Patents

Literature

234results about How to "Solve coking" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

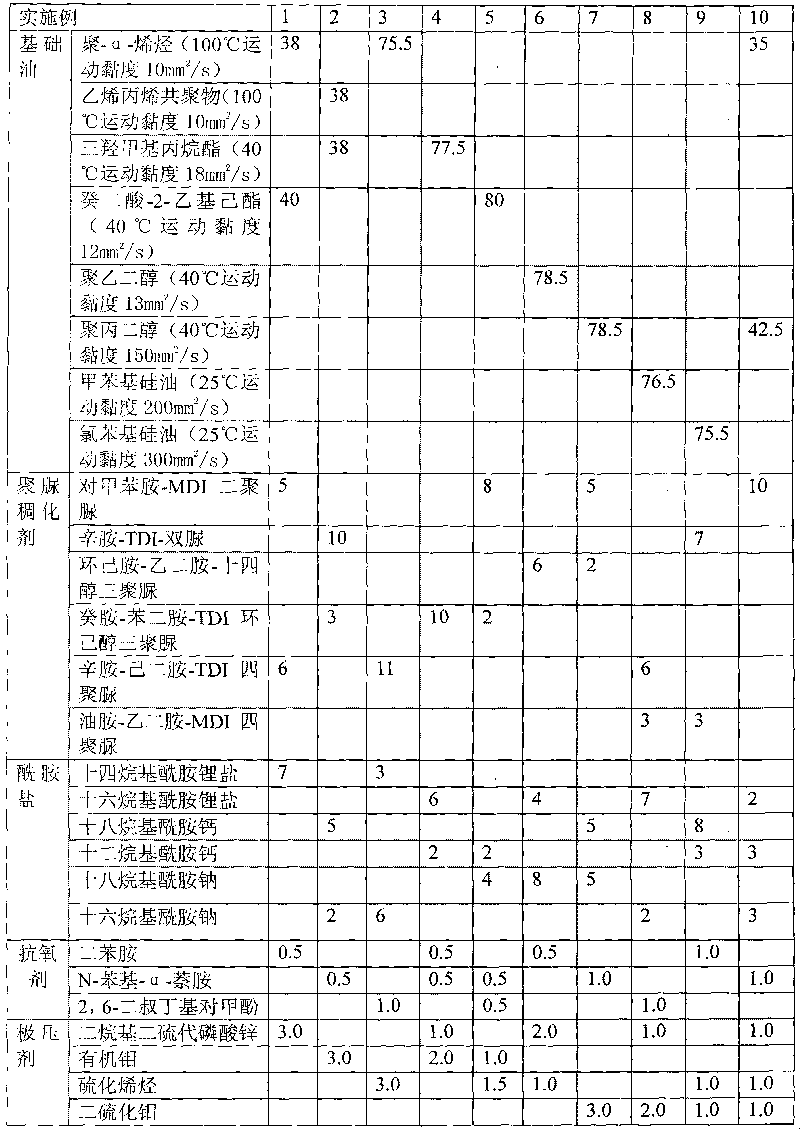

Synthetic high-temperature lubricating grease and production method thereof

InactiveCN101693851AGood colloidal stabilityGood shear stabilityThickenersAdditivesAntioxidantColloid

The invention discloses a synthetic high-temperature lubricating grease and a production method thereof. The synthetic high-temperature lubricating grease is produced by taking synthetic oil as base oil and mixing the base oil with thickening agents, an extreme-pressure additive, an antioxidant and an anticorrosive agent, wherein the weight ratios of all ingredients are as follows: 47-94% of base oil, 2-20% of polyurea thickening agent, 2-20% of acylamide thickening agent, 0.5-5.0% of antioxidant, 1.0-5.0% of extreme-pressure additive and 0.5-3.0% of anticorrosive agent. In the invention, the synthetic base oil, the polyurea thickening agent and the acylamide thickening agent all have excellent high-temperature performance, and the organic combination thereof leads the lubricating grease to obtain excellent high-temperature performance; the polyurea thickening agent endows the lubricating grease with good colloid stability, and the acylamide thickening agent endows the lubricating grease with excellent anti-shear stability, therefore, the organic combination of colloid stability and anti-shear stability leads the lubricating grease to have excellent high-temperature performance and good losing resistance, does not change to thin and avoids losing at high temperature. The extreme-pressure anti-wear additive endows the lubricating grease with excellent extreme-pressure anti-wear performance, and the bearing capacity is high.

Owner:CHINA PETROLEUM & CHEM CORP

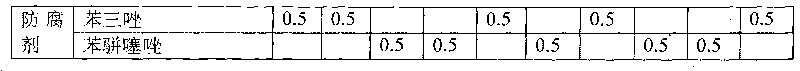

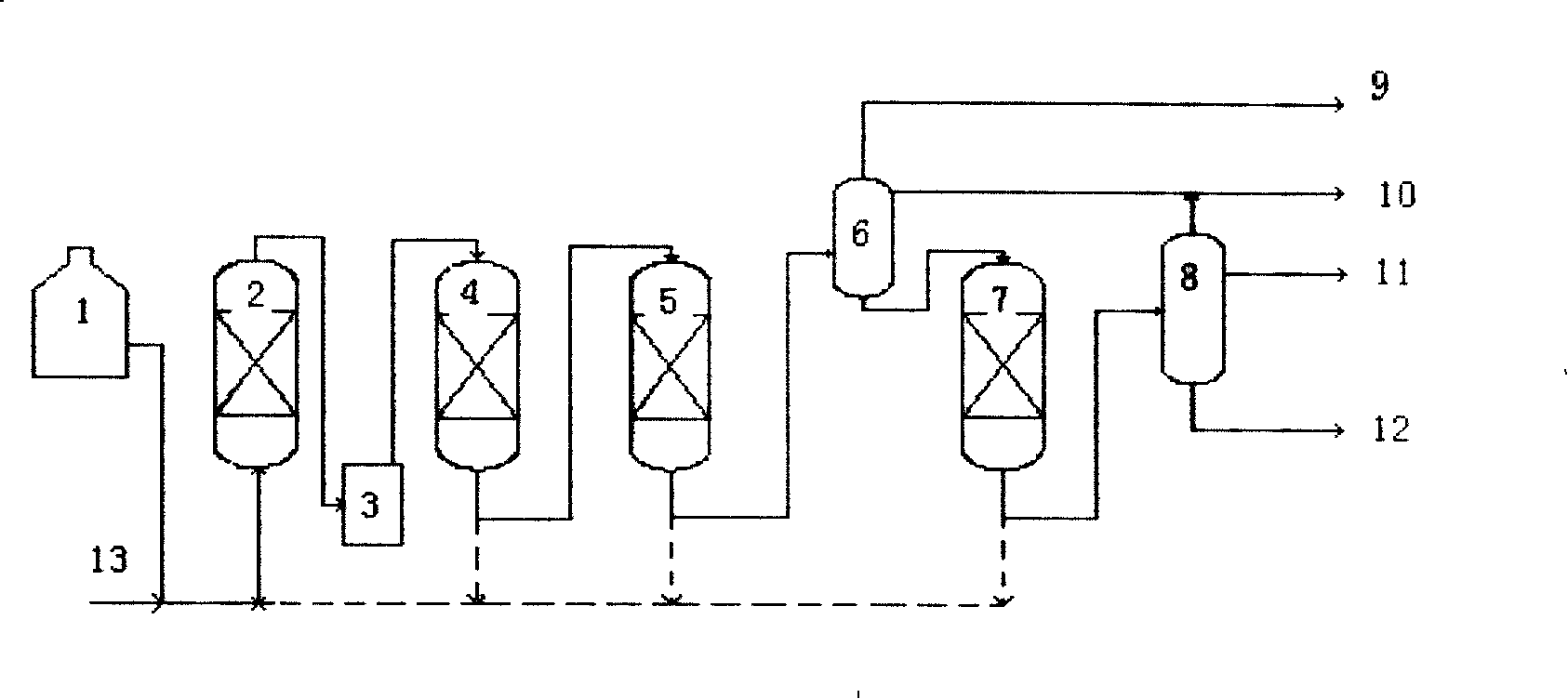

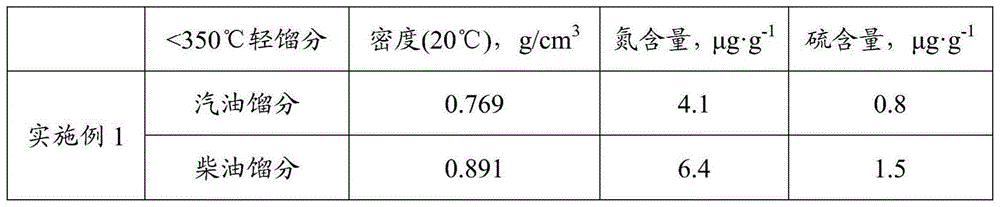

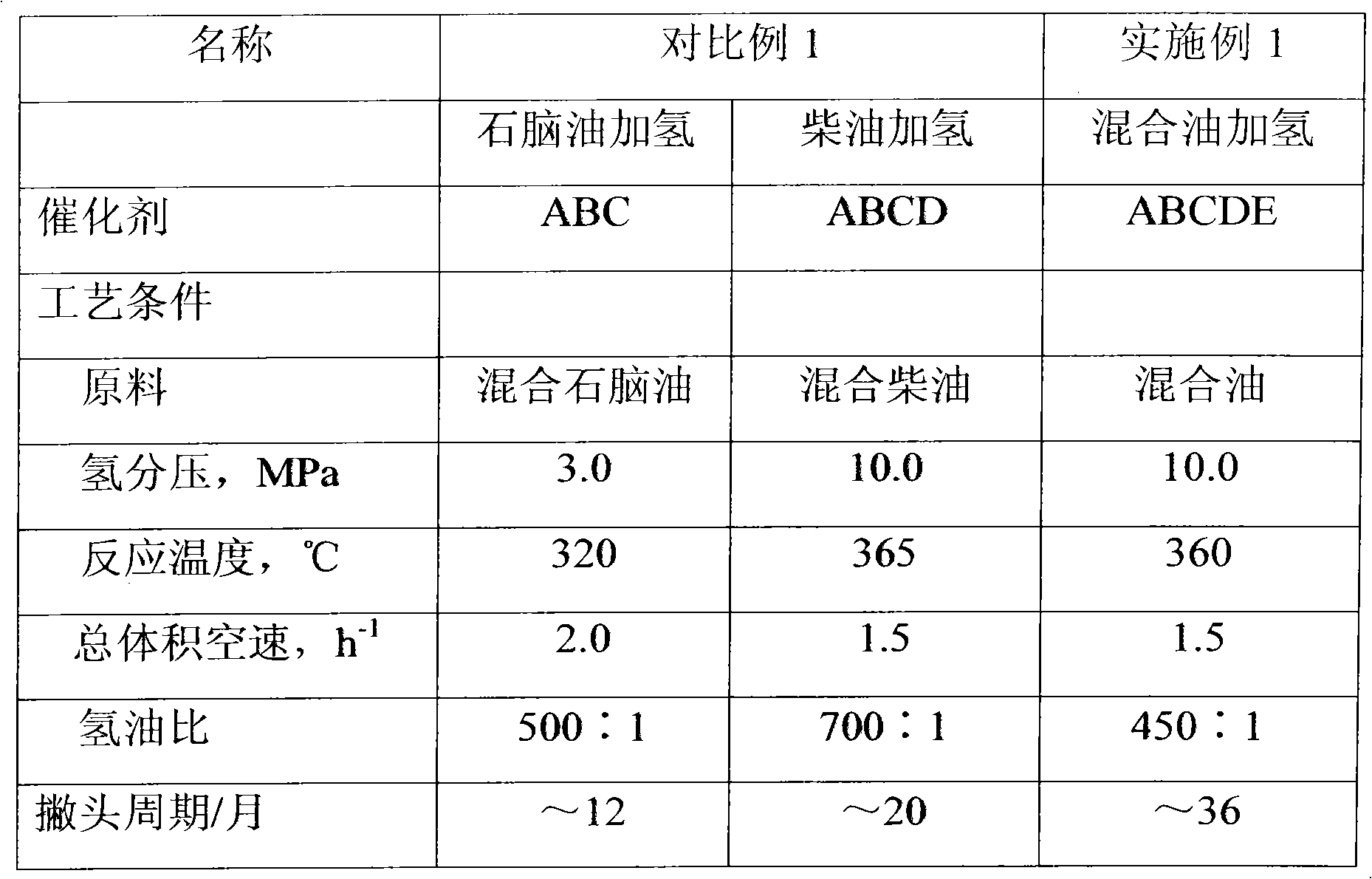

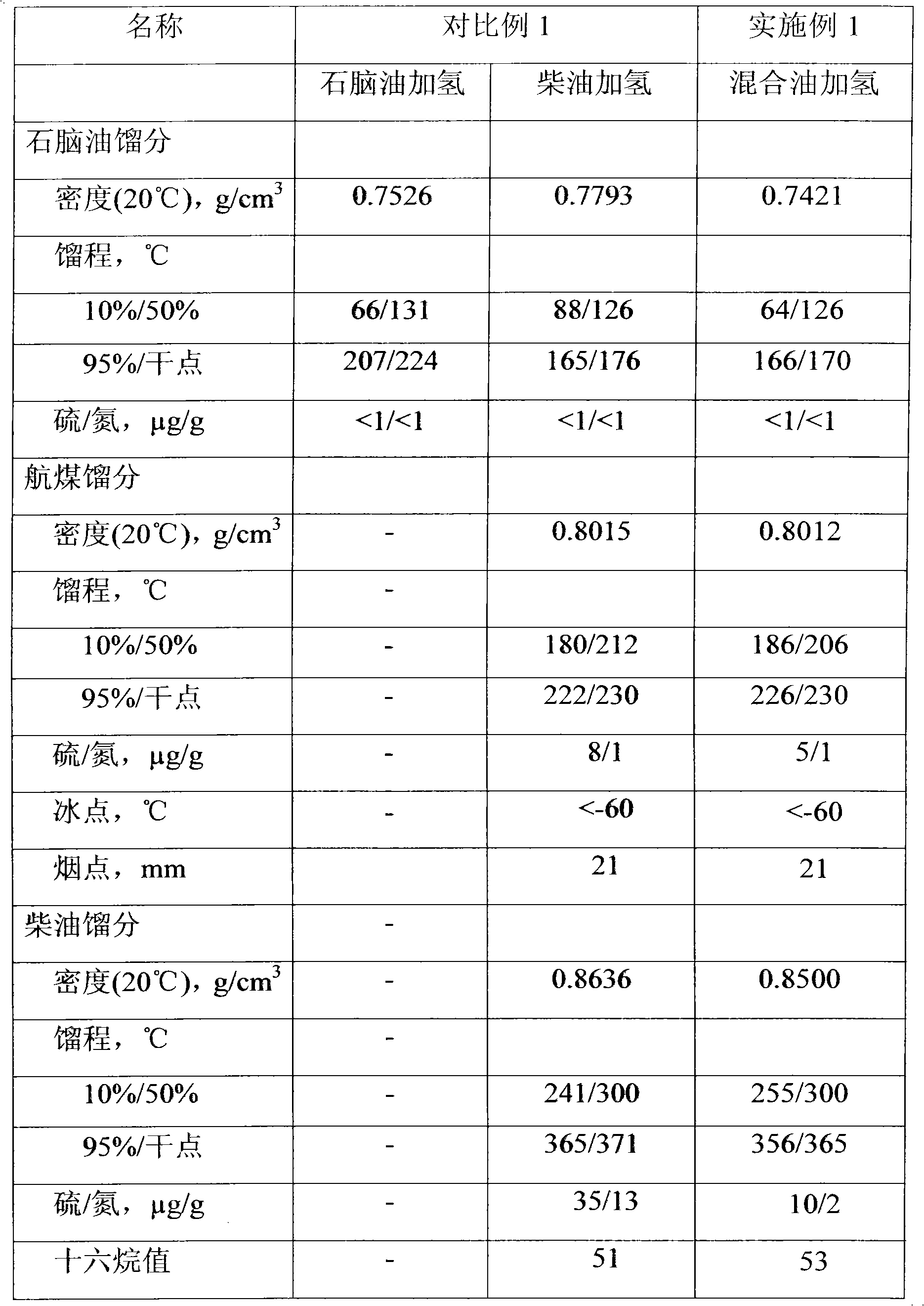

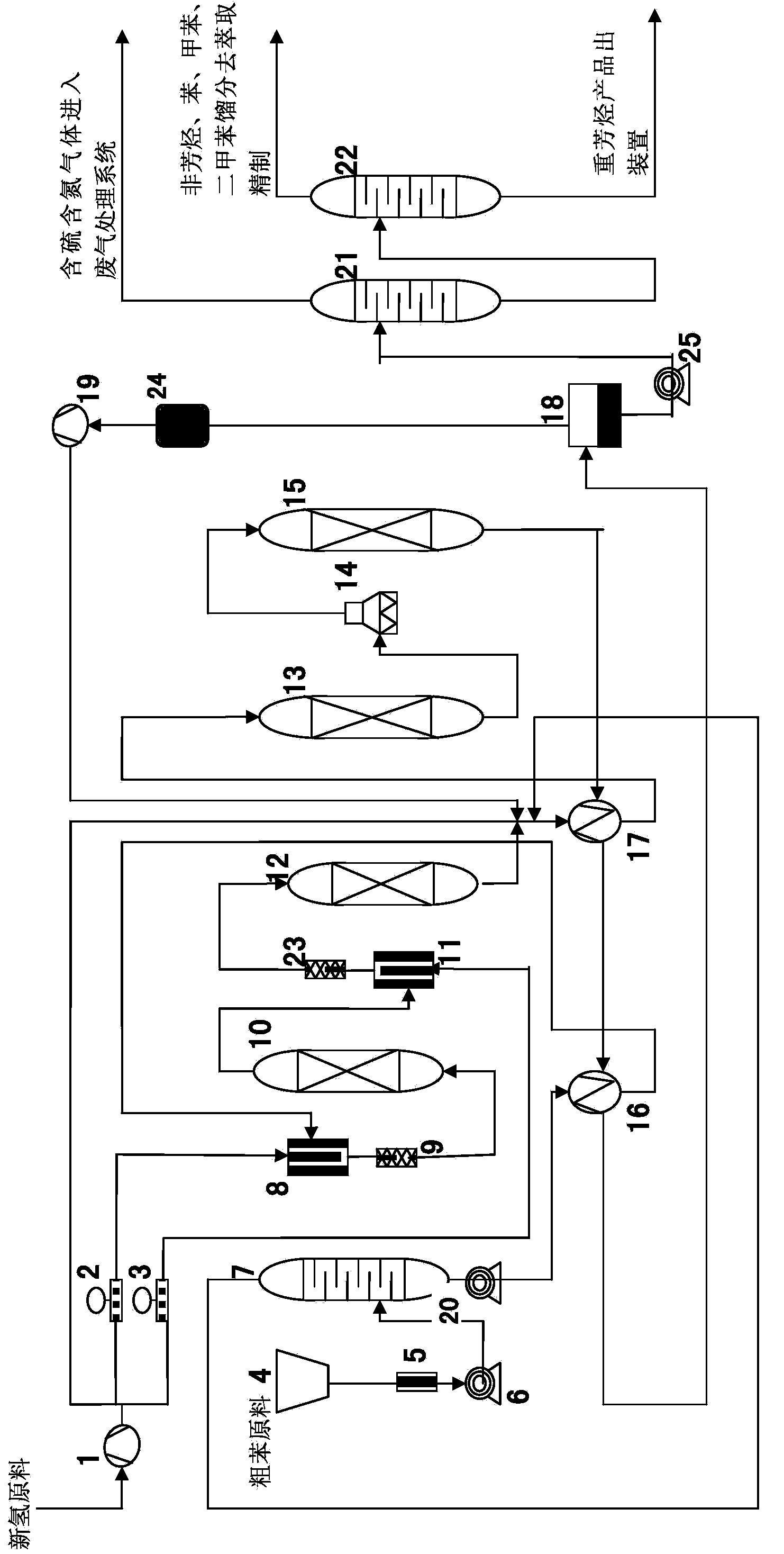

Coal tar multistage hydrogenation treatment technique

ActiveCN101240193AFully activeSolve cokingTreatment with hydrotreatment processesHydrogenation reactionGasoline

The invention discloses a coal-tar oil multistage hydrogenation craft, which belongs to coal chemical industry technology area. The method of the invention is that coal-tar oil fraction oils like impurities, sols, high content, asphaltenes, oxygen element, and so on, with high content or entire fraction are delivered into pre-hydrogenation reaction chamber by pump and are carried on pre-hydrogenation processing, then are successively followed by hydrogenation and demetallization, and depth hydrogenation reaction. After carried on separation of water and lightweight components, the generative fluid enters into a hydrocracking reactor, passes by a distiller to get gasoline fractions, diesel oil and hydrocracking tail oil out. Compared with the prior art, the invention can guarantee the long-period stability operation of the installation.

