Patents

Literature

2399 results about "Surface electrode" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

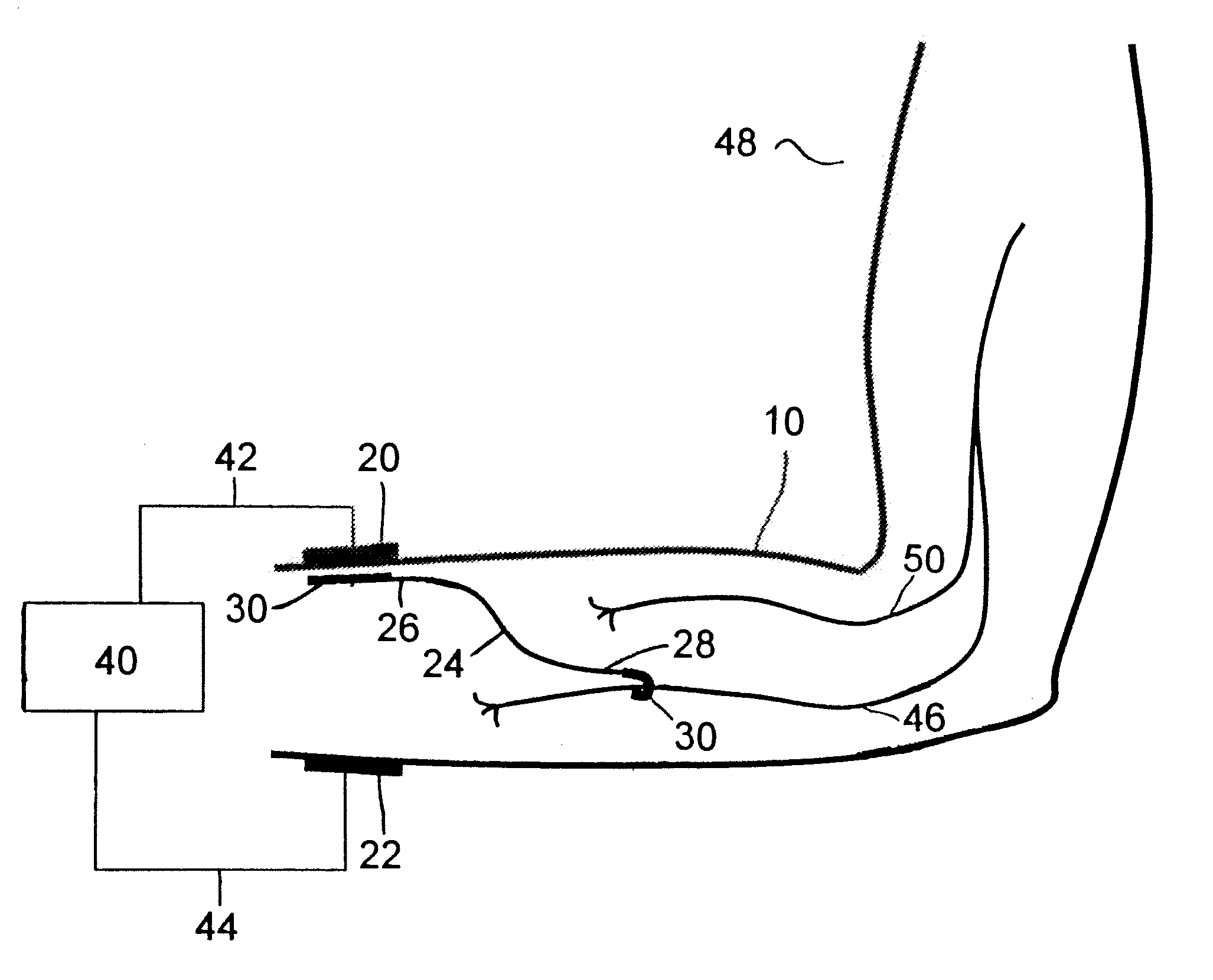

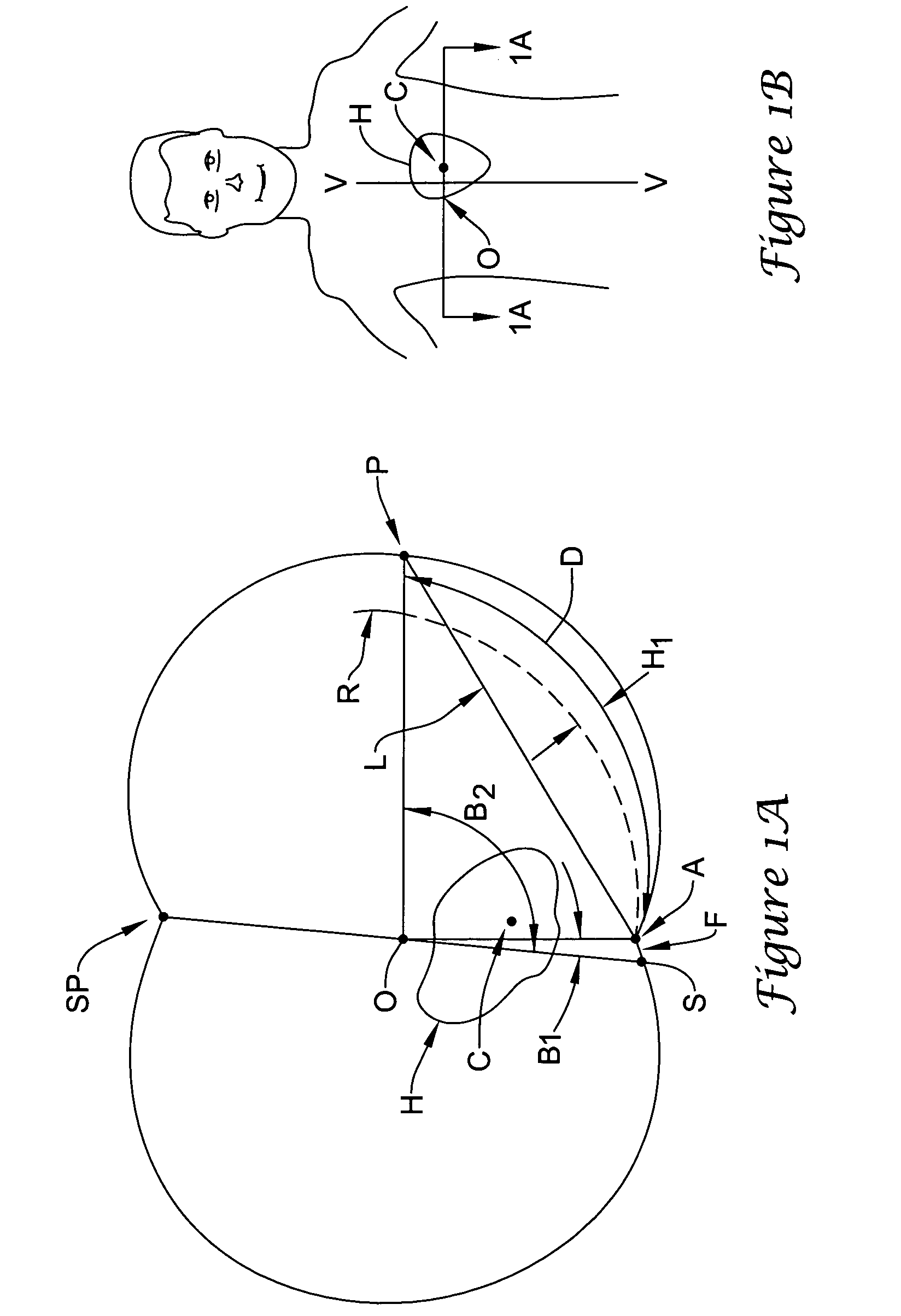

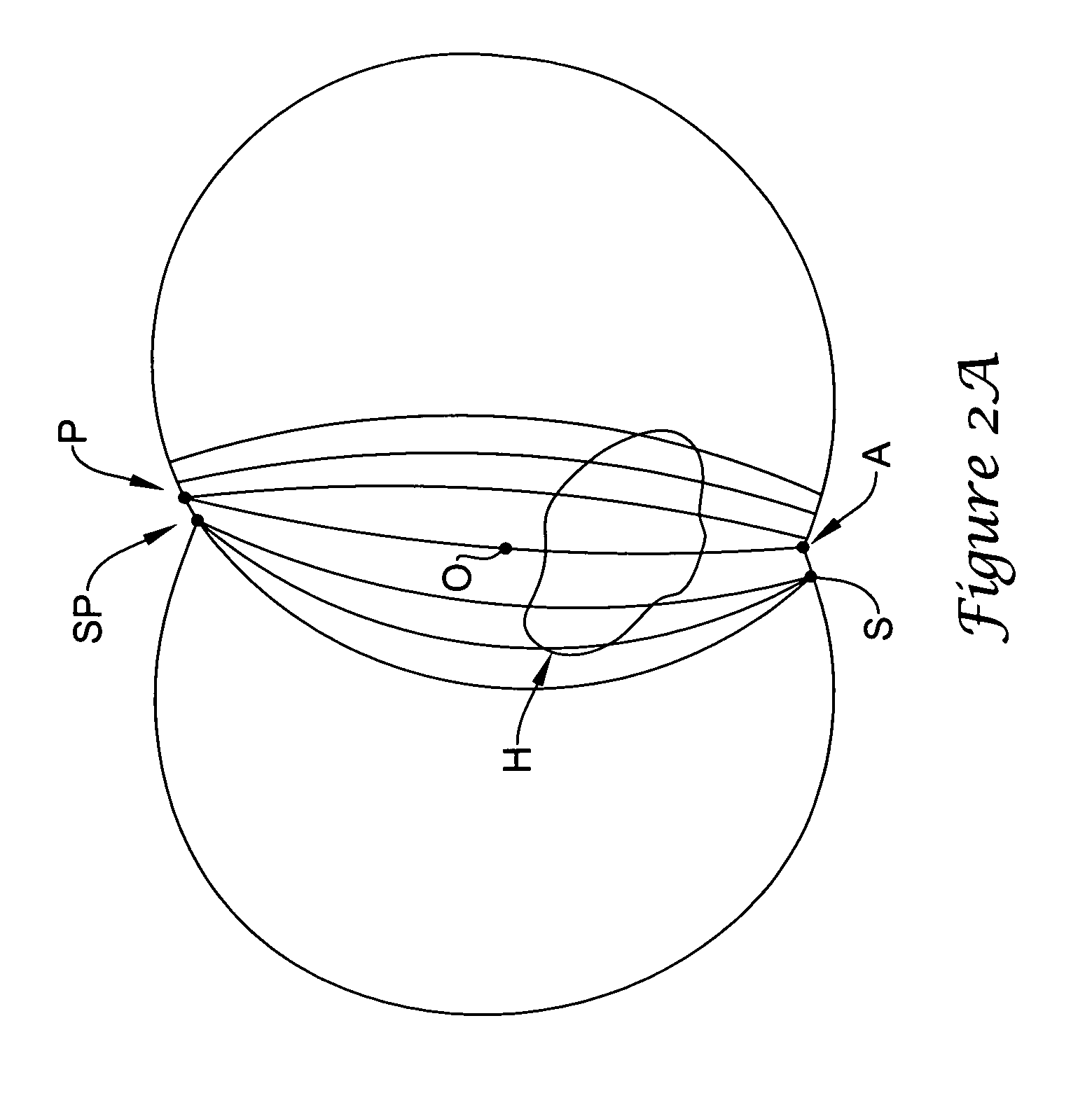

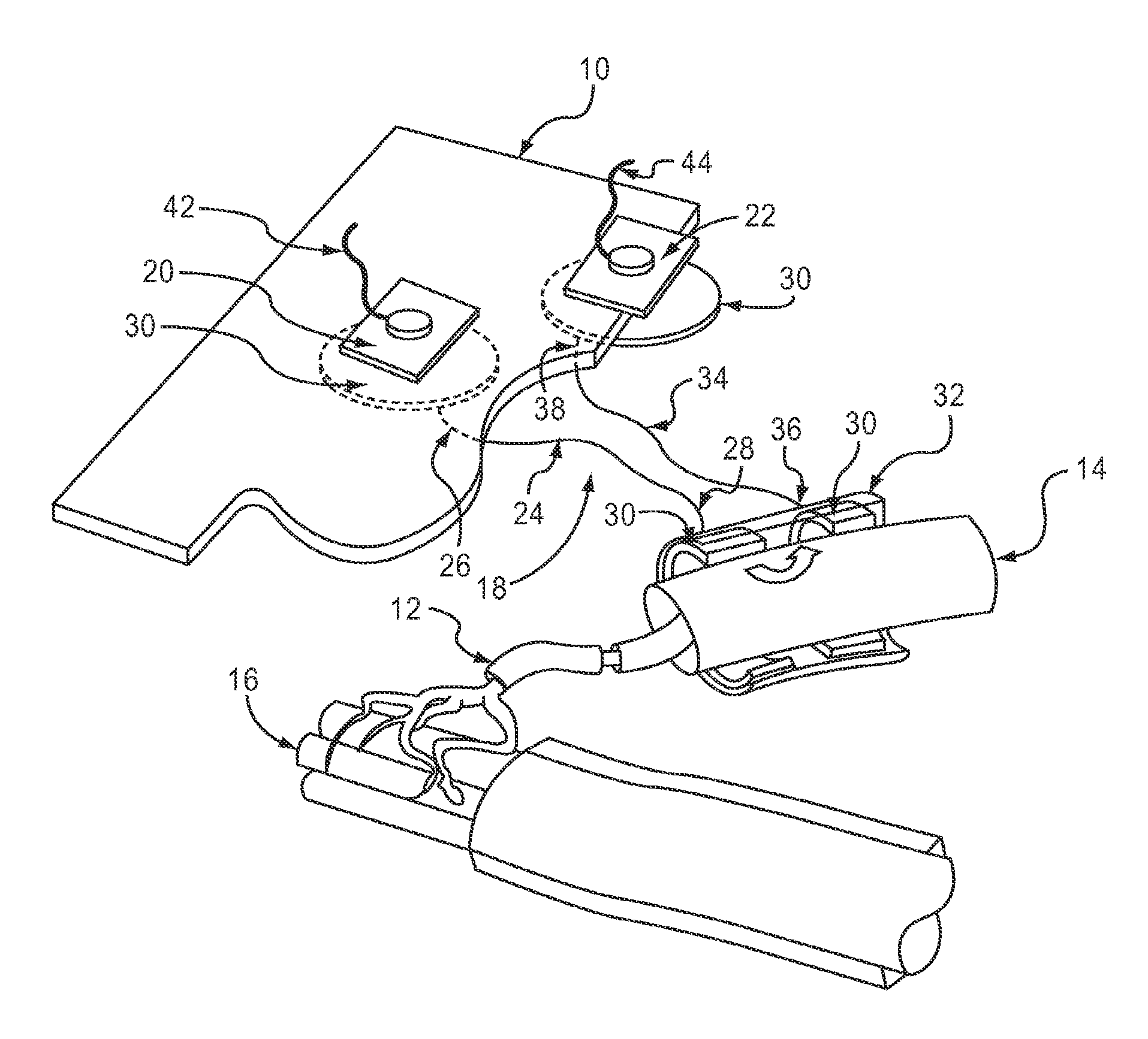

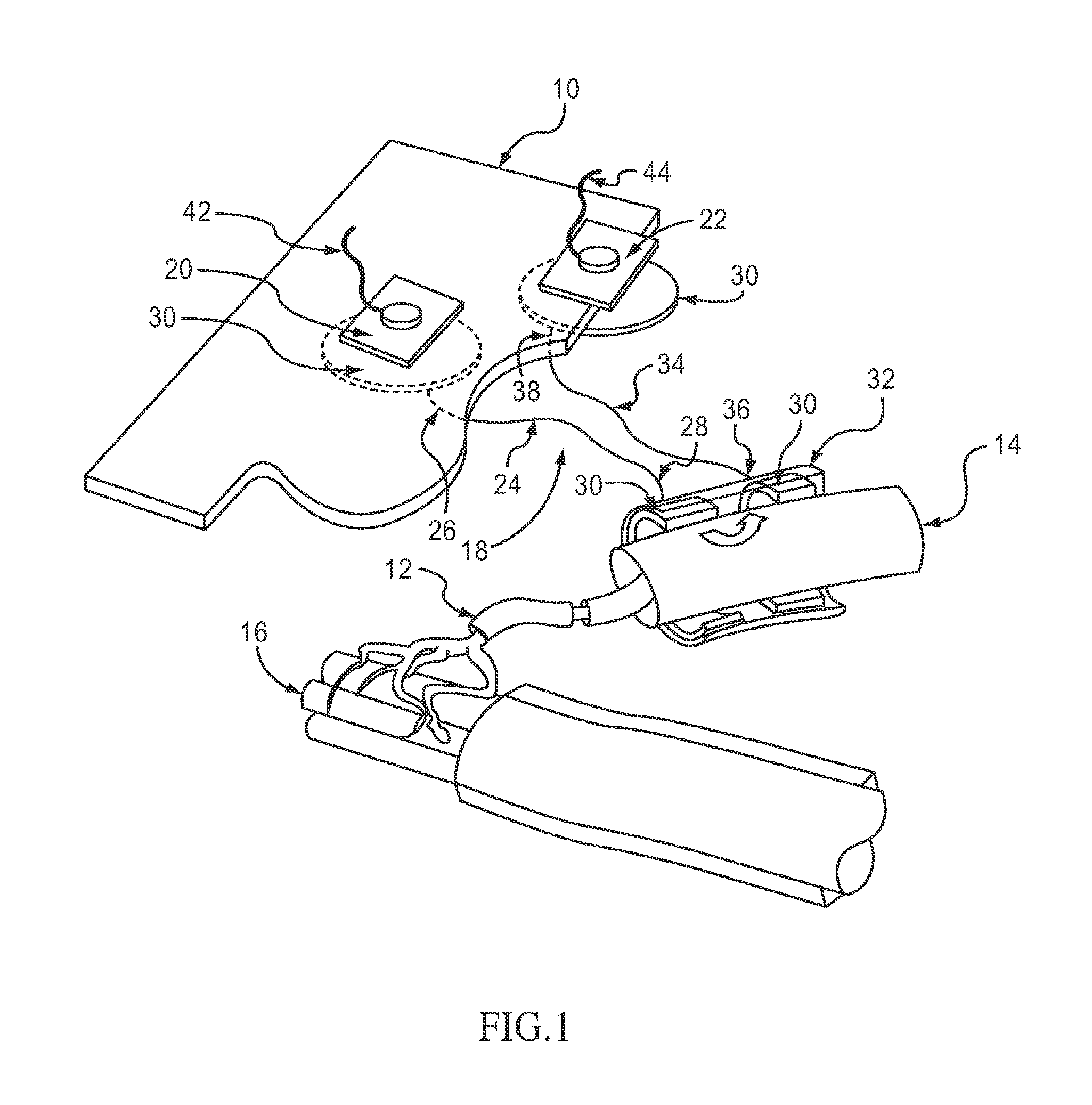

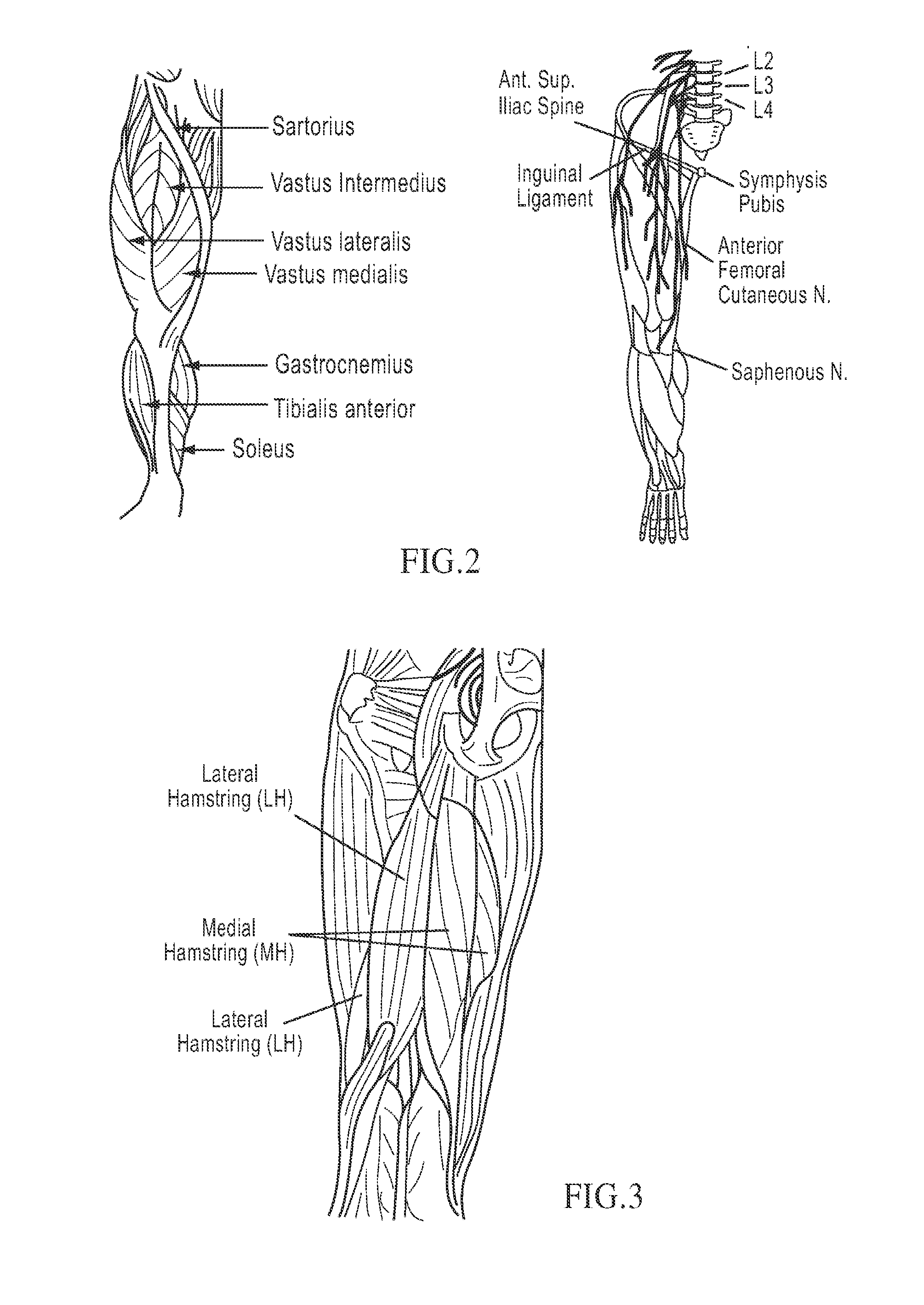

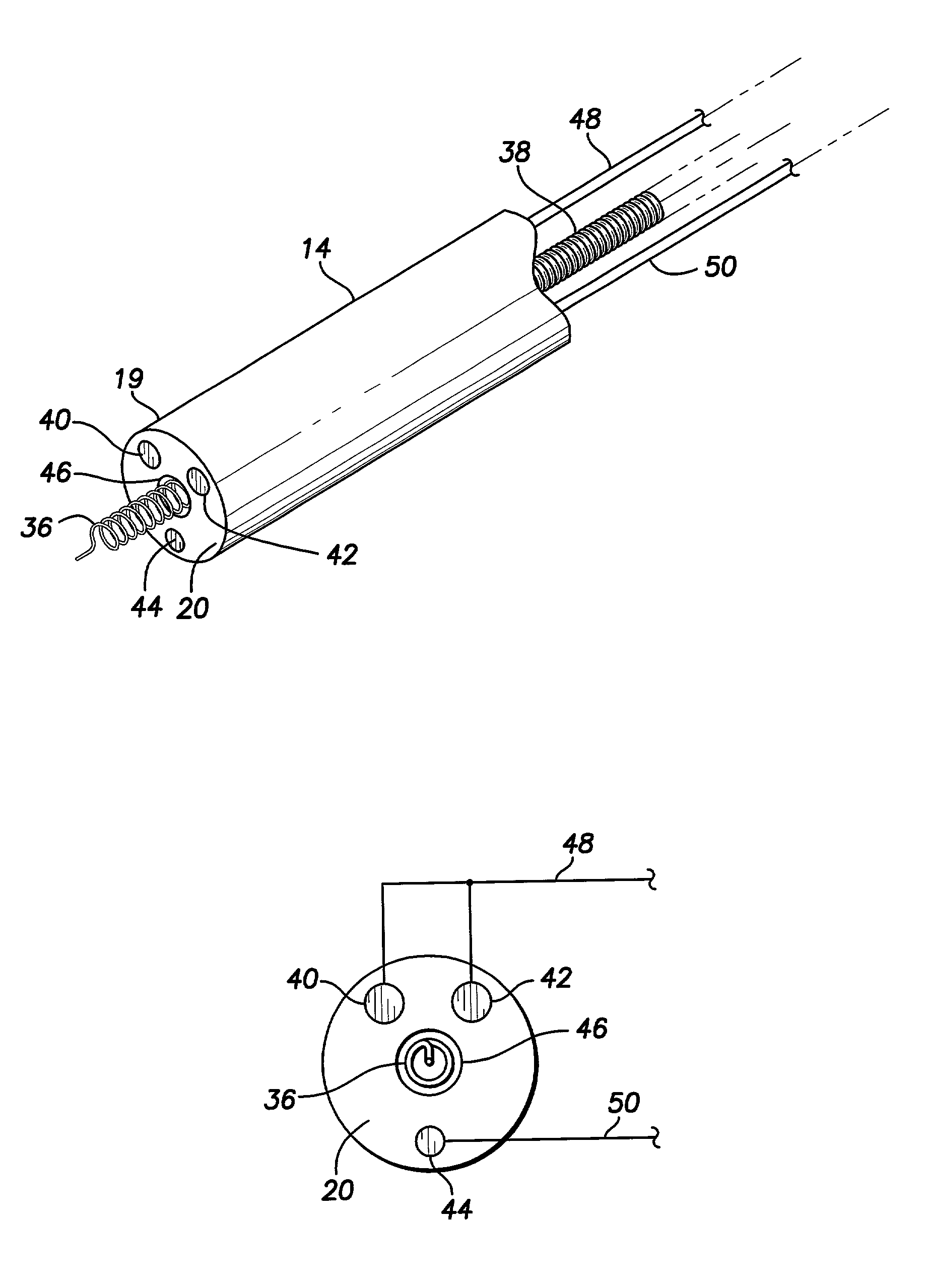

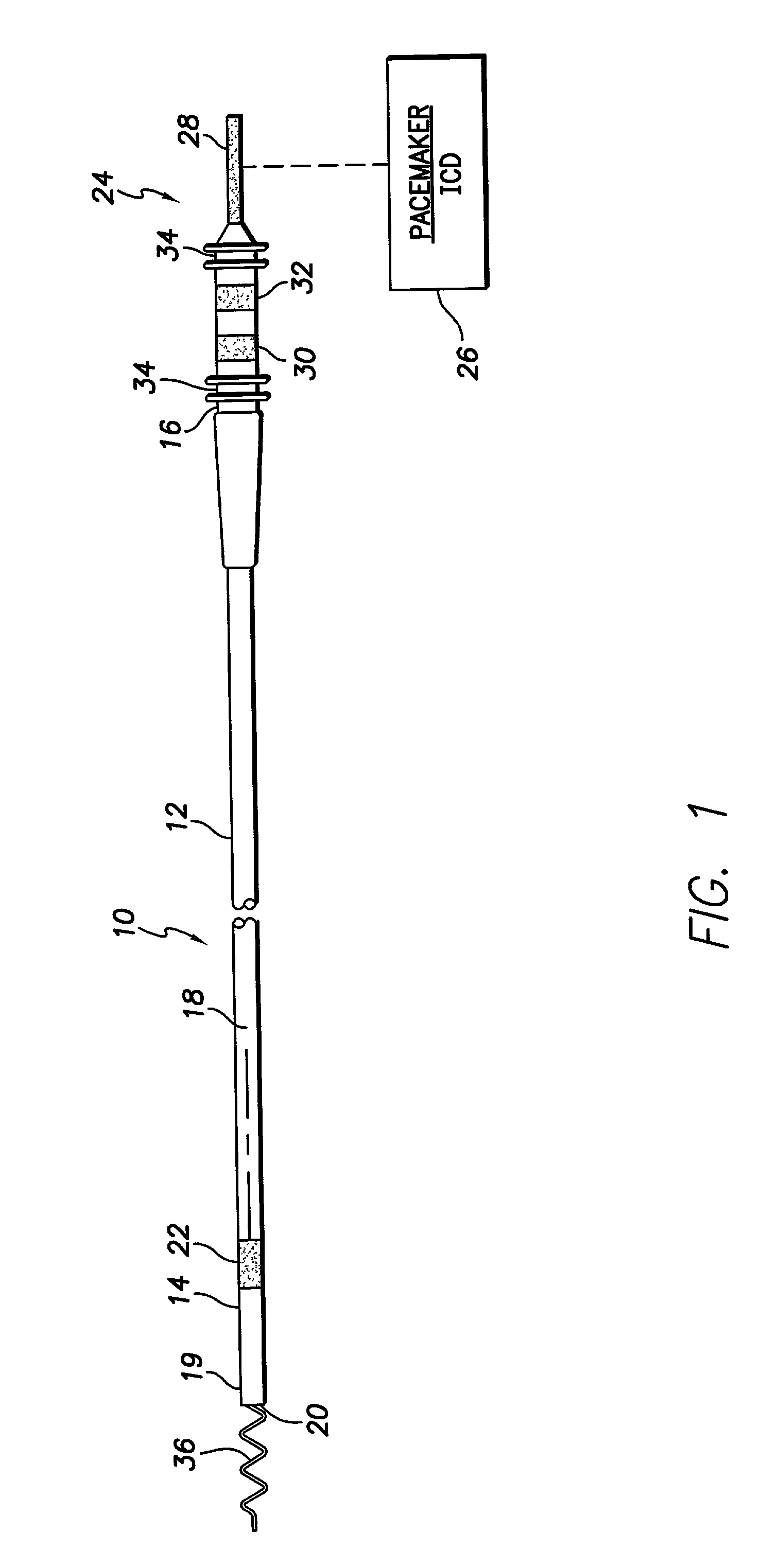

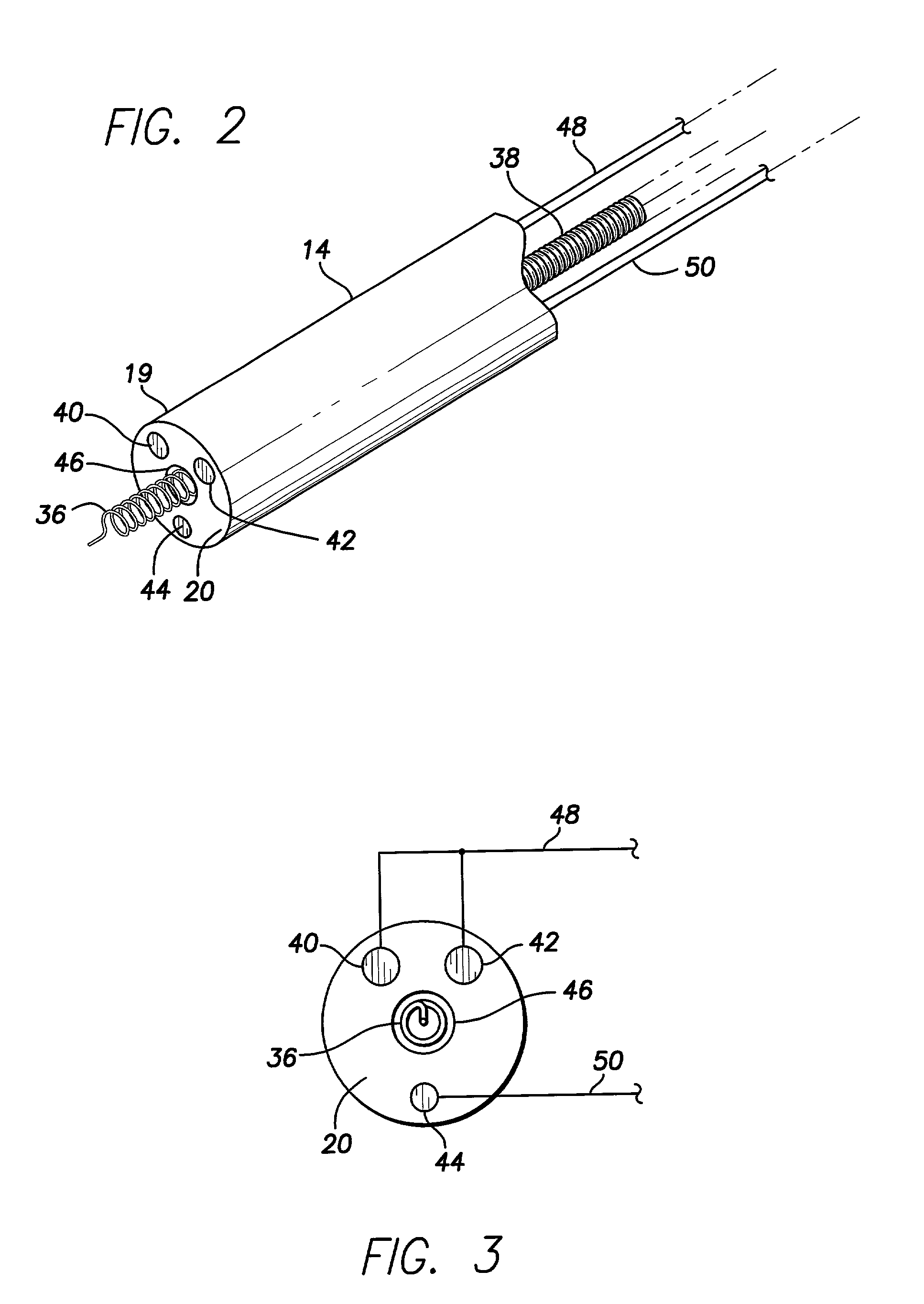

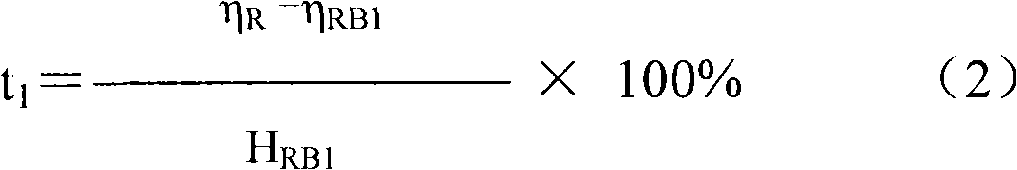

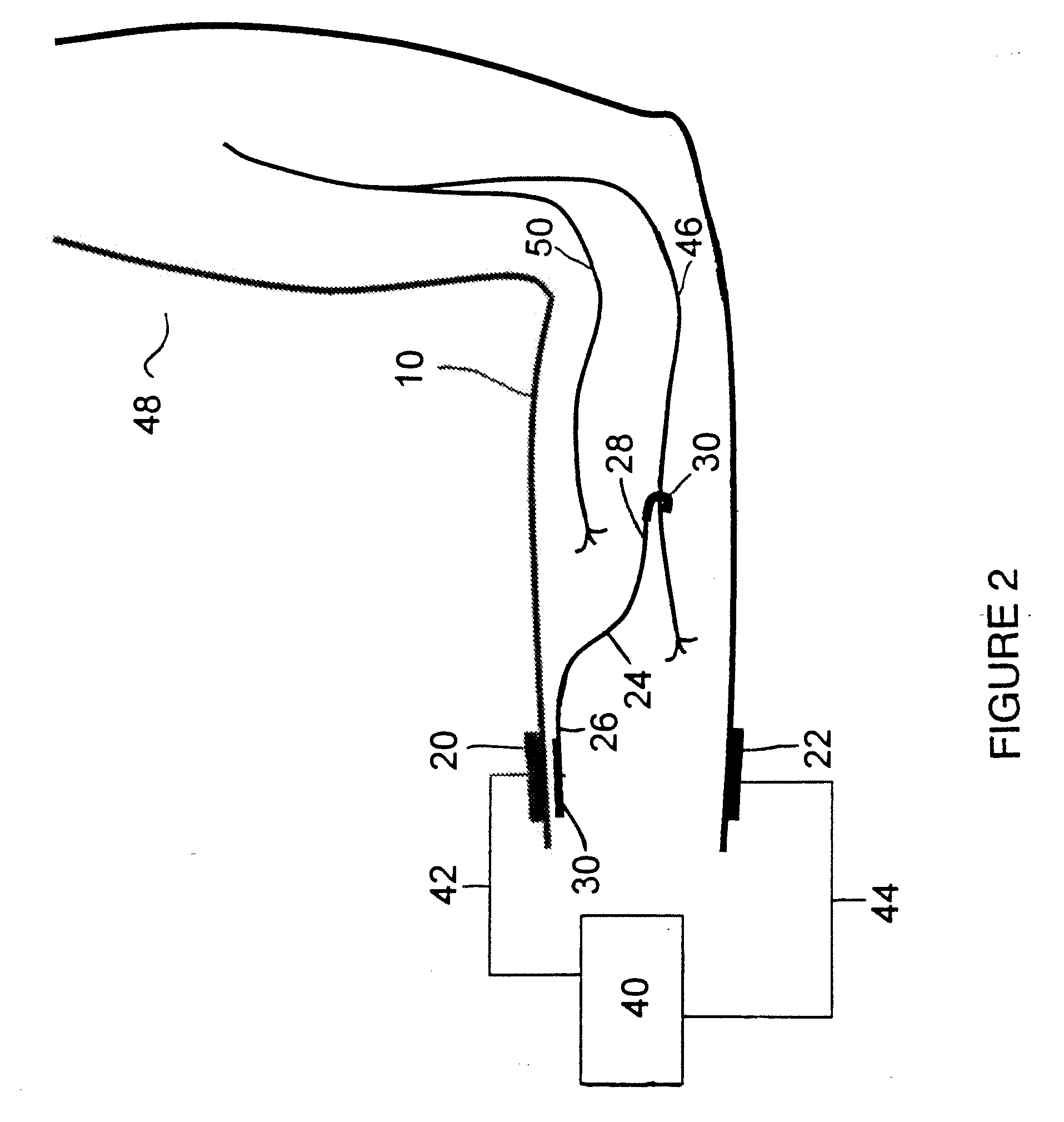

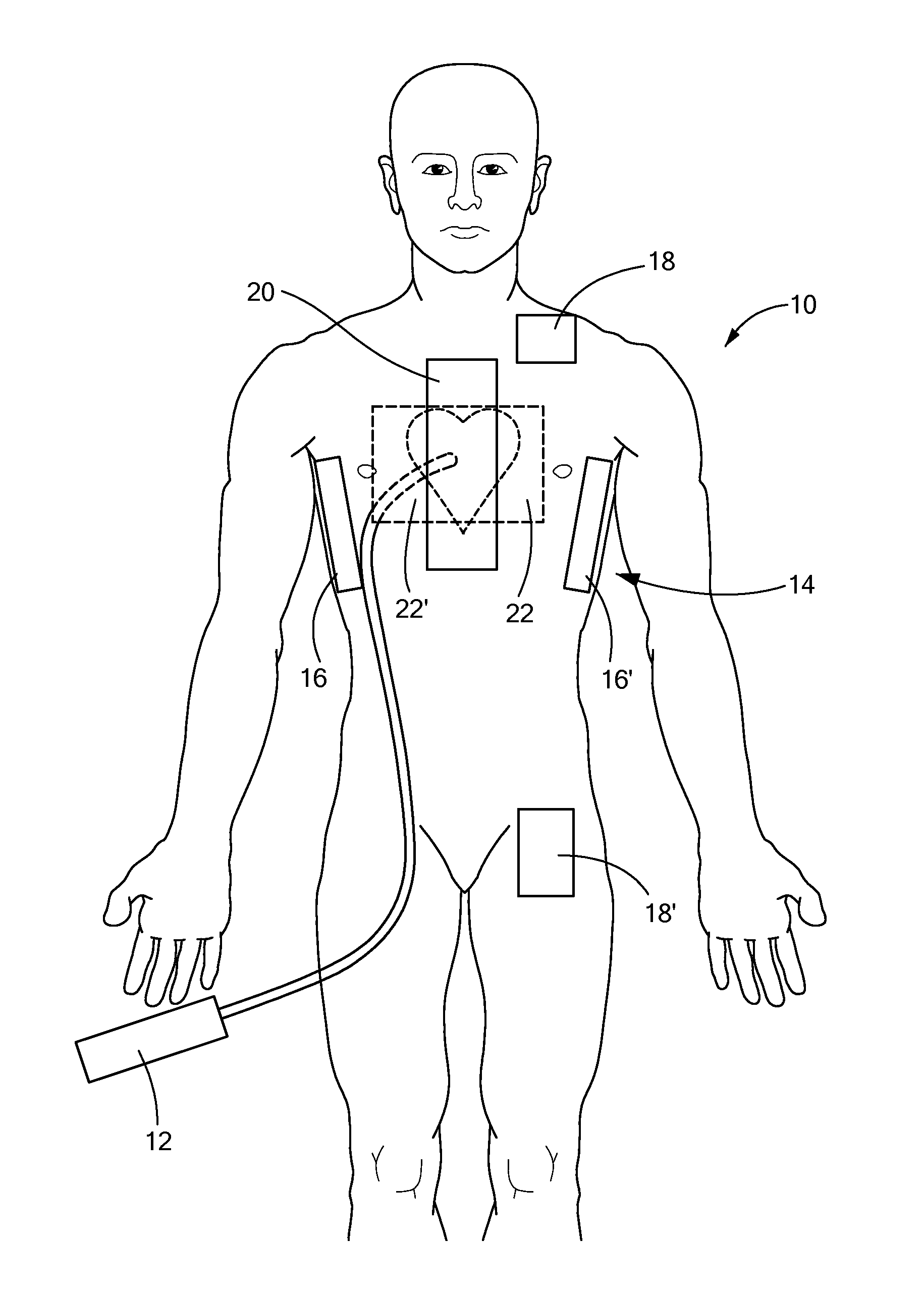

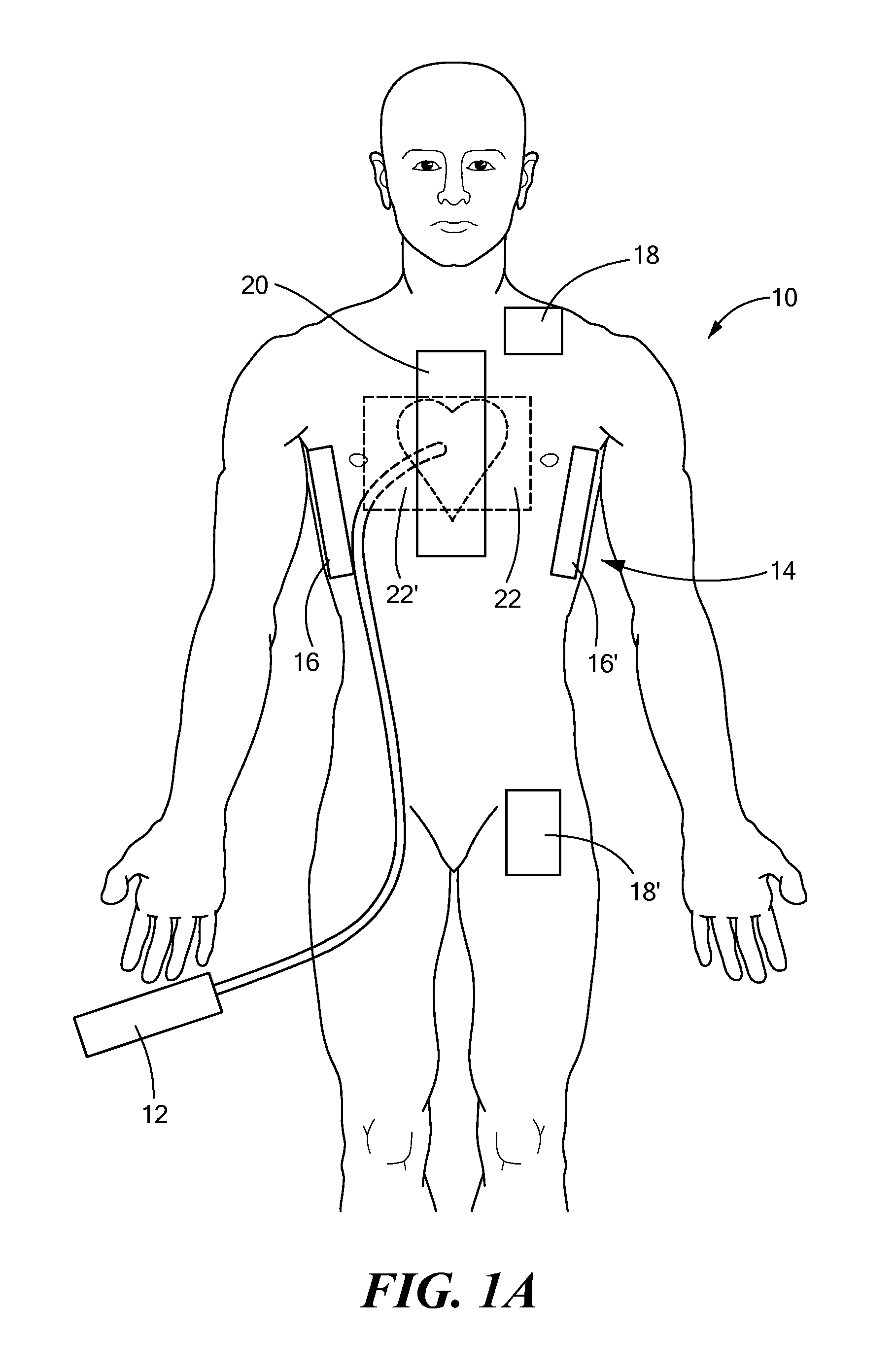

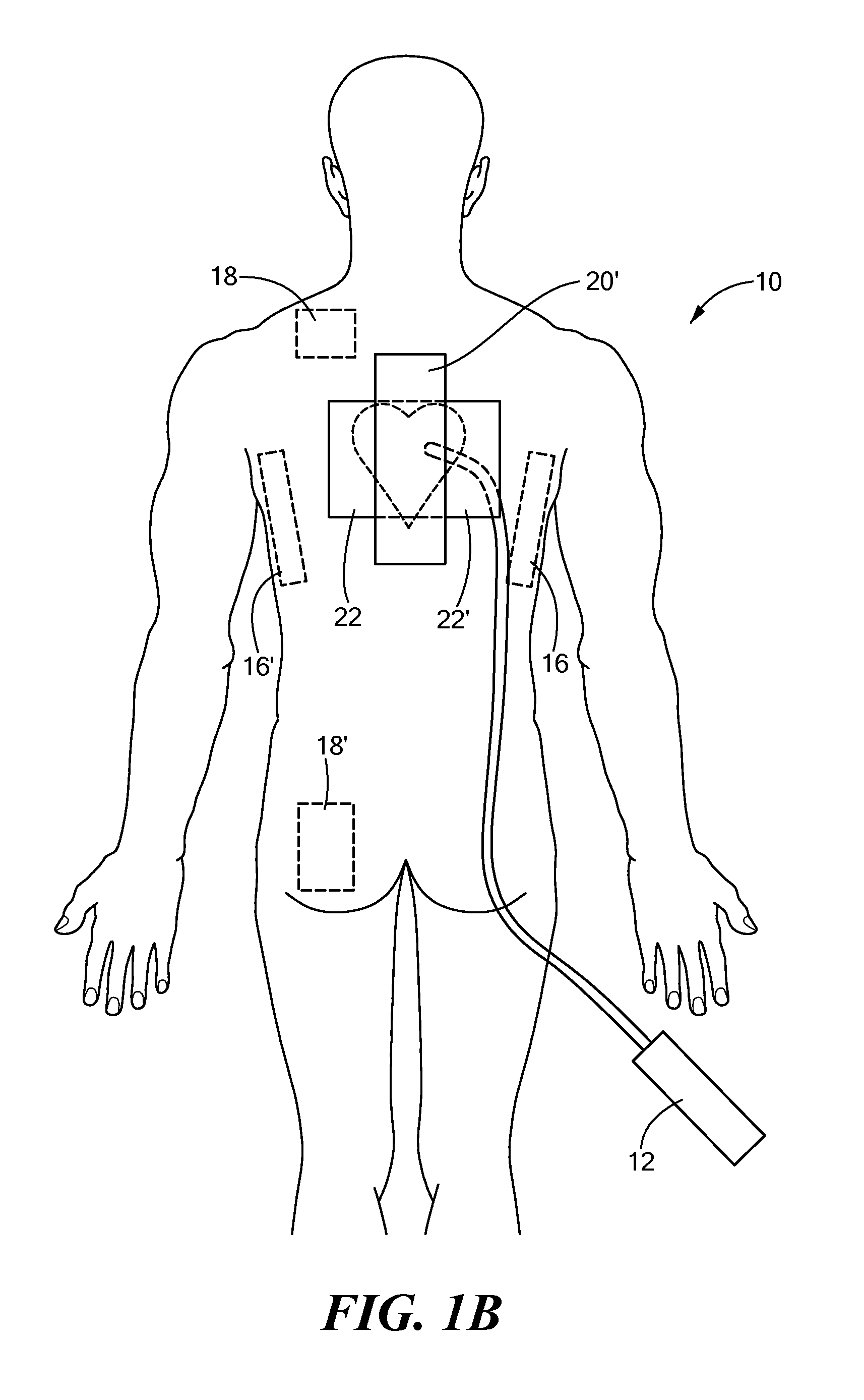

Method of routing electrical current to bodily tissues via implanted passive conductors

