Flexible film tactile sensor and production method thereof

A tactile sensor, flexible film technology, applied in sensors, measurement of the properties of piezoelectric devices, instruments, etc., can solve the problems of complex process, poor film uniformity, strong equipment dependence, etc., to achieve good flexibility Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

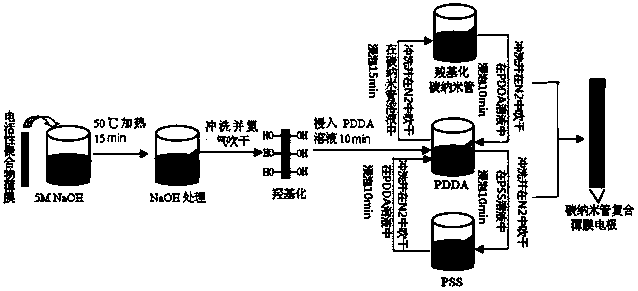

Method used

Image

Examples

Embodiment Construction

[0022] The following embodiments will further illustrate the present invention in conjunction with the accompanying drawings.

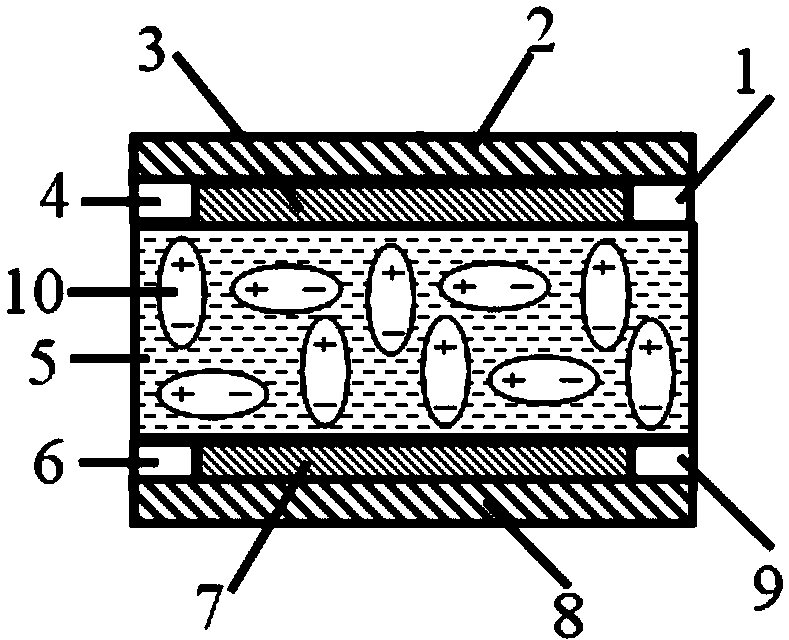

[0023] see figure 1 , the embodiment of the present invention is provided with electroactive polymer film 5, carbon nanotube composite film electrode layer 3 and 7, polyimide flexible insulation protection layer 2 and 8, device surface peripheral electrode anchor region 1, 4, 6 and 9 . The embodiment of the present invention has a sandwich structure. Under the action of no tactile or motion pressure, the electric domains 10 inside the electroactive polymer film are randomly distributed and cancel each other out, and no charge is generated on the surface electrode layer.

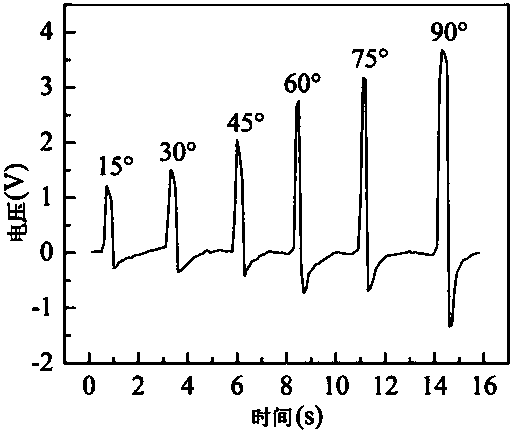

[0024] Embodiments of the present invention are under the action of touch or stress, such as figure 2 As shown, the distribution and orientation of the electric domains 10 inside the electroactive polymer film are consistent, and the upper and lower surfaces of the electrode layer...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| transmittivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com