Patents

Literature

461 results about "Square Rod" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

A traditional unit of area equal the area of a square of 16.5 feet (5.029 meters) in length on each side. It is equal to 25.2929 square meters, 272.25 square feet, 30.25 square yards, or 0.00625 acre.

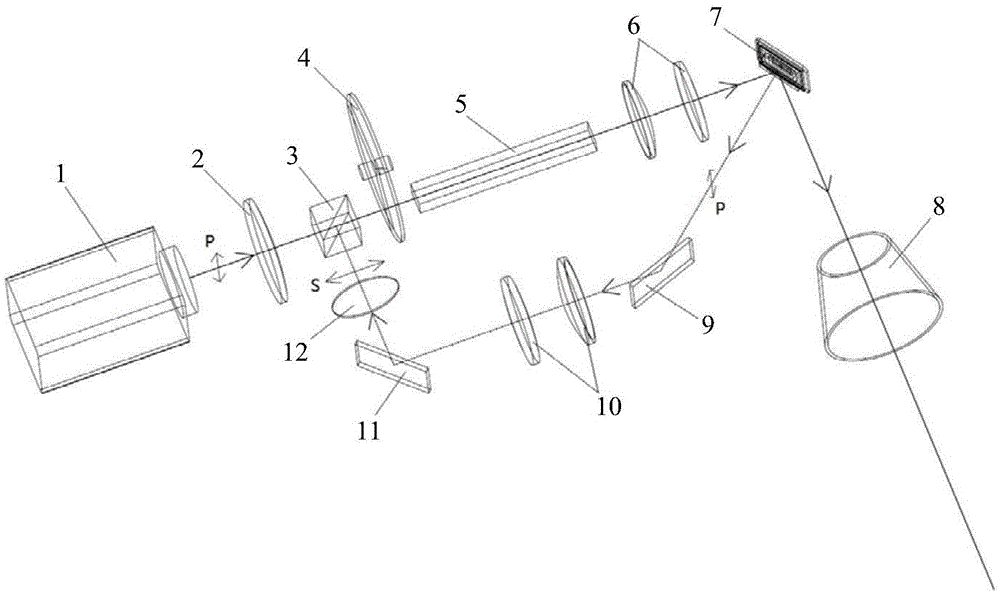

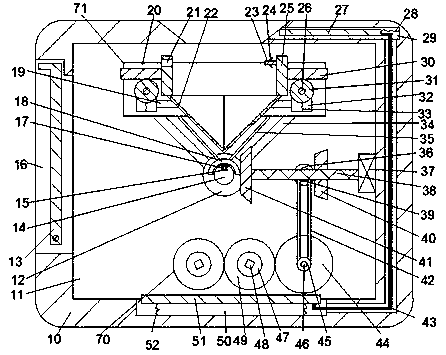

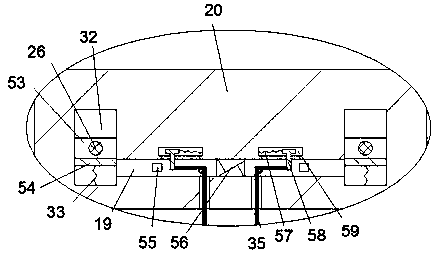

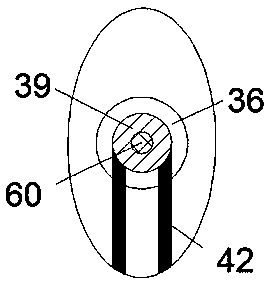

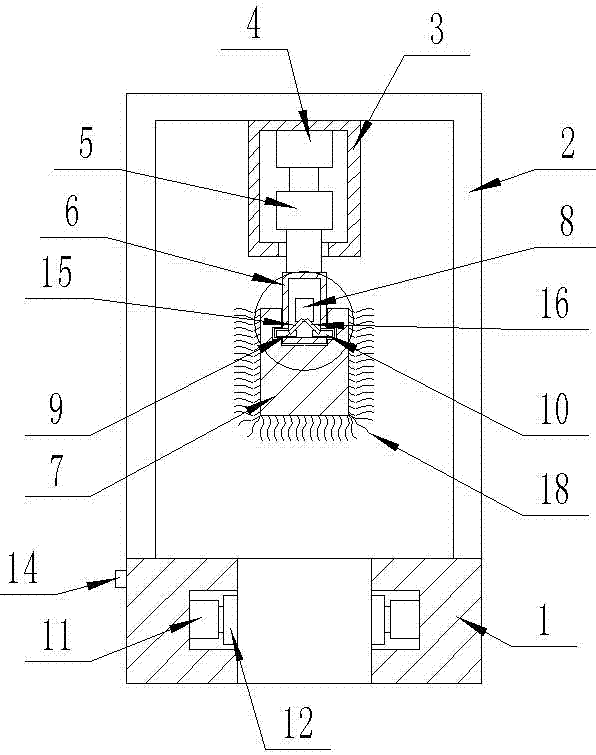

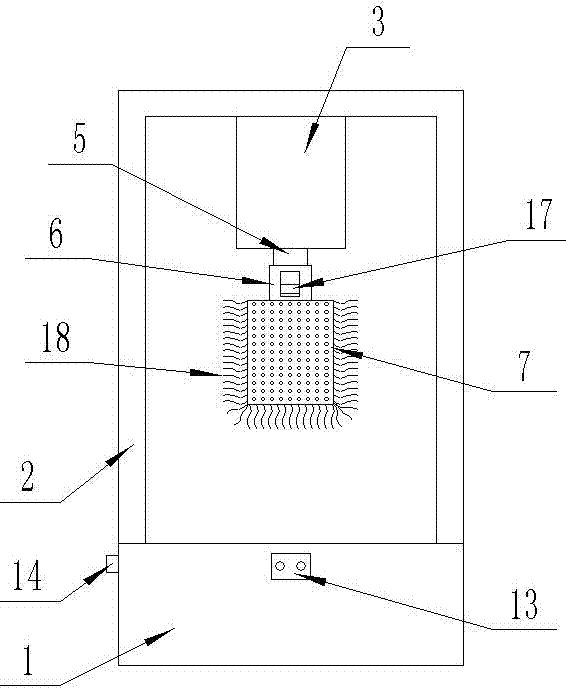

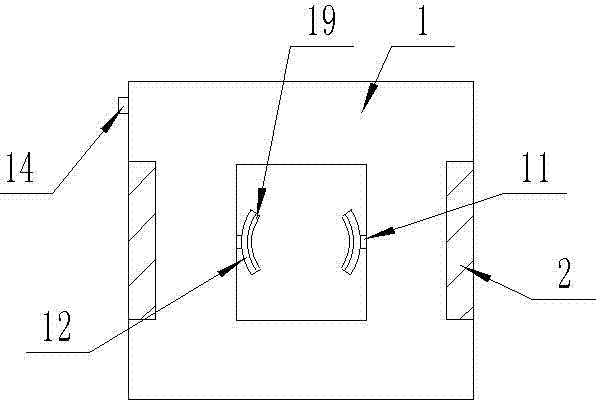

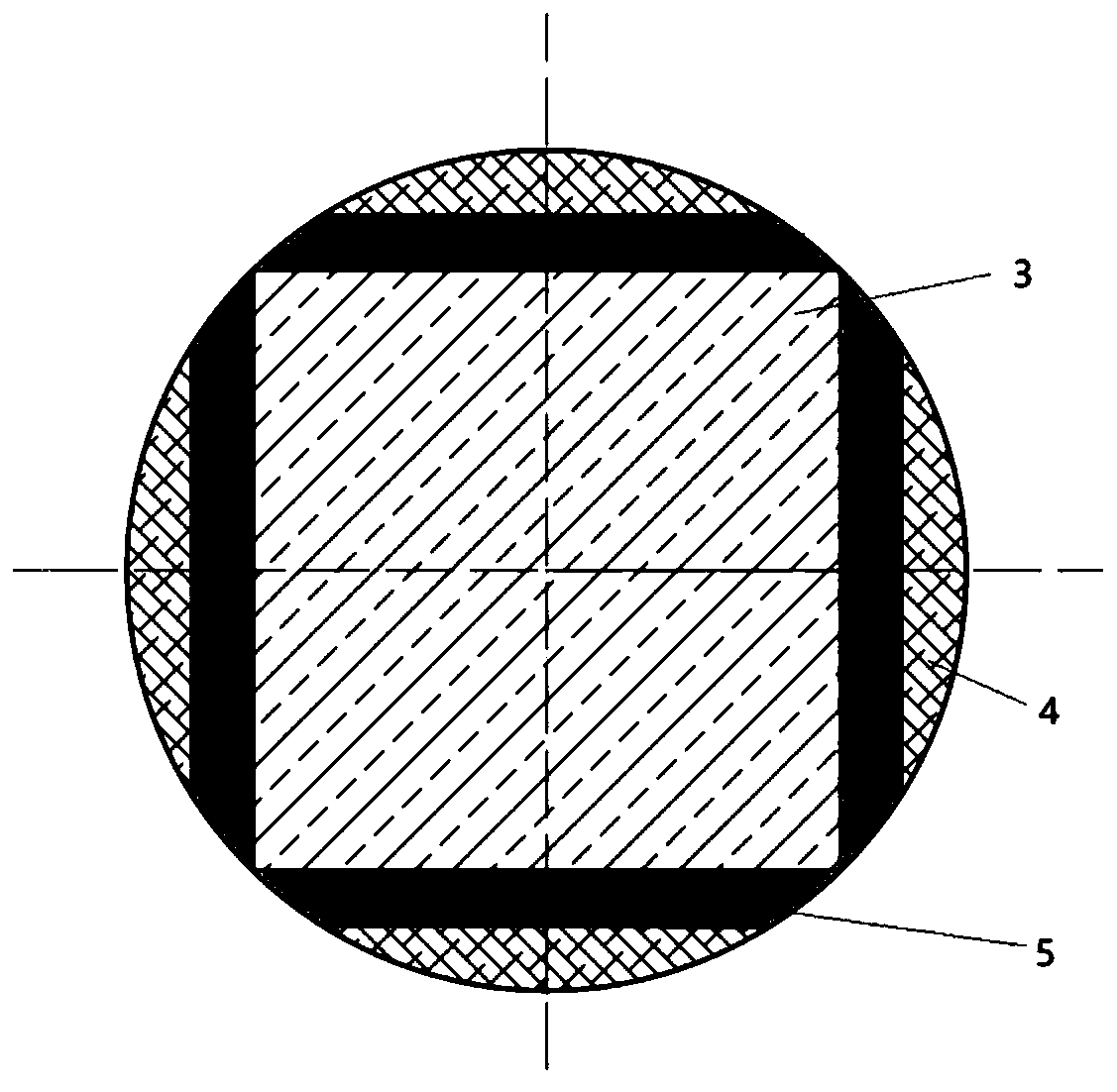

Projection optical system improving light utilization rate and projection brightness

The invention belongs to the field of design projection equipment optical systems, particularly relates to a projection optical system improving a light utilization rate and projection brightness, andaims to solve the problem of low light utilization rate and complex system structure which exist in the prior art. Polarized light P emitted by a laser source passes through a convergent mirror and is transmitted by a polarized beam splitter prism, polarized light P transmitted by the polarized beam splitter prism passes through a color wheel, an integral square rod and a relay lens group in sequence and is incident to a DMD, emergent light in a projection direction of the DMD is emergent through a project lens, emergent light in a non-projection direction of the DMD passes through a reflex lens group to obtain polarized light S, and polarized light S reflected by the polarized beam splitter prism and the polarized light P transmitted by the polarized beam splitter prism are coaxially incident to the color wheel; and the reflex lens group includes a total reflector A, a relay lens group B, a total reflector B and a 1 / 2 wave plate; and the emergent light in the non-projection directionof the DMD is sequentially reflected by the total reflector A and refracted by the relay lens group B and 1 / 2 wave plate to obtain polarized light S.

Owner:BEIJING GUOWANG OPTICAL TECH CO LTD

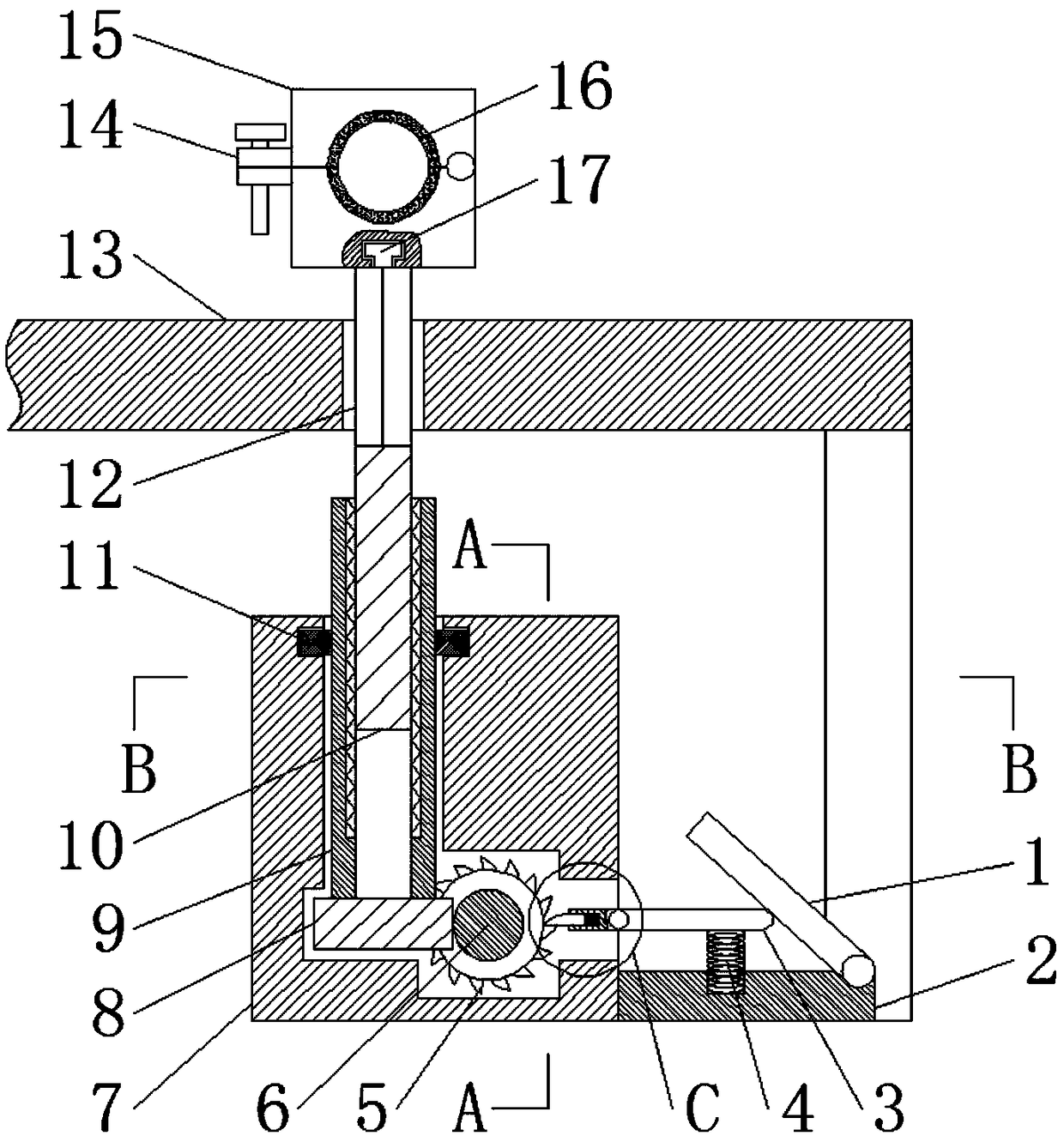

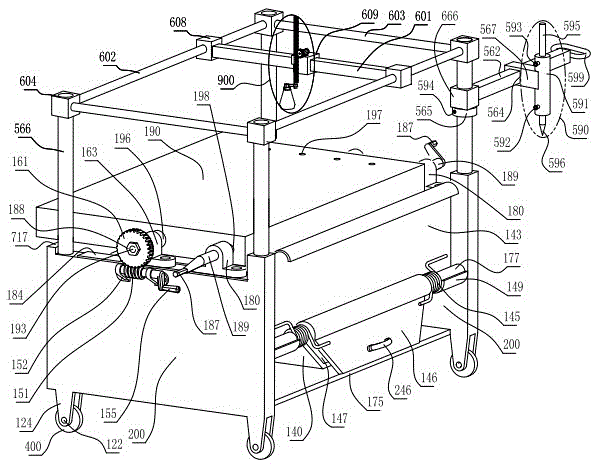

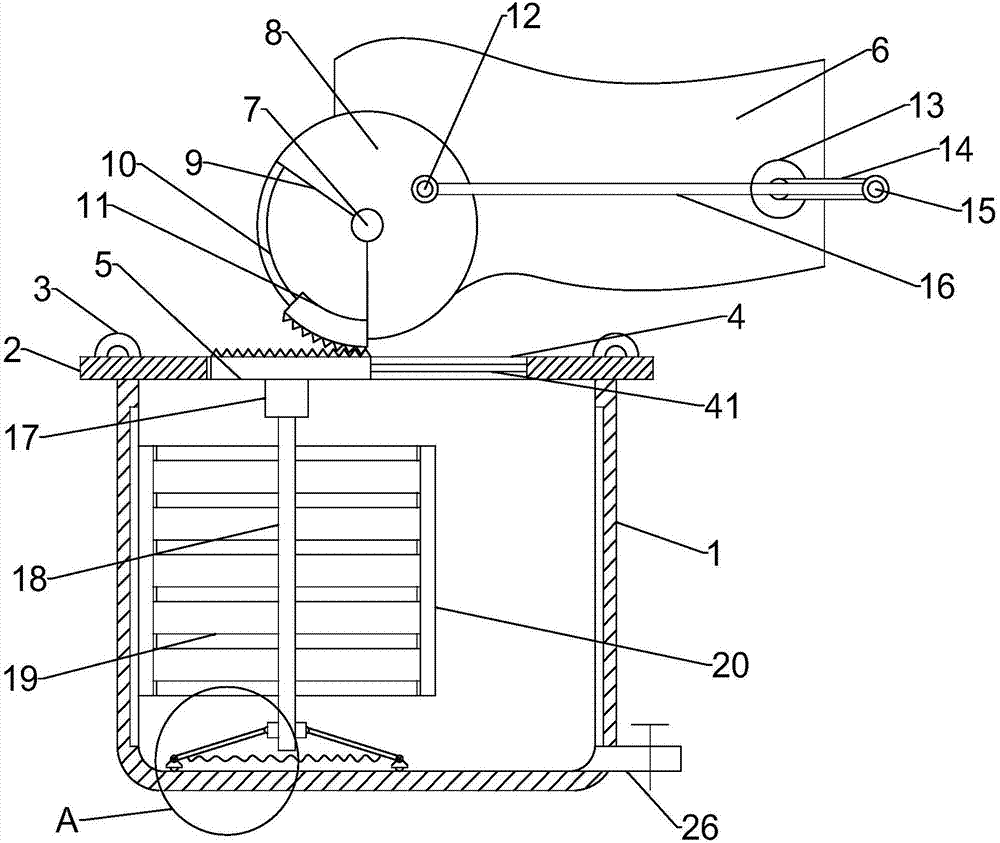

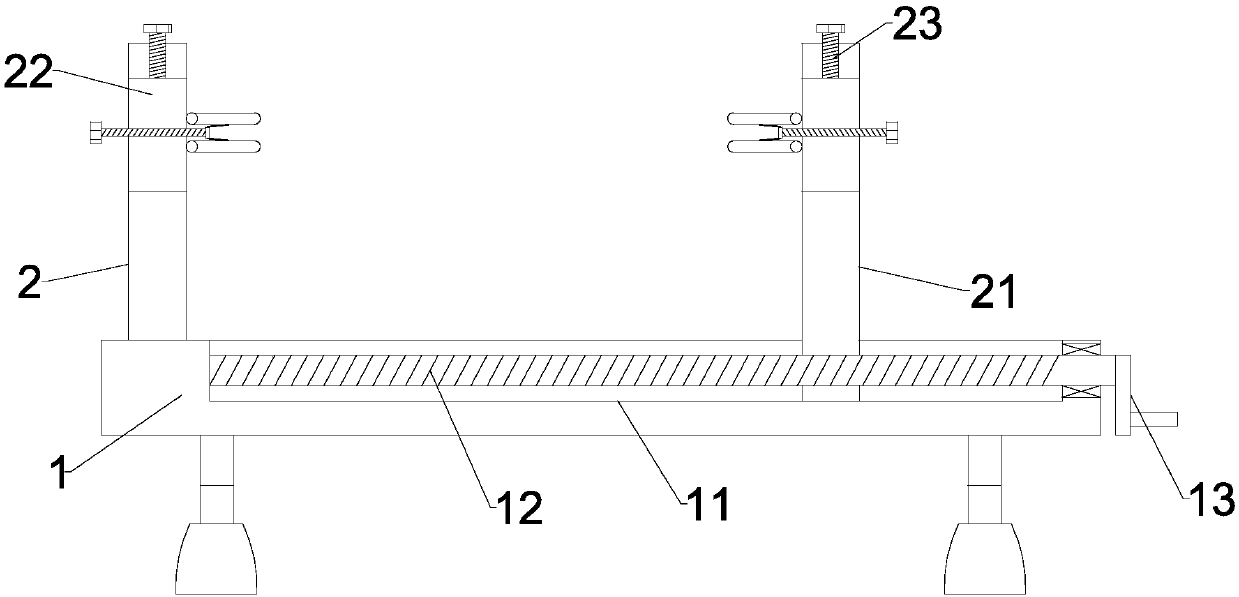

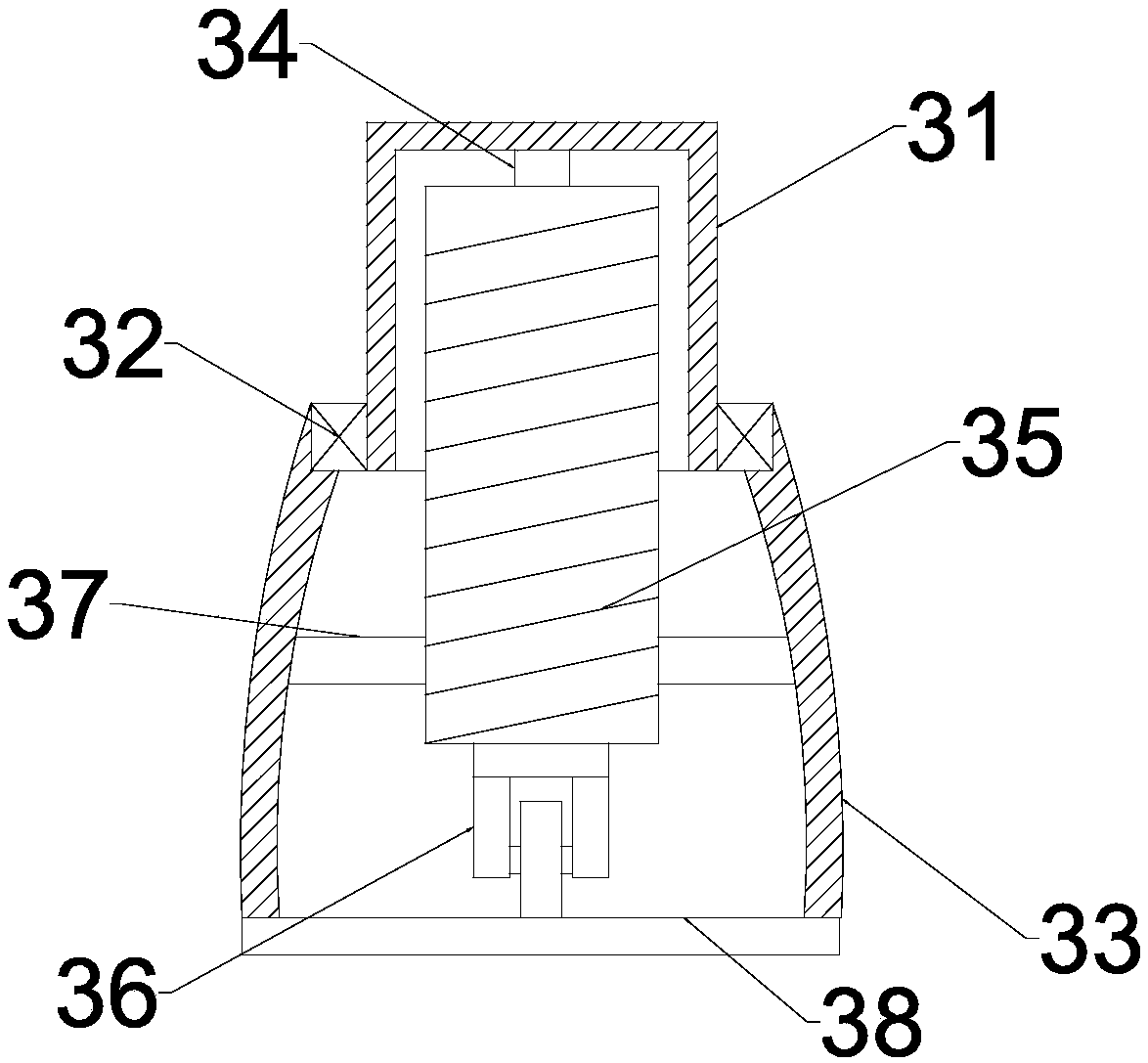

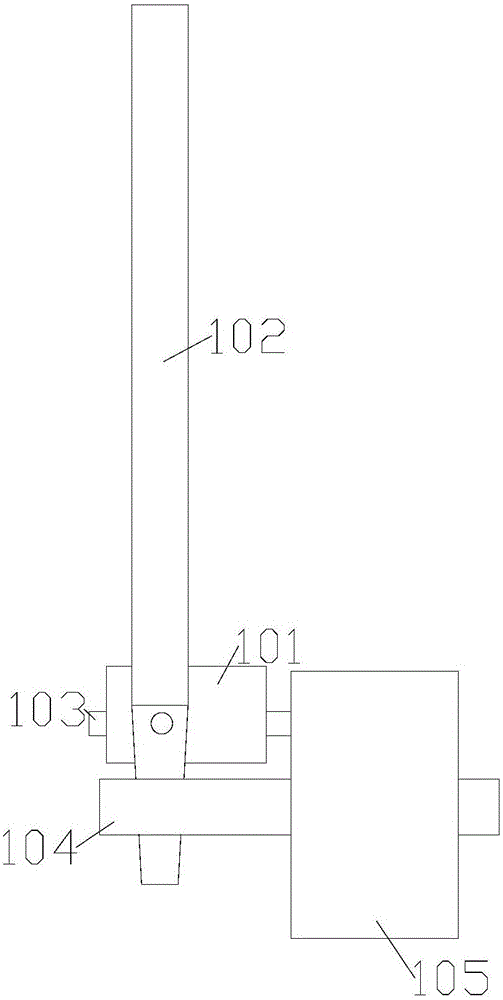

Leg lifting device for orthopedic surgery

InactiveCN108721042ALower leg positionComfortably placedDiagnosticsOperating tablesEngineeringScrew thread

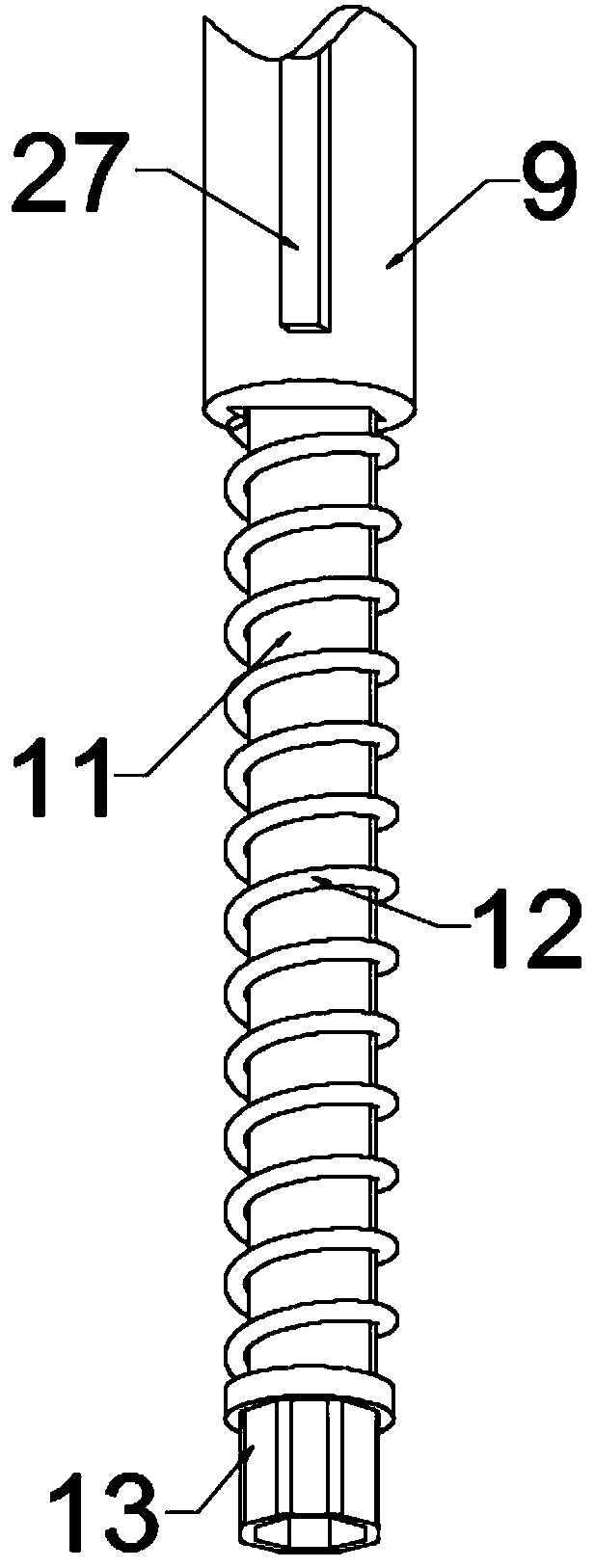

The invention discloses a leg lifting device for orthopedic surgery. The leg lifting device comprises a mounting block, wherein a rotating groove which is formed in a vertical direction is arranged atthe top of the mounting block; a hollow tube is rotationally connected with the inner wall of the rotating groove; inner threads are formed in the inner wall of the hollow tube; a screw rod is in threaded connection with the inner wall of the hollow tube through inner threads; a square rod is fixedly connected with the top of the screw rod; an operating table is arranged above the mounting block;a square hole matched with the square rod is formed in the top of the operating table; the side walls of the square rod are in sliding connection with the inner walls of the square hole; a leg fixingmechanism is fixedly connected with one end above the operating table, of the square rod; a transmission groove communicated with the rotating groove is formed in the bottom end of the rotating groove; a worm gear is fixedly sleeved by the side wall inside the transmission groove, of the hollow tube; a worm meshed with the worm gear is arranged inside the transmission groove. By trampling a petal, the leg fixing mechanism can be driven to lift up and down, and then the purposes that the limb of a patient does not need to be lifted up by an assistant for a long time and the leg lifting devicecan be operated by only one person can be achieved.

