Patents

Literature

564results about How to "Moderate intensity" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Environment-friendly type split mending material for polymer emulsion inorganic powder and nano material composite modified emulsified asphalt

InactiveCN101081933AImprove performanceImprove wear resistanceOther chemical processesSolid waste managementHigh wear resistanceInorganic materials

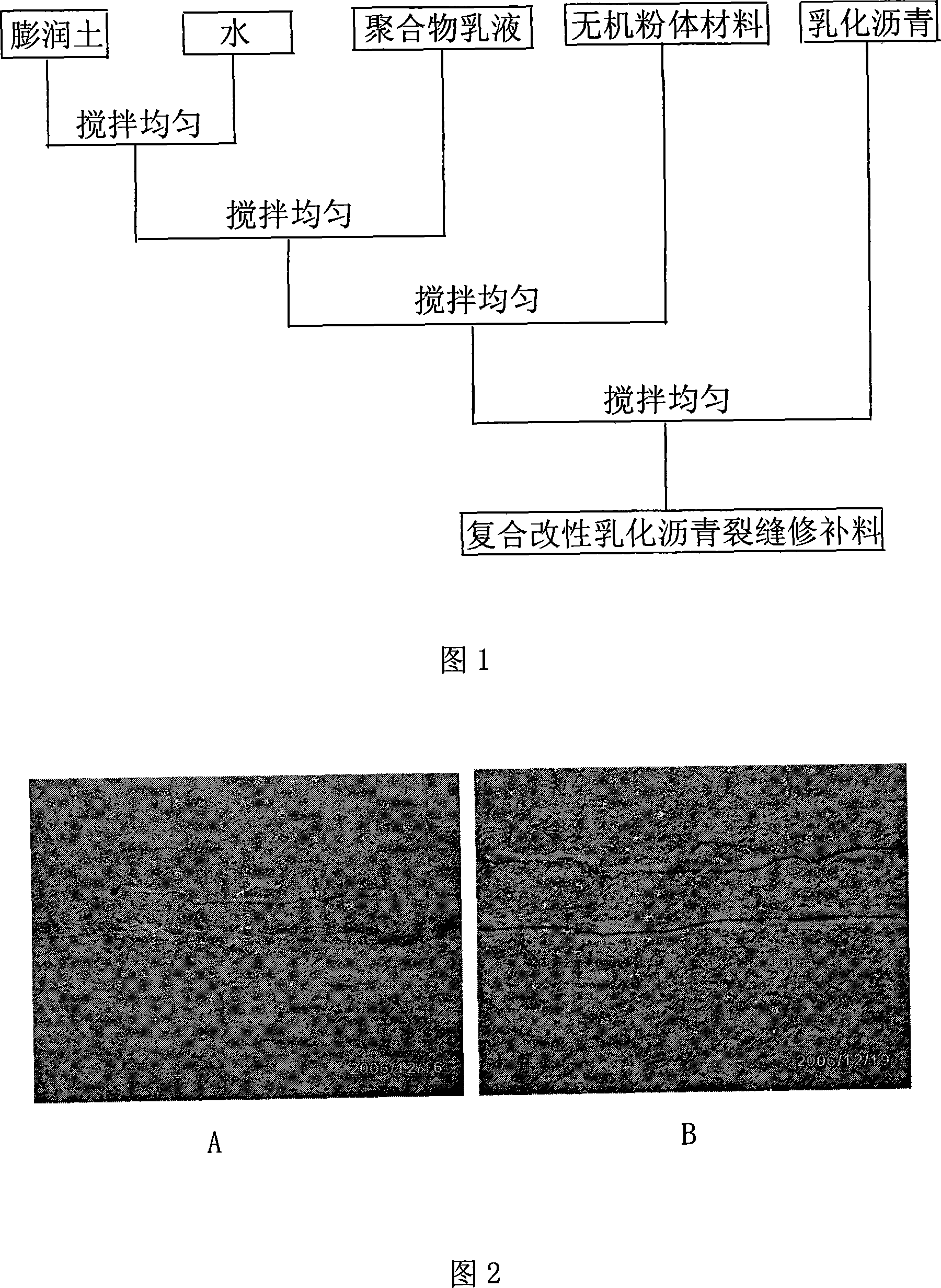

The present invention is one kind of environment friendly composite emulsified asphalt material for grouting and repairing cracks in highway and building. The composite emulsified asphalt material consists of emulsified asphalt40-90 weight portions, powdered inorganic material 50-90 weight portions, nanometer material 5-10 weight portions, polymer emulsion 20-40 weight portions and water 30-80 weight portions mainly. The composite emulsified asphalt material has nanometer particle component with unique surface effect, small size effect and tunnel effect, polymer emulsion component resulting in high interface combining force and high antiaging performance, and inorganic material powder component resulting in high wear resistance, high strength, etc., so that it has high comprehensive performance, good crack repairing effect and low cost.

Owner:HUNAN UNIV

Non-quenched cold heading steel for high-strength fasteners and manufacturing method thereof

InactiveCN101812644AModerate intensityImprove plasticityTemperature control deviceHigh intensityUltimate tensile strength

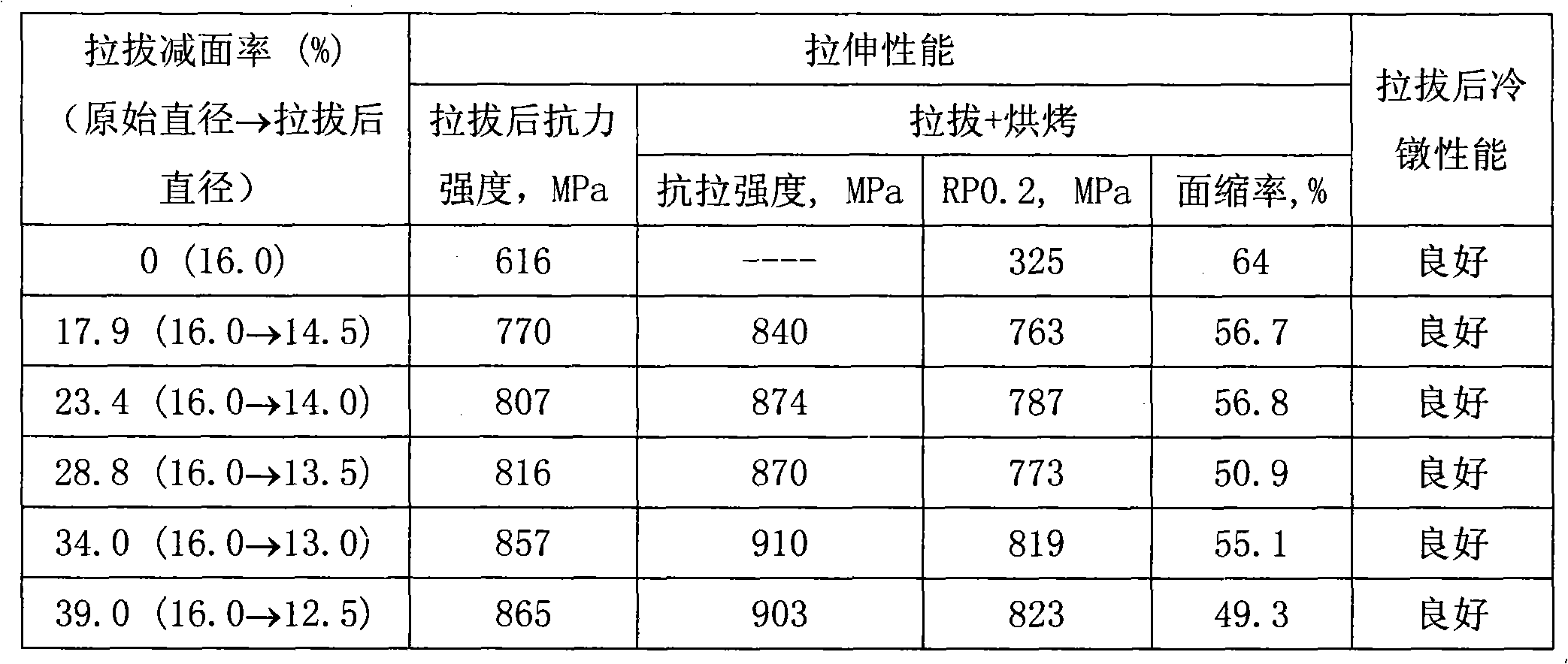

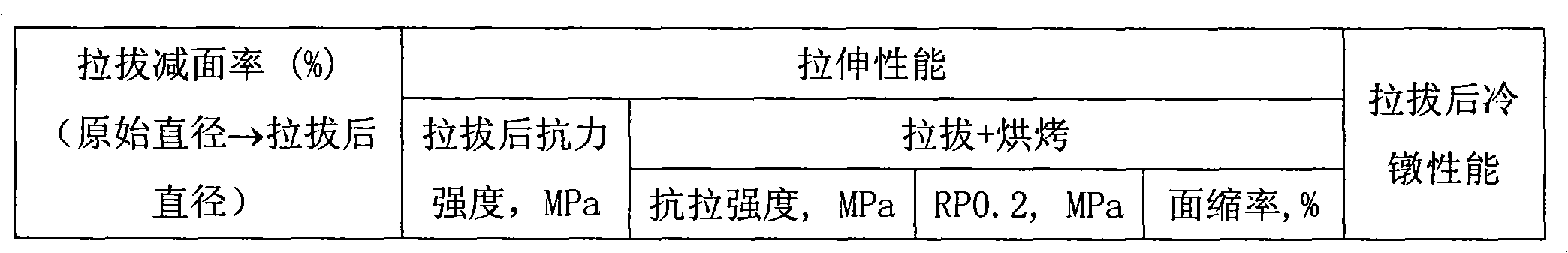

The invention relates to non-quenched cold heading steel for high-strength fasteners and a preparation process thereof. The non-quenched cold heading steel comprises the following components in percentage by weight: 0.15-0.35% of C, not more than 0.30% of Si, 0.8-1.80% of Mn, 0.20-0.80% of Cr, 0.01-0.10% of Al, not more than 0.035% of P, not more than 0.035% of S and the balance of iron and impurities. The process comprises the following steps of: preparing a casting blank having the same components with the non-quenched cold heading steel, heating the casting blank, and carrying out controlling rolling, coil collecting and controlling cooling treatment to form rod bundles as finished products. The non-quenched cold heading steel for high-strength fasteners has moderate strength, good plasticity, low deformation resistance in the cold heading and shaping of the fasteners, simple manufacturing process, effective saving of energy resources, environment pollution reduction and cost reduction, and is suitable for industrial production on a large scale.

