Patents

Literature

522results about How to "Enhanced mixing process" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

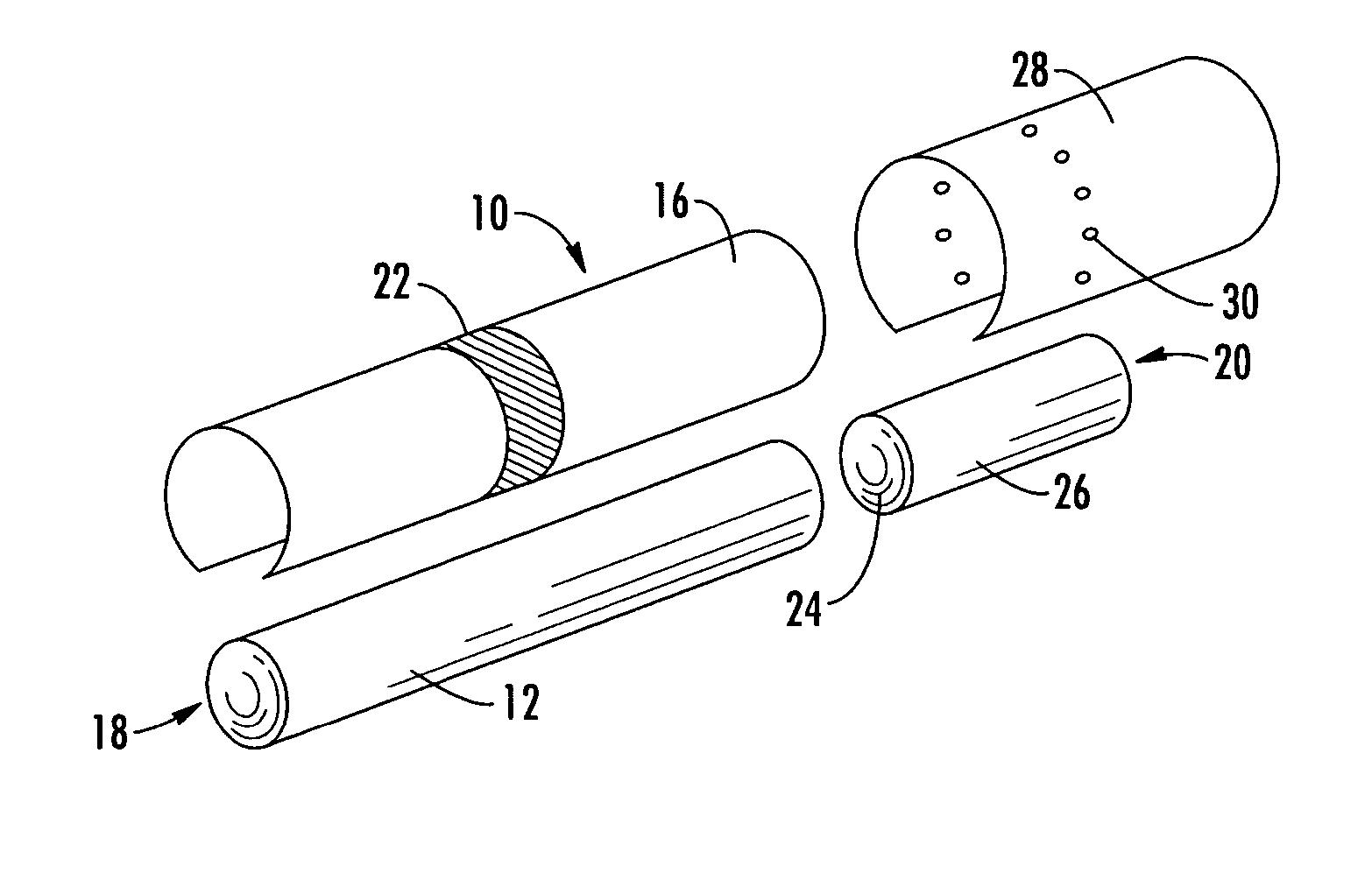

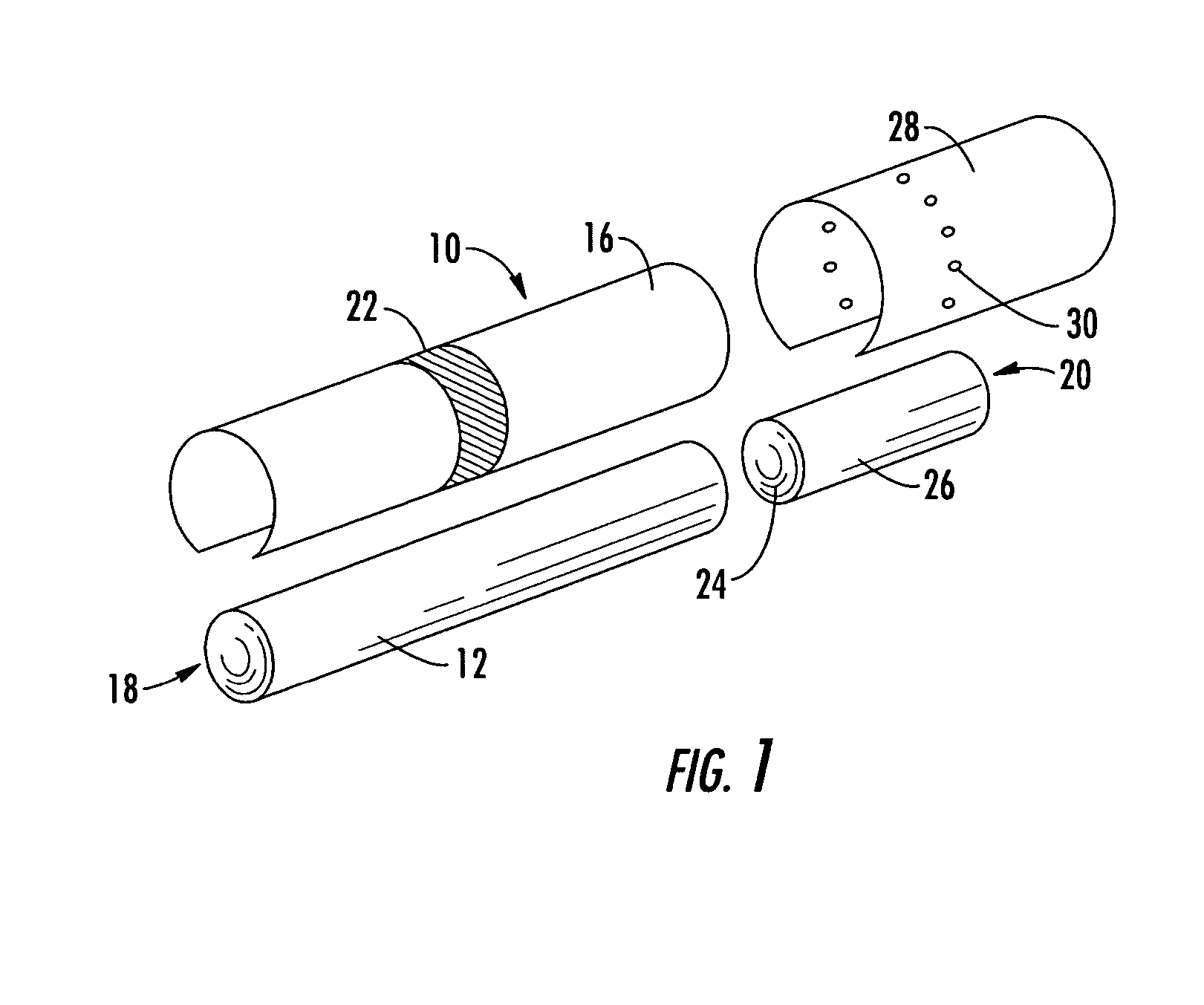

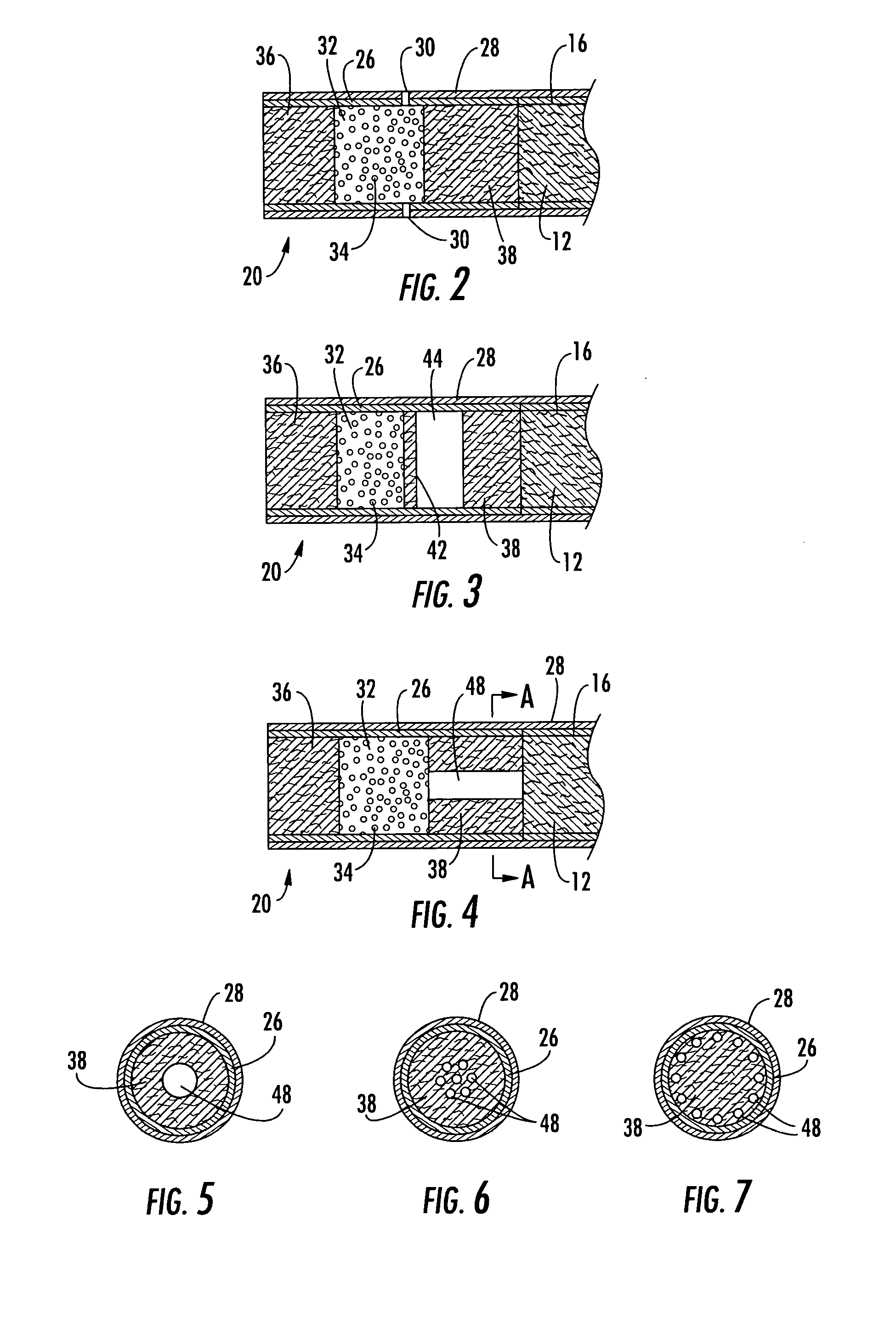

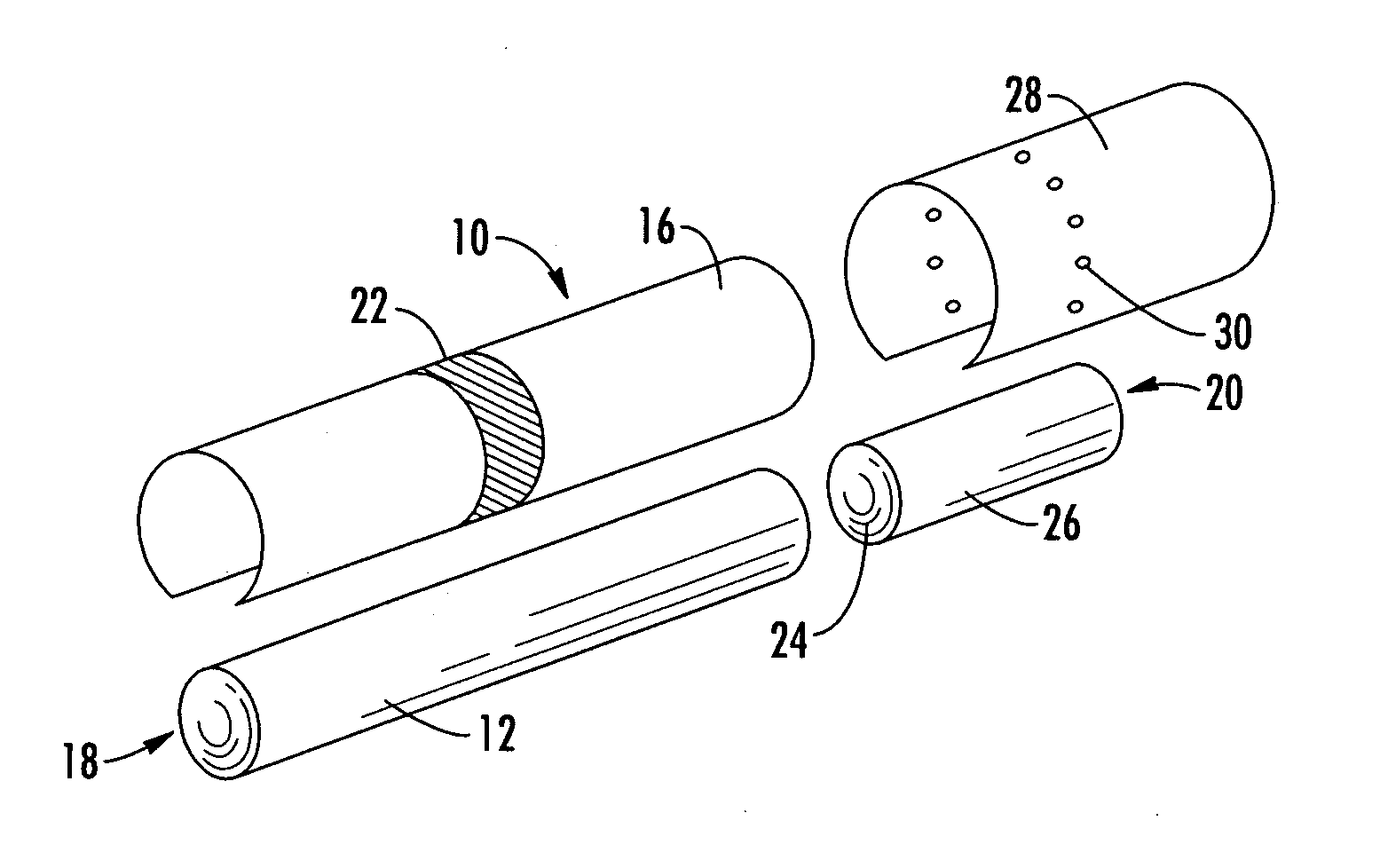

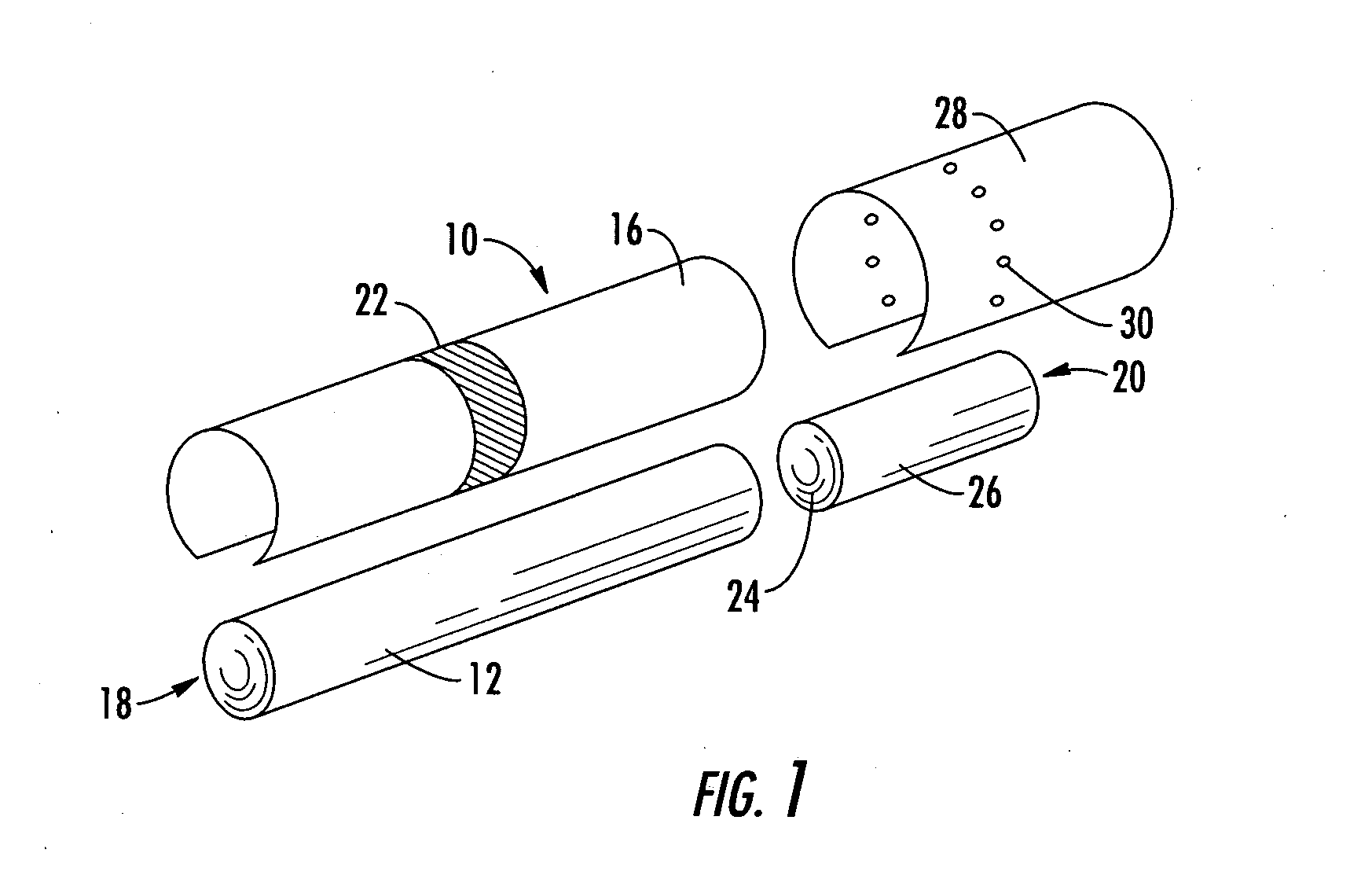

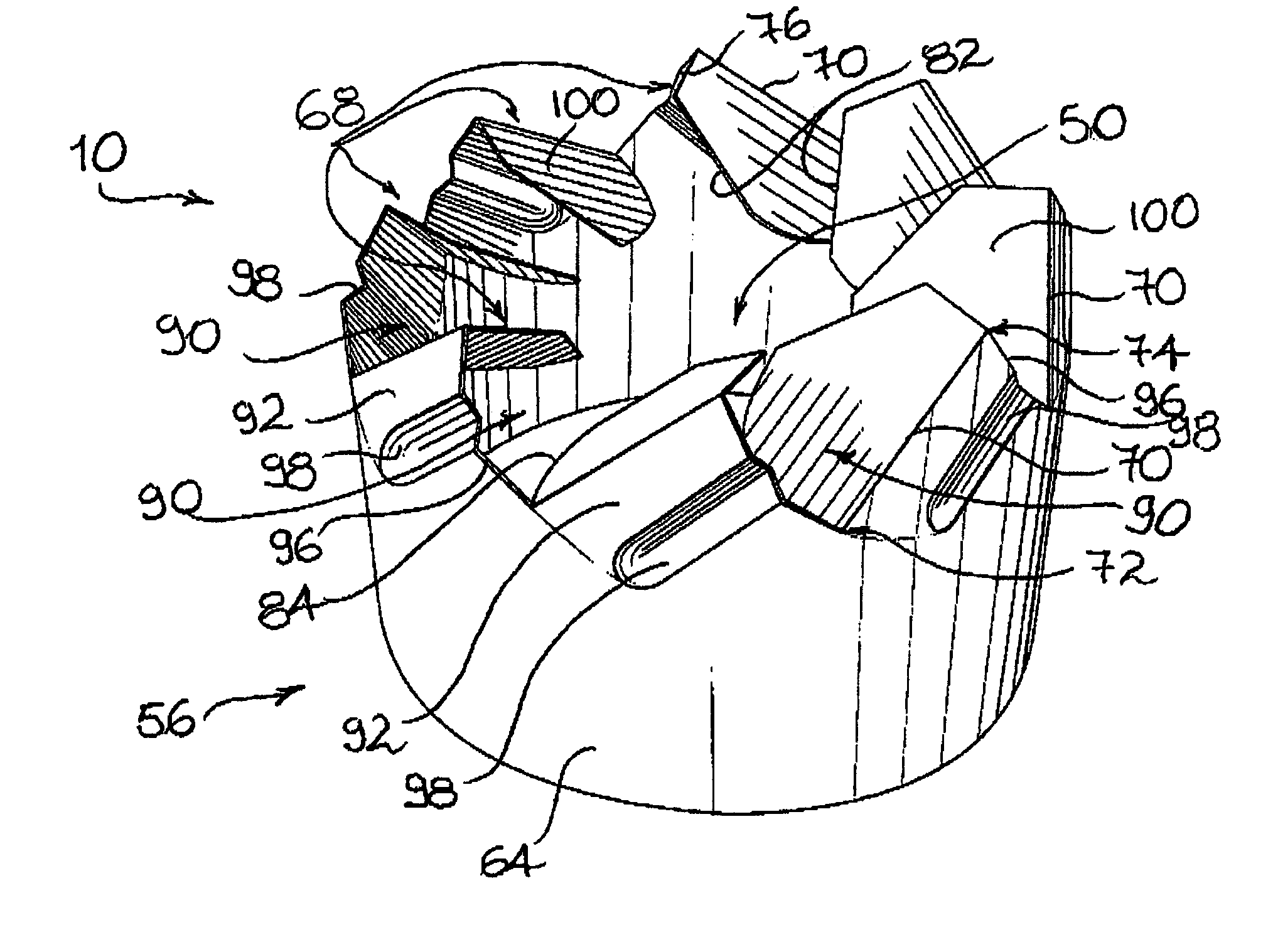

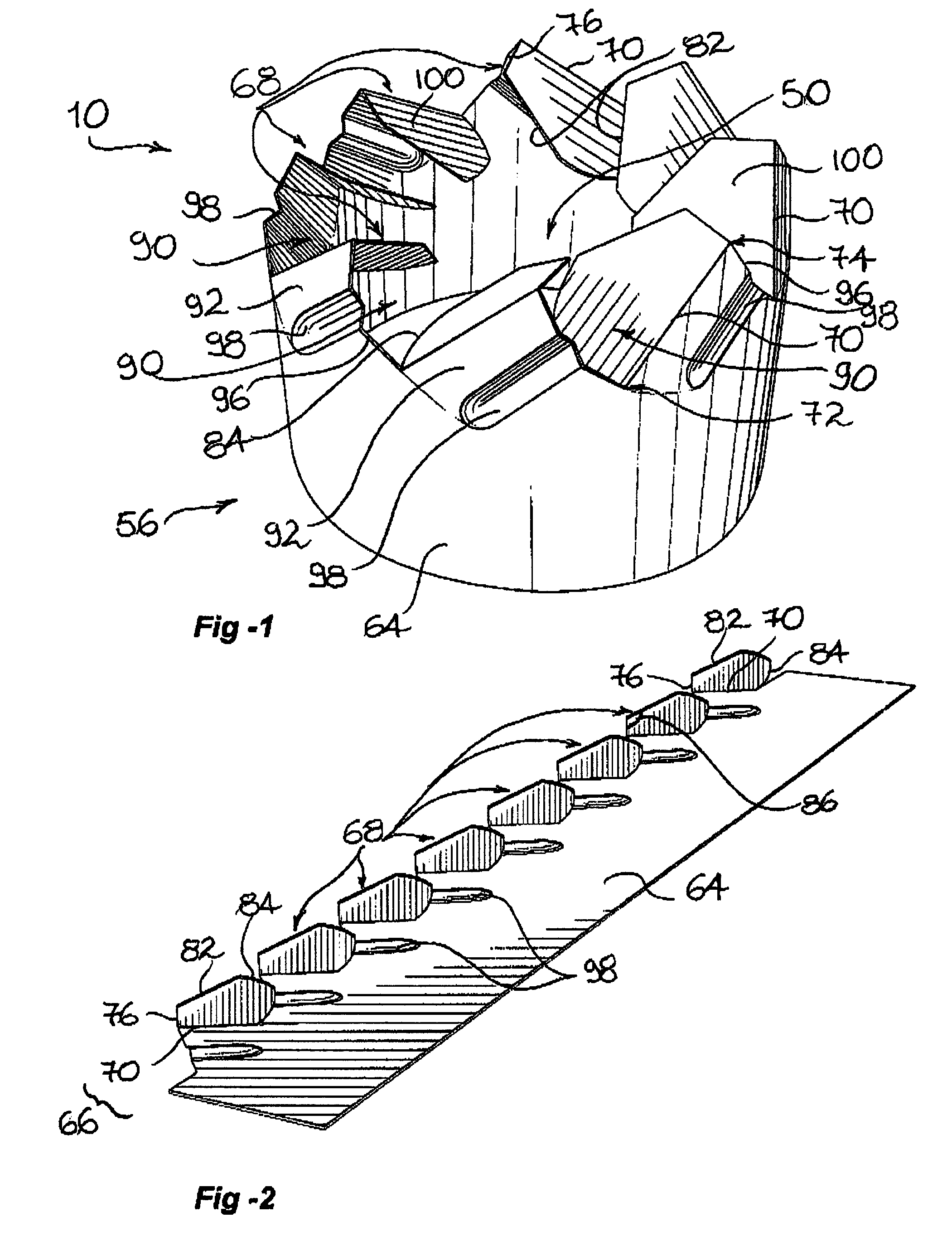

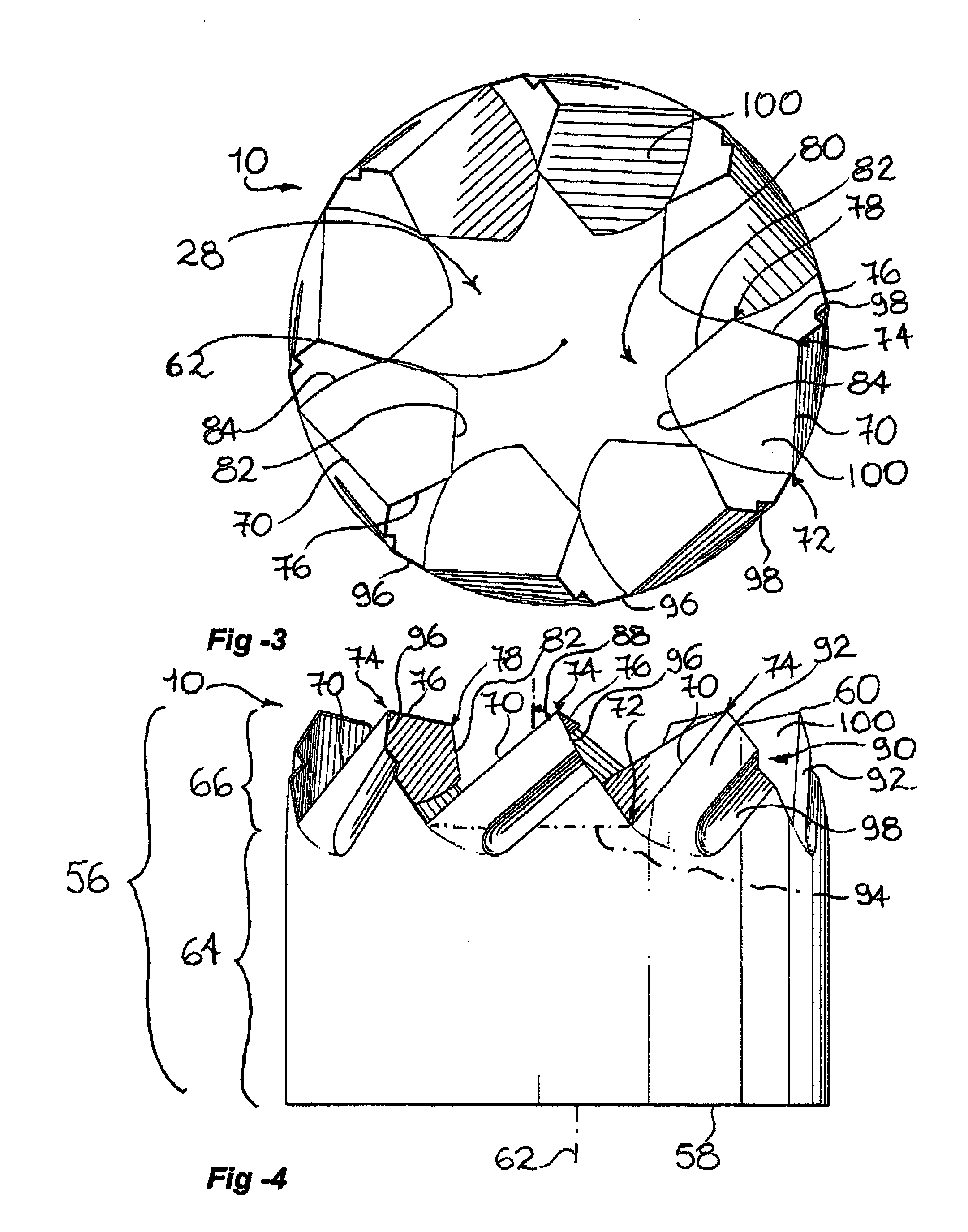

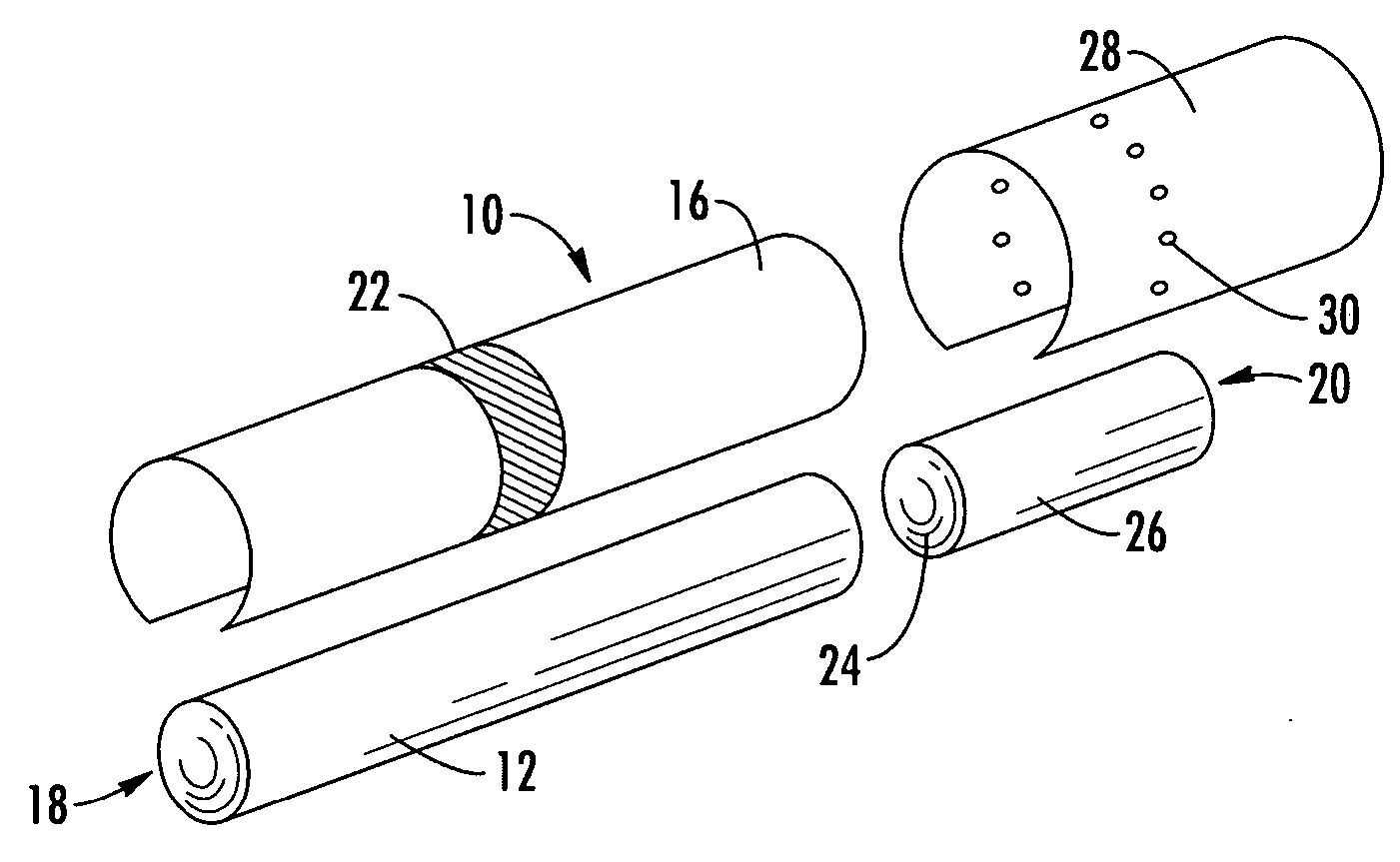

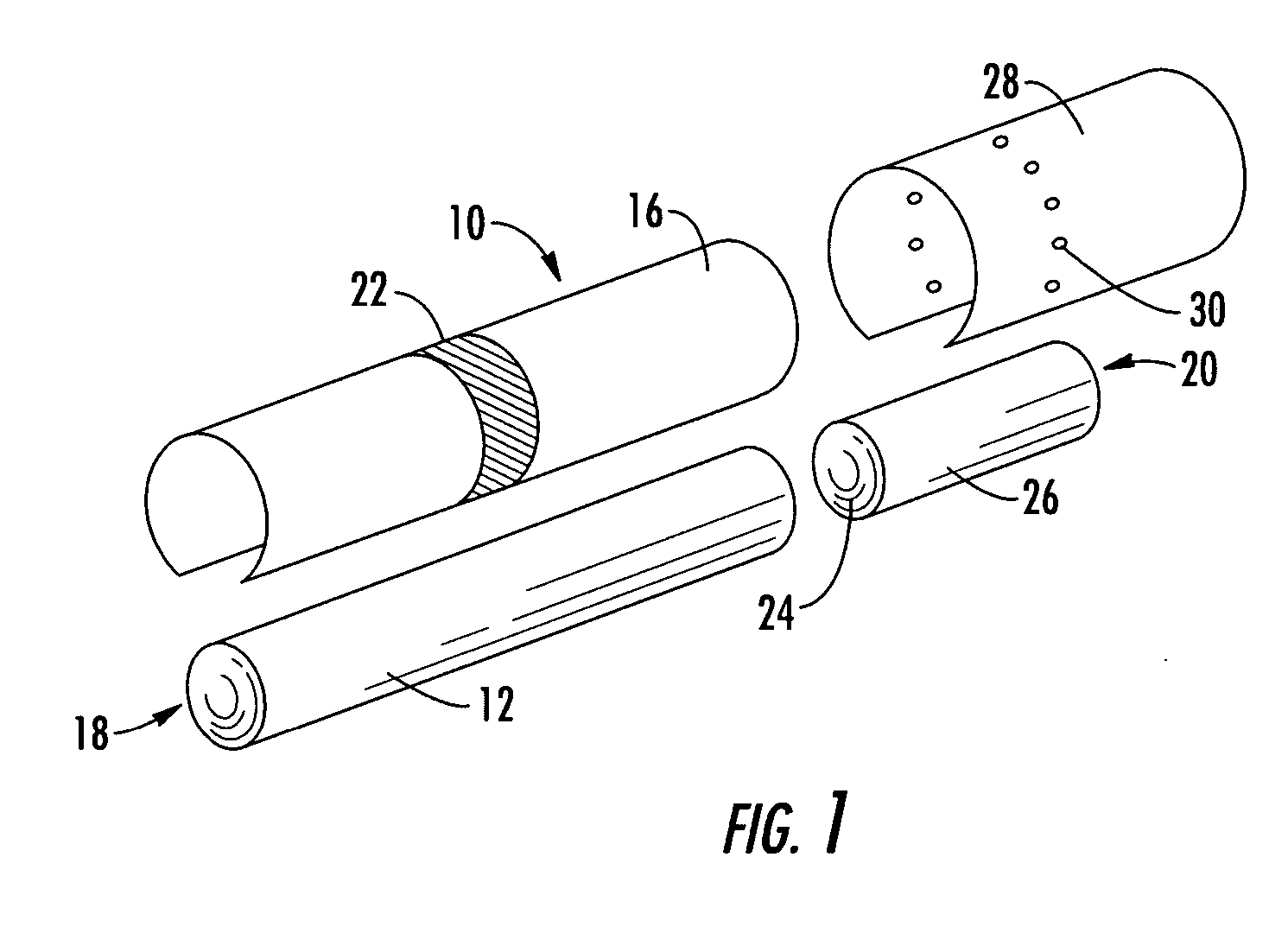

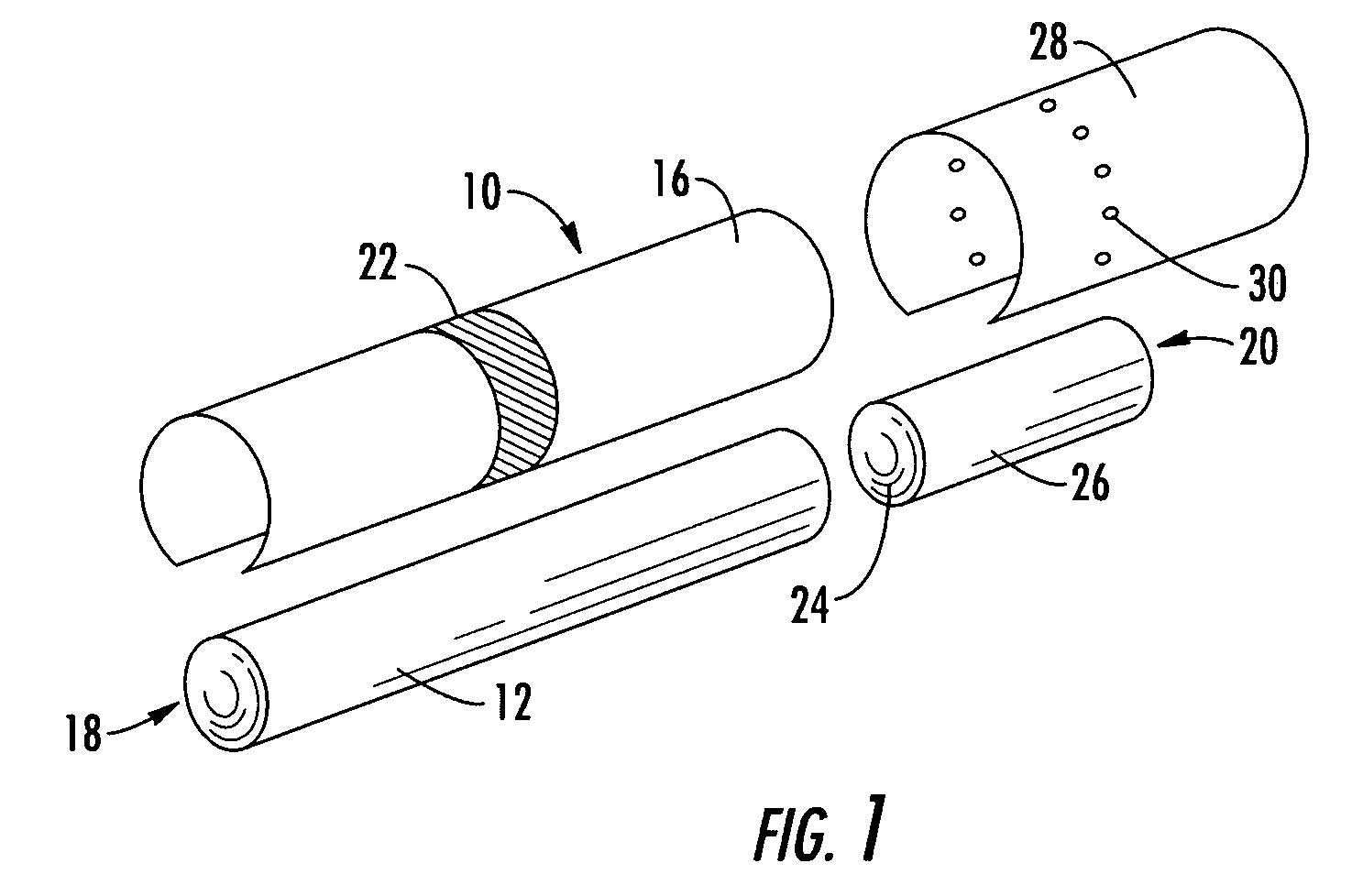

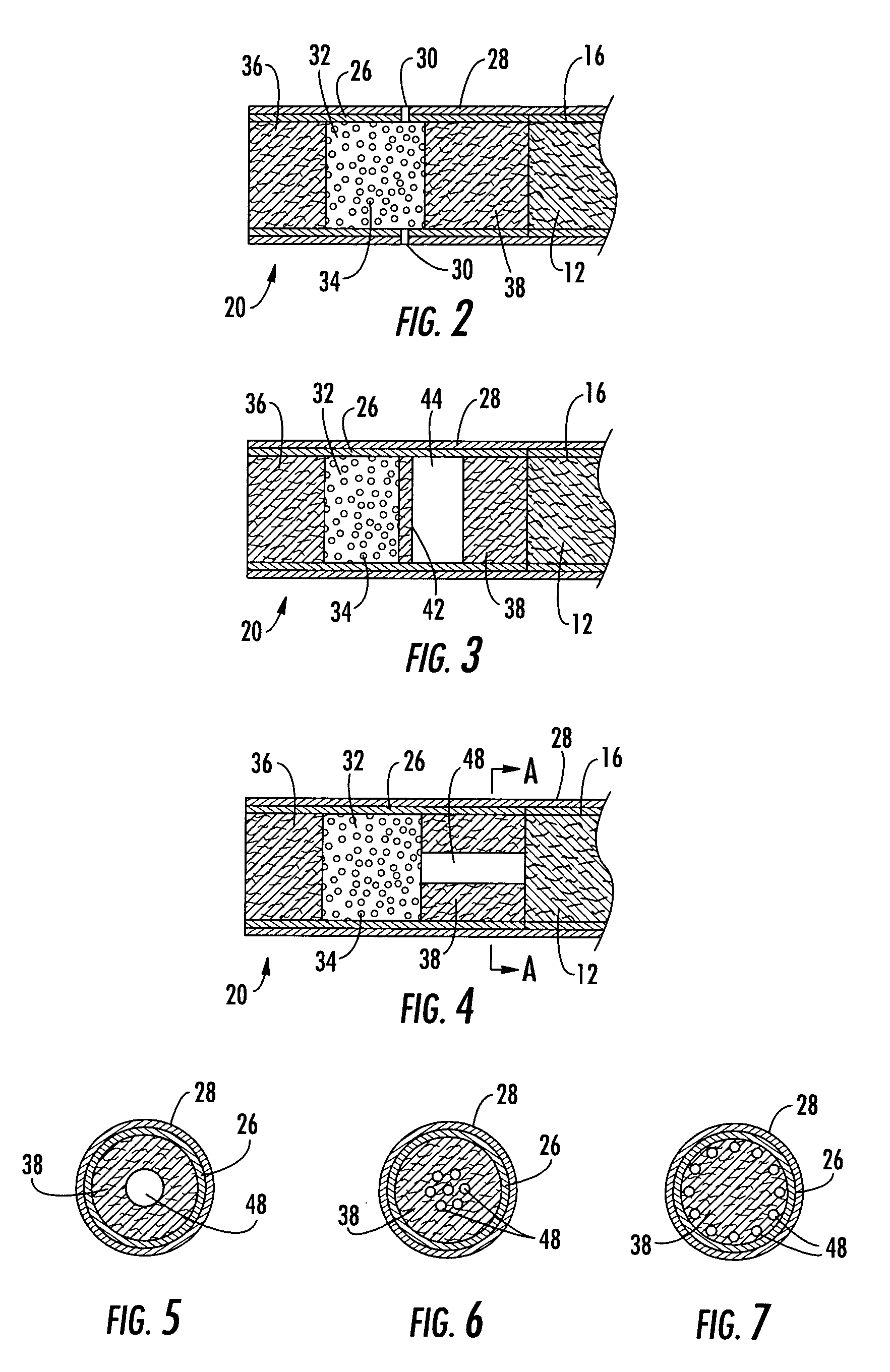

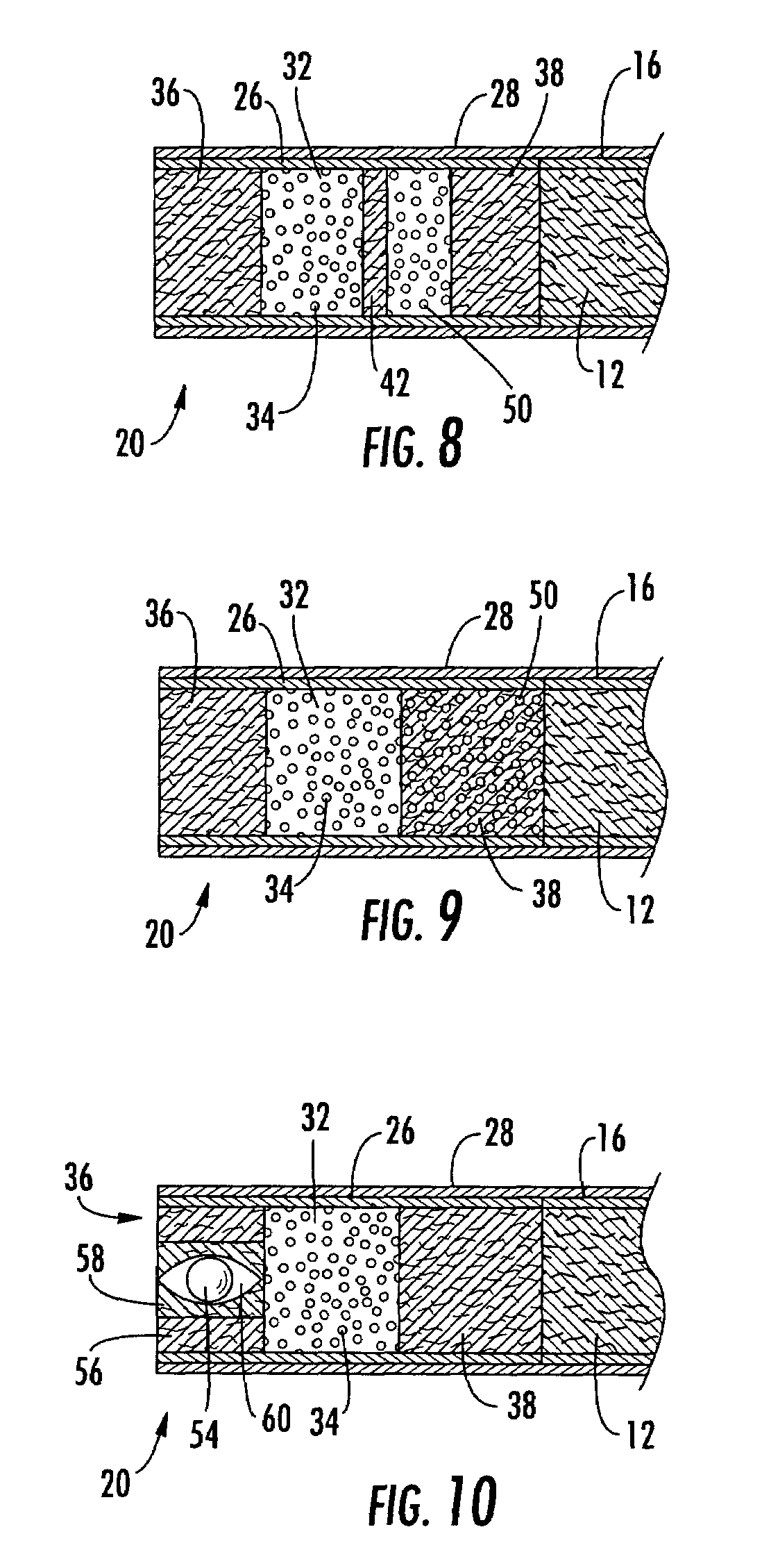

Filtered cigarette incorporating an adsorbent material

ActiveUS20050066984A1Enhanced mixing processTobacco treatmentTobacco smoke filtersFilter materialIon-exchange resin

