Synthesis technique of high-grade self-sharpening polycrystalline diamond

A technology of polycrystalline diamond and synthesis process, which is applied in the application of ultra-high pressure process, etc., can solve the problems of low impact toughness, high processing cost, low grade of polycrystalline diamond, etc., and achieve impact toughness and Excellent thermal stability, comprehensive performance, improved life and processing efficiency, and improved nucleation and growth rates

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

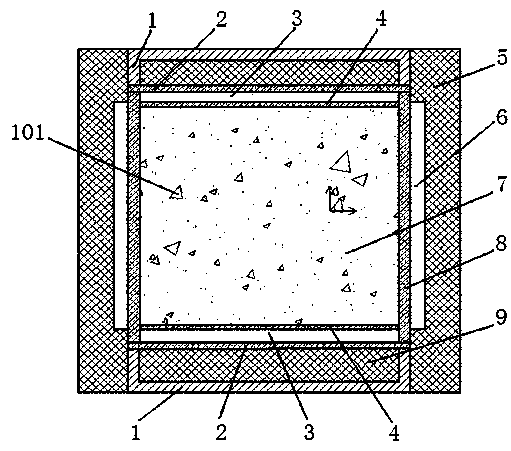

Image

Examples

Embodiment 1

[0023] Embodiment 1: a kind of synthesis process technology of high-grade self-sharpening polycrystalline diamond, comprising the steps:

[0024] (1) The carbon source graphite, catalyst, active rare earth element and nano-diamond, the raw materials of synthetic diamond, are measured, mixed, granulated and pressed into synthetic rods according to the mass percentage; the mass percentage of the raw materials is: carbon source graphite 25~ 30%, active rare earth elements 0.008-0.02%, nano-diamond 0.5-0.8%, and the balance is catalyst.

[0025] (2) The synthetic rod pressed in step (1) is put into a synthetic block, and the assembled synthetic block is placed in a vacuum drying box for constant temperature drying for use.

[0026] (3) The synthetic block assembled in step (2) is synthesized by a six-sided top press through ultra-high pressure and high temperature.

[0027] (4) Take out the synthetic rod synthesized in step (3), obtain self-sharpening polycrystalline diamond afte...

Embodiment 2

[0028] Embodiment 2: a synthetic process technology of high-grade self-sharpening polycrystalline diamond, is characterized in that comprising the steps:

[0029] (1) The carbon source graphite, catalyst, active rare earth element and nano-diamond, the raw materials of synthetic diamond, are measured, mixed, granulated and pressed into synthetic rods according to the mass percentage; the mass percentage of the raw materials is: carbon source graphite 25~ 30%, active rare earth elements 0.008-0.02%, nano-diamond 0.5-0.8%, and the balance is catalyst.

[0030]Among them, the carbon source graphite is a mixture of 99% flake natural graphite and 1% carbon nanotubes, % are mass percentages, and the particle size of flake natural graphite is 200 mesh; the catalyst is used as a catalyst, and the catalyst adopts gas atomized iron, manganese and nickel. Cobalt metal alloy powder: Nanodiamond is produced by the detonation method as a co-nucleating agent, and the particle size distributi...

Embodiment 3

[0037] Embodiment 3: A synthesis technology of high-grade self-sharpening polycrystalline diamond, the drying temperature in step (4) is preferably 800°C. Other steps are the same as in Example 2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com