Owner:CHINA PETROLEUM & CHEM CORP +1

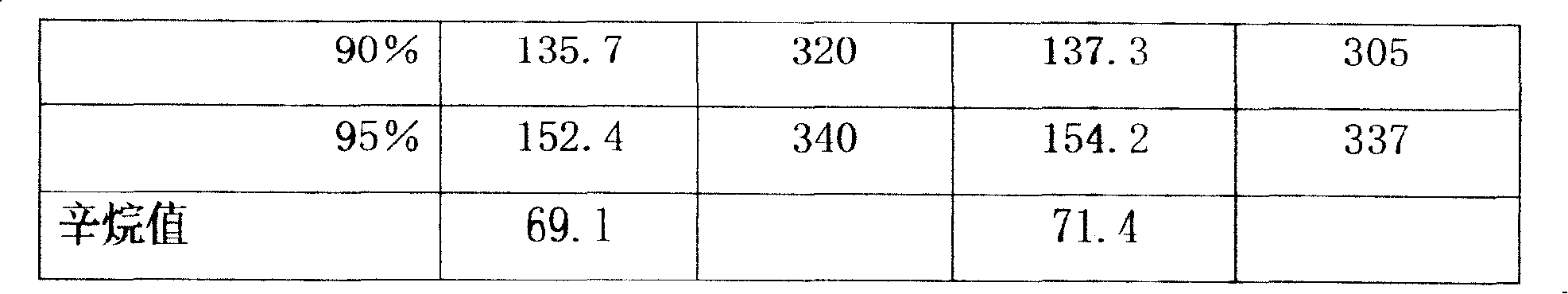

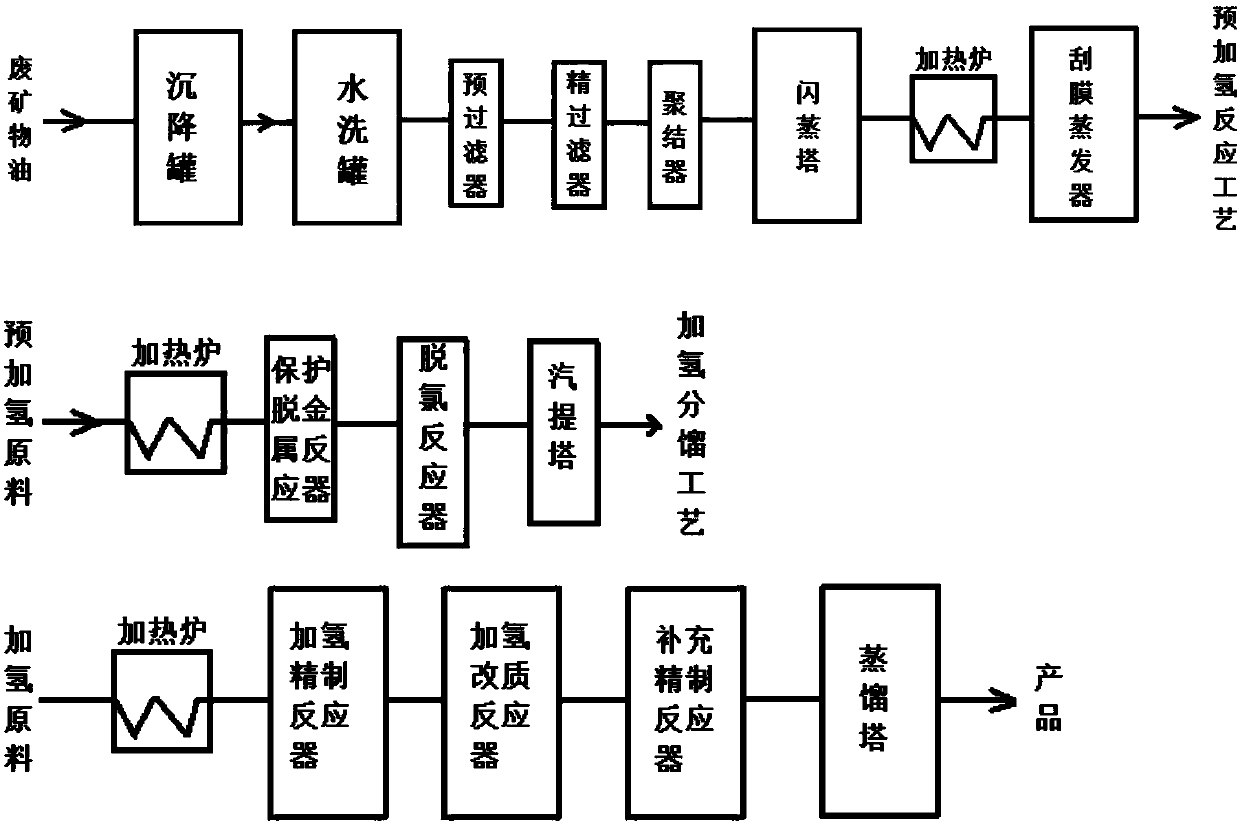

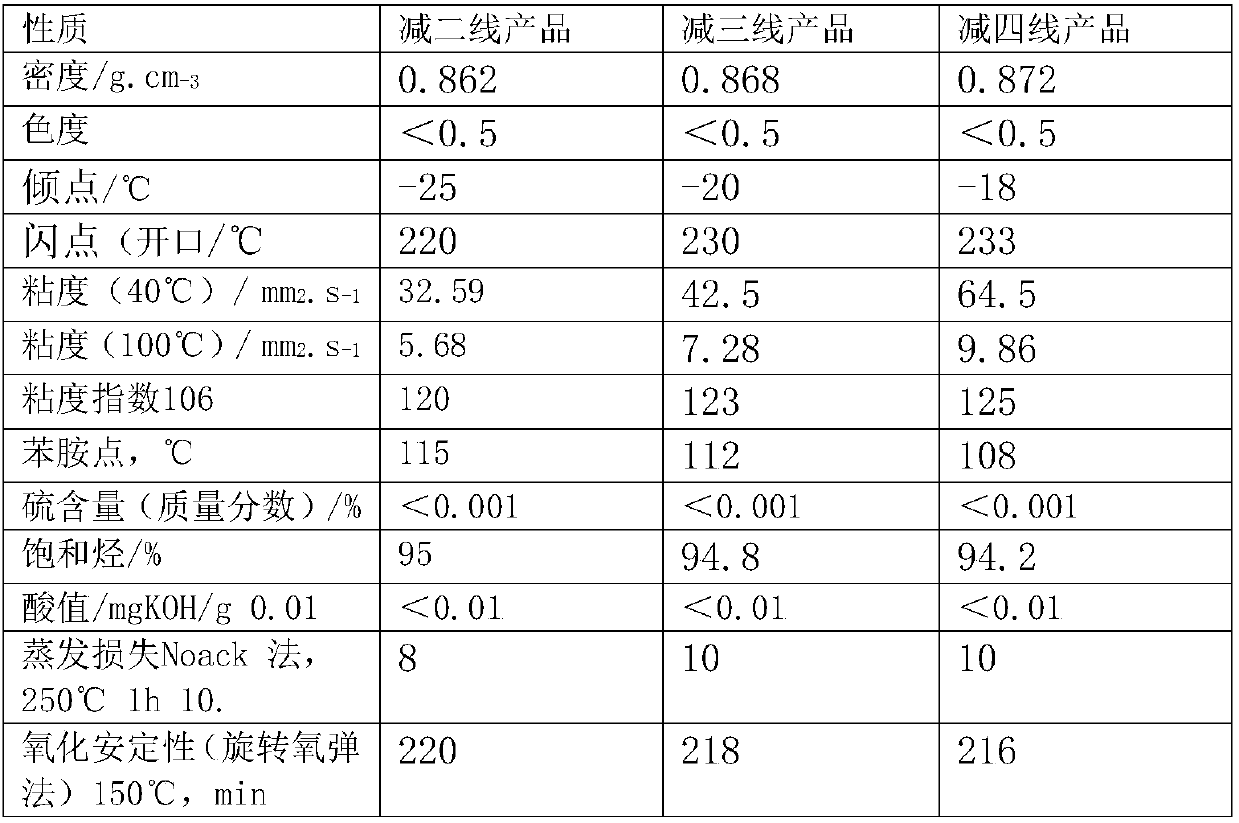

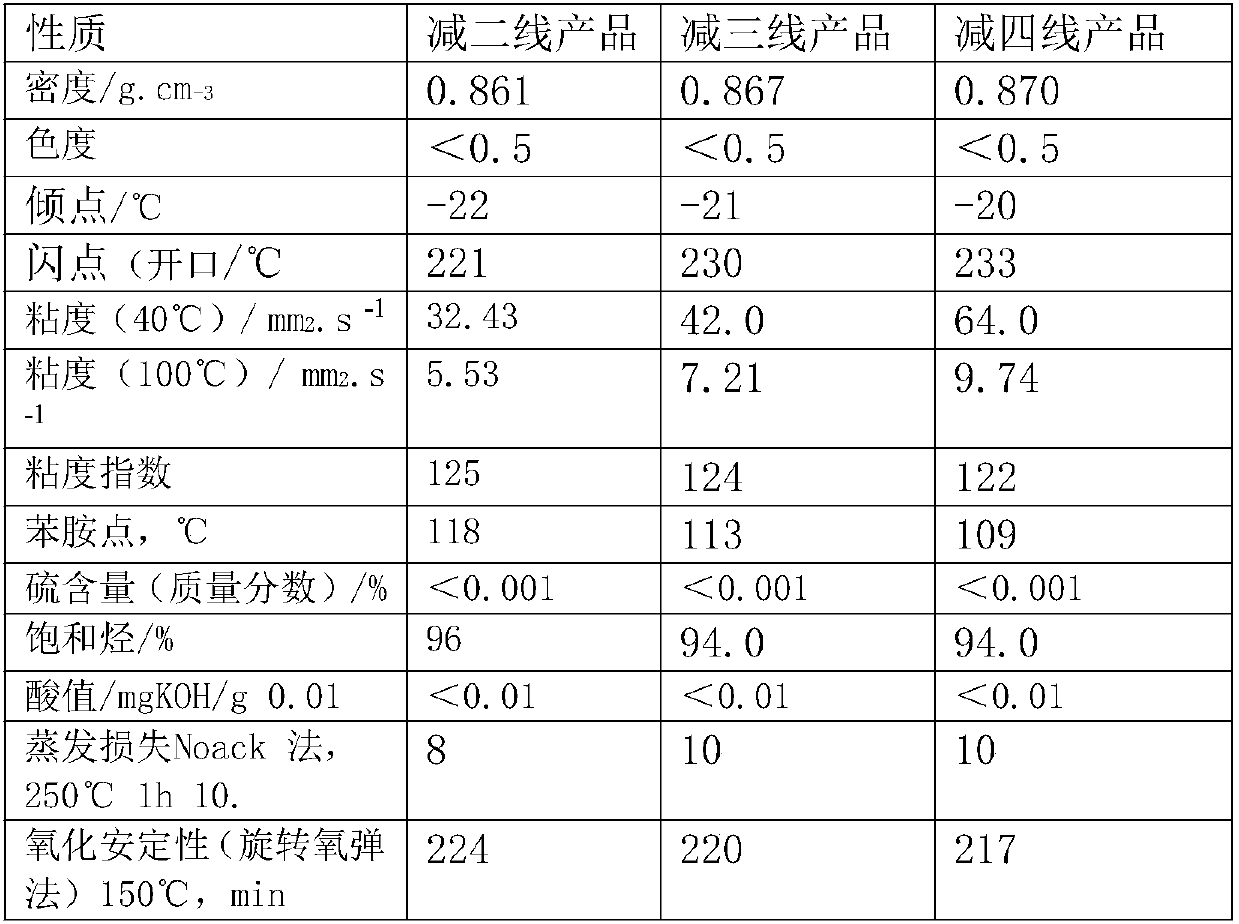

Method for producing high-grade lubricating oil base oil by full hydrogen regenerating of waste mineral oil

ActiveCN107892990ALower product pour pointImprove product viscosity index and oxidation stabilityLubricant compositionChemistryCorrosion

The invention discloses a method for producing high-grade lubricating oil base oil by full hydrogen regenerating of waste mineral oil. According to the method, a pre-hydrogenation reaction process isadded between a raw material pretreatment process and a hydrogenation fractionation process in the prior art; under hydrogen present conditions, heavy metal additives and gum asphalt as well as non-metallic impurities such as chlorine, phosphorus and silicon in a lubricating oil fraction are removed, and by the removal of the impurities, the problem of coking at the top of a hydrotreating reactorin a following high pressure hydrogenation fractionation process step can be solved, the problem of chlorine corrosion in heat exchangers and other equipment used for hydrogenation in the high pressure hydrogenation fractionation process step is also solved, and long-term operation of hydrogenation equipment in the high-pressure hydrogenation fractionation process can be ensured.

Owner:新疆聚力环保科技有限公司

Waste plastic and rubber reduction and reducing system

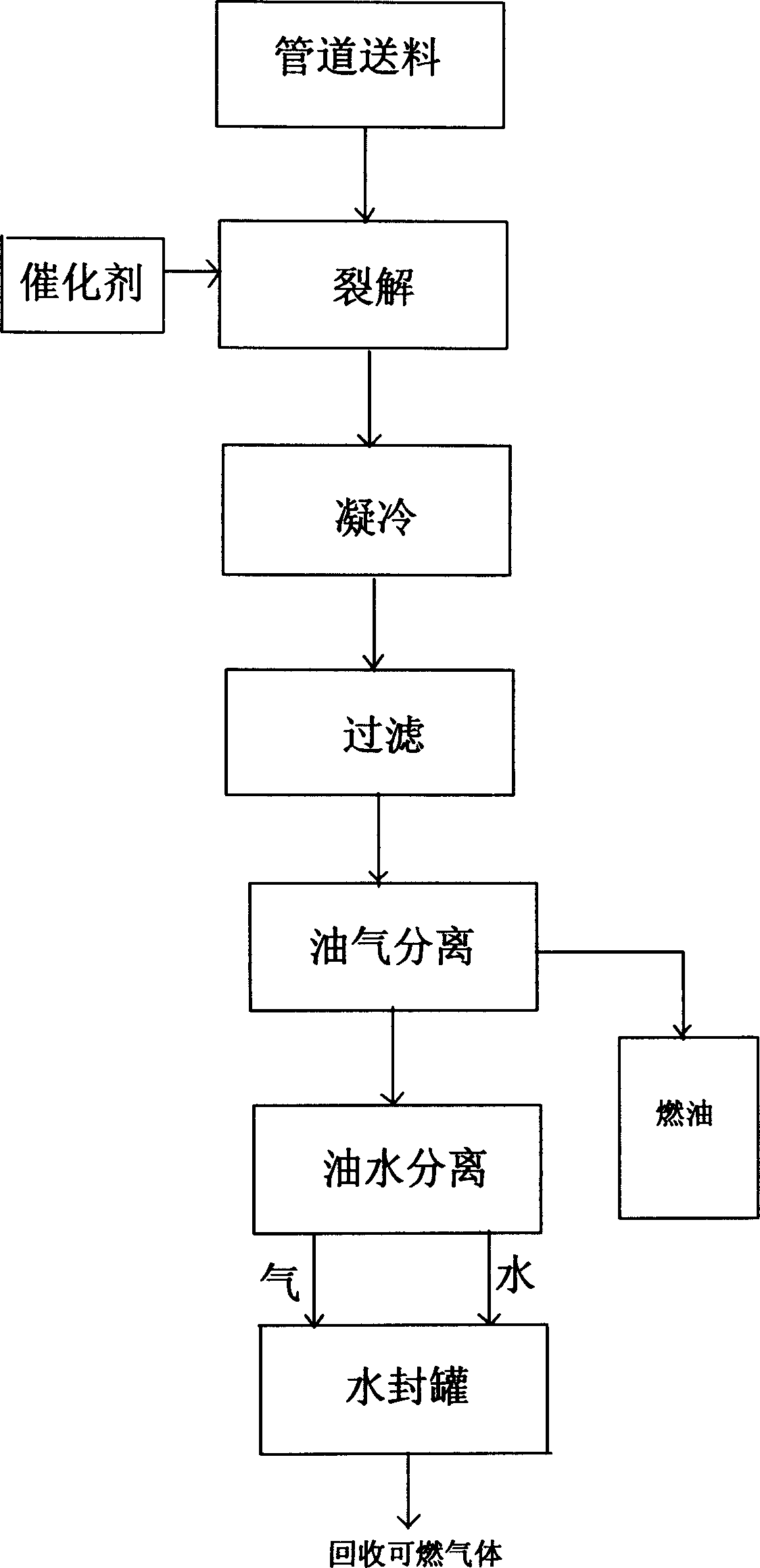

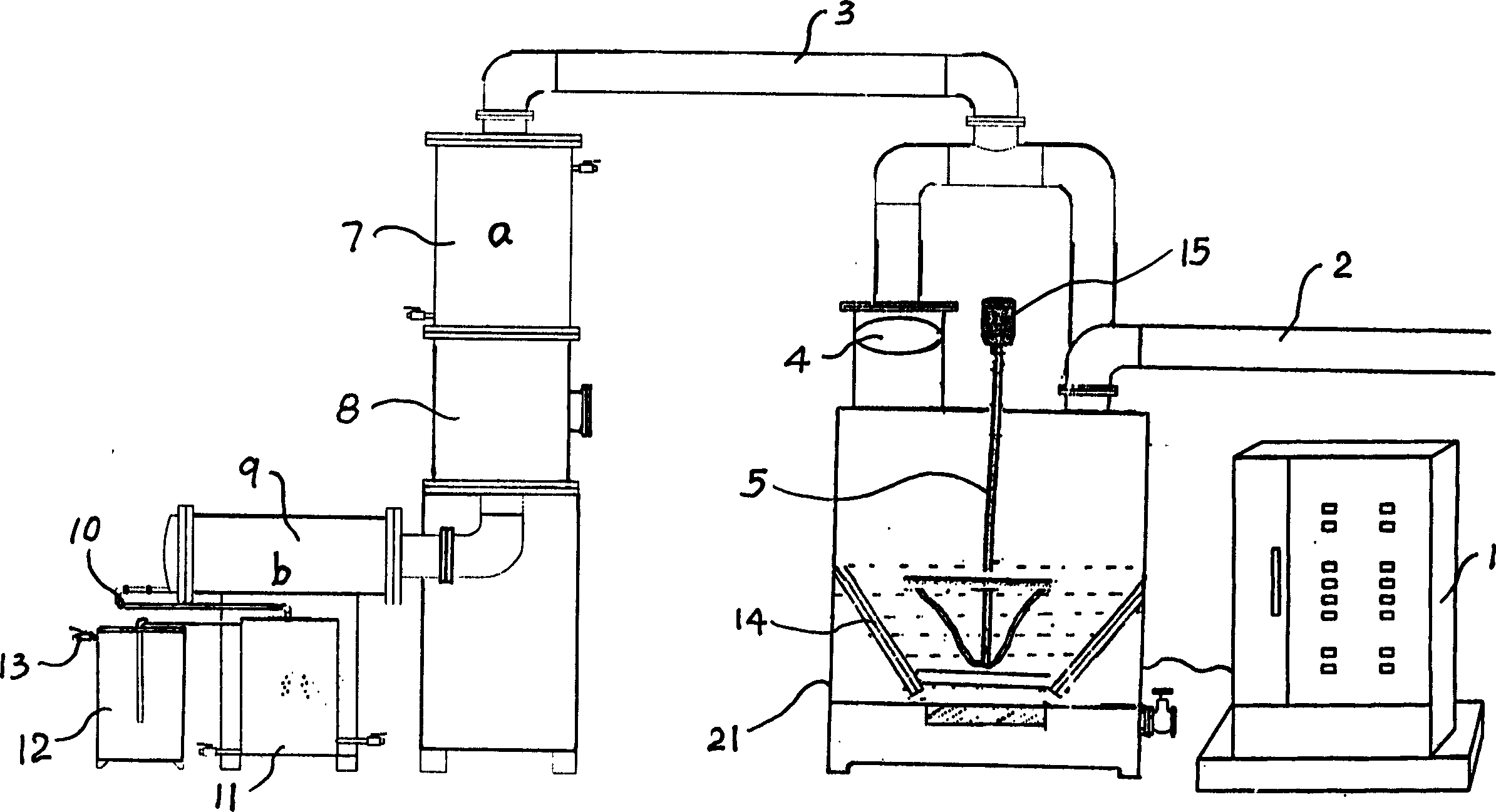

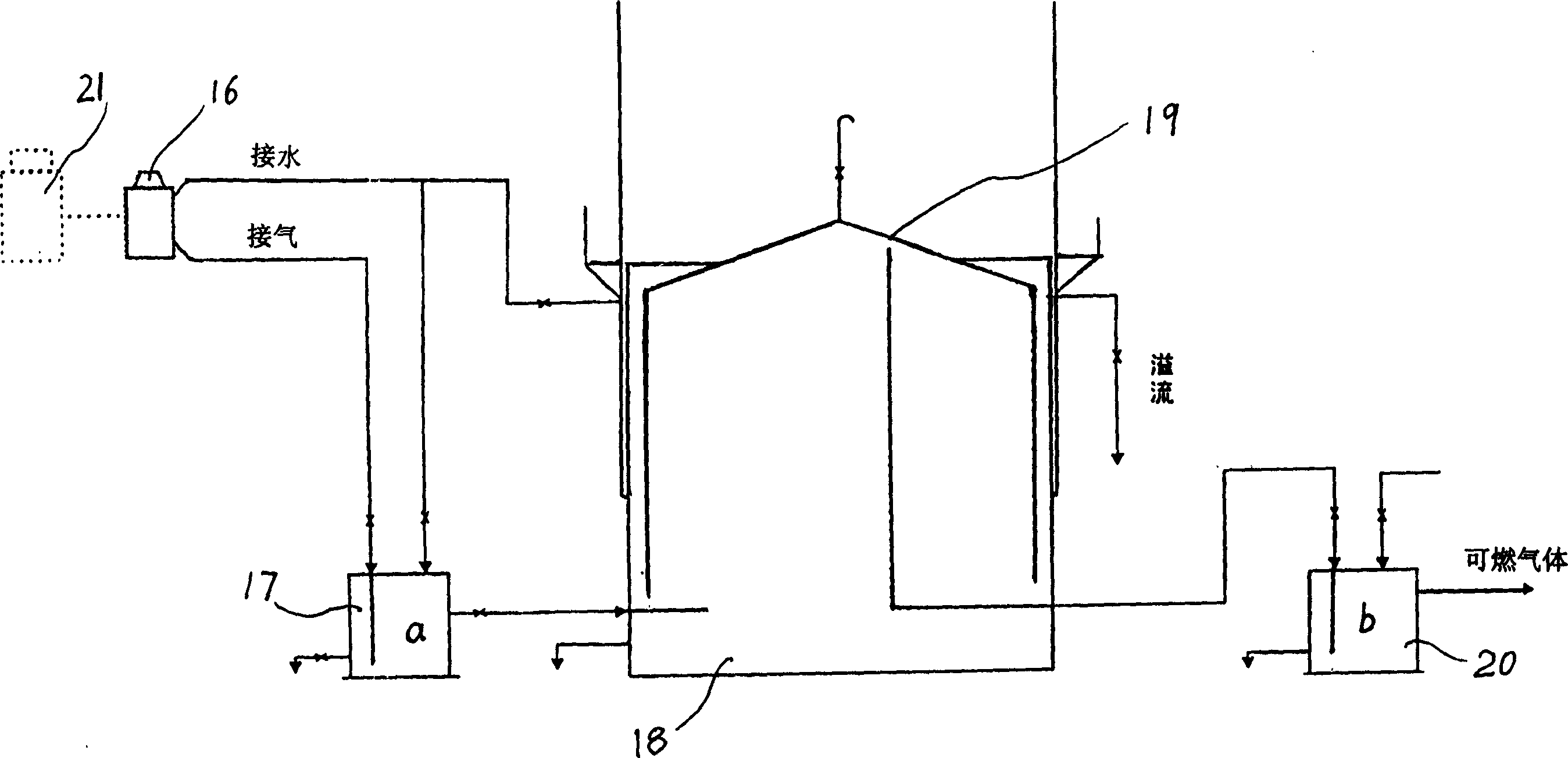

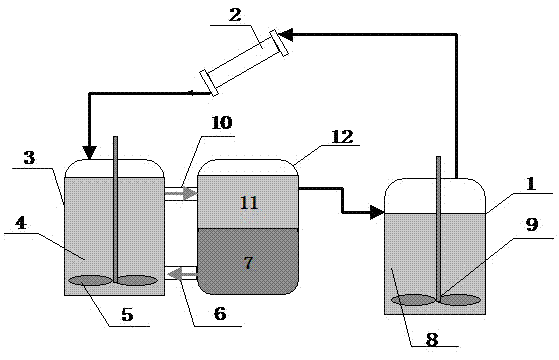

InactiveCN1746263AImprove electricity usage efficiencySolve cokingPigmenting treatmentLiquid hydrocarbon mixture productionCombustible gasProcess engineering

A reduction for treating waste plastic and rubber and its system are disclosed. The system is characterized by air feeding, heat cracking, agitating from anchor agitator, high-temperature slagging, recovering and utilizing fuel oil and gas. It is high efficient, energy saving and has no environmental pollution.

Owner:SOUTH CHINA REBORN RESOURCES ZHONGSHAN

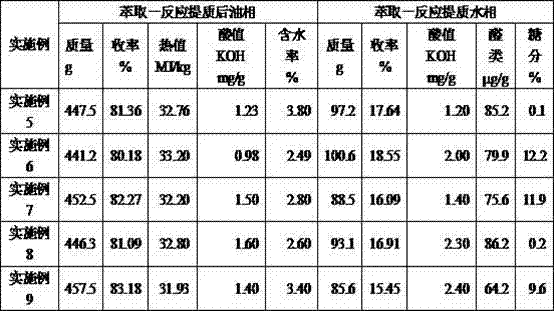

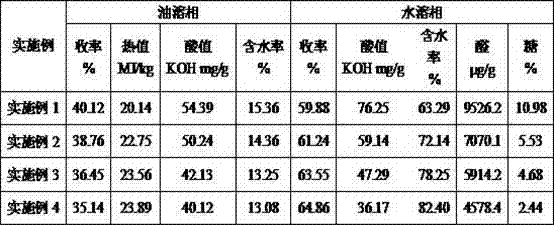

Biological oil phase-division upgrading method and device

ActiveCN103571535AInhibit or reduce side effectsInhibit cokingTreatment with hydrotreatment processesProcess engineeringAldehyde

The invention discloses a method for preparing fuel oil with a high calorific value by upgrading biological oil (high-speed thermally cracked biomass oil), and particularly relates to a method comprising the steps of firstly, adding water to divide the biological oil into a water soluble phase and an oil soluble phase, and then, upgrading the water soluble phase by using a chemical extracting-to-coupling conversion technology and upgrading the oil-soluble phase through hydrodeoxygenation. The method can be used for subjecting compounds such as acid, aldehyde and the like in the water soluble phase and fatty alcohol with 1-4 carbon atoms to esterification and acetalation to obtain ester, acetal, hemiacetal and the like with good combustibility, and the fuel oil with the high calorific valueis prepared after the oil soluble phase is subjected to hydrodeoxygenation. The method has the advantages that few cokes are generated in an upgrading process, and after being upgraded, an oil product is low in water content and acid value, high in calorific value and the like.

