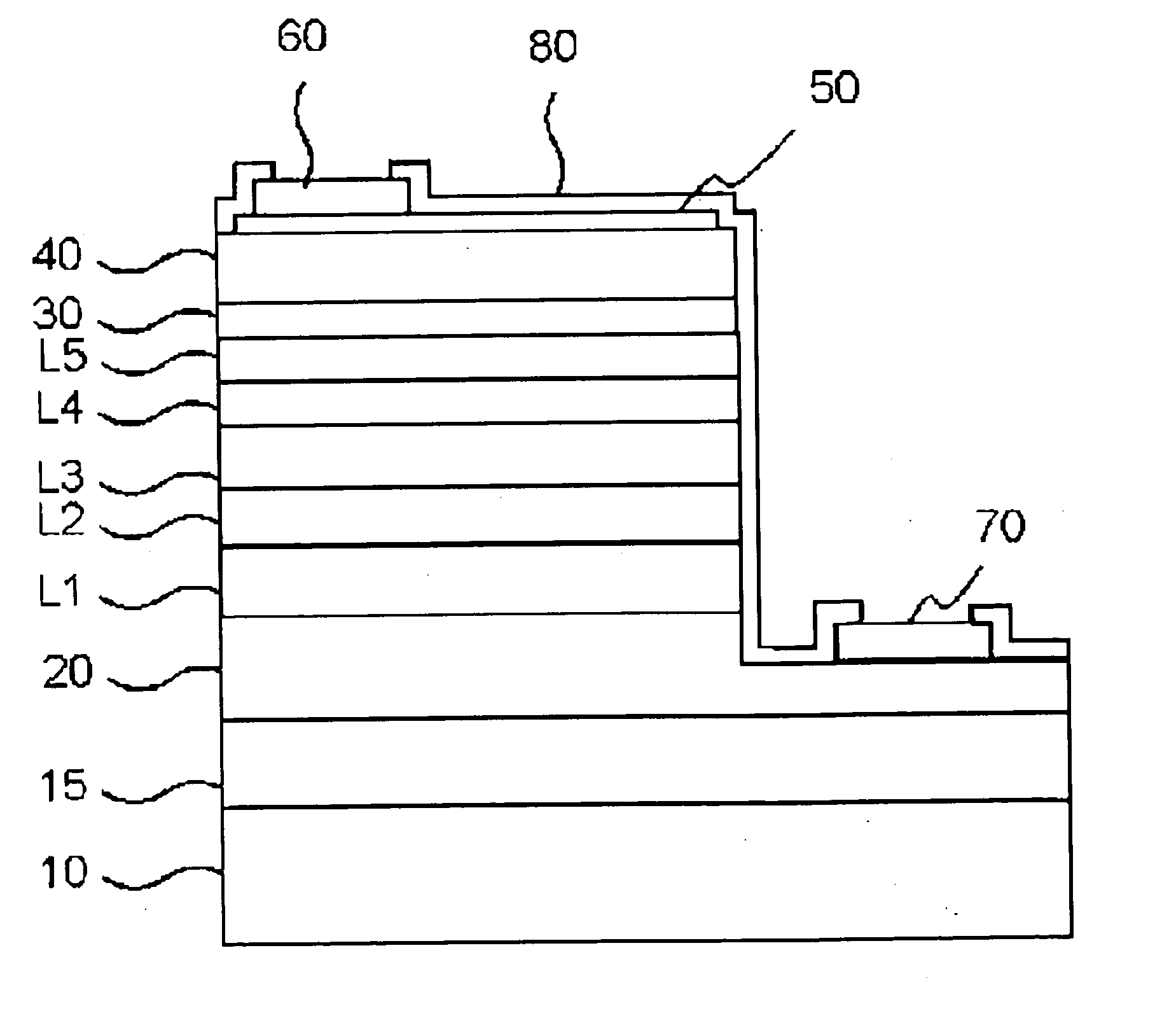

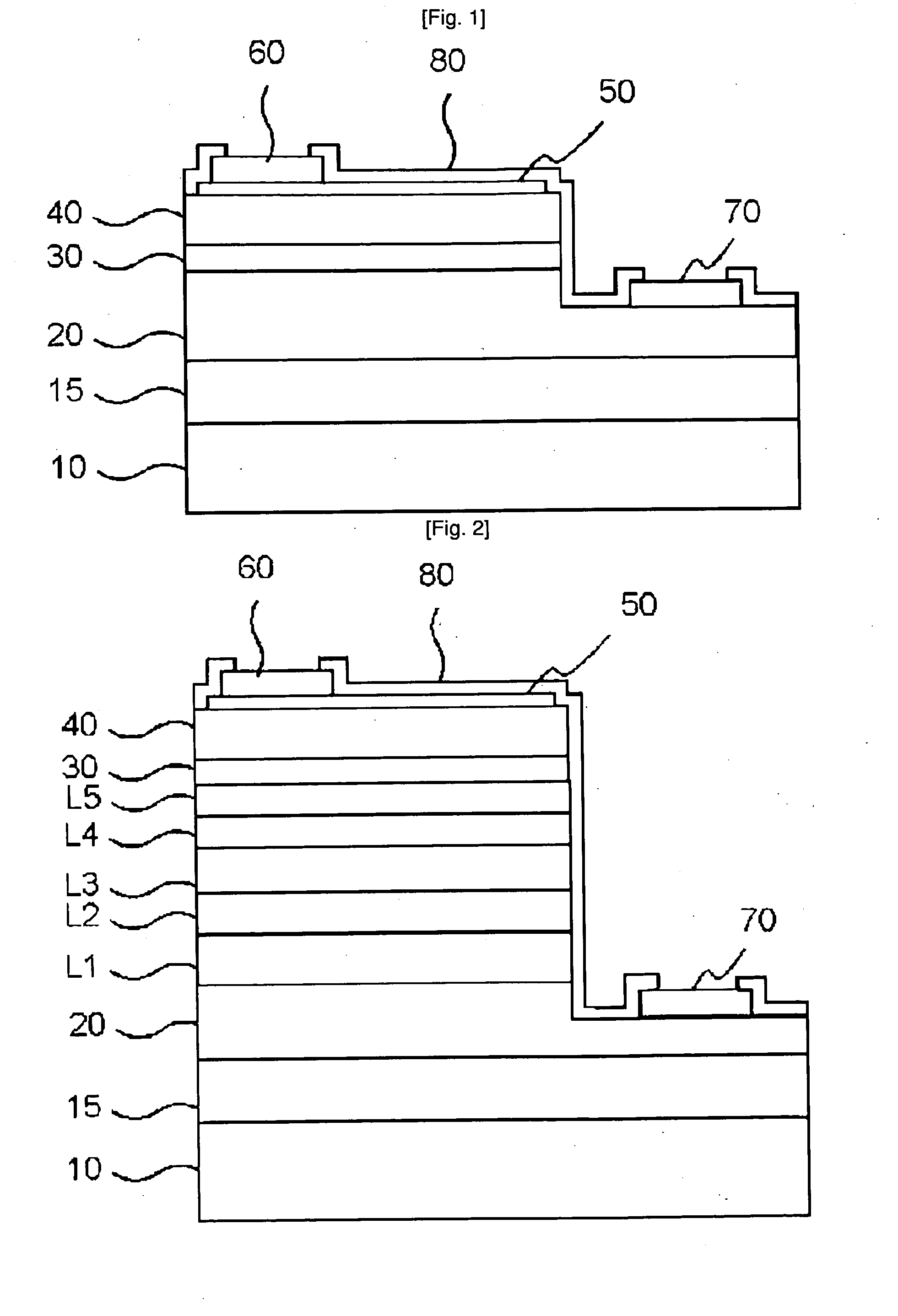

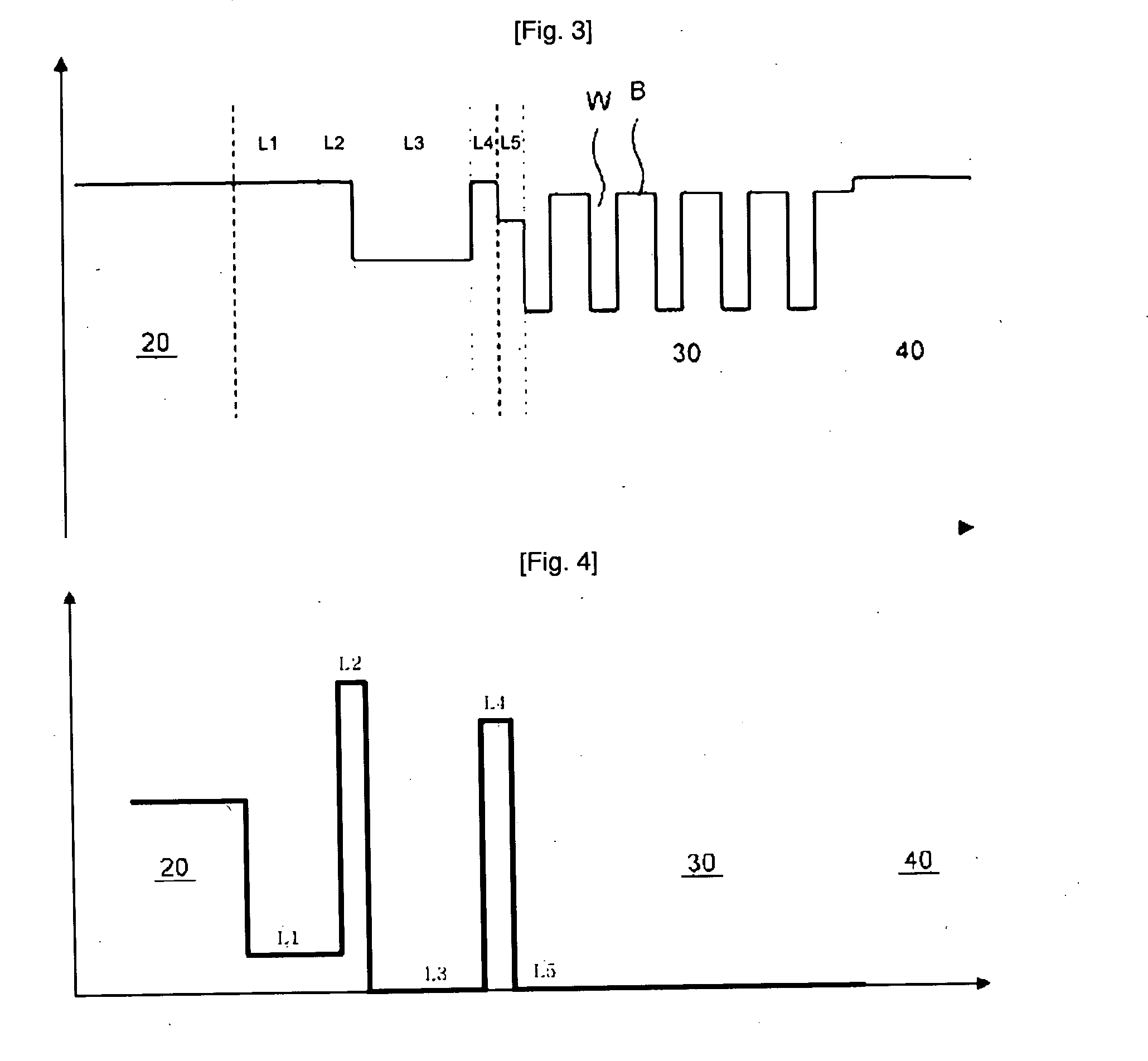

III-Nitride Compound Semiconductor Light Emitting Device

InactiveUS20080149918A1Lattice mismatchEfficient supplySemiconductor/solid-state device manufacturingSemiconductor devicesHeterojunctionLattice mismatch

The present invention provides a III-nitride compound semiconductor light emitting device comprising an active layer (30) which emits light and is interposed between a lower contact layer (20) made of n-GaN and an upper contact layer (40) made of p-GaN, in which a sequential stack of a lattice mismatch-reducing layer L3 made of InxGa1-xN, an electron supply layer L4 made of n-GaN or n-AlyGa1-yN and a crystal restoration layer L5 made of InzGa1-zN is interposed between the lower contact layer and the active layer, and further comprising an electron acceleration layer L1 made of n-GaN or undoped GaN and a heterojunction electron barrier-removing layer L2, thereby the lattice mismatch between the lower contact layer (20) and the active layer (30) can be reduced.

Owner:EPIVALLEY

Solar energy converter and solar energy conversion system

InactiveUS6713668B2Low costEasy to assembleSolar heating energyThermoelectric device with peltier/seeback effectElectricitySUN LIGHT EXPOSURE

A solar energy converter includes: a light-concentrating instrument; an electron emitter in an insulated vacuum vessel, emitting electrons in a vacuum as a temperature rises by sunlight; an electron accelerator within the light-concentrating instrument; a cathode on a surface of the electron emitter opposite to a surface which is irradiated by sunlight, and electrically connected with the electron emitter; an electric field supplier having a positive terminal and a negative terminal; and an electron collector in the vacuum vessel, collecting the emitted electrons flying from the electron emitter toward the electron accelerator; wherein the electron accelerator is connected with the positive terminal and the cathode is connected with the negative terminal to generate an electric field, and the electron collector is used as a negative generator electrode and the cathode is used as a positive generator electrode in which the collected electrons migrate to the electron emitter to generate electricity.

Owner:AKAMATSU NORIO +1

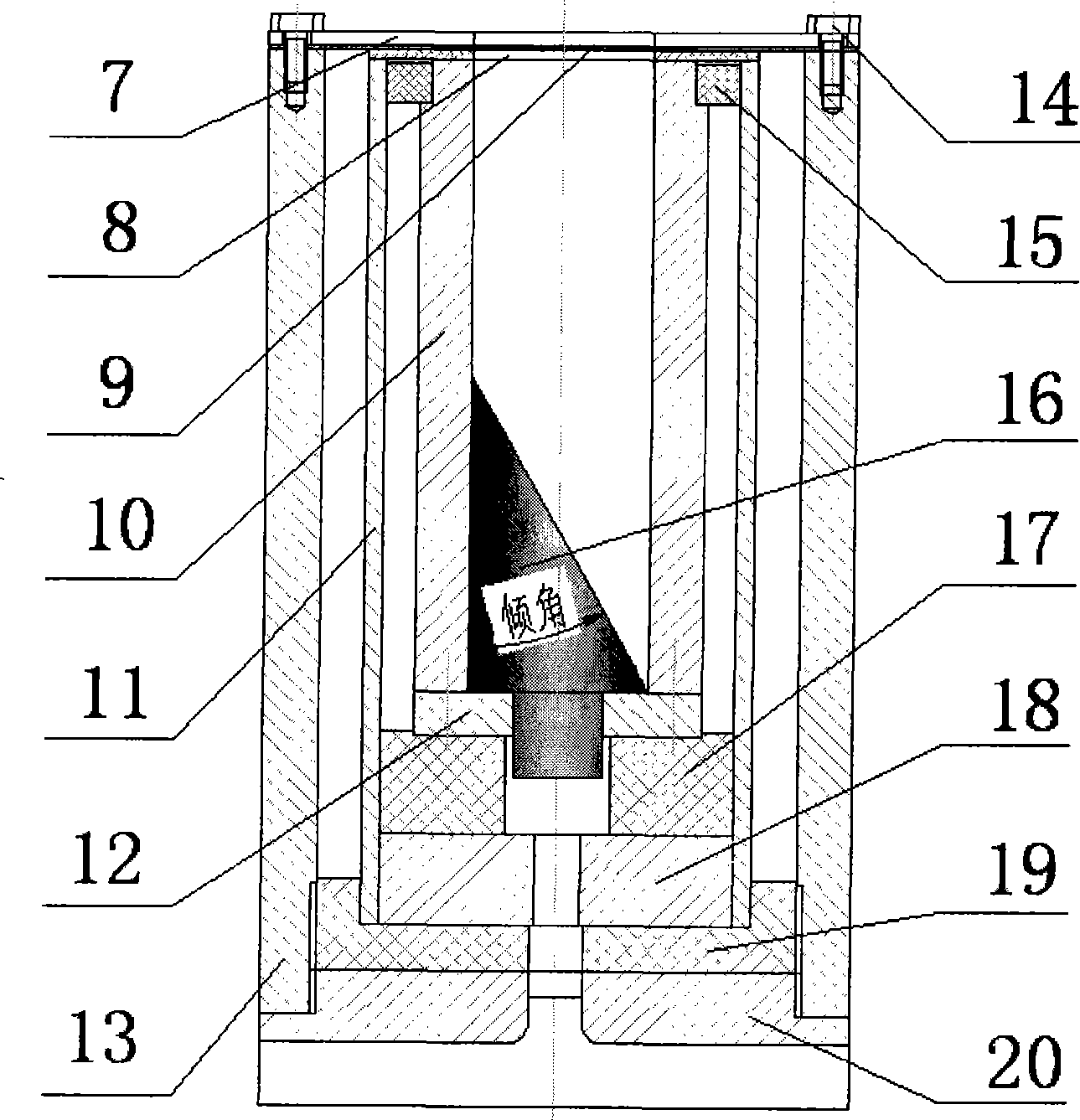

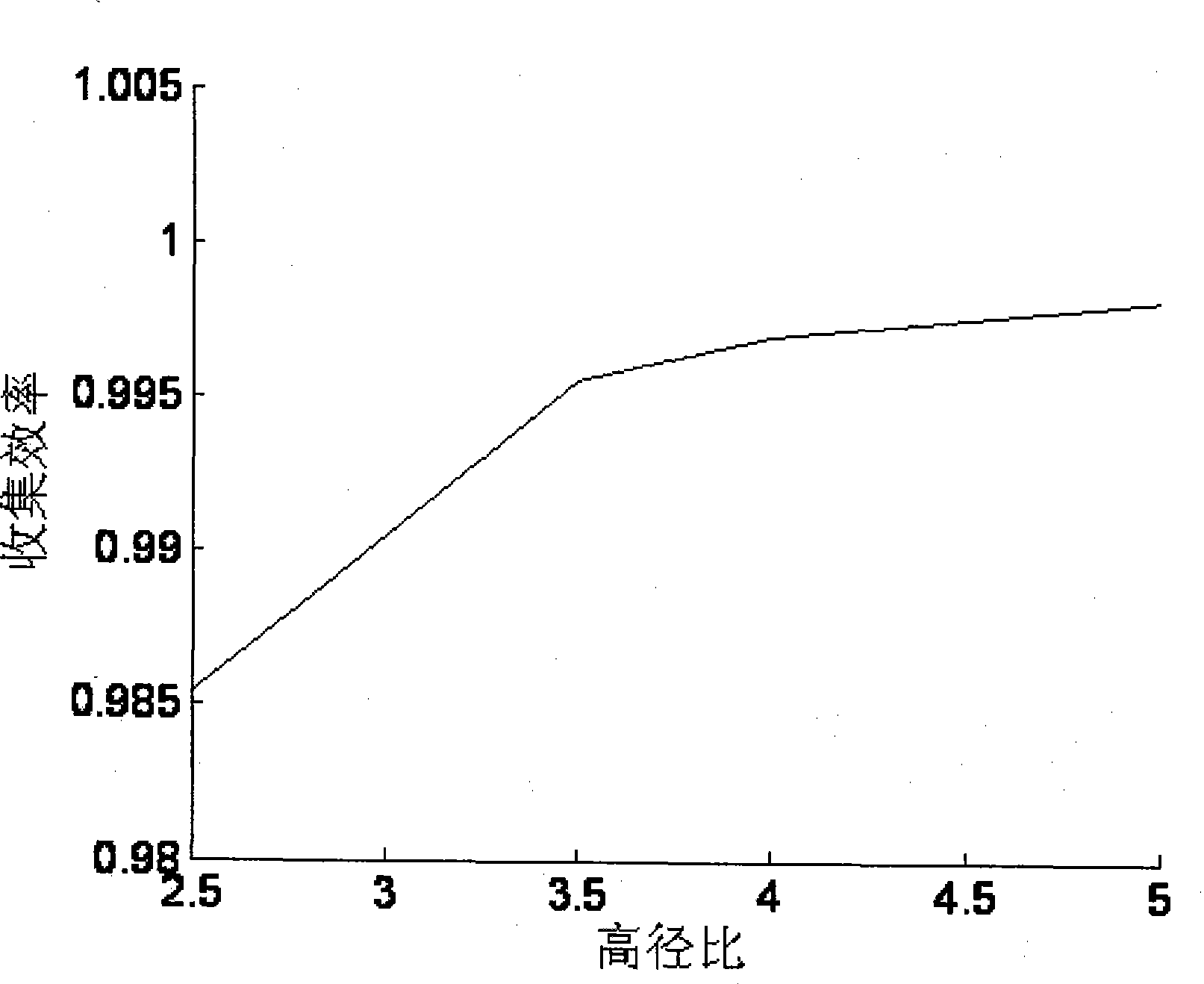

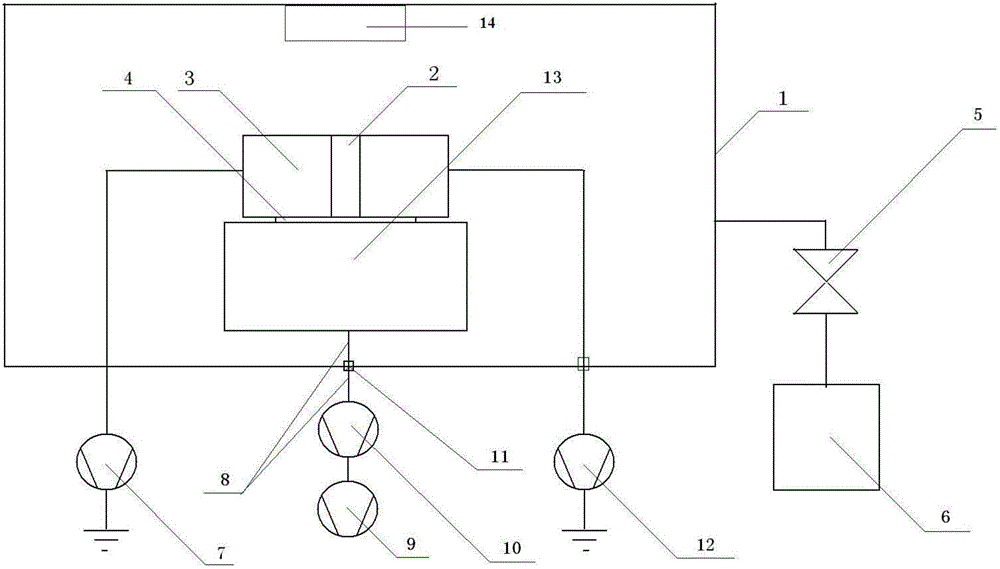

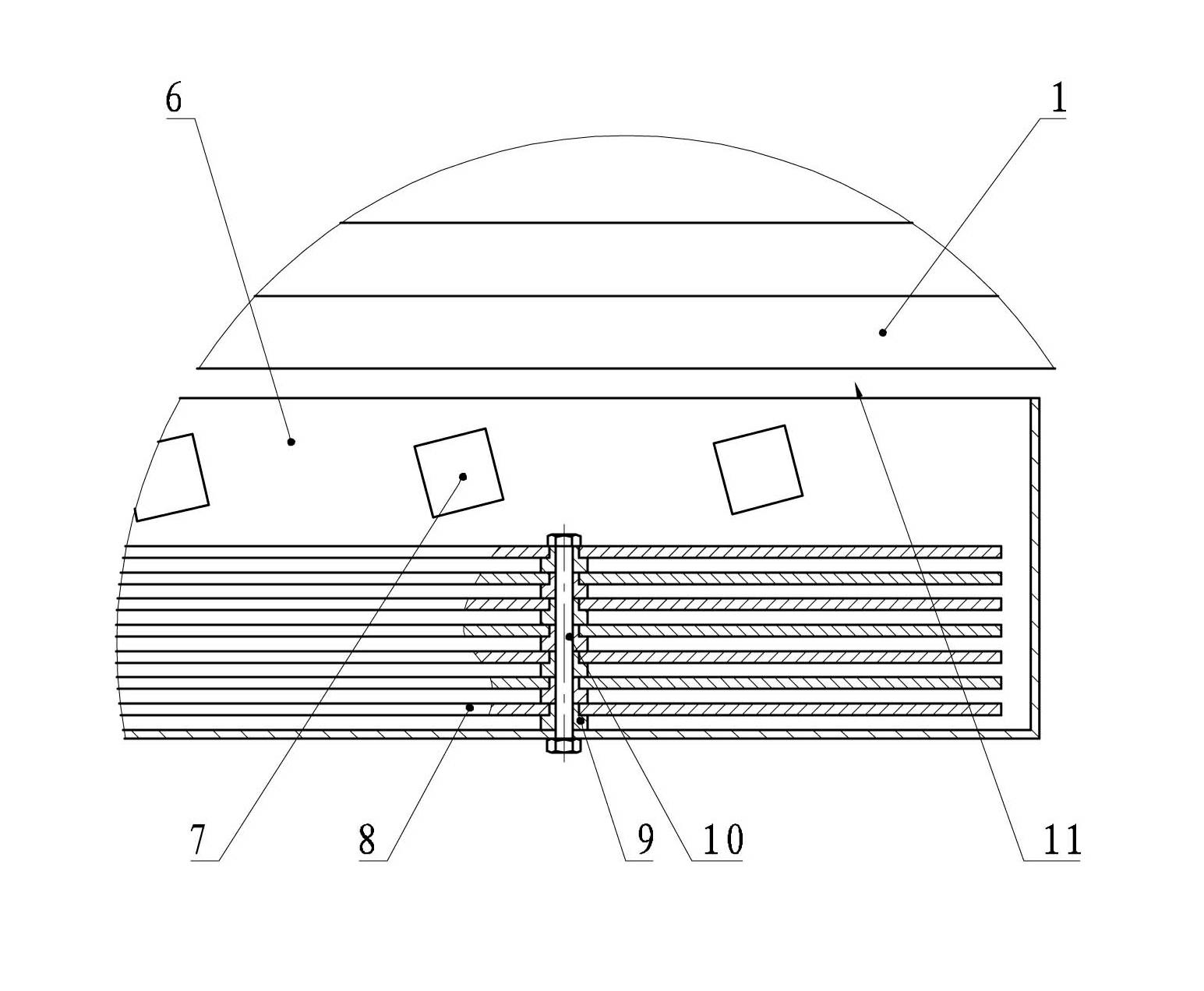

Measuring system for nA/pA electronic beam current of impulse electron accelerator

InactiveCN101470208ASolve the collection efficiency problemSolve beam measurement problemsX/gamma/cosmic radiation measurmentHigh energyElectron radiation

The invention relates to a pulse electronic accelerator nano-pico ampere electron beam flow measuring system, relating to an electronic accelerator pulse electron beam flow measuring system, in particular to the nano-pico (10-10A / cm2) micro beam flow measurement of millisecond pulse, belonging to the electron radiation environment ground simulation and test field. The pulse electronic accelerator nano-pico ampere electron beam flow measuring system is composed of a novel inclined-bottom faraday cup, three coaxial cables and a nano-pico level current amplifier. The measurement result can be obtained by oscilloscope or data acquisition card. The inclined-bottom faraday cup electron collection system resolves the collection efficiency problem of high energy electrons (MeV), to improve collection efficiency. The adopted three coaxial cables can reduce the interference of electromagnetic field. The nano-pico ampere level current amplifier resolves the stable current linear amplification problem under electron radiation, and converts weak current signals to voltage signals, thus being convenient for data acquisition of oscilloscope or data acquisition card. The invention resolves the measurement problem of nano-pico ampere pulse electron beam flow, to confirm the accuracy, real-time property and easy use of measurement.

Owner:NO 510 INST THE FIFTH RES INST OFCHINA AEROSPAE SCI & TECH

Multi-plasma neutral beam source and method of operating

Method and system for producing a neutral beam source is described. The neutral beam source comprises a plasma generation system for forming a first plasma in a first plasma region, a plasma heating system for heating electrons from the first plasma region in a second plasma region to form a second plasma, and a neutralizer grid for neutralizing ion species from the second plasma in the second plasma region. Furthermore, the neutral beam source comprises an electron acceleration member configured to accelerate the electrons from the first plasma region into the second plasma region. Further yet, the neutral beam source comprises a pumping system that enables use of the neutral beam source for semiconductor processing applications, such as etching processes.

