Patents

Literature

1113results about How to "Reduce chroma" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Increasing chroma and edge acuity of dye-based inks by underprinting using vesicle technique

InactiveUS6261350B1Good edge acuityReduce chromaDuplicating/marking methodsInksWater solubleEngineering

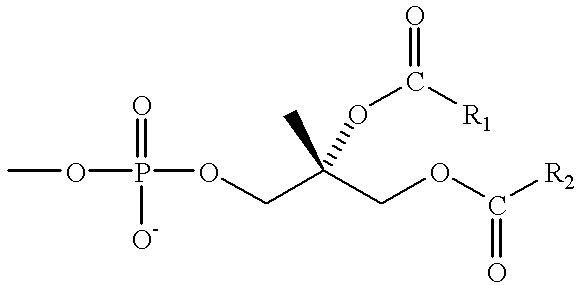

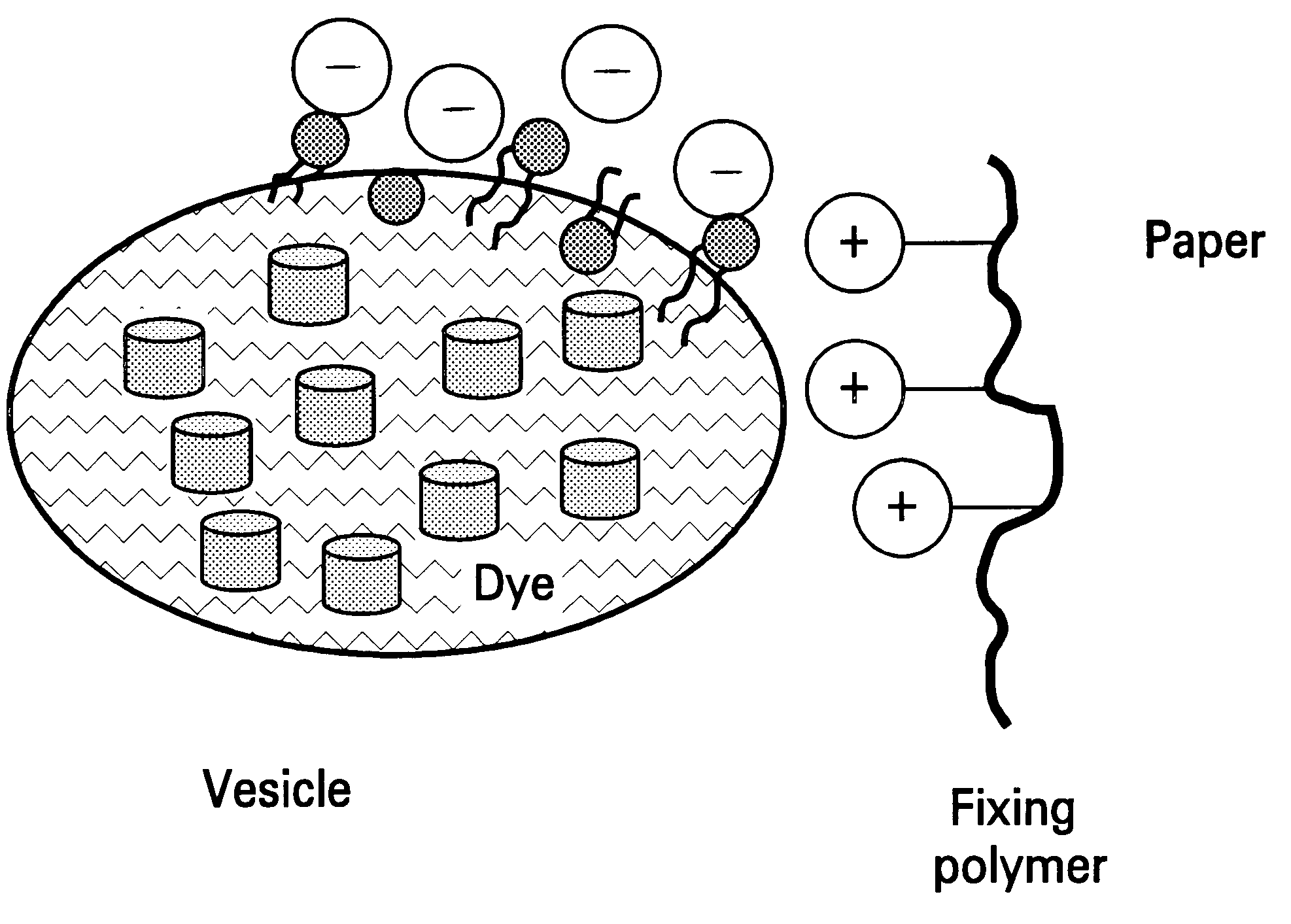

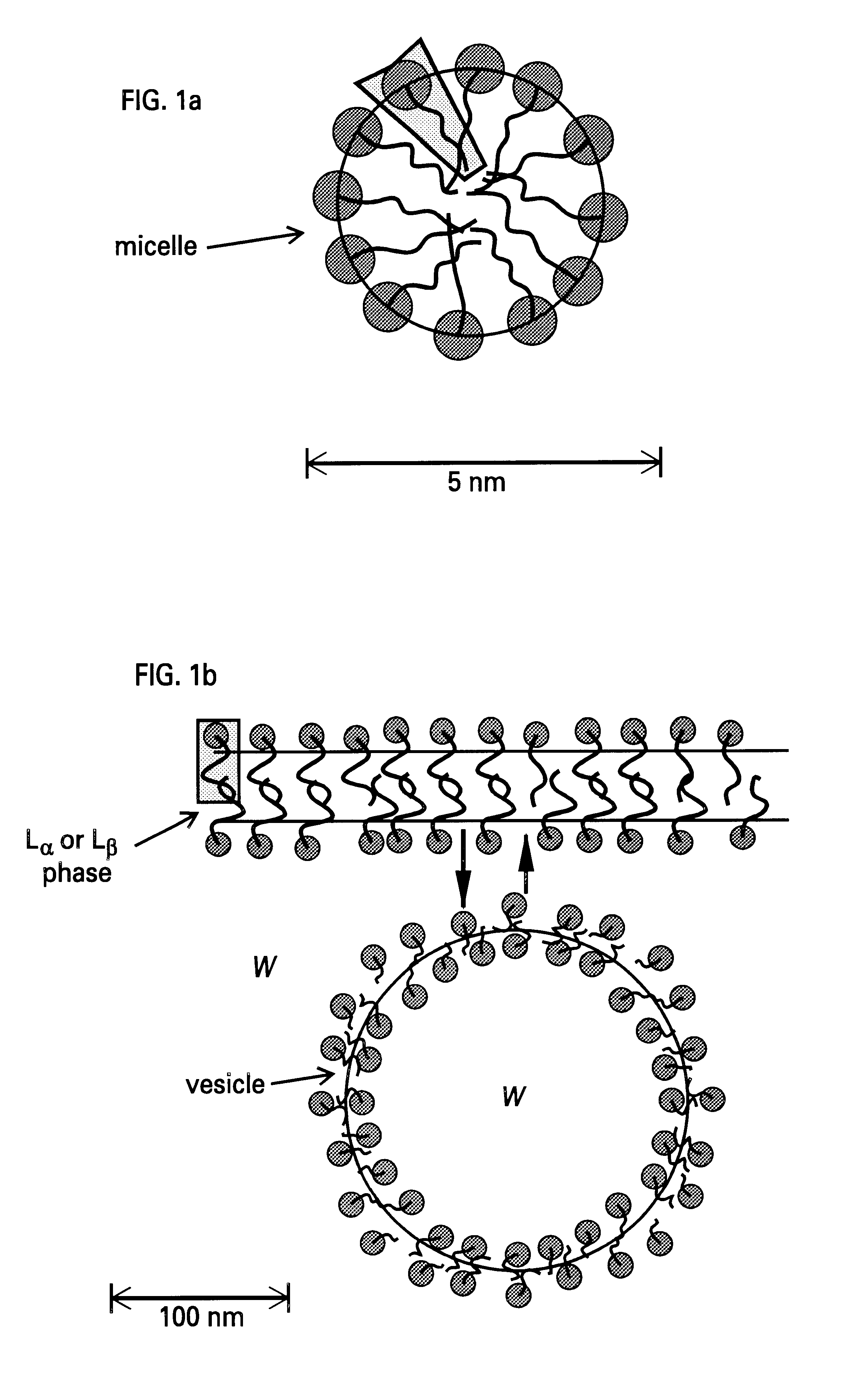

Chroma is increased, color-to-color bleed is reduced, and edge acuity is increase for dye-based inks by an underprinting technique. A dye-based ink-jet ink printing system is provided, comprising cyan, yellow, and magenta inks, each ink contained in a separate ink pen. Each ink contains at least one water-soluble dye and vesicles. The vesicles are present in an amount sufficient to contain a substantial fraction of dye molecules within the water pool of the vesicles. The vesicles formed from a surfactant having a first polarity. The printing system further comprises an additional pen containing a fixer having a second polarity, opposite to the first polarity. Further, an ink-jet printer that includes the dye-based ink-jet ink printing system is configured to print the fixer on a print medium, followed by printing at least one ink on the fixer. A method for improving chroma, color-to-color bleed, and edge acuity in a dye-based ink-jet ink. The method comprises: (a) providing the above ink set; (b) providing an additional pen containing a fixer having a second polarity, opposite to the first polarity; (c) printing the fixer on a print medium; and (d) printing at least one ink on the fixer.

Owner:HEWLETT PACKARD DEV CO LP

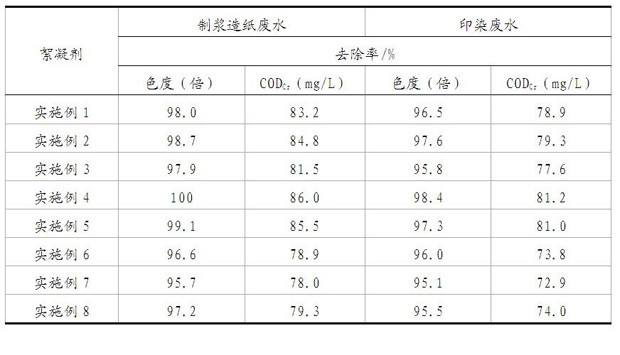

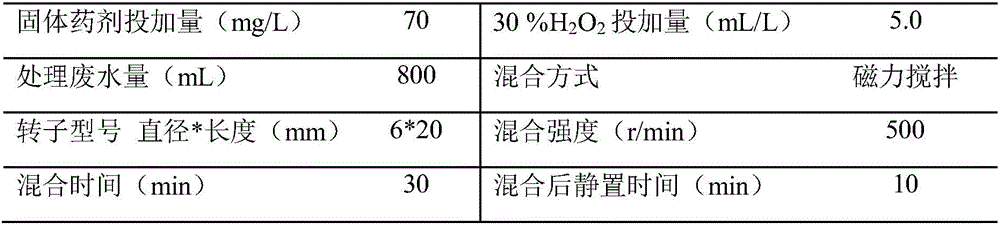

Flocculating agent for waste water treatment, and preparation method thereof

InactiveCN104071881AReduce CODReduce chromaWater/sewage treatment by neutralisationWater/sewage treatment by flocculation/precipitationAluminum IonTurbidity

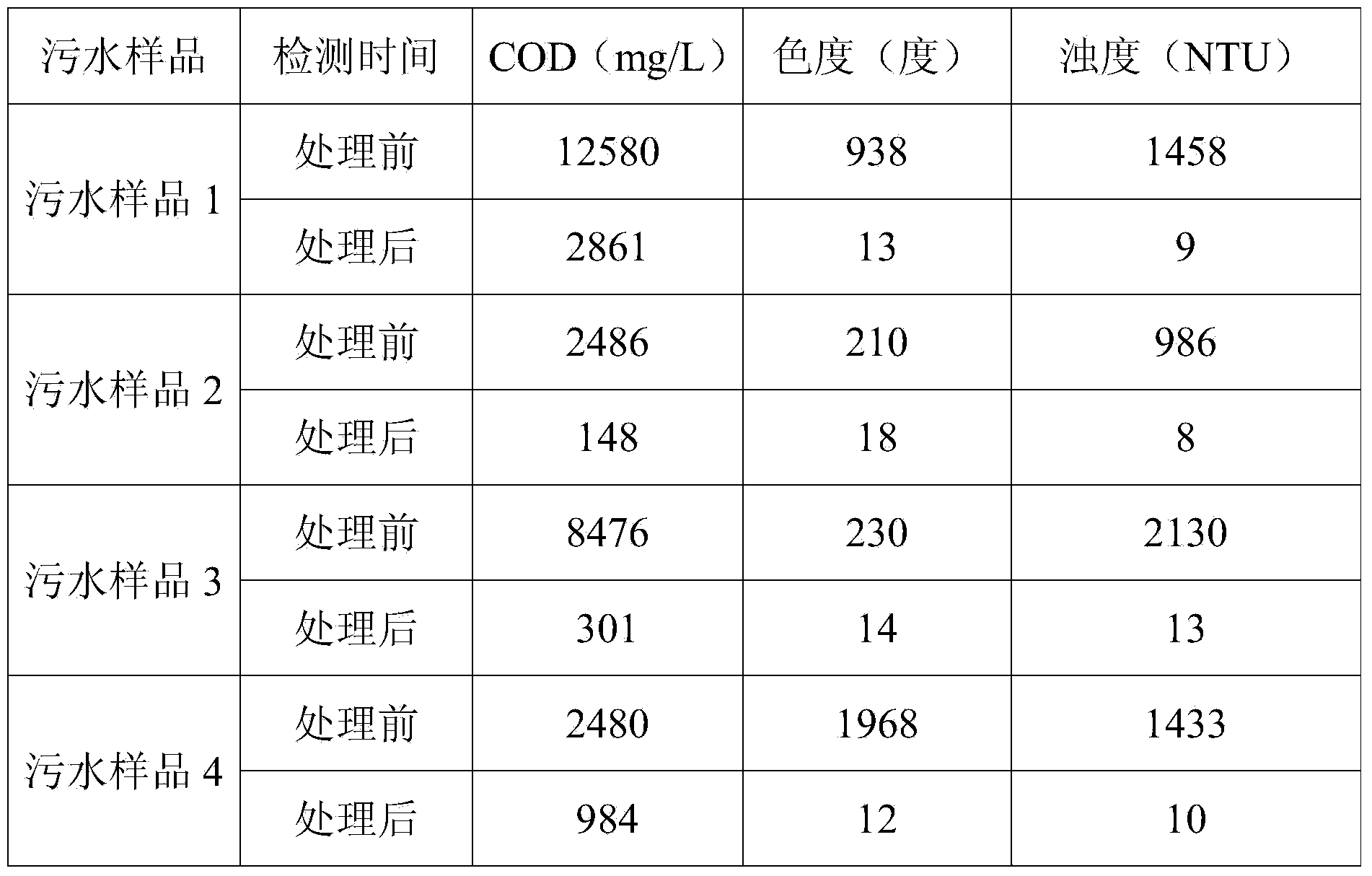

The invention discloses a flocculating agent for waste water treatment. The flocculating agent comprises components of calcium sulfate, aluminum ion salt, sodium carbonate, polyacrylamide, sodium thiosulfate, chitosan, chitosan quaternary ammonium salt, diatomite, cement and a pH adjusting agent, can be used for treating waste water discharged from food processing plants, metal manufacturing plants, chemical plants and the like, can also be used for treating waste water discharged from farms and slaughter plants, can also be used for purification of water quality in river channels and lakes, and can effectively reduce COD, color and turbidity of waste water.

Owner:廉勇

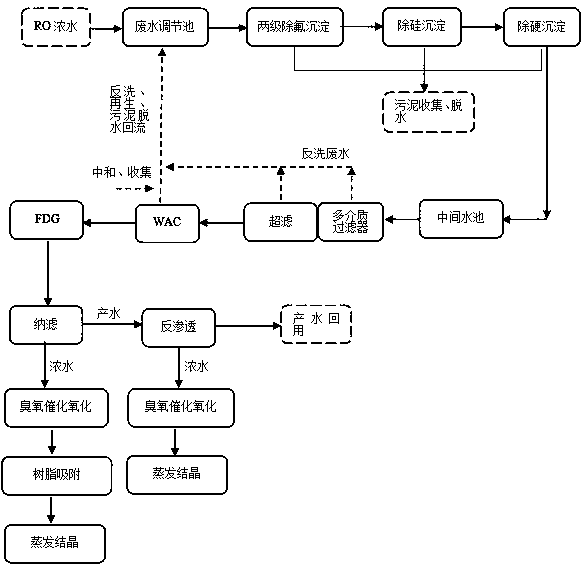

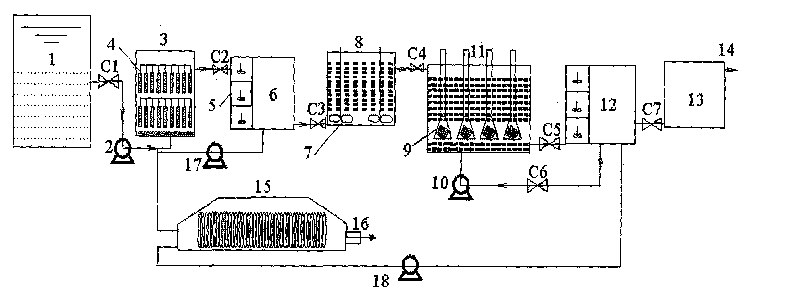

Recycling treatment process for coal coking high-salinity wastewater

PendingCN110606612AAchieving zero emissionsImplement resourcesWater contaminantsTreatment involving filtrationUltrafiltrationResource utilization

The invention relates to a recycling treatment process for coal coking high-salinity wastewater. The process comprises the following steps: (1) fluorine removing; (2) silicon removing; (3) softening;(4) treatment with a multi-medium filter; (5) ultrafiltration; (6) resin softening; (7) FDG; (8) nanofiltration and salt separation; (9) reverse osmosis concentration; (10) advanced oxidation; (11) resin adsorption; and (12) evaporative crystallization. The process has the advantages that the process of pretreatment, nanofiltration salt separation, reverse osmosis concentration, advanced oxidationand evaporative crystallization is adopted, so that zero emission and quality-divided resource utilization of the coal coking high-salinity wastewater are realized.

