Patents

Literature

990results about "Fuel re-atomisation/homogenisation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

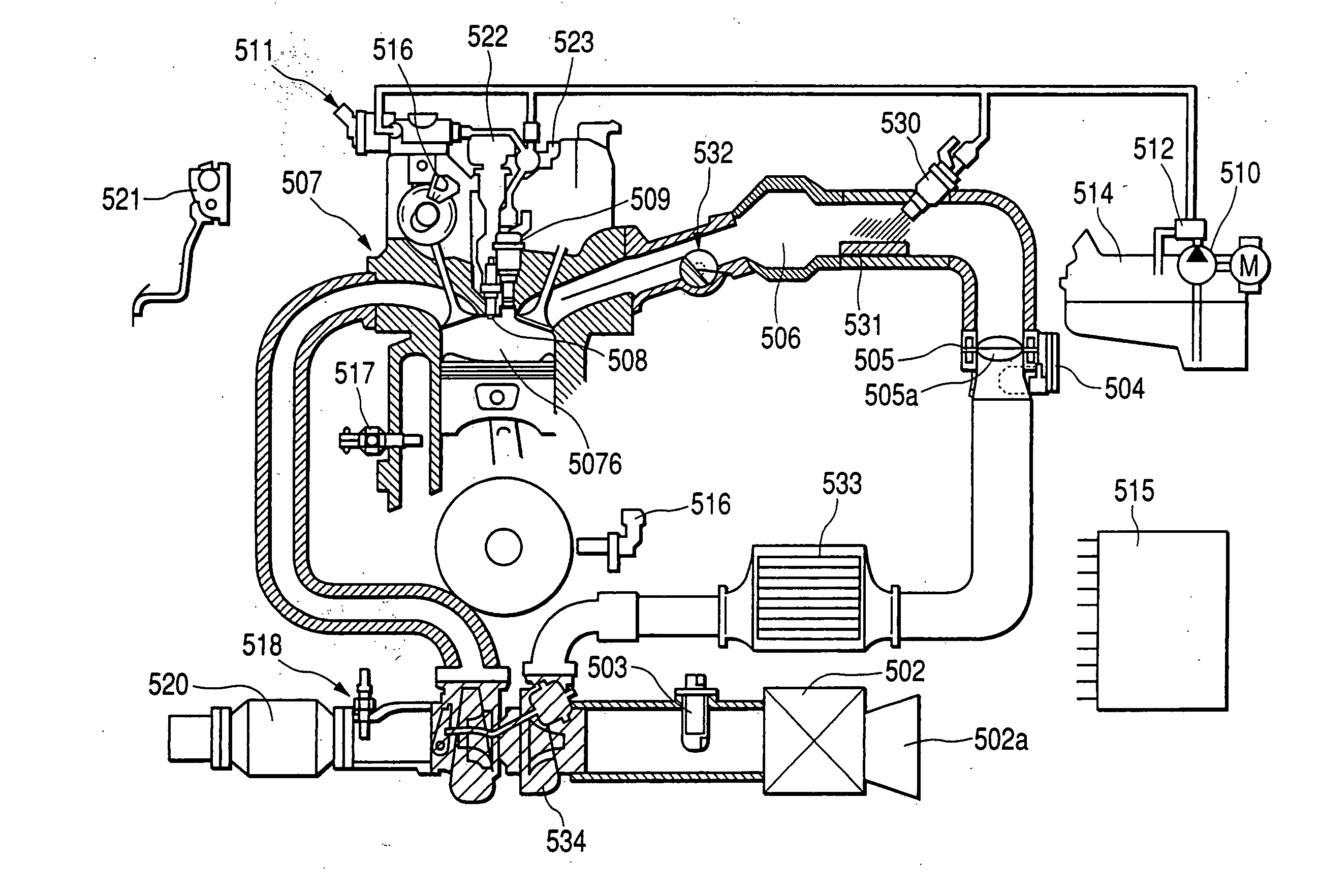

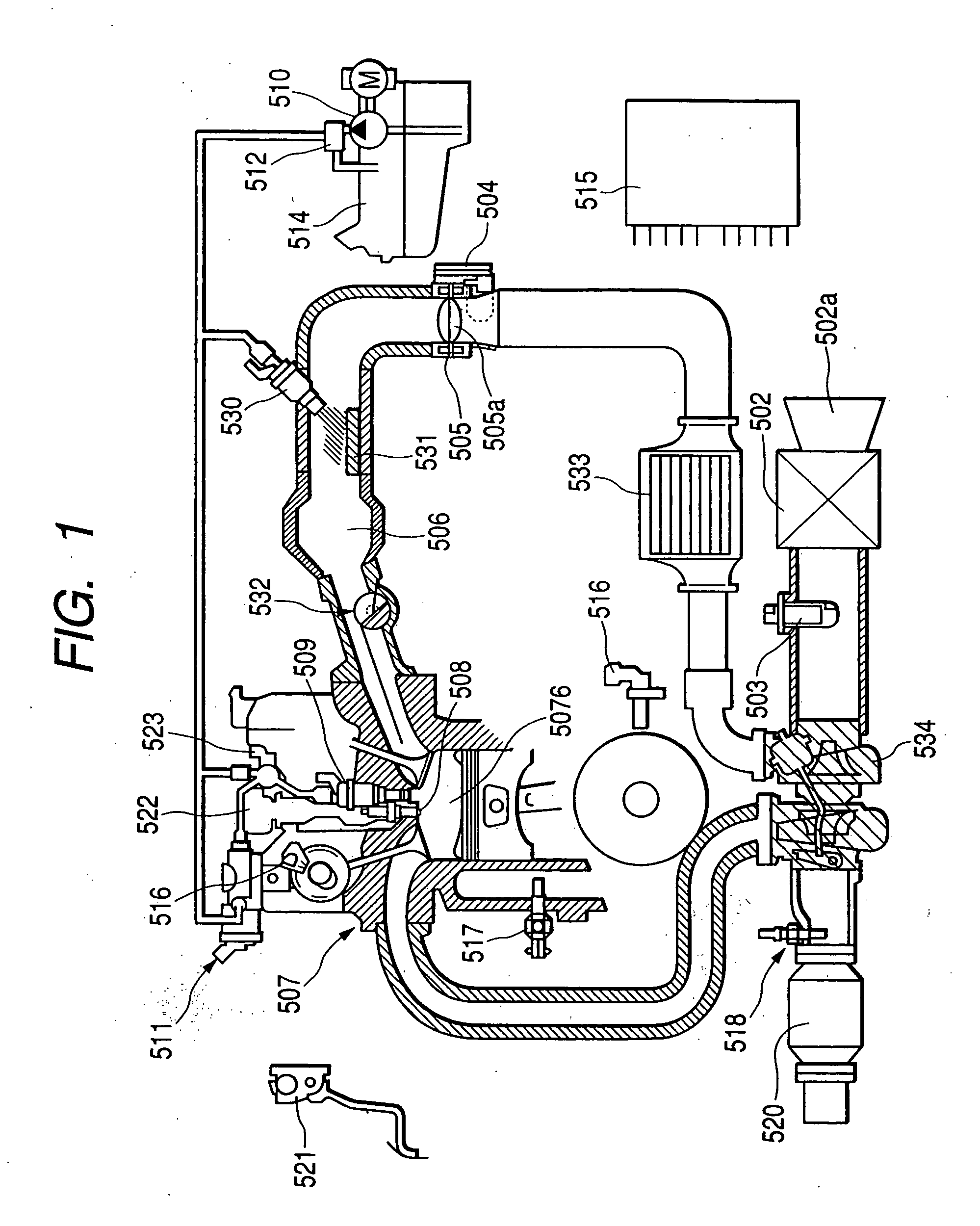

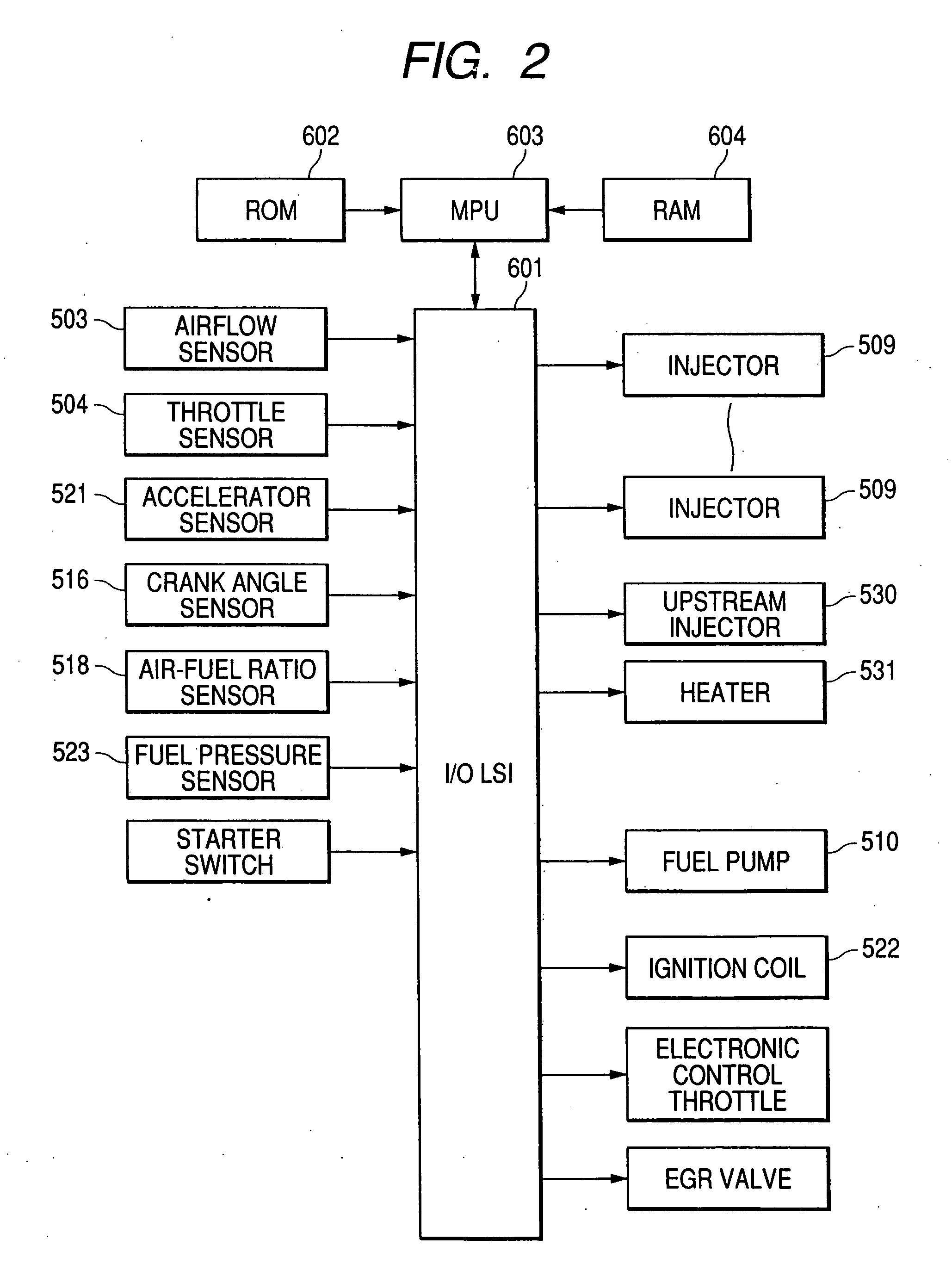

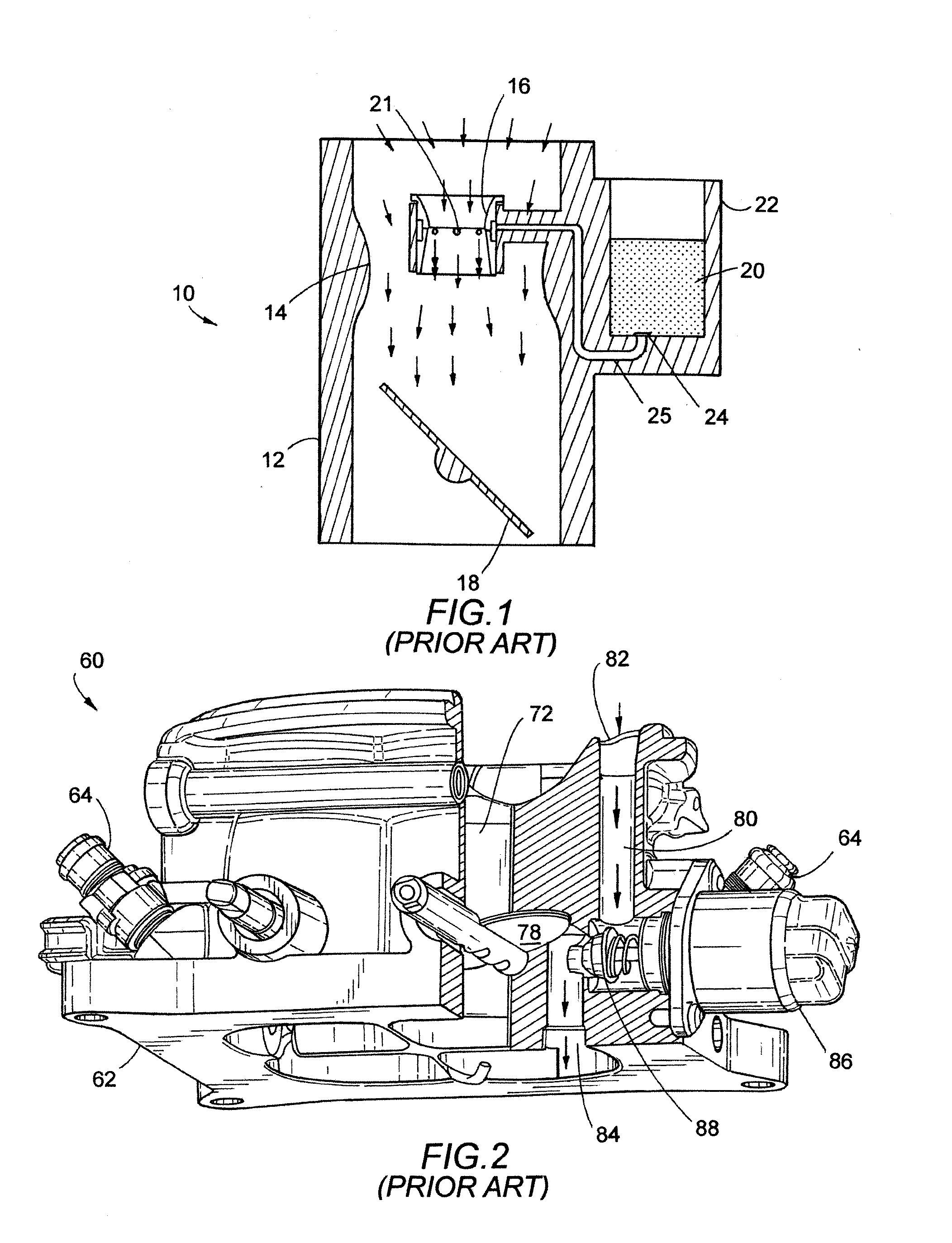

Fuel supply system and fuel supply method for in-cylinder direct fuel injection engine

InactiveUS20050066939A1Increase productionHigh outputElectrical controlInternal combustion piston enginesFuel supplyFuel injection

To offer a fuel supply system and fuel supply method for direct injection engine that realizes higher output. In a fuel supply system for direct injection engine of the present invention, equipped with a primary fuel injector that injects fuel directly into the cylinder of the direct injection engine and supercharger that increase the intake air quantity of the engine, a secondary fuel injector is installed in addition to the primary fuel injector. In a specified engine load area, fuel is supplied using the primary fuel injector and secondary fuel injector. Even though the fuel quantity injected from the primary fuel injector into the cylinder is limited, the fuel supply system for direct injection engine constructed as above can increase the engine output because the fuel insufficiency can be supplied by the secondary fuel injector.

