Water coke slurry buring technology

A combustion technology, water coke slurry technology, applied in the field of water coke slurry combustion, can solve problems such as difficulties in the ignition and stable combustion process of water coke slurry

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

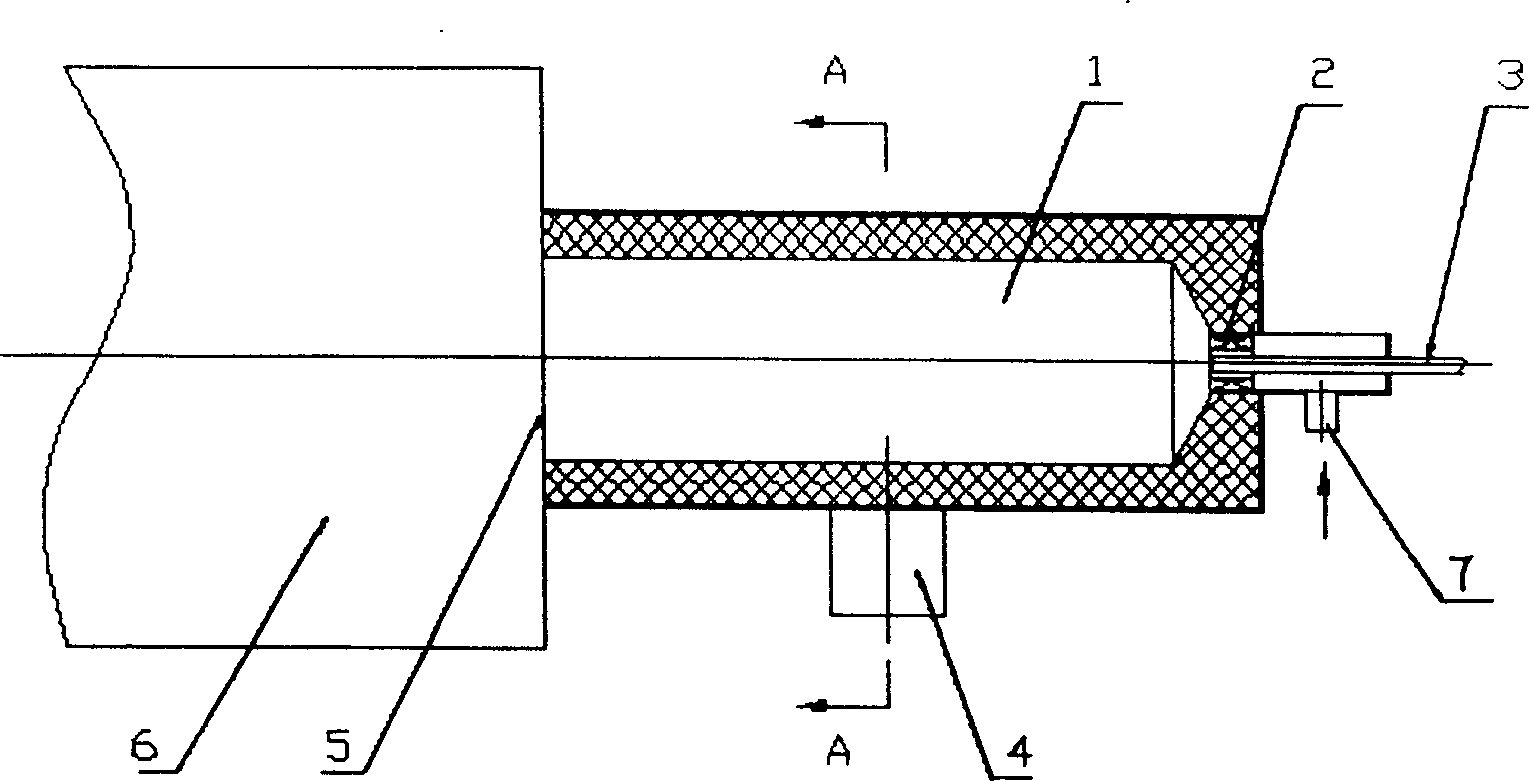

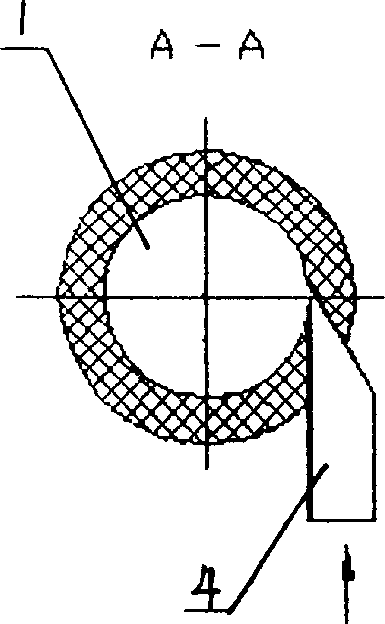

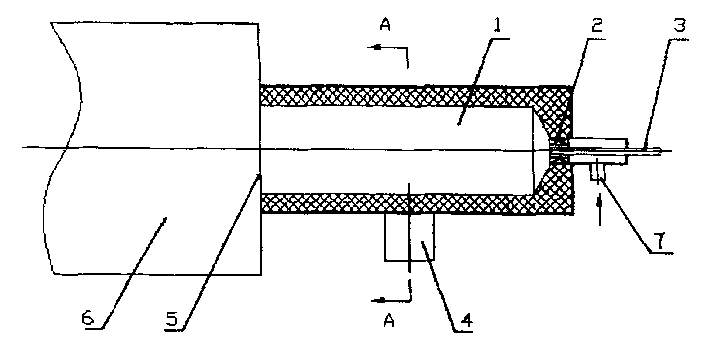

[0011] figure 1 Middle: 1. Pre-combustion chamber 2. Swirl burner 3. Atomizing spray gun 4. Tangential air inlet 5. Open mouth 6. Industrial furnace 7. Air inlet

[0012] One end of the pre-combustion chamber 1 is connected to the primary air swirl burner 2, and the air inlet 7 is located at the bottom of the swirl burner 2. The primary air enters the air inlet 7 and rotates into the pre-combustion chamber 1 through the swirl burner 2. The swirling intensity is greater than 3.0, the secondary air enters from the tangential air inlet 4 near the middle area of the pre-combustion chamber 1, the tangential secondary air velocity is 25-40m / s, and the atomizing spray gun 3 is placed in the center of the swirling burner 2. In the area, the other end of the pre-combustion chamber 1 is an open port 5 connected to an industrial kiln 7. In the initial stage, the oil is burned first. When the temperature in the pre-combustion chamber 1 reaches at least 950~1000℃, the water coke slurry is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com