Patents

Literature

52results about How to "Reduced mass production" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Method of zyme catalyzing cyclo-olefin oxidation

InactiveCN101109016AAvoid Potential ContaminationReduced mass productionFermentationEpoxyCyclohexene

The invention relates to a method of enzyme catalyzing olefin expoxidation. In the aqueous solution, the bromine peroxidase is applied for biological catalyst and hydrogen peroxide or oxygen is taken as oxygen source to oxidate the olefin into expoxidation. Take the cyclohexen as example. The hydrogen peroxide is applied as the source. They react under the 20 DEG C. to 70 DEG C. for two to ten hours. The yield of epoxy cyclohexane to the hydrogen peroxide is more than 50 per cent and the selectivity of the epoxy cyclohexane is more than 85 per cent. After the reaction, the water phase is separated from the organic phase automatically, and the enzymes left in the water phase can be recycled. Boasting easy technical process, recycled enzymes and easy yield separation, the method is an environment-friendly green chemical process.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

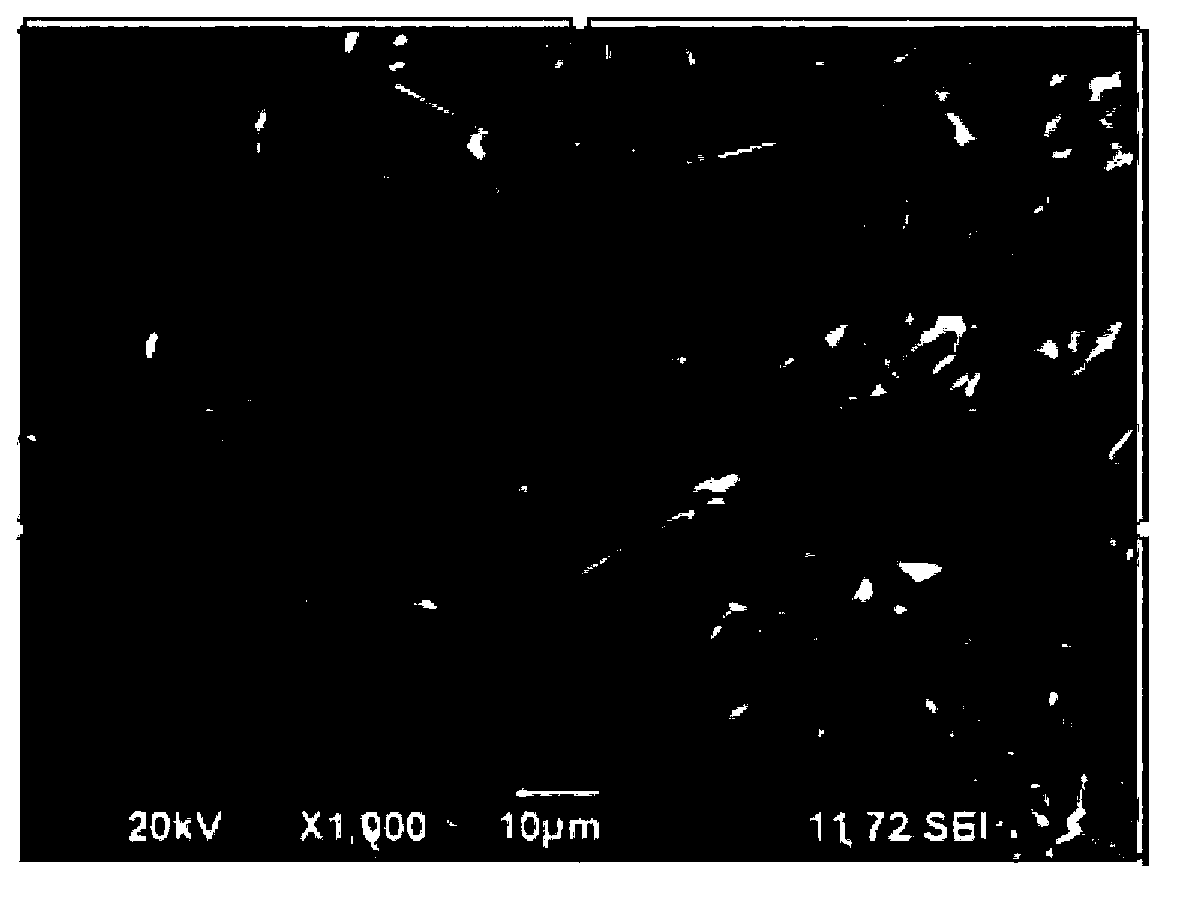

Method for preparing zinc oxide monodimension nano stick crystal film

InactiveCN1749443AFast growthThe process is simple and easy to controlPolycrystalline material growthElectrolytic inorganic material coatingWater bathsGas detector

The present invention discloses the electric field aided process of preparing one dimensional nanometer ZnO crystal rod film. The process includes the following steps: dissolving Zn(NO3)2.6H2O and NaOH in water and stirring homogeneously; constant potential depositing in a three-electrode chemical deposition system with conducting glass of coated ZnO sol as anode, platinum sheet as counter electrode and saturated Ag / AgCl electrode as reference electrode, inside water bath at 30-90 deg.c and with external voltage of 500-1300 mV; and taking out the lining, washing, stoving in an oven to obtain the one dimensional nanometer ZnO crystal rod film. Applying and regulating the external electric field can control the growth form of ZnO and raise the growth speed effectively. The present invention may be applied in making LED, light detector, photosensitive diode, gas-sensitive diode, solar cell, etc.

Owner:TIANJIN UNIV

Capsule mold release agent and preparation method thereof

The invention discloses a capsule mold release agent and a preparation method thereof. The mold release agent is prepared by adding components, namely 230 to 270g of calcium stearate, 230 to 270g of stearic acid and 90 to 110g of lecithin into every 1,450 to 1,550ml of liquid paraffin. The preparation method comprises the following steps of: sequentially adding the calcium stearate, the stearic acid and the lecithin in the process of heating the liquid paraffin; and continuously stirring to obtain the mold release agent. The mold release agent is smectic, can be uniformly coated on an oil coating pipe felt of a capsule production line during use, and has a better effect after being coated once every 12 hours. Due to the adoption of the mold release agent, the transparency and the luminance brightness of a capsule can be greatly improved, so that the aesthetic appearance of the capsule is improved, and product yield can be improved; and the preparation method has a simple process, is easy to operate and low in cost, is beneficial to large-scale production and makes cost reduced.

Owner:潘婕

Method for preparing ellagic acid by solid fermentation with granatum as raw material

ActiveCN102250981ASimple processGreening the manufacturing processMicroorganism based processesFermentationCulture mediumsAdditive ingredient

The invention discloses a method for preparing ellagic acid by solid fermentation with granatum as a raw material and belongs to the field of medicines and health-care products. In the method, solid fermentation is performed by using a culture medium which takes granatum as a main ingredient and by using Aspergillusniger 3.316 as a fermenting bacterial strain. The conditions for the solid fermentation of the granatum include: the pH value is between 5 and 7; and the granatum is initially moisturized by water by 47 to 60 percent, 0.5-percent NH4NO3 is added into a moisturizing agent as an N source, and fermentation is performed at 30 DEG C for 5 to 7 days. The fermented product is purified and dehydrated to produce the high-quality ellagic acid product. The granatum serving as a raw material is cheap, and the high yield and purity of the ellagic acid product are ensured; and the method has an outstanding cost advantage and is suitable for large-scale production.

Owner:安徽德仁生物科技有限公司

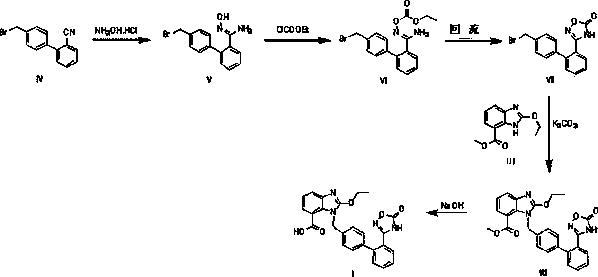

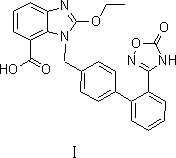

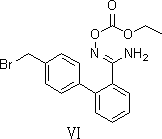

Novel preparation method for azilsartan and intermediate thereof

InactiveCN105669495AConvenient sourceReduce one step reactionOrganic chemistryEthyl chloroformateCarboxylic salt

The invention relates to an intermediate for preparing azilsartan and a novel preparation method for the azilsartan. The method includes the following steps: 1) reducing 2-cyano-4'-bromomethylbiphenyl with hydroxylamine hydrochloride to generate (Z)-4'-bromomethyl-(N')-hydroxy-[1,1'-biphenyl]-2-amidine; 2) performing esterification with ethyl chloroformate to generate (Z)-4'-bromomethyl-(N')-((ethoxycarbonyl)oxyl)-[1,1'-biphenyl]-2-amidine; 3) performing ring closing to prepare 3-(4'-(bromomethyl)-[1,1'-biphenyl]-2-yl)-1,2,4-oxadiazole-5-(4H)-one; 4) performing a condensation reaction to 2-ethoxy-1H-benzimidazole-7-methyl carboxylate and the 3-(4'-(bromomethyl)-[1,1'-biphenyl]-2-yl)-1,2,4-oxadiazole-5-(4H)-one to prepare 2-ethoxy-1-((2'-(2,5-dihydro-5-oxy-1,2,4-oxadiazole-3-yl)biphenyl-4-yl)methyl)benzimidazole-7-methyl carboxylate; and 5) finally performing hydrolysis to prepare the azilsartan. The method employs the raw material being easy to obtain, is short in synthetic route, is low in device cost, is less in side products, is low in toxicity and pollution, is environment-friendly, is high in product purity and is suitable for industrial production.

Owner:CHONGQING LAND TOWER PHARMA

Extraction method for high acyl gellan gum

The invention relates to an extraction method for high acyl gellan gum, which comprises the following process steps of adding alkali metal salt occupying 3%-8% of the volume of fermentation liquid into the fermentation liquid, adjusting the pH value, adding low alcohols with different concentration into the fermentation liquid, repeatedly performing extraction, washing and solid-liquid separation, obtaining high acyl gellan gum fibers, finally scattering the high acyl gellan gum fibers, drying and crushing the fibers at 90 DEG C-120 DEG C, and obtaining the high acyl gellan gum. The extraction process of the extraction method for the high acyl gellan gum is performed in a weak acid environment without high temperature and strong acid and alkali treatments, and has a good protection function on the stability of acyl groups. The gel and floating performance of the high acyl gellan gum is greatly improved, a final product also has weak acidity, and a good prolonging function on the guarantee period of the product is achieved. The extraction method for the high acyl gellan gum adopts a method of washing the low alcohols in a mode of small amount and multiple times, impurities and pigment in the high acyl gellan gum are removed thoroughly, and the appearance of the obtained product is greatly improved.

Owner:杭州健恒生物技术有限公司

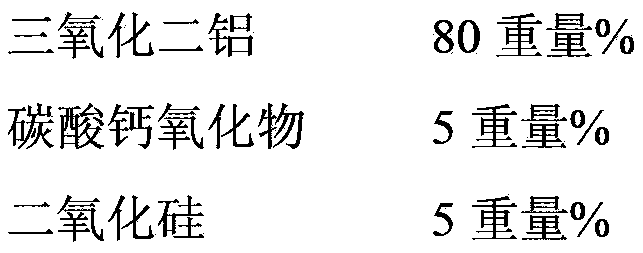

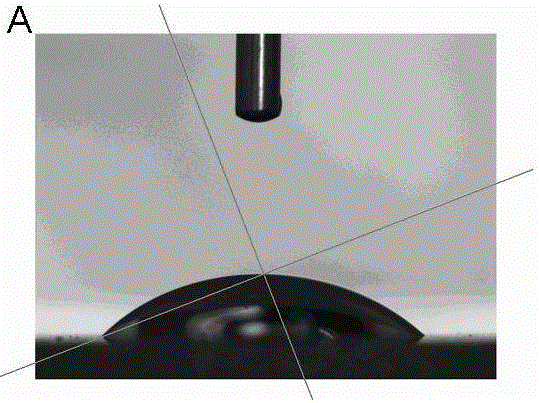

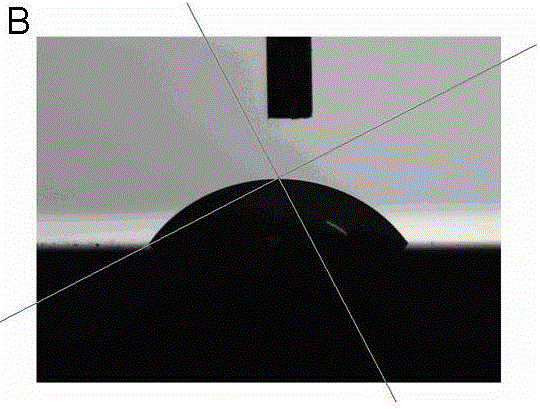

Ceramic material, and preparation method and applications thereof

ActiveCN103508744AHigh hardnessImprove wear resistanceRotary/oscillating piston pump componentsLiquid fuel engine componentsTitanium nitrideTitanium carbide

The invention provides a ceramic material, and a preparation method and applications thereof. The ceramic material comprises a ceramic body and a whisker, wherein the whisker is at least one selected from aluminium oxide, titanium carbide, silicon carbide, titanium nitride, aluminium nitride and aluminum oxynitride; and the whisker, oxides containing silicon and oxides containing calcium are formed in the ceramic body. The ceramic material is light in weight, high in hardness, and excellent in wear resistance and lubricity.

Owner:ANHUI MEIZHI PRECISION MFG

Preparation method of high-dispersity g-C3N4/TiO2 photocatalyst inorganic hydrosol

ActiveCN106238088AImprove stabilityImprove hydrophilic abilityGas treatmentPhysical/chemical process catalystsDispersityHydrogen

The invention discloses a preparation method of high-dispersity g-C3N4 / TiO2 photocatalyst inorganic hydrosol and belongs to the field of functional materials. The method comprises the following steps of: adding a g-C3N4 / TiO2 photocatalyst into a water solution containing an inorganic dispersant according to a certain ratio under a stirring condition; adding a small amount of peptizing agent and adjusting the pH (Potential of Hydrogen) value of a suspension solution; and carrying out shear emulsifying and stirring treatment to obtain the stable high-dispersity g-C3N4 / TiO2 photocatalyst neutral inorganic hydrosol. A preparation process has a simple flow and is simple and convenient to operate; an organic dispersant and a solvent are not used and the preparation cost is low; the prepared photocatalyst hydrosol has high dispersity and stability and is suitable for preparing photocatalyst slurry and a coating agent; the application of the photocatalyst to the field of a coating material is facilitated.

Owner:XINXIANG UNIV

Continuous ion adsorbing preparation of multi-component sulfur photoelectric films

InactiveCN1614790ASolution to short lifeEasy to recycleFinal product manufactureSemiconductor devicesArgon atmosphereThiourea

The invention uses forerunner body solution of cation mixed in different ratio to manufacture solar power photo-electricity films, which are CulnS2, CulnSe2, Cu(In, Ga)Se2. The content and ratio of cation forerunner body solution is CuCl2:GaCl3:InCl3= 0.5:0:1-2:1:1. Ph value: 1-3. Sulphion source can use Na2S aqueous solution (ph value is 10-13, concentration is 0.1-1 mole / liter), Na2SeSO2, aqueous solution or thiourea solution. In the above cation forerunner body solution, anion forerunner solution, coating is made through continuing adsorption reaction, and the photo electrode film is obtained after 400-500deg.C heat treatment under argon atmosphere.

