High-efficiency and environment-friendly coal-fired system for vertical boiler with bottom-built burner

A vertical boiler and burner technology, which is applied in the direction of using various fuel combustion, combustion methods, combustion types, etc., and can solve problems such as destruction, low boiler thermal efficiency, and low dust removal efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0057] In order to further explain the technical solution of the present invention, the present invention will be described in detail below through specific examples.

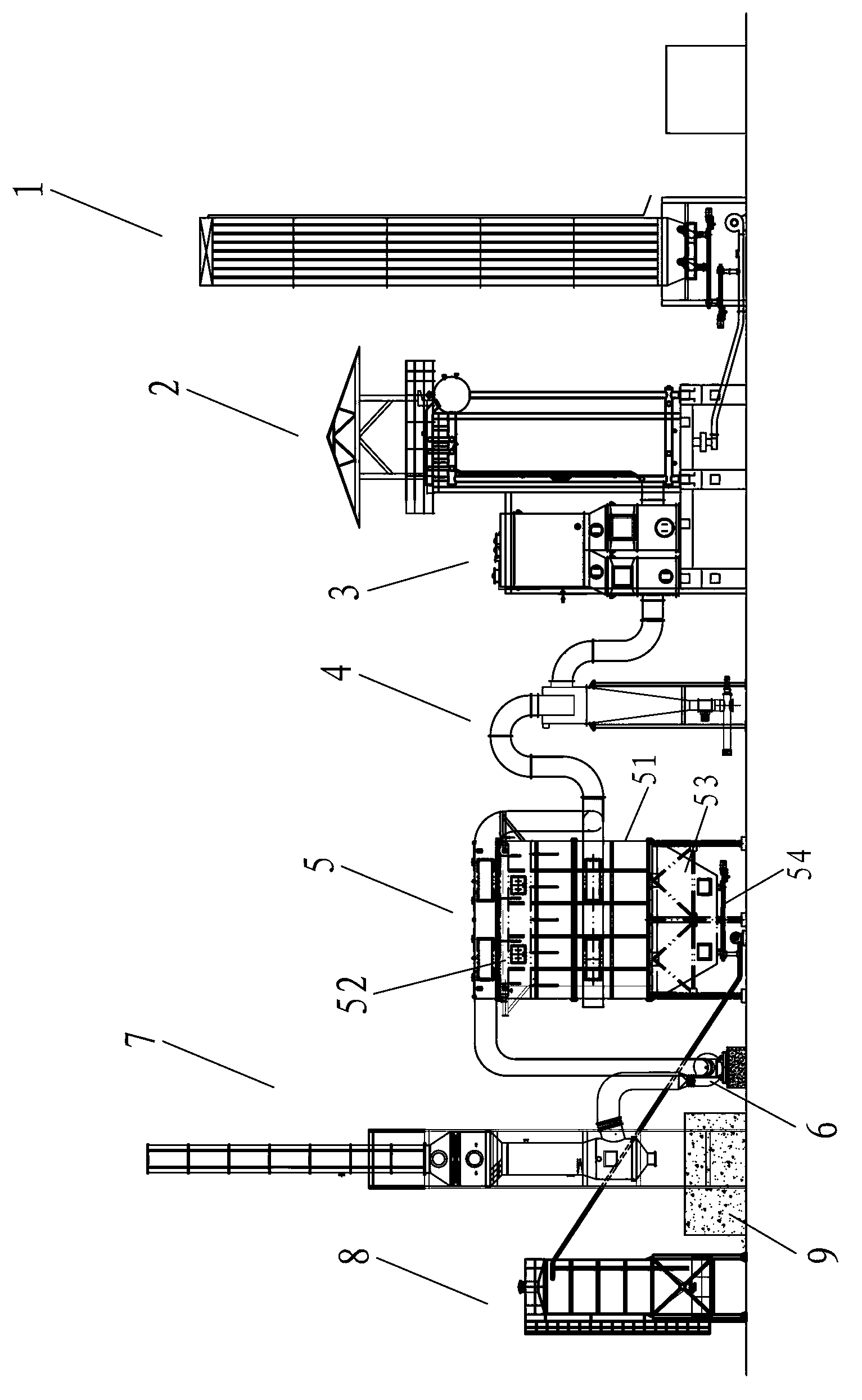

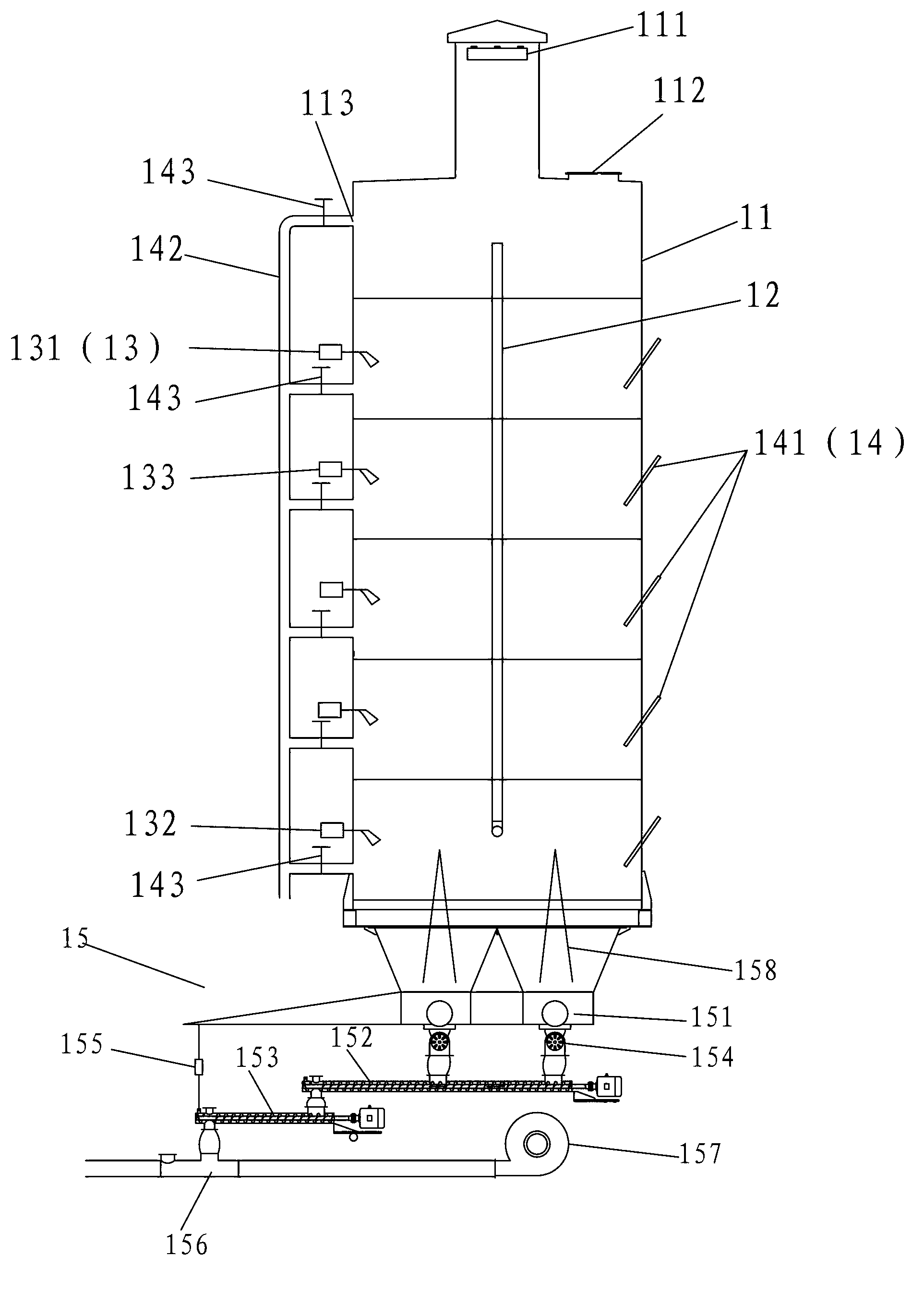

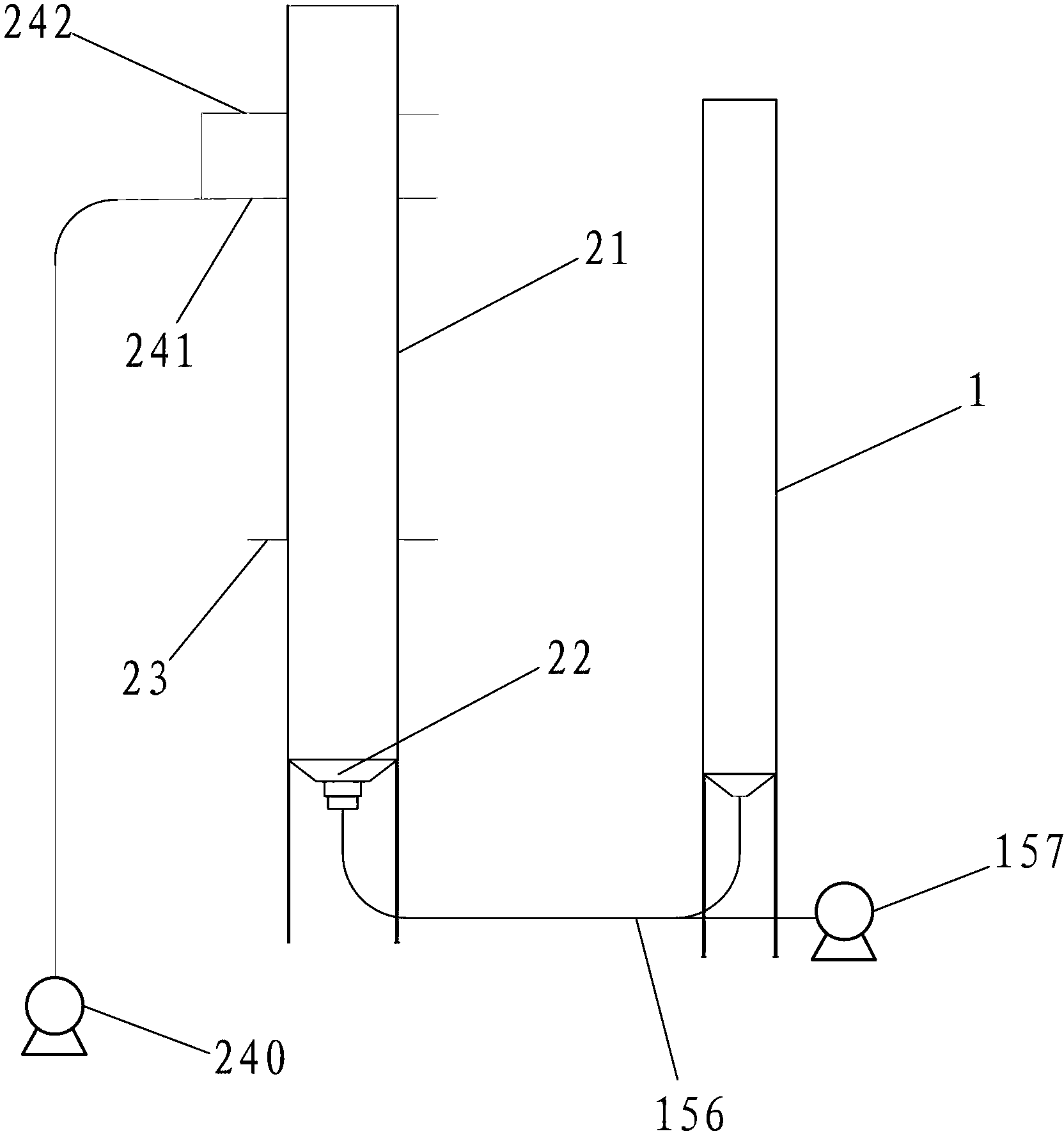

[0058] This case involves a high-efficiency and environmentally friendly coal-fired system with a bottom-mounted burner vertical boiler, such as figure 1 As shown, it includes pulverized coal tower 1, combustion boiler 2, air preheater mechanism 3, cyclone dust collector mechanism 4 and bag filter mechanism 5 which are connected in sequence according to the working connection relationship, and also includes induced draft fan 6, desulfurization tower 7, coal Powder ash tank 8 and pulping tank 9. The following is a further elaboration on each organization and the connection relationship between each organization.

[0059] The pulverized coal tower 1 is used to supply pulverized coal to the combustion boiler 2. The pulverized coal is in the form of powder and is flammable. Therefore, the pulverized coal tower 1 i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com