Patents

Literature

238results about How to "In line with industrial policy" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Pesticide auxiliary agent

ActiveCN1701663AWith characteristicsHave made significant progressBiocideAnimal repellantsActive agentSolvent

Disclosed is a pesticide auxiliary agent whose raw material includes (by mass ratio) plant oil 100, auxiliary solvent 0-50, surface active agent 5-55, the auxiliary agent can be made into the dosage forms of oil miscible concentrate, oil solution, hot mist, aerosol, low-volume spraying agent, pesticide, germicidal agent, sterilizing agent, hygienic pesticide and plant growth agent.

Owner:FUJIAN NUODE BIOTECH

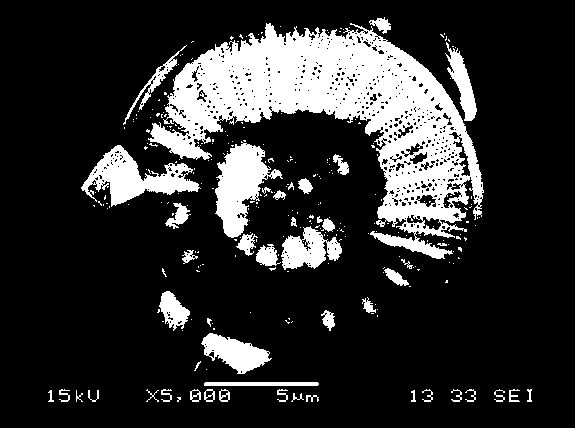

Method for preparing high-performance neodymium iron boron by using secondary recycled materials

InactiveCN102211192ALow costMolecular anisotropy field highMagnetic materialsDecrepitationSintered magnets

The invention relates to a method for preparing high-performance neodymium iron boron by using secondary recycled materials, which comprises the following steps: (1) preprocessing the secondary recycled materials of the neodymium iron boron: removing impurities and dust from the secondary recycled materials and quickly drying the secondary recycled materials; (2) preparing the raw materials of the neodymium iron boron; (3) mixing materials: adding the preprocessed secondary recycled materials into the raw materials so as to form the mixed materials, wherein the weight of the preprocessed secondary recycled materials is 10-40% of the weight of the raw materials; (4) performing disproportionation reaction in a hydrogen decrepitation furnace; (5) crushing and milling by a jet mill; (6) mixing by using a double cone-type blender; (7) profiling; (8) vacuum-sintering; and (9) tempering the sintered materials: tempering at 900 DEG C for 1-3 hours for the first time, continuing to warm and tempering at 480-550 DEG C for 4-8 hours for the second time, and then performing the conventional quick air cooling, thereby acquiring a sintered magnet. The neodymium iron boron prepared by using the method is characterized in that the secondary recycled materials are used as the main ingredients, thereby saving a large amount of cost, shortening the production period, lowering energy consumption and meeting the national industrial policy. The performance of the prepared neodymium iron boron permanent magnet material can reach N42SH, and the performance index is very high.

Owner:TIANJIN YIYANG MAGNETIC MATERIALS

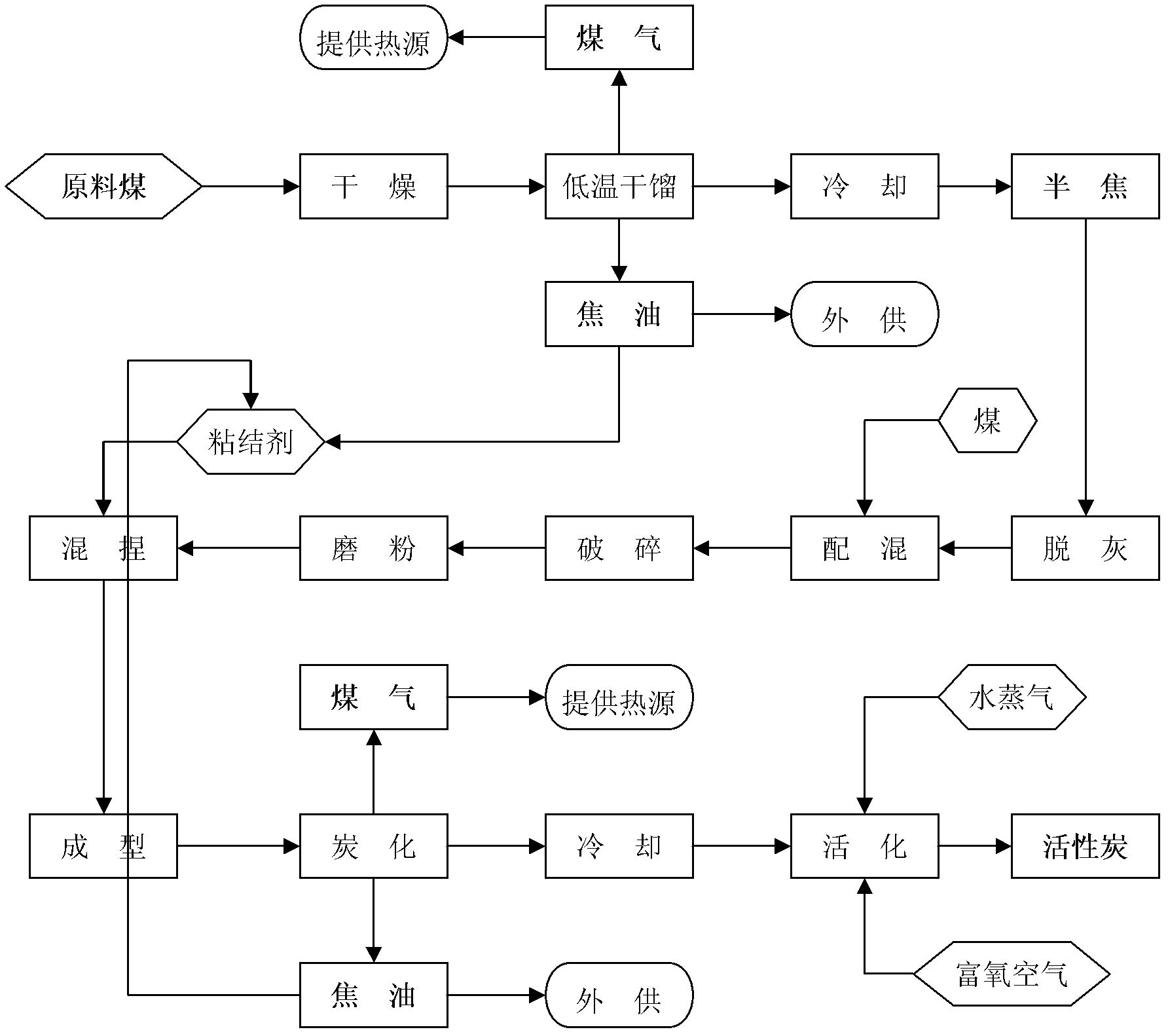

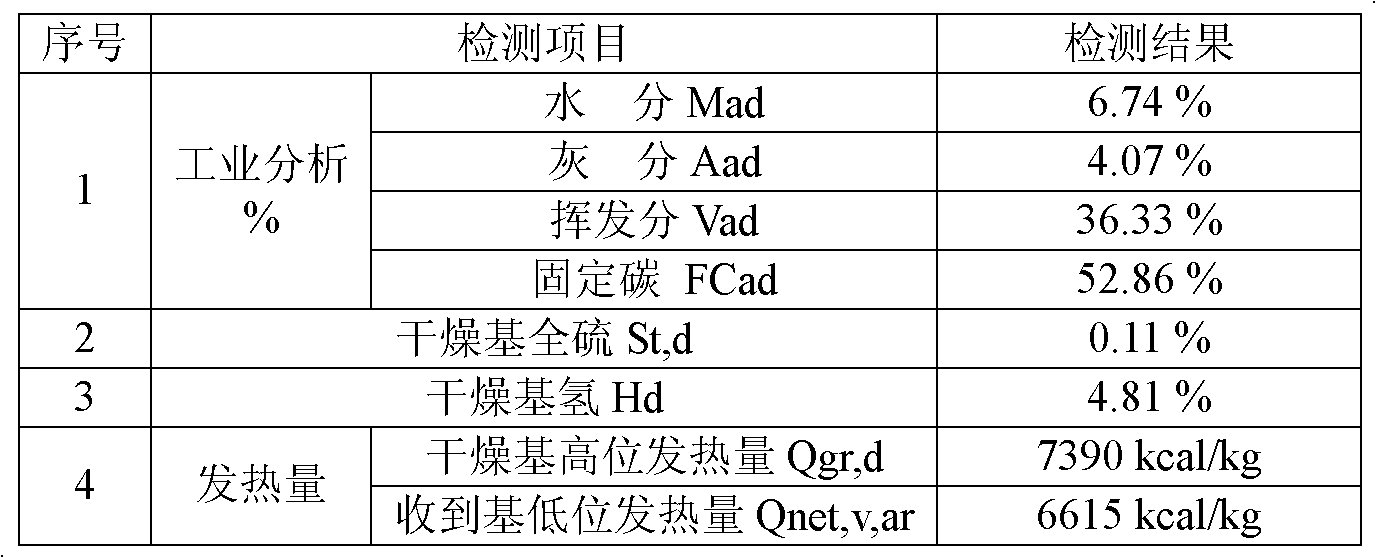

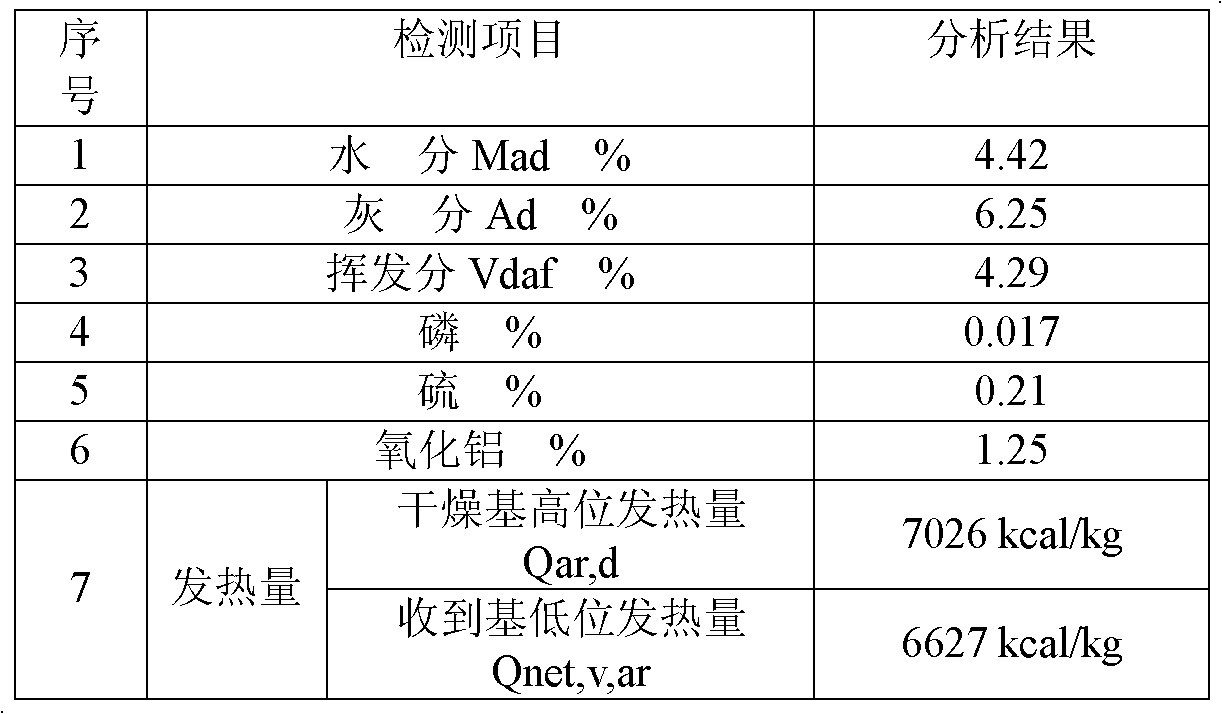

Method for preparing active carbon by using coal

The invention provides a method for preparing active carbon by using coal. The method comprises the following steps: after feed coal is dried, dry-distilled at low temperature and cooled, semicoke is obtained; deashing is carried out on the semicoke in which the ash content can not meet the production requirement of the active carbon; coal is mixed with certain viscosity into the semicoke which can not meet the strength of the active carbon according to the characteristics; after mixed with the coal, the raw materials are mixed fully by crushing and grinding; after a certain amount of binding agent is added, the powder is mixed and kneaded, and is pressed into a forming material with a special shape in forming equipment; the forming material enters a carbonization furnace by a conveying device, carrying out heat treatment, dry-distillation, heat cracking and condensation reaction at different temperature sections to prepare carbonized materials; the carbonized materials are conveyed to a cooling furnace for cooling by the conveying device; and the cooled carbonized materials are conveyed to an activating furnace, and is activated by utilizing an activating agent. The method has the advantages that the industrial chain for comprehensive utilization of subcannel coal is extended, the utilization bottleneck of the semicoke is broken, products with increasing market demand are produced, the strategic resources short in China can be effectively recovered, and large economic and social benefits can be created.

Owner:西安三瑞实业有限公司

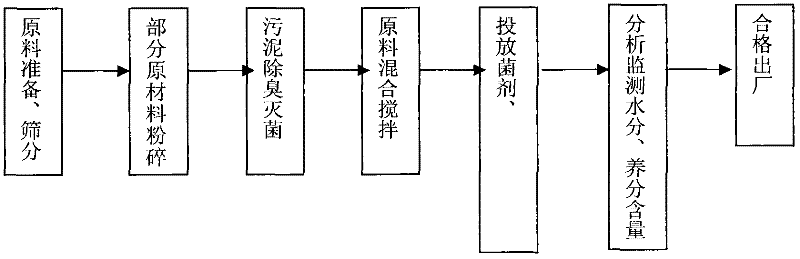

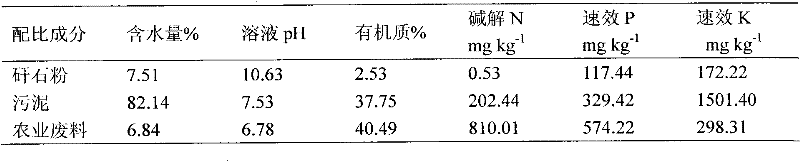

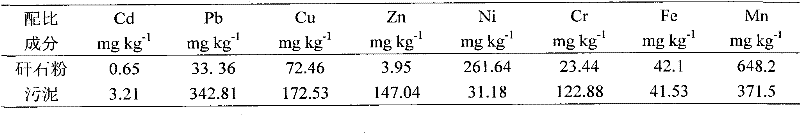

Artificial soil and manufacturing method thereof

The invention discloses an artificial soil and a manufacturing method thereof. The soil comprises components of, by weight: 55-60% of sludge, 25-32% of mining area waste, 6-18% of agriculture and forestry waste, and 2% of an additive. The method for manufacturing the artificial soil comprises steps of: raw material preparing, screening, partial raw material crushing, sludge deodorizing and sterilizing, raw material mixing and stirring, microbial manure adding, and water content and nutrient analyzing and monitoring. According to the invention, the adopted raw materials are wastes which can pollute the environment, such that wastes are turned into valuable matters. With the method provided by the invention, soil reclamation and reparation can be carried out near mining areas.

