Cu/Cu2O film material for reducing CO2 into organic fuel under catalysis

A thin film material, CO2 technology, used in organic chemistry, chemical/physical processes, physical/chemical process catalysts, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

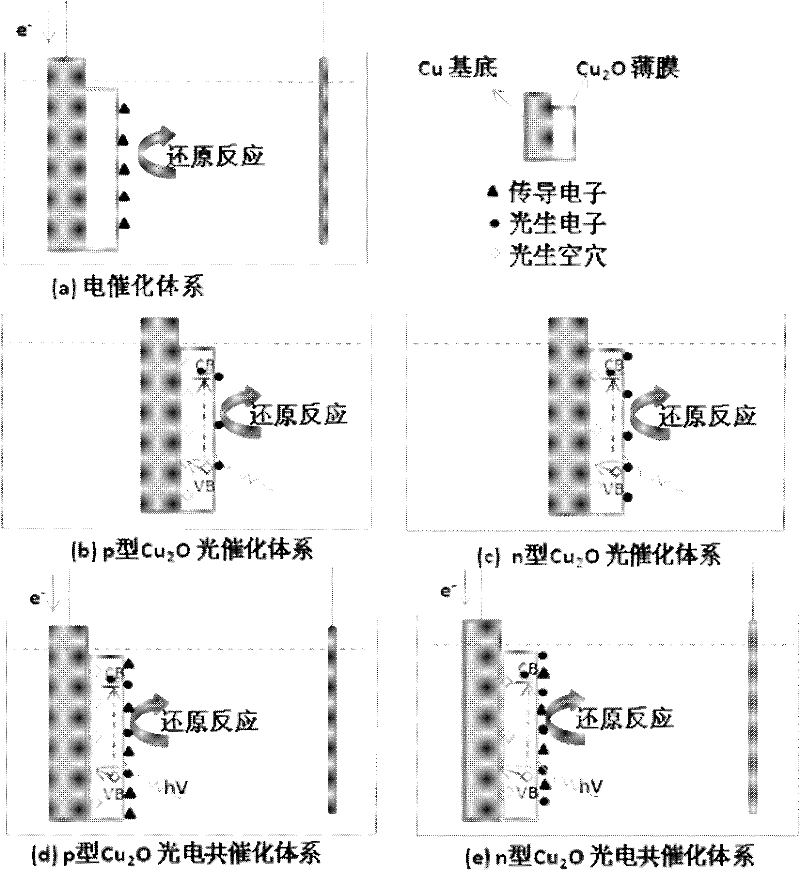

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] p-type Cu 2 Preparation of O

[0031] p-type Cu 2 The preparation of O was carried out in a self-made electrolytic cell, which consisted of an anode chamber and a cathode chamber separated by an anion exchange membrane. The anode material is copper sheet, and the cathode material is titanium mesh. Add the mixed solution of the NaCl of 150g / L and the CTAB (hexadecyltrimethylammonium bromide) of 1g / L in the anode chamber before preparation, add the NaOH aqueous solution of 1mol / L in the cathode chamber, heat described The temperature of the solution is raised to 75°C, and the electrolysis starts. The reaction time is 10 minutes, and the current density during the reaction is controlled at 10A / m 2 , the anolyte was stirred continuously during the reaction. After the reaction was complete, the copper sheet was taken out and washed with distilled water. After drying, put it into an ethanol solution with a mass fraction of 0.1% BTA (benzotriazole) and soak for two hours,...

Embodiment 2

[0033] n-type Cu 2 O film preparation

[0034] Typical n-type Cu 2 O thin films were prepared by a simple boiling method. 0.01mol / L of CuSO 4 The solution was heated to a boiling state, and the copper piece was put into the boiling solution for 2 hours. After the reaction, the copper sheet was taken out, rinsed repeatedly with distilled water, and then dried to obtain n-type Cu / Cu 2 O film material.

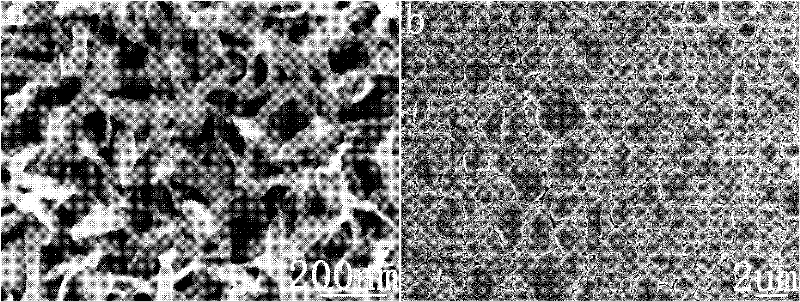

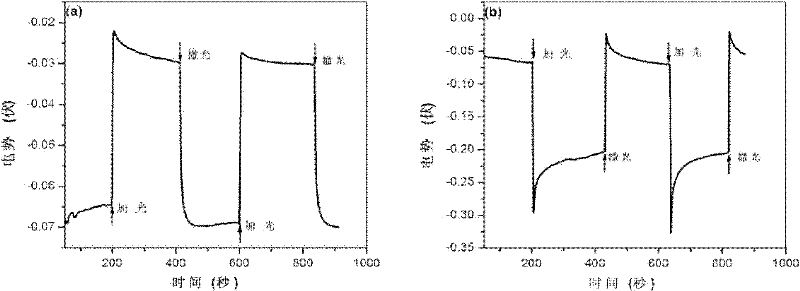

[0035] Cu / Cu prepared by embodiment 1 and 2 2 The electron micrographs and conductive properties of O thin film materials are shown in figure 2 and image 3 shown. Depend on figure 2 It can be seen that Cu with uniform size was obtained by both preparation methods 2 O, where p-type Cu 2 The O film is composed of nanoribbons, while the n-type Cu 2 The O film is formed by the accumulation of larger-sized micron-sized stone-like particles. Two kinds of Cu 2 O films are grown directly from the substrate, so the two Cu 2 The O films are all combined very tightly with ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com