Patents

Literature

3793results about How to "Improve interchangeability" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Two-stage garbage incinerator

ActiveCN101922715AGuaranteed incineration effectFully dryInclined grateIncinerator apparatusLoss rateCombustion

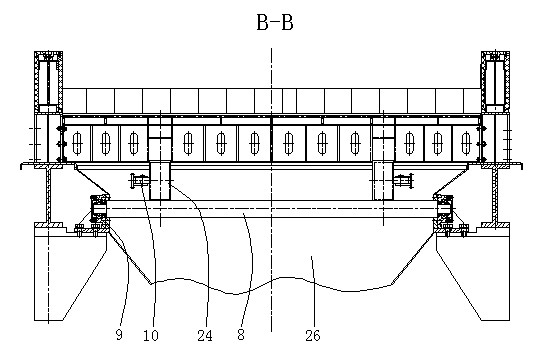

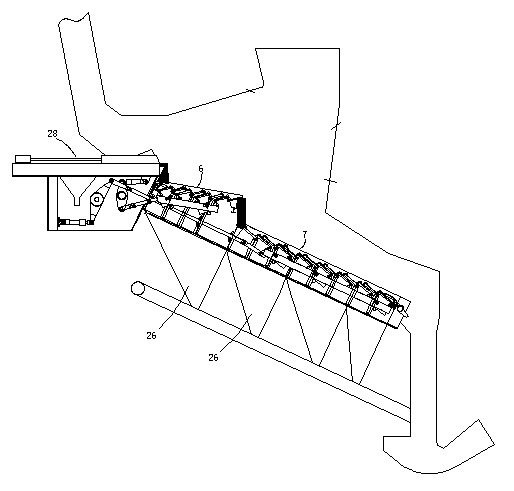

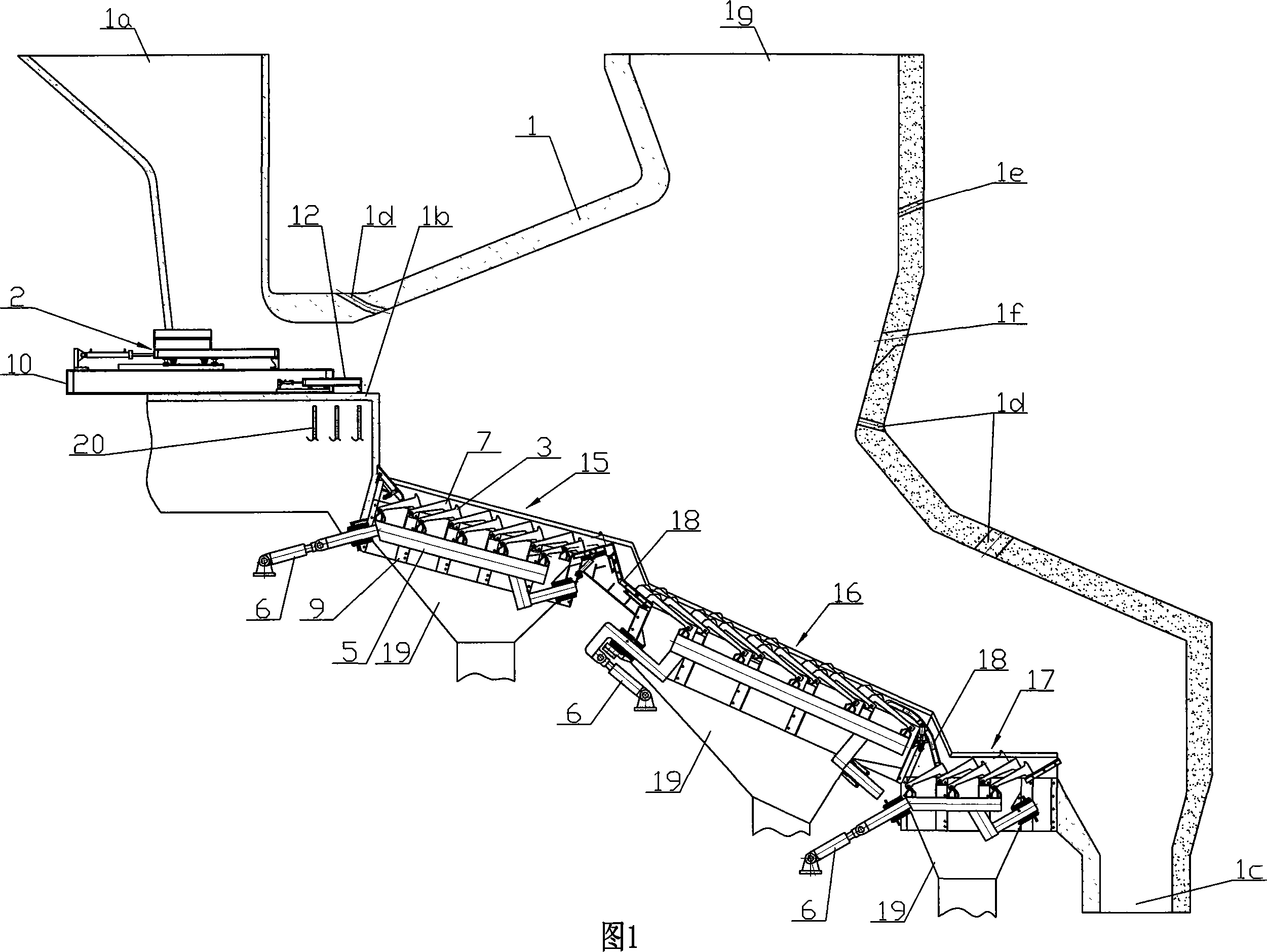

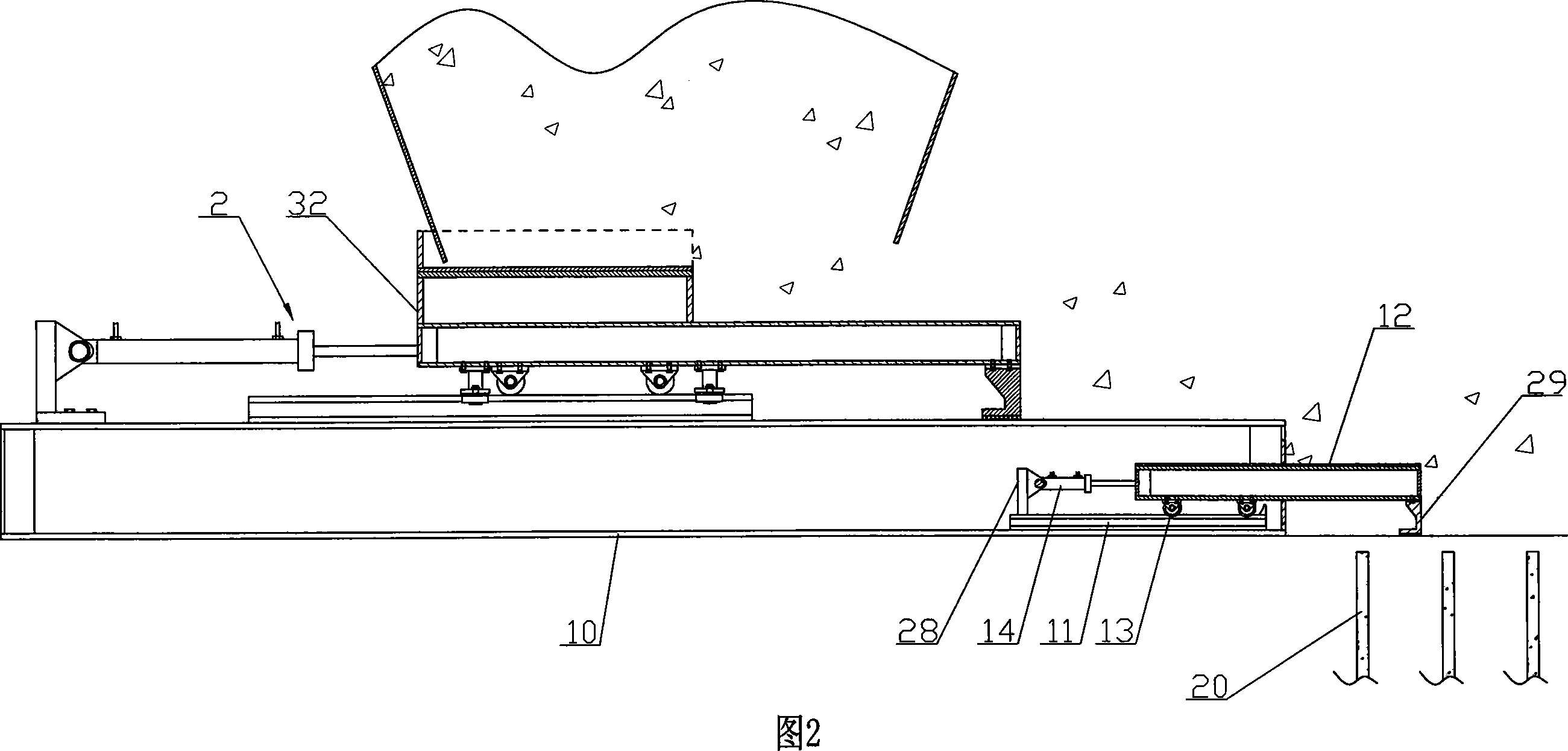

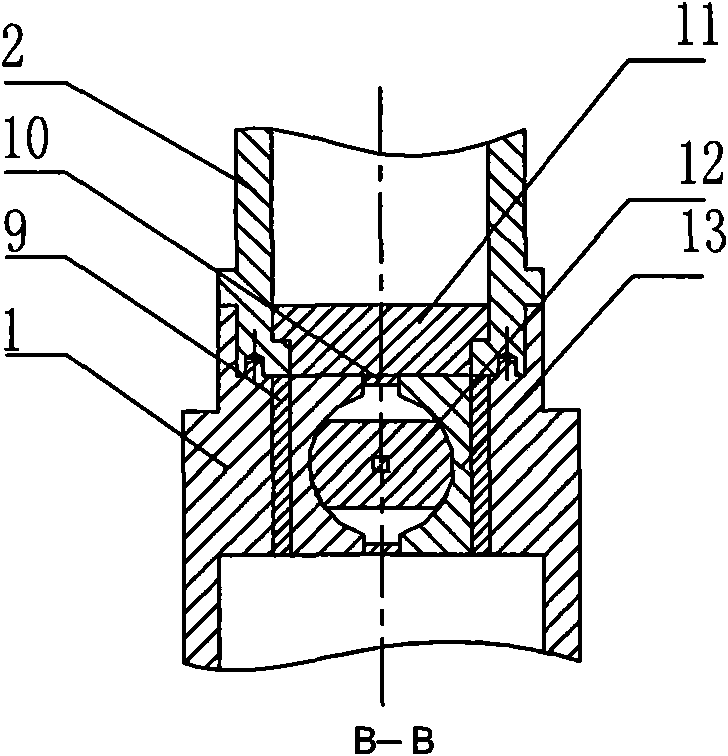

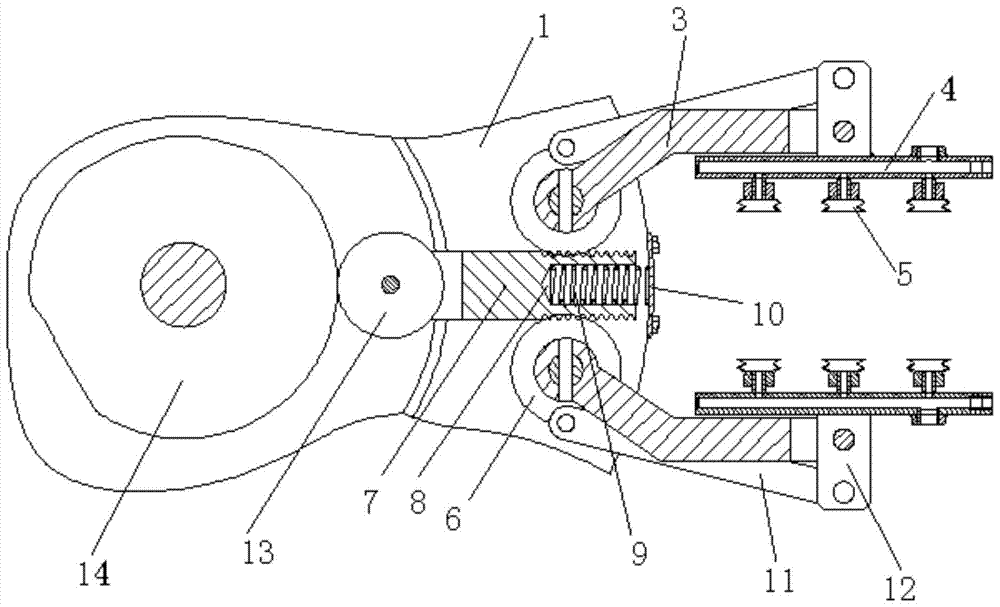

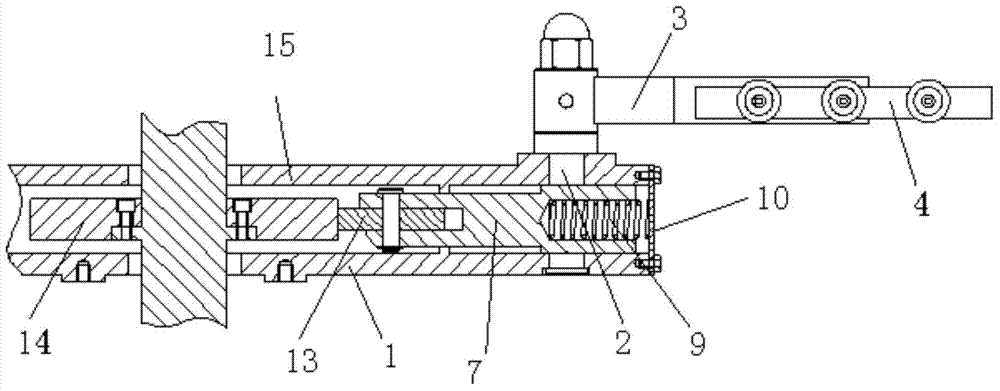

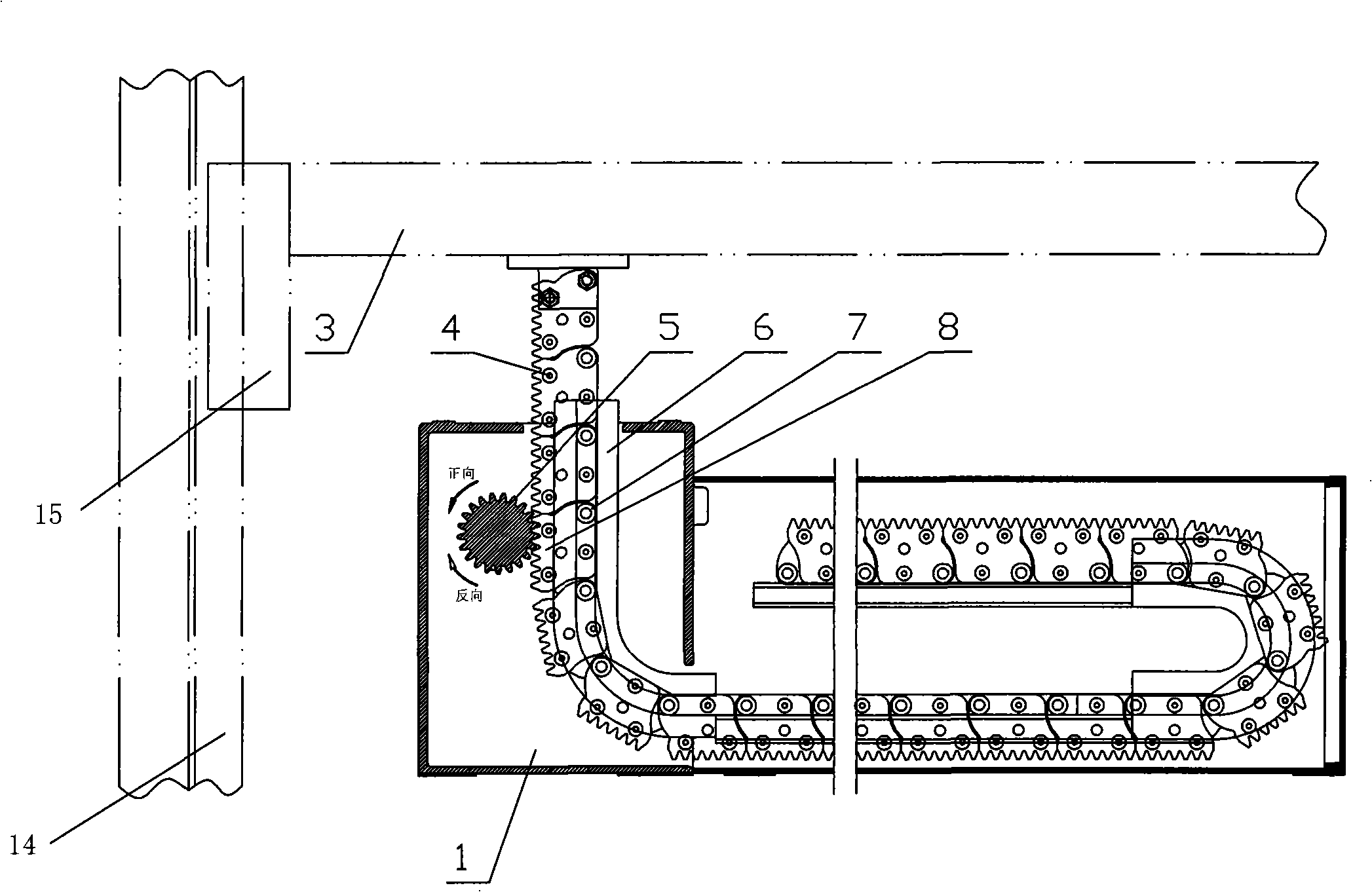

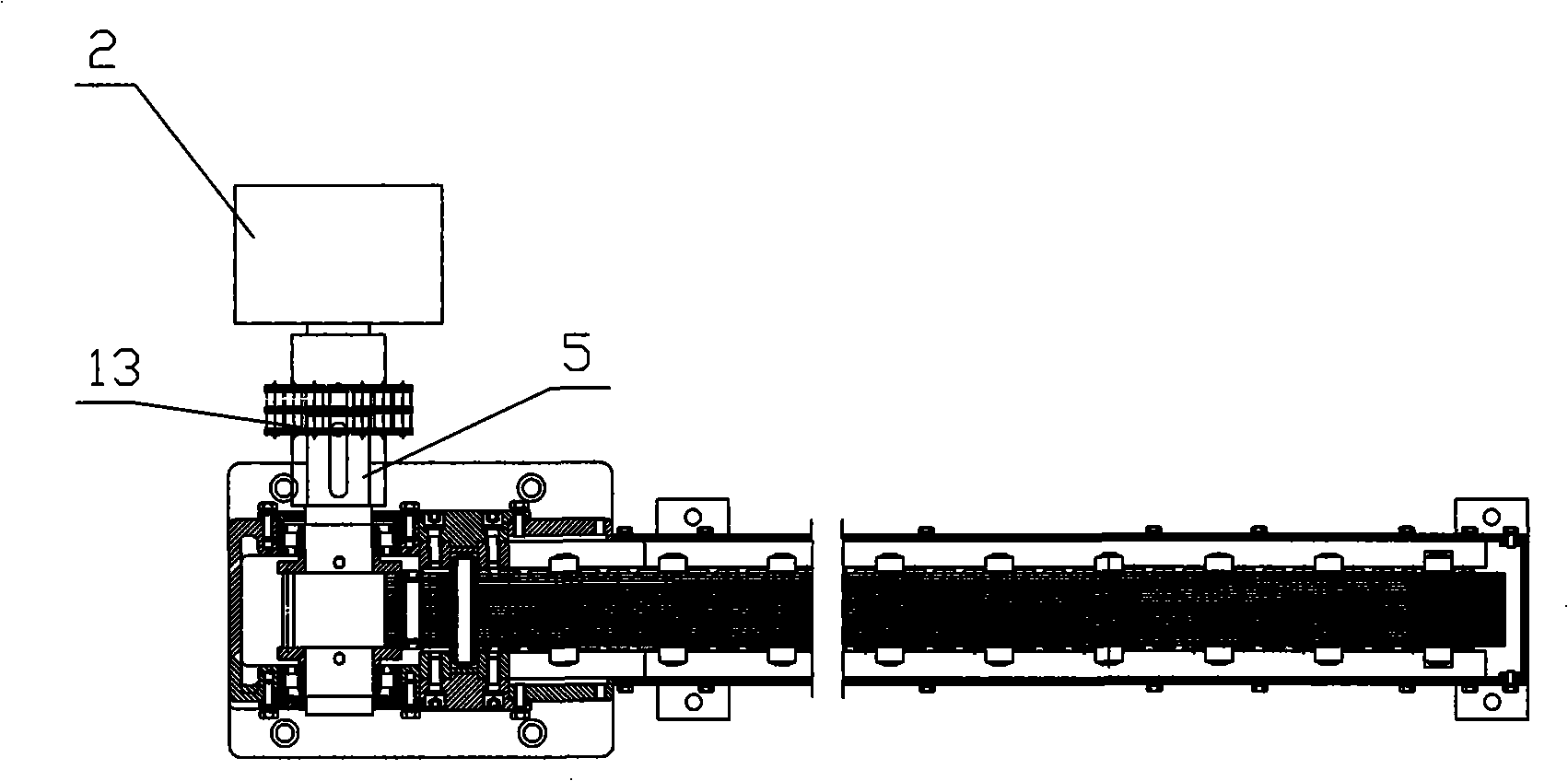

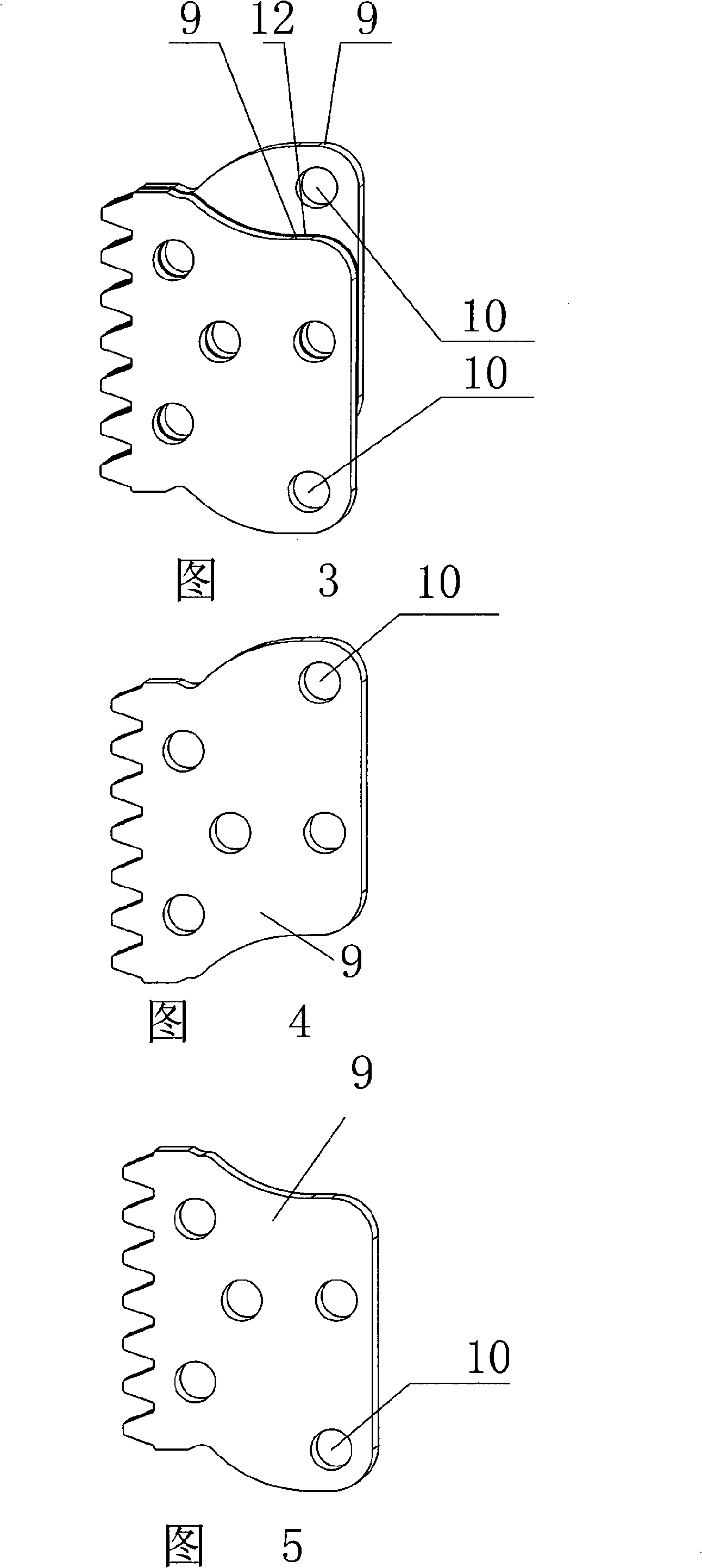

A two-stage garbage incinerator is characterized in that secondary air supply holes are arranged on front and rear arches of a furnace body and an ignition combustion-supporting hole is arranged on the rear arch; a grate in the furnace body is divided into two stages from top to bottom; the upper stage is a forward pushing stage and the lower stage is a backward pushing stage; an independent primary air chamber is arranged below each stage; the heads of the grates on the forward pushing stage face the low point direction of the grates; the heads of the grates on the backward pushing stage face the high point direction of the grates; moving beams of the grates on the same stage are equipped with left and right draw bars arranged side by side; the left and right draw bars are supported by supporting roller devices and are connected with the moving beams to form draw bar frames; and the ends of the draw bar frames are connected with front rocker arm driving mechanisms, lateral rocker arm driving mechanisms or front straight driving mechanisms. The incinerator can realize full drying of the whole garbage material, ensure complete combustion and ensure the garbage incineration effect and hot ignition loss rate. At the same time, the incinerator has less spare parts and spare part specifications, good quick-wear part interchangeability and low manufacture and maintenance costs.

Owner:CHONGQING SANFENG ENVIRONMENTAL IND GRP

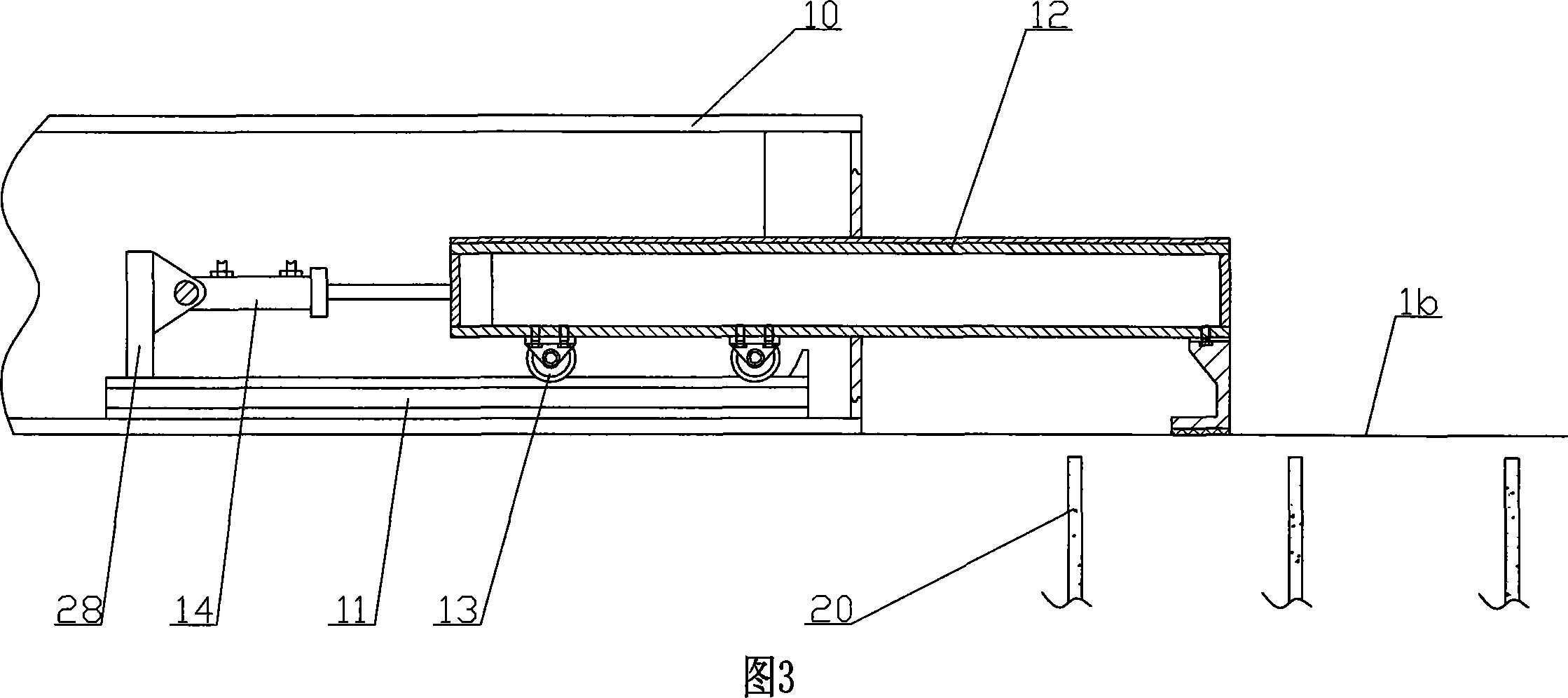

Multiple row sectional drive combined type domestic garbage incinerator

The invention relates to multi-column sectional drive combined type domestic incinerator. It is set three fire-grates that drying section, burning section, and firing section. The middle fire grate is connected between them. There is altitude fall between them that the drying section is the highest point; the firing one is the lowest point. The primary air chamber is respectively set under them. The incinerator fire grate system of the invention has independent drive mechanism, air supply system, and air chamber for each section which is convenient for controlling technical parameter that traveling speed, air quantity, air temperature, air pressure etc to realize full drying and burning for whole garbage layer.

Owner:CHONGQING SANFENG ENVIRONMENTAL IND GRP

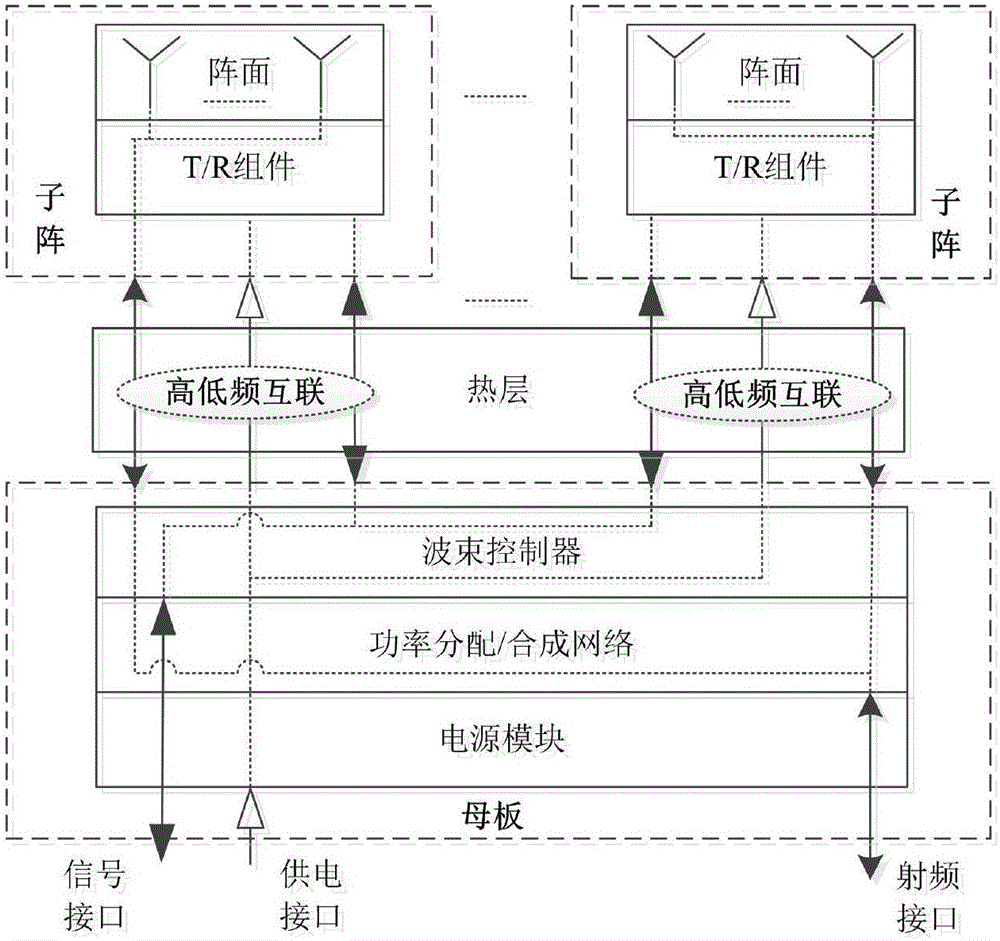

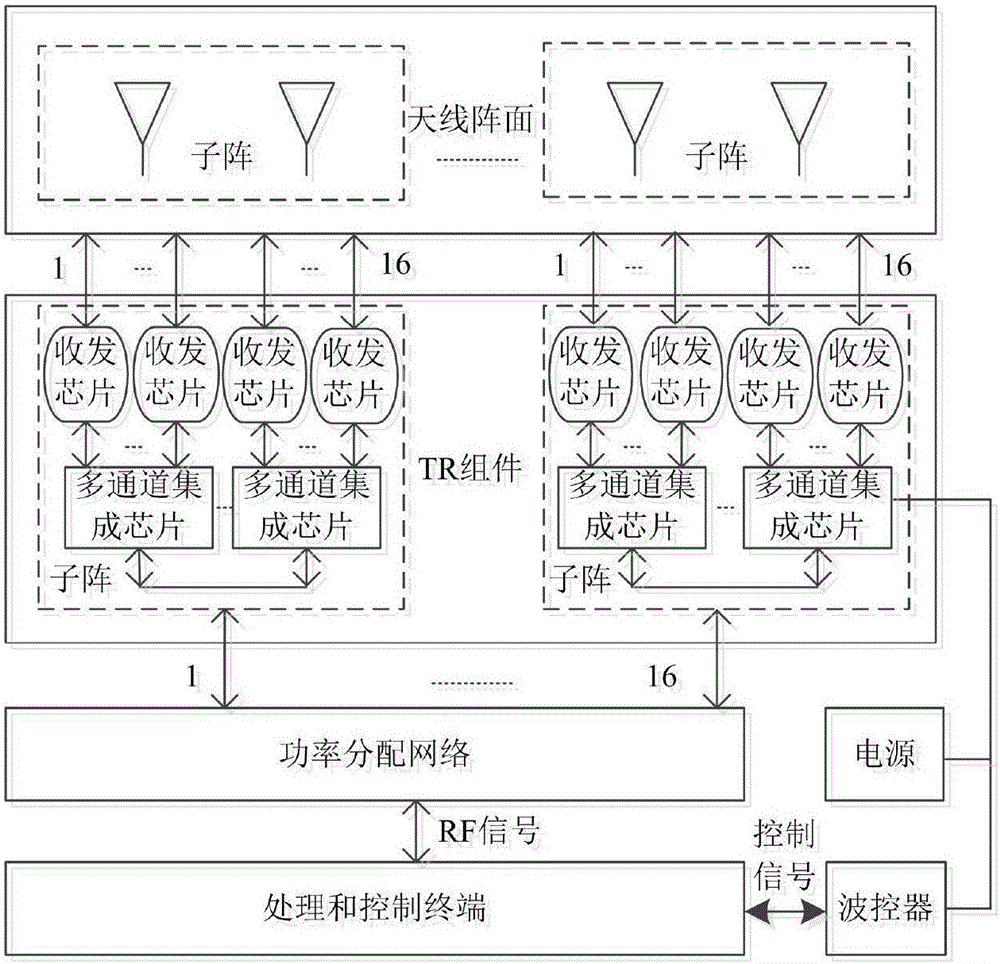

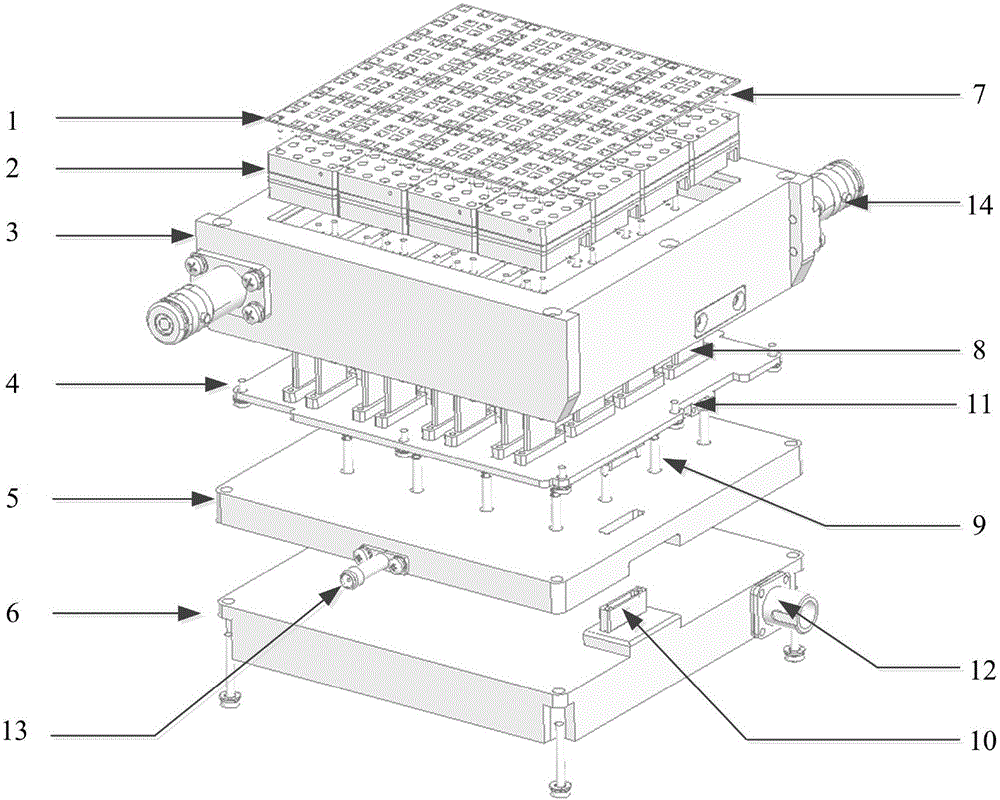

Ka-band tilt-structure active phased array antenna

InactiveCN105914476AHighly integratedImprove performanceAntenna arraysAntennas earthing switches associationArray elementActive phase

The invention provides a Ka-band tilt-structure active phased array antenna, so as to provide an active phased array antenna which is high in integration density and can improve maintainability and interchangeability. According to the technical scheme, one path of RF signals transmitted by a transmitting signal processing terminal are transmitted to a power distribution / synthesis network (5) via a signal interface and a radio frequency interface to be divided into M paths of signals; according to information of an azimuth angle and a pitch angle of the phased array antenna provided by the transmitting signal processing terminal in real time, a beam controller (4) calculates and obtains beam pointing of the phased array antenna in real time through an FPGA; the beam pointing of the phased array antenna is converted into phase data needed by each array element under control of the beam controller (4); the data are transmitted to tilt-type TR assembly sub array modules in N channels respectively via a high and low-frequency interconnected multi-core high and low-frequency socket, and under control of the beam controller, M*N paths of signals are transmitted to an antenna array, and thus signal transmission is completed, and synchronous electric control scanning of beams transmitted by the phased array antenna is realized.