Owner:THE FIRST AFFILIATED HOSPITAL OF ARMY MEDICAL UNIV

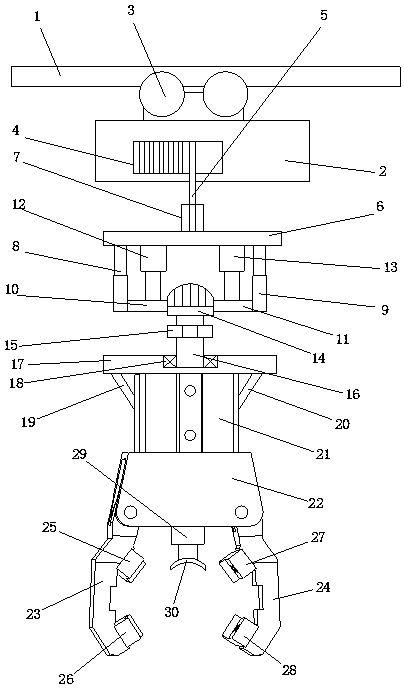

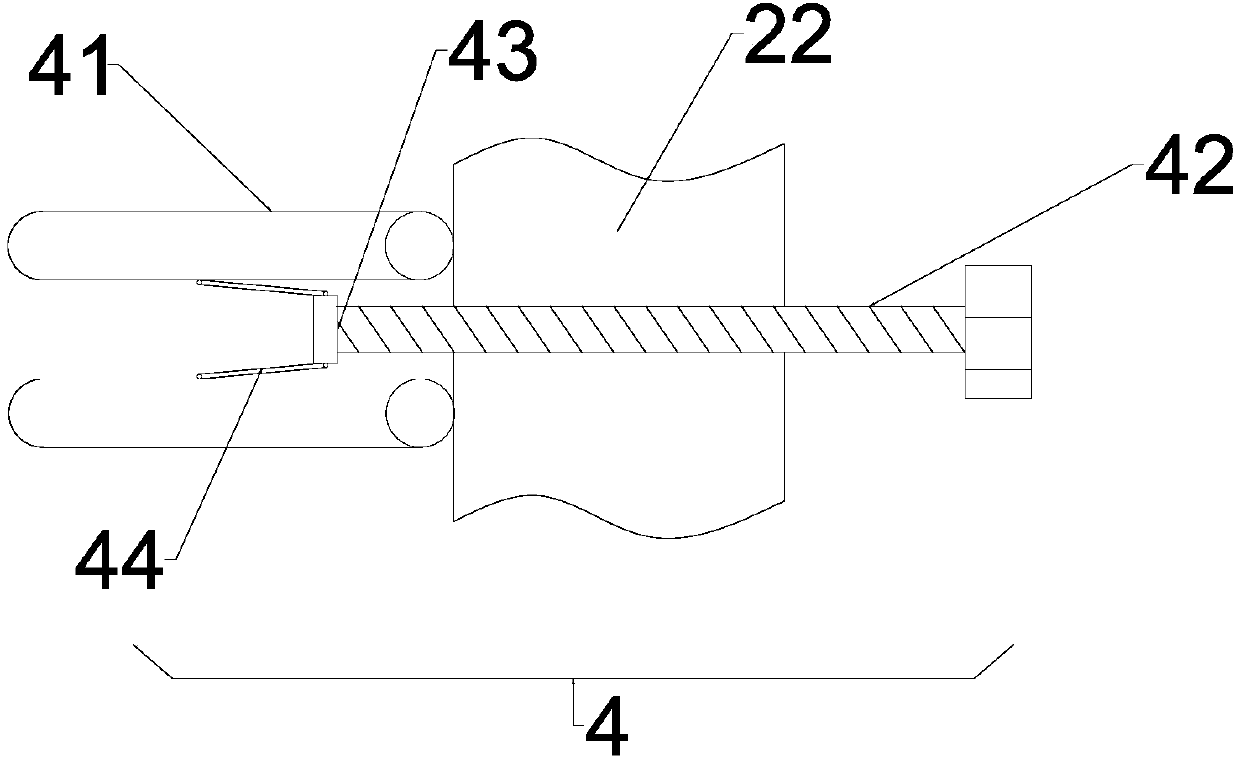

Pneumatic clamping jaw

InactiveCN108068098AConvenient lifting controlPrevent deviationProgramme-controlled manipulatorGripping headsEngineeringSquare Rod

The invention discloses a pneumatic clamping jaw. The pneumatic clamping jaw comprises a slide rail, an electric hoist, a rotary rod, a steel wire, a hook, a first guide telescopic rod, a second guidetelescopic rod, a first supporting square rod, a second supporting square rod, a first driver, a second driver, a motor, a rotary shaft, a rotary plate, a first supporting rod body, a second supporting rod body and an air cylinder. A clamping seat body is installed at the lower end of the air cylinder, a first clamping jaw body is movably installed in the clamping seat body, a second clamping jawbody is movably installed in the clamping seat body, and an air cylinder rod of the air cylinder drives the first clamping jaw body and the second clamping jaw body to move; a first L-shaped clampingblock and a second L-shaped clamping block are fixedly installed on the clamping wall face of the first clamping jaw body through bolts, and a third L-shaped clamping block and a fourth L-shaped clamping block are fixedly installed on the clamping wall face of the second clamping jaw body through bolts; and a driver is fixedly installed at the lower end of the clamping seat body, and an arc-shaped clamping block is installed at the bottom end of the driver.

Owner:TONGCHENG LIQIONG METAL PROD

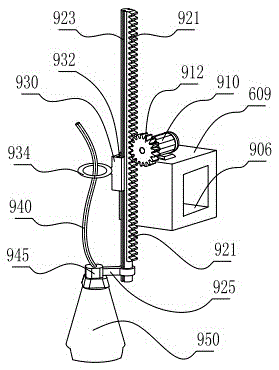

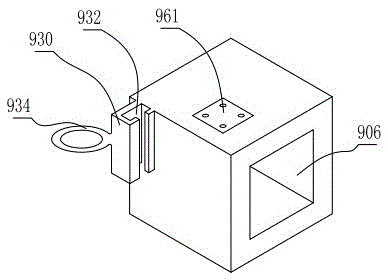

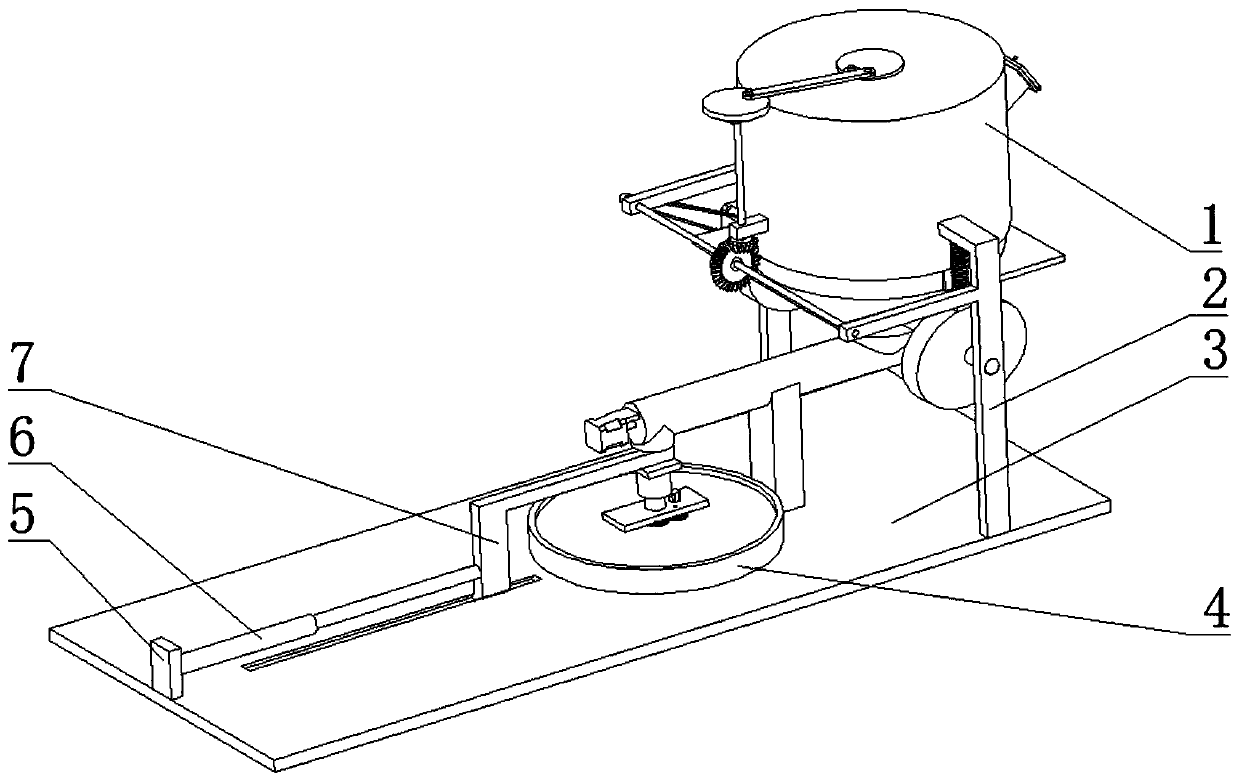

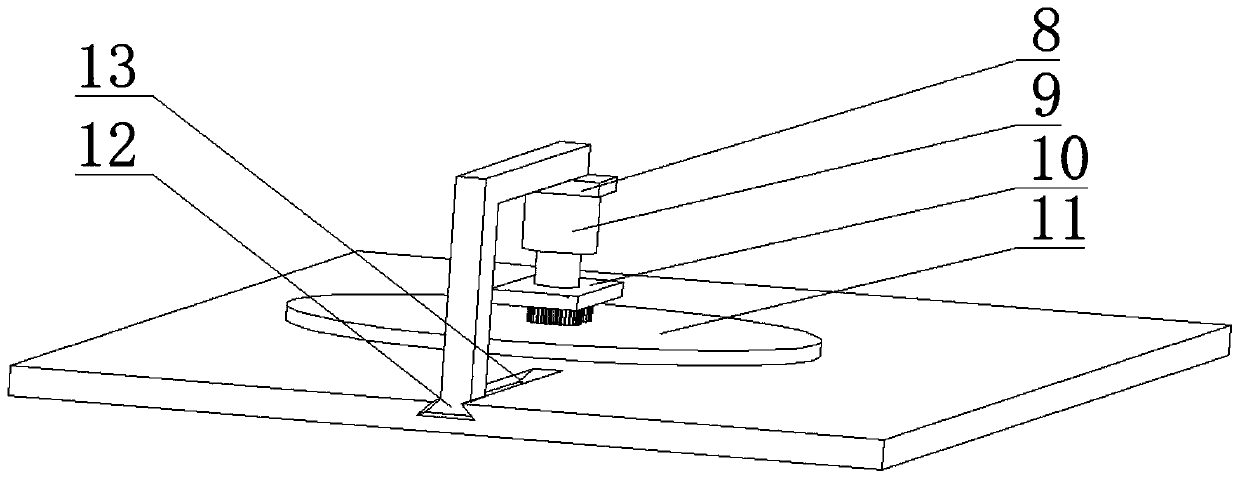

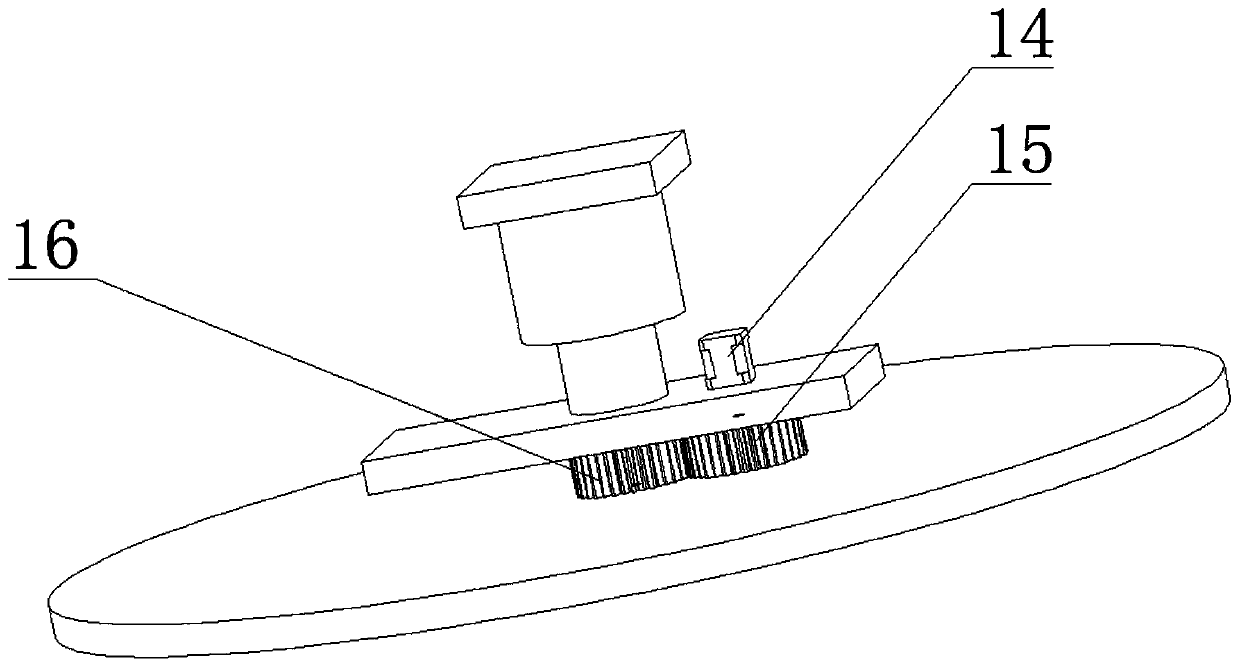

Glass detection instrument adopting worm gear bedplate, rack camera and bearing clamp plate with aluminum alloy plating

InactiveCN105606445AEasy to removeOvercoming the defects of fit clearanceToothed gearingsStrength propertiesMobile cameraToughened glass

The invention relates to a tempered glass testing and checking instrument, in particular to a glass detection instrument adopting a worm gear bedplate, a rack camera and a bearing clamp plate with aluminum alloy plating. A drive worm gear is further fixed on a bedplate rotating shaft on one side and is matched with a worm shaft, two ends of the worm shaft are rotationally fixed in worm supports, the worm supports are fixed on the outer side surfaces of the corresponding support side plates, and a worm crank handle is further arranged at one end of the worm shaft; a mobile camera assembly is arranged on a camera square rod, a cylinder impactor is glidingly fixed on an impact cross rod, a coplanar bearing clamp plate assembly is fixed on the upper surface of the test bedplate, bedplate supports, lock pin supports are arranged on upper planes of the support side plates, and a broken glass recovery container is fixed between the support side plates; the condition that broken piece detection basically depends on workers is changed, and the camera takes pictures and transmits the pictures of broken pieces to a computer processing center. The coplanar bearing clamp assembly is adopted, accordingly, the probability of breaking of an adhesive tape due to explosion force of tempered glass is avoided, and body safety of an operator is better guaranteed.

Owner:WENZHOU ECONOMIC TECH DEV ZONE HAIZHIJIE ELECTROMECHANICAL PROD DESIGN STUDIO

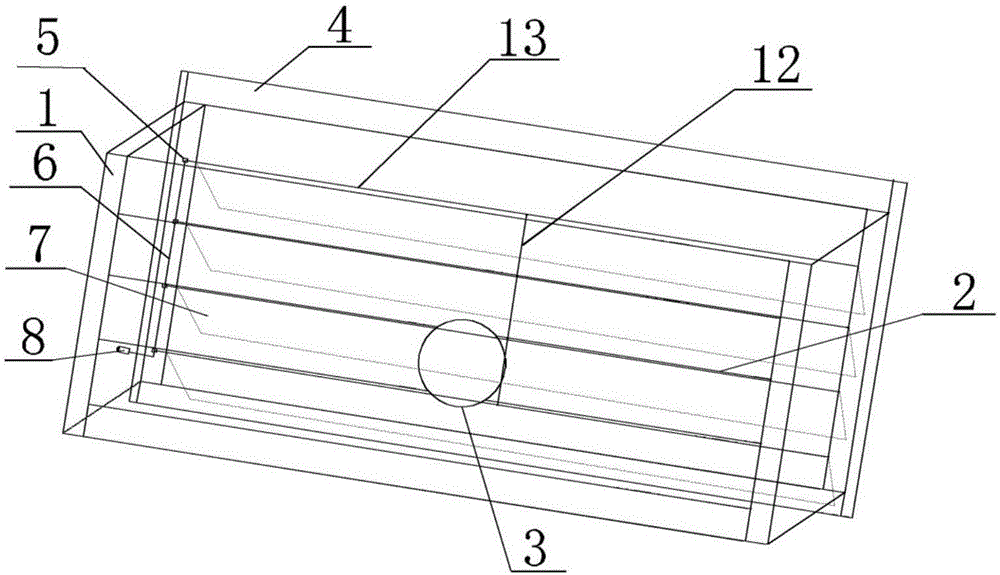

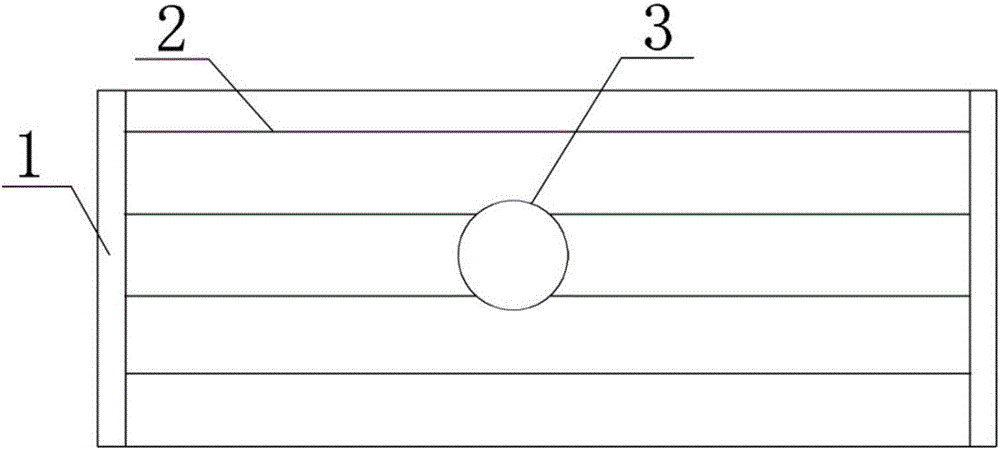

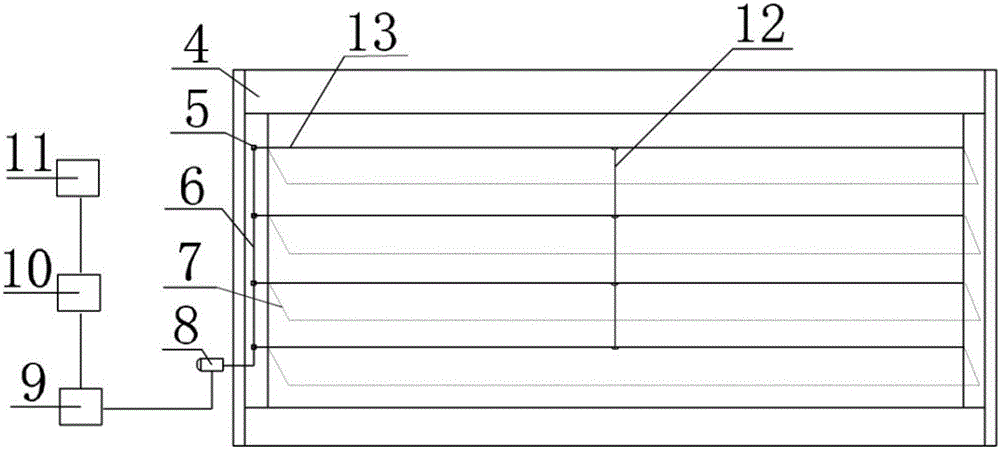

Disposable mask recovery device

InactiveCN110371539AAvoid spreadingSimple structureWaste collection and transferRefuse receptaclesGear wheelRespirator

The invention discloses a disposable mask recovery device. The disposable mask recovery device comprises a recoverer, a packing mechanism is arranged in the recoverer, and friction transmission is achieved in the packing mechanism through a belt. A recovery mechanism is arranged on the upper side of the packing mechanism, and comprises hollow blocks, a square rod, penetrating grooves, a conical block and a compressed pressure spring. The conical block can be driven to move forwards to be meshed with a large bevel gear when the pressure spring is reset. The device is simple in structure, can beused for hospitals and other places where many disposable masks are used, can independently store the masks and quantitatively recover and pack the masks, and prevents the situation that the disposable masks are mixed with other garbage and spread germs.

Owner:杭州医迈医疗器械有限公司

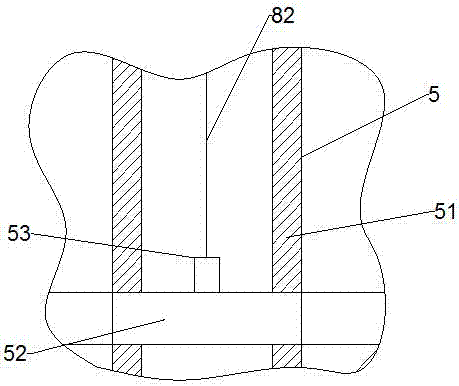

Stable oscillating stirring kettle

InactiveCN107442014AEffective removal of adhesionEliminate attachmentShaking/oscillating/vibrating mixersTransportation and packagingMotor driveElectric machinery

The invention discloses a stable oscillating stirring kettle which comprises a kettle body, a sliding toothed plate and a sliding sleeve, wherein an upper cover is arranged at the upper end of the kettle body; a strip-type hole, a sliding groove, the sliding toothed plate and sliding bars are formed in and arranged on the upper cover; a placement plate is arranged on the rear side above the kettle body; a rotating shaft, a rotating disc, a sliding square rod, the sliding sleeve, a first motor, a driving rotating rod and a transmission connecting rod are arranged on the front surface of the placement plate; and a second motor, a stirring shaft, stirring fan blades, vertical cleaning blades, a support rod, a rotating support block, a rotating steel ball and an extension spring are arranged at the lower end of the sliding toothed plate. According to the stable oscillating stirring kettle, the motor drives the rotating disc to perform reciprocating oscillation, so that the second motor and the stirring shaft are driven to perform horizontal oscillation and perform material stirring by matching of the sliding sleeve and the sliding toothed plate; and the support rod, the rotating support block, the rotating steel ball and the extension spring are additionally arranged, so that the stability can be improved, and better stirring efficiency can be obtained.

Owner:张明克

Automatic cup cleaning device

InactiveCN107280613AEasy to cleanTableware washing/rinsing machine detailsHydraulic cylinderEngineering

The invention discloses an automatic cleaning device for cups, comprising a base, the upper surface of the base is provided with a door-shaped installation frame, the lower surface of the beam of the door-shaped installation frame is provided with an installation box, and the inner upper surface of the installation box is provided with a rotating A rotary motor with the end facing down. The rotating end of the rotating motor is located in the installation box with a hydraulic cylinder with the telescopic end facing down. A No. 1 circular port is processed at the center of the lower surface of the installation box. There is a square rod on the surface, and the telescopic end of the hydraulic cylinder is fixedly connected to the upper surface of the square rod through the No. 1 circular port. The lower surface of the square rod is equipped with a circular brush tube, and the inside of the square rod is a cavity structure. The square rod is provided with a support rod, and the left end of the inner lower surface of the square rod is provided with a No. 1 limit block. The beneficial effect of the present invention is that the cups with different shapes can be cleaned internally, and the cups with different shapes can also be fixed, which is convenient for cleaning and does not need to be manually fixed.

