Patents

Literature

750 results about "Thin film electrode" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

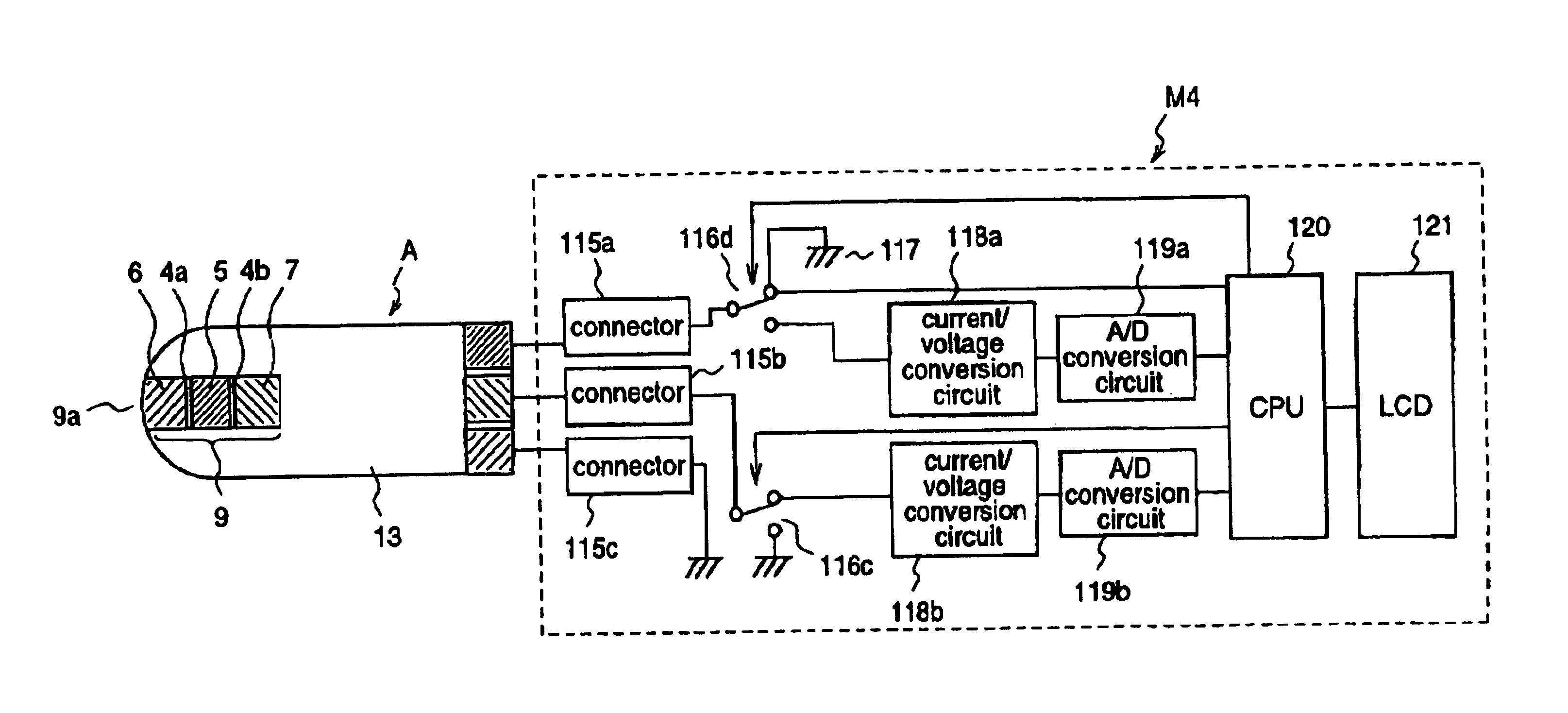

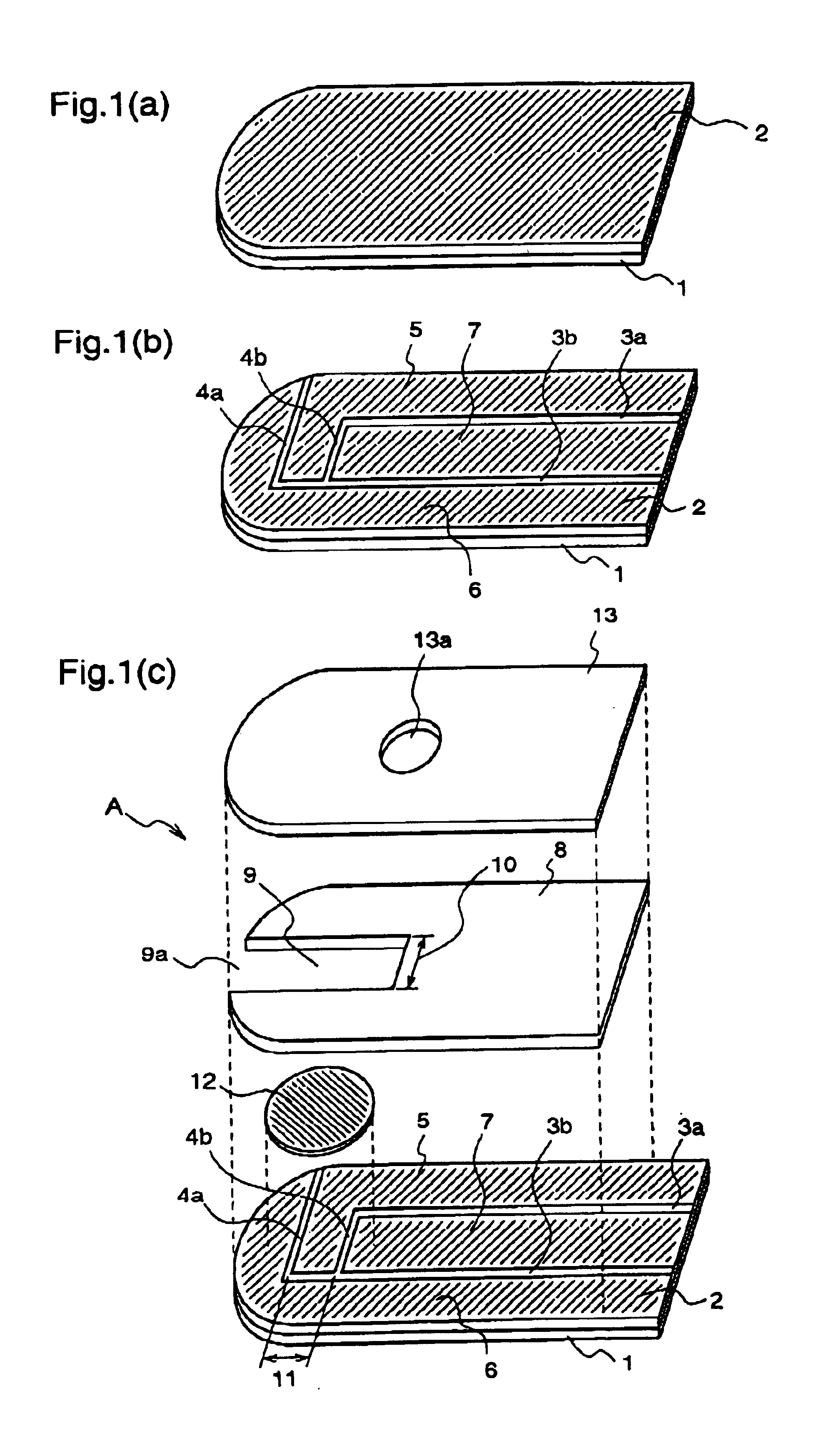

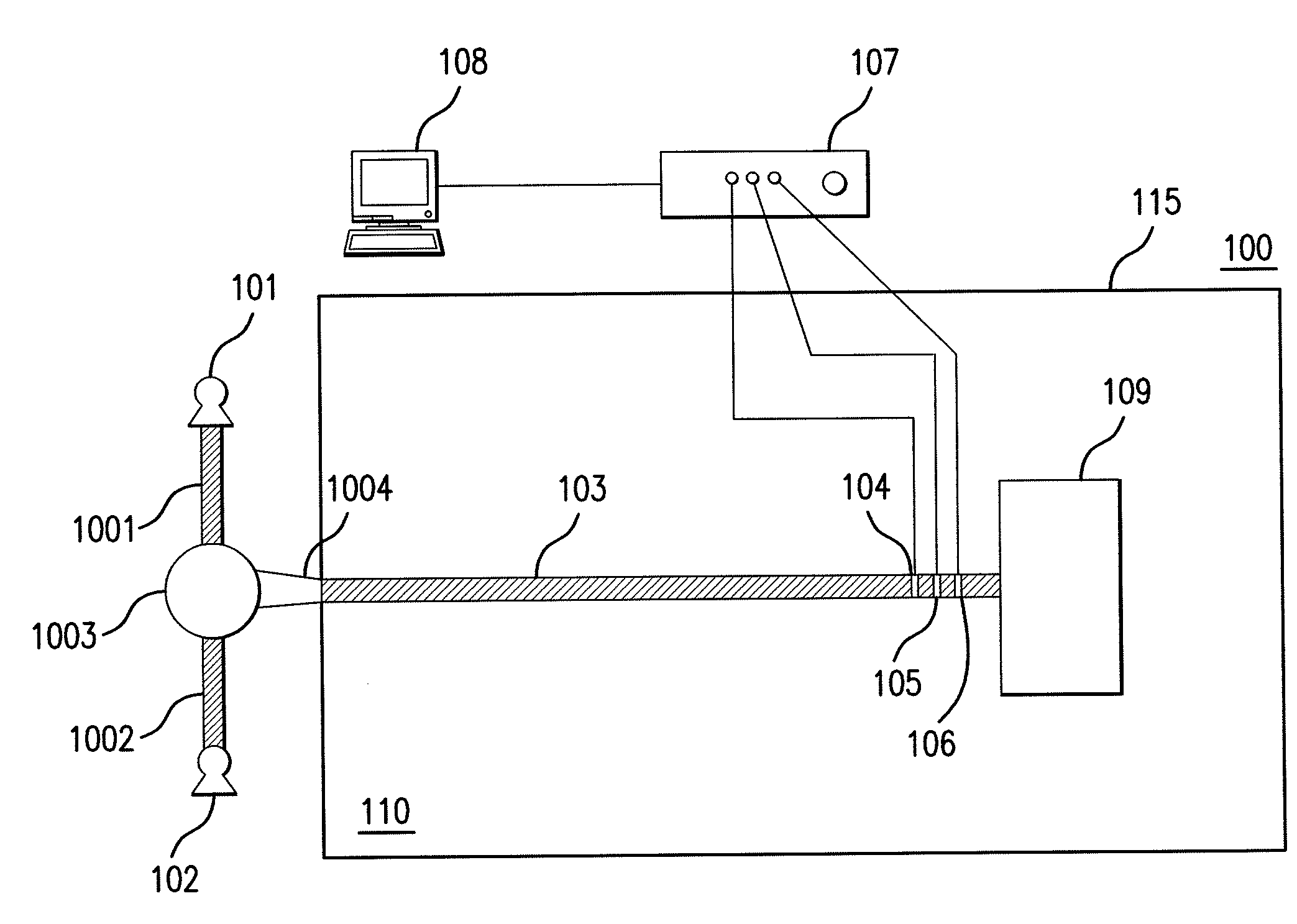

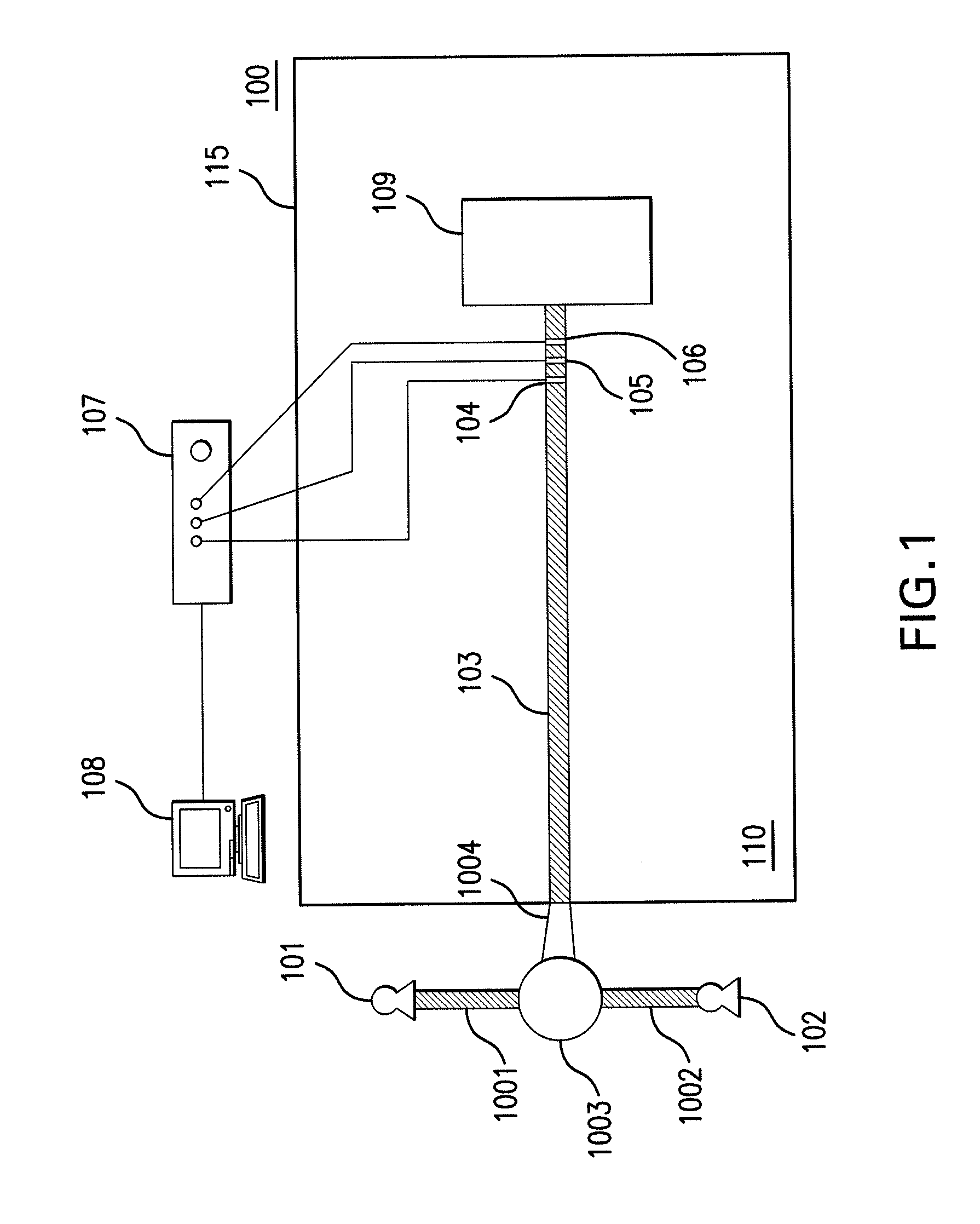

Biosensor, method of forming thin-film electrode, and method and apparatus for quantitative determination

InactiveUS6875327B1Improve convenienceImprove securityImmobilised enzymesBioreactor/fermenter combinationsThin film electrodeQuantitative determination

The invention provides a biosensor comprising a support; a conductive layer composed of a electrical conductive material such as a noble metal, for example gold or palladium, and carbon; slits parallel to and perpendicular to the side of the support; working, counter, and detecting electrodes; a spacer which covers the working, counter, and detecting electrodes on the support; a rectangular cutout in the spacer forming a specimen supply path; an inlet to the specimen supply path; a reagent layer formed by applying a reagent containing an enzyme to the working, counter, and detecting electrodes, which are exposed through the cutout in the spacer; and a cover over the spacer. The biosensor can be formed by a simple method, and provides a uniform reagent layer on the electrodes regardless of the reagent composition.

Owner:PHC HLDG CORP

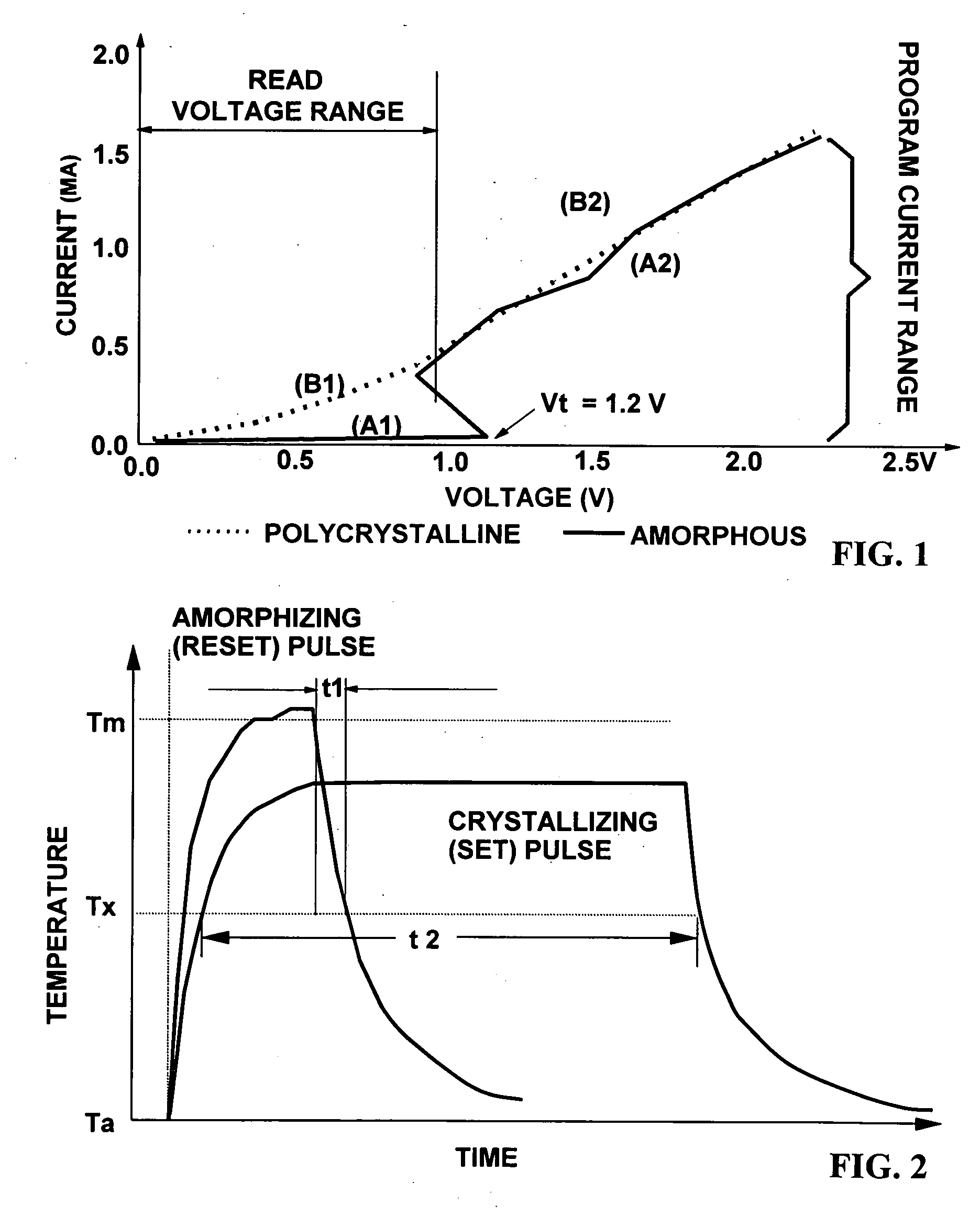

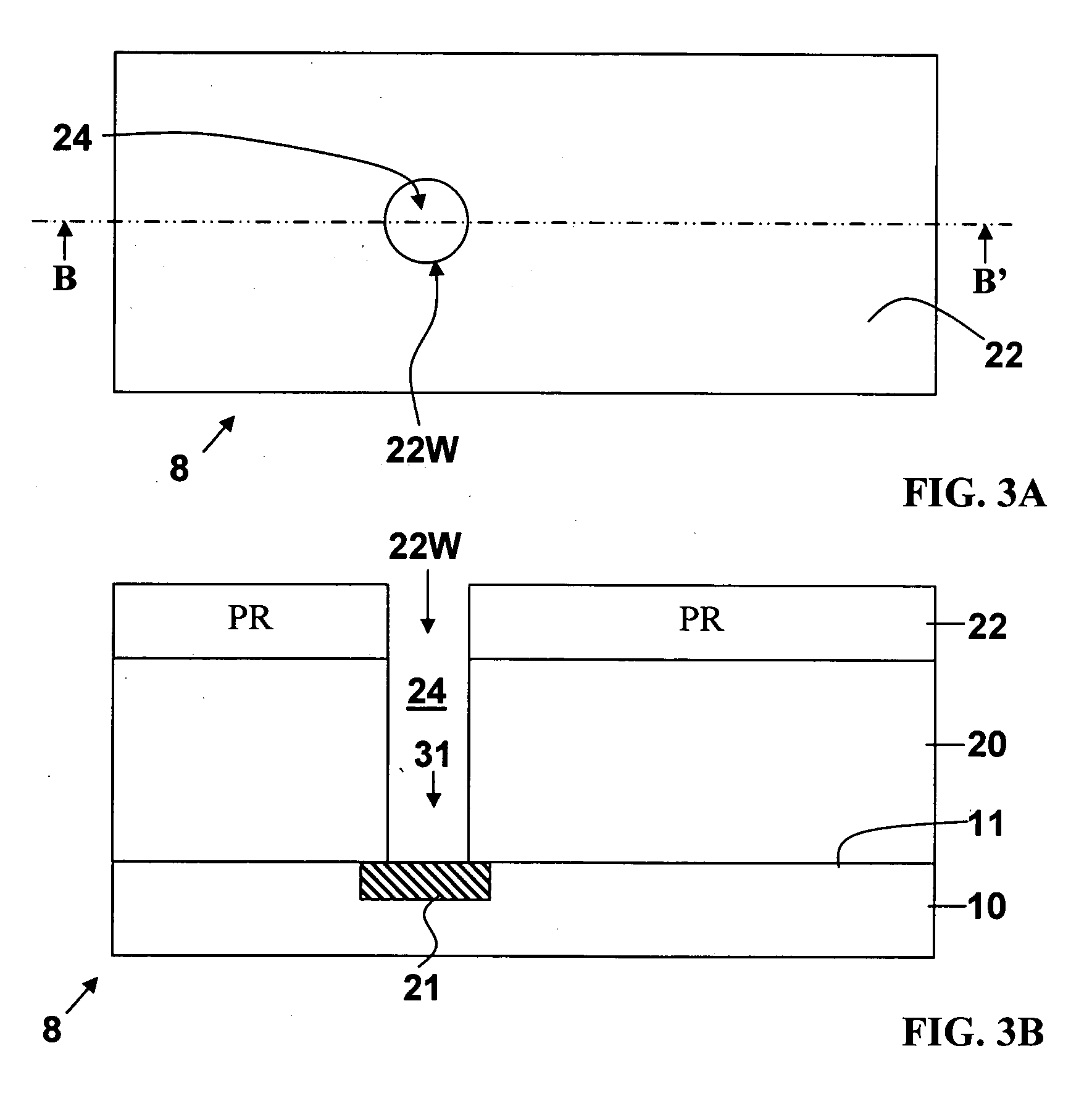

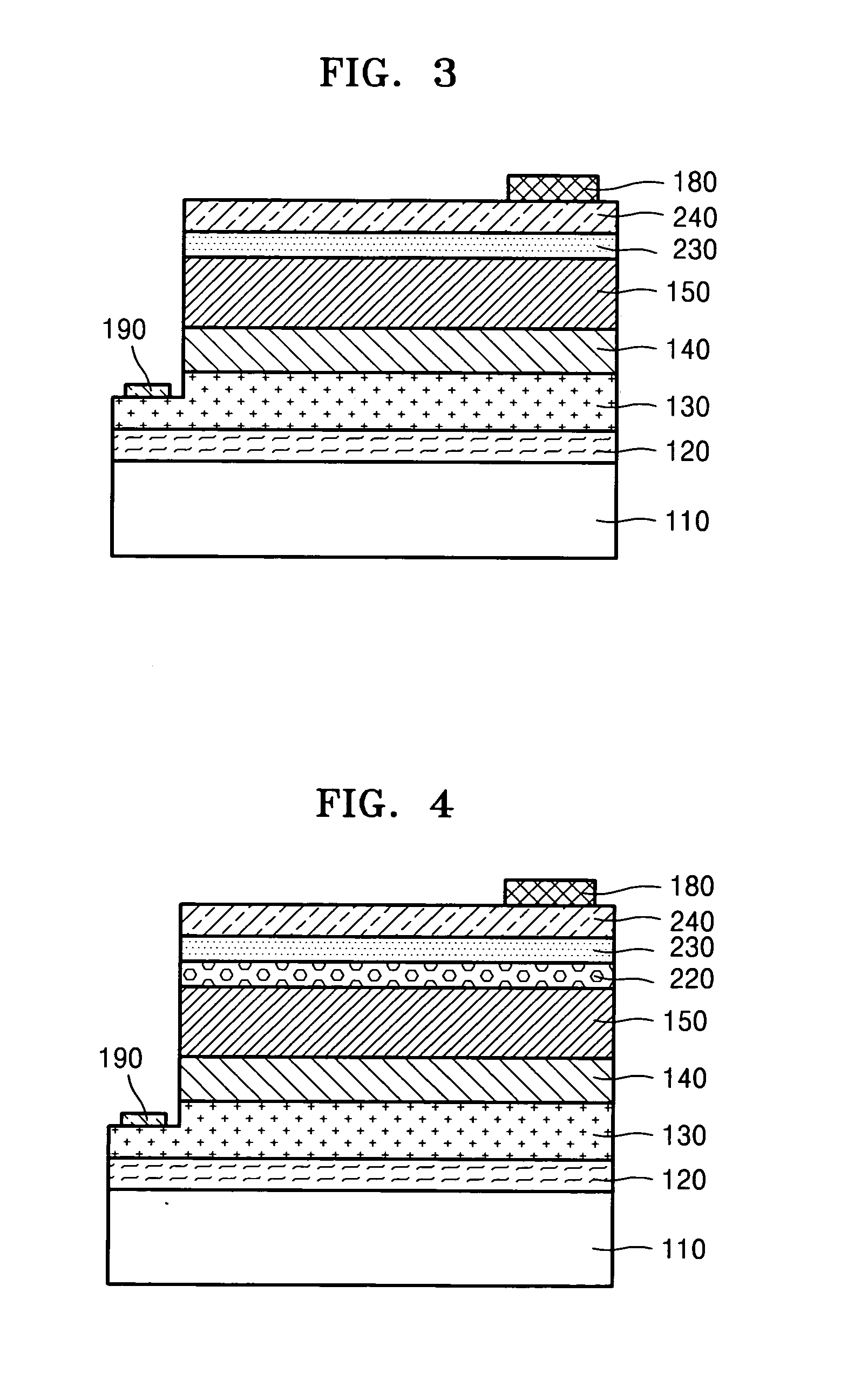

Phase change memory element with a peripheral connection to a thin film electrode and method of manufacture thereof

InactiveUS20070252127A1Increase current densityImprove performanceBulk negative resistance effect devicesSemiconductor devicesThin film electrodePhase-change memory

A PCM cell structure comprises a first electrode, a phase change element, and a second electrode, wherein the phase change element is inserted in between the first electrode and the second electrode and only the peripheral edge of one of the first and second electrodes contacts the phase change element thereby reducing the contact area between the phase change element and one of the electrodes thereby increasing the current density through the phase change element and effectively inducing the phase change at a first programming power.