Owner:10TH RES INST OF CETC

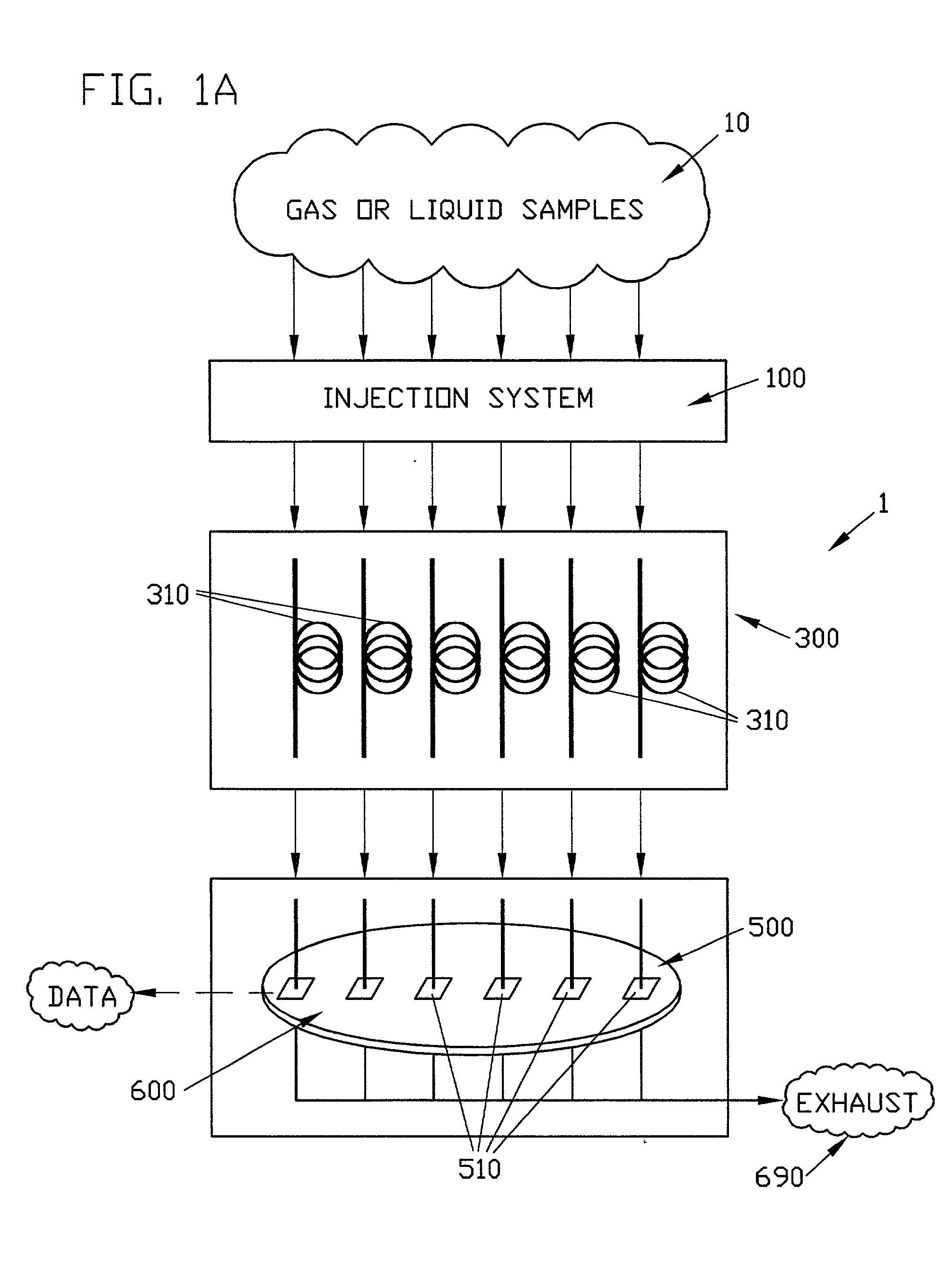

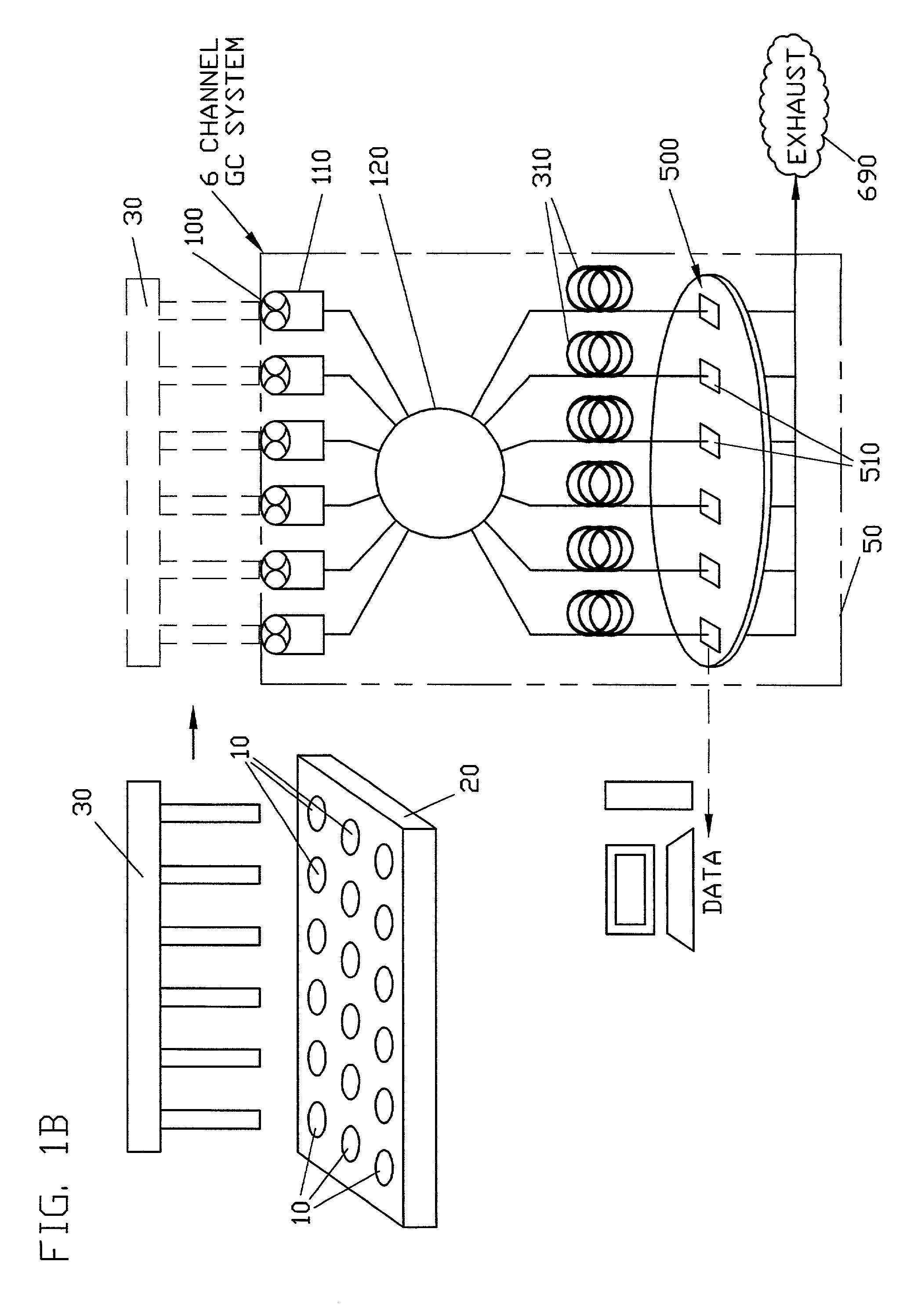

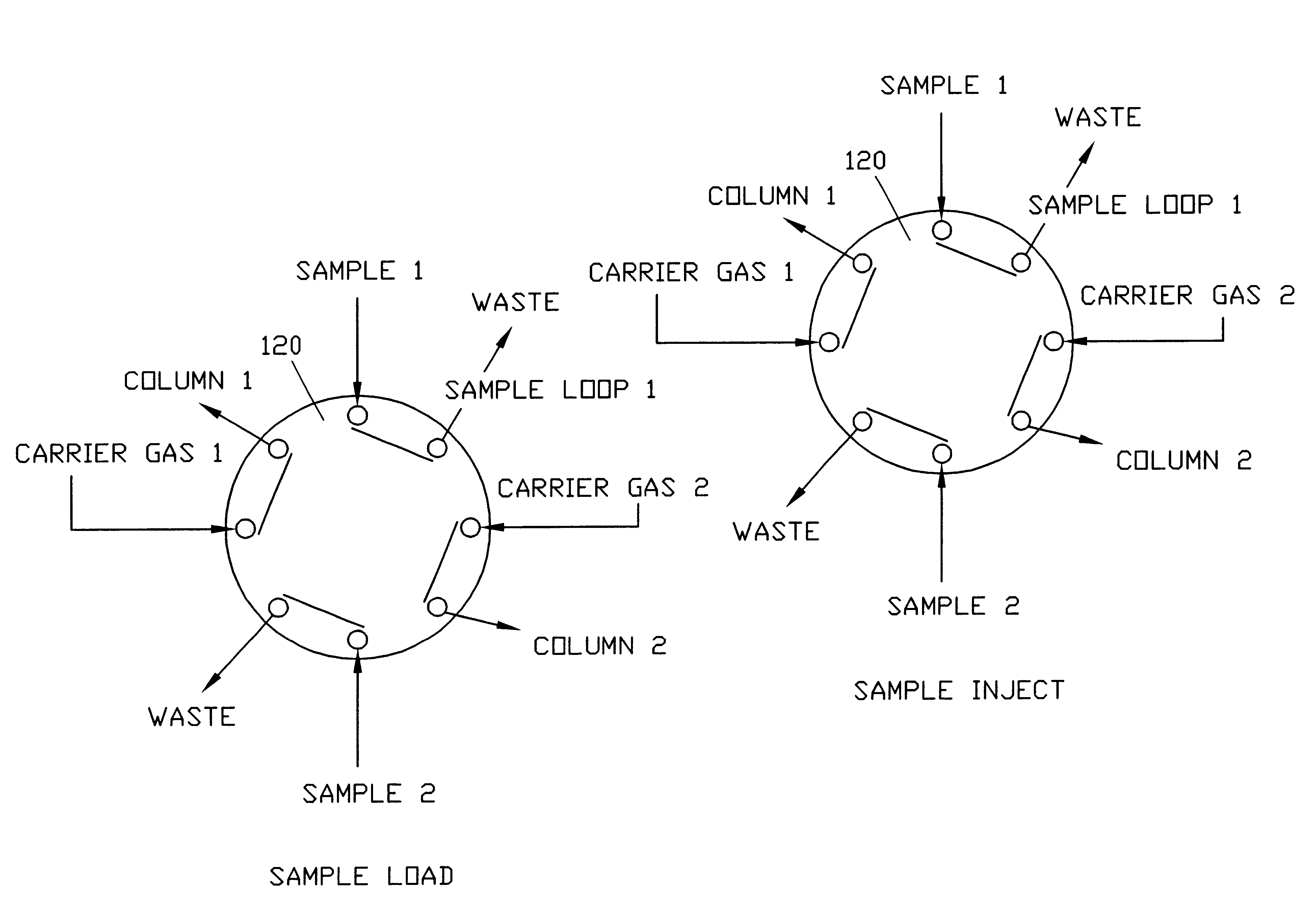

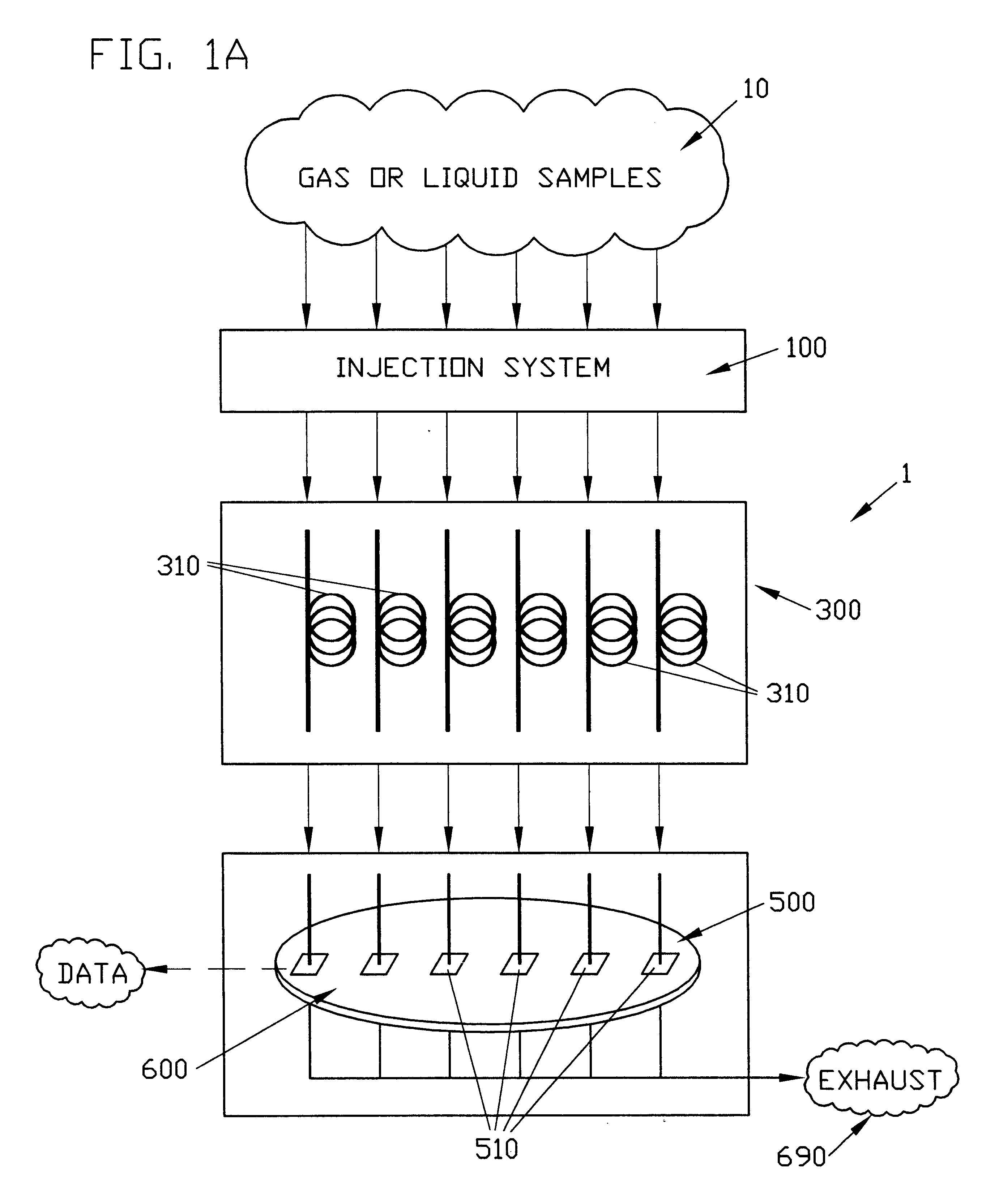

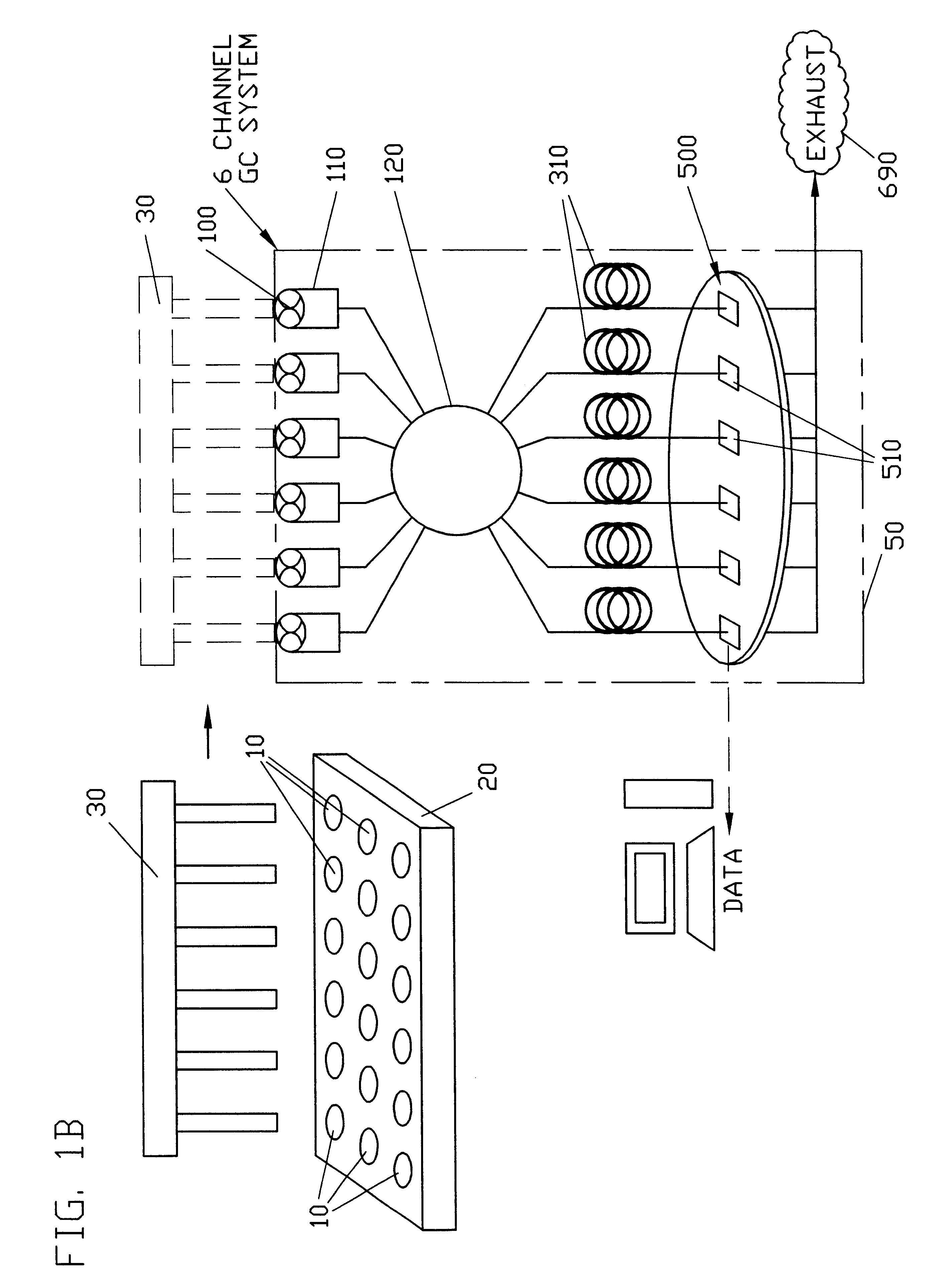

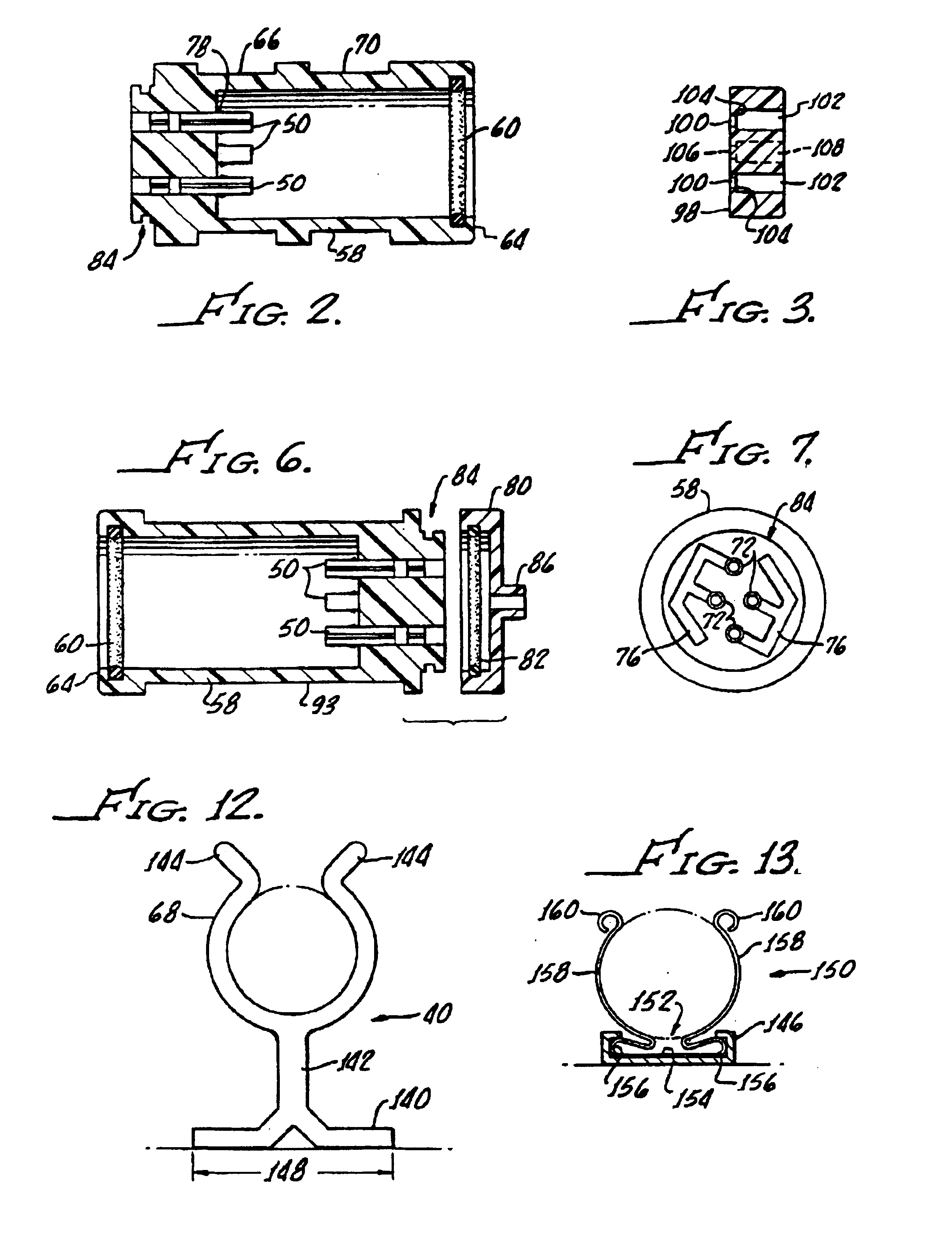

Parallel gas chromatograph with microdetector array

InactiveUS20020014106A1More spatially efficientProvide flexibilitySequential/parallel process reactionsComponent separationDetector arrayThermal conductivity

Gas chromatographs of the invention generally comprise four or more analysis channels. Specifically, four or more gas chromatography columns are configured for parallel analysis of four or more gaseous samples with detection being effected using a microdetector array comprising four or more microdetectors. In one embodiment, the four or more microdetectors 510 are microfabricated detectors, and are integrally formed with a substrate or with one or more microchip bodies mounted on a substrate. In a preferred embodiment, a microdetector array comprises four or more thermal conductivity detectors having one or more thin-film detection filaments. A preferred heated environment for highly parallel gas chromatographs is also disclosed.

Owner:FREESLATE

Parallel gas chromatograph with microdetector array

InactiveUS6701774B2More spatially efficientProvide flexibilityIon-exchange process apparatusSequential/parallel process reactionsDetector arrayThermal conductivity

Gas chromatographs of the invention generally comprise four or more analysis channels. Specifically, four or more gas chromatography columns are configured for parallel analysis of four or more gaseous samples with detection being effected using a microdetector array comprising four or more microdetectors. In one embodiment, the four or more microdetectors 510 are microfabricated detectors, and are integrally formed with a substrate or with one or more microchip bodies mounted on a substrate. In a preferred embodiment, a microdetector array comprises four or more thermal conductivity detectors having one or more thin-film detection filaments. A preferred heated environment for highly parallel gas chromatographs is also disclosed.