Owner:虞徐坚

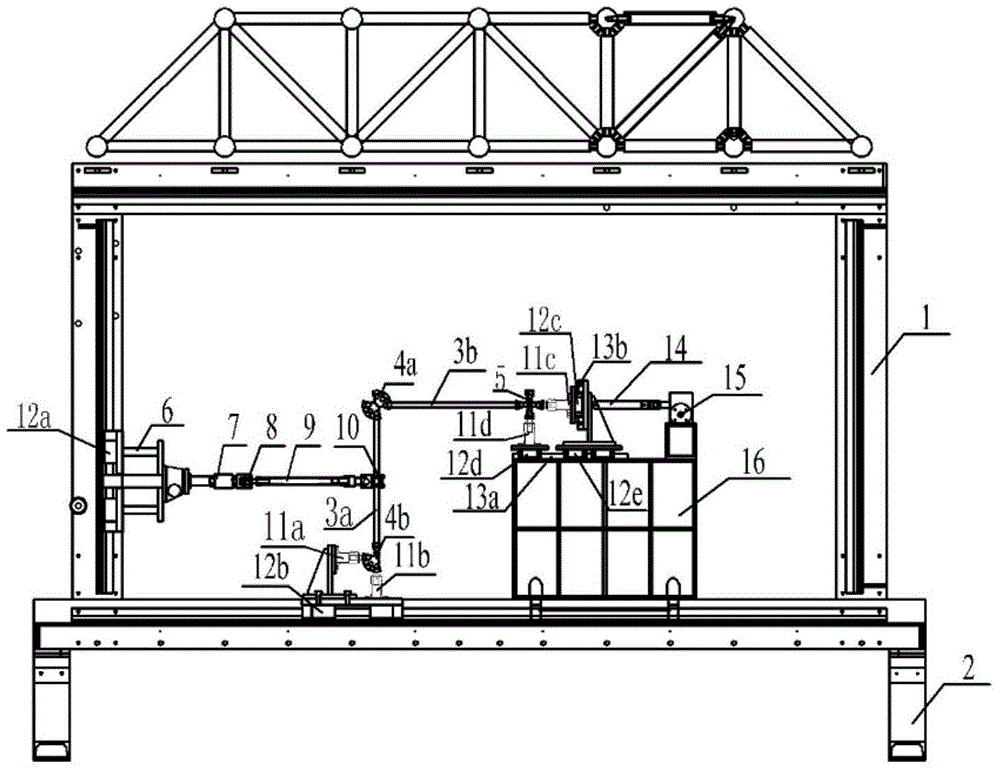

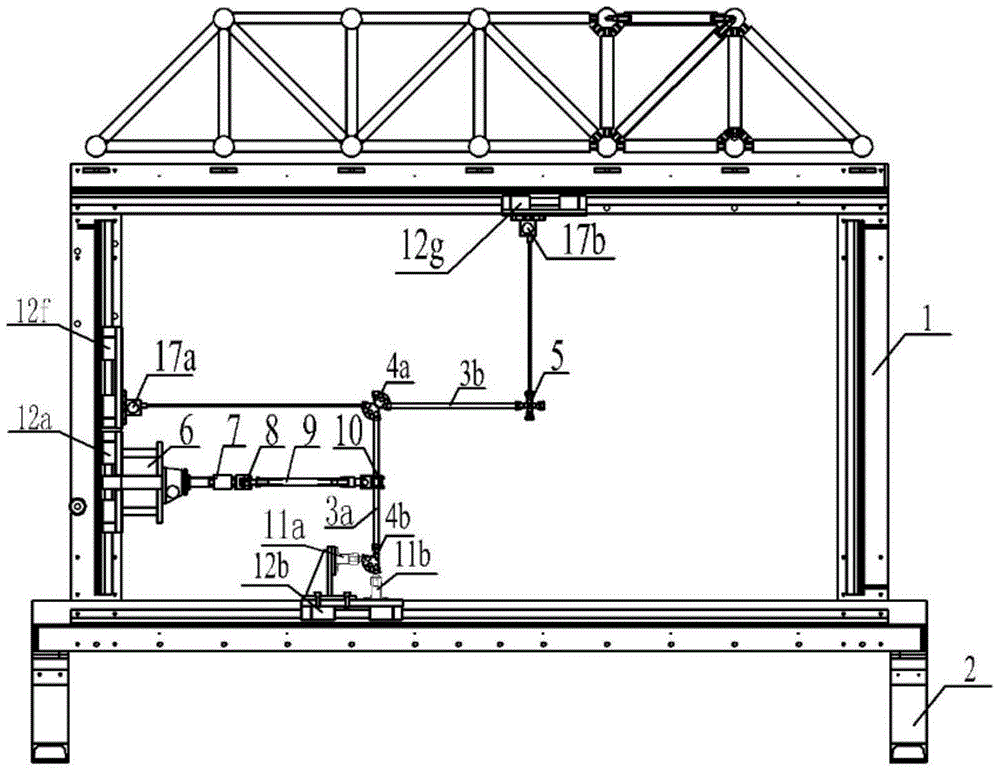

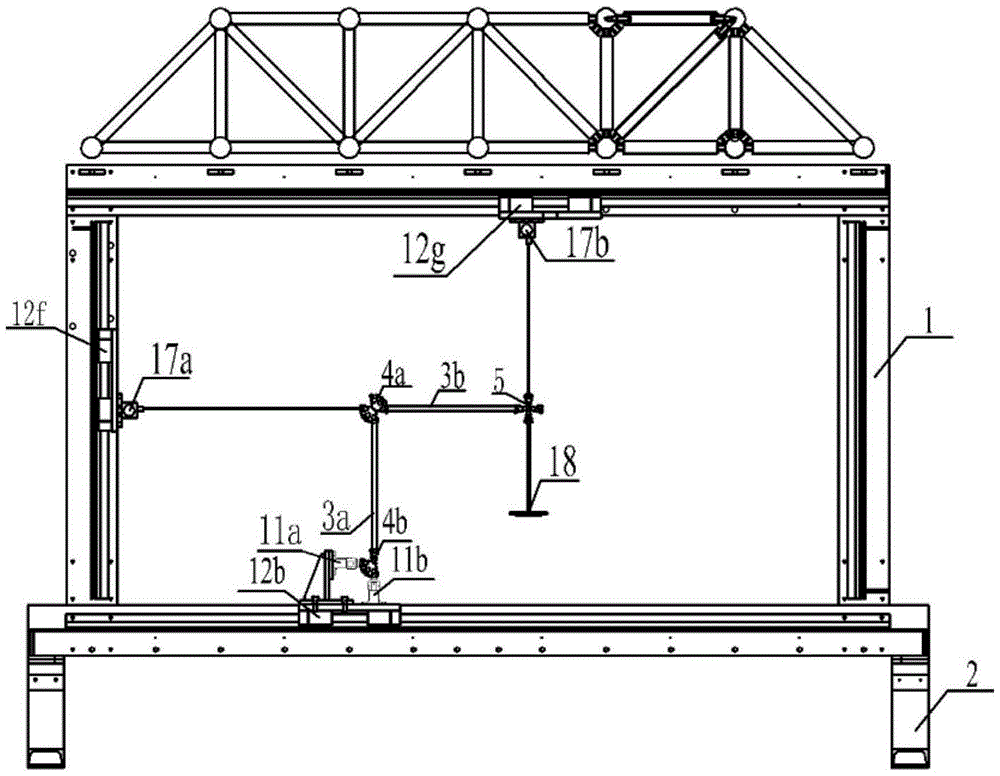

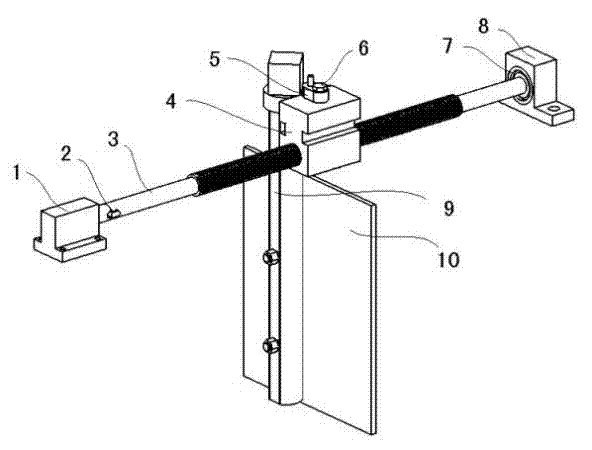

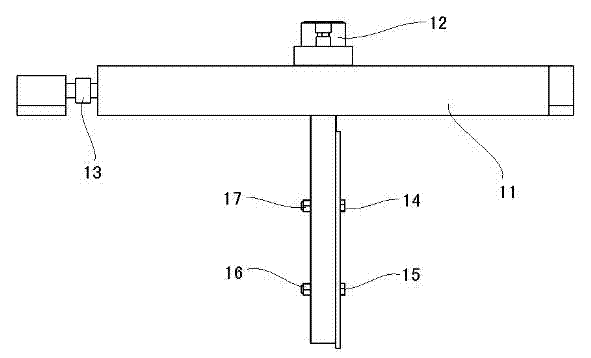

Teaching experiment device making force method visualized

The invention provides a teaching experiment device making a force method visualized. The device comprises a rigid frame structure, a loading device, a support and constraint device and a measurement device. The rigid frame structure is formed by connecting vertical and transverse two hollow square rods, which are mutually perpendicular, through a rigid joint disc. The loading device comprises a worm and worm wheel loading device and a weight loading device, and is used for realizing loading of the rigid frame structure. The support and constraint device comprises a constraint support of the rigid frame structure and a counterforce frame, wherein the constraint support of the rigid frame structure comprises a fixation support and a hinge support, and the counterforce frame is formed by a counterforce rack and a base. The measurement device comprises a force sensor, a strain gauge and stay wire displacement sensors. The device integrates a structural mechanics experimental model, the loading device and the measurement device, and the experimental model is flexible and variable; different branch experimental models can be assembled according to the needs of the experiment content, and force method experiments with a plurality of methods can be carried out; and the results obtained through the various methods can be compared mutually and compared with the theoretical result conveniently.