Owner:TIANJIN UNIV

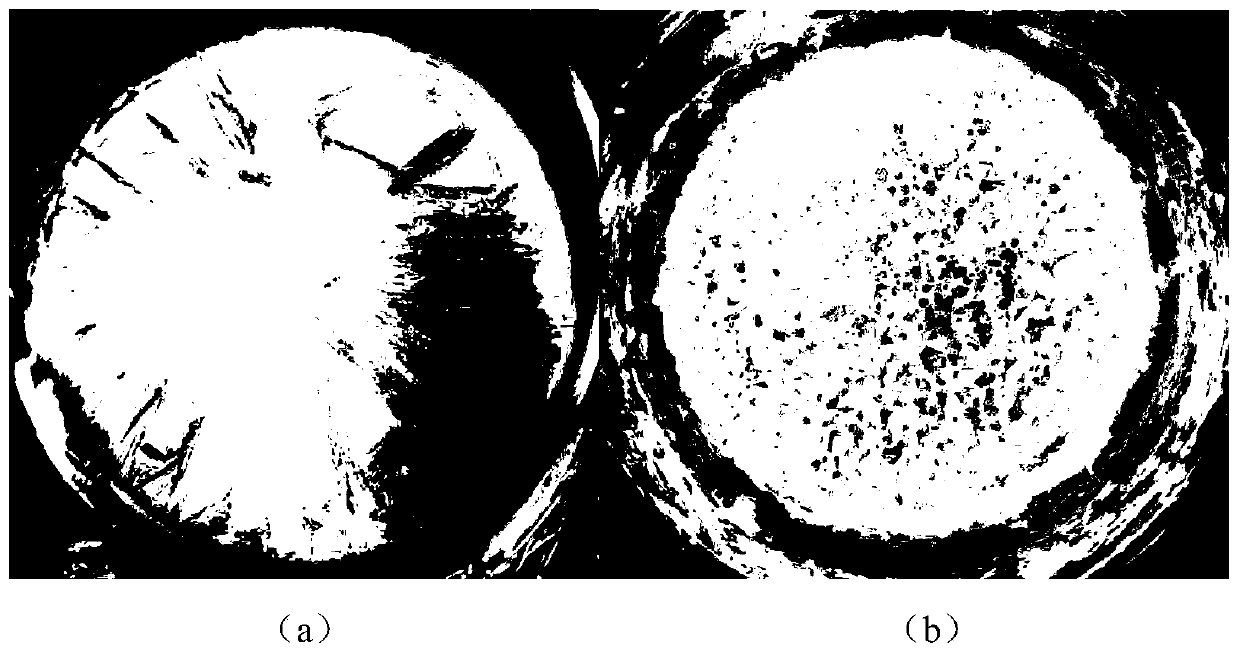

Tremella fuciformis strain and application thereof in tremella polysaccharide production

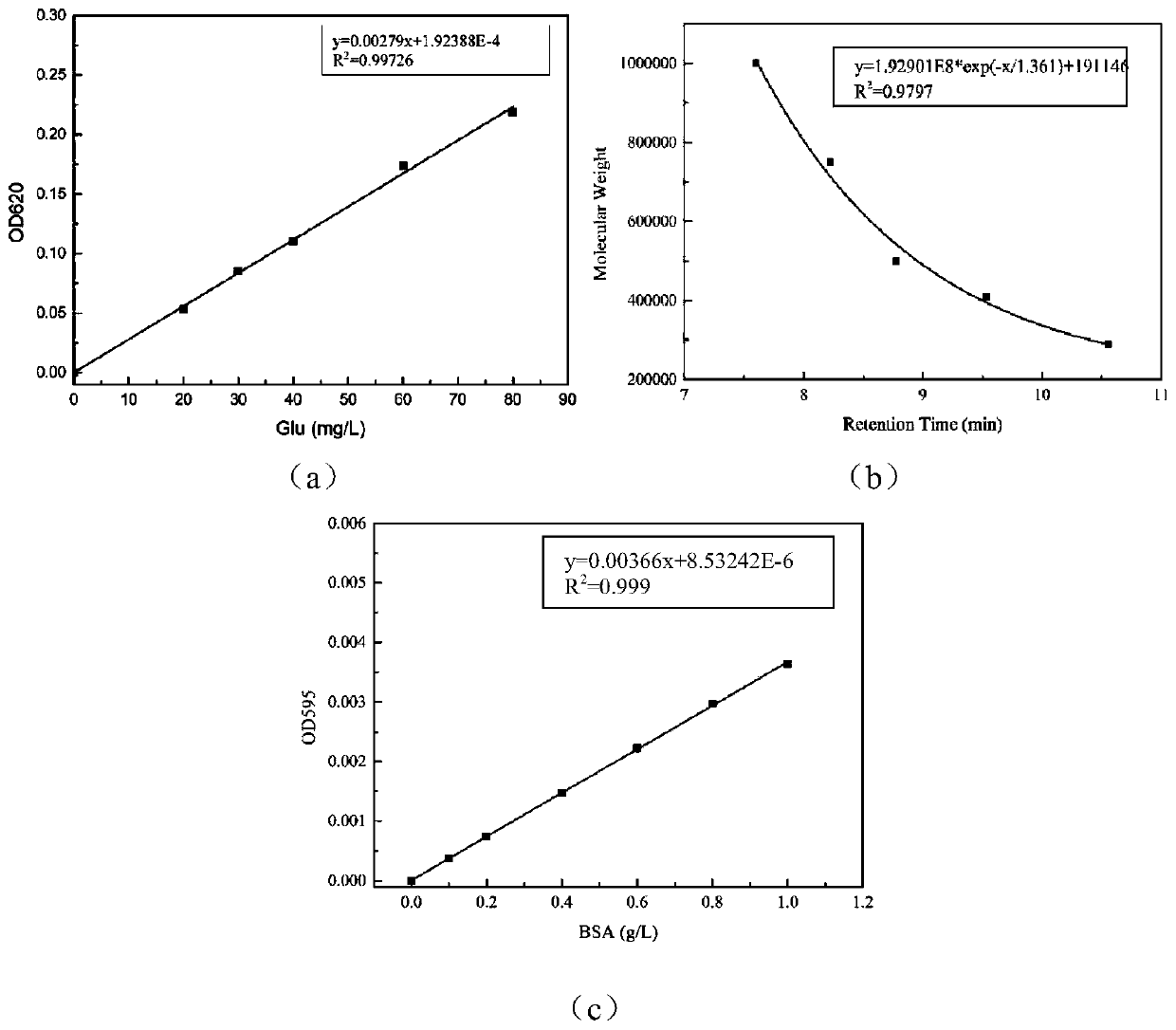

ActiveCN110669681AMild fermentation conditionsEase of extractionFungiFungi productsLaboratory cultureProtein protein

The invention discloses a tremella fuciformis strain which is screened out. The tremella fuciformis strain is named as XY and is preserved in China General Microbiological Culture Collection Center, apreservation date is April 25, 2019, and a preservation number is CGMCC No.17675. The invention further provides application of the tremella fuciformis strain in tremella polysaccharide production. Amain process of using the tremella fuciformis strain for producing tremella polysaccharides includes the steps: a seed solution prepared from CGMCC No.17675 is used for inoculating a solid-state fermentation culture medium, and fermentation is conducted to obtain a fermentation broth. High-molecular-weight polysaccharides with the molecular weight of 1000-1500 kDa and low-molecular-weight polysaccharides with the molecular weight of 100-300 kDa can be prepared, a total yield can achieve 15-25 g / L, the protein content is smaller than 0.3%, compared with a liquid-state fermentation method, theprocess of using the tremella fuciformis strain for producing the tremella polysaccharides has significant cost advantages, and therefore the tremella fuciformis strain has good application prospectsin industrial production of the tremella polysaccharides.

Owner:NANJING UNIV OF TECH

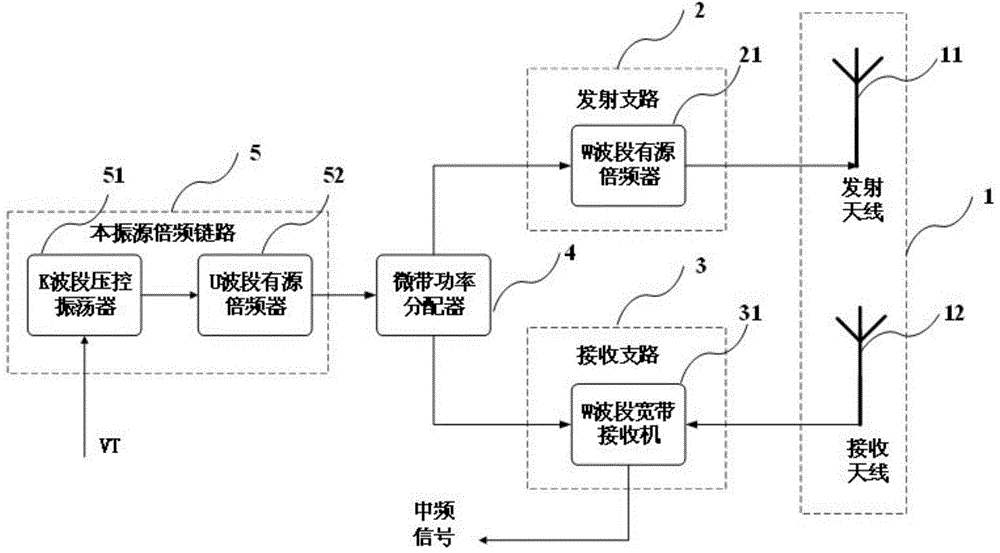

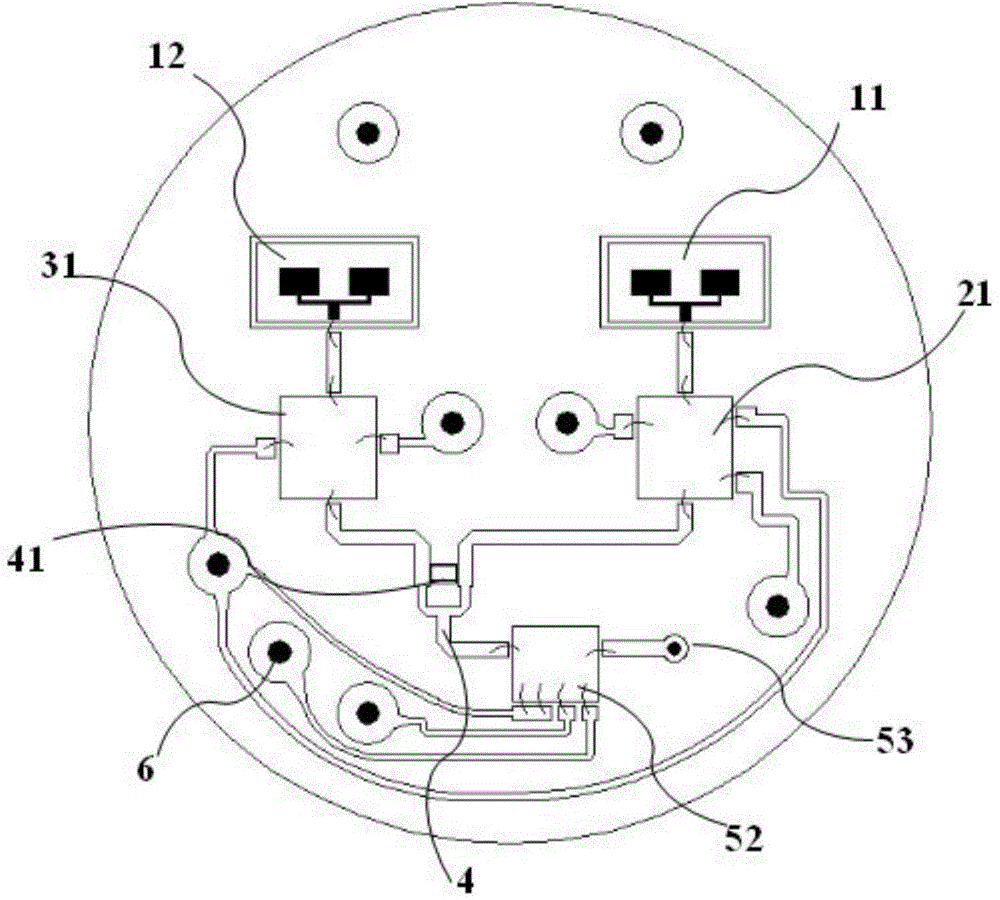

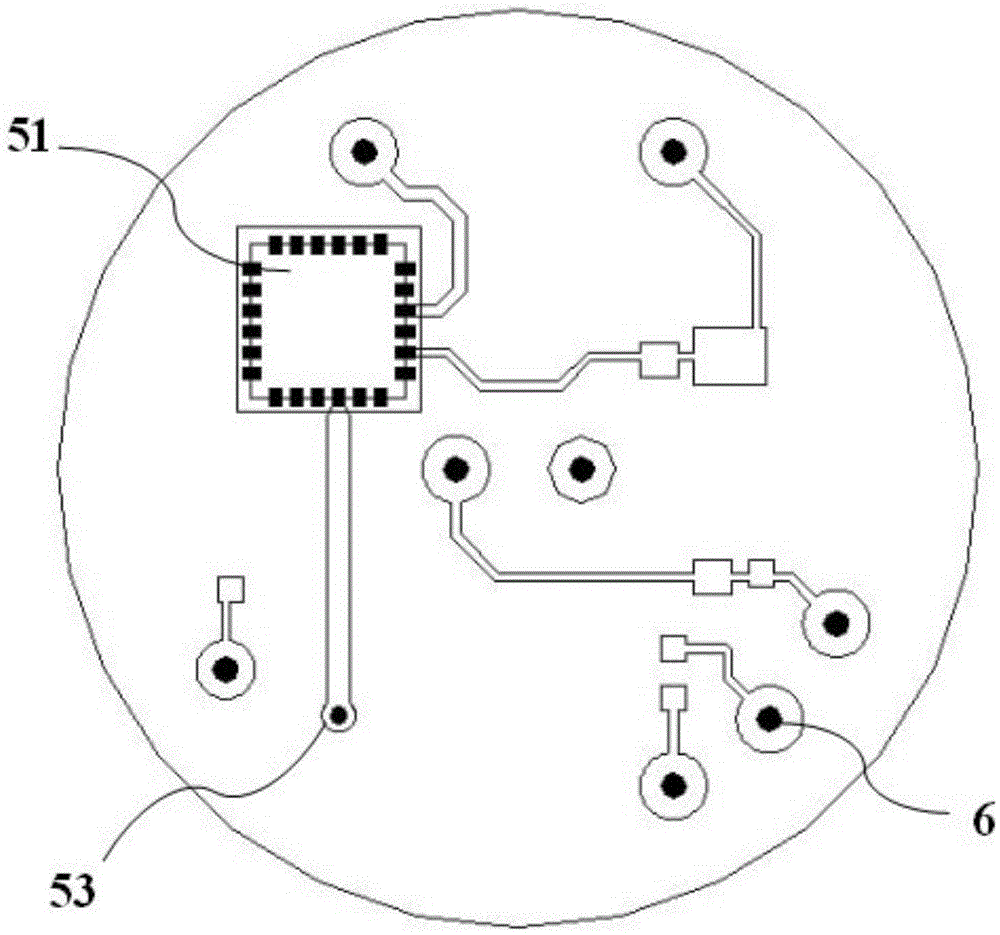

3mm-waveband small detector front-end

InactiveCN104833955ACompact structureReduce volumeRadio wave reradiation/reflectionLocal oscillator signalMiddle frequency

The invention relates to a 3mm-waveband small detector front-end which comprises the components of double 3mm small antennae, a transmitting branch circuit, a receiving branch circuit, a microstrip power divider and a local oscillator frequency doubling link, wherein the double 3mm small antennae comprise a transmitting antenna and a receiving antenna. The local oscillator frequency doubling link is used for supplying an adjustable-frequency local oscillator signal. The microstrip power divider divides the local oscillator signal to two paths. One path of the local oscillator signal is fed to the transmitting branch circuit for supplying an oscillating signal, and the other path is fed to the receiving branch circuit for supplying a local oscillator input. The transmitting branch circuit is used for performing frequency doubling and amplification on one-path signal which is output by the microstrip power divider, obtaining a 3mm-waveband RF signal and transmitting the 3mm-waveband RF signal to the transmitting antenna for transmitting. The receiving branch circuit is used for amplifying a 3mm-waveband echo signal which is received by the receiving antenna and performing secondary harmonic active frequency mixing with the local oscillator input signal for obtaining a middle-frequency output signal. The 3mm-waveband small detector front-end settles the following problems in an existing waveguide-structure 3mm waveband detector front-end: high cost, low integration level and large size.