The invention provides an implant, system and method for electrically stimulating a target tissue to either activate or block neural impulses. The implant provides a conductive pathway for a portion of electrical current flowing between surface electrodes positioned on the skin and transmits that current to the target tissue. The implant has a passive electrical conductor of sufficient length to extend from subcutaneous tissue located below a surface cathodic electrode to the target tissue. The conductor has a pick-up end which forms an electrical termination having a sufficient surface area to allow a sufficient portion of the electrical current to flow through the conductor, in preference to flowing through body tissue between the surface electrodes, such that the target tissue is stimulated to either activate or block neural impulses. The conductor also has a stimulating end which forms an electrical termination for delivering the current to the target body tissue.

Owner:2249020 ALBERTA LTD

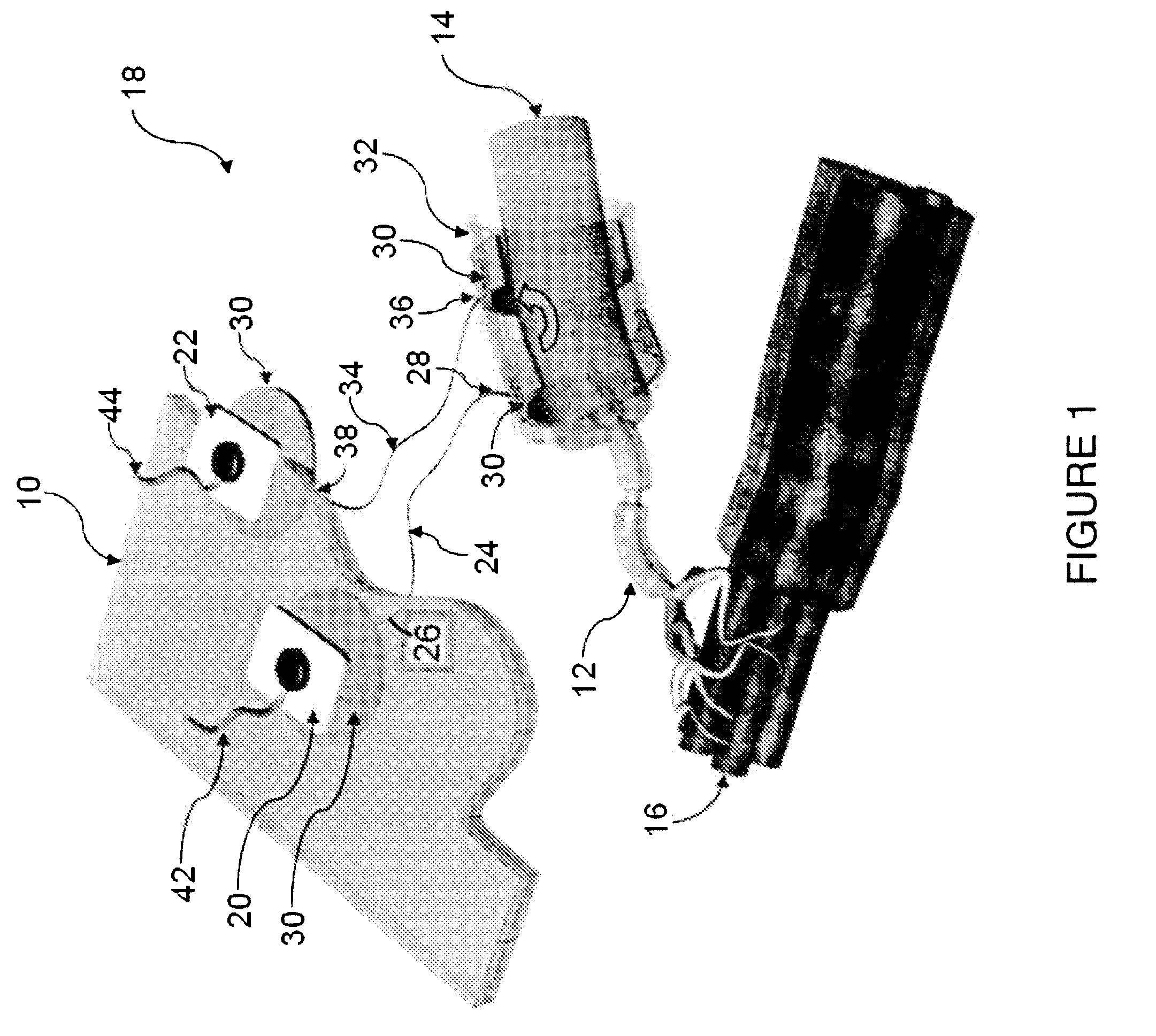

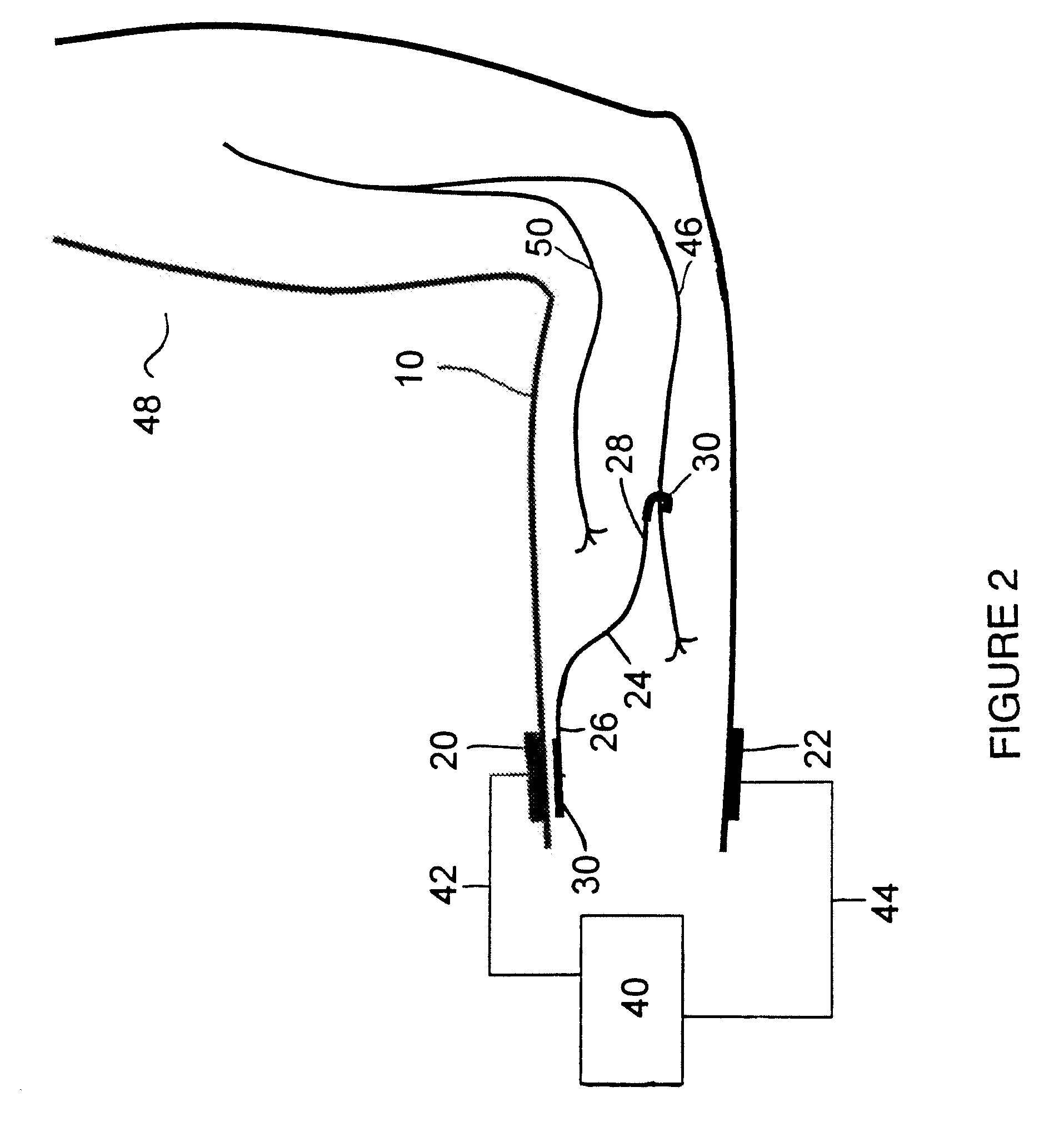

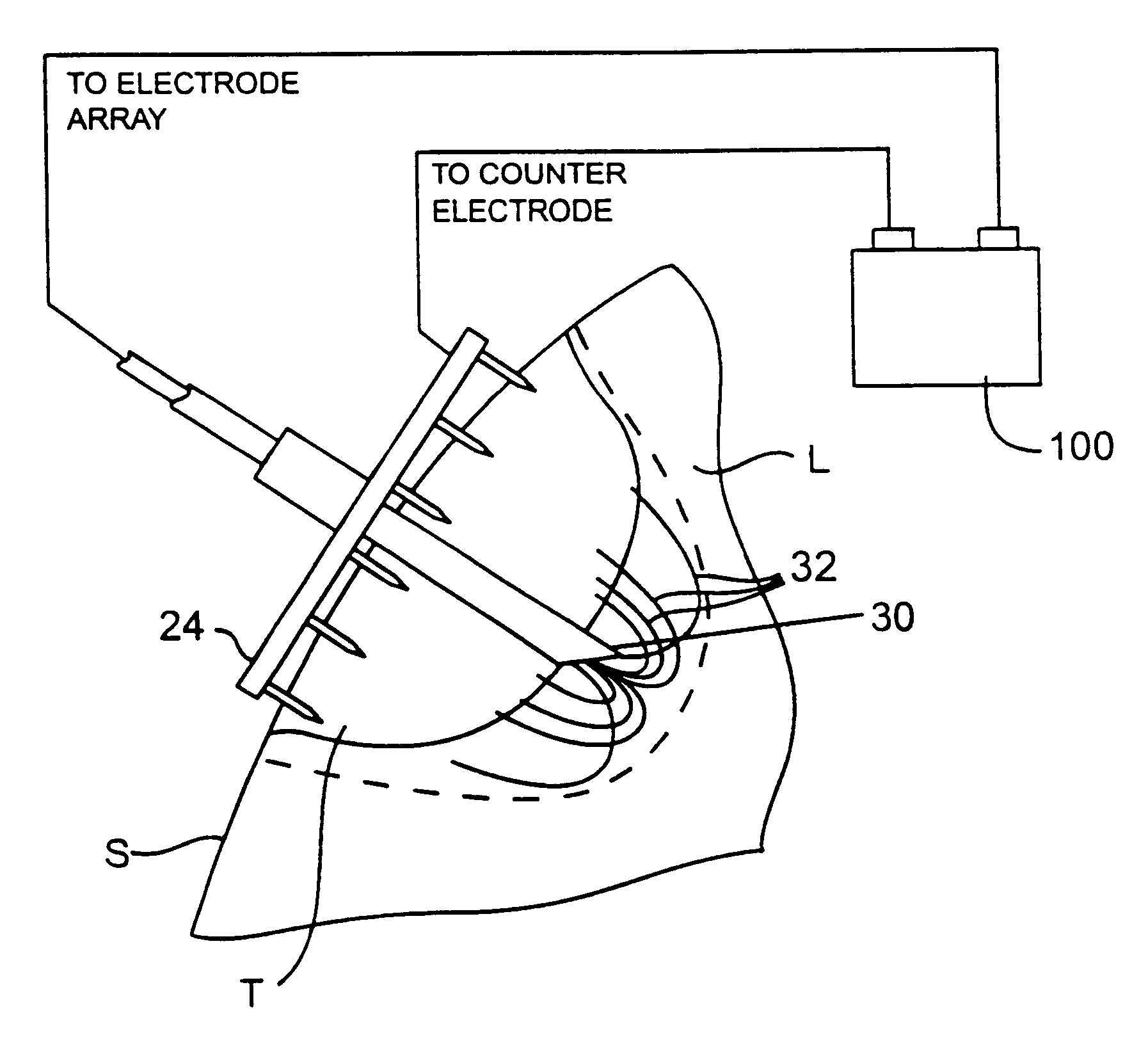

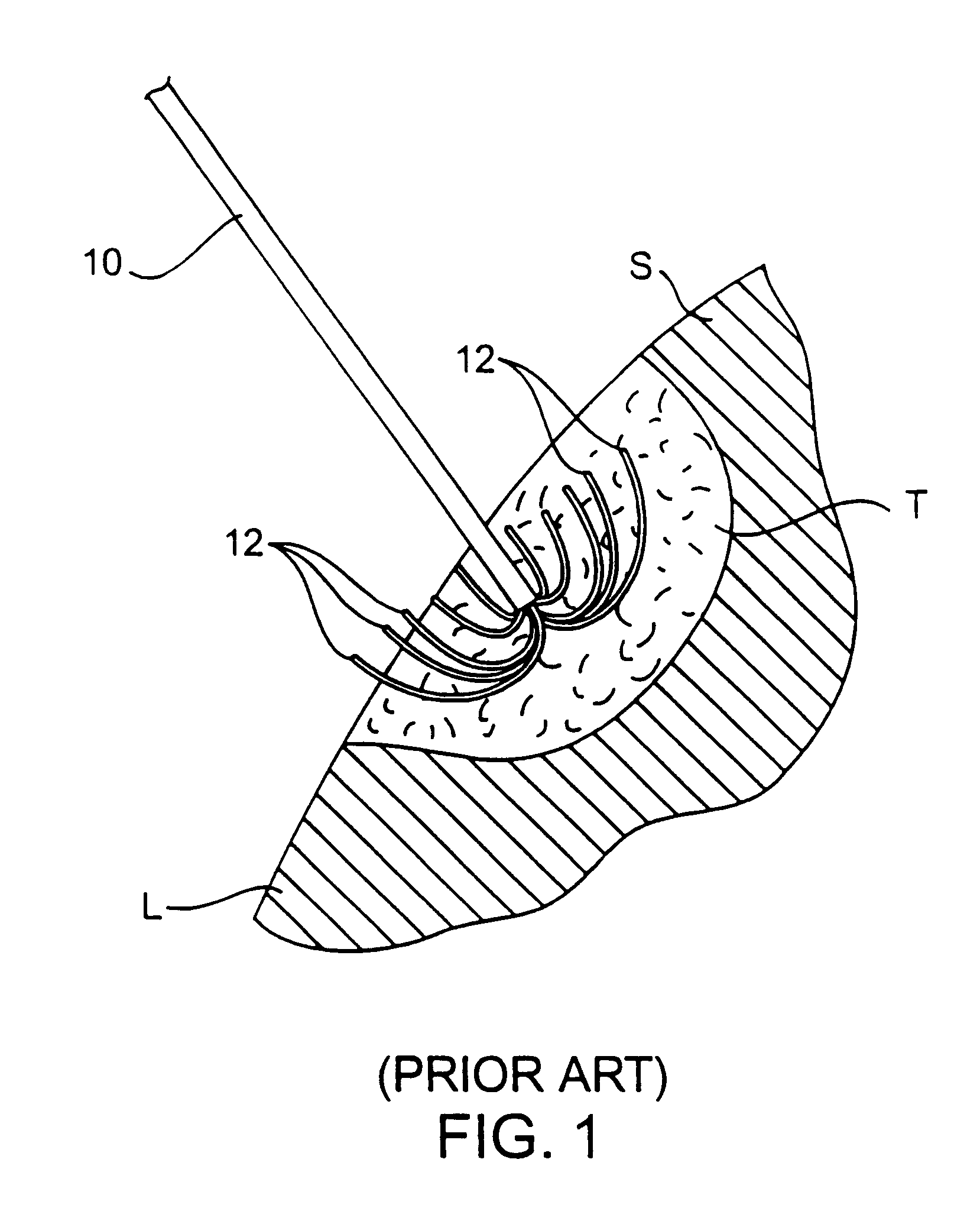

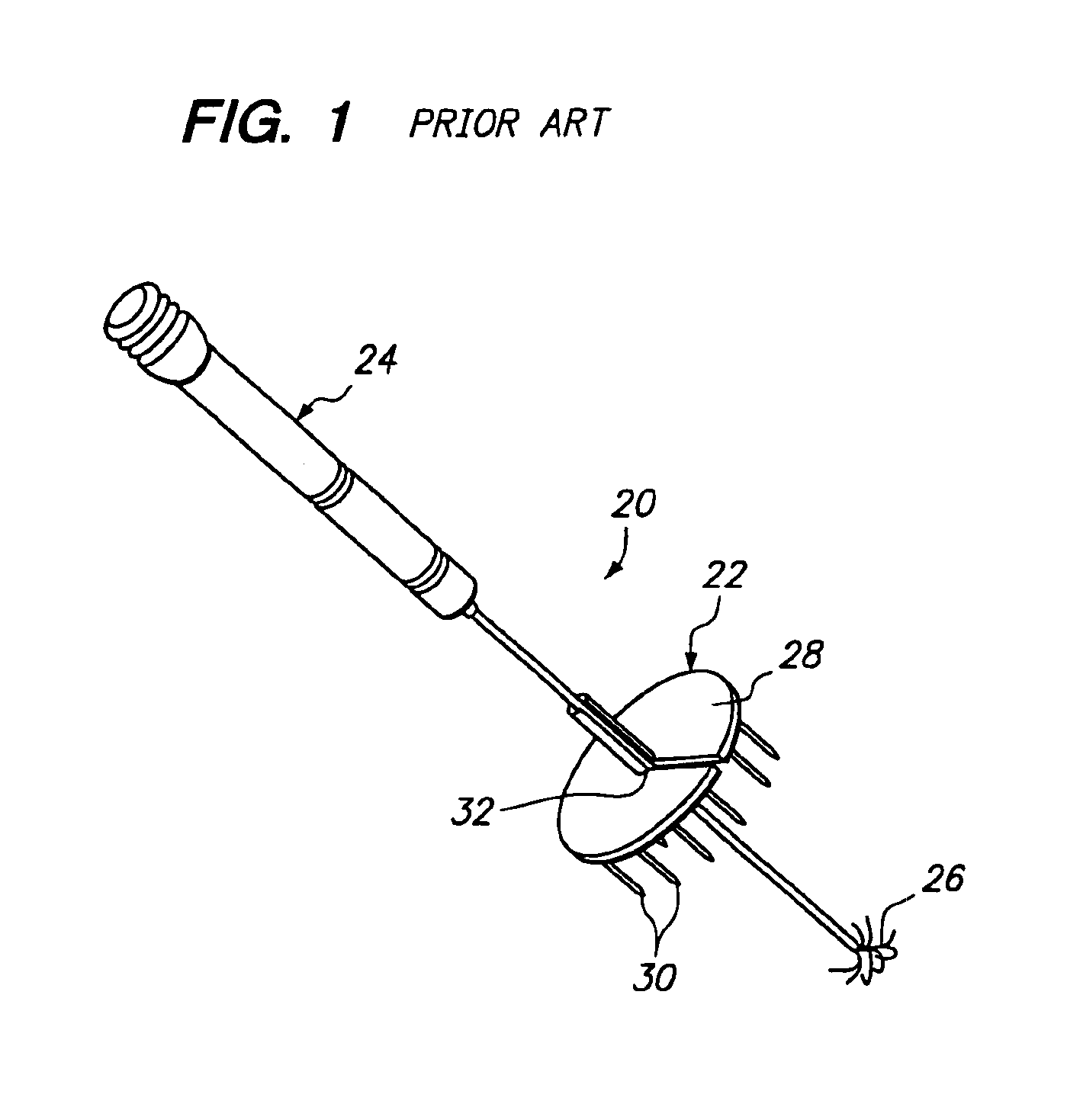

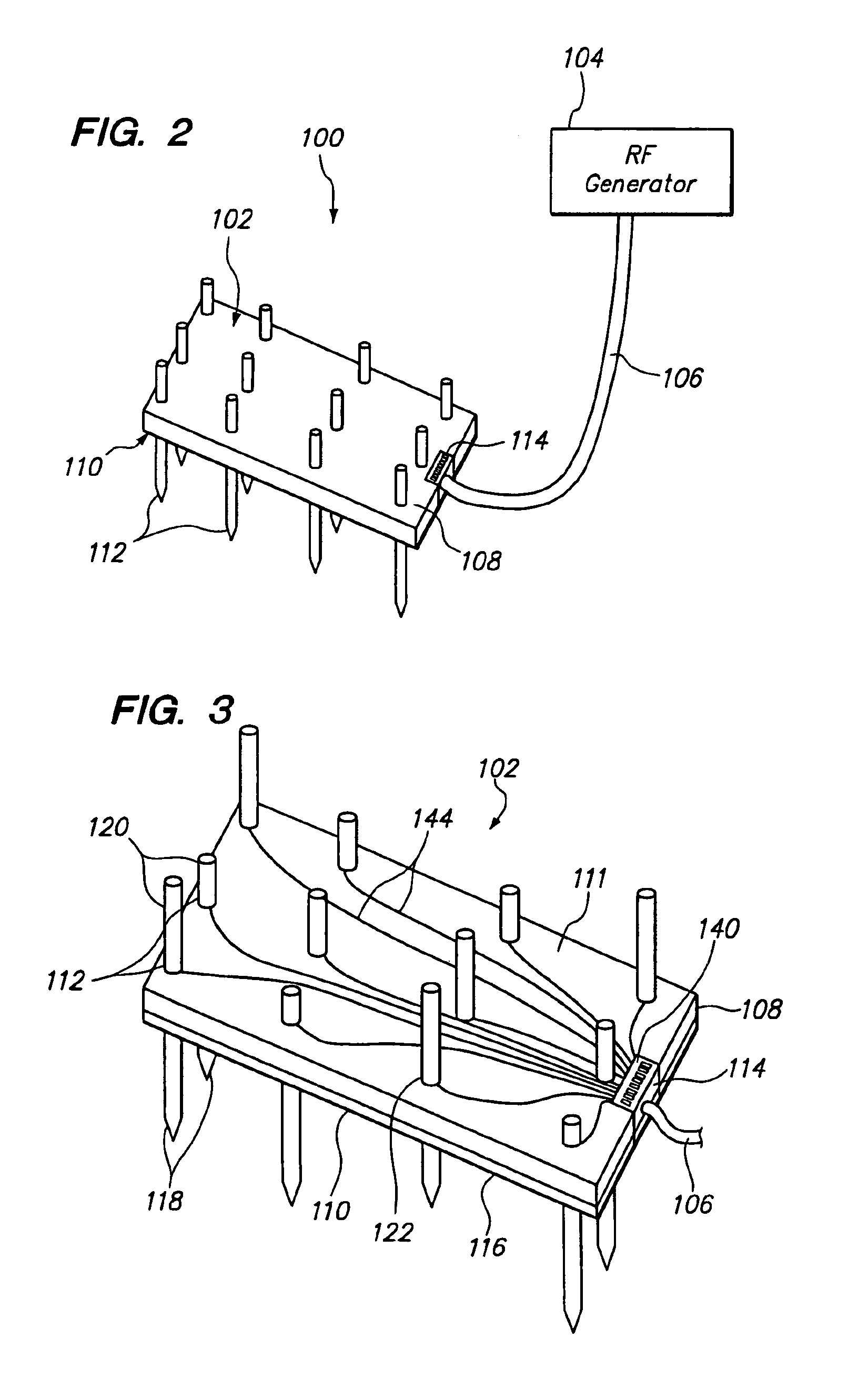

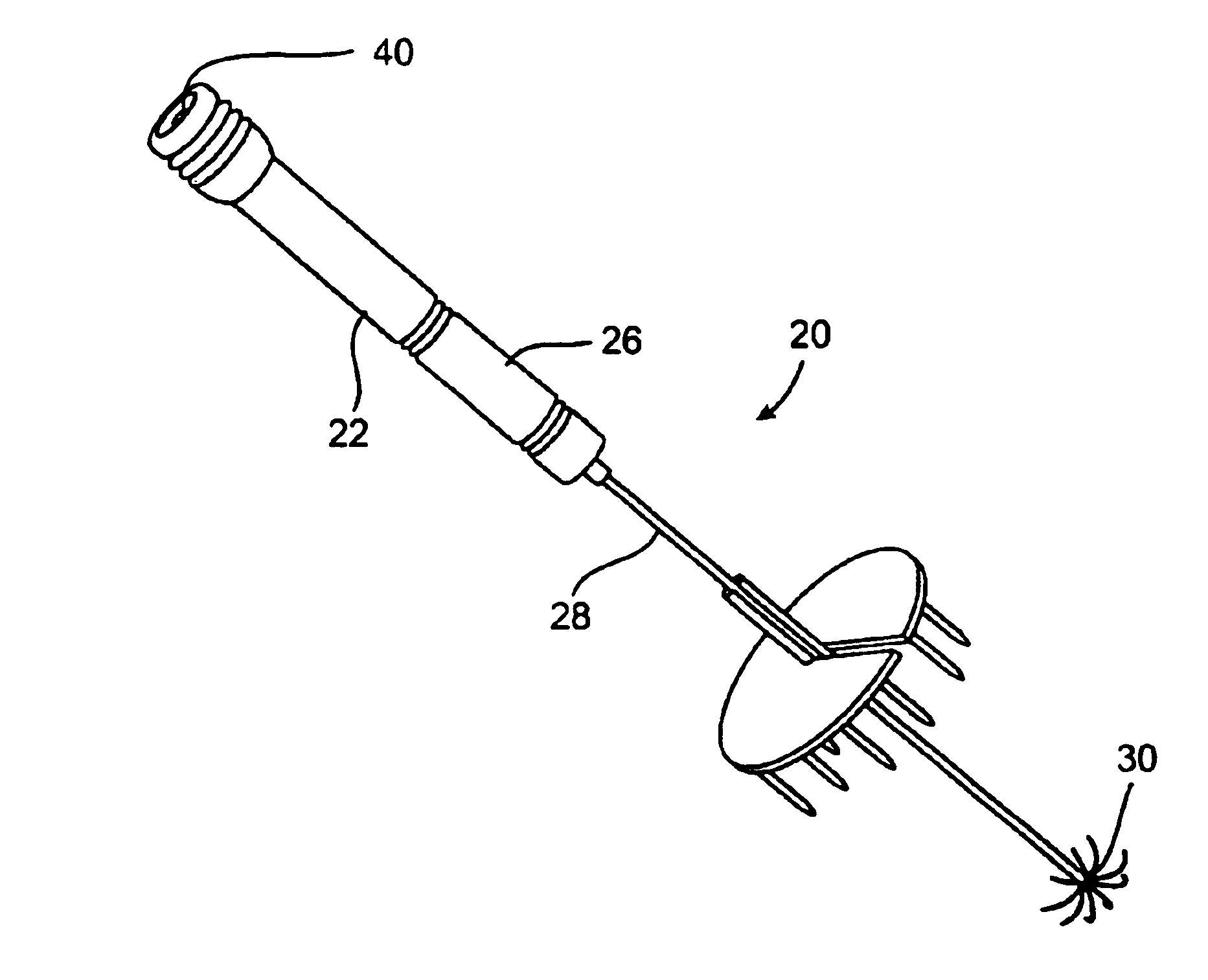

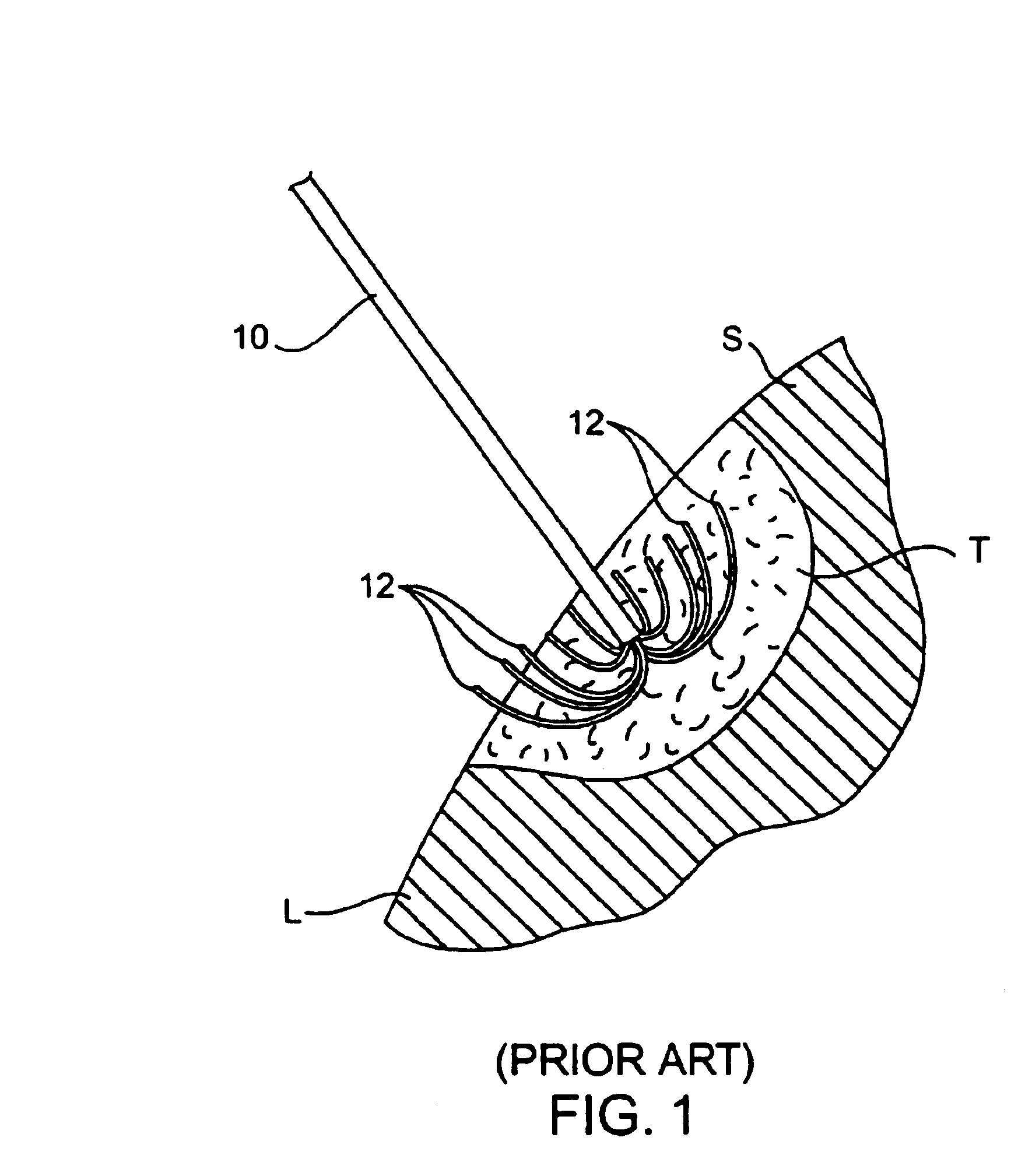

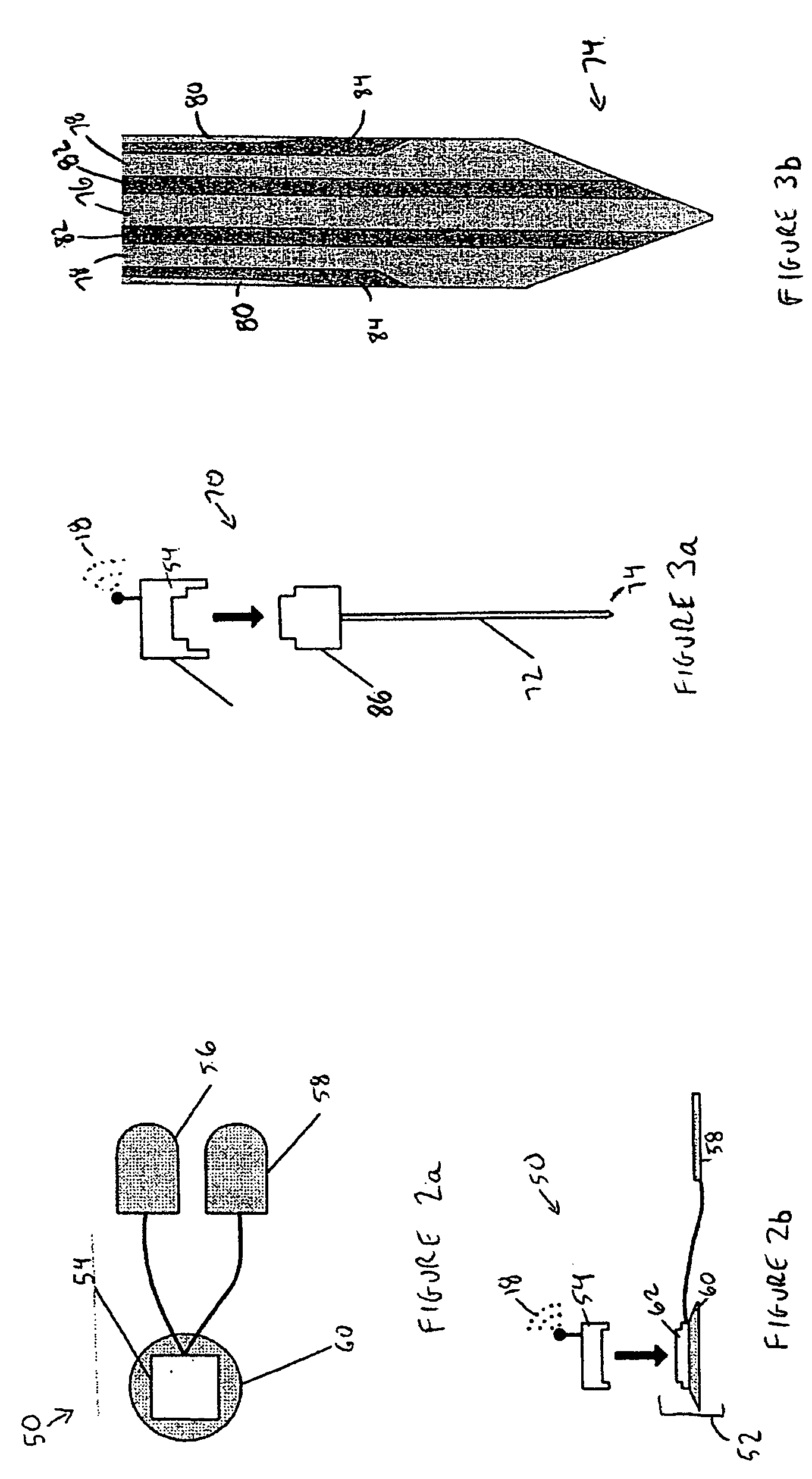

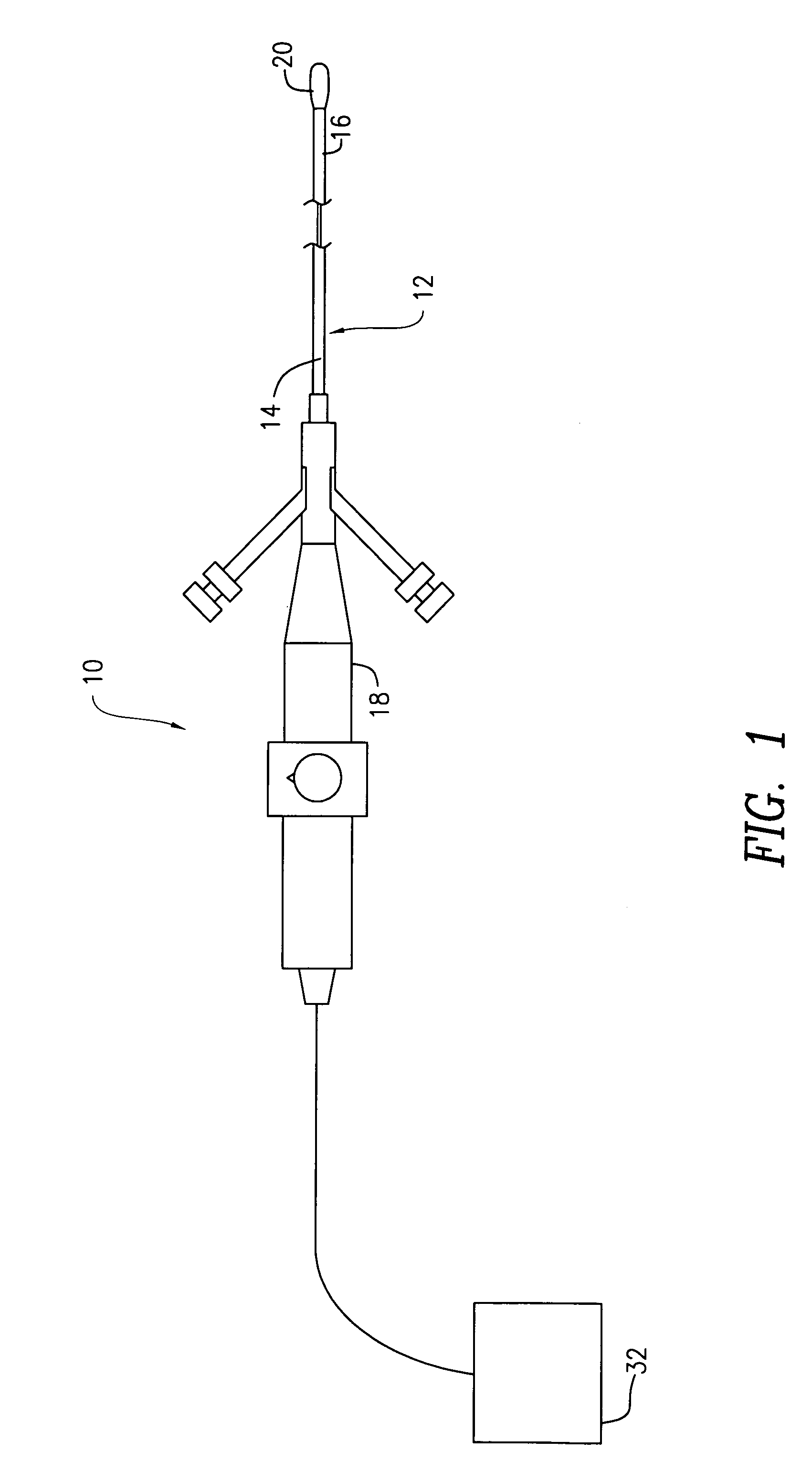

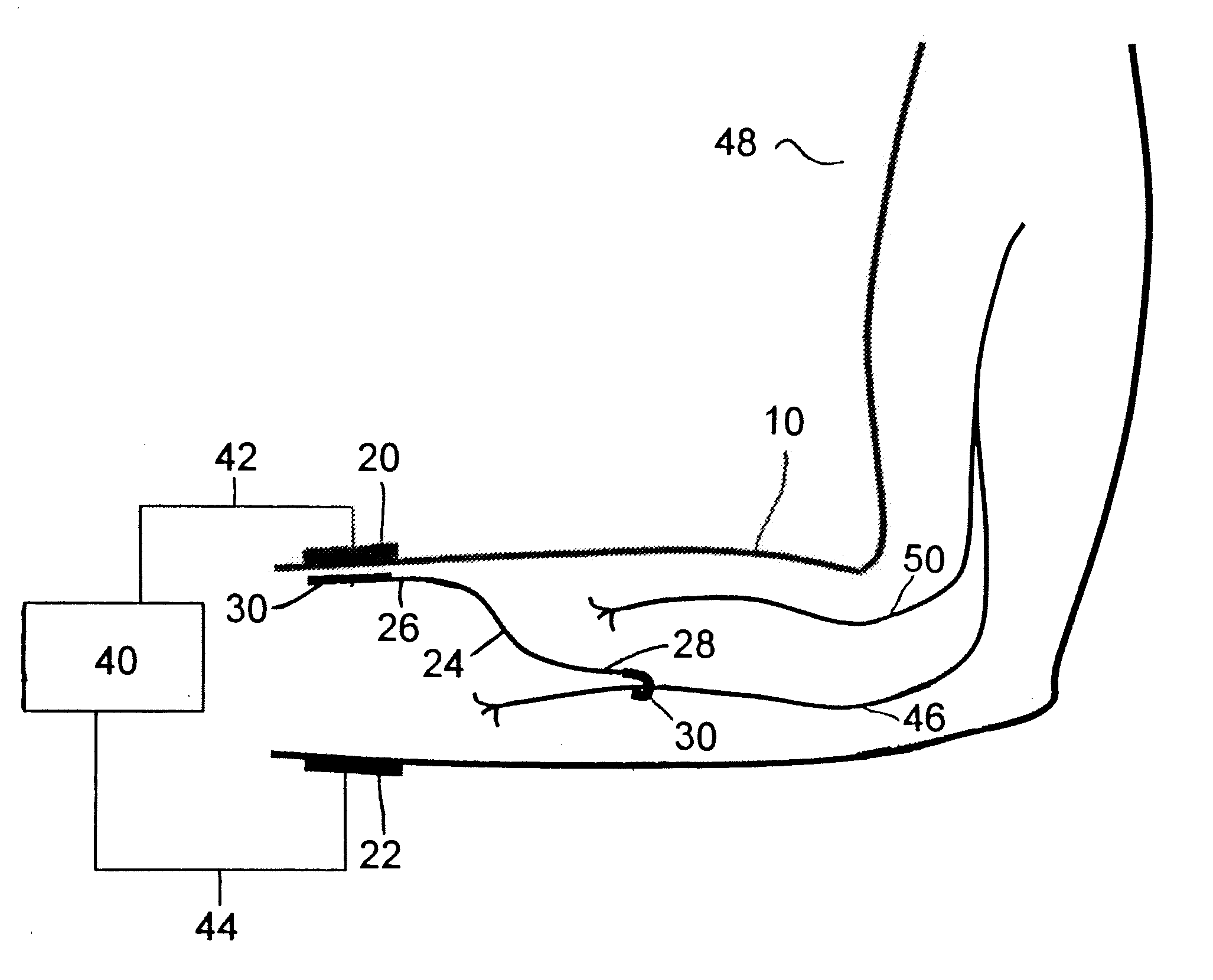

Apparatus and method for treating tumors near the surface of an organ

InactiveUS6337998B1Avoid flowPrevent heat lossElectrotherapySurgical needlesAbnormal tissue growthTherapeutic Area