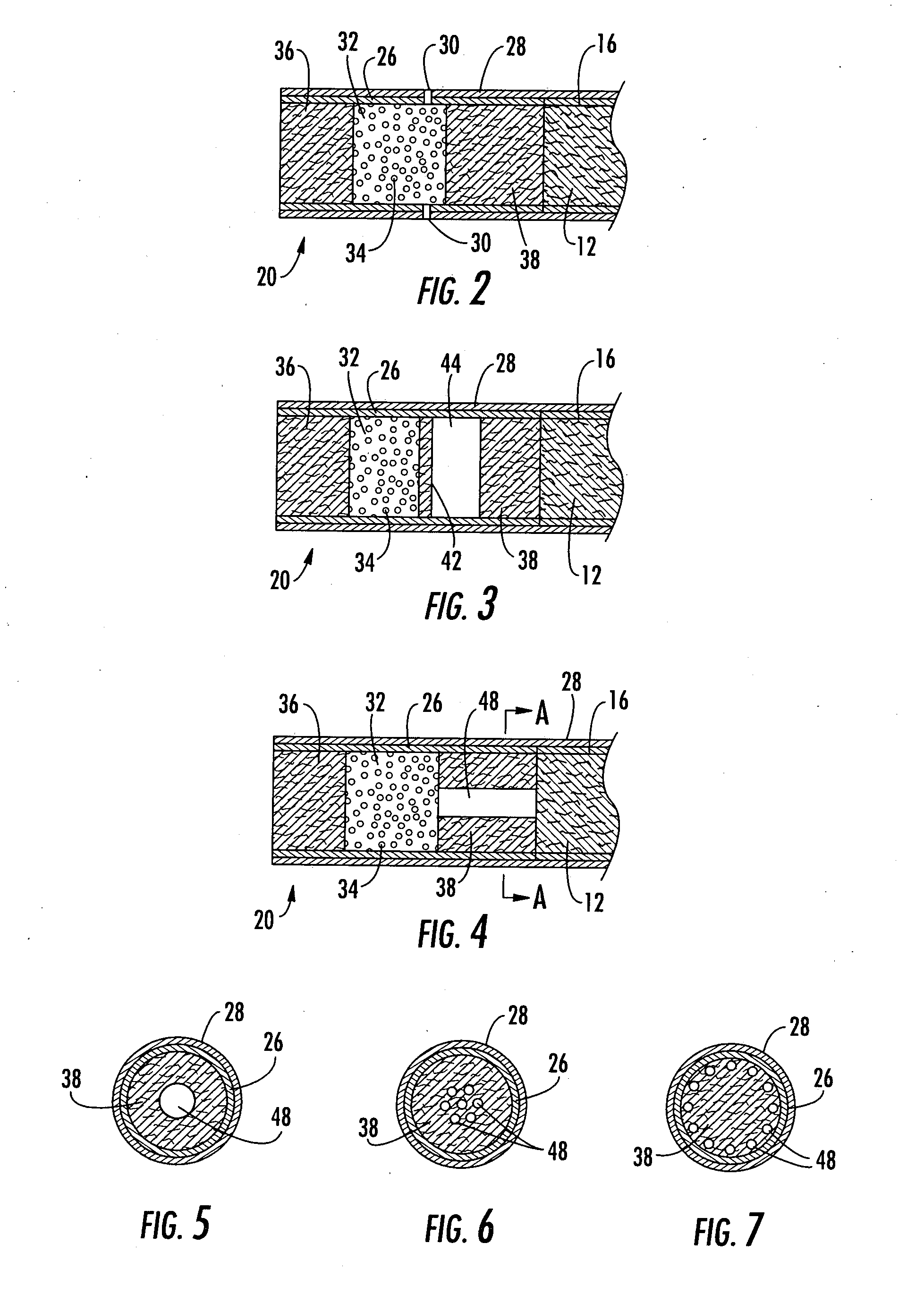

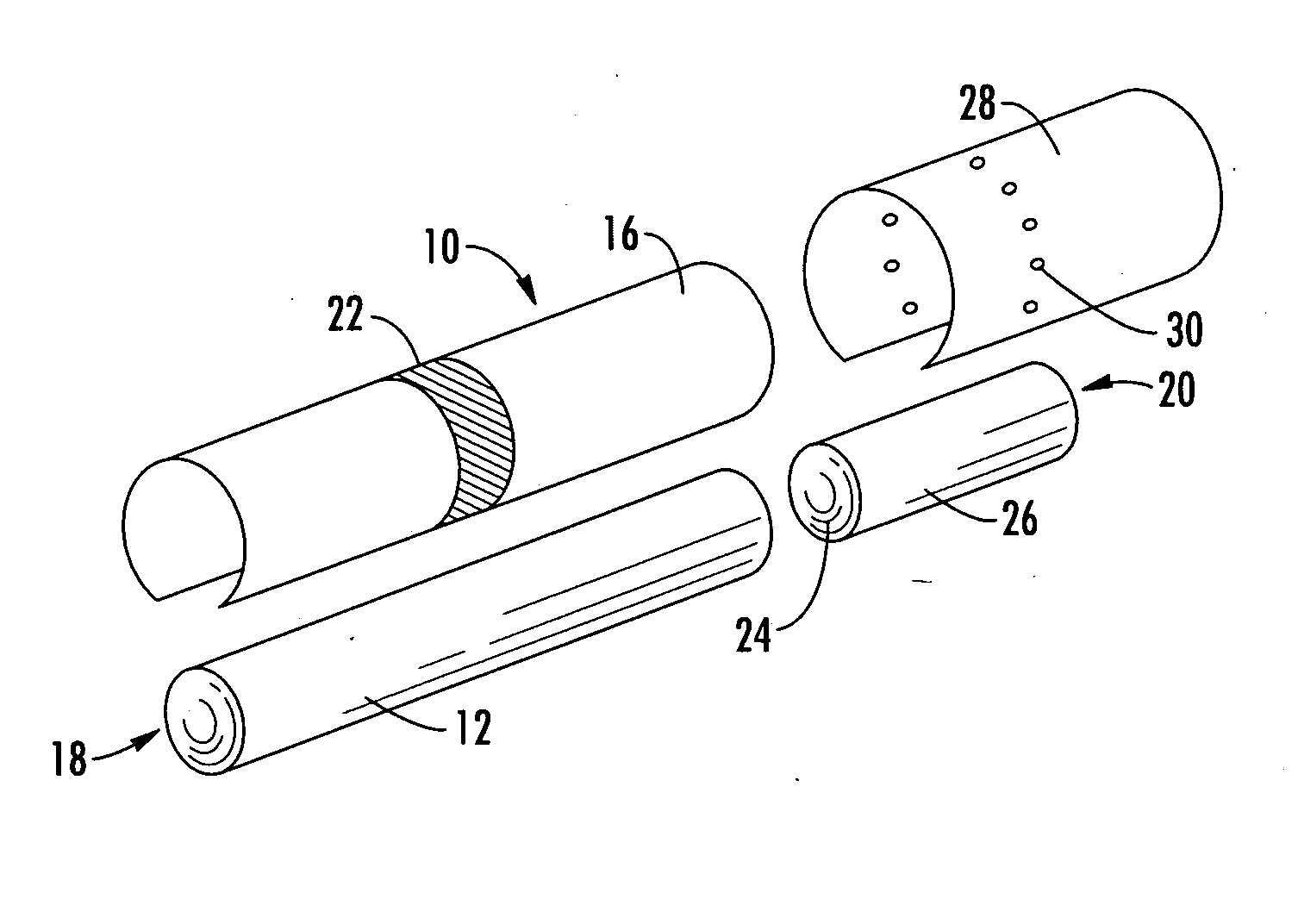

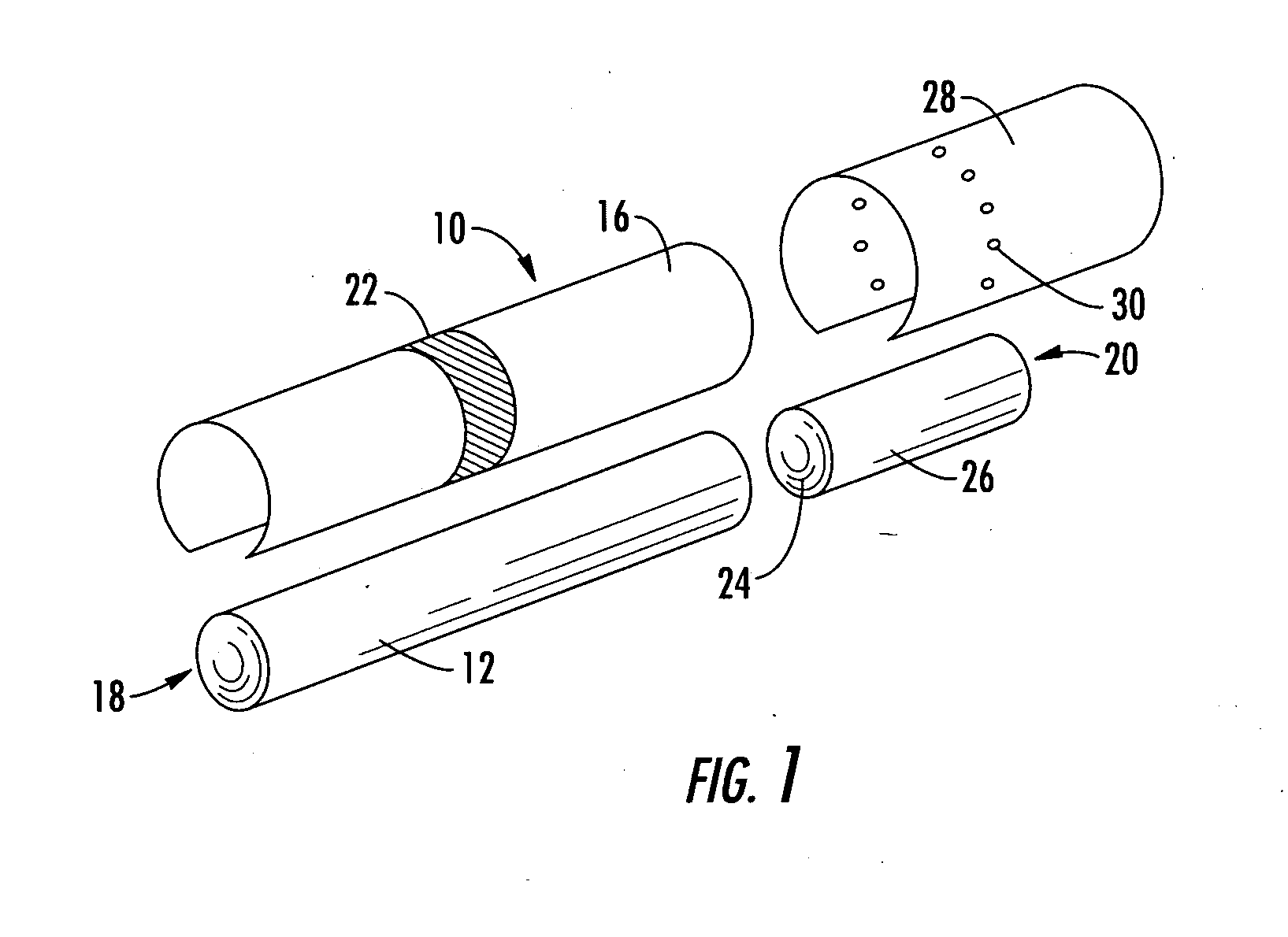

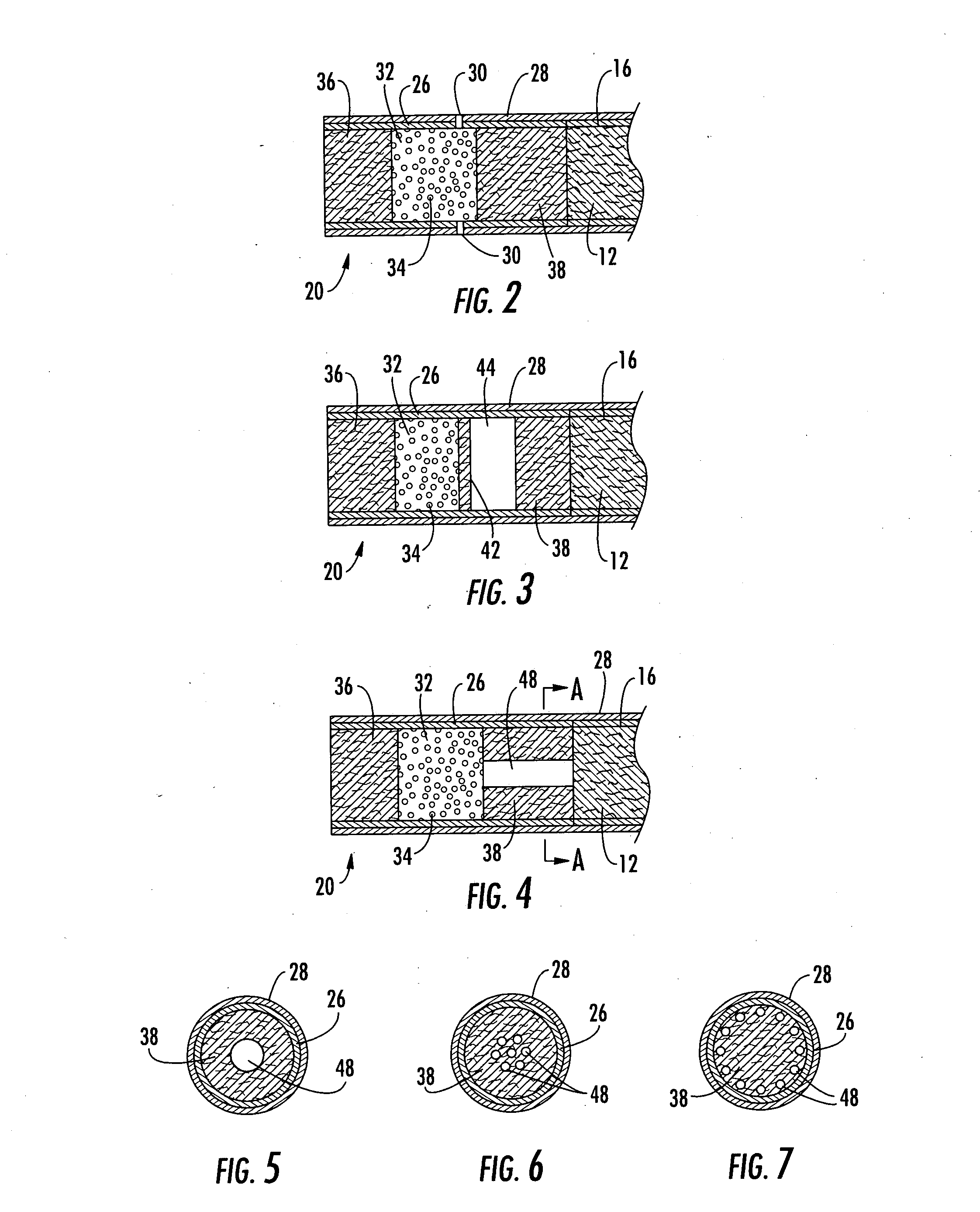

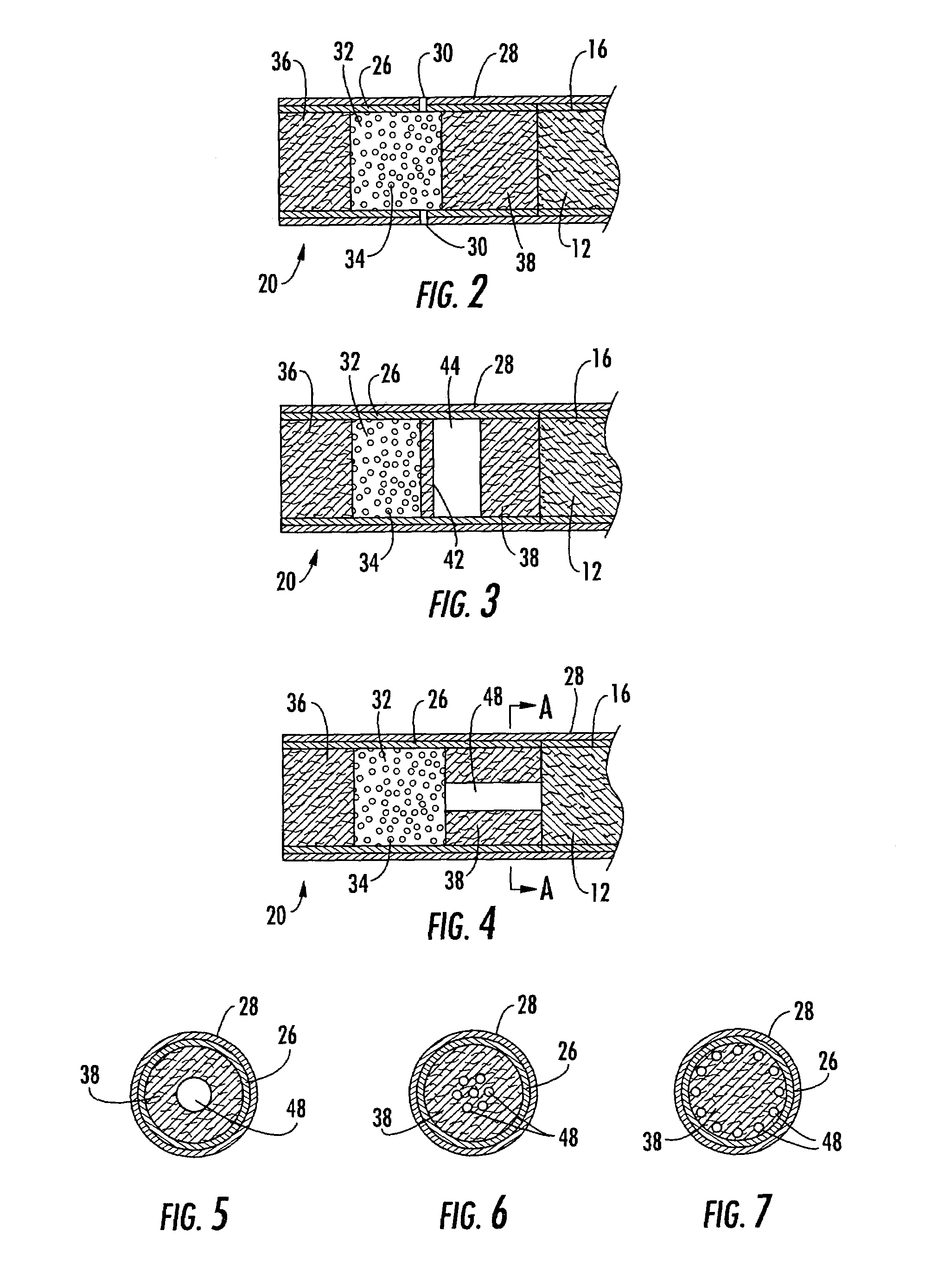

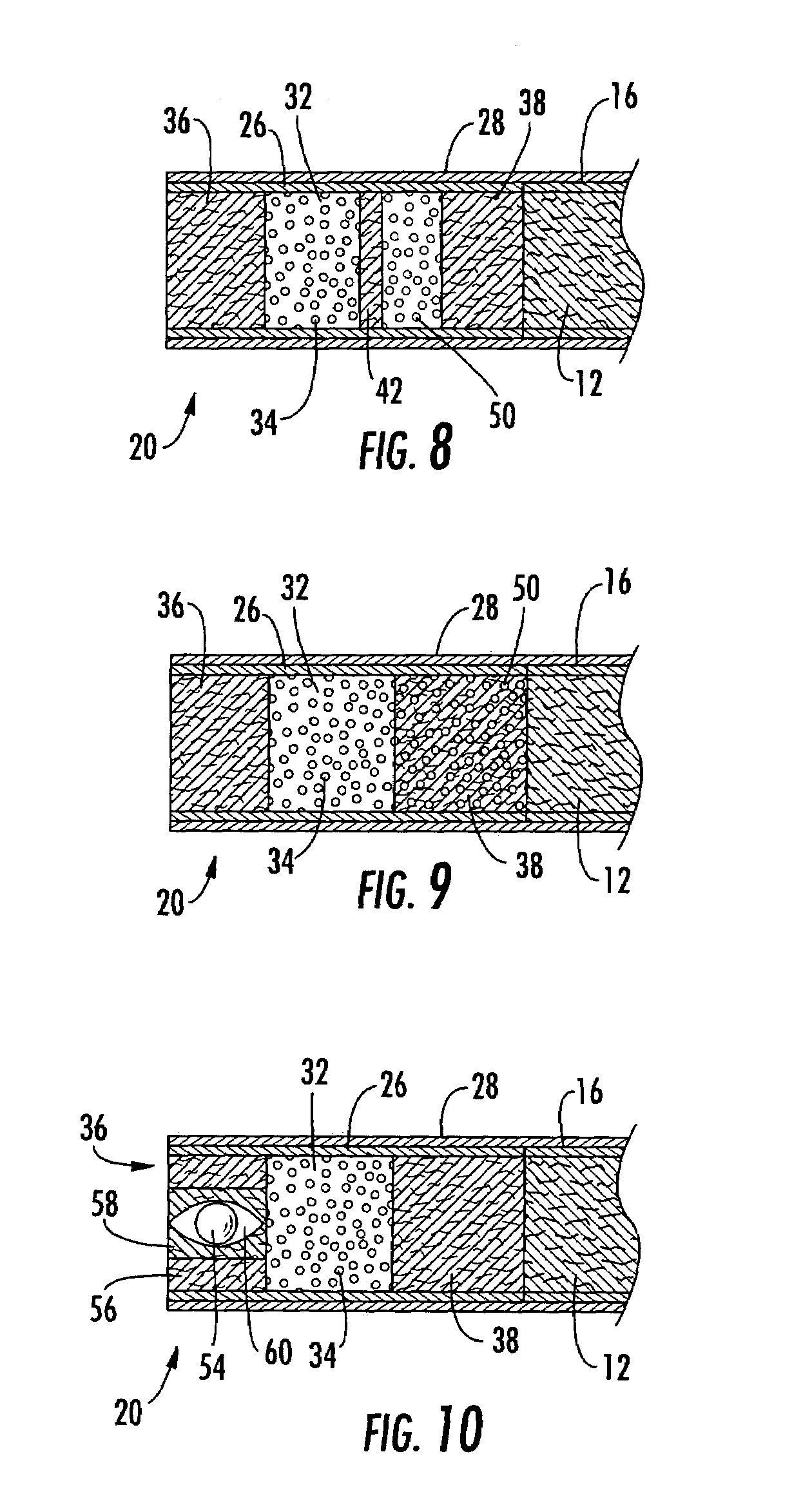

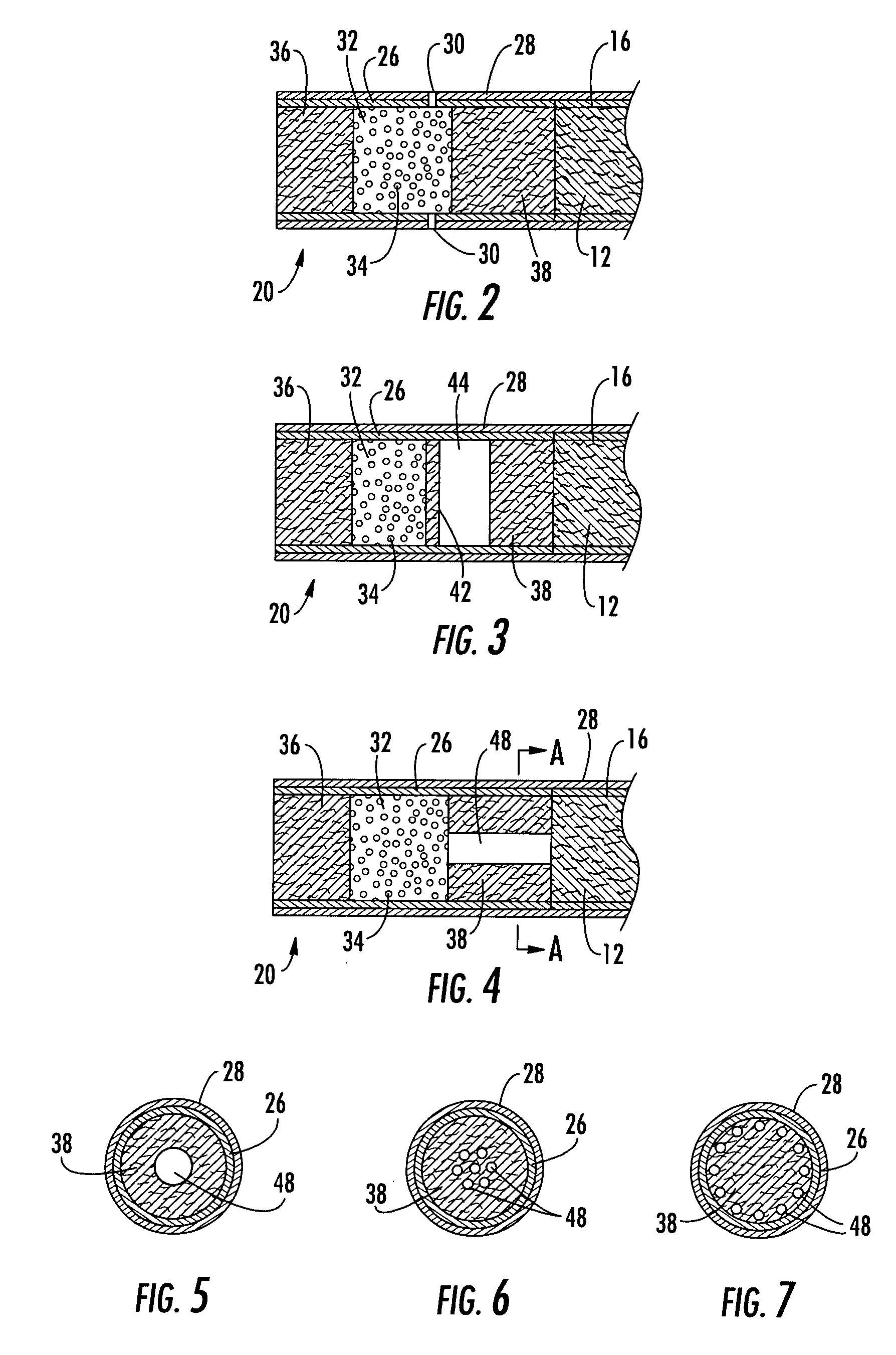

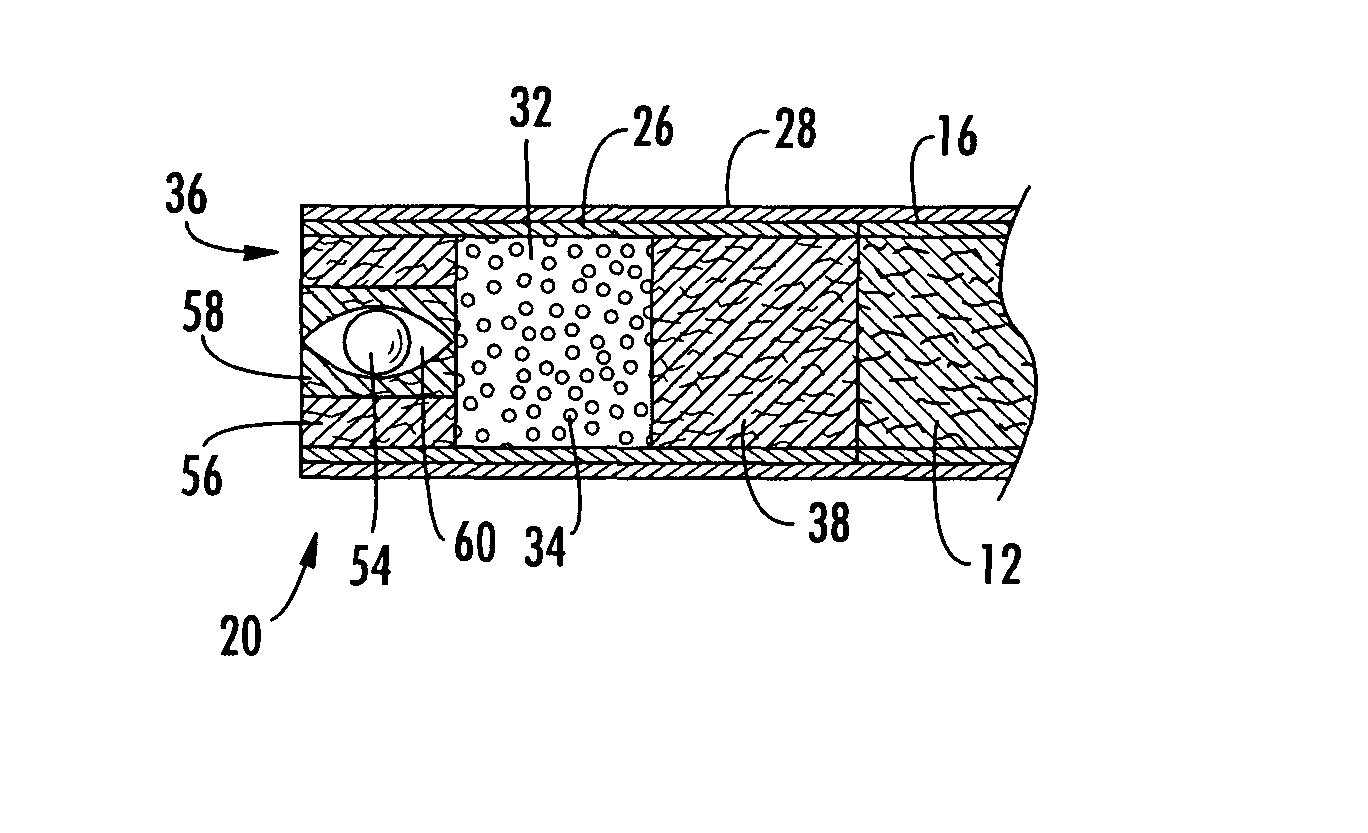

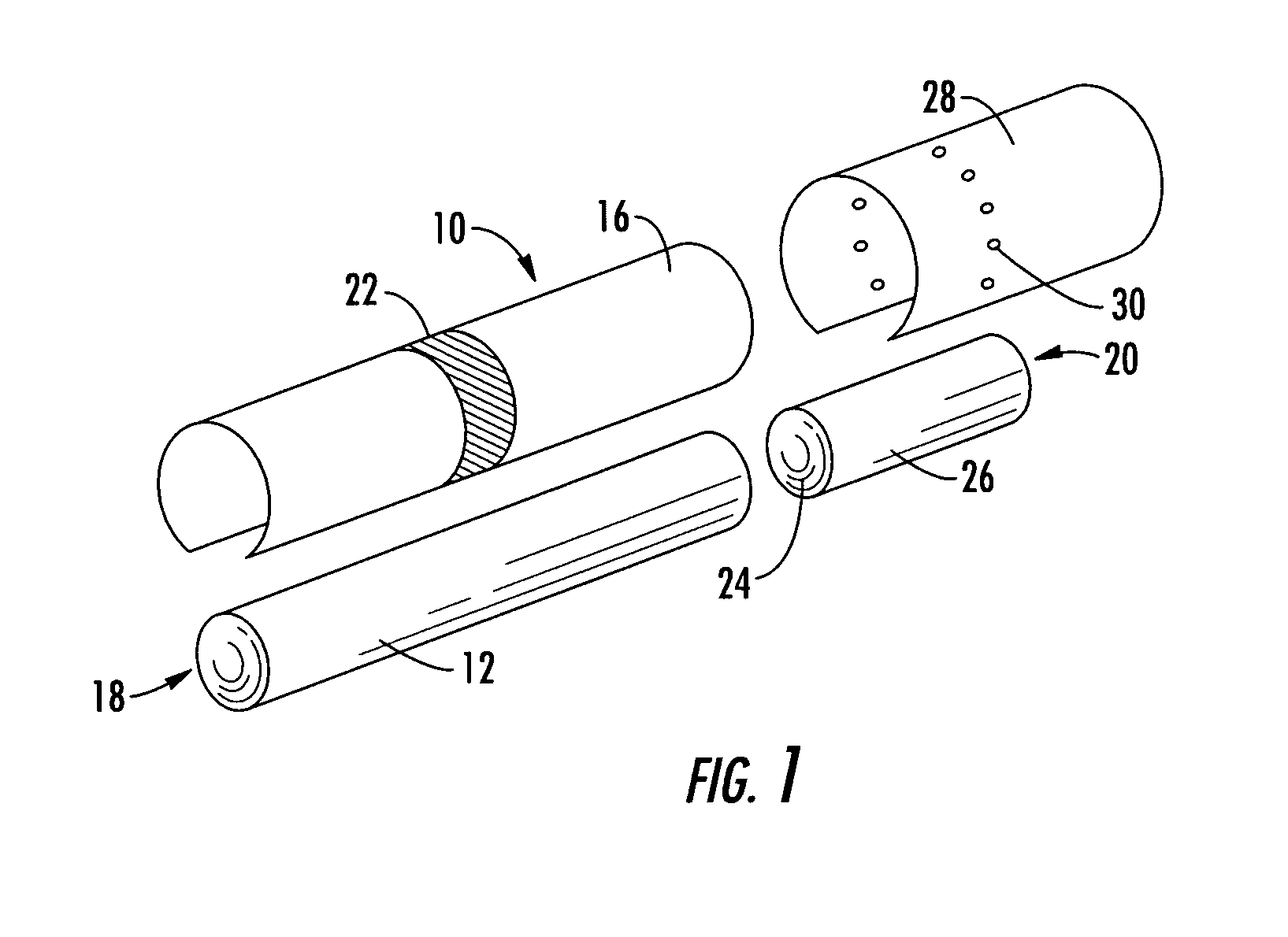

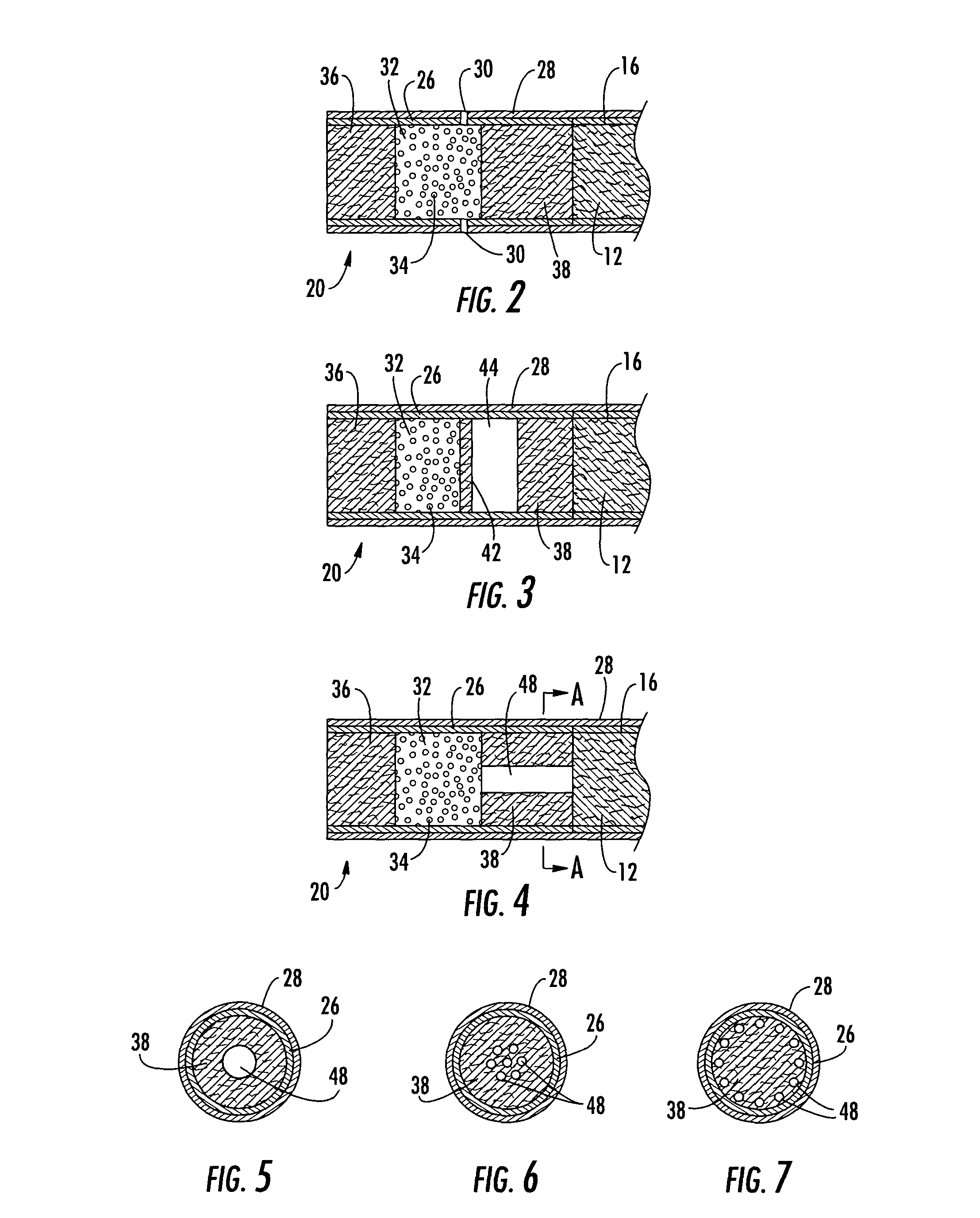

A filter element incorporating an adsorbent material is provided. The filter element may comprise a first section of filter material and a second section of filter material spaced apart to form a compartment therebetween. The compartment may be filled with one or more adsorbents or the compartment may be divided into two regions, wherein one compartment region is filled with an adsorbent and the other compartment region is either filled with an ion-exchange resin or remains empty. The section of filter material adjacent to the tobacco rod may include one or more channels therethrough for passaging smoke directly from the tobacco rod into the adsorbent-filled compartment. The mouth end section of filter material may contain a breakable capsule, wherein the breakable capsule is filled with a flavoring agent capable of altering the taste characteristics of mainstream smoke.

Owner:R J REYNOLDS TOBACCO COMPANY

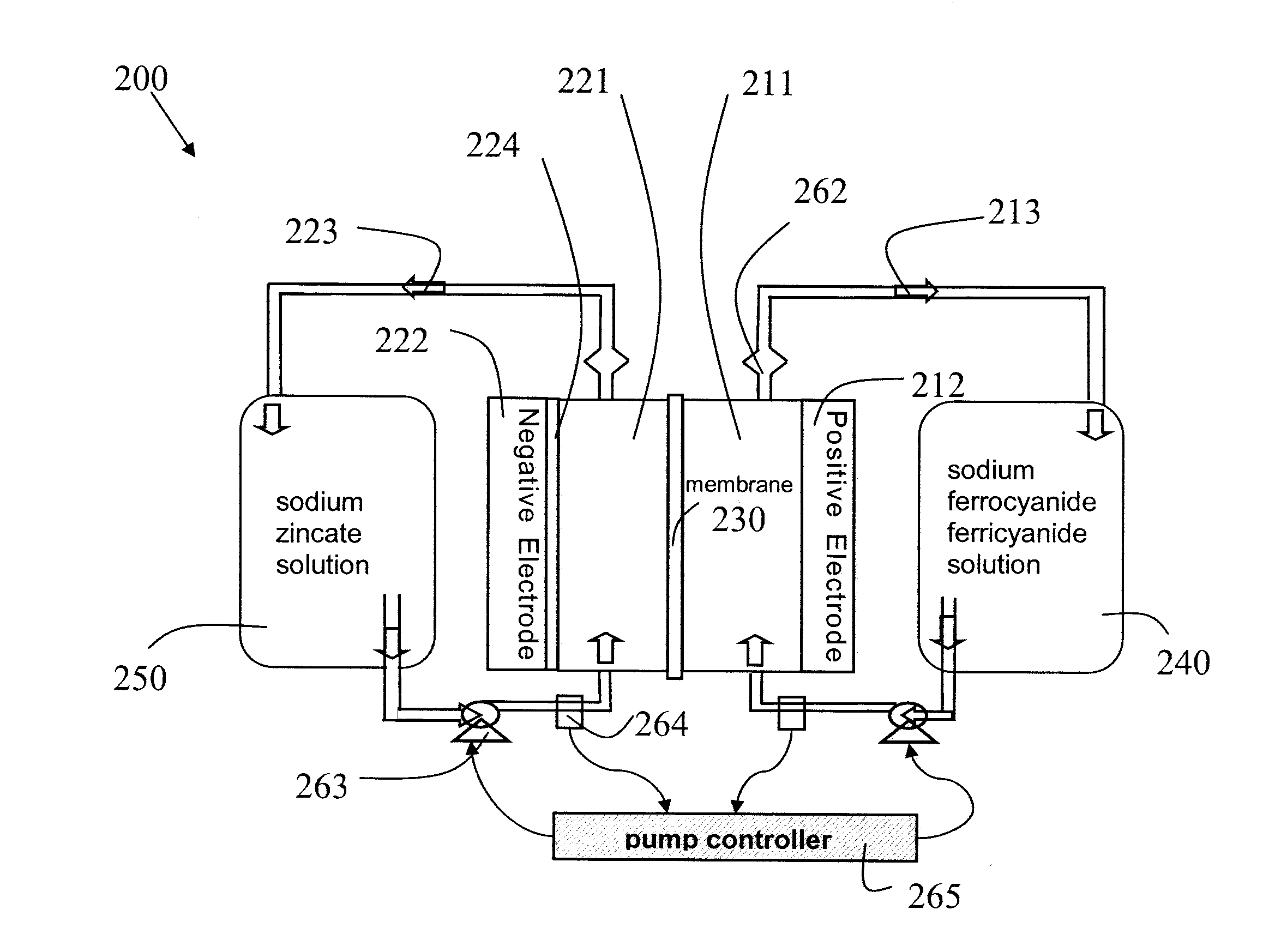

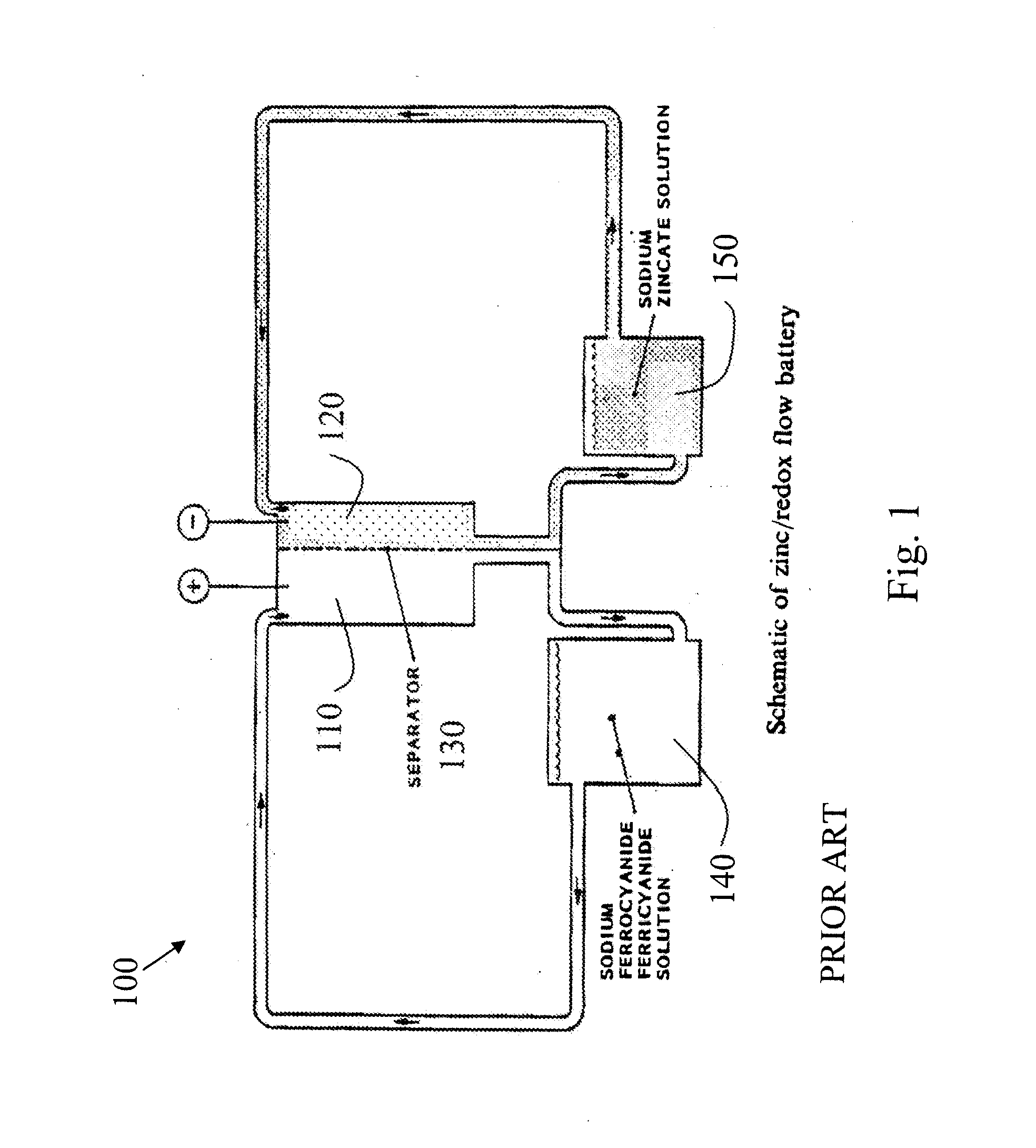

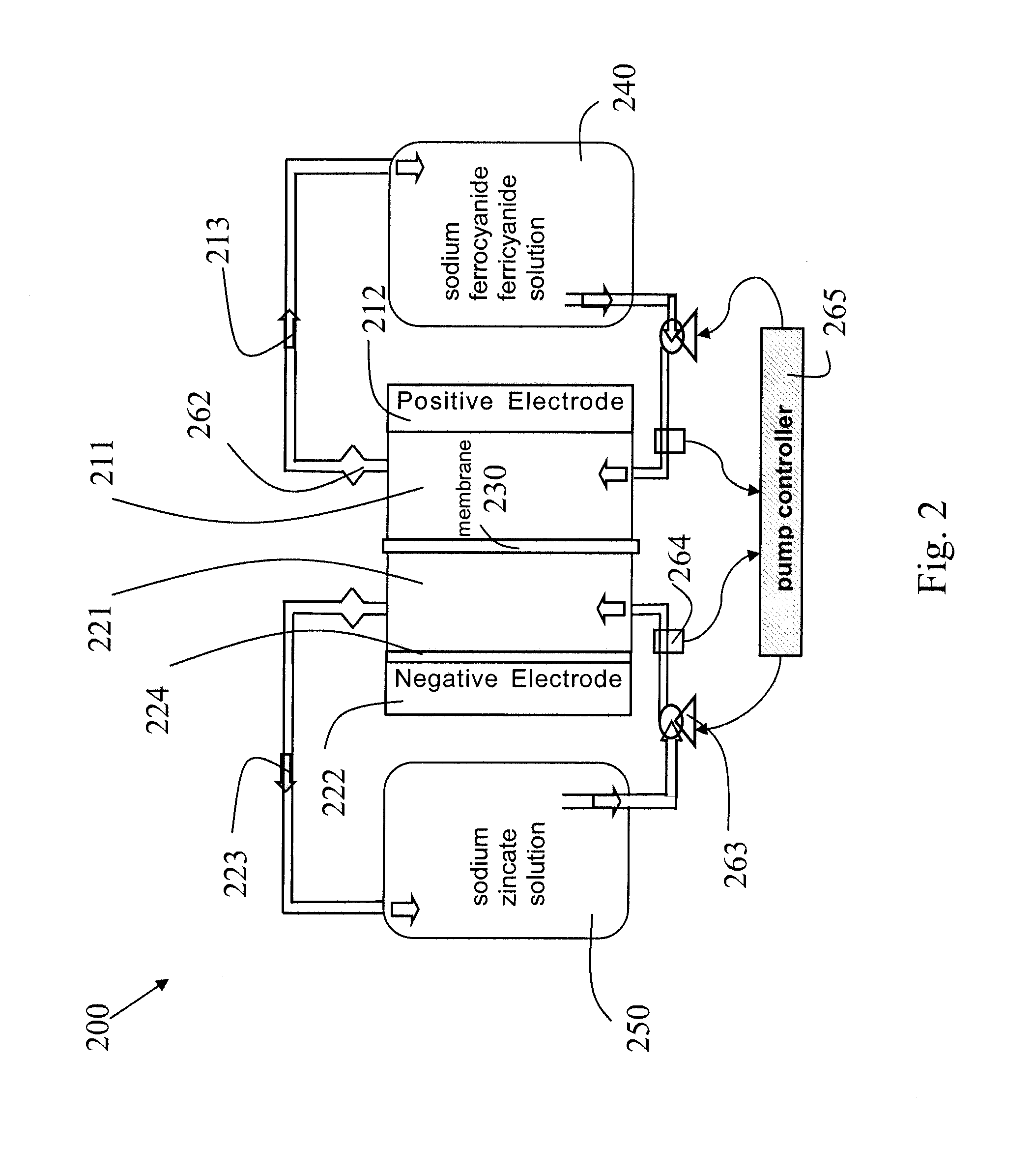

High performance flow battery

InactiveUS20110244277A1High performanceImprove the level ofElectrolyte moving arrangementsIndirect fuel cellsFerricyanideIon

High performance flow batteries, based on alkaline zinc / ferro-ferricyanide rechargeable (“ZnFe”) and similar flow batteries, may include one or more of the following improvements. First, the battery design has a cell stack comprising a low resistance positive electrode in at least one positive half cell and a low resistance negative electrode in at least one negative half cell, where the positive electrode and negative electrode resistances are selected for uniform high current density across a region of the cell stack. Second, a flow of electrolyte, such as zinc species in the ZnFe battery, with a high level of mixing through at least one negative half cell in a Zn deposition region proximate a deposition surface where the electrolyte close to the deposition surface has sufficiently high zinc concentration for deposition rates on the deposition surface that sustain the uniform high current density. The mixing in the flow may be induced by structures such as: conductive and non-conductive meshes; screens; ribbons; foam structures; arrays of cones, cylinders, or pyramids; and other arrangements of wires or tubes used solely or in combination with a planar electrode surface. Third, the zinc electrolyte has a high concentration and in some embodiments has a concentration greater than the equilibrium saturation concentration—the zinc electrolyte is super-saturated with Zn ions.

Owner:APPLIED MATERIALS INC

Filtered cigarette incorporating an adsorbent material

ActiveUS20050066981A1Enhanced mixing processCigar manufactureTobacco smoke filtersFilter materialIon-exchange resin

A filter element incorporating an adsorbent material is provided. The filter element may comprise a first section of filter material and a second section of filter material spaced apart to form a compartment therebetween. The compartment may be filled with one or more adsorbents or the compartment may be divided into two regions, wherein one compartment region is filled with an adsorbent and the other compartment region is either filled with an ion-exchange resin or remains empty. The section of filter material adjacent to the tobacco rod may include one or more channels therethrough for passaging smoke directly from the tobacco rod into the adsorbent-filled compartment. The mouth end section of filter material may contain a breakable capsule, wherein the breakable capsule is filled with a flavoring agent capable of altering the taste characteristics of mainstream smoke.

Owner:R J REYNOLDS TOBACCO COMPANY

Filtered cigarette incorporating an adsorbent material

ActiveUS20050066982A1Enhanced mixing processTobacco treatmentTobacco smoke filtersEngineeringFilter material

A filter element incorporating an adsorbent material is provided. The filter element may comprise a first section of filter material and a second section of filter material spaced apart to form a compartment therebetween. The compartment may be filled with one or more adsorbents or the compartment may be divided into two regions, wherein one compartment region is filled with an adsorbent and the other compartment region is either filled with an ion-exchange resin or remains empty. The section of filter material adjacent to the tobacco rod may include one or more channels therethrough for passaging smoke directly from the tobacco rod into the adsorbent-filled compartment. The mouth end section of filter material may contain a breakable capsule, wherein the breakable capsule is filled with a flavoring agent capable of altering the taste characteristics of mainstream smoke.

