Method for preparing aluminum oxide and co-producing hydrochloric acid from aluminum chloride hexahydrate through pyrolytic crystallization

A technology of aluminum chloride hexahydrate and by-product hydrochloric acid, which is applied in the direction of preparation of alumina/hydroxide, chlorine/hydrogen chloride, and preparation of chloride, etc., to achieve the effect of simple and clear main process, low production cost and single reactant

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

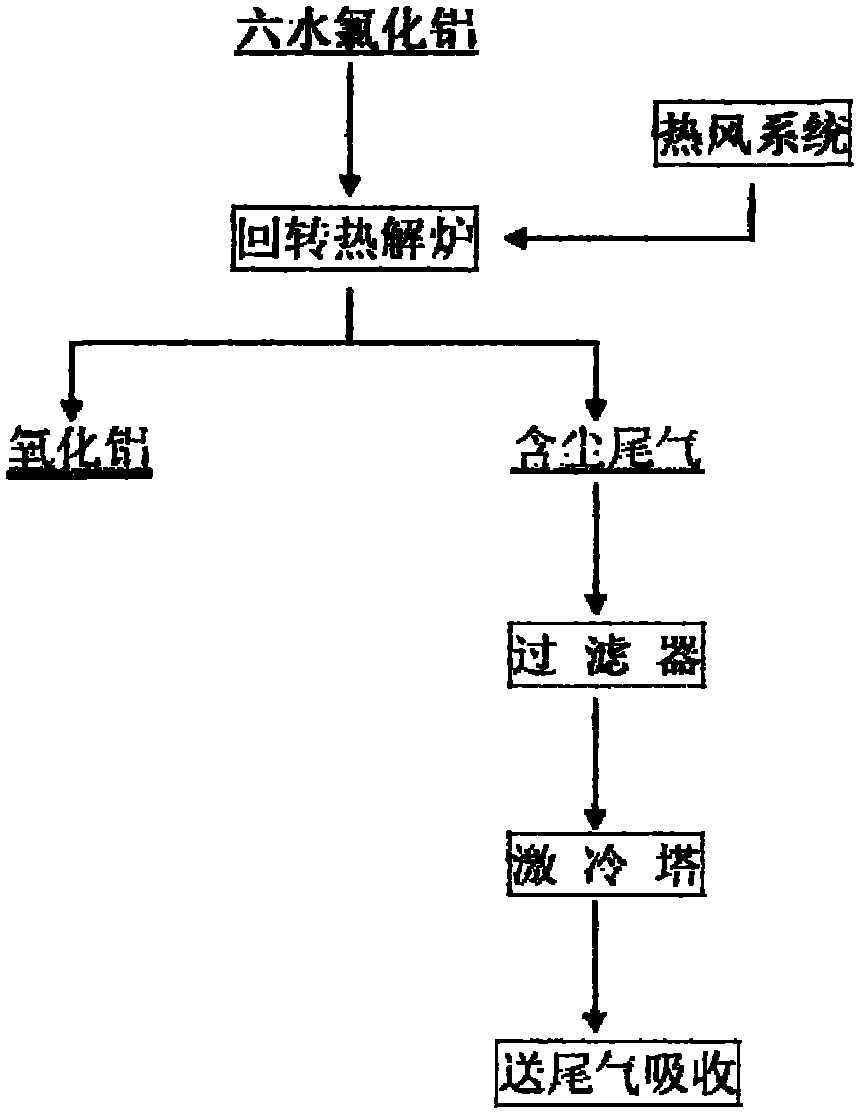

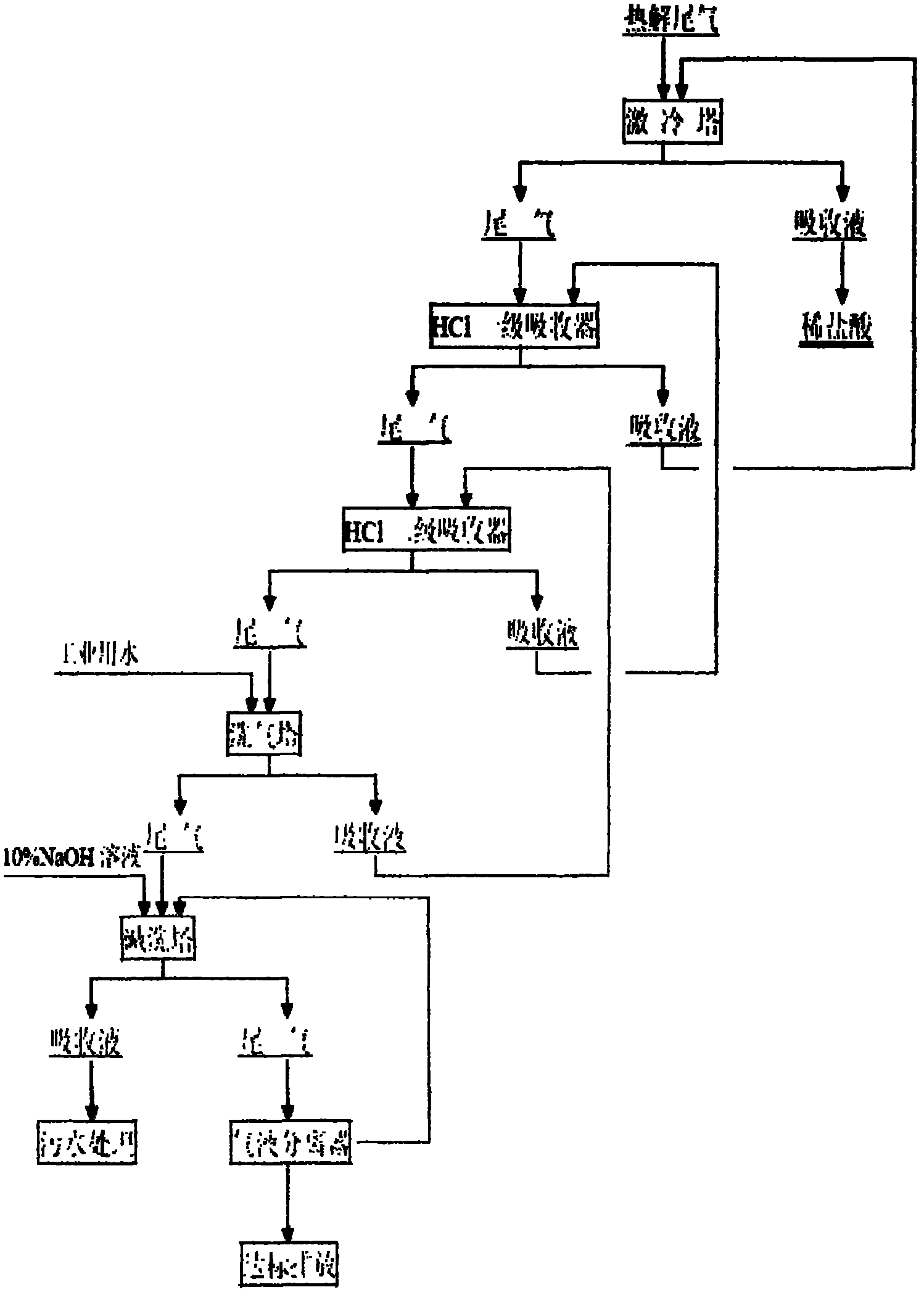

Method used

Image

Examples

Embodiment 1

[0032] (1) Weigh 40kg of crystalline aluminum chloride hexahydrate and send it to the crystalline aluminum chloride hexahydrate silo through the conveying equipment. In the silo, the powder material is discharged into the belt scale through the valve and accurately measured, and then sent to the downpipe In the process, it is fed into the feeding screw of the crystalline aluminum chloride hexahydrate calciner through the feeder, and the feeding screw sends the material into the crystalline aluminum chloride hexahydrate calciner for calcination.

[0033] The raw material crystalline aluminum chloride hexahydrate has a bulk density of 0.819g / cm 3 , the particle size range is 0.6~1.2mm, and the main chemical composition is shown in the following table:

[0034] components

AlCl 3 .6H 2 o

KCl

NaCl

CaCl 2 .2H 2 o

h 2 o

content

93~95%

0.05~0.1%

0.05~0.1%

0.1~0.5%

3~5%

[0035] (2) The heating method of the...

Embodiment 2

[0041](1) Weigh 40kg of crystalline aluminum chloride hexahydrate and send it to the crystalline aluminum chloride hexahydrate silo through the conveying equipment. In the silo, the powder material is discharged into the belt scale through the valve and accurately measured, and then sent to the downpipe In the process, it is fed into the feeding screw of the crystalline aluminum chloride hexahydrate calciner through the feeder, and the feeding screw sends the material into the crystalline aluminum chloride hexahydrate calciner for calcination.

[0042] The raw material crystalline aluminum chloride hexahydrate has a bulk density of 0.819g / cm 3 , the particle size range is 0.3 ~ 0.5mm, and the main chemical composition is shown in the following table:

[0043] components

AlCl 3 .6H 2 o

KCl

NaCl

CaCl 2 .2H 2 o

h 2 o

content

93~95%

0.05~0.1%

0.05~0.1%

0.1~0.5%

3~5%

[0044] (2) The heat-carrying high-t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Density | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com