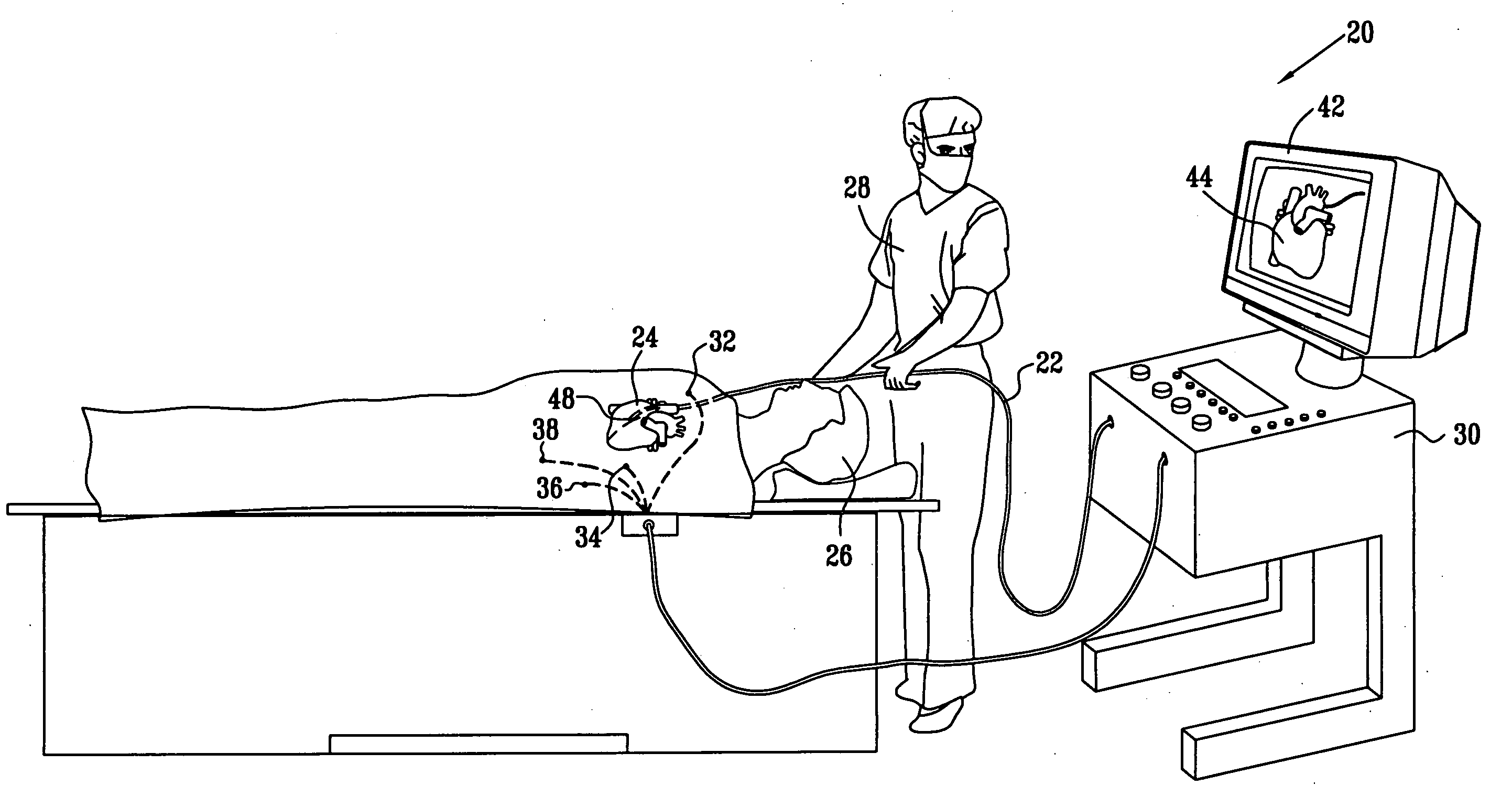

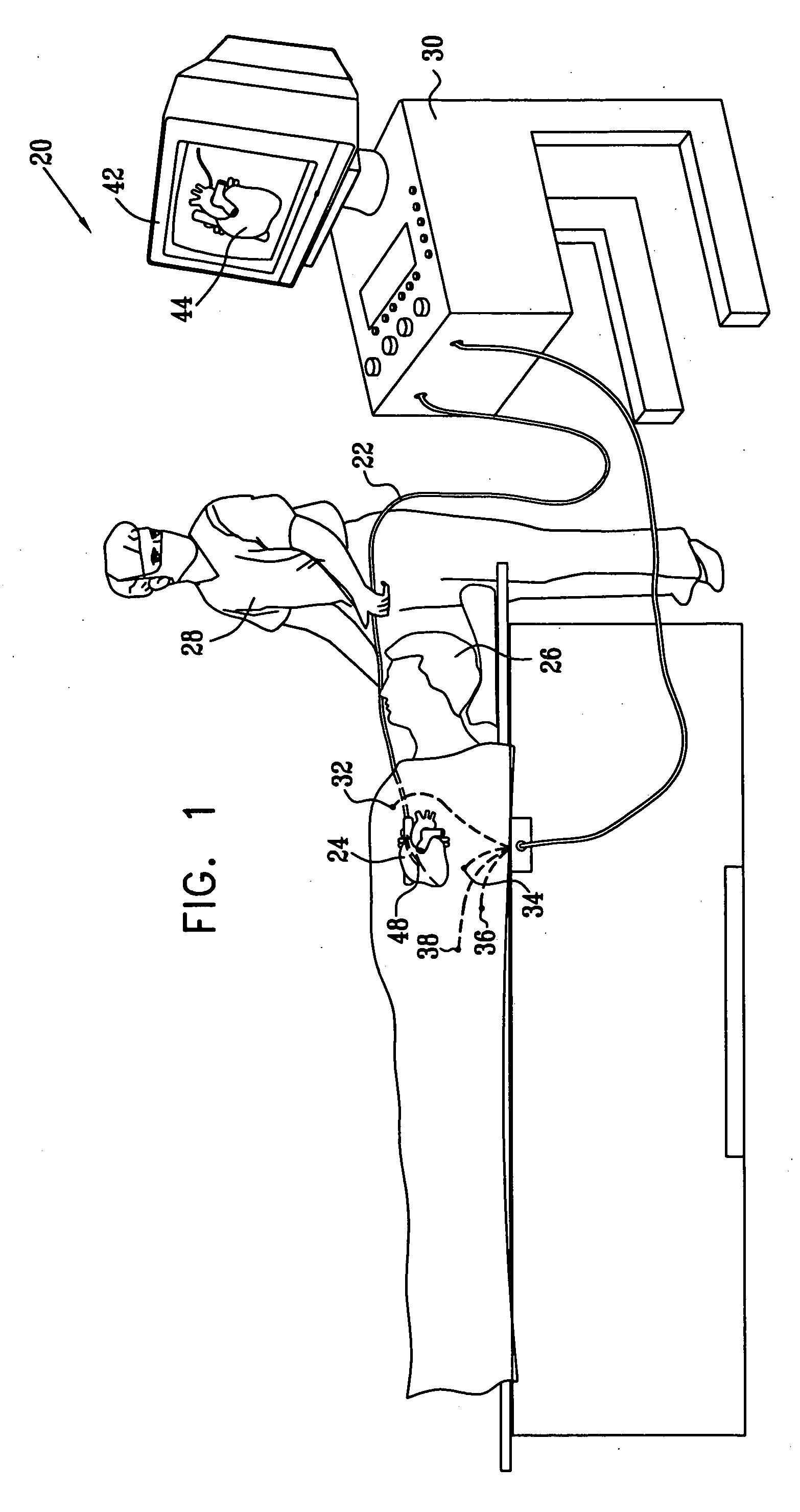

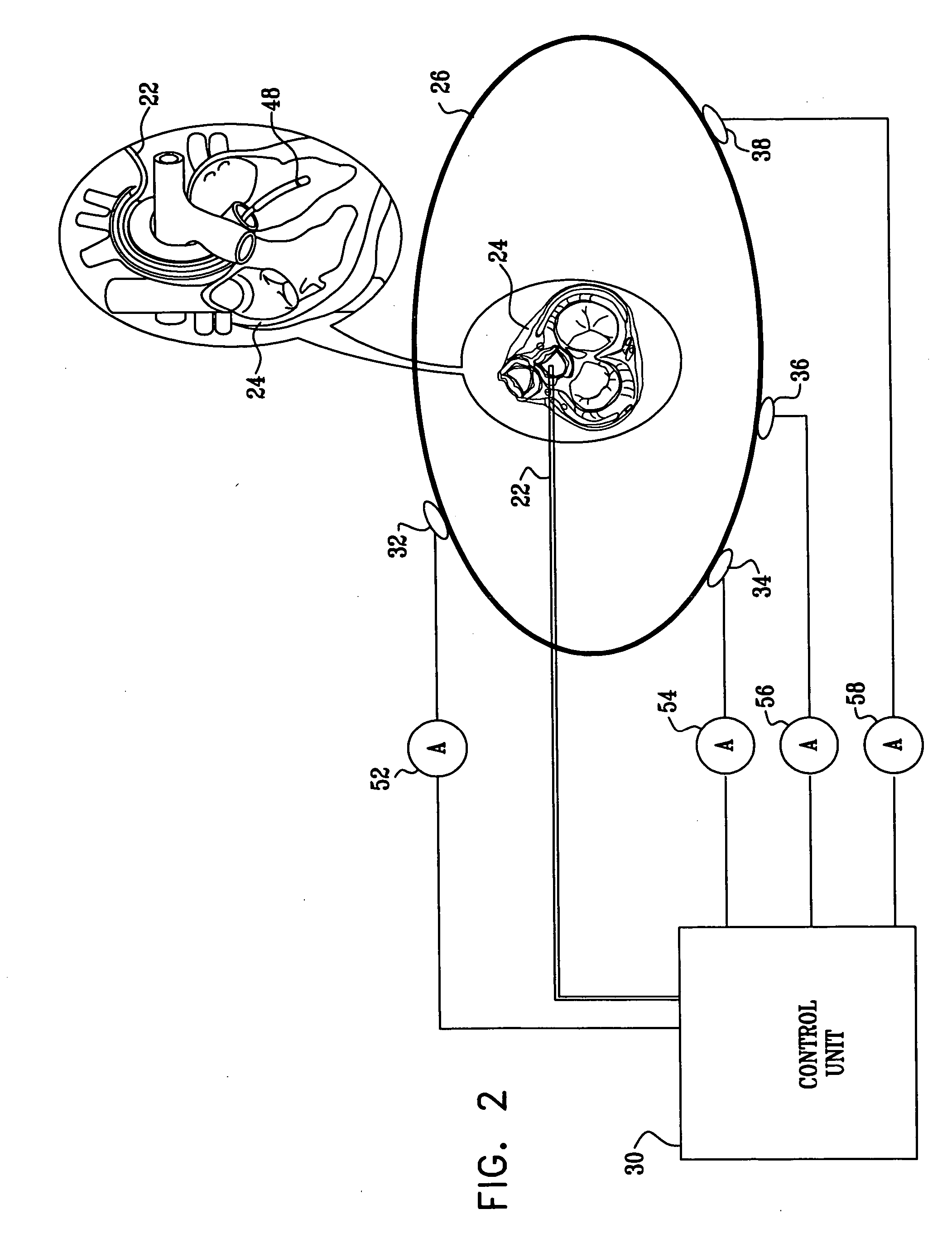

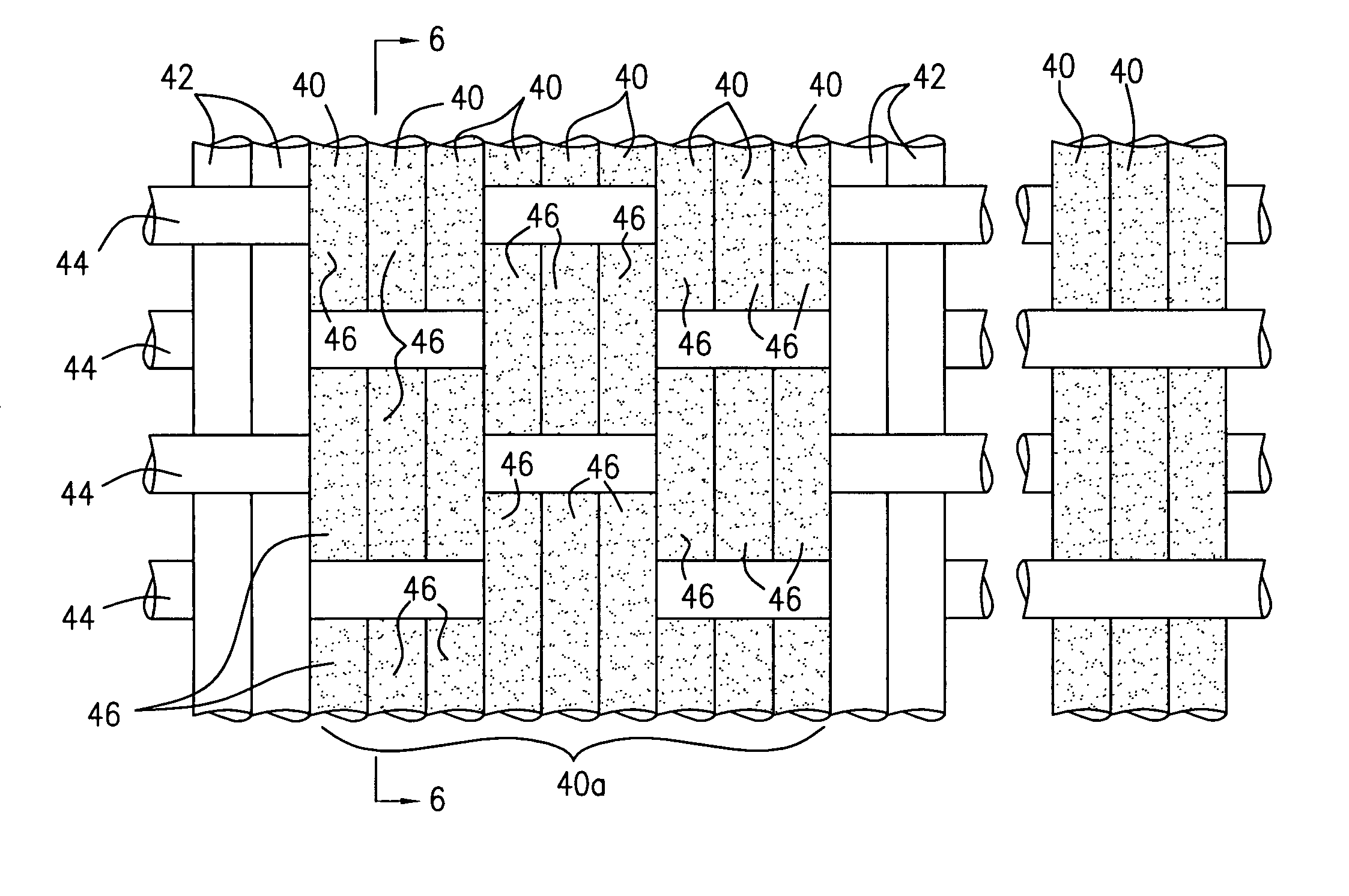

A system for treating a target region in tissue beneath a tissue surface comprises a probe for deploying an electrode array within the tissue and a surface electrode for engaging the tissue surface above the treatment site. Preferably, surface electrode includes a plurality of tissue-penetrating elements which advance into the tissue, and the surface electrode is removably attachable to the probe. The tissue may be treated in a monopolar fashion where the electrode array and surface electrode are attached to a common pole on an electrode surgical power supply and powered simultaneously or successively, or in a bipolar fashion where the electrode array and surface electrode are attached to opposite poles of the power supply. The systems are particularly useful for treating tumors and other tissue treatment regions which lie near the surface.

Owner:BOSTON SCI SCIMED INC

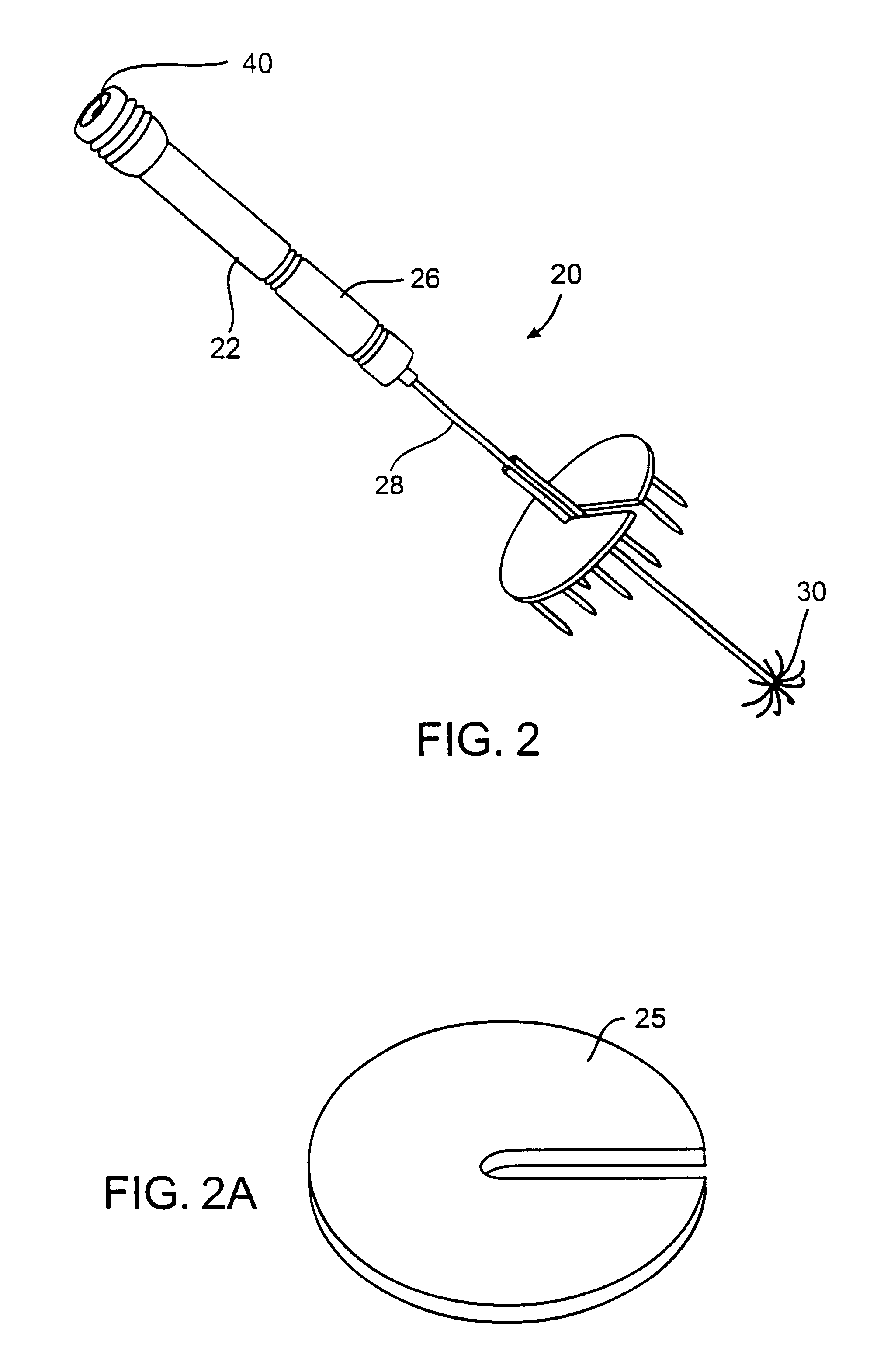

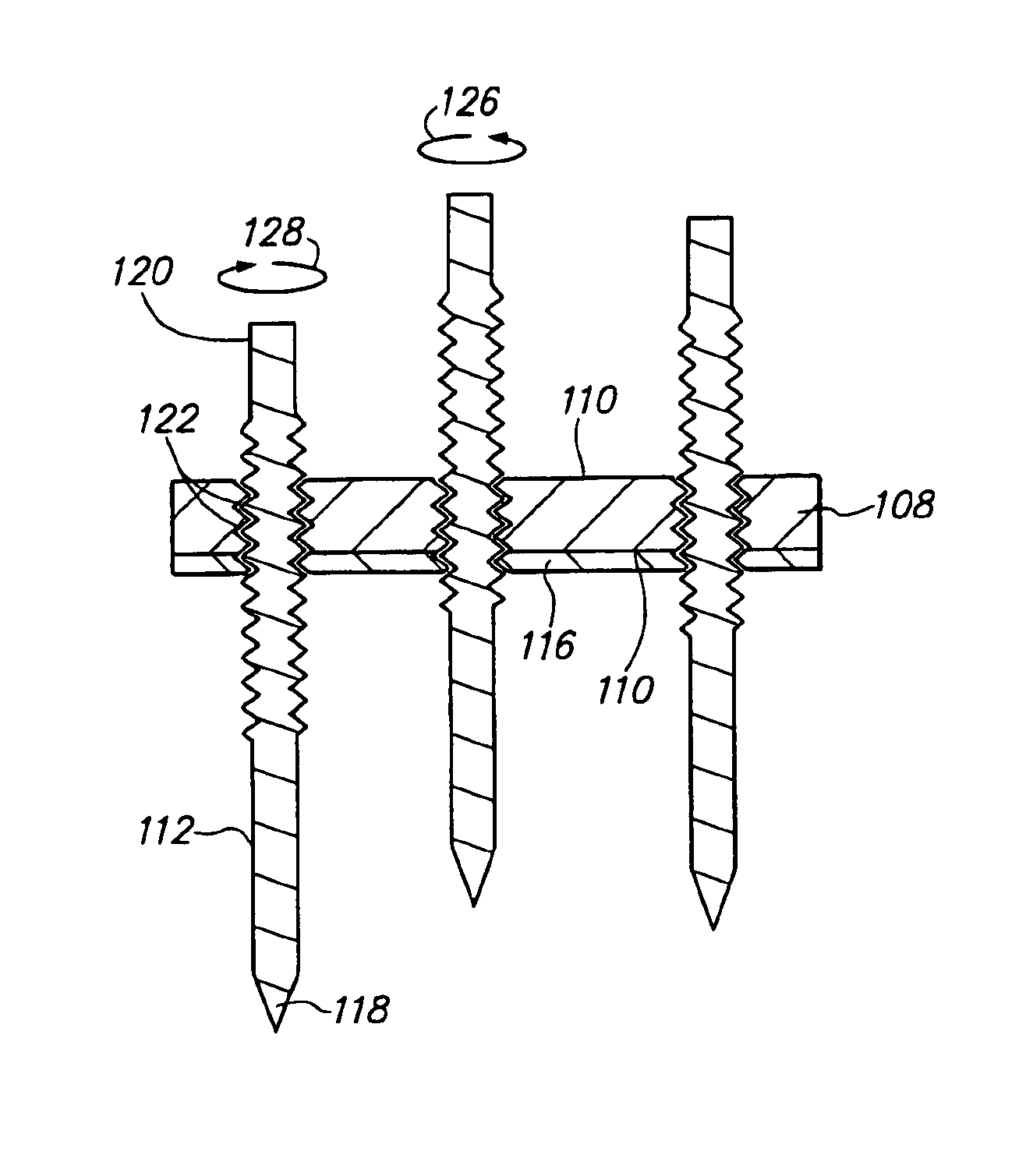

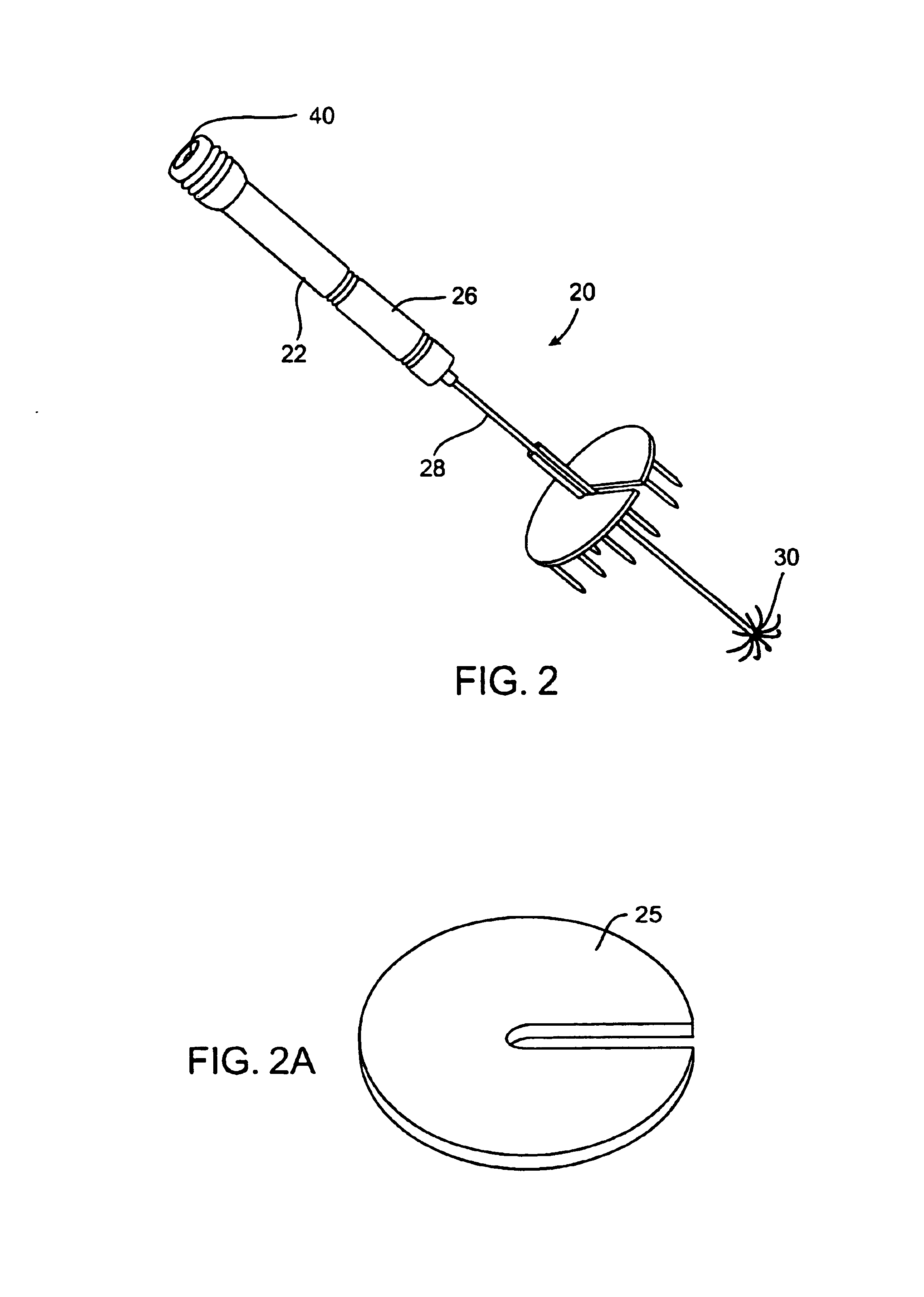

Surface electrode multiple mode operation

InactiveUS6918907B2Minimize inadvertent ablationDepth adjustableSurgical needlesJoint implantsBiomedical engineeringSurface electrode

A surface electrode for ablating tissue is provided. The surface electrode comprises a base, a plurality of tissue penetrating needle electrodes extending from the surface of the base an adjustable distance, and an electrical interface coupled to the plurality of needle electrodes. The adjustability of the needle electrodes allows the depth that the needle electrodes penetrate through tissue to be adjusted.

