Patents

Literature

72results about How to "Lower emissions targets" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

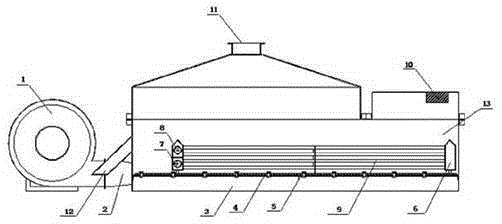

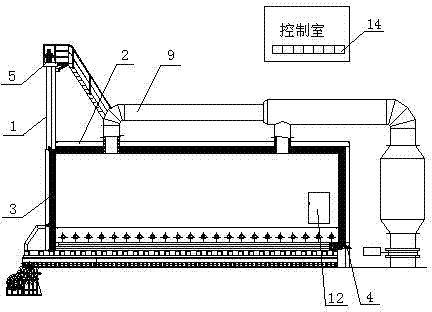

Super-large trolley type gas heat treatment furnace

InactiveCN102703650ASolve the problem of low efficiencyImprove efficiencyFurnace componentsEngineeringMechanical engineering

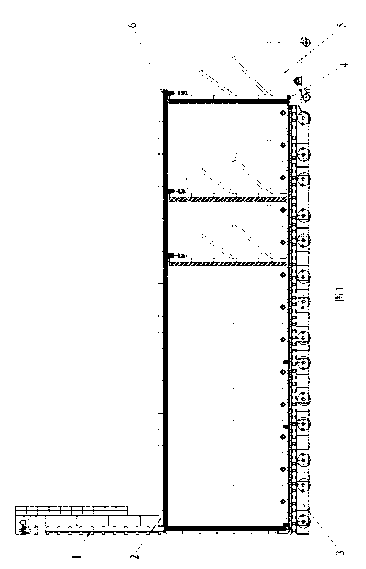

The invention relates to a super-large trolley type gas heat treatment furnace. The gas heat treatment furnace is characterized in that a fixed rear wall of the conventional furnace body is changed into a movable rear wall, a steel member of the movable rear wall is fixed on a travelling mechanism, and a lining is arranged on the lateral surface of the steel member; and a sealing mechanism is arranged on each of the upper, lower, left and right parts of the movable rear wall, so that the movable rear wall, the lining of the furnace body and a trolley are sealed. Moreover, a furnace door dropping preventing device is added in a furnace door and a lifting mechanism and drives a safety pin by means of a reset force of a spring, once the furnace door drops due to loss of pull, the safety pin quickly extends out, and the furnace door is clamped on upright posts on two sides of the furnace door, so that the furnace door is prevented from continuously dropping. The using efficiency of the super-large heat treatment furnace is effectively improved; energy waste caused by ineffective combustion in the redundant space is avoided; the sealing mechanisms of the movable rear wall are reasonable in structure, easy and convenient to operate and convenient to maintain, and can achieve good sealing performance and increase the overall energy-saving effect of the heat treatment furnace; and thefurnace door dropping preventing device promotes the running safety of the furnace body.

Owner:DANYANG JIANGNAN INDAL FURNACE

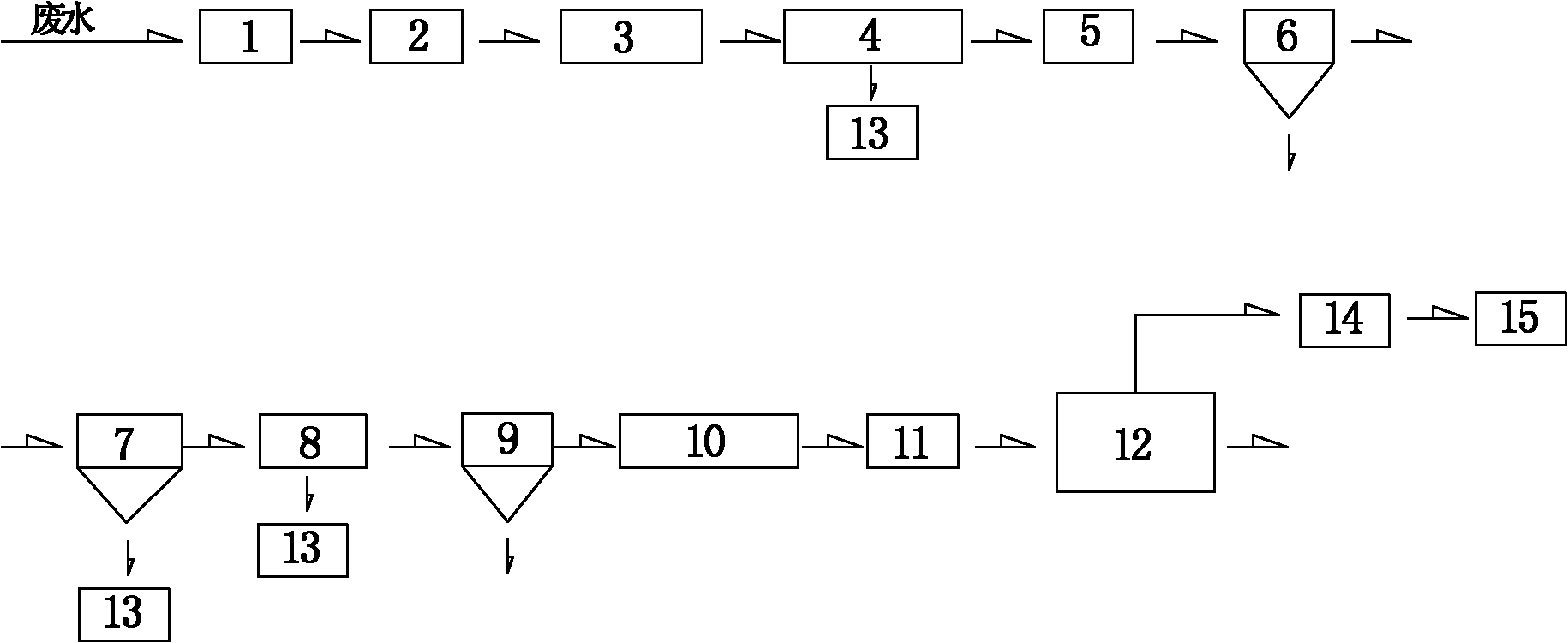

Device and method for treating and recycling printing and dyeing wastewater

InactiveCN102050555AReduce dosageReduce consumptionTreatment using aerobic processesPaint waste treatmentFlocculationElectrolysis

Owner:BOYING XIAMEN SCI & TECH

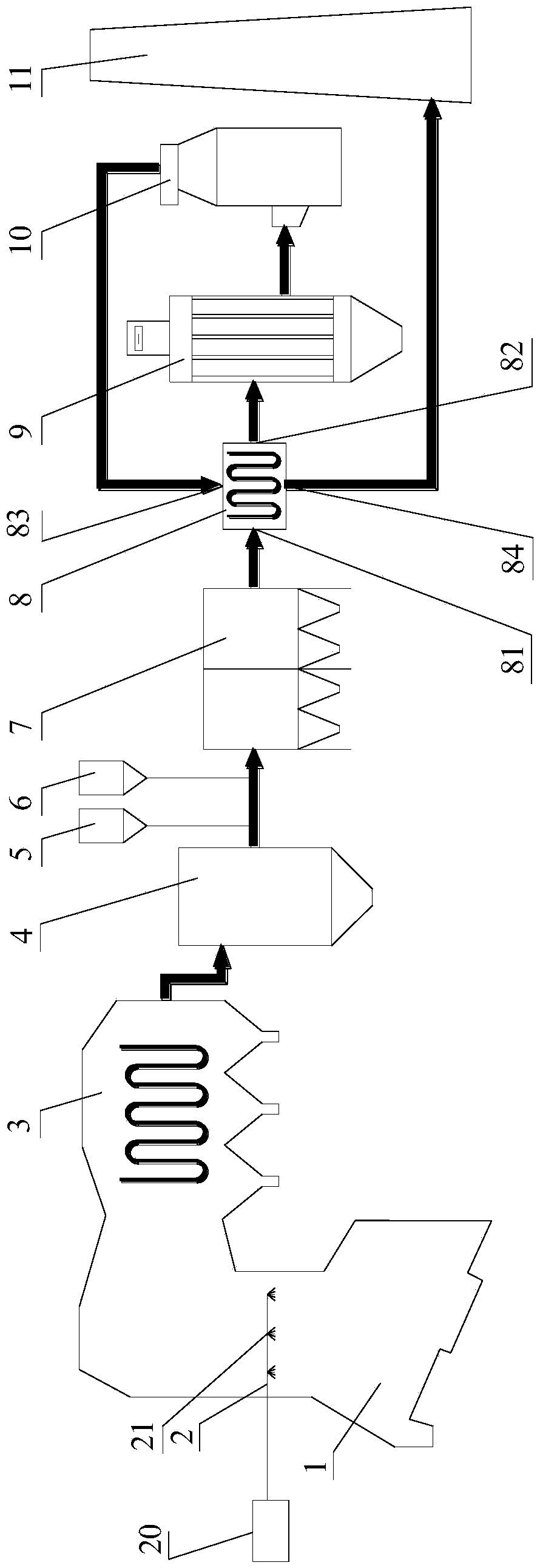

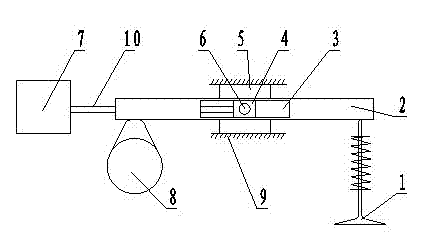

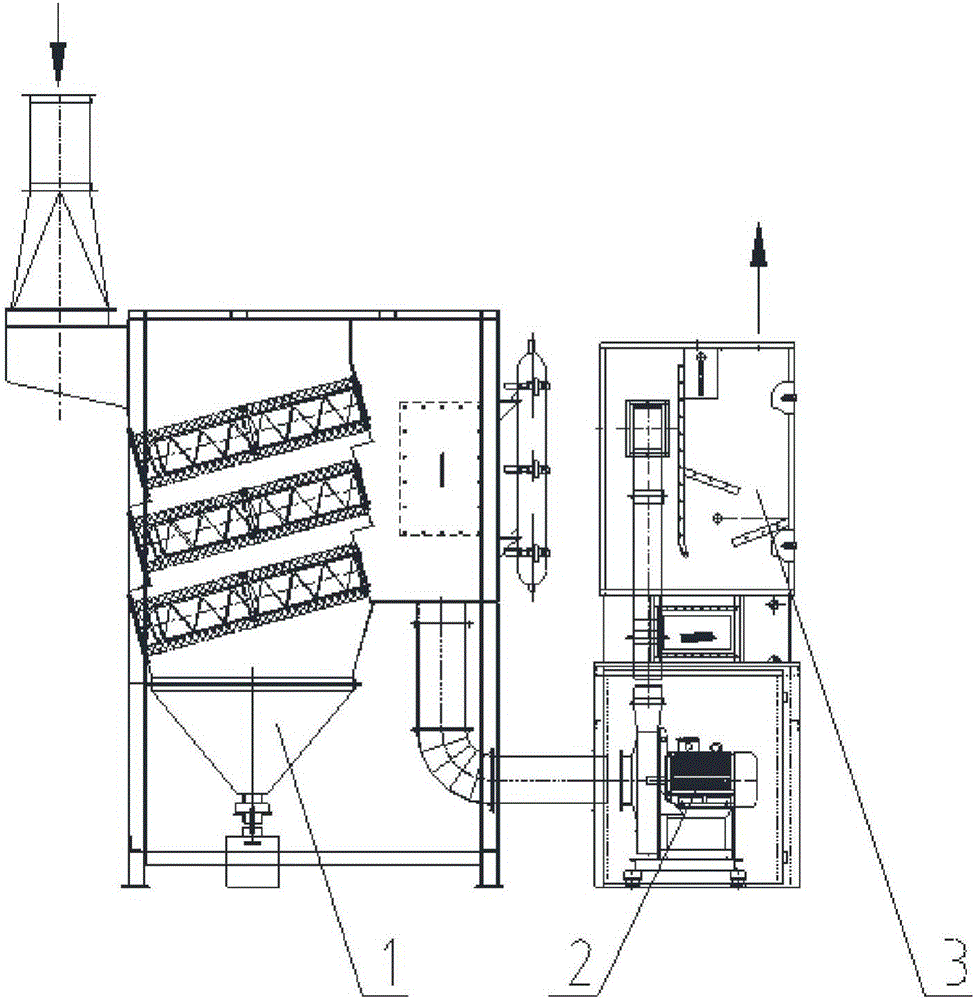

High-efficiency and environment-friendly coal-fired system for vertical boiler with bottom-built burner

ActiveCN103075727ASolve cokingAchieving Thermal EfficiencyCombustion using gaseous and pulverulent fuelCombustion using liquid and pulverulent fuelAir preheaterBaghouse

The invention discloses a high-efficiency and environment-friendly coal-fired system for a vertical boiler with a bottom-built burner. The system comprises a coal powder tower, a burning boiler, an air preheater mechanism, a cyclone dust collector mechanism and a bag-type dust collector mechanism that are sequentially arranged and connected, wherein the burning boiler comprises a boiler body and the bottom-built burner; the bag-type dust collector mechanism comprises a sealed casing, a high-efficiency dust collector and an ash storage bin; a fume outlet of the sealed casing is connected with a tower fume outlet of a desulfurizing tower by an induced fan; and a discharge outlet of the ash storage bin is connected with an ash inlet of a coal powder ash tank by a conveying mechanism. As the coal-fired system is subjected to a series of technological innovations and transformations, the boiler thermal efficiency is very high; the dust collection sealability is good; the collection efficiency is excellent; the desulfurizing tower is very good in desulphurization efficiency, and excellent in scale prevention and scale removal performance; the high-efficiency desulfuration and labor saving are ensured; finally a fume emission index of the system is far lower than the national specified emission concentration; and the system achieves the benefits of high efficiency, energy saving, emission reduction and environmental protection, and is a domestic initiative.

Owner:FUJIAN ETERNAL ENERGY MANAGEMENT

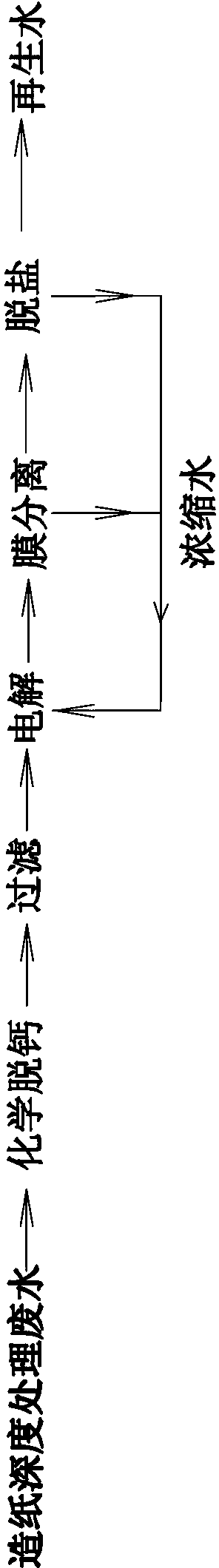

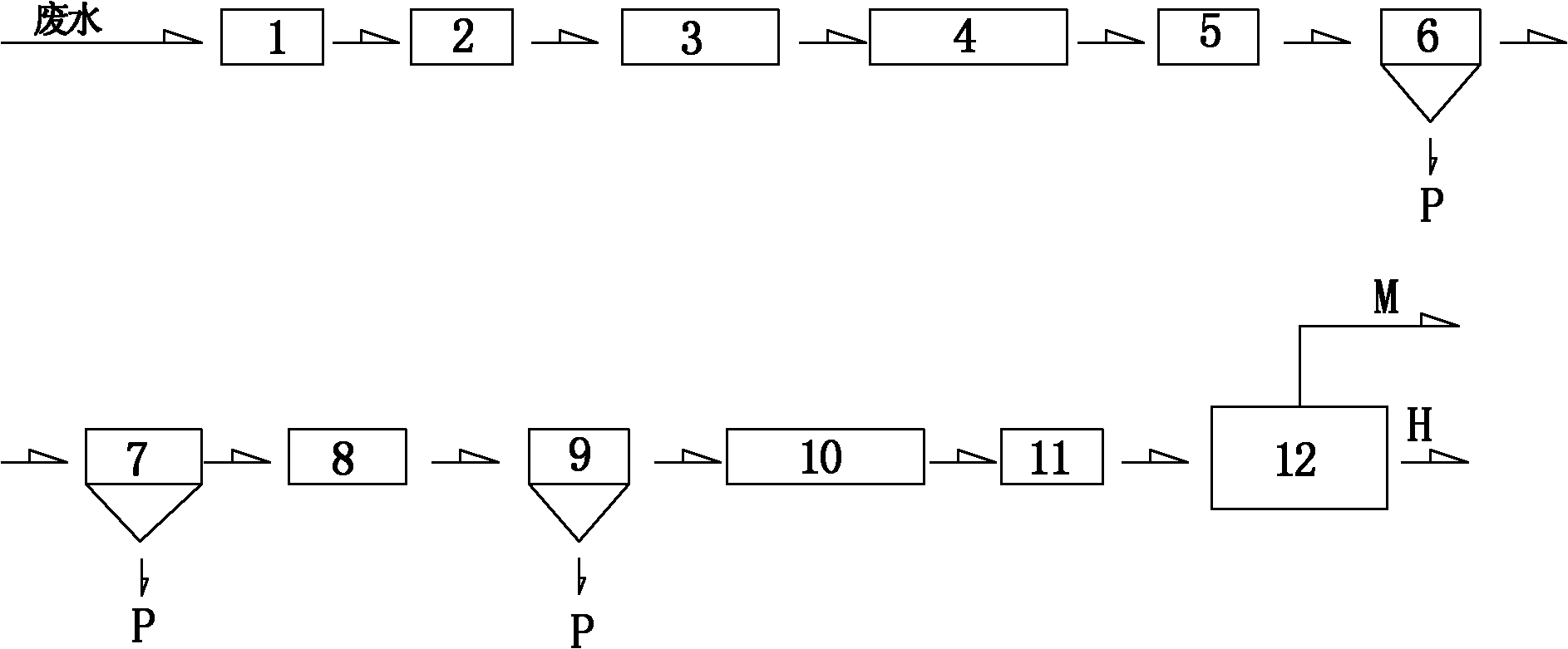

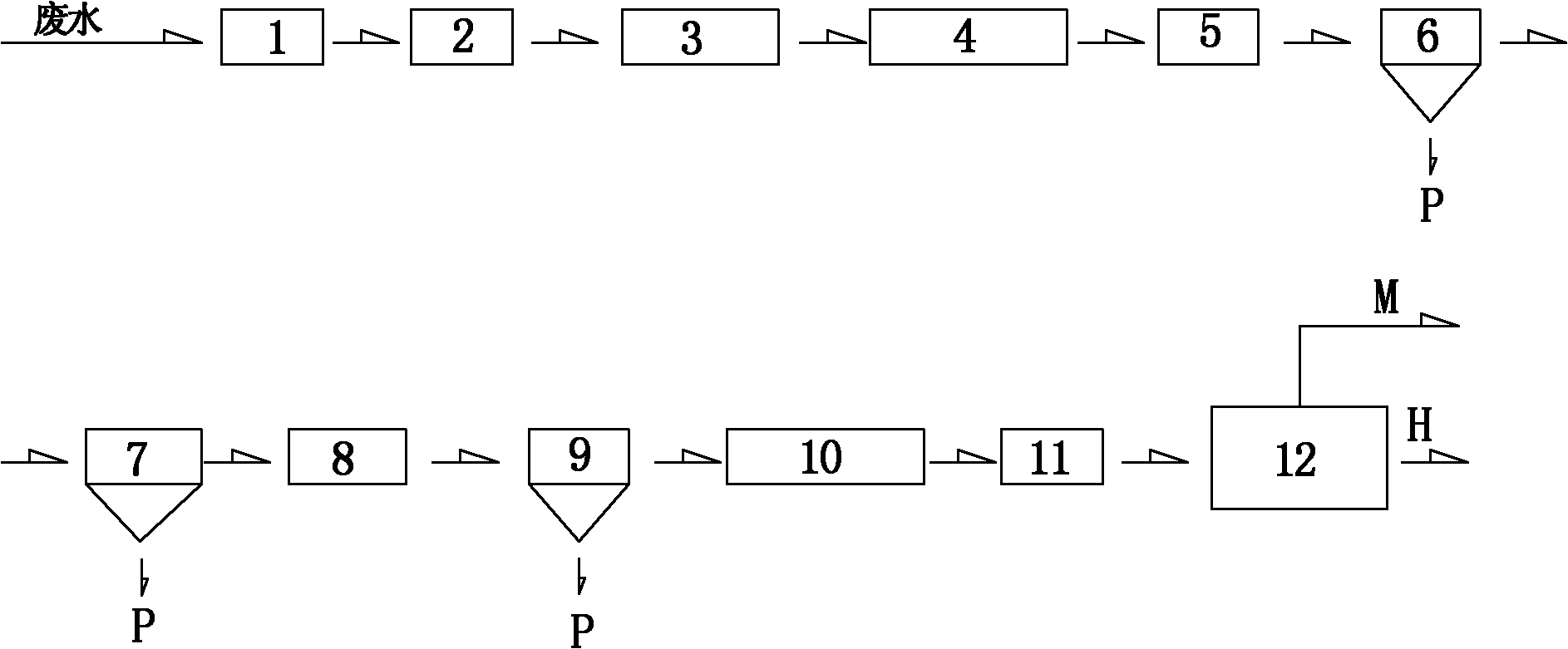

Recycling method of papermaking advanced treatment wastewater based on chemical decalcification

InactiveCN103265133AOvercoming processingOvercome costsGeneral water supply conservationMultistage water/sewage treatmentElectrolysisDesalination

The invention discloses a recycling method of papermaking advanced treatment wastewater based on chemical decalcification. The recycling method comprises the following steps of chemical decalcification, filtering, electrolysis, membrane separation (ultra-filtration / MBR) and desalination. By combination of a chemical decalcification technology, an electrochemical technique and a membrane technology, 70-85% of papermaking advanced treatment wastewater can be recycled after being processed. Thus, wastewater emission is reduced; environmental pollution of the wastewater is avoided; waste of water resources is reduced; and the cost of regenerated circulating water is lower than the price of running water. Therefore, the recycling method is economical and reasonable; good economic benefit is generated; water consumption targets of tons of paper and wastewater discharge targets are greatly reduced; and the economic and technical indexes of enterprises are improved.