Owner:王夕刚

Composite shoat premixing feed

ActiveCN101611829AReduce pollutionEmission reductionAnimal feeding stuffAccessory food factorsPhytaseFeed conversion ratio

The invention relates to a pig feed, in particular to a composite shoat premixing feed. The composite shoat premixing feed comprises the following raw materials according to weight ratio: 60-80 of complex vitamin, 45-65 of low-copper mineral element, 6-12 of tryptophan, 6-12 of liquorice, 5-10 of membranous milkvetch root powder, 9-13 of dangshen, 5-10 of Chinese angelica, 5-8 of ligusticum wallichii, 9-15 of bacillus subtilis, 4-8 of chromium yeast, 5-10 of selenium yeast, 4-8 of zinc methionine, 4-8 of methionine iron, 3-6 of phytase, 10-20 of rovabio enzyme, 30-50 of lysine, 18-30 of choline chloride, 40-60 of steam fish meal, 40-60 of fermentation soybean protein, 15-20 of threonine, 80-100 of salt, 180-250 of calcium carbonate, 100-160 of calcium hydrophosphate and 80-200 of zeolite powder. The product belongs to environmentally-friendly feed with high efficiency; shoats have big feed intake, do not have loose bowels, have high survival rate and have high feed conversion rate and high nutrient; in addition, shoats produced with the method have high growing speed and high feed reward, so that the invention has high economic benefit and social benefit.

Owner:江西大佑农生物科技有限公司

Lightweight fireproof foaming cement door inner filling material and preparation method thereof

InactiveCN101143777AIncrease gas productionWith thermal insulationSolid waste managementCeramicwareReducing agentWeight light

The invention discloses a lightweight flame retardant and foamy filling material of cement doors and manufacturing method thereof, comprising magnesium oxide, magnesium sulphate, fly ash, high alumina refractory cement, calcium chloride, water proofing agent, water reducing agent and foaming agent, with bulk density ranging between 200 kg / m3 and 500kg / m3; the ingredients are formulated by weight at a rate of: magnesium oxide (40 percent -55 percent), magnesium sulfate (15 percent-40 percent), fly ash (5 percent-20 percent), high alumina refractory cement (5 percent-20 percent), calcium chloride (2 percent-6 percent), water proofing agent (2 percent5 percent), water reducing agent (0.2 percent1.5 percent) and foaming agent (0.1 percent-0.5 percent). With the technical solution, the product has the advantages of high strength, light weight, flame retardancy, sound insulation, weather resistance, thermal resistance, energy efficient, freedom from toxicity, harm and irradiation, low manufacturing cost, simple process, etc, which can be widely employed for fire / theft proof metal interior door, building material and like sectors.

Owner:ZHEJIANG MEIXIN IND CO LTD

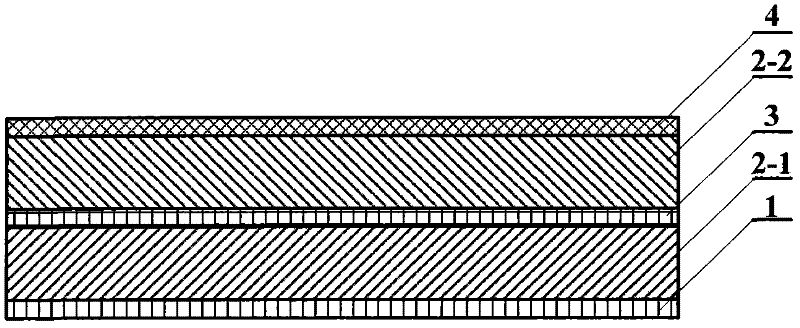

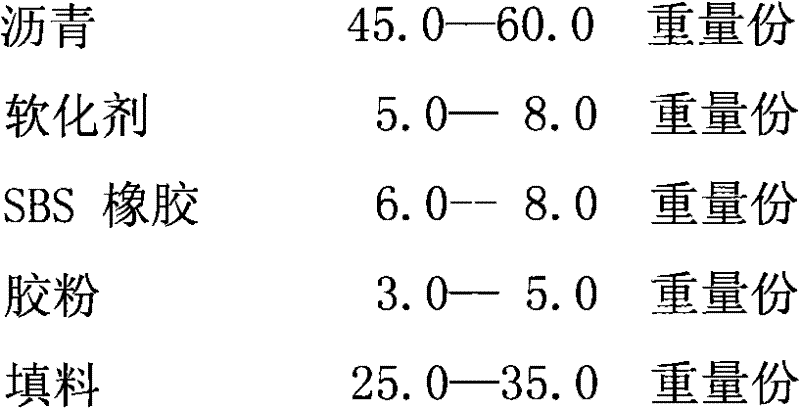

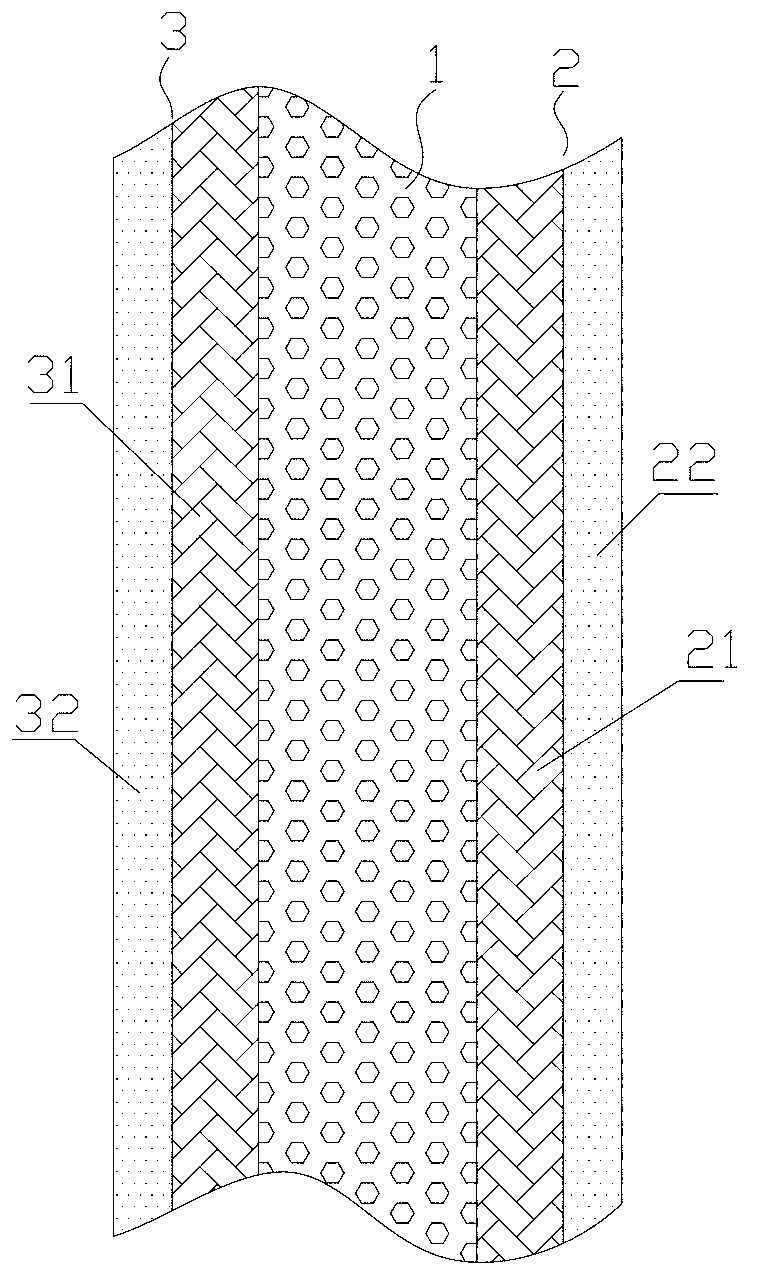

Modified asphalt waterproof coiled material with heat insulation function and preparation method thereof

InactiveCN102409812AReduce absorptionReduce the temperatureRoof covering using flexible materialsSynthetic resin layered productsBituminous waterproofingPolymer science

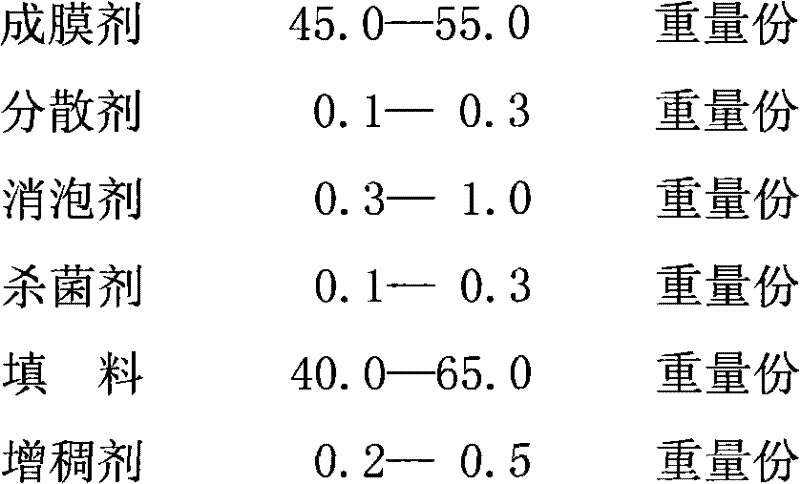

The invention provides a modified asphalt waterproof coiled material with a heat insulation function and a preparation method thereof. The coiled material comprises a bottom film 1, a first modified asphalt layer 2-1, a base layer 3 and a second modified asphalt layer 2-2, and is characterized by also comprising a coverage layer 4, wherein the first modified asphalt layer 2-1 and the second modified asphalt layer 2-2 are sequentially arranged on the upper surface of the bottom film 1; the base layer 3 is arranged between the first modified asphalt layer 2-1 and the second modified asphalt layer 2-2; and the coverage layer 4 is arranged on the upper surface of the second modified asphalt layer 2-2. The surface coverage layer is prepared by proportioning raw materials for a film forming agent, synthesizing the film forming agent and preparing a coverage layer material. The performance of the modified asphalt waterproof coiled material is increased by changing the category and the proportion of a filling material in the raw materials in a waterproof structural layer, so that the modified asphalt waterproof coiled material has extremely high waterproof performance and the heat insulation function and is an ideal building energy-saving product.

Owner:BEIJING LIGAO WATERPROOF ENG CO LTD

Vertical shaft multiple incinerator for refuse pyrolysis, gasification and fusion