Owner:SHANDONG UNIV OF TECH

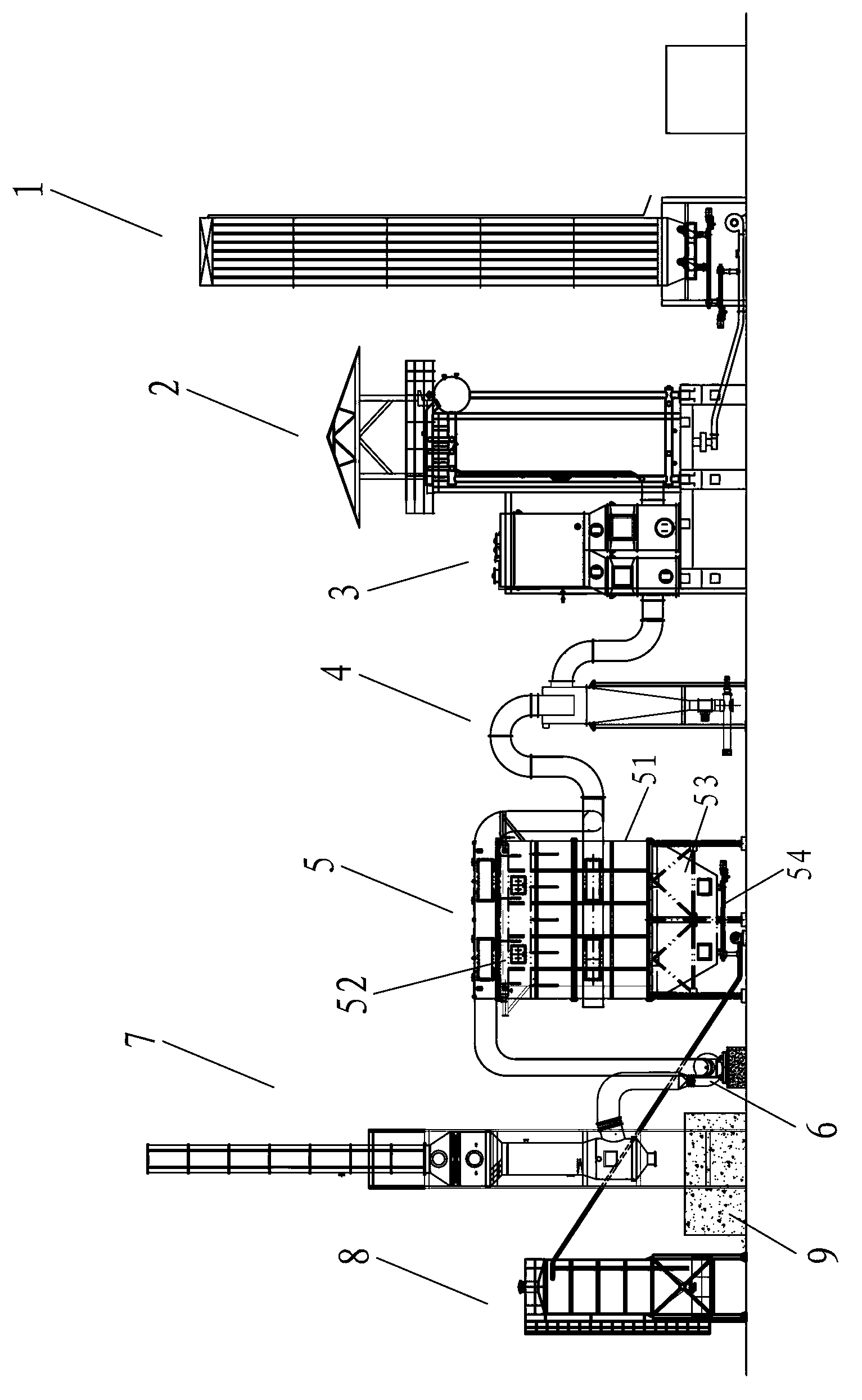

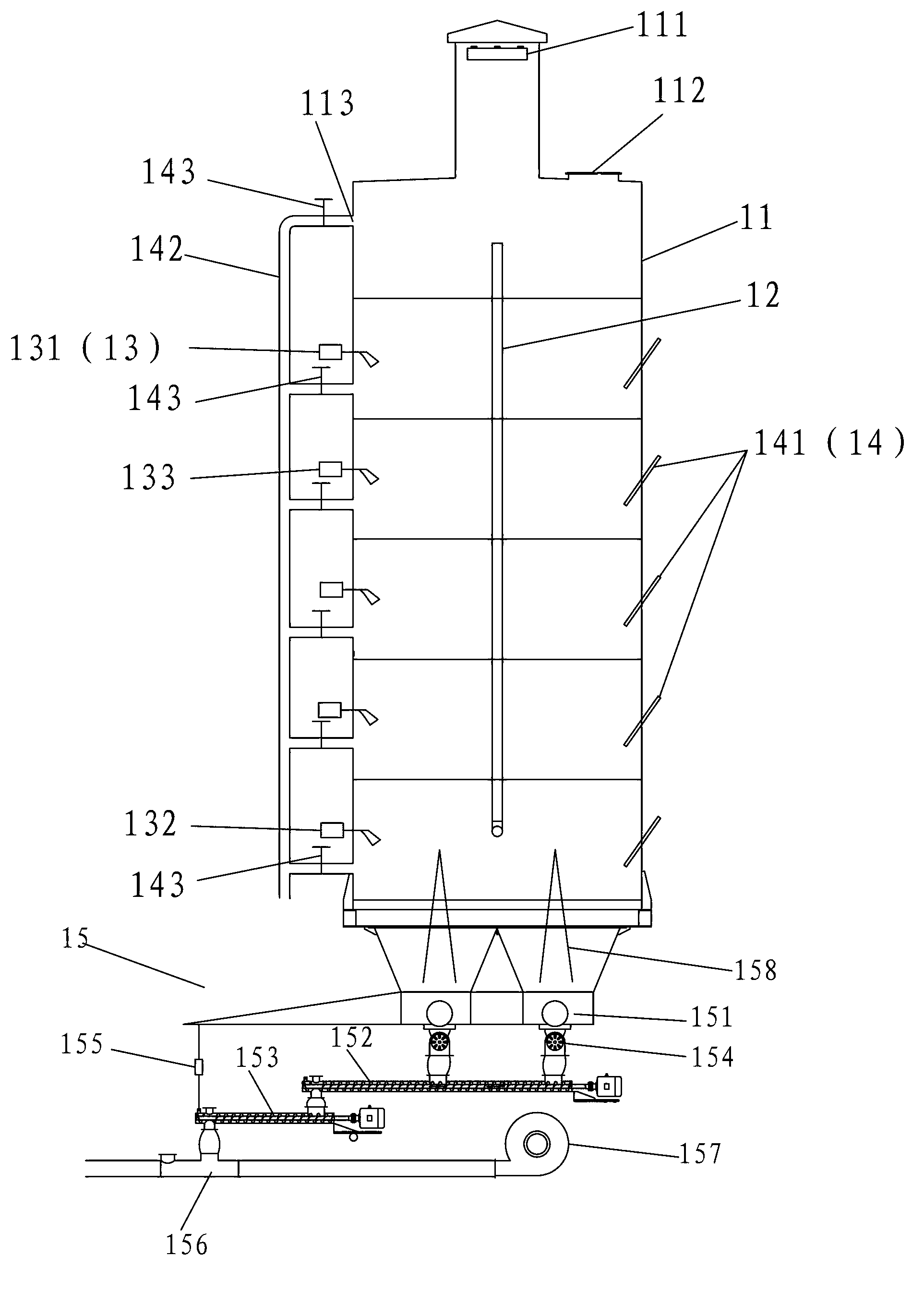

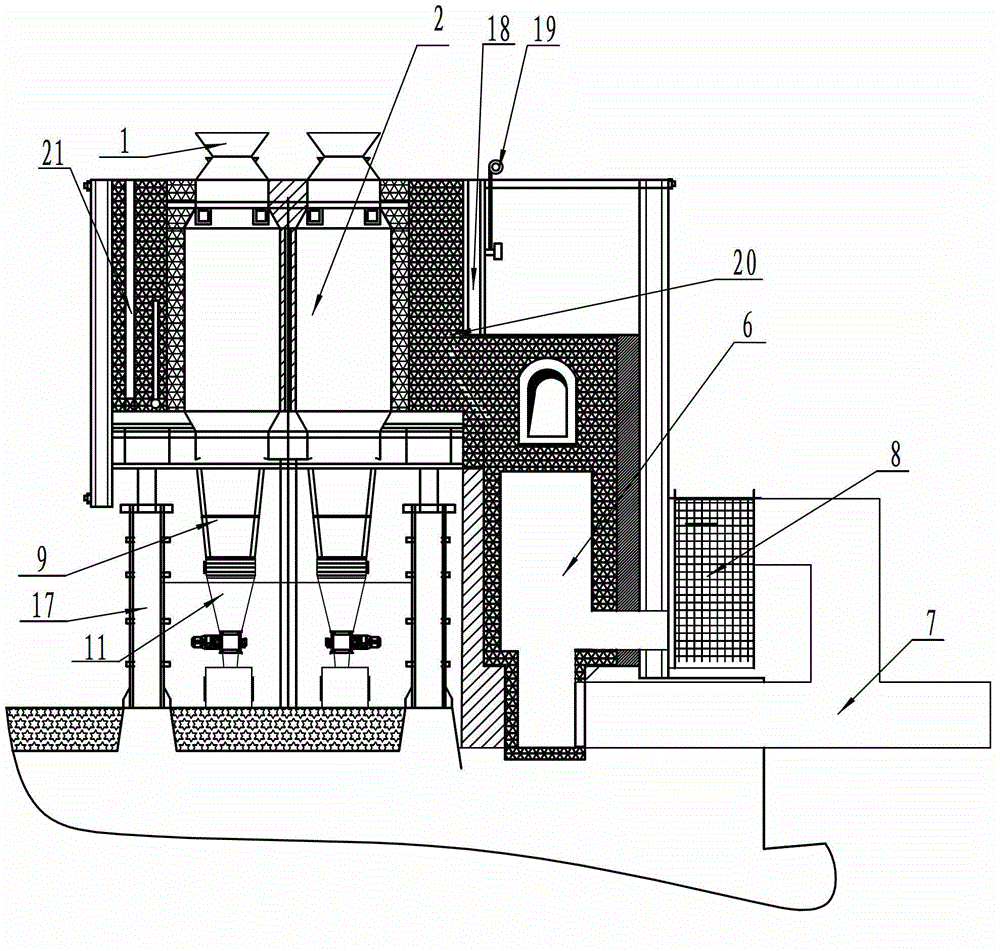

High-efficiency and environment-friendly coal-fired system for vertical boiler with bottom-built burner

ActiveCN103075727ASolve cokingAchieving Thermal EfficiencyCombustion using gaseous and pulverulent fuelCombustion using liquid and pulverulent fuelAir preheaterBaghouse

The invention discloses a high-efficiency and environment-friendly coal-fired system for a vertical boiler with a bottom-built burner. The system comprises a coal powder tower, a burning boiler, an air preheater mechanism, a cyclone dust collector mechanism and a bag-type dust collector mechanism that are sequentially arranged and connected, wherein the burning boiler comprises a boiler body and the bottom-built burner; the bag-type dust collector mechanism comprises a sealed casing, a high-efficiency dust collector and an ash storage bin; a fume outlet of the sealed casing is connected with a tower fume outlet of a desulfurizing tower by an induced fan; and a discharge outlet of the ash storage bin is connected with an ash inlet of a coal powder ash tank by a conveying mechanism. As the coal-fired system is subjected to a series of technological innovations and transformations, the boiler thermal efficiency is very high; the dust collection sealability is good; the collection efficiency is excellent; the desulfurizing tower is very good in desulphurization efficiency, and excellent in scale prevention and scale removal performance; the high-efficiency desulfuration and labor saving are ensured; finally a fume emission index of the system is far lower than the national specified emission concentration; and the system achieves the benefits of high efficiency, energy saving, emission reduction and environmental protection, and is a domestic initiative.

