Patents

Literature

8309results about How to "Burn fully" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

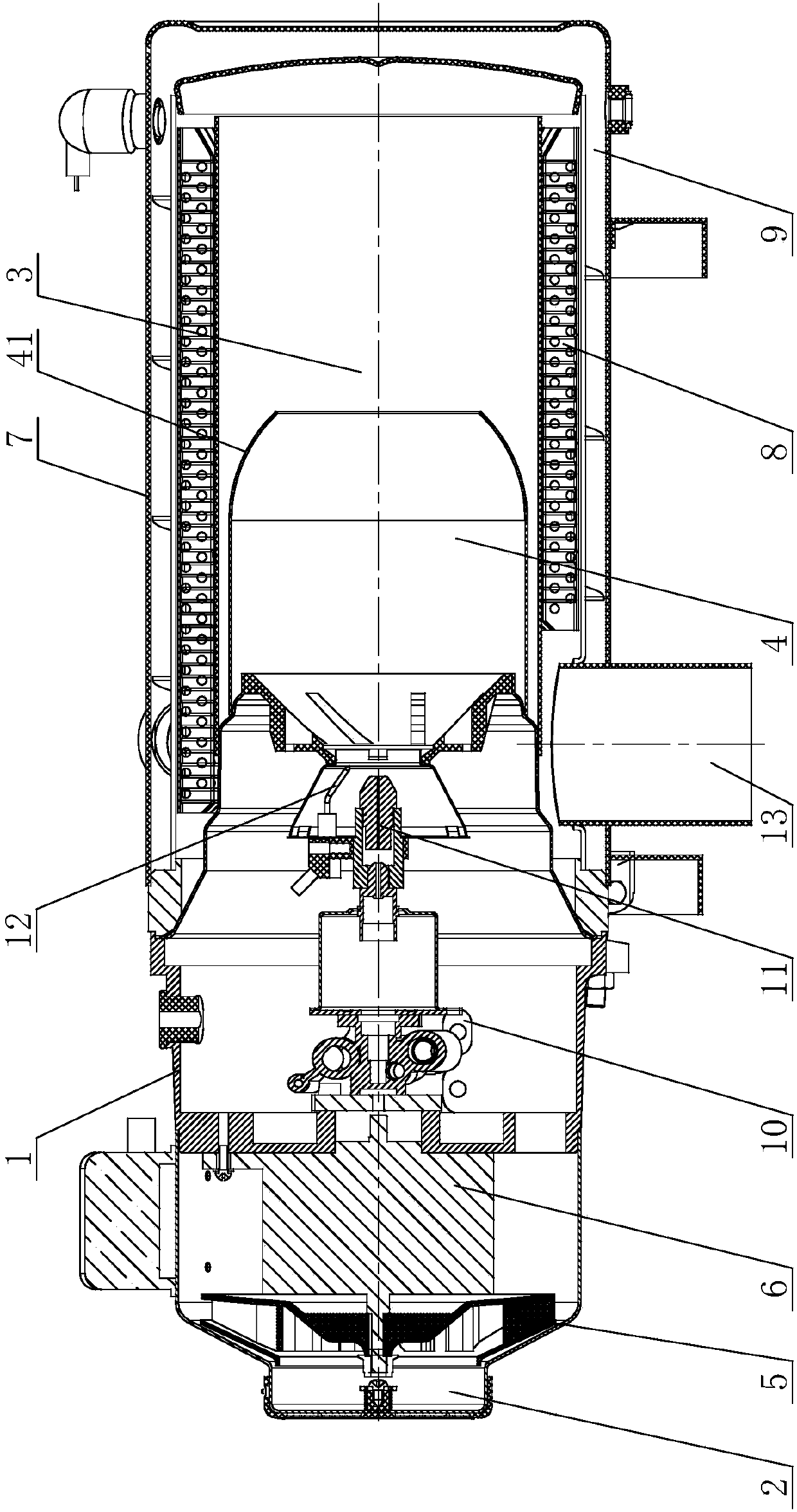

Two-stage garbage incinerator

ActiveCN101922715AGuaranteed incineration effectFully dryInclined grateIncinerator apparatusLoss rateCombustion