Owner:IBM CORP

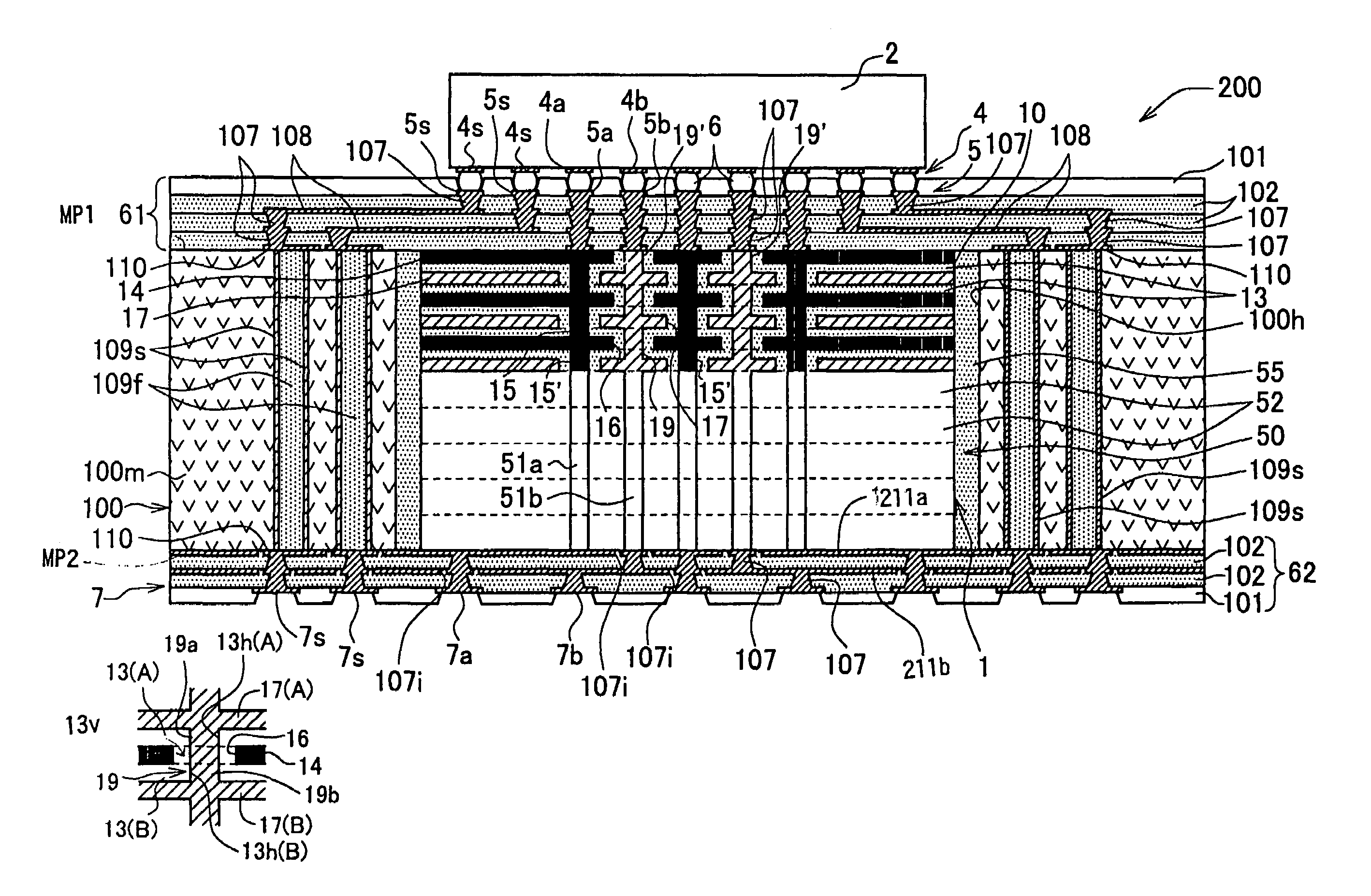

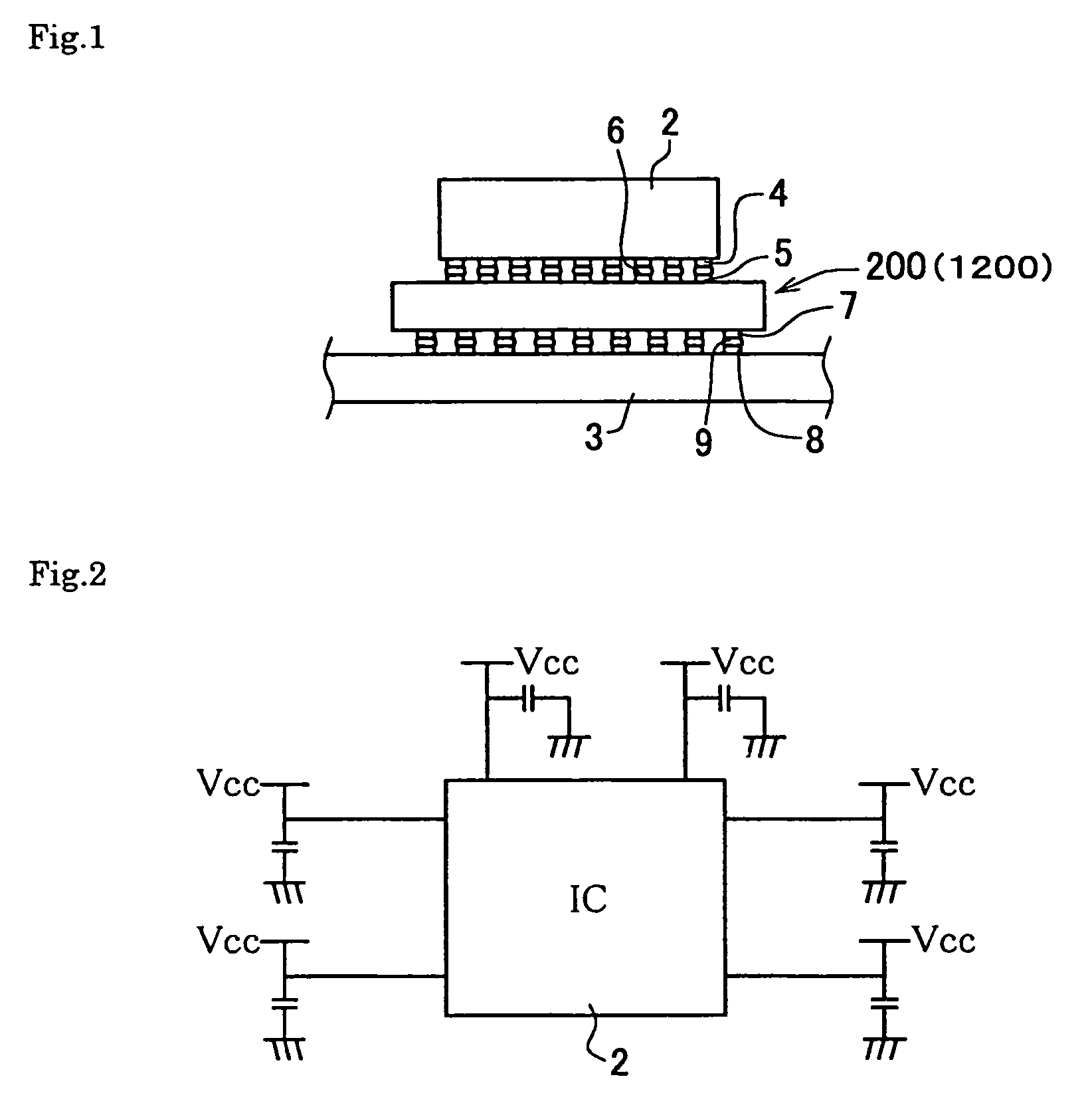

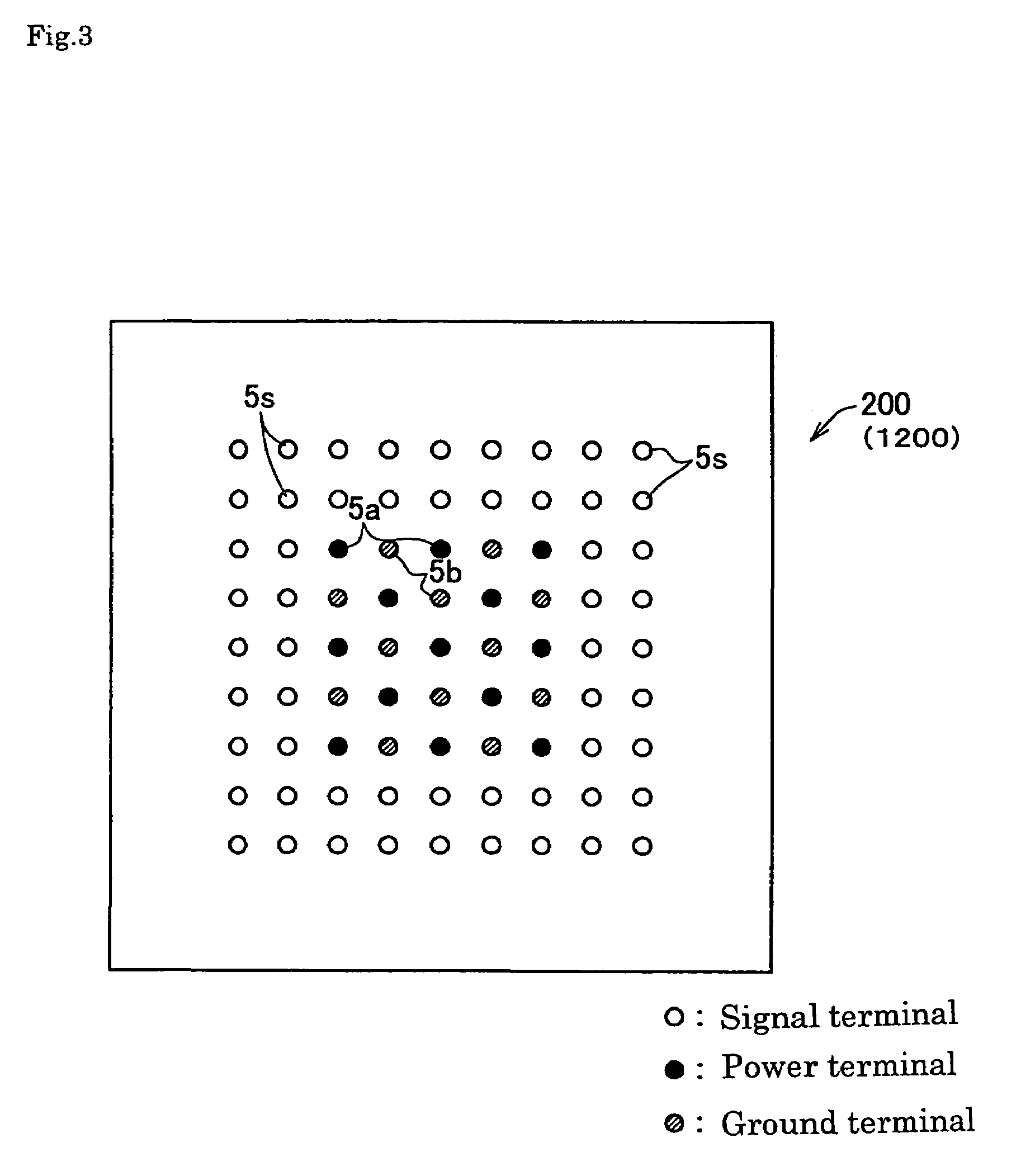

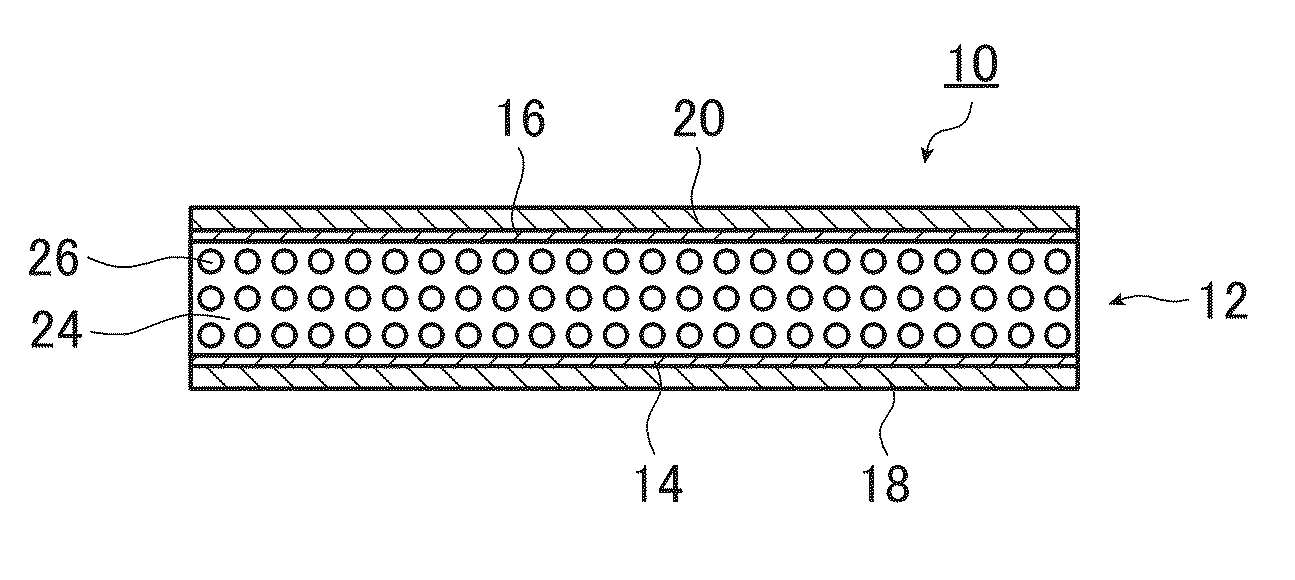

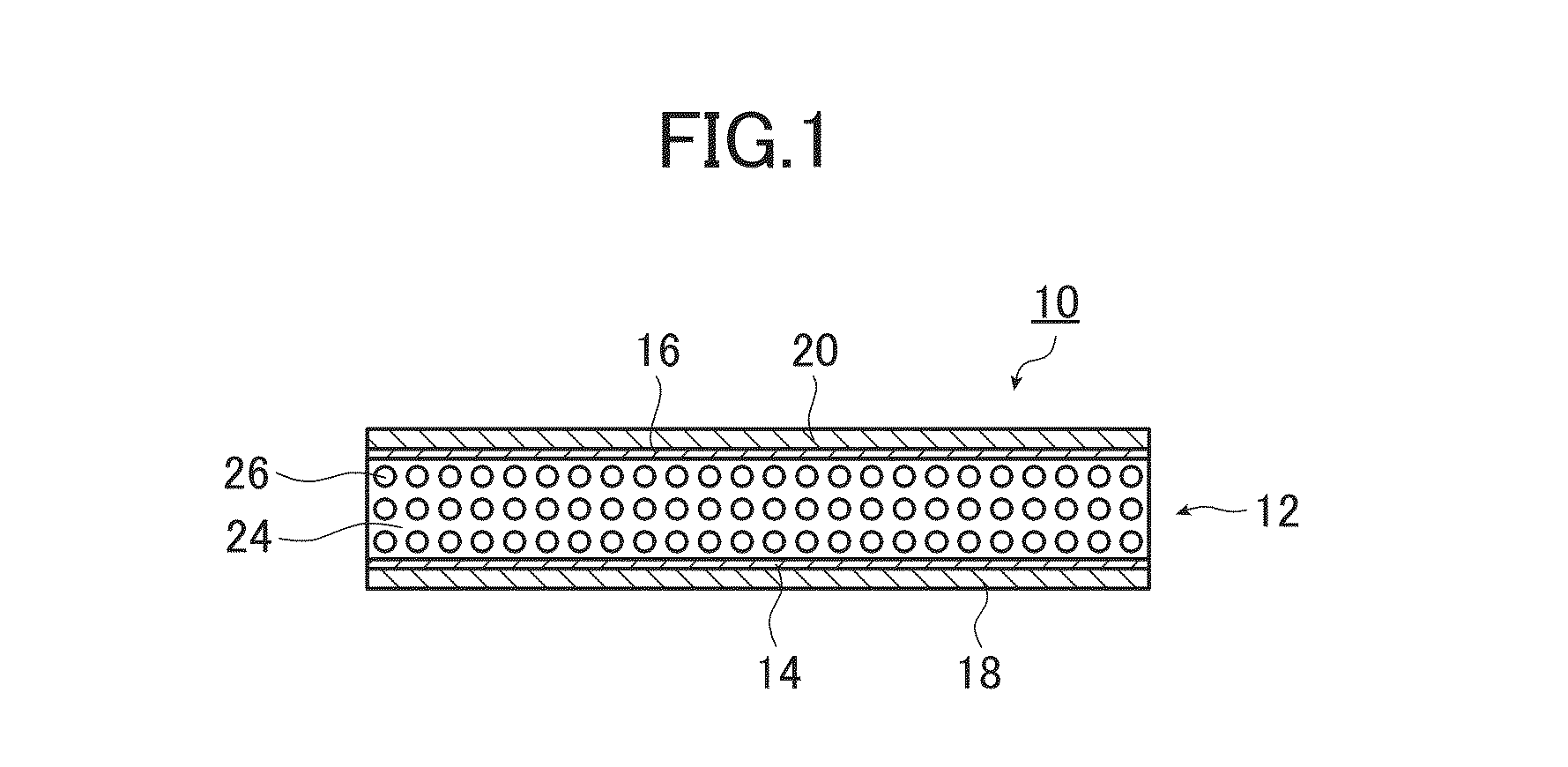

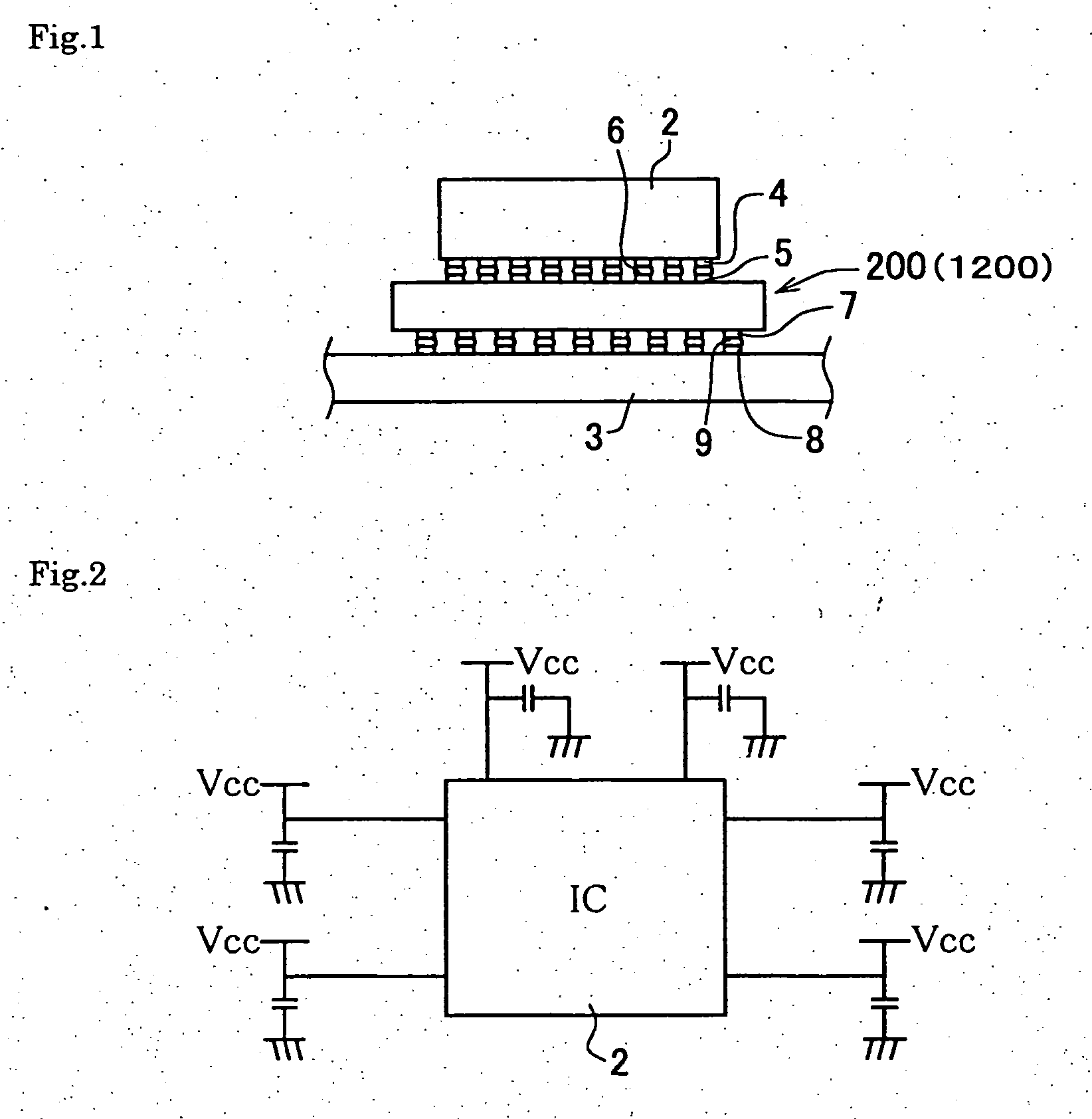

Intermediate substrate

ActiveUS7002075B2Increase stiffnessPrinted electric component incorporationSemiconductor/solid-state device detailsThin film electrodeOptoelectronics

An intermediate substrate includes a substrate core formed by a main core body portion constructed of a sheet of polymer material and having a subsidiary core accommodation portion formed therein. A ceramic subsidiary core portion, which is constructed of a ceramic sheet, is accommodated in the subsidiary core accommodation portion and is of a thickness matching that of the main core body portion. A thin film capacitor is formed on a first main surface side of a plate-like base of the core portion and includes first and second thin film electrodes separated from each other by a thin film dielectric layer so as to provide direct current isolation between the electrodes. First and second direct current isolated terminals of a first terminal array are electrically connected to the first and second thin film electrodes.

Owner:NGK SPARK PLUG CO LTD

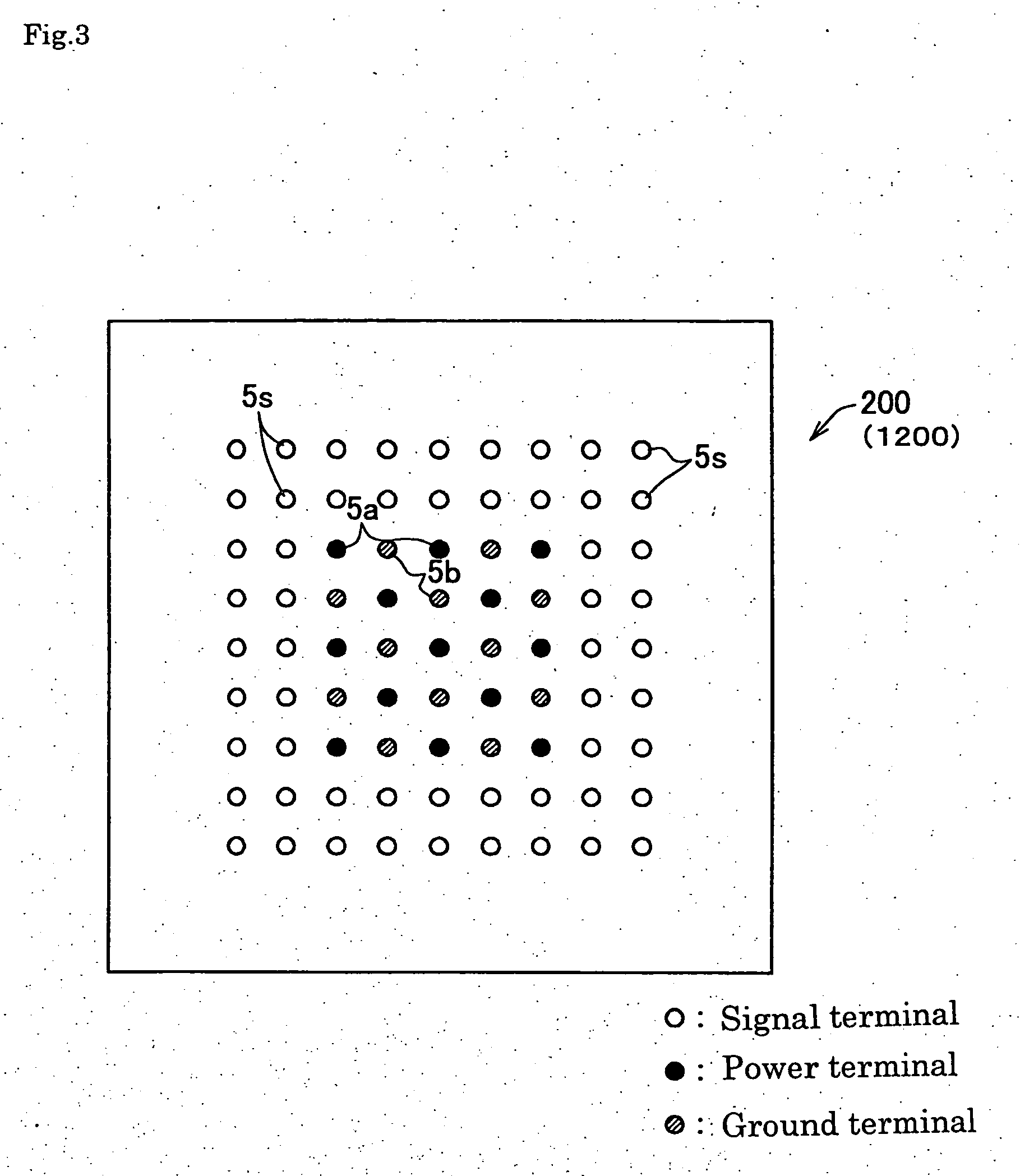

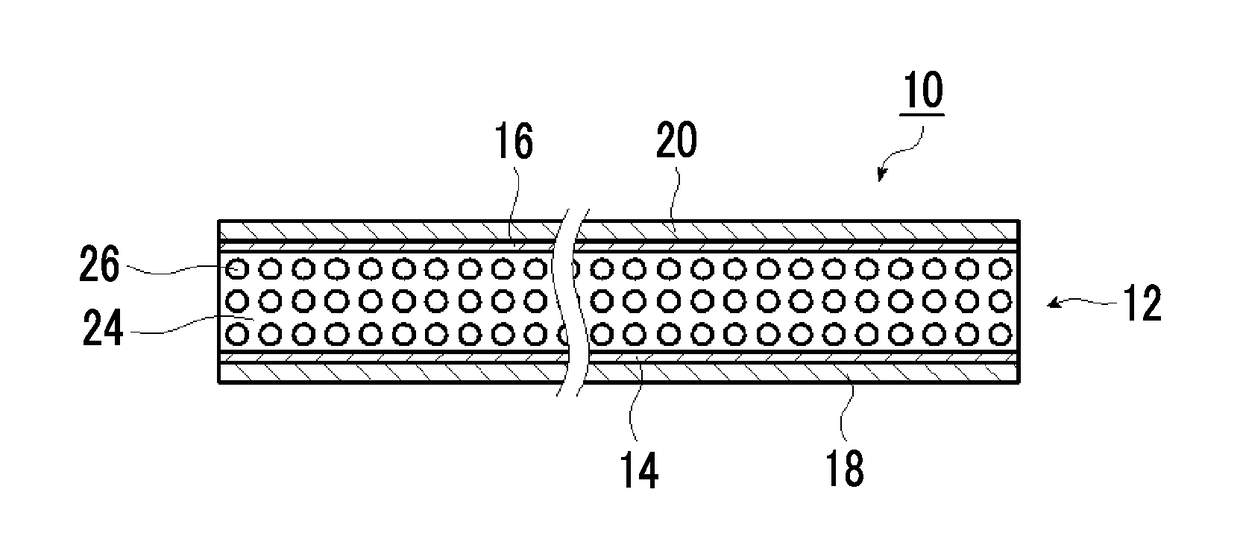

Electroacoustic converter film, flexible display, vocal cord microphone, and musical instrument sensor

ActiveUS20140210309A1Increase flexibilityExcellent acoustic characteristicsElectrophonic musical instrumentsPiezoelectric/electrostriction/magnetostriction machinesThin film electrodeDisplay device

Provided is an electroacoustic converter film including: a polymeric composite piezoelectric body having piezoelectric particles dispersed in a viscoelastic matrix which is formed of a polymer material exhibiting viscoelasticity at ordinary temperatures; thin film electrodes formed on both sides of the polymeric composite piezoelectric body; and protective layers formed on surfaces of the thin film electrodes. The electroacoustic converter film serves as a speaker capable of being integrated with a flexible display without impairing lightweightness or flexibility, and has considerable frequency dispersion in the storage modulus and also has a local maximum of the loss tangent around ordinary temperatures. A flexible display, a vocal cord microphone and a musical instrument sensor, in each of which the electroacoustic converter film is used, are also provided.

Owner:FUJIFILM CORP

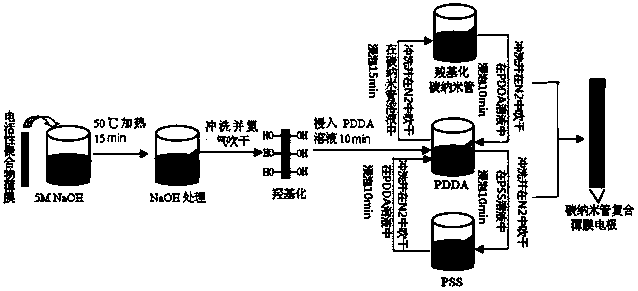

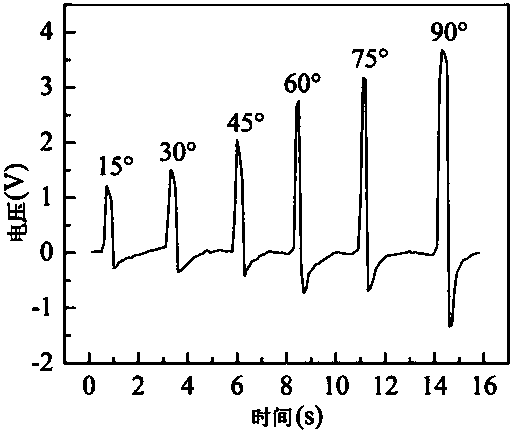

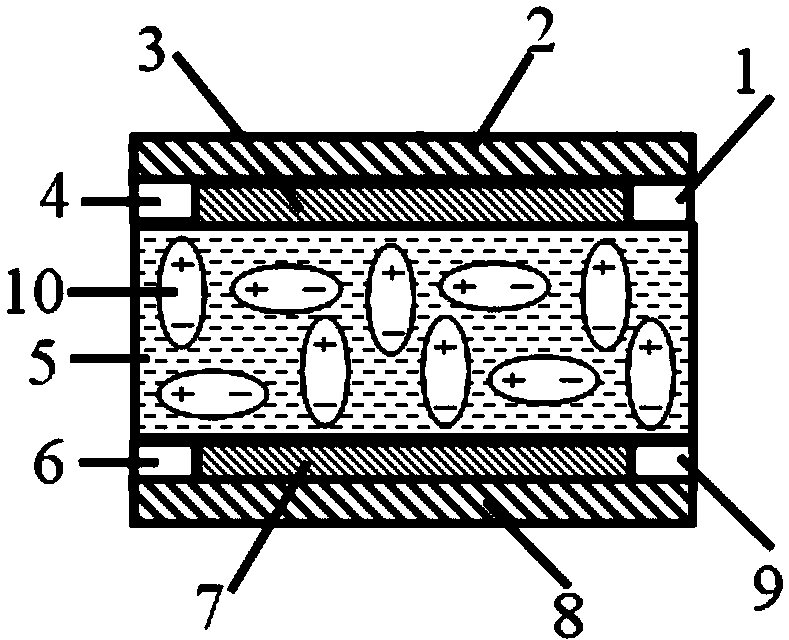

Flexible film tactile sensor and production method thereof

InactiveCN103616097AImprove flexibilityQuick responseForce measurement using piezo-electric devicesUsing electrical meansComposite filmCarbon nanotube

The invention relates to a flexible film tactile sensor which is formed by an electroactive polymer film matrix, a carbon nanotube composite film electrode layer, an electrode lead, and a polyimide film protection layer. The carbon nanotube composite film is a multi-layer network-shaped film composed of a carbon nanotube and polymer electrolyte; an electrostatic induction self-assembly method is used to make a pair of compliant electrode layers on upper and lower surfaces of the electroactive polymer film matrix; a peripheral electrode anchor zone through a metal electrode lead is integrated with a charge amplifier as a whole to from a tactile sensor; and a microprocessor or a computer is used to realize signal acquisition, storage, display and processing. The flexible film tactile sensor can be closely adhered to the surface of the measured object so as to measure the tactile perception performance of the object, can be cut into any shape, and has the characteristics of being reliable, flexible, rapid in response, and the like.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

Intermediate substrate

ActiveUS20050207091A1Increase stiffnessExtra thermal stressCross-talk/noise/interference reductionSemiconductor/solid-state device detailsThin film electrodeOptoelectronics

An intermediate substrate includes a substrate core formed by a main core body portion constructed of a sheet of polymer material and having a subsidiary core accommodation portion formed therein. A ceramic subsidiary core portion, which is constructed of a ceramic sheet, is accommodated in the subsidiary core accommodation portion and is of a thickness matching that of the main core body portion. A thin film capacitor is formed on a first main surface side of a plate-like base of the core portion and includes first and second thin film electrodes separated from each other by a thin film dielectric layer so as to provide direct current isolation between the electrodes. First and second direct current isolated terminals of a first terminal array are electrically connected to the first and second thin film electrodes.

Owner:NGK SPARK PLUG CO LTD

Novel electrode material applicable to intelligent liquid crystal dimming film and preparation method thereof

InactiveCN105761774ALow costLow raw material costCarbon-silicon compound conductorsCable/conductor manufactureThin film electrodeThin membrane

The invention relates to a novel electrode material applicable to an intelligent liquid crystal dimming film and a preparation method thereof. A transparent conductive film is at least composed of a substrate and a graphene conductive layer. The transparent conductive film further comprises a functional layer. Graphene sheets are stacked, tiled and connected with one another on a substrate to form the graphene conductive layer. A flexible liquid crystal dimming film device is prepared through the whole wet coating process of the electrodes of a graphene transparent conductive film. The liquid crystal light adjusting layer of the commercialized flexible liquid crystal dimming film is also prepared through the wet coating process. The above two coating processes can be linked up through the roll-to-roll process. Therefore, the preparation of graphene transparent conductive electrodes and the subsequent preparation of the dimming film are ensured to be continuous, low in cost and large-scale in production.

Owner:江苏天贯碳纳米材料有限公司

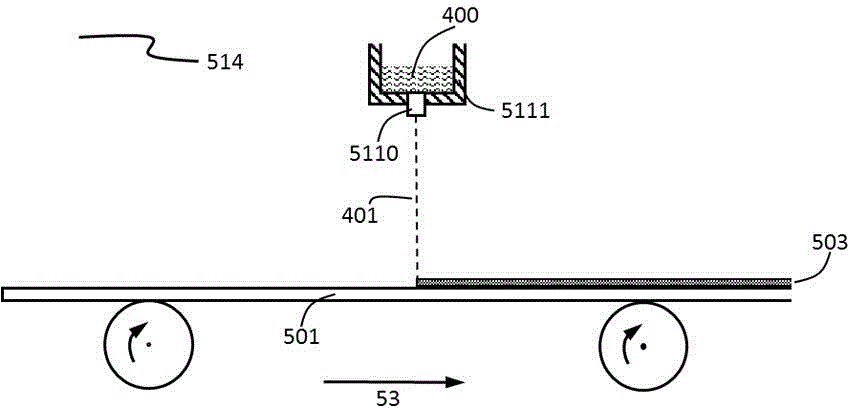

Micro-fabricated electrokinetic pump with on-frit electrode

InactiveUS7086839B2Sludge treatmentMaterial analysis by electric/magnetic meansThin film electrodeFrit

An electroosmotic pump and method of manufacturing thereof. The pump having a porous structure adapted to pump fluid therethrough, the porous structure comprising a first side and a second side, the porous structure having a plurality of fluid channels therethrough, the first side having a first continuous layer of electrically conductive porous material deposited thereon and the second side having a second continuous layer of electrically conductive porous material deposited thereon, the first second layers coupled to a power source, wherein the power source supplies a voltage differential between the first layer and the second layer to drive fluid through the porous structure at a desired flow rate. The continuous layer of electrically conductive porous material is preferably a thin film electrode, although a multi-layered electrode, screen mesh electrode and beaded electrode are alternatively contemplated. The thickness of the continuous layer is in range between and including 200 Angstroms and 10,000 Angstroms.