Owner:BOYING XIAMEN SCI & TECH

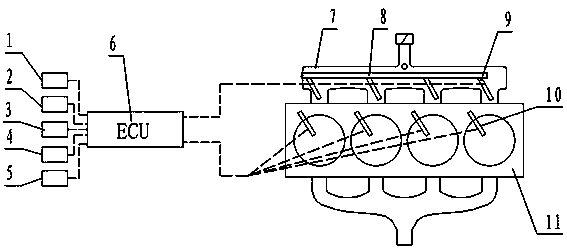

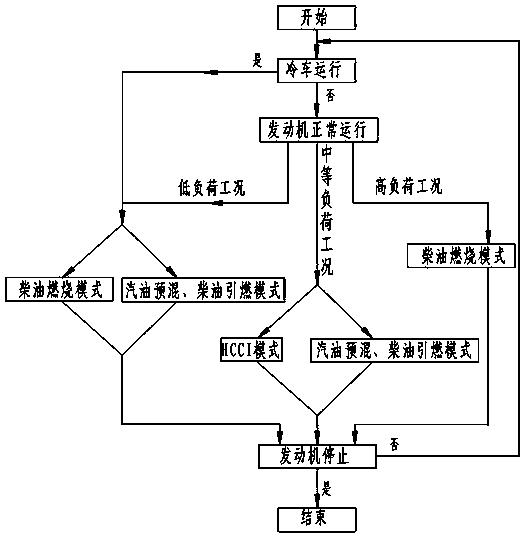

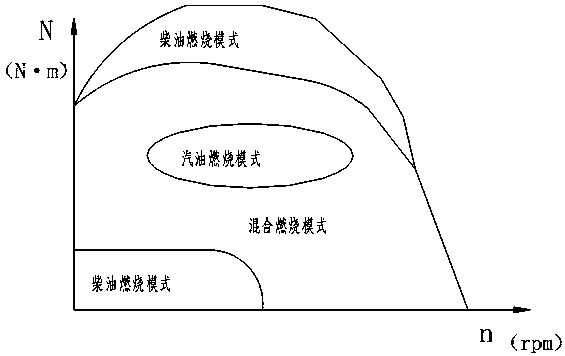

Combustion mode control system of gasoline premixing and diesel igniting engine and control policy thereof

ActiveCN104265471AImprove powerImprove economyElectrical controlMachines/enginesCombustionMode control

The invention discloses a combustion mode control system of a gasoline premixing and diesel igniting engine and a control policy thereof. After an electronic control unit acquires the cooling water temperature, the air inlet temperature, the air flow, the engine crankshaft rotating speed and the accelerator pedal position information to judge the operating conditions of the engine, action commands are sent to a gasoline injector and a diesel injector to control the combustion mode of the engine; the operation steps are as follows: (a) the automobile operation state is judged; and the corresponding engine combustion mode is selected; (b) the engine load state is judged, and the corresponding engine combustion mode is selected; and (c) when the engine is positioned in the working condition of medium load, the engine combustion mode is selected. The dynamic performance and the economic performance of automobiles are guaranteed; and the nitric oxide and PM discharge indexes are reduced.

Owner:GREAT WALL MOTOR CO LTD

Discharge system and process of refuse incinerator flue gas

InactiveCN109569228ARealize ultra-low concentration emissionSimultaneous depth removalCombination devicesGas treatmentParticulatesNitric oxide

The application discloses a discharge system and process of refuse incinerator flue gas. The process includes the steps of denitrifying; removing acid gas and divalent mercury compounds by a semi-dryprocess; carrying out activated carbon adsorbing and dry powder deacidifying; removing dust; carrying out flue gas heat exchanging; decomposing pollutants by low temperature plasma; carrying out wet deacidifying. The system and process herein are suitable for synchronous and efficient deep removal of various pollutants (including particles, nitric oxides, sulfur oxides, dioxin, hydrogen chloride,hydrogen fluoride, mercury and other heavy metals), and can provide ultralow-concentration discharge of refuse incineration flue gas, with NOX<50 mg / Nm<3>, SO2<35 mg / Nm<3>, dioxin TEQ<0.01 ng / Nm<3>, and discharge indexes of HF, HCl, mercury and other heavy metals greatly decreased.

Owner:ZHEJIANG DOWAY ADVANCED TECH CO LTD

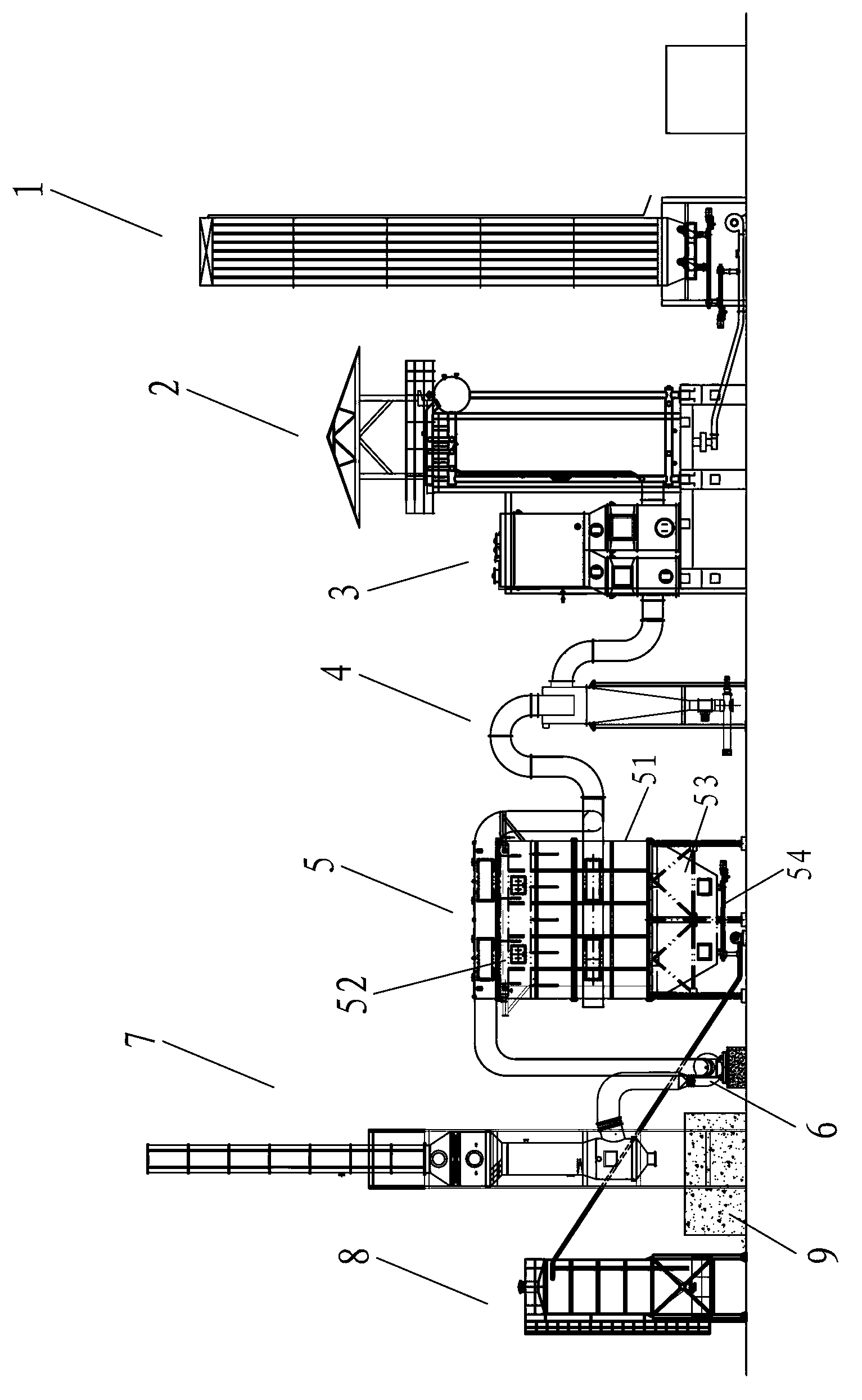

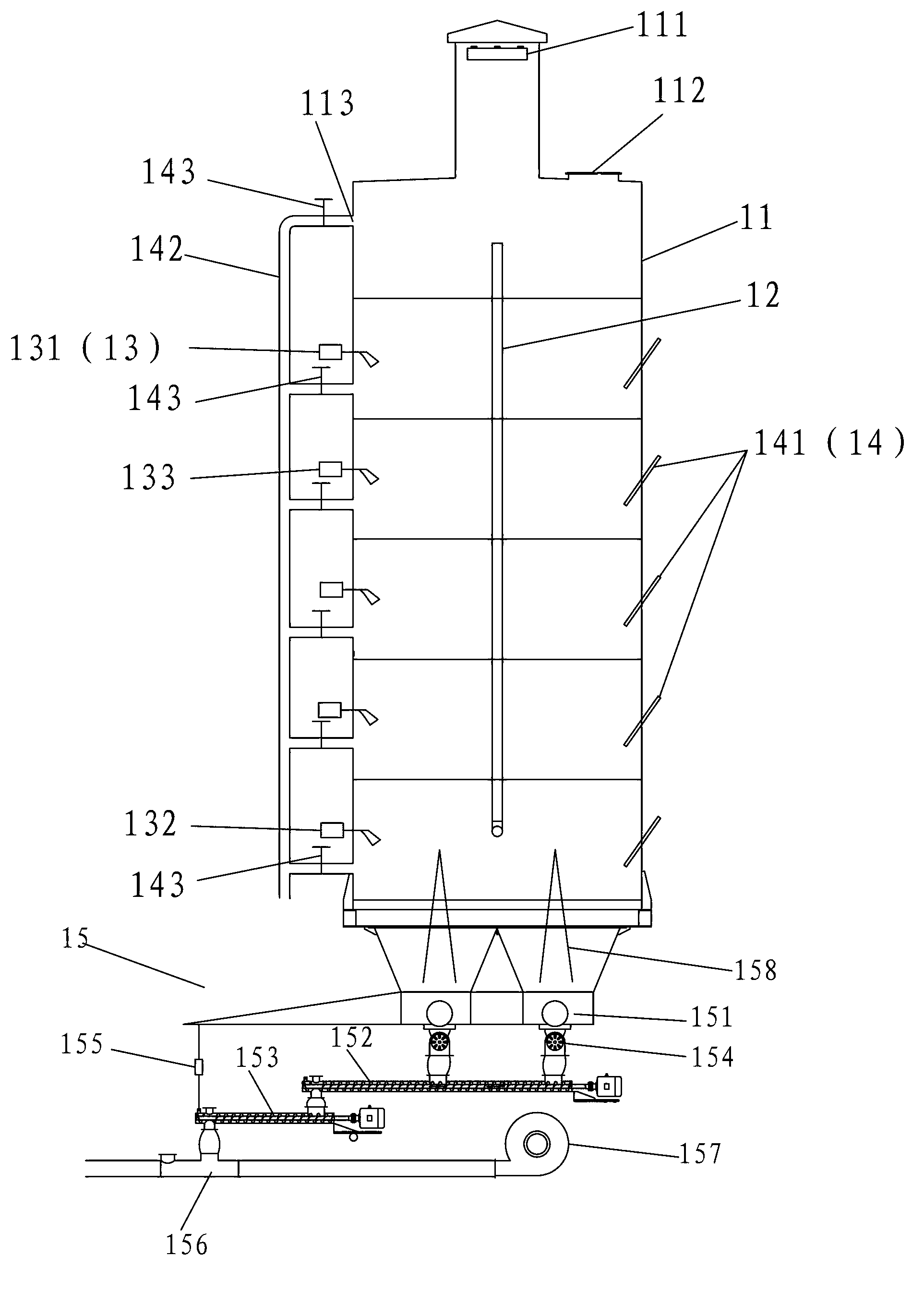

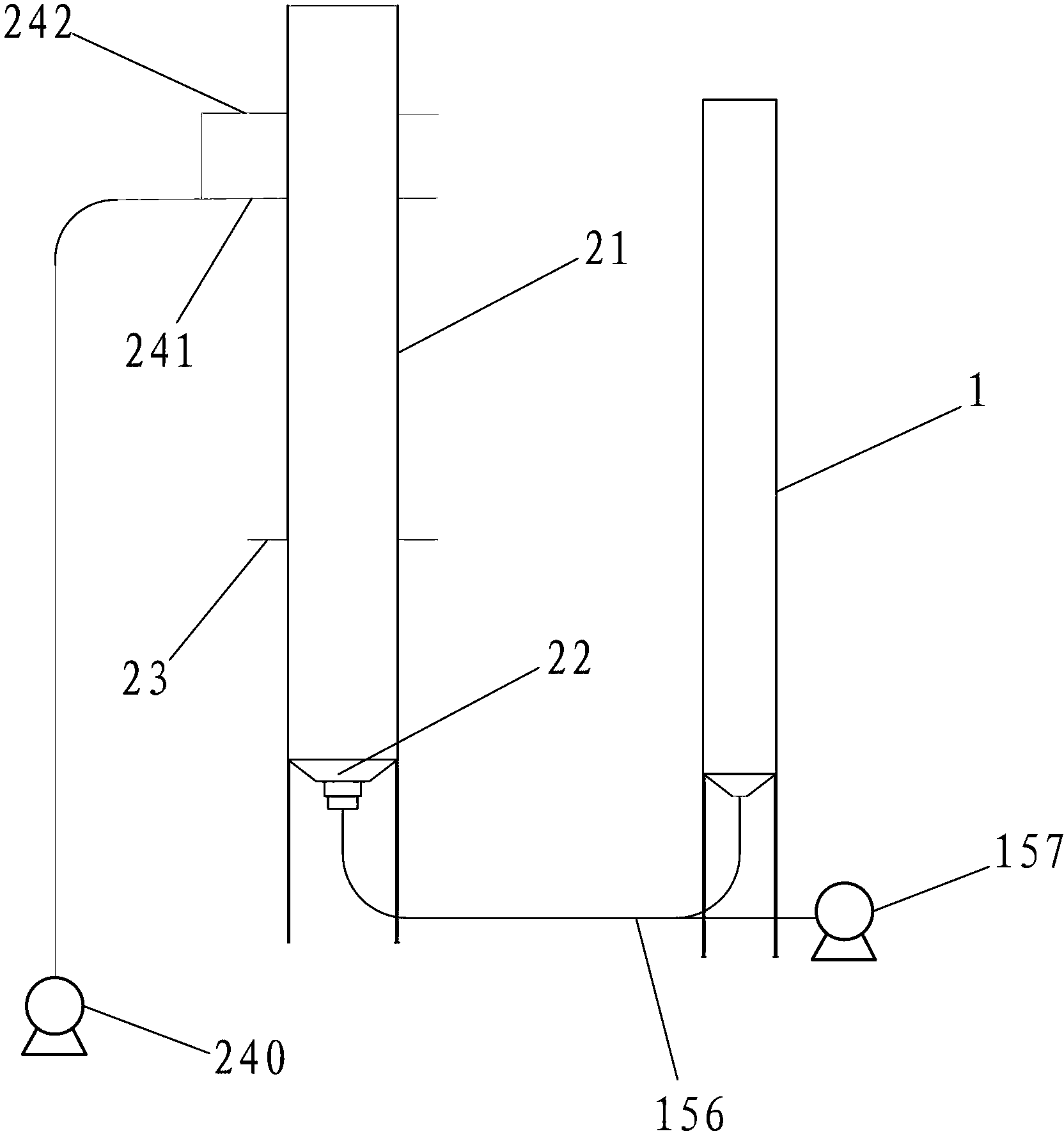

Tanning wastewater recycling device and method based on electrochemistry and ultrafiltration

InactiveCN102145961AReduce dosageReduce consumptionWaste water treatment from animal processingMultistage water/sewage treatmentChemical oxygen demandElectrolysis

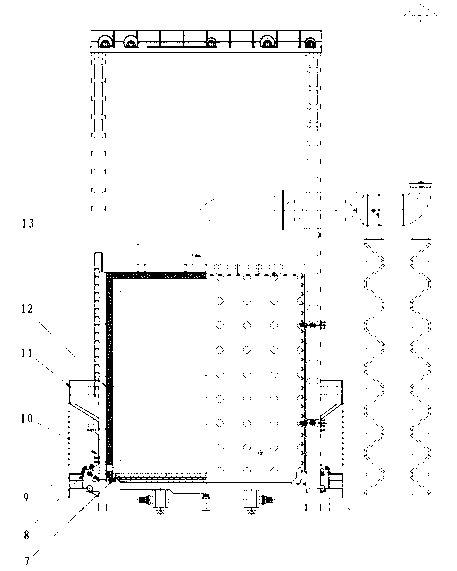

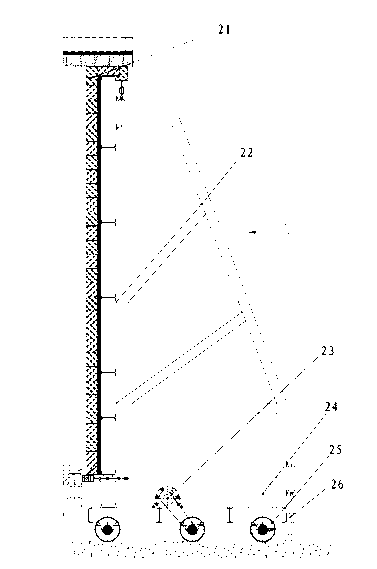

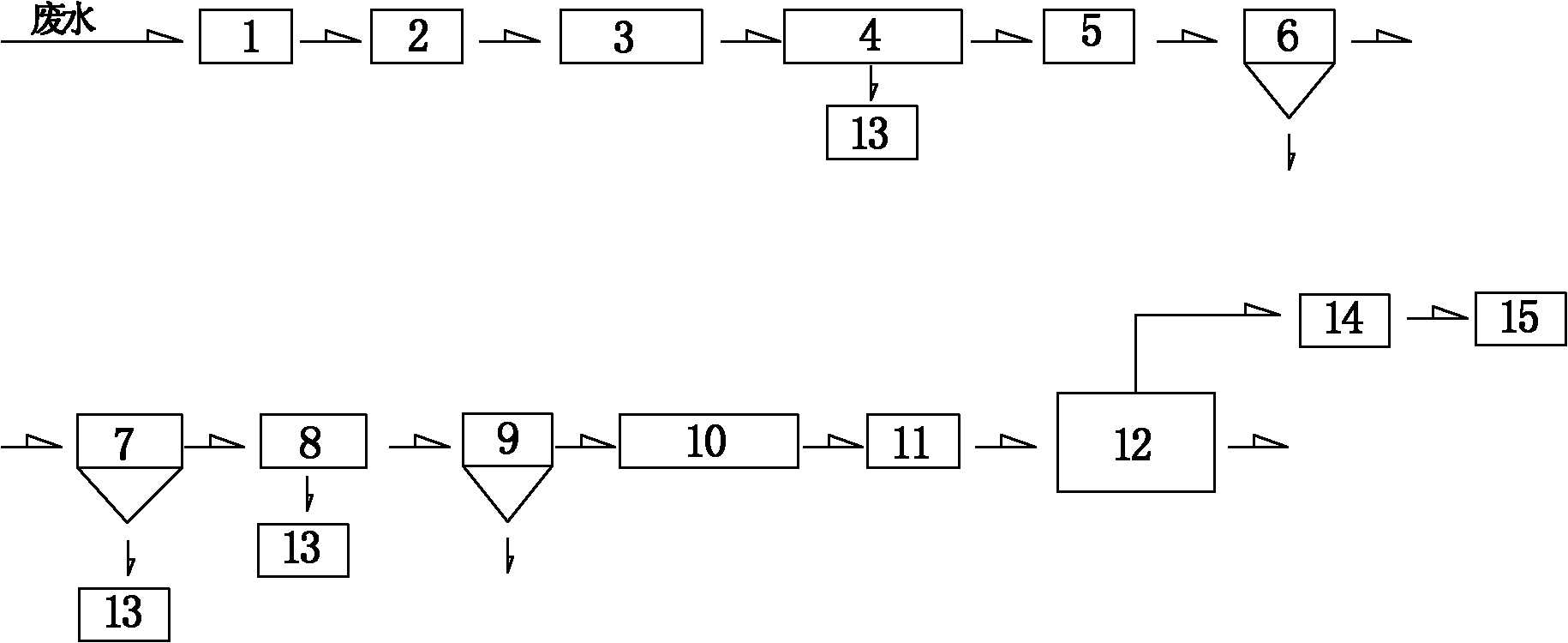

A tanning wastewater recycling device and method based on electrochemistry and ultrafiltration relate to the treatment of one kind of wastewater. The invention provides a tanning wastewater recycling device and method based on electrochemistry and ultrafiltration, wherein the device and method have high CODCr removal rate (chemical oxygen demand), low chemical agent consumption, low sludge yield, thorough treatment and high water reuse rate. The device is provided with a grid filter, an adjusting pool, a hydraulic sizer, a nanocatalysis electrolysis flocculating machine, a sedimentation tank, an air floatation device, a biochemical tank, a secondary sedimentation tank, a secondary nanocatalysis electrolysis flocculating machine, a filter and a filter press. The method comprises the steps of flocculation and filtration, nanocatalysis electrolysis, sedimentation, air floatation, biochemical treatment, secondary catalysis electrolysis, filtration and ultrafiltration.