Owner:HITACHI LTD

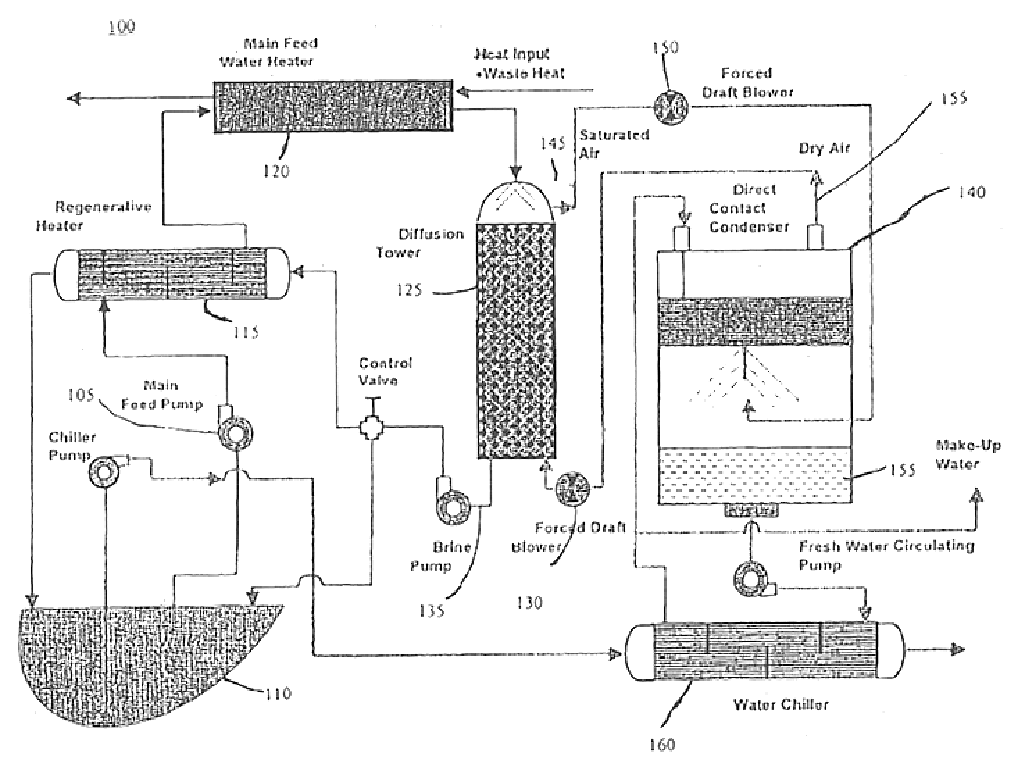

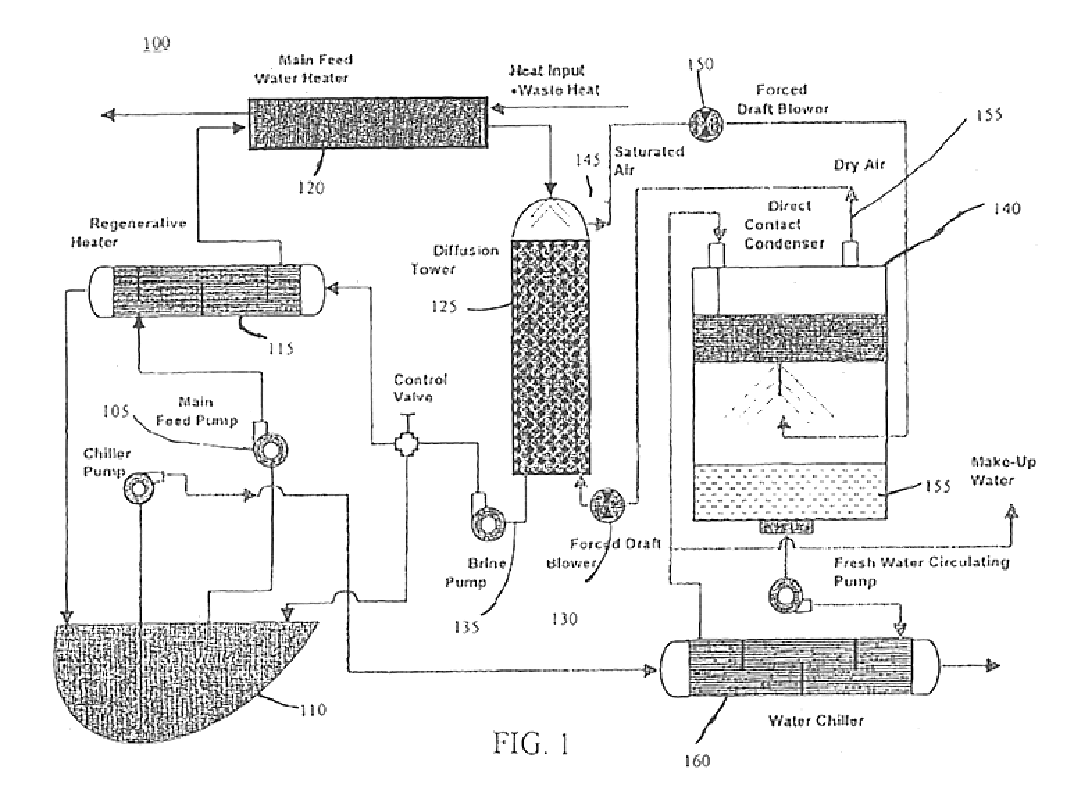

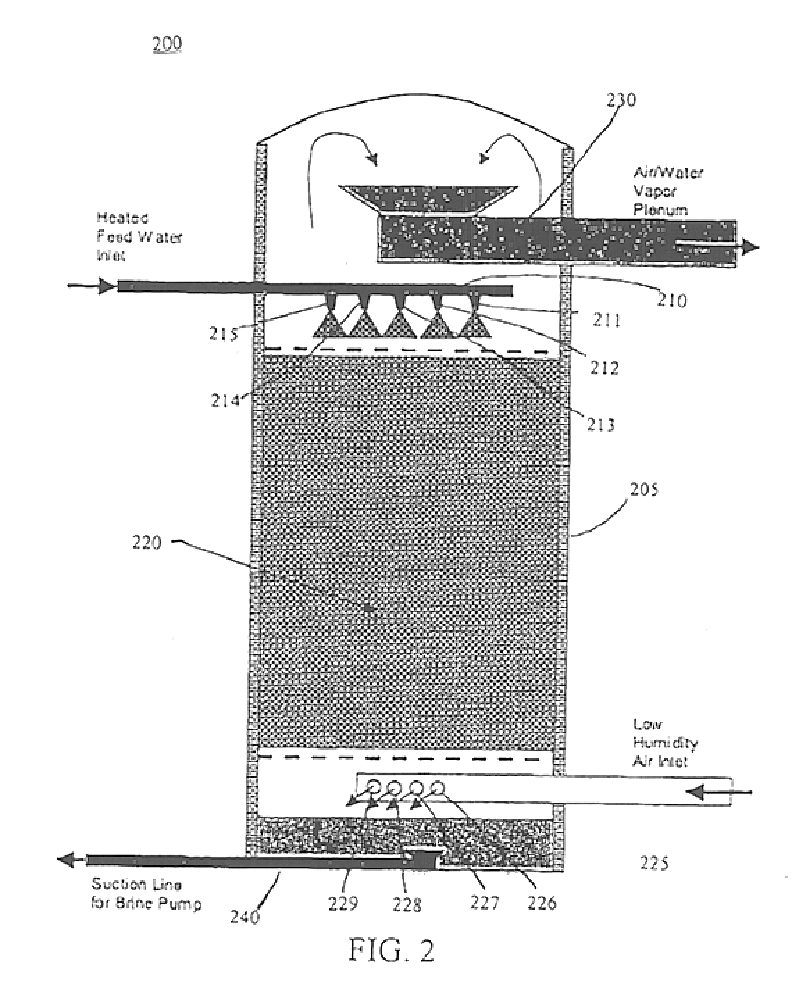

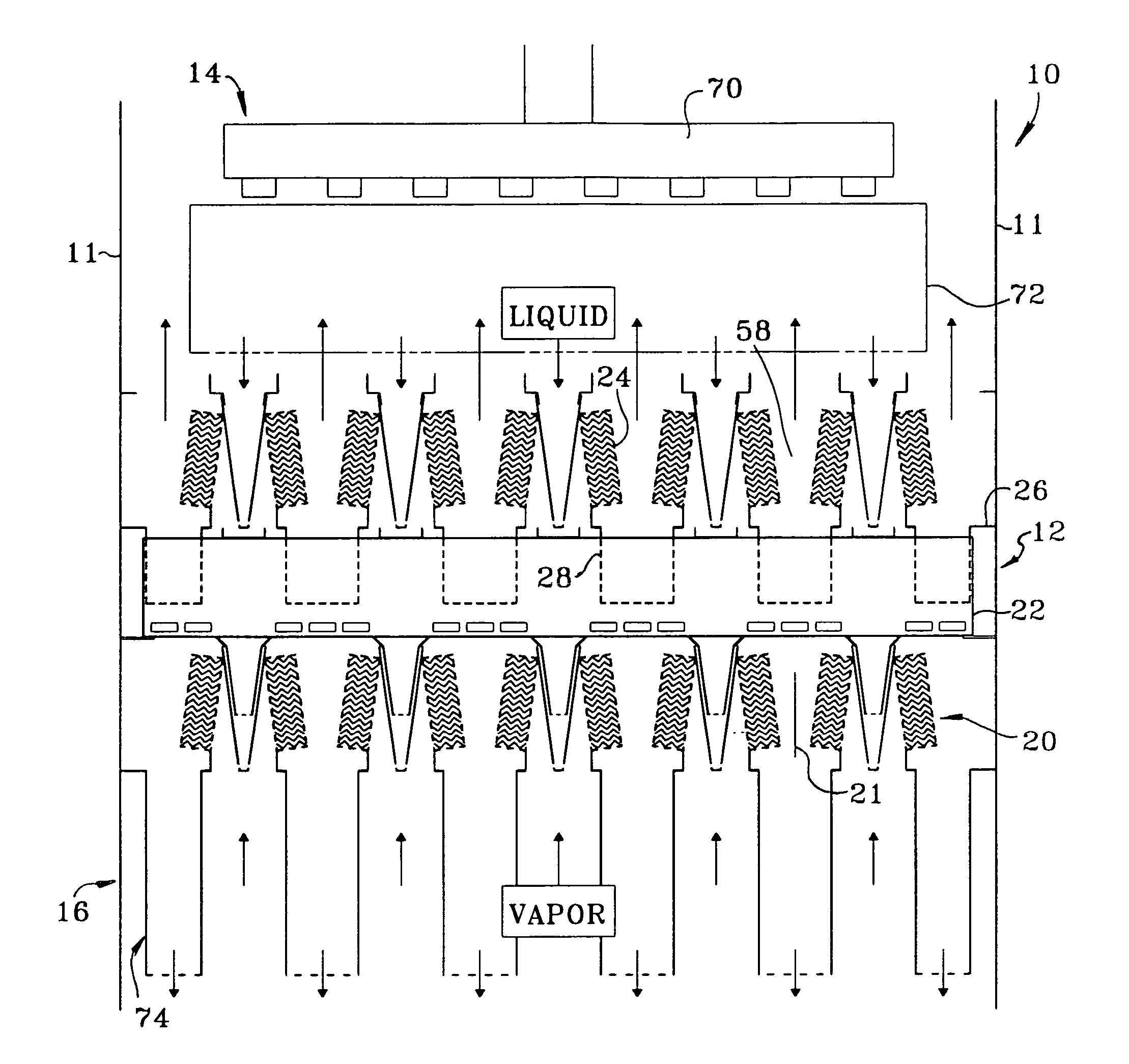

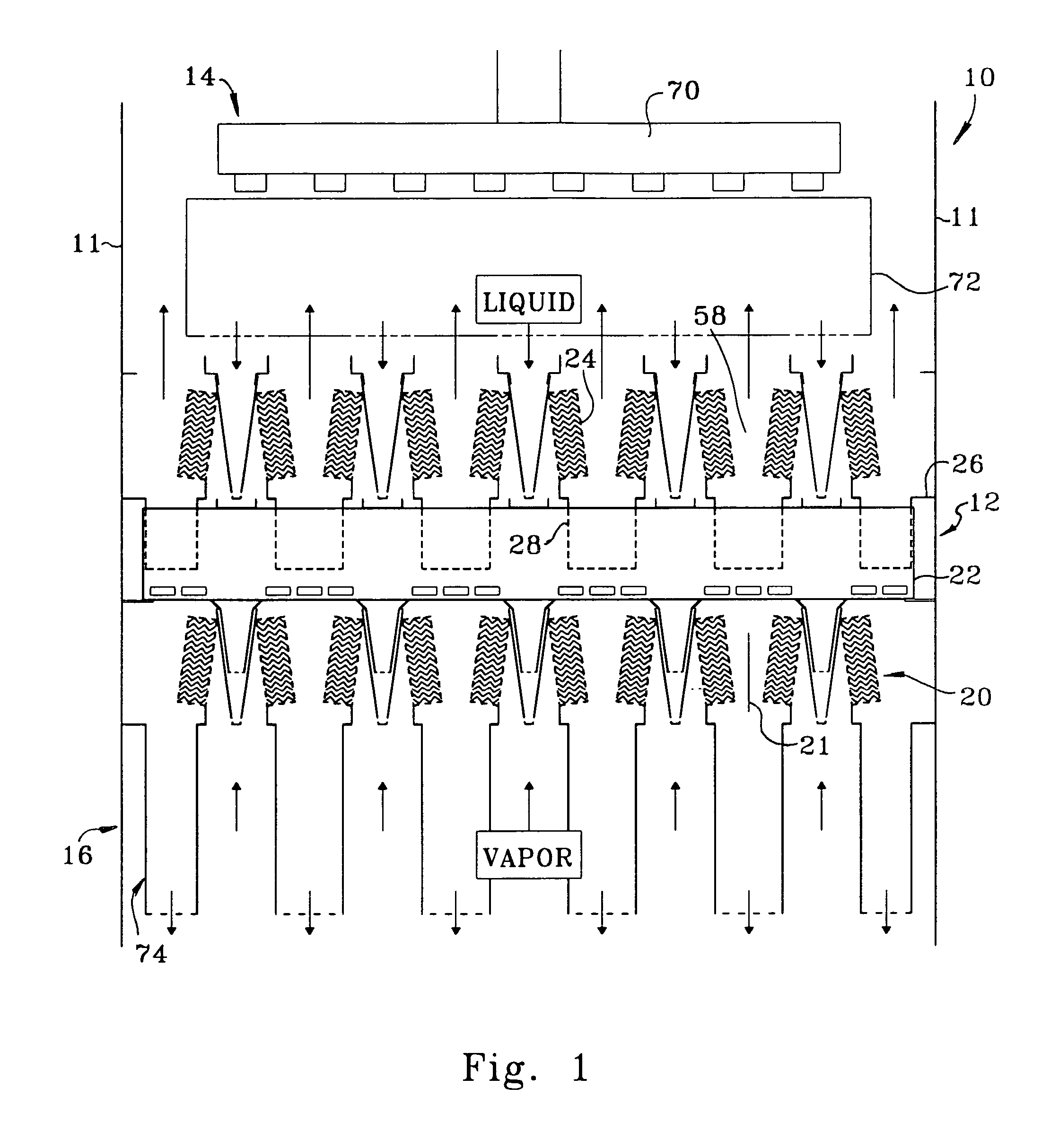

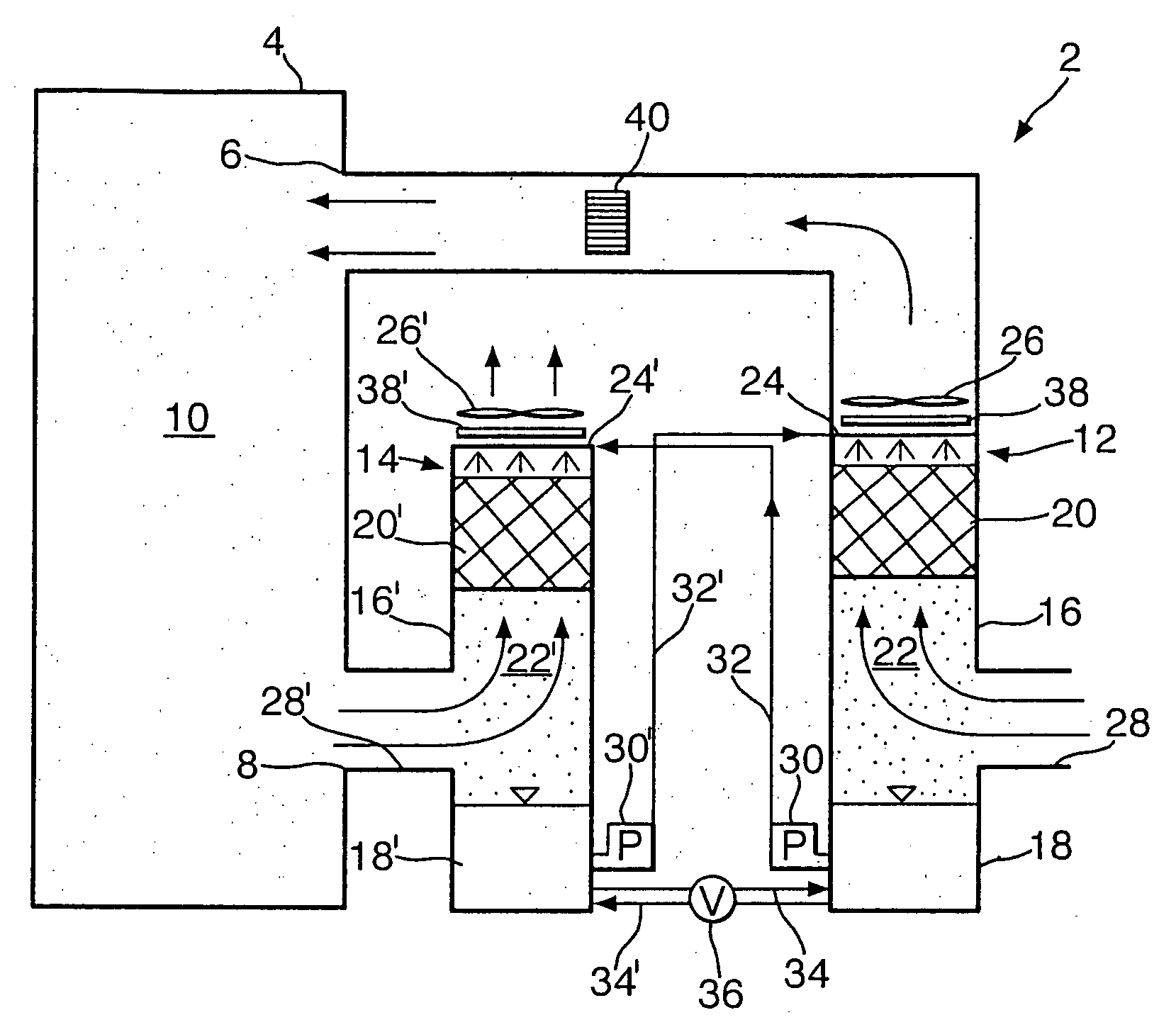

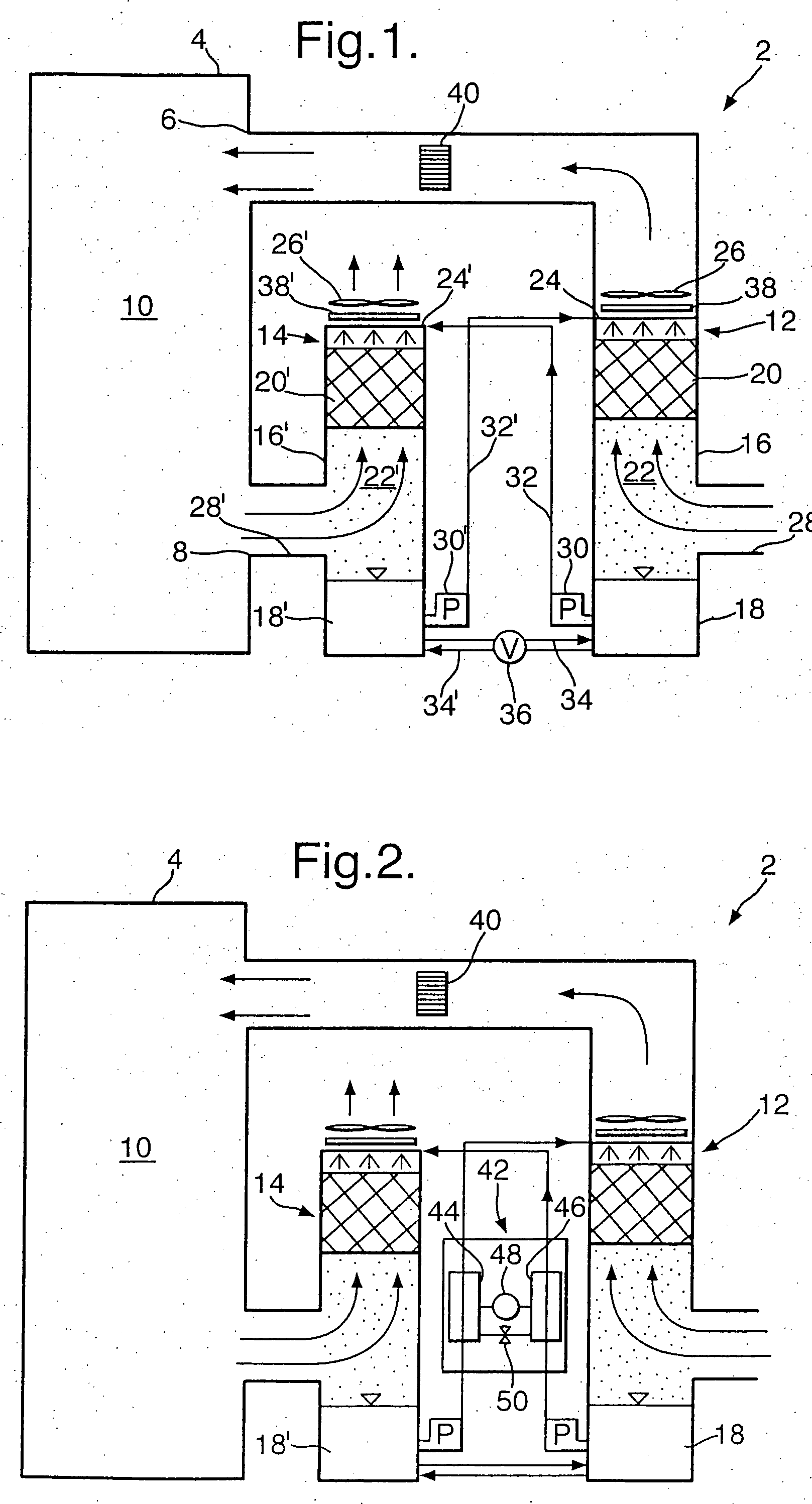

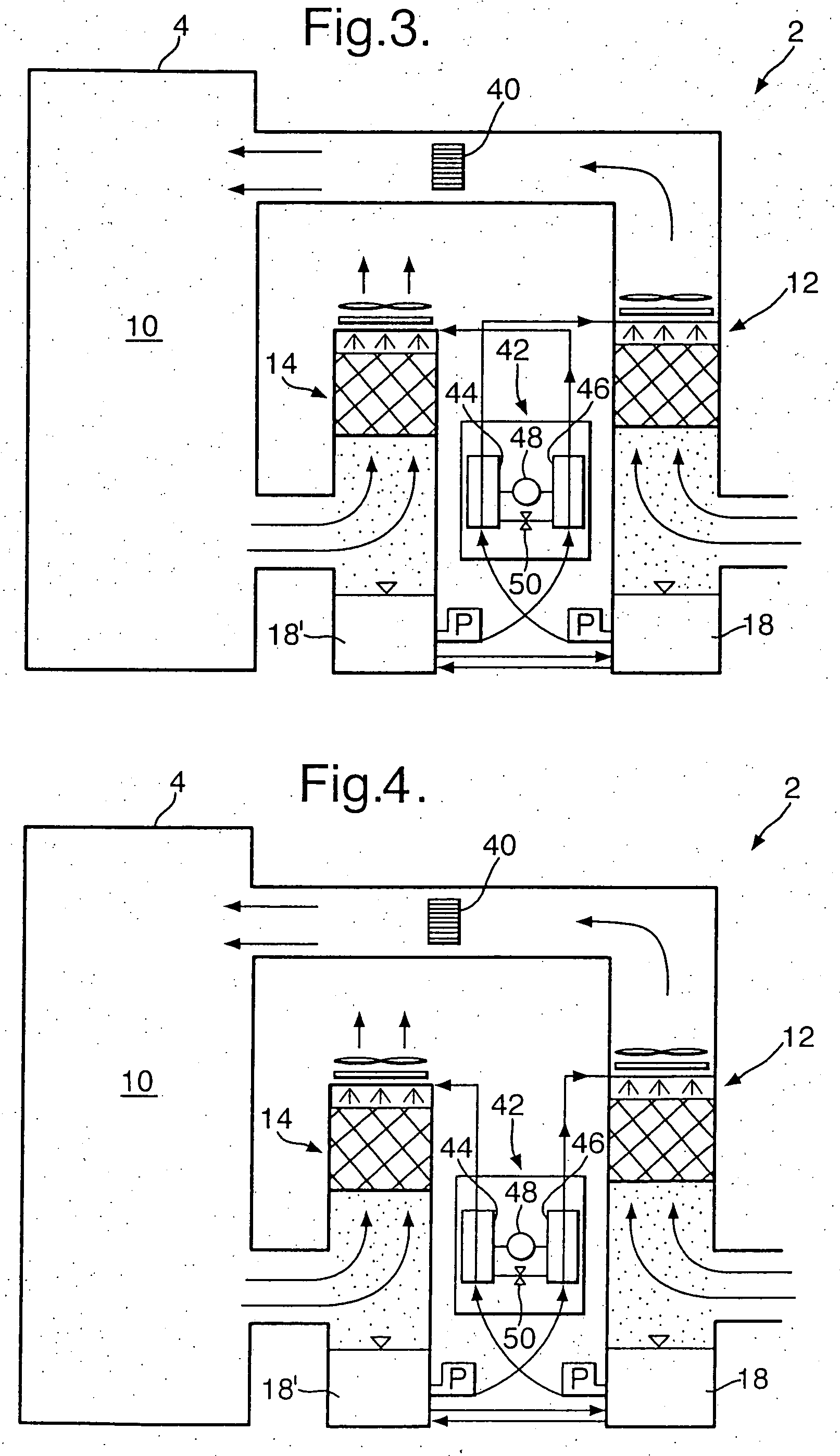

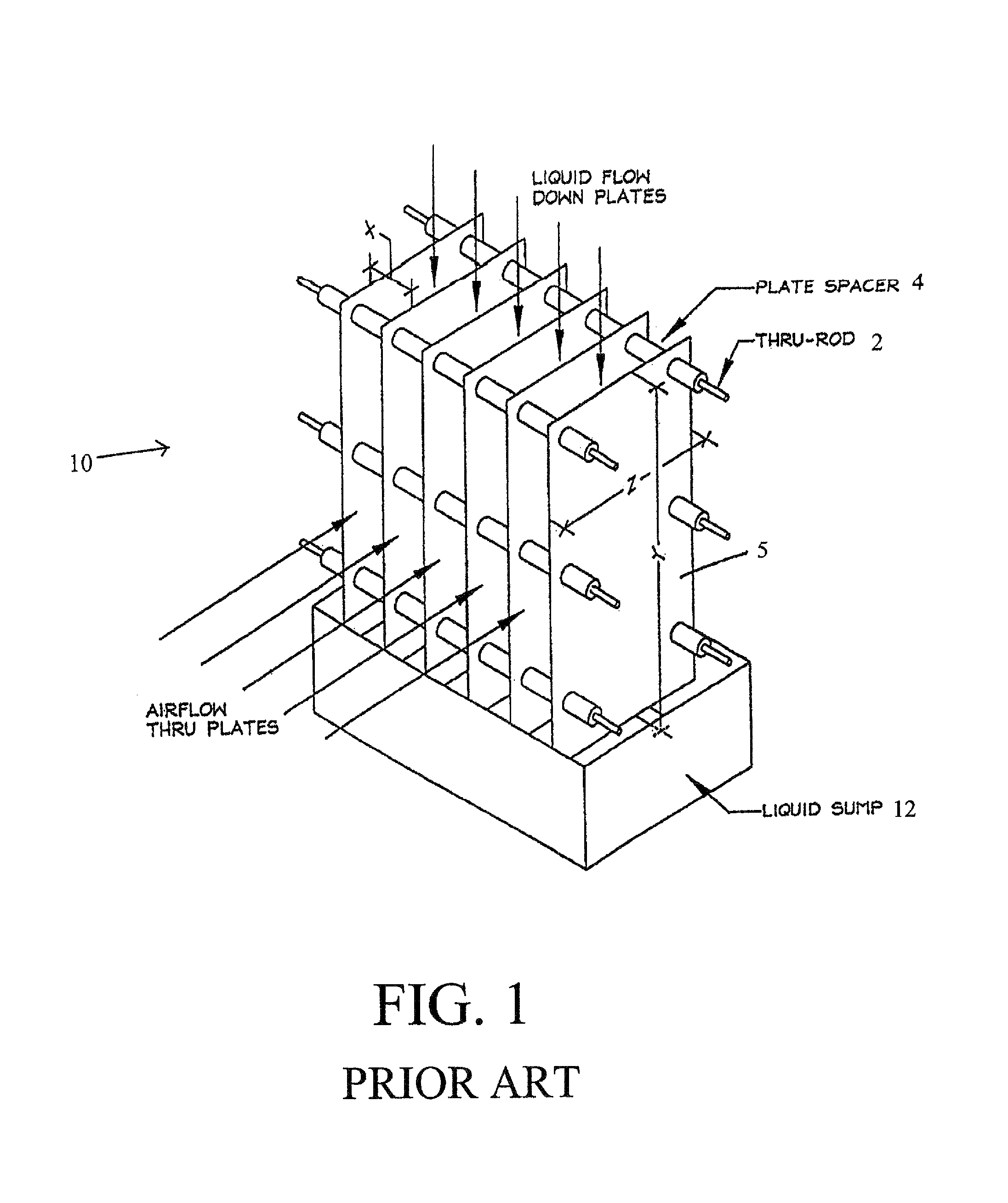

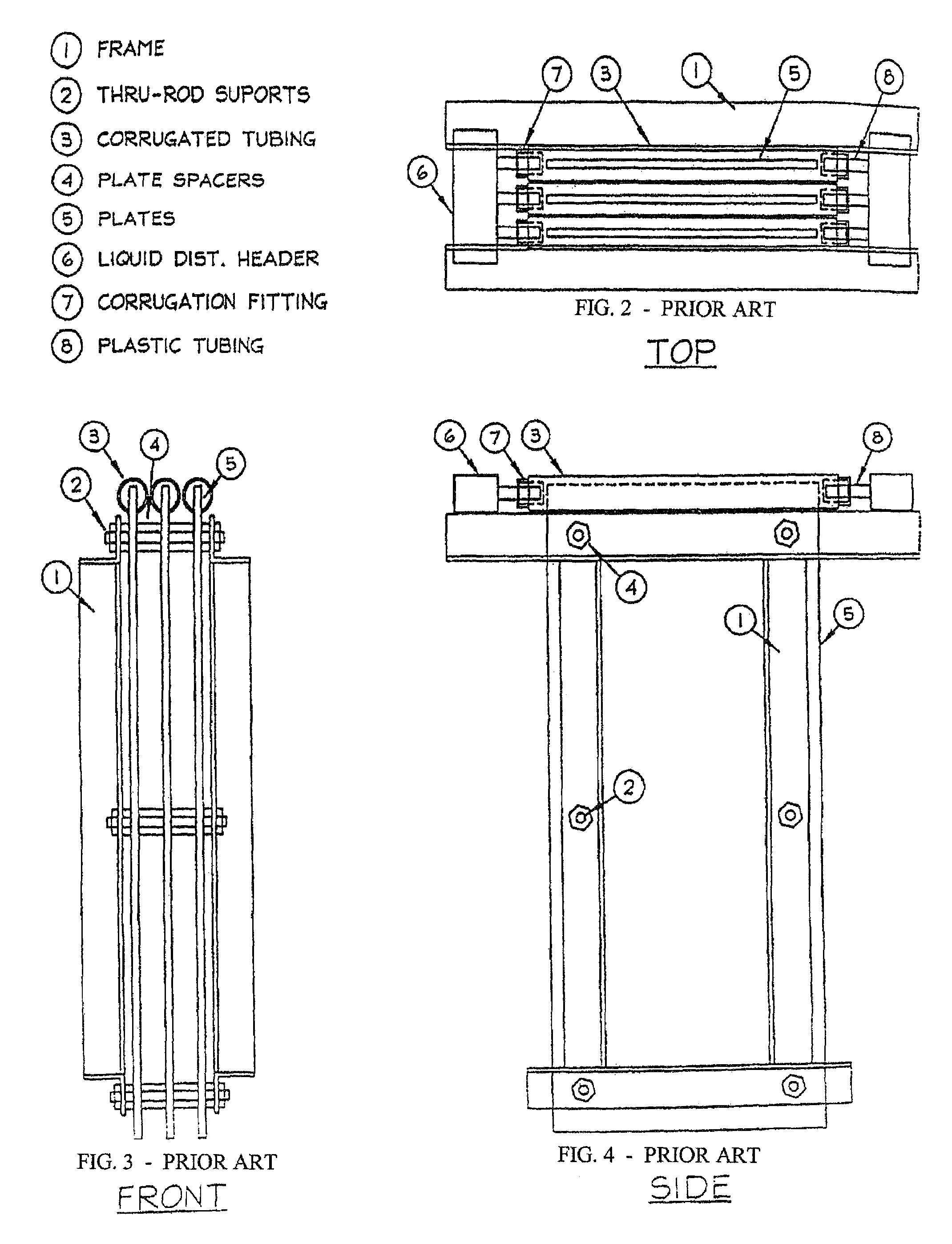

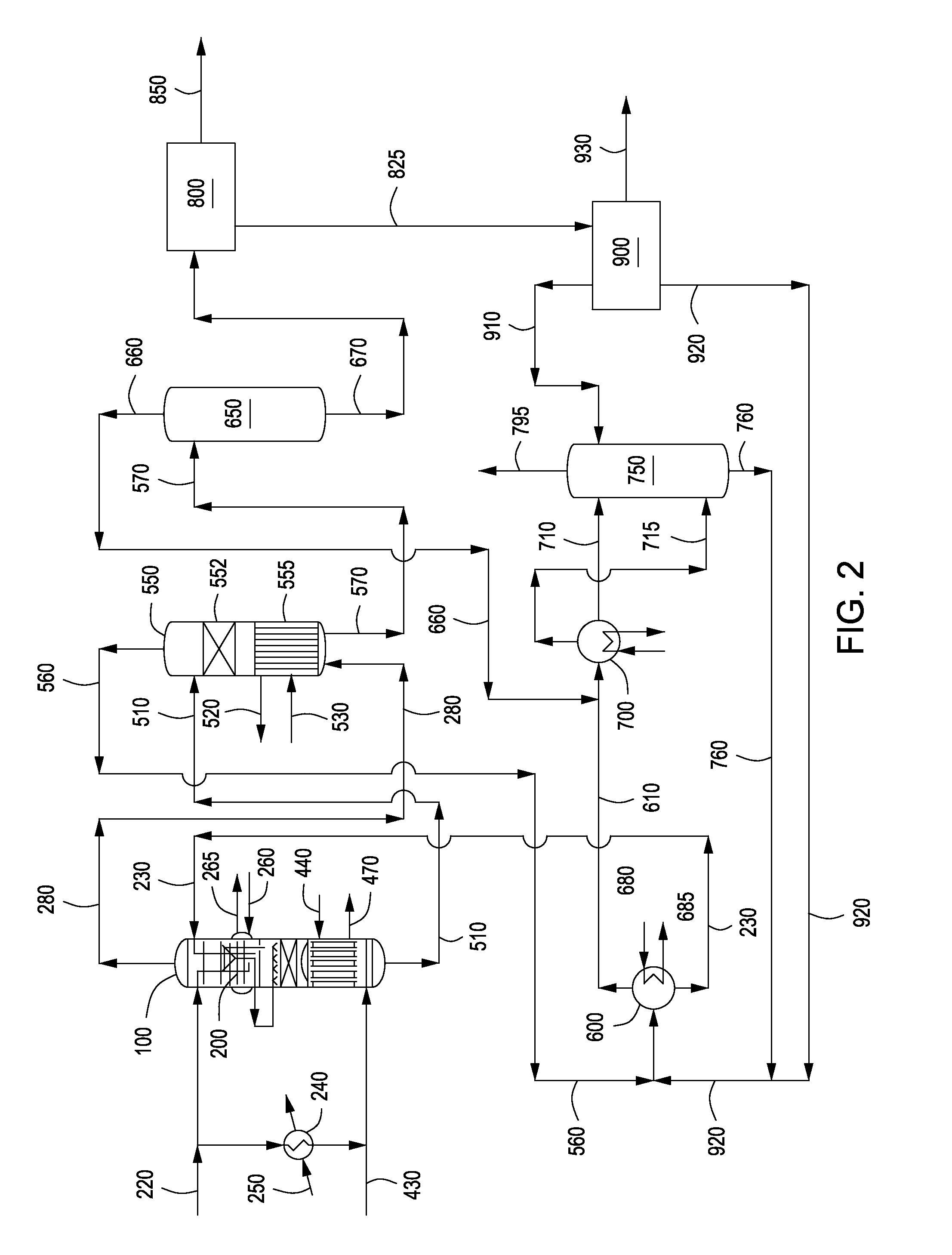

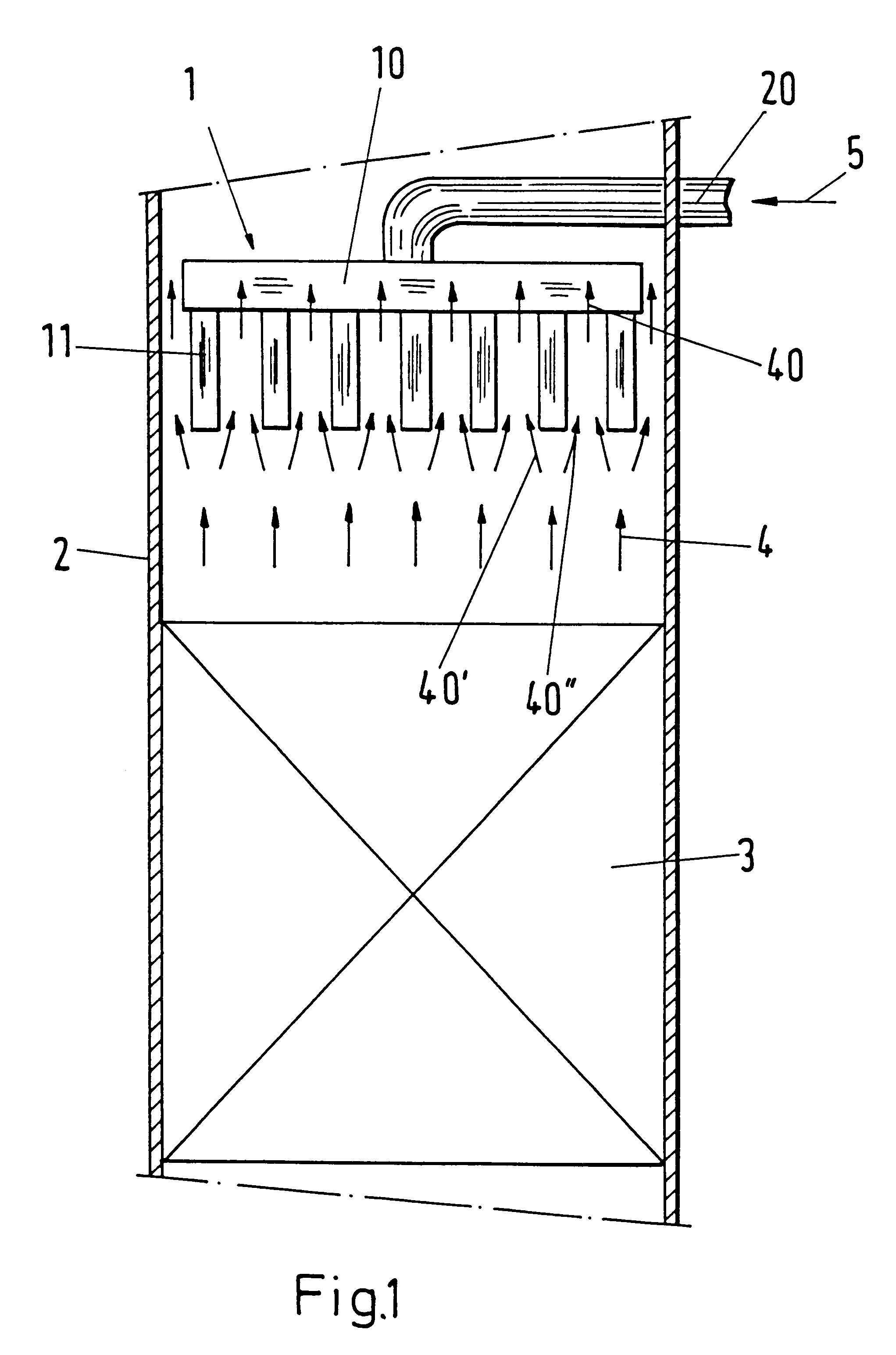

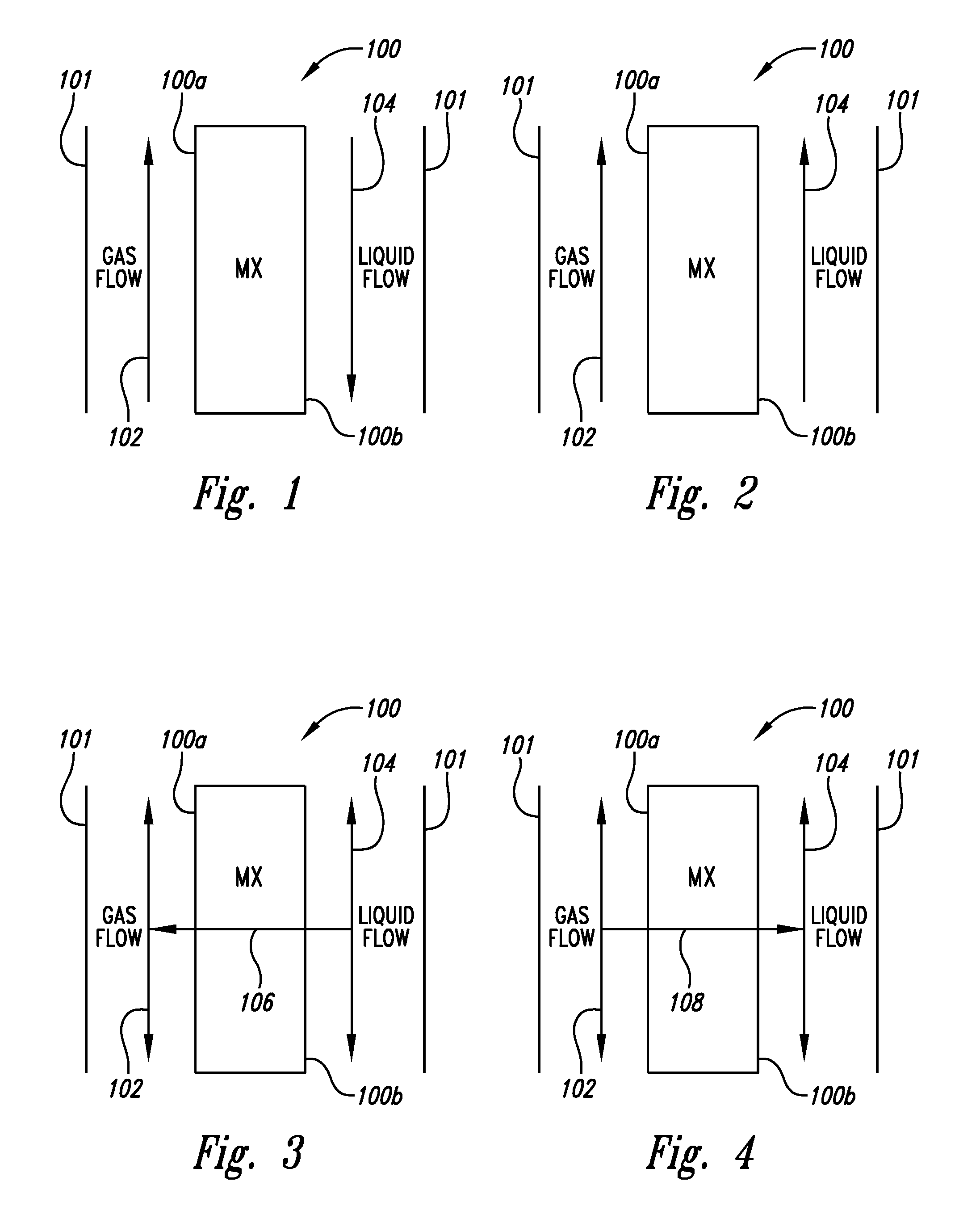

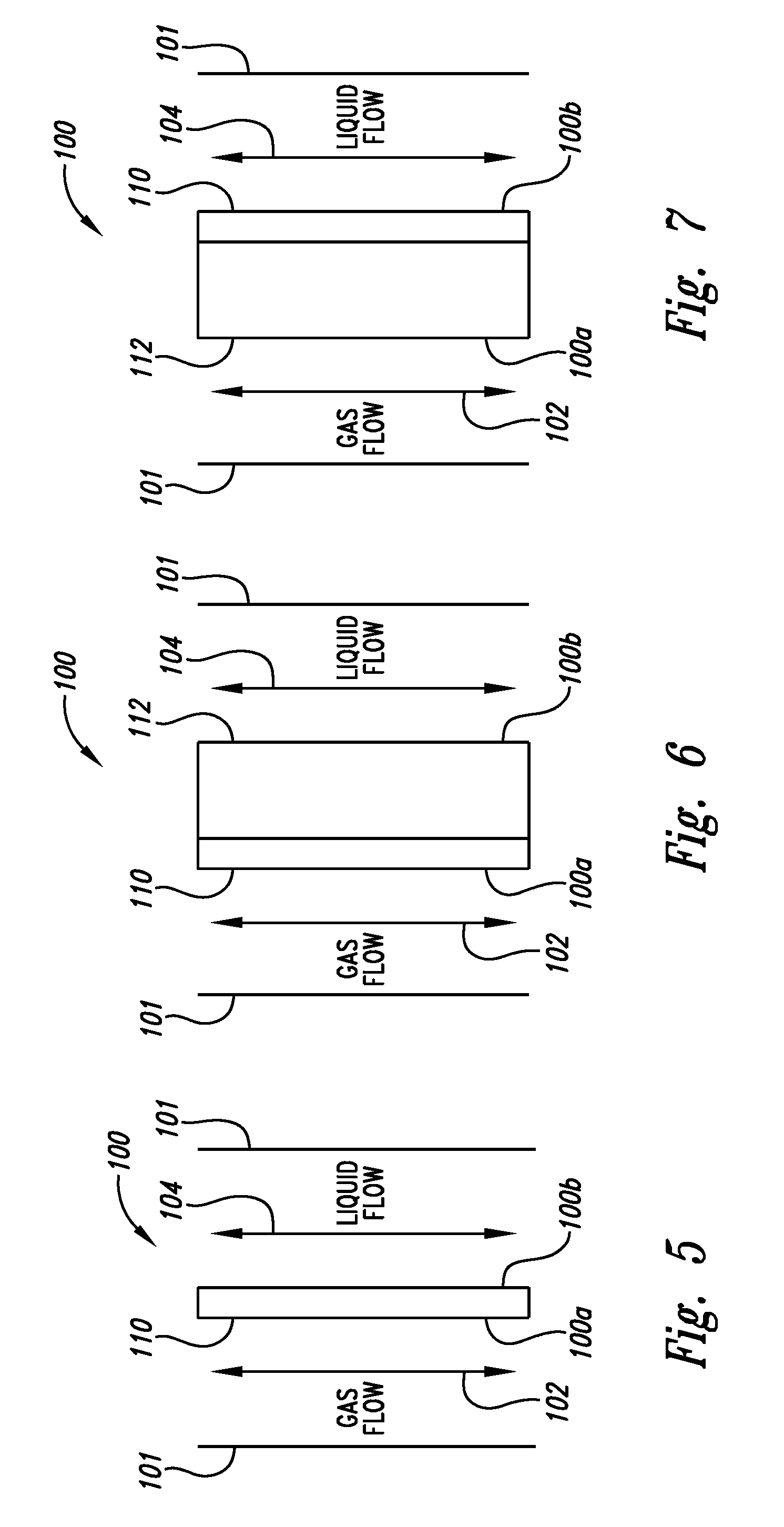

Diffusion driven desalination apparatus and process

A diffusion driven desalination apparatus and related method includes structure for receiving a heated water stream and creating at least one region having a thin film of water and structure for forcing a low humidity air stream over the thin film of water, wherein water from the thin film of water evaporates and diffuses into the air stream to create a humidified air stream. A diffusion tower including at least one plenum can be used to create and transfer the humidified air stream. At least one condenser, such as a direct contact condenser, condenses the humidified air stream, wherein purified water is produced. Waste heat from a power plant can be used to provide the heated water stream and power plants can use the waste heat generated to inexpensively provide purified water.

Owner:UNIV OF FLORIDA RES FOUNDATION INC +1

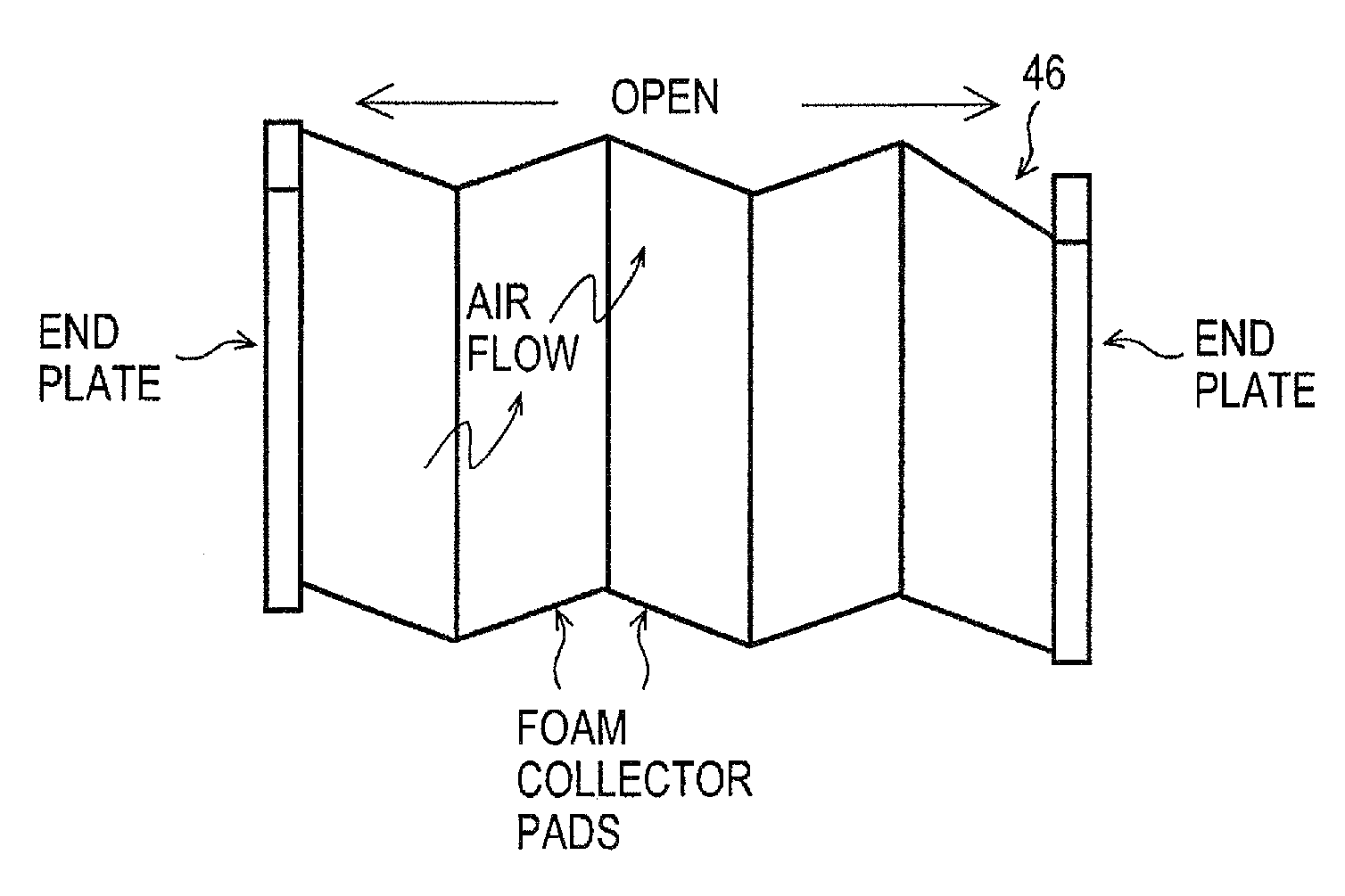

Removal of carbon dioxide from air

ActiveUS20060186562A1Complex structureReduce fluid spillageDispersed particle filtrationUsing liquid separation agentSorbentOpen cell

Owner:CARBON SINK

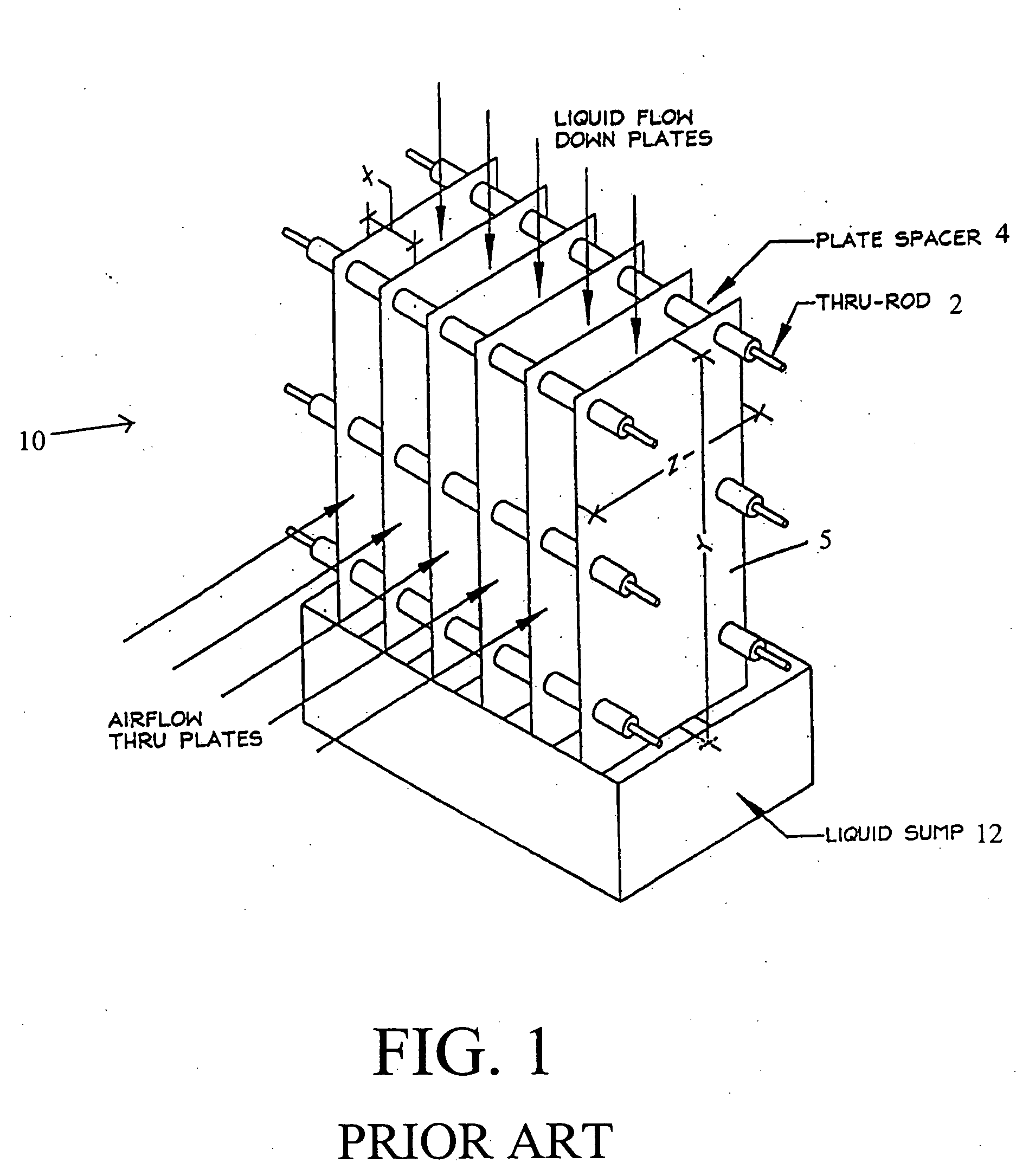

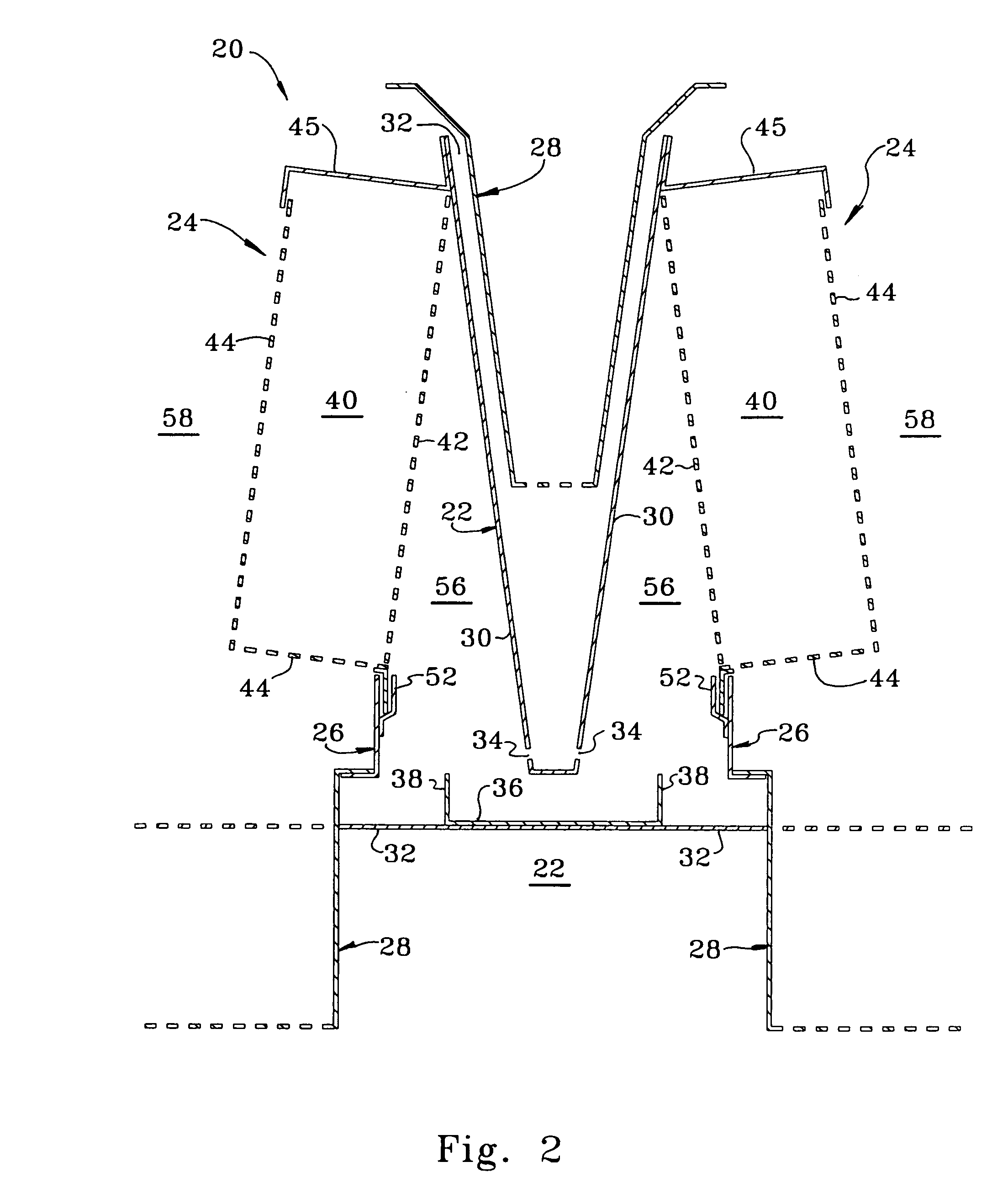

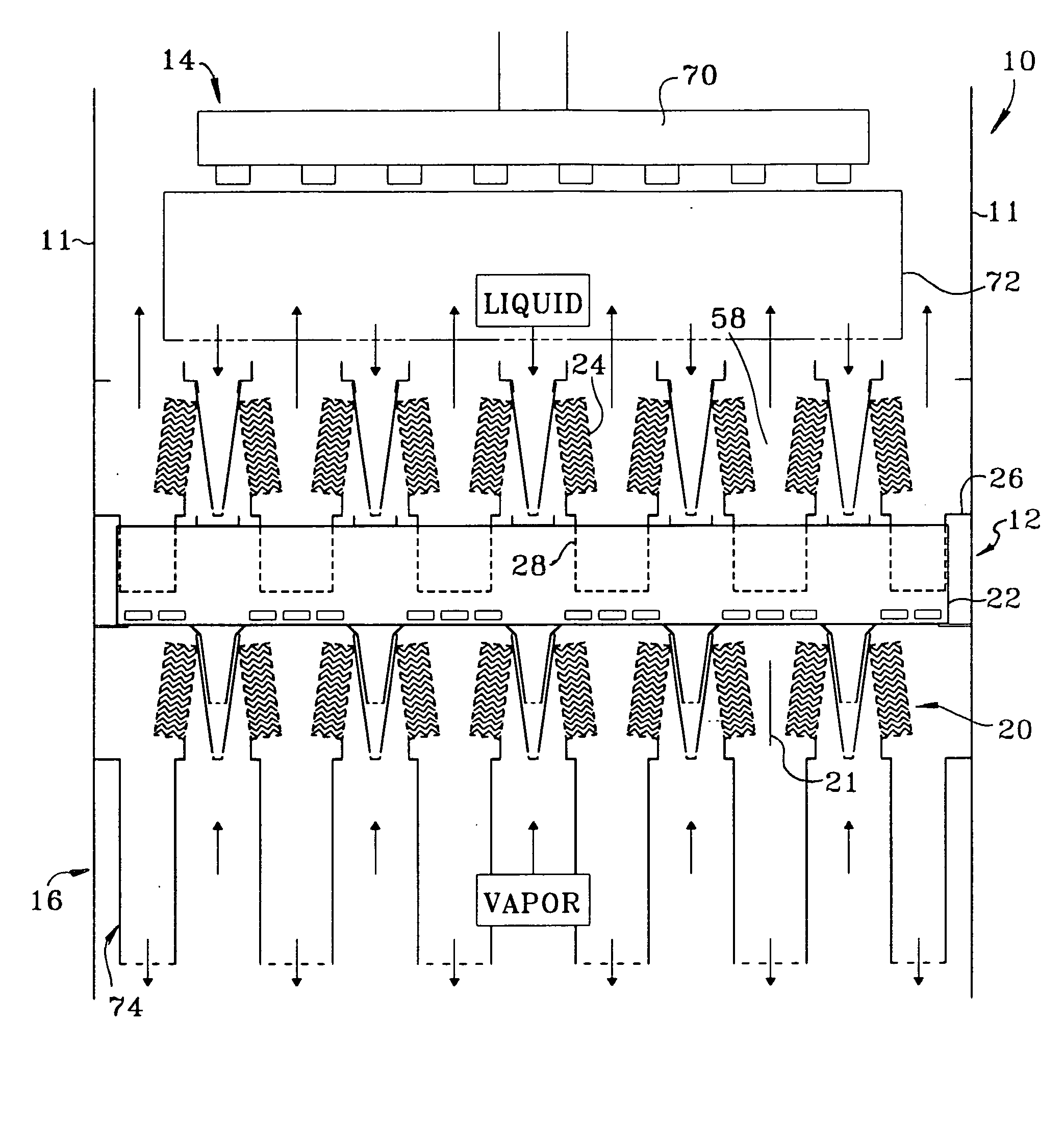

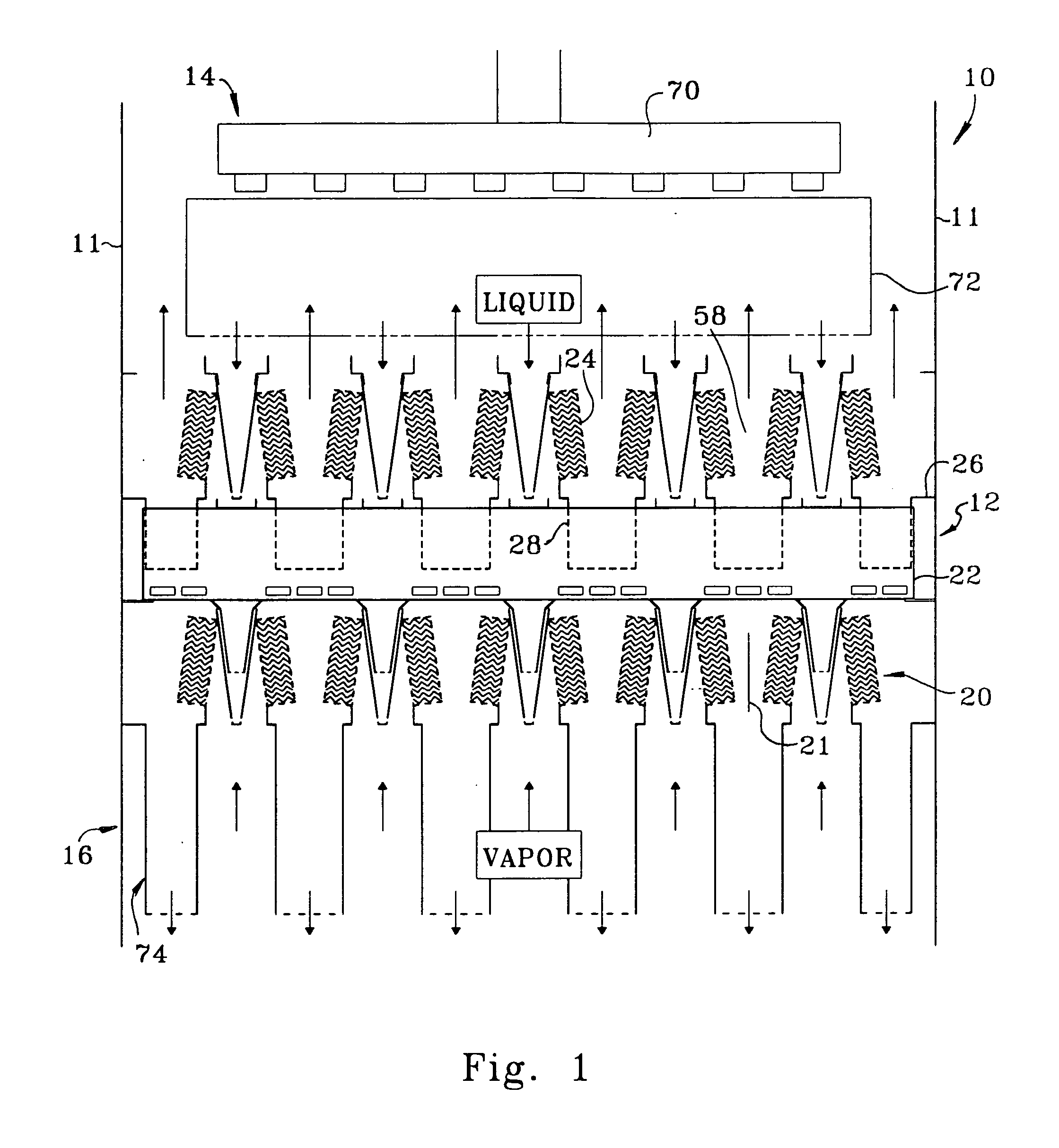

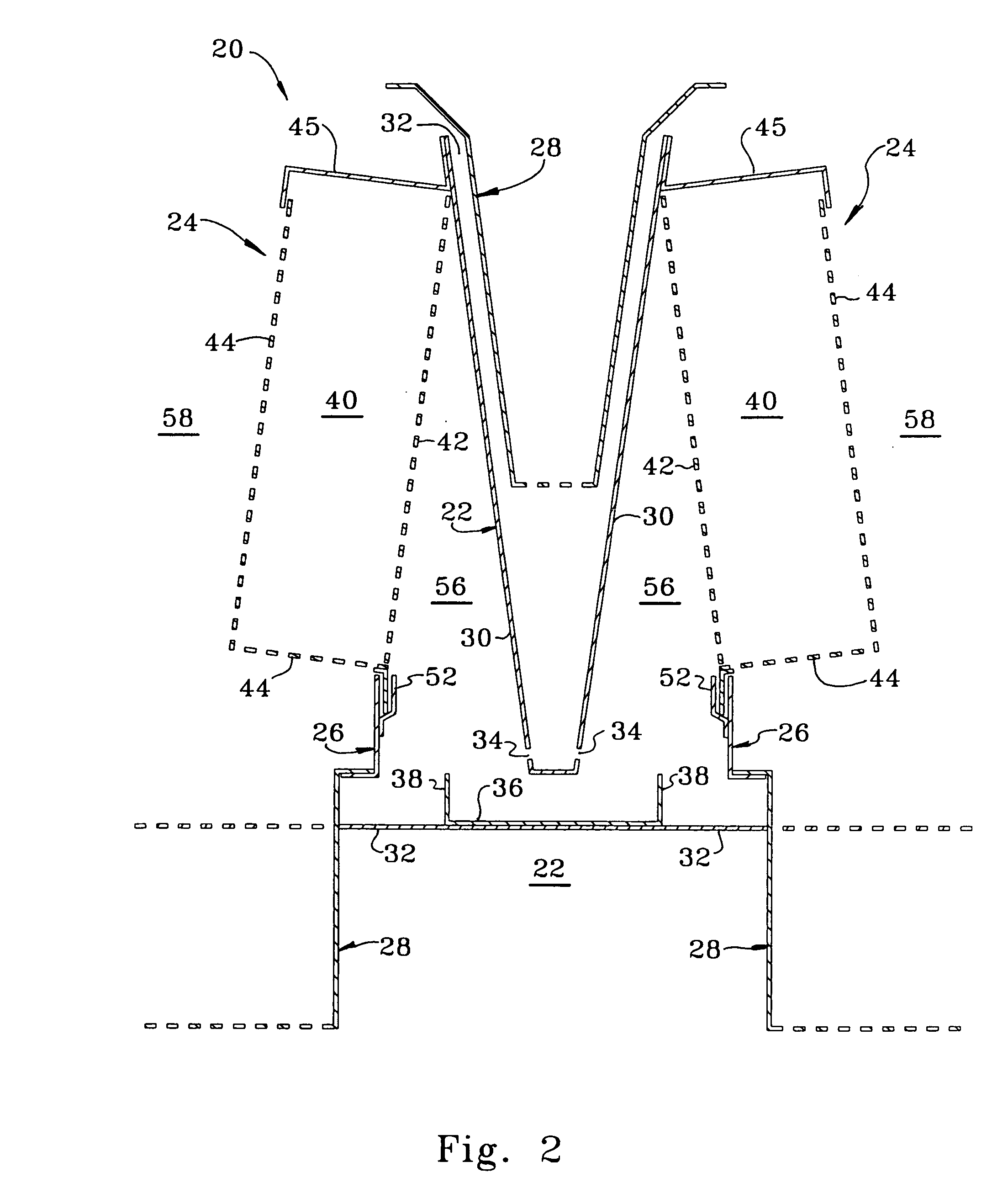

Co-current vapor-liquid contacting apparatus

ActiveUS7424999B2Easily redistributedIncrease capacityCombination devicesLiquid degasificationVapor liquidFractionating column