Owner:VERTIV CORP

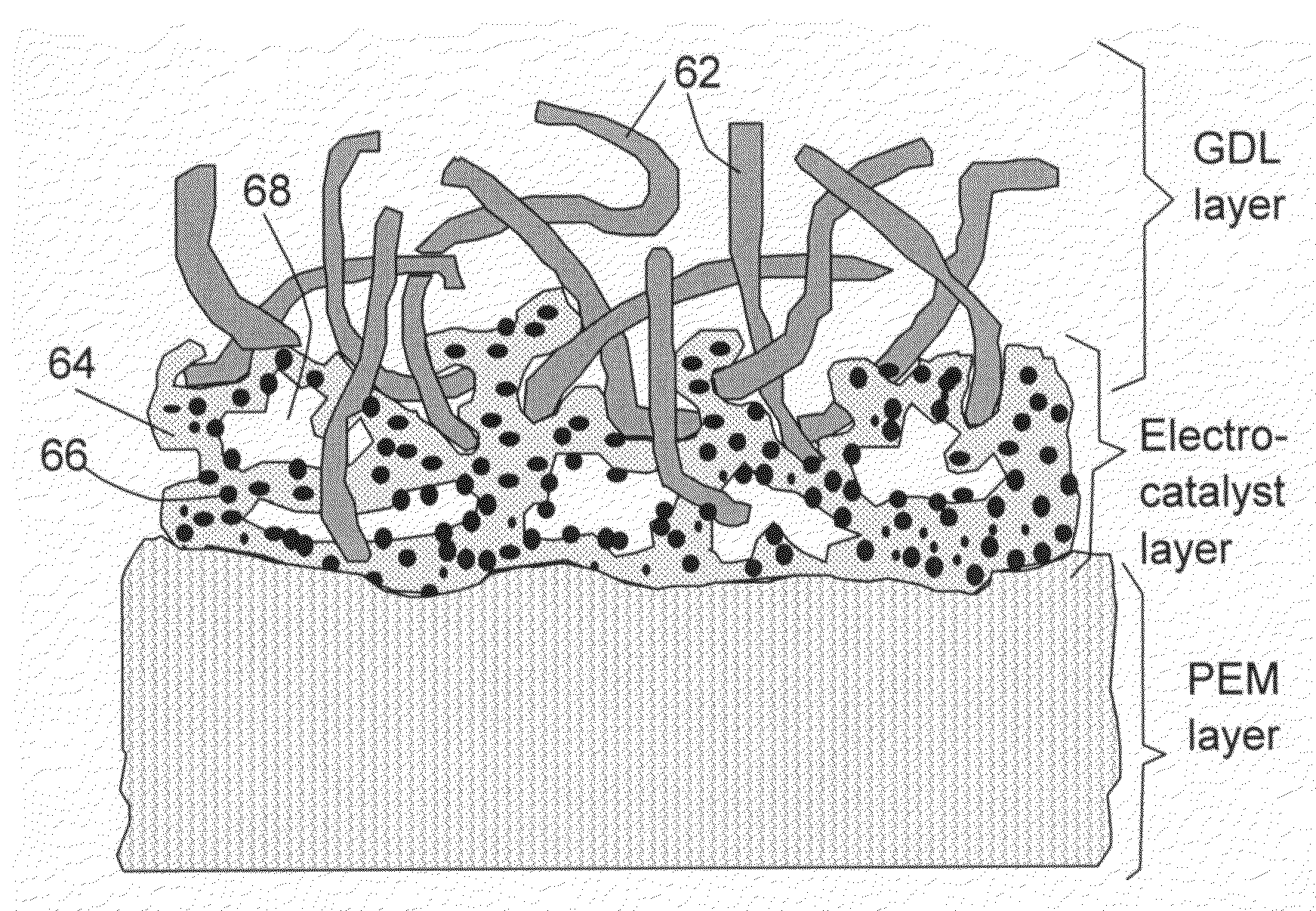

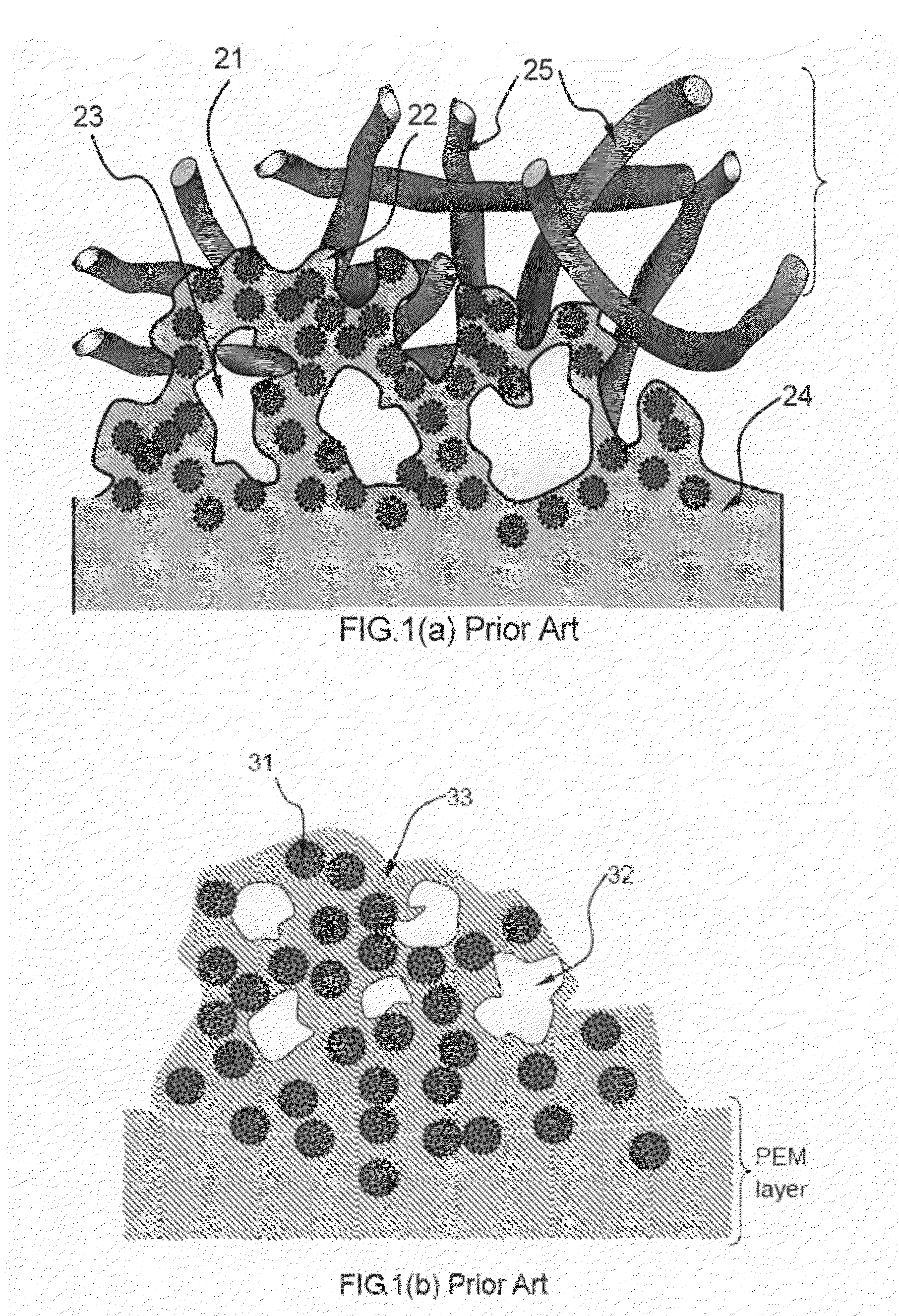

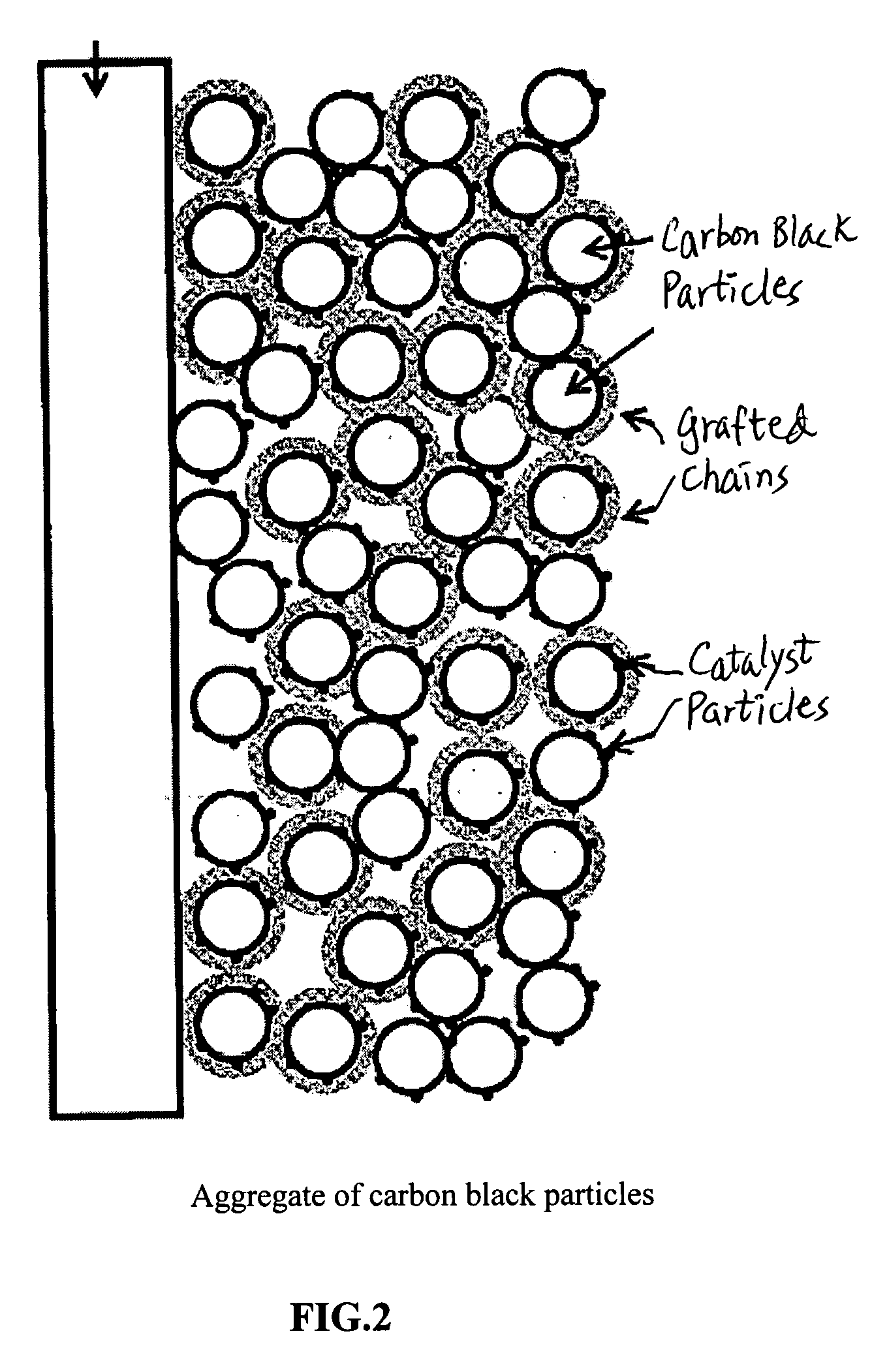

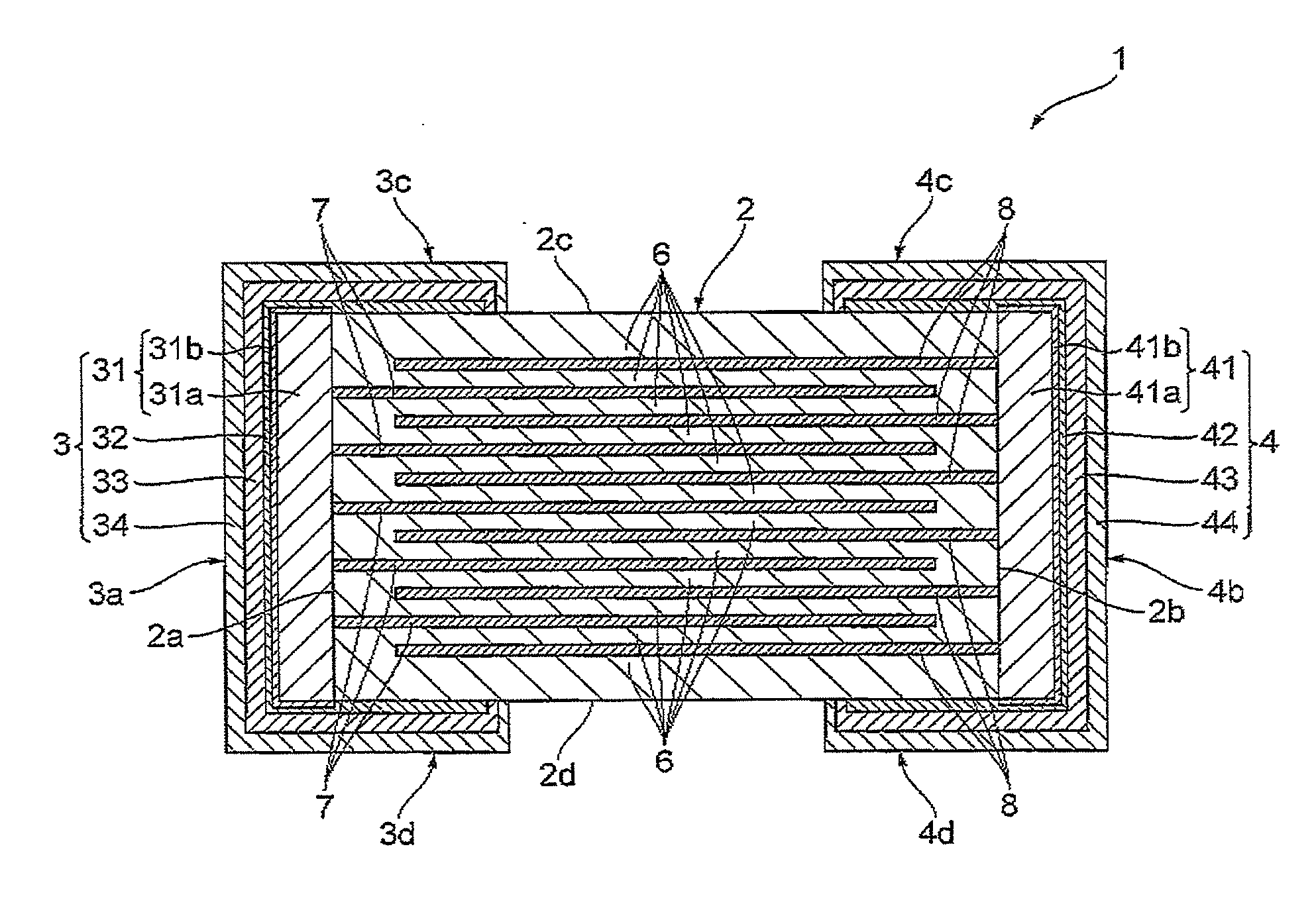

Conducting polymer-transition metal electro-catalyst compositions for fuel cells

ActiveUS20080193827A1Improve fuel cell performanceReduced Ohmic lossCell electrodesConductive materialConductive polymerOxygen

An electro-catalyst composition for use as an electrode, gas diffusion layer-supported electrode, catalytic electrode-coated solid electrolyte layer, and / or membrane-electrode assembly in a proton exchange membrane (PEM) type fuel cell. The composition comprises: (a) a proton- and electron-conducting polymer having at least one heteroatom per backbone monomer unit thereof and a plurality of neutral transition metal atoms covalently bonded to at least a portion of the heteroatoms; wherein the polymer has an electronic conductivity no less than 10−4 S / cm and a proton conductivity no less than 10−5 S / cm. Preferably, the electro-catalyst composition further comprises (b) a plurality of catalytically active particles of a transition metal, nucleated around the covalently bonded transition metal atoms. Also preferably, additional catalytically active catalyst particles with an average dimension smaller than 2 nm (most preferably smaller than 1 nm) are physically dispersed in such a polymer and typically not chemically bonded thereto. A hydrogen-oxygen PEM fuel cell or a direct methanol fuel cell (DMFC) featuring such an electro-catalyst composition in a thin-film electrode exhibits a superior current-voltage response.

Owner:NANOTEK INSTR GRP LLC

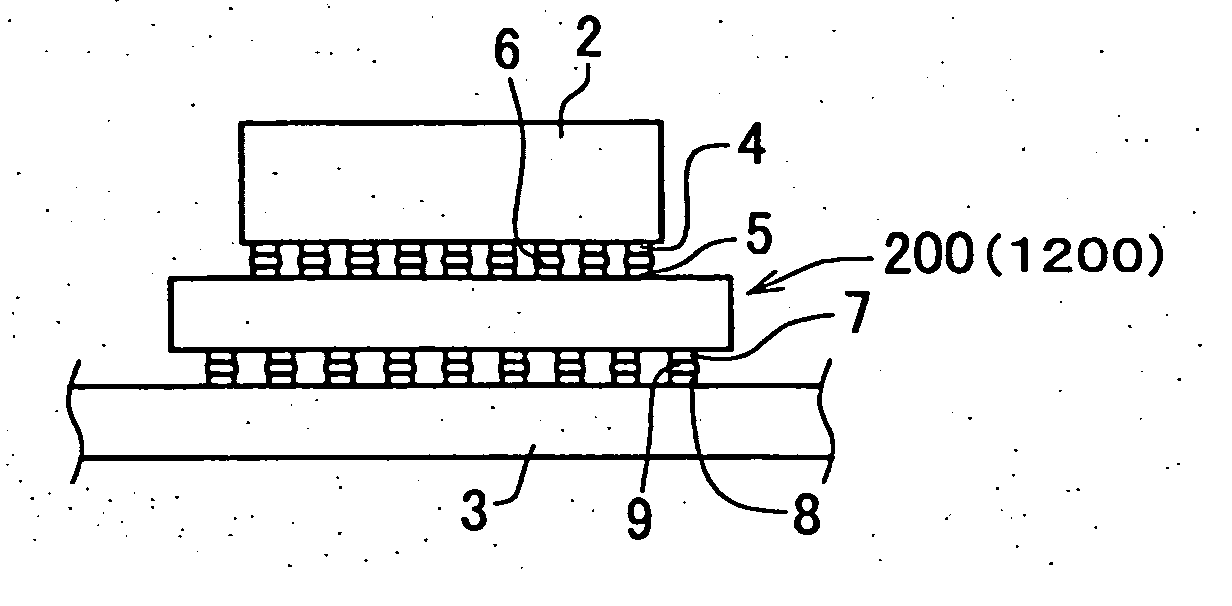

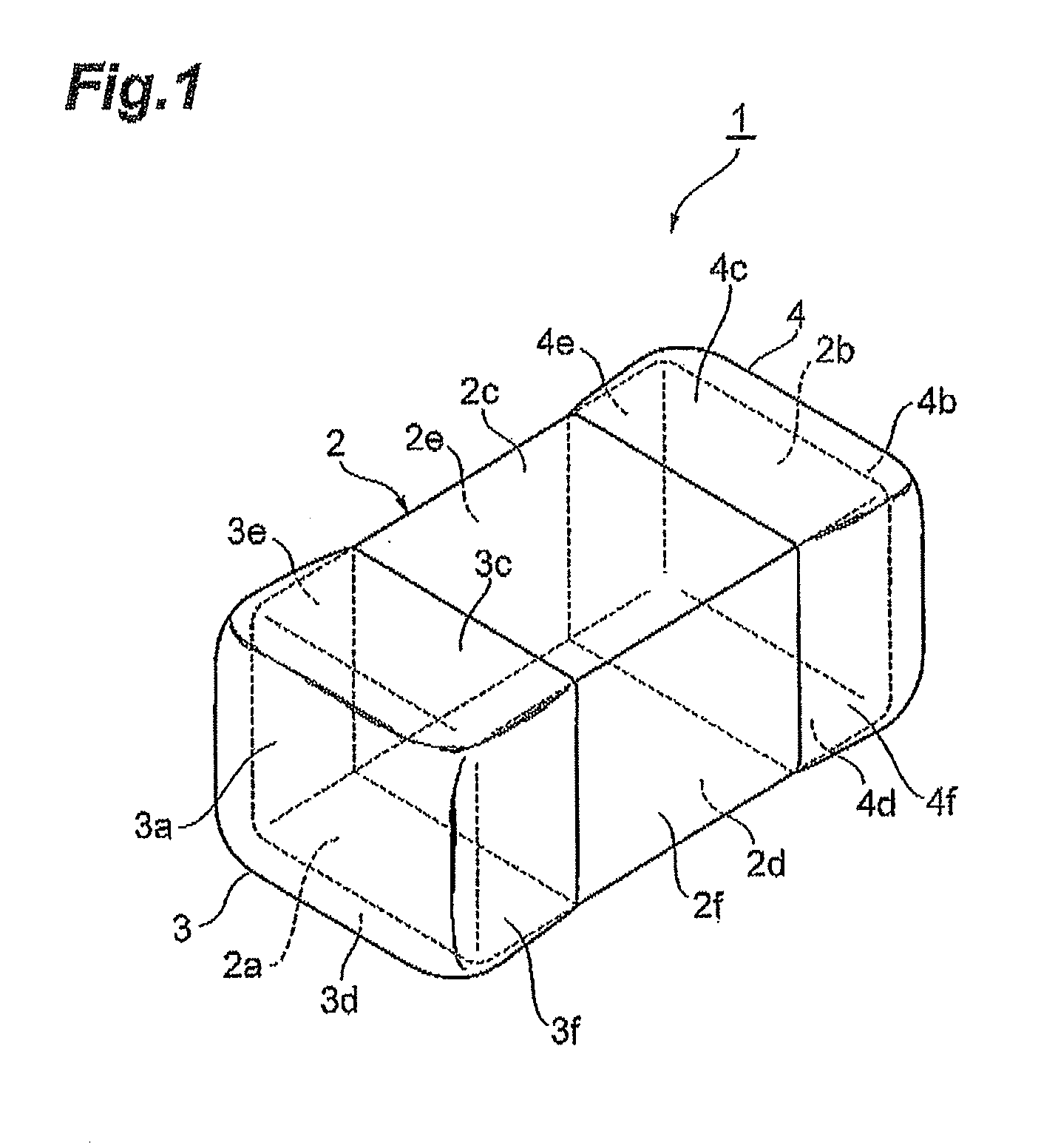

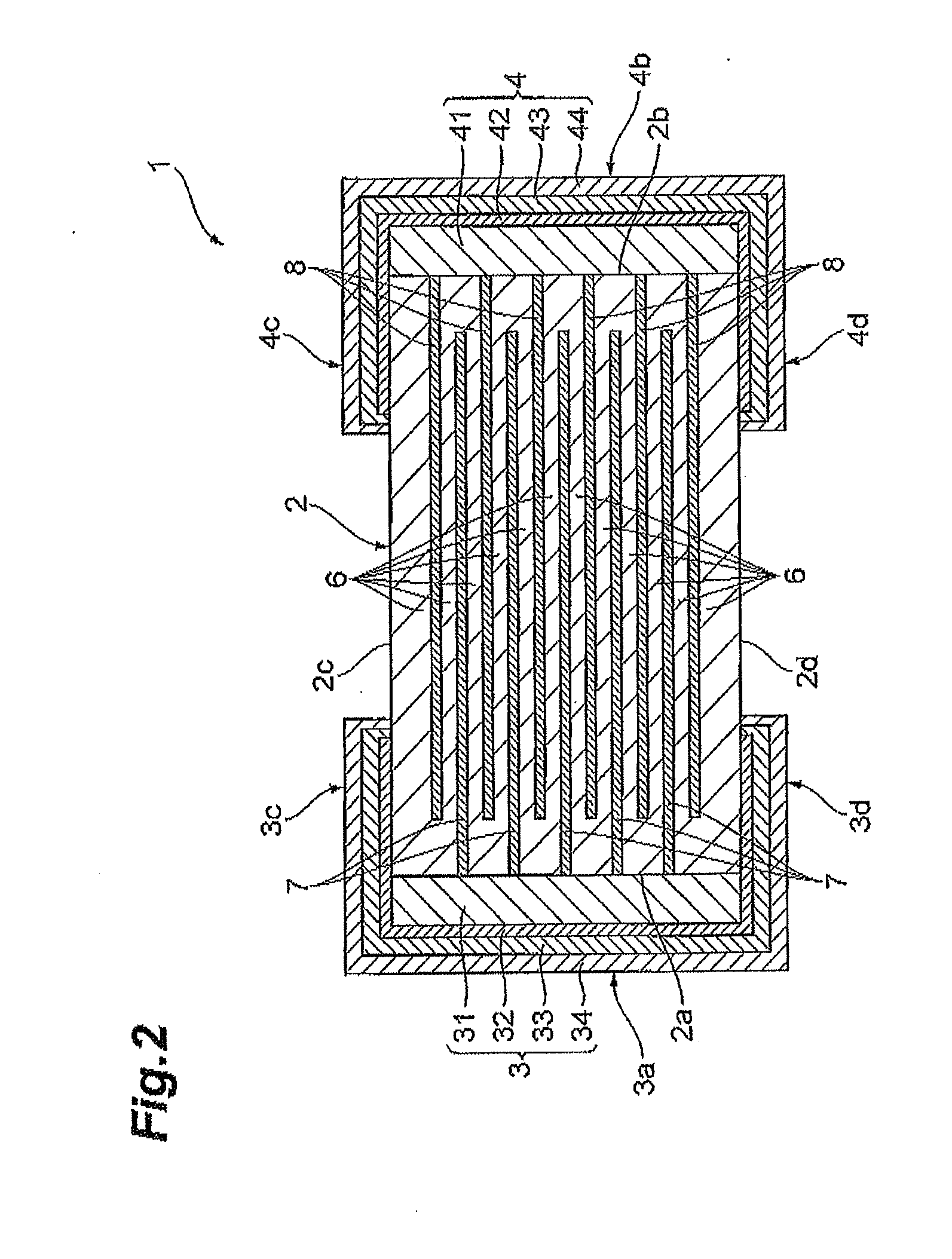

Electronic component and method for manufacturing electronic component

InactiveUS20130208401A1Small sizePrevent penetrationFixed capacitor electrodesFixed capacitor dielectricThin film electrodeAlloy

An electronic component has an element body and an external electrode arranged on the element body. The element body has a pair of end faces opposed to each other, a pair of principal faces opposed to each other, and a pair of side faces opposed to each other. The external electrode is formed so as to cover the end face and a partial region of the principal face and / or a partial region of the side face. The external electrode has a thick film electrode, a thin film electrode, and a plated layer. The thick film electrode is formed on the end face. The thin film electrode is formed so as to cover the thick film electrode and the partial region of the principal face and / or the partial region of the side face. The plated layer is formed outside the thin film electrode and contains Sn or an Sn alloy.

Owner:TDK CORPARATION

Optical switch and production method therefor, information transmission device using it

InactiveUS20050094931A1High deformation efficiencyCoupling light guidesPiezoelectric/electrostrictive devicesInformation transmissionEngineering

On a substrate are configured piezoelectric elements composed of a mirror device, piezoelectric thin films, electrodes, and elastic members, and application of a voltage to the electrodes causes flexure deformation in the piezoelectric thin films, so that the mirror device is actuated. A plurality of the piezoelectric elements are arranged in parallel with a longitudinal direction thereof, and torsion springs are provided so as to extend in a direction orthogonal to the longitudinal direction and so as to hold the mirror device in connection with the substrate. The mirror device is connected to the piezoelectric elements through strain absorbers. In such a configuration, the torsion springs serve as a rotation axis, and the mirror device is inclined about the rotation axis.

Owner:PANASONIC CORP

Etch resistant wafer processing apparatus and method for producing the same

InactiveUS20070138601A1Liquid surface applicatorsSemiconductor/solid-state device detailsThin film electrodeHard metal

A wafer processing apparatus is fabricated by depositing a film electrode onto the surface of a base substrate, the structure is then overcoated with a protective coating film layer comprising at least one of a nitride, carbide, carbonitride or oxynitride of elements selected from a group consisting of B, Al, Si, Ga, refractory hard metals, transition metals, and combinations thereof. The film electrode has a coefficient of thermal expansion (CTE) that closely matches the CTE of the underlying base substrate layer as well as the CTE of the protective coating layer.

Owner:MOMENTIVE PERFORMANCE MATERIALS INC

Self-generation wide-band laminated magnetic induced piezoelectric effect AC magnetic field sensor and production method thereof

InactiveCN101430369ASmall demagnetization factorEasily magnetizedMagnitude/direction of magnetic fieldsThin film electrodeMagnetic field amplitude

A power generation type AC magnetic field sensor based on magneto piezoelectric effect is a laminated structure consisting of magnetostrictive rod, a piezoelectric material, the magnetostrictive rod and a permanent magnetic material; the upper surface and the lower surface of the piezoelectric material are provided with silver membrane electrode respectively, and the magnetostrictive rods is equipped with a signal output lead. The sensor can detect the alternating current without power supply, so the sensor is an energy-saving device with zero power consumption. The sensor has the advantages of small volume and low weight, can detect the AC magnetic field bandwidth ranging from 500Hz to 70kHz, and keeps a good linear relation between the output voltage and the magnetic field amplitude. The sensor adopts a thin rod structure, thus greatly reducing the volume of the sensor, enhancing the sensitivity and the bandwidth of the sensor. A bias magnetic field provided for the thin rod is greatly reduced for using small size of the magnetostrictive material, and can be integrated with a sensitive body. The sensor can be applicable to passive detection of the alternating magnetic fields.

Owner:JIANGSU UNIV

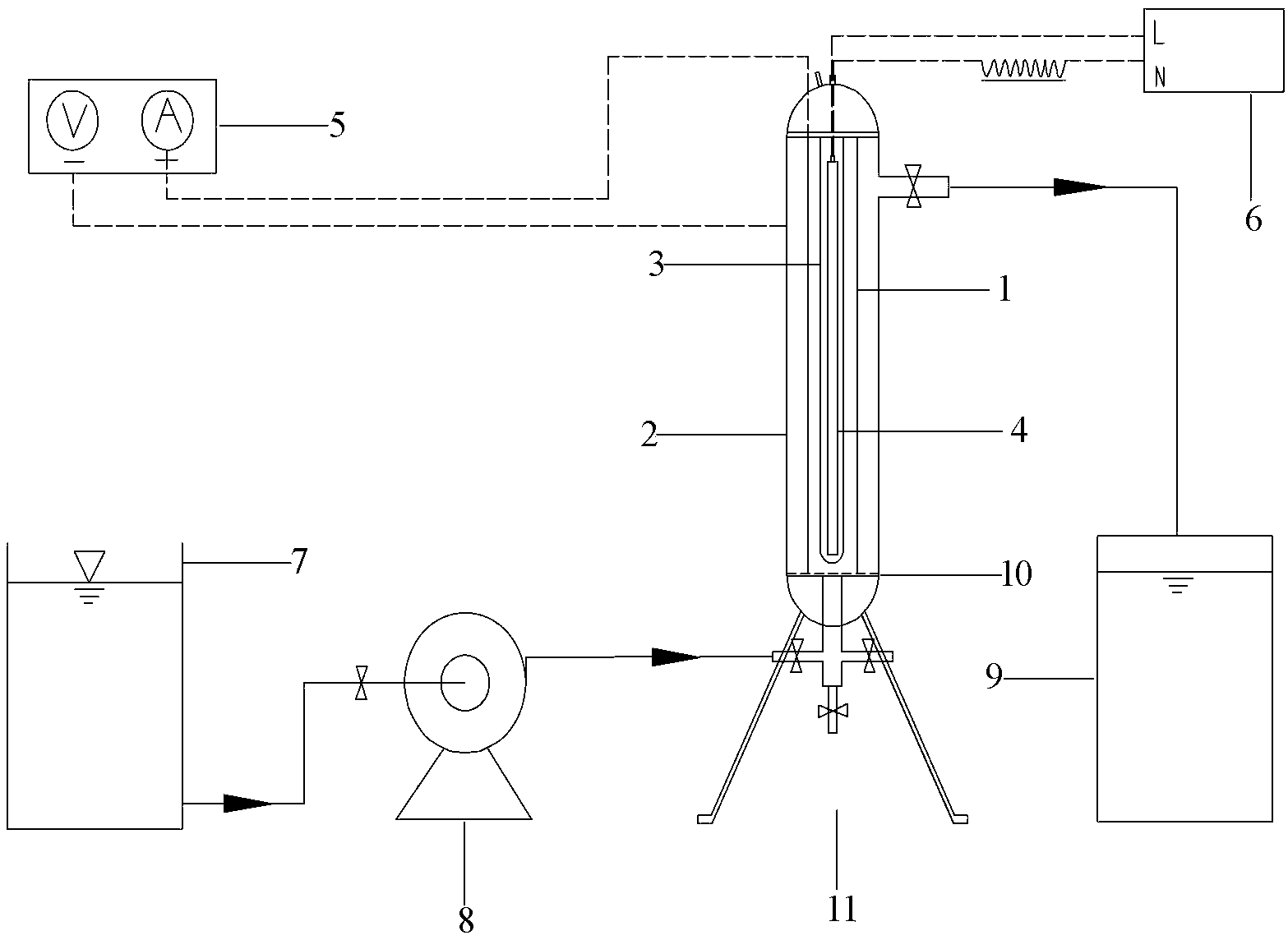

Photoelectrocatalytic method for treating heavy metal complex waste water and recovering heavy metal therefrom

ActiveCN104129830AWater/sewage treatment by irradiationWater/sewage treatment by electrochemical methodsUltraviolet lightsMaterials science

The invention provides a photoelectrocatalytic method for treating heavy metal complex waste water and recovering heavy metal therefrom, and particularly the method includes following steps: irradiating a surface of a TiO2 thin film on an anode in a photoelectro-reactor, in which the waste water is accommodated, through an ultraviolet light with a wavelength being less than 387 nm to generate photo-produced cavities and hydroxyl radicals which are used as a strong oxidant, wherein the strong oxidant enables a heavy metal complex to be degraded; and meanwhile reducing and recovering free metal ions on a cathode through electro-deposition. The photoelectro-reactor comprises an ultraviolet lamp emitting the ultraviolet light, the anode which is a TiO2 thin film electrode with titanium being a substrate, and the cathode, wherein the anode and the cathode are respectively connected to a positive pole and a negative pole of a DC power supply.