Owner:FUJIAN ETERNAL ENERGY MANAGEMENT

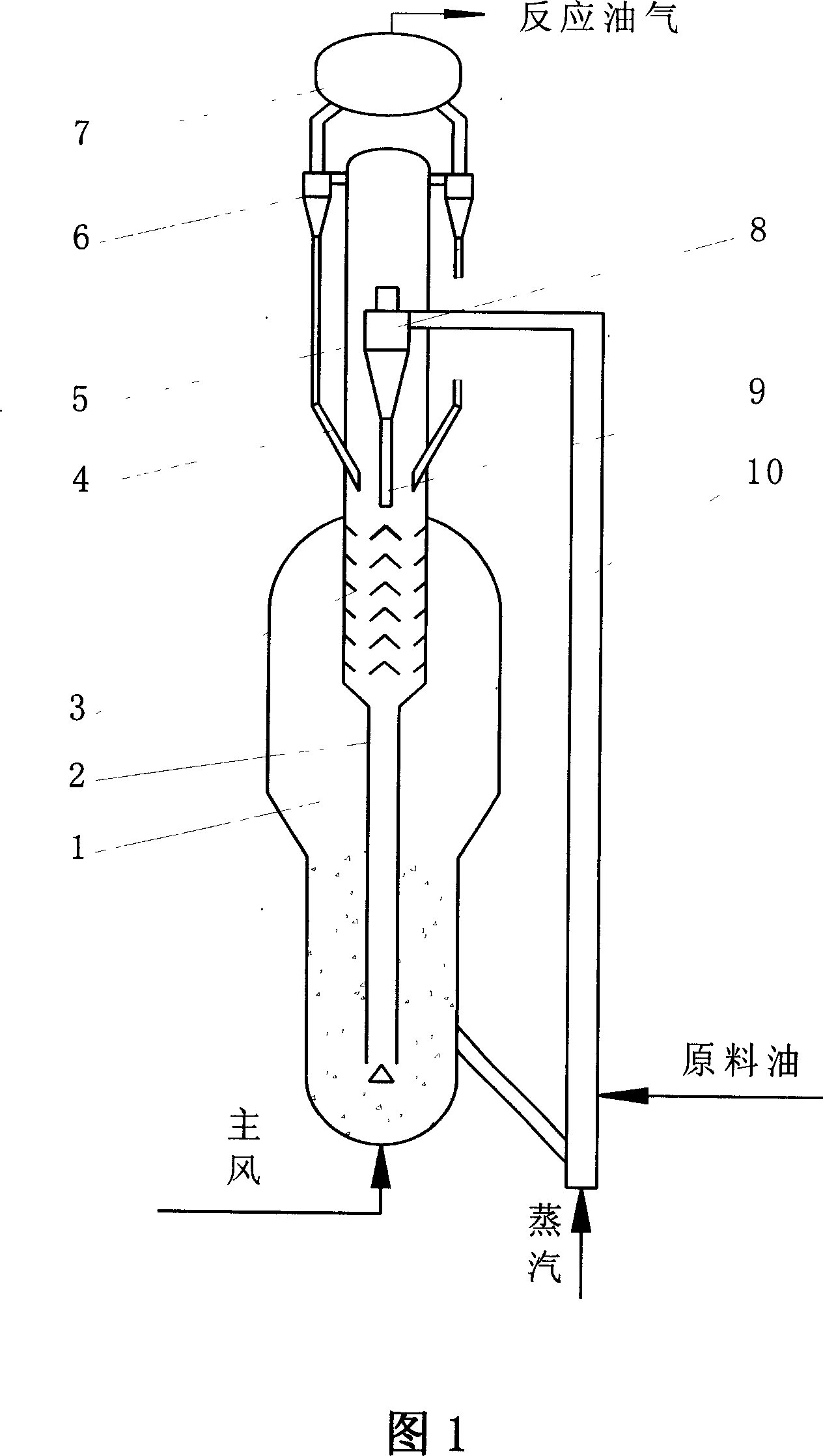

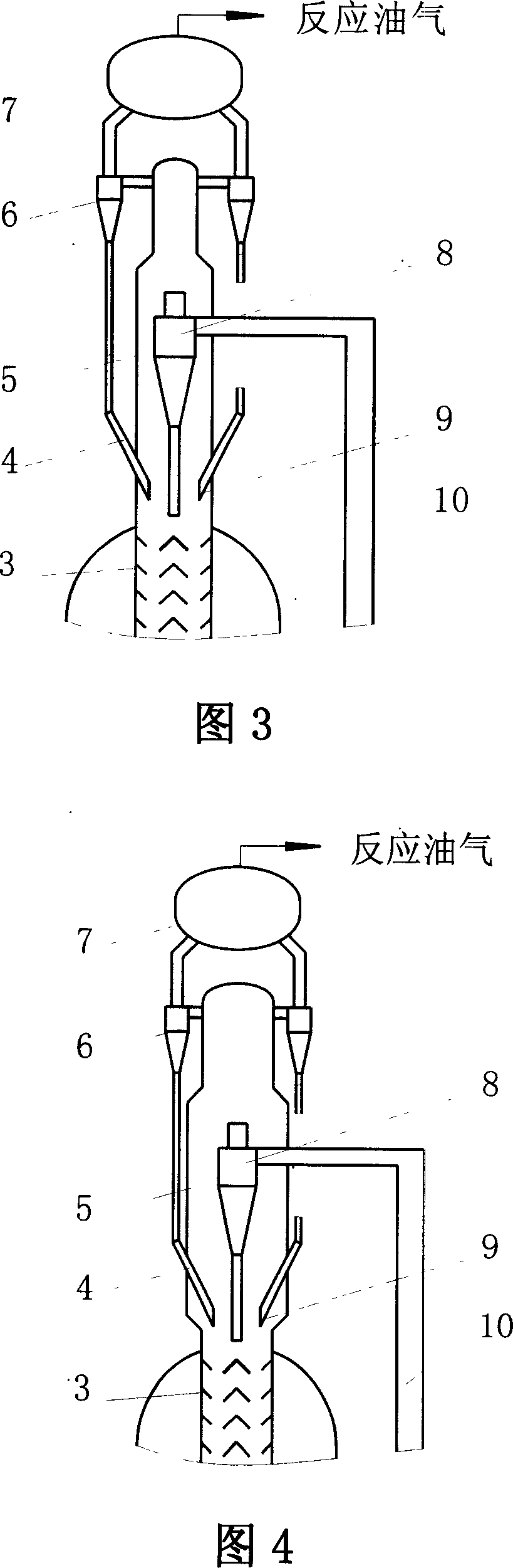

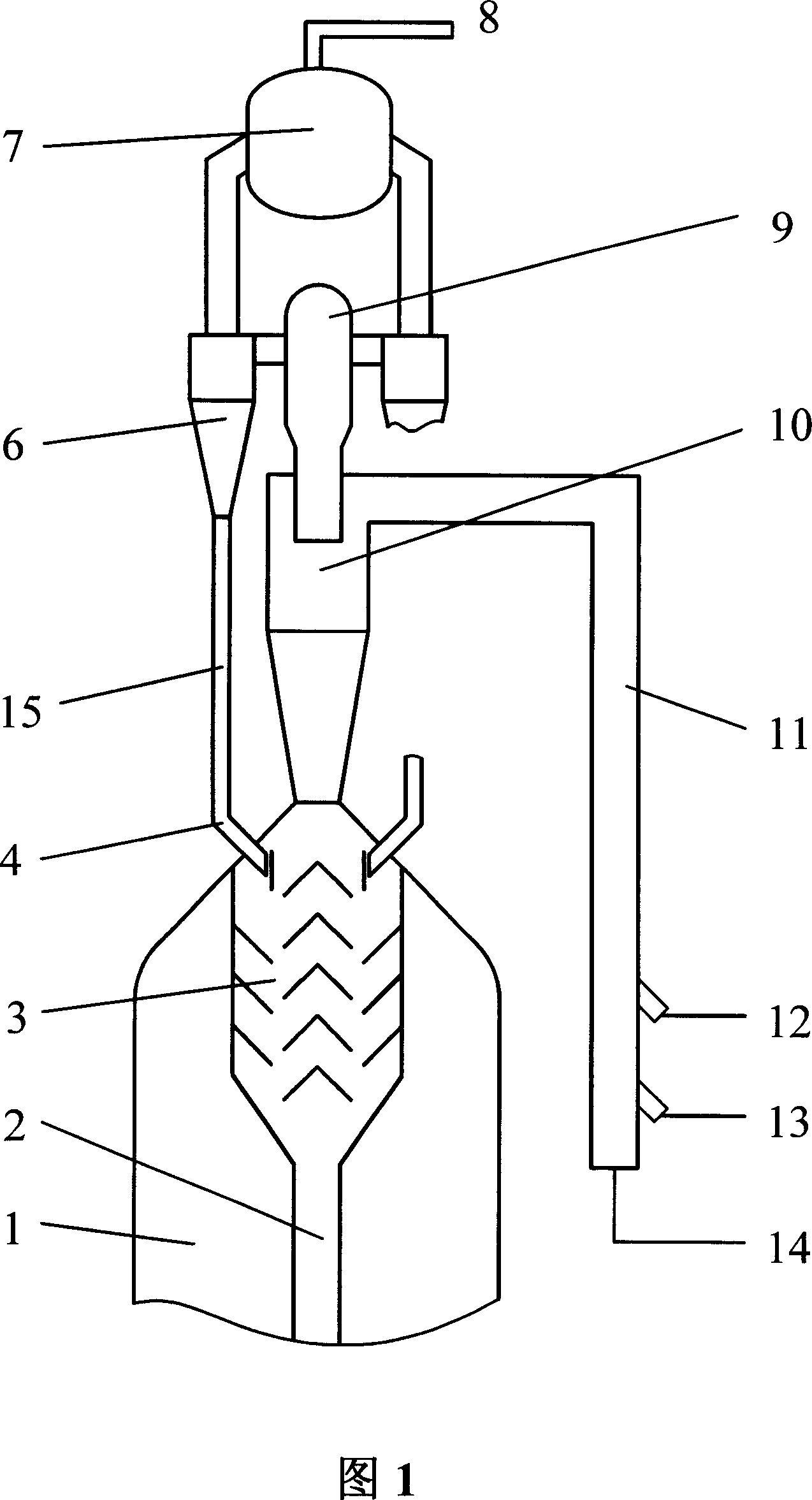

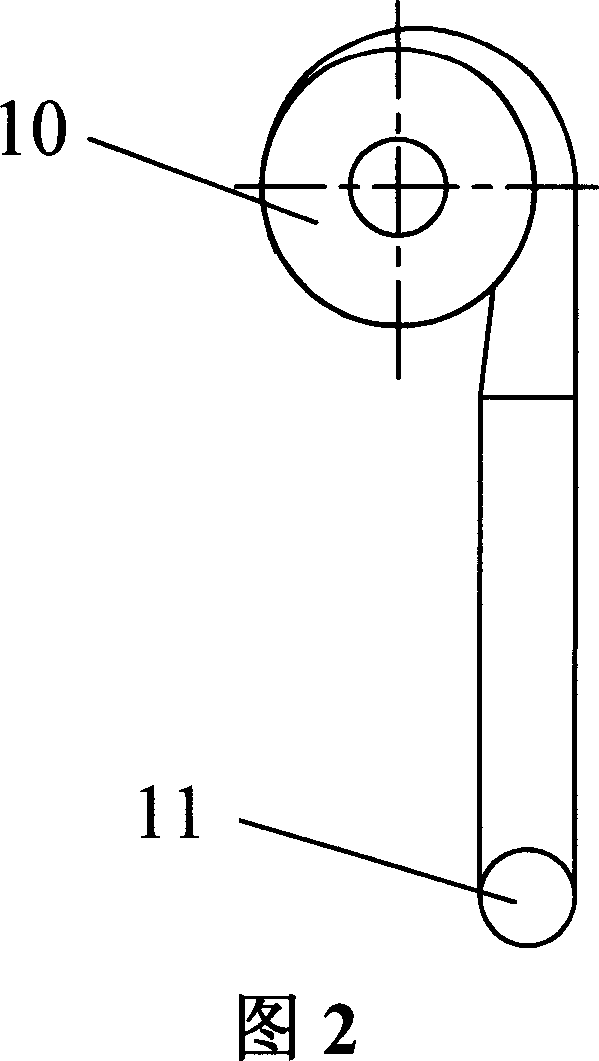

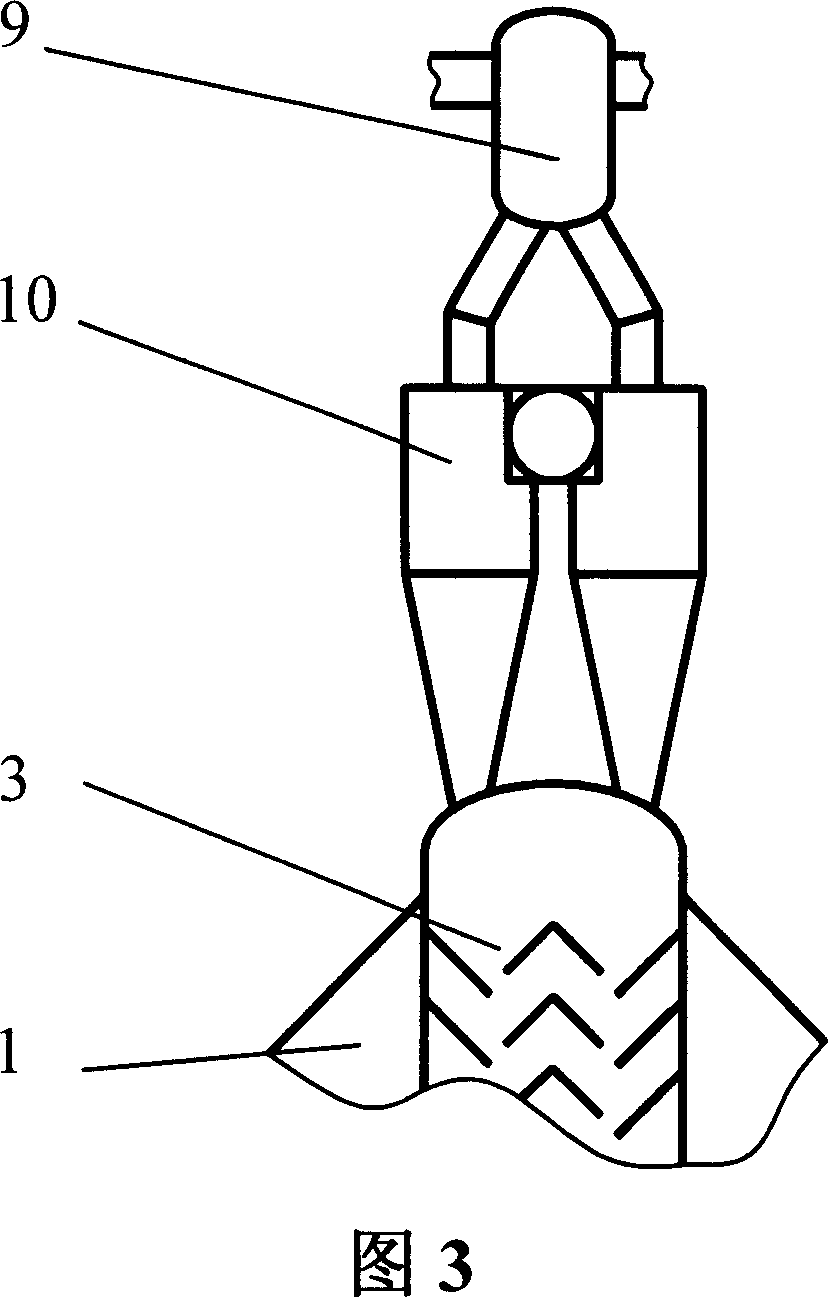

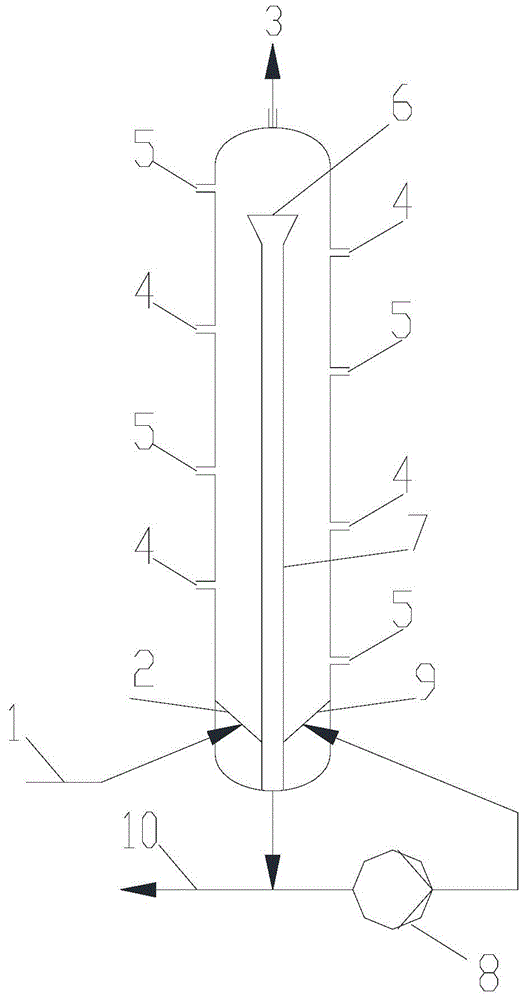

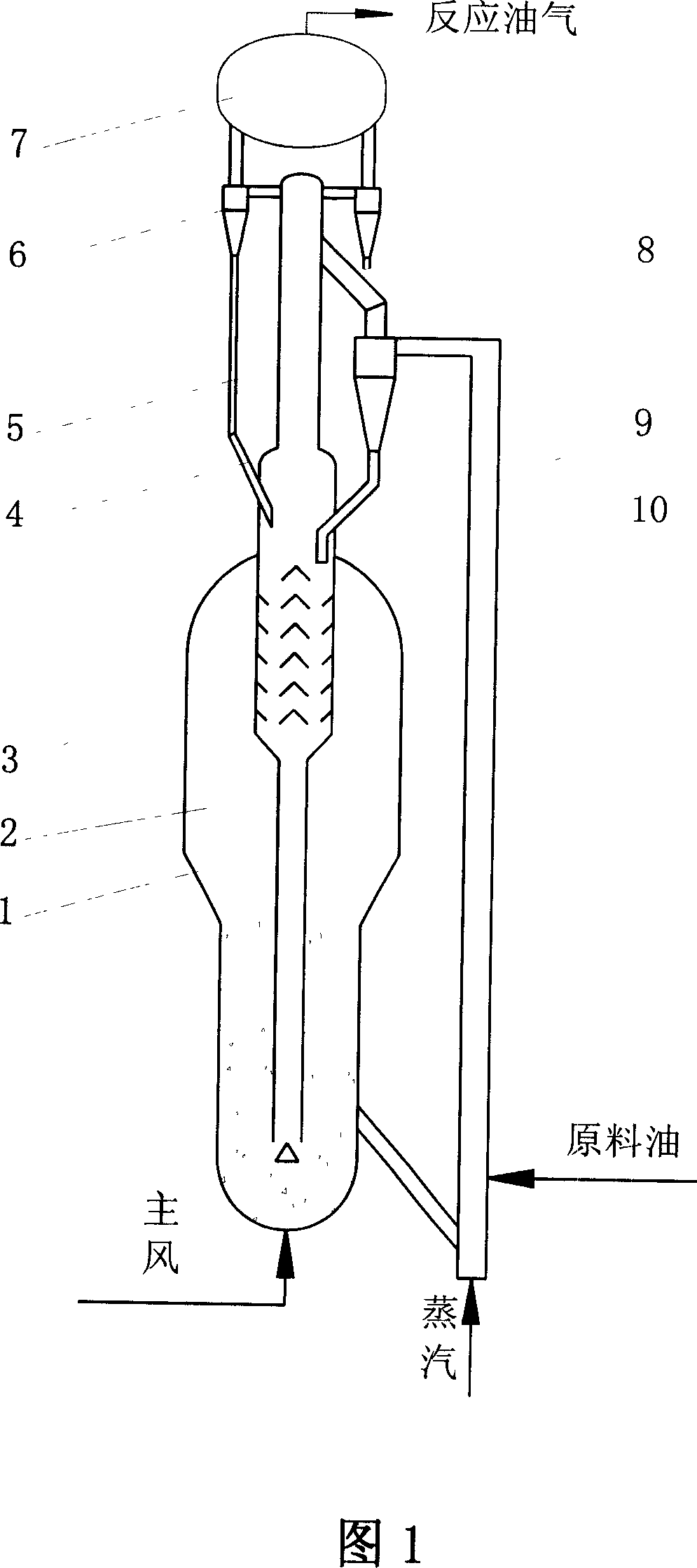

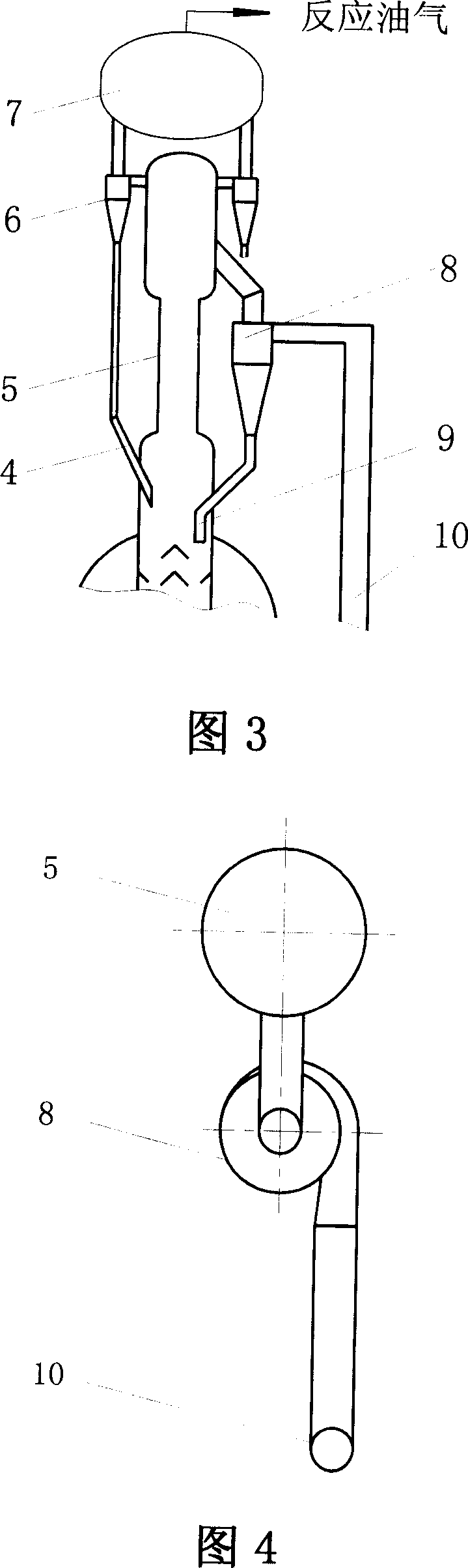

Catalytic cracker with internal tubular settler

The present invention is fluid catalytic cracker with fast separation of oil gas from catalyst. The fluid catalytic cracker has a riser with outlet connected to thick coiled pipe inside the tube settler, a stripping device below the tube settler, a catalyst regenerator connected through pipe tot lower end of the stripping device, and a top coiled pipe outside the tube settler. The fluid catalytic cracker can realize the efficient and fast gas-solid separation in the separation efficiency as high as 99.99 %, reduce average oil gas residence time to less than 2-3 sec and decrease scaling, and has compact structure and low cost.

Owner:CHINA UNIV OF PETROLEUM (BEIJING)

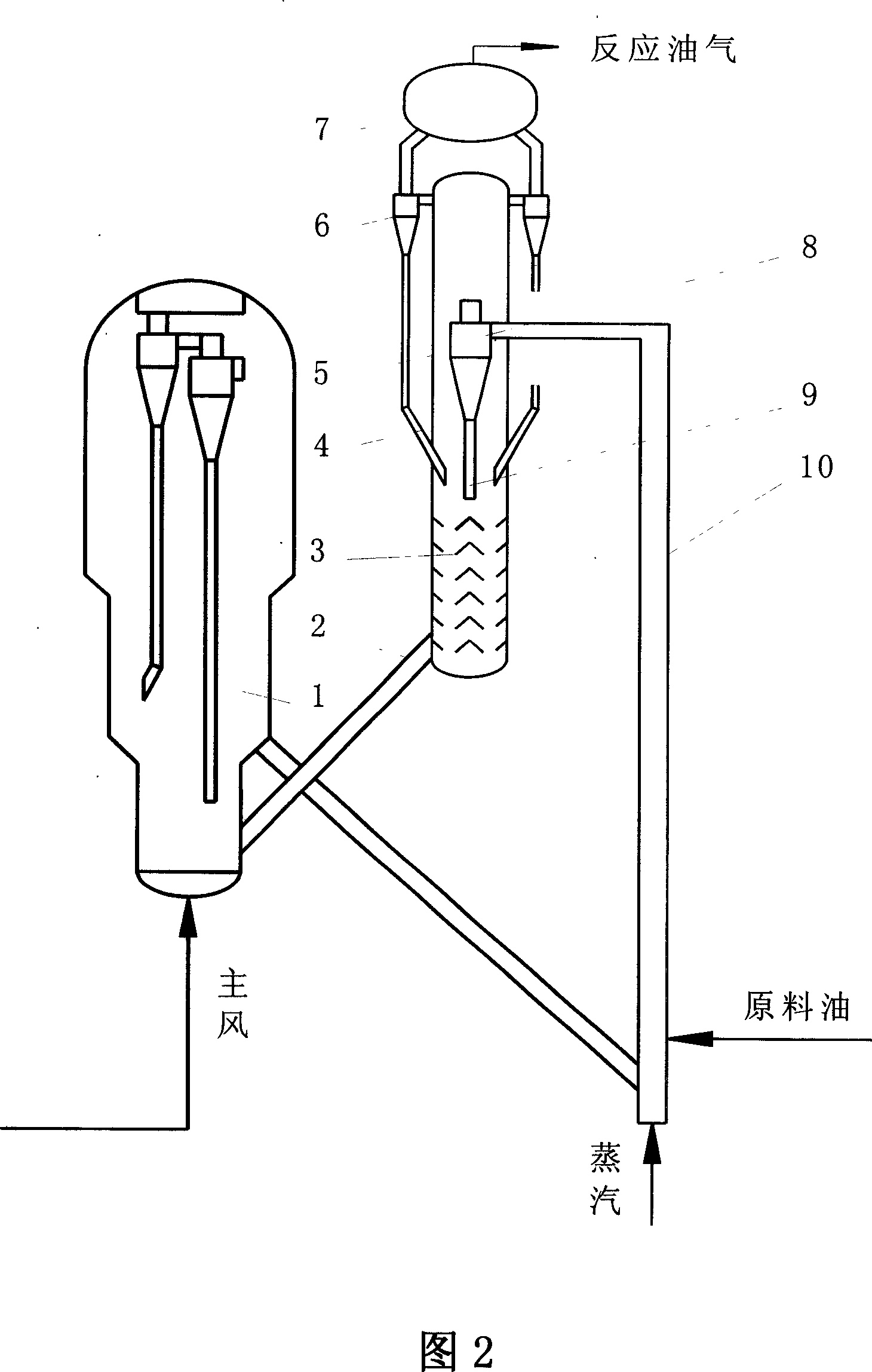

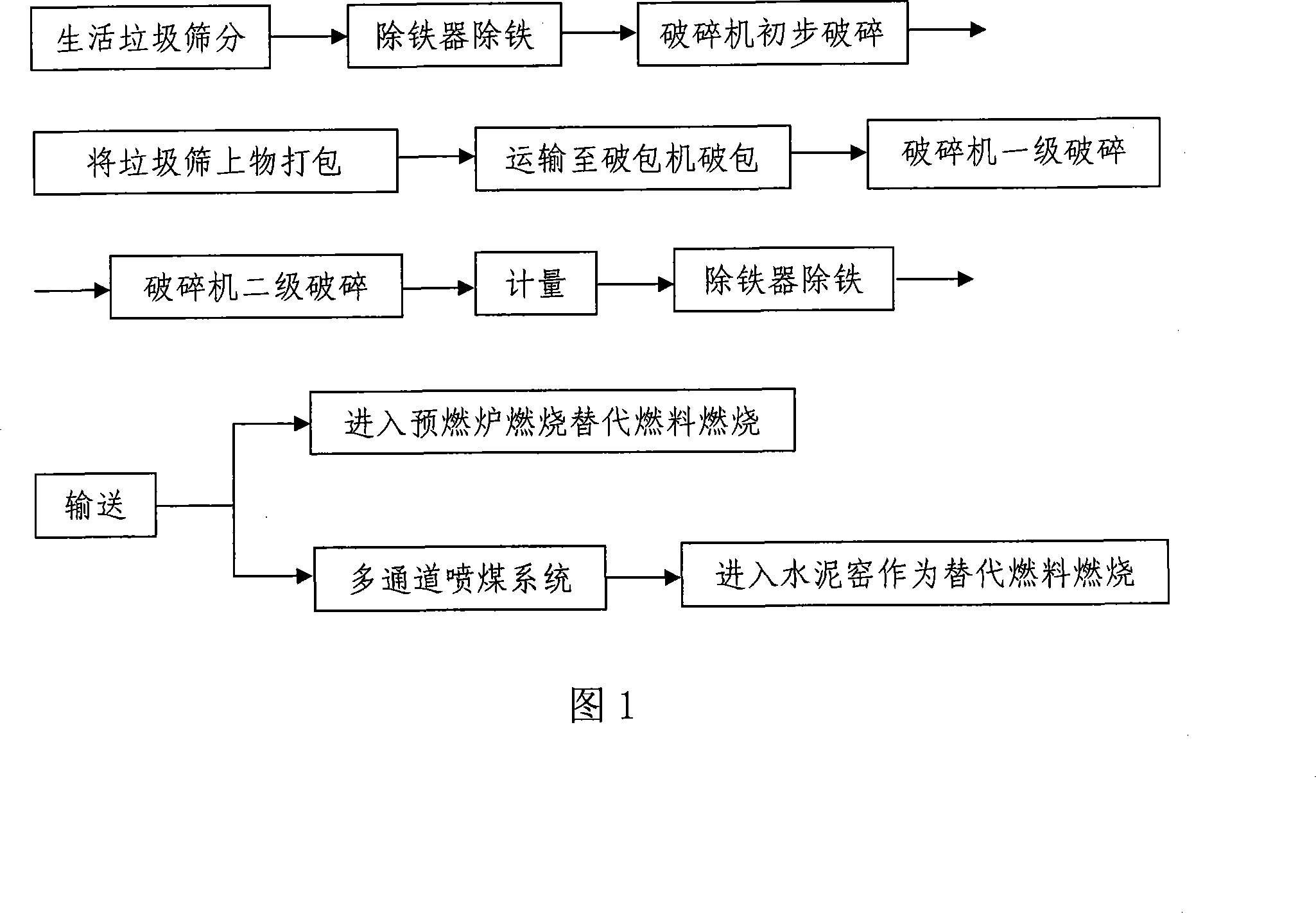

Catalytic cracker without settler

InactiveCN1974728AGood effectEasy to separateCatalytic crackingChemical/physical processesResidence timeHydrocarbon

The present invention relates to fast oil gas and catalyst separation in hydrocarbon material fluid catalytic cracking, and is especially one catalytic cracker without settler. The catalytic cracker without settler features the stripping unit with lower end connected via a vertical pipe to one regenerator, the first cyclone separator connected to the upper end of the stripping unit, the riser tube with outlet connected to the first cyclone separator via pipeline, and the second cyclone separator connected serially to the upper end of the first cyclone separator and with material feeding structure communicated to the stripping unit. The catalytic cracker can realize the efficient fast gas-solid separation in the separating efficiency up to 99.99 % and average oil gas residence time shortened to 2-3 sec, and has less scaling, compact structure and low cost.

Owner:CHINA UNIV OF PETROLEUM (BEIJING)

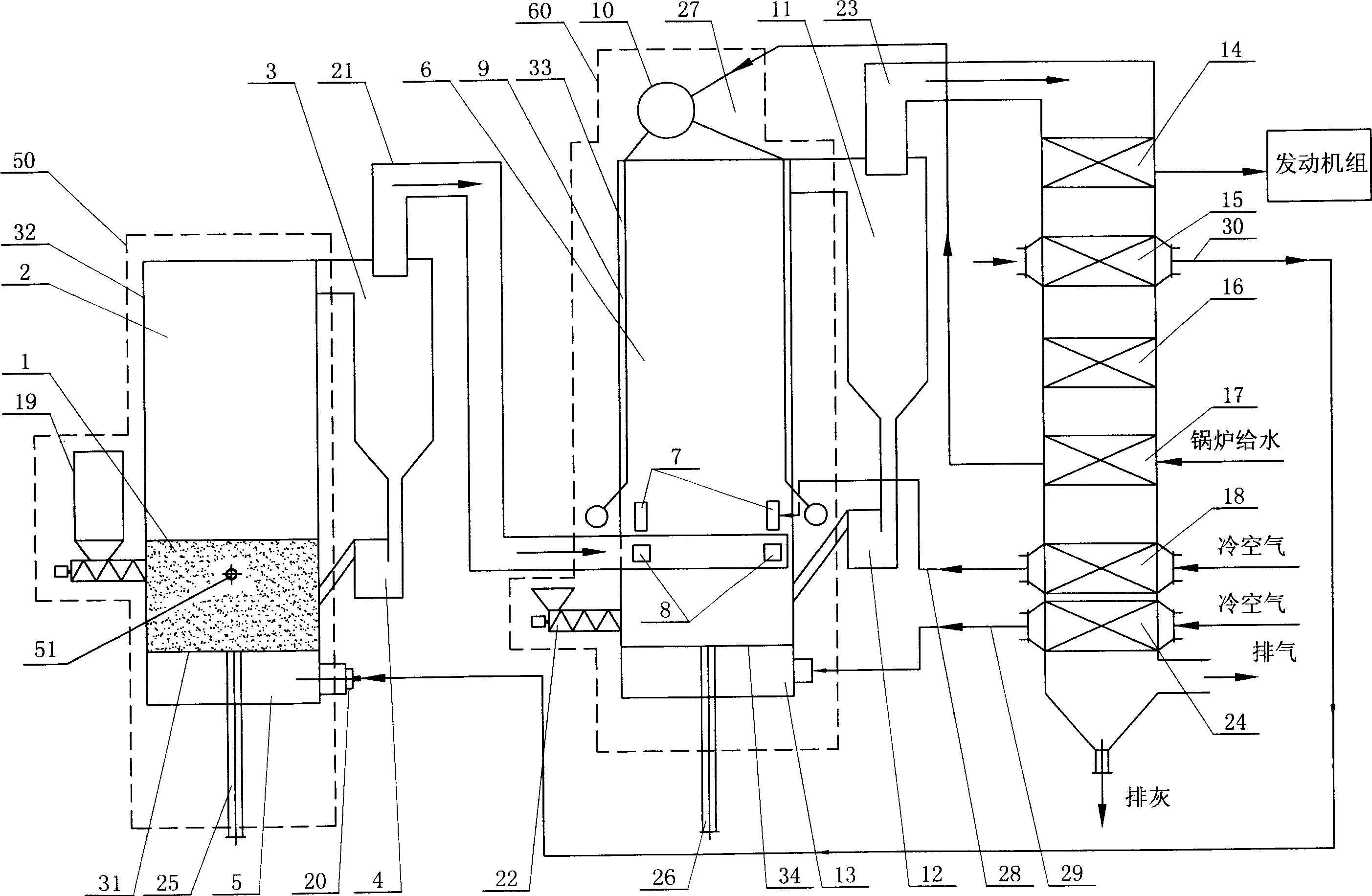

Double temperature double bed gasification, oxidization and fluidized bed incinerator for disposing high concentration organic effluent liquor

InactiveCN1632379ASolve cokingEmission reductionIncinerator apparatusHigh concentrationAir preheater

The utility model relates to a double-temperature double-bed gasification and oxidation fluidized bed incinerator for treating high-concentration organic waste liquid, which relates to a fluidized-bed incinerator for treating high-concentration organic waste liquid. The other end of the low-temperature flue 21 of the present invention is connected to the high-temperature oxidation circulating fluidized bed 60, and the two ends of the high-temperature air pipeline 30 are respectively connected to the high-temperature air preheater (15) and the low-temperature gasification fluidized bed 50. The combination of low-temperature gasification of low-temperature gasification fluidized bed and high-temperature combustion of high-temperature oxidation circulating fluidized bed in the present invention solves the problem of agglomeration and coking of fluidized bed materials, and effectively removes HCl and SO2 produced after incineration of high-concentration organic waste liquid Harmful gases such as NOx and NOx fully suppress the generation of dioxin in the furnace, and can completely incinerate the toxic organic substances in the waste liquid, and the incineration removal rate reaches more than 99.99%. The device almost solves all the problems encountered in incinerating high-concentration organic waste liquid in a fluidized bed.

