Self-ignition machined rod carbonization and carbonized kiln

A self-ignition and carbonization technology, which is applied in biofuels, special forms of dry distillation, and the petroleum industry, can solve problems such as inconvenient loading of machine rods, impact on carbon quality, and lack of channels for proper heat exchange, etc., to achieve forest protection relief, The effect of high production efficiency and uniform quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

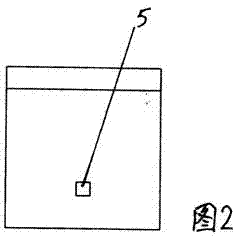

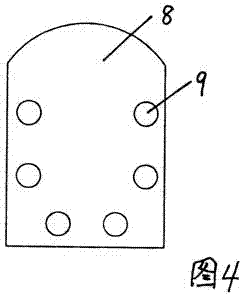

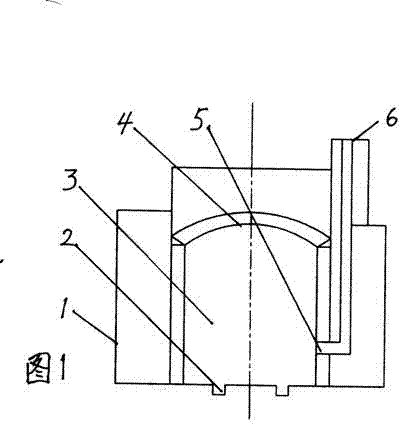

[0024] The present invention will be described in further detail below in conjunction with embodiment and with reference to accompanying drawing: in preparing materials, bamboo chips, sawdust can be sawdust, also can be the end chip of shavings pulverization, and dry fruit peel can be obtained locally, and hickory nut can be used in the middle and north of Zhejiang , Torreya tree peel, sawdust can be pine, fir sawdust. The extruded machine-made rod is a hollow square rod with a square outside and a circle inside. The outside width and height are about 7cm, and the length is about 40cm. The core is circular and hollow, with an inner diameter of about 3cm, and the outer square is good for building height. The hollow is convenient for uniform heating and air circulation, and the size requirements for machine-made rods are not strict. Bamboo sawdust accounts for 20-80 parts by weight, and the ratio of fruit peel accounts for 20-30 parts by weight also has room for expansion and co...

PUM

| Property | Measurement | Unit |

|---|---|---|

| heating value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com