Owner:INST OF RES OF IRON & STEEL JIANGSU PROVINCE

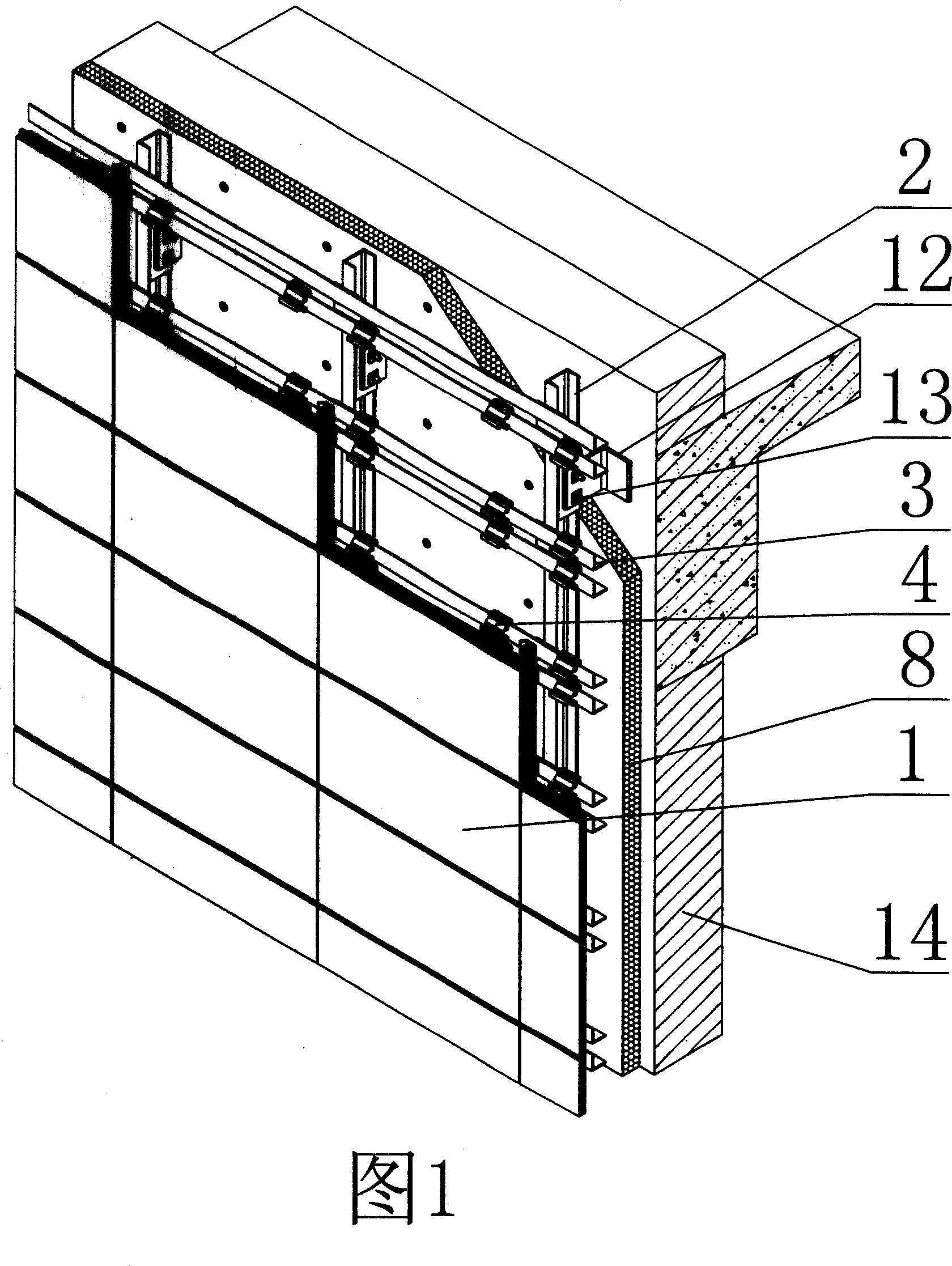

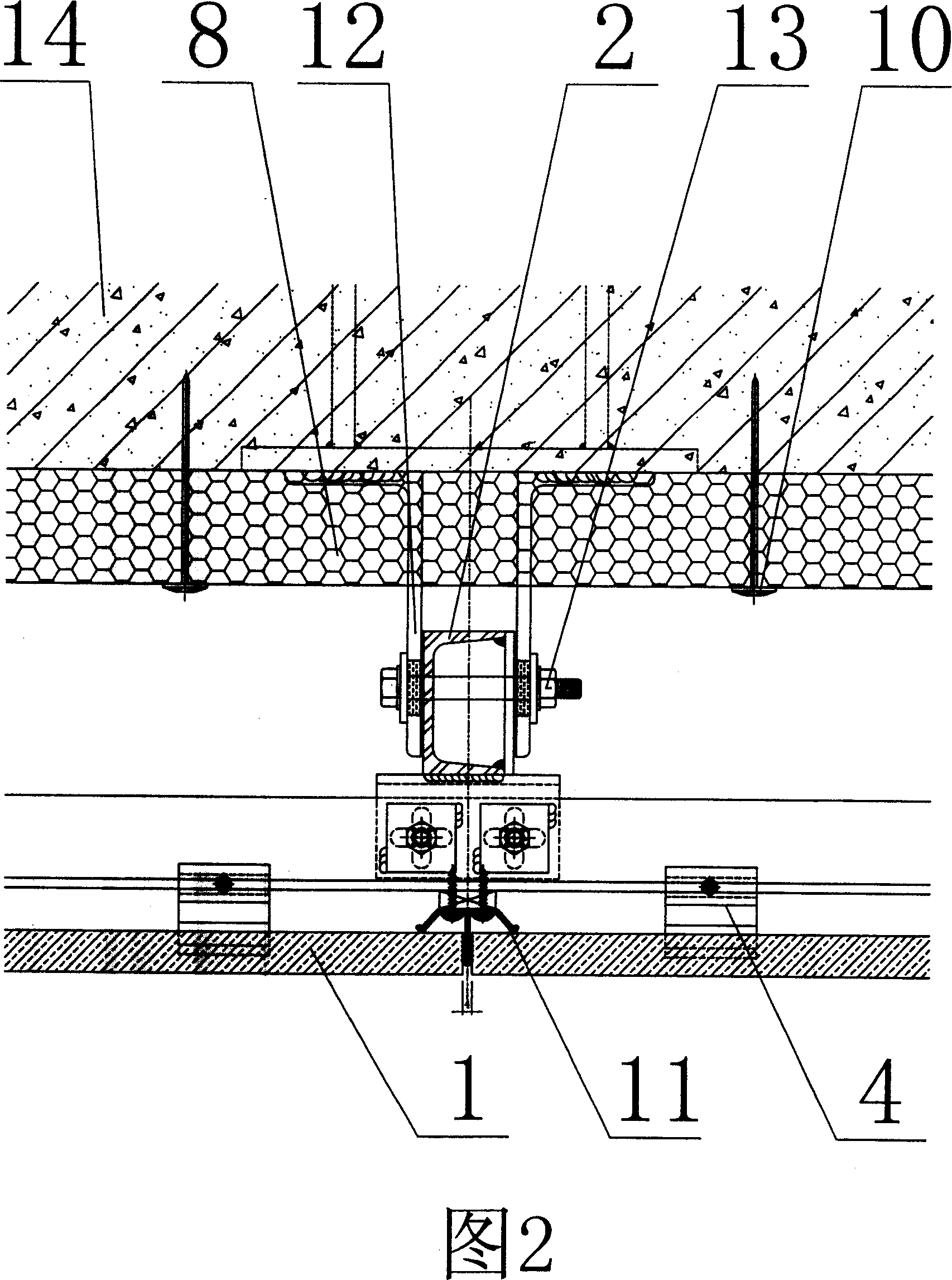

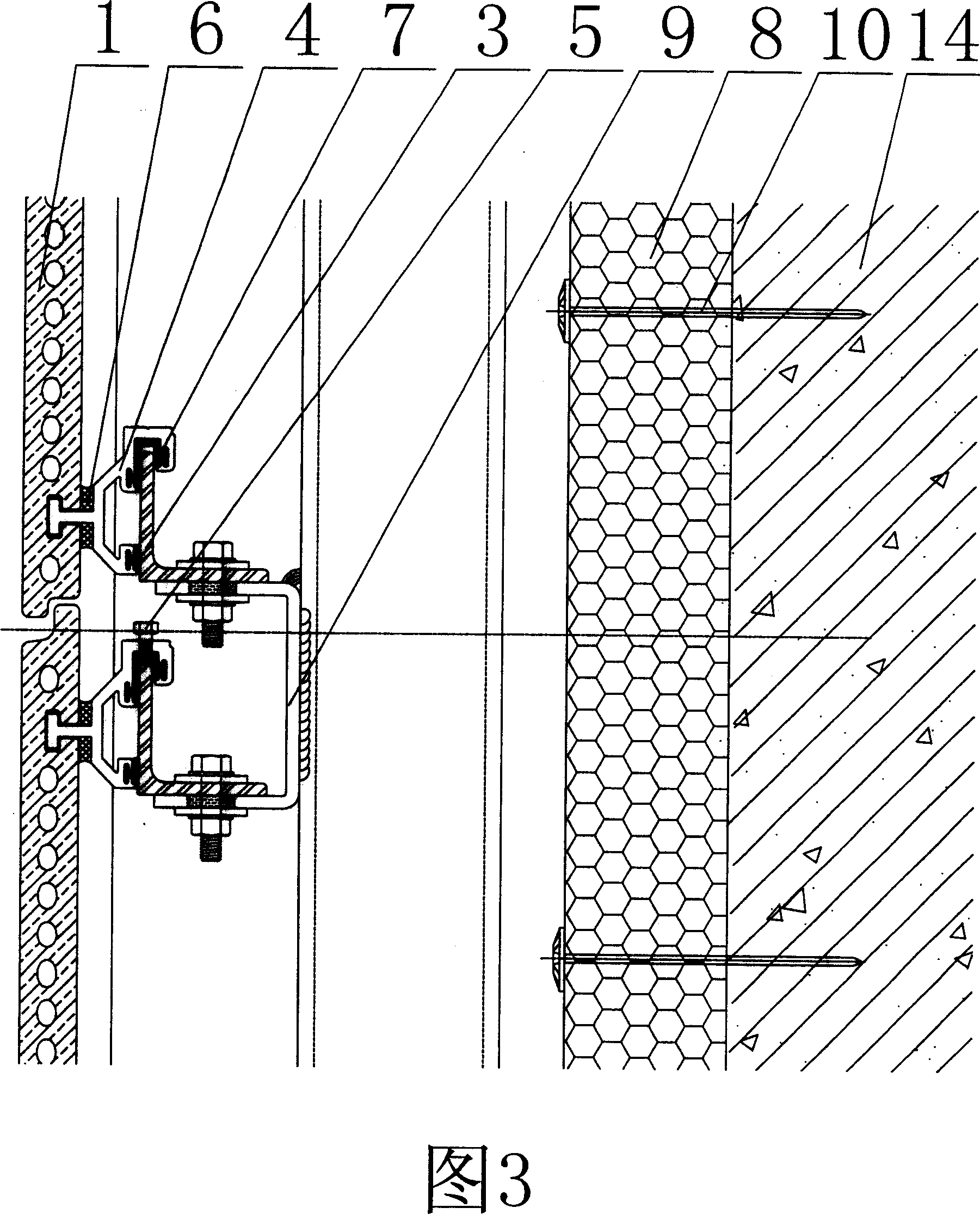

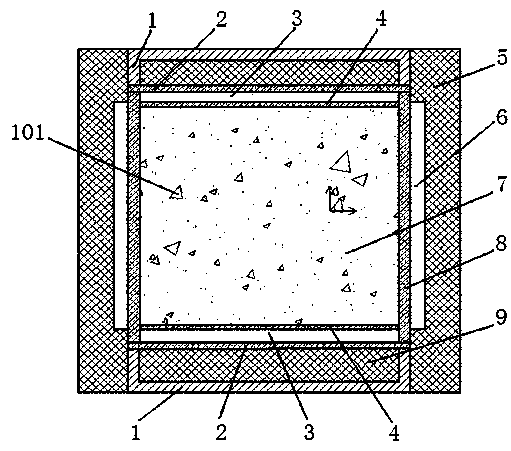

Mounting structure of figuline board curtain wall

The invention discloses an installing structure for the curtain wall of ceramic plate, comprising a vertical skeleton, a horizontal skeleton, a parting connector and a linking part. The vertical skeleton is set vertically and the horizontal skeleton is set horizontally. The vertical skeleton is fixed with the horizontal skeleton in cross. The vertical skeleton is fixed on the wall and the linking part is installed on the horizontal skeleton. The front end of linking part is ligule and the back end is pothook shape. The invention also comprises an adjusting screw and a rubber strip. The rubber strip is set between the linking part and the horizontal skeleton. The adjusting screw passes through the linking part and is connected on the horizontal skeleton by screw connection. The parting connector is installed at the connecting position of horizontal beam of ceramic plate. The invention changes the rigid connection between the horizontal skeleton and the linking part into the flexible connection so as to avoid the noise and eliminate the deformation. Up and down directions of installed ceramic plate are adjusted by the adjusting screw to guarantee that the installed seam is smooth completely. The horizontal skeleton is made of profiled bar. So the material is saved and the cost is decreased.

Owner:沈英 +1

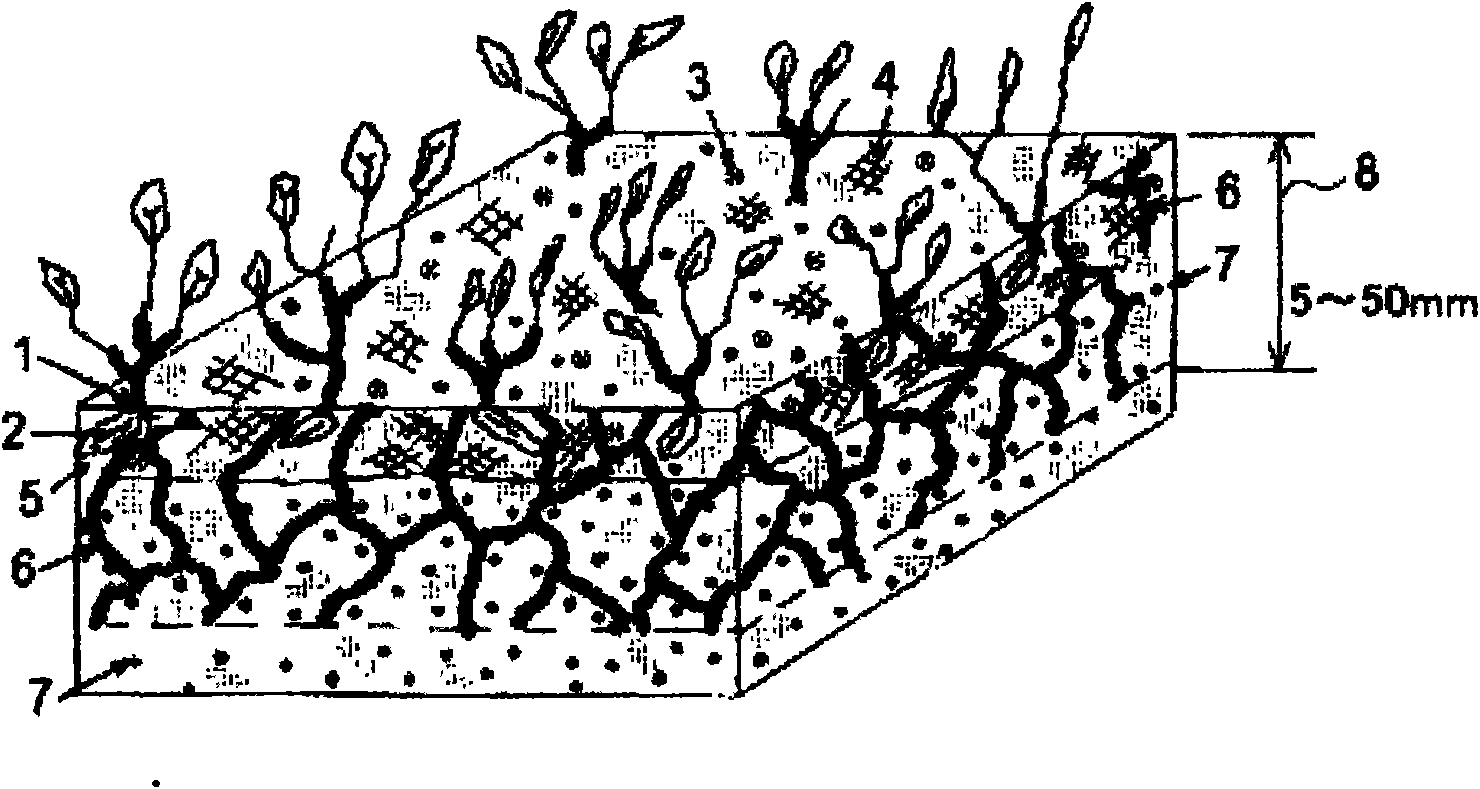

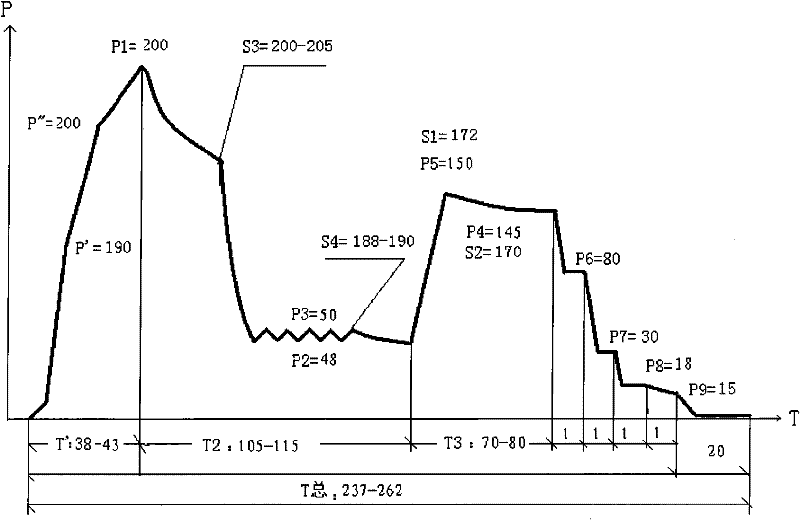

Desert control method of chemical sand-fixing greening technology based on organic composite materials

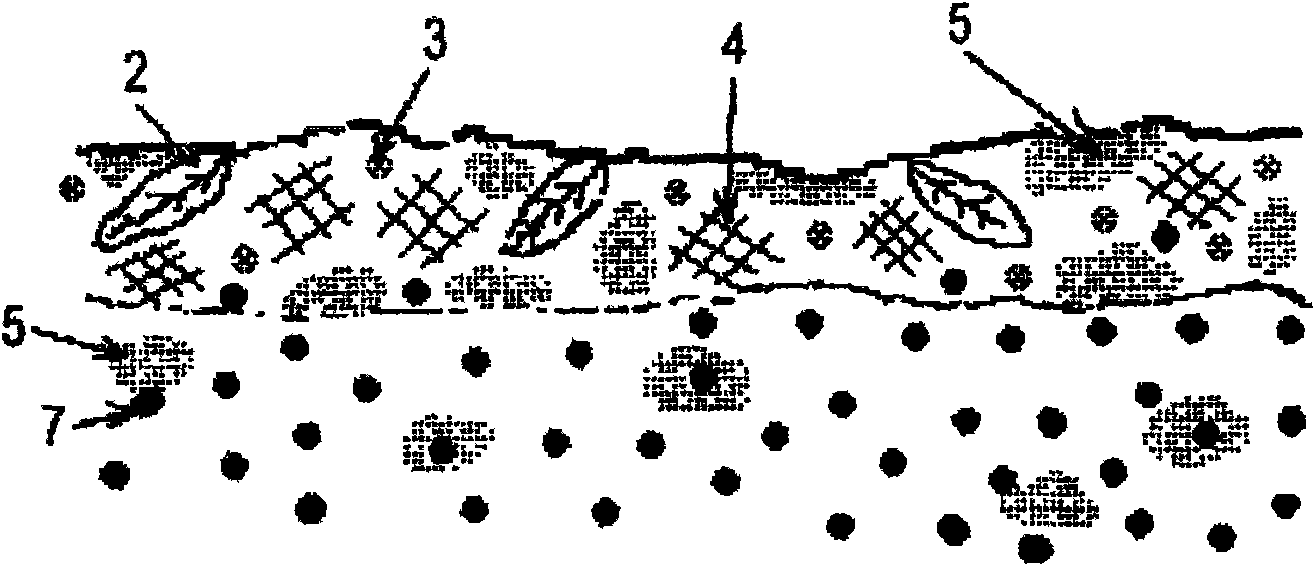

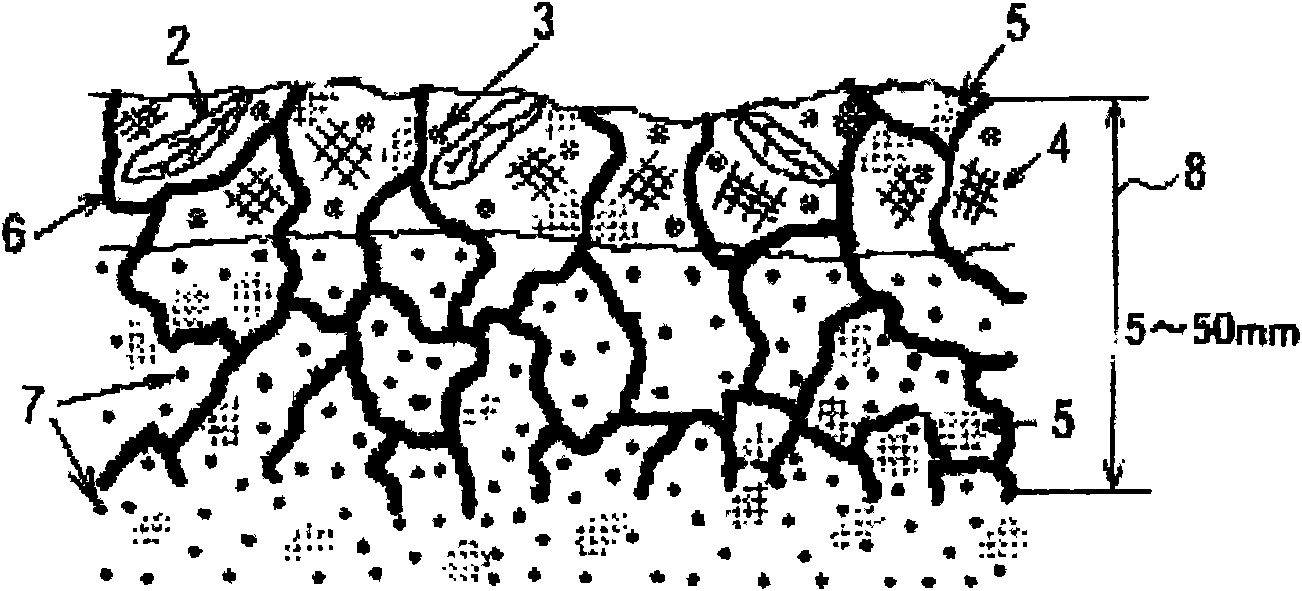

ActiveCN101548595AAvoid flowModerate thicknessClimate change adaptationAfforestationThermal insulationSoil horizon

The invention discloses a desert control method of a chemical sand-fixing greening technology based on organic composite materials, and the desert control method is characterized in that hydrophilic polyurethane resin curing agent solution is sprayed on a sand or soil layer of greening objects for sowing the vegetation for forming a porous fixed sand layer. The fixed sand layer formed by the method has appropriate thickness and strength, good durability, good anti-freeze and melt properties and functions of water retention, thermal insulation, ventilation, vegetation and the like. According to the method of the invention, the stable and effective solidifying can be carried out on sand even under the specific desert environments of no abundant groundwater sources and strong wind erosion, and the purpose of vegetation greening can be also realized. The method has large-scale construction properties and good economic performances, thereby being applicable to the needs of large-scale chemical sand fixing and vegetation greening of the vast desert and realizing the plant greening function and the ecological restoration and the control of desertified land.