Owner:BOYING XIAMEN SCI & TECH

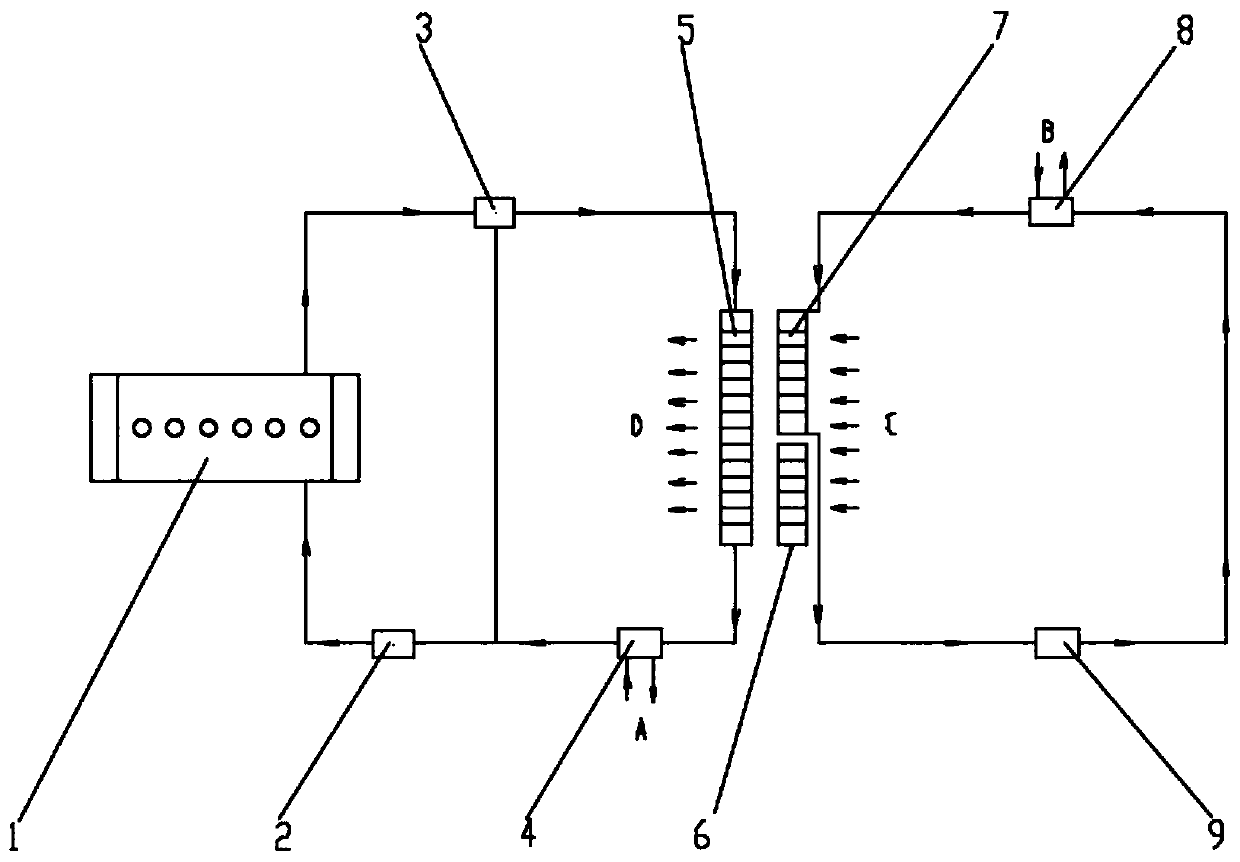

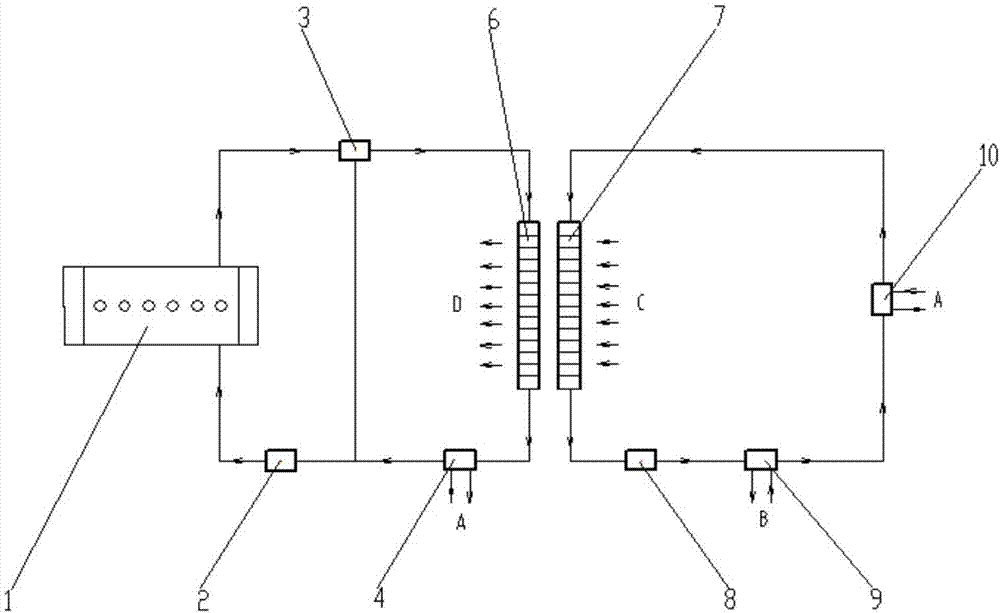

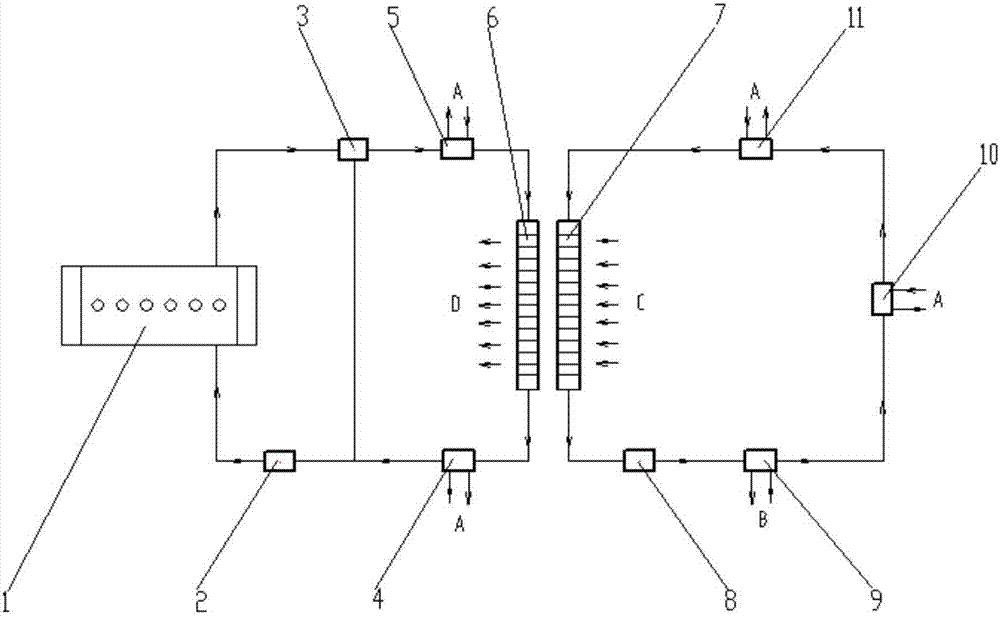

Novel combined vehicle double-circulation cooling system

InactiveCN110173336AReduce manufacturing costMeet cooling needsLiquid coolingInternal combustion piston enginesWorking temperatureIntercooler

The invention belongs to the technical field of vehicle cooling and heat dissipation, and discloses a novel combined vehicle double-circulation cooling system. The system is composed of a high-temperature circulating cooling system and a low-temperature circulating cooling system, a low-temperature radiator and a hydraulic oil radiator are arranged in parallel on a cooling air cooling flowing path, and then a high-temperature radiator is further arranged in a series mode on the path, so that a combined mode of arranging the radiators in the front row and the rear row is formed; the high-temperature circulating cooling system is mainly composed of an engine, an engine water pump, a transmission oil radiator and the high-temperature radiator; and the low-temperature circulating cooling system is mainly composed of the low-temperature radiator, a low-temperature circulating pump and a water-cooling intercooler. According to the system, the working temperature requirements of all the systems of a vehicle are considered, the cooling requirements of all heat sources are met, the radiators on the cooling air flowing path achieve heat exchange with cooling air in a series-parallel combination mode, the number of the radiators is reduced, the manufacturing cost of the cooling system is reduced, the cooling efficiency of the cooling air is improved, and the energy consumption of the vehicle cooling system is reduced.

Owner:JILIN UNIV +1

Dual cycle cooling system for engineering vehicle

PendingCN107882624ASmall structure sizeImprove cooling efficiencyLiquid coolingInternal combustion piston enginesCirculator pumpIntercooler

The invention belongs to the technical field of cooling of vehicles and relates to a dual cycle cooling system for an engineering vehicle. The problems that in the prior art, the heat dissipation efficiency is low, the structure size is large, and cooling energy consumption is large are solved. The dual cycle cooling system is composed of a high-temperature cycle cooling system and a low-temperature cycle cooling system. The high-temperature cycle cooling system is composed of an engine, an engine water pump, a liquid-liquid radiator a and a high-temperature radiator. High-temperature cycle cooling liquid sequentially flows through an inner cooling cavity of the engine and the liquid-liquid radiator a. The low-temperature cycle cooling system is composed of a low-temperature radiator, a low-temperature cycle pump, a water cooling intercooler and a liquid-liquid radiator c. After low-temperature cycle cooling liquid passes through the low-temperature radiator, the low-temperature cyclecooling liquid sequentially flows through the water cooling intercooler and the liquid-liquid radiator c. Cooling air firstly flows through the low-temperature radiator and then flows through the high-temperature radiator, and heat exchange between heat of the systems of the vehicle and air is achieved. By means of the dual cycle cooling system for the engineering vehicle, the structural size of the radiators is reduced, the cooling efficiency of the cooling air is improved, and energy consumption of the vehicle cooling system is reduced.

Owner:JILIN UNIV +2

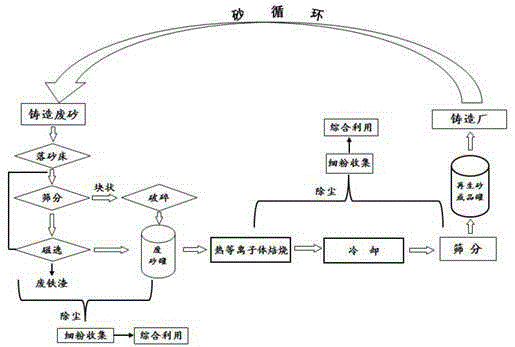

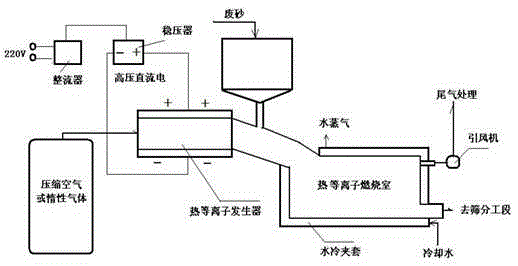

Reclaiming method for cast waste sand hot plasmas

ActiveCN105328115AHigh activityRemove completelyMould handling/dressing devicesFoundryProcess engineering

The invention discloses a reclaiming method for cast waste sand hot plasmas. The reclaiming method includes the technical processes of waste sand pretreatment, hot plasma roasting, cooling and screening. According to plasma roasting, a resin film, an inorganic film and harmful impurities of metallic oxides such as sodium and potassium on the surface of waste sand are removed under the action of the high temperature, thermal shocks and surface melting of a hot plasma torch, and therefore high-performance cast reclaimed sand is obtained. The average temperature of the hot plasma torch is 2000-4500 DEG C, the surface temperature of the waste sand is 1000-3000 DEG C, and the heating time of the waste sand is 5-60 minutes. The reclaiming recycling rate of the reclaiming method is larger than or equal to 85%, the performance index of the reclaimed sand is superior than that of isogenesis new sand and reclaimed sand obtained through other reclaiming methods, the reclaimed sand can be completely recycled and reused through a casting plant, the tail gas exhaust index is far lower than the exhaust standard of China, Europe and America, the amount of generated fine powder is greatly reduced, and due to the high temperature and ionization action, the reclaimed sand is free of pollution and safe to the environment and can be directly used as the recycled building material.

Owner:广西兰科资源再生利用有限公司

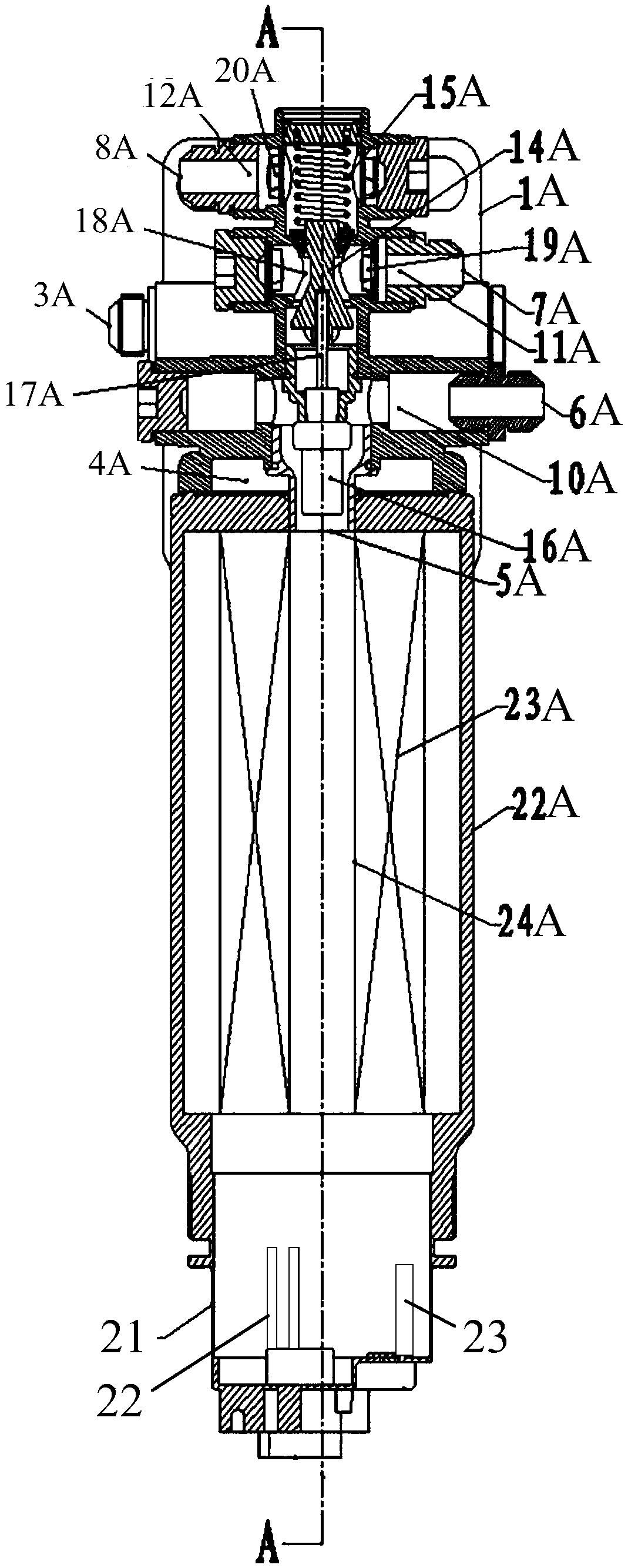

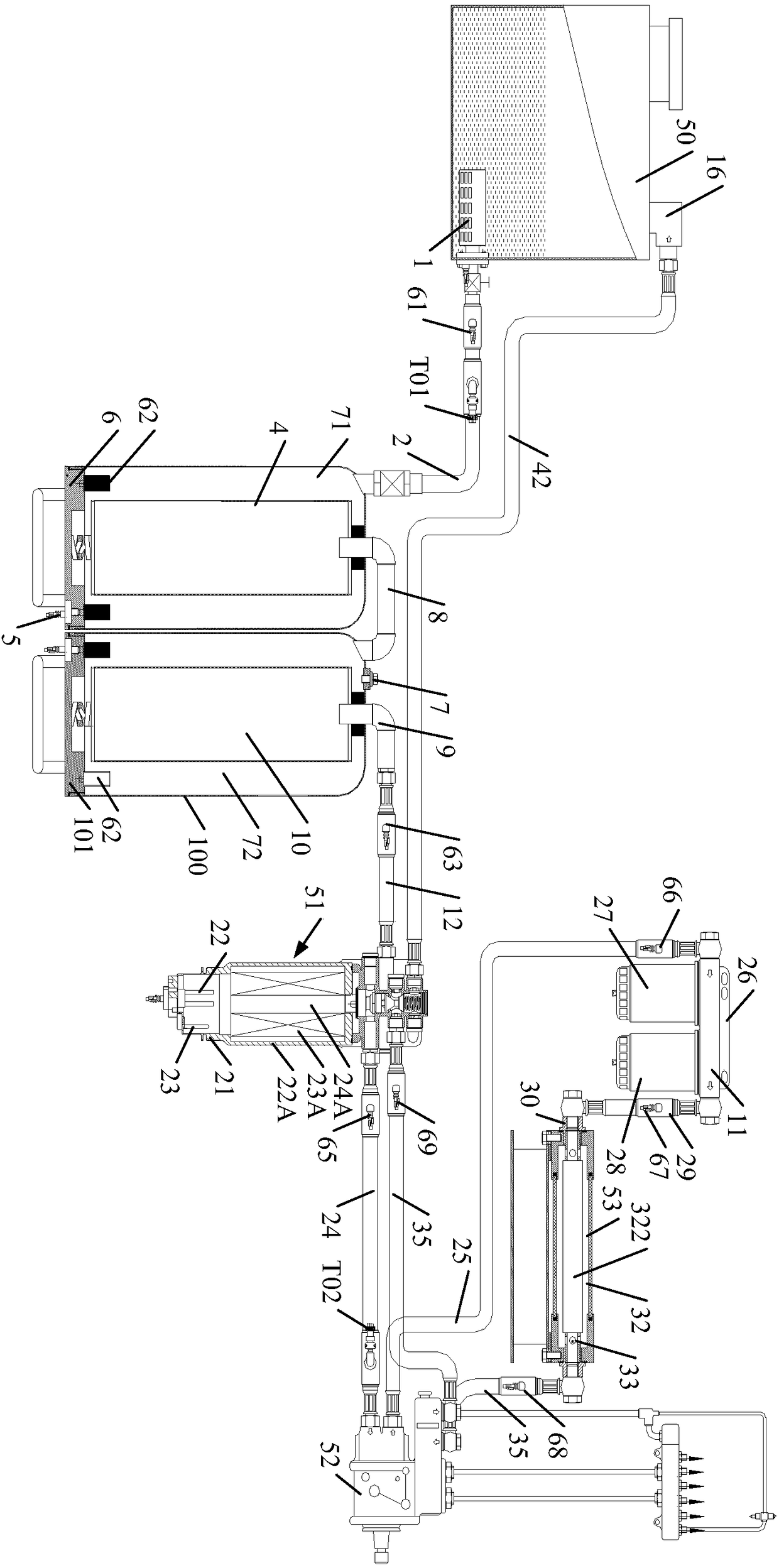

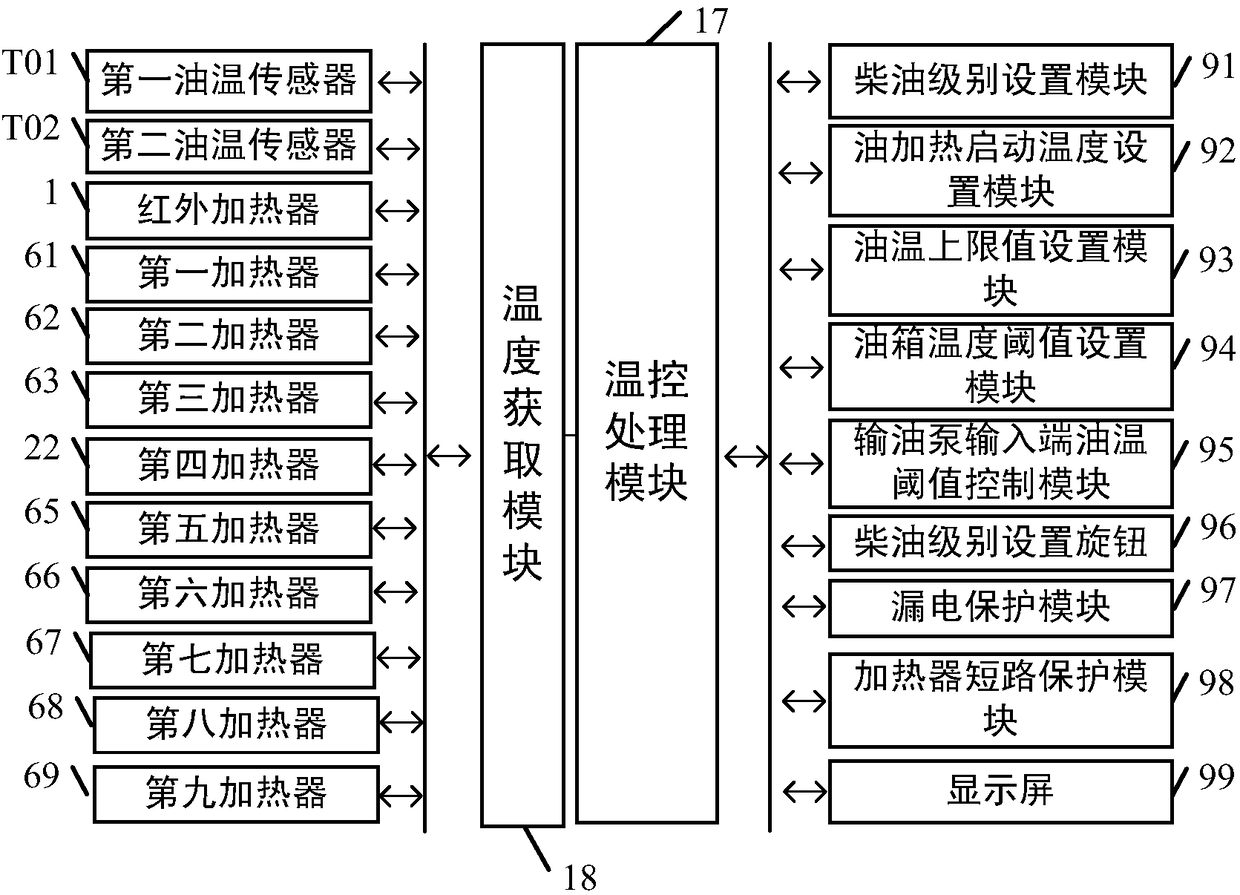

Diesel engine fuel oil constant-temperature purification management system

ActiveCN108590907ABroaden the range of cold useImprove efficiencyMachines/enginesThermal treatment of fuelTemperature controlFuel quality

The invention provides a diesel engine fuel oil constant-temperature purification management system. The system comprises an oil tank, a section-A heat radiation oil conveying pipe, a coarse filter assembly, an output pipe assembly, a section-B heat radiation oil conveying pipe, an oil-water separator, a section-C heat radiation oil conveying pipe, an oil conveying pump assembly, a section-D heatradiation oil conveying pipe, a filter assembly, a section-E heat radiation oil conveying pipe, a purifier and a temperature control unit. For the specific requirement of the fuel oil quality index, the quality index change rule of 5# diesel, 0# diesel, -10# diesel, -20# diesel, -35# diesel and -50# diesel in a normal-temperature state is combined, a temperature regulation and control program forstabilizing the temperature of the diesel and guaranteeing quality to conform to the matching requirement is compiled, through the constant-temperature control using the diesel, the engine fuel oil inlet quality is adjusted and stabilized to be within the range of 0.79-0.84 cm3, so that the maximum power efficiency and the lowest emission index are guaranteed to be exerted under the lowest oil consumption index, and the realization of the green power source is promoted.