Owner:CHINA ELECTRONICS INNOVATION ENVIRONMENTAL TECH CO LTD +2

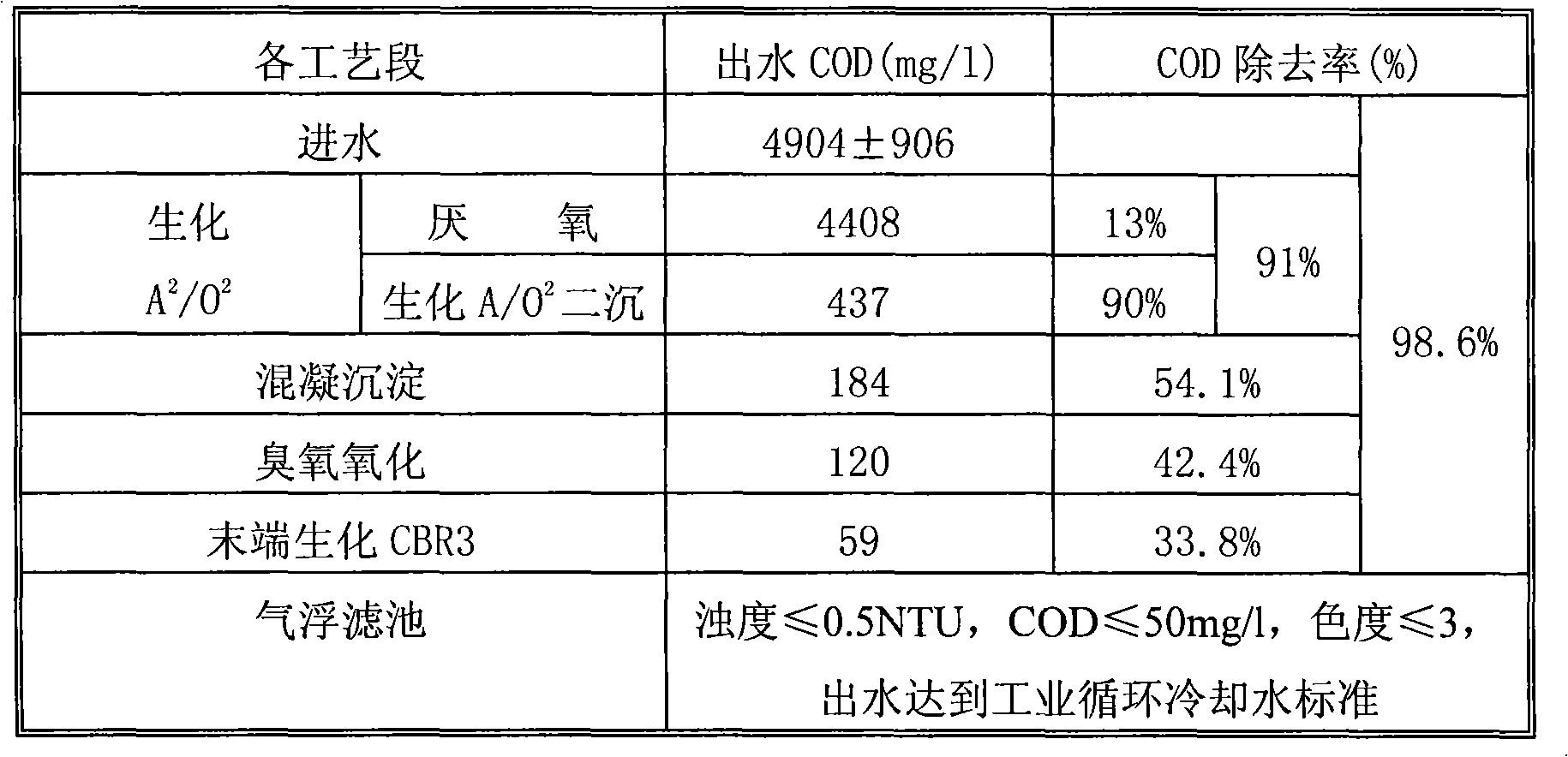

Dyeing and printing waste clearing, synthetic wastewater advanced treatment circulation production and recycle technique

InactiveCN101172741AGood denitrification functionIncrease profitMultistage water/sewage treatmentWater/sewage treatment by oxidationComing outAir bearing

The invention discloses a deep treatment technique used for the printing and dyeing sewage recovery. The technique consists of a BAF pond, an air-bearing system, an ozone contact oxidation tower, a filter, an active carbon filter, an ozone generator and a medicine adding system. The technique is the improvement of the traditional BAF technique, removes the resolvable organism in the sewage through the biological degradation, outtakes the water into the air-bearing system and combines the flocculation medicine adding technique, so as to eliminate the non-solvent organism and colloidal substance in the sewage. The outtaken water enters into the ozone contact oxidation tower and gets mixed with ozone, so that the organism which is difficult to undergo the biological degradation in the printing and dyeing sewage is removed with the help of the strong oxidizing property of the ozone. The water flowing out of the ozone contact oxidation tower enters into the pond at the middle, and 30 percent of the water returns to a gas dissolving can under the action of a pressurizing pump, gets mixed with the pressurized air and then enters into the air-bearing system through utilizing the remaining pressure. The gas-water solution is dispersed into the small and equable drips through a dissolved gas releaser, and the drips drive the suspending substances and the colloidal substance to float up to the water surface so as to achieve the removal. The water coming out of the middle pond enters into the filter to remove the small suspending substances and enters into the ozone / active carbon filtering system so that the reaction of the ozone basic chain is caused under the action of the active carbon, thereby speeding up the decomposition of the ozone into OH and other free radicals, degrades a small amount of organism, eliminates the color and finally ensures that the outtaken water reaches the recovery standard of the printing and dyeing sewage.

Owner:王爱月 +1

Comprehensive treatment method for garbage leachate

ActiveCN102649616AGuarantees long-term operational stabilityReduce energy consumptionWater/sewage treatment bu osmosis/dialysisMultistage water/sewage treatmentMacromolecular SubstancesIon

The invention relates to a comprehensive treatment method for garbage leachate. The comprehensive treatment method for the garbage leachate comprises the following steps: (1) performing foam separation pretreatment; (2) performing coagulation sedimentation pretreatment; (3) performing microfiltration and ultrafiltration treatment; (4) performing gaseous film separation treatment; and (5) performing biochemical treatment. The garbage leachate is subjected to coagulation sedimentation and foam separation pretreatment, so that most of metal ions, floating oil, surfactants and part of organic matters are removed from the garbage leachate and the chemical oxygen demand (COD) and the chromaticity of the garbage leachate are reduced; suspended matters, macromolecular matters and the like are removed from the leachate through the microfiltration and ultrafiltration after pretreatment, so the liquid is clear, the gaseous film is difficult to block and pollute, and long-term operating stabilityof the gaseous film in the subsequence process is guaranteed; and ammonia nitrogen is efficiently removed from the leachate in the gaseous film stabilizing process and the ammonia nitrogen removal rate can be adjusted as required, so that the waste water has the best nitrogen carbon ratio and the successful operation of the subsequence biochemical system is guaranteed.

Owner:天津凯铂能膜工程技术有限公司

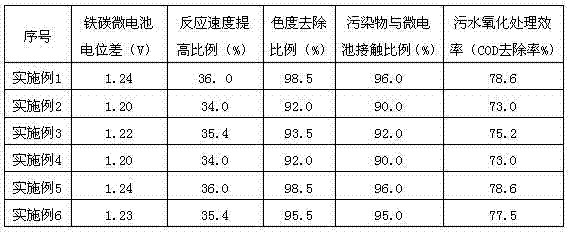

Efficient heterogeneous catalytic oxidation ferric-carbon micro-electrolysis packing and preparation method thereof

ActiveCN104761024ANo compactionHyperactive stateWater/sewage treatmentHigh current densityElectrolysis

The invention discloses efficient heterogeneous catalytic oxidation ferric-carbon micro-electrolysis packing and a preparation method thereof. The packing is prepared from the following raw materials in parts by weight: 45-65 parts of pure iron powder, 10-25 parts of cast iron powder, 2-8 parts of graphite powder, 5-15 parts of active carbon powder, 2-10 parts of copper powder, 2-10 parts of manganese powder, 2-10 parts of aluminum powder, 2-10 parts of fine wood bits, 1-6 parts of sodium silicate, 1-6 parts of sodium borate, 2-6 parts of pyrite dust and 5-15 parts of an adhesive. The efficient heterogeneous catalytic oxidation ferric-carbon micro-electrolysis packing disclosed by the invention is prepared by taking heterogeneous metal alloy with high potential difference as a catalyst and using a high-temperature micropore roasting technology and has the characteristics of heterogeneous metal and ferric-carbon integration, micropore framework type alloy structure, large specific surface area, low density, strong activity, high current density and the like; organic wastewater is treated so that COD, ammonia nitrogen and total phosphorus can be efficiently removed, the chroma can be reduced, the biodegradability can be improved, the treatment effect is extremely stable, and the phenomena of packing passivating, hardening and the like caused in the operation process can be avoided.

Owner:HUBEI QUANSHENG ENVIRONMENTAL PROTECTION SCI & TECH CO LTD

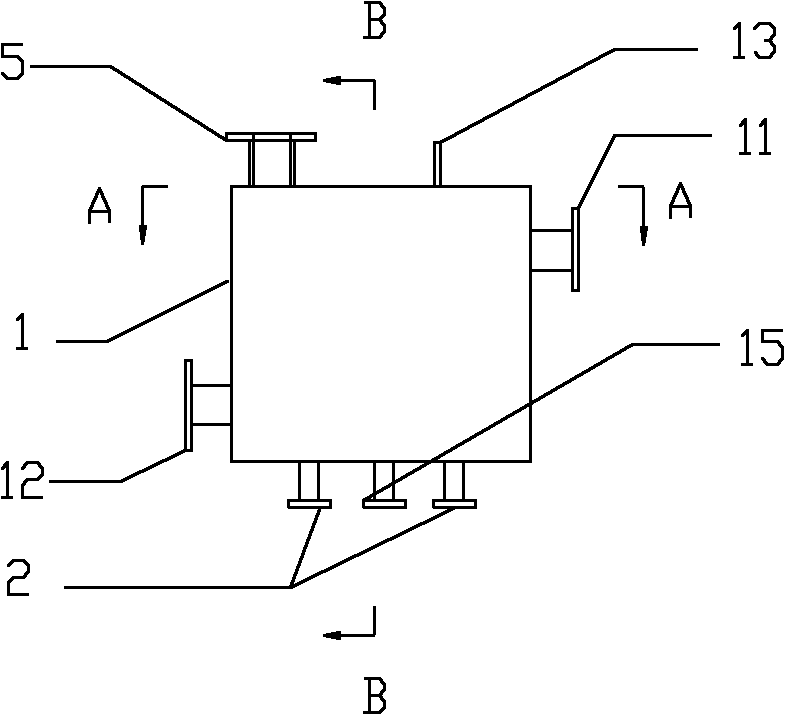

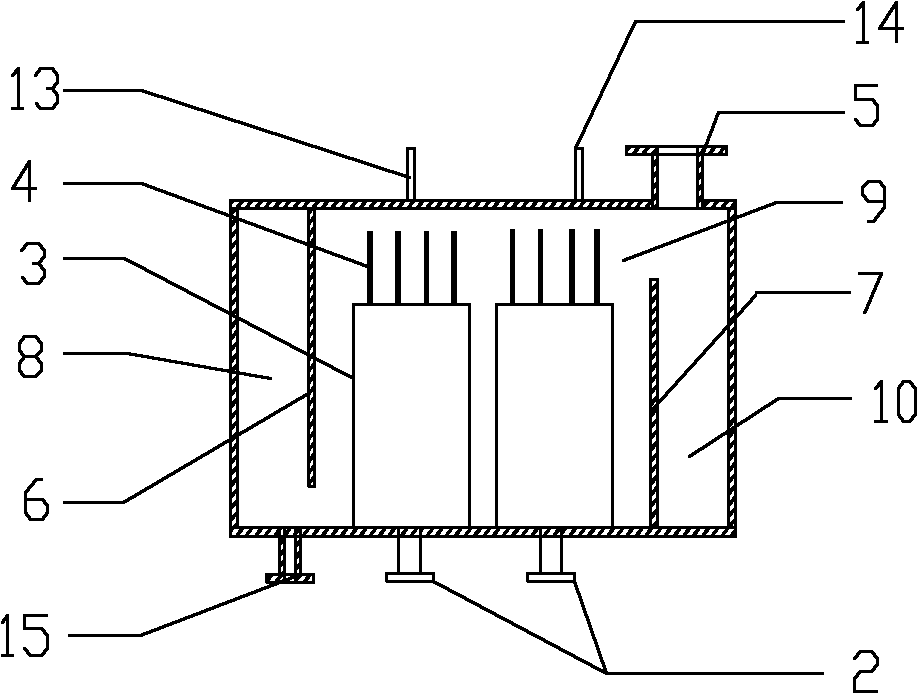

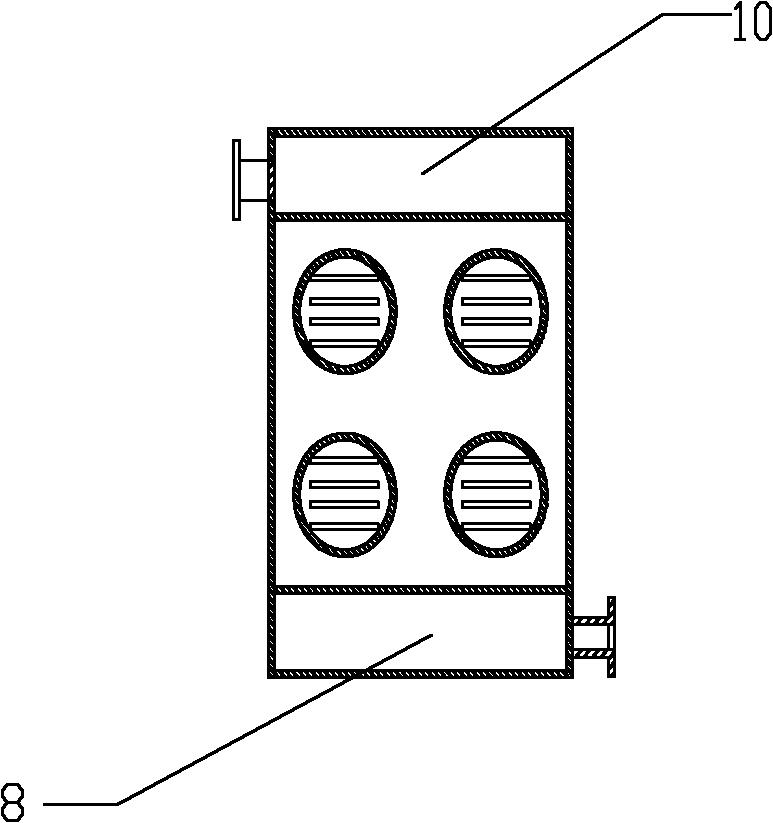

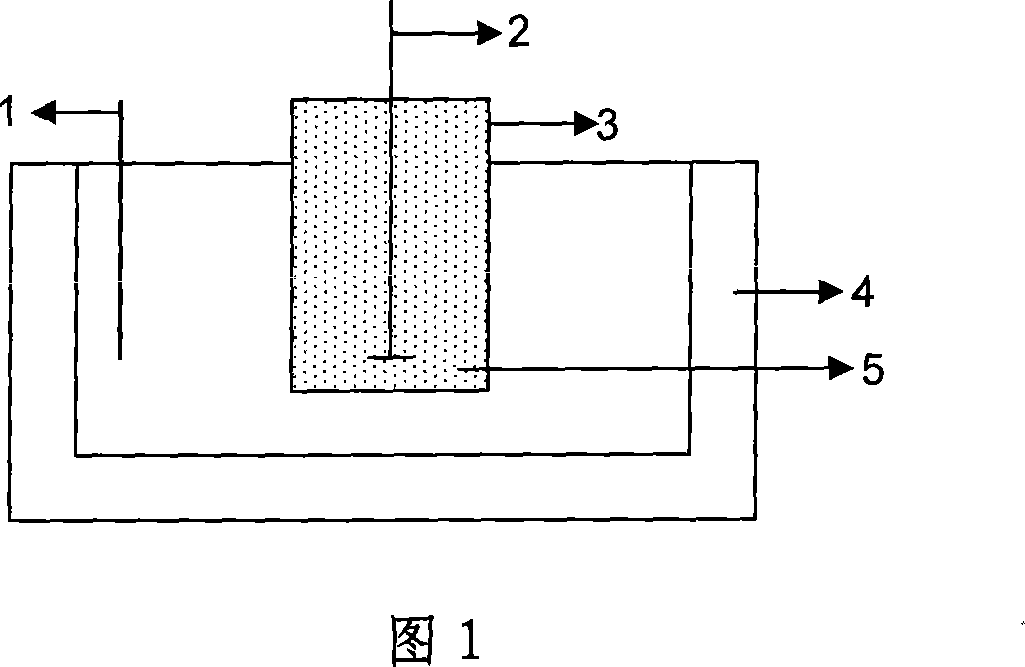

Nano catalytic electrolysis flocculation device

InactiveCN102010038APromote aggregation and sedimentationReduce dosageWater treatment compoundsSpecific water treatment objectivesFlocculationWater discharge

The invention discloses a nano catalytic electrolysis flocculation device, relating to an electrolysis flocculation device. The nano catalytic electrolysis flocculation device has the advantages of extremely low working voltage between two adjacent electrodes, large current density, small energy consumption, high electrical efficiency and no electrode consumption and electrolysis, and integrates solid-liquid separation function and gas-liquid separation function. The bottom of a shell is provided with a water inlet; the shell is internally provided with a scum baffle and a watertight shutter; the scum baffle and one inner side of the shell form a water discharging chamber; a gap is reserved between the bottom of the scum baffle and the bottom of the shell; the scum baffle and the other inner side of the shell form a slag discharging chamber; a gap is reserved between the top of the watertight shutter and the top of the shell; a hydrogen exhaust port is arranged on the top of the shell; an electrolyzer is arranged between the scum baffle and the watertight shutter; the top of the electrolyzer is open and the gap is reserved between the top of the electrolyzer and the top of the shell; electrodes are installed in the electrolyzer; a gas-liquid separation chamber is formed in the shell on the upper part of the electrolyzer; and a drain outlet is arranged at the bottom of the shell and us positioned between the watertight shutter and the adjacent electrolyzer.