Owner:HARBIN INST OF TECH

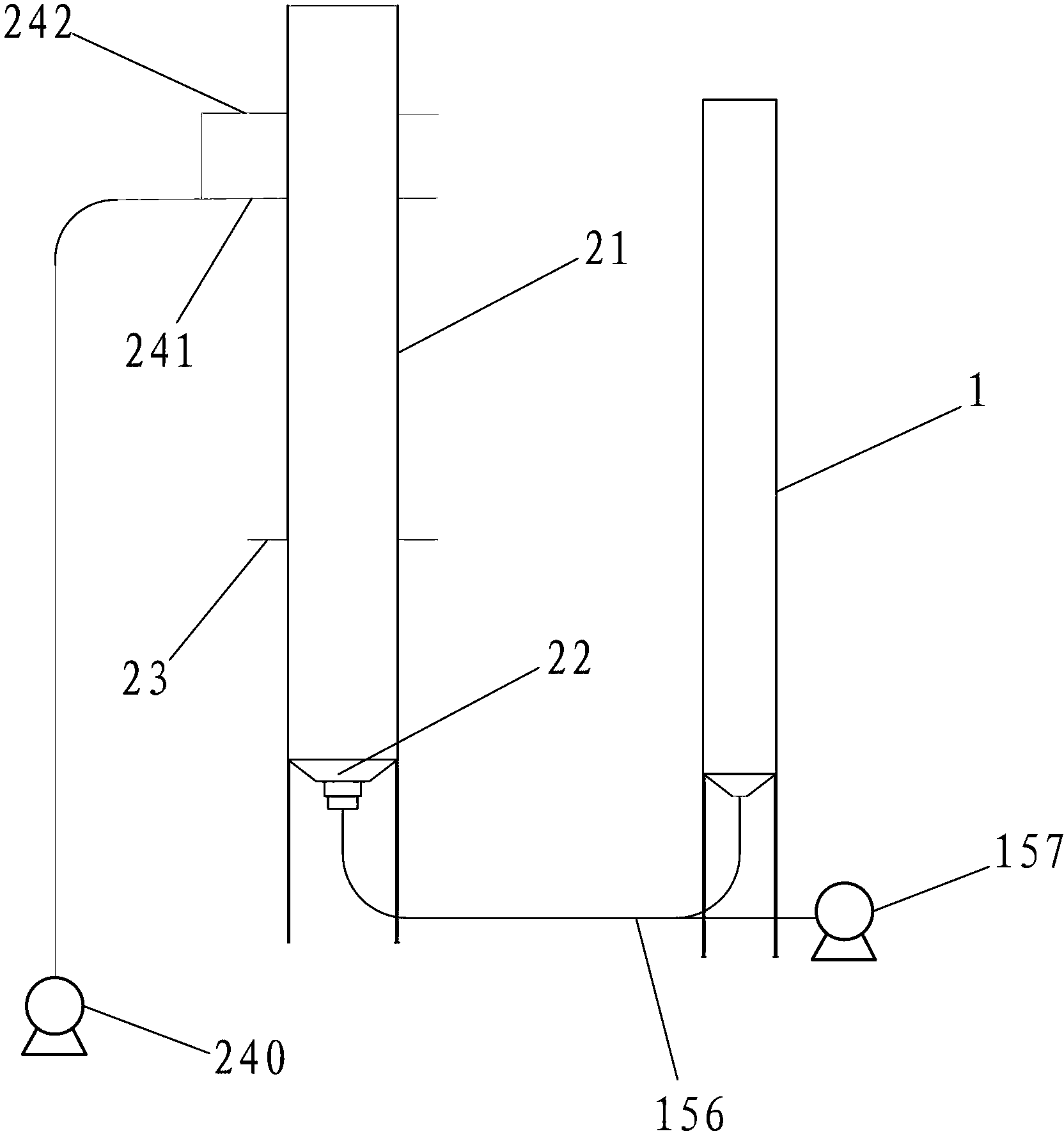

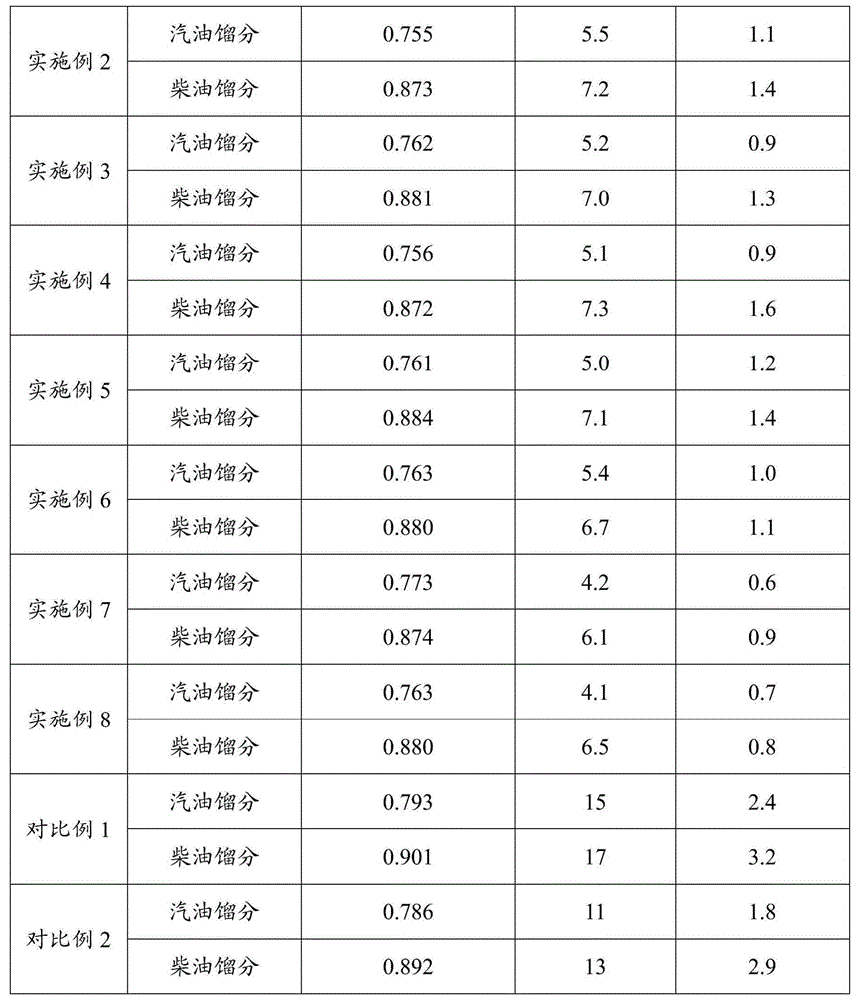

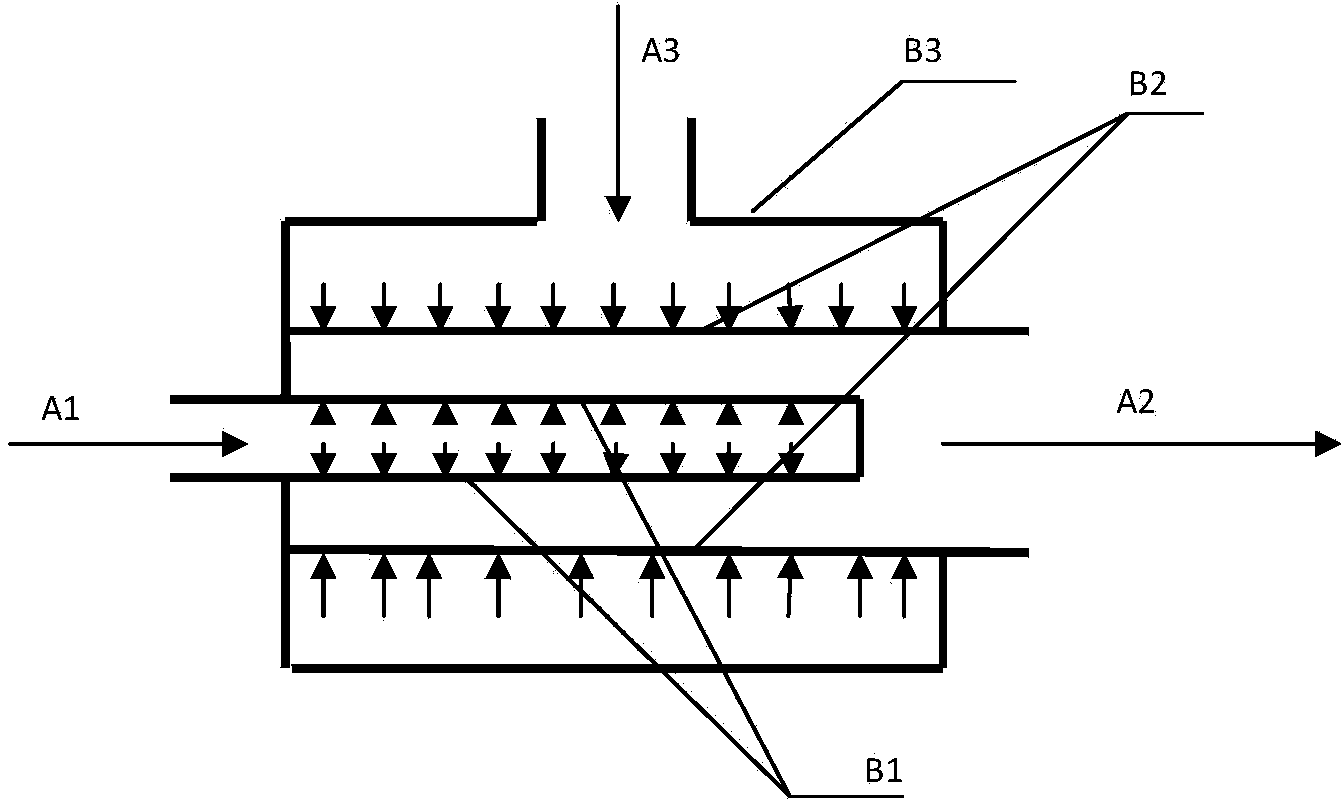

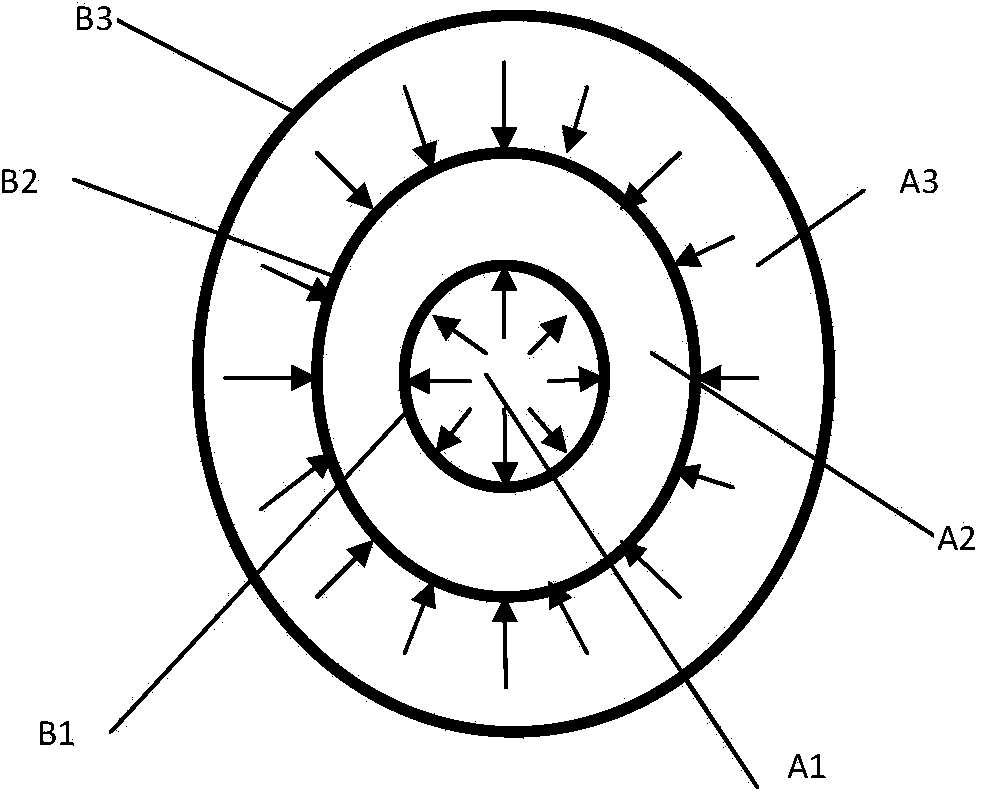

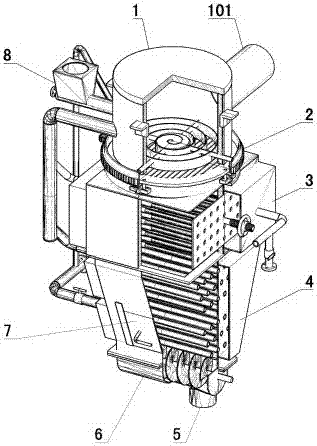

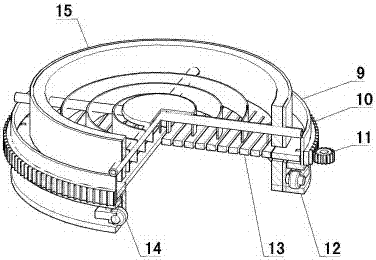

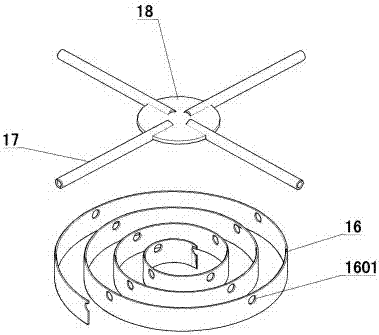

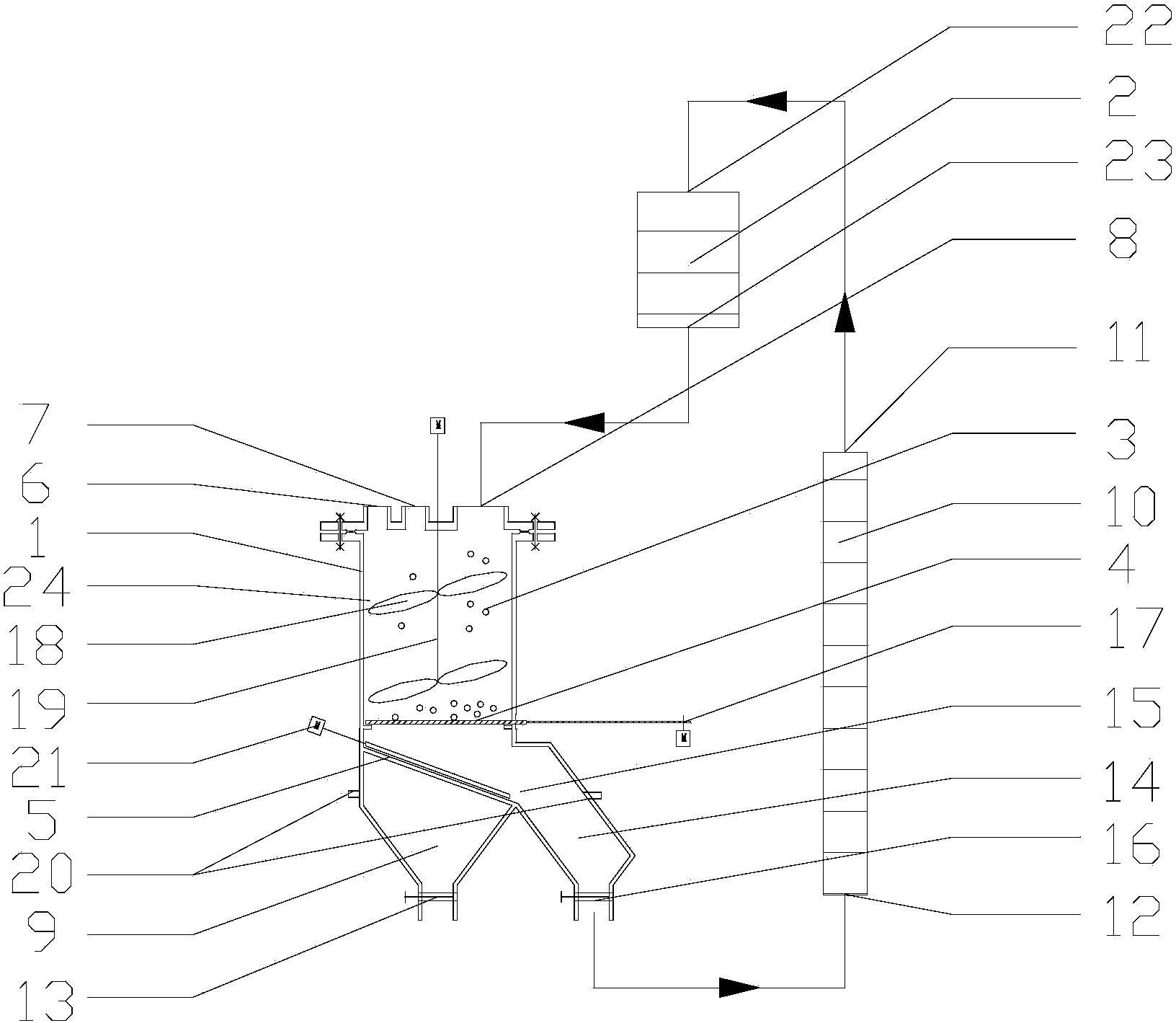

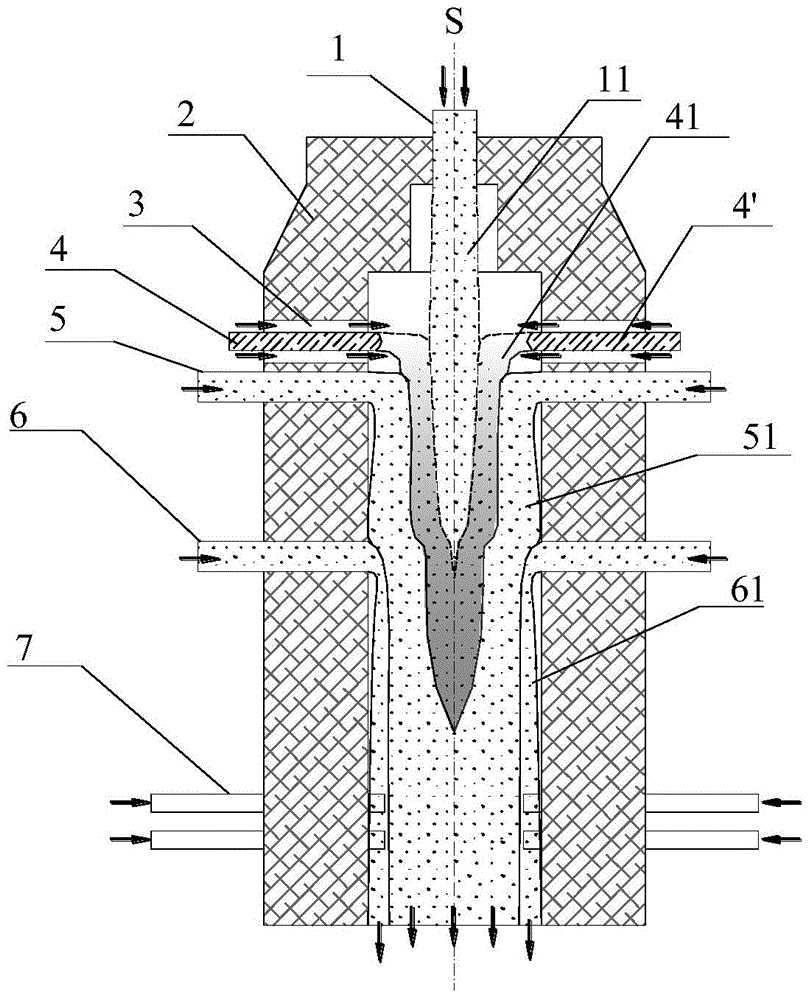

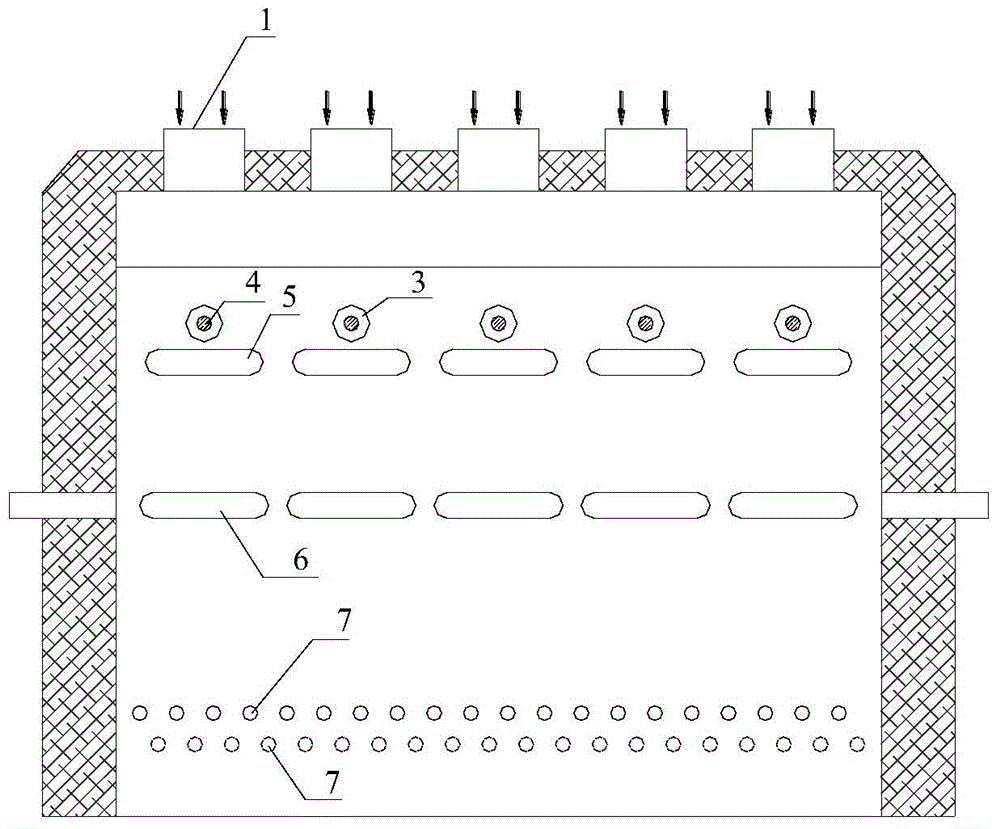

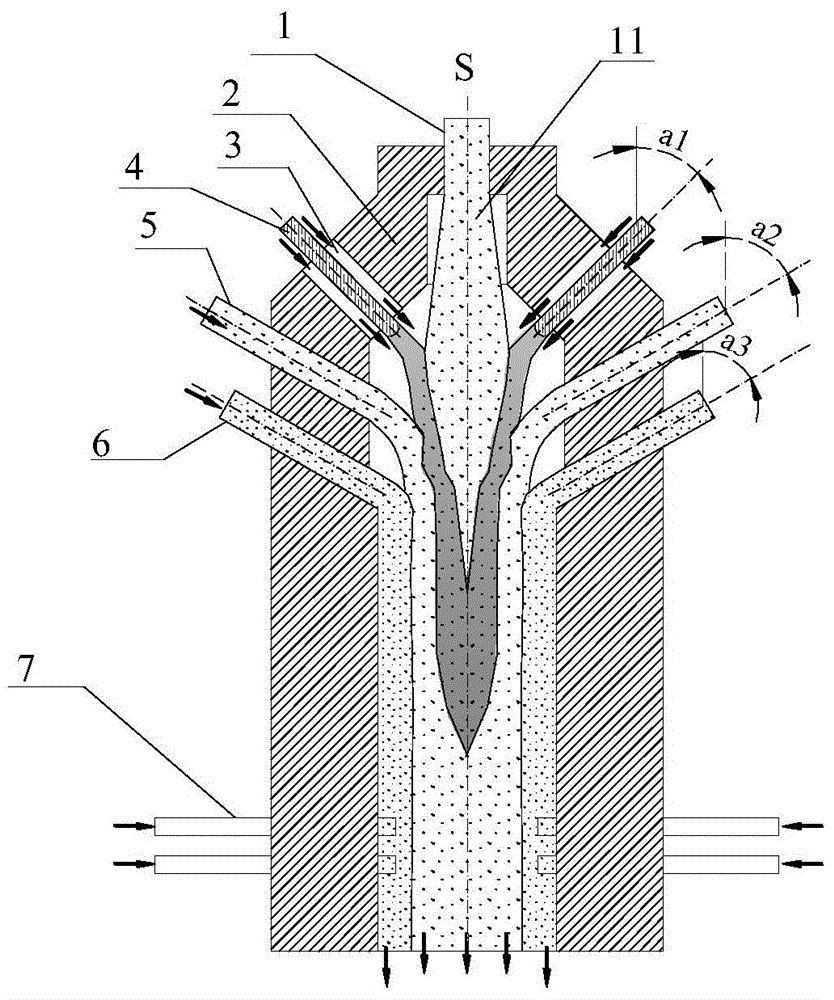

Multi-optimized slurry bed hydrogenation reactor, application and design method thereof

InactiveCN104818050AEnhance heat and mass transferImprove conversion rateHydrocarbon oil crackingHydrocarbon oils refiningBiochemical engineeringSlurry

The invention discloses a multi-optimized slurry bed hydrogenation reactor, an application and a design method thereof, wherein the multi-optimized slurry bed hydrogenation reactor includes an internal circulating structure and a feed distributor. A material inlet is arranged on a lower part of a column body of the reactor while a material outlet is arranged on the top of the column body. The internal circulating structure includes a circulating bubble cap, a circulating tube and a circulating pump. The circulating bubble cap is arranged in the upper part in the column body and is in the structure of an inverted circular truncated-conical hollow cup. The lower end of the circulating bubble cap is connected to the circulating tube, is communicated with the bottom of the column body and is communicated with the circulating pump outside the column body. The feed distributor includes an inlet feed distributor and a circulating feed distributor and is arranged between the inner wall in the lower part of the column body and the circulating tube. The material inlet includes an entrance inlet and a circulating inlet. Reaction materials are fed into the column body through the entrance inlet and then through the inlet feed distributor, wherein circulated material recycled by the internal circulating structure is fed into the circulating inlet through the circulating pump and then is fed into the column body through the circulating feed distributor. The multi-optimized slurry bed hydrogenation reactor is improved in backmixing degree of reactants and is improved in conversion rate of raw materials and yield of light oil.

Owner:CATECH TECH

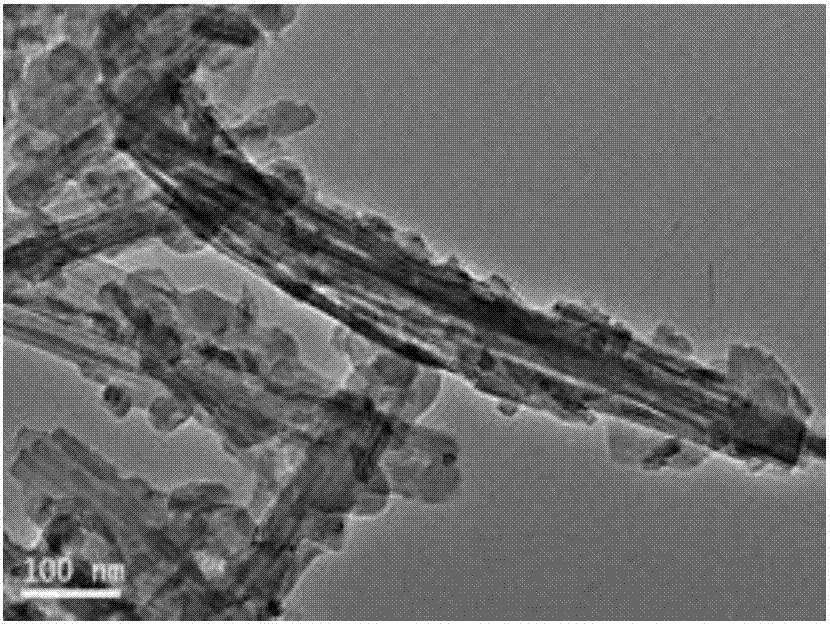

Preparation method of hydrogenation catalyst and slurry bed hydrogenation technology using the catalyst

ActiveCN105126933ALarge specific surface areaGood dispersionCatalyst regeneration/reactivationHydrocarbon oil crackingHydrogenation reactionHydrogenation process

The invention provides a preparation method of hydrogenation catalyst and a slurry bed hydrogenation technology using the catalyst. The preparation method comprises the following steps: a desulphurization waste agent and / or a waste catalyst is placed in a solvent oil at 80-150 DEG C for beating, and a hydrogenation catalyst slurry is obtained. The preparation method of the present invention can increase dispersibility of the catalyst in raw oil and is good for improving activity of the catalyst, and simultaneously can effectively reduce even inhibite the coking problem of slurry bed. According to the slurry bed hydrogenation technology provided by the invention, the desulphurization waste agent generated in the process of slurry bed tail gas desulphurization is prepared into the hydrogenation catalyst, and the hydrogenation catalyst is calculatedly used in the hydrogenation reaction of heavy raw oil, thereby realizing cyclic utilization of catalysts with different functions in the whole slurry bed hydrogenation process flow, solving the coking problem easily generated in the slurry bed hydrogenation technology, and simultaneously developing a low-cost new approach for safety recovery of the desulphurization waste agent, the waste catalyst or the like.

Owner:BEIJING SJ ENVIRONMENTAL PROTECTION & NEW MATERIAL CO LTD

Hydrogenation modification method for coking gasoline and diesel distillates

ActiveCN102465023AAvoid Coking ProblemsFlexible production operationsTreatment with hydrotreatment processesChemistryKerosene

The invention discloses a hydrogenation modification method for coking gasoline and diesel distillates. A coking gasoline and diesel raw material is mixed with heated hydrogen and then introduced to pass through a low-temperature hydrorefining reactor and a hydrogenation modification reactor in sequence; a reaction effluent is separated and modified, and obtained liquid is distilled to obtain gas, gasoline, kerosene and diesel. In the method disclosed by the invention, a process flow of mixing hydrogen behind a furnace is adopted, the heating furnace is only used for heating the hydrogen, the mixed raw material does not pass through the heating furnace, and the temperature of the reactor is controlled based on the quantities of hot hydrogen and cold hydrogen. Compared with the prior art, the hydrogenation modification method disclosed by the invention has the advantage of saving equipment investment and being flexible in production scheme, can be used for flexible production by adjusting process conditions and production distribution according to the differences of raw material properties and product schemes; by implementation of hydrogen mixing behind the furnace, the coking raw material can be effectively prevented from being coked at a furnace tube; and by arrangement of a low-temperature protective agent reactor, olefin saturation is performed at lower temperature so as to reduce coking, meanwhile, coke powder is distributed at a protective agent bed as uniform as possible, so that the long-term operation of a hydrogenation device is ensured.