Owner:DALIAN UNIV OF TECH +2

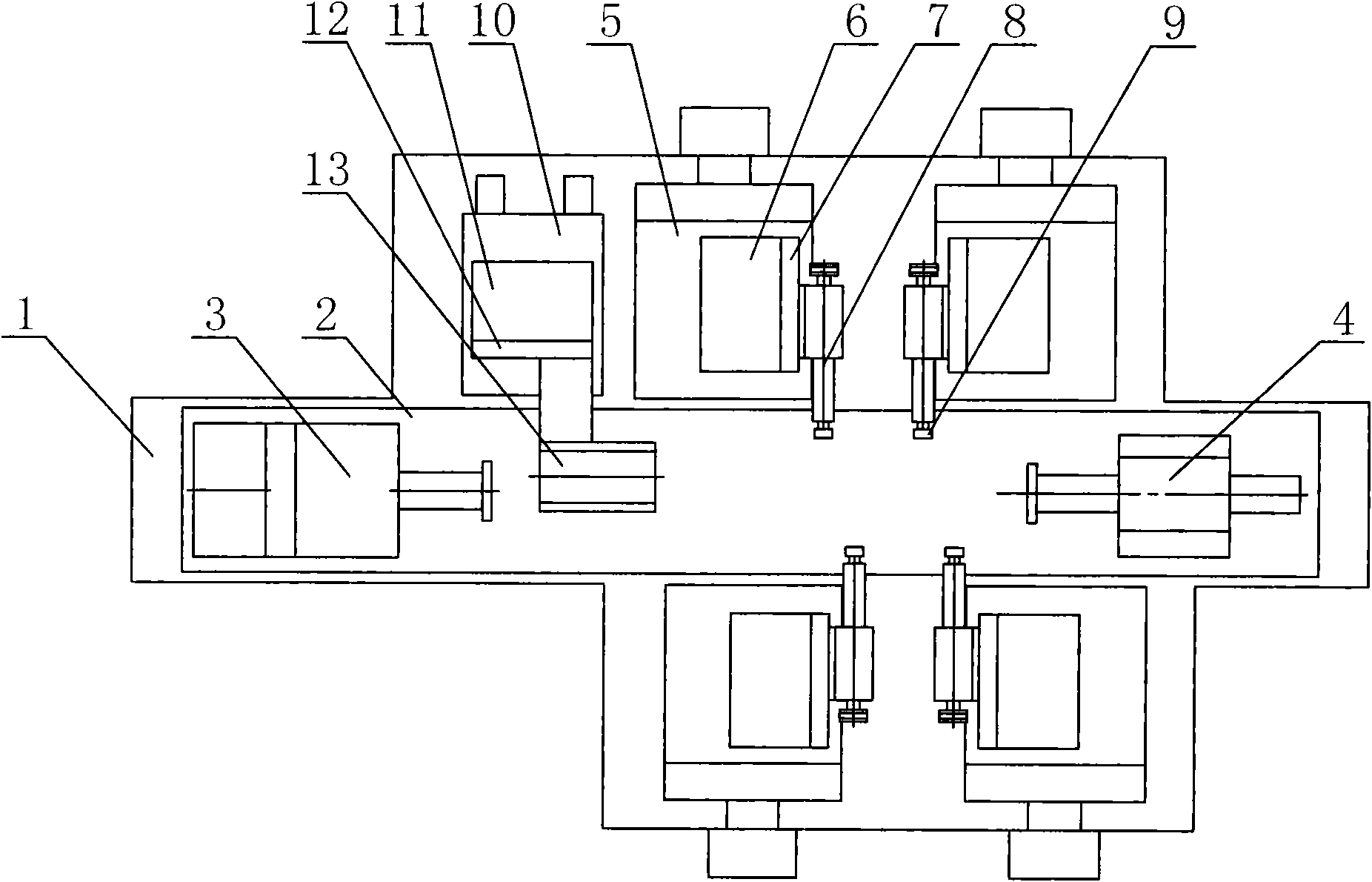

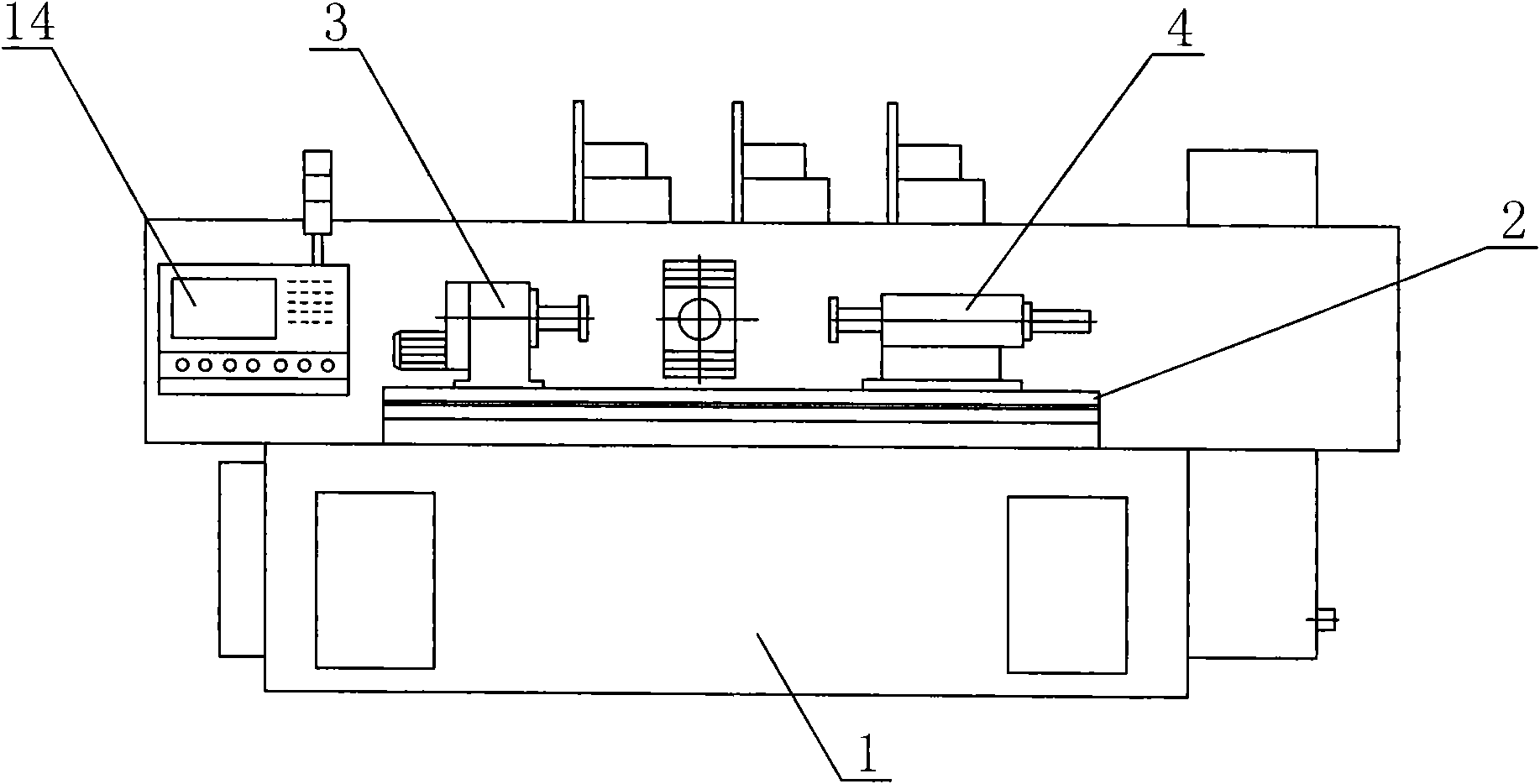

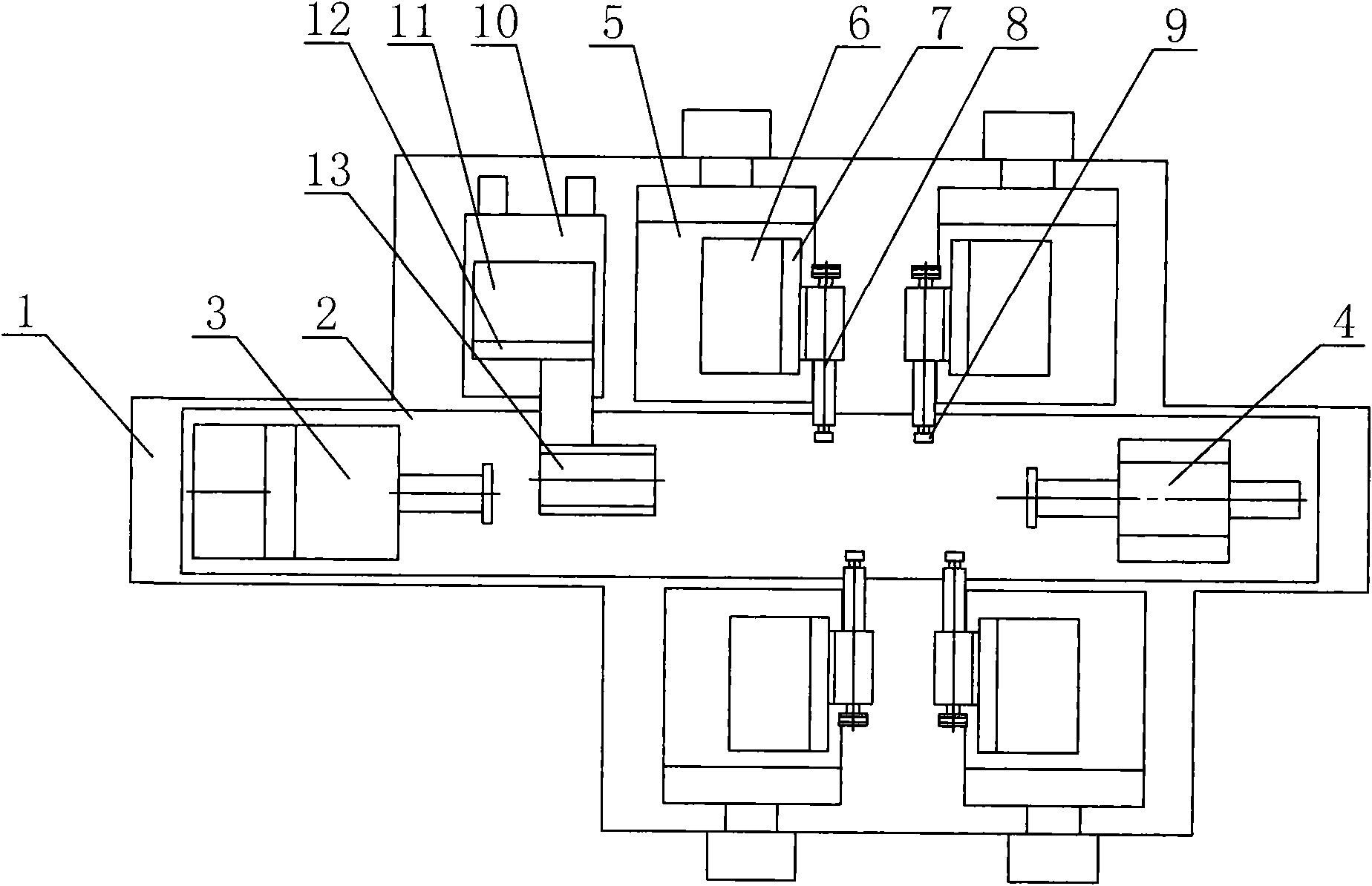

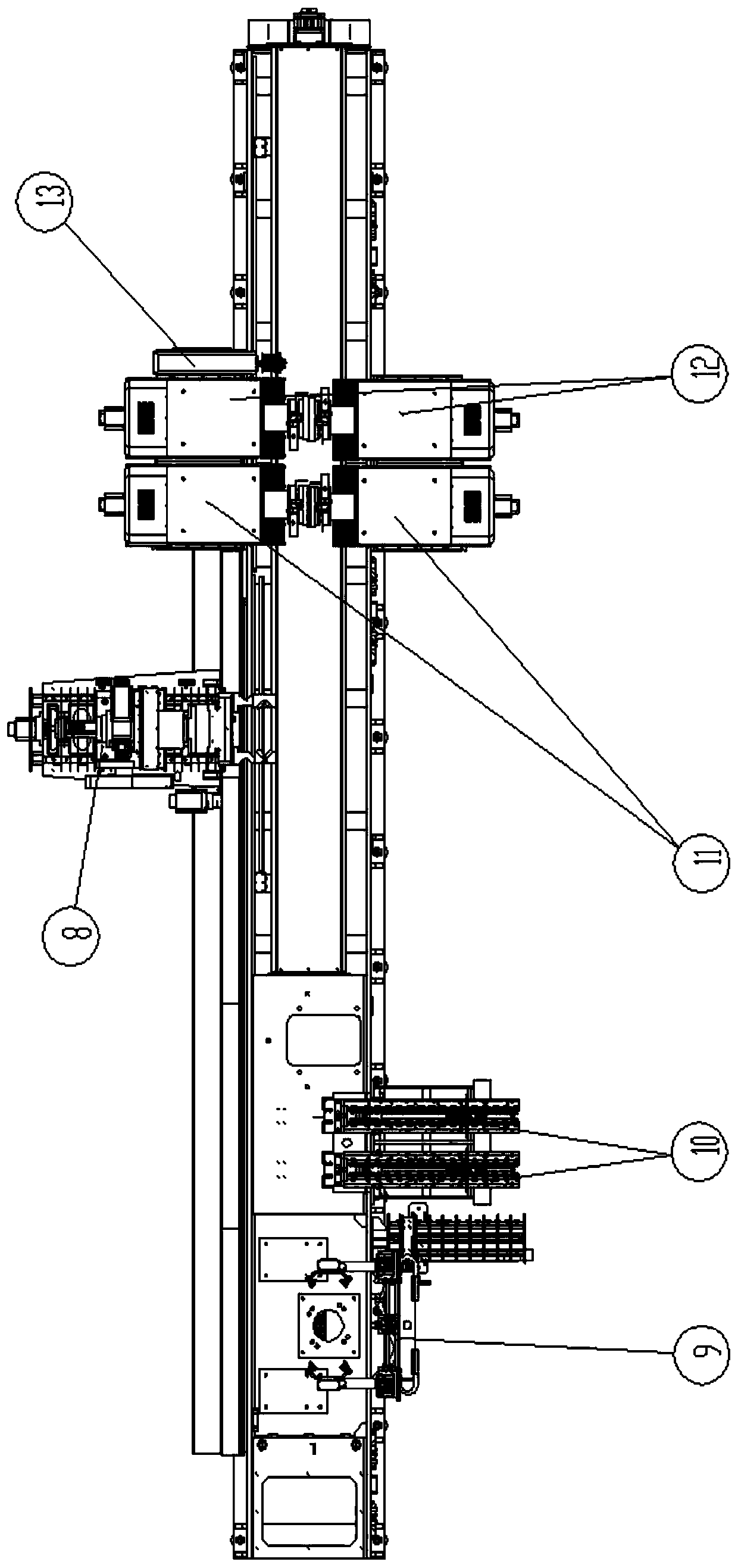

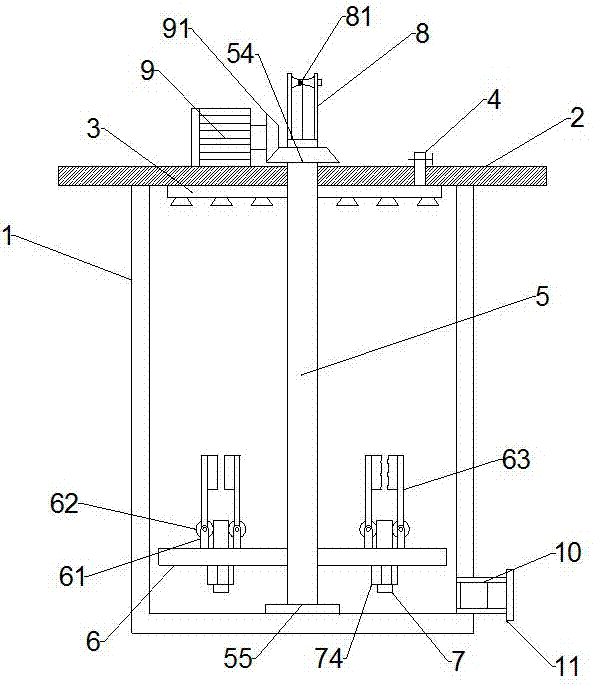

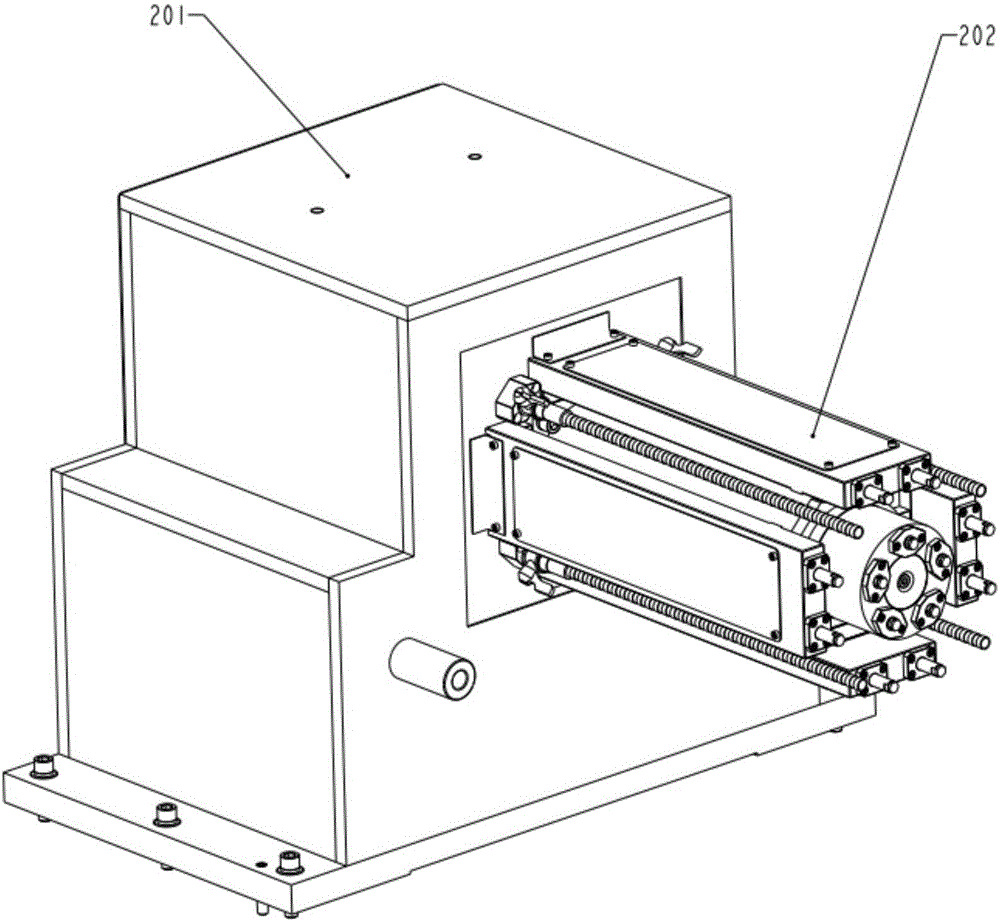

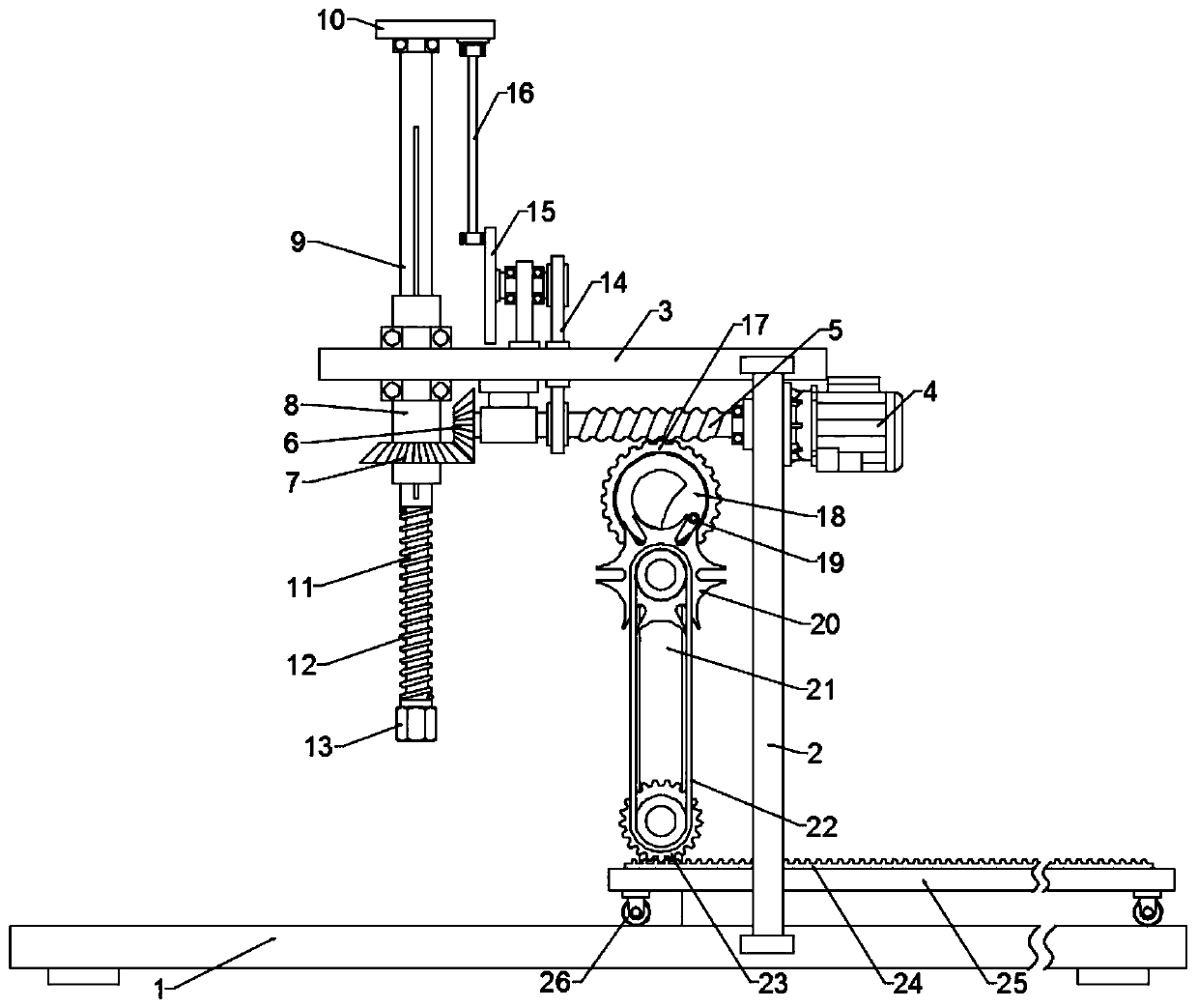

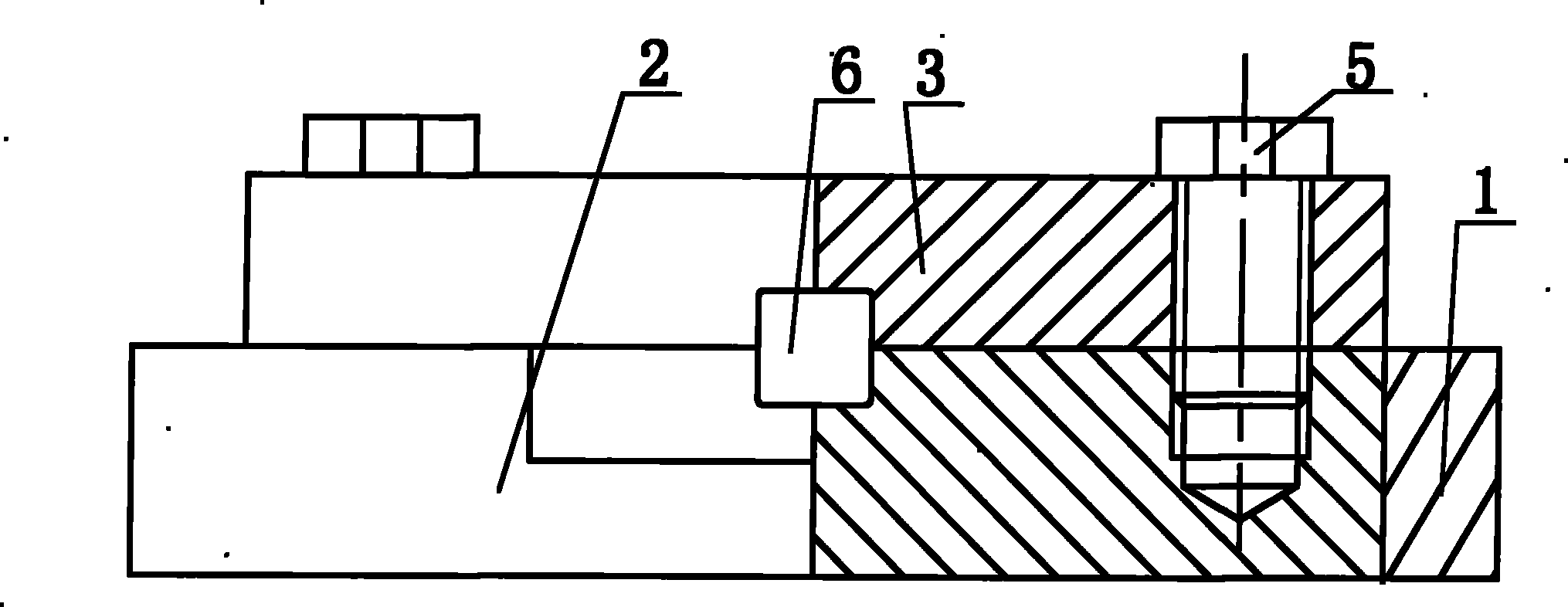

Machining center for polishing and grinding square rod

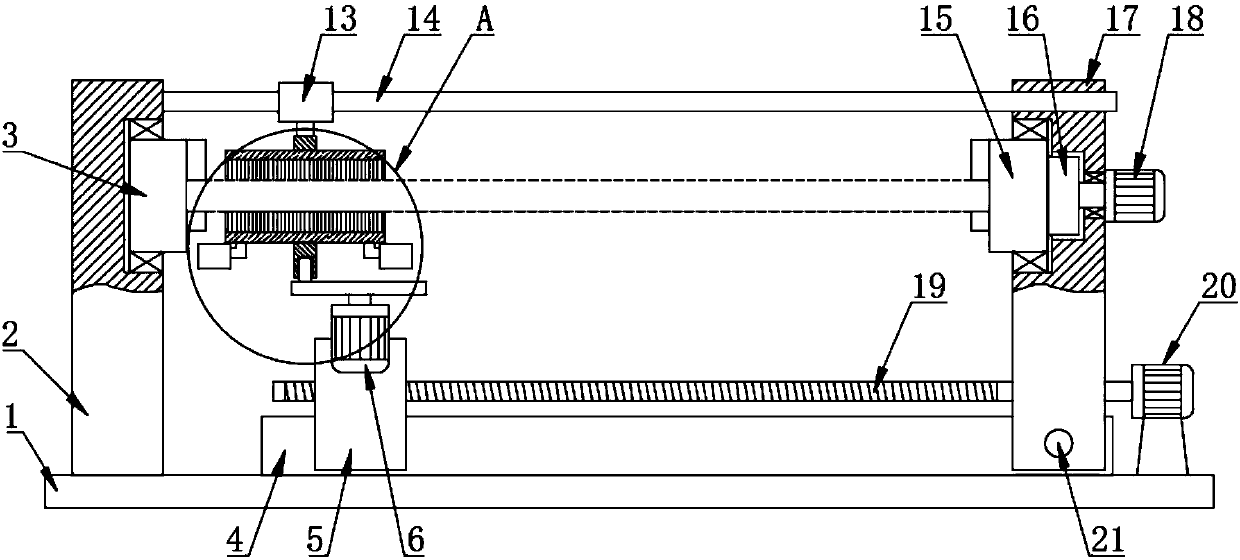

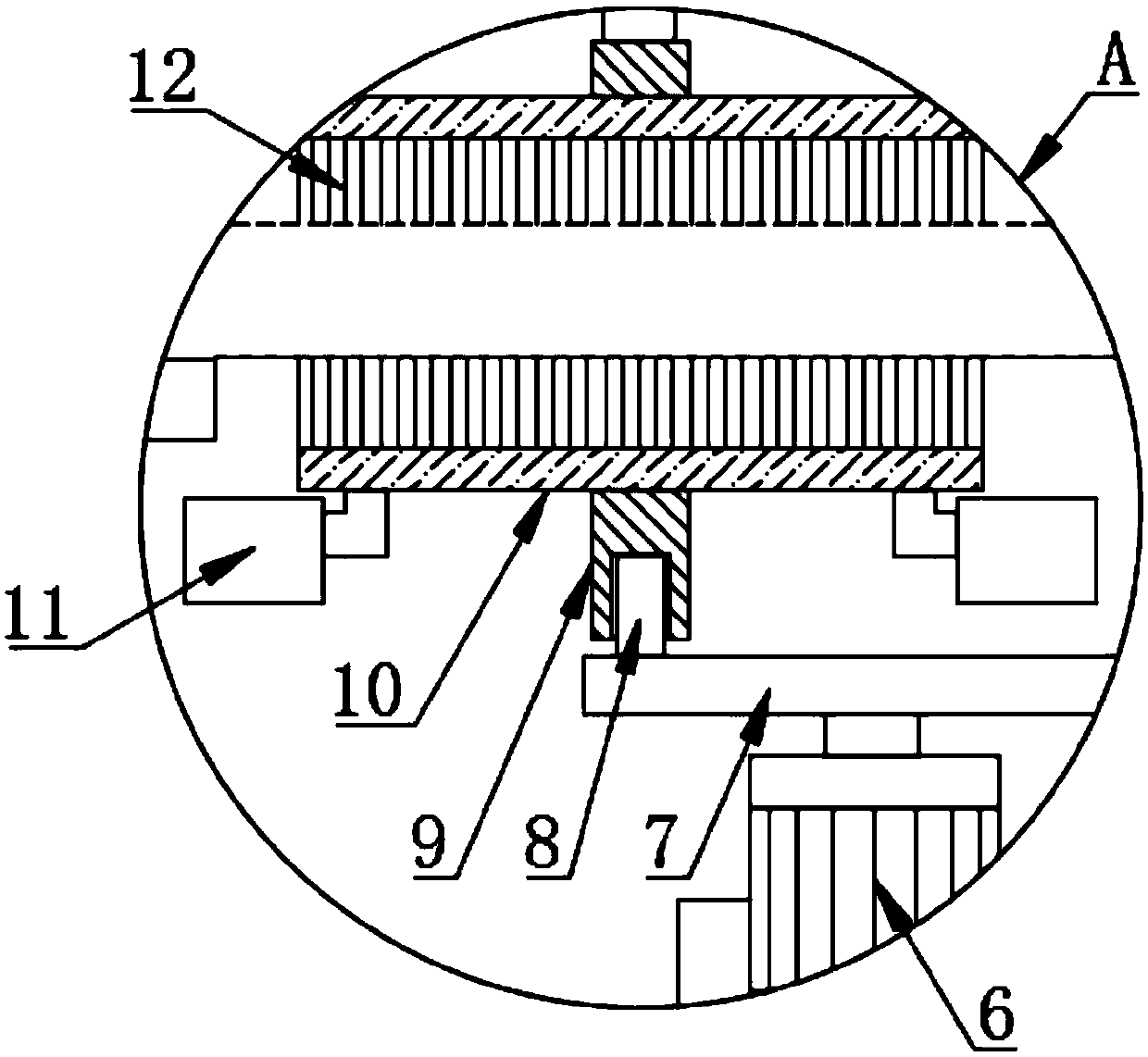

InactiveCN101829942AHigh degree of automationSimple processGrinding machine componentsGrinding machinesNumerical controlReciprocating motion

The invention relates to a machining center for polishing and grinding a square rod, which comprises a lathe bed, a workbench, a clamping device, a positioning device, a grinding device and a numerical control device, wherein the workbench, the clamping device, the positioning device, the grinding device and the numerical device are arranged on the lathe bed; the workbench can do horizontal reciprocating motion relative to the lathe bed; the clamping device comprises a headstock and a tailstock and a headstock main shaft contained by the headstock is driven by a servo motor to gradually or continuously rotate according to numerical program; the grinding device comprises a slide saddle arranged on the lathe bed, a stand column arranged on the slide saddle, an abrasive wheel lifting sliding plate arranged on the stand column, an abrasive wheel main shaft arranged on the abrasive wheel lifting slide plate and an abrasive wheel arranged at the tail end of the abrasive main shaft; and the positioning device can realize the functions of automatic centering and automatic clamping of a rod material. The invention can realize the integration machining of smoothening and polishing a plane and a fillet corner, has simple working procedures, high processing precision and high automation degree for matching the numerical device, and can effectively improve the production efficiency and the excellent rate and reduce the production cost.

Owner:北京京联发数控科技有限公司

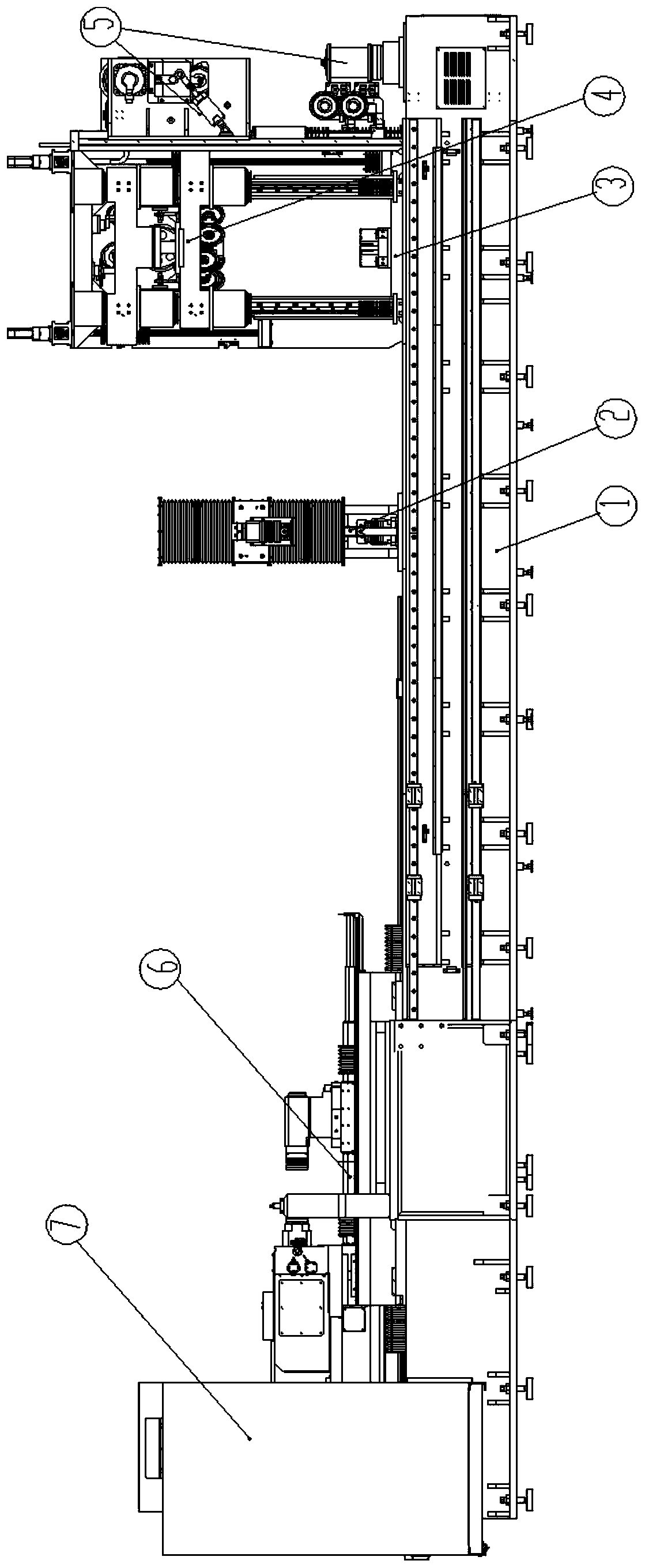

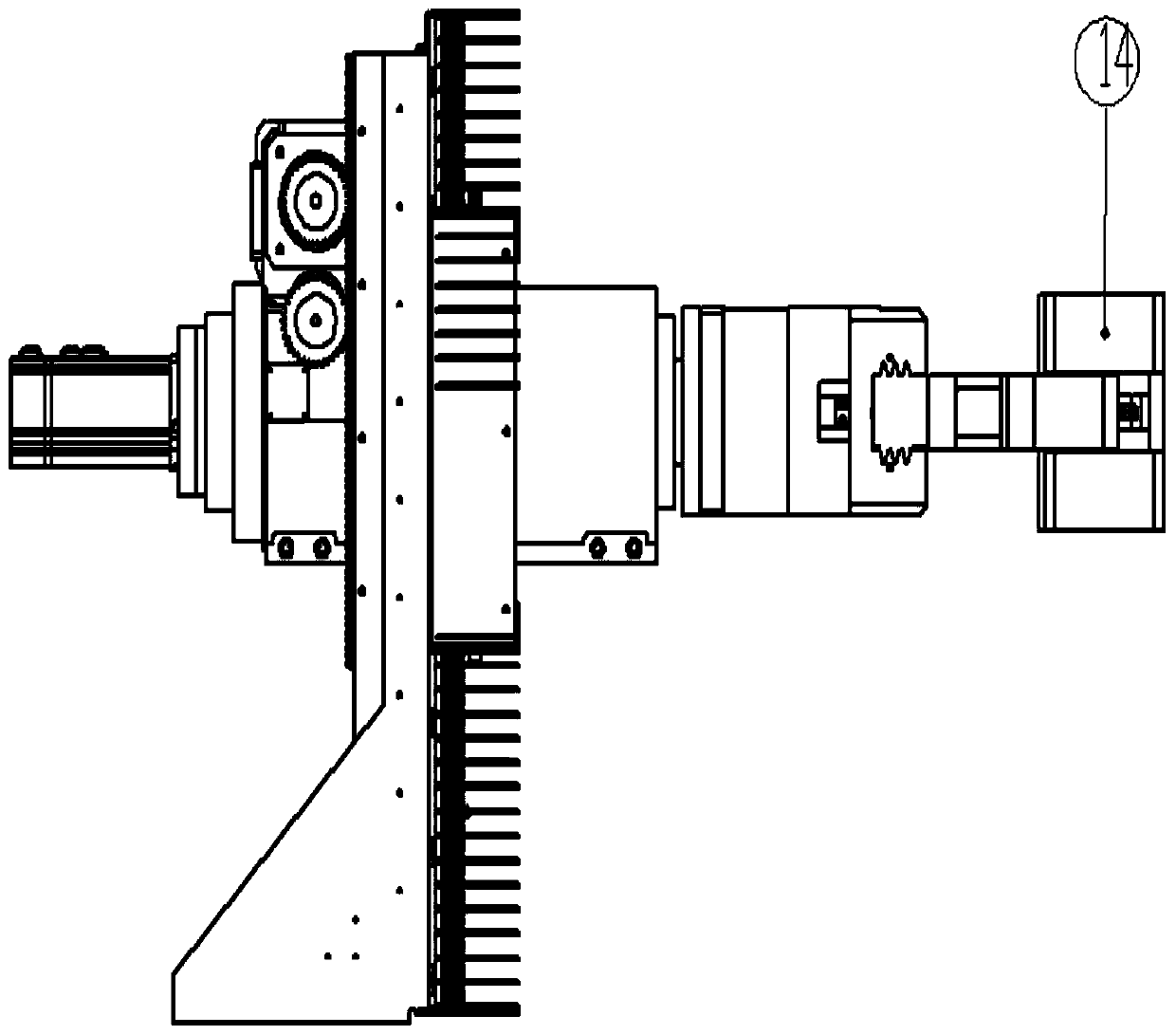

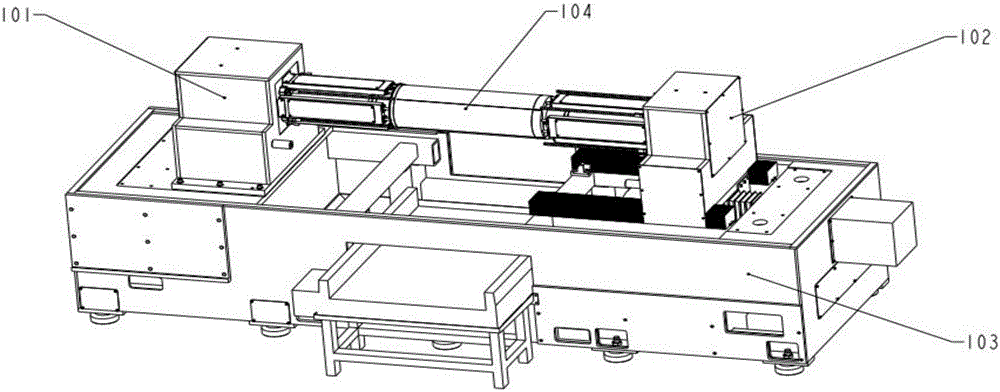

Full-automatic single crystal silicon rod cutting and grinding combined processing integrated equipment and using method thereof

PendingCN110026826AShorten the circulation processProcessing time is shortGrinding carriagesGrinding machinesEngineeringRound bar

The invention relates to full-automatic single crystal silicon rod cutting and grinding combined processing integrated equipment and an using method thereof, and the invention provides the full-automatic single crystal silicon rod cutting and grinding combined processing integrated equipment, which can process a round rod into a square rod by integrated processing of square cutting, corner grinding and surface grinding, so that the problems in the prior art can be solved effectively; the type and quantity of the equipment can be reduced, the area of a plant, the labor and logistics cost can besaved when the processing efficiency of the silicon rod is improved, the processing cost of the silicon rod is reduced and the size precision of the crystal rod is improved. The invention can make asquare cutting assembly and a grinding assembly work independently without interference, and the processing efficiency is improved; in addition, a square cutting grinding power head adopts a symmetrical layout, meanwhile double-sided machining is carried out, so the processing efficiency is doubled.

