Device and method for treating and recycling printing and dyeing wastewater

一种处理循环、印染废水的技术,应用在纺织工业废水处理、废涂料处理、多阶段水处理等方向,能够解决达不到工业废水回用标准、化学药剂消耗多、水资源浪费大等问题,达到减少生产用水量和废水排放量、减少污泥处理成本、减少废水排放的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0075] Step 1 desulfurization

[0076] Printing and dyeing wastewater enters the coarse grid filter 1 to filter and remove large particles of solids, then flows into the adjustment tank 2 for mixing, and then pumps the wastewater from the adjustment tank 2 into the hydraulic sieve 3 to filter and remove impurities such as fibers, and then flows into the desulfurization reaction tank 4. The equivalent concentration of sulfide ions is added to the ferrous sulfate solution in an amount of 1:1.1 of the equivalent concentration, and desulfurization is performed at room temperature. Divalent sulfide ions react with ferrous ions to form ferrous sulfide precipitates, which are separated into iron sulfide pollutants. mud and desulfurization wastewater.

[0077] Step 2 Nanocatalytic electrolysis

[0078] The wastewater desulfurized in step 1 flows into the nano catalytic electrolysis machine 5 for electrolysis, the working voltage of the electrolysis is 2-500V, the voltage between the ...

Embodiment 2

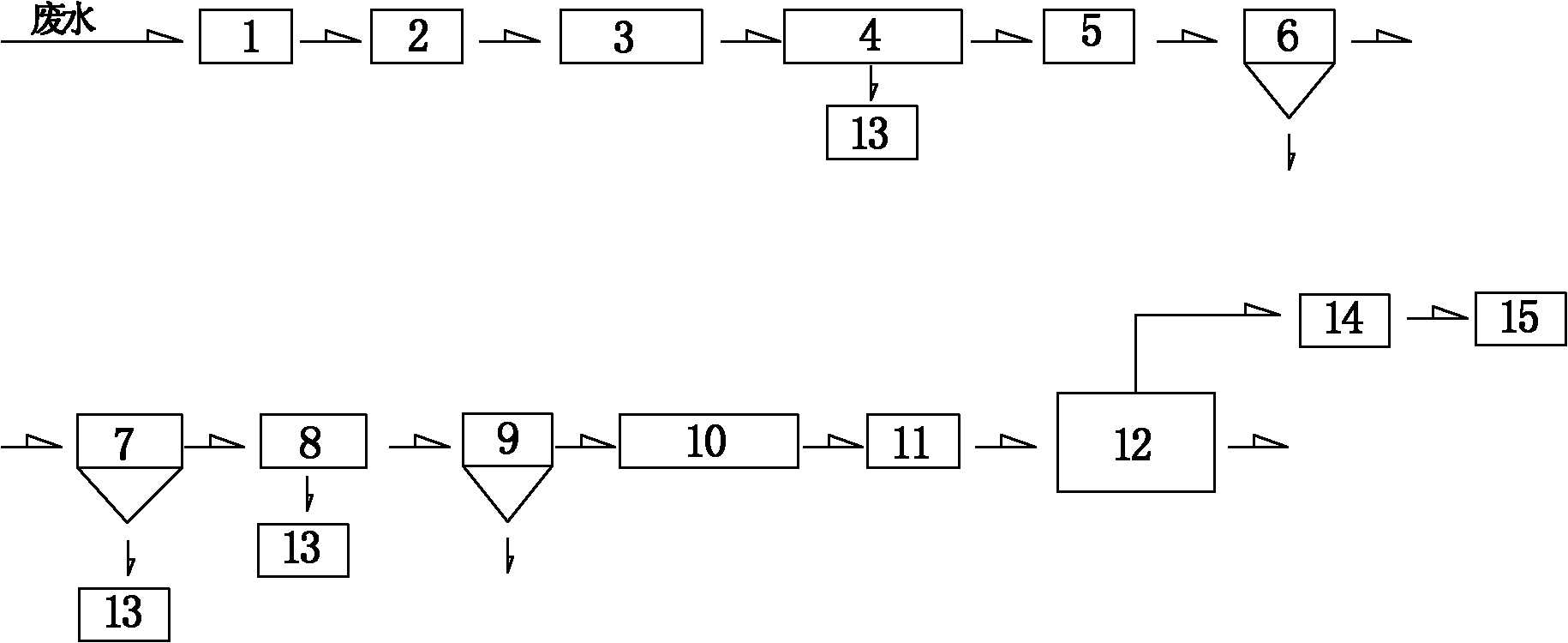

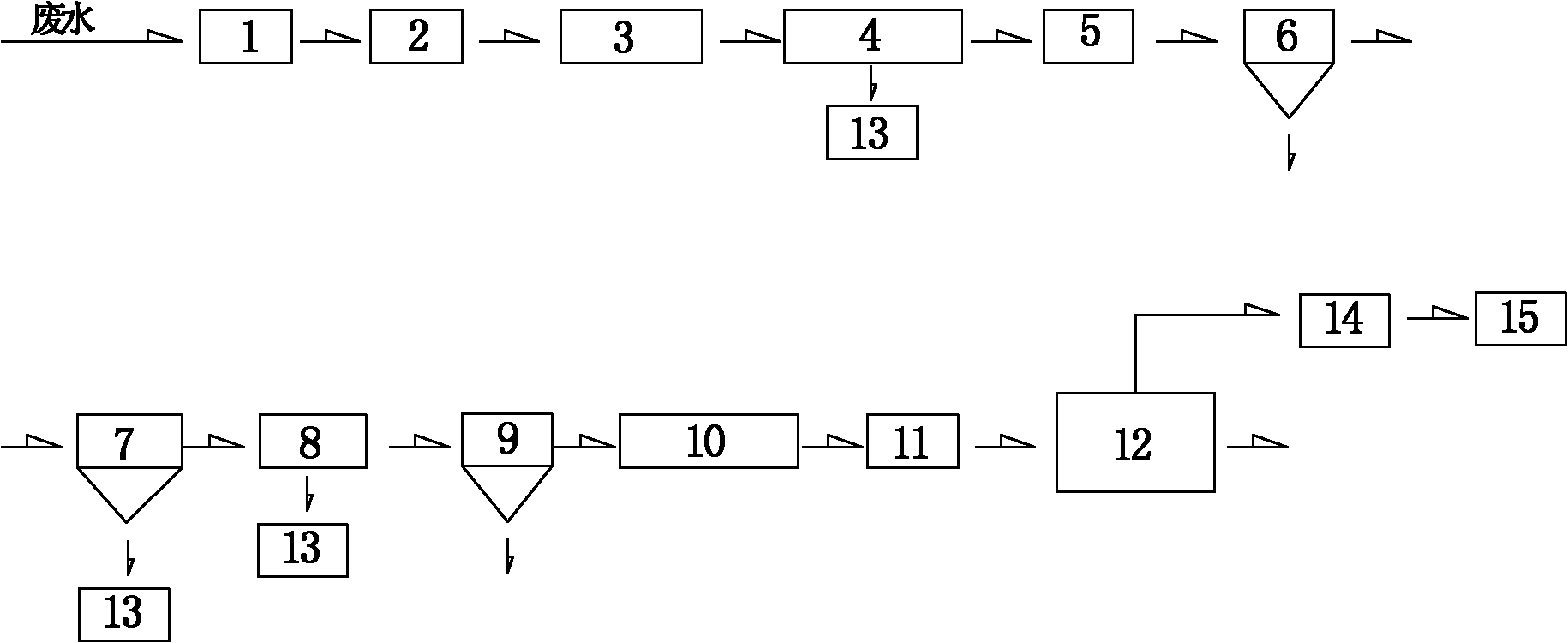

[0093] The following combination figure 1 The illustrated embodiment of the printing and dyeing wastewater treatment and recycling device based on nano-catalytic electrolysis and membrane technology gives an example of the printing and dyeing wastewater treatment and recycling method based on nano-catalytic electrolysis and membrane technology. 300 tons / day printing and dyeing wastewater treatment and purification reuse project. The measured indicators of the printing and dyeing wastewater (comprehensive wastewater) are shown in Table 2.