Owner:BOSTON SCI SCIMED INC

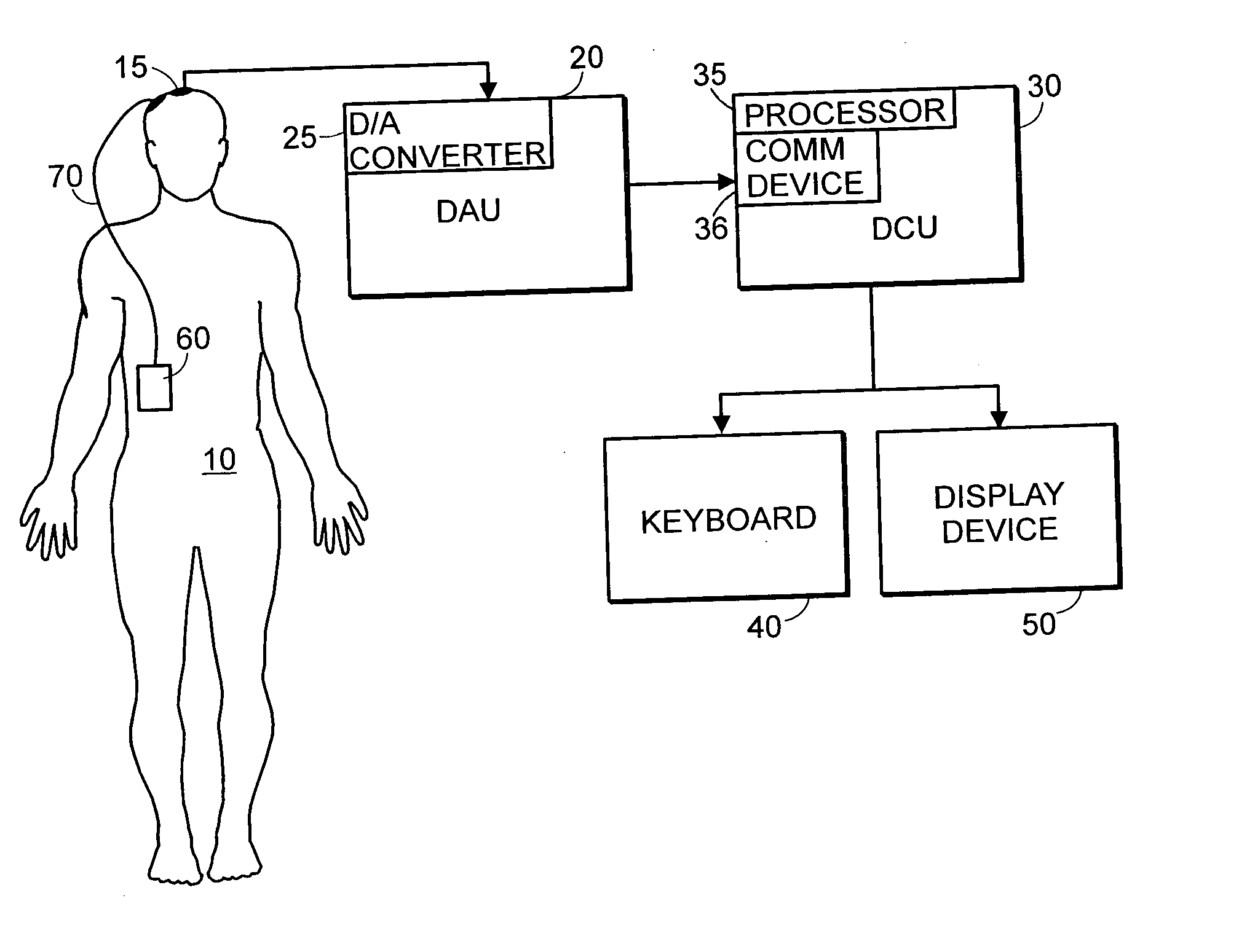

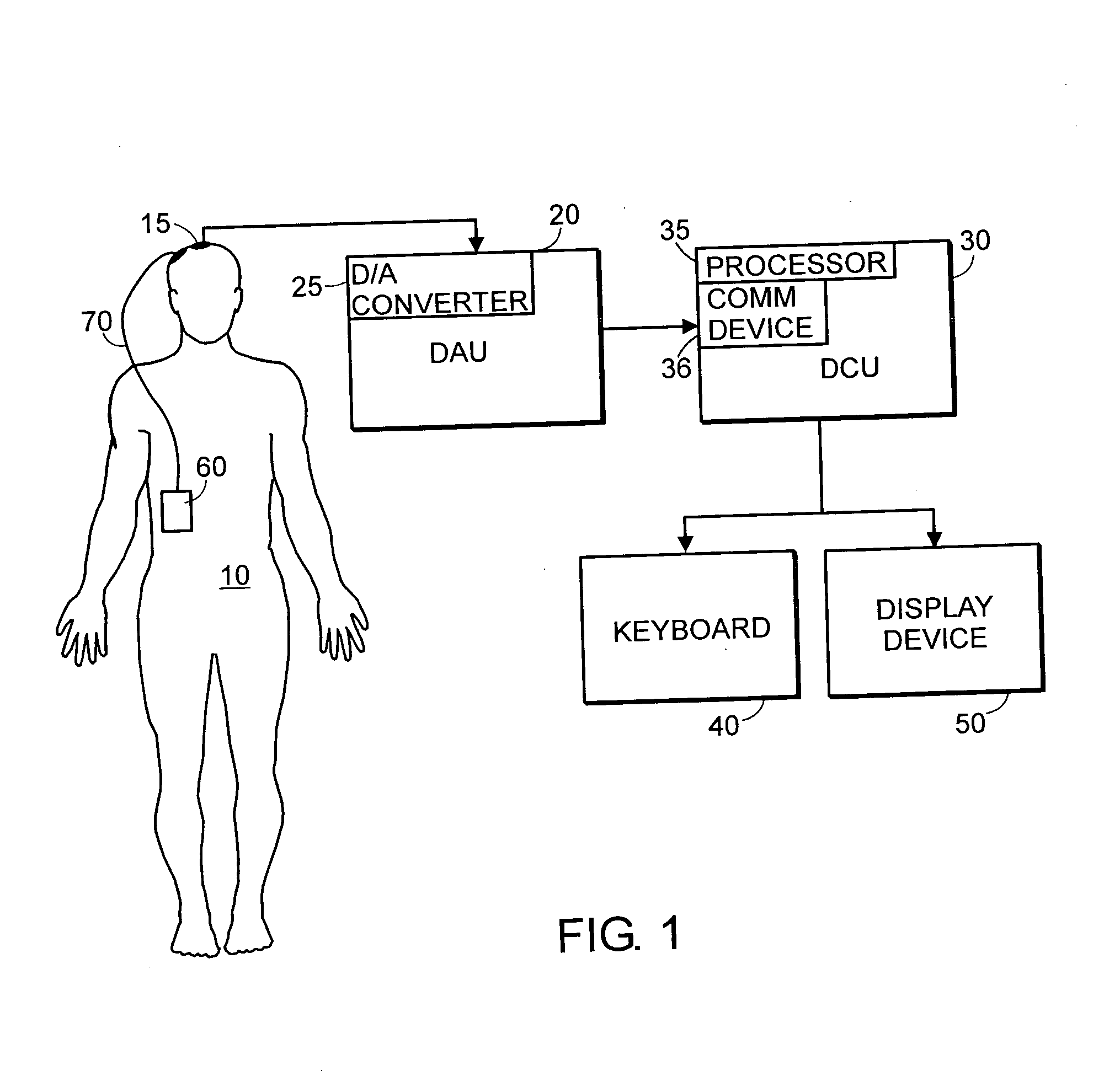

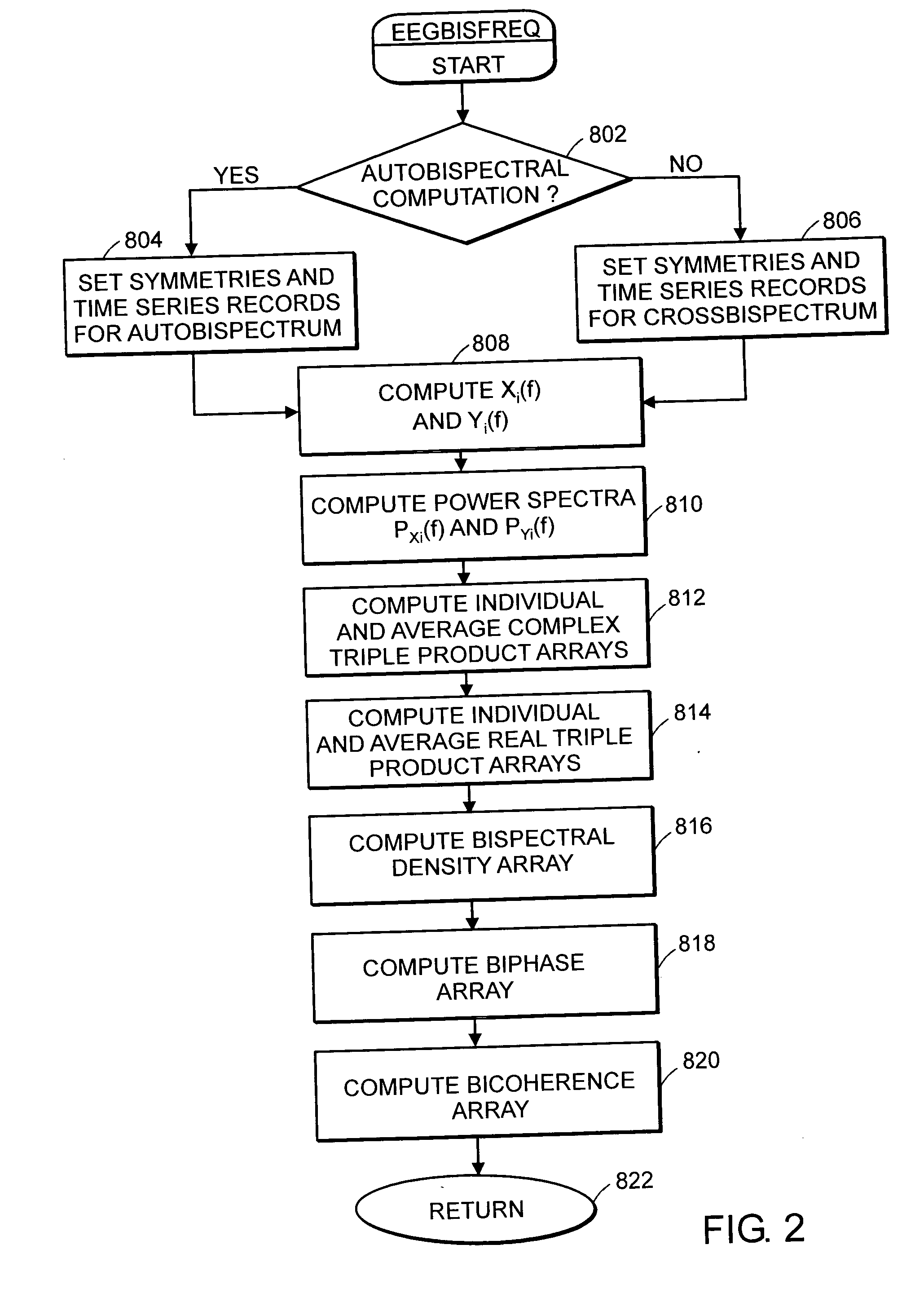

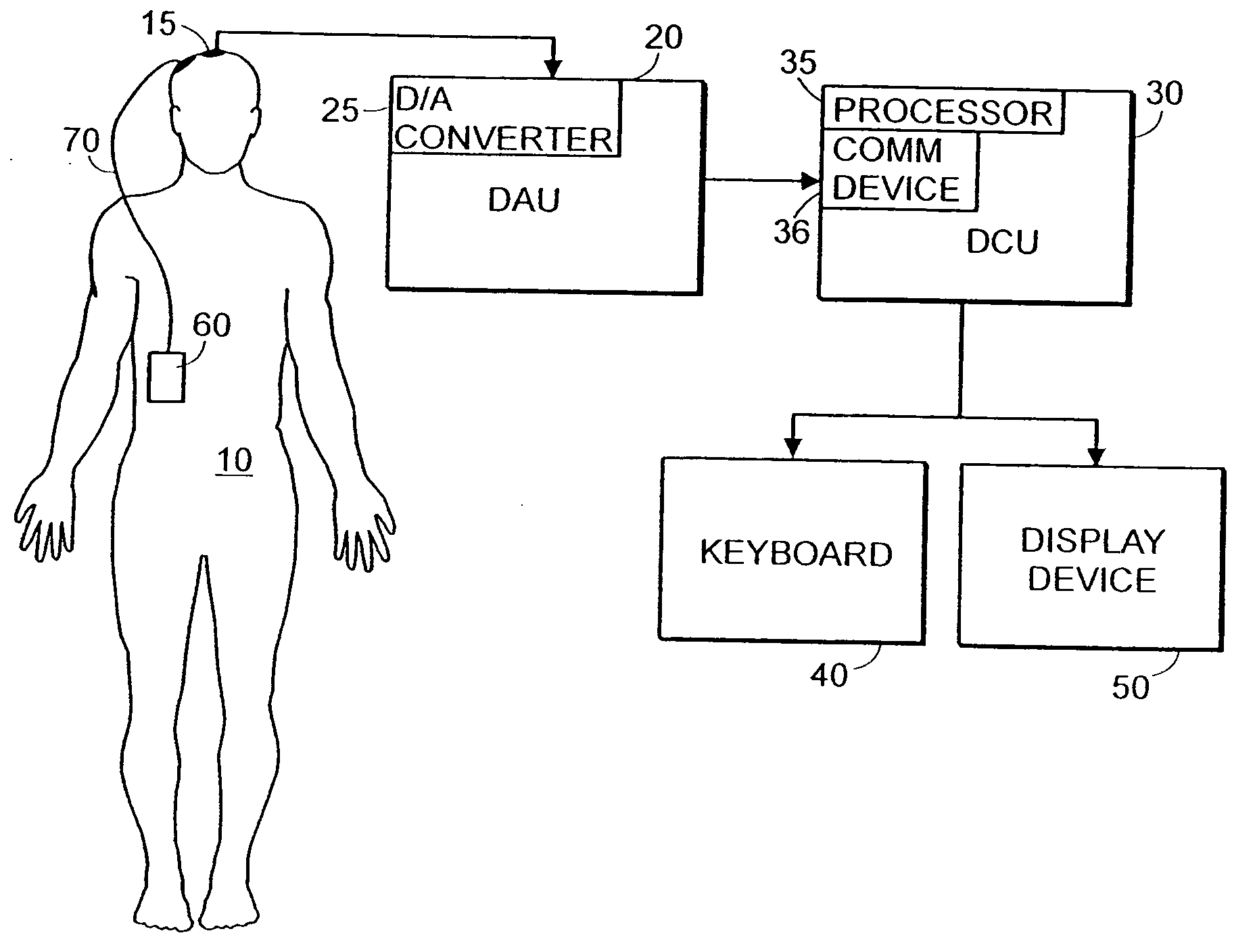

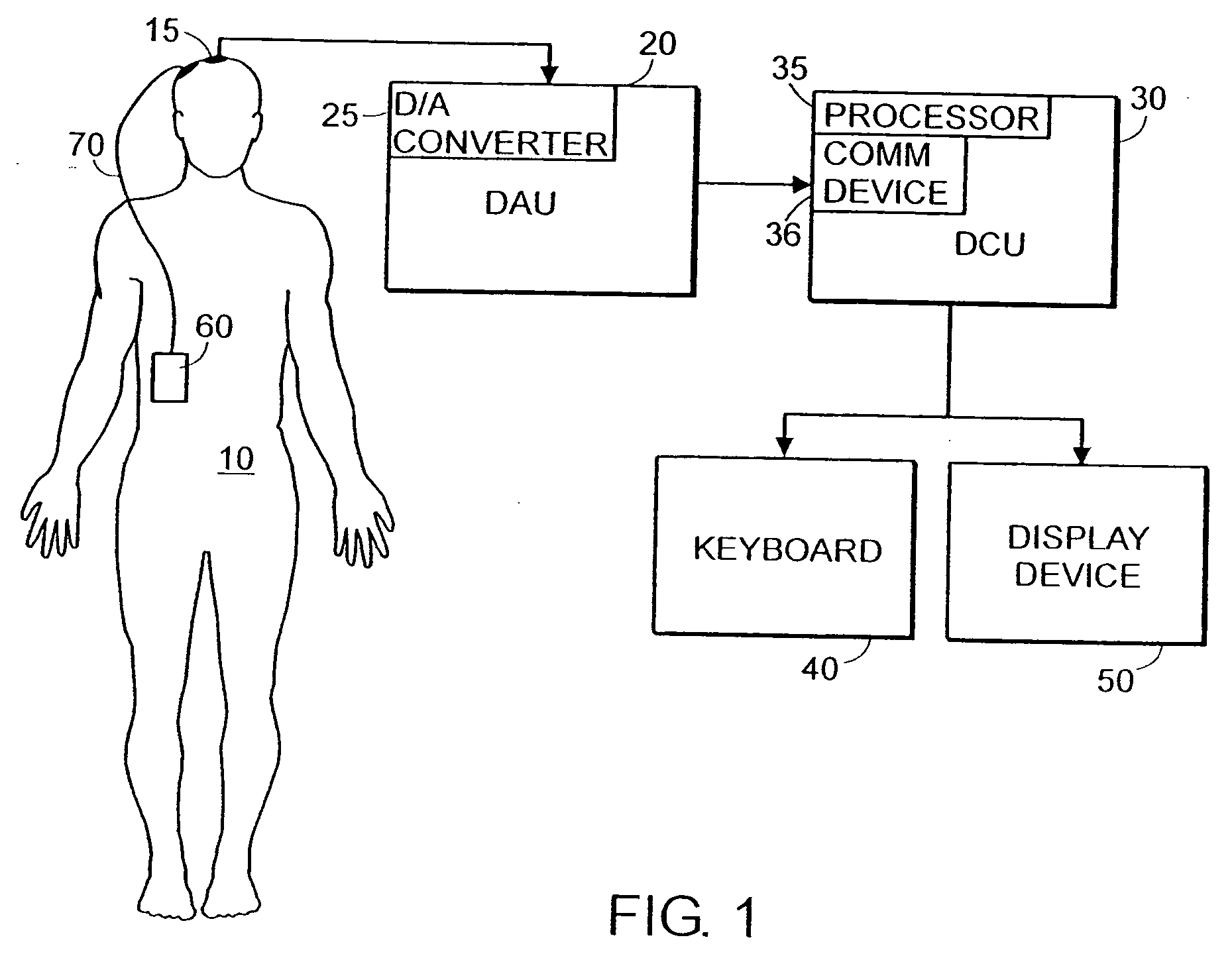

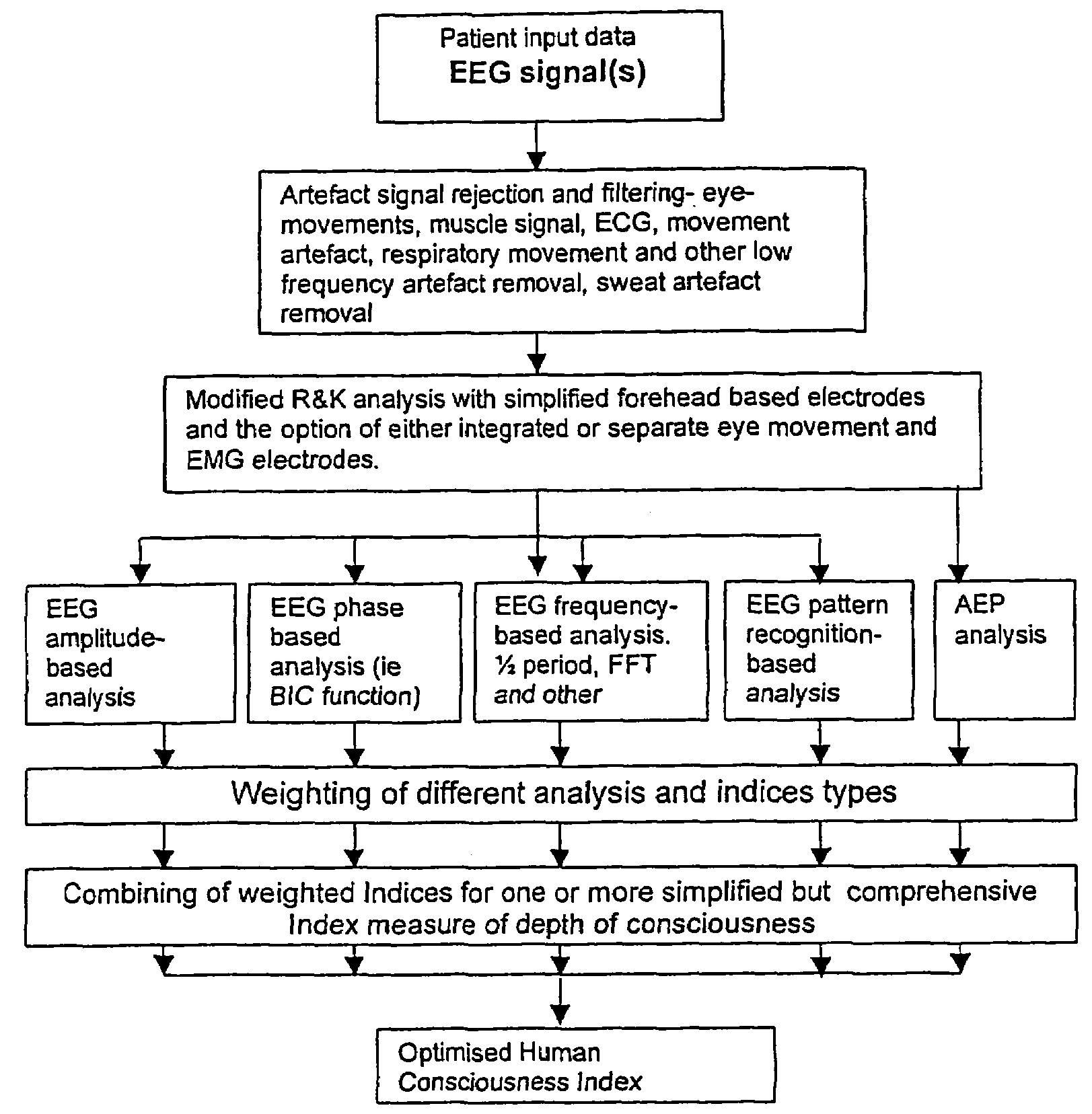

System and method of assessment of the efficacy of treatment of neurological disorders using the electroencephalogram

Disclosed is a system and method of assessing the efficacy of treatment of neurological or psychological disorders. The preferred embodiment uses at least two surface electrodes to acquire EEG signals from the surface of a patient's body, a processor for computing from the EEG signals various features and indices that are representative of the patient's neurological or psychological state. Changes in these parameters may be used to assess the efficacy of treatment and to modify the treatment to optimize the resultant patient state.

Owner:TYCO HEALTHCARE GRP LP

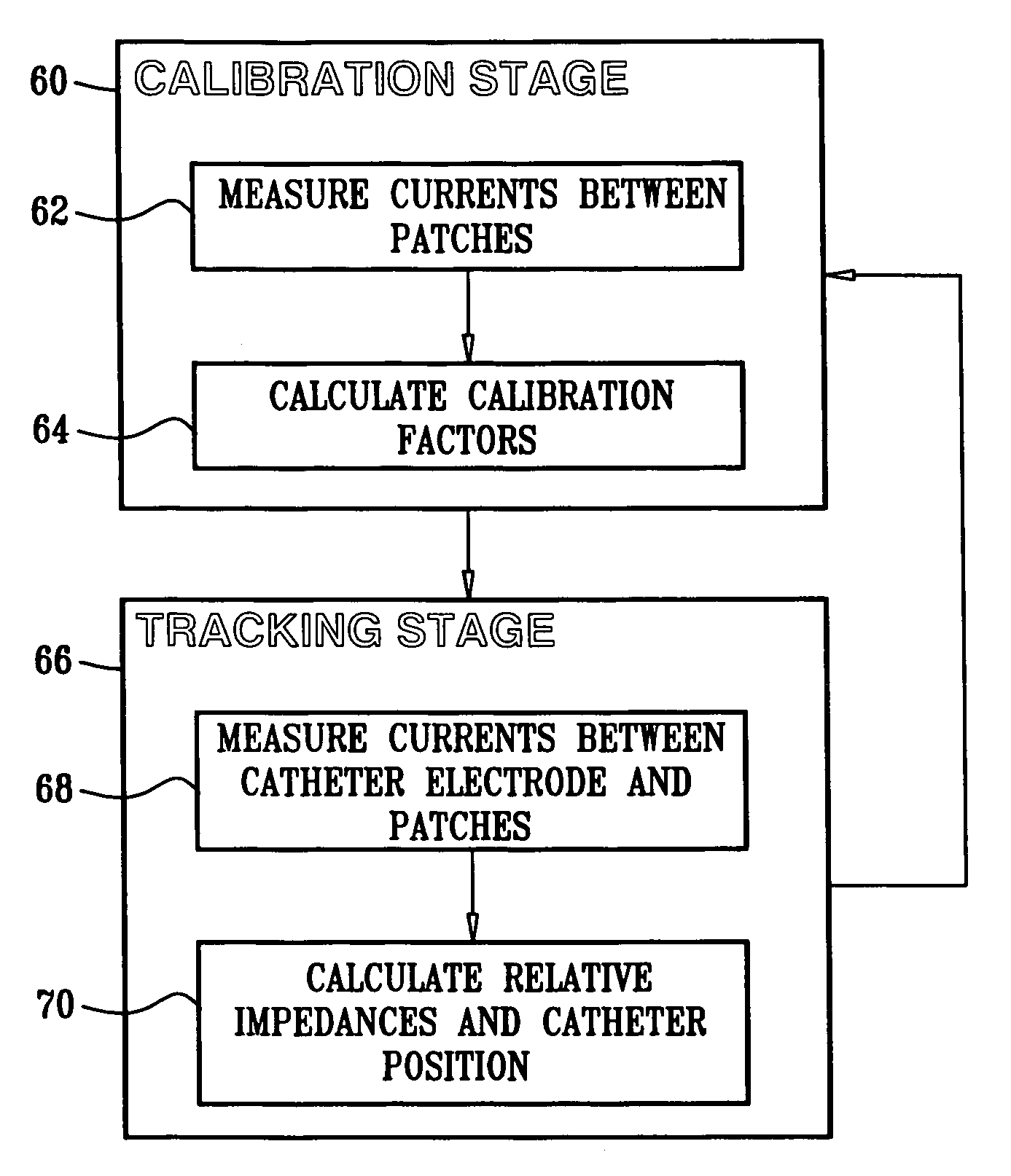

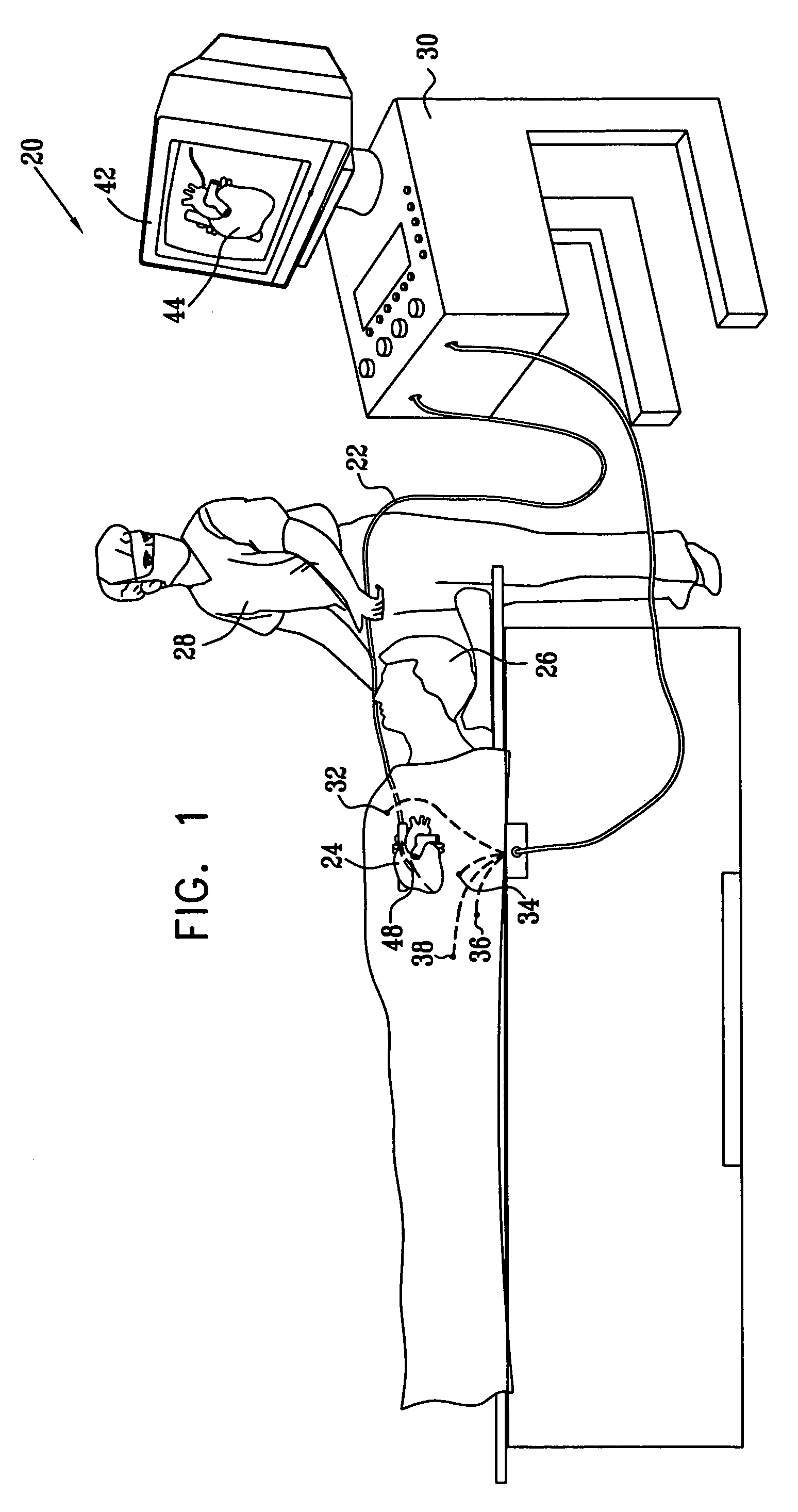

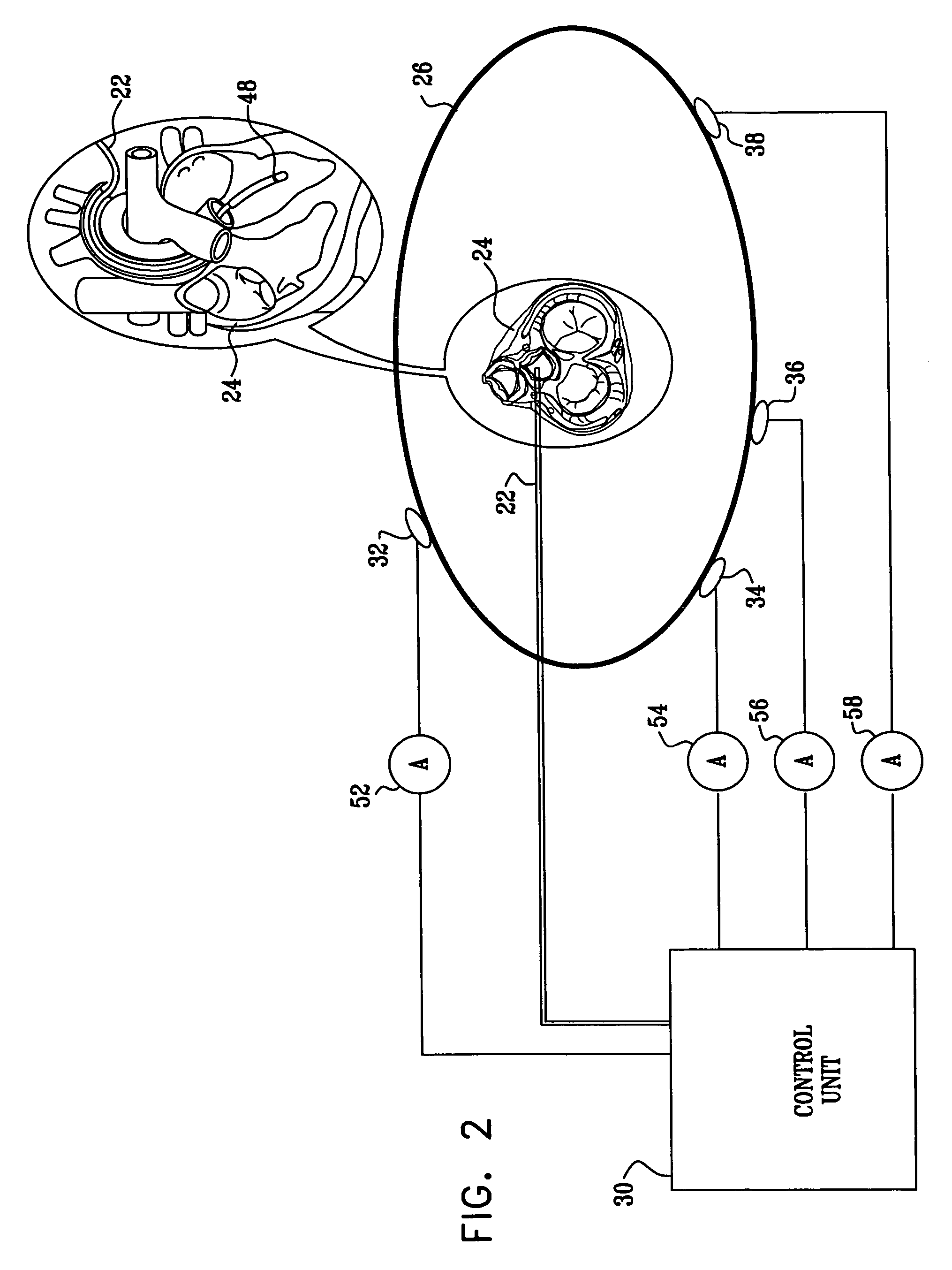

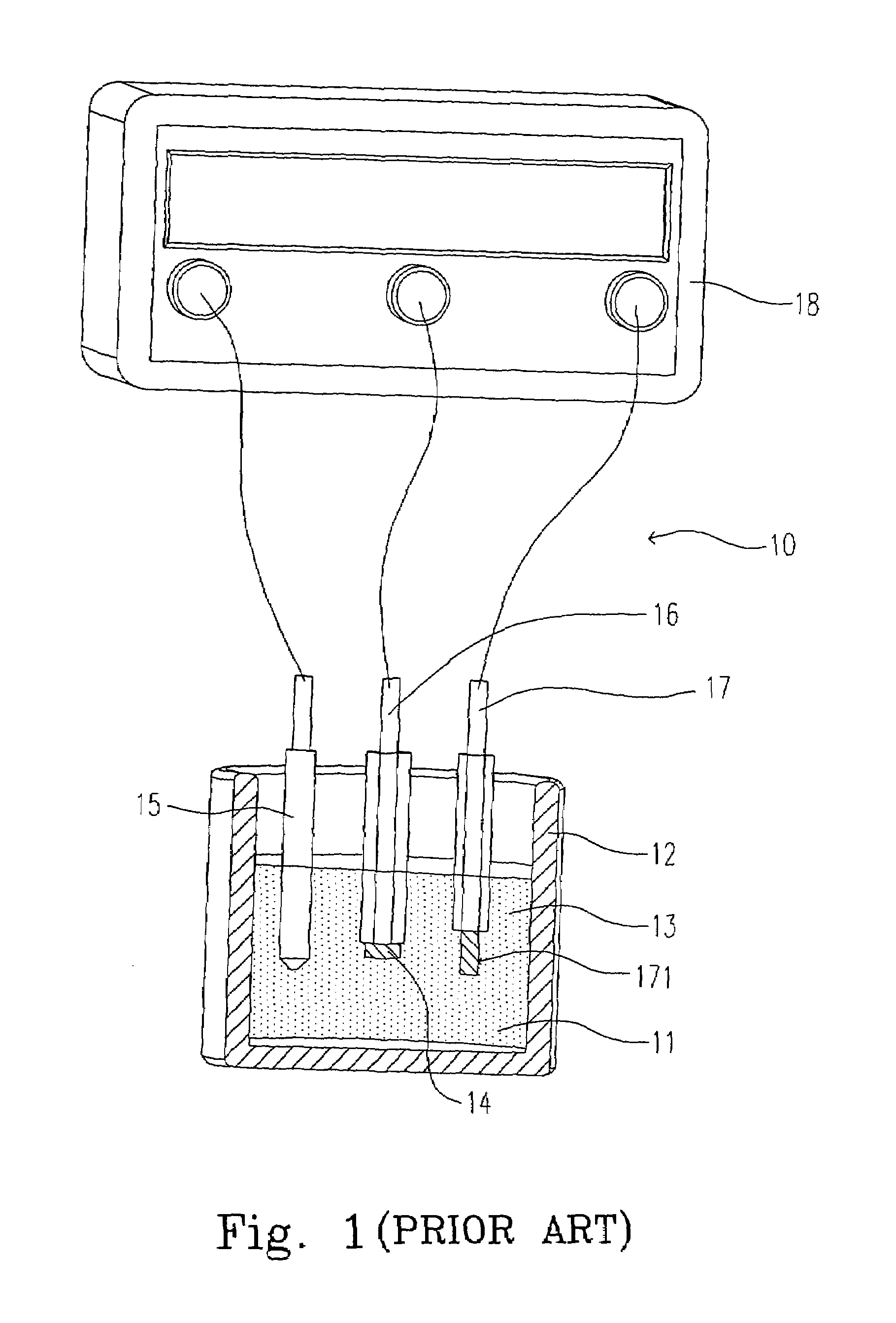

Relative impedance measurement

A method for calibrating impedance includes coupling at least first, second, and third electrodes at respective locations to a surface of a body of a subject. A first current passing through the body between the first and second body-surface electrodes is measured, and a second current passing through the body between the first and third body-surface electrodes is measured. From the first and second currents, a contact factor is derived that is indicative of the impedance between at least one of the body-surface electrodes and the surface of the body. Also described are methods for sensing the position of a probe and for detecting tissue contact based on a relation between currents from the probe to body-surface electrodes.

Owner:BIOSENSE WEBSTER INC

Apparatus and method for treating tumors near the surface of an organ

InactiveUS6889089B2Enhances uniform electrosurgical treatment of tissueEliminate needSurgical needlesSurgical instruments for heatingAbnormal tissue growthElectrode array

A system for treating a target region in tissue beneath a tissue surface comprises a probe for deploying an electrode array within the tissue and a surface electrode for engaging the tissue surface above the treatment site. Preferably, surface electrode includes a plurality of tissue-penetrating elements which advance into the tissue, and the surface electrode is removably attachable to the probe. The tissue may be treated in a monopolar fashion where the electrode array and surface electrode are attached to a common pole on an electrode surgical power supply and powered simultaneously or successively, or in a bipolar fashion where the electrode array and surface electrode are attached to opposite poles of the power supply. The systems are particularly useful for treating tumors and other tissue treatment regions which lie near the surface.

Owner:BOSTON SCI SCIMED INC

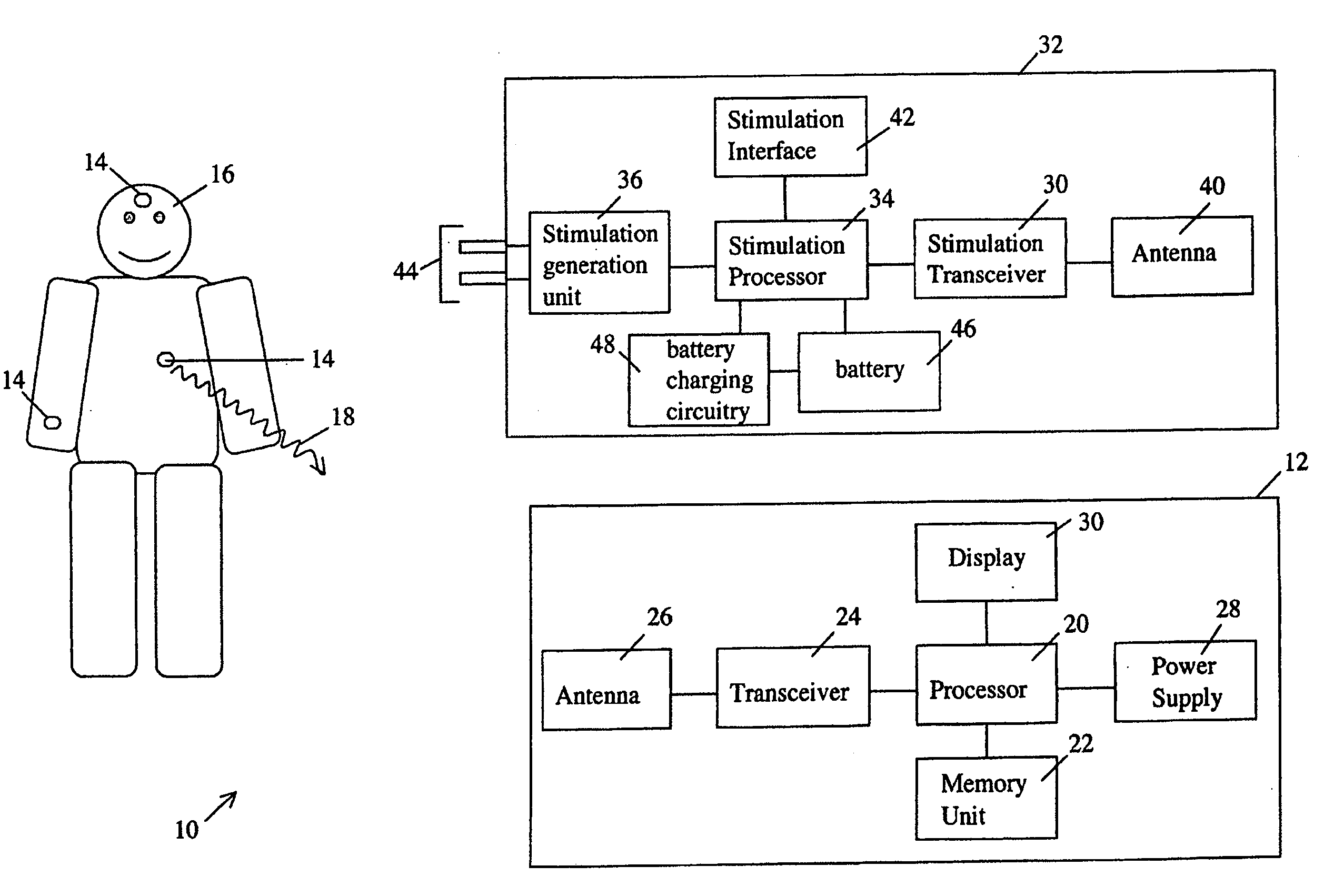

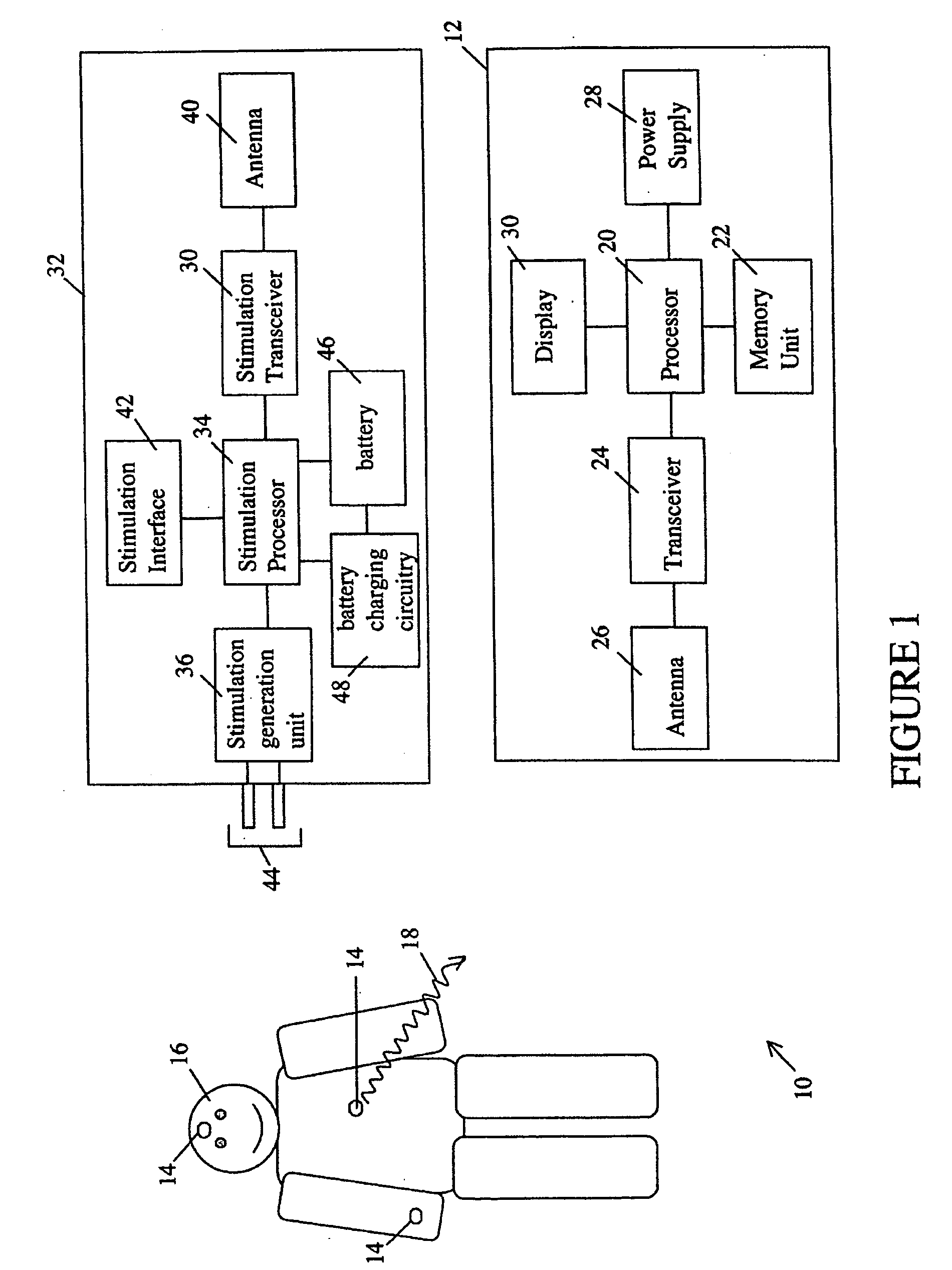

Wireless physiological monitoring system

InactiveUS20050261559A1Quick applicationQuick removalSensorsSkin piercing electrodesLine sensorElectrical conductor

Embodiments of the invention relate to a wireless physiological monitoring system. The system includes at least one wireless sensor and a monitoring device which are linked to one another of a wireless fashion for measuring physiological signals of a patient. The at least one wireless sensor is located on the patient and may comprise a wireless surface electrode assembly or a wireless needle assembly. The system may also comprise a wireless stimulator syncronized with the wireless sensor for performing certain diagnostic tests, such as nerve conduction velocity tests, for example. The wireless sensor preferably includes active, reference and common conductors. The common conductor can be used to measure the common mode voltage of the patient in the vicinity of the testing, and this voltage can then be subtracted from the measured active and reference voltages.

Owner:EXCEL TECH

System and method of prediction of response to neurological treatment using the electroencephalogram

Disclosed is a system and method of assessing the efficacy of and predicting response to treatment of neurological or psychological disorders. The preferred embodiment uses at least two surface electrodes to acquire EEG signals from the surface of a patient's body, a processor for computing from the EEG signals various features and indices that are representative of the patient's neurological or psychological state. Pretreatment indices represent a patient's neurological or psychological state and therefore may be used to predict the response to treatment. Changes in these parameters may be used to assess the efficacy of treatment and to modify the treatment to optimize the resultant patient state.

Owner:TYCO HEALTHCARE GRP LP

Relative impedance measurement

A method for calibrating impedance includes coupling at least first, second, and third electrodes at respective locations to a surface of a body of a subject. A first current passing through the body between the first and second body-surface electrodes is measured, and a second current passing through the body between the first and third body-surface electrodes is measured. From the first and second currents, a contact factor is derived that is indicative of the impedance between at least one of the body-surface electrodes and the surface of the body. Also described are methods for sensing the position of a probe and for detecting tissue contact based on a relation between currents from the probe to body-surface electrodes.

Owner:BIOSENSE WEBSTER INC

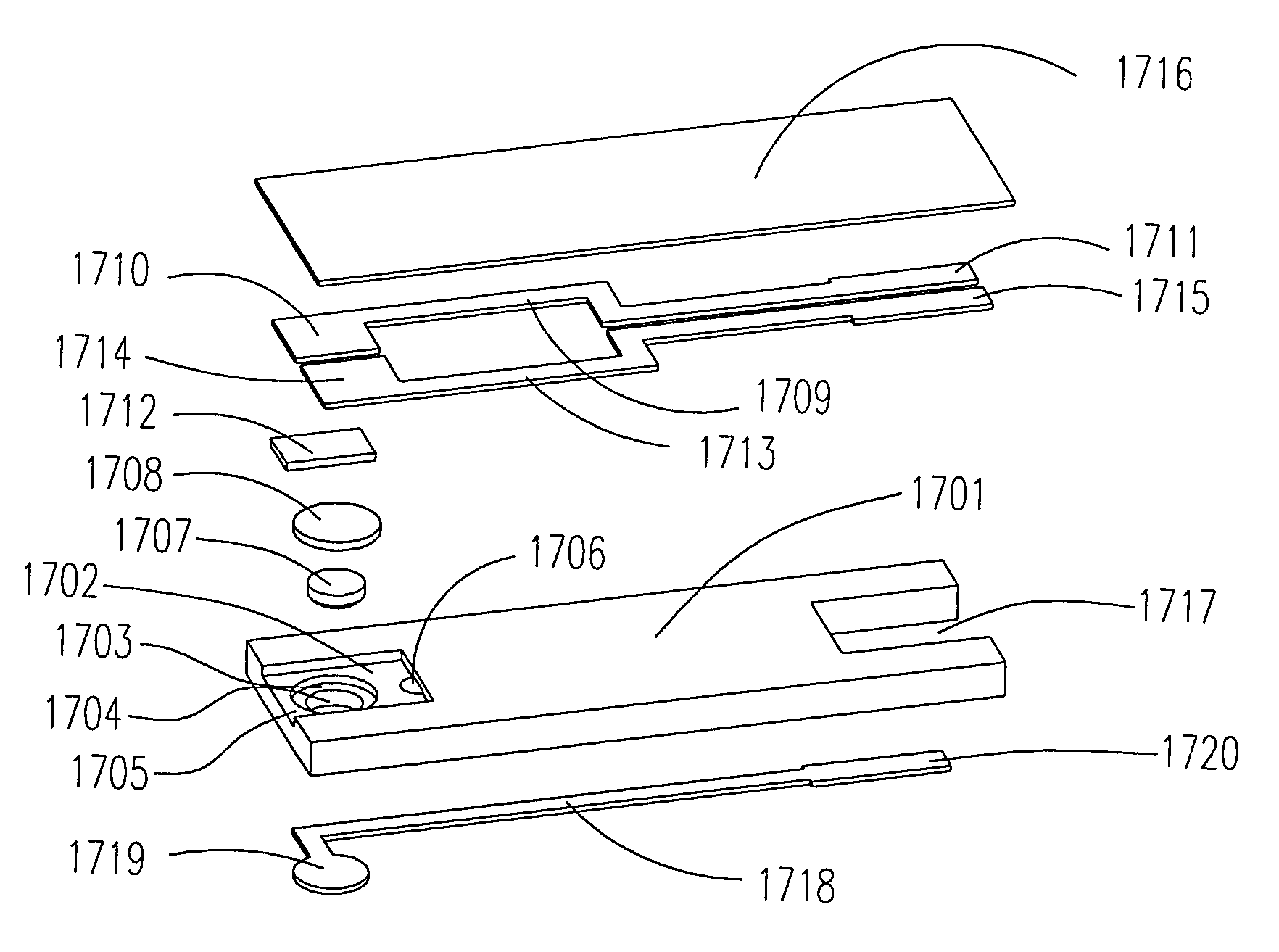

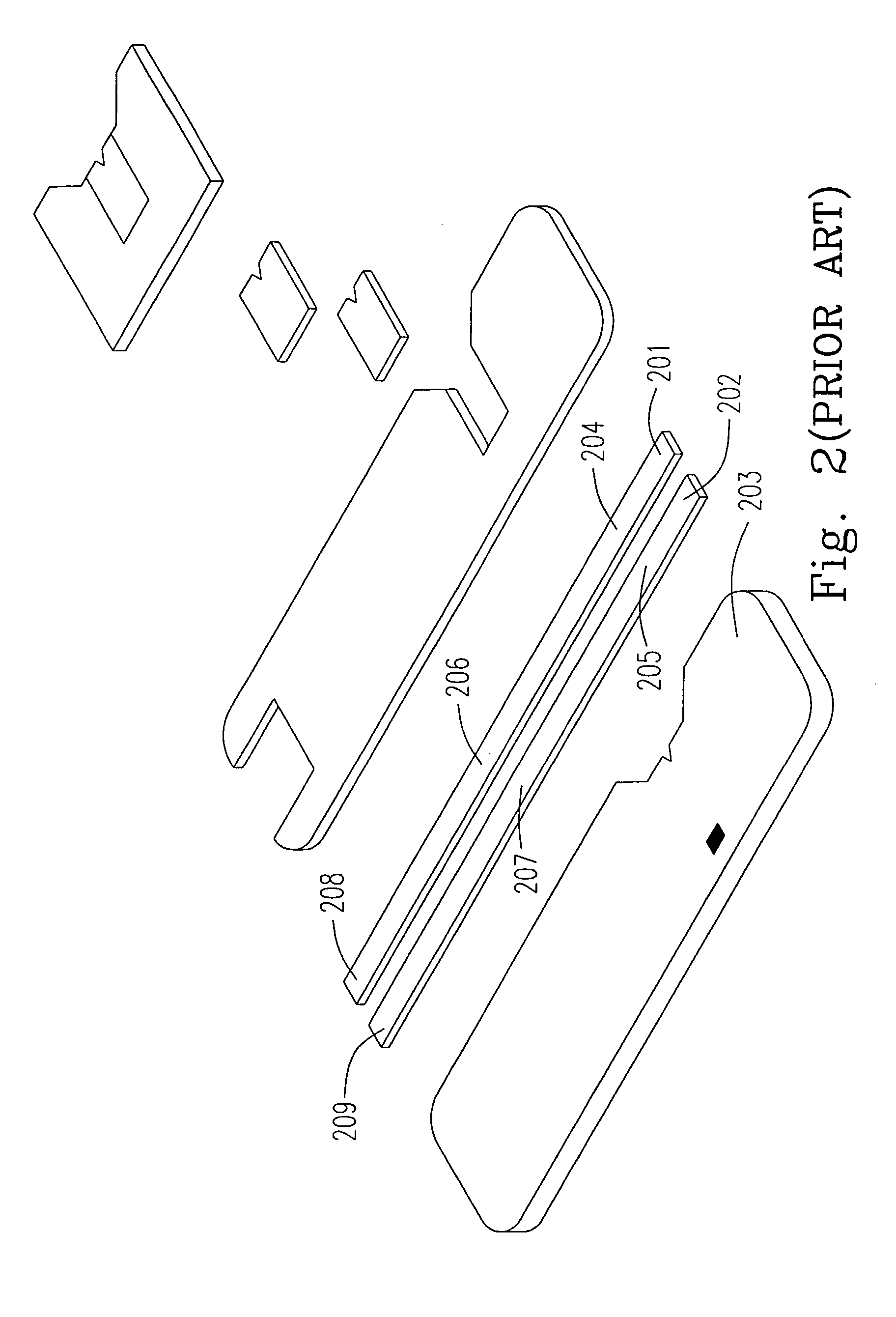

Structure and manufacturing method of disposable electrochemical sensor strip

ActiveUS7063776B2Reduce the amount requiredShorten production timeImmobilised enzymesBioreactor/fermenter combinationsMetalElectrical and Electronics engineering

A disposable electrochemical sensor strip is provided. The sensor strip includes an isolating sheet having at least a through hole, at least a conductive raw material mounted in the through hole, a metal film covered on the conductive raw material to form an electrode which comprises an electrode working surface for processing an electrode action, and an electrode connecting surface, at least a printed conductive film mounted on the isolating sheet and having a connecting terminal for being electrically connected to the electrode connecting surface, and a signal output terminal for outputting a measured signal produced by the electrode action.