Owner:济南凯瑞特汽车零部件有限公司

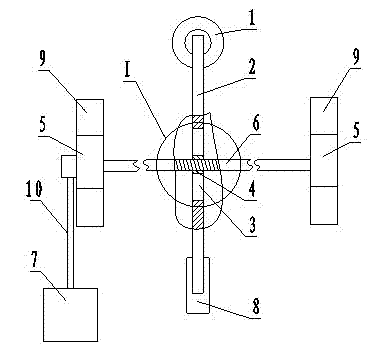

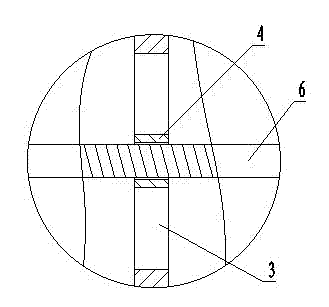

Valve lift continuous variable mechanism of engine gas distribution system

ActiveCN102787879AReduce fuel consumptionLower emissions targetsValve arrangementsInternal combustion piston enginesVariable valve timingDistribution system

The invention relates to a valve lift continuous variable mechanism of an engine gas distribution system; the mechanism is used for realizing the continuous changes of the valve lift of an engine, and comprises a group of valve lift continuous change control units with the number matched with that of engine cylinders, wherein each valve lift continuous change control unit is provided with a cam, a rocker, a rocker shaft and a valve; and the mechanism is characterized in that a slider I is sleeved in the middle of the rocker shaft, the slider I is hinged with the rocker shaft, the middle part of the rocker is provided with a rocker guide rail in a cavity structure, and the slider I can slide in the rocker guide rail. According to the valve lift continuous variable mechanism of the engine gas distribution system, when the molded line of the cam is unchanged, the valve lift can be changed continuously, so that the purpose of matching with the complicated changeable working conditions of the engine is achieved, the oil consumption and the emission indicator of the engine are reduced, and the dynamic performance is fully displayed. The valve lift continuous variable mechanism of the engine gas distribution system has a wide scope of application, is matched with the variable-valve-timing (VVT) system of the engine, realizes the application of gas distribution phase and the fully variable technology of the valve lift, has a compact structure, and is convenient for the deployment of the engine in a cabin.

Owner:GREAT WALL MOTOR CO LTD

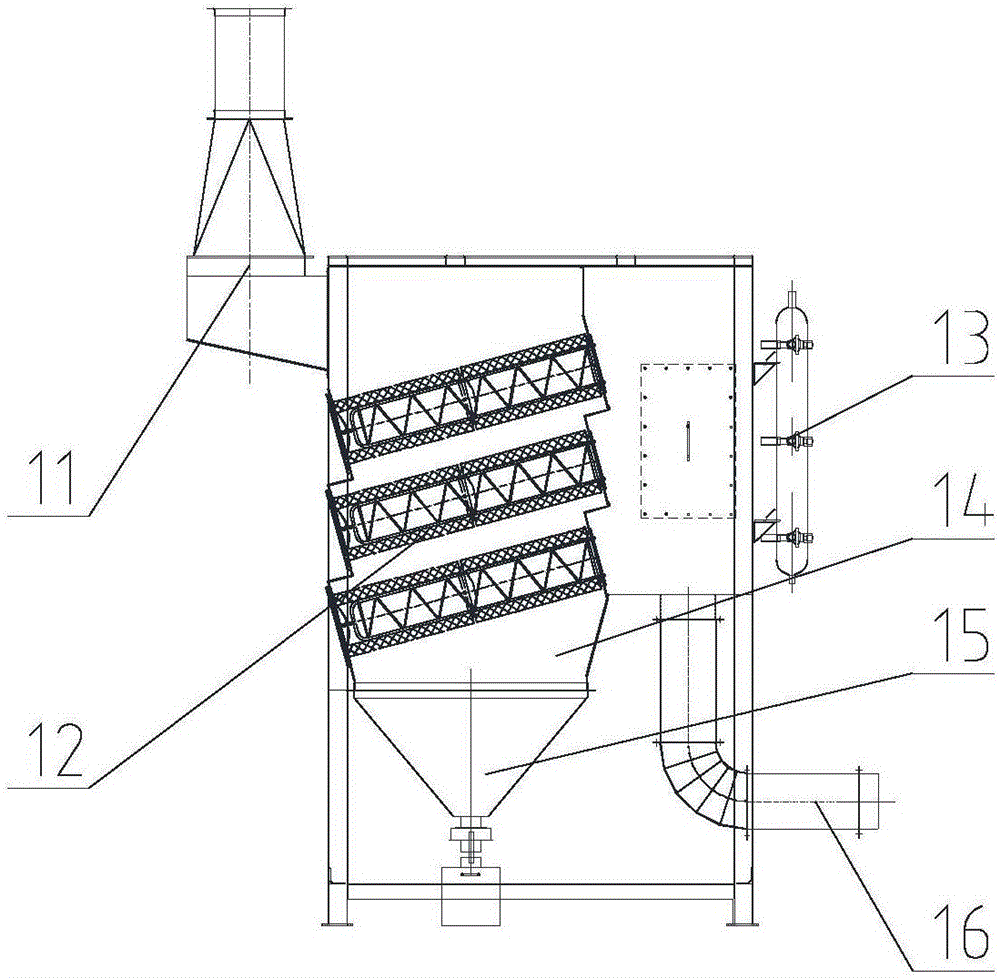

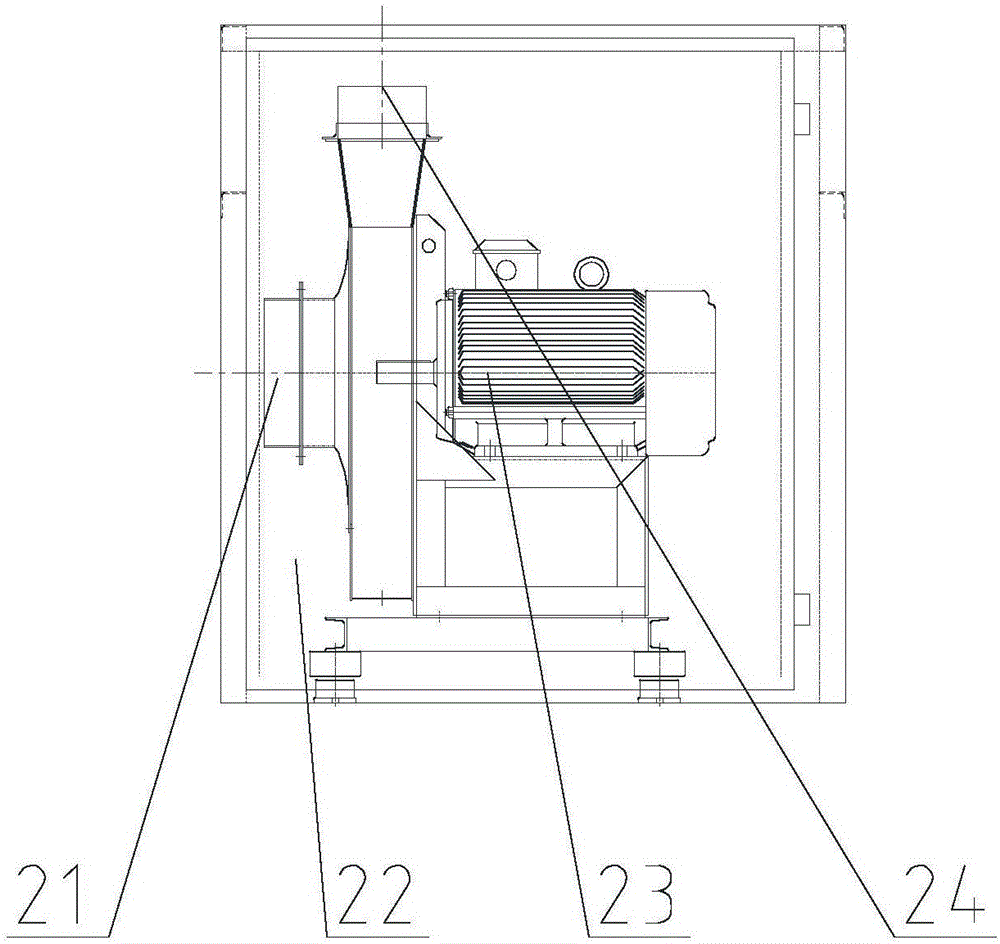

Dry/wet composite dedusting system

InactiveCN106215591AEnsure normal dischargeReduce dust contentCombination devicesDirt cleaningEngineeringWater curtain

The invention relates to the technical field of facility dedusting systems, particularly a dry / wet composite dedusting system. The dry / wet composite dedusting system comprises a pulse backflush filter element deduster and a water-curtain deduster, wherein the pulse backflush filter element deduster comprises a dedusting channel and a filter element dedusting mechanism which are connected to the upper part of the pulse backflush filter element deduster, and a dedusting pipeline outlet which communicates with one side of the filter element dedusting mechanism; and the water-curtain deduster comprise a water tank and a filter structure which sequentially communicate with each other from bottom to top, a water curtain system and a water curtain channel outlet arranged on the upper part of the water-curtain deduster. The dry / wet composite dedusting system can ensure the content of dust discharged into the air to be less than 1mg / m<3> which is lower than the national discharge index requirement; and the dry / wet composite dedusting system does not need to design or manufacture the chimney, is especially suitable for working spaces with higher environmental requirements, and has the advantages of wide adaptability, low discharge index, high stability and reliability, and the like.

Owner:昆山开信精工机械股份有限公司

Dry low-emission burner

ActiveCN109611891ATaking into account stabilityWell mixedContinuous combustion chamberCombustorPulp and paper industry

The invention belongs to the technical field of burner design, and particularly relates to a dry low-emission burner. The dry low-emission burner includes a venturi tube, a premixing outdoor cylinder,a premixing indoor cylinder, a nozzle body, a main combustion premixing spraying rod and a precombustion premixing spraying rod, wherein the outlet end of the premixing outdoor cylinder is connectedwith the inlet end of the venturi tube, the premixing indoor cylinder is arranged on the inner side of the premixing outdoor cylinder to form a main combustion level premixing channel with the premixing outdoor cylinder, and the nozzle body is arranged on the inner side of the premixing indoor cylinder, and a precombustion premixing level channel is formed between the nozzle body and the premixingindoor cylinder; the nozzle body is internally provided with a precombustion diffusion channel, the precombustion diffusion channel penetrates through the nozzle body in the axial direction, the end,close to the venturi tube, of the precombustion diffusion channel is provided with a precombustion diffusion nozzle hole, and the other end, close to the venturi tube, of the precombustion diffusionchannel communicates with a fuel source; and the inlet end of the main combustion premixing spraying rod communicates with the fuel source, the outlet end is arranged at the inlet end of the main combustion premixing level channel, the outlet end of the main combustion premixing spraying rod is provided with a main combustion premixing nozzle hole, the inlet end of the precombustion premixing spraying rod communicates with the fuel source, the outlet end is arranged at the inlet end of the precombustion premixing level channel, and the outlet end of the precombustion premixing spraying rod isprovided with a precombustion premixing nozzle hole.

