Steel for fine grain carburizing gear and method of manufacturing the same

A manufacturing method and technology for carburizing gears, applied in the field of alloy steel, can solve the problems of gear steel hardenability reduction, solid solution C content reduction, and hardenability reduction, etc., and achieve high bending fatigue strength, grain refinement, The effect of long contact fatigue life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

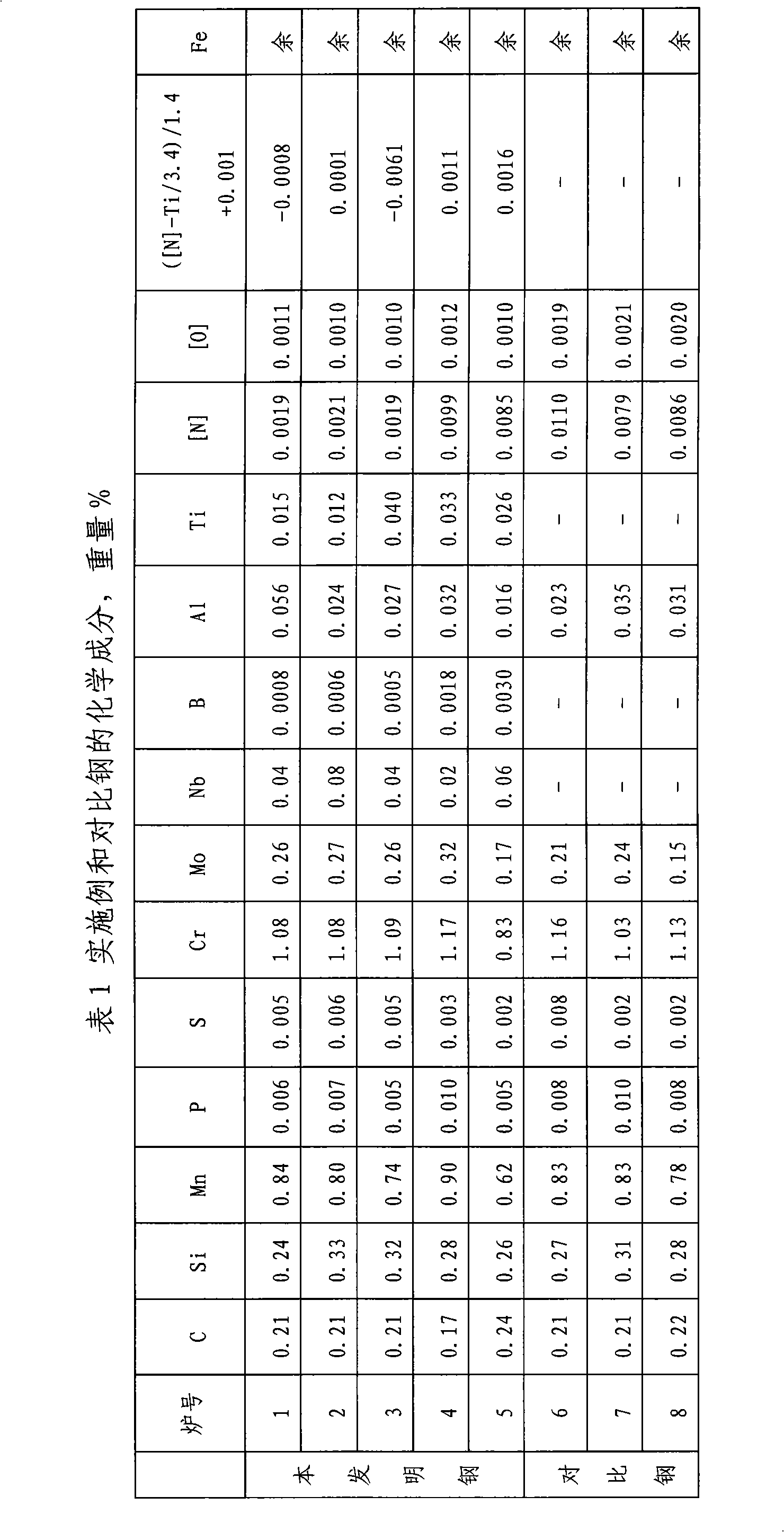

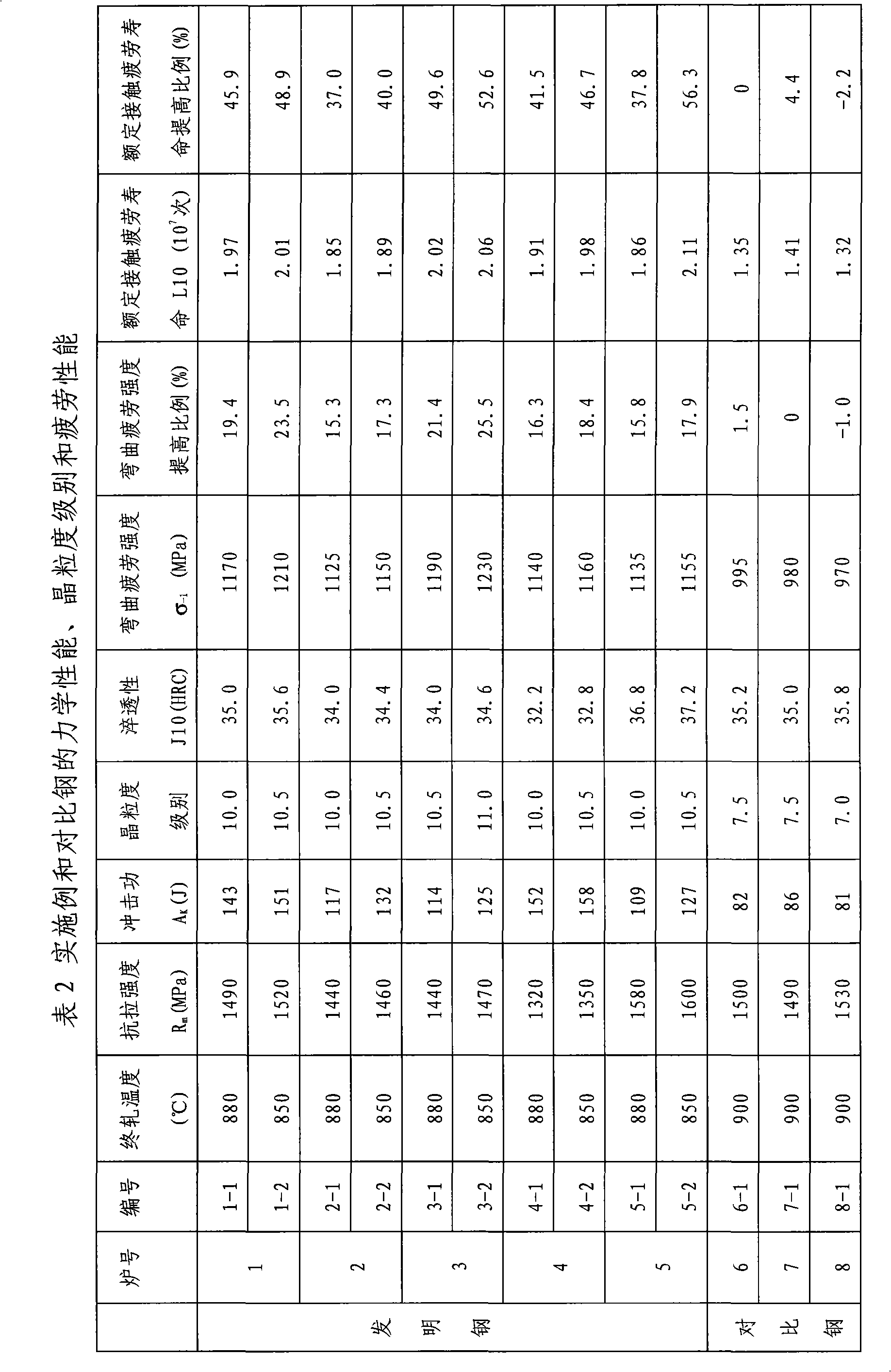

[0027] According to the chemical composition range designed by the present invention, 3 furnaces (furnace number 1-3) of the steel of the present invention were smelted on a 500kg induction furnace, and in addition, smelted by a 30t industrial electric furnace+external refining process (EAF+LF+VD) 2 heats of the inventive steel (heat number 4-5) and 3 heats of 20CrMoH comparison steel (heat number 6-8), the specific chemical composition of which is shown in Table 1. Molten steel is poured into ingots, forged and billeted, and finally rolled into φ55mm bars. The final rolling temperature of 20CrMoH comparative steel is 900°C, while the final rolling temperature of the inventive steel is 880°C and 850°C, Table 2.

[0028] Invention steel and comparison steel were processed into standard room temperature tensile specimens (L 0 =5d 0 , d 0 =5mm), Charpy notched impact test specimen (10mm×10mm×55mm), metallographic specimen for carburizing (φ10mm×25mm), rotating bending fatigue ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| depth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com