Owner:BOYING XIAMEN SCI & TECH

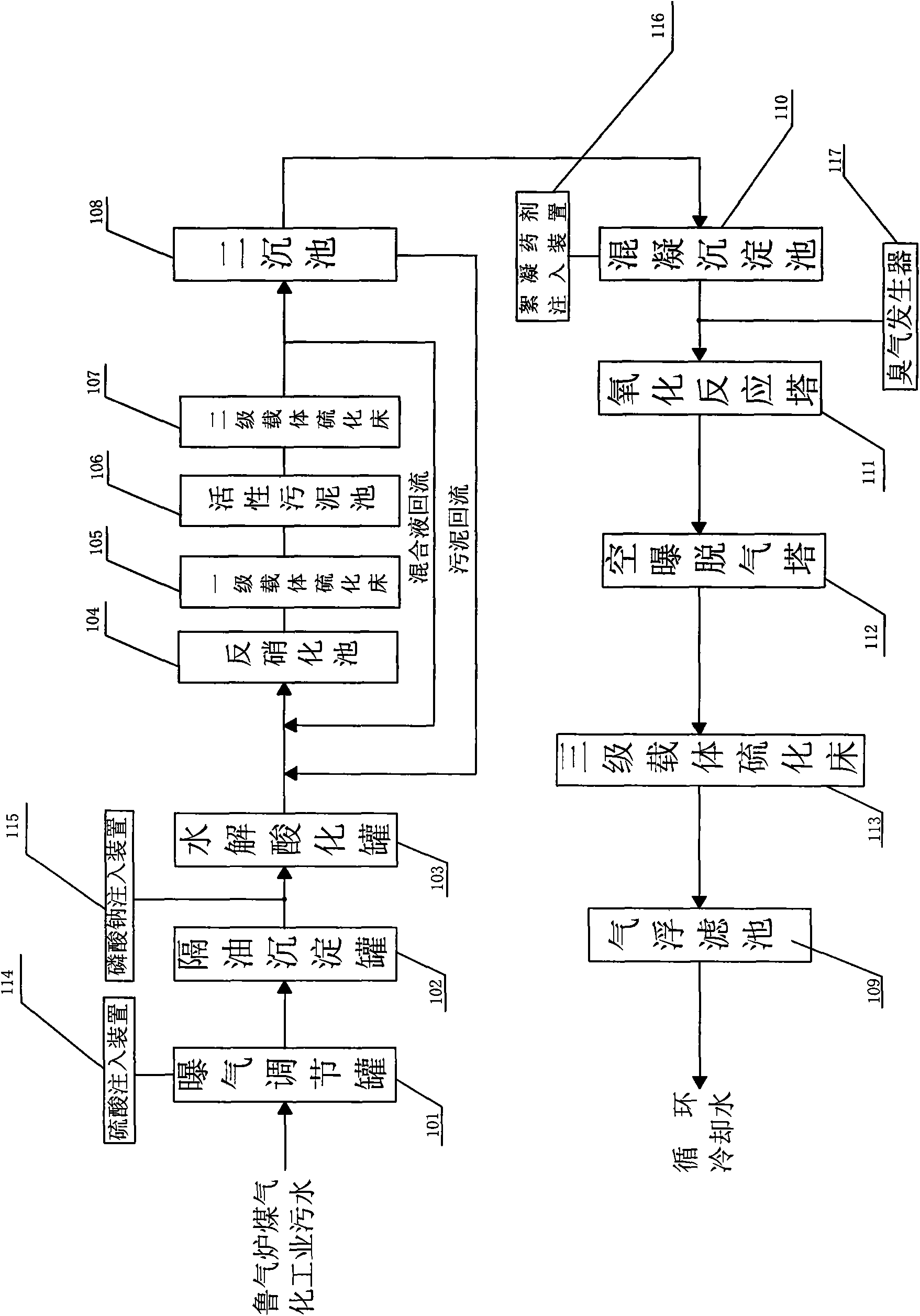

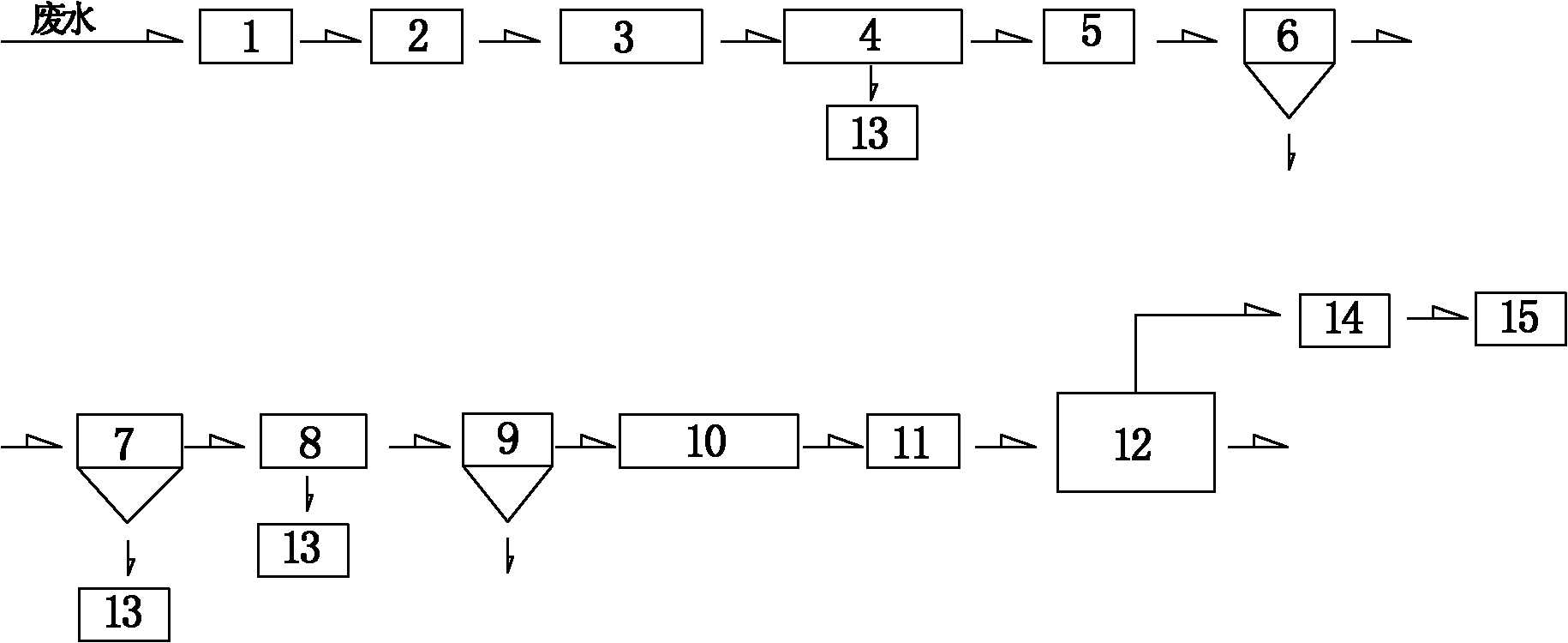

Method for processing high-concentration wastewater containing alkaline mud

ActiveCN101693579ALow toxicityReduce loadTreatment with aerobic and anaerobic processesMultistage water/sewage treatmentAerobic treatment systemHigh concentration

The invention discloses a method for processing wastewater containing alkaline mud with high COD concentration, high toxicity, low biodegradability and high chroma. In the invention, a micro-electrolysis pretreatment, and flocculating and decoloring process are adopted to reduce the COD concentration and chroma and improve the biodegradability, thus providing precondition for the subsequent acidified hydrolysis and aerobic treatment system to further eliminate alkaline mud contamination load; and the yielding water is deposited by a deposition pool and discharged after disinfection. In the invention, the COD concentration (80,000-300,000mg / L) and the chroma (12,500-50,000 times) of inflowing water are improved to maximum degree, stability for the running of system is considered sufficiently, a large amount of diluted water required in the running process is saved, the yielding water can be directly exhausted to urban sewage pipelines, received by waterbody or combined in other treatment systems for treatment, and can comply with the recycling standard. In the whole treatment process, the secondary pollution is not generated, the total emission amount of COD is reduced, the whole system runs conveniently and quickly, and the investment and running expense is far lower than that of the traditional film treatment system.

Owner:TONGJI UNIV +1

Compound microorganism agent for treating black and odorous water body

ActiveCN108441444AImprove the problem of smelly and blackHigh transparencyFungiBacteriaBacillus licheniformisCandida tropicalis

The invention provides a compound microorganism agent for treating a black and odorous water body. The compound microorganism agent comprises compound bacteria and a compound enzyme preparation, wherein the compound enzyme preparation comprises candida tropicalis, candida utilis, bacillus natto, bacillus subtilis, bacillus licheniformis, nitrobacter, achromobacter denitrificans, nitrosomonus, acinetobacter, lactobacillus, aspergillus niger, aspergillus oryzae and photosynthetic bacteria; the compound enzyme preparation comprises protease, amylase, lipase, sucrase, and cellulase.

Owner:POWERCHINA WATER ENVIRONMENT GOVERANCE

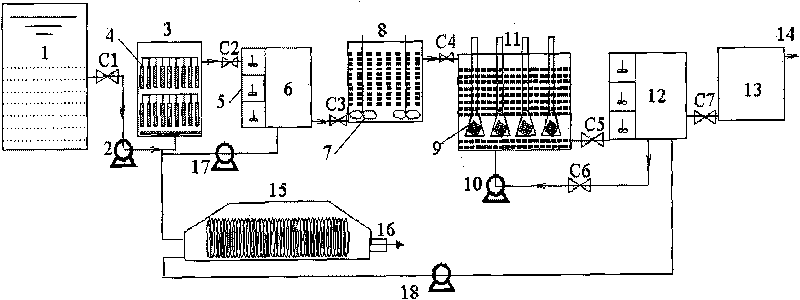

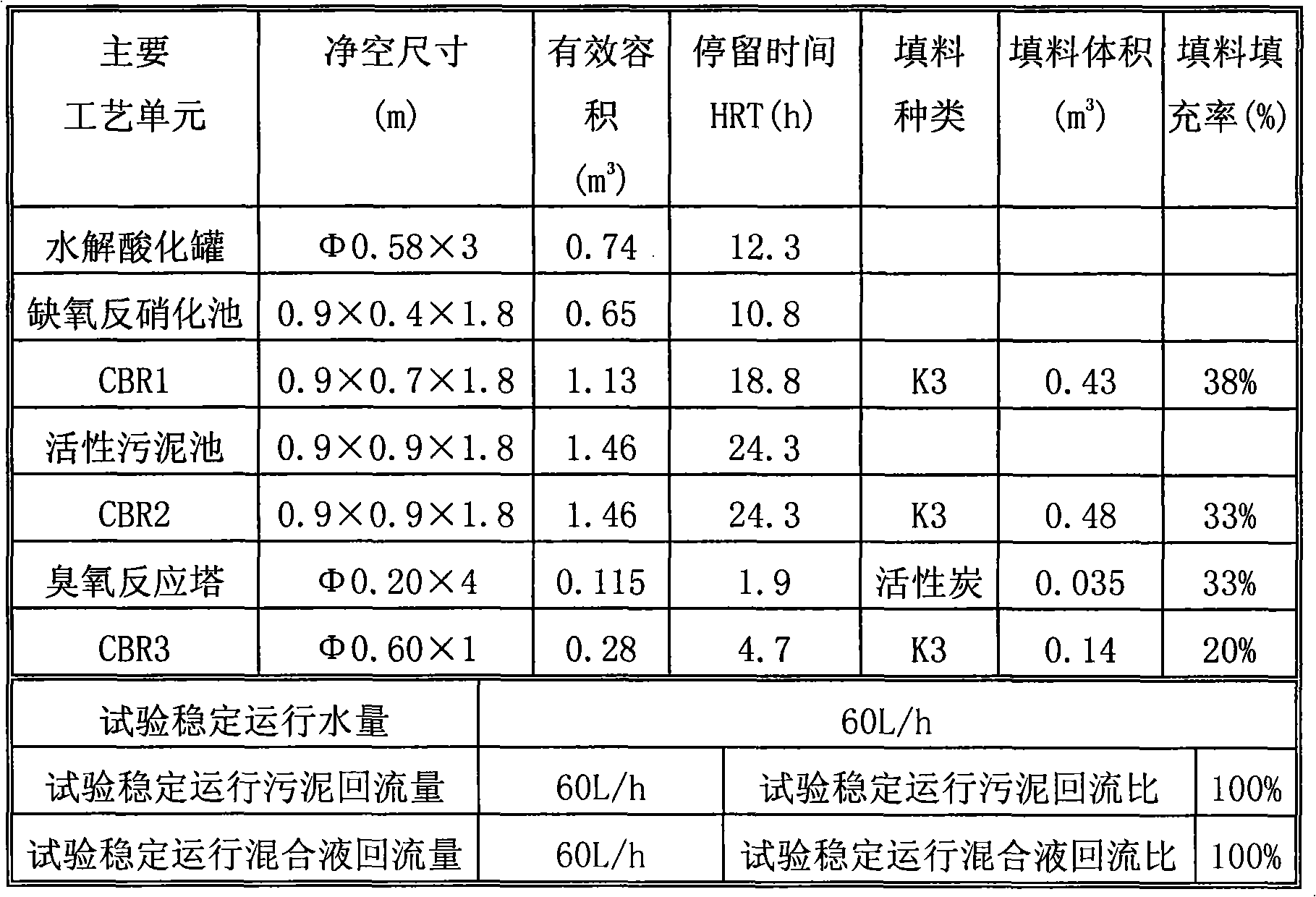

Lurgi furnace coal gasification wastewater treatment and reuse technology

ActiveCN101607777AImprove impact resistanceGuaranteed uptimeTreatment with aerobic and anaerobic processesMultistage water/sewage treatmentCoal gasification wastewaterActivated sludge

The invention discloses a Lurgi furnace coal gasification wastewater treatment and reuse technology, comprising the steps of adopting aeration adjustment, oil separation and sedimentation, hydrolysis acidification, denitrification treatment, first order carrier fluidized bed decarburization, residual COD removement with activated sludge, second order carrier fluidized bed ammonia / nitrogen removement, sludge-water separation, precipitation, oxidation reaction, residual ozone removement, organic waste removement and floating filter treatment to treat the coal gasification wastewater of a Lurgi furnace coal gasification factory and obtaining water which can be reused. The invention has simple operation and low process cost and the treated effluent can be used as the cooling water of boiler furnaces, thus fully recycling the treated Lurgi furnace coal gasification wastewater.

Owner:DASMART ENVIRONMENTAL SCI & TECH (BEIJING) CO LTD

Method for decoloring burned waste water by using zero-valent iron/ultrasonic wave synergistic reaction

InactiveCN101234812AImprove biodegradabilityEasy to handleWater/sewage treatment with mechanical oscillationsWater/sewage treatment by reductionUltrasound - actionReaction temperature

The invention relates to environmental chemistry, in particular to a method for decolorizing coking wastewater by using synergetic effect of zero-valent iron / ultrasonic waves, which specifically comprises the following steps: wastewater and zero-valent iron chips / powders are added into a reactor; the pH value of the wastewater is adjusted to be 1 to 6; then stirring is carried out under the effect of the ultrasonic waves with the power of 150 to 200W; the reaction is lasted for 30 to 60 minutes; the wastewater is decolorized and COD is removed. During the process, the use amount of zero-valent iron in each liter of wastewater is 2 to 500g, and the reaction temperature is 10 to 80 DEG C. By applying the method for decolorizing coking wastewater by using synergetic effect of zero-valent iron / ultrasonic waves, the chromaticity of the coking wastewater can drop from 1,500 times to 140 times, and the removal efficiency can reach over 90 percent; in addition, after the synergetic effect of the zero-valent iron and ultrasonic waves, the removal efficiency of COD in the coking wastewater is higher than the efficiency under the signal effect of the zero-valent iron and the ultrasonic waves. The obtained BOD5 / COD is increased from 0.08 to 0.36, and the biodegradability of the wastewater is also increased remarkably.

Owner:SHENYANG INST OF APPL ECOLOGY CHINESE ACAD OF SCI

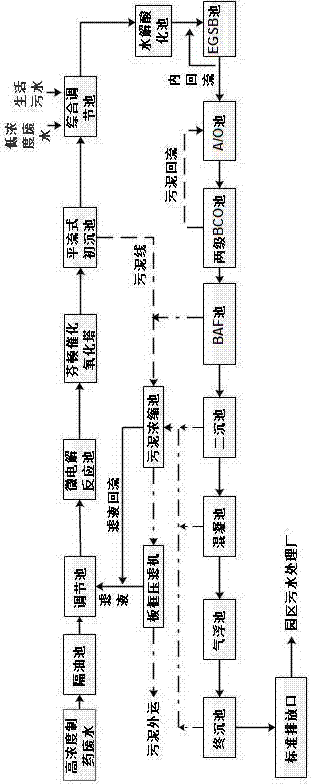

Pharmaceutical wastewater technology using microelectrolysis-Feton-EGSB (expanded granulate sludge bed)-A/O (anaerobic/aerobic)-BCO (biological contact oxidizing)-BAF (biological aeration filtering)-coagulation treatment

InactiveCN106927628AImprove B/C valueEfficient removalWater treatment compoundsSpecific water treatment objectivesHigh concentrationSludge

The invention relates to a pharmaceutical wastewater technology using microelectrolysis-Feton-EGSB (expanded granulate sludge bed)-A / O (anaerobic / aerobic)-BCO (biological contact oxidization)-BAF (biological aeration filtration)-coagulation treatment. High-concentration pharmaceutical wastewater is sequentially sent into an oil separation tank, a conditioning tank, a microelectrolysis reaction tank, a Feton catalytic oxidation tower, a horizontal flow type primary settling tank, a comprehensive conditioning tank, a hydrolysis acidifying tank, the EGSB, an A / O tank, a two-stage BCO tank, a secondary settling tank, a BAF tank, a coagulation tank, an air floating tank and a final settling tank to be treated, and then is drained after the standard is reached. The technology has the advantages that the technique is matured, the treatment effect is stable, and the anti-impact ability is strong; after the pharmaceutical wastewater is treated by the combined technology, the quality of drained water can reach the class-one standard of Comprehensive Drainage Standard of Wastewater (GB8978-1996).