Owner:CHINA PETROLEUM & CHEM CORP +1

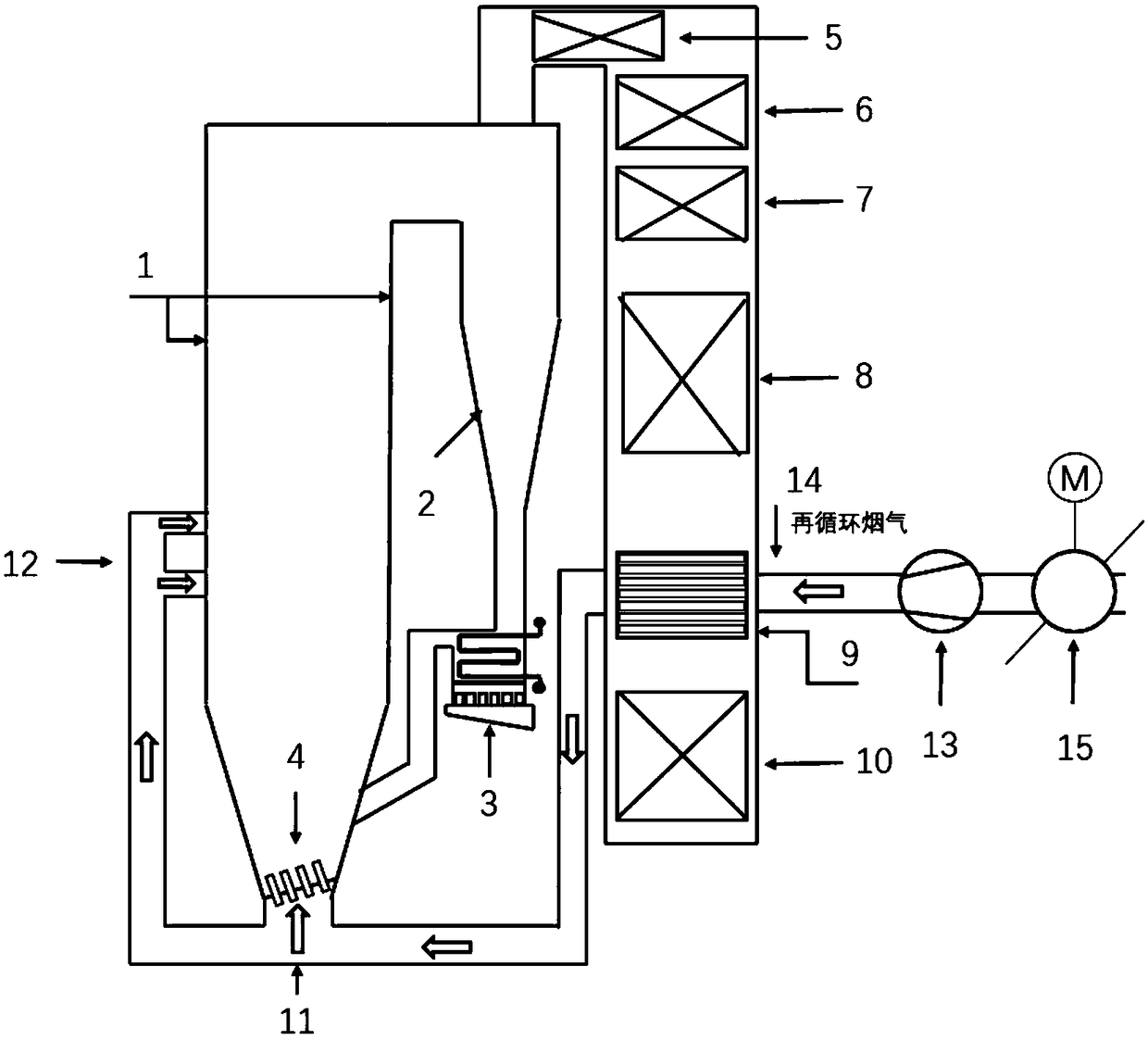

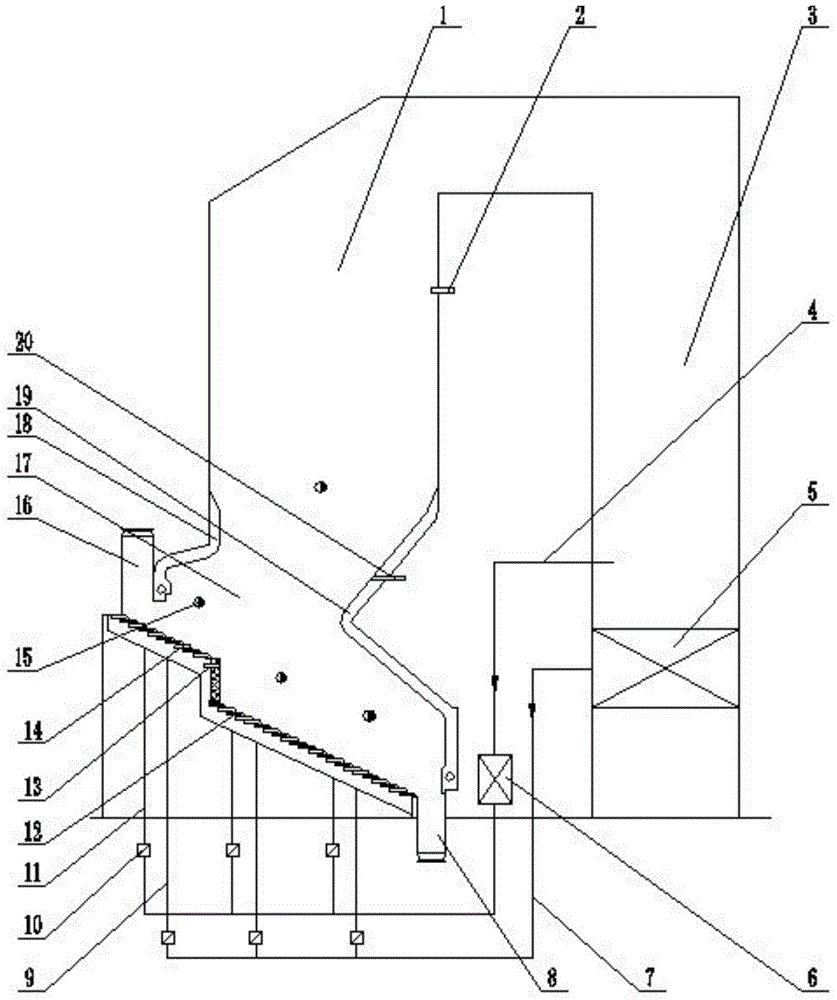

Circulating fluidized bed boiler applicable to garbage incineration

InactiveCN108758651AOvercoming the problem of insufficient combustion temperatureReduce heat absorptionFluidized bed combustionIncinerator apparatusAir volumeEvaporation

The invention discloses a circulating fluidized bed boiler applicable to garbage incineration. The circulating fluidized bed boiler applicable to garbage incineration comprises a hearth, an air distribution device, a separator, a material return valve, an external bed heat exchanger, a tail flue, a water-cooling pipe bundle, an evaporation pipe bundle, a low-temperature superheater, a coal economizer, a recirculating smoke heat exchanger, an air pre-heater and the like. According to the circulating fluidized bed boiler applicable to garbage incineration, an in-boiler water-cooling wall is completely poured-covered with a refractory material, so that a high combustion temperature of the circulating fluidized bed boiler is ensured. Meanwhile, recirculating smoke is heated by virtue of hot smoke in the tail flue, so that charge heat is increased, and the combustion stability of garbage incineration in the circulating fluidized bed boiler is further improved. The heated recirculating smokeis mixed with primary air and secondary air, so that a primary air amount used for fluidization is reduced while an air temperature is increased, the effect of enhanced graded combustion is further achieved, and the original generation of NOx is reduced. The problem of insufficient heating surface in the heat-insulation hearth is solved through arranging a high-temperature superheater in an external bed; and meanwhile, the problems of high-temperature corrosion of smoke, and coking in a biomass and garbage incineration process, are greatly solved.

Owner:HUANENG CLEAN ENERGY RES INST

Catalytic cracker with external tubular settler

The present invention is fluid catalytic cracker with fast separation of oil gas from catalyst. The fluid catalytic cracker has a riser with outlet connected to thick coiled pipe inside the tube settler, a stripping device below the tube settler, a catalyst regenerator connected through pipe tot lower end of the stripping device, and a top coiled pipe outside the tube settler. The fluid catalytic cracker can realize the efficient and fast gas-solid separation in the separation efficiency as high as 99.99 %, reduce average oil gas residence time to less than 2-3 sec and decrease scaling, and has compact structure and low cost.

Owner:CHINA UNIV OF PETROLEUM (BEIJING)

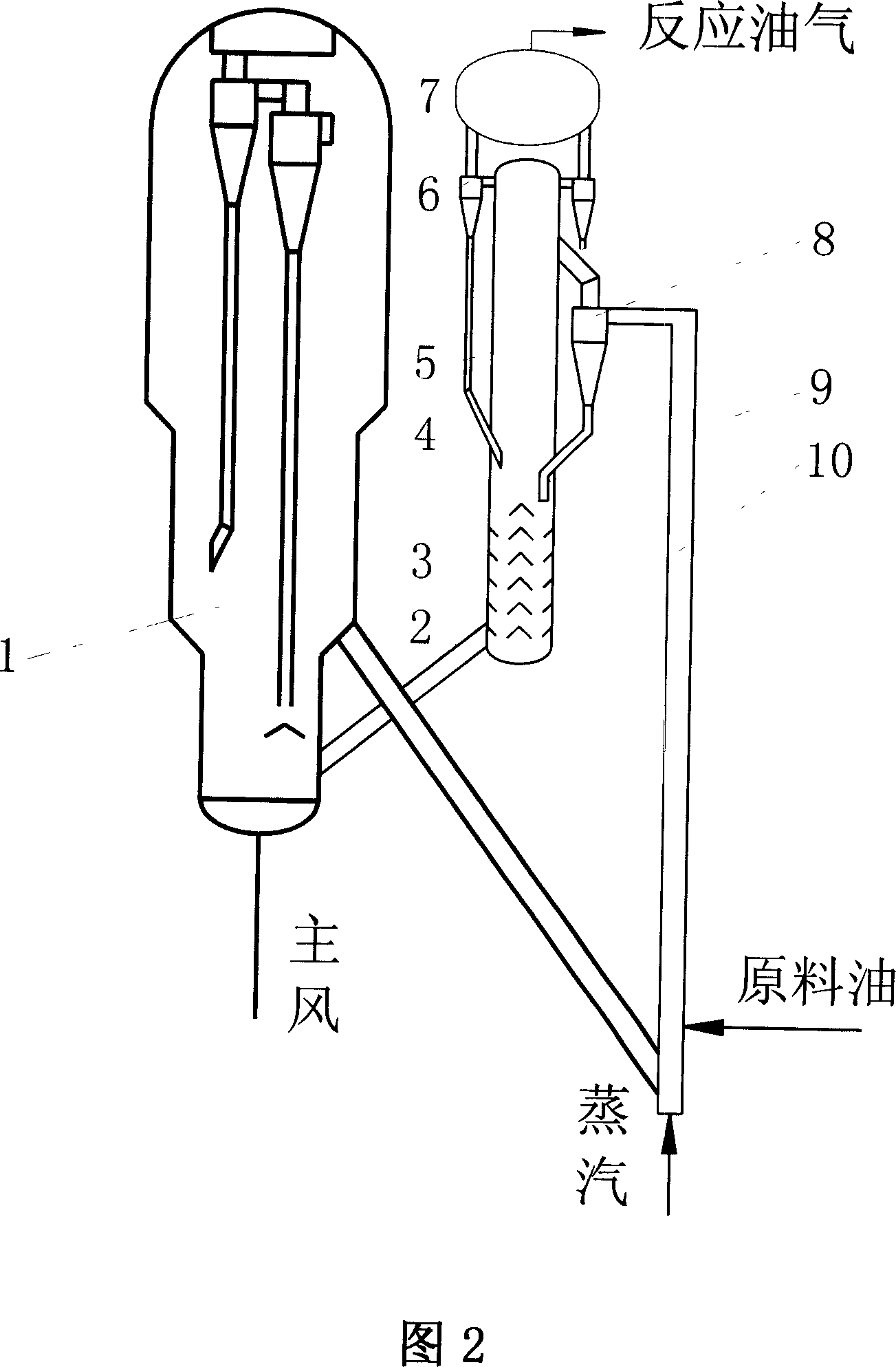

Method for substituting cement kiln fuel with garbage derived overtails

ActiveCN101173196AHigh calorific valueAvoid enteringBiofuelsSolid fuelsAlternative fuelsProcess engineering

The invention relates to a method for adopting waste derivative oversize material as substitute for cement kiln fuel, which is characterized in that the domestic waste in refuse reclamation station is separated and sorted, broken in packages, crushed and completely stirred and mixed, one part of the waste enters a precombustion furnace in the kiln tail of a cement kiln for combustion, while the other part of the waste enters the cement kiln from the kiln hood for combustion, thus the substitute fuel for cement production is produced. The invention has the advantages that the waste derivative oversize material having calorific value is adopted to substitute for industrial fuel in the cement kiln, thus resources of waste derivative oversize material are fully utilized, and coal energy resources are saved; simultaneously the cement kiln has the characteristics of high temperature, large carrying capacity, no residue after waste treatment and no secondary pollution, therefore the invention has the great advantages of energy saving and environmental protection.

Owner:LINGCHUAN JINYU CEMENT

Smoke circulating combusting system for waste palm boiler

InactiveCN104896482ASolve combustion instability and cokingInhibit the combustion processAir supply regulationIndirect carbon-dioxide mitigationFlueEngineering

The invention provides a smoke circulating combusting system for a waste palm boiler. The system is that a fire grate comprises a drying section reciprocating fire grate and a combustion section reciprocating fire grate which are connected through continuously-inclined staggering disconnecting layers; inclination angles of the drying section reciprocating fire grate and the combustion section reciprocating fire grate are 20 to 30 degrees; a plurality of primary air branch tubes and a plurality of smoke circulating branch tubes are arranged in the drying section reciprocating fire grate and the combustion section reciprocating fire grate, wherein the primary air branch tubes and the smoke circulating branch tubes are respectively communicated with an air preheater and a tail smoke channel through primary air head tubes and smoke circulating head tubes; the tail smoke channel, the smoke circulating head tubes, the smoke circulating branch tubes, the smoke circulating branch tubes, a hearth and a smoke outlet are sequentially communicated by a circulating manner; the air preheater, the primary air head tubes, the primary air branch tubes and the hearth are sequentially communicated by circulating. The system can solve the problems of unstable combustion of the hearth and coking, and achieves efficient, energy-saving and safe operation of the waste palm steam boiler.

Owner:天津机电进出口有限公司

Full fraction crude benzene hydrogenation method and catalyst

ActiveCN103910596ARealize long cycle operationImprove use valueHydrocarbon purification/separationHydrocarbonsHydrogenStatic mixer

The invention discloses a full fraction crude benzene hydrogenation method and a catalyst, belonging to the technical field of all fraction crude benzene processing. The method comprises steps of firstly allowing crude benzene fraction over 70DEG C and hydrogen to pass through a corpuscule generator and a static mixer sequentially, so as to mix the two raw materials into uniform corpuscule raw material with diameter of 0.1-20mu m; fully saturating the corpuscule raw material through hydrogenation through the catalytic action of the low temperature hydrogenation catalyst under the conditions of certain pressure, air speed and temperature, so as to convert the corpuscule raw material into stable saturated compound; mixing the oil generated through low temperature hydrogenation with fresh hydrogen, circulating hydrogen and less than 70DEG C crude benzene fraction from a pre-fraction tower, then hydrogenating again, gas stripping and fraction distilling the oil generated by hydrogenating full fraction crude benzene so as to obtain light arene fraction and heavy arene product, then predistilling, extracting and rectifying so as to obtain pure benzene, methylbenzene, xylene and non-arene products. According to the method, the problem of coking of full fraction crude benzene raw material in high temperature hydrogenation is solved, and the crude benzene hydrogenation device can run for long period.

Owner:XUZHOU LONGHUI CHEM TECH

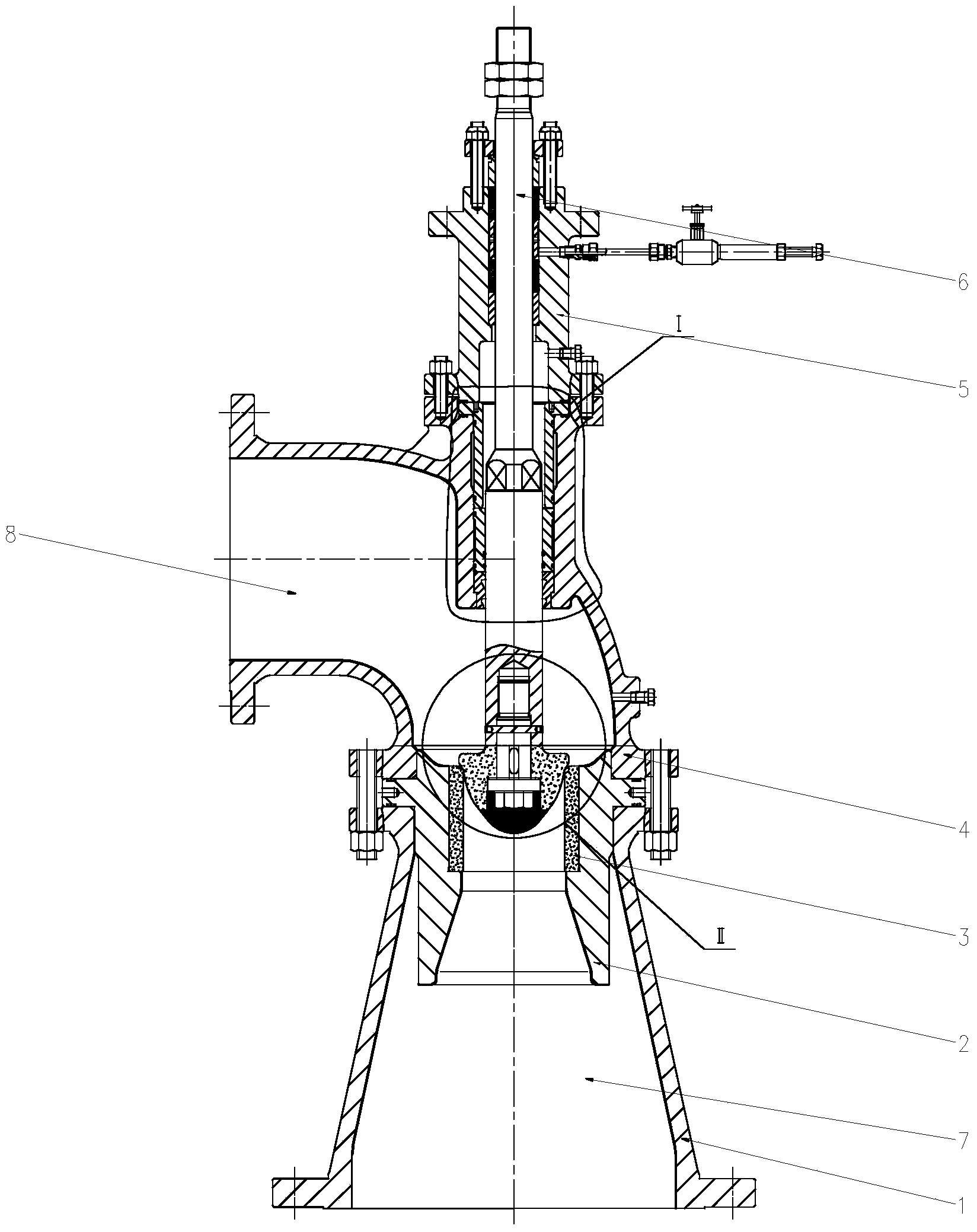

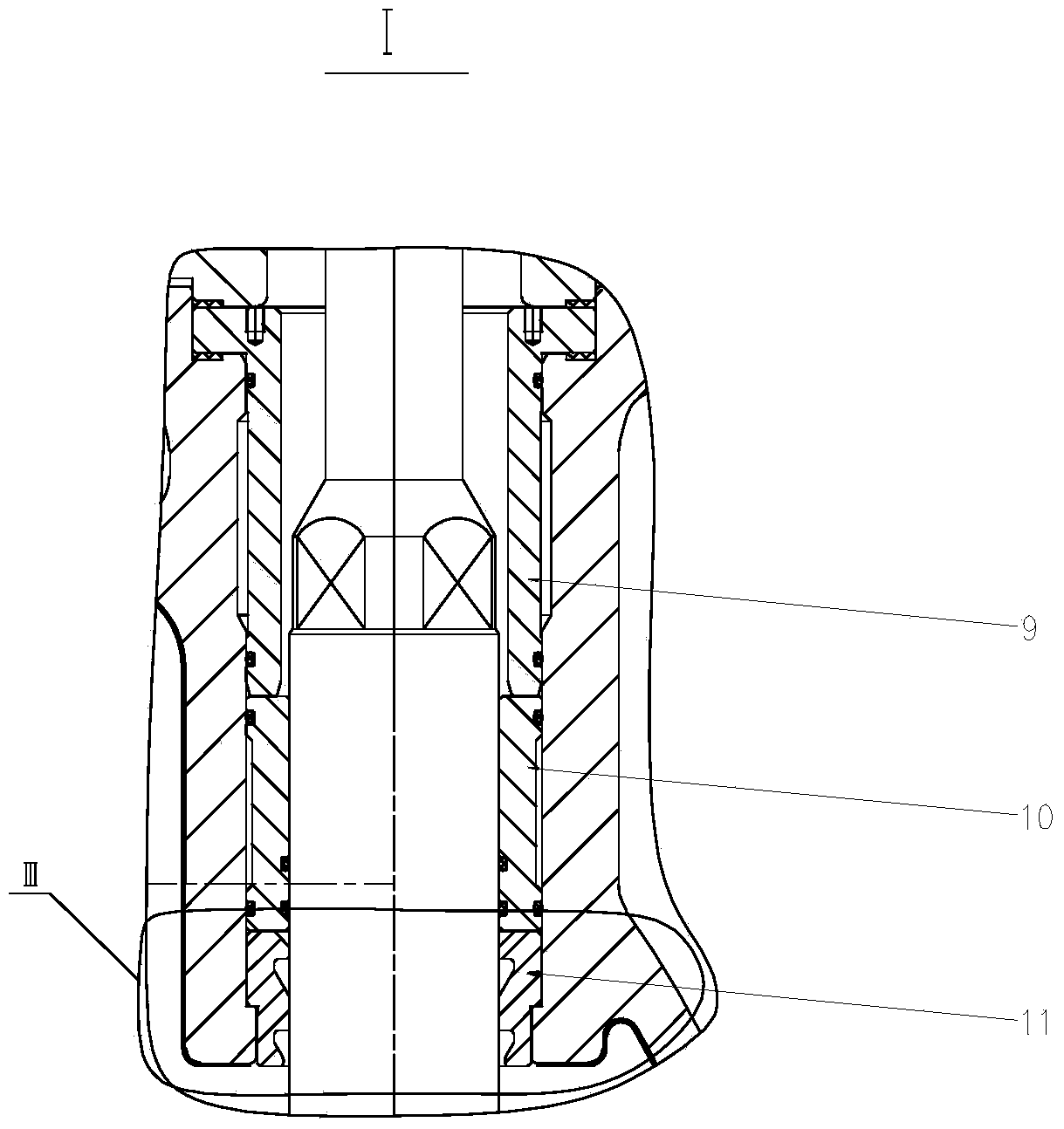

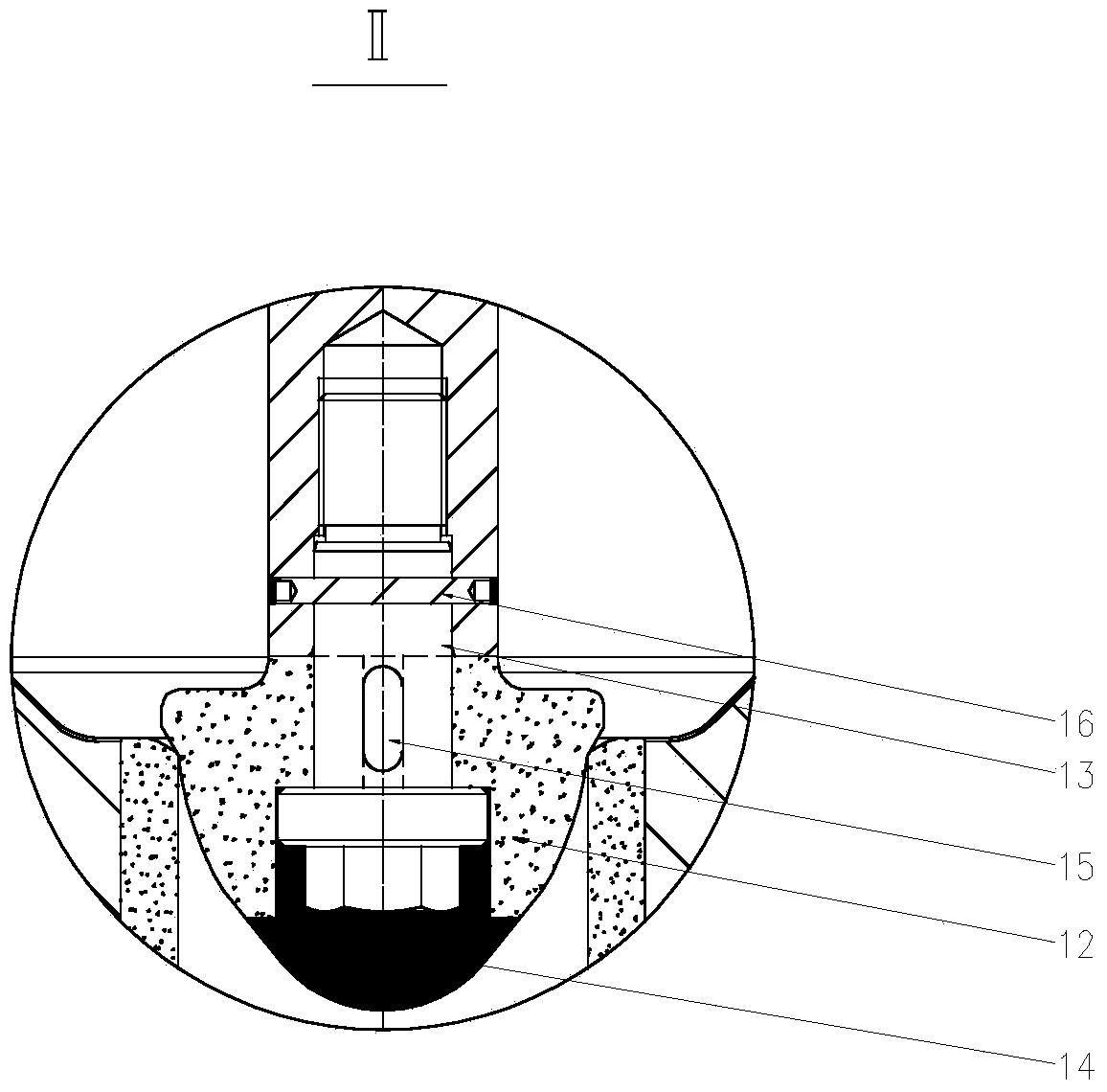

Black water coking-preventing impact-resistant shockproof regulating angle valve special for coal chemical industry

ActiveCN103591303AImprove anti-blocking performanceAvoid vortexLift valveValve housingsFluid controlControl valves

The invention relates to a regulating angle valve, in particular to a black water coking-preventing impact-resistant shockproof regulating angle valve special for the coal chemical industry, and belongs to the field of fluid control valves. The black water coking-preventing impact-resistant shockproof regulating angle valve comprises a diffusion tube and a valve body, wherein the lower end of the valve body is connected with the diffusion tube through a bolt. An inlet flowing channel is arranged in the valve body, an outlet flowing channel is arranged in the diffusion tube and is communicated with the inlet flowing channel, and the inlet flowing channel is perpendicular to the outlet flowing channel. A valve carrier base is arranged in the outlet flowing channel and is clamped through the diffusion tube and the valve body, and a valve carrier is arranged in the valve carrier base. The black water coking-preventing impact-resistant shockproof regulating angle valve is simple in structure and novel in design, can effectively solve the technical problems that a traditional black water regulating angle valve is easy to coke, poor in impact resistant performance, undesirable in shockproof effect and the like in a use process, is widely applied in sites of customers, and effectively lowers production operation cost of the customers.

