Patents

Literature

1174results about How to "Solving Corrosion Problems" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

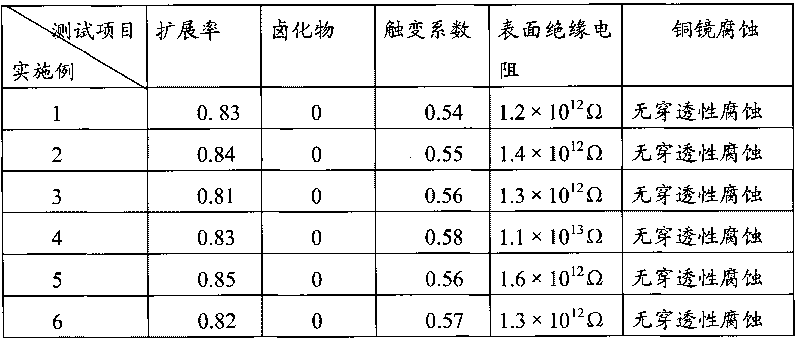

Halogen-free tin-bismuth-copper soldering paste and preparation method thereof

InactiveCN101695794AExtended shelf lifeExtended service lifeWelding/cutting media/materialsSoldering mediaAntioxidantExpansion rate

The invention relates to the technical field of soldering pastes, in particular to a halogen-free tin-bismuth-copper soldering paste and a preparation method thereof. A soldering flux of the halogen-free tin-bismuth-copper soldering paste consists of the following components in percentage by weight: 20 to 40 percent of polymerized rosin, 1 to 6 percent of rosin amine, 4 to 8 percent of thixotropic agent, 5 to 10 percent of organic acid, 5 to 10 percent of organic amine, 1 to 5 percent of antioxidant, 0.5 to 3 percent of surfactant and an organic solvent. The halogen-free tin-bismuth-copper soldering paste is mainly characterized by adopting the organic acid and the organic amine serving as activating agents and comprising no halogens at all, so not only the solderability is not reduced, but also the expansion rate and the insulation resistance value of the soldering paste are improved, and simultaneously the corrosivity of residues after soldering to a base material is reduced and the service life of the soldering paste is prolonged; and particularly, the peak temperature of the soldering paste during soldering is lower in favor of reducing the thermal damages to electronic components.

Owner:东莞市特尔佳电子有限公司

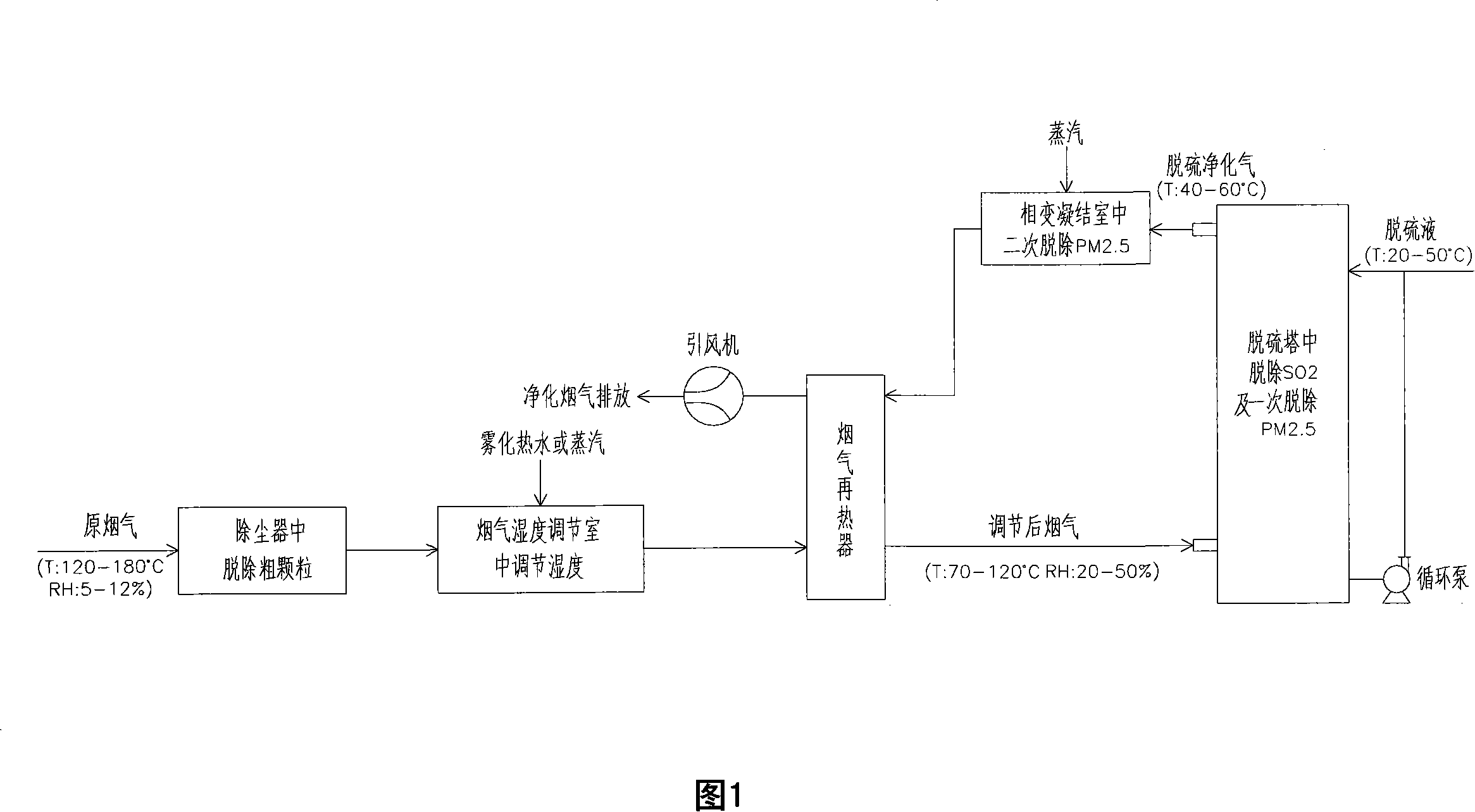

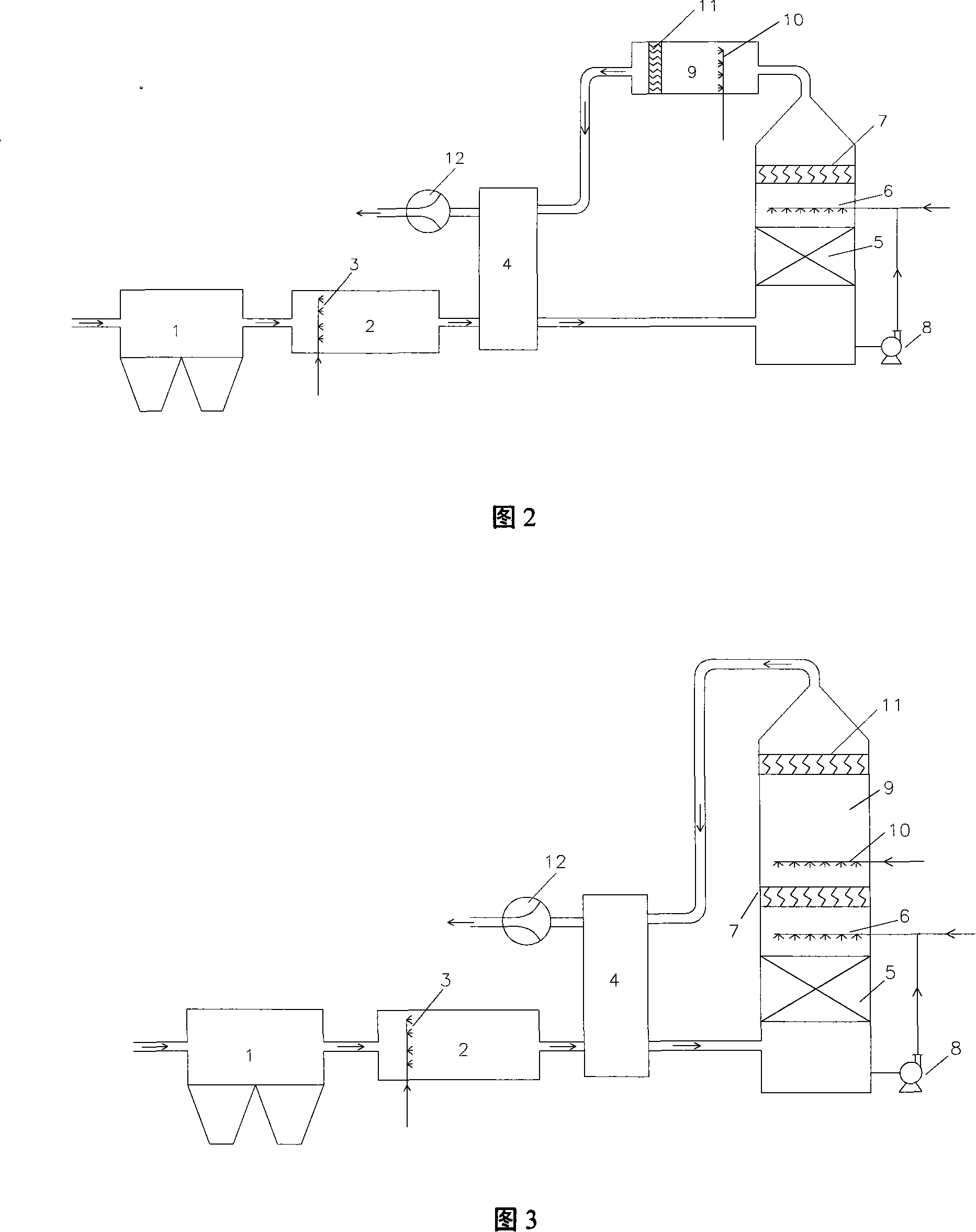

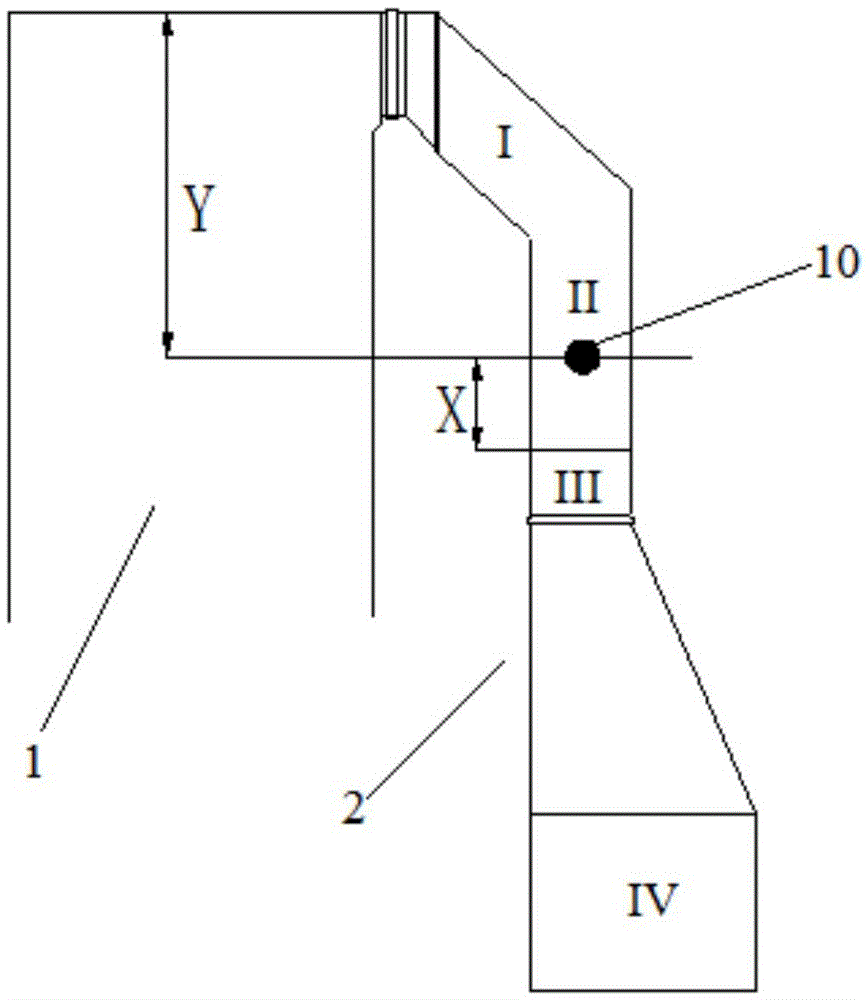

Method and device for cooperation-removal of PM2,5 in flue gas wet desulphurization

InactiveCN101219333AReduce the nucleation critical supersaturationReduce surface tensionDispersed particle separationHigh humidityFlue gas

The invention provides a method that fully utilizes the characteristics of relatively high humidity content of flue gas in the existing wet desulfurization technology and employs vapor phase change theory to effectively remove SO2 through WFGD so as to cause PM2.5 to be condensed and enlarged as well as be removed effectively and a device thereof. The invention has simple technique, and arranging a moisture regulation chamber for the flue gas and a phase change condensing chamber in the existing flue gas wet desulfurization devices can cause the wet desulfurization device to have the effect of enlarging and removing PM2.5 granules. The invention is widely used in the existing wet desulfurization devices for the flue gas generated by power plants.

Owner:SOUTHEAST UNIV

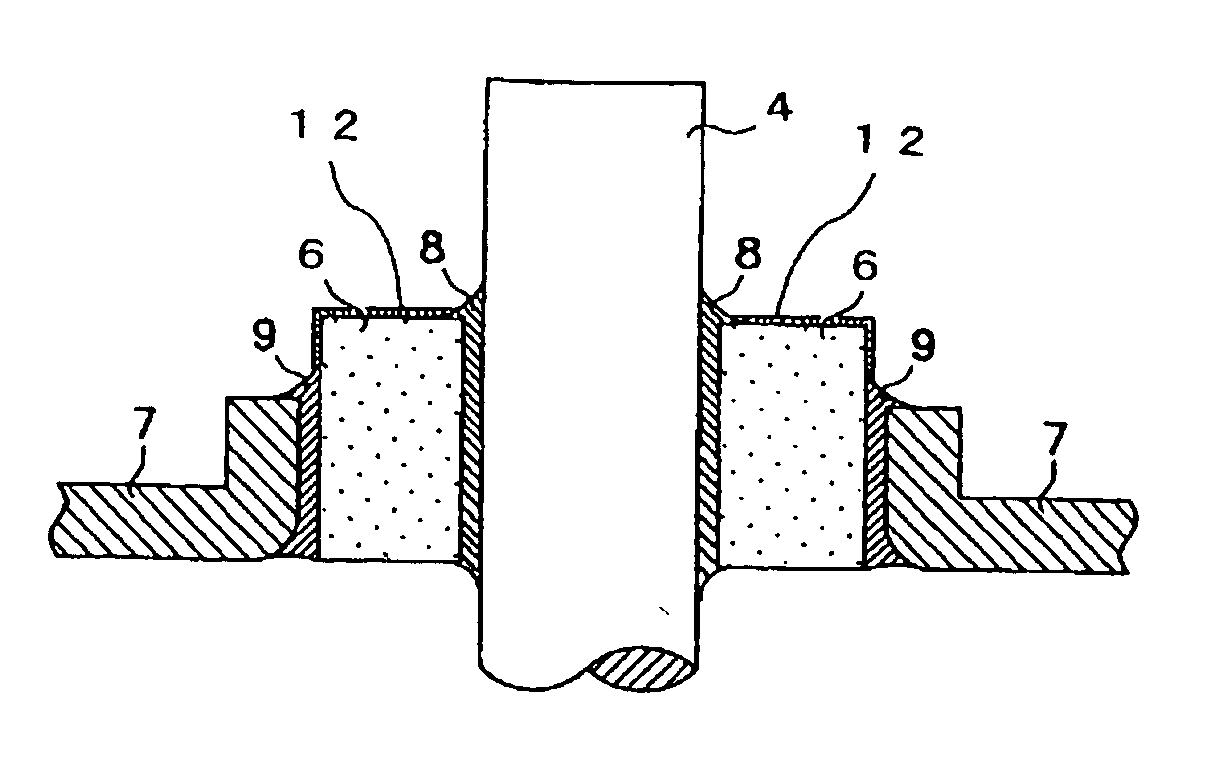

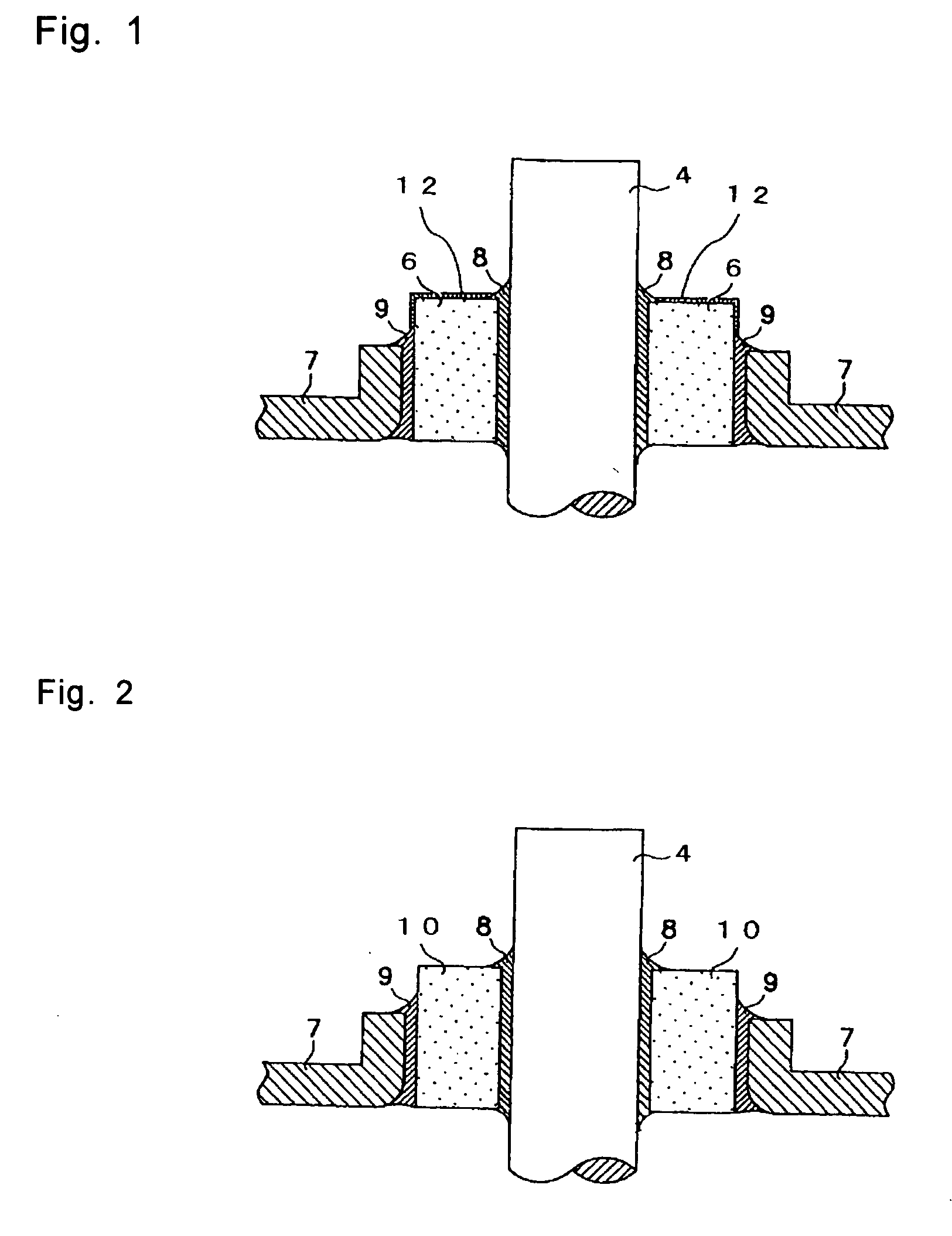

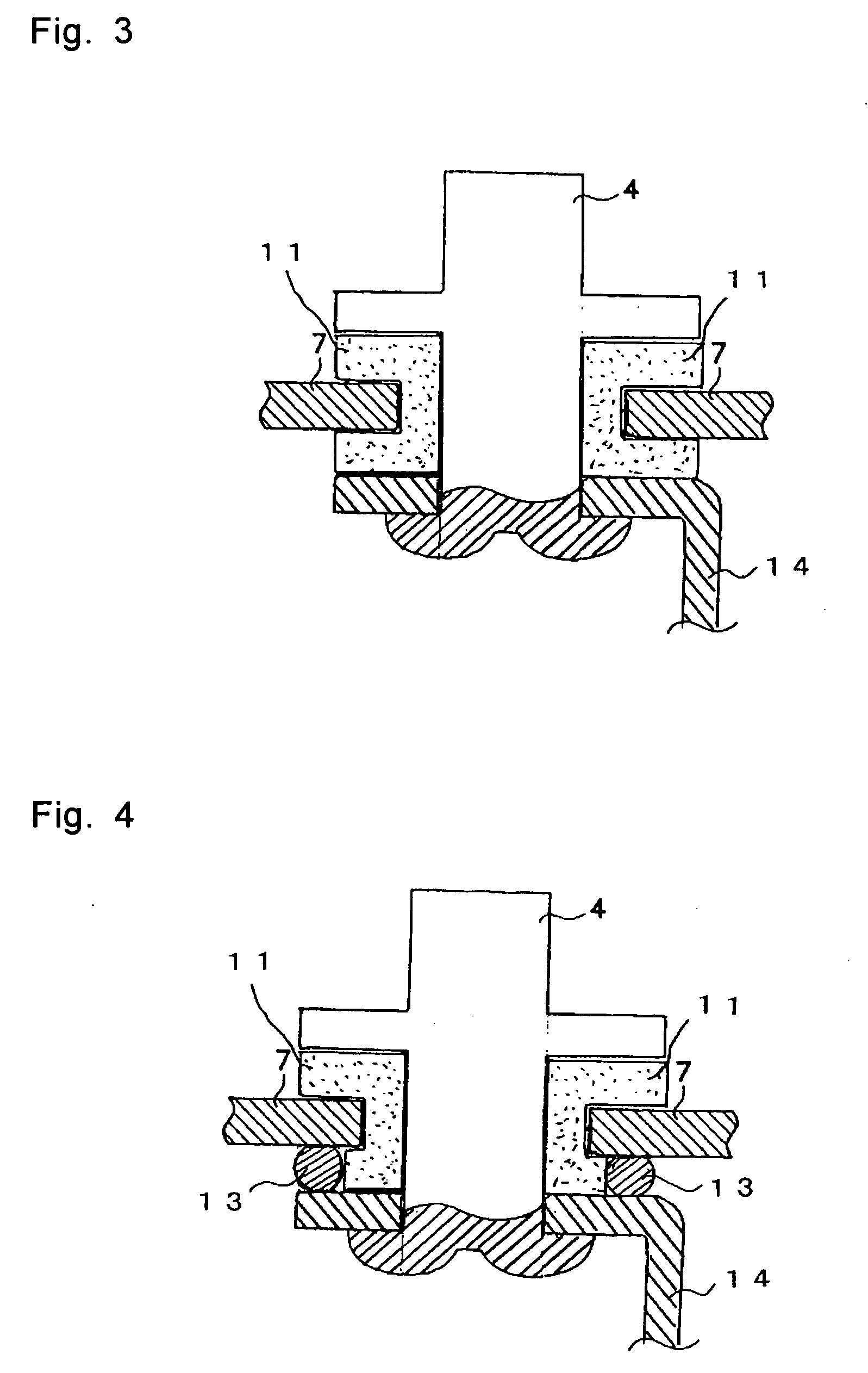

Non-aqueous electrolyte battery wherein a battery case and a terminal are connected through resistance

ActiveUS20050238930A1Inhibition of alloyingSolving Corrosion ProblemsFinal product manufactureSmall-sized cells cases/jacketsEngineeringNon aqueous electrolytes

A non-aqueous electrolyte battery comprising: a battery case containing aluminum; a positive electrode terminal attached to the battery case; and a negative electrode terminal attached to the battery case and insulated from the battery case, wherein the positive electrode terminal and the battery case are connected through a resistor having resistance of 1 Ω to 1 MΩ. Otherwise, A non-aqueous electrolyte battery comprising: a battery case containing iron; a negative electrode terminal attached to the battery case; and a positive electrode terminal attached to the battery case and insulated from the battery case, wherein the negative electrode terminal and the battery case are connected through a resistor having resistance of 1 Ω to 1 MΩ.