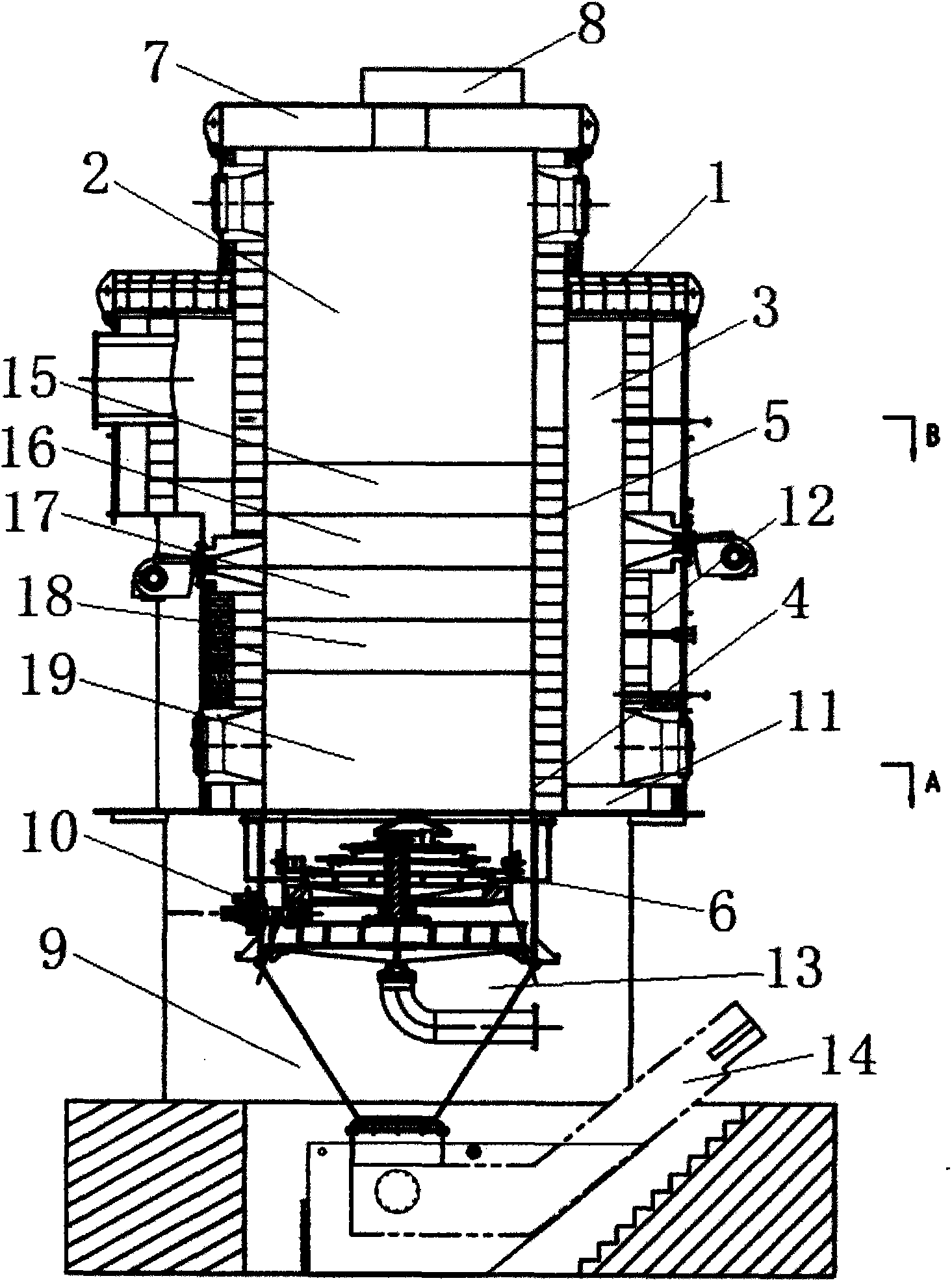

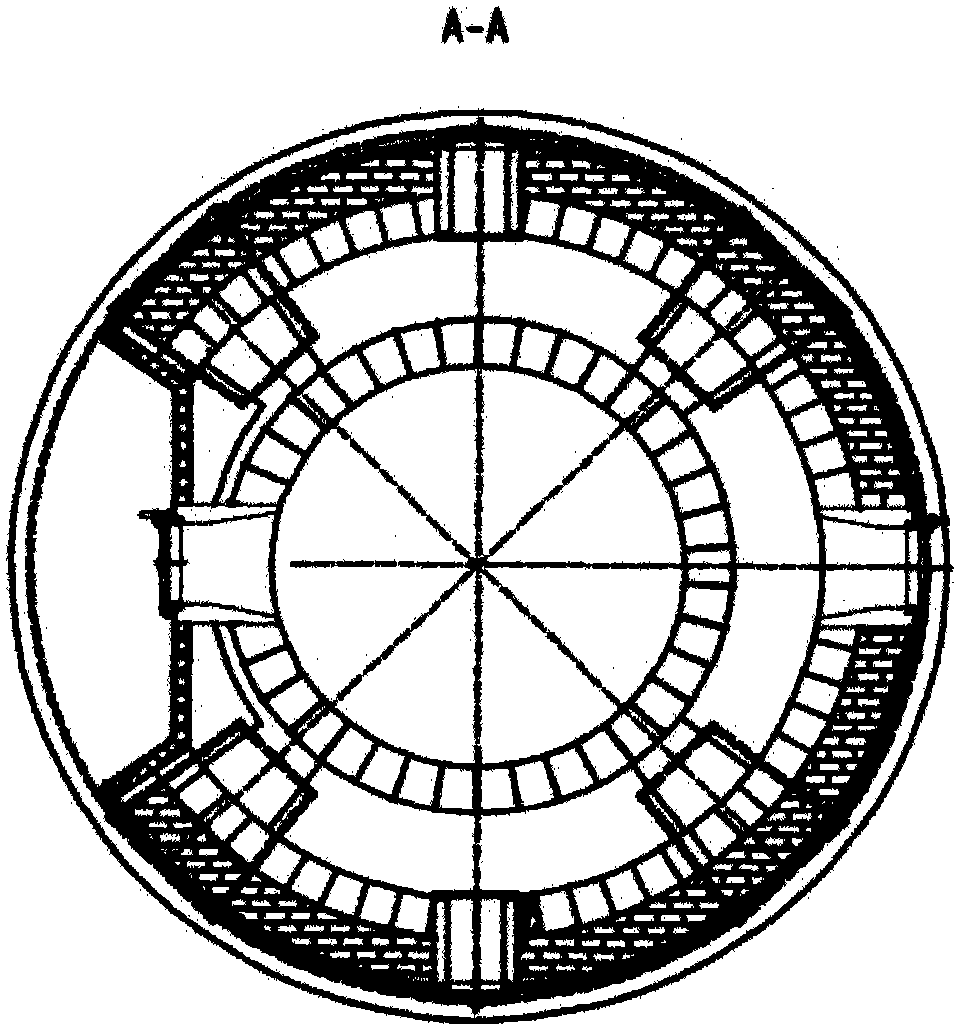

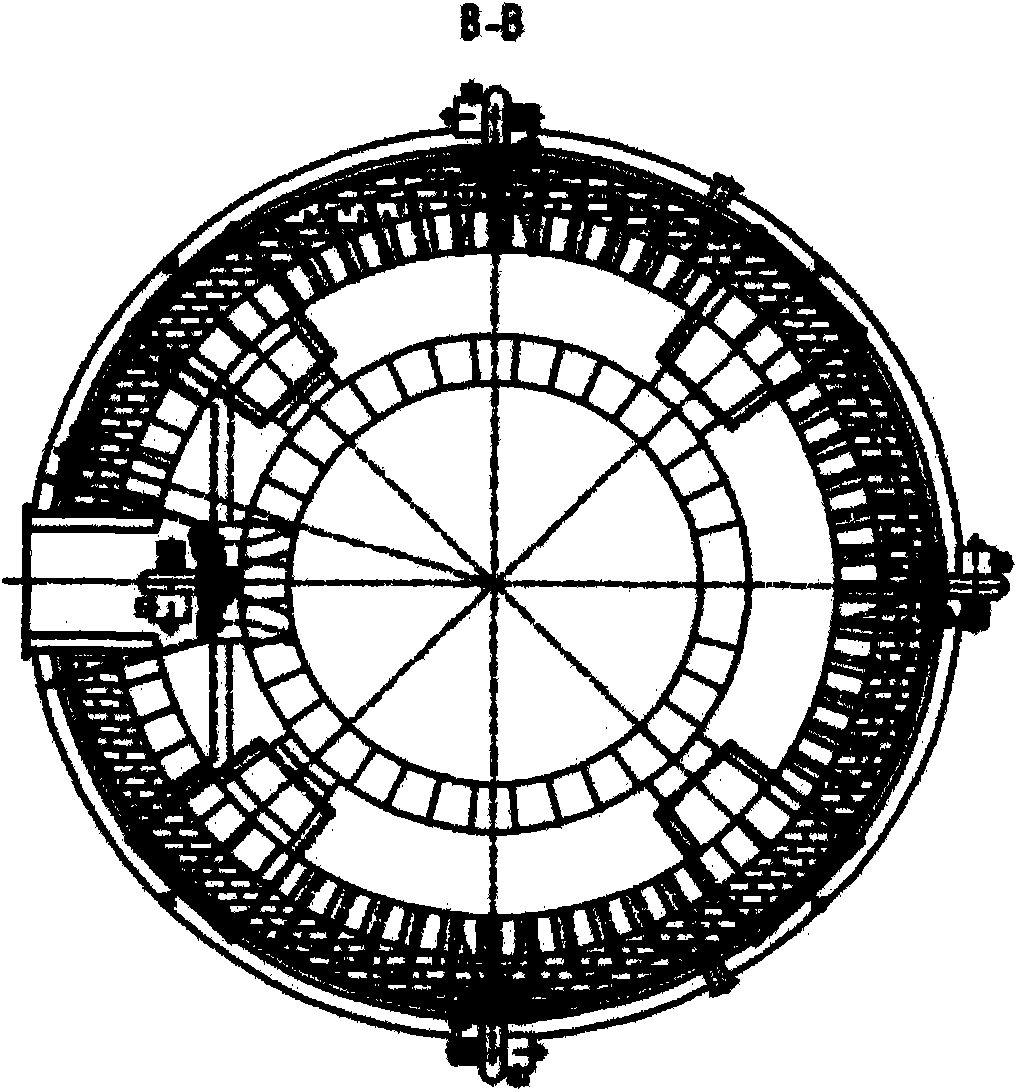

The invention discloses a vertical shaft multiple incinerator for pyrolysis, gasification and fusion. The vertical shaft multiple incinerator for pyrolysis, gasification and fusion comprises a vertical coaxial structure incinerator body, a main combustion chamber and a secondary combustion chamber outside the main combustion chamber are arranged in the incinerator body, the main combustion chamber and the secondary combustion chamber are of a horizontal multiple coaxial structure, an annular fusion combustion hearth is arranged between the main combustion chamber and the secondary combustion chamber, a high temperature fusion wall and a rotary fire grate are arranged in the combustion hearth, a shaft-less spiral conveying discharging device is arranged on an incinerator cover on the top of the incinerator body, a deslagging mechanism is arranged on the lower portion of the incinerator body, and a driving device of the rotary fire grate is arranged outside the incinerator body. The vertical shaft multiple incinerator for refuse pyrolysis, gasification and fusion is stable in combustion and reliable in operation; because smoke can stay for a long time at high temperature, it can be guaranteed that dioxin pollutants in the smoke can be fully decomposed and the smoke reaching the standard is discharged; because combustion assisting agents do not need to be added, operation cost is low and floor area is small.

Owner:广东昕旺环保科技发展有限公司

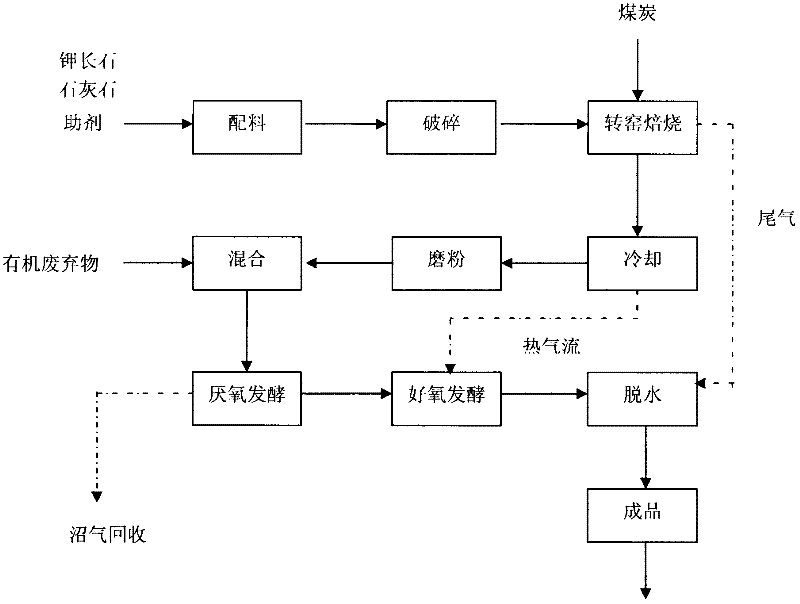

Method for producing long-acting soil conditioning agent by using potassium feldspar and organic waste

ActiveCN102391878ALow costIn line with industrial policyAgriculture tools and machinesOrganic fertilisersPotassiumOxygen

The invention discloses a method for producing a long-acting soil conditioning agent by using potassium feldspar and organic waste. Potassium feldspar, limestone, aid and coal are used as raw materials in the method. The method comprises the following steps of: roasting the crushed raw materials in a rotary kiln by adding the coal, and cooling and milling the roasted raw materials; and mixing the powder and the organic waste such as animal excrement in a farm and the like, performing anaerobic and aerobic continuous fermentation step by step, performing partial dehydration, and thus obtaining a finished product. The produced long-acting soil conditioning agent contains a certain amount of nitrogen, phosphorus, potassium, calcium, magnesium, sulfur, soluble silicon, humic acid and the like, so the soil conditioning agent can effectively improve the soil and provides nutritional components for crops for long time. The soil conditioning agent can be directly applied, and can also be applied with chemical fertilizers. According to the method for producing the long-acting soil conditioning agent by using the potassium feldspar and the organic waste, the production raw materials are mineral in the nature and waste in the farm, the raw materials are extremely rich and cheap, and the production process is energy-saving and environment-friendly.

Owner:SHANGHAI RES INST OF CHEM IND +1

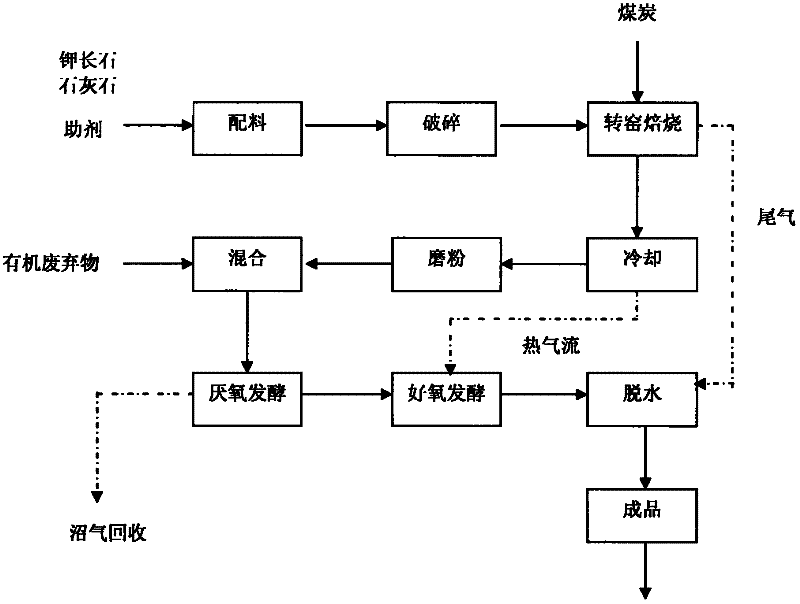

Composite filtering material for activating and regenerating coal ash and production method thereof

InactiveCN101274172ALow costReduce processingOther chemical processesFiltration separationFiltrationGranularity

The invention discloses a fly ash activation regeneration composite filtration material and a manufacture method of the filtration material, belonging to the field of water treatment technique. The fly ash activation regeneration composite filtration material consists of 80 to 90 portions of fly ashes or furnace ashes (by weight) with the grain diameter not less than 80 meshes and 10 to 20 portions of porous aluminosilicate mixed powders (by weight); the fly ash or the furnace ash are bonded as grain shape with the granularity less than 8mm; the porous aluminosilicate mixed powders are enwrapped on the surface of the fly ashes or the furnace ashes and burned so as to form a ceramic layer which is provided with an adsorption micro-hole which is communicated with an internal core. The fly ash activation regeneration composite filtration material is fabricated and formed by the steps of raw material mixing, primary granulation, secondary granulation, drying, roasting, etc., and has the advantages of low cost and good purification effect.

Owner:江苏正本净化节水科技实业有限公司

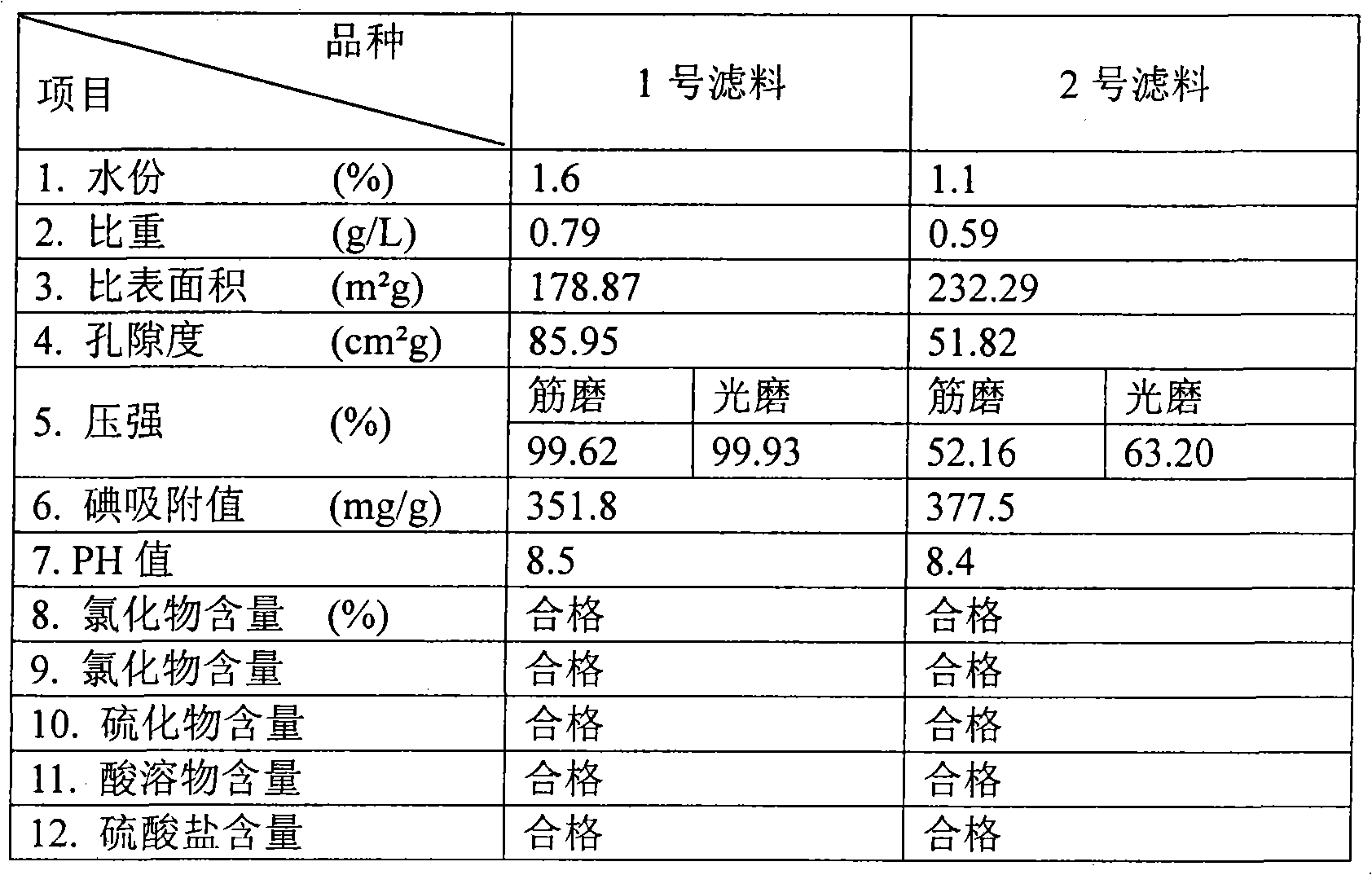

Gold wet purification process

The invention relates to a process for purifying gold by the wet method. Firstly, aqua fortis is used to remove silver; secondly, nitric acid is used to remove impurities such as bismuth and copper, etc.; the separation is performed by filtering; in the richly contained gold solution, the gold is reduced to gold powder deposited by an oxalic acid reducing agent with strong reducibility, and the impurities such as platinum, the bismuth and the copper, which are reduced simultaneously, are redissolved by nitric acid added later and enter the solution, and the solution is subjected to the filtering separation to obtain pure gold powder; and the pure gold powder is made to be ingot-shaped by fushion casting, and the finished gold ingots with a gold content of 99.99 percent are obtained. In the invention, the reduction reaction is made by oxalic acid at a low temperature, so that the process of the invention has the advantages of not causing environmental pollution, favorability for the heath of operators, lowering cost, shortening the period and obvious economic and social benefits.