Owner:R J REYNOLDS TOBACCO COMPANY

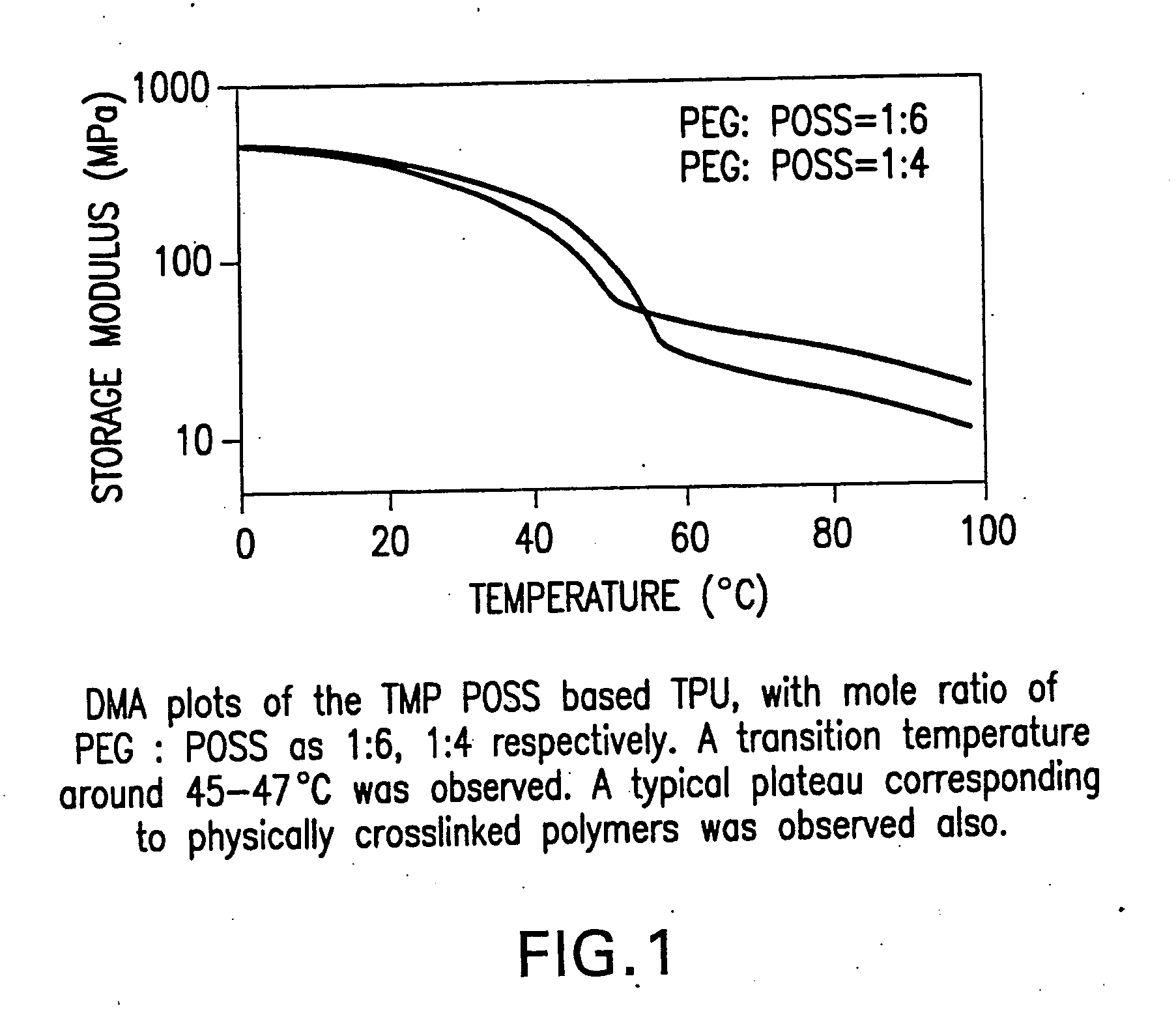

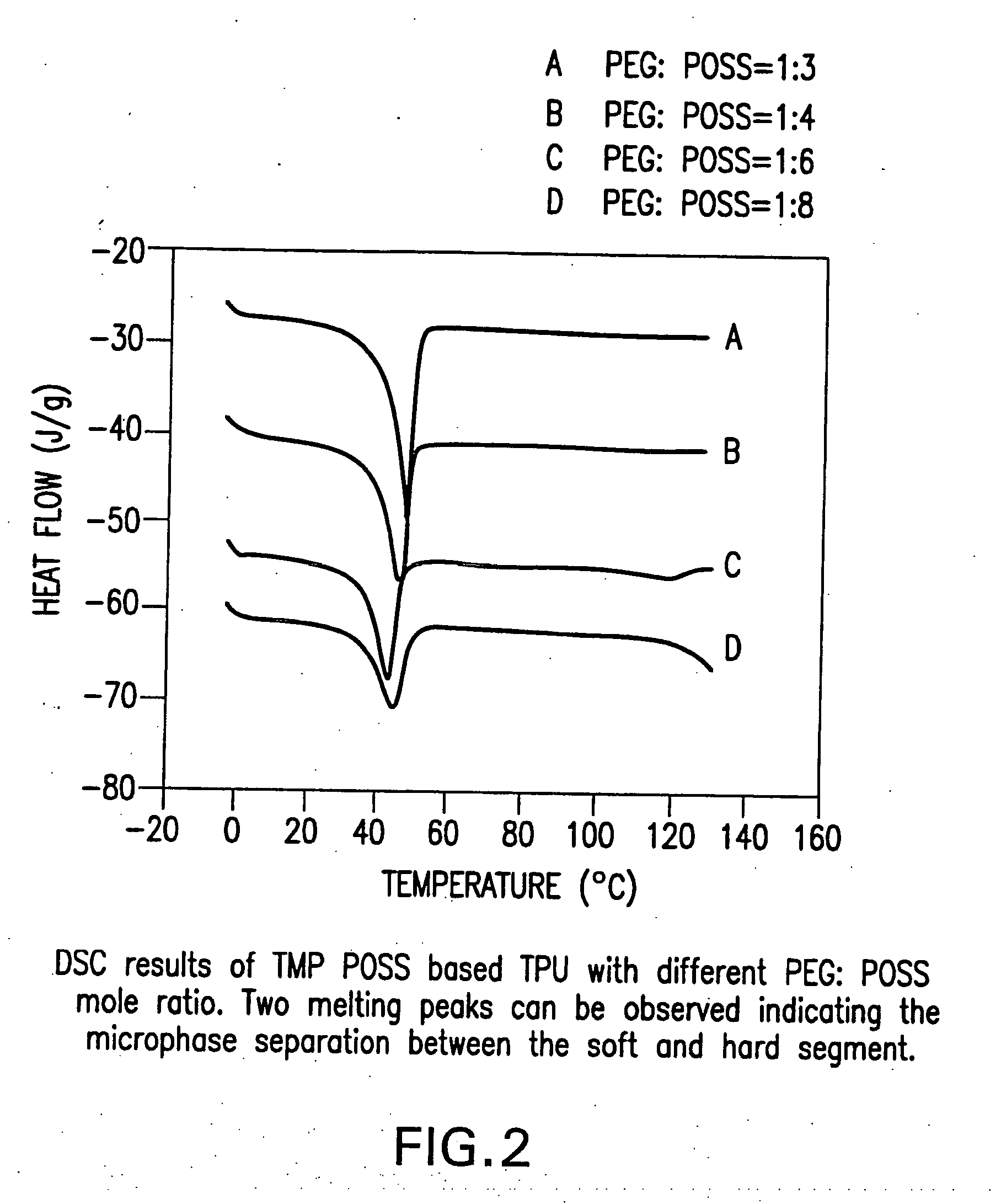

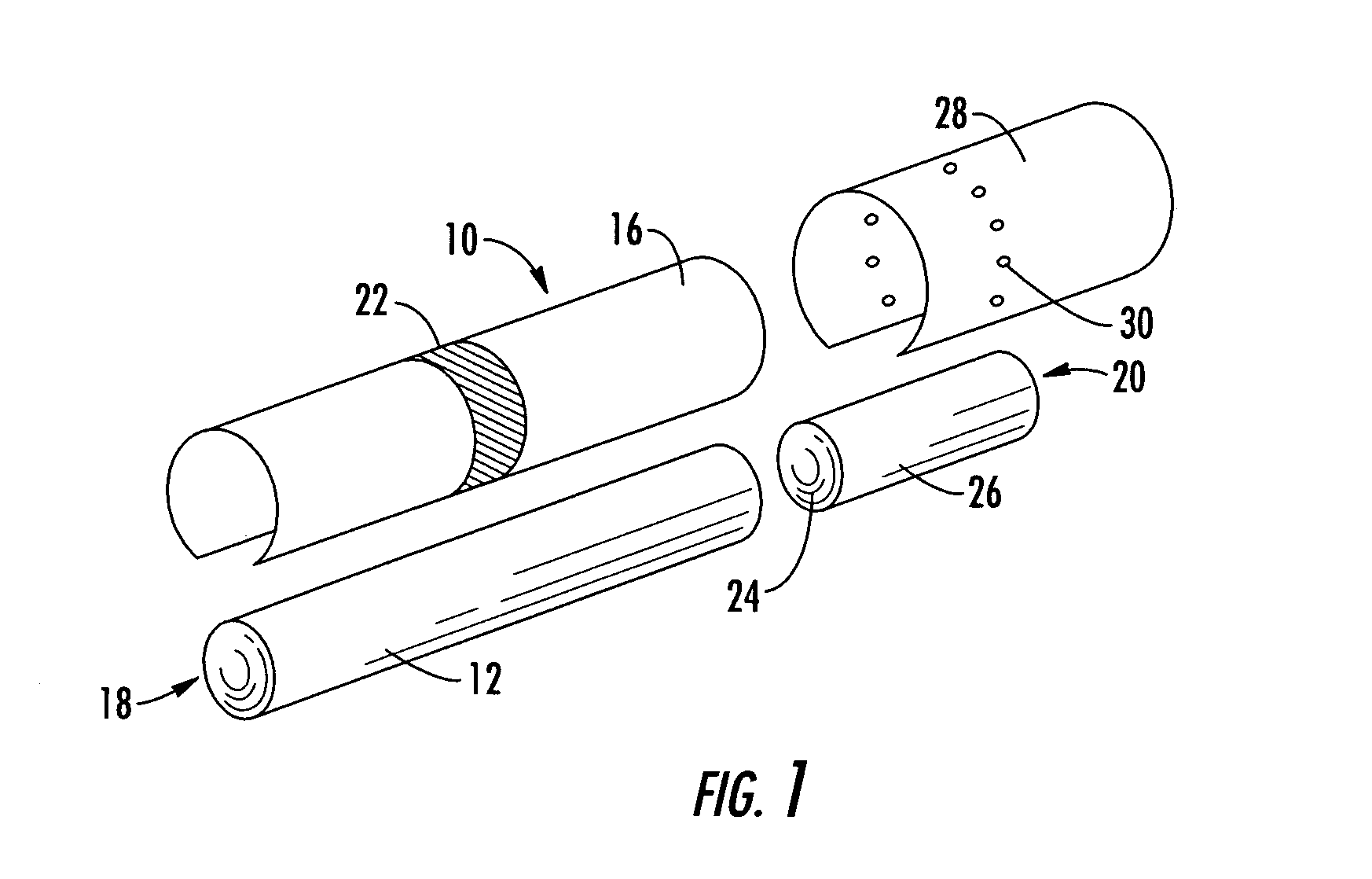

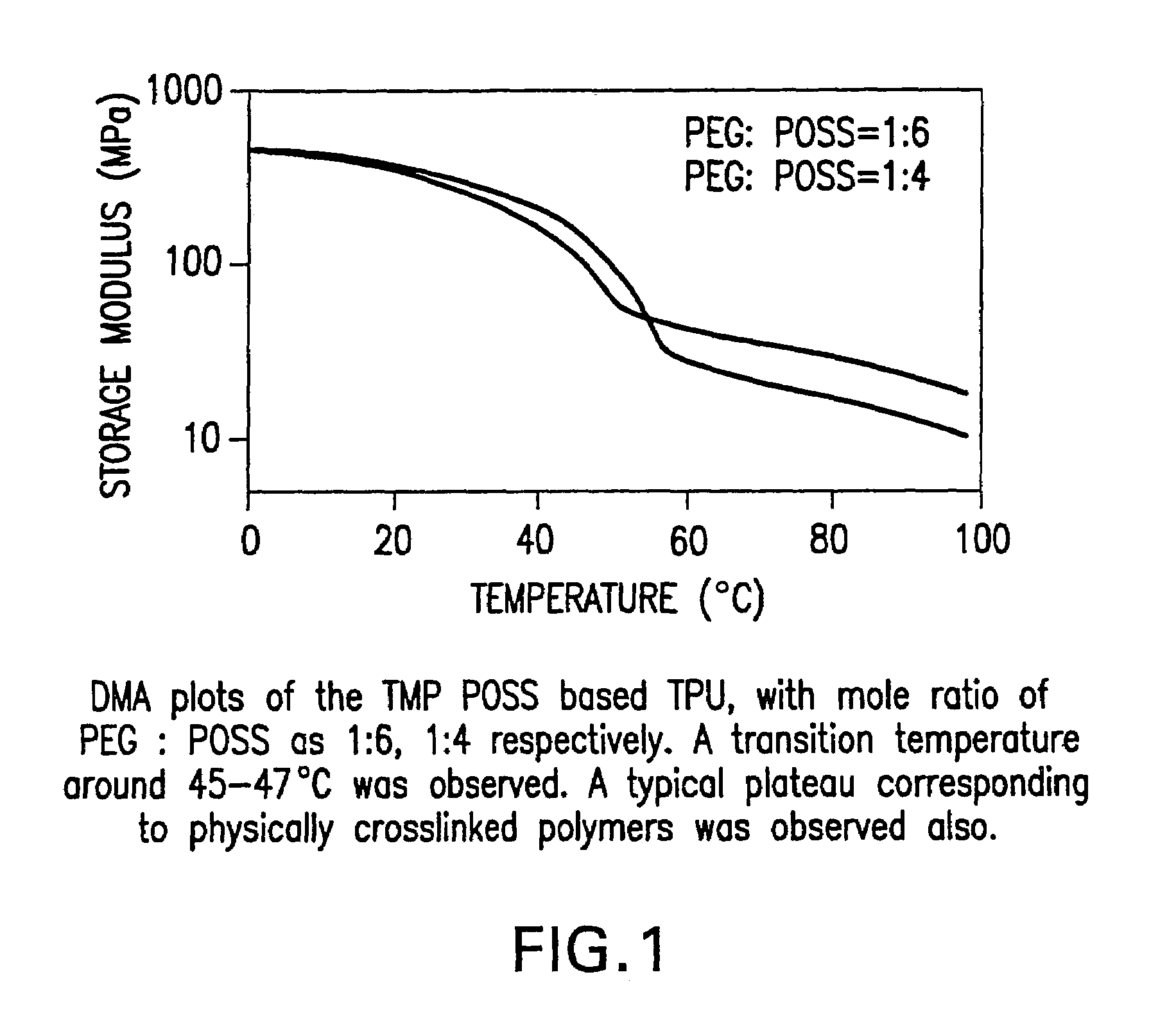

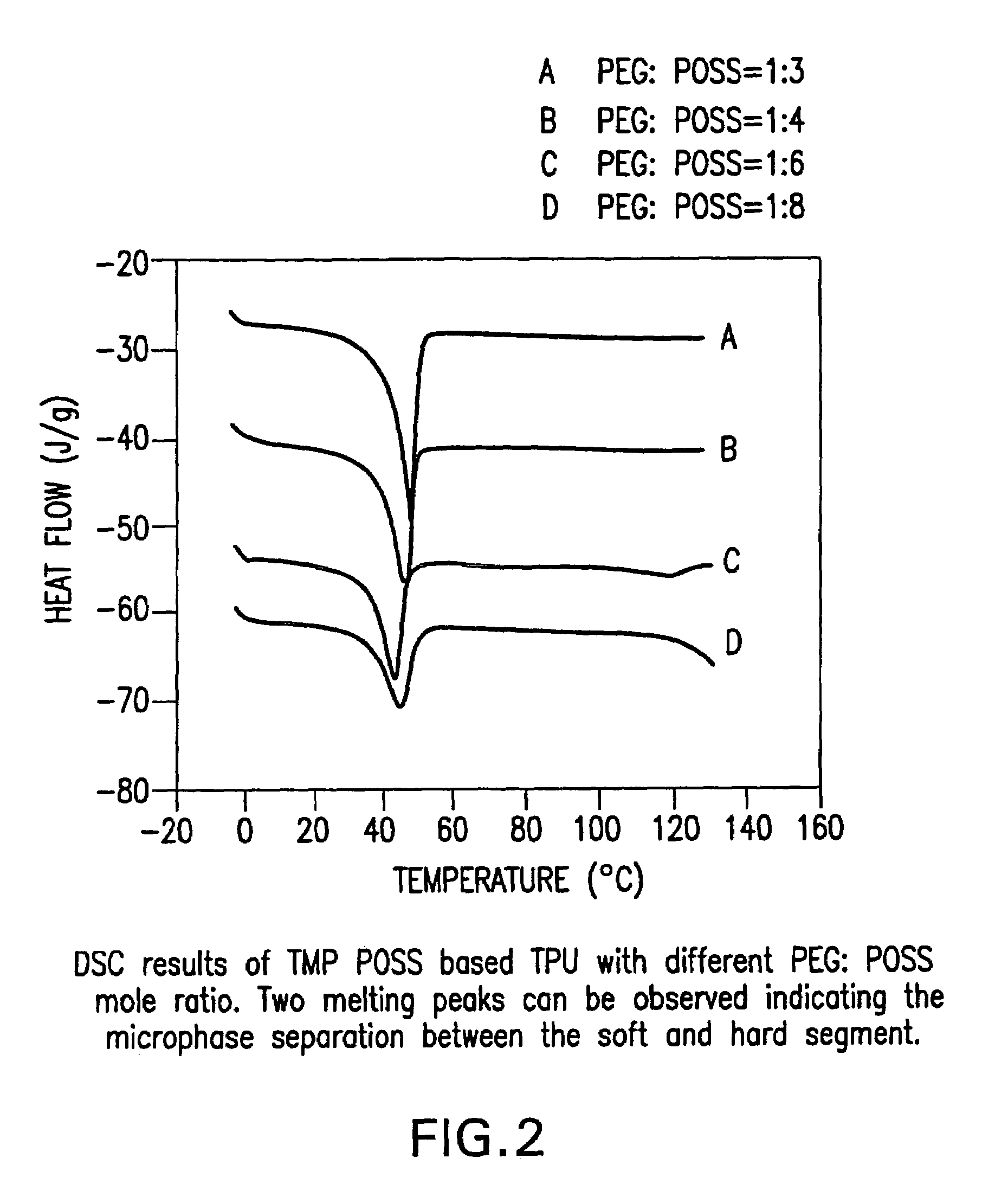

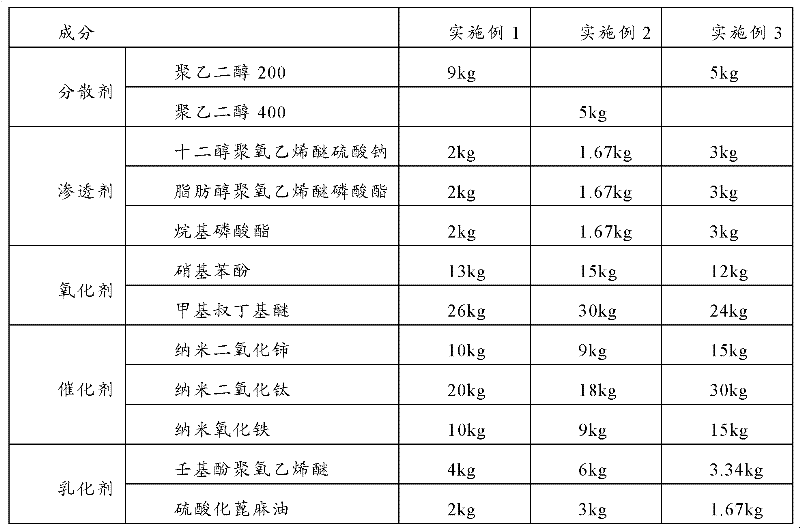

Shape memory polymers based on semicrystalline thermoplastic polyurethanes bearing nanostructured hard segments

InactiveUS20050245719A1Sharp and tunable transition temperatureAbove melting pointPolymer scienceAdhesive

Thermoplastic polyurethanes having an alternating sequence of hard and soft segments in which a nanostructured polyhedral oligosilsesquioxane diol is used as a chain extender to form a crystalline hard segment constituting SMPs. The polyurethanes are formed by reacting a polyol, a chain extender dihydroxyl-terminated polyhedral oligosilsesquioxane and a diisocyanate. The polyurethanes have multiple applications including for example, implants for human health care, drug delivery matrices, superabsorbant hydrogels, coatings, adhesives, temperature and moisture sensors, etc.

Owner:UNIV OF CONNECTICUT

Filtered cigarette incorporating an adsorbent material

ActiveUS7240678B2Enhanced mixing processCigar manufactureTobacco smoke filtersFilter materialIon-exchange resin

A filter element incorporating an adsorbent material is provided. The filter element may comprise a first section of filter material and a second section of filter material spaced apart to form a compartment therebetween. The compartment may be filled with one or more adsorbents or the compartment may be divided into two regions, wherein one compartment region is filled with an adsorbent and the other compartment region is either filled with an ion-exchange resin or remains empty. The section of filter material adjacent to the tobacco rod may include one or more channels therethrough for passaging smoke directly from the tobacco rod into the adsorbent-filled compartment. The mouth end section of filter material may contain a breakable capsule, wherein the breakable capsule is filled with a flavoring agent capable of altering the taste characteristics of mainstream smoke.