Owner:TOKYO ELECTRON LTD

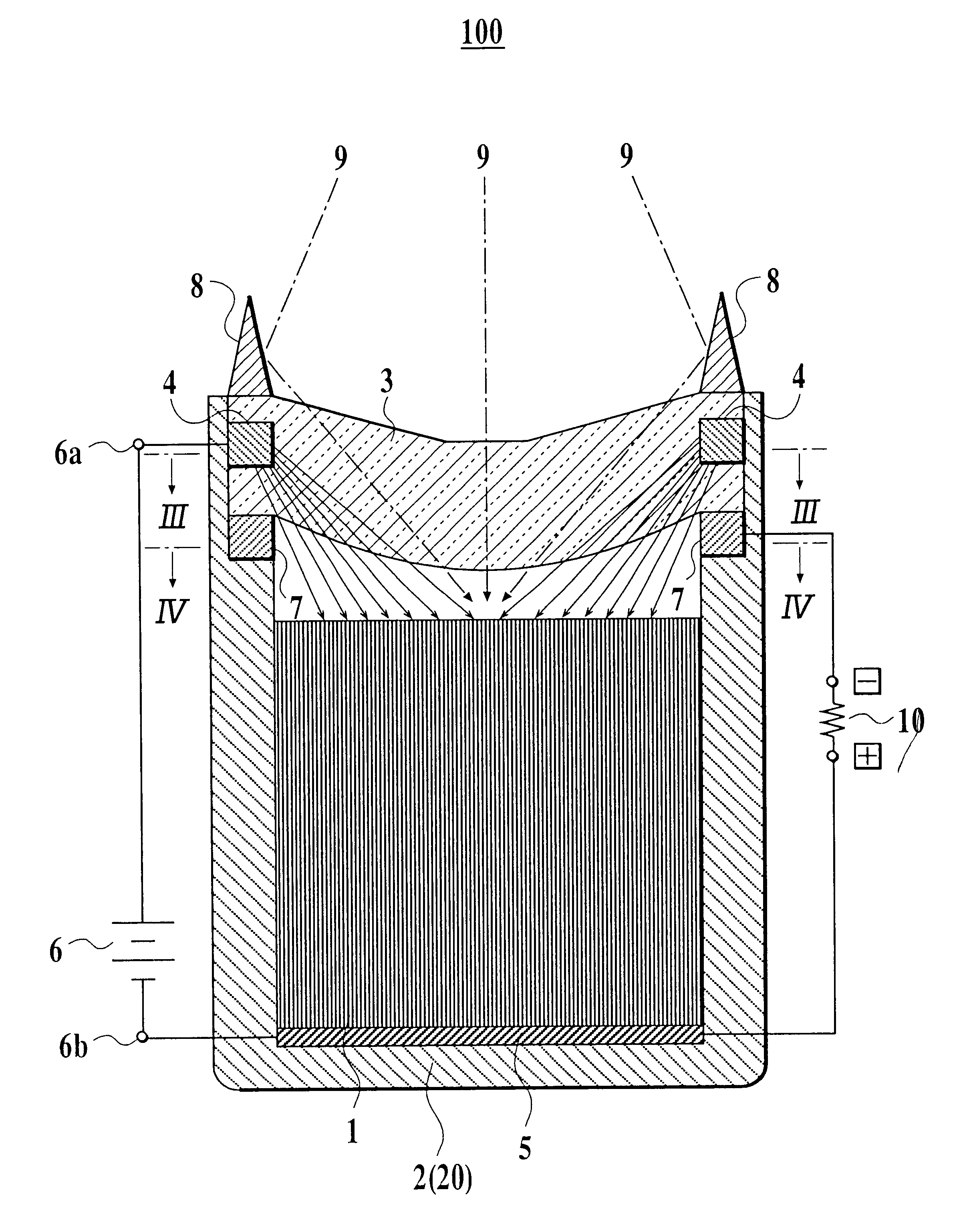

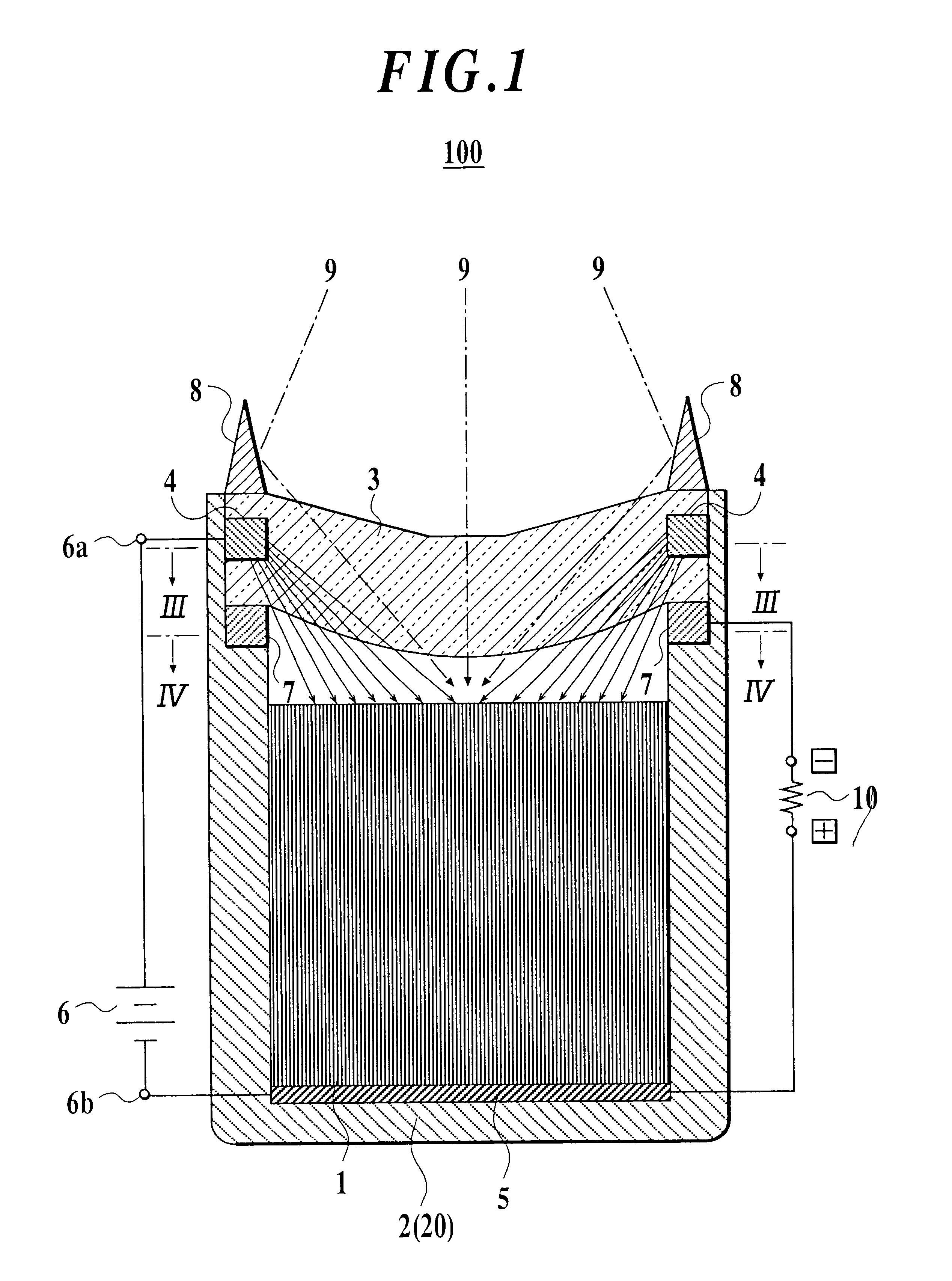

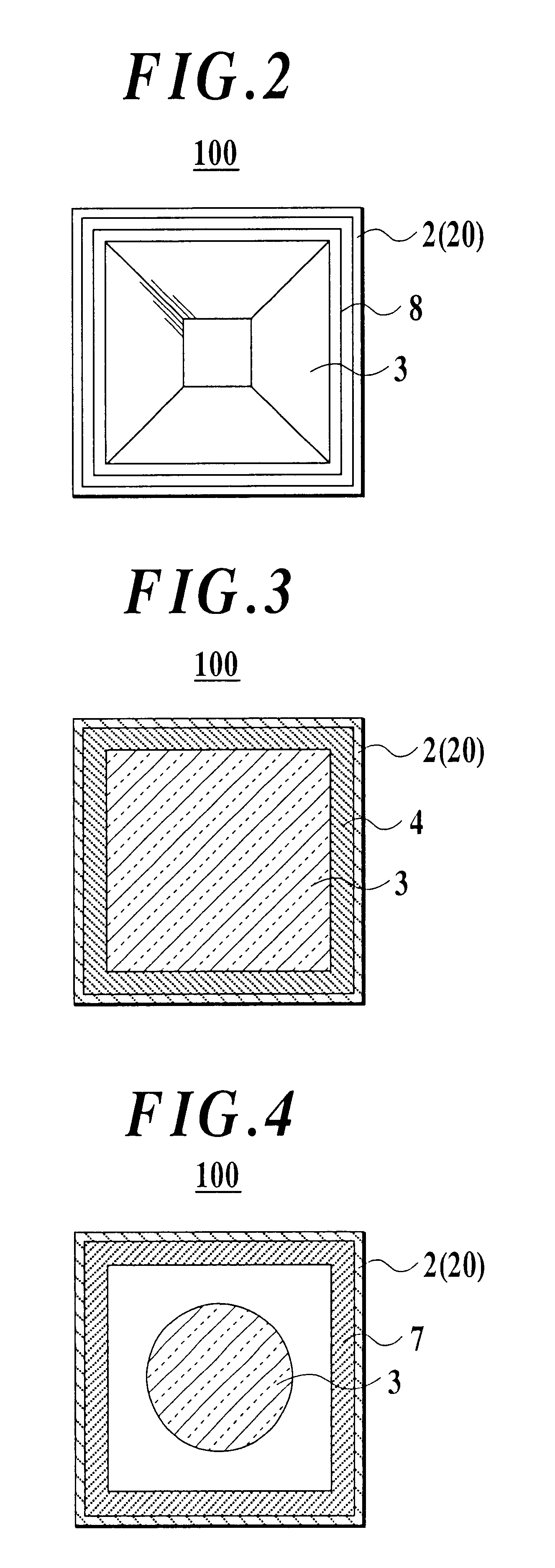

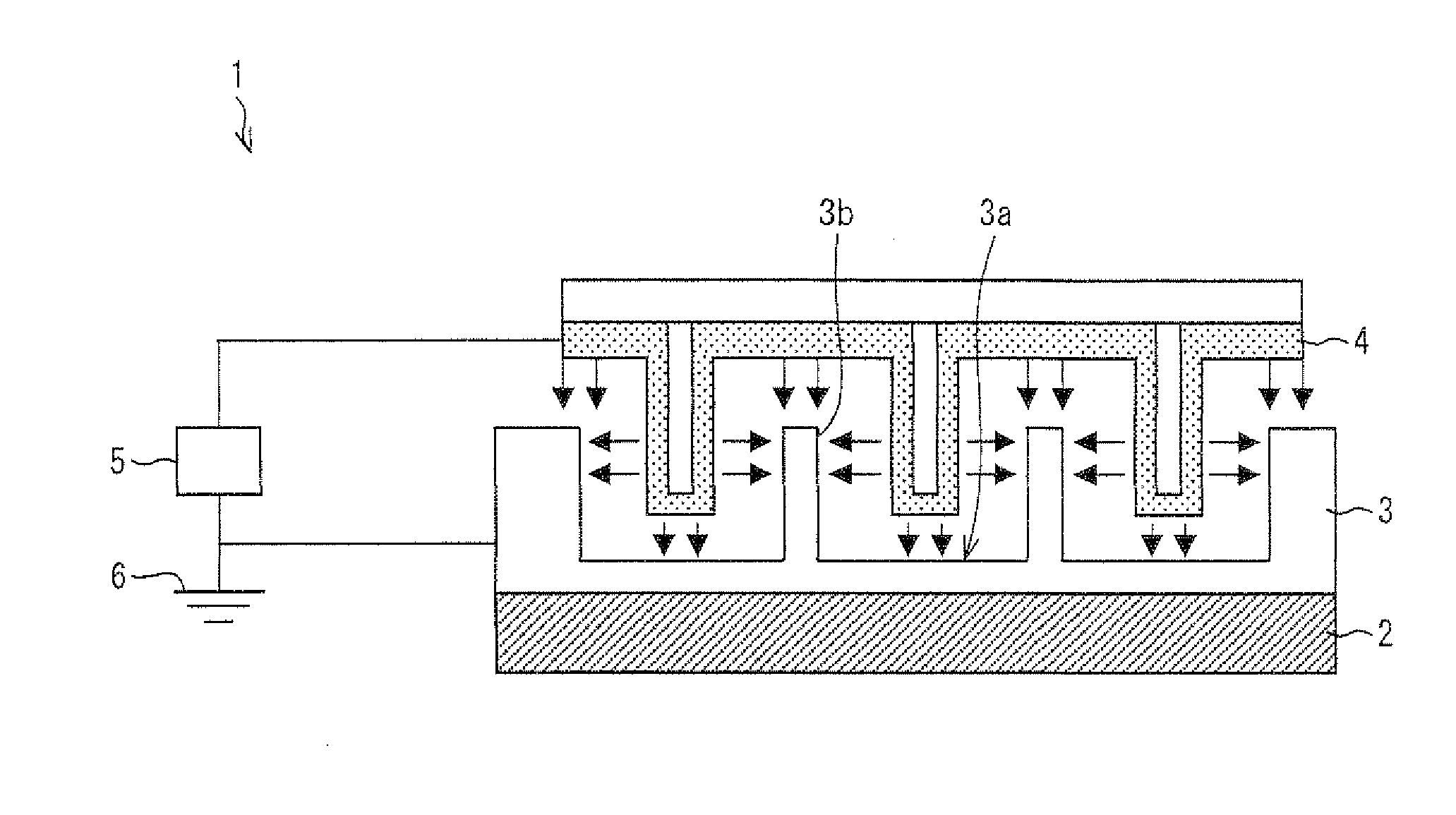

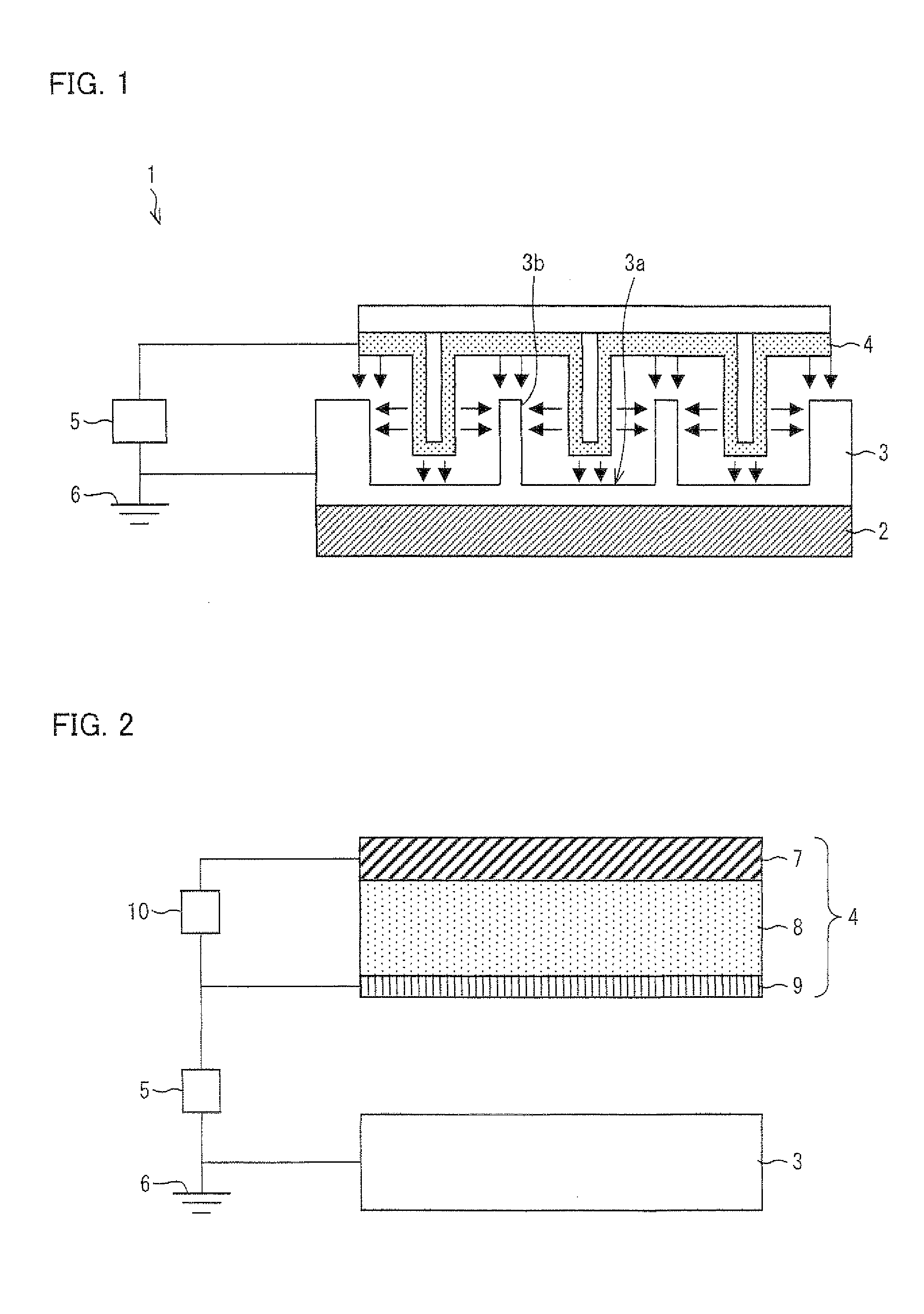

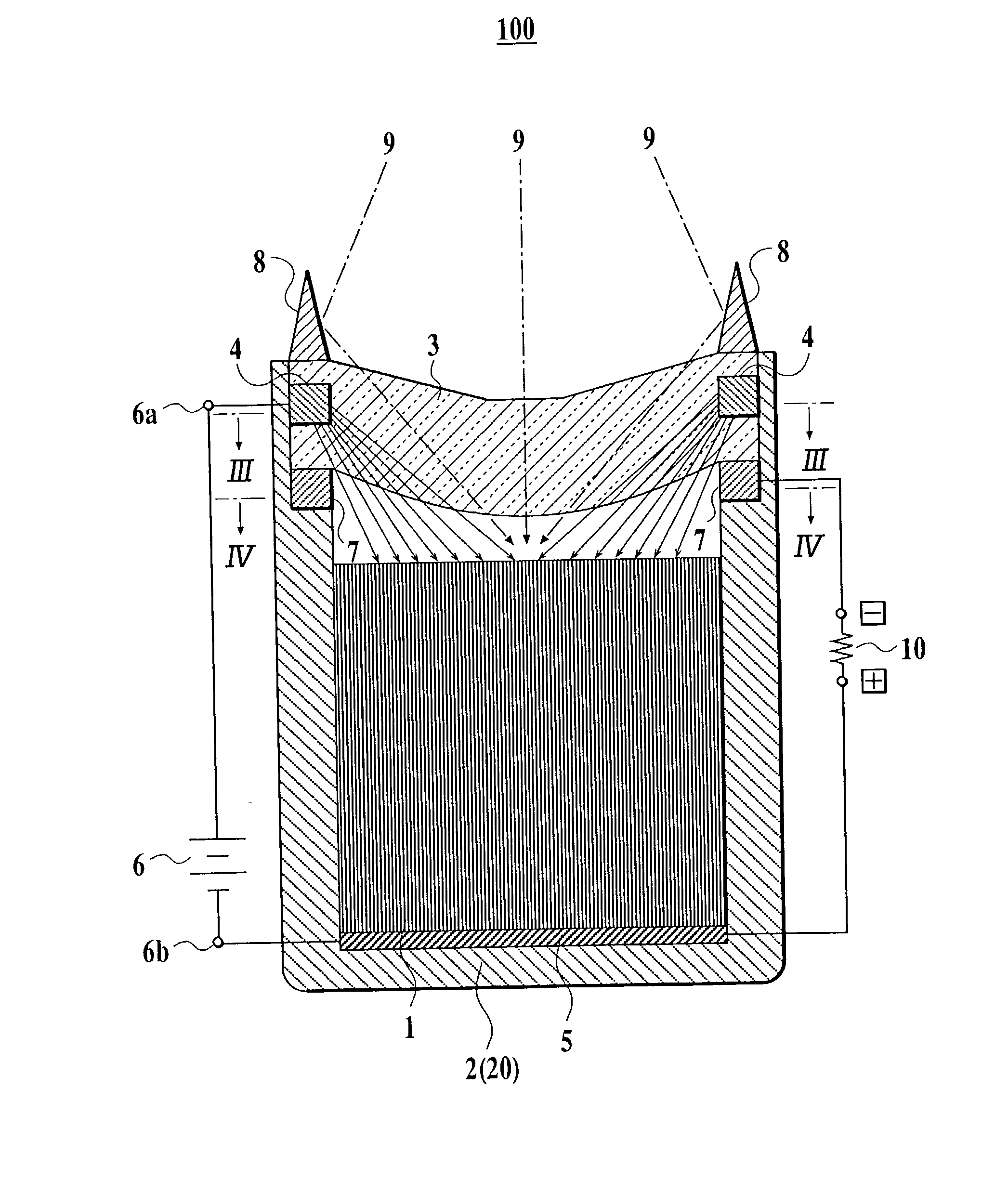

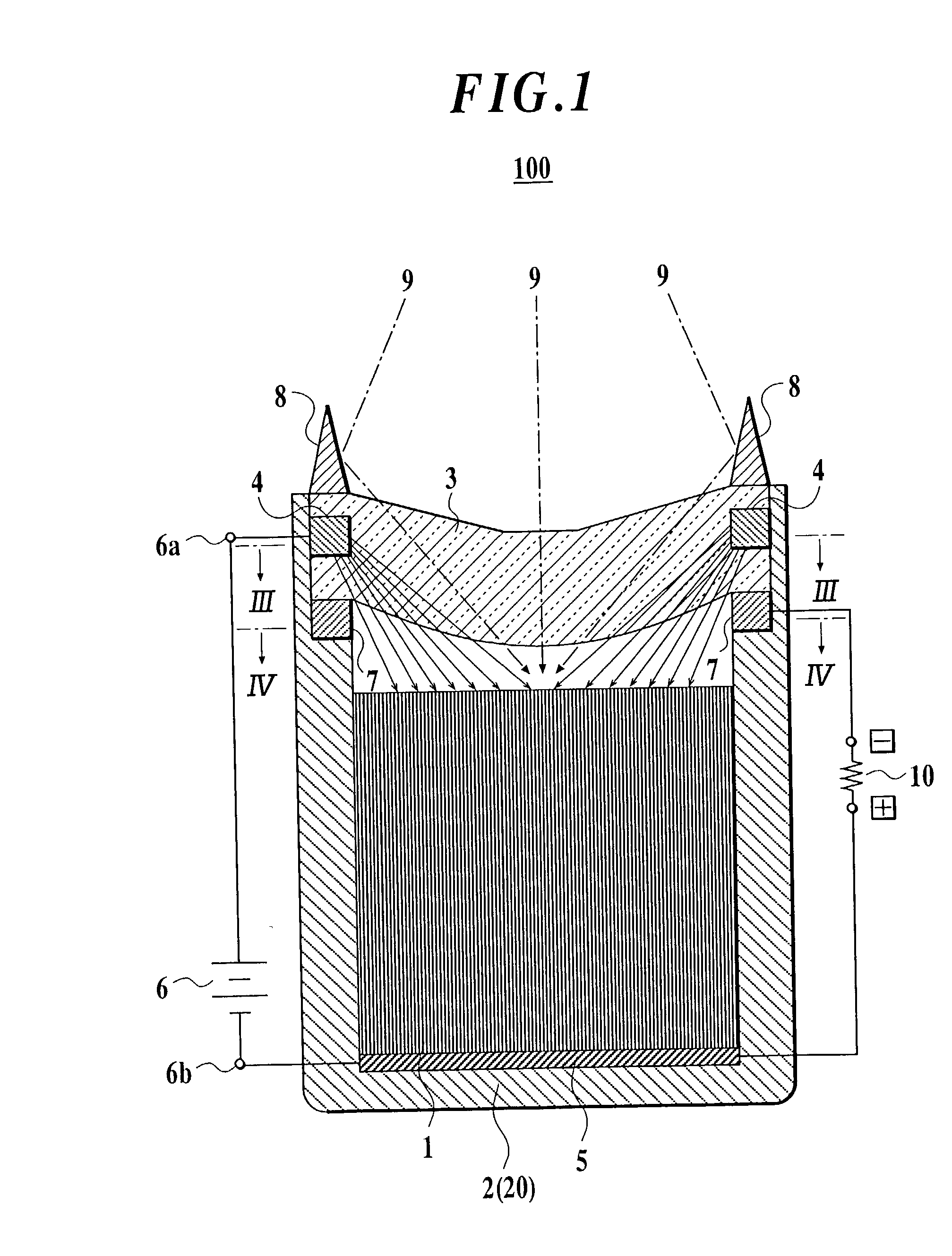

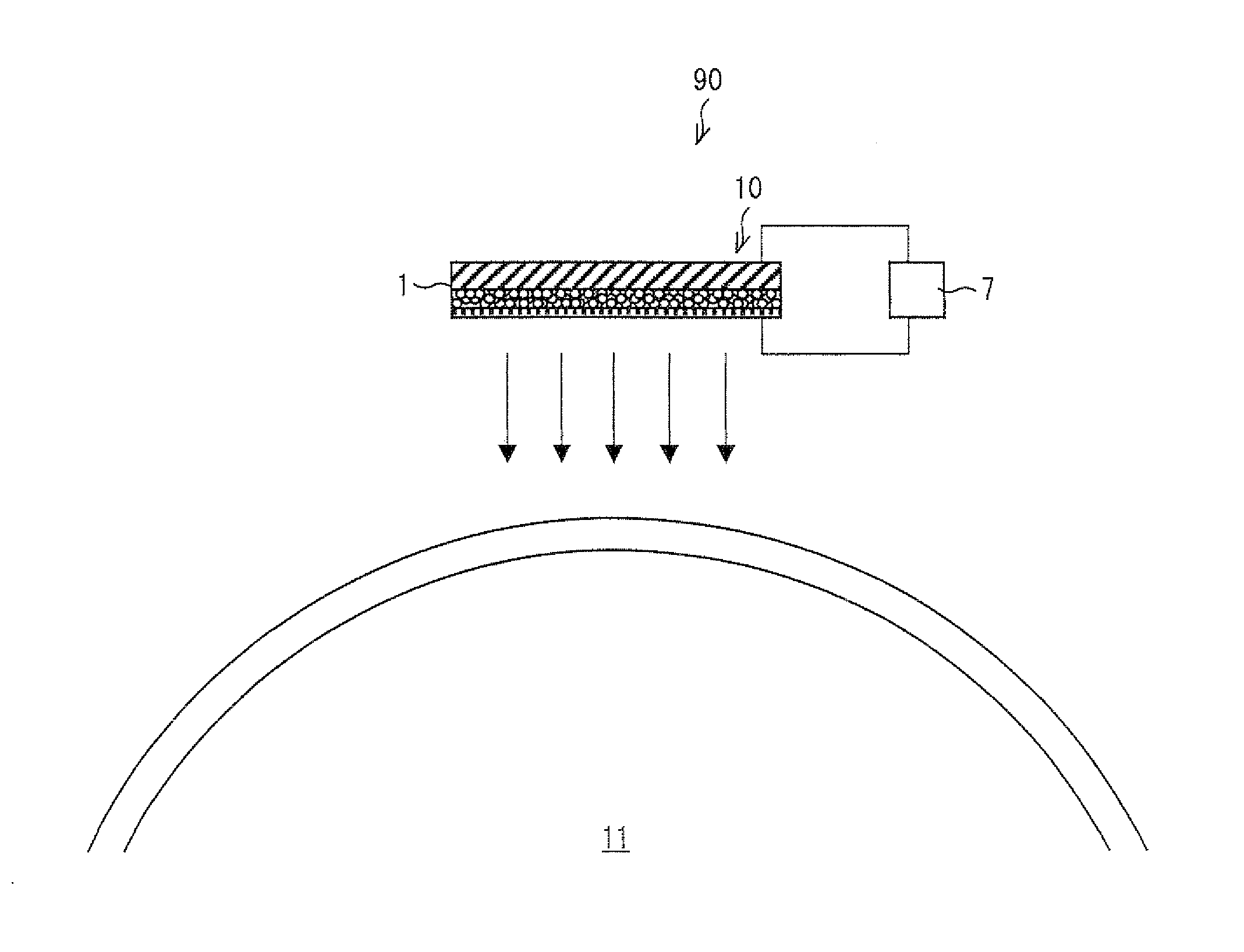

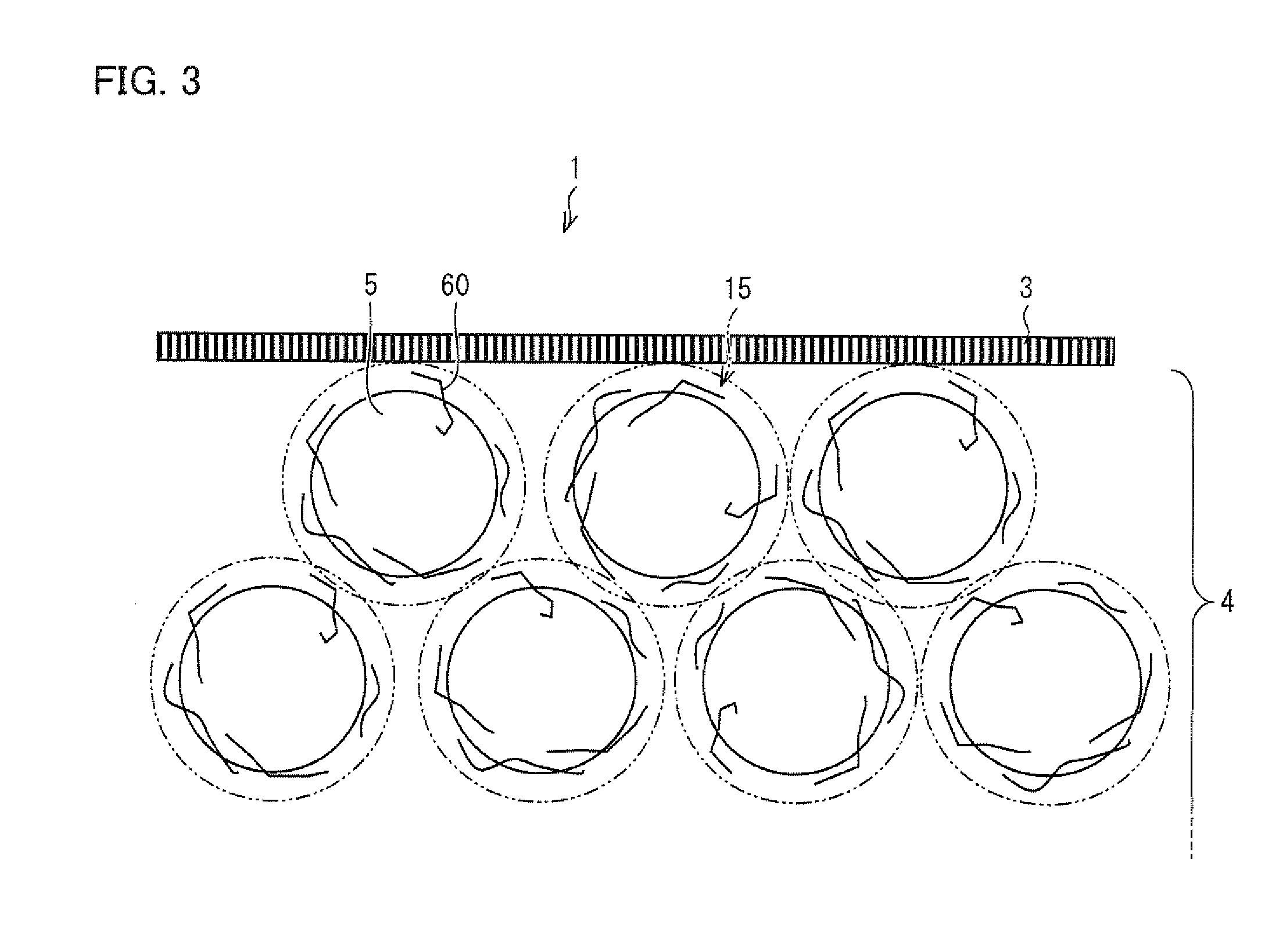

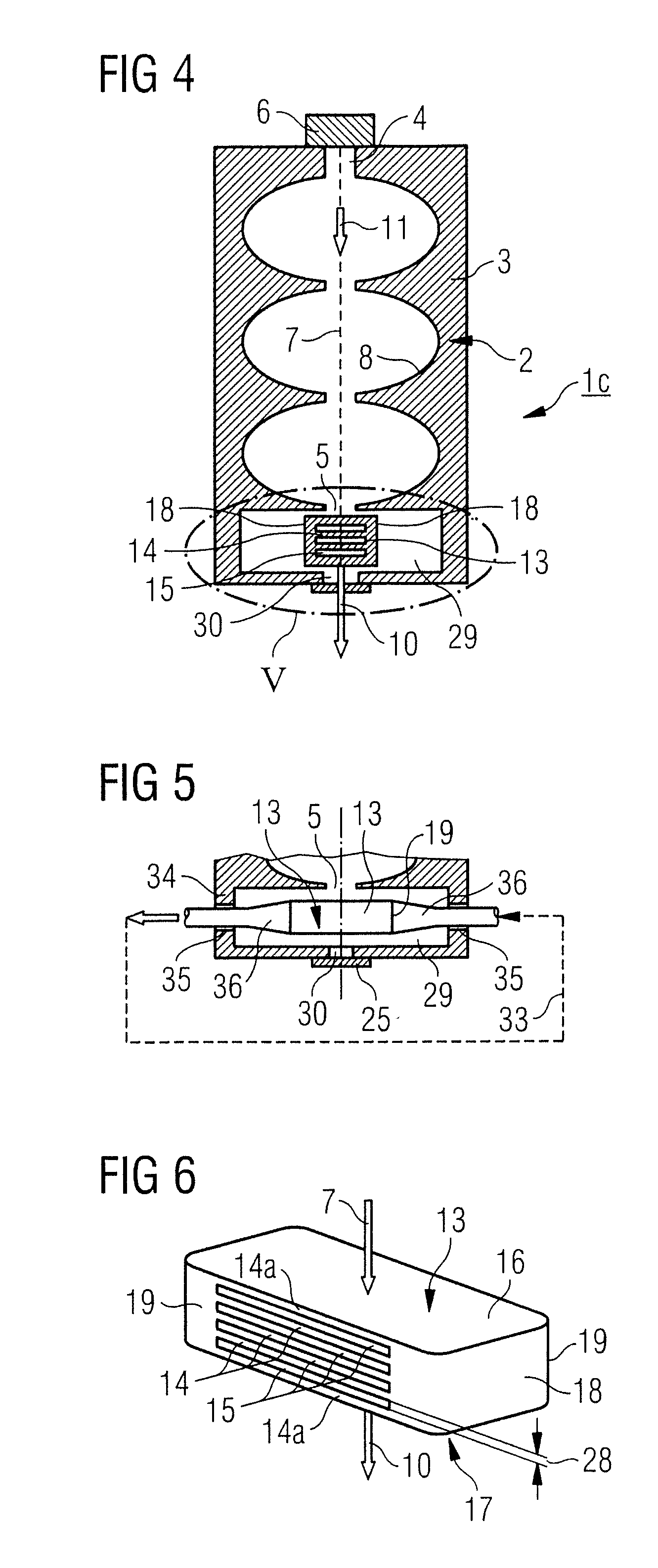

Heat exchanger

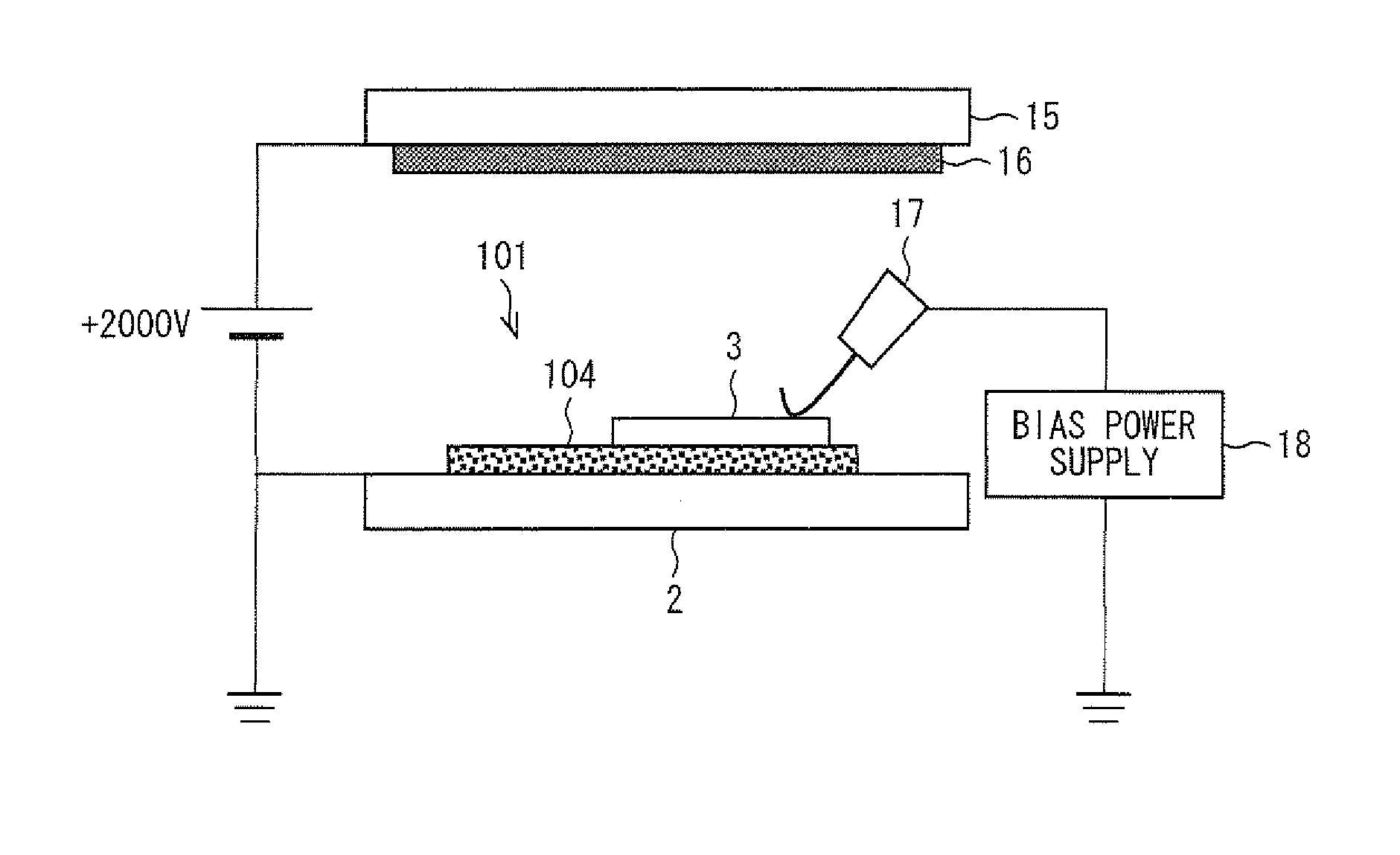

InactiveUS20100307724A1Reduce in quantityImprove heat exchange capacityDigital data processing detailsSemiconductor/solid-state device detailsThin film electrodeEngineering

A heat exchanger (1) includes: a heat sink (3) which is in contact with a heating element (2); and an electron emitting element (4) which is provided so as to be separated from the heat sink (3) by a space and which provides electrons to the heat sink (3) via air in the space. The electron emitting element (4) includes: an electrode substrate (7); a thin-film electrode (9); a power supply (10) which applies a voltage between the electrode substrate (7) and the thin-film electrode (8); and an electron acceleration layer (8) which accelerates the electrons inside itself in response to the voltage applied by the power supply (10) so that the electrons are emitted from the thin-film electrode (9). The electron acceleration layer (8) is made at least partially of an insulating material. As a result, the heat exchanger (1) has a heat exchange capability which can be maintained and improved independently of a structure in which electric field concentration tends to occur.