Owner:WUXI SMART AUTO CONTROL ENG CO LTD

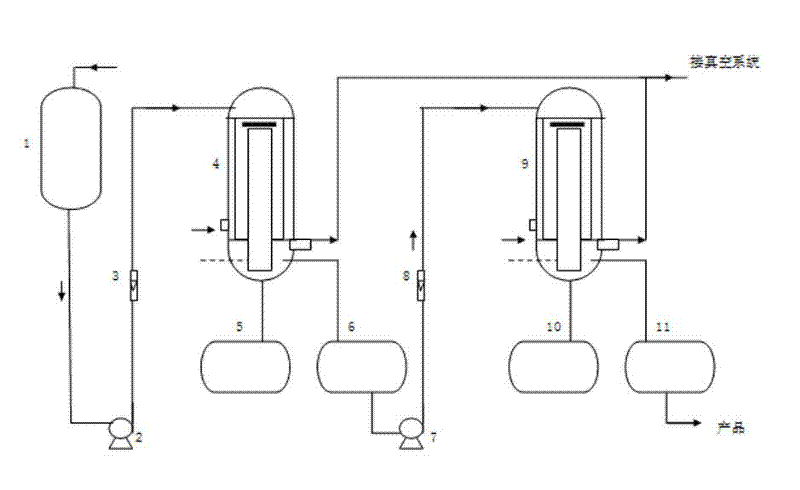

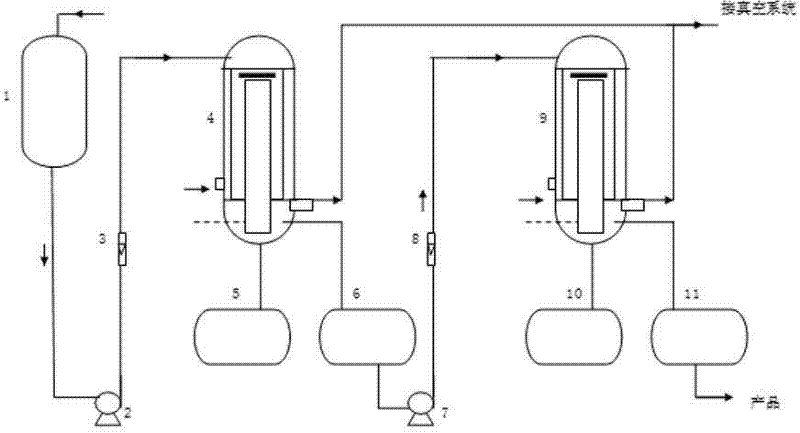

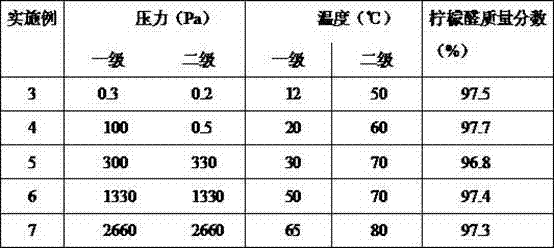

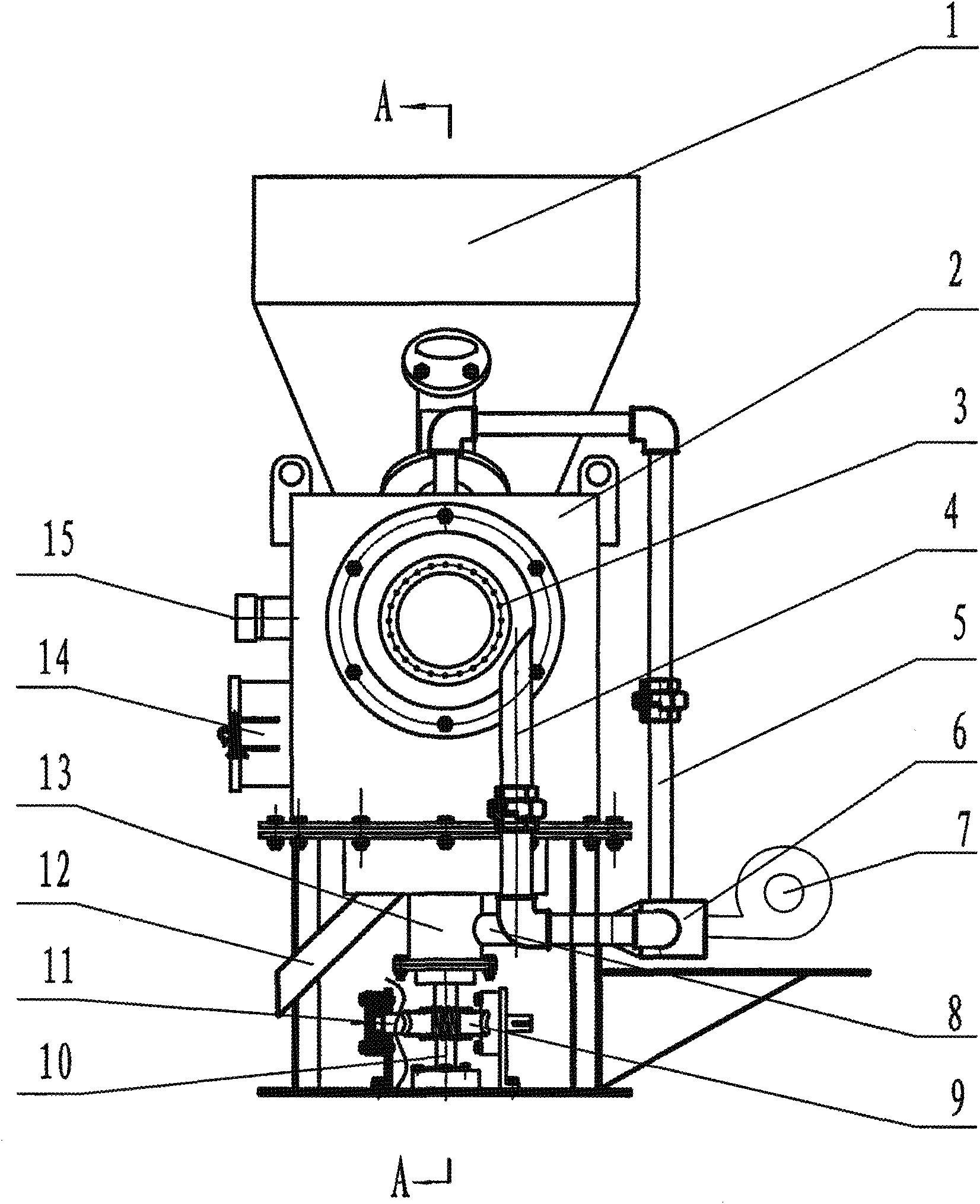

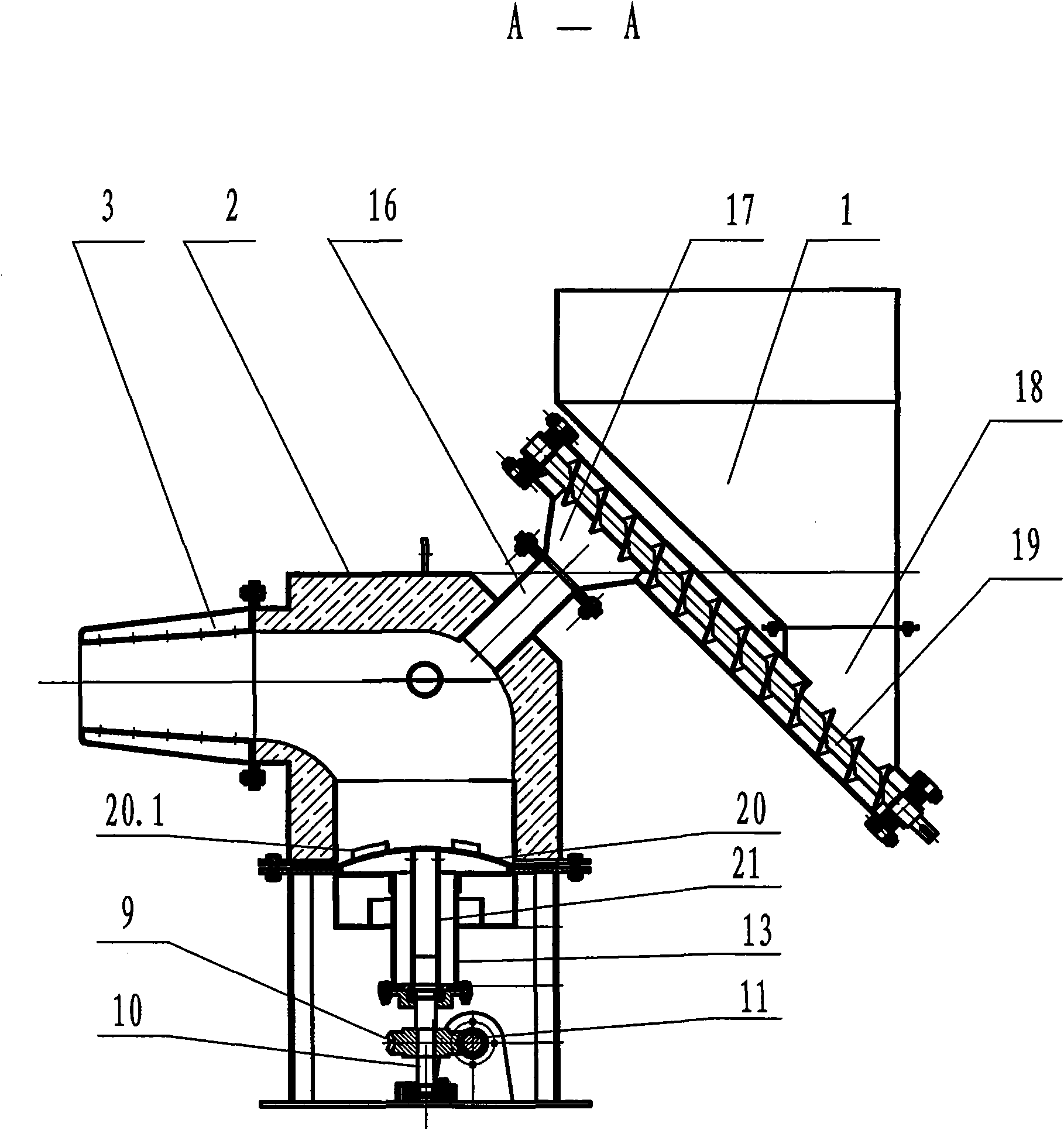

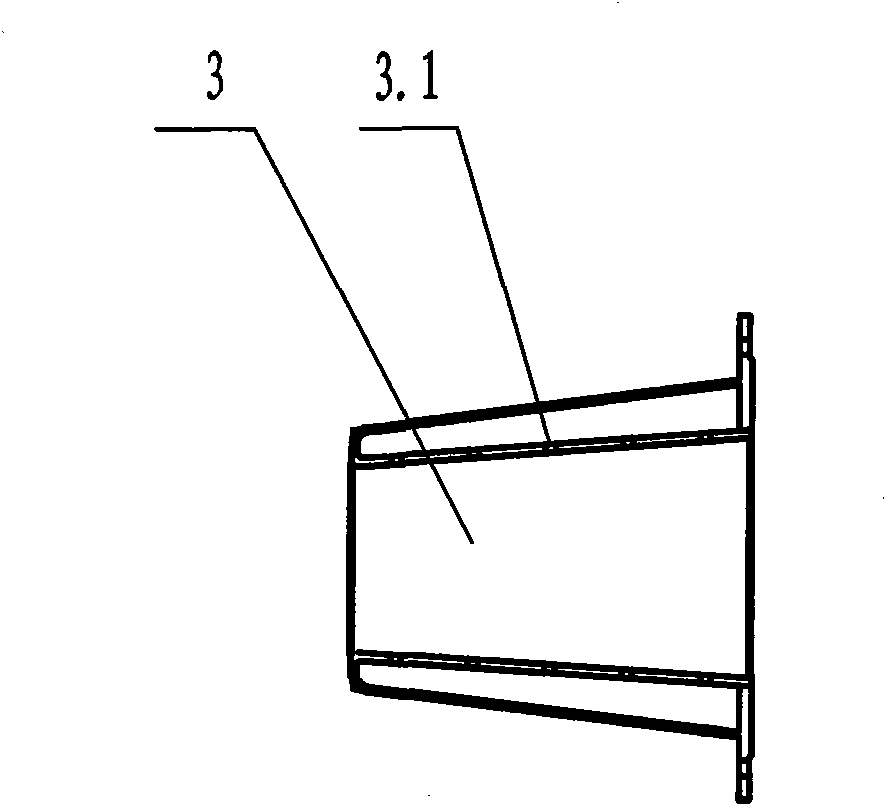

Process and device for extracting citral from Litsea cubeba oil

InactiveCN102211986AShort heating timeImprove stabilityCarbonyl compound separation/purificationChemistryBoiling point

The invention relates to a process and device for extracting citral from Litsea cubeba oil. The process comprises the following steps: feeding Litsea cubeba oil into a first-grade molecular distiller for distillation so as to separate and remove components the boiling points of which are lower than the boiling point of citral; and feeding distilled residue into a second-grade distiller for separating and removing components the boiling points of which are higher than the boiling point of citral, and collecting distillate, namely the citral product. The device consists of a raw material tank, a rotameter, a metering pump, a molecular distiller, a storage tank, a vacuum system, a heating system and a cooling system. According to the invention, the citral product produced by the method has high purity and good quality, production process is easy to control, and cost is relatively low.

Owner:CENTRAL SOUTH UNIVERSITY OF FORESTRY AND TECHNOLOGY

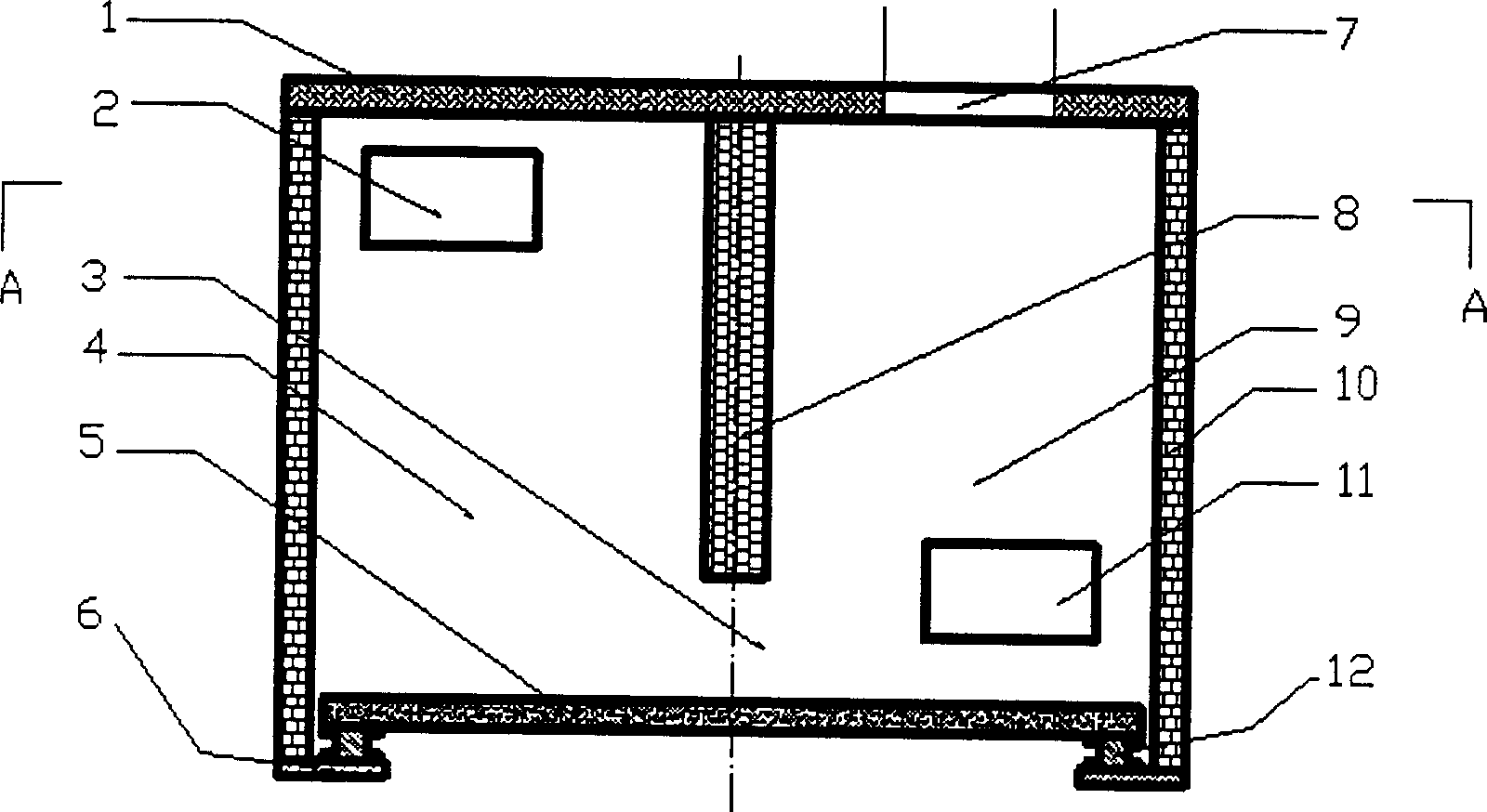

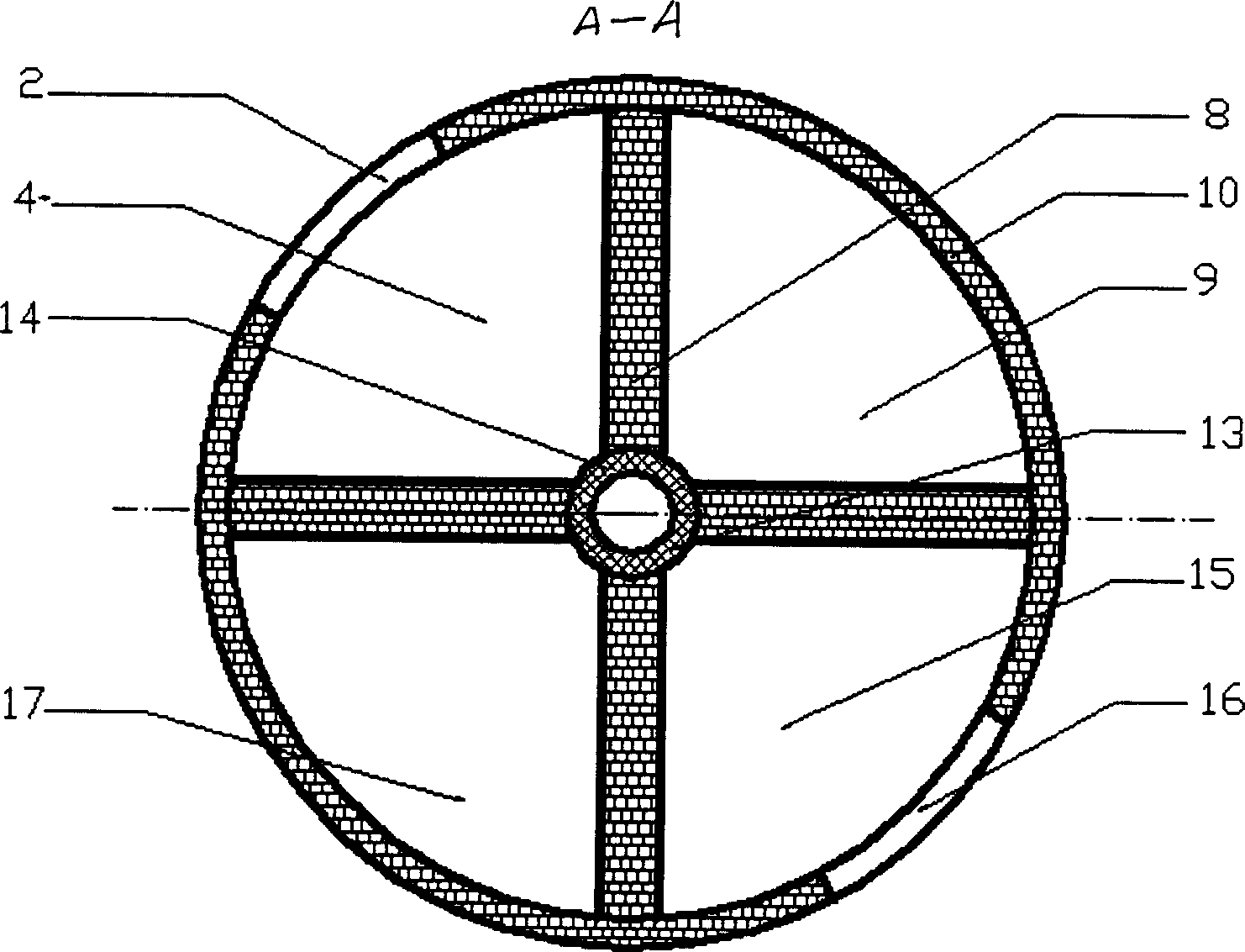

Biomass briquette gasification direct combustion combustor

InactiveCN101660750AEvenly distributedSolve insufficient pile burningChemical industrySolid fuel combustionThermal energyMotor drive

The invention relates to a biomass briquette gasification direct combustion combustor, which comprises a furnace body and a bracket, wherein the furnace body is supported on the bracket; the bottom ofa furnace body is fixedly connected with a bottom support and the middle part of the bottom support is provided with a through hole; a circular fire grate is arranged on the upper part of the bottomsupport; the fire grate is plate-shaped and evenly provided with fire grate air holes and the lower part of the fire grate is connected with a fire grate rotating shaft; and a motor drives the fire grate rotating shaft, the upper part of the furnace body is connected with a cylindrical spray nozzle and the furnace body on the other side opposite to the spray nozzle is provided with a material loading opening. The special combustion mode ensures that biomass fuel is fully gasified and combusted, realizes high-efficiency energy-saving conversion of the biomass and has good energy-saving effect.The biomass briquette gasification direct combustion combustor has compact structure, small volume, great reduction of production cost and obvious environment-friendly effect.

Owner:刘善华

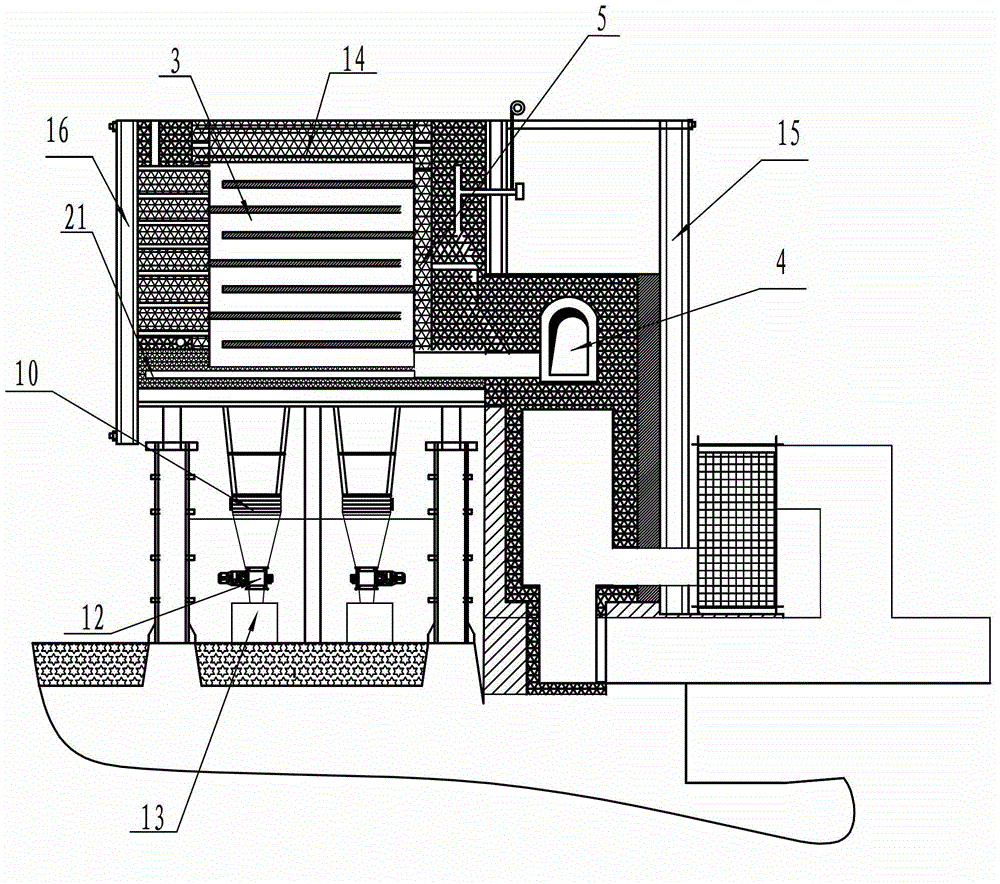

Biomass-forming fuel solid-phase low-temperature gas-phase high-temperature combustion device

ActiveCN106918039ASolve cokingSolve slaggingSolid fuel combustionLump/pulverulent fuel feeder/distributionGas solidSlag

The invention provides a biomass-forming fuel solid-phase low-temperature gas-phase high-temperature combustion device and belongs to the technical field of biomass combustion. The biomass-forming fuel solid-phase low-temperature gas-phase high-temperature combustion device is characterized in that a feeding opening of a smoldering region (3) communicates with a discharging opening of a hearth (1), a discharging opening of the smoldering region (3) communicates with a cooling region (4), a furnace grate (13) is arranged on the lower portion of the hearth (1), a crushing mechanism (2) for crushing materials is arranged on the furnace grate (13), the furnace grate (13) is connected with a rotating mechanism for disturbing biomass fuel so that carbon powder can fall into the smoldering region (3) to be smoldered, meanwhile the block-shaped biomass fuel is made to move to the middle of the furnace grate (13), and the crushing mechanism (2) is used for crushing the block-shaped biomass fuel into the carbon powder and then enabling the carbon powder to fall into the smoldering region (3) to be smoldered. By the adoption of the biomass forming fuel solid-phase low-temperature gas-phase high-temperature combustion device, the problems of coking, slag bonding, the high gas-solid pollutant emission and invalid ash fertilizer existing in combustion equipment for agricultural waste such as straw are solved fundamentally.

