Water-bearing capsule and preparation method thereof

A technology of water-containing capsules and capsule shells, which is applied in the field of cigarette processing, and can solve the problems of not being able to wrap powdery essence, capsule roundness and waxy layer strength, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0094] Embodiment 1: preparation water-containing capsule

[0095] The steps of the preparation method are as follows:

[0096] A. Preparation of water-based capsule core

[0097] 310 parts by weight of sodium chloride, 20 parts by weight of water-soluble lemon flavor and 20 parts by weight of potassium sorbate preservative are dissolved in 650 parts by weight of deionized water to obtain the water-based capsule core;

[0098] B. Preparation of aqueous core

[0099] Mix 80 parts by weight of beeswax, 200 parts by weight of EVA, 20 parts by weight of polyethylene, and 70 parts by weight of Eucommia gum, then heat and melt to obtain a melt modified wax;

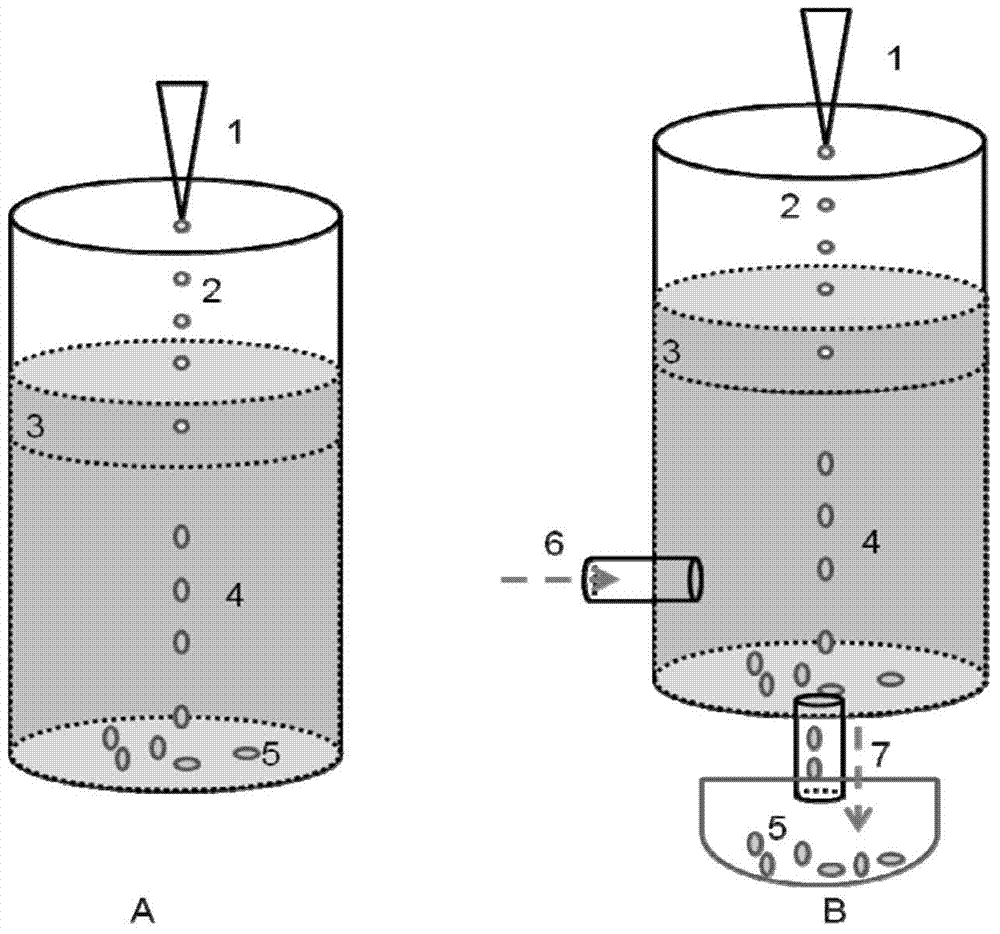

[0100] use attached figure 1 According to the equipment, the temperature of the water-based capsule core obtained in step A is adjusted to 10-15°C, and then the water-based capsule core is added dropwise to the molten modified wax at a temperature of 120-150°C, so that Form a layer of cured hydrophobic modified wax film, t...

Embodiment 2

[0105] Embodiment 2: preparation water-containing capsule

[0106] The steps of the preparation method are as follows:

[0107] A. Preparation of water-based capsule core

[0108] 400 parts by weight of honey and 10 parts by weight of sodium benzoate preservative are dissolved in 590 parts by weight of deionized water to obtain the water-based capsule core;

[0109] B. Preparation of aqueous core

[0110] Mix 6 parts by weight of paraffin wax, 1 part by weight of EVA, 1 part by weight of polyvinyl acetate, 1 part by weight of chicle and 1 part by weight of Eucommia gum, then heat and melt to obtain a melt modified wax;

[0111] Adjust the temperature of the water-based capsule core obtained in step A to 5-10°C, and then add the water-based capsule core dropwise to the melted modified wax at a temperature of 120-150°C, thus forming a layer on the surface of the water-based capsule core Curing the hydrophobically modified wax film, that is, the aqueous core;

[0112] C. Prep...

Embodiment 3

[0116] Embodiment 3: preparation water-containing capsule

[0117] The steps of the preparation method are as follows:

[0118] A. Preparation of water-based capsule core

[0119] 30 parts by weight of honey, 10 parts by weight of citric acid and 1 part by weight of sodium benzoate preservative are dissolved in 59 parts by weight of deionized water to obtain the water-based capsule core;

[0120] B. Preparation of aqueous core

[0121] 7 parts by weight of microcrystalline wax, 2 parts by weight of EVA, and 1 part by weight of polyvinyl acetate are mixed, and then heated and melted to obtain a molten modified wax;

[0122] Adjust the temperature of the water-based capsule core obtained in step A to 5-10°C, and then add the water-based capsule core dropwise to the melted modified wax at a temperature of 110-130°C, thus forming a layer on the surface of the water-based capsule core Curing the hydrophobically modified wax film, that is, the aqueous core;

[0123] C. Preparati...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com