Owner:GS YUASA INT LTD

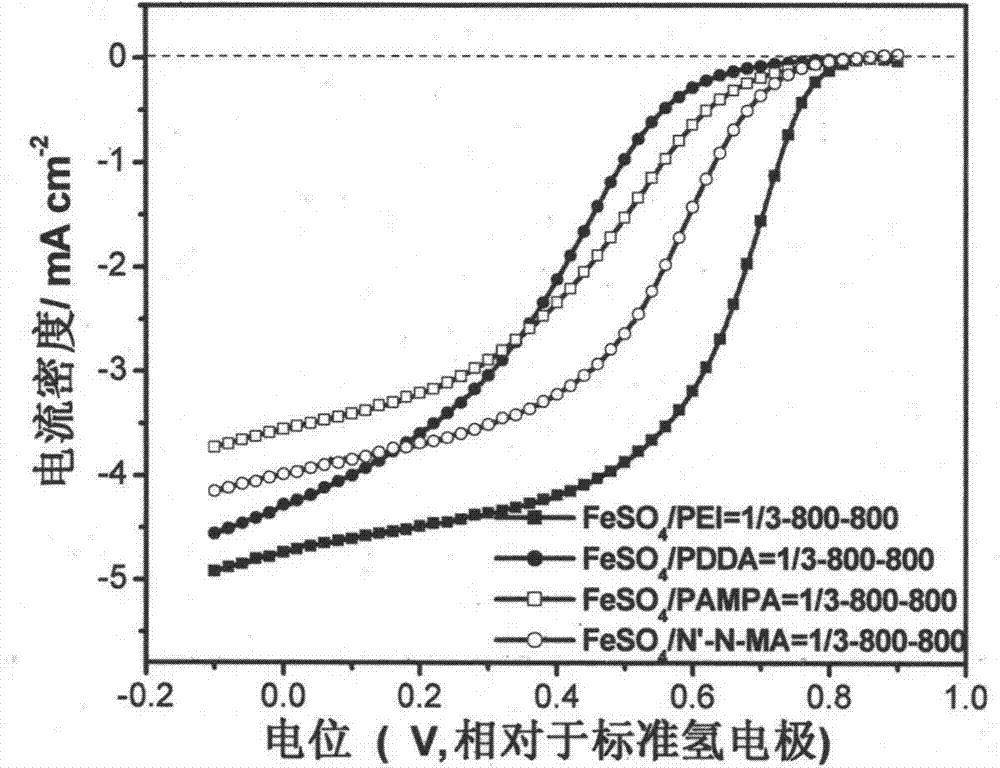

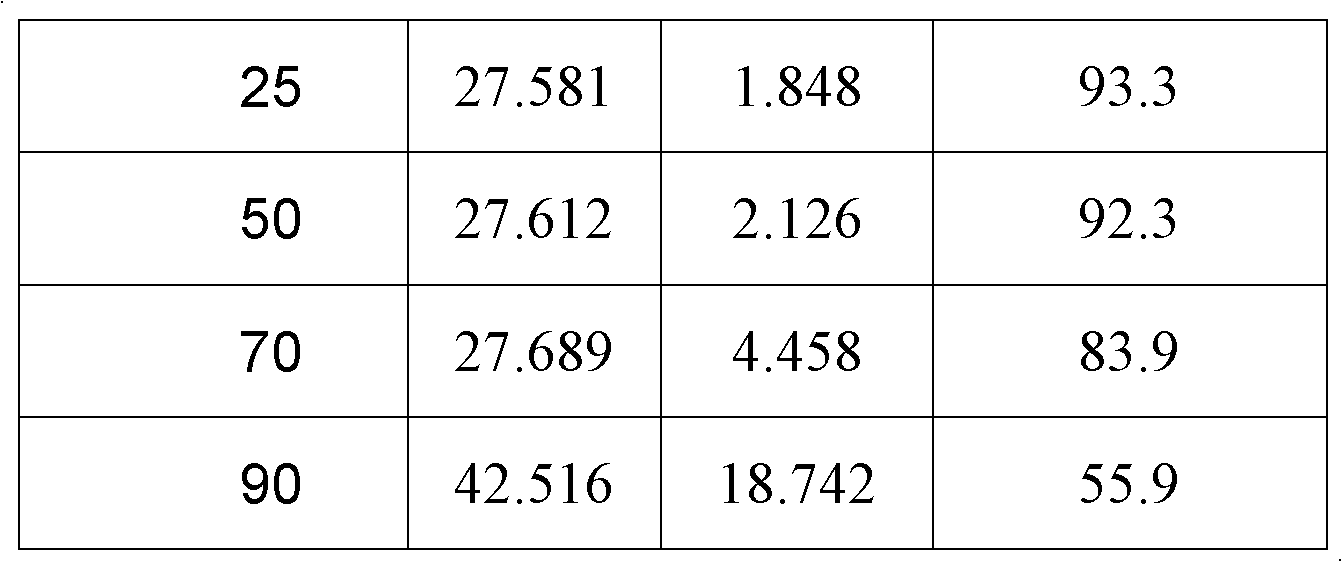

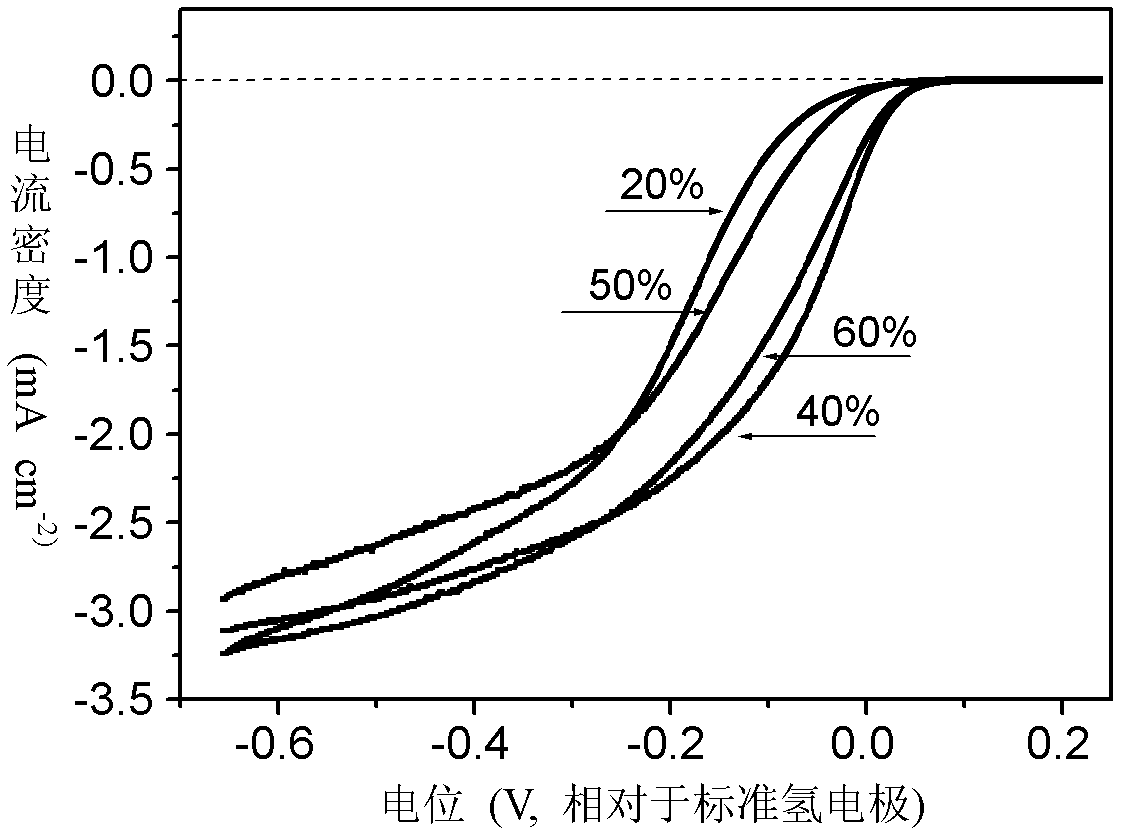

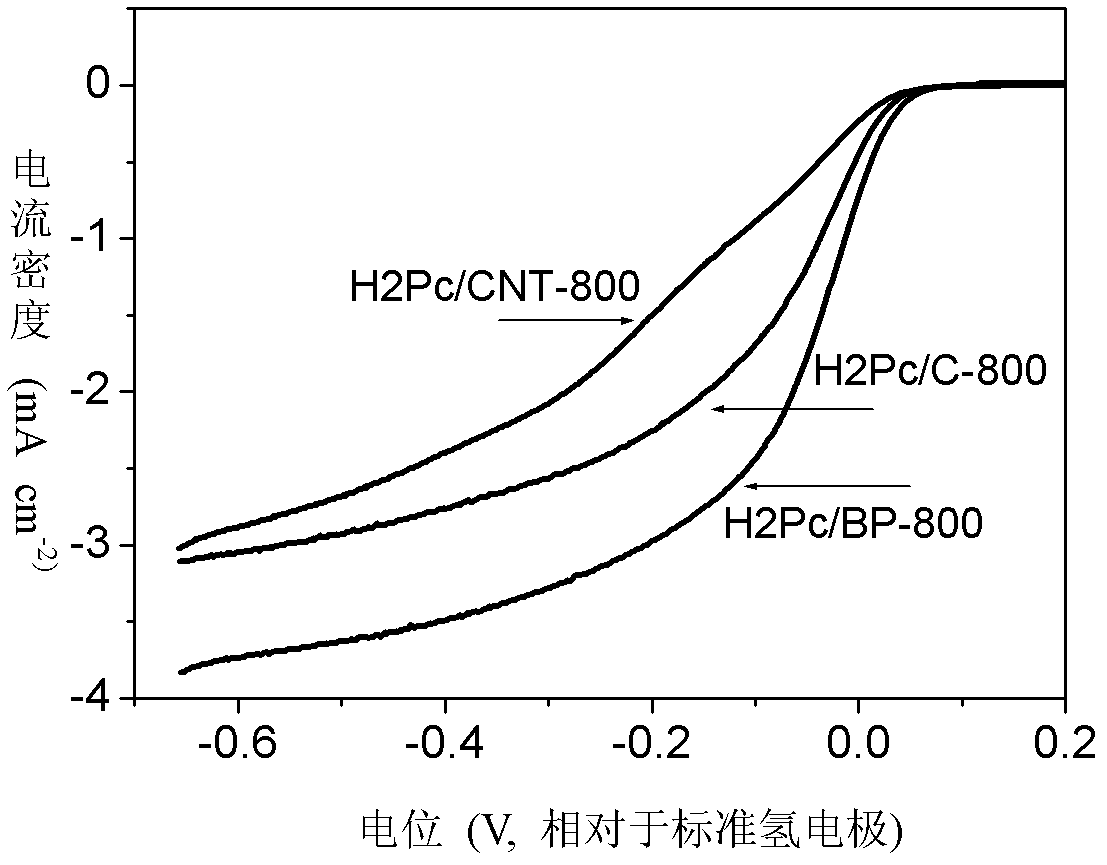

Metal-free nitrogen-doped functionalized mesoporous carbon catalyst and preparation method and applications thereof

InactiveCN103566961AHigh catalytic activityAvoid defects such as deactivation (corrosion)Physical/chemical process catalystsCell electrodesStrong acidsAcid washing

The invention relates to a metal-free nitrogen-doped functionalized mesoporous carbon catalyst and preparation method and applications thereof. A precursor of the metal-free nitrogen-doped functionalized mesoporous carbon catalyst comprises the following components in percentage by mass: 20-85% of template agent, 10-75% of nitrogen compound, and 5-50% of transition metal salt. The nitrogen compound is carbonized at high temperature under the existence condition of transition metal, to form a high-nitrogen-content pyridine and graphite nitrogen (Nx-C) composite structure, and the catalytic activity of oxygen can be remarkably enhanced; the transition metal in the nitrogen-doped mesoporous carbon catalyst can be removed through acid pickling, so that the inactivation (corrosion) of the catalyst containing the transition metal under the conditions of strong acid and strong alkali can be avoided, the characteristics of being high in stability, not easy to poison and the like can be achieved, and the metal-free nitrogen-doped functionalized mesoporous carbon catalyst has excellent application prospects in the fields of treating waste water of fuel batteries, metal-air batteries, supercapacitors, energy-storage batteries, microbial fuel cells, and the like.

Owner:DONGHUA UNIV

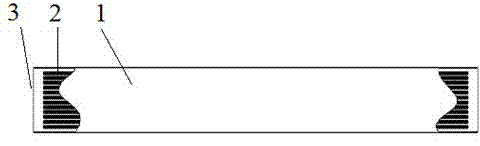

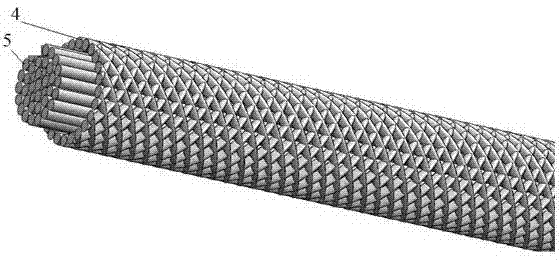

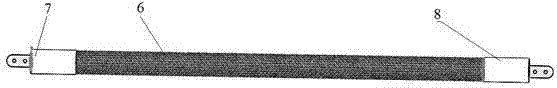

Novel graphite composite grounding material and preparation method thereof

ActiveCN103490180ASolving Corrosion ProblemsIncrease contact areaContact member manufacturingConnection contact member materialYarnCorrosion resistant

The invention discloses a novel graphite composite grounding material and a preparation method thereof. The novel graphite composite grounding material is in the shape of a rope or stranded wire, and comprises a composite graphite yarn inner core and a composite graphite yarn knitted layer wrapped outside the composite graphite yarn inner core, wherein the composite graphite yarn inner core is a composite graphite yarn bundle composed of a plurality of first composite graphite yarns or a single first composite graphite yarn; each first composite graphite yarn is prepared by twisting a first composite graphite belt; the composite graphite yarn knitted layer is prepared by knitting a second composite graphite yarn; and the second composite graphite yarn is prepared by twisting a second composite graphite belt. The graphite composite grounding material disclosed by the invention has the advantages of corrosion resistance, favorable conductivity, high flexibility, low price, precise soil association and the like, and is easy for transportation; since the price is low, artificial theft destroy can be avoided; and the graphite composite grounding material is suitable for the fields of transformer stations, overhead transmission line towers, tall buildings and all other projects in need of electric grounding.

Owner:WUHAN HONGMEN ELECTRICAL TECH CO LTD

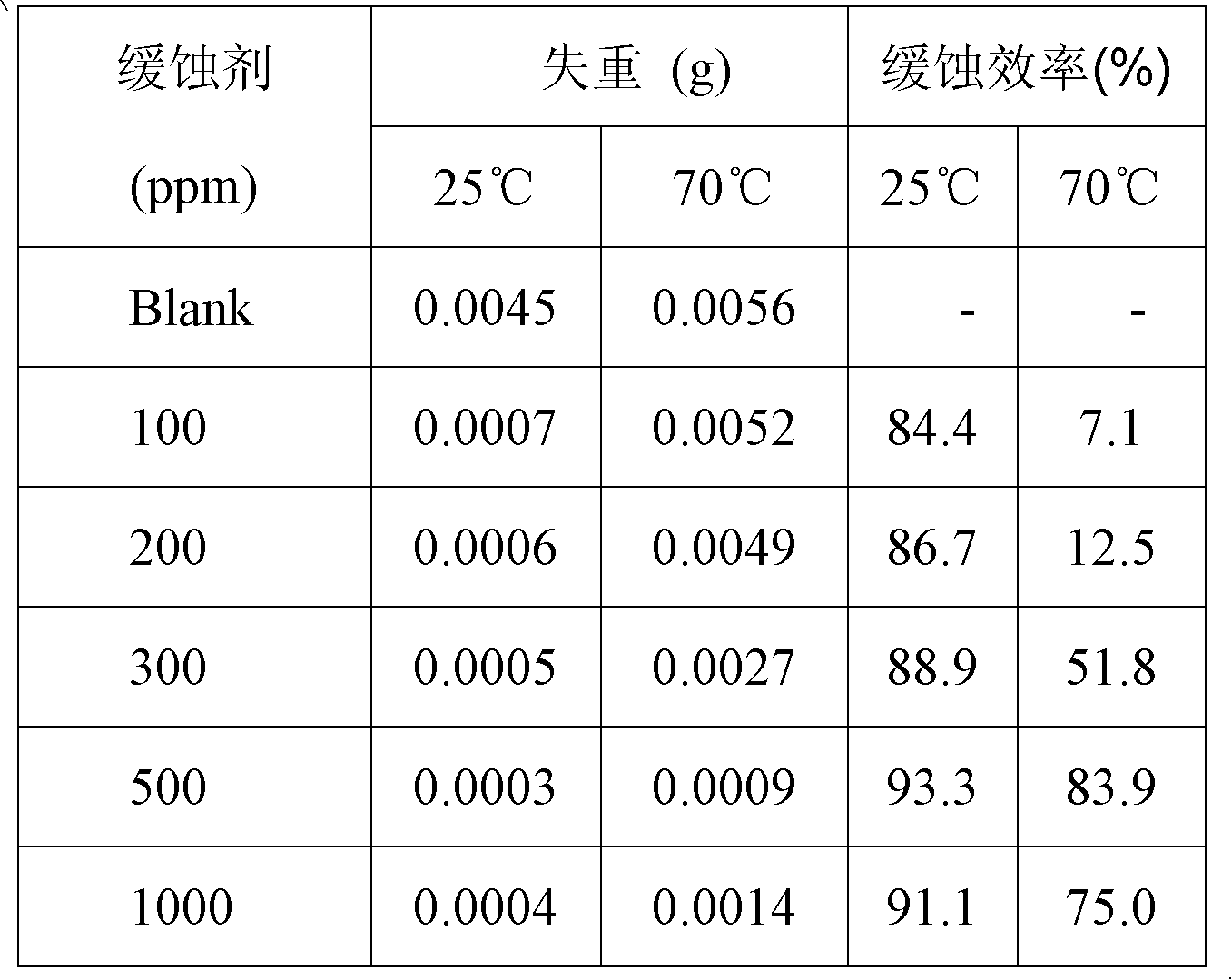

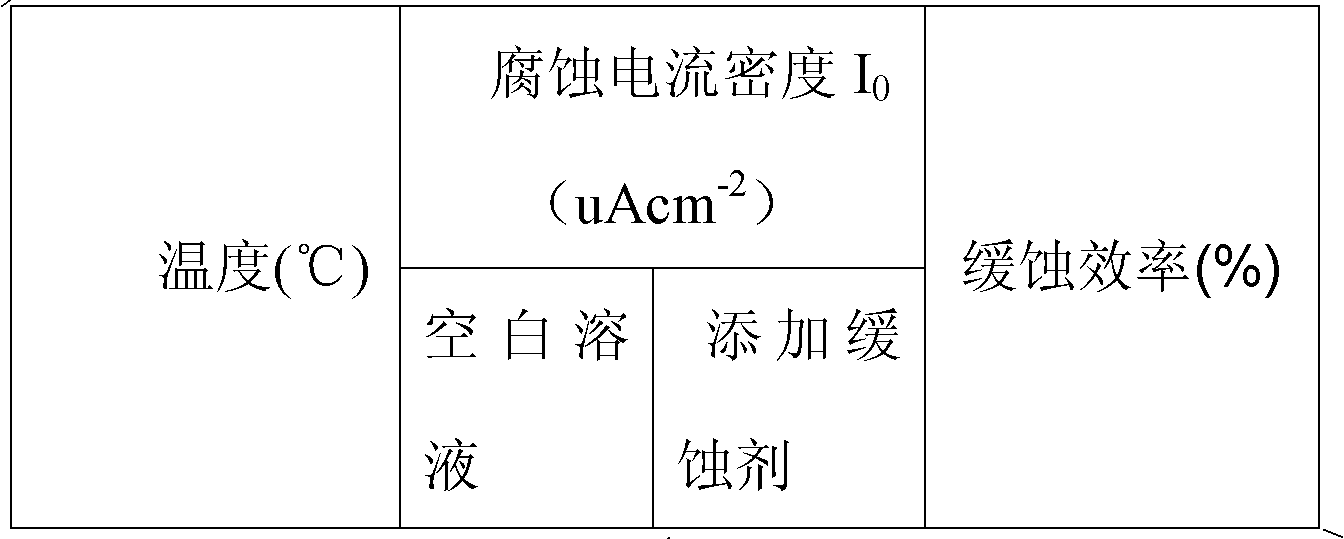

Corrosion inhibitor for inhibiting corrosion of magnesium alloy in automobile cooling liquid

The invention provides a corrosion inhibitor for inhibiting corrosion of magnesium alloy in automobile cooling liquid. The corrosion inhibitor consists of specific adsorption organic substance or / and film-forming inorganic substance, and water or / and ethanol. The corrosion inhibitor is a compound efficient anti-scale corrosion inhibitor, can well inhibit the corrosion of a magnesium alloy material in the cooling liquid in a wider temperature range, and has the characteristics of wide application range, low using amount, high efficiency, no toxicity or peculiar smell, full water dissolution, simple and convenient preparation, low cost, wide applicable temperature range, strong synergistic effect, convenient use, good comprehensive performance and the like. 100 to 1,000ppm corrosion inhibitor directly added into the automobile cooling liquid can inhibit the corrosion of the magnesium alloy, effectively inhibit the corrosion of the magnesium alloy material in the automobile cooling liquid at a normal temperature and a high temperature, and effectively protect the magnesium alloy.