Owner:FREESLATE

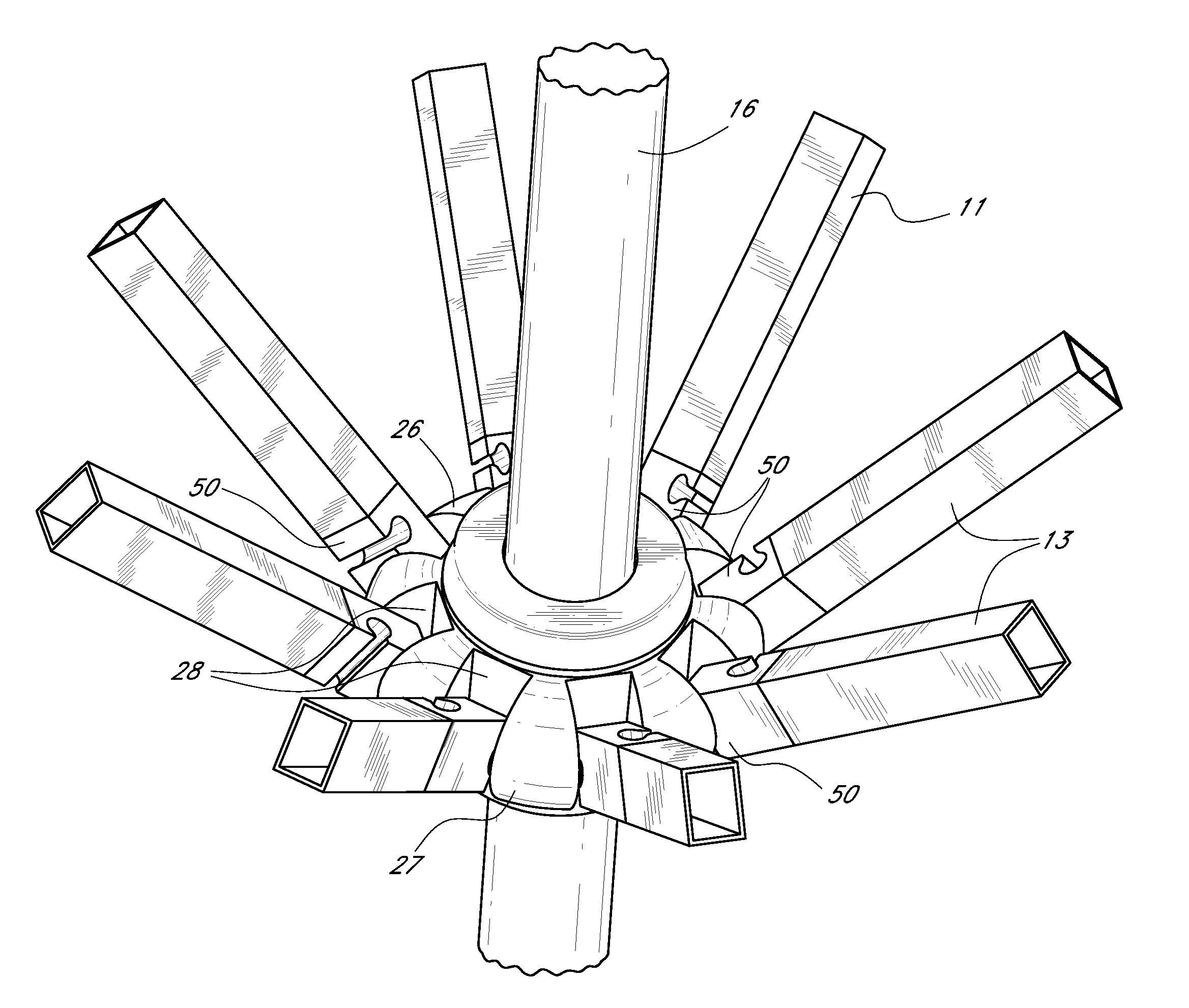

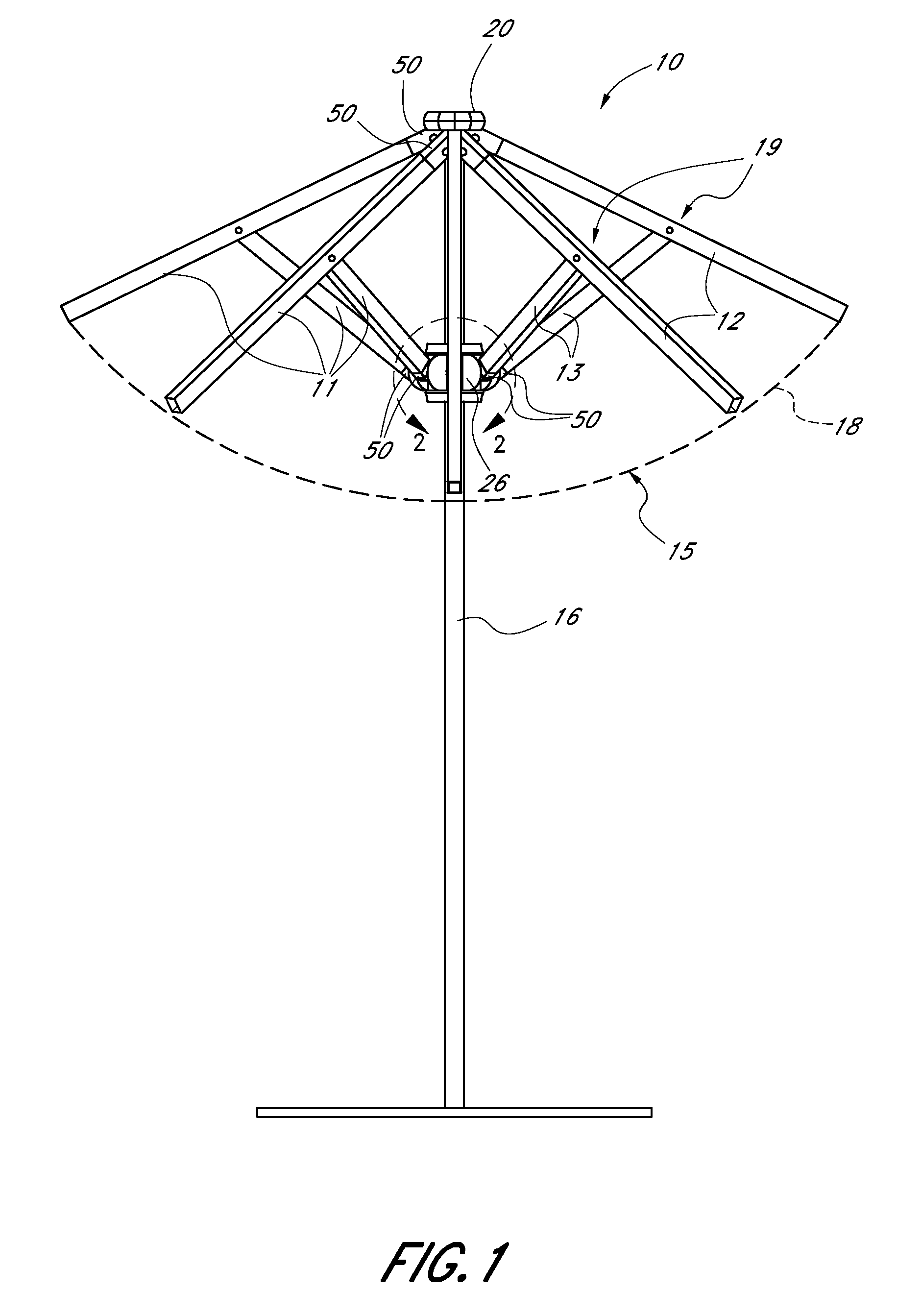

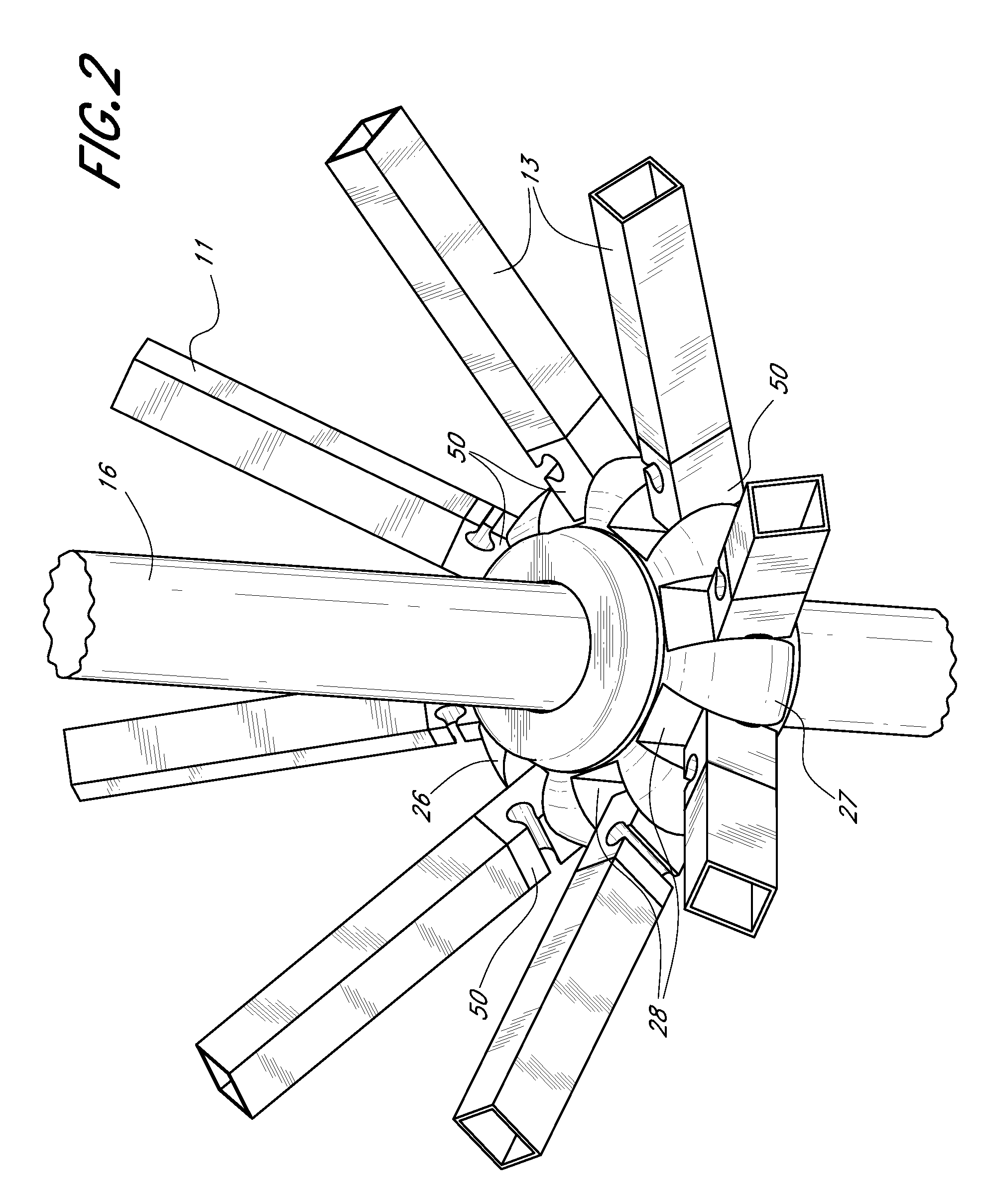

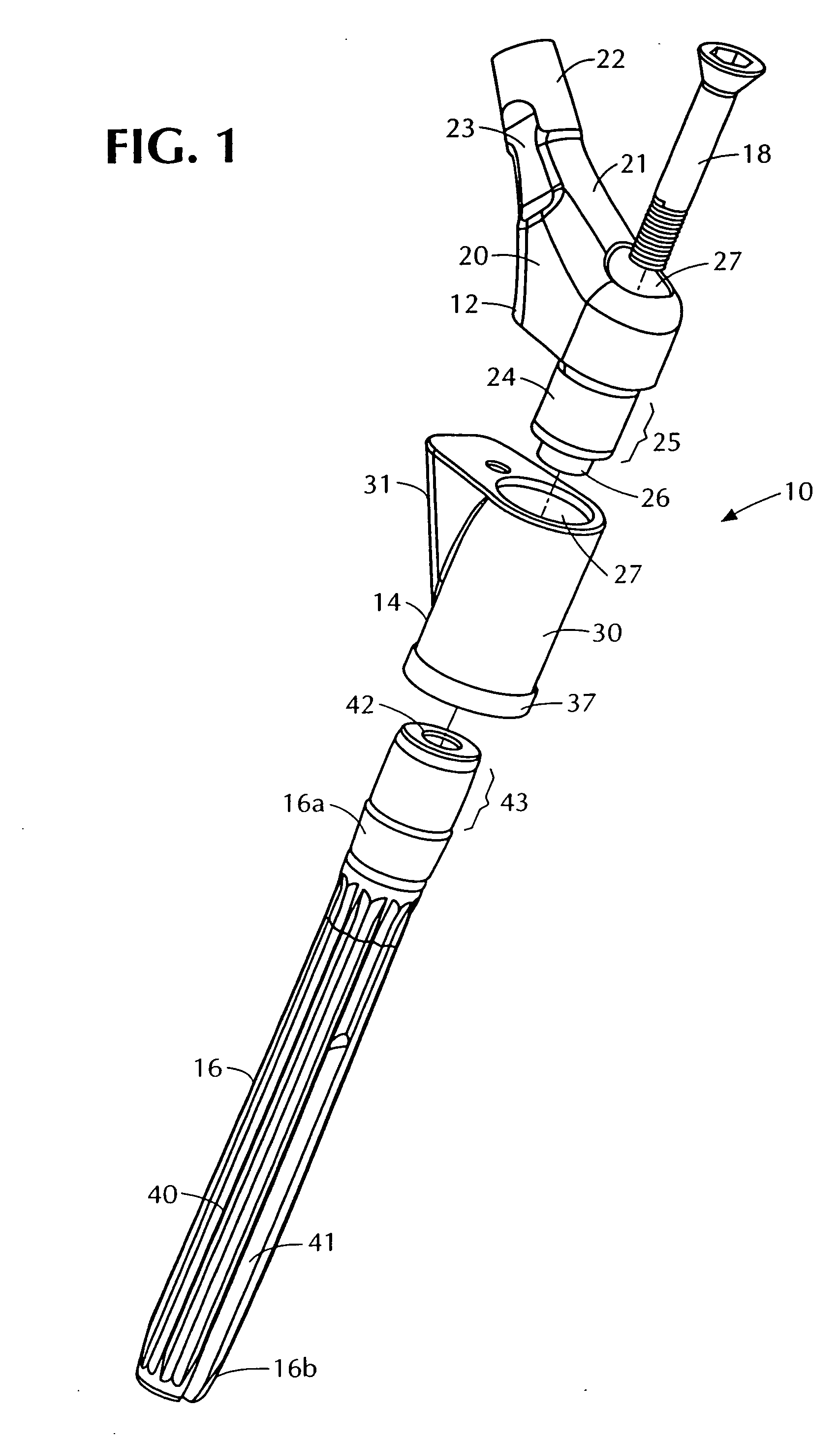

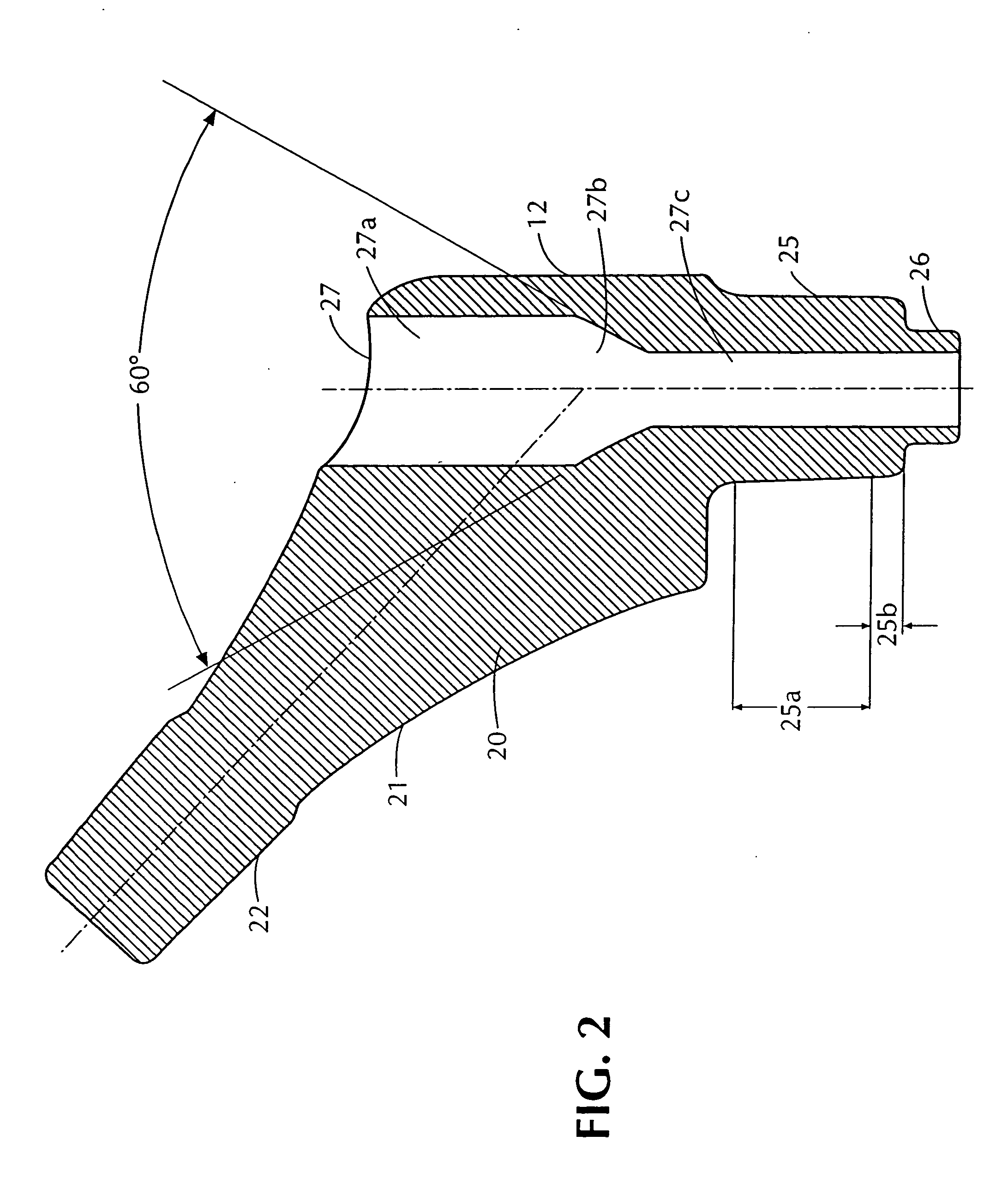

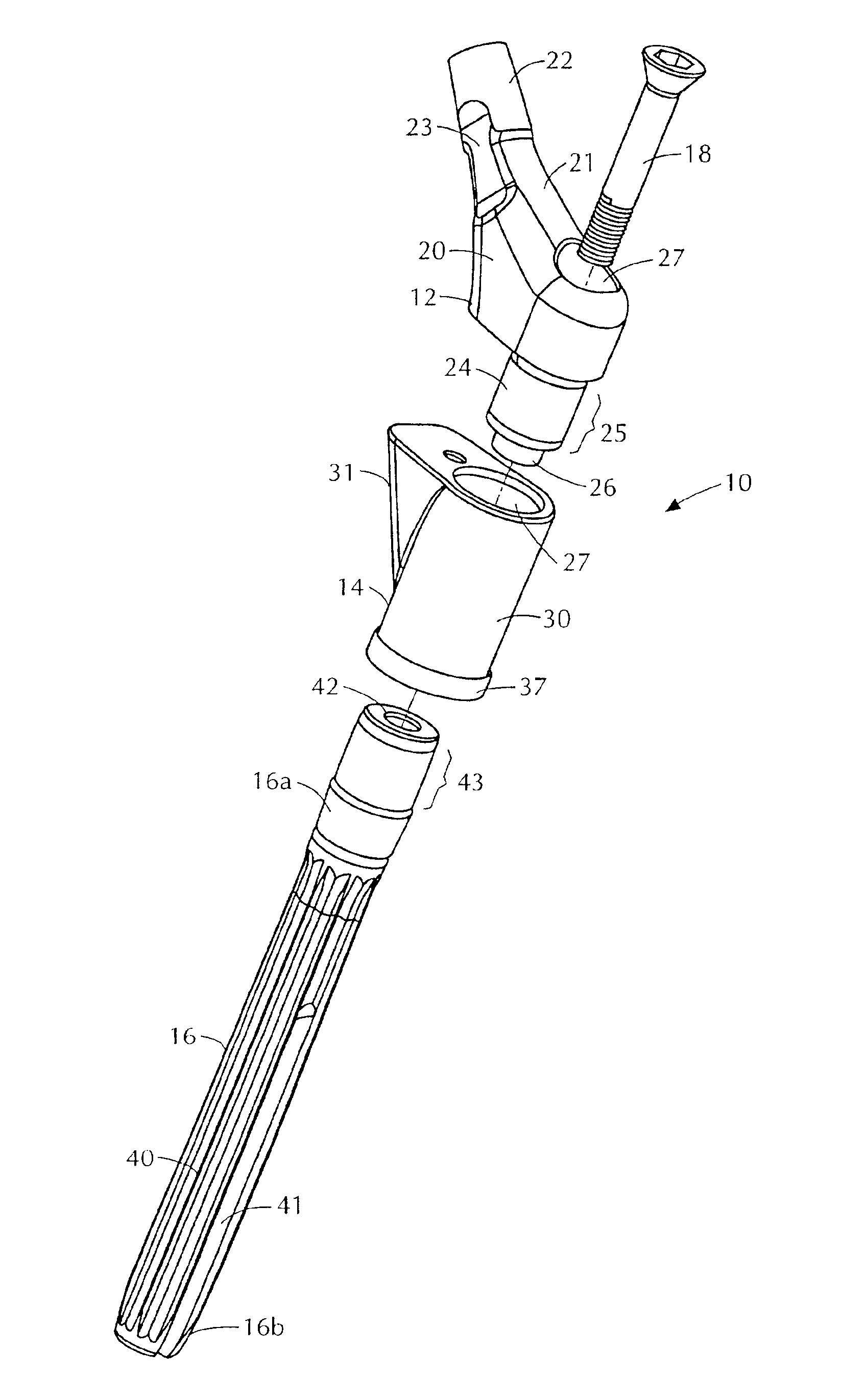

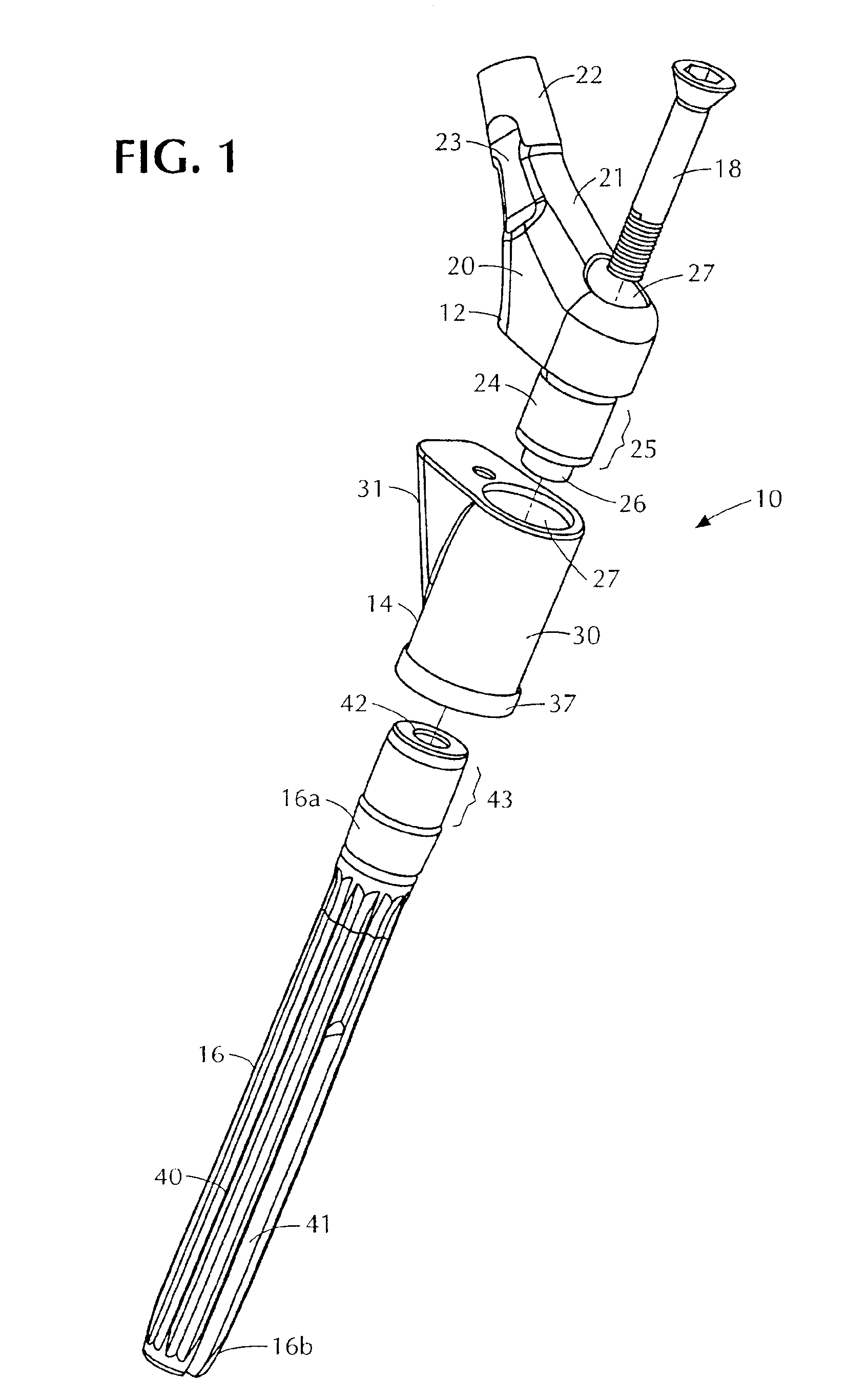

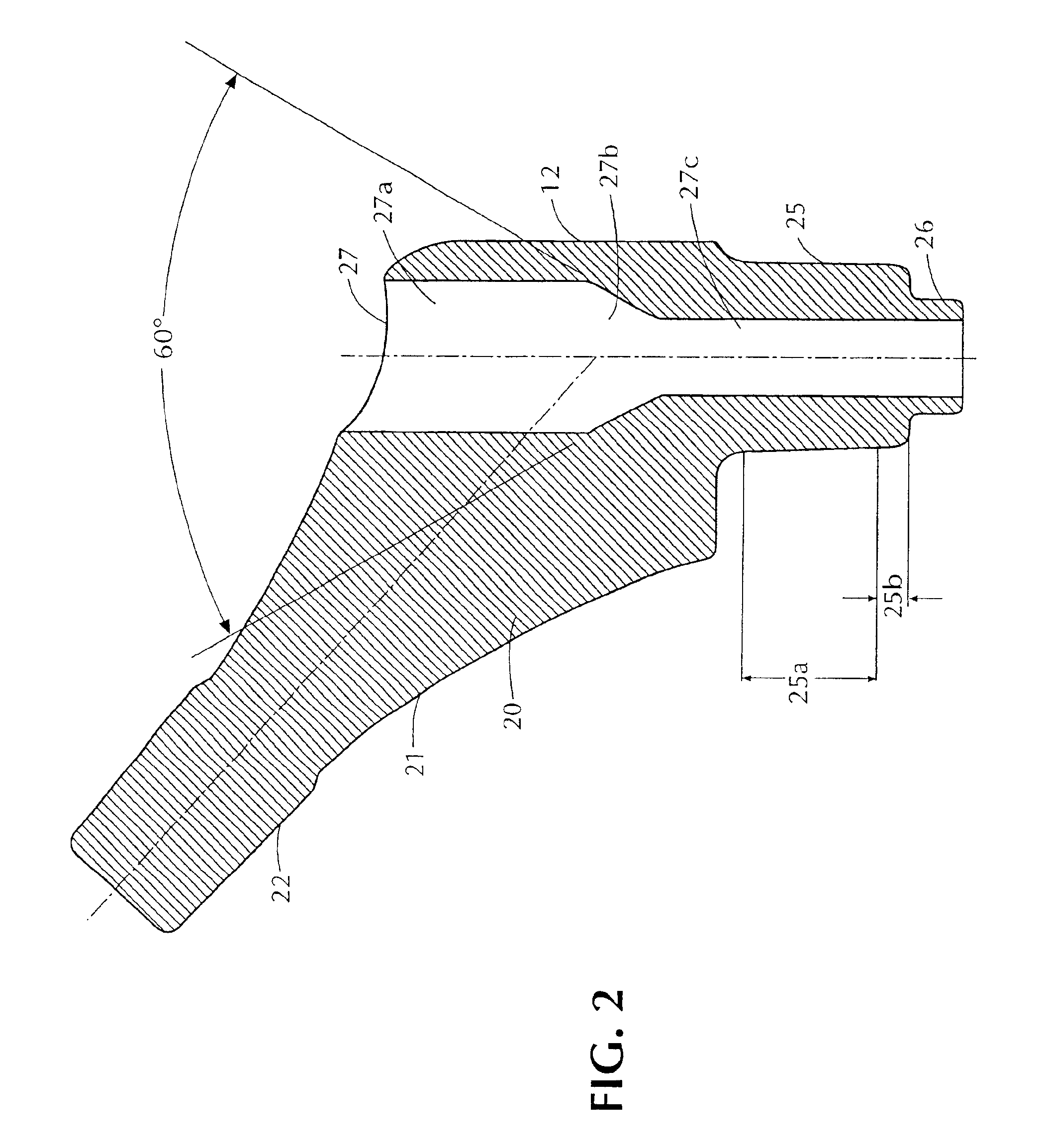

Adjustable rib connectors

ActiveUS8061375B2Improve interchangeabilityLow costWalking sticksYielding couplingMechanical engineeringEngineering

The present inventions relate generally to connectors for interconnecting members of shade structures (e.g. umbrellas and pavilions), such as support ribs and hubs. The connectors can be incorporated or attached to support ribs of shade structures to enable the support ribs to extend from the hubs at various angles to accommodate different shaped canopies. The connectors include an adjustable portion that enables the support ribs to extend to desired points on the periphery of the canopy at an angle that deviates from the angle of the hub channels, which are disposed around the periphery of the hubs.

Owner:MA

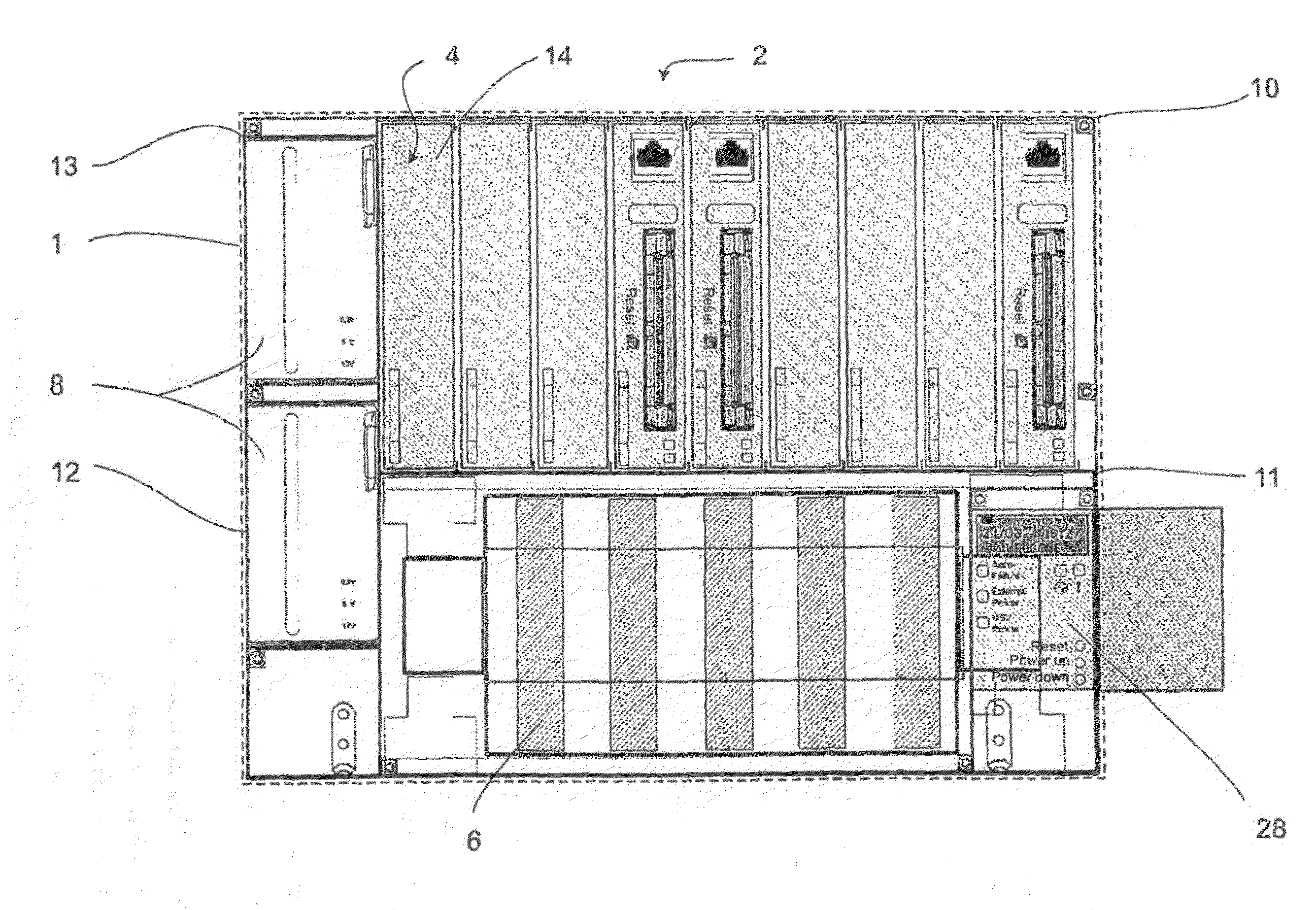

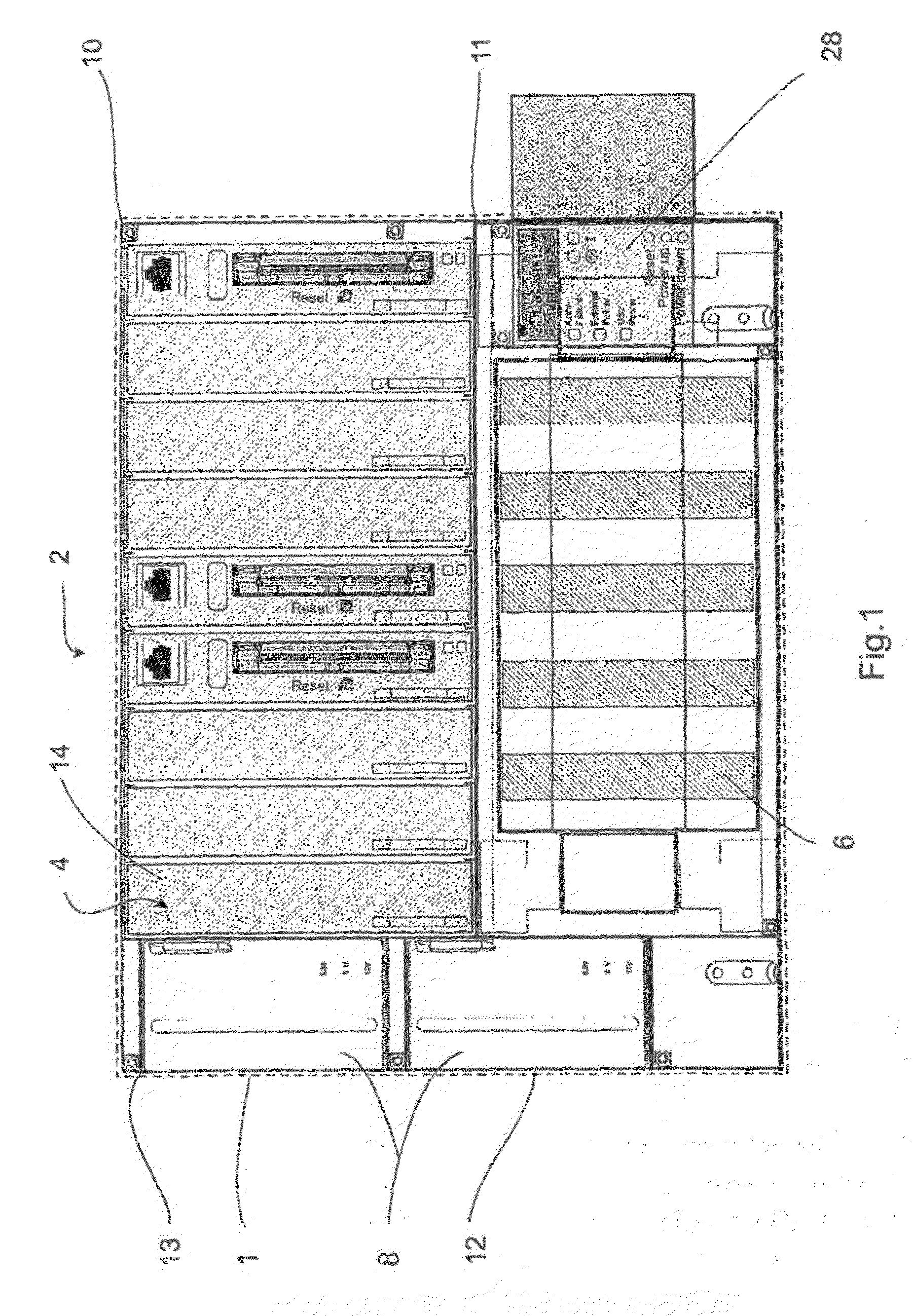

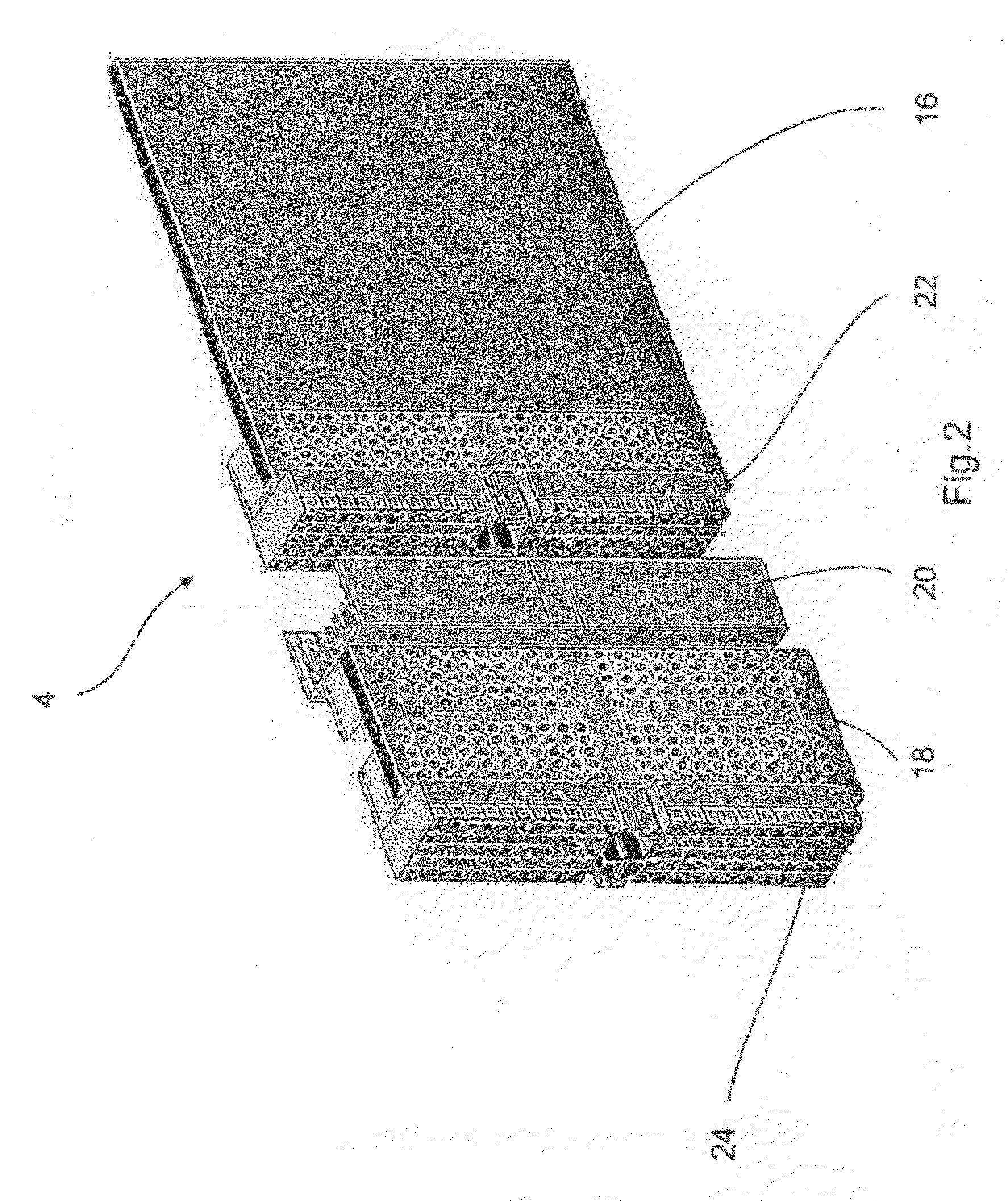

Avionics equipment carrier system with quick-mount housing and quick-mount modules

ActiveUS20100008053A1Improve usabilityImprove interchangeabilityDigital data processing detailsPrinted circuit board receptaclesAviationDisplay device

An avionics equipment carrier system for slide-in modules with data processing, data transmitting, data storage or data displaying devices, such as for example electronics printed circuit boards, network components, storage devices, display devices and the like, or power supply devices, includes a housing, at least one module rack for accommodating the slide-in modules and at least one backplane board with Ethernet connection architecture. When the dimensions of the housing comply with ARINC standards, and the housing is arranged for installation in an avionics module rack as a quick-mount housing, and any desired circuit boards of a specific standard format can be used in the slide-in modules which are designed as quick-mount modules.

Owner:AIRBUS OPERATIONS GMBH

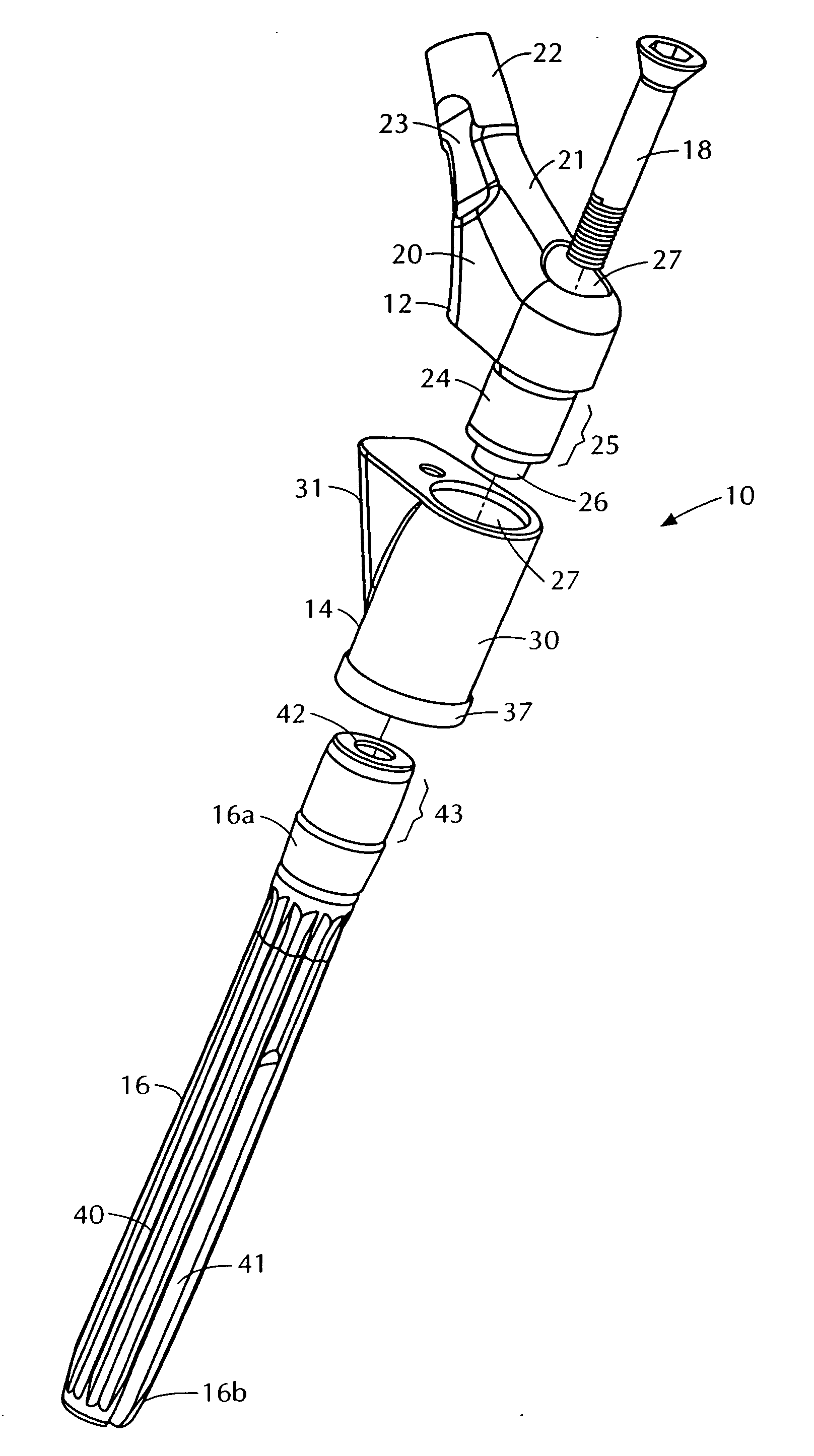

Modular hip prosthesis

InactiveUS20050234559A1Improve the immunityIncreased citationJoint implantsFemoral headsRight femoral headProsthesis

A modular hip prosthesis, comprising: (a) a proximal segment including a neck lockingly engageable with a femoral head component and a male tapered portion; (b) a distal segment having a proximal end and a distal tip, the distal segment further formed with a male tapered portion adjacent the proximal end thereof; and (c) a metaphyseal segment having a proximal end and a distal end, the metaphyseal segment preferably including a bone engaging outer surface portion, and further including an axial bore therethrough, the axial bore including first and second female tapered portions formed adjacent the proximal and distal ends thereof, respectively. The first female tapered portion of the metaphyseal segment is dimensionally configured to lockingly engage the male tapered portion of the proximal segment. The second female tapered portion of the metaphyseal segment is dimensionally configured to lockingly engage the male tapered portion of the distal segment. Optionally, a screw dimensionally configured to pass through aligned bores in the proximal, metaphyseal and distal segments is threadably engaged with a threaded bore formed in the proximal end of the distal segment.

Owner:FERNANDEZ JOSE +2

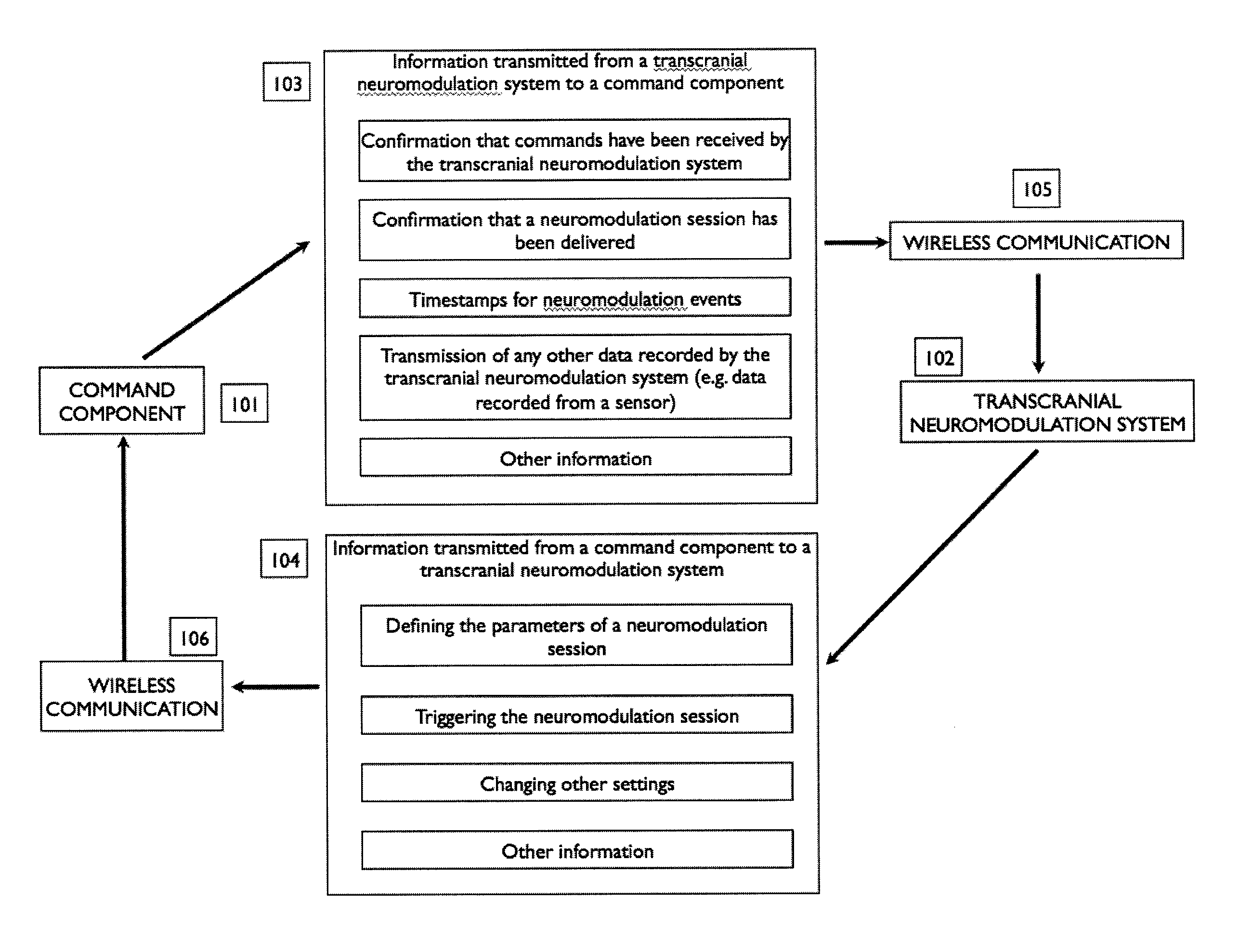

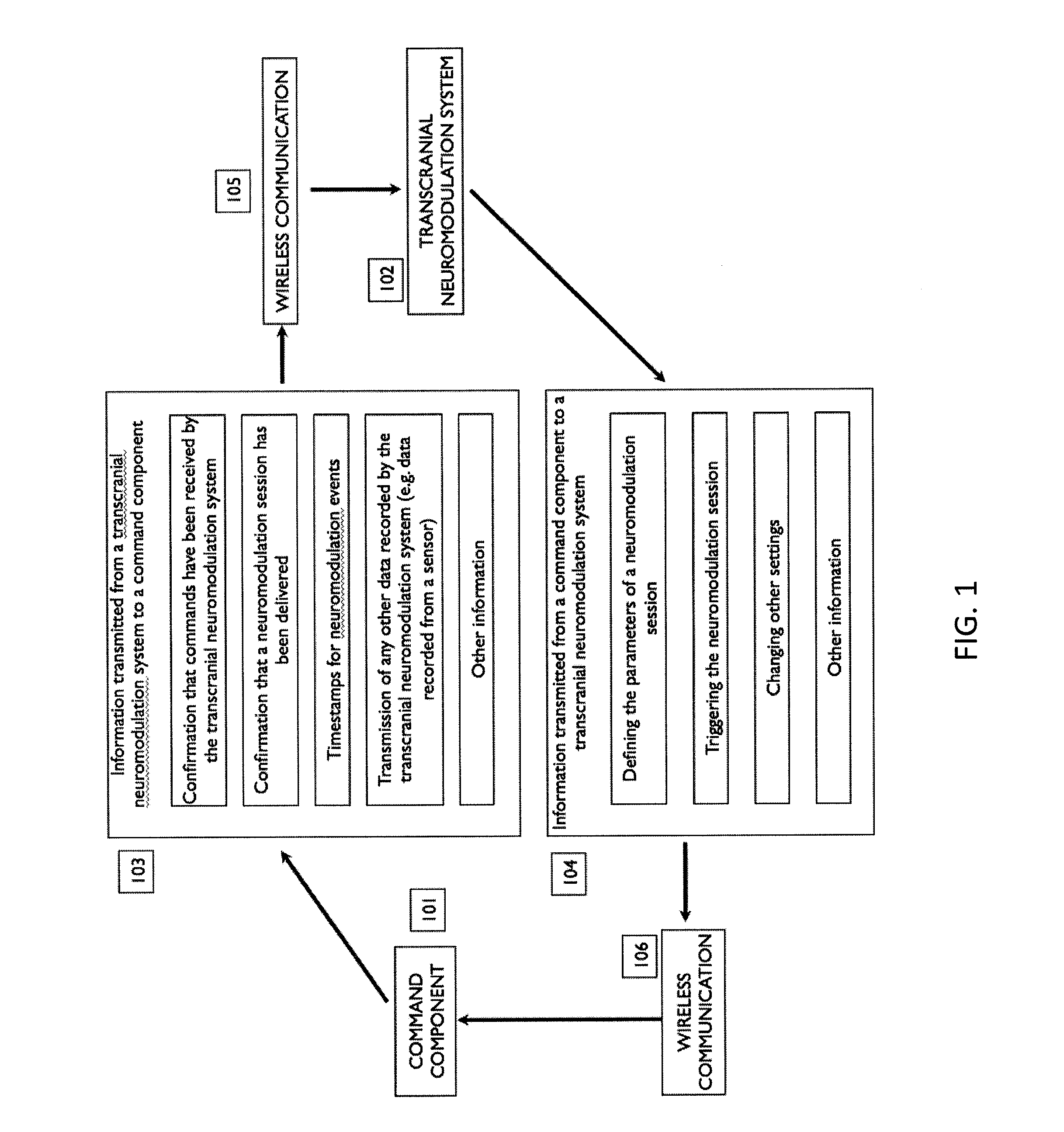

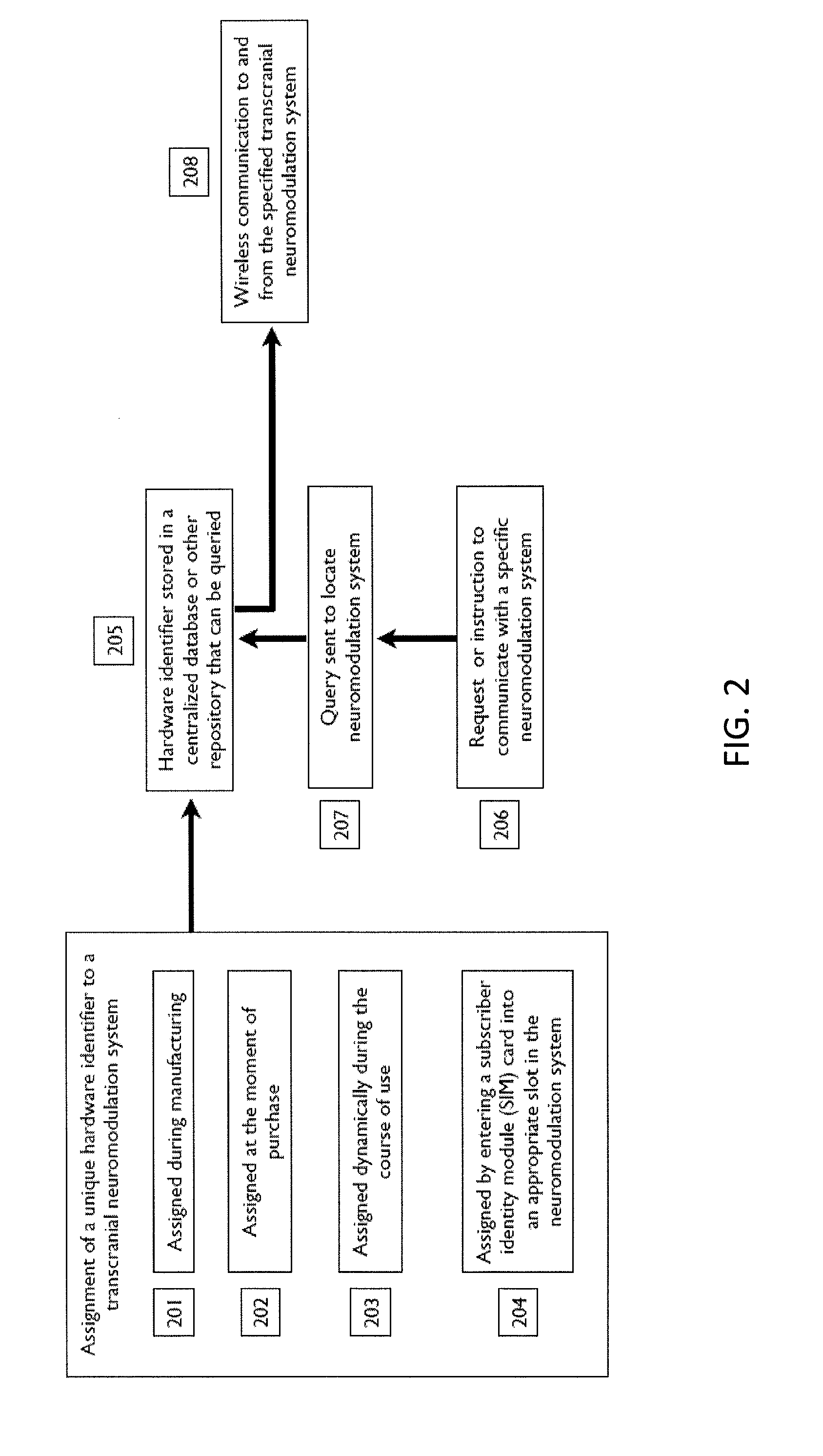

Methods and apparatuses for networking neuromodulation of a group of individuals

InactiveUS20160008632A1Good wearabilityImprove comfortUltrasound therapyElectrotherapyPhysical therapyNeuromodulation

Networkable transcranial neuromodulation apparatuses adapted for safely and effectively applying neuromodulation, including apparatuses adapted for coordination with a group of other individuals, as well as methods for securely and effectively applying neuromodulation, including coordinated neuromodulation.

