[0007] First, the wet

adhesive film is a soft and thin colloidal film. For the convenience of the process or the convenience of

cutting (such as

cutting into the shape of a

mask), the inventor of this case first discovered and thought that if the wet adhesive film can use a It must be the most beneficial for the manufacture of wet adhesive films to carry out transportation with a flat bearing surface or a lower cloth layer and complete the entire film-forming process at the same time during the transportation

stroke, but the current prior art does not reveal such a concept, causing Increase the difficulty of wet adhesive film process, which is not conducive to the development of wet adhesive film (

mask)

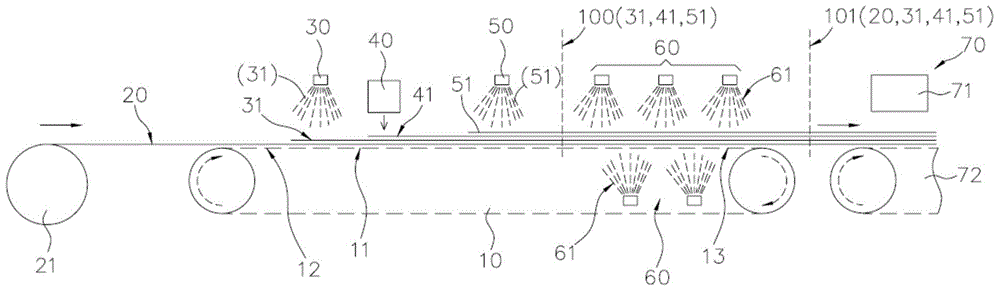

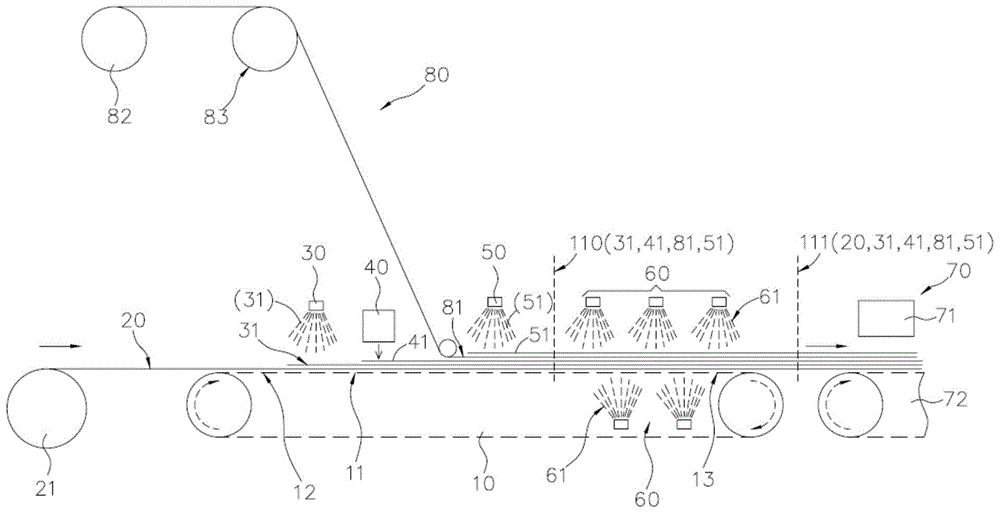

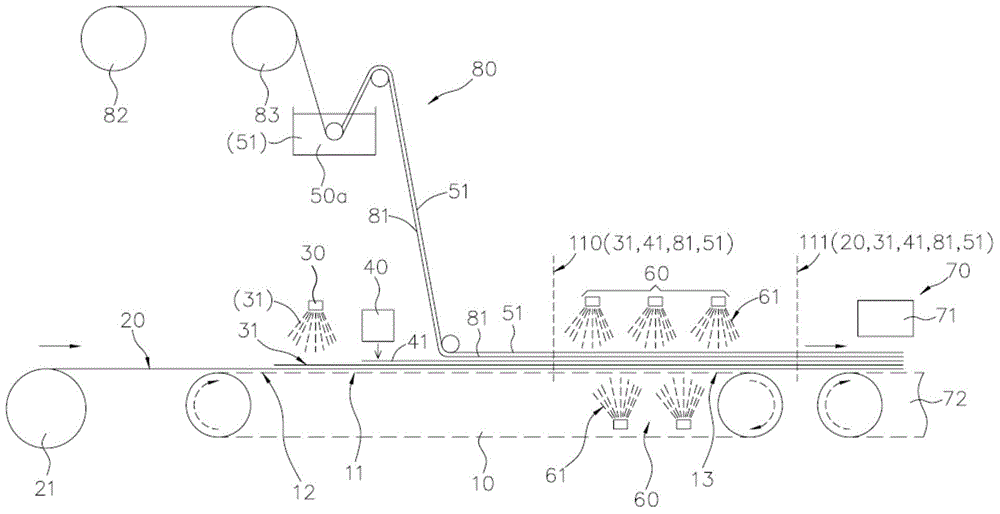

[0008] Second, in terms of the existing film-forming process and related manufacturing equipment, such as the EU patent EP2111926A1 (international application number: PCT / JP2008 / 050822, international publication number: WO2008 / 0090892), manufacturers cannot continue Efficient and rapid production of unsupported or supported wet-laid adhesive films