Owner:UOP LLC

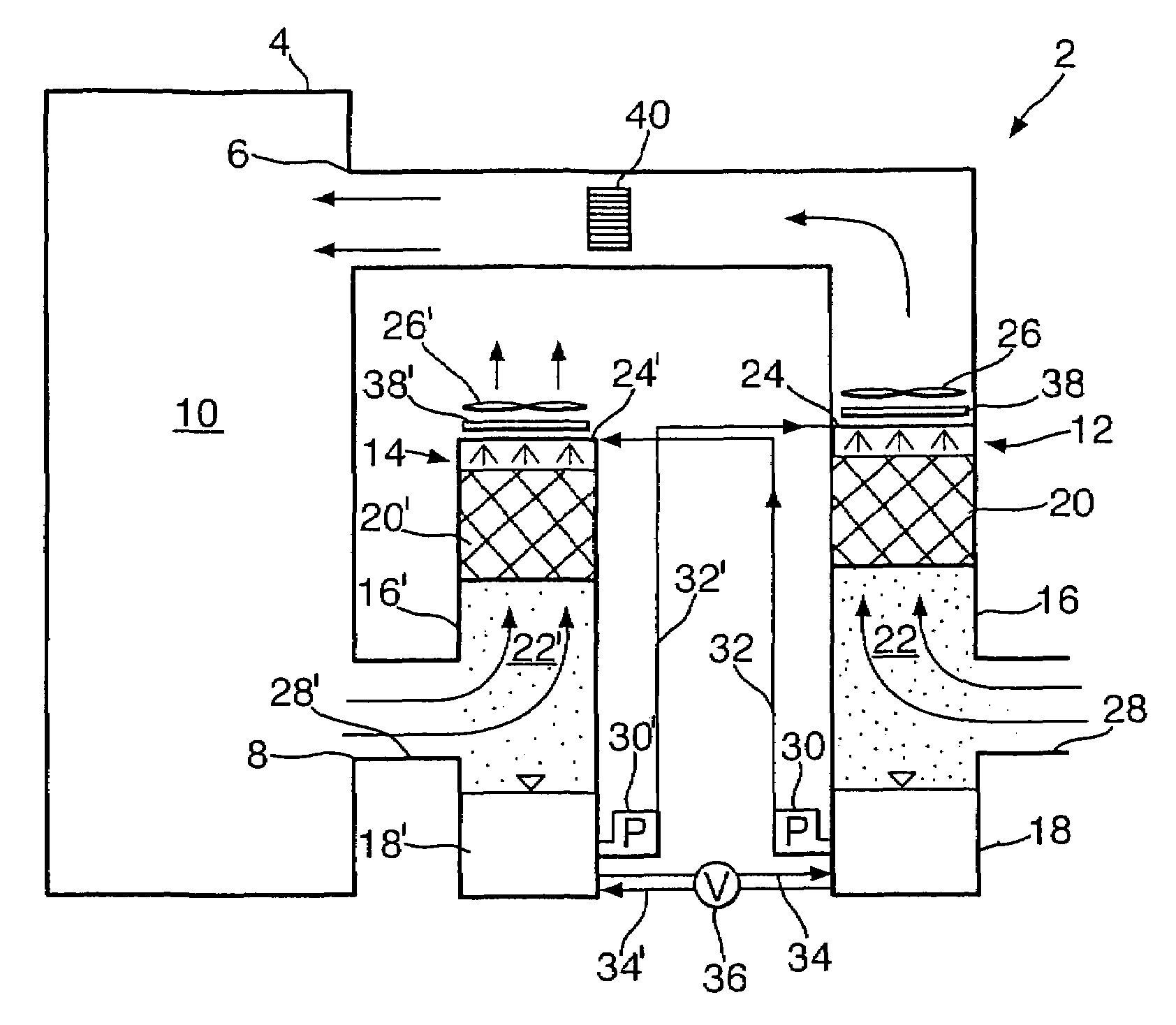

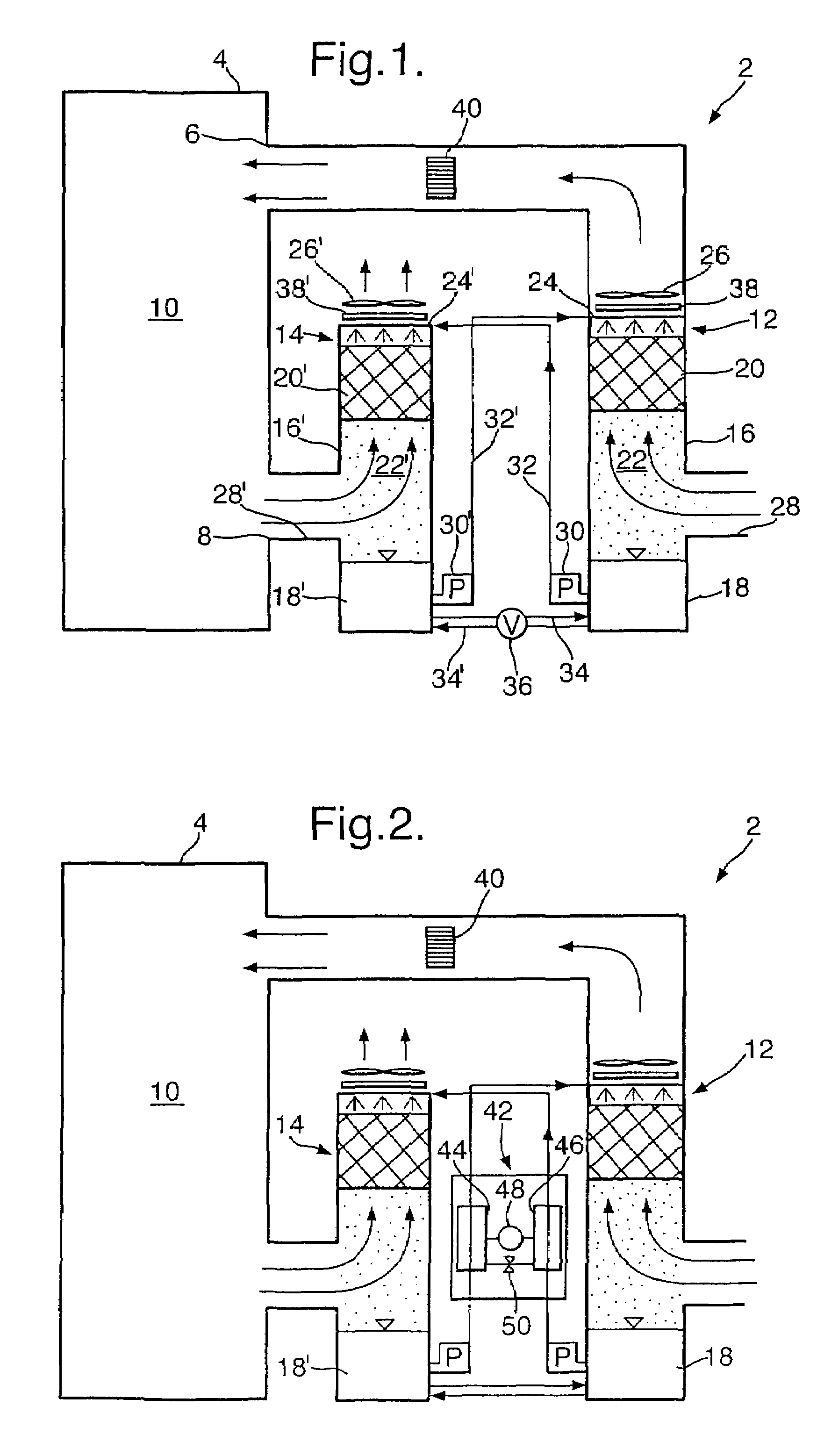

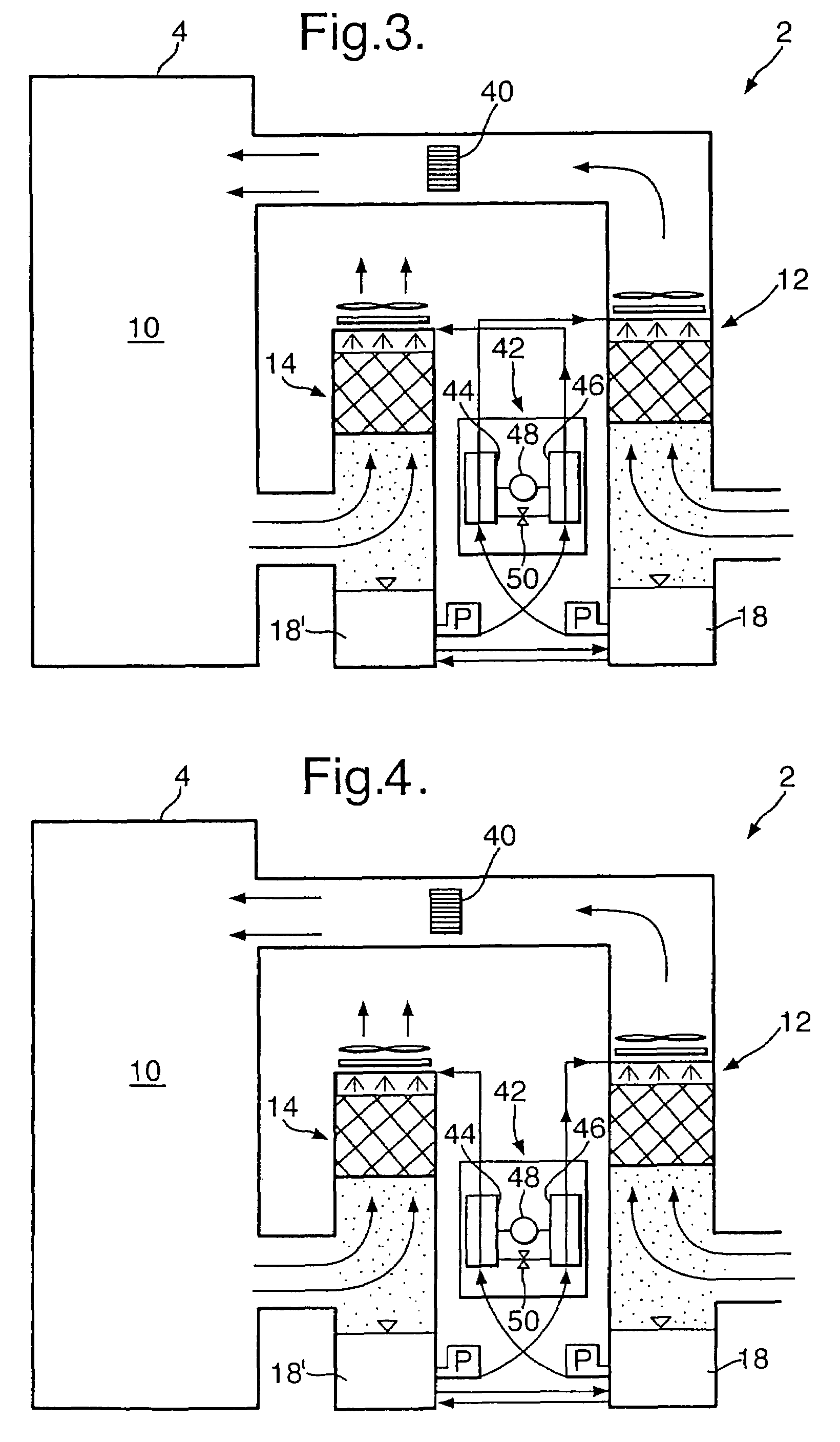

Air conditioning system and methods

An air conditioning system for conditioning the space within an enclosure having at least one inlet and one outlet, the system comprising first and second liquid / air heat exchangers; the first heat exchanger having an opening for receiving fresh air from the environment and for propelling the fresh air through the first heat exchanger to exchange heat with the liquid before it is entered into the enclosure, and the second heat exchanger having an opening for receiving air from the enclosure and for propelling it through the second heat exchanger to exchange heat with the liquid before it is expelled into the atmosphere. There are also provided methods for air-conditioning an enclosed space and for evaporation of industrial wastes.

Owner:AGAM ENERGY SYST

Removal of carbon dioxide from air

ActiveUS7655069B2Complex structureReduce fluid spillageDispersed particle filtrationUsing liquid separation agentSorbentOpen cell

Owner:CARBON SINK

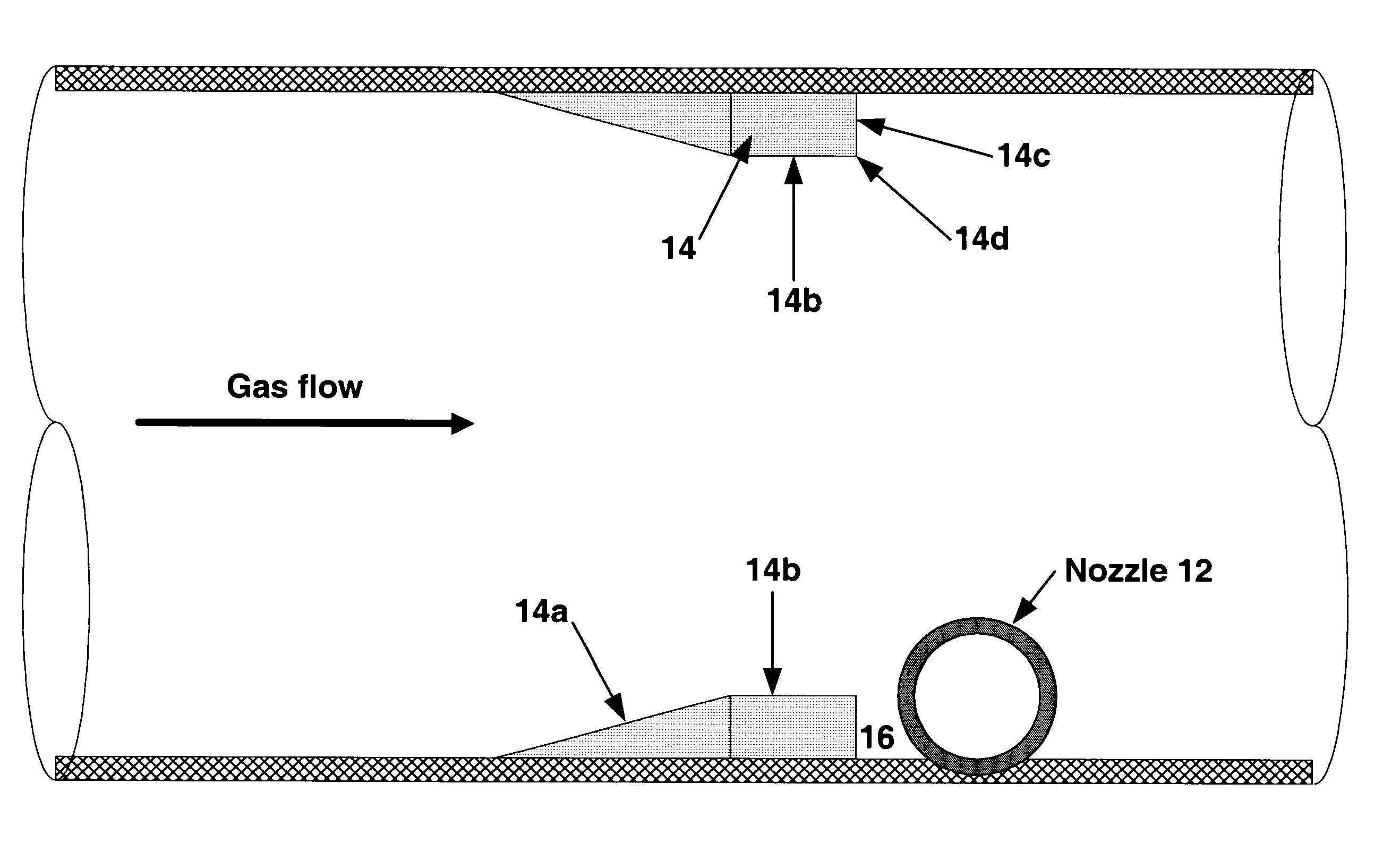

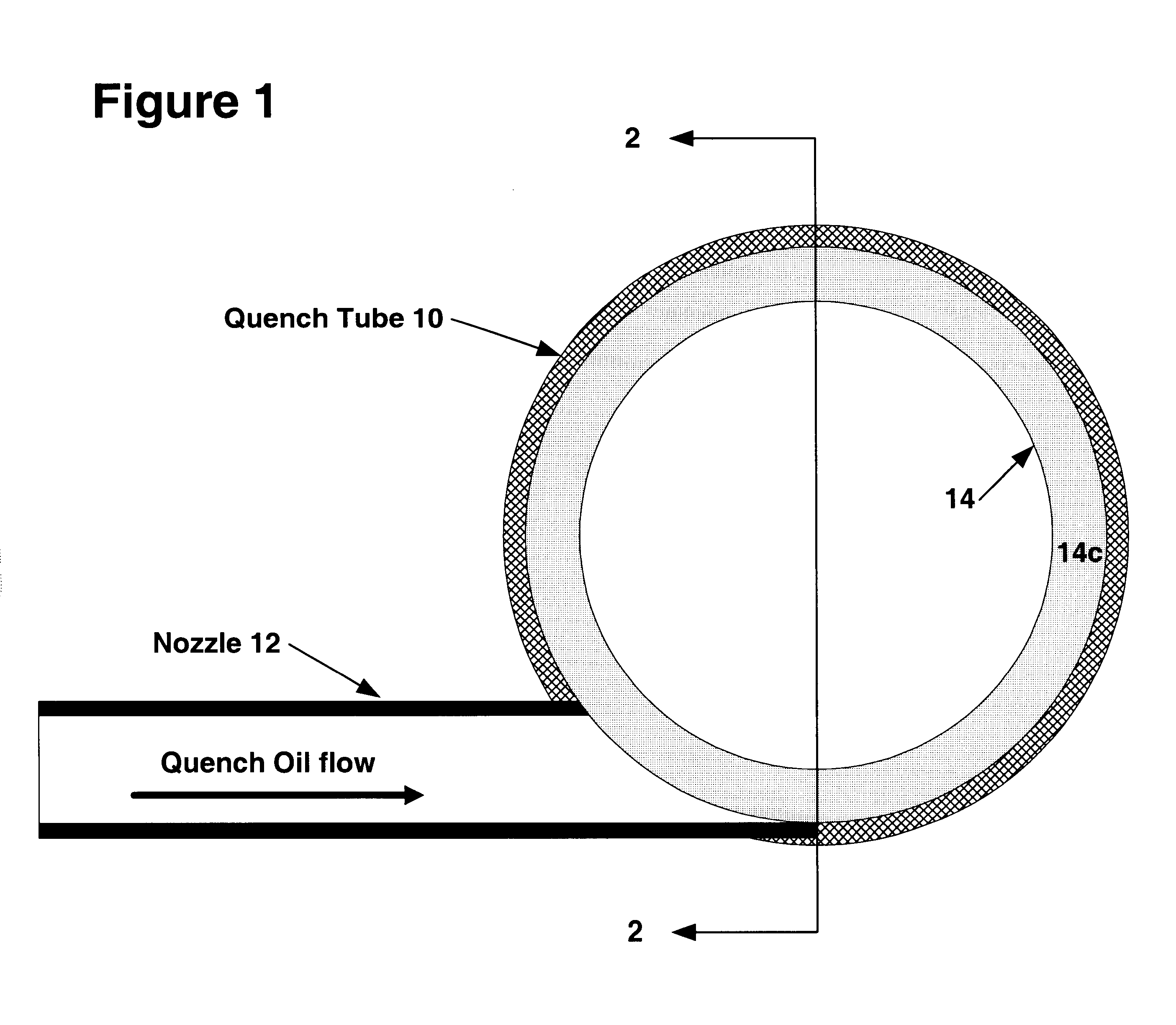

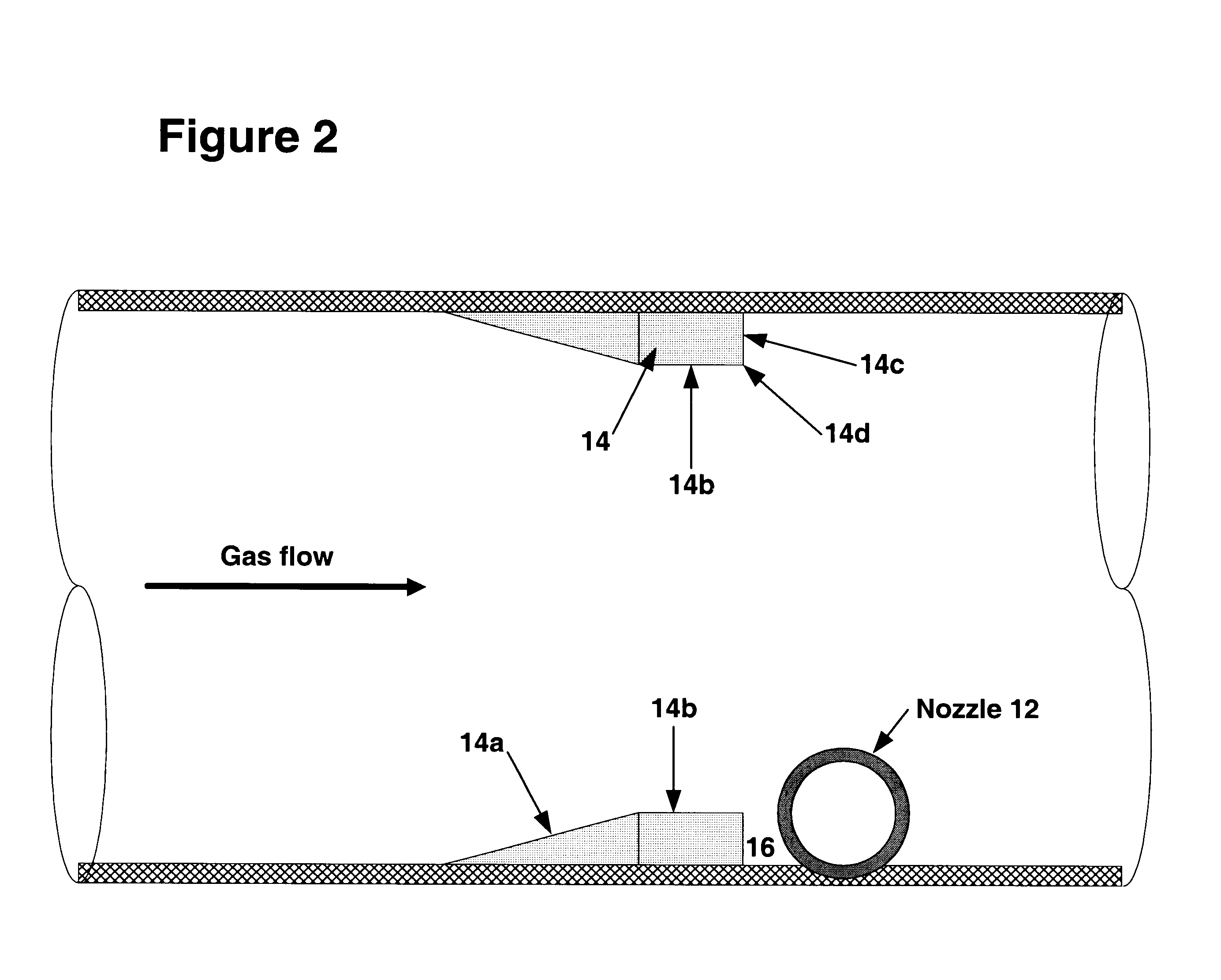

Quench nozzle

A quench nozzle design introduces quench oil tangentially into the quench tube which cools the hot gaseous pyrolysis products coming out of the hot radiant tubes in a pyrolysis furnace (in ethylene manufacture). Besides cooling the hot gases, the quench oil introduced into the quench tube by this nozzle design keeps the wall of the quench tube wetted, which is necessary to prevent coke deposition on the quench tube. The nozzle has one quench oil entry, which eliminates the need for any restriction orifice required to evenly distribute quench oil flows that would otherwise be required with several nozzle entries. Also, the one-nozzle oil introduction has a larger diameter than that required where more than one nozzle is employed in this service. The replacement of multiple nozzles with a single larger diameter nozzle eliminates plugging problems caused by coke solids or, coke solid precursors, present in the quench oil.

Owner:SHELL OIL CO

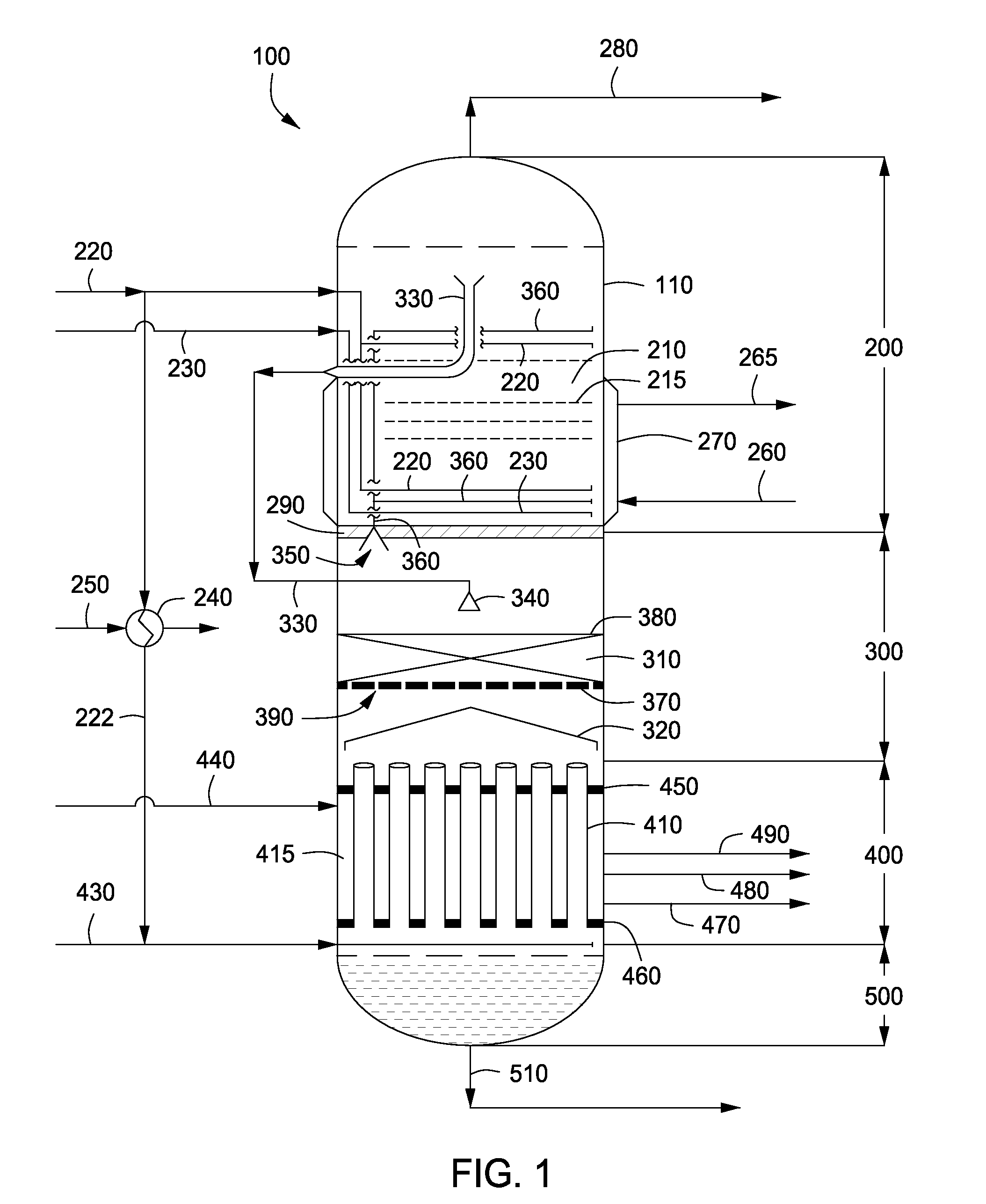

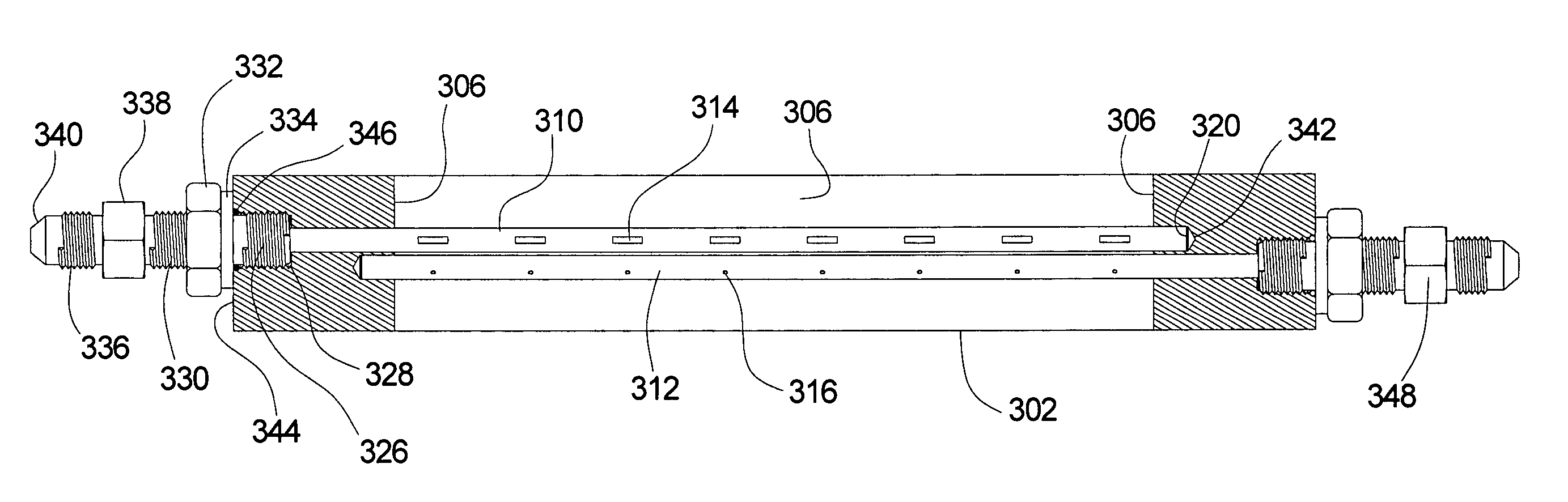

Apparatus and methods for urea production

Apparatus and methods for producing urea are provided. In one or more embodiments, an apparatus for producing urea can include a first zone, which can include a first flow channel in fluid communication with a first tube disposed about a first end of a plurality of trays, a second flow channel in fluid communication with a second tube disposed about the first end of the trays and a second end of the trays, and a third flow channel in fluid communication with a third tube disposed about the first and second ends of the trays. The apparatus can include a second zone, which can include a fixed bed comprising one or more inert packing materials disposed therein to provide additional surface area. The apparatus can include a third zone, which can include a plurality of tubes disposed therein. The second zone can be disposed between the first and third zones.

Owner:KELLOGG BROWN & ROOT LLC

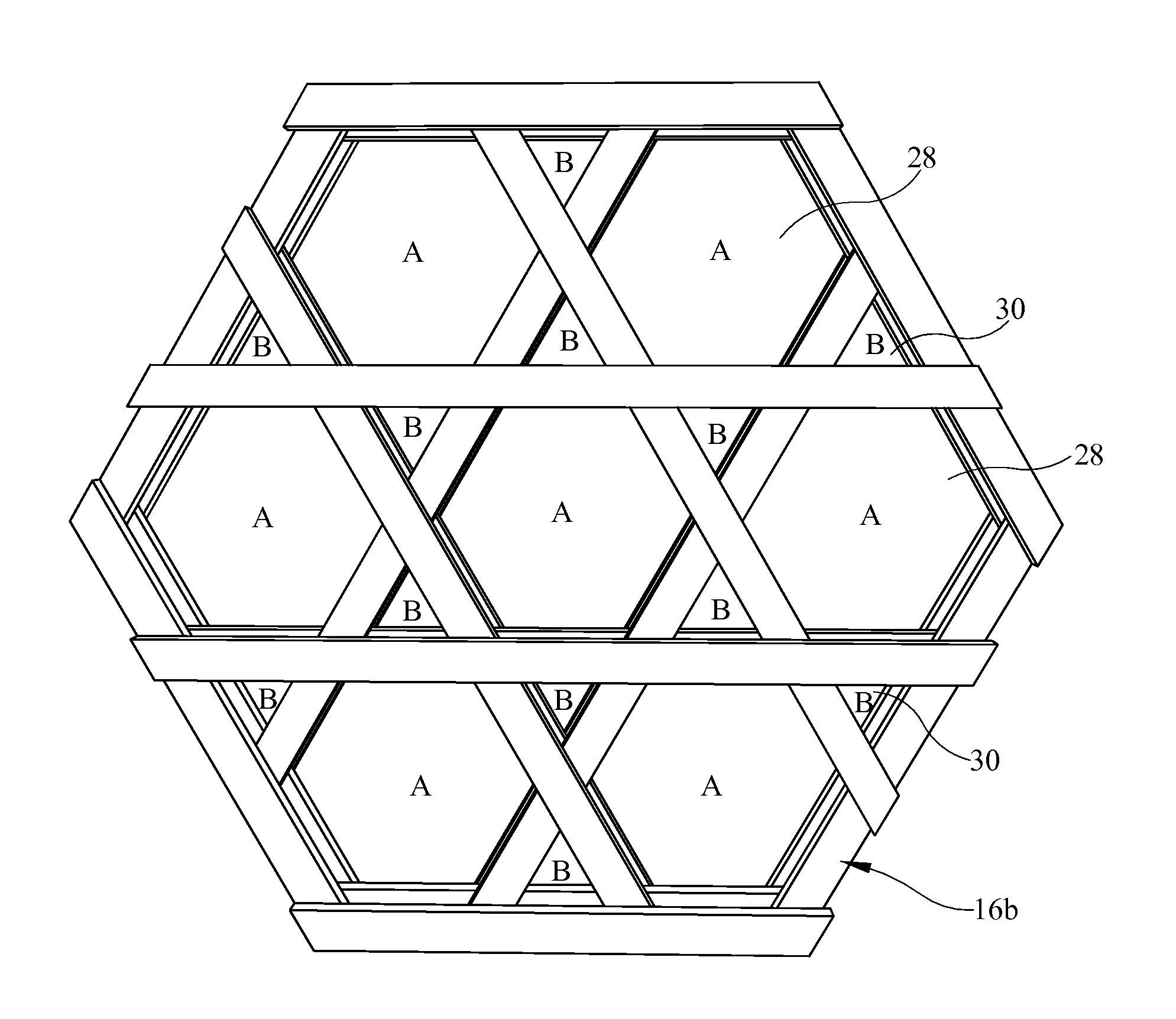

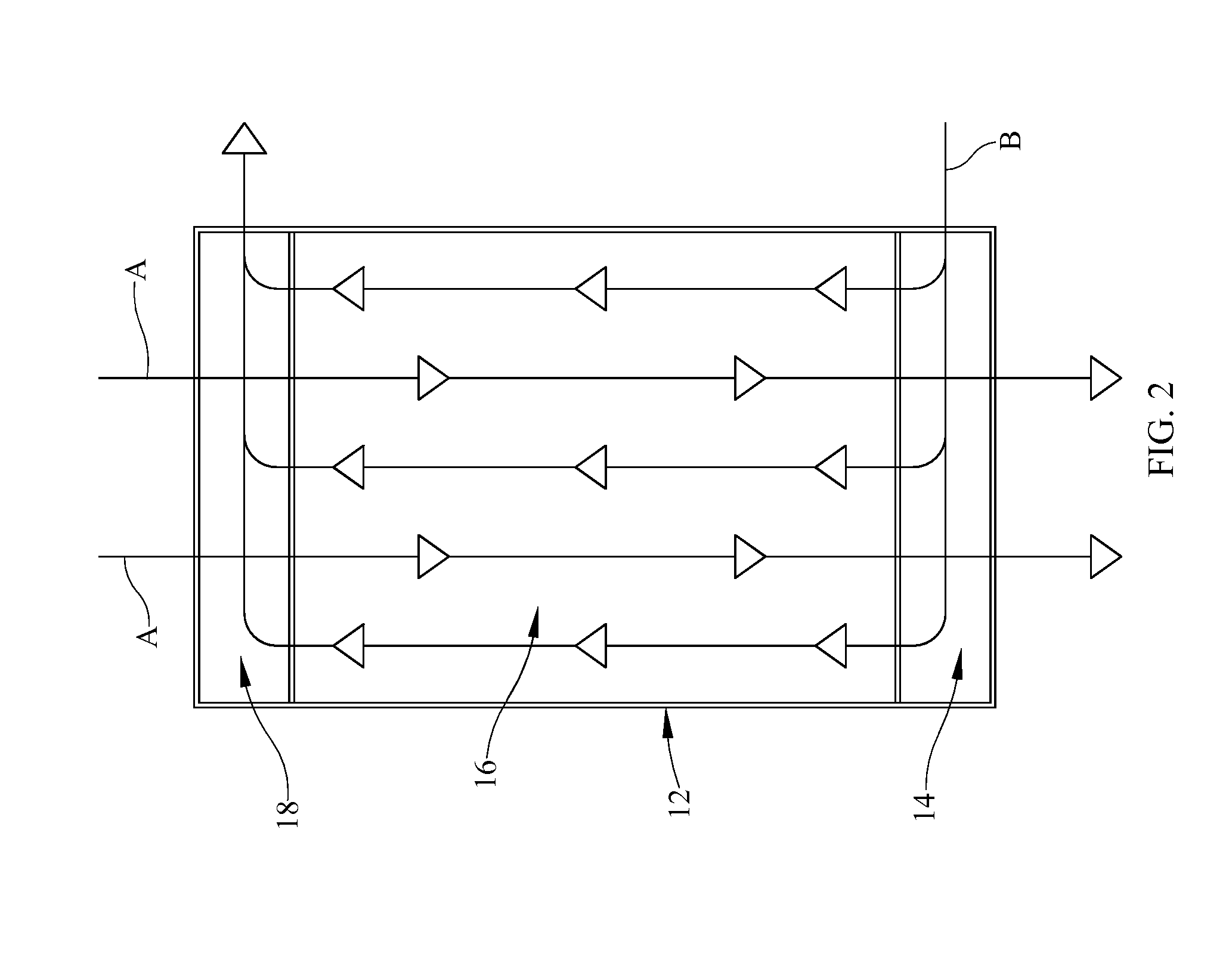

Co-current vapor-liquid contacting apparatus

ActiveUS20070137482A1Easily redistributedIncrease capacityCombination devicesTransportation and packagingVapor liquidFractionating column

The invention is a high capacity and high efficiency co-current vapor-liquid contacting apparatus for use in distillation columns and other vapor-liquid contacting processes. The apparatus is characterized by an arrangement of modules in horizontal stages rather than tray-like construction. The modules define a co-current contacting volume and in an exemplary configuration the modules include a liquid distributor, a demister, a receiving pan and a duct. The modules of one stage are rotated to be non-parallel with respect to the modules of an inferior stage, a superior stage, or both. Variations relate to the design of the individual elements such as the demister, liquid distributor, ducts, and contacting volumes, and the overall arrangement of the apparatus.