Owner:NANCHANG UNIV

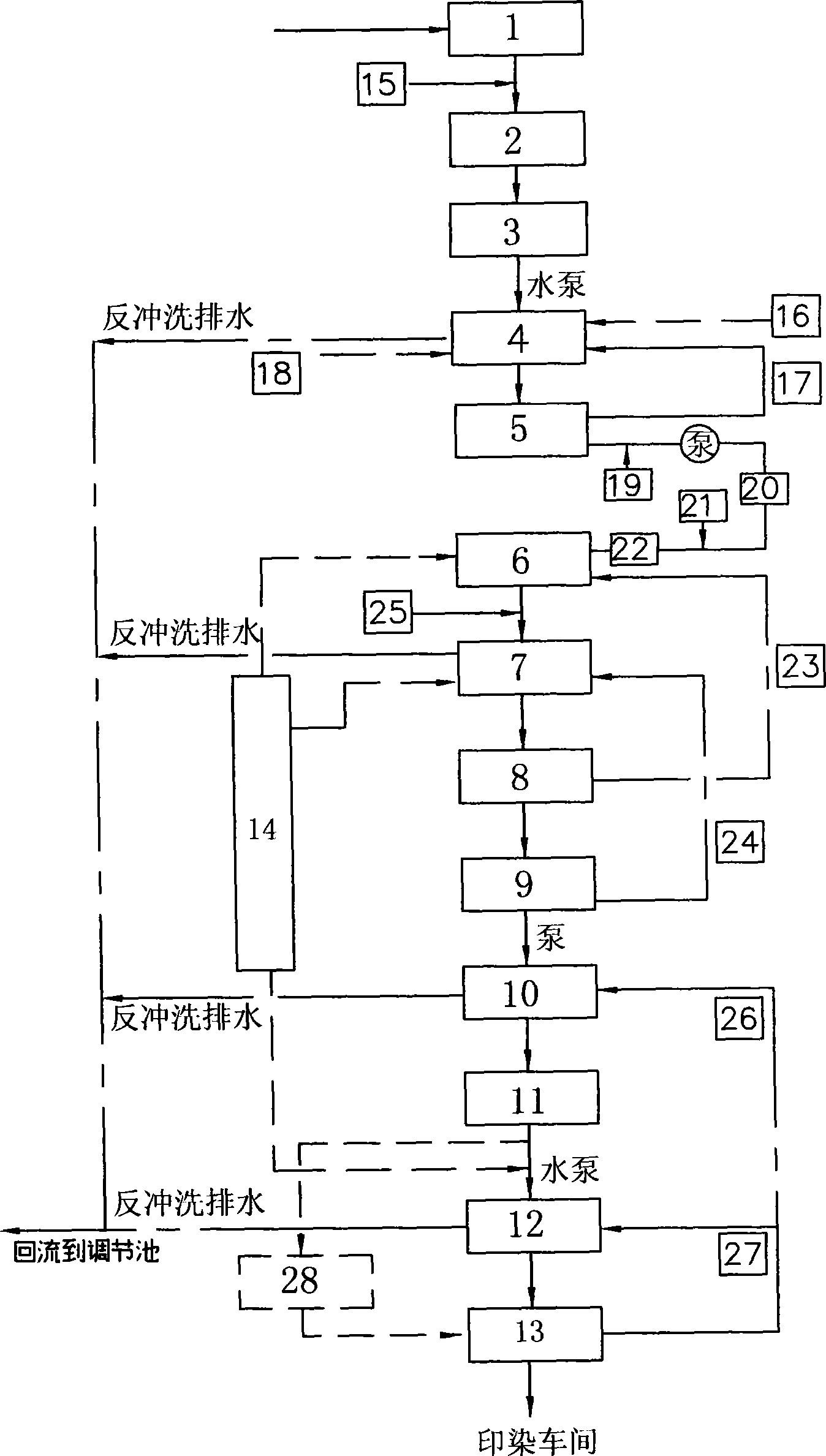

Device and method for treating and recycling printing and dyeing wastewater

InactiveCN102050555AReduce dosageReduce consumptionTreatment using aerobic processesPaint waste treatmentFlocculationElectrolysis

Owner:BOYING XIAMEN SCI & TECH

Method for producing succinic acid

ActiveCN102311332AHigh purityHigh selectivityPreparation from carboxylic acid anhydridesButanedioic acidHydrogenation reaction

The invention discloses a method for producing succinic acid. The method comprises the following steps of: performing hydrogenation reaction by taking 5 to 90 weight percent of a maleic anhydride gamma-butyrolactone solution as a raw material at the reaction temperature of between 50 and 100 DEG C under the pressure of between 0.2 and 2 MPa in the presence of a hydrogenation catalyst, hydrolyzing a hydrogenation product, crystallizing and separating to obtain succinic acid. The method is can be operated flexibly; reaction conditions are mild and controllable; and products are easy to separate and have good quality.

Owner:CHINA PETROLEUM & CHEM CORP +1

Cooperative pretreatment method for biological catalysis and controlled oxidation of cotton and cotton-type fabrics

InactiveCN102191692AReduce dosageReduce wasted waterBiochemical fibre treatmentDry-cleaning apparatus for textilesElectricityChemical oxygen demand

The invention relates to a cooperative pretreatment method for biological catalysis and controlled oxidation of cotton and cotton-type fabrics, comprising the following steps: (1) preparing a biological compound enzyme preparation, a biological enzyme synergist and a non-ionic surfactant into an enzyme working solution, wherein the pH of a processing bath is 6-7.5; padding the fabrics into the working solution; carrying out heat preservation; (2) washing the processed fabrics with cold water; padding the fabrics into a hydrogen peroxide bleaching solution containing the controlled decomposition additive of hydrogen peroxide; and steaming, washing with water and drying to obtain the finished products. In the method, high-density strong base is not required to serve as a scouring agent, thepH value of pretreatment waste water is 7-8, the chromaticity is low, the COD (Chemical Oxygen Demand) value is lowered by 30% compared with that of the traditional alkali kiering pretreatment technology, the water is saved by 10-30%, and the steam and electricity can be saved by 20%. The indexes (whiteness, capillary effect, water absorption, cotton seed hull strainaway rate, desizing rate, strong force and the like) of the processed cotton and cotton-type fabric all reach the quality indexes of a semi-product, cotton seed hulls can be completely removed, and the fabrics have vivid color andgood levelling property after being dyed.

Owner:DONGHUA UNIV

Dissimilar pigments for use in dark and light inkjet inks

InactiveUS7591889B2Reducing differential lightfade and graininessHigh chromaInksLightfastnessChromophore

An ink set providing reduced differential lightfade and graininess. The ink set comprises at least one dark inkjet ink and at least one light inkjet ink. The dark inkjet ink comprises at least one pigment having a high chromaticity and a low lightfastness and the light inkjet ink comprises at least one less chromatic pigment having a high lightfastness. The pigment in the dark inkjet ink is dissimilar from the pigment in the light inkjet ink in at least one of a crystal form, particle size, chromophore, and chemical dispersant. A method of reducing differential lightfade and graininess in a printed image is also disclosed.

Owner:HEWLETT PACKARD DEV CO LP

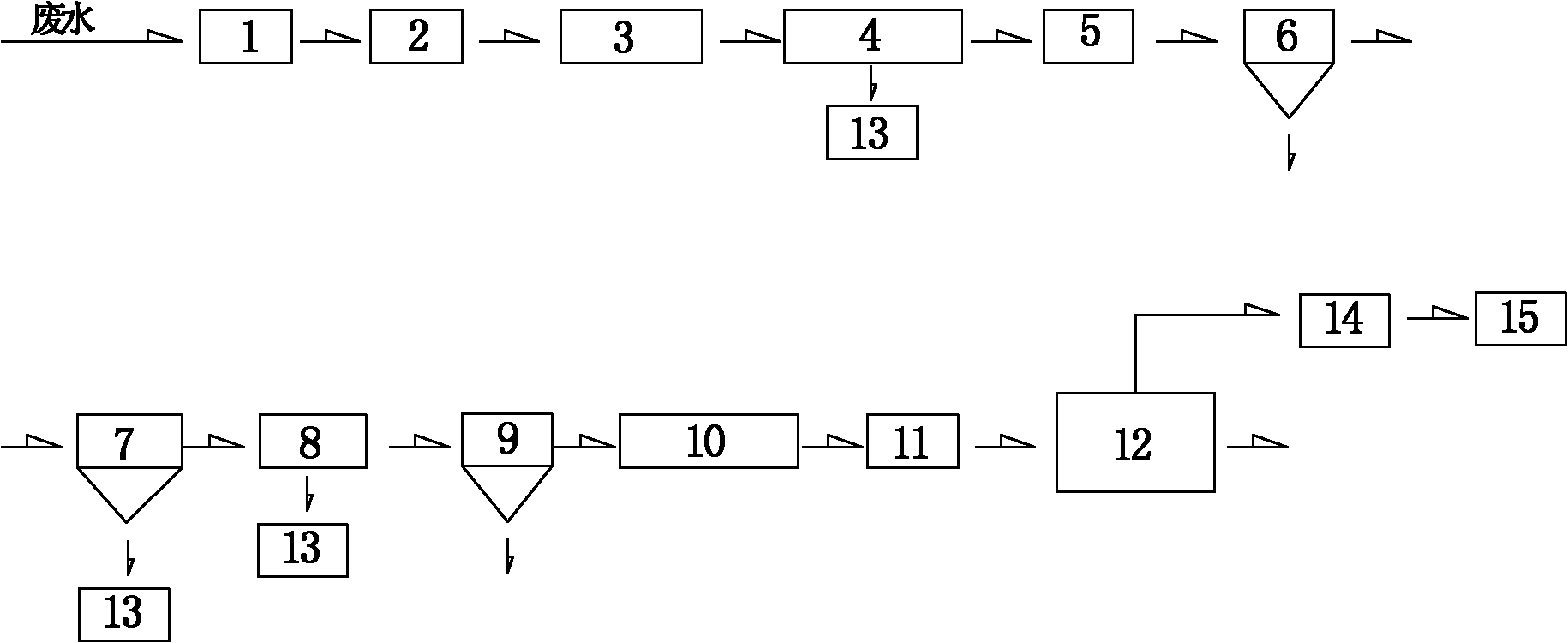

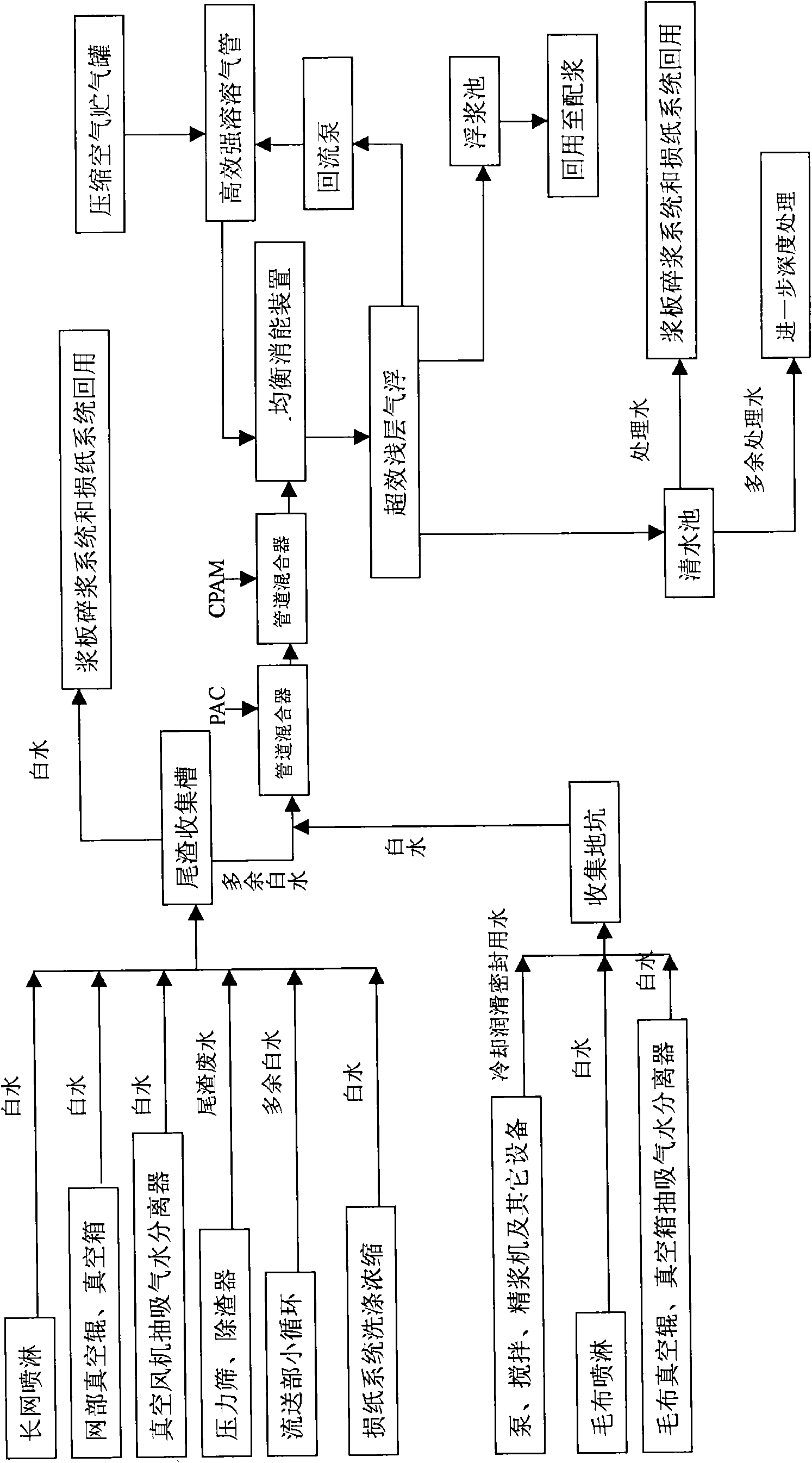

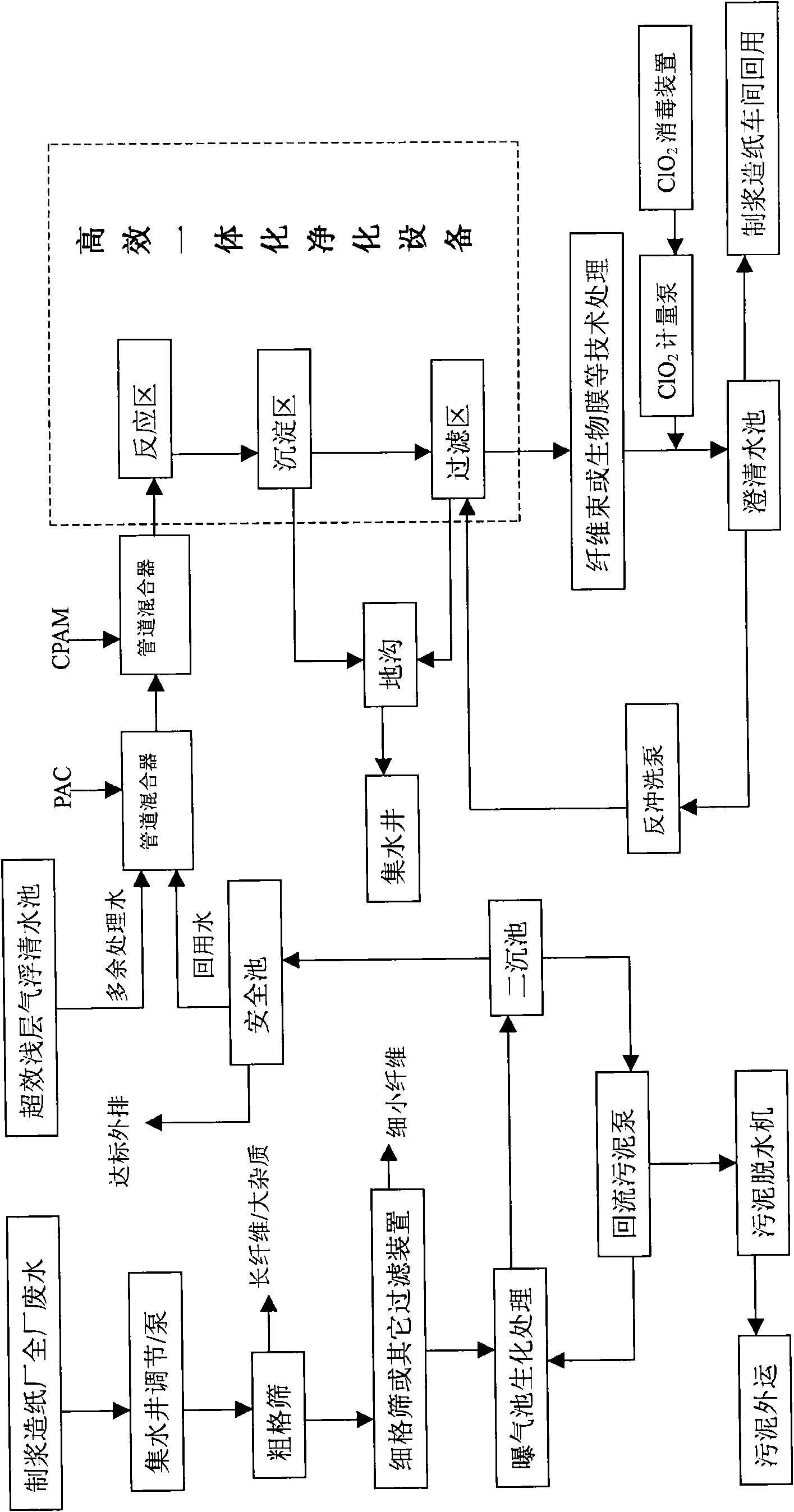

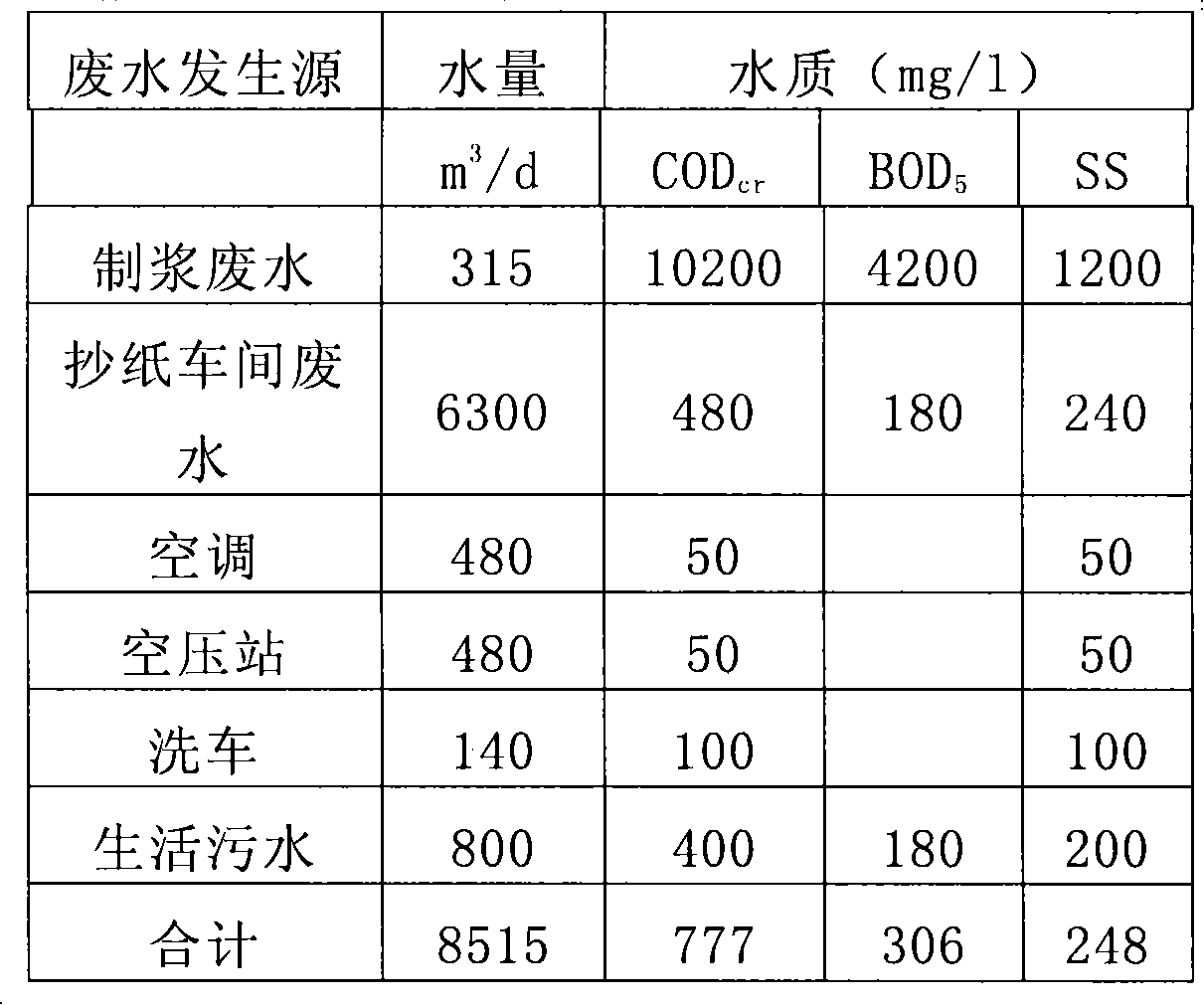

Wastewater treatment and reuse technology for paper mill

InactiveCN101591085AEmission reductionEasy to handleMultistage water/sewage treatmentWaste water treatment from plant processingPaper millReclaimed water

The invention provides a wastewater treatment and reuse method for a paper mill. The method comprises the following steps: (a) physical treatment: providing wastewater from the paper mill, and removing the cellulose and other foreign impurities in the wastewater from the paper mill to obtain the wastewater from the paper mill after the physical treatment; (b) biochemical treatment: performing biochemical treatment and deposition to the paper mill wastewater obtained in the step (a) after the physical treatment to obtain safe pool water conforming to the required emission standard; and (c) advanced treatment: providing air-floatation water after super-efficient shallow air-floating treatment in a machine room and merging the air-floatation water with the safe pool water obtained in the step (b) to obtain intermediate water, and then performing intermediate water advanced treatment, i.e. adding drugs into the intermediate water, coagulating, depositing and filtering to obtain purified water; and performing fiber bunch or the biological film technical treatment to the purified water to obtain effluent.