Owner:HUAZHONG UNIV OF SCI & TECH

Metal-free nitrogen- functionalized carbon catalyst as well as preparation method and application thereof

ActiveCN102637882AHigh catalytic activityReduce dependenceOrganic-compounds/hydrides/coordination-complexes catalystsCell electrodesOxygenWaste treatment

The invention relates to a metal-free nitrogen-functionalized carbon catalyst as well as a preparation method and application thereof. The catalyst consists of a carbon material and a nitrogenous macrocyclic compound according to a mass ratio being 0.10:0.90-0.90:0.10. The preparation method comprises the following steps of: (1) dissolving the carbon material and the nitrogenous macrocyclic compound in a solvent, grinding the materials until the solvent is entirely volatilized, and drying to obtain a catalyst precursor; and (2) heating the precursor under the protection of an inert gas atmosphere at a temperature of 600-1000 DEG C for calcinations and reduction, so as to obtain the metal-free nitrogen-functionalized carbon catalyst. The catalyst is applied to a membrane electrode combination for a fuel battery. The metal-free nitrogen- functionalized carbon catalyst provided by the invention forms a pyridinic nitrogen-graphitic nitrogen (Nx-C) composite structure with high nitrogen content through high-temperature nitrogen modification pyrolysis treatment, so that the catalytic activity to oxygen is obviously improved. The preparation method is simple, and the metal-free nitrogen- functionalized carbon catalyst has good application prospects in field of water waste treatment of the fuel battery, a metal-air battery, a super capacitor, an energy storage battery, a microbial fuel cell and the like.

Owner:DONGHUA UNIV +1

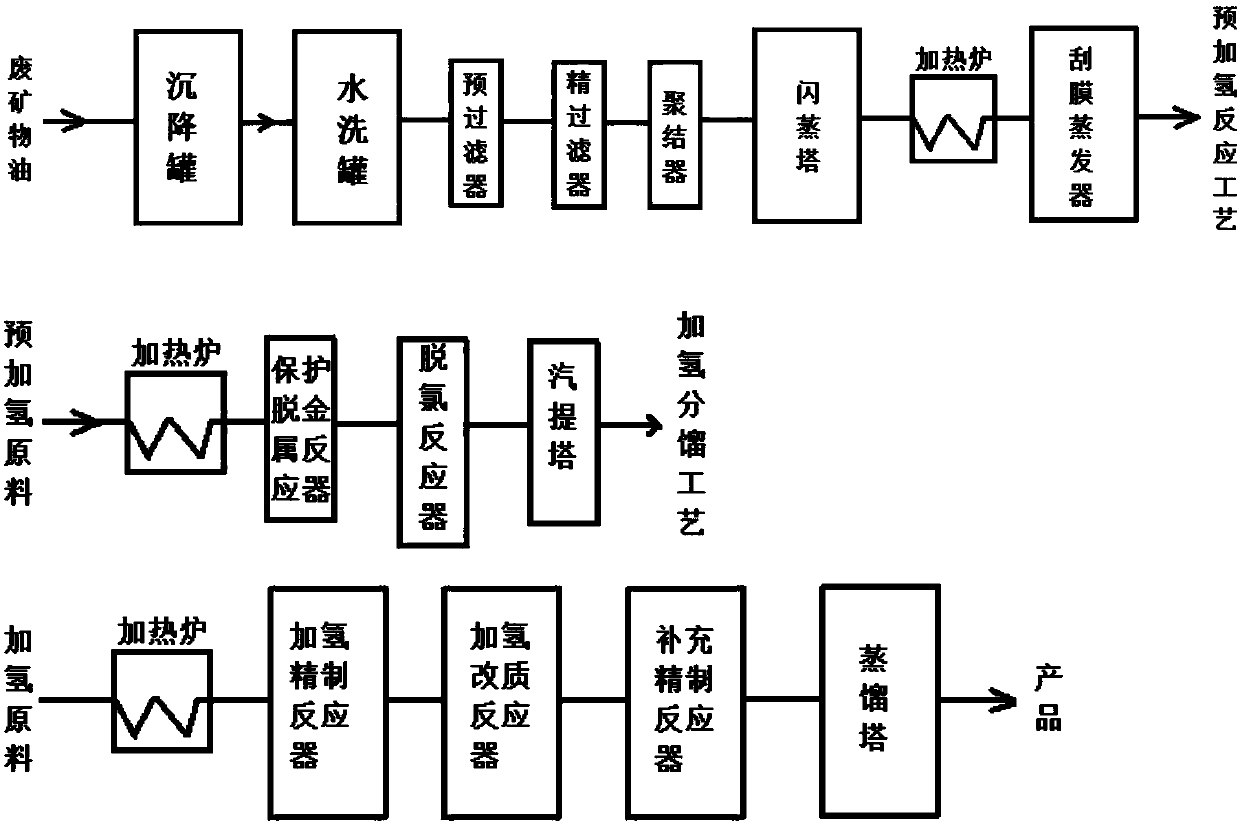

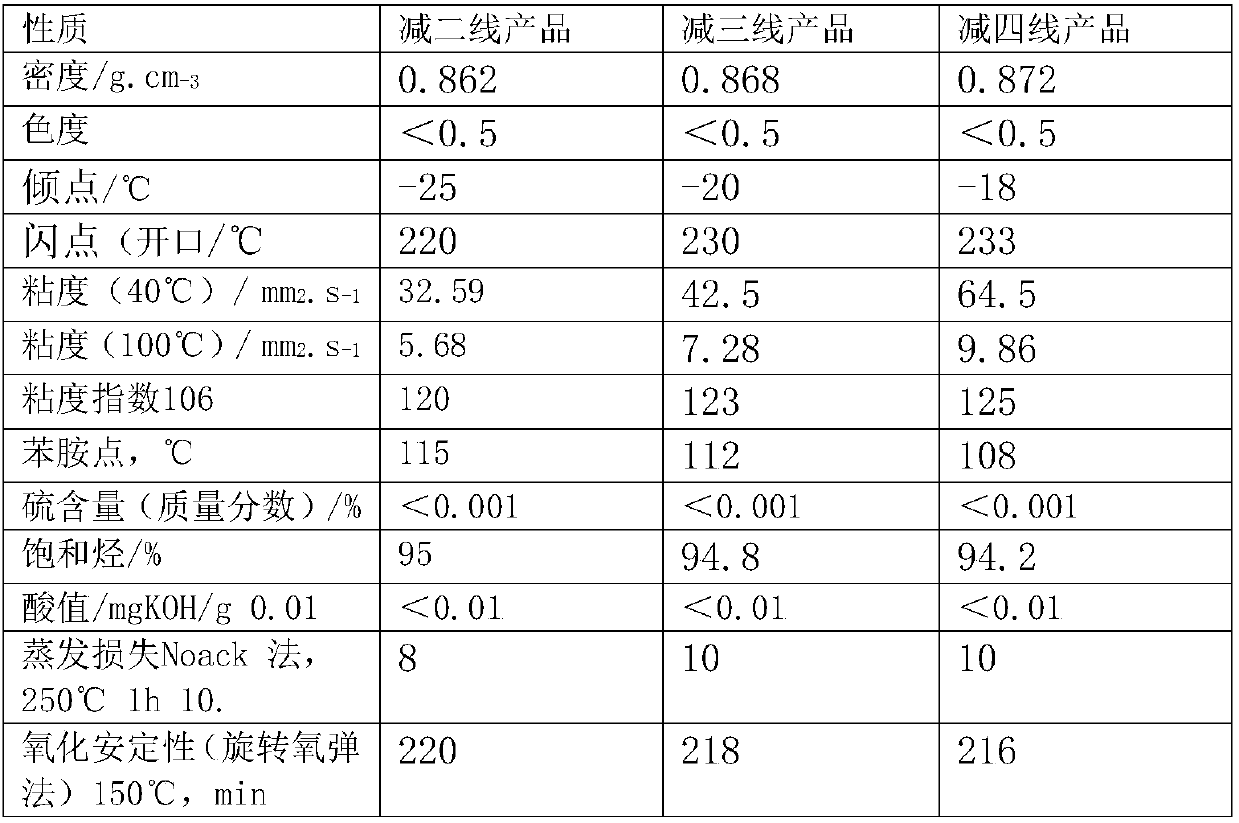

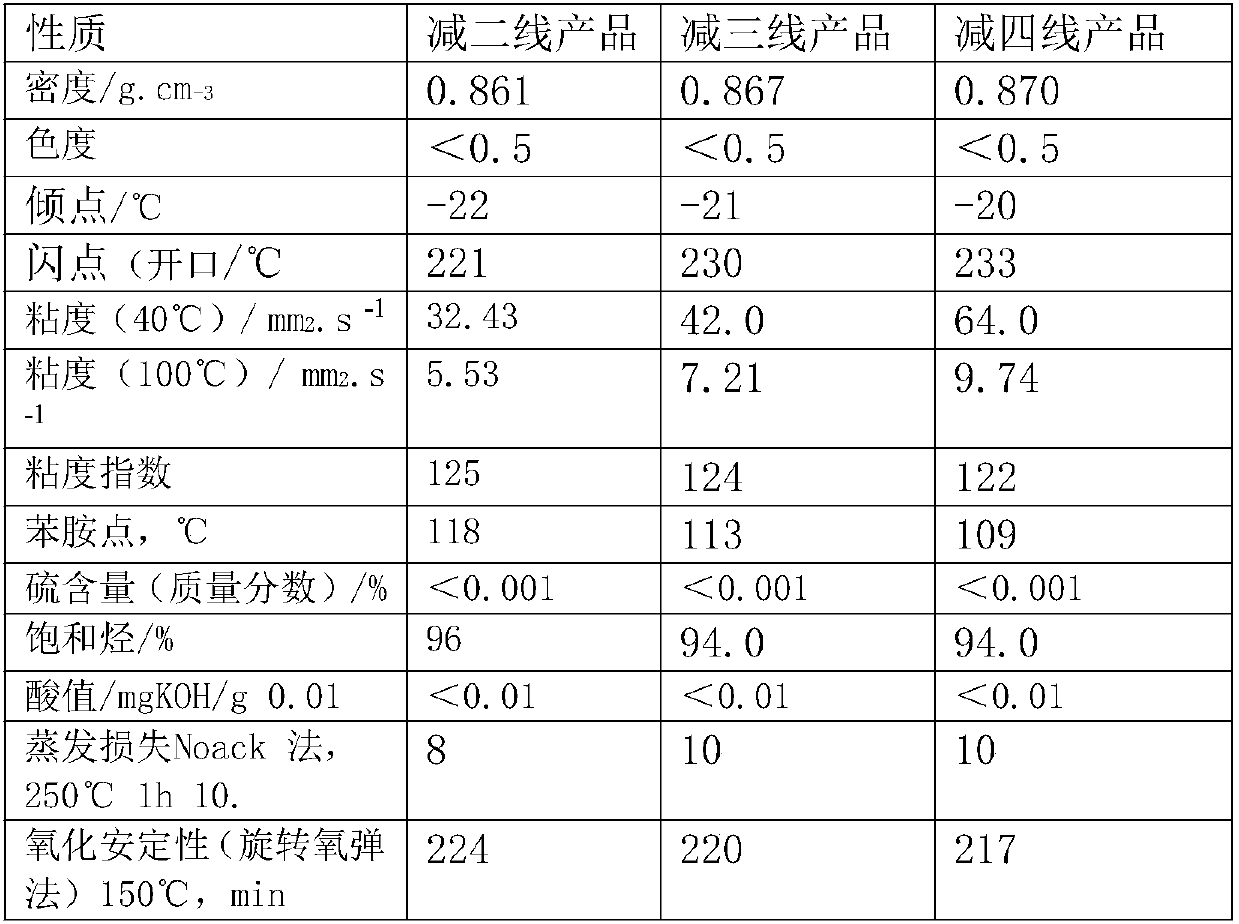

Method for producing high-grade lubricating oil base oil by full hydrogen regenerating of waste mineral oil

ActiveCN107892990ALower product pour pointImprove product viscosity index and oxidation stabilityLubricant compositionChemistryCorrosion

The invention discloses a method for producing high-grade lubricating oil base oil by full hydrogen regenerating of waste mineral oil. According to the method, a pre-hydrogenation reaction process isadded between a raw material pretreatment process and a hydrogenation fractionation process in the prior art; under hydrogen present conditions, heavy metal additives and gum asphalt as well as non-metallic impurities such as chlorine, phosphorus and silicon in a lubricating oil fraction are removed, and by the removal of the impurities, the problem of coking at the top of a hydrotreating reactorin a following high pressure hydrogenation fractionation process step can be solved, the problem of chlorine corrosion in heat exchangers and other equipment used for hydrogenation in the high pressure hydrogenation fractionation process step is also solved, and long-term operation of hydrogenation equipment in the high-pressure hydrogenation fractionation process can be ensured.

Owner:新疆聚力环保科技有限公司

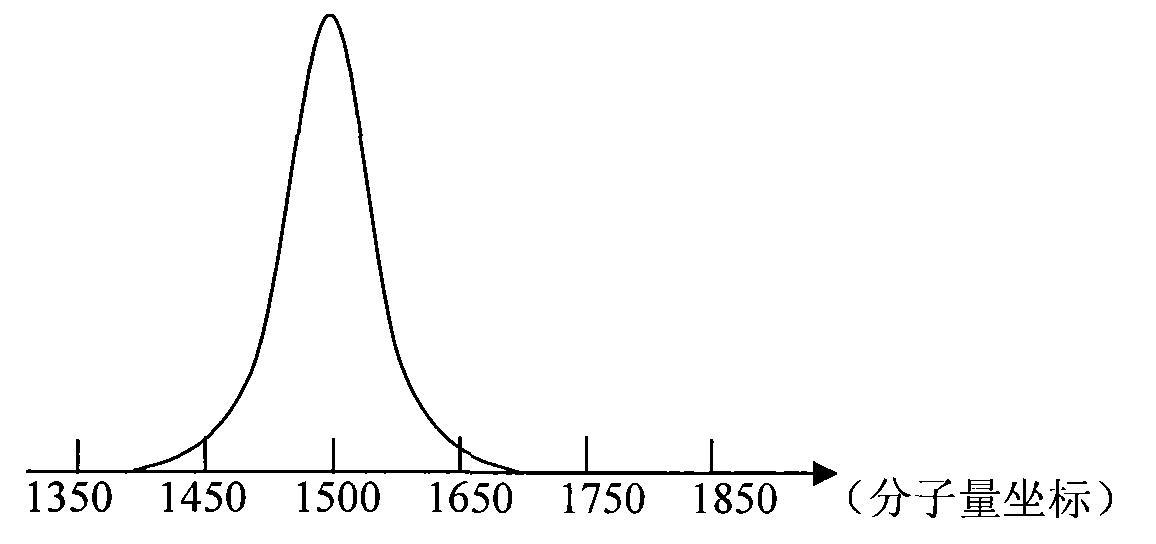

Method for preparing crystal II-type ammonium polyphosphate with distribution of high polymerization degree and narrow molecular weight

ActiveCN101597044AEliminate the effects ofTemperature controlPhosphorus compoundsSolubilityPolymerization

The invention discloses a method for preparing crystal II-type ammonium polyphosphate with distribution of high polymerization degree and narrow molecular weight. The method comprises the following steps: putting phosphorus pentoxide and diammonium phosphate which have equal molar ratio into a malaxator which can accurately control a temperature and heated by conducting oil for mixing; under the protection of inert gas, heating the materials in the malaxator to between 100 and 250 DEG C through the circulatory conducting oil; stopping introducing the inert gas; performing ammonification on the materials and heating the materials under an atmosphere of ammonia gas till the materials are totally molten down; stopping introducing the ammonia gas; after homogenization, introducing the ammonia gas again and heating the materials; throwing a surface treating agent into the malaxator; after material throwing is completed, continuously introducing the ammonia gas, keeping warm and mixing the materials; after reaction is finished, transferring the materials to a closed vessel and reducing the temperature; simultaneously, continuously introducing the ammonia gas till the temperature of the materials is below 100 DEG C; and obtaining a finished product. The method can prepare the crystal II -type ammonium polyphosphate with the distribution of the high polymerization degree and the narrow molecular weight; and the product has the characteristics of uniform granularity shape, small water-solubility, good heat resistance, high polymerization degree, narrow distribution of molecular weight and high crystal II-type purity.

