Pin puller

A pin puller and pin rod technology, applied in the field of overhead transmission lines, can solve the problems of difficulty in ensuring the direction of force application, inconvenient operation, unqualified quality, etc., and achieve the effect of easy force application, convenient operation, and ensuring normal use.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0045] When replacing the insulating porcelain bottle on the overhead transmission line, it is necessary to use wire pliers to manually pull out the pin, that is, the staff uses wire pliers to clamp the locking pin, and then pulls out the locking pin forcefully, because the pin is pulled out at high altitude. Operation, inconvenient operation, low safety, and because it is difficult to ensure that the direction of force applied when pulling out the pin is consistent with the pulling out direction of the locking pin, resulting in insufficient strength, the locking pin is not easy to be pulled out.

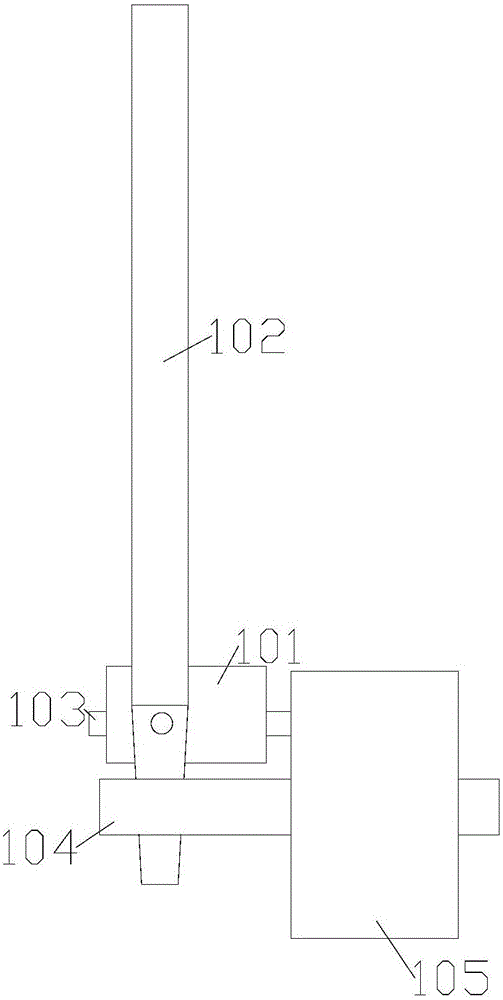

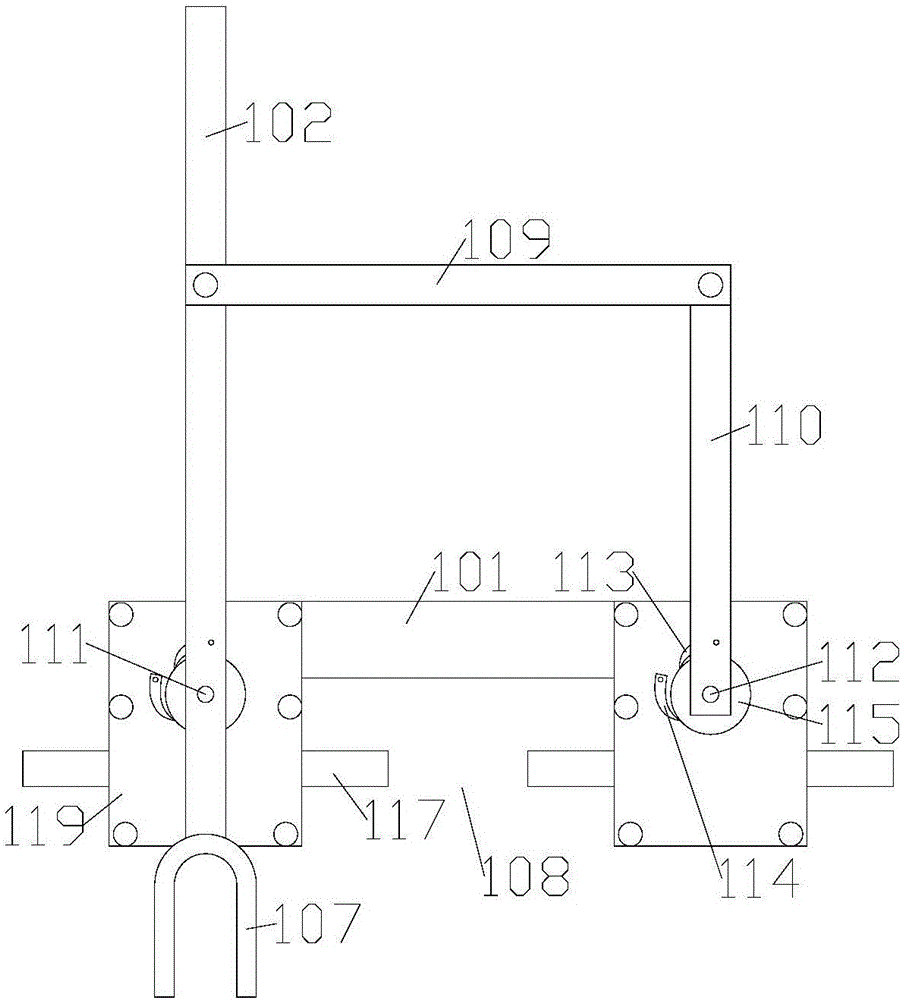

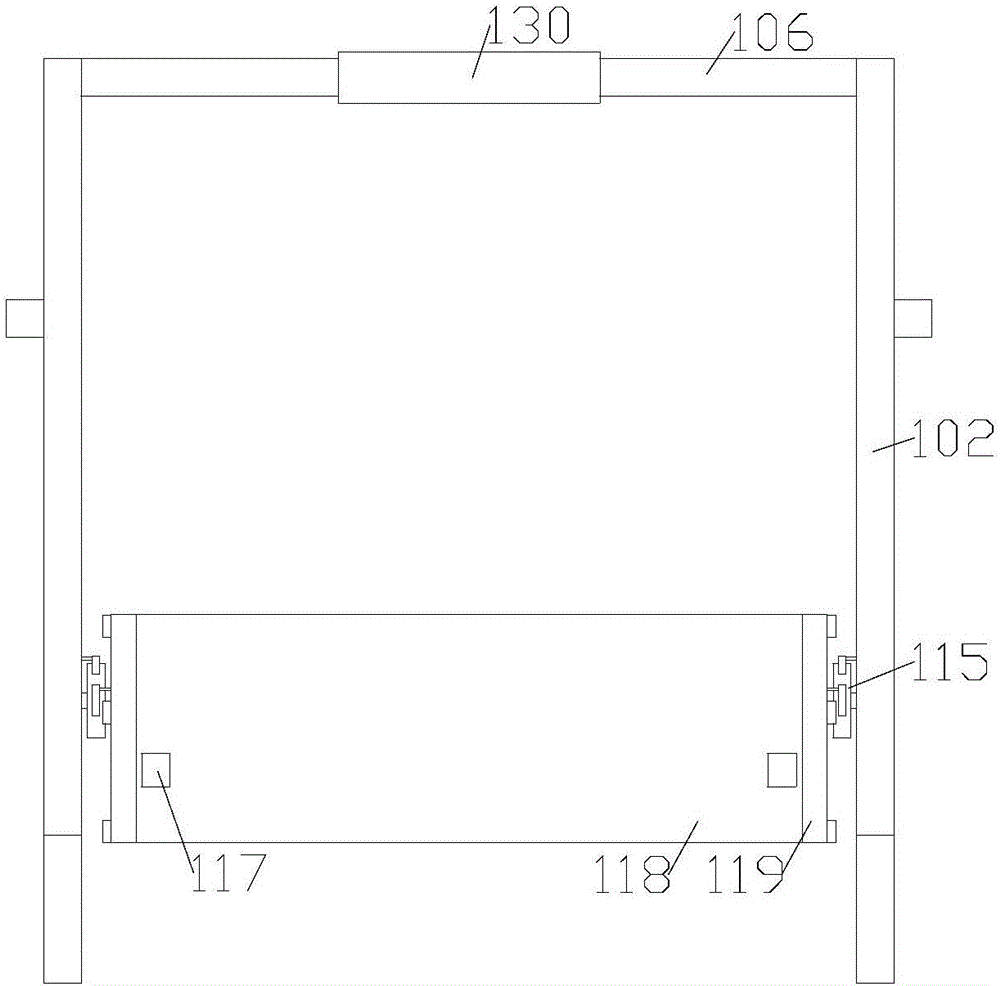

[0046] In order to improve the above problems, the present invention provides a pin puller, including a fixing piece, a pin pulling piece and a positioning piece, the pin pulling piece includes at least one pin pulling lever arranged side by side, the pin pulling lever is rotatably arranged on the fixing piece, The length direction of the positioning piece is perpendicular to the len...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com