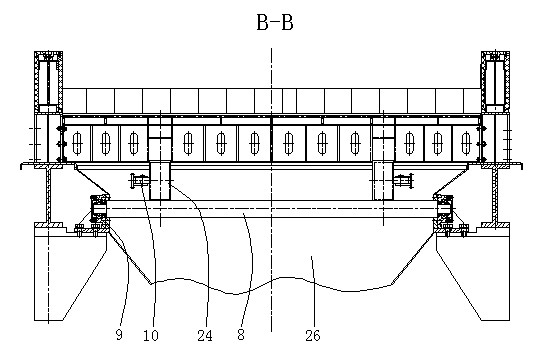

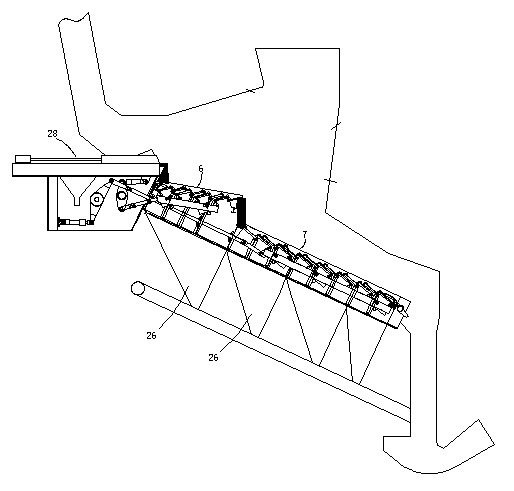

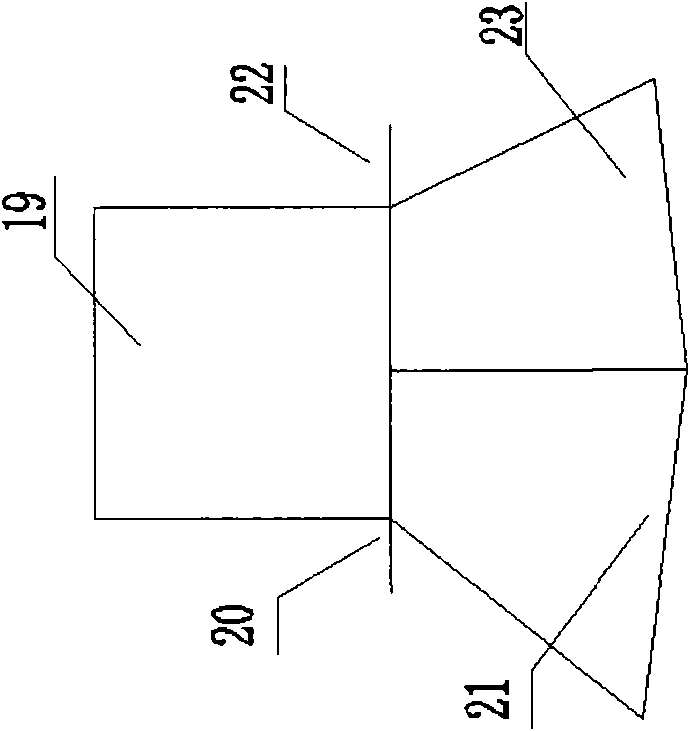

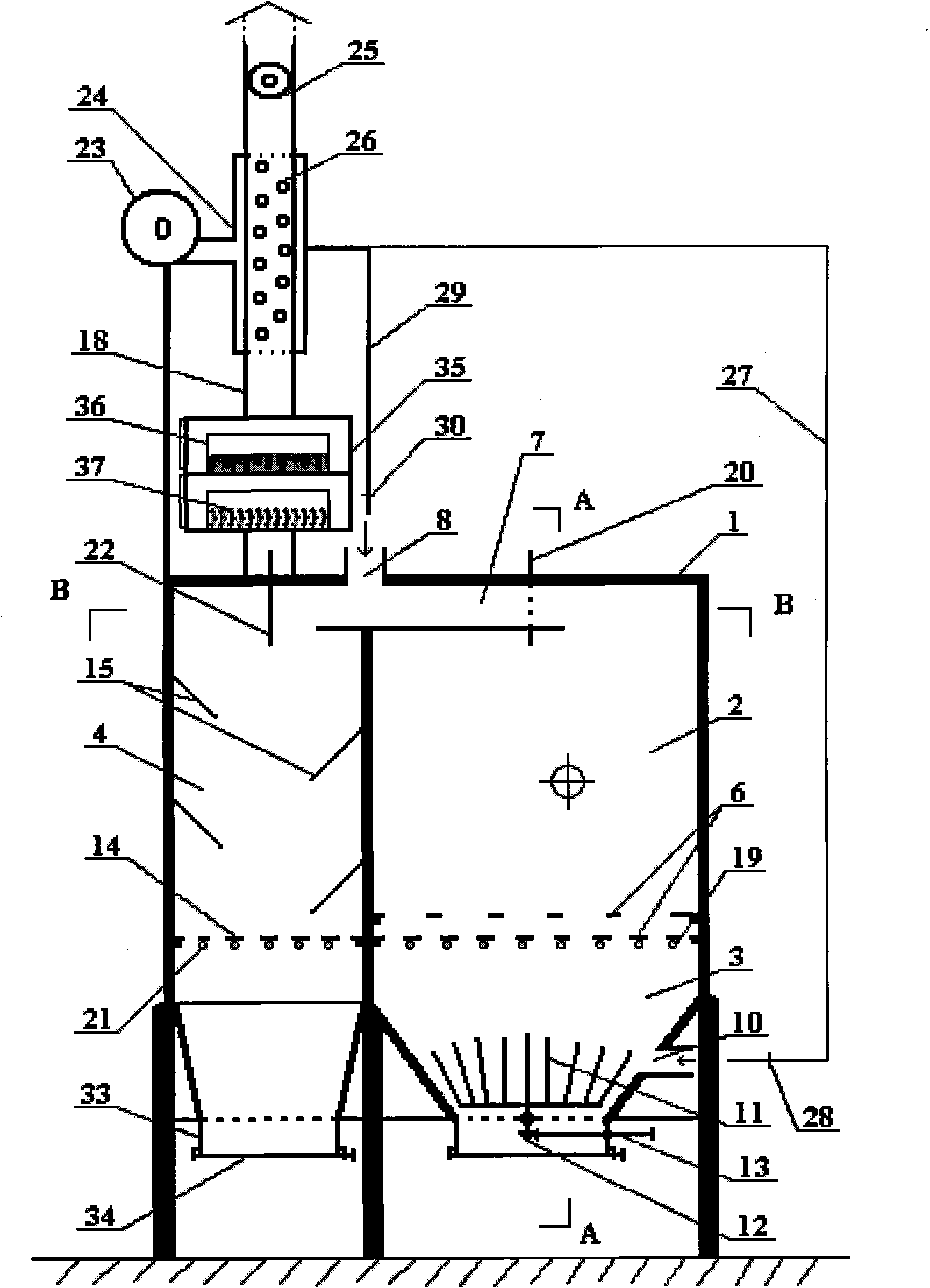

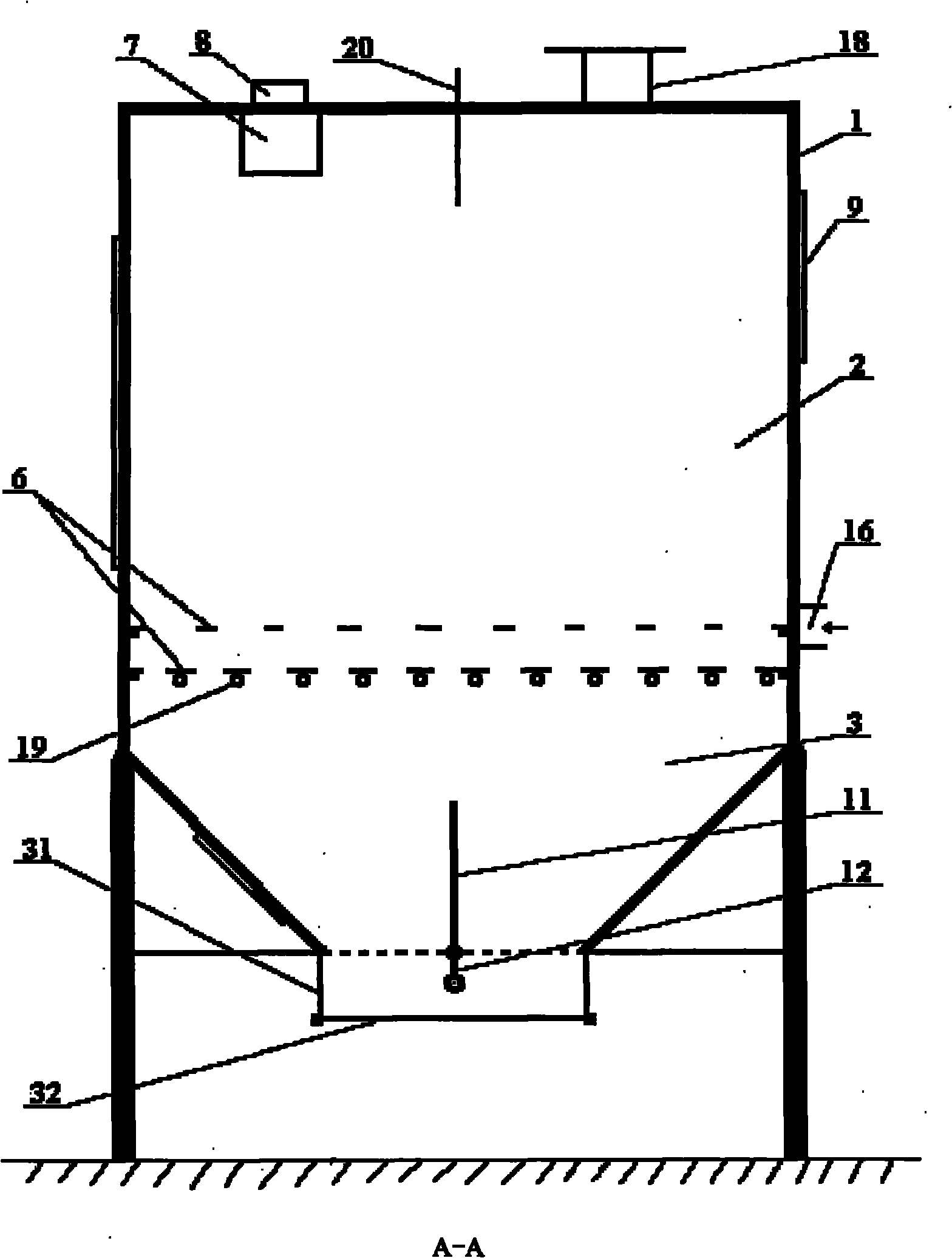

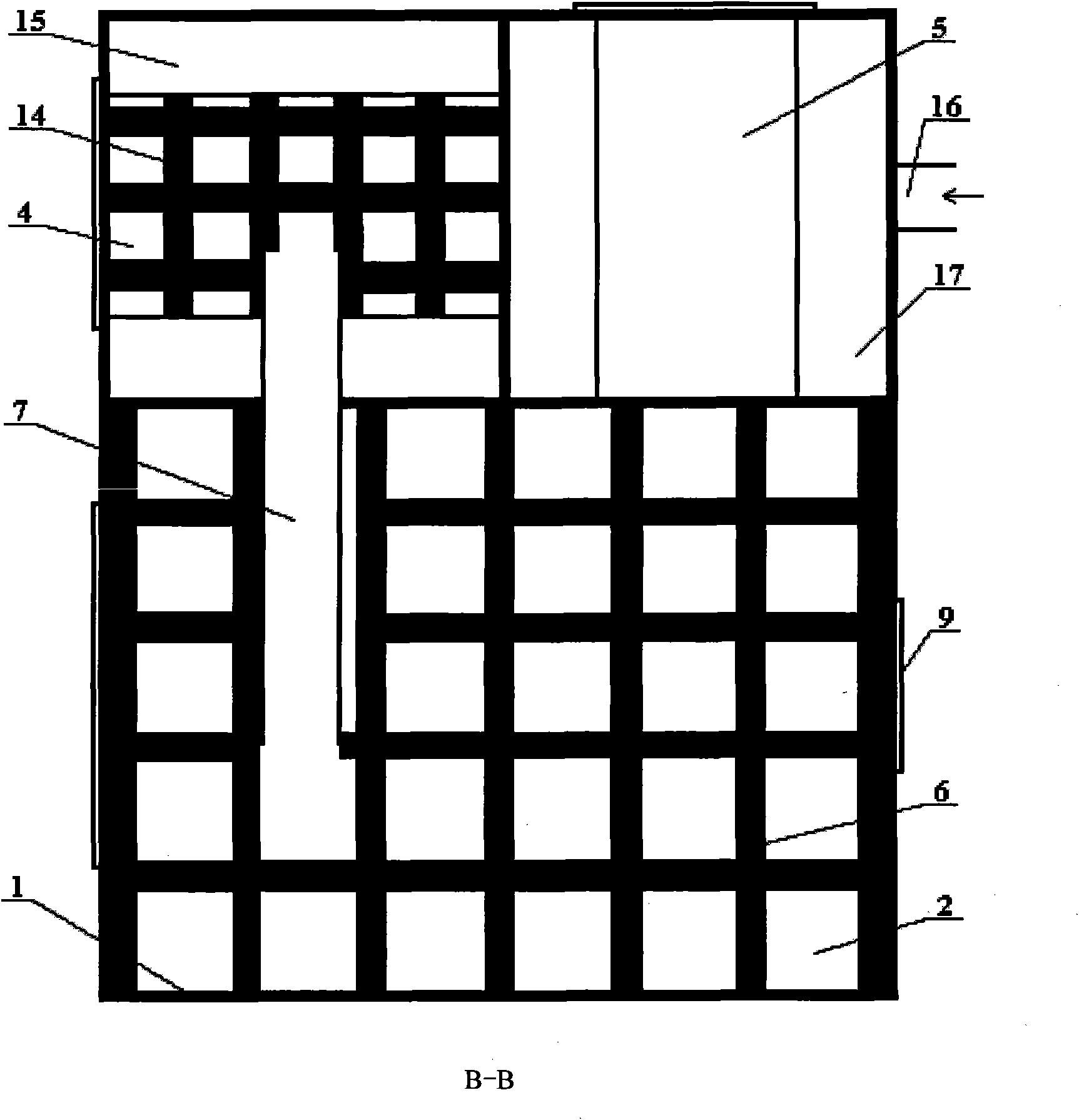

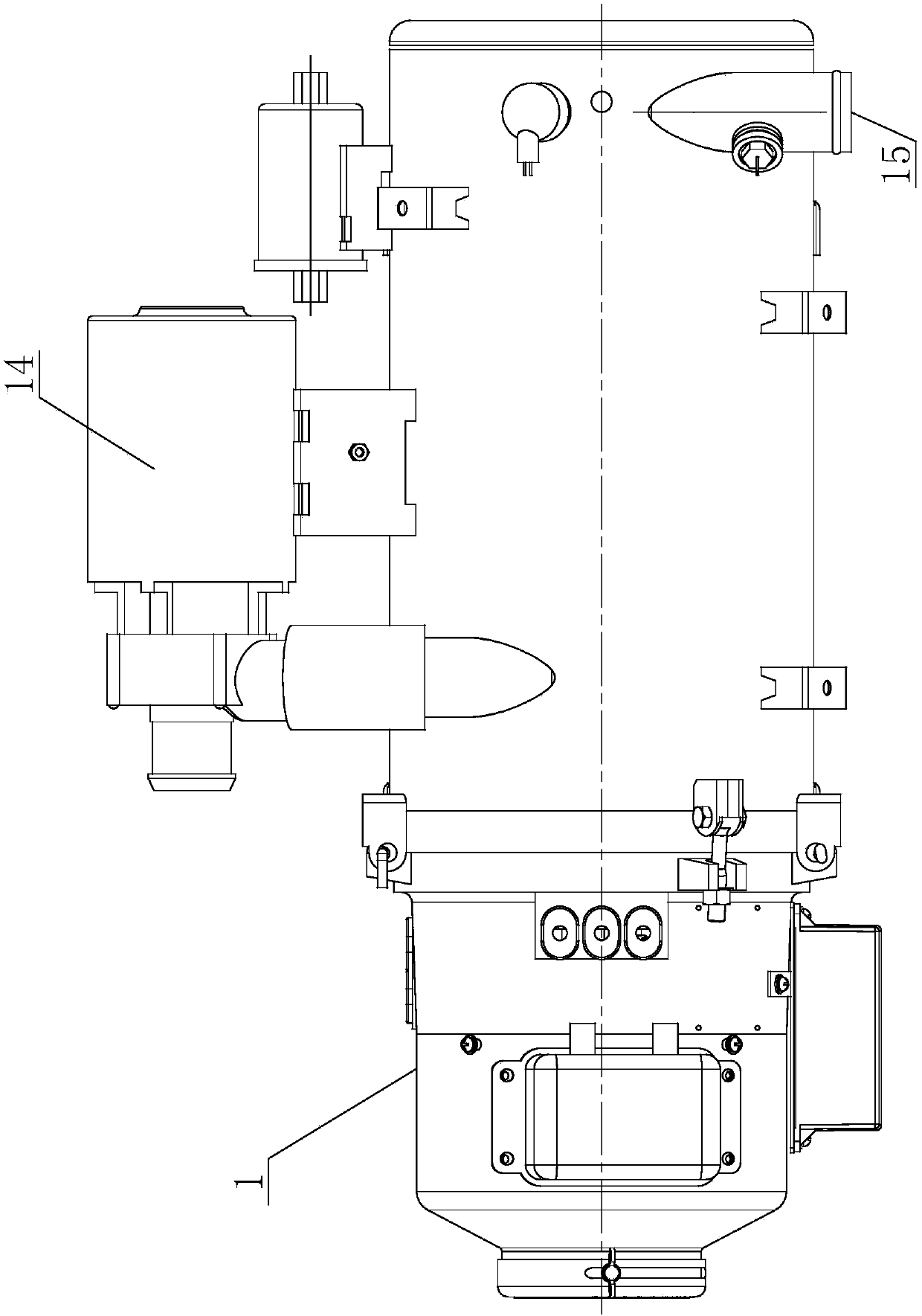

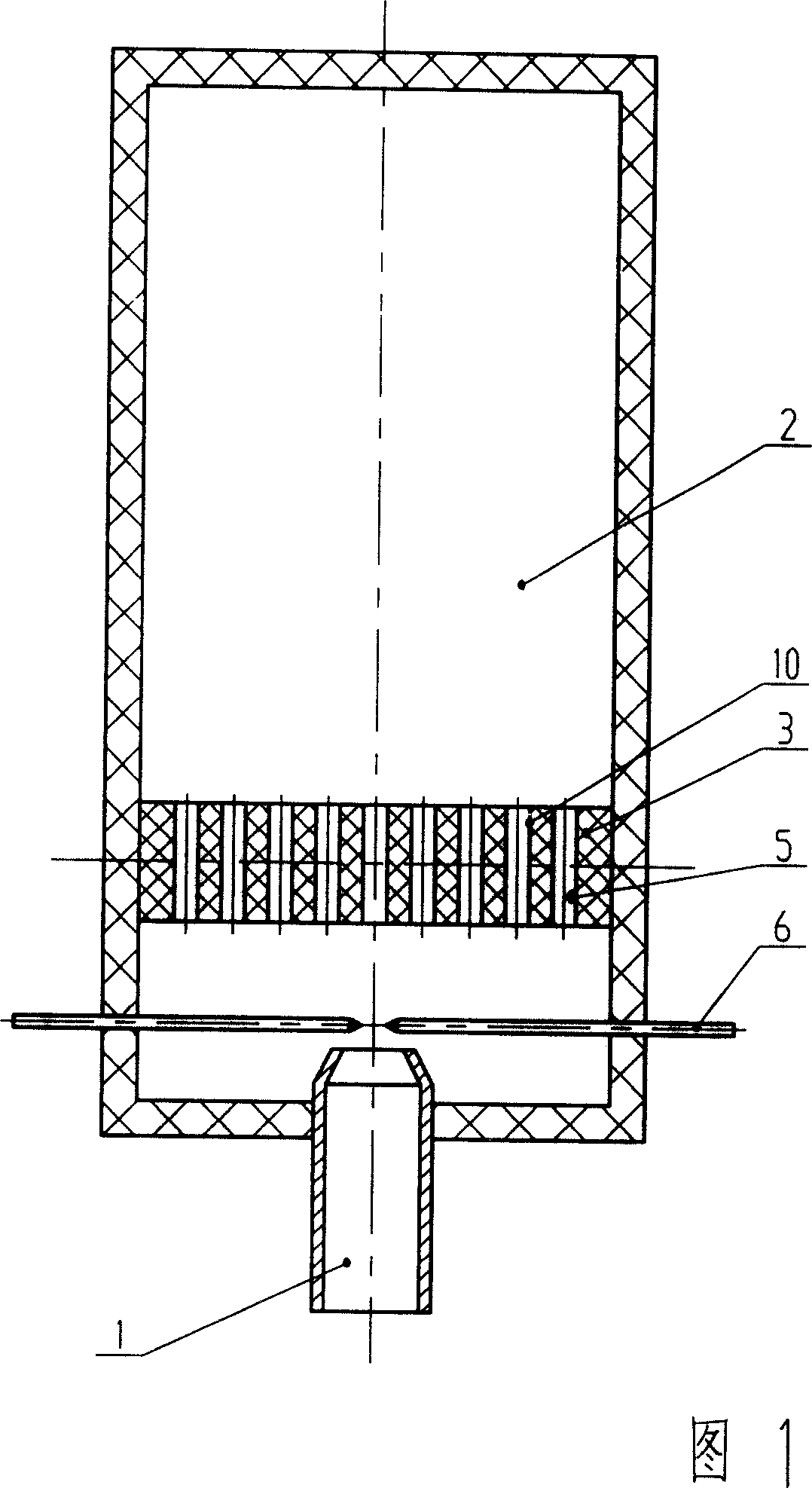

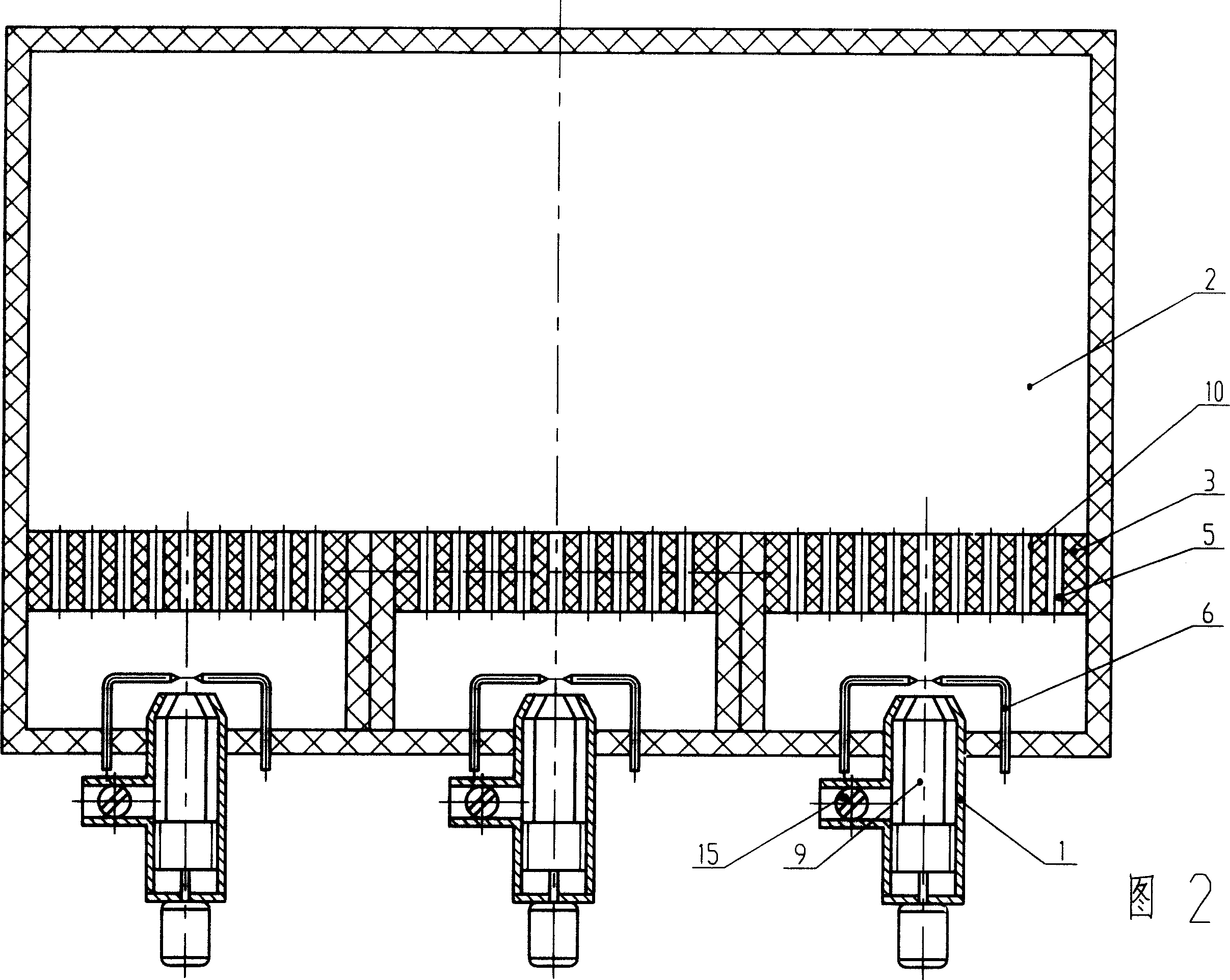

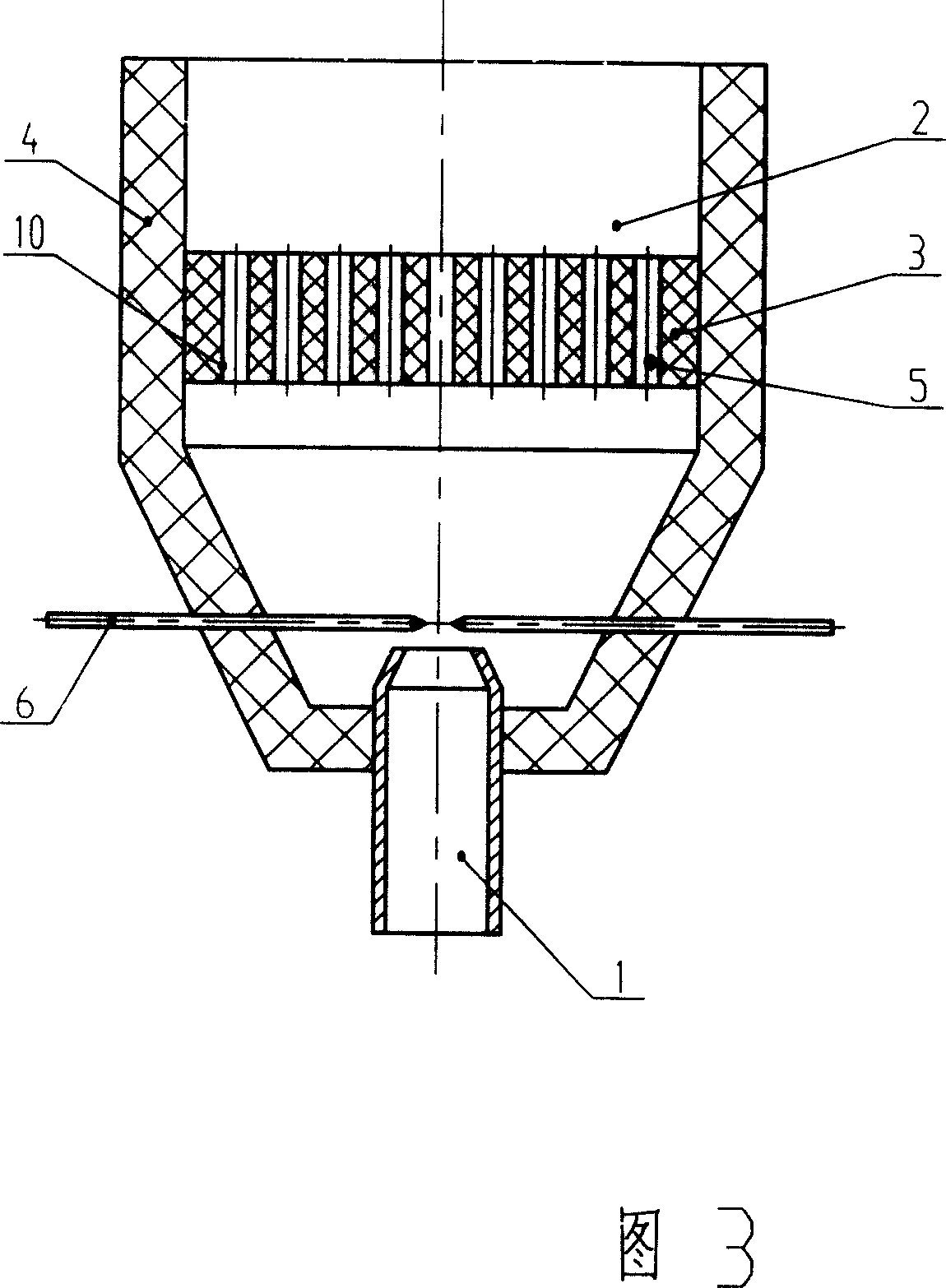

A two-stage garbage incinerator is characterized in that secondary air supply holes are arranged on front and rear arches of a furnace body and an ignition combustion-supporting hole is arranged on the rear arch; a grate in the furnace body is divided into two stages from top to bottom; the upper stage is a forward pushing stage and the lower stage is a backward pushing stage; an independent primary air chamber is arranged below each stage; the heads of the grates on the forward pushing stage face the low point direction of the grates; the heads of the grates on the backward pushing stage face the high point direction of the grates; moving beams of the grates on the same stage are equipped with left and right draw bars arranged side by side; the left and right draw bars are supported by supporting roller devices and are connected with the moving beams to form draw bar frames; and the ends of the draw bar frames are connected with front rocker arm driving mechanisms, lateral rocker arm driving mechanisms or front straight driving mechanisms. The incinerator can realize full drying of the whole garbage material, ensure complete combustion and ensure the garbage incineration effect and hot ignition loss rate. At the same time, the incinerator has less spare parts and spare part specifications, good quick-wear part interchangeability and low manufacture and maintenance costs.

Owner:CHONGQING SANFENG ENVIRONMENTAL IND GRP

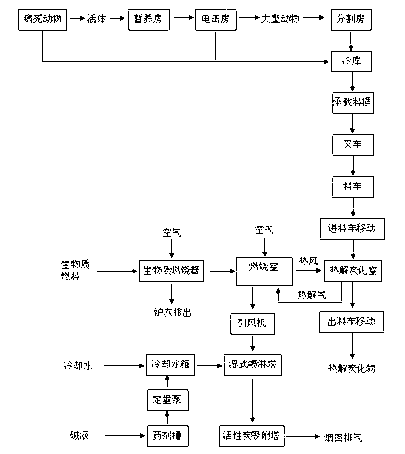

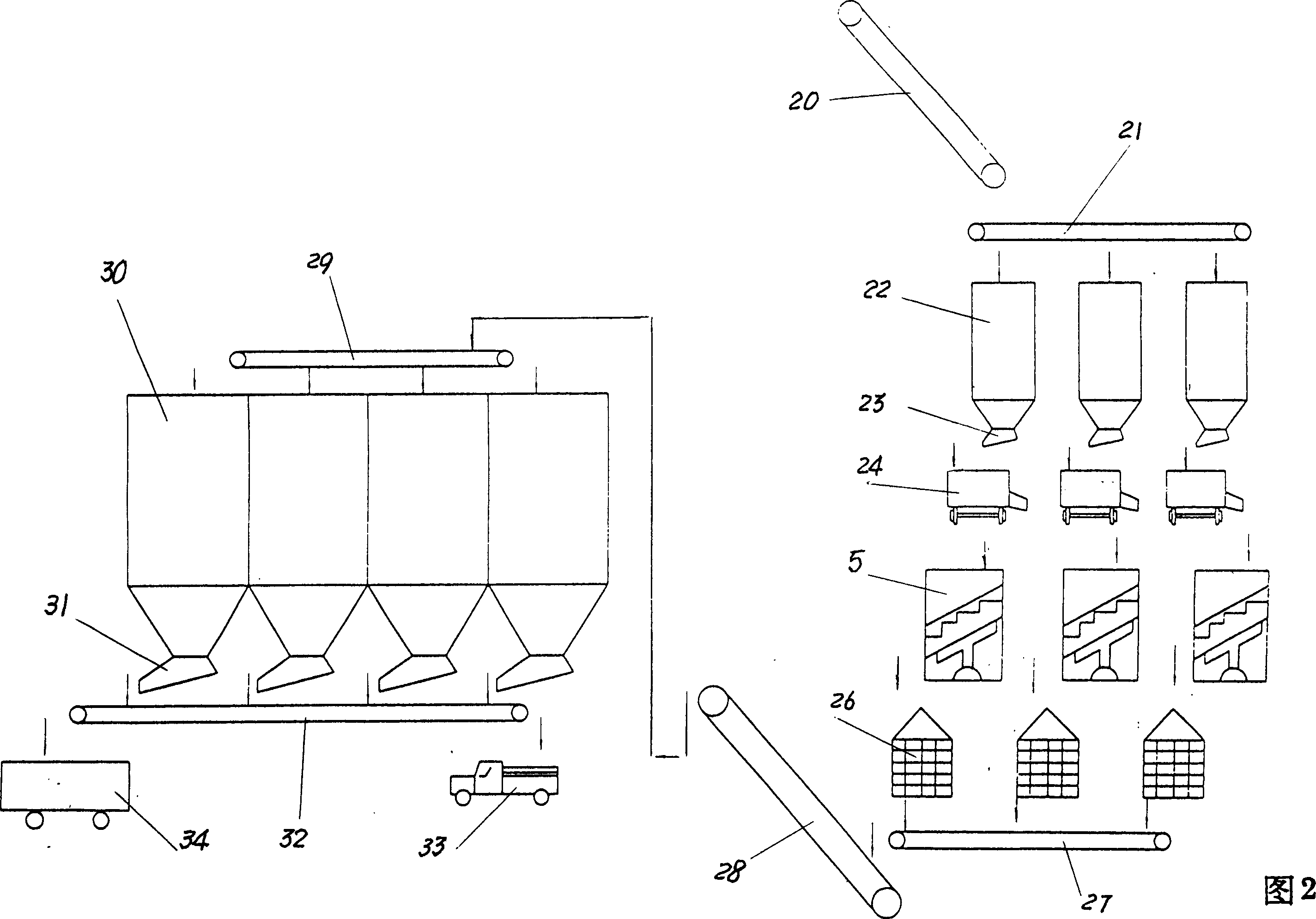

Processing method for biomass solid molding fuel

InactiveCN101555429AImprove processing capacityImprove market competitivenessBiofuelsSolid fuelsBiomassCrop