Owner:R J REYNOLDS TOBACCO COMPANY

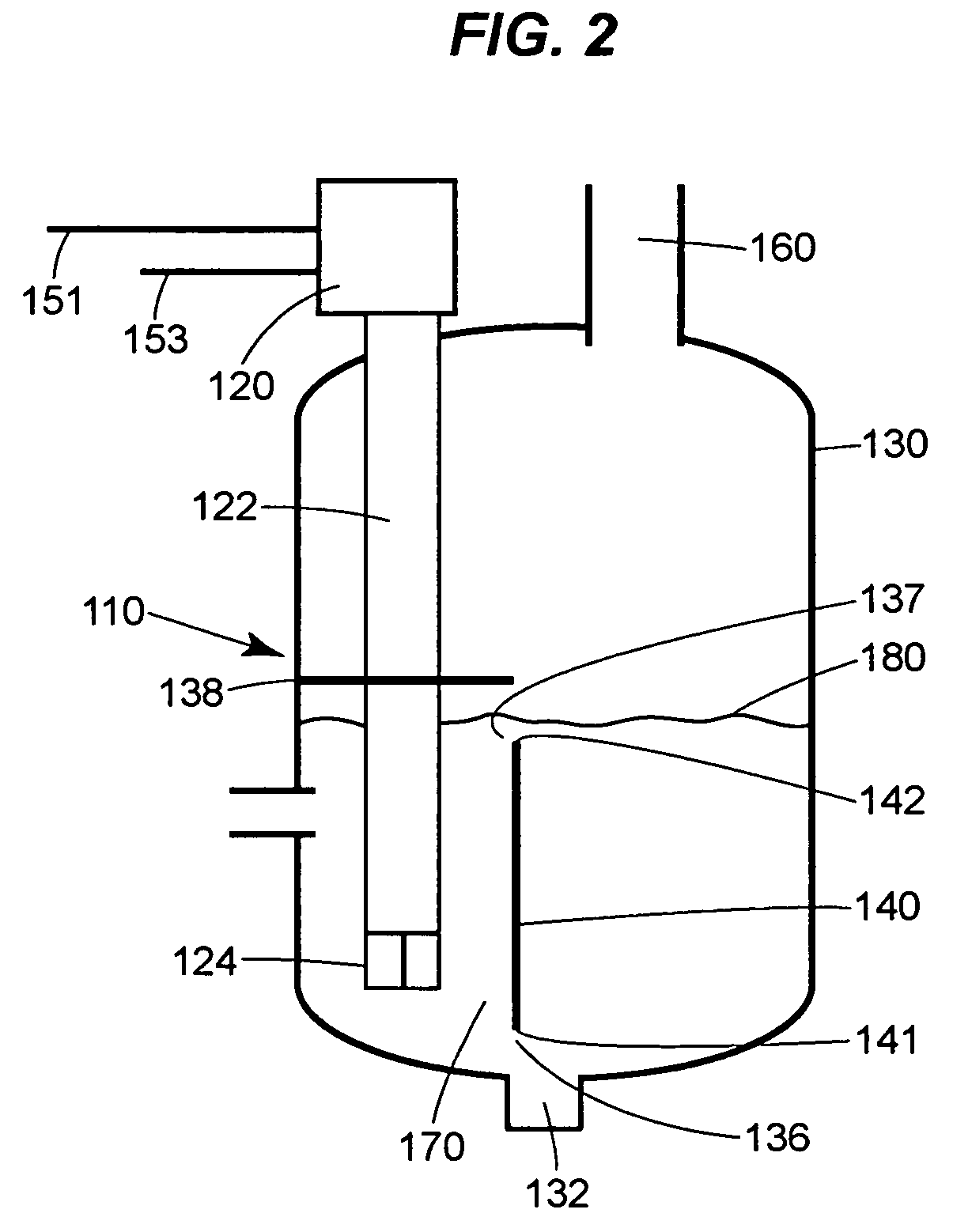

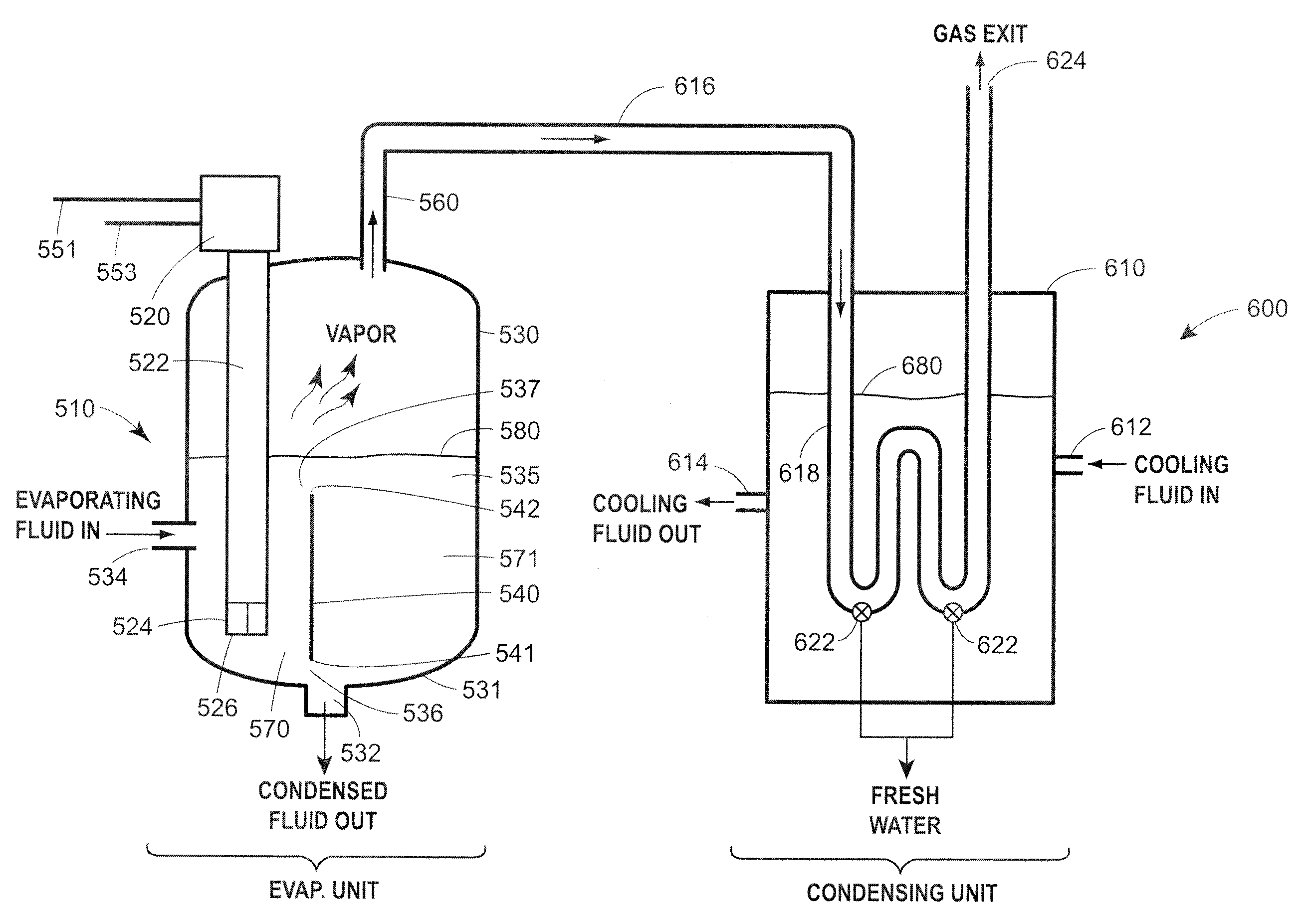

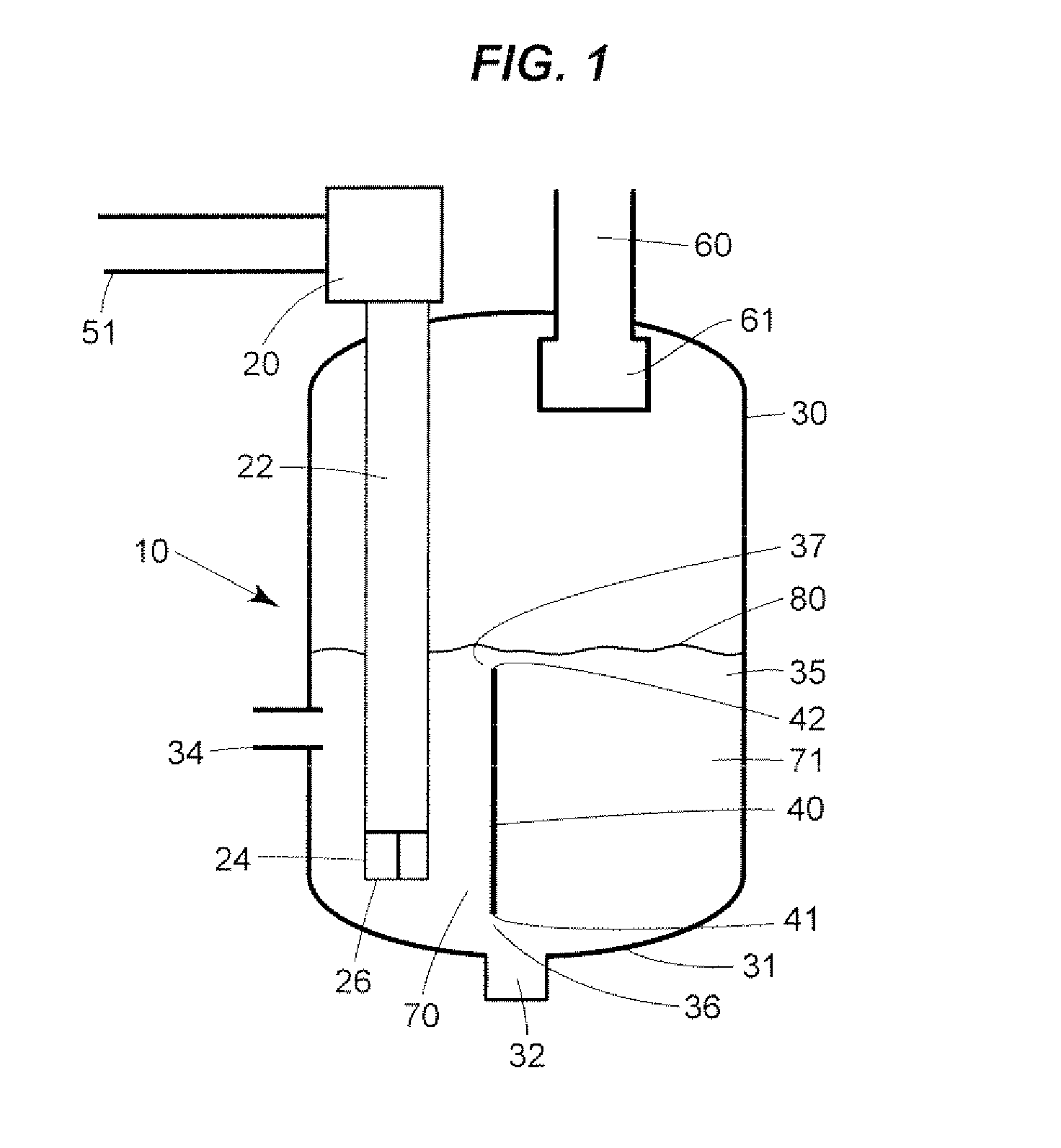

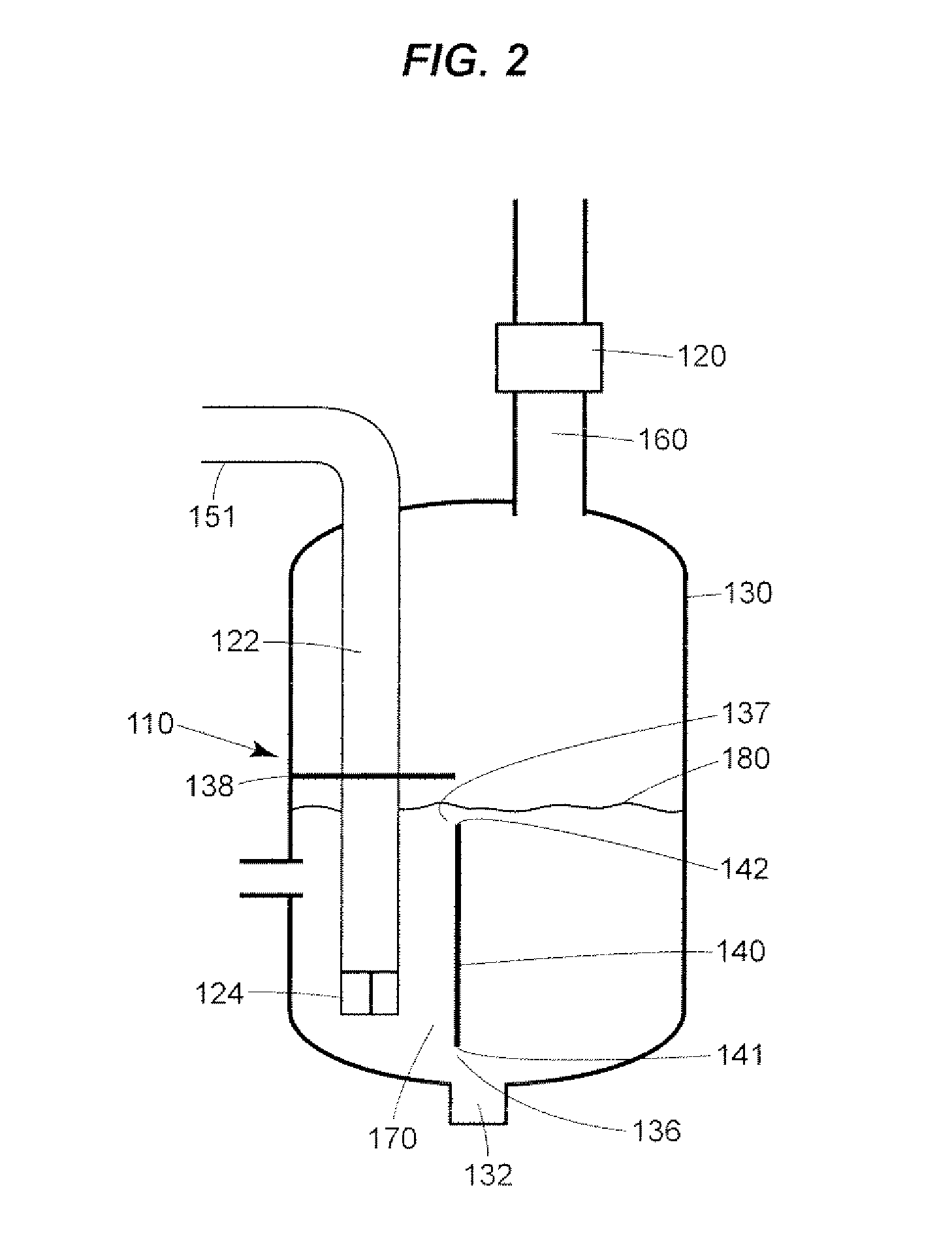

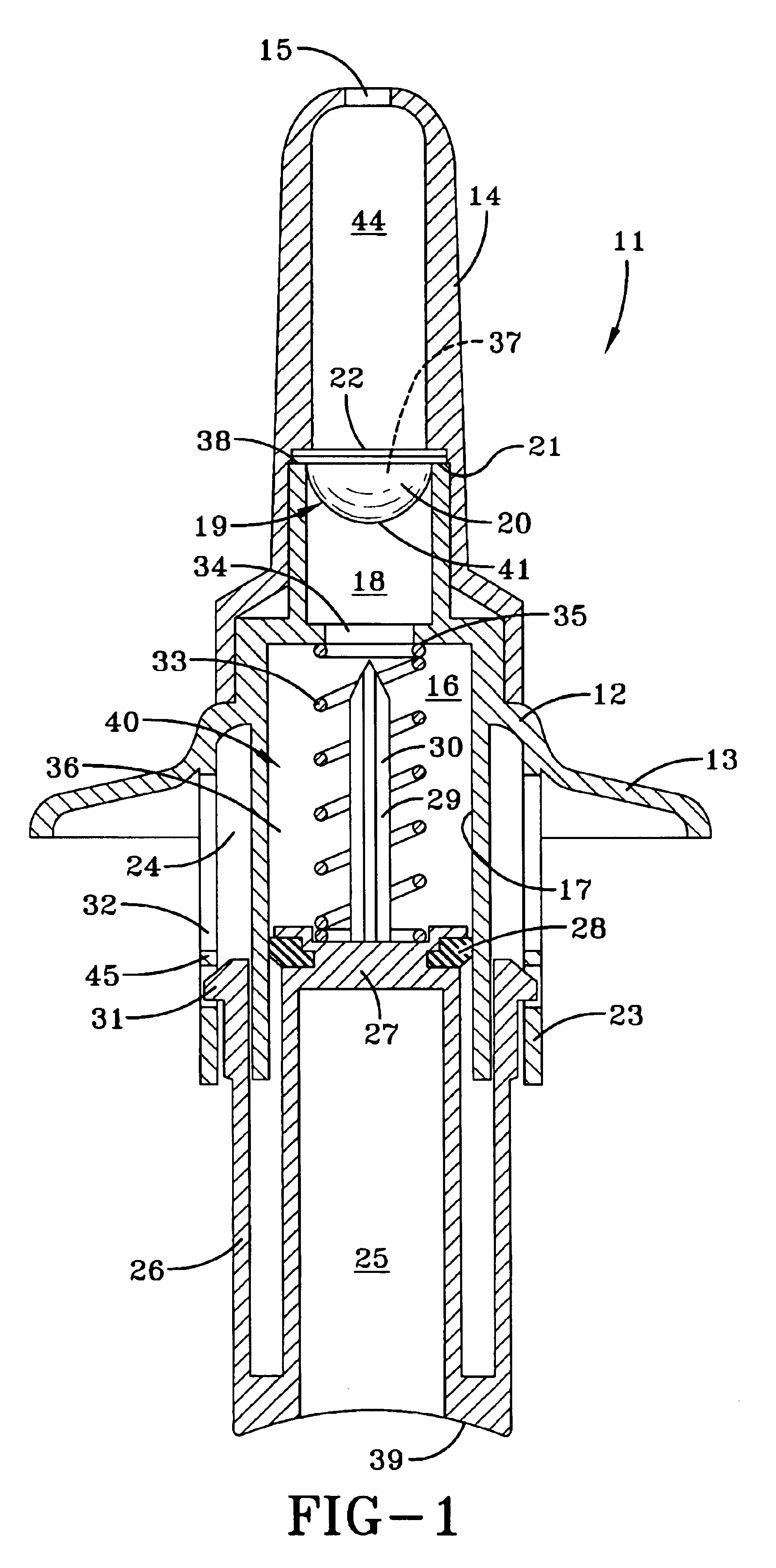

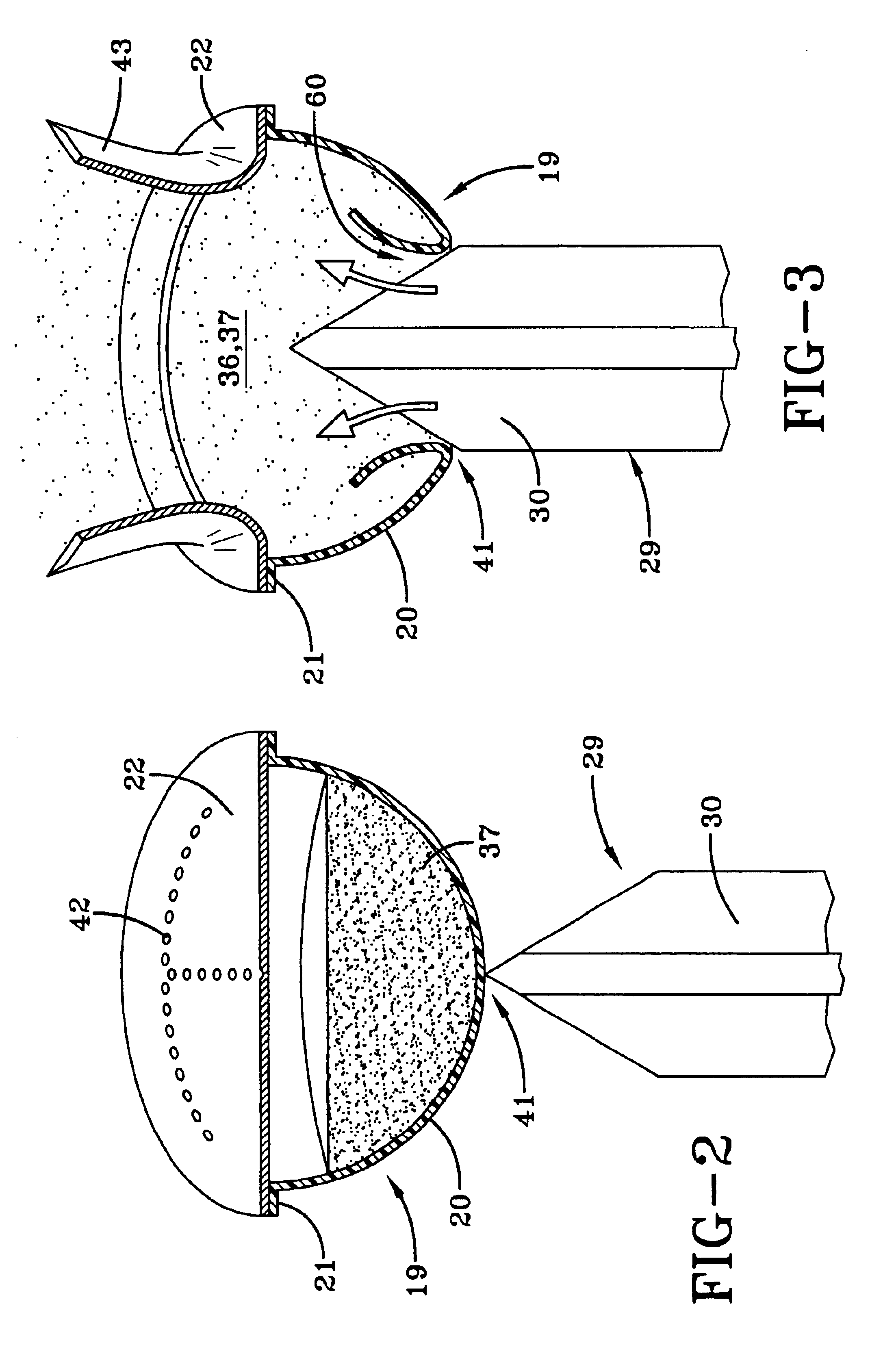

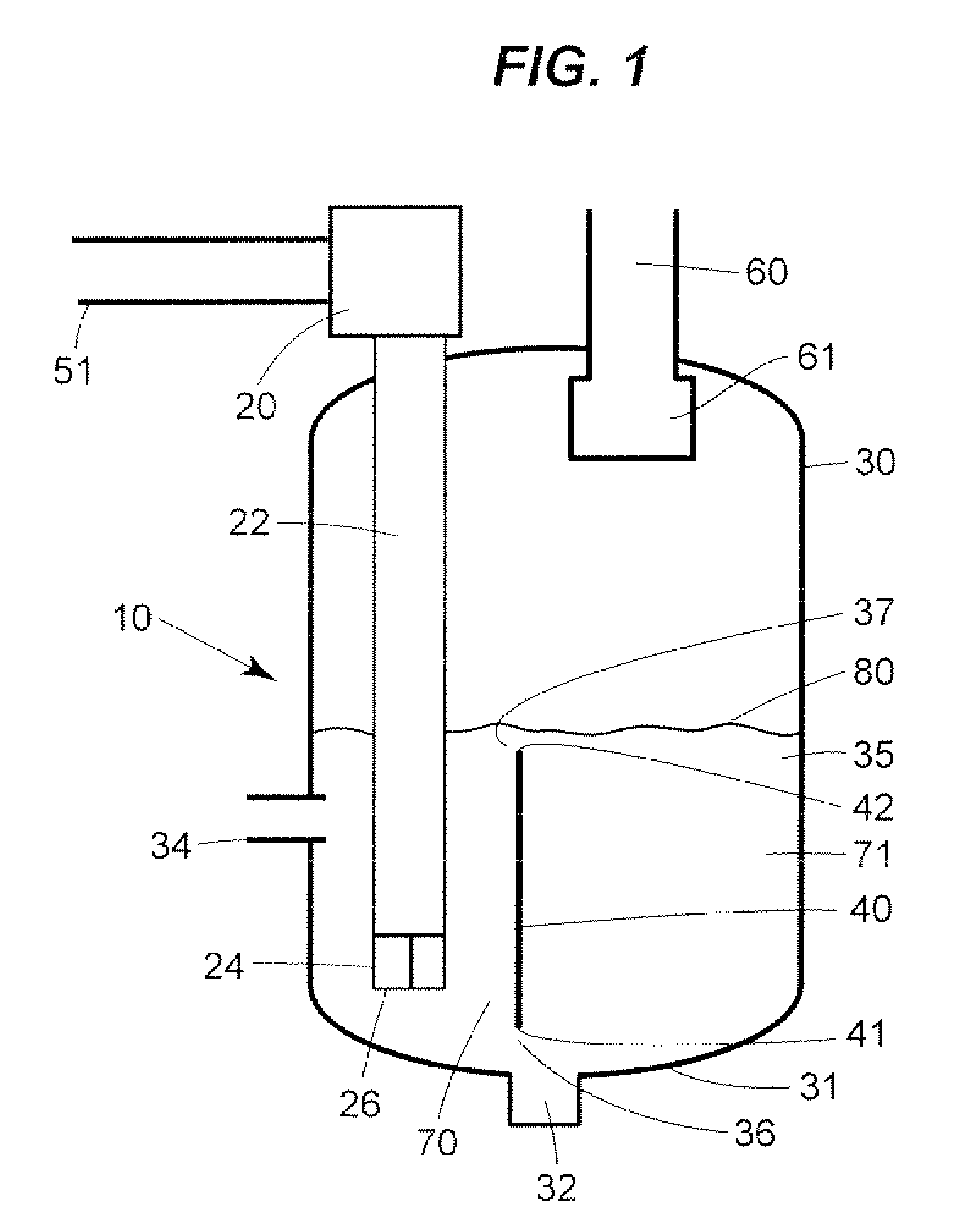

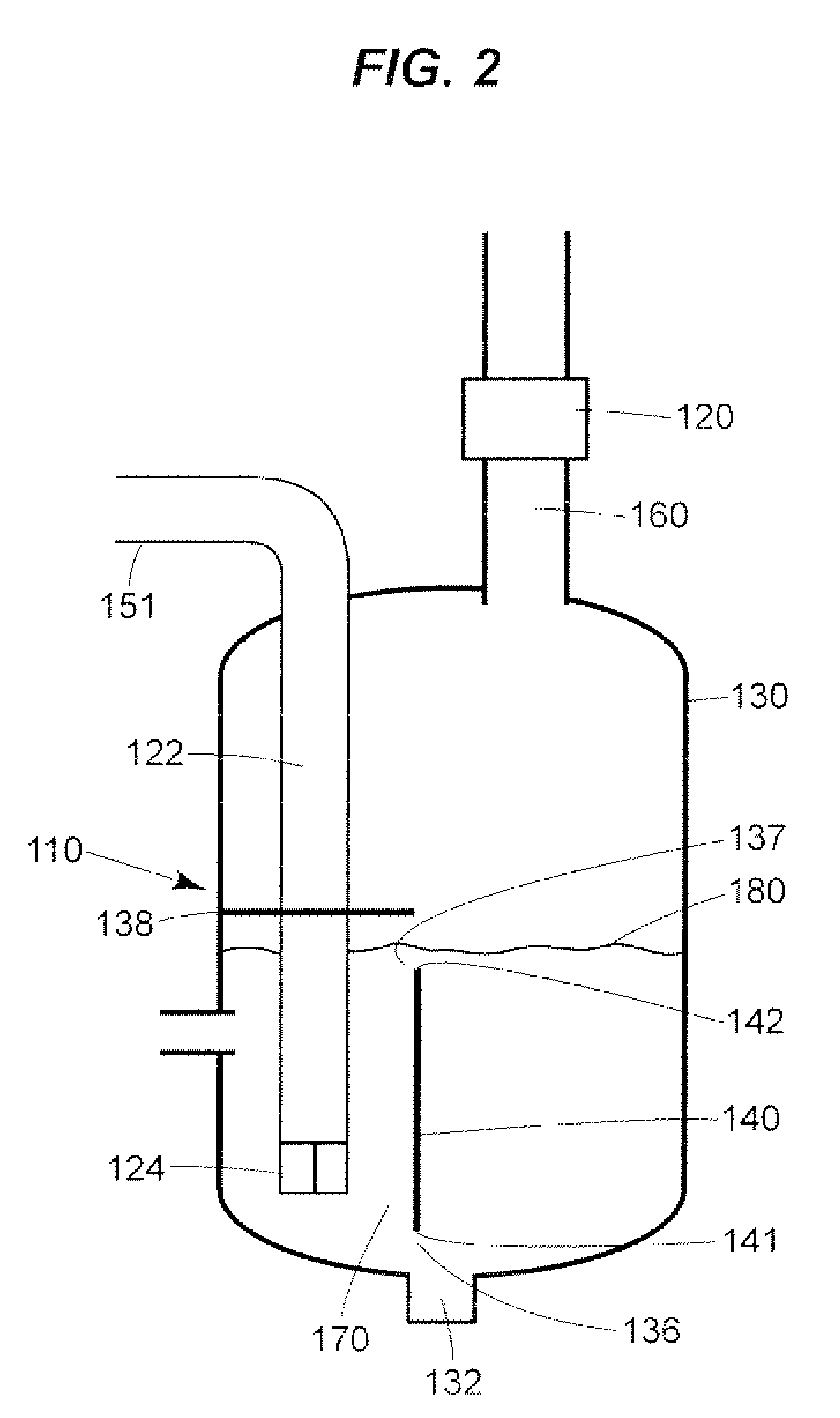

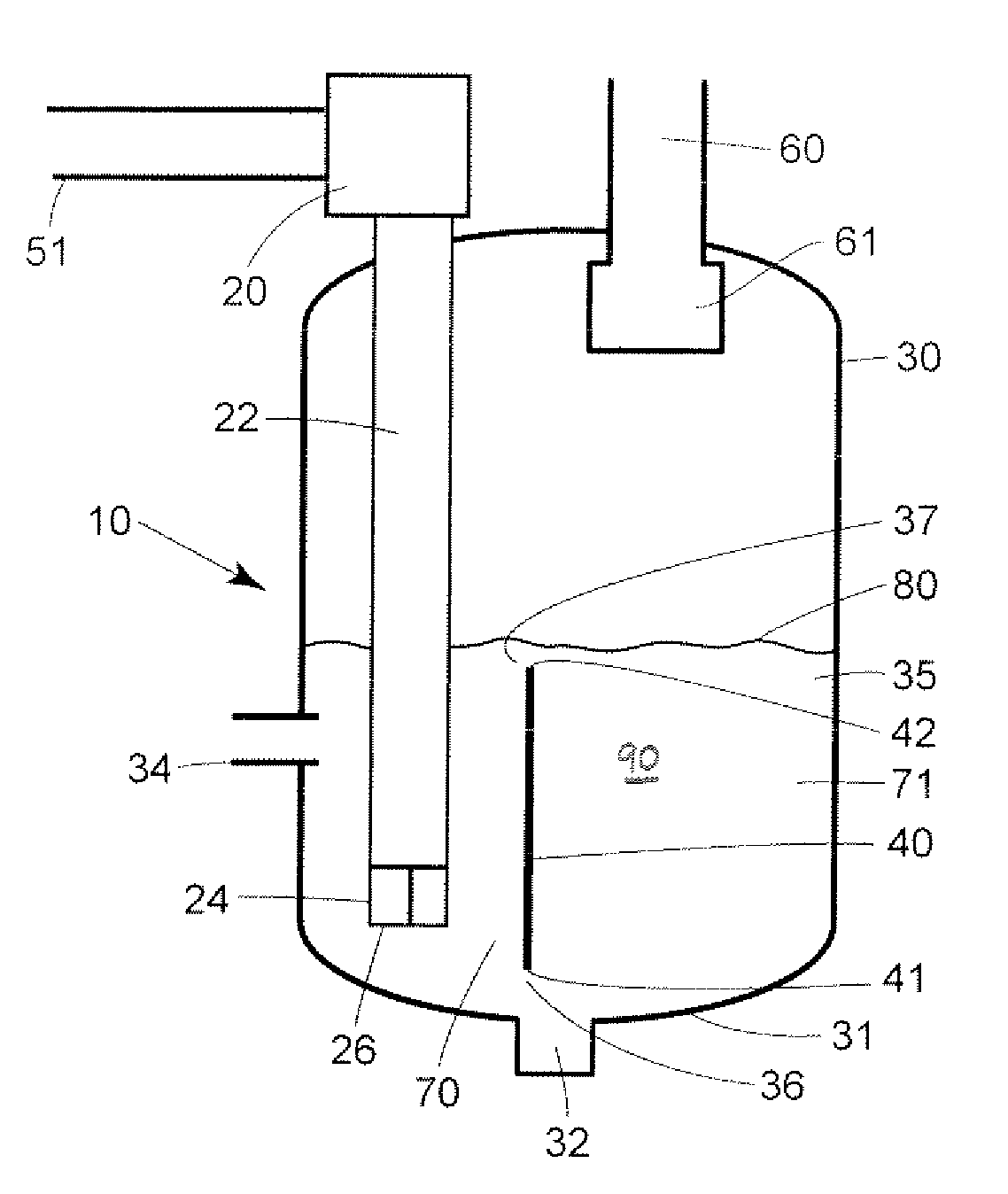

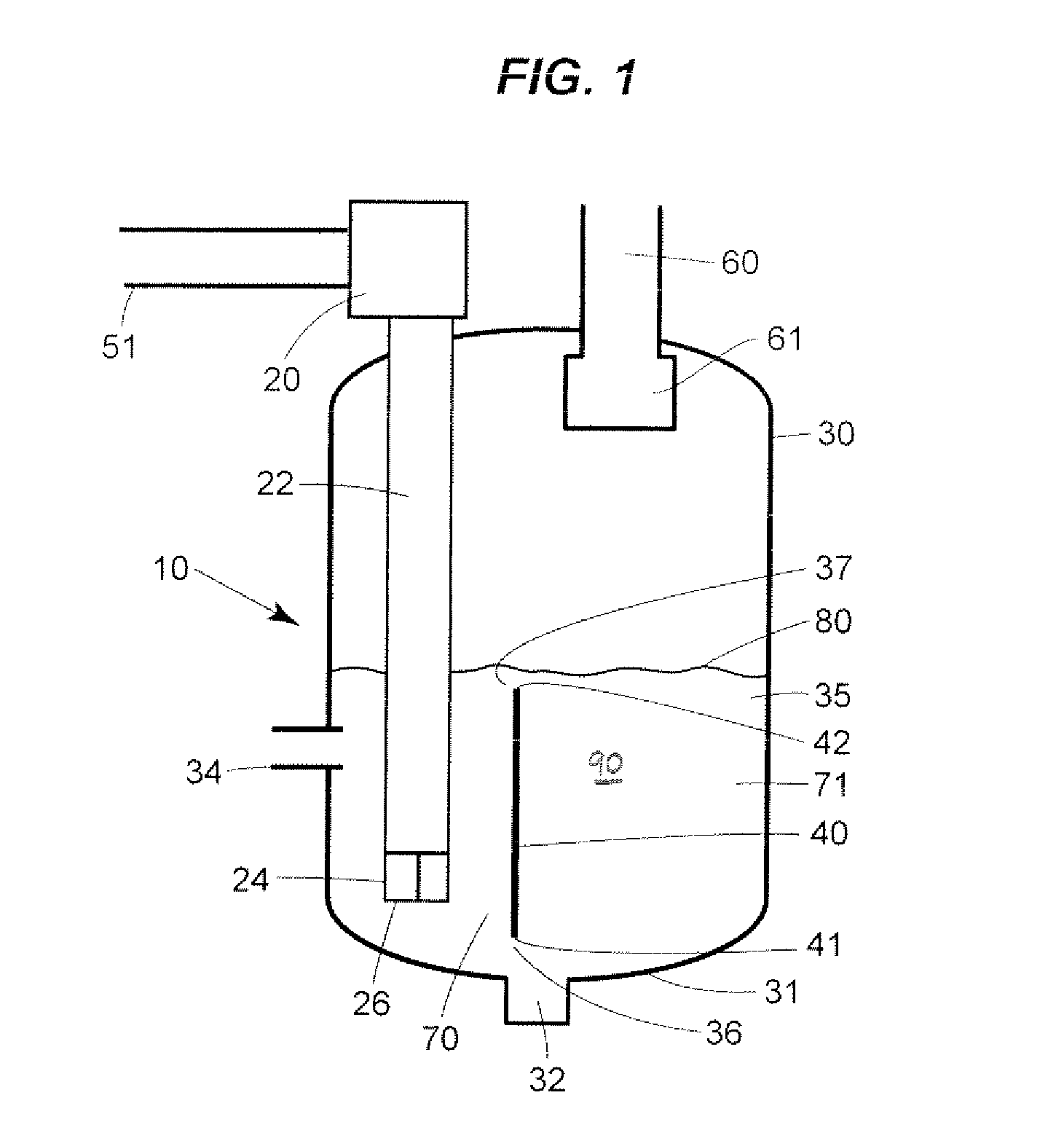

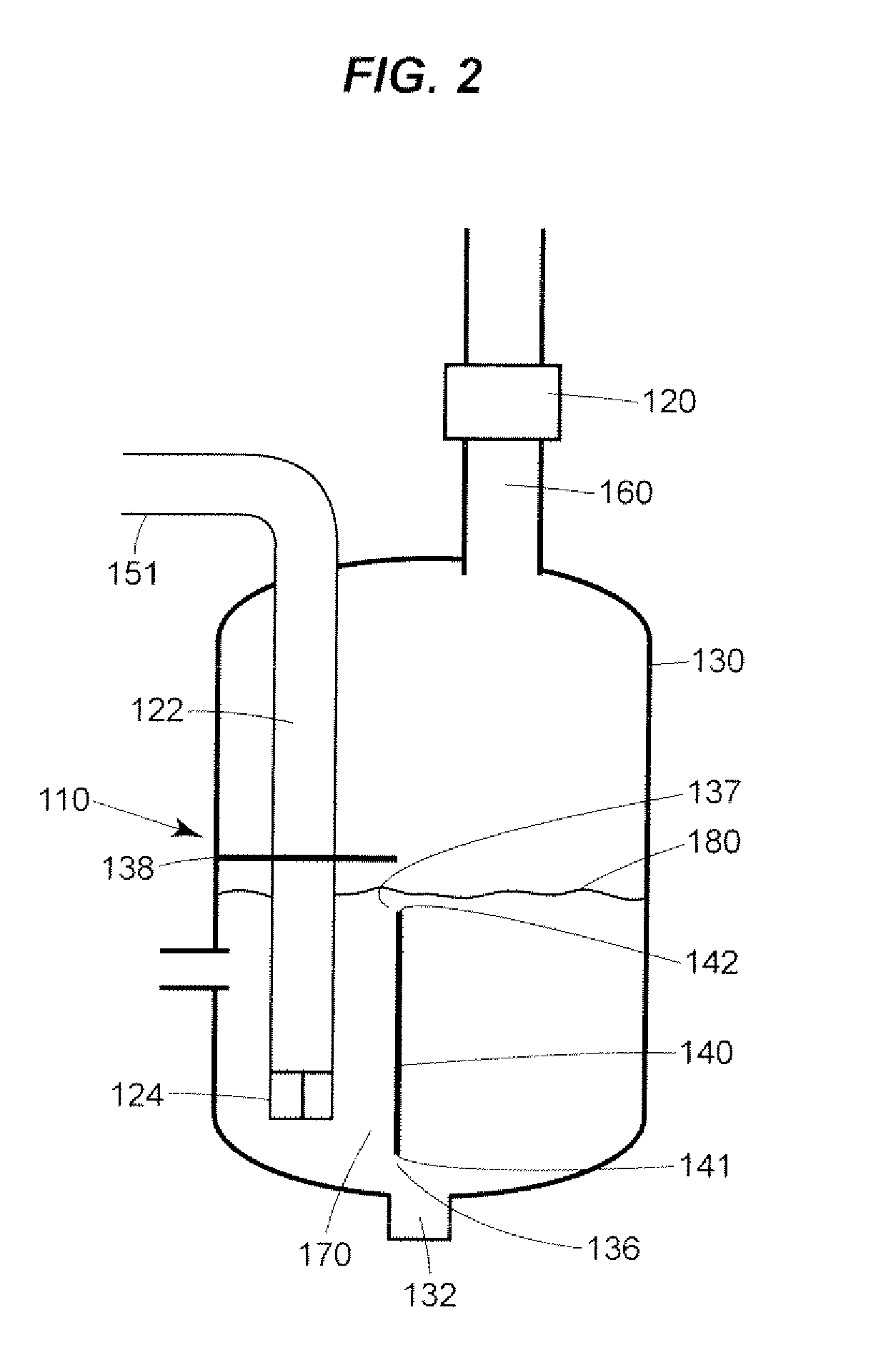

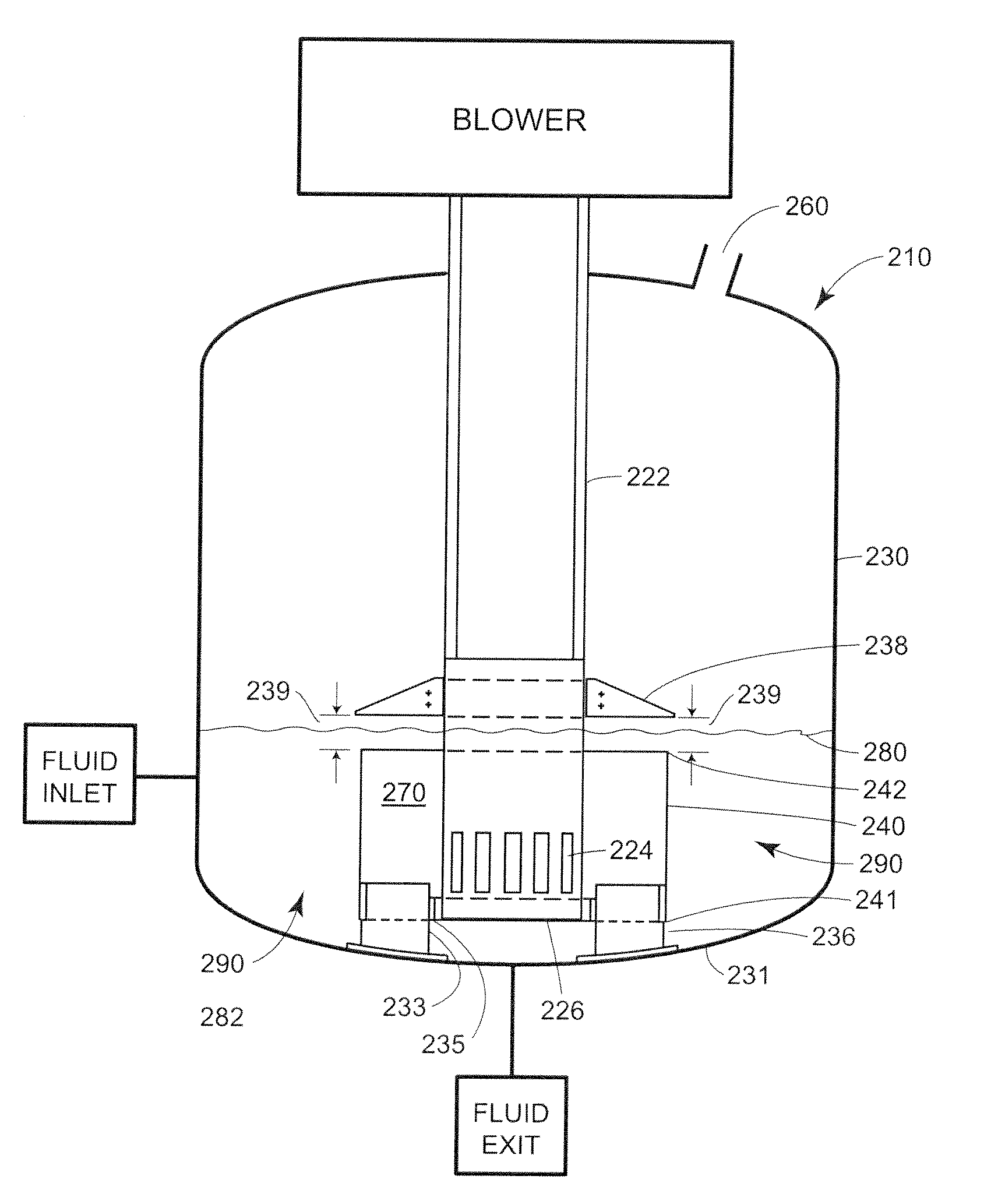

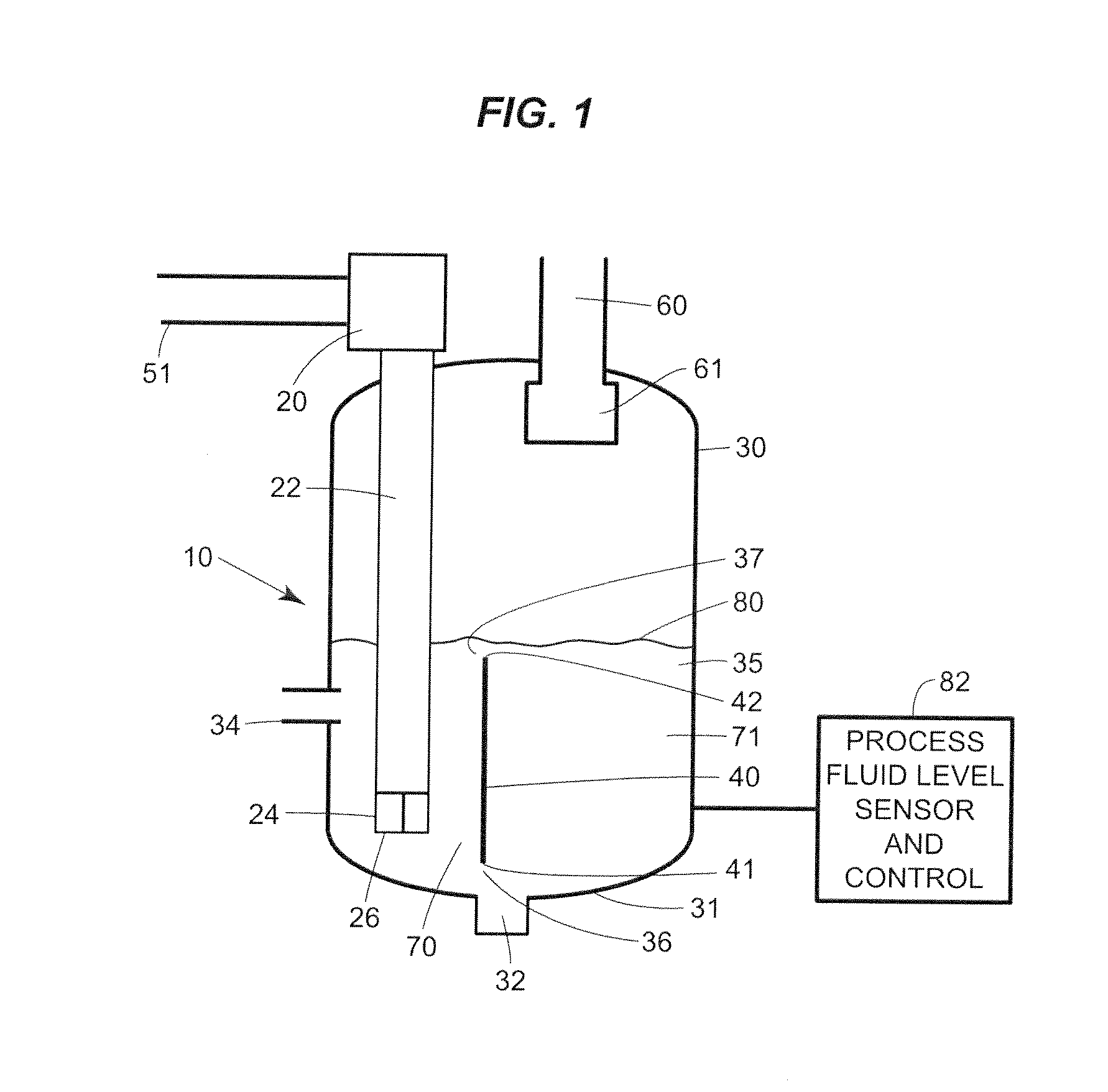

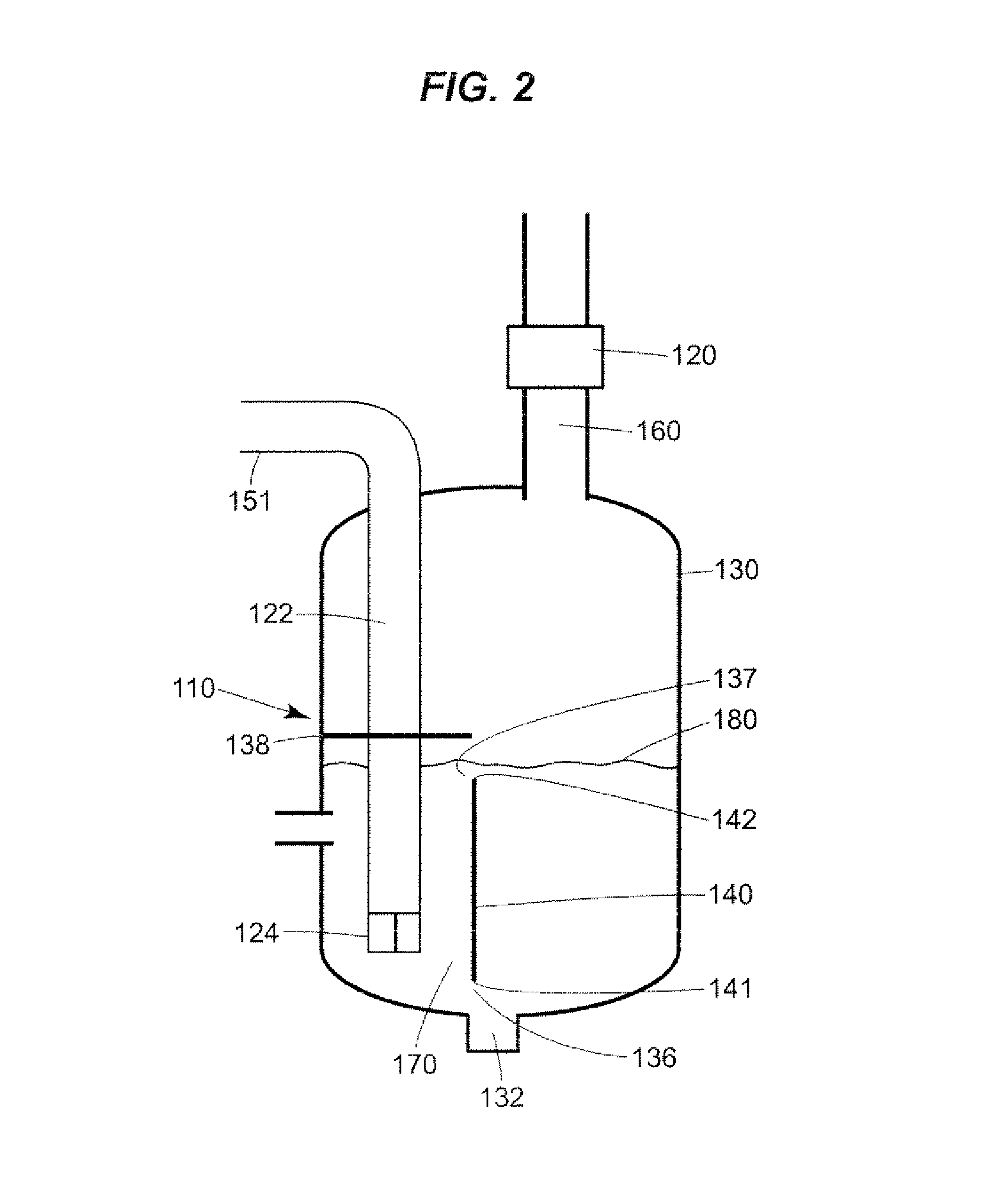

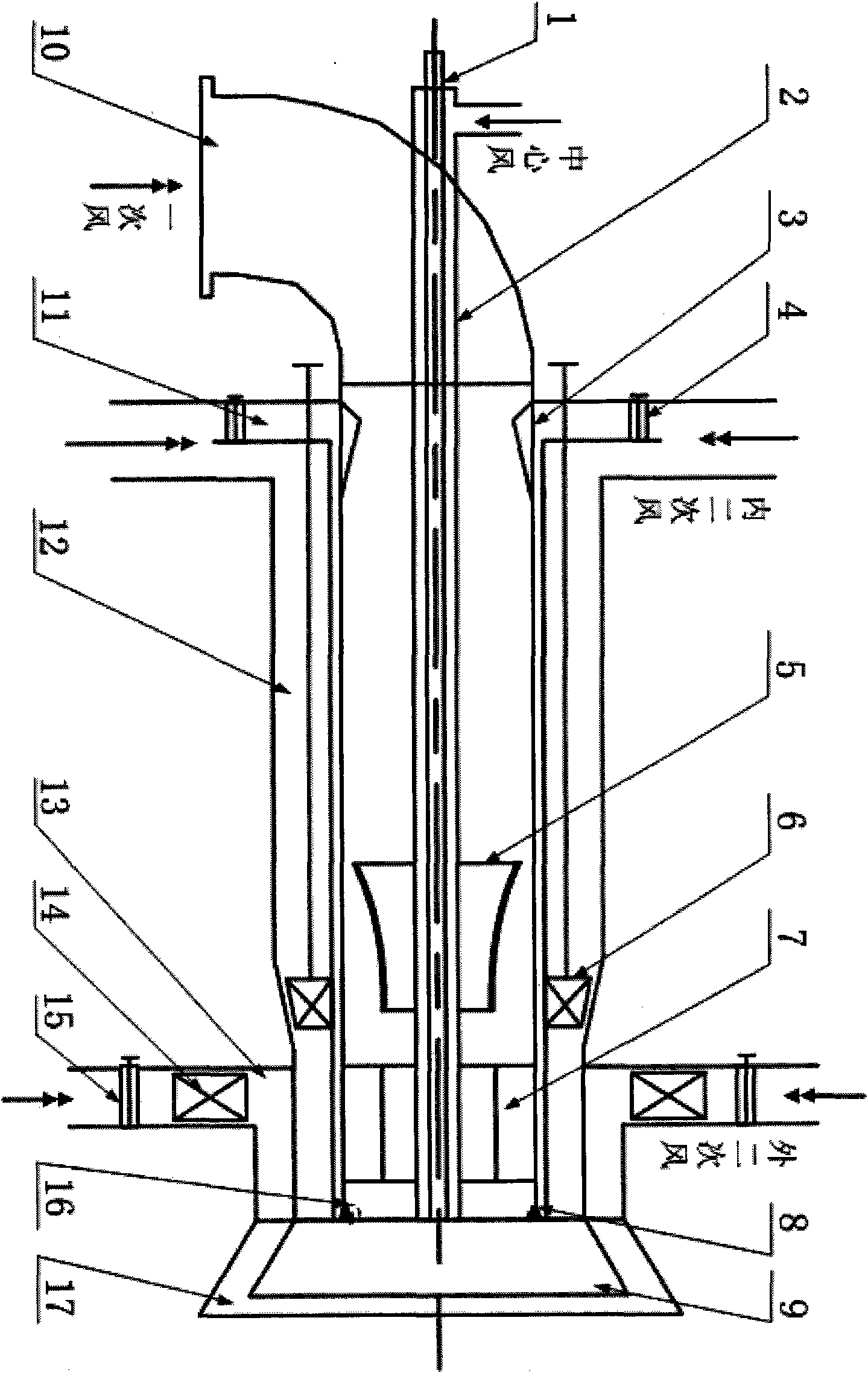

Submerged gas evaporators and reactors

ActiveUS7416172B2Increased turbulenceEnhanced mixing processCarburetting airUsing liquid separation agentChemical reactionHigh rate

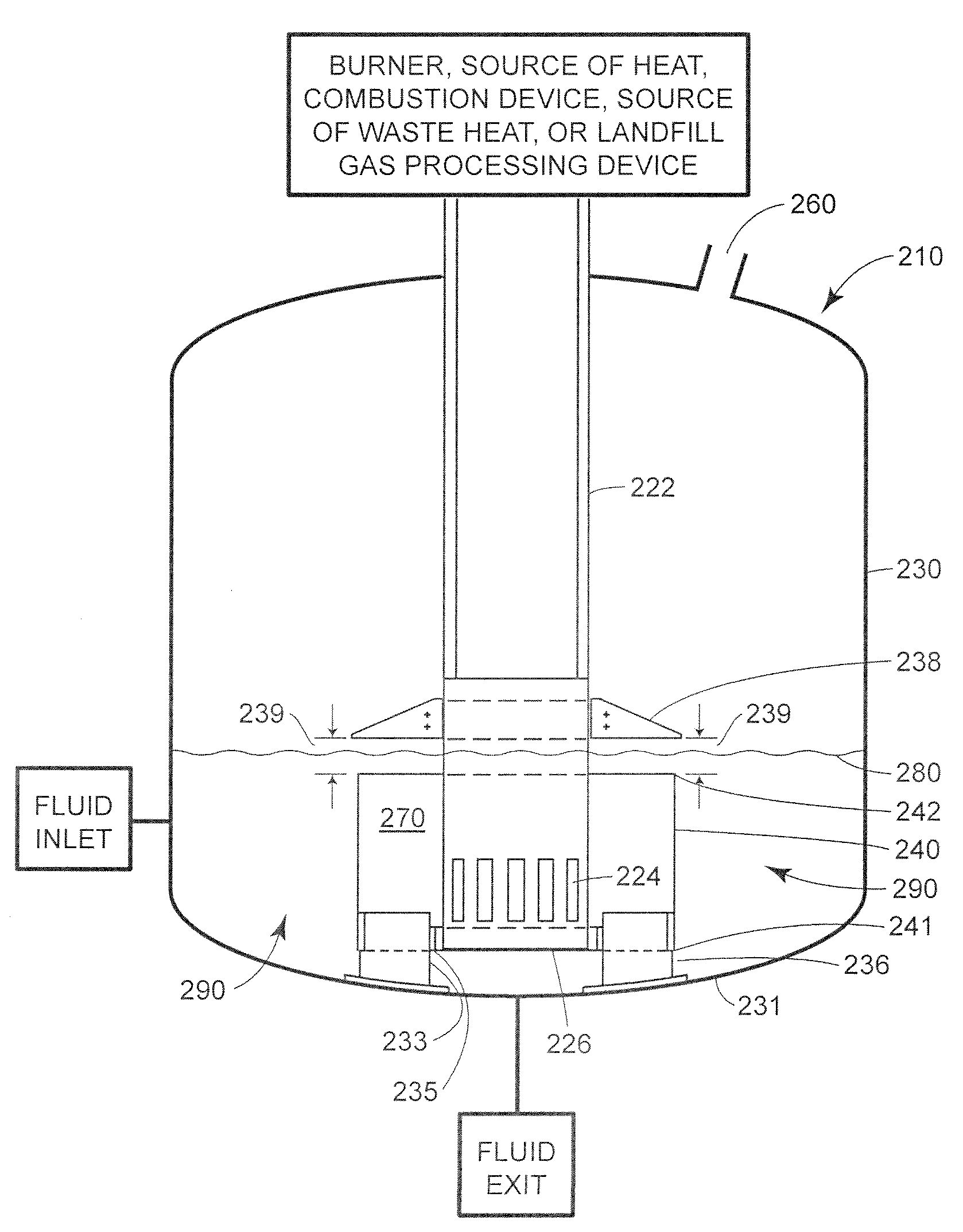

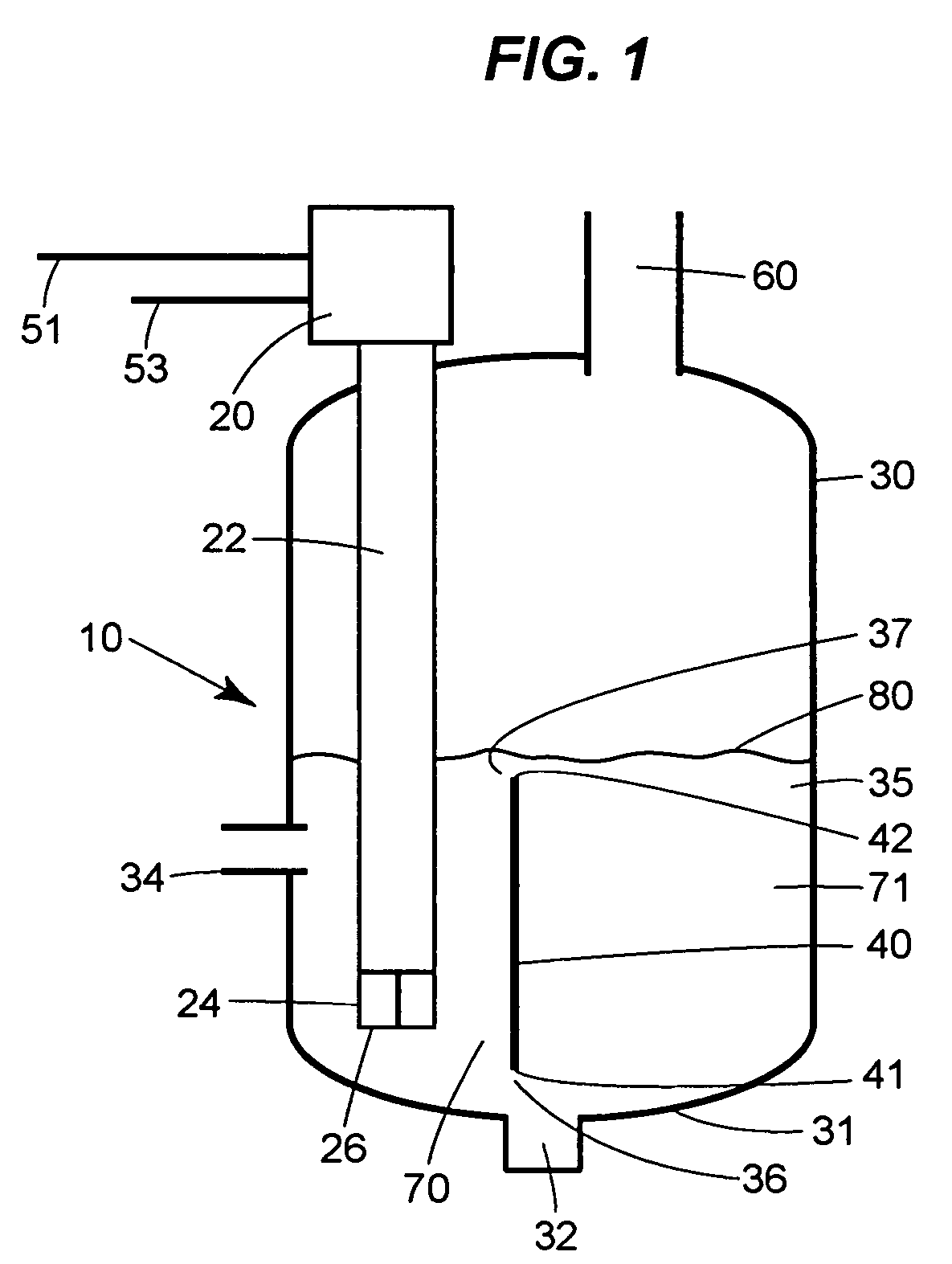

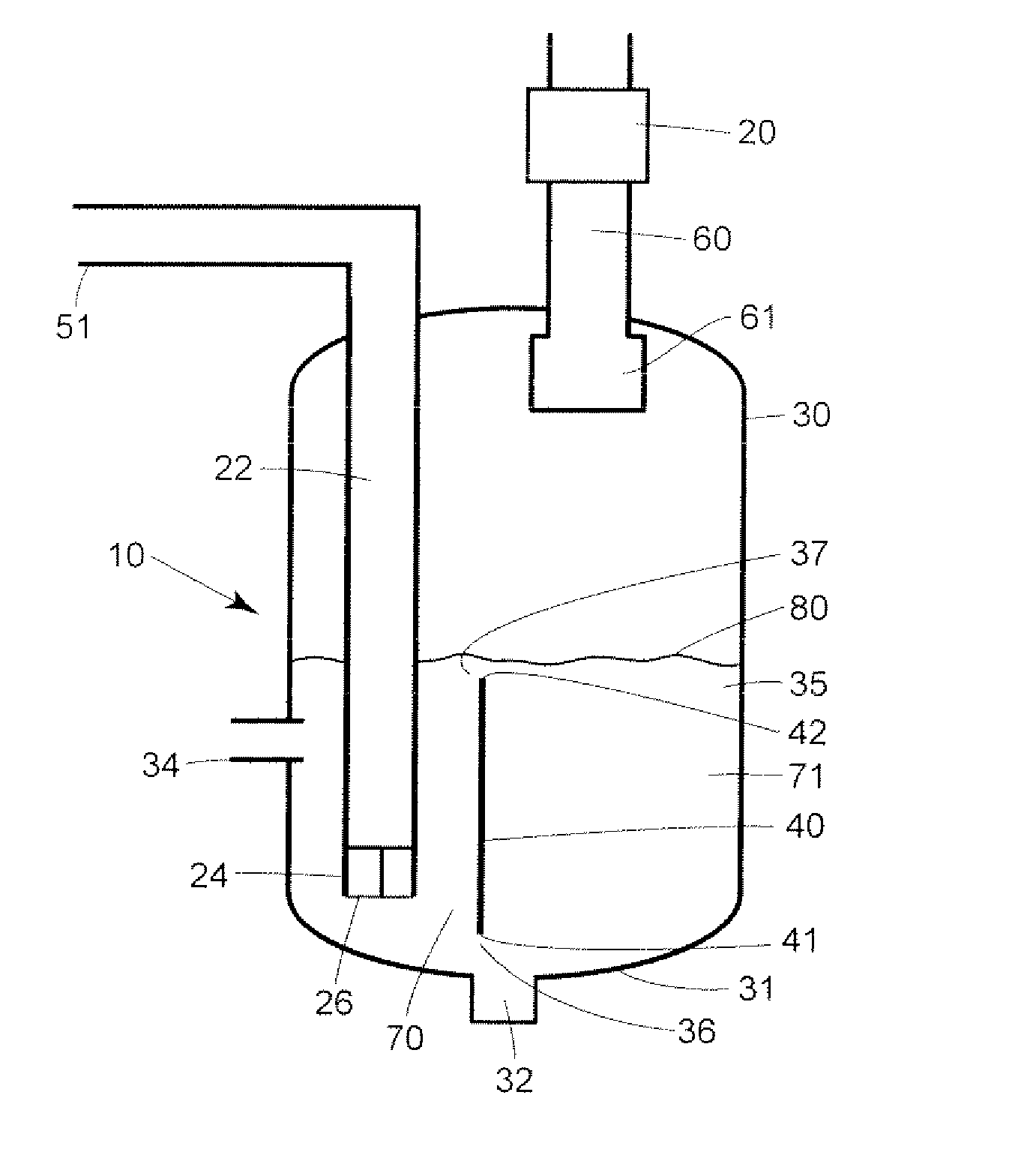

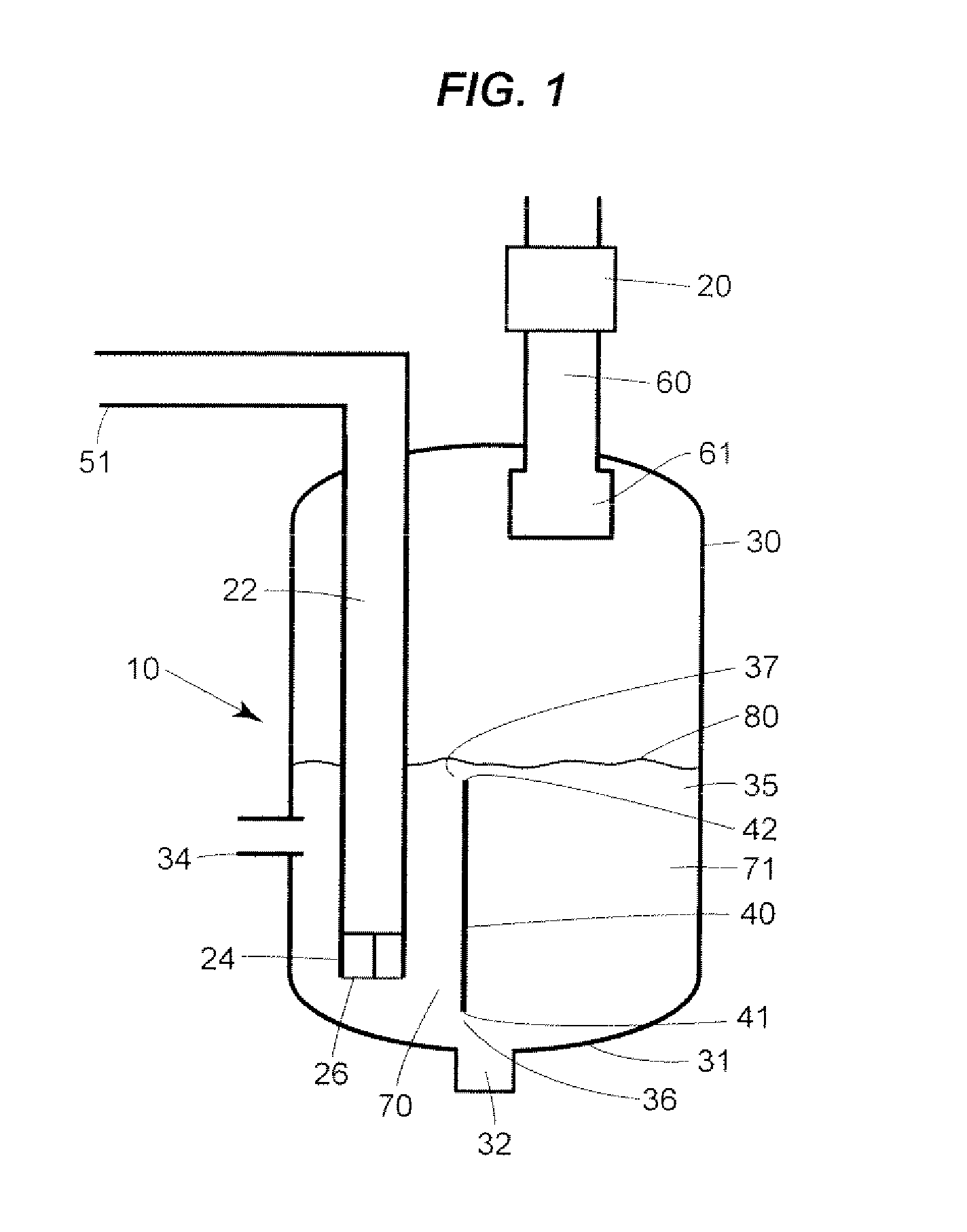

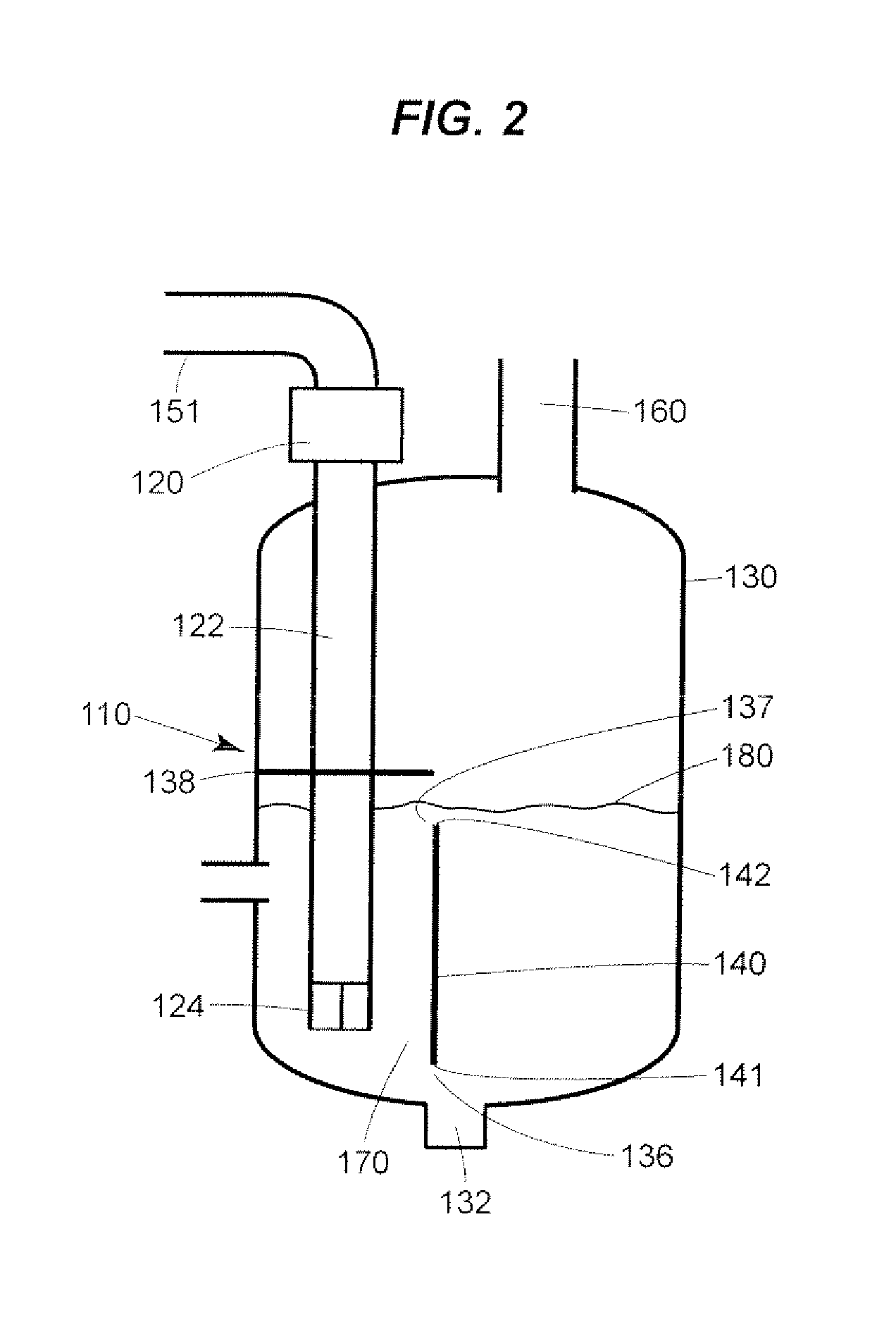

A submerged gas processor in the form of an evaporator or a submerged gas reactor includes a vessel, a gas delivery tube partially disposed within the vessel to deliver a gas into the vessel and a process fluid inlet that provides a process fluid to the vessel at a rate sufficient to maintain a controlled constant level of fluid within the vessel. A weir is disposed within the vessel adjacent the gas delivery tube to form a first fluid circulation path between a first weir end and a wall of the vessel and a second fluid circulation path between a second weir end and an upper end of the vessel. During operation, gas introduced through the tube mixes with the process fluid and the combined gas and fluid flow at a high rate with a high degree of turbulence along the first and second circulation paths defined around the weir, thereby promoting vigorous mixing and intimate contact between the gas and the process fluid. This turbulent flow develops a significant amount of interfacial surface area between the gas and the process fluid resulting in a reduction of the required residence time of the gas within the process fluid to; achieve thermal equilibrium and / or to drive chemical reactions to completion, all of which leads to a more efficient and complete evaporation, chemical reaction, or combined evaporation and chemical reaction process.

Owner:SHAW INTPROP HLDG INC

Shape memory polymers based on semicrystalline thermoplastic polyurethanes bearing nanostructured hard segments

InactiveUS7091297B2High modulusSufficient cross-linkingStentsOther chemical processesPolymer scienceAdhesive

Thermoplastic polyurethanes having an alternating sequence of hard and soft segments in which a nanostructured polyhedral oligomeric silsesquioxane diol is used as a chain extender to form a crystalline hard segment constituting SMPs. The polyurethanes are formed by reacting a polyol, a chain extender dihydroxyl-terminated POSS and a diisocyanate. The polyurethanes have multiple applications including for example, implants for human health care, drug delivery matrices, superabsorbant hydrogels, coatings, adhesives, temperature and moisture sensors, etc.