Owner:CHENZHOU CITY JINGUI SILVER IND CO LTD

Inorganic composite A-class non-combustible insulation board and preparation method thereof

ActiveCN103276826ASolve thermal insulationSolve fire resistanceHeat proofingFire proofingInsulation systemUltimate tensile strength

The invention discloses an inorganic composite A-class non-combustible insulation board. The insulation board comprises an insulation core material layer. An interface reinforcement layer is arranged on the outer surface and the inner surface of the insulation core material layer respectively, and each of the interface reinforcement layers comprises an alkali resistant screen cloth layer on the inner layer and a polymer water-proof anti-crack mortar layer on the outer layer. Meanwhile, the ratio of components of the insulation core material layer and the polymer water-proof anti-crack mortar layer is disclosed. The invention further discloses a preparation method of the inorganic composite A-class non-combustible insulation board. The inorganic composite A-class non-combustible insulation board has the advantages that both excellent heat insulation performances and good fire-proof performances are provided. The insulation core material layer and the interface reinforcement layers form an organic whole, so that defects of poor water-proof performances and low surface strength of common inorganic insulation boards are overcome. The insulation board can be pasted through polymer mortar directly when being installed on the wall, tedious interface treatment is not required, construction operations are convenient and rapid, and the bonding between the insulation board and a wall base layer is safe and firm. The wire-proof performance reaches the A class, and the whole fire-proof performance of a wall insulation system is greatly improved.

Owner:安徽华举建材科技股份有限公司

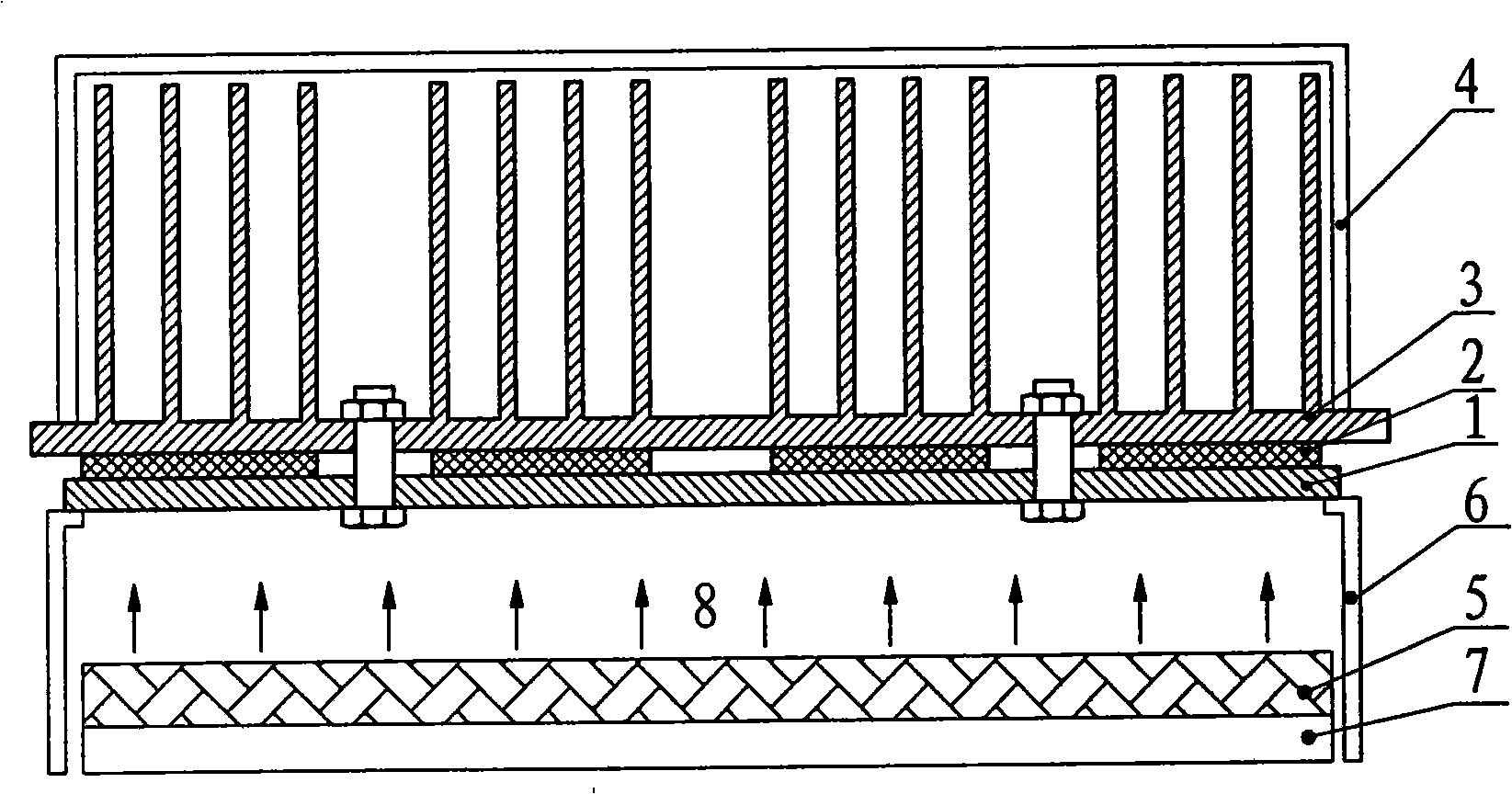

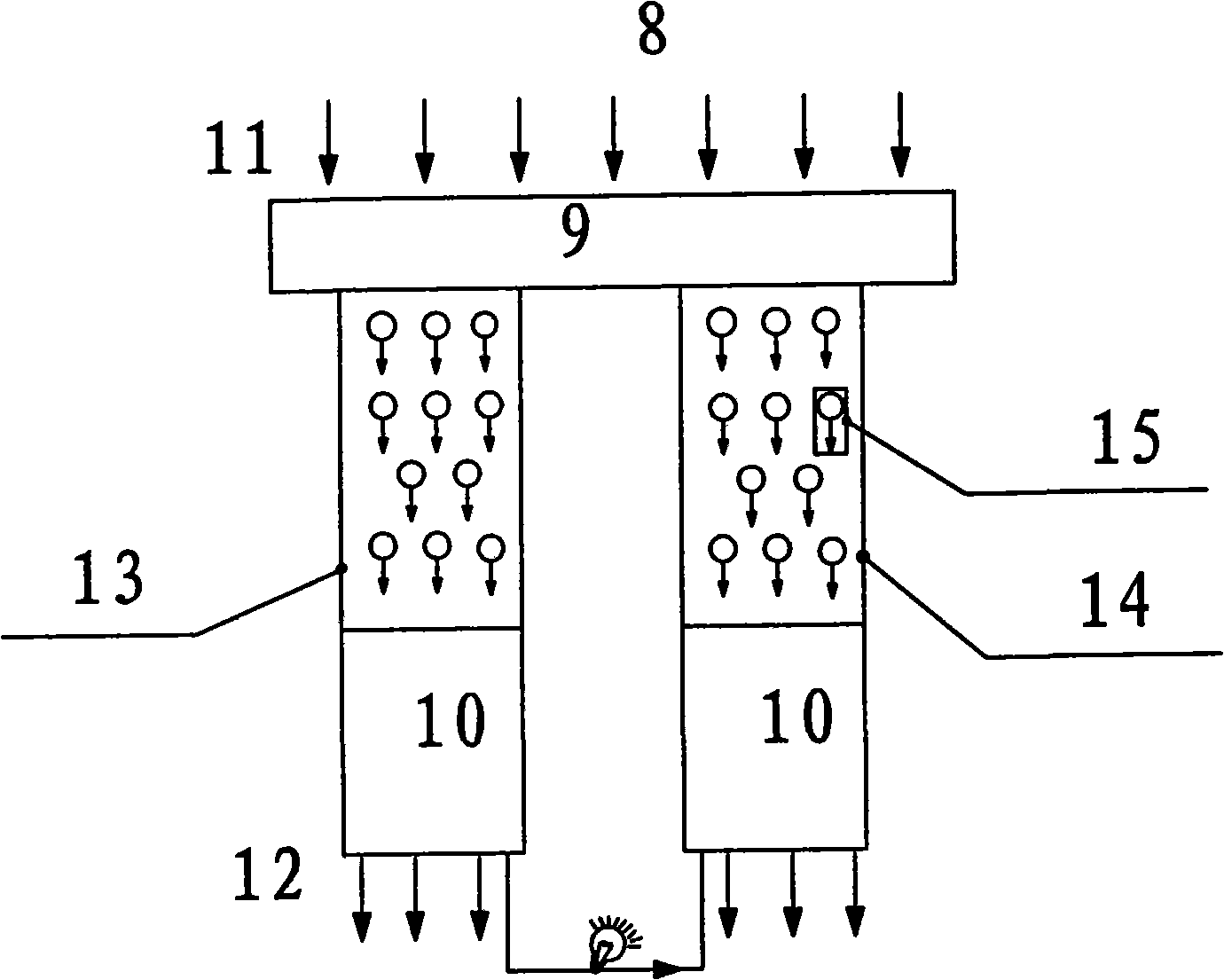

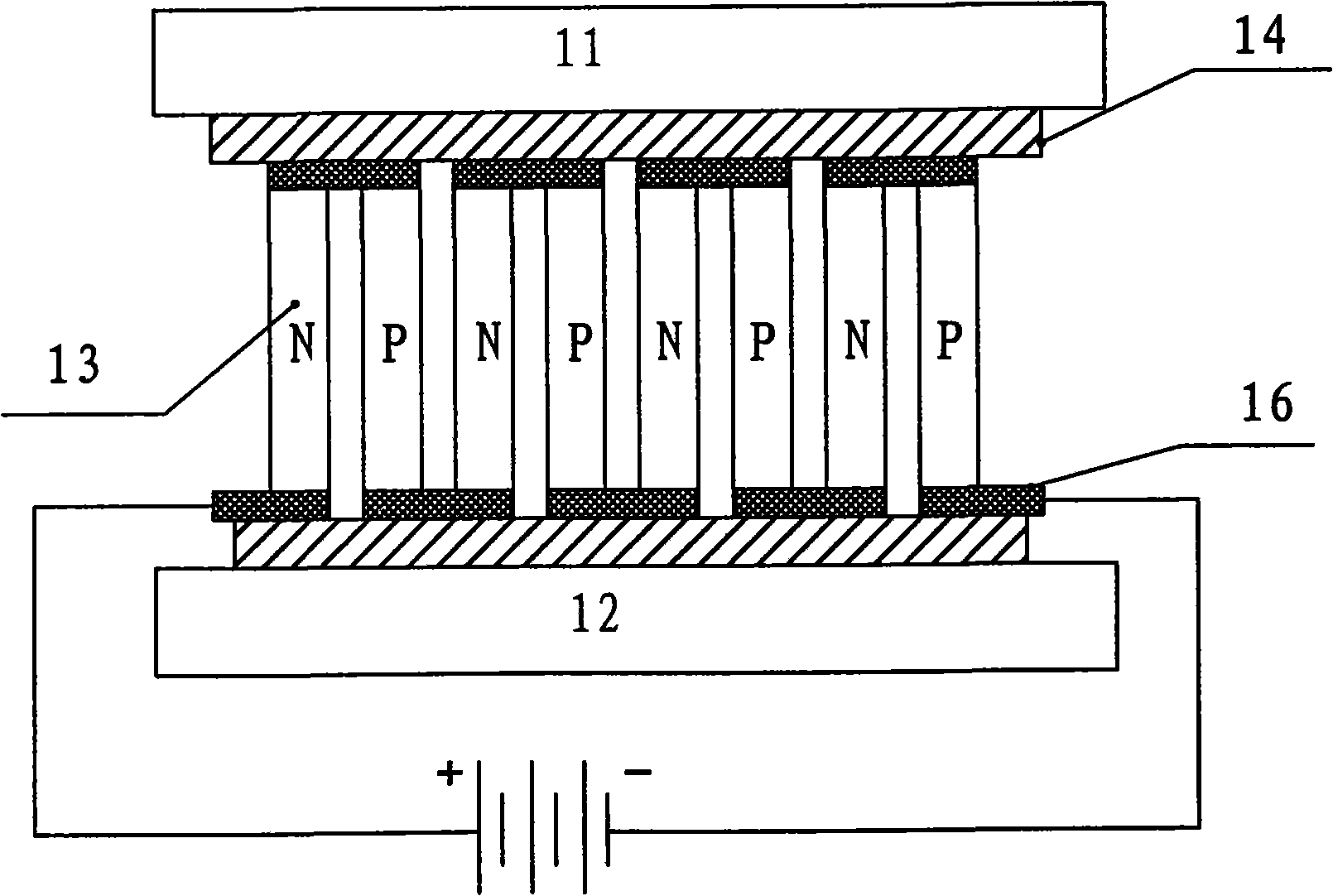

Ceramic kiln-path heat-recovering semiconductor thermal difference generation method and apparatus

InactiveCN101325385AReduce energy consumptionNo noiseGenerators/motorsWaste heat treatmentThermal energyElectric power

Disclosed is a ceramics kiln heat recovery semiconductor thermo-electric generation method of the invention and a device, wherein the ceramics device for emitting the residual heat is arranged below the device, and the radiation heat is adsorbed by a collecting plate, which is transferred to the hot face of the semiconductor thermo-electric generation module; the thermal fin with ribs are arranged above the cold face of the semiconductor thermo-electric generation module, then the hot of the cold face is emitted out, thereby generating the temperature difference at the two end faces of the semiconductor thermo-electric generation module. Due to the Bessel effect in the semiconductor, the electric potential difference is generated, outputted through the voltage stabilization and inverting circuit, namely as the power supply. The structure of the device comprises a semiconductor thermo-electric generation module, a collecting plate, thermal fin with ribs, which has the advantages of directly converting the recovery waste beat into the electric energy, to cause the electric power generation process free of noise, abrasion and dielectric leakage, and having small volume, light weight, convenient movement, no maintenance and long service life and the like.