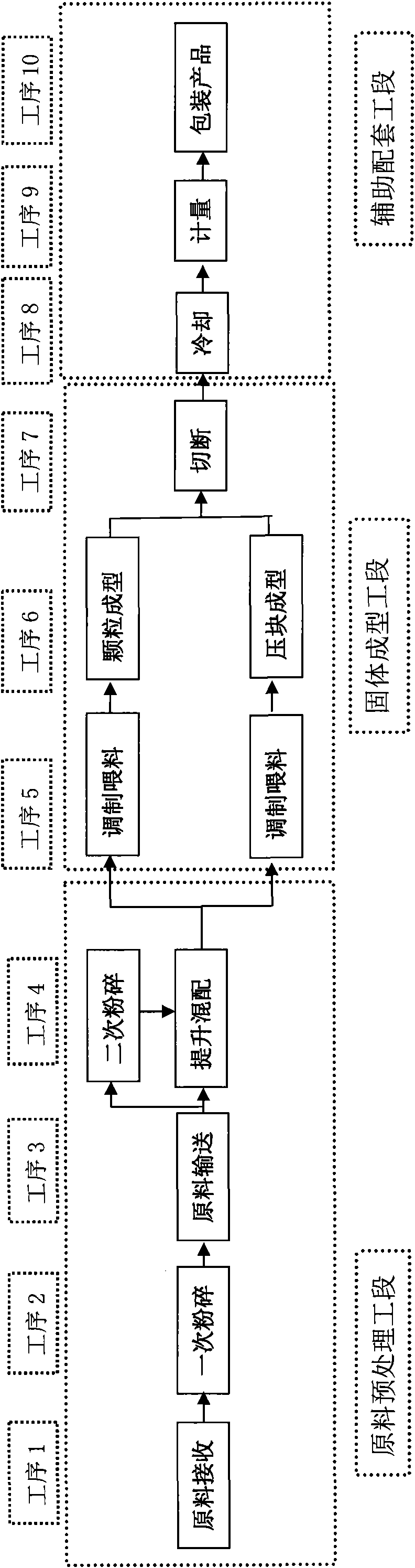

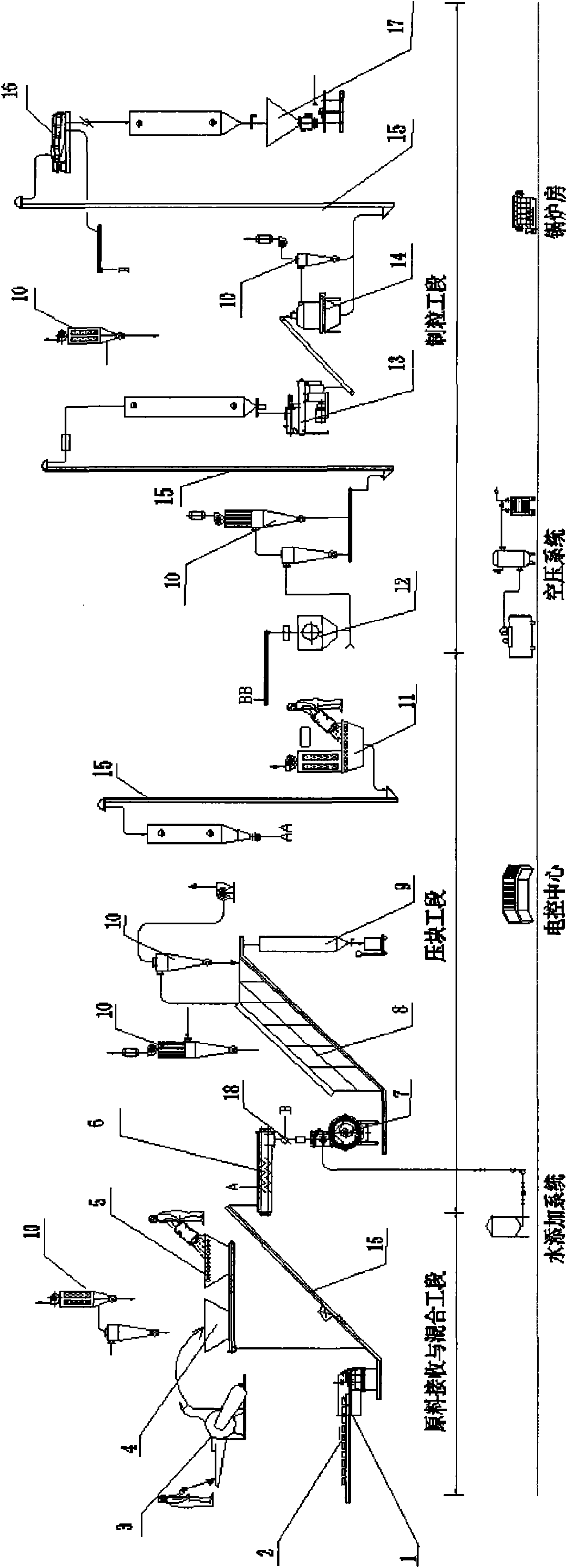

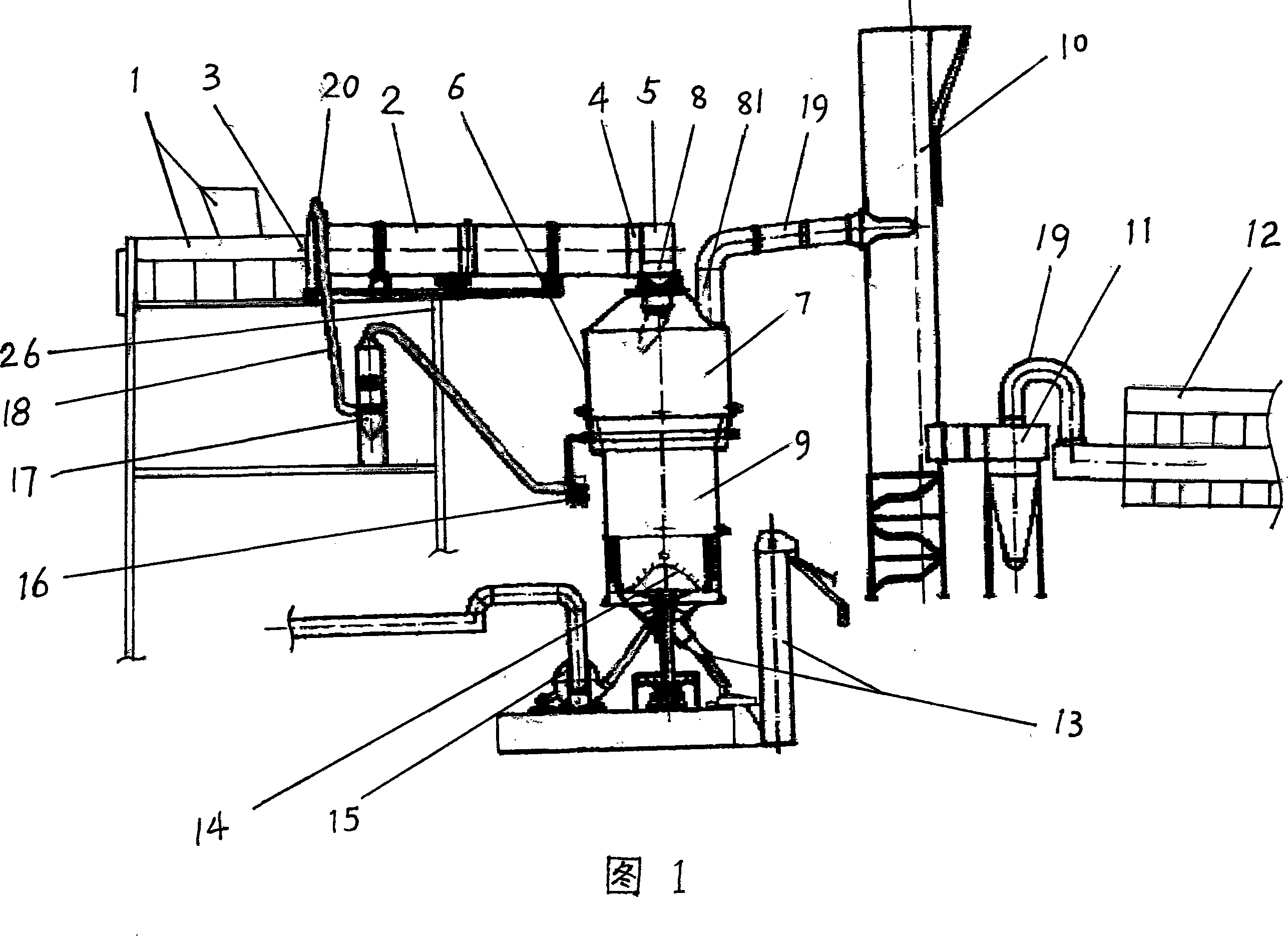

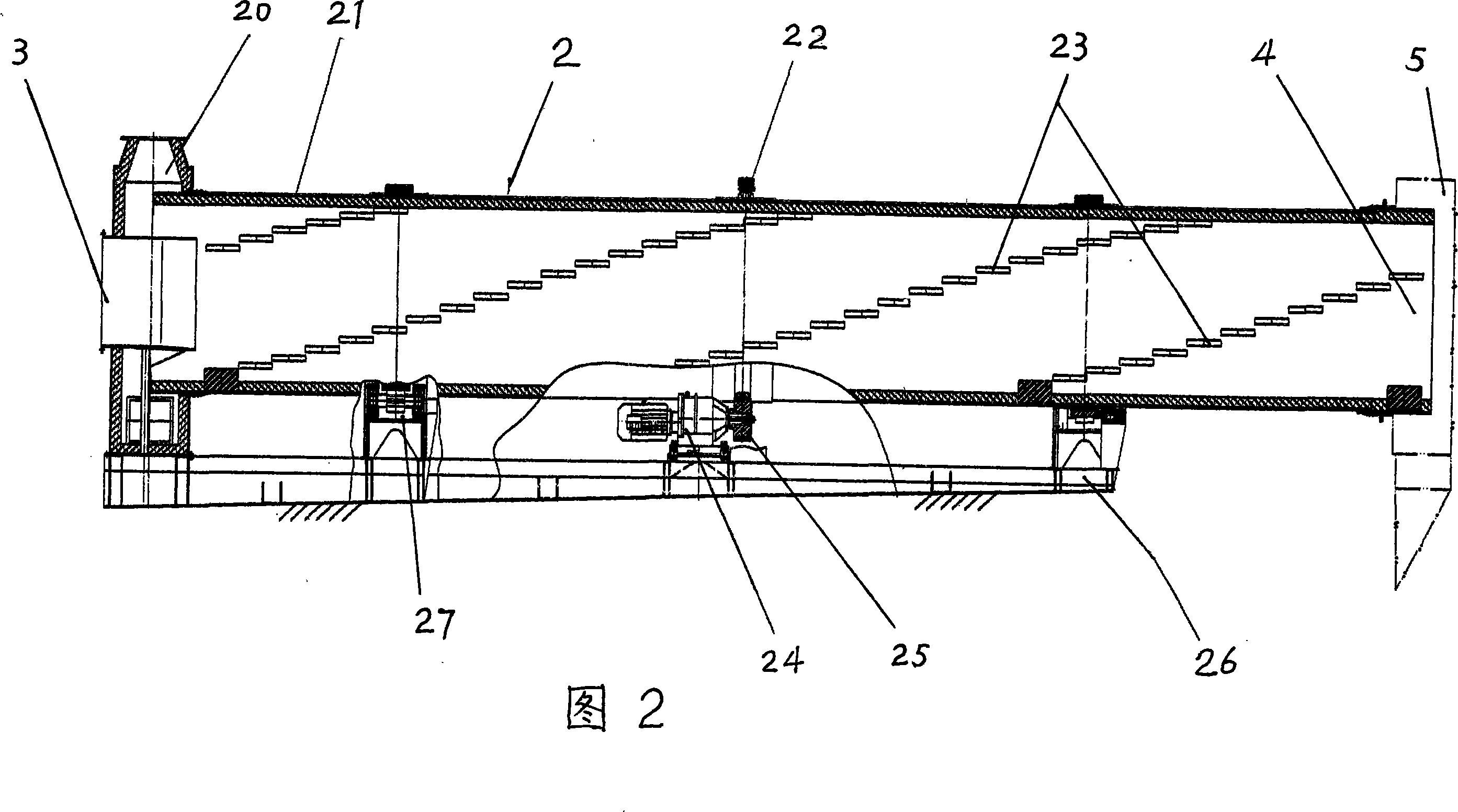

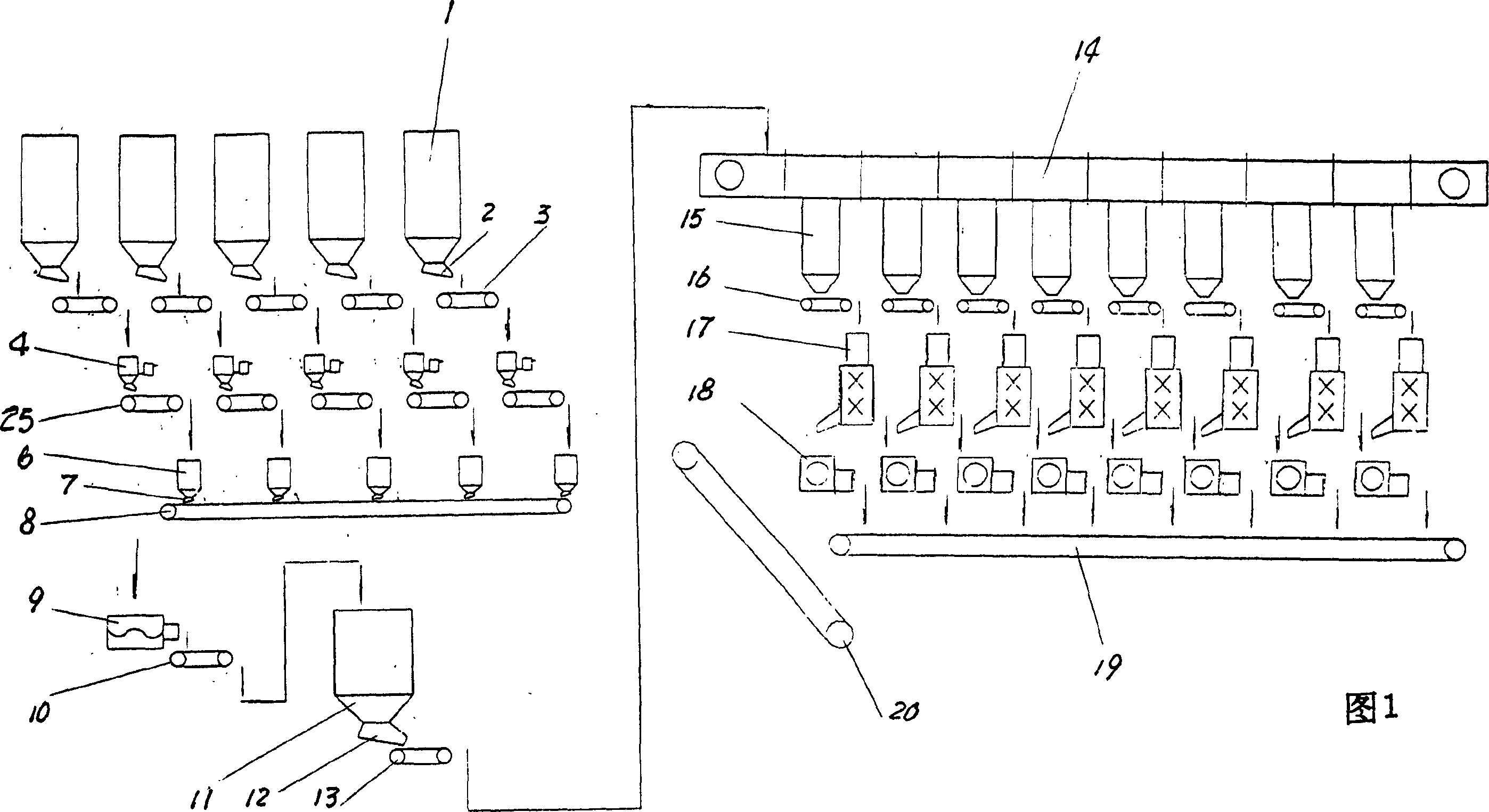

The invention discloses a processing method for biomass solid molding fuel, which pertains to the technical field of solid fuel and aims at solving problem of comprehensive use of energy and biomass energy in rural areas. The technical proposal is as follows: biomass energy such as crop straws, shrub forest, forestry residues and the like are used as raw materials, and the secondary crushing technique and the mixed technique combining continuous feeding with adjustable feeding are adopted, therefore, two types of solid fuels, namely, block-type and granular fuels, can be produced. The technical proposal comprises three stages namely, pre-treatment of raw materials, solid molding and auxiliary assorting, and the specific working procedures comprise raw material cracking, drying, conveying, mixing, feeding, molding, cutting, cooling and measuring and packaging and adding a compulsory ventilating dust-removing system during the whole process. The processing method for biomass solid molding fuel solves the problem of diversification of biomass raw materials, and the biomass solid fuel production line constructed by adopting the processing method realizes the industrial continuous and stable production, solves the problems of high energy consumption and low production efficiency in the existing small workshop-style production, and is also beneficial to solving the rural energy problem and improving the rural environment.

Owner:ACADEMY OF PLANNING & DESIGNING OF THE MINIST OF AGRI

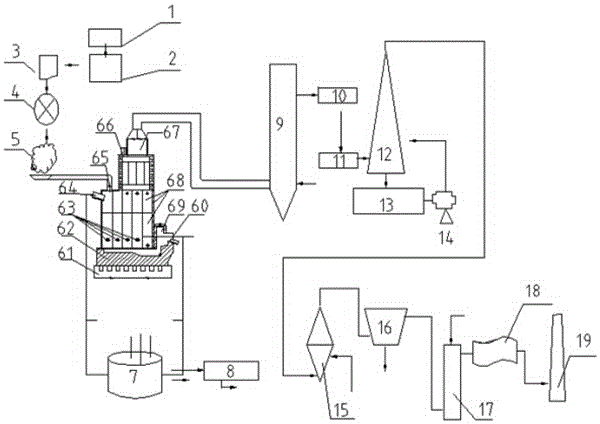

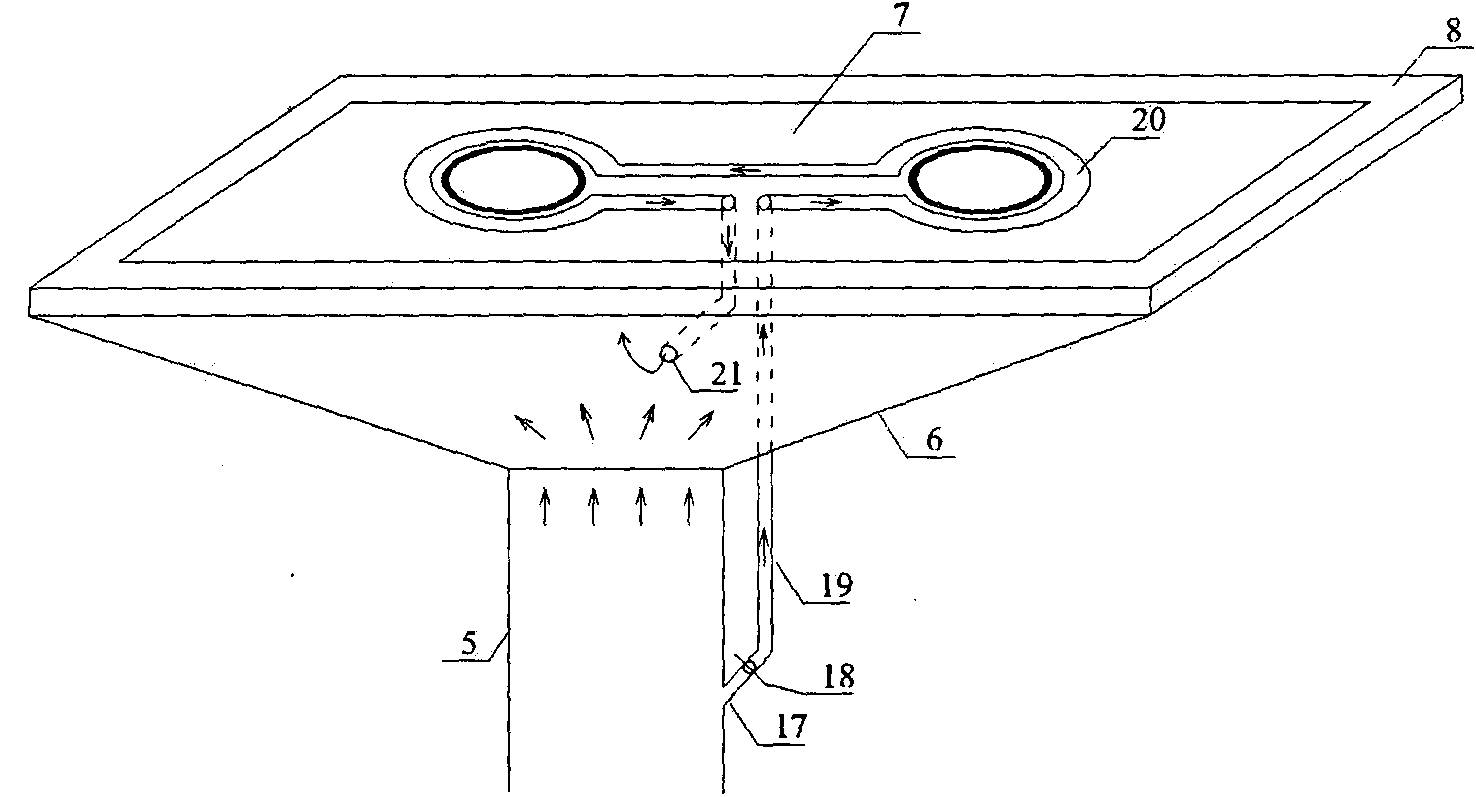

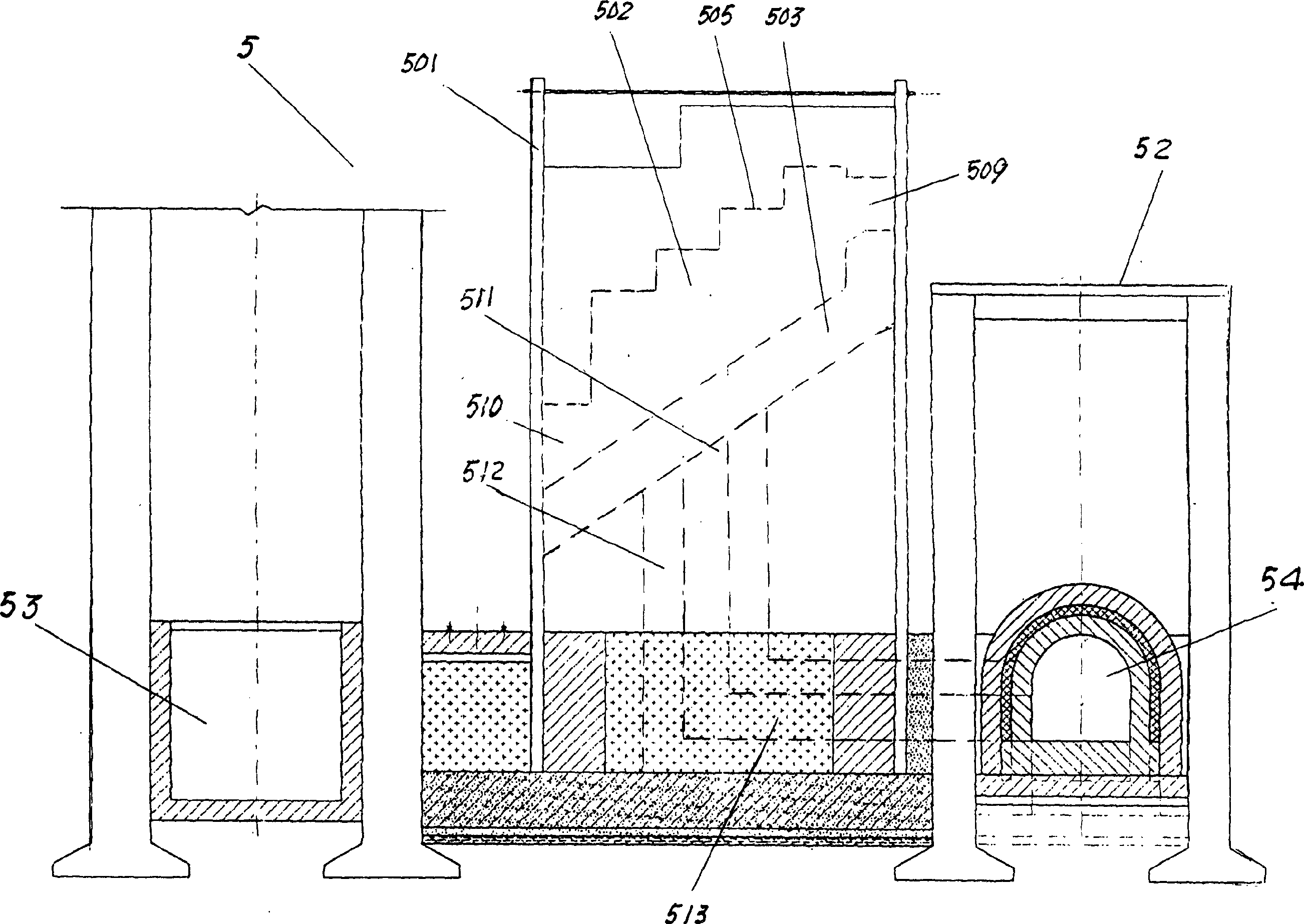

Double-loop double-pyrogenation incinerator for garbage harmless treatment and its usage method

InactiveCN101101120APrevent external consumptionPlay the role of thermal insulationIncinerator apparatusRefluxCombustion chamber

The invention relates to double loop double pyrolysis incinerator and its using method. Its features are that drying apparatus is formed by horizontal rotary kiln drying device, steam separator, and fume reflux line; the feed port of the horizontal rotary kiln is connected with discharge port of the feeding device; its discharge port is connected with the feed port above secondary burning chamber. While running, part of high temperature fume of secondary burning chamber can enter the rotary kiln to process reverse drying preheat and pyrolysis for the garbage; cooled fume is inducted into the secondary burning chamber by secondary fan after dehydrating by steam separator. Compared with exiting technique, the invention has the advantages of continual heat transfer, fast gasification rate, full burning, processing domestic garbage without auxiliary fuel etc.

Owner:福建省丰泉环保控股有限公司

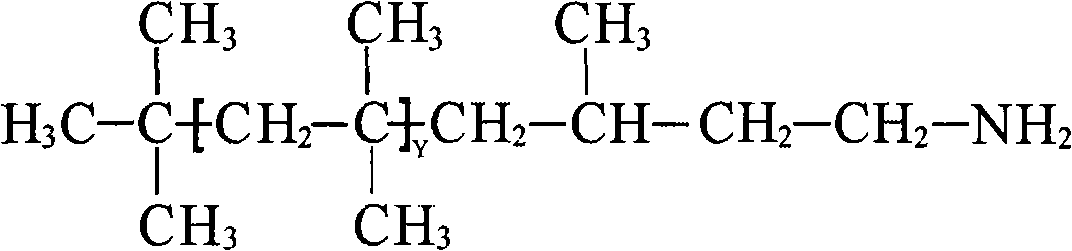

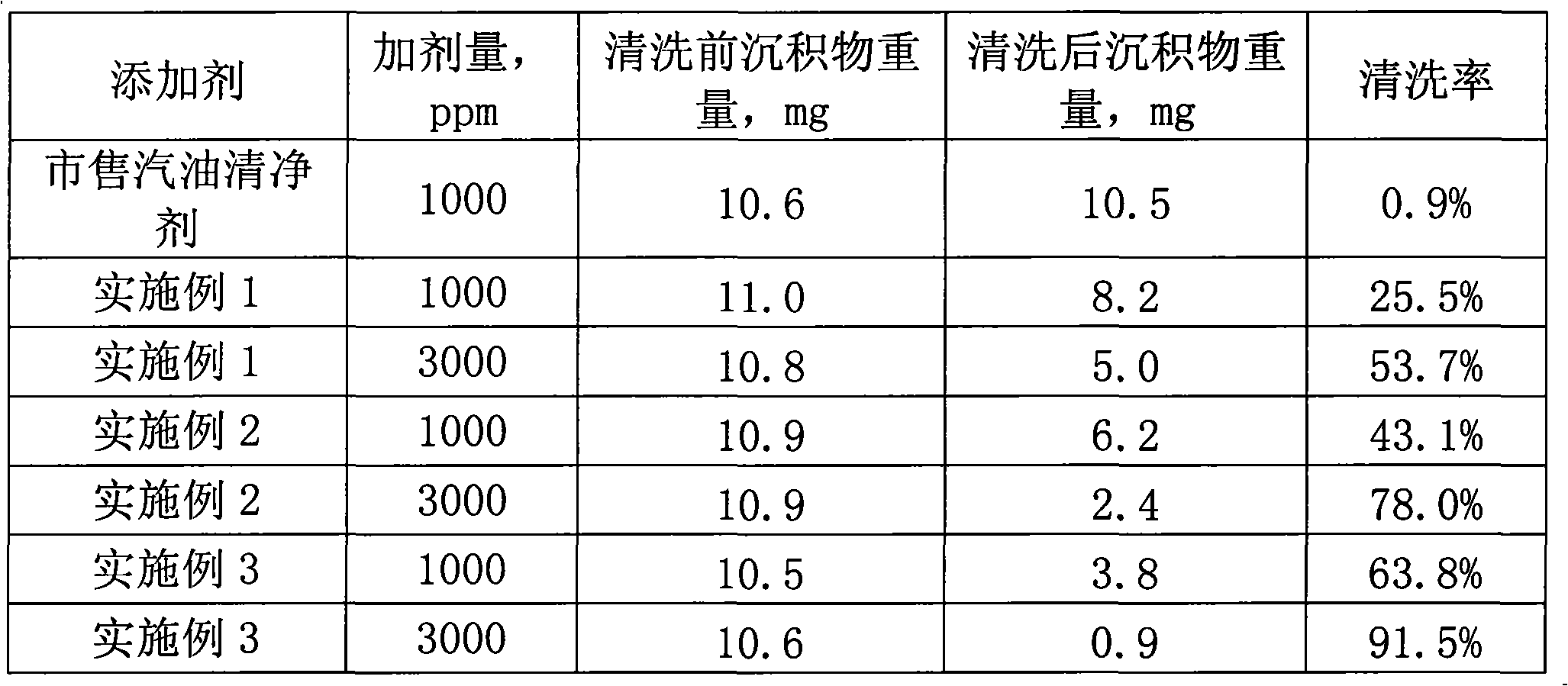

Gasoline detergent with cleaning function and preparation method thereof

InactiveCN101962584AEasy to cleanBurn fullyLiquid carbonaceous fuelsFuel additivesCombustion chamberPreservative

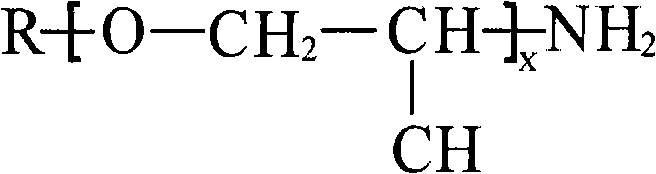

The invention relates to a gasoline detergent with cleaning function and a preparation method thereof. Gasoline containing the detergent can clean deposits in an oil injection nozzle, an air inlet valve and a combustion chamber of a gasoline engine. The detergent comprises at least one type of high-activity polyetheramine, at least one type of high-activity polyisobutene amine, base oil serving as carrying oil, other solvent oil and functional agents such as an antioxidant, an anti-rusting agent, a preservative and a demulsifying agent. Specifically, the detergent comprises the following components in percentage by mass: 10 to 80 percent of polyetheramine, 5 to 20 percent of polyisobutene amine, 5 to 35 percent of carrying oil and 5 to 35 percent of solvent oil and other functional agents. After being added into commercially available motor gasoline according to the dosage of between 1,000 and 3,000 ppm, the detergent of the invention can suppress and clean the deposits of the oil injection nozzle, the air inlet valve and the combustion chamber of an oil-fired air inlet system of the gasoline engine. The motor gasoline containing the detergent of the invention can clean the deposits of the oil injection nozzle, the air inlet valve and the combustion chamber in which the deposits are generated.