Owner:ZHEJIANG JINGSHENG MECHANICAL & ELECTRICAL

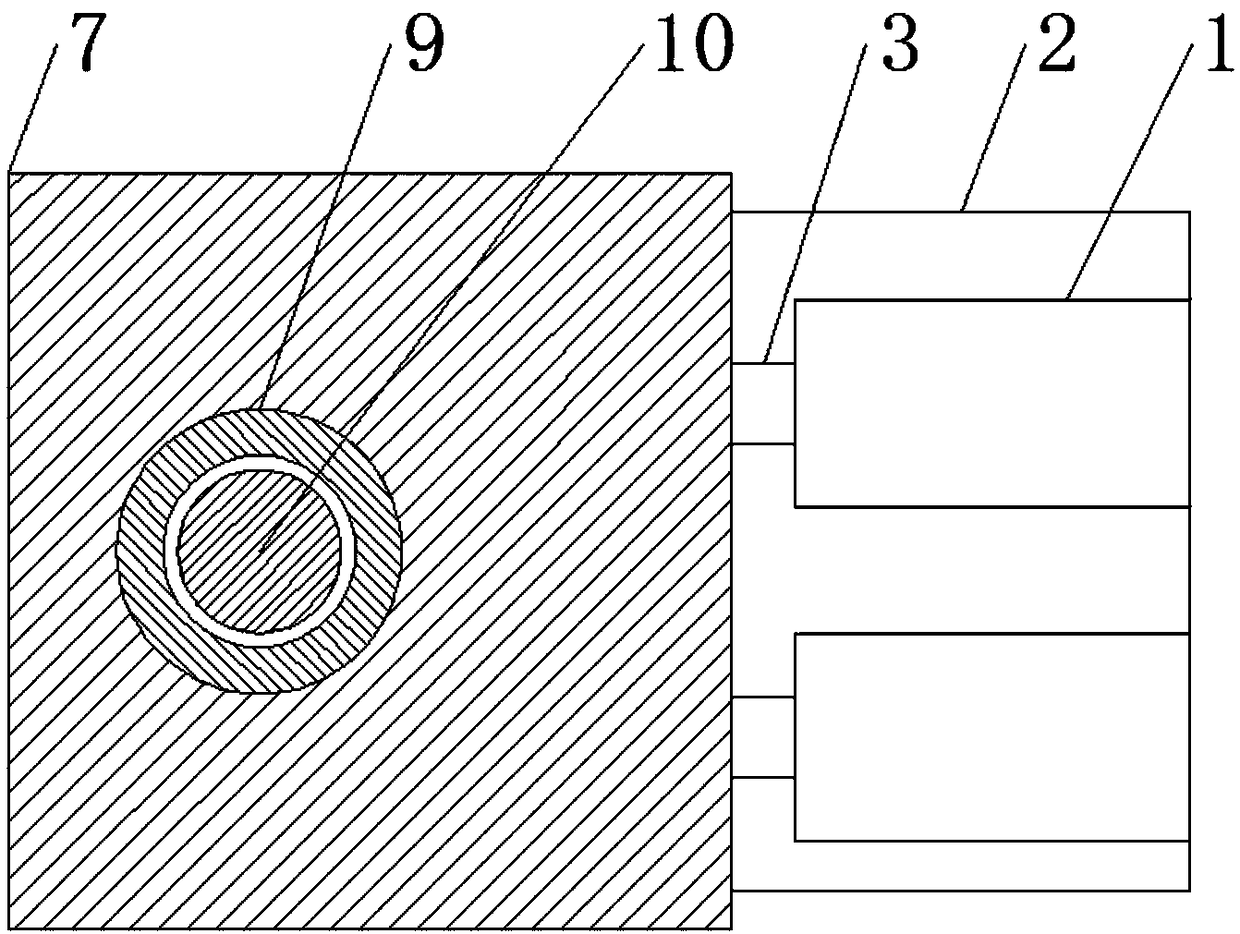

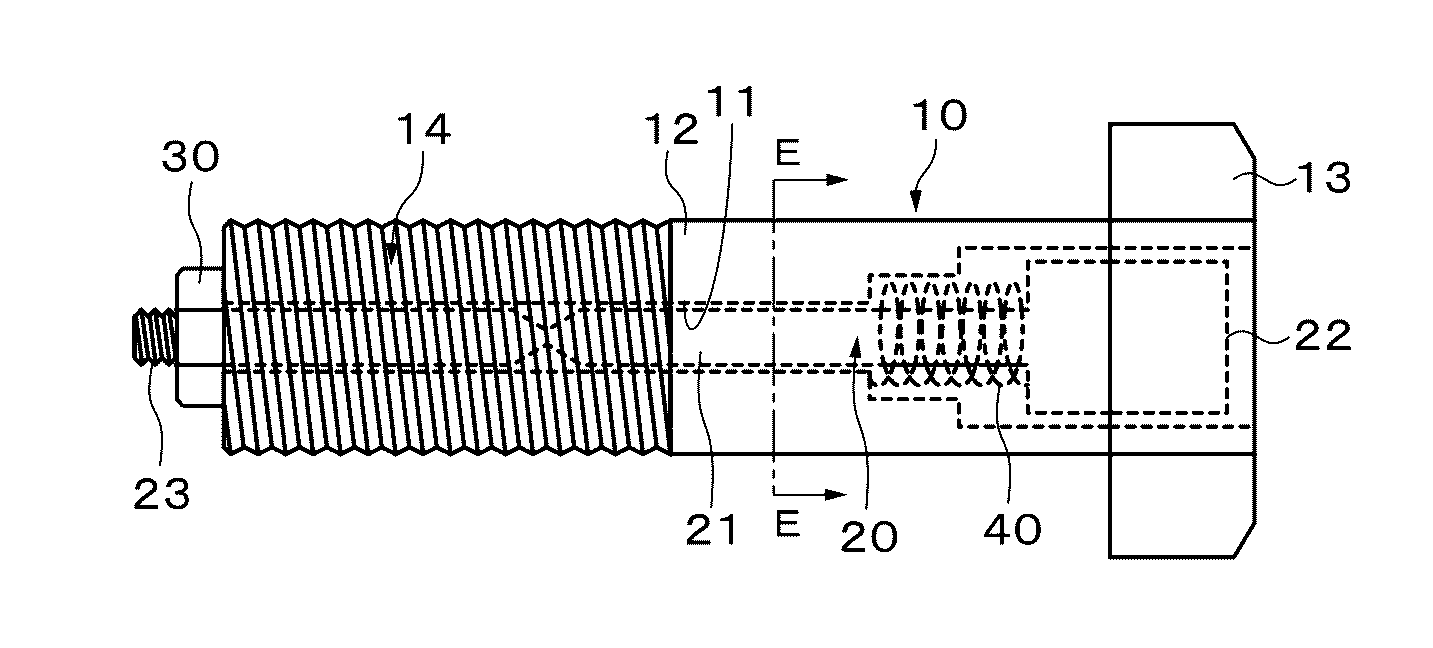

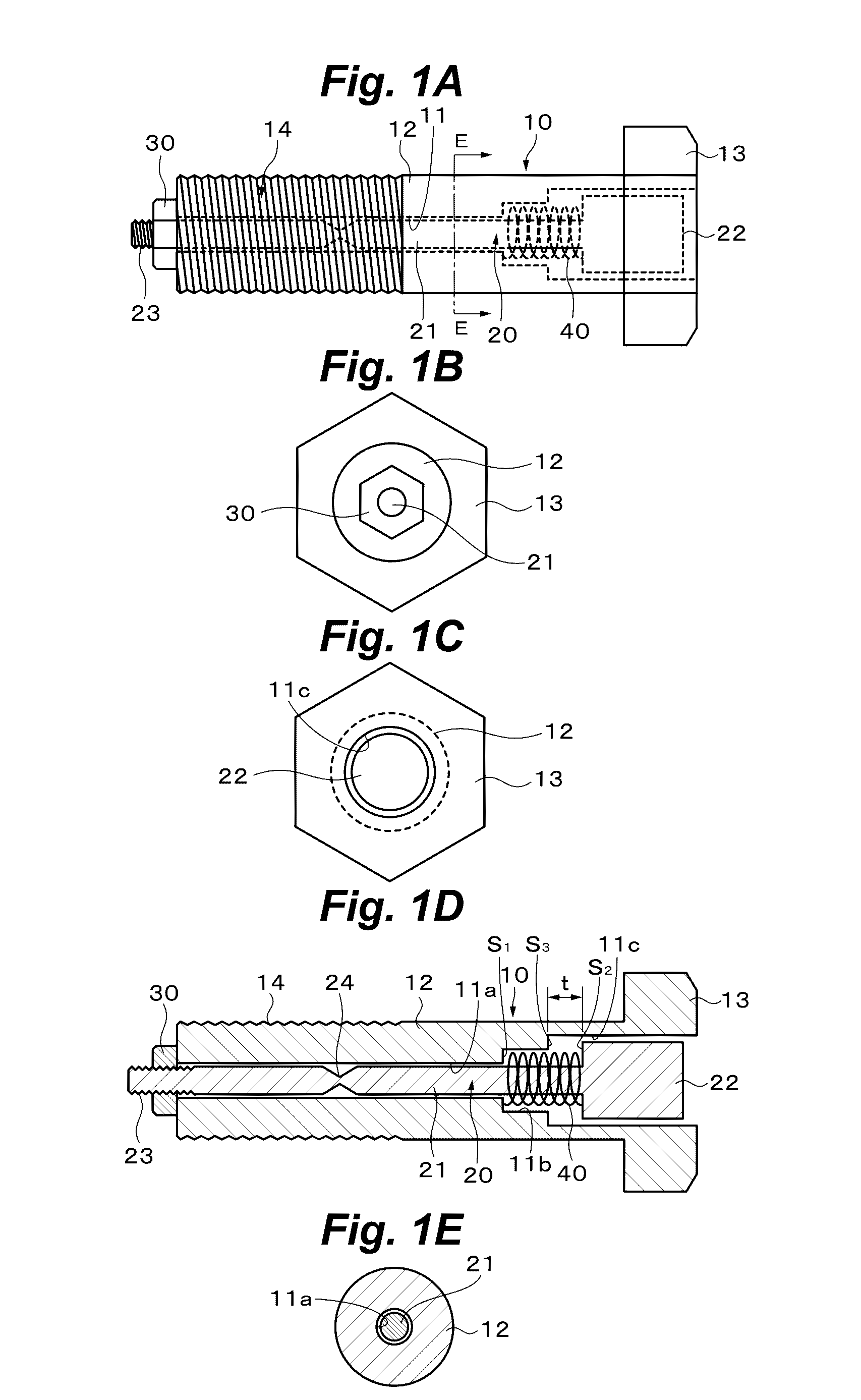

Failure detection sensor, failure detection system, and structure

ActiveUS20160370268A1Easy to detectLow priceLoad modified fastenersMaterial strength using tensile/compressive forcesStress concentrationPull force

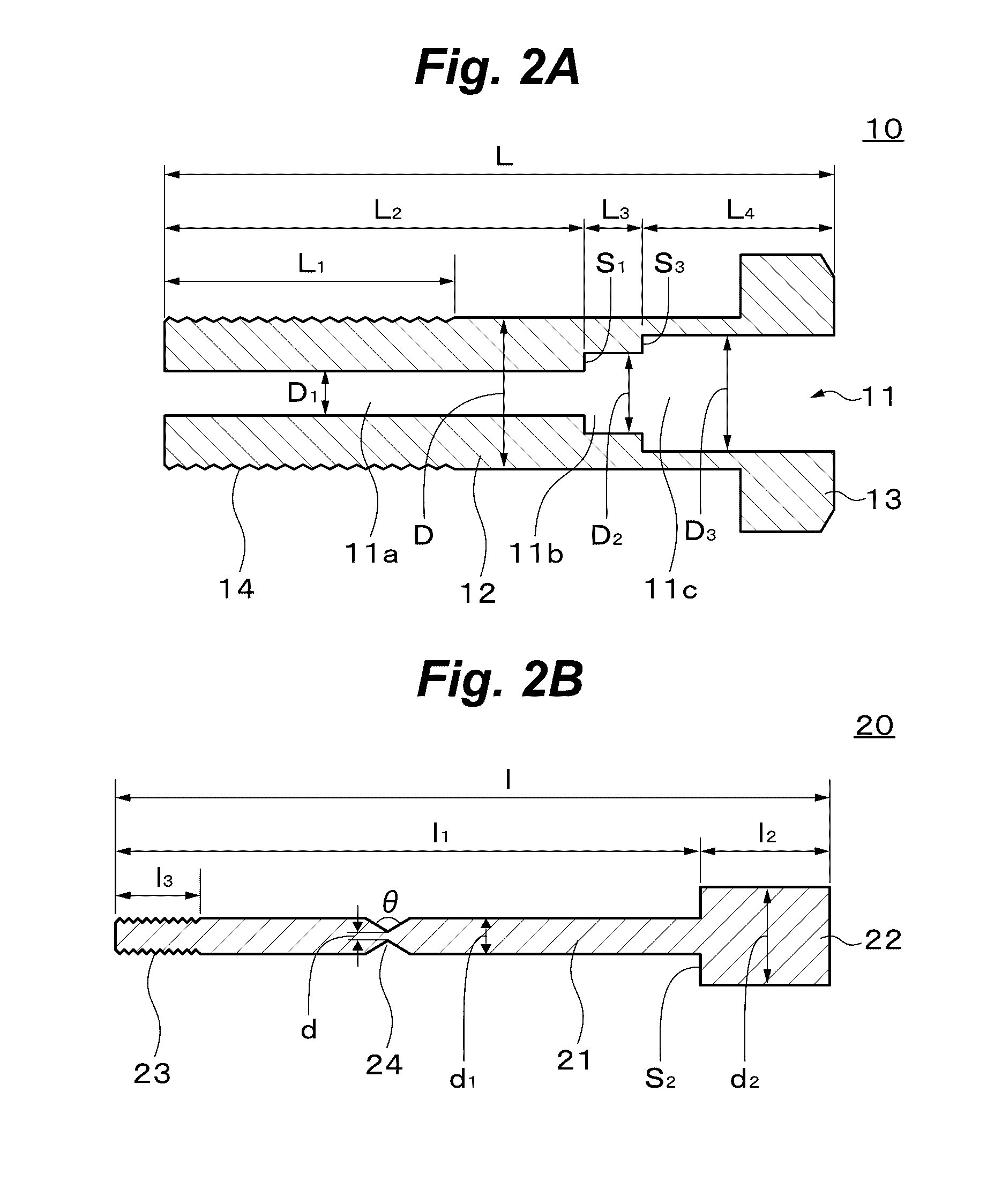

Provided is a failure detection sensor which, when attached to structural members of various structures such as buildings can easily detect the risk of the failure of the structural members, and thus the structure, before such failure occurs and has a simple structure, which leads to realization at a low price.The failure detection sensor comprises: the first member 10 and the second member 20 provided in parallel with the first member 10 such that one end of the second member 20 is fixed to or restricted by the first member 10 and the other end of the second member 20 is not fixed to or restricted by the first member 10, having fracturing characteristics such that the second member 20 fractures during elastic deformation or plastic deformation of the first member 10. The failure detection sensor may have a compression coil spring 40 which applies a tensile force to the other end of the second member 20 on the opposite side of the one end. The first member 10 and the second member 20 are constituted of, for example, a round rod or a square rod and the first member 10 is constituted of, for example, a hollow rod. The second member 20 has a notch 24 which is a stress concentration site between the one end and the other end. The second member 20 is made of brittle materials.

Owner:HIEI KENSETSU

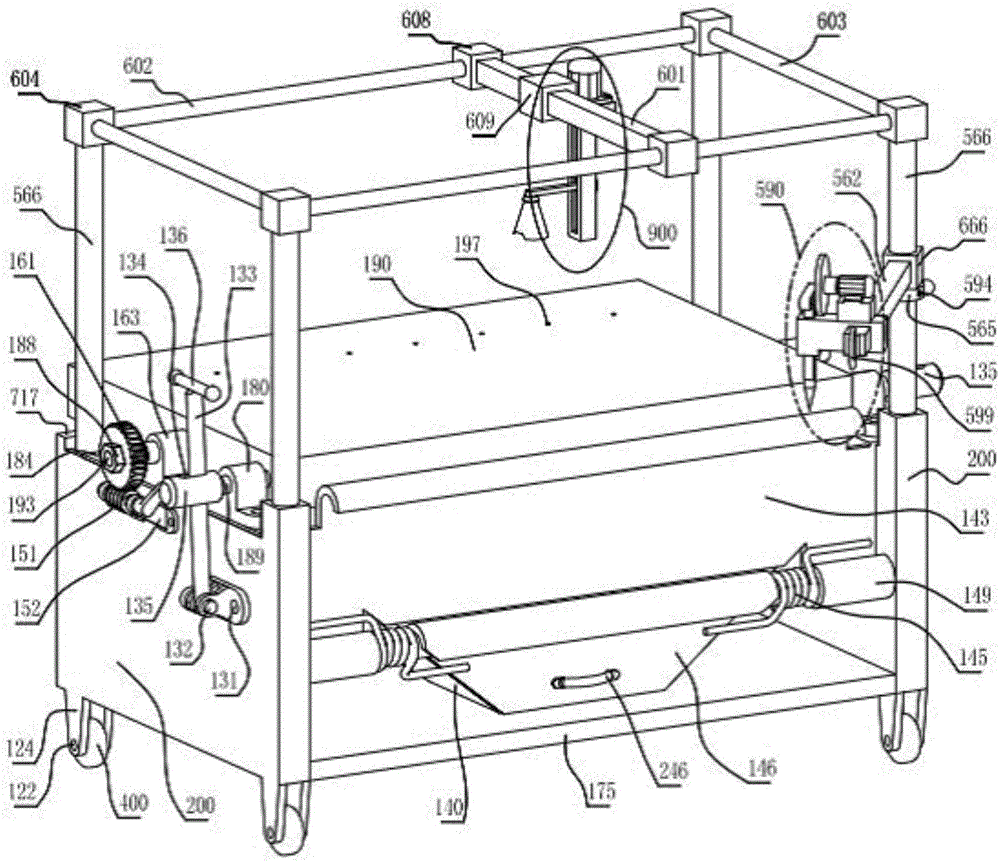

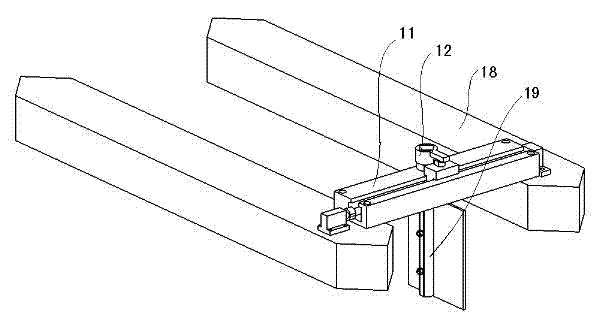

Automatic sorting and conveying device

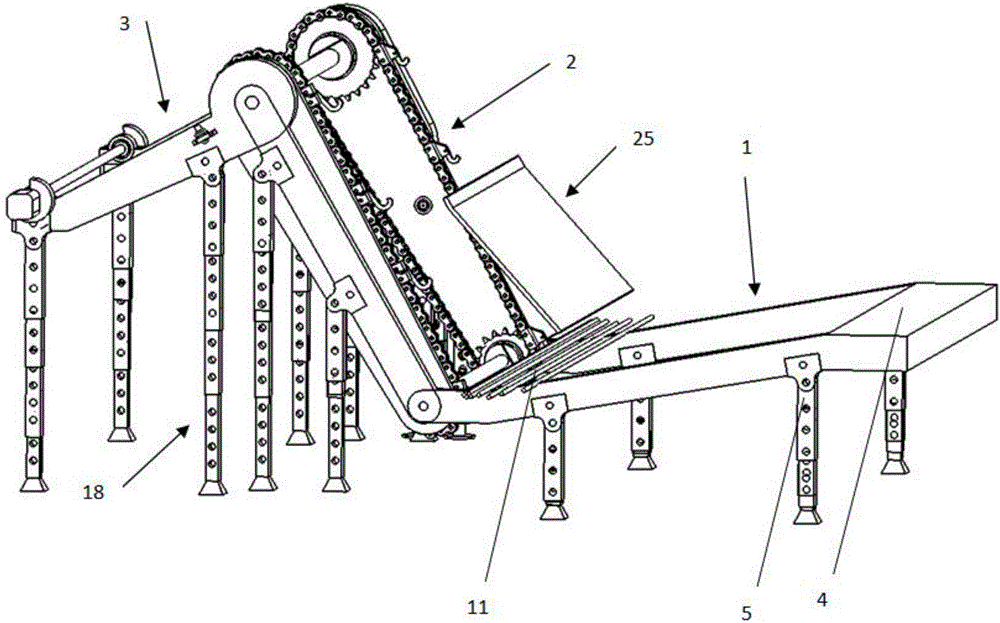

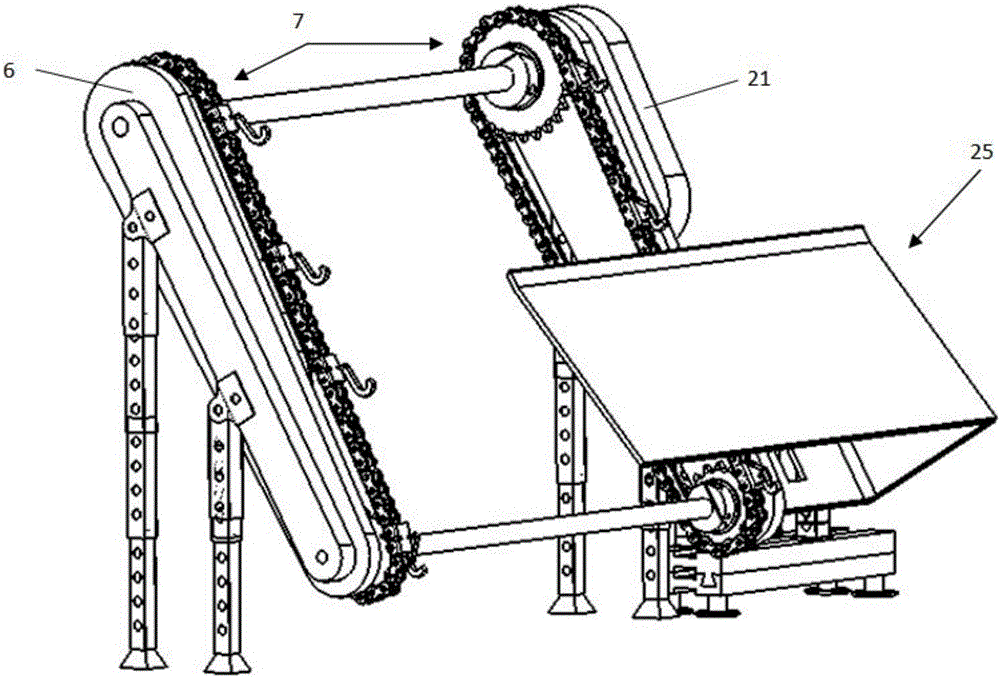

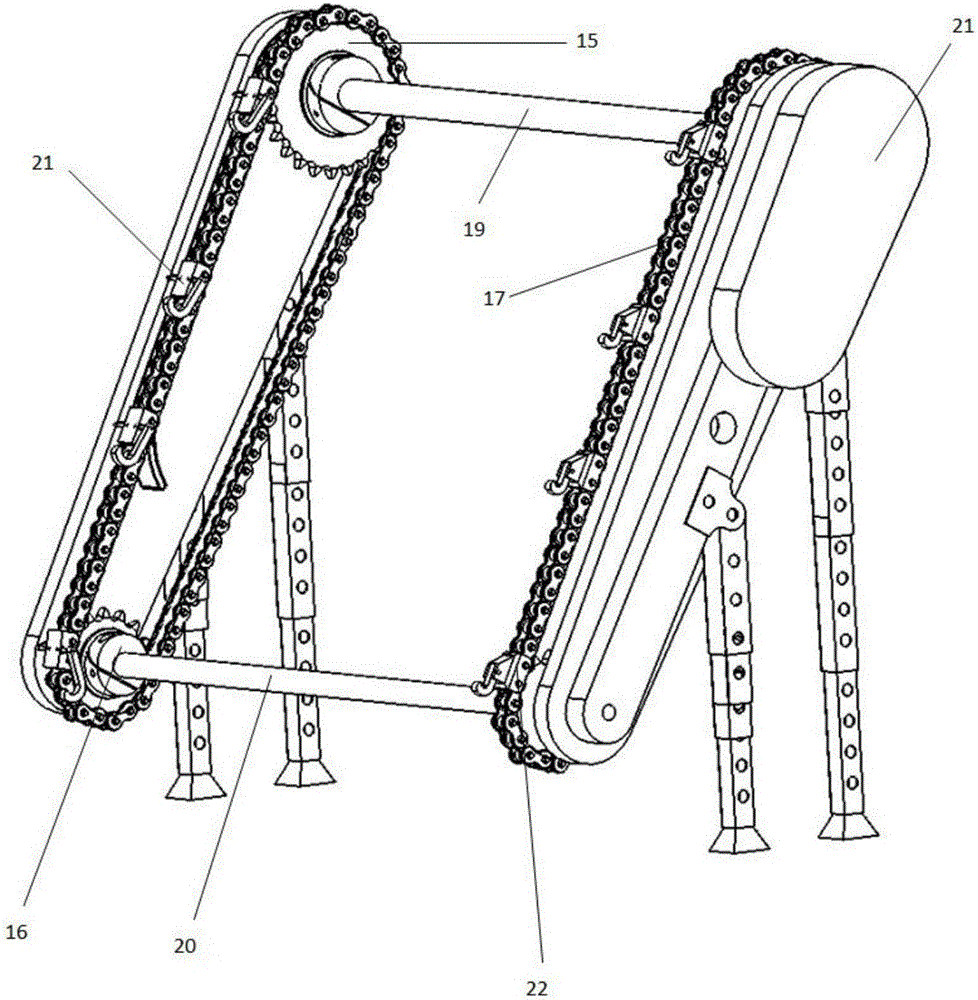

The invention discloses an automatic sorting and conveying device which is used for sorting and conveying materials. The automatic sorting and conveying device comprises a feeding unit, a sorting and conveying unit, a discharging unit, a supporting unit and a single-chip microcomputer, wherein the feeding unit, the sorting and conveying unit and the discharging unit are sequentially hinged and supported by the supporting unit; the sorting and conveying unit sorts and conveys materials arranged on a feeding frame one by one; the discharging unit sorts out and discharges the materials conveyed by the sorting and conveying unit to a next feeding port one by one; the sorting and conveying unit and the discharging unit are both connected with the single-chip microcomputer; the single-chip microcomputer is used for controlling the speed of sorting, conveying and discharging. The structural characteristics that rods are thin, long and bent are effectively overcome through a method of two times of hooking, the production method for sorting and feeding of thin and long round or square rod materials is totally changed, and the automatic sorting and conveying device is good in feasibility, high in intelligence and high in applicability.

Owner:ZHEJIANG UNIV +3

Adjustable round steel rust removing device

InactiveCN107932285AImprove rust removal efficiencyImprove rust removal effectGrinding drivesGrinding machinesEngineeringRapid rotation

The invention discloses an adjustable round steel rust removing device. The adjustable round steel rust removing device comprises a base. A fixing base is fixedly arranged on the left side of the topof the base. A groove is formed in the right end face of the fixing base and internally and rotationally provided with a first three-jaw chuck. A sliding rail is fixedly arranged on the top of the base, and the upper portion of the sliding rail is in sliding connection with a movable base. A step groove in the left end face of the movable base is internally rotationally connected with a second three-jaw chuck. The right end face of the second three-jaw chuck is fixedly connected with a rotation disc. A motor is fixedly arranged on the right end face of the movable base, and the motor is fixedly connected with the rotation disc. A guiding square rod is fixedly connected to the top of the right end face of the fixing base and is in sliding connection with a guiding sleeve. The bottom of theguiding sleeve is fixedly connected with an installing block through a support, and a rust removing barrel is fixedly arranged in the installing block. The adjustable round steel rust removing devicecan conduct rust removal on round steel different in length and diameter, and the application range is wide; and through rapid rotation of the round steel and friction of a rust removal brush in the rust removing barrel, rust can be removed, and the rust removing efficiency is high.