Owner:SHANGHAI INST OF MICROSYSTEM & INFORMATION TECH CHINESE ACAD OF SCI

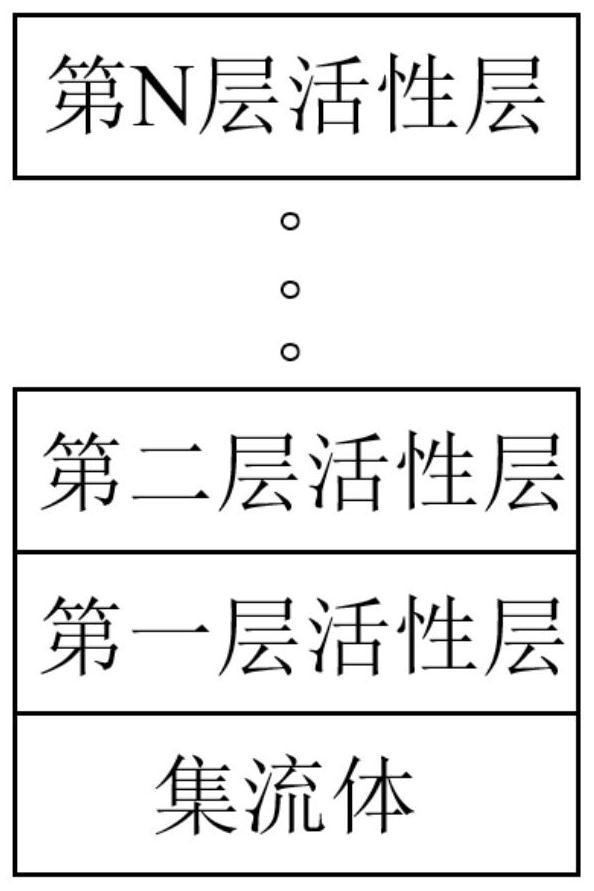

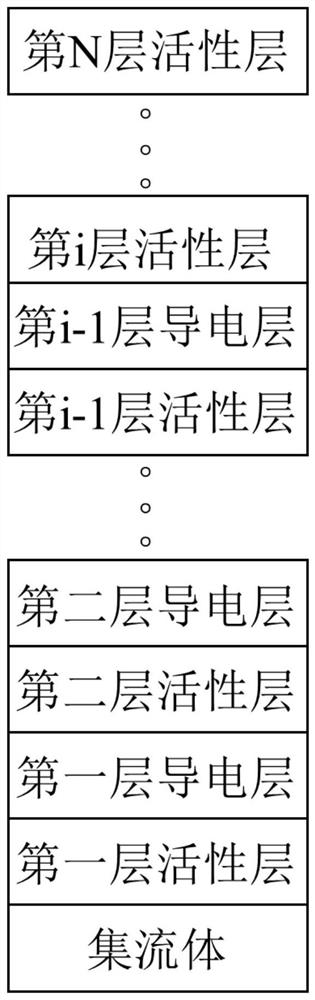

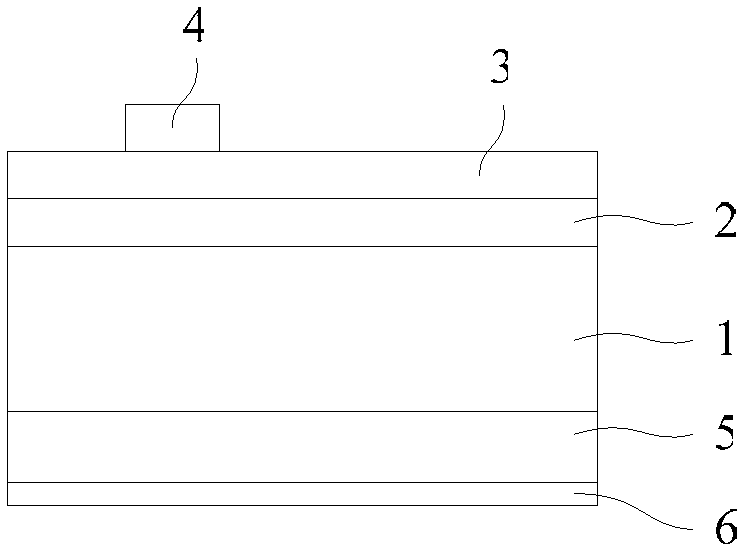

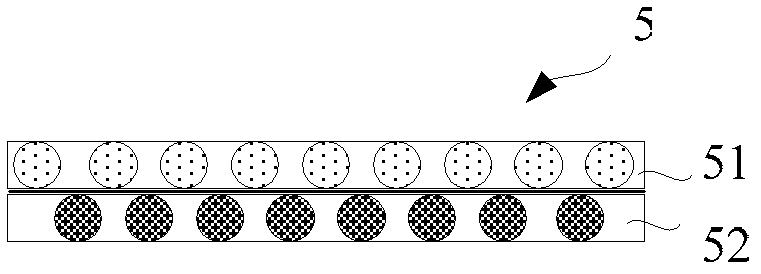

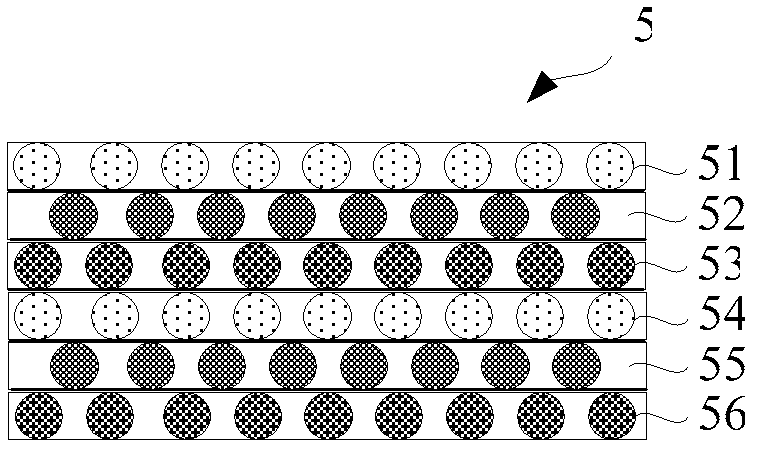

Negative plate as well as preparation method and application thereof

InactiveCN111613774AIncrease energy densityAvoid falling powderSecondary cellsNegative electrodesPhysicsChemistry

The invention provides a negative plate as well as a preparation method and application thereof. On the first aspect, the invention provides a negative plate. The negative plate comprises a current collector and N active layers, wherein the active layer comprises a carbon material and a silicon material, the layer number set of the active layers is recorded as S={1, 2,..., i-1, i,..., N}, N is greater than or equal to 2, and the direction from the first active layer to the Nth active layer is the direction gradually far away from the current collector; and the mass of the silicon material in the (i-1)th active layer is greater than the mass of the silicon material in the ith active layer, and the mass of the carbon material in the (i-1)th active layer is less than the mass of the carbon material in the ith active layer. According to the negative plate provided by the invention, through a mode that the mass of the silicon material is gradually reduced layer by layer and the mass of thecarbon material is gradually increased layer by layer, powder falling of the negative plate in a circulation process can be effectively prevented, the volume expansion rate of the negative plate is reduced, and the circulation performance of the negative plate is improved.