Owner:深圳市超美化工科技有限公司

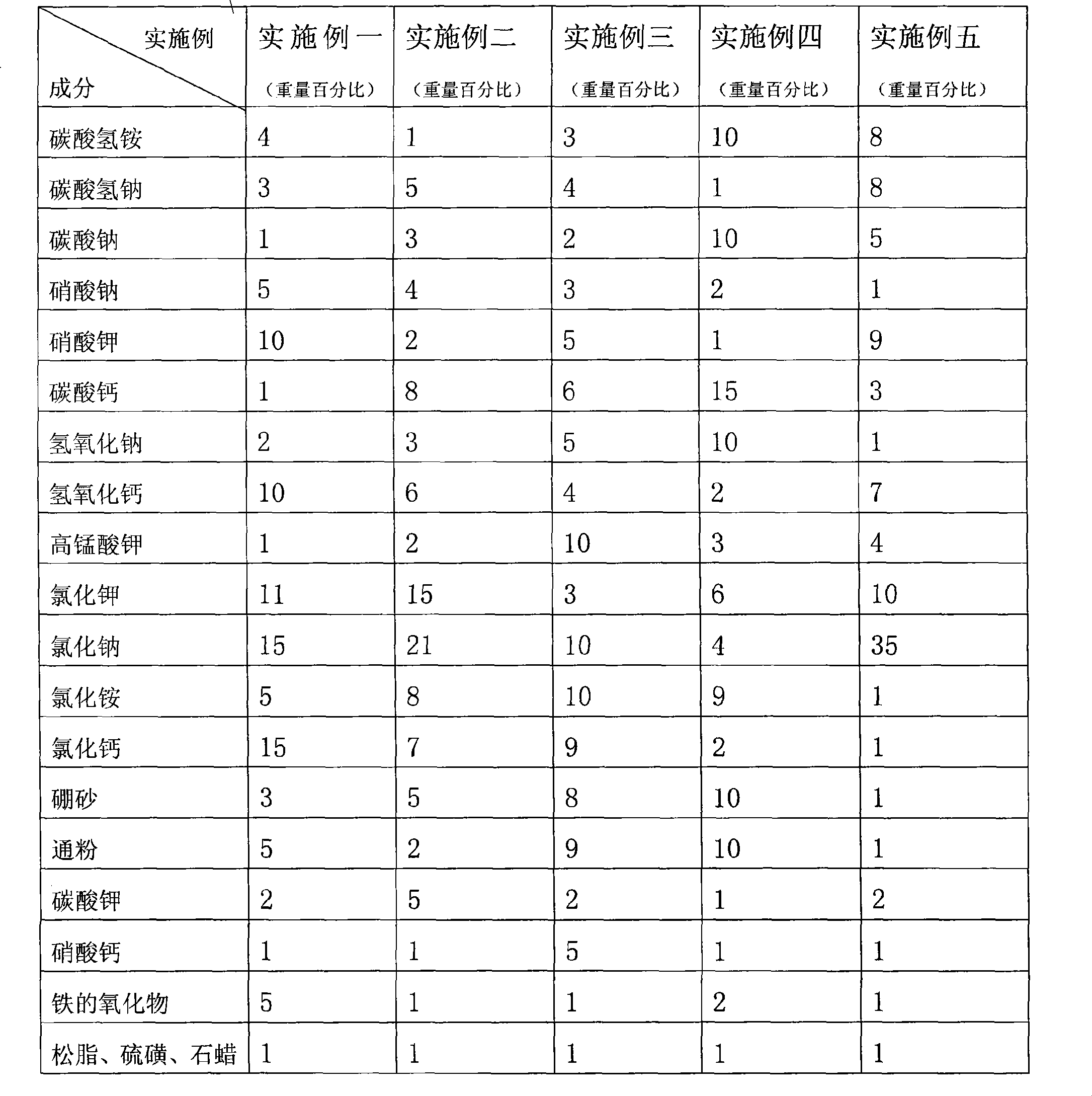

Environment-protecting synergistic agent for fuel coal

InactiveCN101440328AIncreased flammable contentIncreased space gapSolid fuelsFuel additivesSodium bicarbonateFurnace temperature

The invention discloses a bunker coal environment-friendly synergist, which comprises the following components by weight percent: 1 to 10 percent of ammonium bicarbonate, 1 to 8 percent of sodium bicarbonate, 1 to 10 percent of sodium carbonate, 1 to 5 percent of sodium nitrate, 1 to 10 percent of potassium nitrate, 1 to 15 percent of calcium carbonate, 1 to 10 percent of sodium hydroxide, 2 to 10 percent of calcium hydroxide, 1 to 10 percent of potassium permanganate, 3 to 15 percent of potassium chloride, 10 to 35 percent of sodium chloride, 1 to 10 percent of ammonium chloride, 1 to 15 percent of calcium chloride, 1 to 10 percent of borax, 1 to 10 percent of macaroni, 1 to 5 percent of potassium carbonate, 1 to 5 percent of calcium nitrate, 1 to 5 percent of iron oxide, and the balance being micro turpentine, sulfur and paraffin wax. The bunker coal environment-friendly synergist makes flame of combustion be more rampant and denser, the furnace temperature rise to a higher level, the hearth be brighter and cleaner and tail gas be cleaner.

Owner:李政 +1

Biomass curing-forming fuel and preparation method thereof

The invention discloses a biomass curing-forming fuel. The biomass curing-forming fuel consists of straws, saw dust, coal dust, a combustion improver, a sulfur-fixing agent and a dust-falling agent according to parts by weight, wherein the straw is one or combination of the straw of crops such as rice, wheat, soybean, corn, sorghum, cotton, rape and tobacco, a branch and a bark of trees and shrubs, rice hull, chaff and peanut coat; the combustion improver is one or more of table salt, sodium nitrate, potassium permanganate, potassium oxide, sodium nitrite and sodium hypochlorite and capable of realizing decomposition and combustion supporting at different temperatures; the sulfur-fixing agent is in a manner that sodium carbonate, calcium hydroxide and alkyl alcohol amine compounds are synergistically used and is capable of reducing discharging of sulfur dioxide; and the dust-falling agent is selected from iron sesquioxide and capable of lowering a melting point of ash and reducing dust volume. The biomass curing-forming fuel has the advantages that the combustion efficiency is high, the slag bonding and the soot formation are not generated, the black smoke is little, the fire power strong, the combustion is sufficient, the ash does not fly, the biomass curing-forming fuel is clean and sanitary and the like. The invention further discloses a preparation method of the biomass curing-forming fuel.

Owner:JINAN SANNONG ENERGY TECH

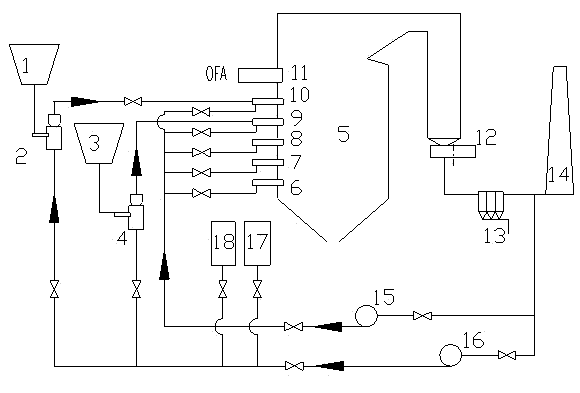

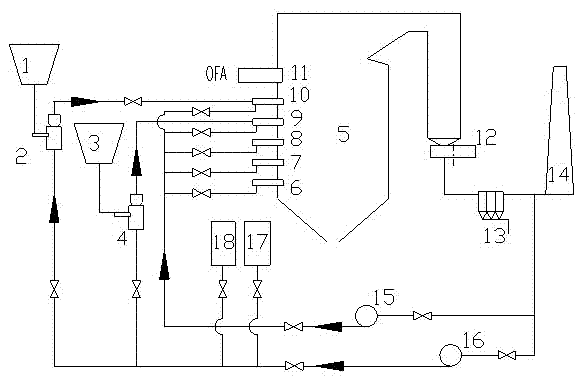

Method for combusting fuel reburning low-nitrogen oxide

ActiveCN102252324AImprove the mixing effectLong reduction reaction timeCombustion apparatusLow nitrogenEvaporation

The invention discloses a method for combusting a fuel reburning low-nitrogen oxide and belongs to a clean combustion method for a coal-fired boiler. Secondary medium air is used as a powder conveying medium of a combustor on the upper layer of the main combustion area of the boiler, coal powder used as a reburning fuel is conveyed into the boiler, the secondary medium air is used as distributed air of the combustor, the secondary air of the combustor on the upper layer is reduced correspondingly, the distributed air in the reburning area is reduced correspondingly, low excess air combustion is formed, the distributed air in a hearth is not enough, and finally over fire air (OFA) complements the required air; and the mixed medium of air and fuel gas is used as the conveying medium of the coal powder of the combustor of the upper layer, and the coal powder with the conventional fineness is conveyed into the boiler from the combustor on the upper layer by using a coal mill and a powder making system and is re-burnt and denitrated, and is burnt out by OFA. The problem that the reburning fuel and the fuel gas are not mixed uniformly, the reduction time is short, and the denitration efficiency is low is solved, the original design working conditions of maximum continuous evaporation capacity of the boiler and the like are not influenced, transformation is easy to realize, and the running cost is low.

Owner:徐州燃烧控制研究院有限公司

High-efficiency energy-saving high speed combustor of gas range

The invention is a high-efficiency, energy-saving and high-speed burner for a gas cooker used in catering industry and includes a burner, a pre-heater, a pre-mixing small fire burner, a fireproof fire ring, an electronic ignition system and a regulating device. After being necked down, the burning flame is ejected with high speed rotation to form the rotary rapid ejection burning flame, thereby realizing sufficient burning, facilitating boiler heating, and increasing the heating speed with low burning noise and high heat efficiency. The high-efficiency, energy-saving and high-speed burner for the gas cooker has the advantages of simple manufacture, easy maintenance, sufficient burning, high flame temperature, convenient boiler heating, improved heating speed, low power of the equipped blower fan, low burning noise, high thermal efficiency, convenient regulation, full-automatic ignition, concentrative firepower, intensive fire, energy conservation, strong adaptability, capability of meeting different requirements, wide application, easy processing, low manufacture cost and suitability for mass production.

Owner:尹华金

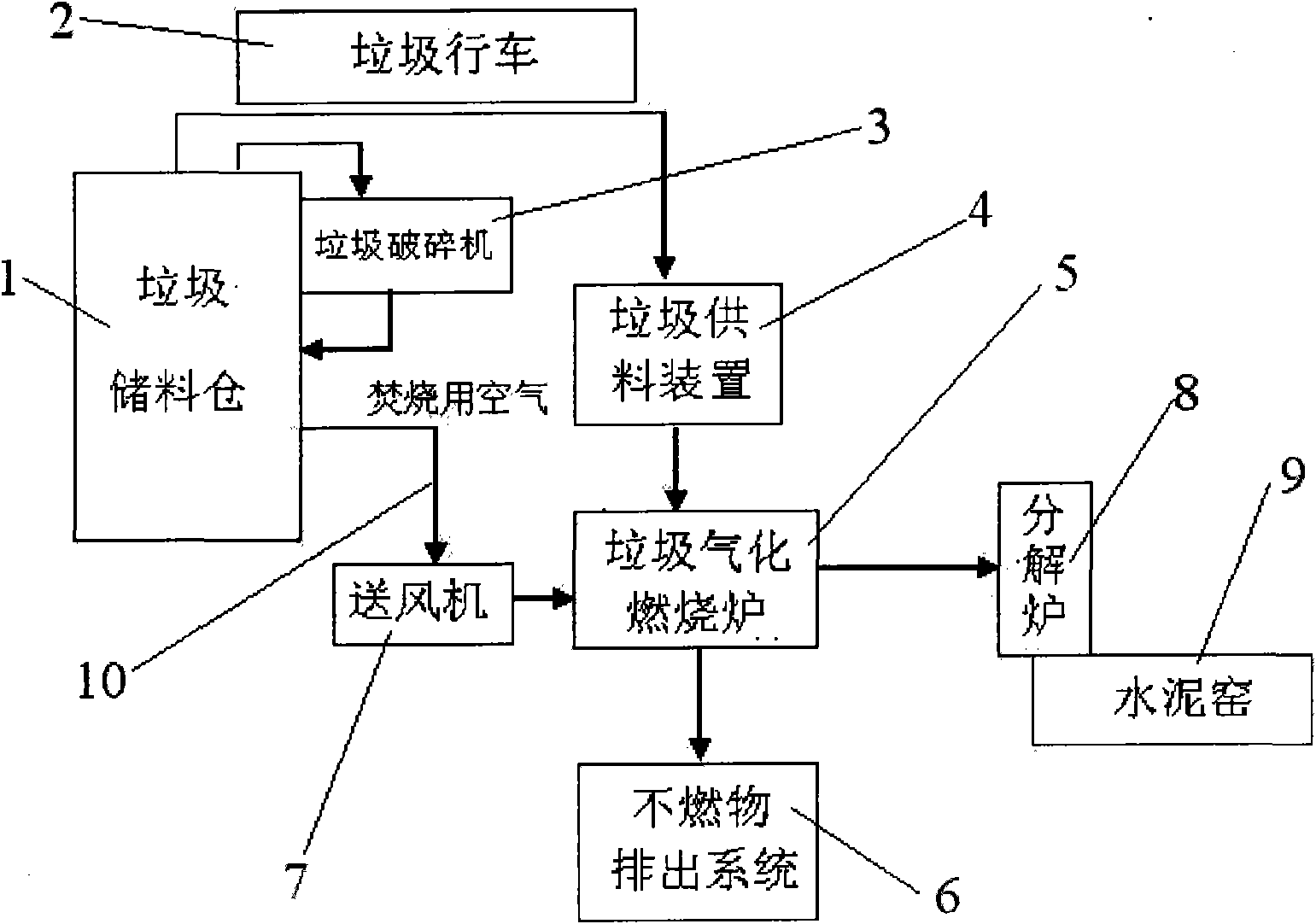

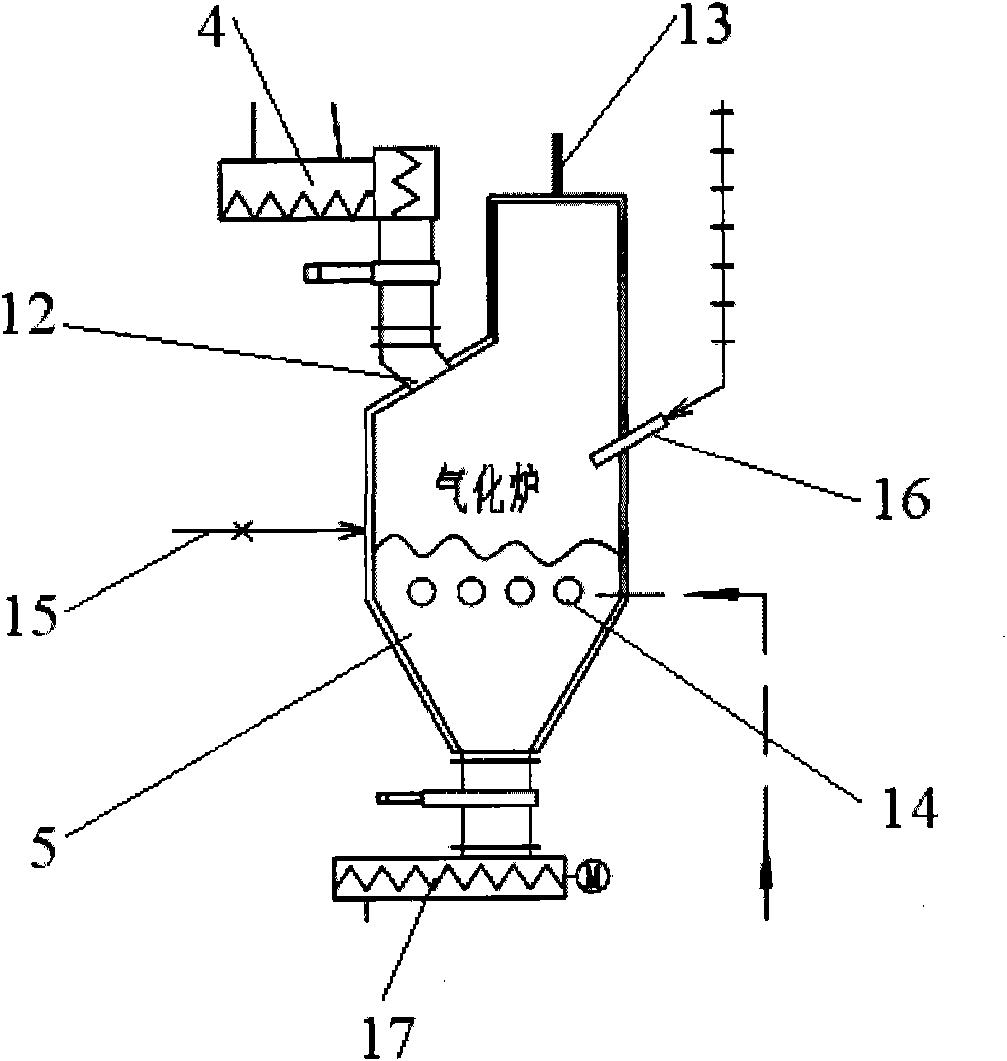

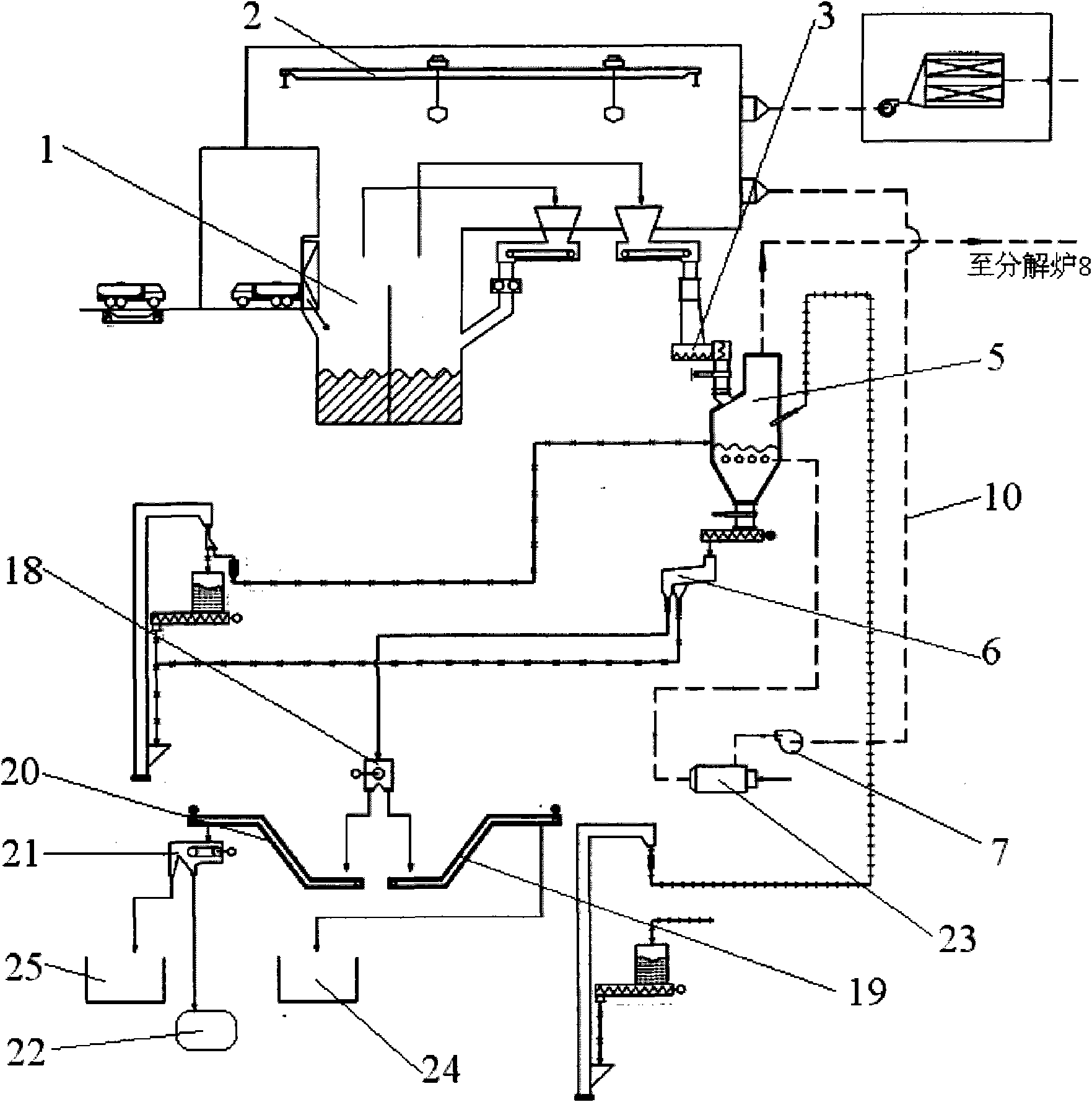

Garbage disposal system used in cement dry kiln production and disposal method thereof

ActiveCN101786809AExtended stayFull combustion processClinker productionCement kilnCombustion process

Owner:ANHUI CONCH GRP +2

Cleaning gasoline with alcohol ether base

InactiveCN1597873AMeet power requirementsIncrease oxygen contentLiquid carbonaceous fuelsCleansing AgentsNuclear chemistry

The invention discloses a clean alcohol ether-base gasoline, prepared of alcohol-base fuel mixed solution, naphtana etherified liquid, C-5 and cleaning agent; and its components in weight percent (wt%): alcohol-base fuel mixed solution 40-50, C-5 10-20, naphtana etherified liquid 30-45, cleaning agent 0.1. The alcohol-base fuel mixed solution is composed of methanol, acetone, hydrogen peroxide, ferrocene-benzene solution and camphor powder. The naphtana etherified liquid is prepared by etherifying naphtana, methyl-tert-butyl ether and isopropyl ether. The finished oil has rich HO molecular groups, high oxygen content and can fully burn. After it is used, the indexes of various harmful matters in the discharged tail gas from engines are obviously lower than those of ordinary gasoline and environmental protection.

Owner:于雷

Biomass solid formed fuel anti-slagging additive and preparation method thereof

The invention discloses a biomass solid formed fuel anti-slagging additive and a preparation method thereof, which belongs to the technical field of renewable energy sources and is used for solving the problems that straw biomass solid formed fuel has high alkali metal content, is slagged in the combustion process and the like. The anti-slagging additive mainly comprises 15% to 25% of magnesium carbonate, 20% to 30% of alumina and 45% to 65% of the calcium carbonate, different formula ratio is made according to different biomass raw materials; and the anti-slagging additive is added into different biomass raw materials according to the proportion of 1% to 5%. The preparation method comprises the following steps: the calcium carbonate is firstly put into a special container, the container keeps dry, then alumina is added, finally the magnesium carbonate is added, the mixture is ground and evenly mixed for 10 to 15 minutes with the grinding particle size less than 1 mm, and then a finished product is obtained. The additive can solve the problem of slagging in the combustion process of the formed fuel and increases the combustion efficiency of the formed fuel.

Owner:ACADEMY OF PLANNING & DESIGNING OF THE MINIST OF AGRI

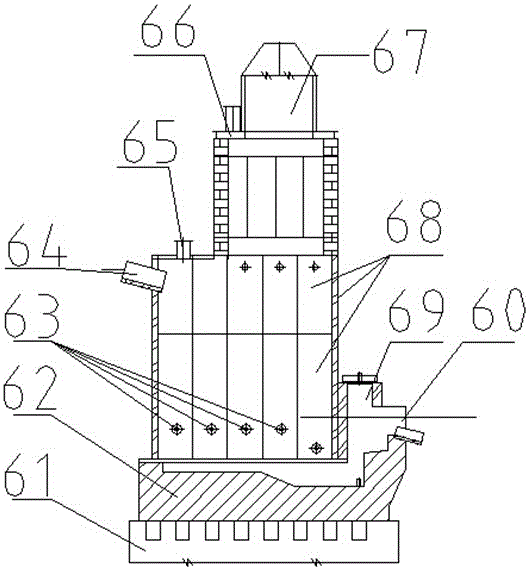

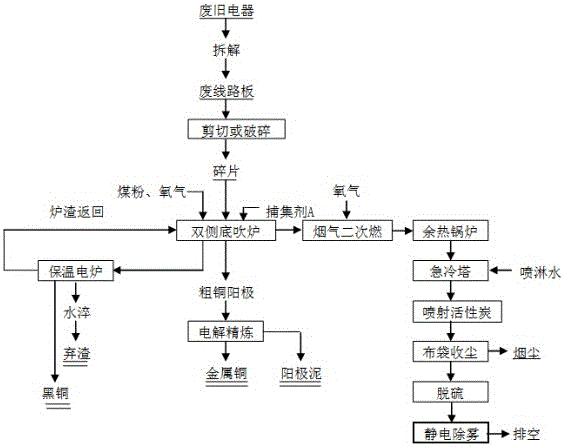

Complete equipment and method for extracting and purifying precious metals from waste circuit boards

ActiveCN106086415AComponent adaptabilitySimple preparationProcess efficiency improvementPrinted circuit boardQuenching

The invention discloses complete equipment and a method for extracting and purifying precious metals from waste circuit boards. The complete equipment comprises a bottom-blowing furnace, a secondary smoke combustion furnace, an absorption tower, a pulsed jet cloth filter, a wet desulfurization device and an electrostatic precipitation defogging device, and is characterized in that smoke generated by the bottom-blowing furnace is discharged through a flue arranged on the top of the bottom-blowing furnace; the flue communicates with an inlet of the secondary smoke combustion furnace; the secondary smoke combustion furnace communicates with a spraying quenching tower through a smoke waste heat boiler; an outlet of the spraying quenching tower communicates with the pulsed jet cloth filter through the absorption tower; an activated carbon spraying device is arranged inside the absorption tower; the pulsed jet cloth filter communicates with the wet desulfurization device; and the wet desulfurization device communicated with a chimney through the electrostatic precipitation defogging device. Effective separation and respective enrichment and recycle of various metals are achieved, organic substances are used as fuel, and no secondary pollution is generated for the environment. The process procedure is short, and the remarkable economic, environment-friendly and social benefits are achieved.