Owner:SHARP KK

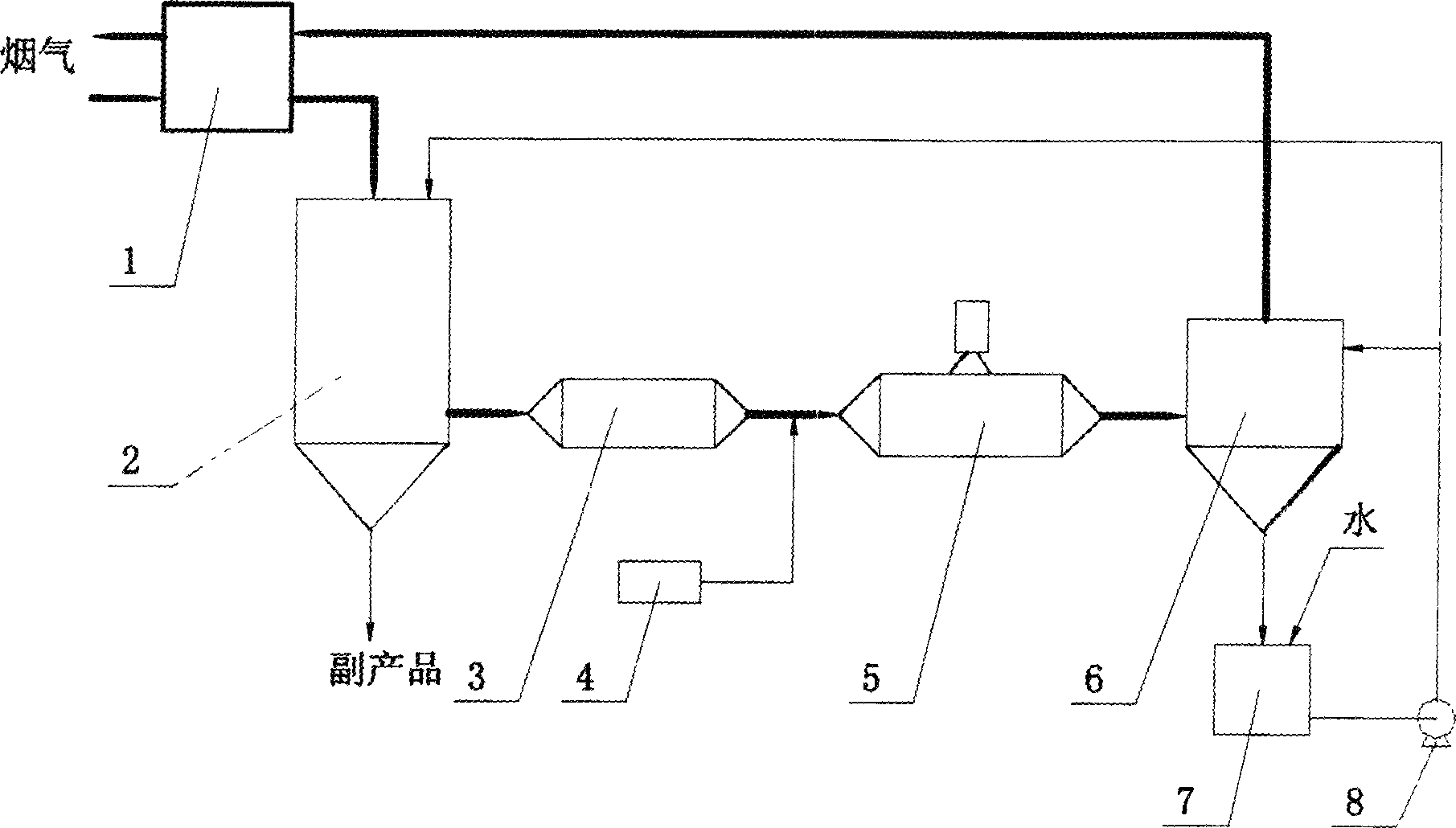

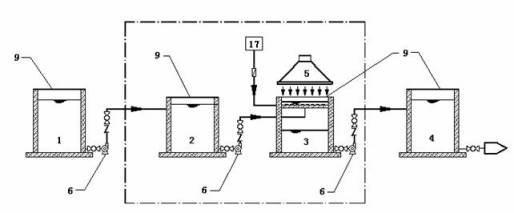

Plasma process for purifying coal-burning boiler smoke gas

InactiveCN1628892AMentioned sync rateEffective absorptionDispersed particle separationParticulatesHazardous substance

This invention relates to coal-burning boiler smoke new process and device by use of corona discharge and electron beam plasm compound technique, which comprises the following steps: the boiler smoke goes through static dust cleaner and exchanges heat with gag to gas converter; then it goes into frog drying tower for wetting and lowering temperature; then it enters the corona discharge chamber to make oxidation to generate acid substance; the product is mixed with smoke and ammonia injected by liquid ammonia tar and then enters the electronic speeder to generate electronic beam reaction; the generated ammonia sulfate and ammonium nitrate mixed particles are collected in the solution groove.

Owner:BEIJING STATE GRID POWER TECH

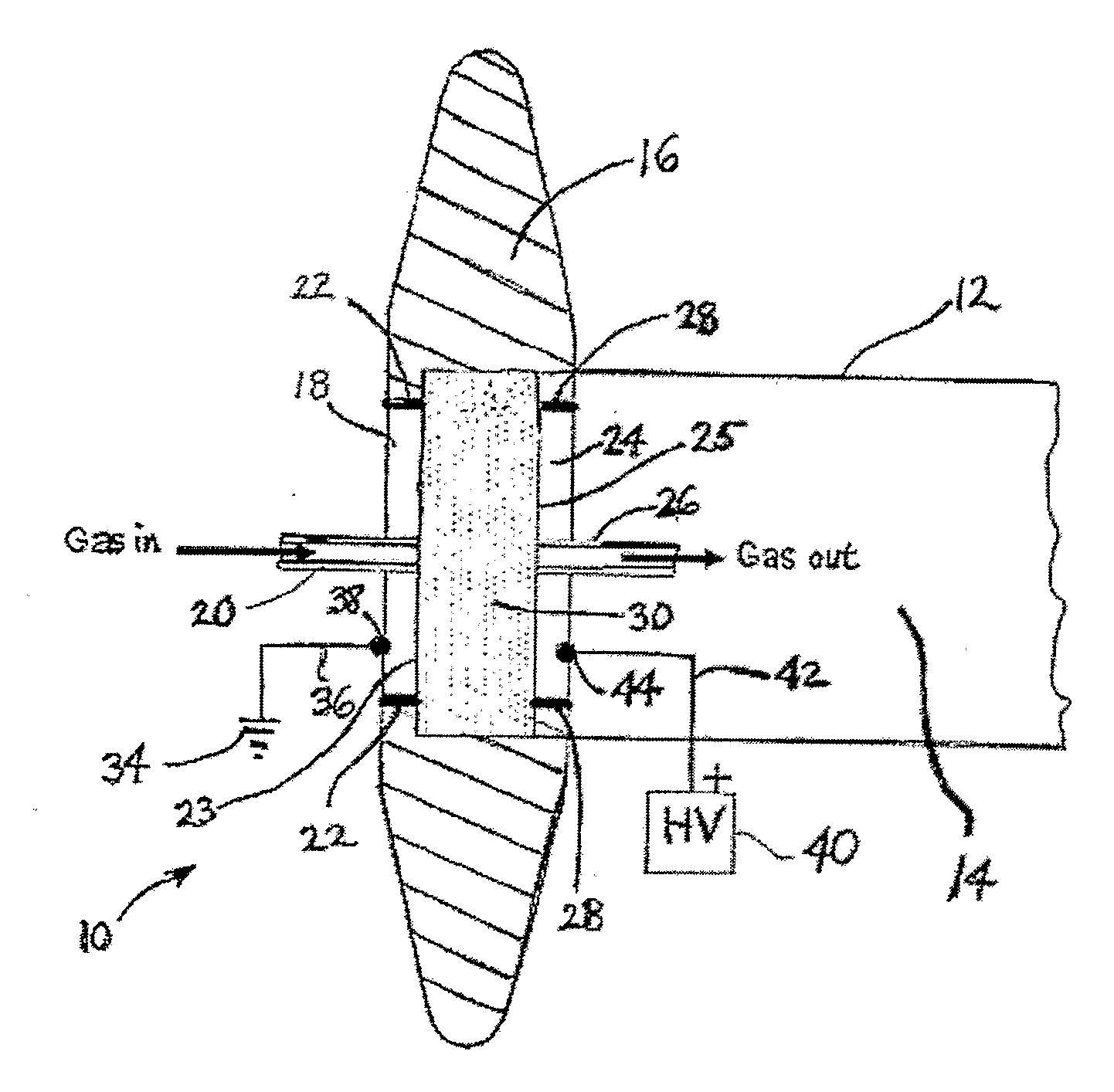

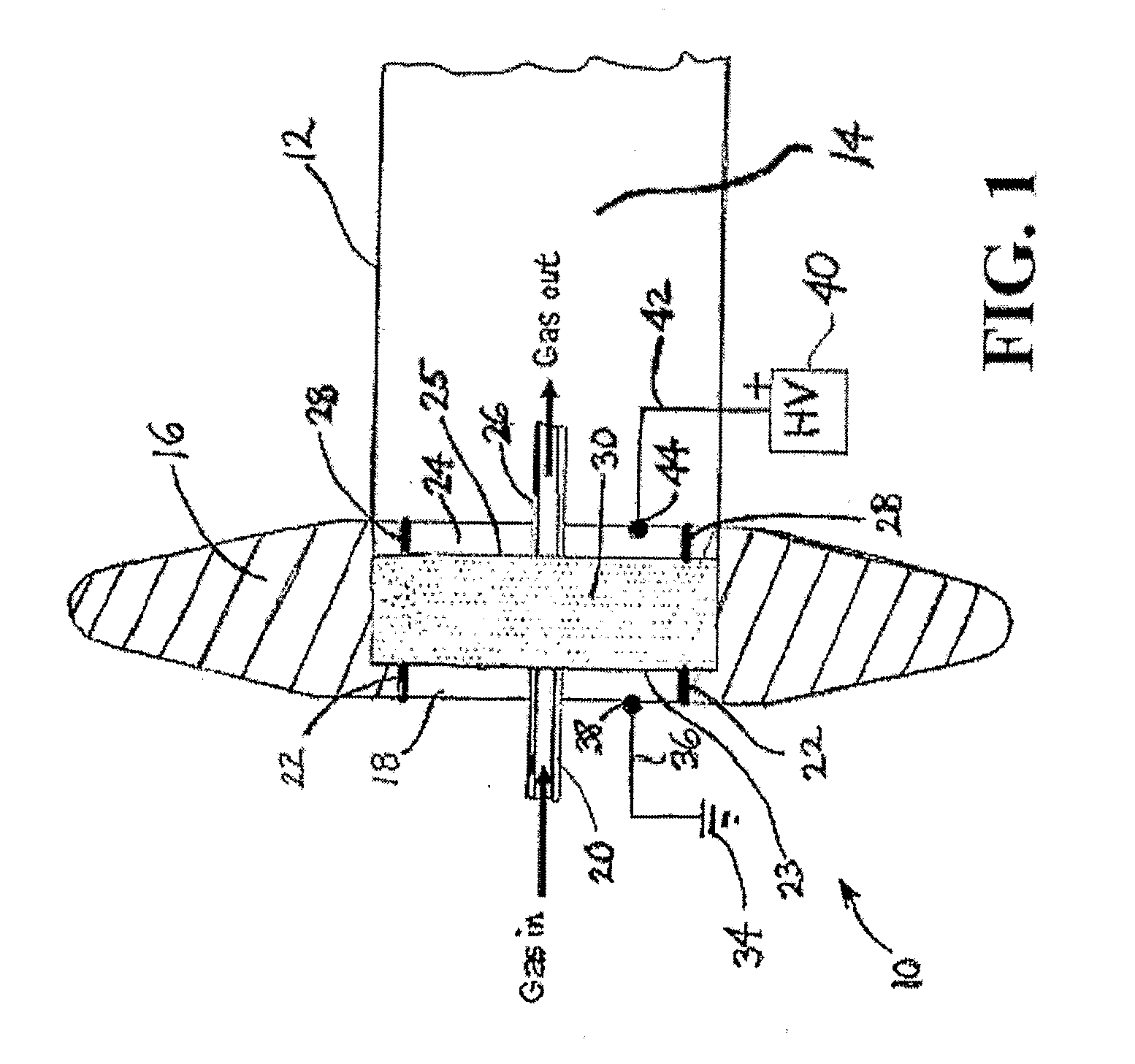

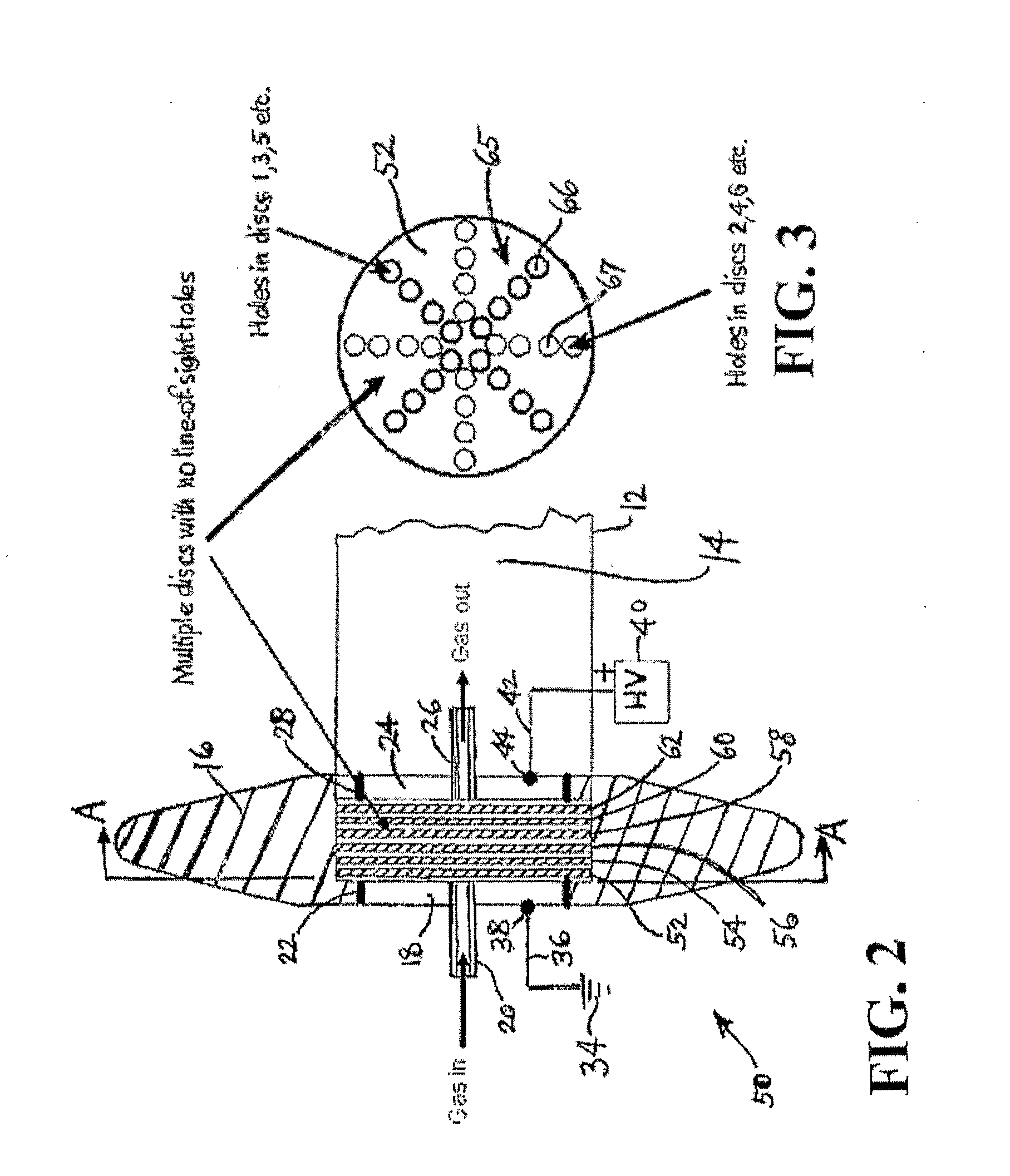

Delivery of Low Pressure Dopant Gas to a High Voltage Ion Source

InactiveUS20080220596A1Ionization suppressionReduce the impactMaterial analysis by optical meansSemiconductor/solid-state device manufacturingDelivery systemHigh voltage

A system for delivery of low-pressure dopant gas to a high-voltage ion source in the doping of semiconductor substrates, in which undesired ionization of the gas is suppressed prior to entry into the high-voltage ion source, by modulating electron energy upstream of the high-voltage ion source so that electron acceleration effects are reduced to below a level supporting an electronic ionization cascade. The gas delivery system in a specific application includes a gas flow passage, a voltage generator electrically coupled with at least a portion of the gas flow passage to impose an electric field thereon, and an obstructive structure that is deployed to modulate acceleration length of electrons of the low-pressure gas in relation to ionization potential of the gas, to suppress ionization in the gas flow passage.

Owner:ENTEGRIS INC

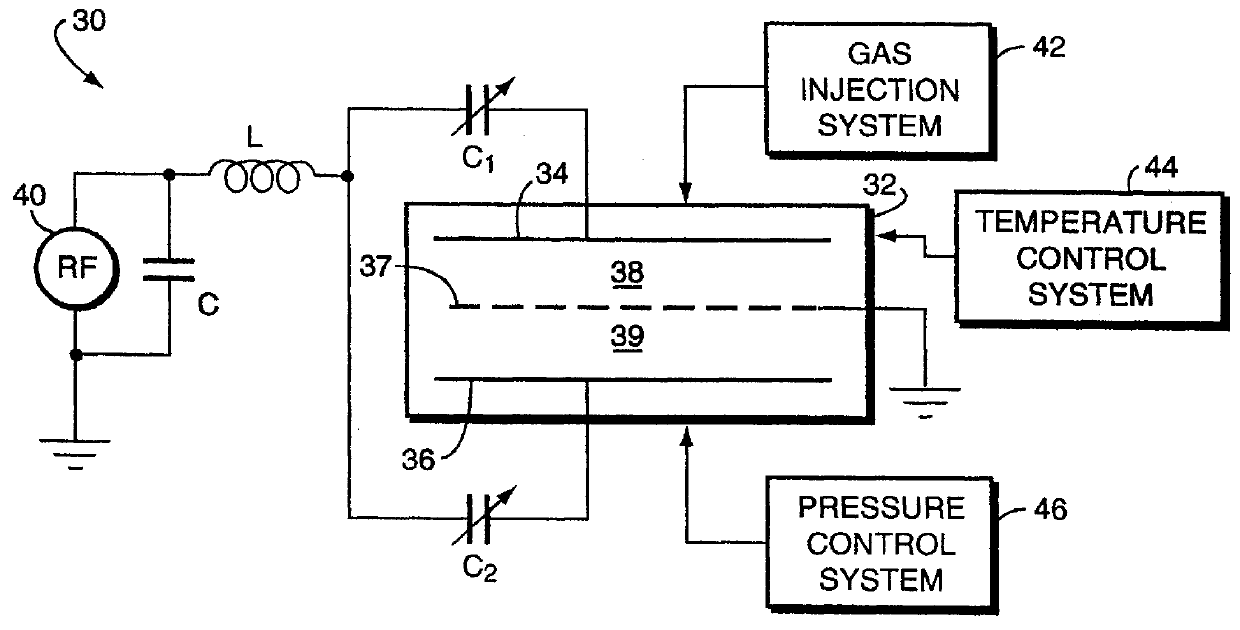

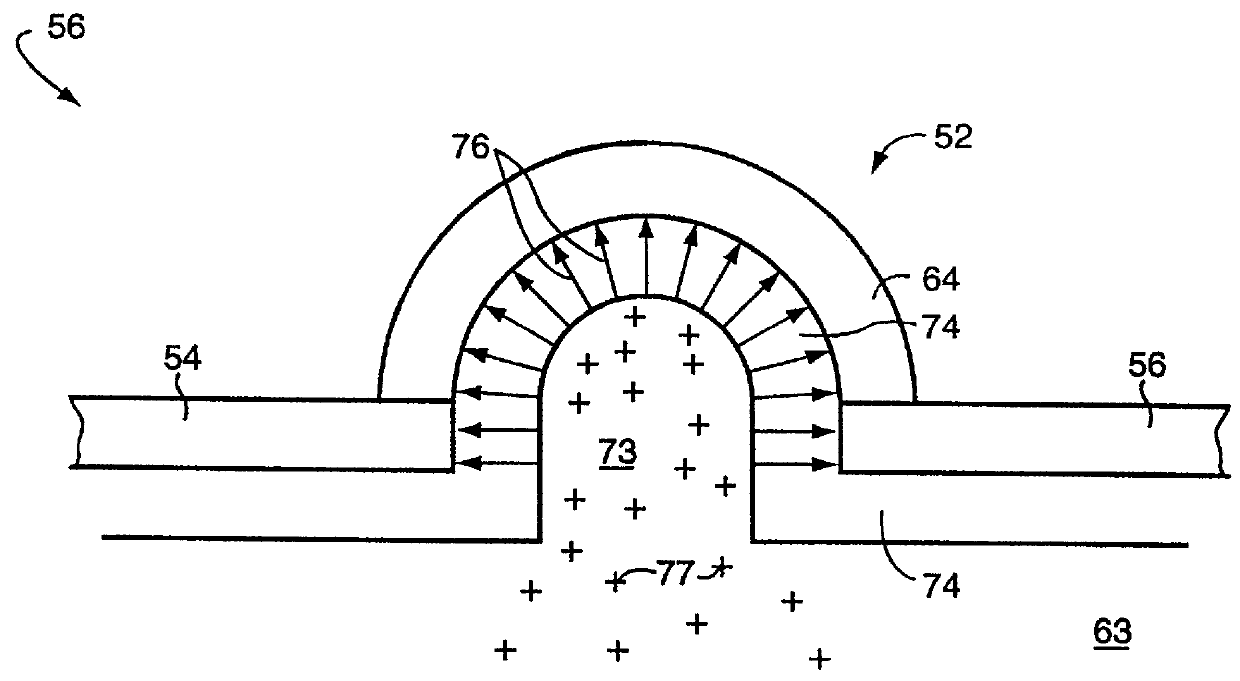

Electrode with domes for plasma focusing

InactiveUS6010636AMinimize escapeInexpensively integrated into existing plasma-driven reactorElectric discharge tubesDecorative surface effectsPlasma densityReaction rate

An improved anode design, incorporating domes, for plasma reactors enhances plasma density at the anode. The domes give rise to a high-divergence, three-dimensional electric field distribution that accelerates electrons to a focused central region in the dome, thereby increasing ionization and dissociation. The enhanced plasma density increases the reaction rate at a substrate opposite the anode.

