Preparation method of high-dispersity g-C3N4/TiO2 photocatalyst inorganic hydrosol

A photocatalyst and hydrosol technology, which is applied in the field of architectural coating materials, can solve the problems of difficulty in using visible light from sunlight, harm to human body and environment, and damage to cement substrates, etc., to achieve shortened dispersion time, good stability, and long-lasting dispersion effect Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

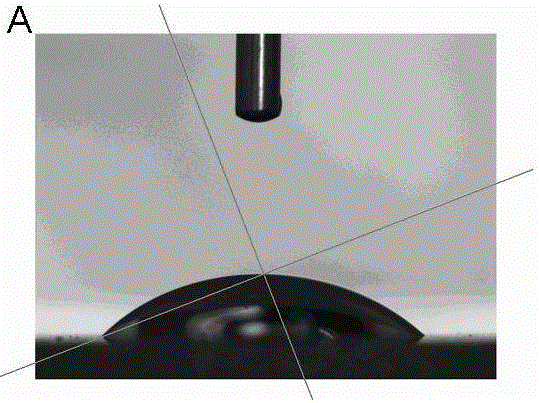

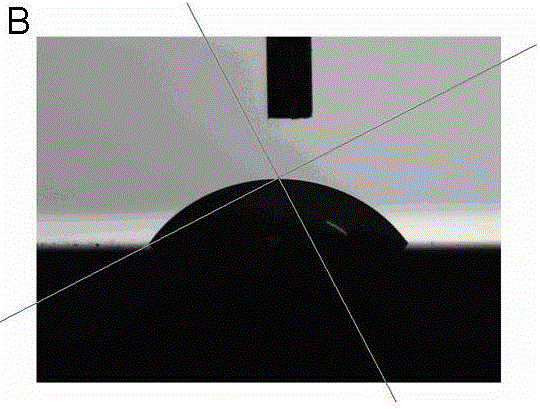

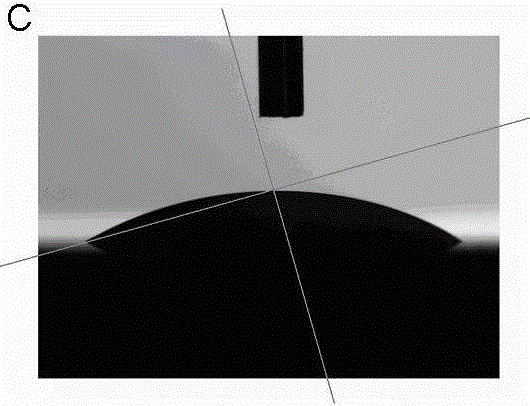

Image

Examples

Embodiment 1

[0020] The highly dispersible g-C 3 N 4 / TiO 2 Photocatalyst inorganic hydrosol preparation method realizes by following method:

[0021] (1), commercial nano-titanium dioxide (anatase) conjugated molecule g-C 3 N 4 After the surface hybridization modification of the visible light active g-C was prepared 3 N 4 / TiO 2 Photocatalyst;

[0022] (2) Add two-component dispersant sodium hexametaphosphate and sodium silicate in sequence in 100ml of water, the amount of dispersant added is 0.1-0.5wt%, stir for 30min to dissolve completely;

[0023] (3), gradually add g-C in the above solution of step (2) 3 N 4 / TiO 2 Photocatalyst powder, the addition amount is 1~3wt%, add 1~3wt% H2 o 2 solution, shear emulsification for 10min, and carry out the peptization process;

[0024] (4), adjust the pH of the suspension to 7-8 with hydrochloric acid or sodium hydroxide solution, continue stirring and dispersing for 30 minutes to obtain g-C 3 N 4 / TiO 2 Photocatalyst hydrosol.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com