Owner:江西自立环保科技有限公司

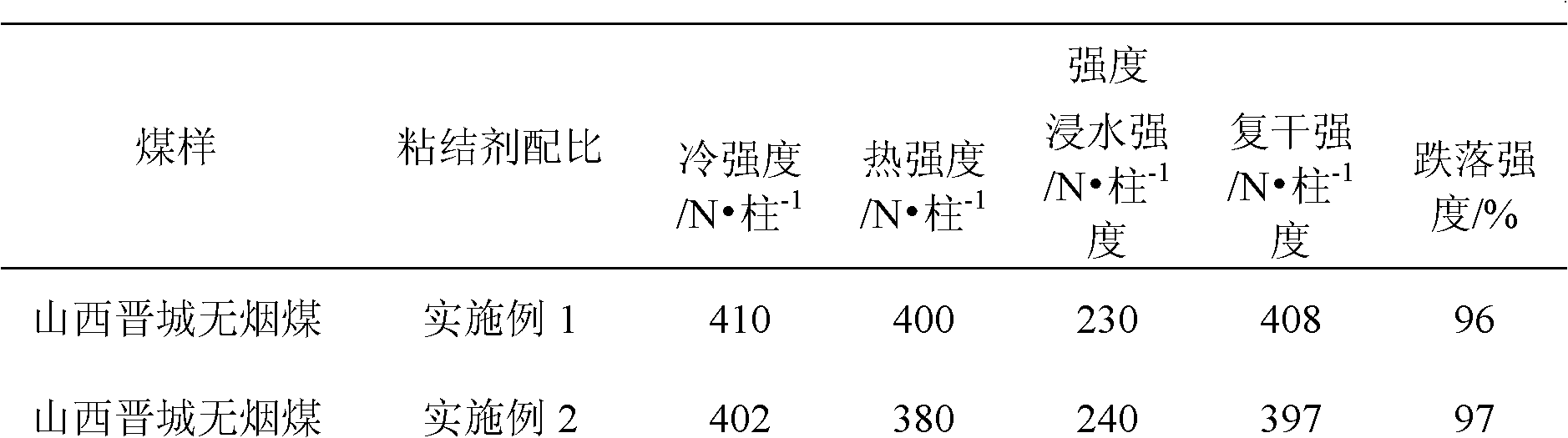

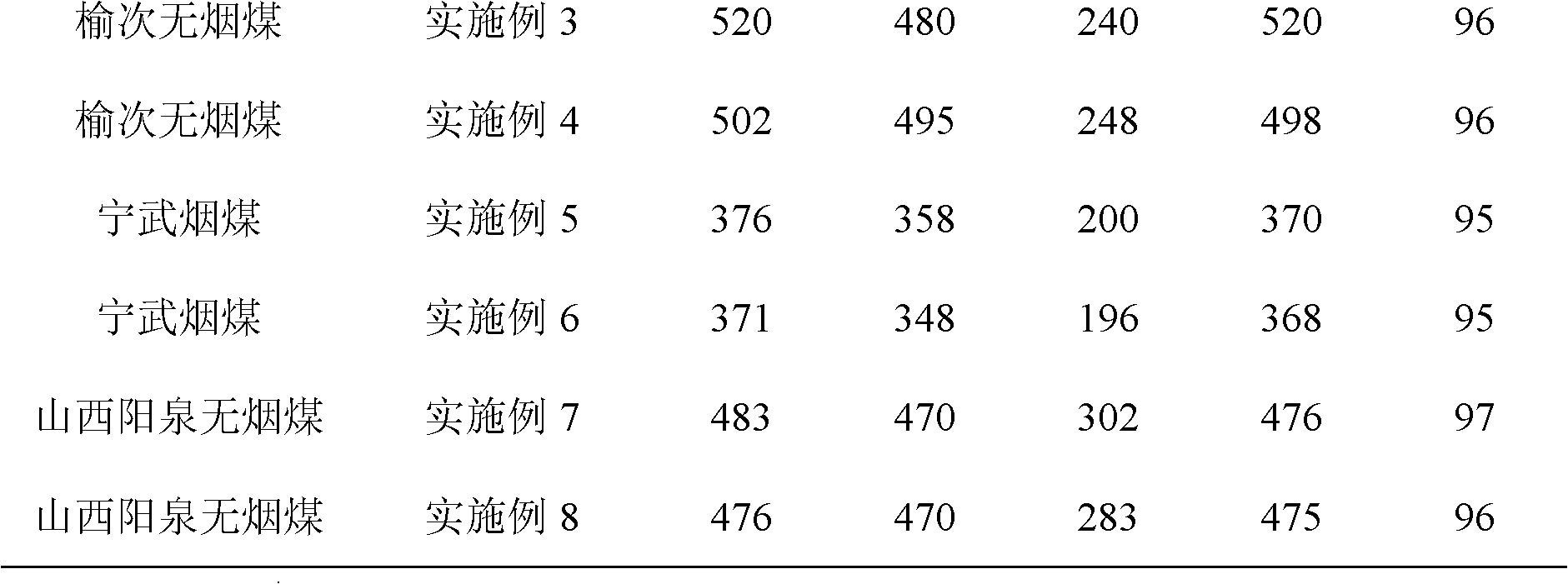

Briquette binder and briquette preparation method based on binder

The invention provides a briquette binder and a briquette preparation method based on the binder. The binder comprises 45 to 75 mass percent of humic acid, 8 to 20 mass percent of bentonite, 5 to 18 mass percent of kaolin, 1 to 5 mass percent of quartz sand, 2 to 8 mass percent of quicklime, 0.1 to 2 mass percent of sodium chloride, 0.1 to 2 mass percent of potassium permanganate and 0.05 to 0.1 mass percent of polyacrylamide. The binder has a simple preparation process, low cost, convenient use and no any secondary pollution and is applicable to various types of coal. The process for preparing the briquette by using the binder comprises the following steps of: only making little pretreatment on raw material coal and the binder, mixing the raw material coal and the binder in proportion, adding water into the mixture, uniformly stirring, pressing the mixture into a cylindrical briquette by using a press machine, and air-drying or drying the cylindrical briquette. The briquette prepared by using the binder of the invention has the characteristics of high cold strength, high water resistance, low cost, low ash increment, high thermal strength, high sulfur retention rate and wide source of raw materials.

Owner:SHAANXI UNIV OF SCI & TECH

Water coke slurry buring technology

A combustion technique for water-coke slurry features that a pre-combustion chamber with secondary tangential air inlet, a cyclone burner of primary air at one end of said pre-combustion chamber and a spray gun in the center of cyclone burner for atomizing the water-coke slurry are used. The outlet of said precombustion chamber is communicated to industrial furnace. The temp in the pre-combustion chamber is at least 950-1000 deg.C.

Owner:SOUTHEAST UNIV +1

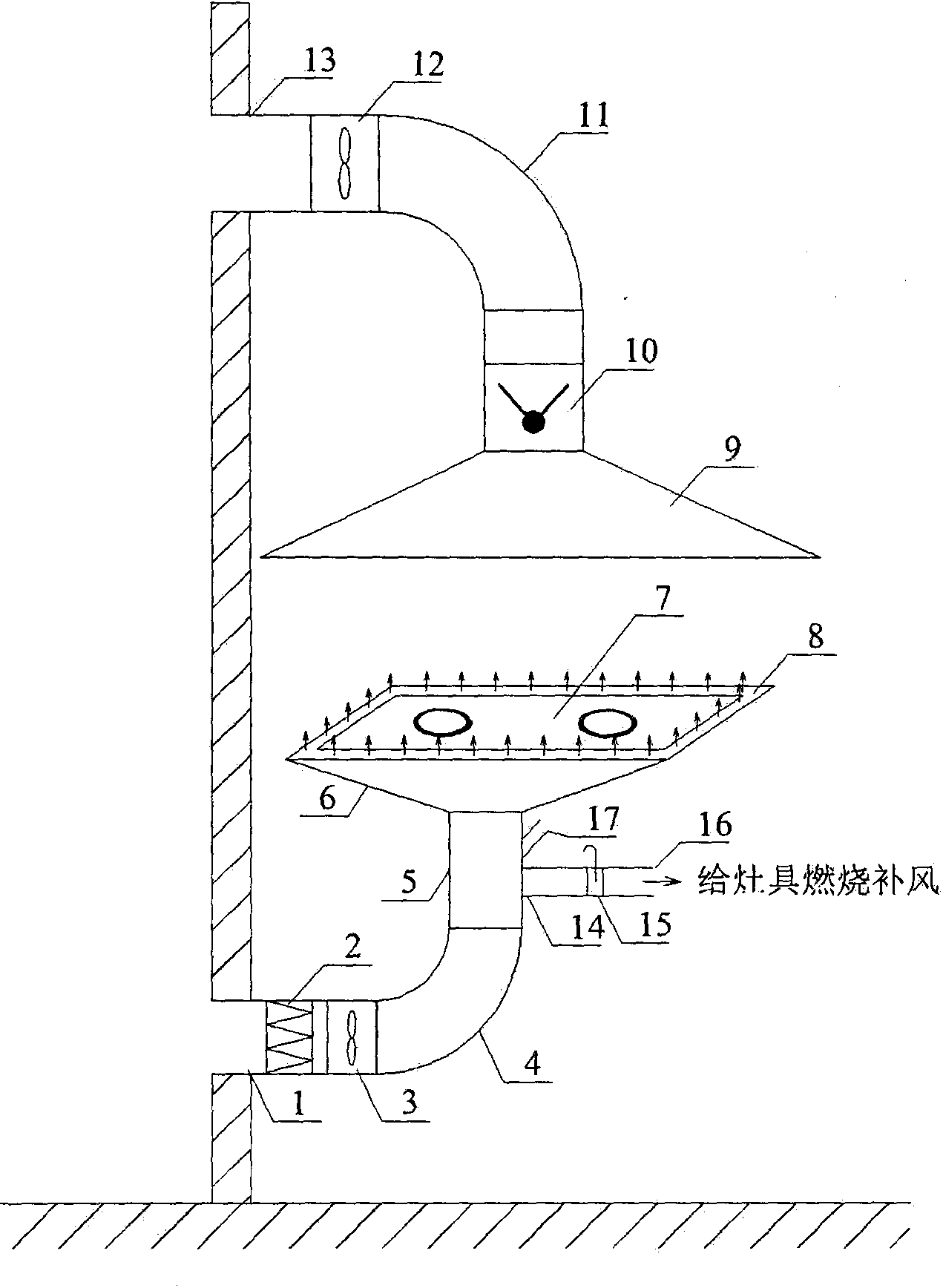

Kitchen ventilation system based on air curtain and filtration

InactiveCN103868187AImprove comfortGood for healthDomestic stoves or rangesLighting and heating apparatusCombustionKitchen ventilation

The invention discloses a kitchen ventilation system based on an air curtain and filtration. The system consists of a fresh air section, an air curtain section and an air exhaust section, wherein the fresh air section consists of a fresh air port, a PM2.5 filter, an air feeder, an injector air-supplement branch pipe and the like; the air curtain section consists of a reducing pipe, a gas stove, an angle-adjustable air curtain, a hot air curtain blowing-in branch pipe and the like; the air exhaust section consists of an exhaust hood, a one-way check valve, an exhaust fan and an air outlet; after being filtered, one path of fresh air is conveyed to the injector air-supplement branch pipe so as to be used for injection of the gas stove, one path of fresh air is conveyed to the air curtain for cooking in summer and transitional seasons, and another path of fresh air is conveyed to the hot air curtain blowing-in branch pipe so as to regulate the temperature of the air curtain and meet the heat comfort requirement of a human body; the jet current and fume of the air curtain are discharged to the outdoors by virtue of the exhaust hood. The system can be used for achieving the effects of insulating heat, reducing indoor cooling load, improving the cooking comfort degree and health degree, preventing cooking fumes from spreading into a horizontal living room, improving the combustion efficiency of the system and the like, is beneficial to formation of an open kitchen and ensures that the architectural space is fully utilized.

Owner:NANJING UNIV OF TECH

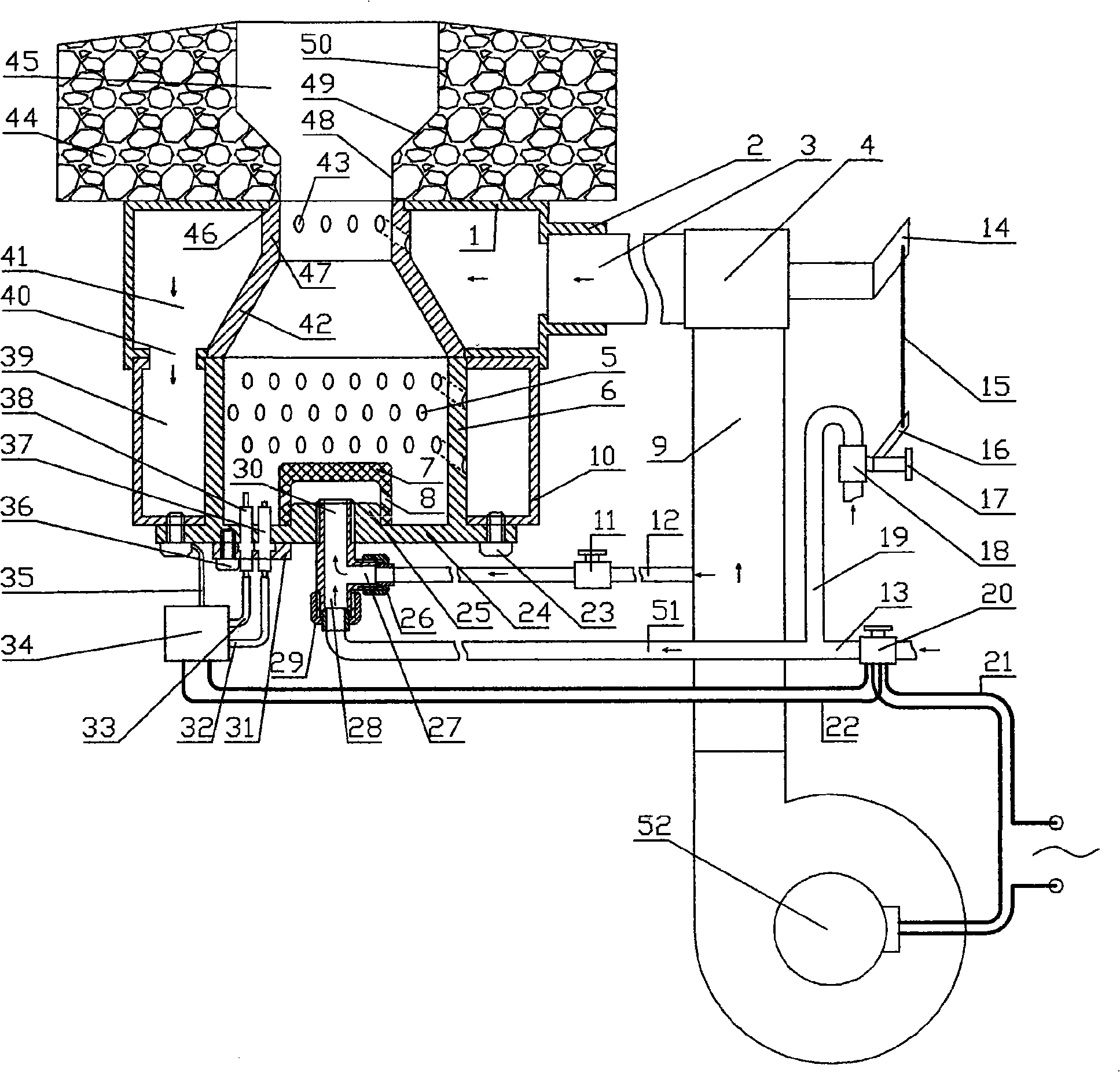

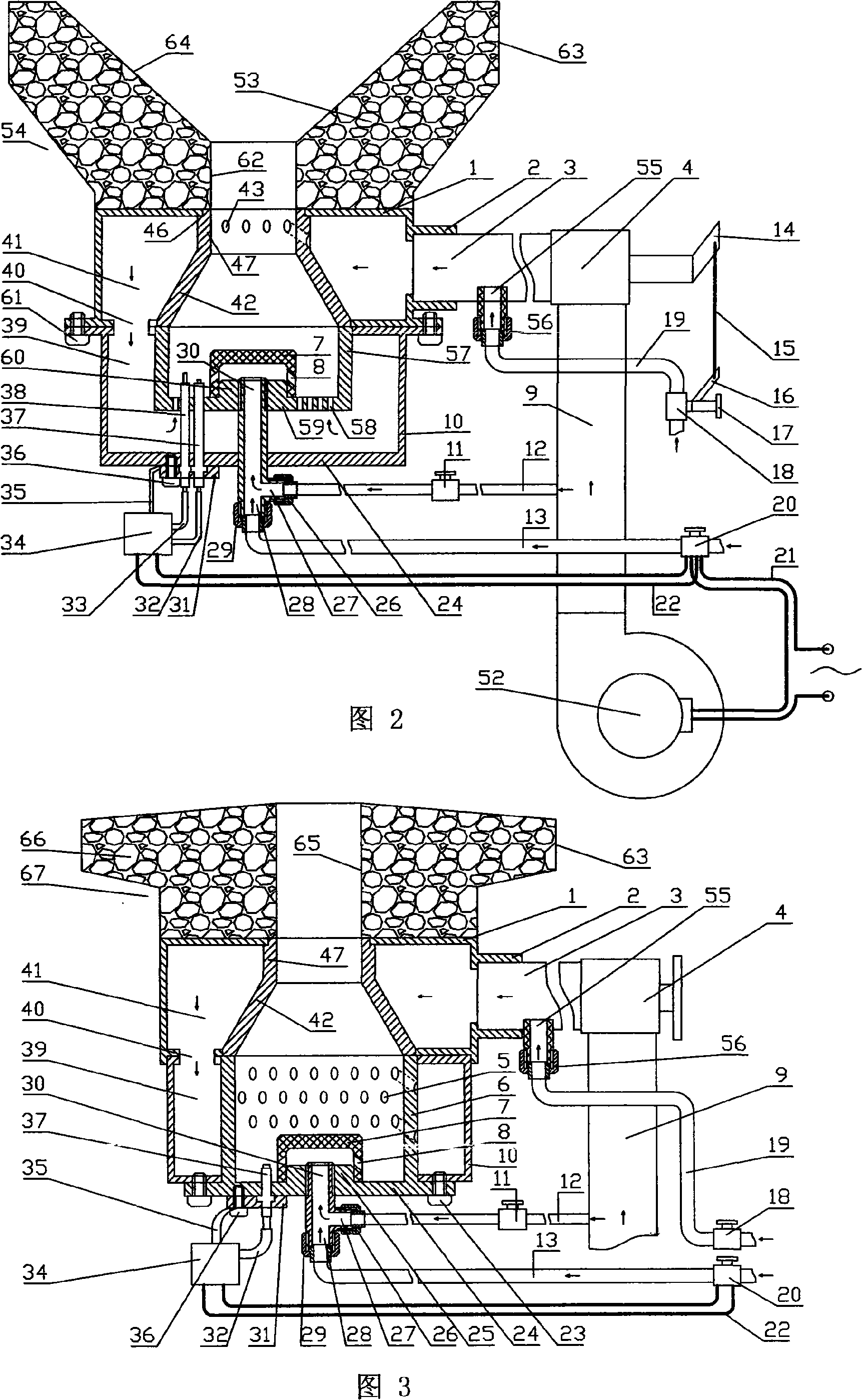

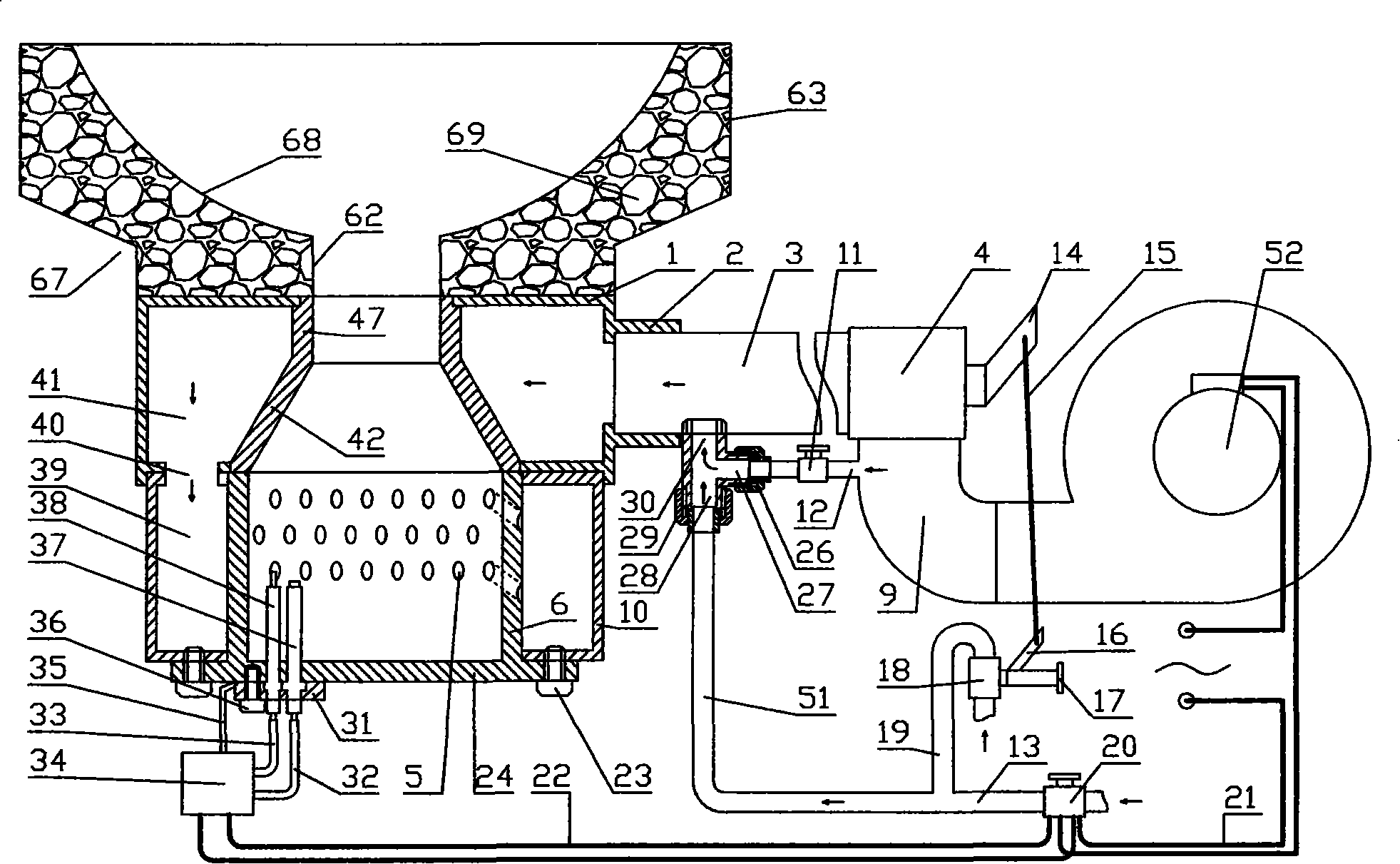

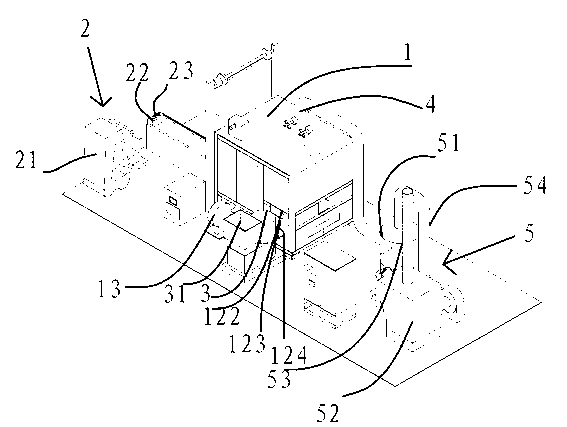

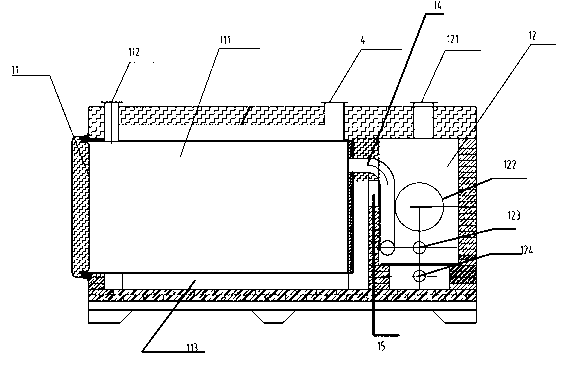

Carbonization treatment process and device thereof of animals died of illness

ActiveCN103254916AReduce post-maintenance costsReduce heat lossSpecial form destructive distillationCombustion chamberFlue gas

The invention relates to a carbonization treatment process and in particular relates to a carbonizing treatment process and device thereof of animals died of illness. The carbonizing treatment process comprises the following steps of: carrying out anaerobic pyrolysis and carbonization treatment for bodies of animals died of illness at the temperature of 300-600 DEG C, automatically outputting combustible pyrolysis gas generated in the pyrolysis and carbonization process and combusting the gas under the condition at the temperature of 800-1300 DEG C, wherein high-temperature flue gas generated by combusting is capable of supporting pyrolysis and carbonization and realizing recycling of heat energy of pyrolysis gas; and subsequently, purifying the flue gas. The device disclosed by the invention comprises a pyrolysis-carbonization device, wherein a pyrolysis-carbonization chamber and a combustion chamber are arranged in the pyrolysis-carbonization device; a pyrolysis-carbonization tank and a cyclic space are arranged in the pyrolysis-carbonization chamber; the pyrolysis-carbonization chamber is connected with a connection opening which is connected with the cyclic space and formed in the pyrolysis-carbonization chamber and the combustion chamber; and a pyrolysis gas exporting tube is connected between the pyrolysis-carbonization tank and the combustion chamber. The carbonization treatment process of animals died of illness can directly treat without need to break the bodies of the animals died of illness, is high in weight and capacity reducing rate, energy-saving and environment-friendly.