Owner:AECC SHENYANG ENGINE RES INST

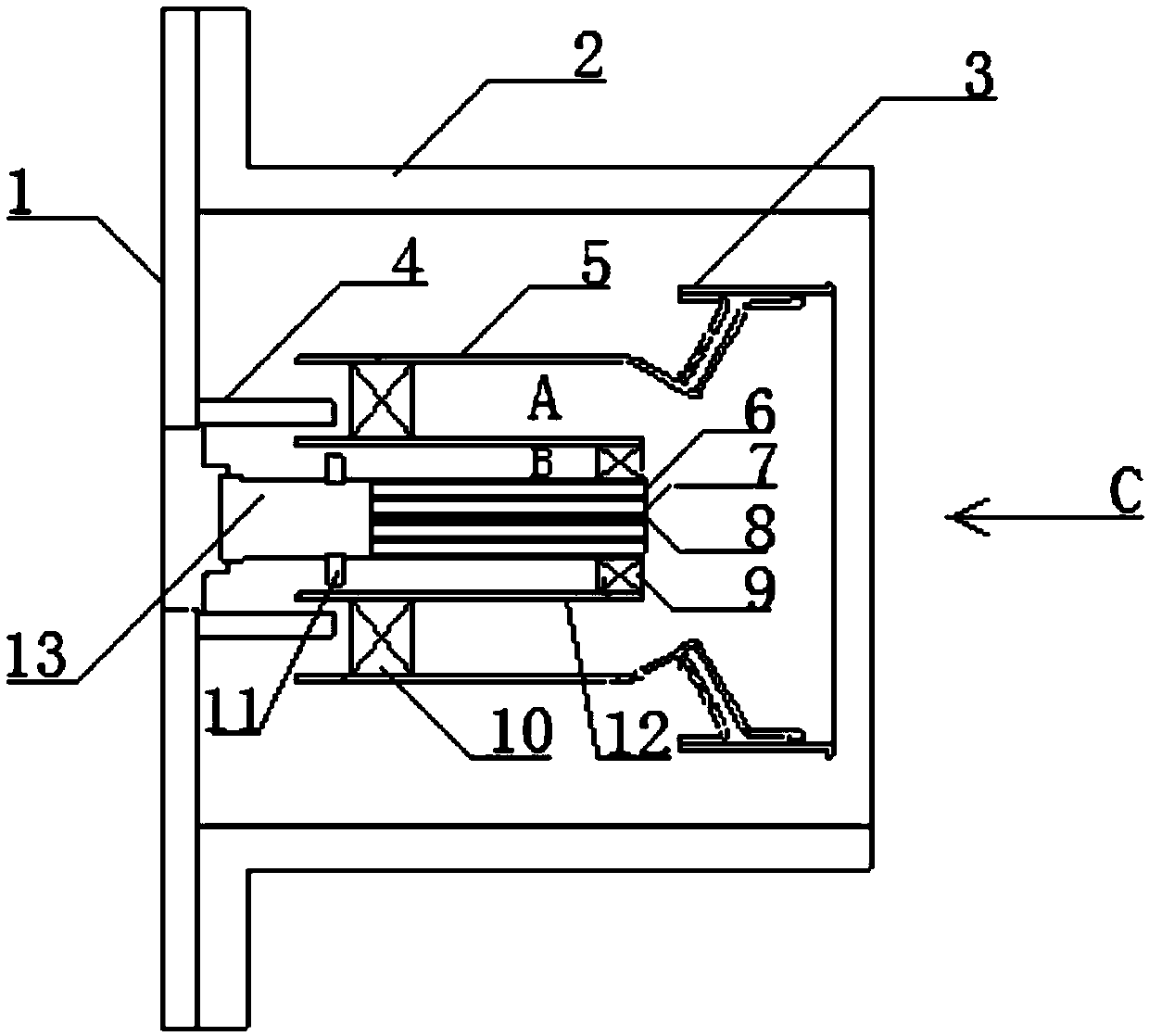

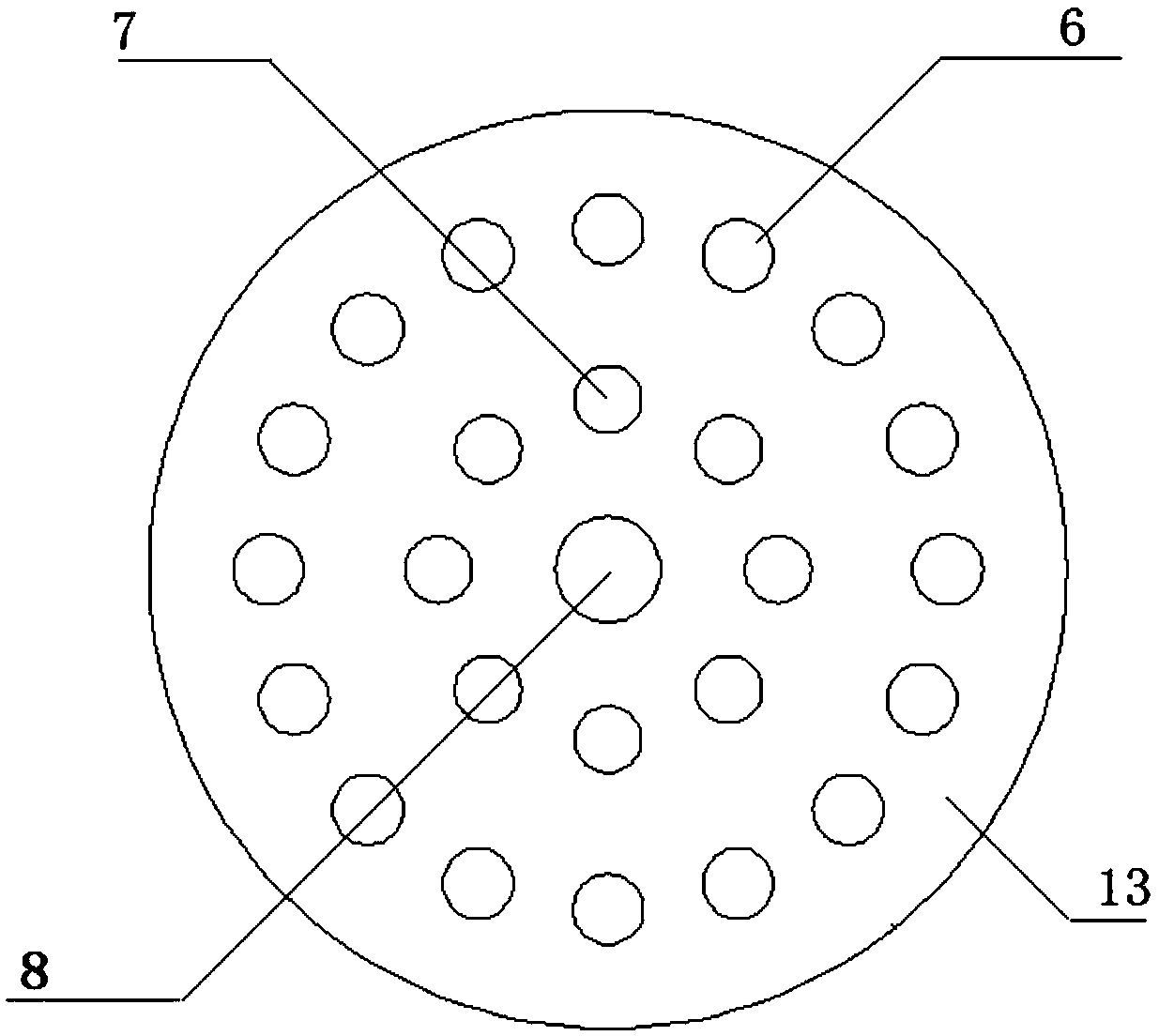

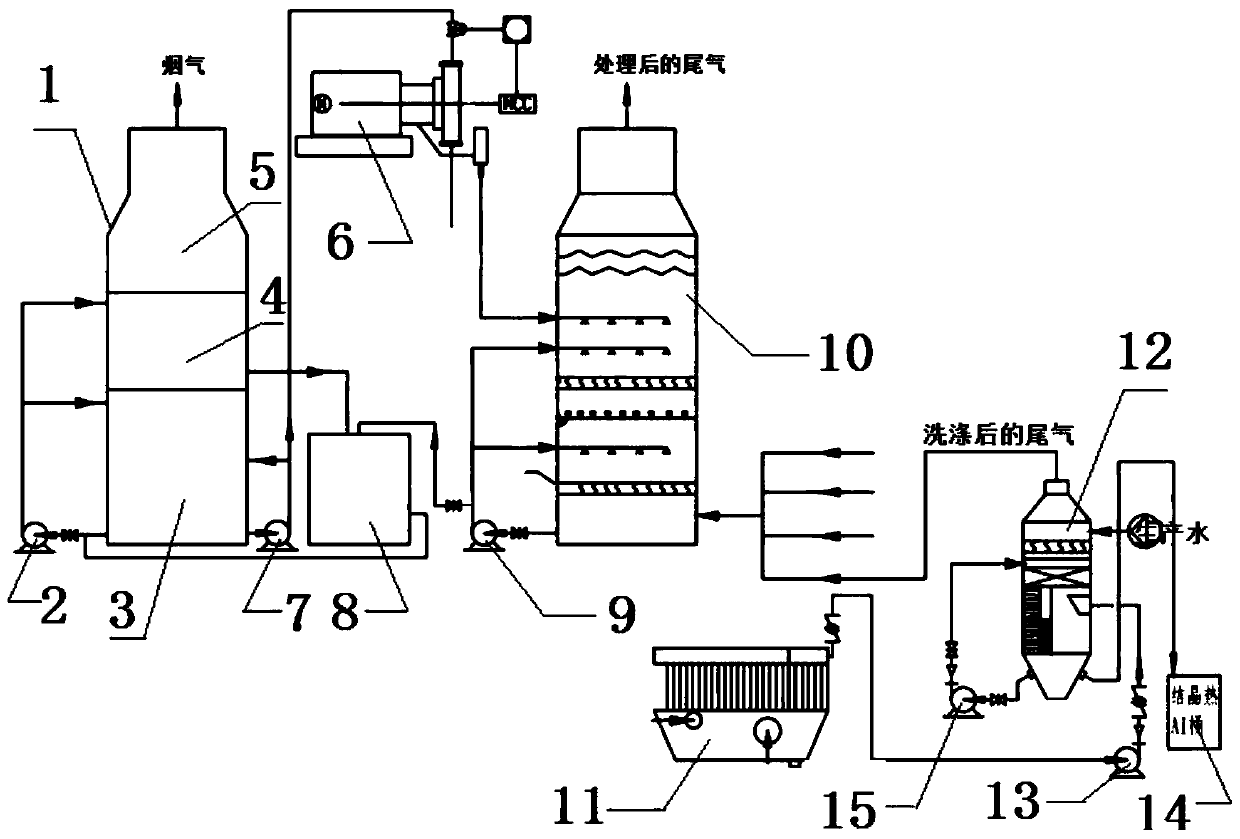

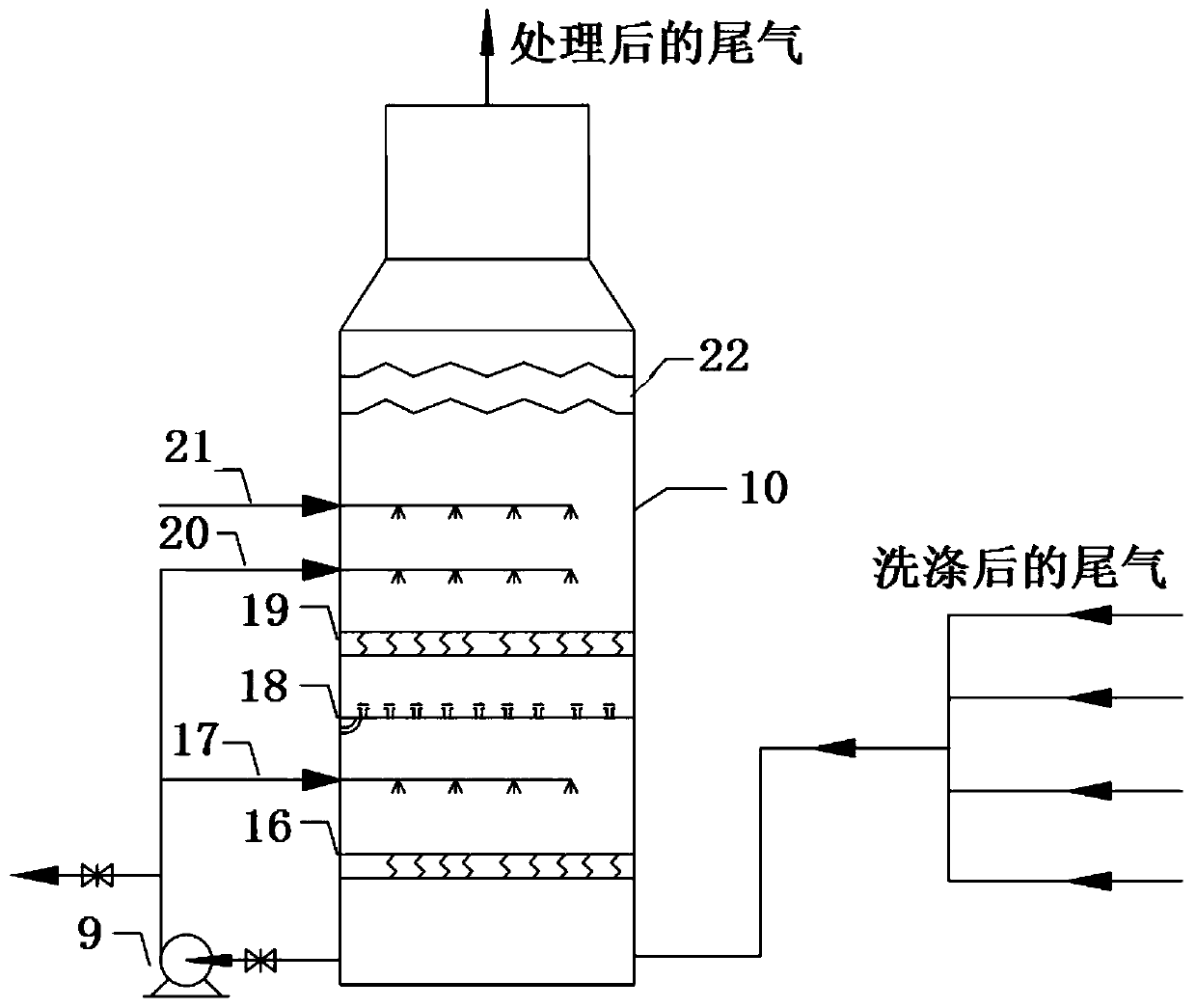

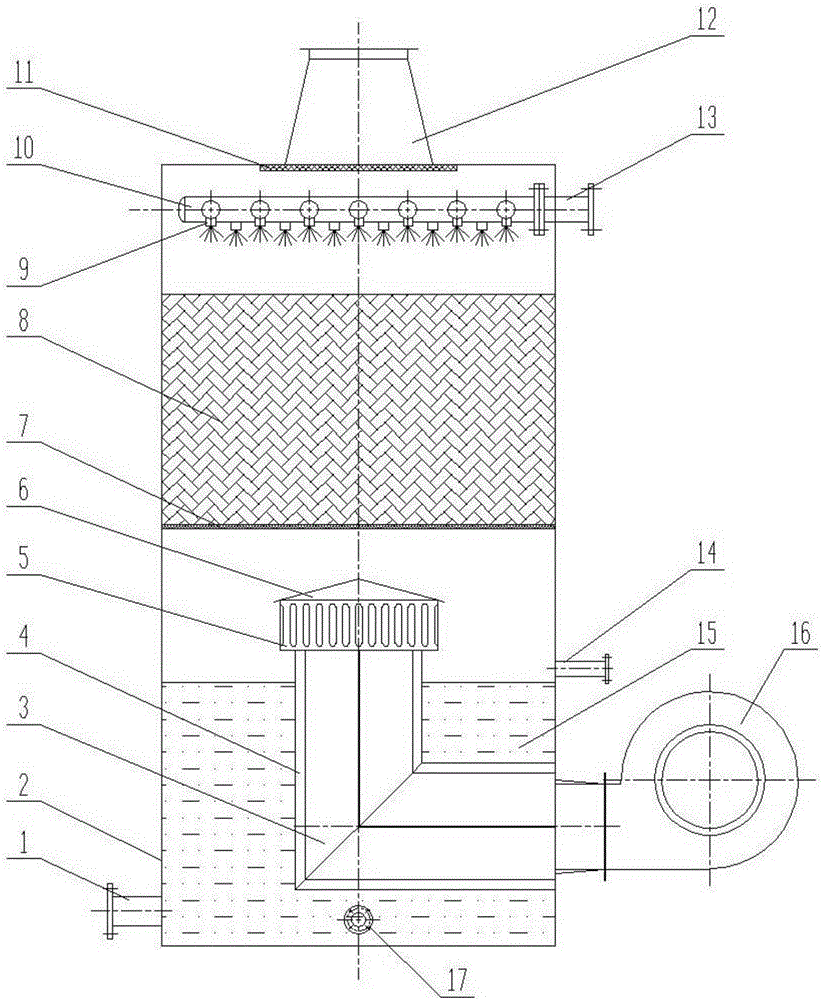

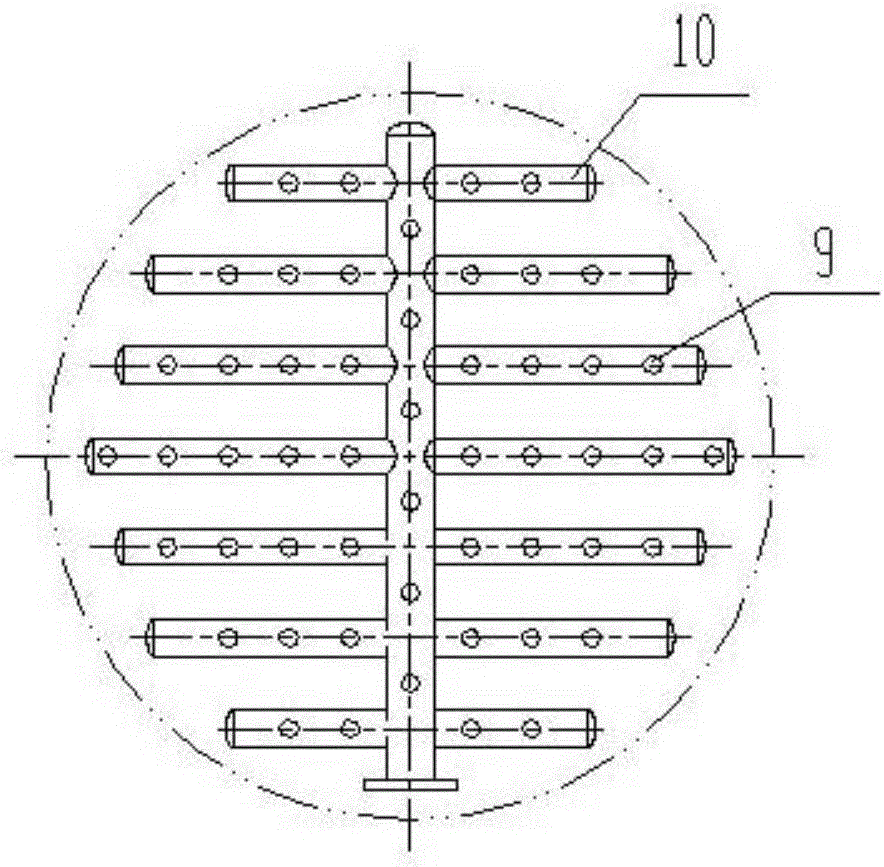

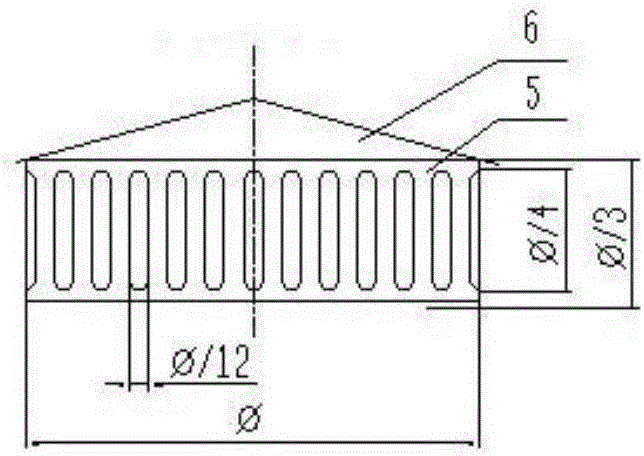

Ammonia containing tail gas treatment device in dry ammonium section of alkali industry and treatment method thereof

PendingCN110314505ALower emissions targetsAchieve recyclingGas treatmentDispersed particle separationAmmonium sulfateChemistry

The invention belongs to the field of odor pollutant (ammonia) treatment in the sodium carbonate industry, and particularly relates to an ammonia-containing tail gas treatment device in a dry ammoniumsection of the alkali industry and a treatment method thereof. The device includes an ammonia method desulfurization device and an associated-alkali dry ammonium ammonia-containing tail gas dedustingand absorption device, and the ammonia method desulfurization device is connected with the associated-alkali dry ammonium ammonia-containing tail gas dedusting and absorption device. The ammonia method desulfurization device includes a desulfurizing tower, an oxidation tank, a flue gas absorption circulating pump, a concentration circulating pump and an ammonium sulfate centrifuge, wherein the desulfurizing tower is connected with the ammonium sulfate centrifuge through the concentration circulating pump, and the desulfurizing tower is in loop connection with the oxidation tank through the flue gas absorption circulating pump. Ammonium sulfate filtrate is connected with an ammonia tail gas absorption tower. The ultra-low emission of an odor pollutant (ammonia) is achieved, no waste liquidis discharged, the recovery and utilization rate of ammonia is increased, and a thermoelectric ammonia desulfurization device is optimized.

Owner:实联化工(江苏)有限公司

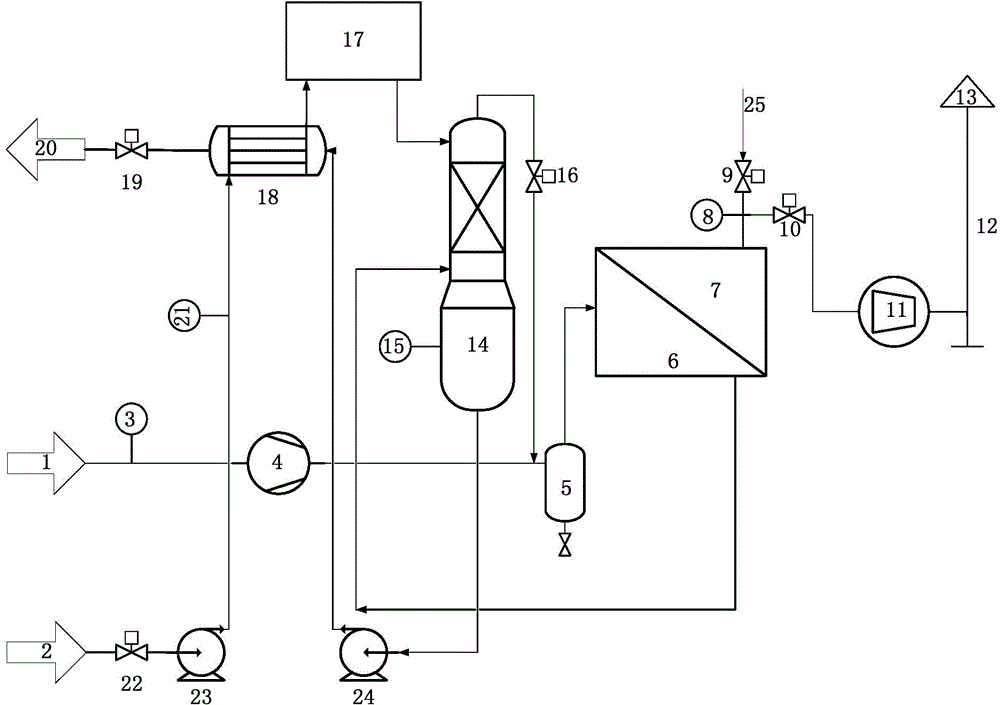

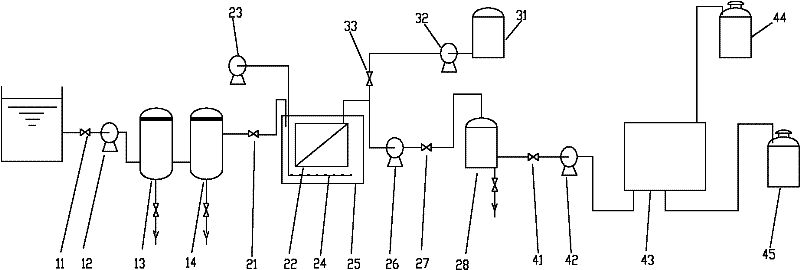

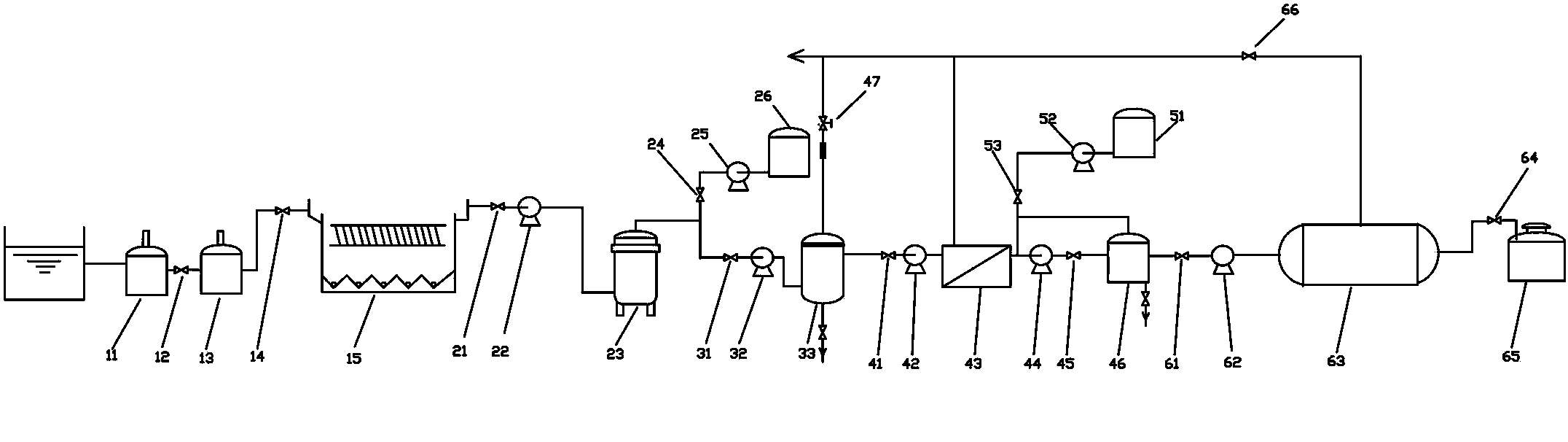

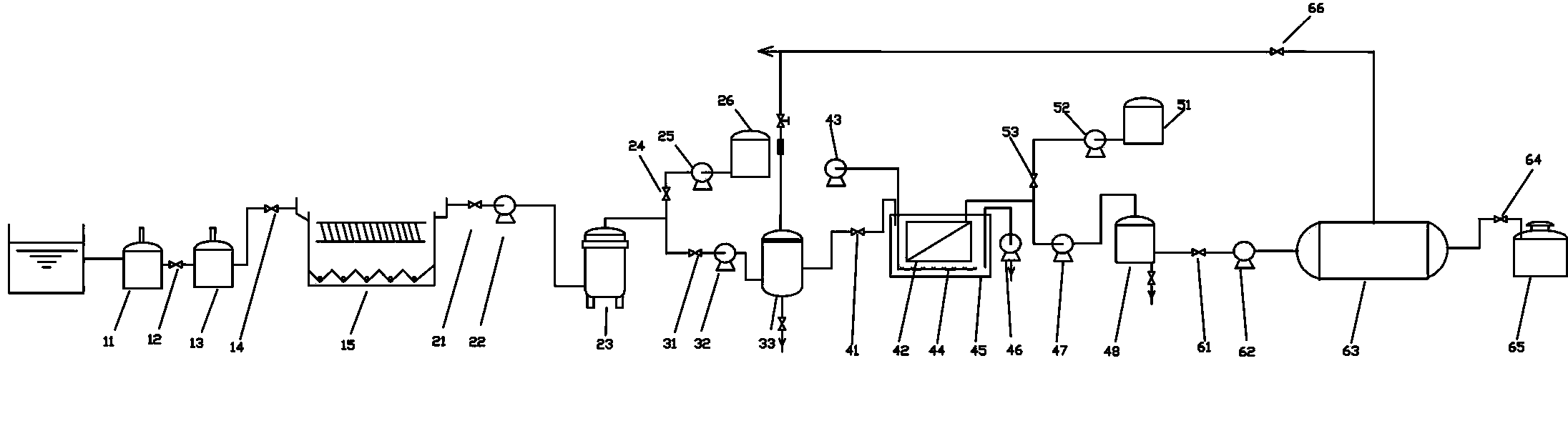

Oil-gas recycling device based on glassy-state membrane separation-absorption process

InactiveCN104083992AHigh selectivityEasy to separateLiquid hydrocarbon mixture recoveryDispersed particle separationHigh concentrationGas phase

The invention relates to an oil-gas recycling device based on a glassy-state membrane separation-absorption process, which mainly solves the problems of poor oil-gas separation effect and high concentration of emitted tail gas in the prior art. The oil-gas recycling device is characterized in that an oil-gas inlet pipeline is connected with an inlet of an induced draft fan, and an outlet of the induced draft fan is connected with an inlet pipeline of a condensate tank; a gas-phase outlet of the condensate tank is connected with the inlet side of a glassy-state membrane assembly, the permeation side of the glassy-state membrane assembly is connected with an inlet of a vacuum pump, and the retentate side of the glassy-state membrane assembly is connected with an absorption tower; a top outlet of the absorption tower is connected with the inlet pipeline of the condensate tank, a bottom outlet pipeline of the absorption tower is connected with a tube pass inlet of a heat exchanger, a shell pass inlet of the heat exchanger is connected with a lean oil inlet pipeline, a shell pass outlet of the heat exchanger is connected with an inlet of a condensing unit, an outlet pipeline of the condensing unit is connected with the absorption tower. According to the technical scheme, the problems are well solved, and the oil-gas recycling device can be applied to recycling of hydrocarbon steam.

Owner:CHINA PETROLEUM & CHEM CORP +1

Papermaking wastewater recycling device and method based on electrochemical and electrodialysis technology

InactiveCN102295373AOvercoming Filtration Separation ProcessingOvercome the disadvantages of polluting the environmentGeneral water supply conservationMultistage water/sewage treatmentElectrolysisDesalination

Provided is an electrochemistry and electrodialysis-based apparatus for recycling wastewater from papermaking. The recycling apparatus is provided with a nano-catalytic electrolysis system, a submerged ultrafiltration separation system, an ultrafiltration membrane cleaning system, and an electrodialysis system. Also provided is a method using the apparatus for recycling the wastewater from papermaking, comprising the following steps: extracting the wastewater from papermaking and introducing same into the nano-catalytic electrolysis system; flowing the wastewater from papermaking that is purified after processing into the submerged ultrafiltration separation system to acquire dialyzed water; then feeding the dialyzed water into the electrodialysis system for desalination by electrodialysis; and acquiring desalinated water and concentrated water.