Owner:UNIV OF CONNECTICUT

Cationic Surfactant Systems Comprising Microfibrous Cellulose

ActiveUS20080146485A1Increase shearEnhanced mixing processCosmetic preparationsCationic surface-active compoundsParticulatesCellulose

Cationic surfactant systems, using microfibrous cellulose to suspend particulates therein, are described. Methods of making these systems are also described.

Owner:CP KELCO U S INC

Flow guiding structure for an internal combustion engine

InactiveUS20050011488A1Well mixedEnhanced mixing processInternal combustion piston enginesFuel re-atomisation/homogenisationCombustion chamberInternal combustion engine

A flow guiding structure for guiding into a clockwise swirling flow pattern gas flowing into a gas passageway leading toward a combustion chamber of an internal combustion engine. The structure includes a tubular peripheral wall having a base section for securing the structure to the gas passageway and an integrally extending guiding section. A plurality of guiding vanes extend radially inward from the guiding section each about a corresponding vane first edge. Each guiding vane includes a vane second edge extending in a geometrical plane perpendicular to the structure longitudinal axis. Each guiding vane further includes a substantially convex vane third edge. The guiding section is provided with a plurality of guiding bents formed therein and extending radially inwardly. The guiding bents are adapted to act as an auxiliary guide and as reinforcement for the structure.

Owner:DOUCET REJEAN

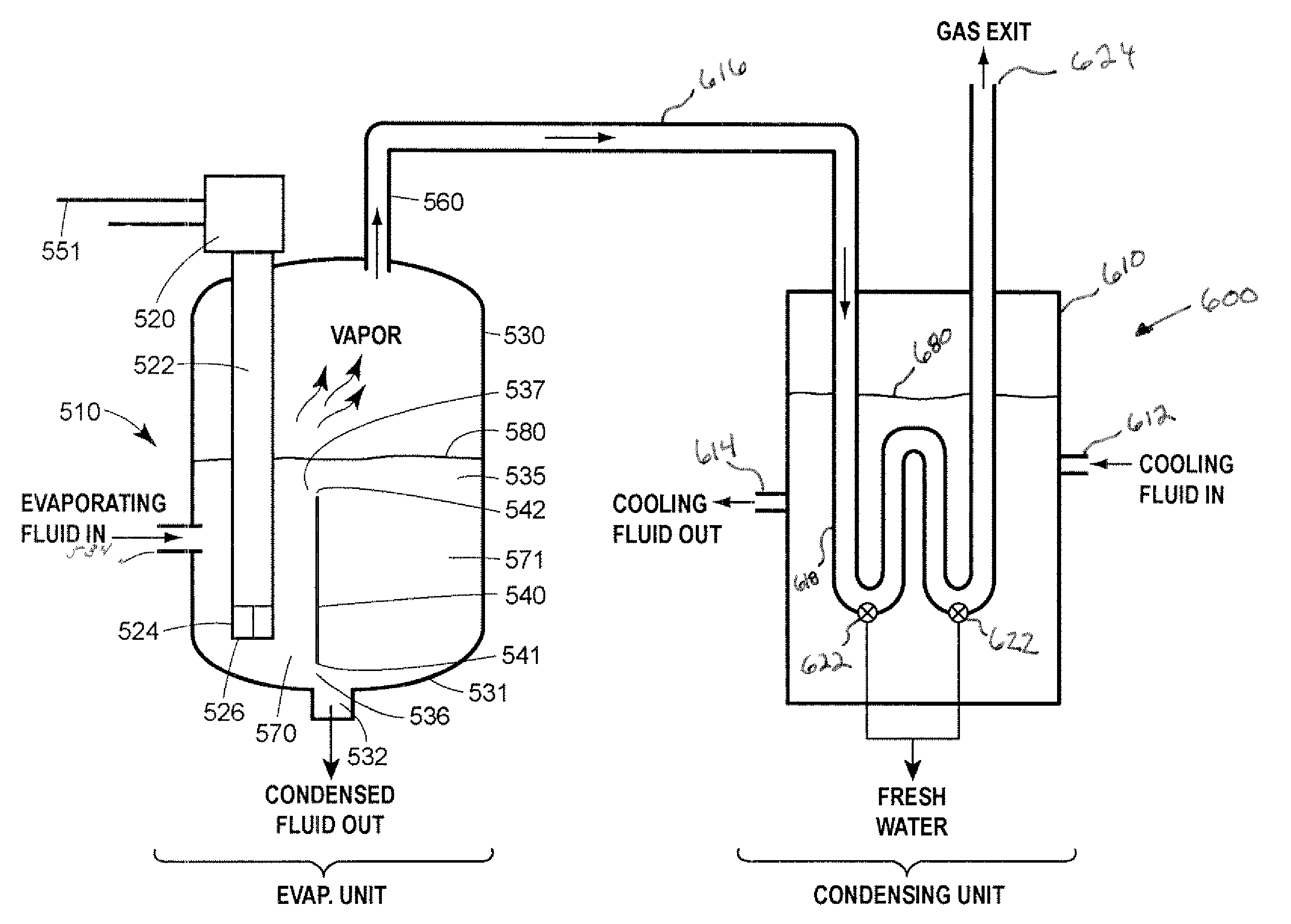

Desalination system

ActiveUS7832714B2Enhanced mixing processReduce cloggingGeneral water supply conservationSeawater treatmentWater desalinationHigh rate

A desalination system in the form of a submerged gas evaporator that includes a vessel, a gas delivery tube partially disposed within the vessel to deliver a gas into the vessel and a fluid inlet that provides a fluid to the vessel at a rate sufficient to maintain a controlled constant level of fluid within the vessel. A weir is disposed within the vessel adjacent the gas delivery tube to form a first fluid circulation path between a first weir end and a wall of the vessel and a second fluid circulation path between a second weir end and an upper end of the vessel. During operation, gas introduced through the tube mixes with the fluid and the combined gas and fluid flow at a high rate with a high degree of turbulence along the first and second circulation paths defined around the weir, thereby promoting vigorous mixing and intimate contact between the gas and the fluid. This turbulent flow develops a significant amount of inter facial surface area between the gas and the fluid resulting in a reduction of the required residence time of the gas within the fluid to achieve thermal equilibrium which leads to a more efficient and complete evaporation. Additionally, vapor exiting the submerged gas evaporator is condensed in a condensing unit thus precipitating vapor into a liquid for removal.