Owner:无锡明惠通科技有限公司

Method for re-manufacturing flame-proof outer shell

InactiveCN1468052ALong economic lifeMeet production needsSubstation/switching arrangement casingsManufacturing dynamo-electric machinesSurface engineeringHardness

A process for re-create the flame-proof hull characterized by that, a plurality of techniques are combined using the surface engineering technology as a key process to realize the re-creation using the wasted flame-proof hull as the blank, producing the long life multifunctional flame-proof hull with high hardness of flame-proof surface and high corrosion-resisting performance. The method by the invention can realize the multiple repeated application for the flame-proof hulls.

Owner:SHANXI QUANAN NEW TECH DEV CO LTD

Polyurethane base paint for coiled material

InactiveCN1702133AFast curingStrong adhesionAnti-corrosive paintsPolyurea/polyurethane coatingsFoaming agentPhosphate

A coiled material using polyurethane priming paint is prepared by homogeneously mixing polyester resin 1, polyester resin 2, cross linker, colourant, epoxy phosphate compound, solidification catalyst with solvent. The priming paint has a high solidification speed, resistance to solvent (MEK) can amount to 20 times, and has excellent adhesive force to metallic backing. The lacquer film has perfect toughness, and T curving can obtain 0-2T, applying to the field T curving highly required, such as construction and household electrical appliance, and so on. And it has fine foamobility, the blowing agent cohering on the lacquer film amounting to above 90% after foaming.

Owner:SHANGHAI HUAYI FINE CHEM CO LTD

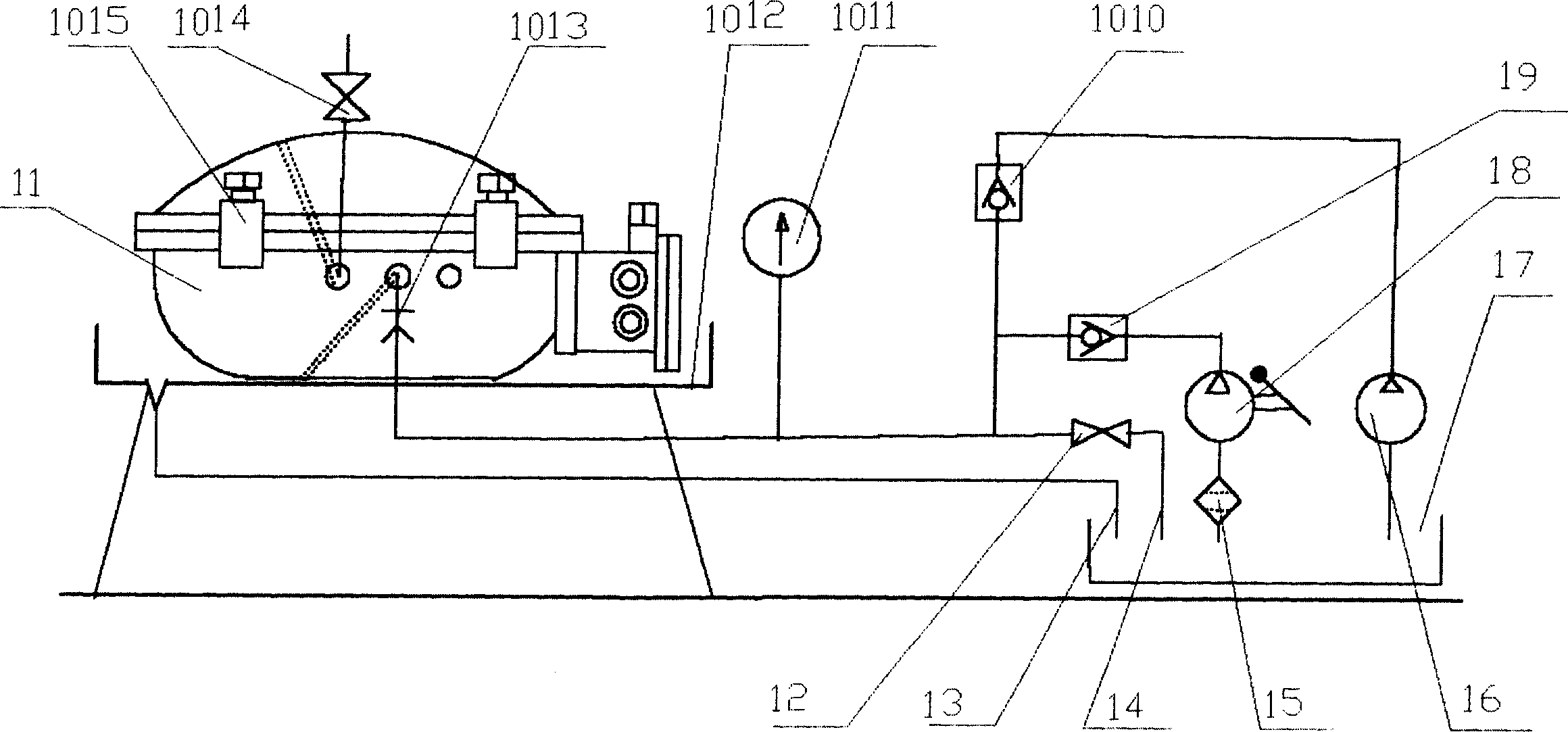

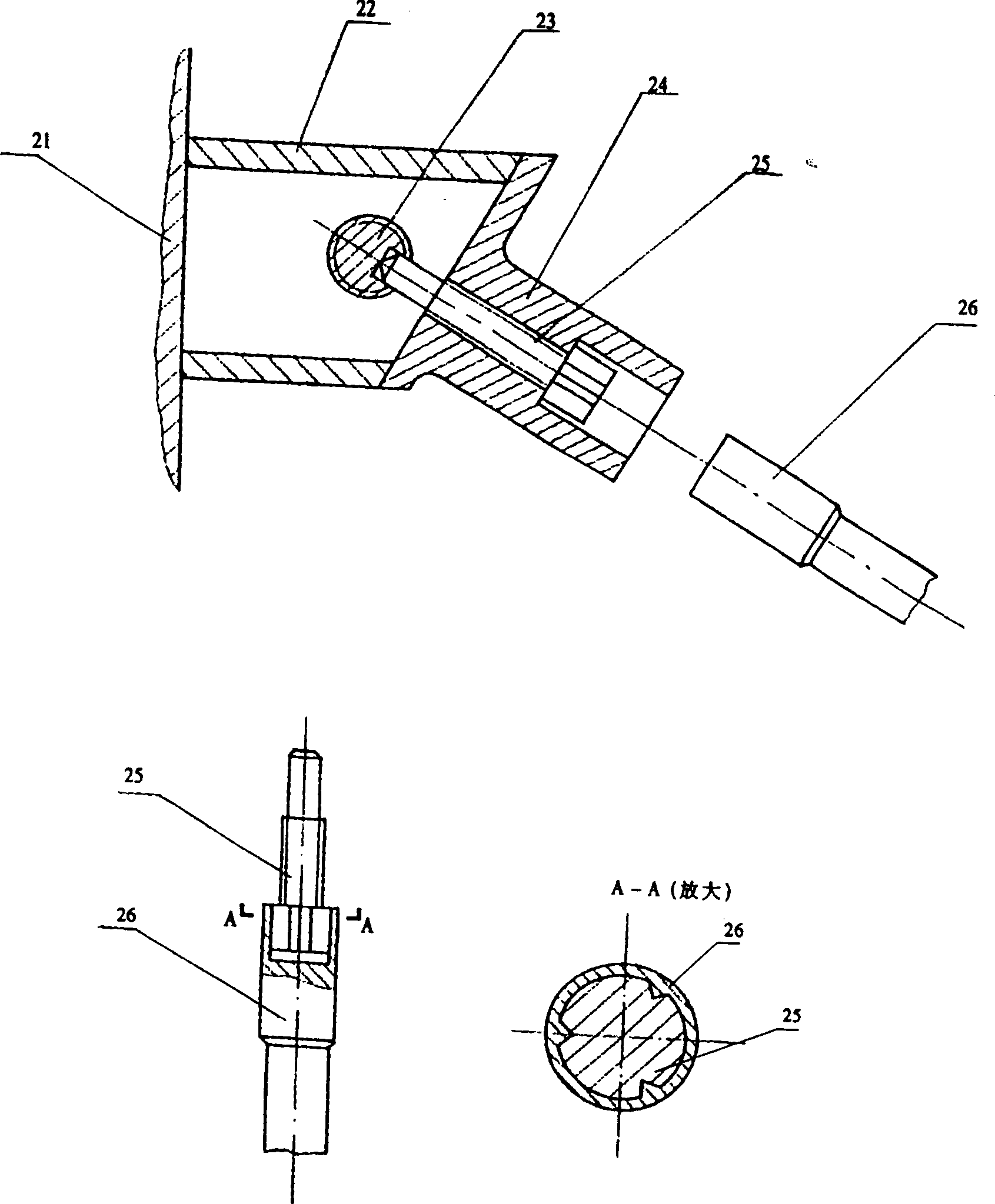

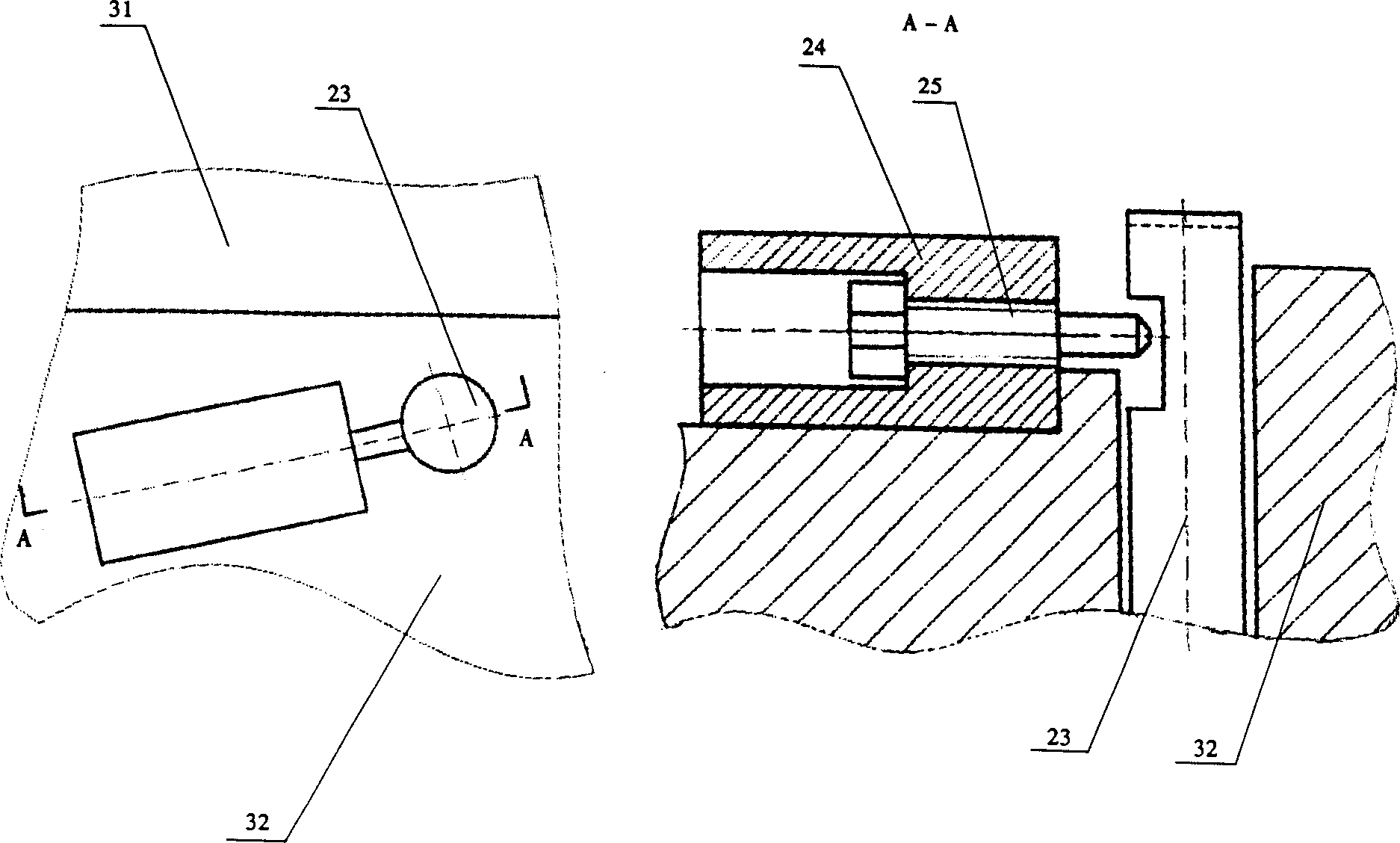

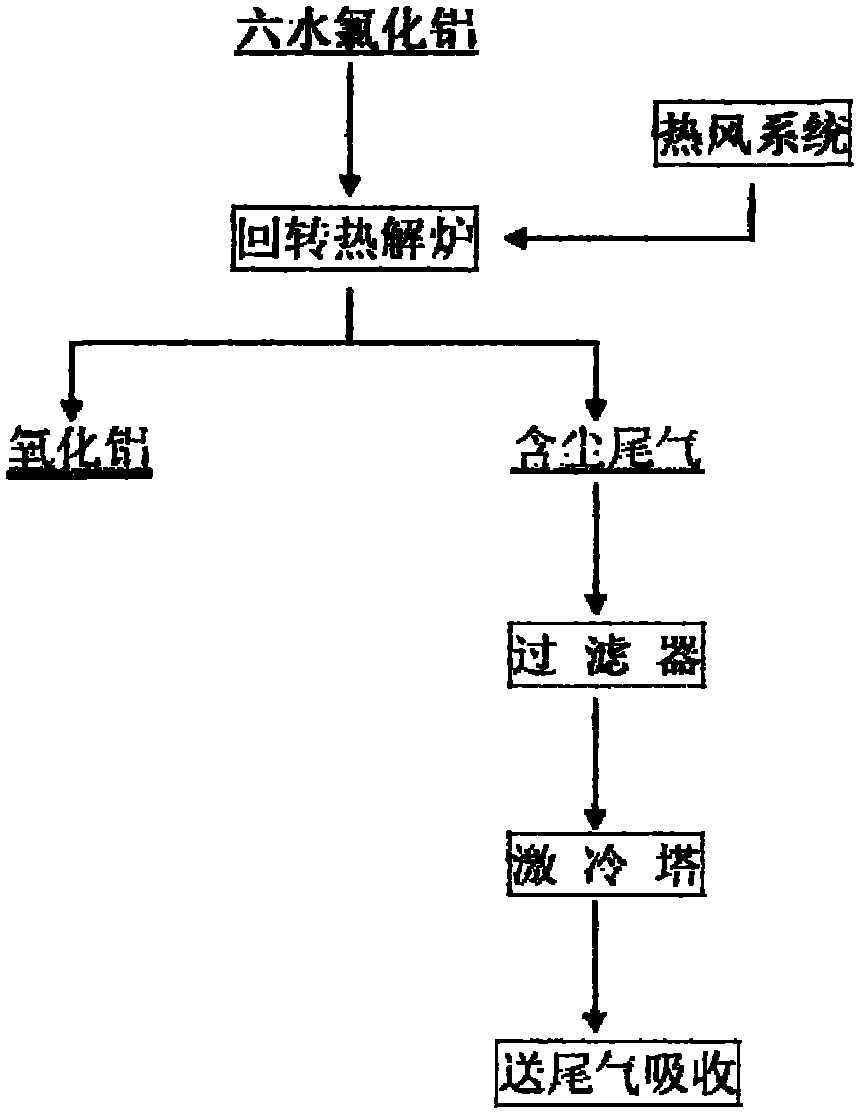

Method for preparing aluminum oxide and co-producing hydrochloric acid from aluminum chloride hexahydrate through pyrolytic crystallization

