Method for producing long-acting soil conditioning agent by using potassium feldspar and organic waste

A technology for organic wastes and soil conditioners, applied in the field of long-acting soil conditioners, can solve problems such as unsatisfactory comprehensive utilization of resources, high fluoride content, environmental or air pollution, etc., achieve a reasonable proportion of ingredients and improve quality , the effect of promoting aging

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

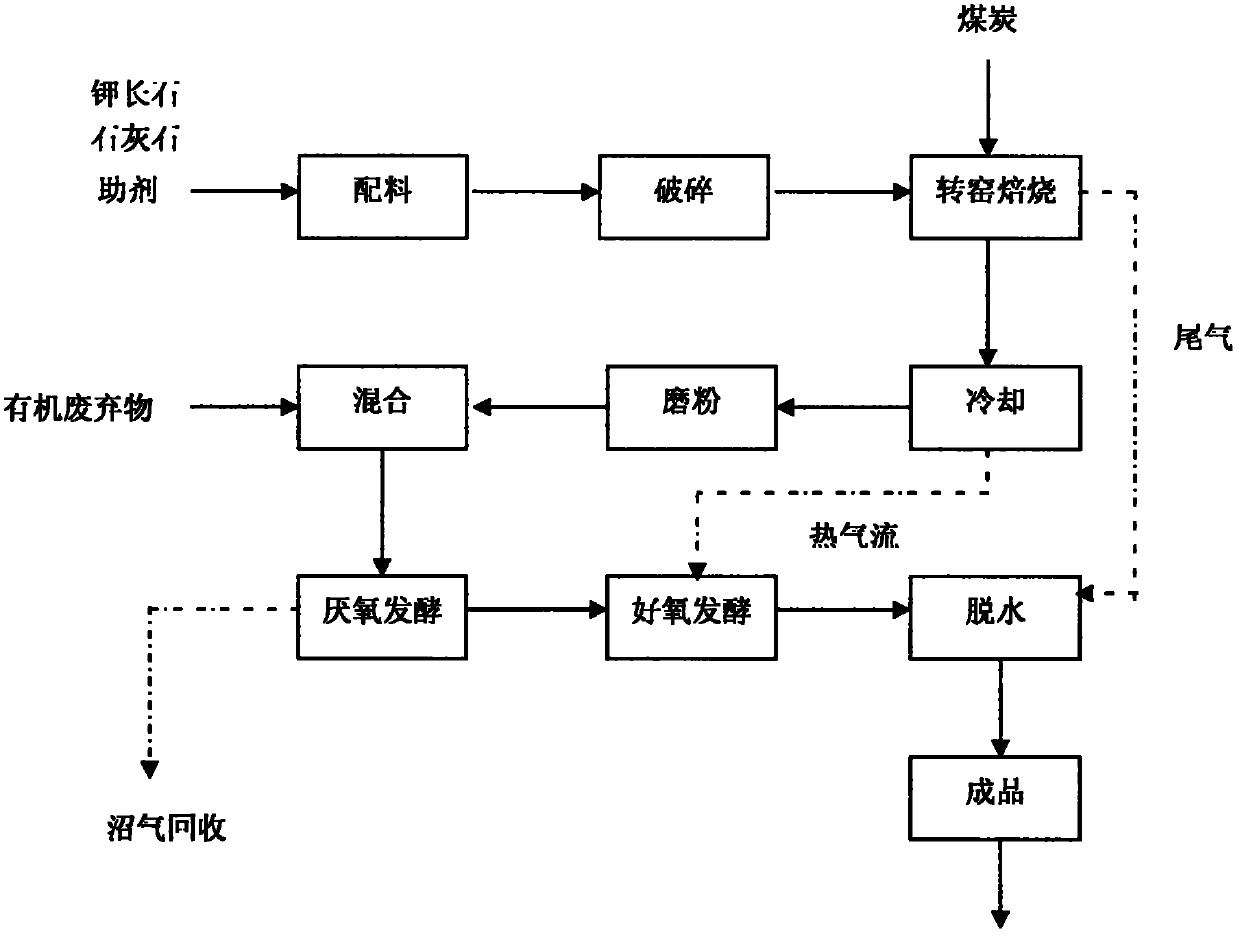

[0035] For the method of producing long-acting soil conditioner using potash feldspar and organic waste, the process flow of this embodiment is as attached figure 1 Shown. Potash feldspar, limestone, gypsum, magnesium sulfate, and sodium sulfate are mixed in weight parts of 10:5:1:1:1, and the mixture is crushed to 50-100mm by a jaw crusher or in other ways. The crushed mixture is roasted by adding a certain amount of coal or other fuels in a rotary kiln, the roasting temperature is controlled at 1000°C, and the roasting time is 10 minutes. After the roasting, the ingredients are cooled to form a sand-like substance, which is then ground into powder with an average particle size of 0.5 to 1.5 mm using an air sweep mill. Add poultry and livestock excrement of equal quality to the powder and mix for 10 days, and then add aerobic bacteria to ferment for 10 days. The fermented mixture is dried and dehydrated by the tail gas produced by the rotary kiln roasting to prepare the prod...

Embodiment 2

[0037] For the method of producing long-acting soil conditioner using potash feldspar and organic waste, the process flow of this embodiment is as attached figure 1 Shown. Potash feldspar, limestone, gypsum, magnesium sulfate, and sodium sulfate are mixed in weight parts of 10:6:1:1:1, and the mixture is crushed to 50-100 mm. The crushed mixture is put into a rotary kiln for roasting, the roasting temperature is controlled at 1000°C, and the roasting time is 20 minutes. After the roasting, the ingredients are cooled to form a sand-like substance, which is then ground into powder with an average particle size of 0.5 to 1.5 mm. Add poultry and livestock excrement of equal quality to the powder and mix for 10 days, and then add aerobic bacteria to ferment for 10 days. The fermented mixture is dried and dehydrated by the tail gas produced by the rotary kiln roasting to prepare the product long-acting soil conditioner.

Embodiment 3

[0039] For the method of producing long-acting soil conditioner using potash feldspar and organic waste, the process flow of this embodiment is as attached figure 1 Shown. Potash feldspar, limestone, gypsum, magnesium sulfate, and sodium sulfate are mixed in weight parts of 10:10:1:1:1, and the mixture is crushed to 50-100 mm. The crushed mixture is put into a rotary kiln for roasting, the roasting temperature is controlled at 1000°C, and the roasting time is 30 minutes. After the roasting, the ingredients are cooled to form a sand-like substance, which is then ground into powder with an average particle size of 0.5 to 1.5 mm. Poultry excrement was added to the powder at a ratio of 9:1 and mixed for anaerobic fermentation for 20 days, and then aerobic bacteria were added for fermentation for 10 days. The fermented mixture is dried and dehydrated by the tail gas produced by the rotary kiln roasting to prepare the product long-acting soil conditioner.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com