Novel electrode material applicable to intelligent liquid crystal dimming film and preparation method thereof

A technology of intelligent dimming and electrode materials, applied in cable/conductor manufacturing, circuits, electrical components, etc., can solve the problems of high manufacturing cost, high price, unaffordable cost of building materials, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0096] The chemical exfoliation preparation of large-scale graphene oxide flakes with natural graphene as the structural unit, usually the process of preparing graphene by chemical exfoliation is divided into low temperature, medium and high temperature processes.

[0097] (1) Raw material selection:

[0098] Large size requires selection of ≤100 mesh natural flake graphite powder. A more preferred mesh is ≤ 50 mesh.

[0099] (2) Low temperature process:

[0100] Mix 1 part of natural graphite powder, 50-300 parts of concentrated sulfuric acid, 0.5-3 parts of potassium nitrate, and 3-15 parts of potassium permanganate in an ice bath at a temperature ≤ 10°C. 0.5~5h.

[0101] Preferably, 1 part of the quality of natural graphite powder, 100 to 200 parts of the quality of concentrated sulfuric acid, 1 to 2 parts of the quality of potassium nitrate, 5 to 10 parts of the quality of potassium permanganate, in an ice bath at a temperature ≤ 5 ° C, the reaction 0.5~3h.

[0102]...

Embodiment 2

[0115] Preparation of graphene flakes with natural graphene as structural unit by high-speed stirring shear exfoliation

[0116] Mix one part of graphite (50 mesh) with six parts of anhydrous ferric chloride, then put it into the reactor, then vacuumize the reactor, then raise the temperature of the reactor to 380°C, and Keep for 24 hours; then take out the intercalated graphite, wash it with dilute hydrochloric acid, dry it after cleaning, add 50 mass of water and 50 mass of ethanol to the intercalated graphite, and stir at 6000 rpm for 1 hour. After it was filtered and cleaned, it was dissolved in N-methylpyrrolidone, and the obtained graphene was prepared into a 5 ml / mg solution.

Embodiment 3

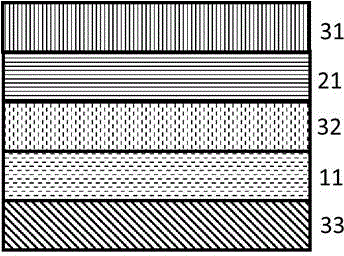

[0118] Preparation of graphene transparent conductive film from graphene flakes prepared by chemical exfoliation

[0119] (1) Substrate pre-treatment

[0120] A 10 cm*10 cm PET with a thickness of 5 μm was used as the transparent substrate. Put the PET into a 150°C oven and age it for half an hour; then put the PET into O 2 Plasma workstation MarchPX250 processing, set parameters to 150W, 30 seconds, O 2 Air flow: 80sccm, pressure: 350mTorr.

[0121] (2) Coating of adhesive functional layer

[0122] Disperse polymethyl methacrylate (PMMA) in dimethyl ether to prepare a solution with a mass concentration of 5%, apply the above solution on the substrate, and remove the solvent by drying to obtain a polymethacrylate film .

[0123] (3) Coating of graphene flakes.

[0124] Coating speed (m / min) 1.5 3 5 10 25 Thickness (nm) 22.5 10.7 6.5 3.01 1.2 GO / PMMA / PET light transmittance (%) 66.2 71.7 78.4 83.2 88.5

[0125] (4) Optimization of...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| electron mobility | aaaaa | aaaaa |

| electrical resistivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com