Owner:GUANGDONG JUSHI CHEM CO LTD

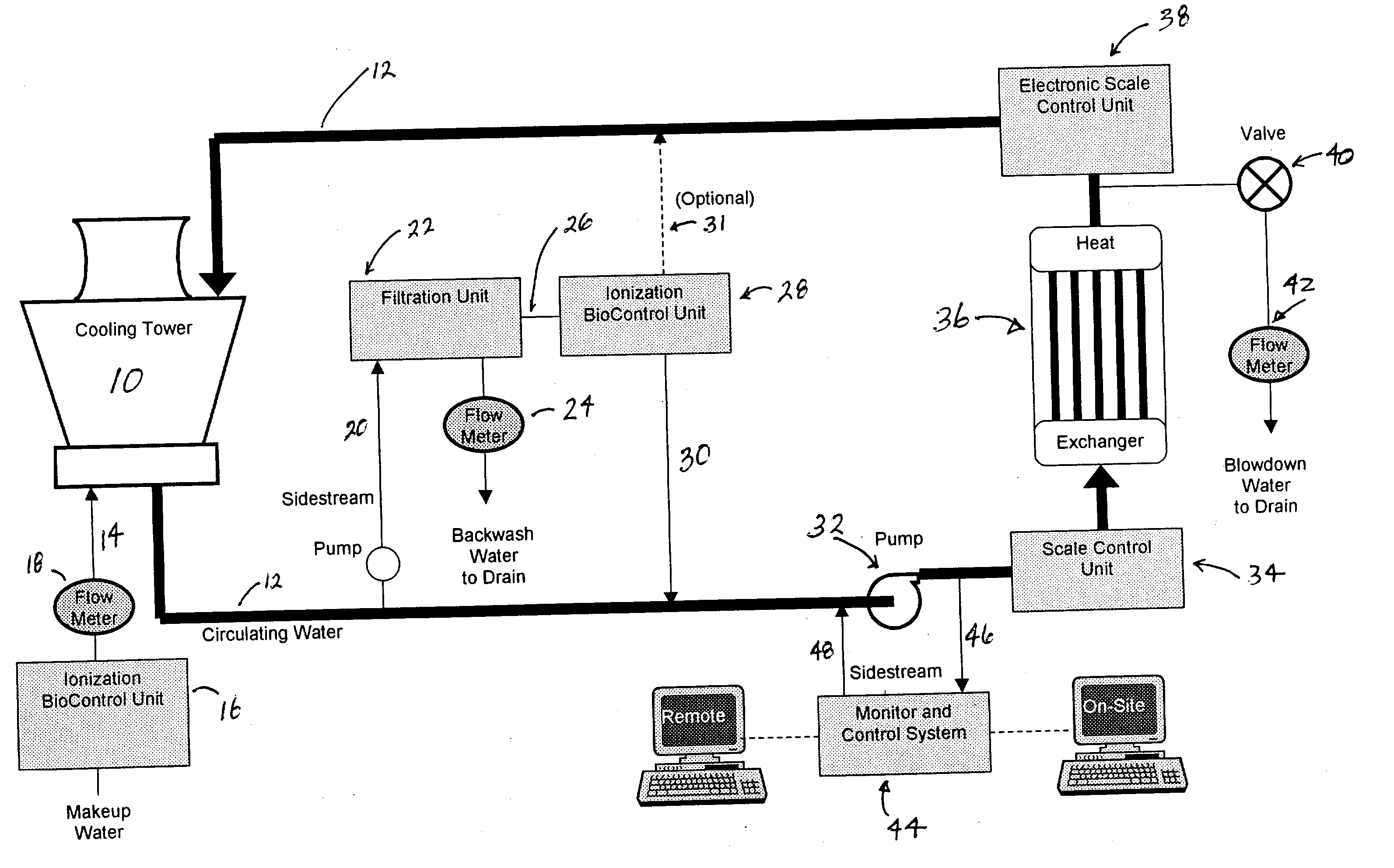

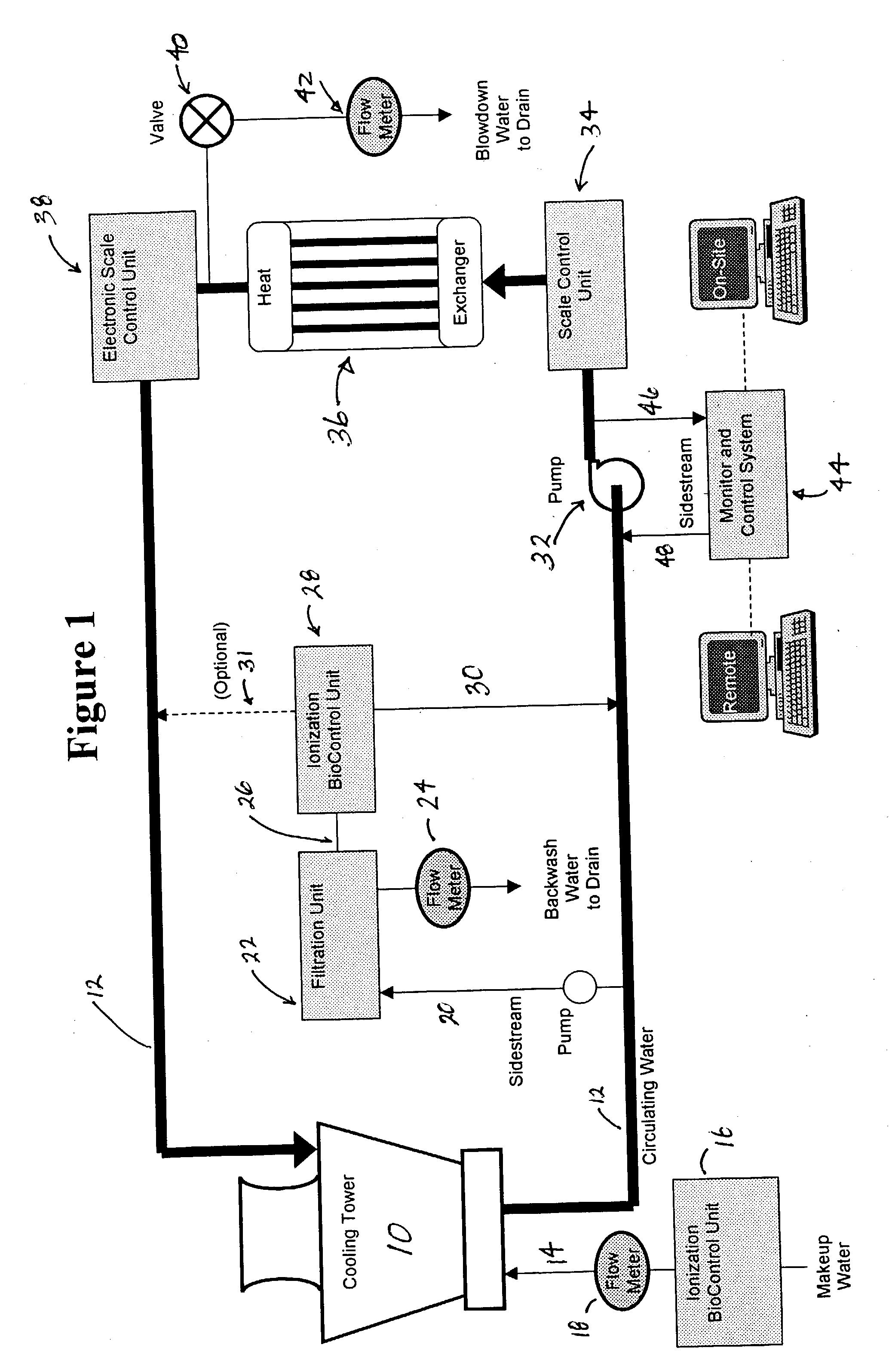

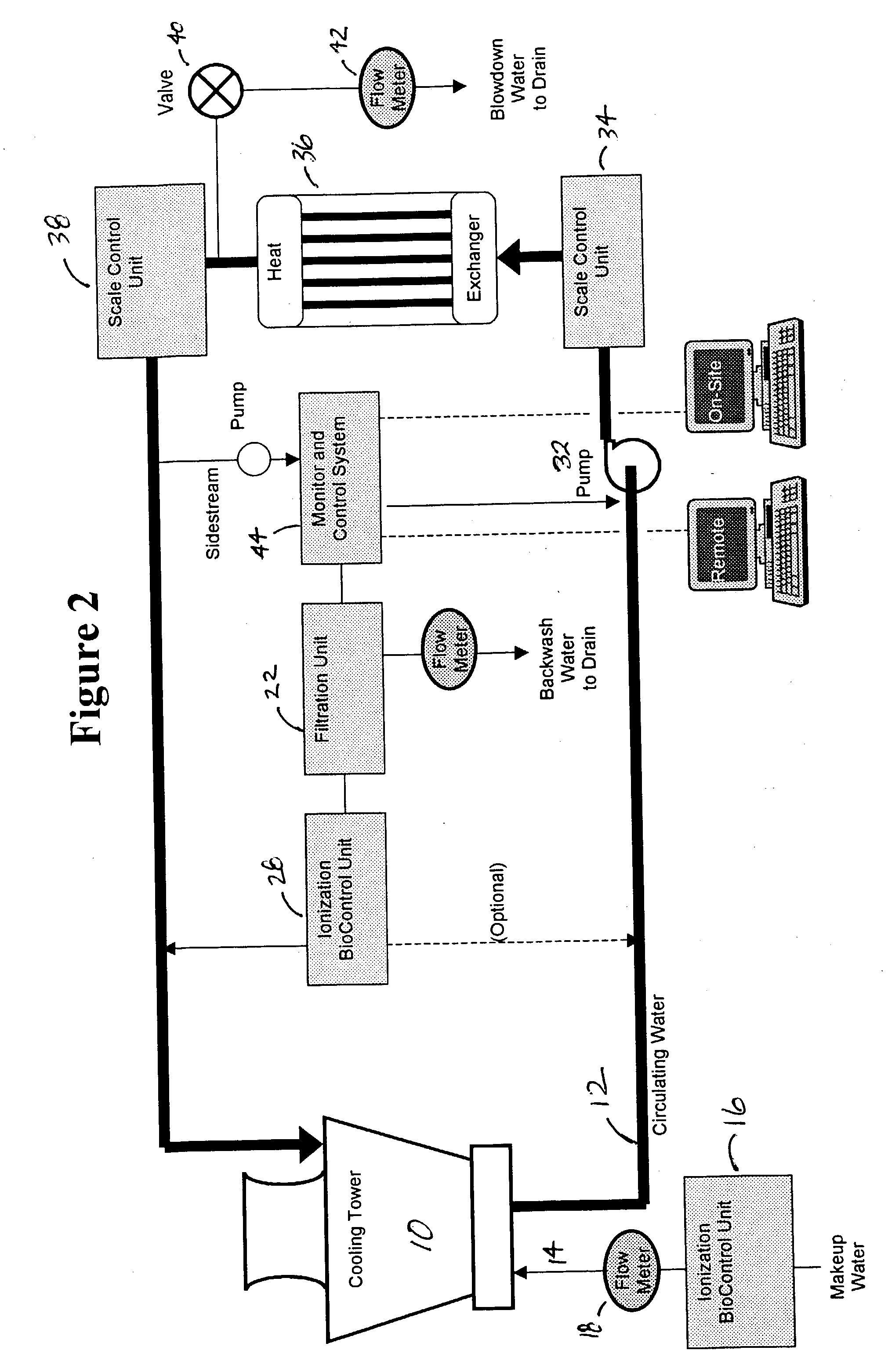

Apparatus, system and method for non-chemical treatment and management of cooling water

InactiveUS20040254682A1Solving Corrosion ProblemsPromote formationSampled-variable control systemsWater treatment parameter controlChemical treatmentMonitoring and control

An apparatus, system and method of providing non-chemical cooling water treatment and management is disclosed. The invention combats the problems of scaling, microbiological growth, corrosion and fouling. The overall system is regulated by a monitoring and control system that allows for full management of cooling water treatment. Without the use of chemicals, the system and method of the present invention is an effective, safe and environmentally sound approach to the treatment of cooling water.

Owner:GLOBAL WATER TECH

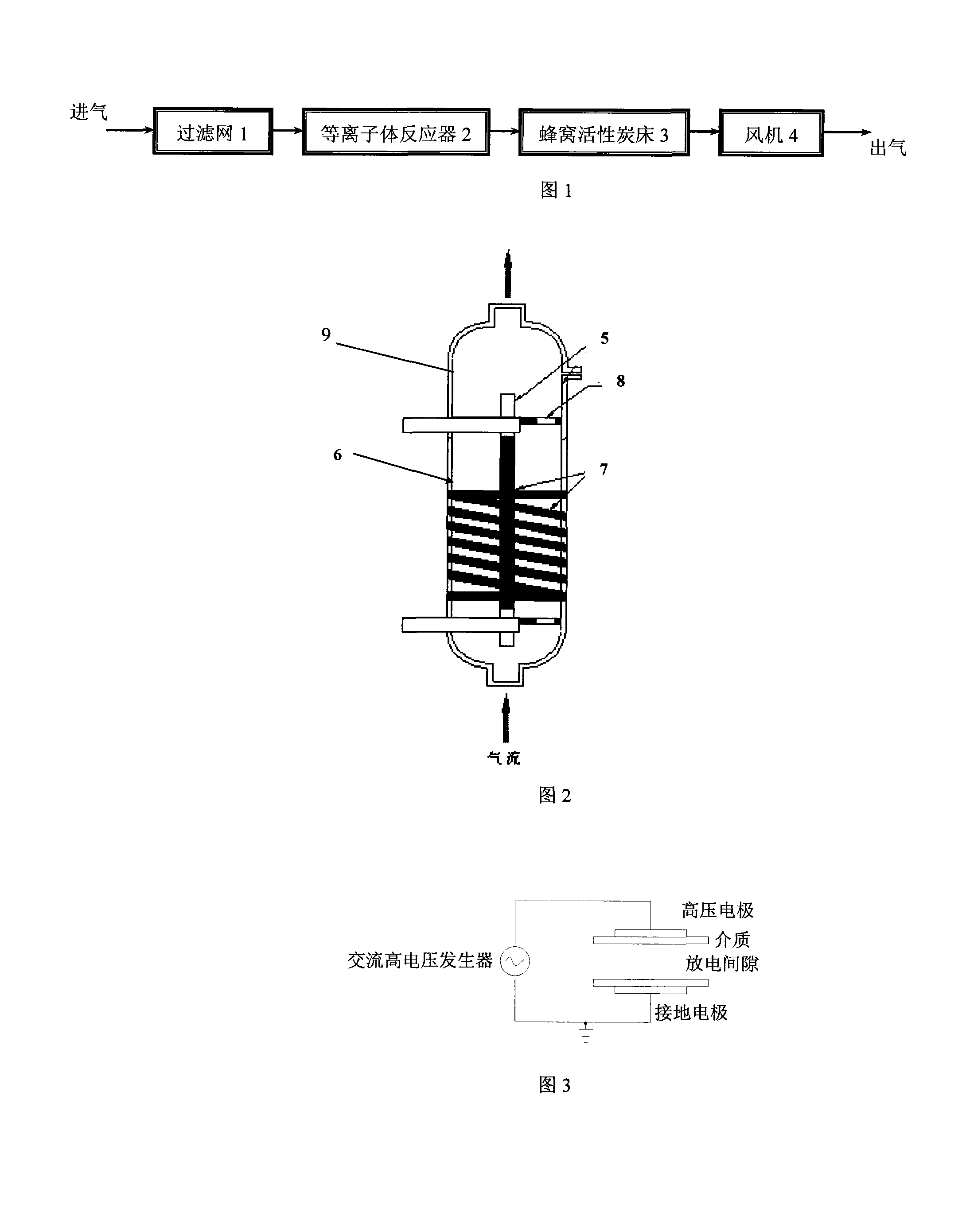

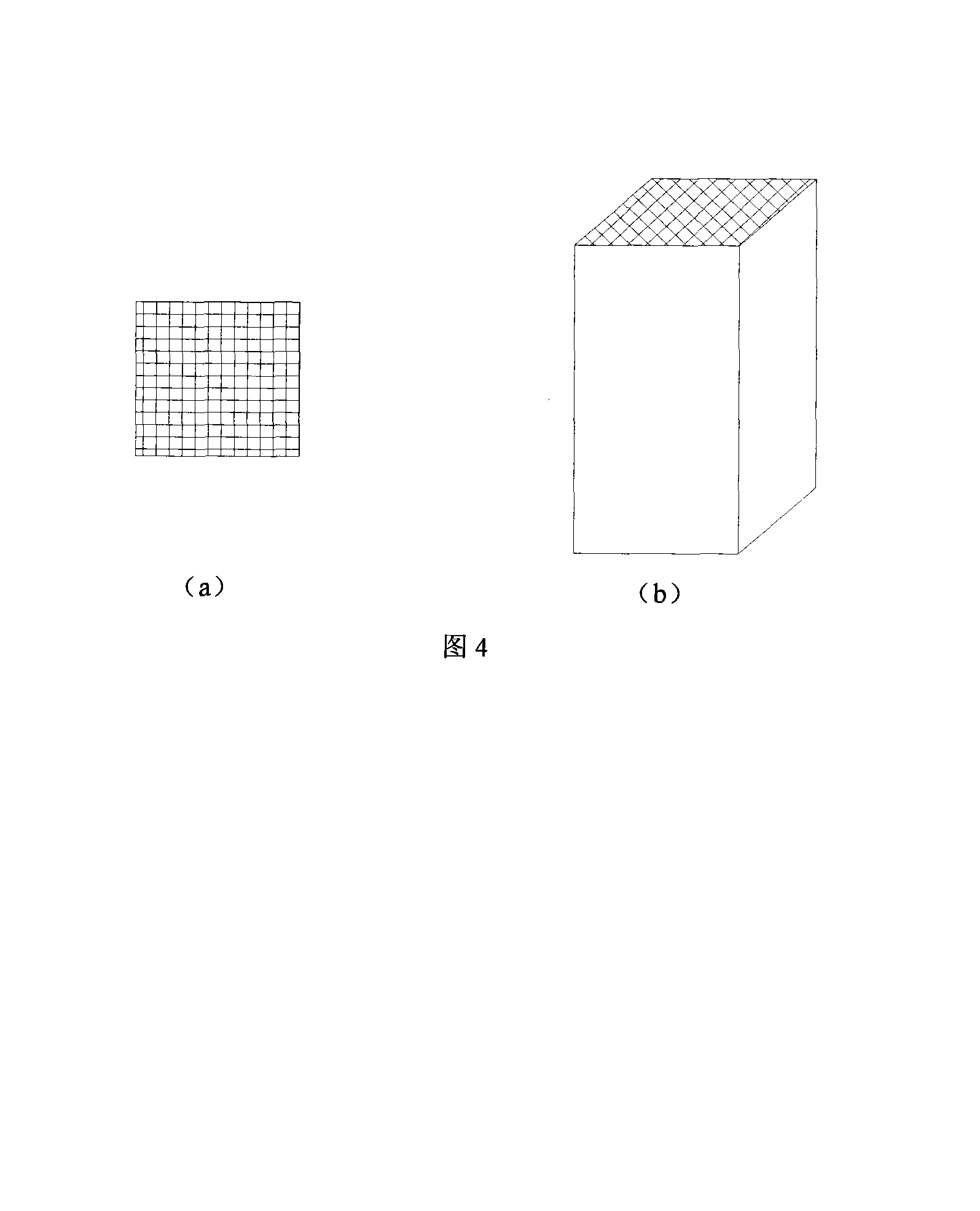

Device and method for processing municipal utilities foul gas

InactiveCN101234211ALarge amount of exhaust gasShort reaction timeDispersed particle separationDeodrantsActivated carbonExhaust fumes

The invention belongs to a technical field of waste gas treatment, in particular to a device used for treating the malodorous gas of municipal facilities and a method thereof. The device of the invention consists of a filter screen, a plasma reactor, a honeycomb activated carbon bed and a blower which are connected in sequence; wherein the plasma reactor adopts the structure form of a double medium barrier discharge plasma and is formed by the combination of a plurality of plasma reaction tubes; the honeycomb activated carbon bed is an absorption-catalysis oxidative bed and adopts the honeycomb activated carbon as a filling layer. The particles such as the dust in the waste gas are filtered out through the filter screen and enter into the plasma reactor, and a series of reactions occur to the malodorous matter in the bombardment of high energy electrons, and a little un-reacted malodorous matter is further treated through the honeycomb activated carbon bed. The blower which is arranged at the back of the device thus ensures the reaction device in negative pressure conditions so as to avoid the leakage of the malodorous gas. The device and the method provided by the invention have a large processing capacity of the malodorous gas and are high in processing efficiency.

