Method for preparing cuprous oxide/titanium dioxide core-shell structure array film through AC electro-deposition method

A technology of core-shell structure and cuprous oxide, which is applied in the direction of electrolytic coating, electrolytic inorganic material coating, surface reaction electrolytic coating, etc., can solve the problems of non-formation, complicated process, easy to destroy nanotube array structure, etc., and achieve easy control , The process is simple, and the effect of realizing cheap mass production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention uses commercially available chemically pure raw materials, and the specific examples are as follows.

[0022] Under stirring conditions, the NH 4 Dissolve F in water, stir evenly, then add glycerin and dimethyl sulfoxide (DMSO), and then stir the mixed solution for 1 hour to obtain a stable transparent solution. See Table 1 for the specific formula.

[0023] Table 1

[0024] NH 4 f

(wt%)

(mL)

h 2 o

(mL)

DMSO

(mL)

oxidation voltage

(V)

Reaction time

(h)

0.5

160

20

20

40

2

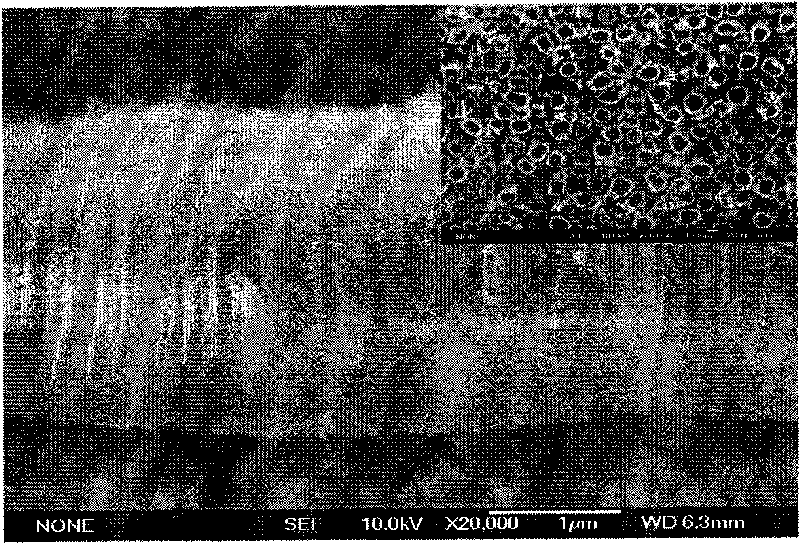

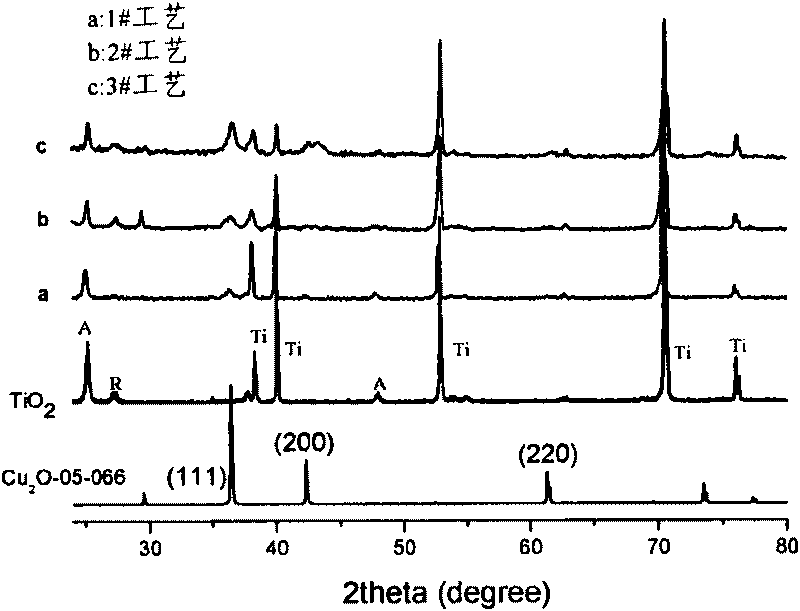

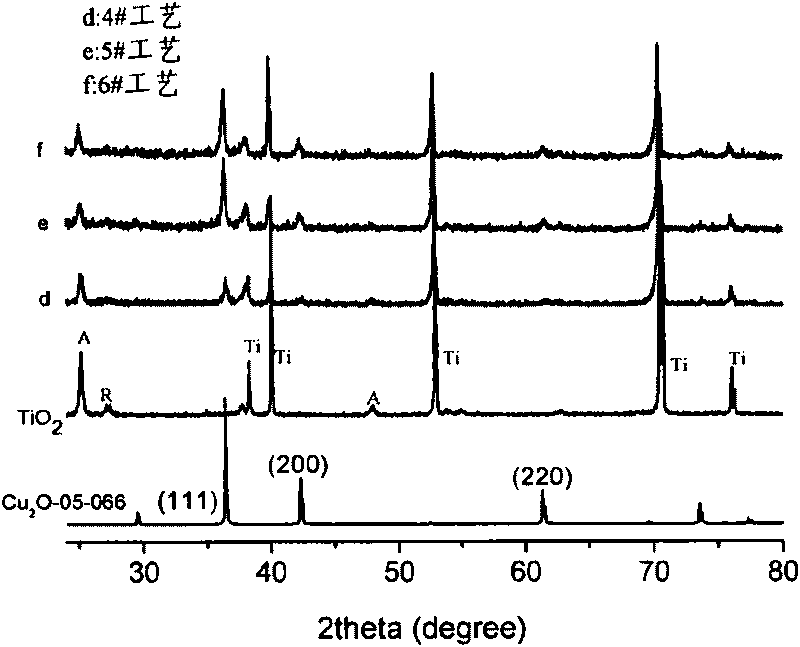

[0025] Using the solution prepared above as the electrolyte, the cleaned Ti sheet is used as the anode, and the Pt sheet is used as the cathode. After oxidizing for 2 hours with a DC current of 40V at room temperature, the Ti sheet is taken out and washed with deionized water to obtain a one-dimensional nano-TiO 2 The material of the array film ( figure 1 ), TiO 2 T...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com