ActiveCN102092751AGood economic benefitsSingle reactantAluminium oxide/hydroxide preparationPreparation from chloridesChemistryCHLORIDE HEXAHYDRATE

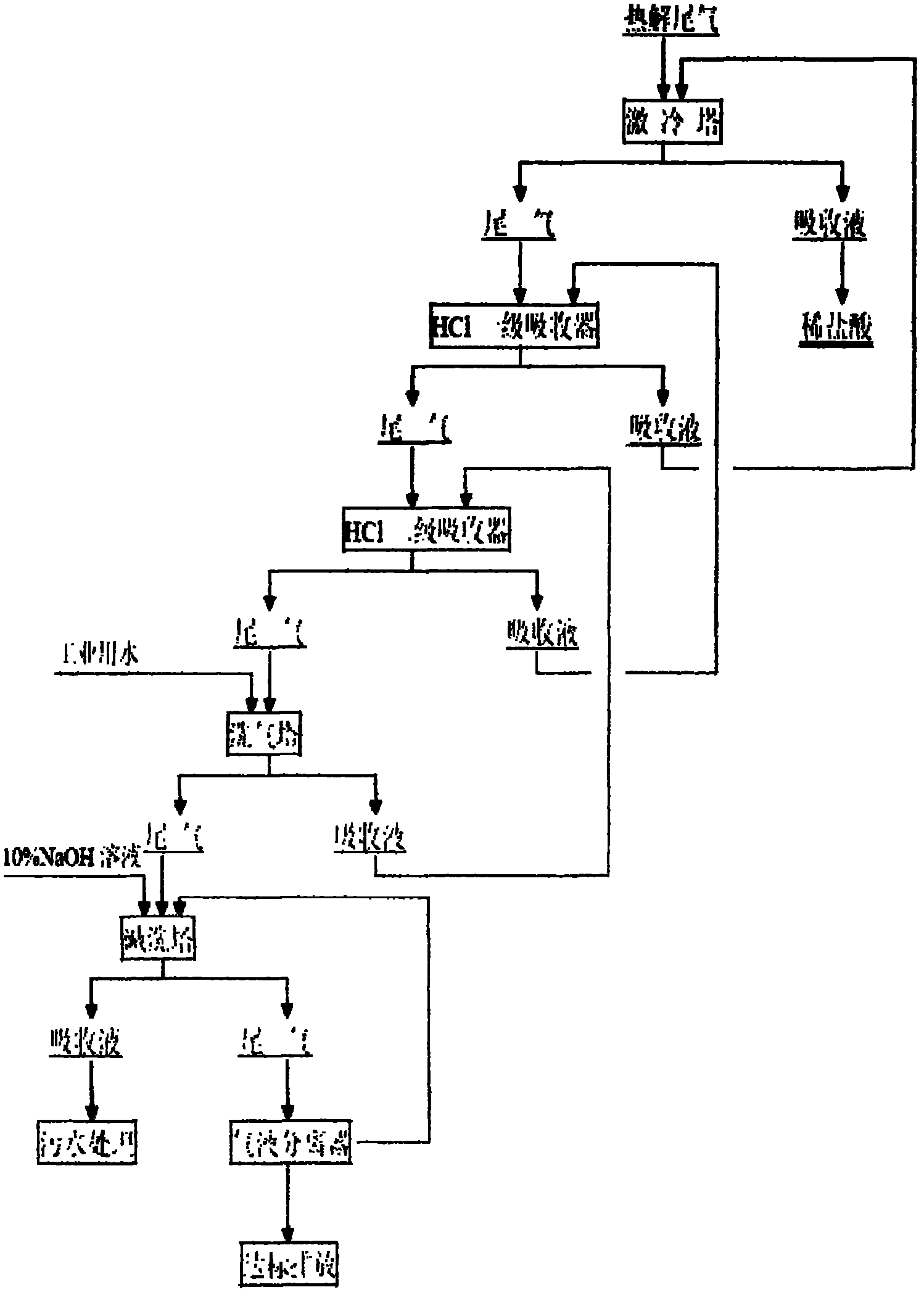

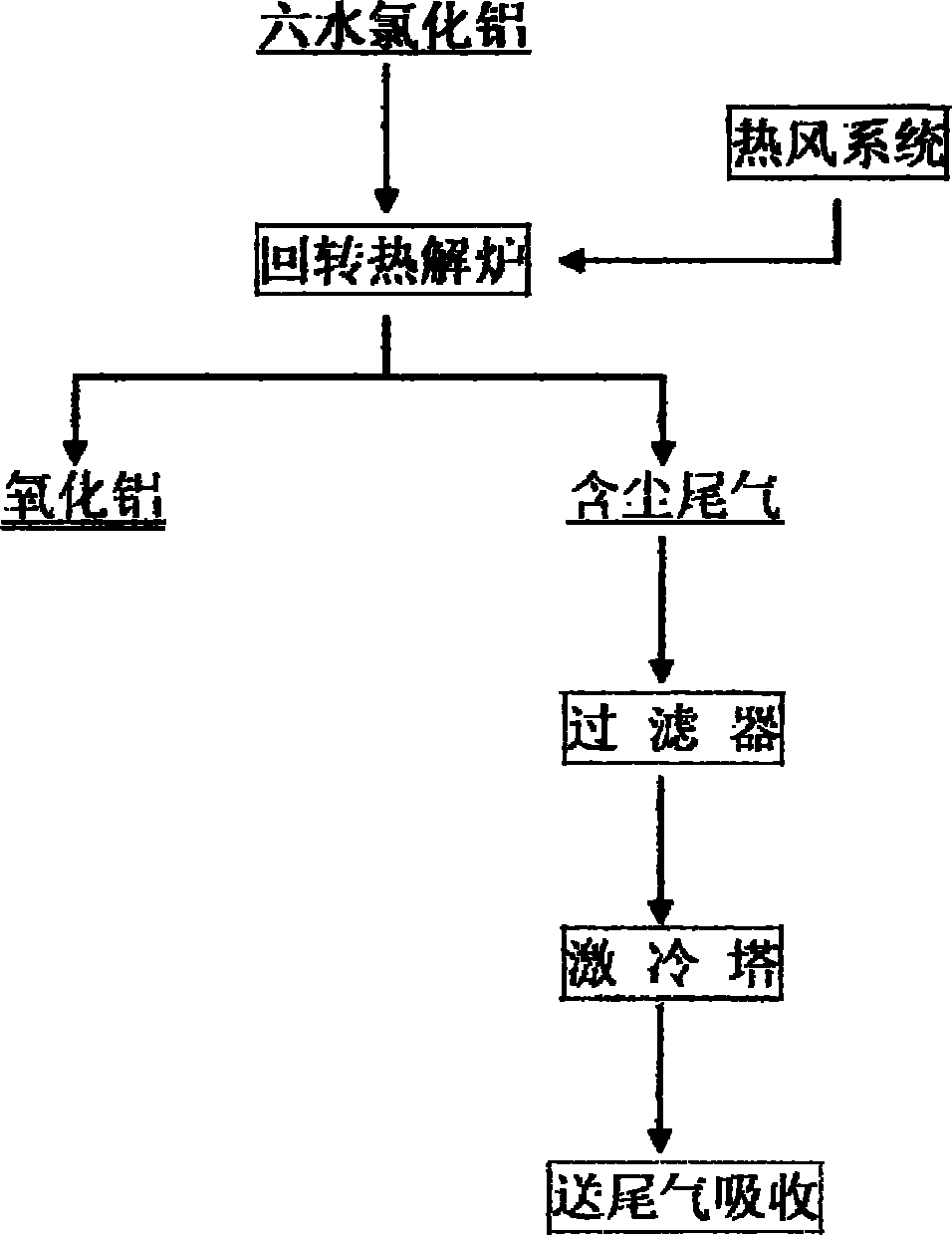

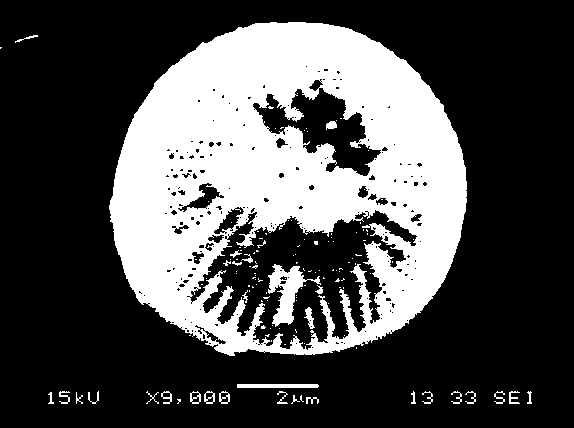

The invention provides a method for preparing aluminum oxide and co-producing hydrochloric acid from crystallized aluminum chloride hexahydrate through pyrolysis crystallization. The method comprises the following steps: sending crystallized aluminum chloride hexahydrate used as a raw material to a pyrolyzing furnace to perform intramolecular dehydration and thermal cracking reaction at 140-900 DEG C and generate the product-aluminum oxide, and using a tail gas treatment system to absorb pyrolytic tail gas and generate the hydrochloric acid byproduct. By adopting the method in the invention, the comprehensive utilization industrial chain of fly ash can be extended, the environmental pollution problem that a lot of fly ash is stored up can be solved, strategic metal resources can be effectively recycled and great economic benefits can be created. The technological process in the invention has the single reactant, concise and clear main process, adequate and stable raw material supply and low production cost; and the emission of three wastes reaches the standard completely, the method in the invention belongs to the comprehensive utilization project of resources and meets the national industrial policy.

Owner:西安三瑞实业有限公司

Process for making light-weight high-strength common gypsum board mask paper

The invention discloses a process for making light-weight high-strength common gypsum board mask paper, which comprises three procedures of material preparation, pulping and paper making. By adding various assistants to domestic waste newspaper and imported American waster paper based on a certain ratio and adjusting corresponding processes, the invention rationalizes the process route, realizes the reasonable matching of long and short fibers, improves the product quality, reduces the weight of the finished paper product, improves the physical strength, saves the resources, and greatly reduces the production cost of the gypsum board. The gypsum board mask paper produced by the process has the characteristics of light weight, high strength, attractive appearance and the like, and can completely substitute the imported product.

Owner:TAISHAN GYPSUM CO LTD

Method for preparing biogas by using peat as raw material

InactiveCN102994564AEasy to adjustIn line with industrial policyWaste based fuelFermentationActivated sludgePeat

The invention belongs to the field of peat reclamation application, and particularly relates to a method for preparing biogas by using peat as a raw material. The method is characterized in that enzyme liquid is added for enzymolysis after the peat is pretreated, activated sludge is mixed for fermenting the biomass, and the content of methane in the biogas is determined to reach 65%. The method has the advantages that energy contained in a peat organic matter is released through an appropriate treatment technology and is converted into biomass energy source biogas, so that the purpose of only using the peat as the raw material for preparing the biogas through anaerobic fermentation is achieved, a new path for comprehensive utilization of abundant peat is opened up, fossil energy can be partly replaced or saved, and the low-carbon cyclic economic development and clean energy substitution are realized in the end.

Owner:INNER MONGOLIA UNIV OF SCI & TECH +1

Method of synthesizing ammonia by hydrogen gas purified by tail gas of sodium cyanide and alkali-chloride production

InactiveCN101016159ASimple methodEasy to implementHydrogen separationAmmonia preparation/separationNaCl - Sodium chlorideChemistry

The invention discloses a synthesizing method of ammonia through purifying hydrogen from tail gas of sodium cyanide and alkali-chloride, which is characterized by the following: adopting natural gas, benzine naphtha and coal carbon as raw material; making nitrogen to synthesize ammonia with nitrogen; protecting environment without polluting; saving power; preparing hydrogen through pressurizing, heating, removing impurity and deoxidizing.

Owner:营口德瑞化工有限公司

Combined process for preparing Fischer-Tropsch synthetic oil raw material gas by utilizing coke-oven gas

ActiveCN102642810AIncrease added valueConform to energy savingHydrogen separationLiquid hydrocarbon mixture productionResource utilizationFuel oil

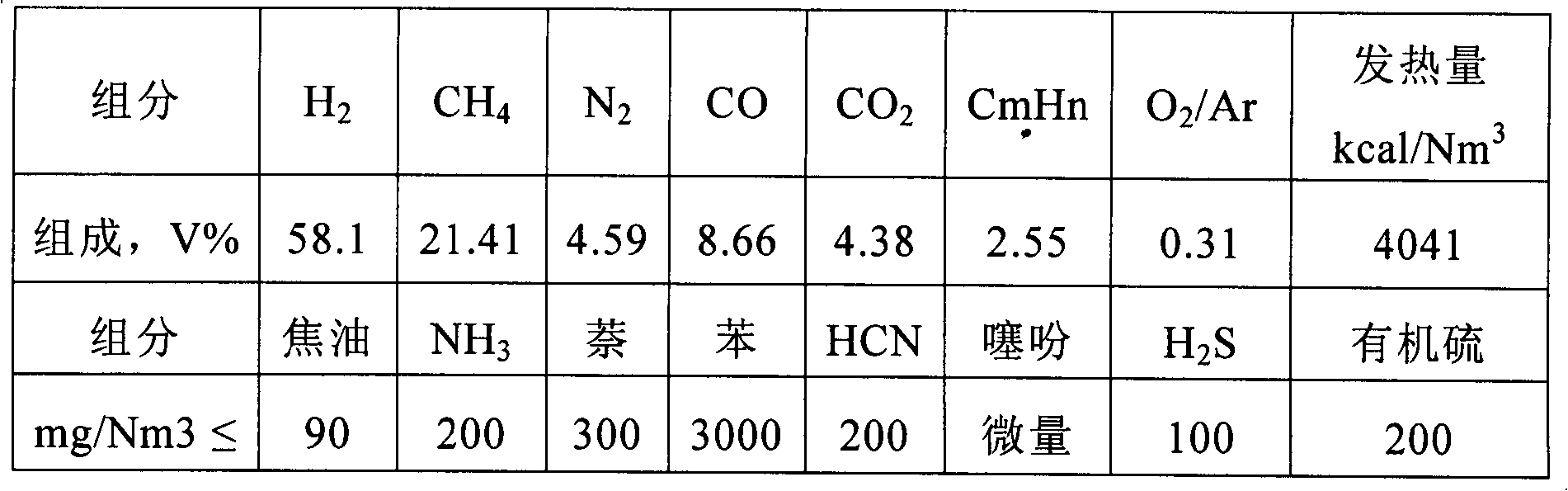

The invention relates to a combined process for preparing a Fischer-Tropsch synthetic oil raw material gas by utilizing a coke-oven gas. The combined process comprises the following steps of: with coarse coke-oven gas as a raw material, removing naphthalene, tar, hydrogen sulfide, hydrocyanic acid, ammonia, organic sulfur and other heavy-hydrocarbon impurities out of coarse coke-oven gas in a pretreatment unit;; then pressurizing the coarse coke-oven gas in a gas compression unit; then converting into CH4 through oxidation of non-catalysis part of the coke-oven gas; and finally carrying out precision desulfurization and deep desulfurization, thereby obtaining the high-quality Fischer-Tropsch synthetic oil raw material gas. According to the invention, through a step-by-step purification combined process, impurities and the sulfurous gas in the coke-oven gas are removed efficiently, so that coke-oven gas becomes the synthetic gas with high additional value and high economic benefit; the coking industrial chain is prolonged; the coke-oven gas is converted into fuel oil, greenhouse gas and toxic gas which are brought about by gas combustion are reduced; the combined process meets national requirements of energy conservation, emission reduction and industry policy and has the advantages of low sulfur, high degree of purification, obvious environment effect, high resource utilization ratio, relative low construction investment in devices, low operating cost and the like.