Owner:RES CENT FOR ECO ENVIRONMENTAL SCI THE CHINESE ACAD OF SCI

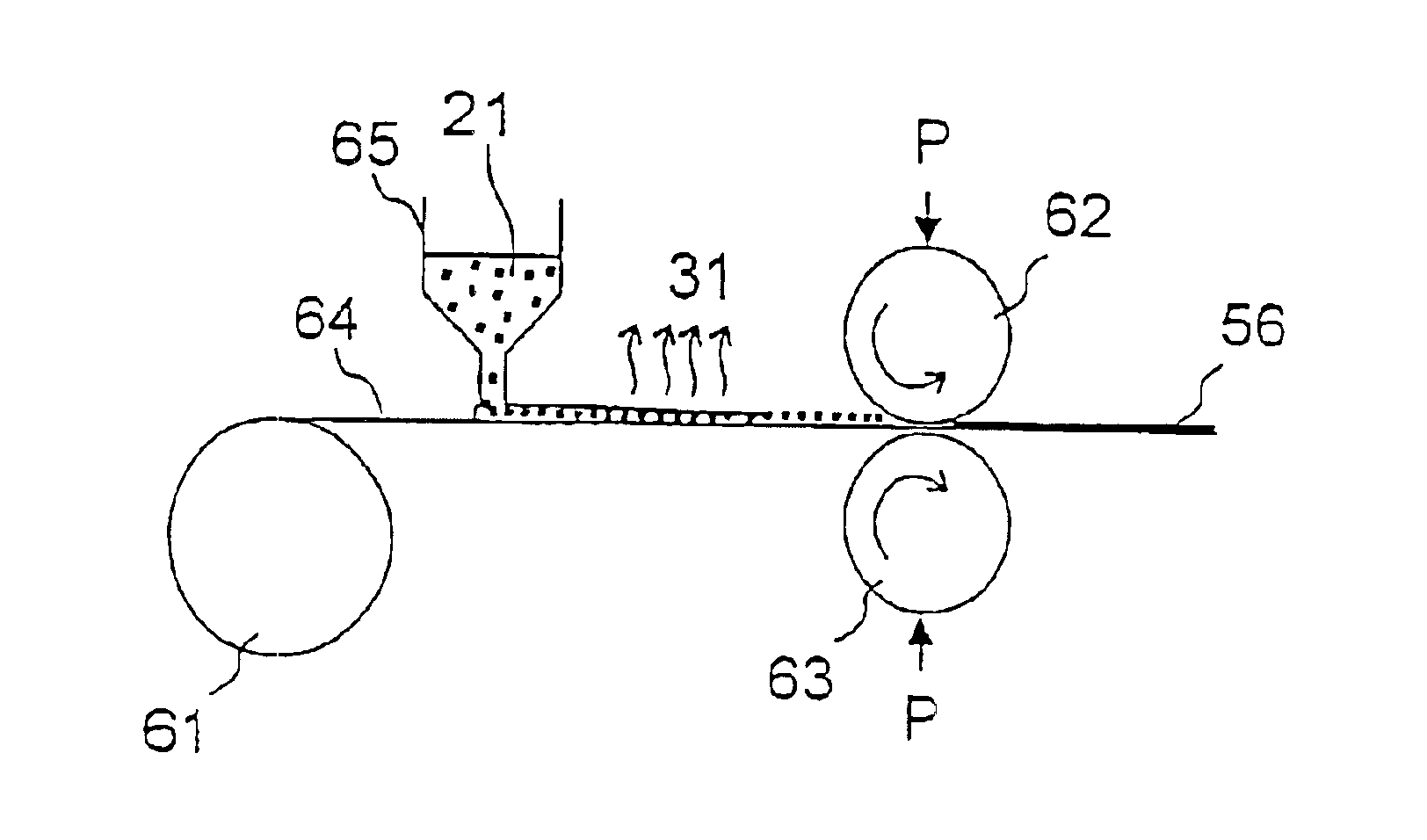

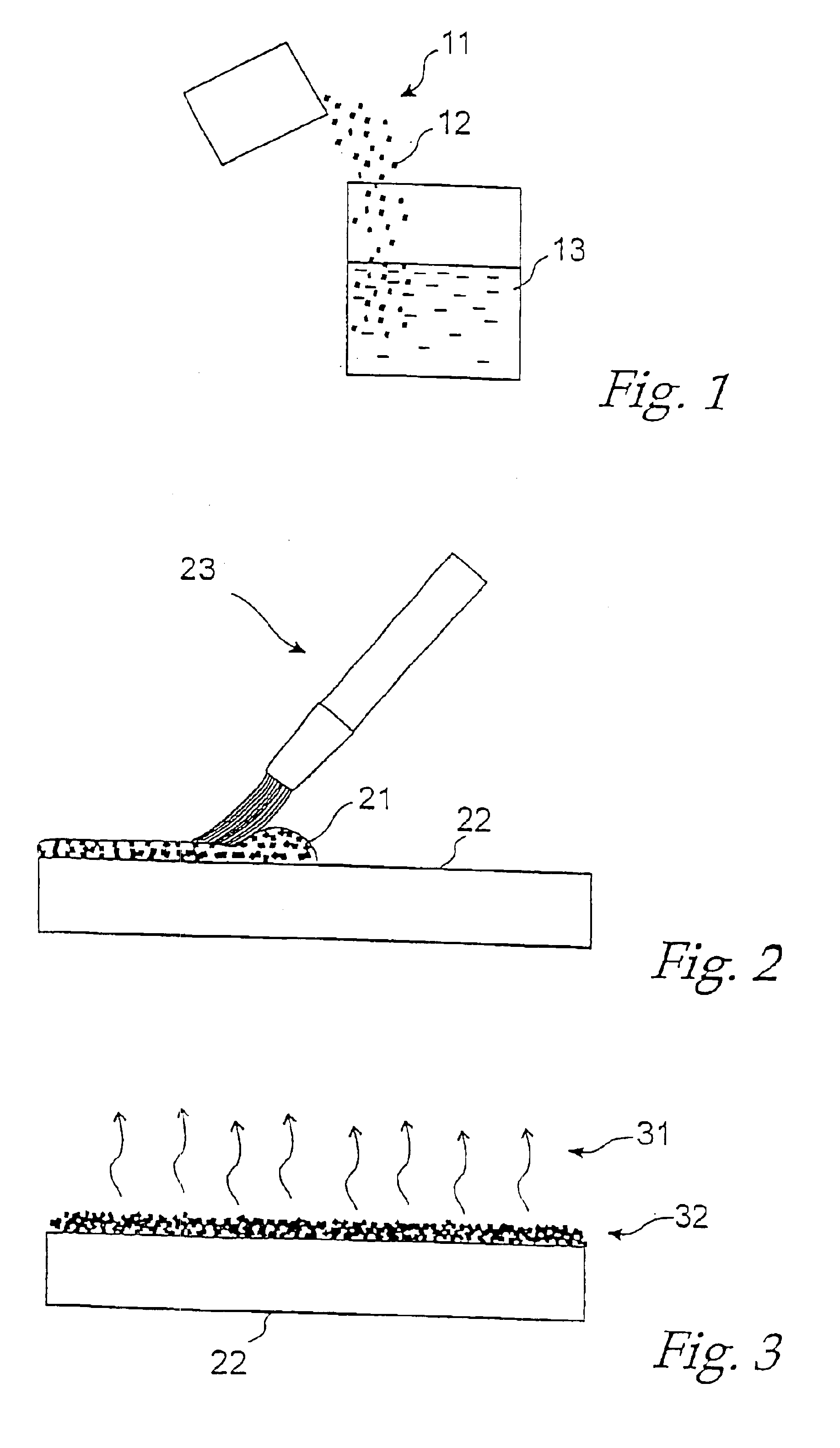

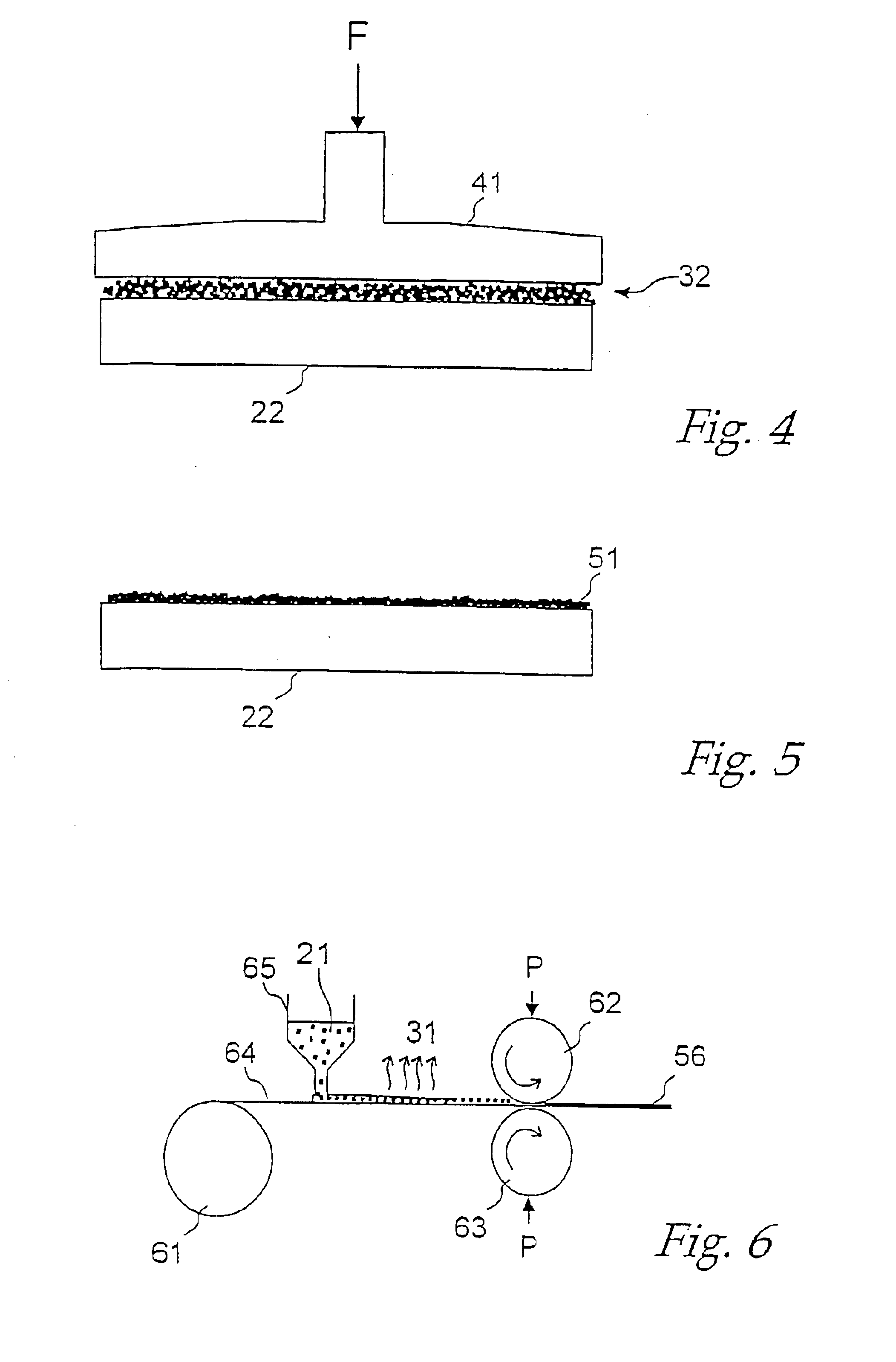

Method for manufacturing nanostructured thin film electrodes

InactiveUS6881604B2Short processing timeLight-sensitive devicesCell electrodesEvaporationSuspending Agents

A method for a binder-free manufacturing a nanostructured porous film, e.g. for use in solar cells, includes the steps of preparing a suspension of semi-conducting nanometer-sized particles in a volatile suspending agent (21), depositing the particle suspension on a conducting substrate, removing the suspending agent by evaporation (31), thereby leaving a particle layer on said substrate and compressing (P) the deposited particle layer for mechanical and electrical interconnection.

Owner:FORSKARPATENT I UPPSALA

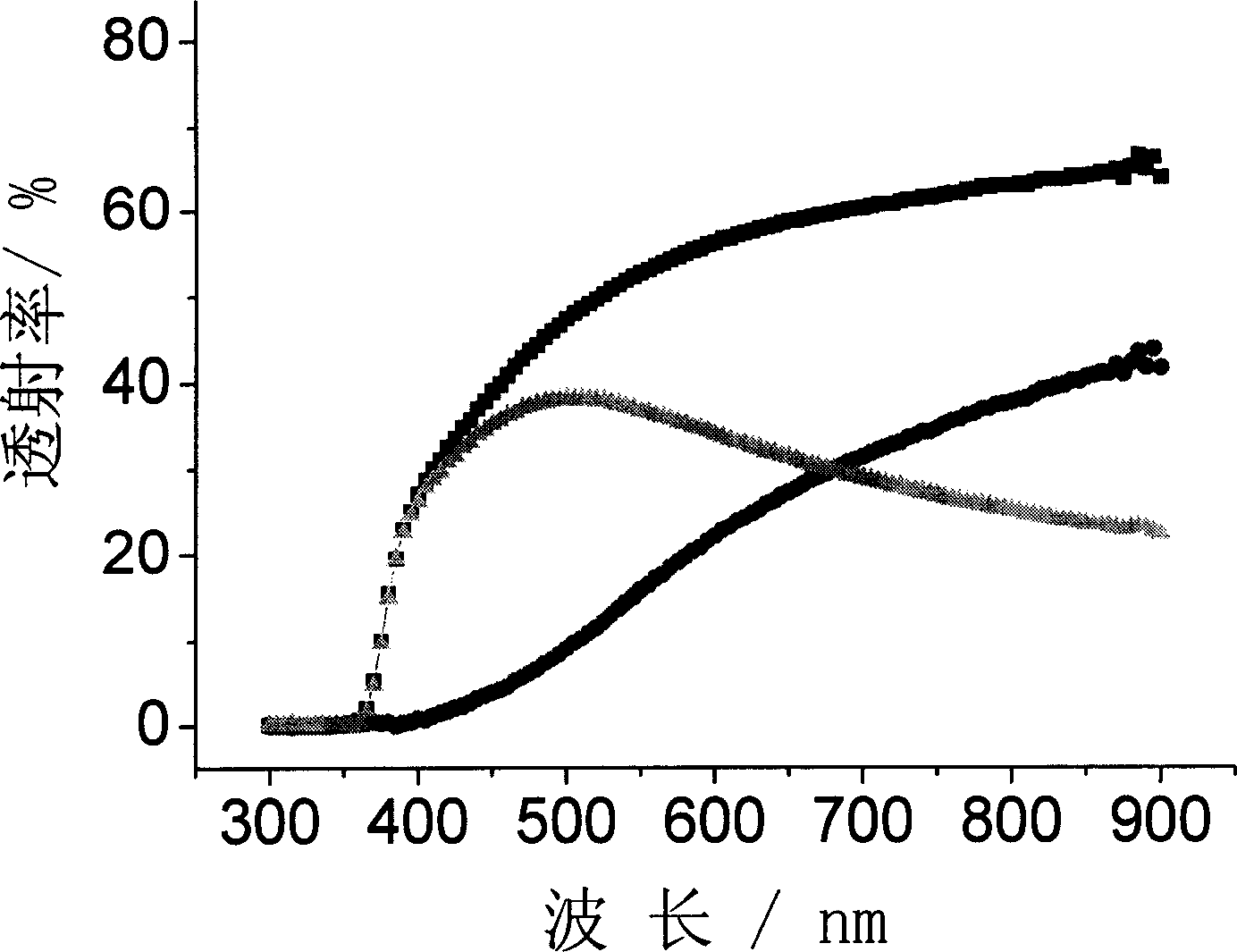

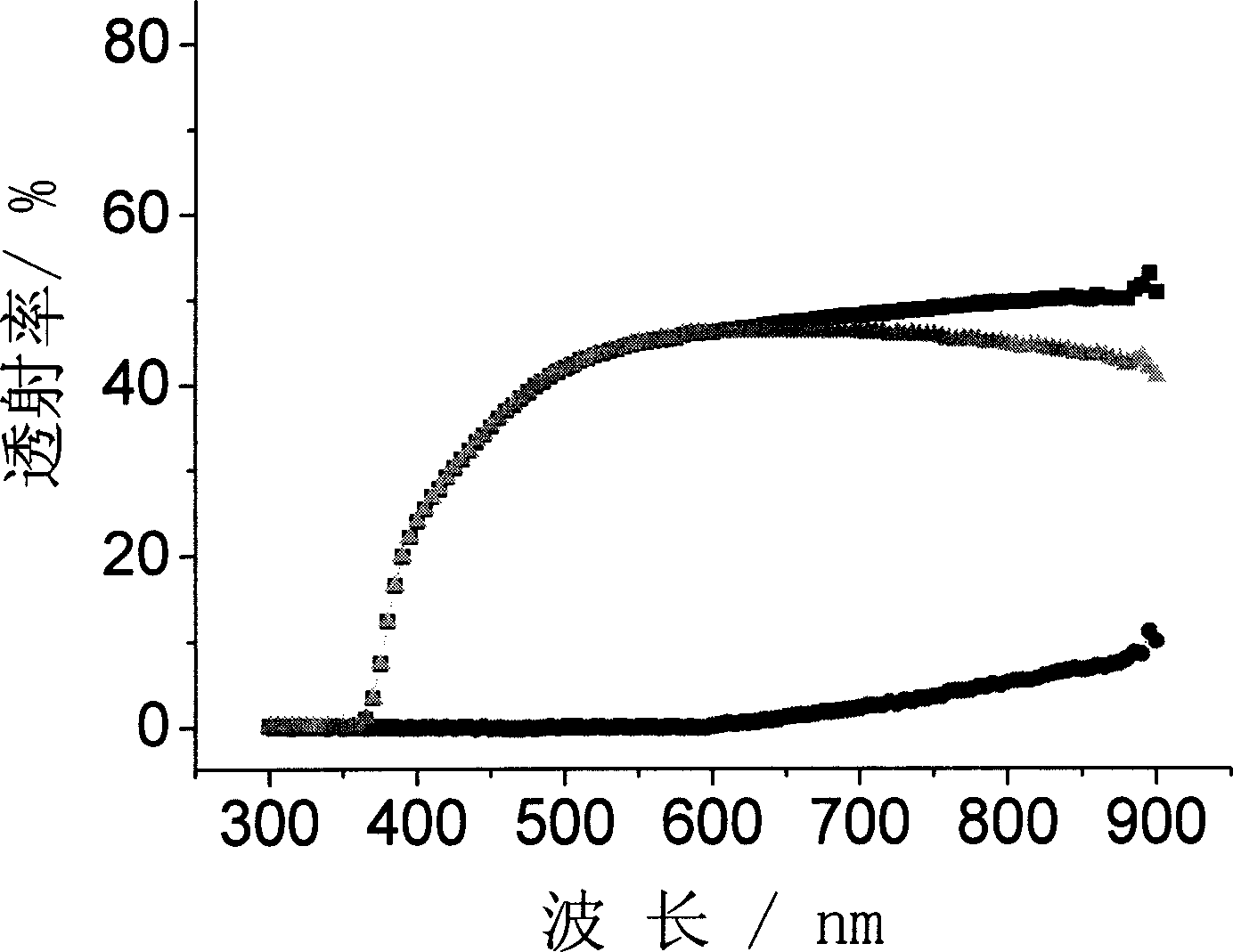

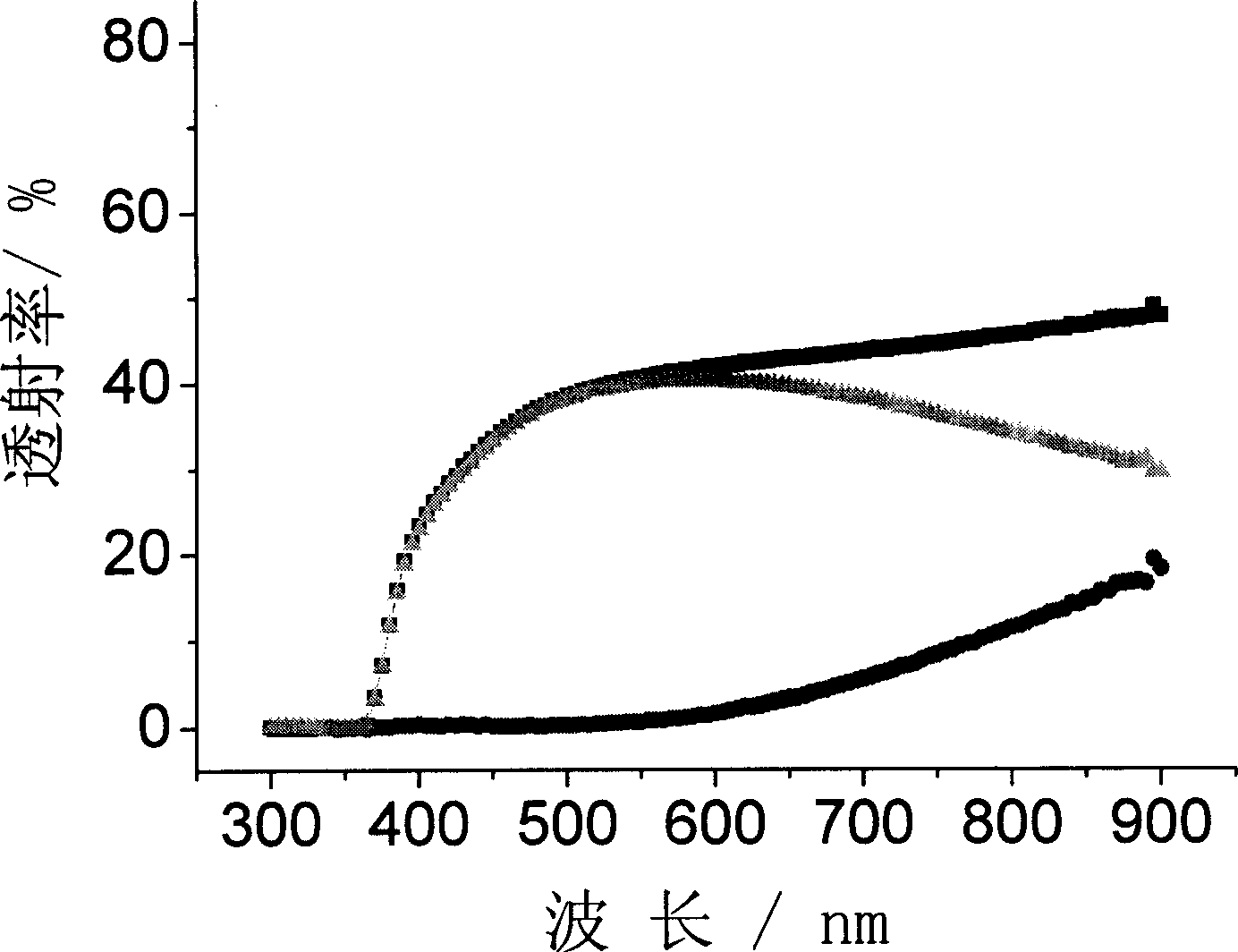

Titanium dioxide crystallized light absorption enhancement thin film electrode and its preparation method

ActiveCN1909261AHigh light transmittanceImprove flatnessLight-sensitive devicesFinal product manufactureThin film electrodeOptoelectronics

The invention relates to a Titania crystal adsorption enhancement film electrode and relative production, wherein said film electrode is formed by the conductive substrate and the composite layer formed by the first layer of dense TiO2 film and the second layer of large-hole film layer; the first dense TiO2 film is formed by the titania particles whose diameter is 2-5nm; the second layer is formed by the titania particle whose diameter is 5-60nm and the ball air hole whose diameter is 80-1500nm. Said Titania dense film can effectively baffle the electron combination between the electrolyte and the conductive substrate; the large-hole emission film has hundreds of nanometer air large holes on the film material, with high light diffuse property.

Owner:TSINGHUA UNIV

Molybdenum disulfide nanosheet/nanocellulose/carbon nanotube/graphene composite lithium battery thin film negative electrode material and preparation method therefor

InactiveCN105633344AAvoid influenceAvoid harmMaterial nanotechnologyElectrode carriers/collectorsEcological environmentCarbon nanotube

The invention relates to a molybdenum disulfide nanosheet / nanocellulose / carbon nanotube / graphene composite lithium battery thin film negative electrode material and a preparation method therefor. The negative electrode material takes nanocellulose as the flexible substrate; the molybdenum disulfide nanosheet, the graphene nanosheet and the carbon nanotube are uniformly mixed and embedded in a network of the nanocellulose to form a flexible self-supporting thin film electrode material with a compact network structure, wherein the composition and the percentage of the thin film negative electrode material are as follows: 60-80wt% of molybdenum disulfide nanosheet, 10-30wt% of nanocellulose, 5-20wt% of carbon nanotube and 5-20% of graphene. By adoption of the method, the renewable energy resource-cellulose can be utilized reasonably and effectively, so that a metal aluminum foil or a copper foil is not required to be used as a current collector; a fluorine-containing polymer is not required to be used as a binder; therefore, influences and hazards to the ecological environment can be greatly avoided; the electrode obtained by the method can be directly filter-pressed, assembled and molded without a tabletting process, so that the preparation method is high in efficiency; and in addition, the thin film negative electrode material is high in mechanical flexibility and continuous bending stability.

Owner:SHANGHAI UNIV

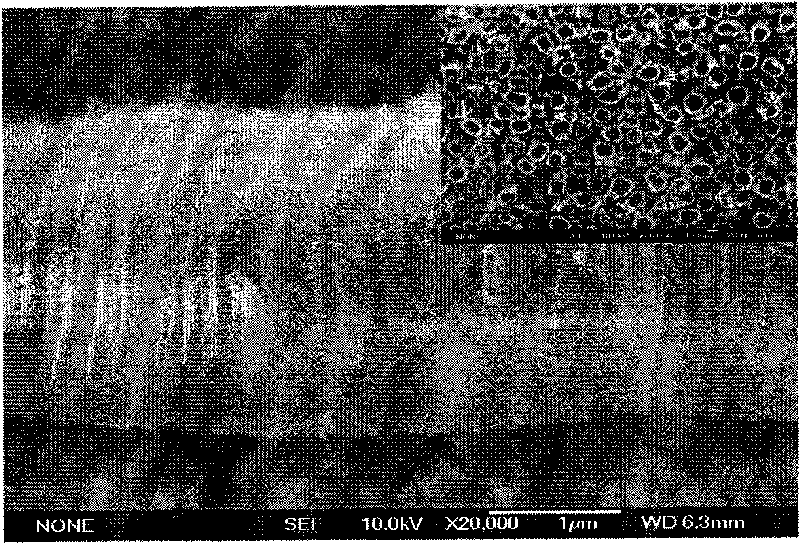

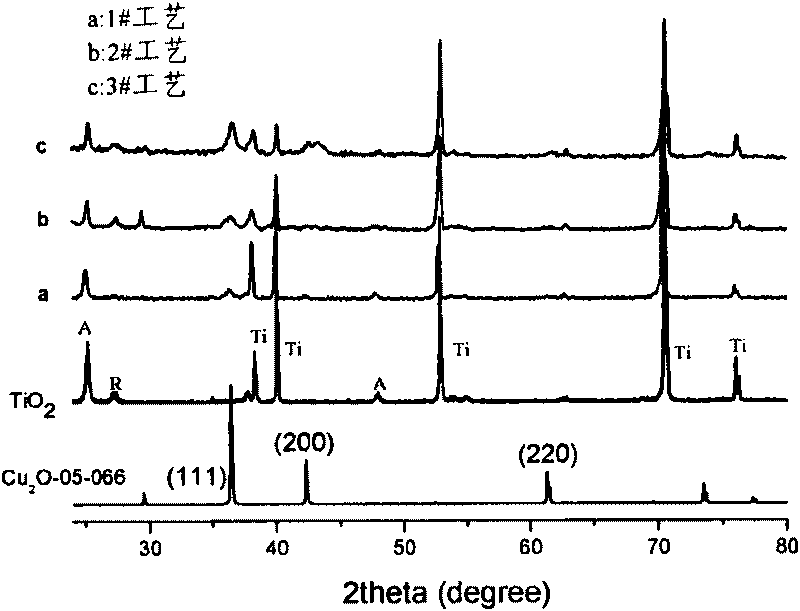

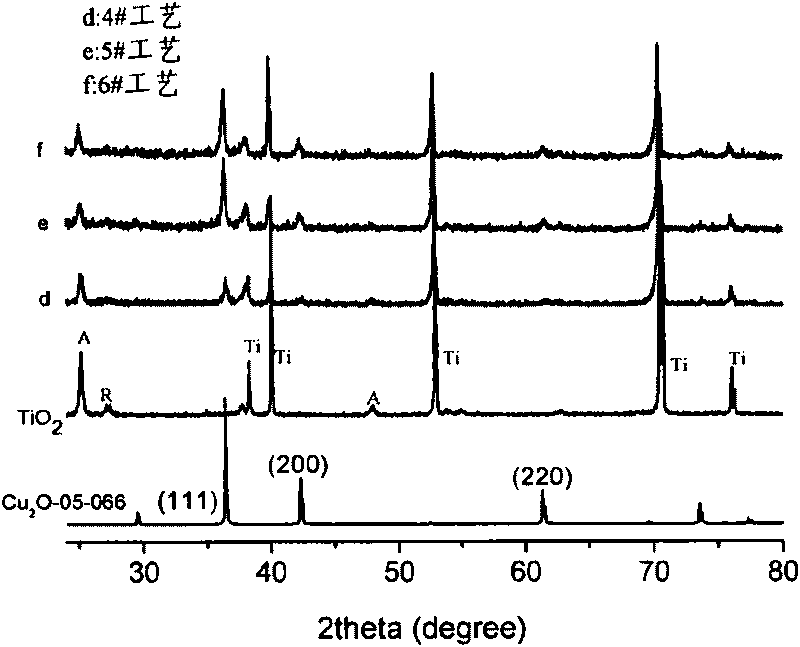

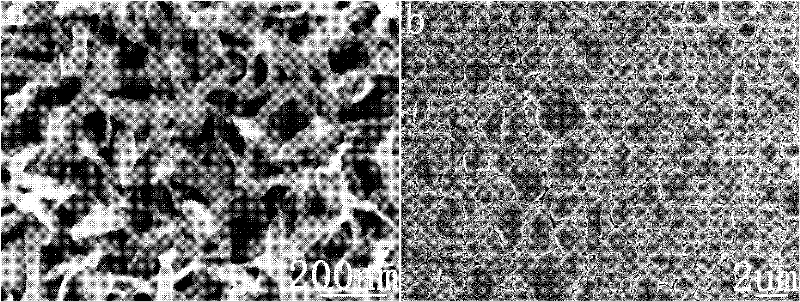

Method for preparing cuprous oxide/titanium dioxide core-shell structure array film through AC electro-deposition method

InactiveCN101717980AAvoid breakingSimple processElectrolytic inorganic material coatingSurface reaction electrolytic coatingThin film electrodeTio2 nanotube

The invention discloses a method for preparing cuprous oxide / titanium dioxide core-shell structure array film through AC electro-deposition method. The method comprises the following steps: (1) adopting anode oxidation method to prepare TiO2 nanotube array film; (2) adopting AC electro-deposition method to prepare one-dimensional Cu2O / TiO2 core-shell structure array film, dissolving CuSO4 in a mixed solution of lactic acid and water to prepare Cu2O electro-deposition solution, using TiO2 / Ti as the working electrode and graphite as the counter electrode to deposit Cu2O under the alternating voltage, washing the electrode surface of the Cu2O / TiO2 nano-array film with deionized water, and drying to prepare the one-dimensional Cu2O / TiO2 core-shell structure array film. The method of the invention has easy technology, is easy to control, is not easy to destroy the TiO2 nanotube array structure, and is possible to realize mass production with low cost.

Owner:TIANJIN UNIV

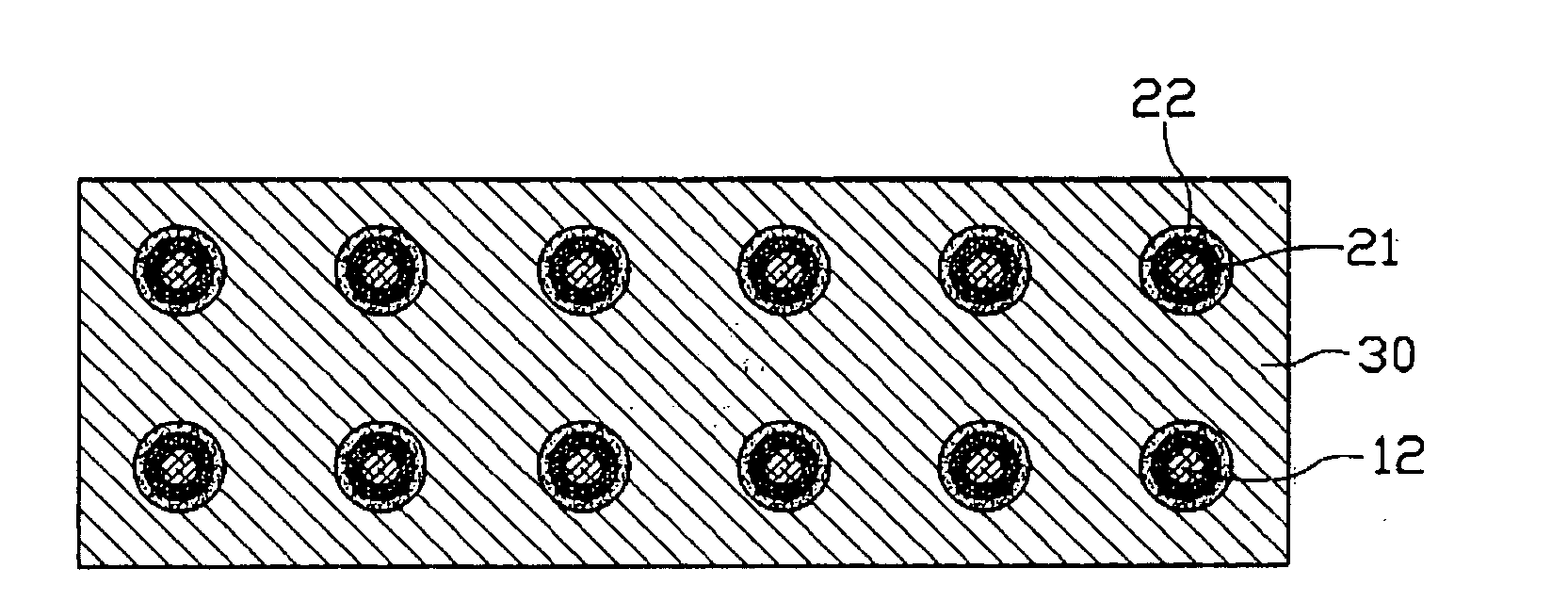

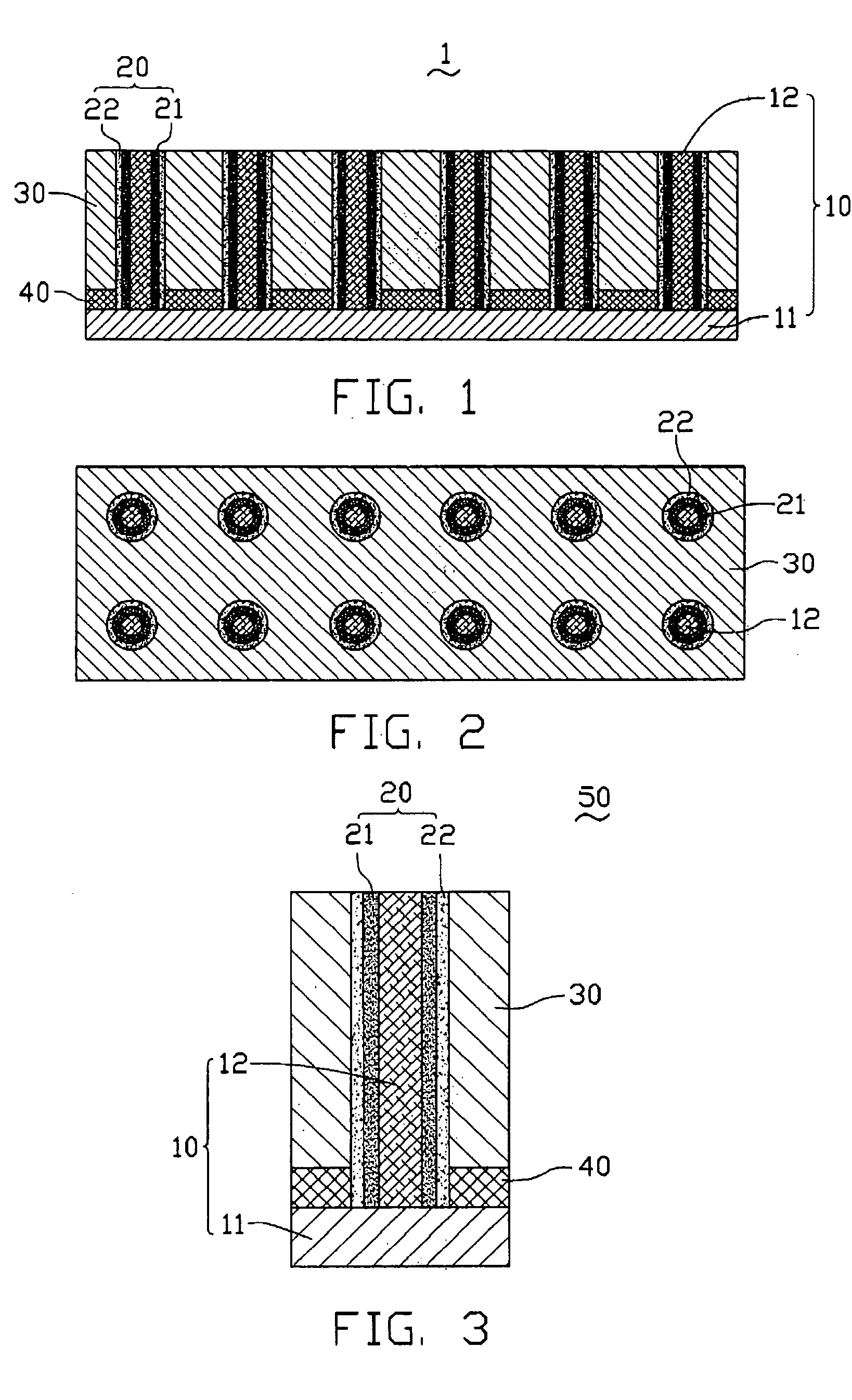

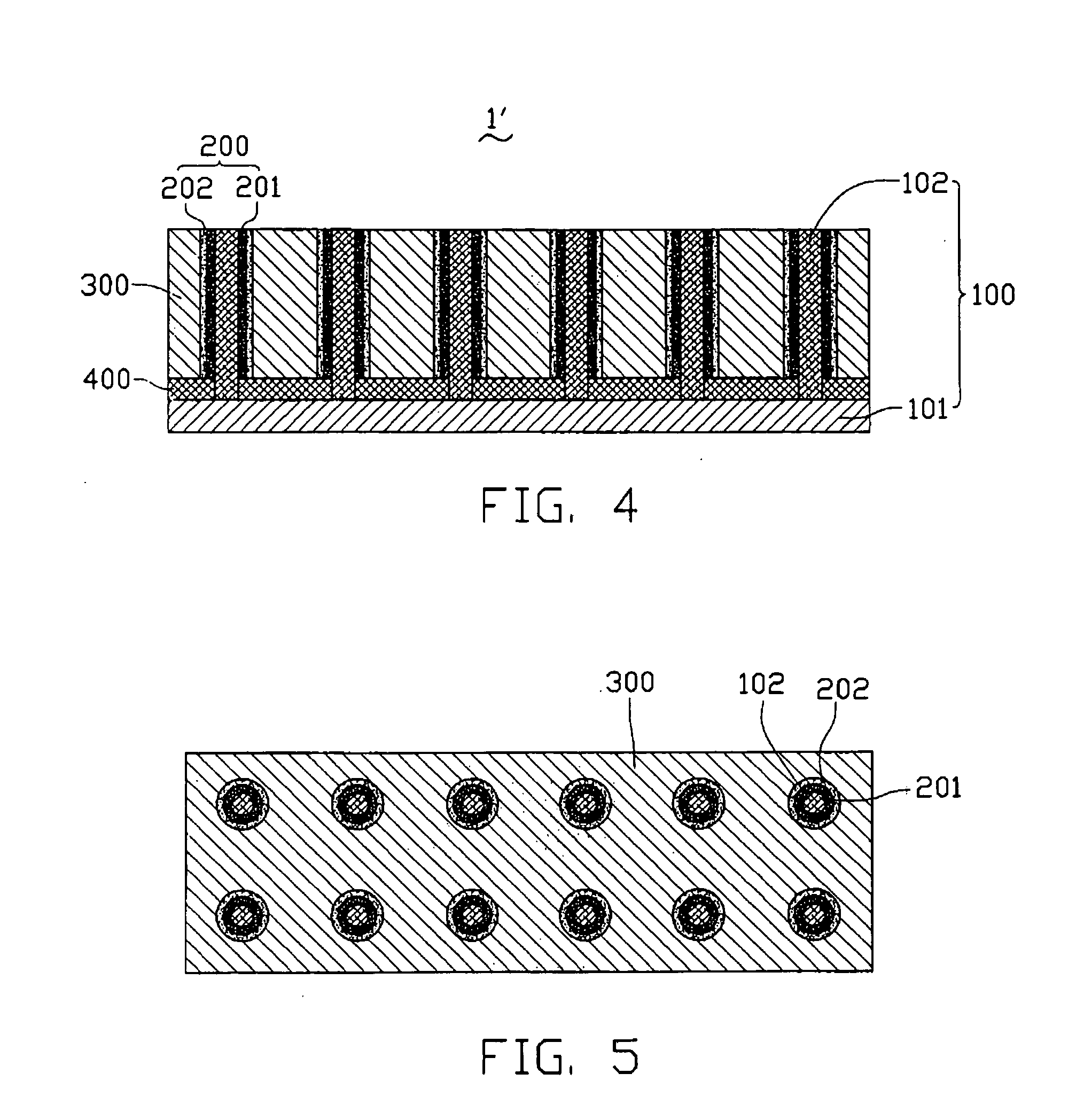

Superlattice nano-device and method for making same

ActiveUS20070057248A1NanoinformaticsSemiconductor/solid-state device manufacturingThin film electrodeNano-device

A nanodevice (1) for a desired function includes a substrate (11), a one-dimensional nanostructure (12), a functional layer (20) having a desired function, a conductive thin film electrode (30), and an insulating layer (40). The one-dimensional nanostructure is operatively extends from the substrate. The functional layer is surrounds at least a portion of the one-dimensional nanostructure. The conducting thin film electrode is surrounds / encompasses the functional layer. The insulating layer is positioned between the substrate and the conductive thin film electrode, thereby electrically insulating the one from the other. Further, the nanodevice can incorporate one or more functional units 50, each unit including a one-dimensional nanostructure and a respective functional layer. The units may or may not share the same conductive thin film electrode and / or insulating layer.