Owner:ZHEJIANG WUNENG ENVIRONMENTAL TECH DEV

Small efficient medicinal rubbish pyrolysis incinerator

InactiveCN102042601AProblem Solving Using Unitary Furnace StructureLarge capacity reduction ratioIndirect carbon-dioxide mitigationIncinerator apparatusCombustion chamberGas phase

The invention discloses a small efficient medicinal rubbish pyrolysis incinerator, which belongs to rubbish burning treatment equipment and solves the problems that a gas combustion chamber has simple structure, an auxiliary fuel is needed, the temperature cannot be accurately measured or controlled, and defects are produced in cloth bag dust removal and the like. The hearth of the incinerator consists of a pyrolysis and gasification chamber, a solid-phase burn-out chamber, a gas-phase combustion chamber and a flue gas treatment chamber; the solid-phase burn-out chamber is positioned below the pyrolysis and gasification chamber and communicated through a netlike fire grate; the gas-phase combustion chamber is arranged in parallel to the pyrolysis and gasification chamber, and the top of the gas-phase combustion chamber is communicated with a flue; the flue gas treatment chamber is arranged in parallel to the gas-phase combustion chamber and the pyrolysis and gasification chamber; and the gas-phase combustion chamber is communicated with the lower part of the flue gas treatment chamber, the gas-phase combustion chamber and the flue gas treatment chamber are provided with a fireproof baffle plate respectively, and the lower part of the gas-phase combustion chamber is provided with the netlike fire grate. The temperature in the incinerator is measured and controlled in real time through an electric heating and automatic temperature measurement and control system. A high-temperature granule dust removal and filter device avoids regeneration of dioxin, and the cost is reduced. The incinerator effectively and cleanly burns the medicinal rubbish on the aspects of incinerator shape design, ignition and combustion modes, temperature measurement and control, high-temperature flue gas treatment and the like.

Owner:杨显志

Casting type coke production method and apparatus system used thereof

The present invention relates to a production method of foundry shaped coke and its equipment system for producing said foundry shaped coke. Said method includes the procedures of preparing material,pulverizing, cold stirring, hot stirring, forming and carbonization and coking, and its equipment system includes material-preparing chamber, pulverizing machine, cold stirring machine, hot stirring machine, forming machine and carbonizing furnace, etc.

Owner:商丘市普天工贸有限公司煤化工研究所

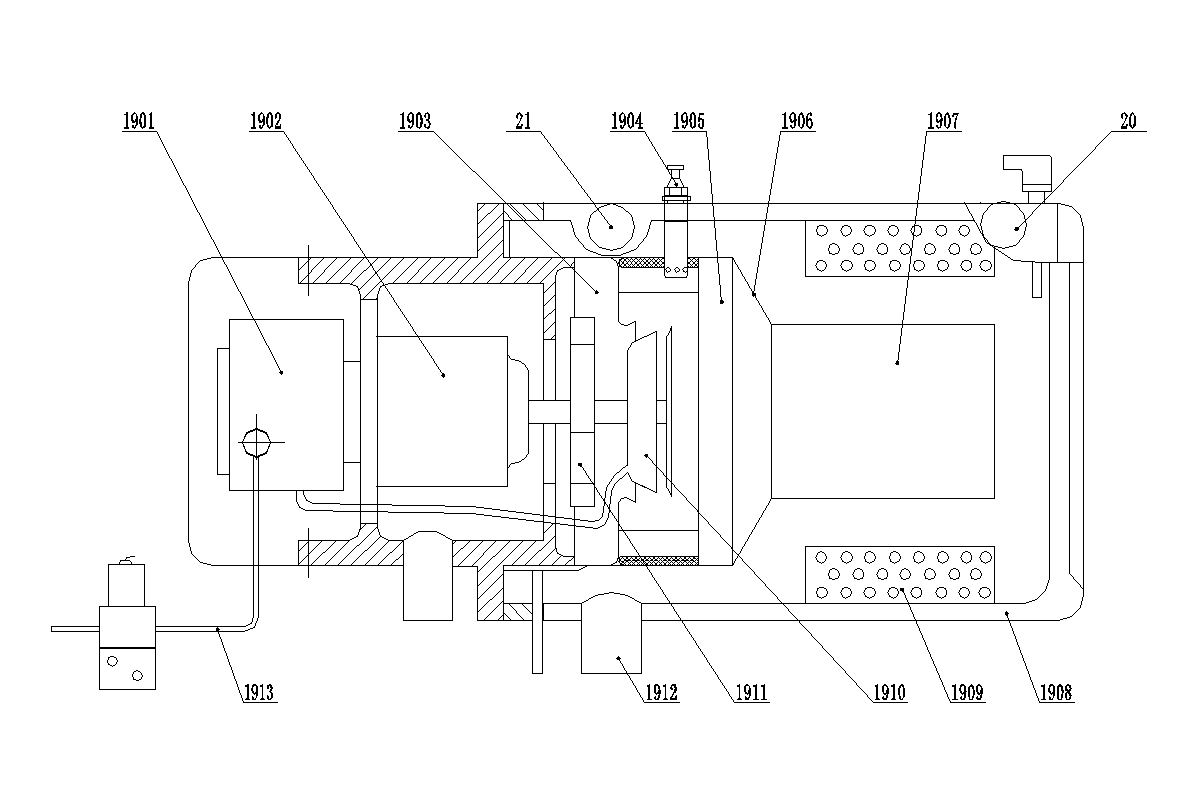

Methyl alcohol heater

PendingCN108049999ASimple structureCompact structureAir-treating devicesVehicle heating/cooling devicesCombustion chamberFuel oil

The invention discloses a methyl alcohol heater. The methyl alcohol heater comprises a machine body, wherein an air inlet is formed in one end of the machine body; a pre-combustion chamber is arrangedat the other end of the machine body; the pre-combustion chamber is arranged in a heat exchanger, and communicates with a main combustion chamber in the heat exchanger; an air exhaust hoe is formed in the heat exchanger; a heat exchange medium outlet of the heat exchanger is connected with a heating medium inlet of a radiator in a car; a heat exchange medium inlet of the heat exchanger is connected with one end of a circulating pump; the other end of the circulating pump is connected with a heating medium outlet of the radiator in the car; a fuel pump used for providing methyl alcohol is arranged between a position, at the air inlet, in the machine body and a pre-combustion chamber; a liquid outlet end of the fuel pump is connected with a spray nozzle; and an ignition electrode is arranged on a position, close to the spray nozzle, in the machine body. The methyl alcohol heater does not affect vehicle endurance mileage, is simple and compact in structure, and has the characteristics ofbeing sufficient in combustion and good in environment friendliness; and according to a test, content of emission pollutants of the methyl alcohol heater is only 1 / 3-1 / 2 that of the fuel oil heater,so that smoke is not generated during starting and stopping.

Owner:KAILONG HIGH TECH

Catalyzed coal powder burning process, coal powder catalyzing burner and coal powder burning catalyst

InactiveCN101046304AImprove coal burn rateReduce waste of coal resourcesCatalyst carriersLighting and heating apparatusSpray nozzleProduct gas

The present invention relates to coal powder catalytically burning process, coal powder catalyzing burner and coal powder burning catalyst. The coal powder catalyzing burner includes one burner, one burning nozzle and one beehive guiding burning plate with coal powder burning catalyst. The mixture of coal powder and air is sprayed through the nozzle into the burner and burnt under the action of the coal powder burning catalyst. The coal powder burning catalyst consists of Al2O3 80-85 wt%, MnO2 1-8 wt%, CuO 1-3 wt%, TiO2 1-3 wt%, NiO2 1-3 wt%, and mixed RE 1-5 wt%. The present invention has raised coal powder burning rate and reduced environmental pollution.

Owner:窦陆军 +1

Methanol gasoline and its preparation method

InactiveCN102260548AEasy to prepareExcellent performanceLiquid carbonaceous fuelsFuel additivesTruckSolvent

The invention discloses a methanol gasoline and a preparation method thereof, relating to the field of new energy. The methanol gasoline comprises 15-30wt% of methanol, 67-83wt% of gasoline and 2-3wt% of additive. The preparation method comprises the following steps: pouring solubilizer, energy increasing and consumption reducing agent, anti-oxidant, metal corrosion inhibitor, rubber swelling inhibitor into a reaction vessel according to a required proportion with stirring, mixing uniformly to obtain an additive; mixing the additive with methanol according to a required proportion to obtain modified methanol; and mixing the modified methanol with gasoline according to a required proportion to obtain the methanol gasoline. The methanol gasoline disclosed in the invention has the advantagesof simple preparation and good performance, can be used mixed with a national standard gasoline in any proportion with similar energy consumption with the national standard gasoline and emission indexes that conforms to requirements of environmental protection, and can be widely used for various petrol-engined motor vehicles, such as car, carriage, fork truck, power-assisted vehicle, farm vehicle, motorcycle, load wagon and forklift.

Owner:永州锦溁新能源开发有限公司

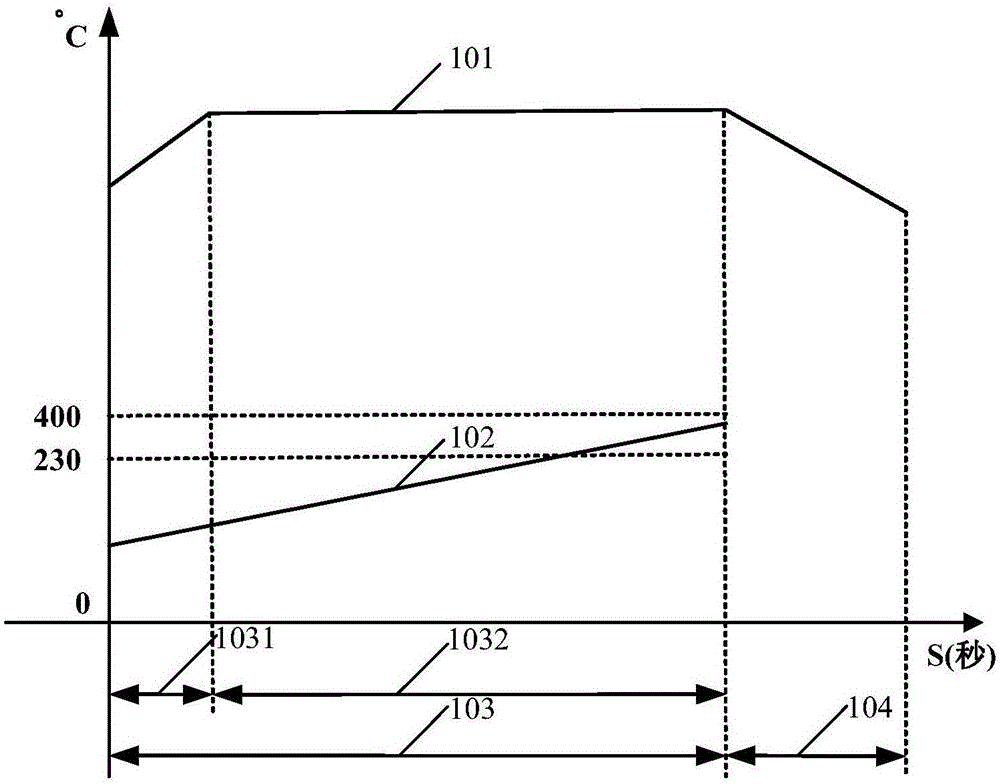

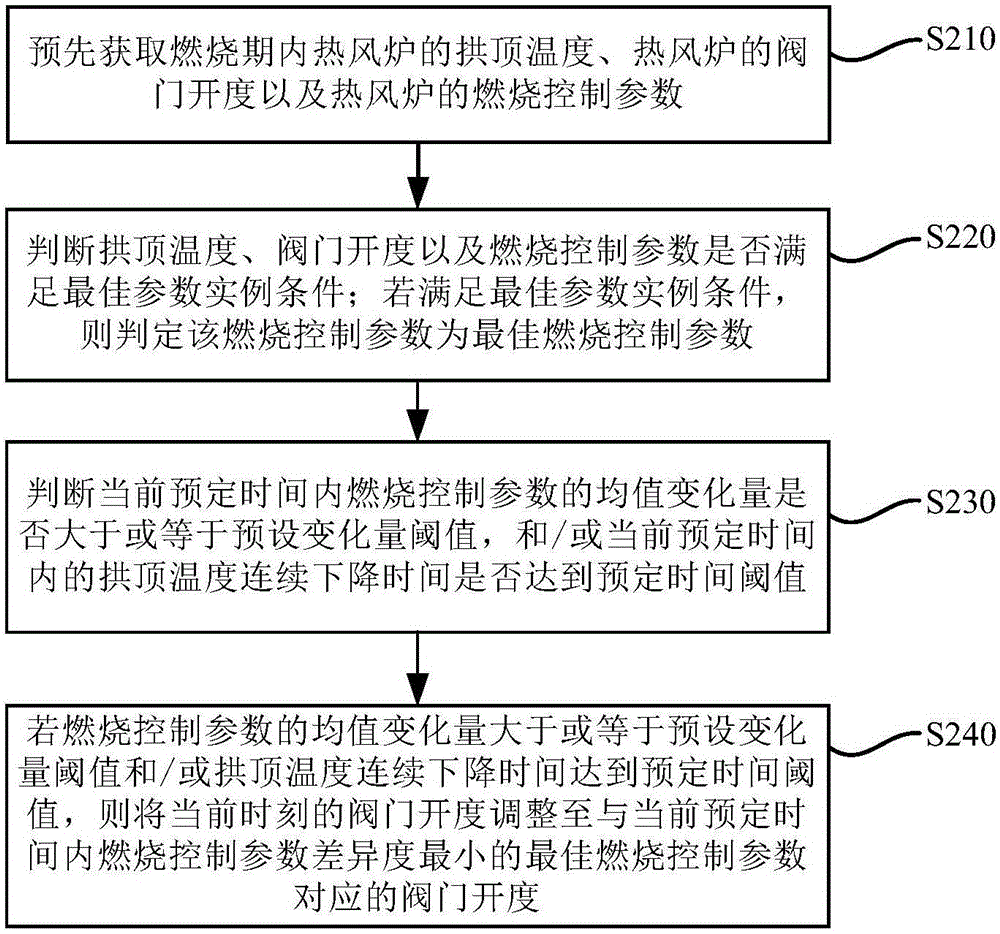

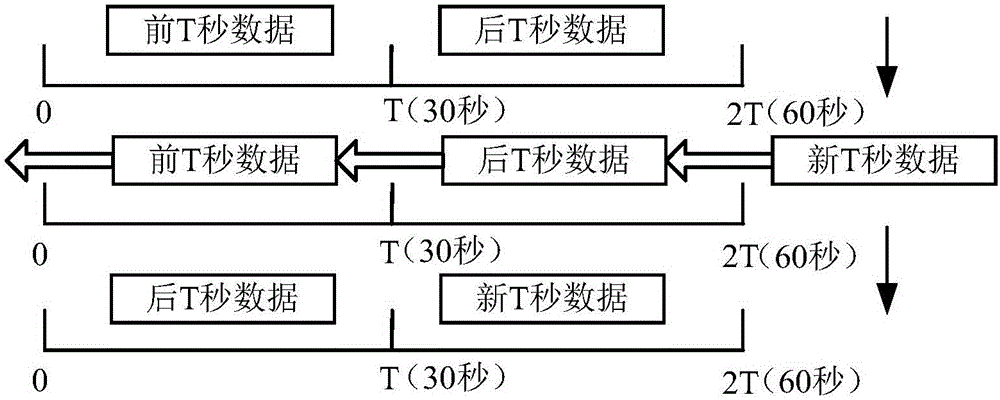

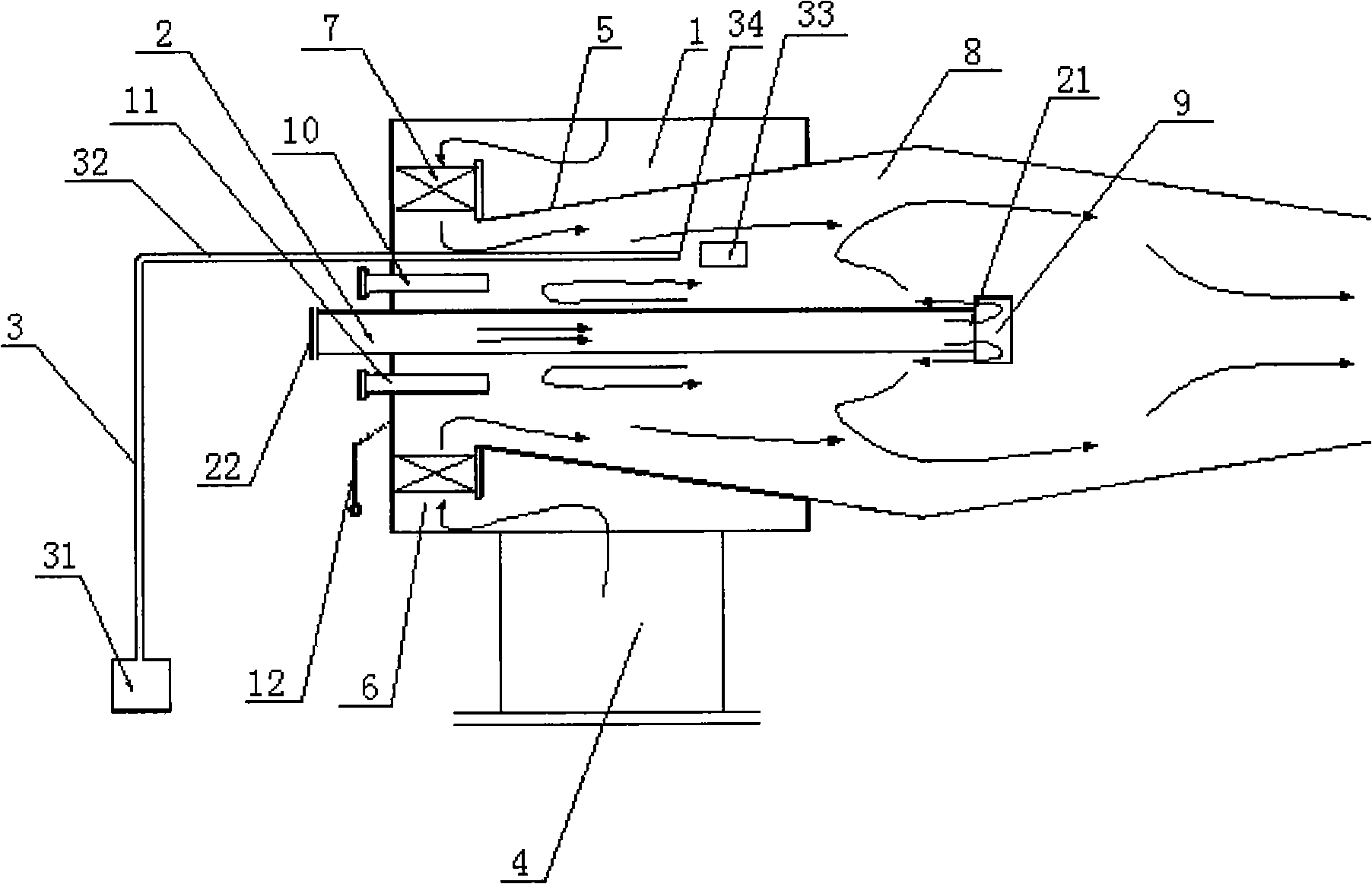

Combustion control method and system for hot blast heater

ActiveCN105157057AVault temperature stabilizationAdjust the air-fuel ratioFluid heatersCombustion regulationAir temperatureAir–fuel ratio

The embodiment of the invention discloses a combustion control method and system for a hot blast heater. The control method comprises the steps of obtaining the dome temperature, the valve openness and the combustion control parameters of a hot blast heater in a combusting period in advance; judging whether the dome temperature, the valve openness and the combustion control parameters meet the optimal parameter example conditions; judging the combustion control parameters are the optimal combustion control parameters if the optimal parameter example conditions are met; judging whether the mean value variation of the combustion control parameters in the current preset time is larger than or equal to a preset variation threshold value and / or whether the continuous descending time of the dome temperature in the current preset time reaches a preset time threshold value; and adjusting the valve openness to the valve openness corresponding to the optimal combustion control parameters with the minimum difference of the combustion control parameters in the current preset time if the mean value variation is larger than or equal to the preset variation threshold value and / or the continuous descending time reaches the preset time threshold value. According to the technical scheme, the air-fuel ratio of the hot blast heater can be accurately adjusted in time, fuel gas of the hot blast heater can be fully combusted, the dome temperature of the hot blast heater is stabilized, and the utilizing level of the blast furnace air temperature is improved.

