Method for recycling fused silica crucible after polysilicon ingot casting

A quartz crucible and fused silica technology, which is applied in the growth of polycrystalline materials, chemical instruments and methods, and crystal growth, can solve the problems of low added value, high production cost, and poor economic feasibility, and achieve high added value and sufficient reserves , economically feasible effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] A fused silica crucible after polysilicon ingot casting, the main components of which are 99.5% of silicon dioxide, 0.3% of silicon carbide and 0.2% of aluminum oxide.

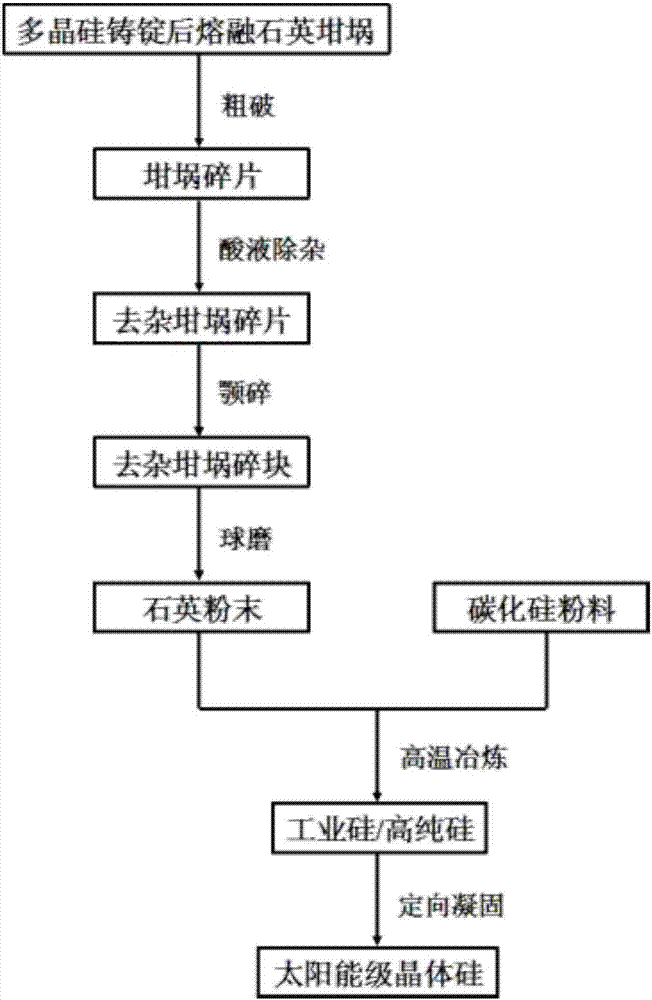

[0029] refer to figure 1 A method for recycling a fused silica crucible after polysilicon ingot casting according to the present embodiment comprises the following steps:

[0030] 1. Use an industrial-grade impact drill to break a large piece of fused silica crucible into 15-30cm crucible fragments;

[0031] 2. Soak the crucible fragments in weak acid for 6 hours, and then perform ultrasonic removal;

[0032] 3. Put the crucible fragments into the jaw crusher for secondary fine crushing, and crush them into crucible fragments with a particle size of 1-2 cm;

[0033] 4. Using ultra-fine powder technology, grind the crucible fragments into quartz powder with a particle size distribution of about 800 mesh in a ball mill, and inject the obtained powder slurry into the raw material slurry pool for standby;...

Embodiment 2

[0037] refer to figure 1 A method for recycling a fused silica crucible after polysilicon ingot casting according to the present embodiment comprises the following steps:

[0038] 1. Use an industrial-grade impact drill to break a large piece of fused silica crucible into 15-30cm crucible fragments;

[0039] 2. Soak the crucible fragments in water for 12 hours, and then perform ultrasonic removal;

[0040] 3. Put the de-impured crucible fragments into the jaw crusher for secondary fine crushing, and crush them into crucible fragments with a particle size of 1-2 cm;

[0041] 4. Using ultra-fine powder technology, grind the crucible fragments in a ball mill into quartz powder with a particle size distribution of about 1000 mesh, and inject the obtained powder slurry into the raw material slurry pool for standby;

[0042] 5. Add silicon carbide powder and binder to the quartz powder slurry, with a weight ratio of 3:2:0.05, press to form, and dry in an oven until the water conte...

Embodiment 3

[0045] refer to figure 1 A method for recycling a fused silica crucible after polysilicon ingot casting according to the present embodiment comprises the following steps:

[0046] 1. Use an industrial-grade impact drill to break a large piece of fused silica crucible into 15-30cm crucible fragments;

[0047] 2. Soak the crucible fragments in water for 12 hours, and then perform ultrasonic removal;

[0048] 3. Put the de-impured crucible fragments into the jaw crusher for secondary fine crushing, and crush them into crucible fragments with a particle size of 1-2 cm;

[0049] 4. Using ultra-fine powder technology, grind the crucible fragments in a ball mill into quartz powder with a particle size distribution of about 1000 mesh, and inject the obtained powder slurry into the raw material slurry pool for standby;

[0050] 5. Add silicon carbide powder and binder to the quartz powder slurry, with a weight ratio of 3:2:0.05, press to form, and dry in an oven until the water conte...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com