Compound water treatment agent based on ferrate and preparation method of compound water treatment agent

A ferrate and water treatment technology, which is applied in the direction of special compound water treatment, water/sewage treatment, oxidized water/sewage treatment, etc., can solve the problems of weak oxidation performance, narrow application range, poor sustainability, etc., and improve the oxidation capacity , broaden the pH range, improve the solubility of the effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

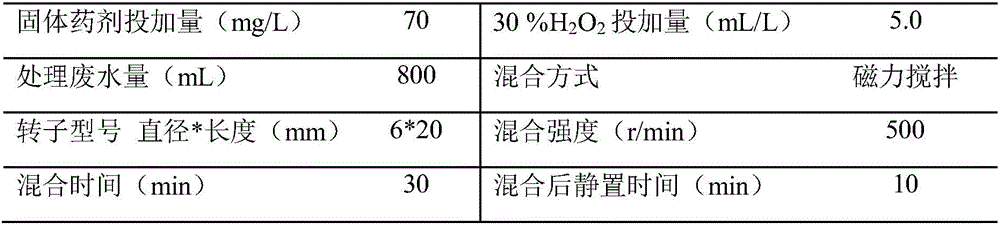

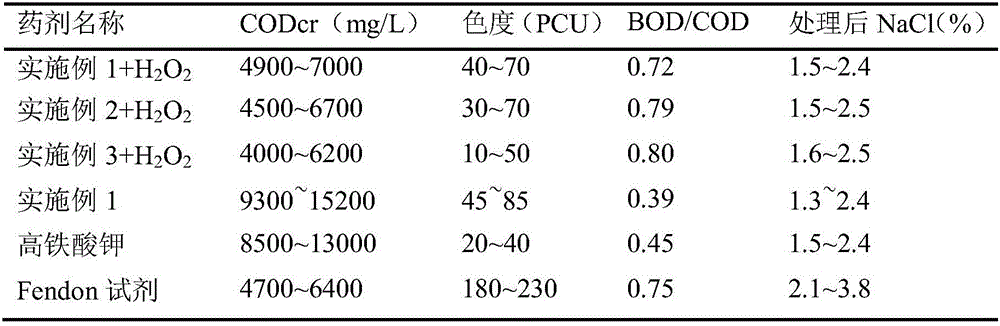

Embodiment 1

[0039] Proportion of raw materials by weight: 18 parts of sodium hydroxide, 15 parts of potassium hydroxide, 10 parts of sodium hypochlorite, 15 parts of ferric nitrate, 1 part of copper chloride, 30 parts of disodium edetate, 18 parts of calcium chloride , the step of preparing compound water treatment agent is: take each component by the ratio described above, sodium hypochlorite is prepared into a 10% (mass fraction) solution, then sodium hydroxide solid is added in the 10% sodium hypochlorite solution , stir, then add ferric nitrate solid and stir to dissolve; add copper chloride solid and edetate disodium solid to the solution, and stir until completely dissolved; add potassium hydroxide solid to the solution, precipitate for 15 minutes after stirring, and pump The filter cake was obtained by filtration, dried at 70°C for 1 hour, and recorded as solid A; the pH of the filtrate was adjusted to 8.0 with sulfuric acid, and calcium chloride was prepared into a saturated soluti...

Embodiment 2

[0041] Proportion of raw materials by weight: 19 parts of sodium hydroxide, 18 parts of potassium hydroxide, 12 parts of sodium hypochlorite, 16 parts of ferric nitrate, 2 parts of copper chloride, 33 parts of disodium edetate, 19 parts of calcium chloride The steps for preparing the composite water treatment agent are basically the same as in Example 1, except that the pH of the solution is adjusted to 8.5 with nitric acid, and the drying condition of the filter cake is 40 minutes at 80° C.

Embodiment 3

[0043] Proportion of raw materials by weight: 20 parts of sodium hydroxide, 20 parts of potassium hydroxide, 14 parts of sodium hypochlorite, 17 parts of ferric nitrate, 3 parts of copper chloride, 34 parts of disodium edetate, 20 parts of calcium chloride , the steps of preparing the composite water treatment agent are basically the same as in Example 1, except that the pH of the solution is adjusted to 8.0 with nitric acid, and the drying condition of the filter cake is 60° C. for 1 hour.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com