Phase change memory element with a peripheral connection to a thin film electrode and method of manufacture thereof

a memory element and peripheral connection technology, applied in the field of memory devices, can solve the problems of reducing the crystallization speed of germanium-antimony-tellurium material with thinner films, the practicality of memory devices in producing and controlling dimensions well below the norms, and the current applied during the reset pulse may actually set the material in some cells, etc., to achieve good performance, small cross-sectional area, and high current density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

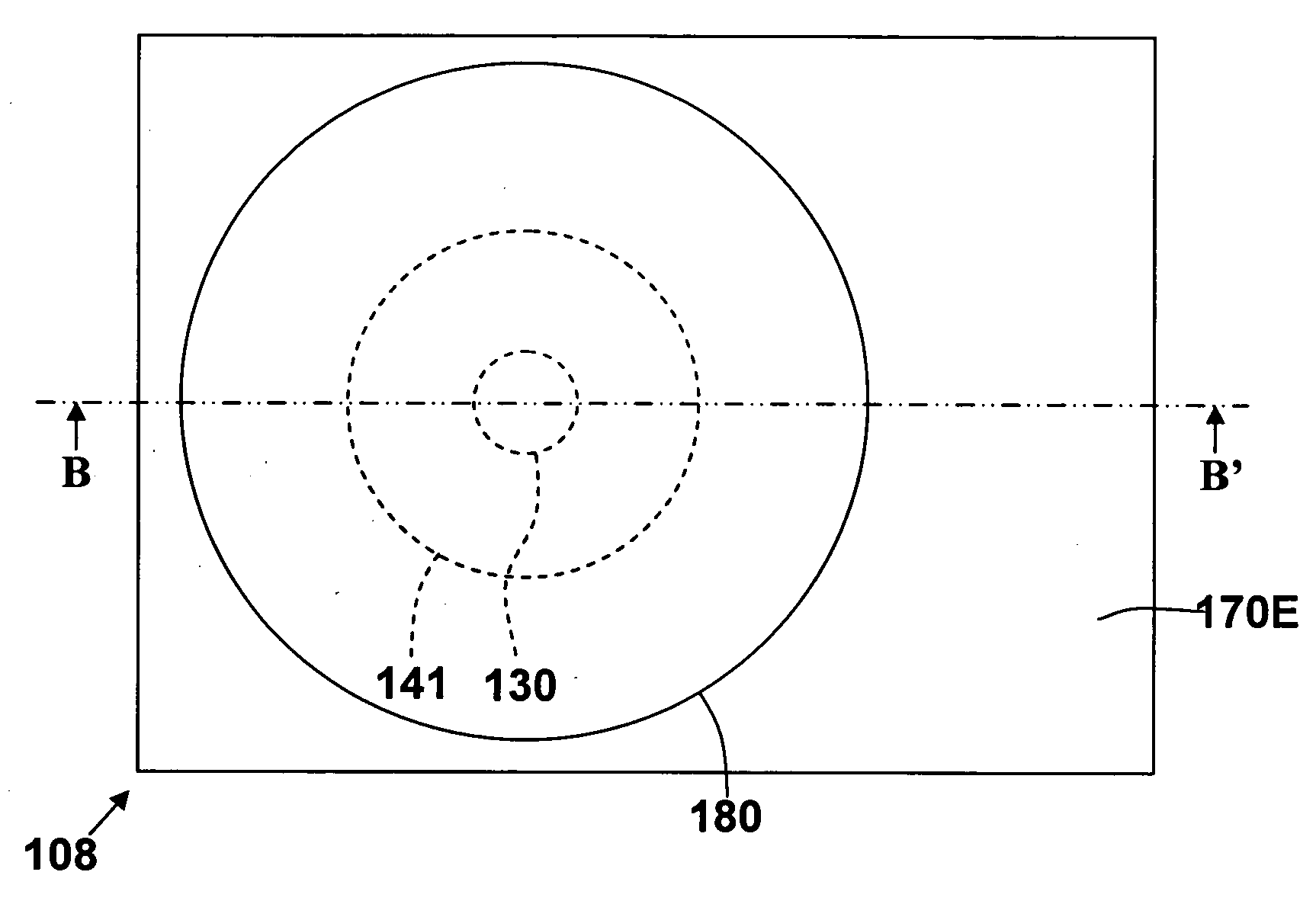

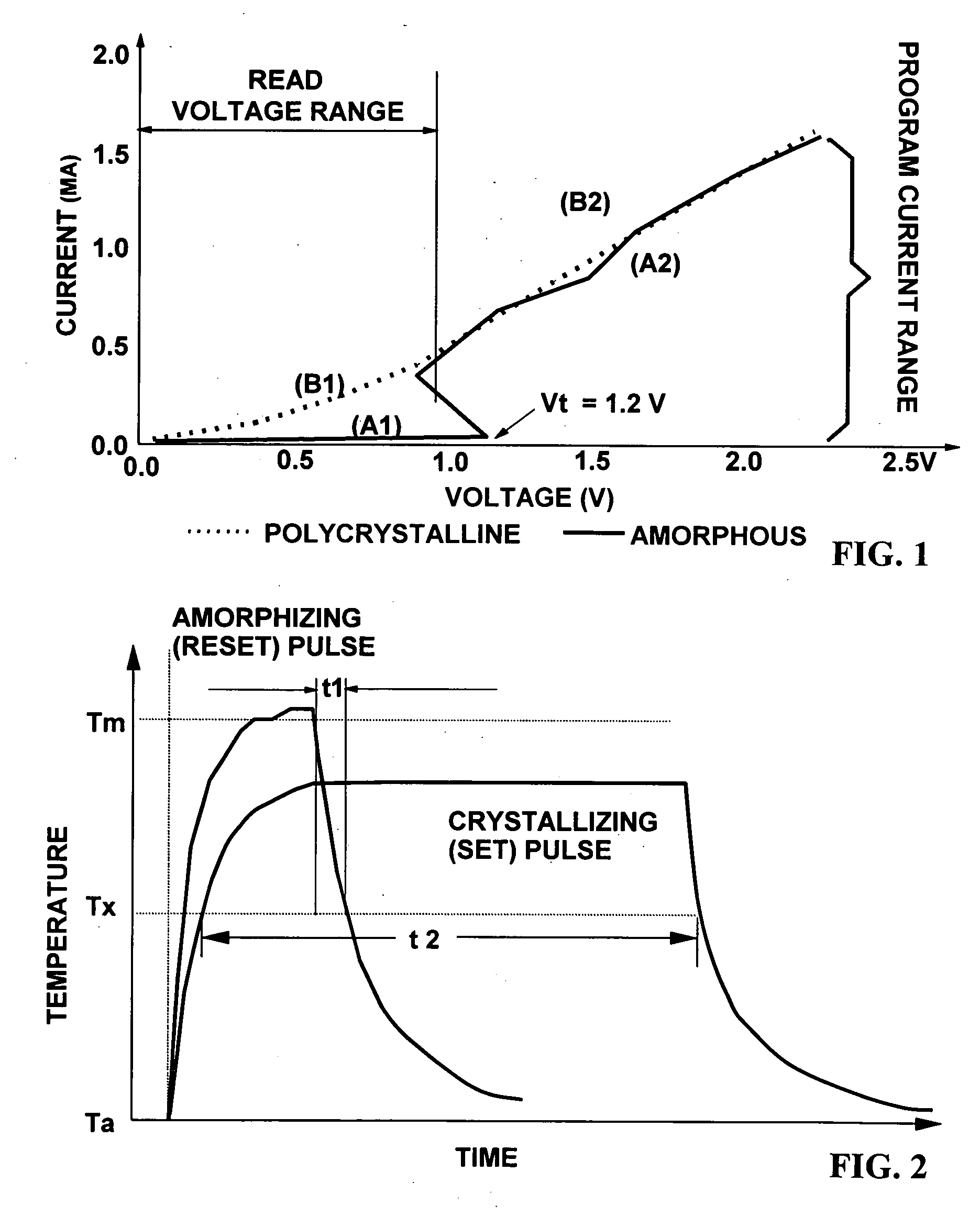

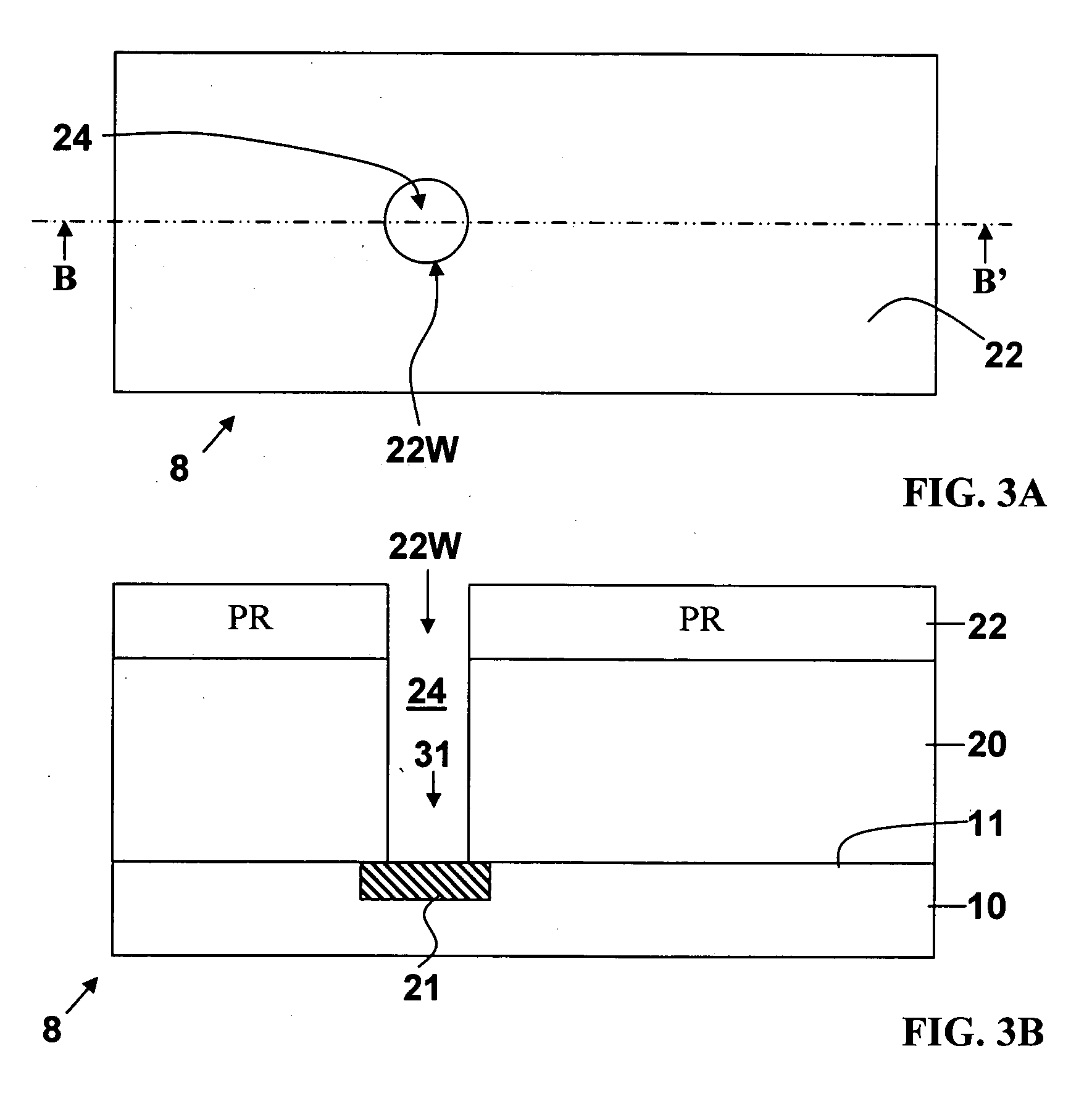

[0042] The present invention provides an improved Phase Change Memory (PCM) cell structure. By reducing the contact area between the phase change material of the PCM cell and one of the electrodes connected thereto, the resulting high current density can induce the necessary heating and phase changes within the PCM effectively with relatively low current (and, thus, low operating power).

[0043] Prior art structures often attempt to realize this method of operating power reduction, but are hampered by complex integration schemes and designs that can result in poor uniformity across arrays of the memory elements. Uniformity is necessary to ensure each element can be switched with the same characteristic current pulse, and, although less difficult with PCM, to ensure that each element's readout resistance is in a desired range for a “high” state and a “low” state—without the two states overlapping. Complex integration schemes are undesirable because they are expensive, and offer greate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com