Owner:THYNC GLOBAL INC

Modular hip prosthesis

InactiveUS6911048B2Improve the immunityAllows interchangeabilityBone implantJoint implantsRight femoral headProsthesis

A modular hip prosthesis, comprising: (a) a proximal segment including a neck lockingly engageable with a femoral head component and a male tapered portion; (b) a distal segment having a proximal end and a distal tip, the distal segment further formed with a male tapered portion adjacent the proximal end thereof; and (c) a metaphyseal segment having a proximal end and a distal end, the metaphyseal segment preferably including a bone engaging outer surface portion, and further including an axial bore therethrough, the axial bore including first and second female tapered portions formed adjacent the proximal and distal ends thereof, respectively. The first female tapered portion of the metaphyseal segment is dimensionally configured to lockingly engage the male tapered portion of the proximal segment. The second female tapered portion of the metaphyseal segment is dimensionally configured to lockingly engage the male tapered portion of the distal segment. Optionally, a screw dimensionally configured to pass through aligned bores in the proximal, metaphyseal and distal segments is threadably engaged with a threaded bore formed in the proximal end of the distal segment.

Owner:EXACTECH INC

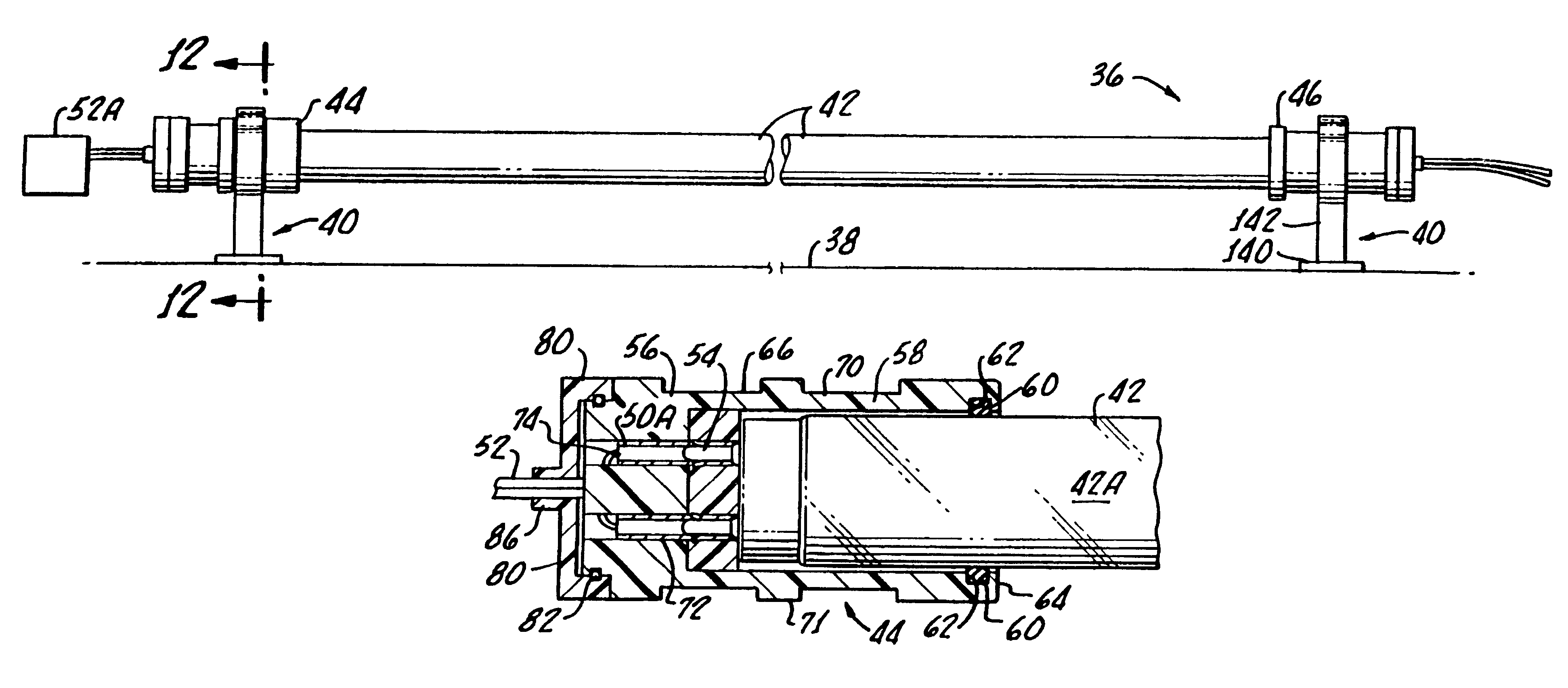

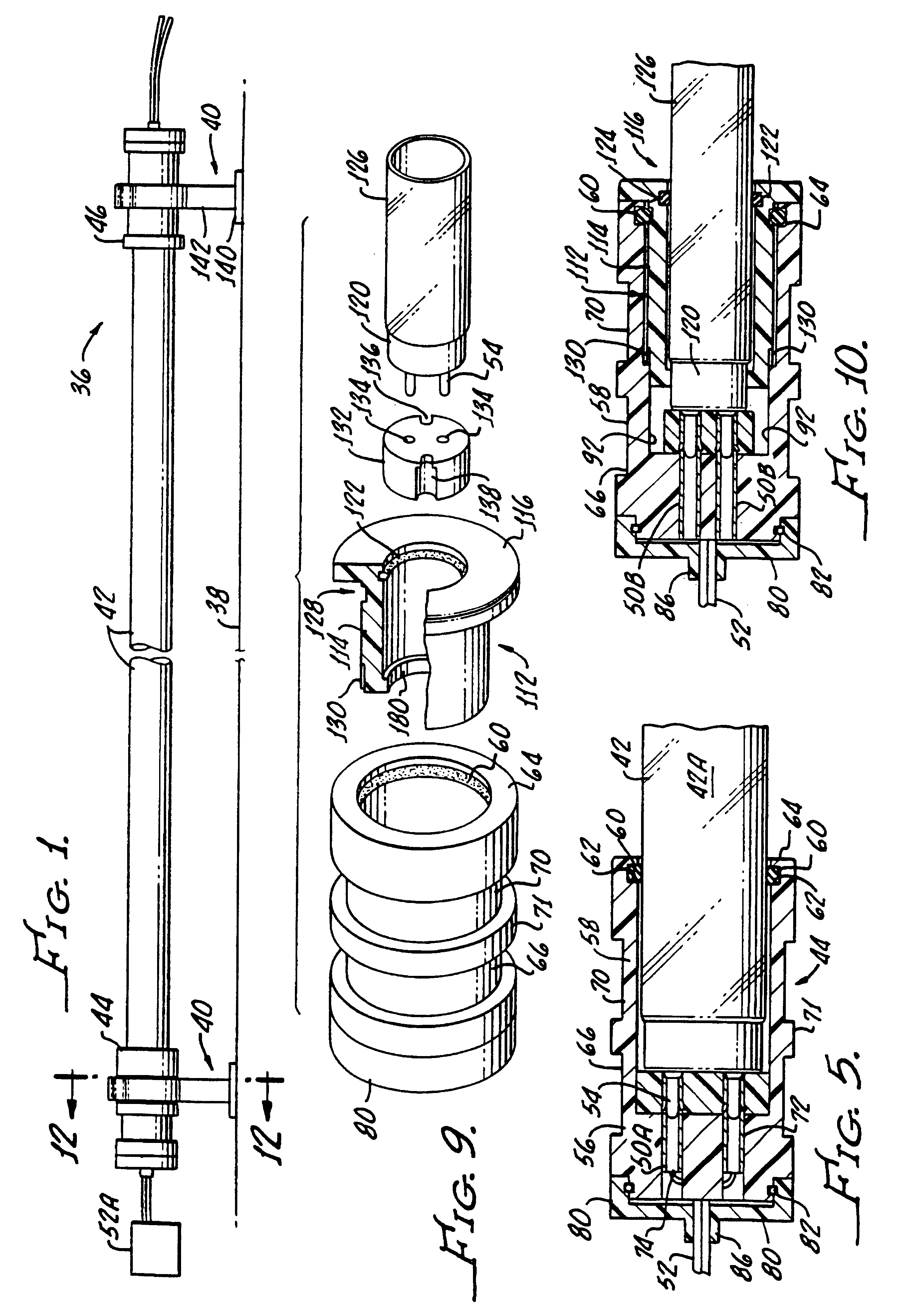

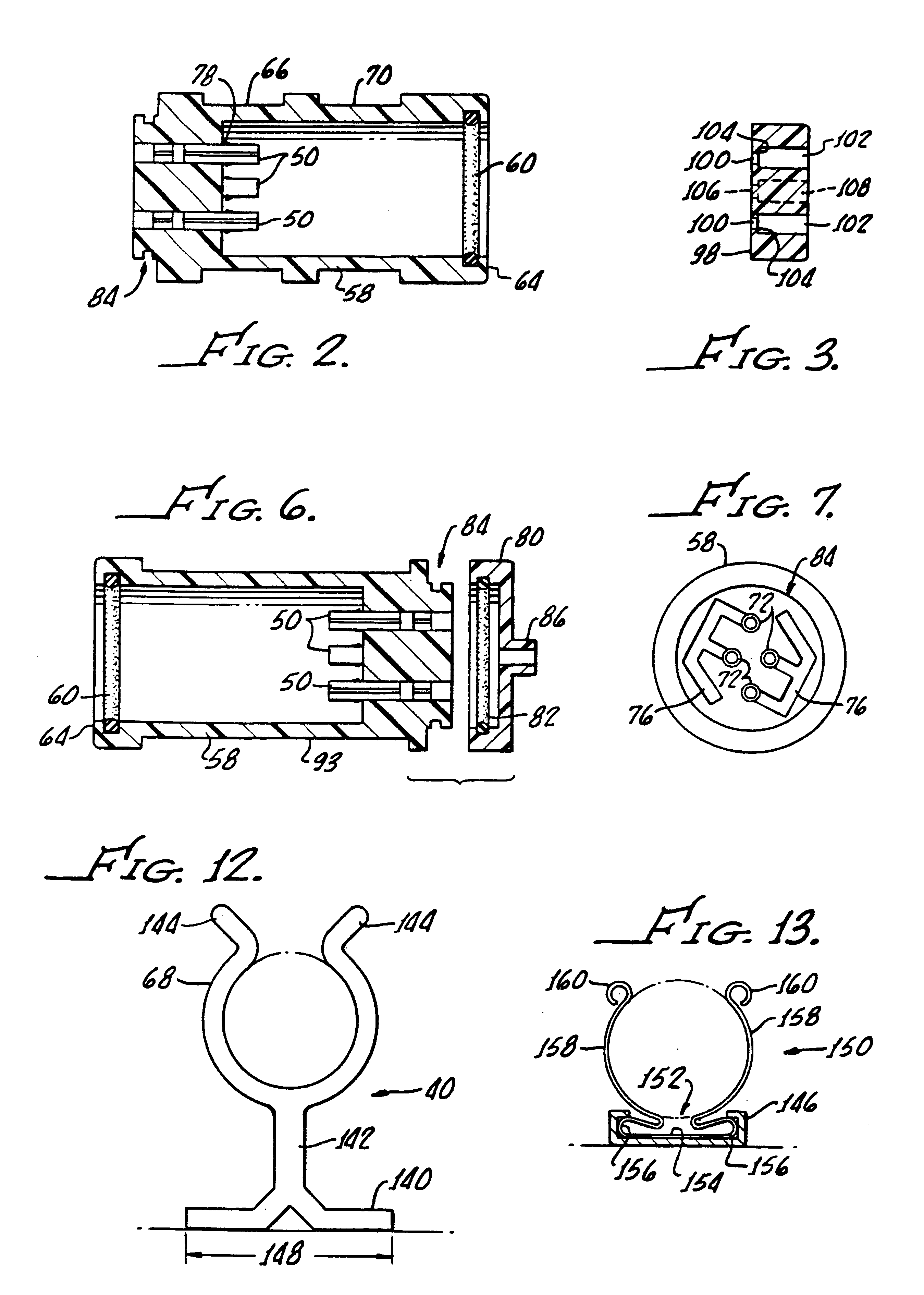

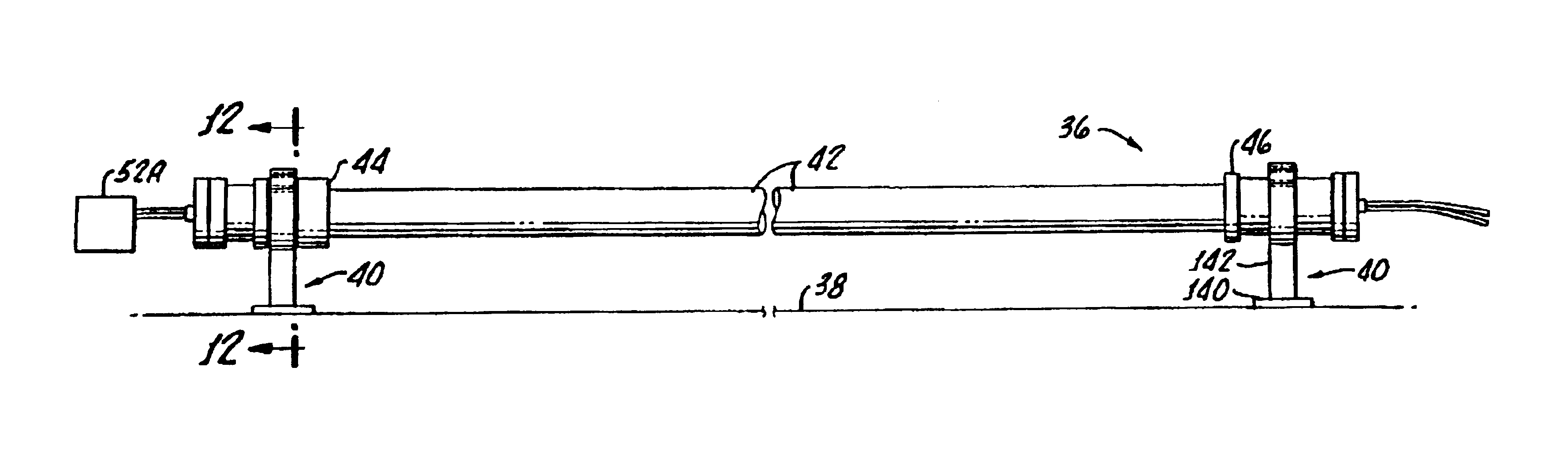

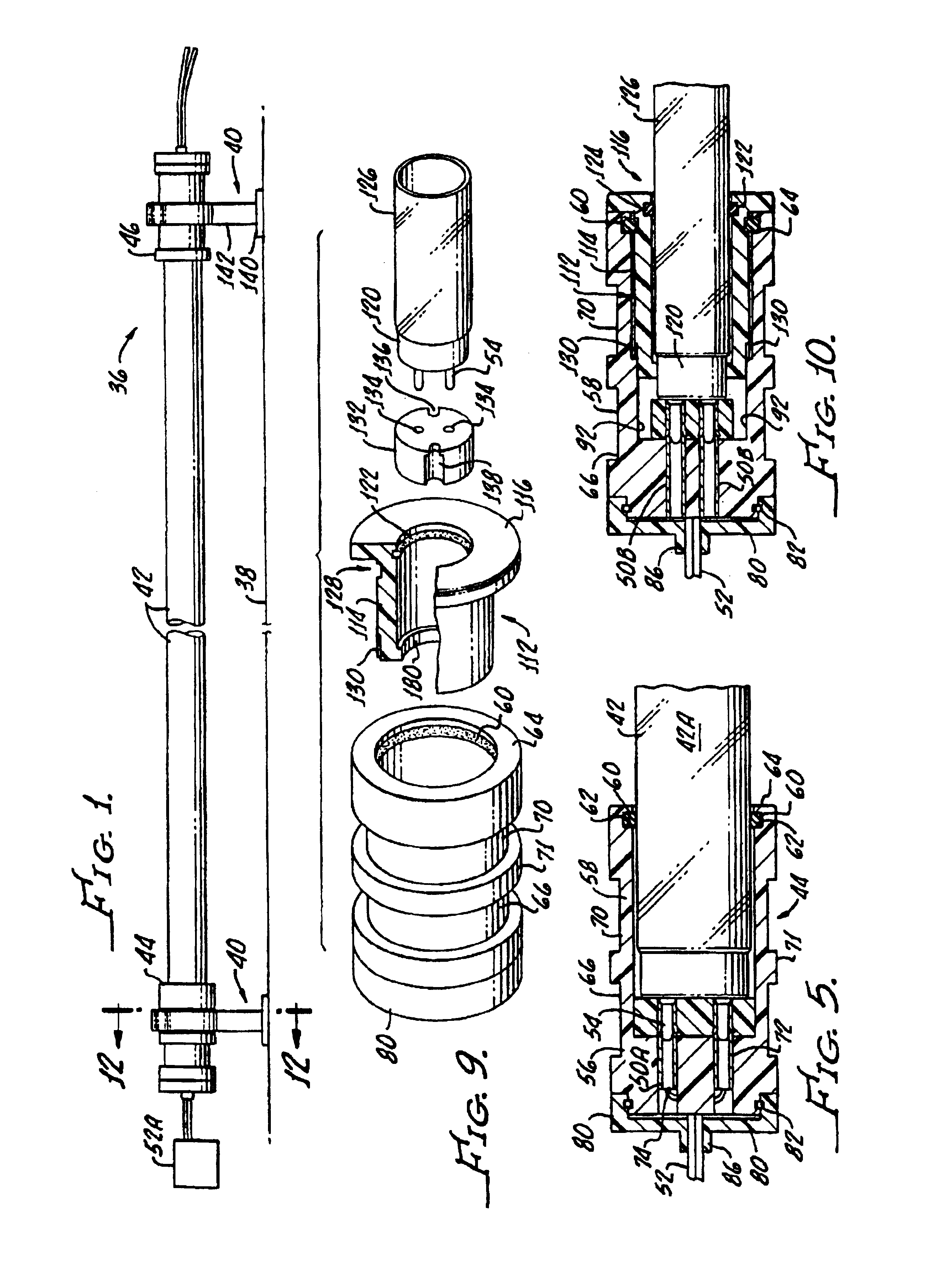

Lighting circuit, lighting system method and apparatus, socket assembly, lamp insulator assembly and components thereof

InactiveUS6641419B1Minimize the possibilityConvenient thermal protectionCoupling device connectionsMechanical apparatusElectrical conductorEffect light

A socket for a lighting assembly includes a socket body defining an enclosure such that a lamp with a pin contact can extend into the enclosure. Electrical connectors extend away from the enclosure in a second direction. The body includes a wall extending away from the enclosure past the electrical connectors and is spaced from the connectors to allow access to the connectors, and a further wall between the electrical connectors. The further wall can provide an insulating barrier between the connectors. The connectors may be cylindrical. The wall extending away from the enclosure may include a cap covering the wall, and one or more conductors can pass underneath the cap to connect to the electrical connectors for powering the lamp.

Owner:ANTHONY INC

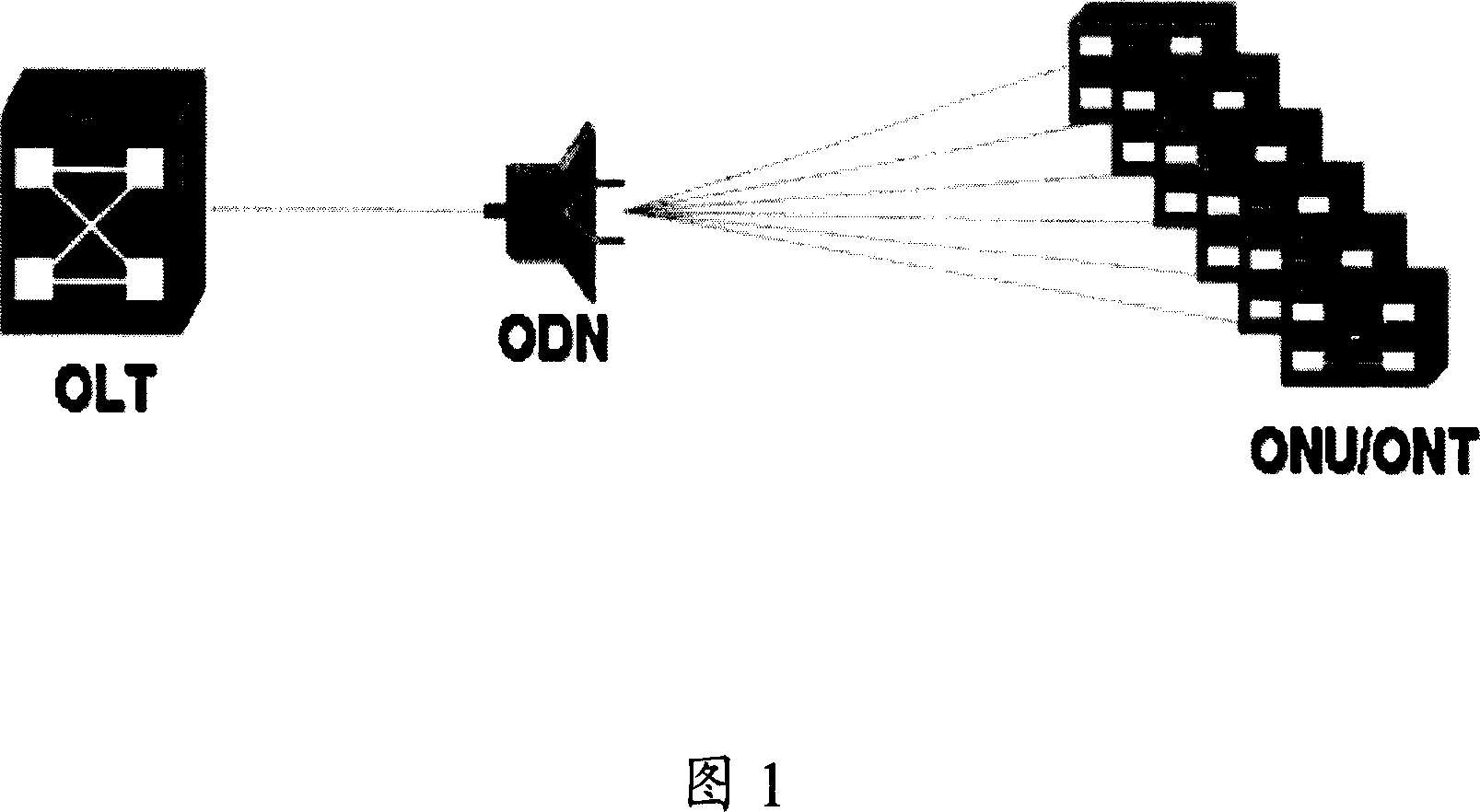

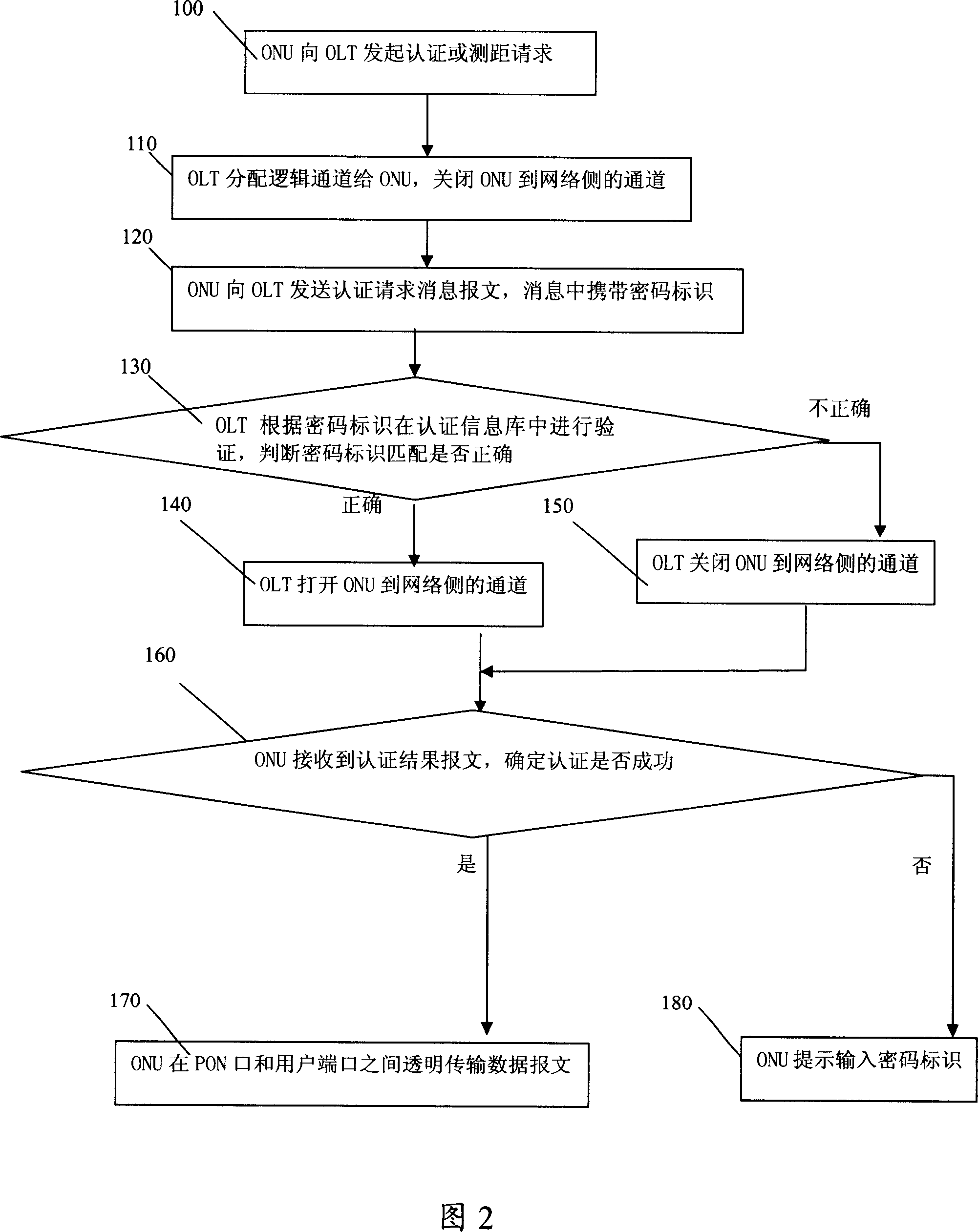

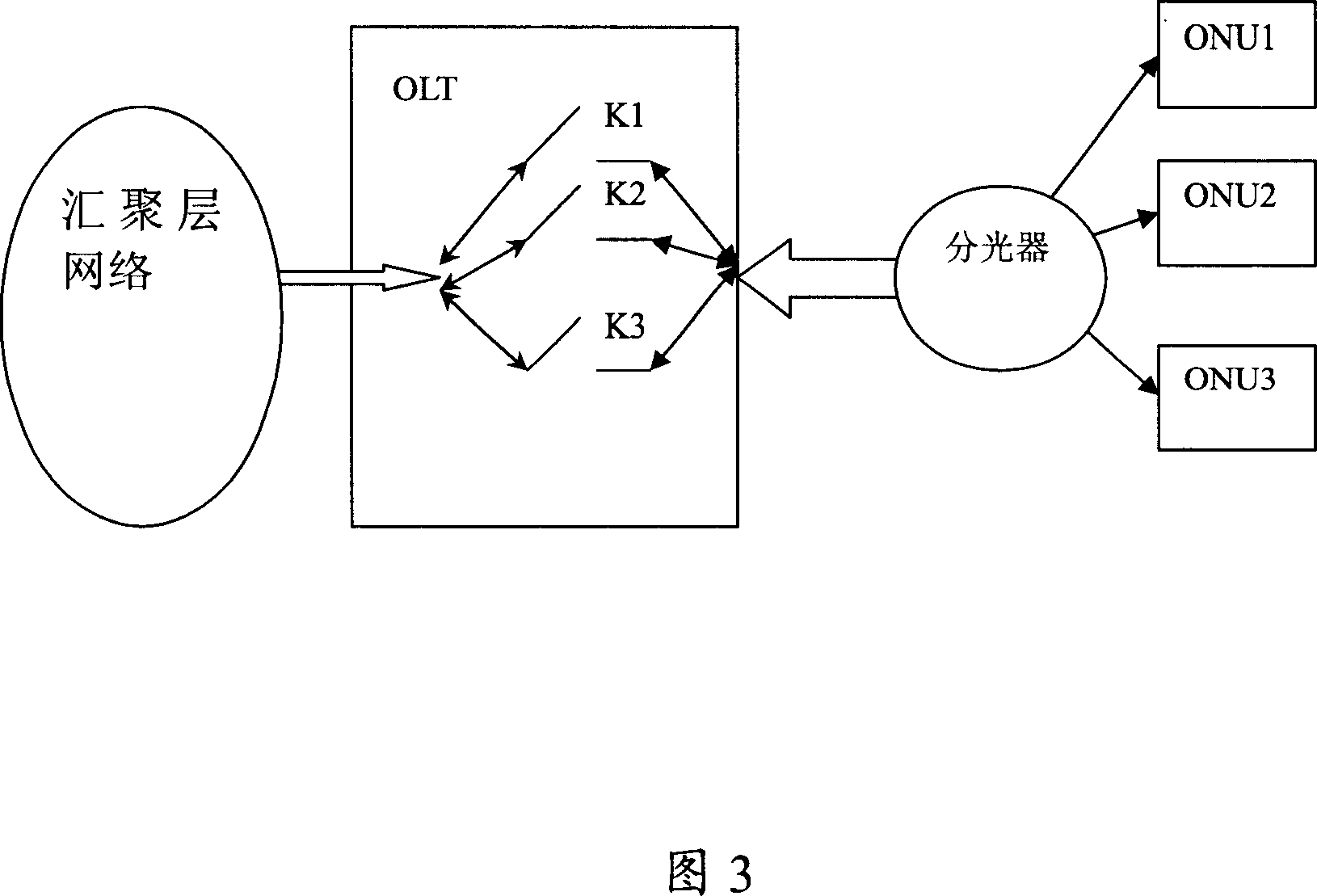

Subscriber authentication method for passive optical network

InactiveCN1968089ASimple and convenient managementEasy maintenanceUser identity/authority verificationData switching networksAccess networkPassword

The invention relates to a user identification method of inactive light network, wherein said method comprises that: light network unit ONU initializes register or ranging request to the light terminal OLT; OLT distributes relative logic channel to ONU, and sets the ONU mark as registered but not identified state, closing the channel from ONU to network; ONU initializes user identification request to the OLT, with carried password mark; OLT based on said password mark identifies, to switch the channel from ONU to network. The invention can improve user safety, while new ONU can access network via password mark.