Owner:HUANG CHUN MU

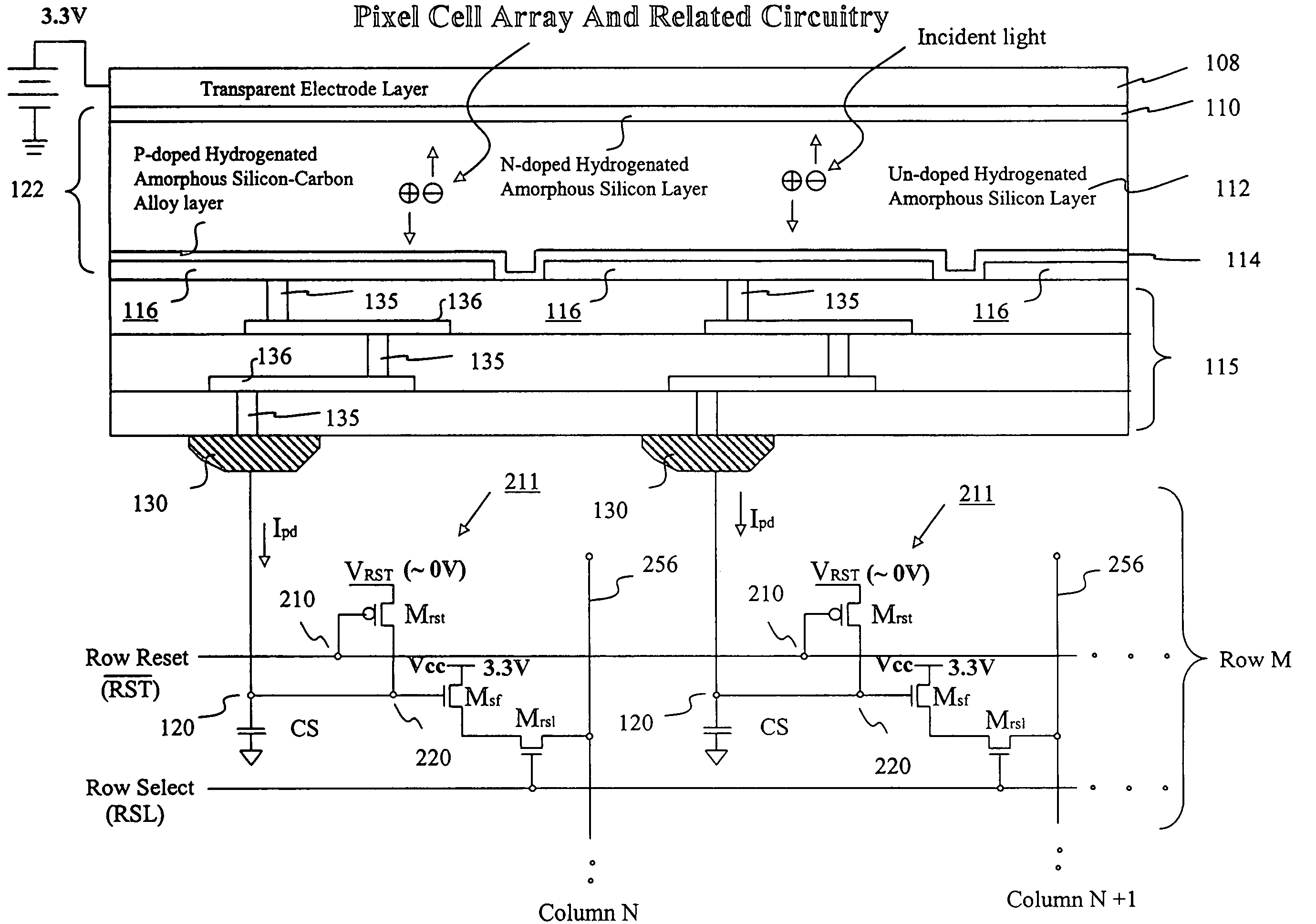

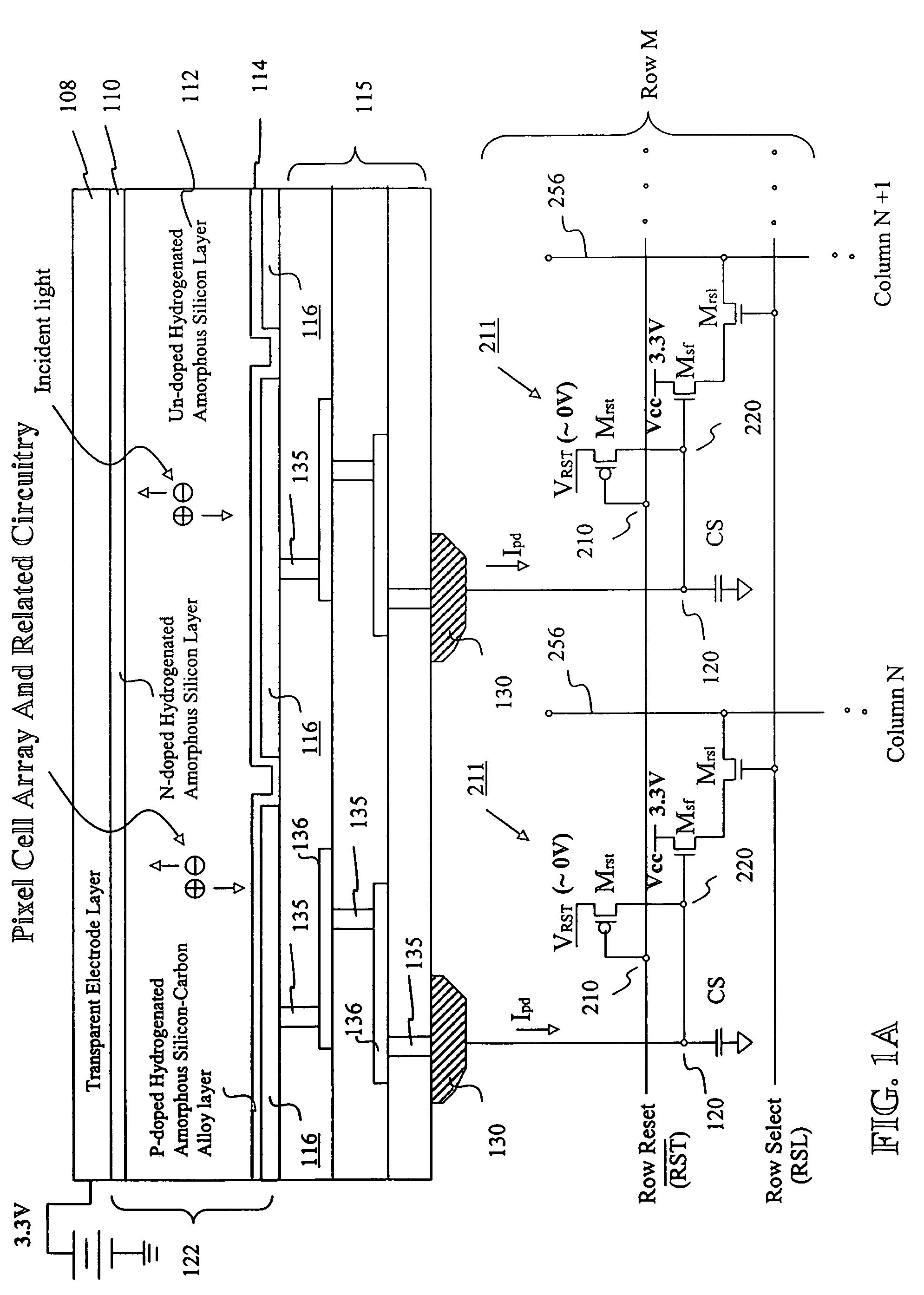

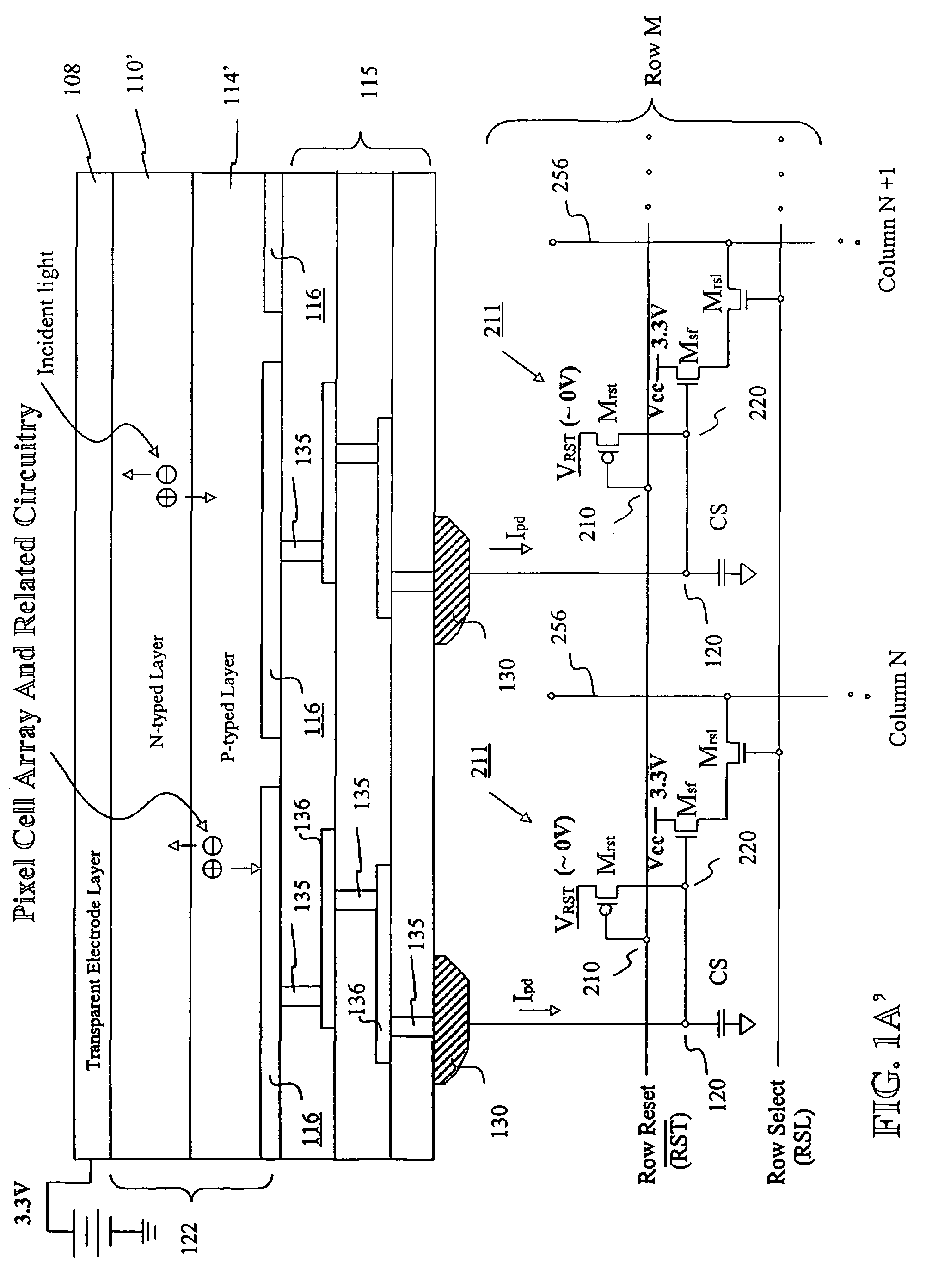

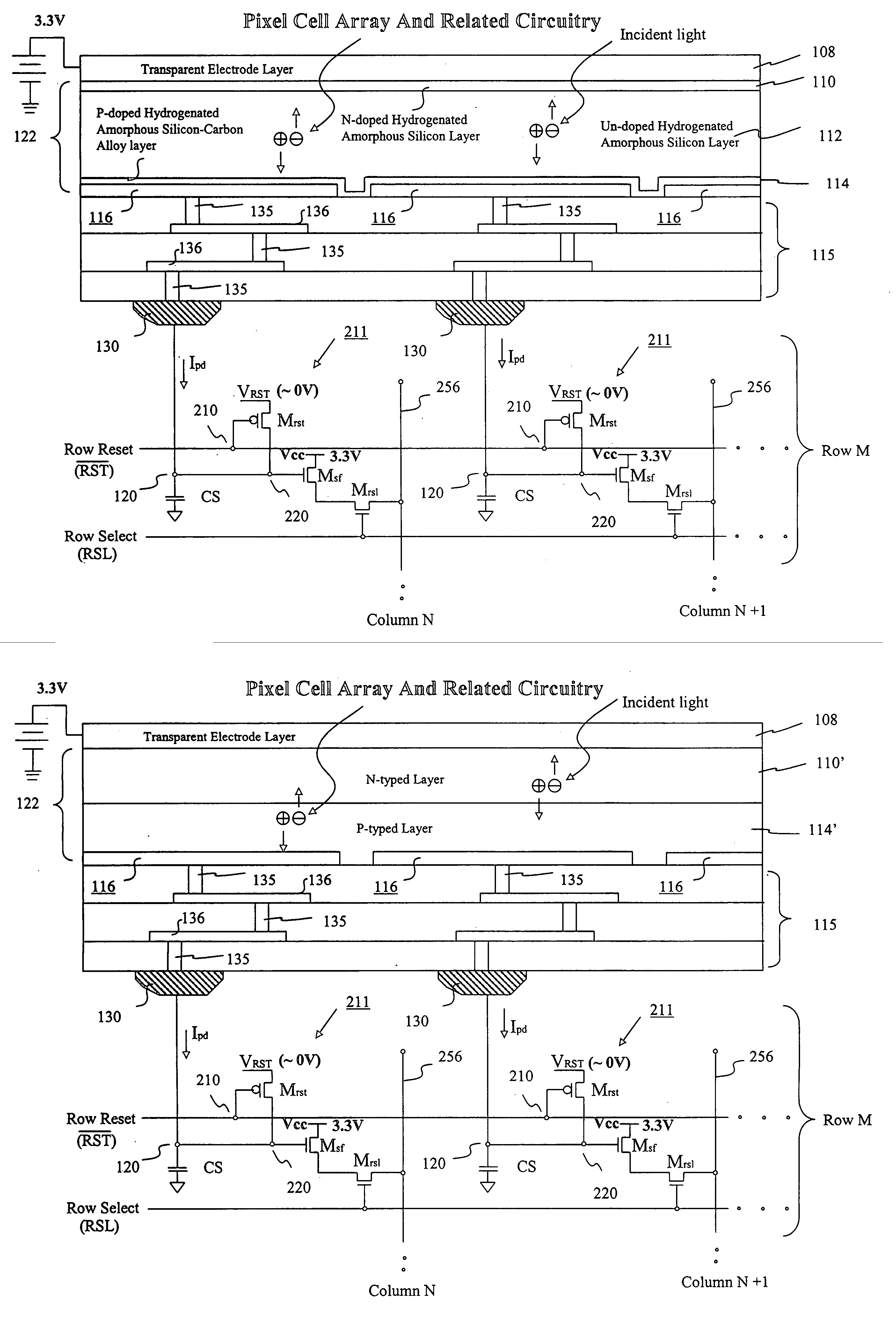

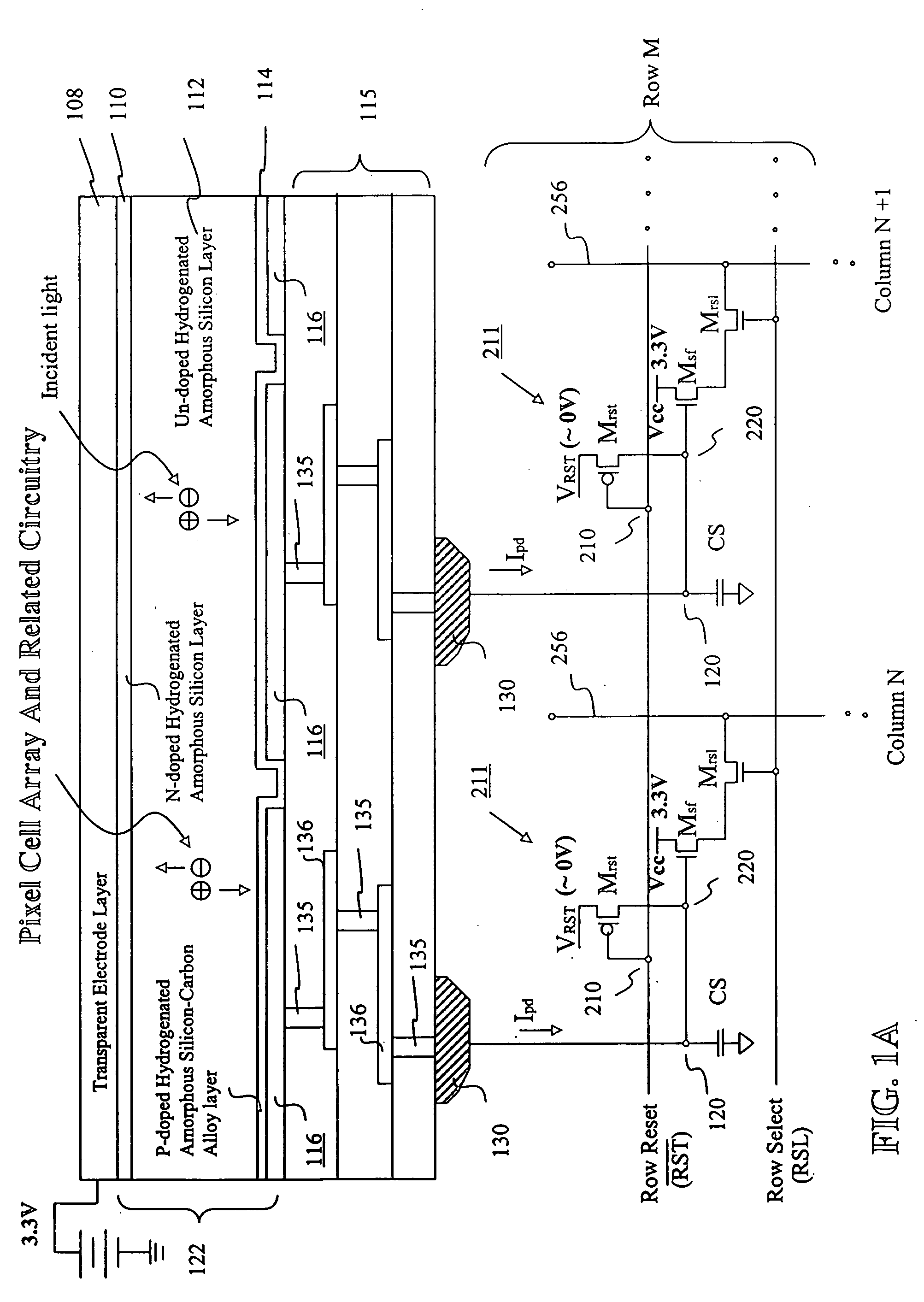

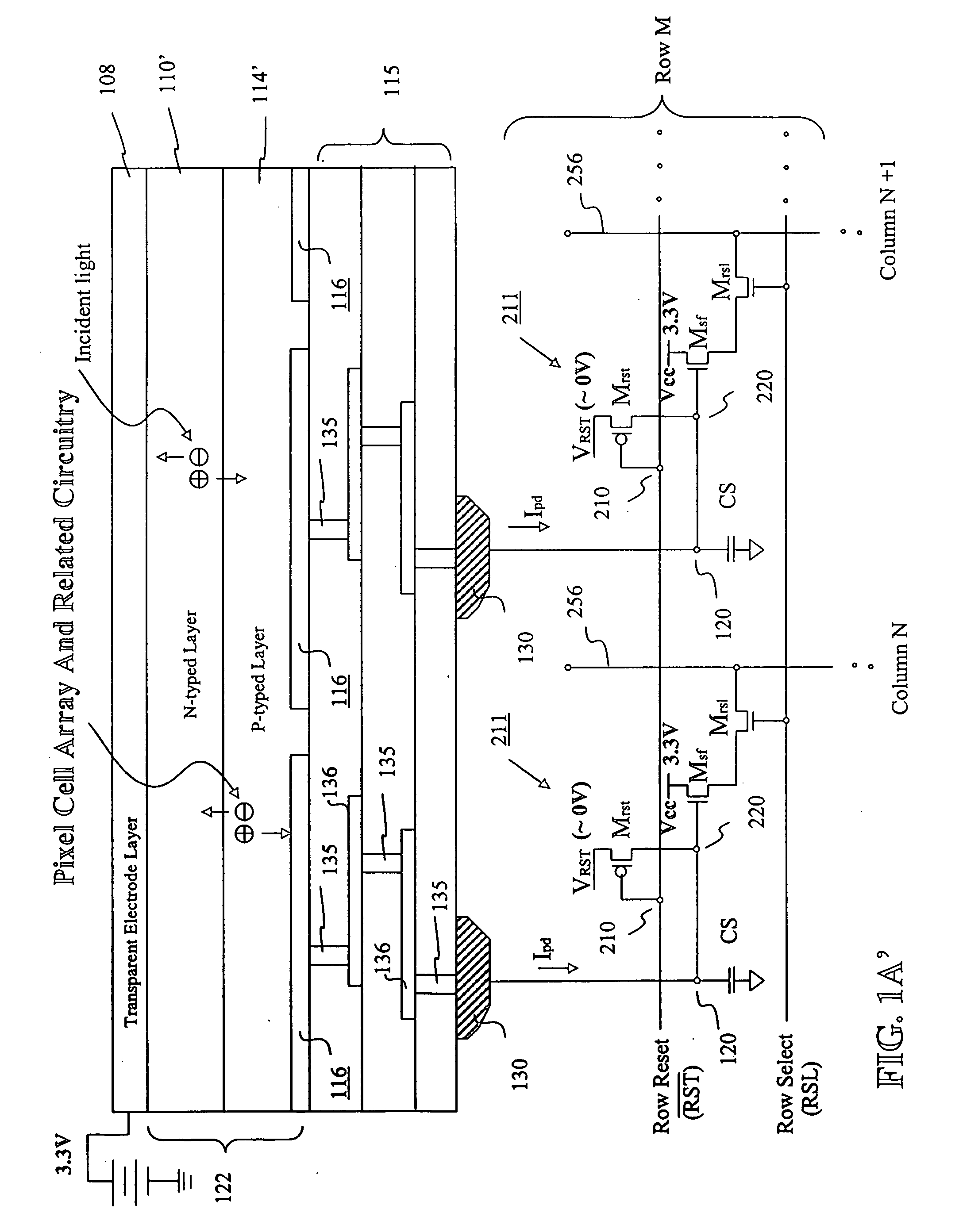

Image sensor with microcrystalline germanium photodiode layer

InactiveUS7276749B2Improve performanceRaise countTransistorSolid-state devicesSensor arrayElectromagnetic radiation

A microcrystalline germanium image sensor array. The array includes a number of pixel circuits fabricated in or on a substrate. Each pixel circuit comprises a charge collecting electrode for collecting electrical charges and a readout means for reading out the charges collected by the charge collecting electrode. A photodiode layer of charge generating material located above the pixel circuits convert electromagnetic radiation into electrical charges. This photodiode layer includes microcrystalline germanium and defines at least an n-layer, and i-layer and a p-layer. The sensor array also includes and a surface electrode in the form of a grid or thin transparent layer located above the layer of charge generating material. The sensor is especially useful for imaging in visible and near infrared spectral regions of the electromagnetic spectrum and provides imaging with starlight illumination.

Owner:E PHOCUS

Image sensor with microcrystalline germanium photodiode layer

InactiveUS20060267054A1High sensitivityEnhanced pixel size pixelTransistorSolid-state devicesSensor arrayElectromagnetic spectrum

A microcrystalline germanium image sensor array. The array includes a number of pixel circuits fabricated in or on a substrate. Each pixel circuit comprises a charge collecting electrode for collecting electrical charges and a readout means for reading out the charges collected by the charge collecting electrode. A photodiode layer of charge generating material located above the pixel circuits convert electromagnetic radiation into electrical charges. This photodiode layer includes microcrystalline germanium and defines at least an n-layer, and i-layer and a p-layer. The sensor array also includes and a surface electrode in the form of a grid or thin transparent layer located above the layer of charge generating material. The sensor is especially useful for imaging in visible and near infrared spectral regions of the electromagnetic spectrum and provides imaging with starlight illumination.