Owner:ZHUHAI COSMX BATTERY CO LTD

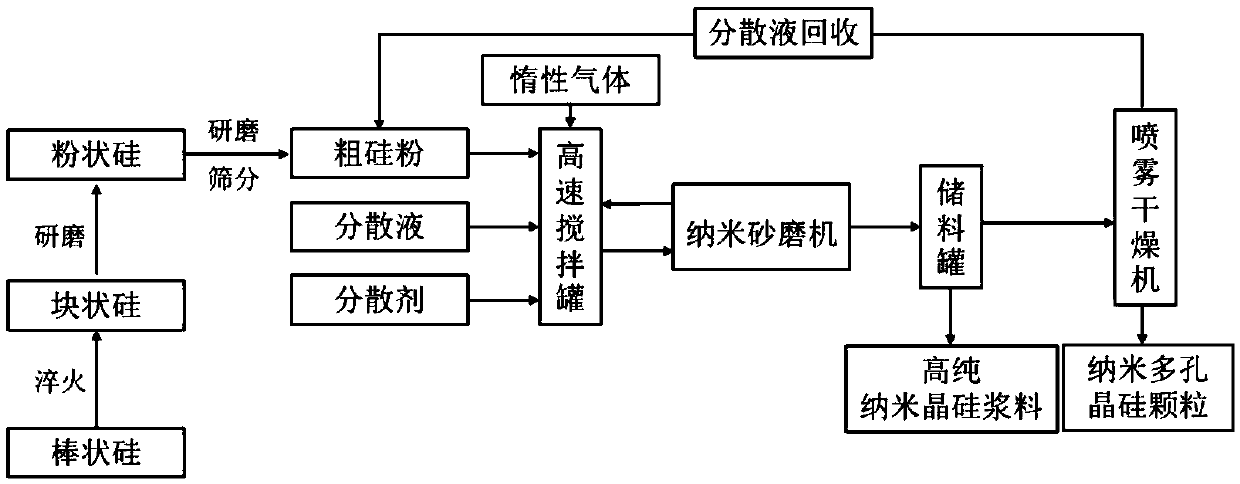

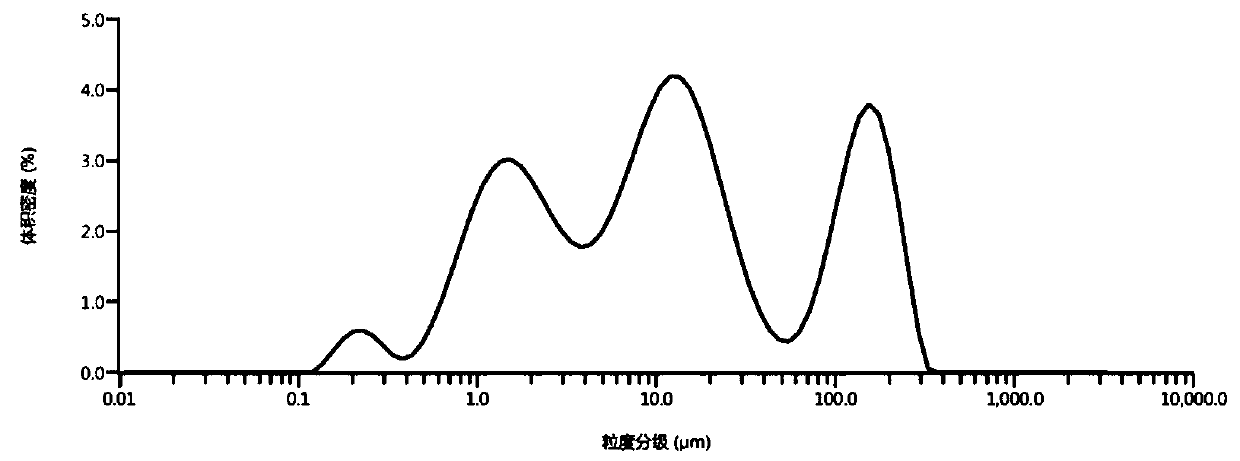

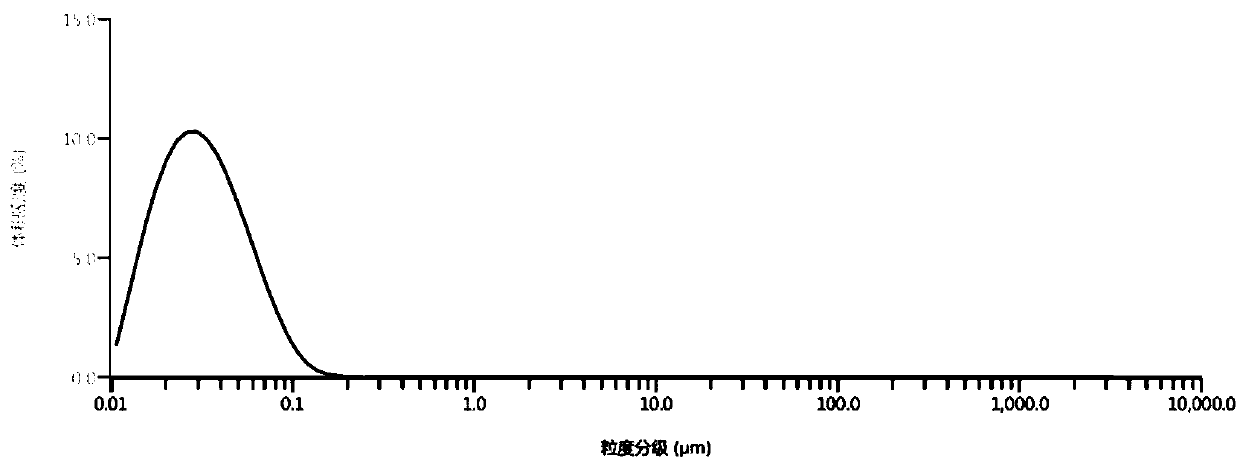

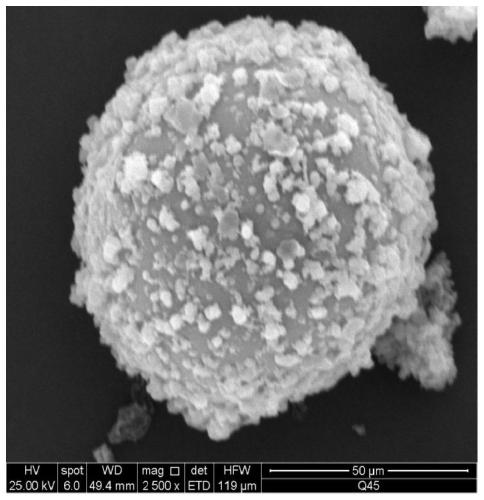

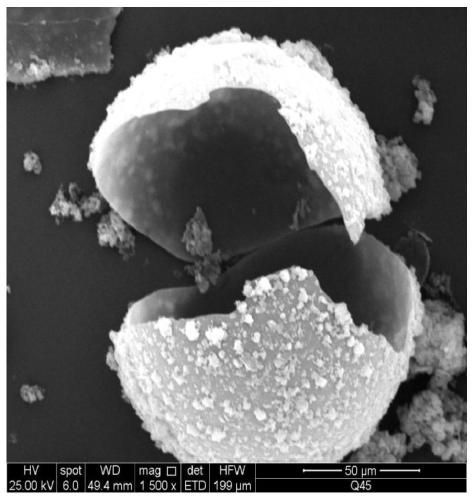

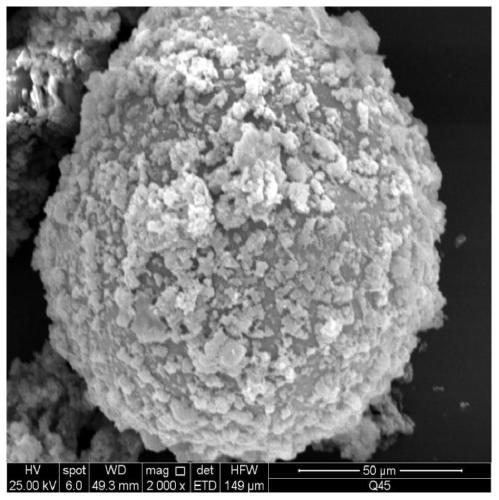

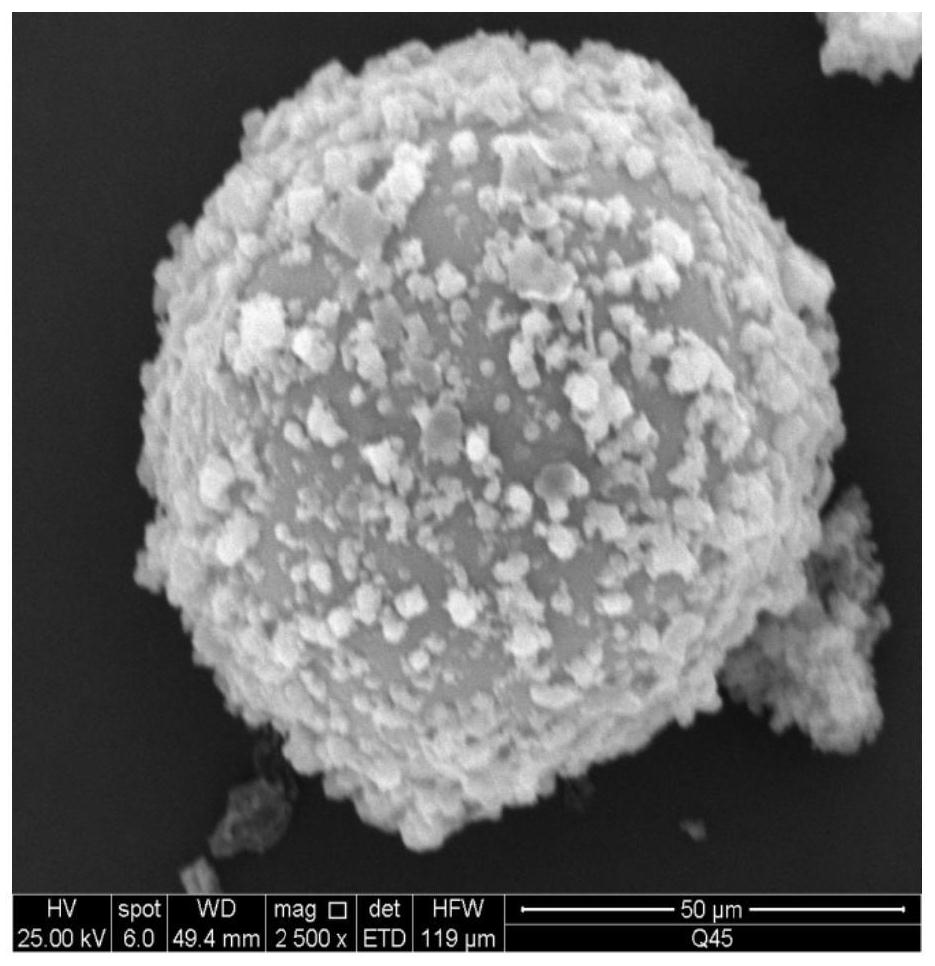

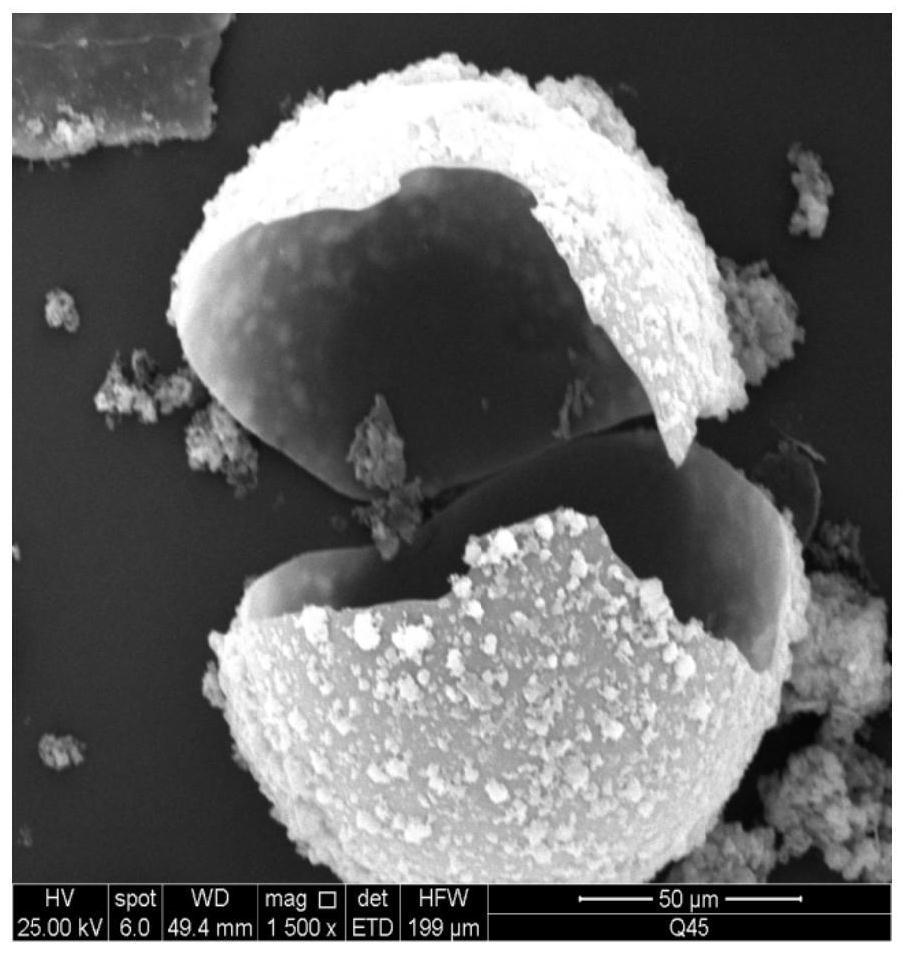

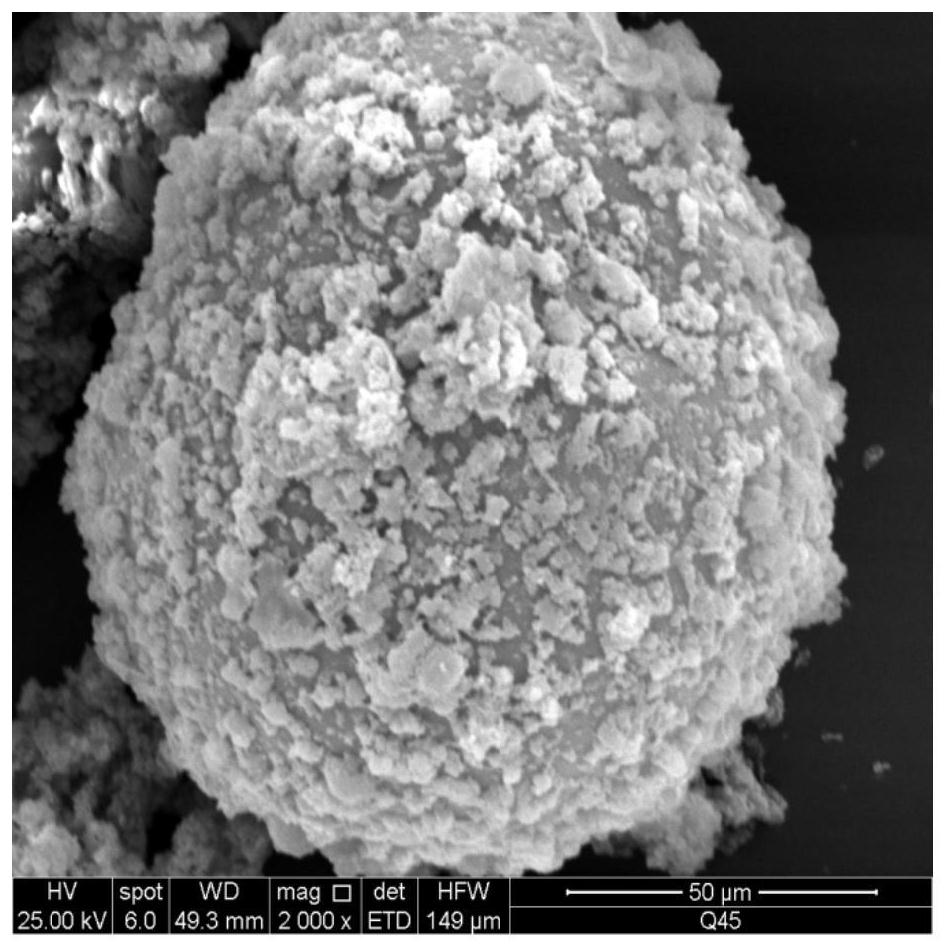

Production method of high-purity nanocrystalline silicon

ActiveCN110890537ALow impurity contentHigh content of impuritiesSiliconCell electrodesNanocrystalline siliconSpray dried

The invention discloses a production method of high-purity nanocrystalline silicon, which comprises the following steps: 1) pretreating a waste silicon material and / or byproduct silicon powder to obtain 10-50 [mu]m silicon powder; (2) adding the silicon powder in the step (1) into dispersion liquid according to the proportion of 5-30wt% of solid content, then adding 1-10wt% of dispersing agent, and performing stirring in a dispersing tank to form silicon powder slurry; 3) pumping the silicon powder slurry formed in the step 2) into a sand mill for grinding to obtain nanocrystalline silicon slurry with the average particle size of 20-30 nm; and 4) conveying the nanocrystalline silicon slurry obtained in the step 3) to a spray drying system to obtain the nano-porous crystalline silicon particles. According to the invention, low-cost large-scale production is realized, the stability, purity and granularity of the nanocrystalline silicon are effectively controlled, the morphology of the produced nano-porous crystalline silicon particles is adjustable, the internal pores of the nano-porous crystalline silicon particles are nano communicating pores, the volume expansion of the silicon iseffectively relieved, and the electrical properties of the silicon negative electrode are also remarkably improved.

Owner:JIANGSU ZHONGNENG POLYSILICON TECH DEV +1

Method for preparing ellagic acid by solid fermentation with granatum as raw material

ActiveCN102250981BStrong specificityHigh purityMicroorganism based processesFermentationAdditive ingredientBacterial strain

The invention discloses a method for preparing ellagic acid by solid fermentation with granatum as a raw material and belongs to the field of medicines and health-care products. In the method, solid fermentation is performed by using a culture medium which takes granatum as a main ingredient and by using Aspergillusniger 3.316 as a fermenting bacterial strain. The conditions for the solid fermentation of the granatum include: the pH value is between 5 and 7; and the granatum is initially moisturized by water by 47 to 60 percent, 0.5-percent NH4NO3 is added into a moisturizing agent as an N source, and fermentation is performed at 30 DEG C for 5 to 7 days. The fermented product is purified and dehydrated to produce the high-quality ellagic acid product. The granatum serving as a raw material is cheap, and the high yield and purity of the ellagic acid product are ensured; and the method has an outstanding cost advantage and is suitable for large-scale production.

Owner:安徽德仁生物科技有限公司

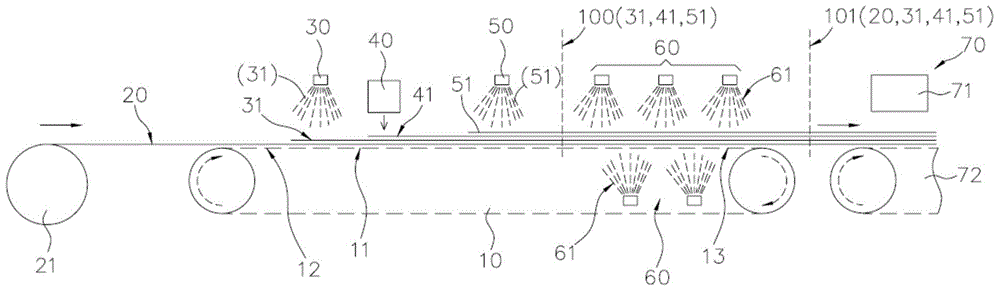

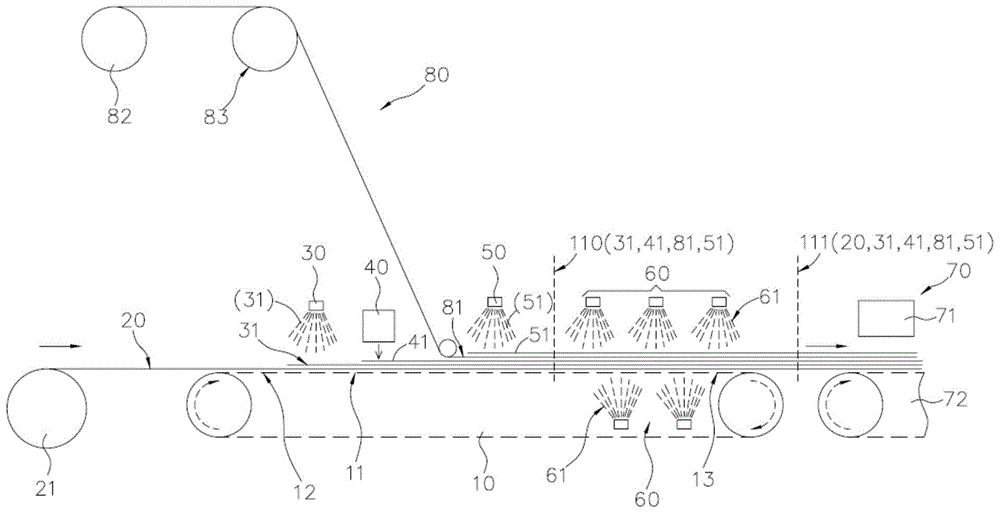

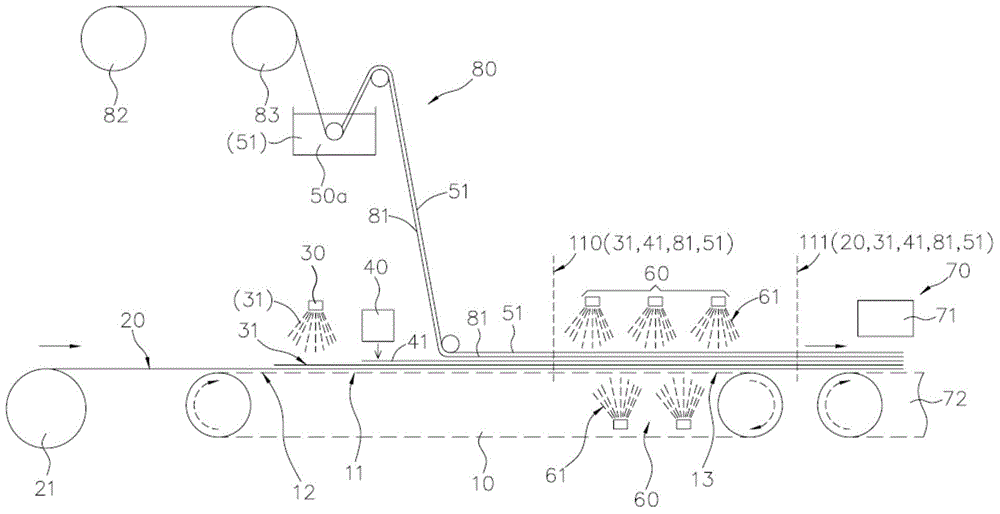

Continuous film-forming manufacturing device of wet-type colloidal film and film-forming method thereof

ActiveCN104972590AContinuous and rapid productionAchieve mass productionCoatingsLiquid layerEngineering

The invention relates to a continuous film-forming manufacturing device of a wet-type colloidal film and a film-forming method thereof. According to the invention, at least one cyclic-type conveyer belt is employed to form at least one bearing surface which moves cyclically along a preset conveying direction, wherein a lower fabric layer is supported on the surface of the bearing surface and can be moved in a synchronously conveying manner. In the front of or above the bearing surface, following parts are arranged successively: a first fixing liquid coating apparatus used for coating the lower fabric layer with a first fixing liquid layer, a colloid coating apparatus used for coating the first fixing liquid layer with a colloid layer so that a crosslinking and cure-shaping effect from bottom to top is carried out; and a second fixing liquid coating apparatus used for coating the colloid layer with a second fixing liquid layer so that a crosslinking and cure-shaping effect from top to bottom is carried out, thereby gradually forming a colloidal film in a proper thickness on the upper surface of the lower fabric layer during the process of synchronously conveying movement of the upper fabric layer, and further forming the continuous film-forming process of the wet-type colloidal film.