Owner:江苏艾特克环境工程设计研究院有限公司 +2

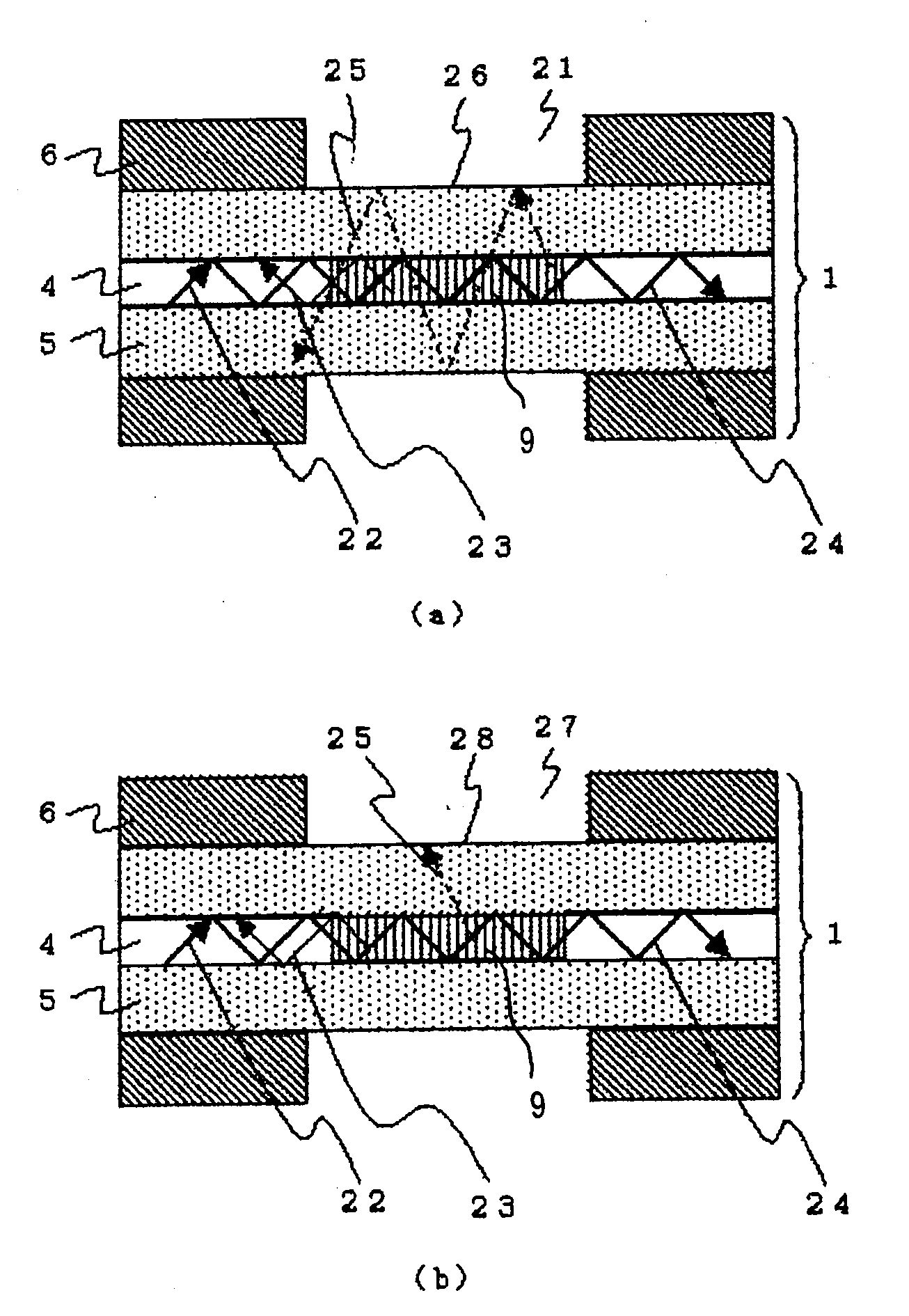

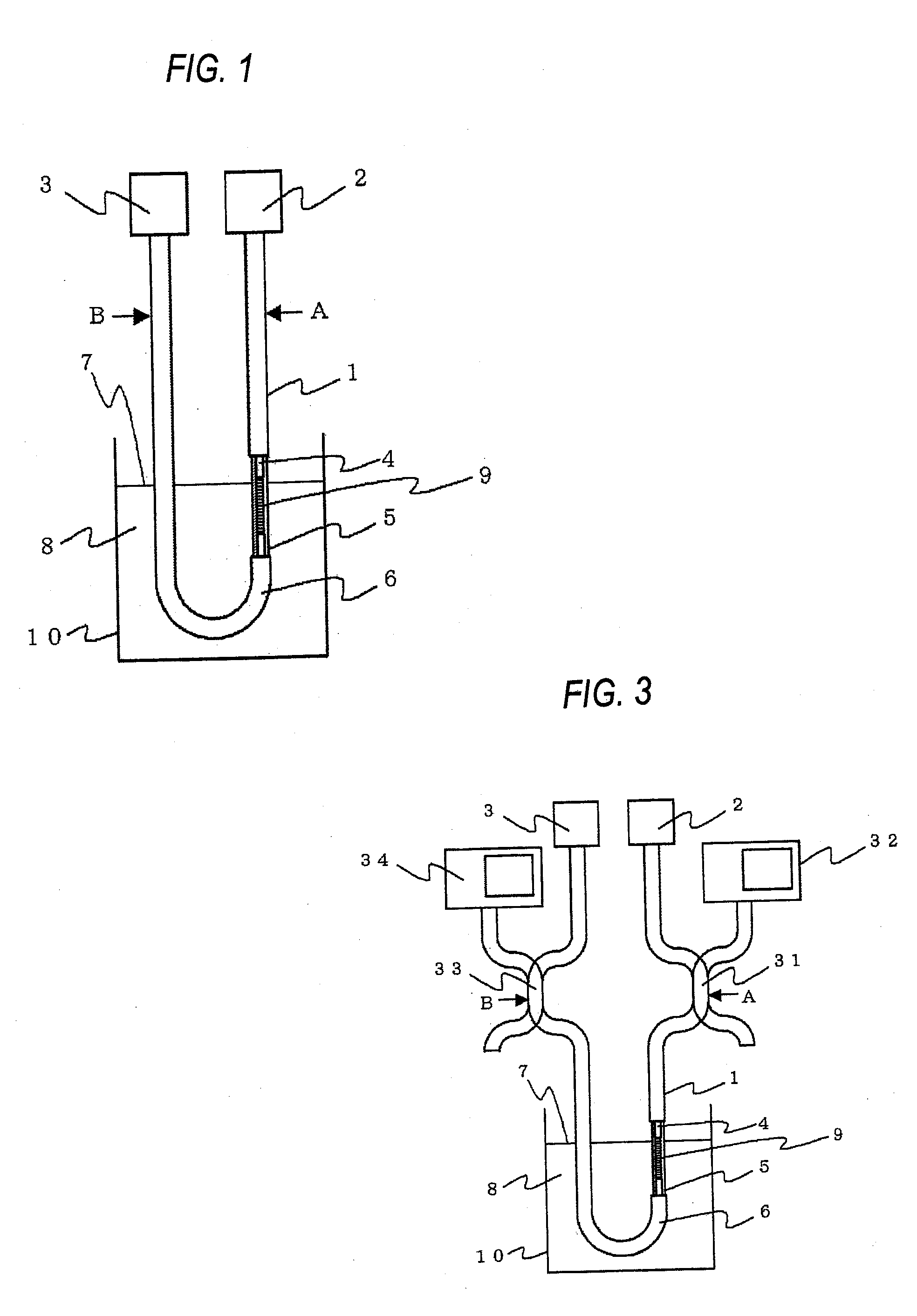

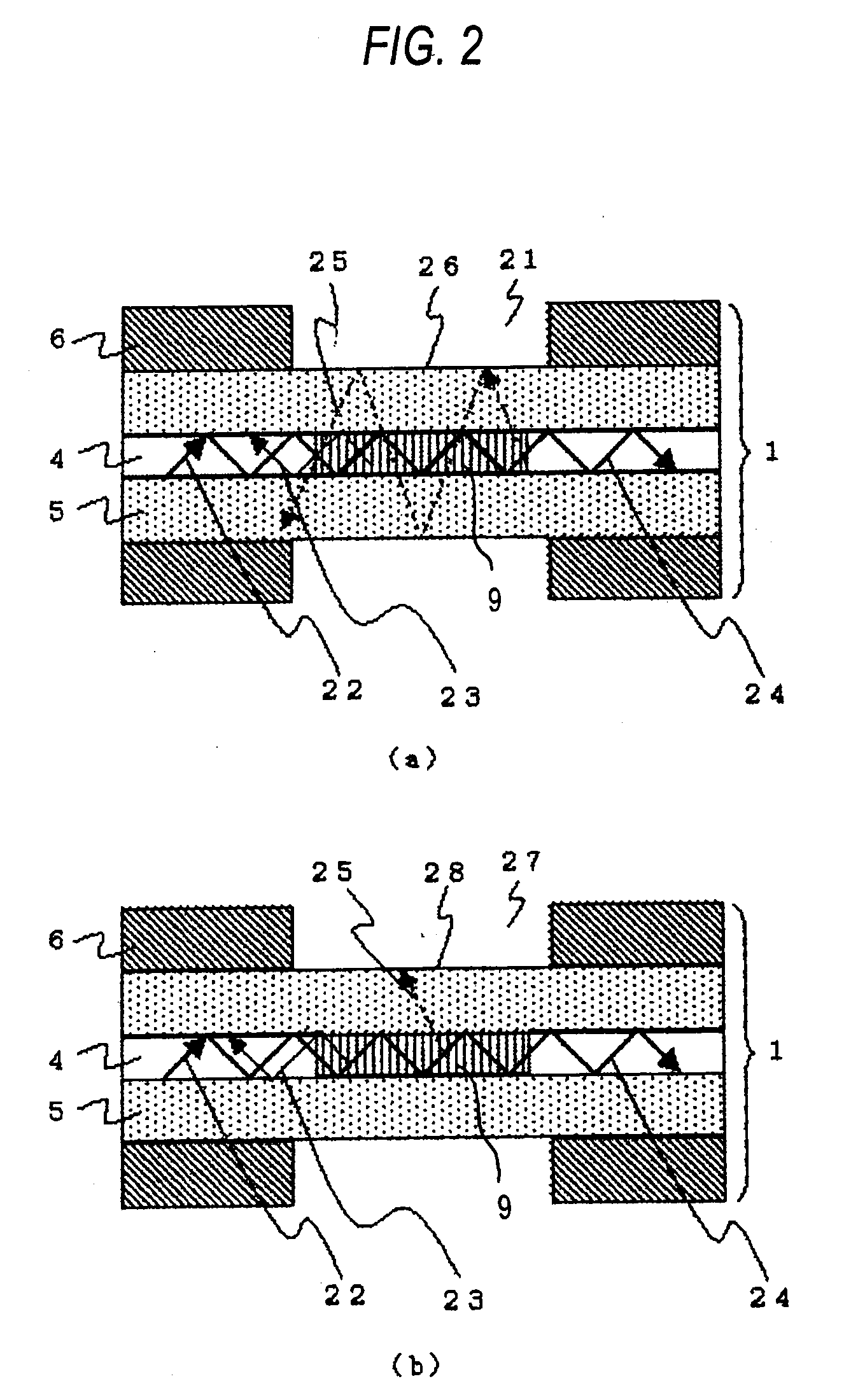

Optical fiber sensor

InactiveUS20090034901A1High reliabilityModerate intensityPhase-affecting property measurementsMachines/enginesFiber optic sensorLight source

An optical fiber sensor that can detect a liquid level or detect a property of liquid with high reliability even under a frequently vibrational environment. The optical fiber sensor includes an optical fiber that includes a core having an area where a grating is formed and a clad, and is disposed so that at least a part of the area with the grating is immersed in liquid, a light source for making light incident to the optical fiber so that a cladding mode light having a wavelength band is occurred by the grating, and a light receiving unit for detecting the intensity of light which is incident from the light source to the optical fiber and transmitted through the grating.

Owner:MITSUBISHI ELECTRIC CORP

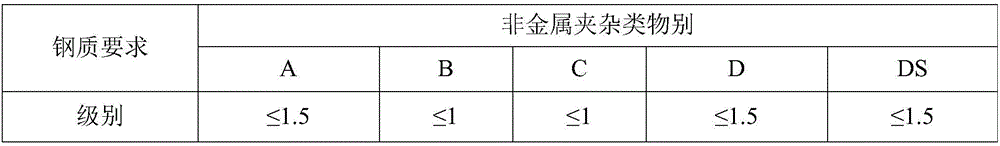

Low-cost steel plate for building structure and manufacturing method thereof

InactiveCN101705423ALow costGood welding performanceTemperature control deviceFurnace typesYield ratioHigh rise

The invention discloses a low-cost steel plate for a building structure and a manufacturing method thereof. The steel plate comprises the following chemical components: C accounts for 0.14 percent to 0.17 percent, Si accounts for 0.20 percent to 0.50 percent, Mn accounts for 1.30 percent to 1.50 percent, P is equal to or less than 0.012 percent, S is equal to or less than 0.005 percent, Alt accounts for 0.020 percent to 0.060 percent, and the balances are Fe and unavoidable foreign impurities. (1) No noble metal elements such as Nb, V, Ti, Ni, Cr, Mo and the like, are added in the steel, the requirement of Q345GJ strength level is met completely though the chemical components C-Si-Mn-Al, and the cost is low; (2) the steel is purer, P is equal to or less than 0.012 percent, and S is equal to or less than 0.005 percent; (3) the impact toughness is good at the temperature of minus 40 DEG C, and the Charpy impact energy of a V-shaped notch is equal to or higher than 80 J; (4) the earthquake resistance is good, and the actual yield ratio is respectively smaller than 0.78; and (5) the lamellar tearing resistance is excellent, and the actual Z-direction section shrinkage ratio in the total-thickness direction is equal to or higher than 38 percent. The hot-rolling Q345GJEZ35 steel plate used for the building structure and provided with thickness of 20-90 mm can be produced, and the steel plate and the manufacturing method can be applied to the manufacture of the steel structure of the high-rise building, have good comprehensive performance and simple production process, can realize the batch production and have low cost.

Owner:SHOUGANG CORPORATION

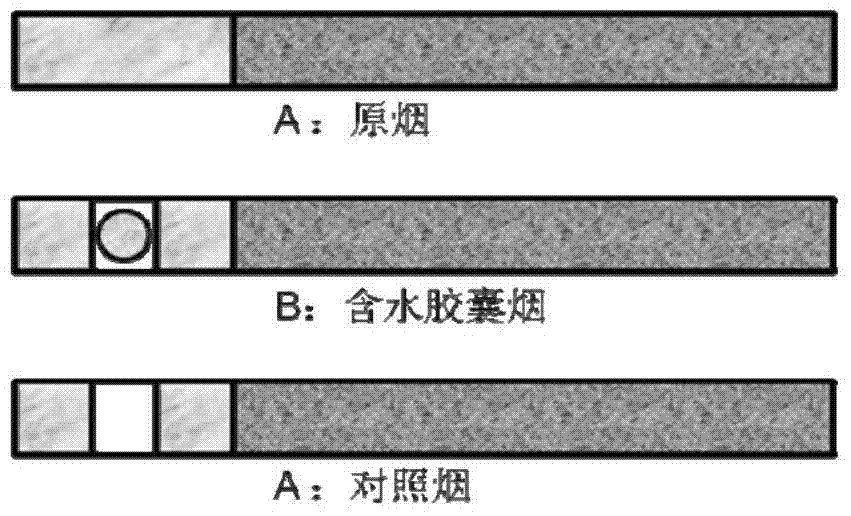

Water-bearing capsule and preparation method thereof

ActiveCN104726199AModerate intensityImprove suction qualityTobacco smoke filtersEssential-oils/perfumesWaxWater based

The invention relates to a water-bearing capsule and a preparation method thereof. The water-bearing capsule consists of a water-based capsule core and a solid capsule shell wrapping the water-based capsule core, wherein the solid capsule shell consists of a hydrophobic membrane layer, a powder wrapping layer and a modified wax layer from outside in sequentially, and the strength of the solid capsule shell reaches 0.5-2.2kg. The water-bearing capsule can significantly reduce multiple harmful ingredients in smoke, reduces harms of a cigarette, and has the efficacy of improving a cigarette smoking moist feeling; the characteristic odor type can be endowed to the cigarette; in addition, the solid capsule shell of the water-bearing capsule is great in strength and difficult to break, so that stable water holding and quality guaranteeing effects of the cigarette are ensured; and the above benefits have very positive significance in improving the cigarette quality.

Owner:江西省华宝芯荟科技有限公司

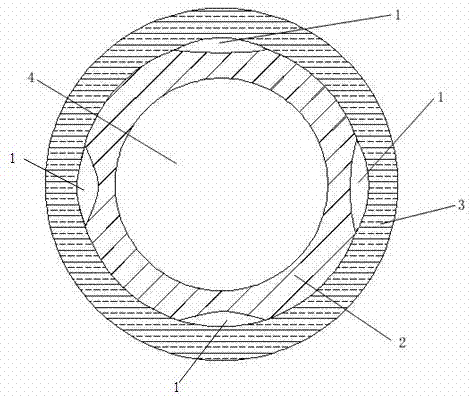

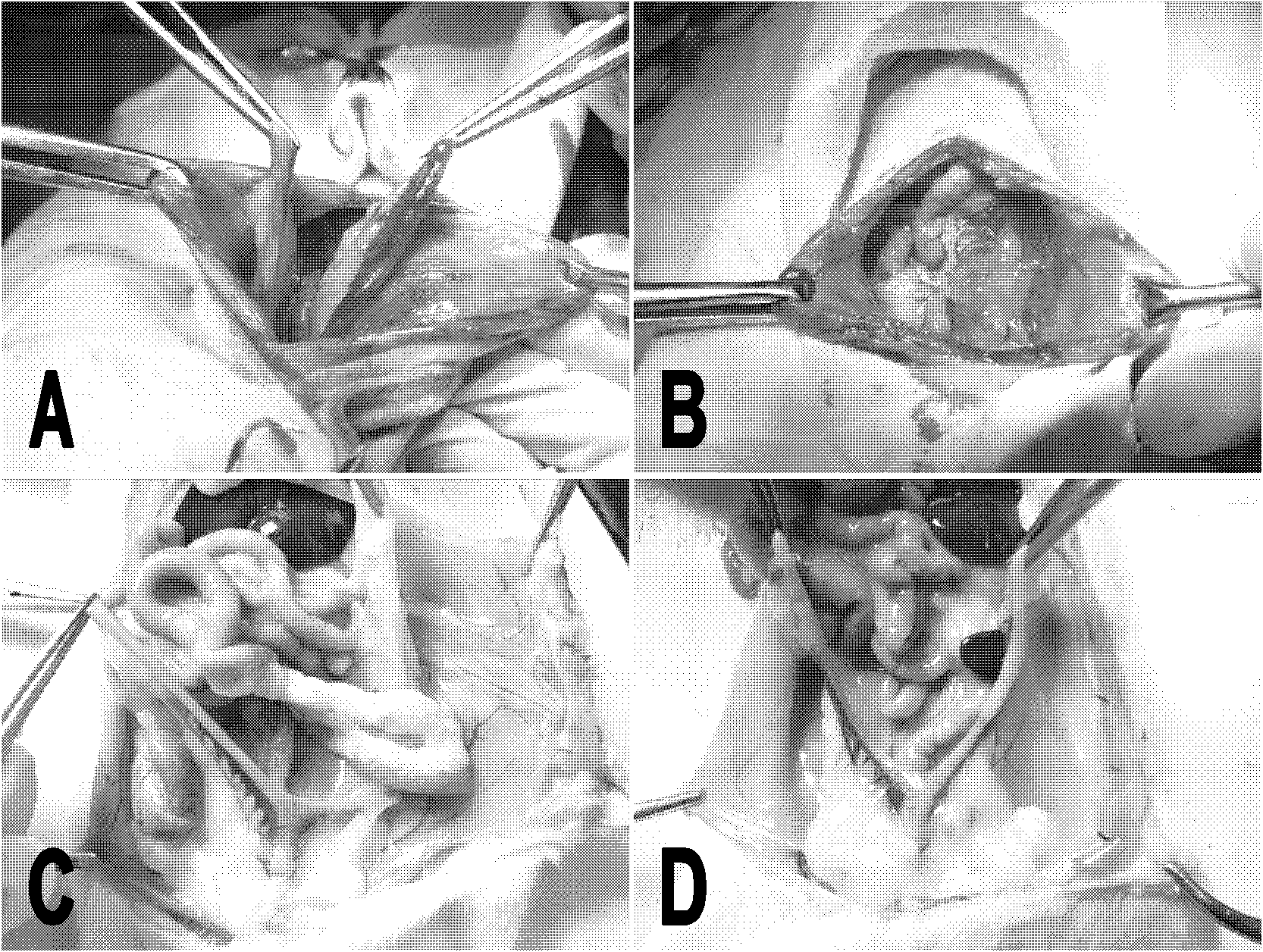

Nerve conduit and preparation method thereof

ActiveCN102688076AAddress barriers to developmentModerate intensitySurgeryCatheterCatheterNerve repair

The invention discloses a nerve conduit and a preparation method thereof. The nerve conduit consists of an inner layer, an outer layer and at least one minitype cavity for storing a bioactive factor solution, wherein the inner layer is of a hydrophilic cell scaffold layer, and the outer layer is of a hydrophobic nerve conduit scaffold layer. The nerve conduit can further comprise a transition layer between the inner layer and the outer layer. The preparation method of the nerve conduit comprises the steps of preparing the inner layer by adopting an electrostatic spinning method, then adding the material for preparing the cavity, then preparing the outer layer, and taking out or dissolving the material for preparing the cavity, thus obtaining the nerve conduit. The nerve conduit has the minitype cavity, so that bioactive factors can be loaded by a manner of injection, soaking and the like as required before operation, thus not only leading the production quality to be easily controlled, but also being capable of greatly improving the survival rate of the bioactive factors, more efficiently promoting the regeneration of nerves, and enhancing the restoration effect of nerves.