Owner:BOYING XIAMEN SCI & TECH

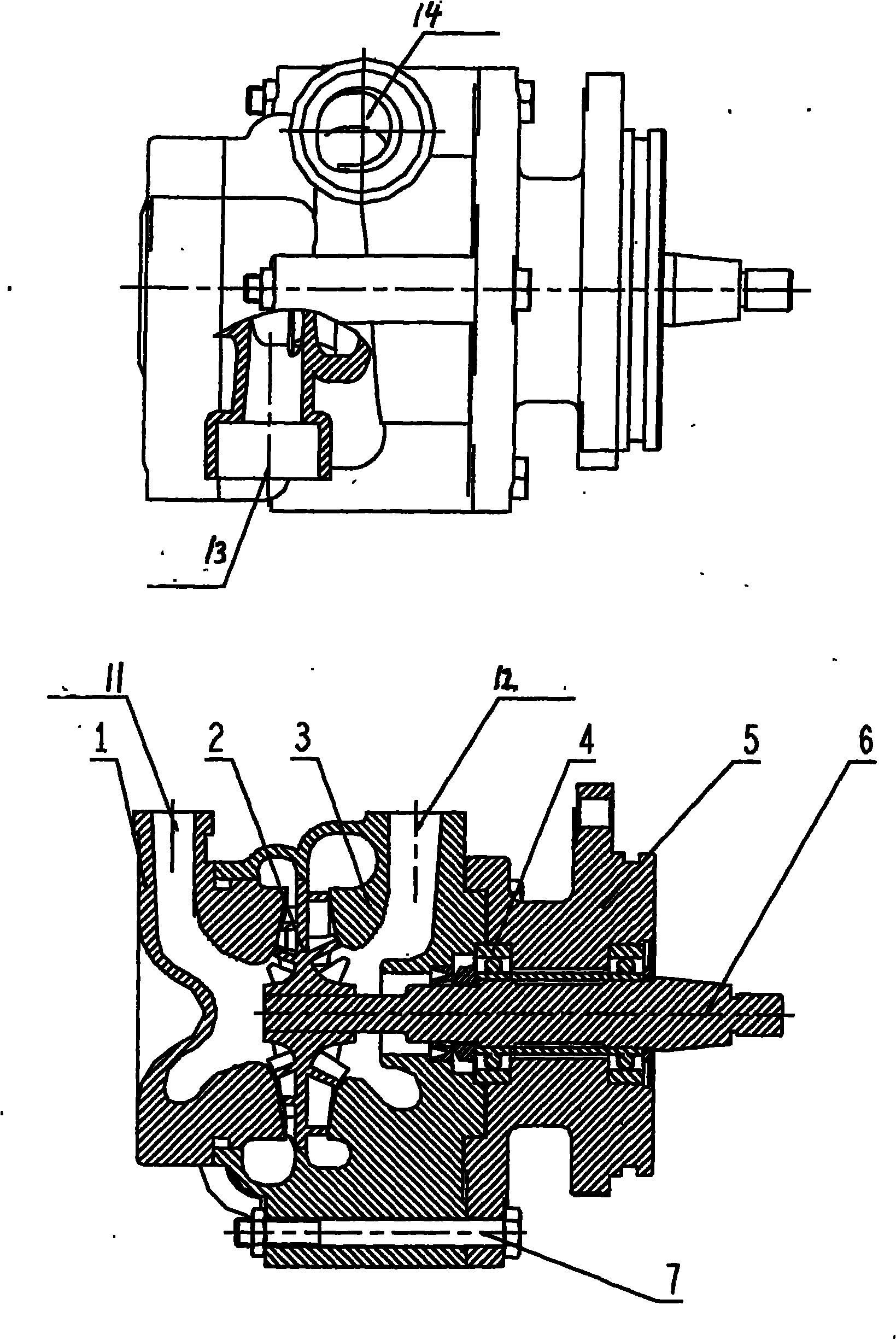

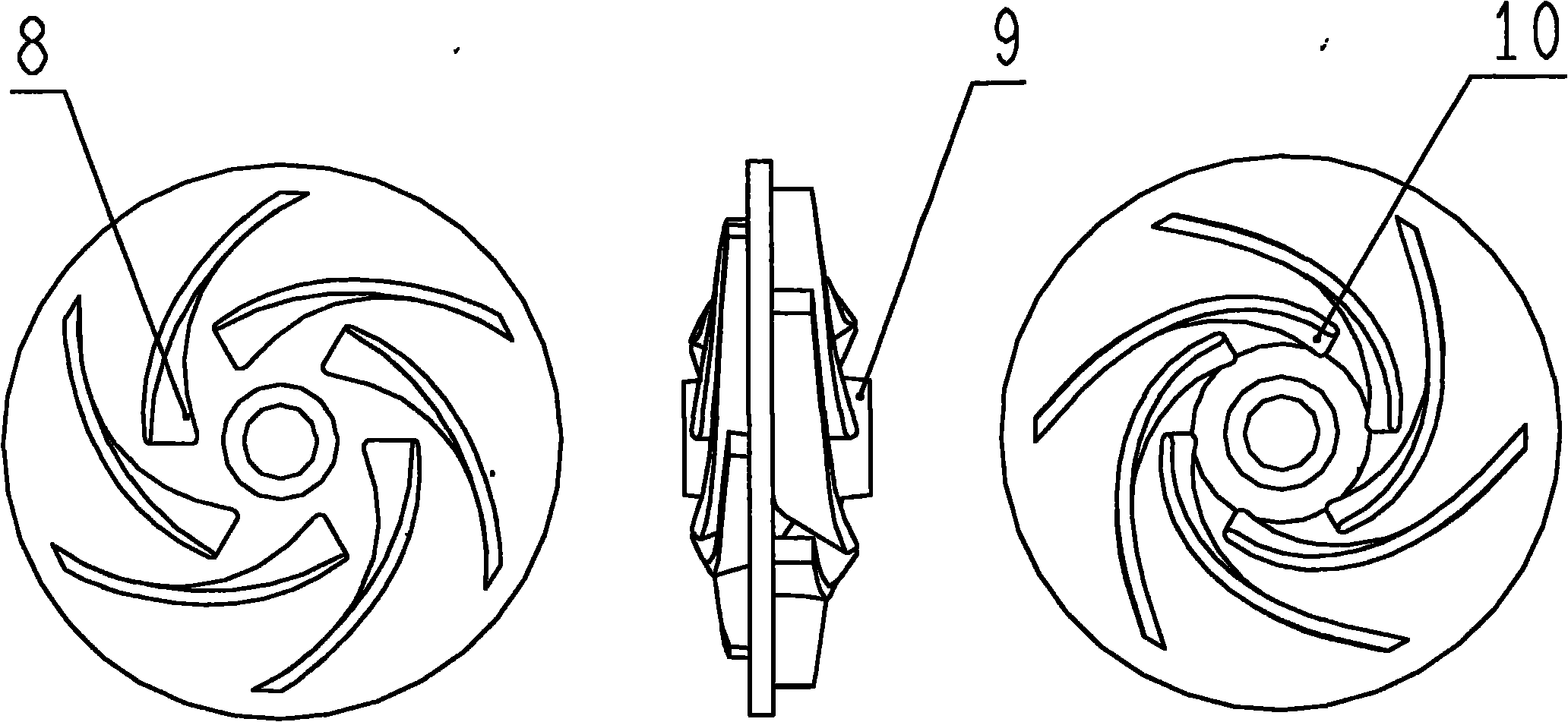

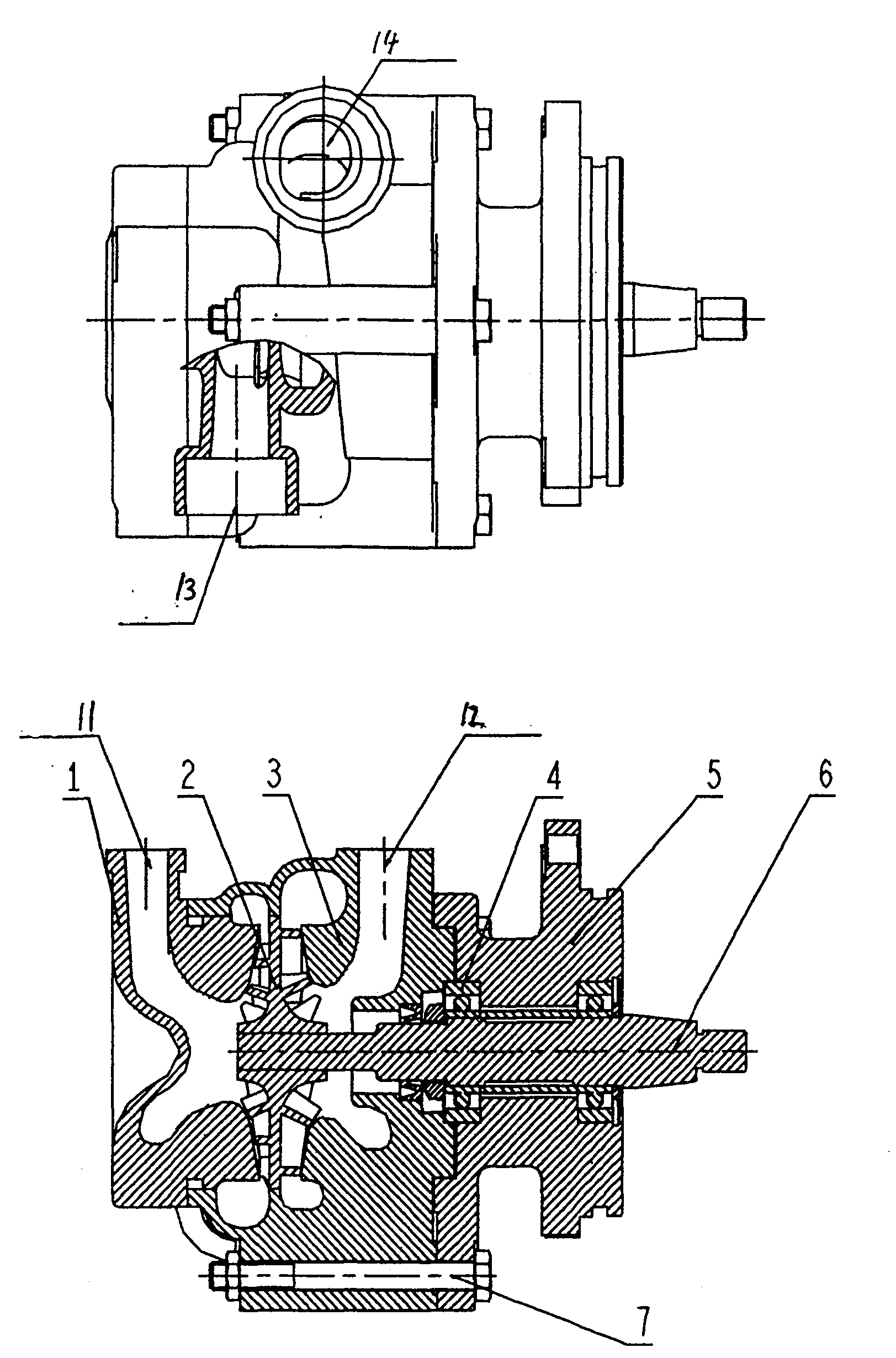

Centrifugal cooling water pump

InactiveCN102080672AImprove temperature balanceTo achieve temperature requirementsPump componentsWorking fluid for enginesImpellerDrive shaft

The invention discloses a centrifugal cooling water pump, which comprises a water inlet receiving tray (1), an impeller (2), a volute (3), a bearing (4), a bearing seat (5), a transmission shaft (6), fasteners (7), a high-temperature impeller (8), a hub (9), a low-temperature impeller (10), a water inlet (11), a water inlet (12), a water outlet (13) and a water outlet (14), wherein the water inlet receiving tray (1) is provided with the water inlet (11); the volute (3) is provided with the water inlet (12), and the volute (3) is connected with the water inlet receiving tray (1) and the bearing seat (5) through the fasteners (7); the bearing seat (5) is in interference connection with the bearing (4); the bearing (4) is in interference connection with the transmission shaft (6); the transmission shaft (6) is in interference connection with the impeller (2); and one side of the impeller (2) is provided with the high-temperature impeller (8), the other side of the impeller (2) is provided with the low-temperature impeller (10), and the impeller (2) is axially provided with the hub (9). The centrifugal cooling water pump can improve the temperature balancing capacity of an engine, improve the heat transfer efficiency, reduce the discharge index of an internal-combustion engine, increase the efficiency of the whole machine and reduce the oil consumption.

Owner:CHINA NORTH IND GRP NO 70 RES INST

Direct-heating hot water boiler

InactiveCN106369816ALower emissions targetsImprove emission targetsWater heatersWater storageCombustor

The invention discloses a direct-heating hot water boiler which is composed of a boiler body, a fume pipe, a combustor, filler, a chimney and the like. The boiler body is of a vertical cylindrical structure and is divided into a filler chamber and a water storage chamber through a supporting partition plate. The fume pipe is located on the middle lower portion of the water storage chamber. Heat dissipation fin plates are installed on the outer wall of the pipe, and the heat exchange area can be increased. An exhaust pipe is assembled to the upper portion of the filler chamber, so that smoke is exhausted upwards evenly. A water blocking cap is used for preventing water from entering the fume pipe. An inlet water distributor is arranged in the filler chamber, so that water is sprayed downwards evenly. Through a temperature-resistant filtering cotton plate, residual water in the smoke can be filtered out and returned back to the water storage chamber. According to the direct-heating hot water boiler, the one cavity design is adopted, the structure is compact, and materials are saved and are about one quarter those of an ordinary boiler; the size is small, the space is saved, the manufacturing cost is low, through the structure, secondary heat exchange can be conducted, and the heat efficiency reaches 97% or over; and smoke exhaust indexes are higher than national standards, the smoke exhaust temperature is lower than 50 DEG C, and the heat efficiency is greatly improved.

Owner:大庆市豪迈德科技有限公司

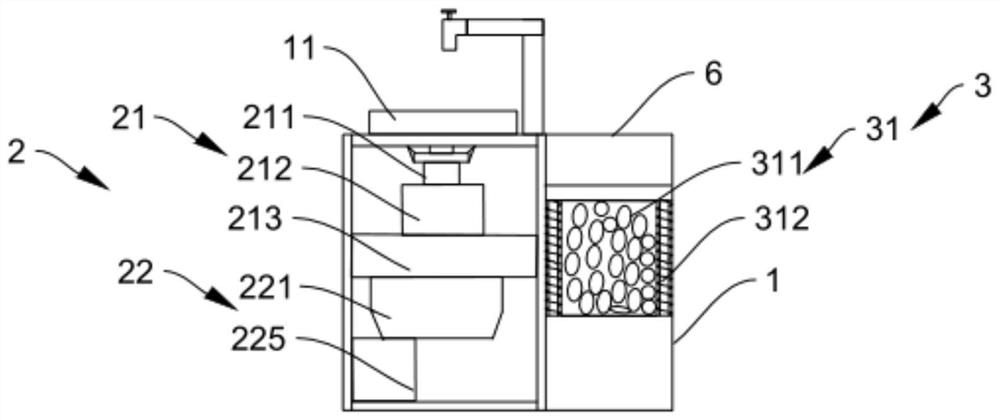

Kitchen waste recovery equipment

PendingCN112916587AReduce pollutionLower emissions targetsTransportation and packagingSolid waste disposalMunicipal sewageOil water

The invention provides kitchen waste recovery equipment, and belongs to the technical field of garbage disposal. The kitchen waste recovery equipment comprises a cabinet body, a waste disposal unit and a purification unit, and the cabinet body is provided with a water pool. The waste treatment unit is arranged in the cabinet body and comprises a crushing assembly communicating with the water pool and a storage assembly communicating with the discharging end of the crushing assembly. . The purification unit communicates with the crushing assembly and comprises an oil-water separator for separating oil stains from water. The kitchen waste recovery equipment provided by the invention can be used for processing, treating and recovering kitchen wastes, reducing the pollution of kitchen household garbage to environment, greatly reducing the COD discharge index of urban sewage, reducing the strength and difficulty of urban sewage treatment, reducing the use of chemicals in the urban sewage treatment process, and realizing effective utilization of resources. The kitchen waste recovery equipment is reasonable in structure, and is safe and reliable, and the popularization and application value is extremely high.

Owner:周宜人 +2

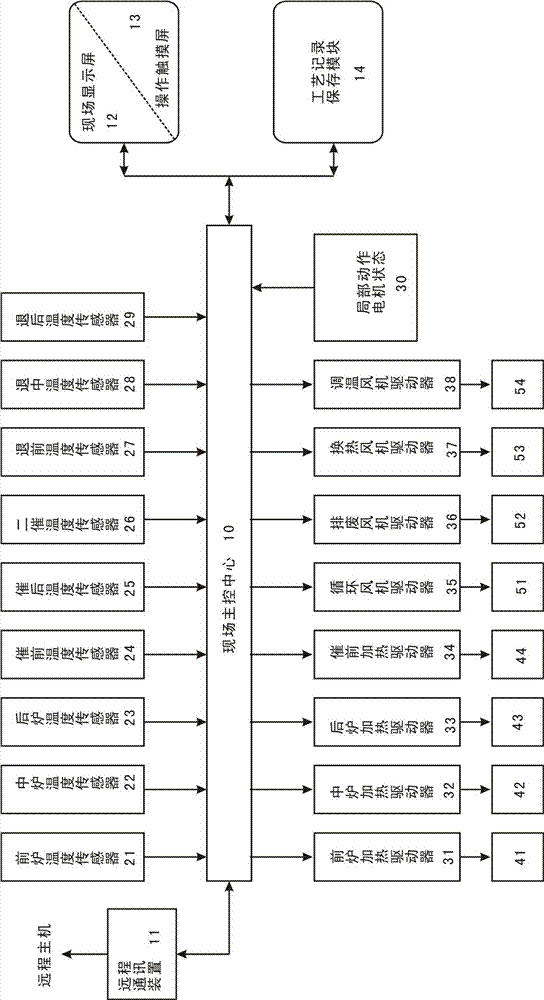

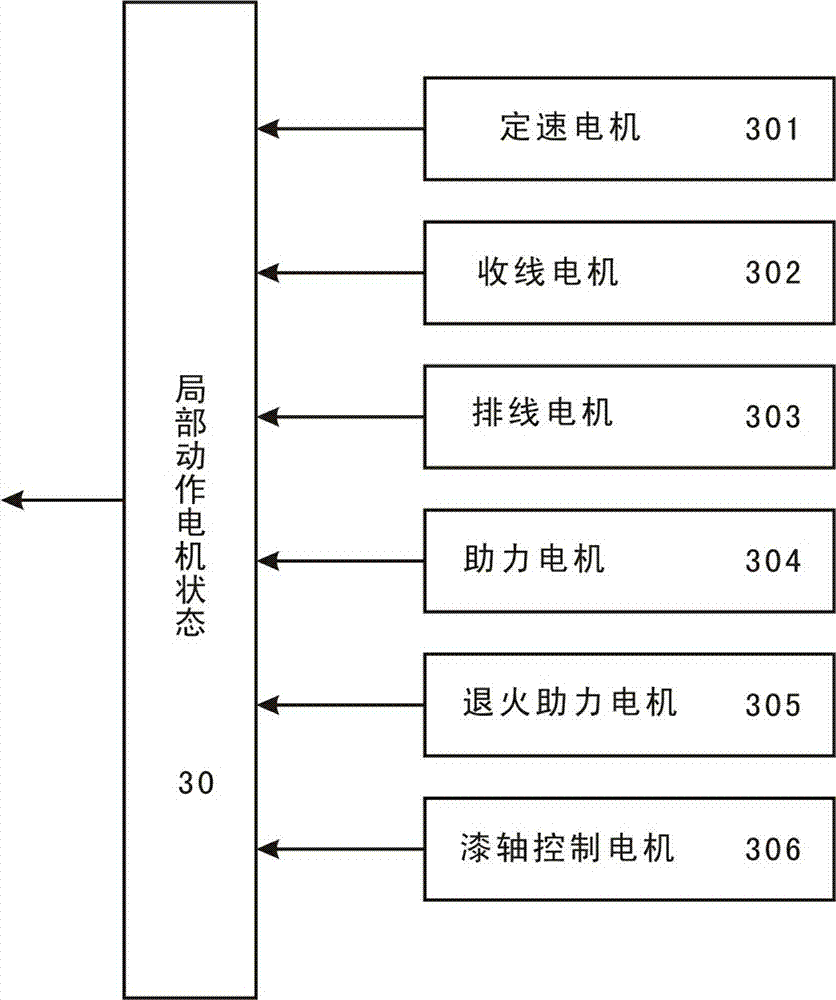

Remote automatic control method for enamelling machine

InactiveCN104267760AEasy to controlCentralized controlTemperatue controlTemperature controlAutomatic control

The invention discloses a remote automatic control method for an enamelling machine. The method comprises the steps that an operator can manually set the upper and lower bounds of the temperature of each temperature control point through a touch screen, and set the rotating speed (rpm) of a motor; all monitoring parameters should have the early warning function, and a sound-light alarm should be given when the monitoring value exceeds the preset range; the automatic control starts from a temperature rising program to be carried out, then adjustment and control are carried out, and historical technological records can be stored in the control method to be prepared to be called; the remote automatic control method can achieve communication between a remote communication device and a remote host, and can carry out data transmission and final management. Compared with the prior art, the remote automatic control method for the enamelling machine can be grasped by operators without rich experience, is accurate and timely in control, visual in display and beneficial to concentrated control, and power consumption and emission targets are much lower than the national standard.

Owner:DONGGUAN ZELONG WIRE & CABLE +1

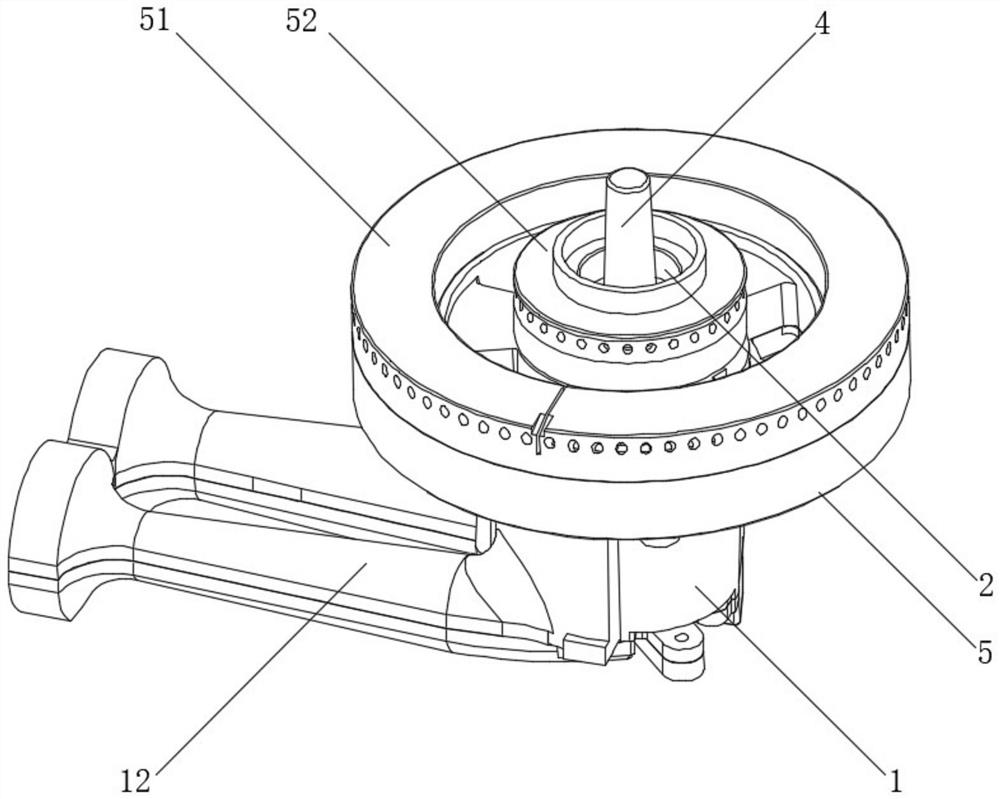

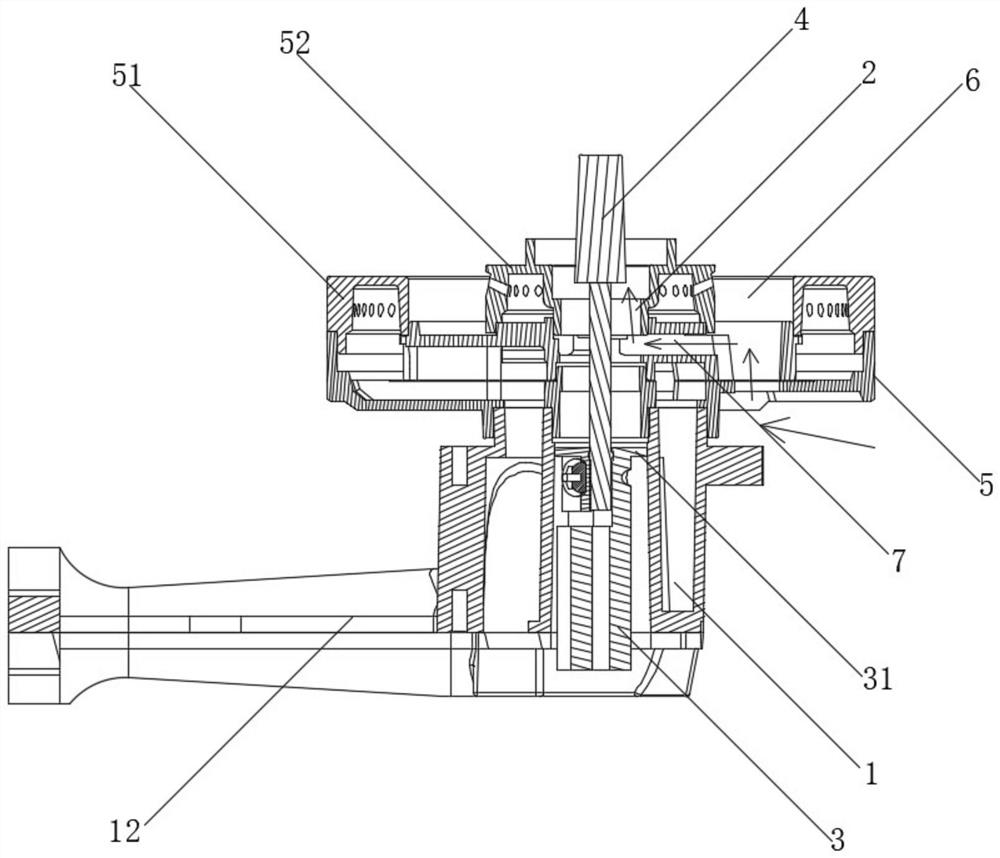

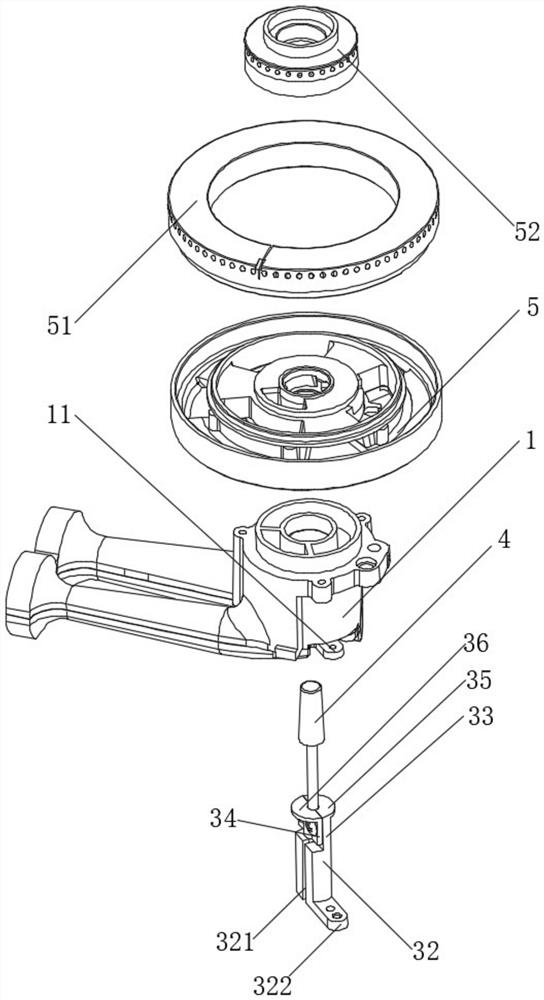

Burner and gas stove

PendingCN112032770APrevent fallingExtended service lifeDomestic stoves or rangesGaseous fuel burnerProcess engineeringMechanical engineering

Owner:GREE ELECTRIC APPLIANCES INC

Method for producing stainless iron cakes by using blast furnace dust, stainless precipitator dust and iron scale

The invention relates to a method for producing stainless iron cakes by using blast furnace dust, stainless precipitator dust and iron scale, comprising the following sequential steps: uniformly mixing the following raw materials by mass proportion: 30-45 parts of the blast furnace dust, 15-30 parts of the stainless precipitator dust, 40-50 parts of the iron scale and 2-6 parts of water glass+ADs- adding 4-8 parts of water into the mixed raw materials to uniformly stir+ADs- extruding and pressing cakes by a cake pressing machine+ADs- filling the pressed cakes in clay pots, 5-6 pressed cakes being in each pot+ADs- putting the pots in a tunnel kiln, increasing the temperature of the pressed cakes in the pots by coal gas to 600DEG C100 DEG C for insulation for 10-16h+ADs- reducing the pressed cakes in the pots for 30-44h at a reduction temperature of 1180 DEG C150 DEG C in the tunnel kiln+ADs- and conveying the pots out of the tunnel kiln and air-cooling the pots and pressed cakes to produce the stainless iron cakes. The method for producing stainless iron cakes by using blast furnace dust, stainless precipitator dust and iron scale has low cost and high efficiency.