Owner:SHANGHAI MUNICIPAL ENG DESIGN INST GRP +1

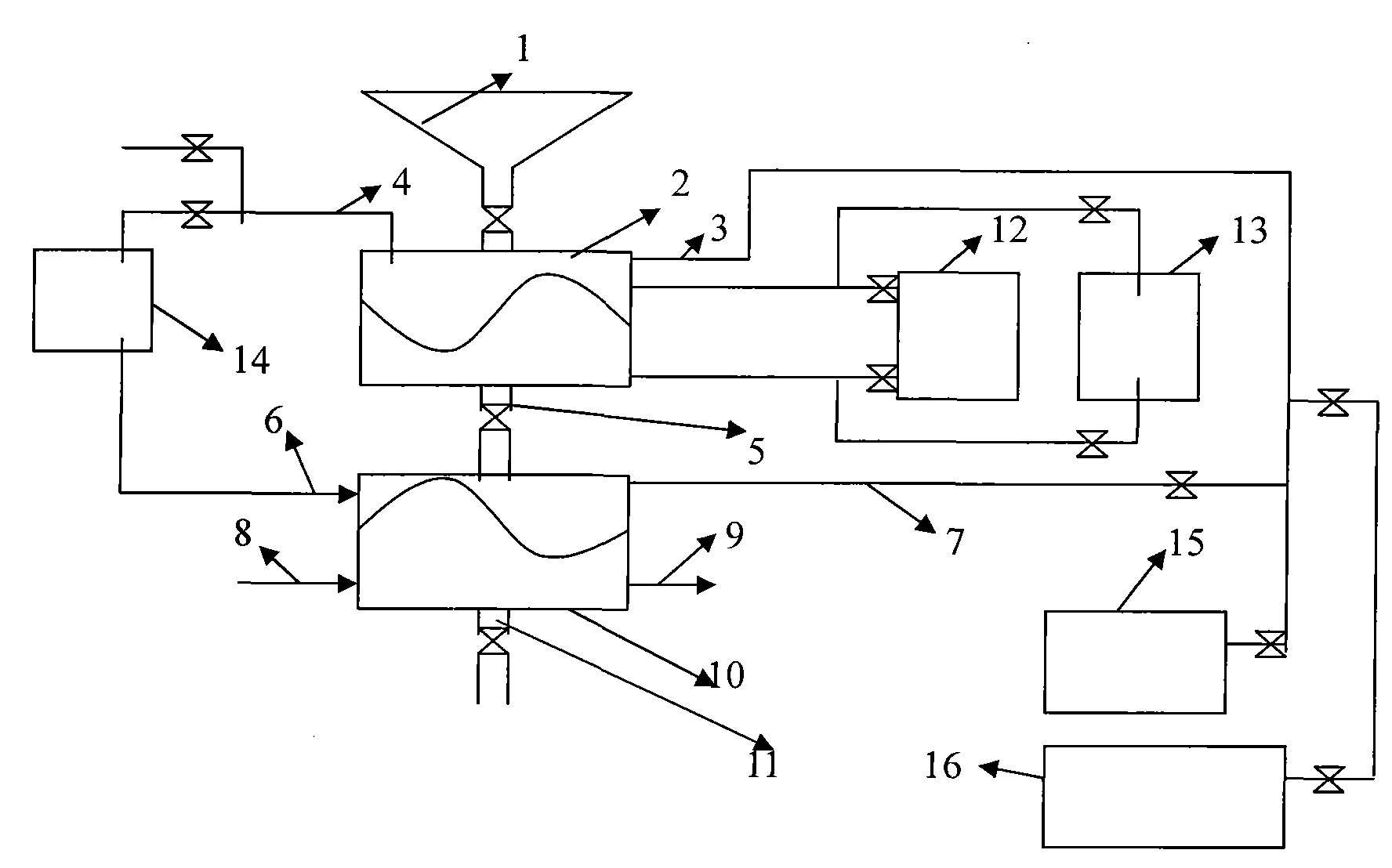

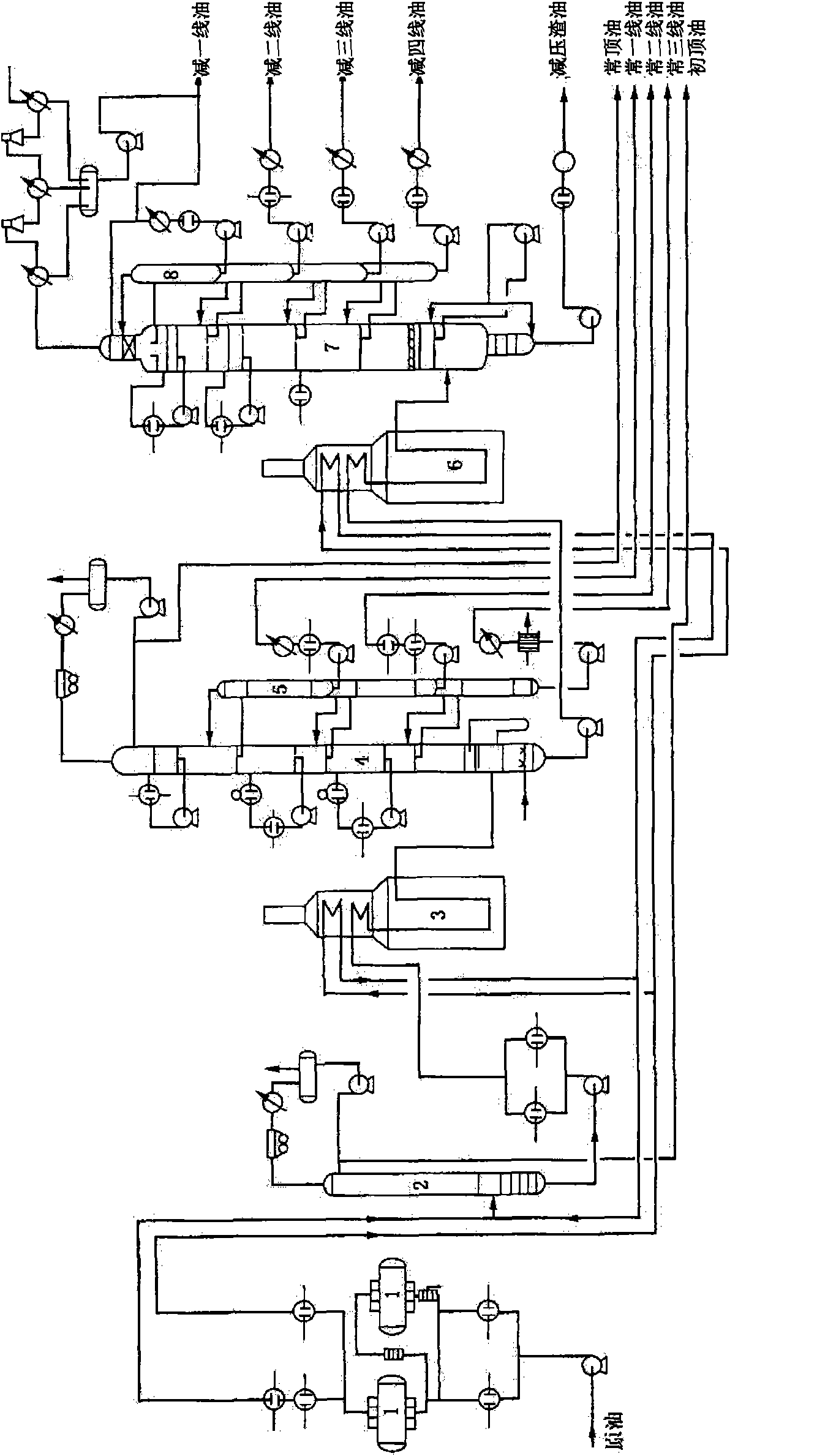

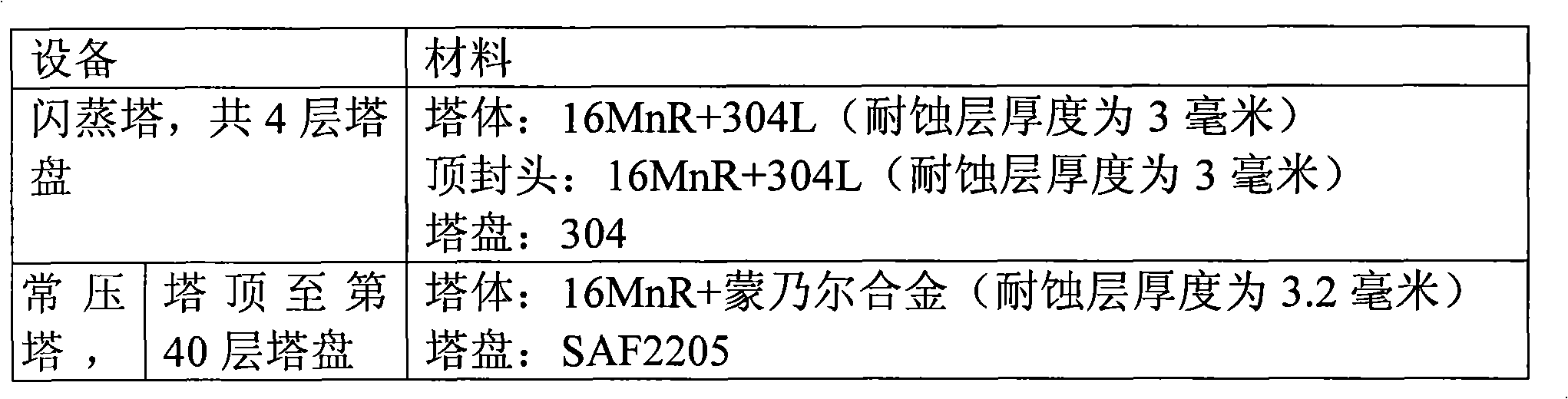

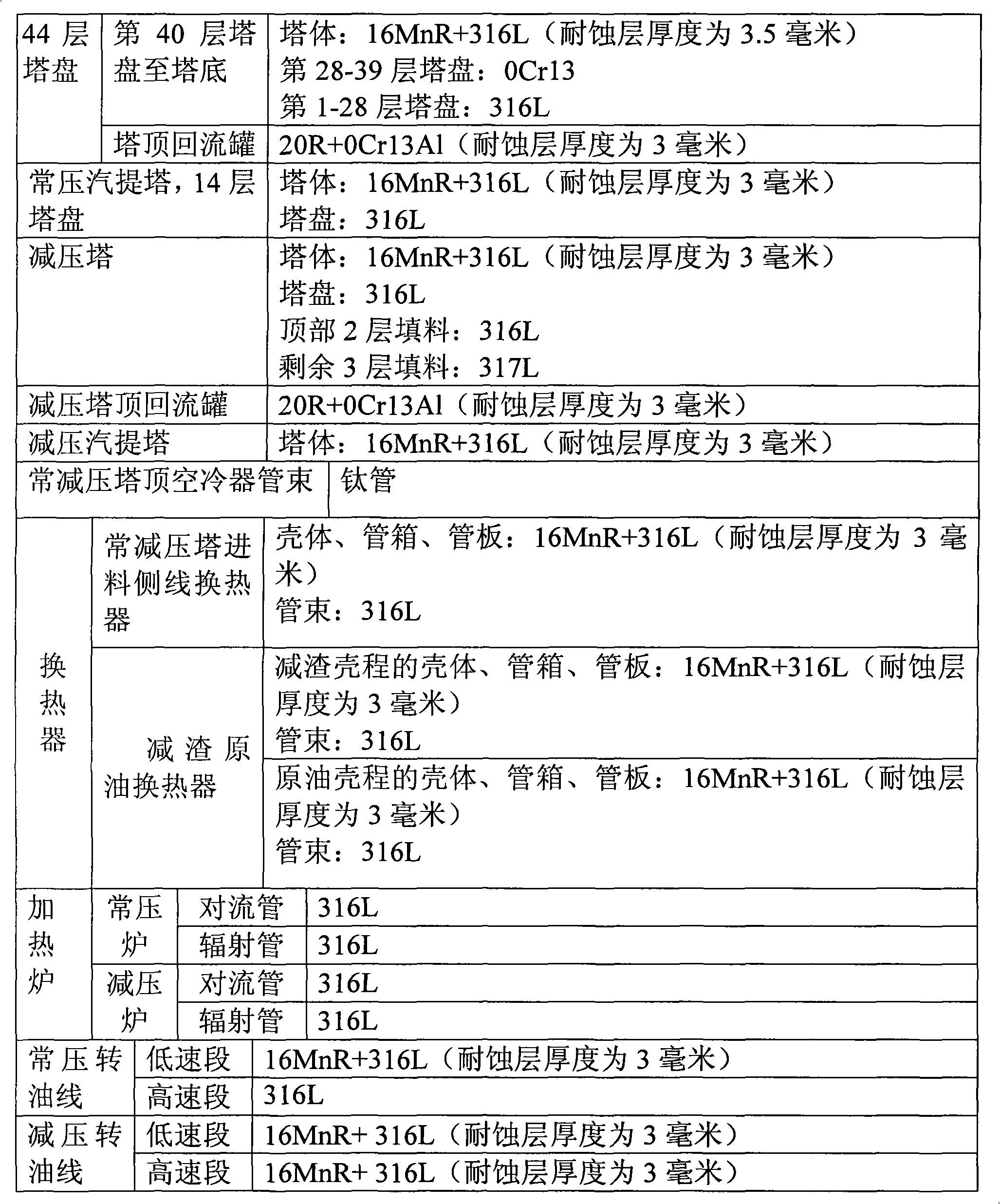

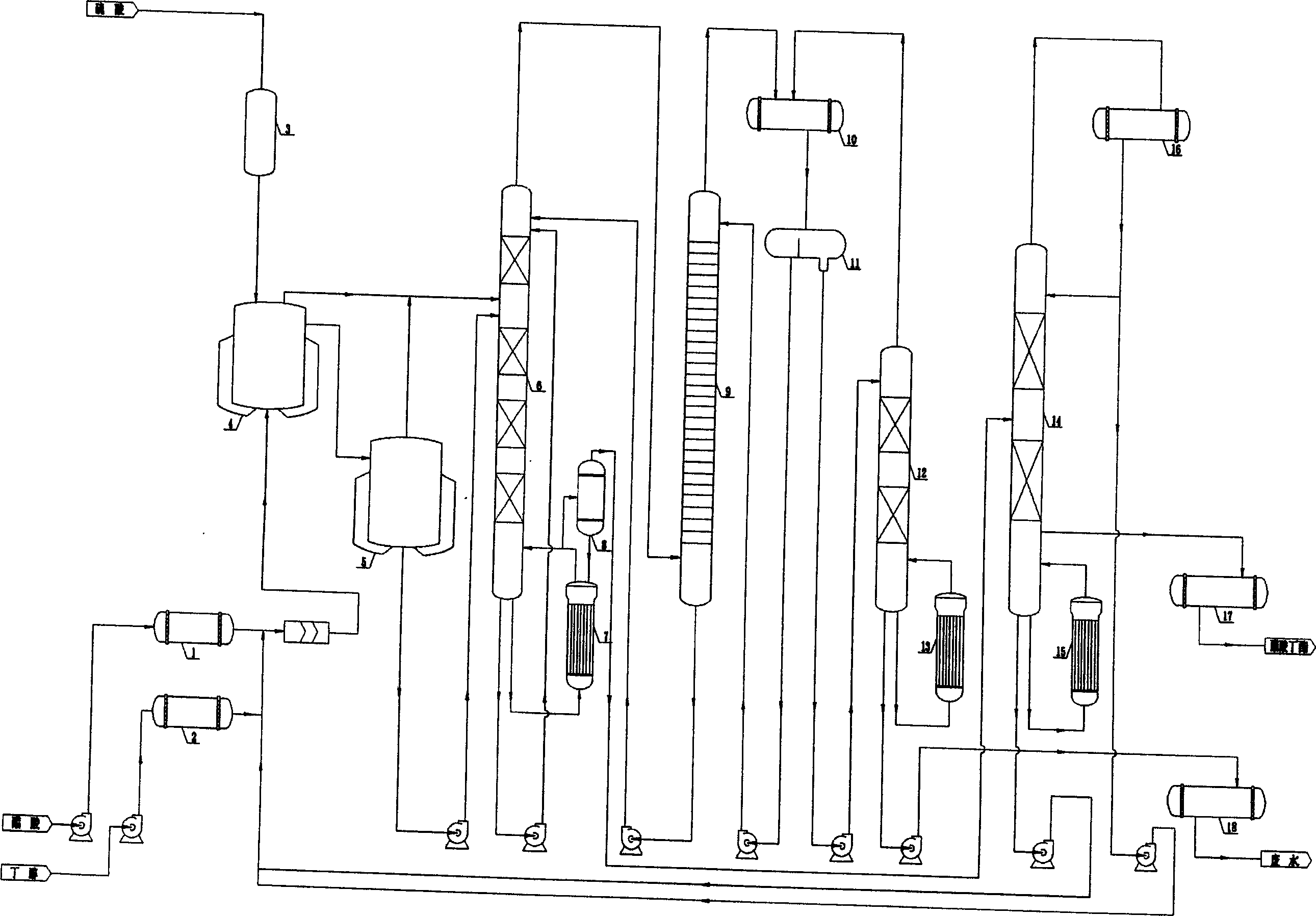

Atmospheric and vacuum distillation device and atmospheric and vacuum distillation method of high acid-content crude oil

ActiveCN101624535ASolving Corrosion ProblemsHigh metal contentHydrocarbon distillationEngineeringTower

The invention provides an atmospheric and vacuum distillation device and an atmospheric and vacuum distillation method of high acid-content crude oil. The device comprises an atmospheric tower, an atmospheric kiln, a vacuum tower and a vacuum kiln, wherein the atmospheric tower comprises a tower body, a tower tray and stuffing. The tower tray of the atmospheric tower has more than 40 layers, wherein the tower body of the atmospheric tower between the 40th layer of the tower tray and the tower top is made of metallic composite of one or a plurality of Monel, 0Cr13, 316L, SAF2205, SAF2507 and SAF 2304 and carbon steel, the tower tray is made of one or a plurality of Monel, 0Cr13, 316L, SAF2205, SAF2507 and SAF 2304, the tower body of the atmospheric tower between the tower bottom and the 40th layer of the tower tray is made of metallic composite of 316 L and carbon steel, the tower trays from the 28th layer to the 39th layer are made of 0Cr13 material and the tower trays from the first layer to the 28th layer are made of 316L. The atmospheric and vacuum distillation device effectively solves the problem of device corrosion in the atmospheric and vacuum distillation of high acid-content crude oil.

Owner:CNOOC OIL & PETROCHEMICALS CO LTD +1

Method for erosion of high pressure high specific volume anode foil

InactiveCN101206956ASolving Corrosion ProblemsHigh mechanical strengthElectrolytic capacitorsPhosphoric acidPolyethylene glycol

The invention relates to a corrosion method of anode foil with high pressure and high specific volume. Firstly, preliminary treatment is performed to aluminum foil; secondly, primary direct current electrolytic corrosion is performed in the mixed liquor with the concentration of 0.5 to 5 wt percent of sulphuric acid and 1 to 10 wt percent of sulphuric acid; thirdly, secondary direct current electrolytic corrosion is performed in the mixed liquor with the concentration of 5 to 15 wt percent of sulphuric acid, 0.01 to 0.1 wt percent of phosphoric acid and 0.01 to 0.1 wt percent of polyethylene glycol (The molecular weight is 10000); thirdly, the tertiary direct current electrolytic corrosion is performed in the mixed liquor with the concentration of 5 to 15 wt percent of chlorhydric acid, 0.01 to 0.1 wt percent of phosphoric acid and 0.01 to 0.1 wt percent of polyethylene glycol; finally, the immersion is performed in the water solution with the concentration of 0.5 to 5 wt percent of nitric acid. The adoption of the corrosion method of the invention not only solves the corrosion problem of the high voltage anode foil, but also improve the surface expand rate of the aluminum foil, the specific volume of the aluminum foil is greatly improved, and the high voltage anode foil has better mechanical strength on the premise of obtaining high specific volume.

Owner:横店集团东磁有限公司

Method for mass producing butyl acetate by reactive distillation method and using sulfuric acid as catalyst

ActiveCN1844076AEasy to separateAvoid corrosionPhysical/chemical process catalystsOrganic compound preparationAcetic acidAlcohol

The refers to a mass production method of isobutyl acetate which uses hydric sulphate as accelerant by reaction fractional distillation, using ethyl acetate and butyl alcohol as raw material, concentrated sulfuric acid as accelerant, continue producing isobutyl acetate by reaction fractional distillation, the whole production system contains three towers, reaction fractionating tower, azeotropy tower and eater fractionating tower, the reaction fractionating tower, azeotropy tower are setted side by side. The ethyl acetate, butyl alcohol and concentrated sulfuric acid are drived into feeder column plate of reaction fractionating tower after esterification prereaction, the gas phase of prereactor going into feeding phase of reaction fractionating tower, the gas phase on top of reaction fractionating tower going into column plate of cellar of azeotropy towder, the liquid phase of towder bottom going into mesomere of eater fractionating tower, the butyl product is continue discharged from side tower. This invention combines the technique which using sulfuric as accelerant by mean improvement of reaction fractional distillation technique, not only ustilizing the advanced technology of reaction fractional distillation, but also making the liquid accelerant's characters of convenience to operate, easy to enlarge production scale getted adequate use.

Owner:NANTONG BAICHUAN NEW MATERIAL CO LTD +1

Method for preparing carbon black and active carbon from waste tyre pyrolytic carbon

This invention relates to a method for preparing carbon-black and activated-carbon, by using waste-tyre as raw material after thermal decomposition and modification. The procedures are as follows: the carbon black from waste tyre is fed into a bag made from filter paper, extracted in flask with organic solvent; the solid is air-dried, weighing, the liquid is proceeded distillation for removing solvent, collecting the residul oil from the carbon black. The carbon black thus treated is put into a flask together with dilute acid, proceeded by agitation, vacuum filtering. The carbon black is then placed in quartz ship, and they are put in quartz tube, connected with flask with distilled water in it; heating the distilled water at 150-1000deg.C for treating the carbon black, drying, obtaining the final carbon black and activated carbon. Advantages are: reutilization of solvent and residual oil, utilization of dilute acid (less corrosion), high purity and high specific superficial area of final products.

Owner:NANKAI UNIV

Process for atomizing desulfurization waste water through recycled flue gas of tower type boiler

InactiveCN105457468AEasy installationAvoid corrosionGas treatmentDispersed particle separationFlueStilling basin

The invention relates to a process for atomizing desulfurization waste water through recycled flue gas of a tower type boiler. The process comprises the steps that the desulfurization waste water of a desulfurization tower is drained to a stilling basin for preliminary sedimentation, and then the desulfurization waste water is pressurized through a pump and conveyed to a pipeline of a nozzle; part of the desulfurized flue gas is sent to the pipeline of the nozzle through a recirculation fan, so that the recirculation flue gas is in contact with the desulfurization waste water in the pipeline of the nozzle, and the initial temperature of the desulfurization waste water is raised; the nozzle is installed in a vertical flue located at the tail of the boiler, the desulfurization waste water is jetted and atomized, atomization liquid drops into the flue and evaporates quickly, and all ions in the desulfurization waste water are separated by crystallization quickly, captured by a dust remover when entering the dust remover along with the flue gas and discharged outward along with dust. By means of the design of the process, atomization performance of the desulfurization waste water is improved, evaporation of the desulfurization waste water is accelerated, blocking of a jet system can be prevented, the desulfurization waste water is effectively prevented from being jet to the pipe wall, the problem of corrosion of the wall surface of a flue which is caused easily when ordinary flues are used for treating desulfurization waste water is avoided, innocent treatment of the desulfurization waste water in the real sense is achieved, reconstruction investment is small, and operation cost is low.

Owner:NORTH CHINA ELECTRIC POWER UNIV (BAODING) +1

Decompression regeneration system and method for hollow fiber membrane contactor of carbon dioxide enriched absorbent solution

ActiveCN101822931ALow regeneration energy consumptionAvoid volatile lossSemi-permeable membranesProductsChemistryDecompression operation

The invention discloses decompression regeneration system and method for a hollow fiber membrane contactor of a carbon dioxide enriched absorbent solution. The method comprises the steps of: heating the carbon dioxide enriched absorbent solution by a heater, and enabling the pressurized carbon dioxide enriched absorbent solution to enter the tube pass of the hollow fiber membrane contactor for regeneration by a booster pump and a liquid flow meter; outputting the obtained barren solution of the absorbent solution after regeneration from the lower end of the tube pass of the hollow fiber membrane contactor; blowing steam by the low temperature generated by a blowing steam generator under the action of a vacuum pump, and feeding the steam from the lower end of the tube pass of the hollow fiber membrane contactor for assisting regeneration; and dewatering the regenerated CO2 by a condenser under the actions of the blowing of the steam with low temperature and the suction of the vacuum pump to obtain the CO2 gas with high concentration. In the invention, the decompression operation is carried out in the membrane contactor for replacing the traditional heating regeneration method, the regeneration energy consumption of the CO2 absorbent solution is reduced, and the problem of high energy consumption of CO2 separation from fire coal and flue gas by using the chemical absorbent method can be solved.