Owner:宁波市江北义盈工贸有限公司

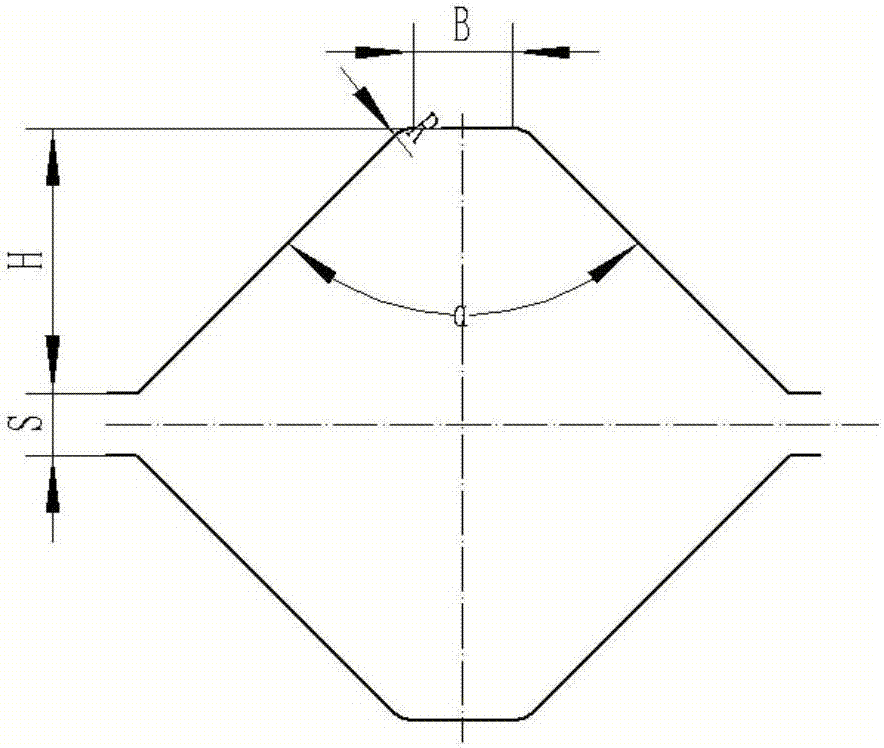

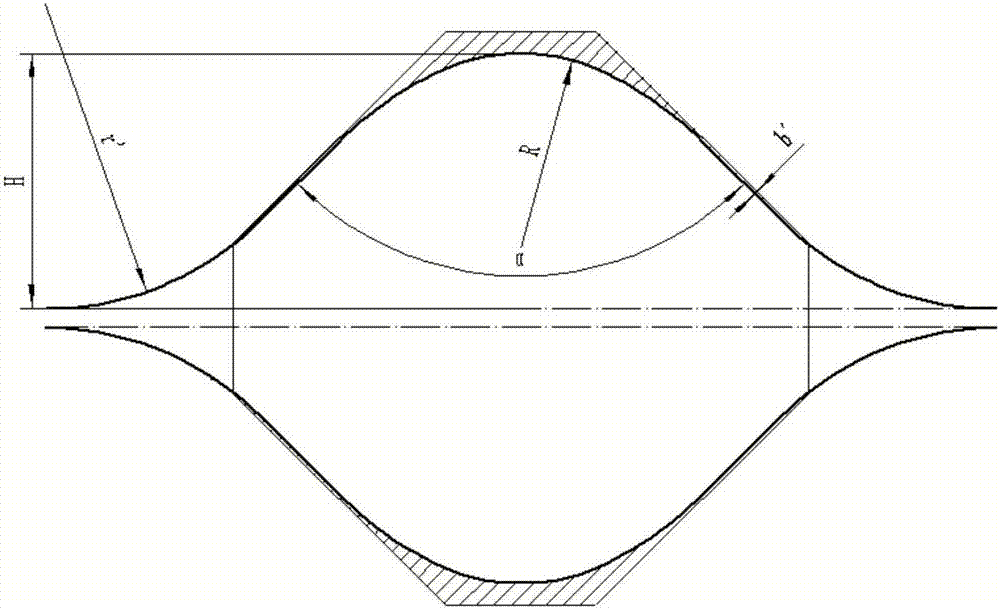

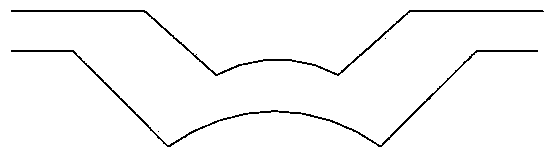

Cutting method for improving utilization rate of monocrystalline silicon rod

InactiveCN110978303AImprove pass rateImprove effective utilizationFine working devicesWire cuttingStructural engineering

The invention discloses a cutting method for improving the utilization rate of a monocrystalline silicon rod. The method comprises the steps of: adding a set of cutting wire net extending outwards for20mm besides the original cutting of a 210mm extraction wire net; after cutting, generating a square rod with the side length of 210 mm, four single crystal plate blanks with the thickness of 20 mm and arc sides and four arched single crystal edge skins with the thickness of about 25 mm; and bonding the plurality of single crystal plate blanks by using hydrosol, cutting edges by using a diamond wire cutting machine, and correcting the single crystal plate blanks into rectangular single crystal plate blanks with the thickness of 20mm, the side length of 158mm and the length equal to that of around rod. According to the cutting method, the volume ratio of available partial crystals after cutting of the monocrystalline silicon rod can be increased, the effective utilization rate of the monocrystalline silicon rod is increased, and the production cost is greatly saved.

Owner:江苏美科太阳能科技股份有限公司 +1

Pipe fixing machining platform based on clamping fixation

InactiveCN107932116AFlexible Adaptive ClampingImprove detection efficiencyPositioning apparatusMetal-working holdersEngineeringScrew thread

The invention discloses a pipe fixing machining platform based on clamping fixation. The machining platform comprises a baseplate, a fixed stand plate, a sliding stand plate, a support bottom rod anda clamping piece; the baseplate is provided with a horizontal moving groove, a thread adjusting rod, a rocking handle, the fixed stand plate and the sliding stand plate; a rotary placing plate and a fixing knob are arranged at the upper parts of the fixed stand plate and the sliding stand plate; a support bottom rod, a mounting sleeve, a first rotary bearing, a bottom cover, a slide square rod, athread support rod, universal wheels, an internal thread annular plate and an antiskid gasket are arranged at the lower end of the baseplate; and two rotary fixing rods, an adjusting thread rod, a second rotary bearing and a support connecting rod are arranged on the opposite inner side of the rotary placing plate. The adjusting thread rod can be screwed to drive the support connecting rod throughthe second rotary bearing to push the rotary fixing rod to rotate on the opposite inner side of the rotary placing plate; and the upper and lower rotary fixing rods are relatively rotated to clamp the inner walls of pipes, so that the pipes can be clamped, and the pipe detecting efficiency can be effectively improved.

Owner:HENAN GAOSHENG ENTERPRISE MANAGEMENT CONSULTING CO LTD

Efficient cleaning device of automobile accessory parts

InactiveCN107377468AEasy to cleanSolve the entanglementCleaning using liquidsGear wheelConductor Coil

The invention discloses a high-efficiency cleaning device for auto parts, which comprises a shell, the upper end of which is provided with an upper cover, and the upper cover is provided with an annular spray pipe, a water injection pipe, a stirring shaft, a motor and a driving helical gear; The shaft is provided with a sliding groove, a sliding block, a rotating protrusion, a driven helical gear and a turntable; the two ends of the sliding groove are provided with a lifting plate, and the lifting plate is provided with a bracket, a rotating gear, a clamping fixed rod and a movable rod; The movable rod is composed of a square rod part, a round rod part, a rack and a fixed nut; the upper end of the stirring shaft is provided with a support plate, a winding wheel and a traction rope; the right wall of the housing is provided with a filter pipe and a sealing plug. The invention installs the auto parts through the fixed clamping part, drives them to rotate through the motor, cooperates with the spray pipe to spray water, and can efficiently clean the dirt on the surface of the auto parts. placement.

Owner:韩祥

Preparing method for Ti45Nb alloy disc circular wire

ActiveCN107282688AImprove performanceMeet the standard requirementsRoom temperatureSurface roughness

The invention discloses a preparing method for a Ti45Nb alloy disc circular wire. A Ti45Nb alloy polishing stick uniform in component and structure is subjected to cold rolling into a square bar blank through a square hole type series roller; then, the square bar blank is sequentially pulled into a circular blank and the wire, and vacuum annealing is conducted; and after annealing, the wire is subjected to cold continuous rolling into the small specification from the large specification through a cold continuous rolling machine. After cold continuous rolling, two racks are flatly and alternately provided with circular hole rolling type rollers, and the circular wire with certain size precision is obtained through rolling. The circular wire is subjected to oil removal treatment and rounding, and the Ti45Nb alloy disc circular wire is obtained. The method is adopted for preparing the Ti45Nb alloy disc circular wire, the head and tail size consistency is high in the whole batch, and roundness is not larger than 0.03 mm. Surface roughness Ra is smaller than or equal to 1.2 microns, and vortex flaw detection is qualified. Transverse and longitudinal structures are fine and uniform, the longitudinal streamline is obvious, and the corresponding standard requirement is met. The wire annealing state room temperature mechanical performance consistency and stability are high.

Owner:西部超导材料科技股份有限公司

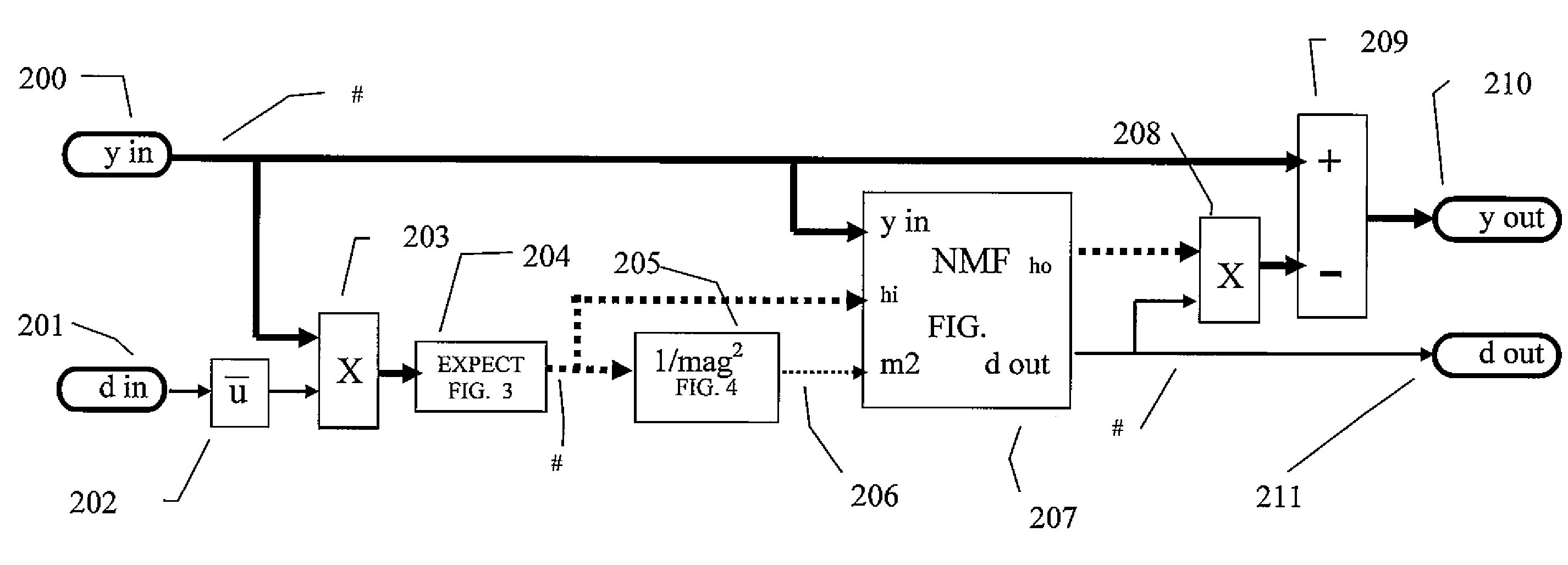

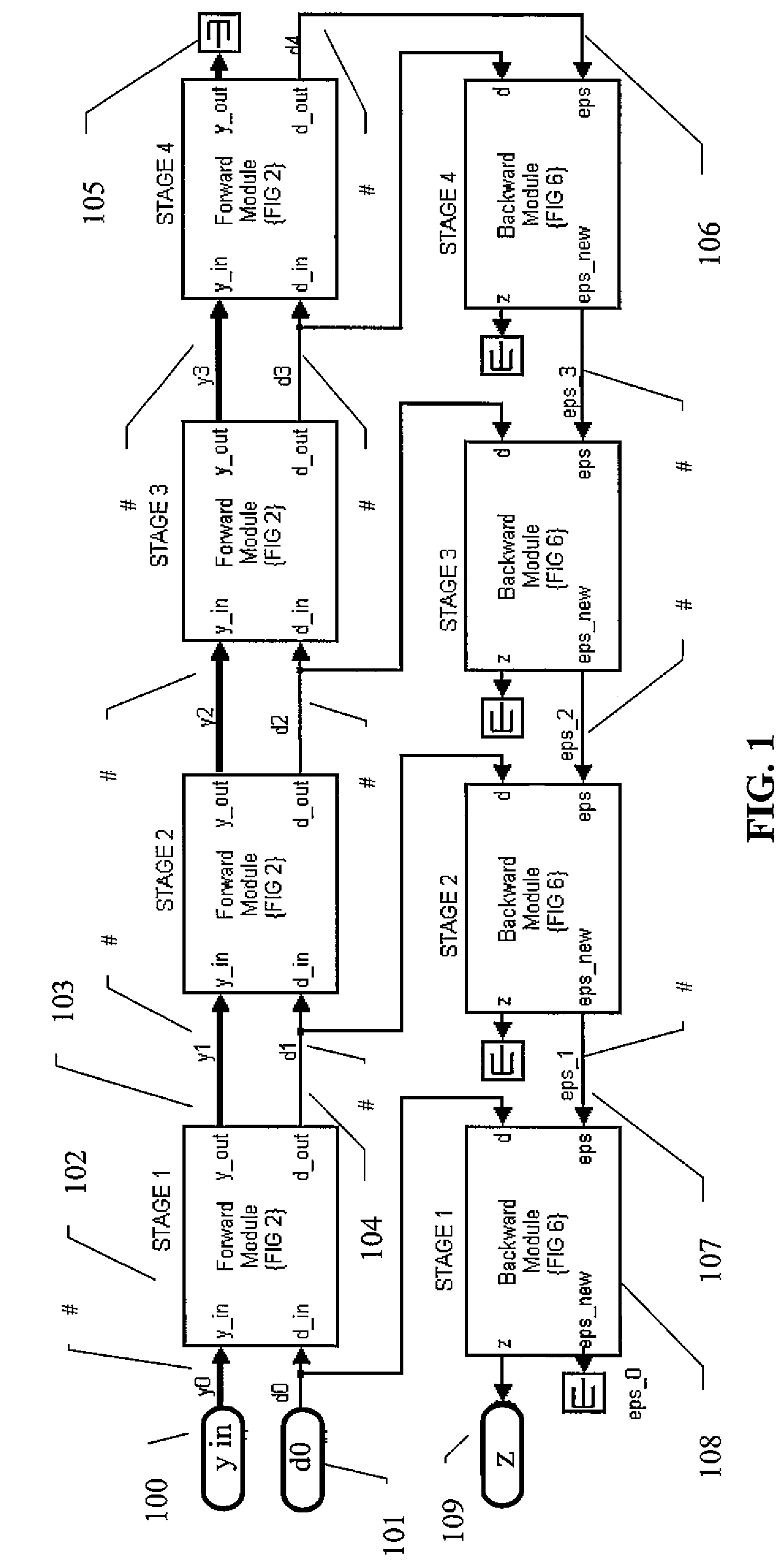

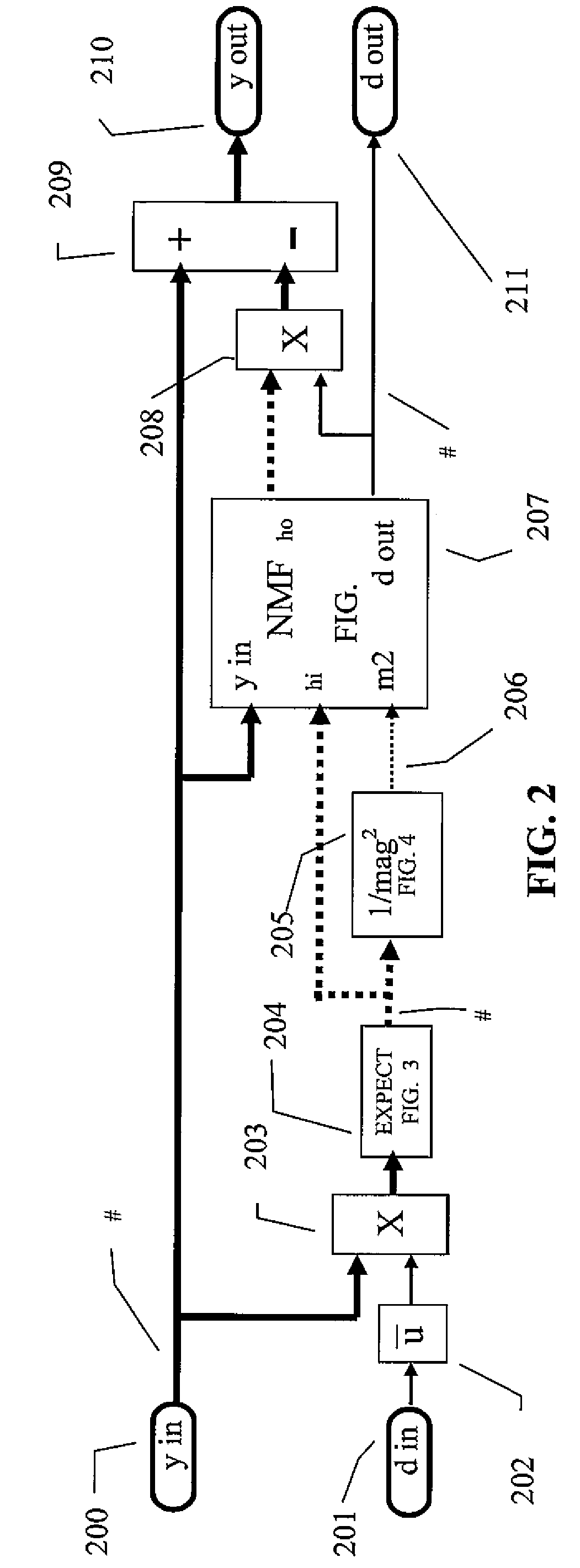

Reduced complexity adaptive multistage wiener filter

ActiveUS8386549B1Digital technique networkDigital data processing detailsFinite impulse responseRound complexity

Multistage Wiener filters (MWF) represent a component of the MWF as an un-normalized vector of filter coefficients within a finite impulse response (FIR) filter in a manner that avoids reliance on the 2-norm operation of the un-normalized vector of coefficients. The 2-norm operation can be replaced by less expensive operations performed elsewhere in the MWF. Preferably the filter adds only a few additional addition, subtraction and multiplication operations to compensate for the elimination of the square root and the division operations used for the 2-norm operation. As a result, it is possible to eliminate all or nearly all of the square rod and arithmetic division operations of at least some implementations of the MWF.

Owner:ACORN TECH INC

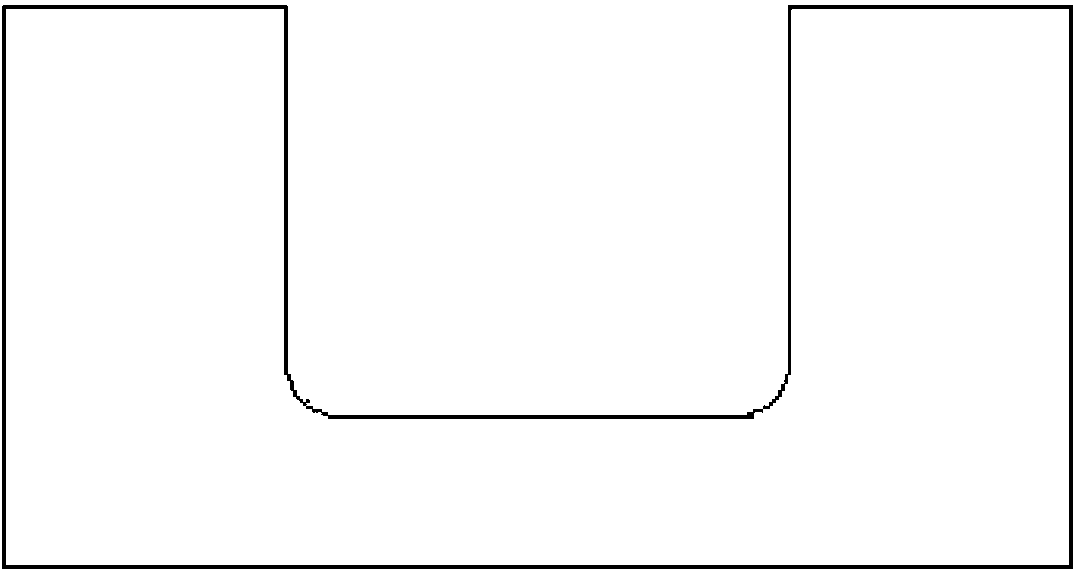

Method for manufacturing titanium alloy U-shaped material

The invention discloses a method for manufacturing a titanium alloy U-shaped material, and belongs to the field of metal processing technologies. The method includes steps of 1, manufacturing titanium alloy round rod from a blank; 2, heating and rolling the round rod by a box-type resistance furnace to obtain a square rod; 3, detecting flaws of the square rod by an ultrasonic flaw detector and polishing the surface of the square rod by a portable grinding machine; 4, rolling the square rod; 5, repairing the surface of the square rod; 6, stretching and straightening the square rod by a tension straightening machine; 7, washing the surface of the square rod by alkaline and acid; 8, detecting flaws of the square rod again by an ultrasonic flaw detector. The method has the advantages that the titanium alloy U-shaped material rolled by the method is high in precision, strength, quality and surface smoothness; requirements on all performance indexes of aviation sectional materials can be met by the rolled U-shaped material; a process for manufacturing the titanium alloy U-shaped material is simple and controllable, the yield can be increased by 35% at least, the material utilization rate can reach about 60%, the product cost can be lowered, and important conditions of batch manufacturing can be met.

Owner:沈阳和世泰通用钛业有限公司

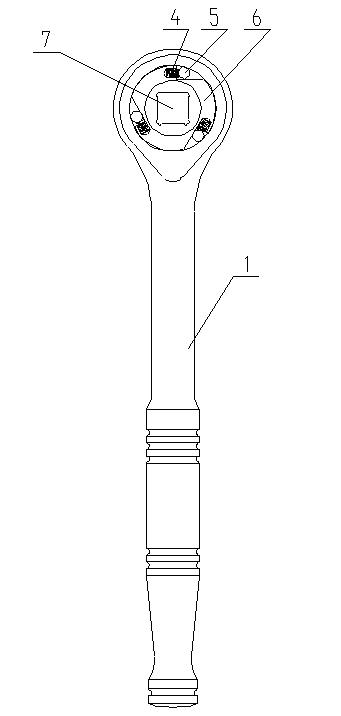

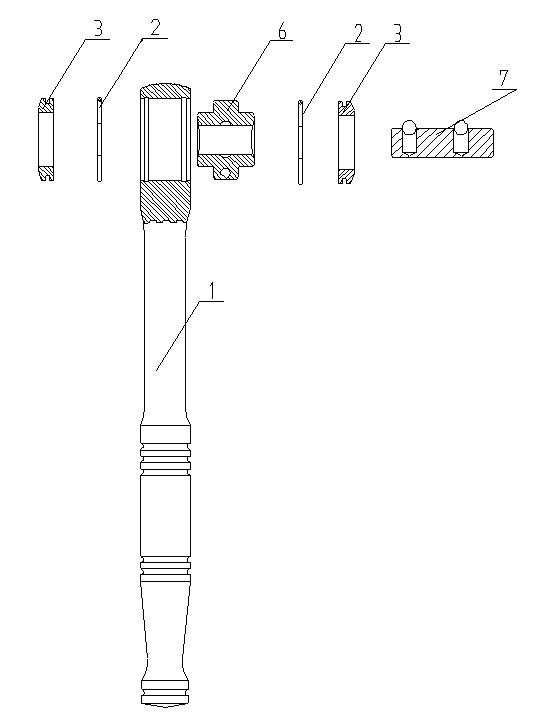

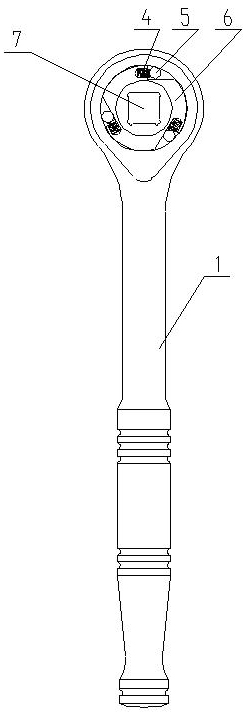

Ratchet wrench

The invention relates to the field of hardware hand tools, in particular to a ratchet wrench. The ratchet wrench is characterized in that one end of a hand shank is connected with a head part; the head part is provided with a round hole; two ends of the inner edge of the round hole are provided with annular slots; a rotatable wrench body head is arranged in the round hole; the middle of the wrench body head is provided with a square through hole; a groove is arranged in the middle of one side surface of the through hole; two ends of the wrench body head are of a circular truncated cone shape; a notch is arranged at the circumference of the wrench body head; the two planes of the notch are perpendicular with each other; one of the two planes is provided with a round hole, and a spring is arranged in the round hole; roller pins are arranged in the notch; the wrench body head is contained in the middle of the round hole; the two ends of the wrench body head are provided with end covers; the end covers are provided with annular grooves; the annular grooves are internally provided with spring retainers; the spring retainers enter into the annular slots of the inner edge of the round hole to fix the end covers; and a square rod is arranged in the square through hole. The ratchet wrench has the advantages that the structure is reasonable, the processing is simple, the assembly is convenient, the requirement on parts is lower as compared with similar products, the use is simple and convenient without space limitation, labor and time are saved, the working efficiency is high, and the reversing of the ratchet wrench is achieved through positive and negative faces so as to complete the fastening and looseness of screws.

Owner:WEIHAISHIWEILI TOP GRADE TOOL CO

Glass detecting rack and method for carrying out glass detection by using glass detecting rack

InactiveCN105758750AEasy to removeReduce frictional resistanceMaterial analysis by optical meansMaterial strength using repeated/pulsating forcesTest specificationUltimate tensile strength

The invention relates to a toughened glass test rack, in particular to a glass detecting rack. As improvement, the glass detecting rack is characterized in that a transmission worm is matched with a worm shaft; the two ends of the worm shaft can be rotatably fixed in worm supporting bases separately; the worm supporting bases are fixedly arranged on the outer side surface of a corresponding supporting side plate; one end of the worm shaft is further provided with a worm cranking handle; a screw lifting camera group is arranged on a camera shooting square rod; a rotary impactor can be fixedly arranged on an impact cross rod in a sliding manner; a step corner pressure plate assembly comprises a first pressure plate, a second pressure plate, a third pressure plate and a fourth pressure plate which are the same in structural dimension; and each pressure plate is composed of a clamping part and a sliding corner part. According to the glass detecting rack, labor intensity of fragment detecting is changed, camera shooting is carried out, and fragment images are transmitted to a computer processing center; the rotary impactor is applied, so that hammering every time is consistent is force, and therefore, breaking test specifications are unified.

