Laser indirect compound micro plastic forming device and method

A micro-plastic and laser technology, which is applied in laser welding equipment, welding equipment, metal processing equipment, etc., can solve the problems that cannot solve the composite process of deep drawing, edge trimming and punching, and cannot achieve mass production of a single part. Low utilization rate and other issues, to achieve the effect of great flexibility, precise and controllable parameters, and strong adaptability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

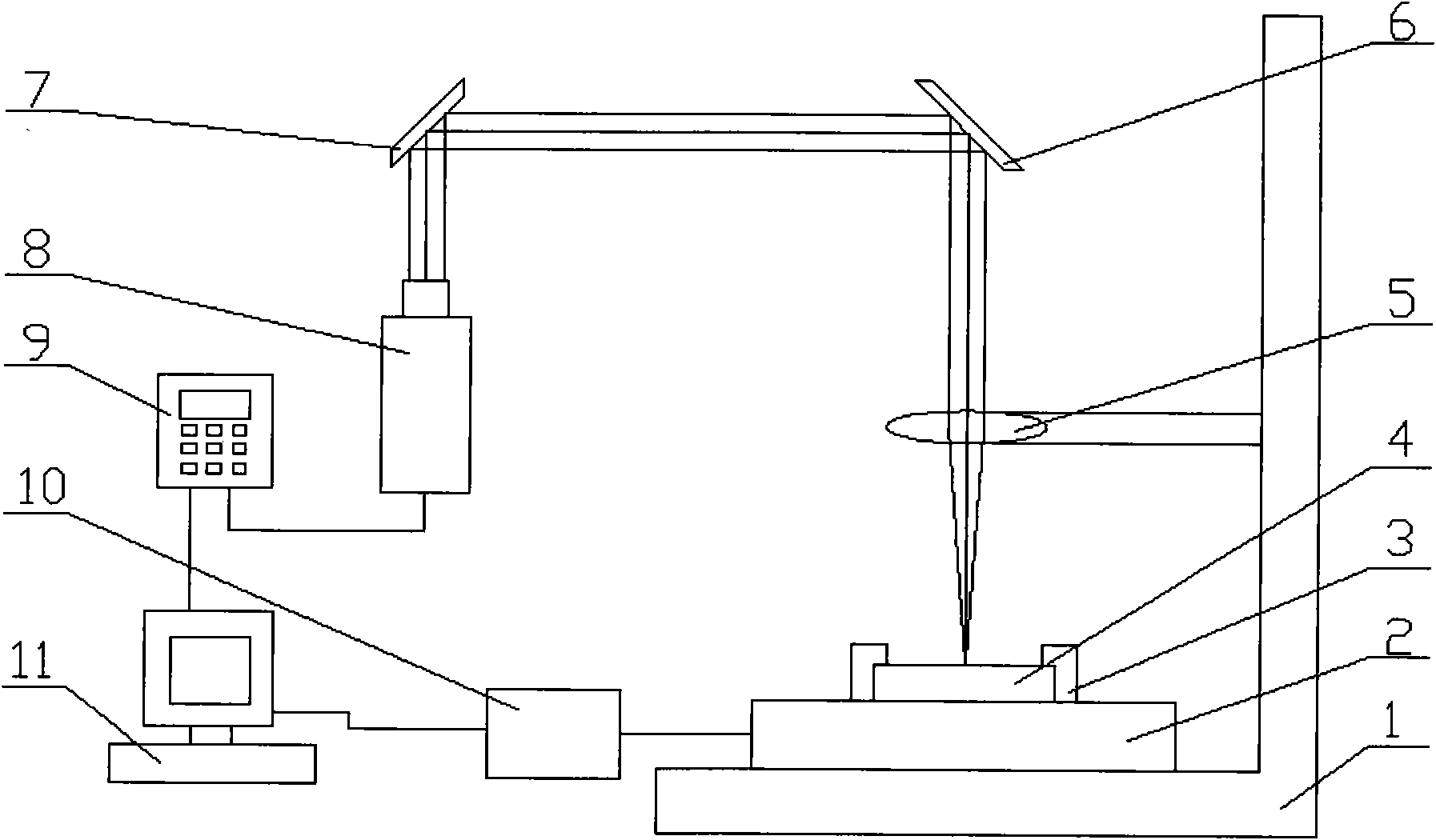

[0028] Combine below figure 1 Describe in detail the details and working conditions of the specific device proposed by the present invention.

[0029] The installation consists of 11 parts. The computer 11 controls the laser controller 9, and the laser controller 9 can adjust the indicating light and laser parameters emitted by the nanosecond laser 8. The indicating light or pulsed laser light emitted by the nanosecond laser passes through the first reflector 7 , the second reflector 6 and the focus lens 5 to the sample system 4 below the focus lens 5 . The sample system is placed in the clamp body 3, and the clamp body 3 is installed on the three-dimensional mobile platform 2. The three-dimensional mobile platform 2 is installed on an L-shaped base, and the displacement adjustment of the three-dimensional mobile platform 2 is regulated by a three-dimensional mobile platform controller 10 controlled by a computer 11 . The specific process of implementation is as follows:

...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com