Owner:博鸿生物科技股份有限公司

Environment-friendly and degradable food-grade plastic packaging film

InactiveCN109111637ALow priceRich sourcesFlexible coversWrappersFiberLinear low-density polyethylene

The invention discloses an environment-friendly and degradable food-grade plastic packaging film. The environment-friendly and degradable food-grade plastic packaging film is prepared from the following raw materials in parts by weight: 65 to 76 parts of modified linear low-density polyethylene particles, 25 to 35 parts of plant starch, 7 to 14 parts of sarcandra glabra fibers, 8 to 18 parts of filling master batch, 3 to 6 parts of a dispersant, 2 to 4 parts of a coupling agent, 2 to 6 parts of a compound plant antibacterial agent, 3 to 5 parts of an amphoteric surfactant, 5 to 7 parts of graphene oxide, 3 to 5 parts of xanthan gum, 1 to 3 parts of cellulose acetate, 2 to 4 parts of a light degradation agent, 1 to 3 parts of an ultraviolet absorbent, 2 to 4 parts of coconut oil, 1 to 3 parts of glycerol, 1 to 3 parts of prunus humilis bunge fibers, 1 to 3 parts of a waterproof agent and 2 to 4 parts of an antioxidant. According to the environment-friendly and degradable food-grade plastic packaging film, the plant starch and the sarcandra glabra fibers have abundant sources and a cheap price, and are environmentally friendly; the prepared plastic thin film has the advantages of high strength, low production cost, biodegradability, antistatic performance, oxidization resistance and ultraviolet resistance, and the problem of white pollution can be alleviated.

Owner:桐城市强峰包装有限公司

Preparation method of tea leaf water soluble dietary fibers

InactiveCN107125773AEasy to operateShorten the production cycleFood ingredient functionsFood treatmentFreeze-dryingHydrogen-Ion Concentrations

The invention relates to a preparation method of tea leaf water soluble dietary fibers. The preparation method comprises the following steps of A, crushing abandoned tea leaves as raw materials, screening the crushed tea leaves, mixing the screened tea leaves with water at the temperature being 60-85 DEG C according to the weight ratio of the screened tea leaves to the water being (1 to 10)-(1 to 30), maintaining the temperature, and performing leaching for 15-30min; B, performing filtration, taking tea leaf filter residues, mixing the tea leaf filter residues with an acid solution of which the hydrogen ion concentration is 0.5-2.0mol / L according to the volume ratio of the tea leaf filter residues to the acid solution being (1 to 20)-(1 to 40), and performing acidolysis at 60-85 DEG C for 1.0-2.5h; C, performing centrifugal filtration, and performing concentration so as to obtain concentrate; and D, mixing the concentrate with ethanol of which the volume concentration is 80%-95% according to the volume ratio of the concentrate to the ethanol being (1 to 3)-(1 to 5), performing standing for 12h or above, performing centrifugal separation, collecting precipitate, and performing freeze-drying so as to obtain the tea leaf water soluble dietary fibers. The preparation method disclosed by the invention is short in production cycle, simple and convenient to operate, not high enough in requirements for production conditions, and low in investment cost, 60% or above of capital investment can be saved, the extraction rate of the water soluble dietary fibers is 55% or above, the purity of the water soluble dietary fibers is 70% or above, and the preparation method is suitable for mass production.

Owner:XINYANG AGRI & FORESTRY UNIV

Ecological garden environment-friendly brick prepared from all waste and preparing method thereof

InactiveCN110317044AReduce manufacturing costHigh strengthAuxillary shaping apparatusCeramic materials productionBrickSludge

The invention discloses an ecological garden environment-friendly brick prepared from all waste and a preparing method thereof. The ecological garden environment-friendly brick is prepared from 60-80parts of construction waste residue sand, 10-25 parts of a waste porcelain granule, 5-15 parts of waste glass powder, 5-10 parts of coal ash, 3-8 parts of cement dust, 2-5 parts of waste glass fiber,2-4 parts of paint slag and 5-19 parts of sludge. The environment-friendly brick is prepared with the construction waste residue sand, waste porcelain granule, waste glass powder and coal ash as the main raw materials, the discharge amount of construction, porcelain production, glass production and industrial coal waste can be reduced, waste is turned into wealth, the environmental pollution problem is solved, the production cost of the environment-friendly brick can be reduced, and the environment-friendly brick is suitable for large-scale production; the materials are press-formed through abrick pressing machine, the strength and density of the all-waste brick can be improved, through holes in the environment-friendly brick are reduced, and the waterproof performance of the environment-friendly brick is improved.

Owner:安徽华洁环保科技股份有限公司

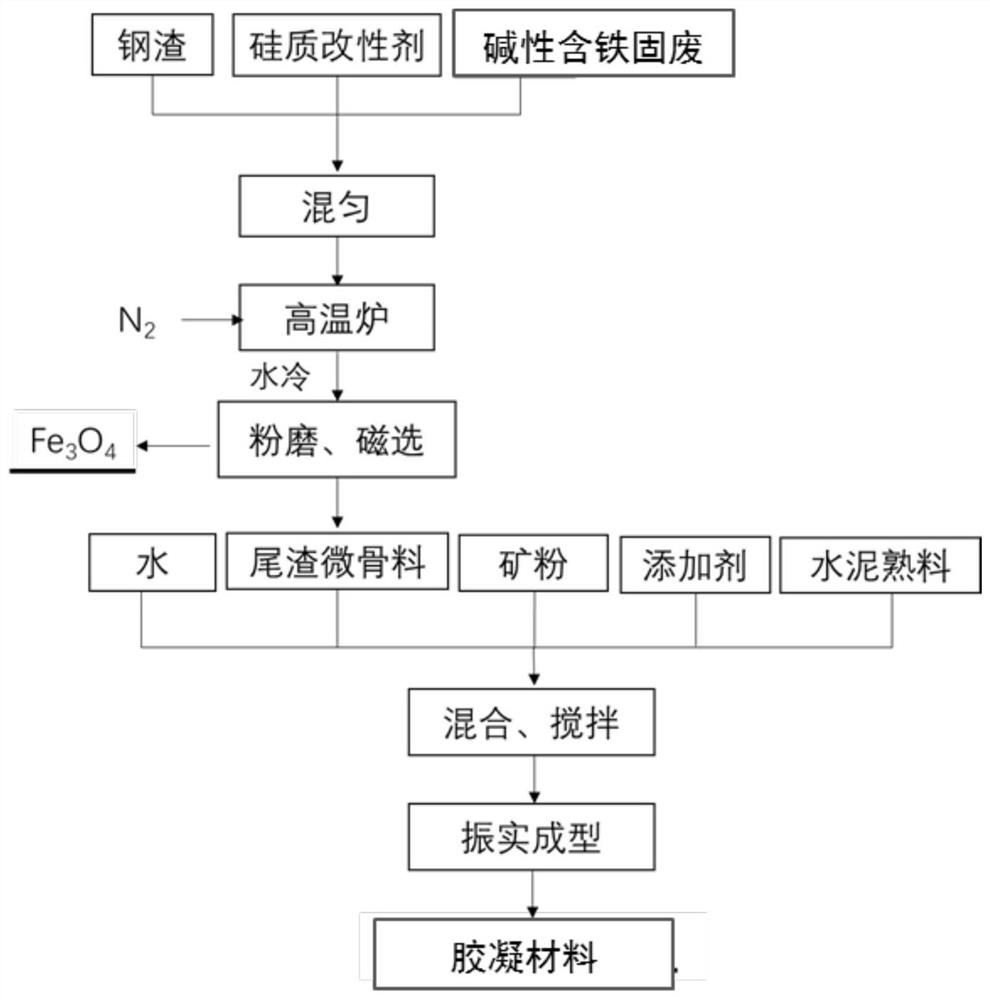

Method for preparing tailing micro-aggregate and simultaneously producing magnetite

ActiveCN114620964AImprove performanceReduce pollutionSolid waste managementIron oxides/hydroxidesSlagRed mud

The method comprises the following steps: mixing steel slag, an alkaline iron-containing solid waste and a siliceous modifier to obtain a mixture, adding the mixture into a high-temperature furnace, calcining in an inert atmosphere, cooling, then carrying out a thermal insulation reaction, and carrying out water cooling, drying, grinding and magnetic separation to obtain the magnetite and the tailing micro-aggregate. The alkaline iron-containing solid waste is selected from red mud or blast furnace ash. The preparation method provided by the invention can simultaneously treat the steel slag and various industrial solid wastes, realizes maximum resource utilization of the industrial solid wastes, reduces environmental pollution, and is simple in preparation process and suitable for large-scale production. The prepared tailing micro-aggregate is excellent in performance and can be used for replacing various building materials.

Owner:UNIV OF SCI & TECH BEIJING +1

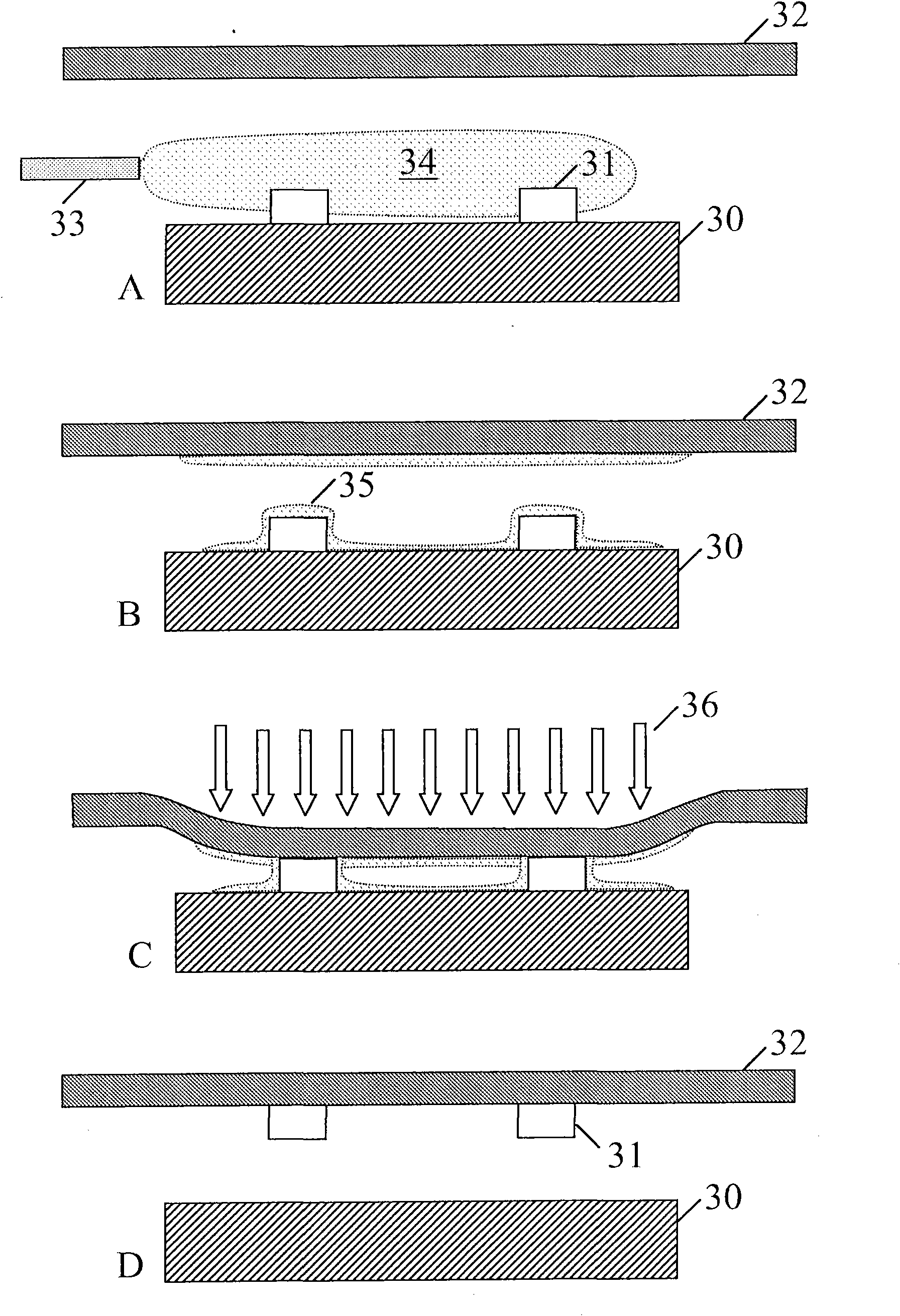

Storage and transfer of organic nanofibers

InactiveCN101632185ASimple and reliable productionReduced mass productionSolid-state devicesSemiconductor/solid-state device manufacturingFiberNanofiber

The present invention relates to a method of transferring nanofibres from a template substrate to a flexible storage medium. The method comprising : a) providing the template substrate supporting nanofibres and the flexible storage medium; b) positioning the flexible storage medium so that a first storage area of the flexible storage medium is facing a first support area of the template substrate; and c) pressing the first storage area of the flexible storage medium in contact with the first support area of the template substrate and remove the first storage area of the flexible storage medium from contact with the first support area of the template substrate, thereby transferring the nanofibres from the template substrate to the flexible storage medium and thereby providing a loaded flexible storage medium. The present invention is advantageous for providing a method of storing and handling of nanofibres for commercial implementation into working devices, by providing a solution to problems concerning compact storage of nanofibres for further use.