Owner:UOP LLC

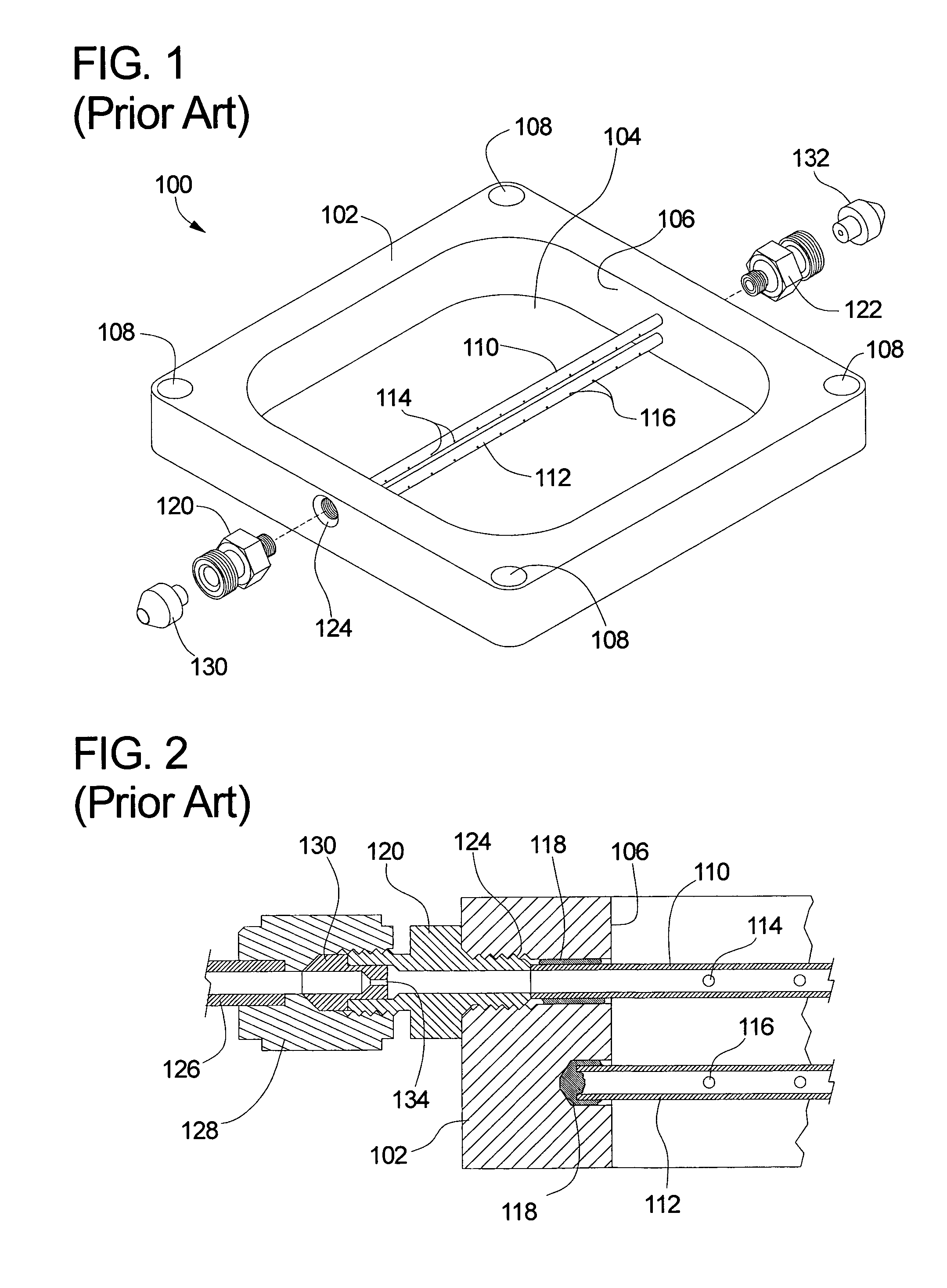

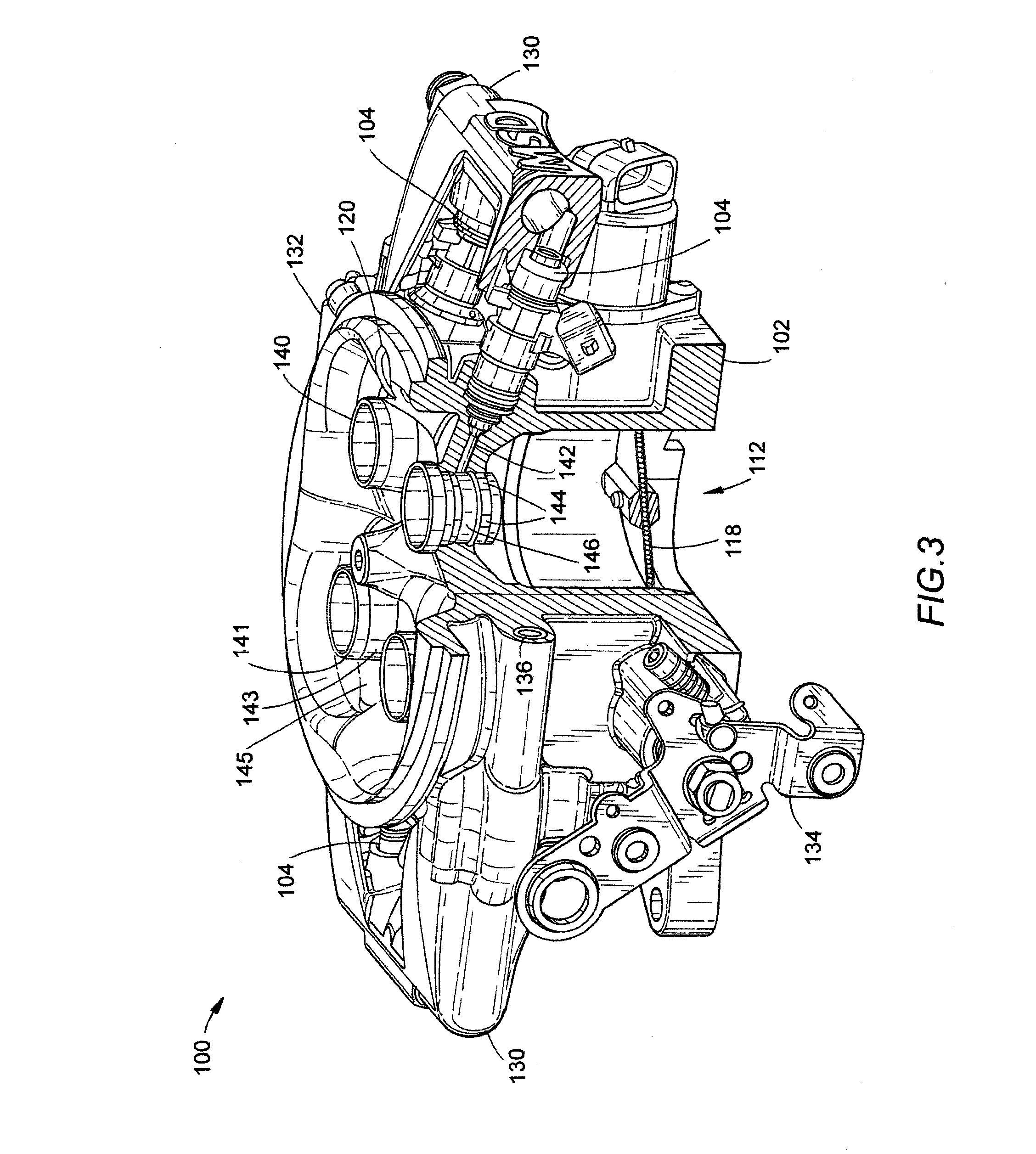

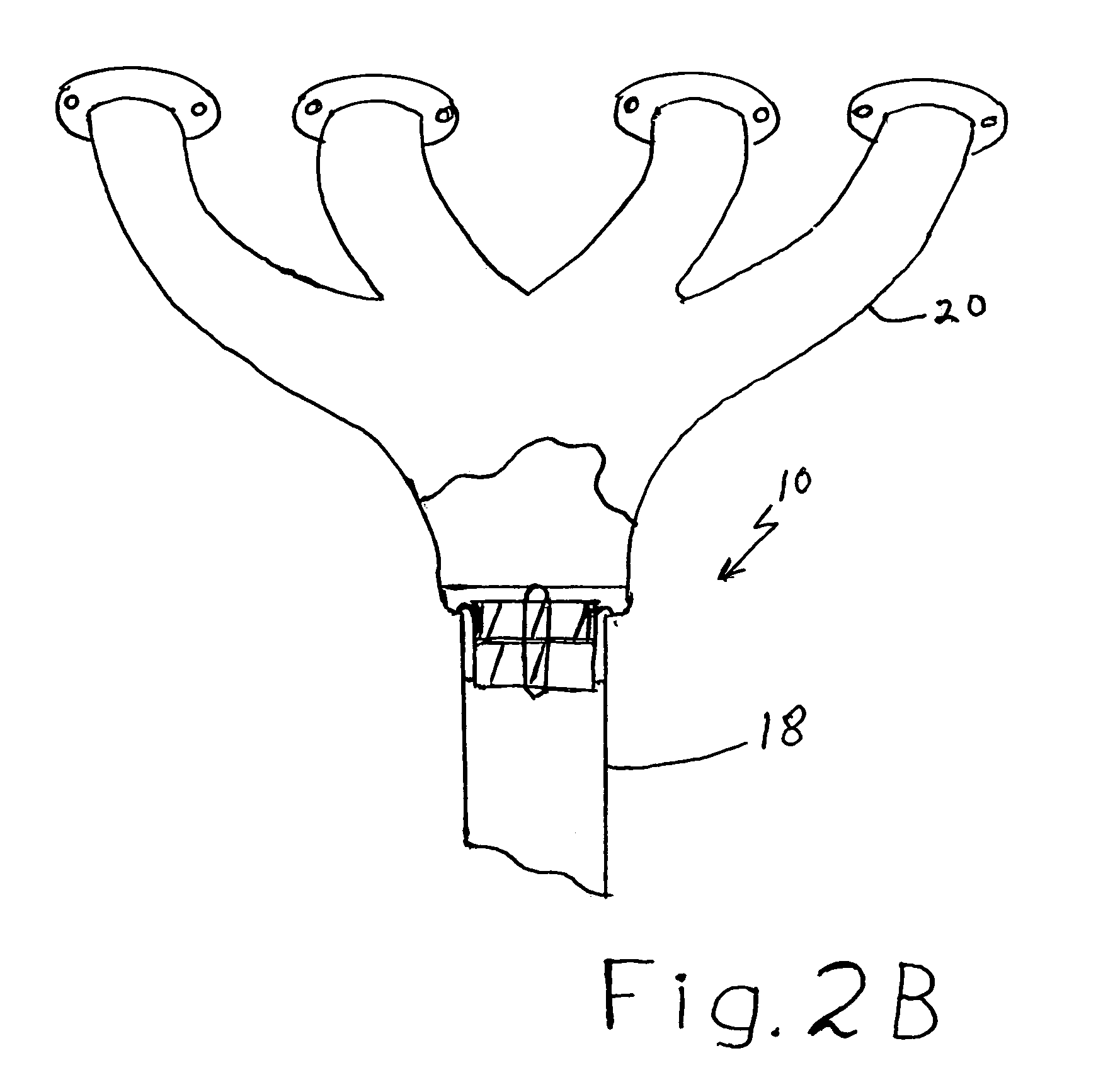

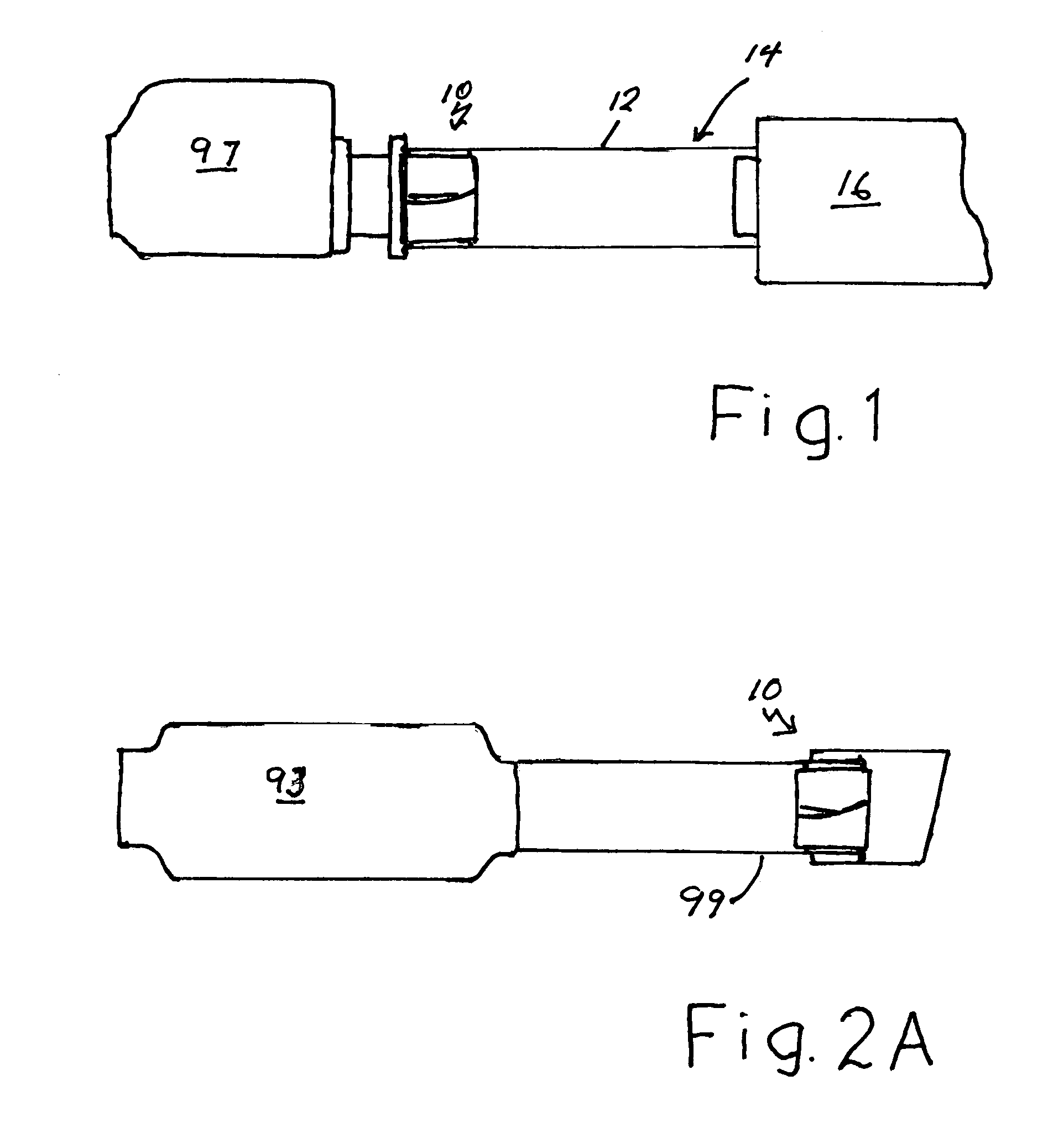

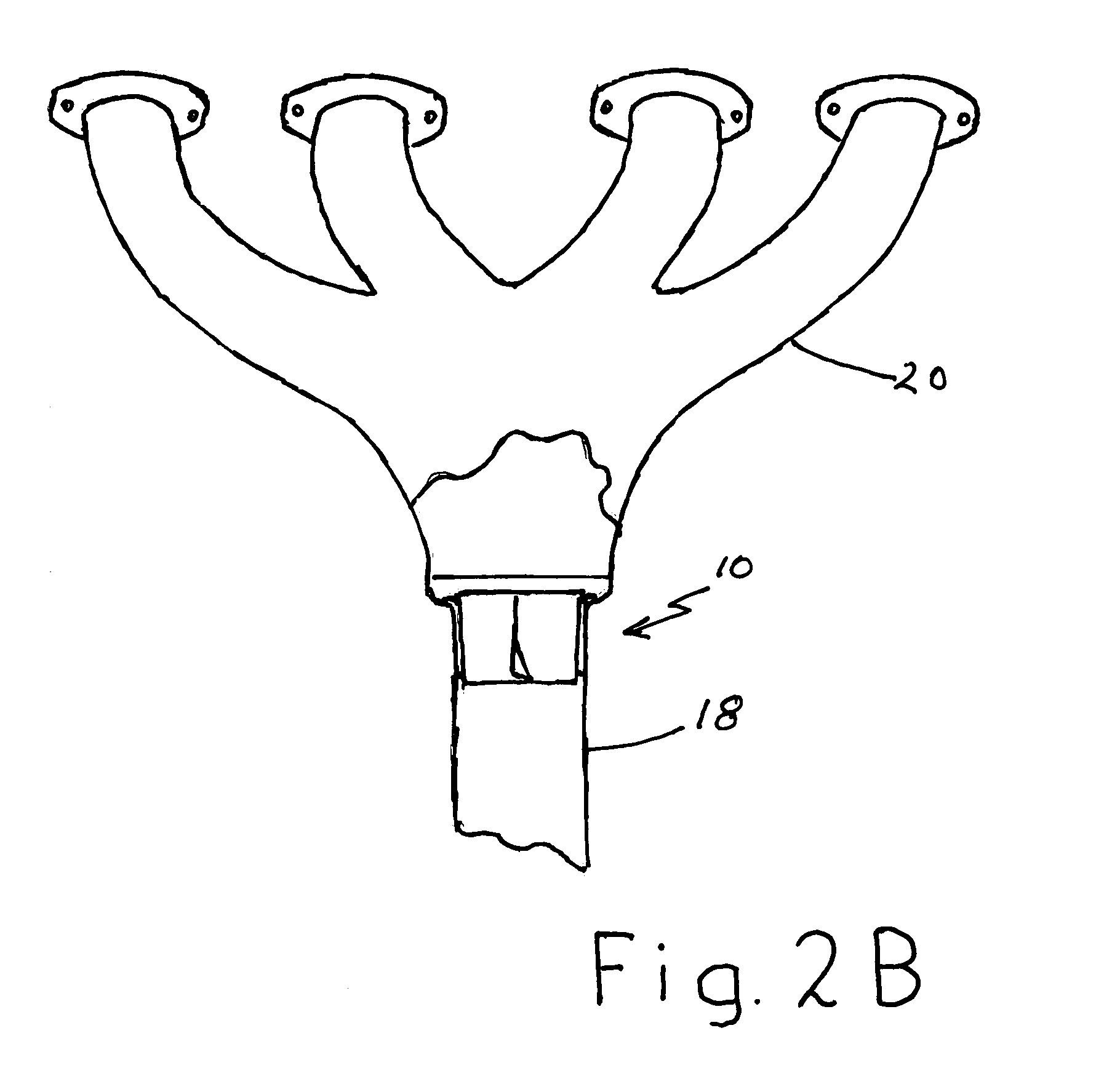

Intake manifold plate adapter

ActiveUS7533661B2Prevent movementNon-fuel substance addition to fuelCombustion enginesEngineeringInlet manifold

A nitrous oxide plate system having a plate adapted to fit in an intake pathway of an internal combustion engine. The plate has at least one central passage therethrough, and this passage forms a portion of the intake pathway when the plate is installed in the engine. The plate system also has a first spray bar port passing into the central passage, and at least two spray bars that are adapted to be interchangeably installed in the first spray bar port. The at least two spray bars include a first spray bar having a first plurality of distribution orifices having a first total area, and a second spray bar having a second plurality of distribution orifices having a second total area. The second total area is different from the first total area. An interchangeable spray bar for a nitrous oxide plate system is also provided. The interchangeable spray bar has a hollow tube having an interior tube passage, an outer wall, a first end, a second end, and a plurality of distribution orifices passing through the outer wall. The interchangeable spray bar also has a fitting adapted to adjoin the first end of the hollow tube. The fitting has a hollow fitting passage therethrough in fluid communication with the interior tube passage when the fitting is adjoining the hollow tube. The hollow tube is adapted to removably fit within a nitrous oxide plate, and the fitting is adapted to engage the nitrous oxide plate to thereby hold the hollow tube within the nitrous oxide plate.

Owner:HOLLEY PERFORMANCE PRODUCTS

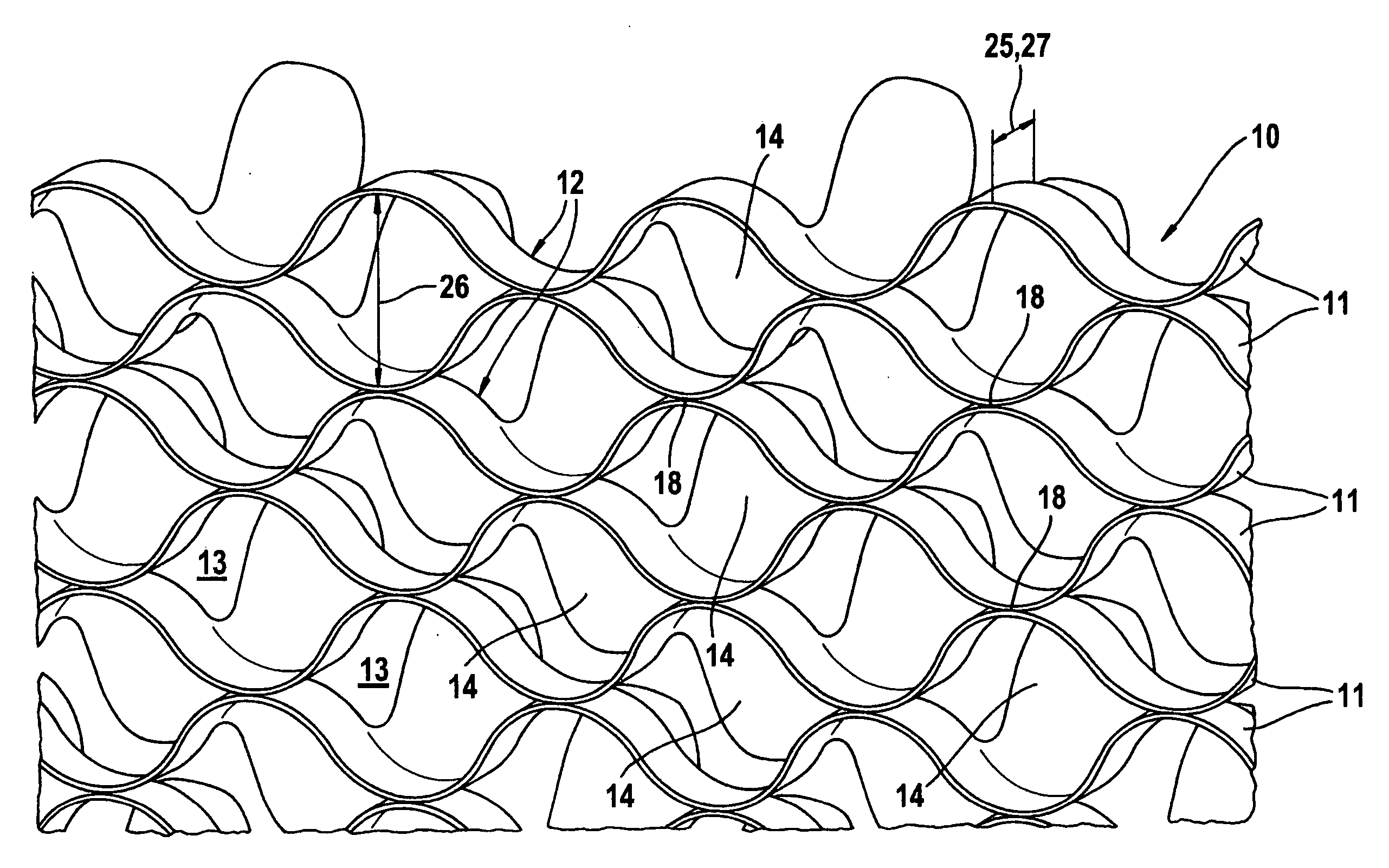

Static mixer and exhaust gas treatment device

InactiveUS20070204751A1Design economyIntense mixing effect and vaporization effectInternal combustion piston enginesFlow mixersExhaust fumesEngineering

The invention relates to a static mixer for an exhaust system of an internal combustion engine. The mixer has a wall structure that is arranged across the directional of flow in a pipe and has several layers of a corrugated sheeting material laying across one another in the direction of flow. The cells through which the flow can pass in the direction of flow are provided between the sheeting material of neighboring layers. The sheeting material has baffles for all or several of the cells. The baffles are arranged on the sheeting material so that they are arranged on their outgoing flow side in the case of said cells and extend in the direction of flow and across it.

Owner:EBERSPACHER EXHAUST TECH GMBH & CO KG

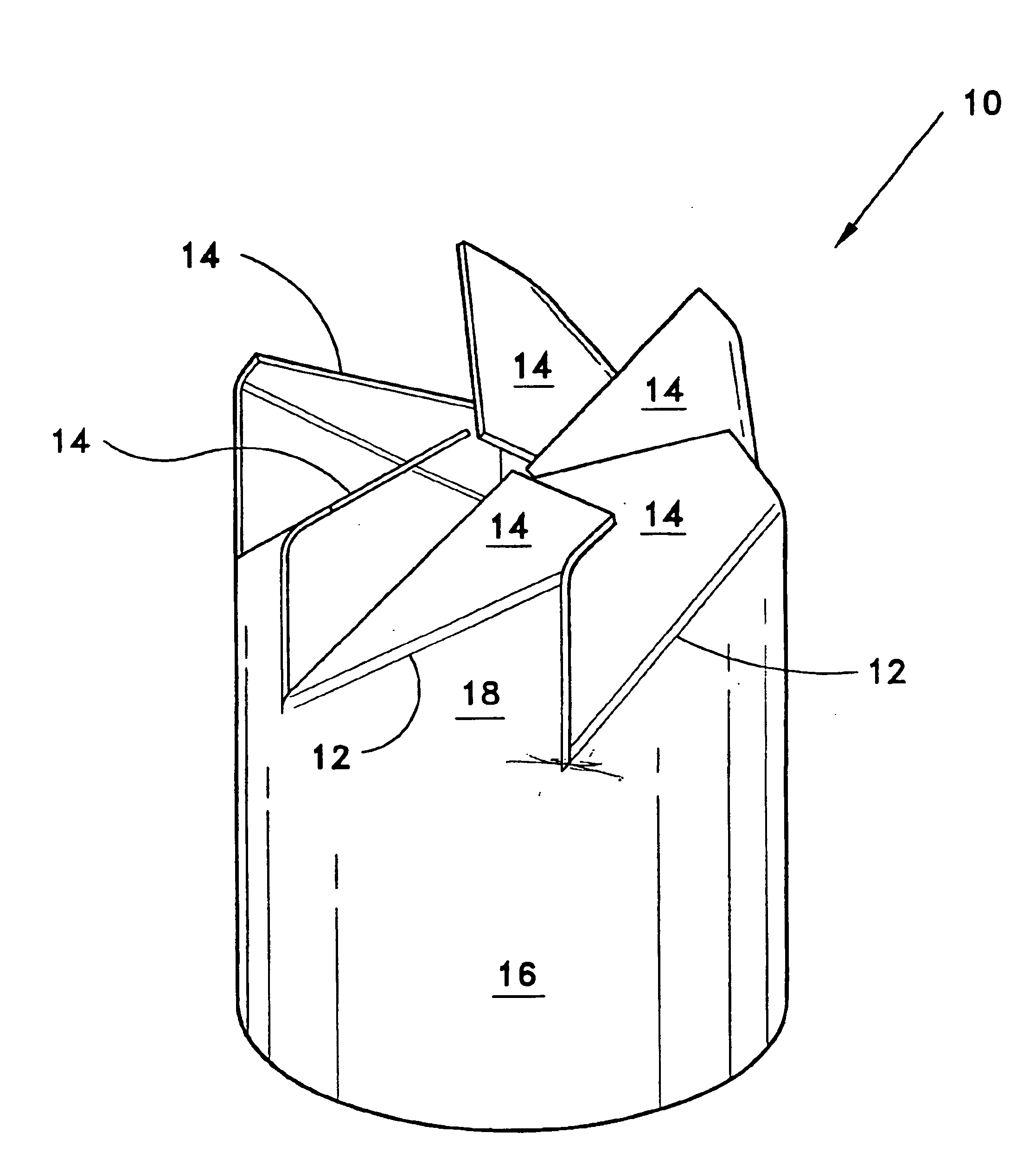

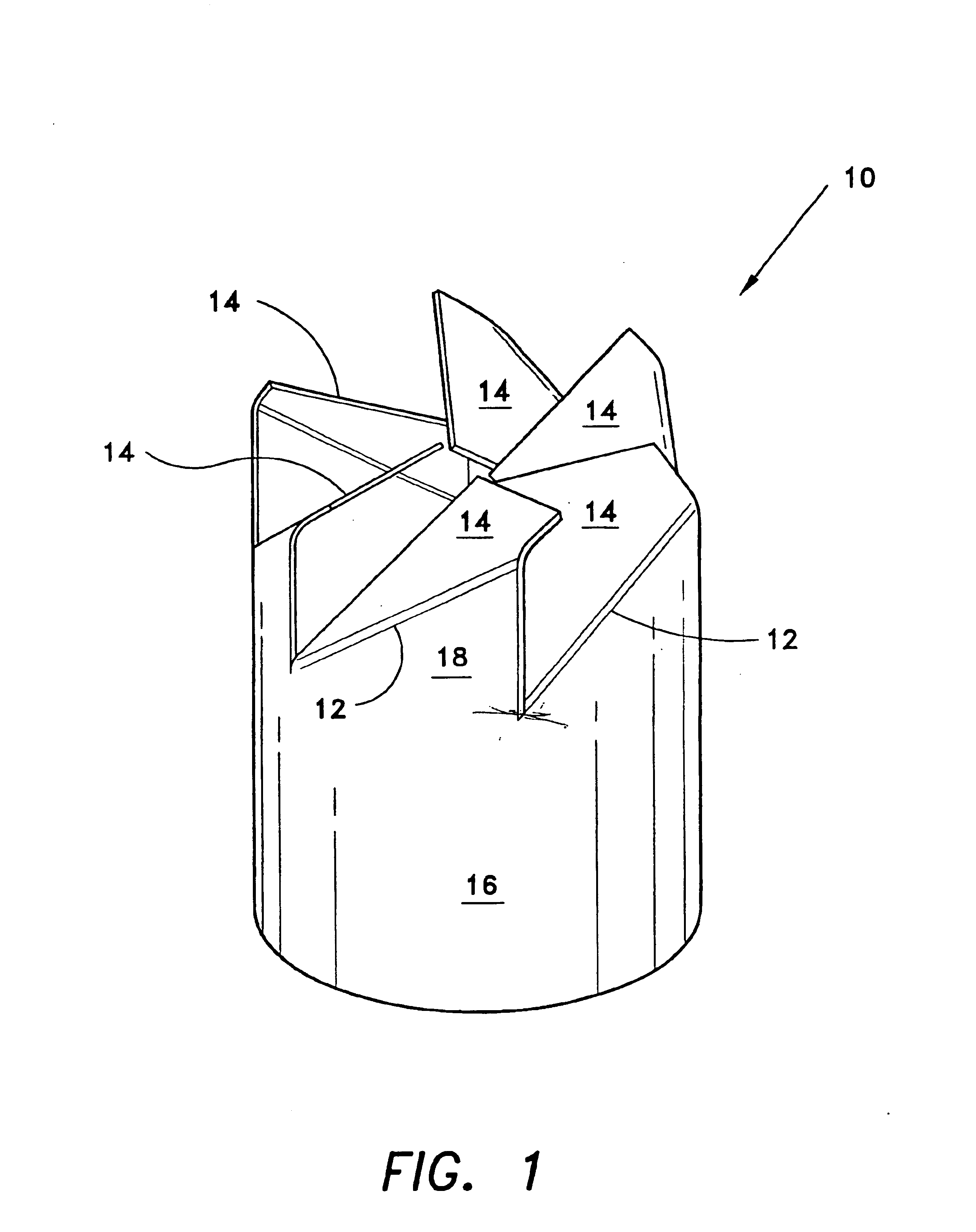

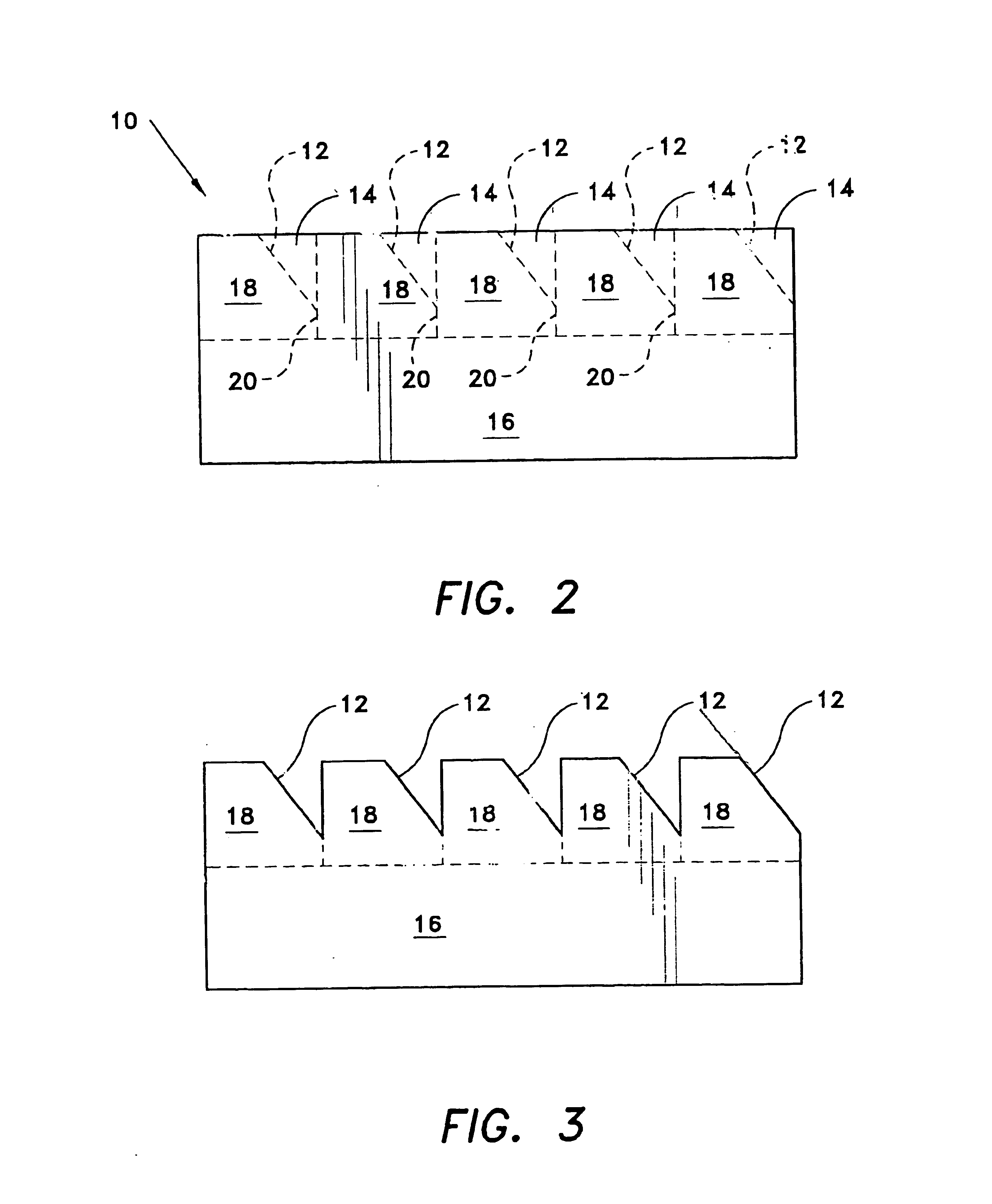

Flow guiding structure for an internal combustion engine

InactiveUS20050011488A1Well mixedEnhanced mixing processInternal combustion piston enginesFuel re-atomisation/homogenisationCombustion chamberInternal combustion engine

A flow guiding structure for guiding into a clockwise swirling flow pattern gas flowing into a gas passageway leading toward a combustion chamber of an internal combustion engine. The structure includes a tubular peripheral wall having a base section for securing the structure to the gas passageway and an integrally extending guiding section. A plurality of guiding vanes extend radially inward from the guiding section each about a corresponding vane first edge. Each guiding vane includes a vane second edge extending in a geometrical plane perpendicular to the structure longitudinal axis. Each guiding vane further includes a substantially convex vane third edge. The guiding section is provided with a plurality of guiding bents formed therein and extending radially inwardly. The guiding bents are adapted to act as an auxiliary guide and as reinforcement for the structure.