Owner:TSINGHUA UNIV +1

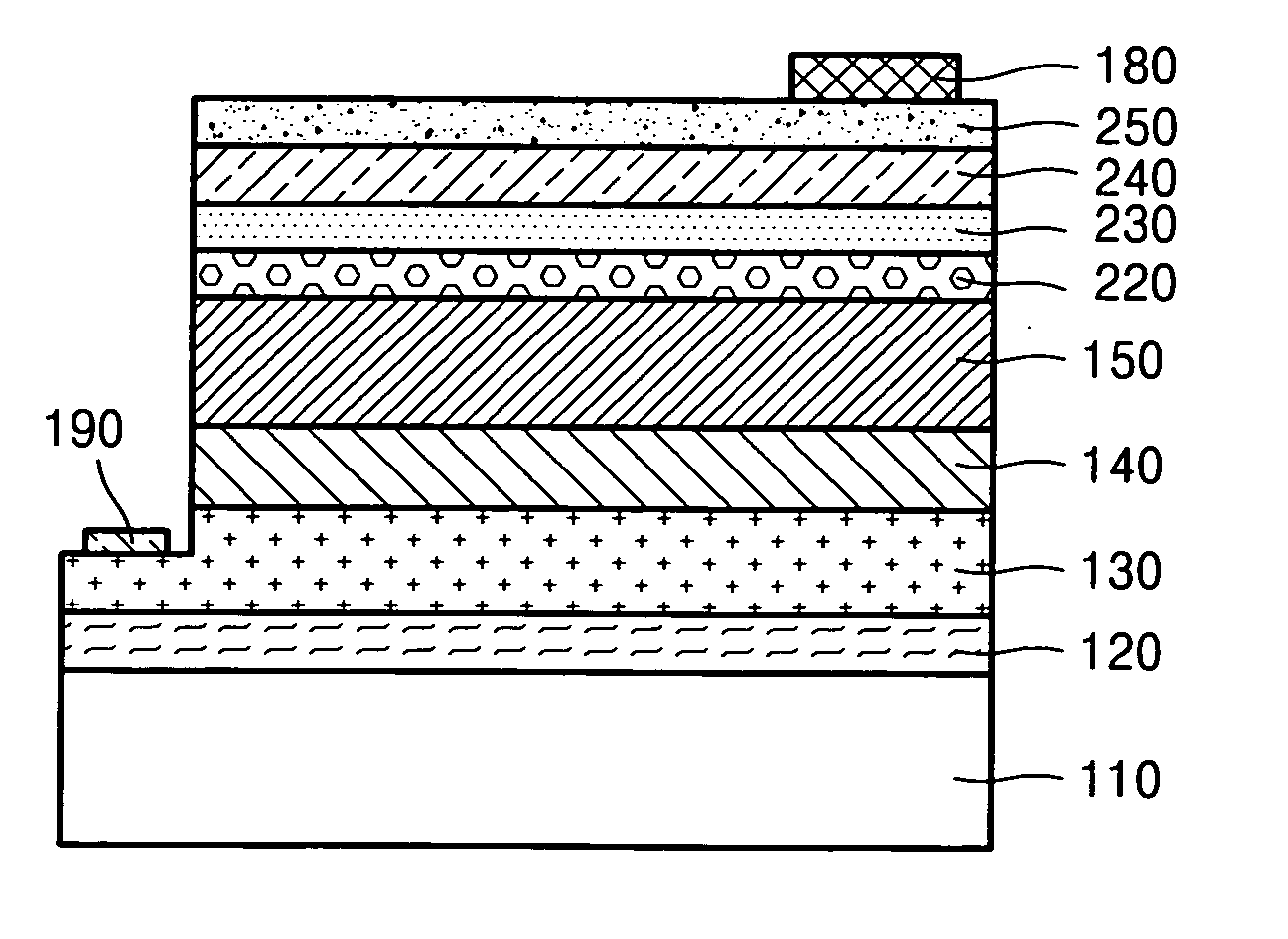

Nitride-based light emitting device and method of manufacturing the same

ActiveUS20050082557A1High light transmittanceLaser detailsSemiconductor/solid-state device detailsThin film electrodeOhmic contact

Provided are a nitride-based light emitting device using a p-type conductive transparent thin film electrode layer and a method of manufacturing the same. The nitride-based light emitting device includes a substrate, and an n-cladding layer, an active layer, a p-cladding layer and an ohmic contact layer sequentially formed on the substrate. The ohmic contact layer is made from a p-type conductive transparent oxide thin film. The nitride-based light emitting device and method of manufacturing the same provide excellent I-V characteristics by improving characteristics of an ohmic contact to a p-cladding layer while enhancing light emission efficiency of the device due to high light transmittance exhibited by a transparent electrode.

Owner:SAMSUNG ELECTRONICS CO LTD +1

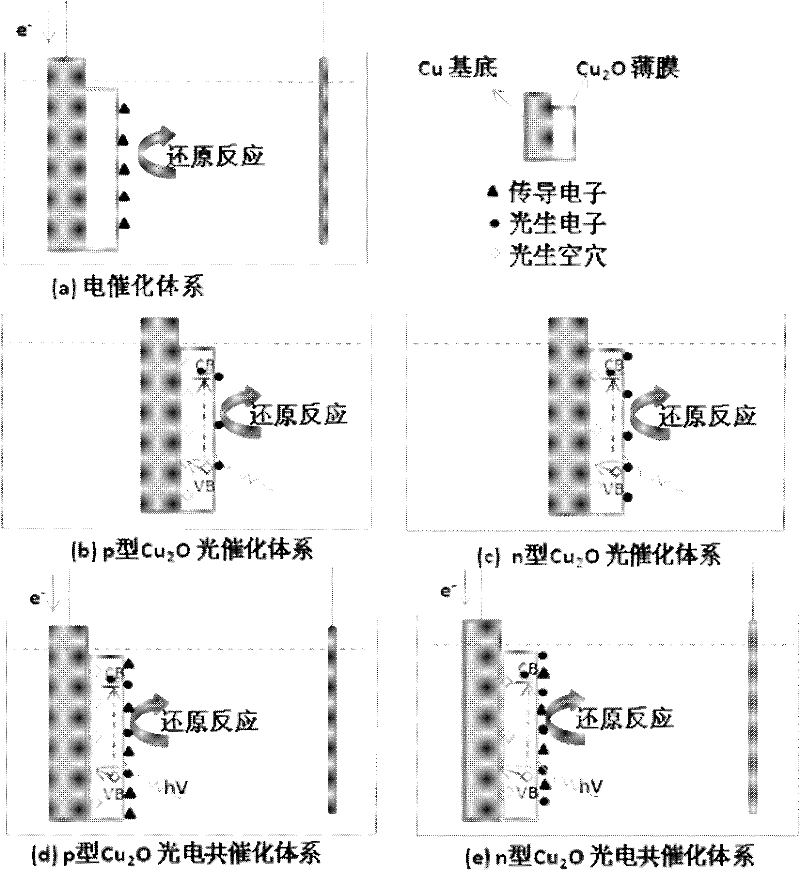

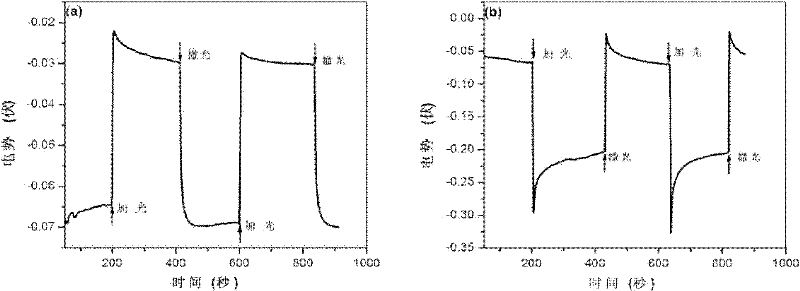

Cu/Cu2O film material for reducing CO2 into organic fuel under catalysis

InactiveCN102284293AGood effectHydrocarbon from carbon oxidesMetal/metal-oxides/metal-hydroxide catalystsThin film electrodeComposite electrode

The invention relates to a Cu / Cu2O film electrode for the photoelectrocatalytic reduction of CO2, which comprises p-type and n-type Cu2O films prepared on a Cu substrate by an electrochemical method and a chemical boiling method. Two Cu / Cu2O electrodes are used for the photocatalytic reduction, electrocatalytic reduction and photoelectrocatalytic reduction of the CO2 respectively; the two electrodes have catalytic activity on the CO2 reduction in three systems, and the selectivity of the electrodes on a product C2H4 is enhanced due to the existence of Cu2O; the two electrodes have the highestCO2 reduction efficiency in a photoelectrocatalytic system; p-type Cu2O and n-type Cu2O have low CO2 photocatalytic reduction efficiency in a photocatalytic system; the CO2 is reduced into the C2H4 through the electrocatalysis of the p-type Cu2O and the n-type Cu2O and the CO2 reduction efficiency of the p-type Cu2O is higher than that of the n-type Cu2O in an electrocatalytic system; and the yield of the C2H4 on the p-type Cu2O electrode and the yield of the C2H4 on the n-type Cu2O electrode are almost the same in the photoelectrocatalytic system and are 1.5 and 2.7 times that of the C2H4 inthe electrocatalytic system, and the CO2 reduction efficiency of the n-type Cu2O in the photoelectrocatalytic system is increased by more times. The composite electrode can be used for reducing the CO2 into the organic fuel under photoelectrocatalysis.

Owner:余颖

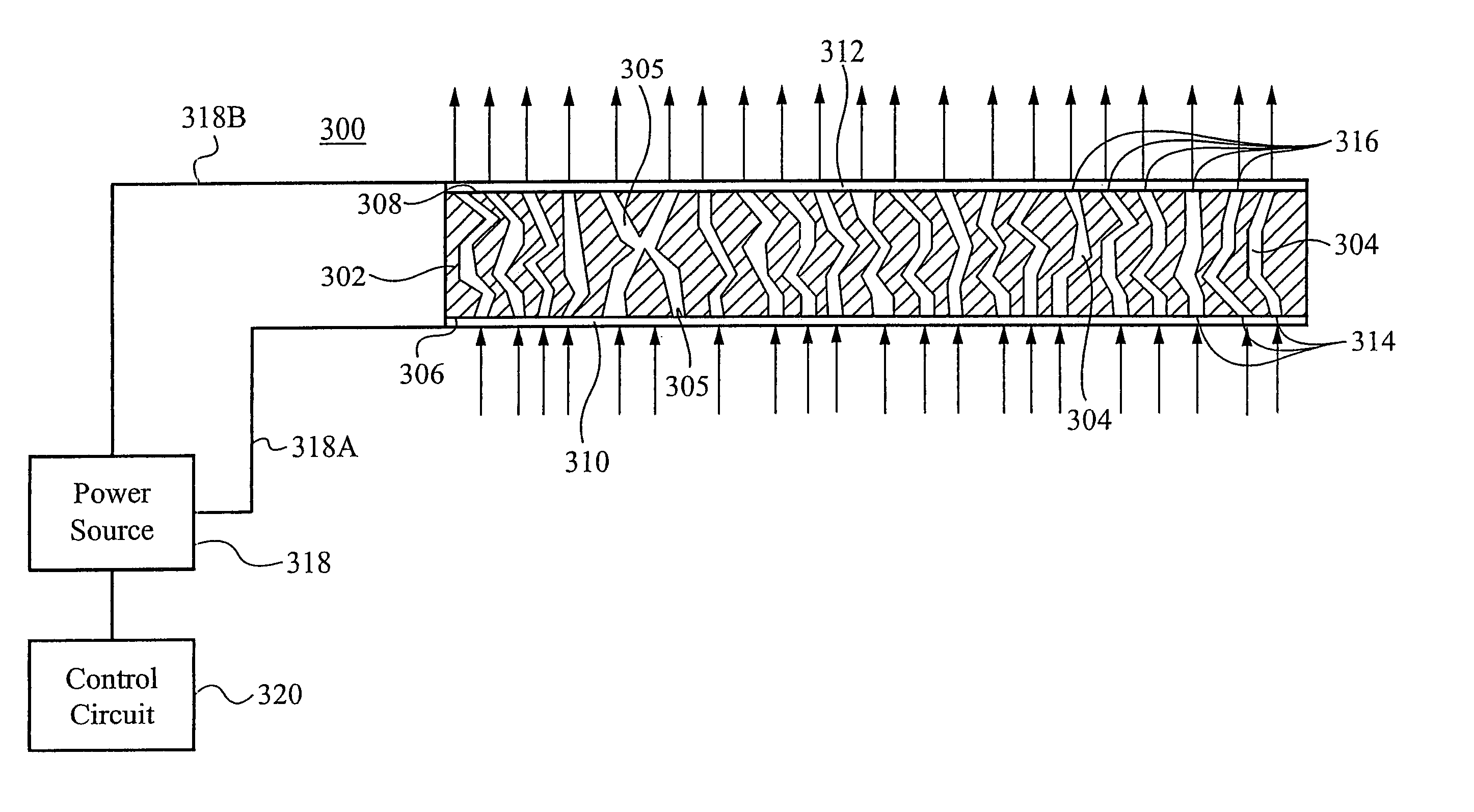

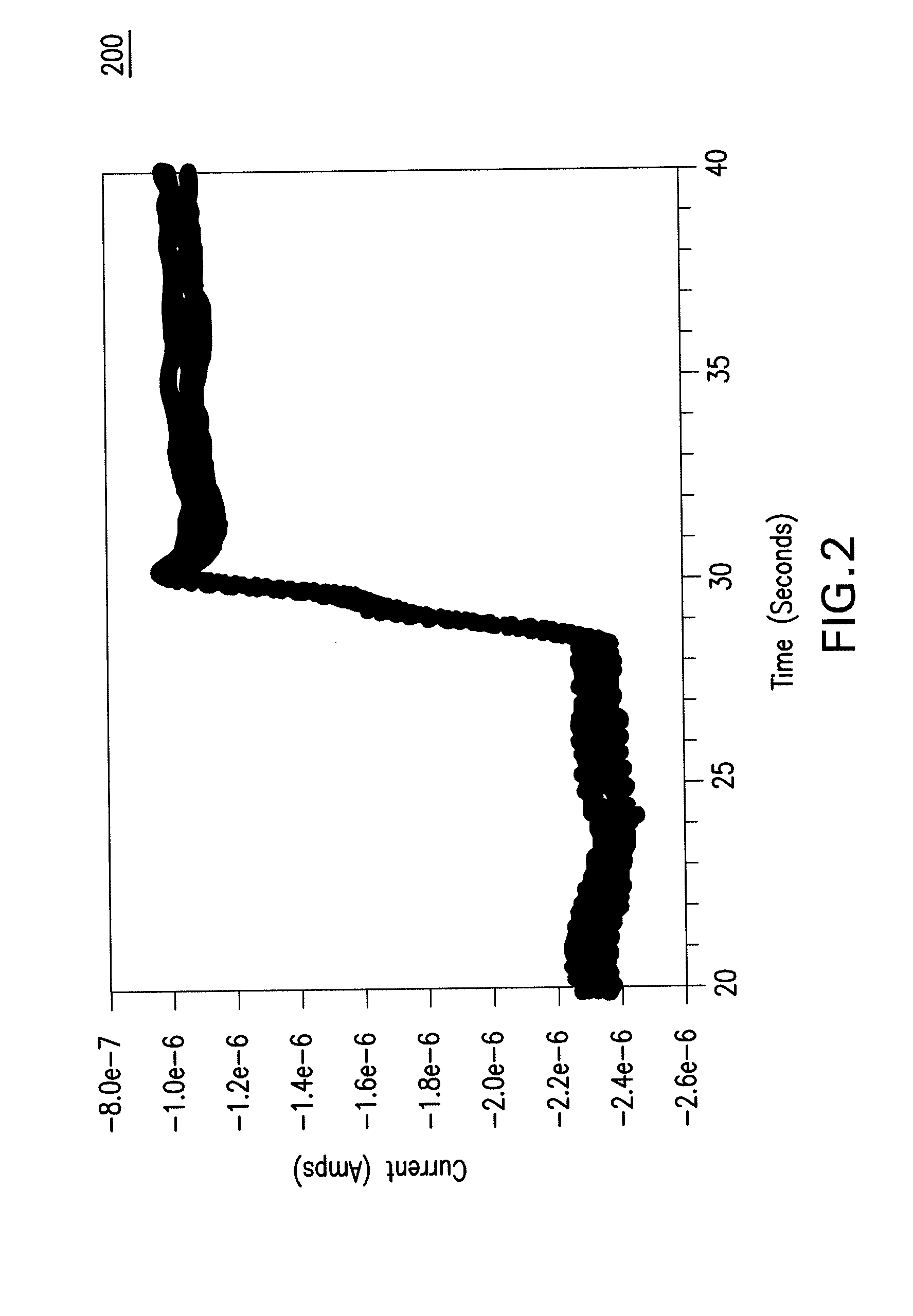

Systems And Methods For Monitoring Plating And Etching Baths

InactiveUS20080264801A1Small sizeReduce system sizeCellsWeather/light/corrosion resistanceThin film electrodeFast measurement

Methods and systems for monitoring electrolyte bath fluids are provided. The electrolyte bath fluids can be electroplating, electroless plating or etching solutions. The monitoring systems employ microfluidic devices, which have built in microfluidic channels and microfabricated thin-film electrodes. The devices are configured with fluid pumps to control the movement and mixing of test fluids through the microfluidic channels. The microfabricated thin-film electrodes are configured so that the plating or etching bath fluid composition can be characterized by electrochemical measurements. The monitoring methods and system provide faster measurement times, generate minimal waste, and occupy dramatically reduced physical space compared to conventional bath-monitor systems. The monitoring systems and method also provide low-cost system and methods for measuring or monitoring electroless plating bath rates.

Owner:THE TRUSTEES OF COLUMBIA UNIV IN THE CITY OF NEW YORK

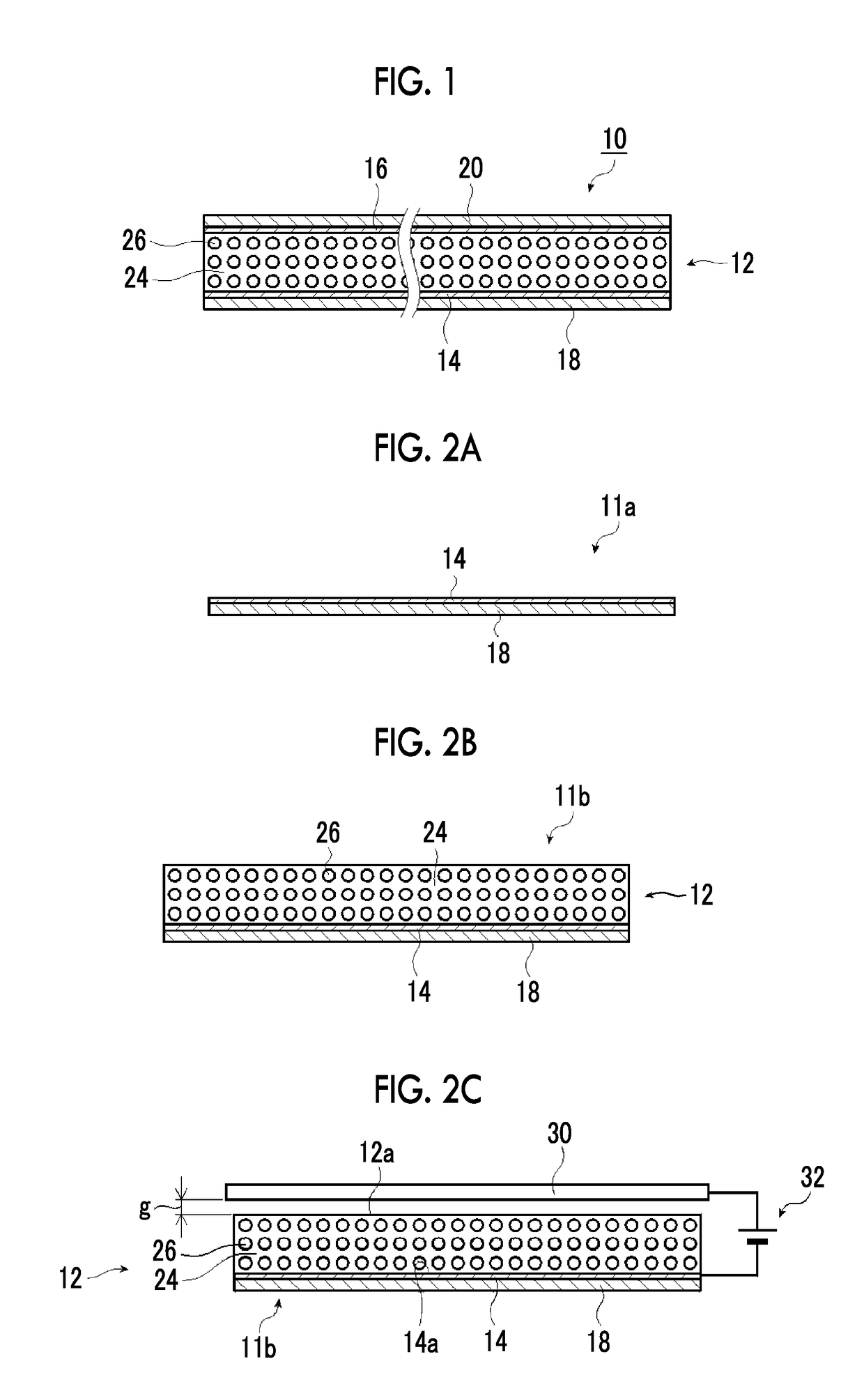

Electroacoustic transduction film and manufacturing method thereof, electroacoustic transducer, flexible display, vocal cord microphone, sensor for musical instrument

ActiveUS20180160248A1Sufficient volumeImprove conversion efficiencyPiezoelectric/electrostrictive microphonesElectrophonic musical instrumentsX-rayEngineering

Provided are an electroacoustic transduction film capable of reproducing a sound with a sufficient sound volume at a high conversion efficiency, a manufacturing method thereof, an electroacoustic transducer, a flexible display, a vocal cord microphone, and a sensor for a musical instrument. The electroacoustic transduction film includes: a polymer composite piezoelectric body in which piezoelectric body particles are dispersed in a viscoelastic matrix formed of a polymer material having viscoelasticity at a normal temperature; two thin film electrodes laminated on both surfaces of the polymer composite piezoelectric body; and two protective layers respectively laminated on the two thin film electrodes, in which an intensity ratio α1=(002) plane peak intensity / ((002) plane peak intensity+(200) plane peak intensity) between a (002) plane peak intensity and a (200) plane peak intensity derived from the piezoelectric body particles in a case where the polymer composite piezoelectric body is evaluated by an X-ray diffraction method is more than or equal to 0.6 and less than 1.