Owner:NANOFIBER

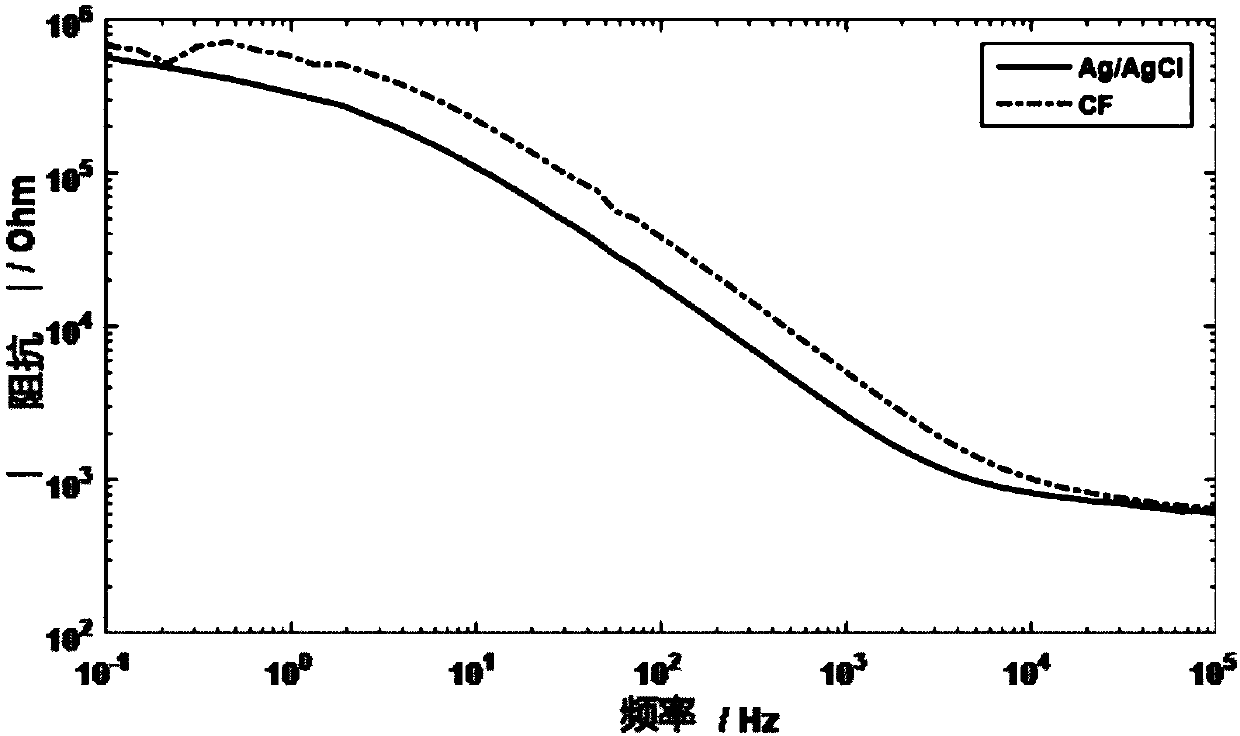

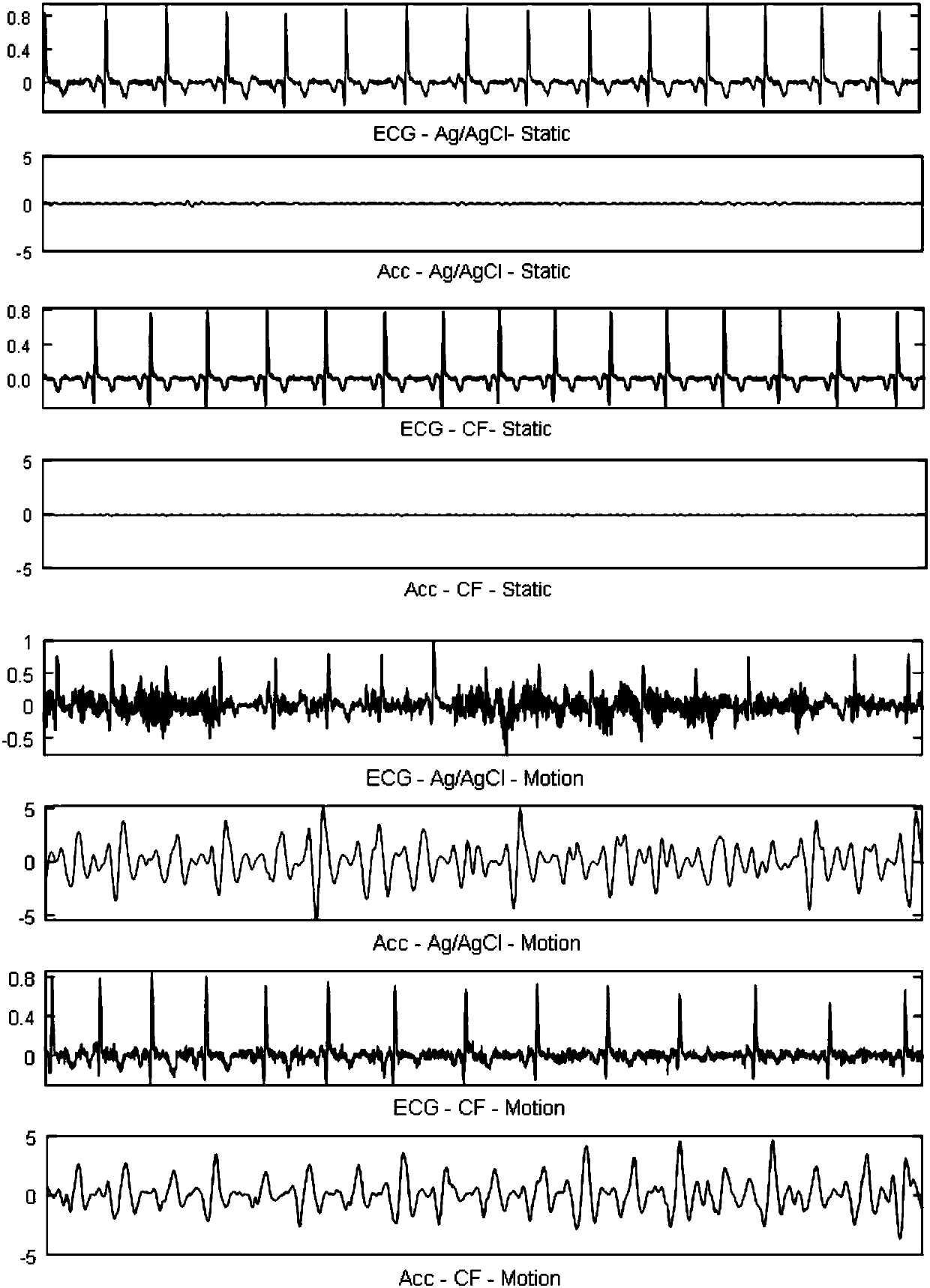

Drying disposable flexible electrocardio-electrode and preparation method thereof

PendingCN107802261AImprove flexibilityIncrease elasticityDiagnostic recording/measuringSensorsMedical equipmentEngineering

The invention belongs to the technical field of medical equipment, and particularly relates to a drying disposable flexible electrocardio-electrode and a preparation method thereof. The electrocardio-electrode comprises a carbonized sponge layer, an electret gel layer, an isolation bottom layer and a conductive buckle; the electret gel layer surrounds the carbonized sponge layer and serves as a protection layer of the sponge layer; the isolation bottom layer is arranged between the carbonized sponge layer and the conductive buckle and used for isolation and protection; the carbonized sponge layer is connected with the conductive buckle through a metal wire. The preparation method comprises the steps of carbonized sponge preparation and electrocardio-electrode assembling. The flexible electrocardio-electrode is good in flexibility and elasticity and is more closely attached to the body surface skin, and the motion artifact resistant capacity is higher; the electrode-skin impedance is low, the electric conductivity is excellent, polarization is not likely to be generated, and interference and noise are resisted. In addition, the carbonized sponge generation cost is extremely low, andthe use cost can be greatly lowered. The electrocardio-electrode is easy to operate, short in manufacturing cycle and easy to produce in a large scale.

Owner:FUDAN UNIV

Double-layer phase-change microcapsules and production method and application thereof

ActiveCN109852350AReduce the temperatureImprove high temperature stabilityHeat-exchange elementsBuilding insulationsRoad surfaceThermal stability

The invention provides double-layer phase-change microcapsules and a production method and application thereof. A phase-change material in a single-layer phase-change micro cavity is used as a capsulecore, and outer layer capsule walls of a flame-retardant material cover single-layer phase-change microcapsules. When temperature of a bituminous mixture rises to temperature of the phase-change material, the phase-change material conducts phase transformation, and absorbs and stores a lot of heat, so that the high-temperature stability of a bituminous pavement is enhanced, and the phase-change material has a good effect on reducing rut depth. When the temperature of the bituminous mixture falls to phase-change temperature of the phase-change material, the phase-change material conducts phasetransformation again, and releases a lot of heat, so that the low-temperature anti-crack performance of the bituminous pavement is enhanced, and the phase-change material has a good effect on reducing crack width. The microcapsule phase-change material has good mechanical performance, thermal stability and durability in a use process of the bituminous mixture, so that the service life of the phase-change material is greatly prolonged.

Owner:CHANGAN UNIV

Preparation method of ziprasidone or its salt inclusion

InactiveCN1839839AImprove stabilityShort timePowder deliveryOrganic active ingredientsZiprasidoneInclusion compound

The invention relates to a process for preparing Ziprasidone or its salt inclusion compound, which comprises the steps of, (1) providing a solution of Ziprasidone or its salts, heating the solution at 78+-1.5 deg C to dissolve Ziprasidone or its salts, (2) filtering non-soluble substance in the solution, then drying the dissolvent.

Owner:SHANGHAI INST OF PHARMA IND

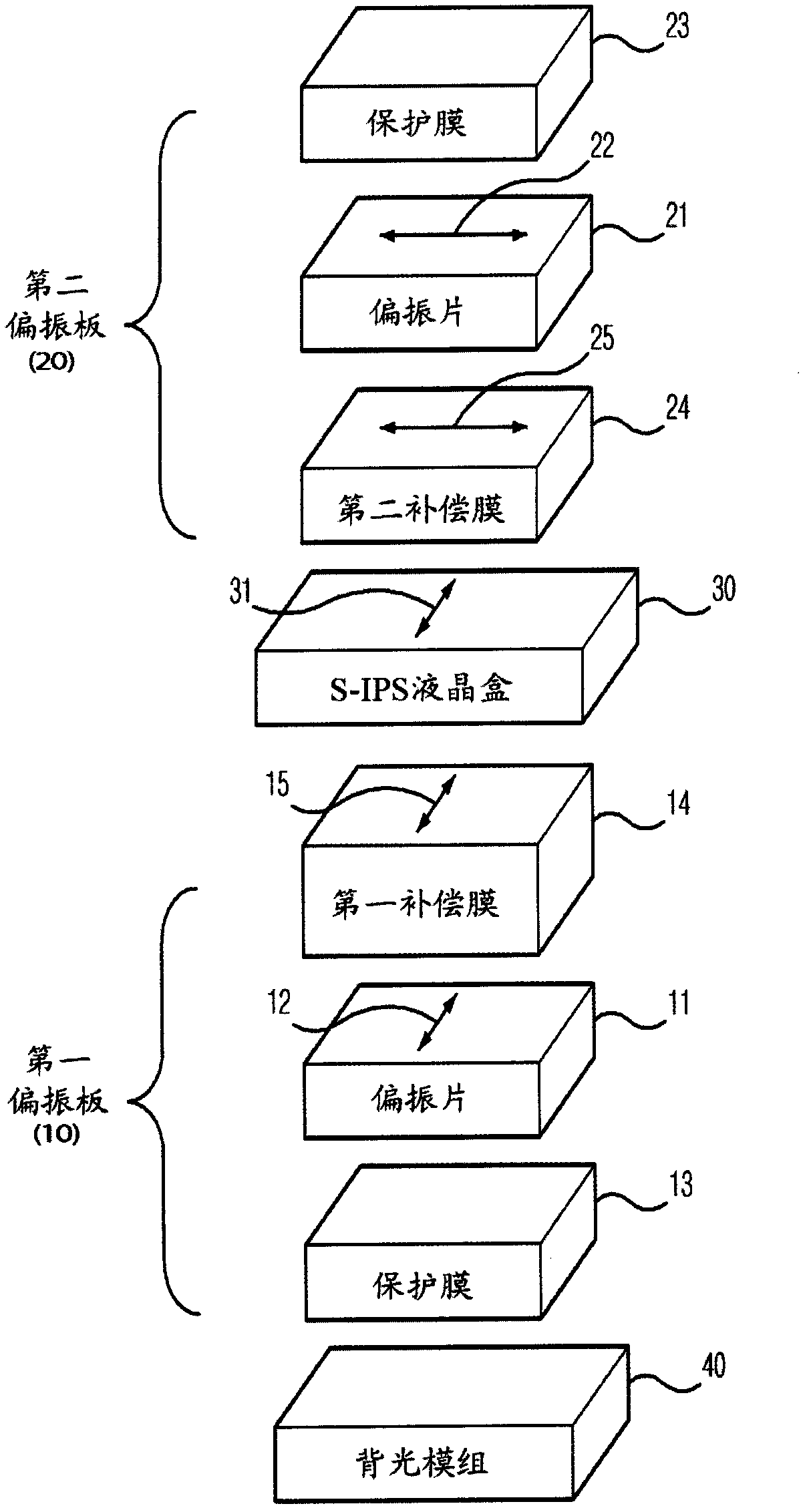

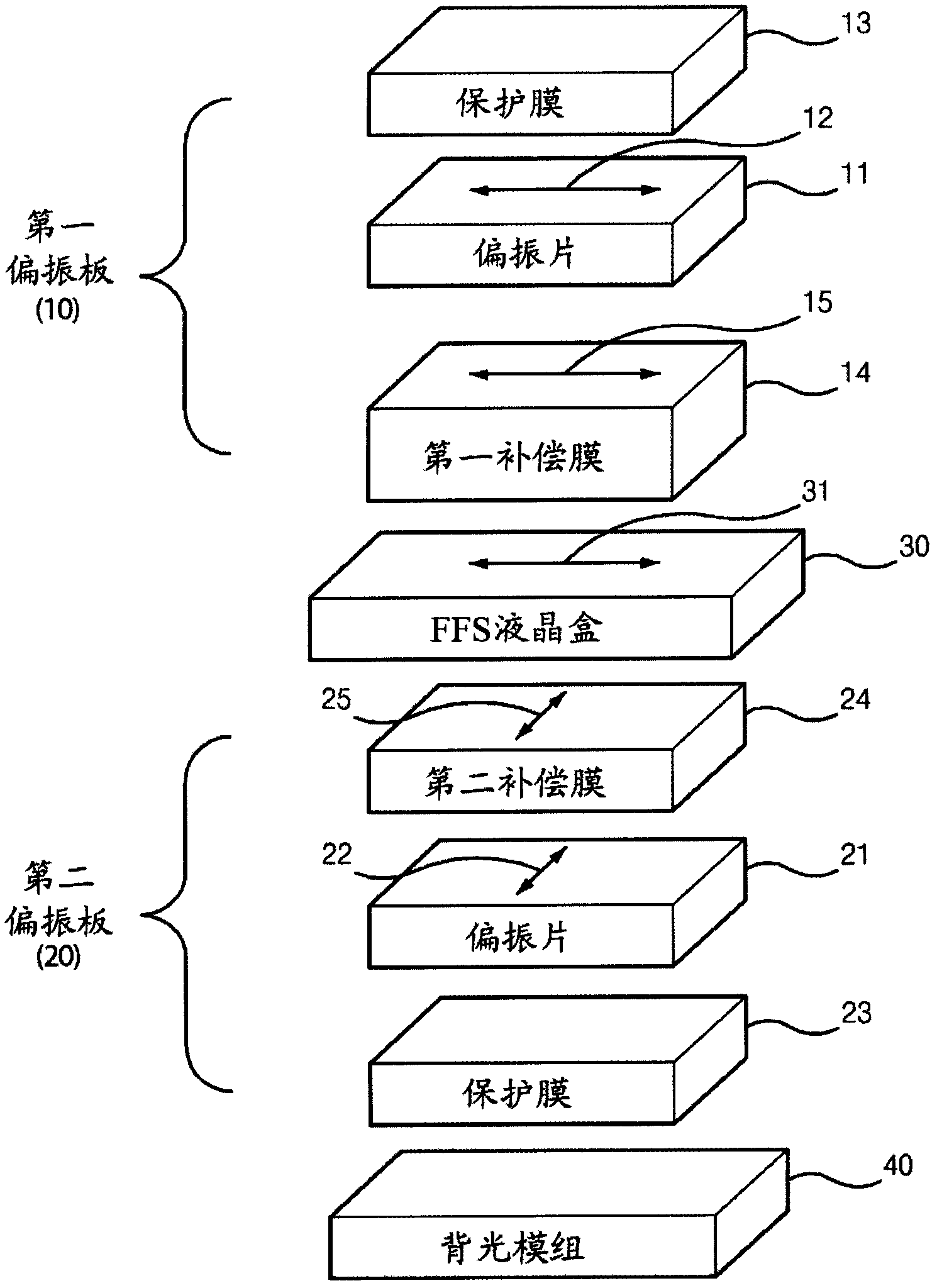

In-plane switching mode liquid crystal display

ActiveCN102483537AHigh yieldReduce defective ratePolarising elementsNon-linear opticsOptical propertyPolarizer

The present invention relates to an in-plane switching mode liquid crystal display. More precisely, the present invention relates to an in-plane switching mode liquid crystal display including a first polarizing plate, a second polarizing plate and a liquid crystal cell, designed to have wide viewing angle and to be economical, because the optical properties of the compensation film are determined by changes of the polarization state of liquid crystal alignment on a Poincare Sphere, and the contrast in the inclined visual direction is improved due to a slow axis of a compensation film of the first polarizing plate to be parallel to the liquid crystal alignment and to an absorption axis of a polarizer. The present invention can implement mass production of thin liquid crystal displays with high yield (reducing defect ratio due to foreign substances or impurities) and can provide a very large liquid crystal display with its possibility to produce larger, coupled polarizing plate since it is possible to ensure a wide viewing angle with only one sheet of compensation film for the upper polarizing plate and the lower polarizing plate.