Owner:HUAWEI TECH CO LTD

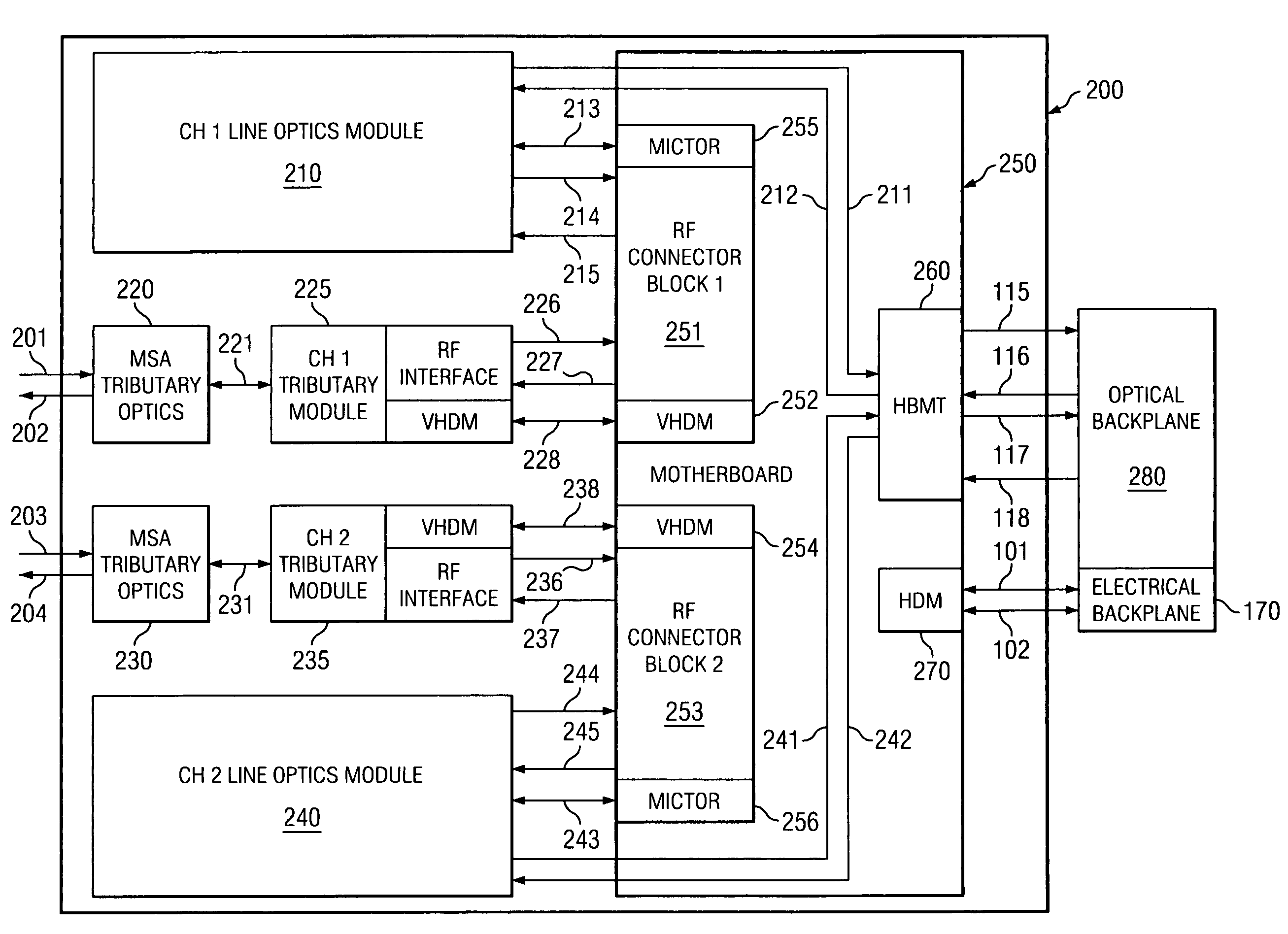

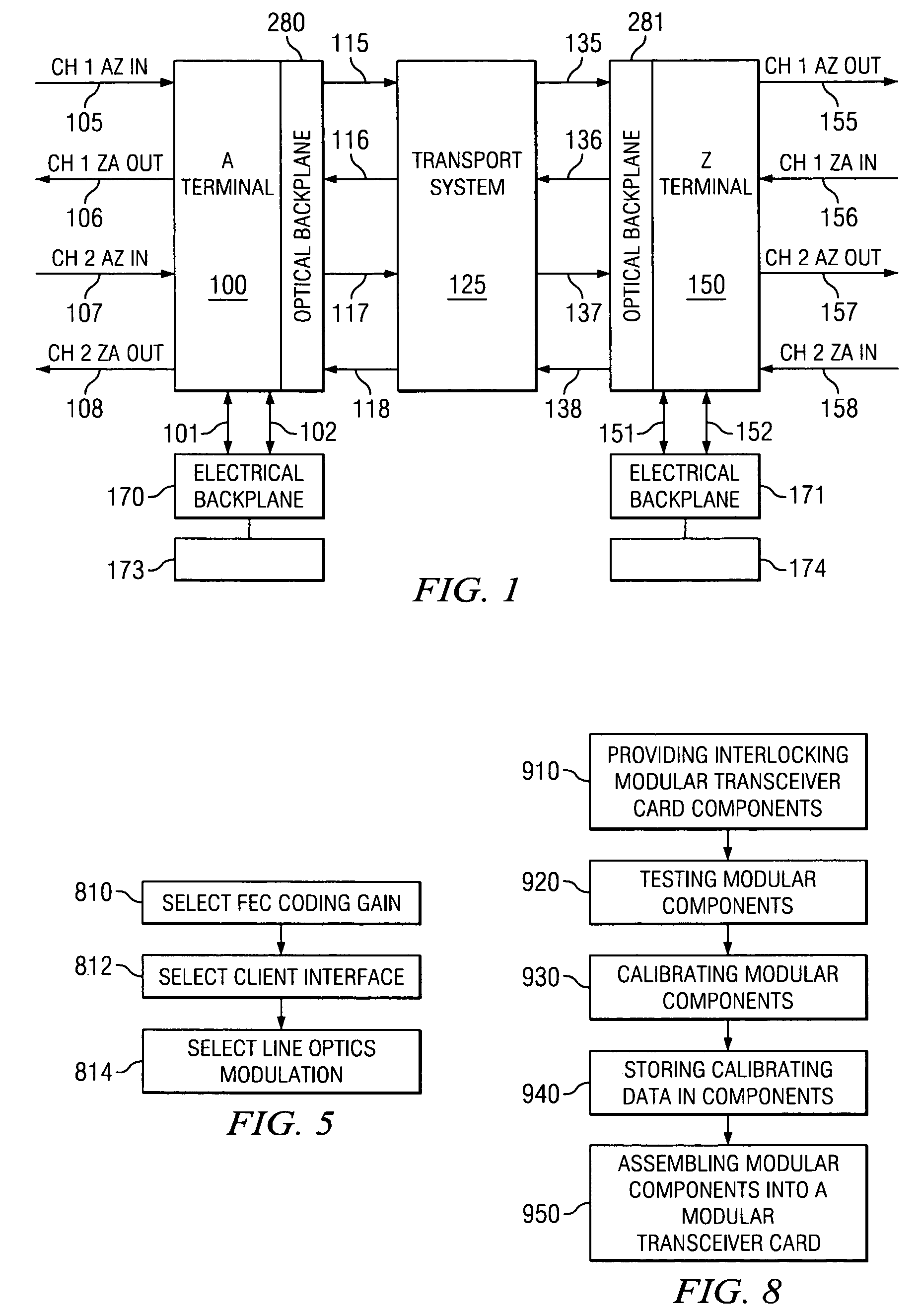

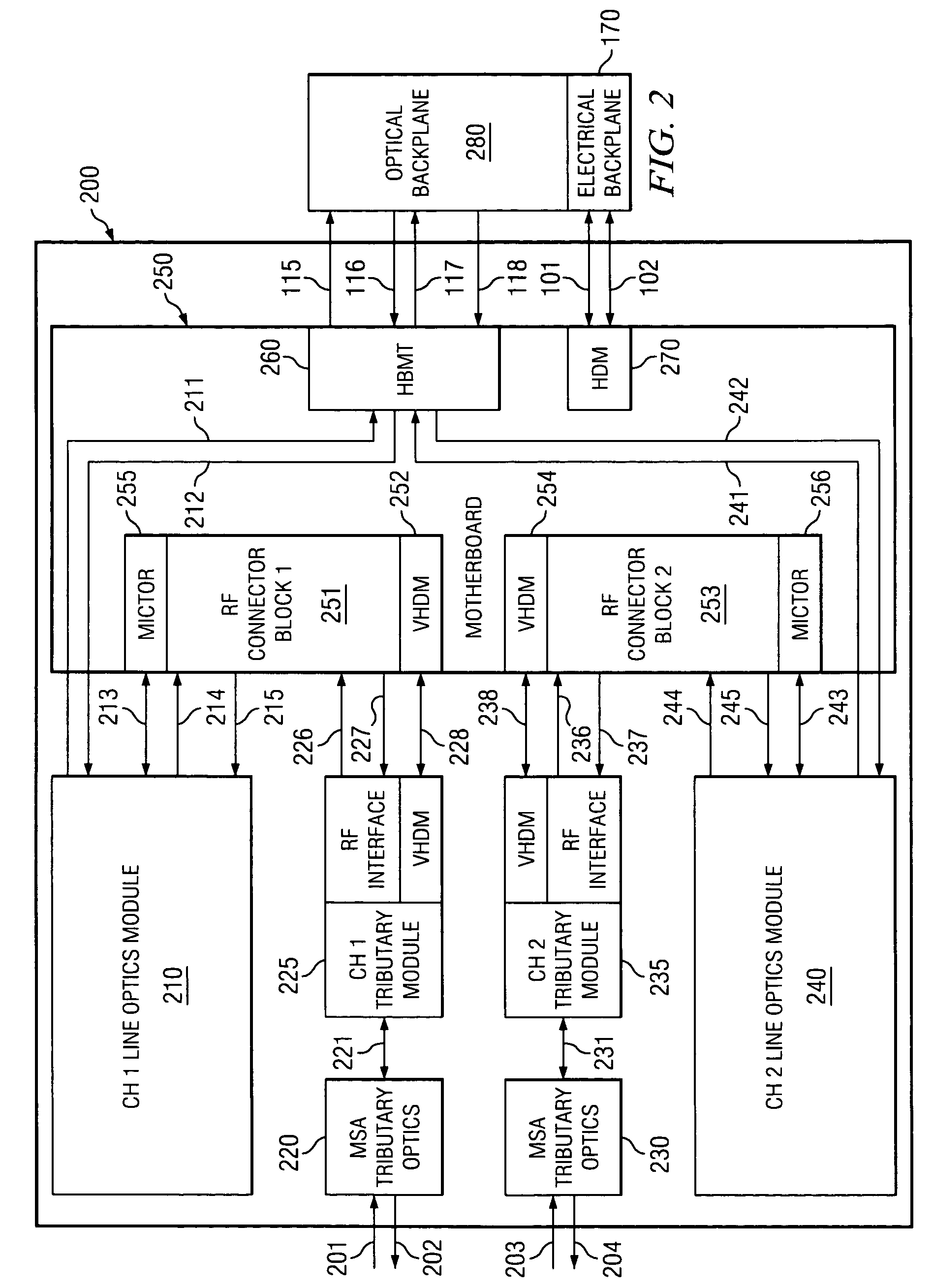

Flexible, dense line card architecture

InactiveUS7729617B2High densityIncrease flexibilityWavelength-division multiplex systemsTime-division multiplexHigh densityTransceiver

The invention is relevant to optical fiber transmission systems, and in particular, pertains to the transceiver cards in an optical fiber transport system. In particular the invention teaches an improved transceiver card architecture that allows high density, flexibility and interchangeability of functionality.

Owner:PIVOTAL DECISIONS

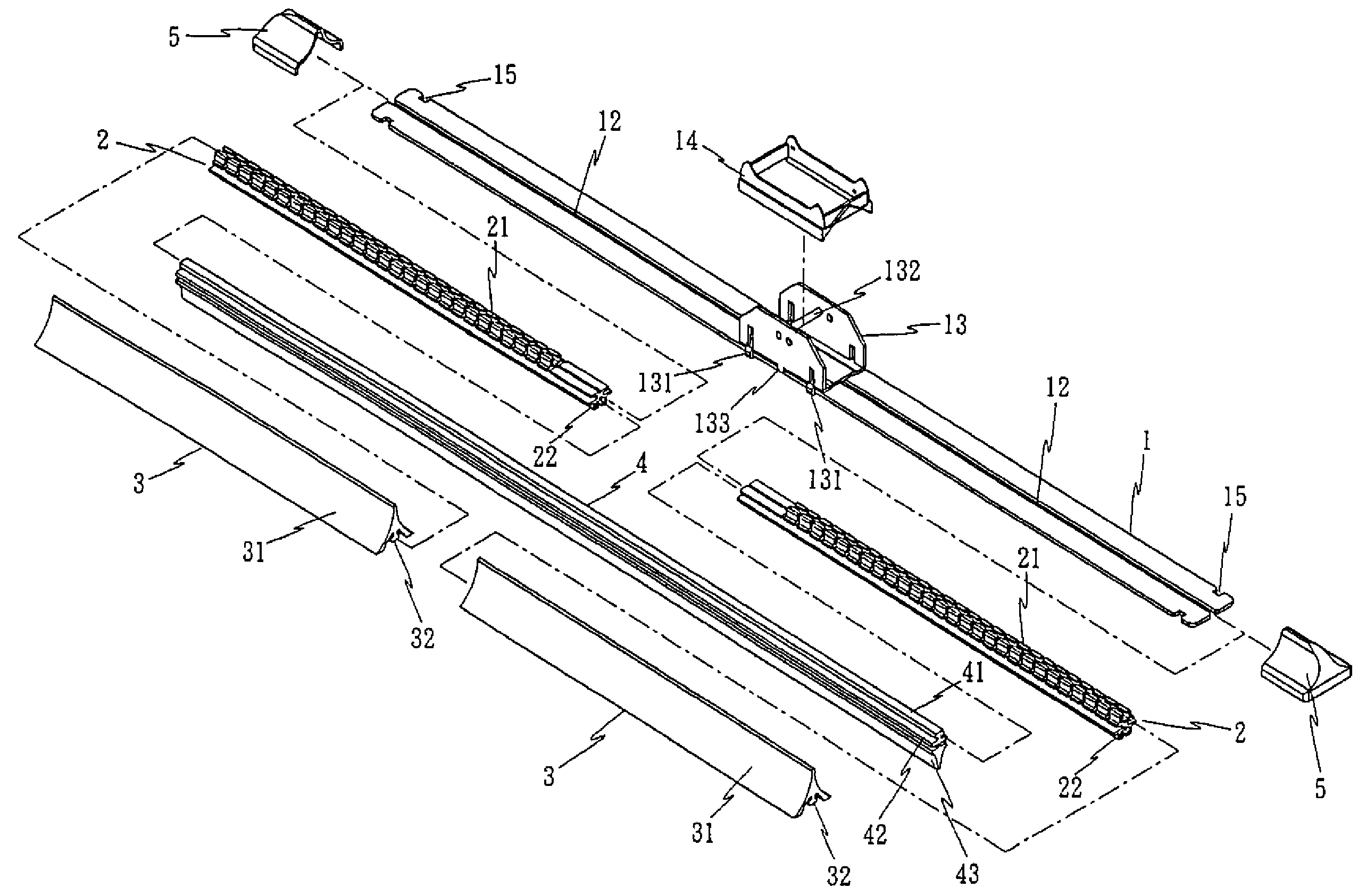

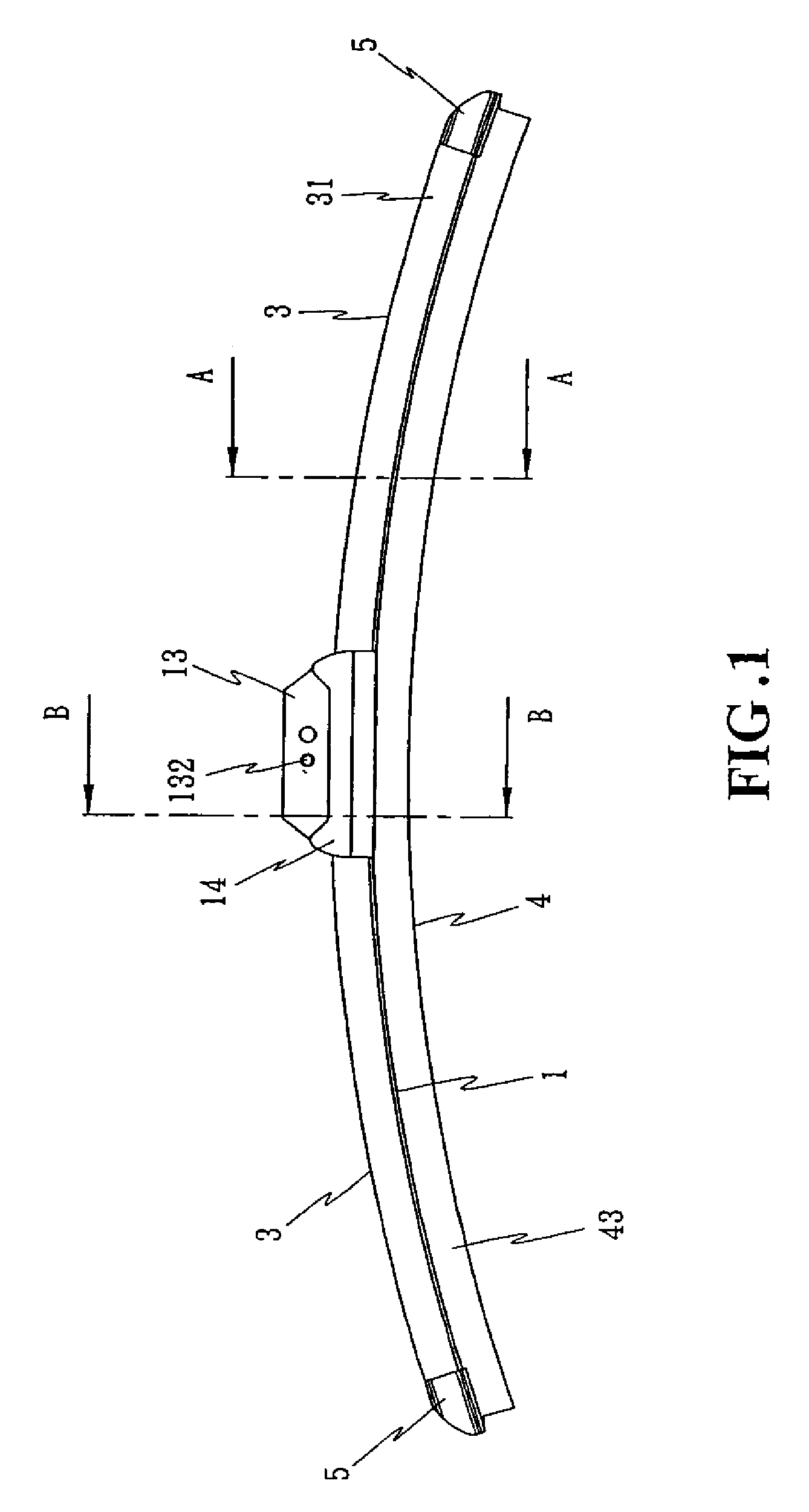

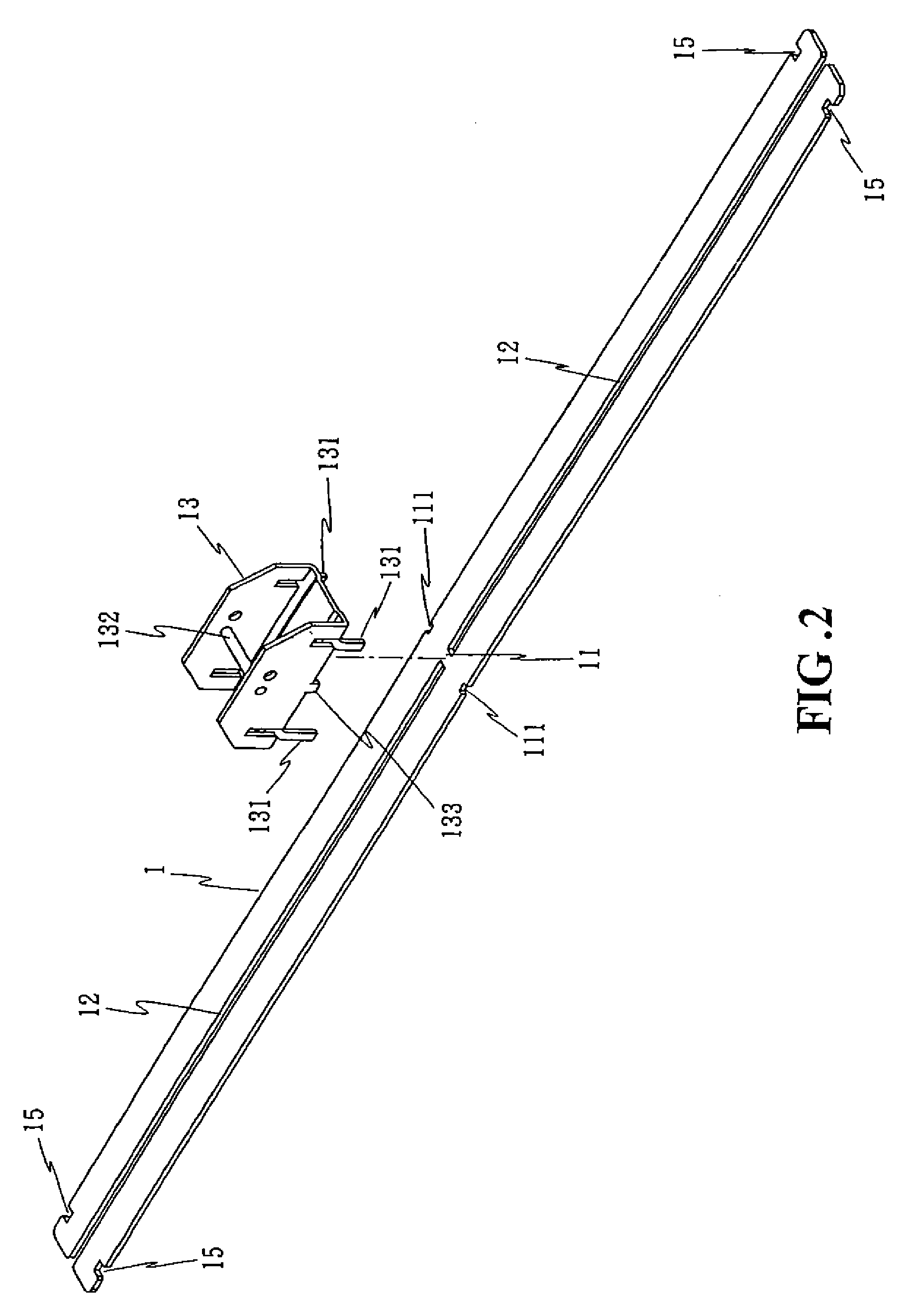

Frameless windshield wiper structure

InactiveUS20100024151A1Simple structureRiveting is eliminatedWindow cleanersVehicle cleaningEngineeringLower face

A frameless windshield wiper includes a curved resilient metal plate, two flexible bars, two rubber back covers, a rubber wiping strip, and two end closure caps. The resilient metal plate is an elongate plate having an H-shape including a central connection section connecting between two strips defining therebetween elongate slits so that the metal plate assumes a fork-like configuration having opposite fork-like open ends. The central section is riveted to a coupler over which a plastic protective cap is fit. The flexible bars have upper and lower faces respectively forming upper and lower retainers to which the rubber back covers and the rubber wiping strip are respectively fit. The end caps are fit to opposite ends of the metal plates. Thus, an automobile windshield wiper that can be efficiently and easily assembled is provided.

Owner:KU YUAN CHIN

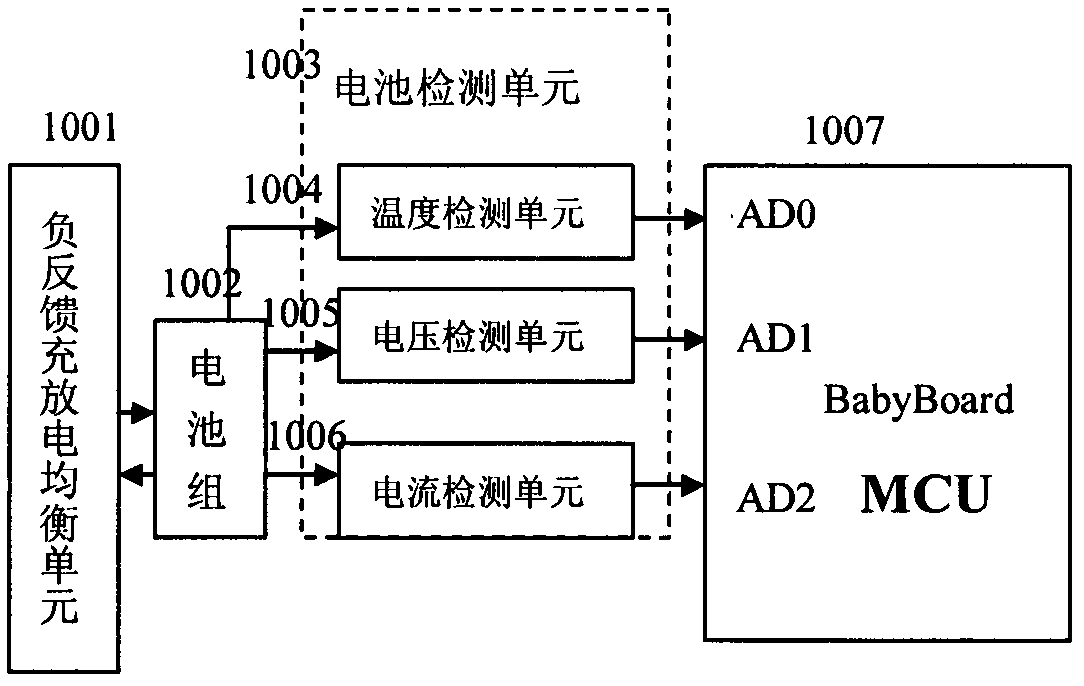

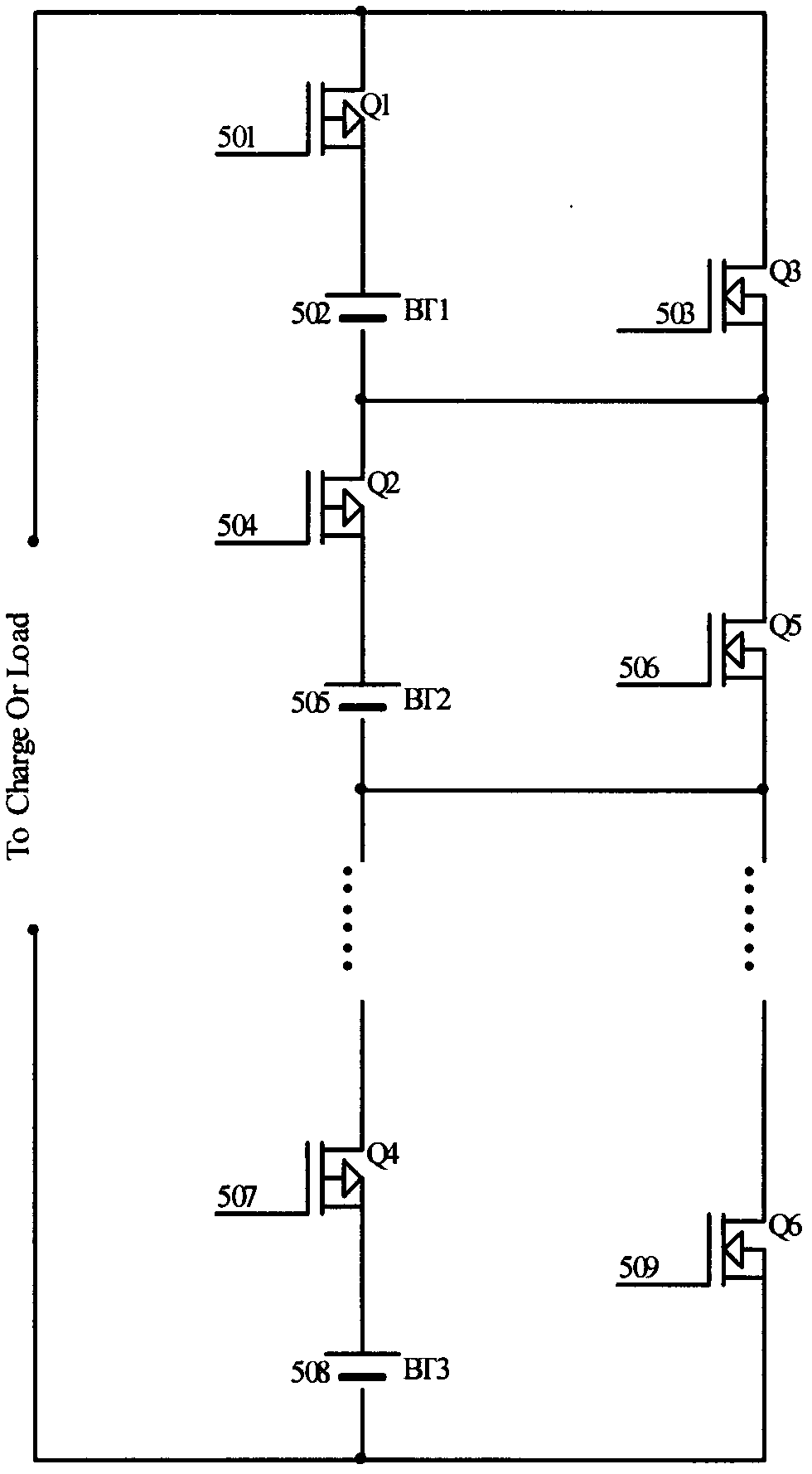

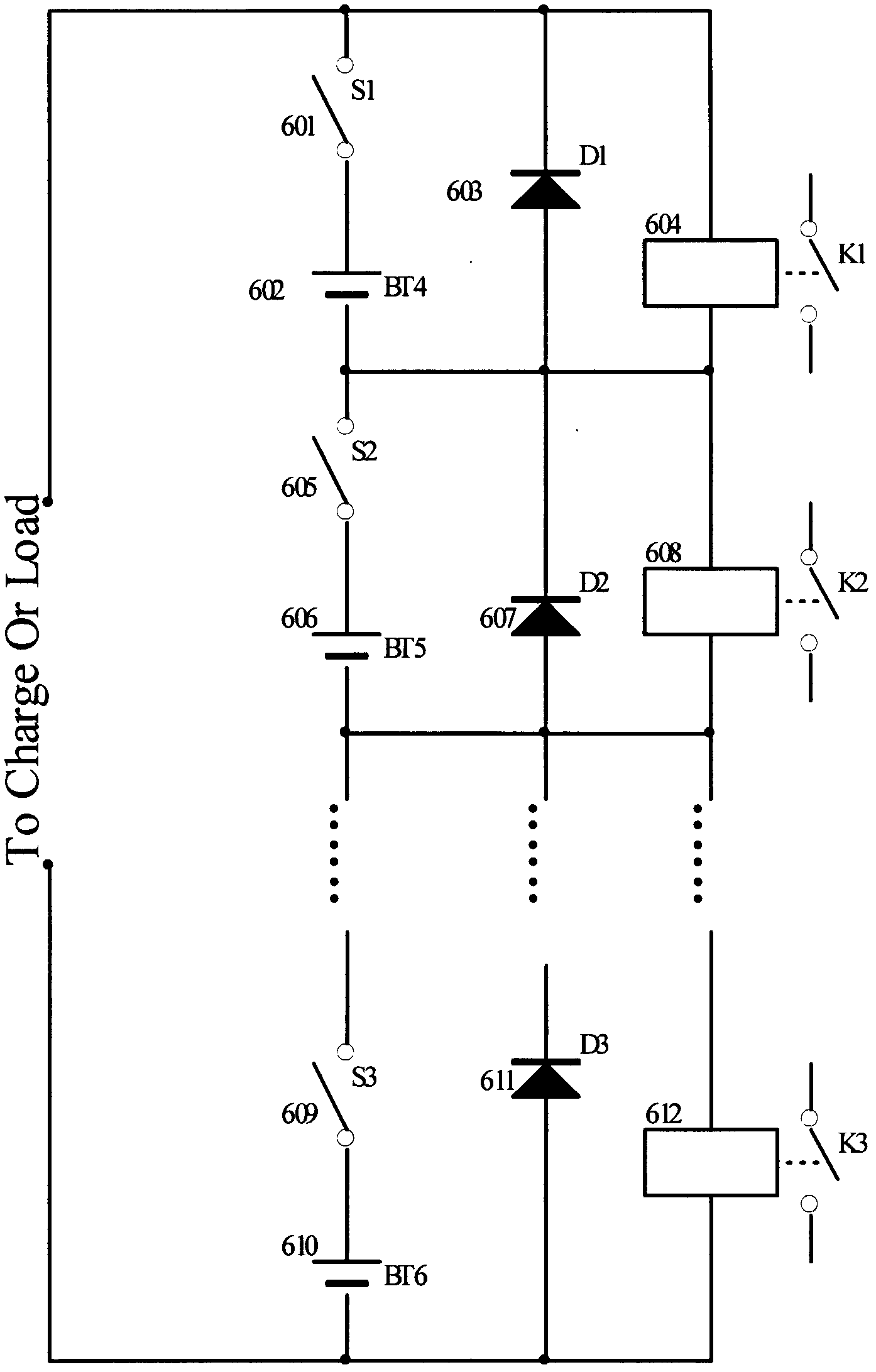

Lithium ion battery management system

InactiveCN102306943AUniform lossImprove protectionBatteries circuit arrangementsElectric powerCapacitanceControl manner

The invention discloses a lithium ion battery management system and a control method thereof, and comprises battery charge and discharge management scheduling, battery information communication and battery life assessment. Adding a battery cell in series or withdrawing the battery cell in a controlled manner is realized by utilizing a switch circuit. Data transmission between series battery cells is realized by utilizing hardware and software forwarding circuits. In a rated charge and discharge condition, through carrying out charge and discharge tests on a lithium ion battery repeatedly, recording charge and discharge times, and voltage curve and battery internal resistance of each charge and discharge operation, constructing a four-dimensional data table, and determining equivalent cycle times and present full charge capacity of the battery by utilizing an interpolation method, an equivalent cycle life of a battery pack is determined. According to the invention, energy transduction devices like an inductance capacitor are not needed, characteristics of batteries in a same battery pack tend to be consistent, a service life of the battery pack is prolonged, overpressure resistant requirements of each component are mitigated, a basic basis of estimating battery full charge capacity and accurate estimation of a battery life is established, and possibility of large scale interchangeability application is provided.

Owner:HEBEI JIANTOU NEW ENERGY CO LTD

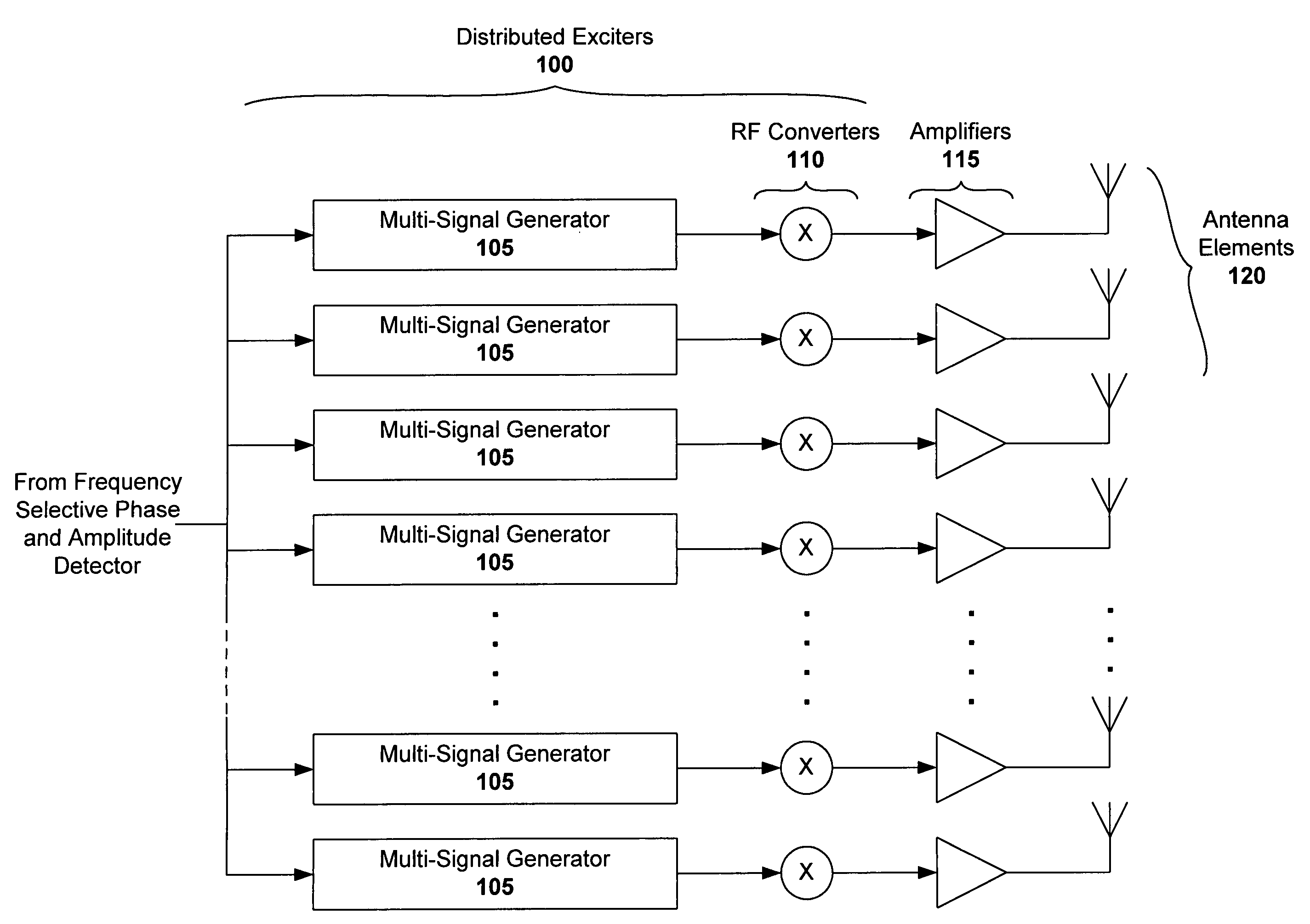

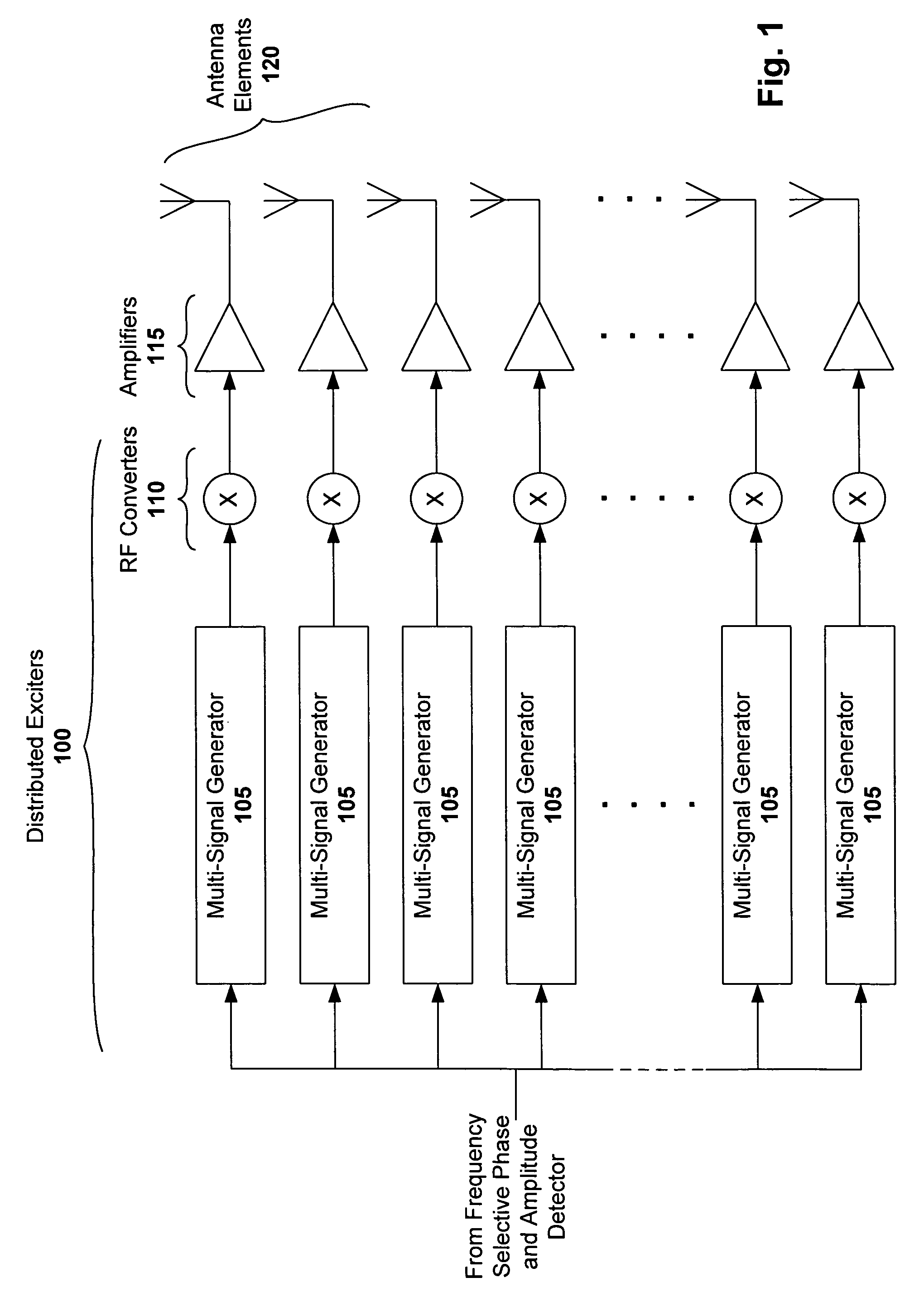

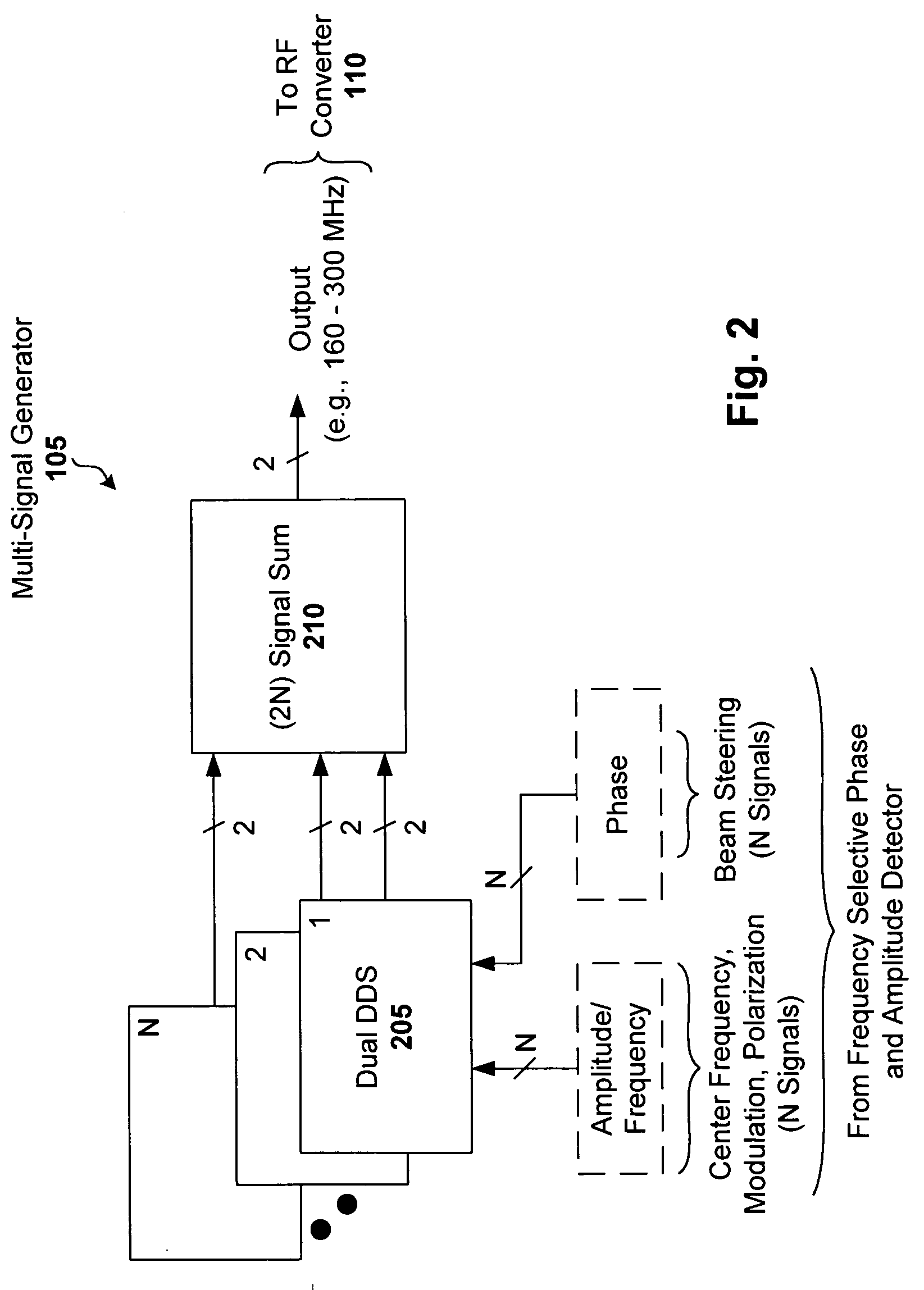

Distributed exciter in phased array

InactiveUS20060125687A1High degreeImprove interchangeabilityParticular array feeding systemsPolarisation/directional diversityFrequency synthesizerModularity

A wideband multi-signal distributed exciter system for use with a phased antenna array is disclosed. The system includes a multi-signal generator that is configured with a dual direct digital frequency synthesizer (DDS) core, and is capable of generating multi-polarization signals over a given frequency range (e.g., 50 to 500 MHz) for each of N signals associated with a corresponding antenna element. An RF converter is adapted to receive multi-polarization signals from the multi-signal generator, and to convert those signals to a transmission frequency (e.g., 100 MHz to 10 GHz). A 2N signal summing module can be used to receive multi-polarization signals from each of the N dual DDS functions, and to generate an overall multi-polarization output signal that is provided for RF conversion. An identical set of multi-signal generator and RF converter modules can be associated with each element, thereby providing a high degree of modularity and interchangeability.

