Method for producing high-grade lubricating oil base oil by full hydrogen regenerating of waste mineral oil

A technology of lubricating base oil and waste mineral oil, applied in lubricating compositions, petroleum industry, etc., can solve problems such as corrosion, achieve the effects of improving product performance, reducing product pour point, and improving poor quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

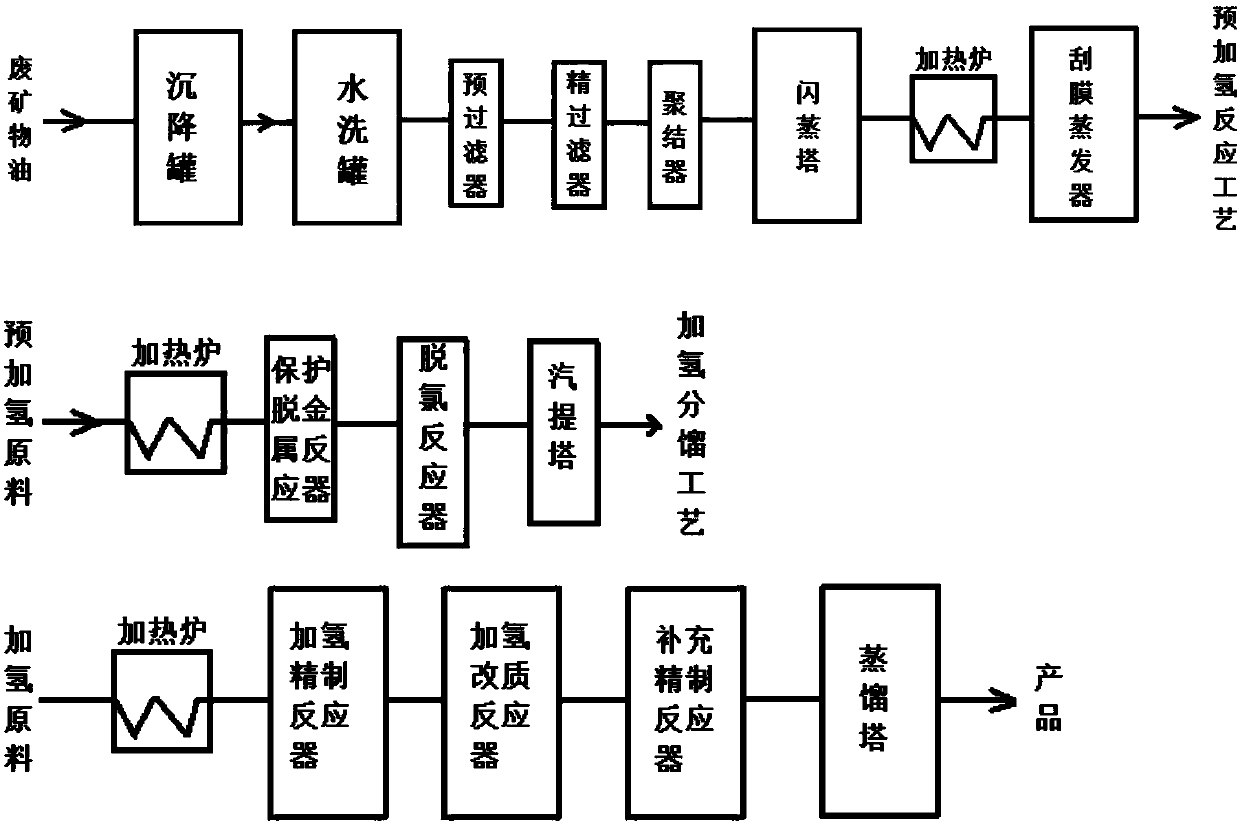

Method used

Image

Examples

Embodiment 1

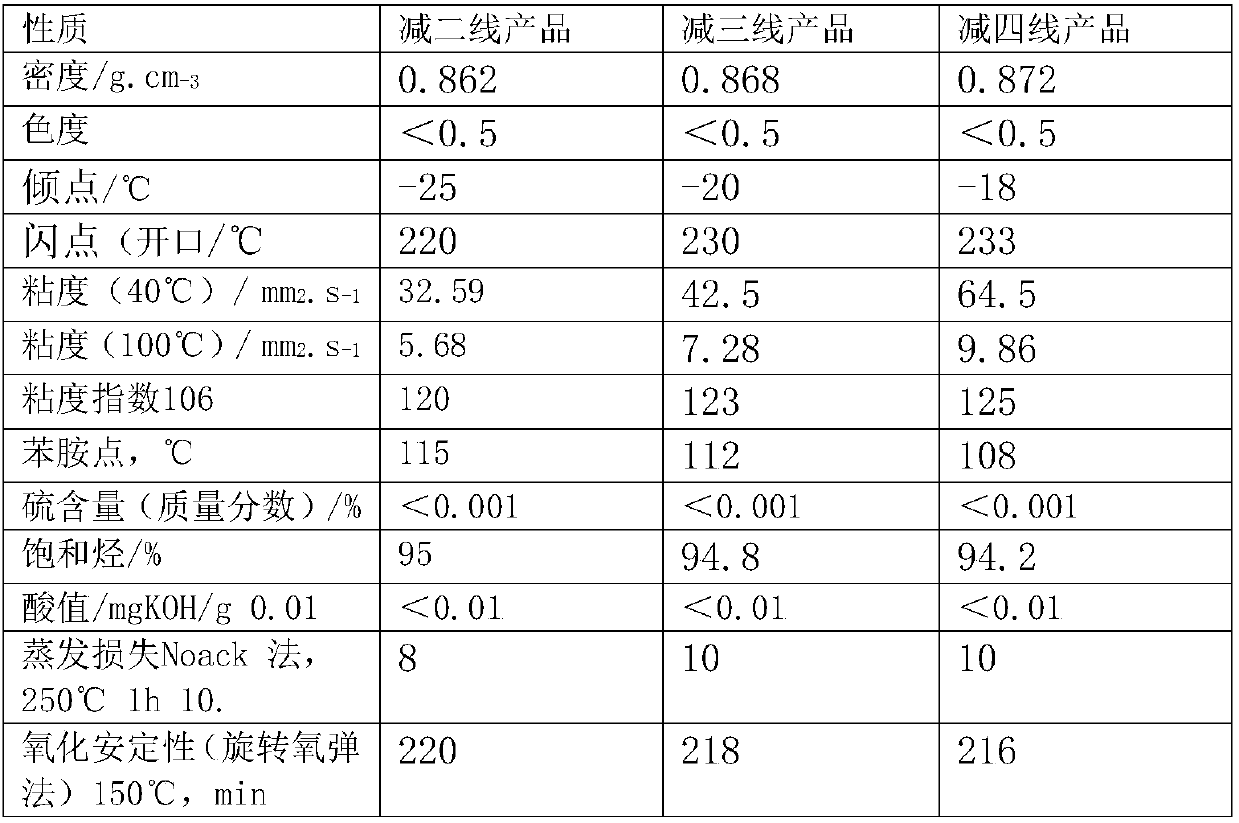

[0069] A method for the production of high-grade lubricating base oil by regenerating waste mineral oil in full hydrogen type. The specific process conditions are as follows: take a sample of waste mineral oil, as shown in sample 1 in Table 1 below. After testing, the raw material of waste mineral oil is dark and With high acid value, high sulfur content, high chlorine content, and high heavy metal content, the raw material passes through the raw material pretreatment process unit and the pre-hydrogenation process unit. The main process conditions for the raw material to enter the three process units are shown in Table 2. Table 3 shows the properties of lubricating base oil raw materials produced by hydrogenation pretreatment. The properties of the product lubricating base oil after hydrofractionation are shown in Table 4.

[0070] Table 1: The raw material properties of waste mineral oil in Example 1

[0071] nature

Waste mineral oil raw materials 1

Waste mineral oil raw ma...