Owner:CHINA BANKNOTE PRINTING & MINTING

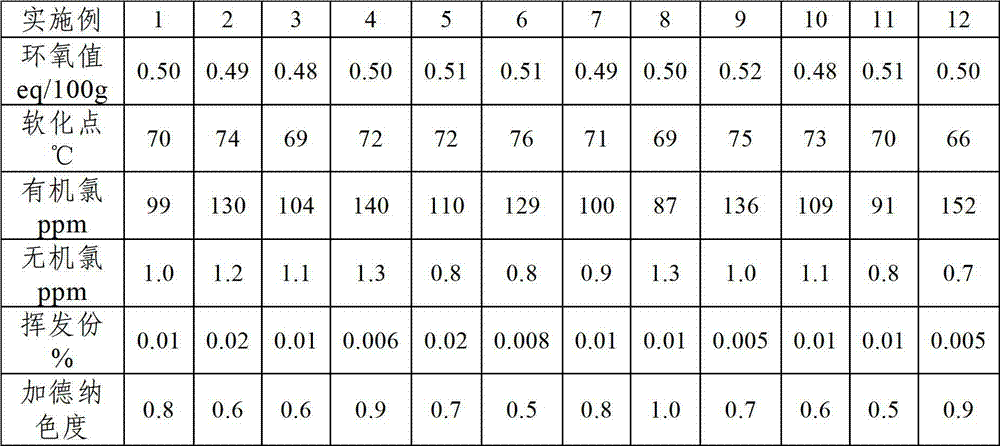

Method for synthesizing light color low-chlorinity o-cresol-formaldehyde epoxy resin

The invention discloses a method for synthesizing a light color low-chlorinity o-cresol-formaldehyde epoxy resin. The method comprises the following steps of: 1, dissolving o-cresol-formaldehyde resin in an organic solvent to obtain an o-cresol-formaldehyde resin solution, adding epoxy chloropropane and a reductant into the o-cresol-formaldehyde resin solution for reductive decoloration reaction of the o-cresol-formaldehyde resin; 2, adding a phase transfer catalyst and a cocatalyst into the reaction system and refluxing under reduced pressure and performing etherification reaction; 3, adding an alkali catalyst into a product of etherification reaction and performing ring-closure reaction; and 4, filtering, washing, reducing pressure and removing the solvent and the unreacted epoxy chloropropane from washed entrapment materials to obtain the light color low-chlorinity o-cresol-formaldehyde epoxy resin of which the Gardner chromaticity is not more than 1 and the chlorinity is not more than 200 ppm. The o-cresol-formaldehyde epoxy resin prepared by the method can meet the requirements for softening point and epoxy value, and is characterized in that the chlorine ion content in the o-cresol-formaldehyde epoxy resin is very low and is less than 200 ppm, and the Gardner chromaticity of the o-cresol-formaldehyde epoxy resin is not more than 1.

Owner:THE NORTHWEST RES INST OF CHEM IND

Shewanella decolorationis

The present invention relates to one new kind of Shewanella decolorationis and is Shewanella decolorationis CCTCC M 203093. By means of the separation and purification of the active sludge in the waste water treating system of Guangzhou printing and dyeing plant, one new kind of Shewanella decolorationis is obtained. The Shewanella decolorationis can degrade dye in waste printing and dyeing water effectively, raise waste water treating efficiency and improve water ecological environment quality.

Owner:GUANGDONG INST OF MICROORGANISM

Low-alkali pretreatment method for in-situ catalytic degradation of impurities in cotton and cotton fabrics

InactiveCN102978960AStrong process adaptabilityGood energy saving and emission reduction effectBiochemical fibre treatmentBleaching apparatusElectricityPretreatment method

The invention relates to a low-alkali pretreatment method for the in-situ catalytic degradation of impurities in cotton and cotton fabrics, which comprises the following steps: (1) preparing a biological compound enzyme preparation, a biological enzyme synergist and a nonionic surfactant into enzyme working fluid; padding a fabric in the enzyme working fluid; and carrying out heat preservation on the fabric; and (2) directly padding the treated fabric into hydrogen peroxide bleaching liquid containing a hydrogen peroxide controlled decomposing additive, and then steaming, washing and drying the fabric. According to the invention, sizes and impurities are subjected to in-situ catalytic degradation in fabrication processing, therefore, an effect of ultrahigh-concentration wastewater treatment is achieved, fabrics are easy to wash, the washing temperature and washing frequency are reduced, more than 25% of water is saved, more than 30% of steam is saved, and more than 10% of electricity is saved. The COD (chemical oxygen demand) value is reduced by more than 30% in comparison with that of a traditional alkali scouring process, the B / C value of pretreated wastewater is about 0.4, and the biodegradability is improved. All indexes (such as whiteness, capillary effect, cottonseed hull removal rate, desizing ratio, strength, and the like) of treated cotton and cotton fabrics meets the quality requirements of semi-finished products.

Owner:DONGHUA UNIV

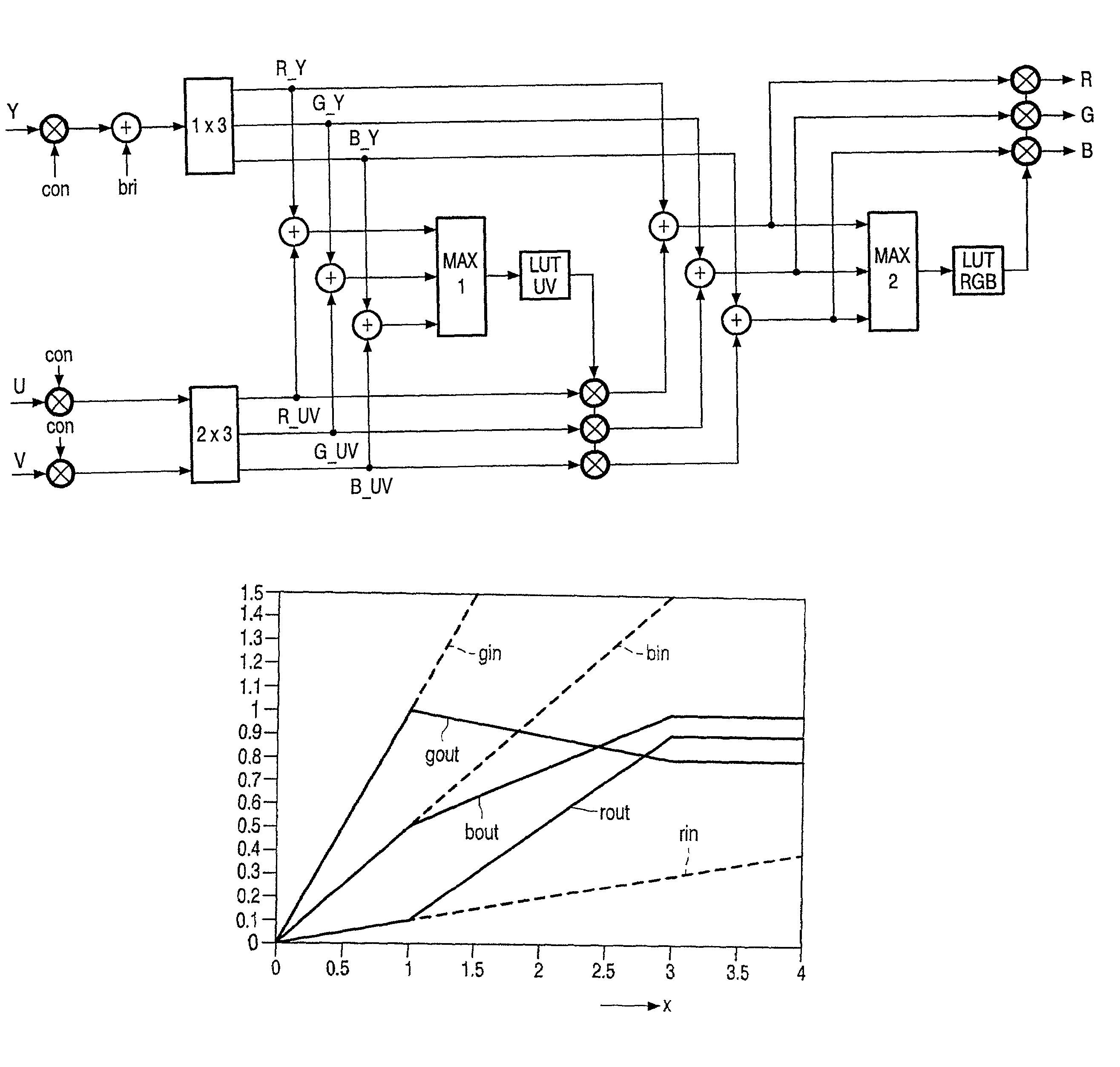

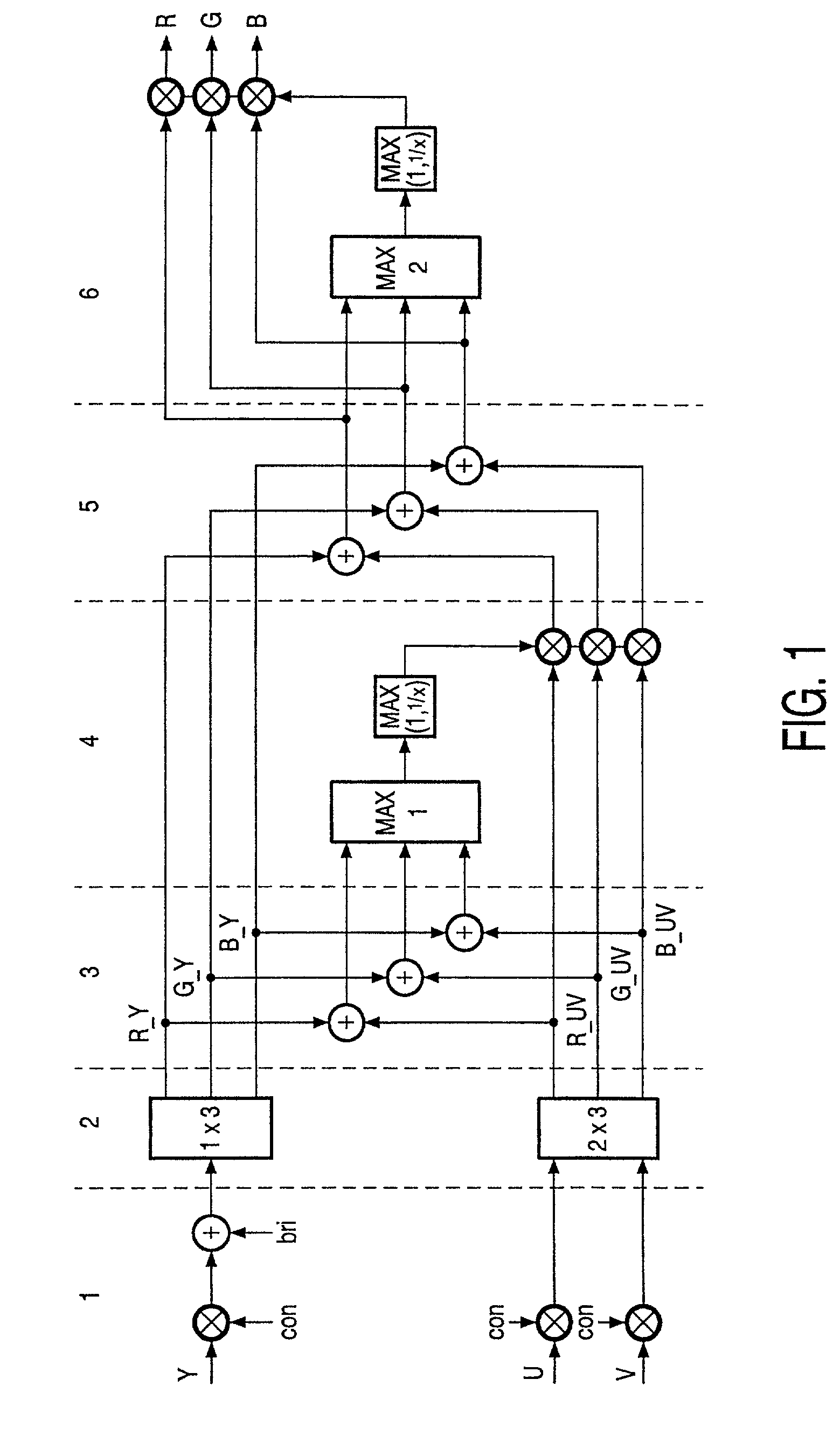

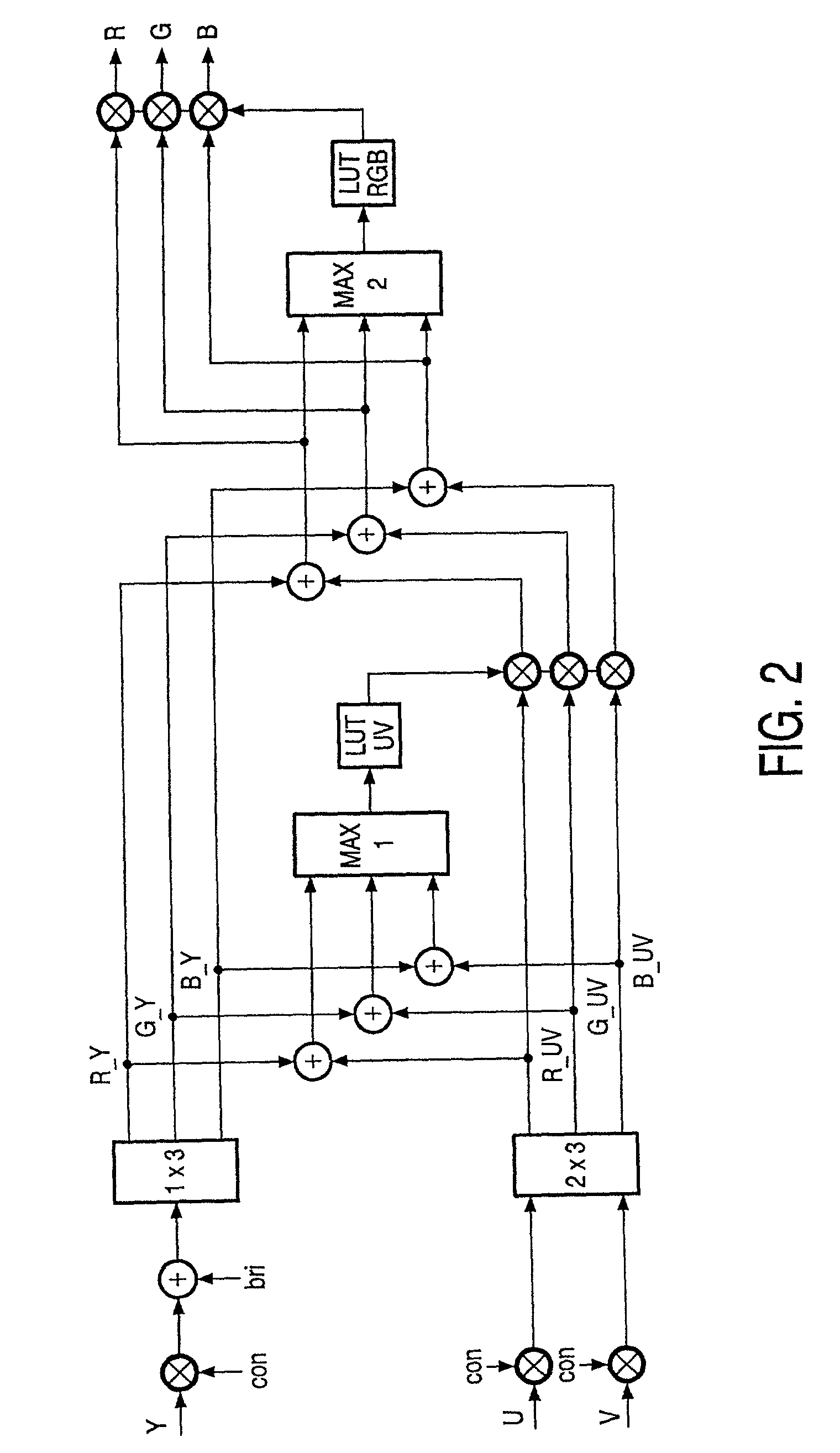

Picture signal contrast control

ActiveUS7050114B2Increase contrastLittle or no light outputTelevision system detailsColor signal processing circuitsComputer scienceContrast ratio

Owner:DYNAMIC DATA TECH LLC

Short-flow environmentally-friendly production method for jute fibers

ActiveCN102031568AShort production processEfficient removalYarnFibre treatment to obtain bast fibreChemical oxygen demandImpurity

The invention relates to a short-flow environmentally-friendly production method for jute fibers. The method is characterized in that: the principle of deep oxidation is adopted, and jute bast is subjected to identical bath degumming and bleaching. The method comprises the following steps of: 1) performing impurity removal and washing on the jute bast; 2) performing first identical bath degumming and bleaching by using 5 to 6 g / l of nano argil preparation, 6 to 7 g / l of caustic soda, 1 to 3 g / l of soda ash and 8 to 10 g / l of hydrogen peroxide; 3) performing second identical bath degumming and bleaching by using 4 to 5 g / l of nano argil preparation, 4 to 6 g / l of caustic soda, 1 to 3 g / l of soda ash and 8 to 12 g / l of hydrogen peroxide; 4) washing after degumming and bleaching; and 5) dehydrating, shaking, softening and drying the washed jute fibers. Compared with the prior art, the method has the advantages that: 1) the production process flow is shortened by adopting a deep oxidation method; 2) the produced jute fibers have good softness and high whiteness; and 3) the process wastewater is little and has low chromaticity, and the discharge of wastewater chemical oxygen demand (COD) is greatly reduced.