Owner:ZHEJIANG UNIV

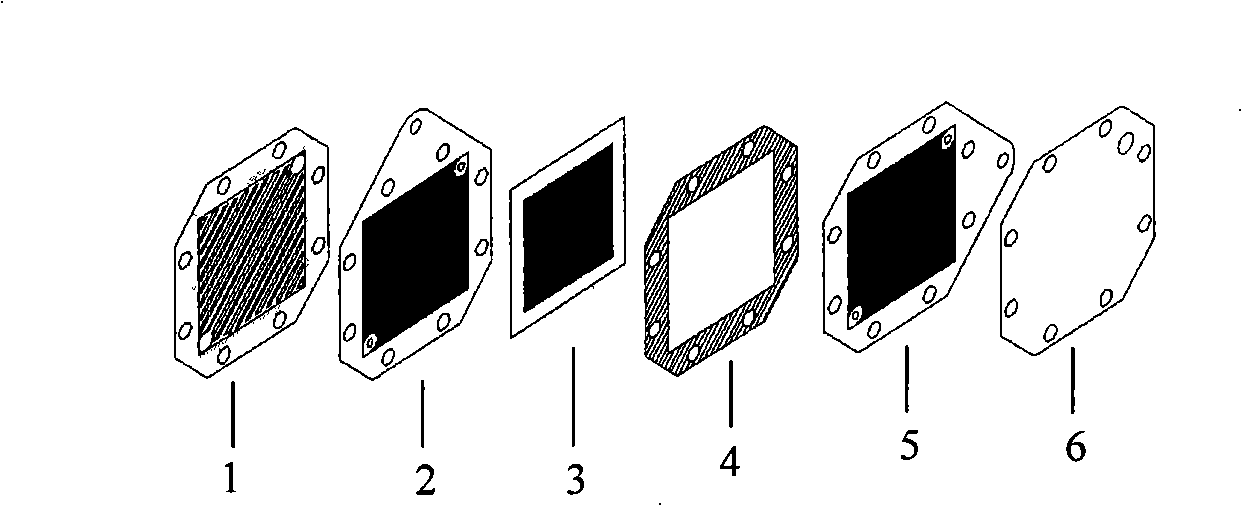

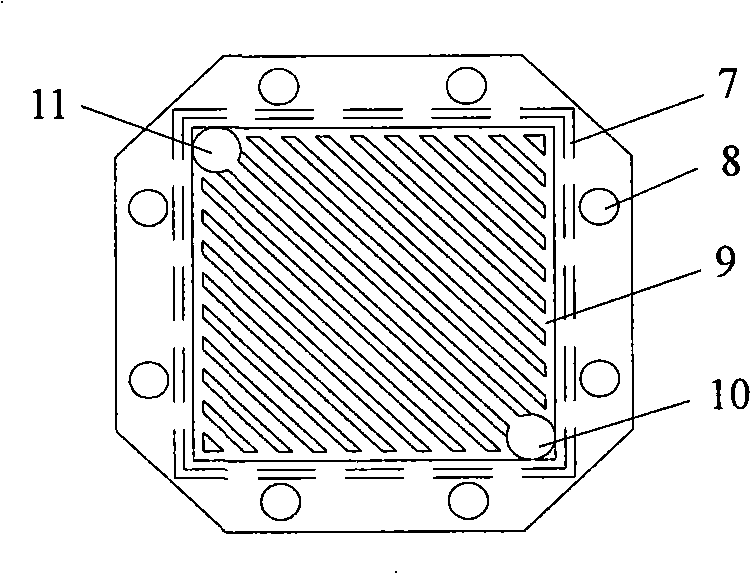

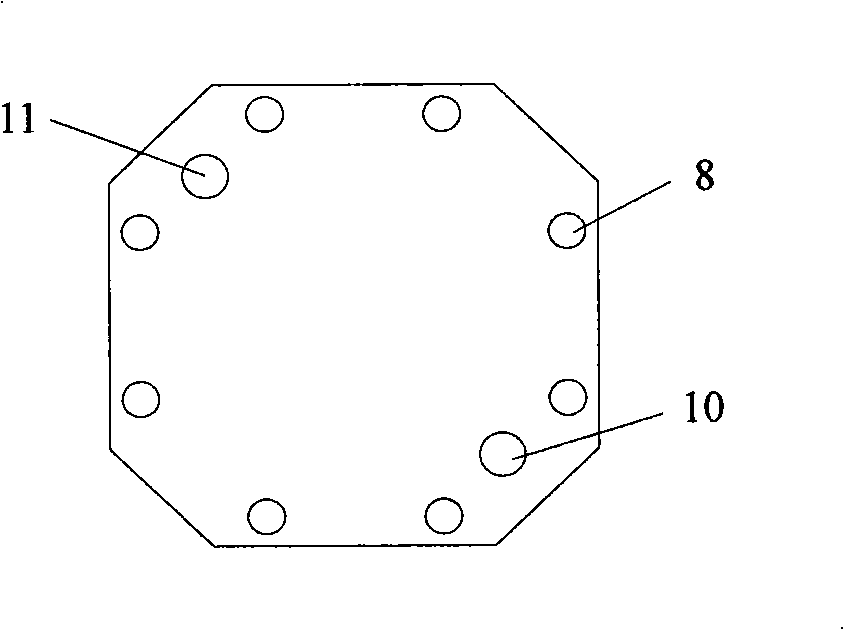

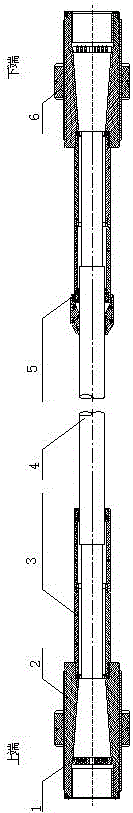

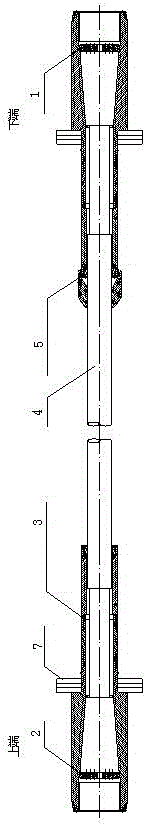

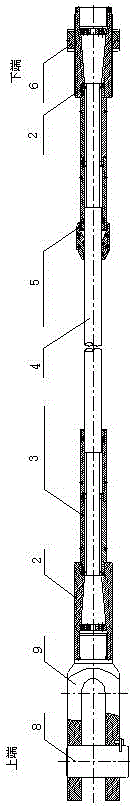

Ultra-pure water membrane electrolyser

An ultra-pure water membrane electrolyser belongs to the technical field of electrolytic cell, comprising an anode clamping plate, an anode current collector, a membrane electrode, a sealing gasket, a cathode current collector and a cathode clamping plate; wherein, the electrolyser is characteristics in that: the anode clamping plate thereon is provided with a horizontal groove flow field, a sealing ring, a water inlet, a water outlet and a fastening bolt hole. The anode clamping plate not only locates and fastens the electrolytic cell, but also has the flow field function of channelizing water and oxygen flowage. The anode current collector transmits the electric energy of an external power to an anode catalytic layer on the surface of the membrane electrode to realise electrochemical oxidization of water, so as to generate oxygen and hydrogen ion. The cathode current collector transmits the electric energy of the external power to a cathode catalytic layer on the surface of the membrane electrode to reduction of hydrogen ion, so as to generate hydrogen. The cathode clamping plate thereon is also provided with a flow field, a sealing ring, a water outlet and a fastening bolt hole, and the components are assembled in sequence and then fastened by screw rods and nuts. The electrolyser has the advantages as follows: simple structure, high working efficiency and long service life.

Owner:北京飞驰绿能电源技术有限责任公司

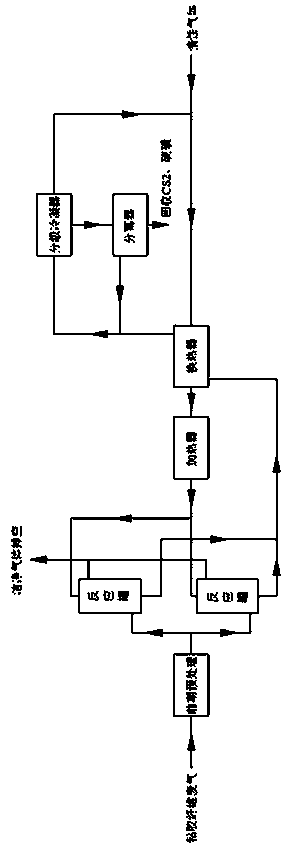

Recycling treatment method of CS2 and H2S in waste gas in production of viscose fiber

InactiveCN103721524ANo emissionsSolving Corrosion ProblemsCarbon disulfideDispersed particle separationDesorptionSorbent

The invention relates to a recycling treatment method of CS2 and H2S in waste gas in production of viscose fiber. The recycling treatment method comprises the four steps of pretreatment at the early stage, enrichment and thickening, desorption and regeneration and separation and recycling. The recycling treatment method particularly comprises the following steps: in the process of pretreatment at the early stage, carrying out dust removal, cooling and drying treatment on the waste gas; in the enrichment and thickening process, carrying out absorption and catching on two types of gases in a concentration-reaction tank filled with an absorbing agent; in the desorption and regeneration process, carrying out stepwise desorption on CS2 and H2S by adopting selected inert gas; and in the separation and recycling process, extracting CS2 and H2S respectively by adopting a fractional condenser. The recycling treatment method solves the problems that the equipment adopting steam as a desorbing carrier is corroded, the microporous surface of active carbon is calcified, and drying is needed after desorption and regeneration, and has the advantages that no waste gas is discharged, the service life of the absorbing agent is prolonged and high-efficiency and environmentally-friendly effects are achieved and the like.

Owner:石家庄科英化工技术有限公司

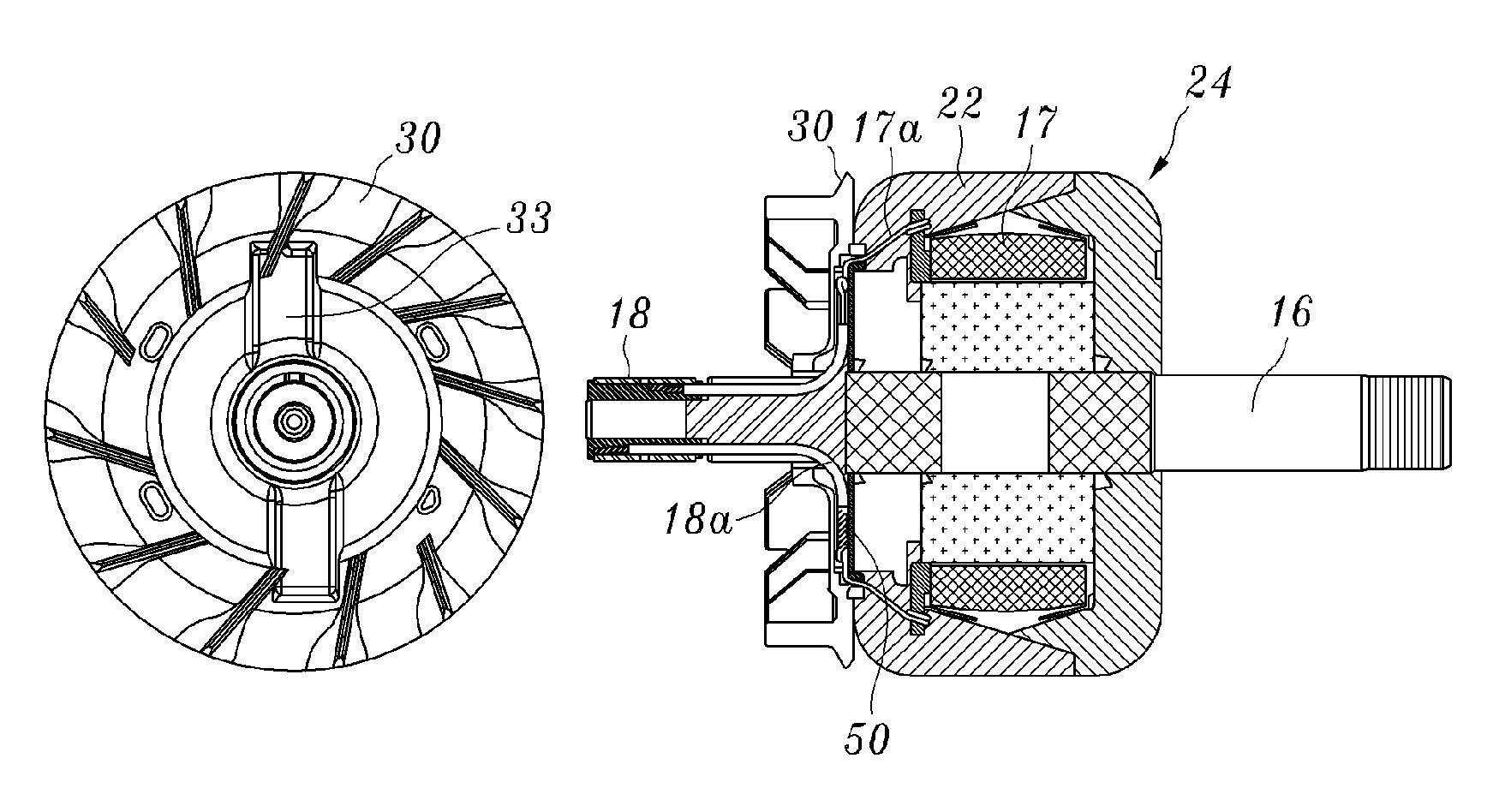

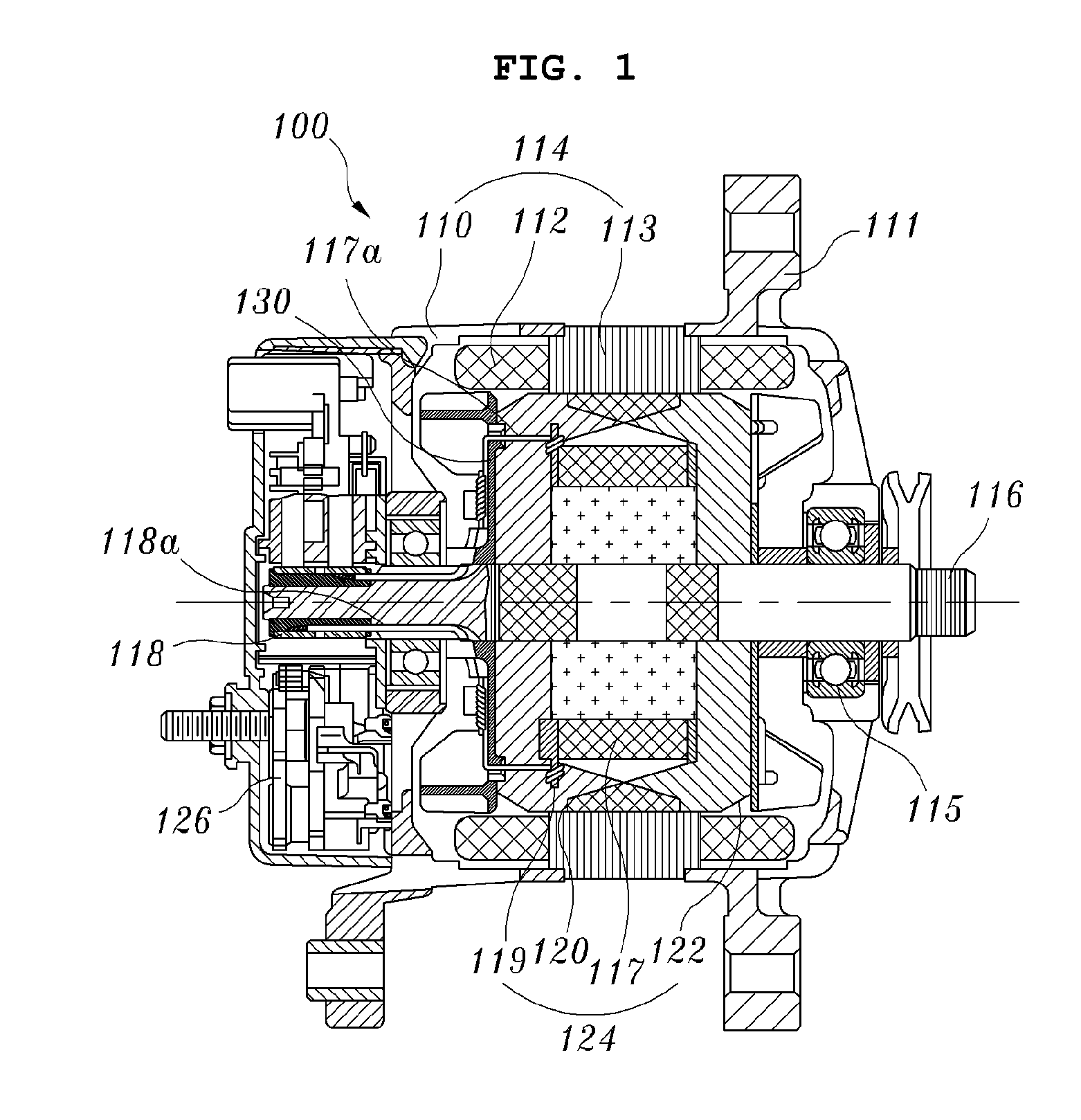

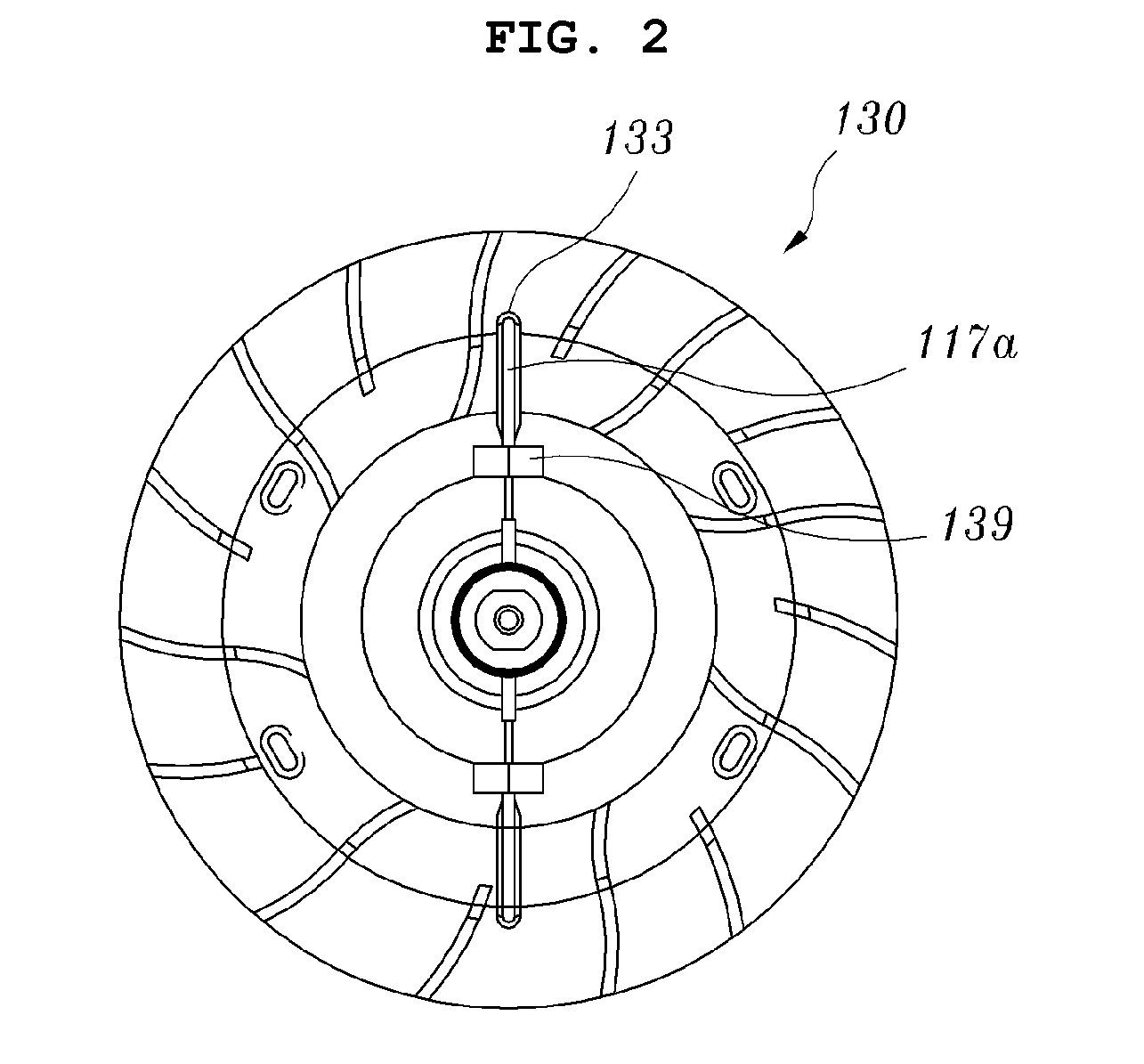

Connection structure and method of connecting field coil and lead wires in vehicle alternator

ActiveUS20090026854A1Difficult to observeSolving Corrosion ProblemsMagnetic circuit rotating partsManufacturing stator/rotor bodiesEpoxyAlternator

A connection structure and a connection method of connecting field coils and lead wires in a vehicle alternator. The connection structure includes a rotor assembly, a rear fan, and a rotor insulator. The rotor assembly includes a rotor shaft, a spool bobbin, and rotor segments. In the connection structure, a soldering or welding process is performed on twisted parts, which are formed by twisting field coils and lead wires around each other, the twisted parts are bent in the guide pockets of the rotor insulator, epoxy is applied to the outer surfaces of the twisted parts and the inner surfaces of guide pockets, and the rear fan is coupled to the front of the rotor insulator so that the inner surfaces of the protrusion hubs of the rear fan are in close contact with the guide pockets of the rotor insulator.