Owner:FUJIFILM CORP

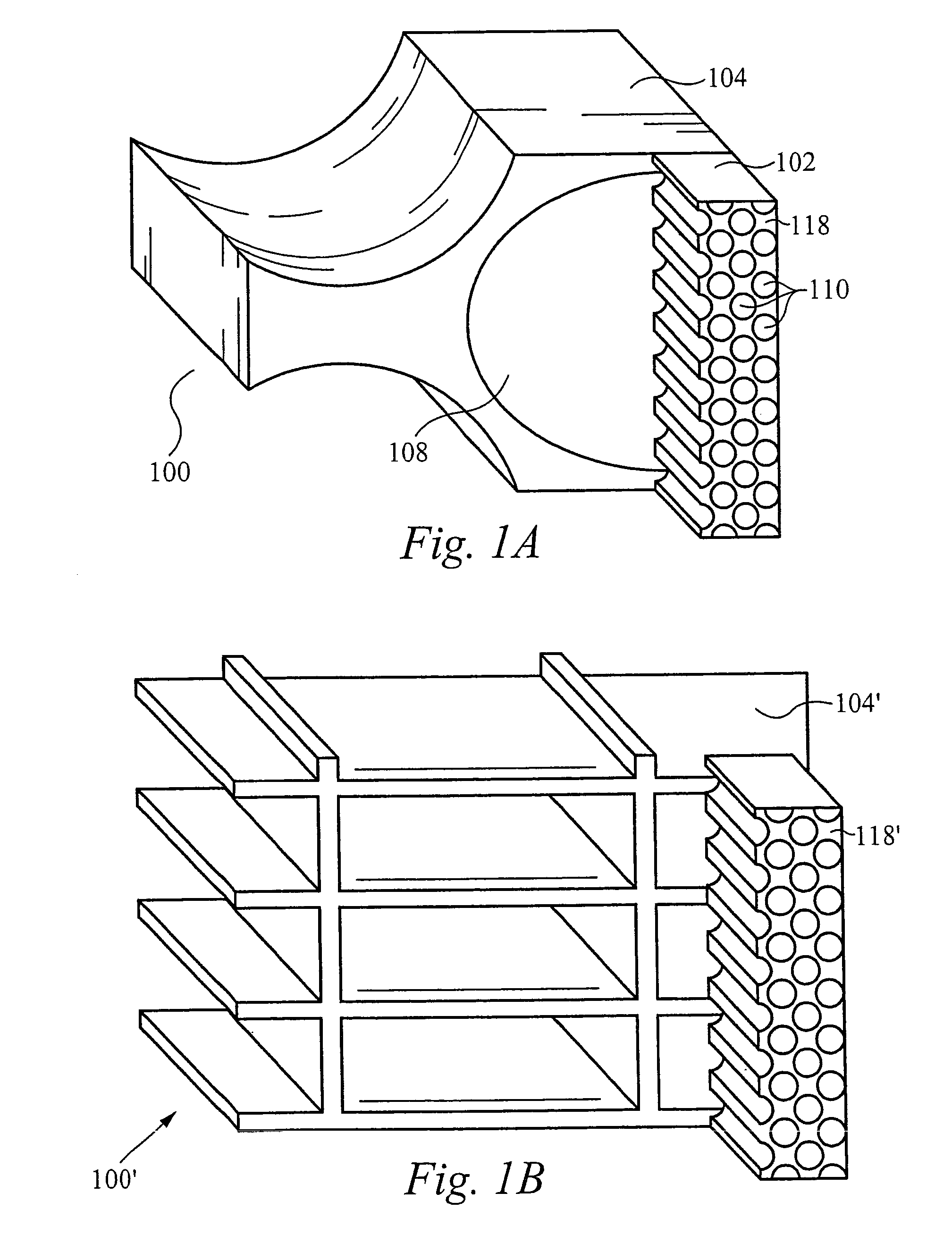

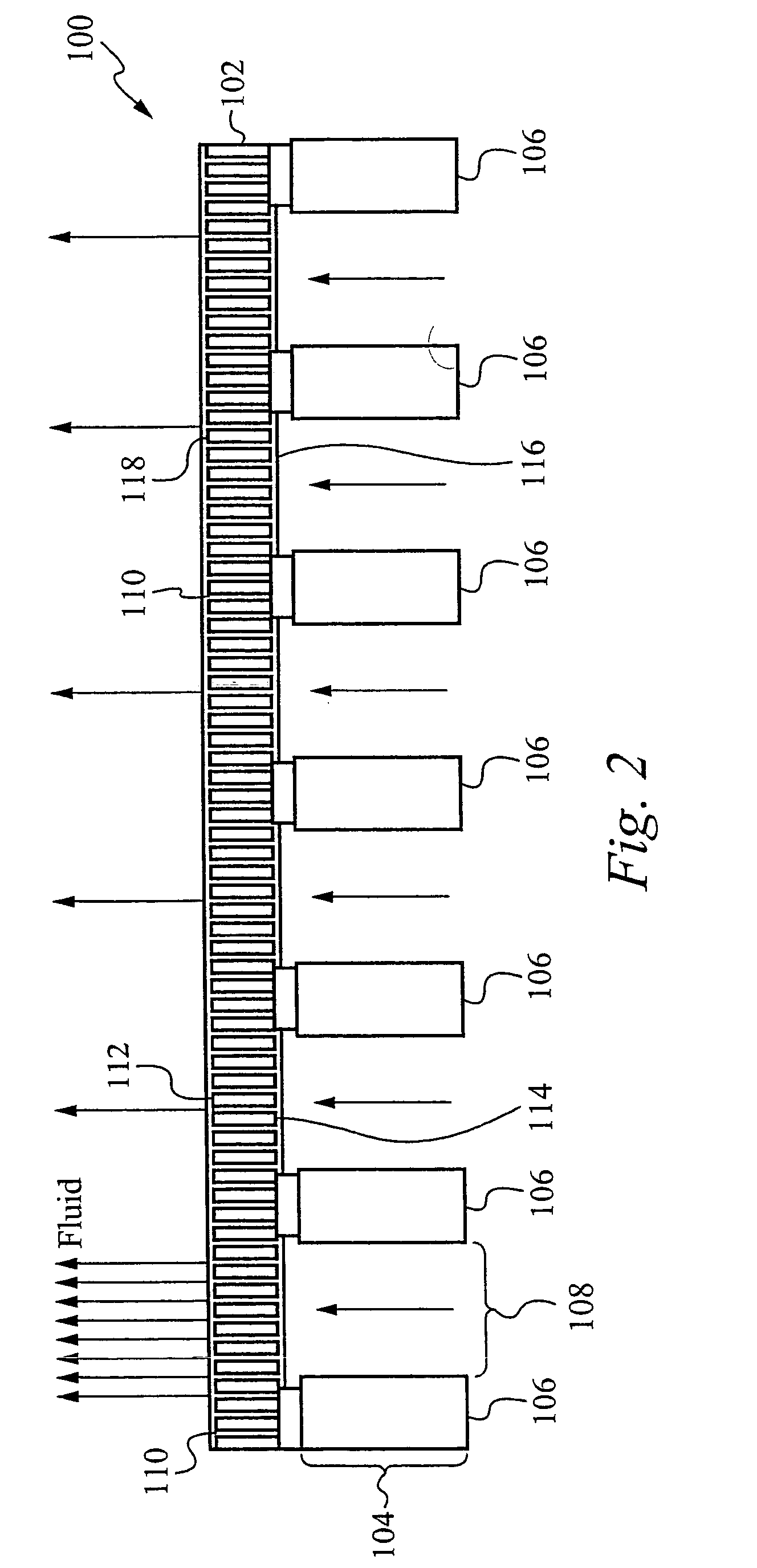

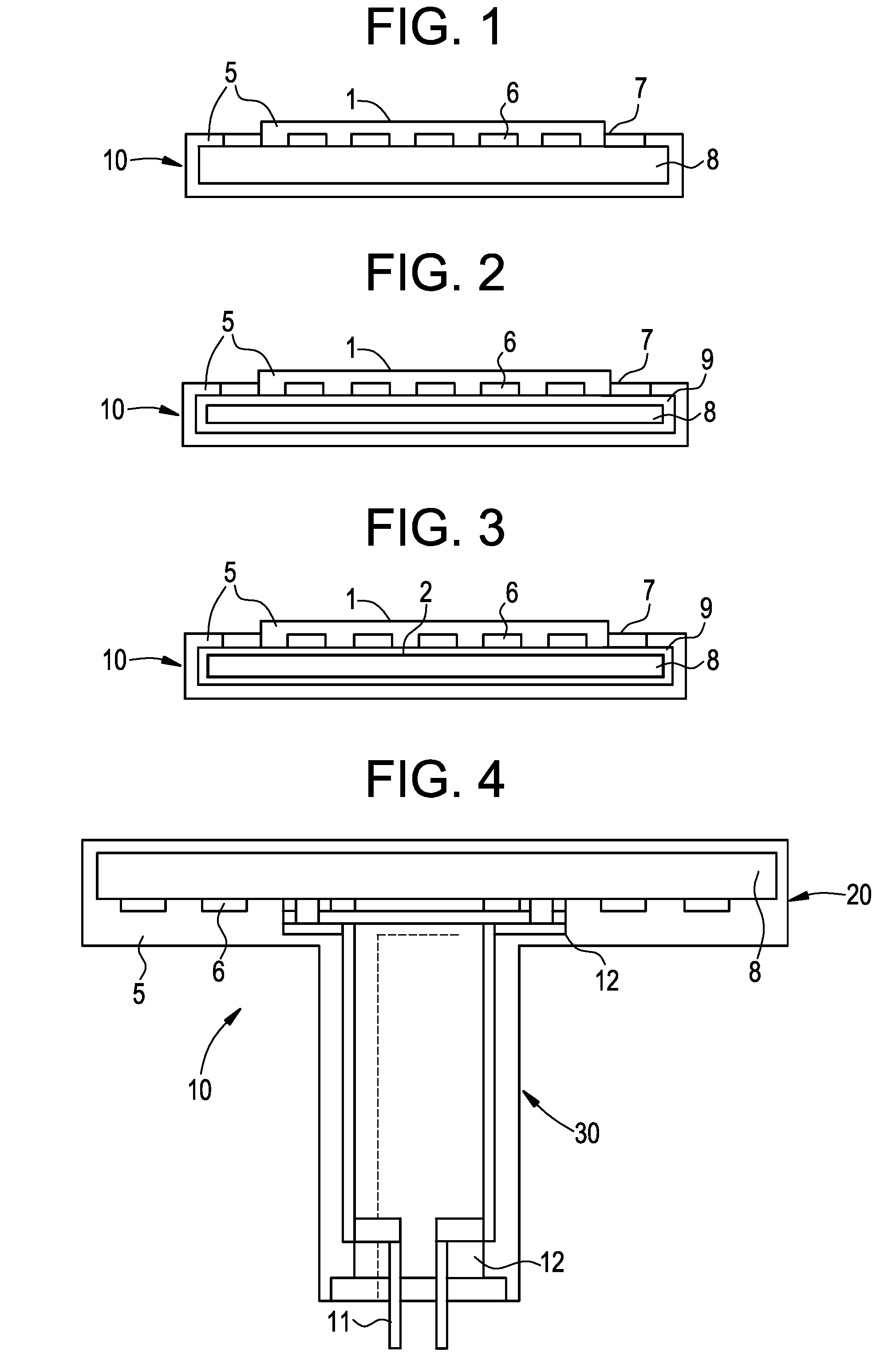

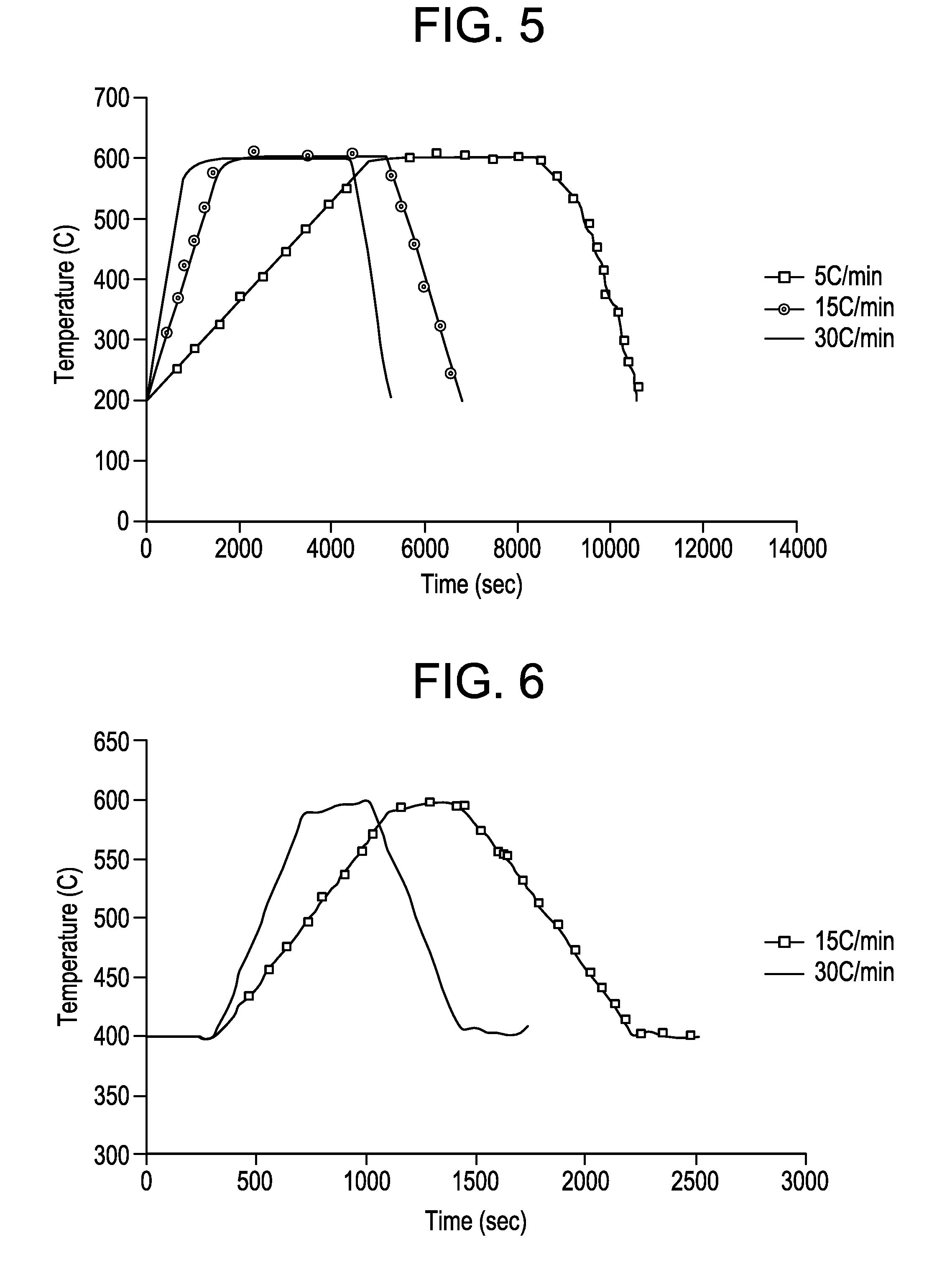

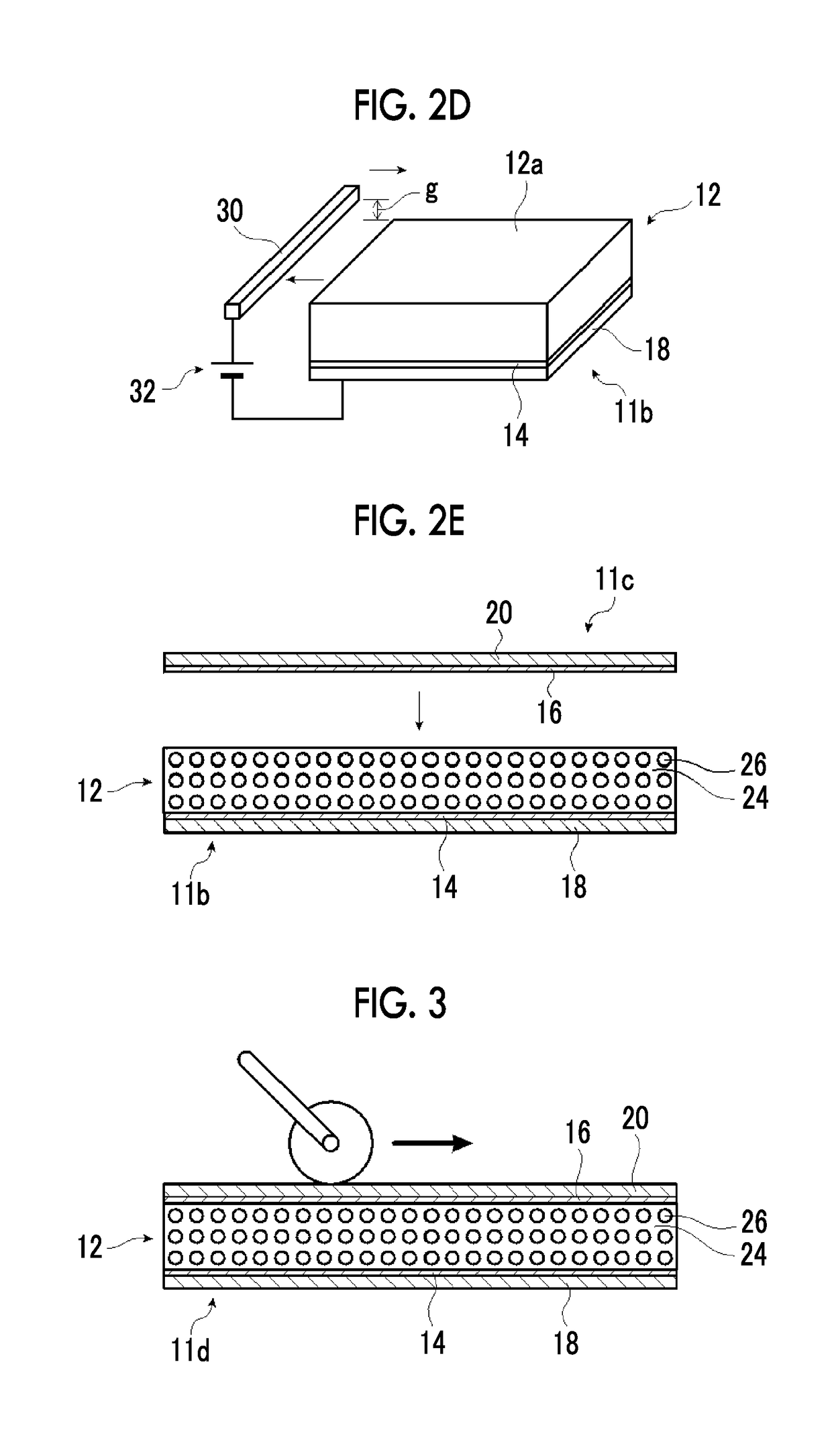

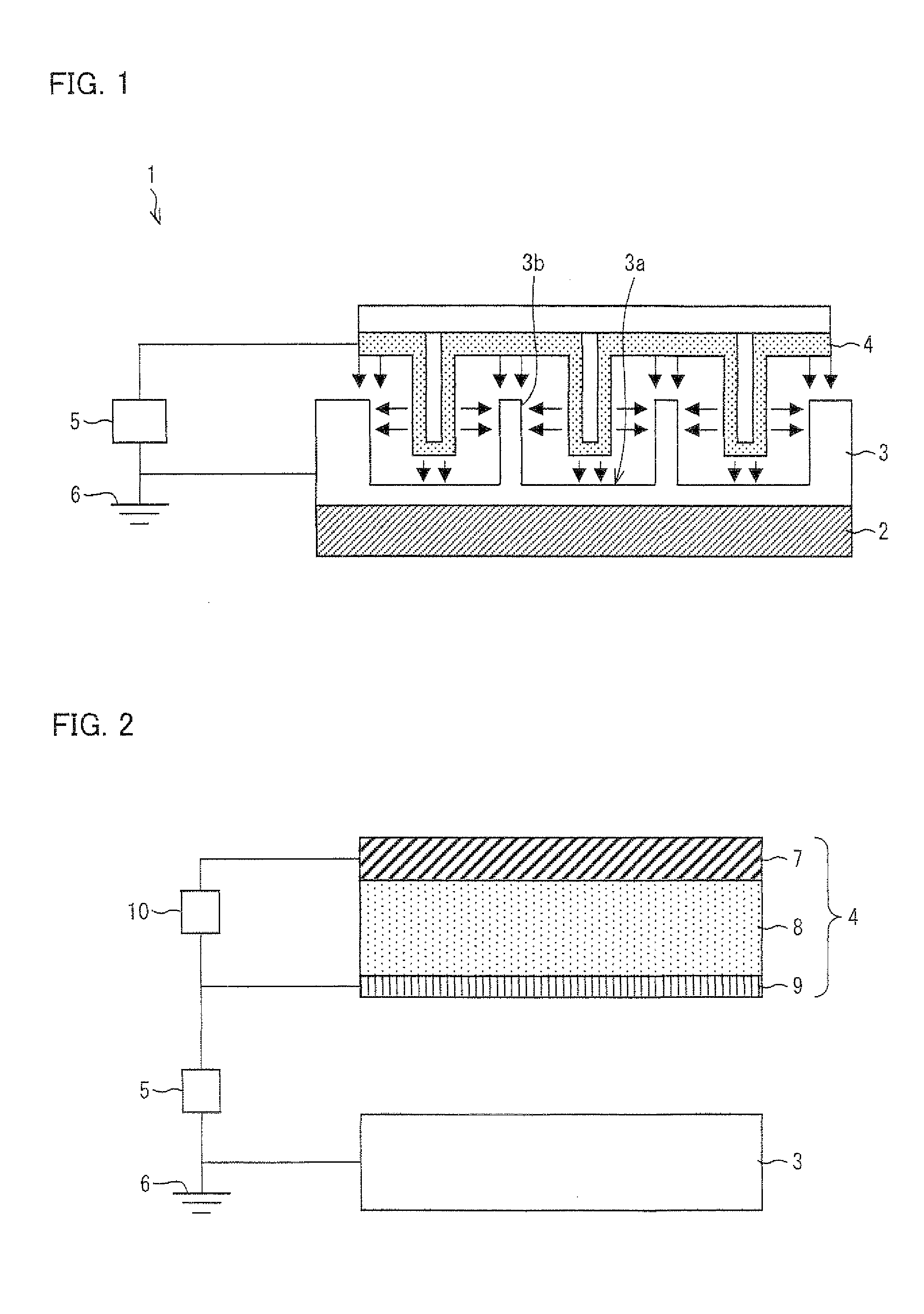

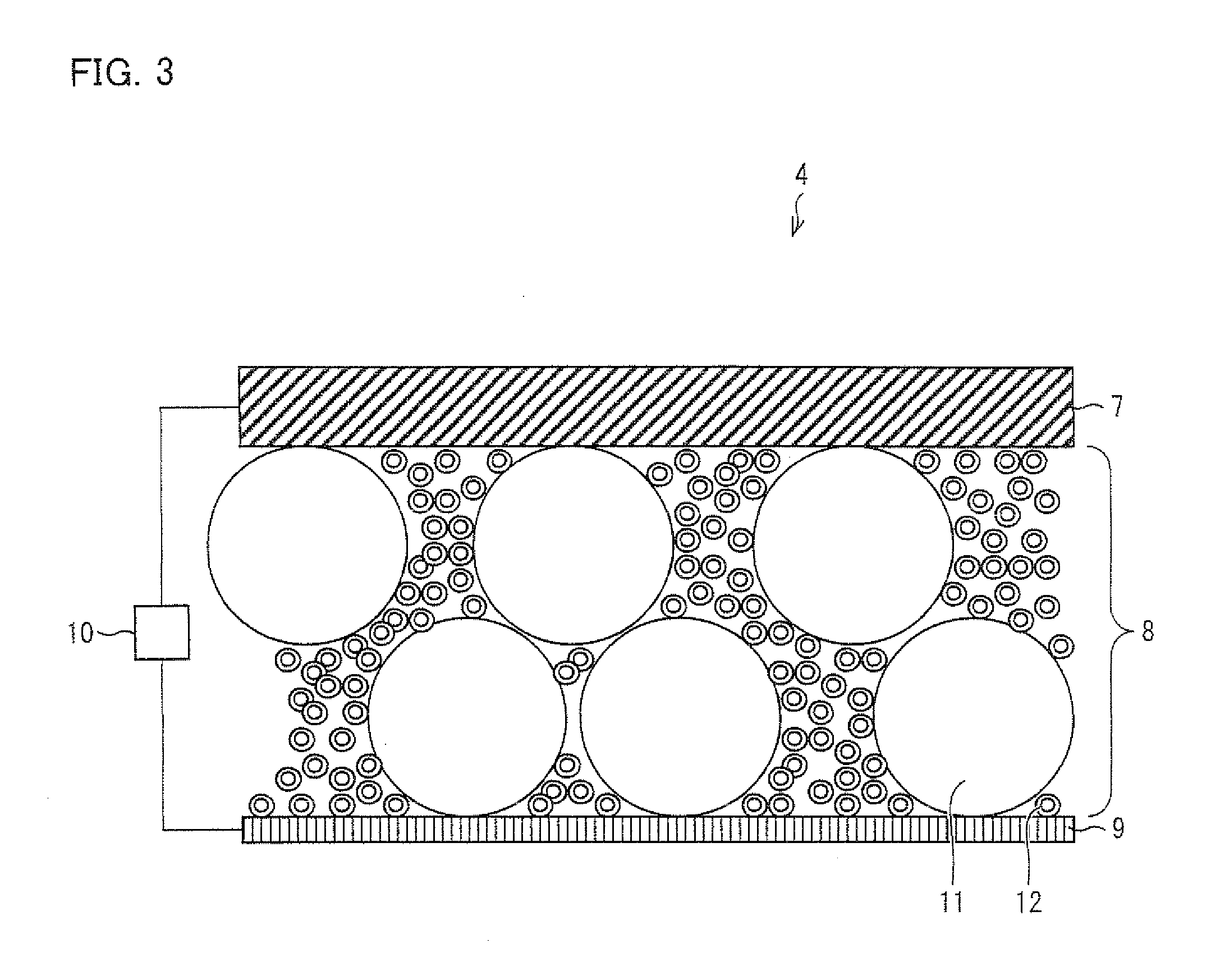

Heat exchanger

InactiveUS20100307724A1Reduce in quantityImprove heat exchange capacityDigital data processing detailsSemiconductor/solid-state device detailsThin film electrodeEngineering

A heat exchanger (1) includes: a heat sink (3) which is in contact with a heating element (2); and an electron emitting element (4) which is provided so as to be separated from the heat sink (3) by a space and which provides electrons to the heat sink (3) via air in the space. The electron emitting element (4) includes: an electrode substrate (7); a thin-film electrode (9); a power supply (10) which applies a voltage between the electrode substrate (7) and the thin-film electrode (8); and an electron acceleration layer (8) which accelerates the electrons inside itself in response to the voltage applied by the power supply (10) so that the electrons are emitted from the thin-film electrode (9). The electron acceleration layer (8) is made at least partially of an insulating material. As a result, the heat exchanger (1) has a heat exchange capability which can be maintained and improved independently of a structure in which electric field concentration tends to occur.

Owner:SHARP KK

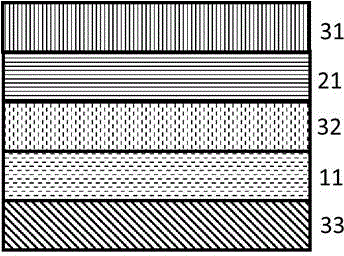

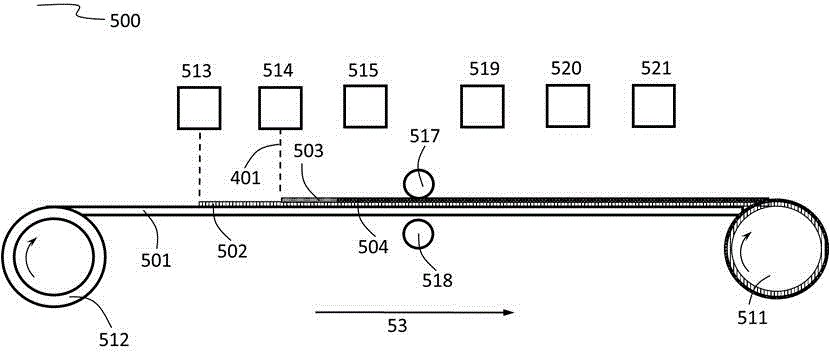

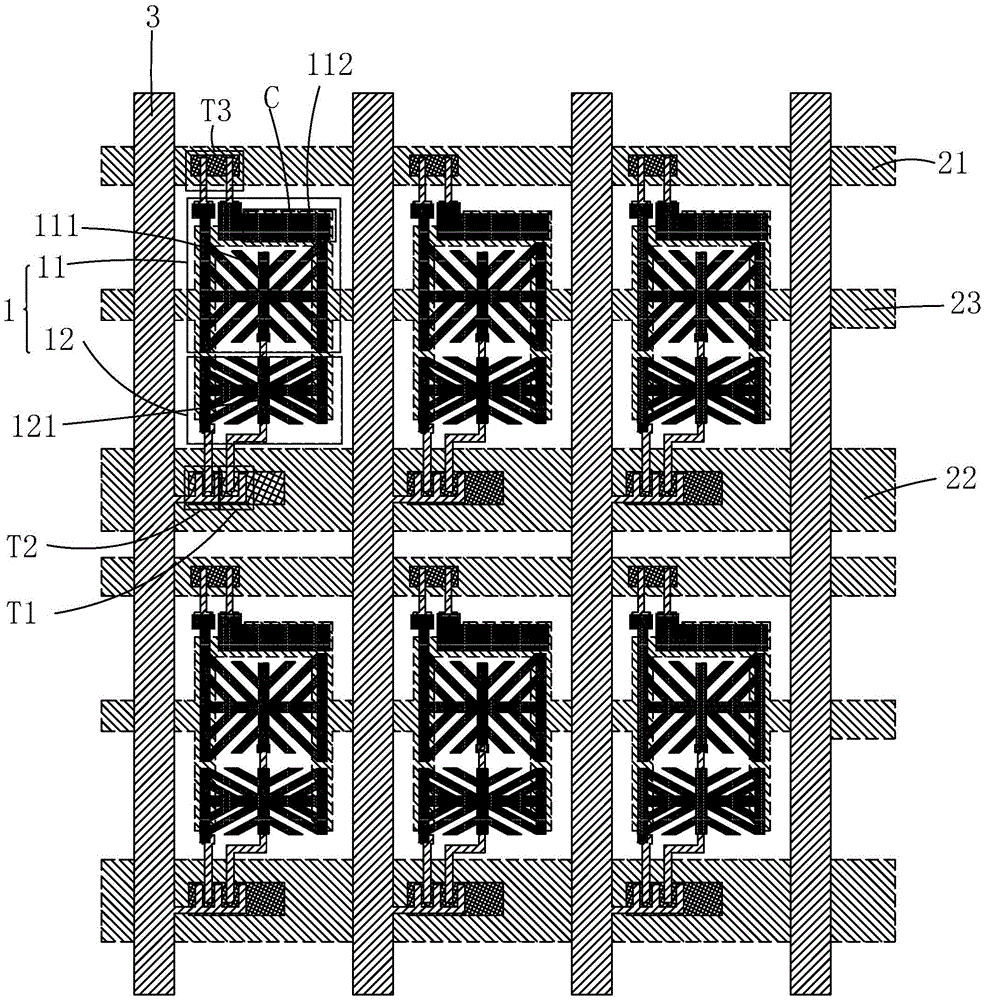

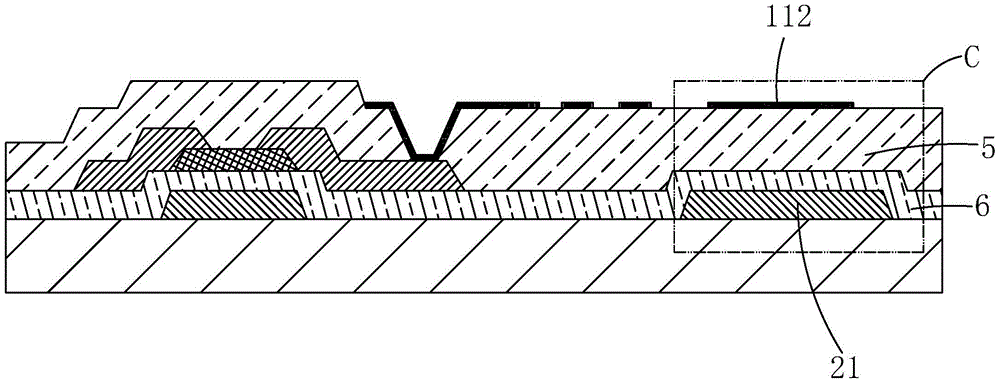

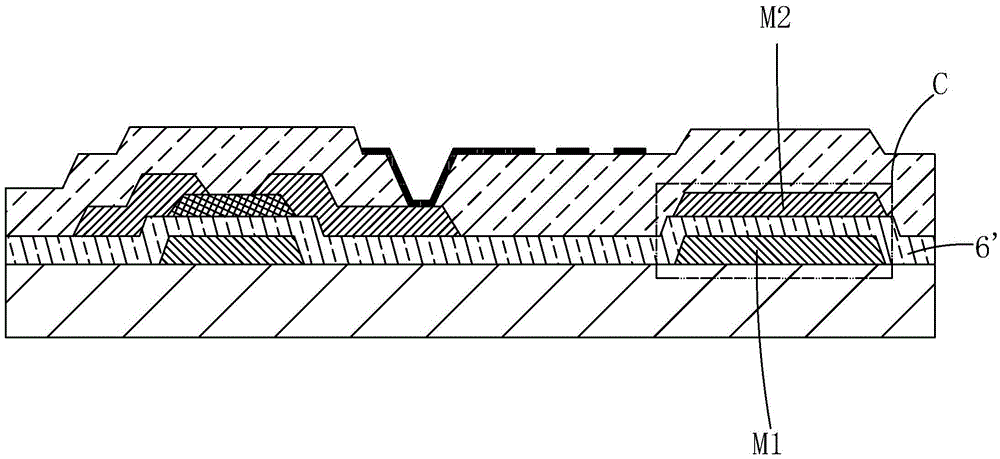

TFT array substrate and manufacturing method thereof

ActiveCN105470269AIncrease capacityImprove display qualitySolid-state devicesSemiconductor/solid-state device manufacturingCapacitanceThin film electrode

The invention provides a TFT array substrate and a manufacturing method thereof. The TFT array substrate is provided with a transparent conducting thin film electrode plate (503), a second metal electrode plate (202) and a common electrode wire (102), wherein the transparent conducting thin film electrode plate (503), a primary area pixel electrode (501) and a secondary area pixel electrode (502) are positioned on the same layer; the second metal electrode plate (202) is positioned on a second metal layer (M20); the common electrode wire (102) is positioned on a first metal layer (M10); a part of the common electrode wire (102), a part of the second metal electrode plate (202) and a part of the transparent conducting thin film electrode plate (503) are overlapped spatially, and the transparent conducting thin film electrode plate (503) is in contact with a part of the common electrode wire (102) through a second via hole (422) penetrating through an insulation protective layer (40) and a gate insulation layer (20); and a part of the common electrode wire (102), a part of the second metal electrode plate (202) and a part of the transparent conducting thin film electrode plate (503) form a charge sharing capacitor (C10) together, so that the capacity of the charge sharing capacitor can be improved, the aperture opening ratio is increased, and the display quality of a liquid crystal display panel is improved.

Owner:SHENZHEN CHINA STAR OPTOELECTRONICS TECH CO LTD

Method for preparing counter electrode of dye-sensitized solar cell

InactiveCN101976608AImprove conductivityImprove thermal conductivityLight-sensitive devicesSolid-state devicesCarbon filmFunctional methods

The invention discloses a method for preparing a counter electrode of a dye-sensitized solar cell, which comprises the following steps of: 1) preparing water-soluble single-layer or multi-layer graphene from graphite through a chemical oxidation method, or preparing organically water-soluble single-layer or multi-layer graphene from the graphite through an organic functional method; 2) preparing the water-soluble or organically water-soluble single-layer or multi-layer graphene onto the surface of a glass substrate for molding, and airing to prepare a thin film of the single-layer or multi-layer graphene; and 3) reducing the glass substrate with the thin film of the single-layer or multi-layer graphene by using a reducing agent, or calcining under the protection of nitrogen or argon to obtain the counter electrode of the dye-sensitized solar cell, which is coated with the single-layer or multi-layer grapheme film on the surface of the glass substrate. Electrons generated by a dye-sensitized TiO2 thin-film electrode are transferred to electrolyte to finish a cycle, so the optical energy is converted into electric energy and the photoelectric conversion efficiency of the cell is improved.

Owner:IRICO

LED module fabrication process with patterned transparent thin-film electrodes

ActiveCN102290506AWith graphic functionReduce manufacturing costSemiconductor devicesManufacturing technologyPolyvinyl chloride

The invention relates to the technical field of a luminous display device, in particular to a novel graphical manufacturing technology of a nanometer material base transparent thin-film electrode; the manufacturing technology is characterized by comprising the following preparing steps of: a. preparing a raw material of a transparent conductive thin-film for standby application; using polyimide or one of PET (Polyethylene Terephthalate), PEN (Polyethylene Naphthalate), PC (Polycarbonate), PVC (Polyvinyl Chloride), PMMA (Polymethyl Methacrylate) and PES (Polyethersulfone) as a transparent flexibility substrate; b. preparing an insulating layer; c. preparing a graphical transparent conductive electrode; d. preparing a double-layer crossing or a multilayer graphical transparent conductive electrode; e. coating an LED (Light Emitting Diode); f. drying; and g. coating the film on the surface. Compared with the prior art, the manufacturing technology has the advantages that the novel thin-film electrode with the graphical function can be manufactured on the flexibly transparent base, the thin-film and the technology are combined with the manufacturing technology of a transparent LED (Light Emitting Diode) display device, a product is transparent and attractive and can be repeatedly bent and used and the manufacturing cost is low.

