Method and device for reducing emission limits of nitrogen oxides in waste incineration flue gas

A technology of waste incineration and nitrogen oxides, which is applied in the direction of combustion methods, exhaust gas devices, chemical instruments and methods, etc., can solve the problems of harmless, reduction, resource disposal, surrounding environment damage, and causing Greenhouse effect and other issues, to achieve good application and promotion value, low operating costs, and improve the use of heat energy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

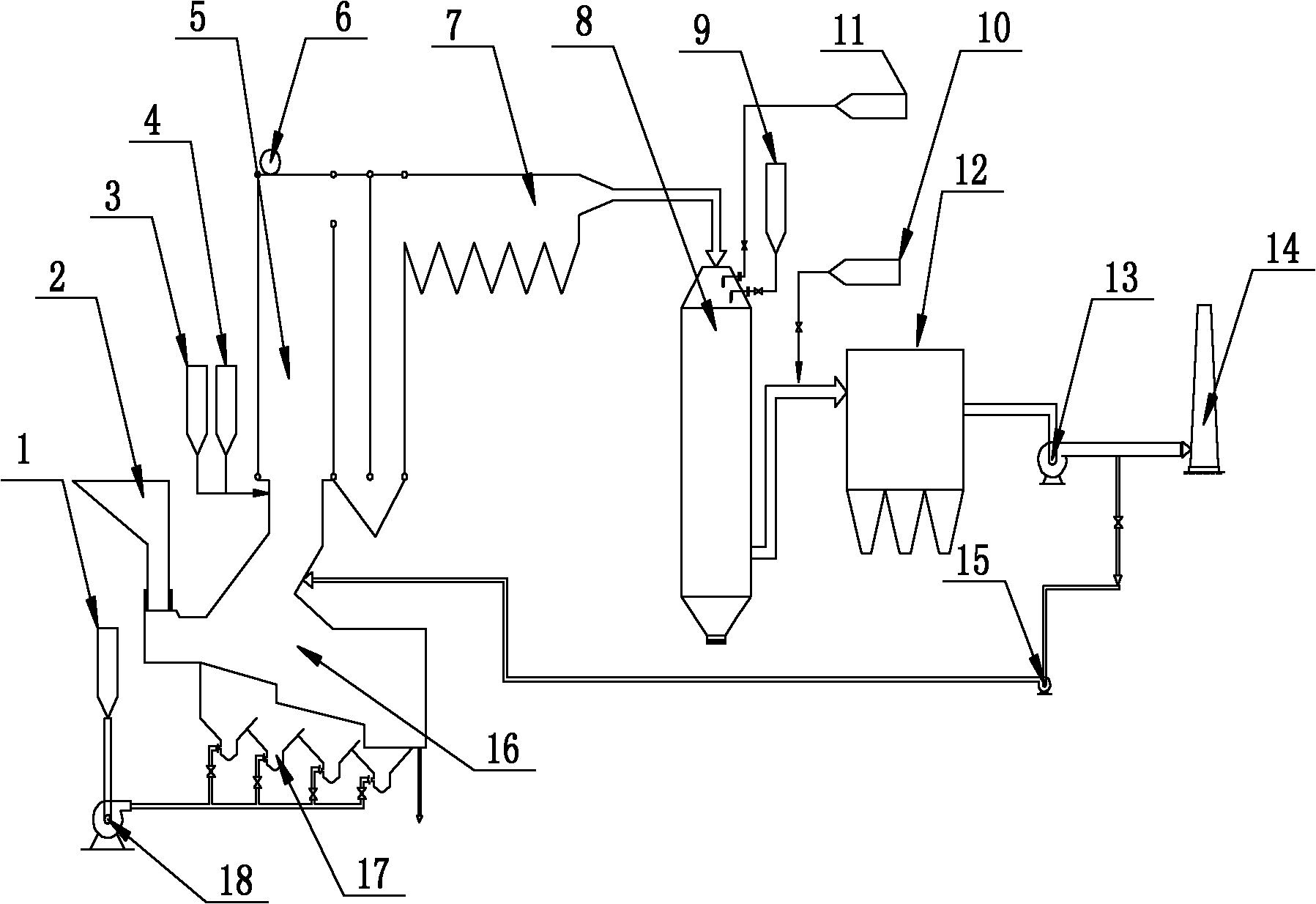

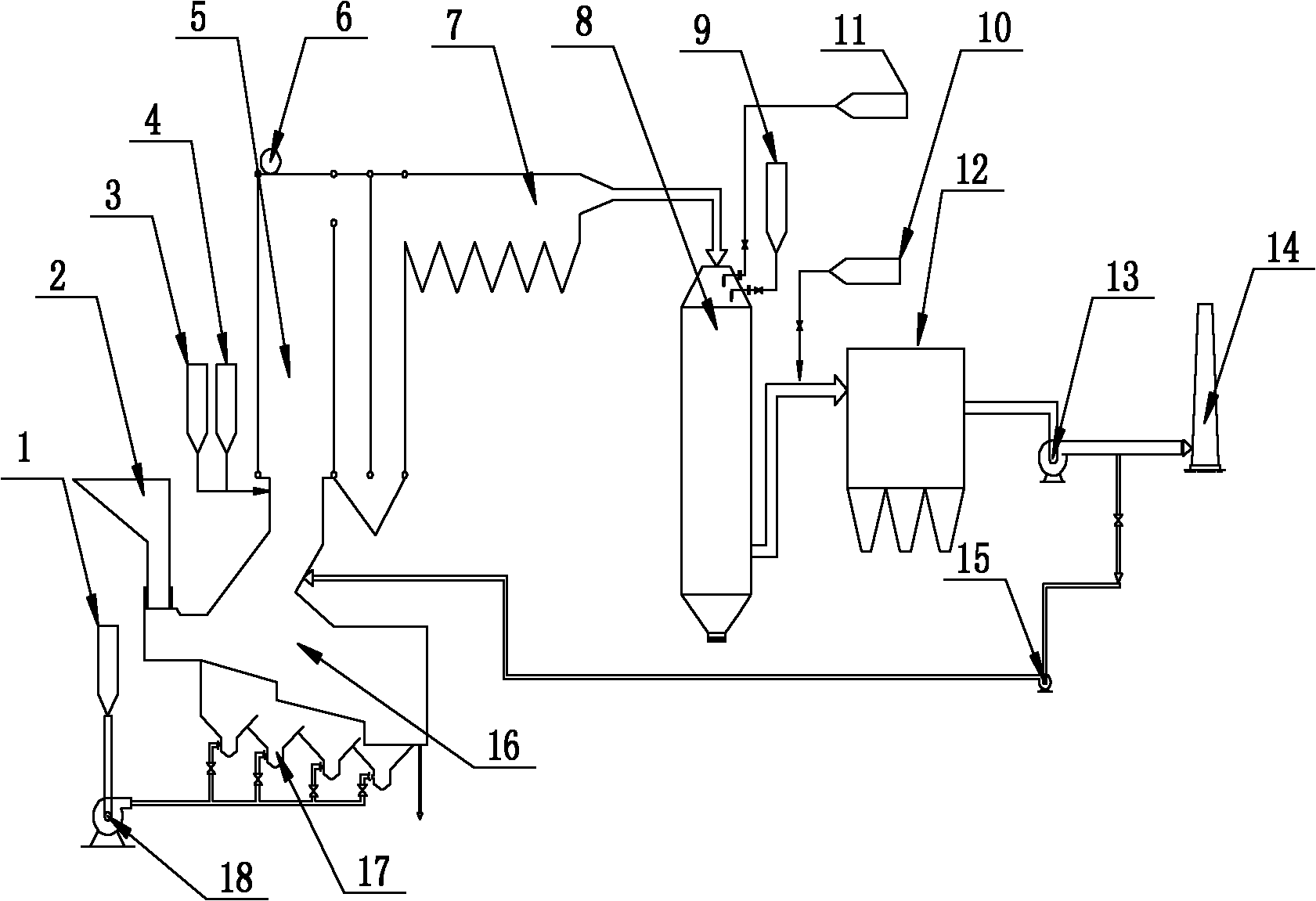

[0064] Such as figure 1 as shown,

[0065] A device for reducing the emission limit of nitrogen oxides in waste incineration flue gas, comprising a waste incineration treatment device, an optimized air supply device, a waste heat boiler device, an SNCR (selective non-catalytic reduction) device, and a tail gas treatment device.

[0066] The waste incineration treatment device includes a waste hopper, an incinerator, a combustion control device, a fire grate, a hydraulic device, an auxiliary burner, and an air inlet hopper;

[0067] The garbage feeding hopper is connected with the incinerator. The bottom of the incinerator is equipped with a cone-shaped air inlet hopper. The upper part of the air hopper is a grate piece. The grate is driven by a hydraulic device, and the stroke of the grate is controlled by a combustion control device; an auxiliary burner is installed at the end of the grate furnace, and when the temperature of the incinerator is lower than 850°C, the auxiliar...

Embodiment 2

[0080] A method for reducing the emission limit of nitrogen oxides in waste incineration flue gas is carried out according to the following steps:

[0081] Step 1: The garbage in the garbage storage pit enters the incinerator after being loaded by the grab bucket, and the incinerator uses the reciprocating motion of the grate to make the garbage fully incinerated through the drying section, burning section, and burning section; the garbage is burned The final ash is discharged from the incinerator. The processing capacity of this waste incinerator is greater than 300t / d, and it is suitable for waste with a calorific value greater than 5000Kj / Kg;

[0082] Step 2: The oxygen supply for garbage incineration is mainly supplied by the primary air. The source of the primary air supply is the gas in the garbage storage pit. The primary air enters the incinerator through the air inlet bucket under the grate, and the stench in the gas passes through the furnace be incinerated and remov...

Embodiment 3

[0089] A method for reducing the emission limit of nitrogen oxides in waste incineration flue gas, which mainly includes the following steps:

[0090] (1) The garbage enters the garbage incinerator smoothly through the feeding device, and the garbage is fully dried, burned and burned by the continuous action of the grate in the furnace, and the temperature in the combustion section reaches above 850°C;

[0091] (2) The oxygen supply for the combustion of materials in the garbage incinerator comes from the primary fan, and the source of the primary air supply is the gas in the garbage storage pit, and the stench in the gas is removed by the high temperature in the furnace;

[0092] (3) The flue gas after the combustion of the materials in the waste incinerator enters the waste heat boiler, and a secondary air supply port is set on the upper part of the connection between the two. The flue gas in the pipe before the chimney, this setting can reduce the oxygen content in the flue...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com