Owner:DOUCET REJEAN

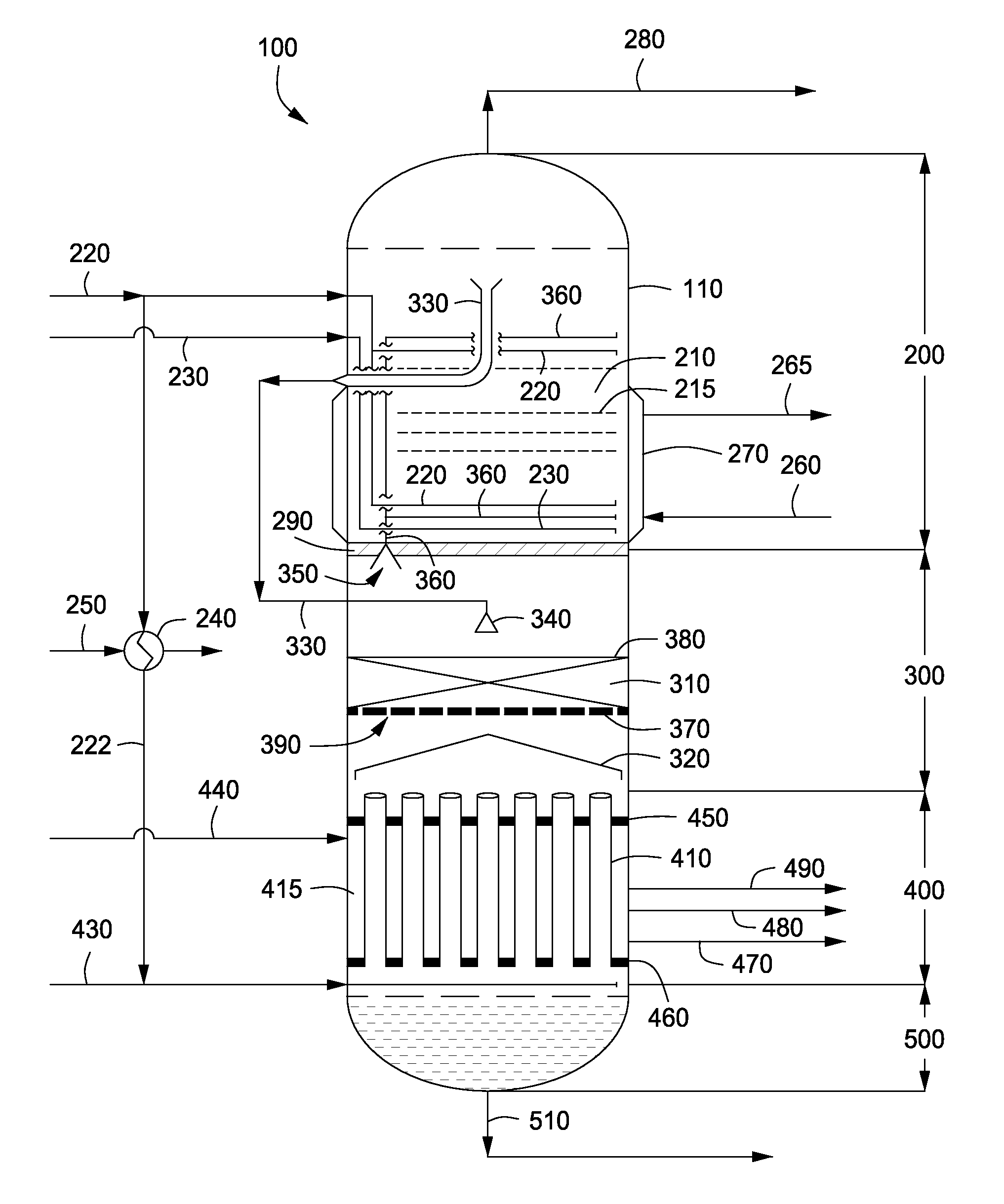

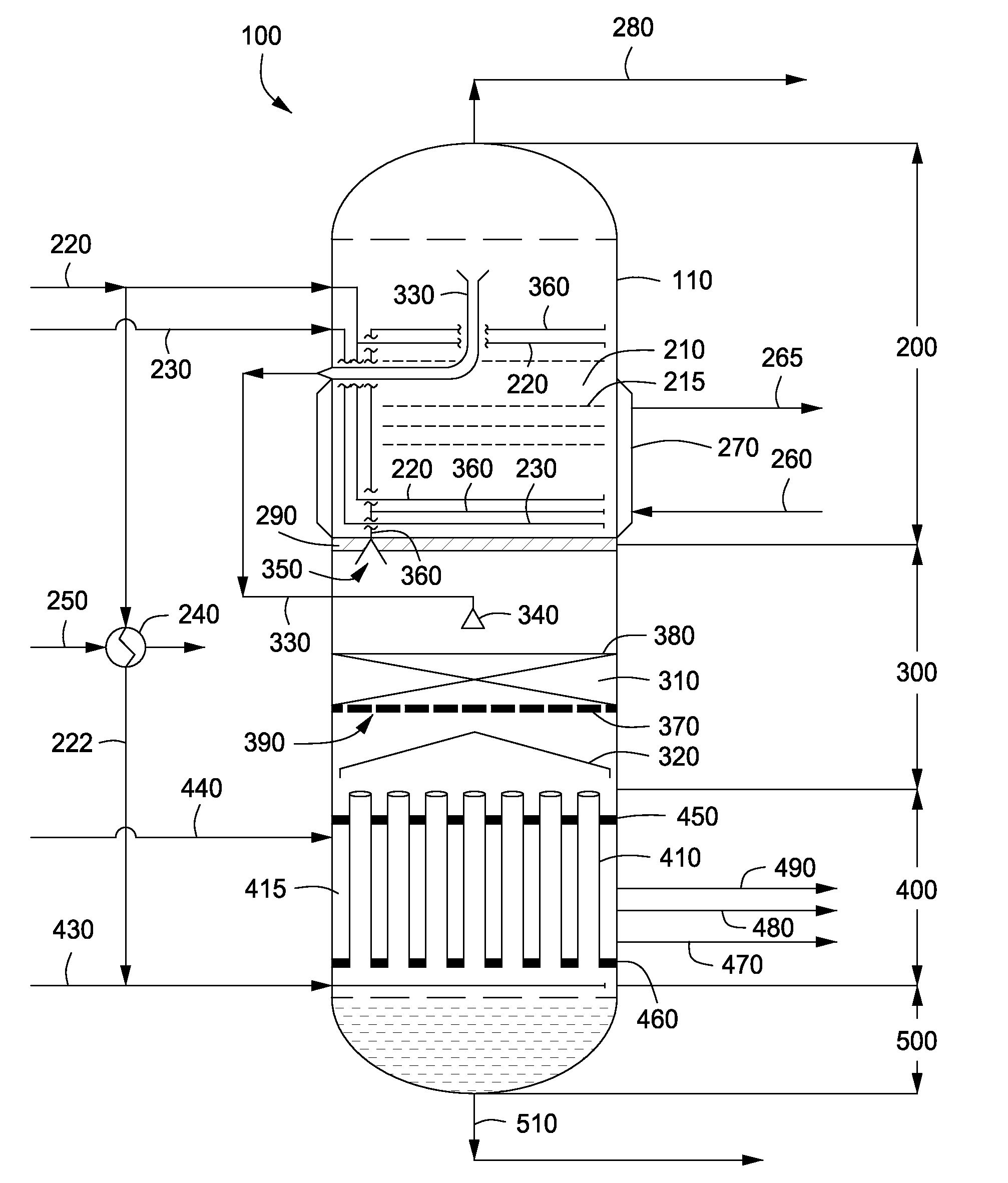

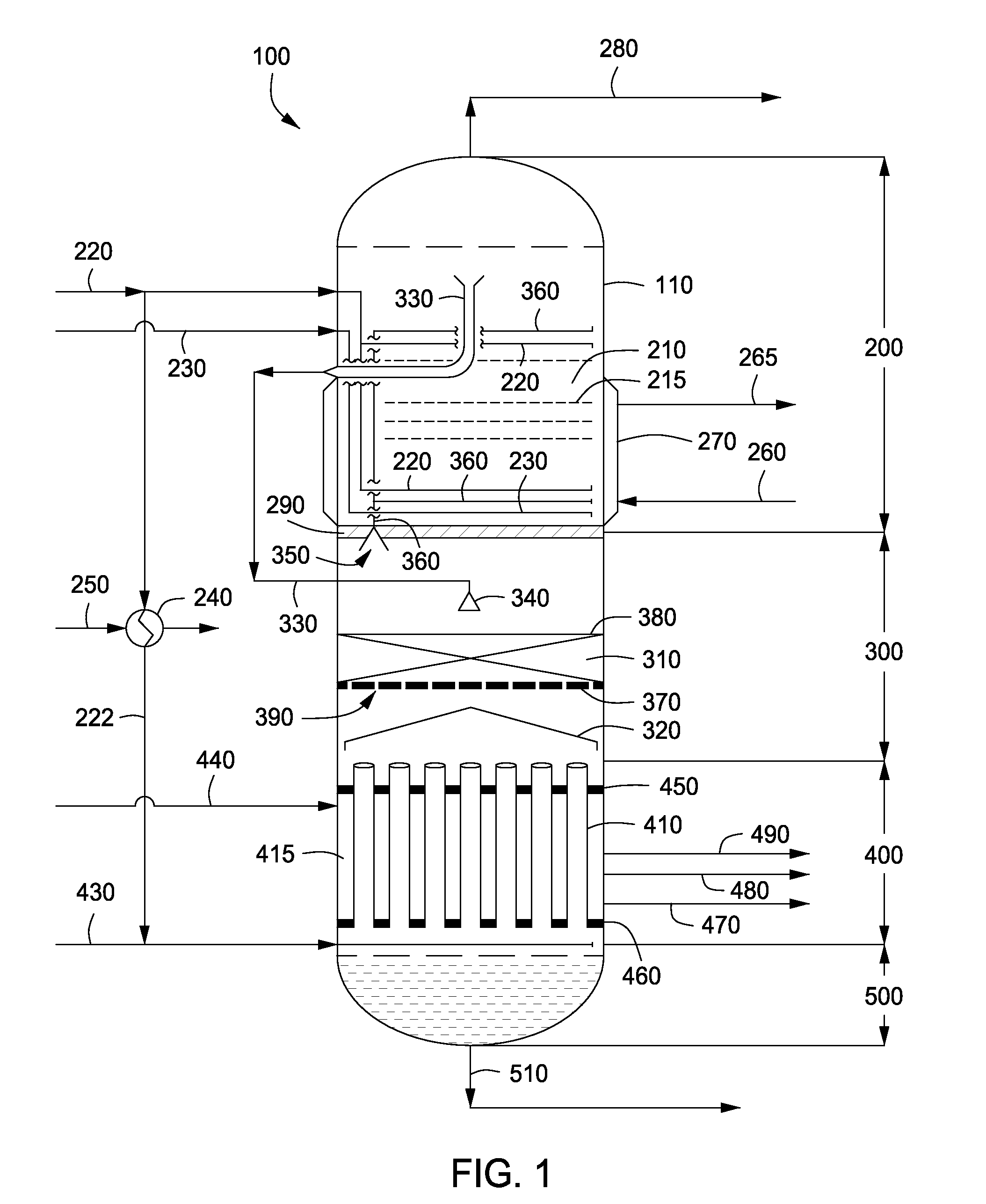

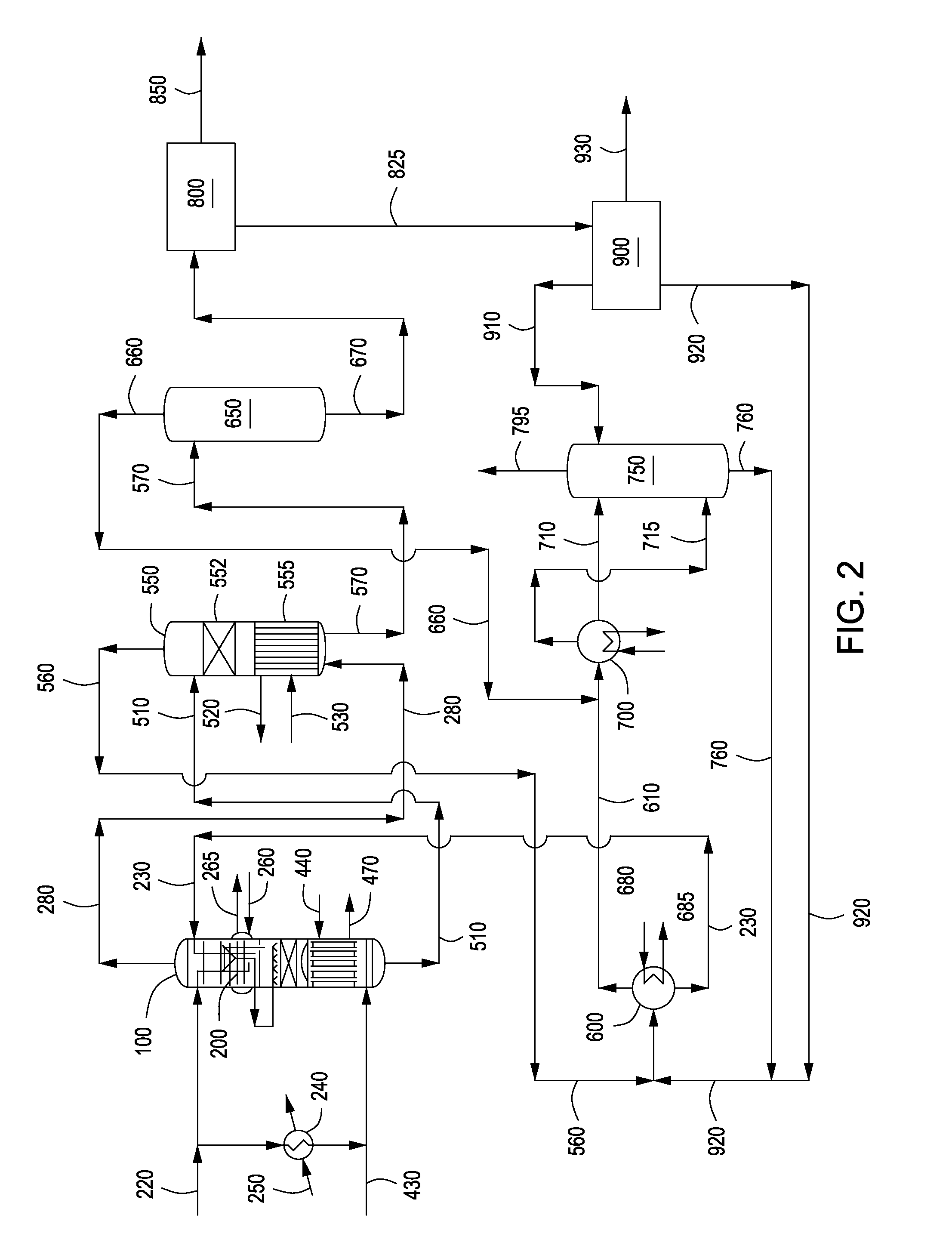

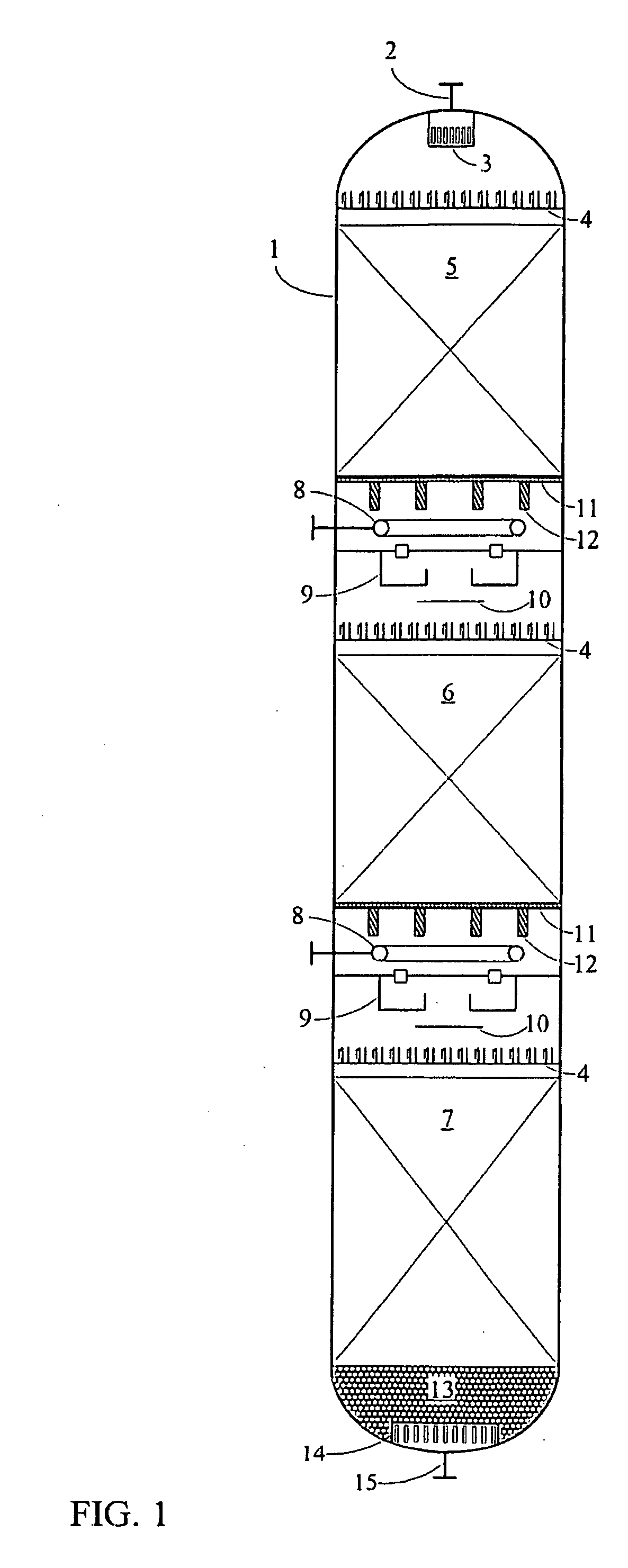

Apparatus and methods for urea production

ActiveUS20090216045A1Urea derivatives preparationOrganic compound preparationFilling materialsFixed bed

Apparatus and methods for producing urea are provided. In one or more embodiments, an apparatus for producing urea can include a first zone, which can include a first flow channel in fluid communication with a first tube disposed about a first end of a plurality of trays, a second flow channel in fluid communication with a second tube disposed about the first end of the trays and a second end of the trays, and a third flow channel in fluid communication with a third tube disposed about the first and second ends of the trays. The apparatus can include a second zone, which can include a fixed bed comprising one or more inert packing materials disposed therein to provide additional surface area. The apparatus can include a third zone, which can include a plurality of tubes disposed therein. The second zone can be disposed between the first and third zones.

Owner:KELLOGG BROWN & ROOT LLC

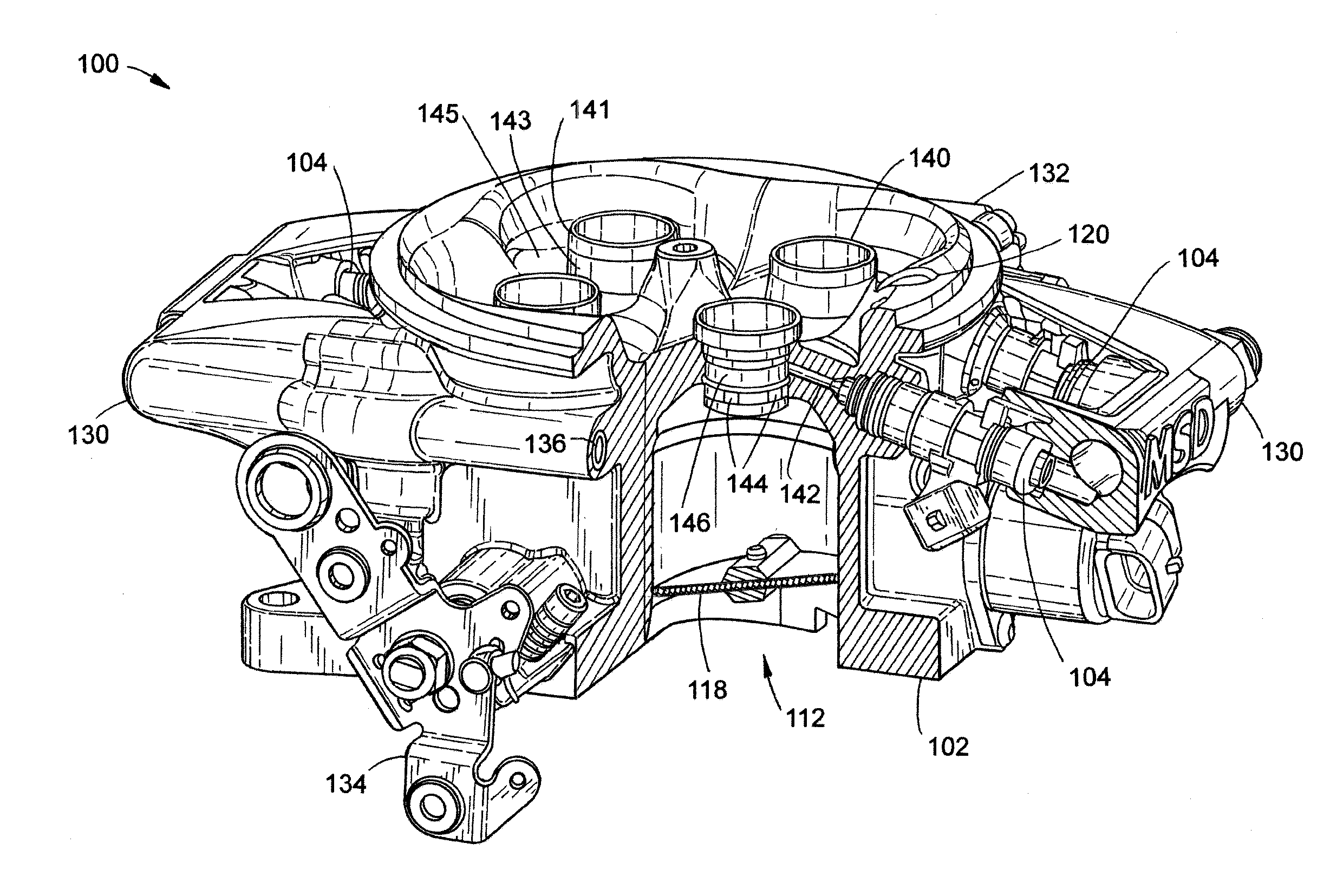

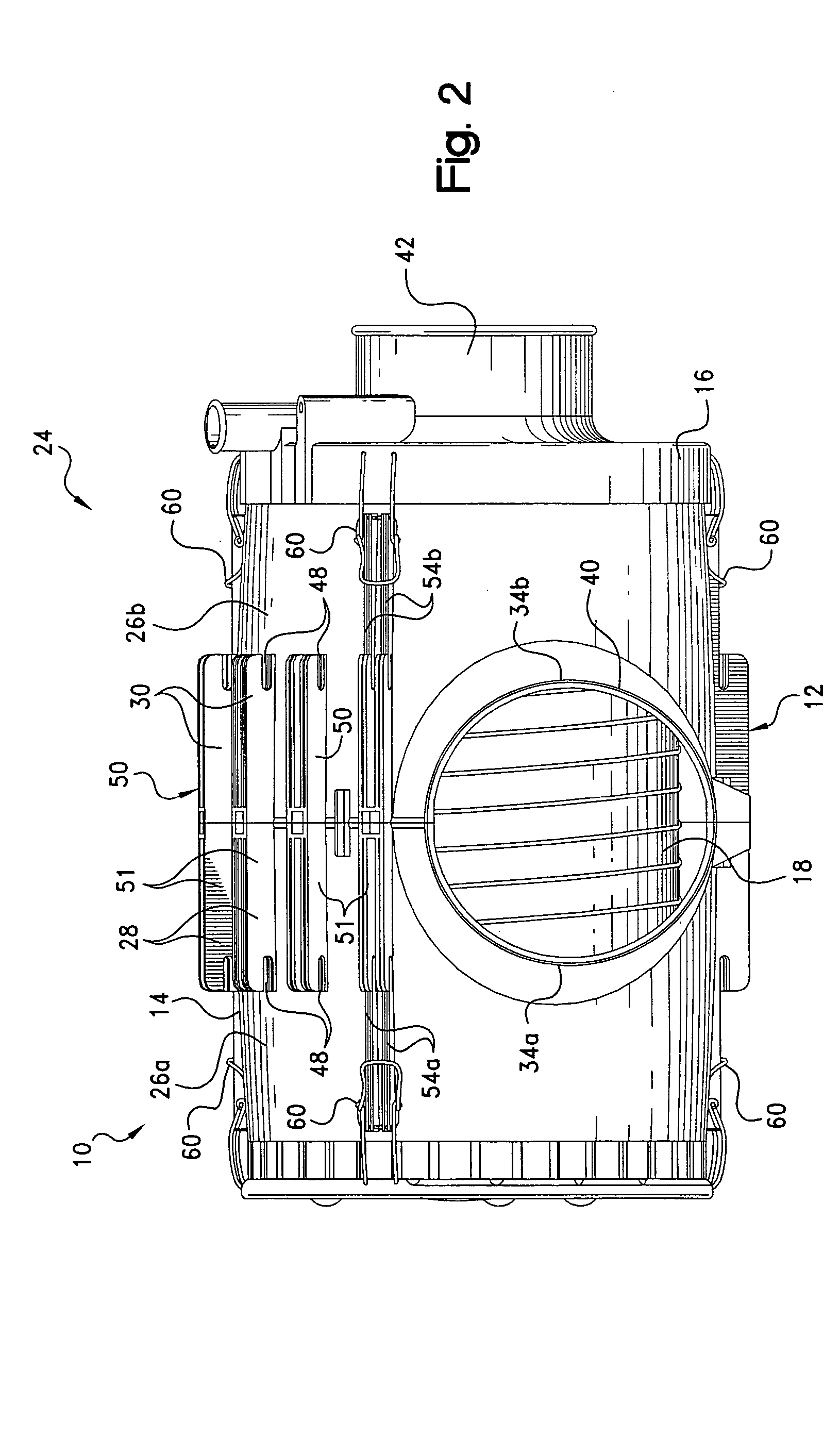

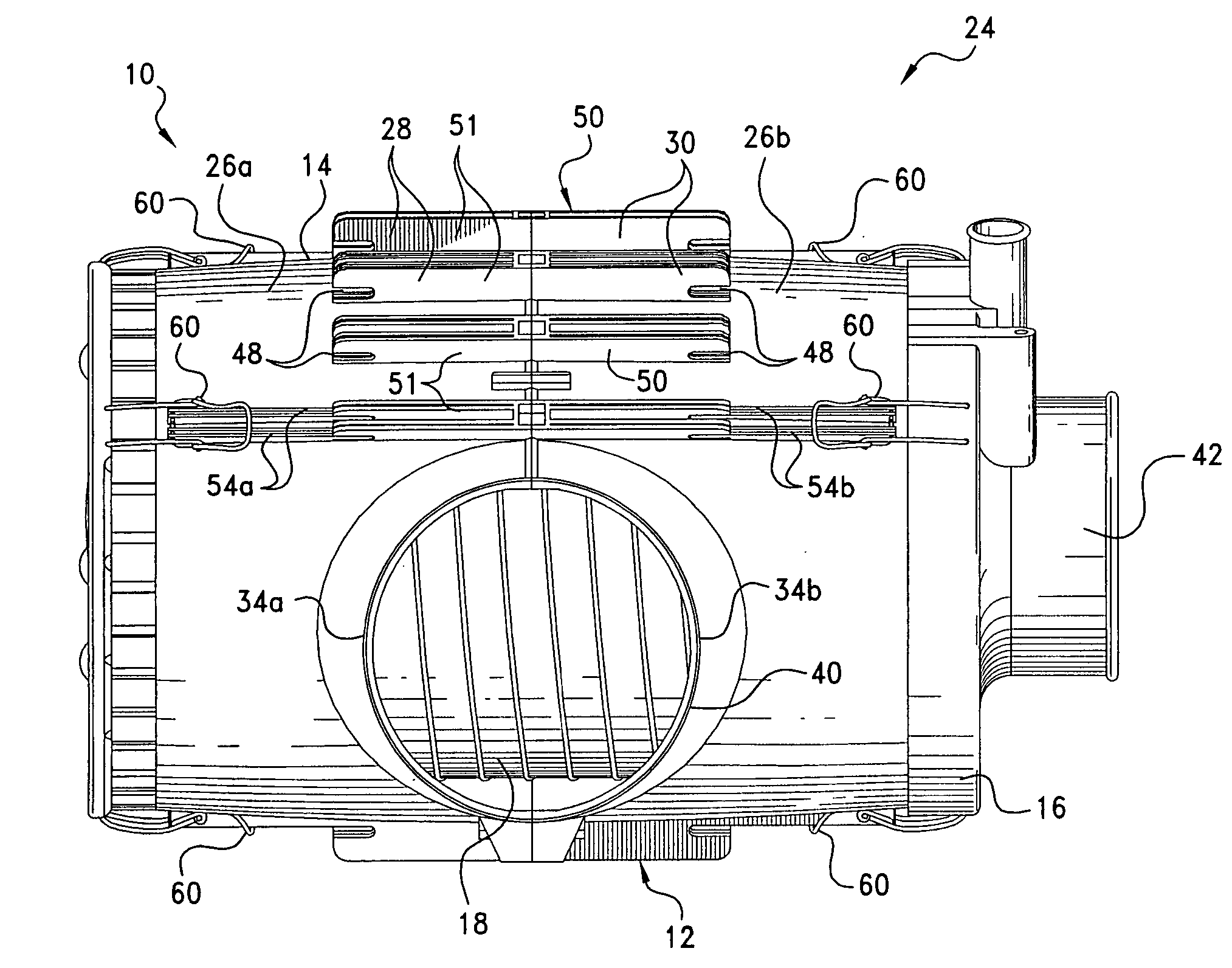

Throttle body fuel injection system with improved fuel distribution

ActiveUS20130298871A1Minimizing any tendencyIncrease the pulse widthElectrical controlInternal combustion piston enginesFuel distributionEngineering

A throttle body fuel injection system and method that is arranged to easily replace four-barrel carburetors includes a throttle body assembly with four main bores, each with a throttle plate and an associated fuel injector. Each injector feeds fuel into a circular fuel distribution ring via a fuel injection conduit, which introduces pressurized fuel into the air stream. The fuel distribution rings and bores have profiles that avoid constrictions for to prevent low pressure zones according to the Venturi effect. Fuel is injected through downward-facing outlets at or near the bottom end of the rings. The fuel injection rings are two-piece, each formed of an insert pressed into an outer housing. The insert includes axial grooves intervaled about its exterior circumference of insert that are joined by a circumferential groove formed about the insert. The grooves are in fluid communication with a conduit that supplies fuel from a fuel injector.

Owner:MSD LLC

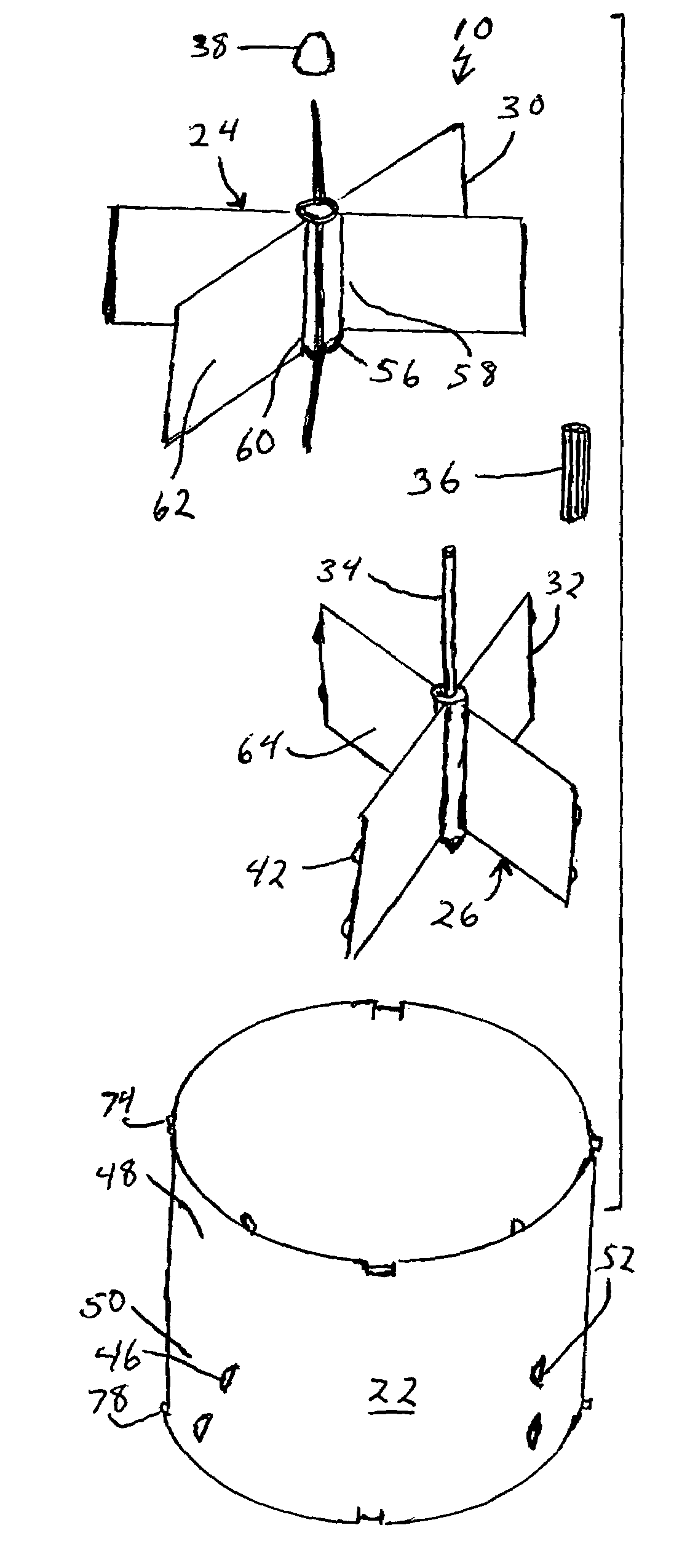

Fluid swirling device having rotatable vanes

InactiveUS7104251B2Improved swirlHigh degreeInternal combustion piston enginesExhaust apparatusEngineeringComplete mixing

The device includes a set of rotatable vanes and a set of stationary vanes which are mounted within a cylindrical housing. The set of rotatable vanes are connected to a post located at the axis of the housing and rotate relative to the post in response to the intake or exhaust fluid impinging on the vanes which are angled relative to the direction of flow of the fluid stream. The set of stationary vanes are rigidly secured to the post and also rigidly secured to the housing walls. The set of stationary vanes are positioned adjacent the set of rotatable vanes and are similarly angled relative to the direction of flow of the fluid stream in order to deflect the fluid stream and impart a swirling motion to the fluid stream in order to provide more complete mixing of the air / fuel mixture of the intake fluid stream or scavenging of the exhaust fluid stream. Tabs which extend radially outwardly from the housing ends secure the device within an intake or exhaust passageway.