Owner:ELECTRON CO LTD

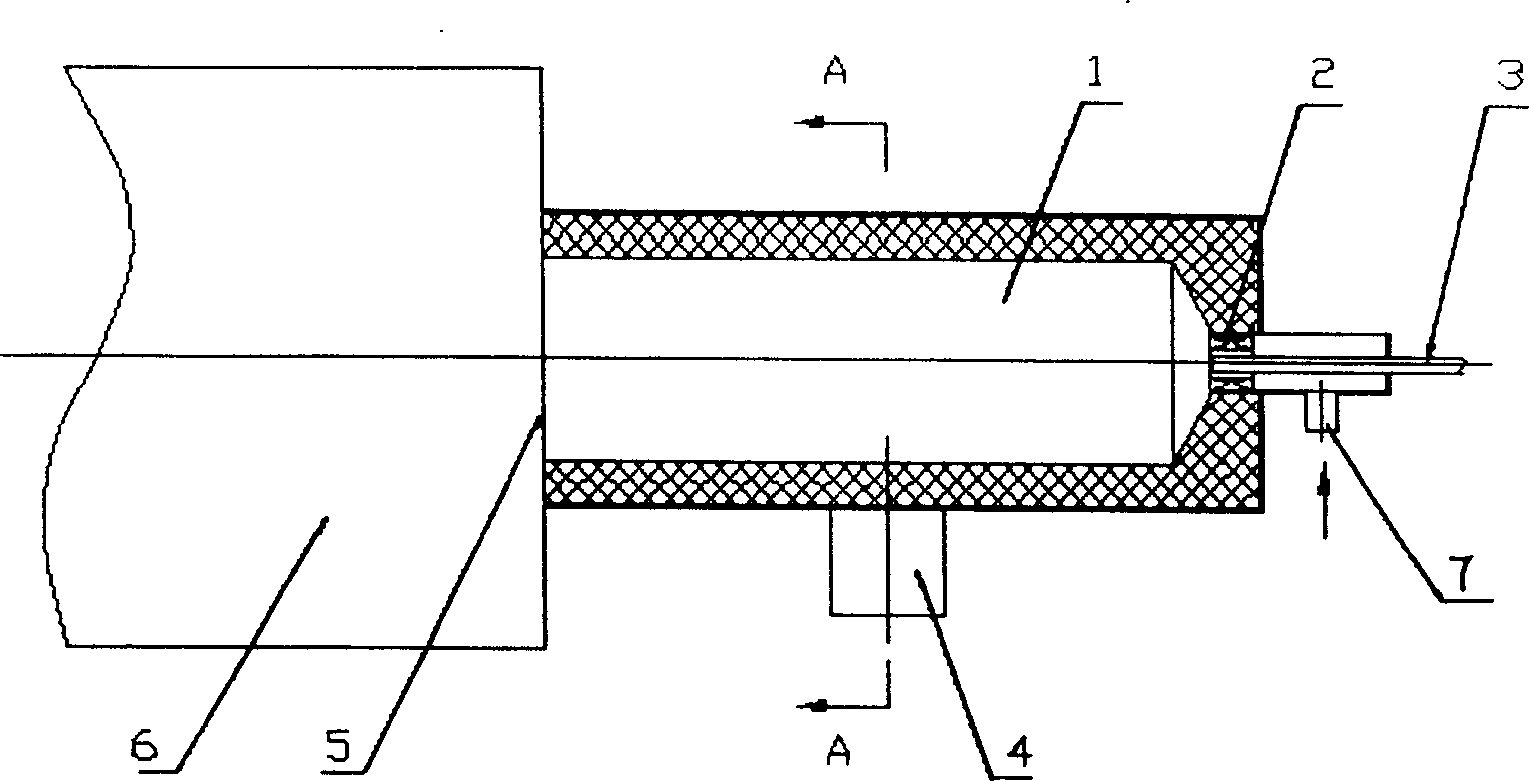

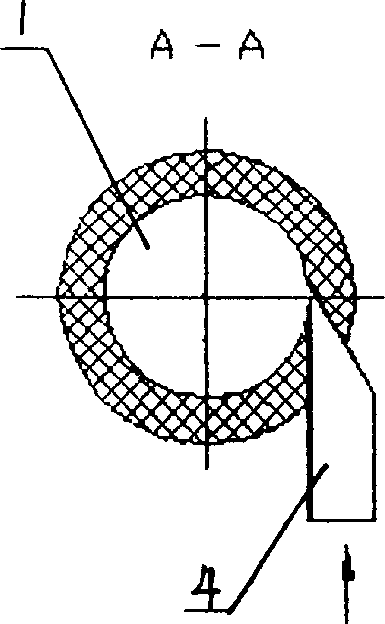

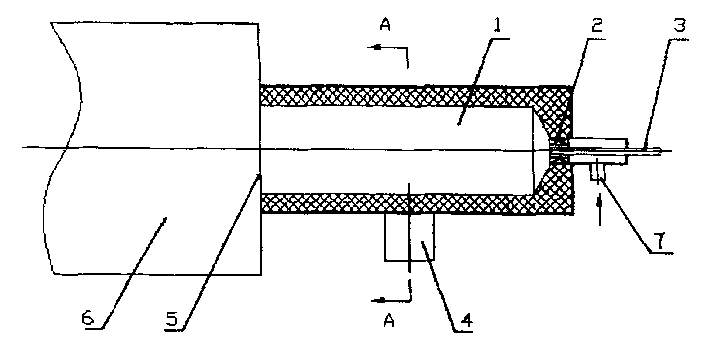

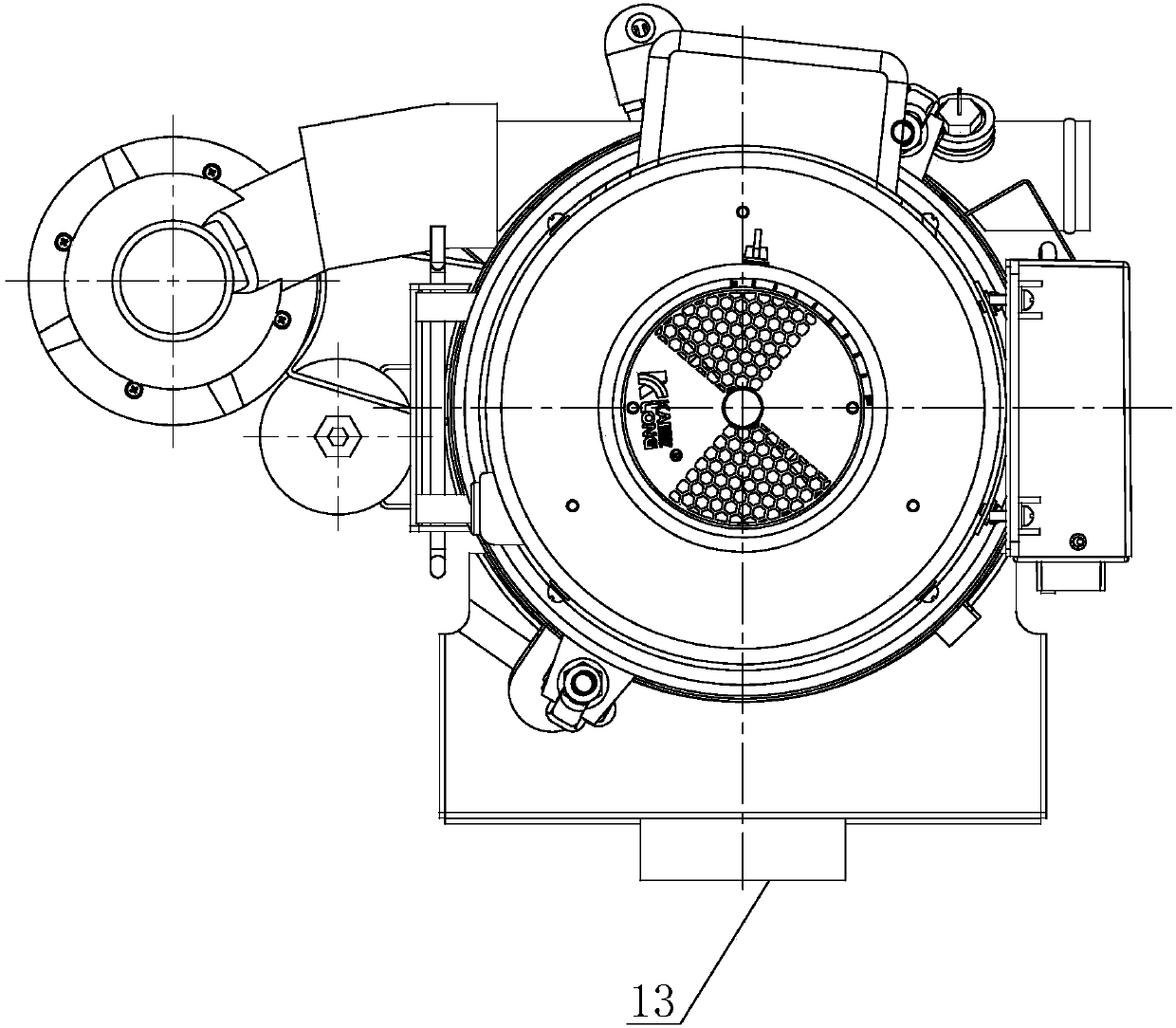

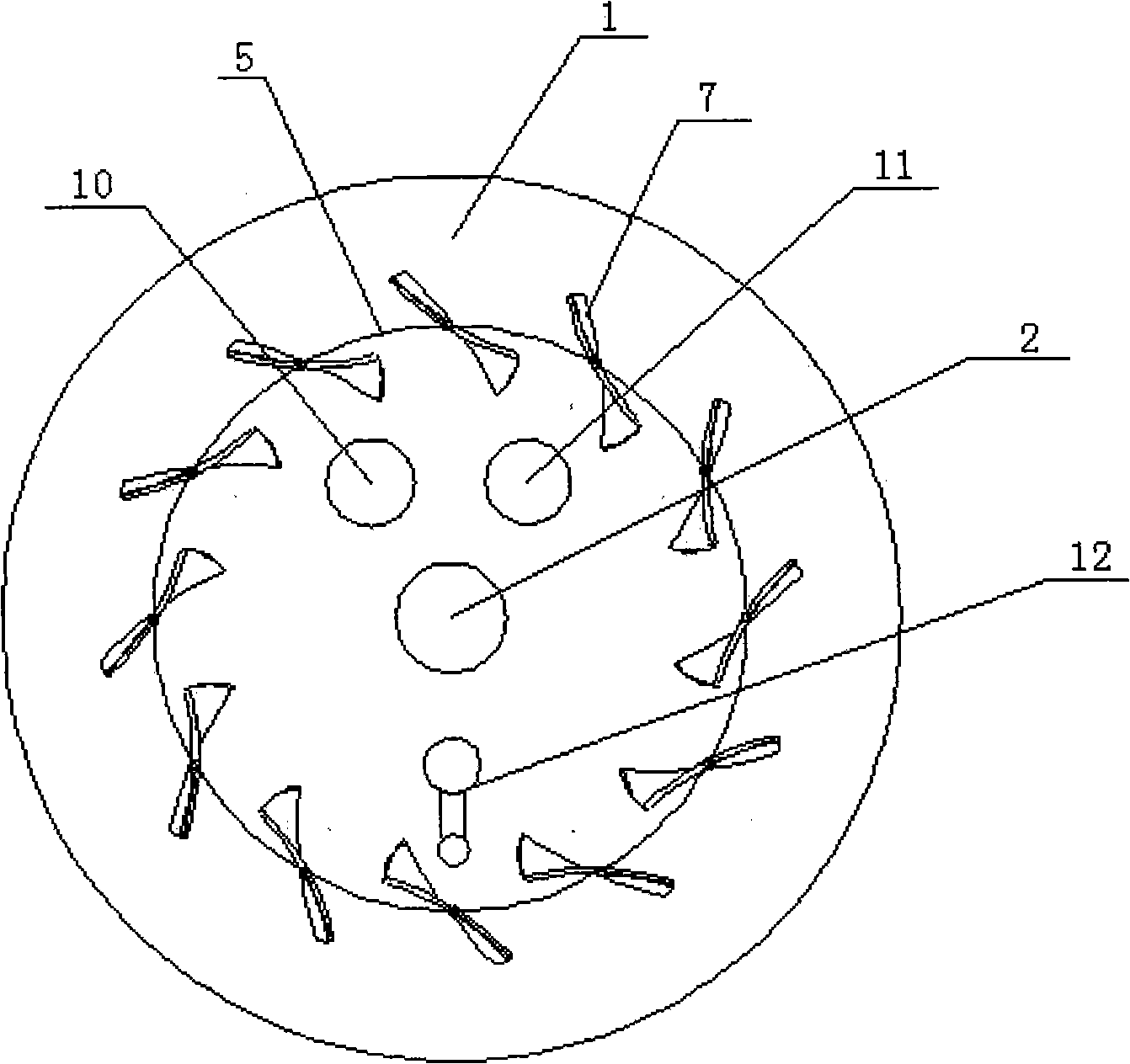

Pulverized coal burner

InactiveCN101576255AHas a burning effectUniform burning effectPulverulent fuel combustion burnersFuel tankEngineering

The invention relates to a pulverized coal burner which is characterized by comprising an air box, a powder feeding pipe, an ignition device and a blast pipe; a cylindrical fixed baffle plate with a conical cross section is axially arranged in the air box, an annular gap is left between one end of the fixed baffle plate and the air box, and a plurality of swirl vanes are circumferentially arranged in the annular gap; a precombustion chamber is arranged inside the fixed baffle plate; the outlet end of the powder feeding pipe penetrates the center of the air box to enter in the precombustion chamber, the inlet end of the powder feeding pipe is arranged outside the air box and connected with a feeder device, and the powder feeding pipe is fixedly connected with the air box; a return flow cap is arranged at the tail end of the outlet end of the powder feeding pipe and a special gap is left between the return flow cap and the outlet end of the powder feeding pipe; the ignition device comprises a fuel tank, a conduct pipe and an ignition electrode, wherein the fuel tank is arranged outside the air box; one end of the conduct pipe is connected with the fuel tank and the other end of the conduct pipe penetrates the air box to enter in the precombustion chamber to form a spouting vent; the ignition electrode is arranged at one side adjacent to the spouting vent; and one end of the blast pipe is connected with the air box and the other end of the blast pipe is connected with an air blower. The invention can be widely used in various small and medium-sized industrial coal powder boilers.

Owner:CHINA COAL RES INST

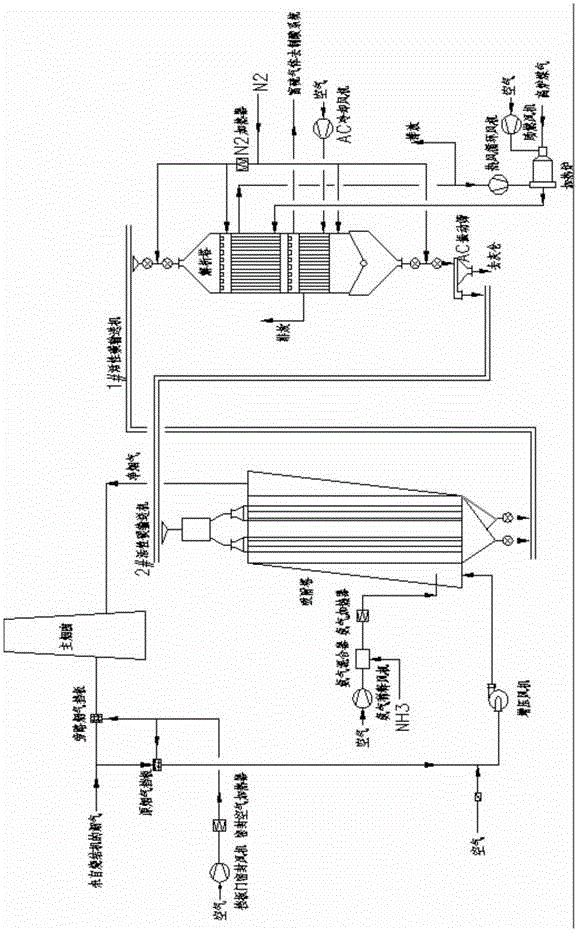

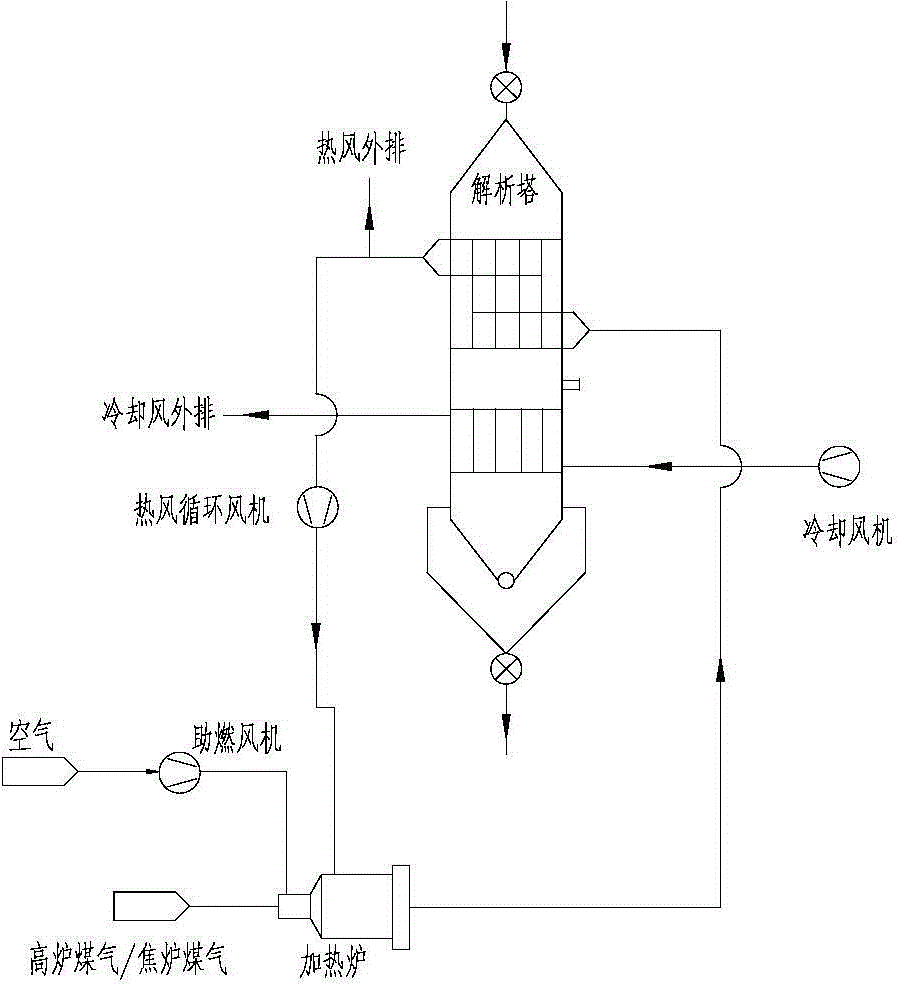

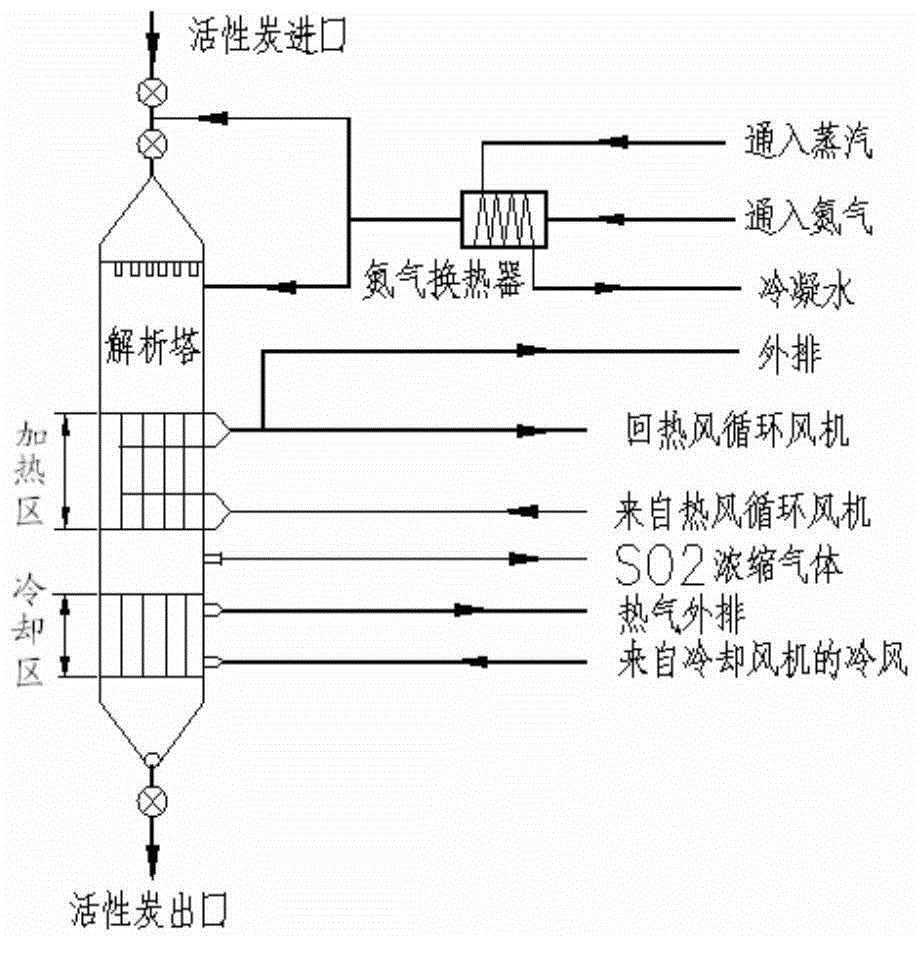

Waste heat utilization-containing active carbon thermal desorption method and apparatus thereof

ActiveCN105618019ALow running costReduce consumptionOther chemical processesDispersed particle separationCombustion chamberThermal desorption

The invention provides a waste heat utilization-containing active carbon thermal desorption method. The method comprises the following steps: adsorbing sulfur oxides, nitrogen oxides and other pollutants in the active carbon adsorption tower of a desulphurization and denitration device by active carbon; allowing blast furnace gas or coking coal gas to flow through a heat exchanger in order to be preheated, conveying the preheated gas to the combustion chamber of a heating furnace, combusting the preheated gas, allowing high temperature hot wind (G0) discharged from the combustion chamber to flow through one temperature adjusting zone of the tail portion of the heating furnace to undergo temperature adjustment and become cooled hot wind (G1), conveying the hot wind (G1) to the heating zone of a desorption tower to desorb the active carbon, and discharging further cooled hot wind (G1') from the heating zone. Parts of the hot wind (G1') are used in preheating of the blast furnace gas or coking coal gas in the heat exchanger. Parts of the cooled wind (G2') discharged from the cooling zone of a desorption tower are used to carry out gas sealing of raw flue gas baffle plates, purified flue gas baffle plates and bypass baffle plates arranged in the whole desulphurization and denitration device. The invention also provides an active carbon desorption apparatus.

Owner:HUNAN ZHONGYE CHANGTIAN ENERGY CONSERVATION & ENVIRONMENTAL PROTECTION TECH CO LTD

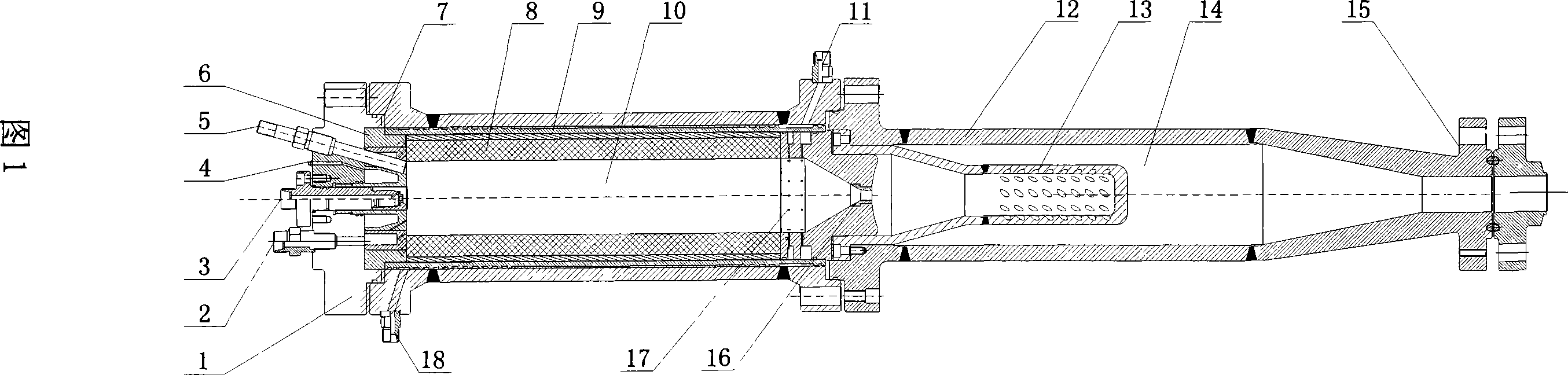

High-pressure mixed gas generator used for petroleum thermal recovery gas injection machine

ActiveCN101067372ALower working temperatureImprove job stabilityFluid removalCombustion chamberWater vapor

The present invention relates to one kind of mixed gas generator for thermal petroleum extraction. The mixed gas generator consists of a head, a combustion section and a mixing section. It features the spiral cooling chamber structure inside the cooling water cap to cool the head effectively, the heat isolating cover and the cooling water jacket with multiple functions of heat insulating, preheating and cooling the combustion section, and the necked bush of the temperature regulator capable of ensuring the sufficient pressure field in the combustor to raise the combustion reaction speed. The mixed gas generator is for burning diesel oil with compressed air as the oxidant to produce high temperature and high pressure fume and spraying water to regulate temperature so as to generate mixed gas of N2, CO2 and water vapor injected into well for thermal petroleum extraction. The present invention is used in oil field to replace steam petroleum extraction.