Owner:HEARTLAND WATER TECH INC

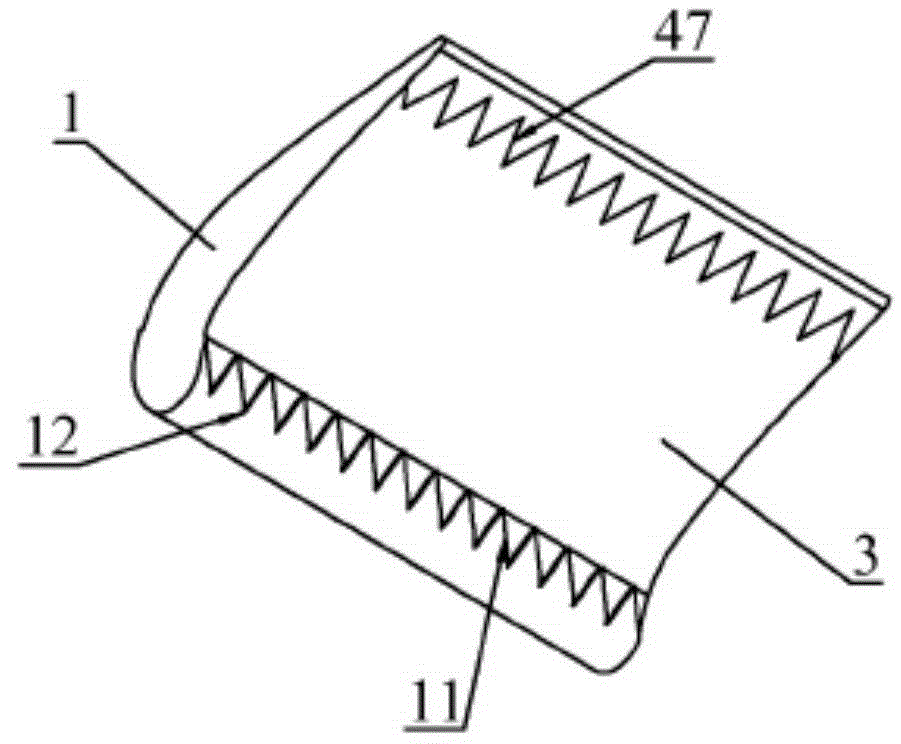

Filtered cigarette incorporating an adsorbent material

ActiveUS20050066983A1Enhanced mixing processTobacco smoke filtersCompartment RegionBiomedical engineering

A filter element incorporating an adsorbent material is provided. The filter element may comprise a first section of filter material and a second section of filter material spaced apart to form a compartment therebetween. The compartment may be filled with one or more adsorbents or the compartment may be divided into two regions, wherein one compartment region is filled with an adsorbent and the other compartment region is either filled with an ion-exchange resin or remains empty. The section of filter material adjacent to the tobacco rod may include one or more channels therethrough for passaging smoke directly from the tobacco rod into the adsorbent-filled compartment. The mouth end section of filter material may contain a breakable capsule, wherein the breakable capsule is filled with a flavoring agent capable of altering the taste characteristics of mainstream smoke.

Owner:R J REYNOLDS TOBACCO COMPANY

Fluid scrubber

ActiveUS20080173176A1Efficient transferEnhanced mixing processCombination devicesGas treatmentHigh rateChemical reaction

A fluid scrubber in the form of a submerged gas reactor includes a reaction vessel, a gas delivery lube partially disposed within the reaction vessel to deliver a gas into the reaction vessel and a scrubbing liquid inlet that provides a scrubbing liquid to the reaction vessel at a rate sufficient to maintain a controlled, constant level of fluid within the reaction vessel. A weir is disposed within the reaction vessel adjacent the gas delivery tube to form a first fluid circulation path between a first weir end and a wall of the reaction vessel and a second fluid circulation path between a second weir end and an upper end of the reaction vessel. During operation, gas introduced through the tube mixes with the scrubbing liquid and the combined gas and liquid flow at a high rate with a high degree of turbulence along the first and second, circulation paths defined around the weir, thereby promoting vigorous mixing and intimate contact between the gas and the scrubbing liquid. This turbulent flow develops a significant amount of interfacial surface area between the gas and the scrubbing liquid resulting in a reduction of the required residence time of the gas within the scrubbing liquid to achieve thermal equilibrium and / or to drive chemical reactions to completion, all of which leads to a more efficient and complete evaporation, chemical reaction, or combined evaporation and chemical reaction process.

Owner:HEARTLAND WATER TECH INC

Filtered cigarette incorporating an adsorbent material

A filter element incorporating an adsorbent material is provided. The filter element may comprise a first section of filter material and a second section of filter material spaced apart to form a compartment therebetween. The compartment may be filled with one or more adsorbents or the compartment may be divided into two regions, wherein one compartment region is filled with an adsorbent and the other compartment region is either filled with an ion-exchange resin or remains empty. The section of filter material adjacent to the tobacco rod may include one or more channels therethrough for passaging smoke directly from the tobacco rod into the adsorbent-filled compartment. The mouth end section of filter material may contain a breakable capsule, wherein the breakable capsule is filled with a flavoring agent capable of altering the taste characteristics of mainstream smoke.

Owner:R J REYNOLDS TOBACCO COMPANY

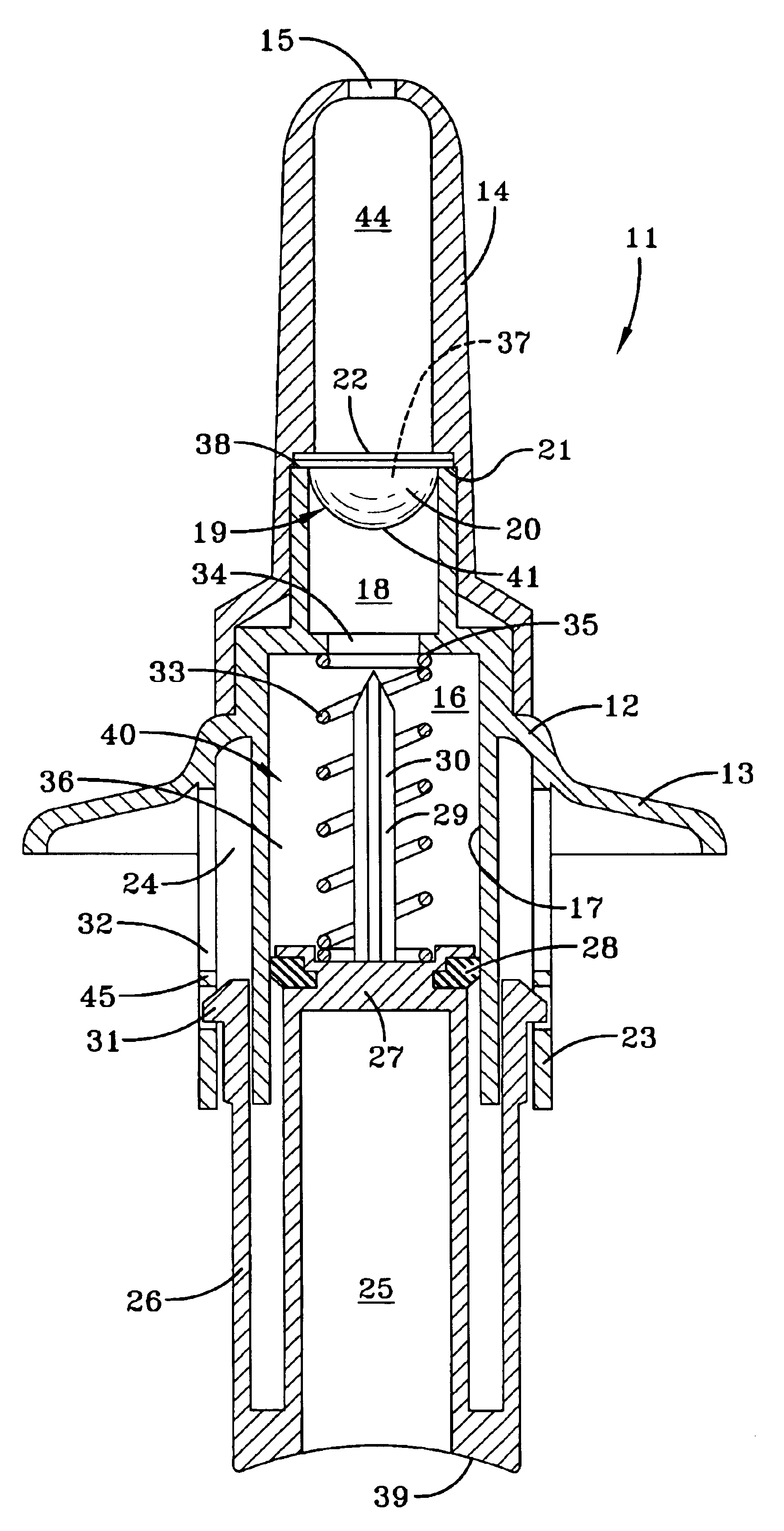

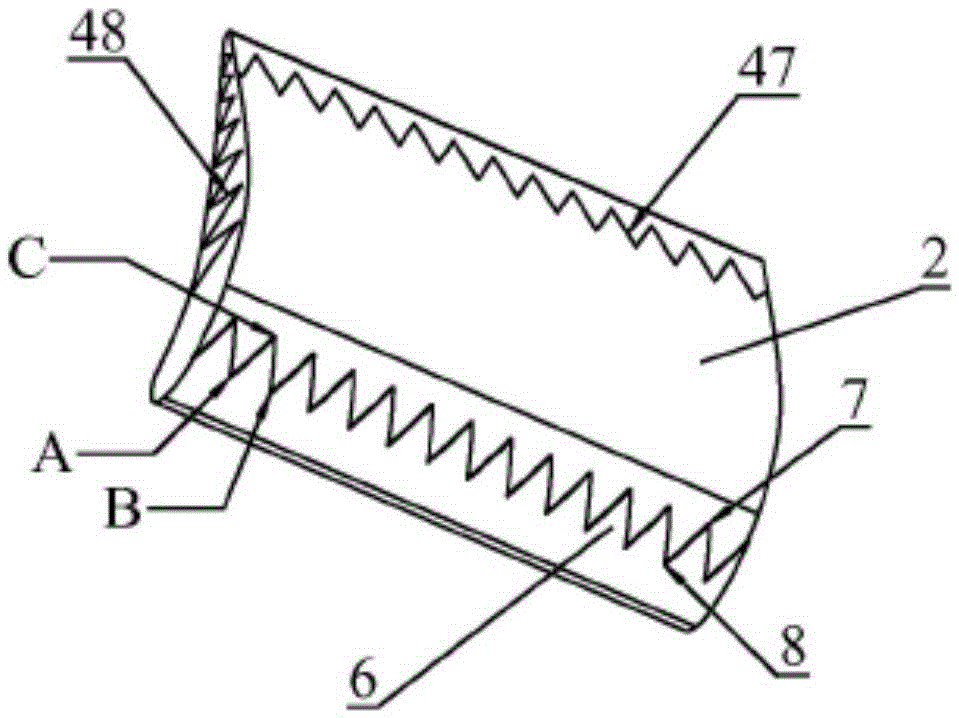

Method and dispenser for mixing and discharging media

InactiveUS6877672B2Simplify guidanceEasy miscibilityMedical devicesFire rescueEngineeringRisk stroke

The object of the invention is to provide a method and a dispenser in which, compared with known dispensers, the fluid path design is simplified. The dispenser has a medium reservoir (19) containing a medium to be discharge during one discharge stroke of the dispenser (11). For this purpose a feed fluid flows through the medium reservoir and discharges the medium through a reservoir discharge opening. For producing a discharge stroke, the dispenser has an actuator (25), whose actuation at least indirectly leads to an impact spike (29) penetrating from the outside into the medium reservoir (19), so as to produce a connection between a pump (40) for a feed fluid and the medium reservoir. As a result of the pressure of the feed fluid flowing into the medium reservoir, at a point in the medium reservoir (19) differing from the entry point of the impact spike (29), an opening is formed.

Owner:APTAR RADOLFZELL

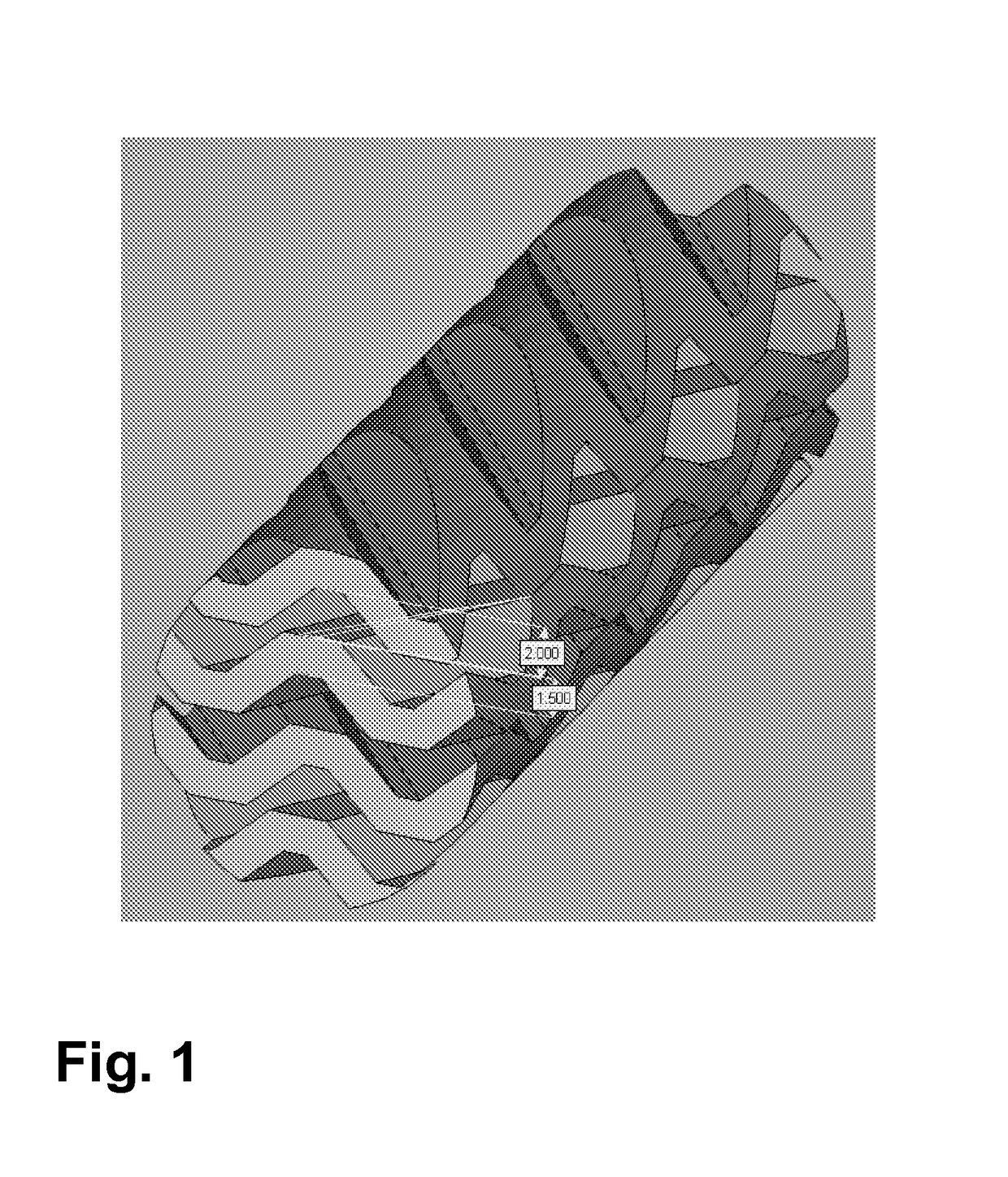

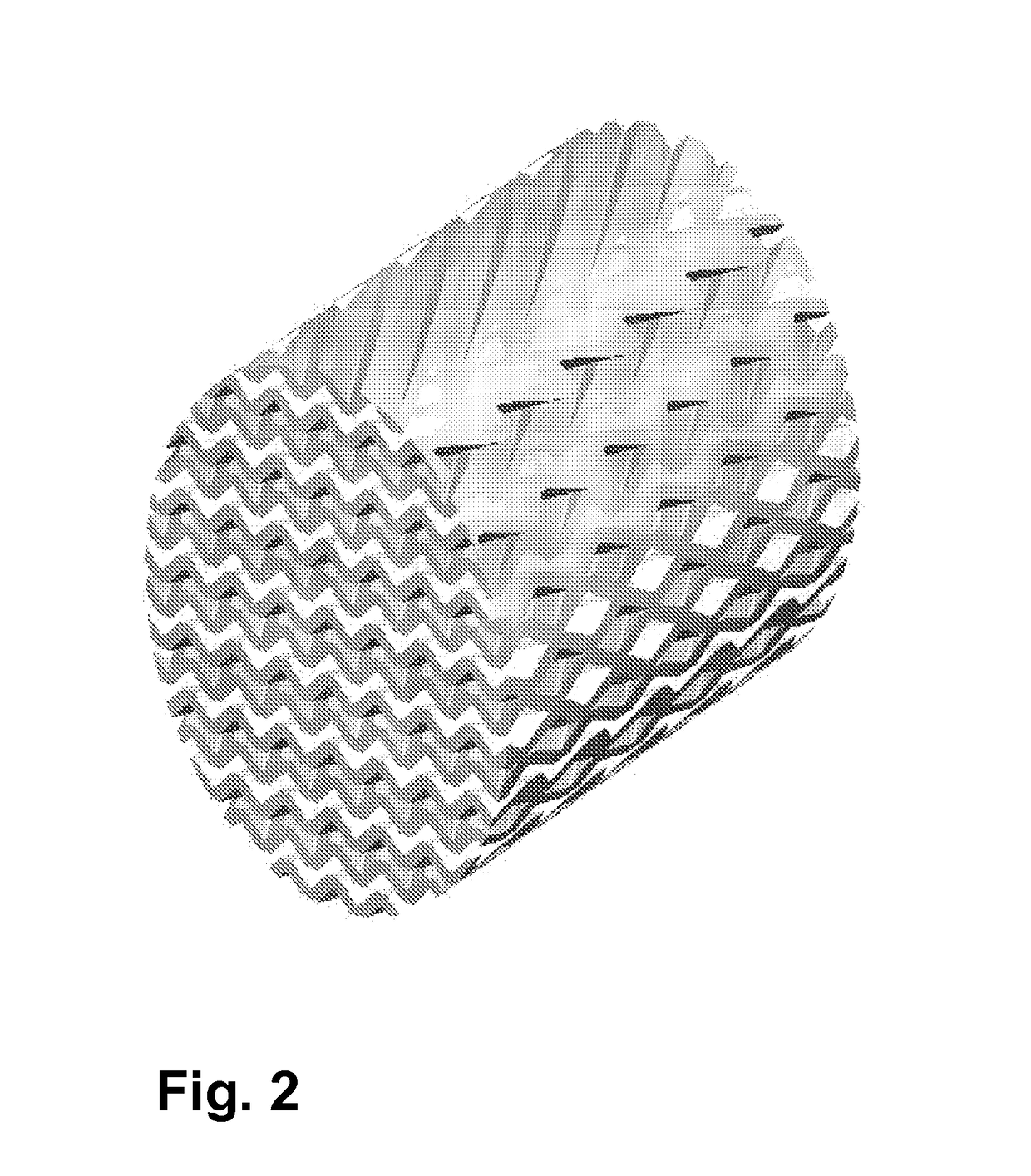

Use of shaped bodies having catalytic properties as reactor internals

InactiveUS8119554B2Easy to useLower overall pressure dropAdditive manufacturing apparatusInorganic chemistryChemical reactionActive component

Shaped bodies having catalytic properties which can be obtained by a process comprising the steps:a) production of a shaped body by means of a powder-based rapid prototyping process,b) if appropriate, a heat treatment of the shaped body,c) if appropriate, application of at least one catalytically active component to the shaped body,d) if appropriate, a further heat treatment,where steps b), c) and / or d) can be carried out a number of times,are used as reactor internals in heterogeneously catalyzed chemical reactions.

Owner:BASF SE

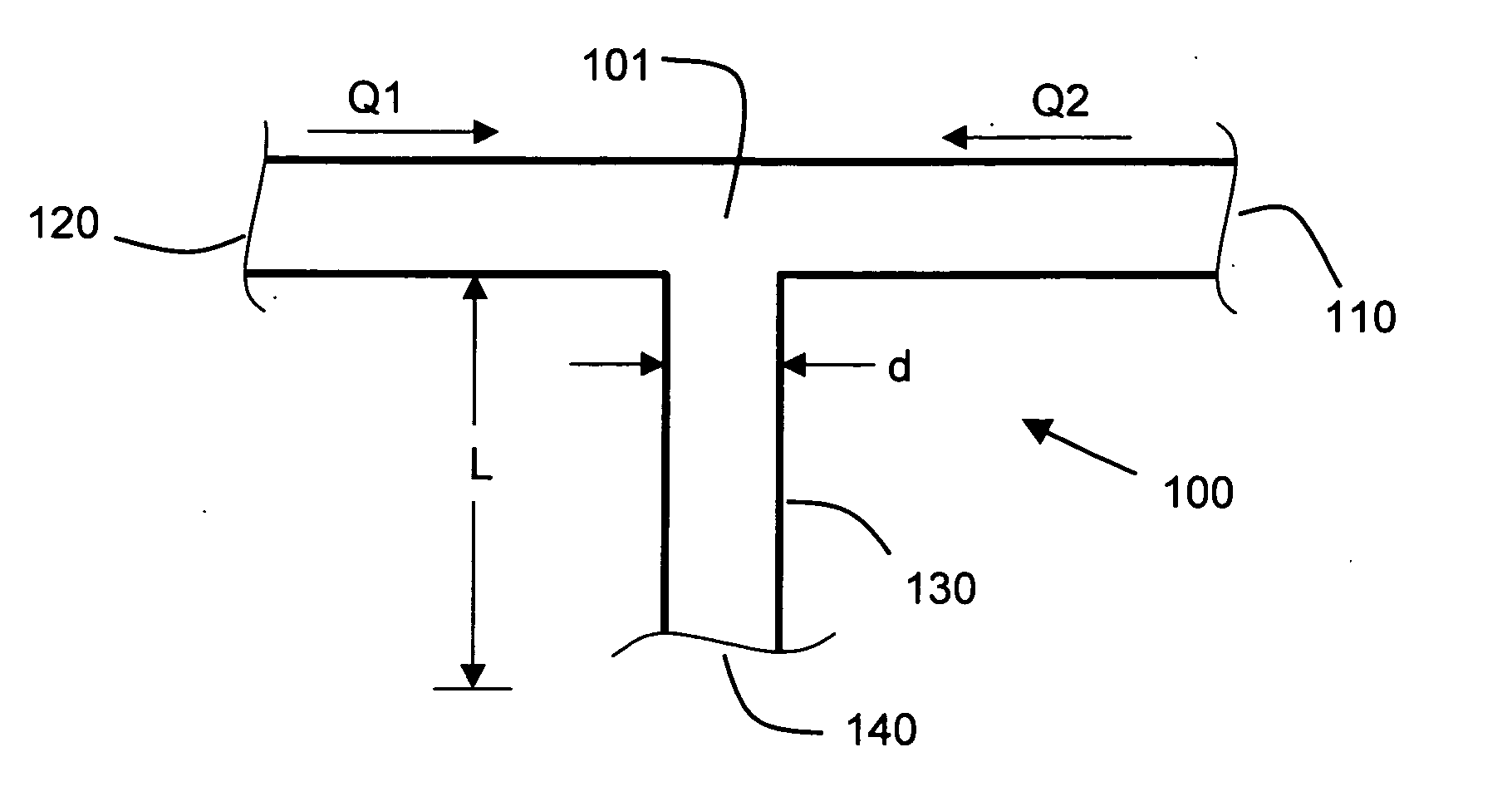

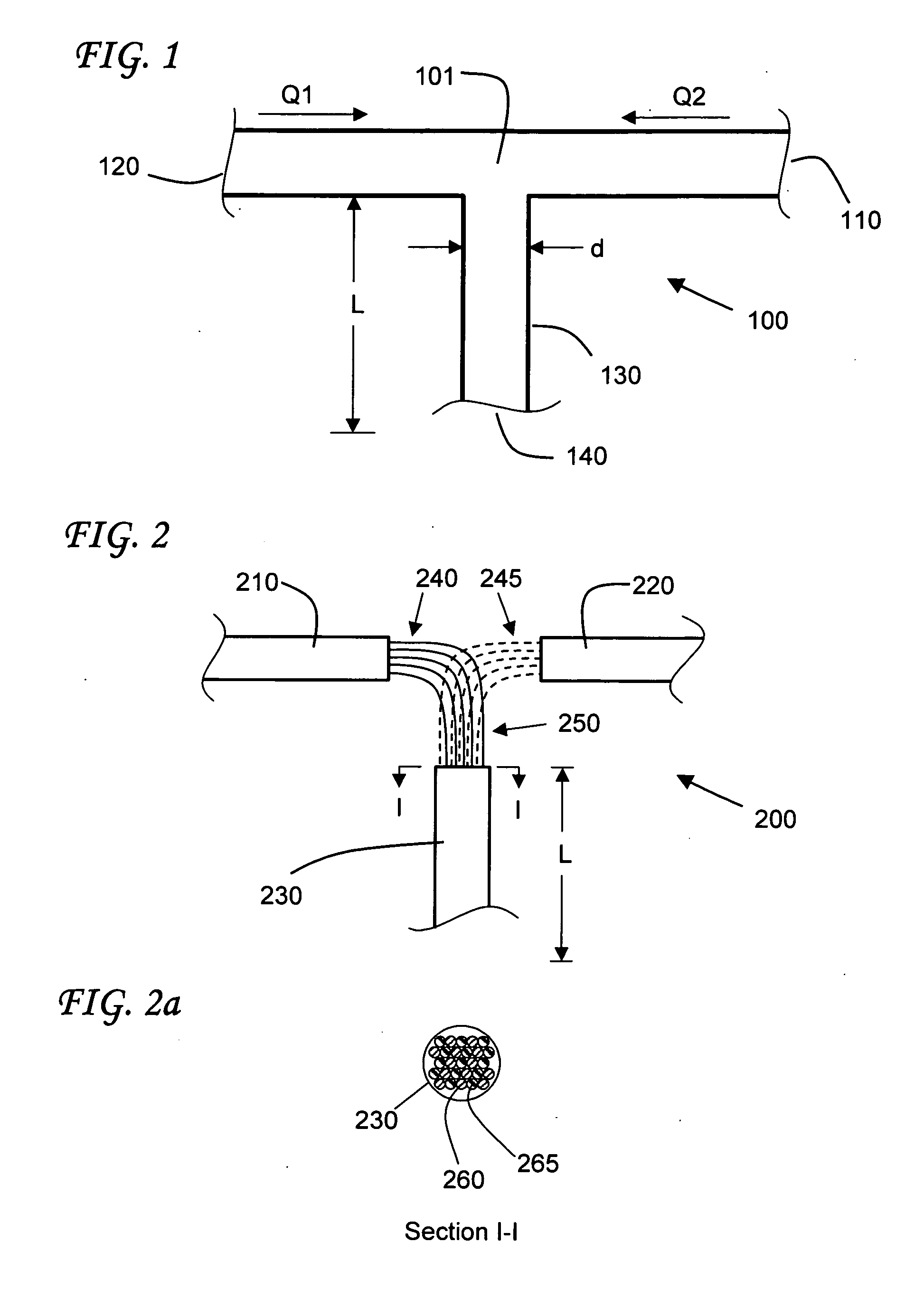

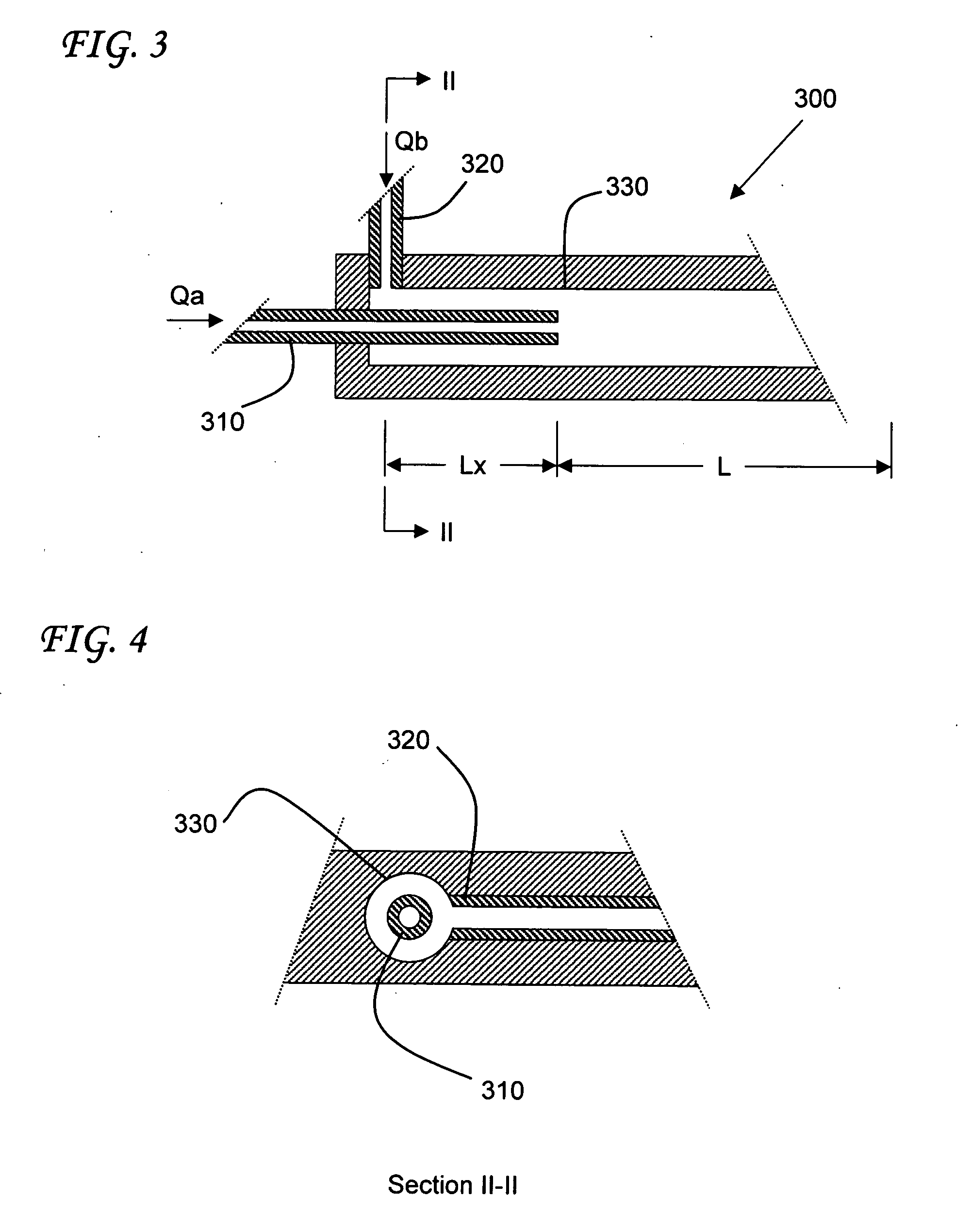

Micromixer

InactiveUS20050252840A1Efficient mixingEnhanced mixing processIon-exchange process apparatusFlow mixersComputer scienceDynamic range

Methods and apparatus for mixing fluids are provided. The devices and methods operate without moving parts, and generate well-mixed fluids over a broad dynamic range of flow rates. Preferred embodiments include junction-type mixers, bundled mixers, and co-axial mixers. The devices and methods are optimized to produce rapid, accurate gradients to improve associated system throughput and reproducibility.

Owner:EKSIGENT TECH

Desalination system

ActiveUS20080173590A1High degree of mixingHigh degree of turbulenceGeneral water supply conservationSeawater treatmentHigh rateSeawater

A desalination system in the form of a submerged gas evaporator that includes a vessel, a gas delivery tube partially disposed within the vessel to deliver a gas into the vessel and a fluid inlet that provides a fluid to the vessel at a rate sufficient to maintain a controlled constant level of fluid within the vessel. A weir is disposed within the vessel adjacent the gas delivery tube to form a first fluid circulation path between a first weir end and a wall of the vessel and a second fluid circulation path between a second weir end and an upper end of the vessel. During operation, gas introduced through the tube mixes with the fluid and the combined gas and fluid flow at a high rate with a high degree of turbulence along the first and second circulation paths defined around the weir, thereby promoting vigorous mixing and intimate contact between the gas and the fluid. This turbulent flow develops a significant amount of inter facial surface area between the gas and the fluid resulting in a reduction of the required residence time of the gas within the fluid to achieve thermal equilibrium which leads to a more efficient and complete evaporation. Additionally, vapor exiting the submerged gas evaporator is condensed in a condensing unit thus precipitating vapor into a liquid for removal.

Owner:HEARTLAND WATER TECH INC

Air stripper

ActiveUS20080174033A1Increased turbulenceEnhanced mixing processMixing methodsUsing liquid separation agentChemical reactionHigh rate

An air stripper in the form of an submerged gas evaporator or a submerged gas reactor that includes a vessel, a gas delivery tube partially disposed within the vessel to deliver a gas into the vessel and a contaminated liquid inlet that provides a contaminated liquid to the vessel at a rate sufficient to maintain a controlled constant level of process fluid within the vessel. A weir is disposed within the vessel adjacent the gas delivery tube to form a first fluid circulation path between a first weir end and a wall of the vessel and a second fluid circulation path between a second weir end and an upper end of the vessel. During operation, gas introduced through the tube mixes with the process fluid and the combined gas and fluid flow at a high rate with a high degree of turbulence along the first and second circulation paths defined around the weir, thereby promoting vigorous mixing and intimate contact between the gas and the process fluid. This turbulent flow develops a significant amount of interfacial surface area between the gas and the process fluid resulting in a reduction of the required residence time of the gas within the process fluid to achieve thermal equilibrium and / or to drive chemical reactions to completion, all of which leads to a more efficient and complete evaporation, chemical reaction, or combined evaporation and chemical reaction process.