Owner:DONGWOO FINE CHEM CO LTD

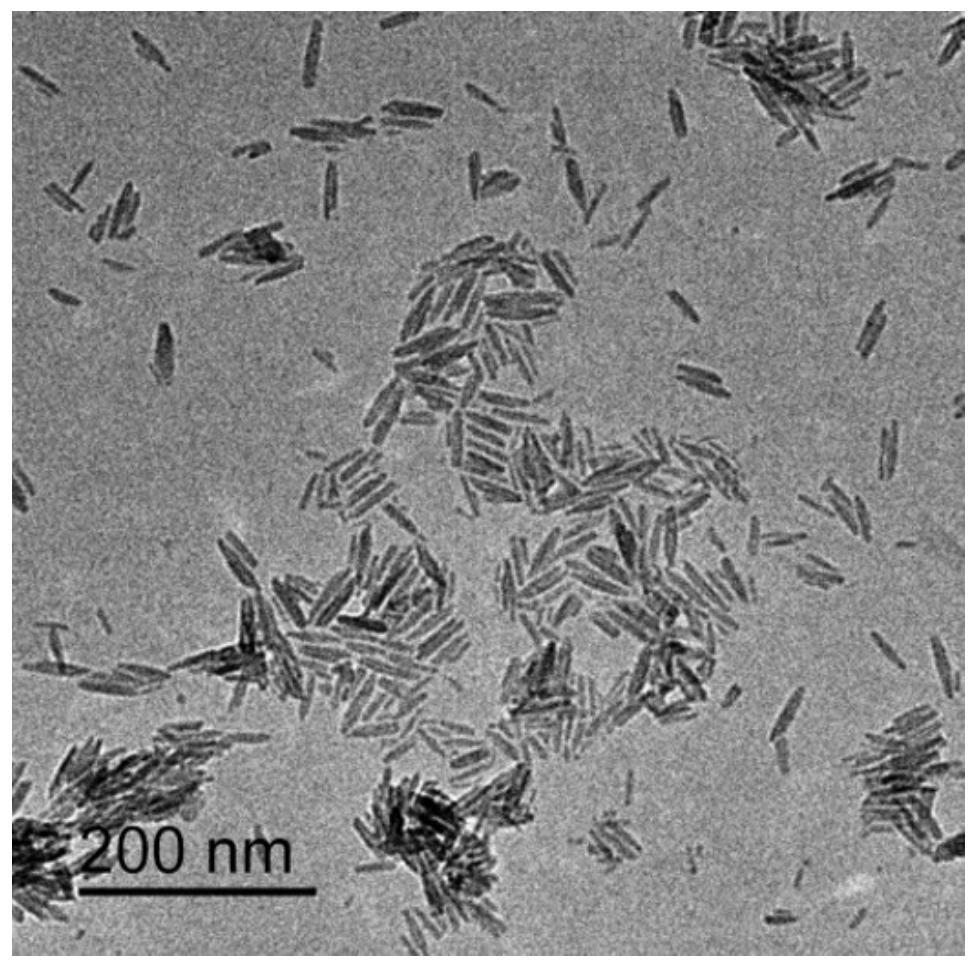

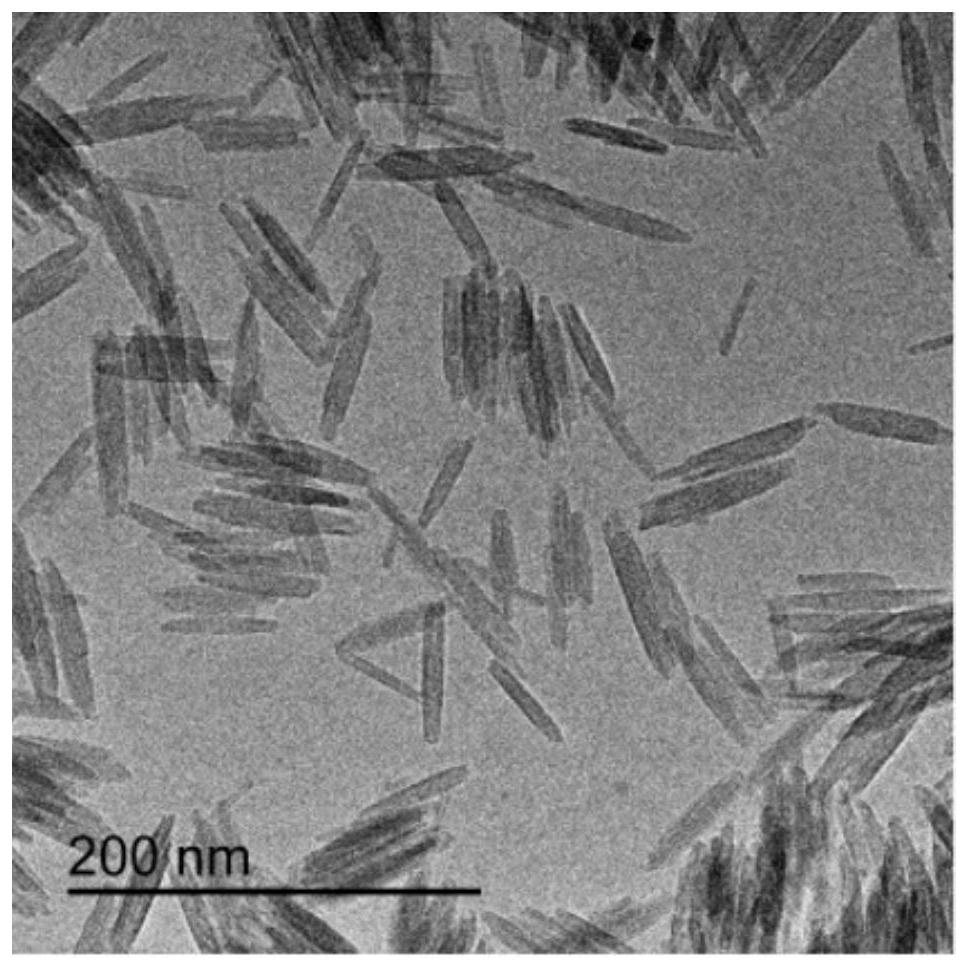

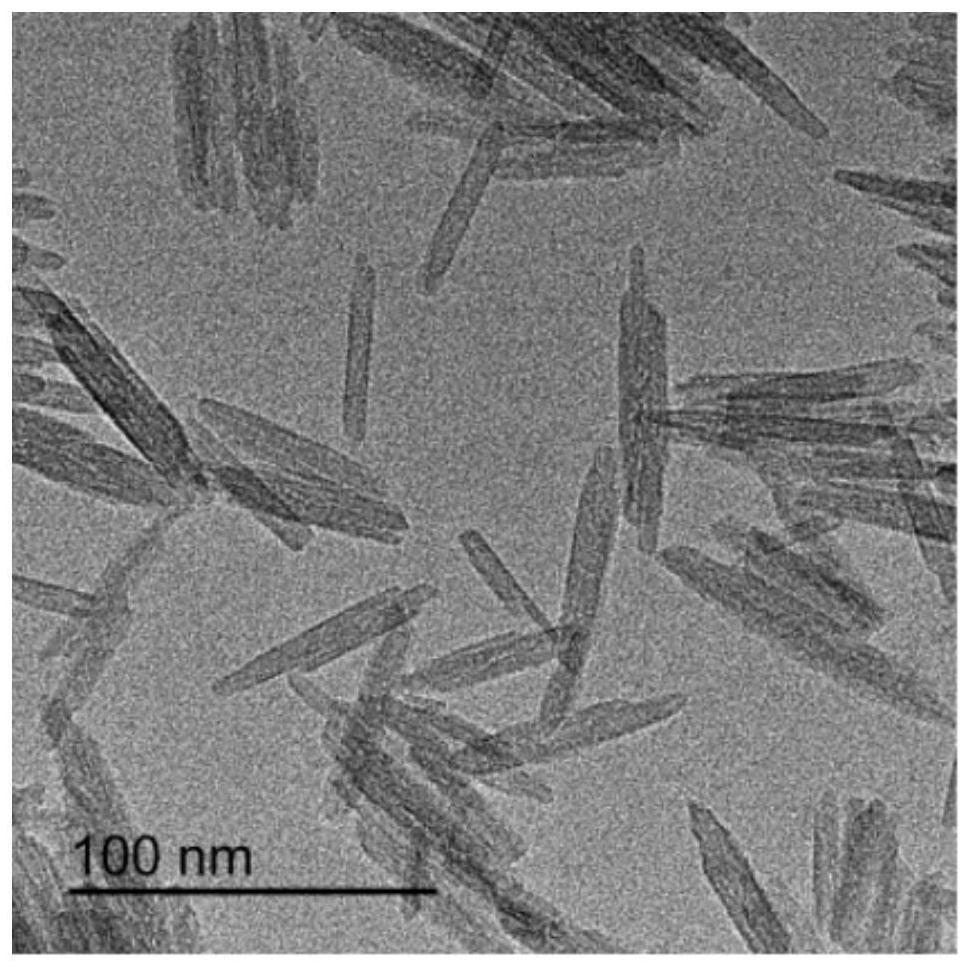

Beta-FeOOH nanorod and preparation method thereof

InactiveCN111620381AGood dispersionStable in natureIron oxides/hydroxidesNanotechnologyAqueous solutionEthylene imine

The invention discloses a beta-FeOOH nanorod and a preparation method of the beta-FeOOH nanorod. The preparation method comprises the following steps: taking ferric trichloride, polyethyleneimine anddeionized water as raw material agents, uniformly dispersing the ferric trichloride into a polyethyleneimine water solution, heating in an oil bath to carry out hydrolysis reaction, cooling a productto room temperature, carrying out centrifugal washing for multiple times, and dispersing precipitates into the deionized water; the prepared beta-FeOOH nanorod is good in dispersity in the deionized water; the diameter of the material is about 10-15nm, and the length of the material is about 35-185nm. The beta-FeOOH nanorod prepared by the invention can stably exist in an aqueous solution, the preparation process is simple, the raw material is wide in source and low in cost, the reaction is carried out under normal pressure, the requirement on reaction equipment is lower, the operation is safe, the beta-FeOOH nanorod is non-toxic and harmless, green and environment-friendly, the process flow controllability is strong, the yield is high, and the method is suitable for large-scale industrialproduction.

Owner:SHAANXI UNIV OF SCI & TECH

Solar cell and method for manufacturing same

ActiveCN102956720AGood back field passivation performanceIncrease photocurrentFinal product manufacturePhotovoltaic energy generationNitrogenSolar cell

The invention provides a solar cell and a method for manufacturing the same. The solar cell comprises a silicon substrate and a back reflecting layer on one side of a backlight surface of the silicon substrate, wherein the back reflecting layer comprises at least two SiX layers which are overlaid, silicon contents of the SiX layers are different, and the X represents carbon, oxygen or nitrogen. The solar cell is high in photo-generated current and stable in structure, and the stable photo-generated current can be kept for a long time. In addition, the process for manufacturing the solar cell is simple, operation is easy, and the solar cell is suitable for large-scale production.