Owner:徐明

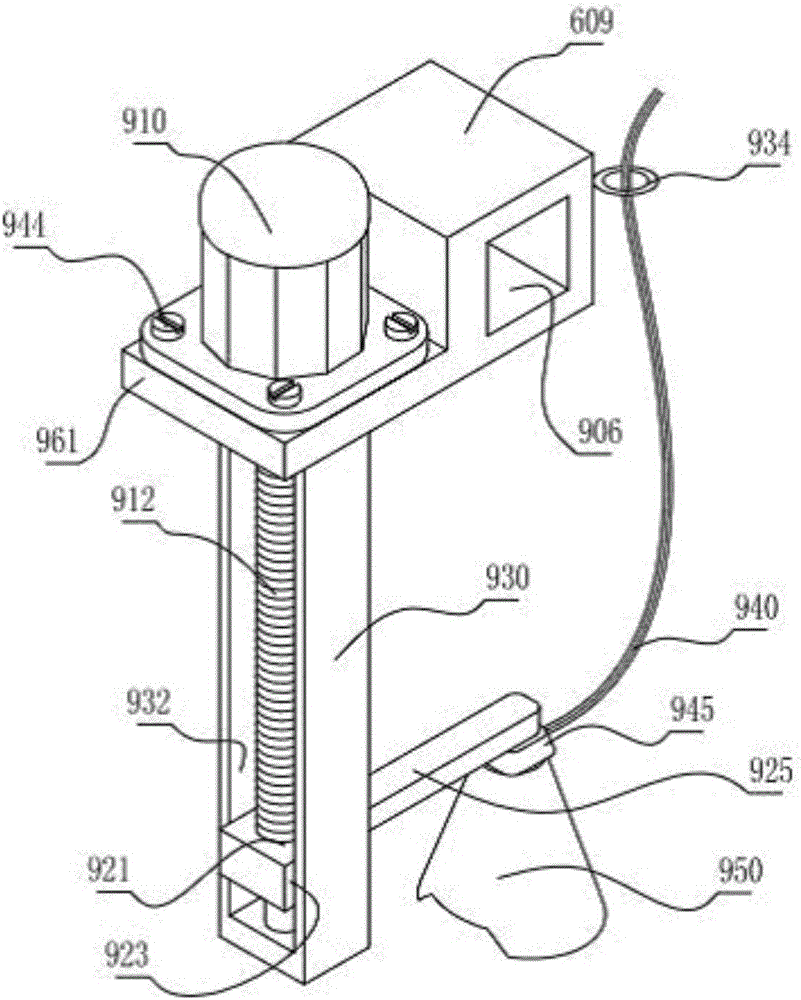

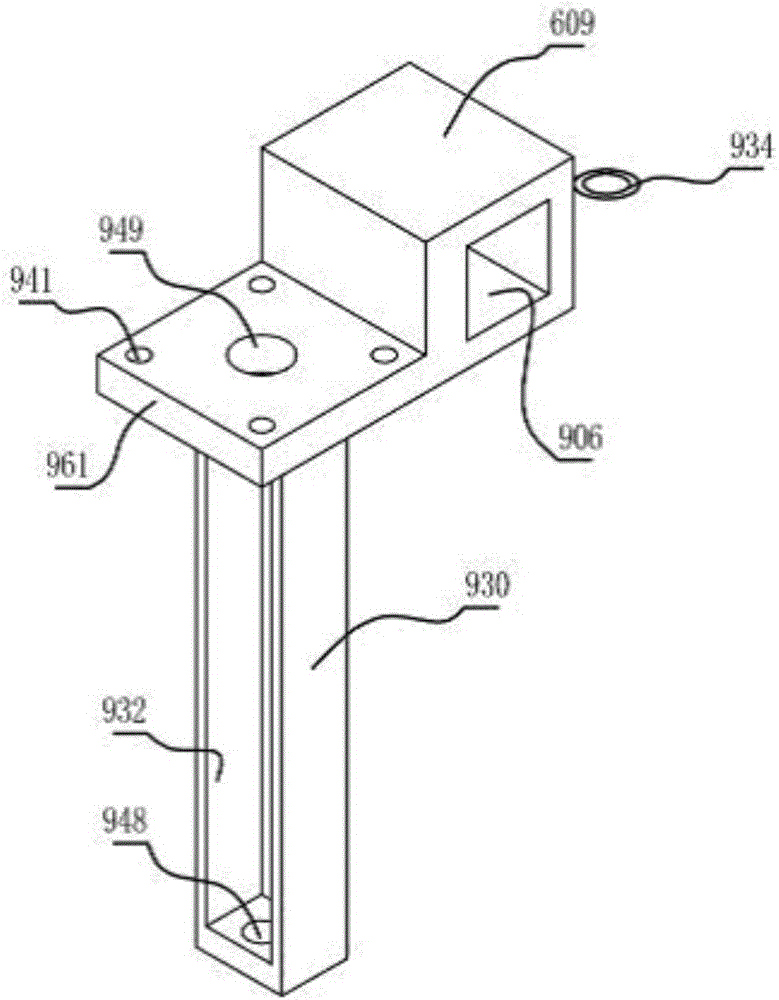

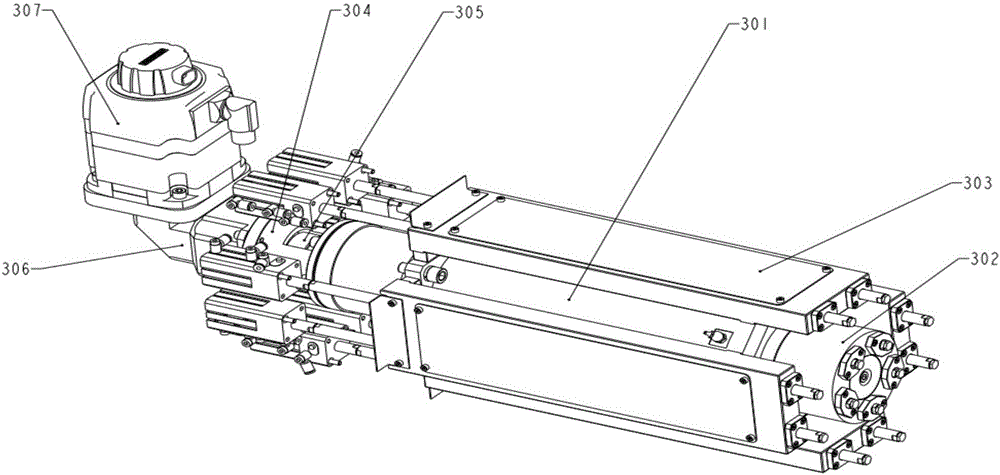

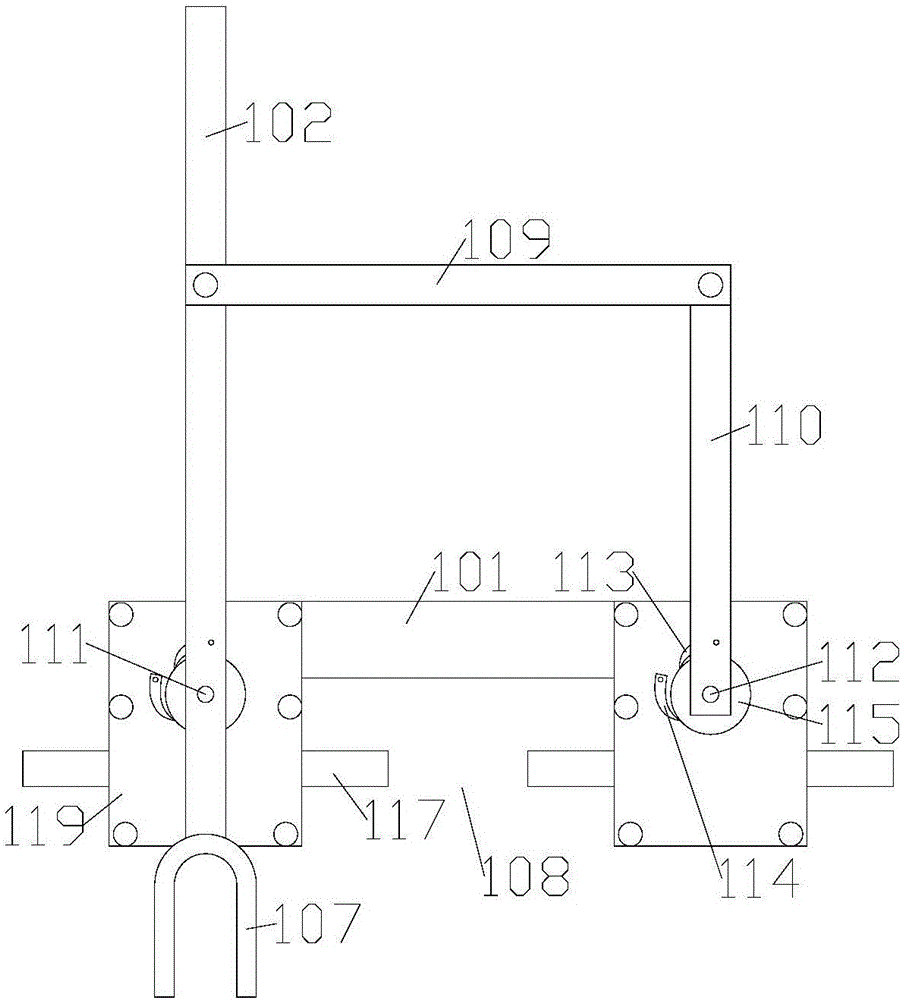

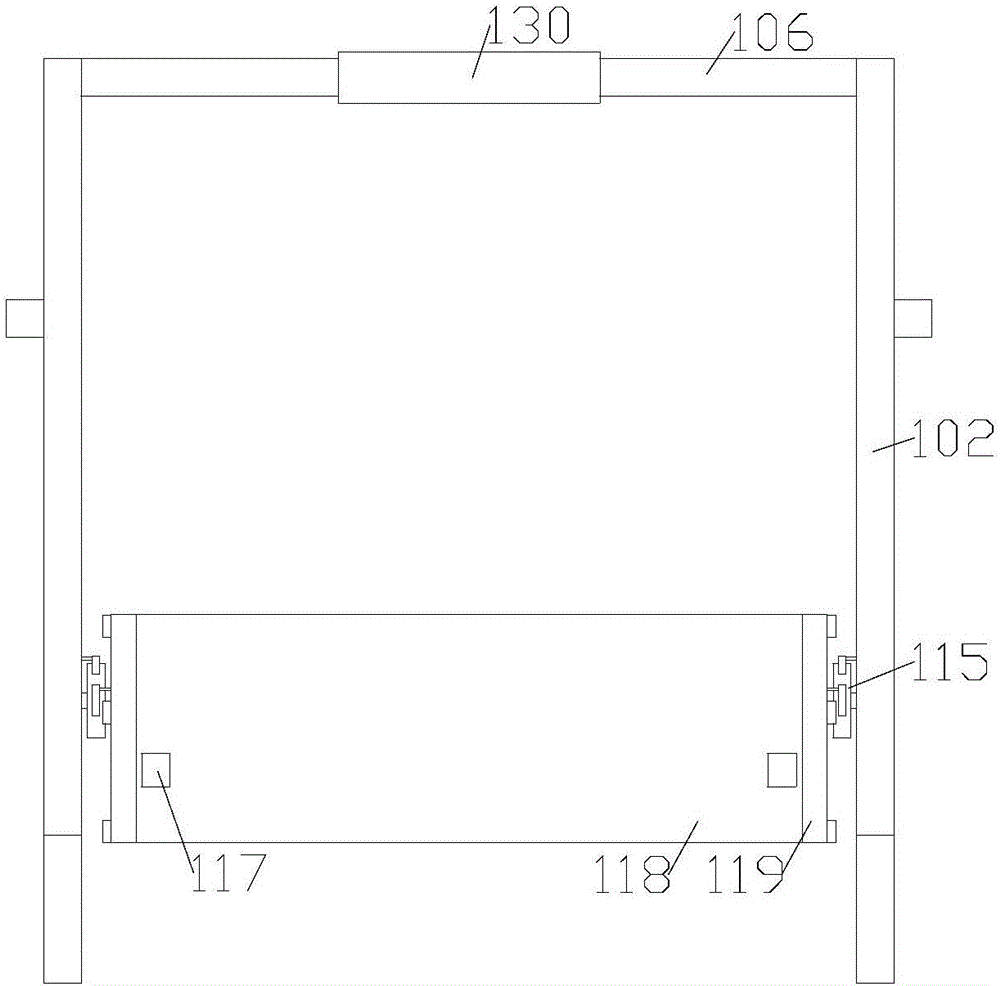

Rod clamping mechanism of monocrystal silicon horizontal single-rod squarer

ActiveCN106042203AEasy to fall off automaticallyWorking accessoriesFine working devicesMechanical engineeringSilicon

The invention discloses a rod clamping mechanism of a monocrystal silicon horizontal single-rod squarer. The rod clamping mechanism comprises a head frame module and a tail frame module mounted on a base for respectively clamping two ends of a silicon rod; the head frame module includes a head frame and a head frame round steel module; the head frame round steel module includes a head frame chuck module, a head frame shaft module, a rotary driving mechanism for driving the head frame shaft module to rotate, and a head frame edge cover clamping module; the tail frame module includes a tail frame and a tail frame round steel module; the tail frame round steel module includes a frame chuck module, a tail frame shaft module and a tail frame edge cover clamping module; and space of rotating a cutting wire net of the squarer around the axis of the silicon rod is respectively formed between the chuck modules and the edge cover clamping modules. The rod clamping mechanism realizes horizontal clamping of monocrystal silicon rod, can rotate the silicon rod through respectively clamping a rod body and four edge covers and improving the structure of the rod clamping mechanism, and can realize automatic fall of the edge covers during rotating the silicon rod without damaging the surface quality of a square rod.

Owner:QINGDAO GAOCE TECH CO LTD

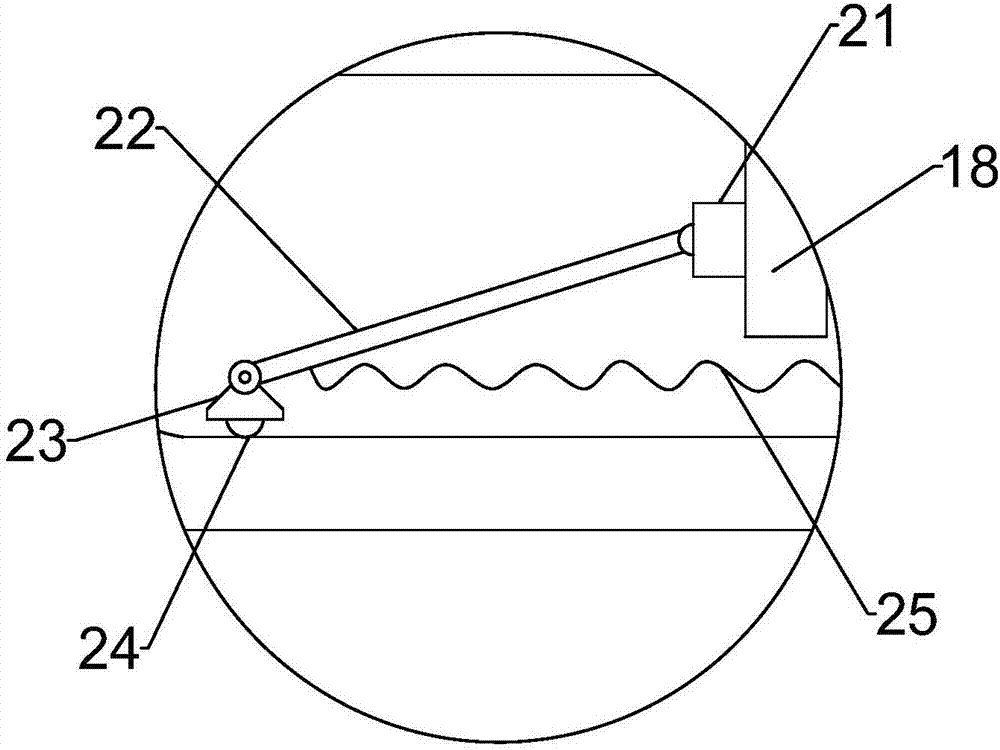

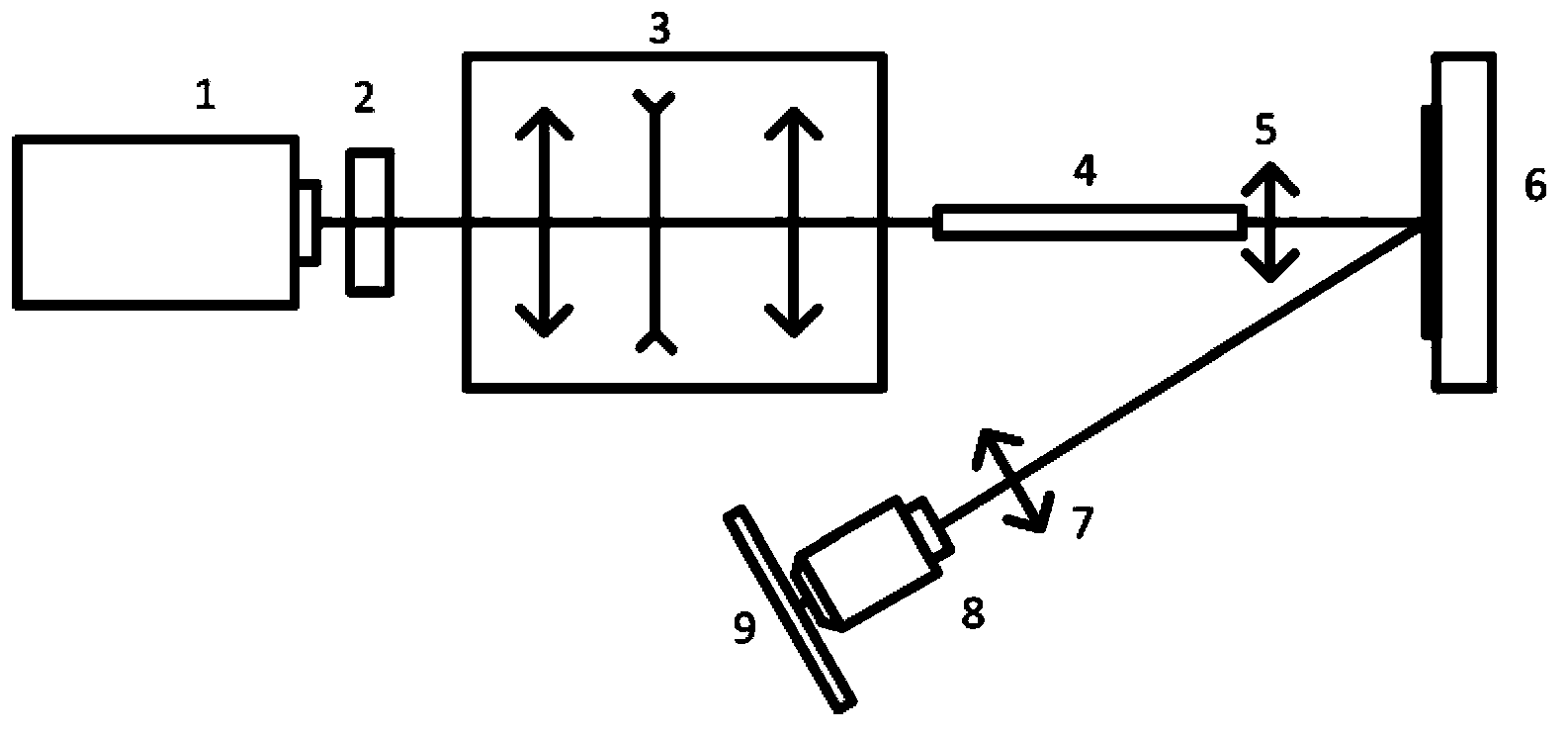

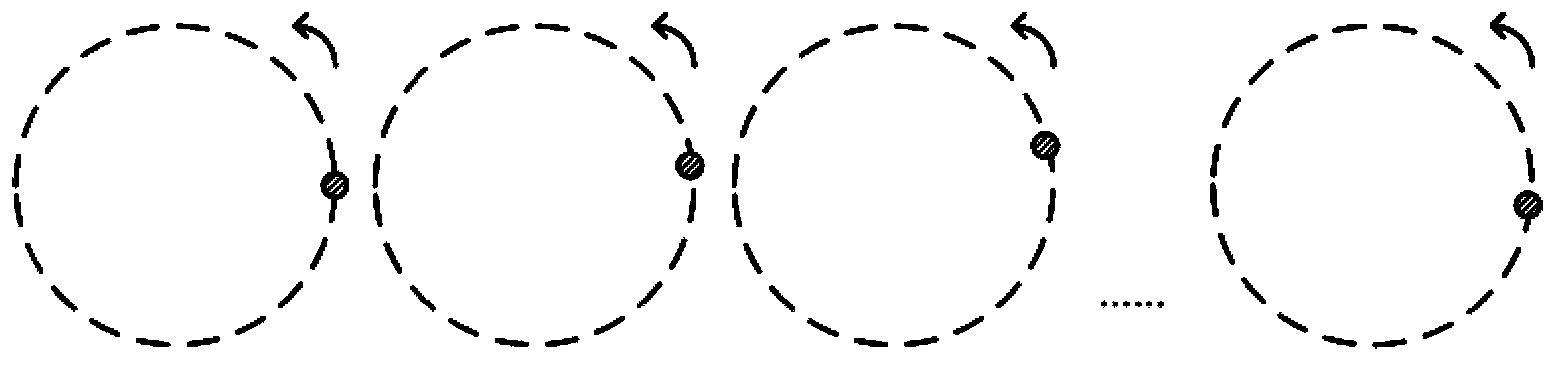

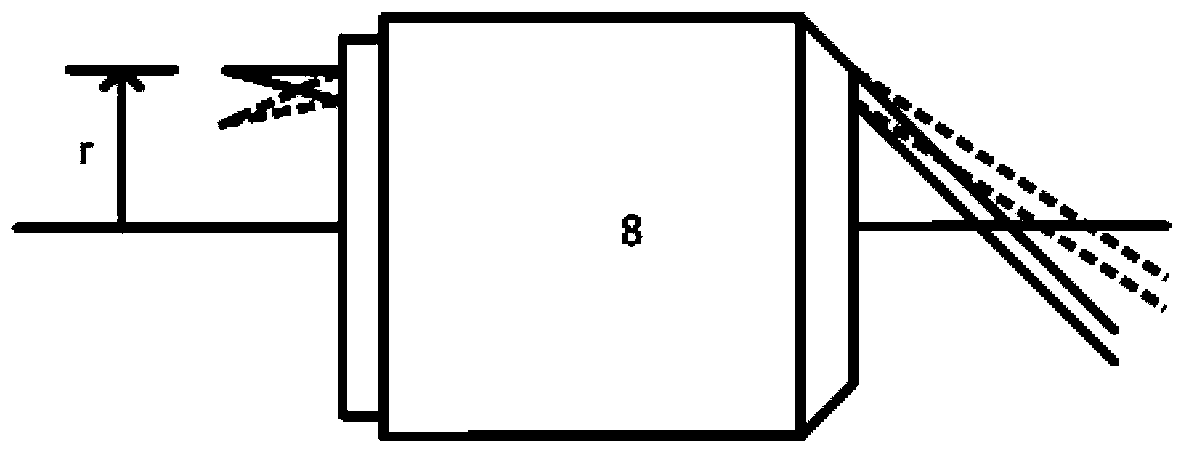

Total-reflection microscope circular scanning method and device based on digital micro-mirror device

ActiveCN103364345ASimple structureFast scanningMicroscopesFluorescence/phosphorescenceTotal internal reflectionDigital micro mirror device

Owner:ZHEJIANG UNIV

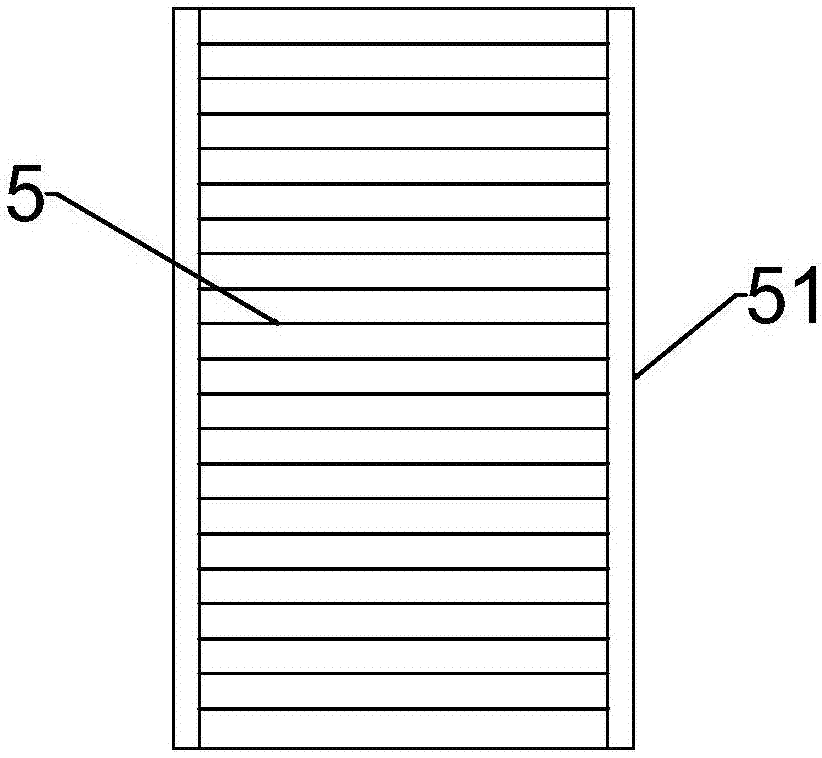

Double-layer ventilation grating for automobile

InactiveCN106240345AImprove work efficiencyTo achieve the effect of energy saving and emission reductionComponent optimizationPropulsion coolingGratingMovable type

A double-layer ventilation grating for an automobile comprises an outer grating frame, an inner grating frame and a controller, wherein a plurality of grating cross bars are arranged in the middle of the outer grating frame, and an automobile logo hole is reserved in the middle of one grating cross bar; grating blades are arranged in the middle of the inner grating frame, and a square rod is arranged on the outer side of the upper end of each grating blade; a drive connecting rod is arranged on one side of the inner grating frame, a square hole is formed in the drive connecting rod and connected with the square rod, and one end of the drive connecting rod is connected with the stepping motor; the stepping motor is connected with a controller, and a temperature sensor is connected to the sensor and inserted into an engine cabin body. The double-layer ventilation grating is designed at the front end of the automobile, the automobile keeps attractive through outer side fixed type gratings, inner side movable type grating blade structures can be automatically opened and closed at any time according to the driving condition of the automobile, the working efficiency of an engine is improved, and the energy saving and emission reduction effects are realized.

Owner:天津奥丽达森模具有限公司

Bolt assembling automatic production robot and assembling method thereof

The invention discloses a bolt assembling automatic production robot and an assembling method thereof. The problem that the existing bolt assembling automation degree is not high is solved. A lockingmechanism comprises a sleeve which penetrates through a top plate and is connected with the top plate through bearings, a bevel gear set connecting the sleeve with a worm, a moving shaft arranged on the sleeve in a sleeved manner, a square rod connected to the lower portion of the moving shaft in a sleeved manner, and a hexagonal lock sleeve fixedly mounted at the lower end of the square rod. Theworm is further connected with a moving mechanism through a first transmission belt. The bevel gear set comprises a first bevel gear fixed to the end, away from an electric motor, of the worm, and a second bevel gear engaged with the first bevel gear and fixed to the sleeve. Two through grooves are symmetrically formed in the inner wall of the sleeve. Limit bars matched with the through grooves inthe inner wall of the sleeve are symmetrically arranged on the outer wall of the moving shaft. The moving mechanism drives the locking sleeve to move up and down, meanwhile, the locking mechanism canfurther drive the moving locking sleeve to rotate, and multiple freedom degrees are achieved.