Owner:LAM RES CORP

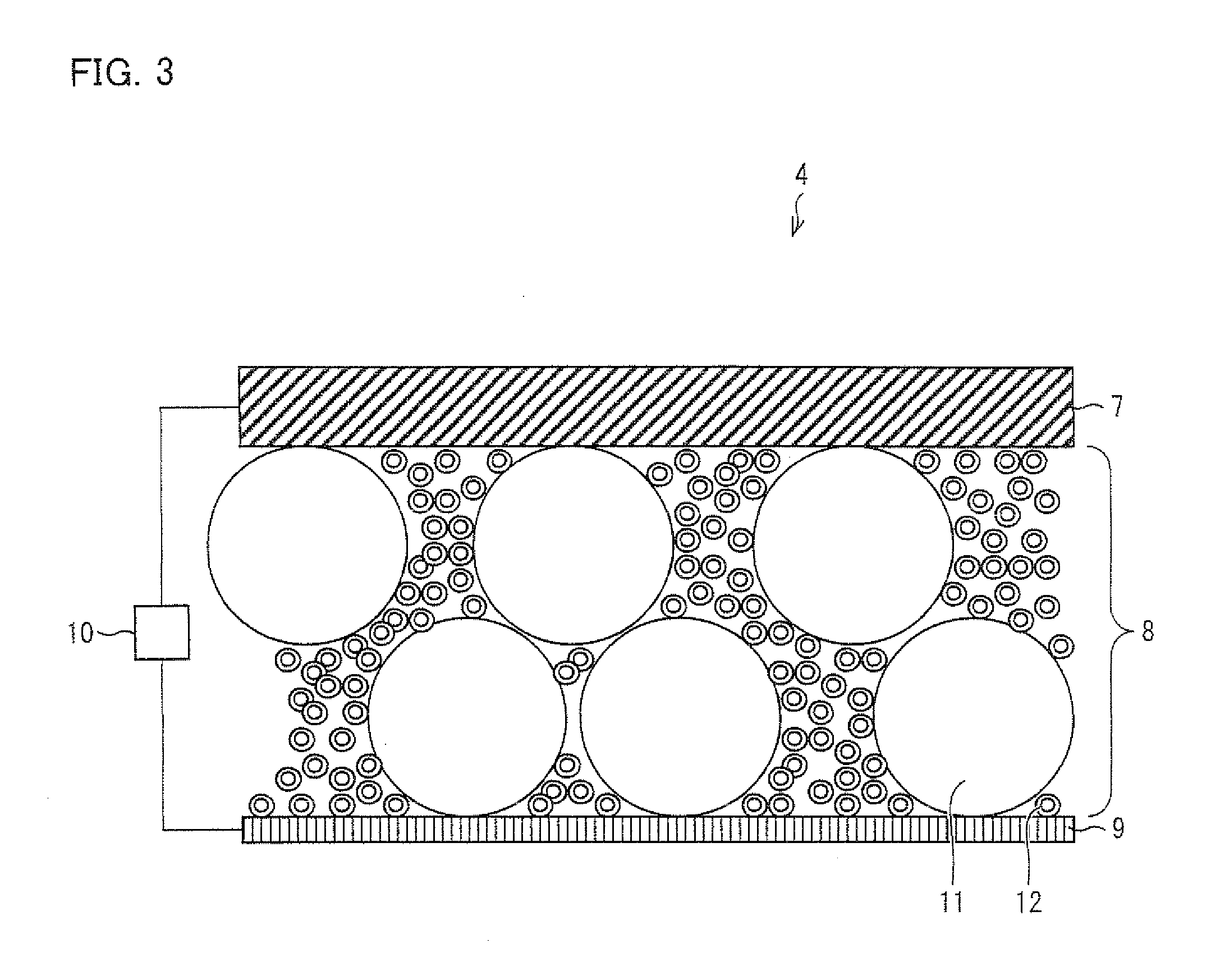

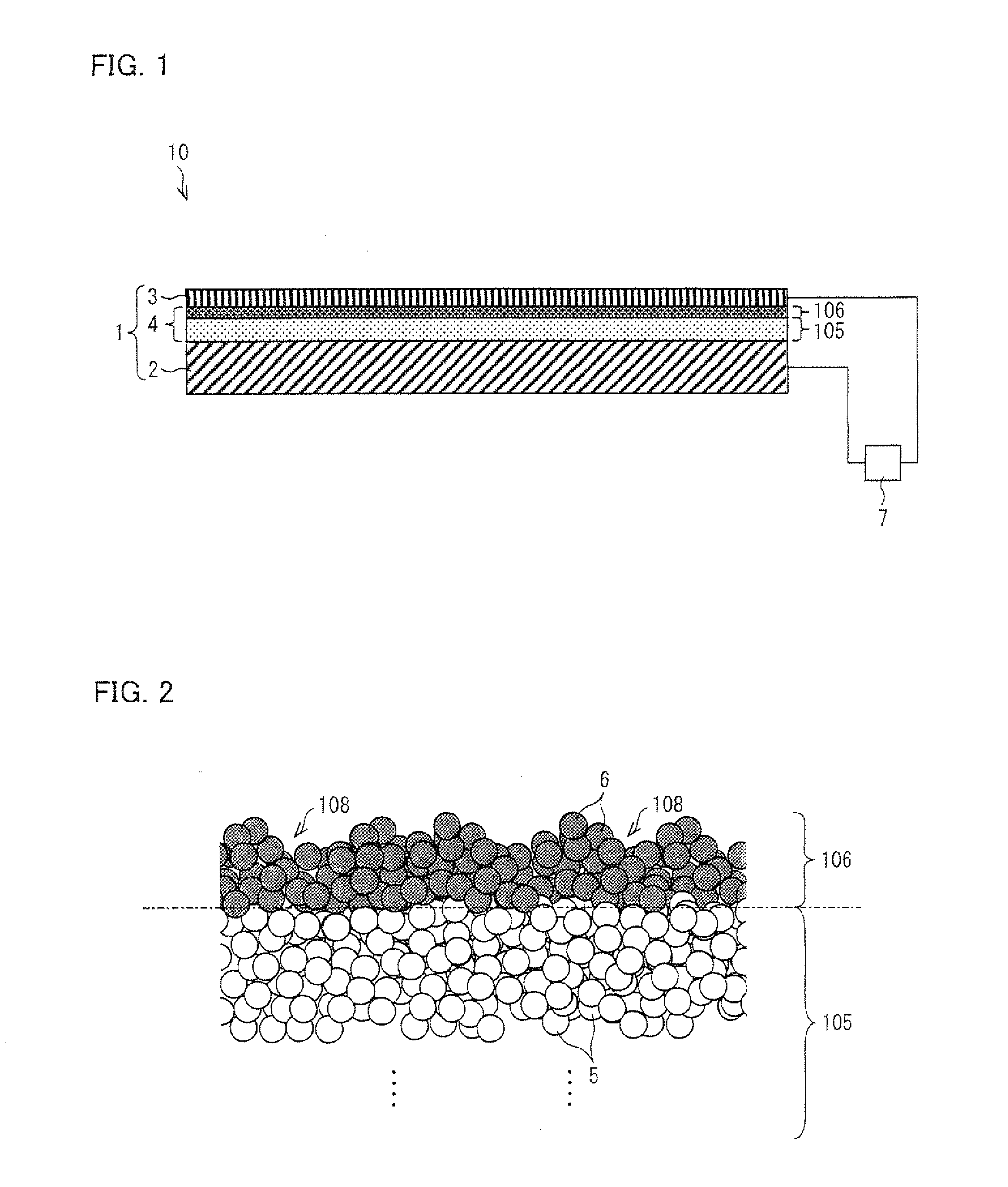

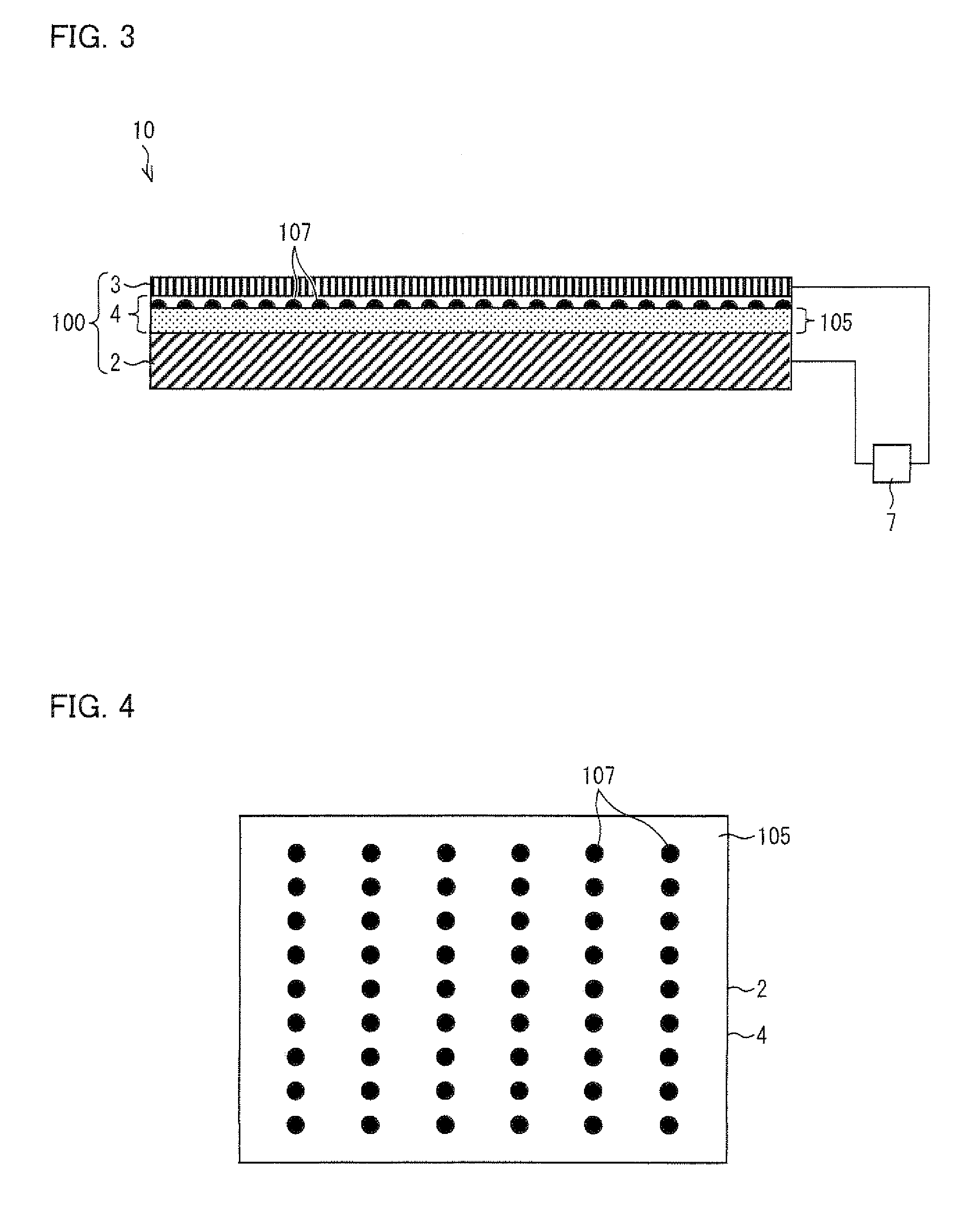

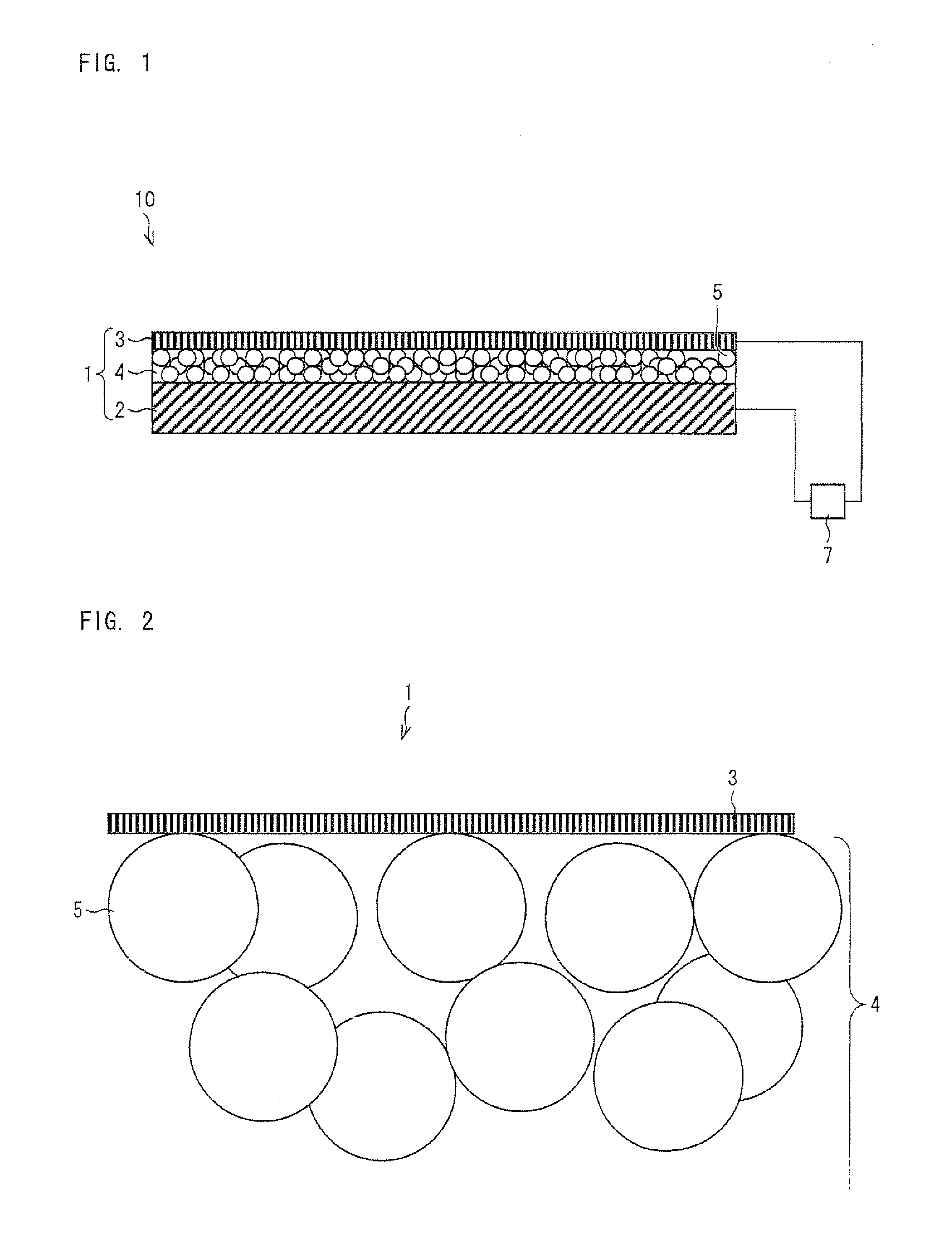

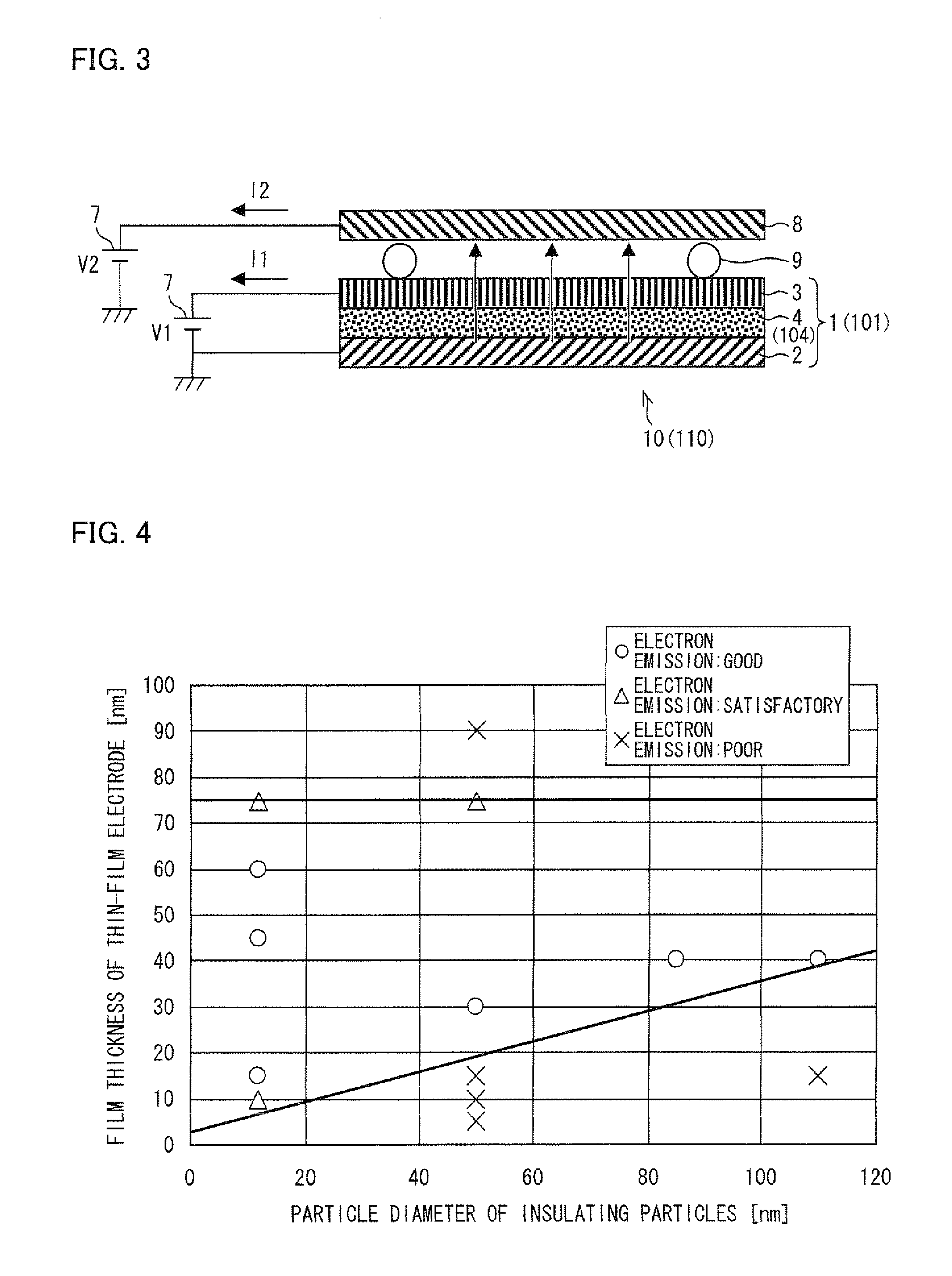

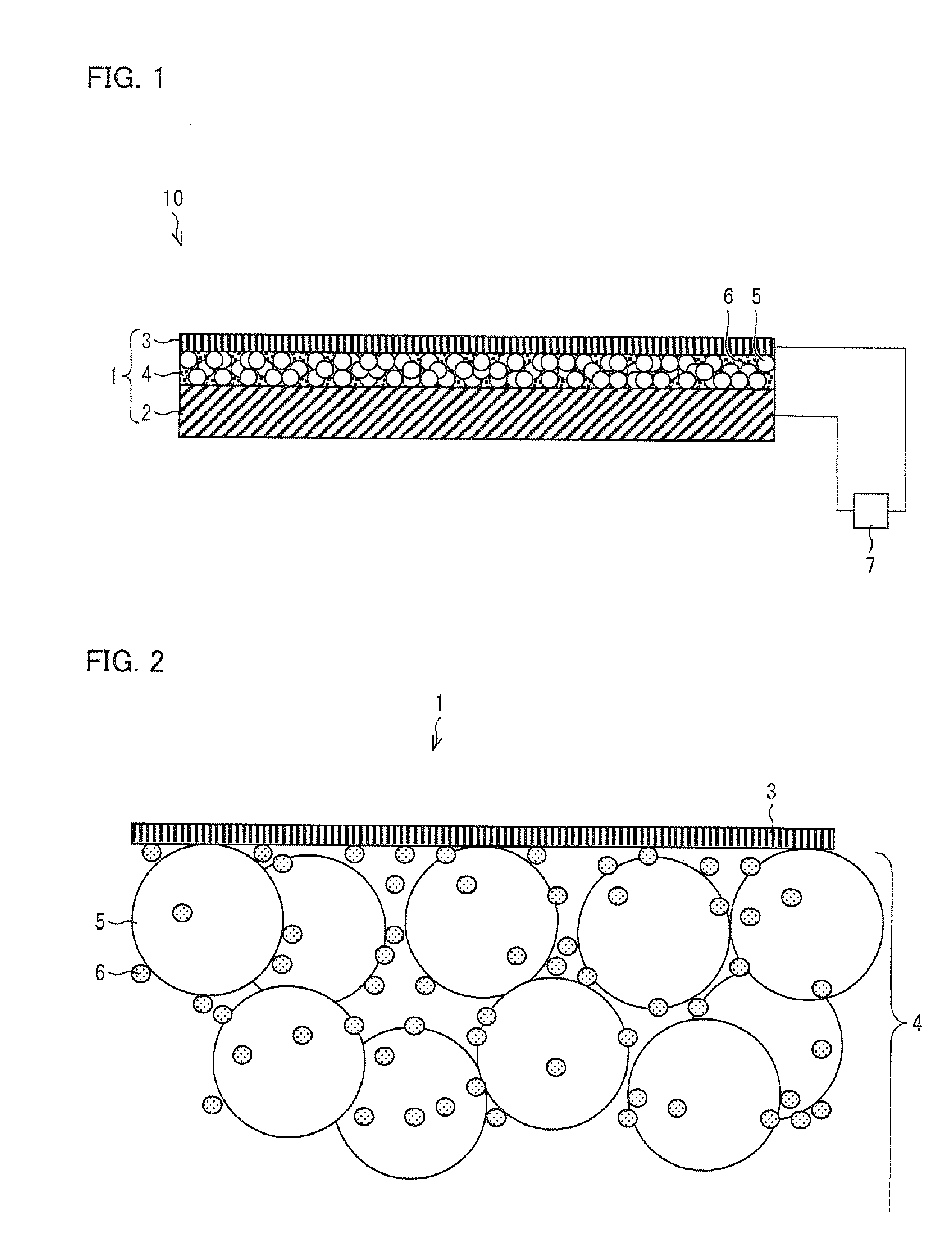

Electron emitting element and method for producing electron emitting element

ActiveUS20100327730A1Facilitates electricity flowWell formedDischarge tube luminescnet screensNanoinformaticsThin film electrodeElectron acceleration

An electron emitting element includes an electrode substrate, a thin-film electrode, and an electron acceleration layer provided between them. The electron acceleration layer includes a fine particle layer containing insulating fine particles, which is provided on a side of the electrode substrate, and a deposition of conductive fine particles, which is provided on a surface of the fine particle layer. In the electron acceleration layer, a conductive path is formed in advance, and the deposition has a physical recess which is an exit of the conductive path and which serves as an electron emitting section. Electrons are emitted via the electron emitting section. With the arrangement, it is possible to realize an electron emitting element which prevents that an electrode on an electron emission side gradually wears off along with electron emission and which can maintain an electron emission characteristic for a long period.

Owner:SHARP KK

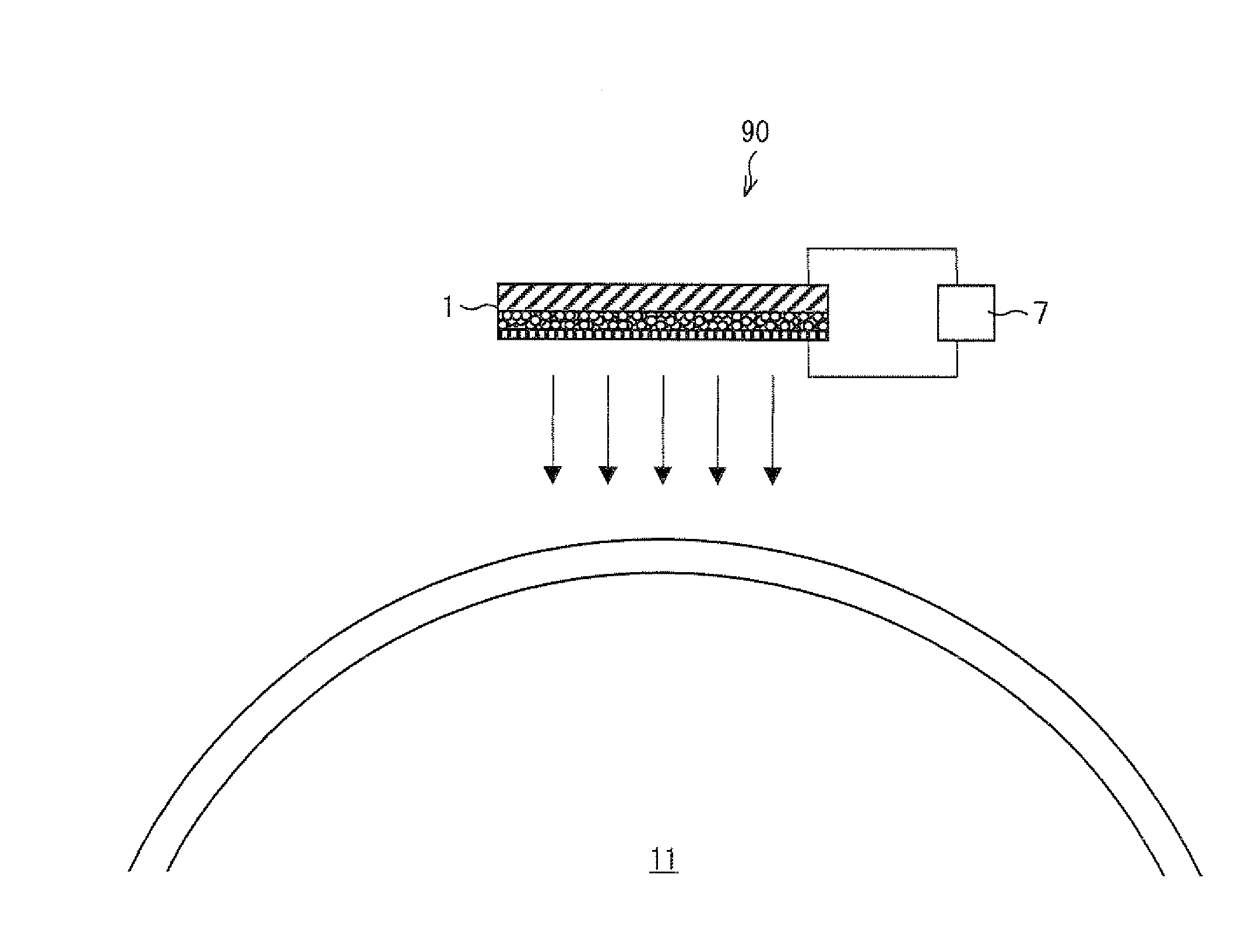

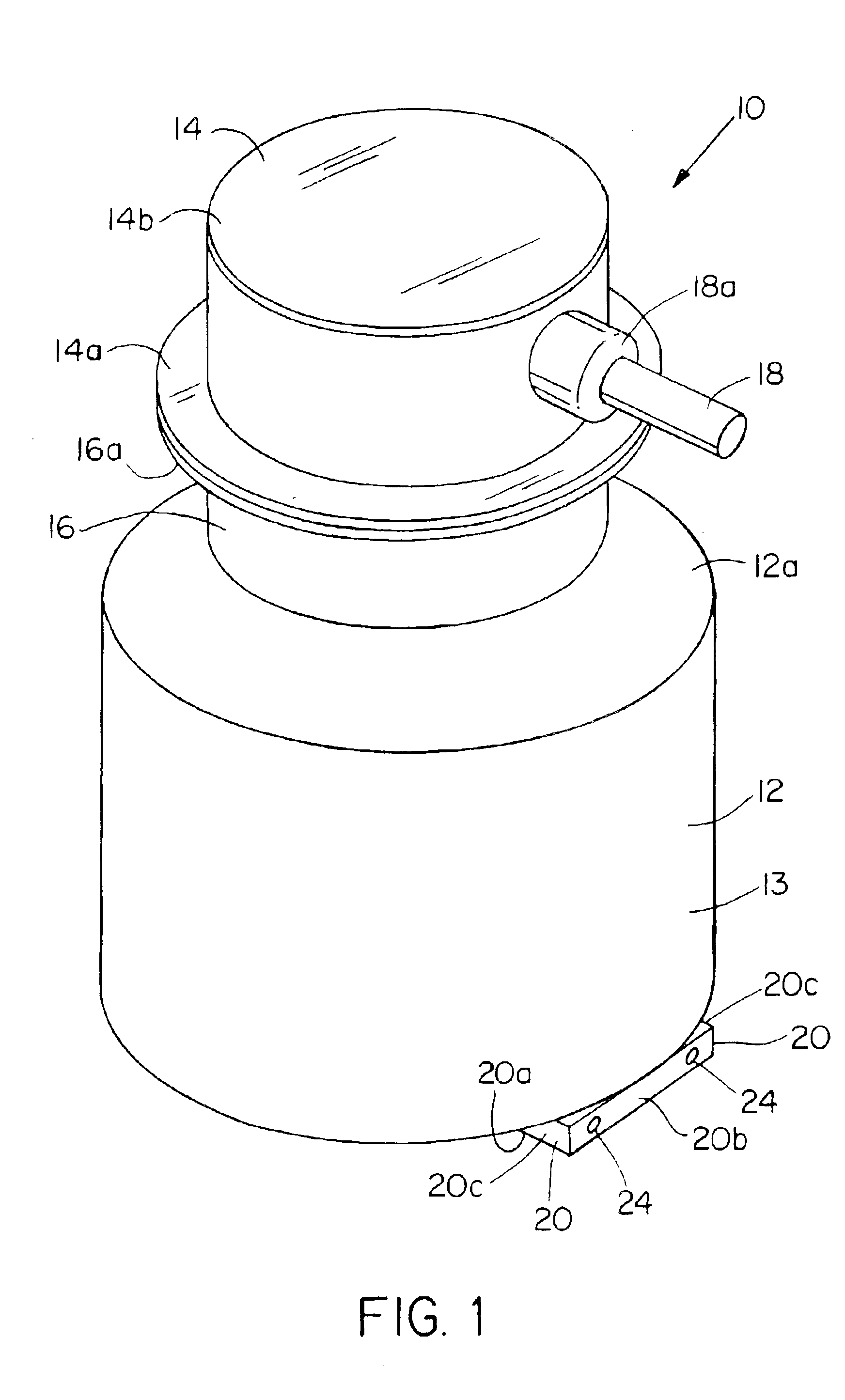

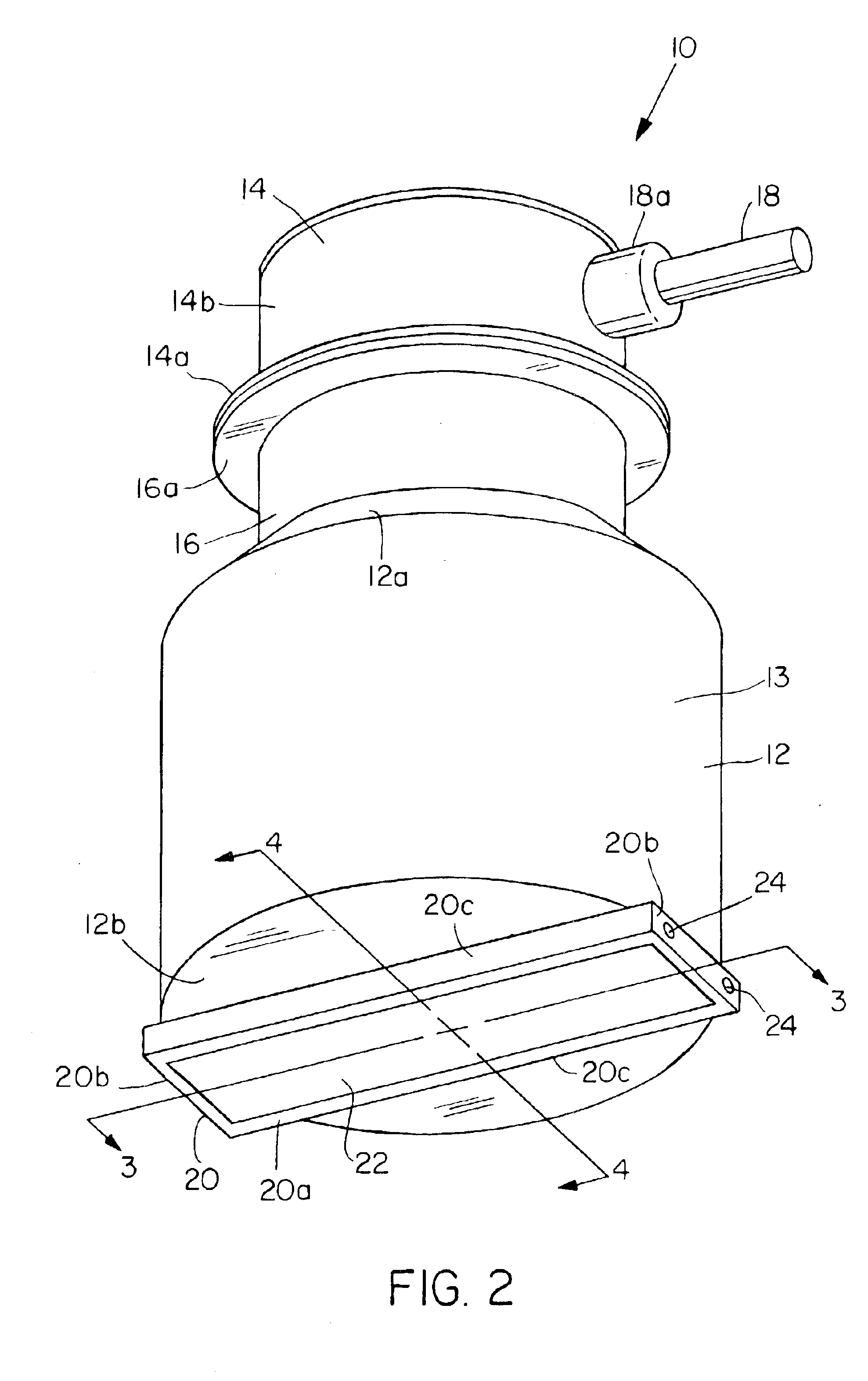

Solar energy converter and solar energy conversion system

InactiveUS20030111104A1Low costEasy to assembleSolar heating energyThermoelectric device with peltier/seeback effectElectricitySUN LIGHT EXPOSURE

A solar energy converter includes: a light-concentrating instrument; an electron emitter in an insulated vacuum vessel, emitting electrons in a vacuum as a temperature rises by sunlight; an electron accelerator within the light-concentrating instrument; a cathode on a surface of the electron emitter opposite to a surface which is irradiated by sunlight, and electrically connected with the electron emitter; an electric field supplier having a positive terminal and a negative terminal; and an electron collector in the vacuum vessel, collecting the emitted electrons flying from the electron emitter toward the electron accelerator; wherein the electron accelerator is connected with the positive terminal and the cathode is connected with the negative terminal to generate an electric field, and the electron collector is used as a negative generator electrode and the cathode is used as a positive generator electrode in which the collected electrons migrate to the electron emitter to generate electricity.

Owner:AKAMATSU NORIO +1

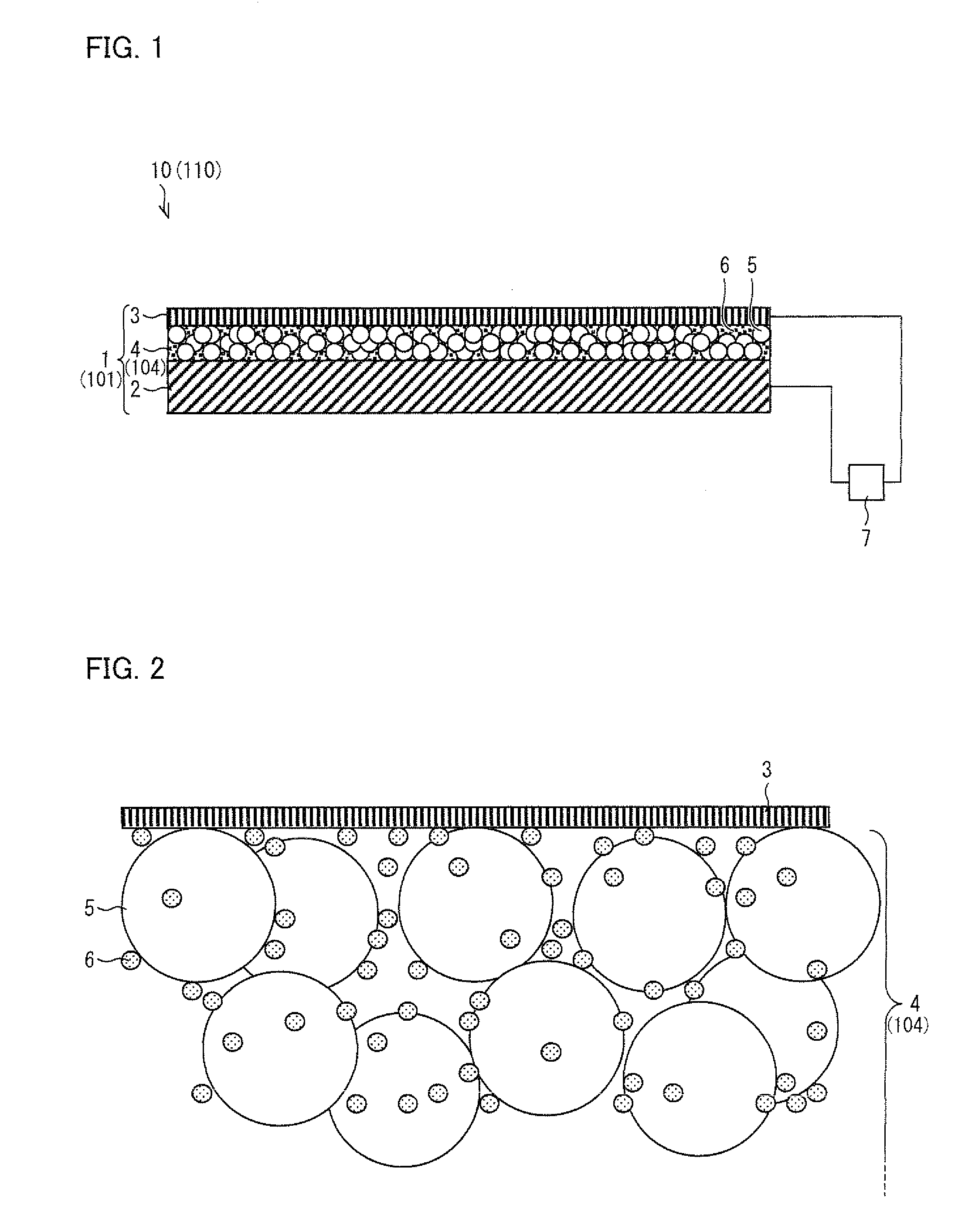

Electron emitting element, electron emitting device, light emitting device, image display device, air blowing device, cooling device, charging device, image forming apparatus, and electron-beam curing device

ActiveUS20100296845A1Improve energy efficiencyNanoinformaticsAlternating current plasma display panelsThin film electrodeDisplay device

The present invention provides an electron emitting element which has good energy efficiency and which is capable of controlling a value of current flowing in an electron acceleration layer and an amount of emitted electrons by adjusting a resistance value of the electron acceleration layer and an amount of generated ballistic electrons. An electron emitting element 1 includes an electron acceleration layer 4 including a fine particle layer containing insulating fine particles. In the electron emitting element 1, Ie=α·R−0.67 where Ie [A / cm2] is electron emission current per unit area during the voltage application and R is element resistance [Ω·cm2] per unit area, the element resistance being obtained by dividing (a) a voltage applied between the electrode substrate 2 and the thin-film electrode 3 during the voltage application by (b) current in element per unit area which current flows between the electrode substrate 2 and the thin-film electrode 3 during the voltage application, and where α is not less than 2.0×10−6, and the electron emission current Ie is not less than 1.0×10−9.