Owner:E PHOCUS

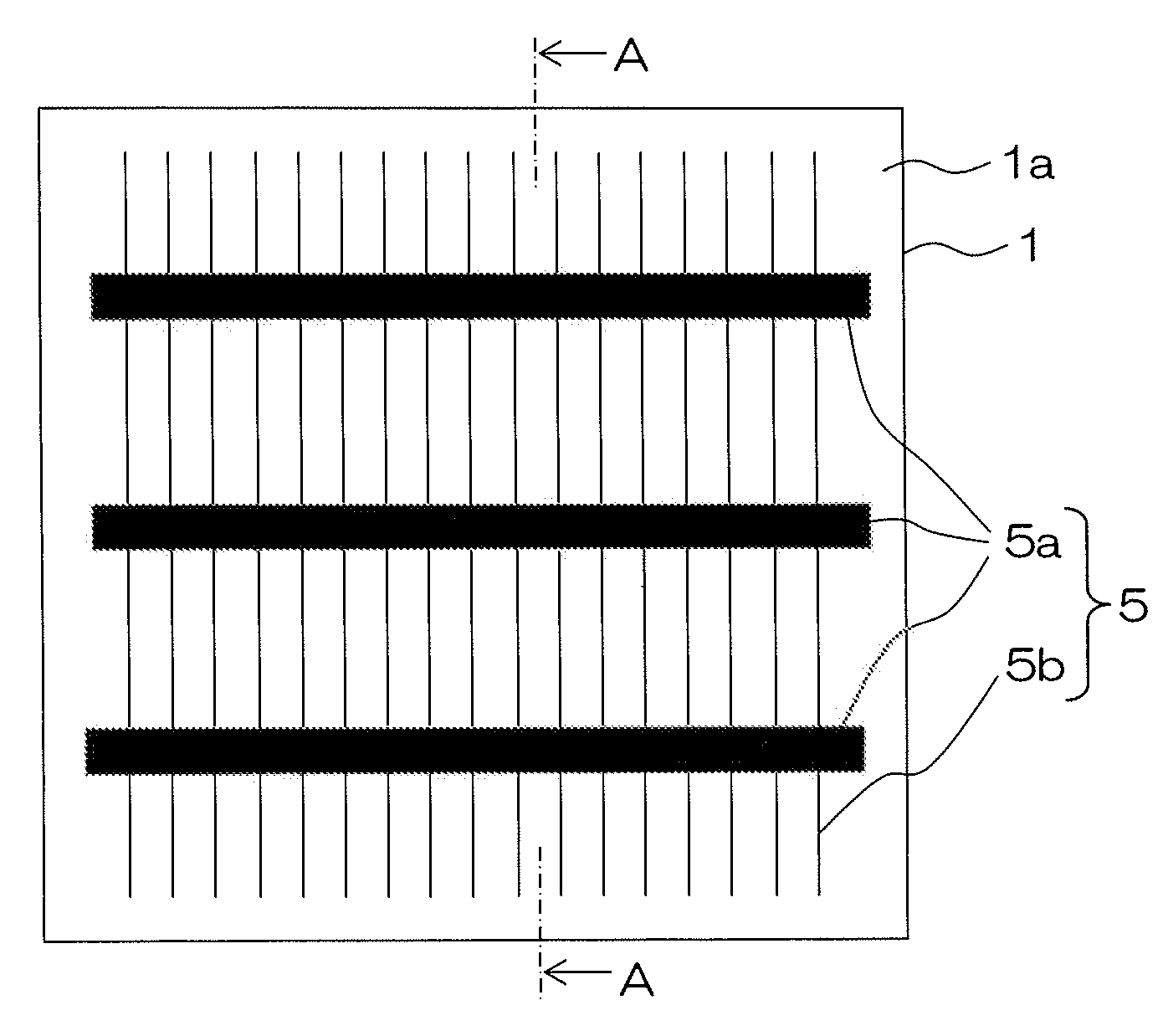

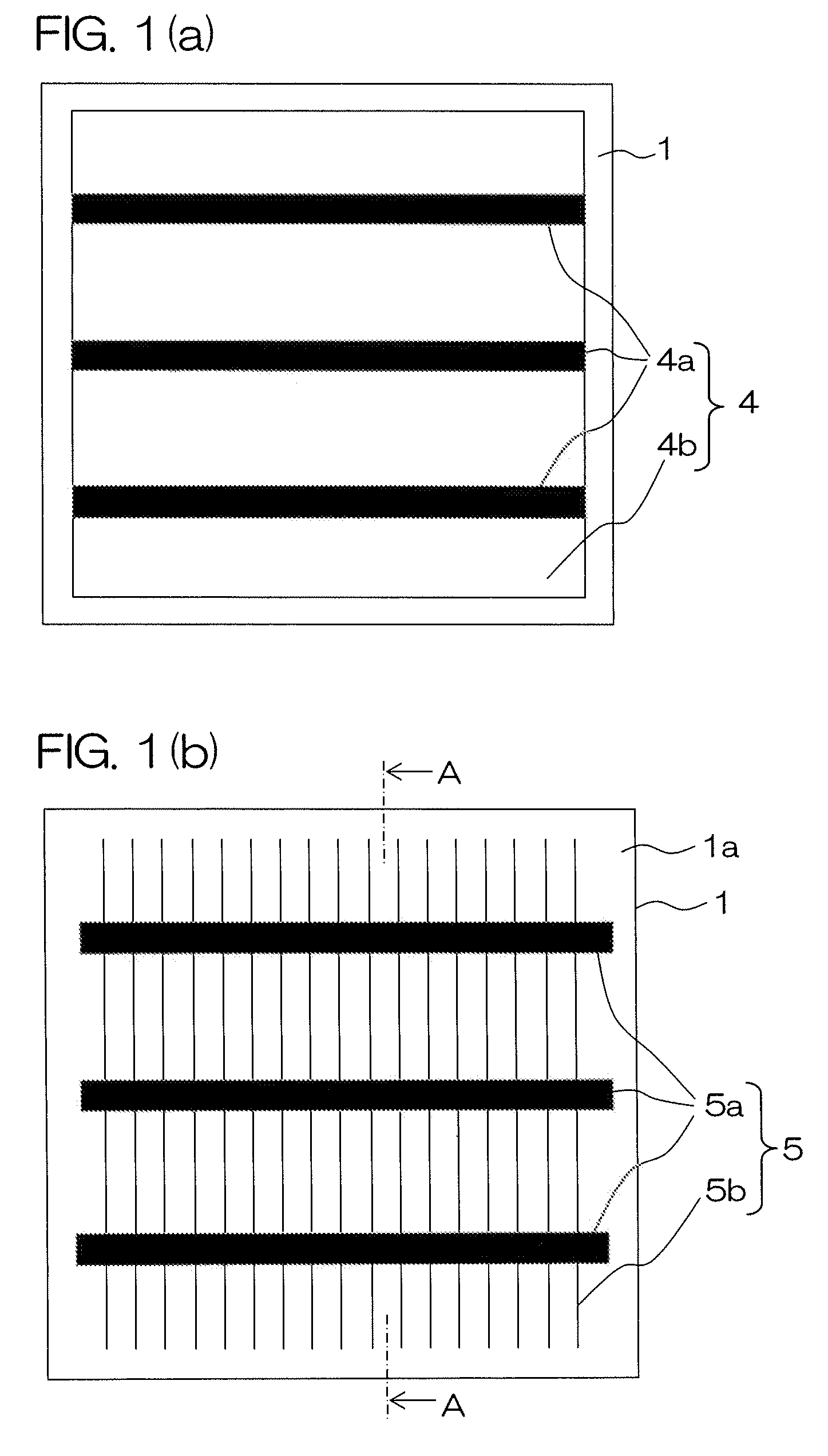

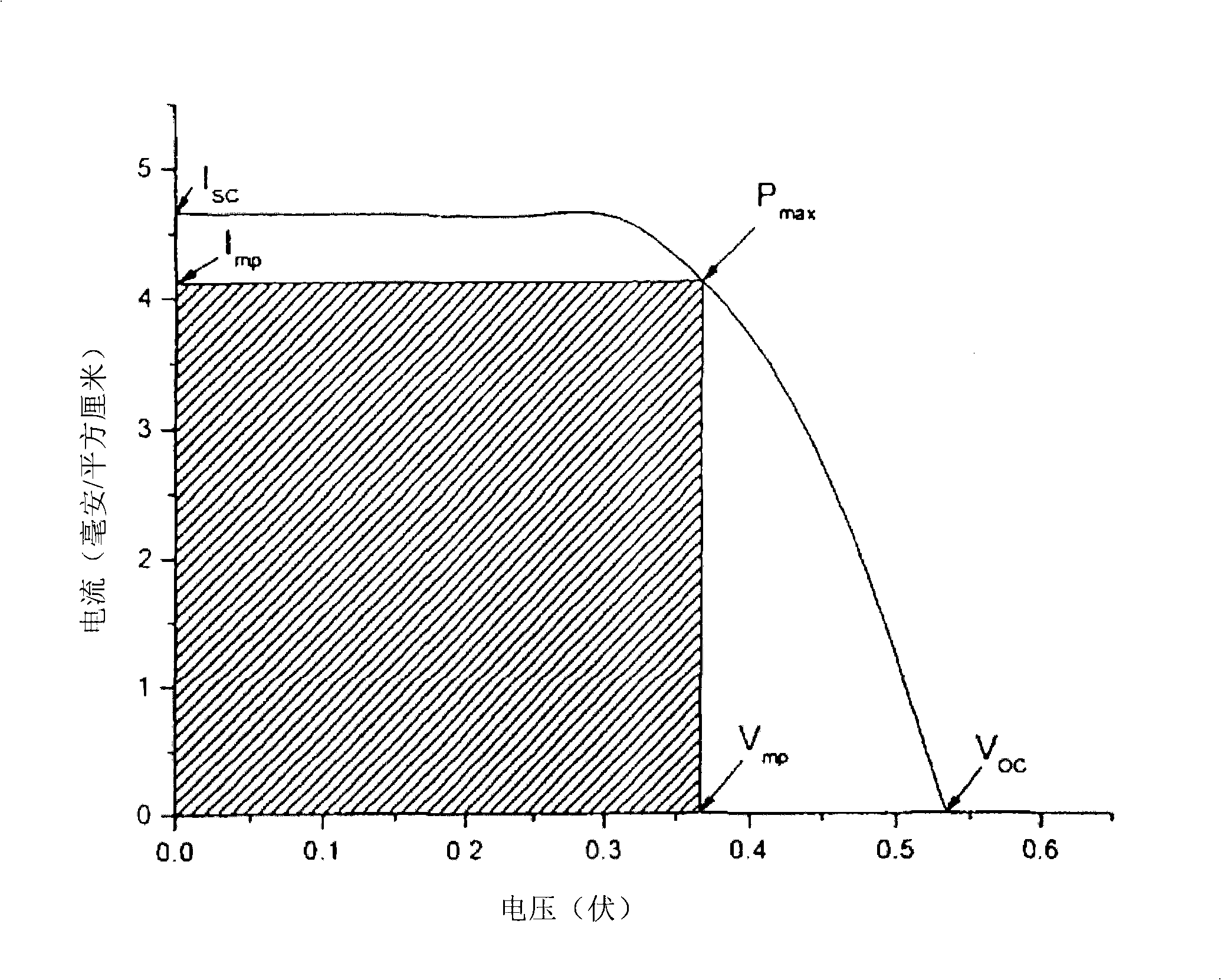

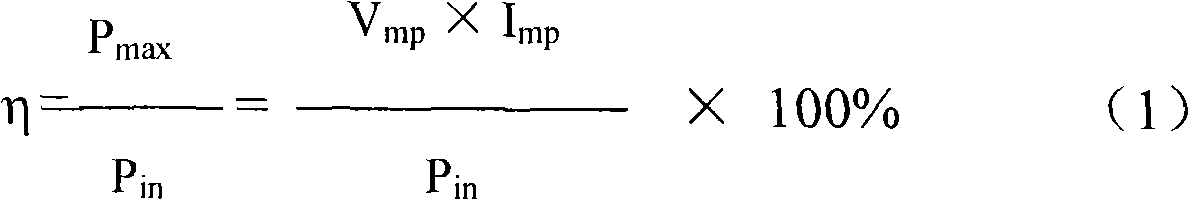

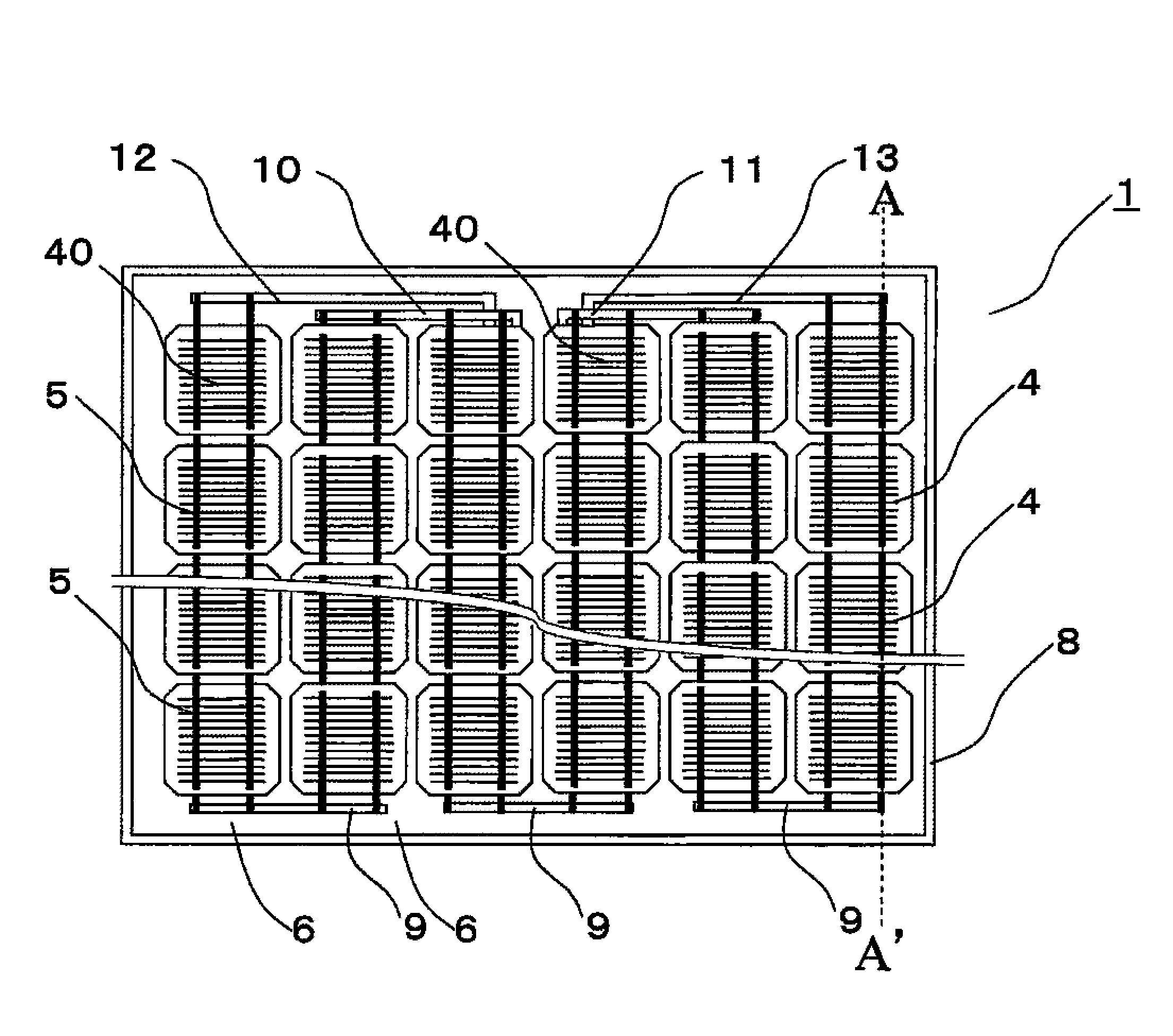

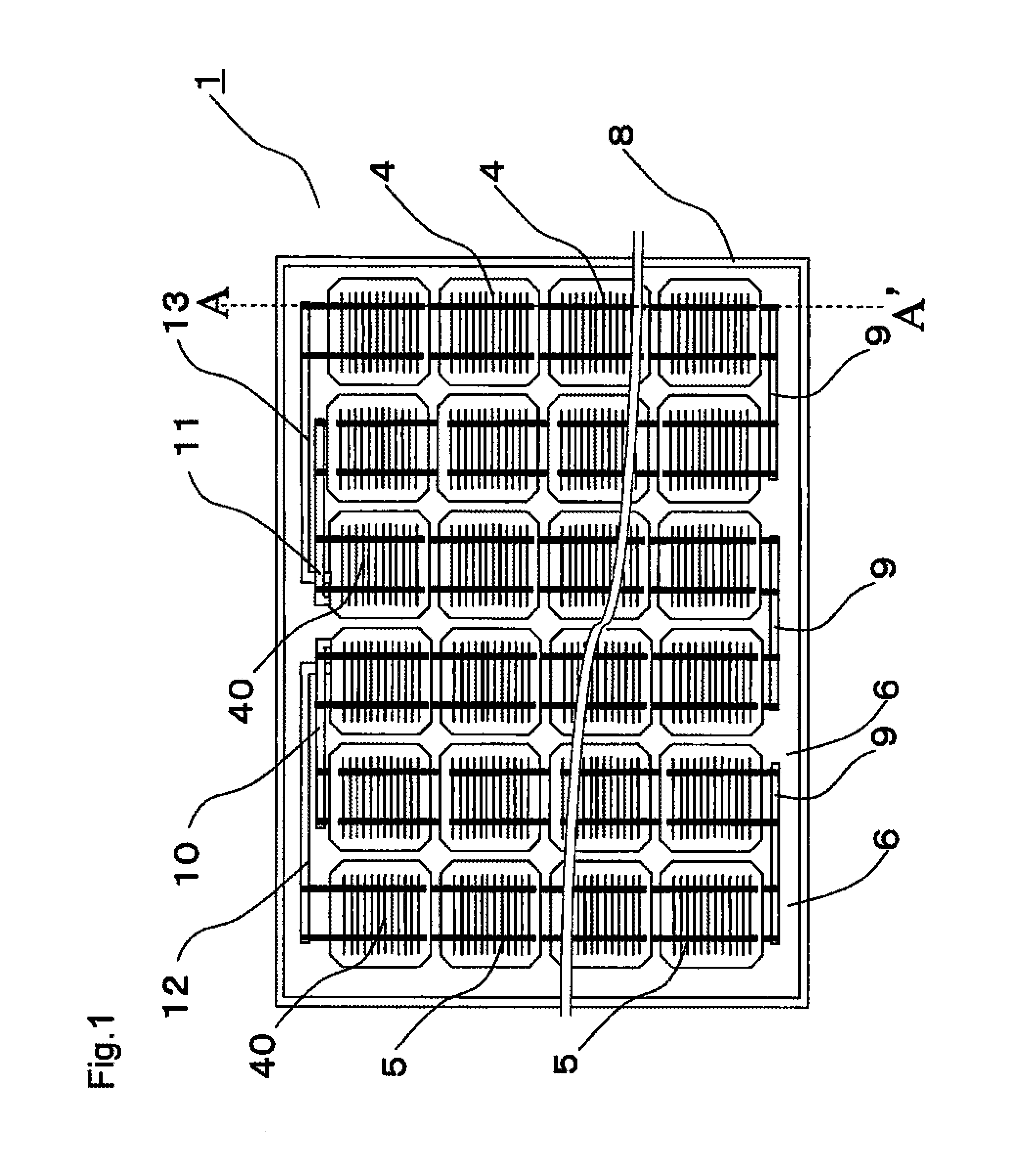

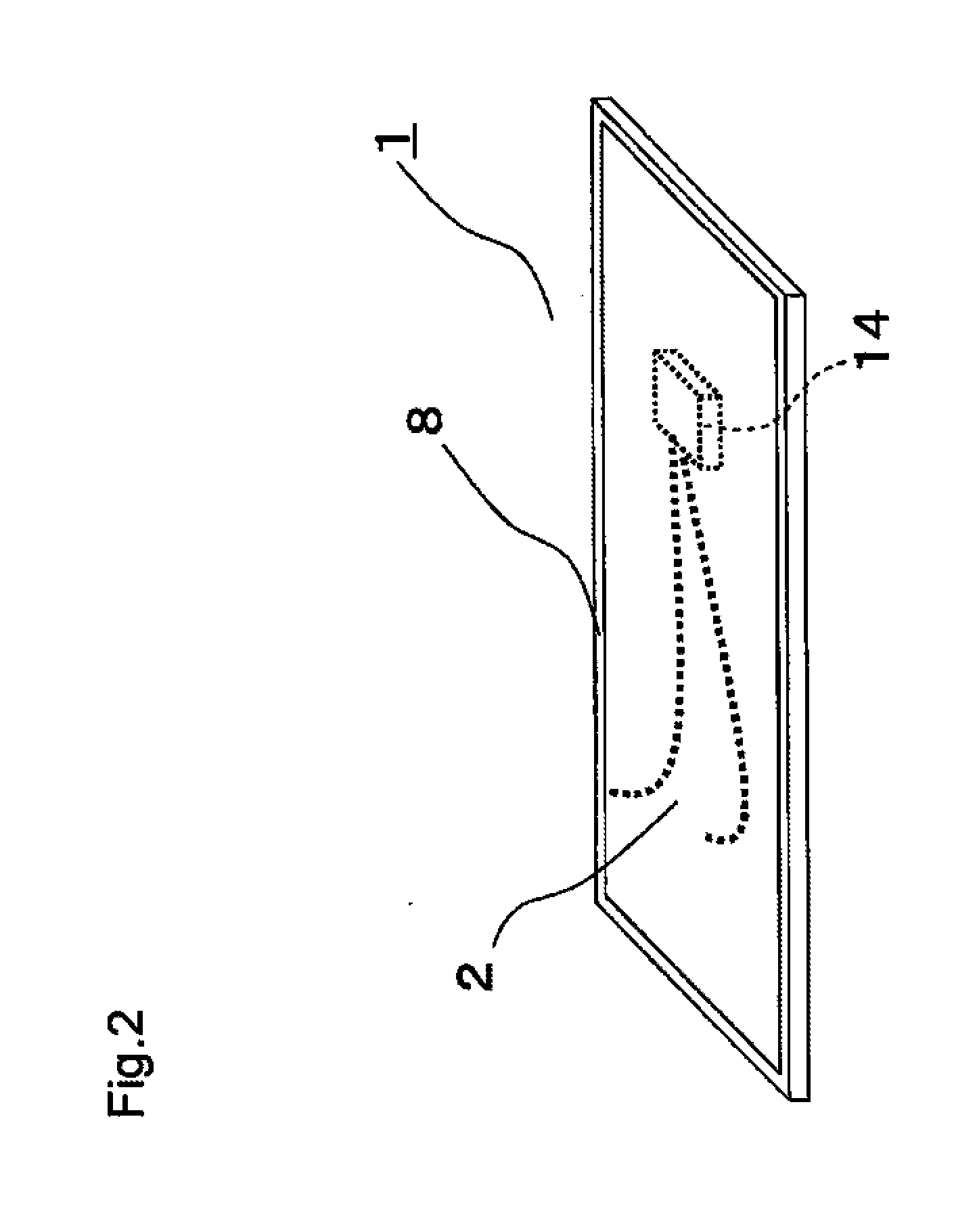

Solar Cell Module and Photovoltaic Power Generator Using This

InactiveUS20070295381A1Reduce rateImprove design qualityPV power plantsPhotovoltaic energy generationPhotovoltaic generatorSolar cell

A surface electrode (5) is installed on the light receiving surface of a solar cell element, the surface electrode (5) comprises three bus bar electrodes (5a) for extracting light-produced at the solar cell element to the outside and collecting finger electrodes (5b) connected to these bus bar electrodes (5a), and the bus bar electrodes (5a) are not less than 0.5 mm and not more than 2 mm in width and the finger electrodes (5b) are not less than 0.05 mm and not more than 0.1 mm in width. A high-efficient solar cell module can be obtained with substantially lowered resistance by increasing the number of bus bar electrode (5a) and thereby decreasing the lengths of the finger electrodes (5b).

Owner:KYOCERA CORP

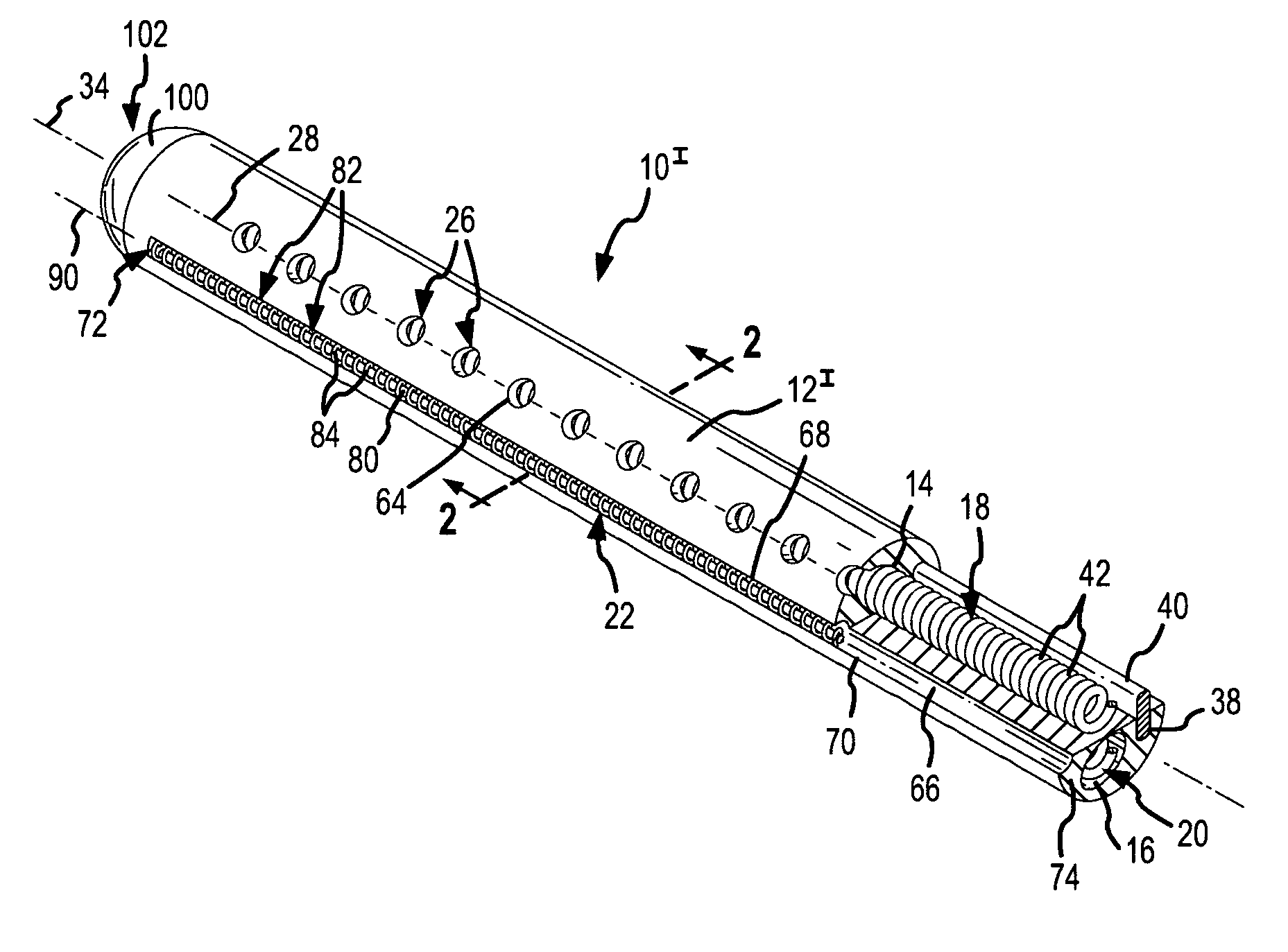

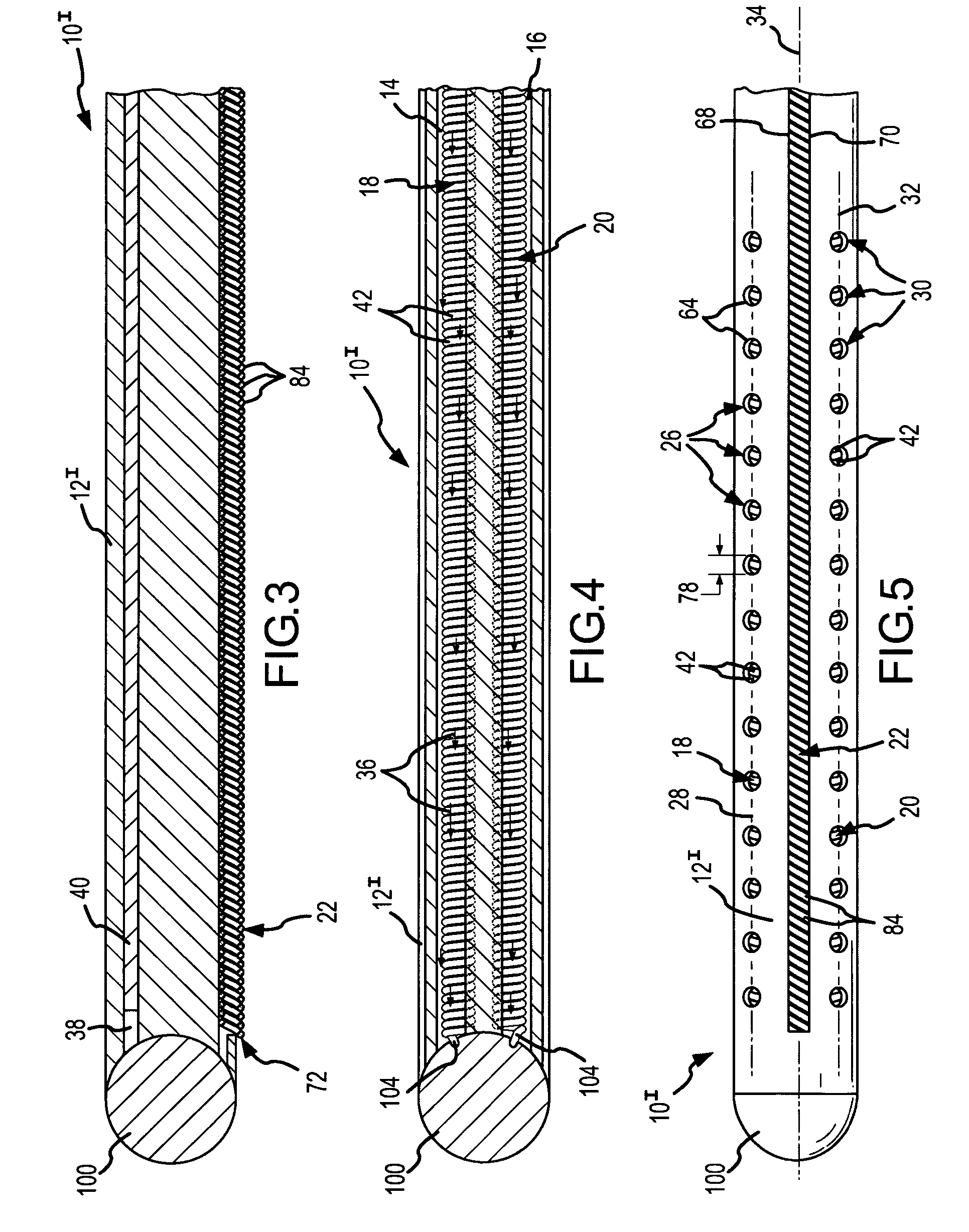

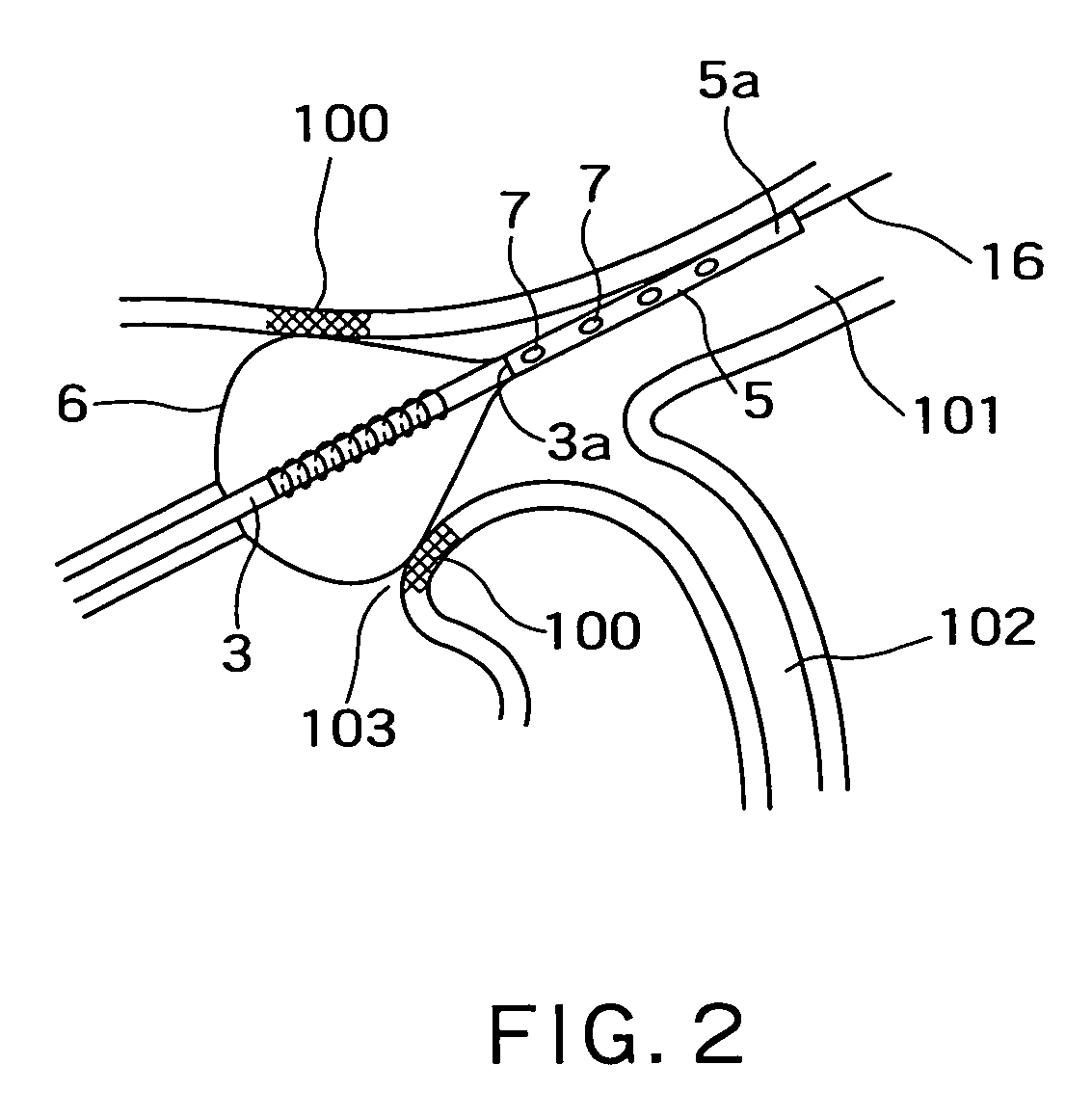

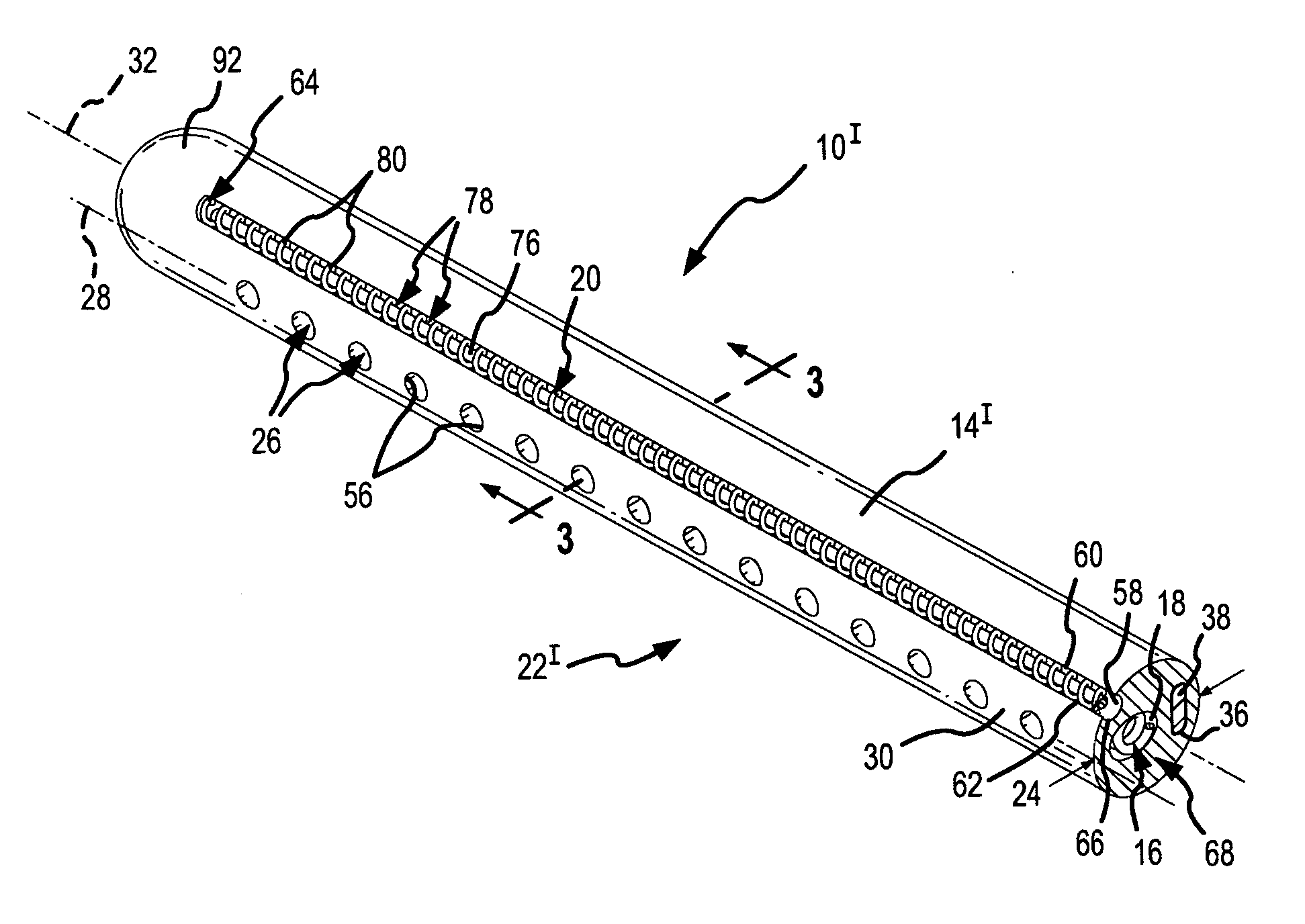

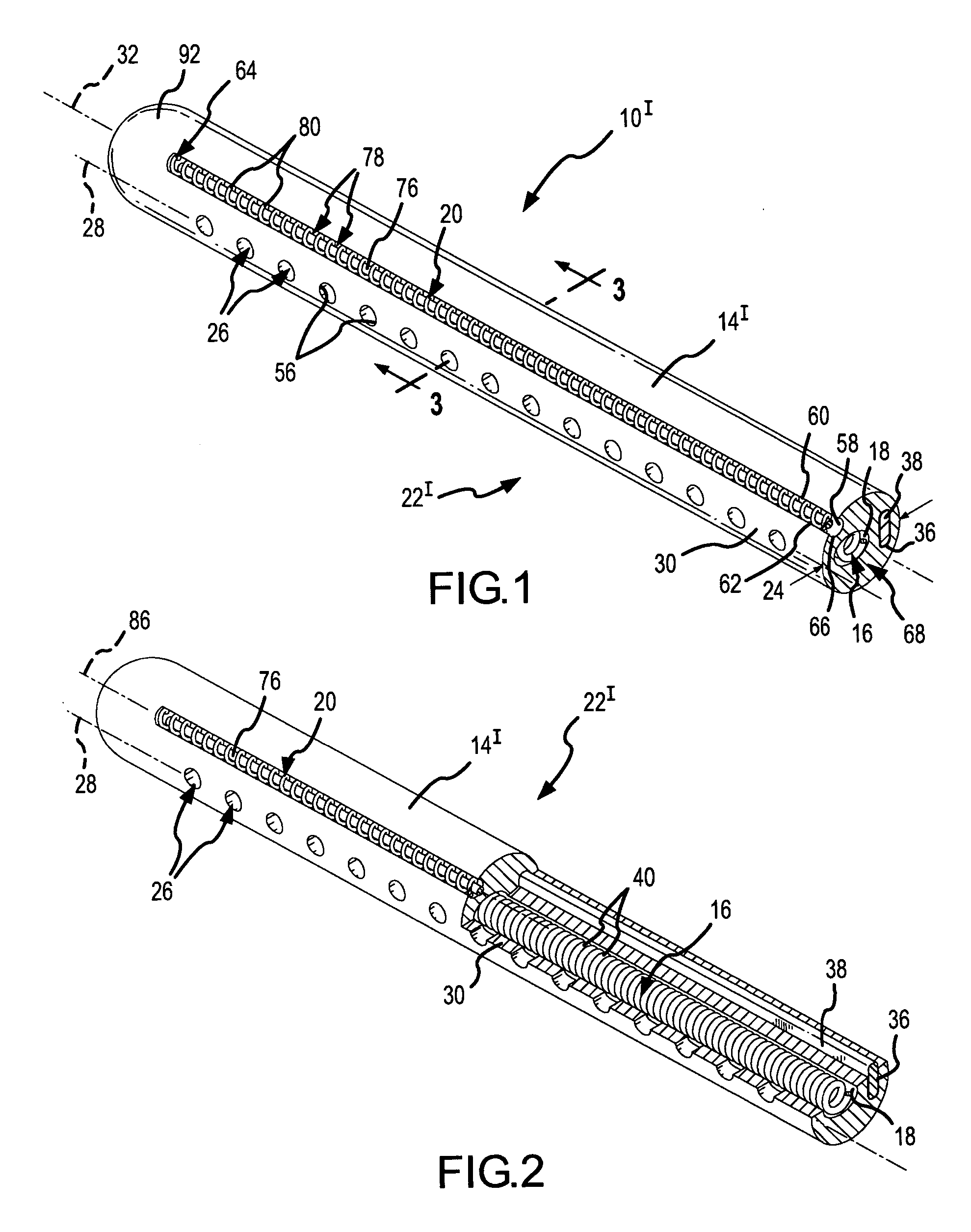

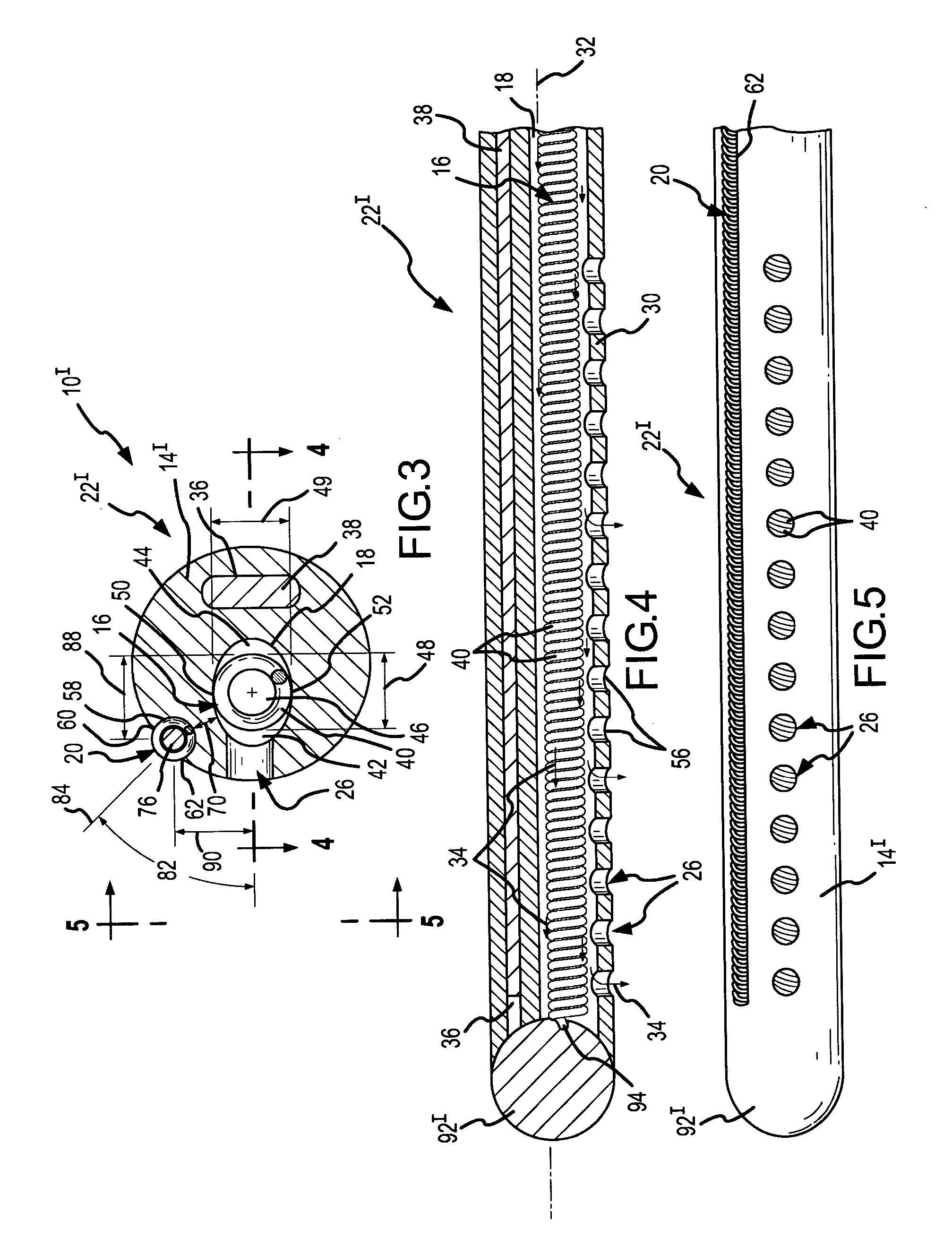

Multipolar, multi-lumen, virtual-electrode catheter with at least one surface electrode and method for ablation

Multipolar, multi-lumen, virtual-electrode catheters having at least one surface electrode, and methods for treatment (e.g., treatment of cardiac arrhythmias) with such catheters are disclosed. The catheters have at least two internal lumens, and at least one internal, flexible electrode rides in each internal lumen. The flexible electrodes carry treatment energy (e.g., radiofrequency energy). The energy exits the catheters via at least one exit feature (e.g., slots, portholes, or micro-pores). The methods for treatment include operating the catheters in different modes depending upon location and type of treatment to be performed. The treatment energy delivered by one of the internal, flexible electrodes may be directed to the other internal, flexible electrode; or the energy delivered by one or both of the internal, flexible electrodes may be directed to one or more surface electrodes. The delivered energy establishes at least one electric field, and possibly one or more lesions, in the tissue.

Owner:ST JUDE MEDICAL ATRIAL FIBRILLATION DIV

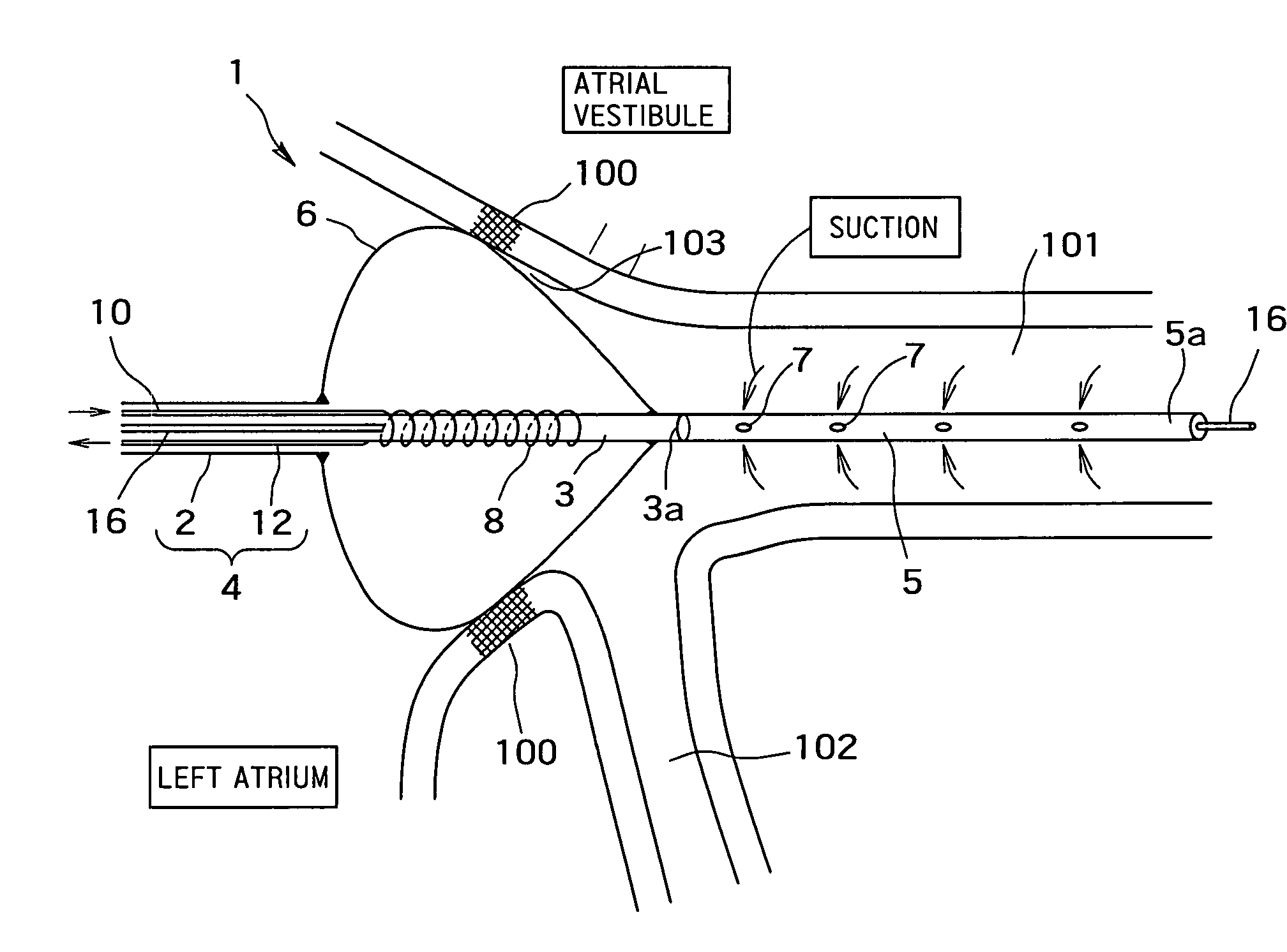

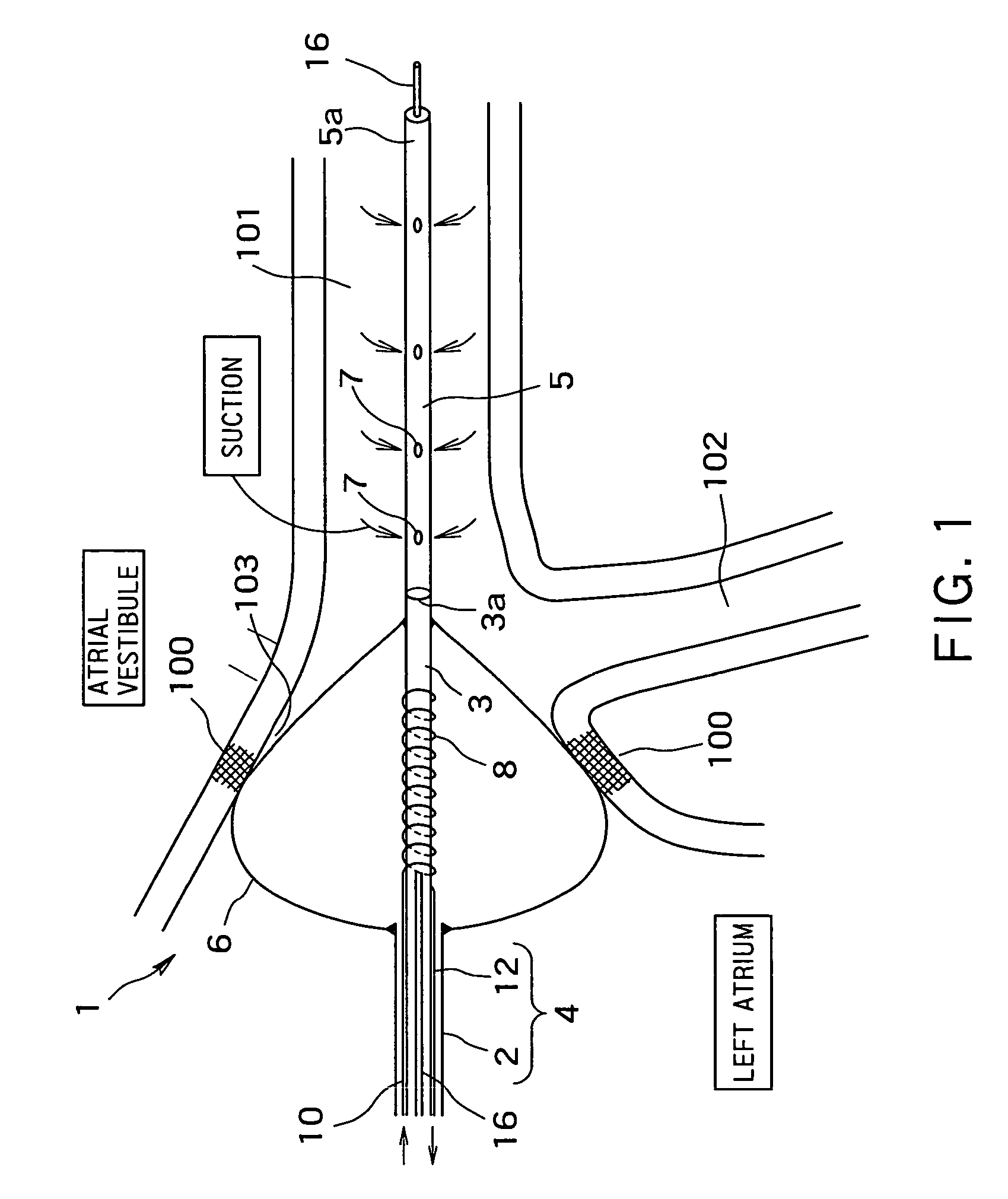

Radio-frequency heating balloon catheter

ActiveUS7112198B2Safely cauterizingShorten the timeCatheterSurgical instruments for heatingBalloon catheterRadio frequency

A radio-frequency heating balloon catheter is capable of cauterizing a target lesion in an atrial vestibule. The radio-frequency heating balloon catheter has a catheter tube including an outer tube and an inner tube slidably extended through the outer tube. An inflatable balloon is connected to an extremity of the outer tube and a part near an extremity of the inner tube, and is capable of coming into contact with a target lesion when inflated. A radio-frequency electrode serves as a counter to a surface electrode attached to a surface of a subject's body and is placed in a wall of the balloon or inside the balloon to supply radio-frequency power between the surface electrode and the radio-frequency electrode. A temperature sensor senses temperature inside the balloon, a guide shaft projects from the extremity of the inner tube and is capable of holding the balloon on the target lesion, and a guide wire extends through the catheter tube and the guide shaft.

