Concrete doped with waste glass

A technology for concrete and waste glass, applied in solid waste management, sustainable waste treatment, climate sustainability, etc., can solve problems such as damage to concrete structure, concrete cracking, and impact on concrete durability, achieve huge economic benefits, and alleviate scarcity Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

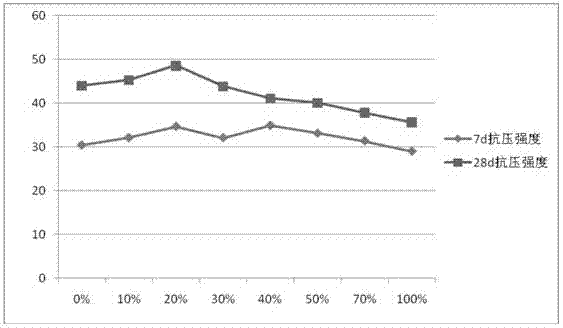

[0039] 1. Obtain the optimal ratio

[0040] This experiment intends to prepare concrete with strength grade C30. Take water-binder ratio (A), mortar-sand ratio (B), and sand ratio (C) as three experimental factors, and compare each factor at three levels. The test index is the 7d compressive strength of concrete, and the result with the highest strength is taken to the optimal level. The selected factors and levels are shown in Table 1 below.

[0041] Table 1 Concrete mix test factor level table

[0042] Level

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com