Owner:SHANGHAI HUANQIU ENG

Method for recovering Pb<2+> from electrolytic zinc rinsing wastewater with calcium-carbonate-modified kieselguhr

InactiveCN103159278AEfficient use ofHigh recovery rateOther chemical processesProcess efficiency improvementFiltrationSorbent

The invention discloses a method for recovering Pb<2+> from electrolytic zinc rinsing wastewater with calcium-carbonate-modified kieselguhr, which comprises the following steps:(1) adding 10g of fine kieselguhr into 50mL of 0.4-0.5 mol / L Na2CO3 solution, putting in a rotary thermostatic water bath oscillator, stirring, and dropwisely adding 5-5.2 mL of saturated CaCl2; after stirring, taking out, removing the supernatant solution, carrying out vacuum filtration, washing with pure water to a neutral state, centrifuging for solid-liquid separation, drying, pulverizing, and passing through a 200-mesh sieve to prepare a calcium-carbonate-modified kieselguhr adsorbent; and (2) adding 10mL of 0.1 g / L calcium-carbonate-modified kieselguhr adsorbent prepared in the step (1) into a 250 mL a conical flask with a stopper, adding 100mL of Pb<2+>-containing electrolytic zinc rinsing wastewater solution with the pH value of 4.83-4.85, adsorbing at 25-30 DEG C for 120-125 minutes, plugging, and oscillating in the rotary thermostatic water bath oscillator at the speed of 150 r / min to adsorption equilibrium. The invention can be used for recovering Pb<2+> from electrolytic zinc rinsing wastewater, and enhances the recovery rate.

Owner:GUILIN UNIVERSITY OF TECHNOLOGY

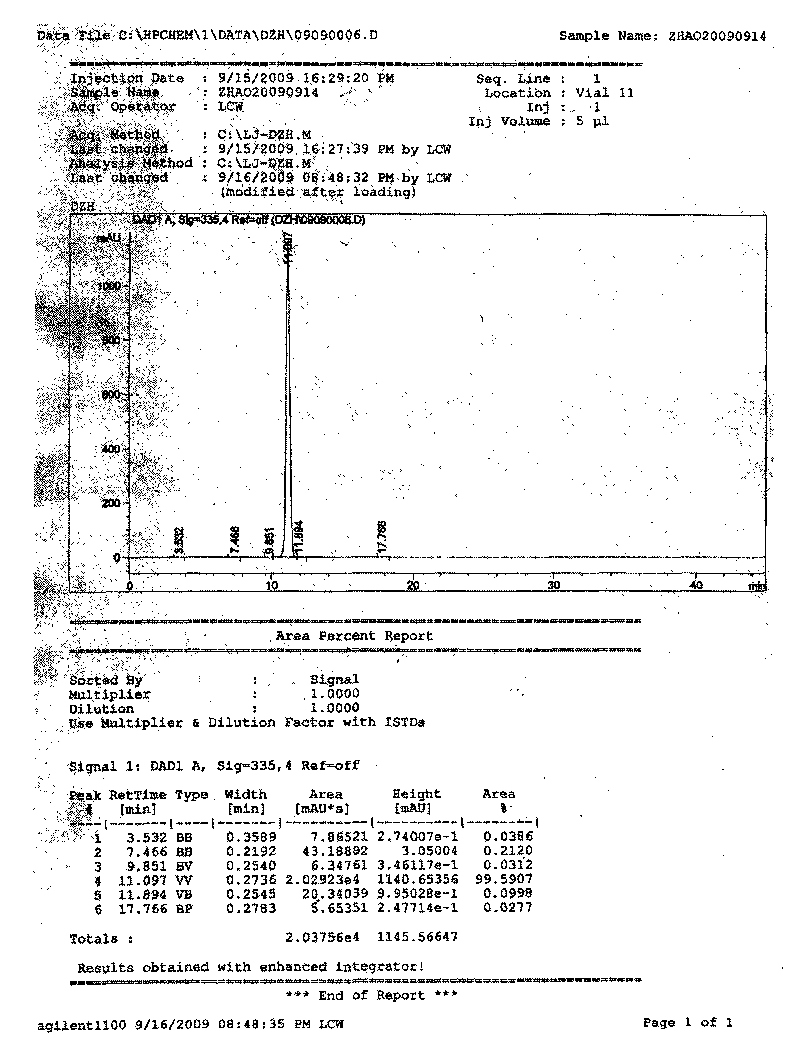

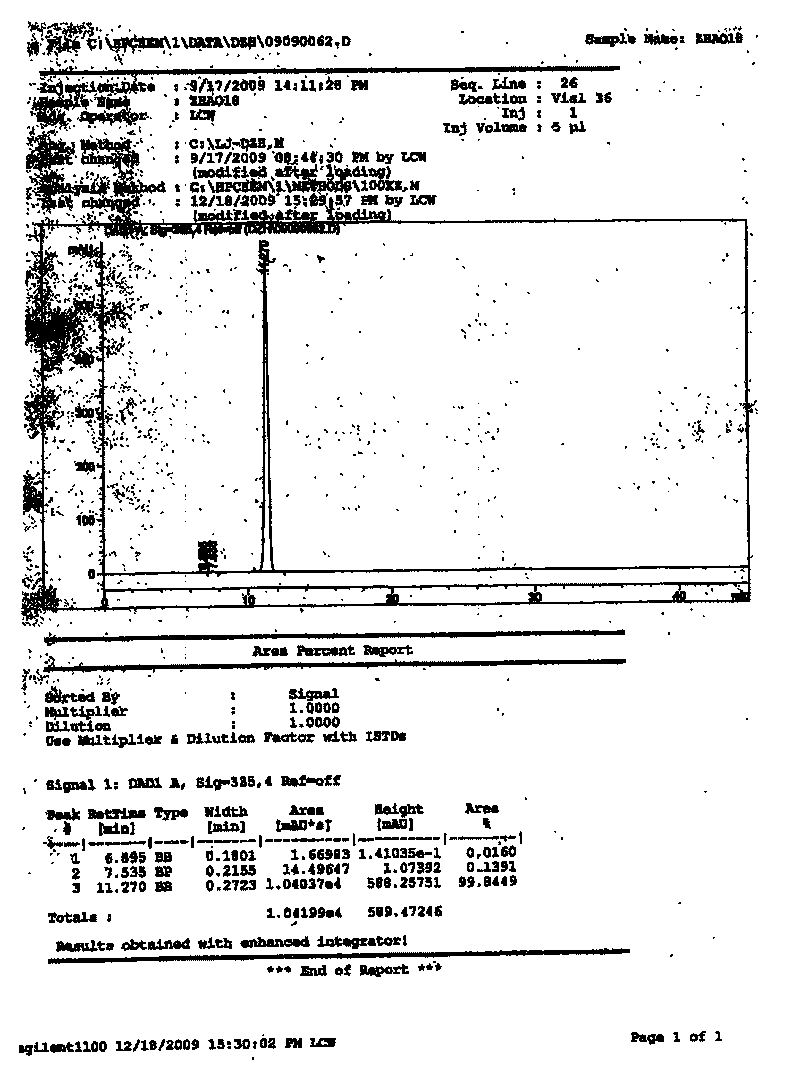

Process for preparing high-purity scutellarin bulk drug

ActiveCN101735291ASolve the problem that is not easy to handle qualifiedSolving hot and cold reactionsSugar derivativesSugar derivatives preparationOrganic acidHydroxylysine

The invention relates to a process for preparing a high-purity bulk drug in pharmaceutics. The process comprises the following steps: (1) adding water with the weight 2-15 times of the weight of a crude product into the breviscapine crude product, stirring, then adding arginine, lysine or hydroxylysine with the weight 35-55% of the weight of the crude product, heating at the temperature of 45 DEG C until boiling off to prepare a stable water solution, filtering and removing the discarded filter residue; (2) adding acid phosphate with the weight 0.1-2.0 times of the weight of the breviscapine crude product into the hot filtrate and preparing the acid phosphate into a water solution with the weight percent of 10-30%; then adding an organic solvent with the volume 2-3 times of the volume of merging liquid and crystallizing scutellarin; and (3) adding the water with the weight more than 10 times of the weight of the breviscapine crude product into the crystal, boiling off, then adding a transforming agent of organic acid with the weight 0.2-1.0 time of the weight of the breviscapine crude product after cooling the solution to the temperature below 60 DEG C and reducing scutellarin salt into the scutellarin so as to obtain the high-purity scutellarin raw material after filtering a precipitate and drying.

Owner:KUNMING LONGJIN PHARMA

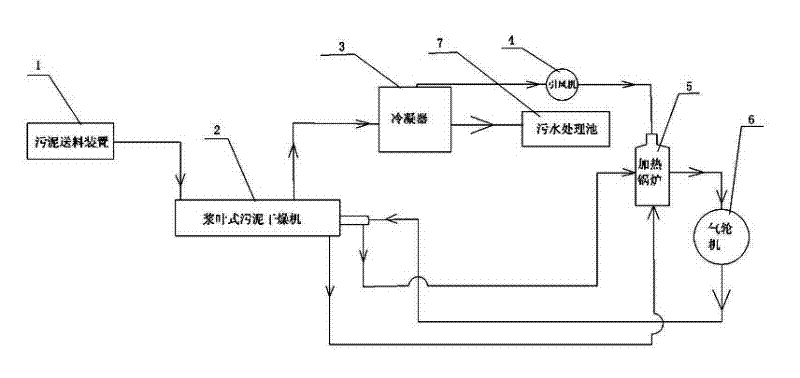

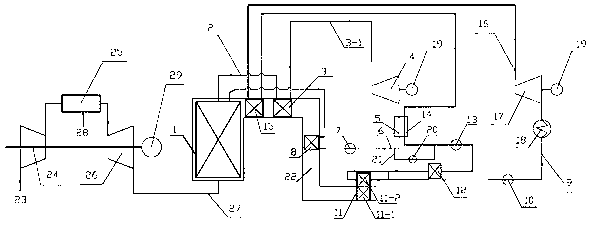

Sludge drying processing device and technology thereof

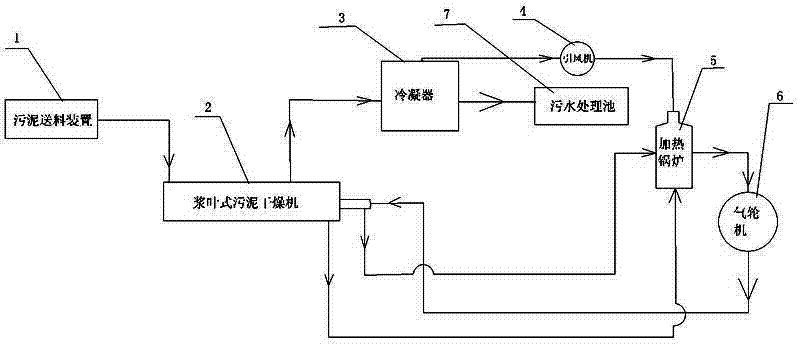

InactiveCN102515458AReduce volumeReduce weightSludge treatment by de-watering/drying/thickeningIncinerator apparatusSludgeProcess engineering

The invention discloses a sludge drying processing device and a technology thereof. The device comprises a sludge feeding unit, a paddle sludge drying machine, a condenser, an induced draught fan, a heating boiler, and a gas turbine, wherein the sludge feeding unit is connected with the paddle sludge drying machine, the water outlet of the paddle sludge drying machine is connected with the heating boiler, the gas outlet of the paddle sludge drying machine is connected with the condenser, the gas outlet of the condenser is connected with the induced draught fan, the induced draught fan is connected with the heating boiler, the gas outlet of the heating boiler is connected with the gas turbine, the gas turbine is connected with the gas inlet of the paddle sludge drying machine, the sludge outlet of the paddle sludge drying machine is connected with the bottom sludge inlet of the heating boiler. According to the invention, the volume and weight of the sludge can be greatly reduced, partial heat energy and waste residues can be recycled, thus the invention is significant in protecting the environment, promoting the sustainable developments of nation economy and ecological environment, has important social meaning, and is in compliance with the national industrial policy.

Owner:SHAOXING UNIVERSITY

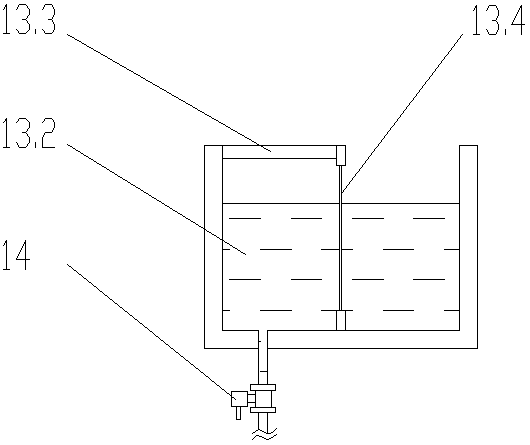

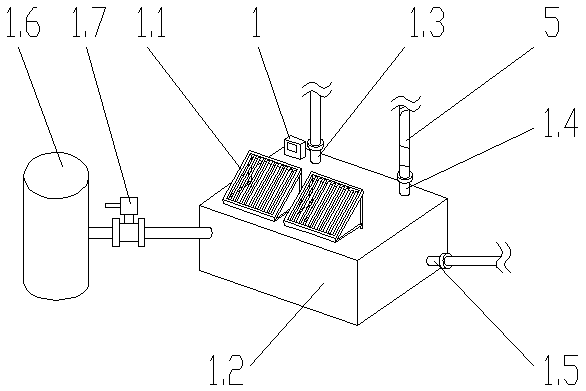

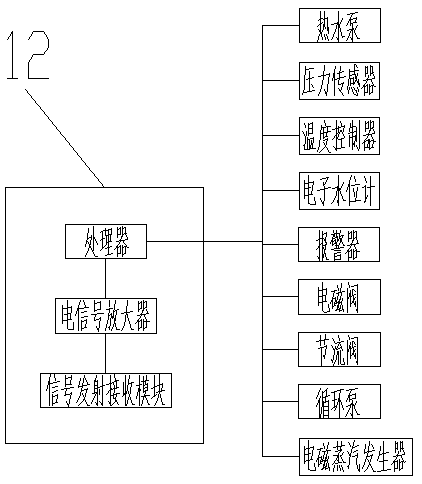

Intelligent steam generator system assembly with auxiliary heating through solar energy and a method for making steam

ActiveCN109899774AEasy to operateNo pipe lossSteam generation heating methodsAutomatic controlIntelligent control system

The invention provides an intelligent steam generator system assembly with auxiliary heating through solar energy. The intelligent steam generator system assembly includes a cold water supply system,a solar heating system, an electromagnetic steam generator and a hot water recovery system, the cold water supply system, the solar heating system and the electromagnetic steam generator are successively connected in series, and the intelligent steam generator system assembly further includes a central intelligent control system; and the central control system is electrically connected with the cold water supply system, the solar heating system, the electromagnetic steam generator, a detection control device of the hot water recovery system and the electromagnetic steam generator. The invention further includes a method for making steam through the intelligent steam generator system assembly with auxiliary heating through the solar energy. According to the intelligent steam generator system assembly with auxiliary heating through the solar energy, the central intelligent control system is additionally arranged on the intelligent steam generator system assembly with auxiliary heating through the solar energy, automatic control of the steam making process is realized, operation is convenient, it is ensured that process parameters of various links meet industrial production standards,the steam pressure of all equipment is in the safe range, and the steam making process is inherently safe.