Owner:ERAE AMS CO LTD

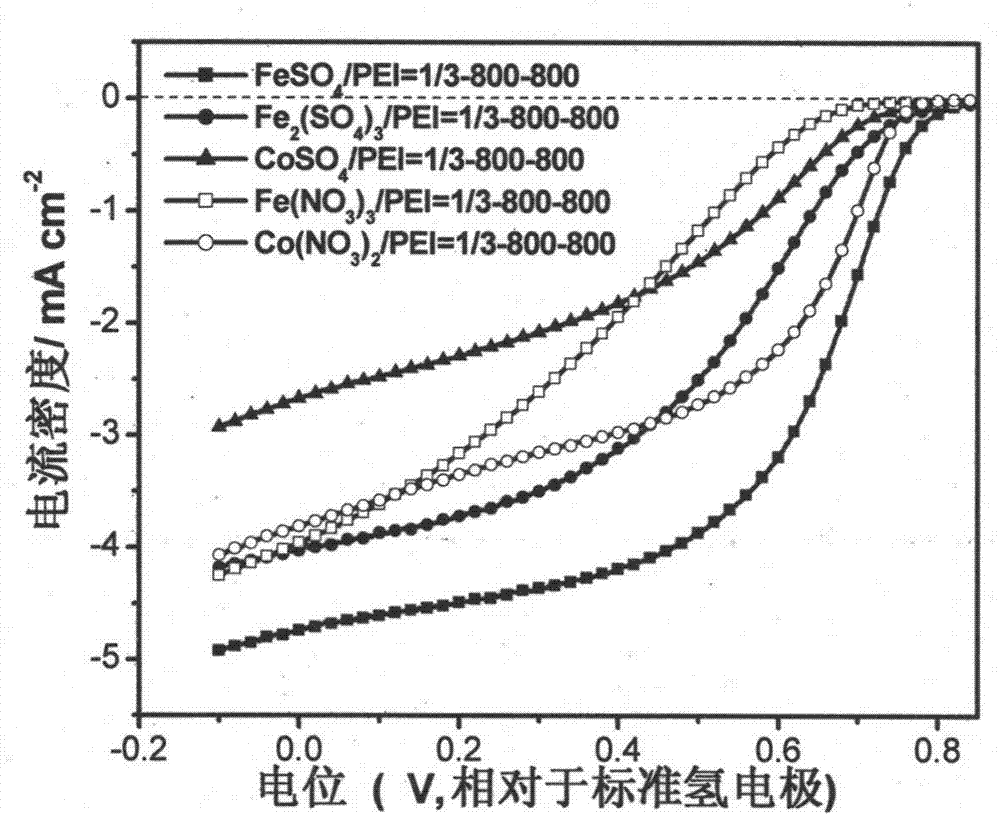

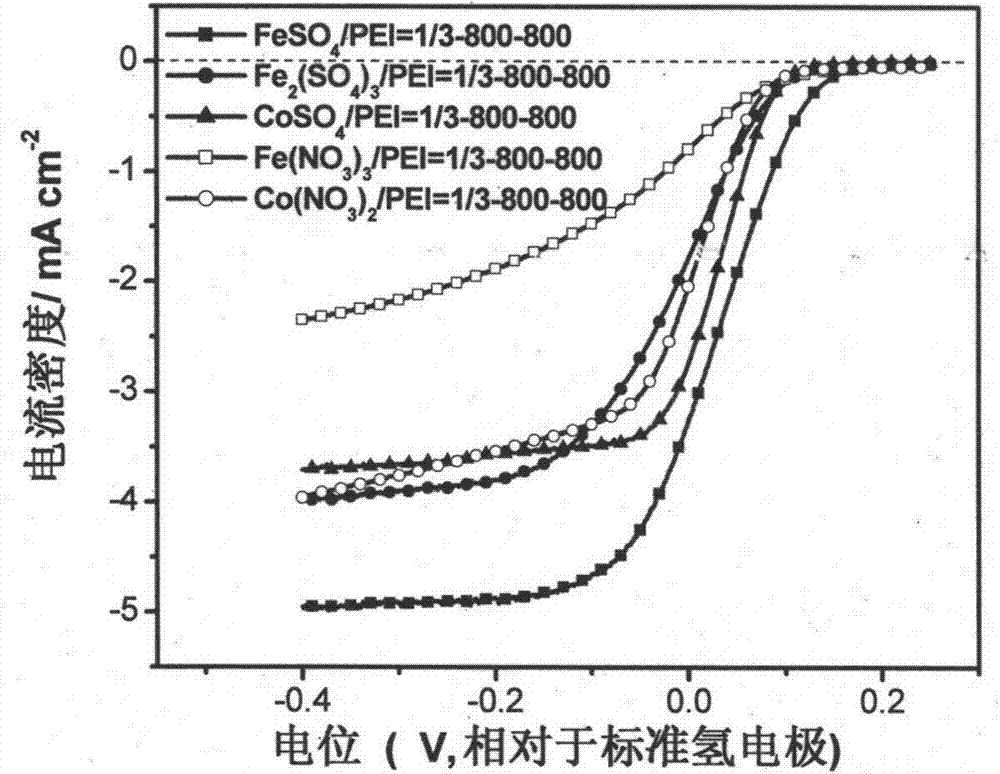

Nitrogen/transition metal-codoped hierarchical-pore carbon oxygen reduction catalyst, and preparation method and application thereof

The invention relates to a nitrogen / transition metal-codoped hierarchical-pore carbon oxygen reduction catalyst, and a preparation method and application thereof. The catalyst comprises the following raw materials by mass: 10 to 60% of a template, 5 to 60% of a nitrogen-containing polymer and 15 to 40% of a transition metal salt. The method comprises the following steps: separately dissolving the nitrogen-containing polymer, the template and the transition metal salt in solvents to obtain a nitrogen-containing polymer solution, a template solution and a transition metal salt solution respectively; subjecting the three solutions to mixing under stirring and to drying so as to obtain a precursor; roasting the precursor so as to obtain a catalyst intermediate; and subjecting the catalyst intermediate to alkali washing, acid pickling and roasting again so as to obtain the catalyst. The preparation method is simple to operate, has low cost and high yield and greatly reduces dependence on the precious metal Pt; and the prepared catalyst overcomes the problem of corrosion caused by usage of a non-noble metal catalyst and has wide application prospects in the aspects of a metal-air battery and a flow battery.

Owner:DONGHUA UNIV

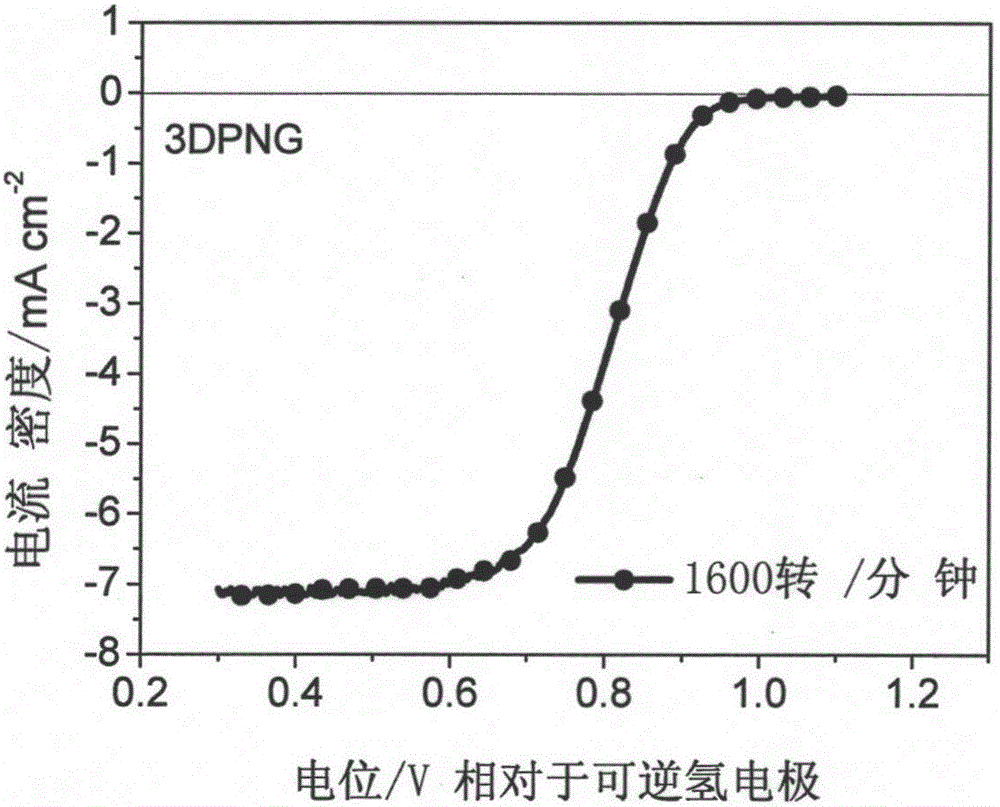

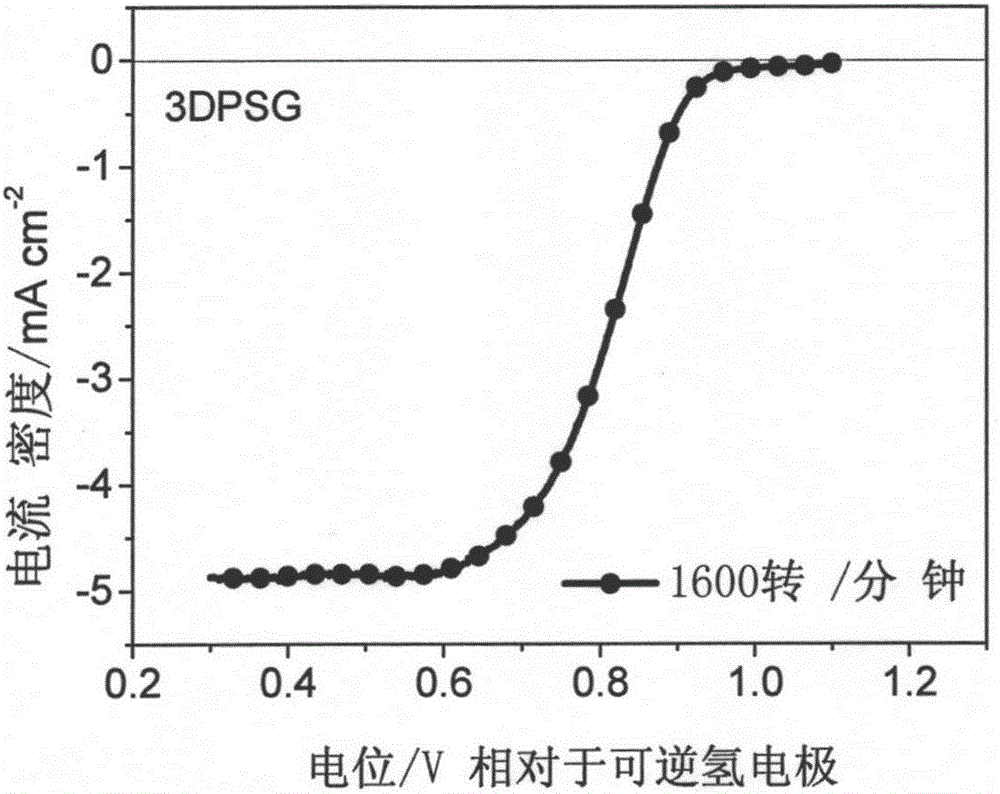

Preparation and application of nitrogen, sulphur or chlorine-doped three-dimensional porous graphene catalyst

InactiveCN105680060AIncrease the areaIncreased porous structureCell electrodesPorous grapheneReduction treatment

The invention provides a preparation and an application of a nitrogen, sulphur or chlorine-doped three-dimensional porous graphene catalyst. The preparation comprises the following steps: dissolving graphene oxide, an alkyl compound, a transition metal salt containing nitrogen, sulphur or chlorine and hydrochloric acid into a solvent, and carrying out ultrasonic treatment and drying to obtain a precursor; heating the precursor to 600-1,000 DEG C under inert gas protection and carrying out roasting reduction treatment for 1-3 hours to obtain primary carbide; carrying out pickling treatment on the obtained primary carbide with a mixed solution of hydrofluoric acid and hydrochloric acid at a room temperature for 12-24 hours, centrifuging the primary carbide, cleaning the primary carbide with deionized water and then drying the primary carbide to obtain the three-dimensional porous graphene material containing nitrogen, sulphur or chlorine; and heating the three-dimensional porous graphene material to 600-1,000 DEG C under inert gas protection, and carrying out roasting reduction treatment for 1-3 hours to obtain the nitrogen, sulphur or chlorine-doped three-dimensional porous graphene catalyst. The nitrogen, sulphur or chlorine-doped three-dimensional porous graphene catalyst has the characteristics of being high in stability, not easy to poison and the like, and has a good application prospect in the fields of wastewater treatment of a fuel cell, a metal-air cell, a super capacitor, an energy storage battery and a microbial fuel cell and the like.

Owner:DONGHUA UNIV

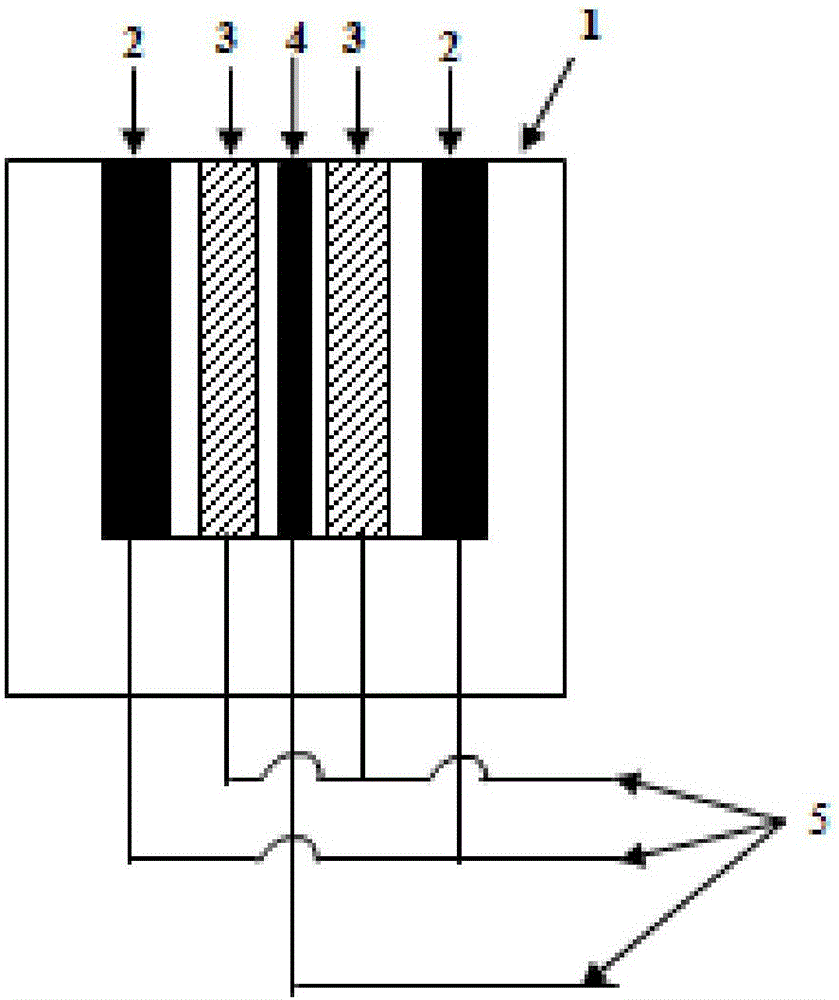

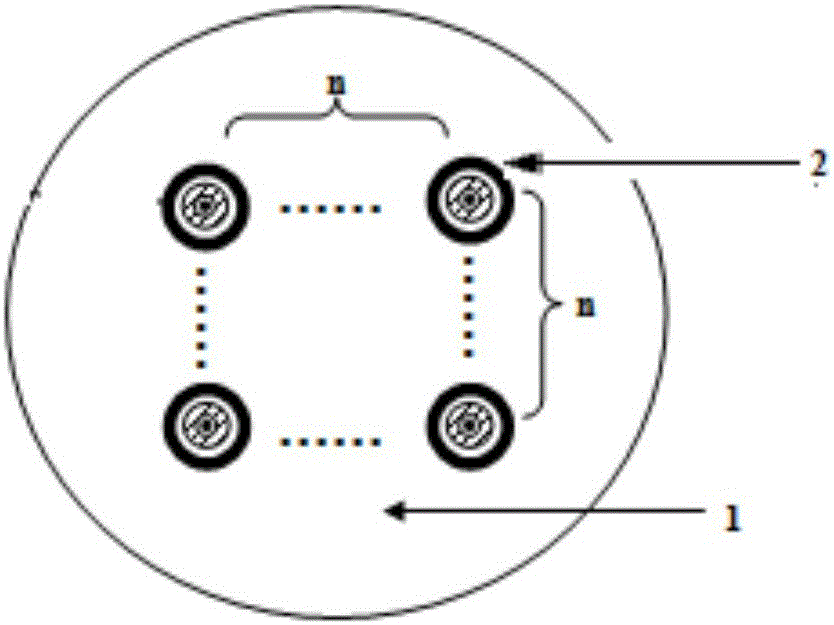

On-line atmospheric corrosion measuring device

ActiveCN105021519AReduce distractionsAccurately monitor the potential change processWeather/light/corrosion resistanceMeasurement deviceOptoelectronics

The invention relates to an on-line atmospheric corrosion measuring device which mainly solves the problems that in the prior art, the measurement accuracy is low and operation is complex. The on-line atmospheric corrosion measuring device comprises epoxy resin daub, at least one electrode set and lead wires; each electrode set is composed of a work electrode with the lead wire, a counter electrode and a reference electrode, and all the electrode sets are entirely packed in the epoxy resin daub; the section of each counter electrode is in the shape of a circular ring, the work electrodes penetrate through the center of the circular rings and are insulated, and the section of each work electrode is in the shape of a circle, wherein a hole is formed in the center of the circle; the reference electrodes penetrate through the holes and are insulated. According to the technical scheme, the problems are well solved, and the device can be applied in on-line atmospheric corrosion measuring.

Owner:CHINA PETROLEUM & CHEM CORP QINGDAO RES INST OF SAFETY ENG +1

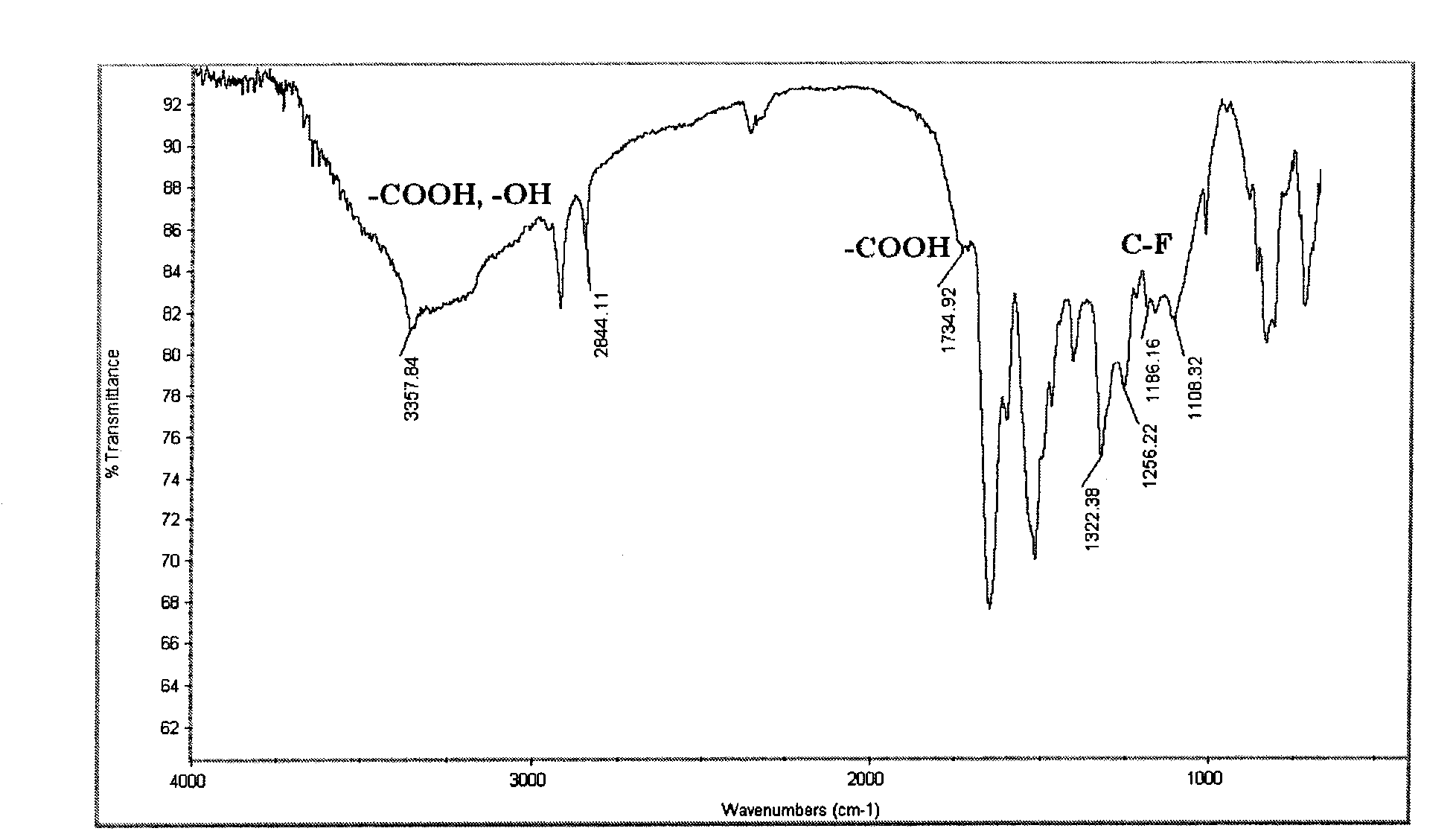

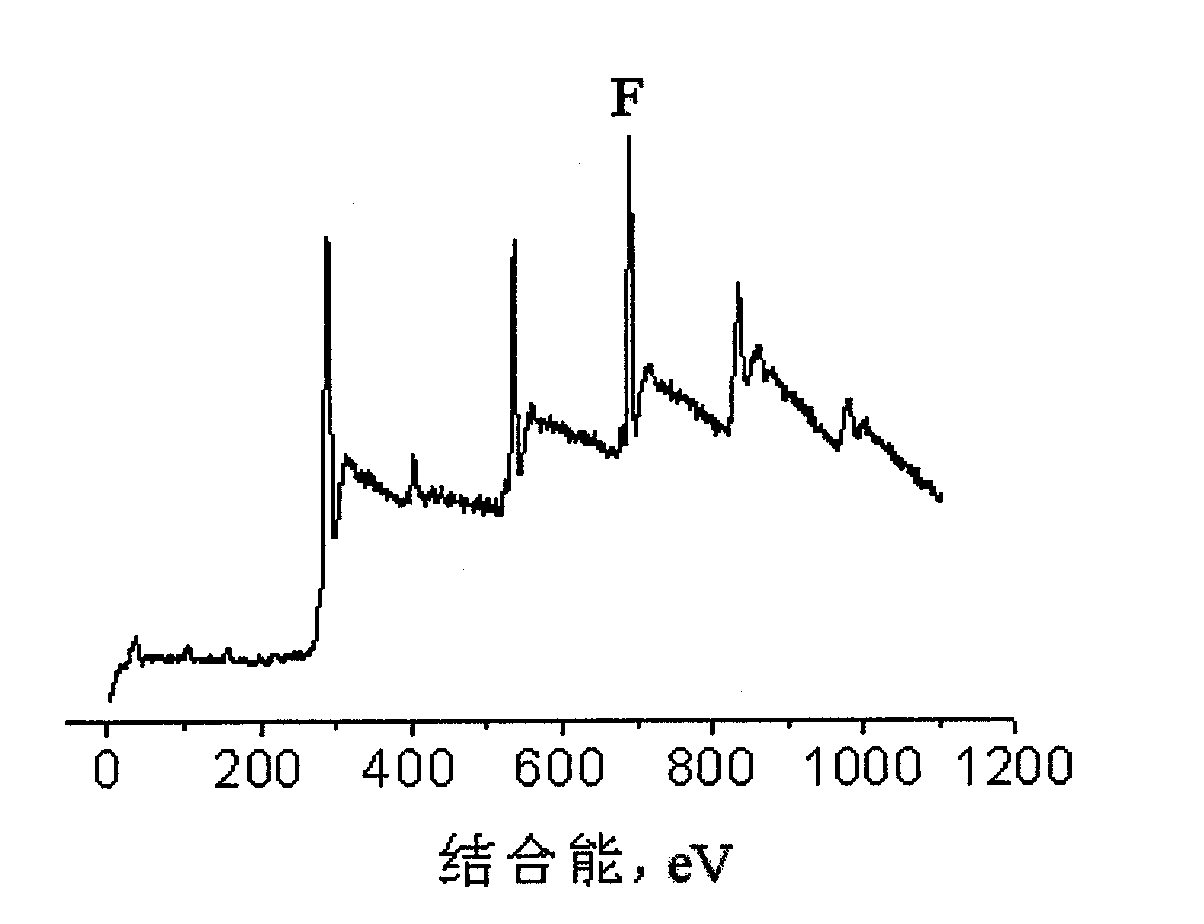

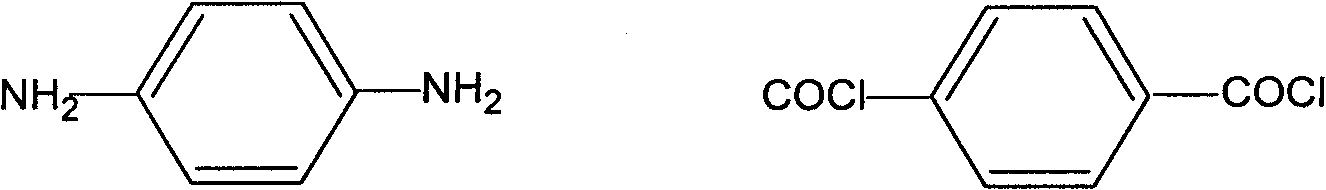

Aramid III fiber with fluorine-containing surface and preparation method thereof

InactiveCN101798748AHigh activityImprove mechanical propertiesFibre typesMonocomponent copolyamides artificial filamentAfter treatmentBiological activation

The invention discloses an aramid III fiber with a fluorine-containing surface, which is characterized in that: the surface of the fiber contains a carbon-fluorine covalent bond structure and a carboxyl-hydroxyl group; the contact angle between the surface of the fiber and water is 68 to 82 degrees; the shear strength between composite material layers prepared from the fiber is 47.3 to 55 MPa; and the tensile strength of gum dipped filaments is 4.6 to 5.4 GPa, and the tensile modulus is 145 to 168 GPa. The invention also discloses a method for preparing the aramid III fiber with the fluorine-containing surface. The fiber surface hydrophilicity of the aramid III fiber subjected to fluoridation is obviously improved; and the shear strength between the prepared composite material layers, and the tensile strength and the tensile modulus of the gum dipped filaments all can be improved by 20 to 30 percent. The method has the advantages of high fluoridation rate, short treatment time, can continuous surface treatment for the fiber on line, high stability of the surface activation effect after treatment, low cost and good application prospects.