Owner:MEDPRIN REGENERATIVE MEDICAL TECH

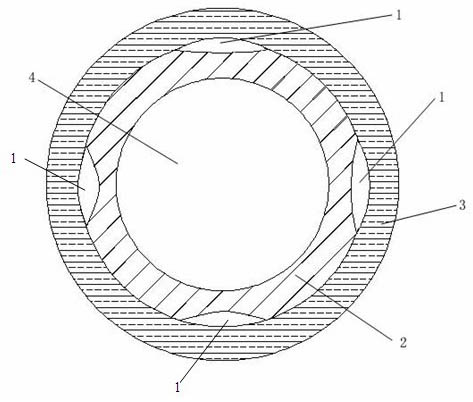

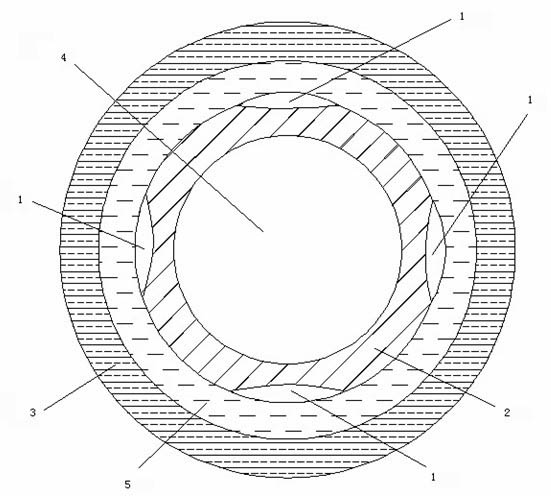

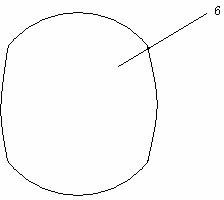

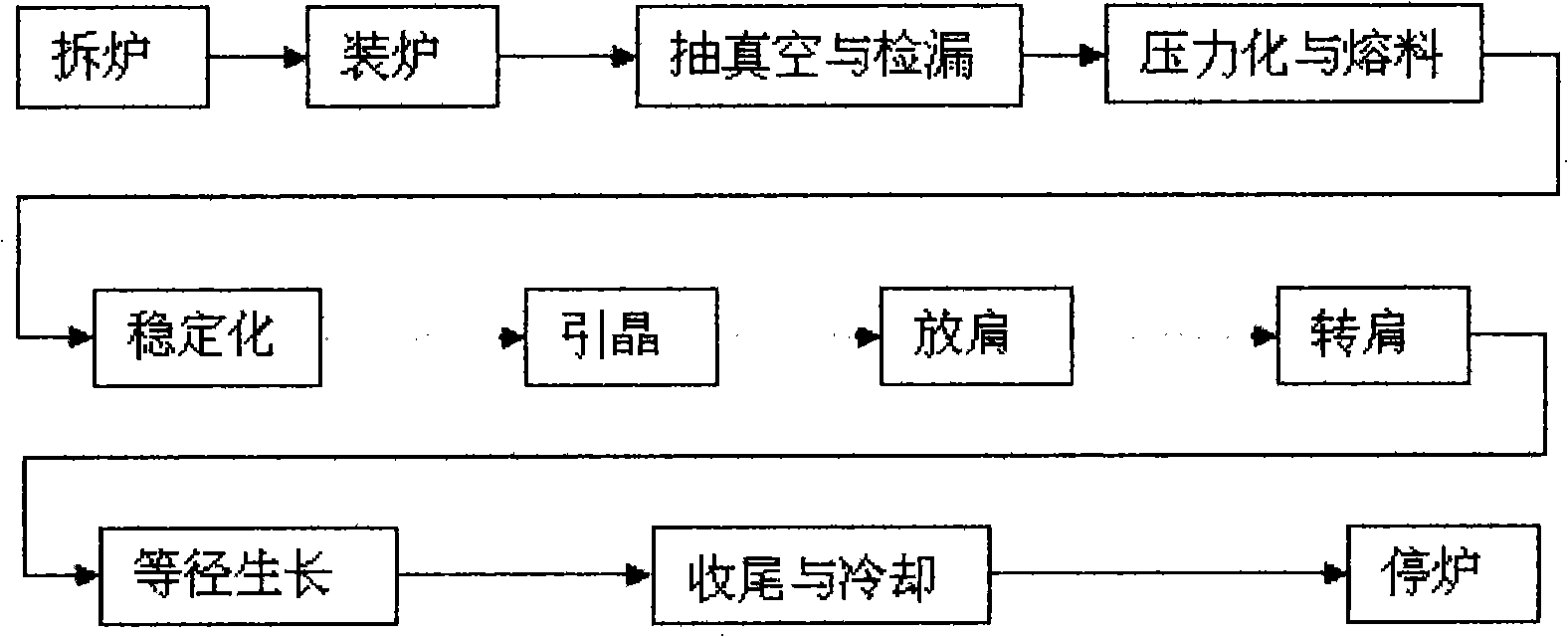

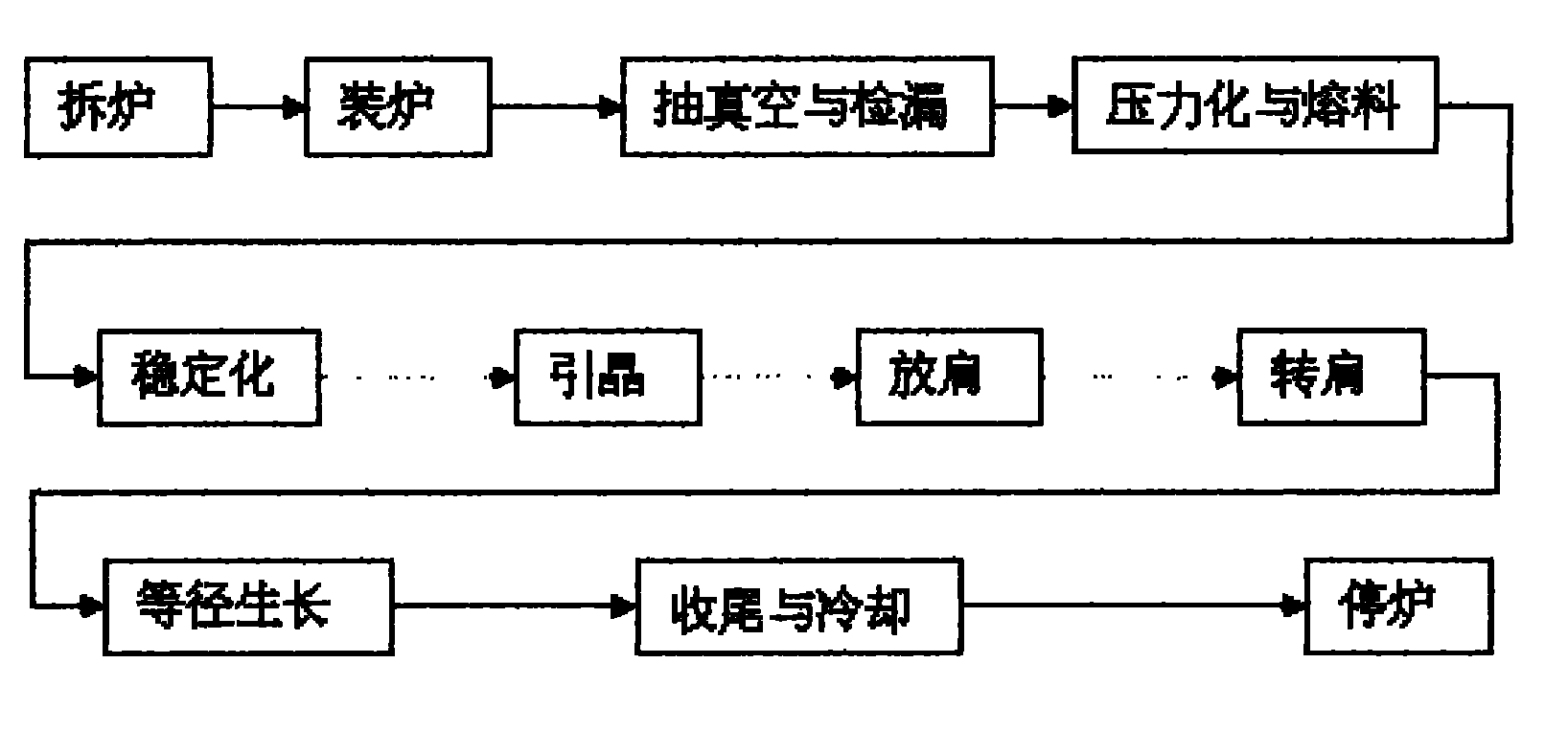

Gallium and indium doped single crystal silicon material for solar battery and preparation method thereof

ActiveCN101805925AReduce precipitationReduce crystal defectsPolycrystalline material growthBy pulling from meltIndiumHearth

The invention discloses a gallium and indium doped single crystal silicon material for a solar battery, which consists of the following components according to atom number per cubic centimeter of the single crystal silicon material: 1.0X10<14> to 1.0X10<18> gallium, 5.0X10<12> to 5.0x10<16> indium and the balance of single crystal silicon. The invention also discloses a method for preparing the gallium and indium doped single crystal silicon material for the solar battery, which is implemented by the following steps of: dismantling a furnace by using a regular method, cleaning a hearth and assembling the furnace; vacuumizing the inside of a single crystal furnace and detecting the leakage of the single crystal furnace by using a regular method; pressuring materials and smelting the materials; stabilizing the melt; seeding crystals; performing shouldering; performing shoulder rotation; performing isodiametric growth; performing ending and cooling the obtained product; and stopping the furnace. The gallium and indium doped single crystal silicon material for the solar battery has the advantages of high conversion efficiency, low light attenuation, low oxide content in the single crystal silicon and uniform radial distribution in a single crystal silicon rod; and the preparation method of the invention effectively controls the thermal conversion of silicon melt and grows the high-quality gallium and indium doped single crystal silicon material for the solar battery.

Owner:LONGI GREEN ENERGY TECH CO LTD

Method of preparing alumina ceramic prilling powder for sealed ring

The invention relates to a preparation method for alumina ceramic granulated powder used by a sealing ring, which is characterized in that the preparation process comprises: (1) weighting and mixing alpha alumina, silicon powder, light calcium carbonate, kaolin, burning talc magnesia and yttria, carrying out dry milling, crashing and uniformly mixing; (2) placing the uniformly mixed powder in a ball mill, diluting, adding a dispersant, a binder and a release agent and milling into slurry; (3) screening the milled slurry, removing iron, putting in a spray drying tower to carry out spray granulation; and (4) screening the spray granulated powder by a 40-mesh screen and a 200-mesh screen, taking the powder between the two screens as the finished product. The granulated powder prepared by the method of the invention has the advantages of solid granule, reasonably distributed granularity, large loose packed density, moderate strength, good fluidity and easy mold release. Moreover, the alumina sealing ring can be provided with microcrystalline structure only through the common dry pressing and sintering technology. The ceramic article has high tightness, and the surface of which has no pores found when being amplified by 20 times after abrasive polishing.

Owner:ZHENGZHOU HICER HIGH TECH CERAMICS

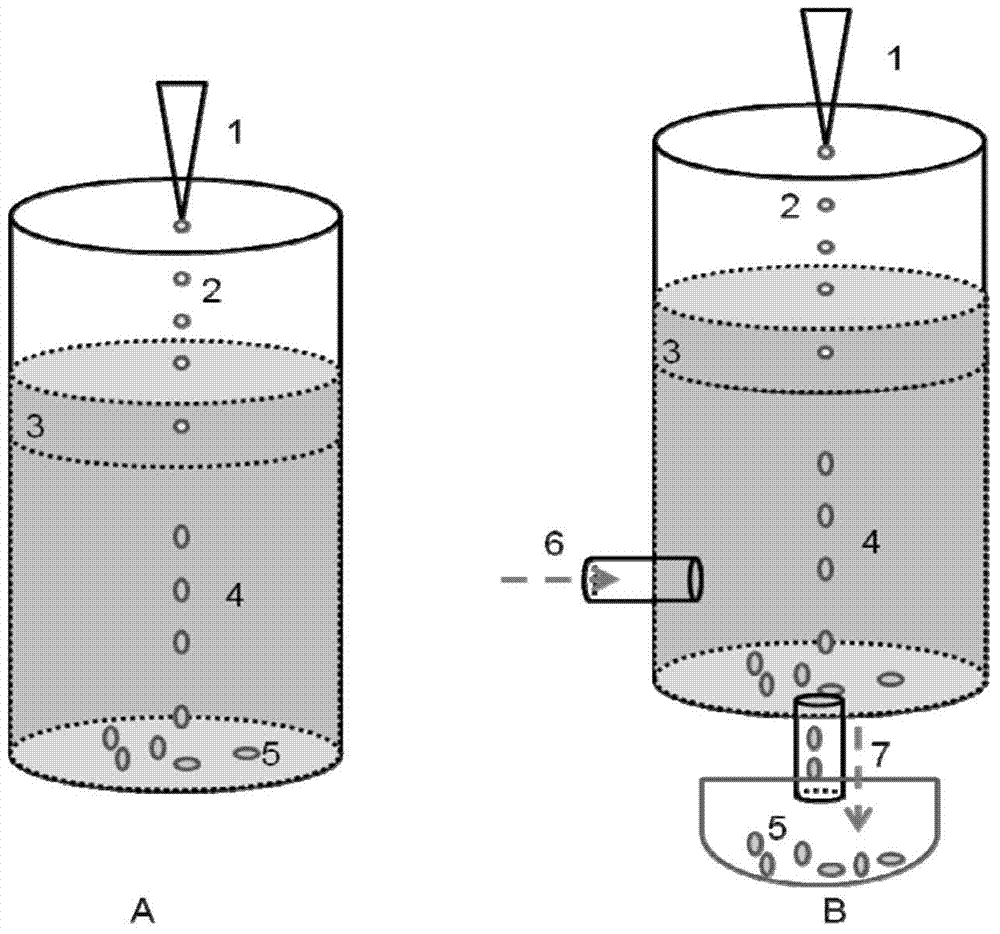

Suspending porous biological carrier and preparation

ActiveCN101148289AGood buoyancy retentionReduce colonization timeSustainable biological treatmentBiological water/sewage treatmentBiological wasteSpecific weight

The present invention relates to one kind of suspended microbial carrier for biological waste water treatment. The mixture of rubber powder in 35-70 wt%, resin in 25-55 wt%, chemical foaming agent in 0.1-5 wt% and specific weight regulating material in 0-10 wt% is hot extruded to form shaped body of 0.90-1.1 g / cu cm specific weight and with great amount of closed bubbles. The suspended microbial carrier has great buoyancy, and can maintain suspension state in treated water after microbe attachment. In addition, nutritious matter may be added into the carrier material for promoting the colonization and growth of microbe.

Owner:JIANGSU YULONG ENVIRONMENTAL PROTECTION

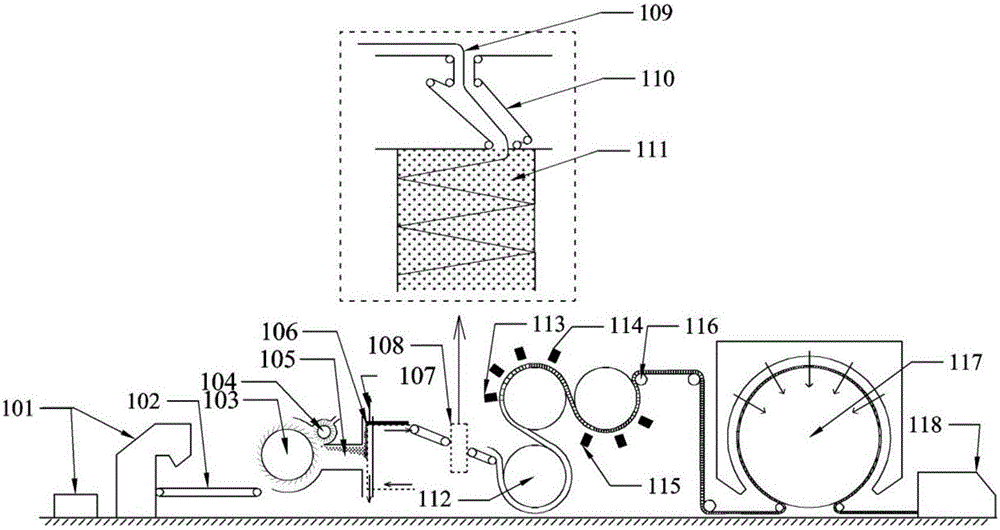

Preparation method of spun-laced regenerated leather for automotive interior surface

ActiveCN105970657AImprove product added valueMany categoriesNon-woven fabricsWettingCost performance

The invention provides a preparation method of spun-laced regenerated leather for an automotive interior surface. The preparation method comprises the following specific steps: (1) loosening and mixing fibers; (2) forming a net; (3) spreading the net; (4) pre-wetting; (5) spun-lacing; (6) drying; (7) carrying out vacuum plastic-absorption and molding. The requirements on material molding properties and mechanical properties by the automotive interior surface and industrial standards are sufficiently considered at the beginning of designing, and raw material ratios and a production process are reasonably optimized, so that collaboration of design, preparation and molding machining of a composite material is realized. Compared with traditional automotive interior surfaces including polyvinyl chloride, polyurethane and the like, the prepared automotive interior surface has the advantages of greenness and environmental friendliness, no odor, excellent elasticity, moderate strength, comfortable hand feeling, high cost performance and the like and is suitable for large-scale industrial production.