Owner:黔西南州乐呵化工有限责任公司 +2

Brayton-cascade steam Rankine combined cycle power generation system

ActiveCN103075216AEfficient use ofReduce loadSteam useGas turbine plantsBrayton cycleSteam condensation

The invention relates to a Brayton-cascade steam Rankine combined cycle power generation system. The gas exhaust of a Brayton cycle is adopted as a heat source for a high-temperature end steam Rankine cycle, a steam condenser in a high-pressure end steam Rankine cycle is adopted as one of heat sources for a low-pressure end steam Rankine cycle, the latent heat of vaporization of the steam in the high-pressure end steam Rankine cycle is efficiently recovered to be used for power generation in the low-pressure end steam Rankine cycle, consequently, the load of the steam condenser of the conventional steam Rankine cycle system can be effectively reduced by more than absolute 20 percent, and by adopting a system optimization technique, the absolute thermal efficiency of the cycles of the whole system can be increased by more than 5 percent. The Brayton-cascade steam Rankine combined cycle power generation system not only can be used in the energy-saving alteration of conventional units, but also can be used in the design and construction of new units, and economic, social and environmental protection benefits are remarkable.

Owner:NANJING RECLAIMER ENVIRONMENTAL TEKNIK

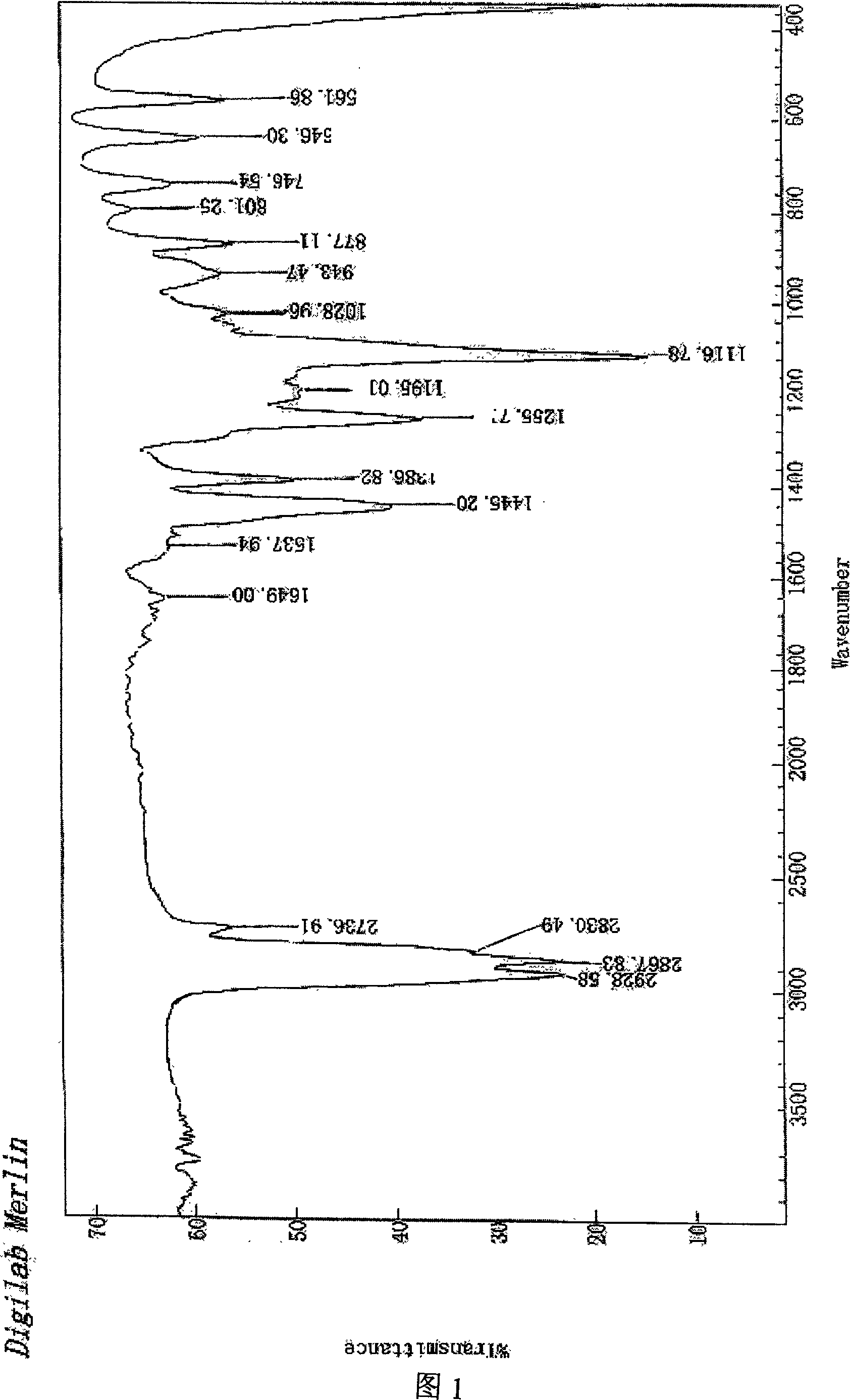

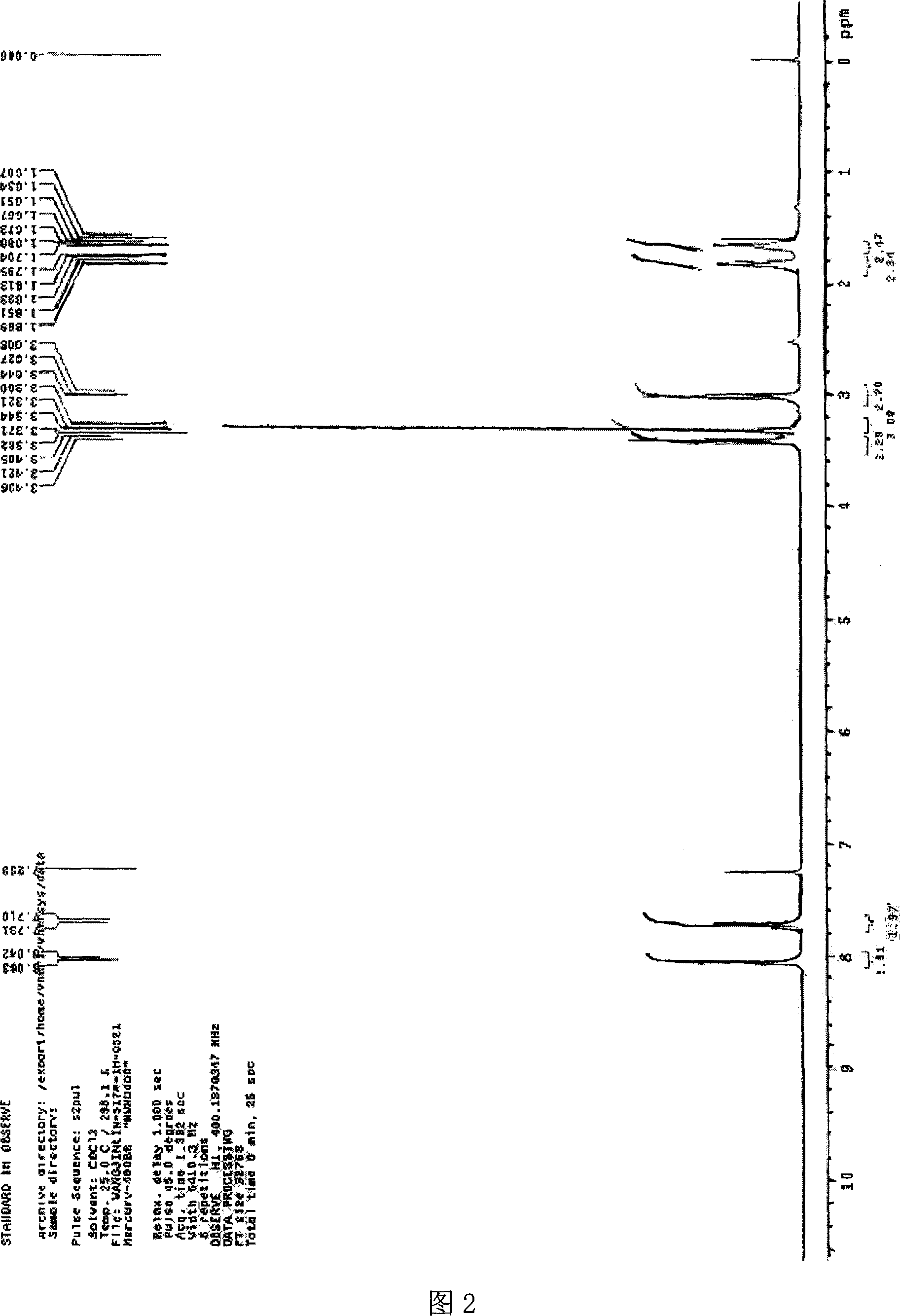

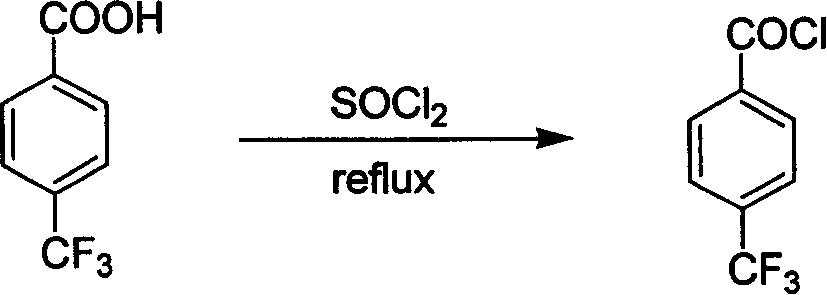

Method for preparing 5-methoxy-1-(4-trifluoromethyl phenyl)pentanone

The present invention discloses process of preparing 5-methoxyl-1-(4-trifluoromehyl phenyl) pentanone as one key intermediate for preparing depression treating medicine fluvoxamine maleate with p-trifluoromethyl benzoyl chloride and magnesium 4-methoxyl butyl halide in the presence of catalyst. The process includes following four steps: 1. preparing p-trifluoromethyl benzoyl chloride with p-trifluoromethyl benzoic acid and thionyl chloride through chlorination; 2. preparing 1-halo-4-methoxyl butane; 3. preparing Grignard reagent through reaction of 1-halo-4-methoxyl butane and metal Mg; and 4. preparing 5-methoxyl-1-(4-trifluoromehyl phenyl) pentanone through reaction of p-trifluoromethyl benzoyl chloride and the Grignard reagent. The process has the features of facile material, low cost, short reaction period, high efficiency and environment friendship.

Owner:NORTHWEST NORMAL UNIVERSITY

Gasoline power and tail gas discharge improved type additive

InactiveCN1590516ABoost octaneQuality improvementLiquid carbonaceous fuelsFuel additivesGasolineMethyl acetate

An additive for improving the power performance of gasoline and decreasing the harmful components from its tail gas is prepared from methanol, ethanol-butanol mixture, acetal dimethanol, methyl acetone, butaneone, methyl acetate, toluene, ethylbenzene, solvent oil No.6 and 200, and N-methyl phenylamine.

Owner:雷腾

Synthesis method for magnesium potassium phosphate slow release fertilizer

InactiveCN103232269AHigh synthesis efficiencyHigh purityAlkali orthophosphate fertiliserAmmonium orthophosphate fertilisersSynthesis methodsPotassium hydroxide

The invention relates to a synthesis method for a magnesium potassium phosphate slow release fertilizer. The synthesis method comprises the following steps of: (1) adding potassium hydroxide or sodium hydroxide in a mixed solution of potassium salt and phosphate, and adjusting the pH value between 9.0 and 10.5, wherein the mole ratio of the potassium salt to the phosphate is 1.0-3.0; (2) adding the mixed solution in the step (1) into a magnesium-containing solution according to the mole ratio that Mg:P=(0.6-1):1, controlling the pH value between 9.0 and 10.5, and reacting at 15-40 DEG C for 10-30min; and (3) carrying out solid-liquid separation after the reaction is ended, and drying a sediment to obtain a magnesium potassium phosphate crystal. The method is simple in process flow and easy to operate; the purity of the synthesized magnesium potassium phosphate is higher; and a clear liquid obtained after the reaction can be still used as the fertilizer after being concentrated, so that the raw material utilization ratio is very high.

Owner:HUBEI FORBON TECH

Processing method of konjac refined flour

The invention discloses a processing method of konjac refined flour. A process comprises the following steps: fresh konjac corm cleaning, peeling, slicing, color protecting, crushing, desolventizing purifying, washing, drying, dry-grinding, screening, homogenizing, examining, packing and storing; according to an operation key point, during grinding, konjac flour and an ethanol solution are mixed according to a certain ratio, and are placed in a grinding wheel mill for grinding, the purpose of the operation key point is to grind out impurities on surfaces of refined flour particles, the final concentration of ethanol used for liquid medium selection during separation is better not be lower than 30%, the ethanol solution with the concentration higher than 30% is used for washing the konjac refined flour particles in a filter screen, and then centrifugation separation is conducted. According to the processing method of the konjac refined flour, after ethanol washing and filter pressing are conducted, the content of the impurities in the konjac refined flour is reduced, and the property of the konjac refined flour in aspects of color and lustre, solubility, viscosity, purity and the like is improved.

Owner:周建兵

Superfine slag powder prepared by doping steel slag into mineral slag

InactiveCN103755166ALow manufacturing costReduce manufacturing costChemical compositionCement Material

The invention relates to superfine slag powder prepared by doping steel slag into mineral slag. The steel slag is waste residues discharged in a steel-making process; a plenty of steel slag blending stocks are added in the process of producing the superfine slag powder so as to prepare the superfine slag powder. Main chemical components of the steel slag comprise 18%-25% of SiO2, 4%-10% of Al2O3, 15%-35% of Fe2O3, 31%-50% of CaO and 5%-15% of MgO. When the superfine slag powder is produced, 20%-25% of the steel slag is adopted and 5%-10% of an exciting agent is doped into equipment for grinding superfine powder or grinding the mineral slag; 7d and 28d active indexes of the superfine slag powder are improved by 2%-15% when being compared with the active index of previous superfine slag powder. The production of the superfine slag powder is realized by grinding the mineral slag into certain fineness (specific surface area) to have a certain activity and doping the mineral slag into cement or concrete, so as to improve the performance of buildings and reduce the production cost.

Owner:李喜才

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com