Owner:BAE SYST INFORMATION & ELECTRONICS SYST INTERGRATION INC

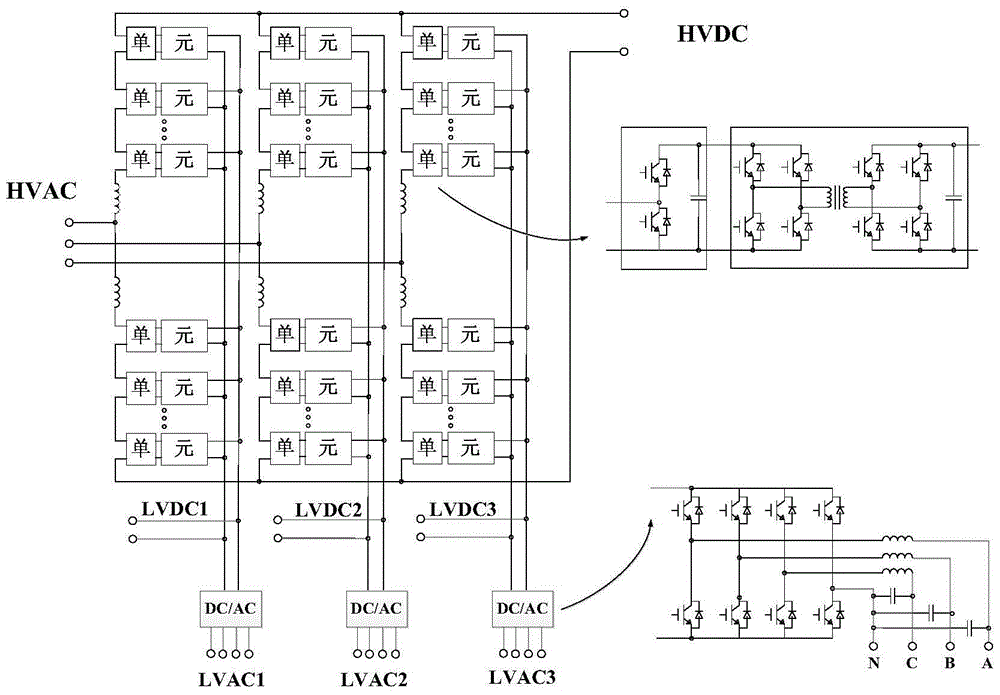

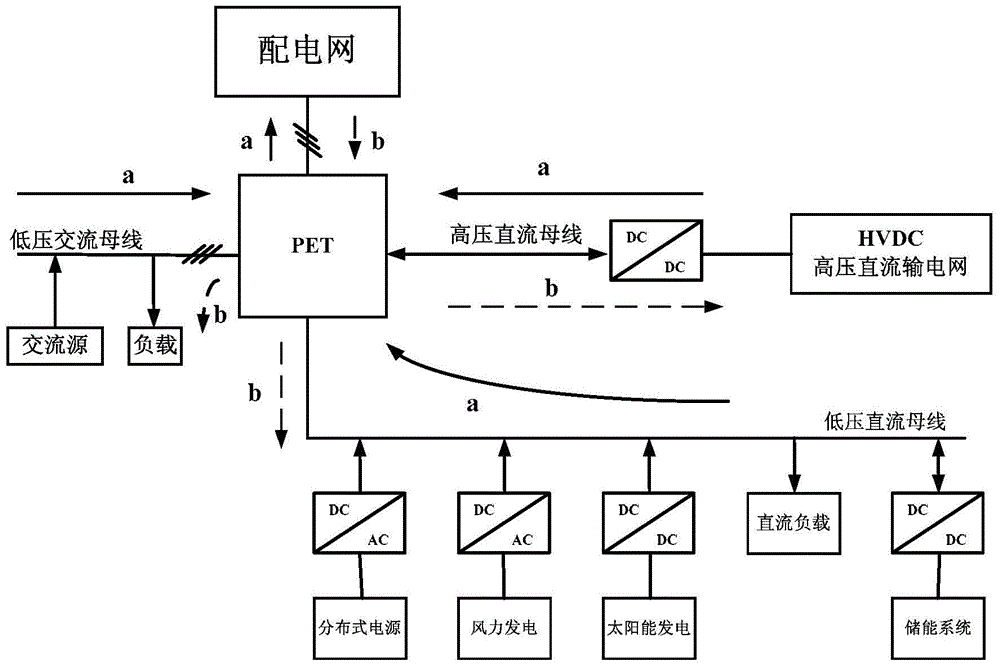

MMC (modular multiple converter) type multi-port power electronic transformer applied to alternating current/direct current hybrid power distribution network

InactiveCN105680488AImprove power densityReduce volumeAc networks with different sources same frequencyPower qualityLow voltage

The invention discloses an MMC (modular multiple converter) type multi-port power electronic transformer applied to an alternating current / direct current hybrid power distribution network. The multi-port power electronic transformer comprises an input level, a middle level and an output level, and are equipped with four kinds of universal interfaces: a high-voltage alternating current interface, a high-voltage direct current interface, a low-voltage alternating current interface and a low-voltage direct current interface; the input level refers to the MMC; the middle level refers to an isolating dual active full-bridge DC / DC converter; and the output level refers to a three-phase four-wire-system full-bridge inverter. Except the basic functions of voltage transformation, isolation, energy transfer and the like as a common transformer, the transformer provided by the invention can realize access of voltages of various forms with the multiple working modes, can perform functions of power flow control, electric quality adjustment and the like; and therefore, an intelligent power distribution network interface with higher applicability is configured.

Owner:SOUTHEAST UNIV

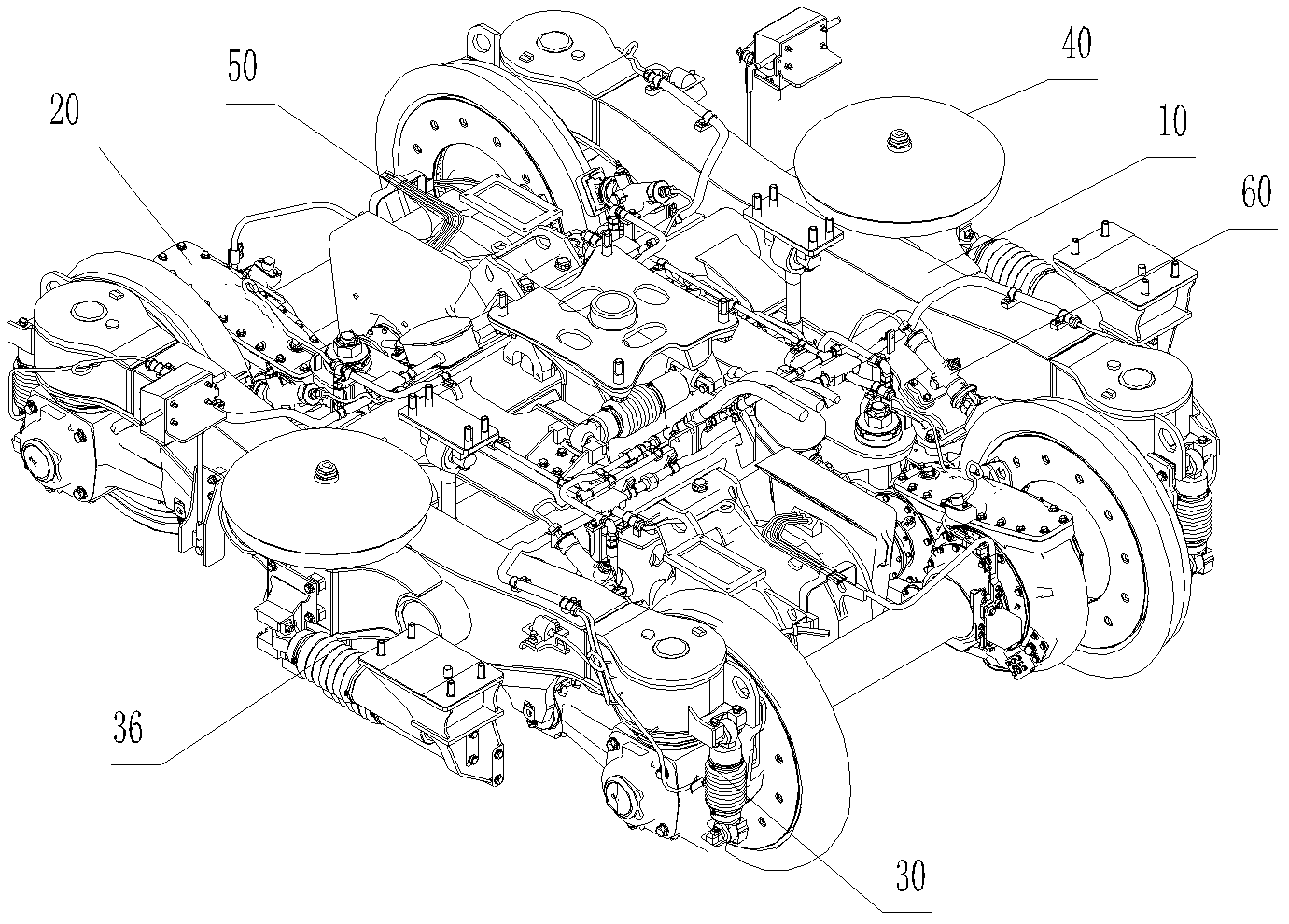

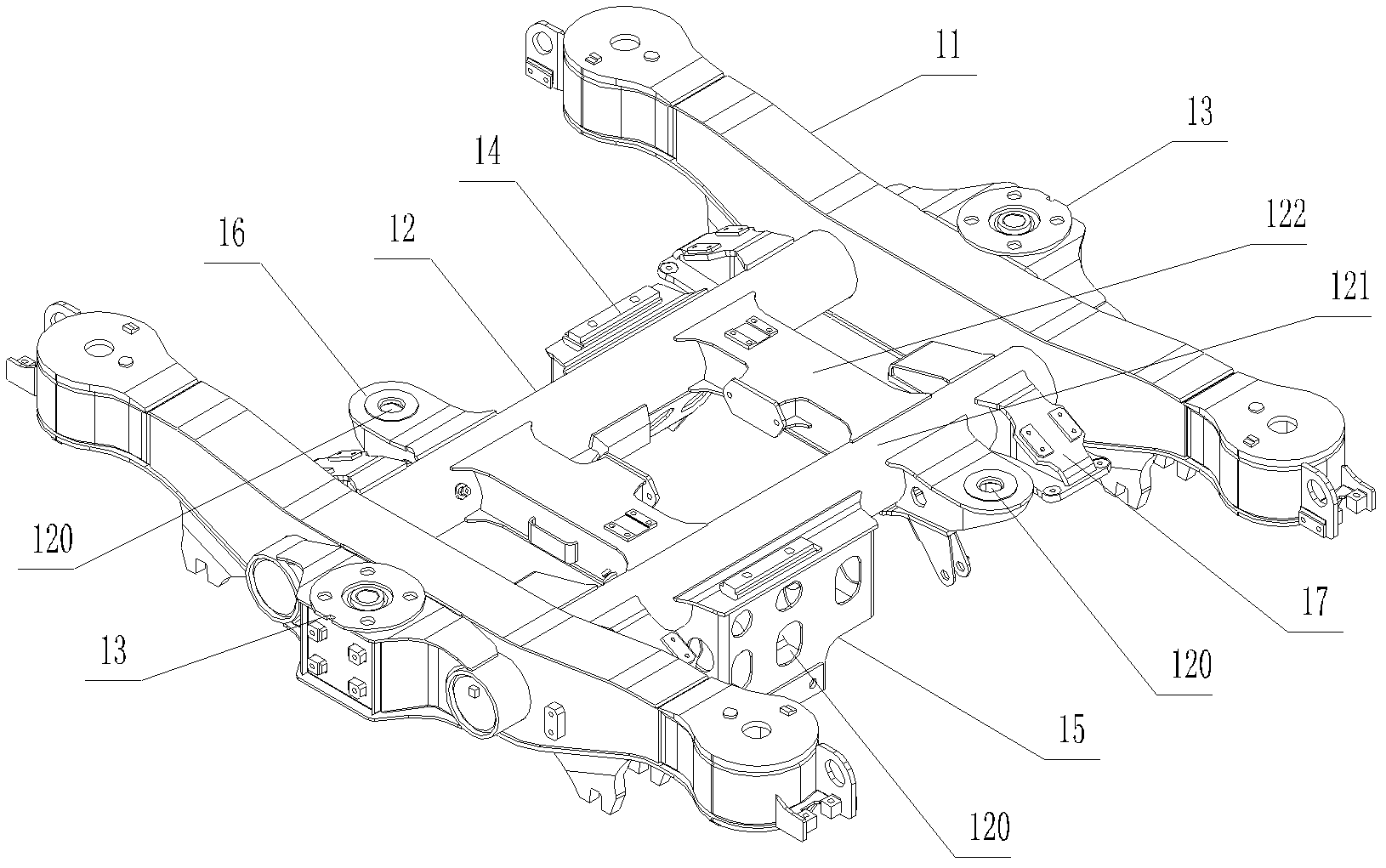

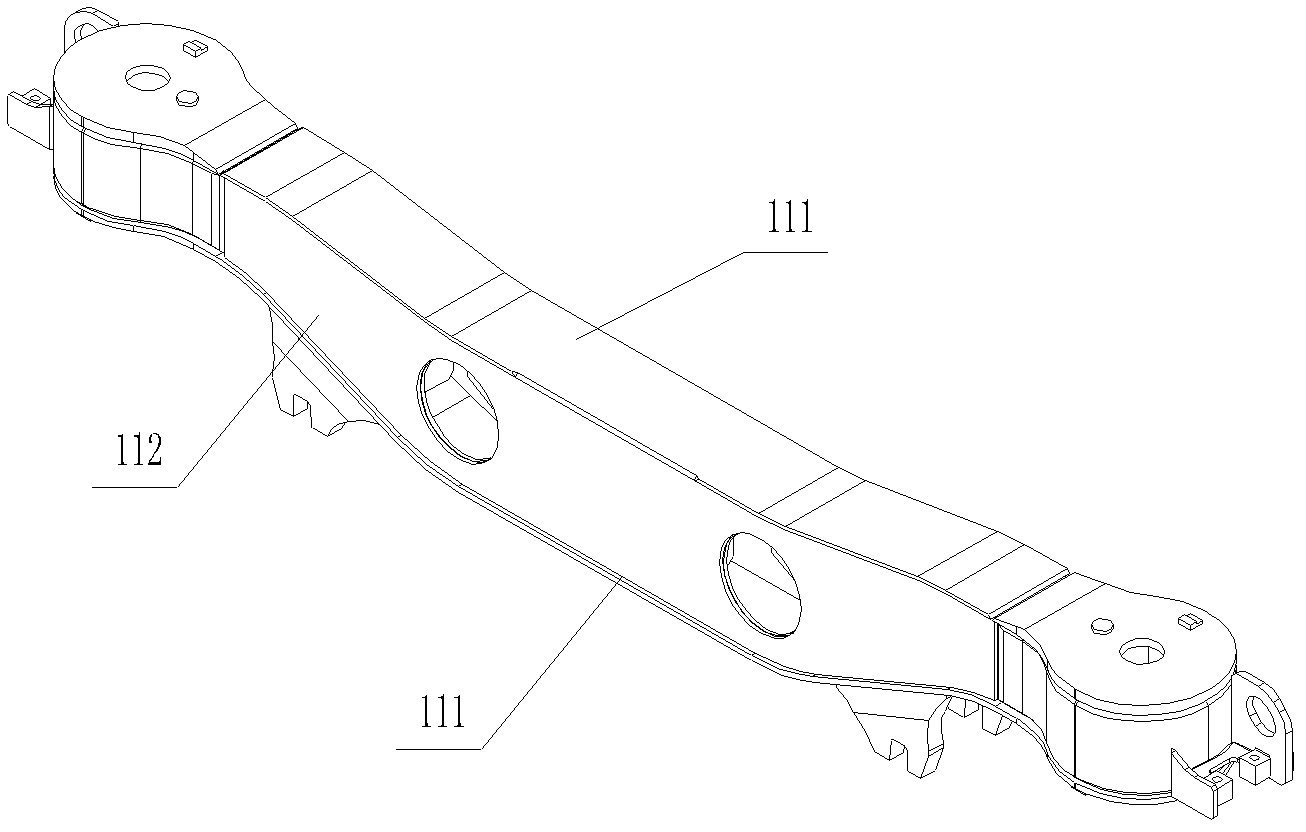

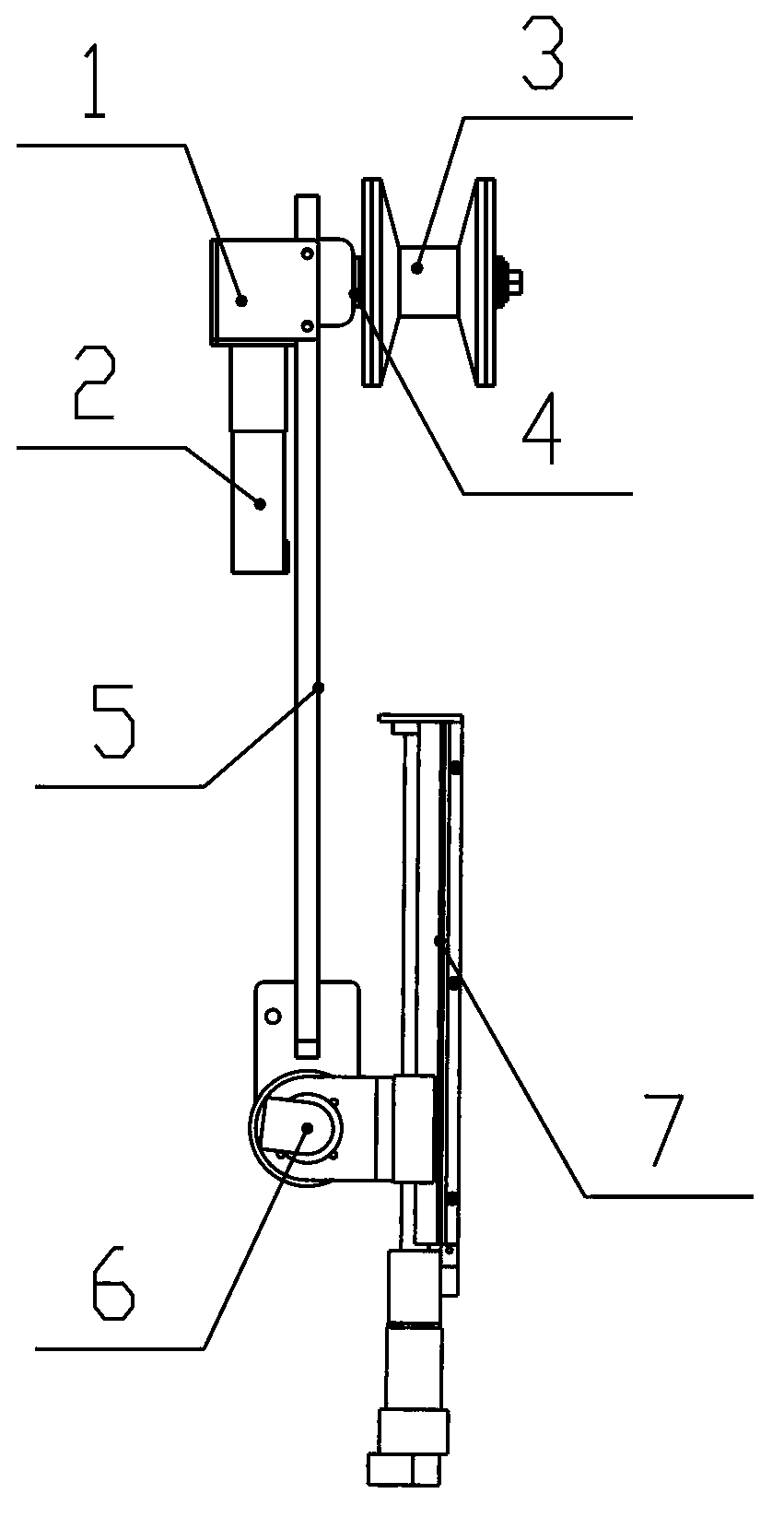

Bogie of high-speed motor train unit

InactiveCN102923153AAchieve lightweight designGuaranteed stabilityBogiesWheel-axle combinationsBogieAir spring

The invention discloses a bogie of a high-speed motor train unit. By adopting a brand-new bogie structure and a hanging connection and traction mode, overall lightweight design is realized, the unsprung weight of the bogie is reduced, and the hanging parameter between the bogie and a body is optimized. On the basis that the high-speed running speed is met, stability when the bogie passes through a big corner and good traction and braking performance are expected. The bogie comprises a framework, two groups of wheel set travelling devices, a linear motor, a first hanging device, a second hanging device, a traction device and a foundation brake device. The framework comprises a pair of side beam assemblies and a pair of cross beam assemblies which are connected with each other; each side beam assembly has a hollow box body structure, and comprises a pair of upper and lower cover plates and a pair of lateral web plates which are welded; each cross beam assembly comprises a pair of hollow steel pipes penetrating the lateral web plates and welded with the lateral web plates; and a pair of air spring supporting beams is welded at two ends of a steel pipe and outside the lateral web plates.

Owner:CRRC QINGDAO SIFANG CO LTD

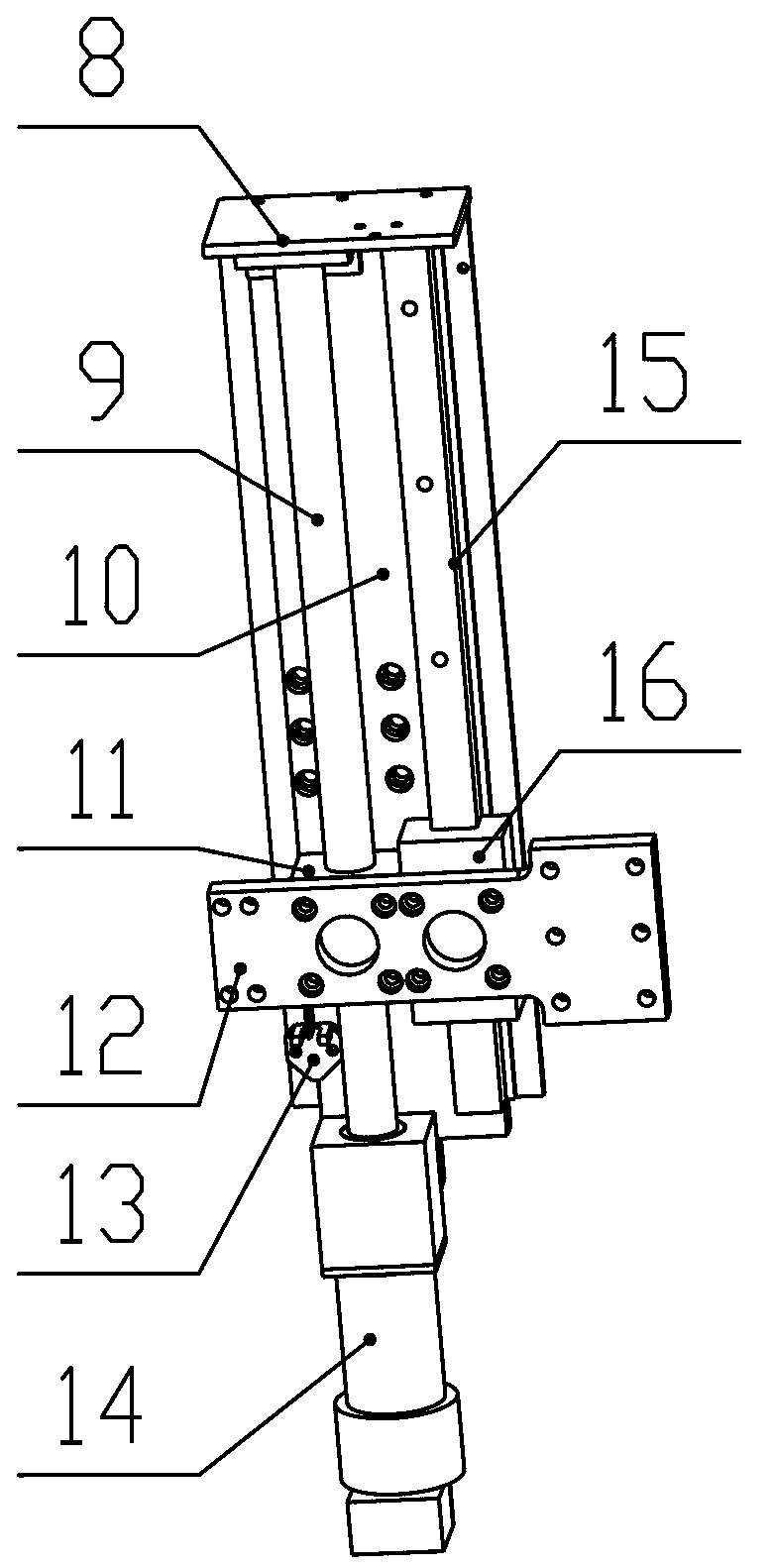

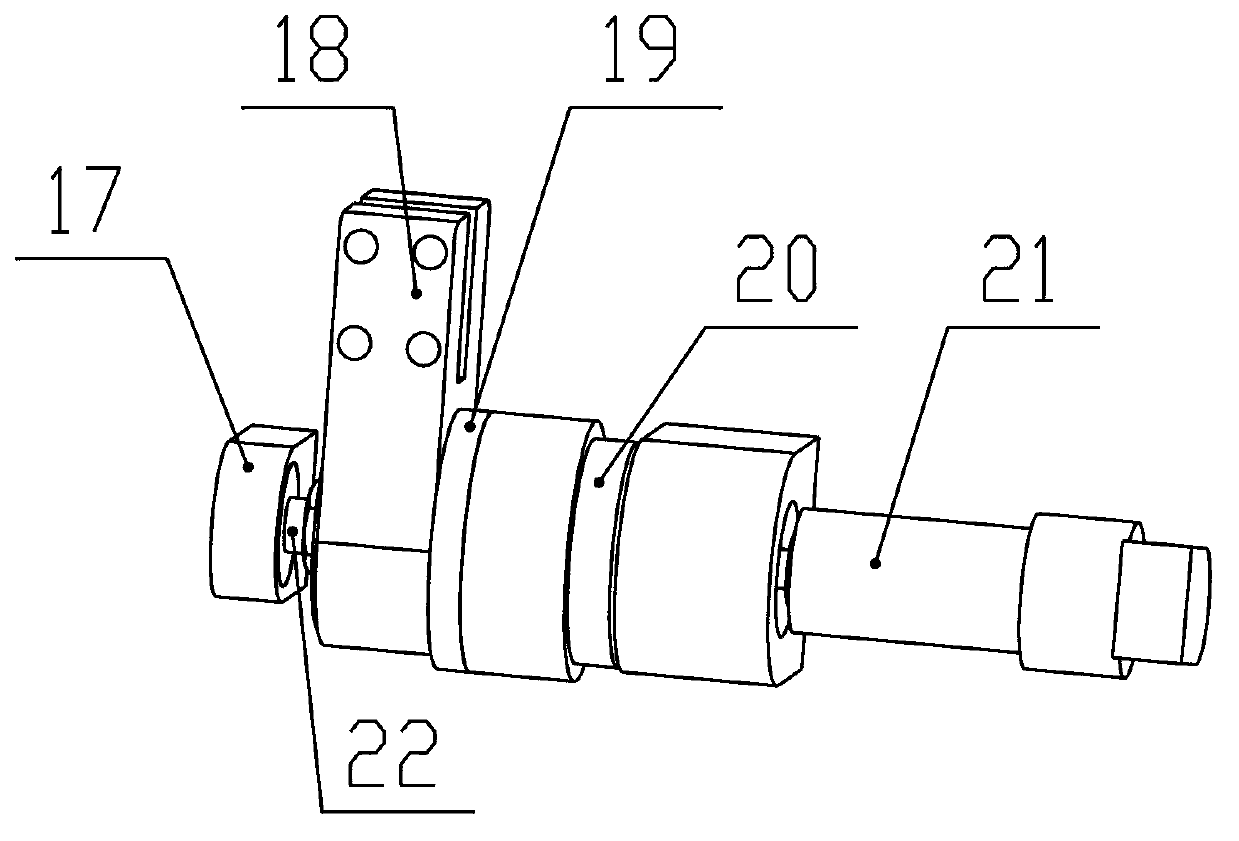

Line robot drive arm with obstacle crossing function

ActiveCN103001151AAdaptive Spacing ChangesImprove interchangeabilityApparatus for overhead lines/cablesVehiclesDrive wheelElectromagnetic clutch

The invention discloses a line robot drive arm with an obstacle crossing function. The line robot drive arm is a high-voltage transmission line patrolling and operating robot drive arm and is particularly used for walking along the transmission conductor line and performing detection and operation. The line robot drive arm comprises a drive wheel mechanism, a rotary joint and a lifting joint, wherein the drive wheel mechanism comprises a fixing plate, and a drive device is movably connected onto the fixing plate. The rotary joint comprises a rotary shaft and an electromagnetic clutch, wherein the electromagnetic clutch is sleeved on the rotary shaft, and the middle of the rotary shaft is movably connected with a connecting piece. The lifting joint comprises a base plate, wherein a sliding device and a lead screw device are arranged on the base plate and are fixedly connected through a connecting plate. The drive wheel mechanism is connected with the connecting part of the rotary joint through the fixing plate, and one end of the rotary shaft of the rotary joint is connected with the connecting plate of the lifting joint. The line robot drive arm can be freely combined according to an overall structure of a robot, and each drive arm can provide drive force for the robot, is similar to modular design and is strong in interchangeability.