Owner:SHANDONG UNIV

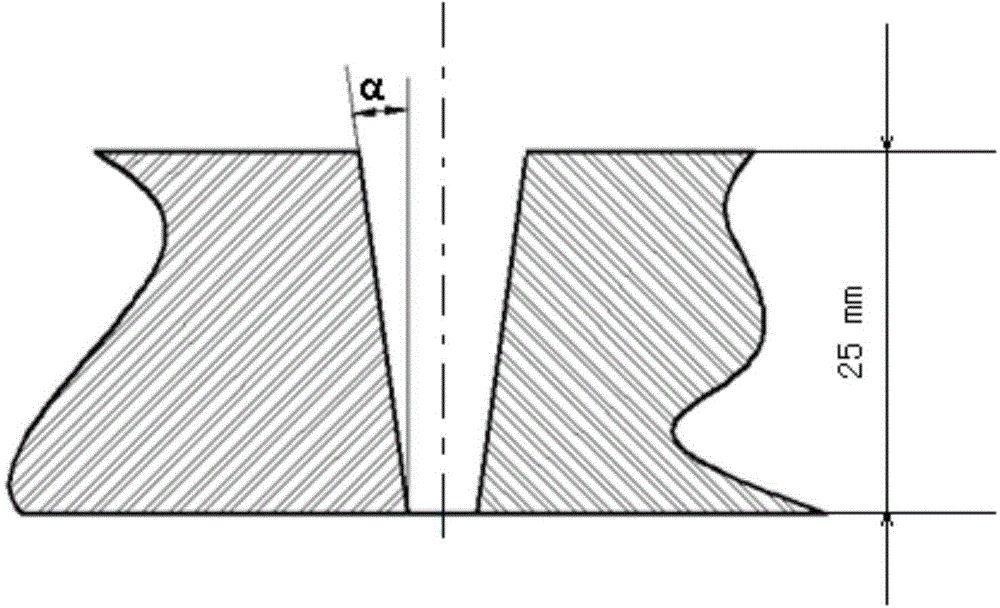

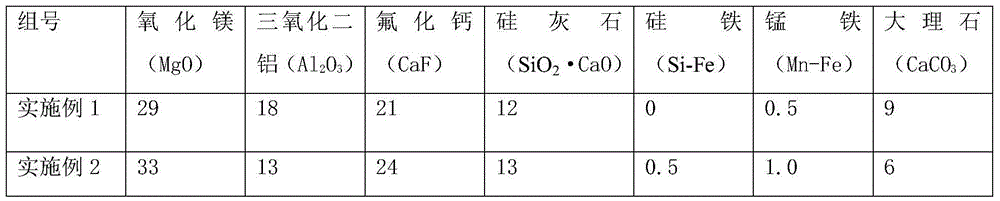

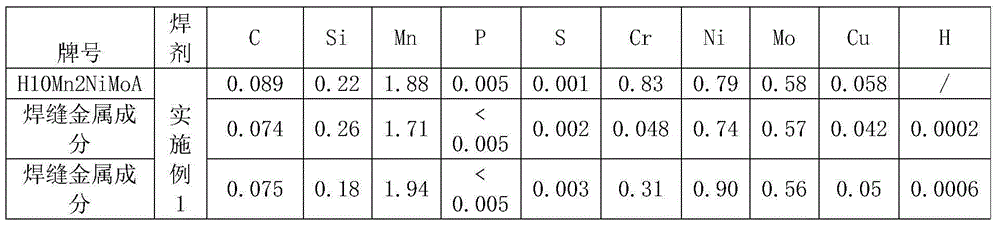

Submerged-arc welding flux for low-alloy-steel narrow-gap welding and preparation method thereof

ActiveCN104668816AExcellent transition abilityEasy transitionWelding/cutting media/materialsSoldering mediaSlagMechanical property

The invention relates to a submerged-arc welding flux for low-alloy-steel narrow-gap welding and a preparation method thereof. A high-alkalinity MgO-CaO-Al2O3-CaF slag system is adopted, and the submerged-arc welding flux is mainly made from raw materials including calcium fluoride, aluminum oxide, wollastonite, marbles, silicon iron and ferromanganese iron. The preparation method of the submerged-arc welding flux mainly comprises the steps of 1 dry mixing in proportion, 2 impurity removal, 3 bonding agent adding for wet mixing and 4 baking and high-temperature sintering. The alkalinity of the welding flux ranges from 2.0 to 3.0, low-hydrogen and low-oxygen deposited metal containing ultra low P and S impurity contents can be obtained through welding, and accordingly it can be ensured that the deposited metal has excellent comprehensive mechanical property. When the submerged-arc welding flux is matched and welded with a low-purity low-alloy steel welding wire, S and P are not added into the deposited metal by adopting the welding flux. The submerged-arc welding flux has excellent alloy transition capacity.

Owner:TIANJIN HEAVY EQUIP ENG RES +1

Sand fixation method of green degradable inorganic sand fixation material

InactiveCN106753384AReduce the impactHold onOther chemical processesOrganic fertilisersCalcium silicateEcological environment

The invention relates to a sand fixation method of a green degradable inorganic sand fixation material, belonging to the field of environmental protection. The inorganic sand fixation material is prepared by mixing calcium silicate slag, fly ash, industrial mineral slag powder, gypsum, cement and solid aggregate used as main raw materials. The sand fixation material and water are mixed to prepare a sand fixation slurry; and the sand fixation slurry is sprayed or spread on sand soil to form a solidifying layer on the sand soil surface. The solidifying layer can satisfy the mechanical property requirements for fixing traveling dunes. After the sand fixation layer is laid, the sand fixation region is subjected to soil improvement and plant growth, so that the sand fixation layer can be degraded into substances which are nontoxic and harmless to the environment within 1-5 years, thereby obtaining the soil components and lowering the influence of artificial buildings on the desert ecological environment. After the sand fixation material reacts with water, no toxic component resides, and thus, the sand fixation material has the advantages of high safety and no secondary pollution. Besides, abundant industrial solid wastes are doped to lower the influence of solid waste piling on the environment; and the method has the advantages of low cost, simple construction technique and high practicality, and is applicable to related fields of desertification control and the like.

Owner:UNIV OF SCI & TECH BEIJING +1

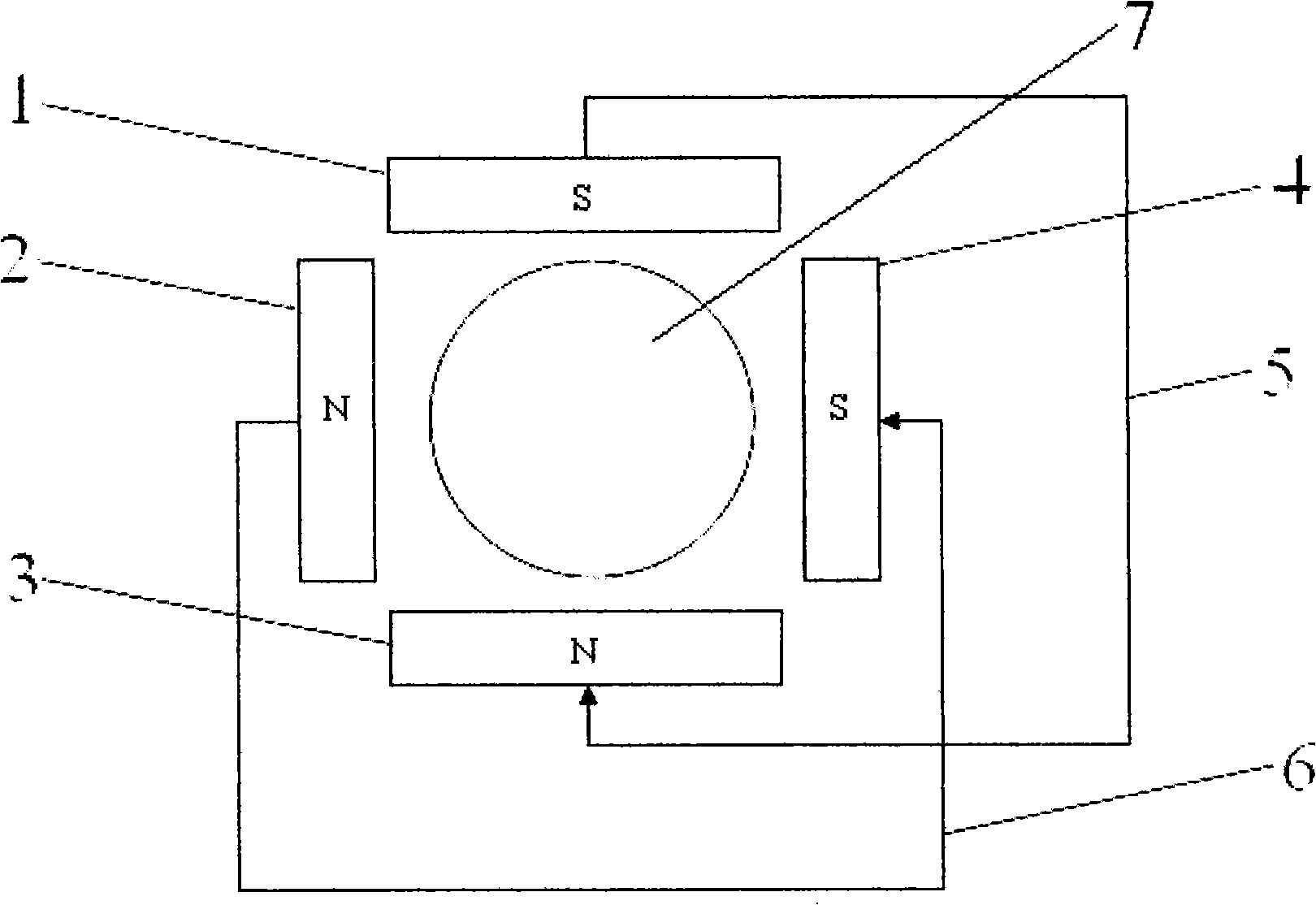

Cubic boron nitride synthetic method

The invention relates to a synthetic method of cubic boron nitride; the method adopts the nitride of alkali metals and alkaline earth metals and the mixture of magnesium aluminum alloy as a catalyst and uses the hexagonal boron nitride as material; the nitride, the magnesium aluminum alloy and the hexagonal boron nitride are evenly mixed according to the mass ratio of 7 to 10 : 1 to 4 : 100 and the single crystal of the cubic boron nitride with the amber color from semitransparent to transparent is synthesized according to the synthetic technique processes of the invention. The method overcomes the defects that the nitride and the metal catalyst material are used separately, and leads the advantages of the two catalyst materials to have good combination; the synthesized cubic boron nitride crystal has the advantages of amber color, regular shape, proper intensity, synthetic temperature, wide pressure range and high yield, etc.

Owner:ZHENGZHOU ZHONGNAN JETE SUPERABRASIVES

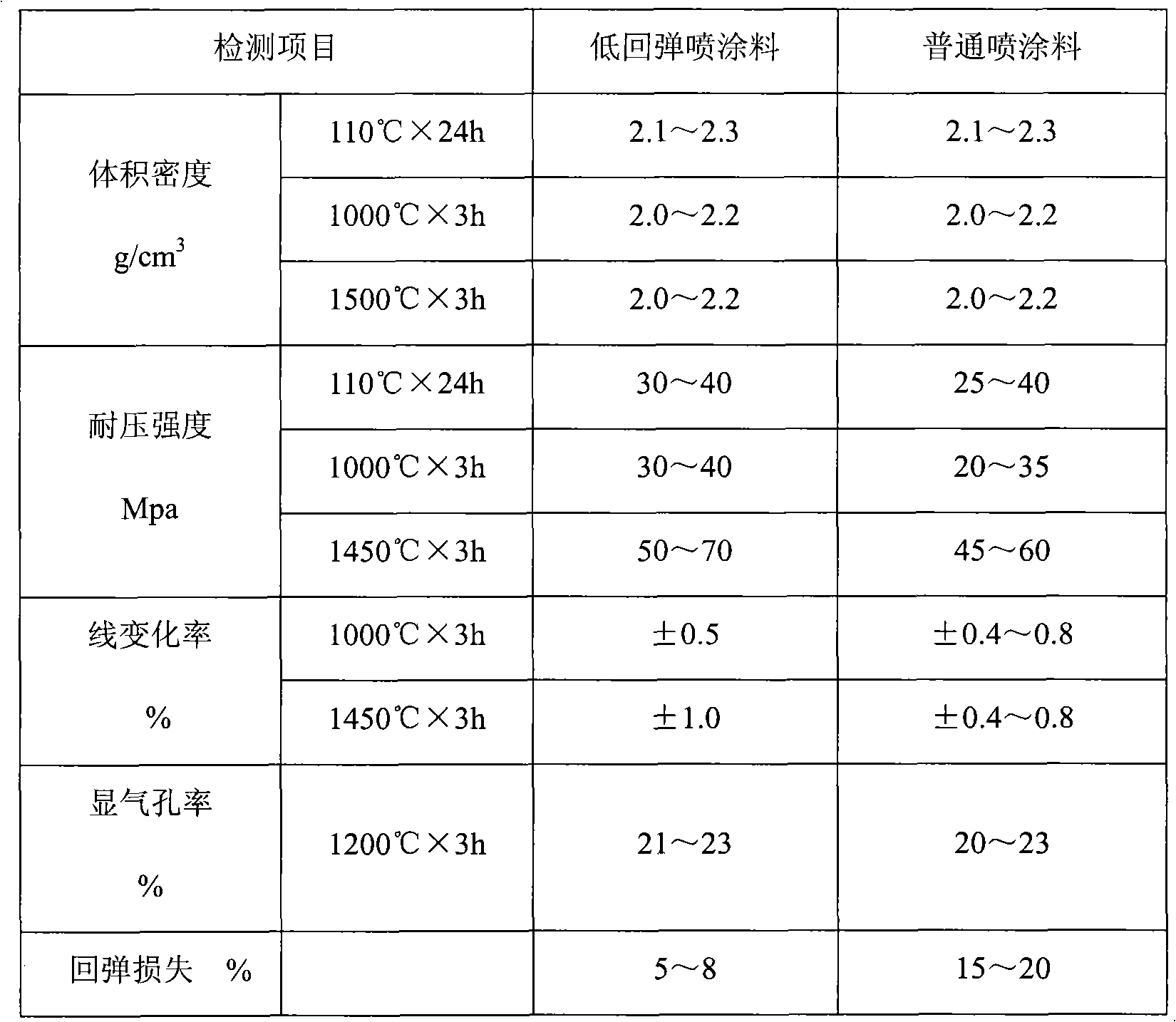

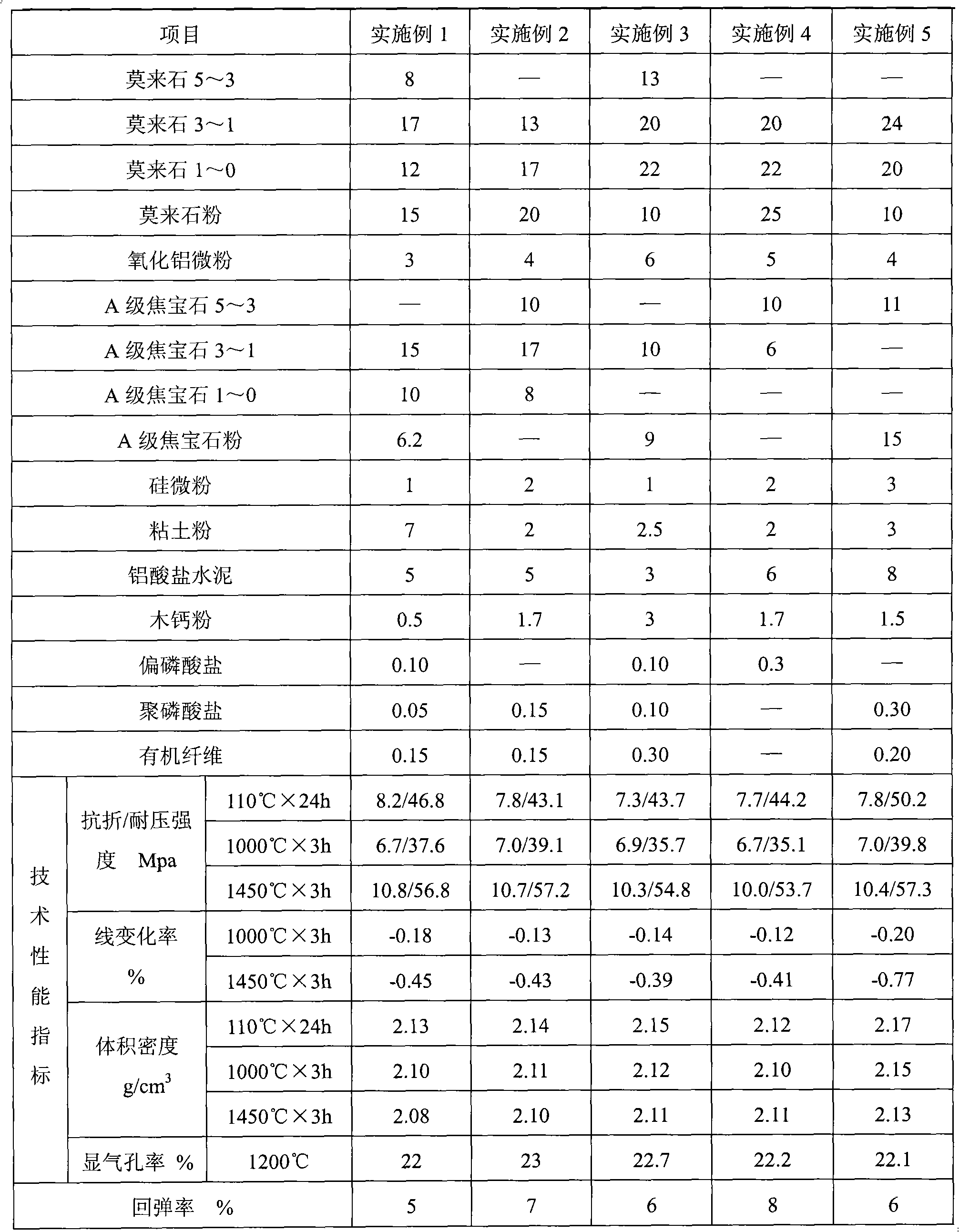

Low springback rate spraying and coating material for thermal-state blast furnace maintenance and preparation method thereof

The invention provides a low springback rate spraying and coating material for thermal-state blast furnace maintenance and a preparation method thereof. The spraying and coating material comprises the following raw materials in percentage by weight: 30-50% of synthetic mullite particles with the diameter of 5-0mm, 30-50% of A-level flint clay particles with the diameter of 5-0mm, 10-25% of synthetic mullite powder of 200-325 meshes, 0-15% of A-level flint clay powder of 200-325 meshes, 3-8% of aluminate cement, 2-7% of clay powder, 1-3% of silica micropowder of 2-5mu, 3-6% of aluminum oxide micropowder of 5mu, 0-0.3% of polyphosphate, 0-0.3% of metaphosphate, 0.5-3% of lignosulphonate calcium powder and 0-0.3% of organic fiber,The invention has the outstanding characteristics that the springback loss is small, waste of raw materials in the process of construction is reduced on one hand, and the start-up operation of the furnace is facilitated on the other hand; and the spraying and coating material provided by the invention meets the performance requirements on performances such as strength, scouring resistance, scouring and permeation resistance, rapid construction at 150-300 DEGC and the like, and is especially suitable for an unshaped refractory for thermal-state blast furnace lining maintenance. The invention has the outstanding characteristics that the springback loss issmall, waste of raw materials in the process of construction is reduced on one hand, and the start-up operation of the furnace is facilitated on the other hand; and the spraying and coating material provided by the invention meets the performance requirements on performances such as strength, scouring resistance, scouring and permeation resistance, rapid construction at 150-300 DEG C and the like, and is especially suitable for an unshaped refractory for thermal-state blast furnace lining maintenance.