Owner:SHANXI TAIGANG STAINLESS STEEL CO LTD

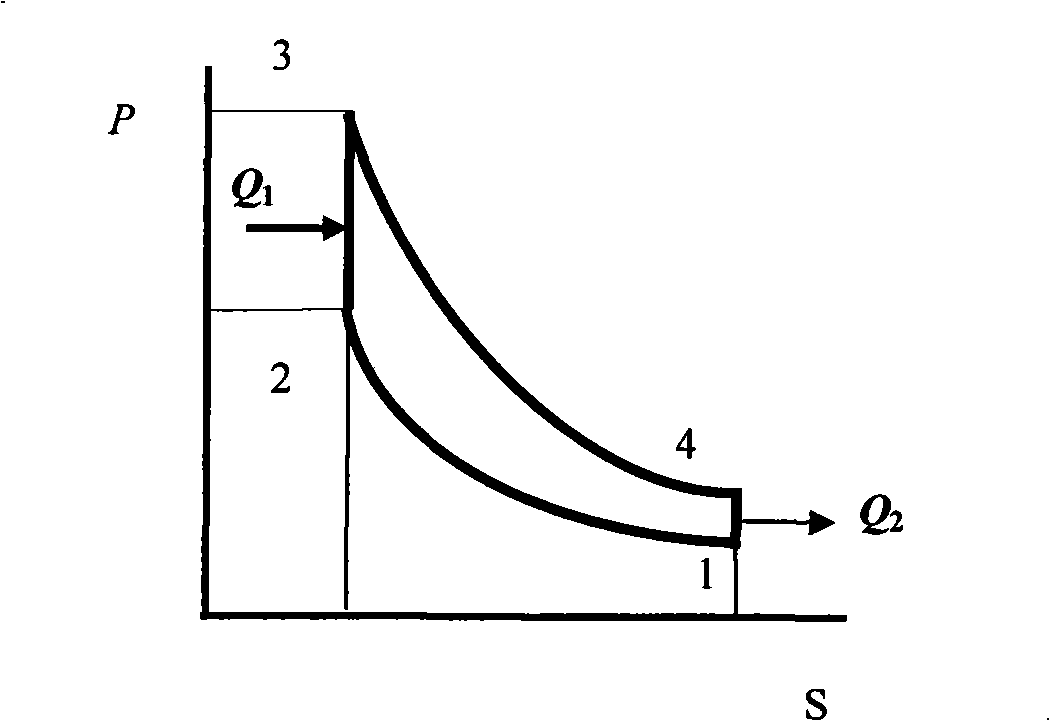

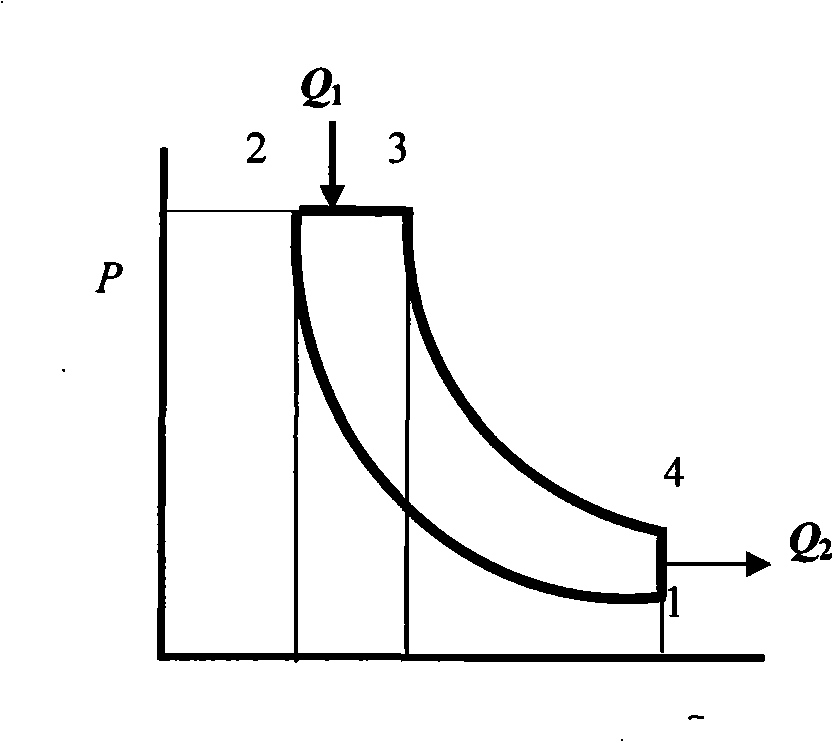

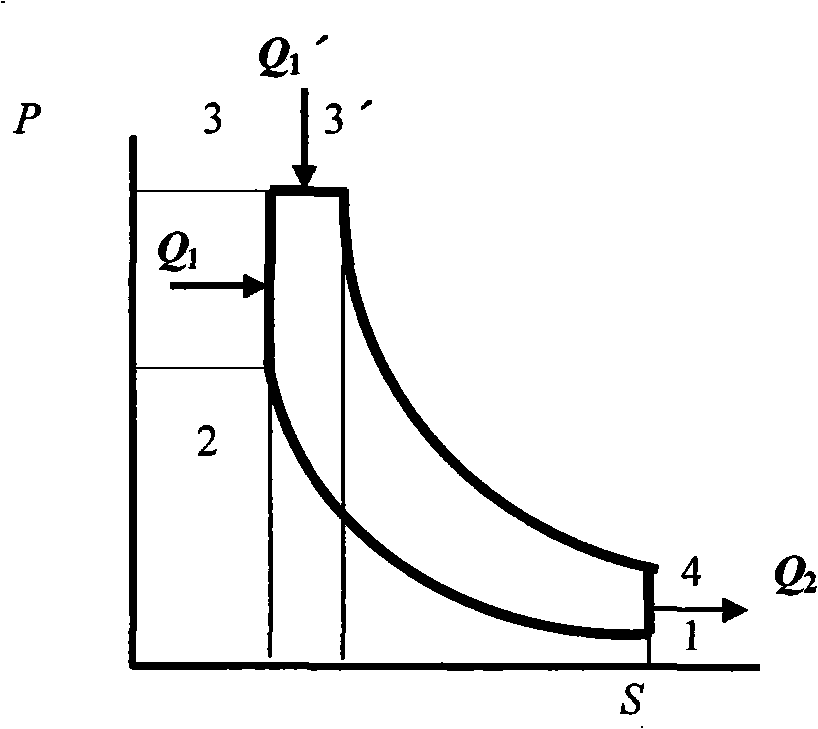

Gasoline and diesel general purpose internal-combustion engine

InactiveCN101338696AImprove powerImprove economyInternal combustion piston enginesGeneral purposeStored energy

The present invention discloses an universal gasoline-diesel internal combustion engine. A combustion chamber (16) is a high compression ratio combustion chamber. An explosion preventing and energy storing device which is communicated with the high compression ratio combustion chamber (16) is arranged on a cylinder cover (17). The energy q1of Pbz max larger than the allowed combustion pressure P1z during the combustion process is stored by the explosion preventing and energy storing device of the present invention to eliminate peak value and avoid detonation; when a piston descends, the stored energy q1 is transferred into q2 to be discharged under a controlled condition to form an isobaric combustion area between P1z and P2z, so as to obtain a full indicating diagram. The universal gasoline-diesel internal combustion engine is not provided with an electronic ignition system, processes for compression combustion ignition by high temperature produced by high compression ratio and has the advantages of good dynamic preoperty, economical efficiency and discharging performance, and the universal gasoline-diesel internal combustion engine is particularly advantaged under cold start, idle speed, warming up and low load and low temperature. When the universal gasoline-diesel internal combustion engine is applied to a diesel engine, the universal gasoline-diesel internal combustion engine also can improve the discharge and eliminate the influence caused by rough combustion, is good for the diesel engine to develop towards light weight and high speed and improves the performance of the diesel engine completely.

Owner:CHANGFENG GROUP

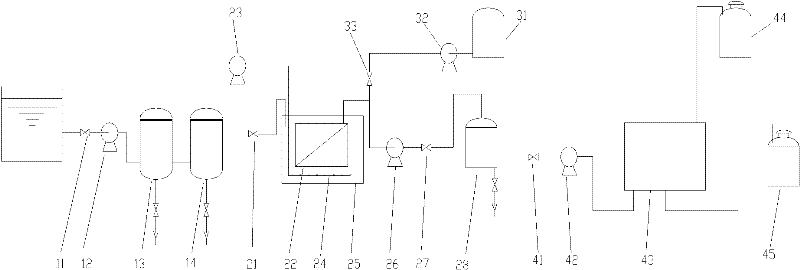

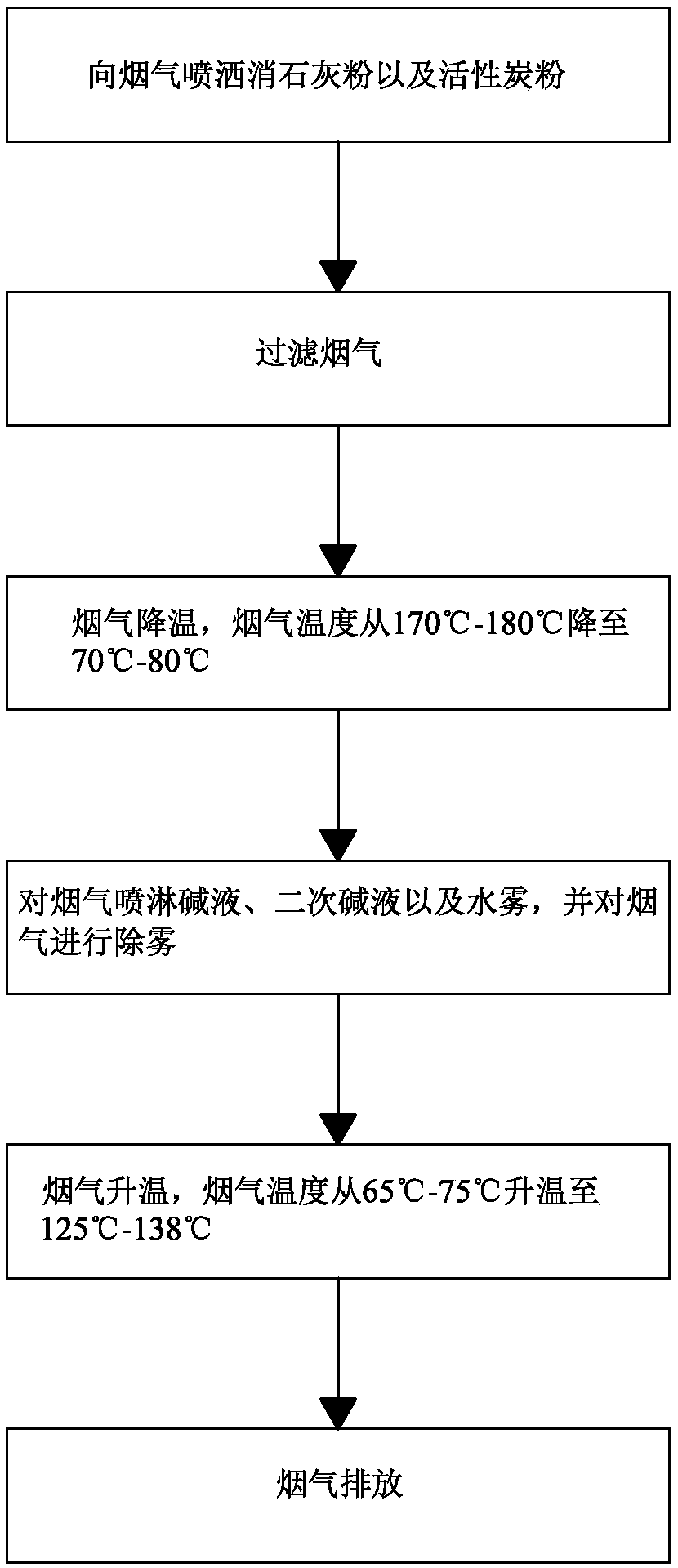

Waste gas purification process and purification system

PendingCN109224806ALow costEfficient removalGas treatmentDispersed particle filtrationWaste gasTreatment costs

The invention discloses a waste gas purification process and purification system, which comprises a combustion furnace, a bag type dust remover, a high-temperature section of a smoke gas heat exchanger, a precooler, a washing tower, a low-temperature section of the smoke gas heat exchanger and a chimney in sequential communication through a smoke gas pipeline, wherein a power spraying mechanism isarranged between the combustion furnace and the bag type dust remover; a spray nozzle of the powder spraying mechanism is arranged in the pipeline; a filling material layer, an alkali liquid sprayer,a secondary alkali liquid sprayer, a water mist sprayer and a mist eliminator are sequentially arranged inside the washing tower from bottom to top. The smoke gas is sequentially subjected to lime hydrate and active carbon spraying, filtering, temperature reduction, alkali liquid spraying, secondary alkali liquid spraying, water mist spraying, mist elimination and temperature rise; acid gas, dioxin and heavy metal can be effectively eliminated; the operation is simple, so that the discharge index can be greatly lower than the environmental protection standard level; meanwhile, the smoke gas heat exchanger is used; the smoke gas afterheat is effectively utilized; the heat utilization efficiency is improved; the waste gas treatment cost is effectively reduced.

Owner:珠海市斗门区永兴盛环保工业废弃物回收综合处理有限公司

Flue gas waste heat recovery and purification device for small household biomass boiler

ActiveCN111365727AIncrease moisture contentWater dew point temperature increasesCombustion technology mitigationStationary tubular conduit assembliesParticulatesNitrogen oxides

The invention relates to the technical field of flue gas treatment of small household biomass boilers, in particular to a flue gas waste heat recovery and purification device for a small household biomass boiler. The device is structured such that the lower end of a flue gas inlet pipe passes a top cover of a body and enters a cavity of the body, the flue gas inlet pipe is fixed to the top cover,and a drain outlet is formed in the bottom of the body; a humidifying spray pipe is arranged in the flue gas inlet pipe; a double pipe exchanger comprises a flue and a heat exchange unit, and the lower port of the flue gas inlet pipe communicates to the flue; filler is arranged around the flue gas inlet pipe and / or the double pipe exchanger; a dust removal spray pipe is arranged in the cavity of the body and is located above the filler; a fin tube heat exchanger is arranged in the cavity of the body and is located above the dust removal spray pipe; a flue gas outlet pipe is arranged on the topcover, and a liquid outlet is formed in the body below the double pipe exchanger. The device not only can recycle sensible heat of flue gas and latent heat of water vapor in the flue gas, but also can eliminate harmful substances such as soot particulates, sulfur dioxide and oxynitride in the flue gas.

Owner:ENERGY RES INST OF SHANDONG ACAD OF SCI

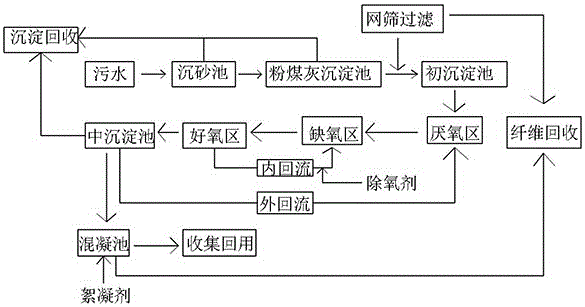

Paper making sewage treatment and reuse process

ActiveCN106277575ASimple stepsEasy to operateTreatment involving filtrationTreatment with aerobic and anaerobic processesFiberEngineering

The invention belongs to the technical field of waste water treatment, and particularly relates to a paper making waste water treatment and reuse process. The process involves a regulating primary precipitation system, an AAO middle precipitation system and a coagulation reaction reuse system in sequential arrangement, wherein the coagulation reaction reuse system comprises a coagulation pool used for extracting liquid supernatant from the middle precipitation pool; flocculating agents are added into the coagulation pool so as to remove precipitate fiber; then, collection is performed for reuse; the flocculating agents are prepared from sequentially added polyaluminium sulfate and anionic polyacrylamide through being metered in parts by weight; before the addition of the flocculating agents, the water body pH in the coagulation pool is regulated to 7.2 to 7.4 by diluted hydrochloric acid. The process has the advantages that waste water generated by paper making is subjected to physicochemical and biochemical treatment so as to be collected and reused; the steps are simple; the operation is convenient; the treatment period is short; the cost is low; the treatment effect is obvious; each discharge index is lower than the national standard.

Owner:ZHEJIANG HUAQIANG ENVIRONMENTAL TECH

Clean fuel for replacing diesel

A clean fuel that replaces diesel oil. The invention provides a liquid fuel that has high calorific value, good environmental performance and can replace existing diesel oil. The composition of this product includes: solvent oil, methanol, C 17 , water, dimethyl ether, amyl nitrate, the weight ratio of the components is solvent naphtha 30-45%; methyl alcohol 20-35%; C 17 25-30%; water 2-5%; dimethyl ether, amyl nitrate 3-5%. The invention is applicable to various diesel vehicles, household vehicles, tractors and other diesel engines as fuel oil.