Owner:郑州银泰企业管理咨询有限公司

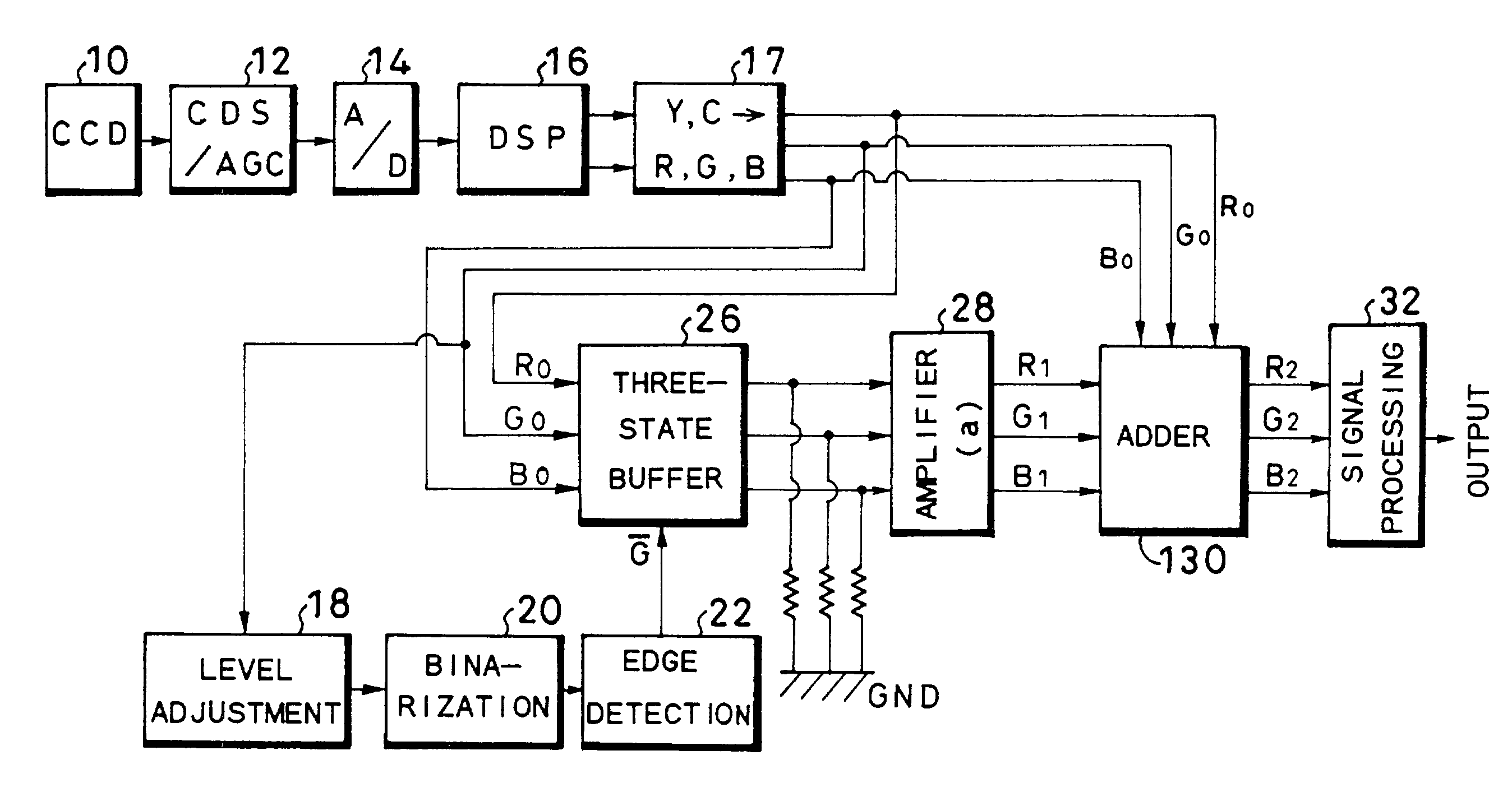

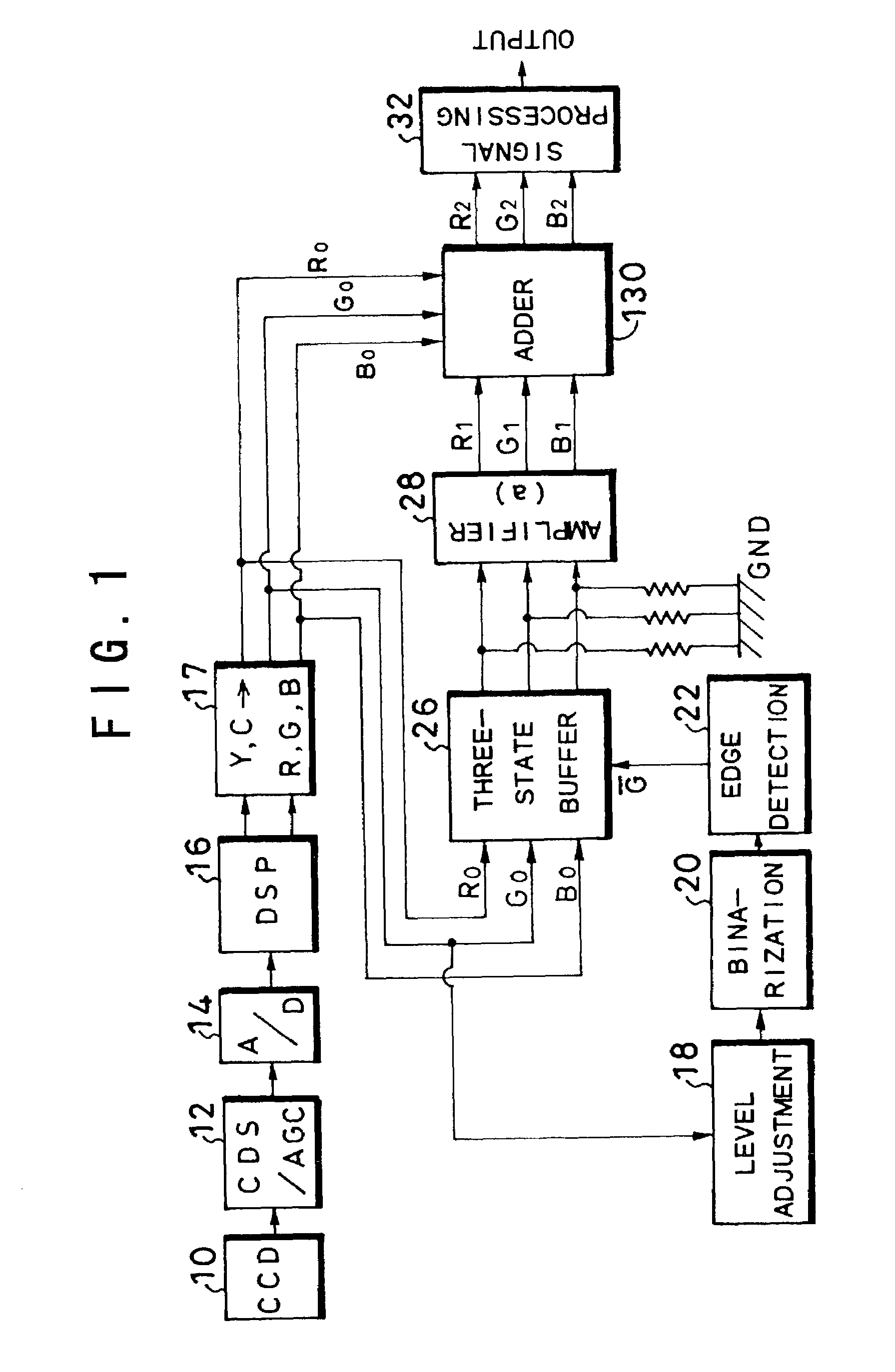

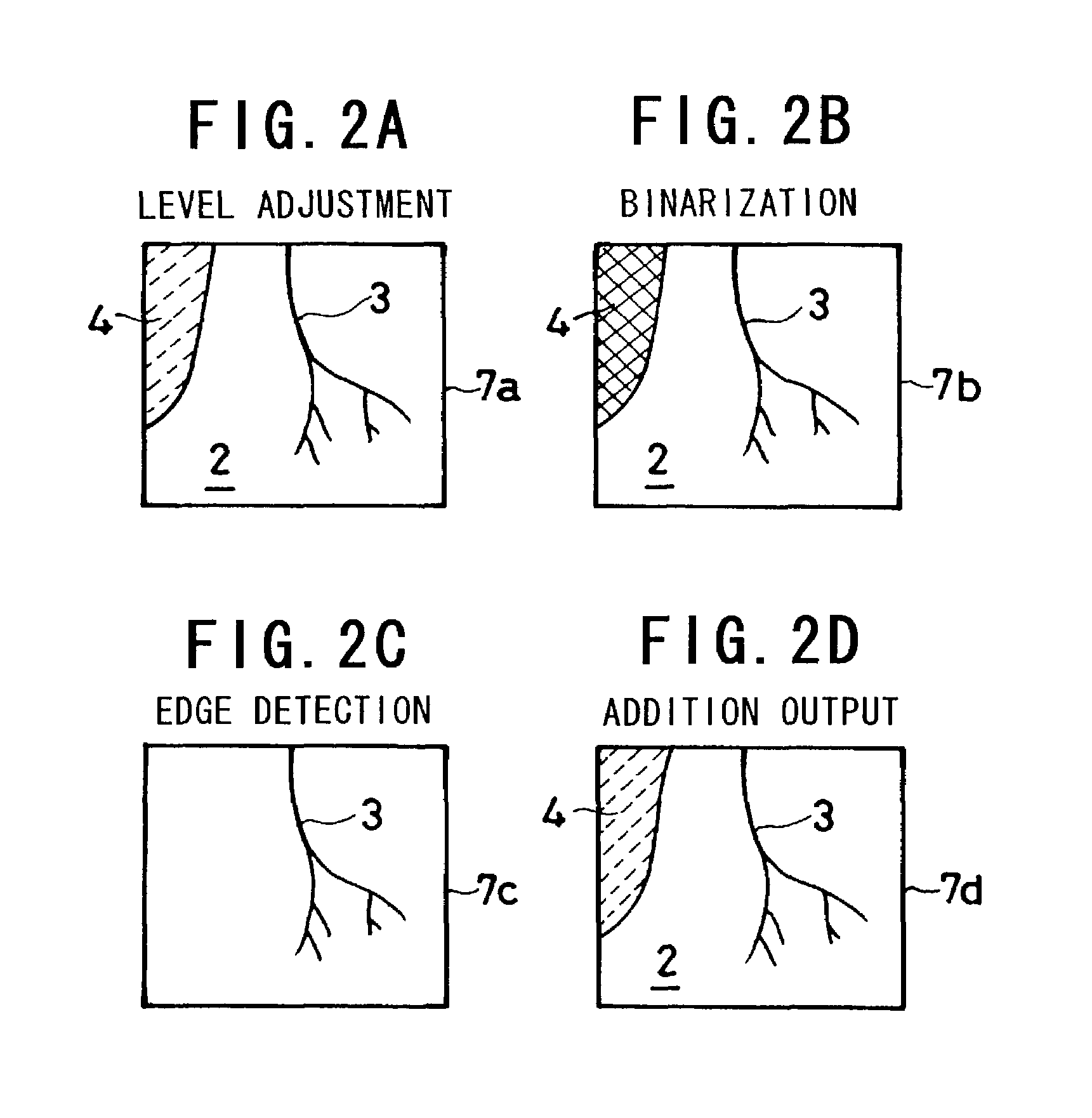

Electronic endoscope for highlighting blood vessel

InactiveUS6956602B2Distinction is very difficultIncrease contrastSurgeryEndoscopesProminent blood vesselSignal extraction

The apparatus according to the present invention includes a level adjusting circuit that increases a gain of a G (or B) signal output from a color conversion circuit, a binarization circuit that forms a binarized image from this G signal and an edge detection circuit that extracts blood vessel position signals through edge detection based on this binarized signal. Then, the apparatus extracts RGB color signals making up a blood vessel image by using the above-described blood vessel position signals, increases the gains of these blood vessel color signals and then adds the blood vessel color signals to the color signals of an original image. This allows blood vessels to be displayed in high contrast to mucous membranes, etc. Furthermore, the apparatus can also amplify the R signal and B signal by using a signal obtained by differentiating the above-described G signal as a gain signal to highlight blood vessels.

Owner:FUJI PHOTO OPTICAL CO LTD

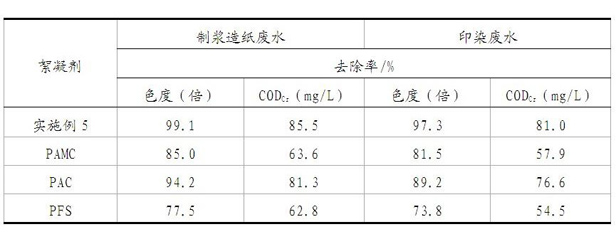

Quaternary ammonium salt positive ion-type organic polymeric flocculant and preparation method thereof

ActiveCN102070233AReduce dosageReduce COD

<sub>Cr </sub>

valueWater/sewage treatment by flocculation/precipitationQuaternary ammonium cationWastewater

The invention relate to a quaternary ammonium salt positive ion-type organic polymeric flocculant and a preparation method thereof. The polymeric flocculant contains a quaternary ammonium group, the positive ion degree is between 40% and 50%, and the raw material of the flocculant comprises the following components in parts by mass: 5-50 parts of dimethylamine, 1-45 parts of urea, 20-60 parts of epichlorohydrin, 1-40 parts of water, 1-5 parts of catalyst and 2-8 parts of cross-linking agent. In the invention, the product is less in dosage, is obvious in waste water-treating effect, and is especially suitable for treating slurry-preparing and paper-making paper waste water, printing and dyeing waste water and organic waste water containing active groups; and the preparation method is simple, the process conditions are mild, the preparation method is carried out by adopting a conventional device under the ordinary pressure, and no three wastes are discharged.

Owner:FUZHOU UNIV

Method for preparing pentaerythritol triacrylate

InactiveCN101462953AReduce pollutionReduce by-productsOrganic compound preparationCarboxylic acid esters preparationPentaerythritolColor intensity

The invention belongs to a method for preparing pentaerythritol trimethylacrylate, comprising the steps as follows: (1) pentaerythritol, acrylic acid, catalyst, solvent and polymerization inhibitor are put into a reaction kettle to be fully mixed and stirred so as to form a miscible liquid; (2) a steam valve of the reaction kettle is opened to slowly heat the miscible liquid, and the temperature is controlled and maintained at 70-90 DEG C for a 20-40min reaction; (3) the mixture is continued to be heated, when the temperature is increased to 80-115 DEG C, reflow is carried out for 3-5h and then the reaction is finished; (4) soda water solution and sodium chloride water solution are added into the mixture and after washing the upper organic phase is extracted; (5) the upper organic phase is separated from the solvent; (6) and filter pressing is carried out to obtain the end product. The method has simple process, good quality, activity and flexibility, low shrinking percentage and color intensity and high yield coefficient, and produces few by-products or little waste water.