Owner:CENT RES INST OF BUILDING & CONSTR CO LTD MCC GRP +2

Synthesis technique of high-grade self-sharpening polycrystalline diamond

InactiveCN103521132ALow oxygenGuaranteed synthetic yieldUltra-high pressure processesIn situ polymerizationPolycrystalline diamond

The invention relates to a synthesis technique of a high-grade self-sharpening polycrystalline diamond, which comprises the following steps: metering and mixing the raw materials for synthesizing the diamond according to percentage by mass, granulating, and pressing into a synthetic stick; putting the synthetic stick into a synthesis block, and drying in a vacuum drying oven at constant temperature for later use, wherein the synthesis block is synthesized at high temperature under superhigh pressure with a cubic press; and taking out the synthetic stick, carrying out after-treatment to obtain a self-sharpening polycrystalline diamond, carrying out in-situ polymerization by a sol-gel process, and applying a zirconia coating on the diamond surface to form the high-grade self-sharpening polycrystalline diamond. The product has the advantages of favorable impact toughness, favorable thermal stability and favorable comprehensive properties, can obviously enhance the holding force of the self-sharpening polycrystalline diamond in a grinding tool, can keep the self-sharpness in the grinding process, and finally, is beneficial to prolonging the service life of th grinding tool and enhancing the machining efficiency of the grinding tool.

Owner:ZHONGYUAN ENGINEERING COLLEGE +1

Preparation method of high-carbon hot-continuous-rolling acid-pickling steel strips for hot forming

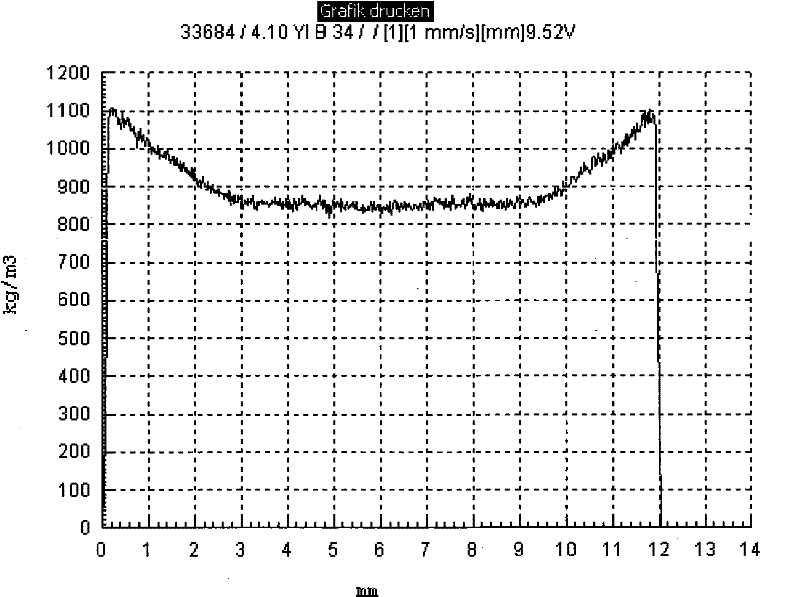

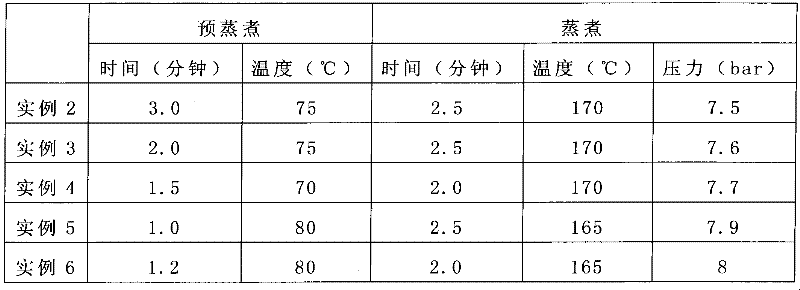

The invention relates to a preparation method of high-carbon hot-continuous-rolling acid-pickling steel strips for hot forming, belongs to the technical field of preparation of acid-pickling steel strips, and aims at solving the technical problem of providing a low-cost preparation method of high-carbon hot-continuous-rolling acid-pickling steel strips for hot forming. According to the method, C and Mn serve as main elements, and the C content is increased; on the condition that alloy elements such as Nb, Ti, V, B, Mo, La and Cr are not added, on the premise of ensuring steel purity and chemical component uniformity of a cast blank by controlling the smelting procedure, and by means of reasonable rolling control and cooling control technological processes, hot-rolled steel plates which are moderate in strength and high in elongation rate are obtained, the hot-rolled steel plates are subjected to trimming, blanking and heating and then subjected to hot forming and hot treatment, and parts which are moderate in strength and high in ductility and toughness are obtained finally. The steel strips are widely applied to automotive structural parts and can replace part of hot-rolled and cold-rolled continuous annealing steel plates and steel strips which are high in alloy content and product cost and are used for high-strength automobile structures.

Owner:PANZHIHUA IRON & STEEL RES INST OF PANGANG GROUP

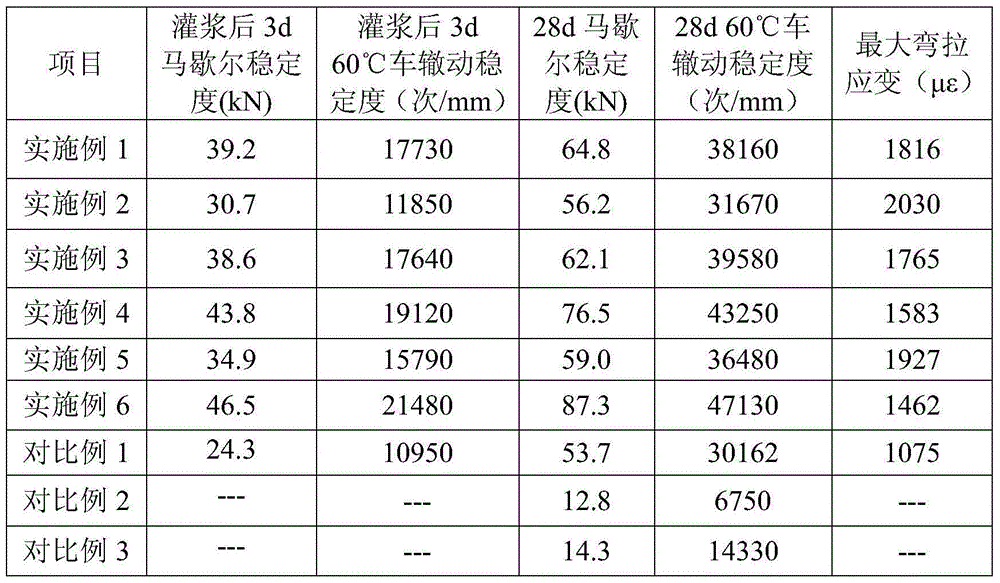

Semi-flexible anti-rut pavement material and preparation method thereof

The invention relates to a semi-flexible anti-rut pavement material which comprises the following components in percentage by weight: 65-88% of big-void cement-base mixture and 12-35% of flexible grouting material. The big-void cement-base mixture comprises 1 part of cement, 4-6 parts of coarse aggregate, 0.4-1.0 part of fine aggregate, 0.1-0.3 part of water and 0-0.006 part of water reducing agent. The flexible grouting material comprises 1 part of cement, 0.65-1 part of modified emulsified asphalt, 0.1-0.35 part of water-based epoxy resin emulsion, 0-0.03 part of ground tire, 0.0025-0.007 part of water reducing agent, 0.05-0.2 part of expanding agent and 0.05-0.15 part of water. The semi-flexible anti-rut pavement material has the characteristics of high rut resistance, favorable flexibility and toughness, no seam, fewer cracks, low carbon, environmental protection and the like, can be constructed at room temperature, and is suitable for road rut treatment.

Owner:JIANGSU SOBUTE NEW MATERIALS +1

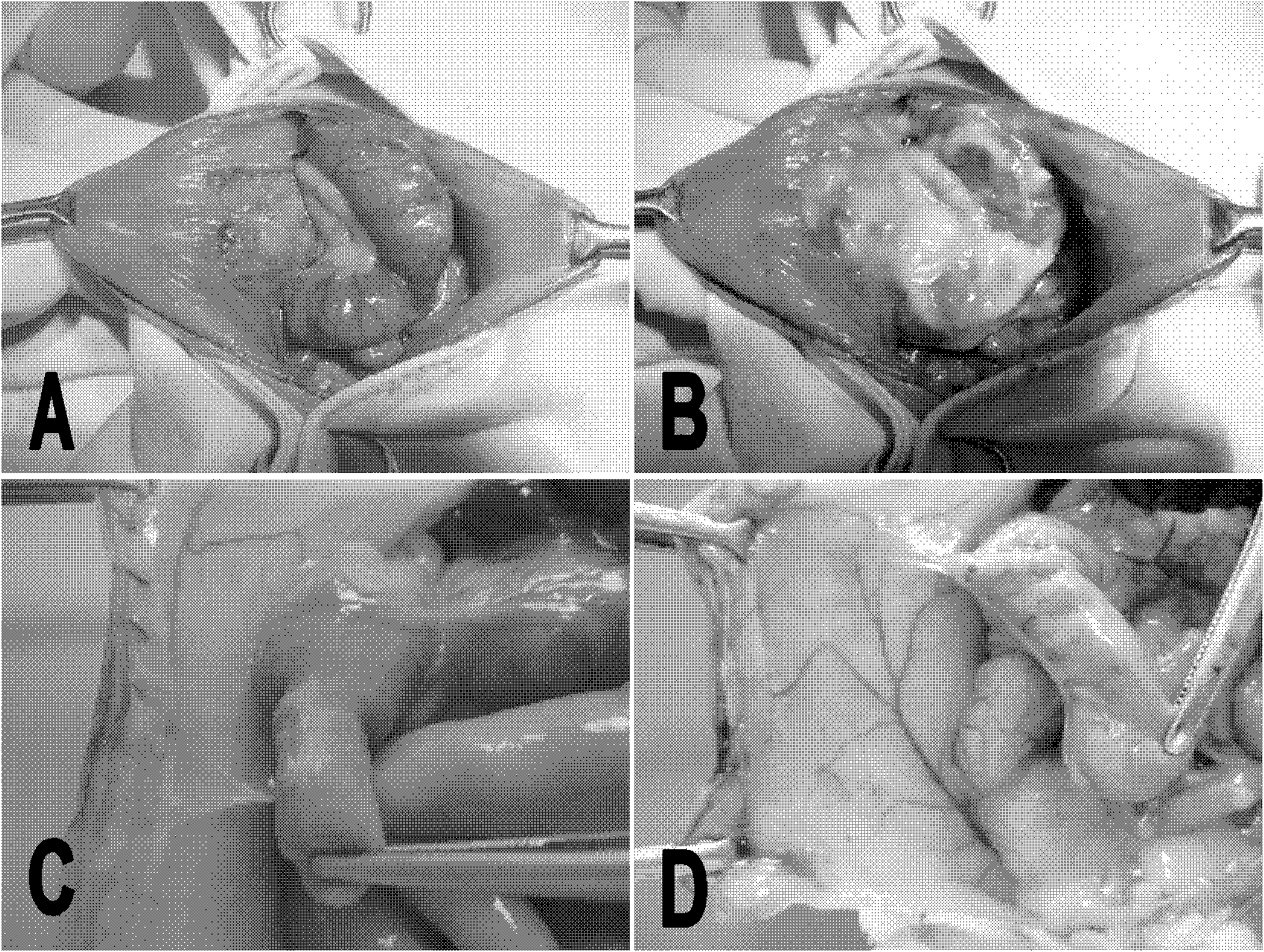

Nerve conduit and preparation method thereof

The invention discloses a nerve conduit and a preparation method thereof. The nerve conduit comprises an inner layer, a transition layer, an outer layer and at least one cavity used for storing a bioactive factor solution, wherein the outer surface of the inner layer is sequentially coated with the transition layer and the outer layer; the cavity is positioned between the inner surface of the outer layer and the outer surface of the transition layer and / or between the outer surface of the inner layer and the inner surface of the transition layer; the inner layer is a hydrophilic cytoskeleton layer made by adopting an electrostatic spinning method; and the outer layer is a hydrophobic nerve conduit scaffold layer made by adopting the electrostatic spinning method. The nerve conduit can be used for loading bioactive factors before an operation in a required mode, such as injection, soaking and the like due to the miniature cavity, so that the production quality of the product is easy to control, the survival rate of the bioactive factor can be greatly improved, the nerve regeneration can be promoted in high efficiency, and the nerve repairing effect can be reinforced.

