High-toughness hot-rolled 530 MPa-grade automobile cold stamping bridge shell steel plate and manufacturing method thereof

A manufacturing method and 530mpa technology, applied in the field of automobile axle housing steel plate manufacturing, can solve the problems of increasing product safety hazards and performance fluctuations, and achieve the effects of excellent ductility, moderate strength, good weldability and ductility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

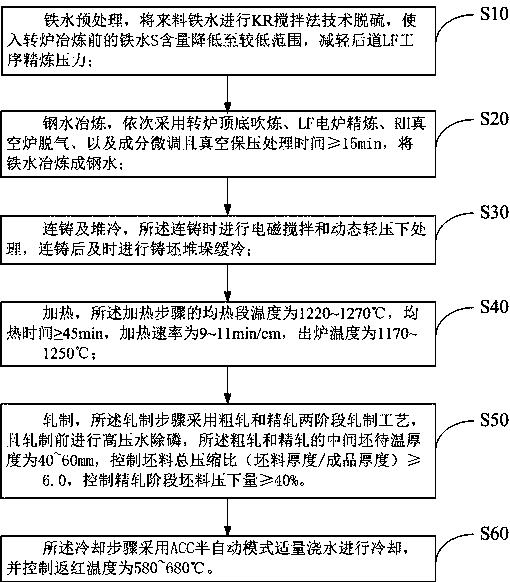

Method used

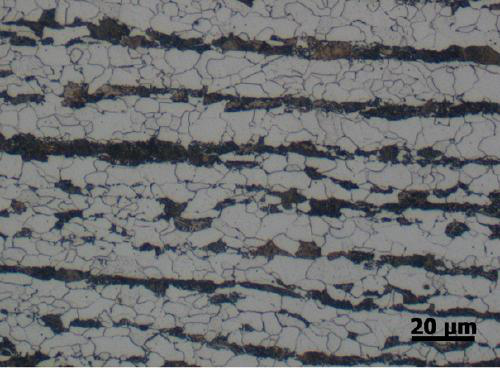

Image

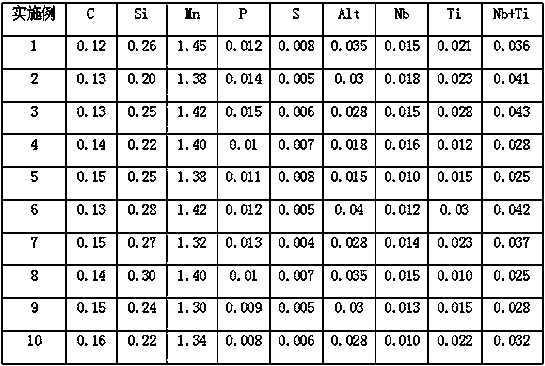

Examples

Embodiment Construction

[0028] It should be noted that, as used herein, the term "comprises", "comprises" or any other variation thereof is intended to cover a non-exclusive inclusion such that a process, method, article or system comprising a set of elements includes not only those elements, It also includes other elements not expressly listed, or elements inherent in the process, method, article, or system. Without further limitations, an element defined by the phrase "comprising a..." does not preclude the presence of additional identical elements in the process, method, article or system comprising that element.

[0029] The serial numbers of the following embodiments of the present invention are only for description, and do not represent the advantages and disadvantages of the embodiments.

[0030] In this document, the use of the words first, second, and third etc. does not indicate any order. These words can be interpreted as names.

[0031] It should be understood that the specific embodime...

PUM

| Property | Measurement | Unit |

|---|---|---|

| yield strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com