Owner:BEIJING NAURA MICROELECTRONICS EQUIP CO LTD

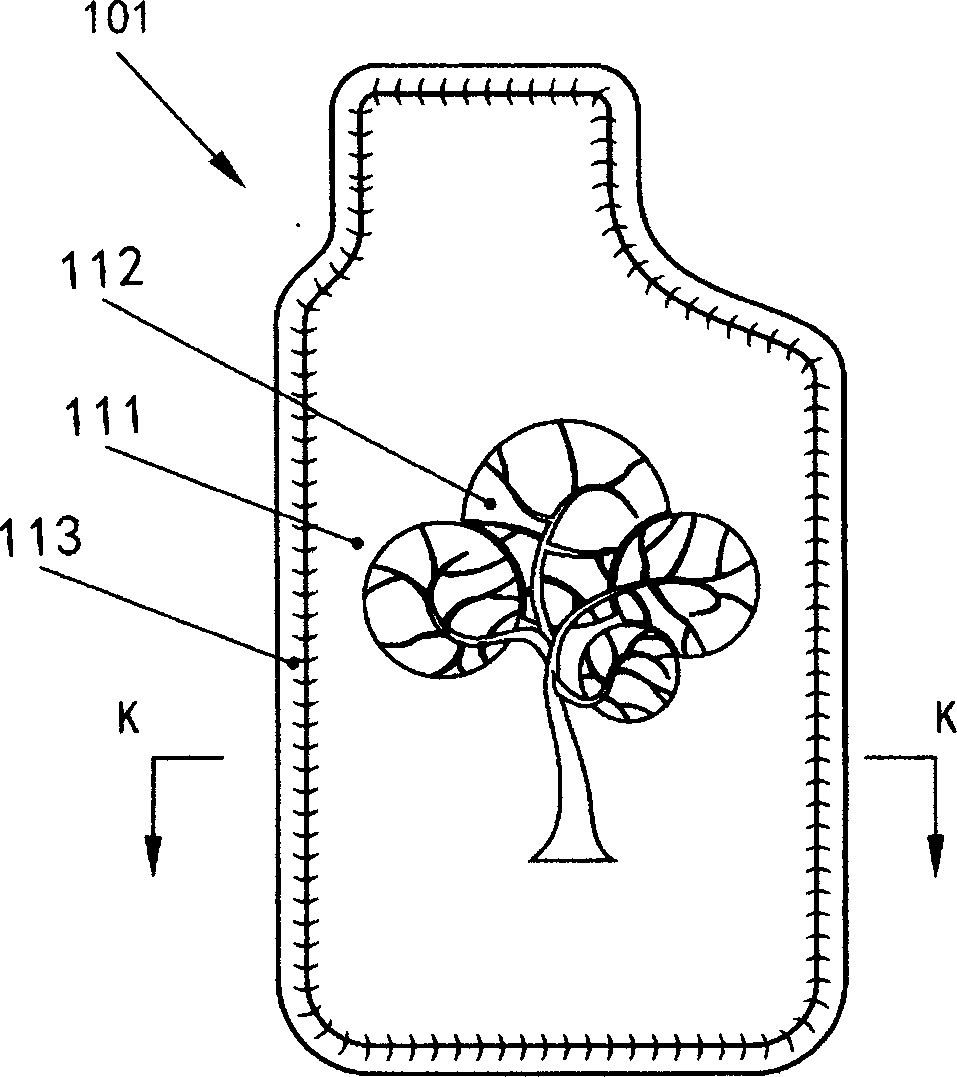

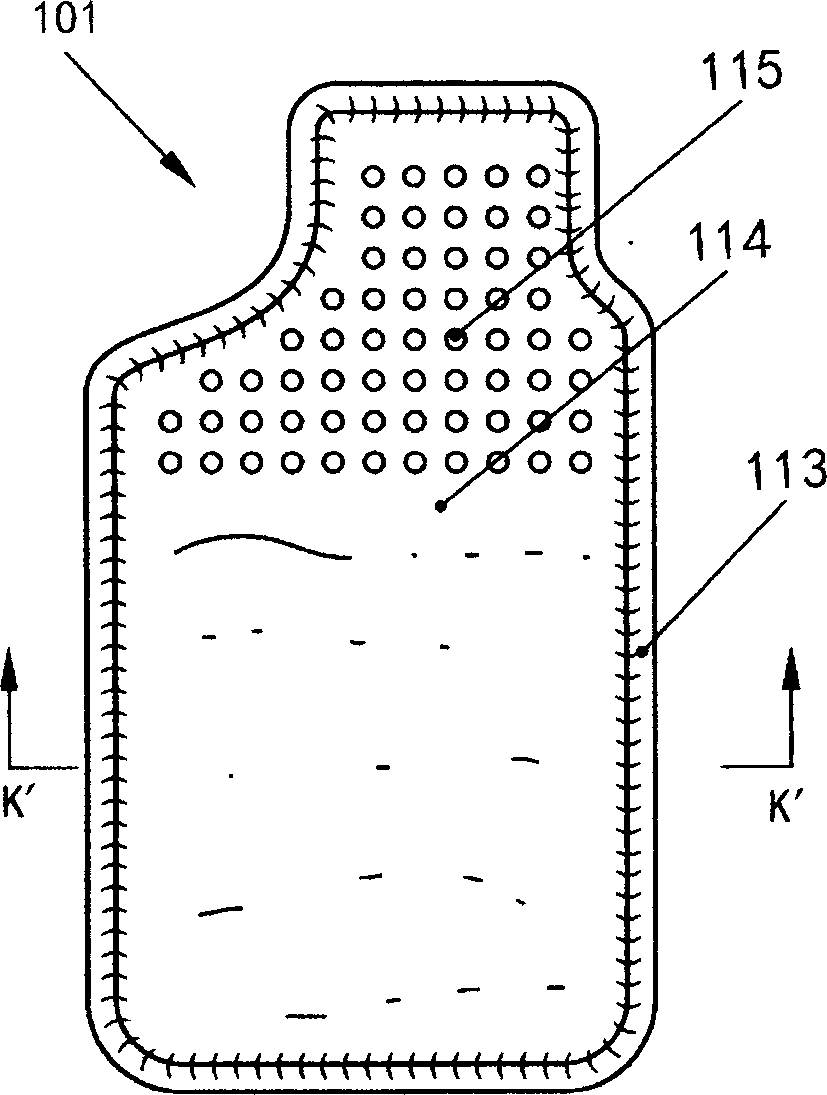

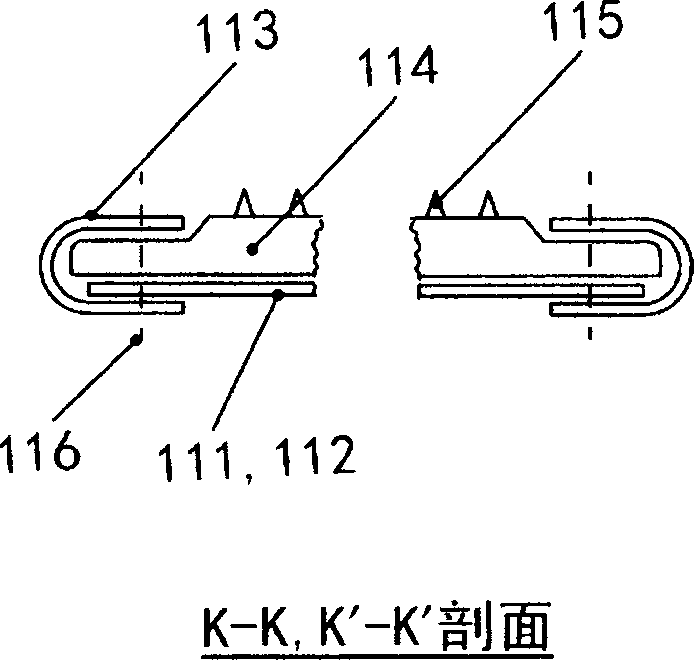

Plastic floor mat and manufacturing method thereof

InactiveCN102415804ASignificant technological progressSuitable for mass productionFloor carpetsEngineeringInjection molding machine

The invention discloses a plastic floor mat, which comprises a surface piece facing the upper part for pedaling, a main body piece which is below the surface piece and is adhered to the ground during use, and an edge surrounding all peripheries, wherein the surface piece facing the upper part for pedaling is made of a transparent or semitransparent plastic film or a plastic sheet; aesthetic patterns or characters are printed on one side of a non-pedaled main body piece facing the lower part for the surface piece; the main body piece which is below the surface piece and is adhered to the ground or floor during use is molded by plastic raw materials and is molded and adhered with the surface piece into a whole; the edge surrounding all the peripheries is molded by the same plastic raw material or another plastic raw material in the same injection molding and adhering operation or another injection molding operation; and the edge wraps all the peripheries of the whole which is formed by injection molding and adhering the main body piece and the surface piece. The invention also comprises a method for manufacturing the plastic floor mat.

Owner:汪玉华

Vapor reaction preparation process of continuous ion layer in polyelement sulfide film

InactiveCN1638154ASolution to short lifeEasy to recycleFinal product manufactureSemiconductor/solid-state device manufacturingGas phasePhysical chemistry

The present invention discloses the vapor reaction preparation process of continuous ion layer in polyelement sulfide film of film solar cell. Polyelement semiconductor photoelectronic sulfide film of CuInS2, Cu(In, Ga)S2, etc. with stable performance and controllable composition is prepared with CH3CH2OH, rather than CH3CN, as solvent and H2S as sulfur source, and through one-step fluidizing process, rather than two-step fluidizing process. The film is used in assembling film solar cell with low cost and high photoelectronic efficiency. The cation precursor so of the present invention consists of CuCl2, GaCl3 and InCl3 in the weight ratio of 0.25:0:0.37 to 0.47:0.22:0.73. The present invention has the film prepared at room temperature and through filming and heat treatment.

Owner:TIANJIN UNIV

A kind of double-layer phase-change microcapsule and its preparation method and its application

ActiveCN109852350BReduce the temperatureImprove high temperature stabilityHeat-exchange elementsBuilding insulationsCrack resistancePhysical chemistry

A double-layer phase-change microcapsule and its preparation method and application provided by the present invention use the phase-change material inside the single-layer phase-change microcapsule as the capsule core, and the surface of the single-layer phase-change microcapsule is coated with an outer layer of a flame-retardant material cyst wall. When the temperature of the asphalt mixture reaches the temperature of the phase change material, the phase change material undergoes phase transition, absorbs and stores a large amount of heat, enhances the high temperature stability of the asphalt pavement, and has a good effect on reducing the rut depth. When the temperature of the asphalt mixture drops to the phase change temperature of the phase change material, the phase change material undergoes a phase change again, releasing a large amount of heat, which enhances the low-temperature crack resistance of the asphalt pavement, and has a good effect on reducing the crack width . The microcapsule phase change material has good mechanical properties, thermal stability and durability during the use of asphalt mixture, which greatly prolongs the service life of the phase change material.

Owner:CHANGAN UNIV

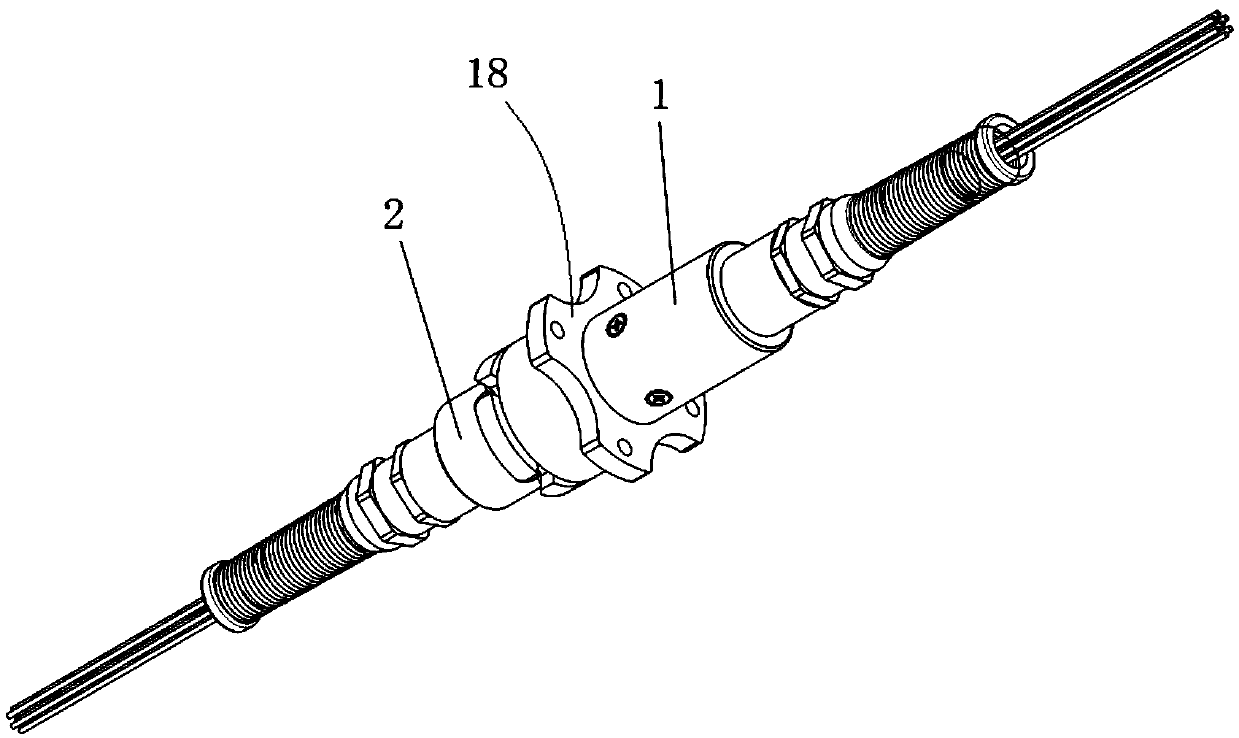

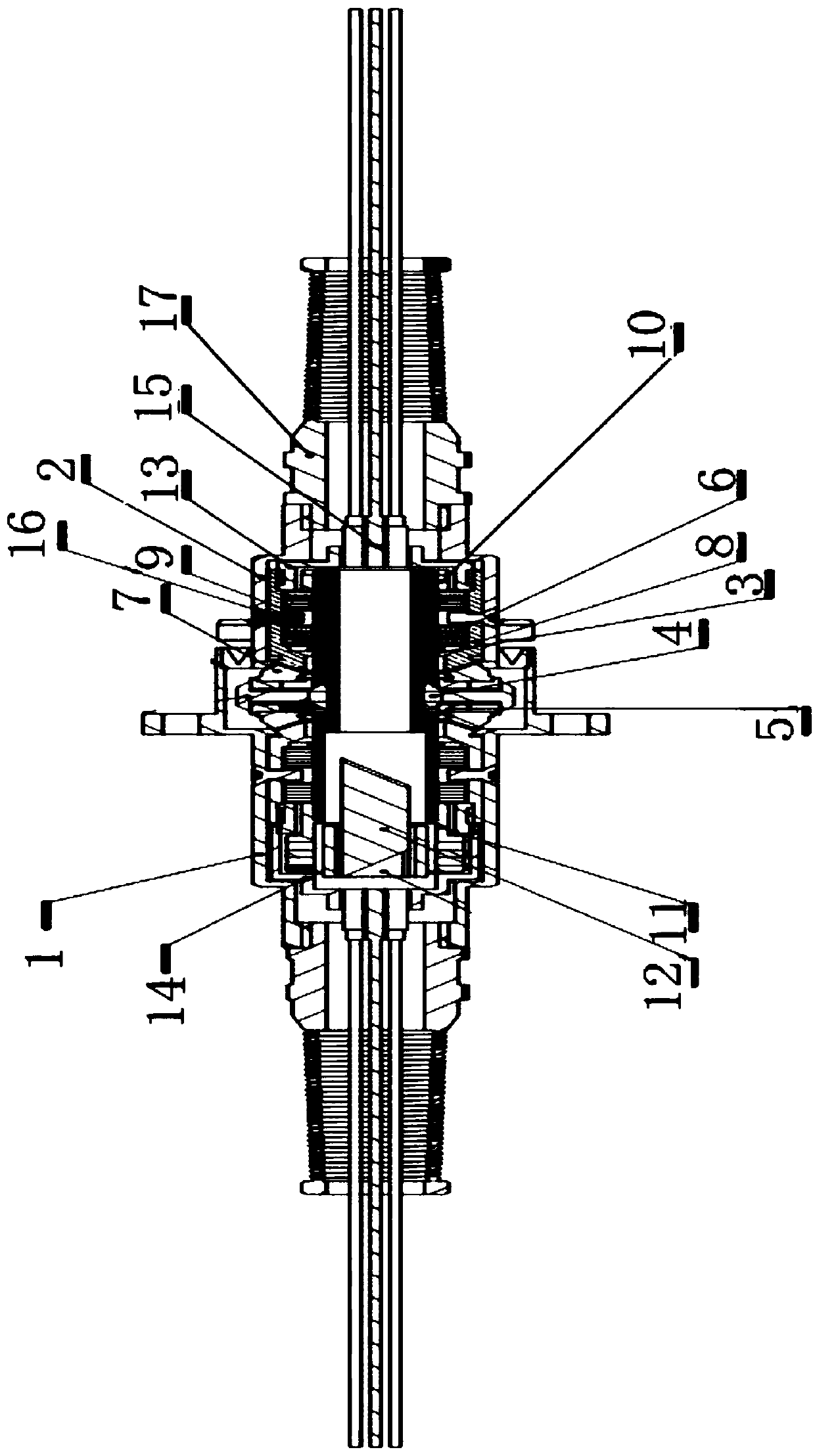

Optical fiber rotary connector

PendingCN110687637AReasonable structural designHigh densityCoupling light guidesMechanical engineeringMaterials science

The invention relates to optical fiber connecting equipment, in particular to an optical fiber rotary connector. The use problem of the optical fiber rotary connector is solved. The optical fiber rotary connector comprises a connector shell body, wherein the connector shell body comprises a stator outer shell and a rotor outer shell; connected cavities are formed in the stator outer shell and therotor outer shell; a sun shaft and a planetary shaft are arranged in the cavities; the sun shaft and the planetary shaft are connected and fixed by means of screws; the planetary shaft is provided with an upper sleeving part and a lower sleeving part in the radial direction; planetary bearings are arranged on the upper sleeving part and the lower sleeving part; a sun bearing is arranged on the sunshaft; and planetary gears are arranged on the planetary bearings. The optical fiber rotary connector is reasonable in design, facilitates the size-reduced and mass-reduced production, improves the connection efficiency, reduces the production and usage cost, improves the density of optical fiber channels, and is practical and economical.

Owner:ANHUI LANXUAN PHOTOELECTRIC TECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com