Owner:JAPAN ELECTEL

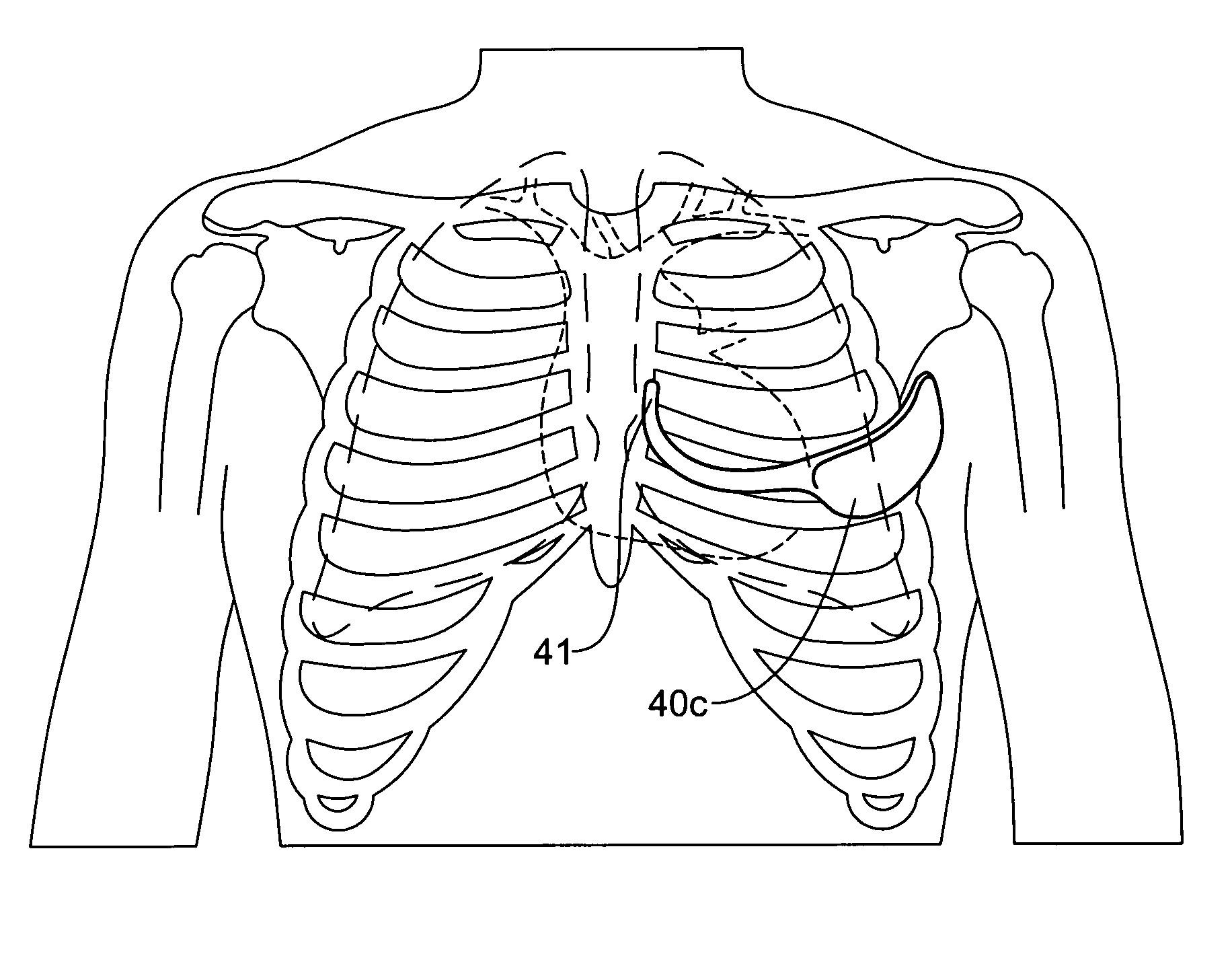

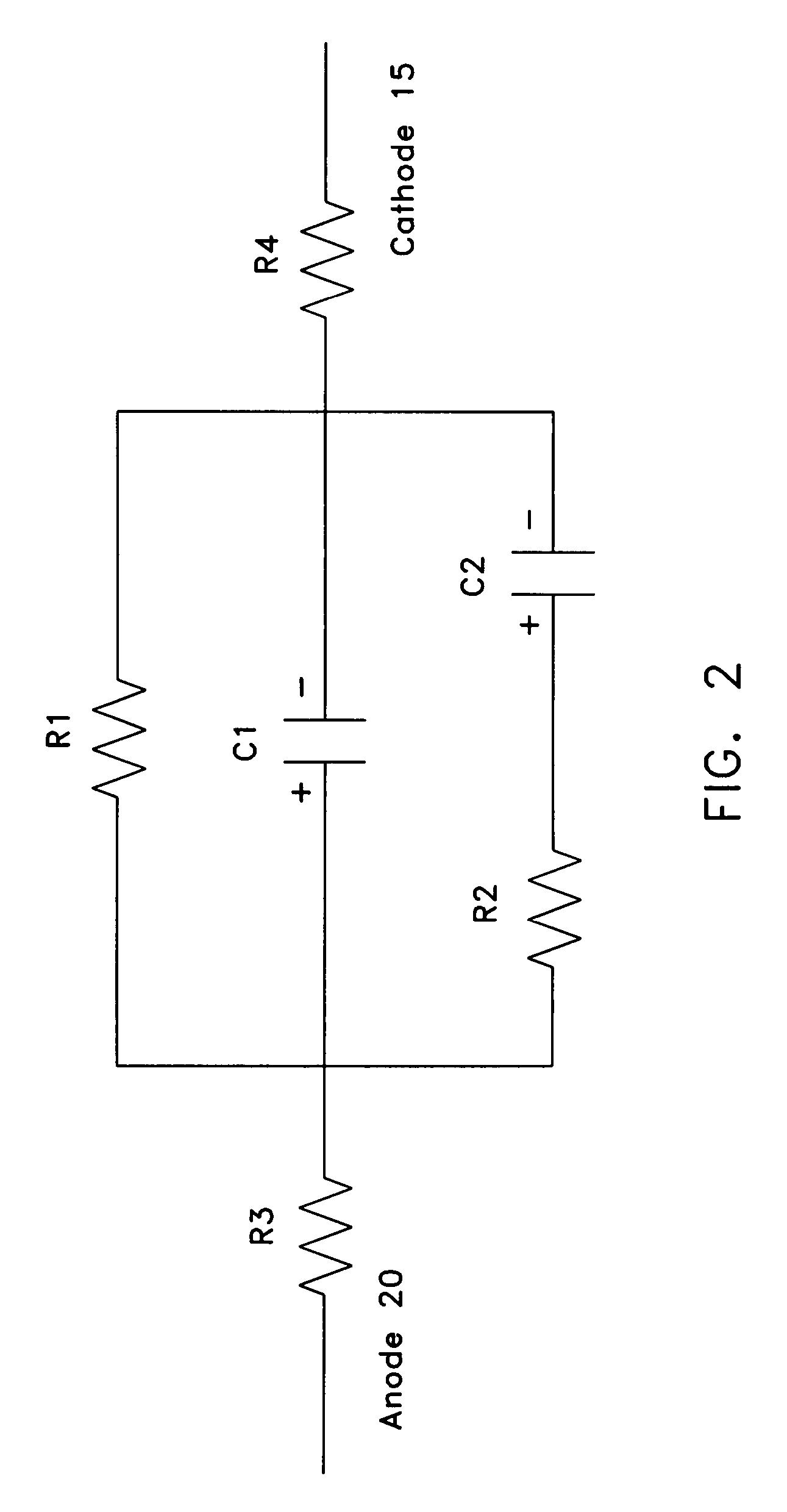

Subcutaneous cardiac stimulator with small contact surface electrodes

InactiveUS7194302B2Reducing electrode interface resistanceReduce energy consumptionHeart defibrillatorsHeart stimulatorsCardiac activityCardiac device

A subcutaneous cardiac device includes two electrodes and a stimulator that generates a pulse to the electrodes. The electrodes are implanted between the skin and the rib cage of the patient and are adapted to generate an electric field corresponding to the pulse, the electric field having a substantially uniform voltage gradient as it passes through the heart. The shapes, sizes, positions and structures of the electrodes are selected to optimize the voltage gradient of the electric field, and to minimize the energy dissipated by the electric field outside the heart. More specifically, the electrodes have contact surfaces that contact the patient tissues, said contact surfaces having a total contact area of less than 100 cm2. In one embodiment, one or both electrodes are physically separated from the stimulator. In another embodiment a unitary housing holds the both electrodes and the stimulator. Sensor circuitry may also includes in the stimulator for detecting intrinsic cardiac activity through the same electrodes.

Owner:CAMERON HEALTH

Treatment of indications using electrical stimulation

ActiveUS20110282412A1Promote wound healingReduce joint painElectrotherapyArtificial respirationElectrical conductorElectrical stimulations

In one embodiment, a method includes implanting an implant entirely under the subject's skin. The implant includes a passive electrical conductor of sufficient length to extend from subcutaneous tissue located below one of a surface cathodic electrode and a surface anodic electrode to the tibial nerve. The surface electrodes are positioned in spaced relationship on the subject's skin, with one of the electrodes positioned over the pick-up end of the electrical conductor such that the portion of the current is transmitted through the conductor to the tibial nerve, and such that the current flows through the tibial nerve and returns to the other of the surface cathodic electrode and the surface anodic electrode. An electrical current is applied between the surface cathodic electrode and the surface anodic electrode to cause the portion of the electrical current to flow through the implant to stimulate the tibial nerve.

Owner:BIONESS

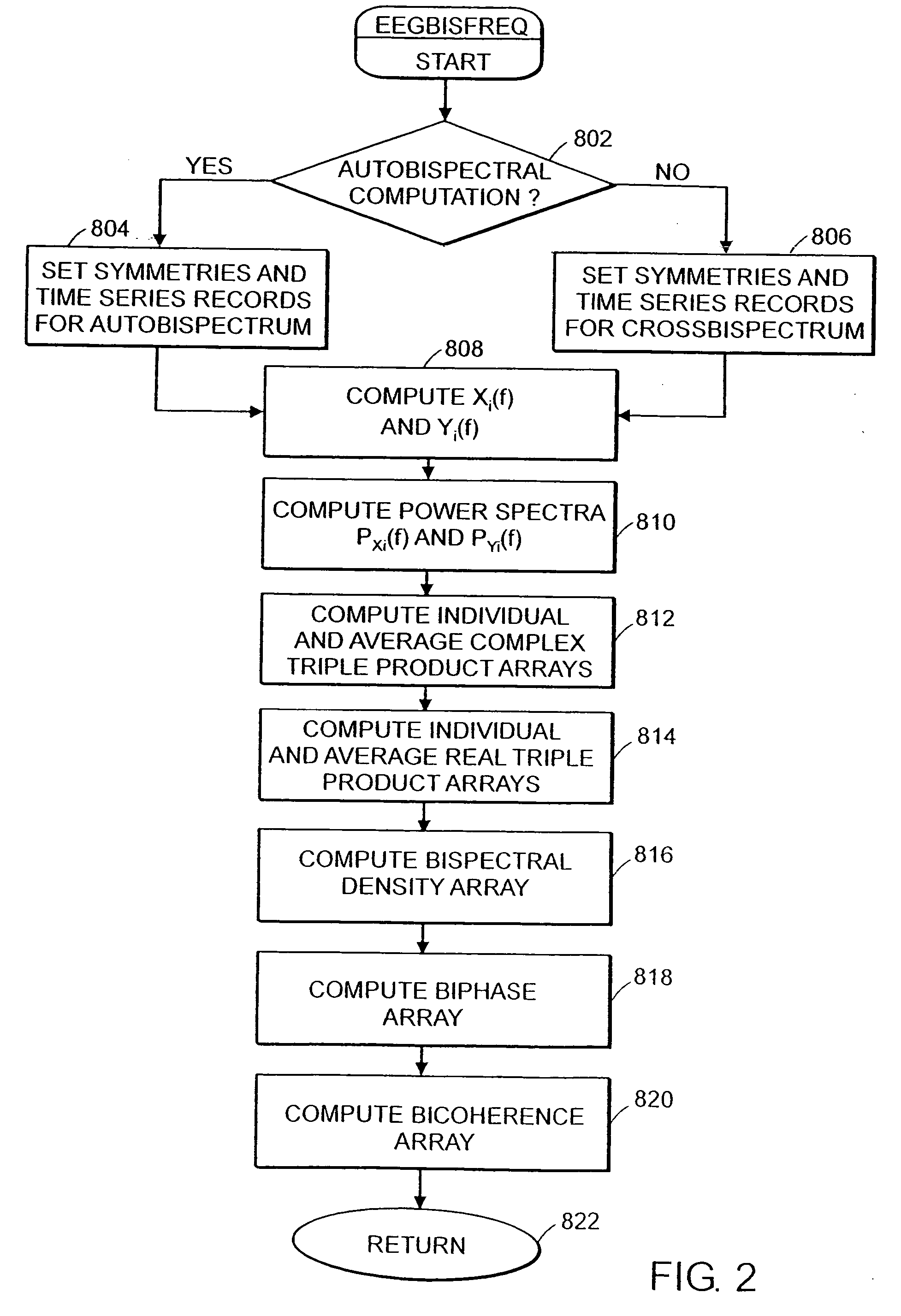

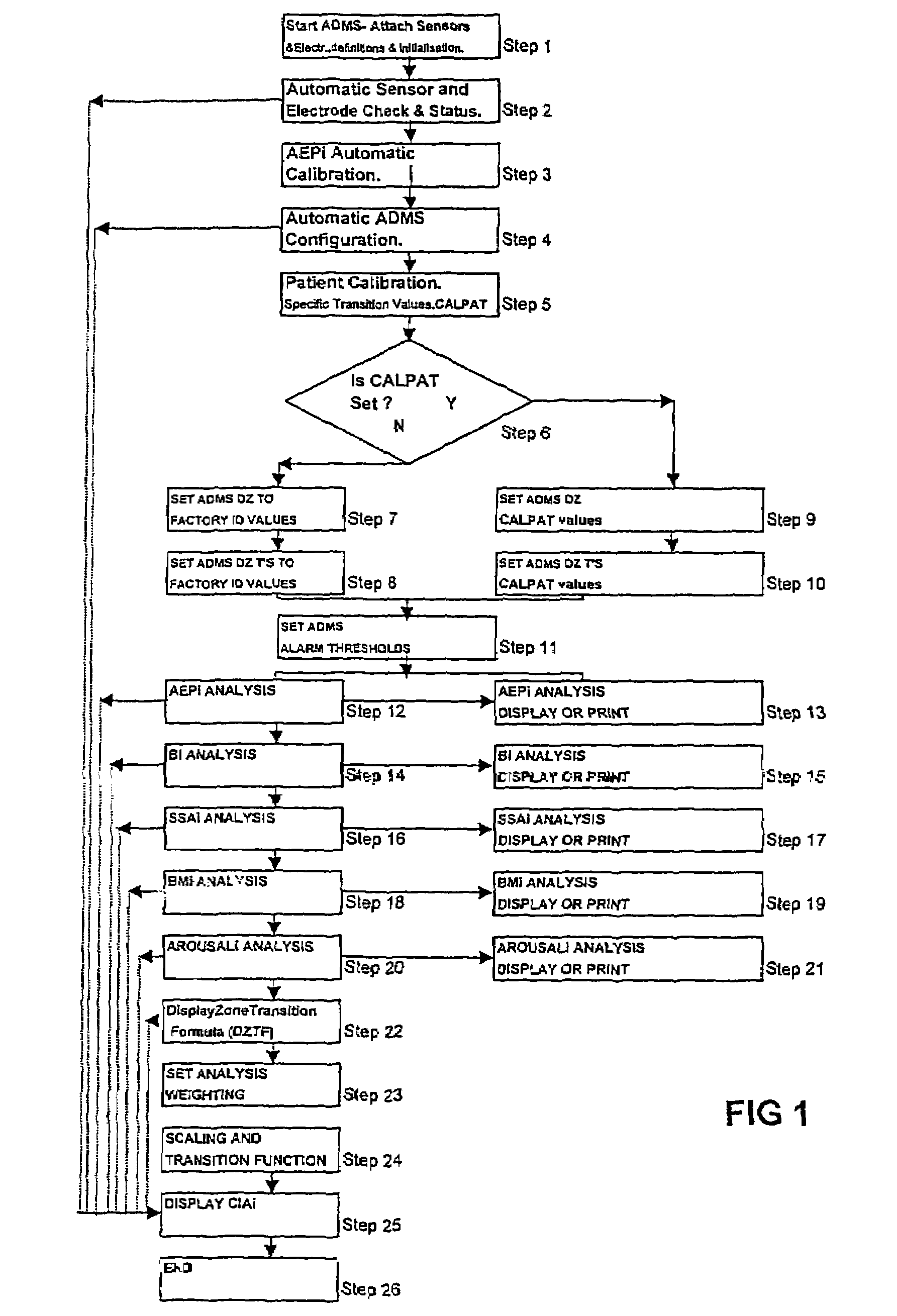

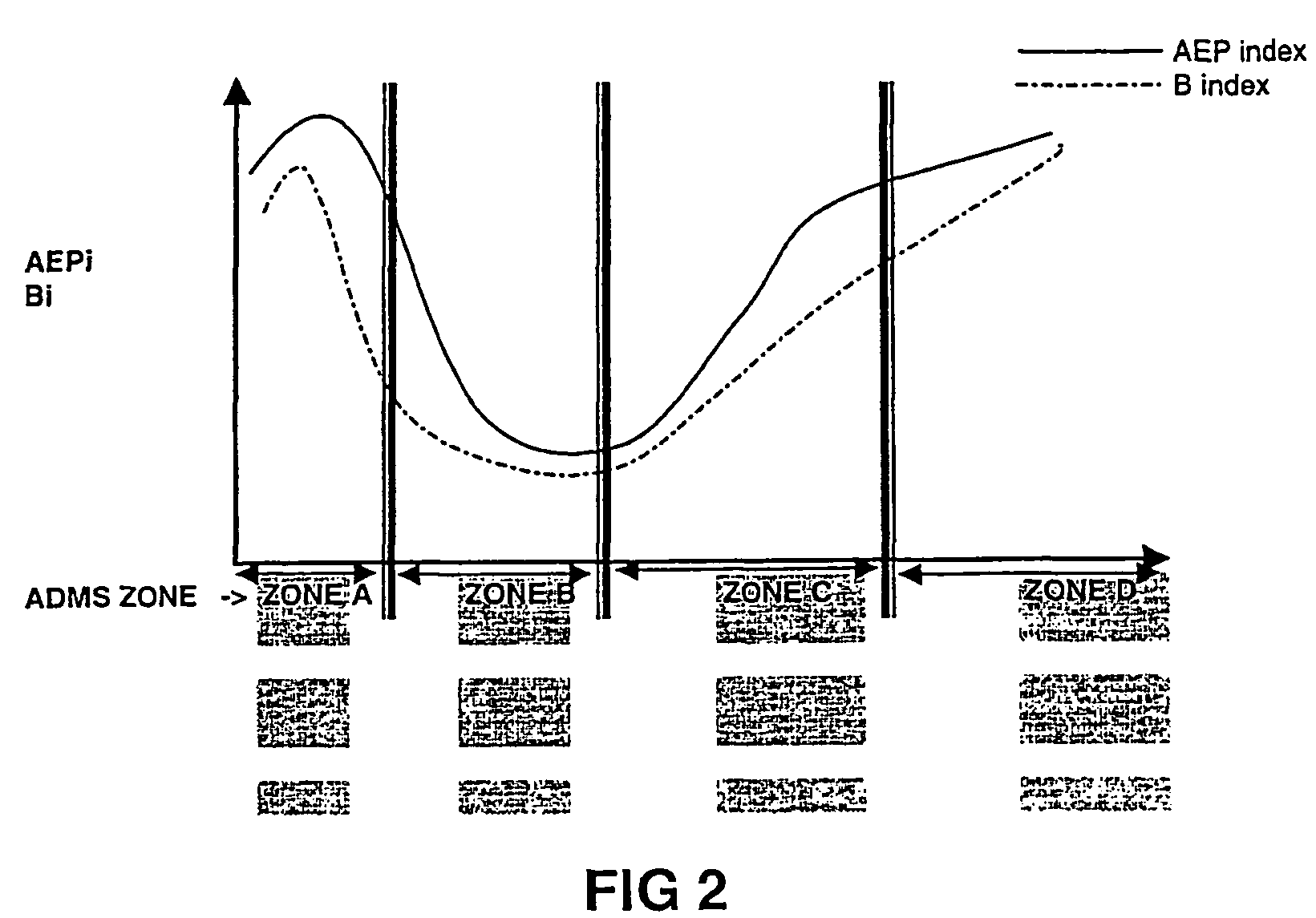

Methods and apparatus for monitoring consciousness

ActiveUS7774052B2Improve accuracyReduce impactElectroencephalographyElectrocardiographySpectral edgeCoherence analysis

Owner:COMPUMEDICS

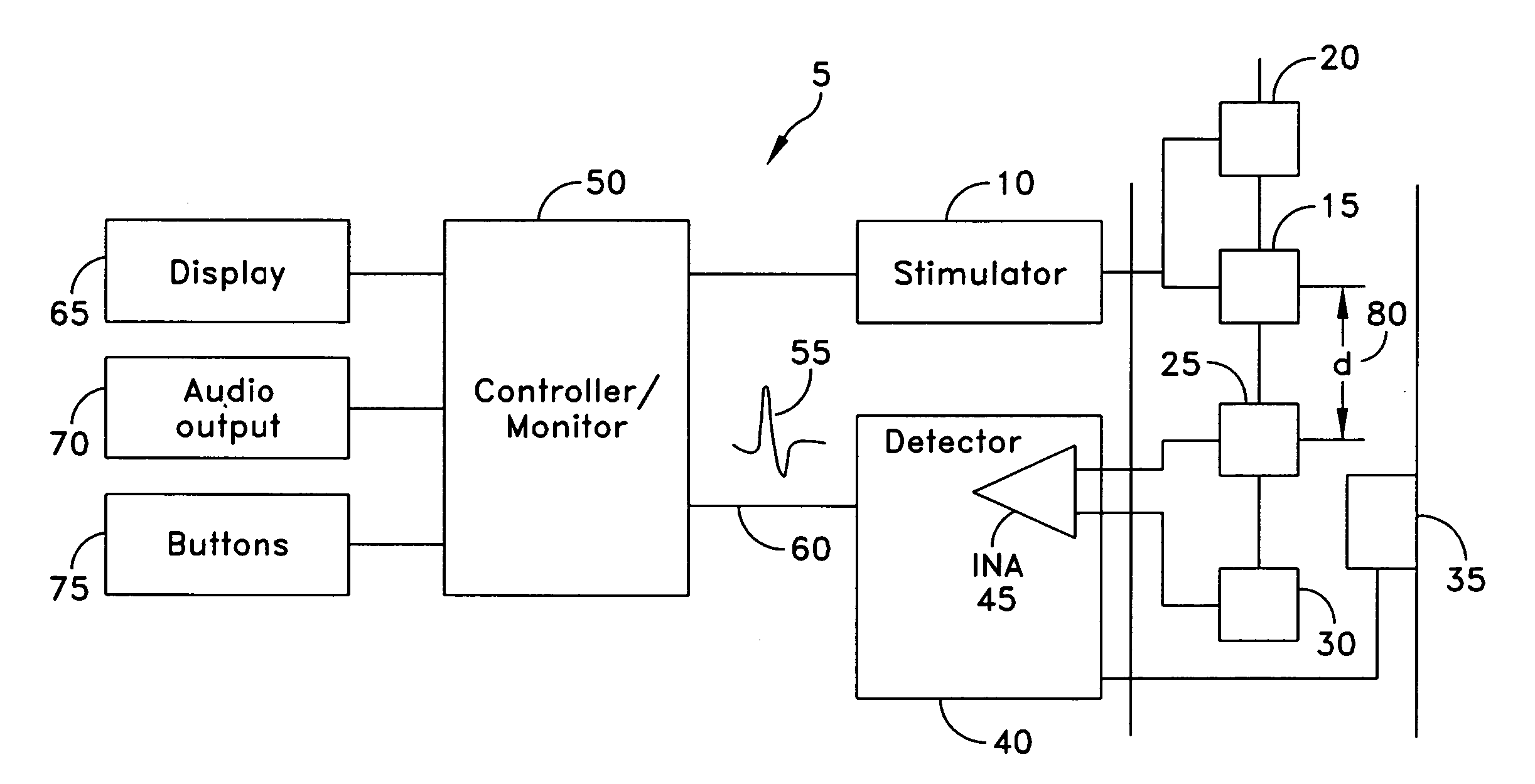

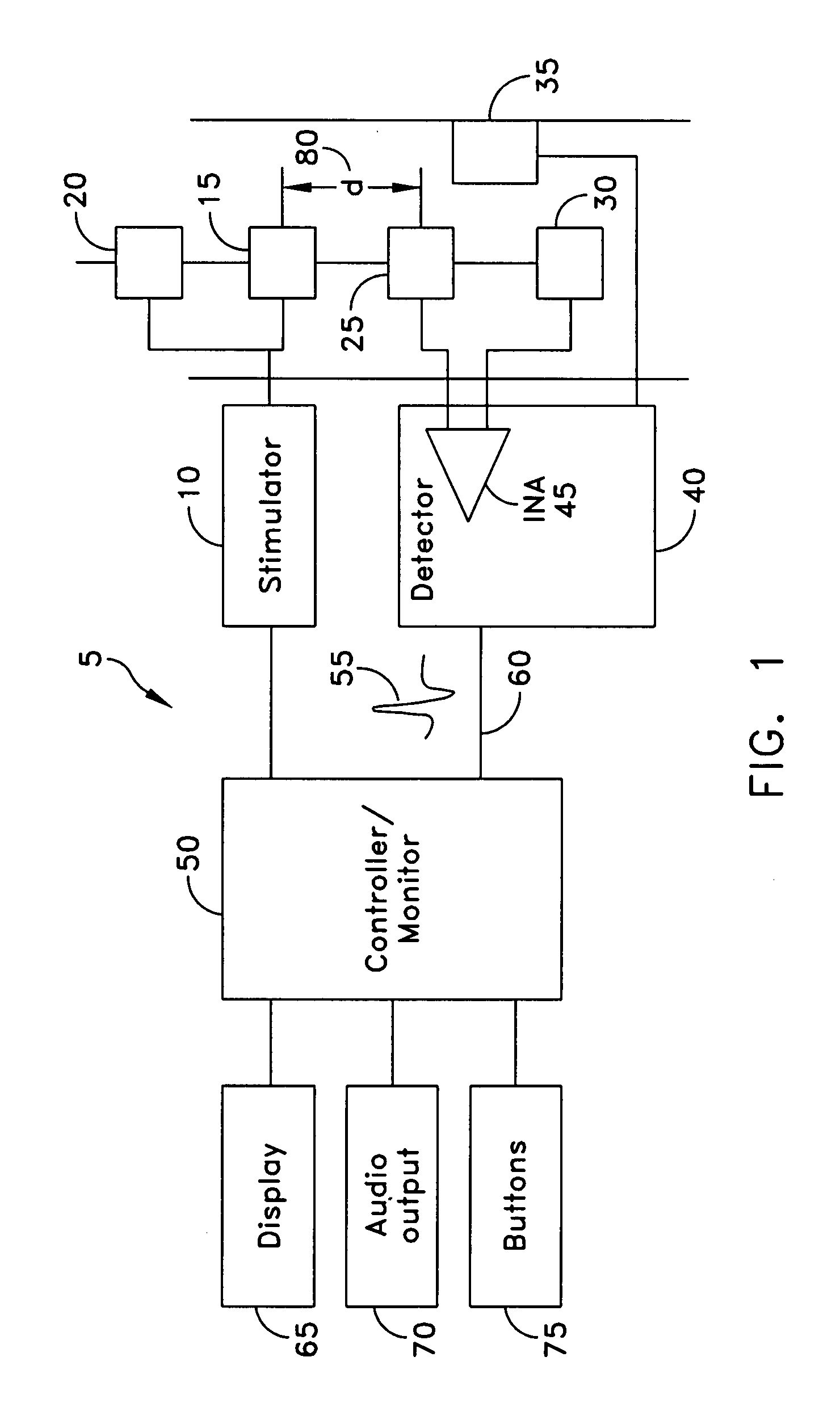

Non-invasive acquisition of large nerve action potentials (NAPs) with closely spaced surface electrodes and reduced stimulus artifacts

InactiveUS20080051647A1Effectively minimizingEliminate effectiveSensorsExternal electrodesMedicineNon invasive

Owner:NEUROMETRIX

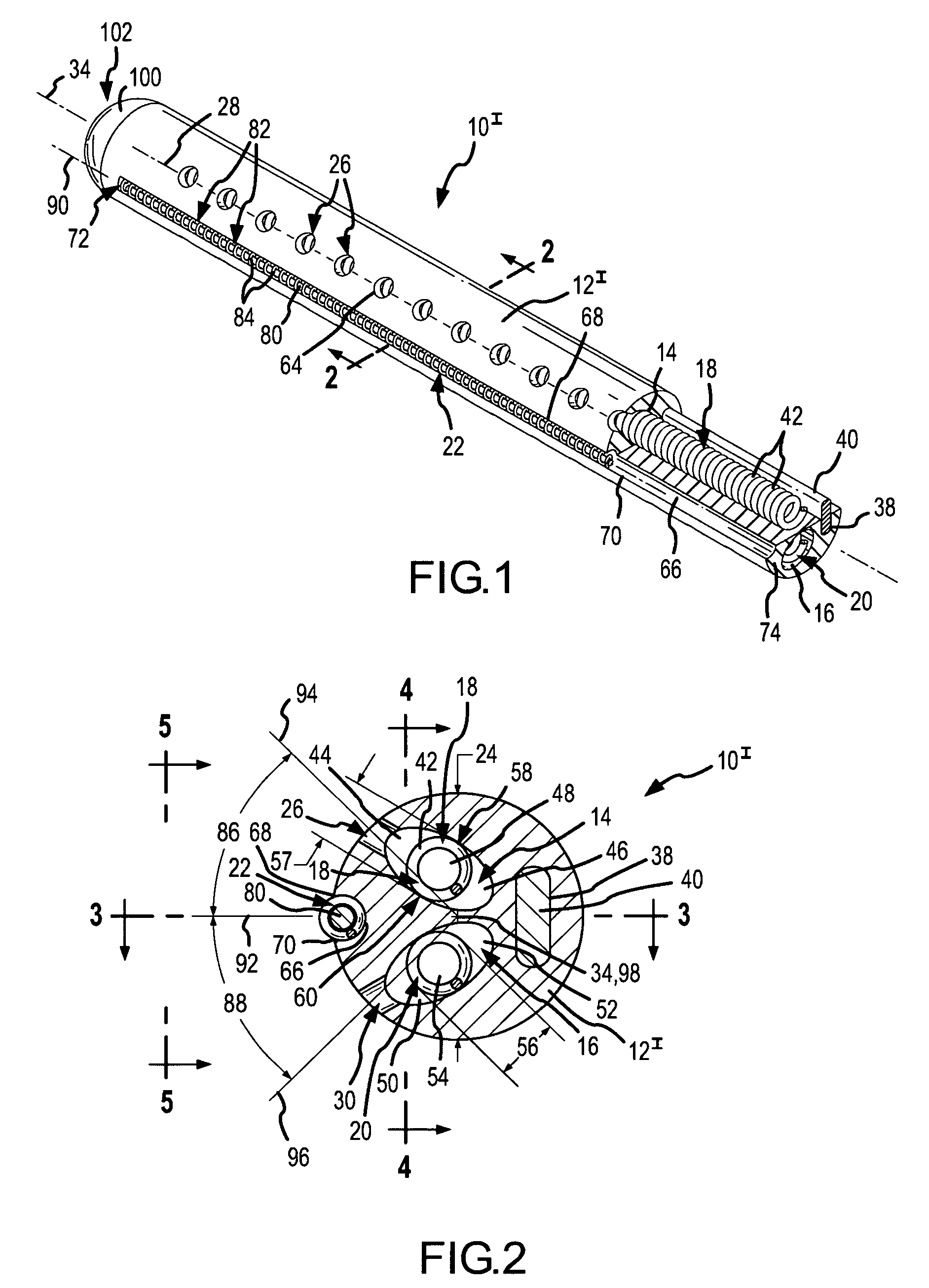

Lead with distal tip surface electrodes connected in parallel

InactiveUS7027852B2High pacing impedanceAdvantageous anode-to-cathode surface area ratioTransvascular endocardial electrodesDiagnostic recording/measuringLow noiseWavefront

An body implantable stimulation lead is provided including tip electrode patterns and configurations producing low noise, clean sensed signals devoid of far field components, such sensed signals being generated irrespective of the direction of the incident depolarization wavefront. The invention also provides high pacing impedances and advantageous anode-to-cathode surface area ratios. Further, implantable leads utilizing the features of the present invention are particularly suitable for left side stimulation therapies.

Owner:PACESETTER INC

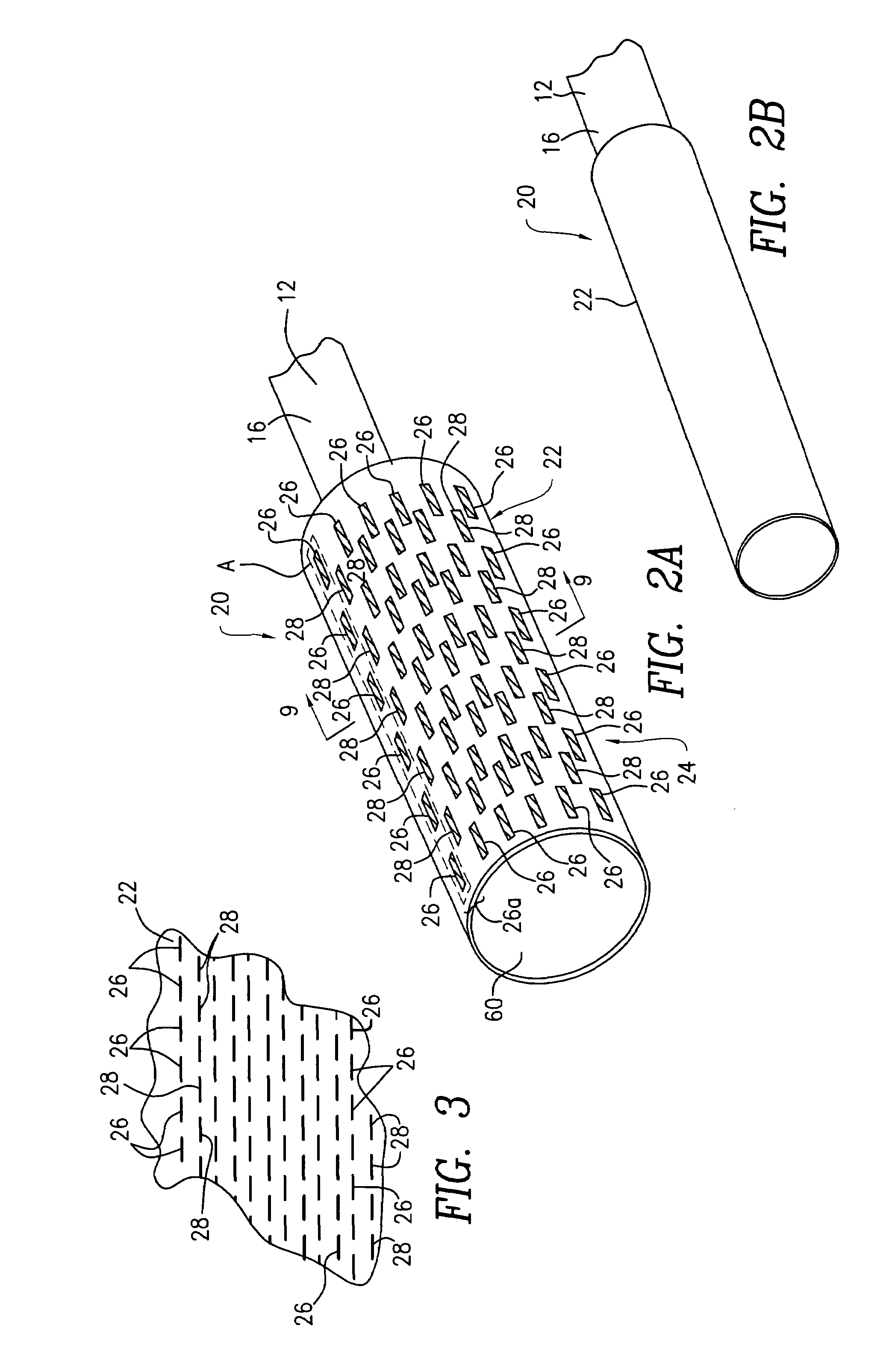

Flexible electrode device and surgical apparatus equipped with same

An electrode device adapted for use in medical devices, such as tissue ablation apparatus, includes a sheet of flexible fabric including at least one surface electrode formed as part of the fabric. More particularly, the sheet is made from a plurality of filaments. At least some of the filaments are made at least partially from an electrically conductive material and cooperate so as to form the electrode. The filaments are formed into a plurality of yarns which are interwoven to form the sheet.

Owner:ETHICON INC

Conductive slurry for solar battery front side electrode and production method thereof

ActiveCN101295739AImprove photoelectric conversion efficiencyImprove adhesionFinal product manufactureNon-conductive material with dispersed conductive materialConductive pasteElectrical battery

The invention relates to a conductive paste for the surface electrode of a solar cell, which comprises conductive metal powders, organic carriers, adhesives, solvents and addition agent, wherein, the conductive paste also comprises additives which are selected from phosphorus pentachloride and one or more VIII group metal halide. The additive in the conductive paste of the invention can help improve the adhesive force between the conductive paste and silicon substrate, and lead adhesion between compounds obtained after electrode sintering and silicon substrate to be more firm; the formed compound does not have cracks and bubbles and the electrode surface is flat and smooth, thus providing the solar cell finally prepared with higher photoelectric conversion efficiency.

Owner:BYD CO LTD

Method of routing electrical current to bodily tissues via implanted passive conductors

The invention provides an implant, system and method for electrically stimulating a target tissue to either activate or block neural impulses. The implant provides a conductive pathway for a portion of electrical current flowing between surface electrodes positioned on the skin and transmits that current to the target tissue. The implant has a passive electrical conductor of sufficient length to extend from subcutaneous tissue located below a surface cathodic electrode to the target tissue. The conductor has a pick-up end which forms an electrical termination having a sufficient surface area to allow a sufficient portion of the electrical current to flow through the conductor, in preference to flowing through body tissue between the surface electrodes, such that the target tissue is stimulated to either activate or block neural impulses. The conductor also has a stimulating end which forms an electrical termination for delivering the current to the target body tissue.

Owner:2249020 ALBERTA LTD

Multipolar, virtual-electrode catheter with at least one surface electrode and method for ablation

ActiveUS20070027448A1Surgical instruments for heatingTherapeutic coolingBiomedical engineeringCatheter device

Virtual-electrode catheters and methods for using such virtual-electrode catheters are disclosed. For example, bipolar and multipolar, virtual-electrode catheters having at least one internal electrode and at least one surface electrode, and methods of using these catheters for treatment of cardiac arrhythmias via, for example, radiofrequency (RF) ablation are disclosed. The catheters may comprise a catheter body with an internal lumen extending within it and adapted to flowingly receive a conductive fluid. An exit feature defining a flow path from the internal lumen to the catheter's outer surface may exist through a sidewall of the catheter body. A conductor is mounted within the internal lumen adjacent to the exit feature and is adapted to deliver treatment energy to the tissue via the conductive fluid in the internal lumen. At least one surface electrode is mounted on the outer surface of the catheter body adjacent to the exit feature.