Owner:STATE GRID INTELLIGENCE TECH CO LTD

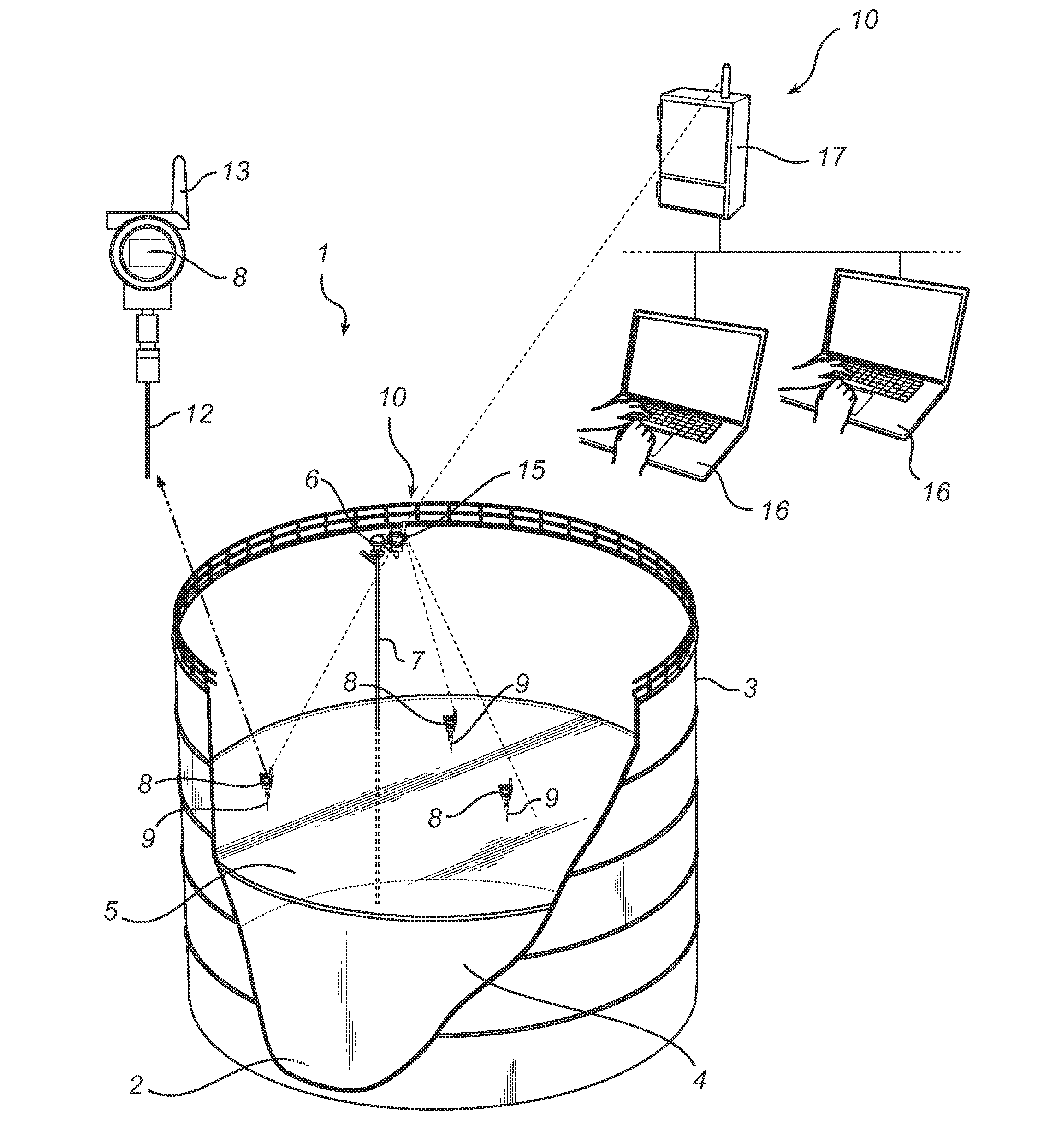

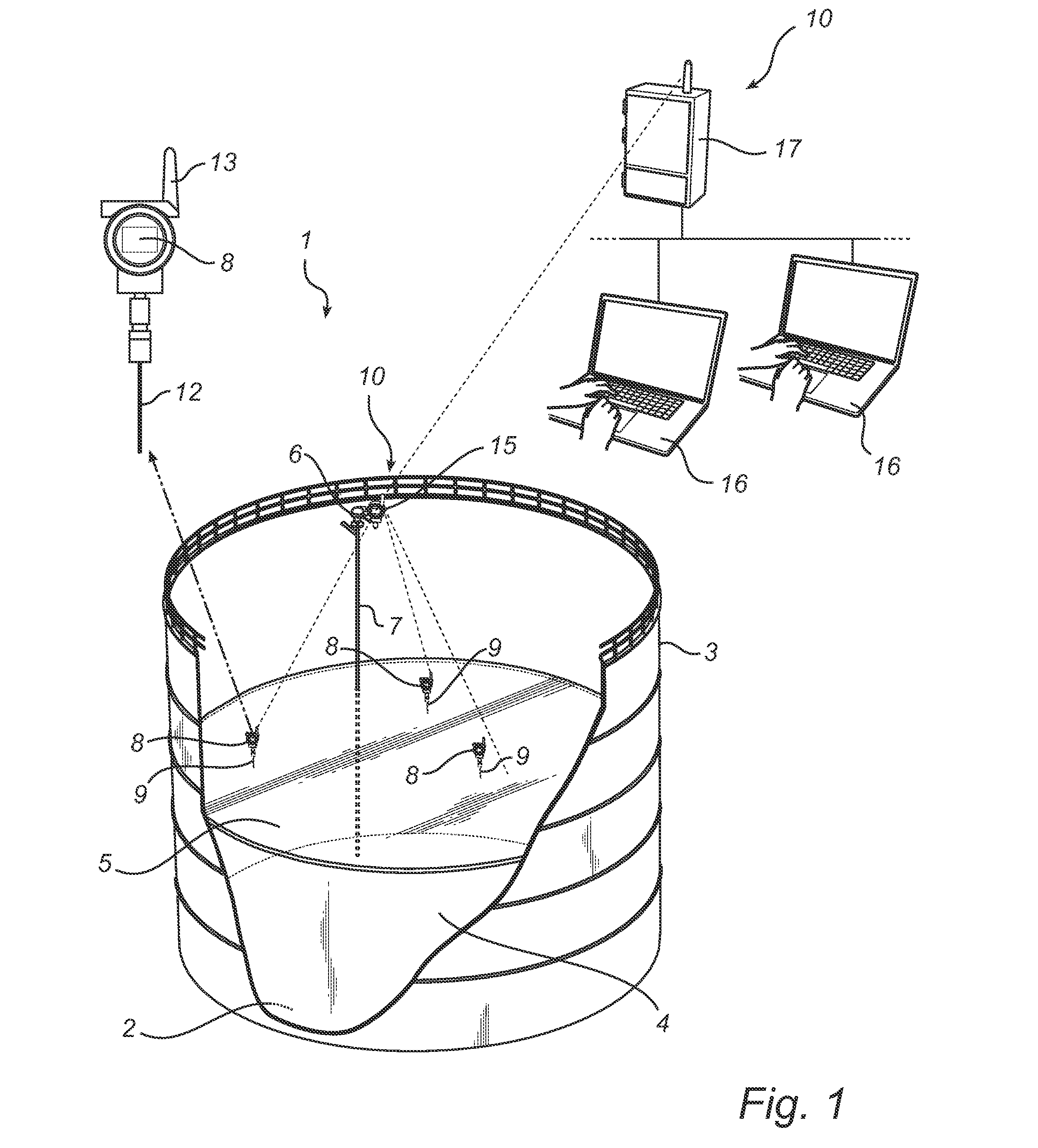

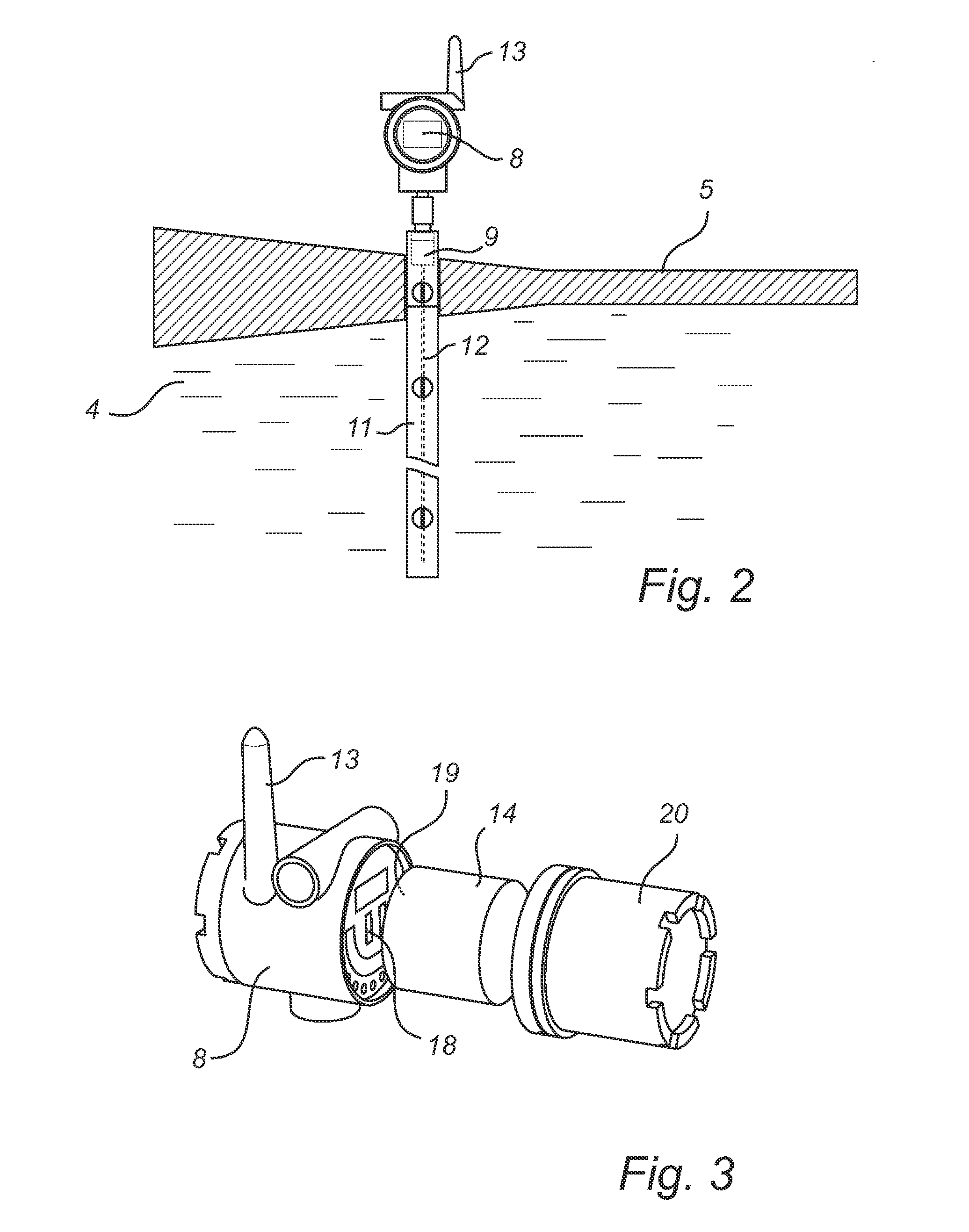

Monitoring of floating roof tank

ActiveUS20130120155A1Life maximizationMinimize maintenanceElectric signal transmission systemsSub-station arrangementsIntrinsic safetyTelecommunications

System for monitoring a floating roof of a tank containing a liquid, wherein the system determines a local status of the floating roof in spaced apart sensing element locations. In a hazardous or potentially hazardous environment, there is an on-roof subsystem including a sensing element in each sensing element location, intrinsically safe measuring circuitry coupled a sensing elements and arranged for determining said local status, intrinsically safe radio communication on-roof circuitry coupled for communicating externally of the on-roof subsystem the local, an intrinsically safe power supply circuitry connected to an intrinsically safe and interchangeable energy storage unit for powering the on-roof subsystem. The system further includes monitoring circuitry for receiving the indication of local status and for determining an overall monitored status of said floating and further radio communication circuitry. The on-roof subsystem is wireless in its power supply and communication.

Owner:ROSEMOUNT TANK RADAR

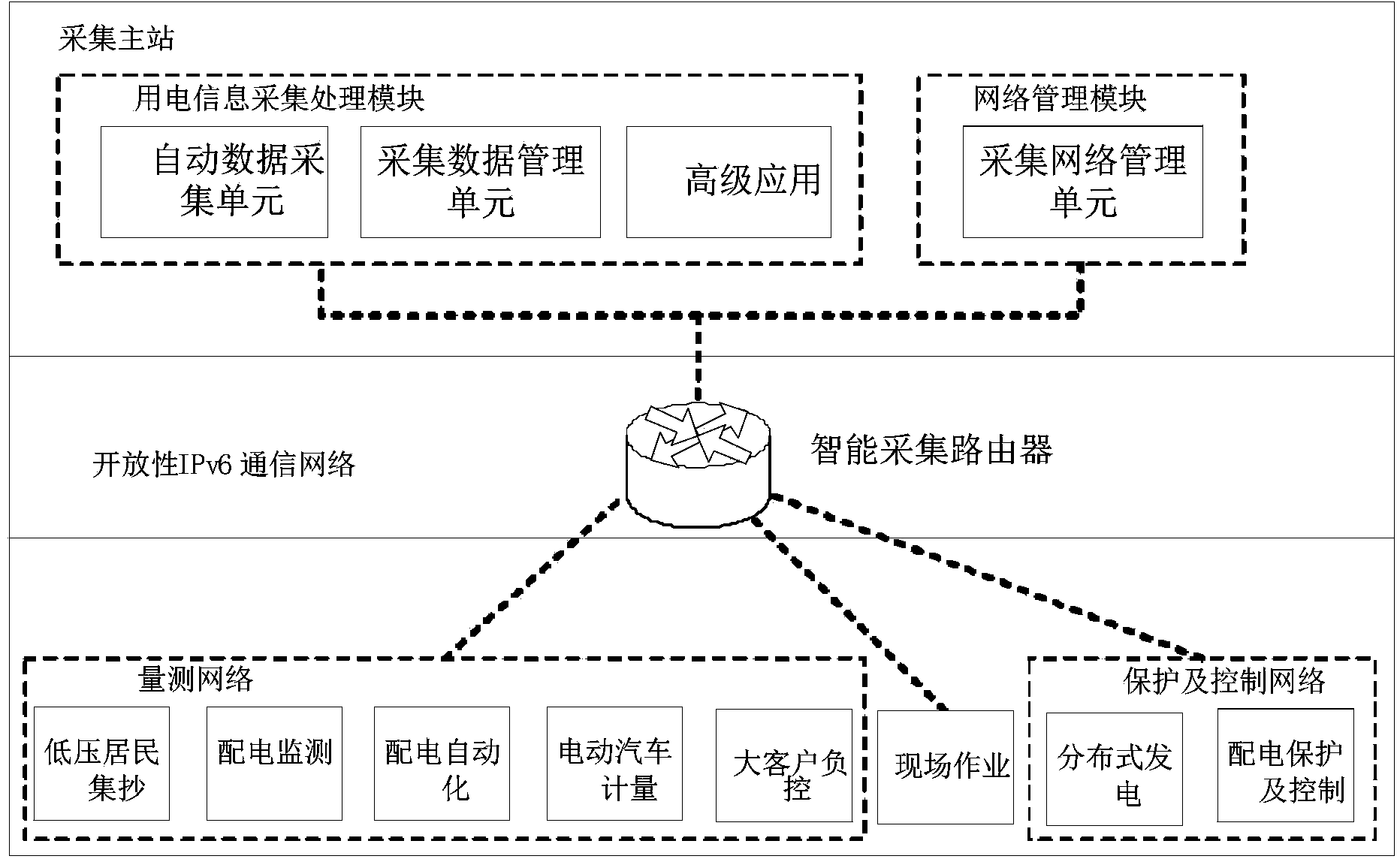

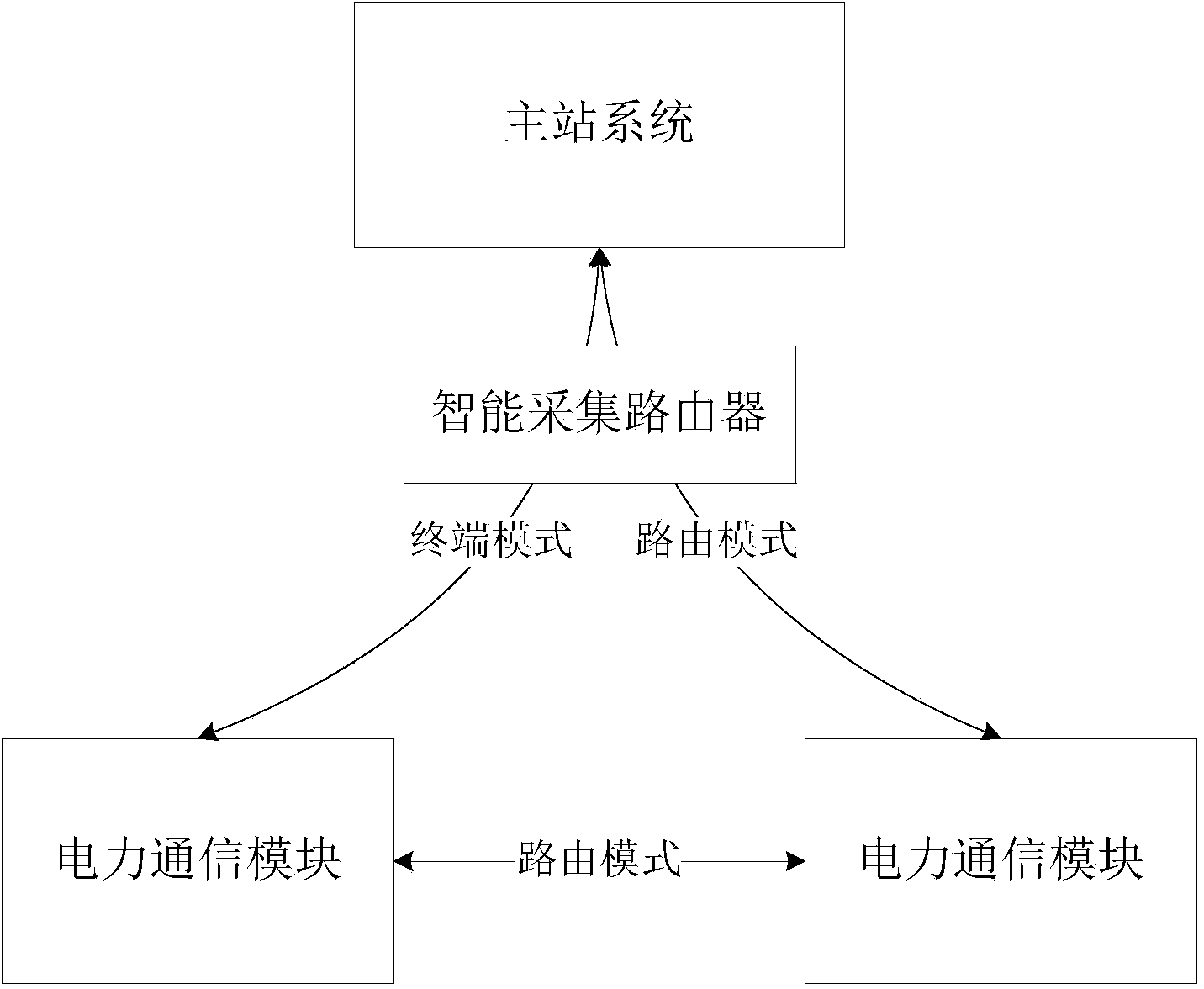

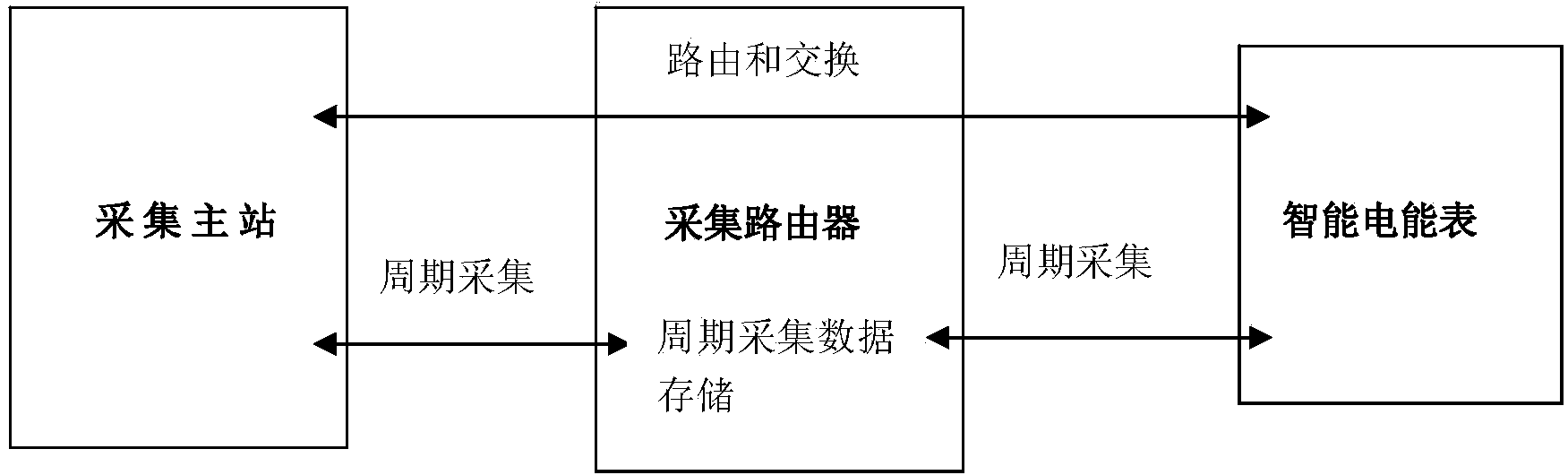

IPv6 (Internet protocol version 6) based electricity information collection system and method

ActiveCN104243595AFix compatibility issuesImprove interchangeabilityTransmissionInternet protocol suitePrimary station

The invention relates to an IPv6 (Internet protocol version 6) based electricity information collection system and method. The electricity information collection system comprises intelligent measuring devices, an intelligent collecting router and a main collection station. The main collection station is in end-to-end communication with the intelligent measuring devices through the intelligent collecting router; the intelligent measuring devices in a local network are in end-to-end communication. The method includes that 1), the intelligent collecting router collects control instructions issued by the main collection station; 2), the intelligent collecting router forwards the control instructions to the intelligent measuring devices; 3), an intelligent electric meter acquires the control instructions and collects data prior to returning to the intelligent collecting router; 4), the intelligent collector router selects route modes; 5), the intelligent collecting router collects and stores measurement data; 6), the intelligent collecting router forwards the measurement data to the main collecting station.

Owner:STATE GRID CORP OF CHINA +3

Lighting system method and apparatus socket assembly lamp insulator assembly and components thereof

InactiveUS6632100B1High open circuit voltageGreat flexibilityCoupling device connectionsMechanical apparatusLighting systemEnvironmental effect

A socket is described for a lighting assembly having a socket body and an electrical connector with a seal in the socket to seal around a light source. The socket is preferably configured to be independent of the mounting arrangement for the lighting assembly. An insulator is also disclosed for a lamp such as a fluorescent lamp having a body which covers the contact on the lamp so as to form a recessed lamp conductor. The combination of a socket and lamp insulator is also disclosed for providing a socket and insulator assembly for reducing the possibility of injury or damage due to high open circuit voltage, environmental effects and the like. Additionally, a lighting assembly is disclosed incorporating the insulator, socket and mounting arrangements.< / PTEXT>

Owner:ANTHONY INC

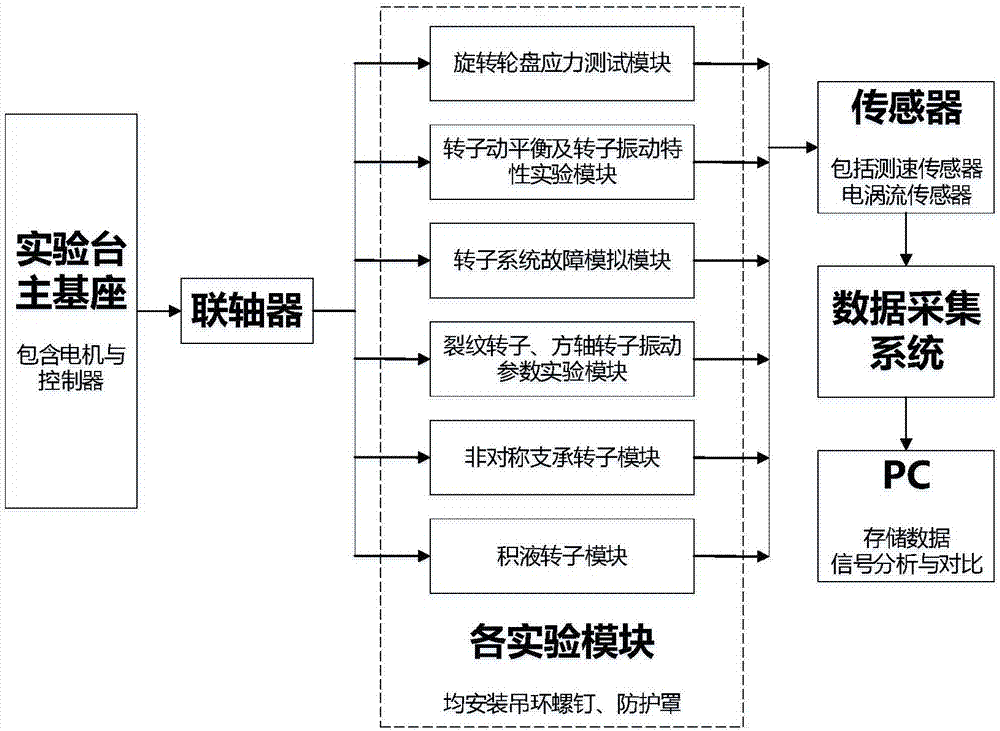

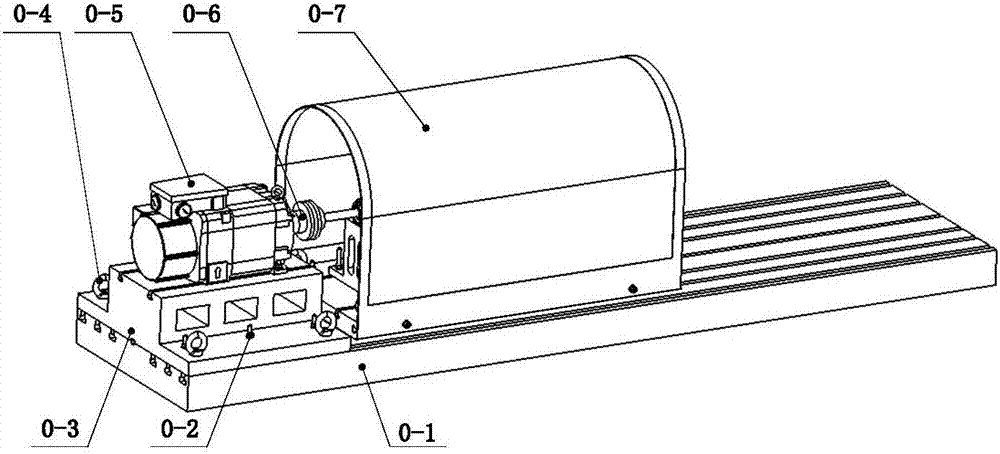

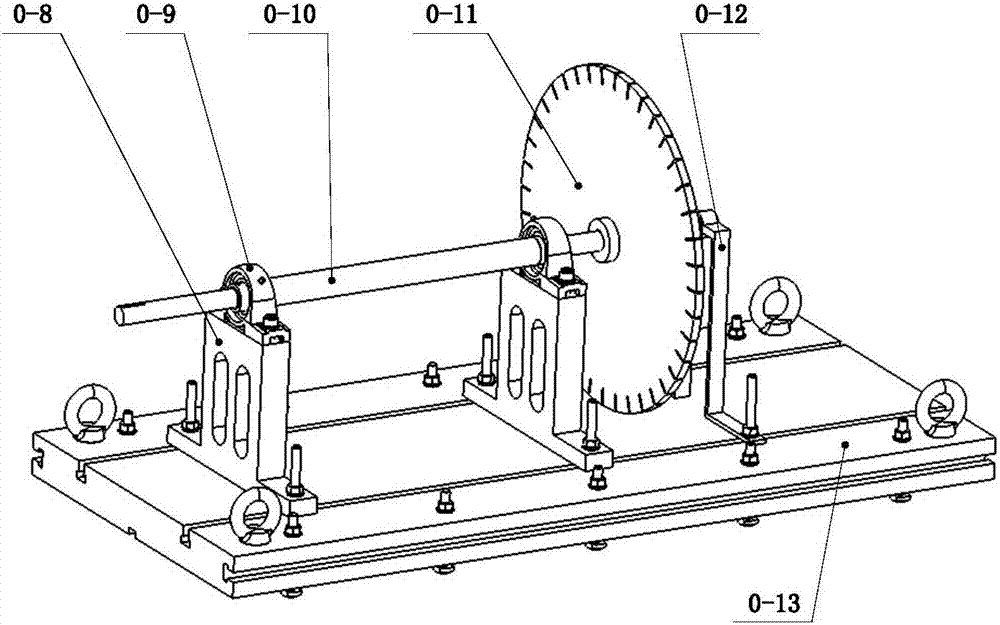

Modularization multifunctional rotor experiment table

The invention provides a modularization multifunctional rotor experiment table. The experiment table comprises an experiment table main substrate, a rotation roulette stress test module, a rotor dynamic balancing and rotor vibration characteristic experiment module, a rotor system fault simulation module, a crack rotor and square shaft rotor vibration parameter experiment module, a non-synchronous support rotor module and a hydrops rotor module. Each module consists of a corresponding module substrate, a rotation shaft, a roulette and a bearing, equipped with a displacement and speed measurement sensor and connected with a data acquisition system and a PC. Each experiment module retains an installation positioning port of the experiment table main substrate towards the outside, and is achieved through a flexible coupling. According to the invention, the experiment table is high universal and interchangeable; the experiment device is convenient to install and disassemble; the rotor system on the experiment table can be timely improved; and the experiment table has multiple functions, is capable of simulating multiple states of rotor operation and can be applied to the field of teaching experiments or scientific research of rotor dynamics and fault diagnosis.