Owner:SHARP KK

Electron emitting element, electron emitting device, light emitting device, image display device, cooling device, and charging device

ActiveUS20100196050A1Reduce the amount requiredInadequate flowNanoinformaticsAlternating current plasma display panelsThin film electrodeDisplay device

An electron emitting element of the present invention includes an electron acceleration layer provided between an electrode substrate and a thin-film electrode, which electron acceleration layer includes (a) conductive fine particles and (b) insulating fine particles having an average particle diameter greater than that of the conductive fine particles. The electron emitting element satisfies the following relational expression: 0.3x+3.9≦y≦75, where x (nm) is an average particle diameter of the insulating fine particles, and y (nm) is a thickness of the thin-film electrode 3. Such a configuration allows modification of the thickness of the thin-film electrode with respect to the size of the insulating particles, thereby ensuring electrical conduction and allowing sufficient current to flow inside the element. As a result, stable emission of ballistic electrons from the thin-film electrode is possible.

Owner:SHARP KK

Low-energy scanning electron microscope system, scanning electron microscope system and sample detection method

ActiveCN109300759AHigh-resolutionControl backscattered electronsMaterial analysis using wave/particle radiationElectric discharge tubesScanning tunneling microscopeSecondary electrons

Owner:FOCUS E BEAM TECH BEIJING CO LTD

Electron emitting element, electron emitting device, charging device, image forming apparatus, electron-beam curing device, light emitting device, image display device, air blowing device, and cooling device

ActiveUS20100296844A1High film thicknessImprove surface roughnessNanoinformaticsAlternating current plasma display panelsThin film electrodeDisplay device

According to an electron emitting element of the present invention, an electron acceleration layer sandwiched between an electrode substrate and a thin-film electrode contains (i) insulating fine particles and (ii) at least one of (a) conductive fine particles having an average particle diameter smaller than an average particle diameter of the insulating fine particles and (b) a basic dispersant. The electron acceleration layer has a surface roughness of 0.2 μm or less in centerline average roughness (Ra). The thin-film electrode has a film thickness of 100 nm or less. As such, according to the electron emitting element of the present invention, it is possible to reduce the thickness of the thin-film electrode to an appropriate thickness. Accordingly, it is possible to increase electron emission.

Owner:SHARP KK

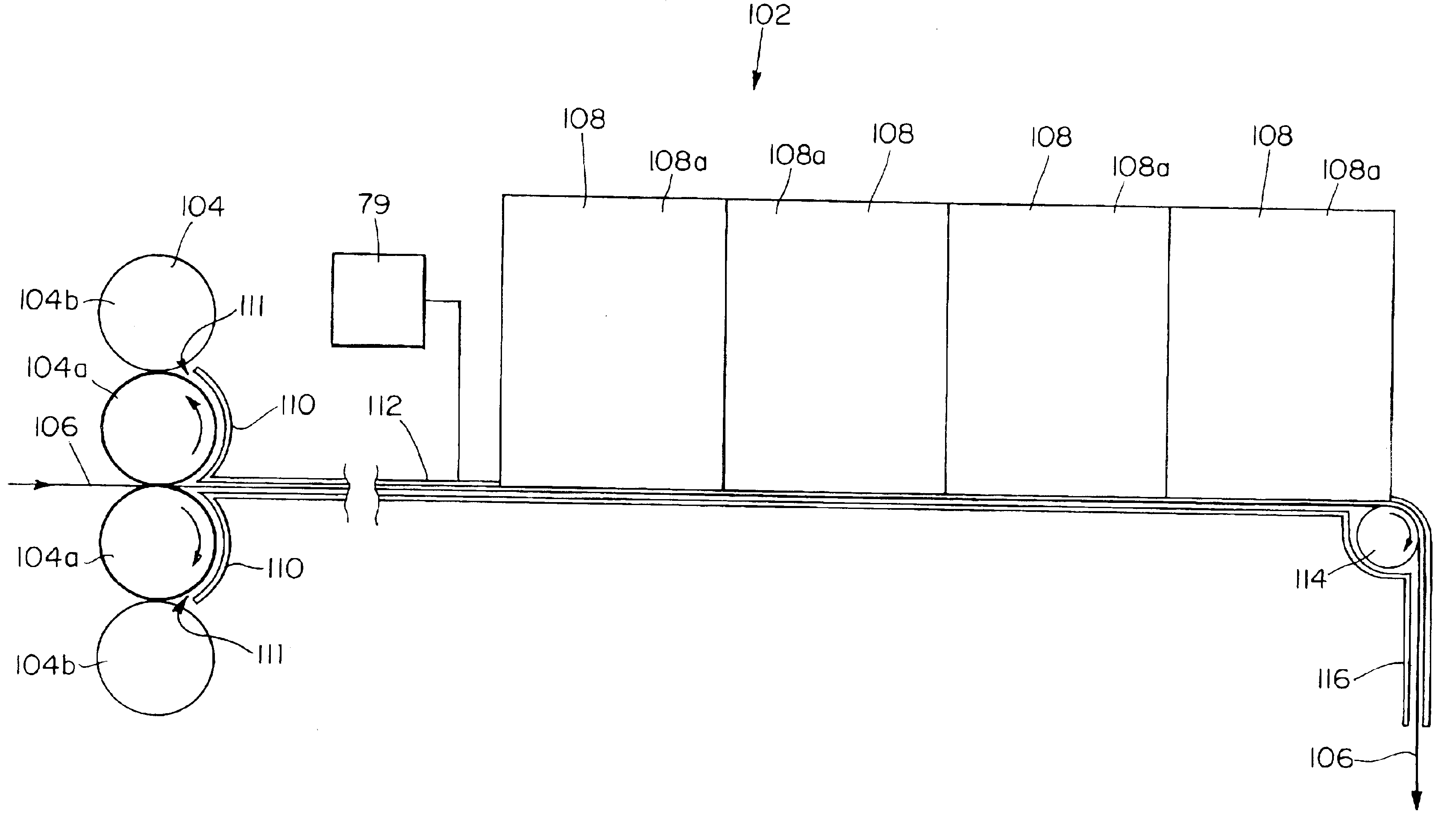

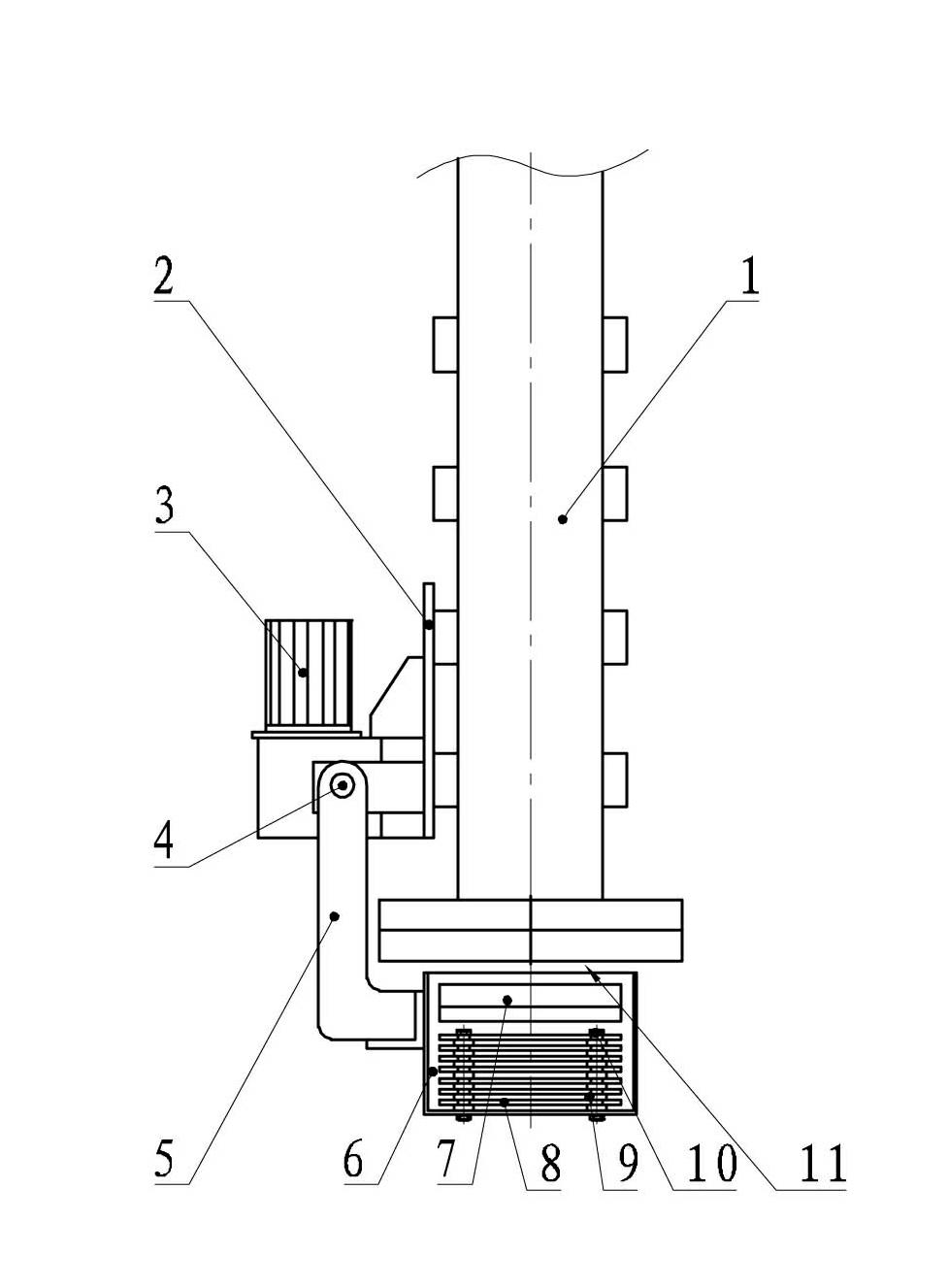

Electron accelerator having a wide electron beam

InactiveUS6882095B2Easy accessSubstantial intrusion of air into the enclosure is preventedLiquid surface applicatorsElectric arc lampsElectron accelerationVacuum chamber

An electron accelerator for generating an electron beam includes a vacuum chamber having an outer perimeter and an electron beam exit window. The exit window has a central region and a first end region. An electron generator is positioned within the vacuum chamber for generating electrons. The electron generator and the vacuum chamber are shaped and positioned relative to each other to accelerate the electrons in an electron beam out through the exit window. The electrons pass through the central region of the exit window substantially perpendicular to the exit window and through the first end region of the exit window angled outwardly relative to the exit window. At least a portion of the outwardly angled electrons are directed beyond the perimeter of the electron accelerator.

