A kind of red sandstone aerated concrete and preparation method thereof

A technology of aerated concrete and red sandstone, which is applied in the field of building materials, can solve the problems of low utilization rate of red sandstone, low utilization rate of red sandstone, and high engineering cost, so as to alleviate the shortage of river sand resources, improve the level of development and utilization, The effect of improving the utilization rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

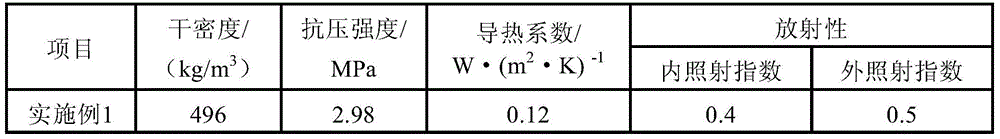

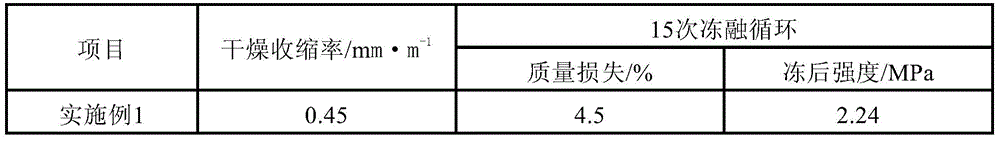

Embodiment 1

[0031] A kind of red sandstone aerated concrete, it is prepared by dry material and water; Water material (dry material) ratio is 0.63;

[0032] The dry material includes cement, red sandstone, quicklime, gypsum, metakaolin, calcined hydrotalcite, aluminum powder paste, water glass and modifier, and the mass percentages of each raw material in the dry material are: cement 13%, red 60% of sandstone, 20% of quicklime, 2% of gypsum, 1.5% of metakaolin, 1.5% of calcined hydrotalcite, 0.11% of aluminum powder paste, 1.5% of water glass, and 0.39% of modifier. The water in the material ratio includes the water contained in the water glass.

[0033] In the above-mentioned technical scheme, SiO in the described red sandstone 2 The content is 84.5wt%, Al 2 o 3 The content is 11.7wt%, the iron content is 1.57wt%, and the rest is other; the red sandstone is ground to a 0.08mm sieve and the remaining 12%, and the homogenization treatment is carried out according to "flat laying and str...

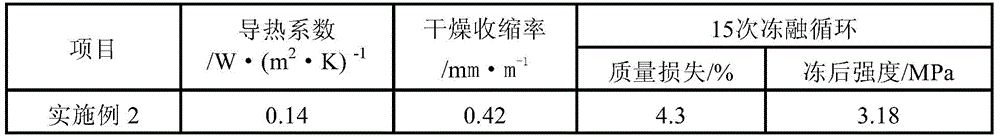

Embodiment 2

[0053] A kind of red sandstone aerated concrete, it is prepared by dry material and water; Water material (dry material) ratio is 0.58;

[0054] The dry material includes cement, red sandstone, quicklime, gypsum, metakaolin, calcined hydrotalcite, aluminum powder paste, water glass and modifier, and the mass percentages of each raw material in the dry material are: cement 13%, red 61% of sandstone, 19% of quicklime, 2% of gypsum, 1.3% of metakaolin, 1.7% of calcined hydrotalcite, 0.11% of aluminum powder paste, 1.5% of water glass, and 0.39% of modifier. The water in the material ratio includes the water contained in the water glass.

[0055] In the above-mentioned technical scheme, SiO in the described red sandstone 2 The content is 84.5wt%, Al 2 o 3 The content is 11.7wt%, and the iron content is 1.57wt%. It is produced in Enshi, Hubei. Grind the red sandstone to a 0.08mm sieve with 12% remaining, and perform homogenization treatment according to "straight-laying and dir...

Embodiment 3

[0078] A red sandstone aerated concrete, which is prepared from dry materials and water; the ratio of water to material (dry materials) is 0.62;

[0079] The dry material includes cement, red sandstone, quicklime, gypsum, metakaolin, calcined hydrotalcite, aluminum powder paste, water glass and modifier, and the mass percentages of each raw material in the dry material are: cement 14%, red 60% of sandstone, 19% of quicklime, 2% of gypsum, 1.3% of metakaolin, 1.7% of calcined hydrotalcite, 0.11% of aluminum powder paste, 1.5% of water glass, and 0.39% of modifier. The water in the material ratio includes the water contained in the water glass.

[0080] In the above-mentioned technical scheme, described red sandstone SiO 2 The content is 84.5wt%, Al 2 o 3 The content is 11.7wt%, and the iron content is 1.57wt%, produced in Enshi, Hubei. Grind the red sandstone to a 0.08mm sieve with 11% remaining, and perform homogenization treatment according to "straight laying" to obtain ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com