Owner:KIM JAY S

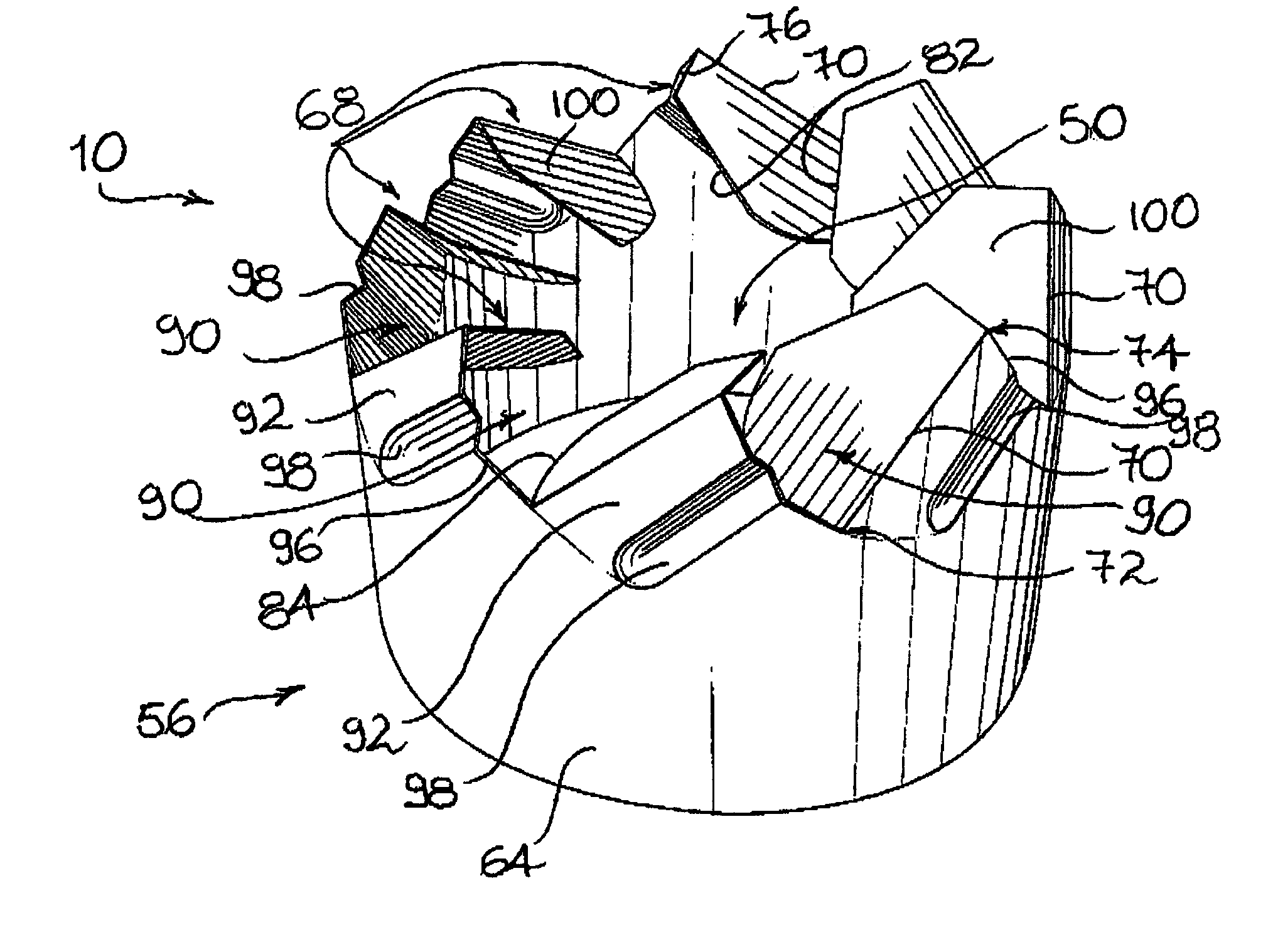

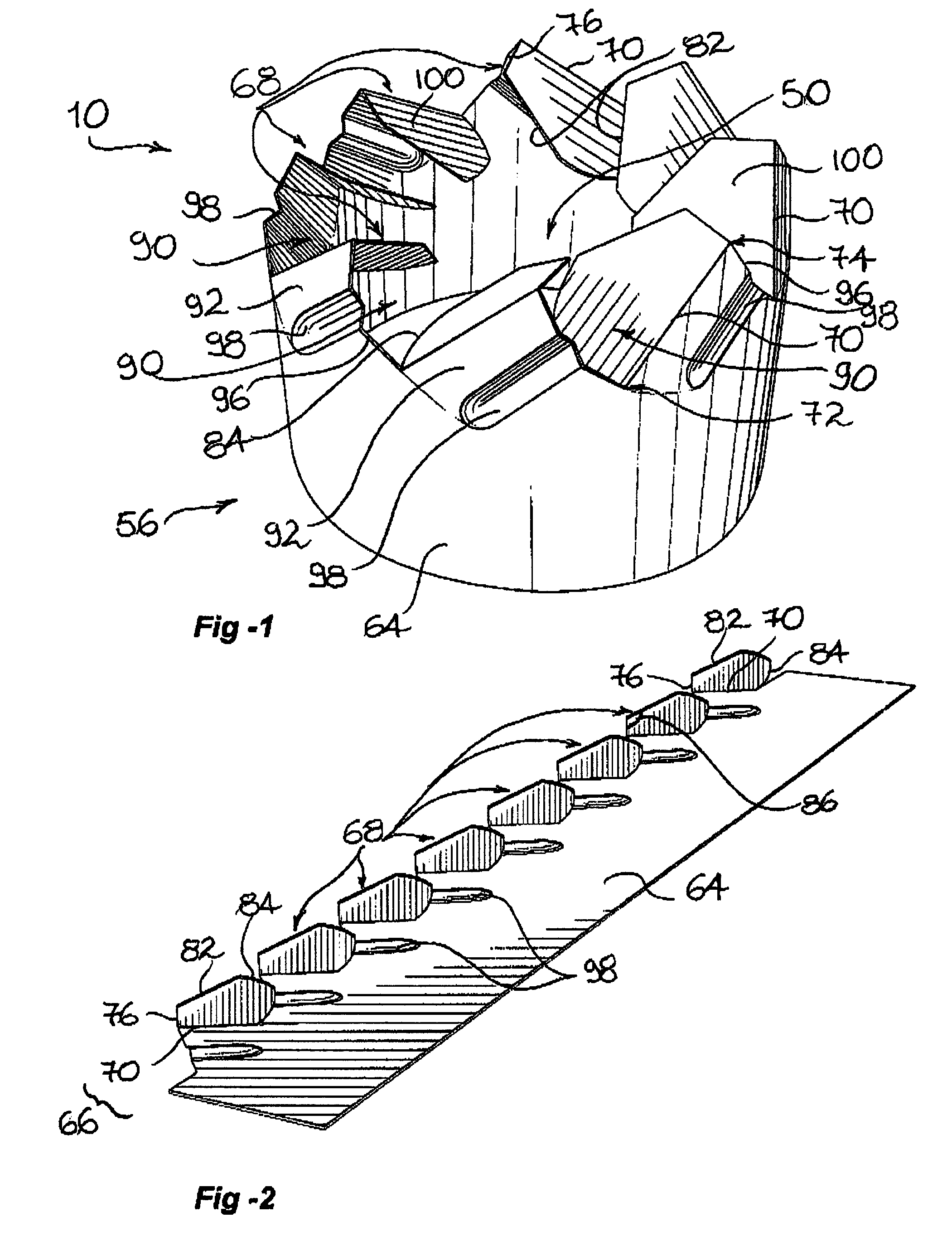

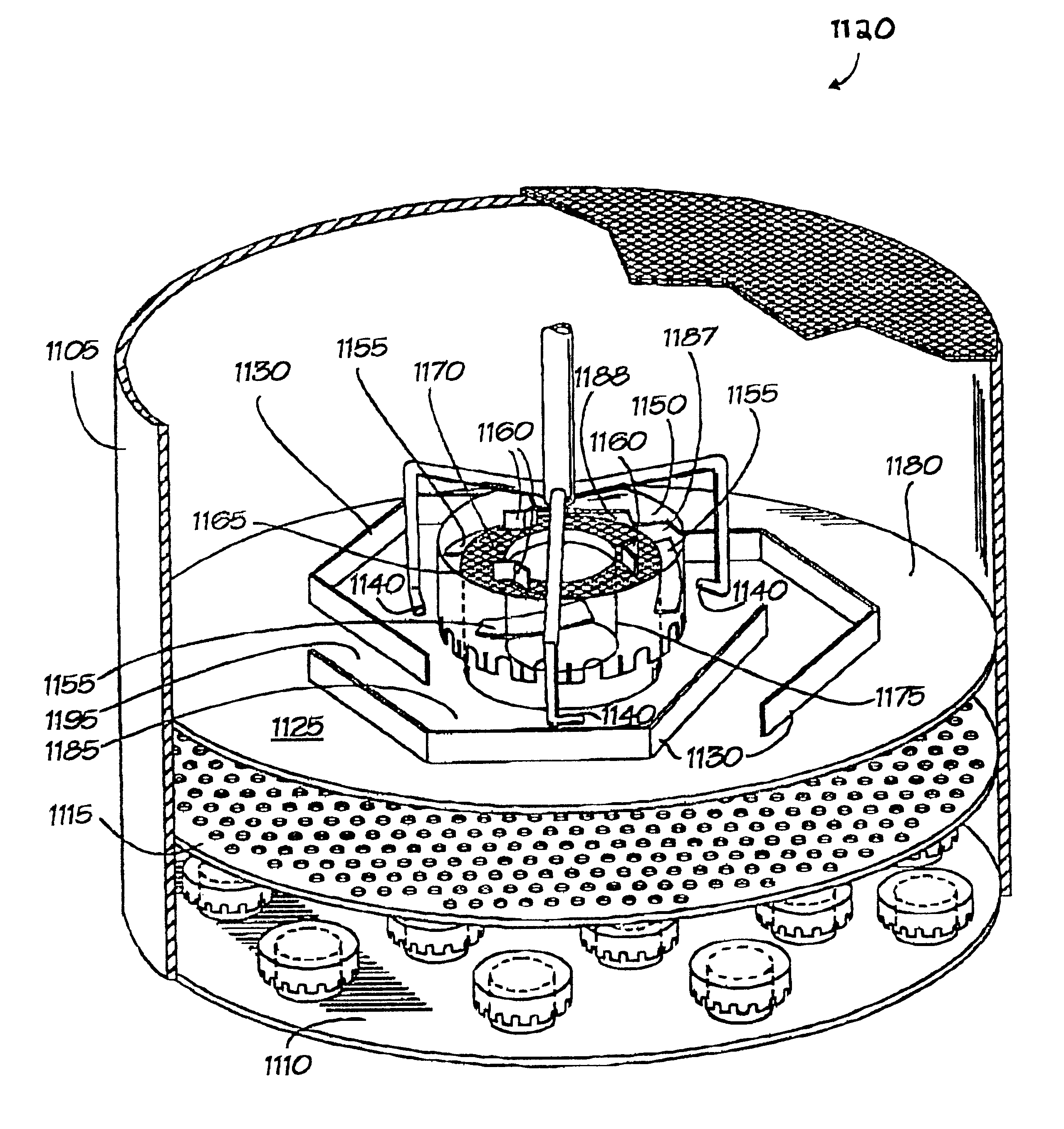

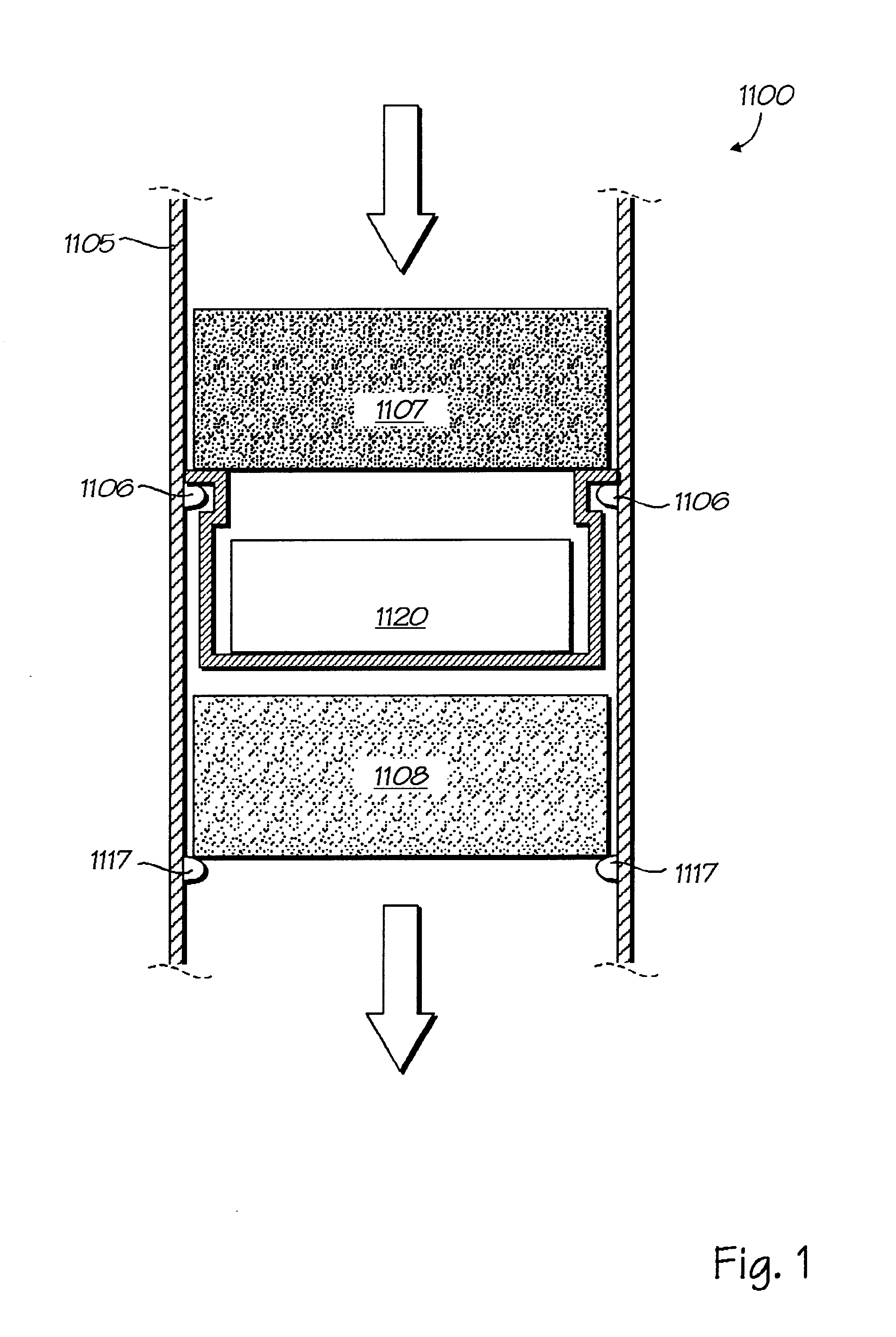

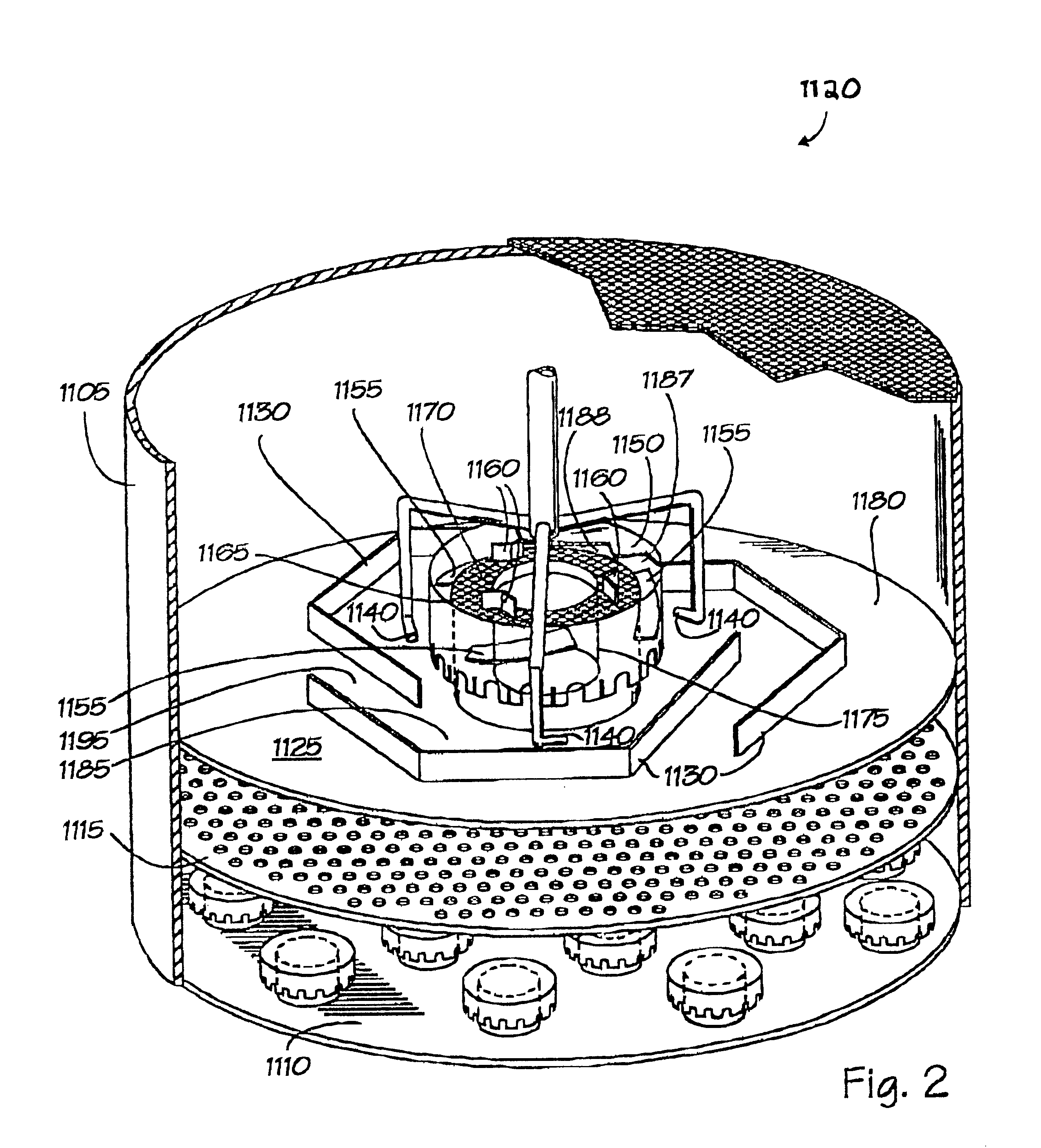

Fluid distributor assembly for a multi-bed, downflow catalytic reactor

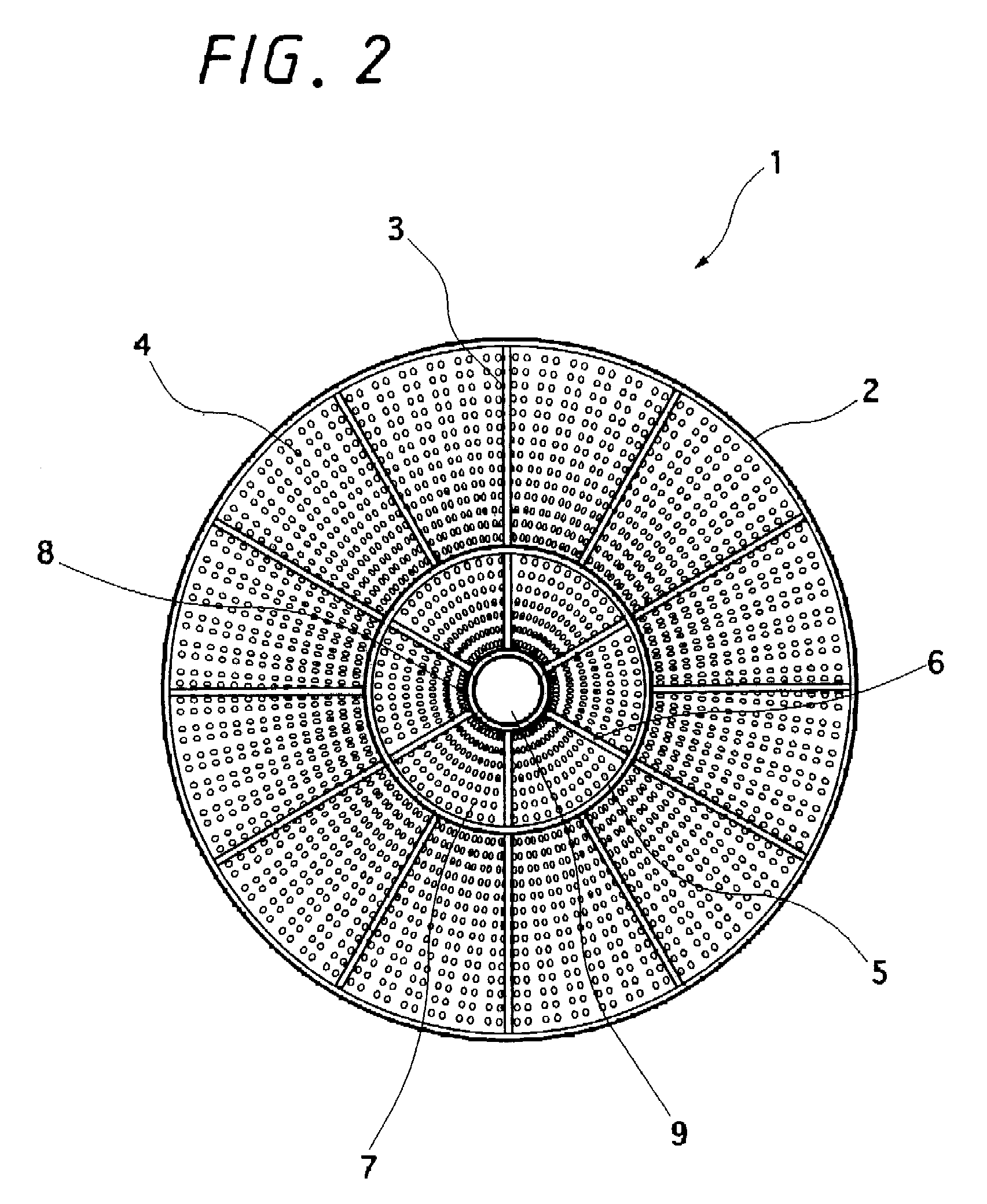

InactiveUS6183702B1Low liquid holdupWell mixedPhysical/chemical process catalystsFuel re-atomisation/homogenisationProduct gasEngineering

A distributor assembly for a multi-bed, downflow catalytic reactor is disclosed. The distributor assembly is configured for disposal and fixable attachment between the inner surfaces of the walls of a multi-bed downflow cylindrical reactor wall and for disposal between vertically stacked catalyst beds within the reactor. The assembly includes:(a) a collection plate configured for substantially horizontal disposal between the walls of a cylindrical reactor;(b) a plurality of generally arc-shaped elongated baffles disposed in a staggered, substantially symmetrical pattern about the collection plate;(c) a first mixing zone configured to be bounded on the bottom by the collection plate, on one side by a wall of a cylindrical reactor, and on the opposite side by the outer surface of the elongated baffles;(d) a cylindrical weir fixably attached to the collection plate about the outlet;(e) a second mixing zone bounded on the bottom by the collection plate, on one side by the outer surface of the cap and the first cylindrical weir, and on the opposite side by the inner surface of the elongated baffles;(f) a cap disposed over and about the first cylindrical weir, thereby forming a third mixing zone, plurality of semi-spiral-shaped baffles disposed in the third mixing zone, the semi-spiral-shape;(g) baffles having an elongated shape, having one lateral edge fixed to an inner surface of the cap or an opposite lateral edge fixed to an outer surface of the first cylindrical weir;(h) a substantially doughnut-shaped screen member disposed over a top portion of the cylindrical weir;(i) a plurality of fourth-mixing-zone baffles fixably attached to a top surface of the doughnut-shaped screen member; and(j) a plurality of quench gas ports disposed in the second mixing zone.

Owner:CHEVROU USA INC

Dividing wall column fractionation tray

InactiveUS6645350B1Thermal non-catalytic crackingHydrocarbon distillationShortest distanceFractionation

Problems generated by heat transfer through the vertical dividing wall of a trayed "dividing wall column" and into a downcomer of a tray are mitigated by providing a separate vertical isolation wall between the downcomer and dividing wall. The isolation wall forms one side of the downcomer and is spaced a short distance outward from the dividing wall to form an isolation volume which thermally insulates the downcomer from the dividing wall. The added wall is parallel to the dividing wall and supplants the dividing wall as a part of the downcomer. It eliminates a need to insulate the dividing wall.

Owner:UOP LLC

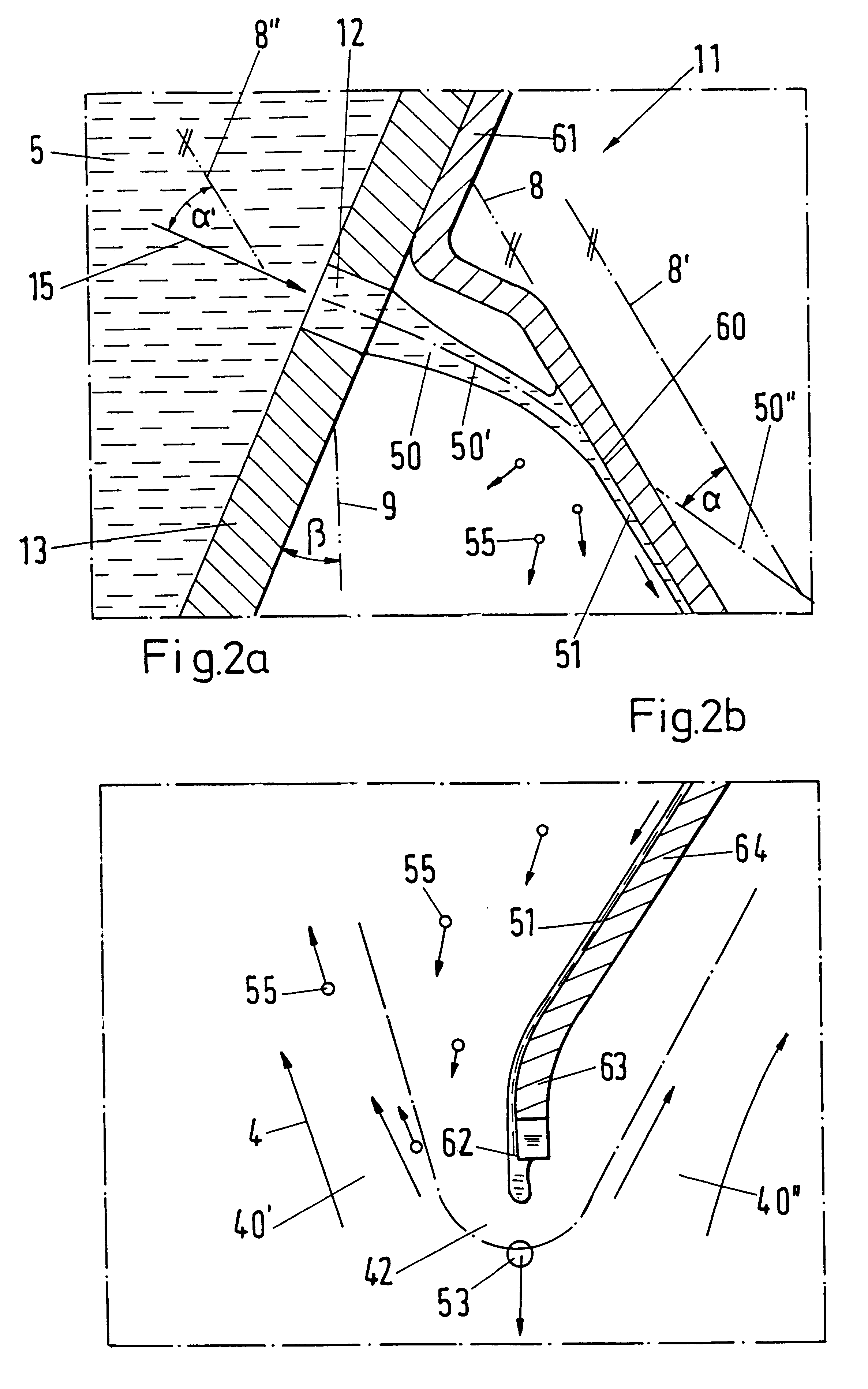

Liquid distributor for packing columns

InactiveUS6293526B1Obstruct passageCarburetting airUsing liquid separation agentLiquid jetEngineering

A liquid distributor for packing columns. The liquid distributor includes at least one tubular or trough-like distributor member including outlet openings for an output of liquid in the form of jets. Screens are arranged ahead of the outlet openings onto which the incident liquid jets are deformed to liquid films flowing off. The outlet openings screen the outlet openings against an upwardly flowing gas flow. In the event of a maximum output of liquid, the liquid jets are incident onto the screens at angles that are less than 60°, and even as much as less than 10°.

Owner:SULZER CHEMTECH AG

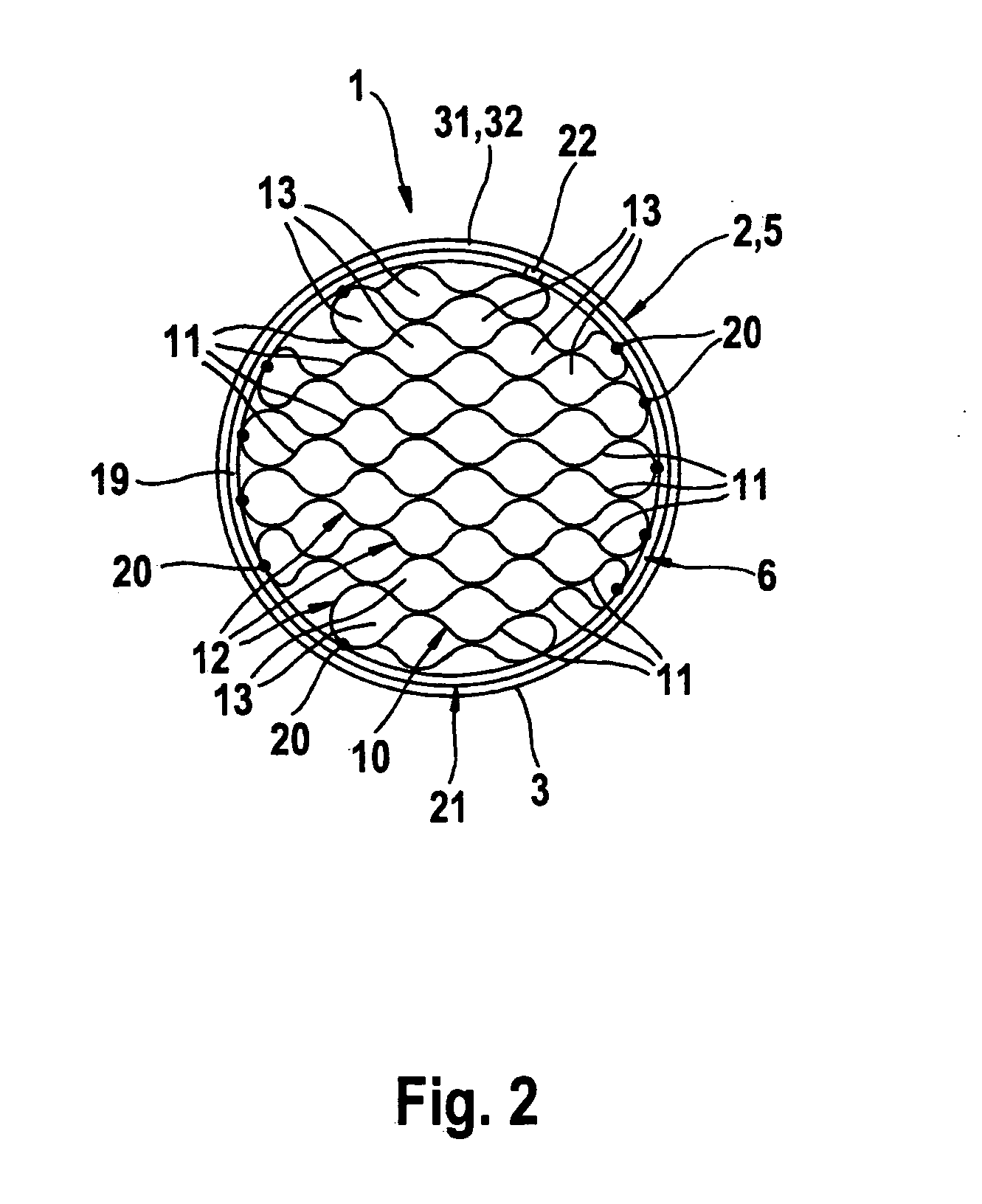

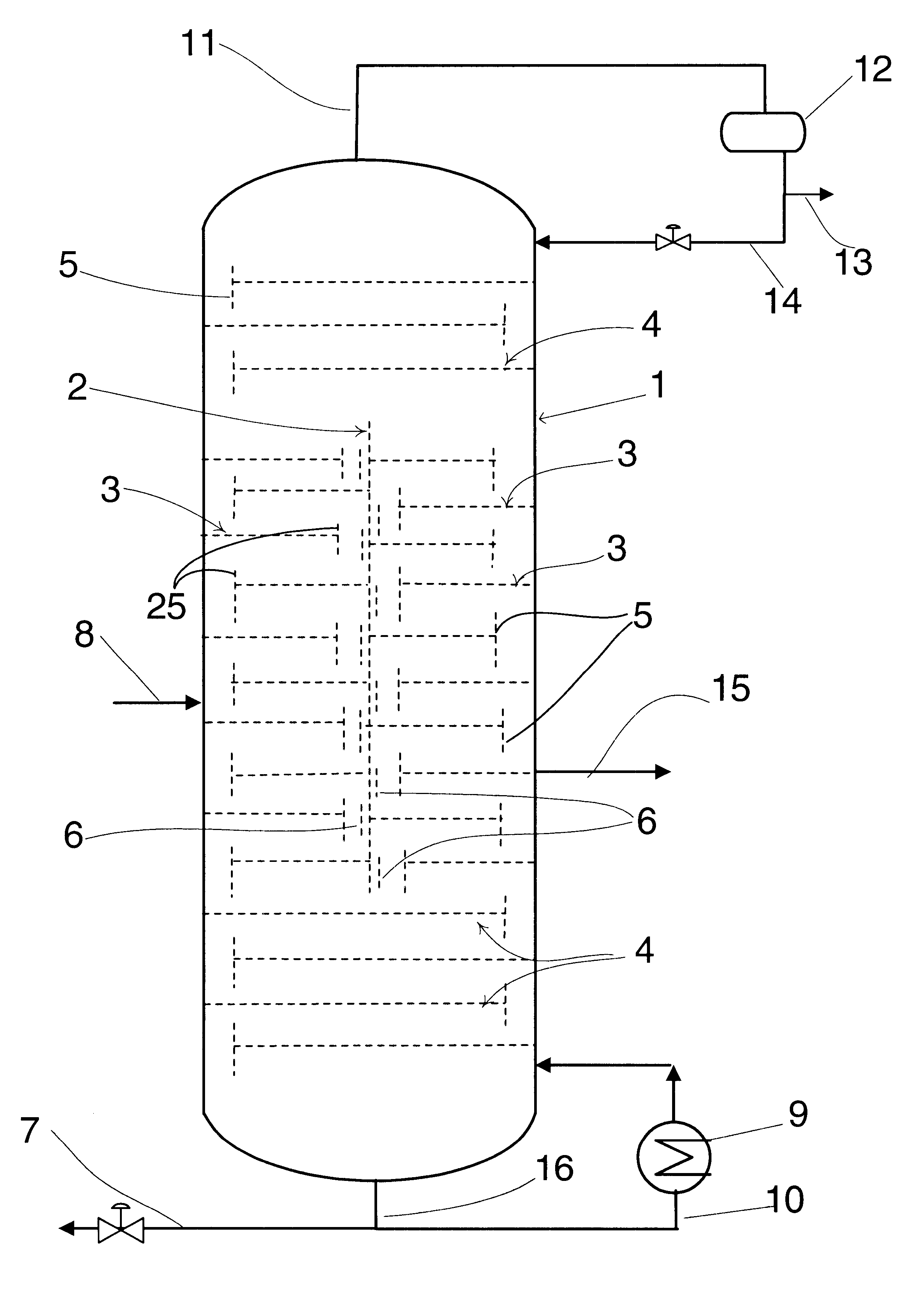

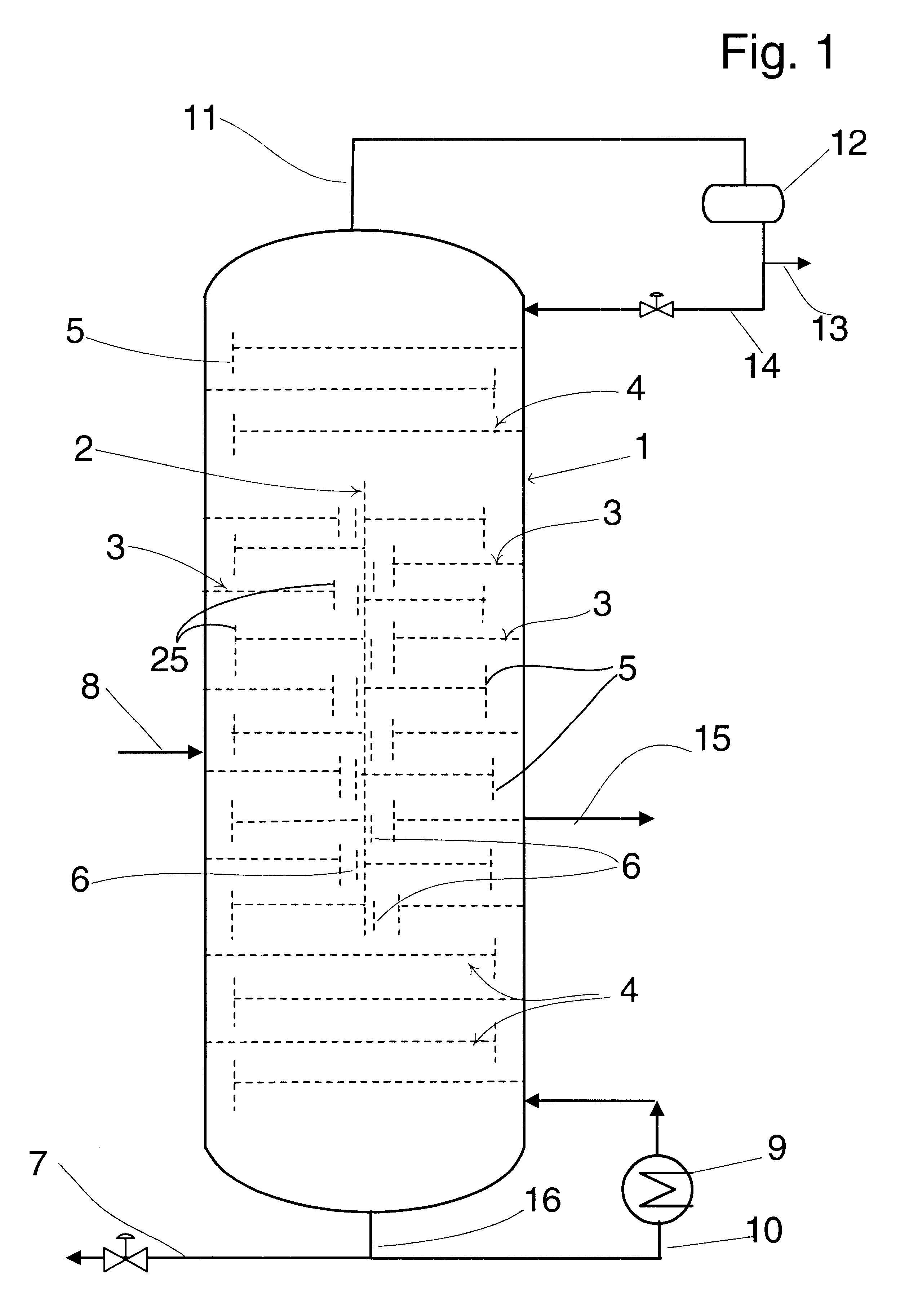

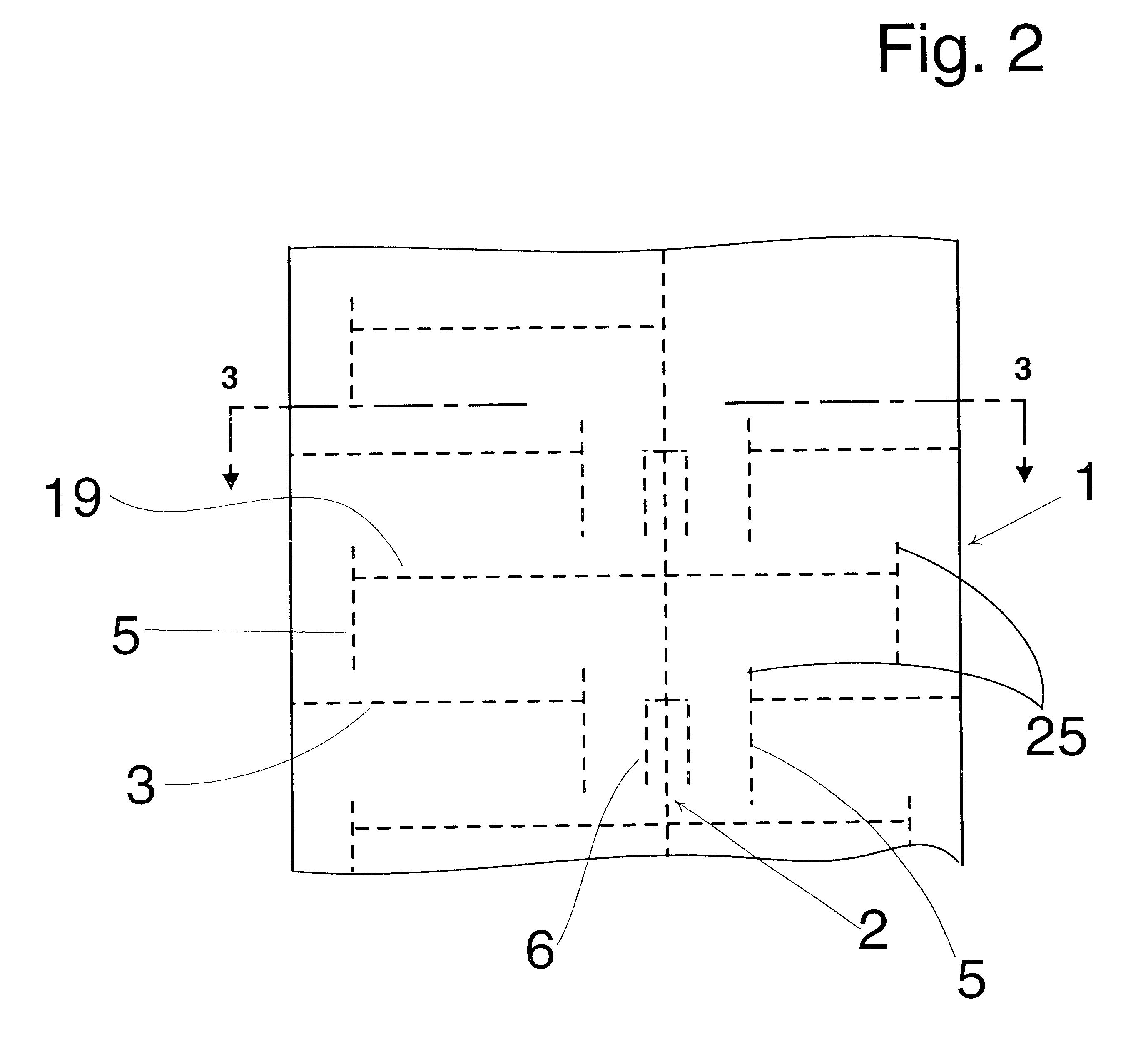

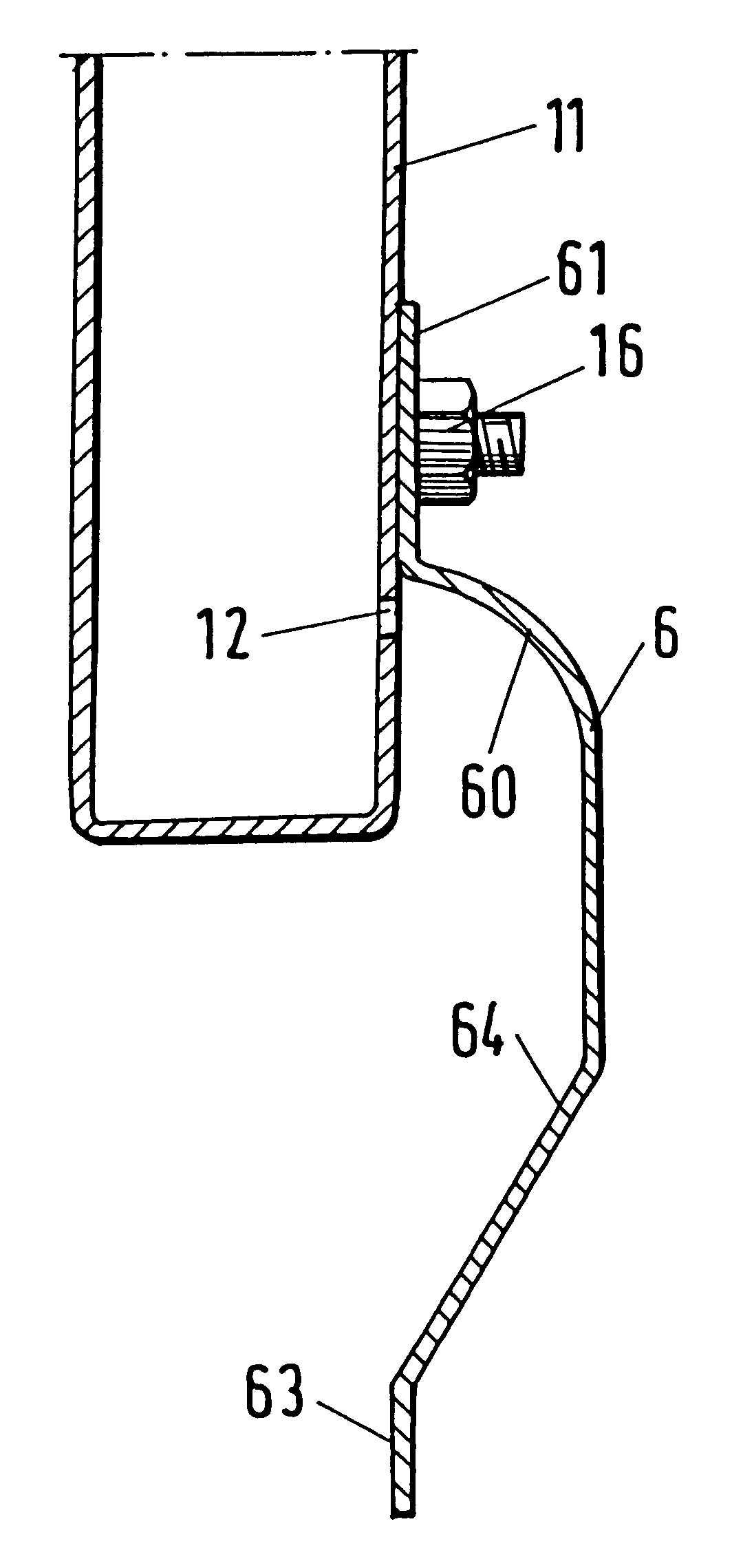

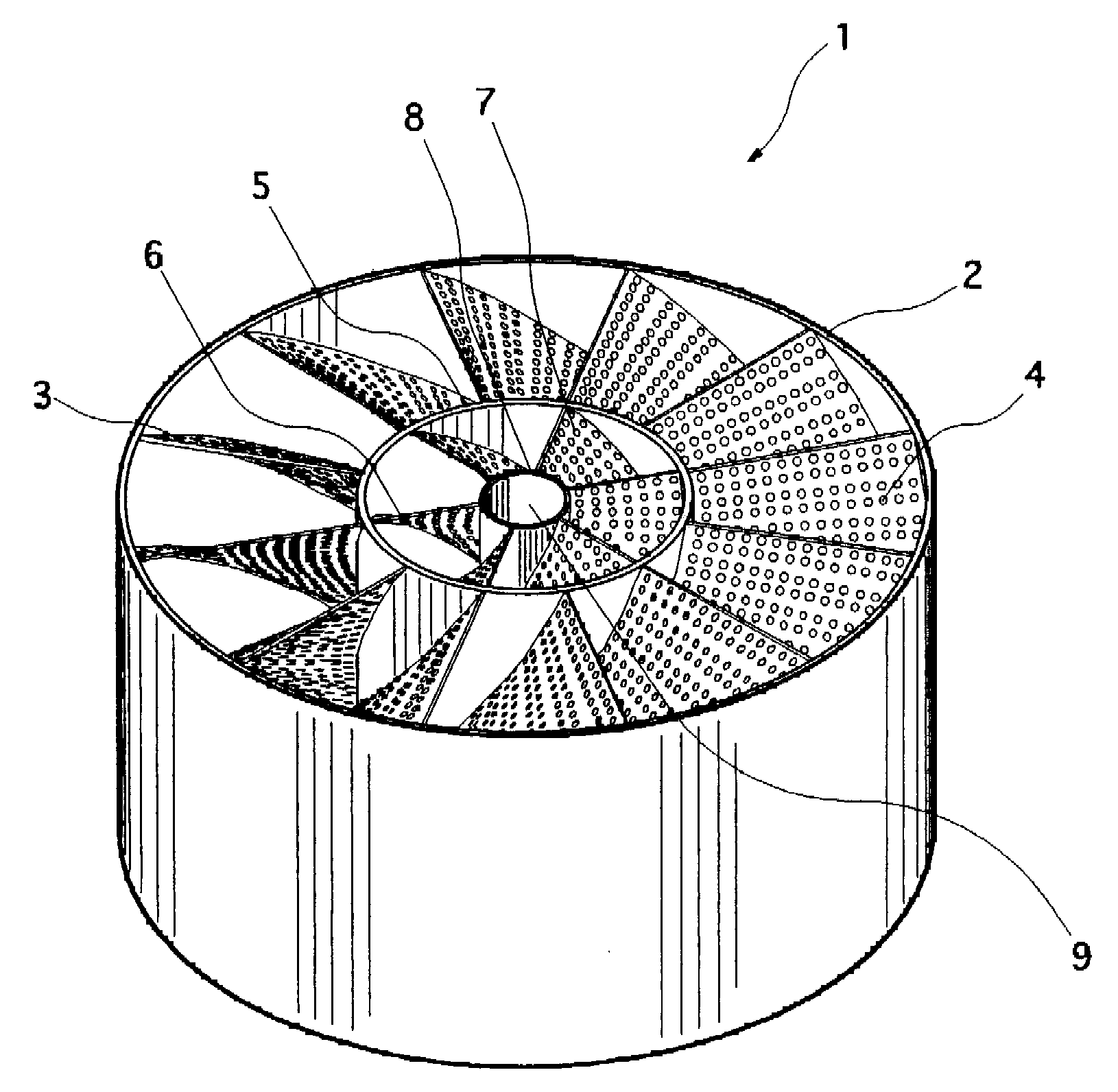

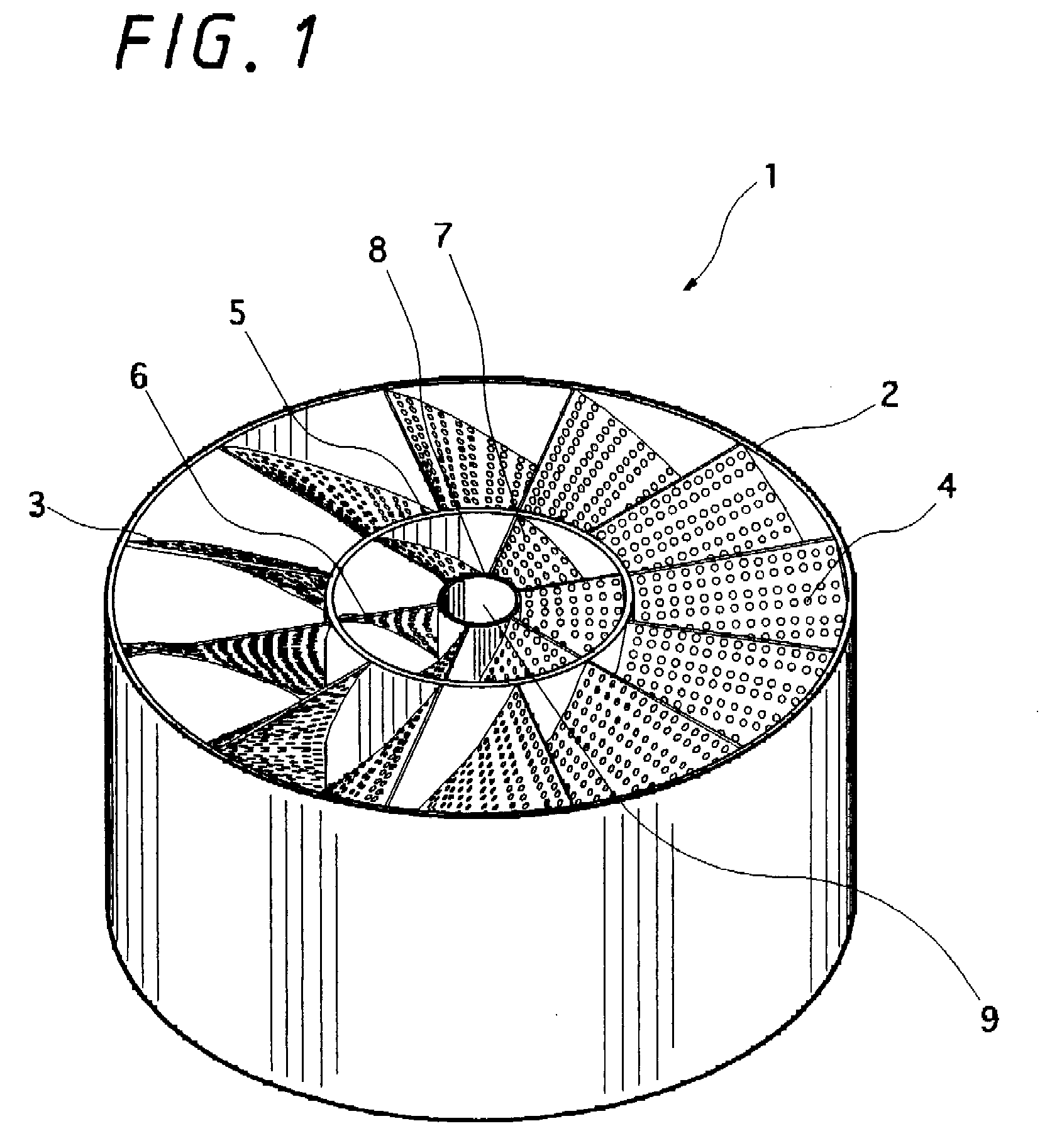

Mixing Element and Static Fluid Mixer Using Same

ActiveUS20070205523A1High mixture efficiencyEasy to produceFlow mixersUsing liquid separation agentEngineeringCylindrical tube

A mixing element, which is produced at low cost, has high mixture agitation effectiveness, and is easily made large, and a static fluid mixer using the mixing element are provided. Further, a gas-liquid treatment apparatus with high treatment ability is provided. A mixing element 1 includes: a cylindrical passage tube 2 trough which fluid flows; a plurality of spiral rightward rotation type first blades 3 formed of a perforated object, which are provided in the passage tube 2; a first inner cylindrical tube 5 shaped like a cylinder and disposed inside the blades 3; a plurality of spiral rightward rotation type blades 6 provided in the inner cylindrical tube 5; and an opening 9 formed in the axial center portion of the blades 6. A static fluid mixer is formed by using at least one mixing, element 1 mentioned above.