Owner:SHANDONG UNIV OF TECH

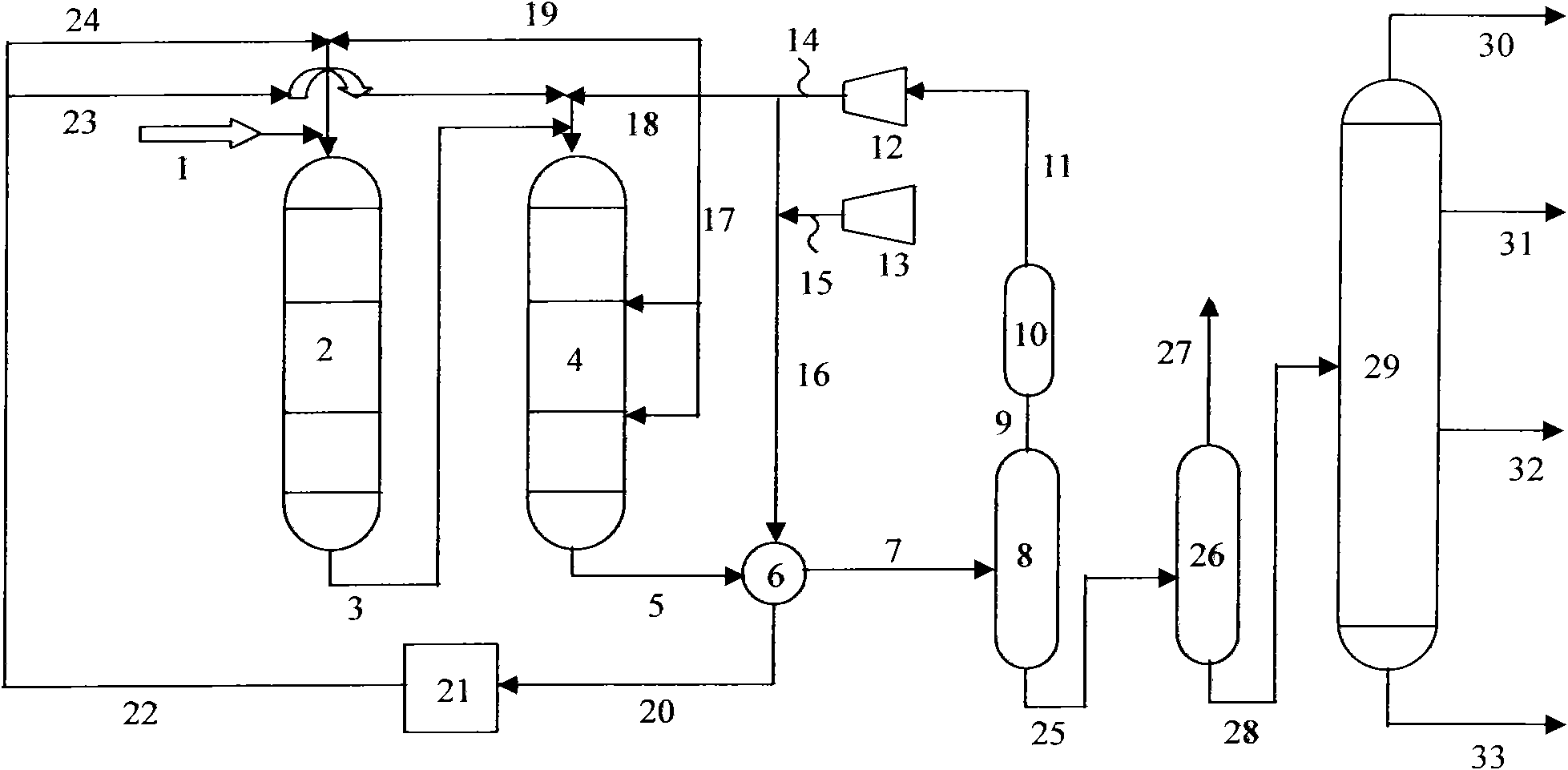

Boiling-bed residual-oil hydrocracking and catalytic-cracking combined process method

ActiveCN101942339AReduce heat loadSolve cokingTreatment with hydrotreatment processesGasolineReaction temperature

The invention discloses a boiling-bed residual-oil hydrocracking and catalytic-cracking combined process method which comprises the following steps that: a residual-oil raw material enters a boiling-bed residual-oil hydrogenation device for hydrocracking reaction after exchanging heat with a high-temperature regeneration catalyst from a catalytic cracking regenerator, total or partial boiling-bed hydrocracked tail oil enters a catalytic cracking device for cracking reaction to obtain a gasoline fraction and a diesel oil fraction, and after a catalytic cracking catalyst is regenerated, one part of the regenerated catalyst is circulated back to the catalytic cracking device, and the other part of the regenerated catalyst is used for preheating the incoming material of the boiling-bed residual oil to reaction temperature. The process characteristics of the hydrocracking and the catalytic cracking of a boiling bed are organically combined together through the combined process, respective advantages are fully exerted, the incoming material of a boiling-bed device is preheated by utilizing the high-temperature regenerated catalytic cracking catalyst, energy sources are saved, meanwhile, the heat load of a heating furnace is reduced.

Owner:CHINA PETROLEUM & CHEM CORP +1

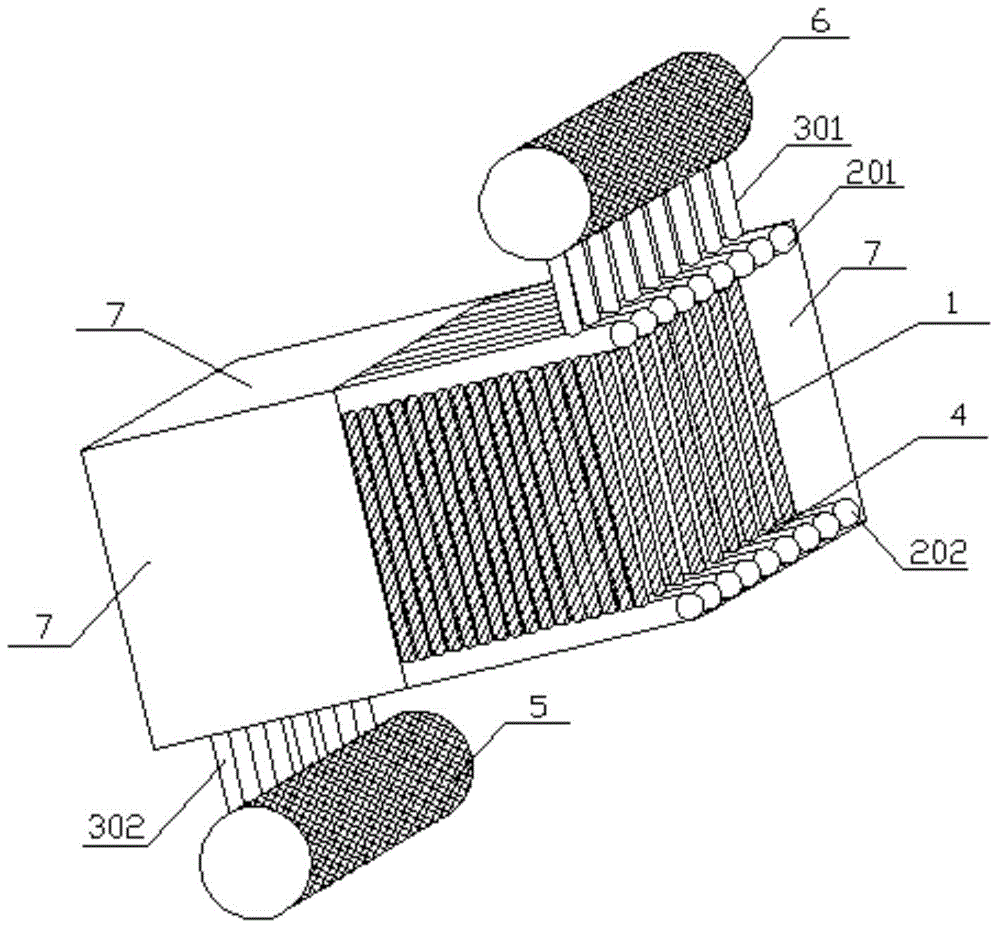

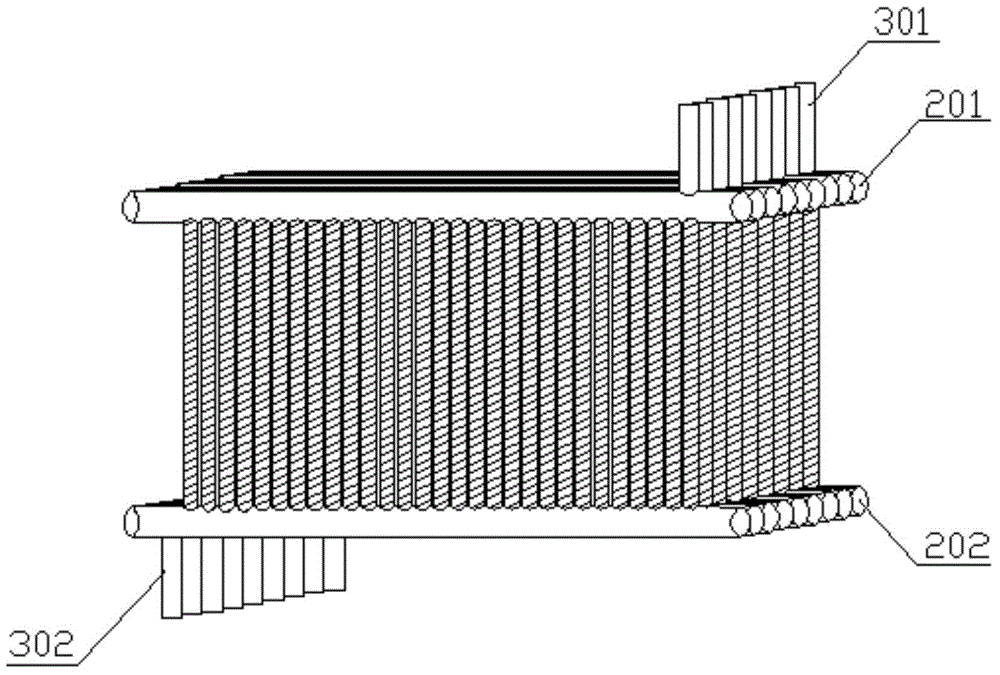

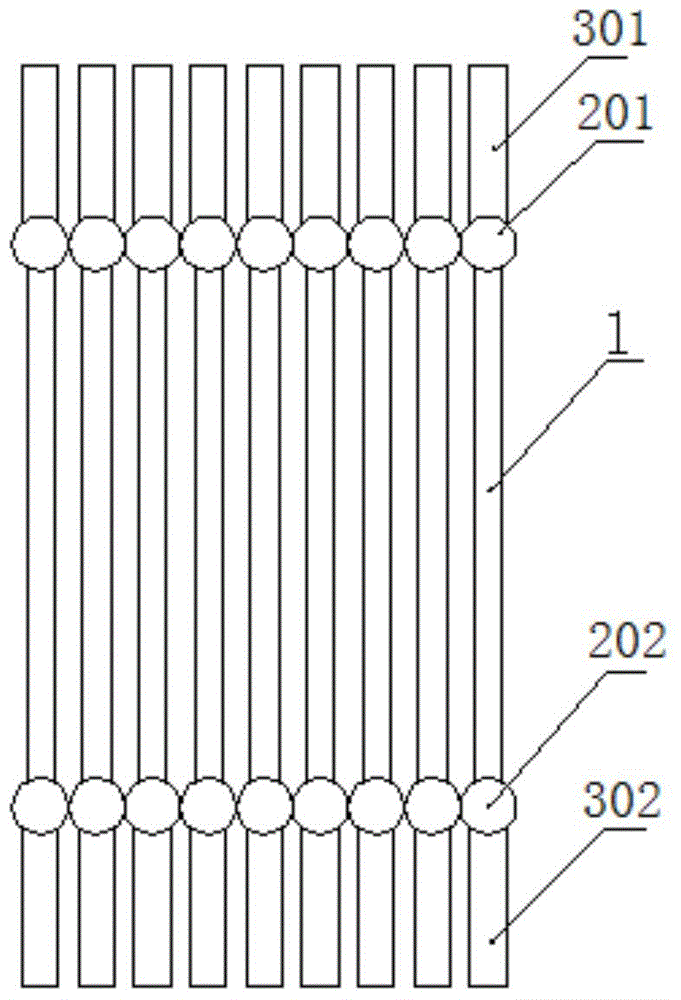

Raw gas waste heat recycling and exchanging unit of anti-bonding gravity-flowing coke oven

ActiveCN104677143AAvoid stickingAvoid cokingStationary tubular conduit assembliesCoatingsTarGravity flow

The invention discloses a raw gas waste heat recycling and exchanging unit of an anti-bonding gravity-flowing coke oven, and belongs to the technical field of recycling raw gas waste heat produced in the coking process. A heat exchange unit body comprises a plurality of single-row components, the plurality of the single-row components are arranged in same spaces and fixed together to form a cuboid structural heat exchange unit body, the single-row components are formed by welding heat exchange vertical pipes, heat exchange transverse pipes and heat exchange working medium conveying pipes in a permutation and combination way. Non-viscous coatings are coated on the surfaces of the single-row components, and the heat exchange unit body is inclined upwards along a horizontal plane. According to the arrangement, the tar bonding problem, which is produced in the process of recycling the raw gas waste heat, is solved; and meanwhile, recycled tar is reused, and resources are saved. According to the raw gas waste heat recycling and exchanging unit of the anti-bonding gravity-flowing coke oven, after heat is exchanged, the discharge temperature of the raw gas is reduced below 250 DEG C, the heat exchange effect of the raw gas is greatly improved, effective sensible heat in the raw gas is completely recycled, heat waste is prevented, and requirements on energy conservation and emission reduction are met.

Owner:MAANSHAN TIANZHOU ENERGY SAVING ENG TECH

Multi-side stereo combustion boiler capable of realizing clean combustion of coal and combustion method thereof

InactiveCN1789806AEmission reductionSuppress sootSolid fuel combustionCombustion apparatusCombustion chamberNitrogen oxide

This invention relates to one multi-surface stand burst furnace and method to realize coke cleaning burst, wherein, the burst furnace comprises the following parts: column furnace with channel exit located on top cover and rotation row located on the bottom of the furnace; at least one gas chamber and one pair of burst stand symmetric cross isolation element and space burst mouth between the isolation parts down end and furnace row with gas room and burst room connected; each gas chamber top furnace wall is located with each coke adding mouth with smoke exit mouth and reside exit mouth downside as secondary mouth. The burst method is to cooperate with multiple gas rooms through rotation furnace row.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

Oil-containing sludge pyrolysis device

The invention provides an oil-containing sludge pyrolysis device which comprises heat carriers for exchanging heat with oil-containing sludge, a pyrolysis reaction unit and a screening piece, wherein a pyrolysis cavity for pyrolyzing the oil-containing sludge is formed in the pyrolysis reaction unit; a flashboard capable of being opened and closed is arranged at the bottom or on the side wall of the pyrolysis cavity; a first inlet for feeding the oil-containing sludge into the pyrolysis cavity, a pyrolyzed gas outlet for discharging pyrolyzed gas from the pyrolysis cavity and a second inlet for feeding the heat carriers into the pyrolysis cavity; the screening piece is arranged below the flashboard; a plurality of screening holes of which the areas are smaller than the cross sectional areas of the heat carriers are formed in the screening piece. According to the oil-containing sludge pyrolysis device provided by the invention, pyrolysis in an oil-containing sludge pyrolysis process can be effectively realized.

Owner:PETROCHINA CO LTD

Pot-type carbon calciner

ActiveCN102745671ARealize two-way utilizationGood effectEnergy inputCarbon preparation/purificationCombustion chamberEngineering

The invention discloses a pot-type carbon calciner and belongs to calciners for carbon production. One combustion chamber is formed by each four calcination pots and furnace walls with heating fire channels, the furnace walls with the heating fire channels are located on two sides of a pot body, expansion joints and smoke converging flues are arranged among the combustion chambers, each of the furnace walls with the heating fire channels has 8 to 10 layers of fire channels, the fire channels are communicated with a preheated air channel, the calcination pot body is connected with a material discharge pot, and an interlayer cooling water jacket is disposed on the periphery of the material discharge pot. The pot-type carbon calciner is characterized in that the entire calciner is formed by 18 combustion chambers which are linearly arranged and 72 calcination pots, a calciner protection large cutter frame is arranged outside the front wall of the calciner, a calciner protection frame is arranged outside the rear wall of the calciner, the bottoms of the combustion chambers are supported by supporting columns at the bottom of the calciner, a feed opening is disposed at the top of the calcination pot body, the material discharge pot is connected with the bottom of the calcination pot body, the interlayer cooling water jacket is disposed on the periphery of the material discharge pot, a material discharge device is installed at the lower end of the material discharge pot, and a small storage bin is mounted between the material discharge device and a discharge valve, so that volatile matter two-way utilization is achieved, the full-automatic closed type continuous discharging is achieved, and the pot-type carbon calciner has good economic and environmental benefits.

Owner:JINAN AOHAI CARBON PROD +1

Attapulgite-biomass activated carbon soil restoration material and preparation method thereof

ActiveCN106947486AEasy curingAvoid pollutionOrganic fertilisersSoil conditioning compositionsCarbon compositesActivated carbon

The invention belongs to the field of high-value utilization of biomass resources and especially relates to an attapulgite-biomass activated carbon soil restoration material and a preparation method thereof. According to the preparation method, attapulgite and rapeseed oil residue which are used as raw materials firstly undergo one-step high-temperature pyrolysis to prepare an attapulgite / carbon composite material; and then the attapulgite / carbon composite material undergoes acid activation treatment to prepare an attapulgite / activated carbon composite material.

Owner:常州纳欧新材料科技有限公司

Device for preparing acetylene through pulverized coal pyrolysis by electric arc

ActiveCN104451762AEfficient heatingImprove energy efficiencyCellsElectrolytic organic productionSpray nozzleProcess engineering

The invention provides a device for preparing acetylene through pulverized coal pyrolysis by an electric arc. The device comprises a reaction vessel and at least one reaction unit, wherein the reaction vessel is internally provided with a reaction cavity, and the reaction unit comprises at least one first pulverized coal spray nozzle, at least one second pulverized coal spray nozzle and at least one group of electrode couples of a direct-current electric arc; pulverized coal is conveyed by airflows to enter the reaction cavity through the first pulverized coal spray nozzle and the second pulverized coal spray nozzle to flow so as to form a first pulverized coal gas mixing area and a second pulverized coal gas mixing area, the first pulverized coal gas mixing area is provided with a symmetry plane parallel to the pulverized coal flowing direction, the second pulverized coal gas mixing area is positioned at two sides of the first pulverized coal gas mixing area according to the symmetry plane, the arc column of the electric arc between the electrode couples at two sides of the first pulverized coal gas mixing area is extended along the pulverized coal flowing direction according to the symmetry plane, the arc column can form a stable configuration structure under the constraining and controlling actions of the pulverized coal gas mixture, and most of the arc column is located in the pulverized coal gas mixing area. The device for preparing acetylene through pulverized coal pyrolysis by the electric arc has the advantages that the pulverized coal heating efficiency is high, the energy efficiency is high, the capacity of a reactor can be increased optionally, and the like.

Owner:合肥碳艺科技有限公司

Boiler chromium-based decoking and coal saving agent composition and preparation method thereof

The invention relates to a coal additive for coal-fried boilers in industries such as electricity generation, thermoelectricity, petroleum, chemical industry, metallurgy and the like and particularly relates to a boiler chromium-based decoking and coal saving agent composition, which is prepared from the following components in parts by weight: 65-80 parts of chromium oxide, 12-20 parts of copper sulfate, 8-13 parts of cerium oxide, 8-13 parts of vanadium pentoxide, 10-16 parts of manganese dioxide, 12-18 parts of potassium permanganate, 6-11 parts of potassium chlorate, 15-22 parts of zinc oxide, 10-15 parts of potassium molybdate, 8-13 parts of cobalt carbonate, 9-15 parts of barium carbonate, 30-40 parts of sodium carbonate, 6-10 parts of ferric trichloride, 40-55 parts of active white attapulgite clay and 0.1-0.3 part of a penetrant JFC. By using the boiler chromium-based decoking and coal saving agent composition, the problems of boiler coking and dust deposition, which are not solved for a long time, of the coal-fried boilers, are solved, the coal saving rate is larger than 4%, the problem that boiler parts are corroded by acidic substances is solved, the service life of a boiler is prolonged, and the atmospheric environment pollution is reduced. The boiler chromium-based decoking and coal saving agent composition is also suitable for deslagging of the coal-fried boilers.

Owner:LANZHOU XINXING NEUTRAL CLEANING TECH

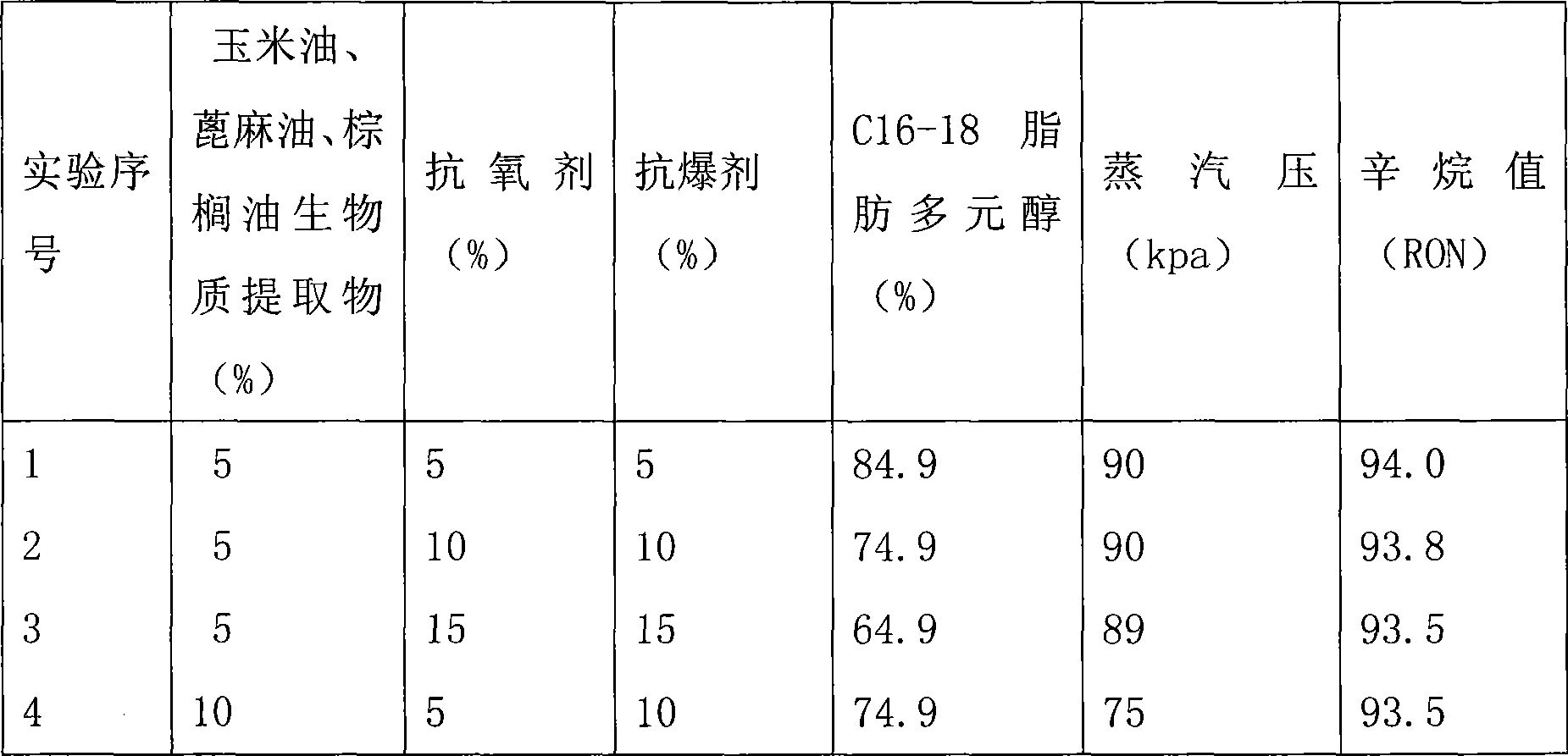

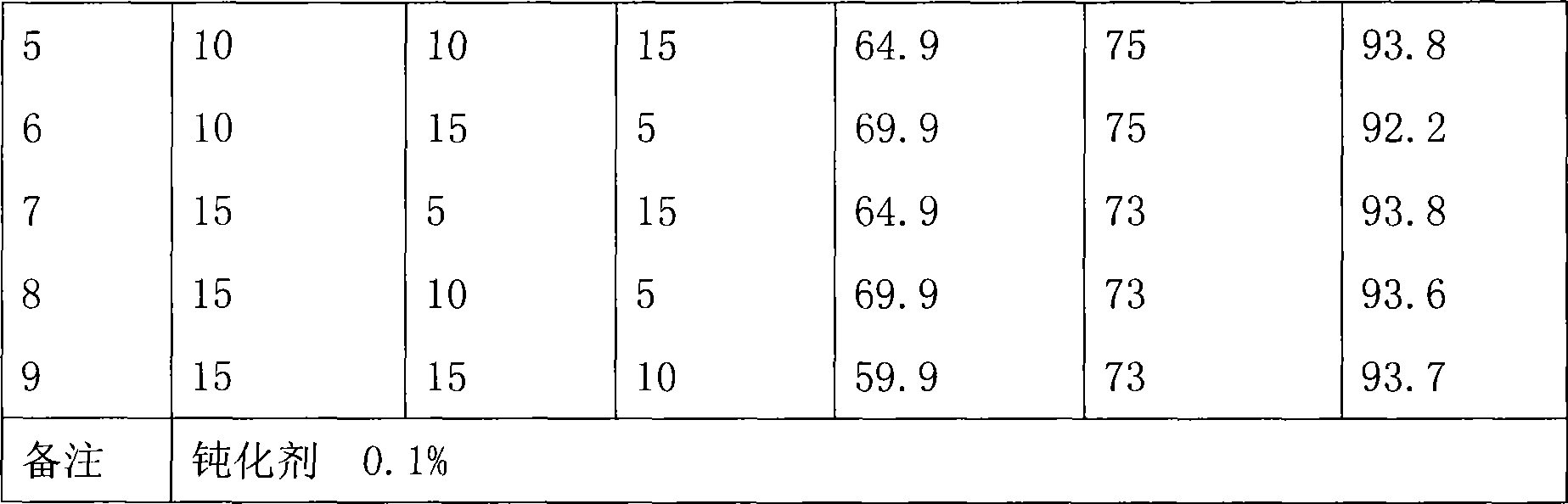

Automobile composite fuel

InactiveCN101386798ASolve cokingSolve the problem of carbon accumulationLiquid carbonaceous fuelsGasoline fuelAntioxidant

The invention discloses a composite fuel oil for automobiles, which belongs to the technical field of automobile fuel oil. The fuel oil product of the automobiles is compounded by a fuel oil additive and gasoline, wherein the fuel oil additive is prepared by mixing a mixture of extractives of biomass such as corn oils, castor oils and palm oils, fatty polyol, antioxidants, antiknock agents, passivation agents and modified C5 according to certain proportion. The composite fuel oil product can partly substitute gasoline as well as improve gasoline performance so as to combust gasoline more fully and reduce coking and carbon deposition in an engine and emission of harmful substances in automobile tail gas. Through inspection of Chinese Ethanol Gasoline Quality Supervision and Testing Center, the product reaches national standard.

Owner:HENAN ACAD OF SCI

Popular searches

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com