Owner:TIANJIN CHEM REAGENT RES INST

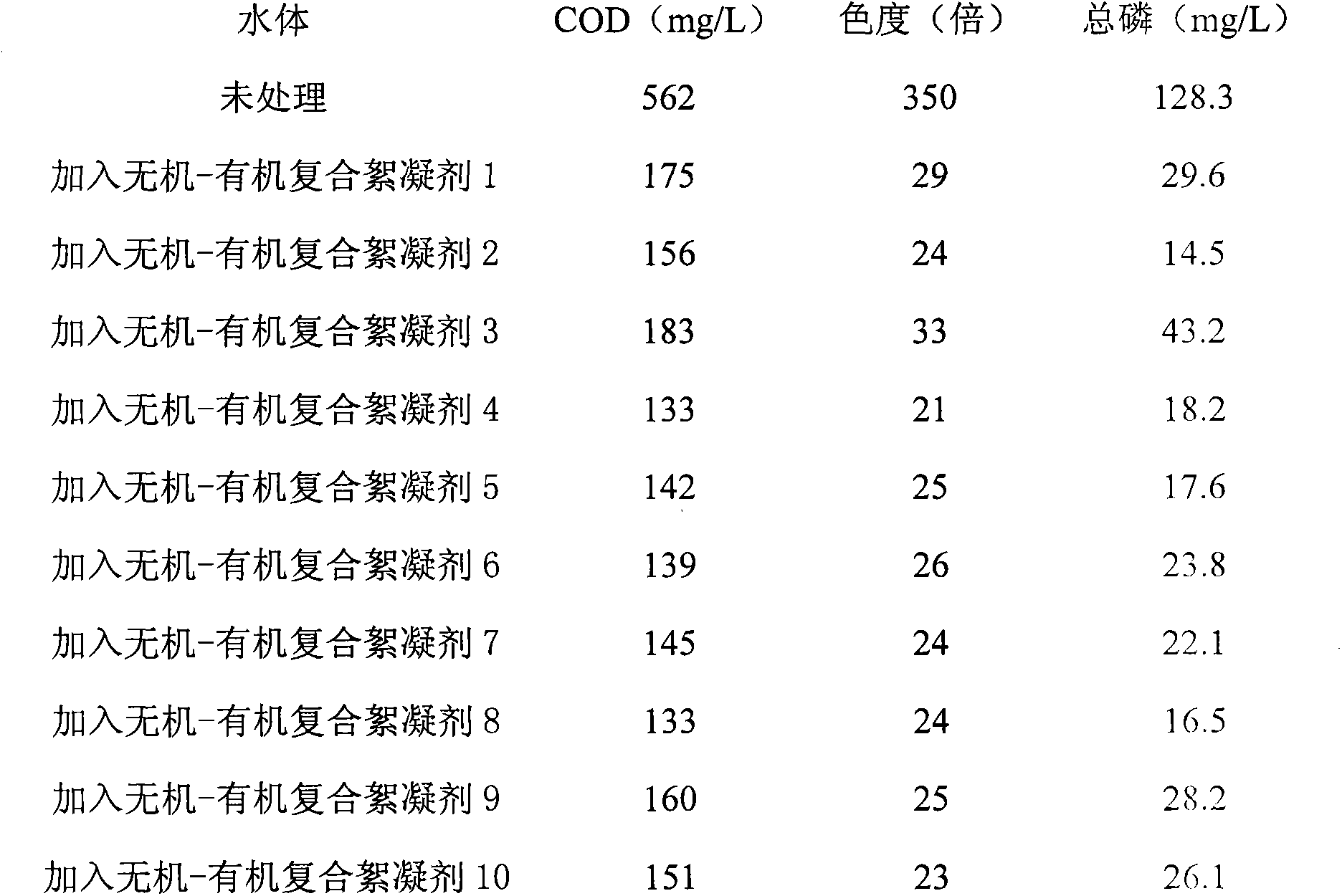

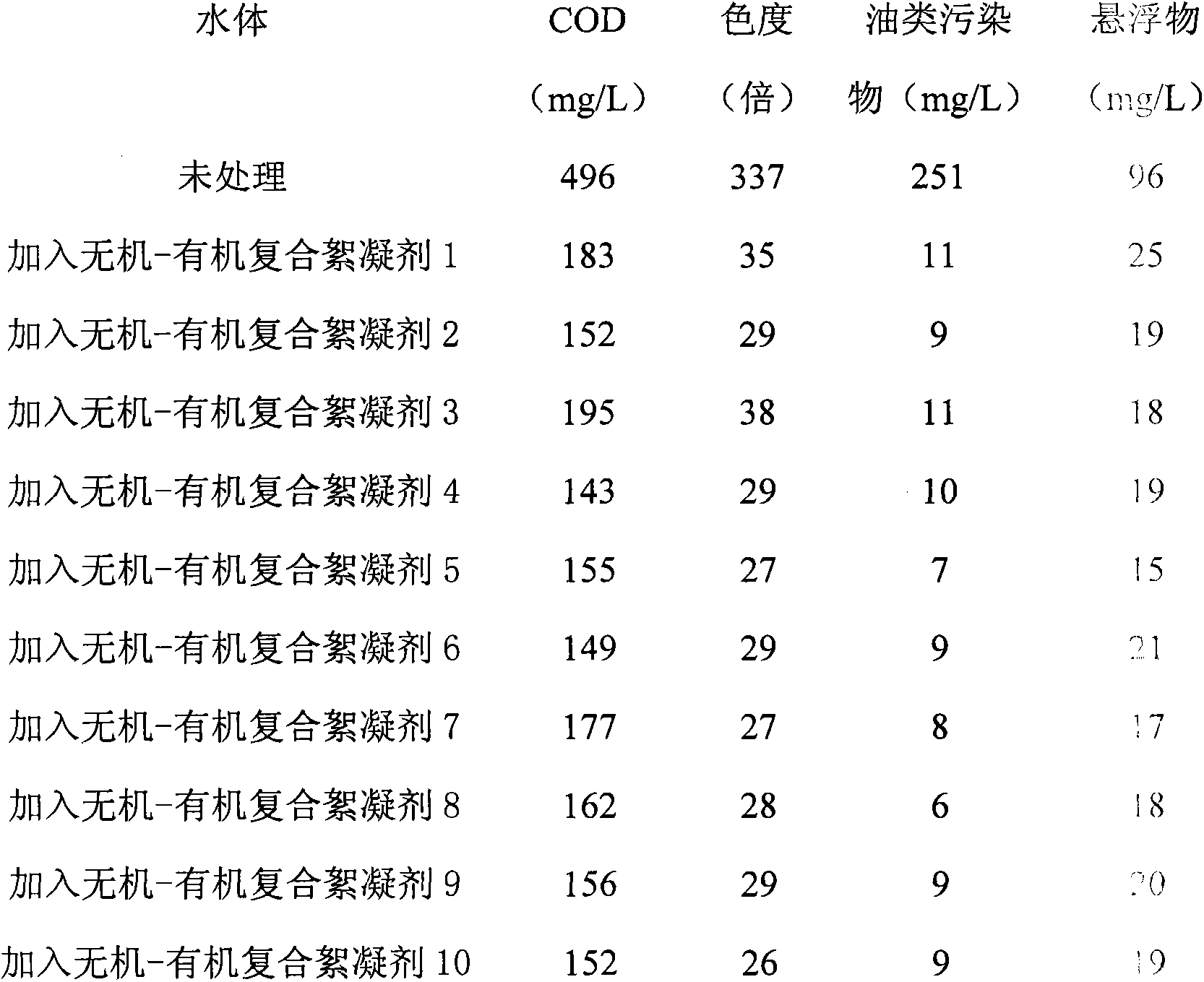

Dephosphorization flocculating agent and preparation method thereof

ActiveCN104261530AGood flocculation effectGood dephosphorization effectWater/sewage treatment by flocculation/precipitationAluminateWater quality

The invention discloses a dephosphorization flocculating agent and a preparation method thereof. The dephosphorization flocculating agent is formed by compounding an inorganic flocculating agent and an organic flocculating agent. The raw materials of the inorganic flocculating agent comprise sodium ferrate, borax, ferrous sulfate, silicate or aluminate; the raw materials of the organic flocculating agent comprise modified chitosan or modified polyacrylamide. The preparation process comprises the following steps: firstly adding a non-oxidizing acid into the silicate or aluminate to obtain a polysilicate colloid or an aluminum hydroxide colloid, then adding a borax solution and a sodium ferrate solution sequentially while stirring, further dropping a ferrous sulfate solution, mixing to form the inorganic flocculating agent, standing, then adding the modified polyacrylamide or modified chitosan into the inorganic flocculating agent, curing and adding the acid till the pH value is less than 7 to obtain the finished dephosphorization flocculating agent. The flocculating agent is suitable for a wide range of water quality, is little affected by co-existing salts, the pH value of sewage and temperature and is particularly effective for dye wastewater, oilfield sewage and the like.

Owner:内蒙古昕晟科贸有限责任公司

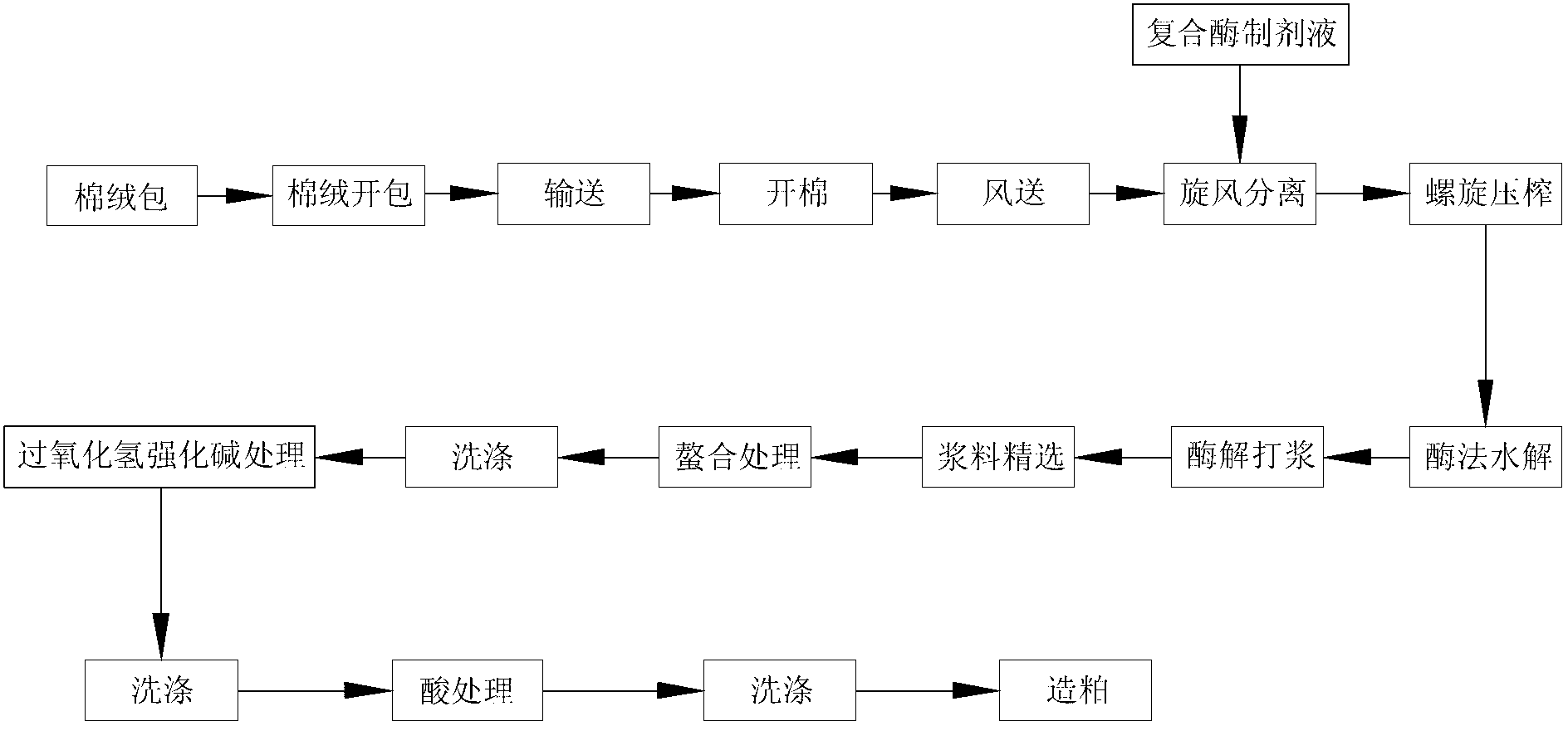

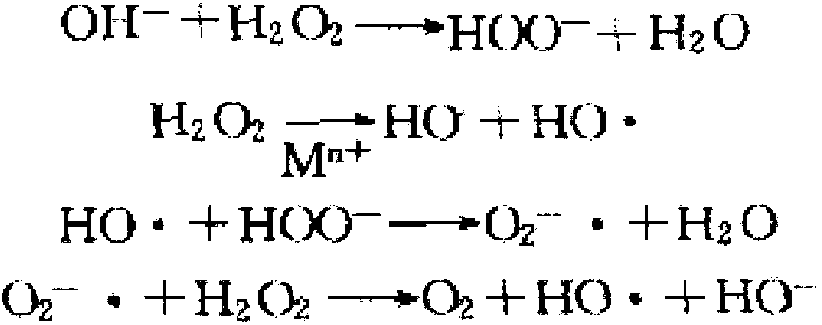

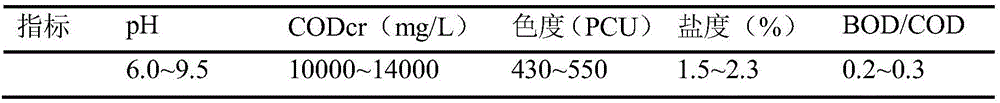

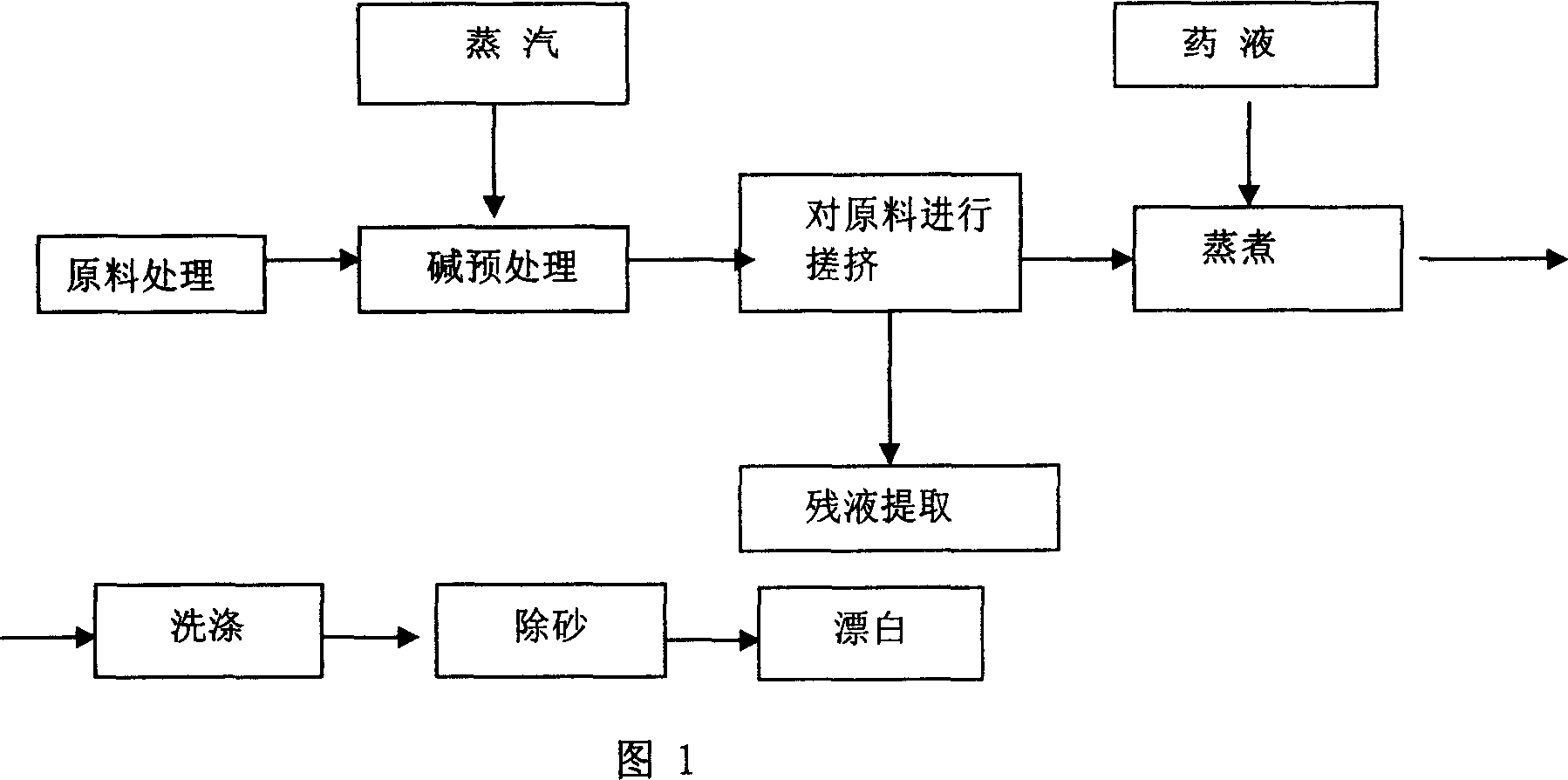

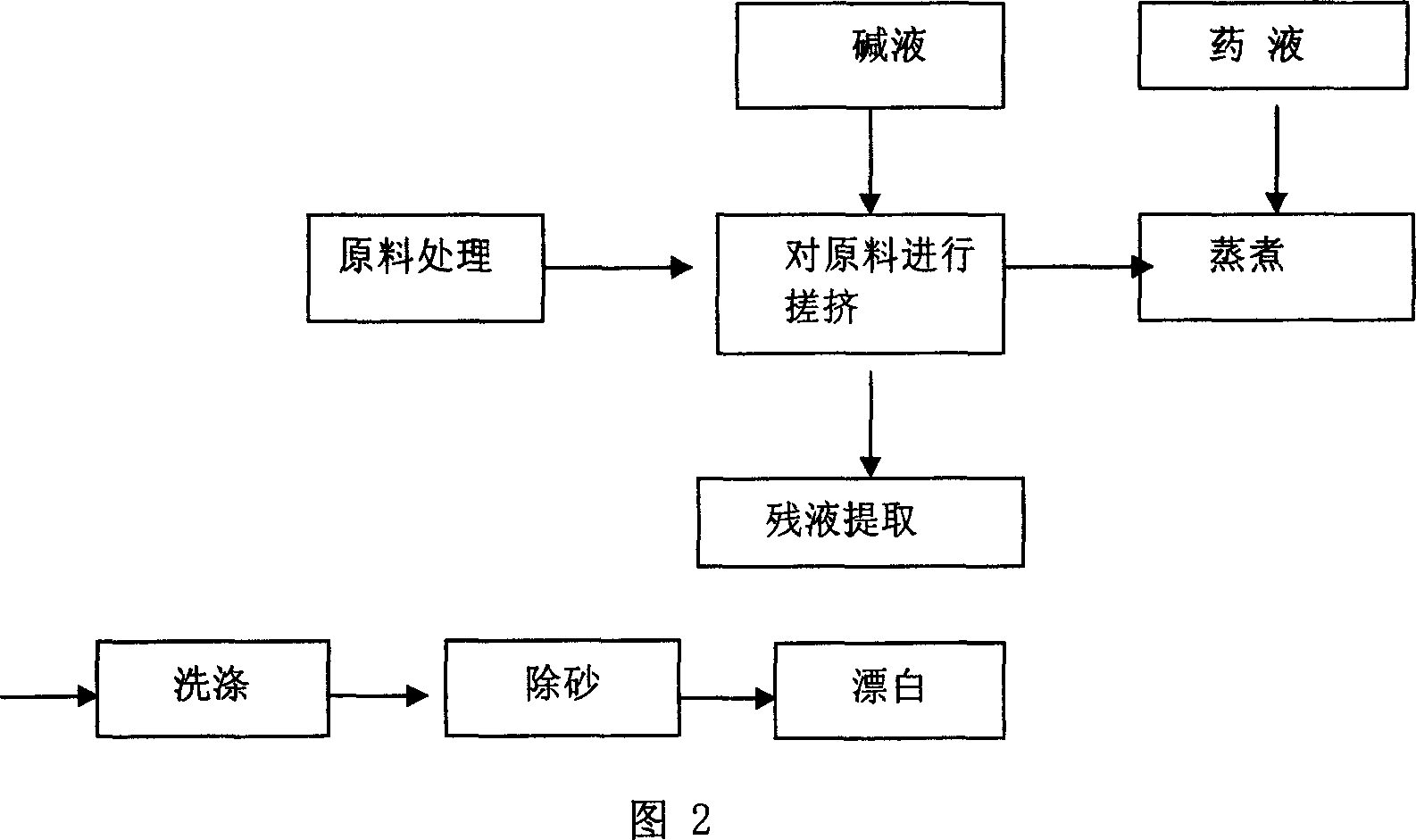

Complex enzyme preparation and technique for preparing dissolving pulp by using same

ActiveCN103061181ALoose structureEnhancement and effectPaper material treatmentChemical oxygen demandCellulose fiber

The invention relates to the technical field of production of regenerated cellulose fiber, in particular discloses a complex enzyme preparation applied in the preparation of dissolving pulp and a technique for preparing the dissolving pulp by using the enzyme preparation. The complex enzyme preparation is divided into a complex enzyme preparation I and a complex enzyme preparation II, wherein the complex enzyme preparation I mainly consists of feruloyl esterase, lipase and the like; and the complex enzyme preparation II mainly consists of xylanase, cellulase and the like. The complex enzyme preparation is applied in the technique for purifying alpha-cellulose and preparing the dissolving pulp; and the technique comprises the following steps of impurity removal for raw materials, enzyme method pretreatment, enzymolysis pulping, chelation treatment, alkali hydroxyl active oxygen cooking, acid treatment, washing, sand removal and pulp mixing. The method has the simple preparation technique, and adopts the complex enzyme preparation to treat the raw material pulp so as to effectively remove lignin, hemicellulose, pectin substance and waxiness and to reduce the degree of polymerization of the alpha-cellulose; the energy consumption is low under the normal pressure condition; the COD (Chemical Oxygen Demand) value of the pulping waste water is low; the yield of the dissolving pulp is high; the alpha-cellulose has high content and uniform degree of polymerization; and the production requirements of viscose can be satisfied.