Owner:ANEMOS

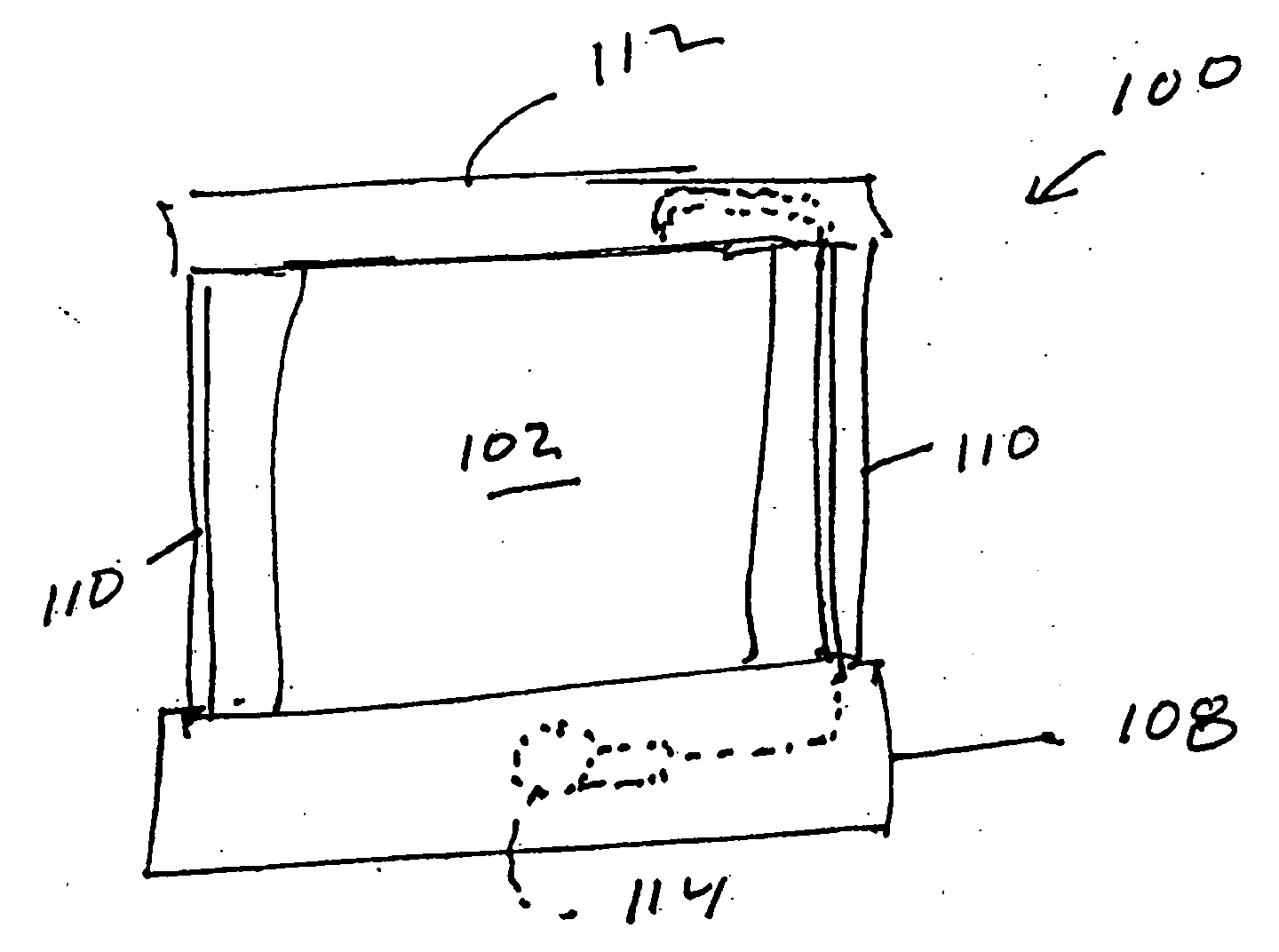

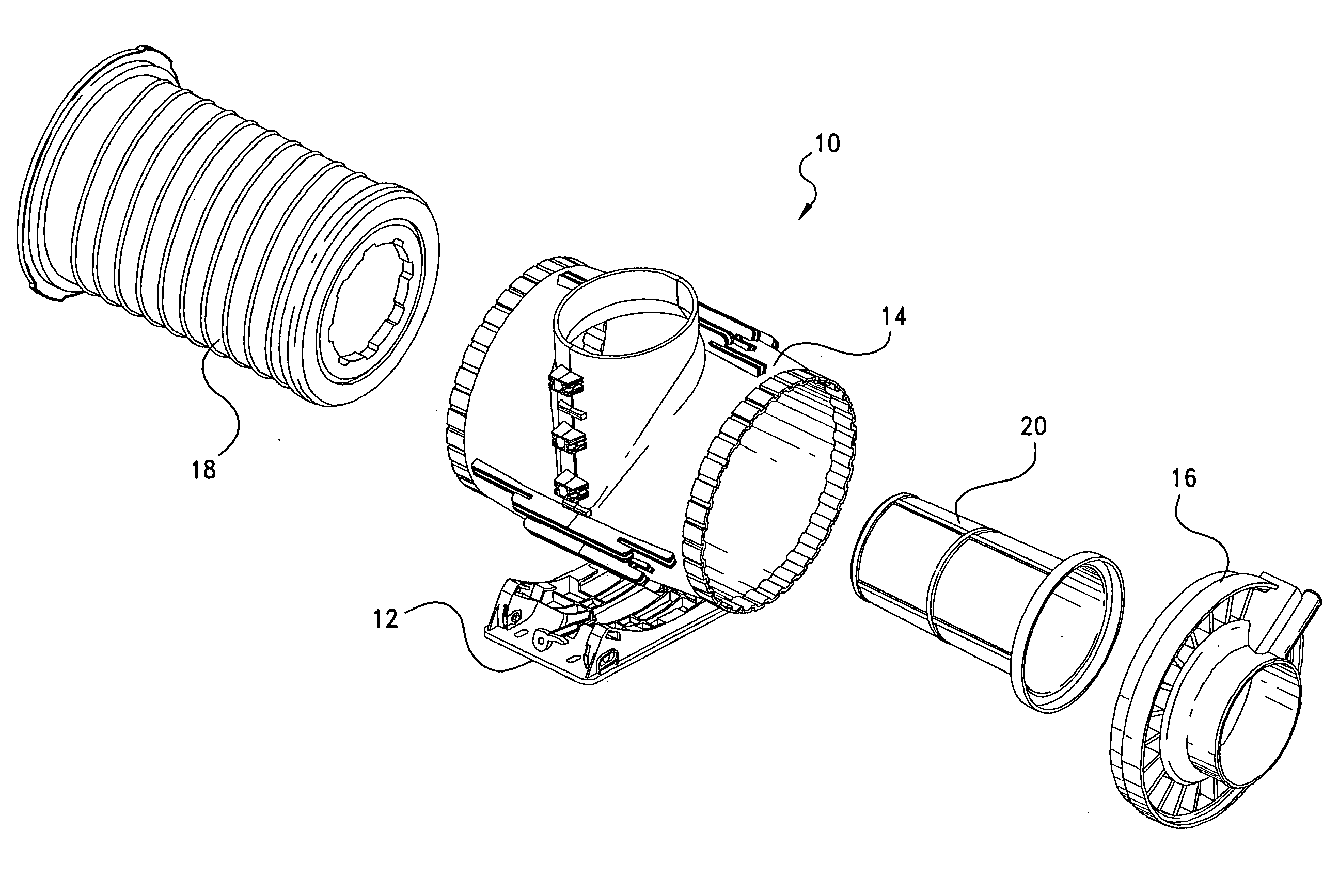

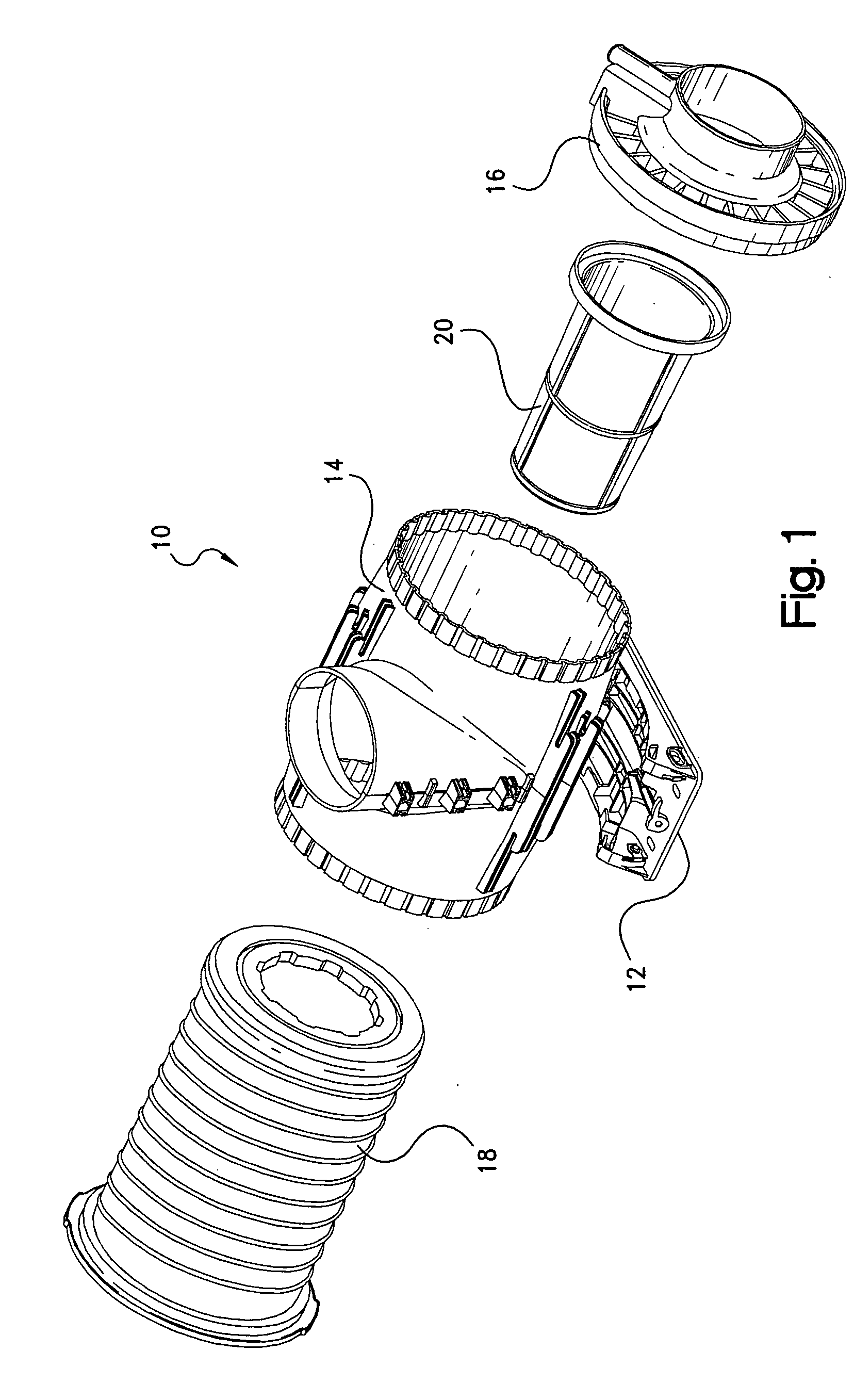

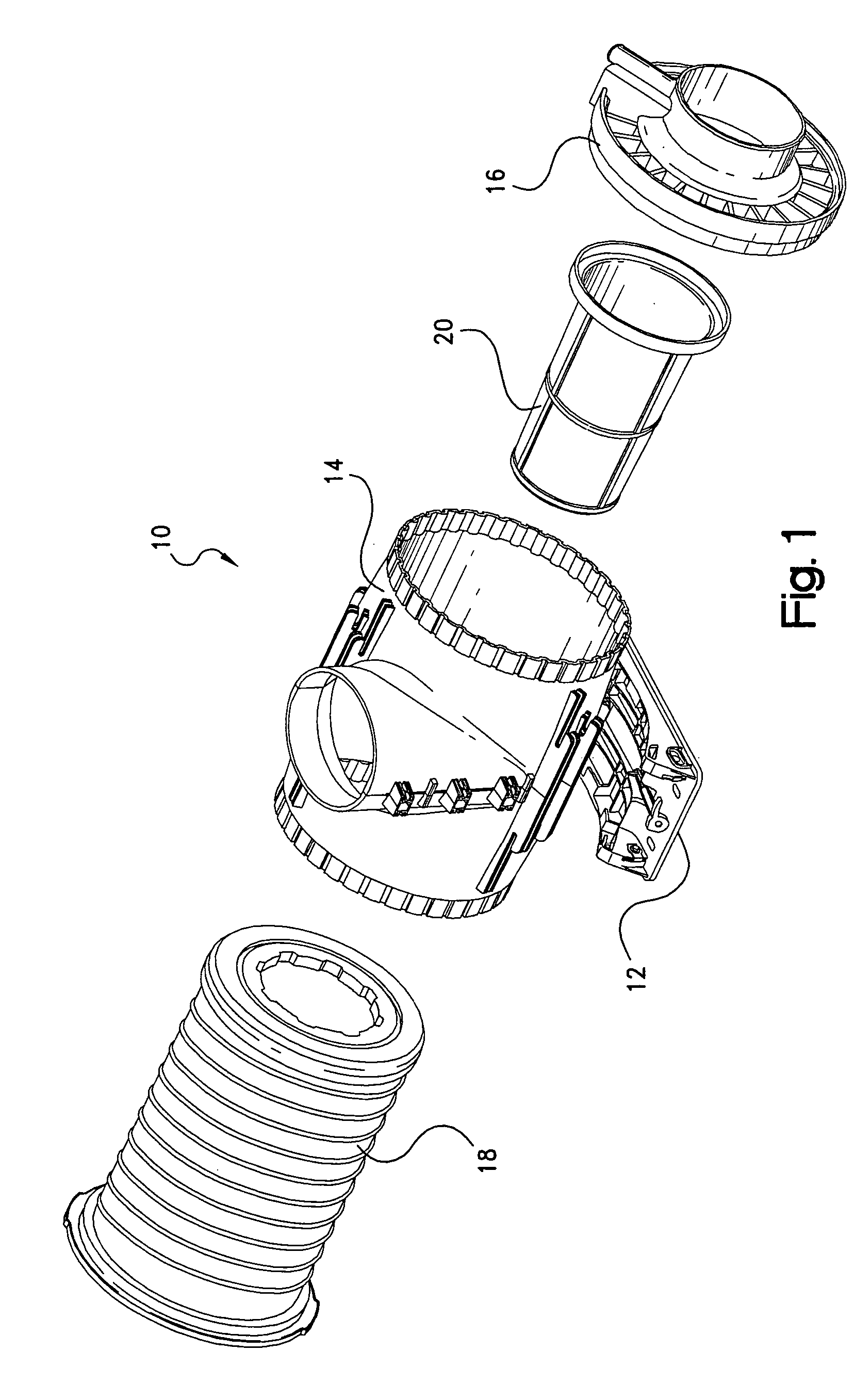

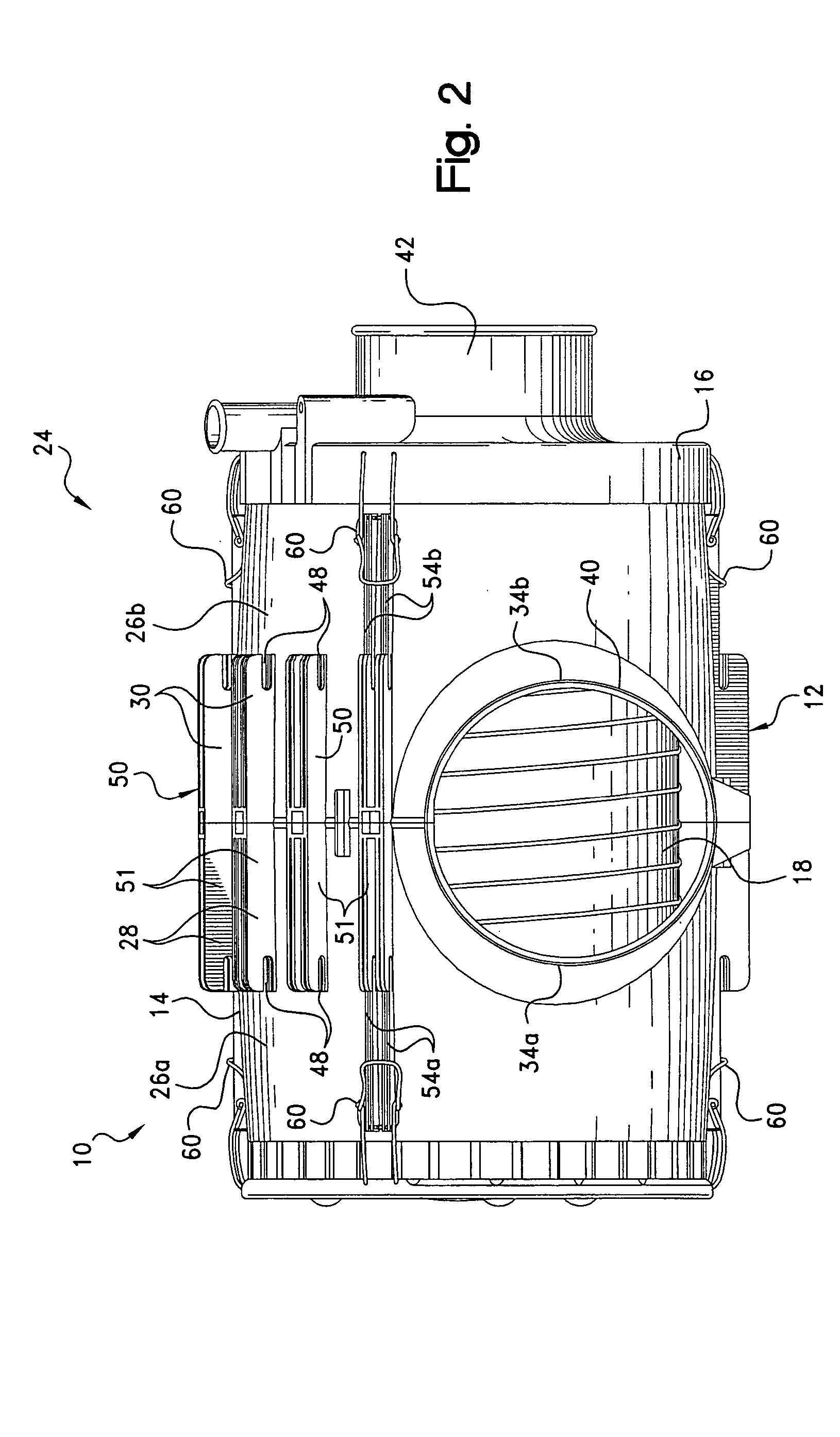

Air filter assembly system and method

ActiveUS20050193695A1Undesired movement is also preventedCombination devicesDispersed particle filtrationLocking mechanismAir filter

An air filter assembly including abutting, cylindrical housing halves, with toothed outer ends, joined via spaced, T-shaped appendages; a cylindrical air inlet of abutting semi-cylindrical housing inlet portions; a primary filter pack, for slip-fit insertion into either housing half, having an end cap integral with a cylindrical primary filter pack having sealing material on its inner end; a filter outlet end with a toothed peripheral portion, for slip-fit insertion into and angular adjustment relative to either housing end, and a plurality of ribs defining locating surfaces for an air outlet portion, and main and safety filters; the latter having a truncated cone body and an inverted conical portion; and a filter attachment base having curved bed portions, for receiving a housing periphery portion, including spaced support pads and slot portions for angularly adjustably receiving like numbers of T-shaped appendages, with a locking mechanism joining the housing and attachment base.

Owner:PARKER INTANGIBLES LLC

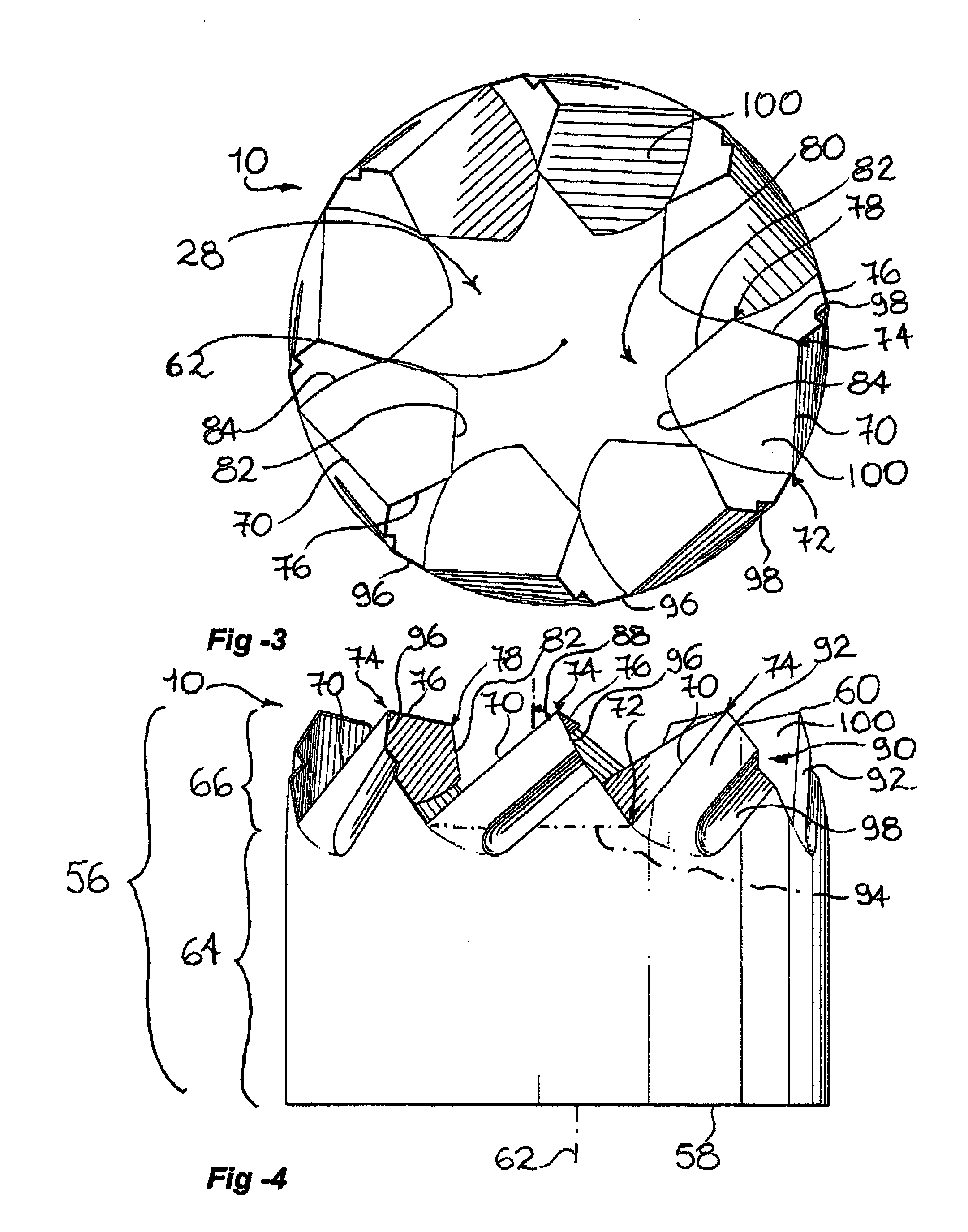

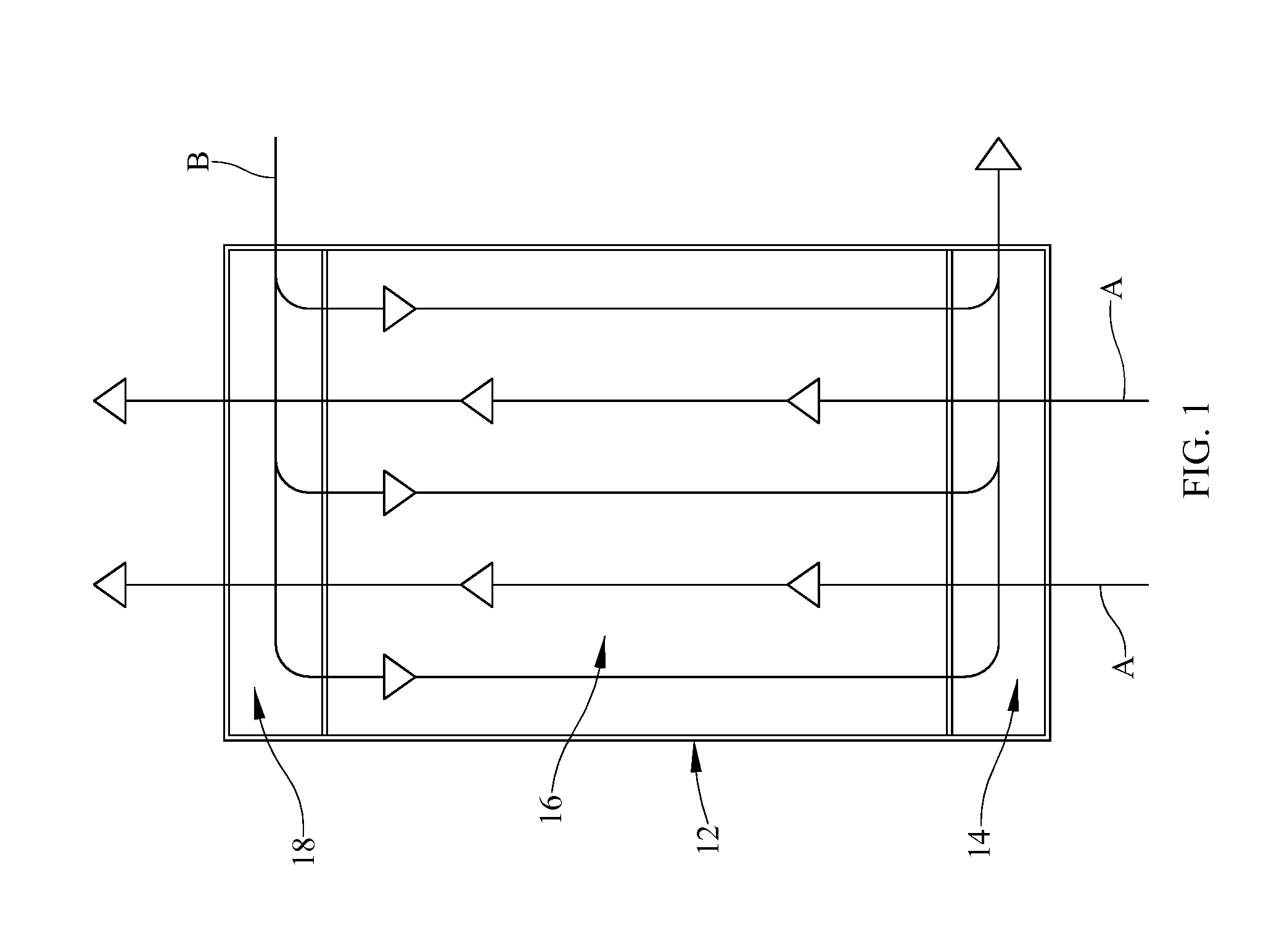

Distribution device for two-phase concurrent downflow vessels

ActiveUS20060163758A1Easy to spreadImprove distribution performanceCarburetting airMixing methodsLiquid diffusionStream flow

A distribution tray for distribution of vapor and liquid across a vessel has a plurality of downcomers extending above the tray and having open upper and lower ends. A liquid conduit for each downcomer has an inlet, a section for upward liquid flow, and openings in fluid communication with the downcomer. A reduced flow area section and a device for improved liquid spread may be used at the outlet of the downcomer. During operation, vapor enters the upper downcomer end. Liquid collected on the tray flows through the inlet, upward through the conduit, and through the openings into the downcomer, where the liquid is mixed with downwardly-flowing vapor. The two-phase stream passes the reduced flow area section with increased velocity for improved dispersion of the liquid before the stream flows through the device for improved liquid spread, and then exits through the lower end of the downcomer.

Owner:MORTEN MULLER LTD APS

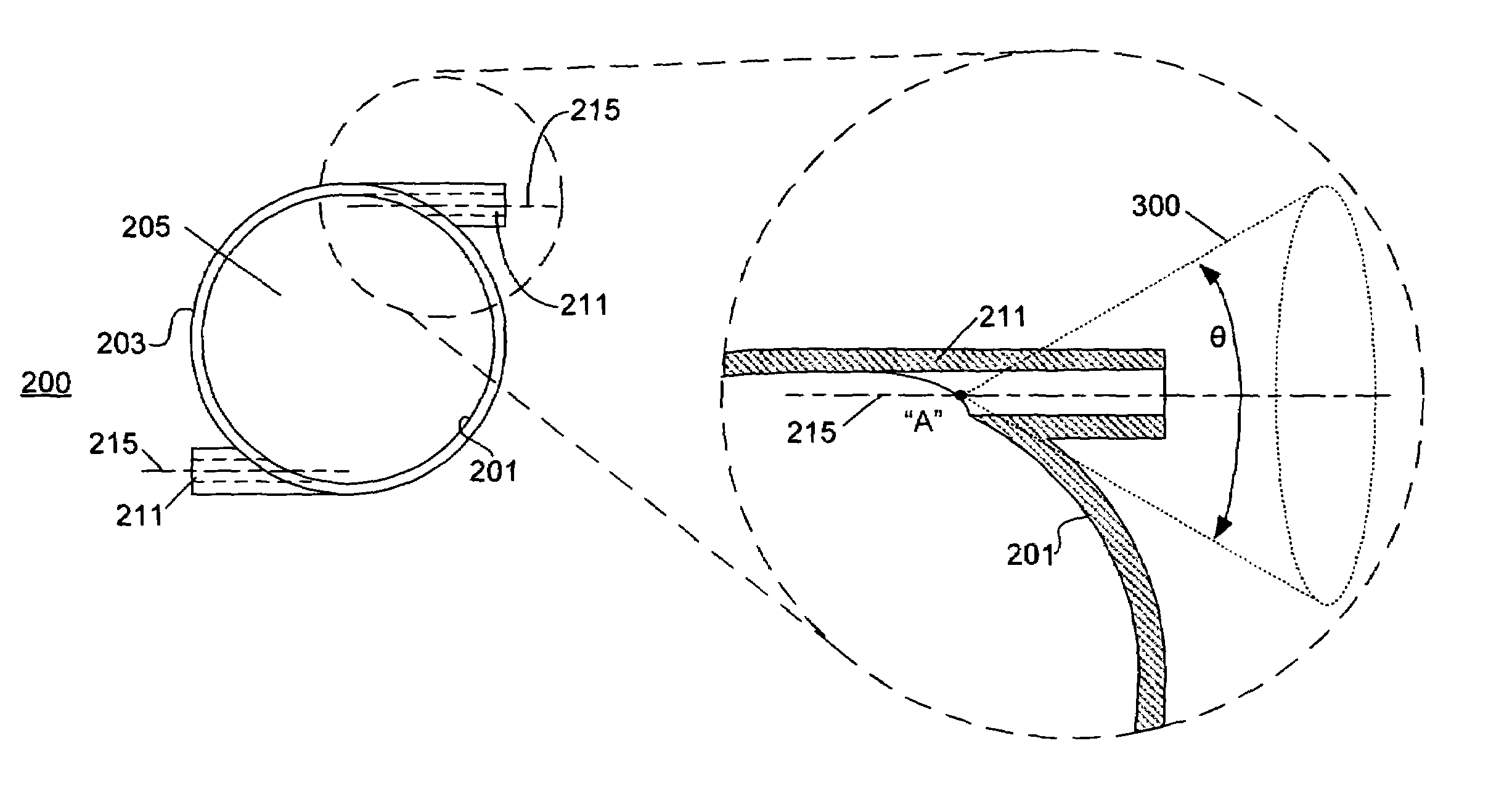

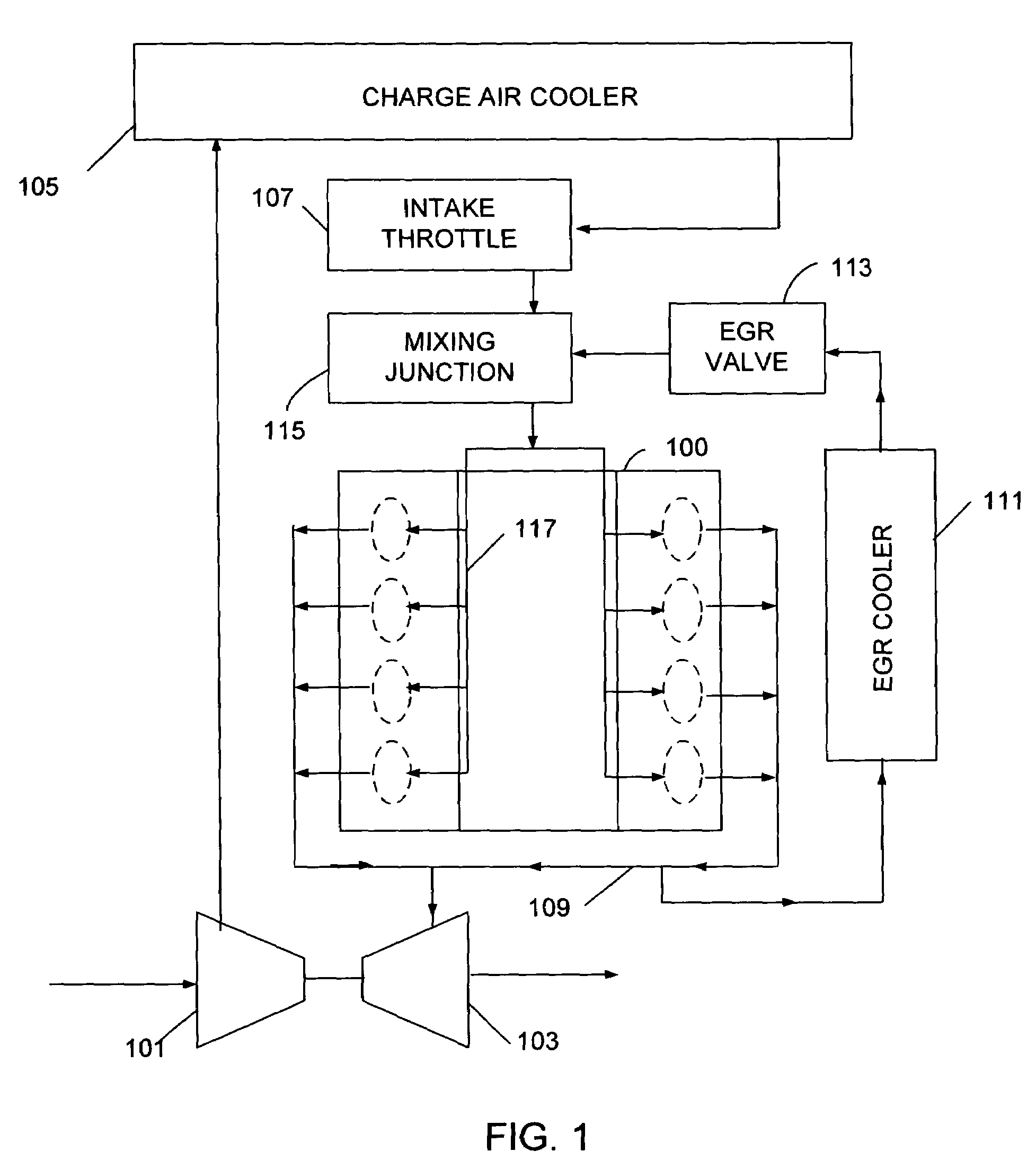

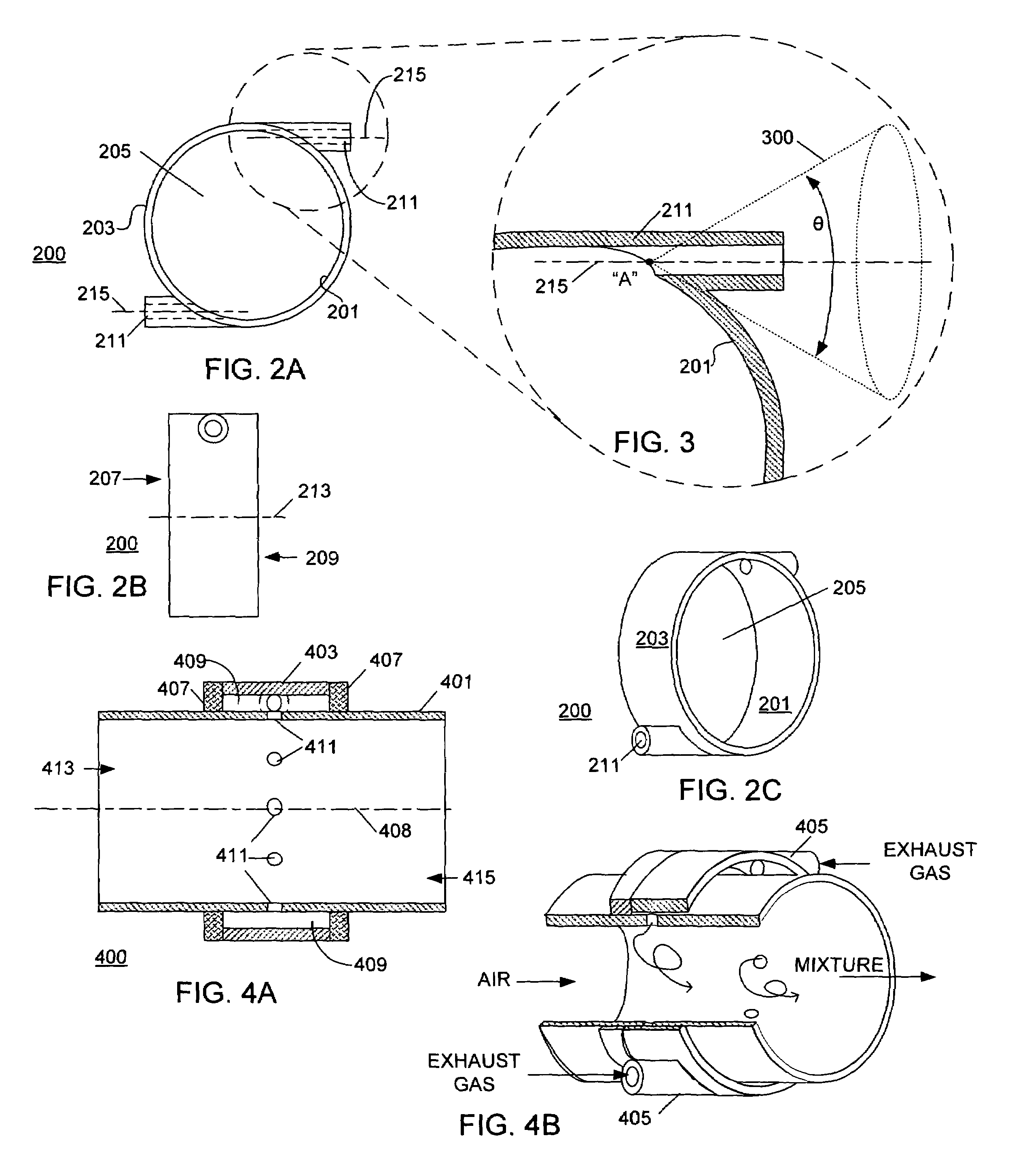

Tangential mixer and method

An apparatus includes a tangential mixer (200) having an air inlet (207) and a mixture outlet (209). A bore (205) has a bore centerline (213) and a bore perimeter (201). At least one gas inlet (211) has an inlet centerline (215) oriented tangentially to the bore perimeter (201). The inlet centerline (215) is within a cone (300). The cone (300) has a vertex point “A” on the inlet centerline (215).

Owner:INT ENGINE INTPROP CO LLC

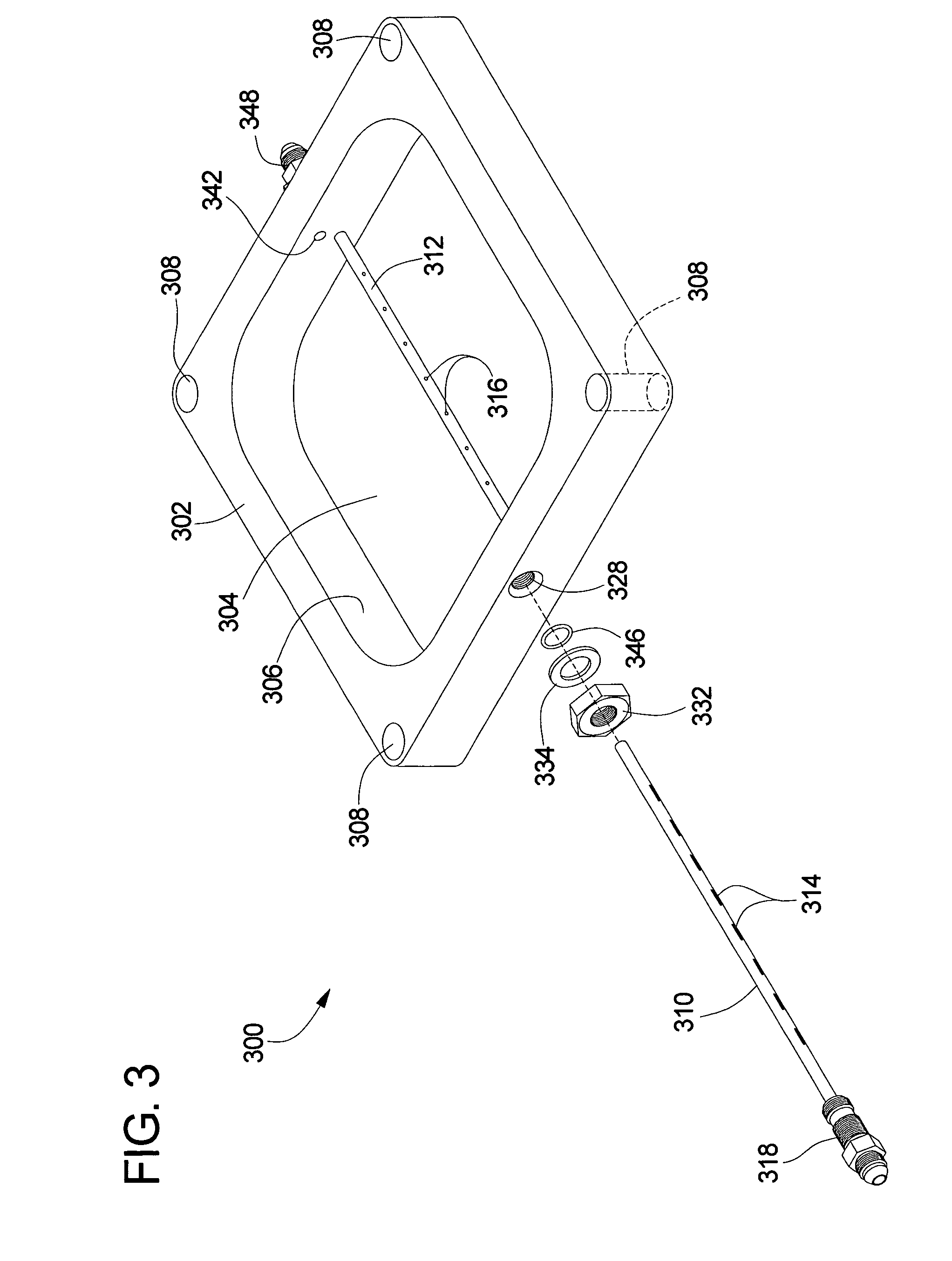

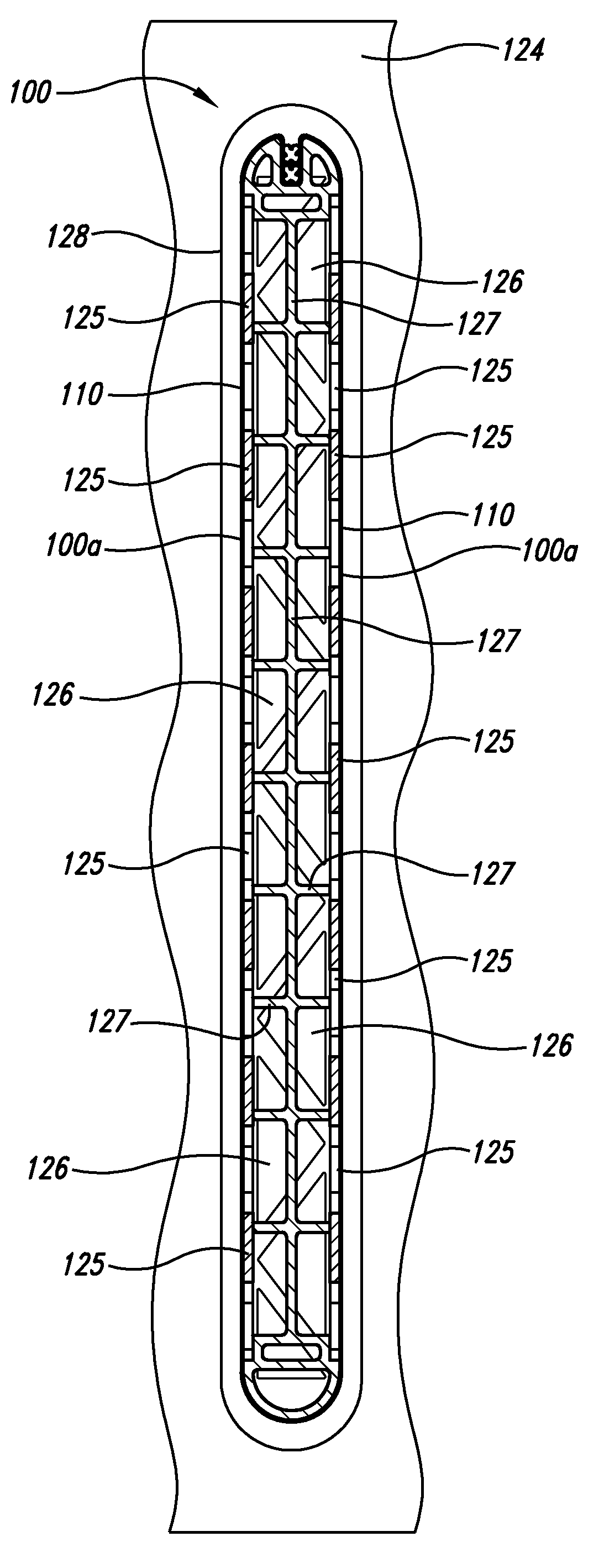

Fill material for direct-contact heat/mass exchangers

InactiveUS20150048528A1Reduced dysfunctionSmall sizeAdditive manufacturing apparatusUsing liquid separation agentFilling materialsLinear element

Fill material for a direct contact heat exchanger wherein the fill material has flow pathways bounded by an array of linear elements, namely a mesh. The invention intentionally uses surface tension and capillary action to anchor the fluid / fluid interface in a desired location. The heat exchanger is wick or collector in direct contact with the fill material (matrix) to extract fluid without formation of large droplets. The mesh is made from a neutrally wetting material.