Owner:哈尔滨市呼兰中丹建业生物能源股份有限公司

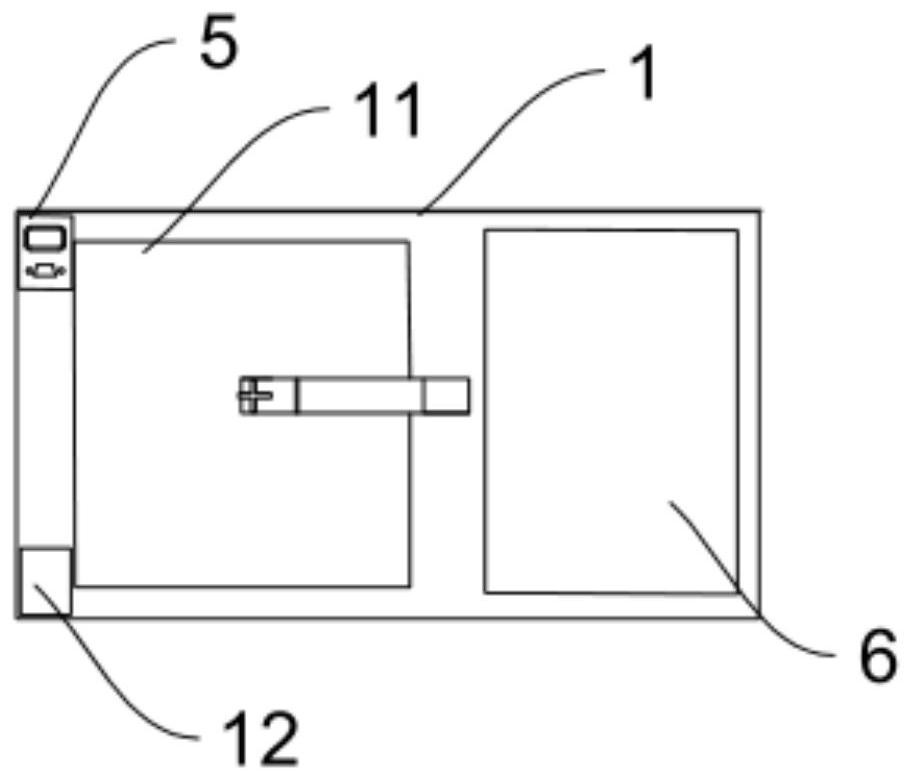

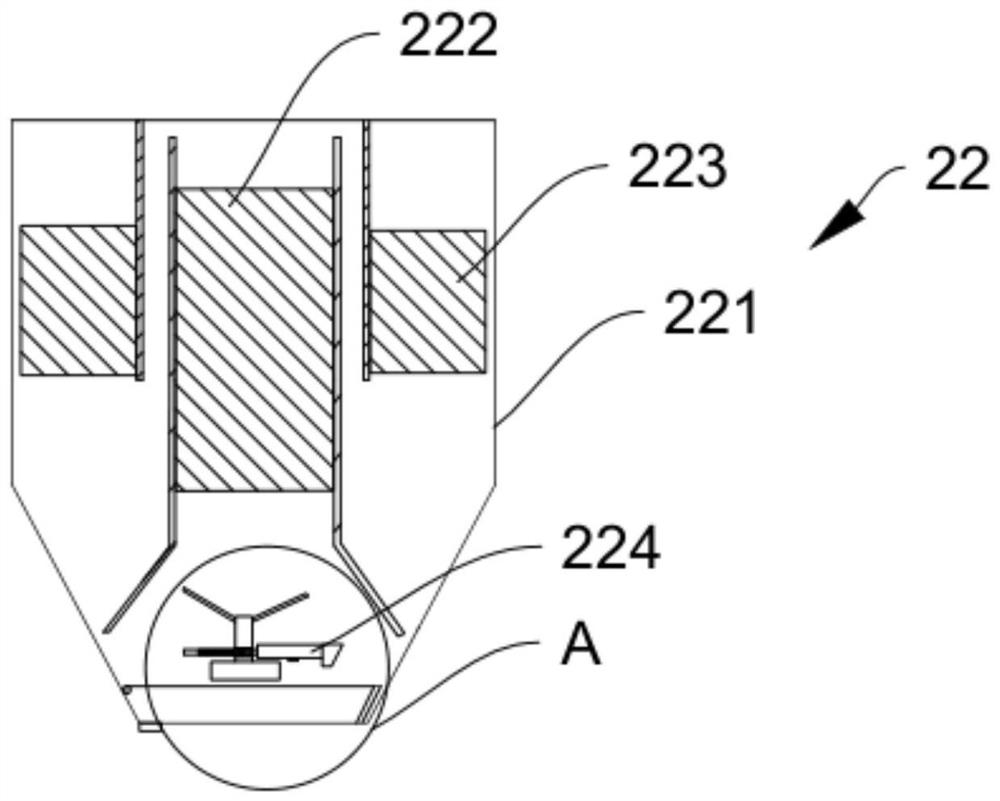

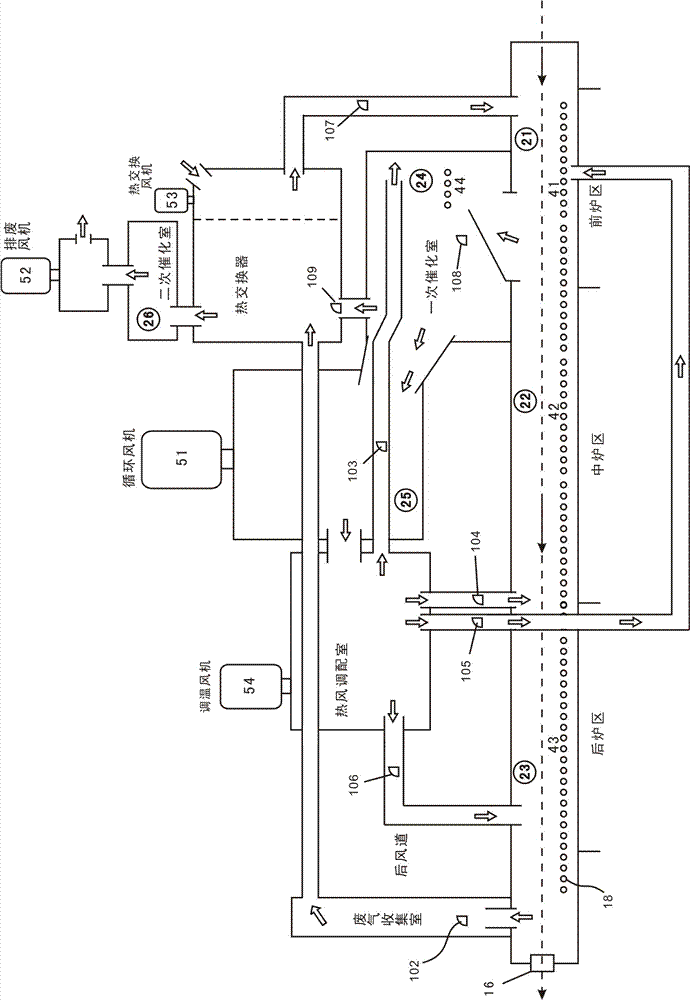

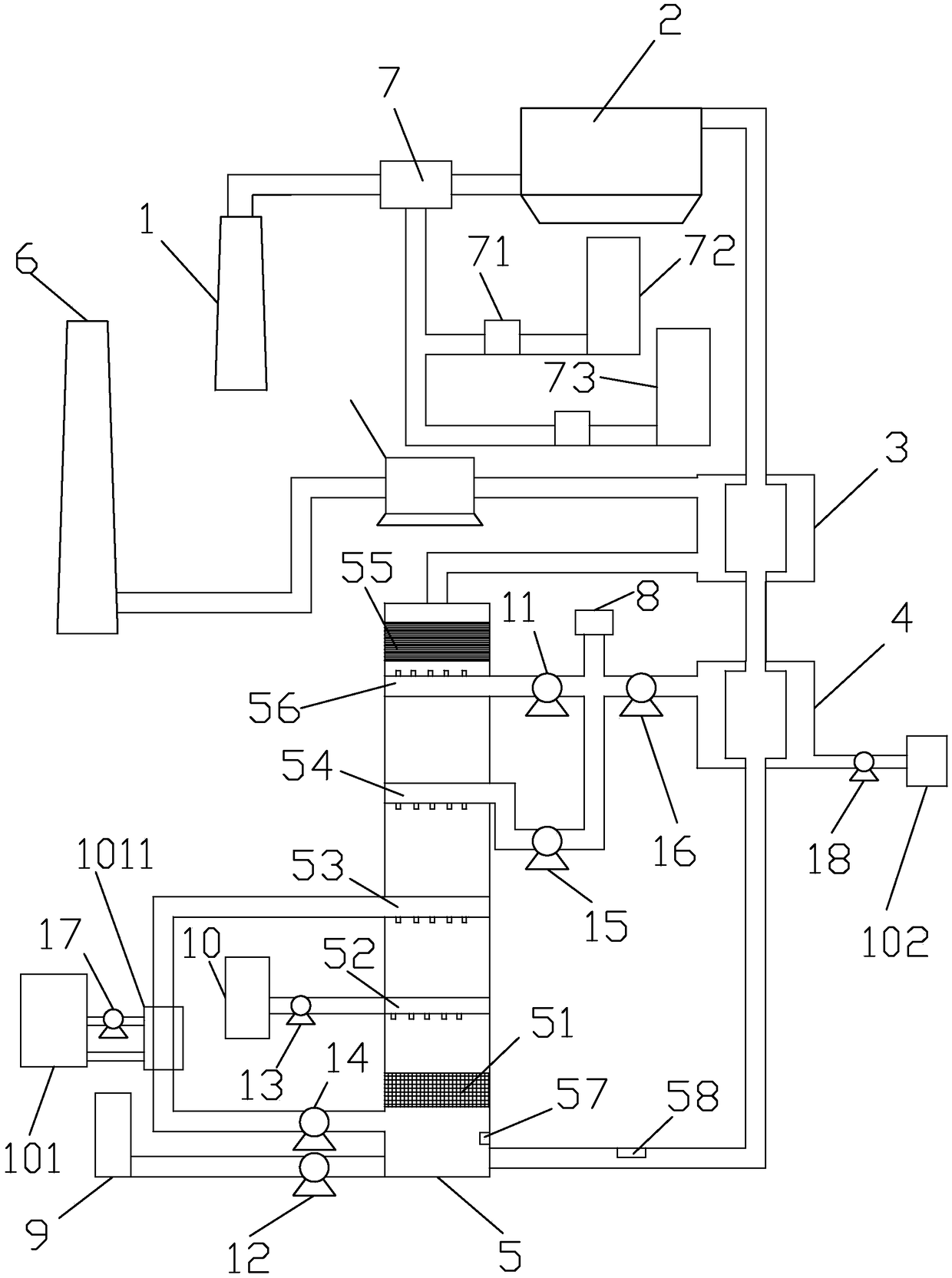

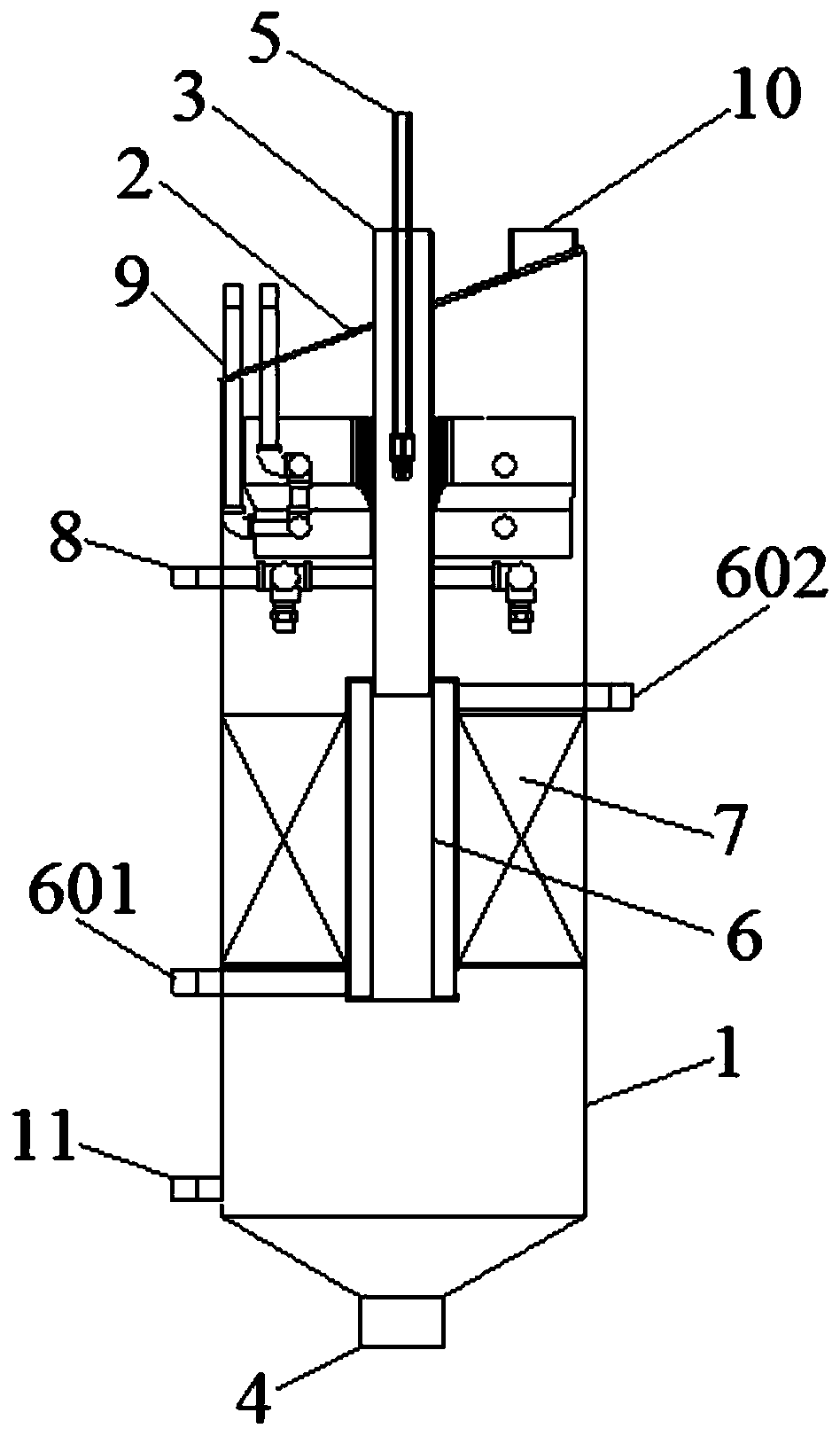

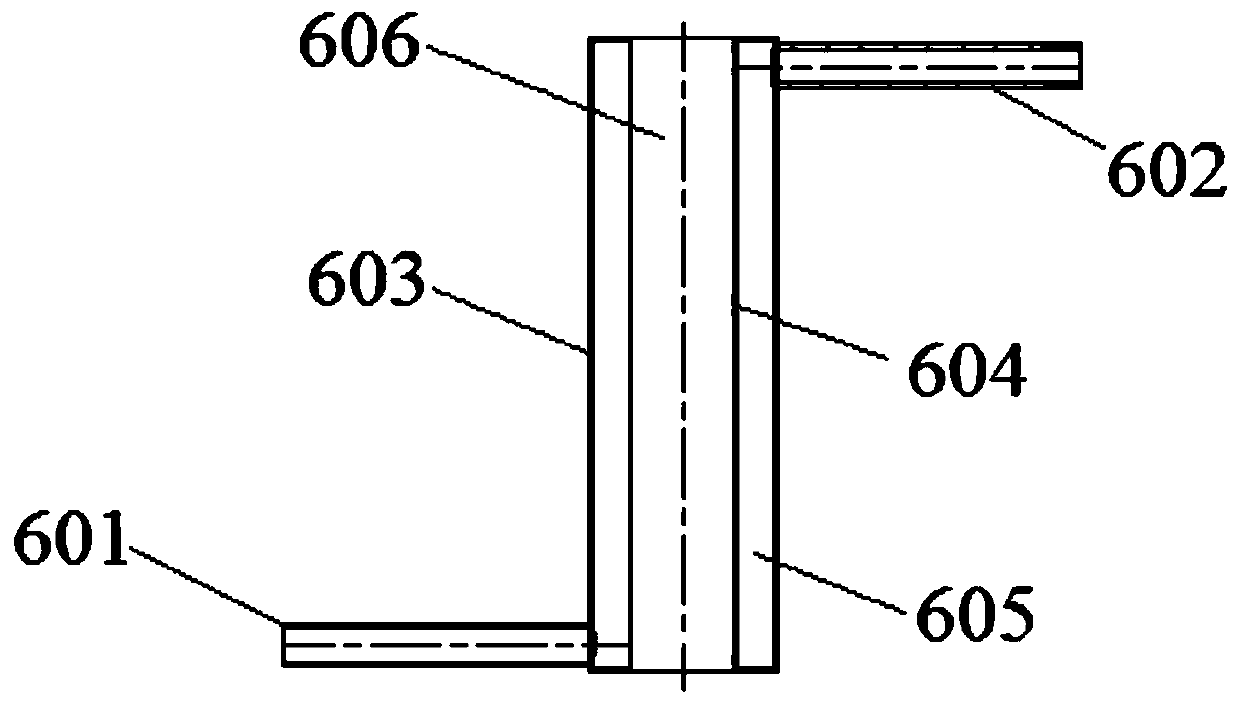

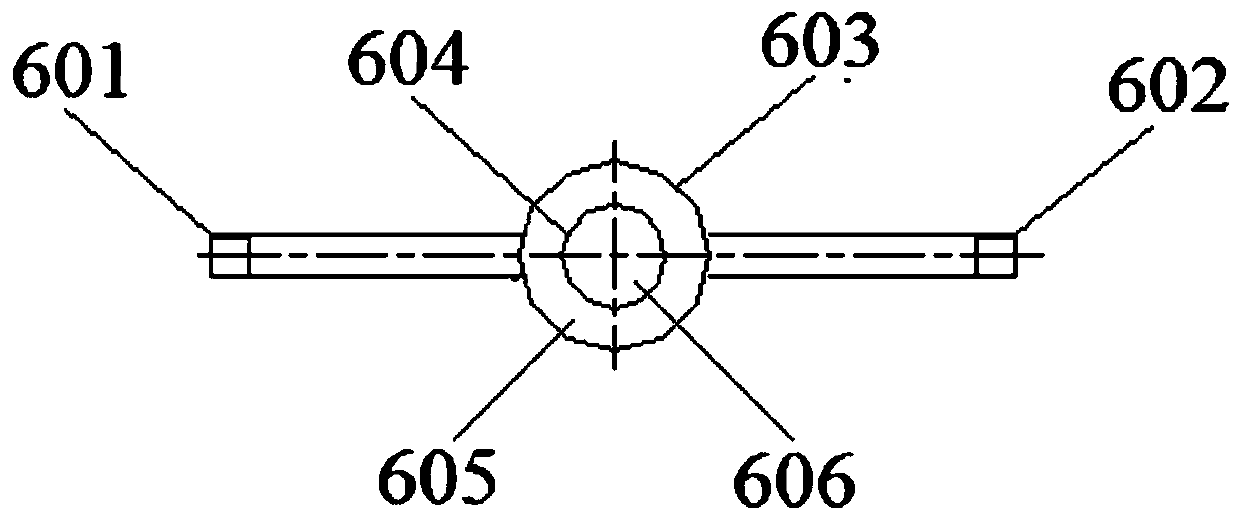

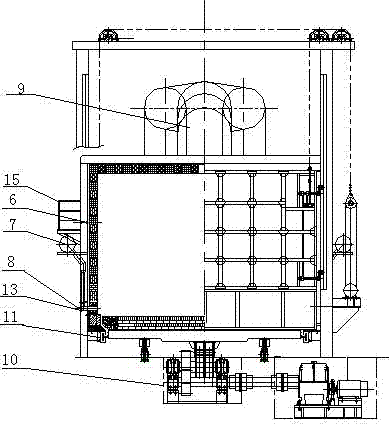

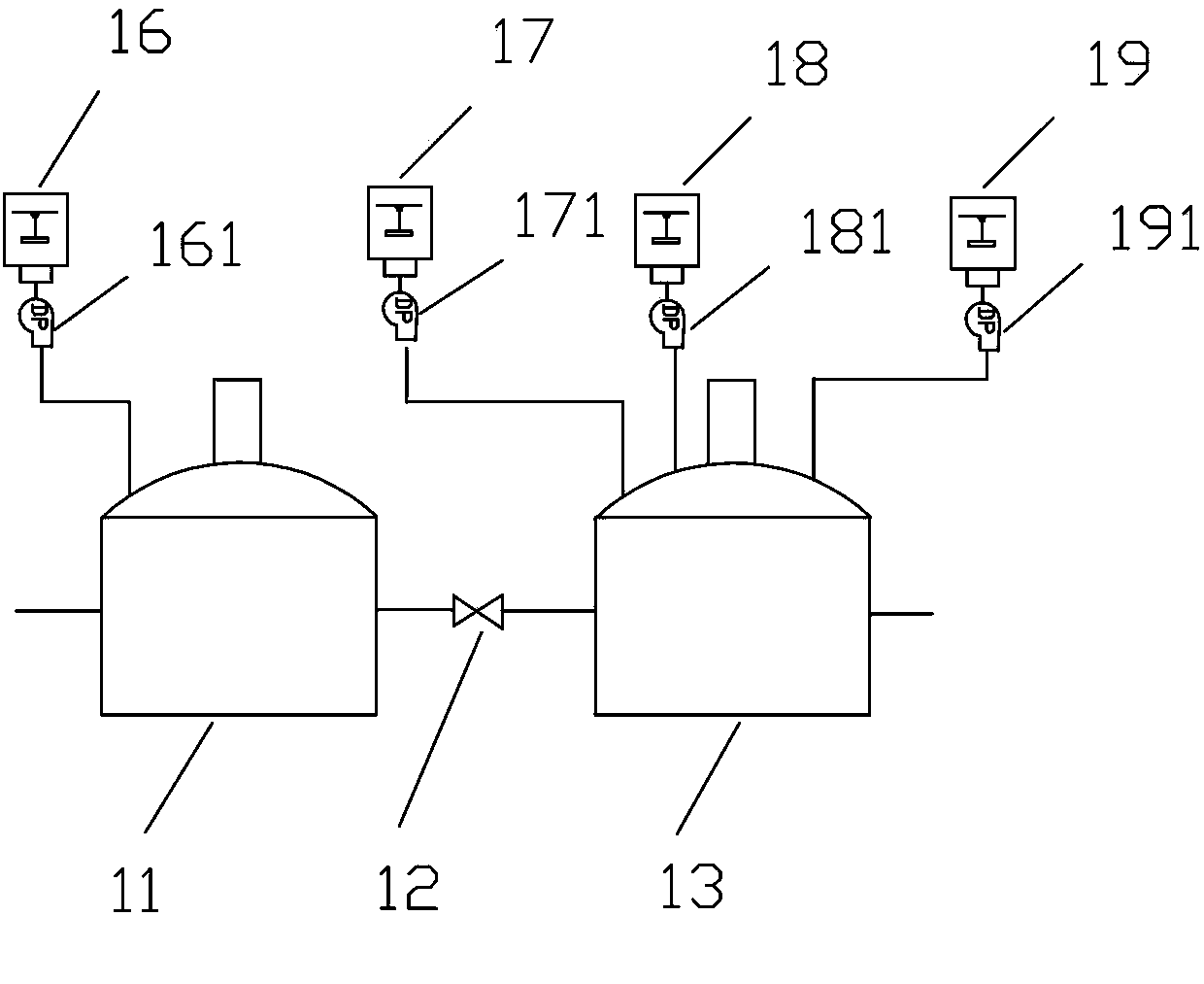

Distributed control system for car-bottom type heat treatment furnace groups

InactiveCN103712467AStructure Simplification and IntegrationFlexible and convenient operationControl devices for furnacesDistributed control systemProcess engineering

The invention provides a distributed control system for car-bottom type heat treatment furnace groups. The distributed control system comprises slave station cabinets, a master control cabinet and at least one heat treatment furnace. The slave station cabinets are arranged on the heat treatment furnaces, each heat treatment furnace comprises a furnace door, a lifting mechanism, a furnace body and a heat-insulation system, each furnace door is connected with the corresponding lifting mechanism, each lifting mechanism is arranged on the corresponding furnace body, each heat-insulation system is arranged in the corresponding furnace body, each furnace body is provided with an air pipeline, a gas pipeline, a smoke discharge pipeline and a burner, both each air pipeline and the corresponding gas pipeline are connected with the corresponding burner, and each smoke discharge pipeline is communicated with the corresponding furnace body. The distributed control system for the car-bottom type heat treatment furnace groups has the advantages that the slave station cabinets are communicated with the master control cabinet via profibus-DP (process field bus-DP), accordingly, large quantities of connecting cables which extend from the slave station cabinets to the master control cabinet can be omitted, the structure of the distributed control system can be simplified and integrated, the distributed control system can be operated conveniently and flexibly, a large quantity of cost can be saved, maintenance workload can be greatly relieved, and the furnace groups can be assuredly smoothly controlled in a centralized manner.

Owner:DANYANG JIANGNAN INDAL FURNACE

Recycling device used for papermaking advanced treatment wastewater and based on chemical decalcification

InactiveCN103253838BOvercome defects such as polluting the environmentEmission reductionGeneral water supply conservationMultistage water/sewage treatmentElectrolysisFiltration

The invention discloses a papermaking advanced treatment waste water recycling device based on chemical decalcification, which includes a chemical decalcification system, a filtration system, an electrolysis system, a membrane separation system and a desalination system. The chemical decalcification system is equipped with a dosing system and a membrane separation system. It is one of ultrafiltration system and MBR system. The present invention combines chemical decalcification technology, electrochemical technology and membrane technology, and 70% to 85% of papermaking advanced wastewater treatment can be recycled and recycled, which not only reduces wastewater discharge, avoids environmental pollution of wastewater, but also reduces waste of water resources , It can also make the cost of regenerated circulating water lower than the price of tap water, which is economically reasonable, produces better economic benefits, greatly reduces the water consumption index and wastewater discharge index of tons of paper, and improves the economic and technical indicators of the enterprise.

Owner:BOYING XIAMEN SCI & TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com