Method for preparing crystal II-type ammonium polyphosphate with distribution of high polymerization degree and narrow molecular weight

A technology with narrow molecular weight distribution and high degree of polymerization, which is applied in the field of preparation of crystalline type II ammonium polyphosphate, can solve the problem that the complete transformation of the material state in the kneader cannot be realized, the mixing, kneading, and crushing functions of the kneader are not strong enough, and no Measures to control the severity of the reaction and other issues, to achieve the effect of high purity of crystal type II, promotion of the formation of prepolymers, and high degree of polymerization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

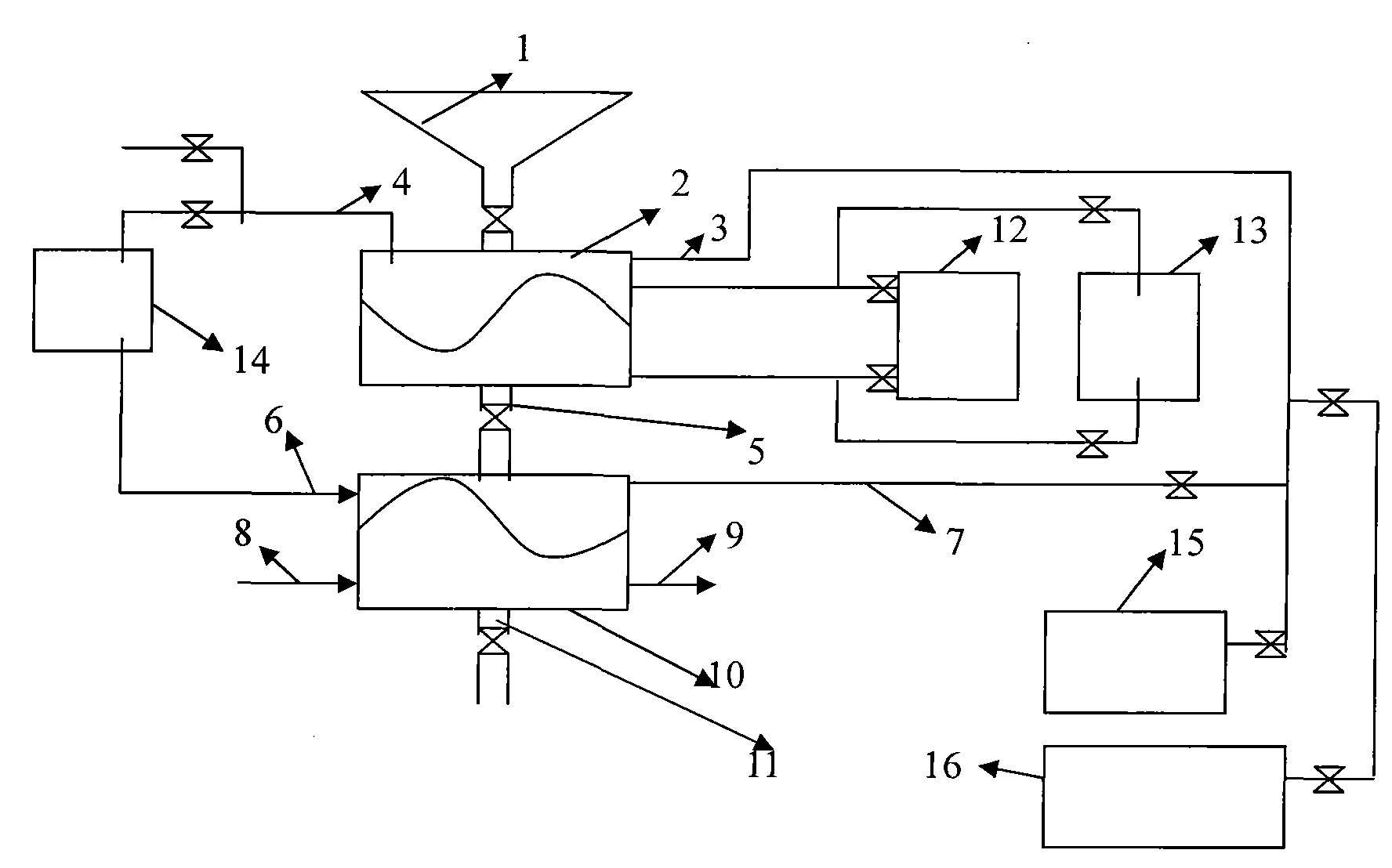

Method used

Image

Examples

Embodiment 1

[0024] Put 110Kg phosphorus pentoxide and 102Kg diammonium hydrogen phosphate into 0.5m 3 In the kneader, the flow rate is 8m 3 Preheat and mix at the same time under the protection of helium gas per hour; control the temperature rise rate of the material to 5°C / min, when the temperature of the material in the kneader rises to 200°C, stop the flow of helium and start the flow of ammonia. Flow control is 15m 3 / h, after the flow rate is maintained for 1.0h, the ammonia gas flow is stopped, the temperature is controlled at 220°C, the ammonia gas flow is resumed after the homogenization process is carried out for 1.0h, and the flow rate is controlled at 20m 3 / h; continue to heat up for 2 hours, when the temperature of the material rises to 300 ° C, put 3.18Kg of melamine cyanurate into the kneader, continue to keep stirring for 4 hours under the condition of ammonia gas; then transfer the material to a closed container, that is, through the feeding Transfer the material to the...

Embodiment 2

[0026] Put 130Kg phosphorus pentoxide and 121Kg diammonium hydrogen phosphate into 0.5m 3 In the kneader, at a flow rate of 2m 3 Carry out preheating and mixing under nitrogen protection at the same time; control the temperature rise rate of the material to 5°C / min, when the temperature of the material in the kneader rises to 150°C, stop the nitrogen flow and start the ammonia flow, the flow control of the ammonia gas 5m 3 / h, after the flow rate is maintained for 0.5h, the ammonia gas flow is stopped, the temperature is controlled at 150°C, the ammonia gas flow is resumed after the homogenization process is carried out for 0.5h, and the flow rate is controlled at 15m 3 / h; continue to heat up for 2h, when the temperature of the material rises to 250°C, put 3.765Kg of epoxy resin into the kneader, continue to keep stirring under the condition of ammonia for 1h; then transfer the material to a closed container, that is, through the feeding Transfer the material to the materia...

Embodiment 3

[0028] Put 150Kg phosphorus pentoxide and 139Kg diammonium hydrogen phosphate into 0.5m 3 In the kneader, at a flow rate of 10m 3 Preheat and mix at the same time under the protection of argon gas per hour; control the temperature rise rate of the material to 5°C / min, when the temperature of the material in the kneader rises to 250°C, stop the flow of argon and start the flow of ammonia, the ammonia gas Flow control is 20m 3 / h, after the flow rate is maintained for 3.0 hours, the ammonia gas flow is stopped, the temperature is controlled at 200°C, the ammonia gas flow is resumed after the homogenization process is carried out for 1.5 hours, and the flow rate is controlled at 25m 3 / h; continue to heat up for 2h, when the temperature of the material rises to 350°C, put 4.335Kg of aminosilane into the kneader, and continue to keep stirring under the condition of ammonia for 4h; then transfer the material to a closed container, that is, through the feeding port Transfer the ma...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com