Owner:HITACHI ZOSEN CORP

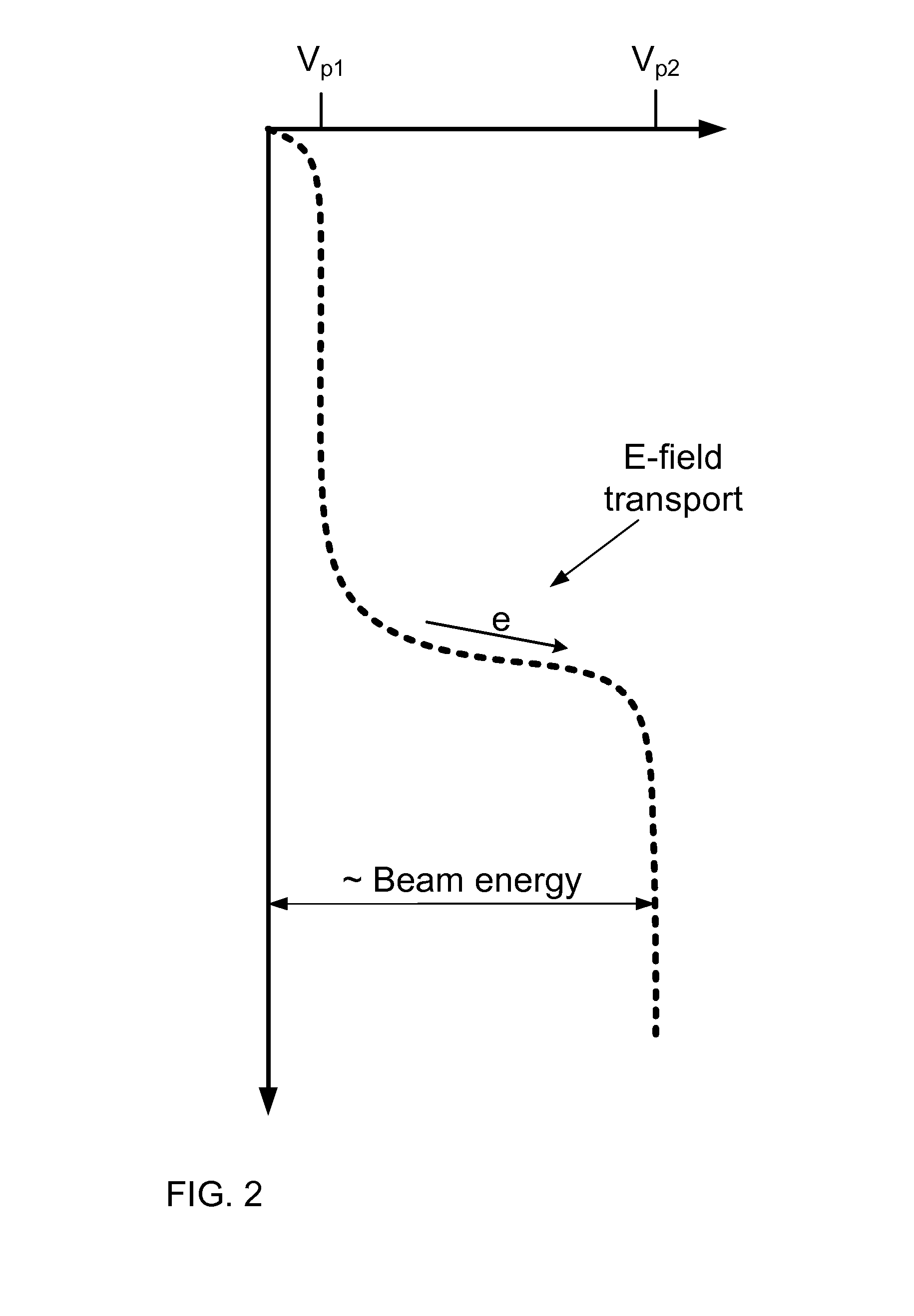

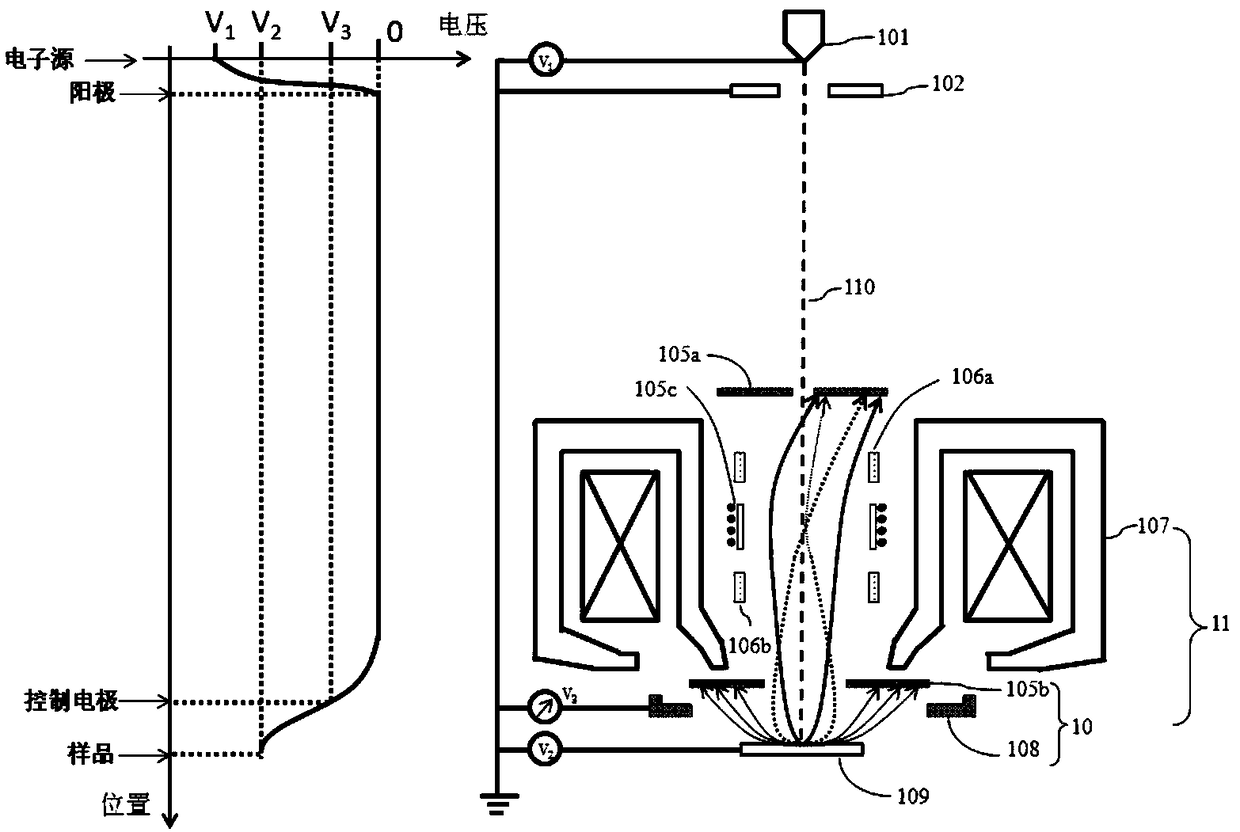

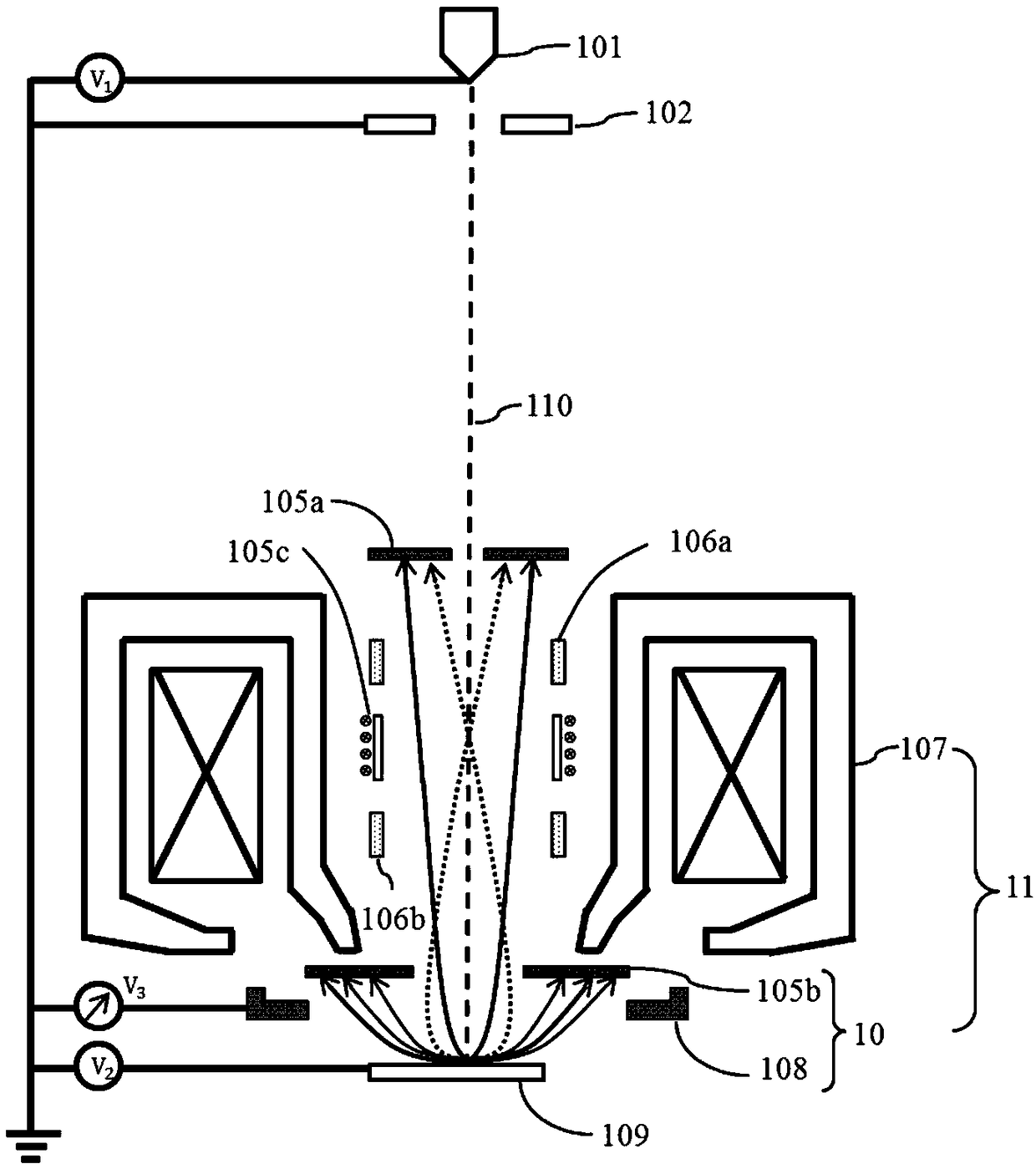

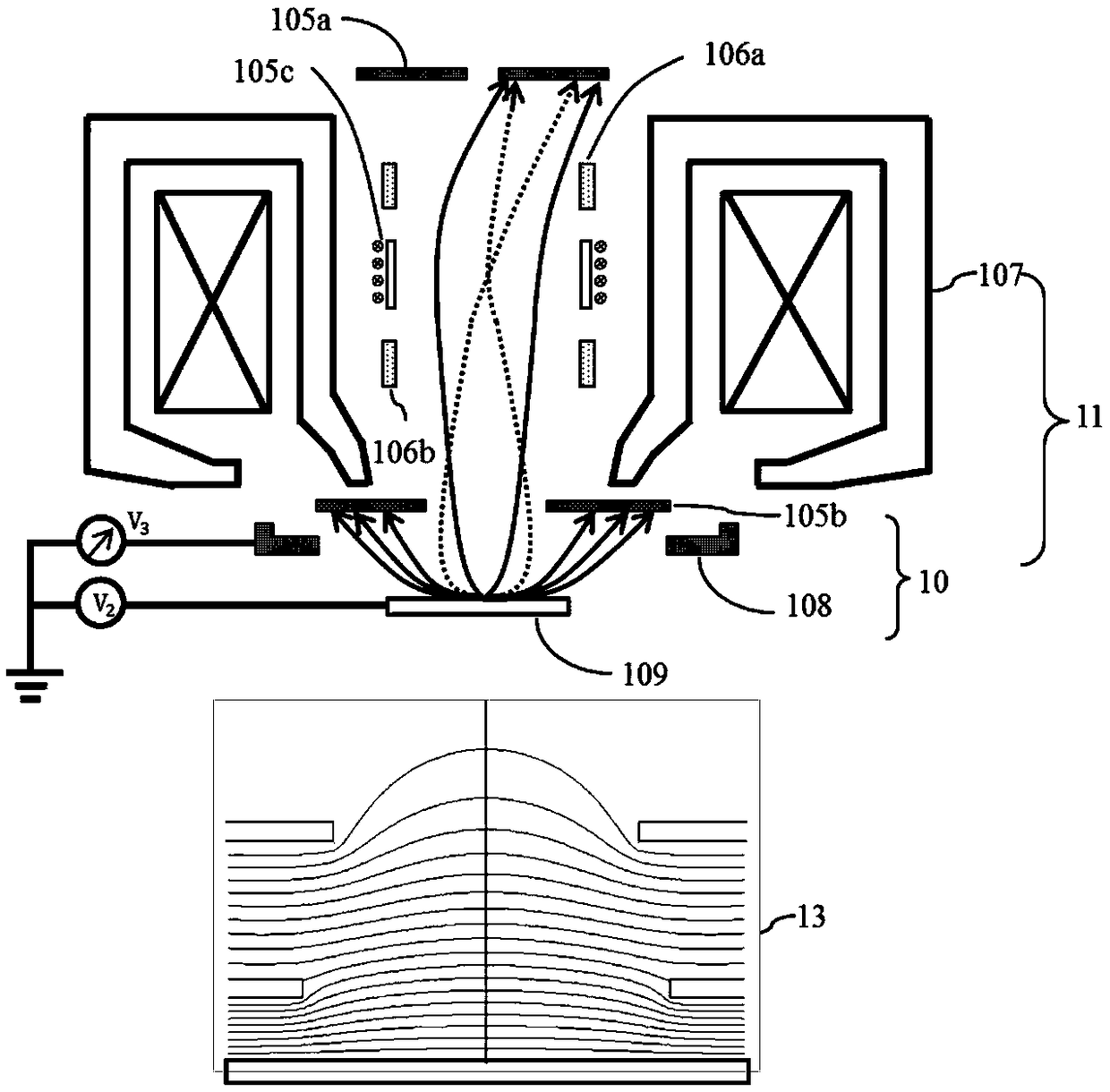

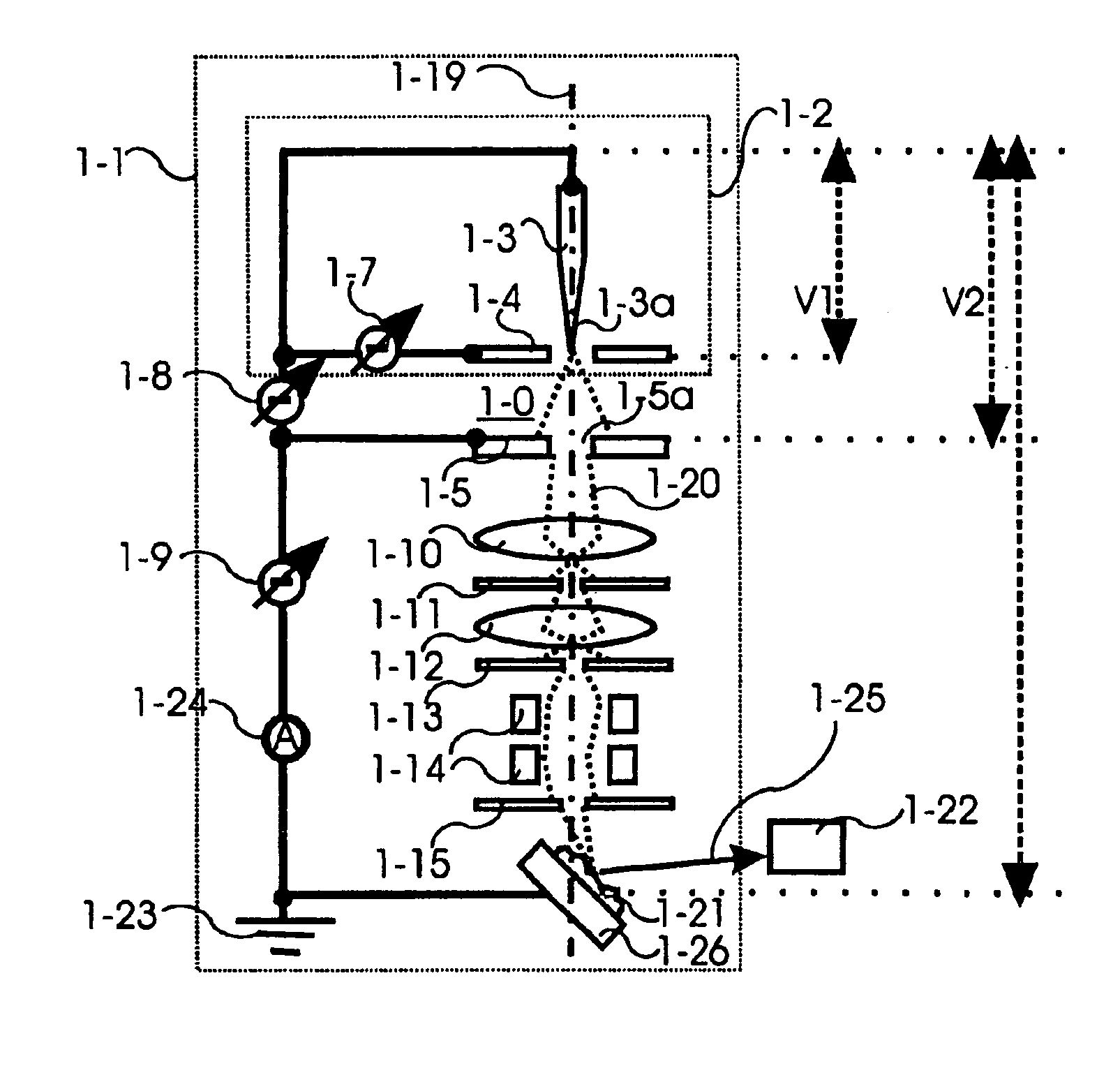

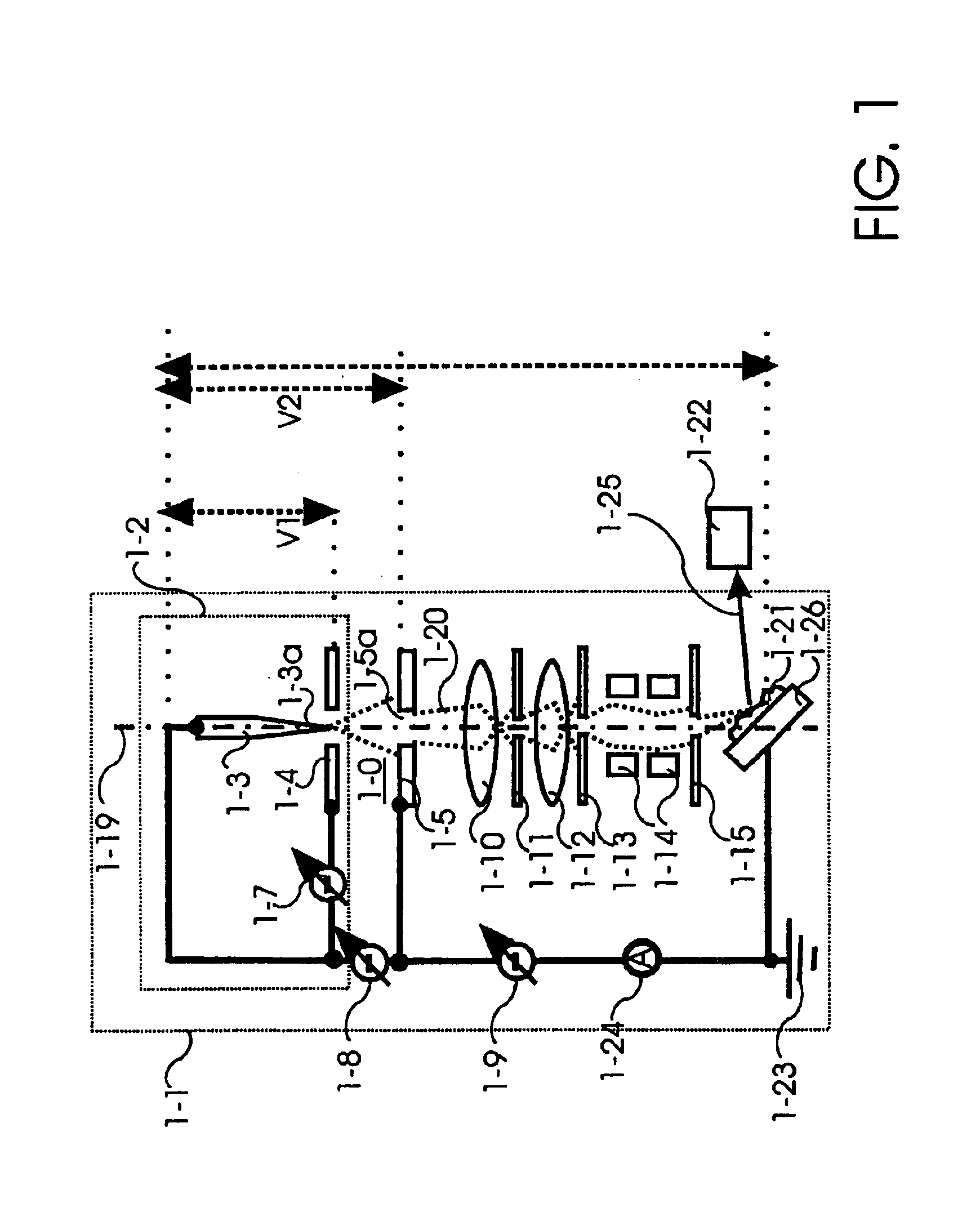

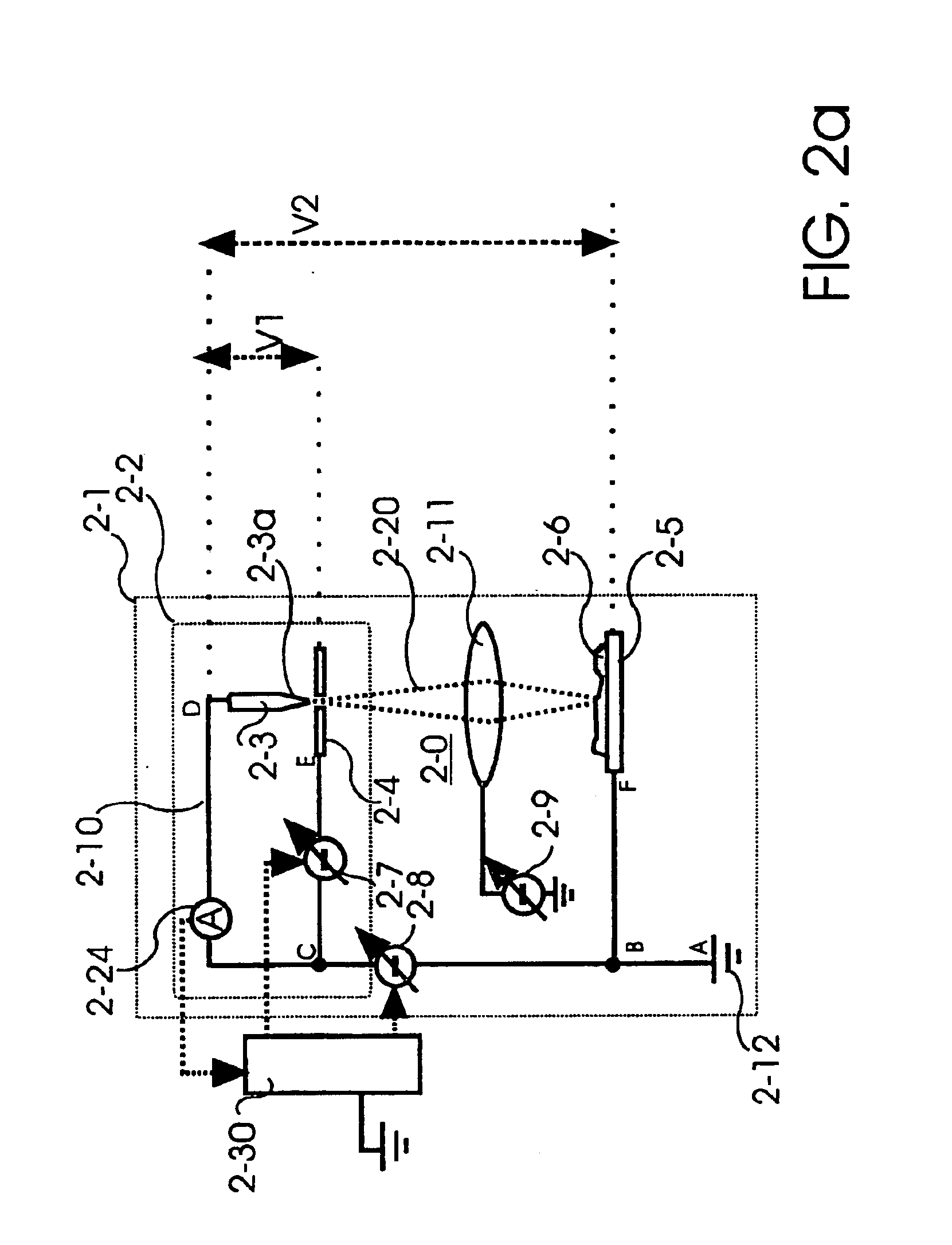

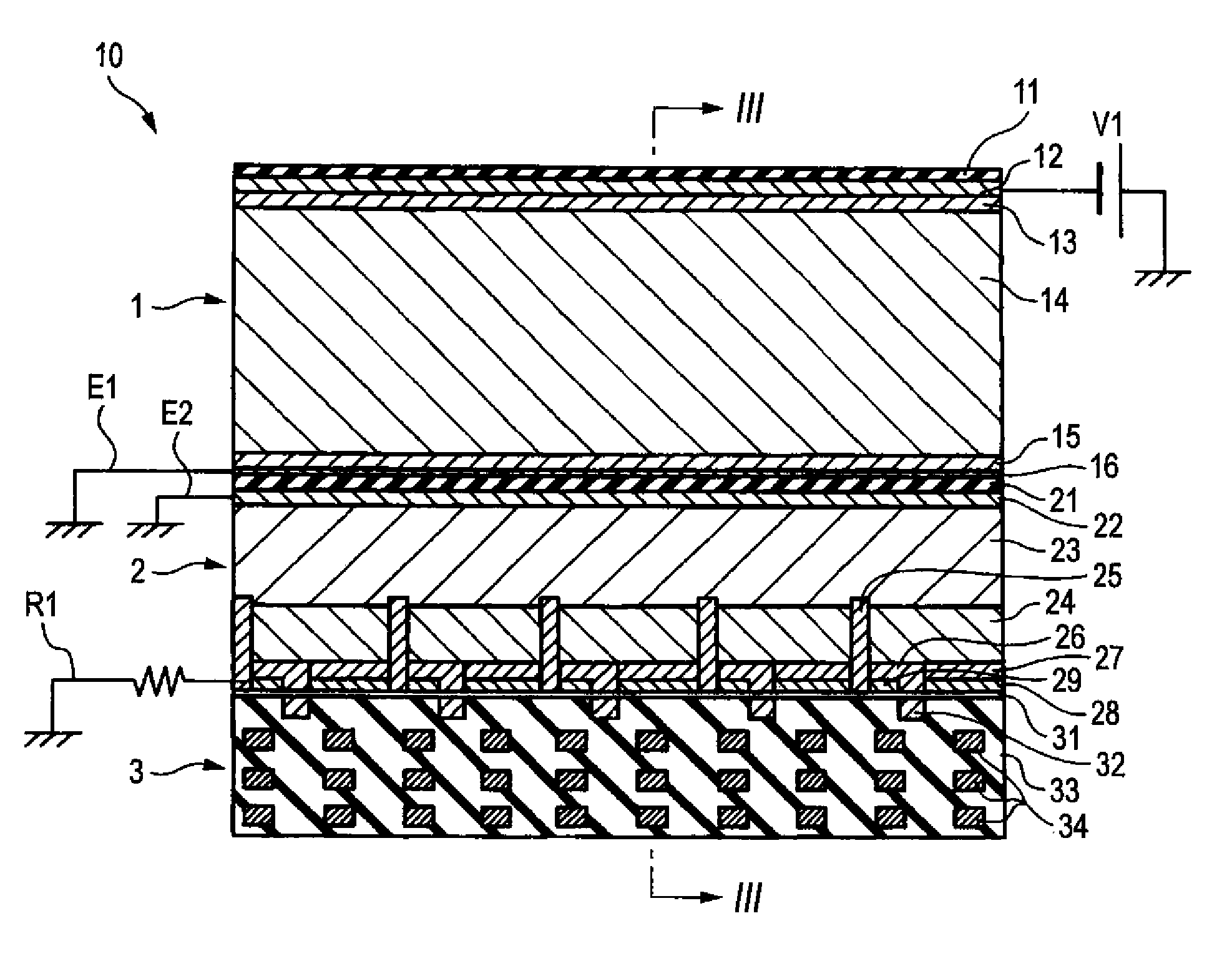

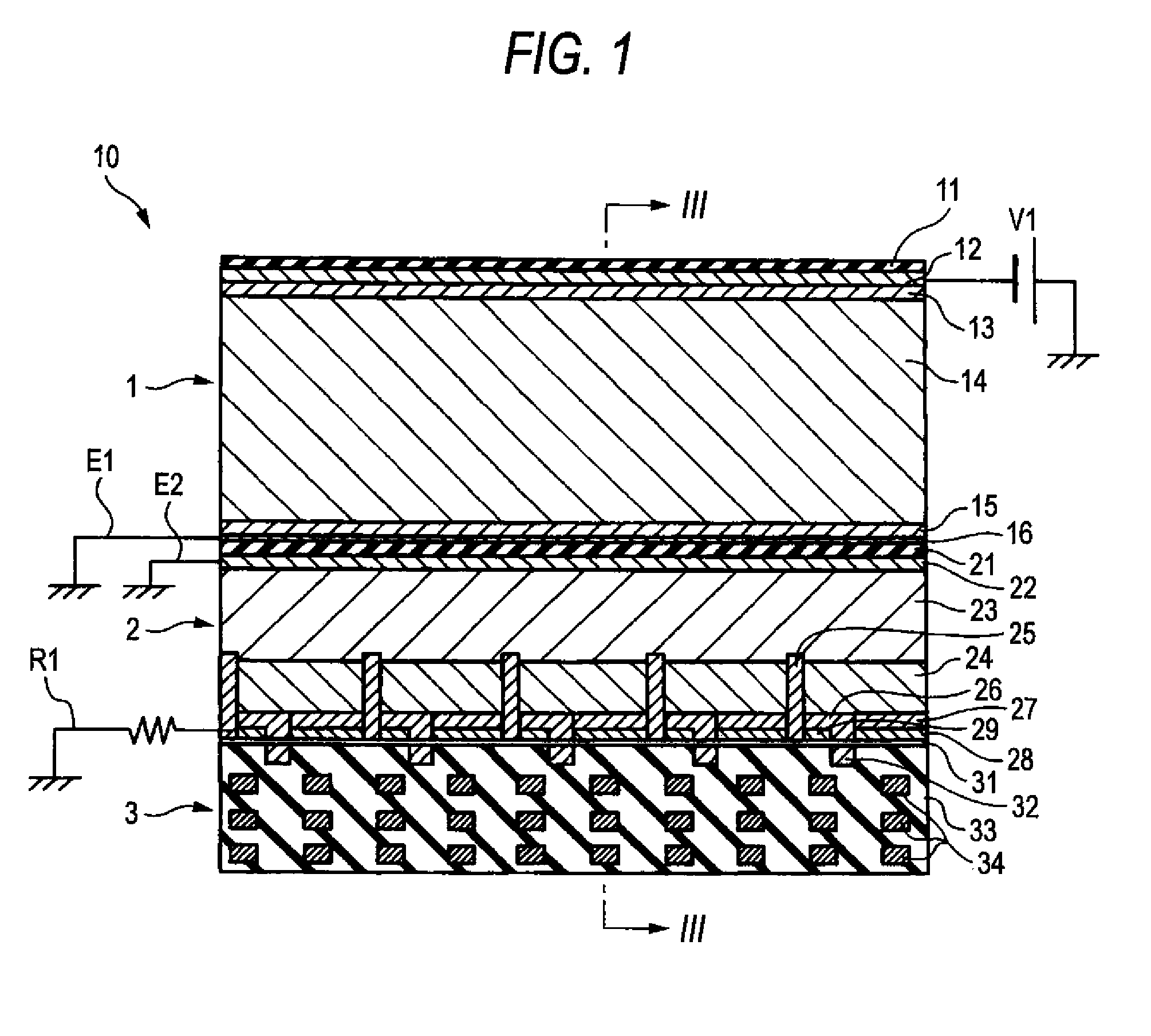

Device and method for controlling focussed electron beams

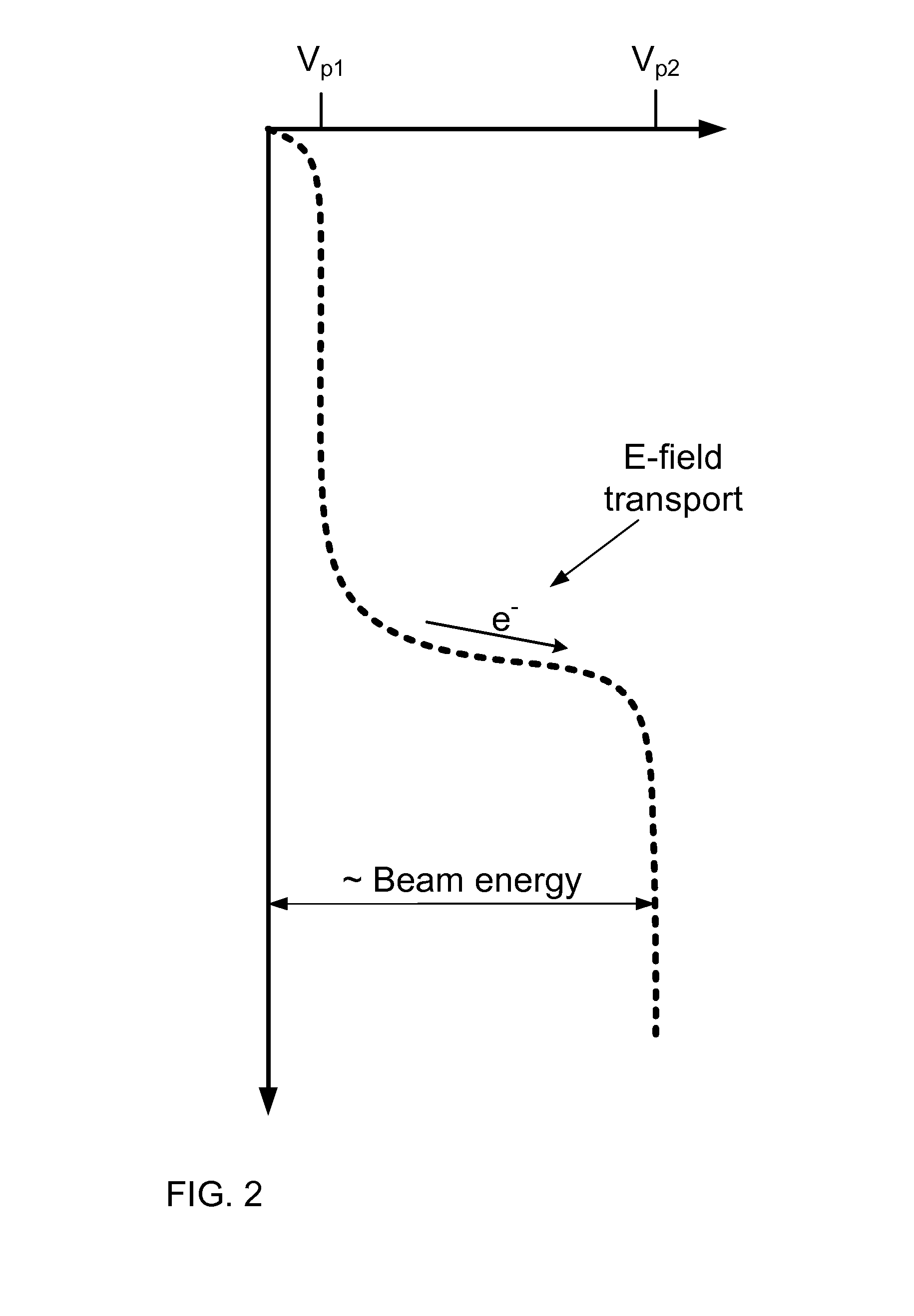

InactiveUS6943507B2Sacrificing controlWithout sacrificing controlDischarge tube luminescnet screensLamp detailsBeam sourceControl electronics

The invention provides a focussing electron beam device with a single or an array of field emitter beam sources to generate electron beams with field emitter beam sources, at least one anode capable of accelerating the electrons of the electron beams towards a specimen, focussing components capable of focussing the electron beams onto the specimen and a control circuit that a) senses for deviations of the actual current values of the electron beams from desired current values; b) controls first voltages V1 to adjust the actual current values of the electron beams to the desired current values and c) controls second voltages V2 to adjust the actual focus positions of the electron beams to the desired focus positions. The voltage control circuit adjusts the actual current values of the electron beams to the desired current values and makes it possible to adjust the current values of an array of electron beams to a single value. Furthermore, a focussing electron beam device is disclosed with an array of field emitter beam sources integrated onto a substrate, which makes it possible to have arrays of field emitter beam sources with thousands or even millions of field emitter beam sources. With the integration of the control circuits for each field emitter beam source it is possible to adjust the current values and focus positions of each electron beam individually. Furthermore, methods are disclosed describing the operation of a single field emitter beam source or an array of field emitter beam sources.

Owner:ICT INTEGRATED CIRCUIT TESTING GESELLSCHAFT FUER HALBLEITERPRUEFTECHNIK GMBH

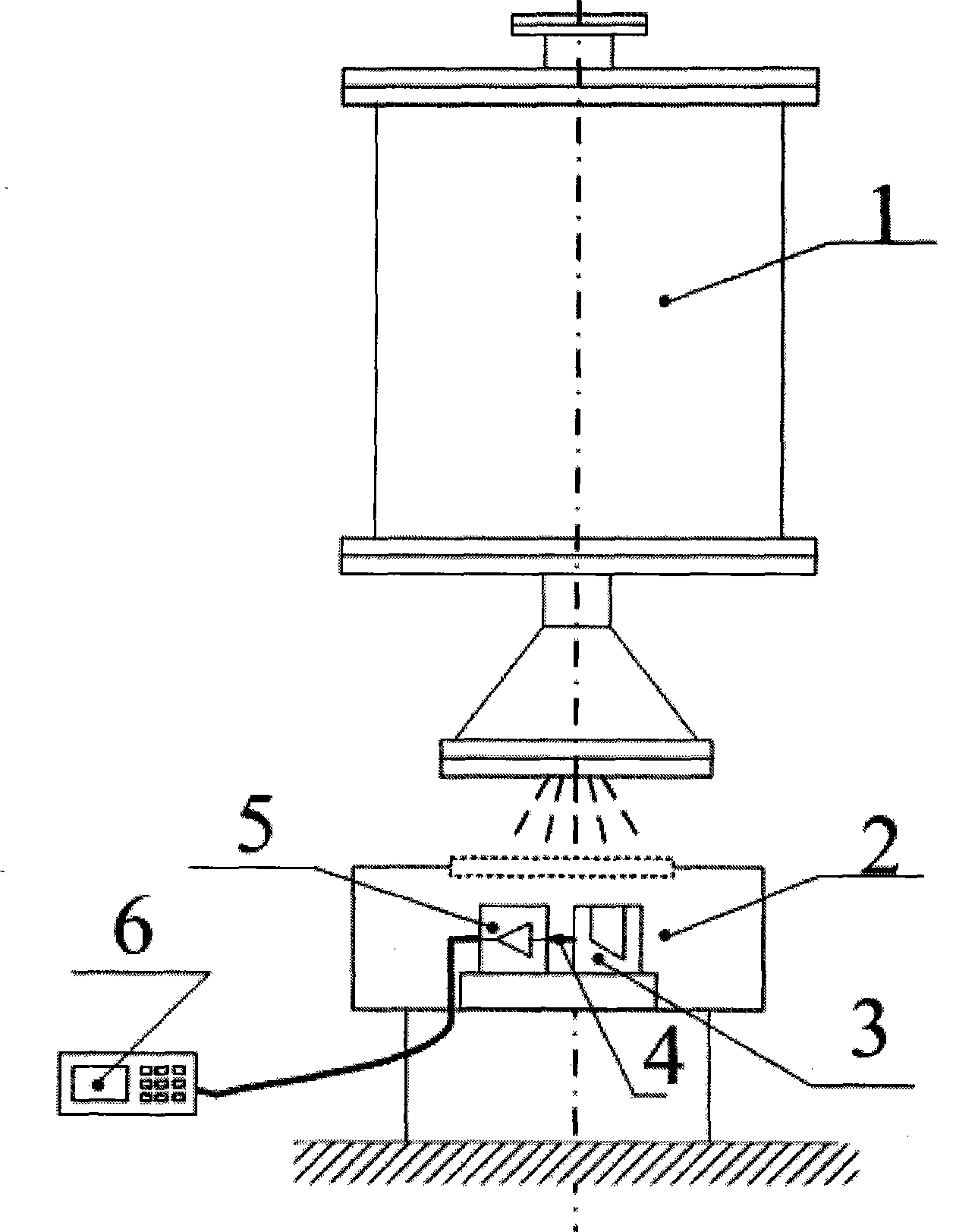

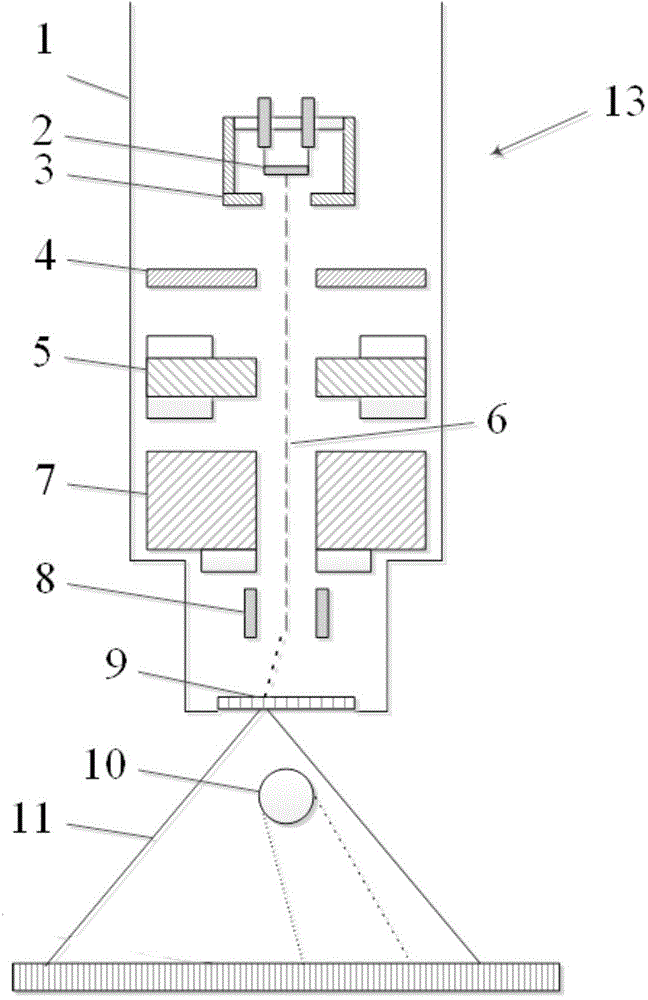

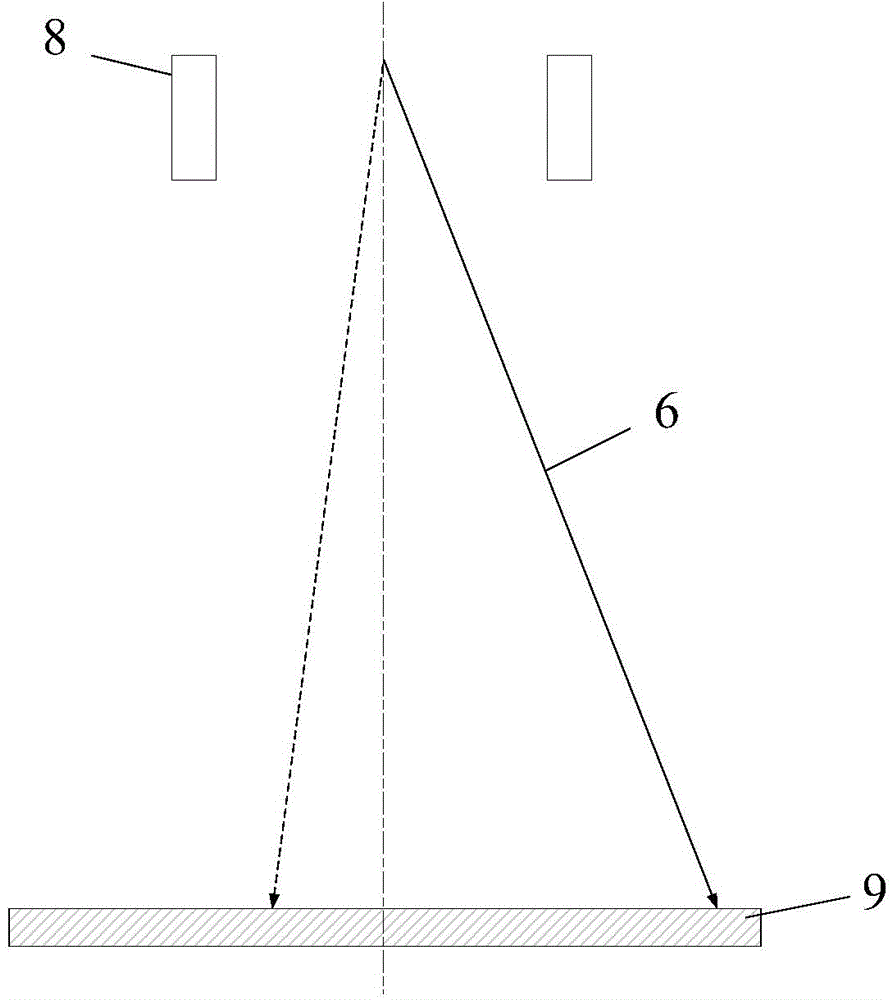

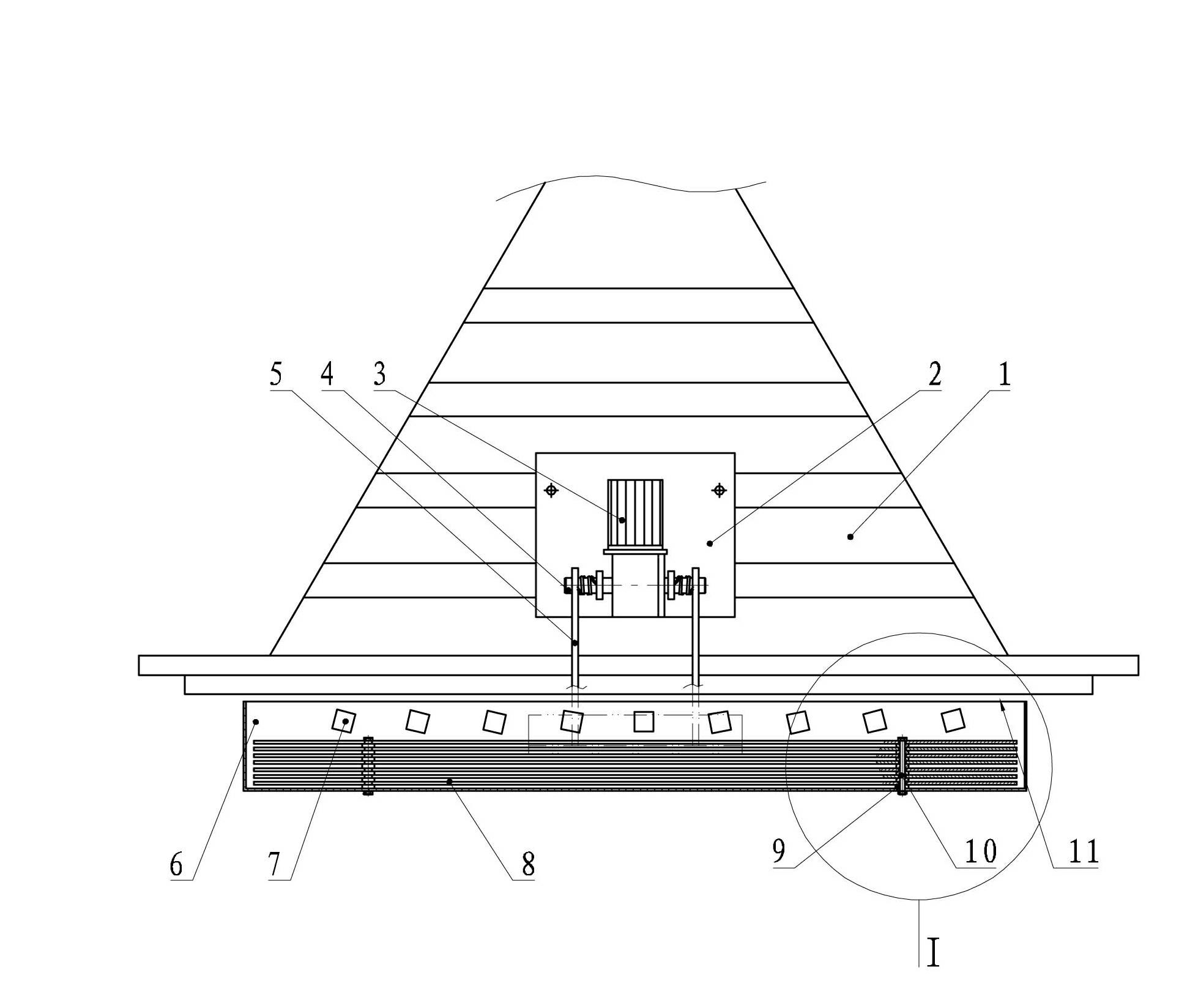

Linear array micro-nano focus X-ray source for micro-nano CT (computer tomography) system

InactiveCN104411081AIncrease temperatureReduce radiation doseX-ray apparatusMicro nanoComputed tomography

The linear array micro-nano focus X-ray source for a micro-nano CT system. The linear array micro-nano focus X-ray source for the micro-nano CT system comprises cathodes 2, grids 3, anodes 4, focusing electrodes 5, magnetic solenoids 7, deflecting electrodes 8 and a target 9; the cathodes are used for producing electrons, the anodes are used for electron acceleration, the grids are arranged between the anodes and the cathodes and used for adjusting beam intensity of electron emitted by the cathodes, the focusing electrodes are used for completing first-time focusing of accelerated electrons, the magnetic solenoids are used for completing second-time focusing of the electrons, and the deflecting electrodes are used for controlling the position that the electrons hit on the target. By means of the linear array micro-nano focus X-ray source for the micro-nano CT system, static CT scanning can be achieved, namely, a radiation source, an object to be detected and a detector are all in a static state, electron beam scanning substitutes for mechanical scanning, thus error caused by mechanical scanning can be avoided, small external disturbance, small size, light weight and fast detection speed can be obtained, and linear array micro-nano focus X-ray source for the micro-nano CT system can be applied to CT systems of different types.