Owner:MEDPRIN REGENERATIVE MEDICAL TECH

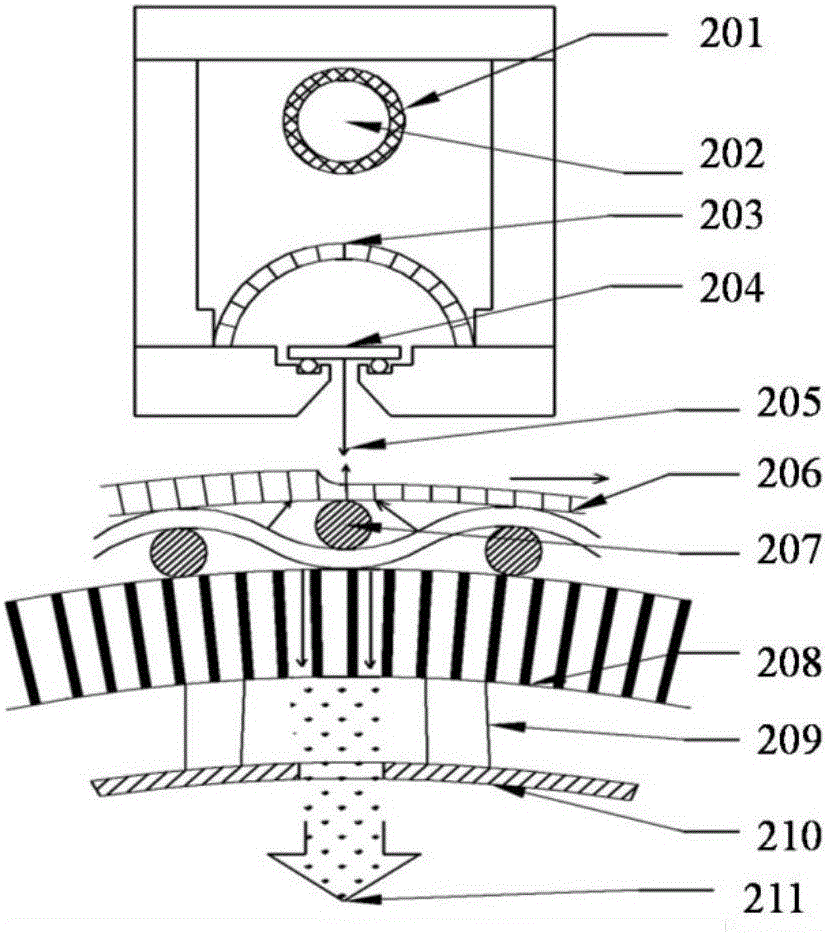

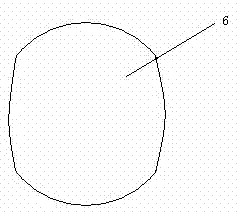

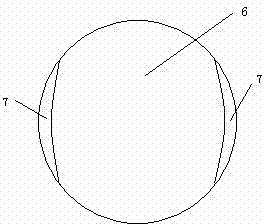

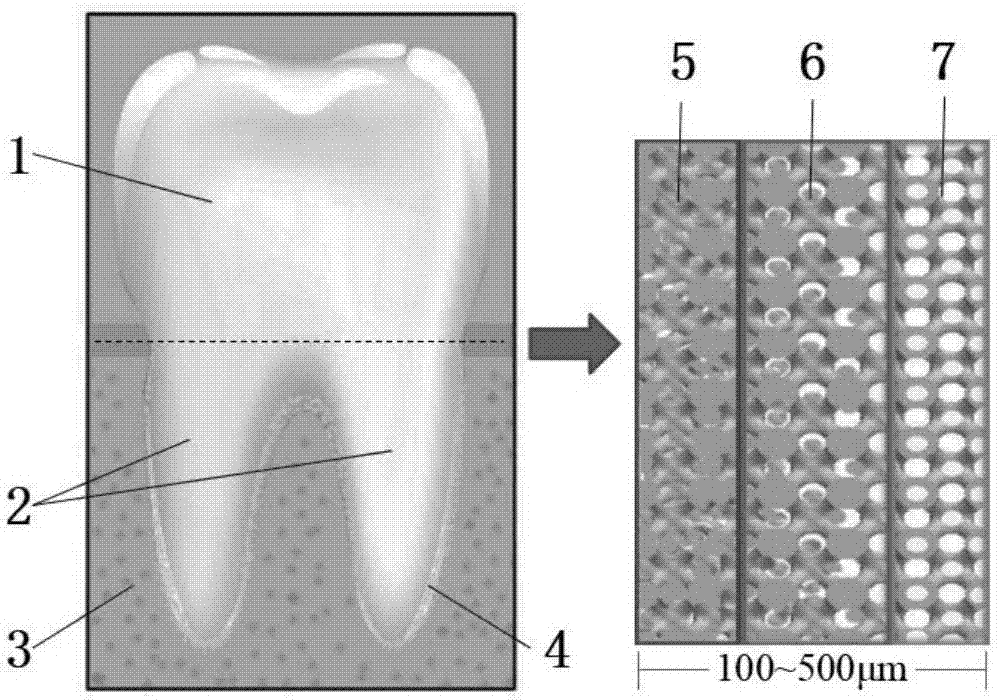

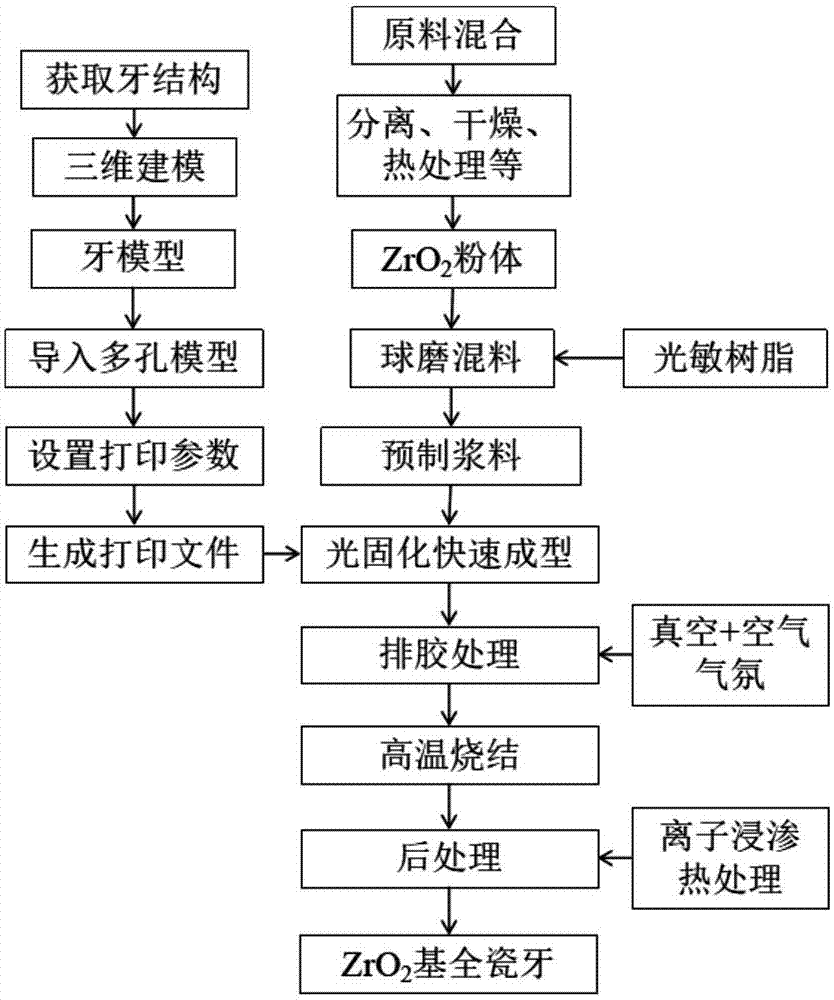

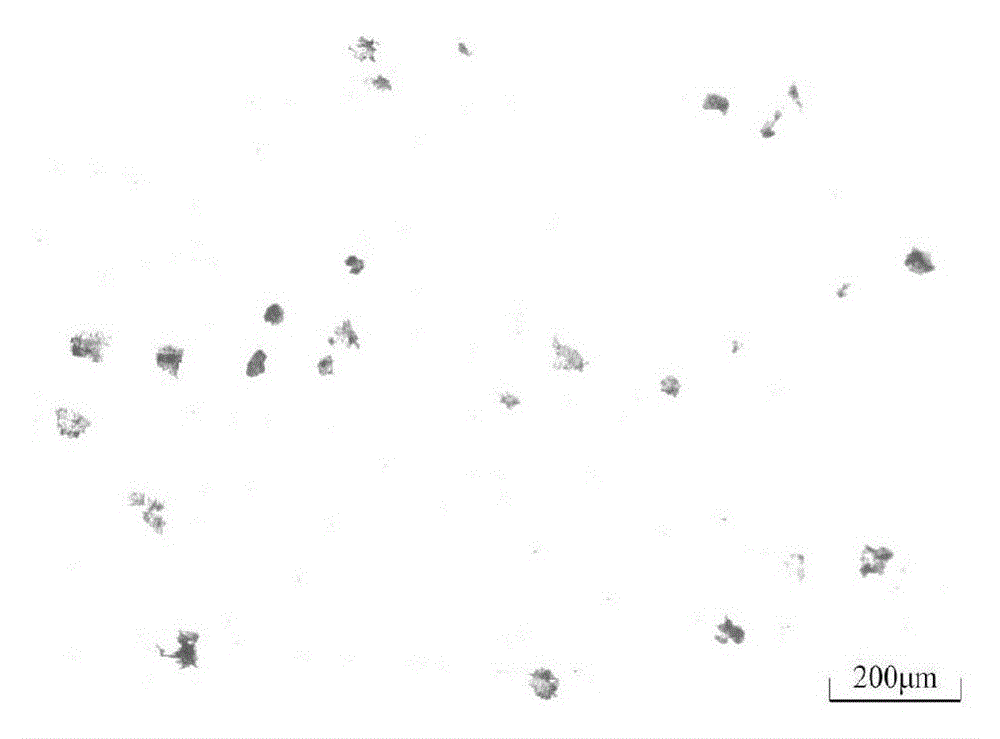

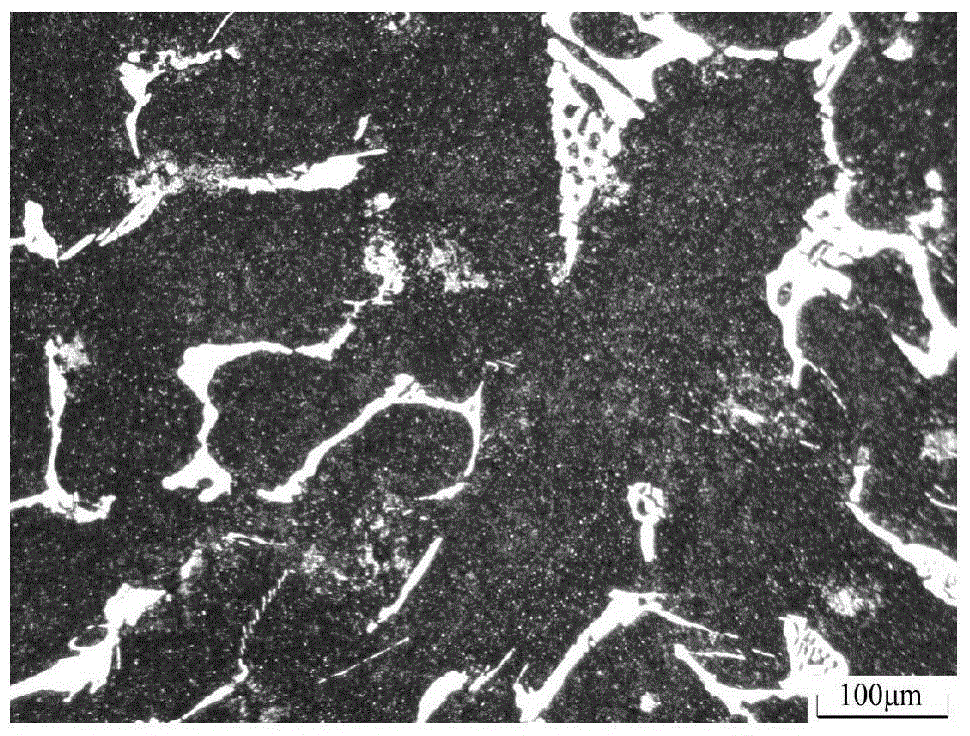

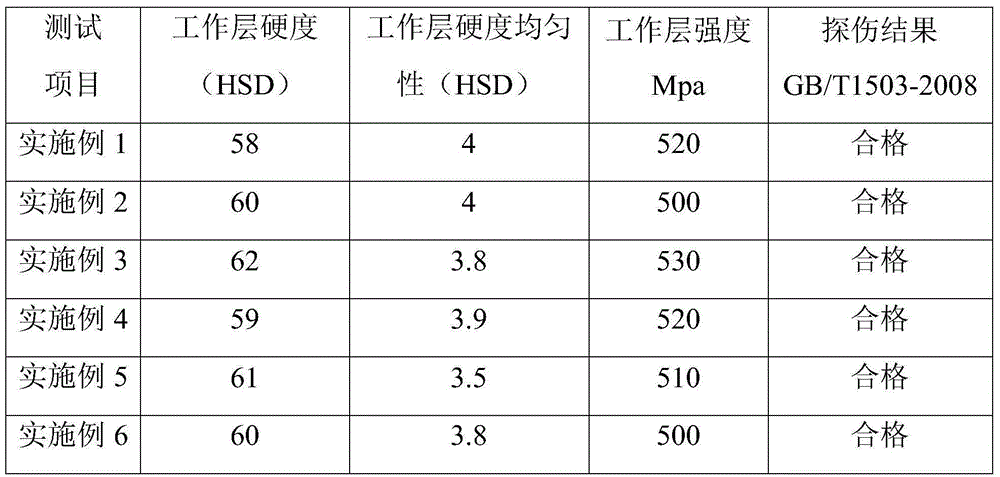

ZrO2-based all-ceramic dental implant and preparation method thereof

ActiveCN107500758AOptimal Control StructurePromote osseointegrationTissue regenerationProsthesisIonDental implant

The invention provides a ZrO2-based all-ceramic dental implant and a preparation method thereof. The method comprises steps as follows: ZrO2 nano powder with stable doping elements is obtained from soluble zirconium salt, strong base and a solution containing doping elements with a nano powder preparation technology; the ZrO2 nano powder is mixed with photosensitive resin, and ceramic-photosensitive resin prefabricated slurry is obtained; the ceramic-photosensitive resin prefabricated slurry is printed with an additive manufacturing technology according to a true tooth simulation model, a ZrO2 ceramic biscuit is obtained and subjected to gel removal and sintering, and a ZrO2 ceramic matrix is obtained; finally, ion penetration, sintering and mineralization are performed, and the ZrO2-based all-ceramic dental implant is obtained. The dental implant is controllable in structure and highly simulated with the additive manufacturing technology; in combination with ion penetration, sintering and mineralization treatment, synostosis of the dental implant and alveolar bone is advantageously improved; chemical ingredients of the dental implant are in gradient distribution on the whole, and the ZrO2-based all-ceramic dental implant has moderate strength, hardness, toughness and bioactivity.

Owner:GUANGDONG UNIV OF TECH

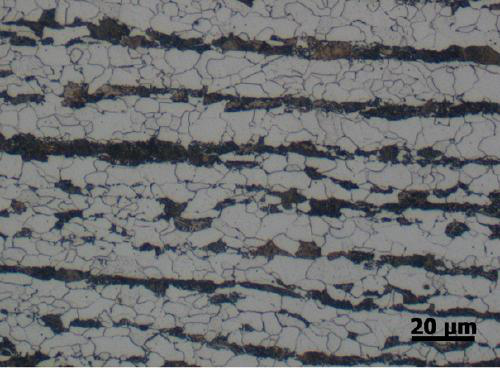

High-carbon graphitic steel roller ring for profile steel universal mill and manufacturing method of high-carbon graphitic steel roller ring

The invention discloses a high-carbon graphitic steel roller ring for a profile steel universal mill and a manufacturing method of the high-carbon graphitic steel roller ring. The outer layer of the roller ring is composed of, by mass, 1.70%-2.30% of C, 1.50%-2.20% of Si, 0.50%-1.20% of Mn, 0.03% of P or less, 0.03% of S or less, 1.00%-1.80% of Cr, 0.20%-1.20% of Ni, 0.20%-0.80% of Mo and the balance Fe. A core is composed of, by mass, 1.00%-2.00% of C, 1.00%-2.00% of Si, 0.50%-1.50% of Mn, 0.03% of P or less, 0.03% of S or less, 0.5% of Cr or less and the balance Fe. The manufacturing method comprises the steps of smelting, inoculation and spheroidizing, centrifugal casting and heat treatment. Spheroidizing is carried out at least two times. The metallographic structure of the roller ring obtained after heat treatment comprises a pearlite base body, carbide with the area rate of 10.36% and graphite, the form of the graphite is in a mass shape or a mass insect shape, and the area rate of the graphite is 1.7%. The high-carbon graphitic steel roller ring has high wear resistance, breaking resisting strength, toughness, hot crack resistance and accident impact resisting capacity, and the steel bonding tendency is avoided.

Owner:SINOSTEEL XINGTAI MACHINERY & MILL ROLL

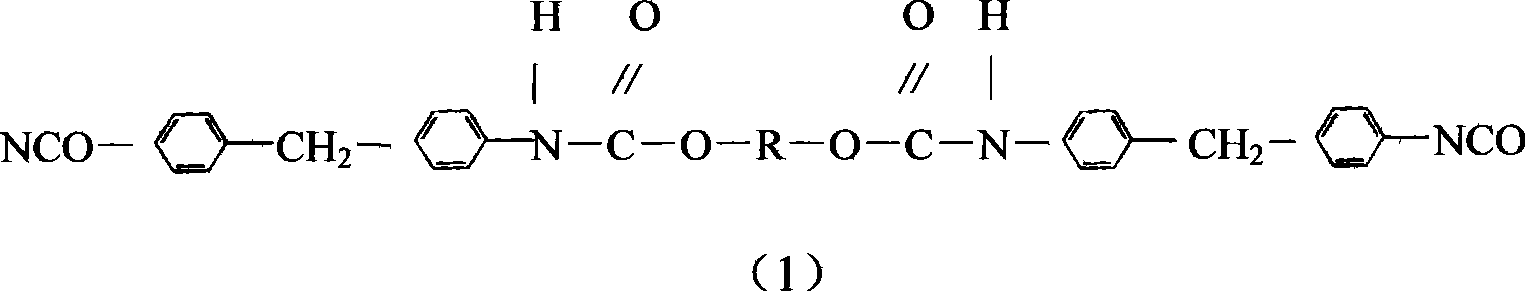

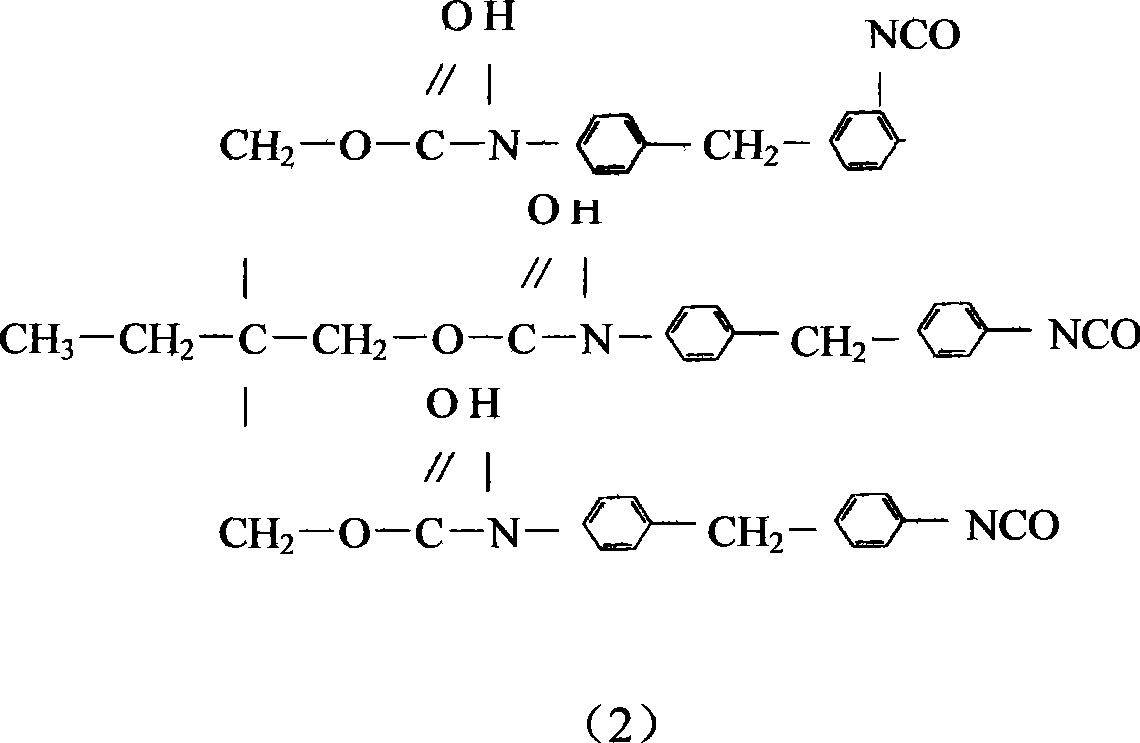

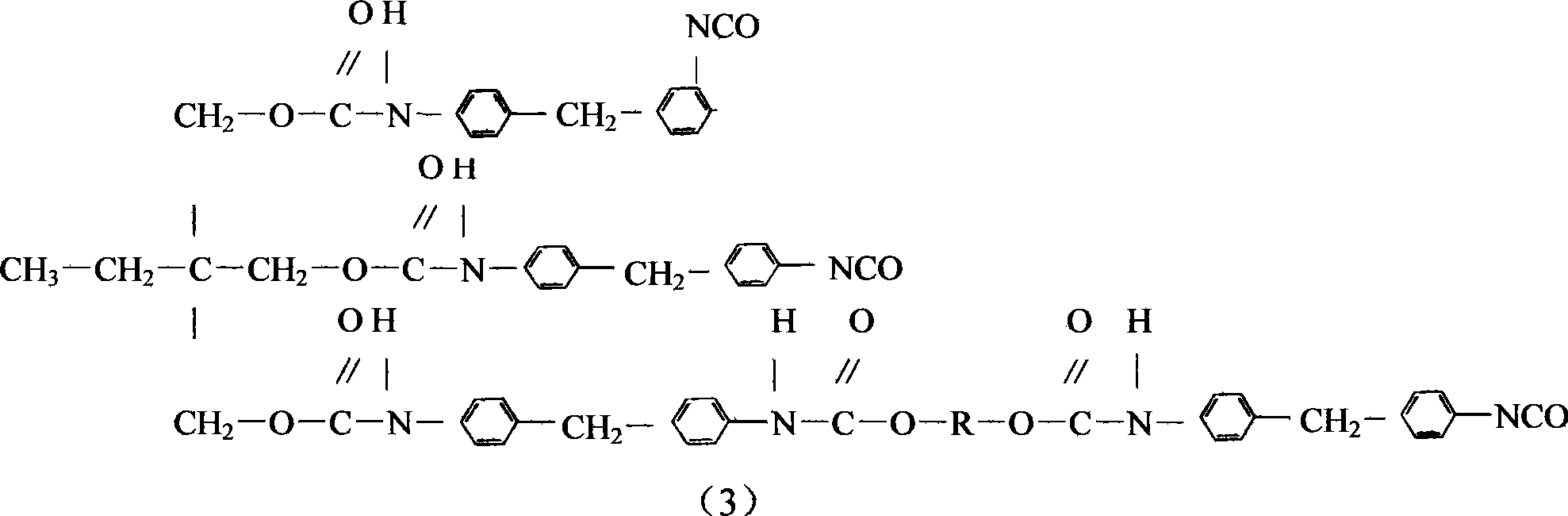

Curing agent 4,2'- and 4,4'-methyl diphenylene diisocyanate prepolymer and preparation thereof

The invention provides a prepolymer of 4,2'-methyl diphenylene diisocyanate (MDI) and 4,4'- methyl diphenylene diisocyanate (MDI) as a curing agent, and a preparation method thereof. The method comprises the following steps: 4,4-MDI and organic solvent are added to a reaction kettle, heated to between 50 an d 90 DEG C and added with dehydrated polyol, and then react for 2 to 4 hours so as to prepare 4,4-MDI modifier; a mixture of 4,2'-MDI and 4,4'MDI is added and then cooled; and trimethylolpropane and the organic solvent are dripped and thermally insulated, and react for 1 to 6 hours, so as to obtain a product. The method modifies the 4,4-MDI and then blends the 4,4-MDI with the mixture of 4,2'-MDI and 4,4'-MDI and TMP for pre-polymerization, thereby solving the problem of manufacturing the prepolymer with two isomers of MDI in an arbitrary proportioning form. A series of produced prepolymers can meet different requirements of coatings and adhesives in the polyurethane industry on the curing agent, and have the advantages of wide application range, high strength, low toxicity, adjustable room-temperature curing speed, good storage stability, capability of obtaining the products with high solid content, and the like.