Owner:SINOSELEN HI TECH

Use of plastic film and plastic board as construction member, mechanical device protection layer, and reinforced layer

InactiveCN1963057AExtend your lifeIncreased durabilityCovering/liningsBuilding repairsAdhesiveMechanical equipment

The invention is an application of plastic film and plastic sheeting as building components, mechanical equipment protection layer and reinforcement layer, and it involves applications of plastic thin films, plastic complex film or plastic plate. The invention is aimed at the resolution of the durability of construction, the quality problems of concrete element cracking and the plaster cracking, the corrosion problems of mechanical equipment and the problem of concrete components is bad flexible. The invention daubs the adhesive or the polymer prepared of adhesive and inorganic powders or cement to the outer surface of buildings, then bonds the plastic thin films, plastic complex film or plastic plate on the outer surface of buildings or mechanical devices which is daubed with adhesive or polymer. The advantages of the invention are: it resolves the durability of construction and mechanical equipment effectively, increases the flexibility of concrete components and improve the performance of concrete structures; it is low cost, durable, easy operation, no complicated equipment needed, it bonds directly using adhesive or prepares polymer on site according adding other filler into adhesive and stirring.

Owner:吴淑环

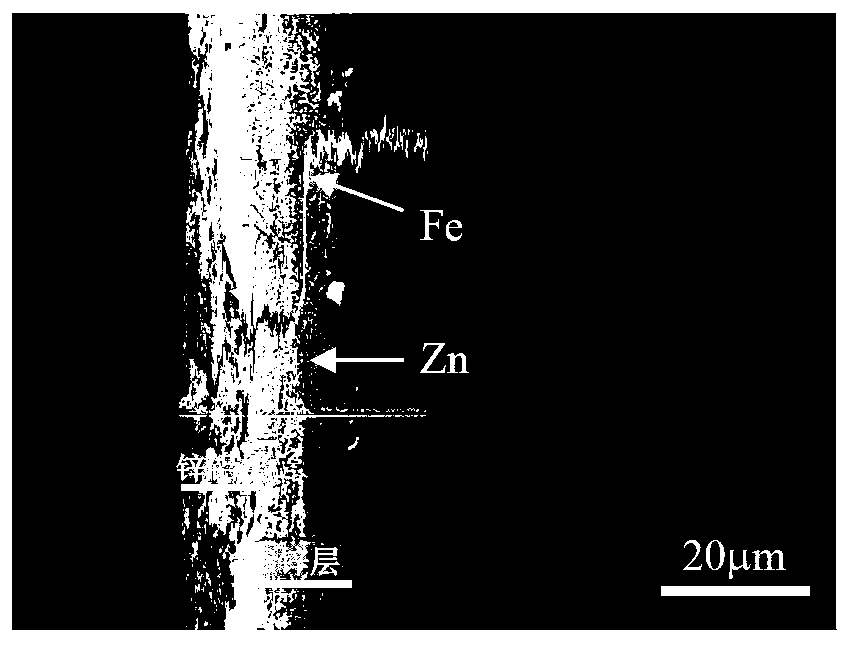

Production method for ship fastener complex coating

ActiveCN103316828AIncrease the effective thicknessSmall effective thicknessPretreated surfacesSpecial surfacesMetallic materialsDip-coating

The invention belongs to the technical field of metal material surface processing and relates to a production method for a ship fastener complex coating. A zinc impregnation coating, a zinc-aluminum coating and an epoxy coating are arranged on the fastener surface from internal to external and zinc impregnation, washing, zinc-aluminum coating liquid dip-coating, zinc-aluminum coating solidification, epoxy coating liquid dip-coating and epoxy coating solidification are performed on the faster after sequentially being performed on oil removing and rust removing to form into a protective layer. The production method for the ship fastener complex coating has the advantages of being simple in production technology and reasonable in principle. The complex coating has the advantages of being good in corrosion resistance, being capable of effectively solving the problem that the faster is corroded in the seawater environment and being environmentally friendly.

Owner:725TH RES INST OF CHINA SHIPBUILDING INDAL CORP

Soldering flux and preparation method thereof

InactiveCN101983828AHigh activityGood welding effectWelding/cutting media/materialsSoldering mediaOrganic acidFilm-forming agent

The invention discloses a soldering flux, prepared by the following components by weight percent: 0.1-3% of organic acid activator, 0.01-2% of surfactant, 1-4% of wetting agent, 0.01-0.1% of corrosion inhibitor and 90.9-98.88% of film-forming agent. The preparation method thereof includes: (1) in weight percent, organic acid activator, surfactant, wetting agent, corrosion inhibitor and film-forming agent are accurately weighed; (2) the film-forming agent is added into a kettle with heating function and is heated to 110 DEG C, and mixing to be uniform is carried out; (3) slaw warming to 140 DEG C is carried out, the organic acid activator, surfactant, wetting agent and corrosion inhibitor are added once in ratio at 140 DEG C, and stirring is carried out for 0.5h; (4) cooling is carried out, thus obtaining the soldering flux finished product. The invention is mainly used in air conditioning and refrigeration industries, and the soldering flux can cause a welding ring to completely meet the welding requirement of the existing copper aluminium composite tube.

Owner:LICHUANG TAISHAN ELECTRONICS TECH

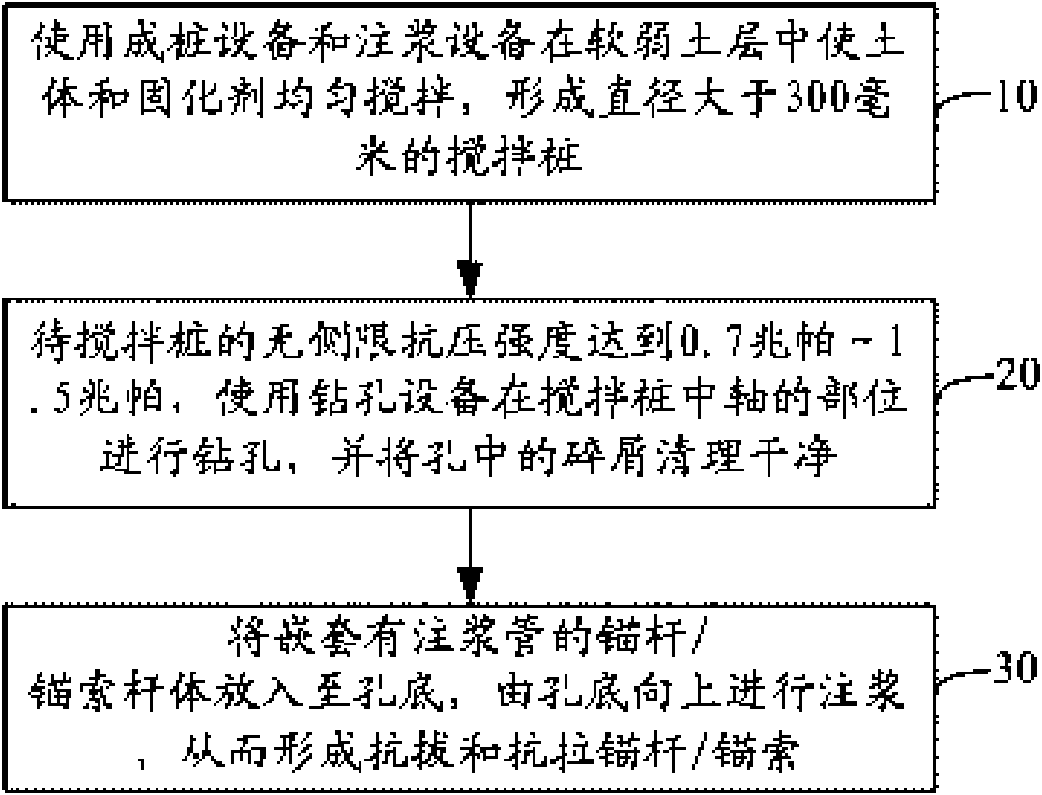

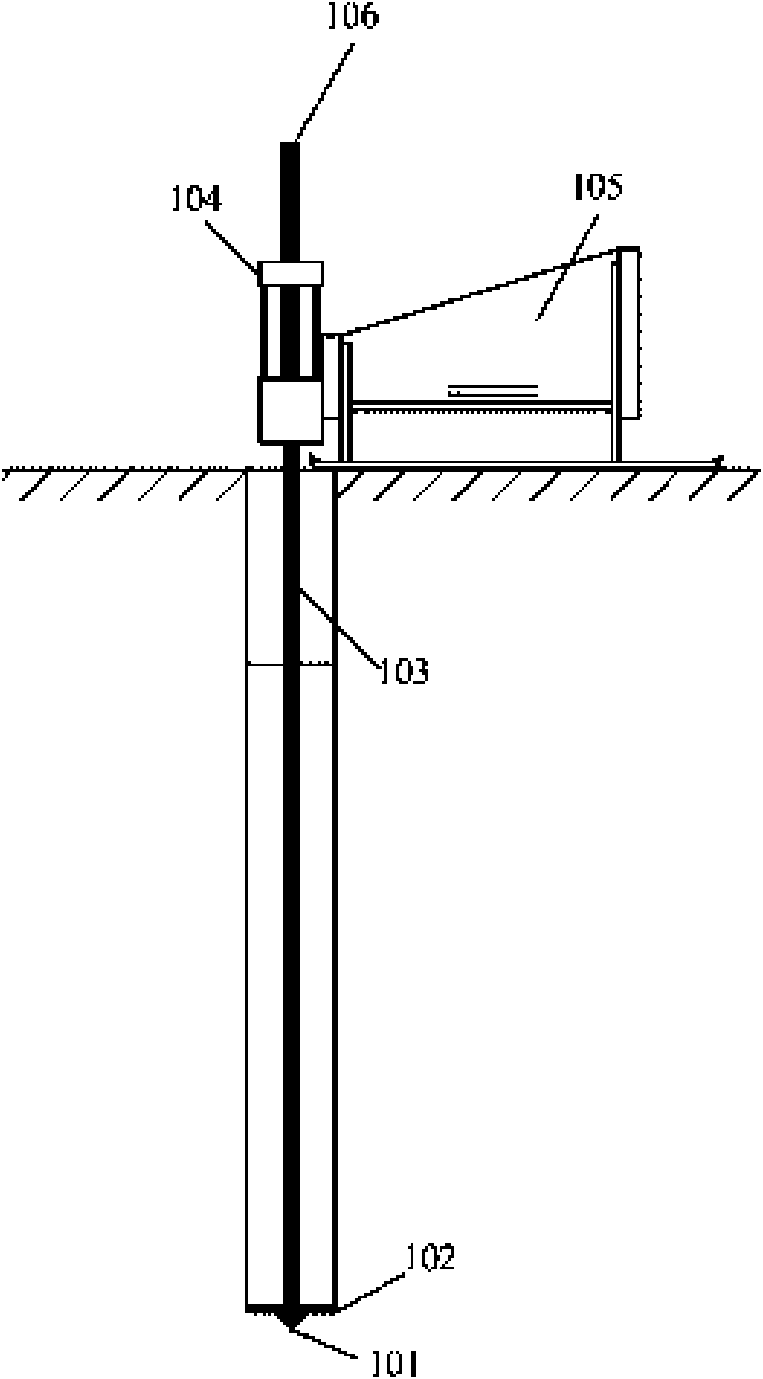

Method for enhancing pulling-resistant and tensile-resistant capability of soft and weak soil layer anchor rod/anchor rope

The invention relates to a method for enhancing pulling-resistant and tensile-resistant capability of a soft and weak soil layer anchor rod / anchor rope. The method comprises the following steps: evenly stirring soil body and a solidifying agent in the soft and weak soil layer by using pile-forming equipment and grout injecting equipment, and forming a stirring pile; drilling holes at the positionof a central shaft in a stirring pile by using drilling equipment when unconfined compressive strength of the stirring pipe reaches 0.7MPa to 1.5MPa, and cleaning detritus in the holes; and placing the anchor rod / anchor rope rod body embedded with a grout injecting pipe into the bottom of the holes, and carrying out grout injection from the hole bottom to top to form the pulling-resistant and tensile-resistant anchor rod / anchor rope. The method solves the problem that the soil layer anchor rod / anchor rope can not be used in soft soil areas, solves a series of problems of slurry pollution, longconstruction period, complex technique, high cost and the like due to pile injecting by the use of the pulling-resistant drilling and solves the problems of easy corrosion and nondurability of a reinforced pile anchor.

Owner:凌光荣 +1

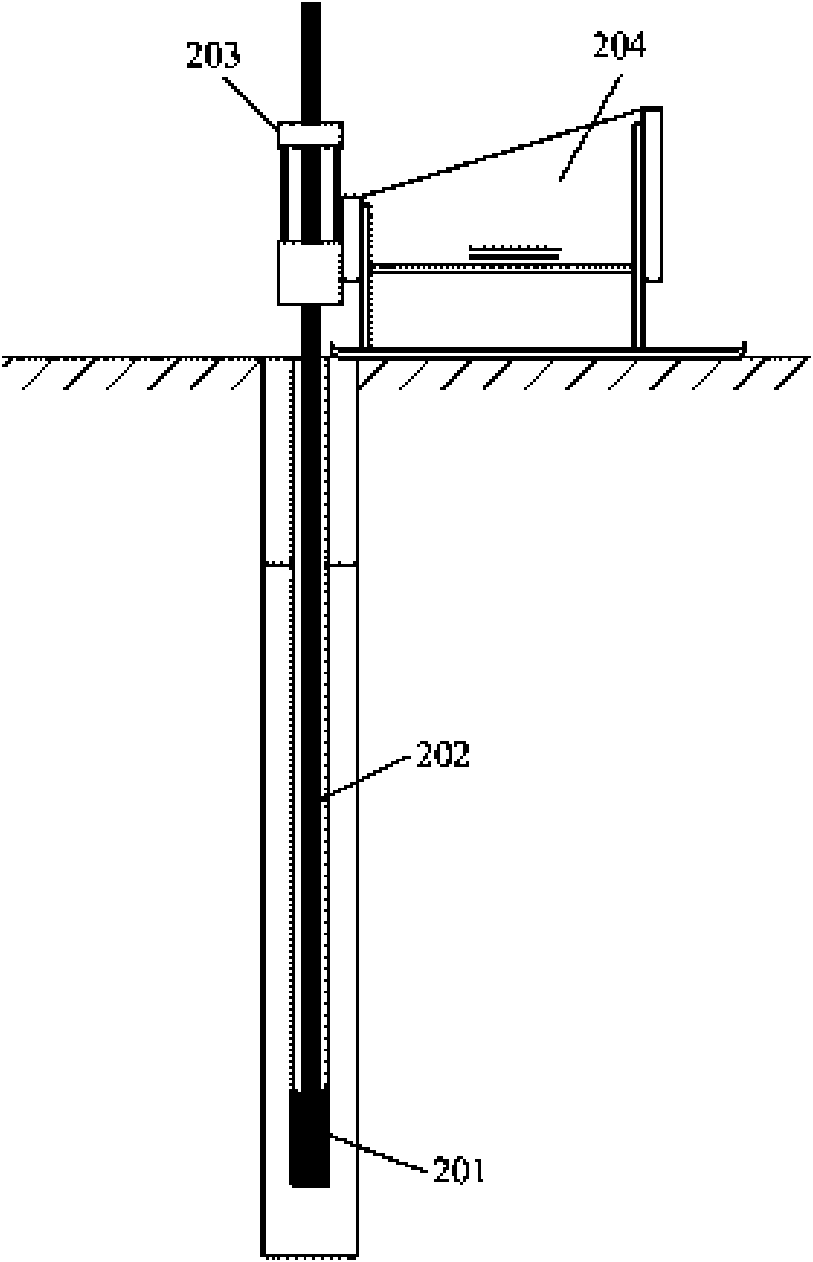

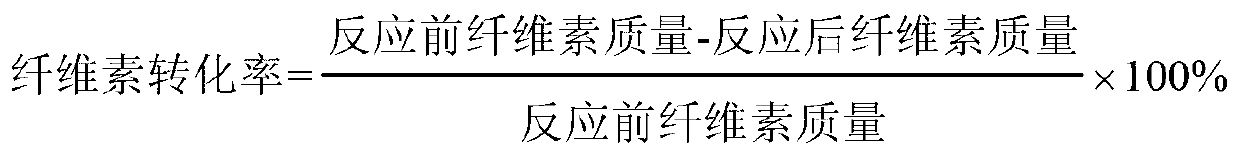

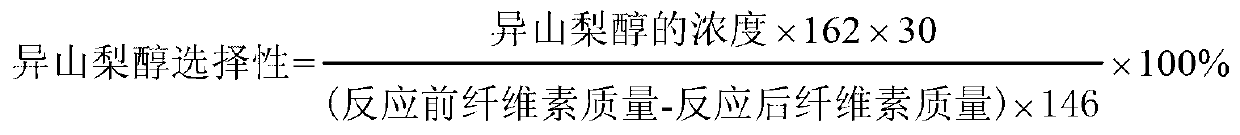

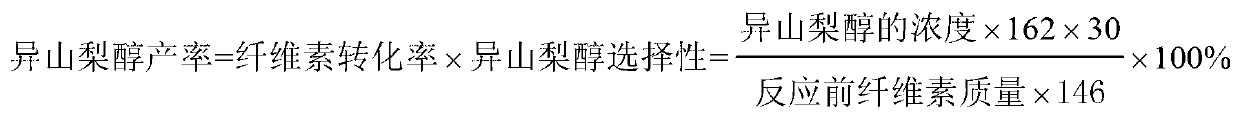

Catalyst for preparing isosorbide by utilizing celluloses and preparation method of catalyst

InactiveCN103272595AImprove stabilityMaintain catalytic performanceOrganic chemistryMetal/metal-oxides/metal-hydroxide catalystsCelluloseIsosorbide

The invention relates to the technical field of fine chemical engineering and discloses a catalyst for preparing isosorbide by utilizing celluloses and a preparation method of the catalyst. The catalyst is a bifunctional catalyst comprising a solid acid loading metal. The bifunctional catalyst disclosed by the invention can be used for realizing the process of catalyzing the celluloses to obtain the isosorbide under the reaction condition that no inorganic liquid acid is added, and avoiding the corrosion problem of equipment caused by using the inorganic liquid acid, and is easy to recycle; the maximum conversion rate of the celluloses can reach 100%, and the maximum selectivity of the isosorbide can reach 55%; the catalyst has very high stability under the existing reaction condition, still maintains the catalytic performance without loss after being cycled for ten times and has low requirements on equipments; and the catalyst is suitable for the existing common industrial production conditions and has very good application prospect.

Owner:SUZHOU INST OF NANO TECH & NANO BIONICS CHINESE ACEDEMY OF SCI +1

Manufacturing method of hot extrusion polyethylene zinc-aluminum alloy coating steel wire cable

ActiveCN105862592ASolving Corrosion ProblemsOvercome the fragile problemCable-stayed bridgeBinding endsPolyesterAlloy coating

The invention relates to a manufacturing method of a hot extrusion polyethylene zinc-aluminum alloy coating steel wire cable. In accordance with the arrangement rule of steel wires at the cross section of the cable, the length of the cable is controlled through the center standard wire, zinc-aluminum alloy coating steel wires are bundled through the twisting angle being 2-4 degrees, a high-strength polyester belt is wound on the outside of the steel wire bundle, a double-layer high-density polyethylene protection layer is hot-extruded through the double-cavity co-extrusion one-time forming process, wind-rain induced vibration prevention embossing is arranged on the outer layer of the polyethylene protection layer according to the wind-rain induced vibration design requirement of the cable, and coiling down and storage are performed after the two ends of the cable are anchored. Finally, the cables are transported to the erection scene according to the delivery request, and erected one by one. The manufacturing process of the cable is free from site limits of construction sites, small in climate factor influence, convenient to control due to factory production management, and capable of meeting the use requirements for long length, high accuracy and durability of stay cables in super-large long-span bridges at the marine environment.

Owner:JIANGSU FASTEN STEEL CABLE CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com