Owner:CHONGQING UNIV

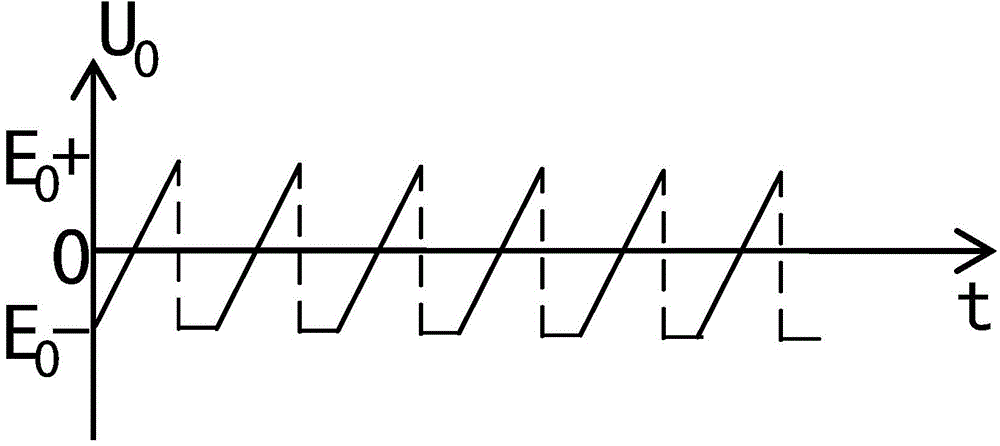

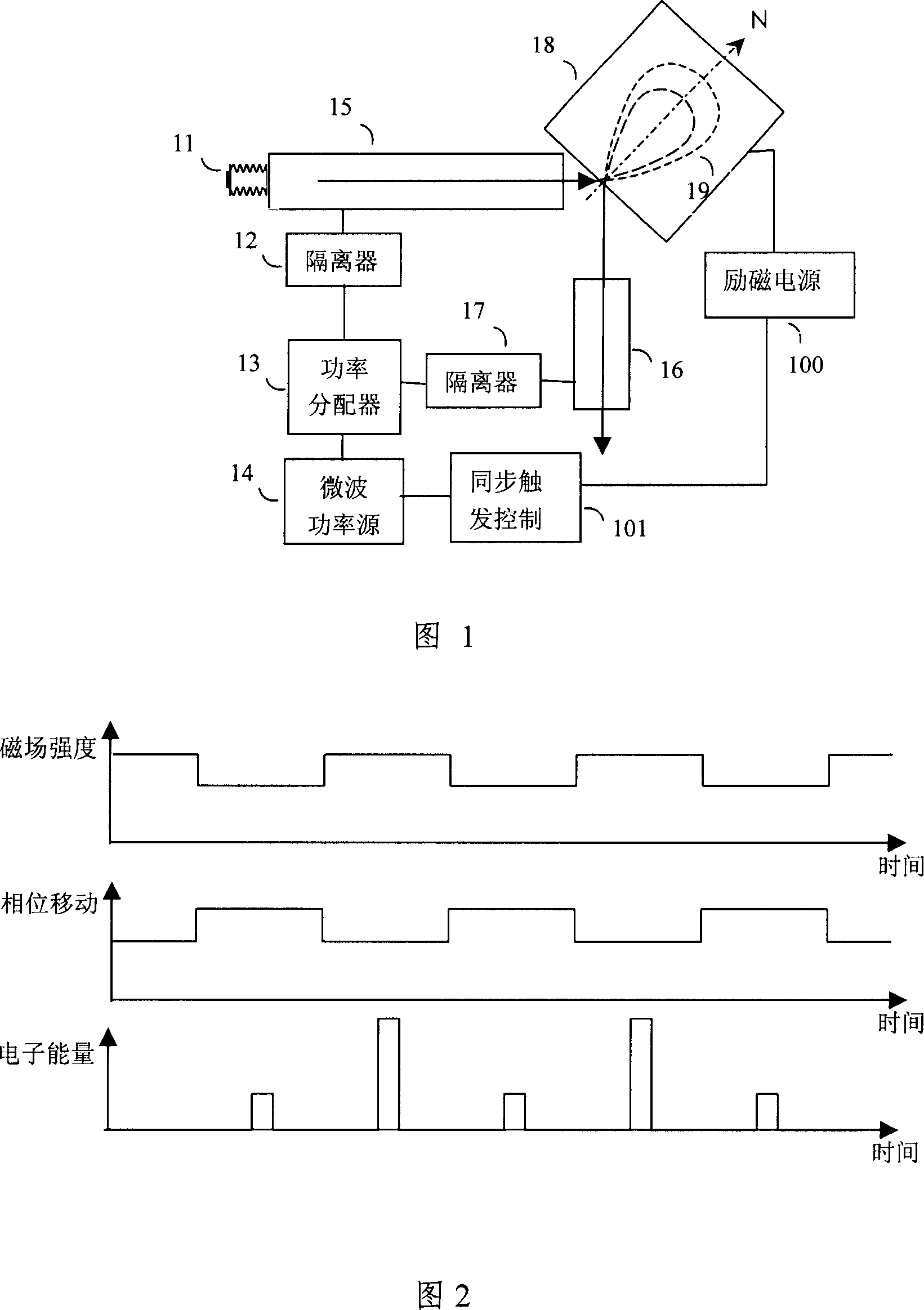

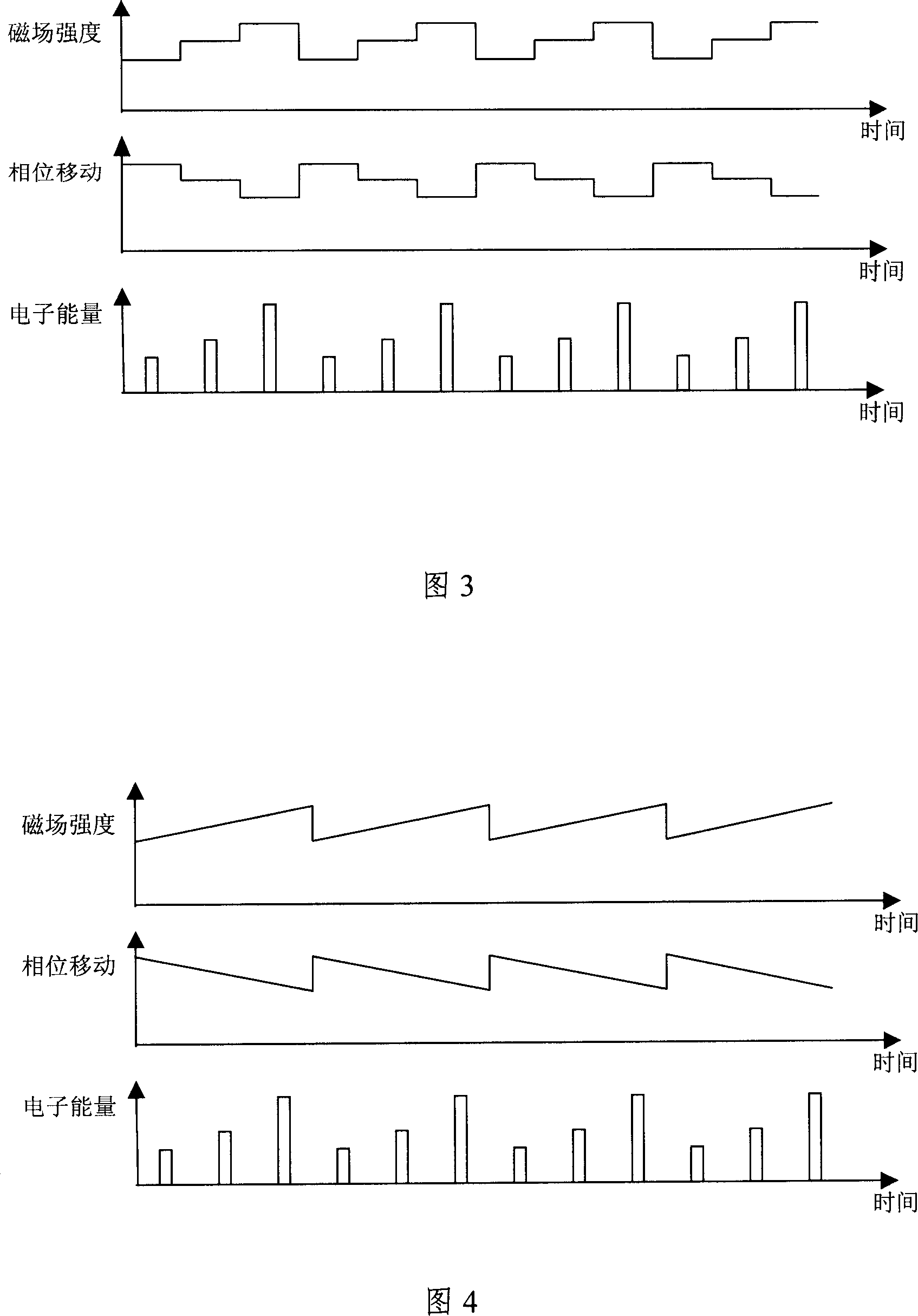

An electronic linear accelerator and its using method

ActiveCN1997260AEasy to controlRealize regulationMagnetic induction acceleratorsEnergy regulationMicrowave power

This invention provides one electron line speeder with multiple gear energy adjusting, which comprises electron gun, speeding structure, microwave power source, isolator and magnetic exciting power, wherein, the speeding structure has two parts separately connected to power align machine through isolator and to get micro wave power from microwave power source; the two sections of speeding structure are connected by magnetic iron in certain microwave phase; through changing magnetic iron sensor intensity to change electron beam track length.

Owner:TSINGHUA UNIV +1

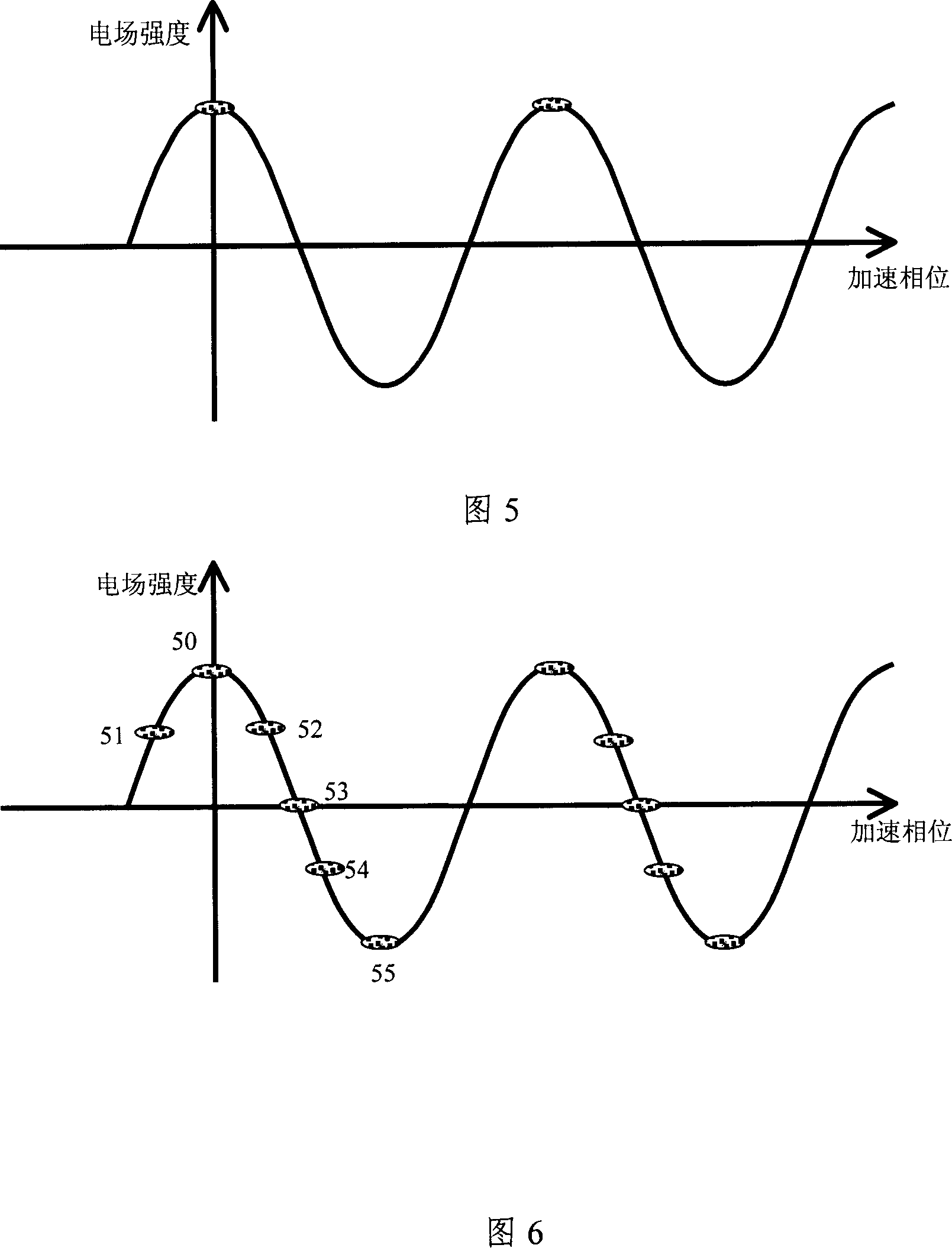

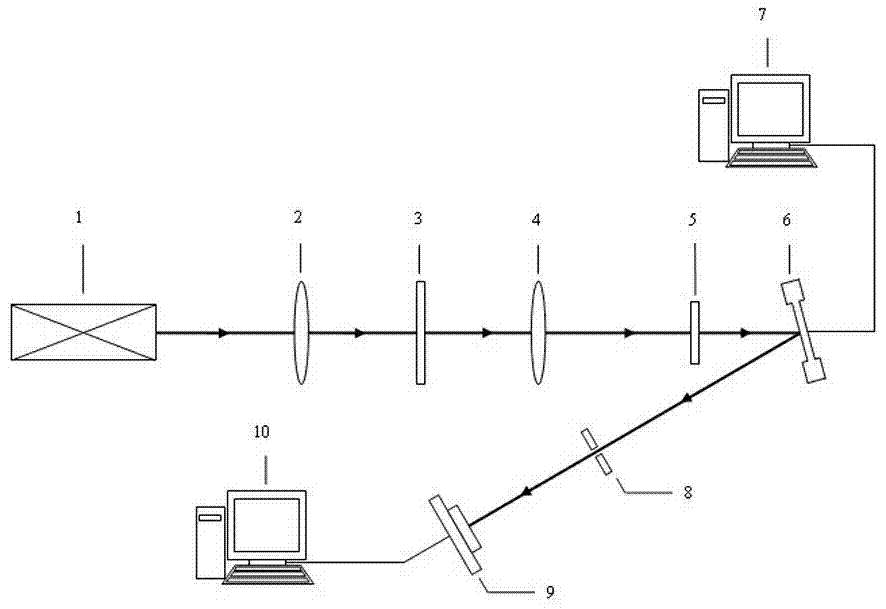

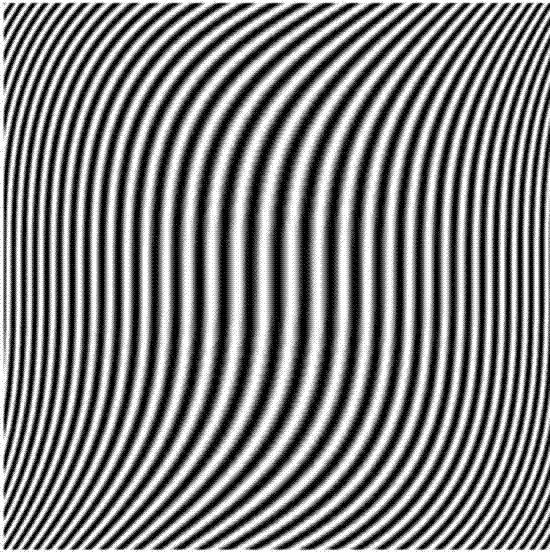

Method for producing partially coherent Airy beams

InactiveCN103048791AThe principle is simpleEasy to implementOptical elementsSpatial light modulatorGaussian beam

The invention relates to a beam transmission and conversion technology, and discloses a method for producing partially coherent Airy beams. The method comprises the following steps that: a laser device emits a fully coherent gauss beam, and a convex lens and a rotary frosted glass sheet regulate the coherence of the gauss beam to get a partially coherent gauss beam; and after being collimated by a second convex lens, the partially coherent gauss beam is subjected to beam intensity distribution shaping by a gauss amplitude filter, a spatial light modulator to which a phase information graph is loaded modulates the phase of the partially coherent gauss beam, and a first-stage diffracted beam is captured through a circular aperture diaphragm, thus obtaining the partially coherent Airy beam. The method produces the partially coherent Airy beam by directly using the gauss beam, and is scientific in principle and easy to realize; and the device for implementing the method is simple in structure, easy to regulate, excellent in stability and low in production cost. The beam provided by the method can be practically used in the fields of optical particle cleaning, biomedical therapy, particulate trapping, electron acceleration, and the like.

Owner:SUZHOU UNIV

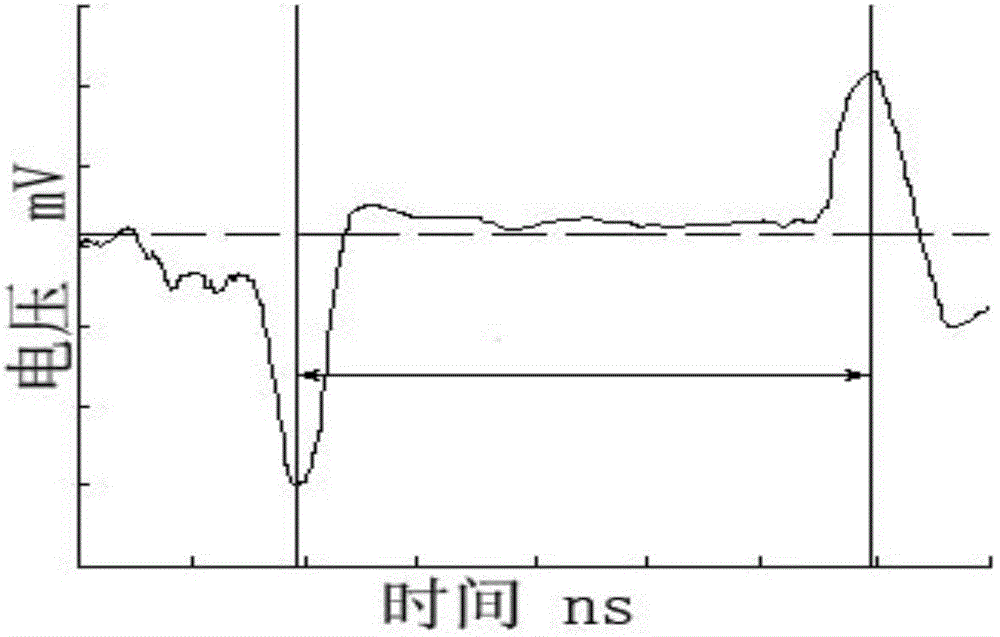

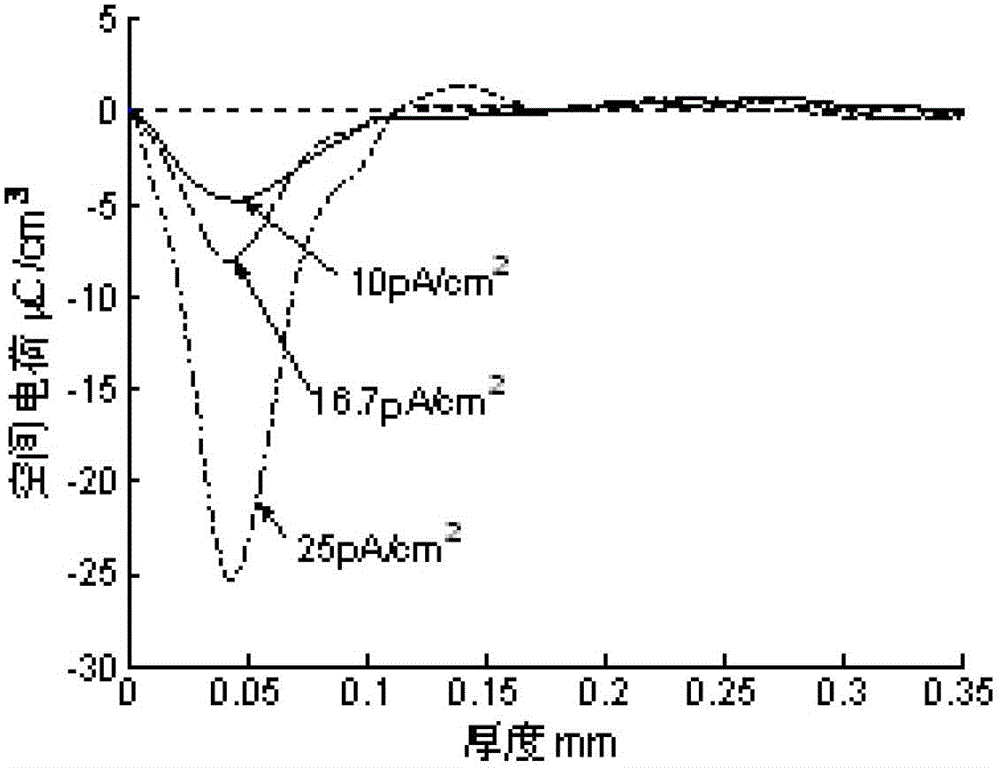

System and method for in-situ testing of internal electric charge and electric field distribution of dielectric material

InactiveCN102944763ADoes not affect high voltage pulse signalUndisturbedElectrostatic field measurementsSolenoid valveHigh energy

The invention relates to a system and method for in-situ testing of internal electric charge and electric field distribution of a dielectric material and belongs to the field of measurement. The system comprises a vacuum tank, a top electrode, a solenoid valve, a vacuum-pumping system, a direct-current high-voltage power supply, a testing signal line, an industrial personal computer, an oscilloscope, a shielding flange, a high-voltage nanosecond pulse generator, a space charge detector main machine and an electron accelerator. The method comprises the steps of enabling high-energy electrons to pass through electrode holes to be filled onto the surface of a sample through the electron accelerator, recording tested wave forms through the oscilloscope and the industrial personal computer, and performing data processing to calibrated wave forms recorded by the industrial personal computer and tested wave forms to obtain the electric charge distribution in the sample. The system and the method can perform in-situ monitoring to the internal electric charge and the electric field distribution produced by produced by a space high-energy electron jetting-in space material simulated on the ground. Errors caused by measurement of the sample subjected to irradiation are avoided, and a test signal is not interfered.

Owner:NO 510 INST THE FIFTH RES INST OFCHINA AEROSPAE SCI & TECH

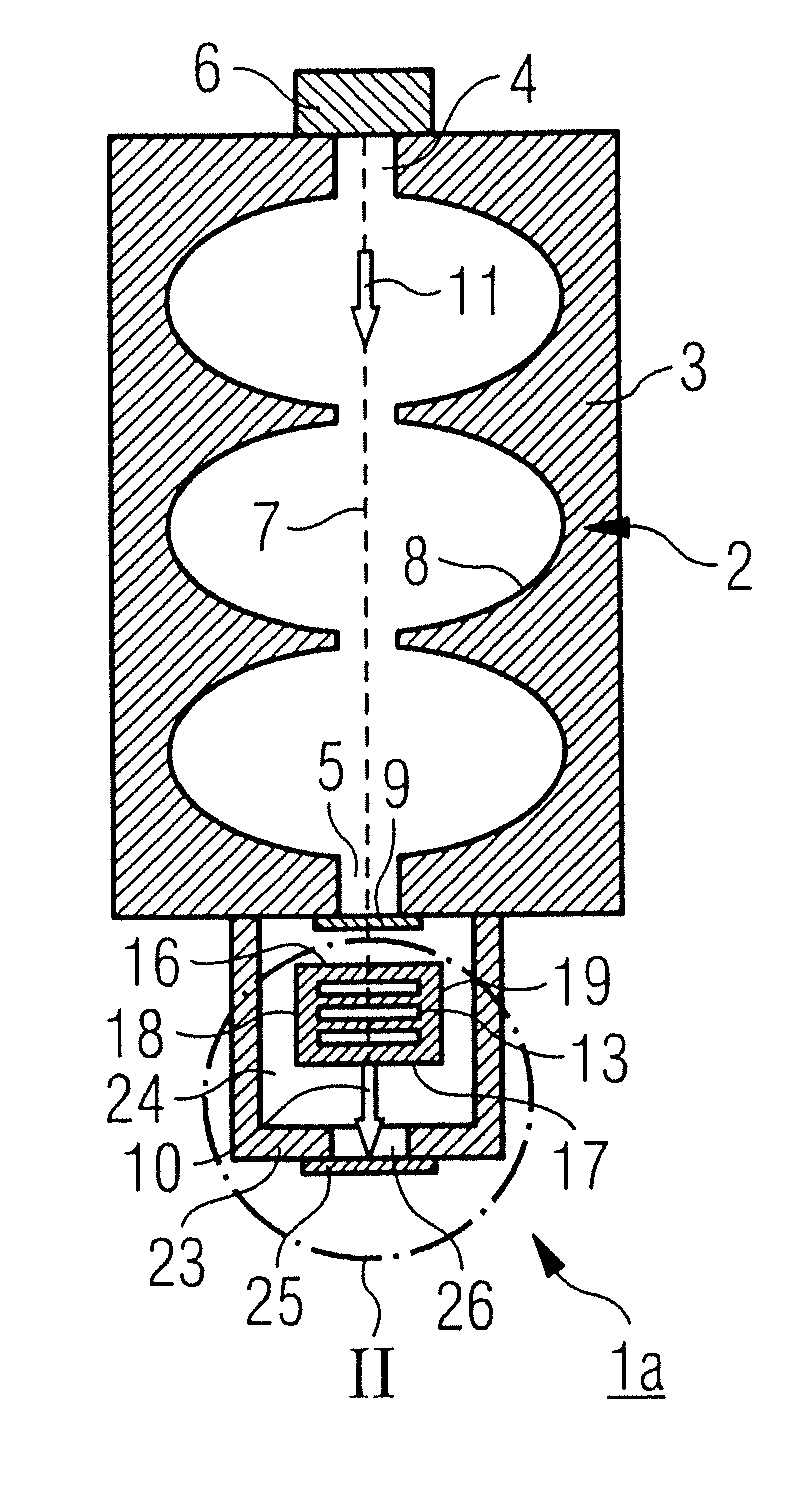

Electron accelerator to generate a photon beam with an energy of more than 0.5 mev

InactiveUS20100201240A1Thermal overloading of the target is preventedAdequate heat dissipationX-ray tube anode coolingNuclear targetsElectron sourceBeam direction

An electron accelerator that generates a photon beam with an energy of more than 0.5 MeV by means of an electron beam charging a target has a vacuum chamber with an intake opening and an exit opening, and an electron source at the input side. The target is arranged outside the vacuum chamber in the region of the exit opening in a housing in which a window is present that is permeable to photons and that is arranged opposite the exit opening in the beam direction of the electron beam. The target is permeated by at least one cooling channel.

Owner:SIEMENS AG

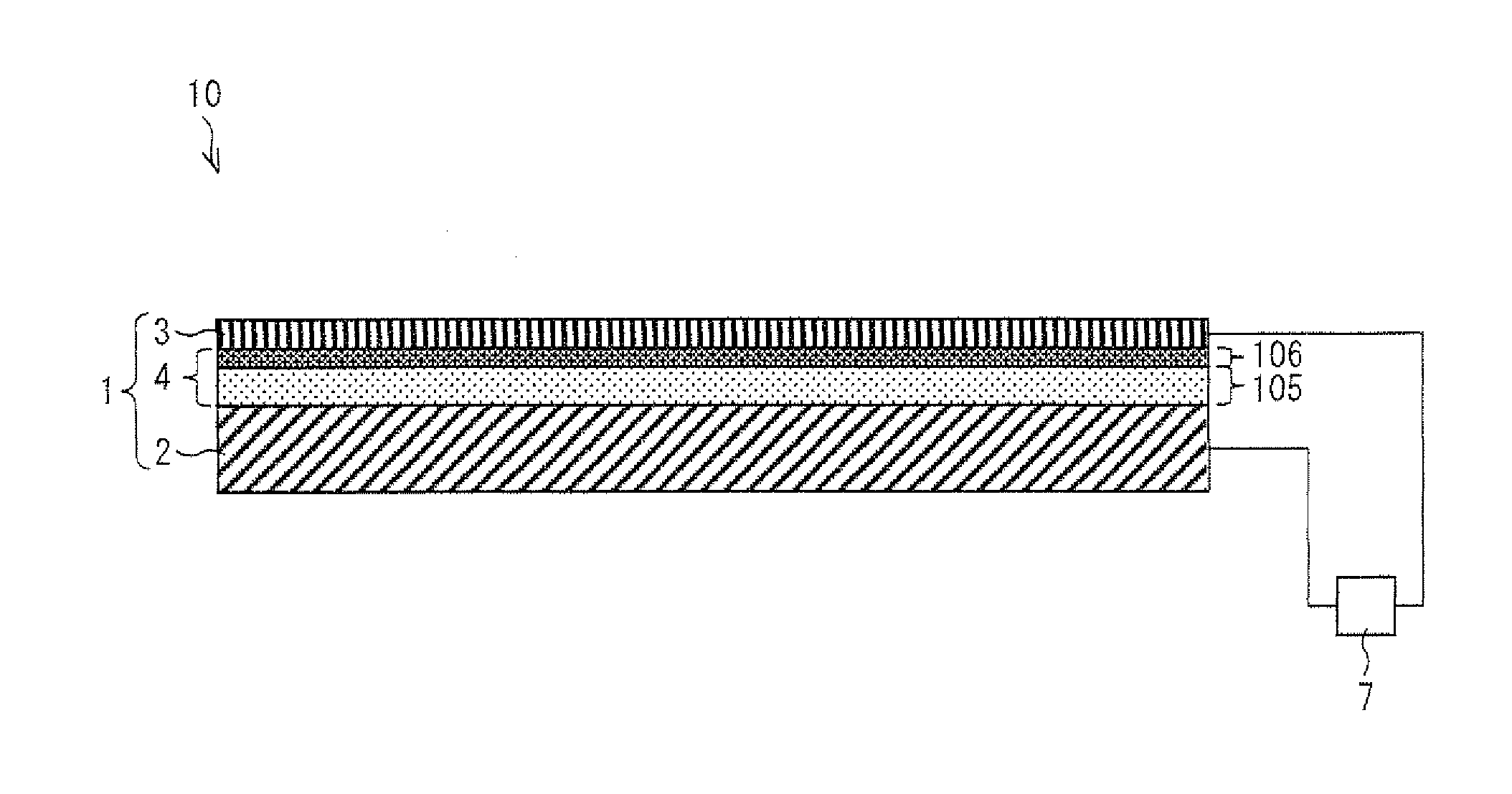

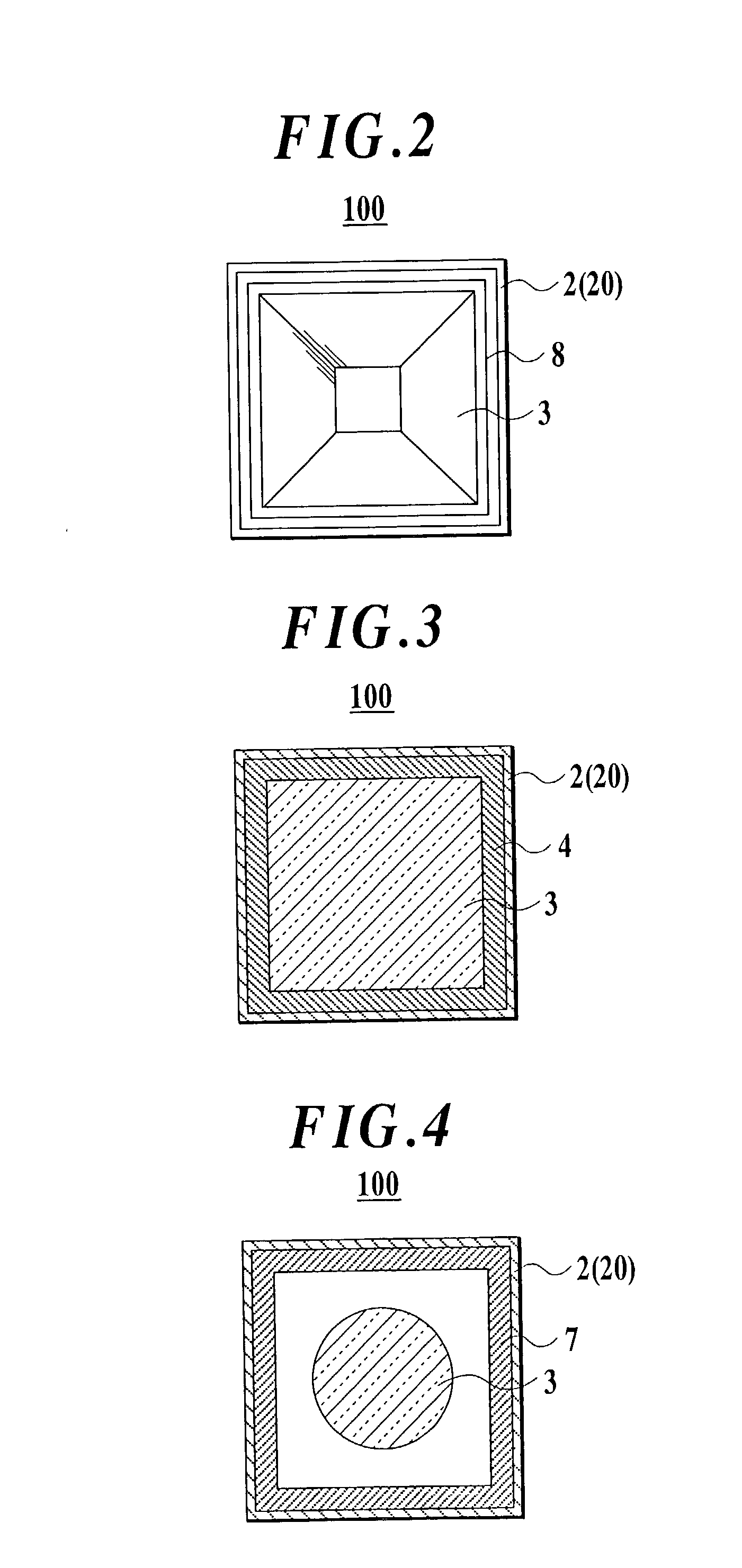

Imaging device, method of driving imaging device, and method of manufacturing imaging device

InactiveUS20080303112A1Improve reliabilityTelevision system detailsTelevision system scanning detailsElectron multiplicationCrystal structure

An imaging device is provided and includes: a photoelectric conversion layer that has a silicon crystal structure and generates signal charges upon incidence of light; a multiplication and accumulation layer that multiplies the signal charges by a phenomenon of avalanche electron multiplication; and a wiring substrate that reads the signal charges from the multiplication and accumulation layer and transmits the read signal charges. The photoelectric conversion layer includes: a first conductive impurity layer containing first impurities in an impurity concentration; an electron acceleration layer containing the first impurities in a lower impurity concentration than the first conductive impurity layer; and a second conductive impurity layer to which a voltage is applied, the second conductive impurity layer containing second impurities and disposed on a side opposite a light incidence side of the electron acceleration layer, and an insulating layer is disposed between the electron acceleration layer and the multiplication and accumulation layer.