Owner:苏州红橙蓝机器人有限公司

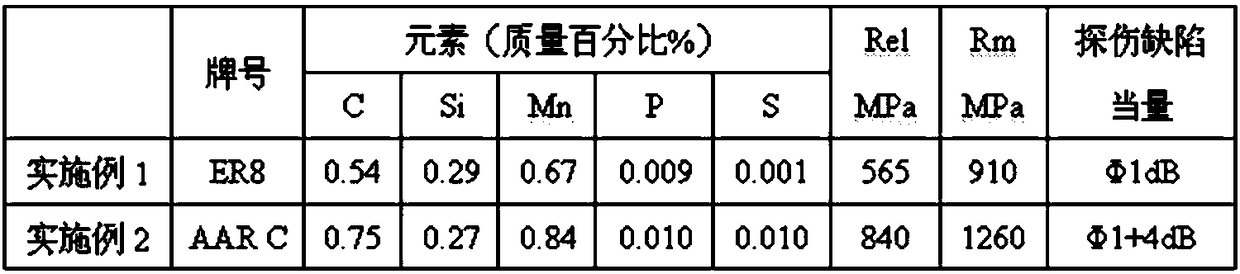

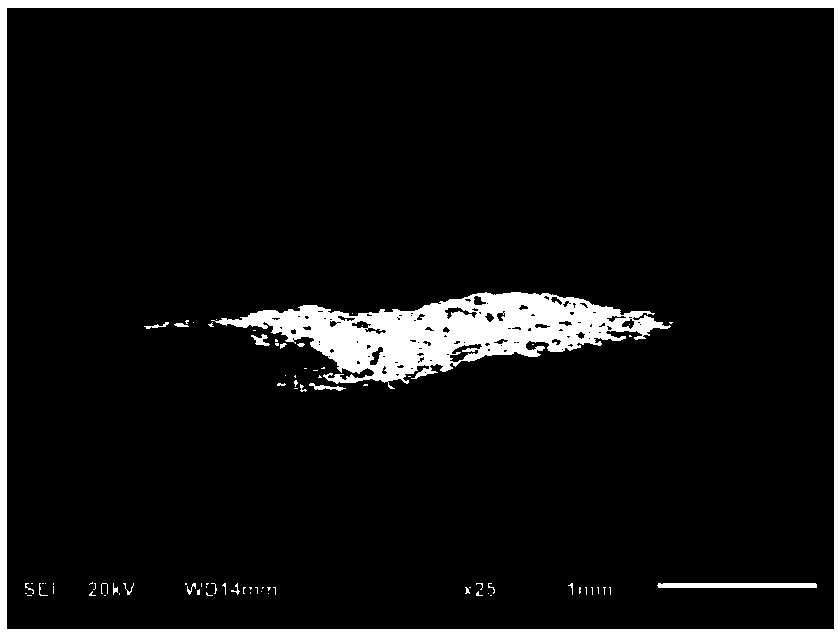

Method for ultrasonic inclusion detection of train wheels

InactiveCN108088904AQuality improvementSimple stepsAnalysing solids using sonic/ultrasonic/infrasonic wavesSurface fatigueEngineering

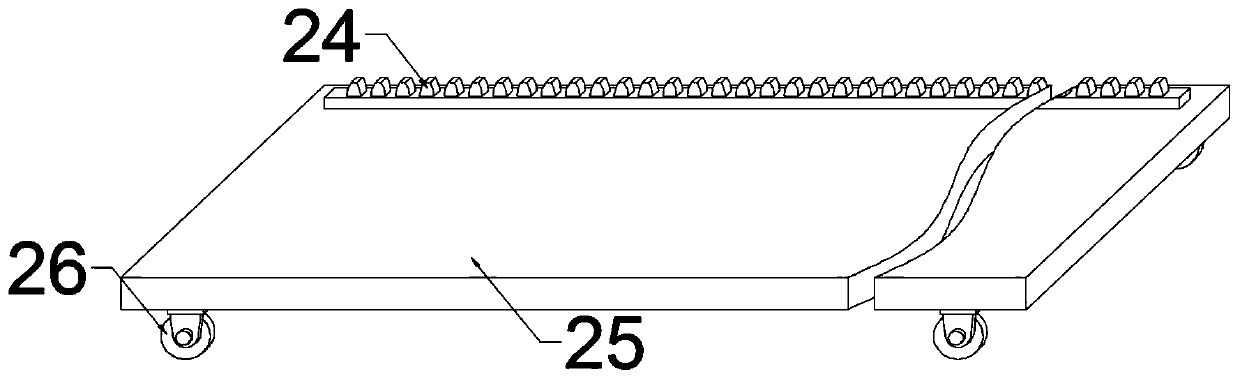

The invention provides a method for ultrasonic inclusion detection of train wheels. The method is applied to the technical fields of train wheel manufacturing and performance detecting processes. Themethod comprises the following steps: (1) performing ultrasonic flaw detection on a rim inner side surface and a rim tread of a train wheel, and determining that a detection surface with a strong defect reflection signal is parallel to a length direction of an inclusion; (2) cutting a cross section sample of a rim which contains the inclusion, and taking a sample square rod by linear cutting, wherein the inclusion exists in the middle of the sample square rod; (3) by taking the sample square rod as a sample, performing micro-particle shot blasting on the sample; and (4) applying a stair load fatigue test on the sample, wherein an initial load is lower than a fatigue limit of surface fatigue, and under a load load, ensuring that a fatigue crack cracks and expands from the inclusion. The method provided by the invention can completely display the full view of the inclusion which is discovered by ultrasonic flaw detection and can accurately measure the size of a defect.

Owner:MAANSHAN IRON & STEEL CO LTD

Preparation device and process of puer tea with jujube leaves

ActiveCN110169477AAchieve flippingRealize the kneading operationTea substituesEngineeringElectric machine

The invention discloses a preparation device and process of puer tea with jujube leaves. The preparation device comprises a base, and is characterized in that the base is fixedly connected to a circular barrel I through symmetrical L-shaped rods I; one side of each L-shaped rod I is fixedly connected to a motor III through a motor bracket II; the output shaft of the motor III is fixedly connectedto one end of a circular shaft I; one end of a belt surrounds a rotating wheel on the output shaft of the motor III; the other end of the belt surrounds one end of a circular shaft III; the circular shaft III is hinged to the end part of a square rod; the middle part of the circular shaft III is fixedly connected to the center of a bevel gear II; the other end of the circular shaft III is hinged to the end part of an another square rod; the other ends of the symmetrical square rods are fixedly connected to the upper parts of one sides of the L-shaped rods I respectively; the bevel gear II is meshed with a bevel gear I.

Owner:LUOYANG NORMAL UNIV

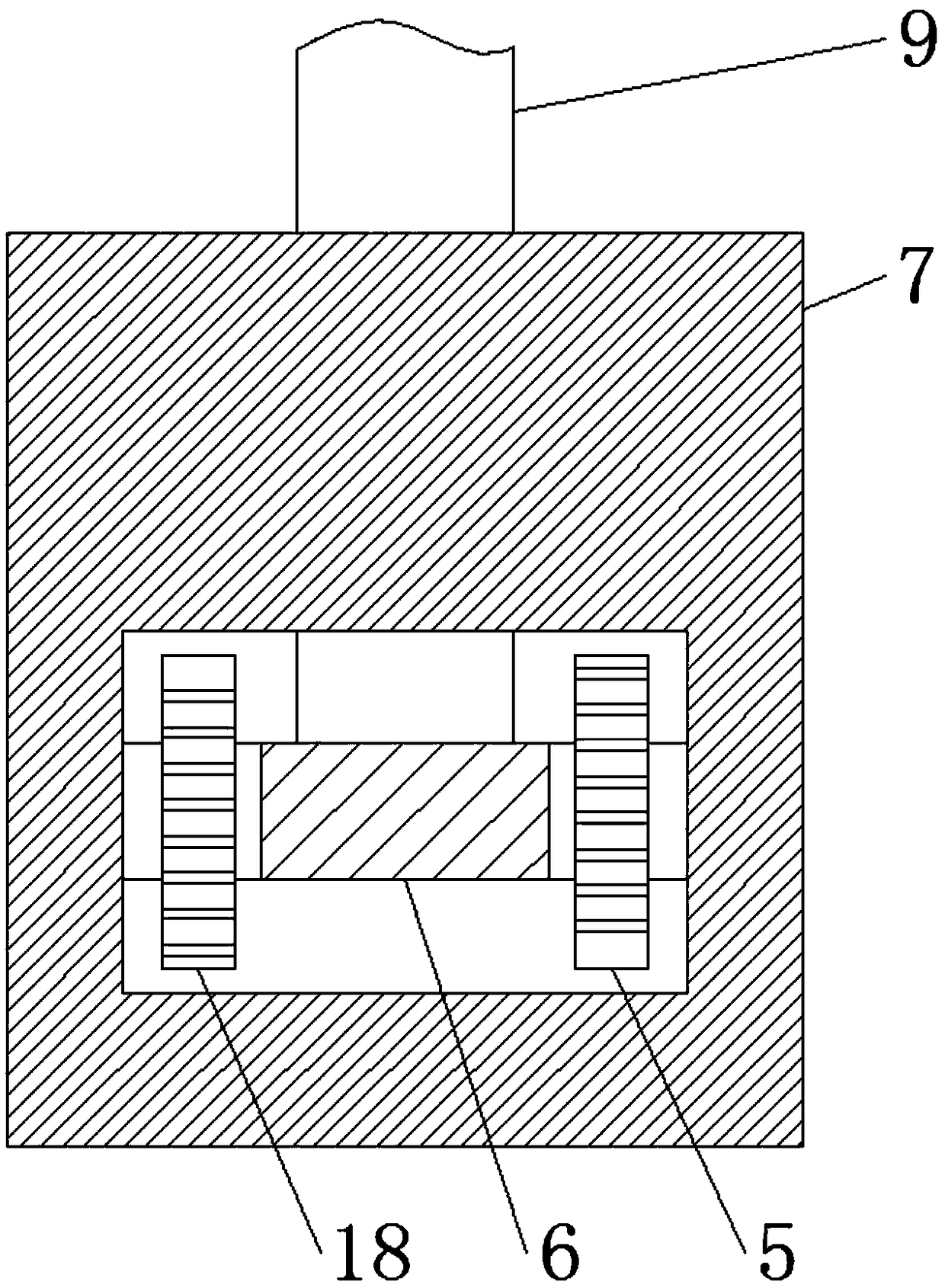

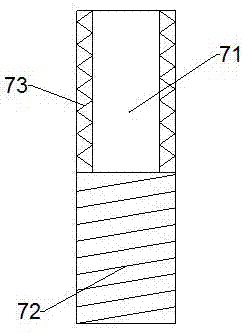

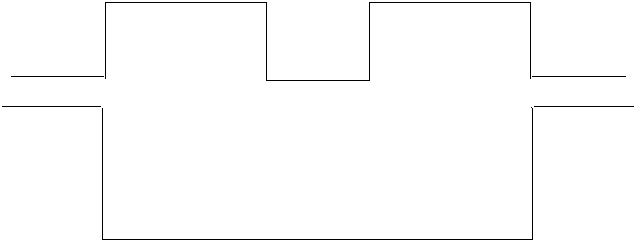

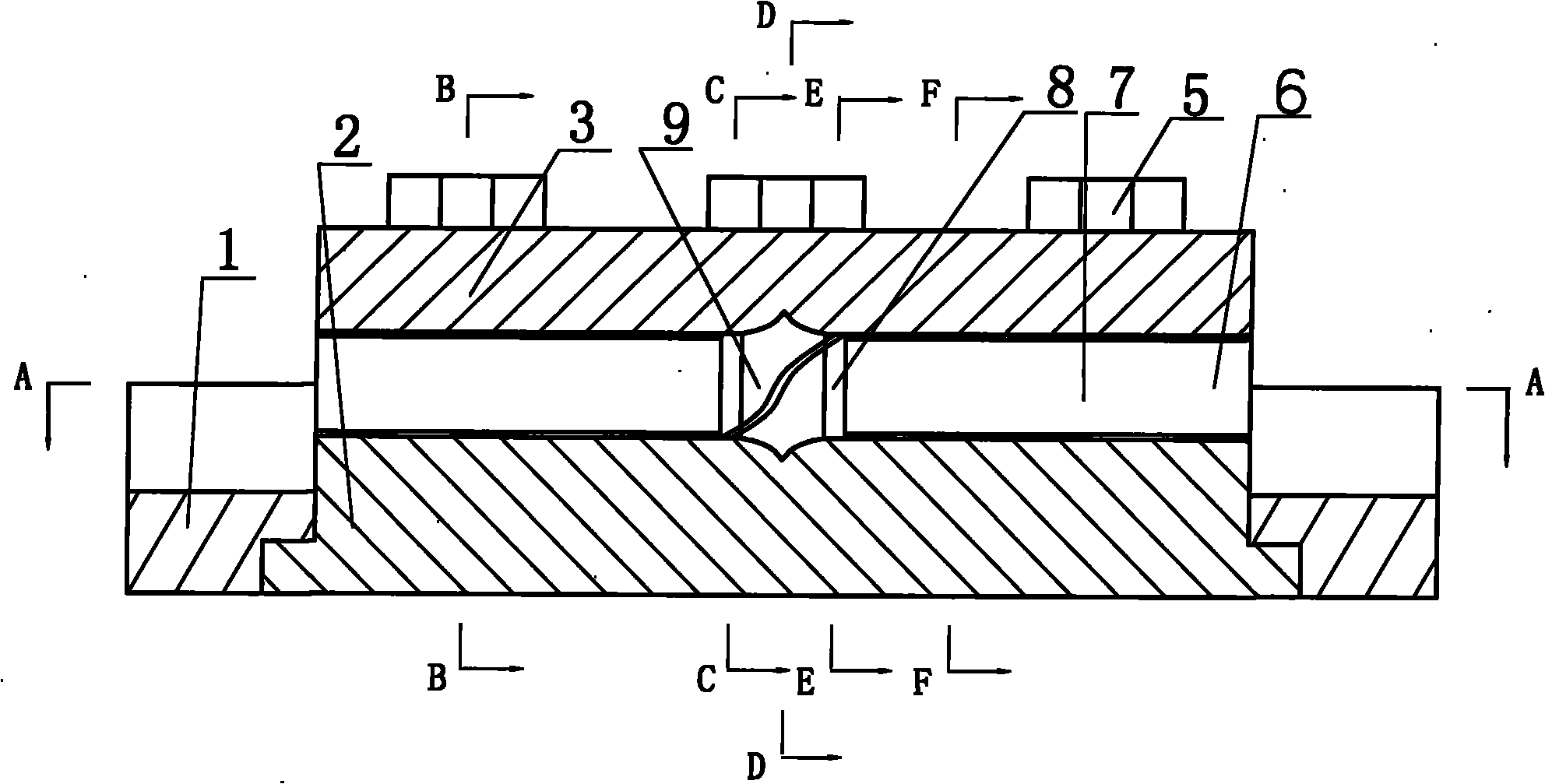

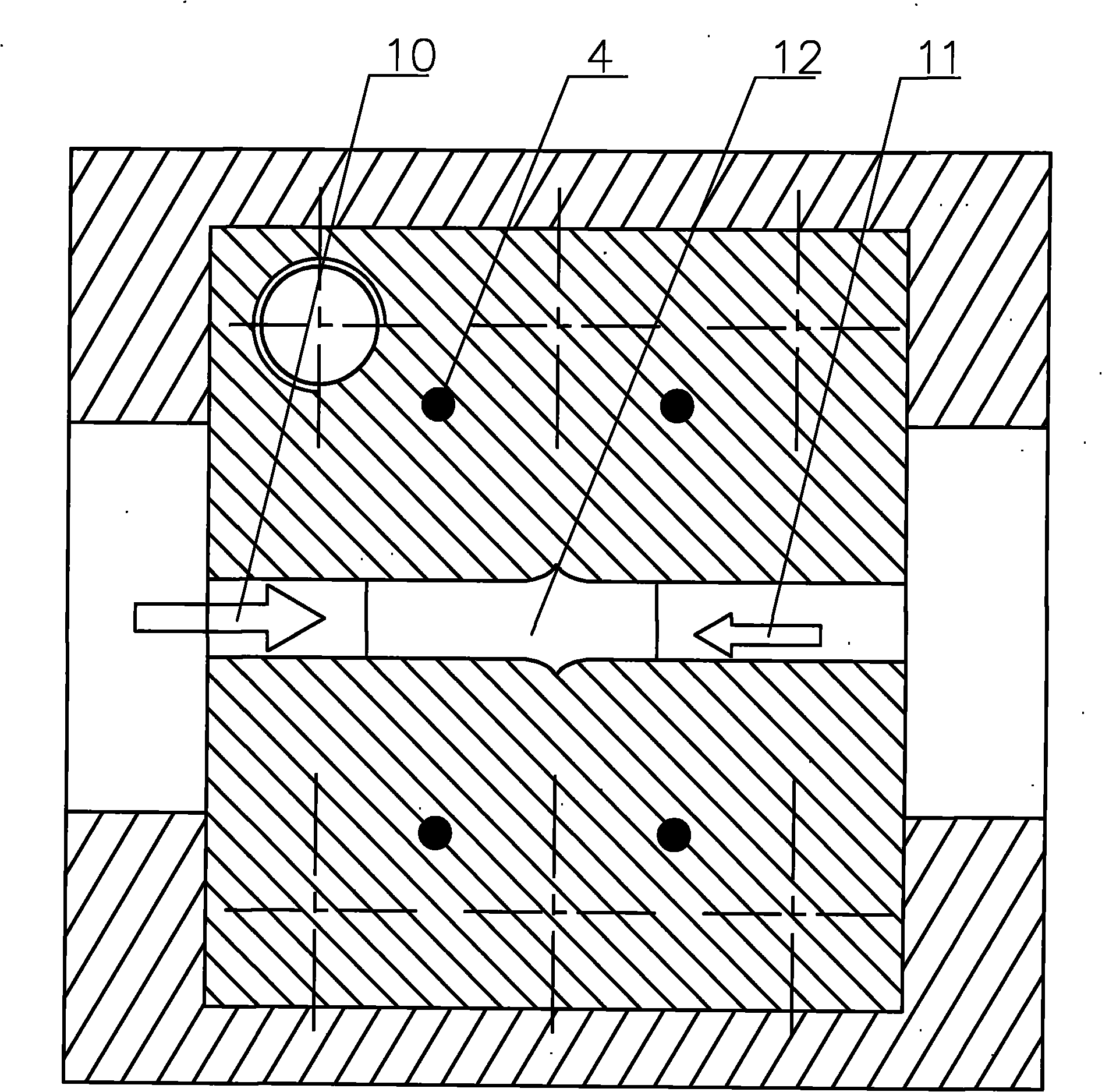

Extrusion die with an equal-passage spiral cavity for molding magnesium alloy square rods and extrusion method

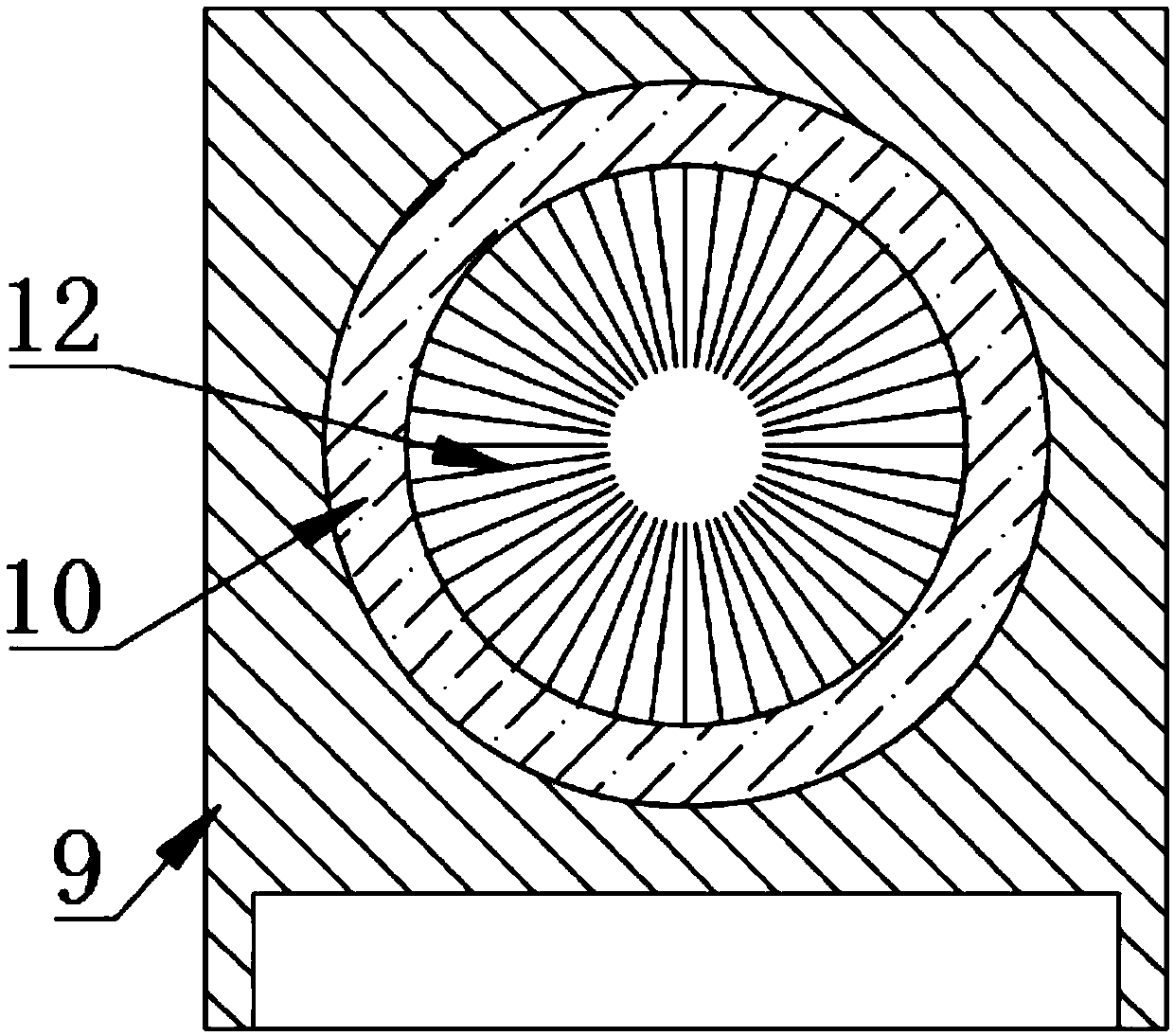

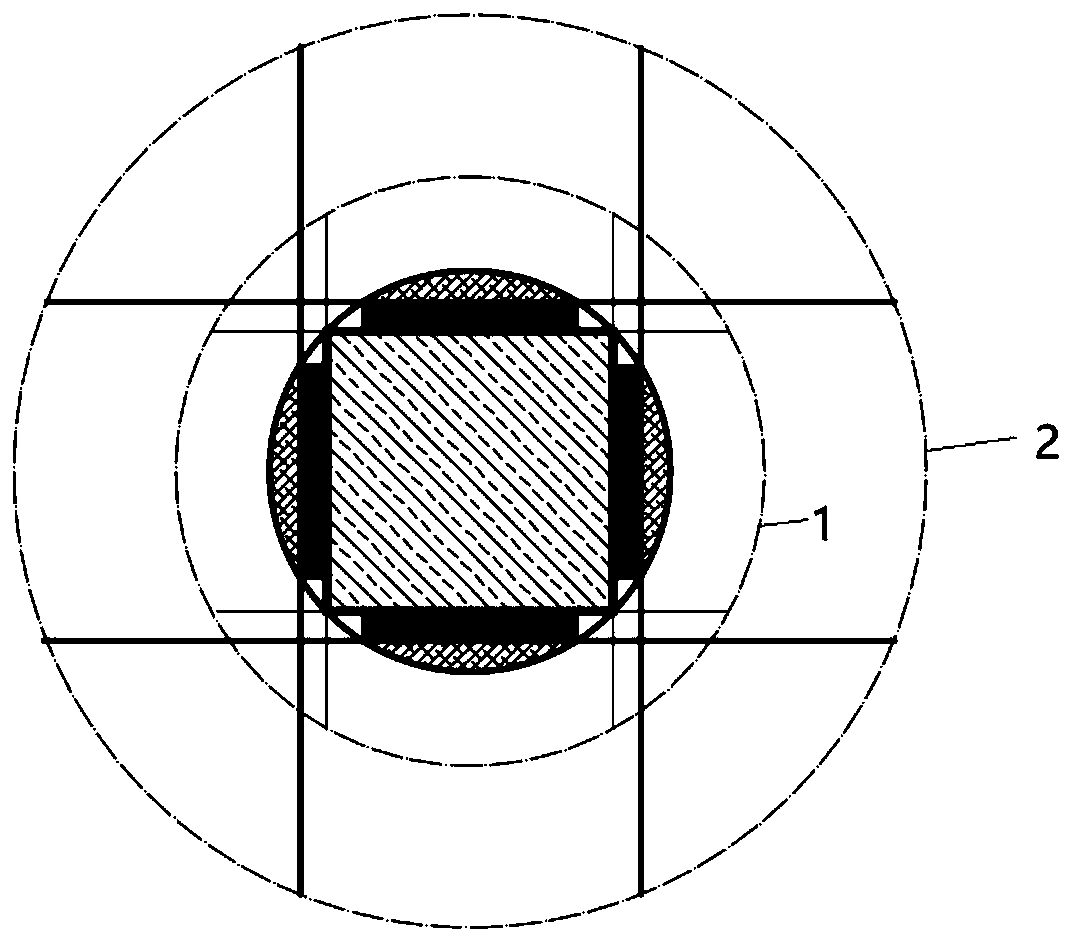

InactiveCN101773946AImprove uniformityFine surface grainsExtrusion diesExtrusion control devicesMaterials scienceMagnesium alloy

The invention relates to an extrusion die with an equal-passage spiral cavity for molding magnesium alloy square rods and an extrusion method. Currently, magnesium alloy rods made through extrusion molding have uneven texture at the positions with equal radius because the bending radii of the blanks are different in the bending process. The extrusion die with the equal-passage spiral cavity for molding the magnesium alloy square rods comprises a fixed plate (1) which is connected and fixed with a lower die (2); the lower die and an upper die (3) are fixed through positioning pins and are connected with each other through bolts (5); the curved surfaces of the opposite end faces of the upper die and the lower die form a passage (6); and a spiral passage(9) is arranged at the middle segment of the passage. The extrusion die is used for producing the magnesium alloy rods through extrusion molding.

Owner:HARBIN UNIV OF SCI & TECH

Pin puller

InactiveCN106141988AEasy to useAvoid abnormal exerciseMetal-working hand toolsElectricityInsulation layer

The invention provides a pin puller and belongs to the overhead transmission line field. The pin puller comprises a fixing part, a pin pulling part and a locating part; the pin pulling part comprises at least two pin pulling rods arranged side by side, the pin pulling rods are square rods, and the outer sides of the pin pulling rods are sleeved with insulation layers, and the pin pulling rods are rotatably arranged on the fixing part; and the length direction of the locating part is perpendicular to the length direction of the pin pulling rods. The locating part abuts against a socket and one end of each pin pulling rod is inserted into a locking pin, so that the pin puller is formed into a lever; and a certain force is applied to the end, away from the locking pin, of each pin pulling rod, and force is applied to the locking pins through the pin pulling rods and the locking pins are pulled out. According to the pin puller, firstly, the locking pins can be pulled out more easily by adopting the leverage principle; secondly, force application becomes easier as force can be applied to the end of each pin pulling rod from different angles, and operation is more convenient; and finally, one hand can operate the pin puller for pin pulling, the pin pulling progress is safer and more reliable, and electricity does not need to be cut off in the pin pulling progress.

Owner:JIANGXI ELECTRIC VOCATIONAL & TECHN COLLEGE +1

Middle drag plate type tail vane device of catamaran

InactiveCN102756802AEnsure balanceImprove interchangeabilitySteering ruddersRemote controlMechanical engineering

The invention discloses a middle drag plate type tail vane device of a catamaran. A part of the tail vane device consists of a motor, a screw rod, a middle drag plate, a crank, a bolt, a bearing and a bracket, wherein the part is arranged on a catamaran body by the motor at one end of the screw rod and the bracket at the other end of the screw rod, the middle drag plate is sheathed on the screw rod, and the crank is arranged on the middle drag plate; the other part of the tail vane device consists of a tail vane shaft, a tail vane and a T-shaped groove crossbeam platform, the tail vane is fastened on the tail vane shaft and is arranged on the T-shaped groove crossbeam platform by the tail vane shaft, and the top end of the tail vane shaft is a square rod section; the screw rod is embedded in a T-shaped groove of the T-shaped groove crossbeam platform by a groove structure in the middle drag plate, and a connecting rod is sheathed on a boss of the crank and the square rod section so as to connect the square rod section and the crank together; and the middle drag plate moves horizontally due to the rotation of the screw rod with the power provided by the motor, and the crank and the connecting rod drive the tail vane shaft to rotate so as to drive the tail vane to rotate. According to the middle drag plate type tail vane device, a screw rod-crank-connecting rod mechanism can control the turning of a rudder, the tail vane can be controlled conveniently, and the basis is provided for the remote control.

Owner:SHANGHAI DIANJI UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com