Owner:江苏神速石油装备有限公司

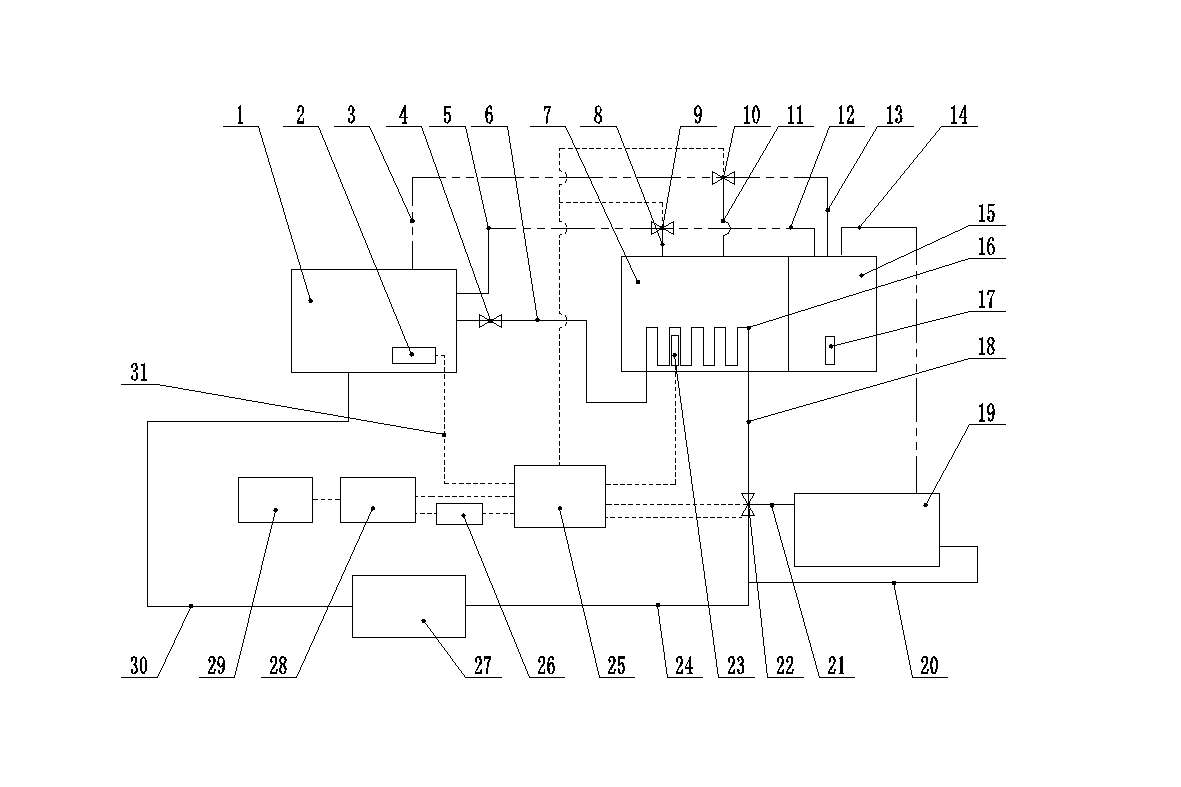

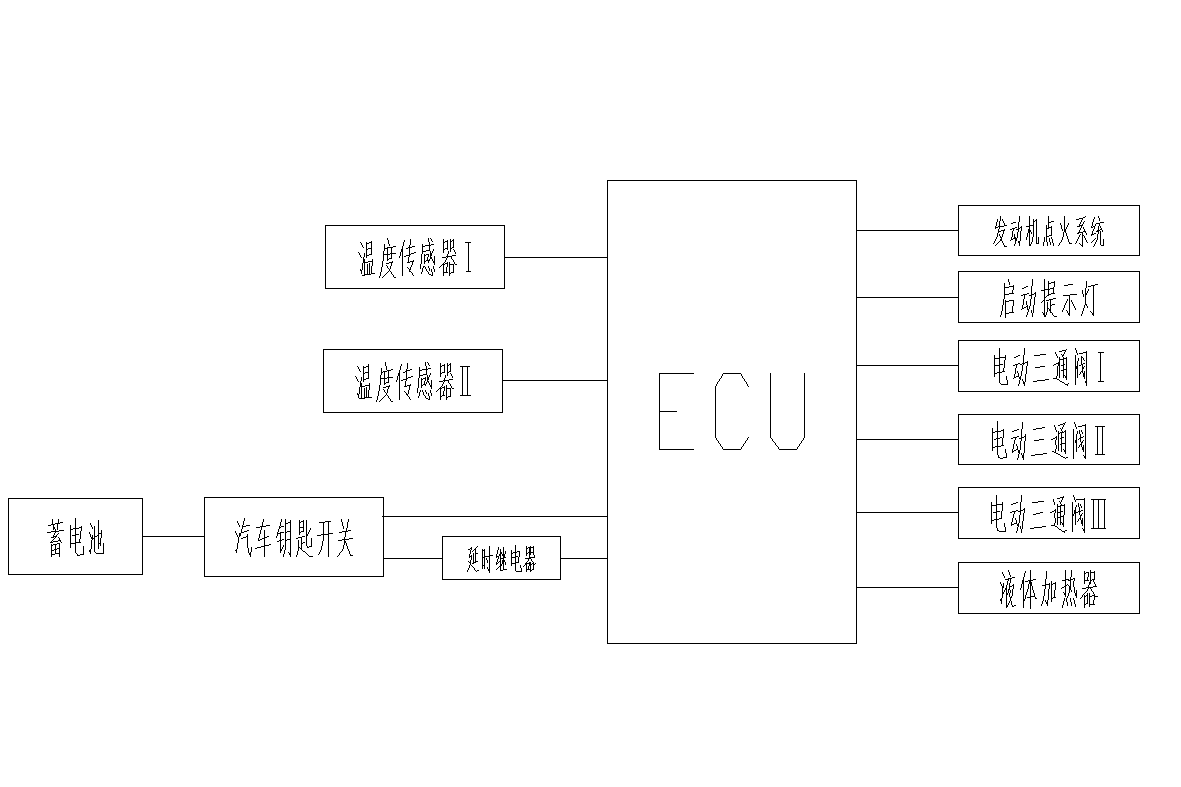

System for preheating fuel oil of automotive diesel engine in winter and control method of system

InactiveCN103061926AReduce usageReduce oil costAir-treating devicesFuel re-atomisation/homogenisationAutomatic controlElectronic control unit

The invention relates to a system for preheating fuel oil of an automotive diesel engine in winter and a control method of the system. The system is characterized in that an electric three-way valve I is arranged on a connecting pipeline of a fuel feed pipe of an engine, a main fuel feed pipe of a main fuel tank and an auxiliary fuel feed pipe of an auxiliary fuel tank, an electric three-way valve II is arranged on a connecting pipeline of an oil return pipe of the engine, a main oil return pipe of the main fuel tank and an auxiliary oil return pipe of the auxiliary fuel tank, an electric three-way valve III is arranged on a connecting pipeline of a warm-wind water inlet pipe, a water return pipe of an aluminum heating pipe, and a water inlet pipe of a liquid heater, an ECU (Electronic Control Unit) and the liquid heater are supplied with power through a storage battery, a power supply circuit is connected and disconnected by an automotive key switch, a time-delay relay is arranged on the power supply circuit, and a temperature sensor I of the engine, a temperature sensor II in the main fuel tank, the liquid heater and the electric three-way valves I, II and III are respectively connected with the ECU by leads for realizing automatic control. With the fuel oil preheating system provided by the invention, the normal working of the automotive diesel engine with No.0 diesel oil in winter can be realized, and enormous economic benefits are brought to an automobile owner.

Owner:LIAONING UNIVERSITY OF TECHNOLOGY

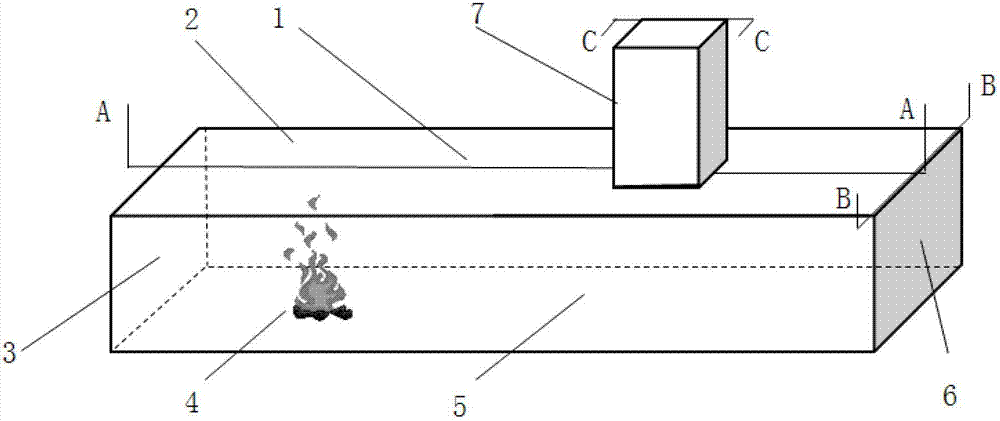

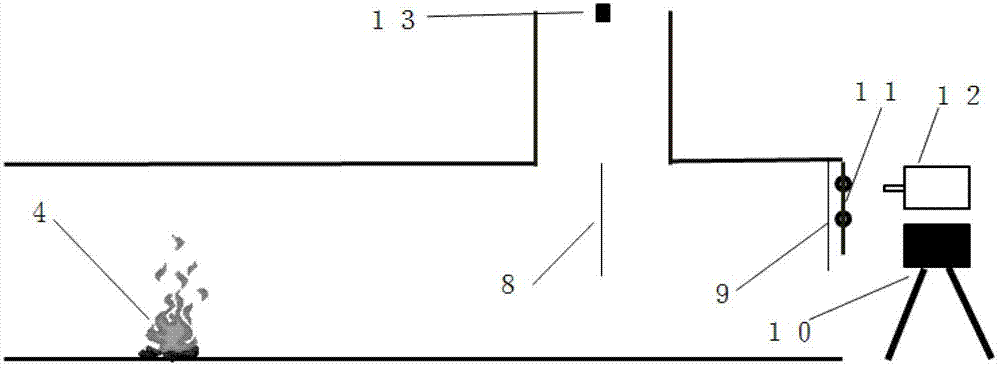

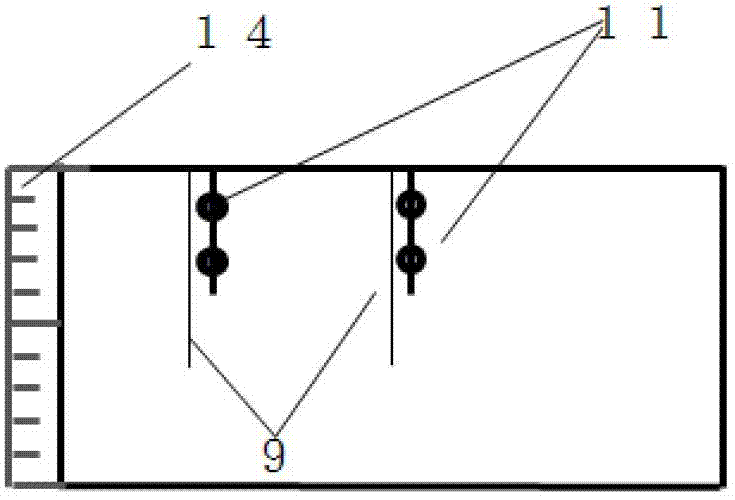

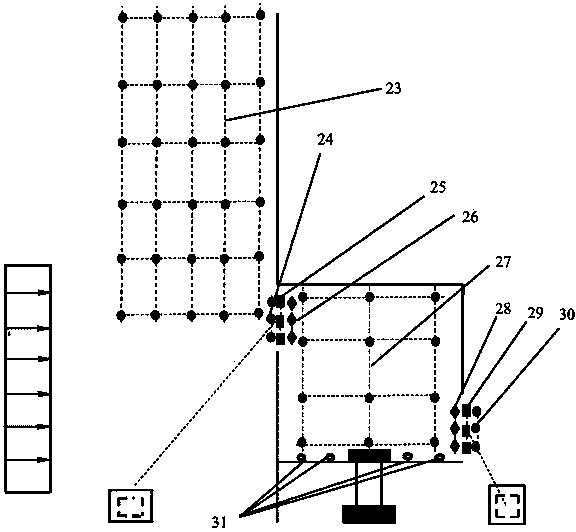

Underground highway tunnel fire disaster experiment simulating device adopting vertical shaft to carry out natural smoke extraction

The invention provides an underground highway tunnel fire disaster experiment simulating device adopting a vertical shaft to carry out natural smoke extraction. The device comprises a main experiment table body and a matched measuring and controlling system. The experiment device serves as a small-sized experiment table which is specially used for carrying out comprehensive system researches on heat release rates, smoke movement, fire disaster detection and putting-out and the like in a fire disaster of an underground highway tunnel adopting the vertical shaft to carry out the natural smoke extraction. On the basis of previous experience, the device disclosed by the invention overcomes the defects of high cost of a full-sized experiment and inaccuracy of a numerical value simulating tool, and also guarantees the repeatability of experiments, thus having great application values on implementing a laboratory scientific research and simulating tests of actual tunnel smoke control, vertical shaft smoke extraction effects, and a detection and putting-out system. Therefore, the device disclosed by the invention has wide application prospect and important actual guiding meanings on the smoke control, the design of the detection and putting-out system, and test evaluation and research of the fire disaster of the underground highway tunnel adopting the vertical shaft to carry out the natural smoke extraction.

Owner:UNIV OF SCI & TECH OF CHINA

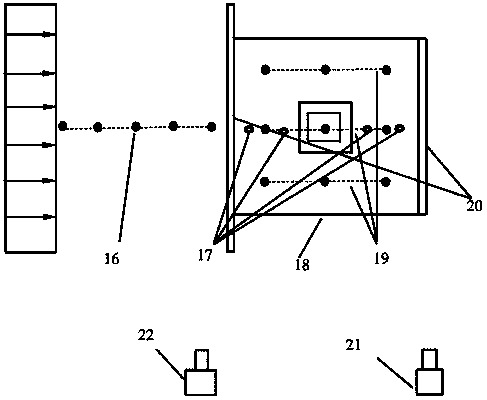

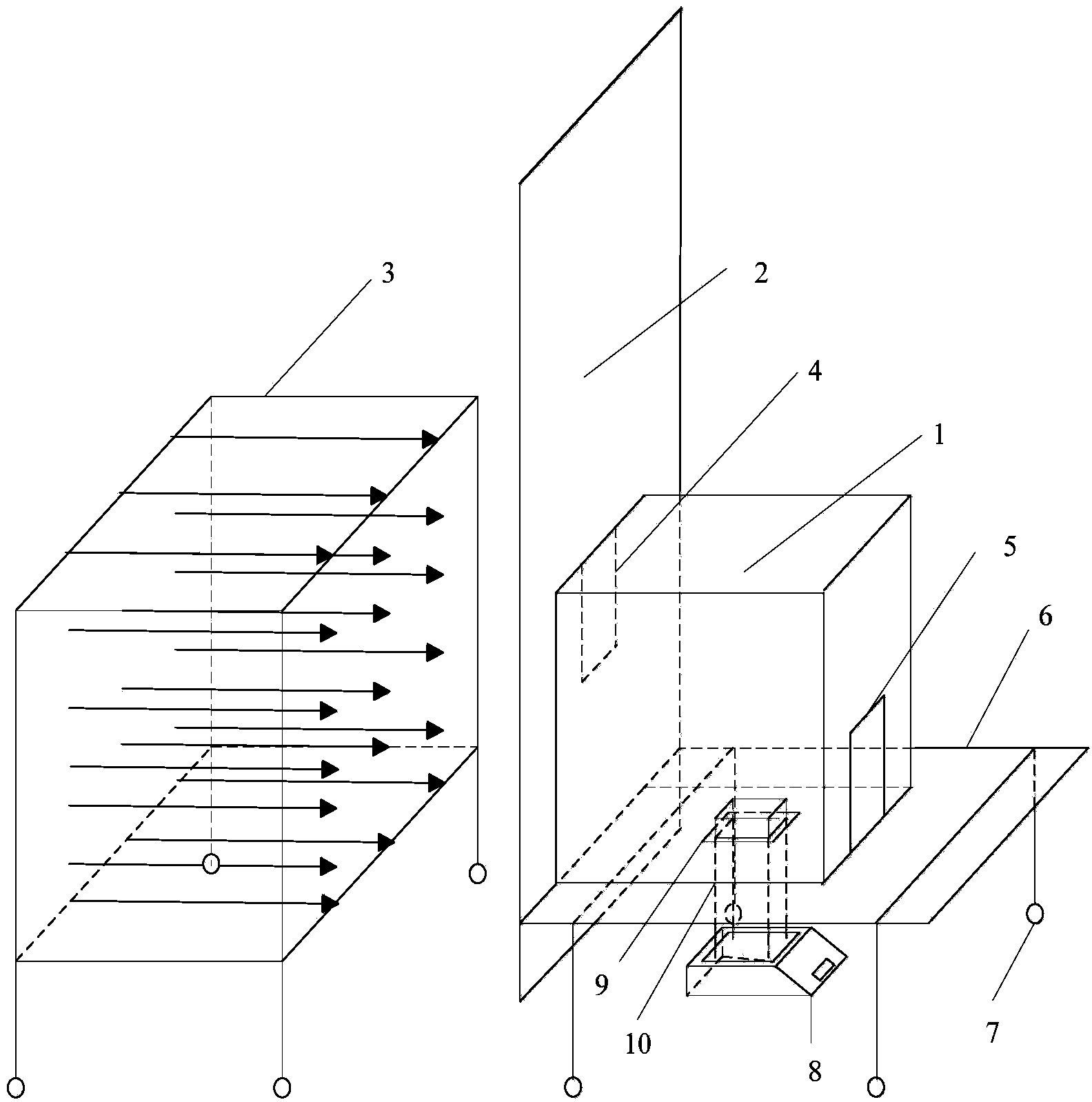

Chamber fire simulation experiment device under action of external wind

The invention provides a chamber fire simulation experiment device under the action of external wind. The device can simulate chamber fire combustion conditions in a laboratory under the action of the external wind and can be used for researching chamber fire development and windowsill overflow rules under the action of the external wind. The chamber fire simulation experiment device under the action of the external wind comprises an experiment table body, an outer vertical face, an external wind system and a matched measurement and control system. The device is designed according to a medium-size model proportion of 1:3 and is the first experimental device carrying out comprehensive and systematic study on the heat release rate, smoke flowing, temperature distribution, smoke compositions, the air supplement speed, thermal radiation flux, flame forms, sill overflowing and the like of a chamber fire under the action of the external wind. On the basis of previous experimental bases, the defects that a full-scale experiment is high in cost and a numerical simulation tool is not precise enough are overcome, repeatability of the experiment is guaranteed, and the device has great application value and important guiding significance in conducting laboratory scientific research and influences of actual external wind on the chamber fire.

Owner:UNIV OF SCI & TECH OF CHINA

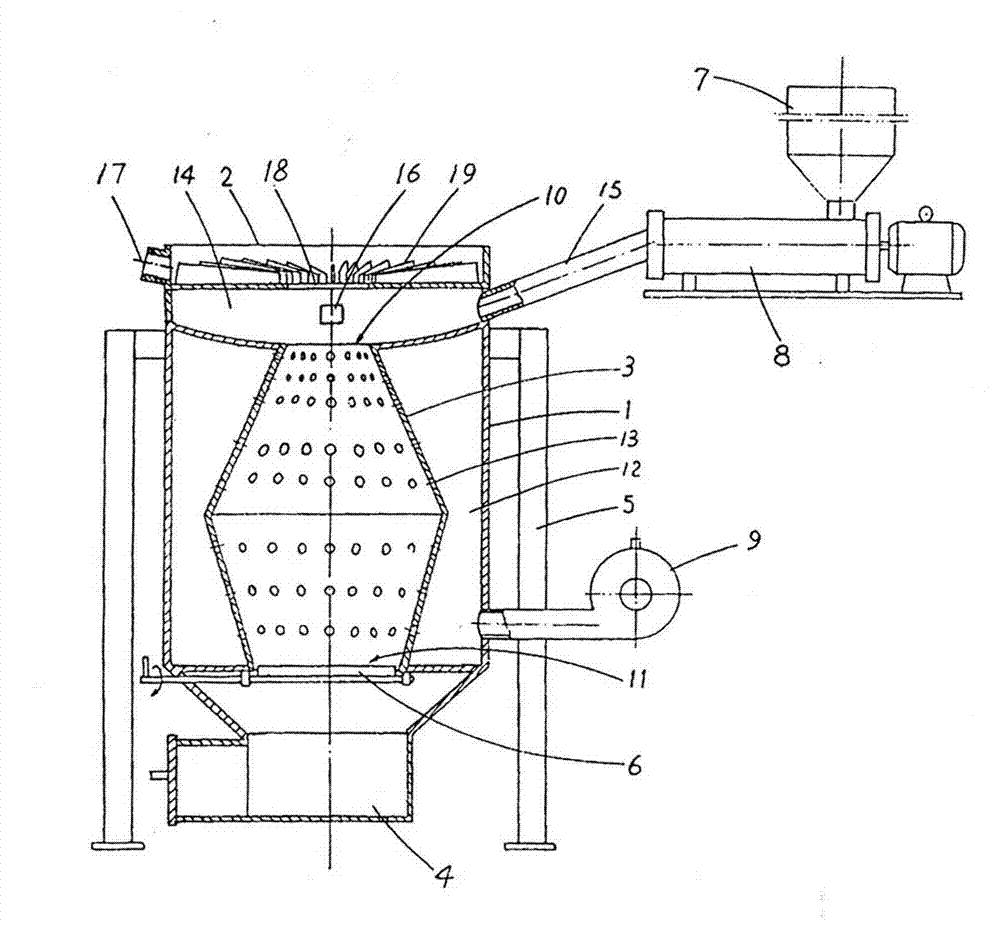

Combustor for gasification combustion of biomass formed particles

InactiveCN102818256ALow priceNo pollution in the processSolid fuel combustionCombustion apparatusCombustorEngineering

The invention discloses a combustor for gasification combustion of biomass formed particles. The combustor comprises a furnace body, a furnace head, a furnace pipe, an ash collecting box and a support, and is characterized in that the combustor further comprises a mobile ash discharging plate, a hopper, a screw feeder and a blower fan, wherein the furnace pipe is of the shape of a truncated rhombus, an upper through hole is of a fire outlet hole, a lower through hole is of an ash discharge hole, the whole furnace pipe is arranged at the middle of the furnace body and forms a closed wind box with the furnace body, the blower fan is communicated with the wind box through a ventilation pipe, a plurality of wind holes are uniformly formed on the furnace pipe, the top surface of the furnace body is of the shape of a cauldron, the furnace body and the furnace head form a feeding cavity, the screw feeder is connected with the hopper and connected with the feeding cavity on the side wall between the top surface of the furnace body and the furnace head through a material conveying pipe, an ignition hole is formed on the feeding cavity, a fire through hole is formed at the center of a bottom plate of the furnace head, the rotating ash discharging plate is arranged on the ash discharge hole on the bottom surface of the furnace pipe, and a smoke exhaust port is arranged on the side wall of the furnace head. The combustor takes biomass as fuel, fuel sources are abundant, and environmental pollution is avoided; and furthermore, the combustor has the advantages of reasonable structure, fast ignition, full combustion, high calorific value and great convenience in operation, and is particularly suitable for boilers, tobacco curing furnaces and other drying equipment.

Owner:曾巨泓

High-performance clean methanol gasoline

InactiveCN101914394ARaw materials are easy to getWide variety of sourcesLiquid carbonaceous fuelsAlcoholEther

The invention discloses a high-performance clean methanol gasoline which has the advantages of low cost and high efficiency. The methanol gasoline comprises the following components in percentage by weight: 15 to 48 percent of methanol, 50 to 84 percent of crude gasoline and 1 to 2 percent of composite additive, wherein the composite additive comprises the following components in percentage by weight: 15 to 20 percent of multi-effect energizer, 30 to 41 percent of benzene compound, 0.5 to 24 percent of complexing agent, 8 to 24 percent of ether compound, 0.7 to 1.2 percent of detergent additive and 16 to 19 percent of multi-carbon alcohol. The product of the invention has the advantages of readily available raw materials, wide source and low cost, can meet the requirements of No.93 unleaded petrochemical gasoline and above when used as a vehicle fuel, can be used independently or mixed with gasoline and is not limited by the proportion and the engine does not need to be retrofitted inuse.

Owner:李东升

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com