Owner:FUJIFILM CORP

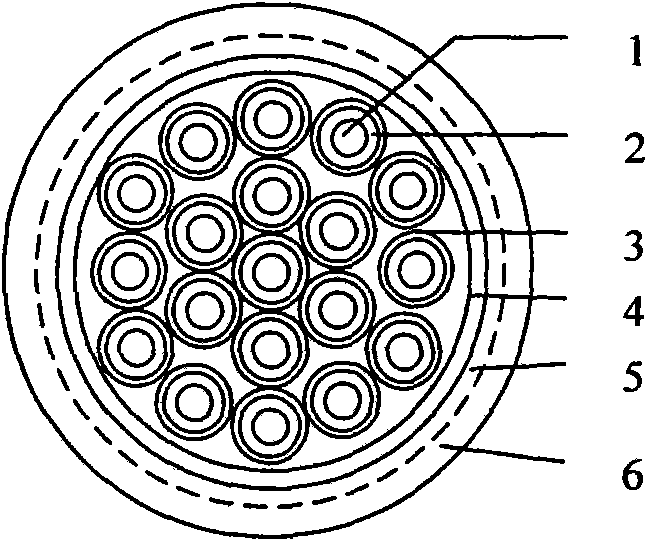

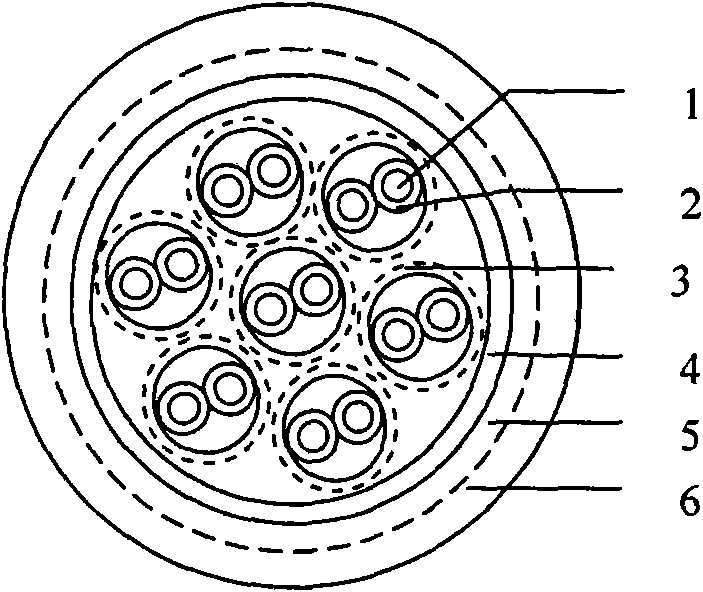

Thin-wall crosslink low smoke cables for ships communication or control signal and preparation method thereof

ActiveCN101656127AImprove flexibilityRounded outer diameterPlastic/resin/waxes insulatorsClimate change adaptationElectrical conductorCopper wire

The invention relates to a thin-wall crosslink low smoke cable for ships communication or control signal and a preparation method thereof. The cable structure is that the outer layer of a multi-strandconductor is an insulating layer, the outer layer of the insulating layer is a shielding layer, the outer layer of the shielding layer is a lapped covering, the outer layer of the lapped covering isarmor, and the outer layer of the armor is a sheathed layer. The preparation method is as follows: a line-cable stranding machine strands tin plated copper wire as a conductor; an extruder is utilizedto manufacture the insulating layer outside the conductor, the insulating layer is subjected to irradiation and crosslinking by an electron accelerator; a cable former is ustilized to strand insulated wires together; the shielding layer and the armor are braided by utilizing a braiding machine; and the sheathed layer is manufactured by the extruder, and the sheathed layer is subjected to irradiation and crosslinking by the electron accelerator. The thin-wall crosslink low smoke cable has the advantages of small outside diameter, light weight, ageing resistance, tear resistance, heat oil resistance, high flame retardancy, low smoke, no halogen, low toxicity and good ability of keeping excellent electrical performance and mechanical property in hostile environment, wherein the weight of thethin-wall crosslink low smoke cable is 30%-45% lighter than that of common cables.

Owner:NANJING QUANXIN CABLE TECH

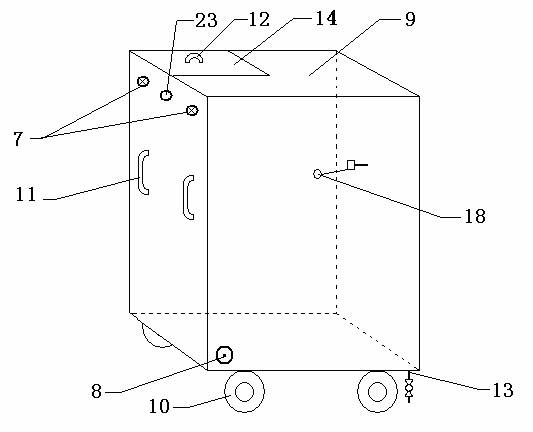

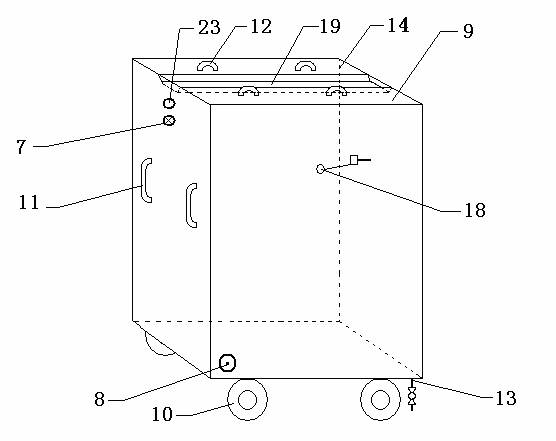

Measuring equipment of electron accelerator output beam parameter

The invention provides measuring equipment of an electron accelerator output beam parameter. The measuring equipment comprises: an electron absorption board (8) and a plurality of electron absorption rods (7), wherein the each electron absorption rod is insulated with other components. The electron absorption rods possess a same rectangular section which is parallel to the electron absorption board. A length direction is parallel to the width direction of an accelerator scanning output window (11). Side surfaces with the same width of the electron absorption rods are vertical to an electron ray direction which is located in a position of the electron absorption rods. The electron absorption board and each electron absorption rod are connected to a current measurement device through leads respectively. Compared to the prior art, by using the measuring equipment of the invention, the electron beam energy measurement is integrated with the scanning uniformity measurement. Therefore, amounts of the accelerator output beam, a spectral distribution situation, the scanning uniformity can be simultaneously determined. The equipment and the apparatus needed by electron beam output parameter measurement can be simplified. In the prior art, the different apparatuses are needed by the electron beam energy measurement and the electron beam scanning uniformity measurement. By using the measuring equipment of the invention, the above problem can be solved.

Owner:广东雷大科技有限公司

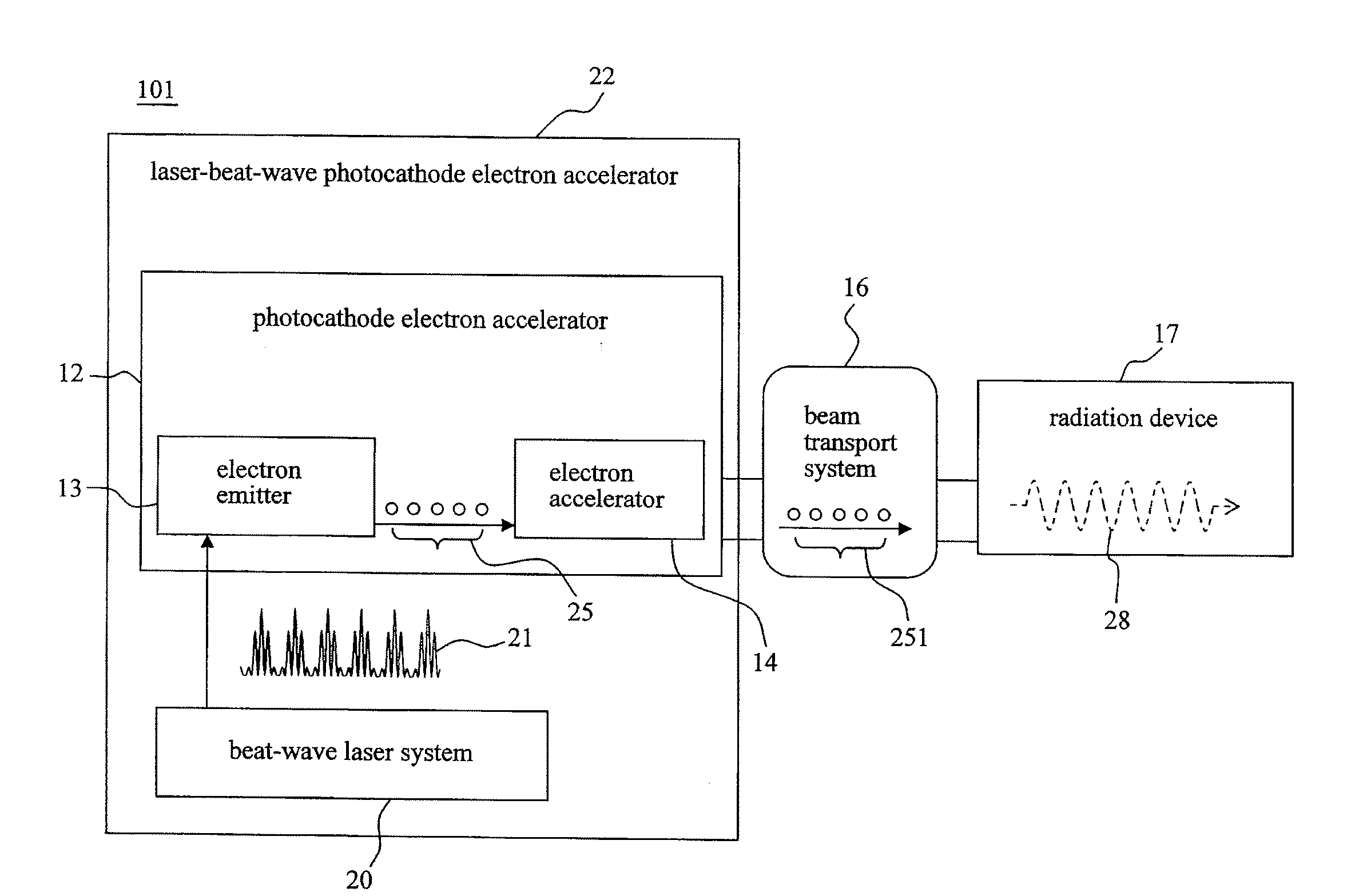

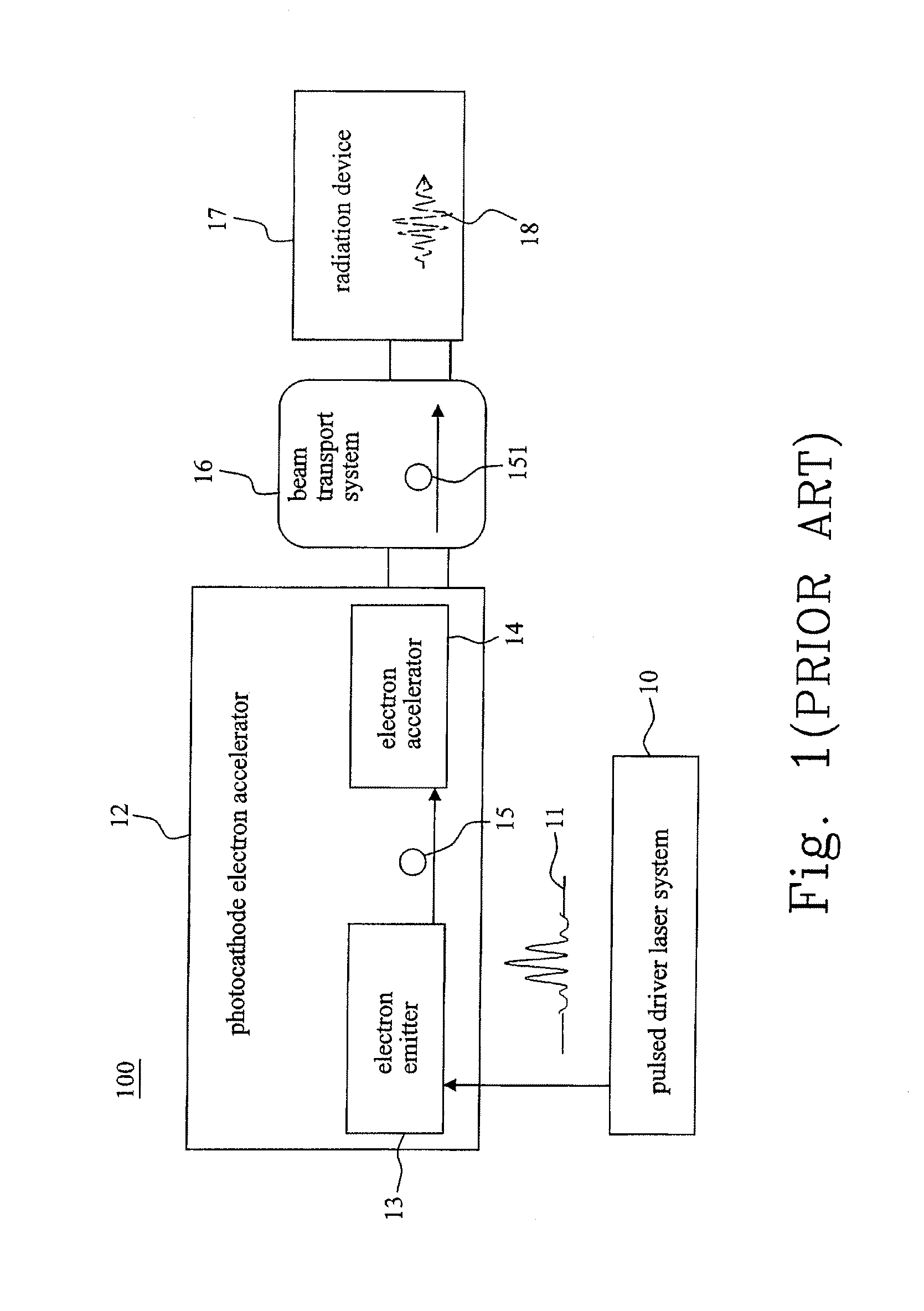

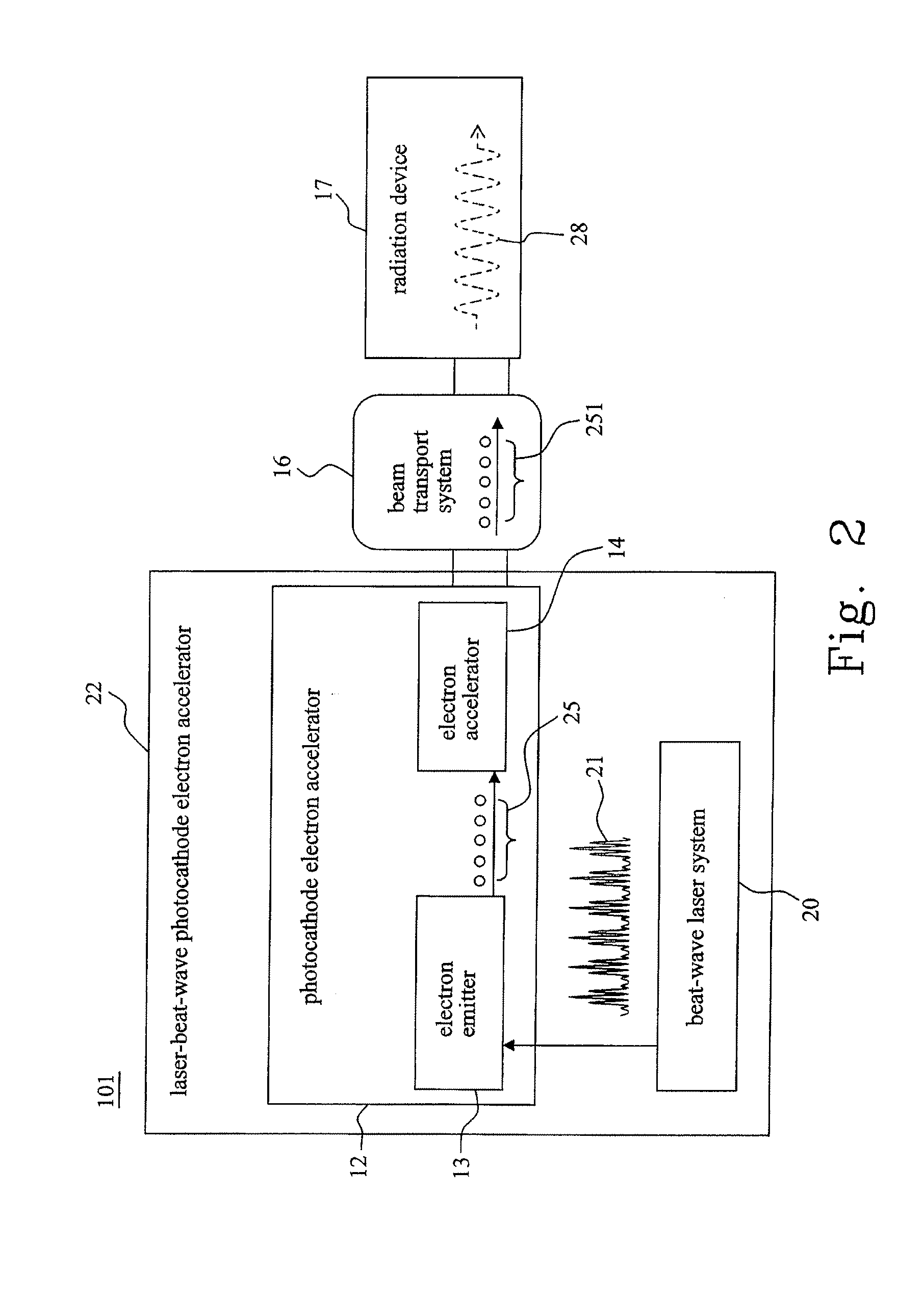

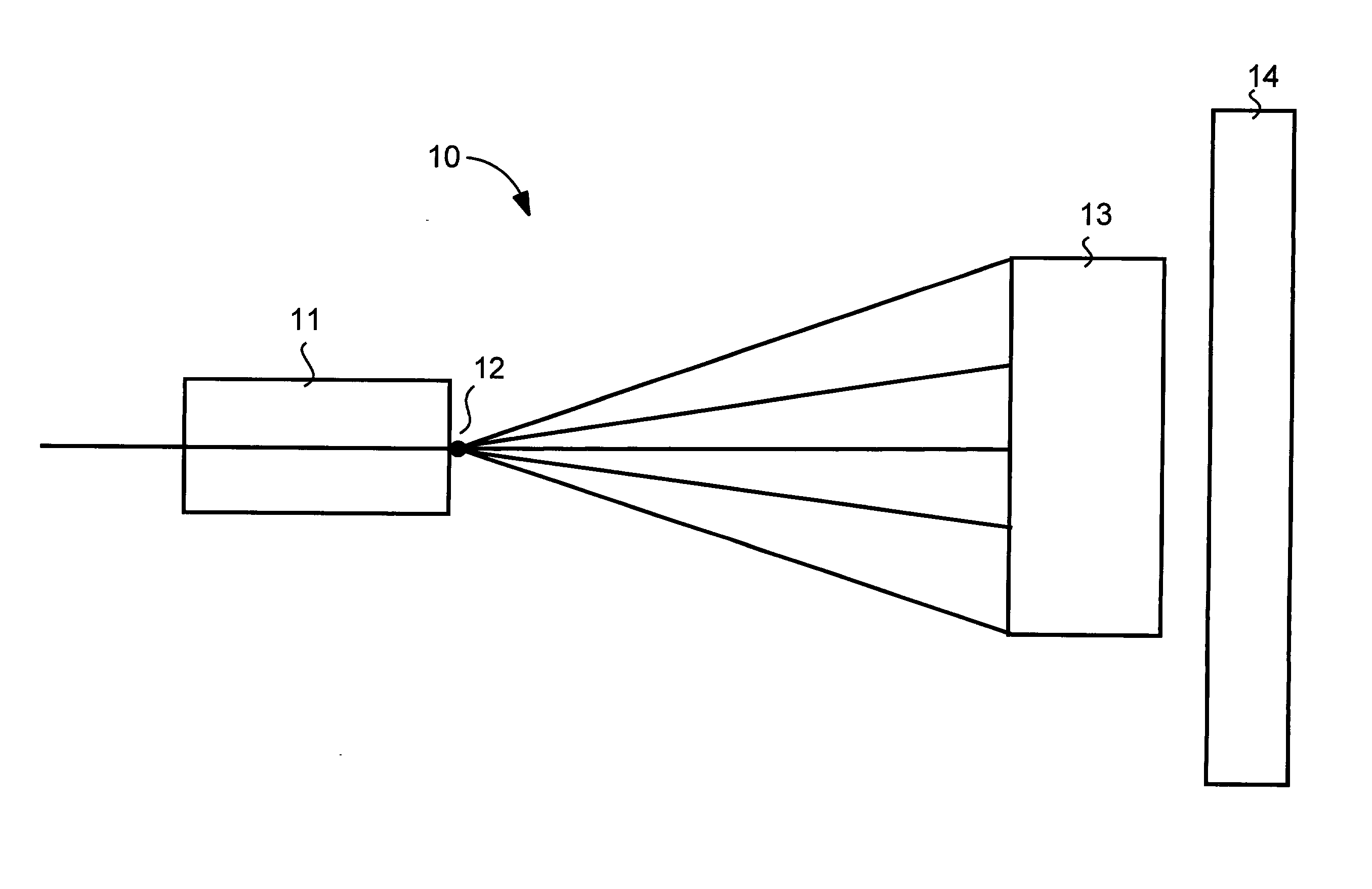

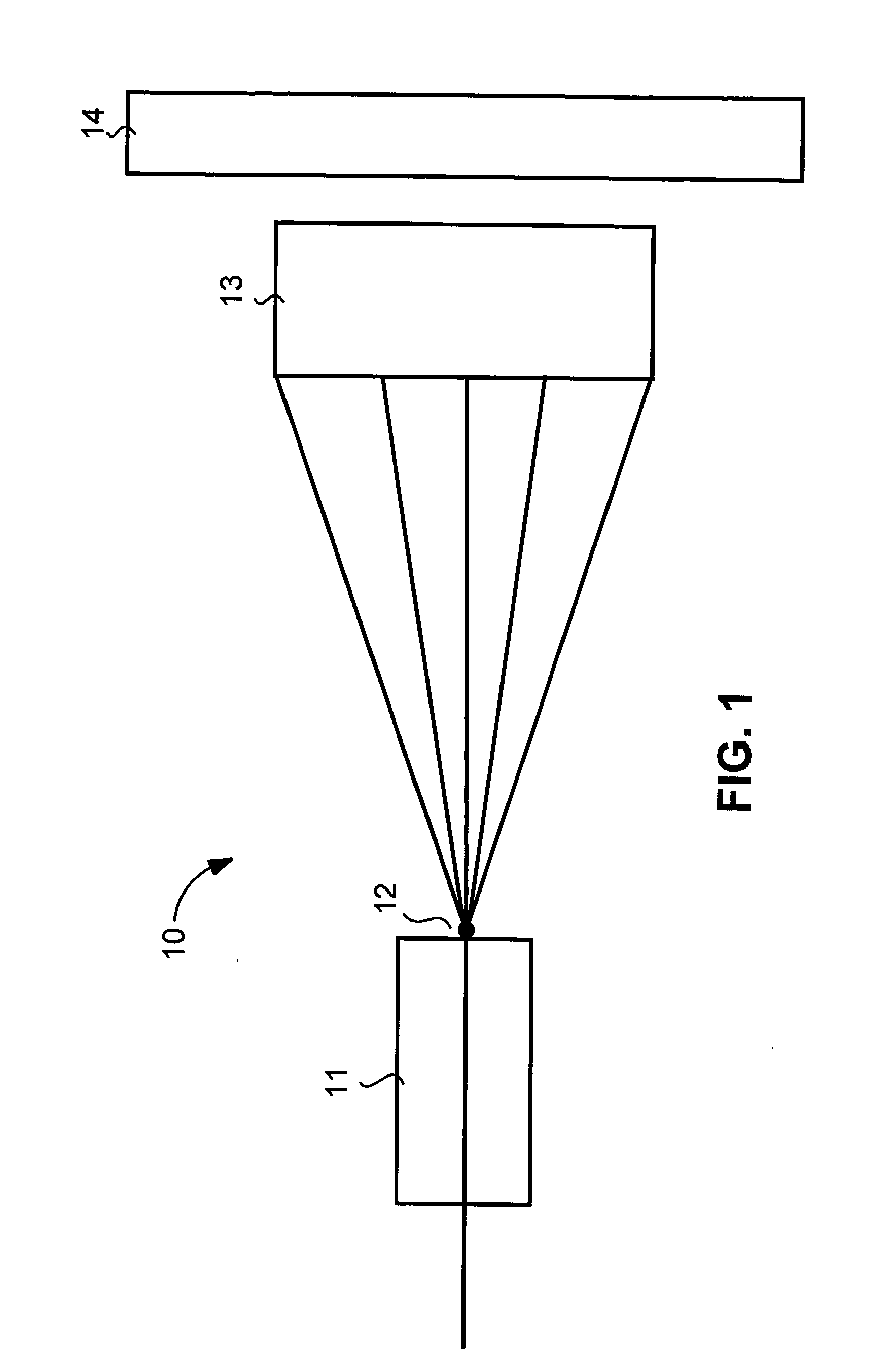

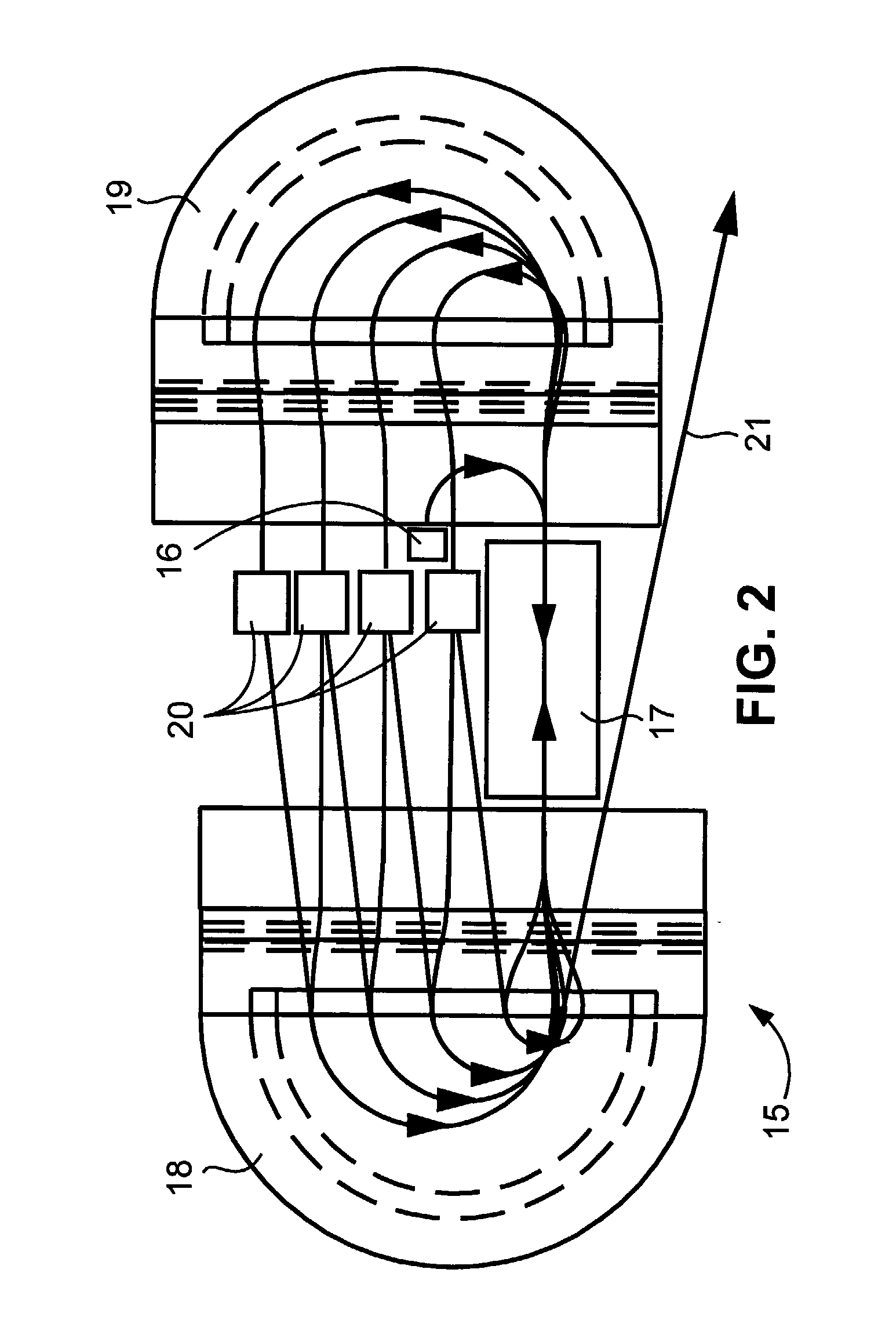

Laser-Beat-Wave Photocathode Electron Accelerator And Electron Radiation Apparatus Using The Same

ActiveUS20090059969A1Excitation process/apparatusRadioactive sourcesElectron currentElectron radiation

An electron radiation apparatus is provided. The electron radiation apparatus includes a beat-wave laser system generating a laser beat wave, an electron emitter emitting a density-modulated electron current induced by the laser beat wave, an electron accelerator accelerating the density-modulated electron current and generating a periodically bunched electron beam, and a radiation device receiving the periodically bunched electron beam and generating an electron radiation with a radiation frequency matched to one of the harmonics of the bunching frequency of the periodically bunched electron beam.

Owner:NATIONAL TSING HUA UNIVERSITY

Multi-Energy Cargo Inspection System Based on an Electron Accelerator

InactiveUS20100195791A1More efficientLess expensiveEnergy spectrometersMagnetic resonance acceleratorsElectron accelerationElectron linac

A multi-energy cargo inspection system features a compact electron accelerator is used that is more compact, more efficient and less expensive than a single linear accelerator with the same energy. The system has enhanced capabilities to recognize the elemental content of a container which can be used to detect concealed explosive and fissionable materials.

Owner:HAZARDSCAN

Device for treating waste water by electron beam irradiation method

InactiveCN102320677AImprove processing efficiencyHarm reductionWater/sewage treatment by irradiationTreatment pondOutfall

The invention discloses a device for treating waste water by an electron beam irradiation method, which comprises a waste water collecting pool, an irradiation preparing pool, an irradiation treating pool, and a clear water pool which are communicated by water conveying pipes orderly; an electron accelerator is disposed right above the irradiation treating pool; each water conveying pipe is equipped with a water pump; a sinking-mode irradiation flowing water trough is disposed in the center of a pool cover of the irradiation treating pool; uniformly-arranged flowing water trough water inlets are disposed at the bottom surface of the irradiation flowing water trough; waste water to be treated spews upwards and flows into the irradiation flowing water trough from the flowing water trough water inlets; water-distributing pipelines are disposed below the irradiation flowing water trough; flowing water trough water outlets are uniformly arranged at the trough bottom of the irradiation treating pool; the flowing water trough water outlets are communicated with the irradiation treating pool; switch valves are mounted on the flowing water trough water outlets; when the switch valves are open, water treated by the electron beam irradiation method flows into the irradiation treating pool. The invention has high treatment efficiency for industrial organic waste water, can effectively solve the problem of industrial water pollution, has a simple structure, is safe and reliable, and has low treatment cost.

Owner:SHANGHAI UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com