Owner:CHAMBROAD CHEM IND RES INST CO LTD

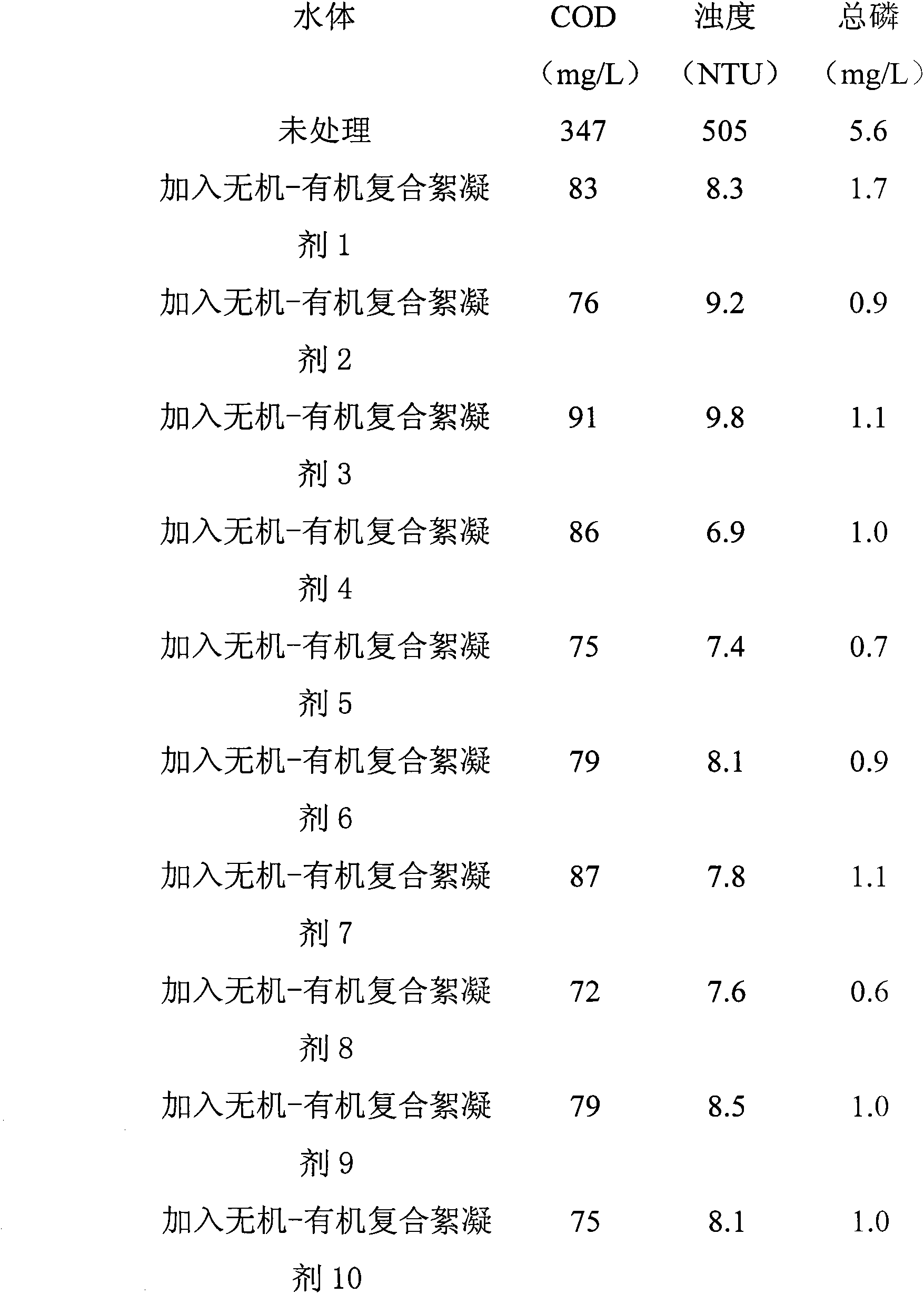

Compound water treatment agent based on ferrate and preparation method of compound water treatment agent

ActiveCN105923735AHigh yieldIncrease profitWater treatment compoundsWater/sewage treatment by flocculation/precipitationSludgePotassium hydroxide

The invention discloses a compound water treatment agent based on ferrate and a preparation method of the compound water treatment agent, and belongs to the field of industrial wastewater treatment. The compound water treatment agent is prepared from the following raw materials: 18-20 parts of sodium hydroxide, 15-20 parts of potassium hydroxide, 10-15 parts of sodium hypochlorite, 15-18 parts of ferric nitrate, 1-3 parts of copper chloride, 30-35 parts of ethylene diamine tetraacetic acid and 18-20 parts of calcium chloride. The prepared water treatment agent is good in stability and high in oxidability, has the characteristics that the oxidizing capacity is continuous, the decolourising property is good, the pH application range is wide, the added amounts of acid, base and chemicals are small, sludge is unlikely to float and the content of ferric salt in the sludge is relatively low, and has adsorption and flocculent precipitation performance, so that the heavy metals such as Cd, Cr and Pb in industrial wastewater can be effectively removed, and the biodegradability of the wastewater is greatly improved.

Owner:NANJING UNIV

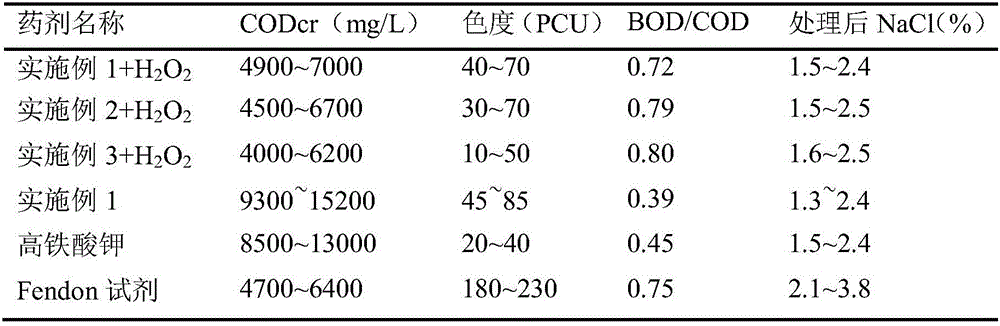

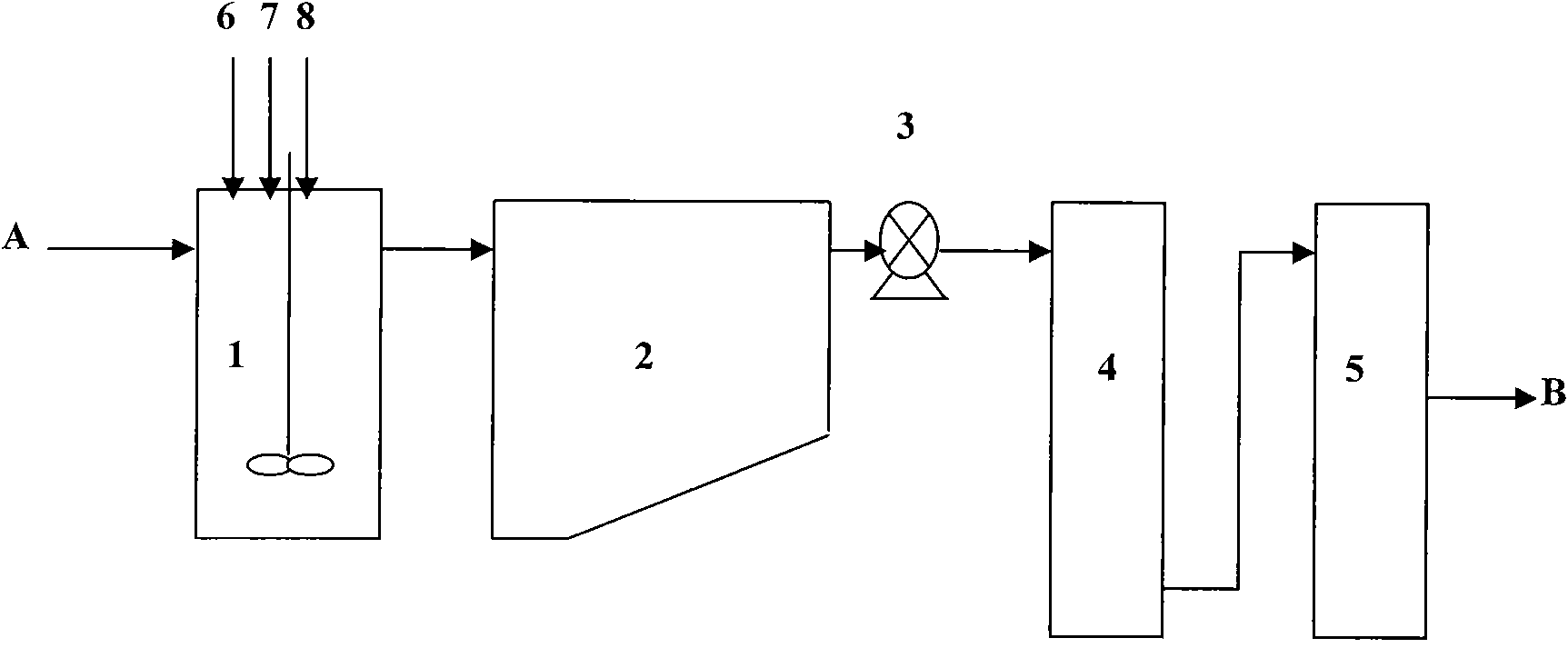

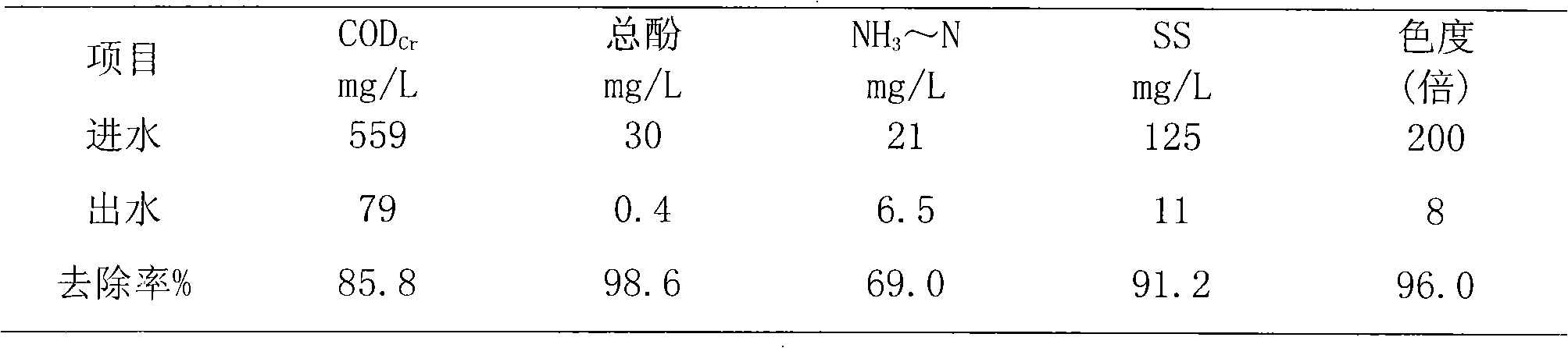

Coking wastewater treatment device and coking wastewater posttreatment method

InactiveCN101987762AReduce CODAchieve emission standardsMultistage water/sewage treatmentWater/sewage treatment by neutralisationChemical oxygen demandActivated carbon filtration

The invention relates to a coking wastewater treatment device which comprises a flocculation reaction tank, wherein the flocculation reaction tank is connected with a flocculation settling pond, the flocculation settling tank is connected with a sand filter, and the sand filter is connected with an active carbon filter. A coking wastewater posttreatment method comprises the steps of: adding an efficient composite flocculating agent, a polymer coagulant aid and a mineral powder absorbing agent into the coking wastewater subjected to common treatment; regulating the pH value to be 8-9 with alkali, wherein the flocculation reaction settling time is 1-2.5h; and then carrying out sand leaching and active carbon filtration, wherein the effluent quality fully reaches the standard for emission or recycling. The COD (Chemical Oxygen Demand), the total phenol, the ammonia nitrogen, SS (Suspended Substances) and the chromaticity in the coking wastewater subjected to the treatment with the method are respectively reduced by above 80 percent, 90 percent, 60 percent, 90 percent and 95 percent; and by treating the coking wastewater according to the invention, the purposes of good effect, simple operation and convenience in management are achieved.

Owner:SHANGHAI WEILAI ENTERPRISE

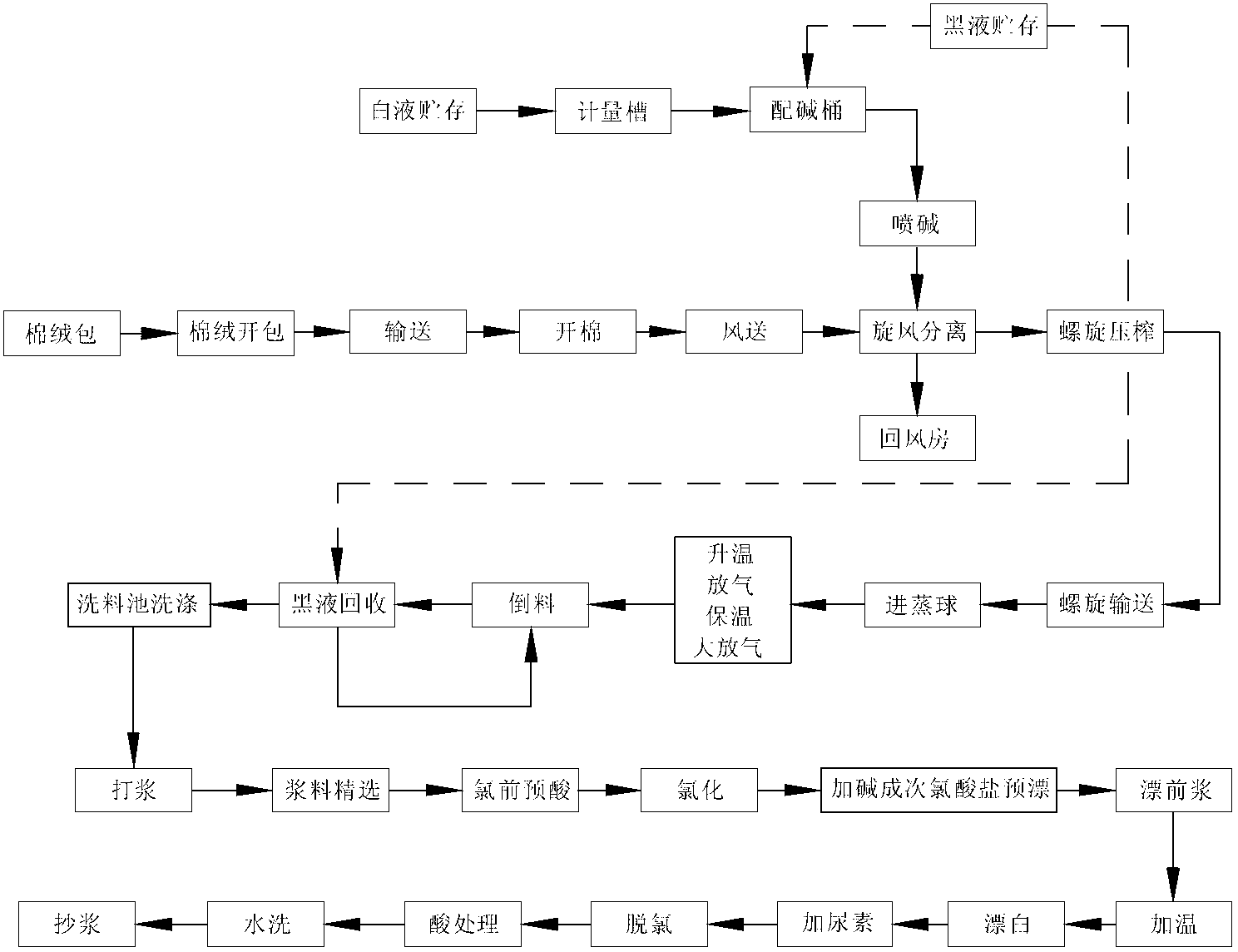

Method for producing chemical fiber pomace with fiber as raw material

InactiveCN1974922APerformance activationImprove impregnation effectCellulosic pulp after-treatmentDigestersBlack liquorPlant fibre

The present invention relates to a method for producing chemical fibre pulp by using plant fibre as raw material. Said method includes the following several steps: raw material treatment, making the treated raw material undergo the processes of rubbing and extruding, cooking, washing, removing sand and bleaching treatment. It is characterized by that in the preparation process of said chemical fibre pulp a screw extruding machine and a rubbing-extruding machine are adopted.

Owner:湖南吉湘生物科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com