The film-forming process of the wet adhesive film at least includes: the coating operation of colloid (such as

alginic acid) and its device (or

workstation); the coating operation of fixative liquid (such as salt compound) and its device (or

workstation); and A device (or

workstation) for the colloid and fixative of the above two film-forming materials to be cross-linked to a predetermined level and / or a stop device (or workstation) capable of stopping the cross-linking so as to solidify and form a suitable soft permanent wet adhesive film; but the existing manufacturing equipment lacks an efficient

layout in the arrangement of the film forming process, such as the manufacturing equipment disclosed in EP2111926A1, which is mainly divided into an injection coating

machine (impregnation coater) and a gravure printing

machine (gravure coater) Two main workstations, and then use multiple idlers (rollers without power, used to support or change the direction of the

conveyor belt) or the steering and / or traction of the runners to make a continuous support substrate Can pass through the two main working areas in sequence, for performing salt compounds (i.e., the fixative solution referred to in the present invention) and

alginic acid (i.e., the referred to in the present invention) on the surface of the continuous support substrate

Colloid) coating operation, so the entire manufacturing equipment and film-forming process lack a continuous

conveyor belt for carrying the supporting substrate, so that various film-forming materials such as alginic acid (colloid) or salt compounds (fixative solution) ) cannot continuously and quickly carry out and complete the film-forming process of the wet mask through the supporting substrate; that is, manufacturers often have to set up separate and independent multiple workstations (such as in EP2111926A1 Figure 2-4 Injection coating

machine (impregnation coater) and gravure printing machine (gravure coater) two main working areas shown separately) and multiple additional conveying devices (such as multiple idler wheels or runner), in order to carry out and complete the film-forming process of the wet adhesive film, resulting in the overall manufacturing equipment and its manufacturing process being relatively complicated (such as in EP2111926A1 Figure 2-4 As shown), it occupies a large volume, relatively increases equipment and manufacturing costs, but cannot achieve the effect of continuously and rapidly performing and completing the film forming process

[0009] Third, the wet adhesive film mainly includes carrierless and carrierless. However, based on the existing technology, the manufacturer cannot use the basic device of the same set of manufacturing equipment, so that it can choose to manufacture the carrierless film through simple replacement or addition. And any kind of wet adhesive film (mask) with carrier, that is, if the manufacturer originally used a set of manufacturing equipment to manufacture non-carrier wet adhesive film, when the needs of consumers or customers change from non-carrier wet adhesive film When forming a wet-type adhesive film with a carrier, the manufacturer cannot use the basic device of the same set of manufacturing equipment to simply replace or add it for the production of a wet-type adhesive film with a carrier; generally speaking, the manufacturer designs another set New manufacturing equipment is used to manufacture wet adhesive films with carriers, which relatively causes waste of manufacturing equipment and increased manufacturing costs, and increases the use of space, which is not conducive to the competition of the adhesive film (mask) industry

[0010] In fact, the inventors of this case have found that, as far as a set of manufacturing equipment is used to manufacture wet-type adhesive films, no matter whether they are carrier-based or carrier-free, the adhesive films used to form the main part of the wet-type adhesive film (such as alginate different basic devices (or workstations), such as a first fixative coating device disclosed in this case, a colloid coating device and a second fixative coating device and other workstations (described later) As far as the operation functions of each workstation and the arrangement in the production process are concerned, they can generally be regarded as the same or similar, that is, the operation functions of each workstation have commonality; however, the prior art such as EP2111926A1 is often only designed It is used to manufacture a

single type of wet mask, such as one with a carrier or one without a carrier. Therefore, when the manufacturer wants to manufacture two kinds of wet masks without a carrier and with a carrier, it is necessary to set up two sets of different manufacturing equipment to manufacture them separately. Therefore, the prior art does not take into account the commonality of the operating functions of each workstation, and therefore does not make proper arrangements for the production process, so that the device structure and the manufacturing process of each workstation in the overall manufacturing equipment are relatively complicated (such as in EP2111926A1 Figure 2-4 As shown), it occupies a large volume, and the manufacturer cannot use the same set of manufacturing equipment, so that it can be simply replaced or added, so that the manufacturing end can choose to manufacture two kinds of wet masks without a carrier and with a carrier, and the relative increase in equipment and Manufacturing costs, but still unable to achieve the effect of continuous and rapid film formation process

Login to View More

Login to View More  Login to View More

Login to View More