Owner:SHANGHAI JIAO TONG UNIV

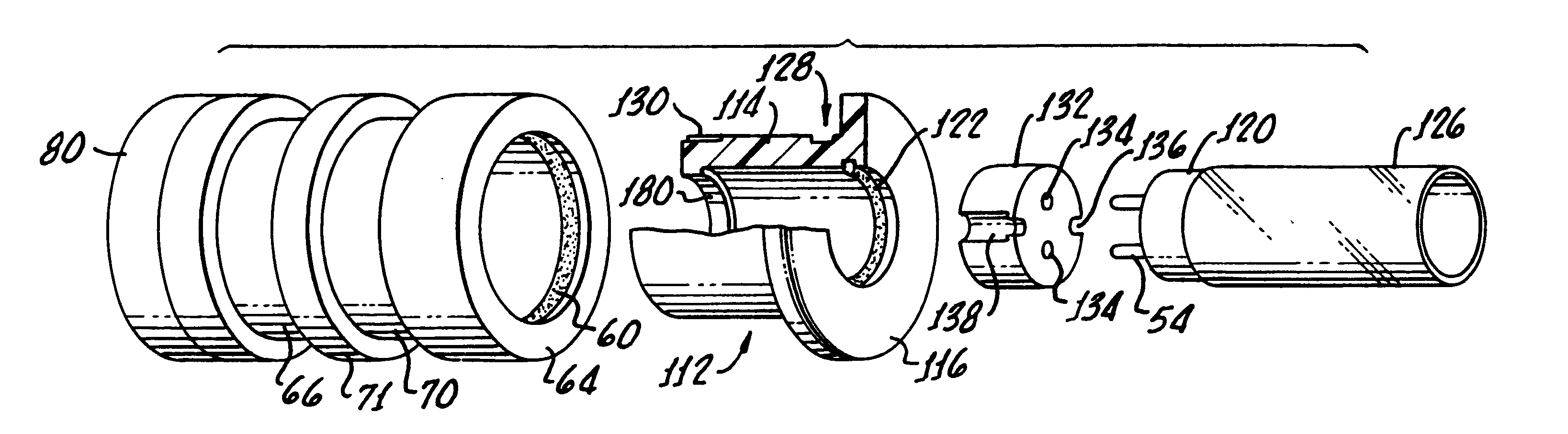

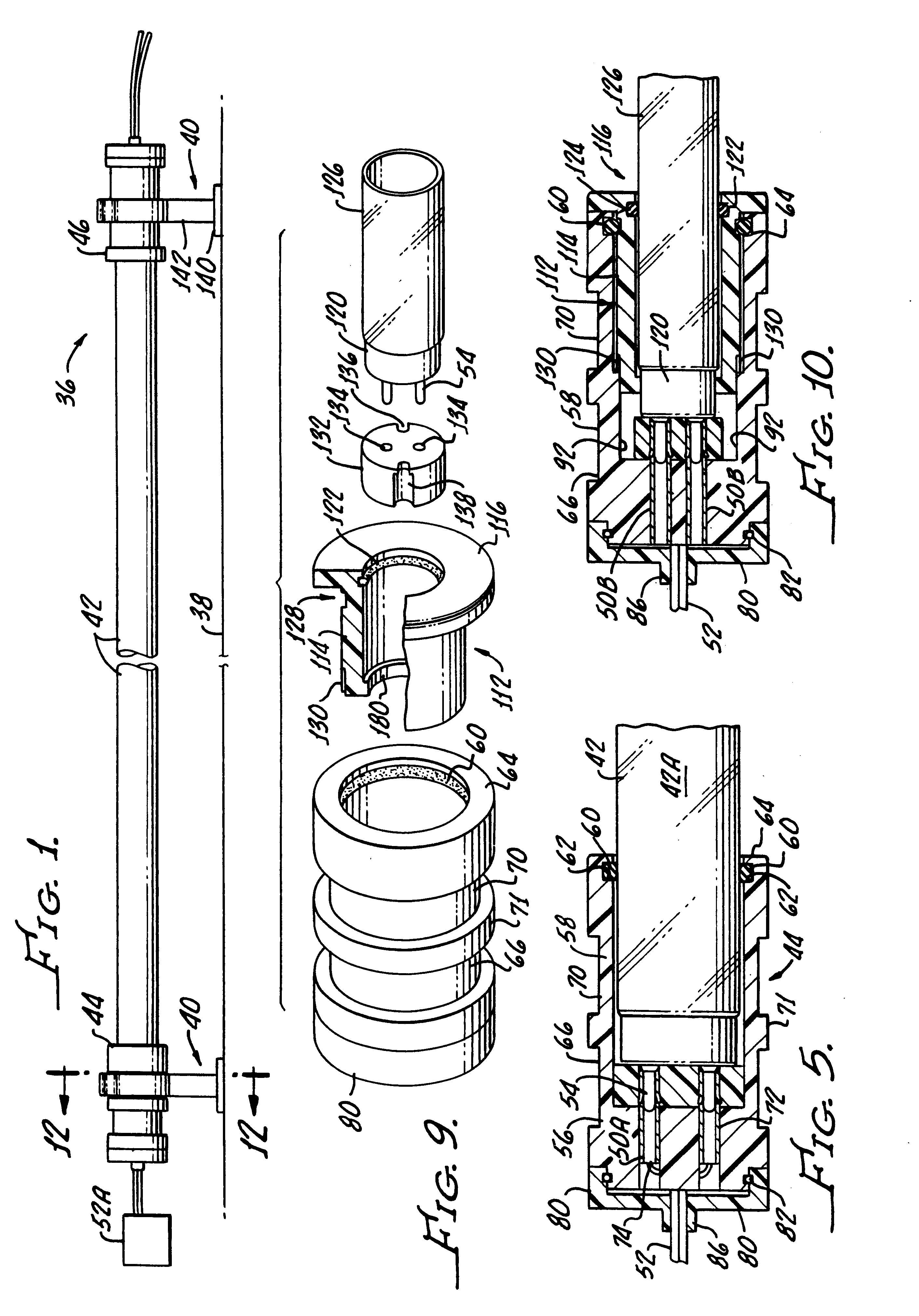

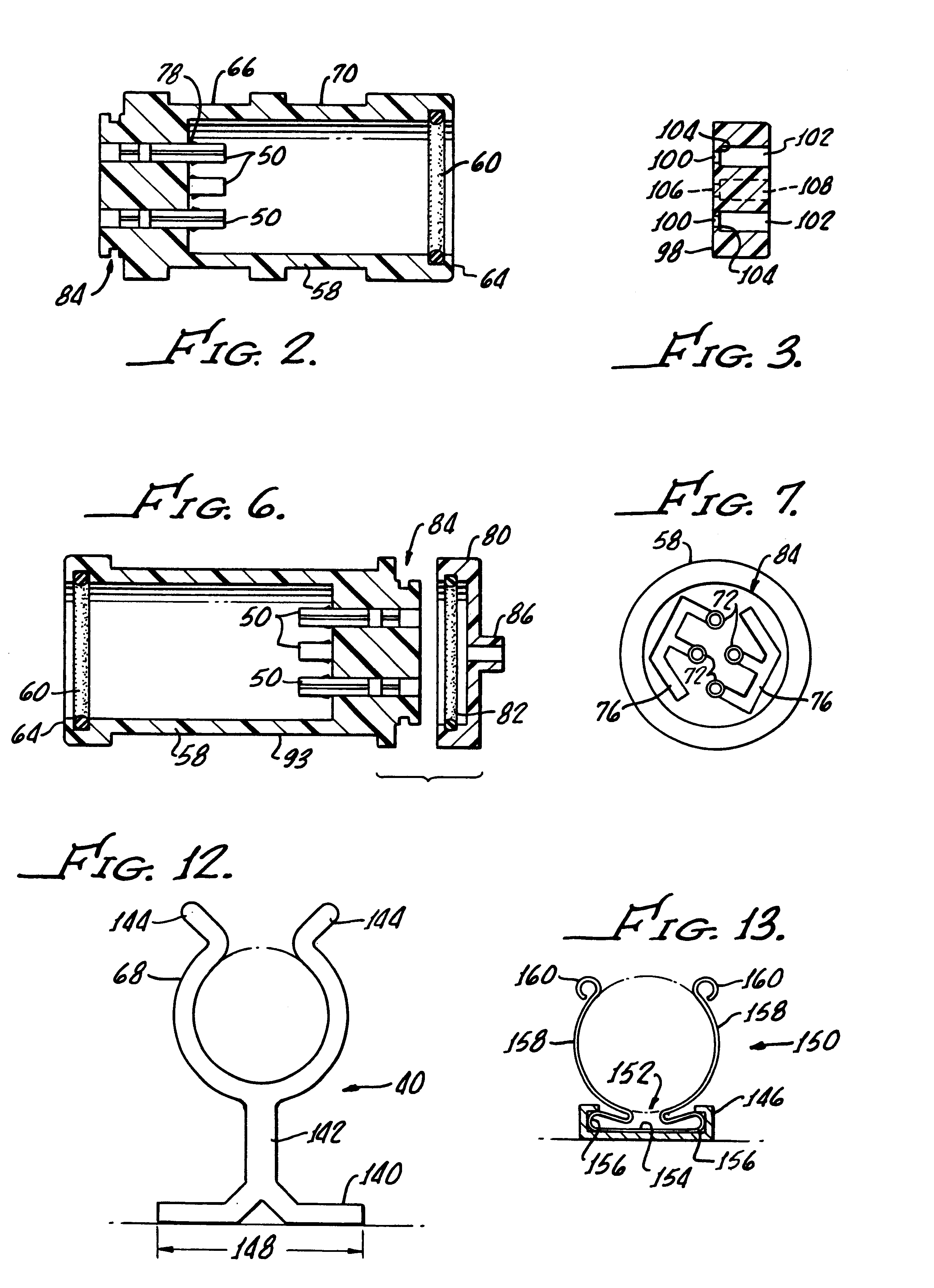

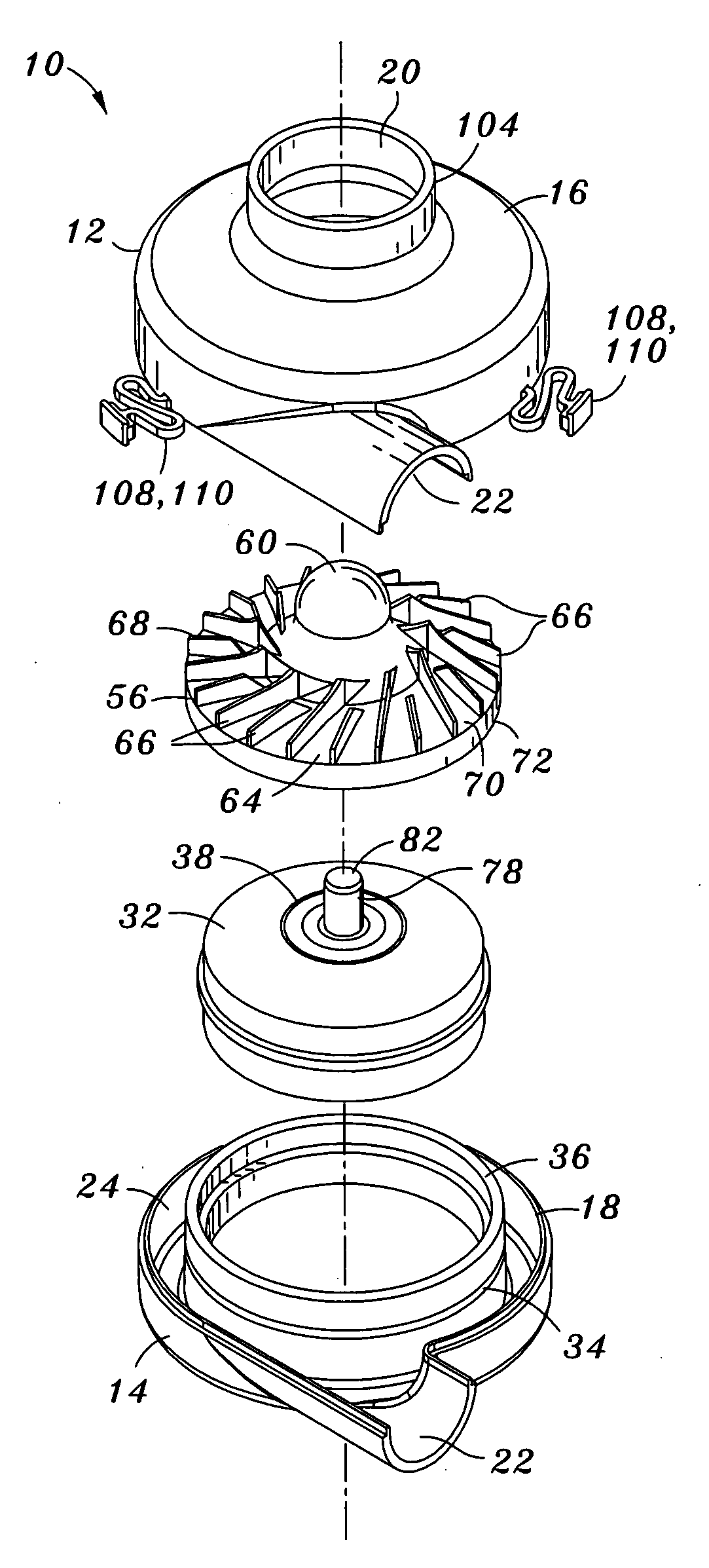

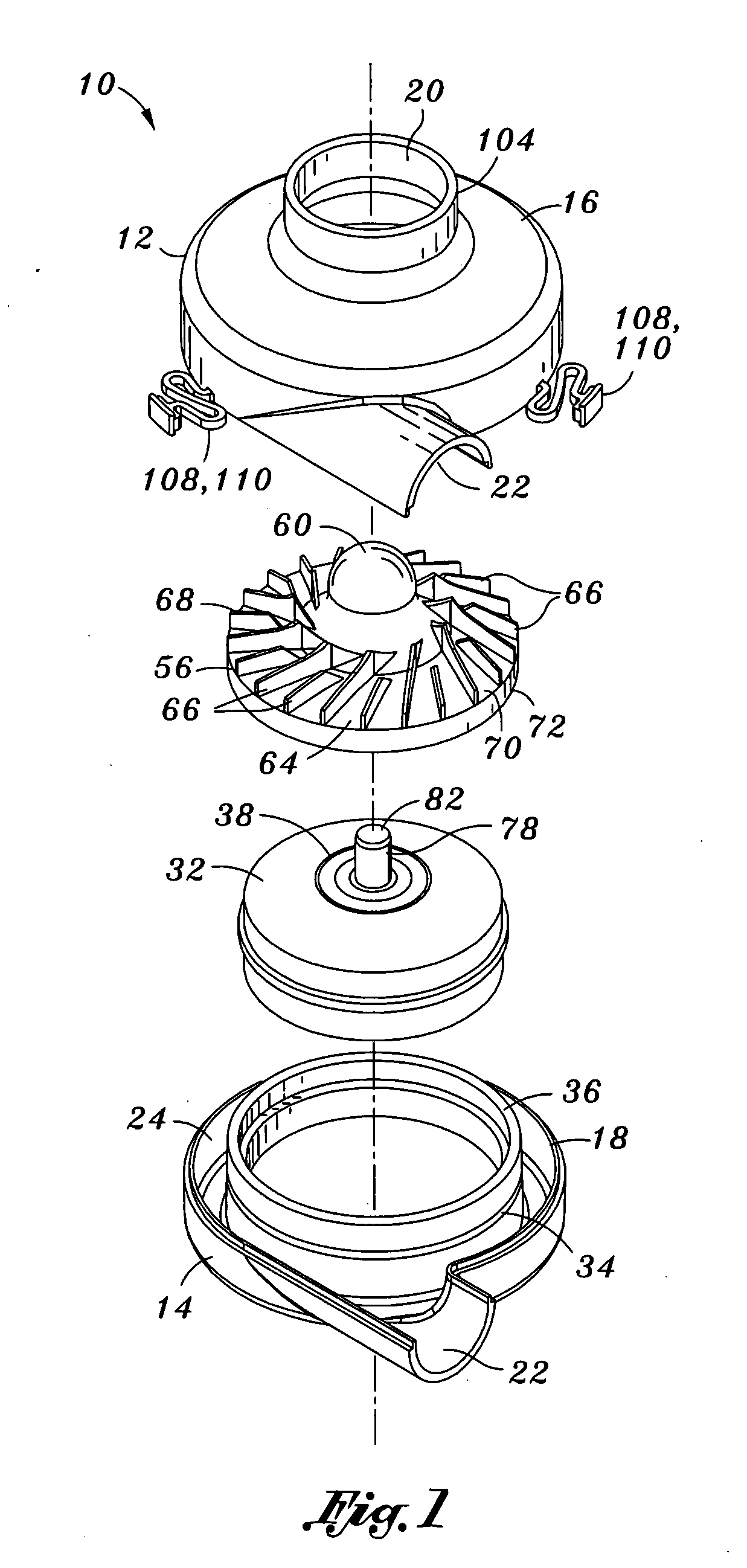

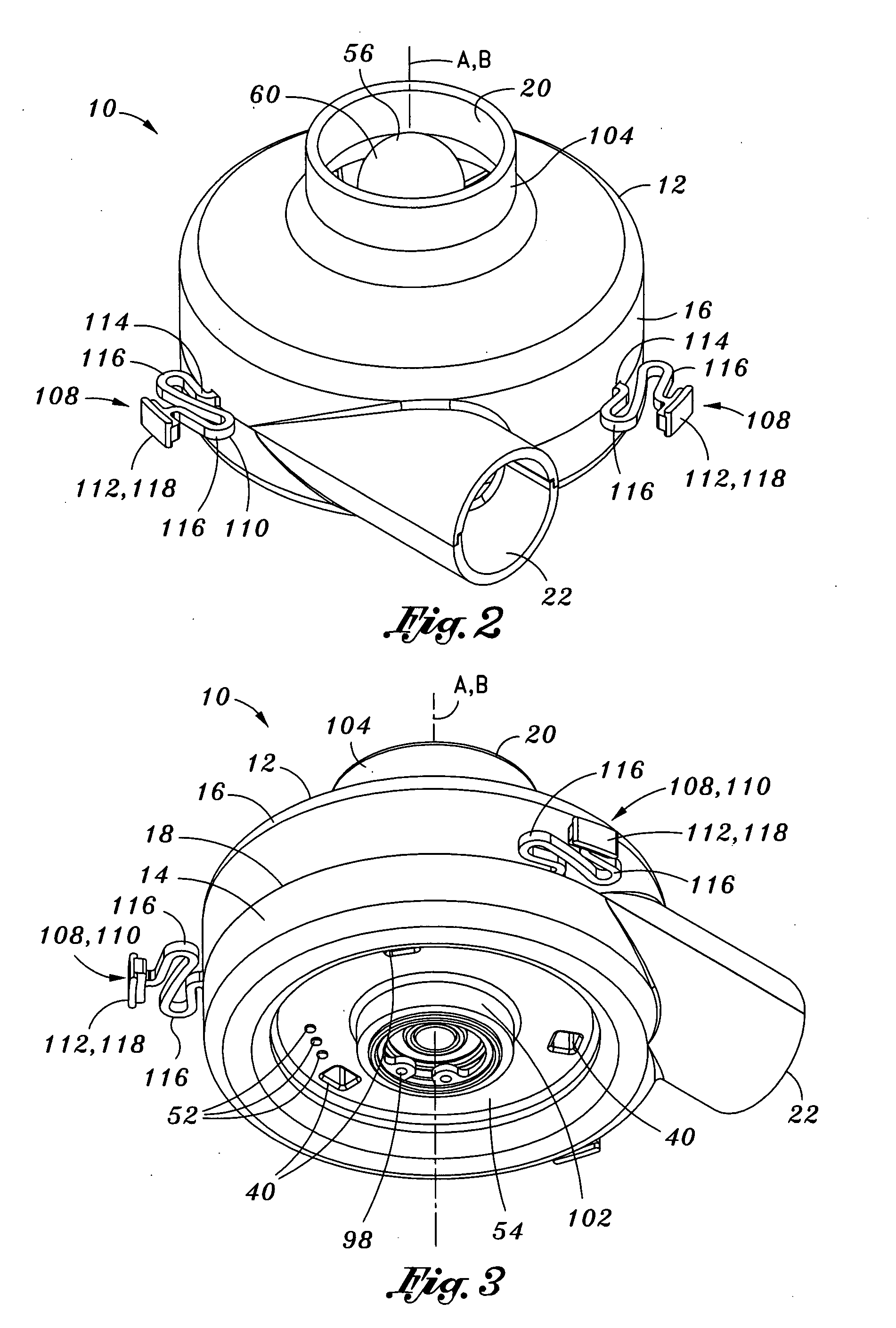

Modular CPAP compressor

InactiveUS20080310978A1Minimizes aerodynamic lossSmall air gapPump componentsMedical devicesImpellerRotor magnets

A modular compressor assembly comprises a common motor assembly, an impeller, a blower housing and an engagement mechanism. The common motor assembly includes a stator housing containing a stator assembly and having a rotor magnet rotatably disposed therewithin. The impeller is mounted to and rotatable with the rotor magnet. The blower housing is selectable from among a plurality of blower housings each having a different cross-sectional geometry. The engagement mechanism is formed on the stator housing and / or the blower housing and allows interchangeable mounting of different blower housing configurations to the common motor assembly in order to achieve varying flow characteristics of the compressor assembly.

Owner:CAREFUSION

Lighting circuit, lighting system method and apparatus, socket assembly, lamp insulator assembly and components thereof

InactiveUS6773130B1Minimize the possibilityConvenient thermal protectionCoupling device connectionsMechanical apparatusElectrical conductorEnvironmental effect

Owner:ANTHONY INC

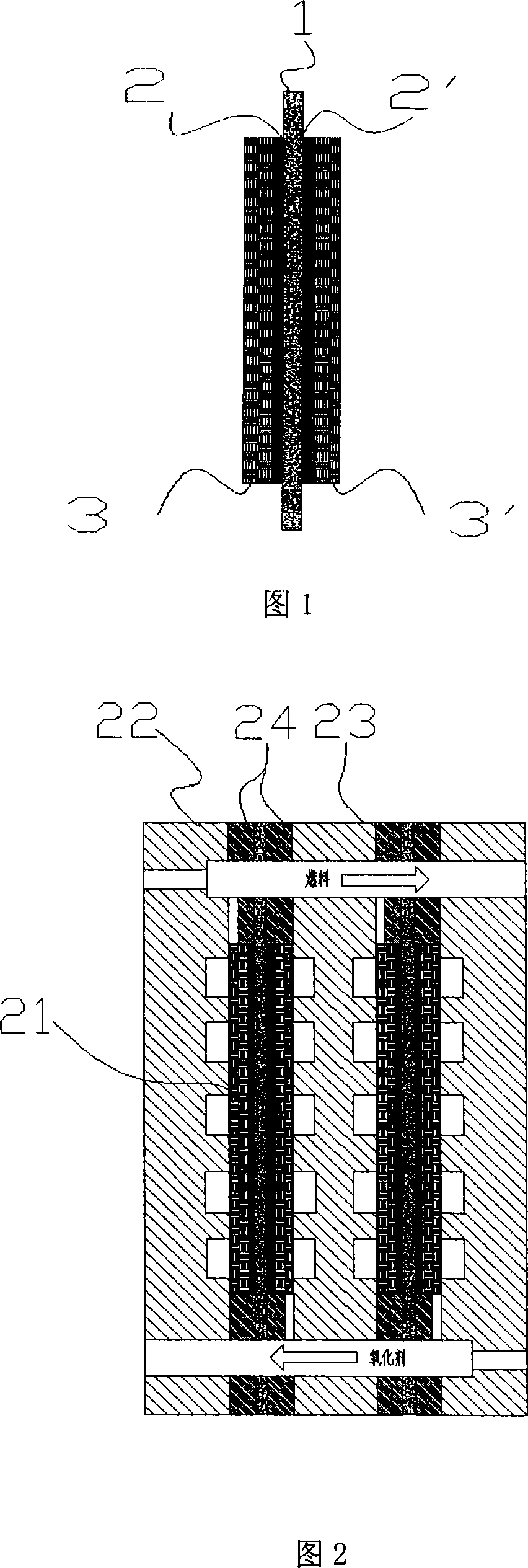

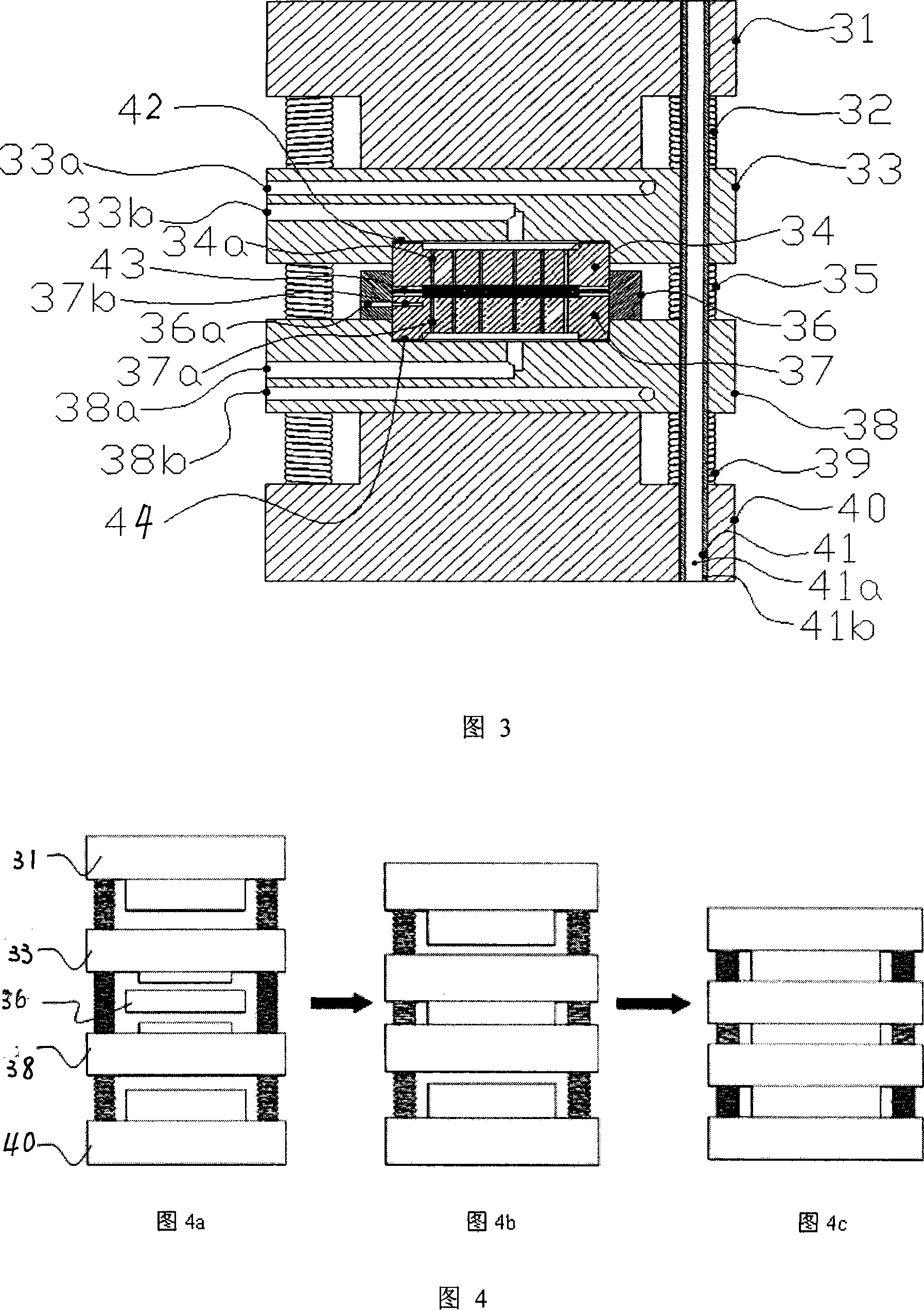

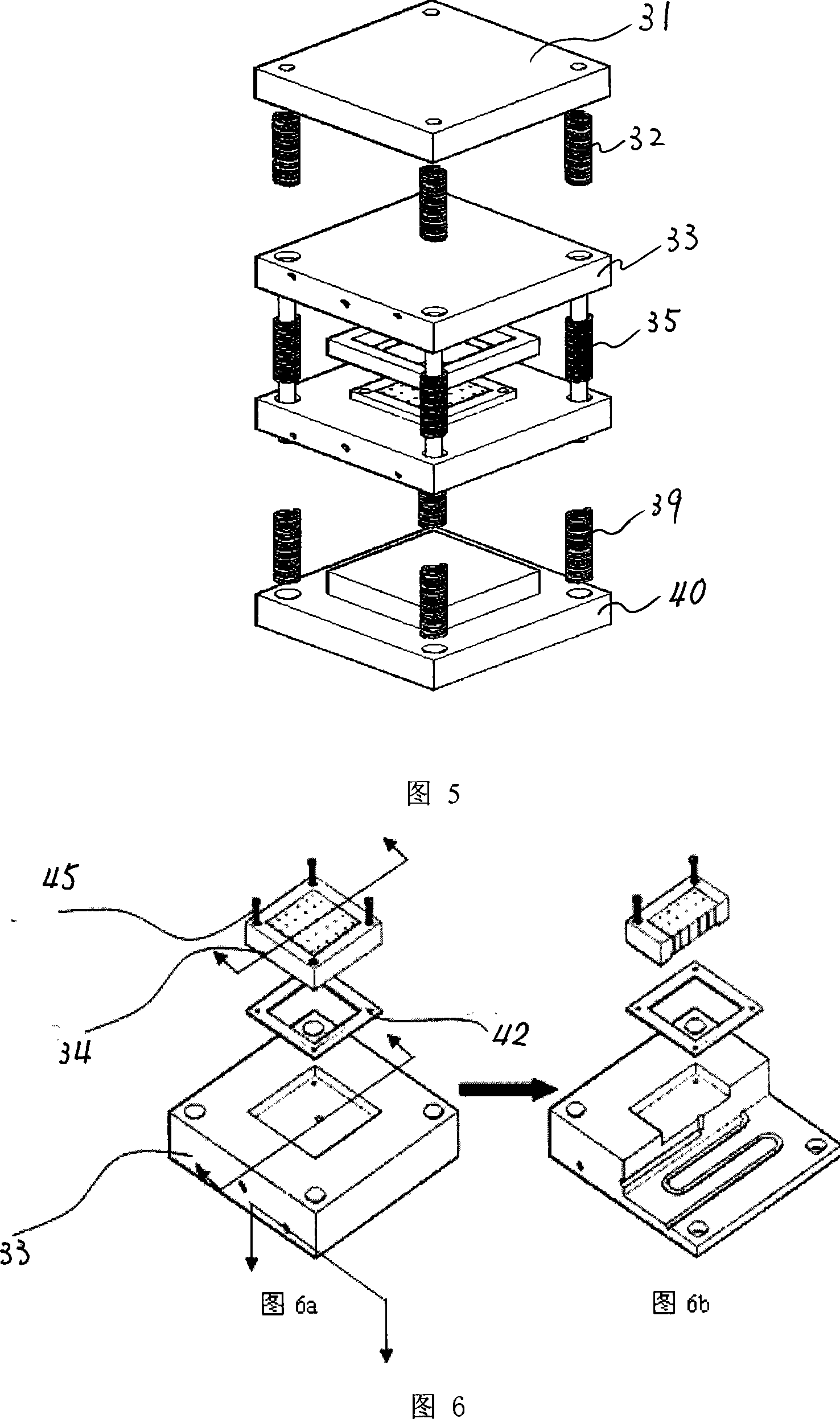

Pressing mold device for hot pressure prepared fuel cell membrane electrode

ActiveCN101183717AGuaranteed vertical alignmentImprove general performanceCell electrodesFuel cell detailsFuel cellsEngineering

The invention discloses a compound die device used in a hot pressing fuel battery film electrode, comprising a top pressing board, a top die, a positioning frame, a bottom die, a bottom pressing board, a plurality of positioning guide pillars and catapult springs; wherein the top die comprises a top die head and a top die base. A positioning groove for diffusion layers is arranged at the center ofthe contact surface between the top die head and the film electrode, so as to position the first diffusion layer of the film electrode. The bottom die comprises a bottom die head and a bottom die base, which has the same structure as the top die; wherein the bottom die head is used to position the second diffusion layer of the film electrode. The positioning frame is arranged between the top dieand the bottom die, a center bore in the positioning frame is used to position an ion exchange membrane. At least two positioning guide pillars are arranged on the bottom pressing board, aligning andpositioning the top pressing board, the top die, the positioning frame, the bottom die and the bottom pressing board in order. The catapult springs are respectively arranged between the pressing boards and the top, the bottom die, as well as between the top and the bottom die. The invention has the advantages of easy positioning and alignment, convenient, fast and energy-saving hot pressed film electrode.

Owner:雄川氢能科技(广州)有限责任公司

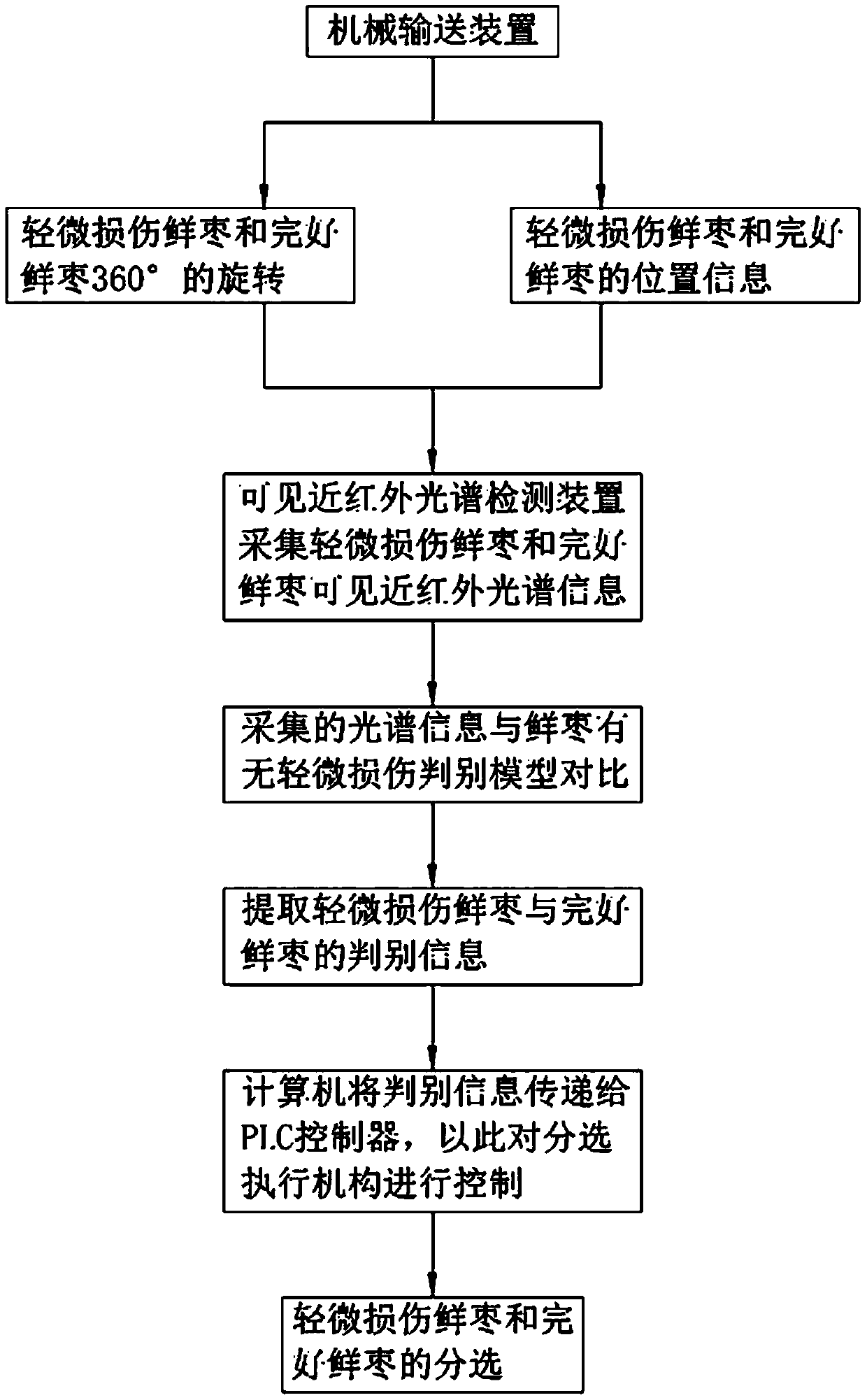

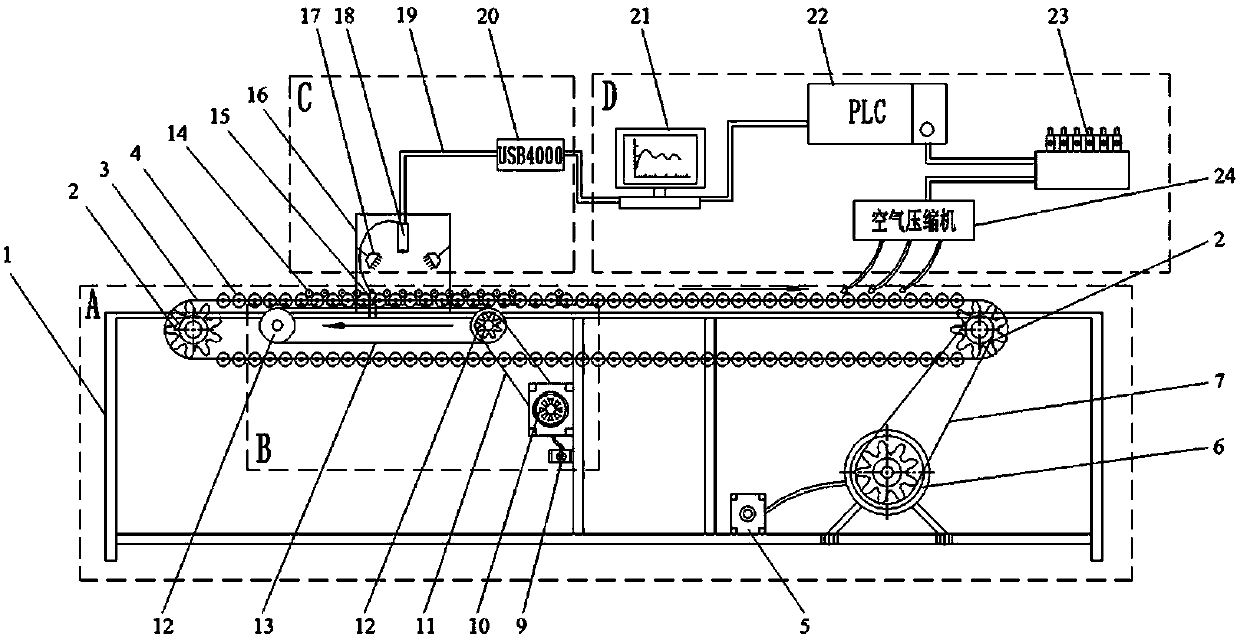

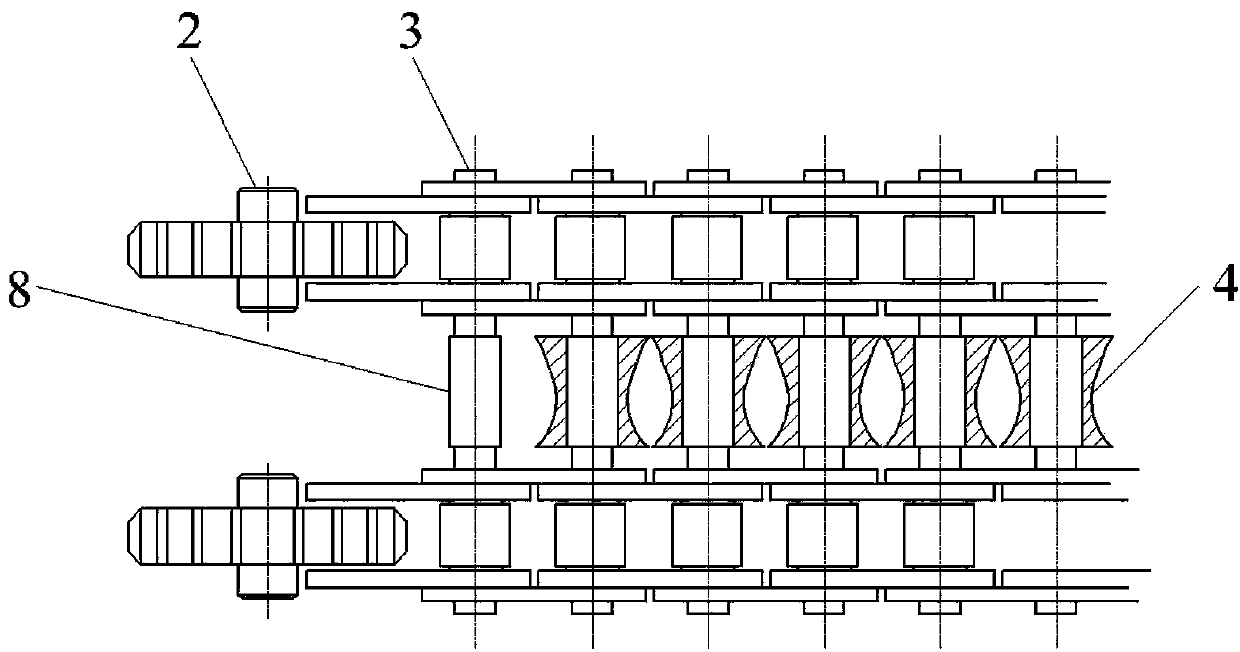

On-line rapid non-destructive detection and sorting device for slightly damaged fresh dates

InactiveCN104174597ARealize dynamic detectionHigh degree of automationMaterial analysis by optical meansSortingNon destructiveProgrammable logic controller

The invention discloses an on-line rapid non-destructive detection and sorting device for slightly damaged fresh dates. The device comprises a mechanical conveying device, a rotation device, a visible near-infrared spectrum acquisition device and a sorting device, wherein the mechanical conveying device is used for conveying fresh dates to a transmission roller at the station of the visible near-infrared spectrum acquisition device; the rotation device is used for enabling the roller to drive the fresh dates to rotate for 360 degrees; the position information of the fresh dates is judged through a sensor; the position information is transmitted to a micro optical fiber spectrometer through an optical fiber; the acquired spectrum information is transmitted to a model for judging whether the fresh dates are slightly damaged or not in computer system software; a signal that whether the fresh dates are slightly damaged is transmitted to a PLC (programmable logic controller) through the software in a computer; an electromagnetic control valve and a whole sorting execution mechanism which is connected with an air compressor are controlled by the PLC, and thus automatic sorting on slightly damaged fresh dates and complete fresh dates is achieved. By adopting the device, rapid, non-destructive, dynamic and real-time detection and sorting on slightly damaged fresh dates can be achieved.

Owner:SHANXI AGRI UNIV

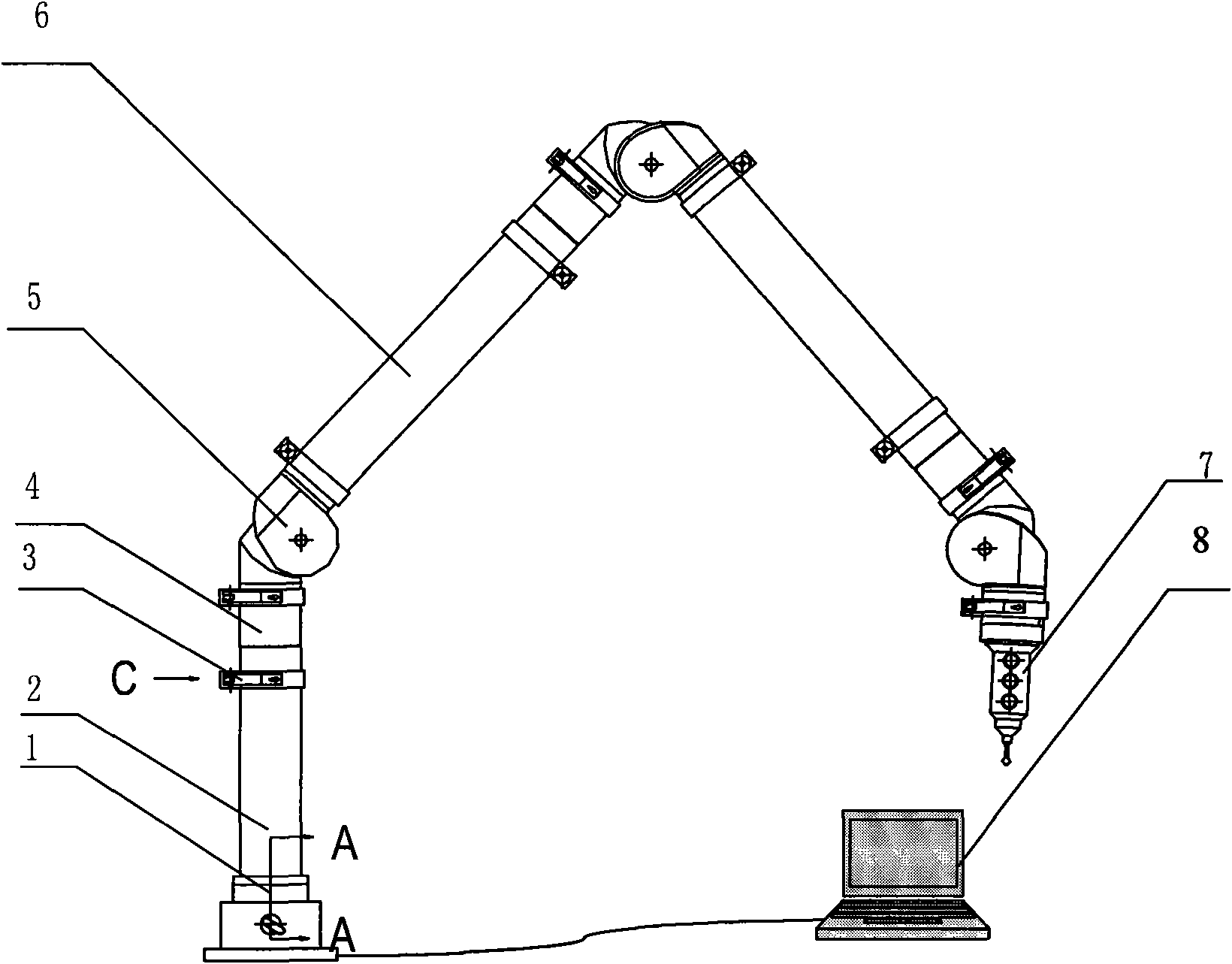

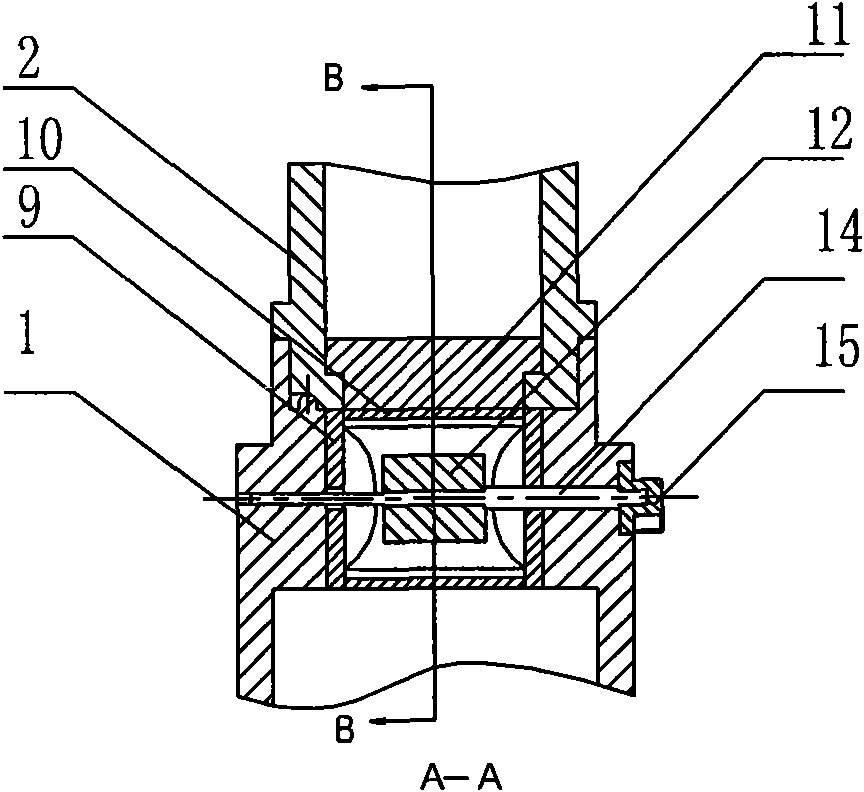

Restructurable joint arm type coordinate measurer

InactiveCN101806574AStrong adaptability to measurement tasksImplement fault separationPoint coordinate measurementsDegrees of freedomEngineering

The invention discloses a restructurable joint arm type coordinate measurer. A pedestal is connected with one end of a pedestal measuring arm through a magnetic joint; turning joints and swinging joints are connected through locking notches and locking convex openings and are locked through locking rings; the turning joints and the pedestal measuring arm or the turning joints are connected through the locking notches and the locking convex openings and are locked through the locking rings; the swinging joints and non-pedestal measuring arms are connected through the locking notches and the locking convex openings and are locked through the locking rings; and the turning joints and the non-pedestal measuring arms are connected through the locking notches and the locking convex openings and are locked through the locking rings. When the measurer is required, types and numbers of the turning joints, the swinging joints and the measuring arms required can be determined according to spatial degrees of freedom and a measurement range required by a measurement task; corresponding parts are selected and are connected into the complete coordinate measurer through connecting joints; and in the measurement process, the degrees of freedom and measurement space size of the measurer can be instantly changed through the removal or addition of each part. The measurer can be restructured on the spot according to specific measurement needs and has high measurement task adaptability.

Owner:ZHEJIANG UNIV

M-shaped packaging bag opening mechanism

The invention discloses an M-shaped packaging bag opening mechanism, which comprises a rotary master disc, wherein the front end of the rotary master disc is rotatably provided with two corresponding swing arm spindles; the upper ends of the swing arm spindles are respectively provided with a swing arm; the front ends of the swing arms are respectively provided with a sucking disc seat; the lower ends of the swing arms are respectively provided with a gear; a rack respectively meshed with the two gears is arranged between the gears; a guide hole is arranged in the front end of the gear; a spring is installed in the guide hole; a connecting plate is arranged between the gear and the sucking disc seat; one end of the connecting plate is rotatably installed on the outer edge of the gear; the other end of the connecting plate is rotatably installed on a fixed support plate on the sucking disc seat; an idler wheel is rotatably installed in the rear end of the rack; and the idler wheel is in rolling cooperation with a swinging cam behind the idler wheel. The M-shaped packaging bag opening mechanism disclosed by the invention has the advantages of reasonable layout, small part amount, reliability in acting, stability in operation, high bag opening efficiency, pure mechanical mechanism, small travel, high operation speed, small inertial impact, convenience in regulation, high interchangeability, good adaptation on the packaging bag material and long service life.

Owner:合肥远新包装机械有限公司

Stacked flexible rack gear type elevating gear

The invention discloses a stacked flexible rack-type lifting device, which comprises a fixed support, a driving device, a lifting support and a flexible rack used for jacking the lifting support. The upper end of the fixed support is provided with a gear which is connected with the driving device, the flexible rack is positioned in the fixed support which is provided with a guide rail, the upper part of the guide rail is vertical and provided with an arcuate extension section to the horizontal position, the flexible rack is provided with a pulley wheel matched with the guide rail and is a rigid chain formed by articulating a plurality of gear blocks, one side of the gear block takes the shape of teeth meshed with the gear, the adjoining teeth of adjacent gear blocks are jogged to form the complete tooth form, the adjacent gear blocks are articulated with each other at the side of no tooth form, and the gear block is formed by the superposition of lamellar toothed sheets. The invention provides the stacked flexible rack-type lifting device which reduces the process cycle, has good interchange capability and reduces the maintenance cost.

Owner:ZHEJIANG DAFENG IND

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com