Owner:SUZHOU SUNLIGHTS TECH

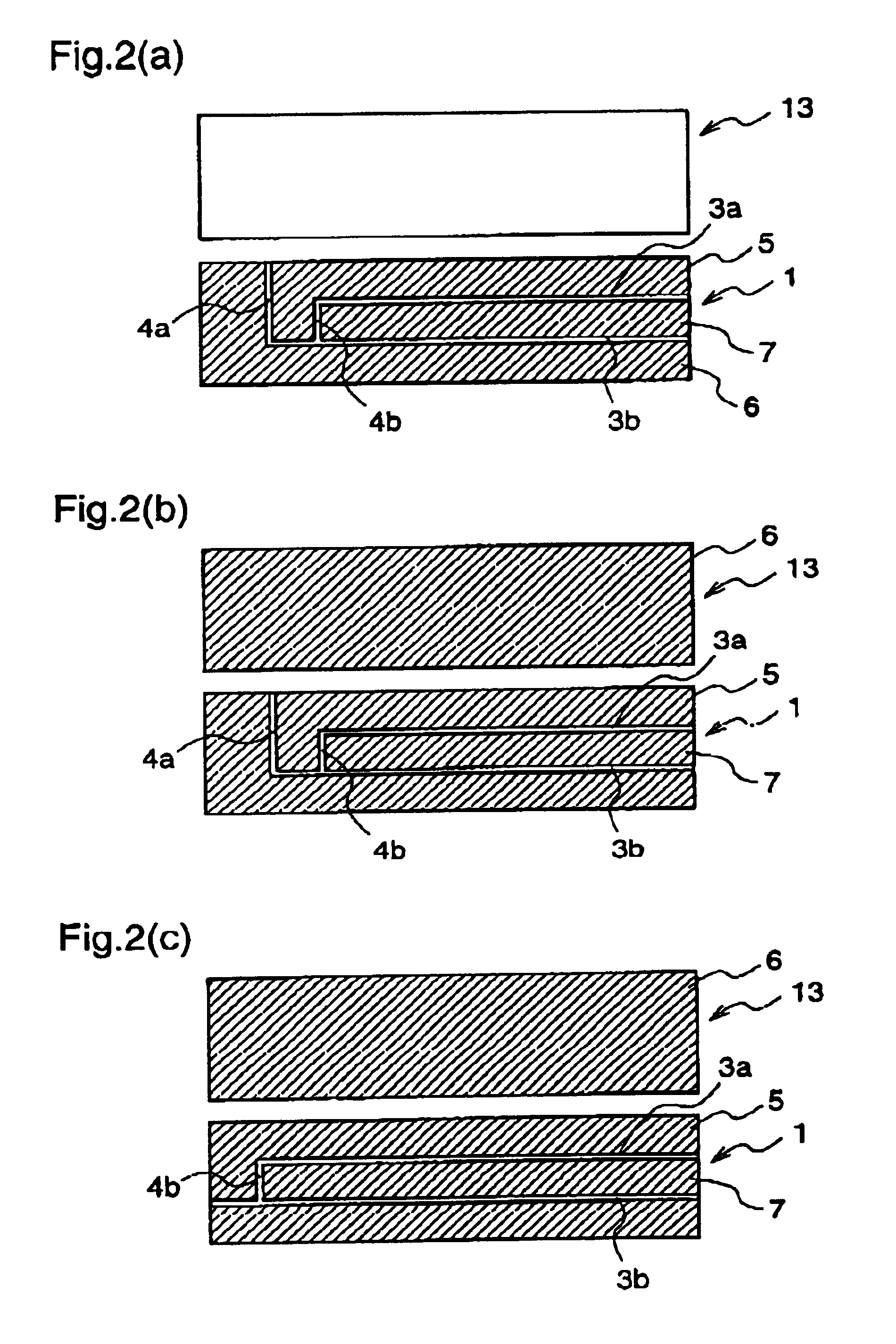

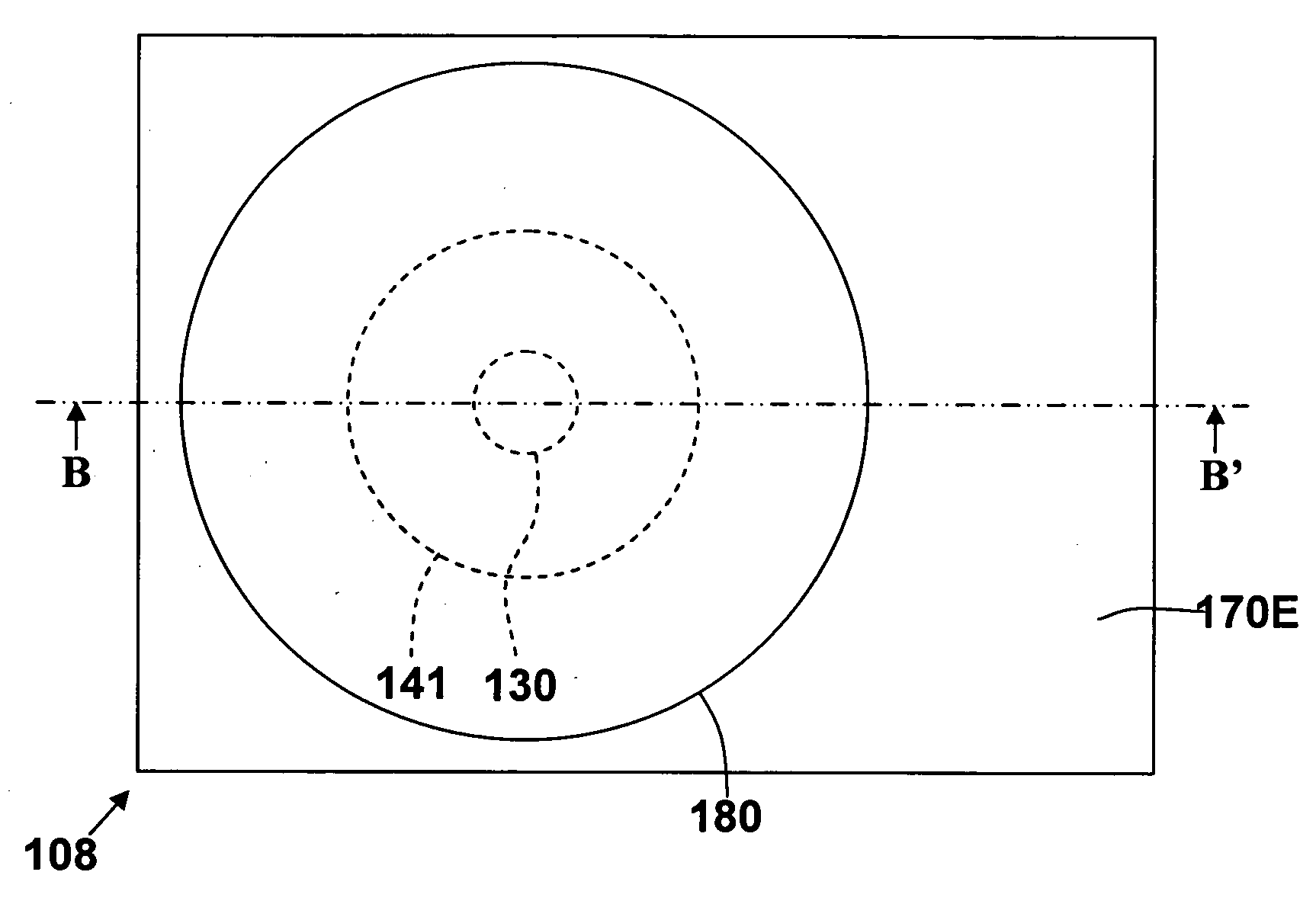

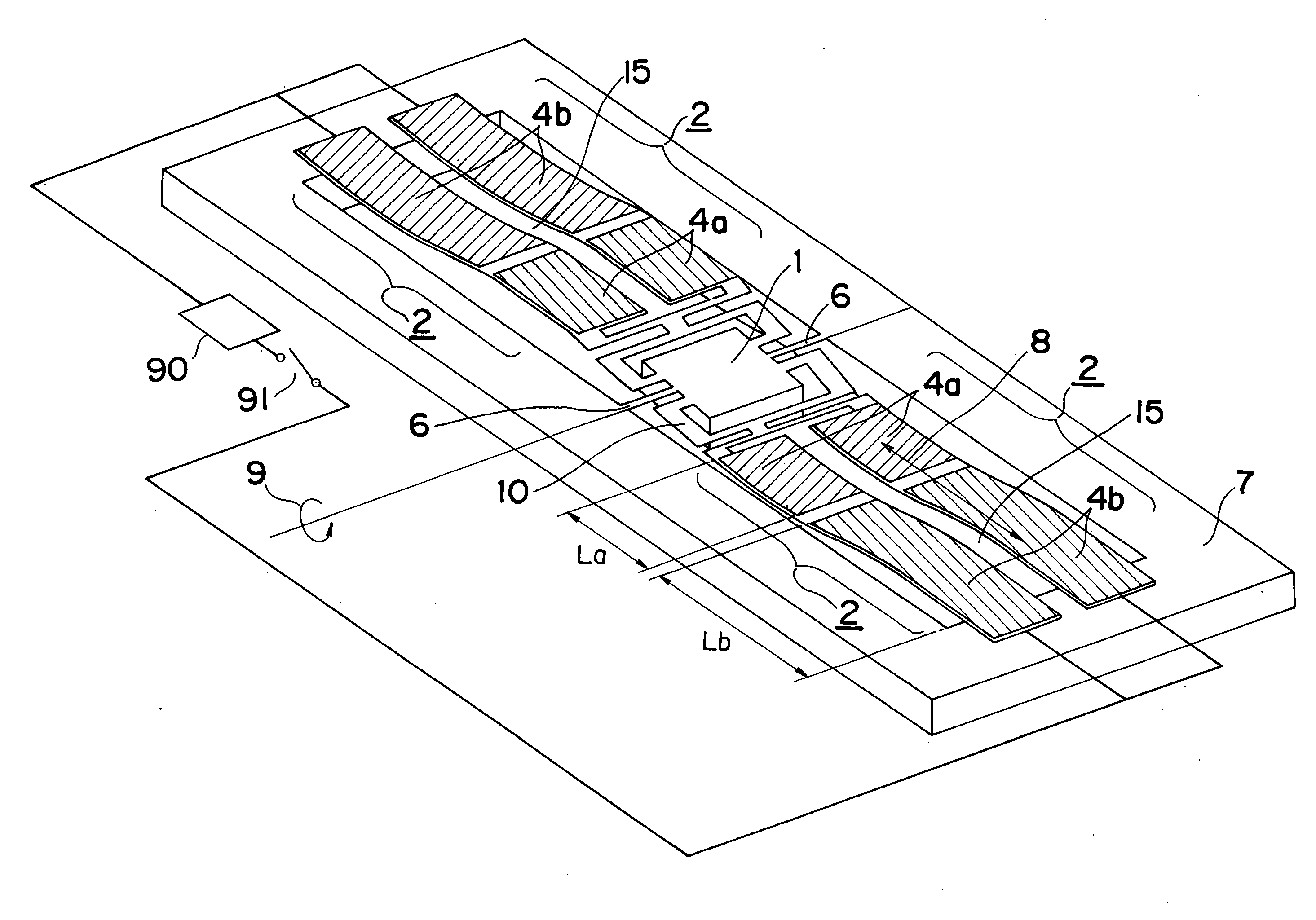

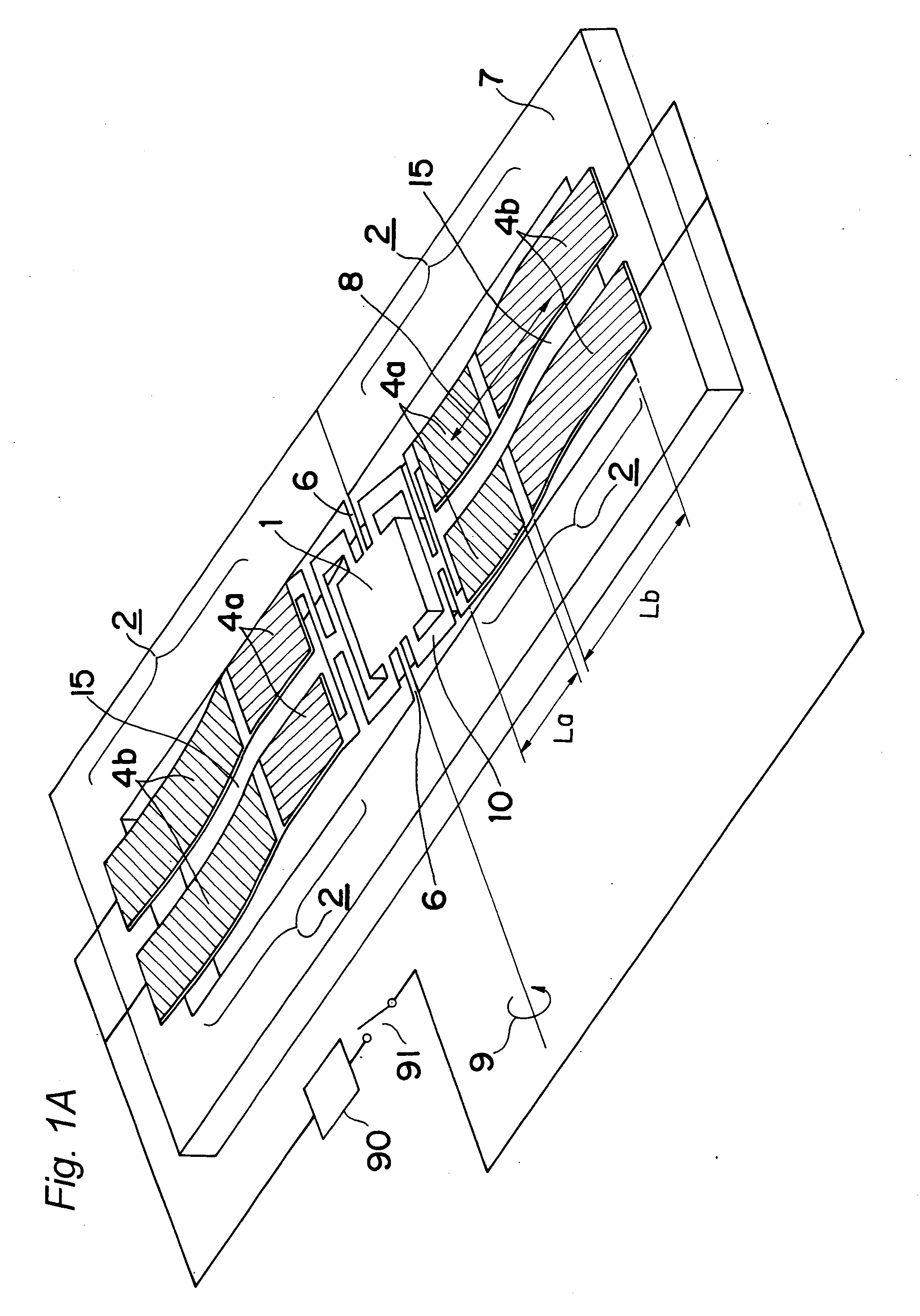

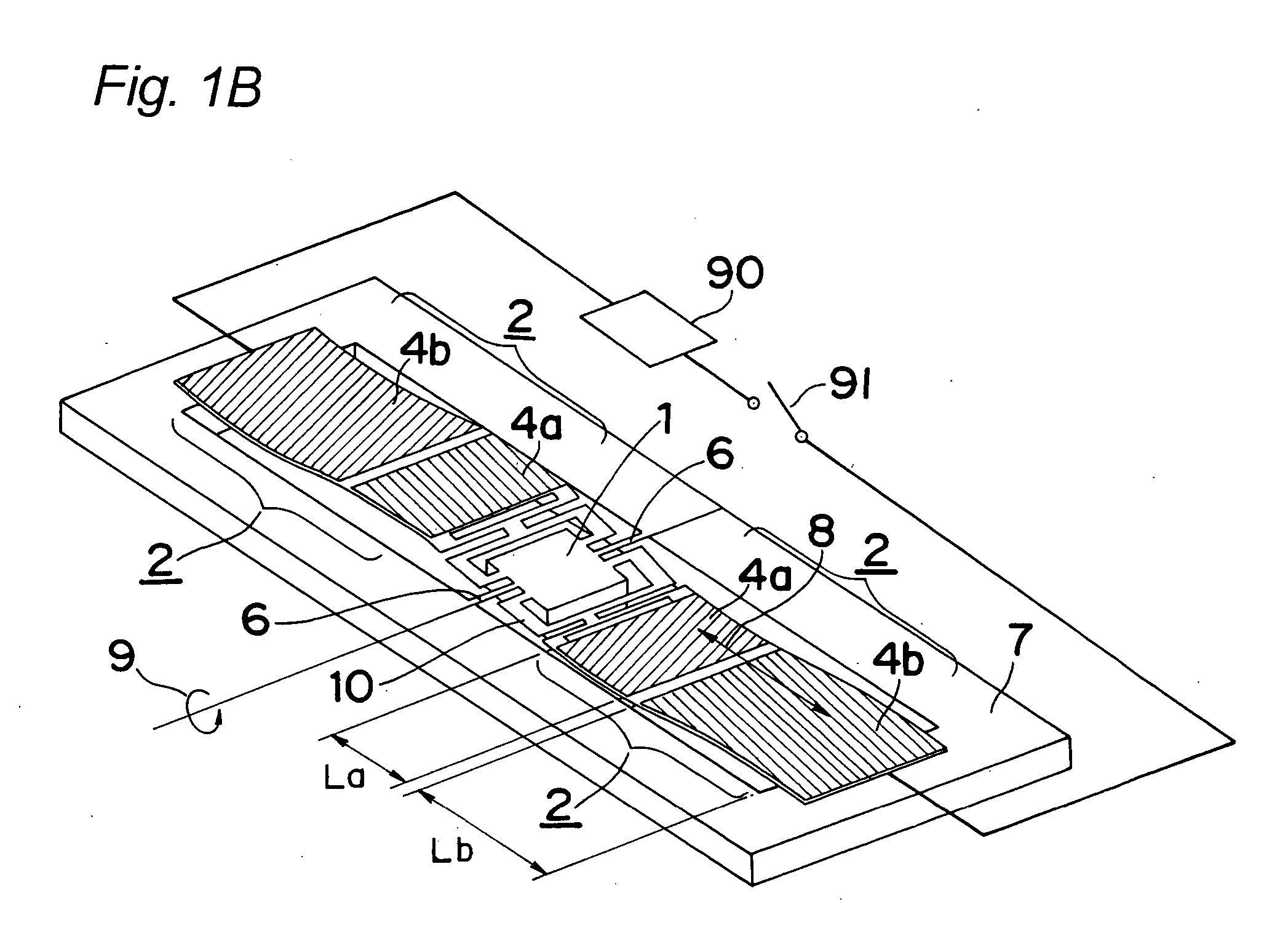

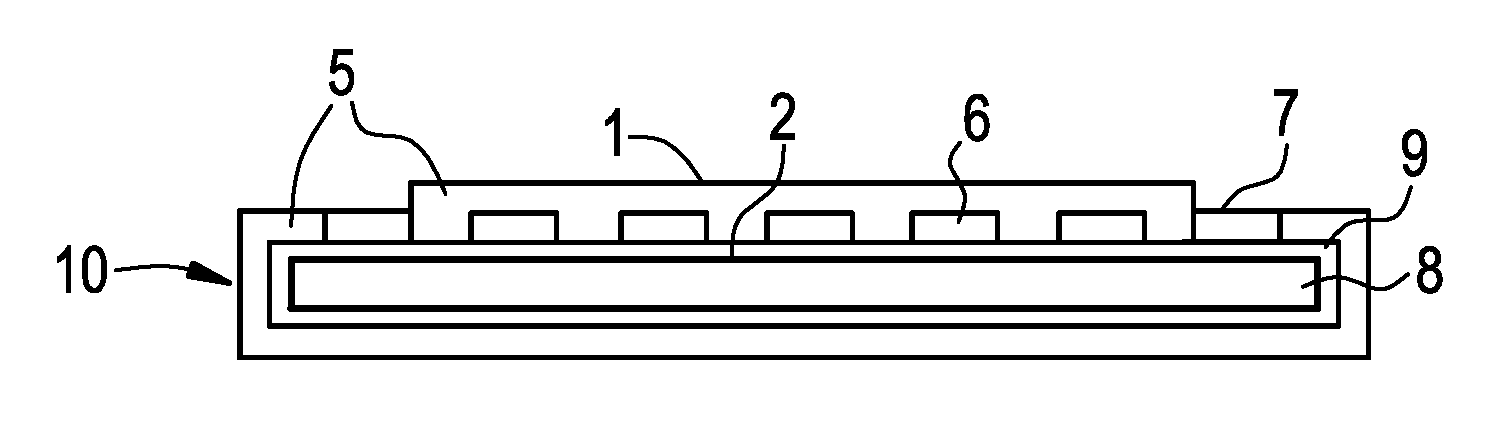

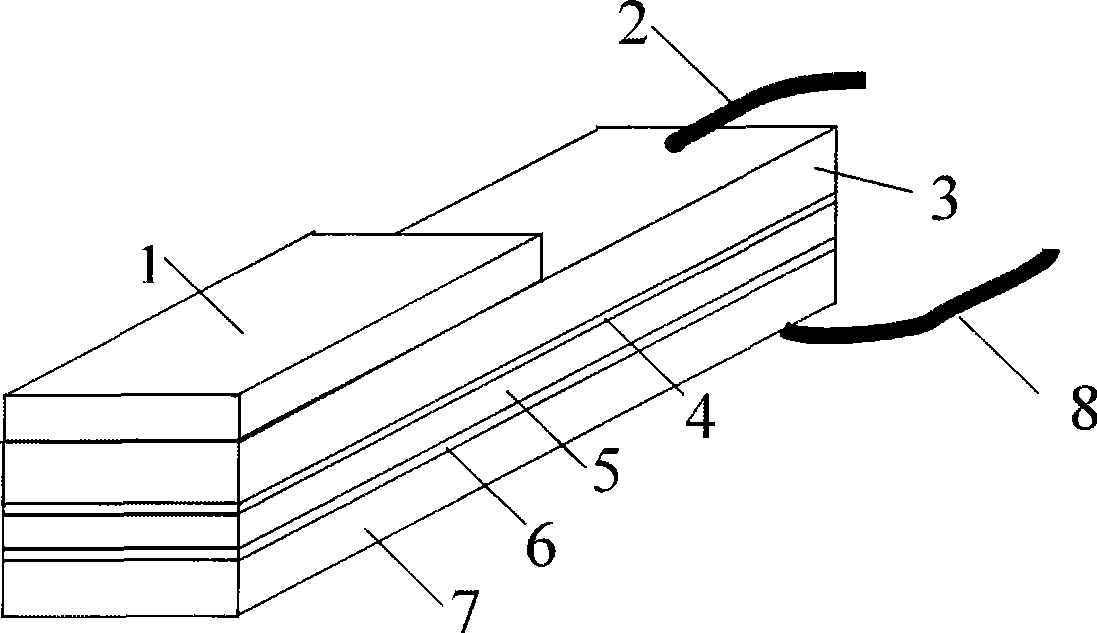

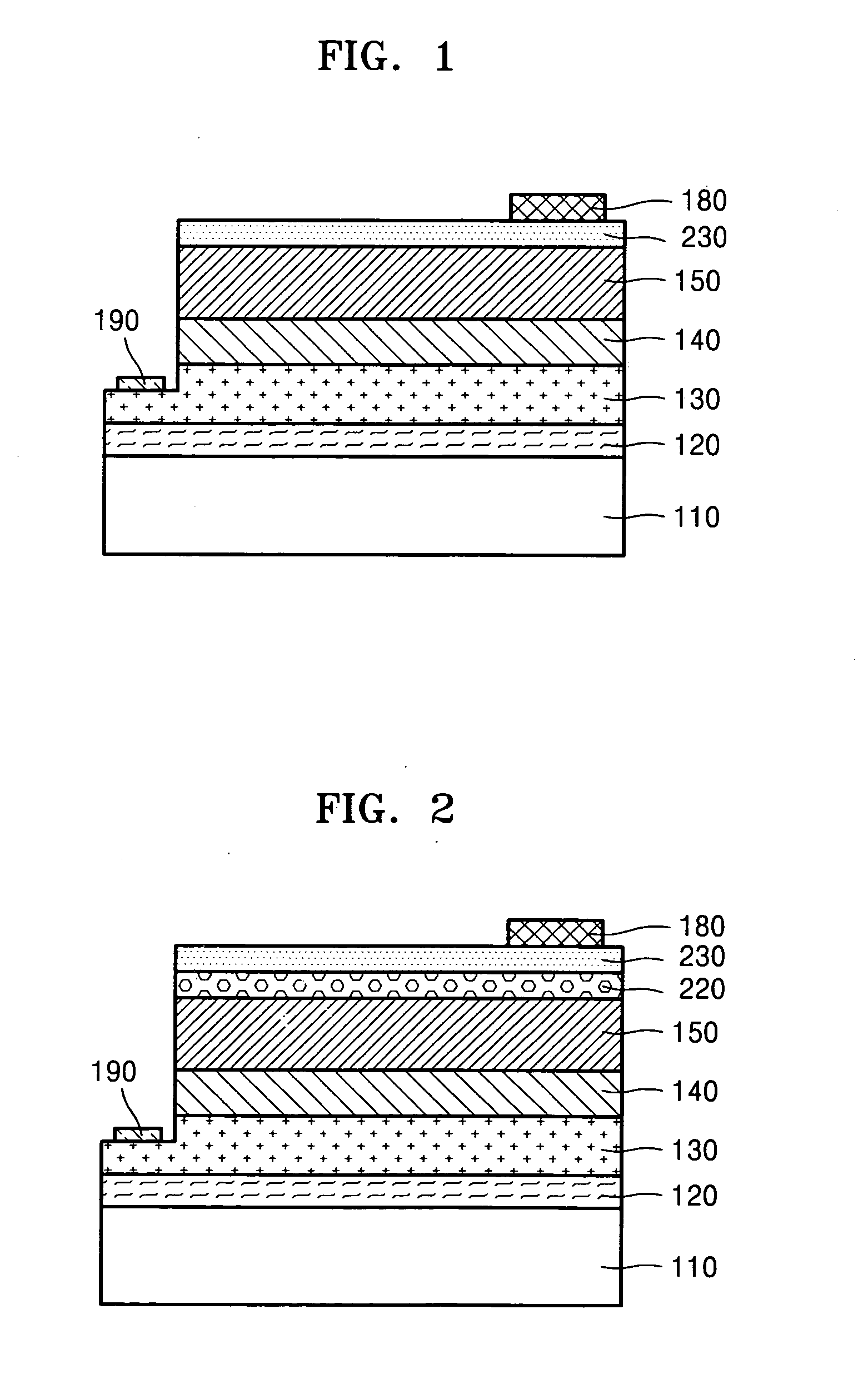

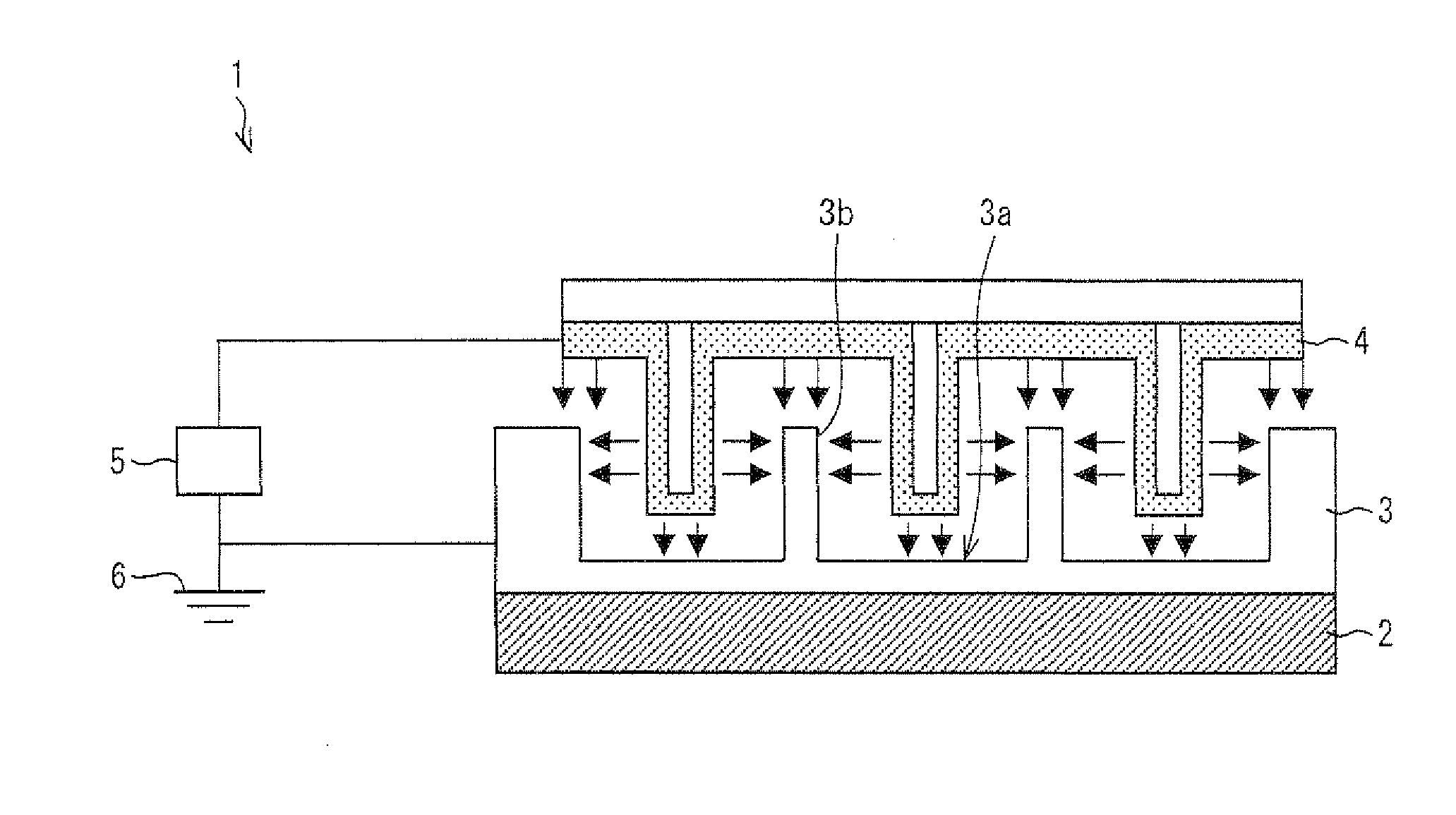

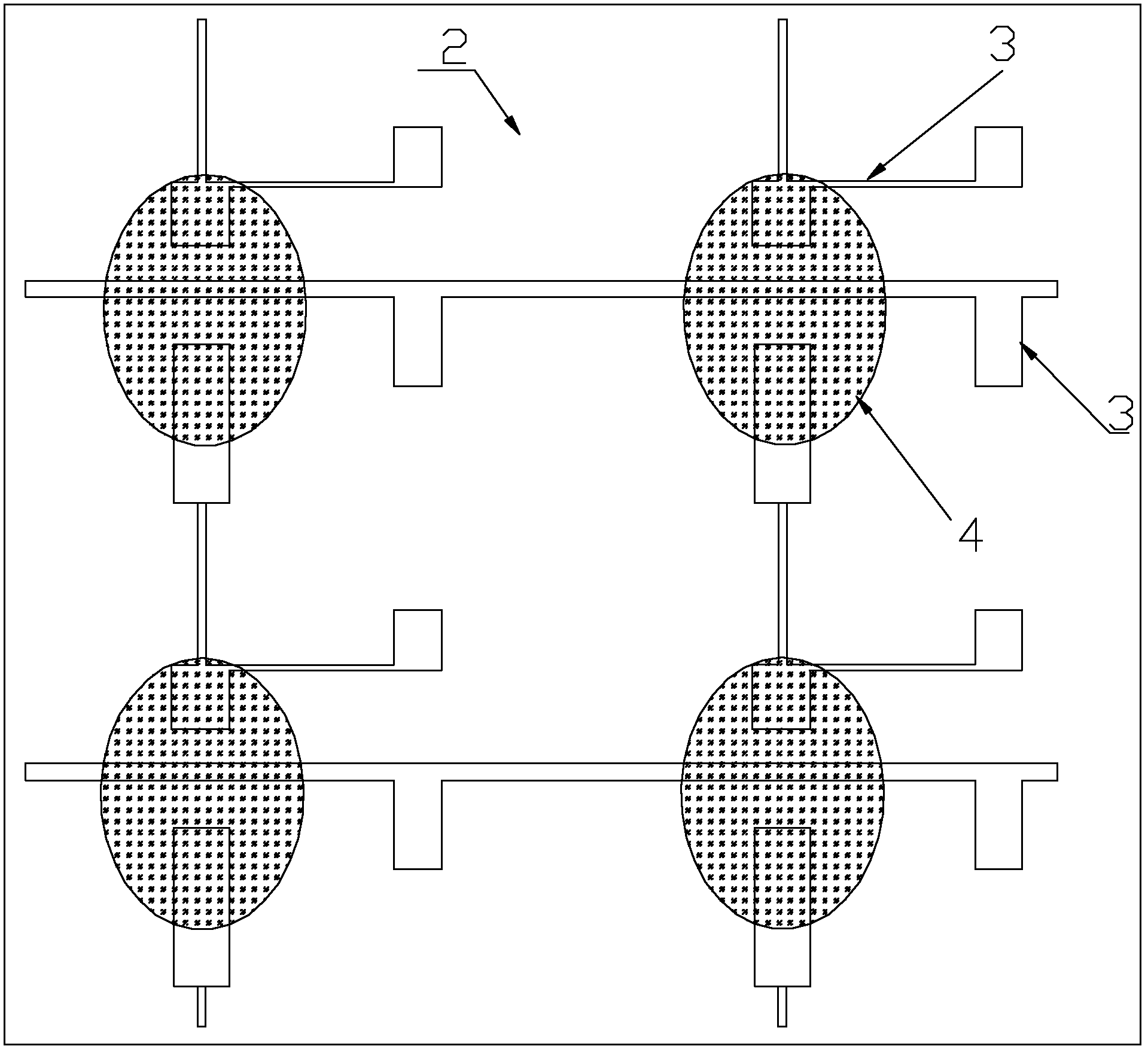

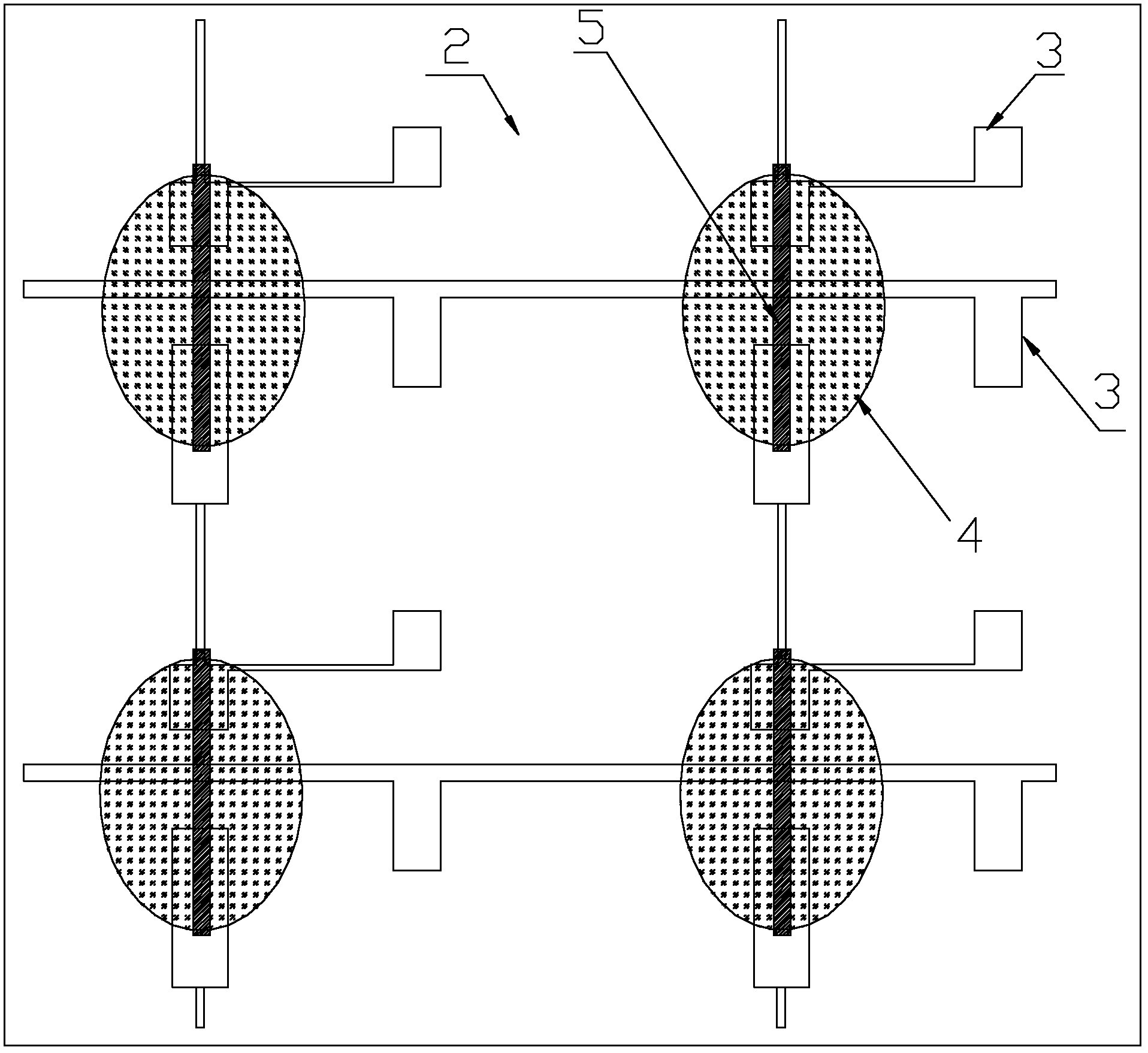

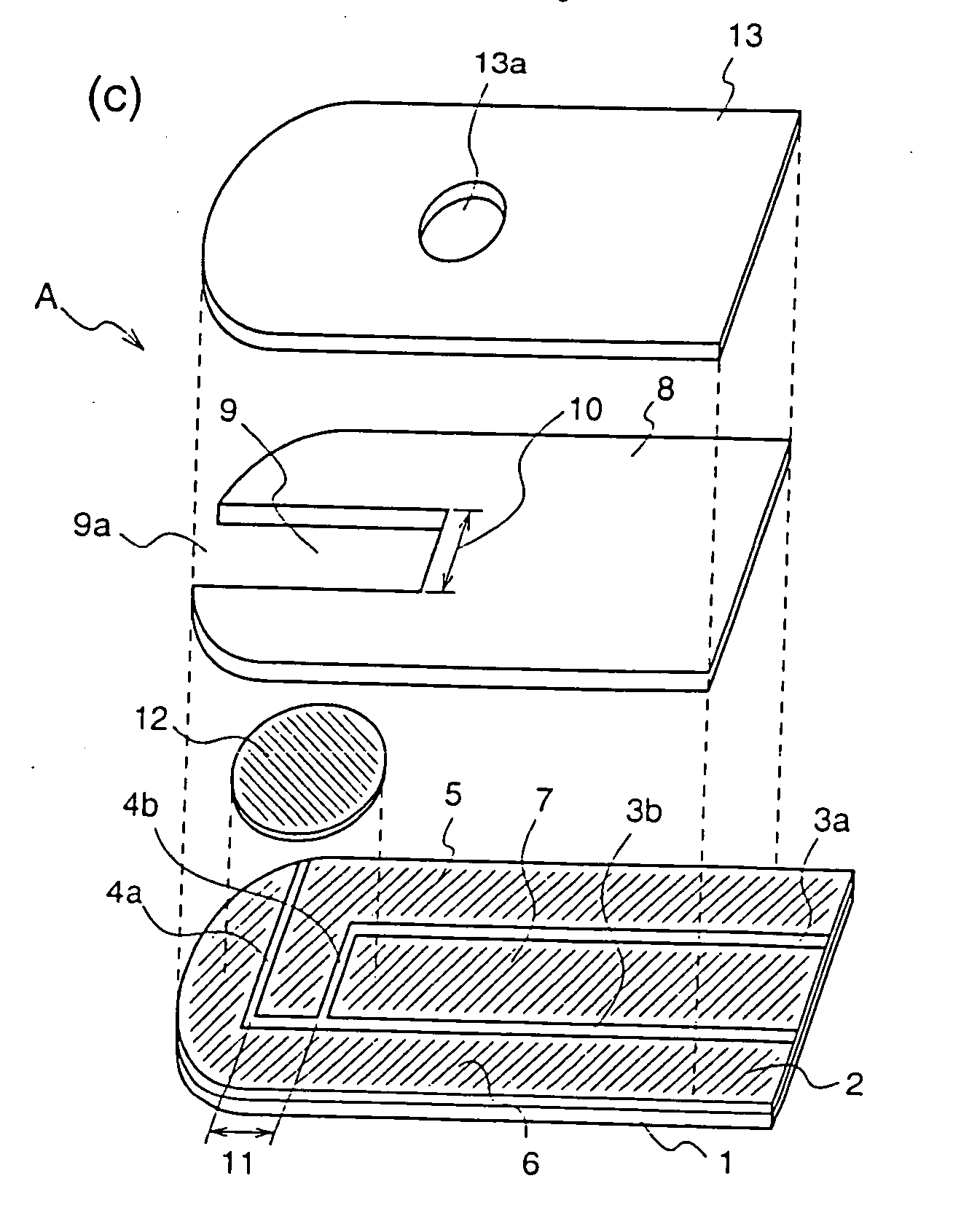

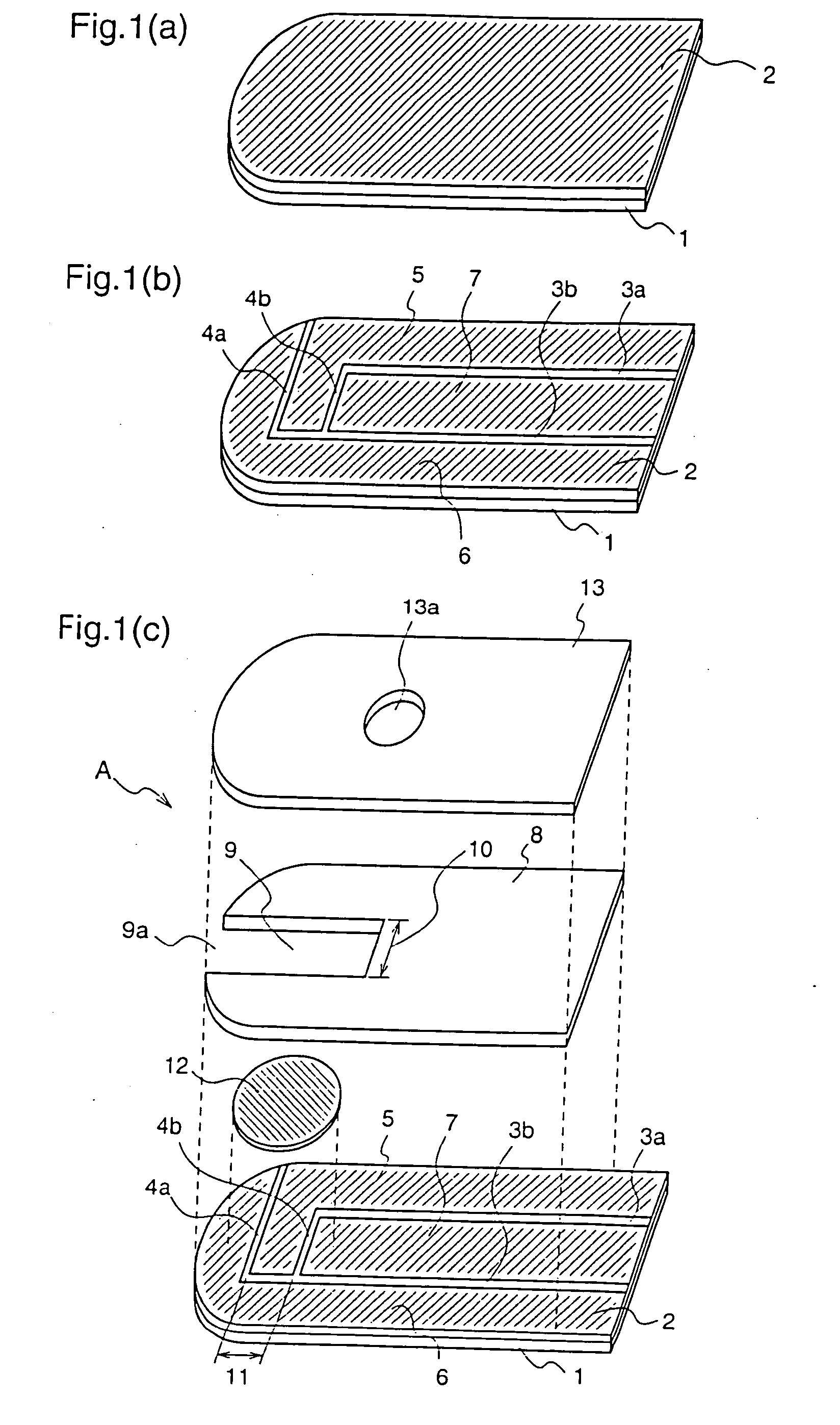

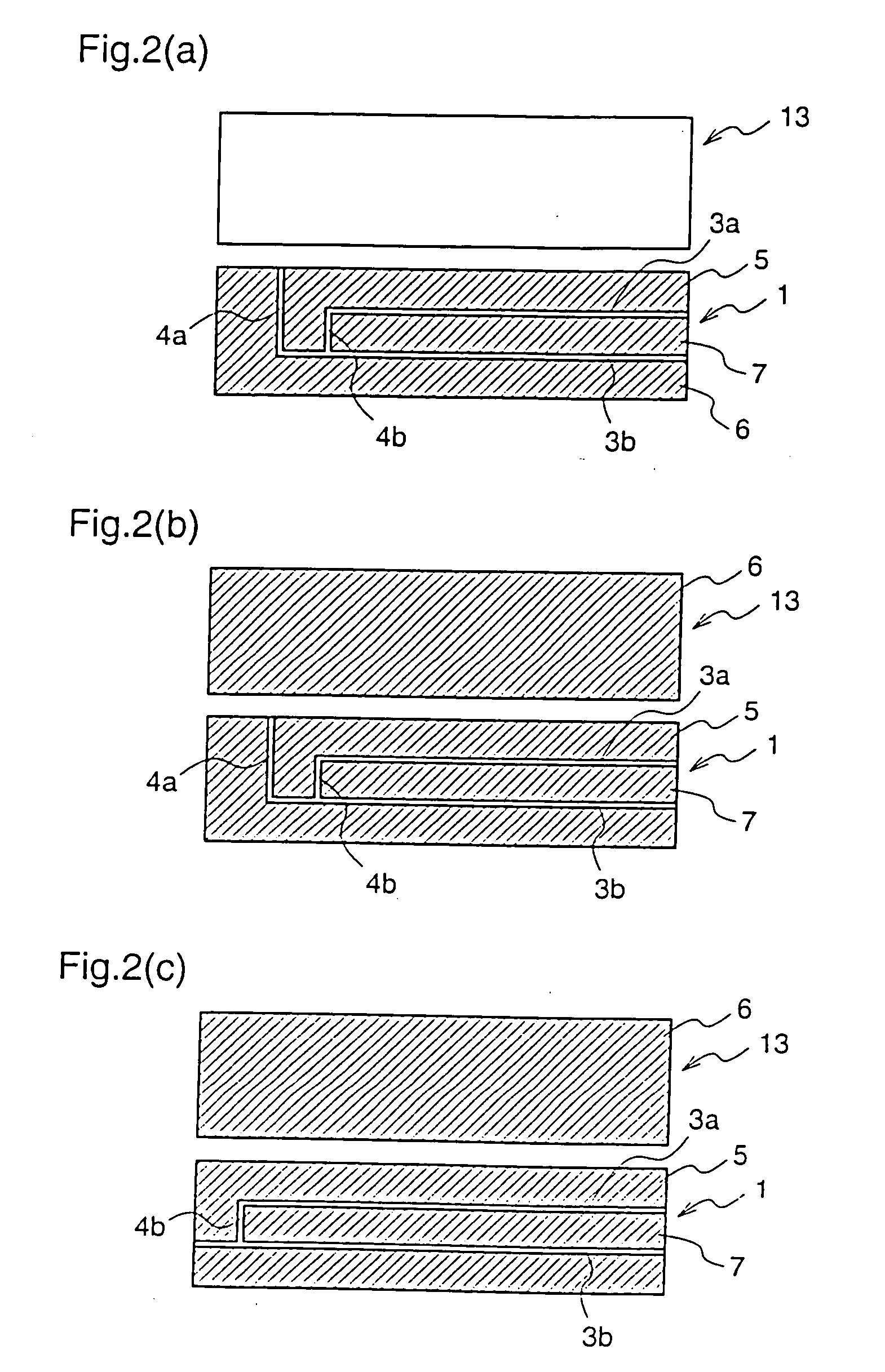

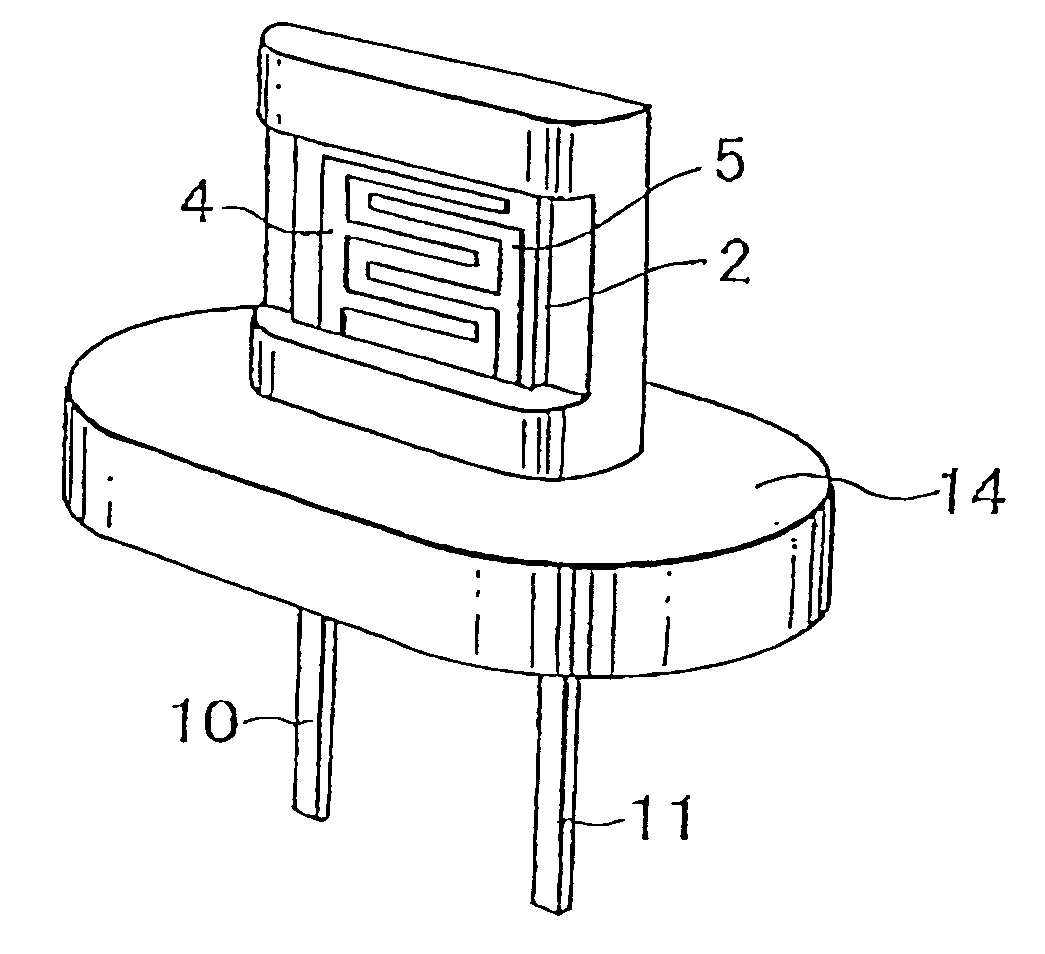

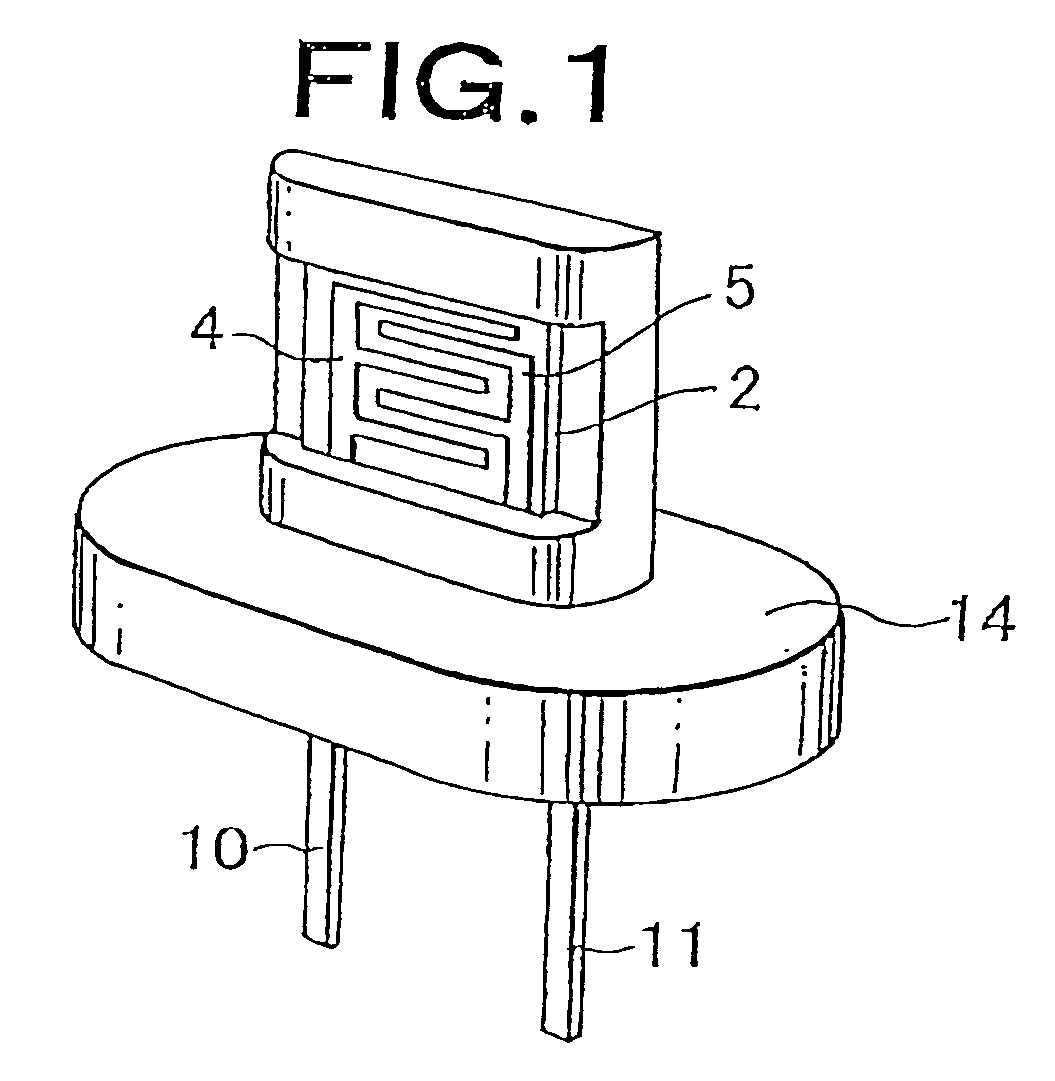

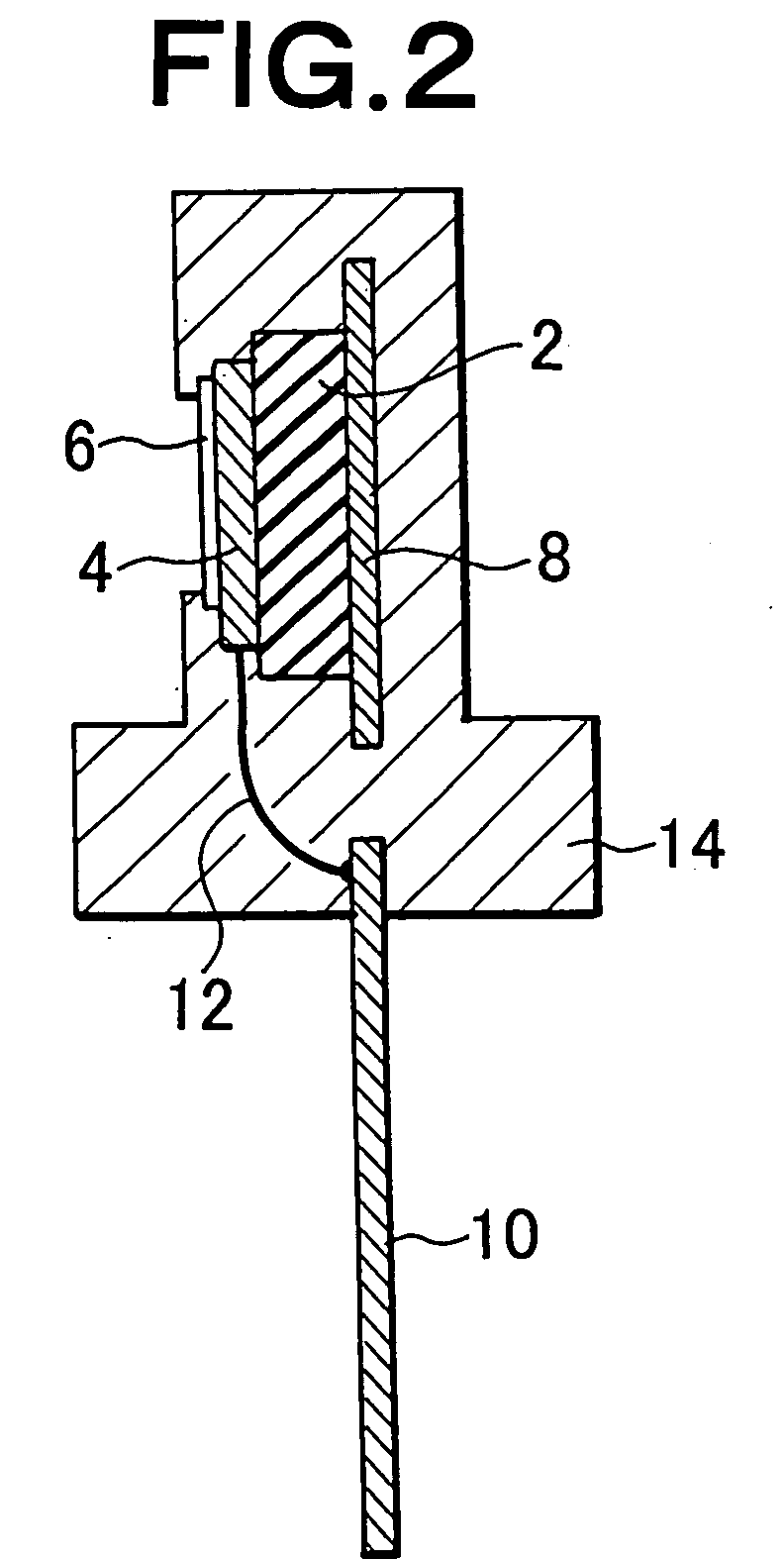

Biosensor, thin film electrode forming method, quantification apparatus, and quantificaion method

InactiveUS20090152111A1Well formedSimple definitionImmobilised enzymesBioreactor/fermenter combinationsThin film electrodeConductive materials

A biosensor according to the present invention comprises a support 1, a conductive layer 2 composed of an electrical conductive material such as noble metal, for example gold, palladium or the like, and carbon, slits 3a and 3b parallel to the side of the support 1, slits 4a and 4b vertical to the side of the support 1, a working electrode 5, a counter electrode 6, a detecting electrode 7, a spacer 8 which covers the working electrode 5, the counter electrode 6 and the detecting electrode 7 on the support 1, a rectangular cutout part 9 forming a specimen supply path, an inlet 9a of the specimen supply path, a reagent layer 12 formed by applying a reagent including an enzyme or the like to the working electrode 5, the counter electrode 6 and the detecting electrode 7, which is exposed from the cutout part 9 of the spacer 8, and a cover 13 which covers the spacer 8, as shown in FIG. 1. The so-constructed biosensor can be formed by a simple method, and a biosensor which is excellent in a measuring accuracy as well as a biosensor in which a reagent layer is placed uniformly on the electrodes regardless of a reagent liquid composition, and which has a uniform performance can be realized.

Owner:PHC HLDG CORP

Method for producing synthetic resin mold package, alcohol concentration sensor and apparatus for measuring alcohol concentration

InactiveUS20090100911A1High yieldAccurate measurementComponent separationResistance/reactance/impedenceThin film electrodeAlcohol