[0094] Table 2

[0095] serial number

project

unit

measured value

serial number

project

unit

measured value

1

COD Cr

mg / L

3160

5

S 2-

mg / L

132

2

SS

mg / L

311

6

Chroma

600

[0096] 3

NH 3 -N

mg / L

265

7

pH

9.3

4

BOD5

mg / L

1030

8

Sodium chloride

...

Embodiment 3

[0101] 3,000 tons / day tannery treatment wastewater reuse project.

[0102] The measured indicators of the printing and dyeing wastewater (comprehensive wastewater) are shown in Table 4.

[0103] Table 4

[0104] serial number

[0105] Waste water through water according to 150m 3 The flow rate of / H enters the coarse grid filter 1 to filter and remove large particles of solids, then flows into the adjustment tank 2 for mixing, and then the wastewater in the adjustment tank 2 is divided into 150m 3 After the flow rate of / H is pumped into the hydraulic sieve 3 to filter impurities such as fibers, it flows into the desulfurization reaction tank 4, and the equivalent concentration of divalent sulfide ions is measured online, and the ferrous sulfate solution is added in an amount of 1:1.1 of the equivalent concentration, and reacted at room temperature Desulfurization, the desulfurized wastewater flows into the nano catalytic electrolysis machine 5 for electrolysis, th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| current density | aaaaa | aaaaa |

| decolorization ratio | aaaaa | aaaaa |

| decolorization ratio | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com