Owner:周建明

Alumium Foil for air conditioner

The present invention discloses one kind of aluminum foil for air conditioner and refrigerator. The aluminum foil is produced with the materials including Al 99-99.50 weight portions, Fe 0.15-0.28 weight portion, Si 0.08-0.18 weight portion, Mn 0.20-0.25 weight portion, Mg <0.05 weight portion, Zn <0.1 weight portion, Cu <0.1 weight portion, Ti <0.08 weight portion, Ni <0.05 weight portion, and Cr <0.05 weight portion, and through smelting, casting and rolling, cold rolling, annealing and other steps. The aluminum foil has homogeneous structure, high elongation and cupping value, moderate strength, and excellent machining and forming performance, and is especially suitable for punching in a high speed punch.

Owner:JIANGSU DINGSHENG NEW MATERIAL JOINT STOCK CO LTD

Composite alginate hydrogel dressing as well as preparation method and application thereof

InactiveCN105169454AIntensity controllableReduce intensityAbsorbent padsBandagesCross-linkWater soluble polysaccharides

The invention provides a composite hydrogel material containing alginate as well as a preparation method thereof. The method comprises the following steps: adding polyvalent metal modified carboxyl-containing water soluble polysaccharide and derivatives thereof as a gel cross-linking agent to an alginate (potassium salt, sodium salt or ammonium salt) water solution in advance, mixing and stirring, and directly casting a film so as to obtain gel or further drying so as to obtain a film. The method is simple in technology, and the obtained gel is good in intensity controllability and good in stability; and the gel has effects of promoting wound healing and accelerating wound tissue repairing.

Owner:吴玉松

Manufacturing method of high density fiberboard for whitened type E1 grade floor substrate

InactiveCN102407553ASmall aspect ratioReduce cellulose contentWood working apparatusFlat articlesHexamethylenetetraminePhosphoric acid

The invention relates to a manufacturing method of a high density fiberboard for a whitened type E1 grade floor substrate, which comprises the steps of wood chipping and screening, pre-stewing and stewing, defibrator process for causing fiber separation, concoction of E1 grade urea formaldehyde resin glue, curing agent preparation, the application of urea-formaldehyde glue, curing agents and paraffins, drying, paving, hot pressing, cooling and tempering, and sanding and saw cutting, and is characterized in that woods are selected from major diameter cottonwoods with diameters larger than 8cm, are evenly chipped and are then placed in an outdoor storage yard to be fermented for 5 to 15 days; in the concoction process of the E1 grade urea formaldehyde resin glue, urea is added at 5 times; and the curing agents are formed by preparing phosphoric acid accounting for 3 to 5 percent of the total content, urotropin accounting for 1 to 3 percent of the total content, triethanolamine accounting for 1 to 3 percent of the total content, and ammonium sulfate accounting for 19 to 21 percent of the total content. The obtained whitened type E1 grade floor substrate has the advantages of little surface impurity, fine and smooth fiber, white color, good visual effect, reasonable density distribution and moderate intensity, and is frequently used for producing top grade indoor laminate flooring and composite floors.

Owner:DARE TECH

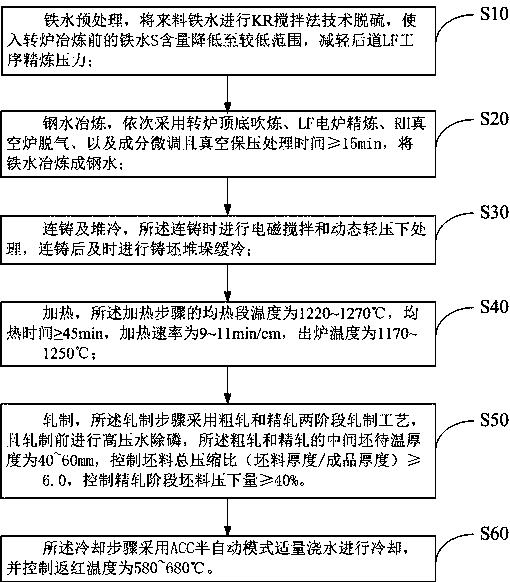

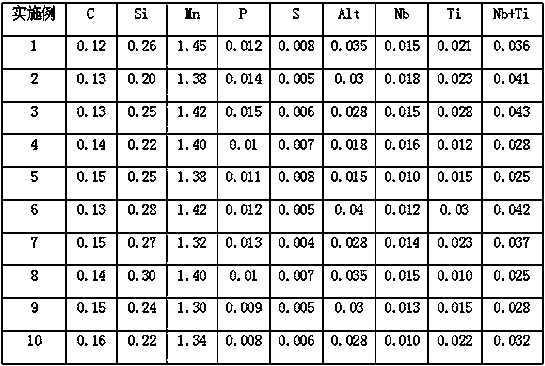

High-toughness hot-rolled 530 MPa-grade automobile cold stamping bridge shell steel plate and manufacturing method thereof

The invention discloses a high-toughness hot-rolled 530 MPa-grade automobile cold stamping bridge shell steel plate and a manufacturing method thereof. The high-toughness hot-rolled 530 MPa-grade automobile cold stamping bridge shell steel plate comprises the following components of C, S, Mn, P, S, Al, Nb, Ti and the balance Fe and impurities; the content of the elements has to meet the followingrelationship at the same time, Nb+Ti is greater than or equal to 0.025% and is less than or equal to 0.045%, CEV is equal to C+Mn / 6+(Cr+Mo+V) / 5+(Ni+Cu) / 15 and is less than or equal to 0.45%; the manufacturing method is characterized in that V is not added to the component design, Mn content is properly adjusted, a certain amount of Si, Nb, Ti and the like are added, molten iron pretreatment, molten steel smelting, continuous casting, cooling, heating, rolling, cooling, finishing, inspection and the like are carried out, so that the surface quality and strength of the steel meet the cold stamping and welding processing processes of the bridge shell steel; the yield strength ReL of the steel plate is greater than or equal to 375 MPa, the tensile strength Rm is greater than or equal to 530 MPa, the elongation percentage A after fracture is greater than or equal to 26%, the impact power KV2 at 0 DEG C is greater than or equal to 180 J, the grain size is 8-10 grades, the strip-shaped gradeis 1-3 grades, and cold stamping and forming of 10-16 mm specifications can be realized.

Owner:WUHAN IRON & STEEL GRP ECHENG IRON & STEEL CO LTD

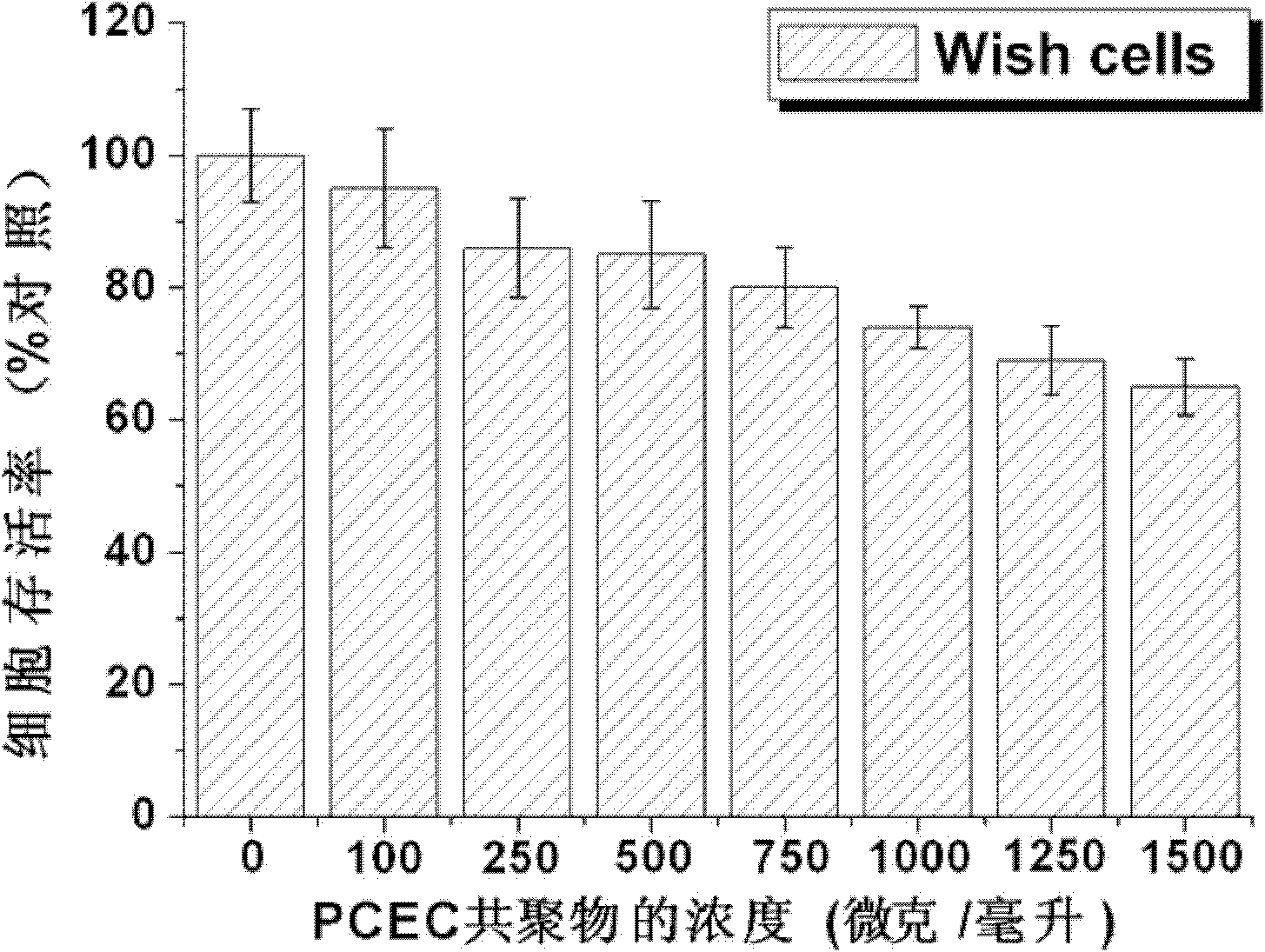

Application of PCL-PEG-PCL tri-block copolymer in preparation of medical anti-blocking material

ActiveCN101837006AModerate intensityGood biocompatibilityOrganic active ingredientsSurgical drugsPolyethylene glycolMolecular materials

The invention relates to the field of medicinal macromolecular materials, in particular to the application of a tri-block copolymer in the preparation of a medical anti-blocking material, aiming to provide a new choice for using the medical anti-blocking material in the field. A technical scheme of the invention is to provide the application of the polycaprolactone-polyethyleneglycol- polycaprolactone (PCL-PEG-PCL) tri-block copolymer in the preparation of the medical anti-blocking material, wherein the PCL-PEG-PCL copolymer has a molecular weight ranging from 1,500 to 8,000, the ratio of themolecular weight of the PEG chain segment to that of the PCL chain segment ranges from 0.2 to 2.5. The copolymer can be dissolved in water to form a solution and can form when a certain concentrationis achieved. Experiments show that the hydrogel of the PCL-PEG-PCL block copolymer can effectively prevent post-operation adhesion, thereby the invention provides a new choice for this field.

Owner:SICHUAN UNIV

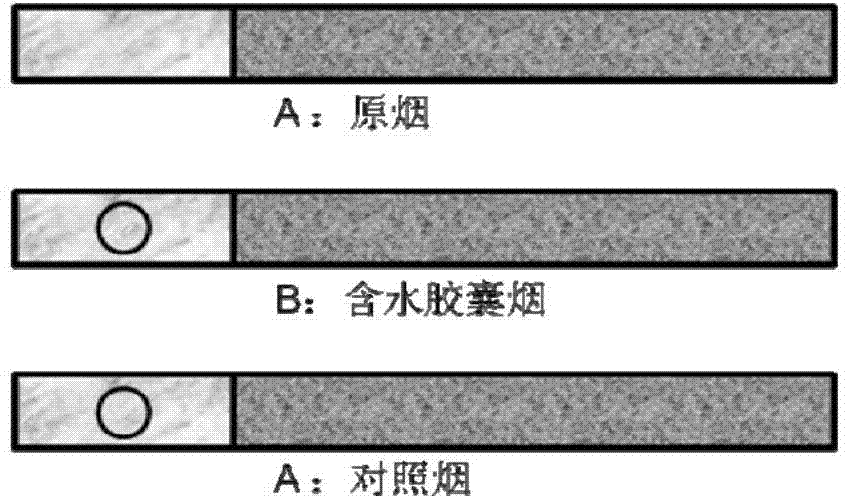

Brittle solid spice bead for cigarette filter stick and preparation method thereof

ActiveCN105105328AEvenly dispersedModerate intensityTobacco smoke filtersPlasticizerAdditive ingredient

The invention provides a brittle solid spice bead for a cigarette filter stick. The brittle solid spice bead comprises a spherical soft kernel and a brittle shell, wherein the brittle shell covers the surface of the spherical soft kernel in a lagging cover manner, and raw materials of the spherical soft kernel is prepared from the following ingredients in percentage by mass: 65 to 90 percent of PEG (polyethylene glycol) polymer or a PEG polymer mixture with a molecular weight of 2000 to 6000, 5 to 25 percent of glycerinum and 0.5 to 15 percent of essence, and raw materials of the brittle shell is prepared from the following ingredients in percentage in mass: 3 to 50 percent of natural high polymer material, 1 to 10 percent of plasticizer, and 60 to 90 percent of water. The invention also provides a preparation method of the brittle solid spice bead for the cigarette filter stick. The brittle solid spice bead is not subjected to the limitation of the essence type and characteristics and high in applicability.

Owner:HUBEI CHINA TOBACCO IND +1

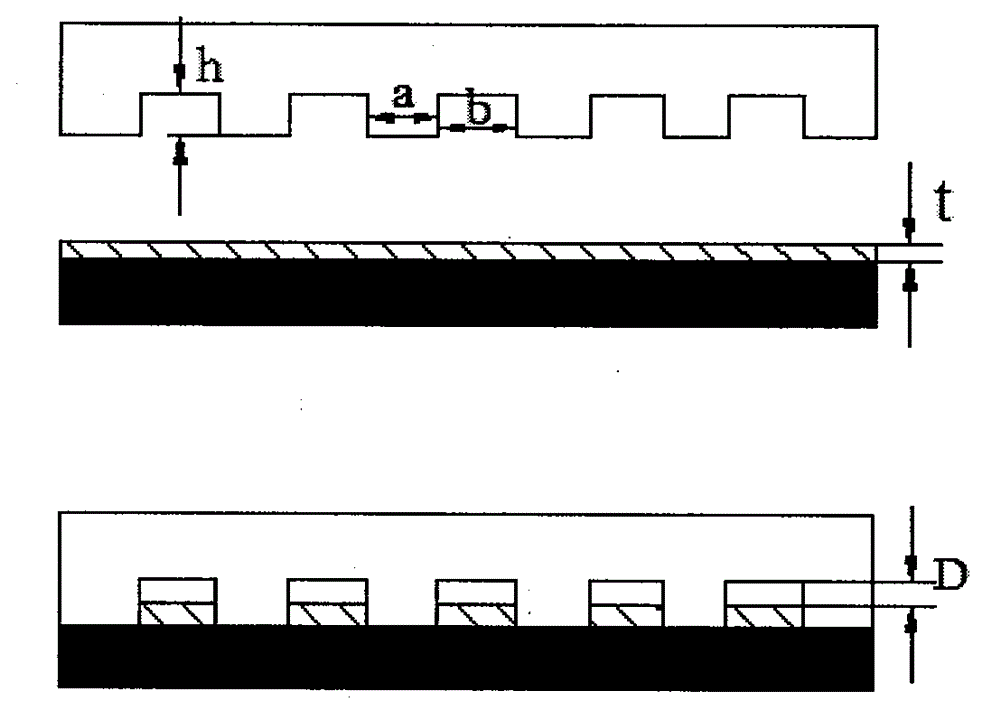

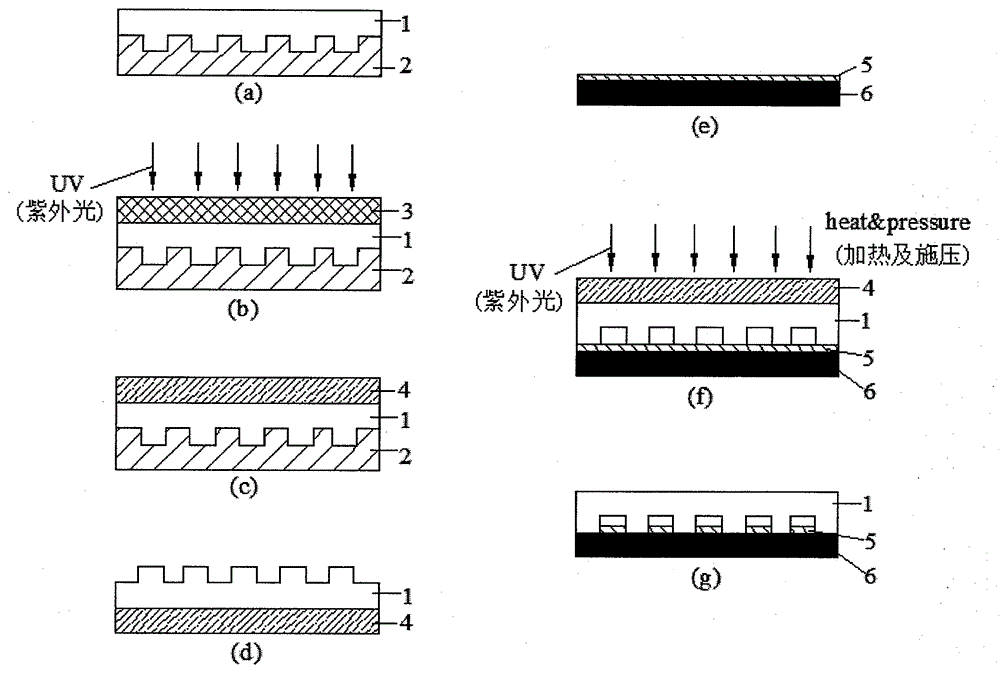

Reverse thermal bonding technology for making micro and nano fluid system with controllable size

InactiveCN103145089ASmall sizeIncrease contactDecorative surface effectsChemical vapor deposition coatingGratingThin layer

The invention discloses a reverse thermal bonding technology for making micro and nano fluid system with controllable size. The technology comprises steps of: coating a pretreated grating template with a layer of SU 8 photoresist; copying a graph to the SU-8 photoresist through a reverse embossing technology; then tearing off the cured SU-8 photoresist by using an adhesive UV tape according to different adhesion among interfaces, so as to successfully transfer the graph to a flexible UV adhesive tape; spinning a thin layer of SU-8 photoresist on another Si sheet to form a sealing layer Si substrate; covering the prepared SU-8 adhesive graphic structure layer on the Si substrate; and preparing the micro and nano fluid system through the reverse bonding technology. The invention combines an embossing technology and a bonding technology together, and has advantages of simple operation, no requirement on high temperature and high pressure, controllable channel size and no clogging; and a low manufacturing cost is conducive to mass production.

Owner:HEFEI UNIV OF TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com