Disclosed is a method for producing a synthetic resin mold package at high yield from which package a pair of the surface of an internal device is exposed. A to-be-exposed part of the surface of the internal device composed of an insulating substrate (2) and thin film electrodes (4, 5) and an insulating protective film (6) formed on the substrate is covered with a coating agent (42), and a die pad portion (8) is bonded to the back surface of the internal device. After placing the thus-obtained structure in a mold consisting of a lower mold (46) and an upper mold (48), a pin (50) is inserted into the mold so that the front end of the pin is pressed against the die pad portion (8), thereby keeping the surface of the coating agent (42) pressed against the inner surface of the upper mold (48). Then, a synthetic resin (52) is injected into the mold and cured therein. The thus-obtained resin sealed body is taken out from the mold, and the coating agent (42) is removed from the resin sealed body.

Owner:MITSUI MINING & SMELTING CO LTD

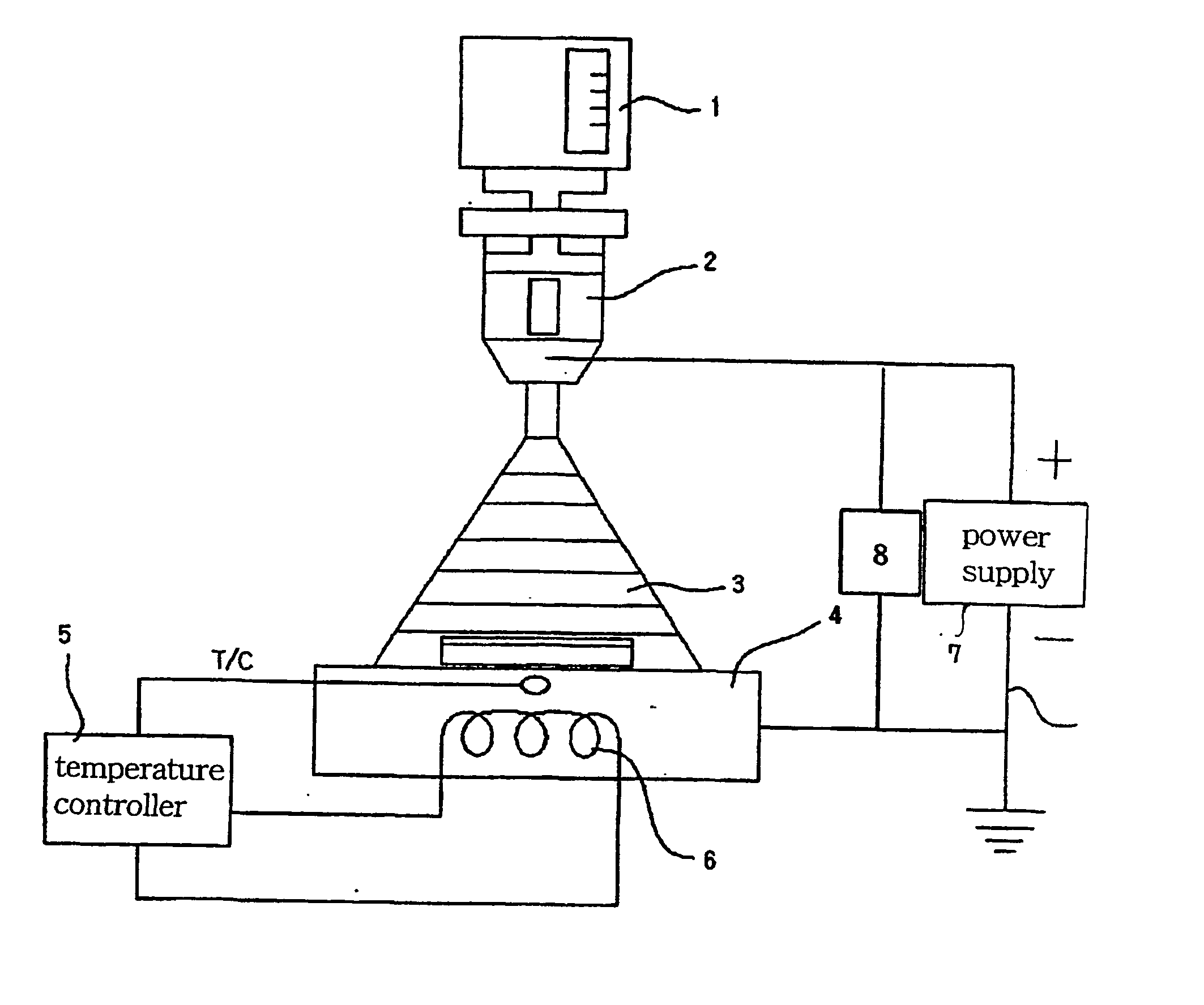

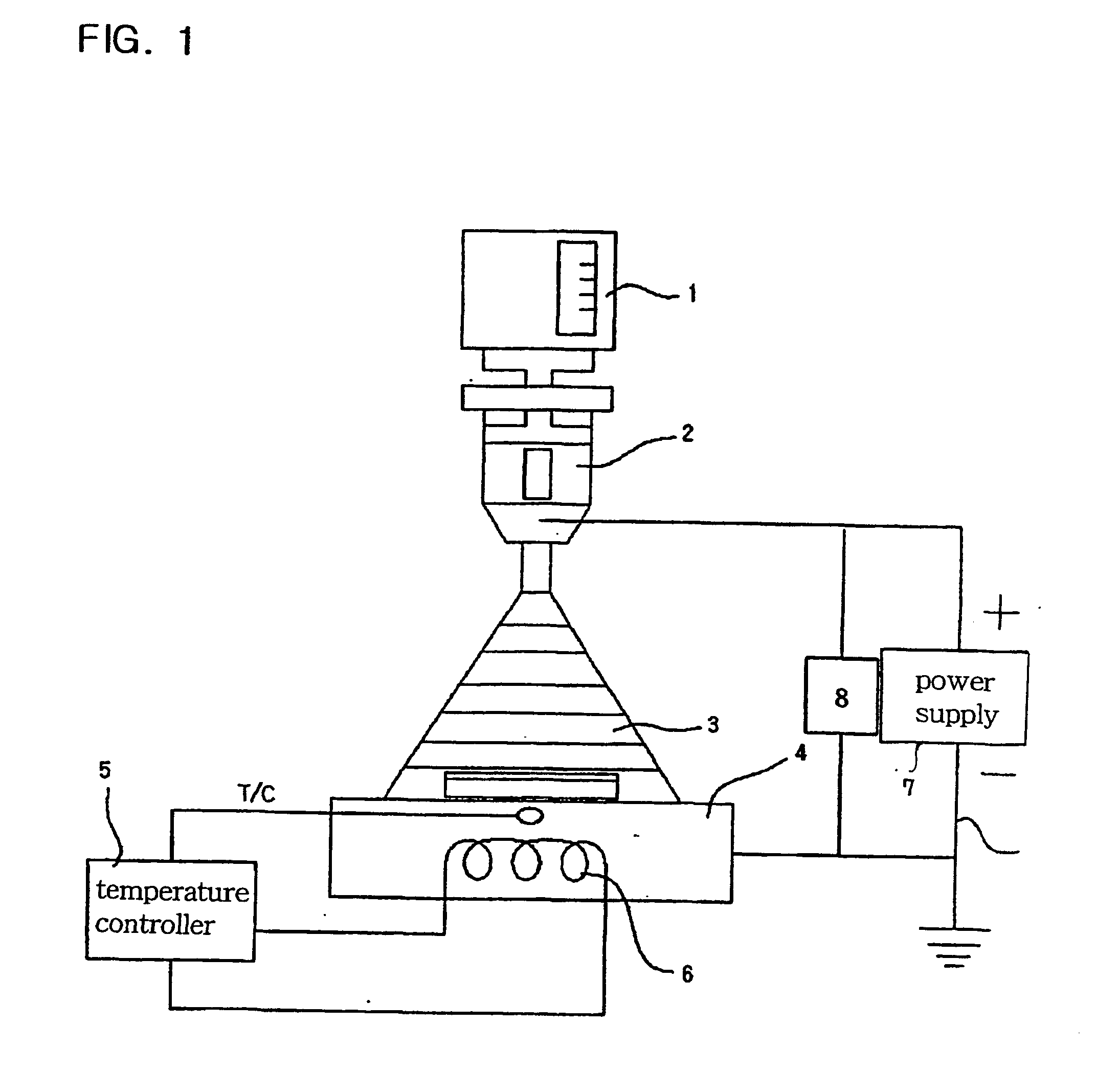

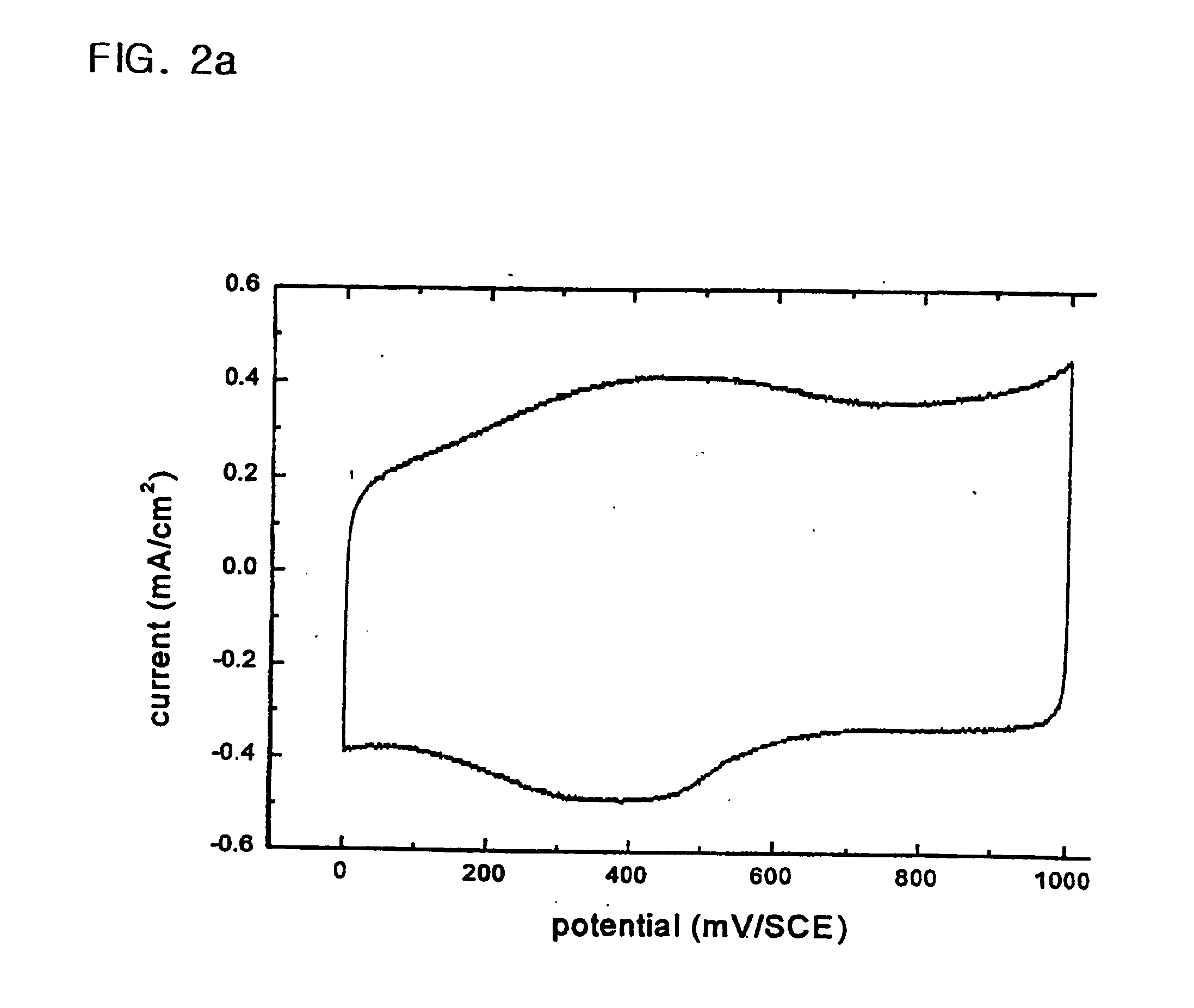

Apparatus and method for manufacturing thin film electrode of hydrous ruthenium oxide

InactiveUS20040013799A1Electrode thermal treatmentFinal product manufactureEngineeringElectric field

An apparatus and a method are provided for manufacturing an electrode of hydrous ruthenium oxide thin film. The apparatus comprises an injector for introducing a precursor solution and spraying the precursor solution; a substrate having the precursor solution sprayed thereon; a substrate-supporting base for supporting the substrate and including a halogen lamp therein for heating the substrate; a direct current power supply connected to the substrate-supporting base and the injector; a distance adjuster for adjusting the distance between the substrate-supporting base and the injector; and a temperature controller for controlling the substrate-supporting base. Under a strong electric field, the ruthenium precursor solution is sprayed, to yield a porous thin film electrode having very fine particles. The electrode prepared by the method which is advantageous in terms of simplified preparation process and shorter period of time required for preparation, compared to conventional methods, has more excellent properties than those of a conventional ruthenium oxide electrode for super capacitor or a composite electrode of ruthenium oxide and activated carbon.

Owner:KIM WOO SIK

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com