Embodiment 2

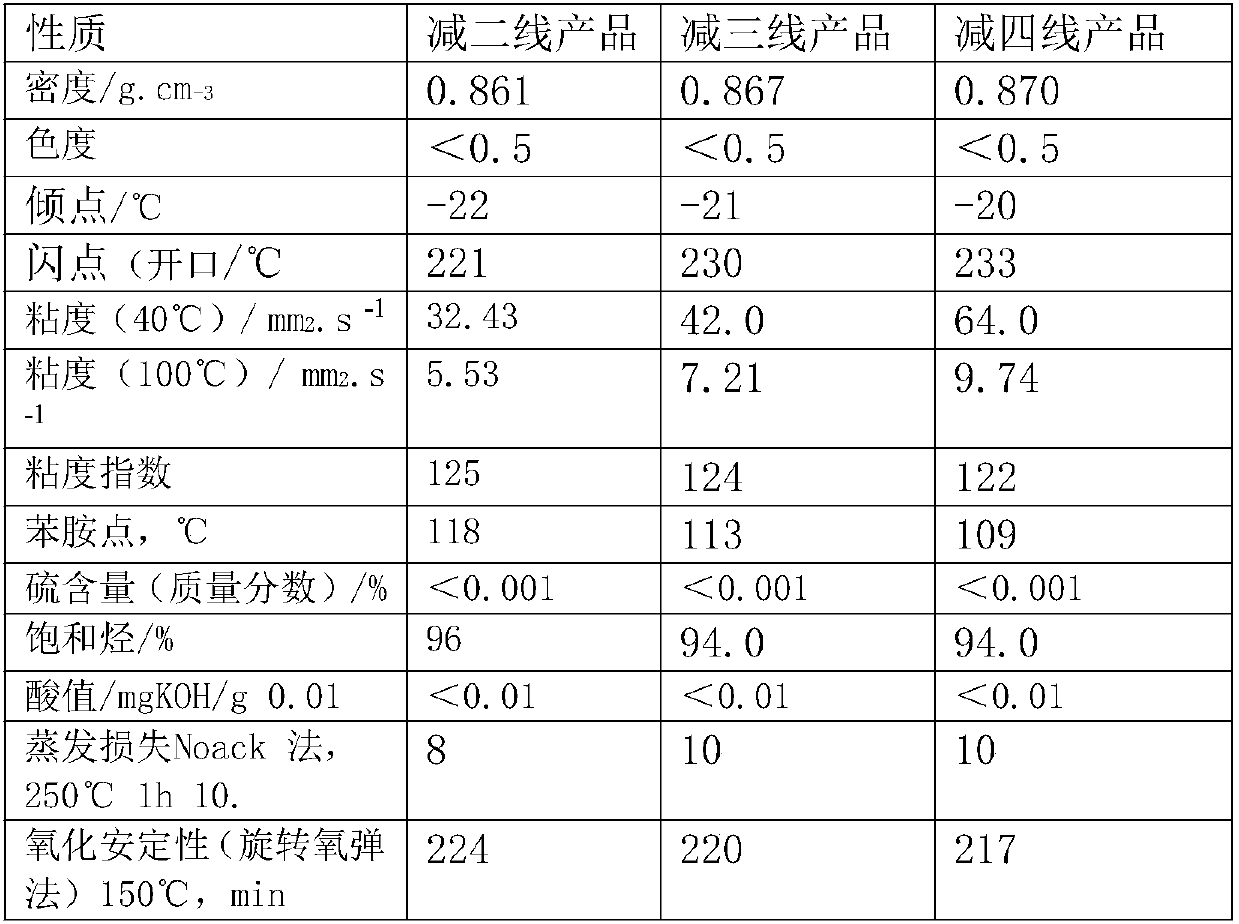

[0082] A method for producing high-grade lubricating base oil by regenerating waste mineral oil in full hydrogen type. The specific process conditions are as follows: Raw material 2 in Table 1 passes the following process conditions. The raw material passes through the raw material pretreatment process unit and the pre-hydrogenation process unit. The main process conditions of the three process units are shown in Table 5, and the properties of lubricating base oil raw materials produced by raw material pretreatment and hydrogenation pretreatment are shown in Table 6. The properties of the product lubricating base oil after hydrofractionation are shown in Table 7.

[0083] Table 5 The main process conditions of the raw materials of Example 1 into the three process units

[0084] Process conditions

Raw material pretreatment process unit

Pre-hydrotreating process unit

Hydrofractionation process unit

Temperature / ℃

Into the scraped film evaporator raw material 340

Raw materia...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com