Owner:ST JUDE MEDICAL ATRIAL FIBRILLATION DIV

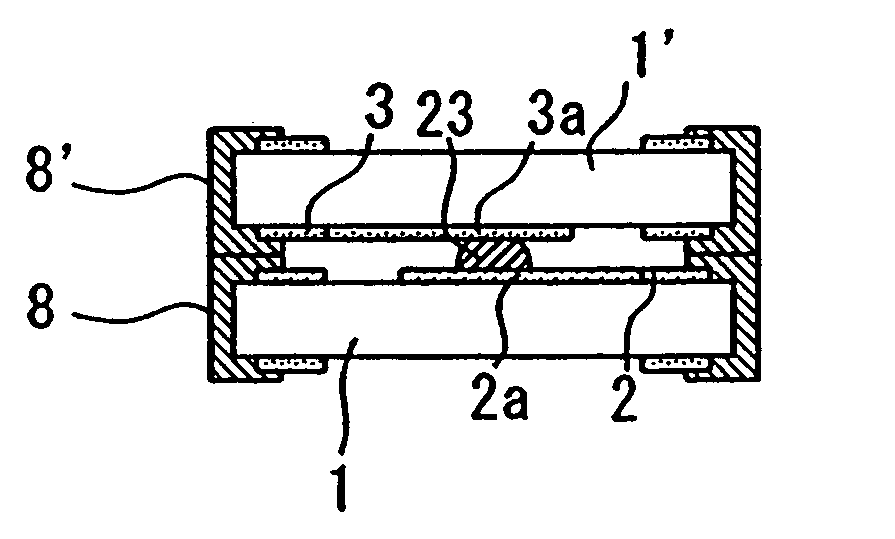

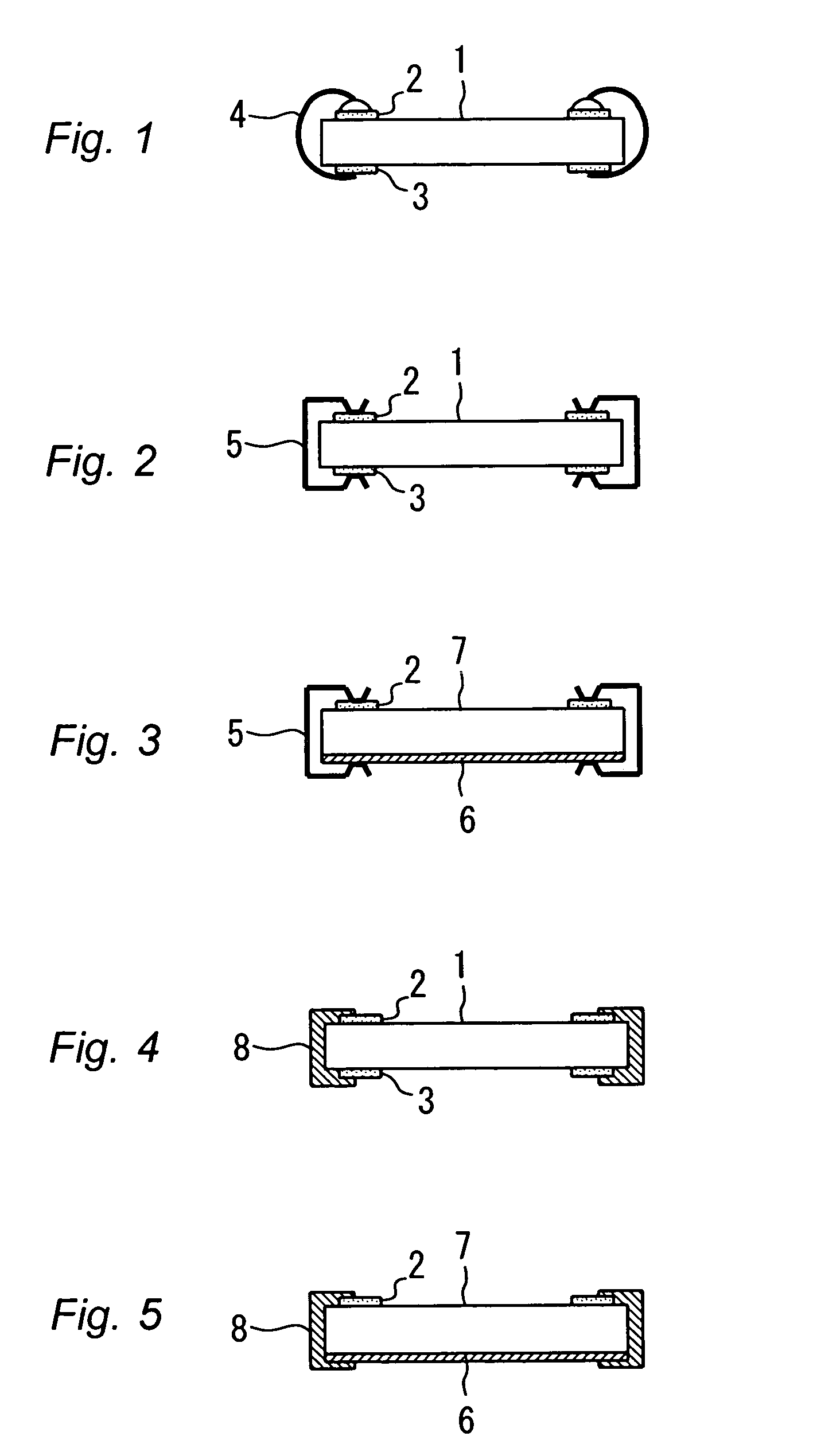

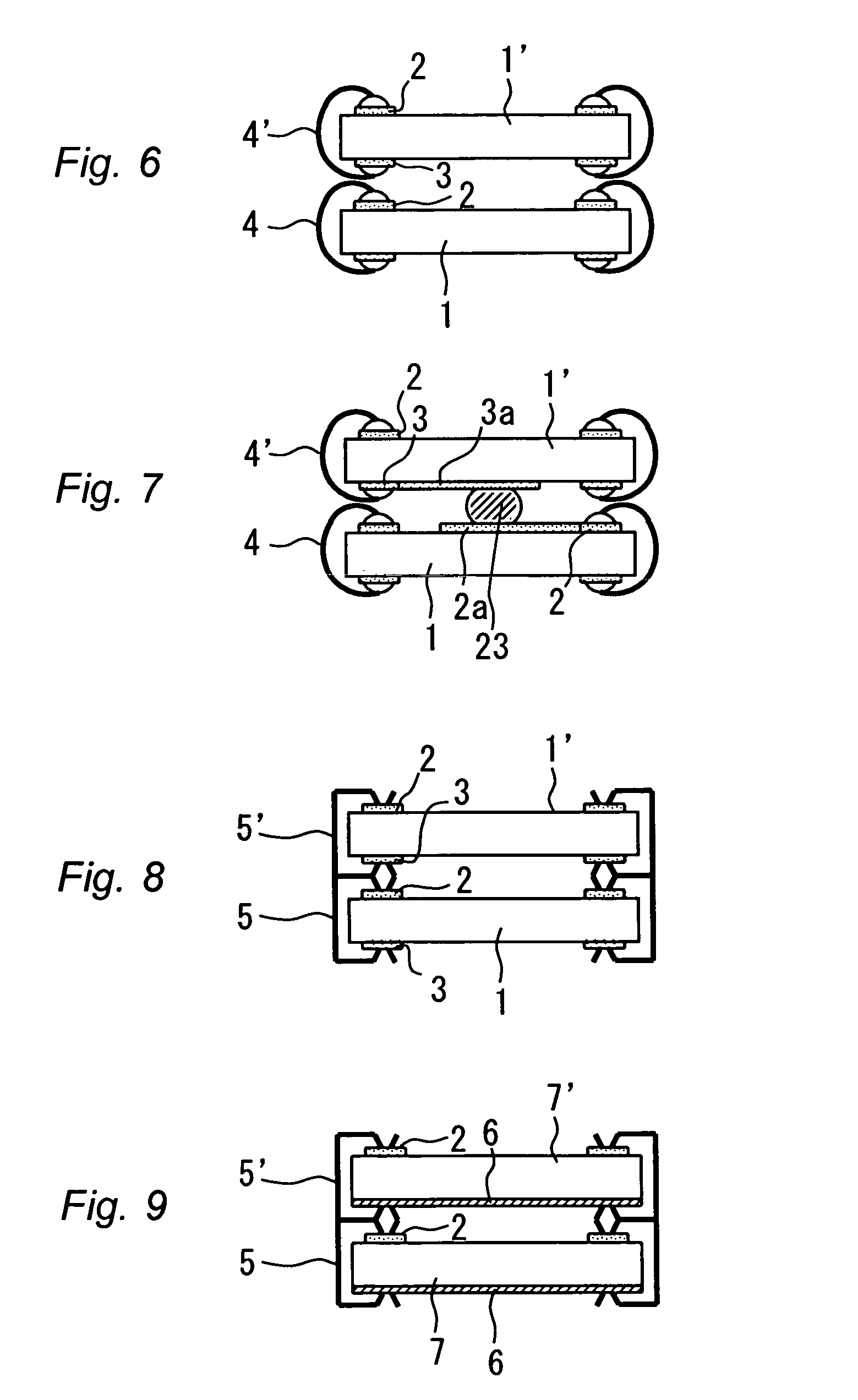

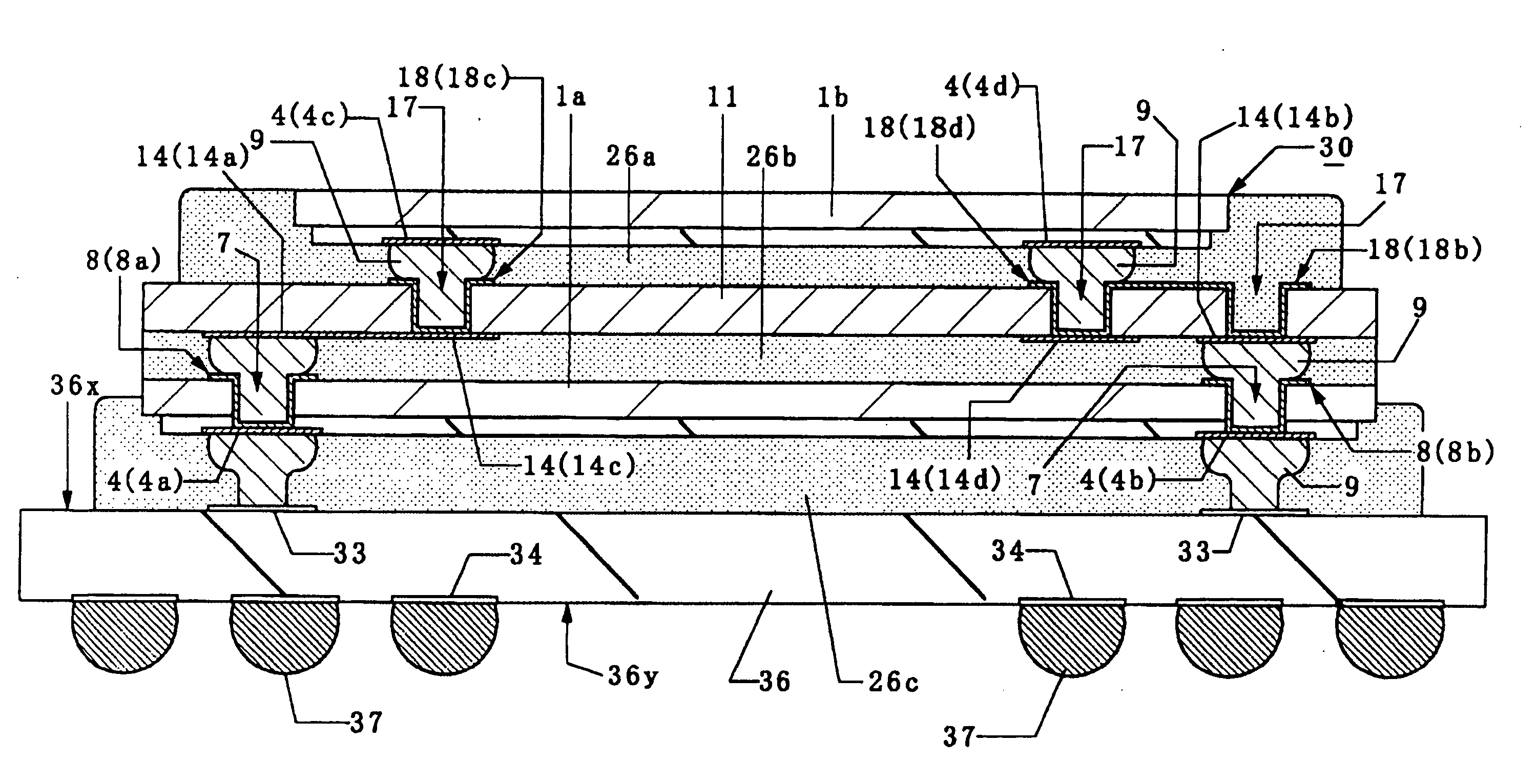

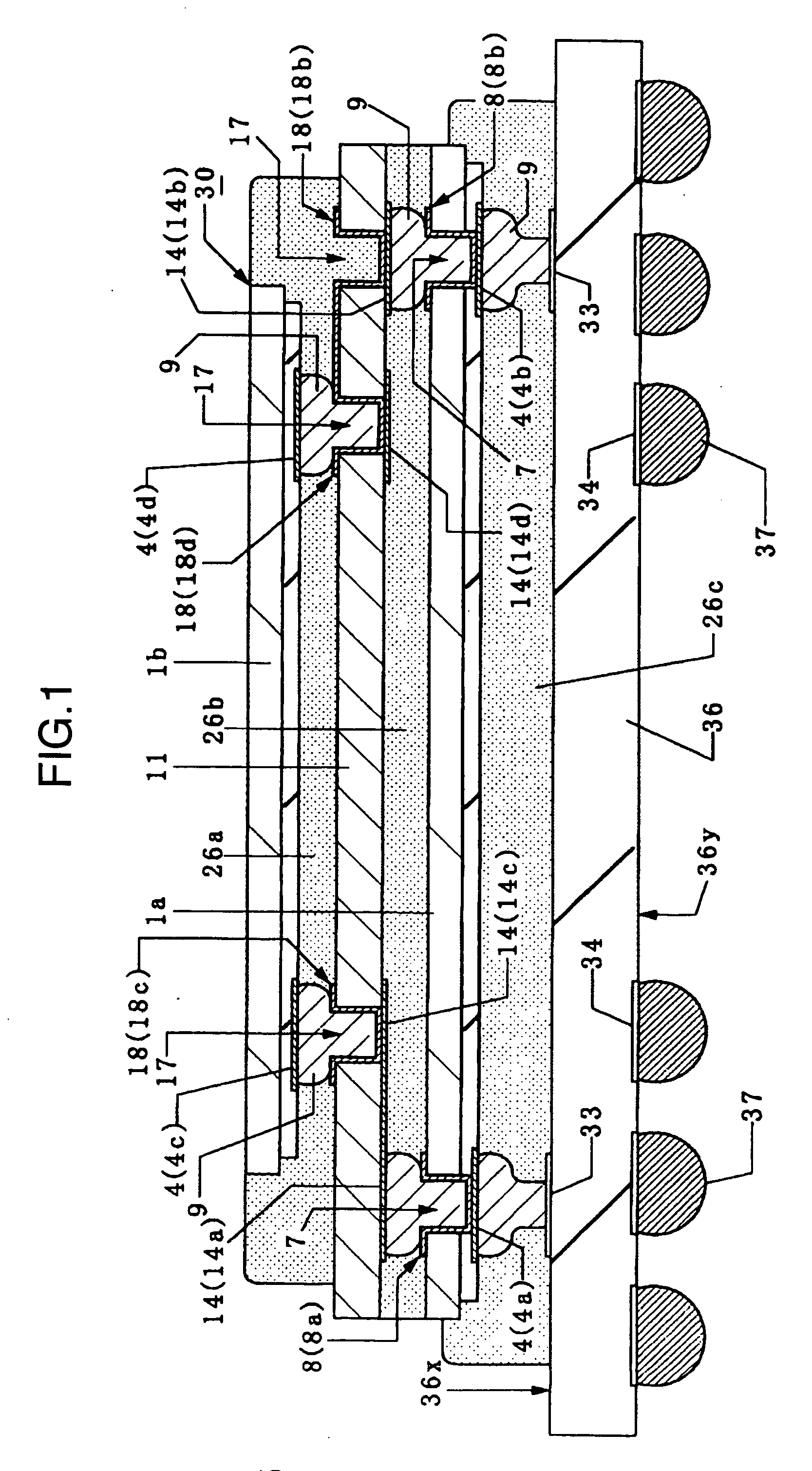

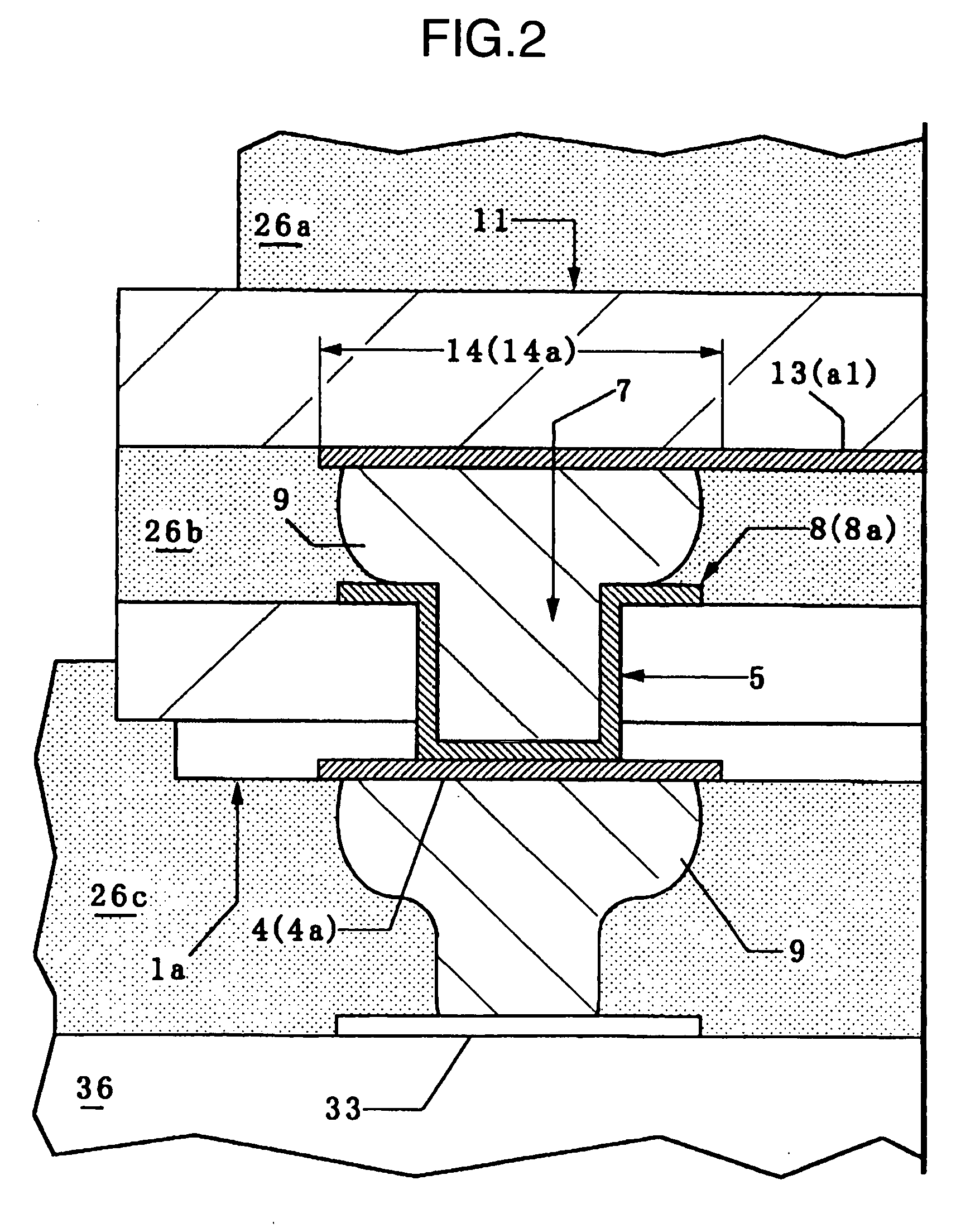

Semiconductor device having densely stacked semiconductor chips

InactiveUS6984885B1High-density packagingSemiconductor/solid-state device detailsSolid-state devicesInsulation layerLead bonding

In a semiconductor chip having electrodes formed on the top surface, and electrodes or an insulation layer formed on the back surface, the top-surface electrodes are loop-connected with the back-surface electrodes by wire bonding, or, the top-surface electrodes are connected with the back-surface electrodes or an insulation layer by conductive clip, or by deposited conductive materials. The semiconductor chips thus produced are stacked, and wires, conductive clips, or conductive materials are connected and fixed to each other to produce a stacked semiconductor device in which semiconductor chips of the same size are densely packaged. Thus, a semiconductor device is provided which enables high-density packaging of semiconductor chips even of the same size.

Owner:RENESAS ELECTRONICS CORP

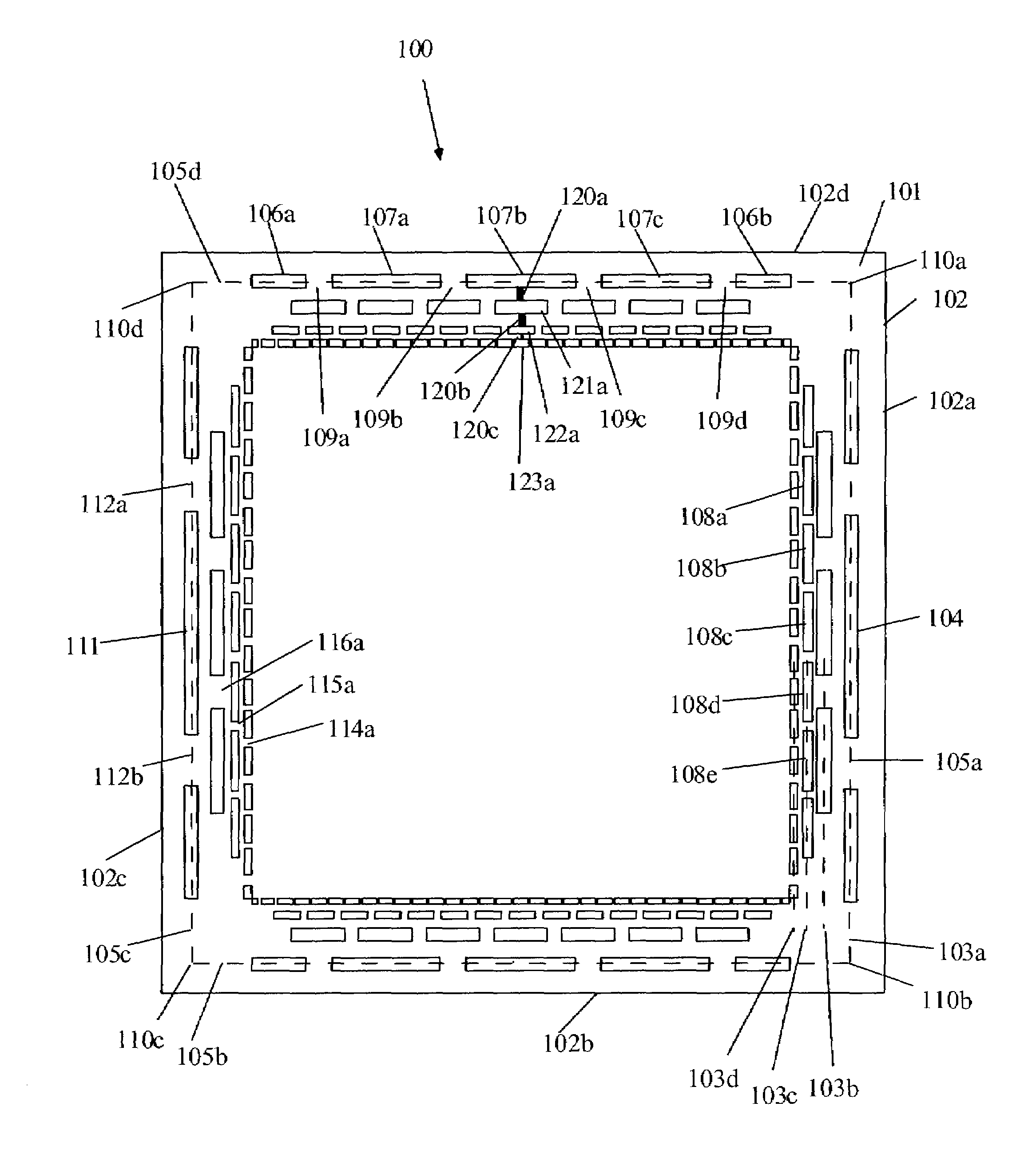

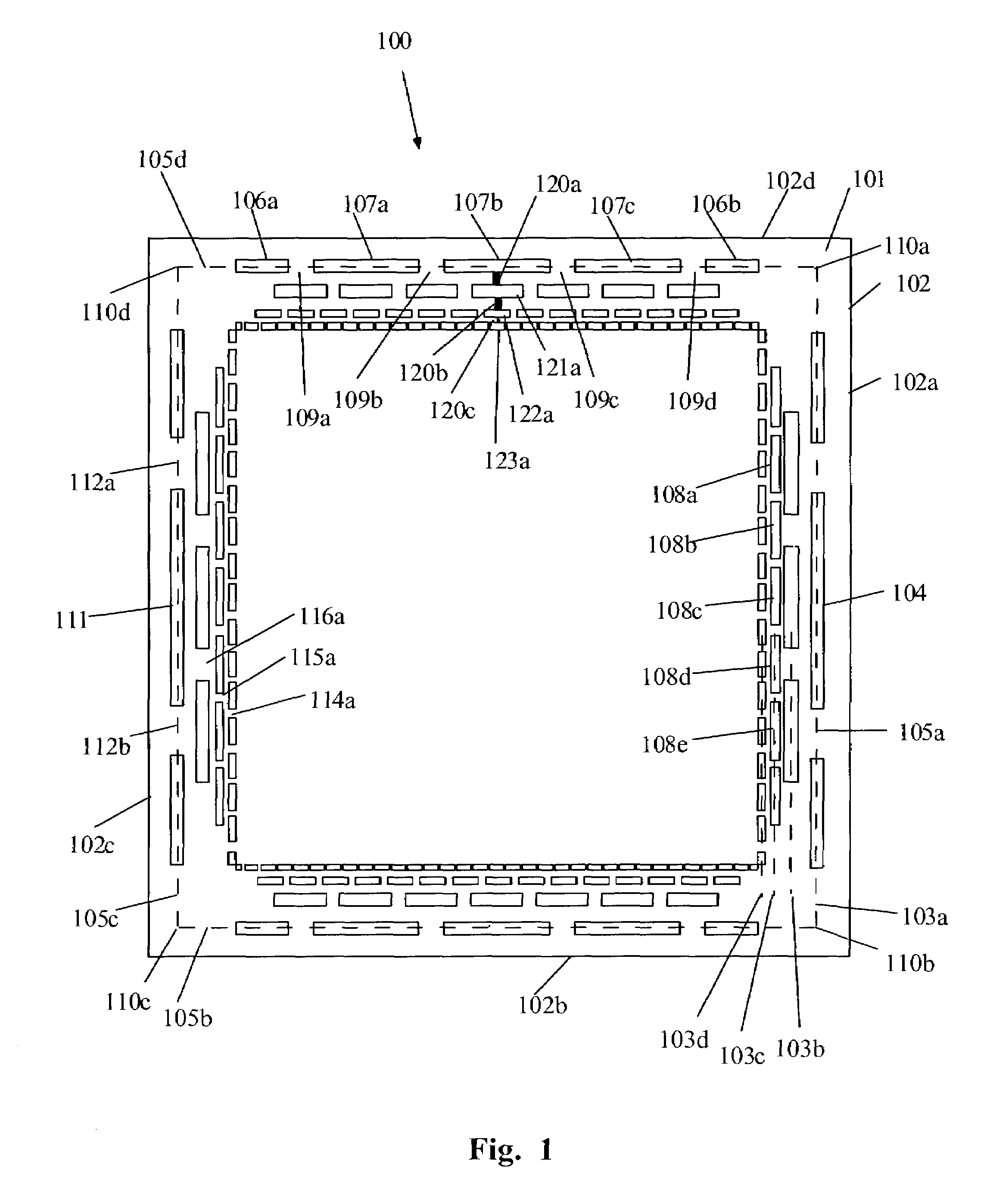

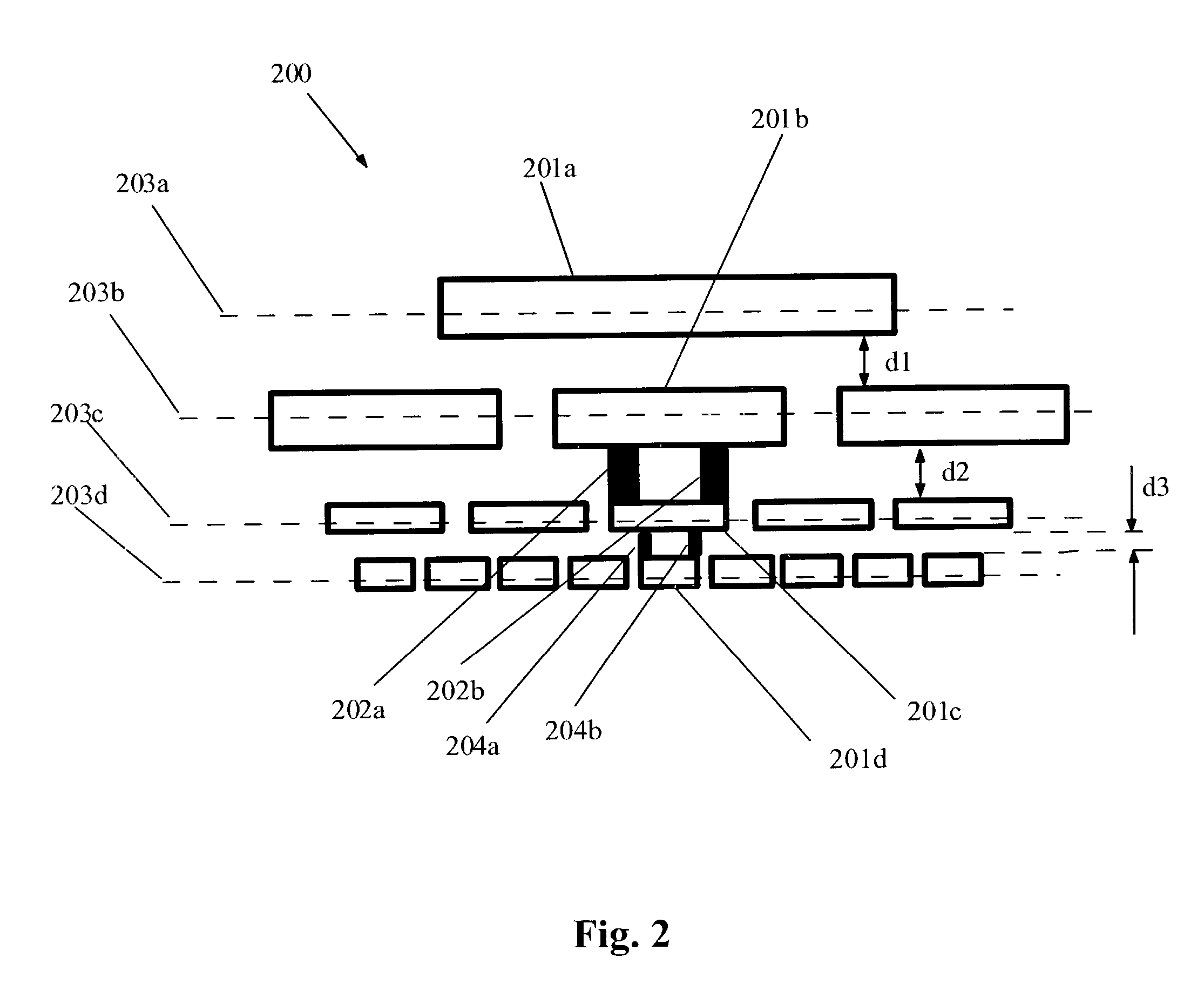

Linearized conductive surface

Electrode pattern disposed on a conductive surface is disclosed. The electrode pattern includes a plurality of conductive segments. The conductive segments are located along the edges of two or more concentric parallel polygons. Each edge of each polygon has one or more middle segments disposed between two end segments. For each edge of each polygon the middle segments are equal in length, and the segments are equally spaced. A touch sensor is disclosed that includes such an electrode pattern.

Owner:3M INNOVATIVE PROPERTIES CO

Semiconductor device and method of manufacturing thereof

InactiveUS20060170112A1Low costShort TATSemiconductor/solid-state device detailsSolid-state devicesLow noiseDevice material

A connection method for materializing a high-performance semiconductor system which is small-sized and high dense, is capable to three-dimensionally connecting a plurality of different kinds of semiconductor chips through piercing electrodes with shortest wiring lengths. The connection method enables high-speed operation with low noise, so as to obtain reliable and excellent connection in a short TAT at low costs. In a three-dimensional chip lamination composed of different kinds of semiconductor chips laminated one upon another with an interpose chip being interposed therebetween for connecting the upper and lower semiconductor chips, the semiconductor chips and the interposer chips are polished by grinding or the like at their rear surfaces so as to have thin thickness, holes are formed at rear surface positions corresponding to external electrode parts on the device side (front surface side) so that the holes extend to front surface electrodes, by dry etching or the like, and metal plating films are applied to the side walls of the holes and rear surface side, metal bumps of another semiconductor chip laminated at an upper stage being press-fitted into the holes applied with the metal plating films through deformation and being geometrically calked in the through holes formed in the semiconductor chip so as to electrically connected thereto.

Owner:RENESAS ELECTRONICS CORP

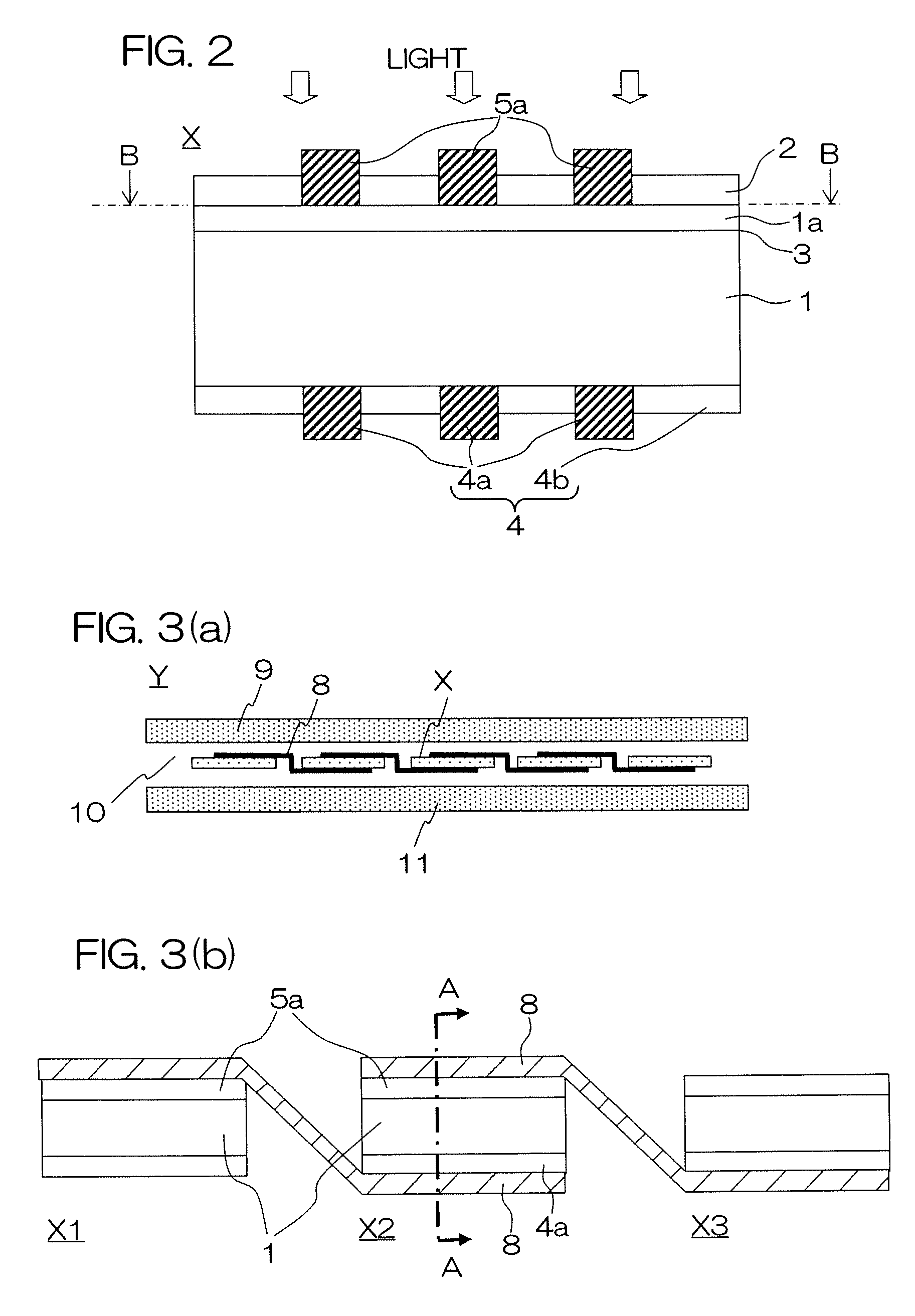

Solar cell, solar cell module and solar cell system

InactiveUS20100243024A1Reduce widthLow costPV power plantsPhotovoltaic energy generationEngineeringPhotoelectric conversion

A solar cell includes: a front surface electrode having a first current-collecting electrode and non-straight line electrodes connected to the first current-collecting electrode; a semiconductor substrate serving as a photoelectric conversion body; and a rear surface electrode having a second current-collecting electrode and line electrodes connected to the second current-collecting electrode. The front surface electrode, the semiconductor substrate and the rear surface electrode are arranged in that order. The non-straight line electrodes of the front surface electrode and the line electrodes of the rear surface electrodes are opposed to each other with the semiconductor substrate interposed there-between. The non-straight line electrodes of the front surface electrode and the line electrodes of the rear surface electrodes are different in shape while having a portion where the electrodes intersect each other, as seen in a direction perpendicular to the front surface of the semiconductor substrate.

Owner:PANASONIC INTELLECTUAL PROPERTY MANAGEMENT CO LTD

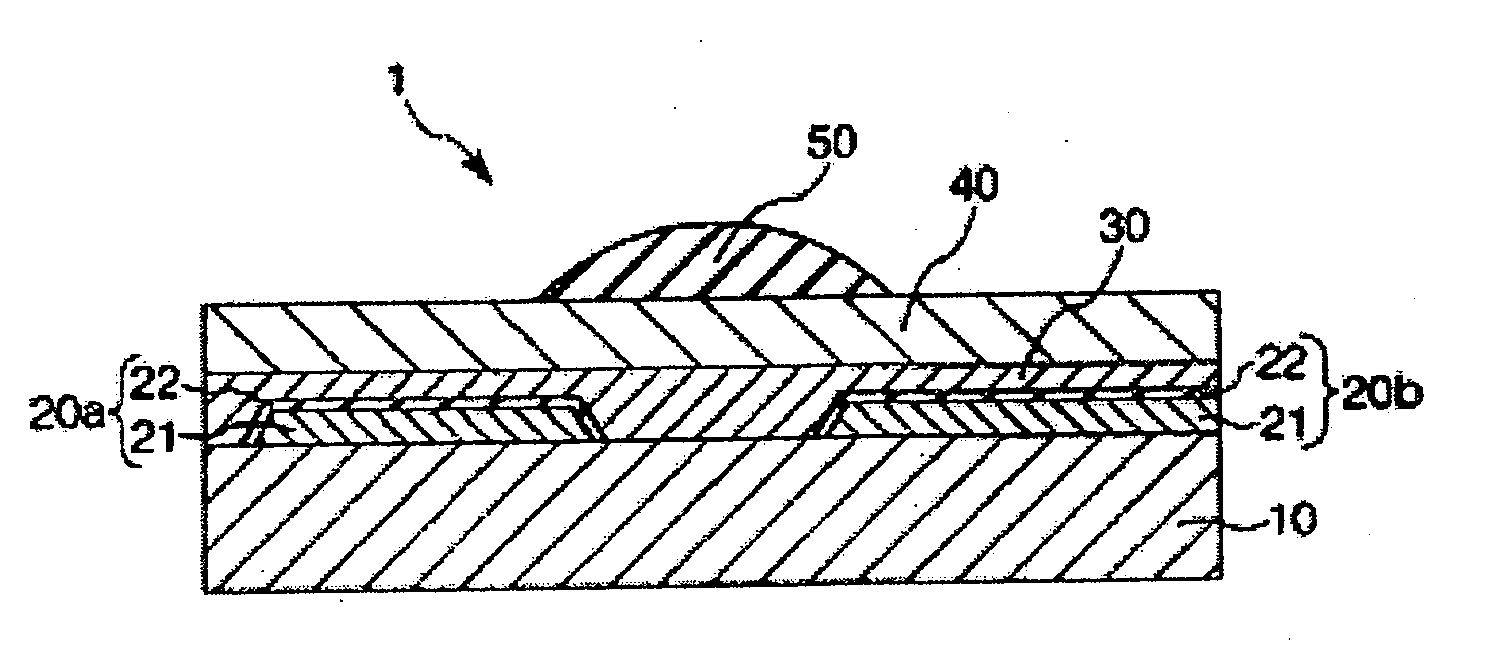

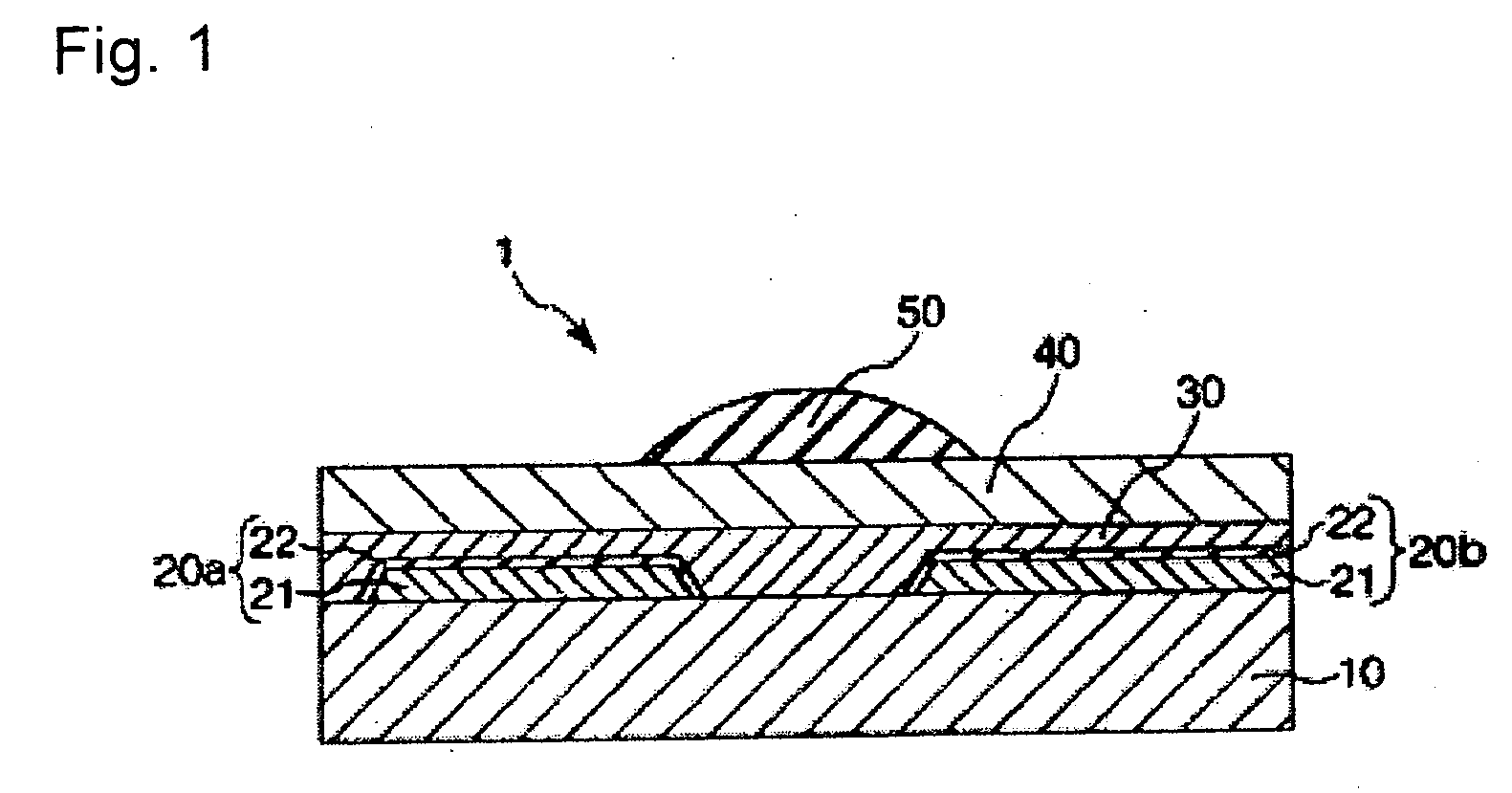

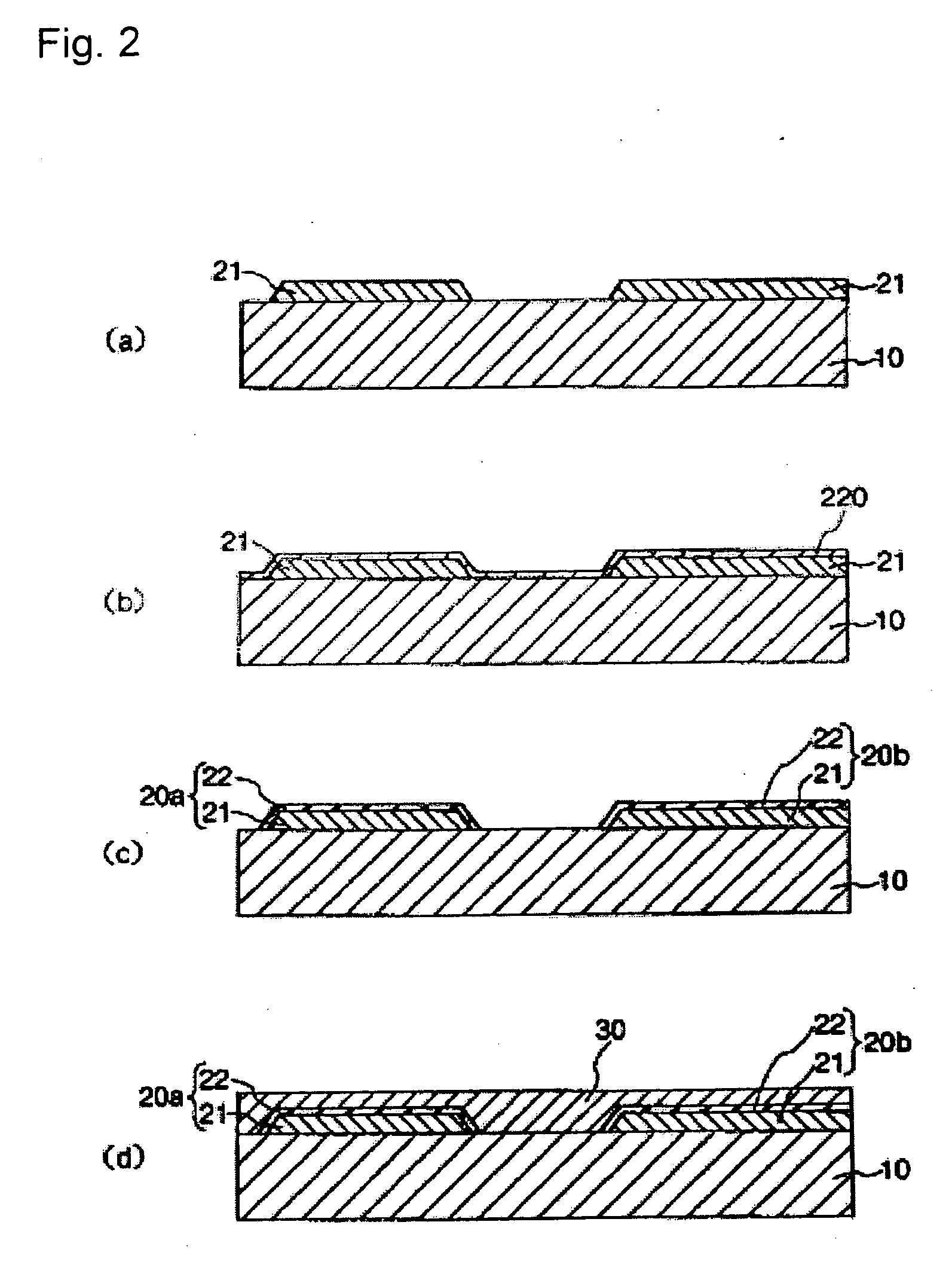

Electrode, method for forming an electrode, thin-film transistor, electronic circuit, organic electroluminescent element, display, and electronic equipment

ActiveUS20050057136A1Produced economicallyEfficiently injecting holeTransistorDischarge tube luminescnet screensDisplay deviceEngineering

An electrode is provided that is economically produced and capable of efficiently injecting holes. Also provided are a method to form an electrode that is capable of easily manufacturing such an electrode, a highly reliable thin-film transistor, an electronic circuit using this thin-film transistor, an organic electroluminescent element, a display, and electronic equipment. A thin-film transistor is a top-gate thin-film transistor. The thin-film transistor includes a source electrode and a drain electrode that are placed separately from each other. The thin-film transistor also includes an organic semiconductor layer that is laid out between the source electrode and the drain electrode, and a gate insulating layer that is provided between the organic semiconductor layer and a gate electrode. This structure is mounted on a substrate. Each of the source electrode and the drain electrode is composed of two layers, that is, an underlying electrode layer and a surface electrode layer. The surface electrode layer includes an oxide containing at least one of Cu, Ni, Co, Ag.

Owner:E INK CORPORATION

Systems and methods of performing medical procedures

A medical method is provided, including a medical device having a distal assembly including at least one electrode and at least one treatment element, the medical device generating information regarding at least one of a physiological measurement and an operational parameter of the medical device; a plurality of surface electrodes affixable to a skin of the patient, wherein the surface electrodes are in electrical communication with the distal assembly to obtain position information of the medical device; and a processor pairing the position information and the at least one of a physiological measurement and an operational parameter of the medical device.

Owner:MEDTRONIC ABLATION FRONTIERS

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com