Owner:BARTON SEAN ANDERSON

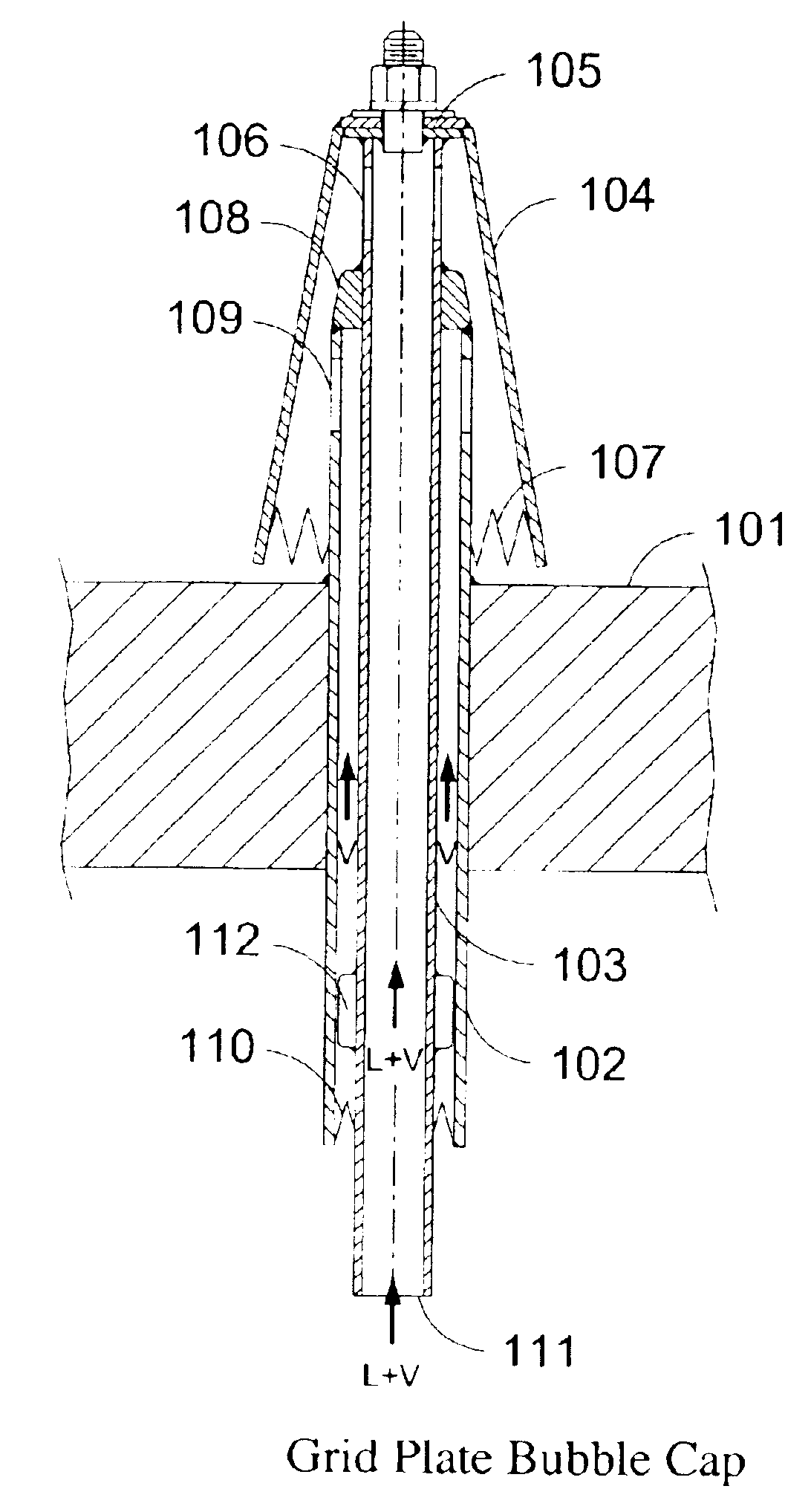

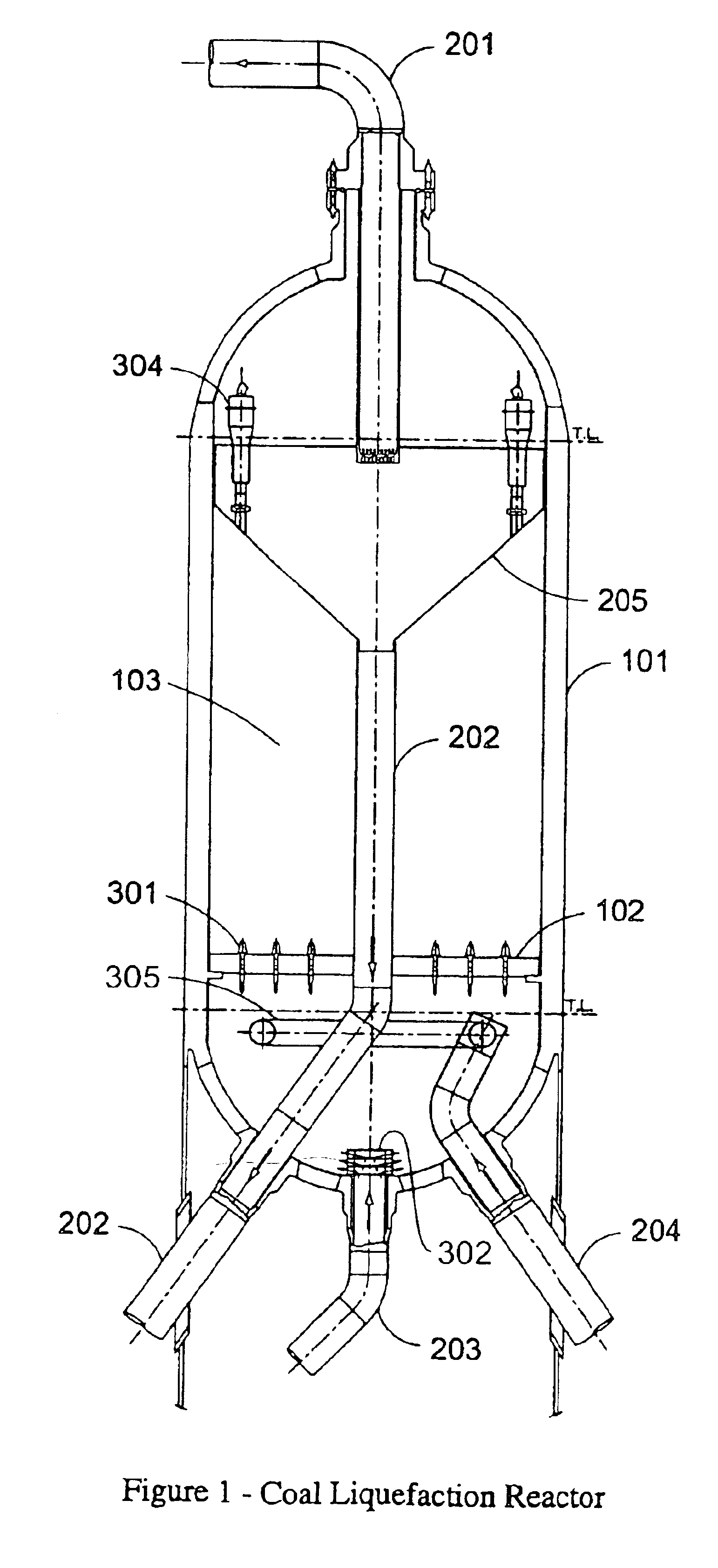

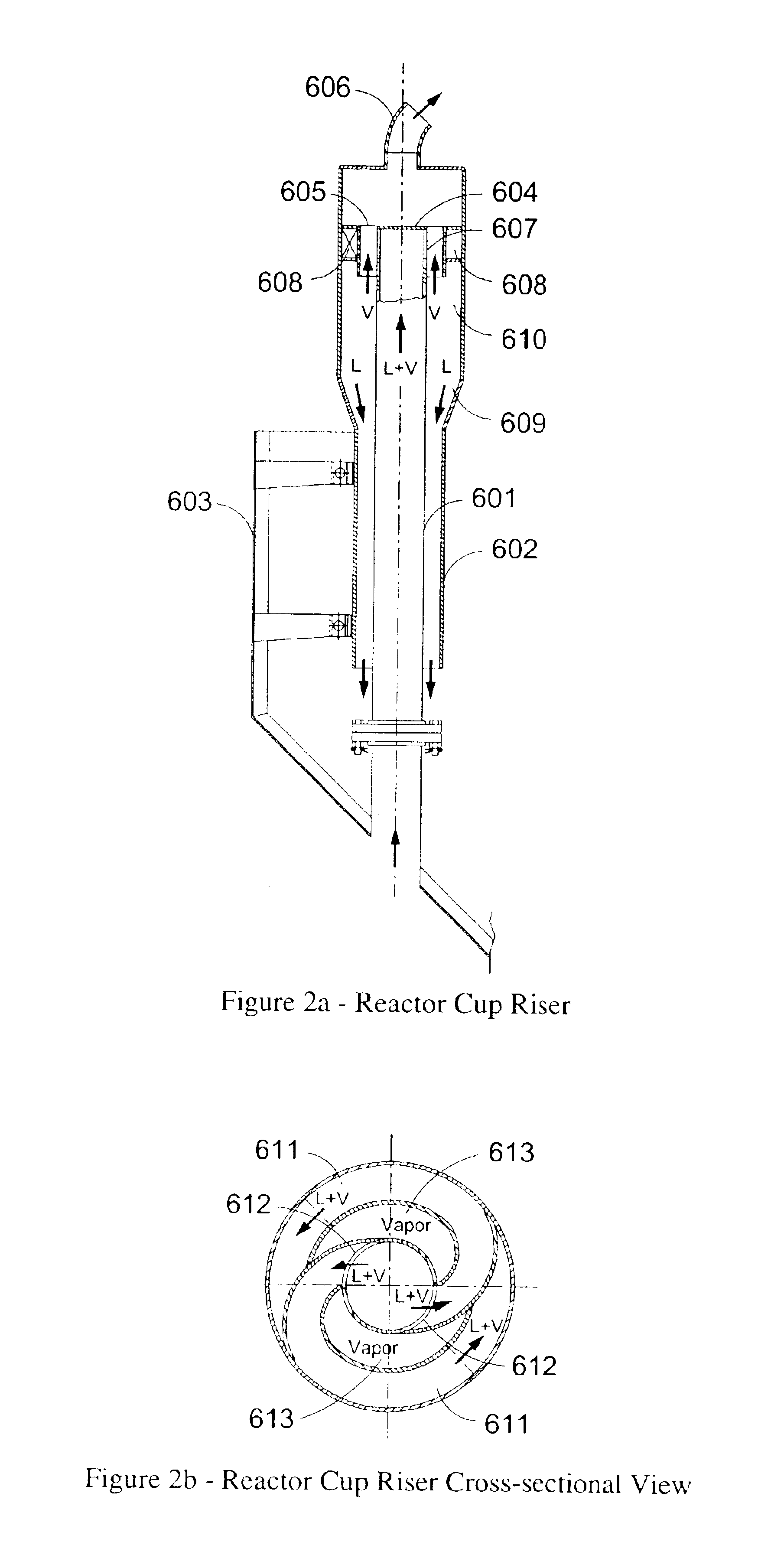

Apparatus for hydrocracking and/or hydrogenating fossil fuels

InactiveUS6960325B2Liquid mixed wellIncrease surface areaCarburetting airUsing liquid separation agentLiquid hydrocarbonsSolid particle

A catalytic hydrocracking reactor vessel for the conversion of a hydrogen gas and fossil fuel feedstream to light liquid hydrocarbons. The reactor vessel comprises reactor cup riser with a helical cyclonic separator conduit for separating a liquid and vapor product stream to provide an essentially vapor-free liquid recycle stream, a grid plate bubble cap with a tapered bell cap wall housing having serrated edges for producing small hydrogen bubbles of increased total surface area of bubbles at lower pressure drop, optionally a feedstream inlet pipe sparger containing rows of downward directed slots for even distribution of the feedstream across the cross-sectional area of the reactor and providing free drain of solid particles from the sparger, and optionally a liquid recycle inlet distributor containing vertically curved plates for creating a whirling motion in the liquid recycle stream for better mixing with the feedstream with minimal solids settling.

Owner:HEADWATERS TECH INNOVATION LLC +1

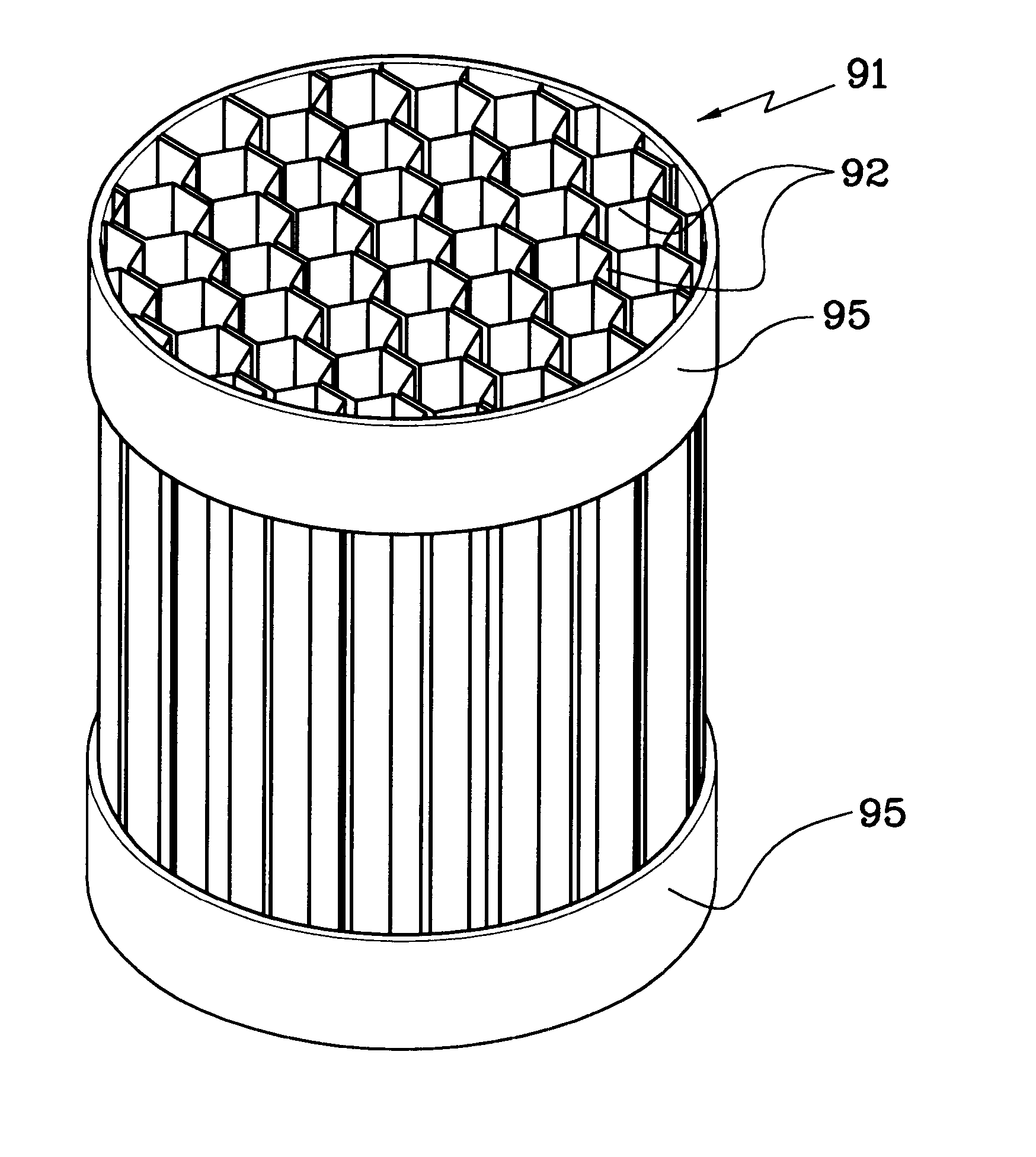

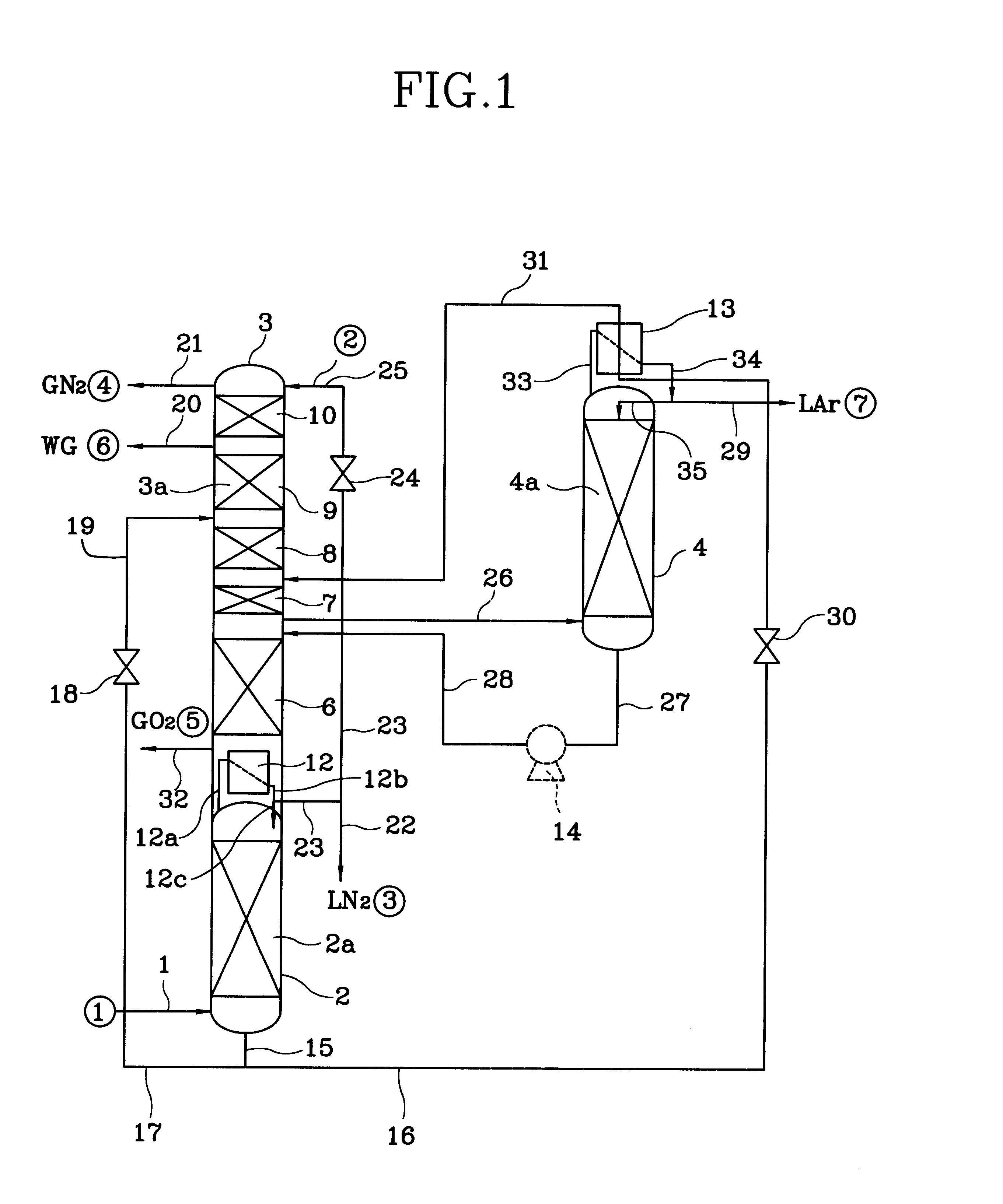

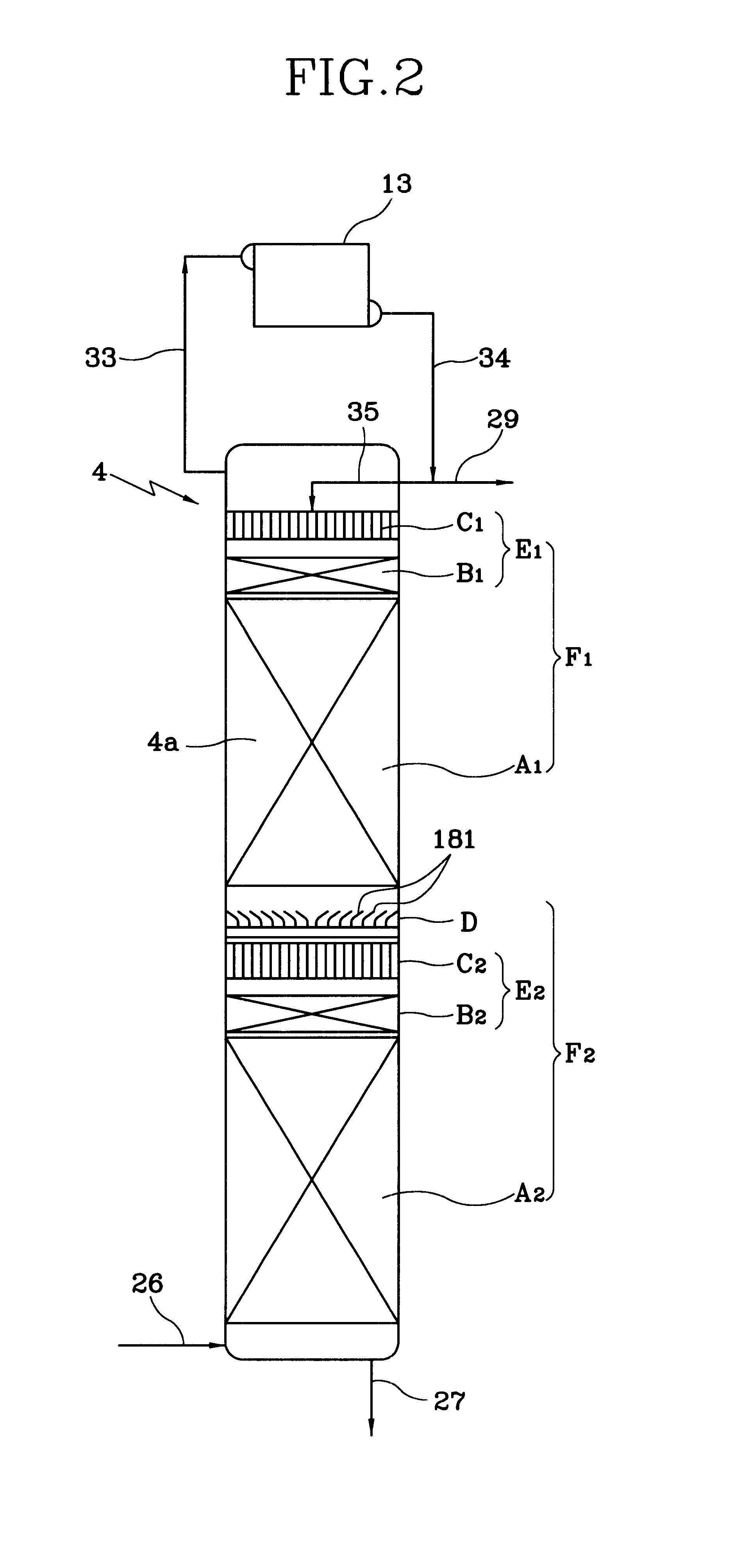

Vapor-liquid contactor, cryogenic air separation unit and method of gas separation

InactiveUS6565629B1Increased pressure lossIncrease flow resistanceCarburetting airSolidificationAir separationMechanical engineering

In an vapor-liquid contactor 4a for flowing down a liquid along the surface of a packing and contacting said liquid with the vapor while ascending the vapor, the improvement being characterized in that said packing is a non-promoting-fluid-dispersion type structured packing A1, A2 in which various types of thin sheets or tubes for determining the flow direction of the above liquid or vapor is laminated and arranged in the perpendicular direction, and said contactor includes at least one fluid distribution unit E1, E2 formed of a rough distribution part C1, C2 to distribute the liquid roughly and a minute distribution part B1, B2 to distribute the liquid minutely and equally.

Owner:NIPPON SANSO CORP

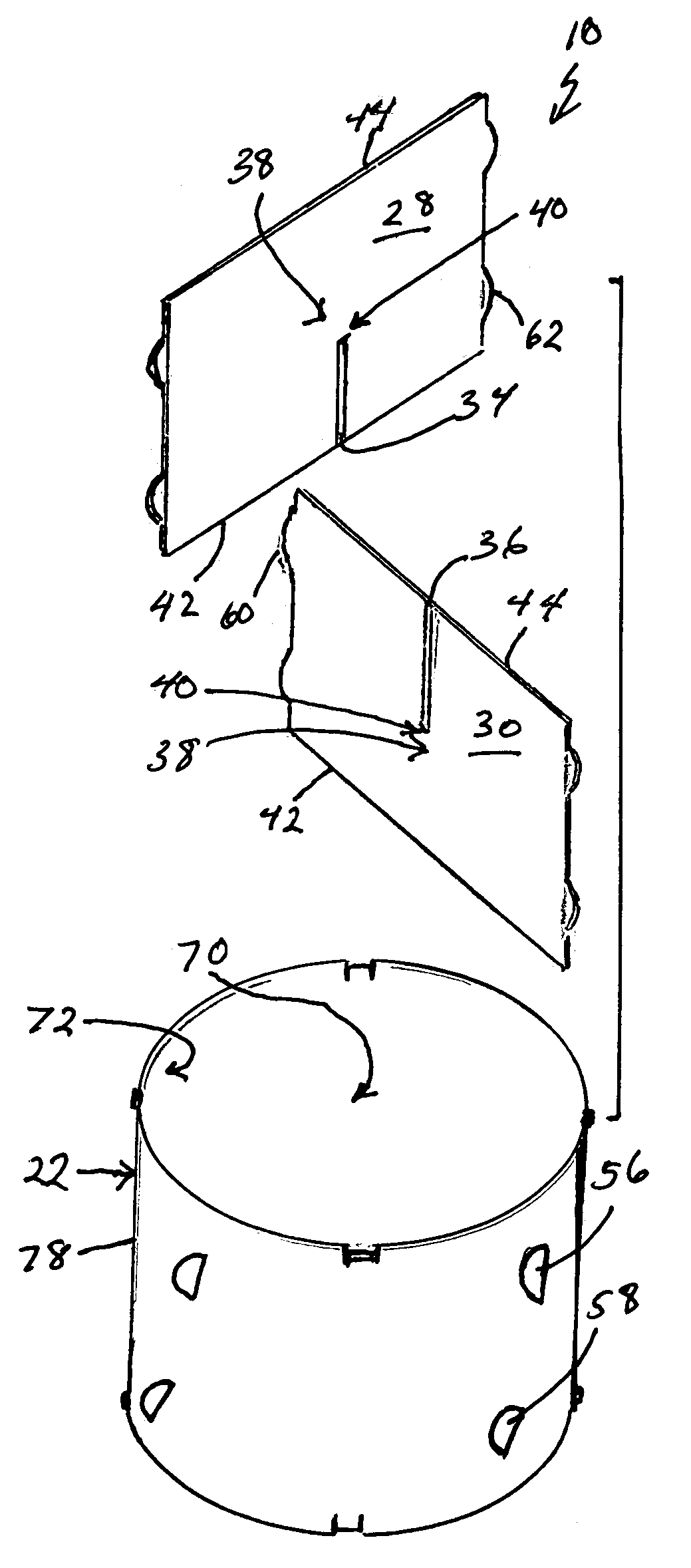

Fluid swirling device

InactiveUS7028663B1Minimizes force actingIncrease airflowInternal combustion piston enginesExhaust apparatusComplete mixingExhaust gas

The device includes a pair of flat planar vanes securely mounted within a cylindrical housing. The vanes have a medial slit extending from the center to a longitudinal end of the vane. The vanes are interconnected at the slits so that they are in criss-cross positioning. The vanes are axially angled so that when positioned in an intake air duct the vanes impart a swirling motion to the air entering the engine providing more complete mixing of the air and fuel and when positioned in an exhaust passageway the vanes impart a swirling motion to the exhaust gases exiting the engine providing scavenging of the exhaust gases.

Owner:KIM JAY S

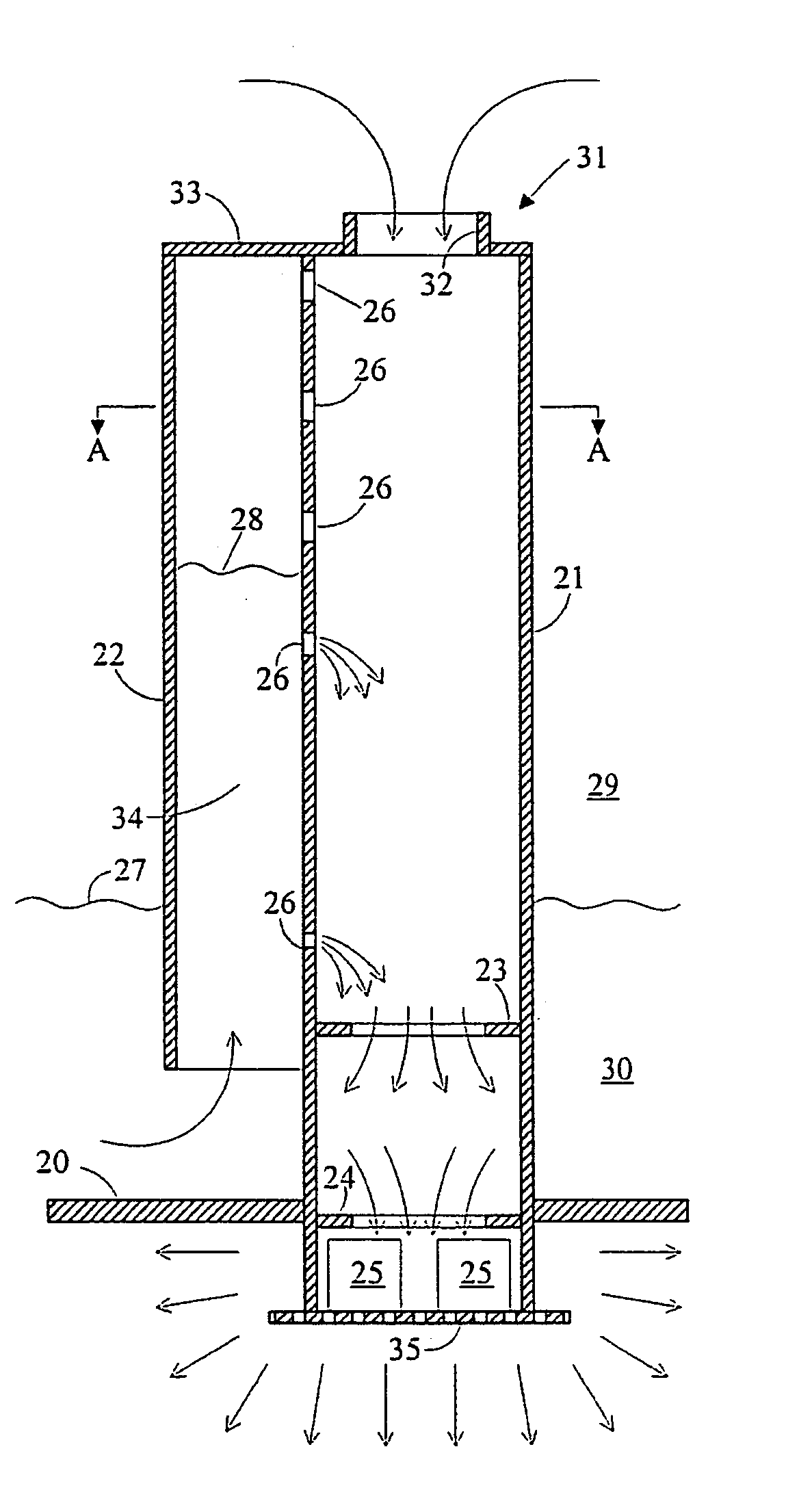

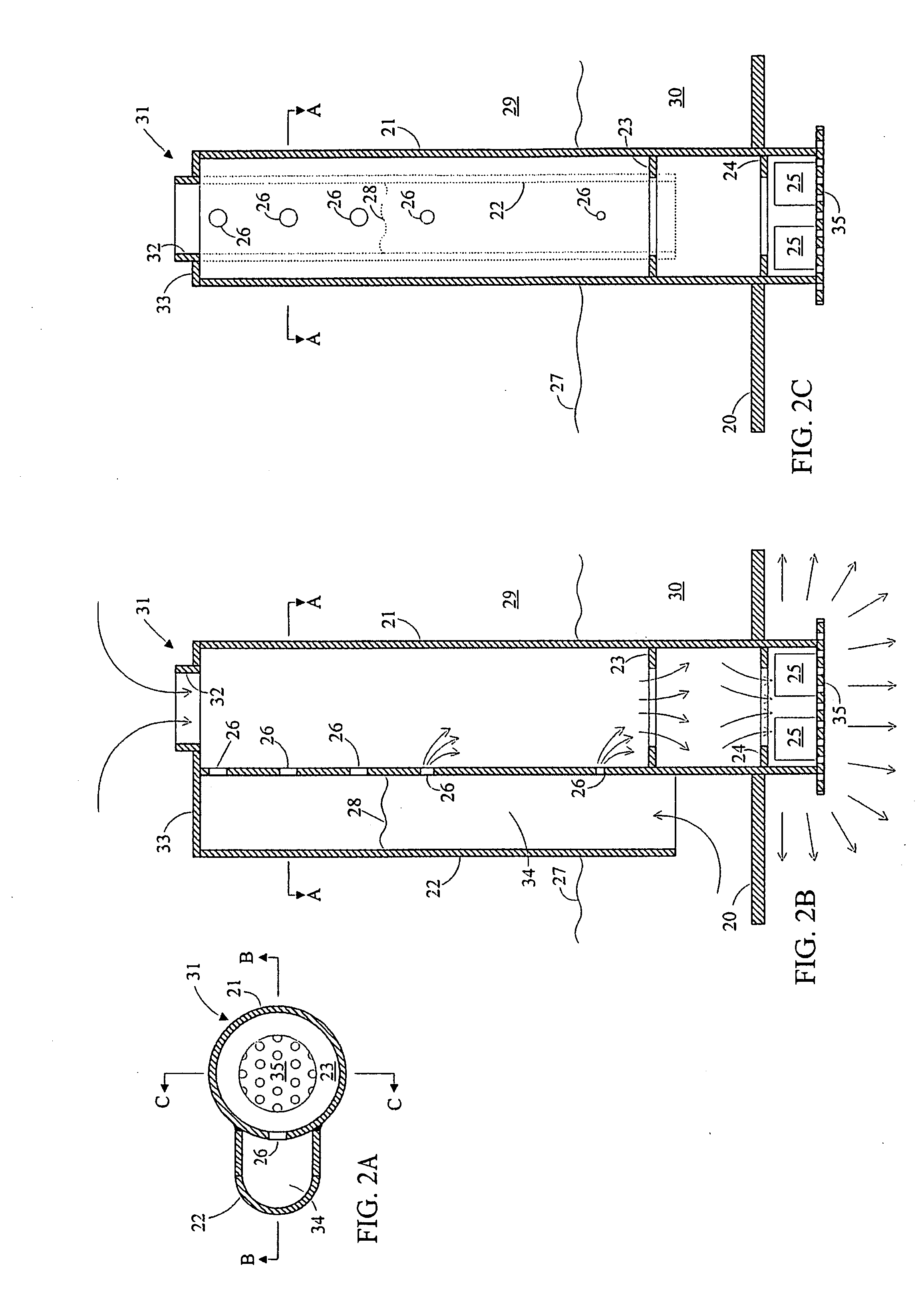

Air conditioning system and methods

An air conditioning system for conditioning the space within an enclosure having at least one inlet and one outlet, the system comprising first and second liquid / air heat exchangers; the first heat exchanger having an opening for receiving fresh air from the environment and for propelling the fresh air through the first heat exchanger to exchange heat with the liquid before it is entered into the enclosure, and the second heat exchanger having an opening for receiving air from the enclosure and for propelling it through the second heat exchanger to exchange heat with the liquid before it is expelled into the atmosphere. There are also provided methods for air-conditioning an enclosed space and for evaporation of industrial wastes.

Owner:AGAM ENERGY SYST

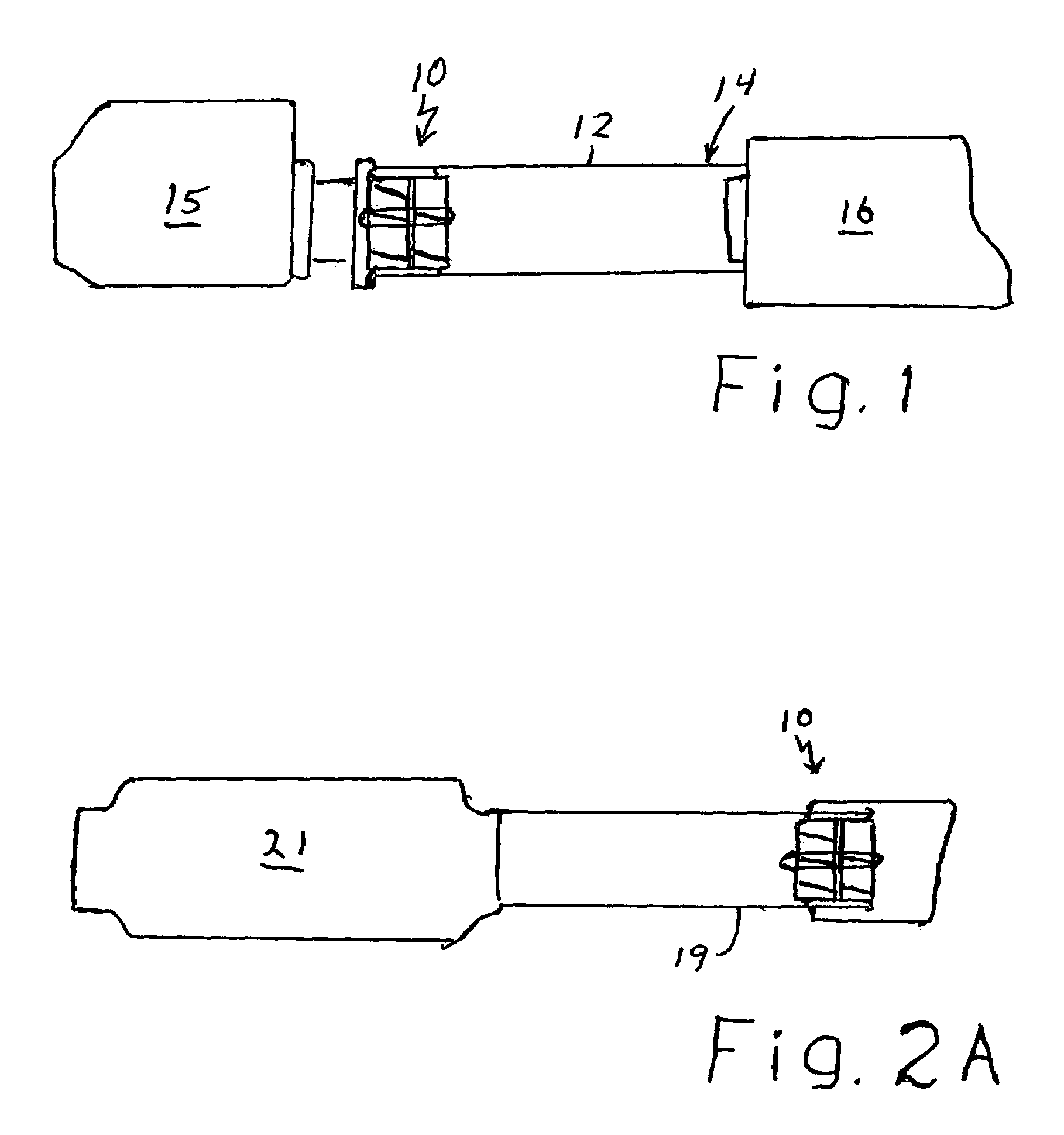

Power booster fuel saver

InactiveUS6837213B1Improve vehicle performanceInternal combustion piston enginesFuel re-atomisation/homogenisationDiagonalExhaust pipe

The power booster fuel saver is made of a cut and formed piece of stainless steel in the shape of a cylinder. The strip is provided in a length sufficient to correspond to the inner diameter of the inlet pipe to a vehicle engine or from its turbo fan outlet, or into the inlet pipe leading to the turbo fan or in the exhaust pipe from the engine. A series of square-shaped tabs are cut along one side of the strip and then bent diagonally to form a series of dog-ears. Finally, the strip is rolled into the shape of a cylinder in which the edges meet and the resulting device is inserted into the intake of a vehicle.

Owner:BURNETT DAVID T

Enhanced HVAC system and method

Particular embodiments disclosed herein relate to methods, compositions, and systems relating generally to heating, ventilation, and air conditioning (HVAC) systems, and more specifically, to HVAC systems that transfer sensible and / or latent energy between air streams, humidify and / or dehumidify air streams. In certain embodiments, a polymeric membrane is utilized for fluid exchange, with or without an additional support. Certain embodiments allow for individual regulation of air temperature and humidity.

Owner:TANGREDI PATRICIA

Air filter assembly system and method

ActiveUS7311748B2Undesired movement is also preventedCombination devicesOther chemical processesLocking mechanismAir filter

An air filter assembly including abutting, cylindrical housing halves, with toothed outer ends, joined via spaced, T-shaped appendages; a cylindrical air inlet of abutting semi-cylindrical housing inlet portions; a primary filter pack, for slip-fit insertion into either housing half, having an end cap integral with a cylindrical primary filter pack having sealing material on its inner end; a filter outlet end with a toothed peripheral portion, for slip-fit insertion into and angular adjustment relative to either housing end, and a plurality of ribs defining locating surfaces for an air outlet portion, and main and safety filters; the latter having a truncated cone body and an inverted conical portion; and a filter attachment base having curved bed portions, for receiving a housing periphery portion, including spaced support pads and slot portions for angularly adjustably receiving like numbers of T-shaped appendages, with a locking mechanism joining the housing and attachment base.

Owner:PARKER INTANGIBLES LLC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com