Owner:HEARTLAND WATER TECH INC

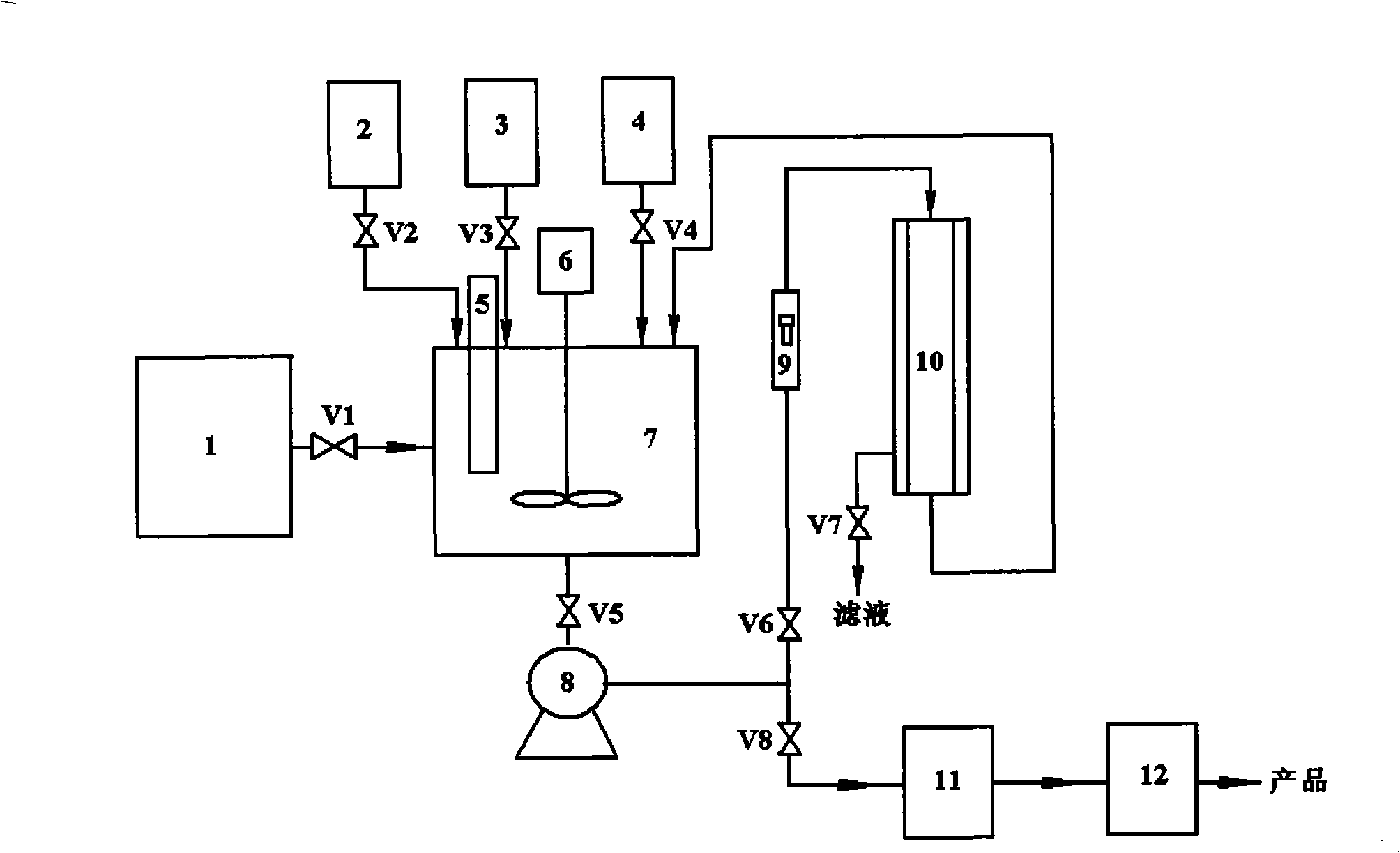

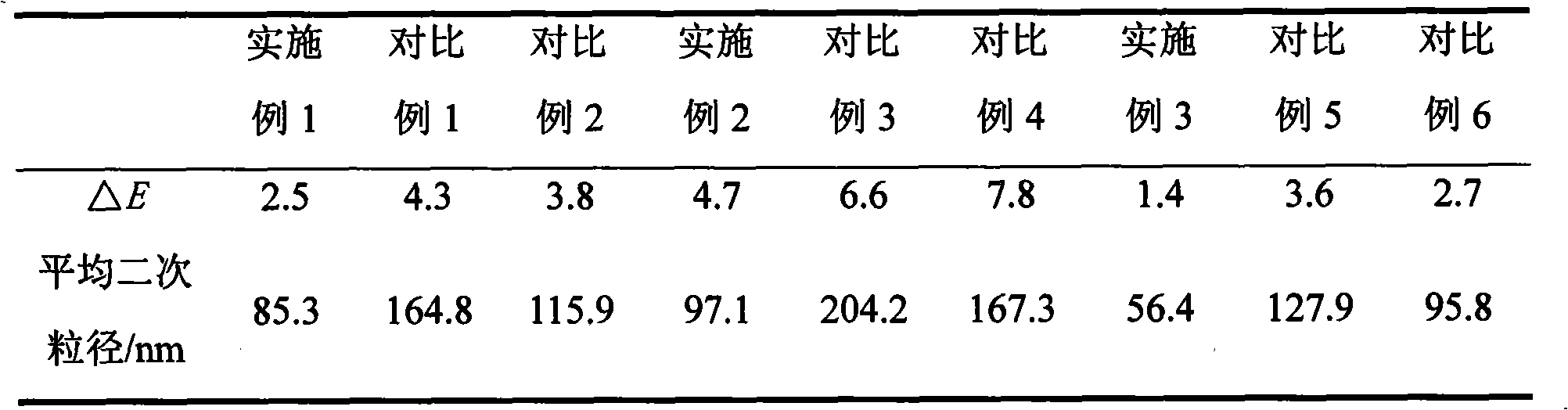

Nano titanium oxide inorganic surface treatment method

ActiveCN101255288AAvoid flocculationReduce clumpingInorganic pigment treatmentNanometreTitanium dioxide

The invention discloses a nm titanium dioxide inorganic surface treating method. The inorganic surface treating is performed when the nm titanium dioxide is in good dispersed state and the inorganic surface treatment effect is increased using the said method. The invention solves the flocculation and dispersion problem of nm titanium dioxide using ultrasonic field, mechanical agitation and film separation and phase integrating. During the process of treating the inorganic surface, on the one hand the nm titanium dioxide dispersion liquid is always under the action of mechanical agitation and ultrasonic, on the other hand, the impurity ions are continuously removed using membrane separation device, so as to make sure the inorganic surface coating reaction under the full dispersed state of the nm titanium dioxide.

Owner:江苏河海纳米科技股份有限公司 +1

Cooling tower

InactiveUS8136797B2Enhanced mixing processReduce cloggingCarburetting airLiquid degasificationHigh rateCooling tower

Owner:HEARTLAND TECH PARTNERS

Shape memory polymers based on semicrystalline thermoplastic polyurethanes bearing nanostructured hard segments

InactiveUS7524914B2Above the melting point of the POSS domainsAdjustable stiffnessPolymer scienceAdhesive

Thermoplastic polyurethanes having an alternating sequence of hard and soft segments in which a nanostructured polyhedral oligosilsesquioxane diol is used as a chain extender to form a crystalline hard segment constituting SMPs. The polyurethanes are formed by reacting a polyol, a chain extender dihydroxyl-terminated polyhedral oligosilsesquioxane and a diisocyanate. The polyurethanes have multiple applications including for example, implants for human health care, drug delivery matrices, superabsorbant hydrogels, coatings, adhesives, temperature and moisture sensors, etc.

Owner:UNIV OF CONNECTICUT

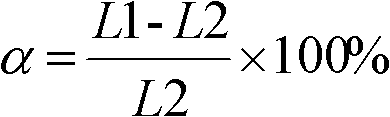

A kind of coal combustion accelerant

The invention provides a coal combustion improver which comprises 5 to 10 percent of dispersing agent, 5 to 10 percent of penetrant, 35 to 50 percent of oxidizing agent, 35 to 50 percent of catalyst and 5 to 10 percent of emulsifying agent, wherein the oxidizing agent is a mixture of nitrophenol and methyl tertiary butyl ether; and the catalyst is nano-scale metallic oxide. The coal combustion improver provided by the invention has high combustion improving efficiency and is safe and environmental-friendly. The invention also provides a method for preparing the coal combustion improver.

Owner:安徽海螺材料科技股份有限公司

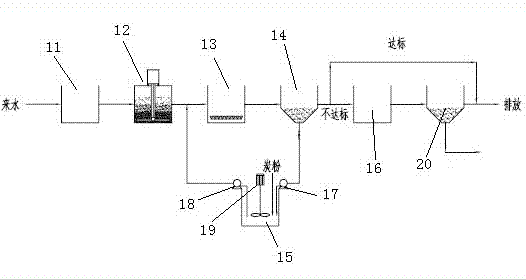

PACT (powdered activated carbon treatment) process and device, and activated carbon-microbial zoogloea culture method using same

ActiveCN103086503AImprove settlement performanceProportionally largeSustainable biological treatmentWater/sewage treatment by sorptionZoogloeaWater treatment system

The invention relates to a PACT (powdered activated carbon treatment) process and an PACT process device. The activated carbon-microbial zoogloea culture method comprises the following steps: selecting activated sludge, and culturing until the activated sludge is mature; and adding powdered activated carbon to ensure that the powdered activated carbon serving as a core is wrapped by microorganisms to form activated carbon-microbial zoogloea floccules, and acclimating, thus increasing the specific gravity of the powdered activated carbon and enhancing the precipitability. In the PACT process device, a sludge return tank is added, and the powdered activated carbon is added into the sludge return tank, so that the powdered activated carbon and the microorganisms can form activated carbon-microbial zoogloeae in the sludge return tank, thereby prolonging the retention time of the powdered activated carbon in a water treatment system; and sludge in the sludge return tank is lifted into a sewage inlet at the front end of an aerobic tank through a lifting pump, so that the sludge and sewage can be better mixed, thereby prolonging the retention time of the powdered activated carbon in the aerobic tank and enhancing the treatment effect. On the basis of prolonging the water retention time of the aerobic tank, the invention does not need to increase the volume of the original aerobic tank, and is small in occupied area and easy to implement.

Owner:GUANGDONG XINDAYU ENVIRONMENTAL PROTECTION TECH CO LTD +1

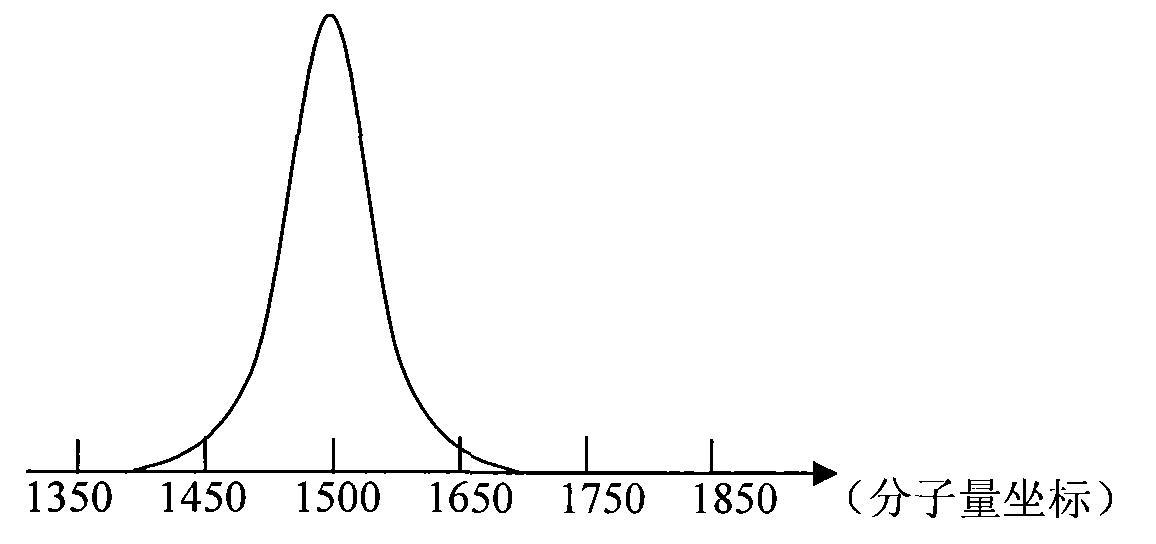

Method for preparing crystal II-type ammonium polyphosphate with distribution of high polymerization degree and narrow molecular weight

ActiveCN101597044AEliminate the effects ofTemperature controlPhosphorus compoundsSolubilityPolymerization

The invention discloses a method for preparing crystal II-type ammonium polyphosphate with distribution of high polymerization degree and narrow molecular weight. The method comprises the following steps: putting phosphorus pentoxide and diammonium phosphate which have equal molar ratio into a malaxator which can accurately control a temperature and heated by conducting oil for mixing; under the protection of inert gas, heating the materials in the malaxator to between 100 and 250 DEG C through the circulatory conducting oil; stopping introducing the inert gas; performing ammonification on the materials and heating the materials under an atmosphere of ammonia gas till the materials are totally molten down; stopping introducing the ammonia gas; after homogenization, introducing the ammonia gas again and heating the materials; throwing a surface treating agent into the malaxator; after material throwing is completed, continuously introducing the ammonia gas, keeping warm and mixing the materials; after reaction is finished, transferring the materials to a closed vessel and reducing the temperature; simultaneously, continuously introducing the ammonia gas till the temperature of the materials is below 100 DEG C; and obtaining a finished product. The method can prepare the crystal II -type ammonium polyphosphate with the distribution of the high polymerization degree and the narrow molecular weight; and the product has the characteristics of uniform granularity shape, small water-solubility, good heat resistance, high polymerization degree, narrow distribution of molecular weight and high crystal II-type purity.

Owner:GUANGDONG JUSHI CHEM CO LTD

Cationic surfactant systems comprising microfibrous cellulose

ActiveUS7888308B2Increase shearEnhanced mixing processCosmetic preparationsCationic surface-active compoundsCelluloseParticulates

Owner:CP KELCO U S INC

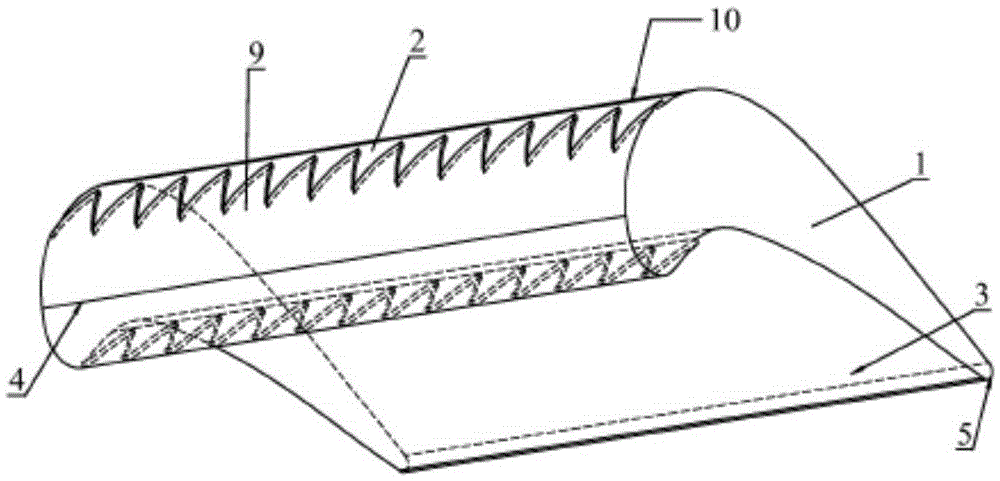

Filtered cigarette incorporating an adsorbent material

ActiveUS8066011B2Enhanced mixing processTobacco treatmentTobacco smoke filtersFilter materialIon-exchange resin

A filter element incorporating an adsorbent material is provided. The filter element may comprise a first section of filter material and a second section of filter material spaced apart to form a compartment therebetween. The compartment may be filled with one or more adsorbents or the compartment may be divided into two regions, wherein one compartment region is filled with an adsorbent and the other compartment region is either filled with an ion-exchange resin or remains empty. The section of filter material adjacent to the tobacco rod may include one or more channels therethrough for passaging smoke directly from the tobacco rod into the adsorbent-filled compartment. The mouth end section of filter material may contain a breakable capsule, wherein the breakable capsule is filled with a flavoring agent capable of altering the taste characteristics of mainstream smoke.

Owner:R J REYNOLDS TOBACCO COMPANY

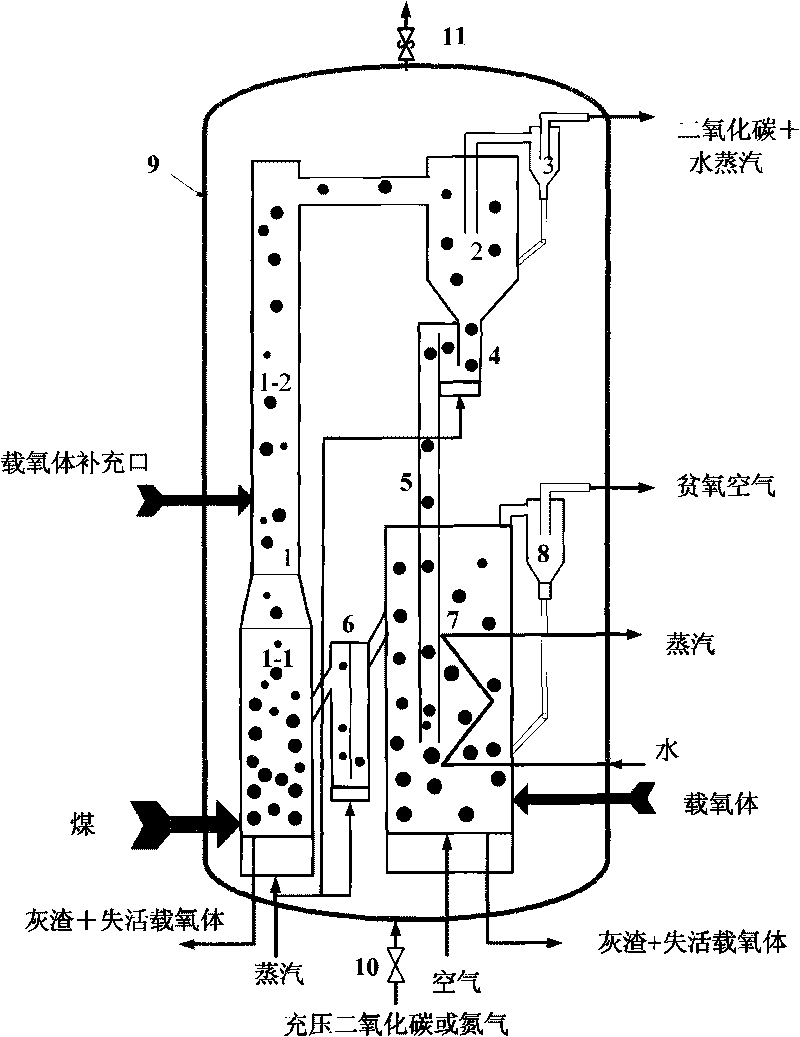

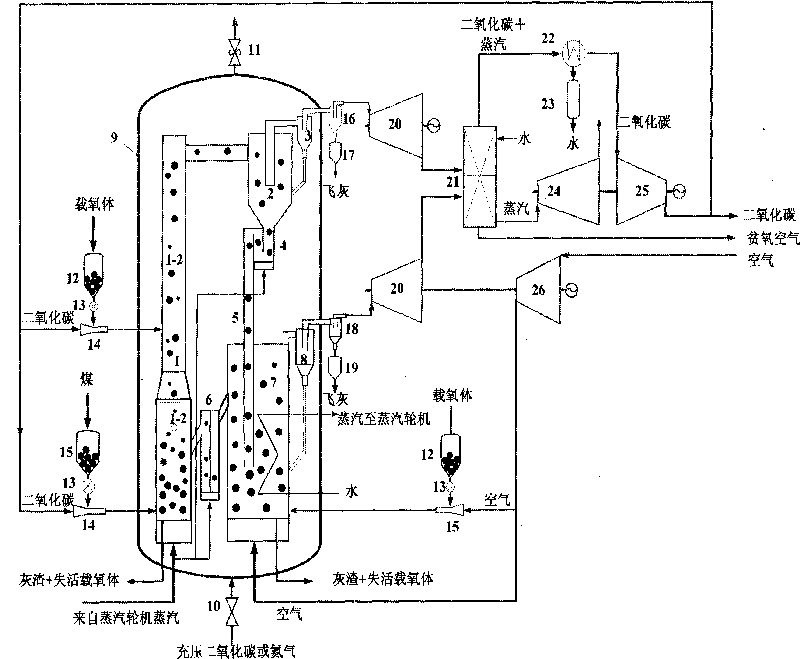

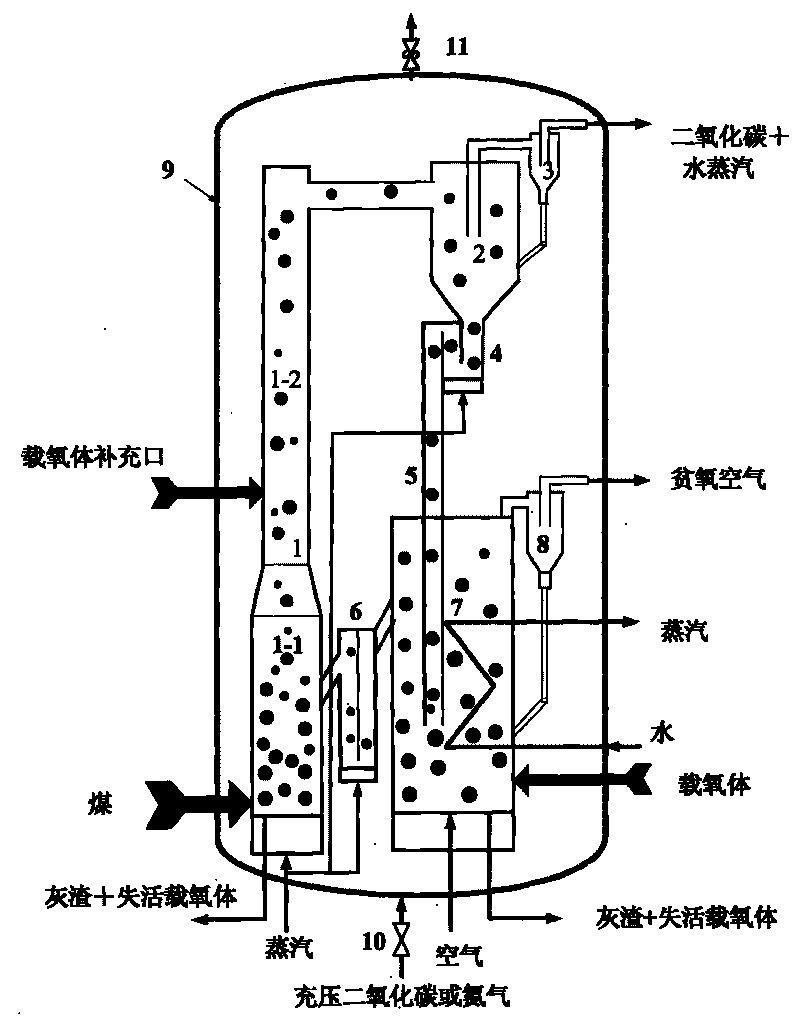

Coal combustion apparatus capable of separating carbon dioxide and separation method thereof

InactiveCN101699187AEasy to handleReduced compression energy consumptionExothermal chemical reaction heat productionCarbon compoundsCycloneEngineering

The invention provides a coal combustion apparatus capable of separating carbon dioxide, which is mainly formed by connecting a fuel reactor, a primary cyclone separator, a dipleg and an air reactor in series; wherein the lower part of the fuel reactor is provided with a mixing chamber with large cross section, and the upper part thereof is provided with a lifting tube with small cross section; and the height of the lifting tube is over three times higher than that of the mixing chamber. The invention also provides a method using the coal combustion apparatus capable of separating the carbon dioxide to separate the carbon dioxide. The fuel reactor adopts the structure of a reactor with long residence time, internal circulation can be formed by granules, and the gas-solid turbulence is improved; the air reactor adopts a moving fluidized bed to ensure the operation to be stable, so that the heat can be evenly released; meanwhile, a heat exchanger is arranged inside the bed, so that coking caused by local overheating since a great deal of heat is released in a centralized way in oxidation reaction can be avoided. Furthermore, the fuel reactor and the air reactor run under the pressure, so that the equipment can be compact, the utilization efficiency of system energy is high, and the subsequent carbon dioxide compression energy consumption is reduced.

Owner:SOUTHEAST UNIV

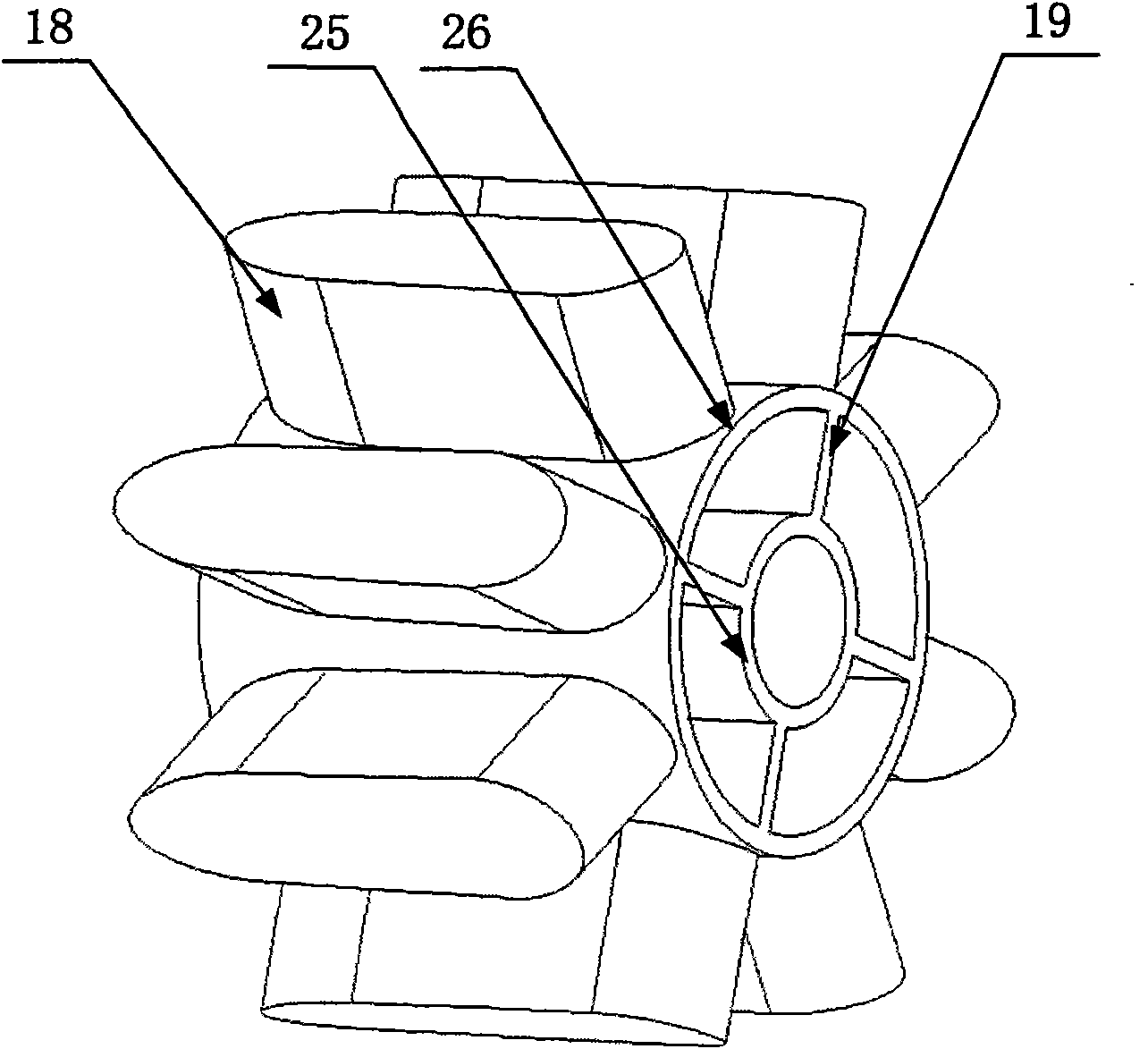

Composite concentration triple-wind-regulating low-NOx cyclone pulverized-coal burner

ActiveCN102062396AFire stableExtended service lifePulverulent fuel combustion burnersIndirect carbon-dioxide mitigationCycloneConvex structure

The invention relates to a composite concentration triple-wind-regulating low-NOx cyclone pulverized-coal burner which comprises a central wind passage, wherein a primary wind passage, an internal direct-flow secondary wind passage, an internal rotational-flow secondary wind passage and an external rotational-flow secondary wind passage are sequentially and concentrically arranged at the outer side of the central wind passage from inside to outside, a conical pulverized-coal concentrating device and a star-shaped pulverized-coal concentrating device are arranged in the primary wind passage, and a reversed V-shaped expanded opening and a zigzag axial and radial double concave-convex structured burning-stabilizing device are arranged at the outlet of the primary wind passage; and after primary wind passes through the pulverized-coal concentrating device, an intense standing-vortex burning-stabilizing firing area with obvious circumferential and radial pulverized-coal concentration distribution is formed at the outlet of the burner, and the burning conditions of high-temperature reflow smoke gas and oxygen-deficient rich fuel are generated. The burner has extremely strong firing-stabilizing performance and good coal adaptability and effectively reduces the concentration of nitrogen oxides.

Owner:XI AN JIAOTONG UNIV

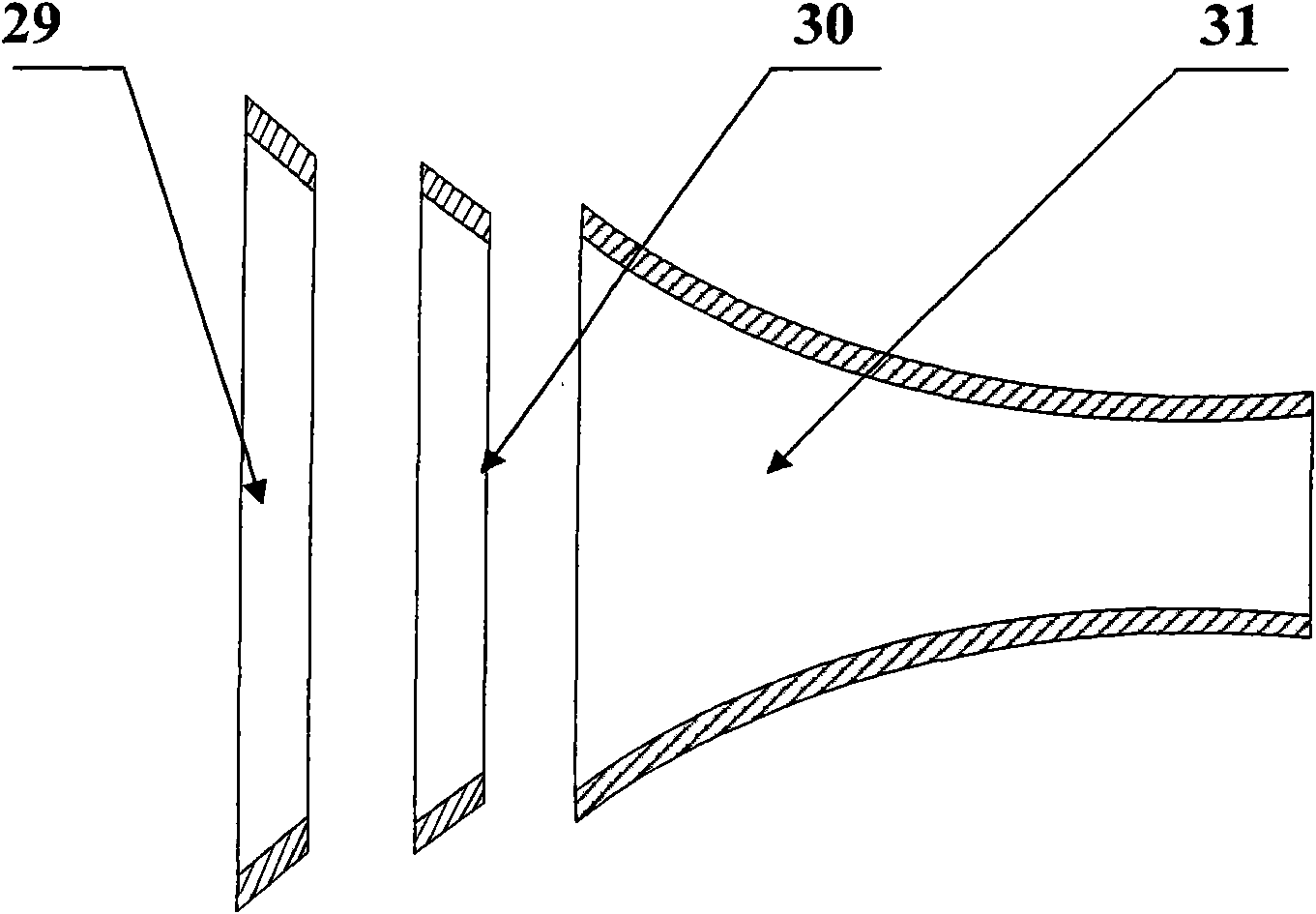

Energy efficiency improvements for turbomachinery

InactiveCN105307931ALower absolute dragReduce resistanceContinuous combustion chamberInfluencers by generating vorticesProcess engineeringEnergy analysis

A method and apparatus are disclosed that allow Conformal Vortex Generator art to improve energy efficiency and control capabilities at many points in a turbomachine or device processing aero / hydrodynamic Newtonian fluid-flows.

Owner:彼得·艾瑞兰德 +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com